Patents

Literature

2411results about "Alignment for track following on disks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

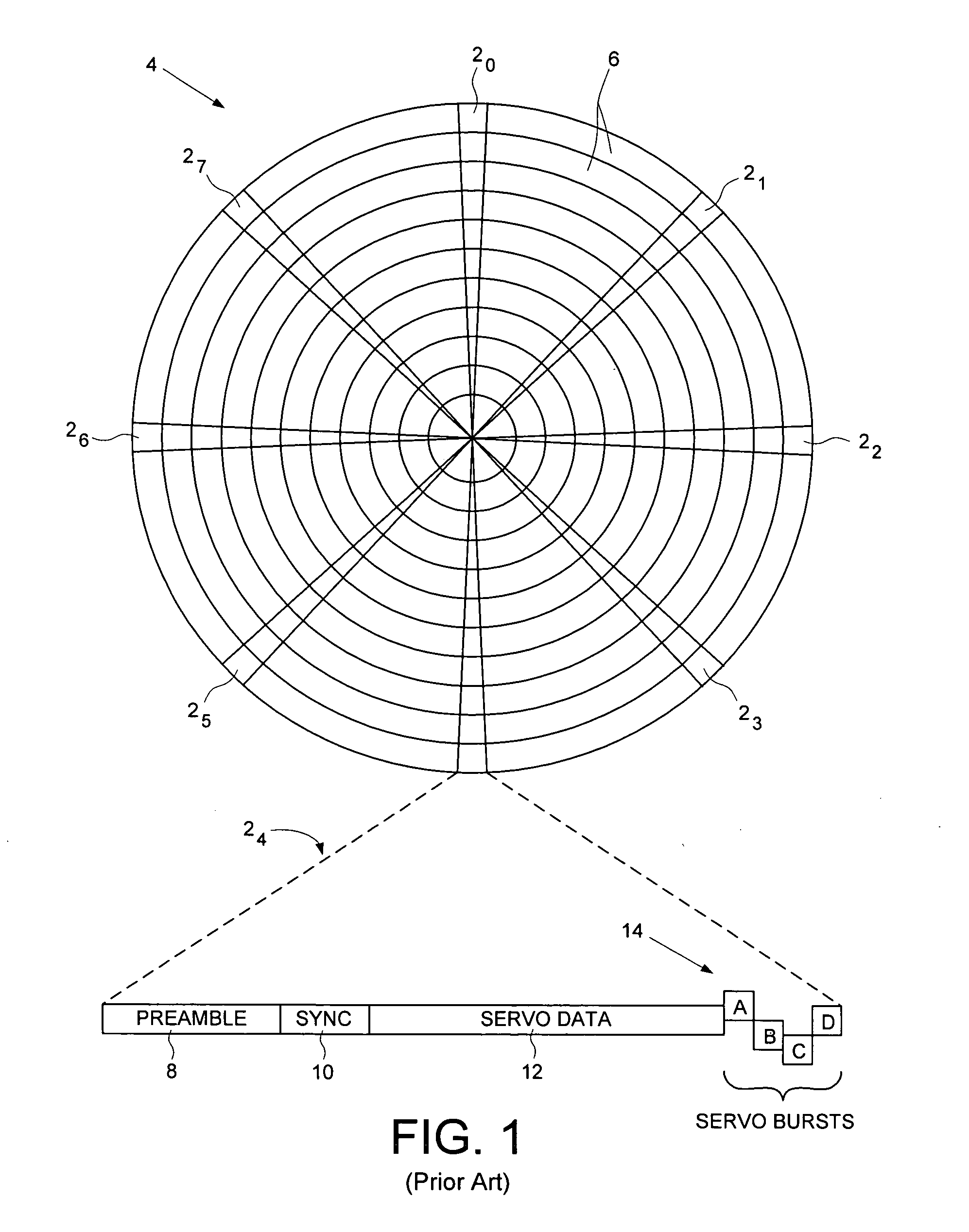

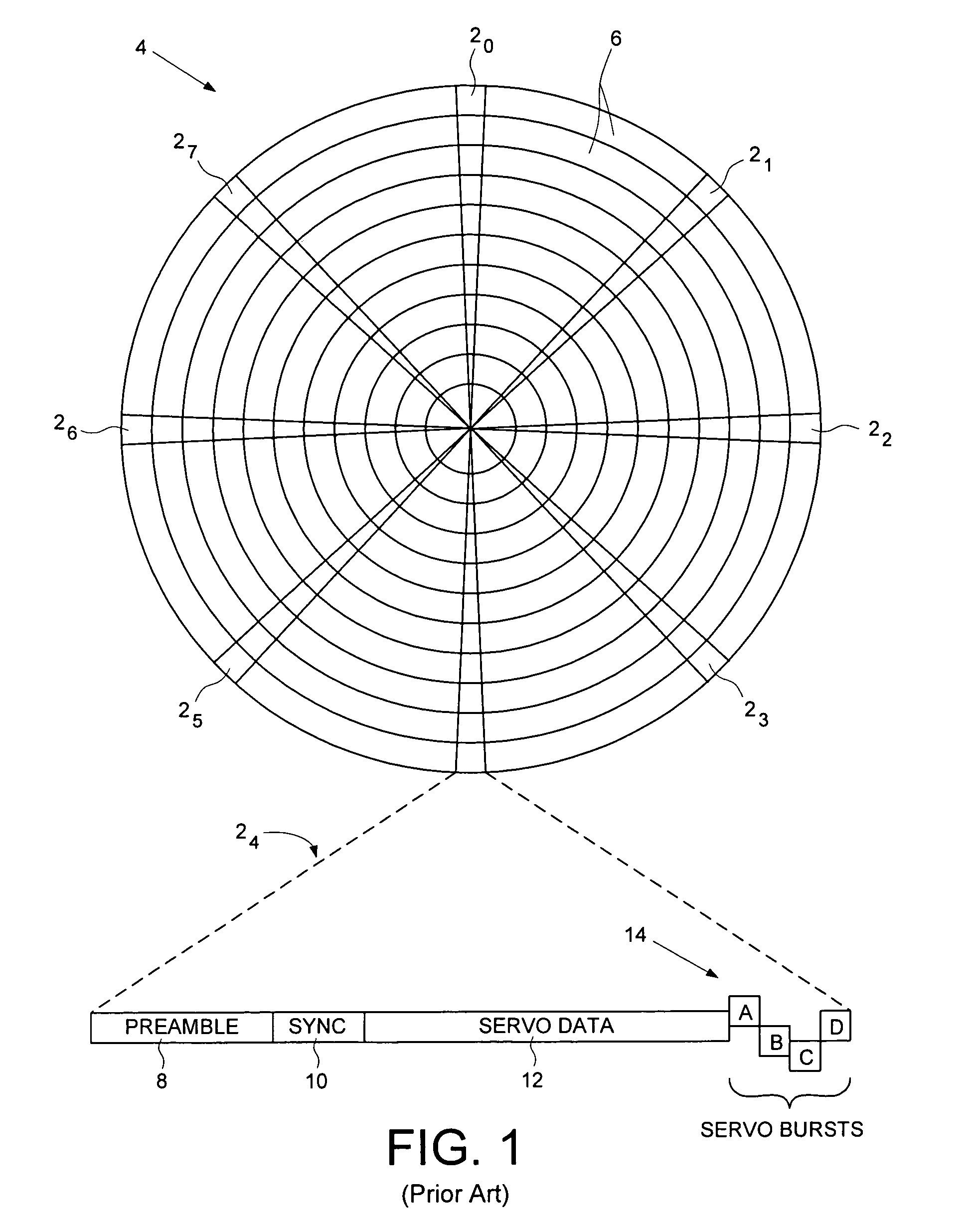

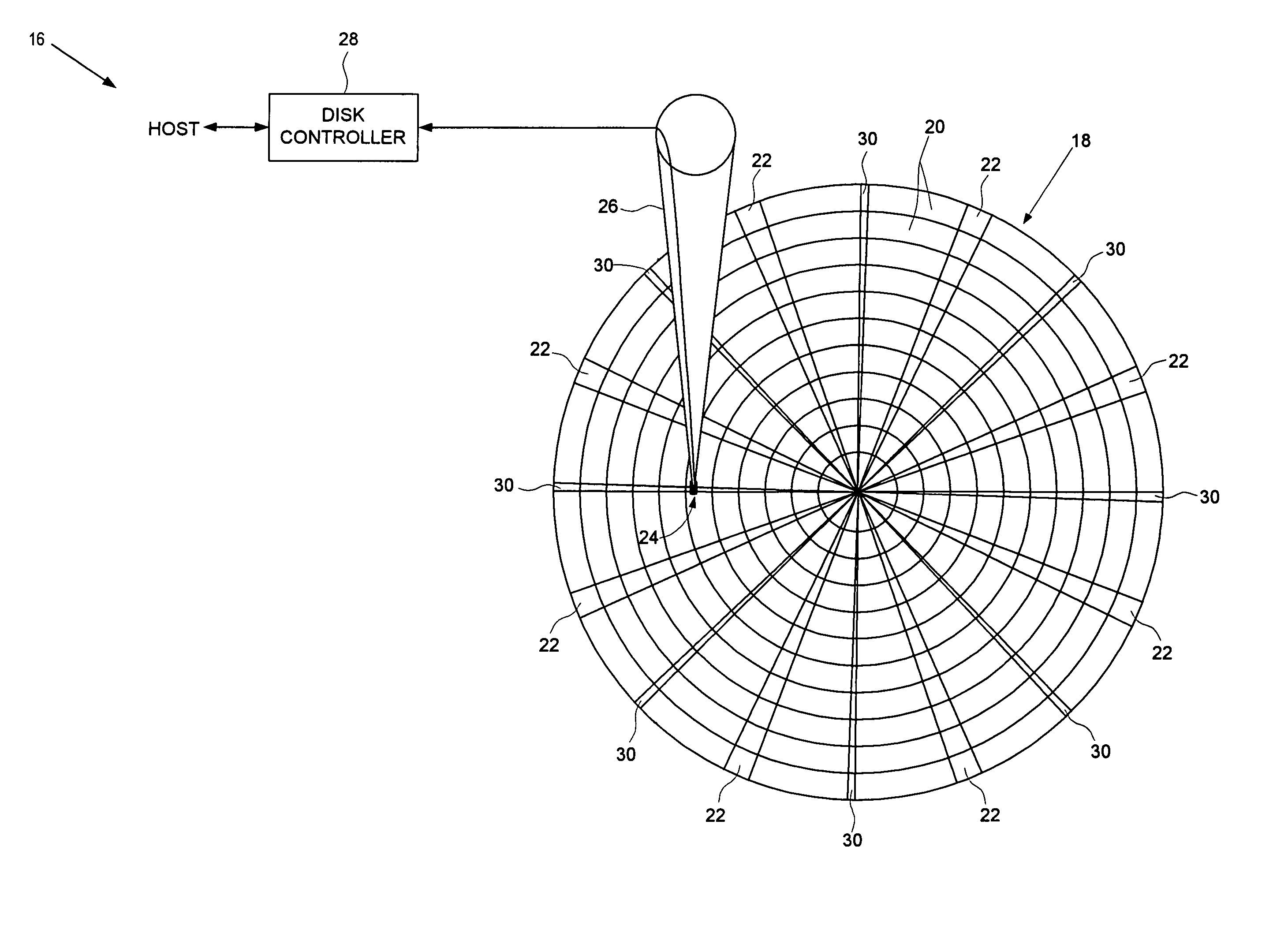

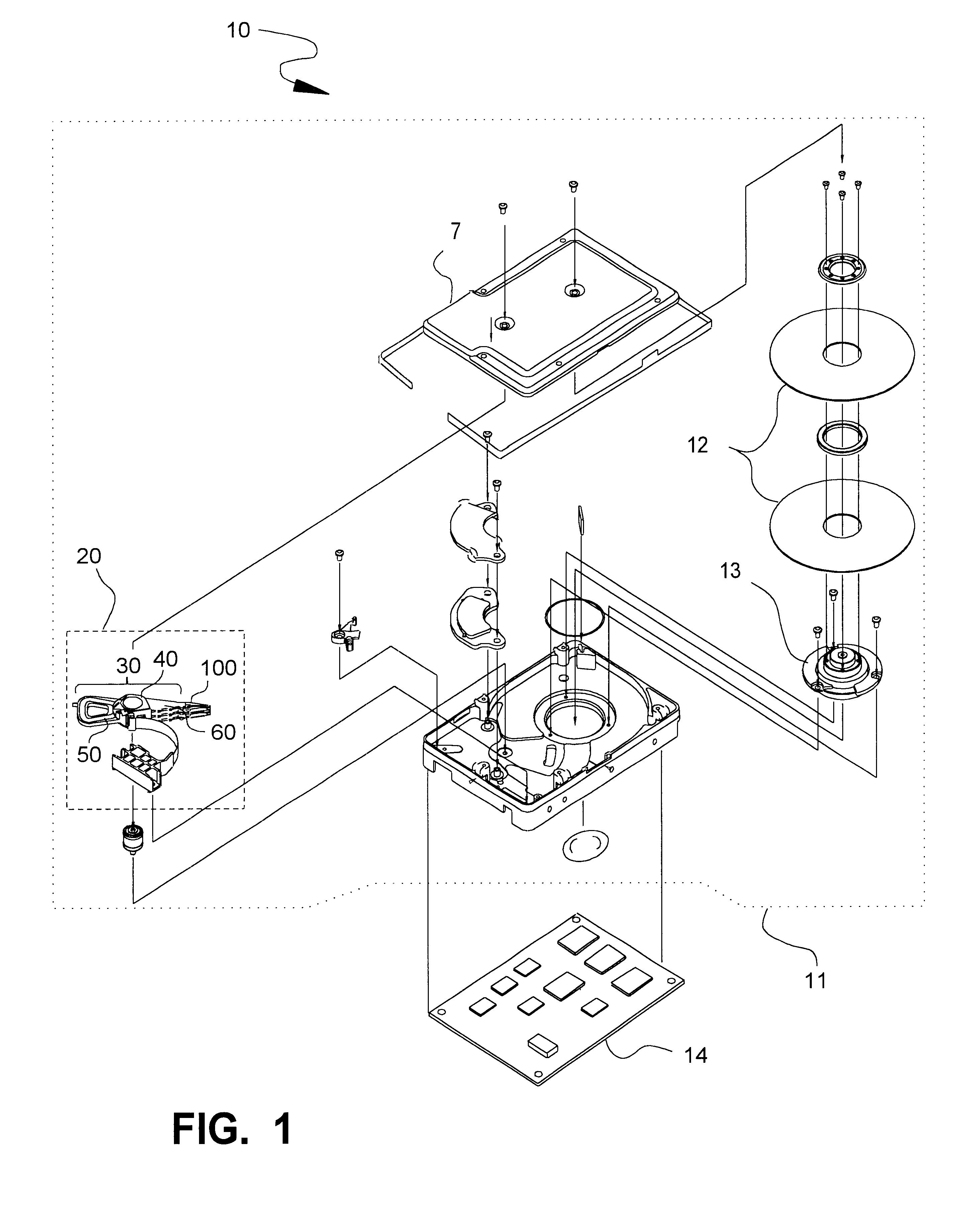

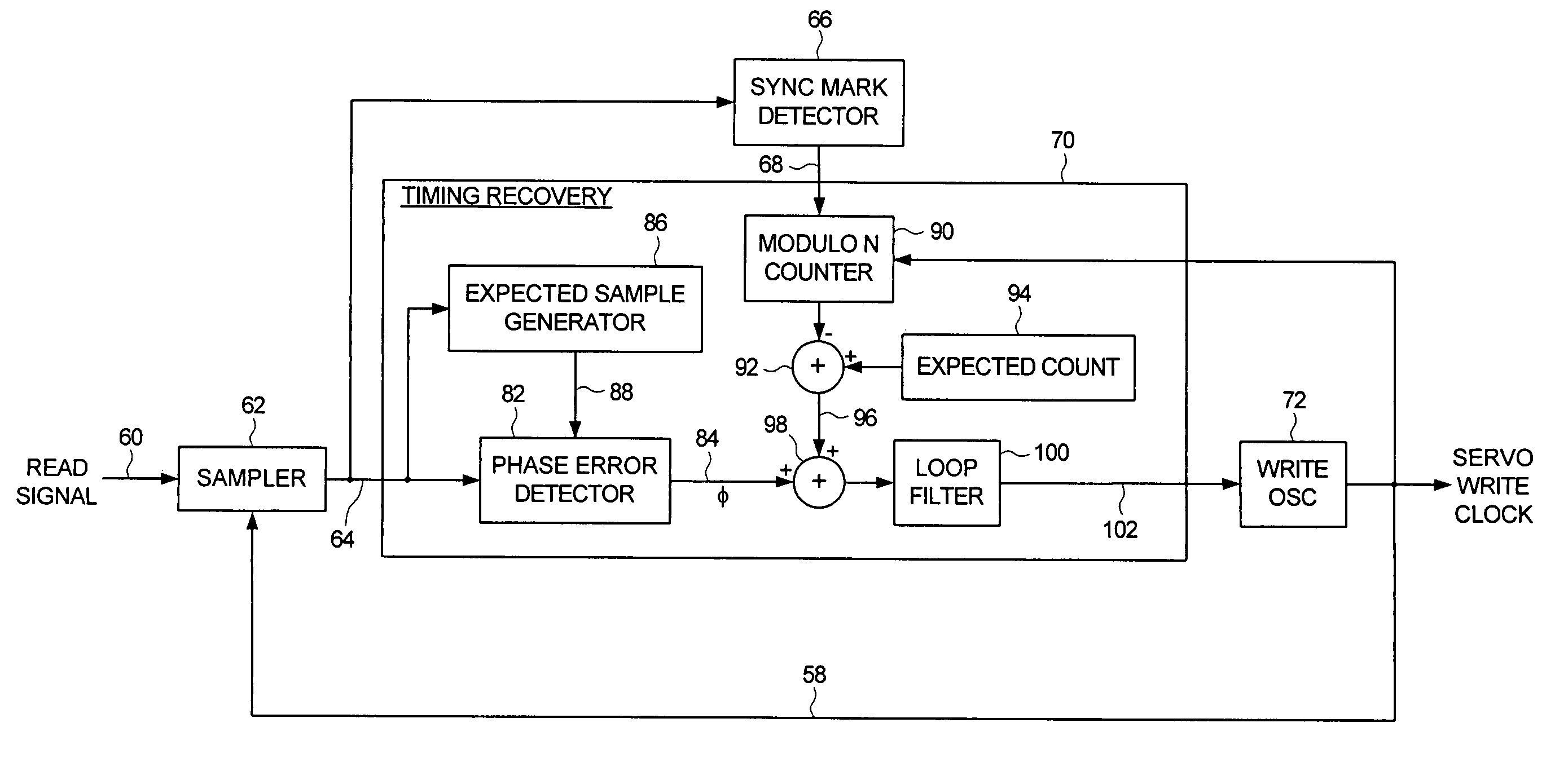

Servo writing a disk drive by synchronizing a servo write clock to a high frequency signal in a spiral track

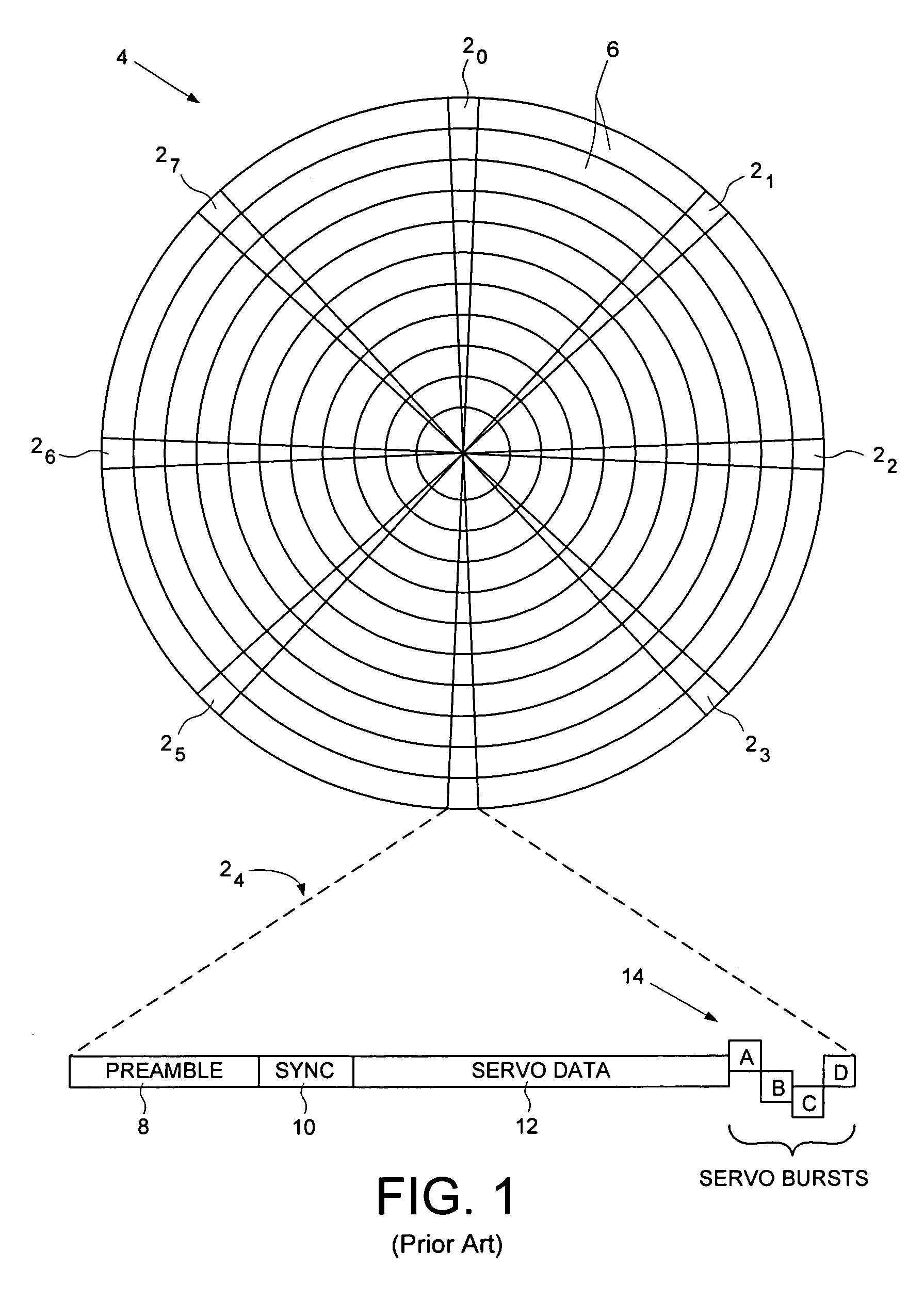

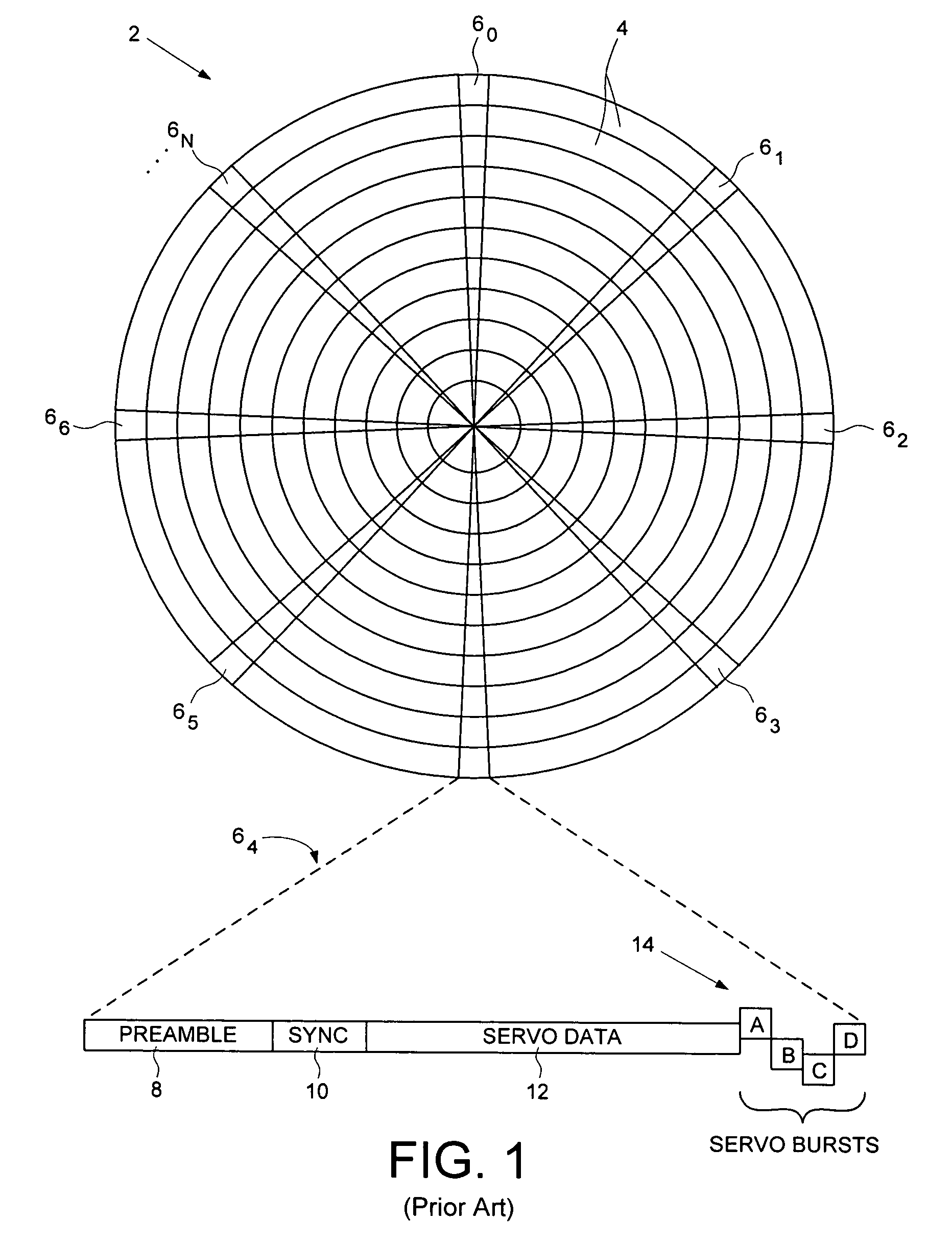

InactiveUS6943978B1Driving/moving recording headsRecord information storageControl theoryControl circuit

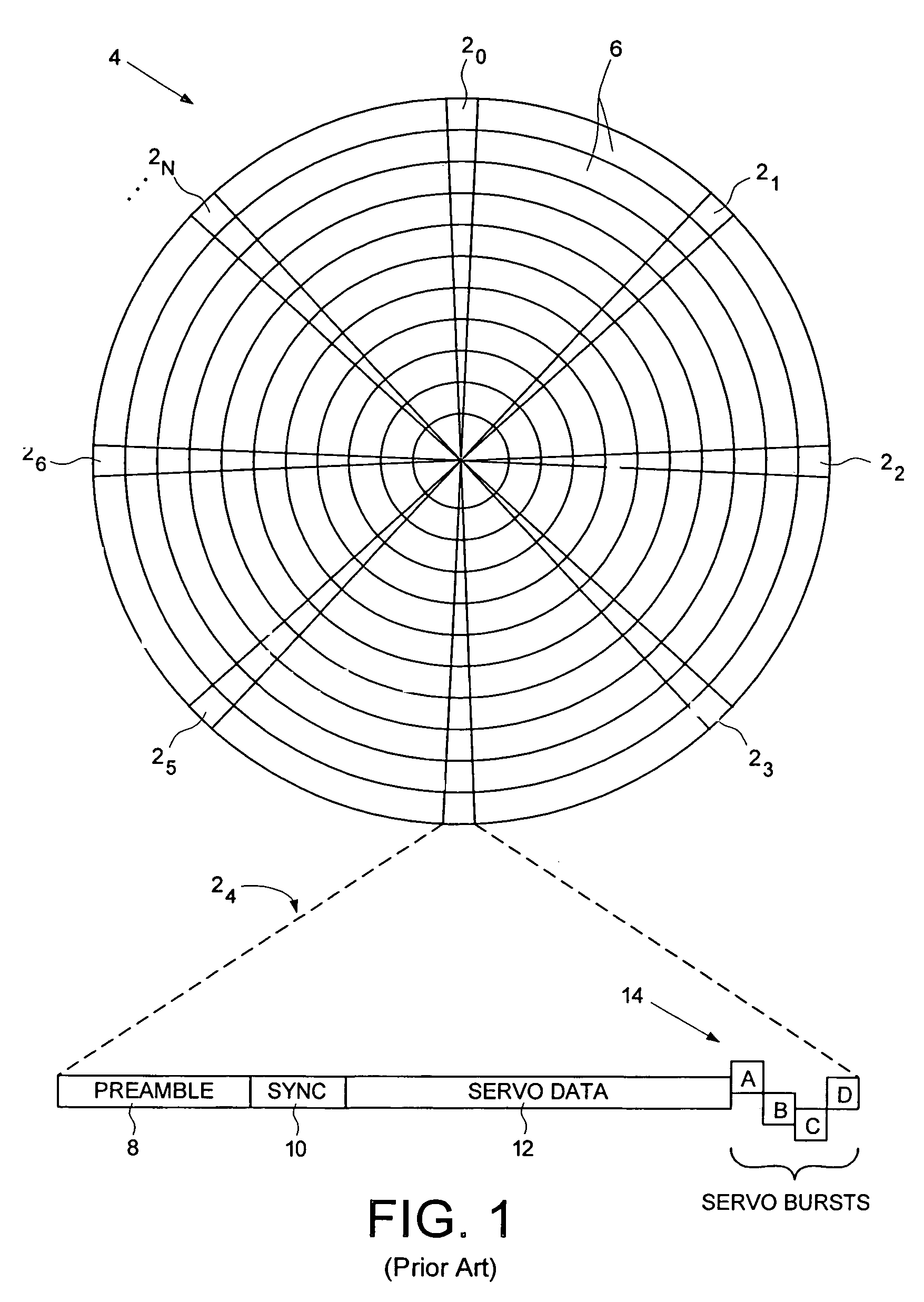

A method of writing product servo sectors to a disk of a disk drive is disclosed. A plurality of spiral tracks are written to the disk, wherein each spiral track comprises a high frequency signal interrupted at a predetermined interval by a sync mark. During the product servo writing process, the sync marks in the spiral tracks are read to generate a coarse timing recovery measurement, and the high frequency signal in the spiral tracks is read to generate a fine timing recovery measurement. The coarse and fine timing recovery measurements are processed to synchronize a servo write clock used to write the product servo sectors to the disk. In one embodiment the control circuitry within the disk drive synchronizes the servo write clock by reading the spiral tracks, and in an alternative embodiment an external product servo writer synchronizes the servo write clock by reading the spiral tracks.

