Disk drive mapping out data tracks to avoid thermal asperities

a technology of mapping out data tracks and data, applied in the direction of maintaining head carrier alignment, recording information storage, instruments, etc., can solve the problems of physical damage to the head, unreliable write/read performance, and disk surface agitation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

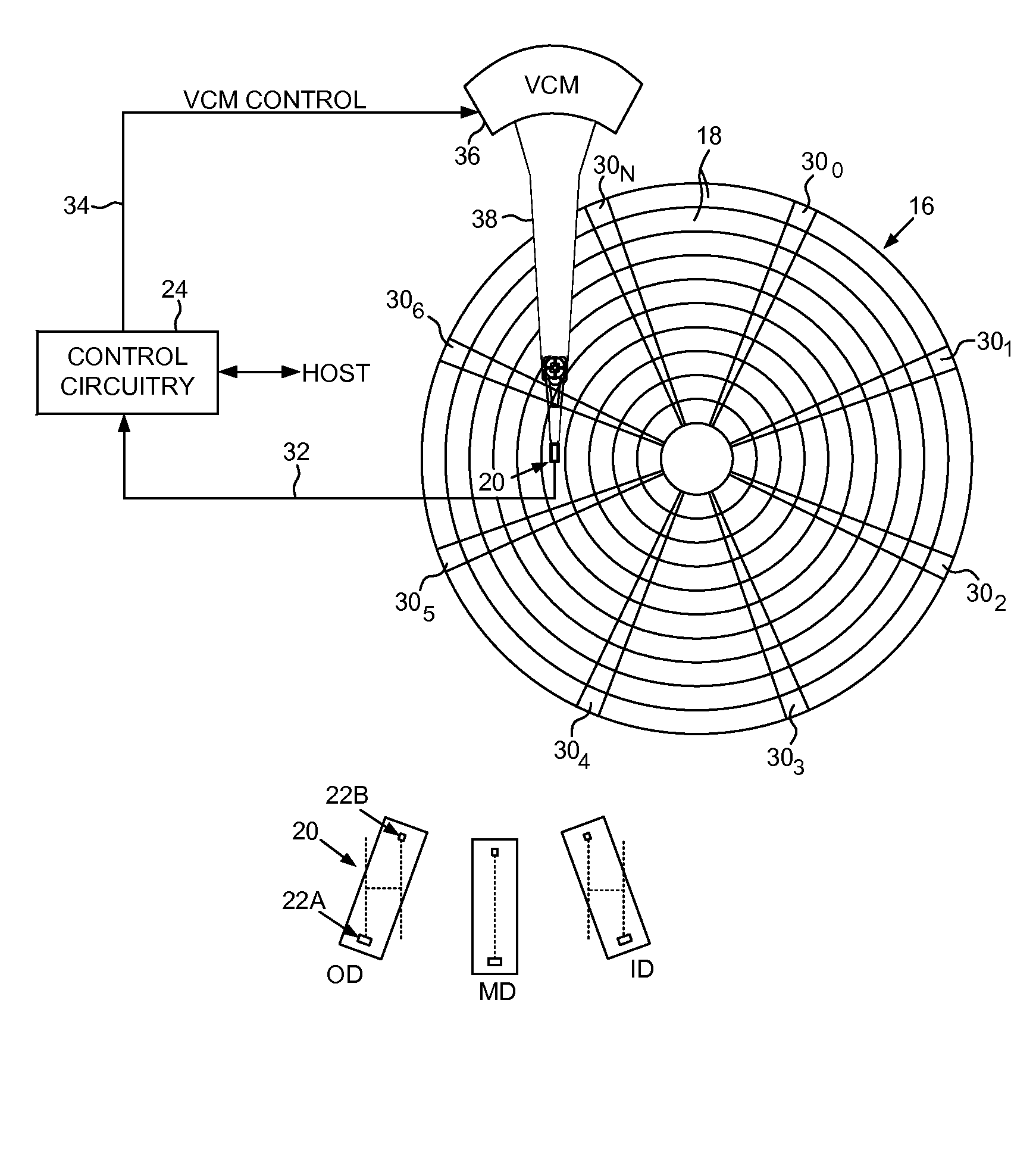

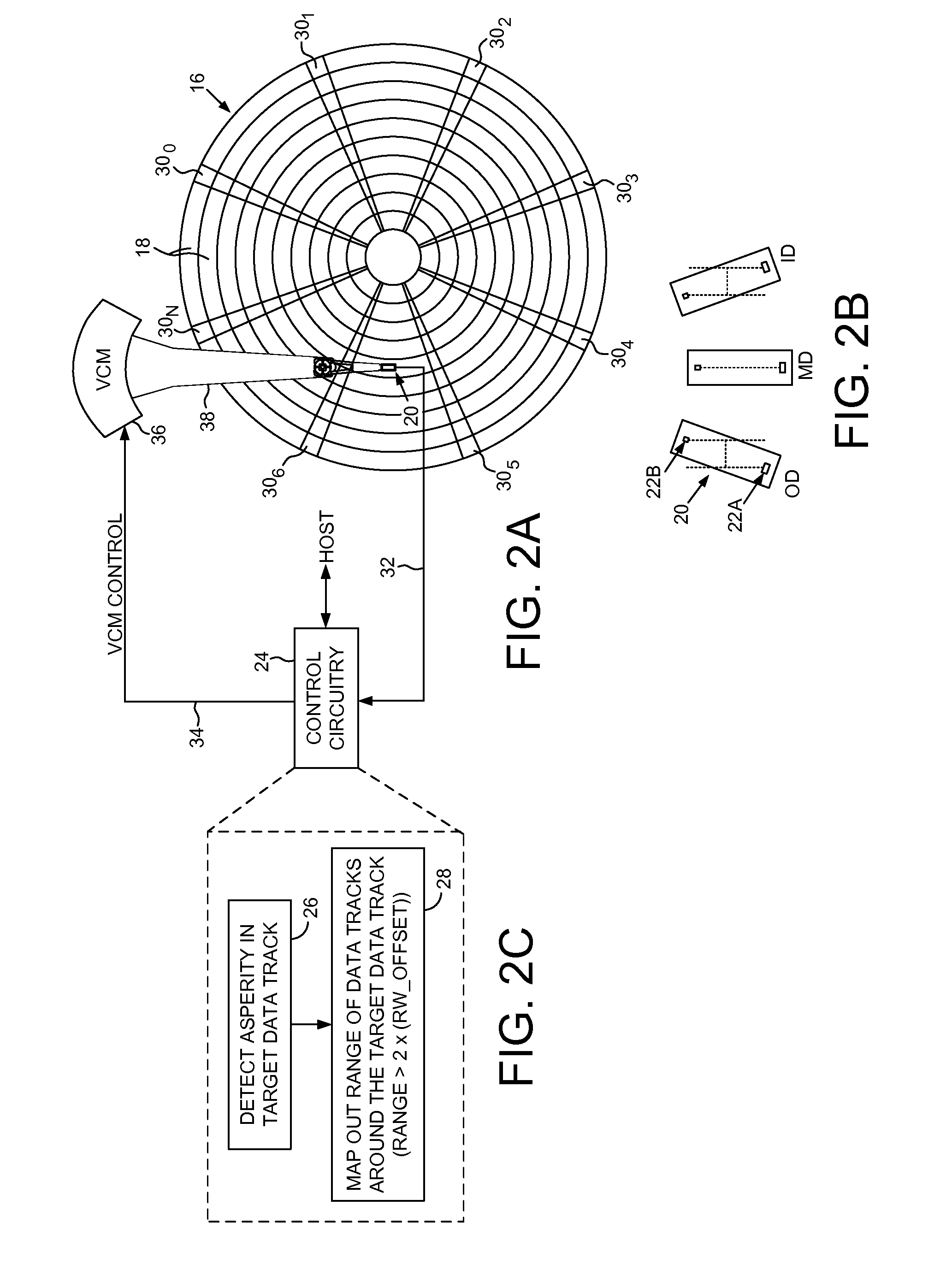

[0014]FIG. 2A shows a disk drive according to an embodiment of the present invention comprising a disk 16 having a plurality of data tracks 18, and a head 20 actuated over the disk 16, wherein the head 20 comprises a write element 22A and a read element 22B (FIG. 2B). The disk drive further comprises control circuitry 24 operable to execute the flow diagram of FIG. 2C, wherein an asperity is detected in a target data track (step 26). A range of data tracks proximate the target data track is mapped out (step 28), wherein the range of data tracks spans at least twice a radial offset between the read element and the write element at the radial location of the target data track.

[0015]In the embodiment of FIG. 2A, the disk 16 comprises embedded servo sectors 300-30N that define the plurality of data tracks 18. The control circuitry 24 processes a read signal 32 emanating from the head 20 to demodulate the servo sectors 300-30N and generate a position error signal (PES) representing an er...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| seek distance | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com