Owner:WESTERN DIGITAL TECH INC

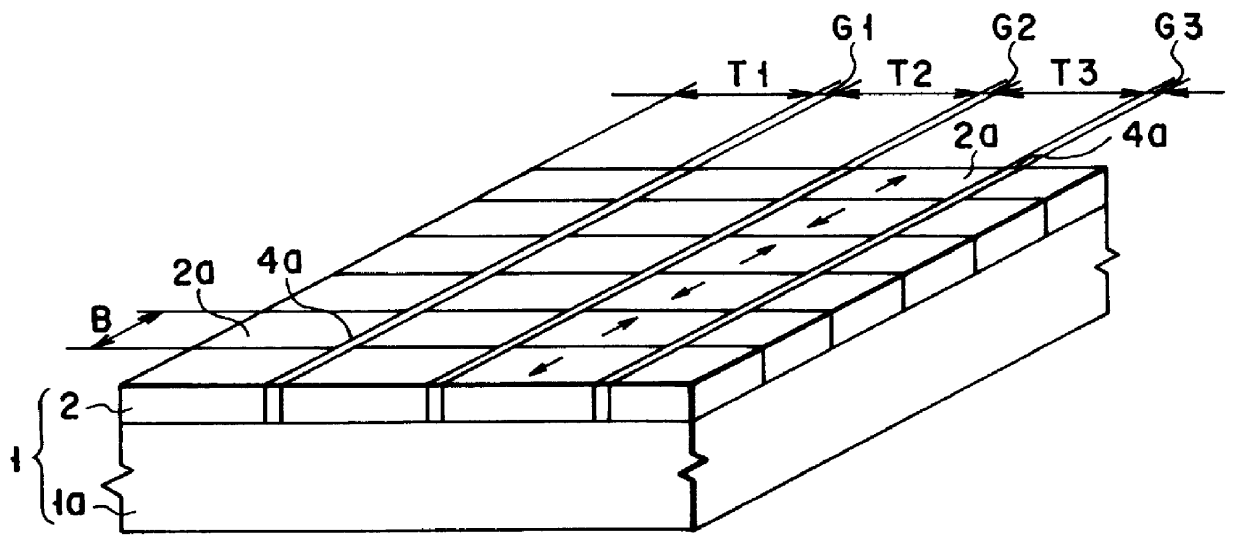

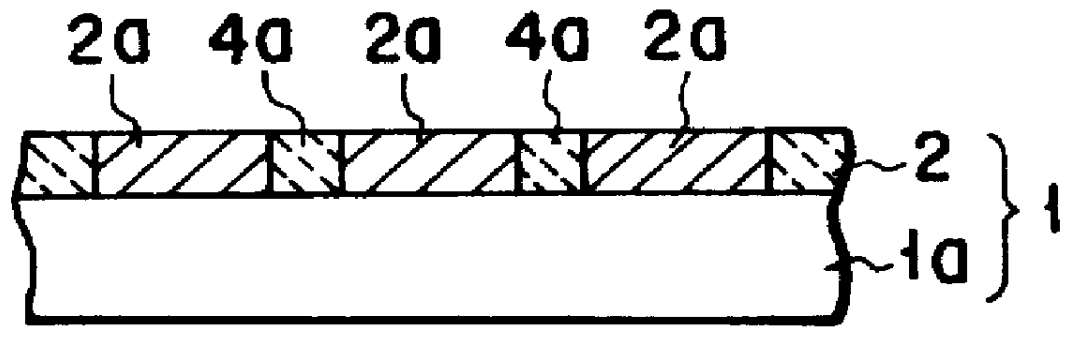

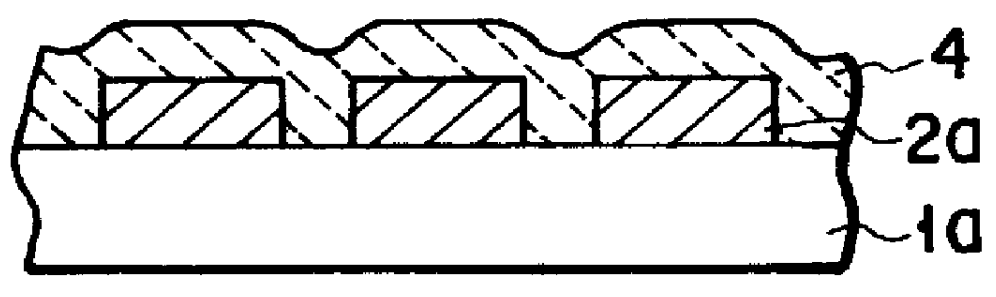

Magnetic disk with a guard band arrangement

A magnetic disk including a substrate, a recording track section which is made of a magnetic member for recording and reproducing information magnetically and is provided on the substrate, and a guard band member which is provided between the recording track sections adjacent to each other so that they are substantially continued in a track direction and is harder than the magnetic member and is made of a non-magnetic material. Moreover, the magnetic member is not provided or magnetic members with a different thickness from the magnetic member forming the recording track section is provided on a lower area of the guard band member.

Owner:KK TOSHIBA

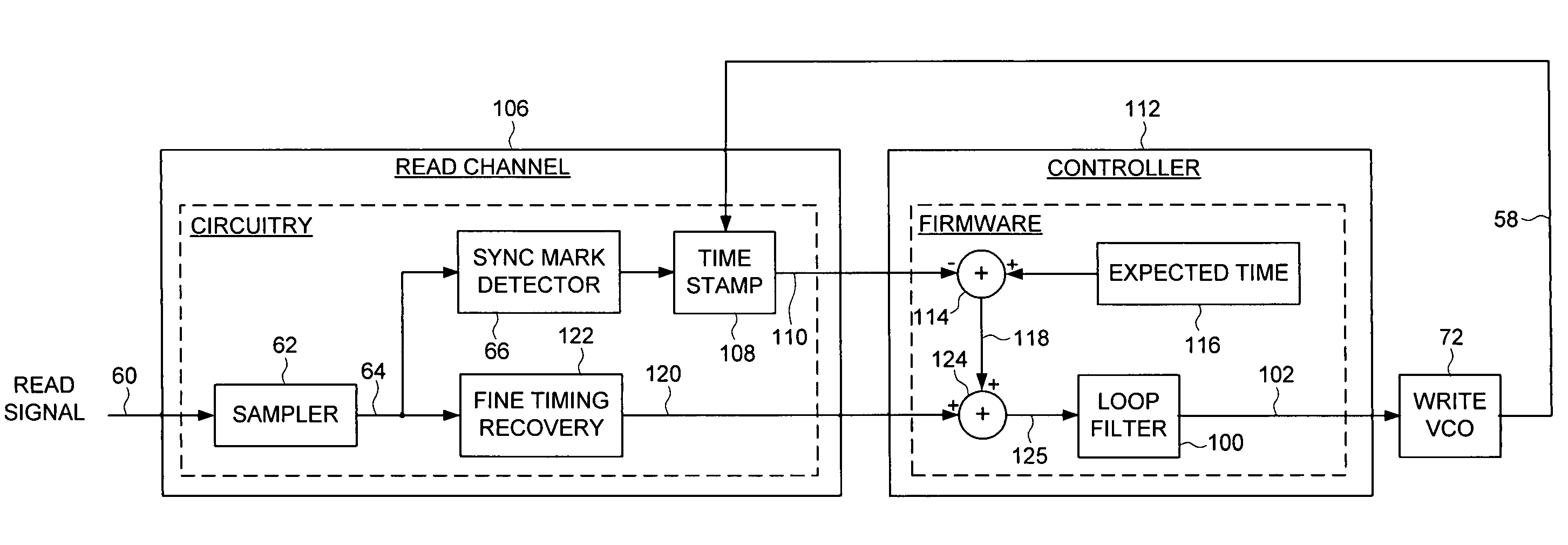

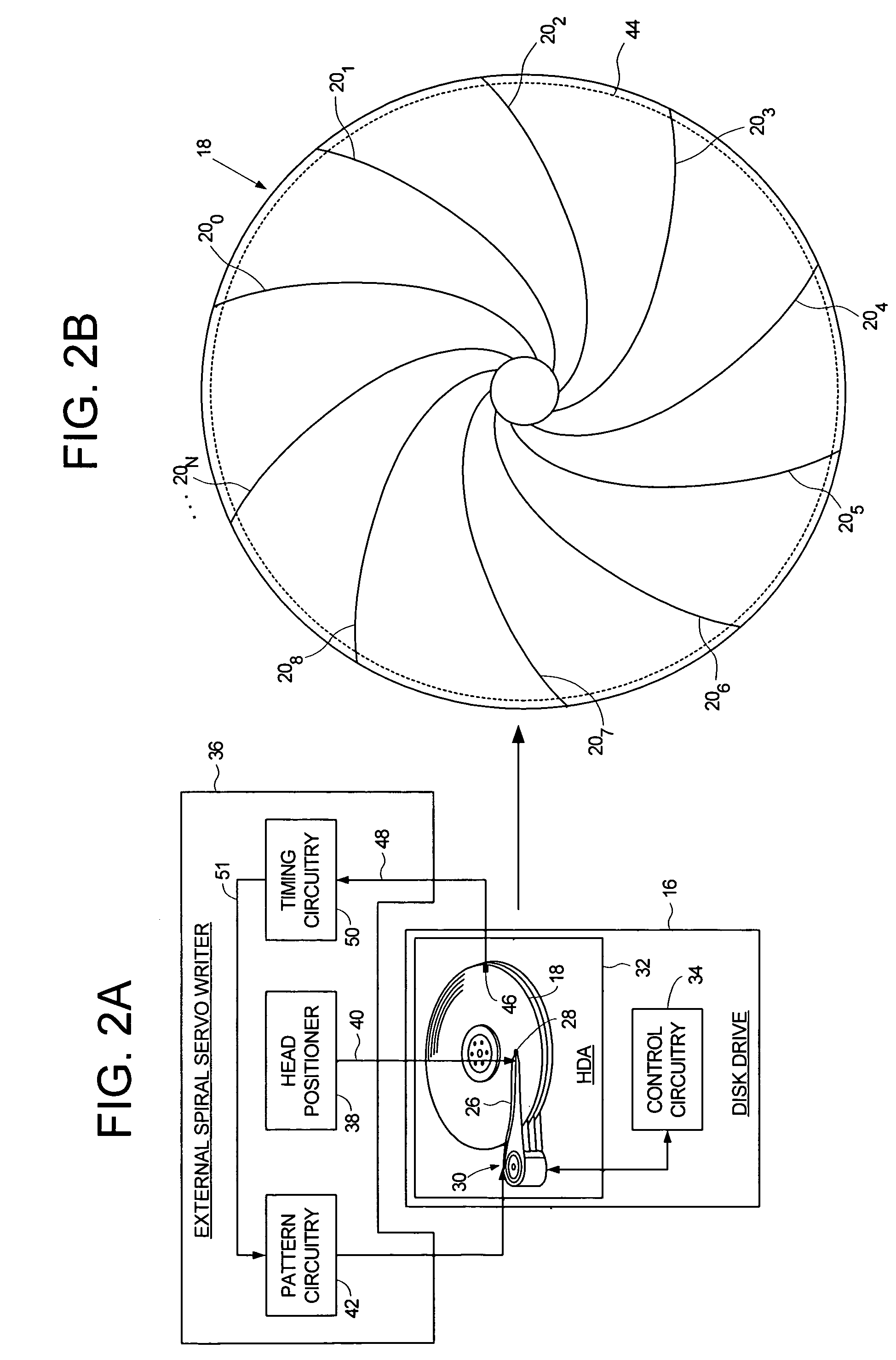

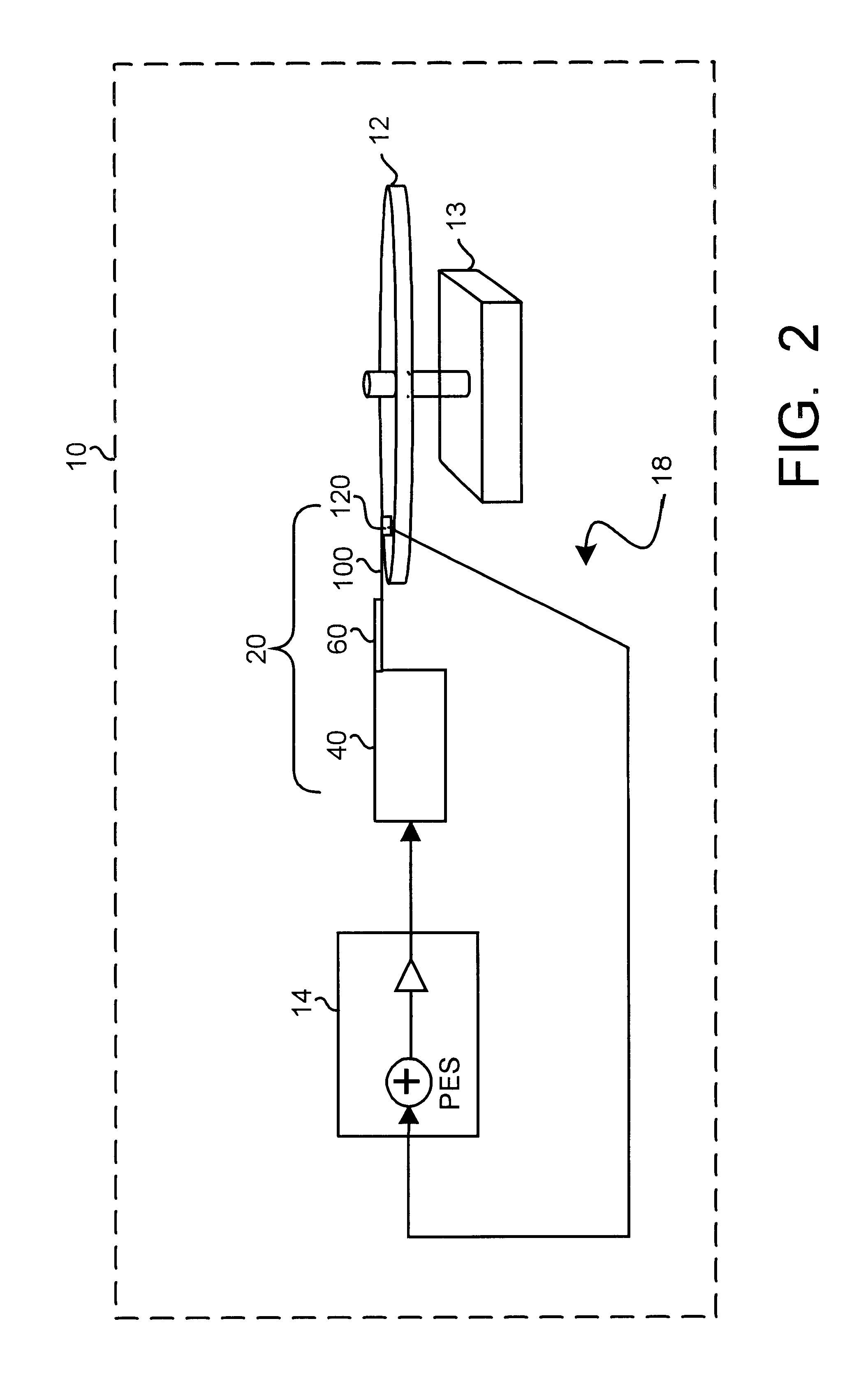

Servo writing a disk drive from spiral tracks by generating a time-stamped sync mark detect signal processed by timing recovery firmware

ActiveUS6967799B1Disc-shaped record carriersRecord information storageControl theorySignaling process

A disk drive is disclosed servo written from spiral tracks by generating a time-stamped sync mark detect signal processed by timing recovery firmware. A plurality of spiral tracks are written to the disk, wherein each spiral track comprises a high frequency signal interrupted at a predetermined interval by a sync mark. The head internal to the disk drive is used to read the spiral tracks, and a time-stamped sync mark detect signal is generated when one of the sync marks is detected. The time-stamped sync mark detect signal represents a time when the sync mark was detected relative to a servo write clock. A difference between the time-stamped sync mark detect signal and an expected time is computed in firmware to generate a coarse timing recovery measurement used to synchronize the servo write clock. The servo write clock and the head internal to the disk drive are used to write product servo sectors along a substantially circular target path.

Owner:WESTERN DIGITAL TECH INC

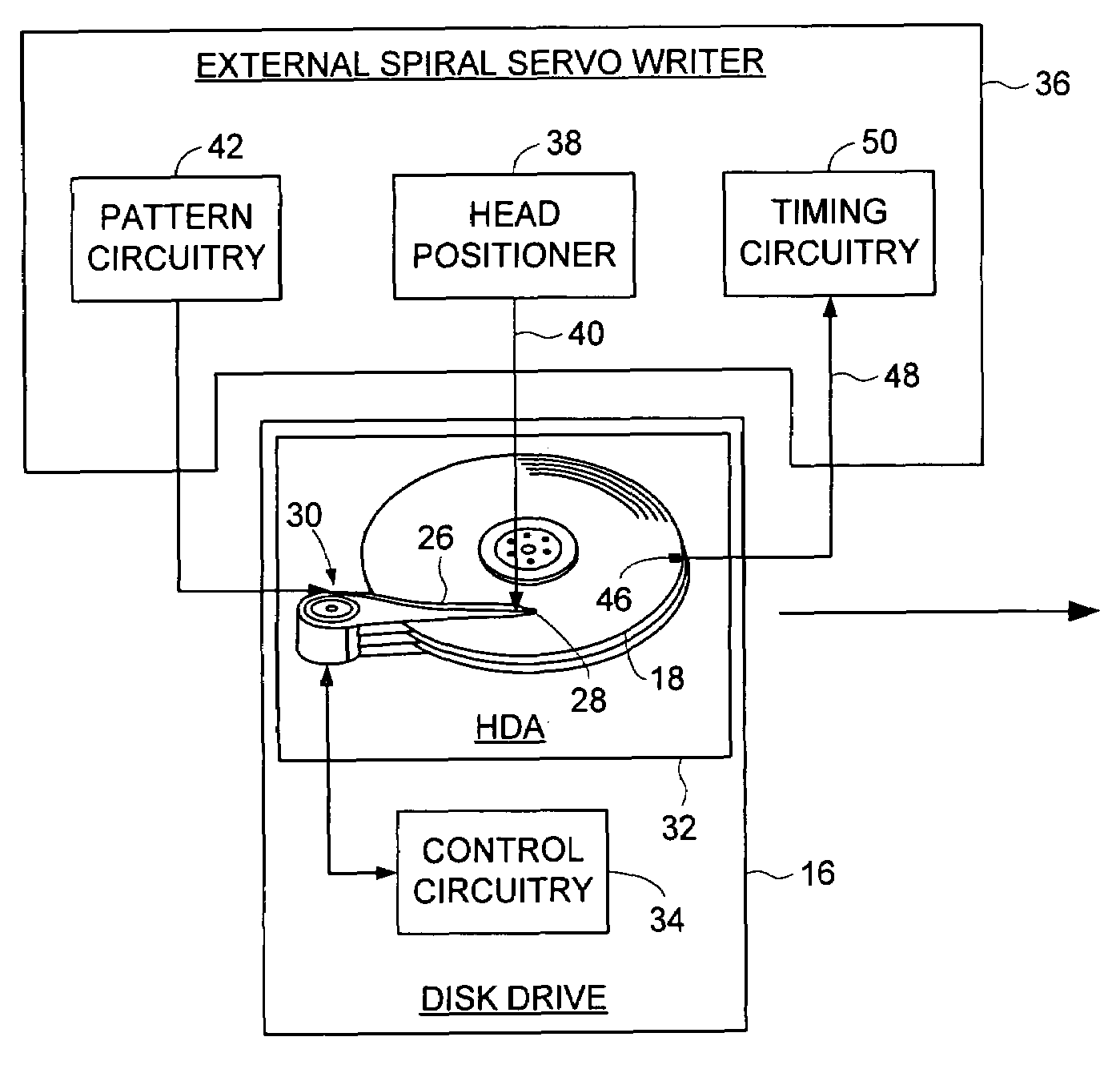

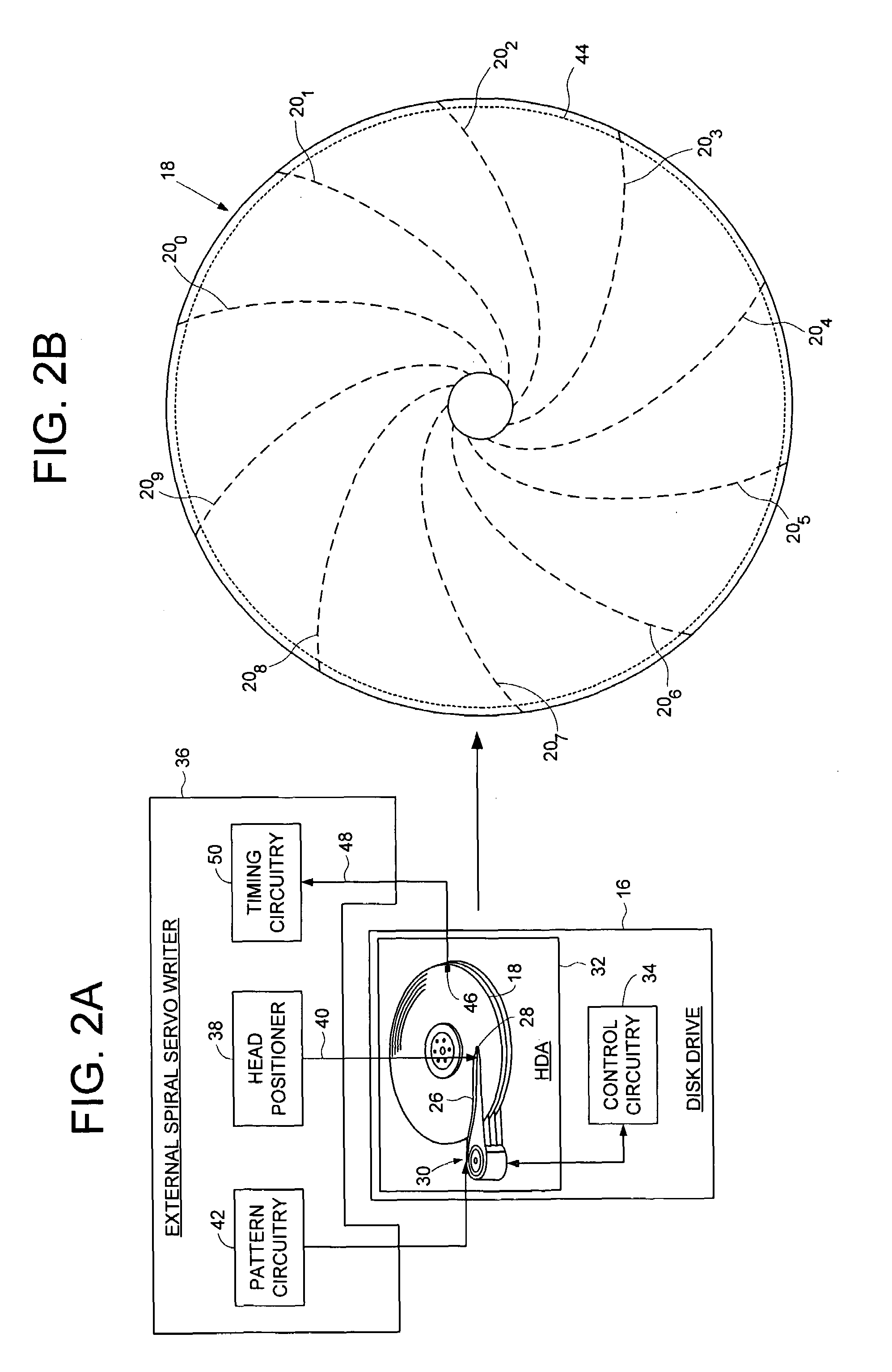

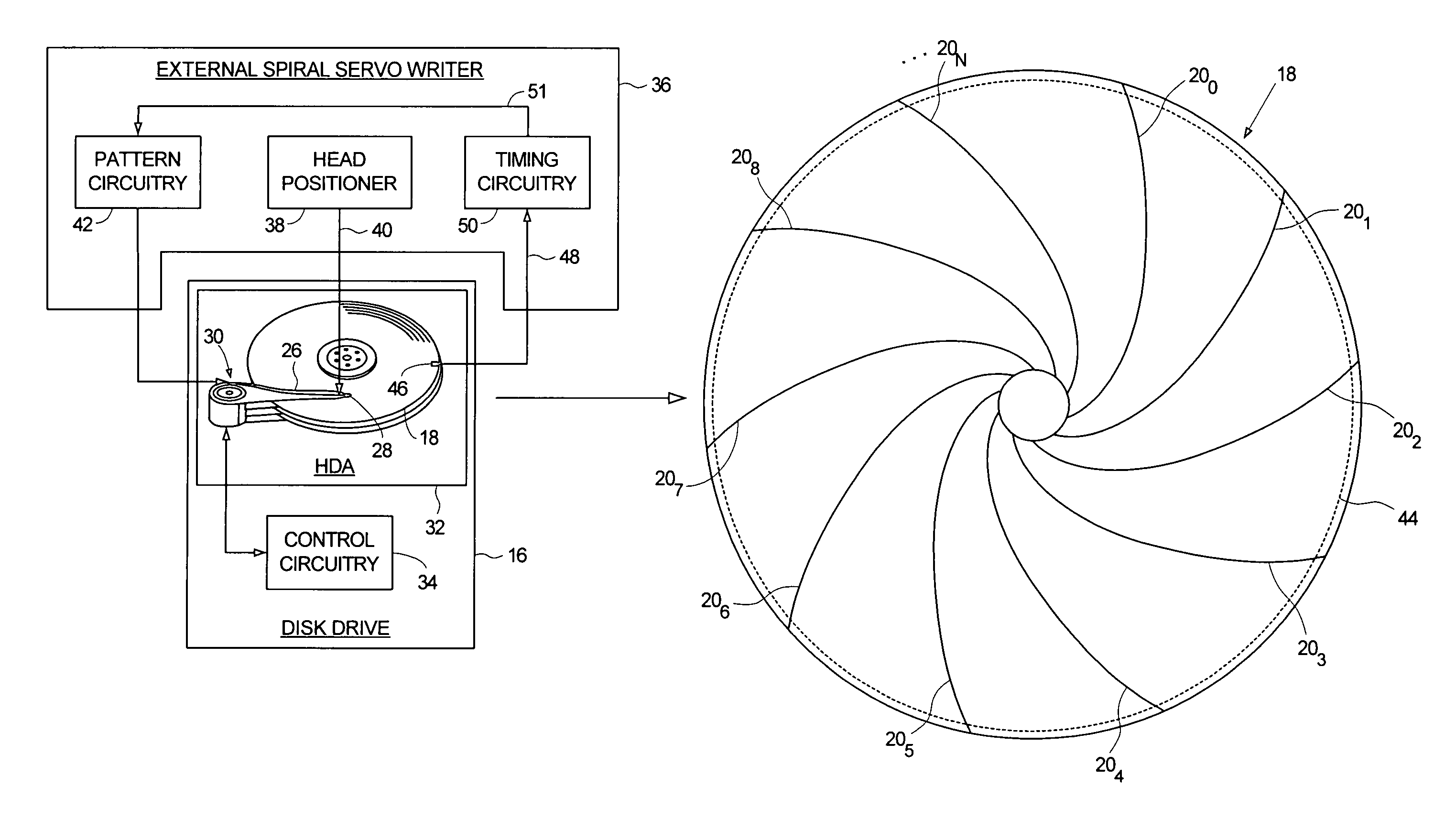

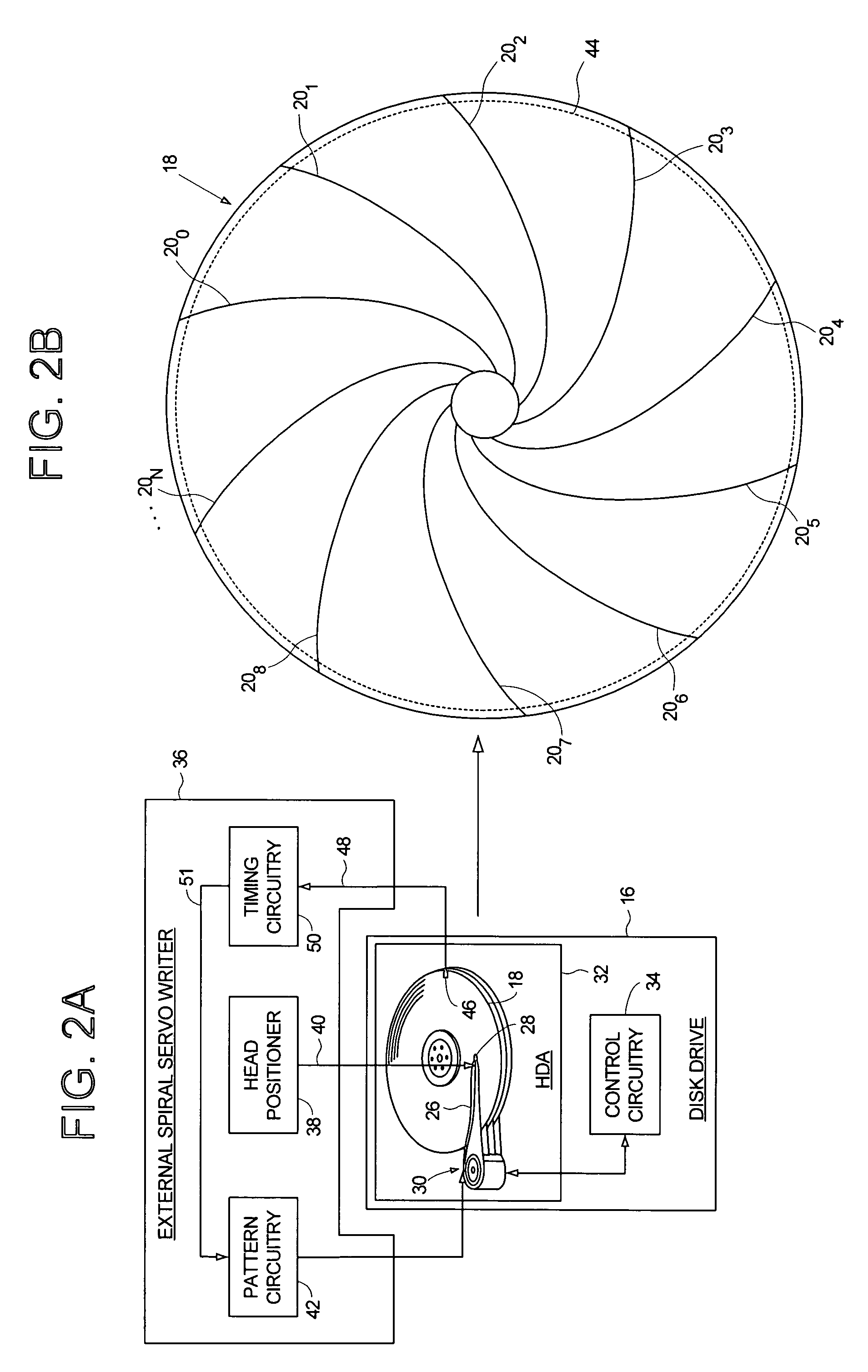

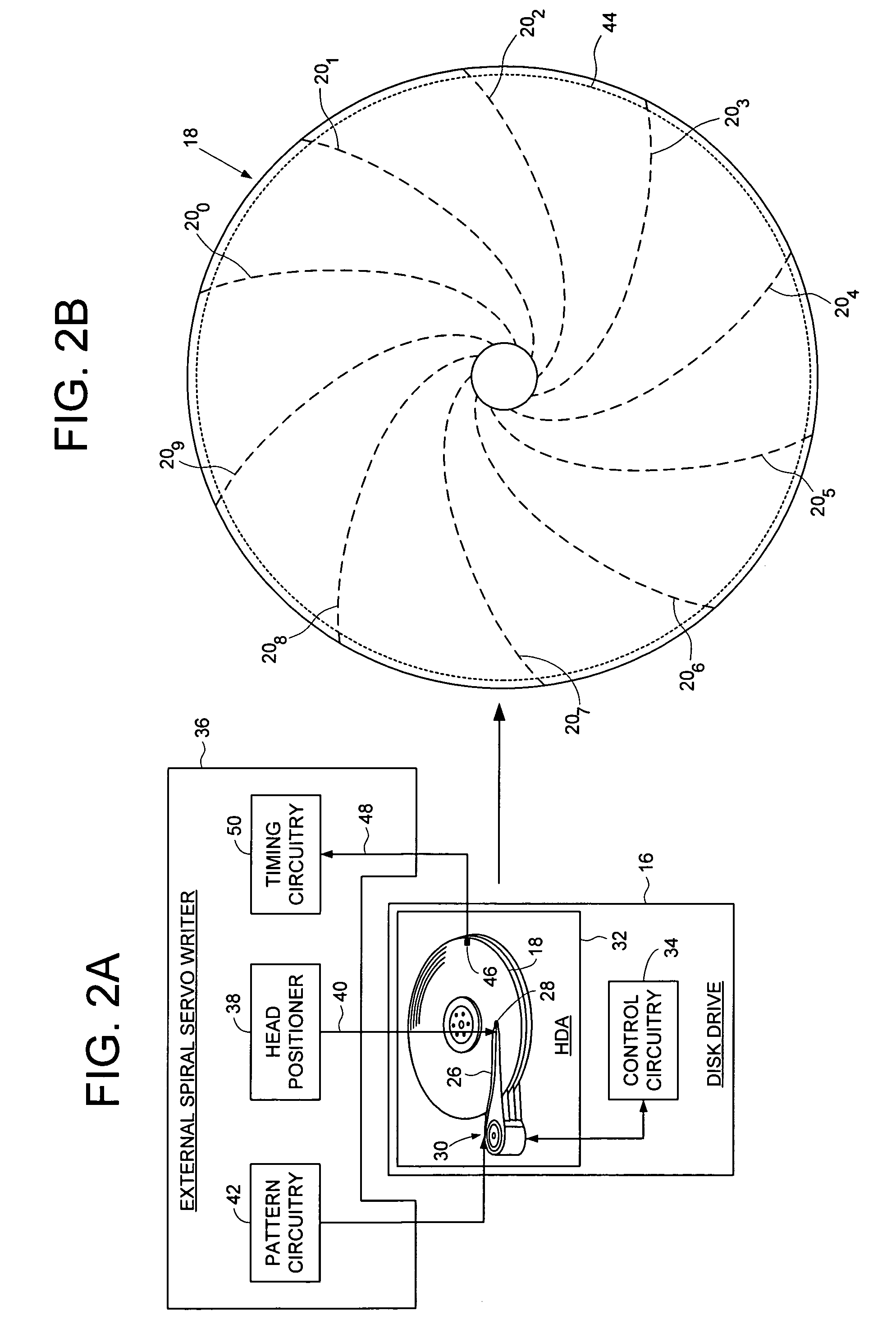

Using an external spiral servo writer to write reference servo sectors and spiral tracks to a disk to facilitate writing product servo sectors to the disk

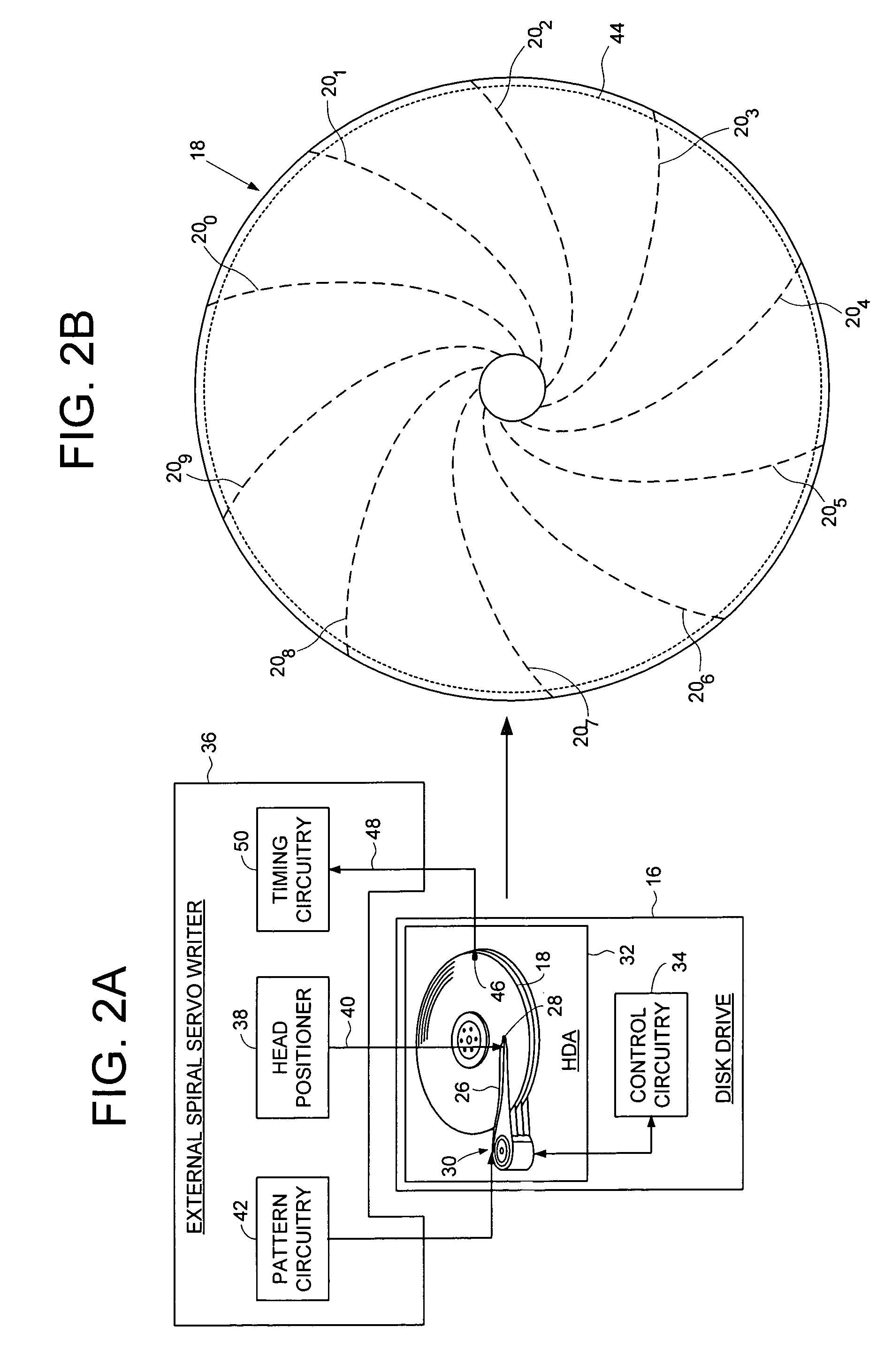

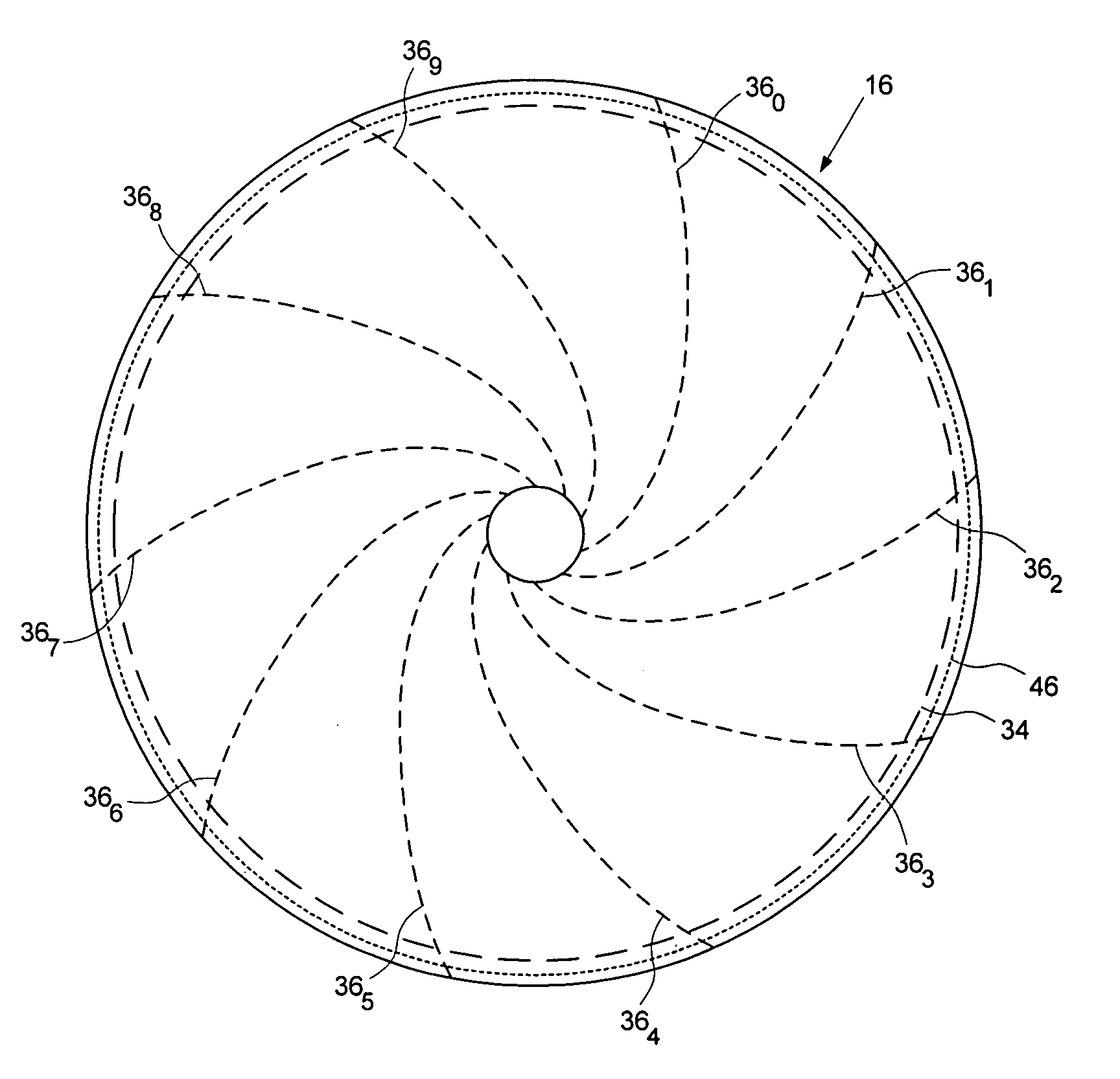

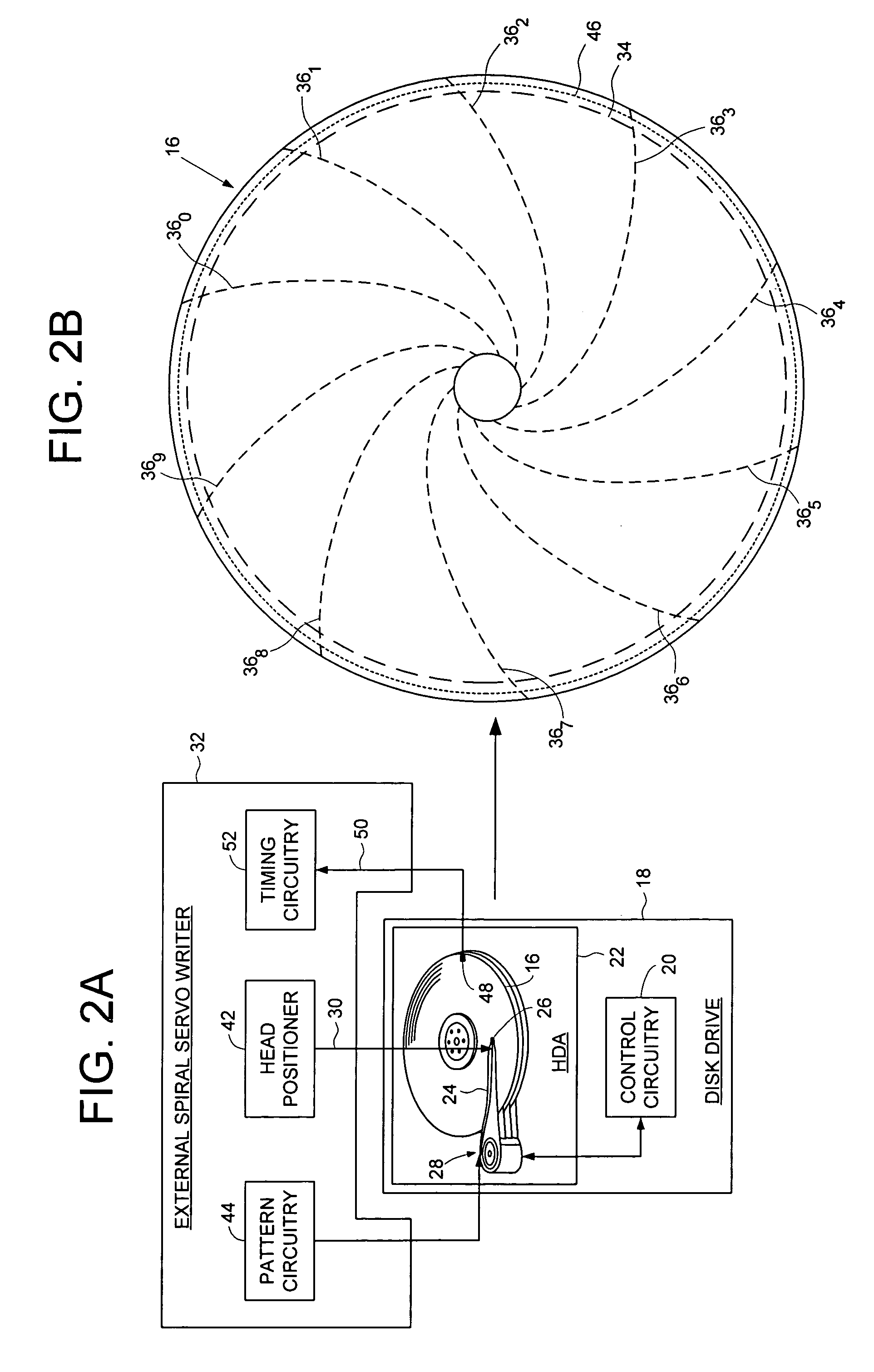

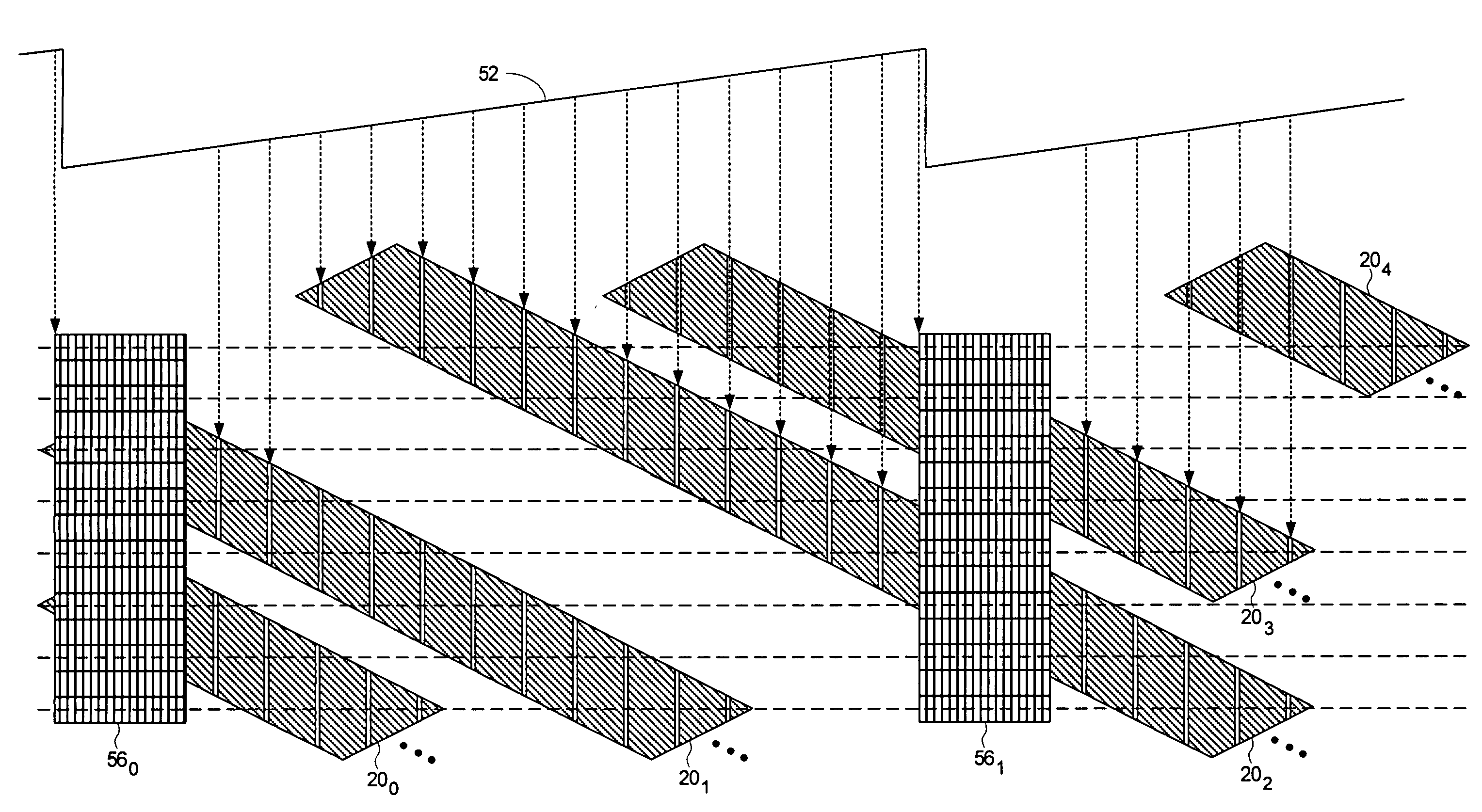

A method of writing product servo sectors to a disk of a disk drive is disclosed. An external spiral servo writer writes a plurality of reference servo sectors at an outer diameter of the disk and a plurality of spiral tracks that spiral from an outer diameter to an inner diameter of the disk. At the beginning of the product servo writing process, the reference servo sectors are demodulated to initially synchronize a servo write clock. The spiral tracks are then demodulated to maintain synchronization of the servo write clock as well as maintain the head along a target circumferential path while writing product servo sectors to the disk.

Owner:WESTERN DIGITAL TECH INC

Adjusting track density by changing PES algorithm when servo writing a disk drive from spiral tracks

InactiveUS7068459B1Driving/moving recording headsRecord information storageTrack densityControl theory

A method and apparatus is disclosed for writing product servo sectors to a disk of a disk drive to define a plurality of data tracks. The disk drive comprises the disk and a head actuated over the disk. The disk comprises a plurality of spiral tracks which are read using the head to synchronize a write clock and to generate a position error signal (PES) according to a PES algorithm used to maintain the head along a first servo track while writing product servo sectors along the first servo track. The PES algorithm is adjusted to seek the head to a second servo track, and the head is used to write product servo sectors along the second servo track.

Owner:WESTERN DIGITAL TECH INC

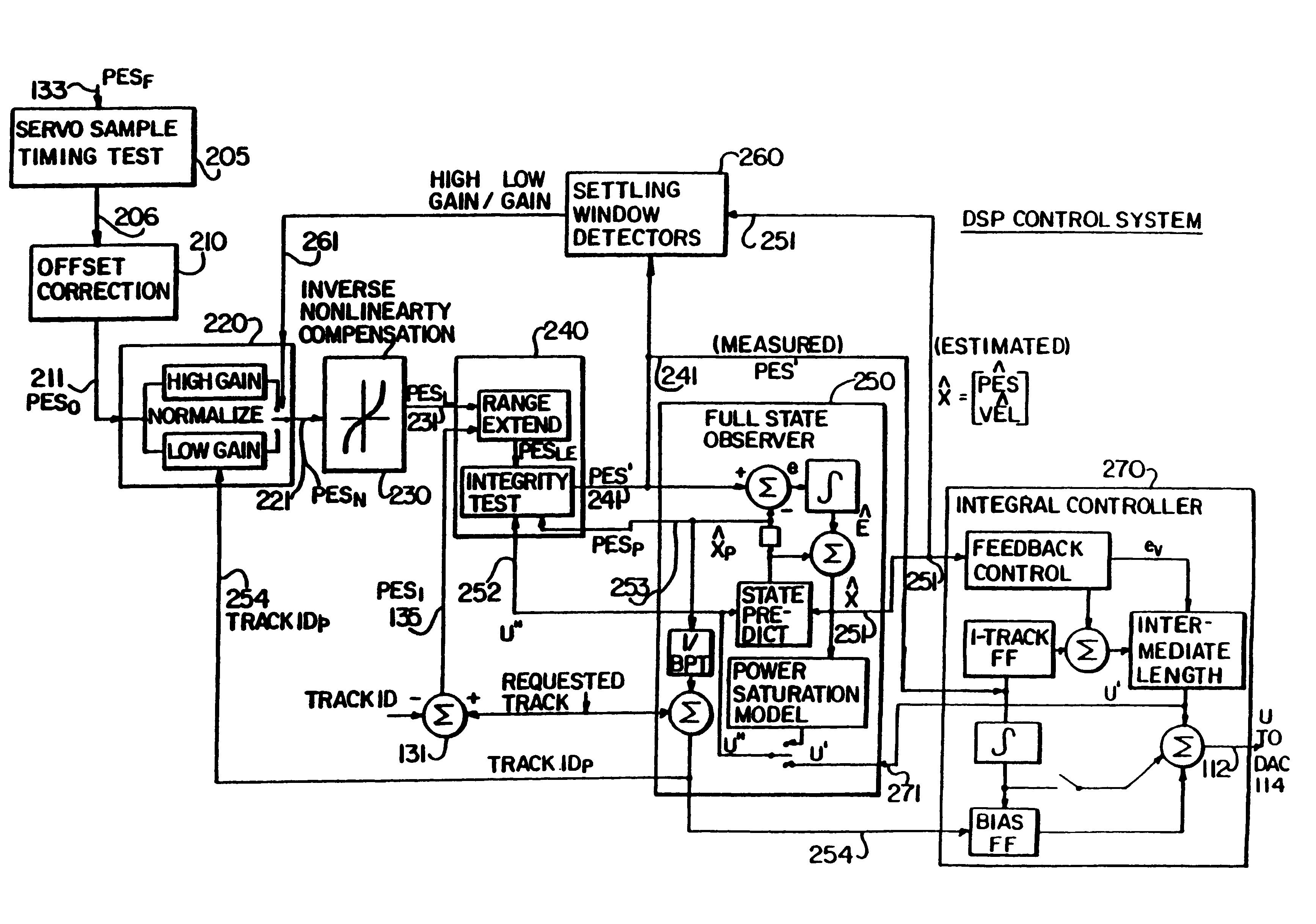

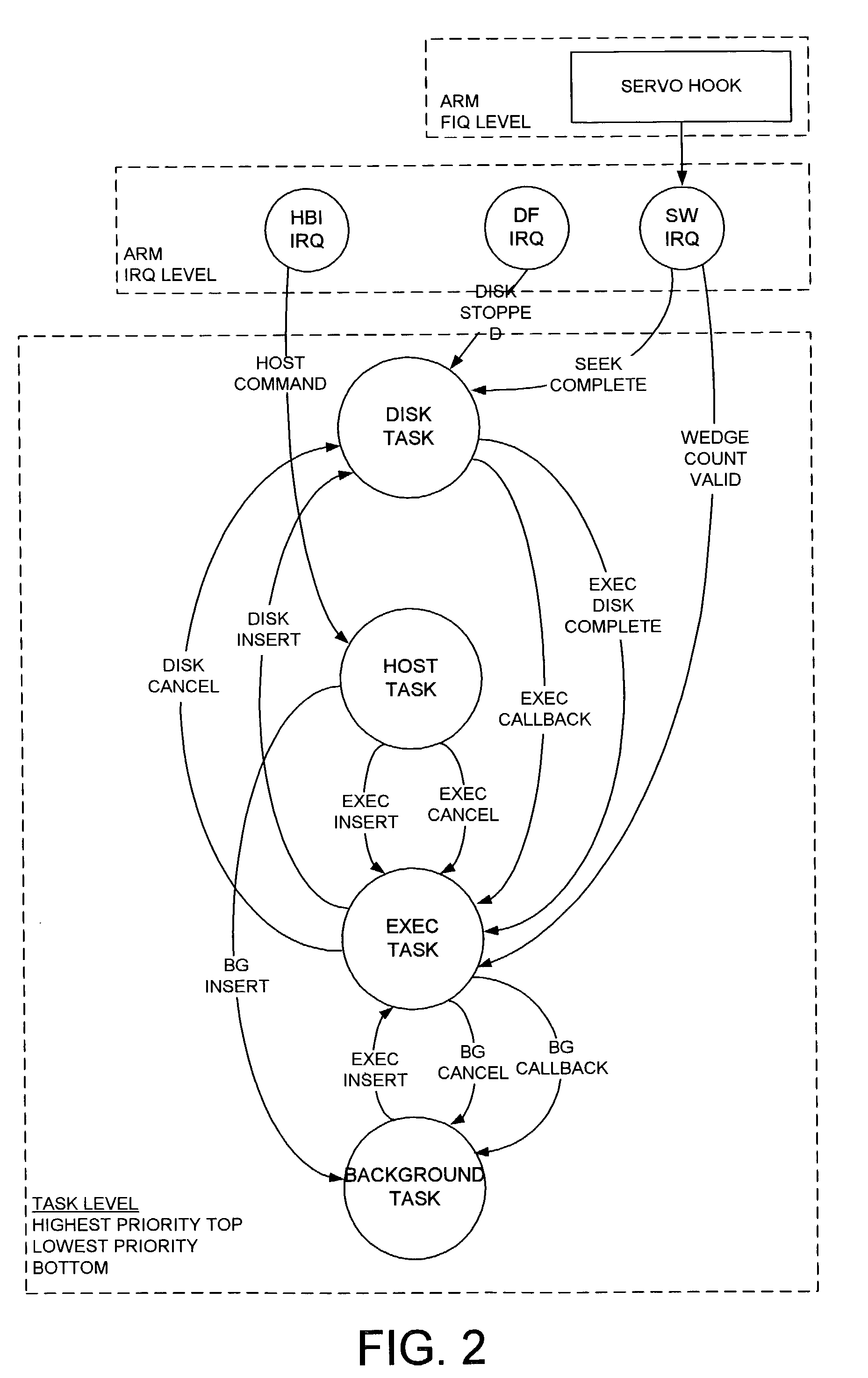

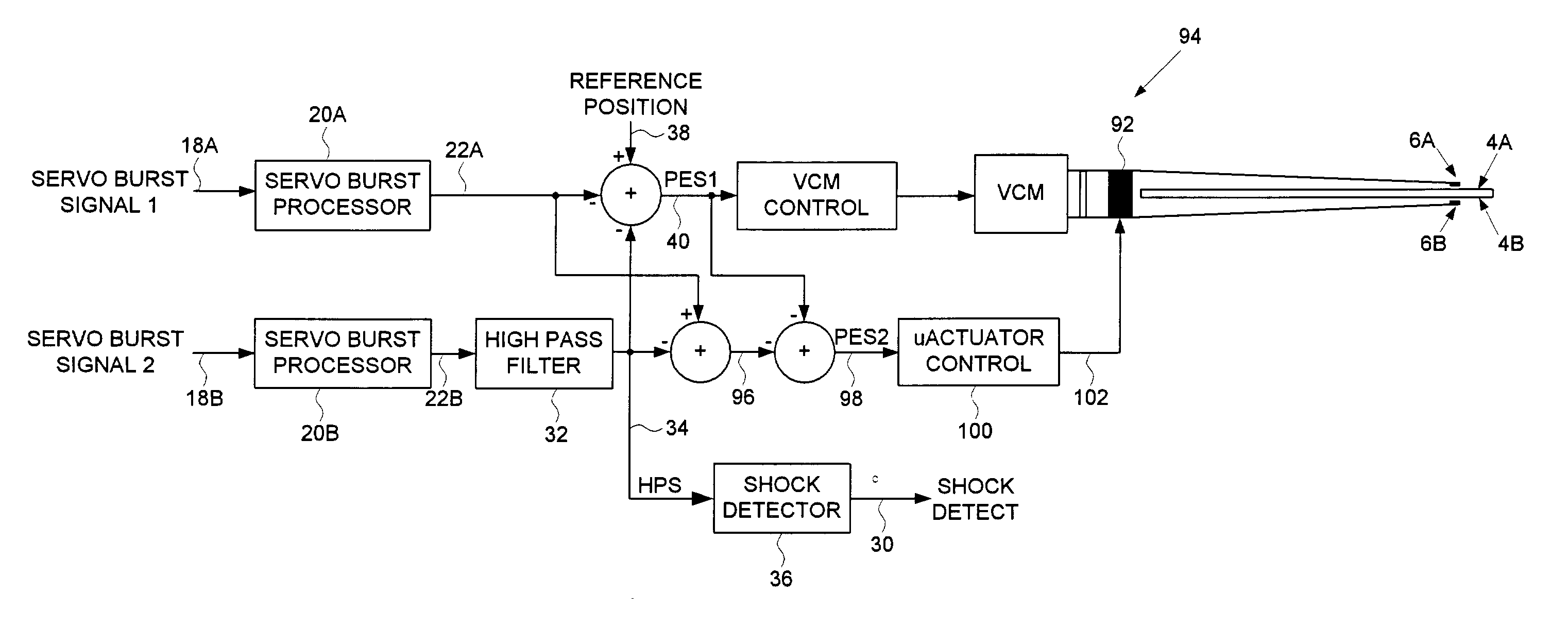

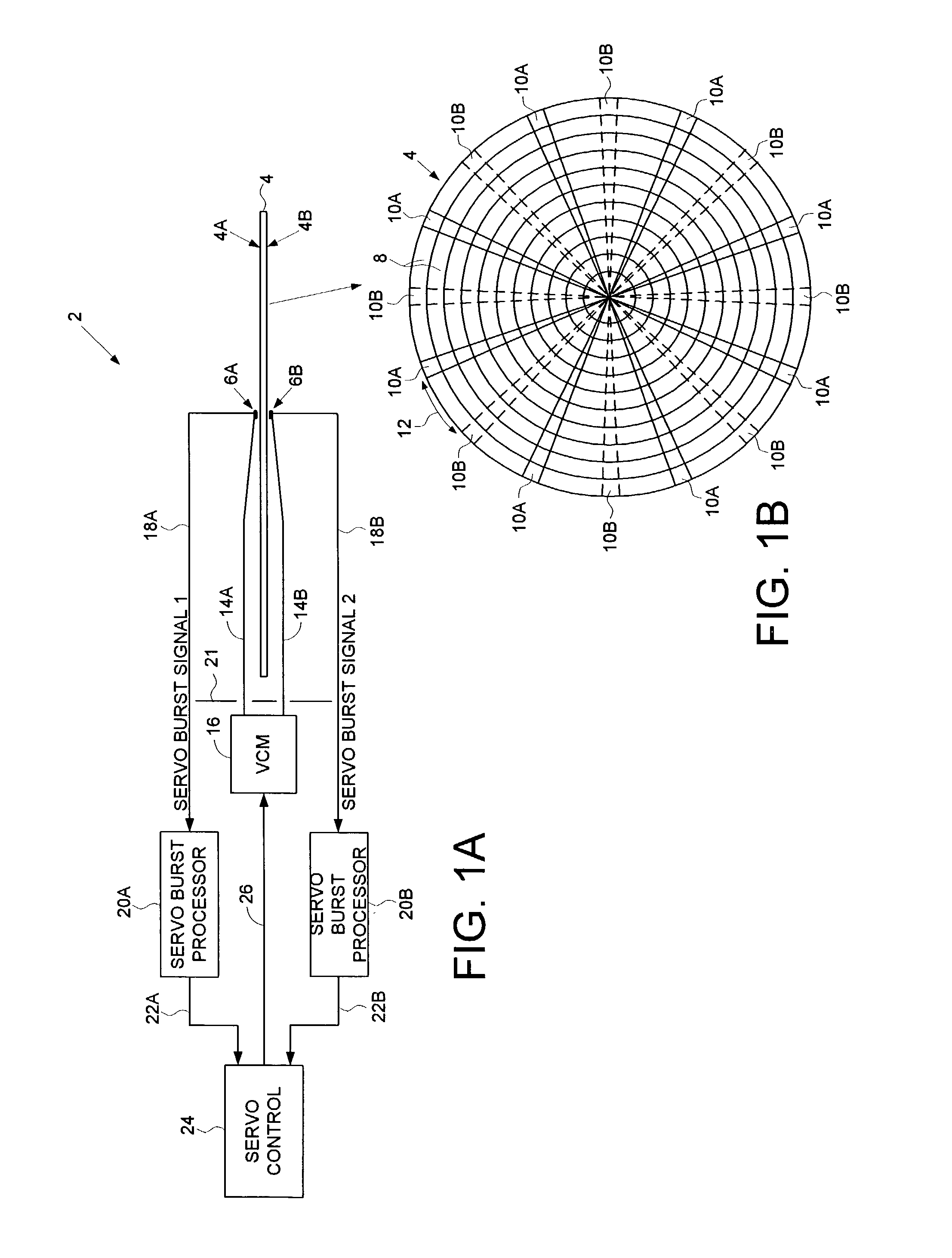

Digital servo control system for use in disk drives

InactiveUS6347018B1Stable trackingSeek efficiencyTrack finding/aligningRecord information storagePretreatment methodControl theory

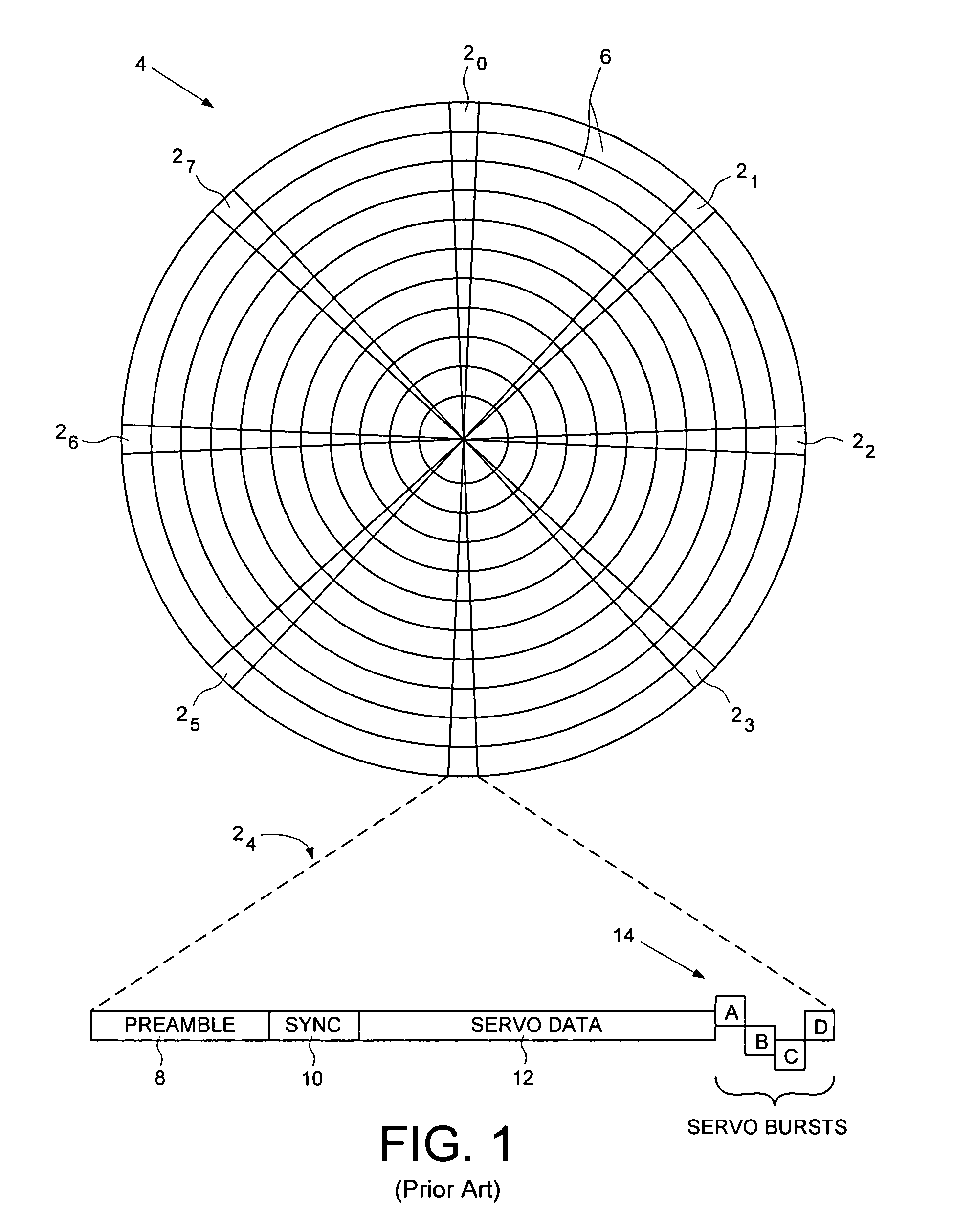

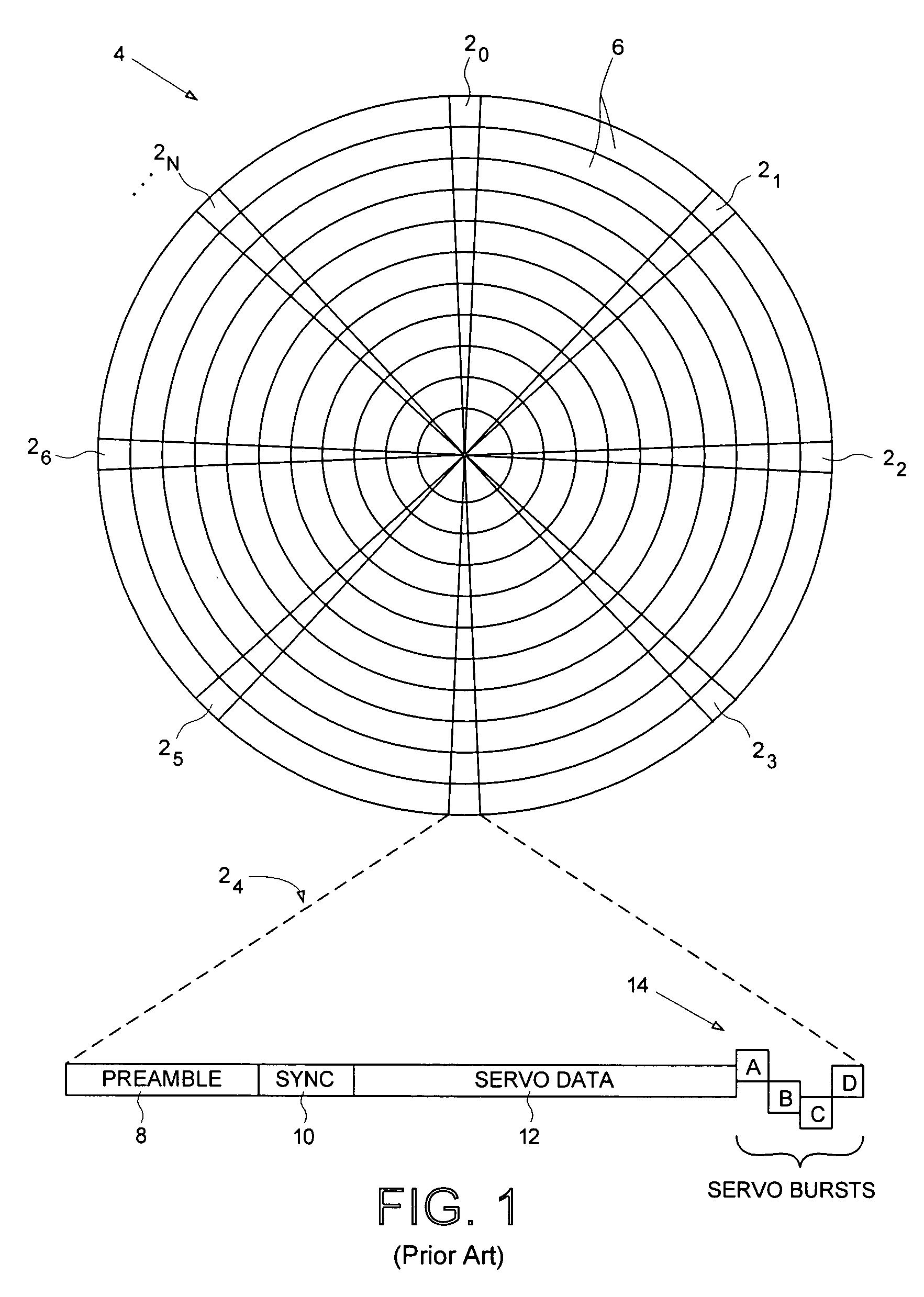

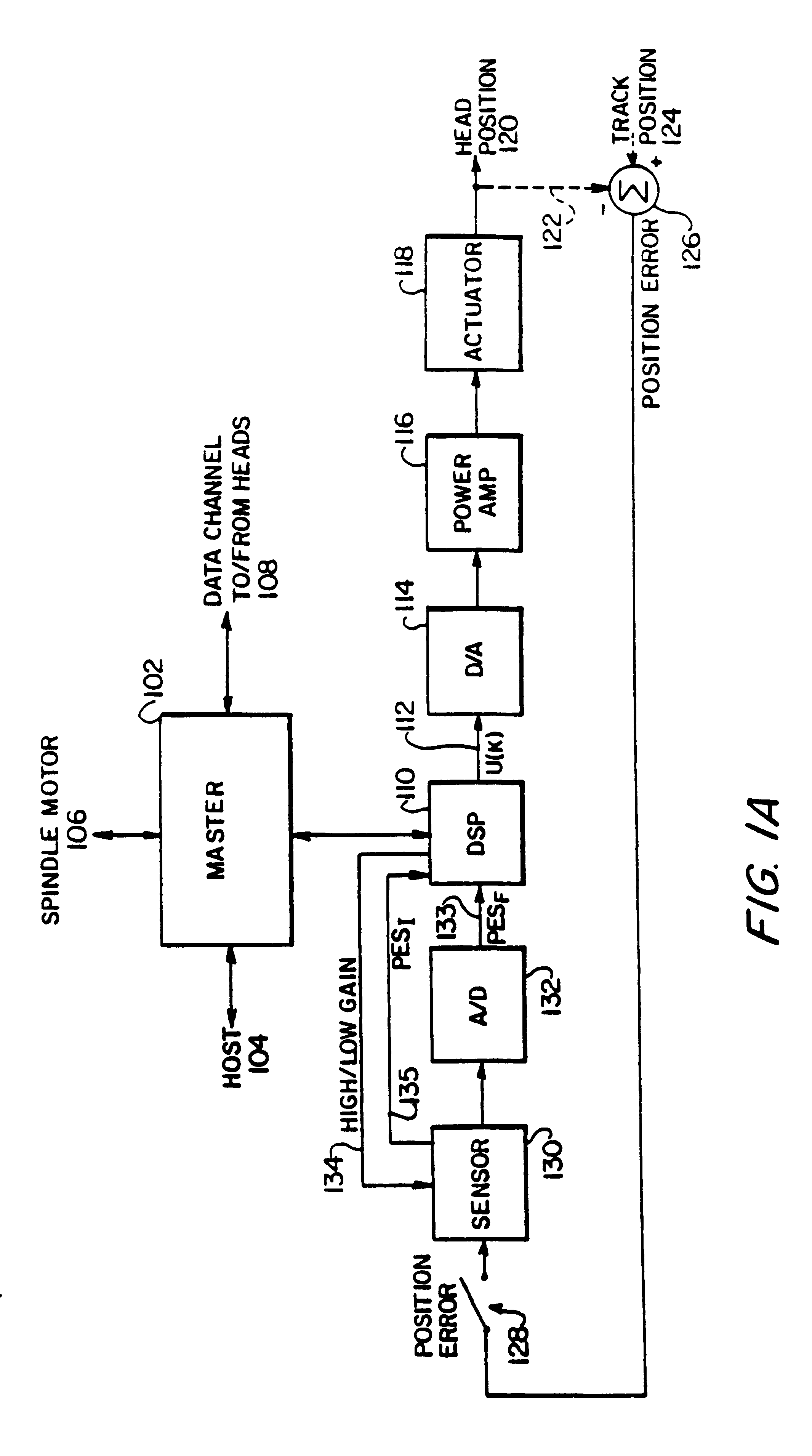

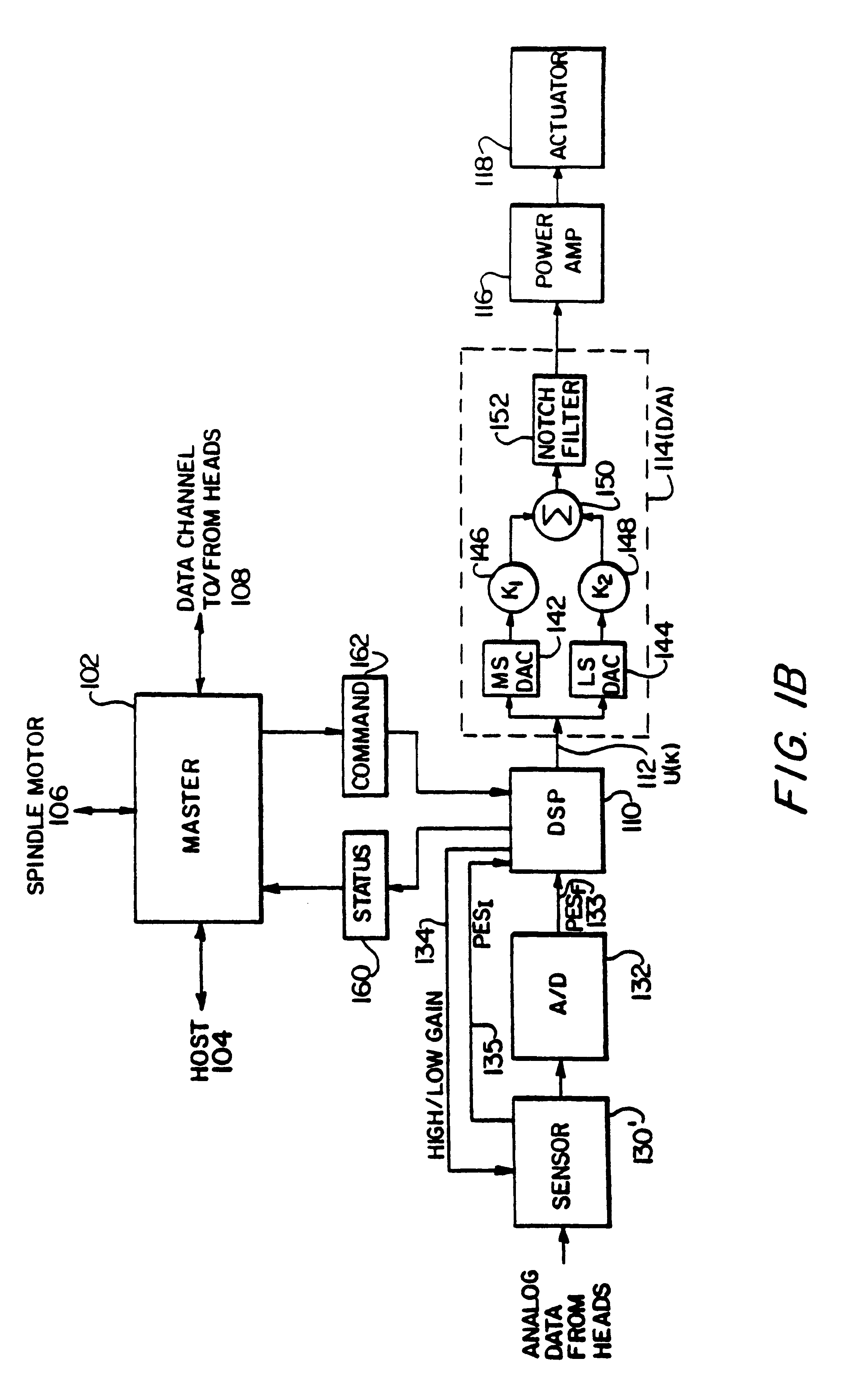

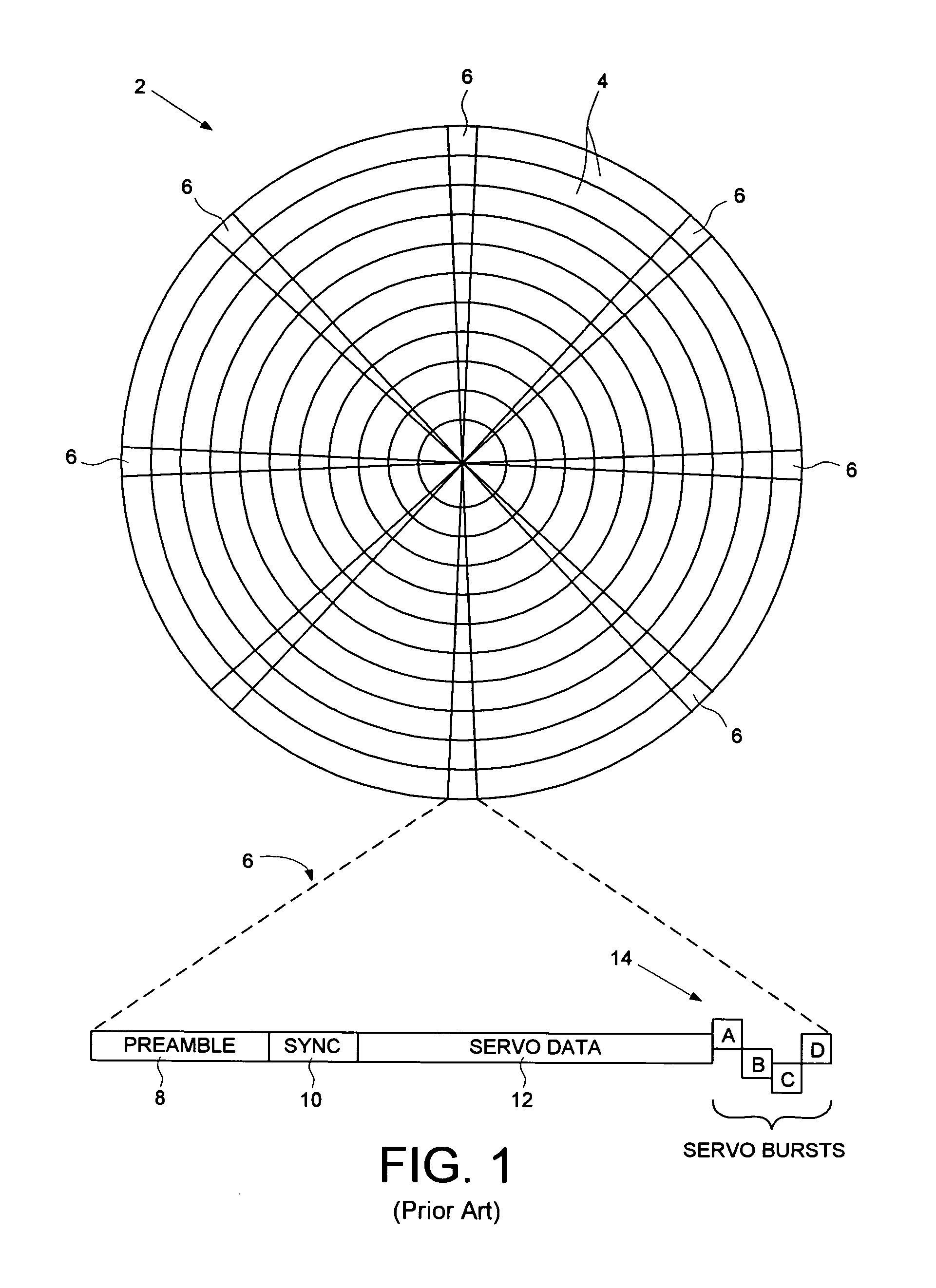

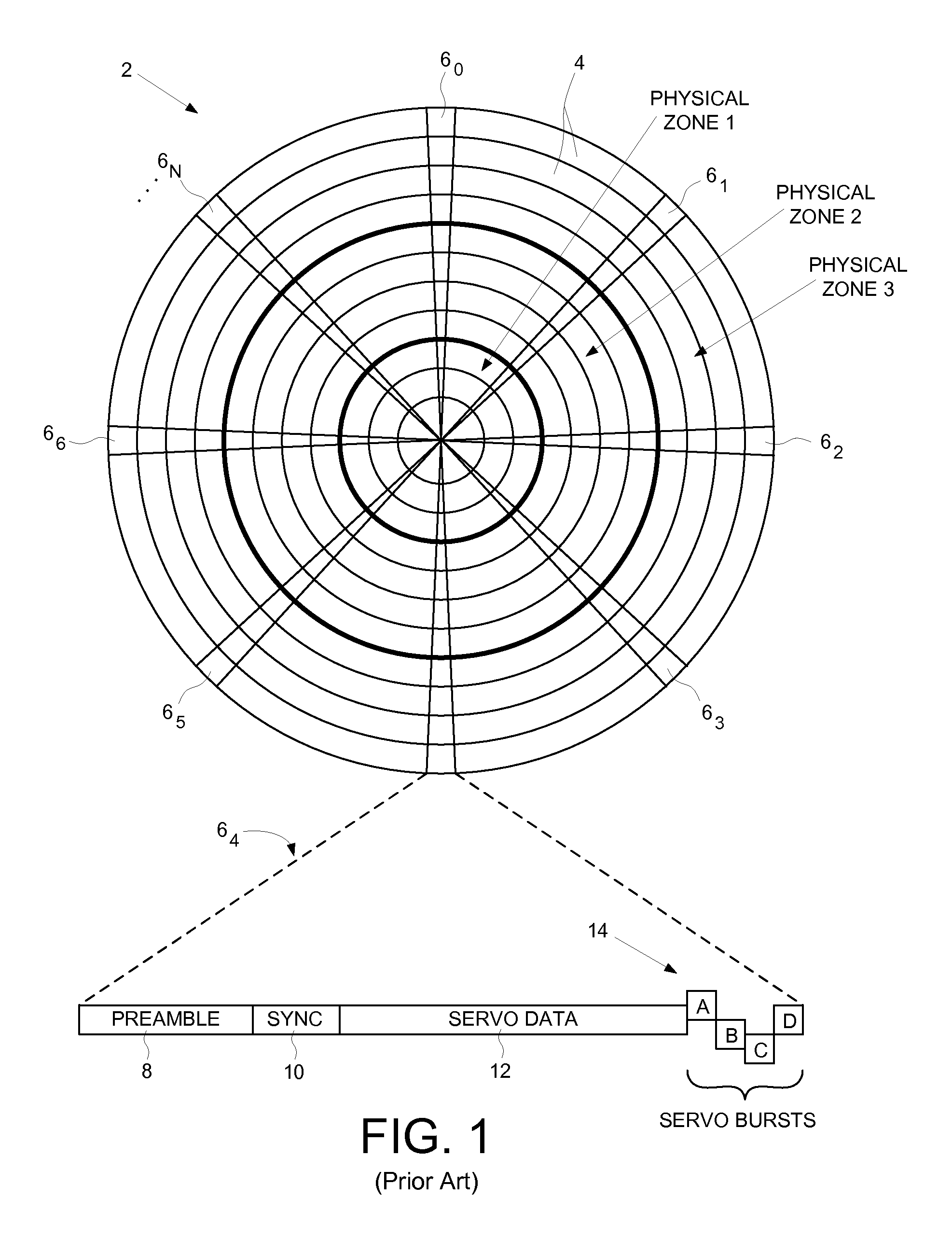

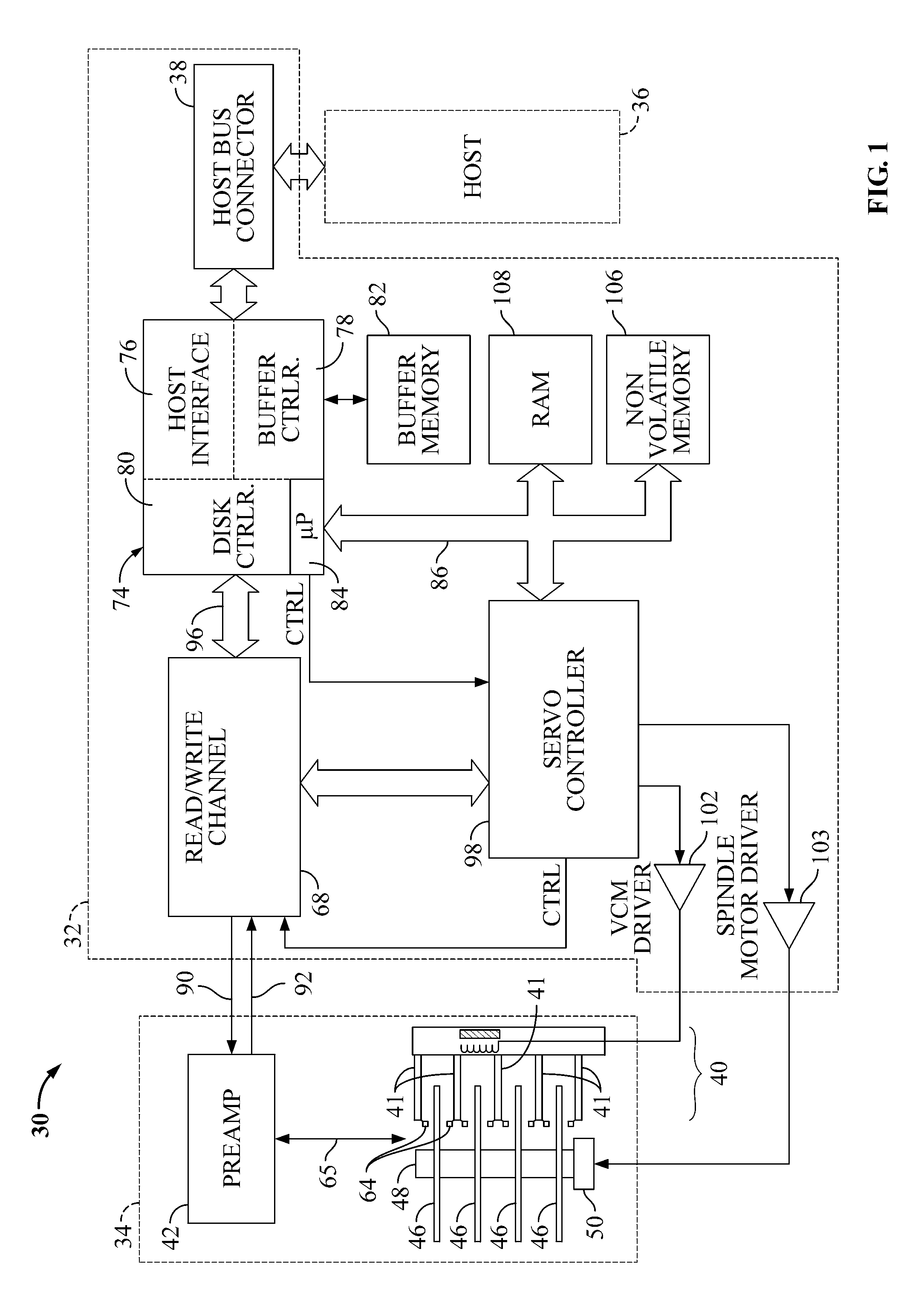

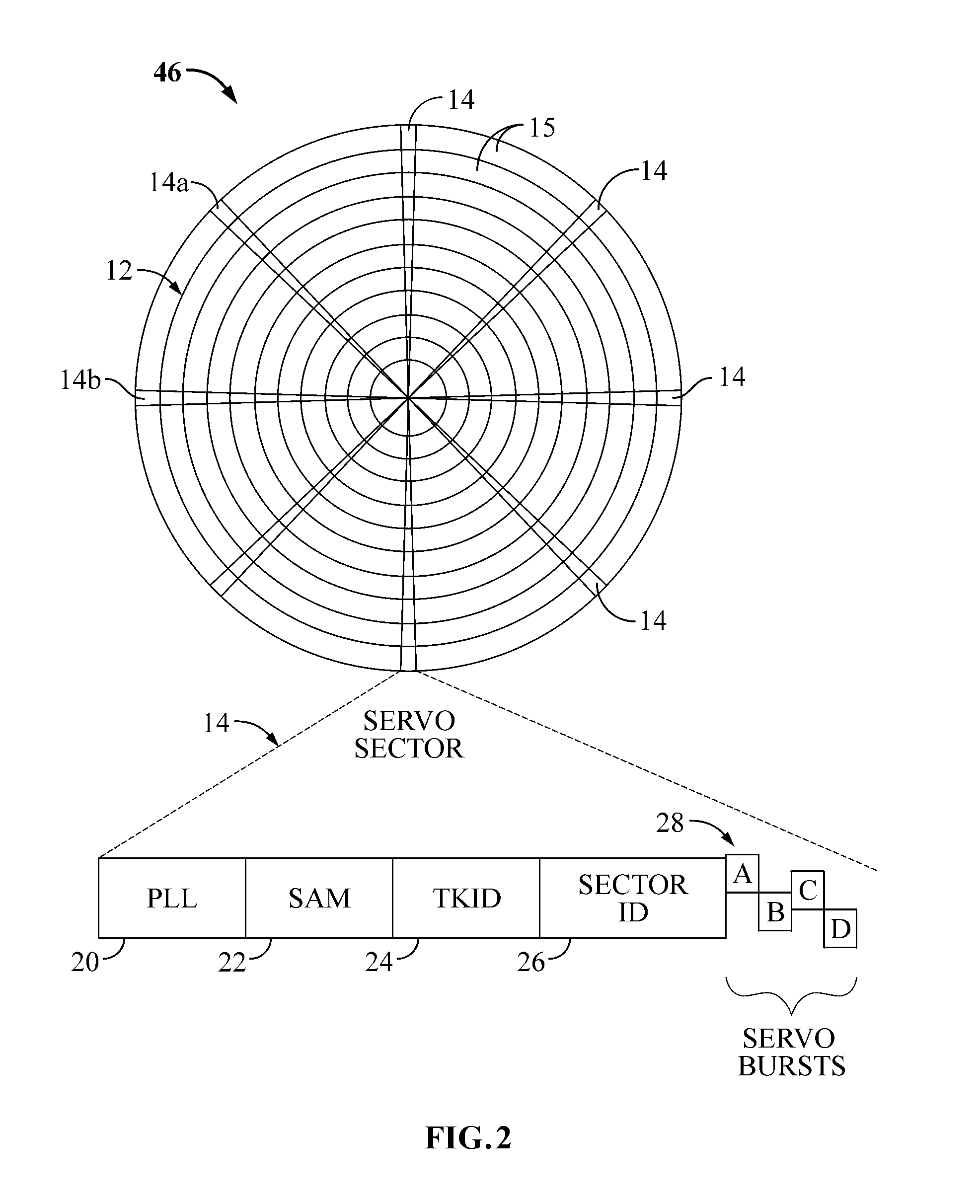

A digital servo control system for disk drives is an "embedded" system-one in which servo control information is embedded on the same disk surface as the user data. In contrast to known embedded-servo systems in which a space-consuming series of many dibit pairs is present, the present system provides only a single dibit pair in a fractional positional error (PESF) area. Thus, the disk drive's read head encounters only a single dibit pair per sample period (or per data sector), thus saving valuable disk space that may be used for user data. Various pre-processing methods may be provided so as to pre-process the measurement derived from the single dibit pair per sample period (or data sector), so as to compensate for non-ideal characteristics of the dibit measurement. The system thus provides an accurate and robust servo control system, while sacrificing a minimum amount of valuable disk space to the servo information field.

Owner:MAXTOR +1

Adjusting track density over disk radius by changing slope of spiral tracks used to servo write a disk drive

InactiveUS6987636B1Steep slopeDriving/moving recording headsRecord information storageTrack densityEngineering

A method and apparatus is disclosed for adjusting the track density over the disk radius by changing the slope of spiral tracks used to servo write a disk drive. A plurality of spiral tracks are written to the disk wherein each spiral track comprises a high frequency signal interrupted at a predetermined interval by a sync mark. A slope of the spiral tracks over a first radial segment of the disk is substantially steeper than the slope of the spiral tracks over a second radial segment of the disk. The head internal to the disk drive is used to read the spiral tracks in order to write product servo sectors to the disk to define a plurality of data tracks. The steeper slope of the spiral tracks over the first radial segment causes a track density of the data tracks to be lower over the first radial segment compared to the track density of the data tracks over the second radial segment.

Owner:WESTERN DIGITAL TECH INC

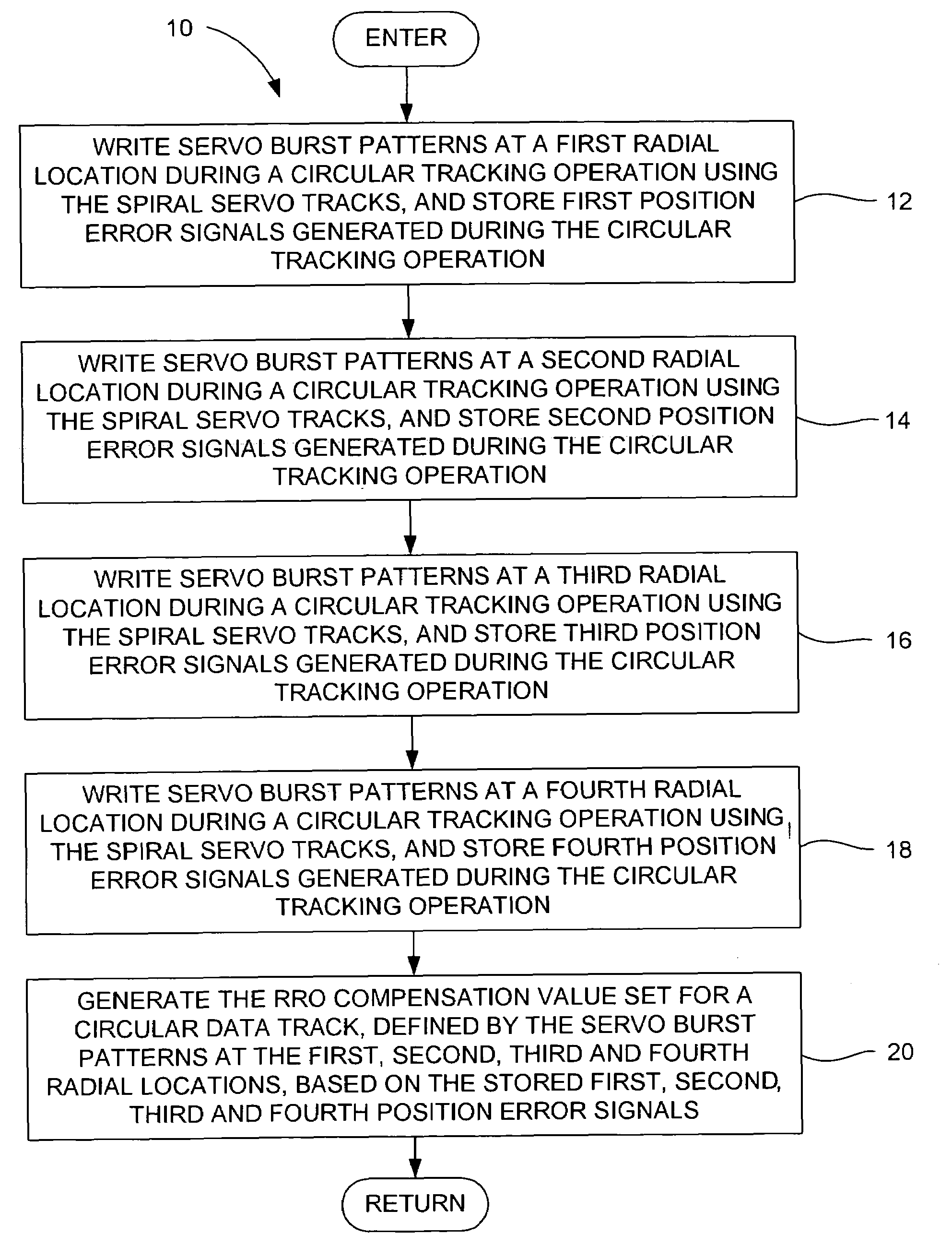

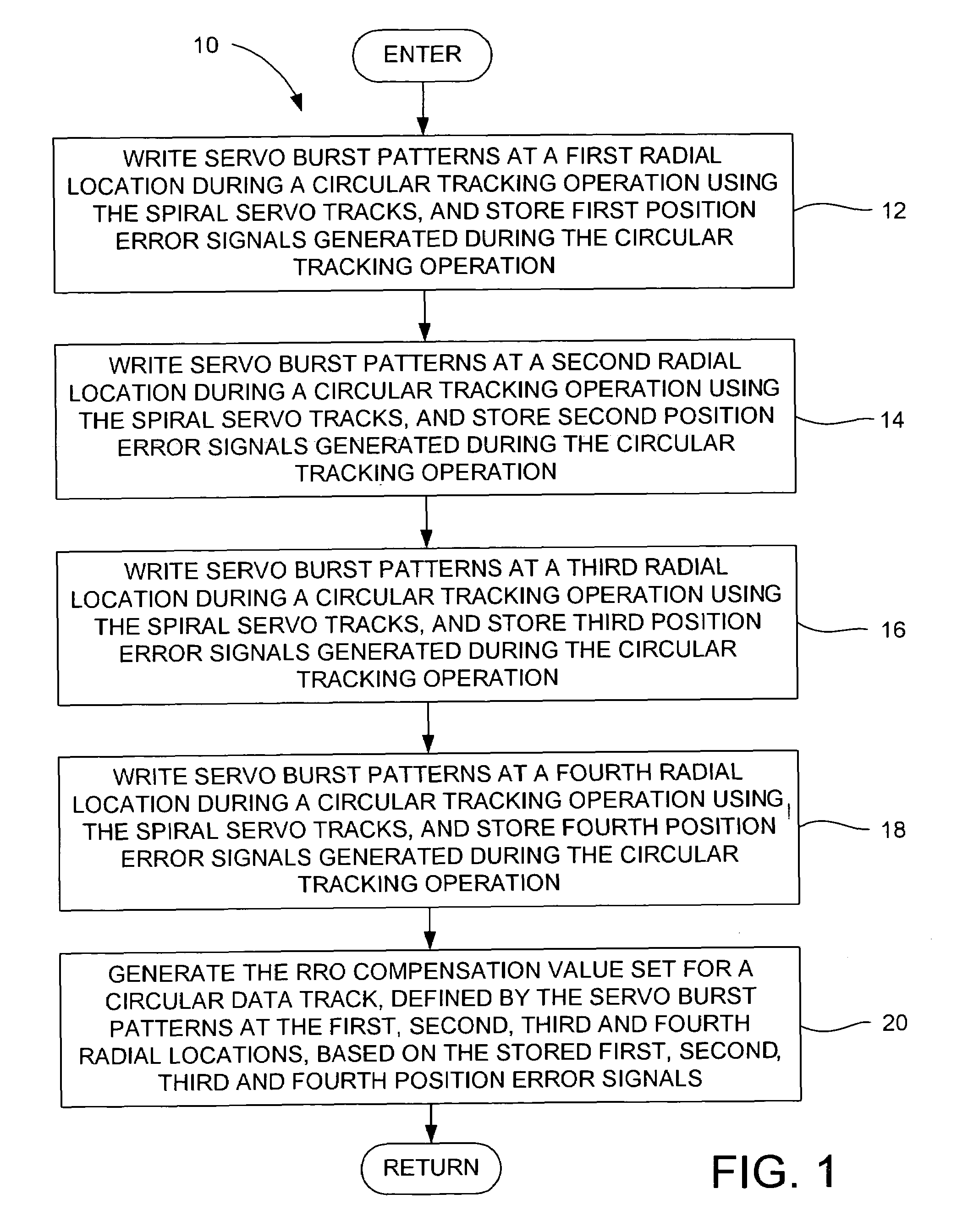

Determining repeatable runout cancellation information using PES information generated during self servo-writing operations

Disclosed is a method for generating a repeatable runout (RRO) compensation value set for a circular track on a magnetic medium on a surface of a disk in a disk drive. The magnetic medium has a plurality of previously written spiral servo tracks for providing position information during a self servo-writing operation. In the method, servo burst patterns are written at a plurality of radial locations on the magnetic data storage surface during circular tracking operations using the spiral servo tracks, and respective position error signals generated during the circular tracking operations are stored. The servo burst patterns at the plurality of radial locations define a circular data track. The RRO compensation value set for the circular data track may be generated based on the respective stored position error signals generated during the circular tracking operations for writing the servo burst patterns at the plurality of radial locations.

Owner:WESTERN DIGITAL TECH INC

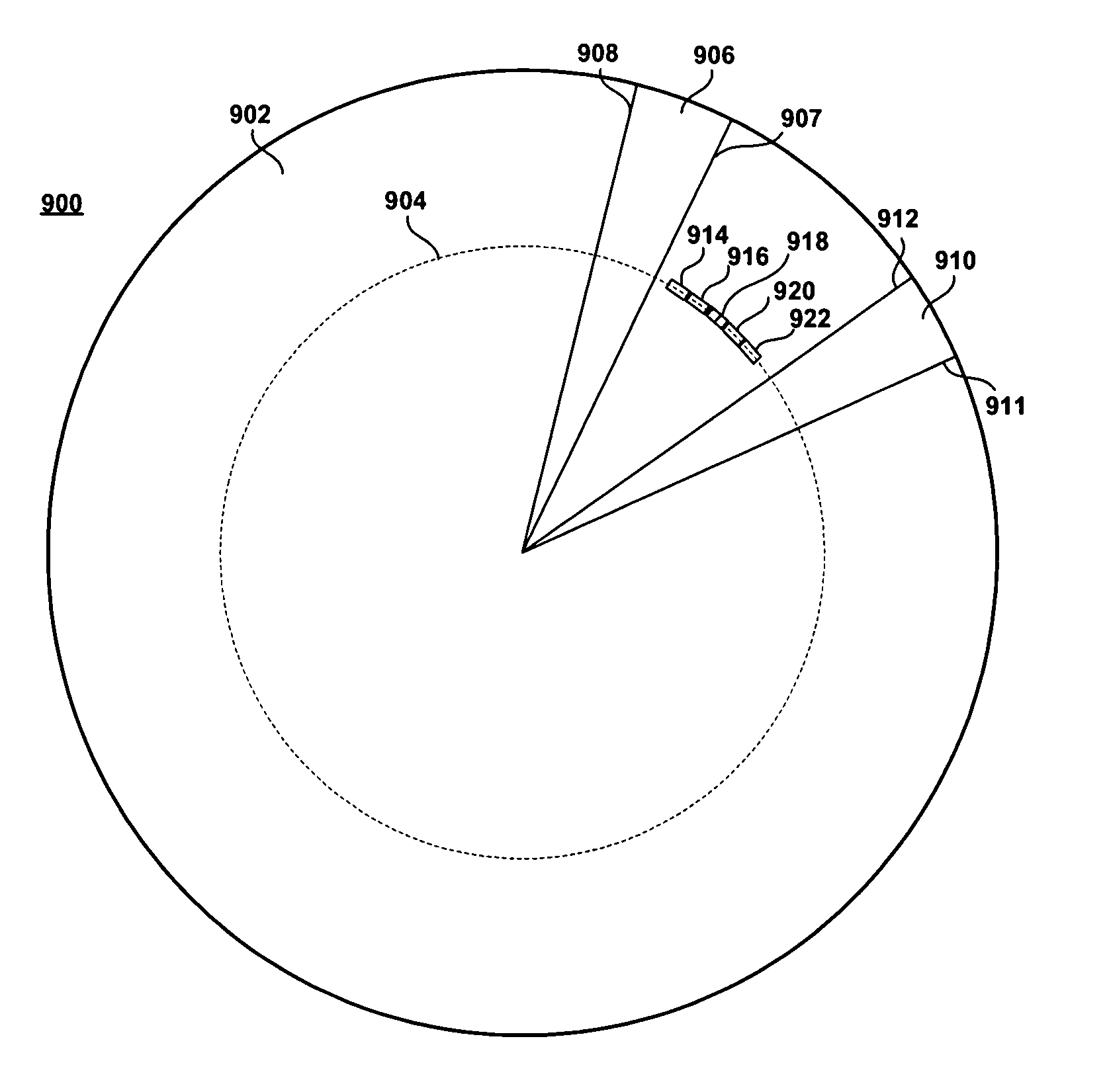

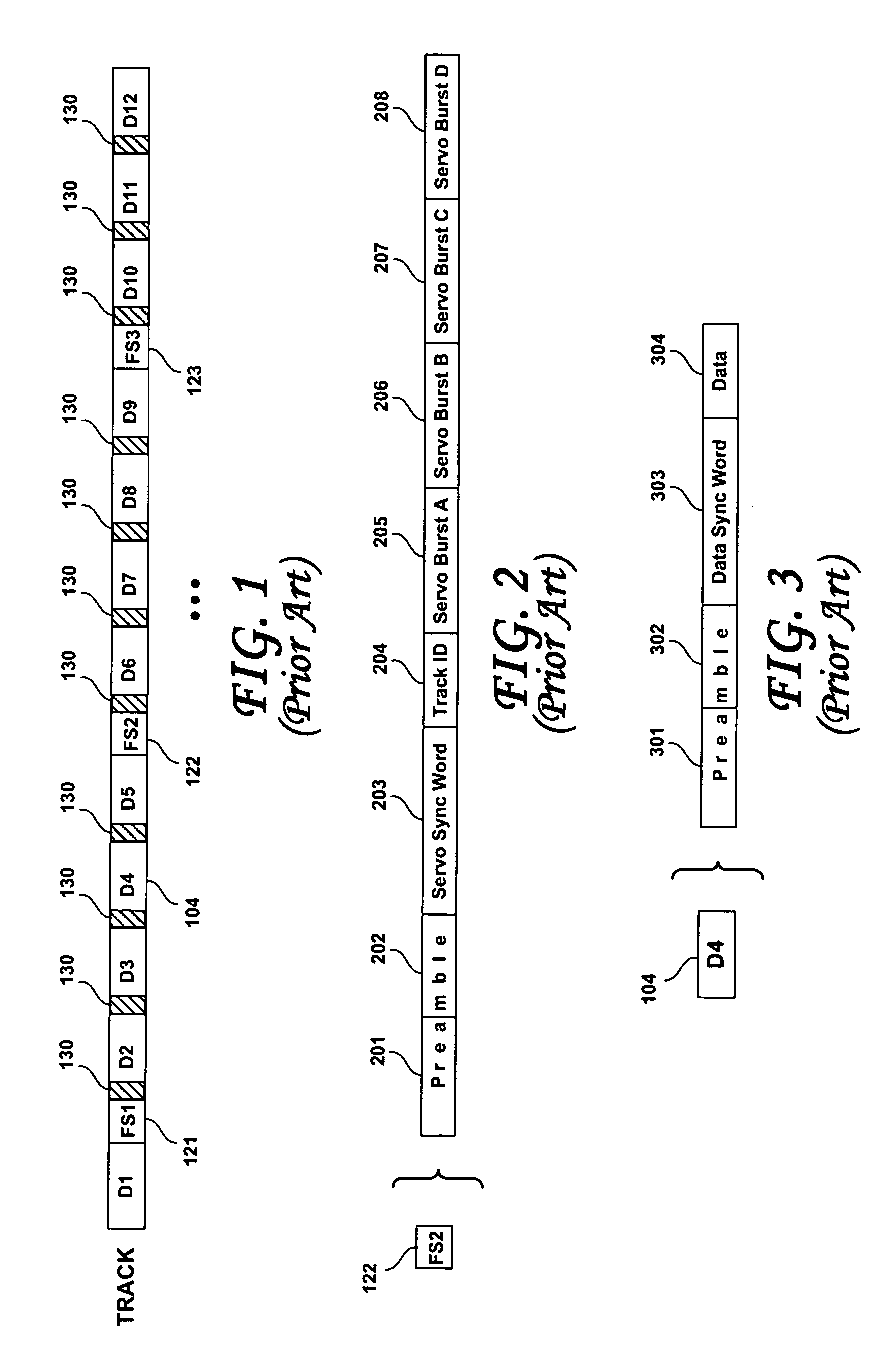

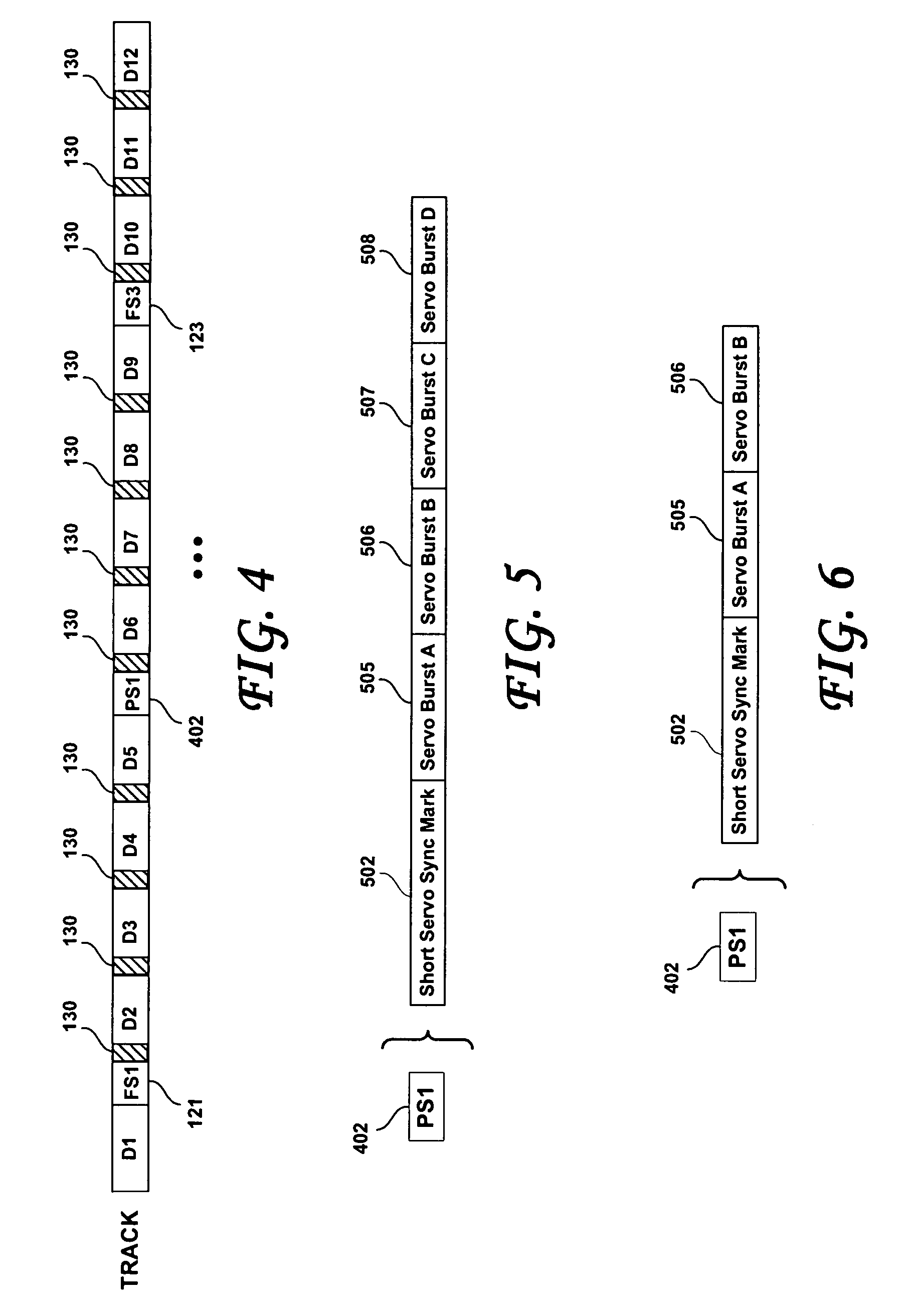

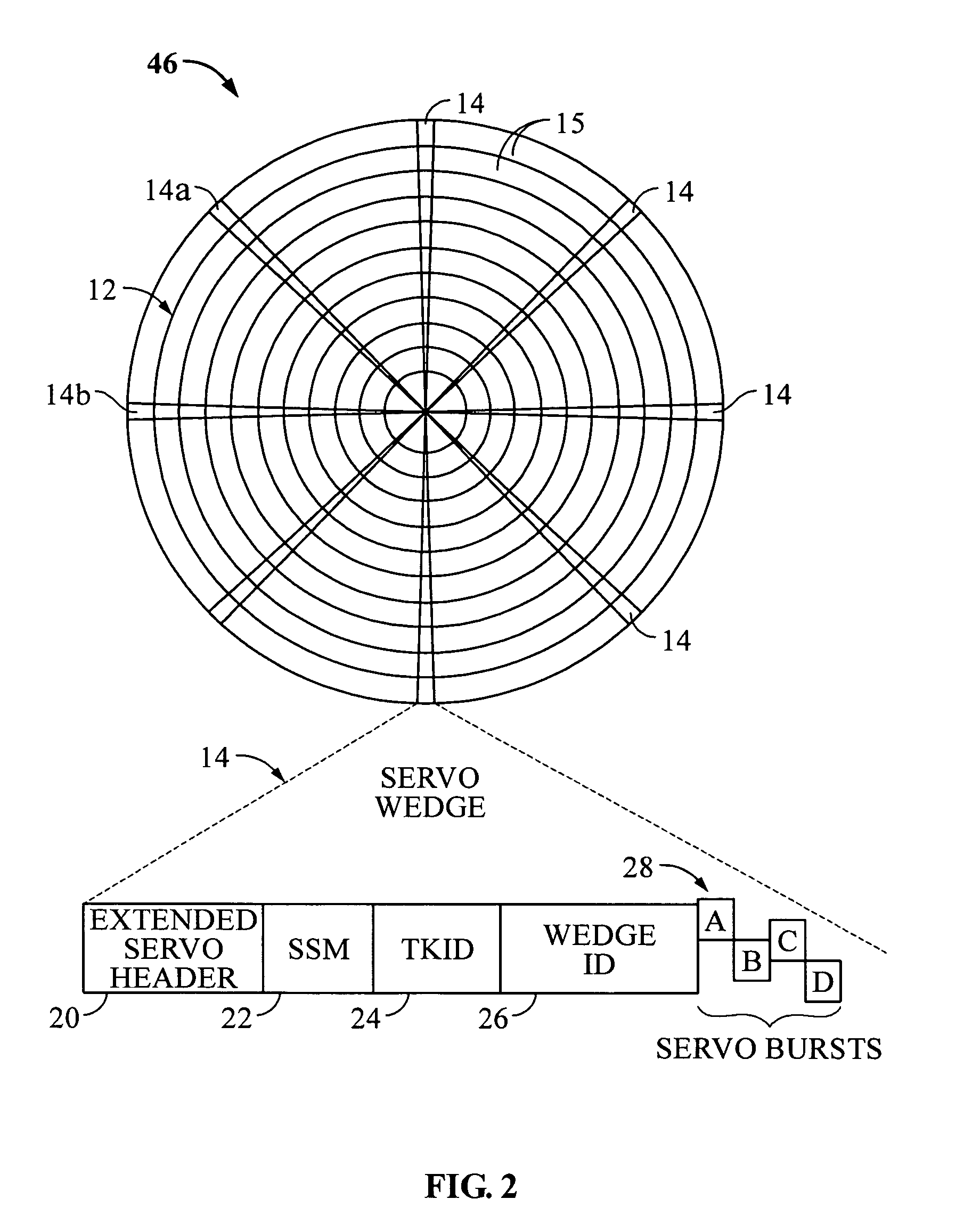

Disk drive having one or more partial servo wedges that includes a short servo sync mark that is different than the servo sync word of full servo wedges

ActiveUS7046465B1Record information storageAlignment for track following on disksEngineeringData location

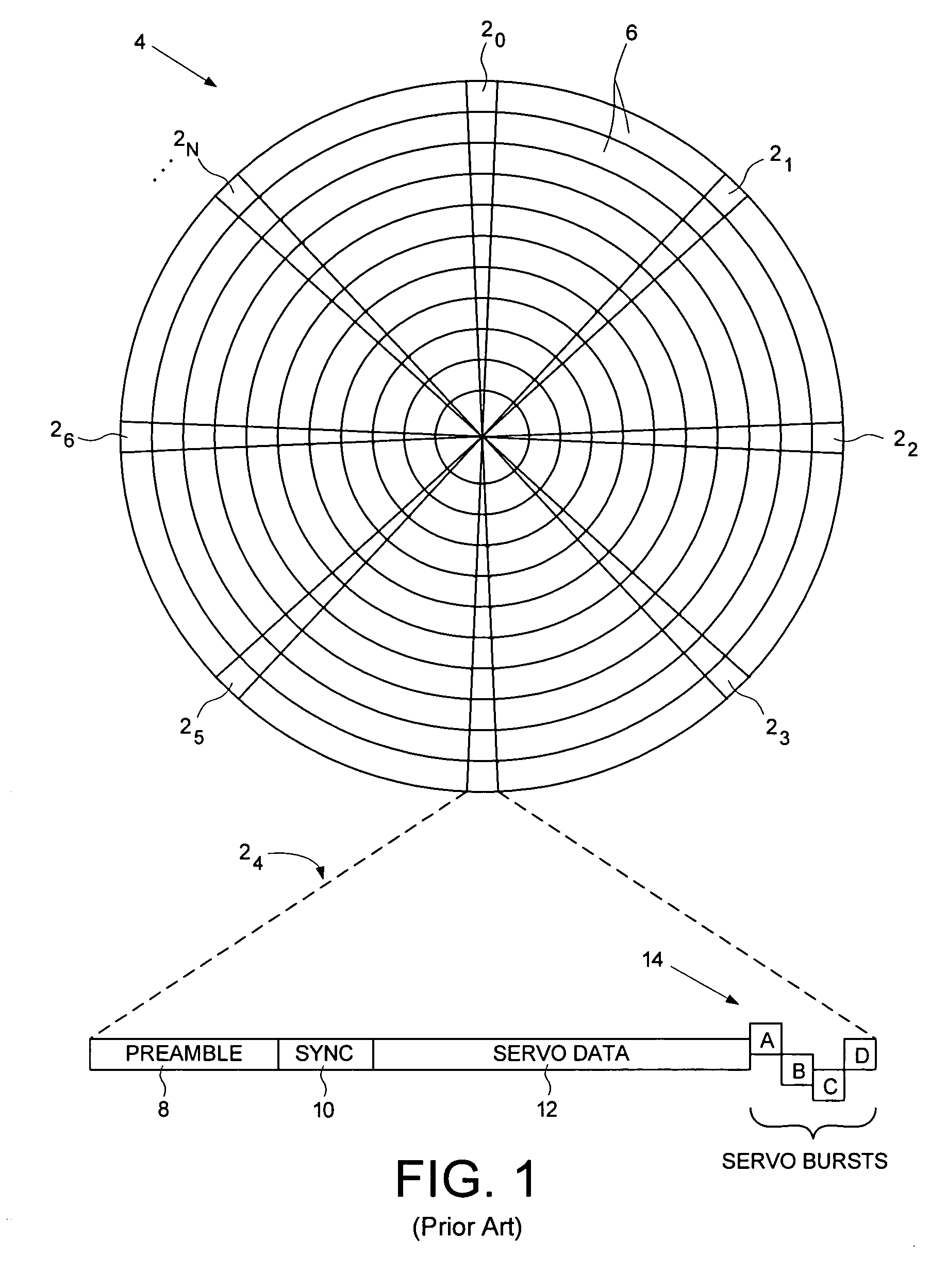

A disk drive has a spindle motor, a disk mounted for rotation on the spindle motor, and a head for reading from and writing to the disk. The disk includes a recording surface having a track that includes a first full servo wedge and a second full servo wedge, each of the first full and second full servo wedges defining a leading end and a trailing end and having, between leading and trailing ends, a preamble, a servo sync word, a track ID, and a plurality of servo positioning burst fields. The recording surface further includes user addressable data locations and a first partial servo wedge disposed between the trailing end of the first full servo wedge and the leading end of the second full servo wedge. The first partial servo wedge is devoid of preamble, track ID and wedge ID and includes a short servo sync mark that is different from the servo sync word. The servo sync mark defines a predetermined bit pattern that is immediately followed by a plurality of servo bursts.

Owner:WESTERN DIGITAL TECH INC

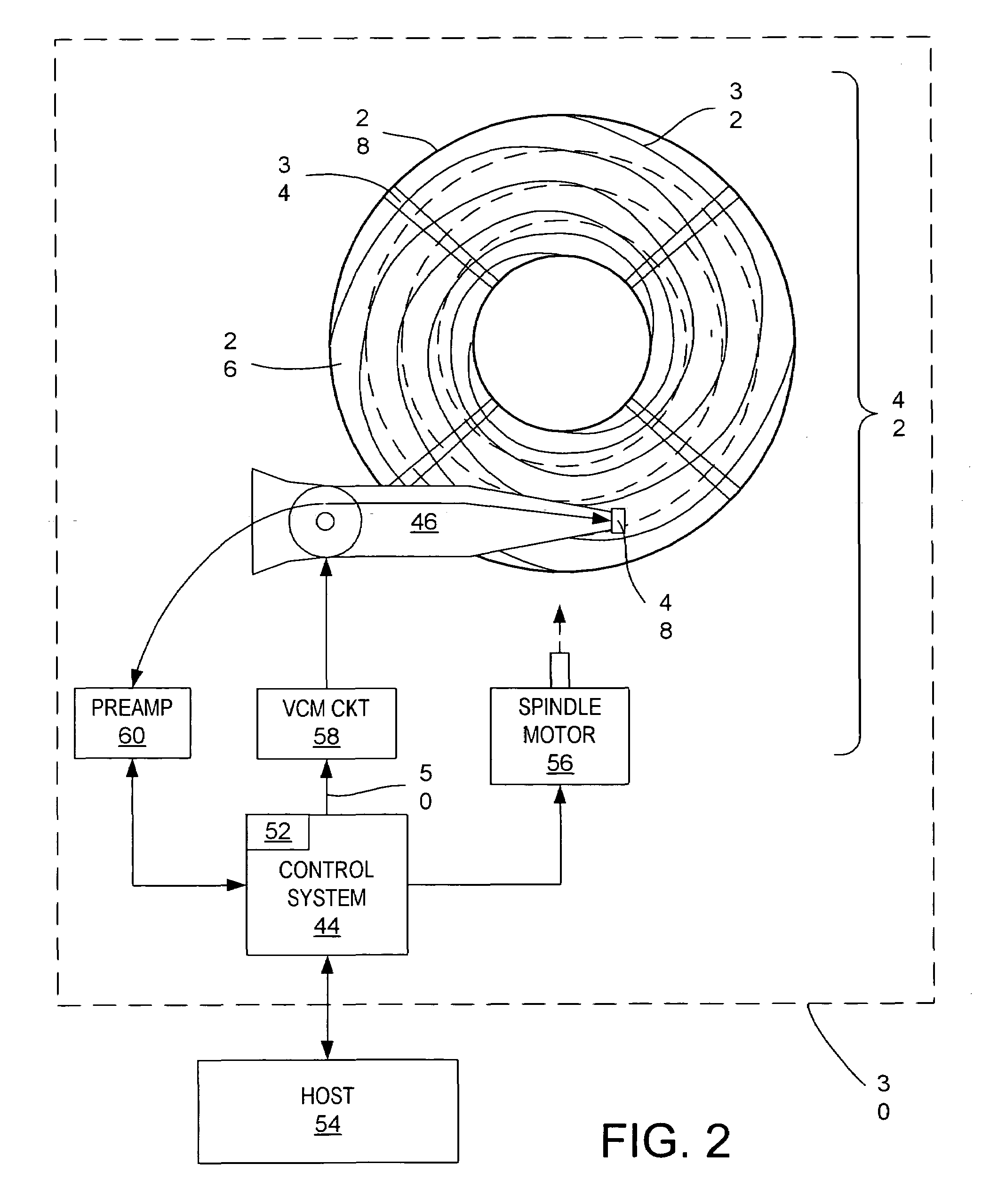

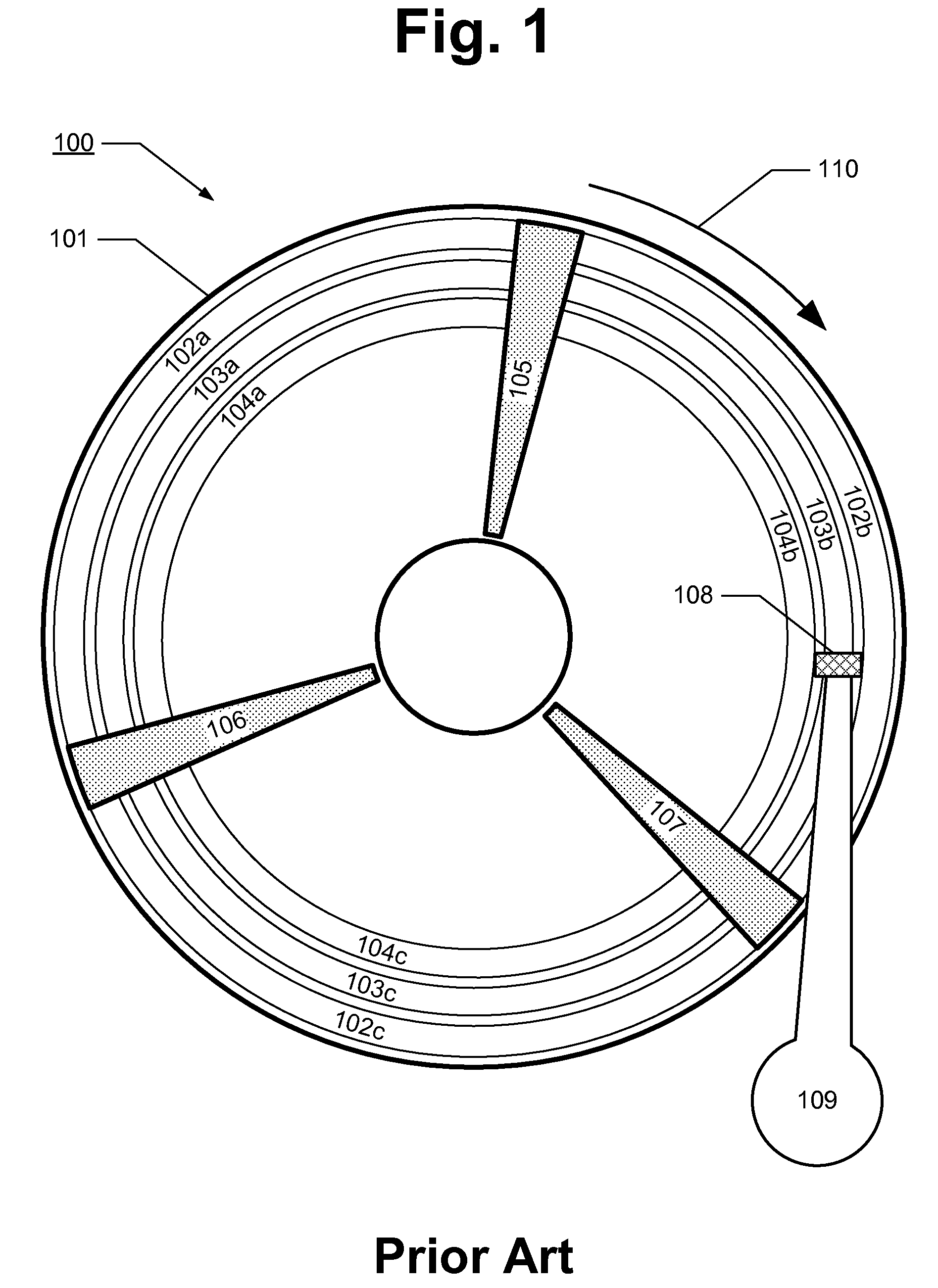

Disk drive for circular self servo writing and spiral self servo writing using prewritten reference servo bursts

InactiveUS6977789B1Driving/moving recording headsRecord information storageImage resolutionControl theory

A disk drive is disclosed comprising a disk and a head actuated radially over the disk. An external servo writer is used to write reference servo bursts to the disk at a coarser radial resolution than product servo bursts. During a self servo writing operation, the reference servo bursts are processed to servo circularly to write a first set of product servo bursts to the disk. The reference servo bursts are also processed to servo spirally to write a second set of product servo bursts to the disk.

Owner:WESTERN DIGITAL TECH INC

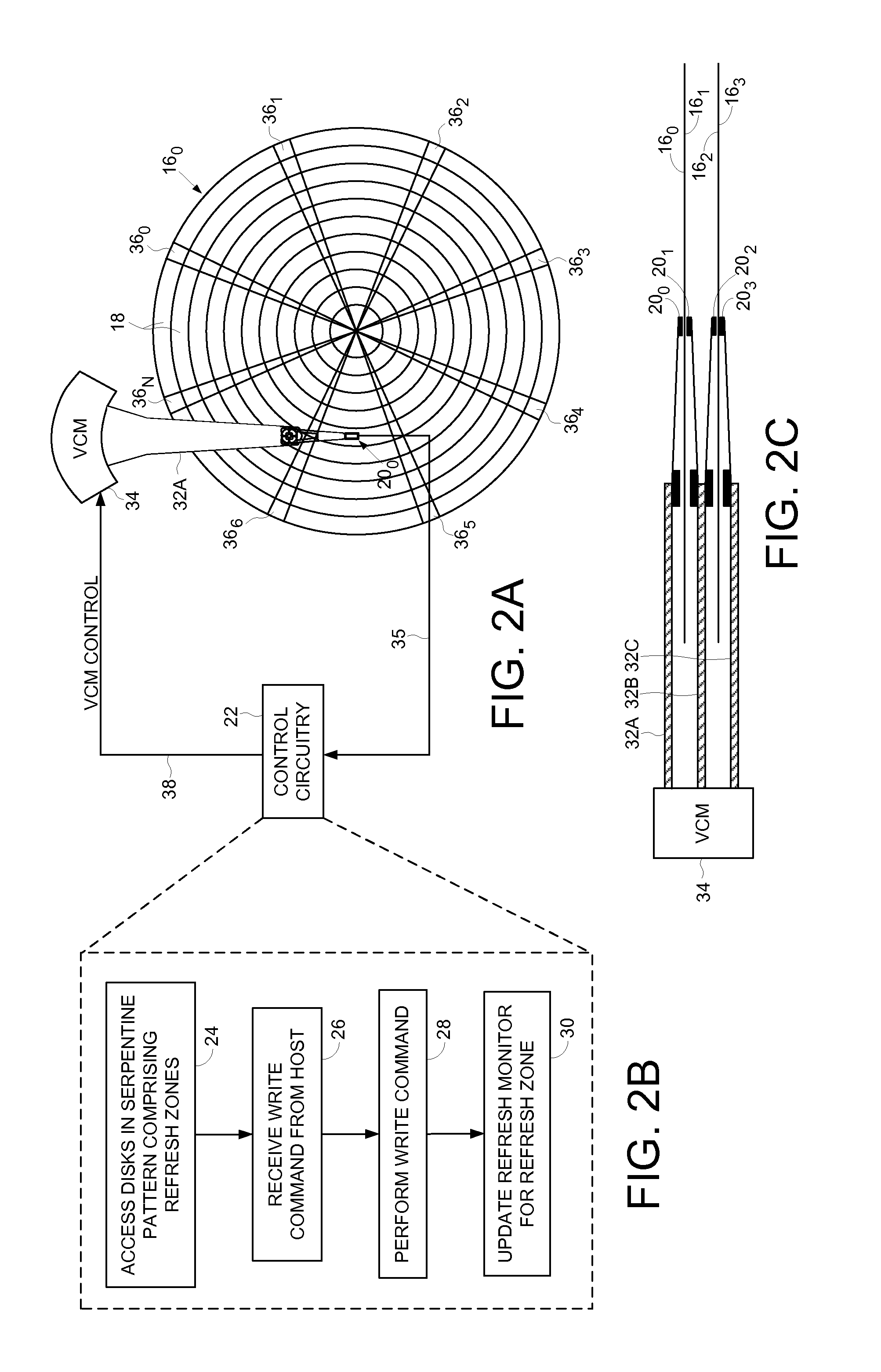

Disk drive refreshing zones based on serpentine access of disk surfaces

Owner:WESTERN DIGITAL TECH INC

Disk drive with method of constructing a continuous position signal and constrained method of linearizing such position signal while maintaining continuity

InactiveUS6369974B1Driving/moving recording headsRecord information storageControl theoryPosition error signal

A method for constructing and linearizing a position error signal (PES) derived from primary and quadrature servo burst pairs in an embedded servo disk drive. The construction method mathematically provides predetermined transition values at the commutation positions connecting adjacent PES segments so that the overall, indicated position signal is numerically continuous from segment to segment. The linearization method compensates for nonlinearity in the PES segments, and thereby in the indicated position signal, without affecting the predetermined transition values at all, or by modifying the predetermined transition values while maintaining continuity.

Owner:WESTERN DIGITAL TECH INC

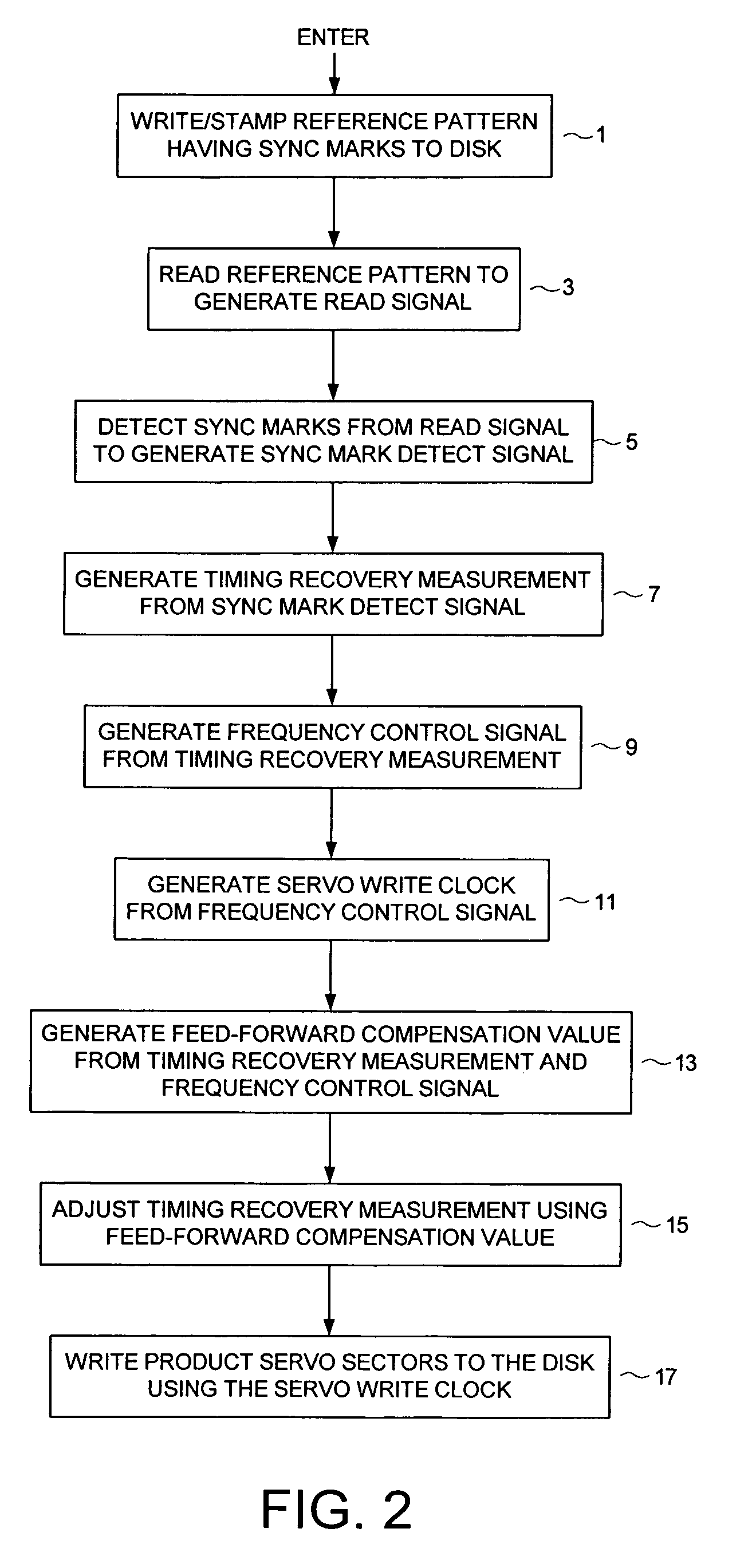

Servo writing a disk drive by synchronizing a servo write clock to a reference pattern on the disk and compensating for repeatable phase error

InactiveUS7333280B1Compensating for such errorDriving/moving recording headsRecord information storageControl signalReference patterns

A method of writing product servo sectors on a disk of a disk drive is disclosed. The disk comprises a reference pattern having a plurality of sync marks written around the disk. The sync marks are detected to generate a sync mark detect signal, and a timing recovery measurement is generated in response to the sync mark detect signal. A frequency control signal is generated in response to the timing recovery measurement, and a servo write clock is generated in response to the frequency control signal. A feed-forward compensation value is generated in response to the timing recovery measurement and the frequency control signal, and the timing recovery measurement is adjusted in response to the feed-forward compensation value to compensate for a repeatable phase error in the timing recovery measurement. The servo write clock and the head internal to the disk drive are used to write the product servo sectors to the disk.

Owner:WESTERN DIGITAL TECH INC

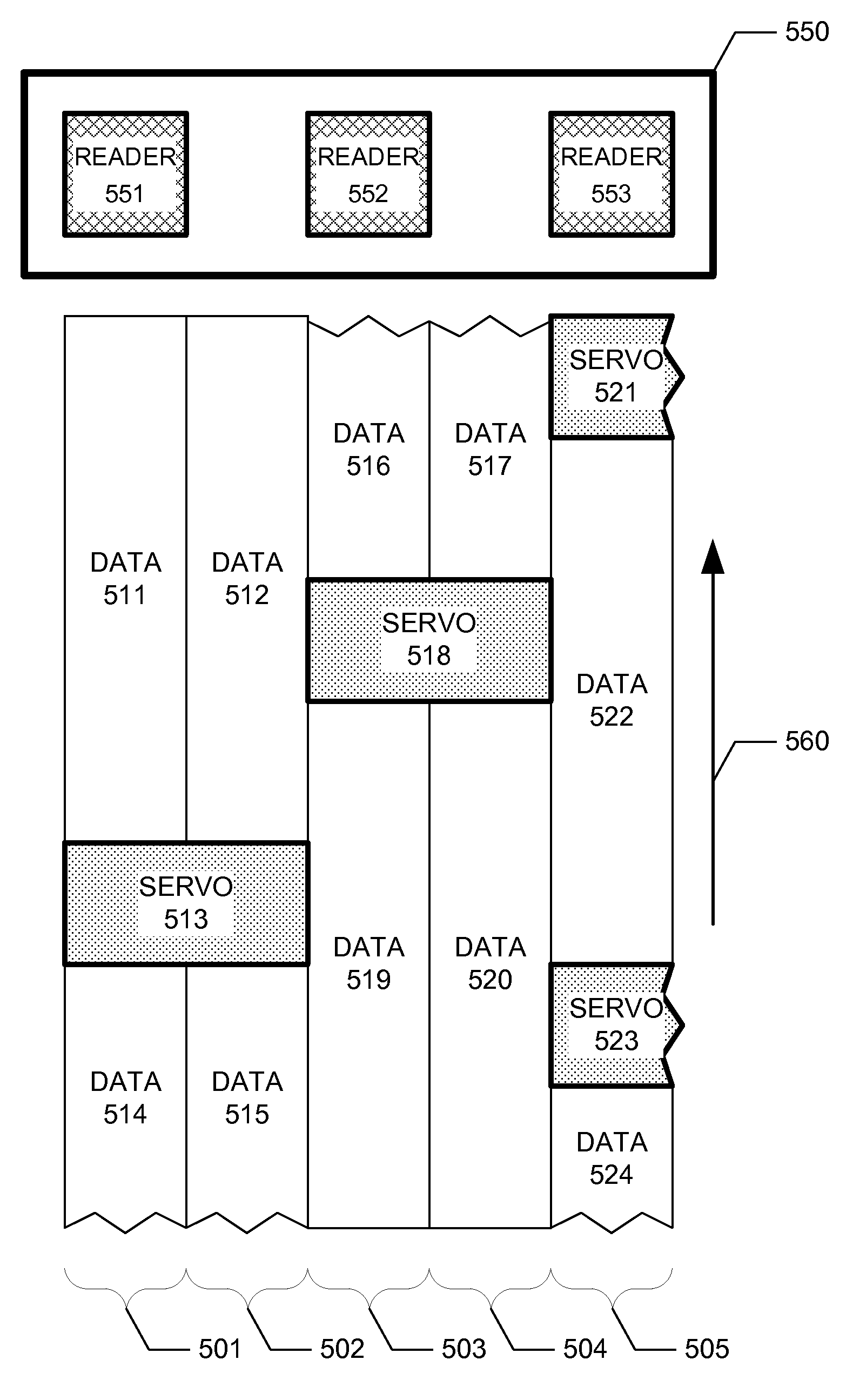

Servo design in data storage media

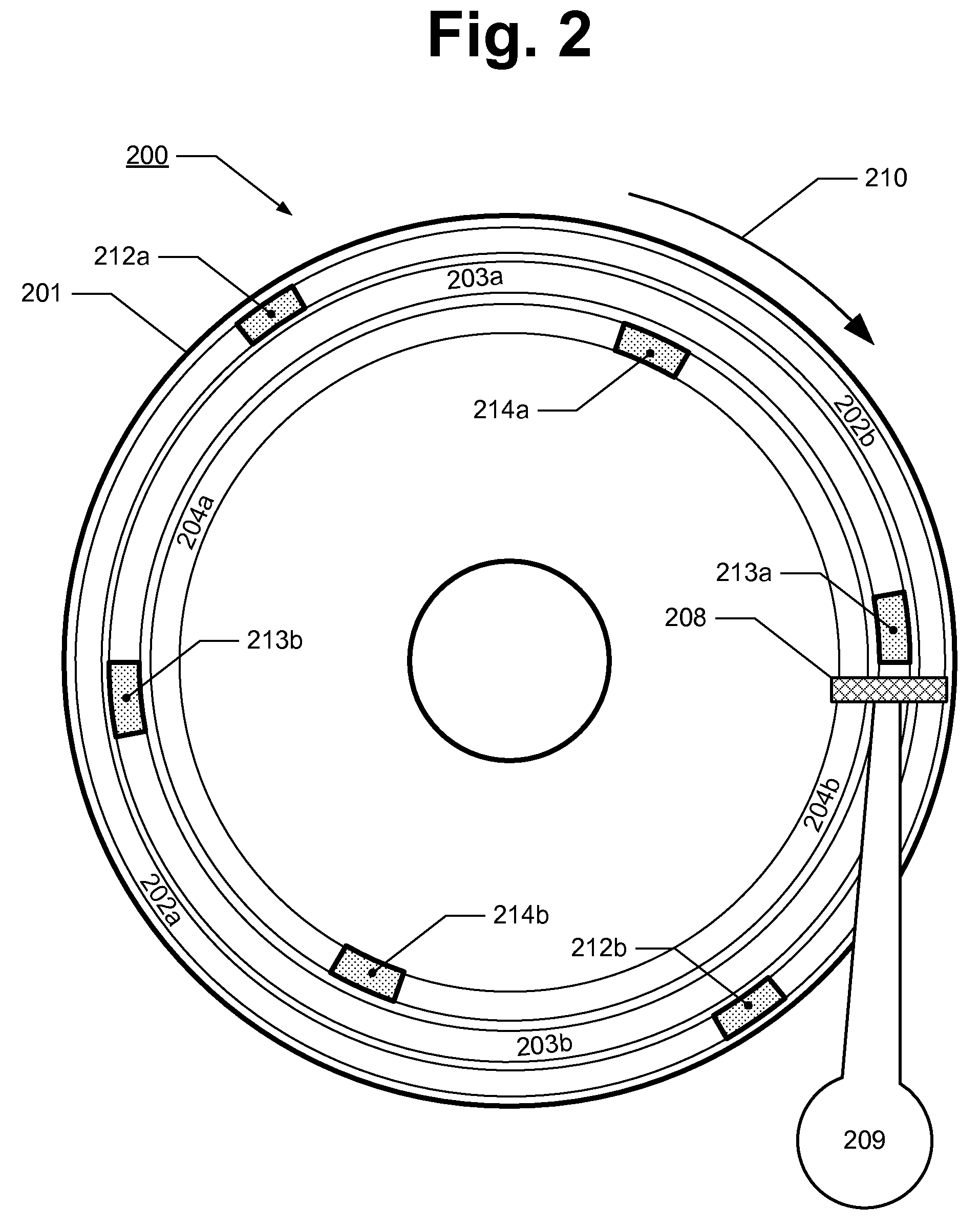

InactiveUS8203800B2Good synchronizationRecord information storageAlignment for track following on disksData operationsReal-time computing

A data storage medium comprises a plurality of data regions, and a plurality of servo regions configured to provide positioning information to a reading device. Each of the plurality of data regions corresponds to more than one of the plurality of servo regions. The more than one of the plurality of servo regions are configured to provide positioning information to the reading device at discrete times corresponding to a data operation of a corresponding data region.

Owner:WESTERN DIGITAL TECH INC

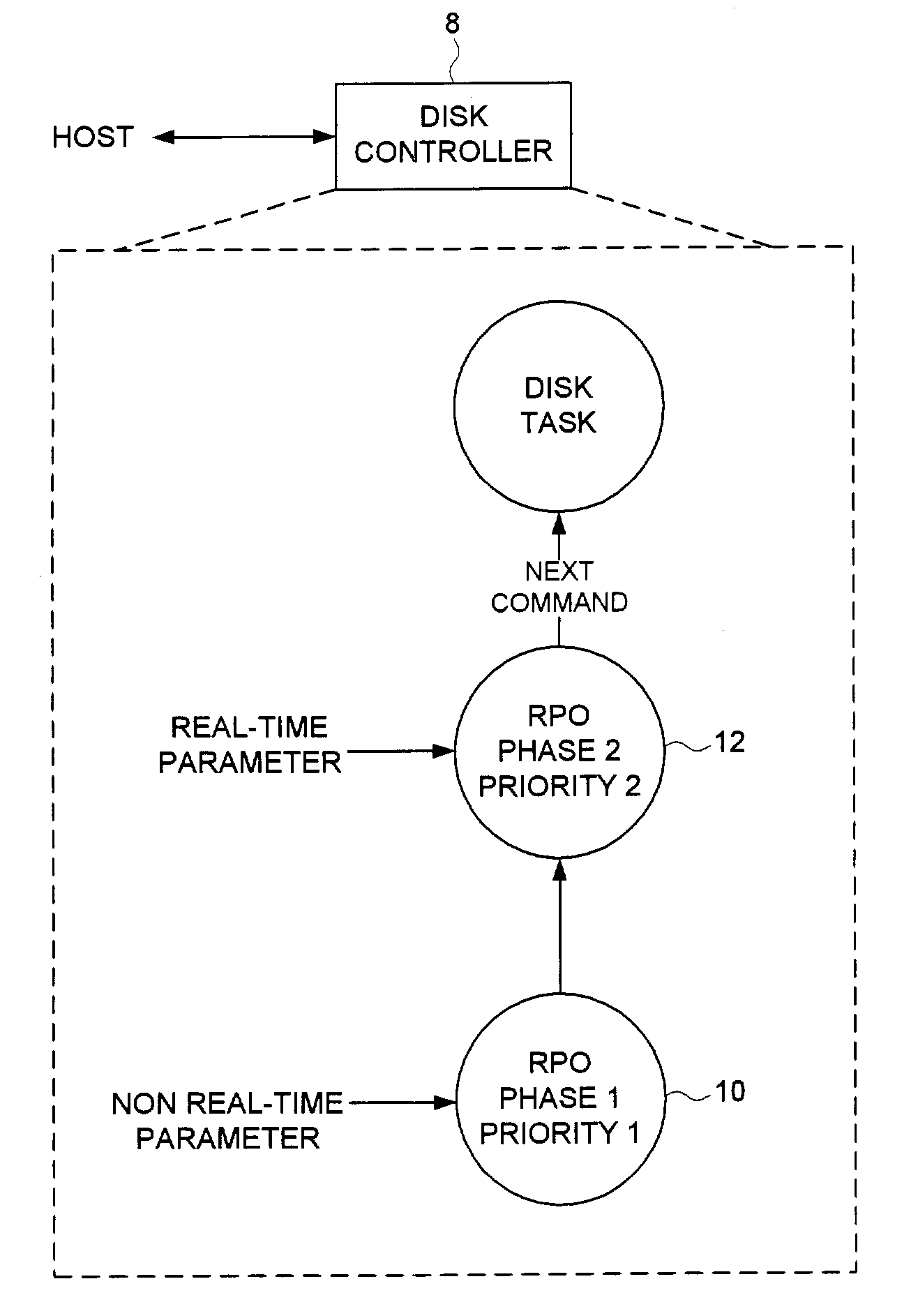

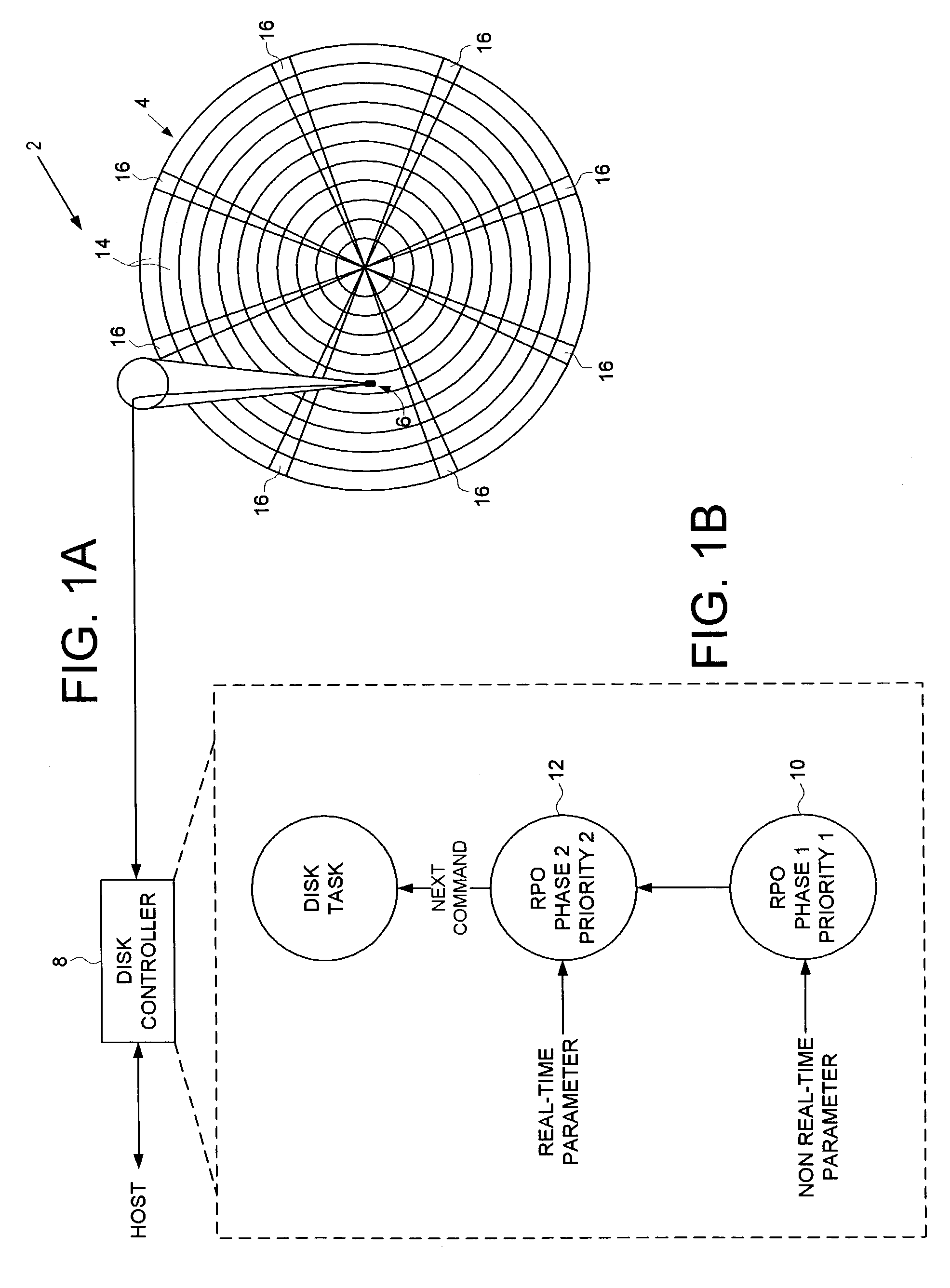

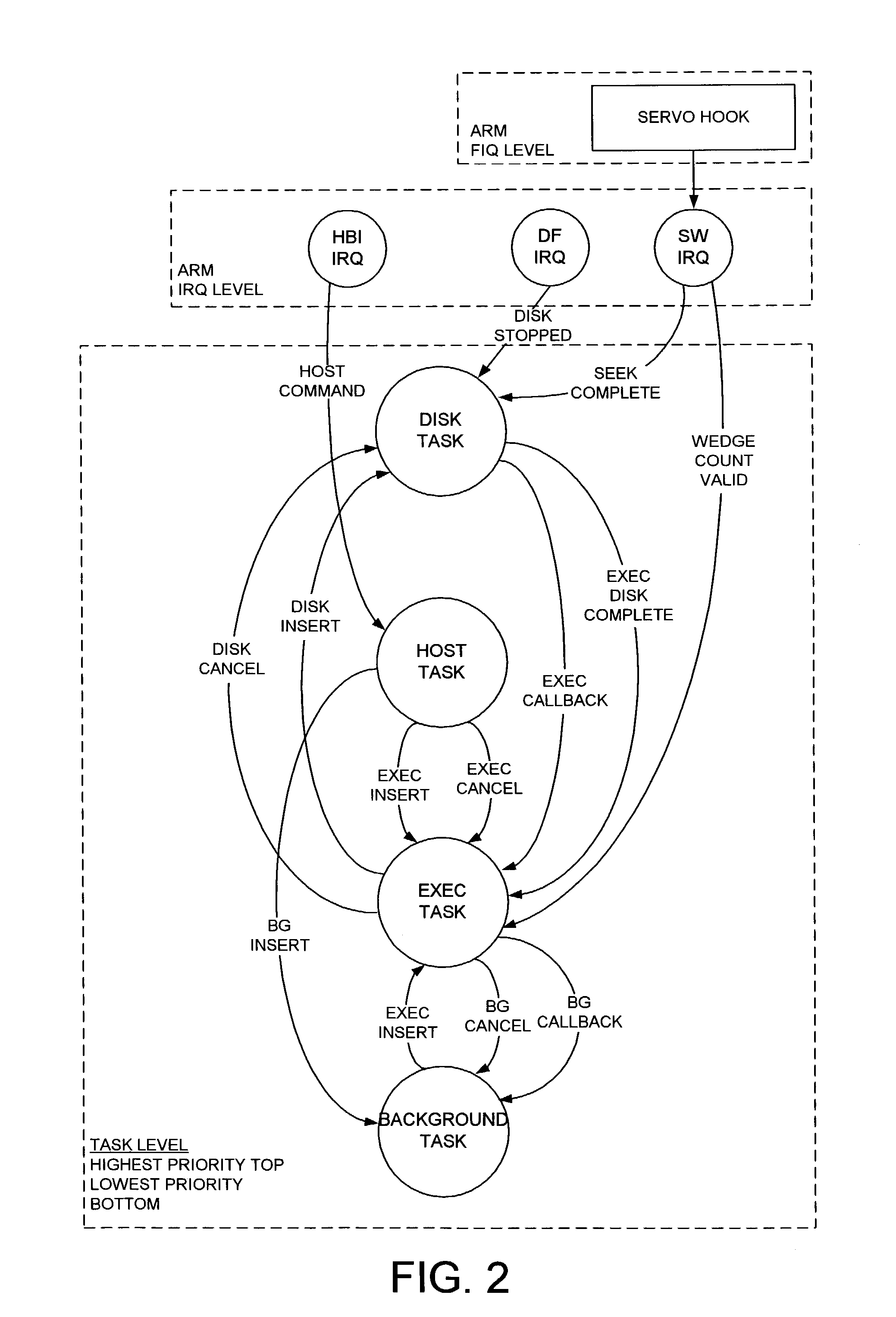

Disk drive employing a multi-phase rotational position optimization (RPO) algorithm

InactiveUS7114029B1Record information storageAlignment for track following on disksNon real timeMulti phase

A disk drive is disclosed which executes a rotational position optimization (RPO) algorithm for selecting a next command to execute out of a plurality of pending commands. The RPO algorithm comprises a first phase and a second phase. The first phase of the RPO algorithm is executed relative to a first priority and in response to at least one non-real-time parameter. The second phase of the RPO algorithm is executed relative to a second priority higher than the first priority and in response to at least one real-time parameter.

Owner:WESTERN DIGITAL TECH INC

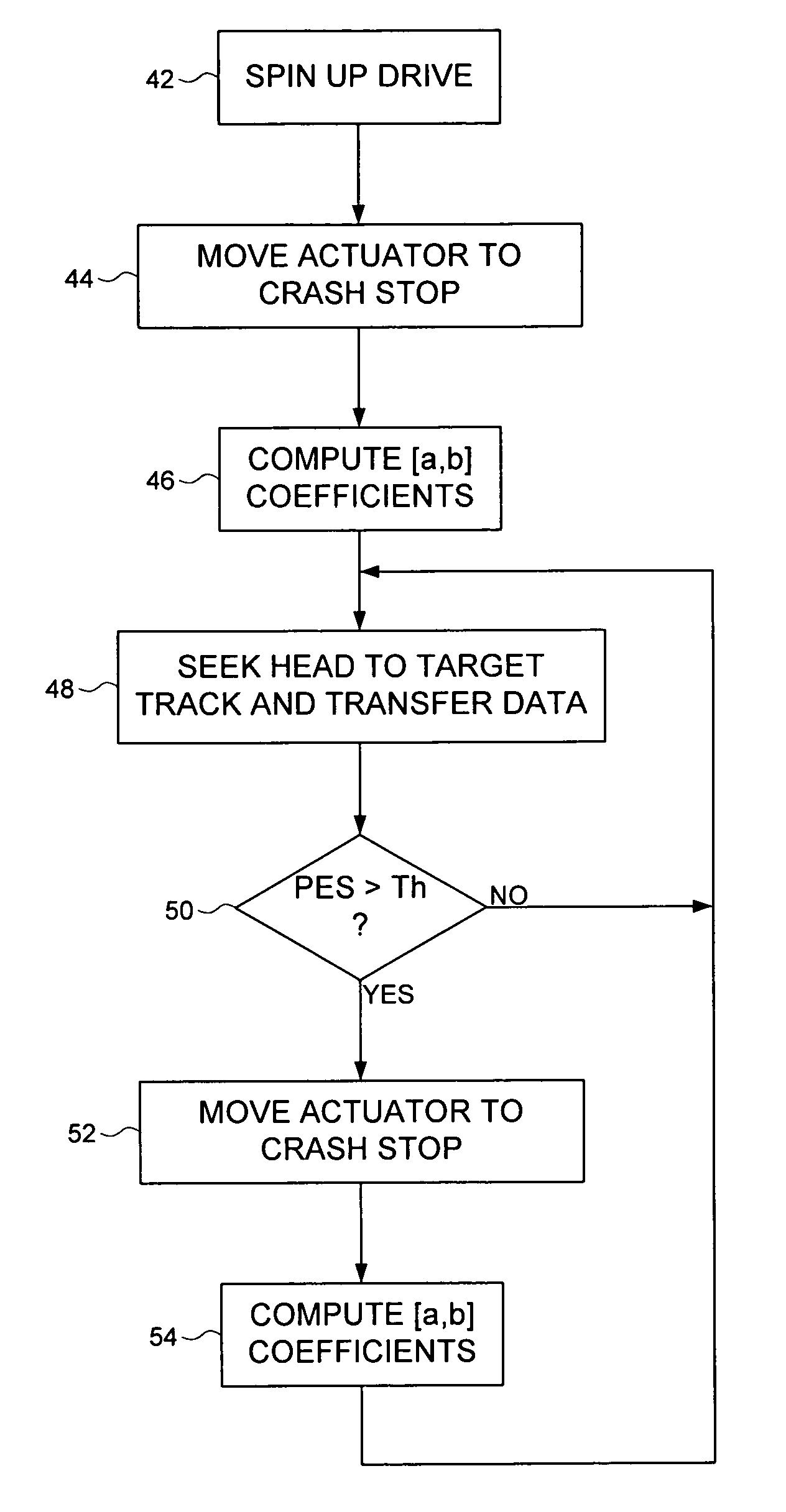

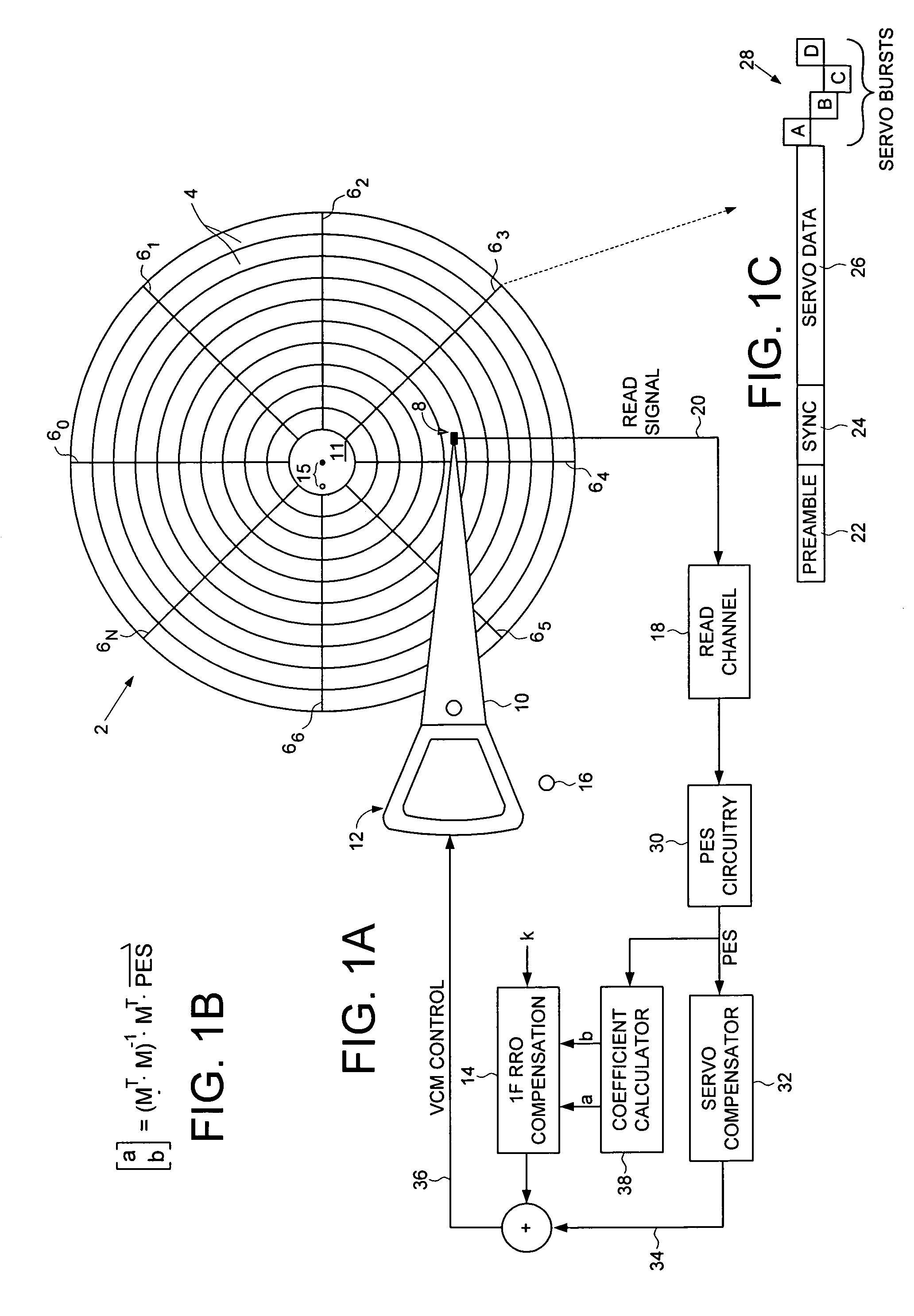

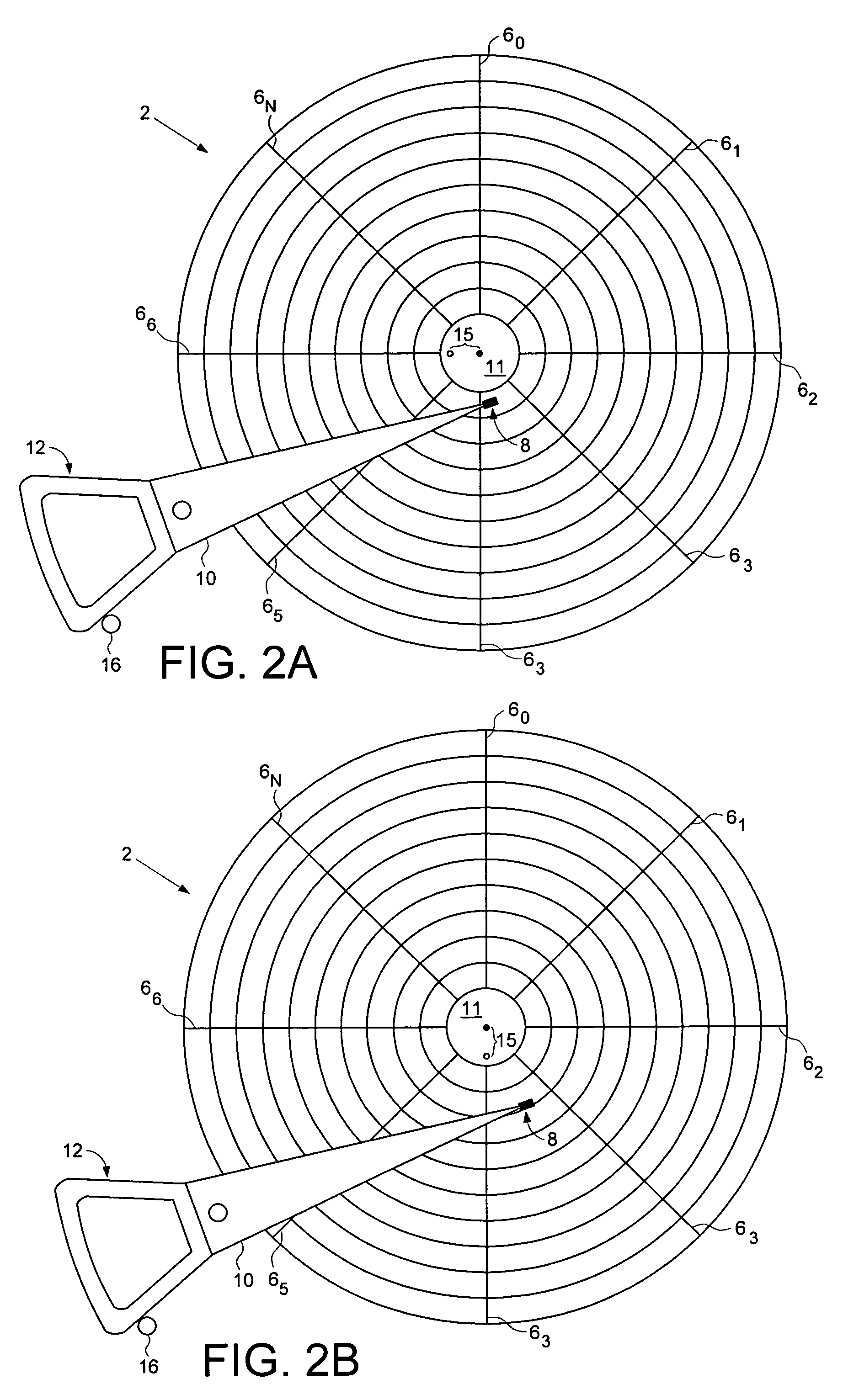

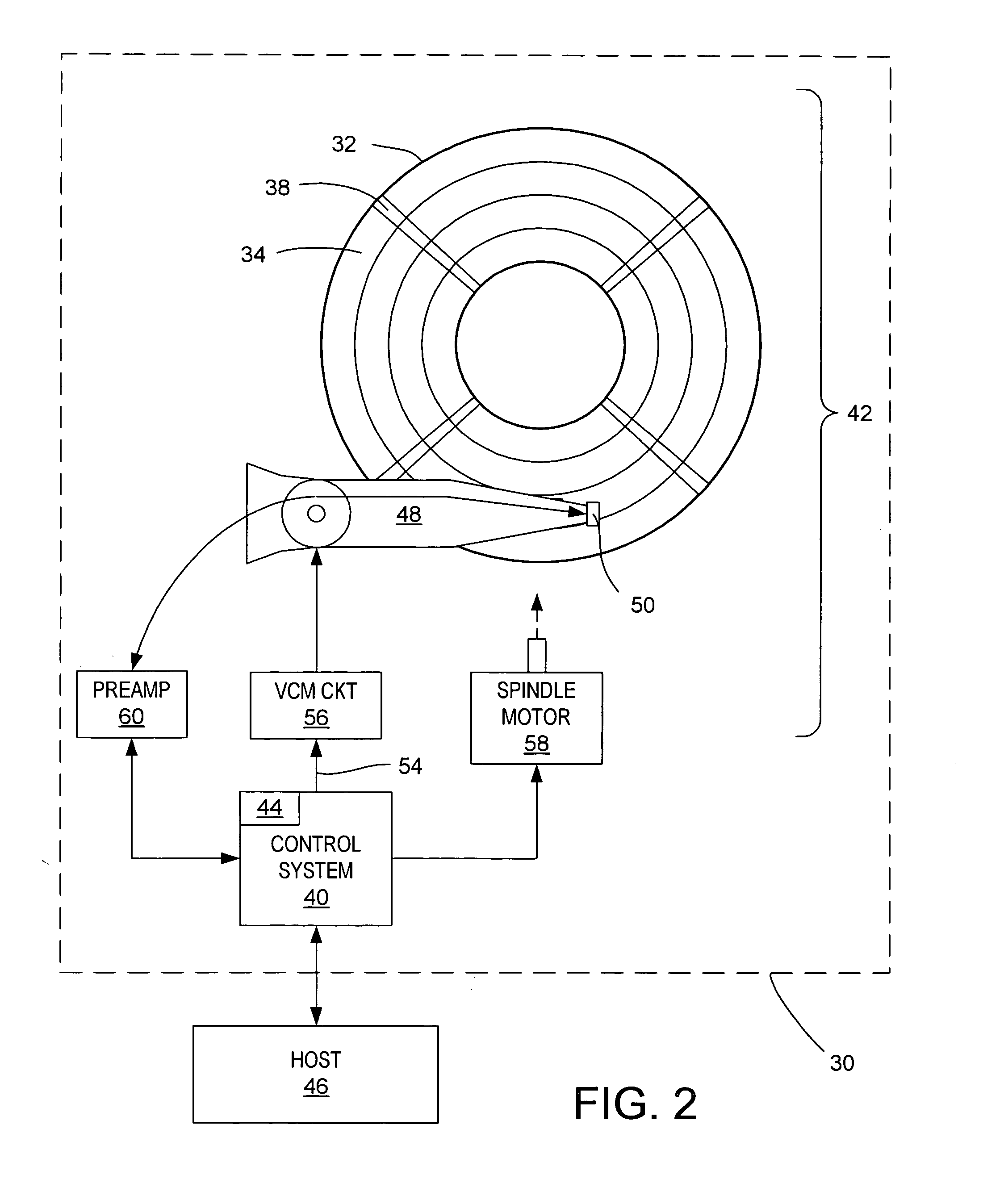

Disk drive computing repeatable run out while actuator arm is pressed against crash stop

InactiveUS7265933B1Record information storageAlignment for track following on disksControl theoryRotary actuator

A disk drive is disclosed comprising a voice coil motor (VCM) for rotating an actuator arm about a pivot in order to actuate a head over a disk. The disk is rotated by a spindle motor, and a feed-forward compensation value is computed that compensate for a non-centric alignment of the disk with respect to the spindle motor. During a calibration mode, the VCM is controlled to press the actuator arm against a crash stop, and the feed-forward compensation value is computed in response to a position error signal (PES). The PES is generated in response to embedded servo sectors recorded on the disk, wherein each embedded servo sector comprises a track address for coarse alignment and servo bursts for fine alignment.

Owner:WESTERN DIGITAL TECH INC

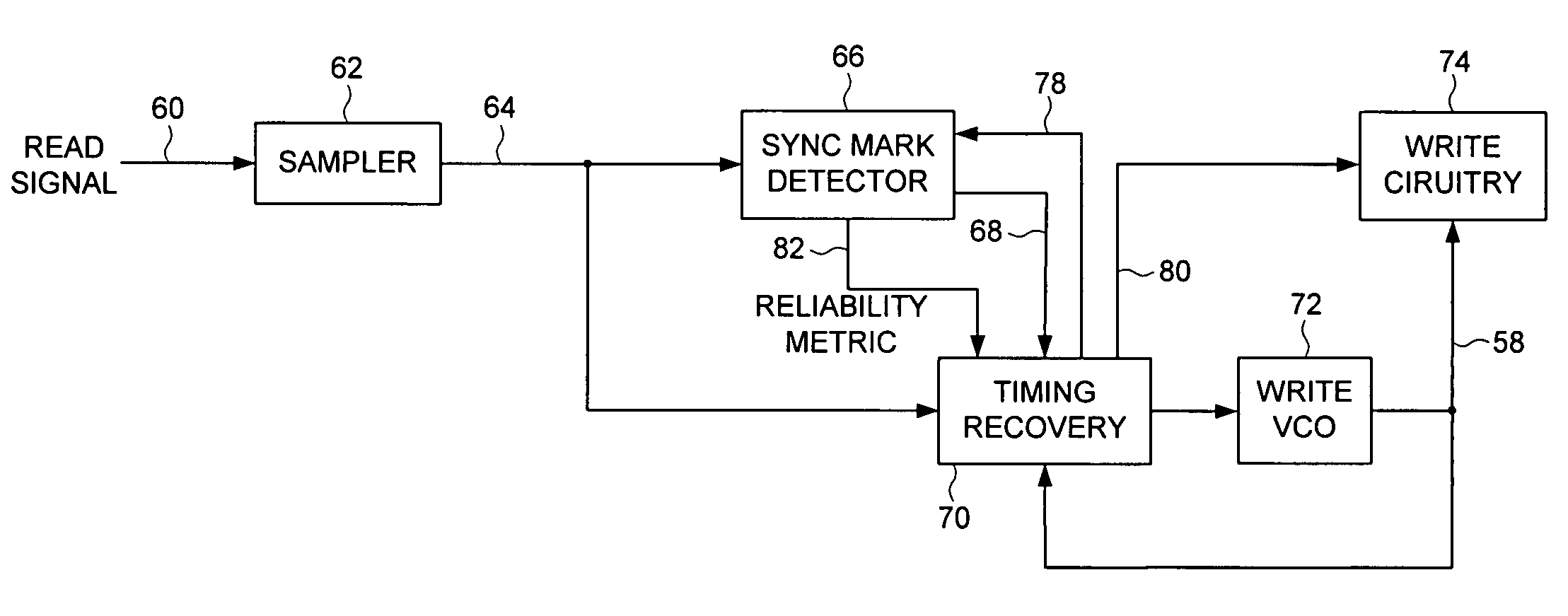

Servo writing a disk drive by synchronizing a servo write clock in response to a sync mark reliability metric

InactiveUS7212364B1Accurate detectionRecording carrier detailsDriving/moving recording headsComputer scienceHigh frequency

A method of writing product servo sectors to a disk of a disk drive is disclosed. A plurality of spiral tracks are written to the disk, wherein each spiral track comprises a high frequency signal interrupted at a predetermined interval by a sync mark. During the product servo writing process, the sync marks in the spiral tracks are detected and a sync mark reliability metric is generated, wherein the sync mark reliability metric represents a probability that the sync mark was detected accurately. A timing recovery measurement is generated in response to the detected sync marks and the sync mark reliability metrics. A servo write clock is synchronized in response to the timing recovery measurement and used to write the product servo sectors to the disk while serving on the spiral tracks.

Owner:WESTERN DIGITAL TECH INC

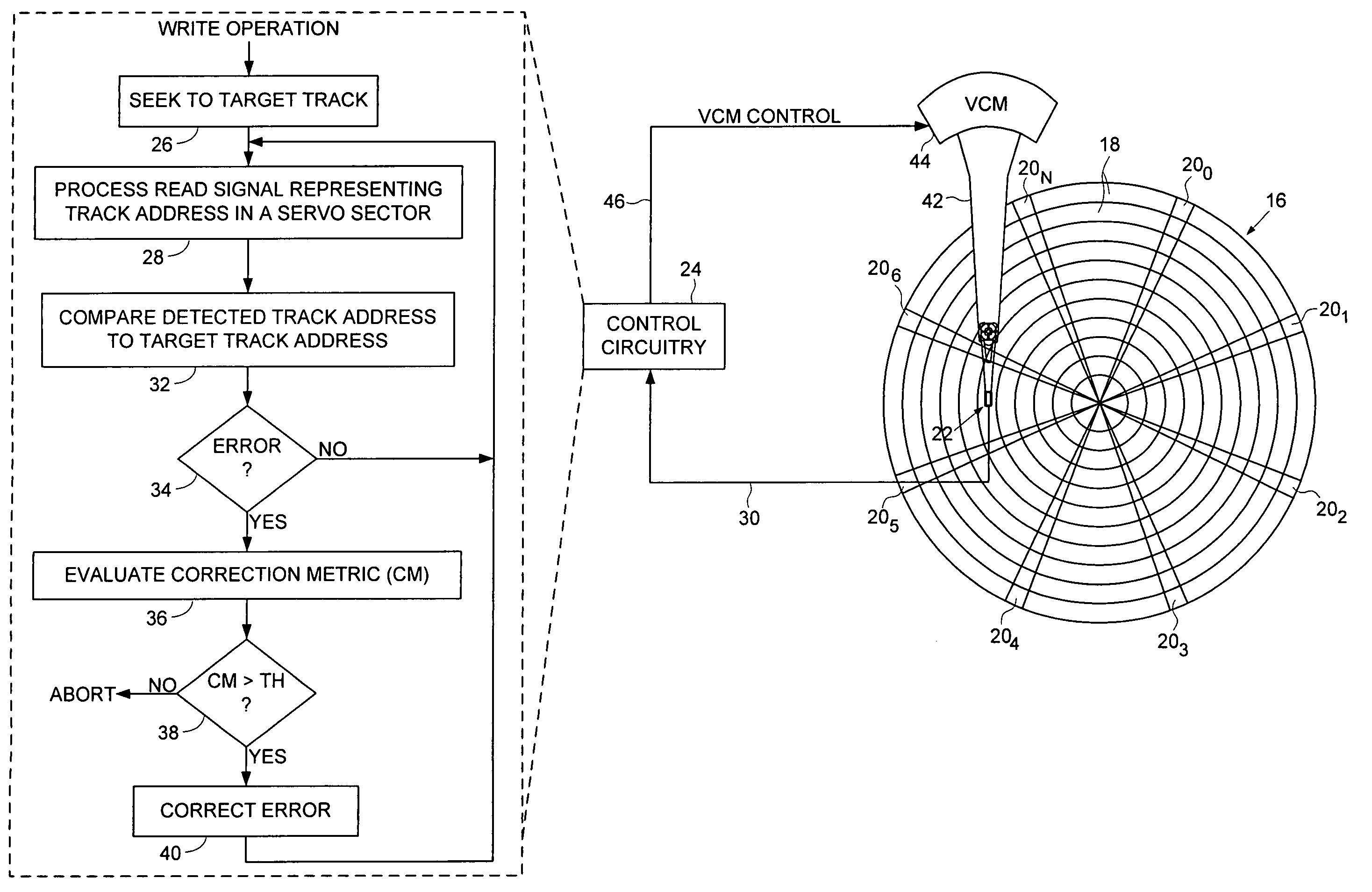

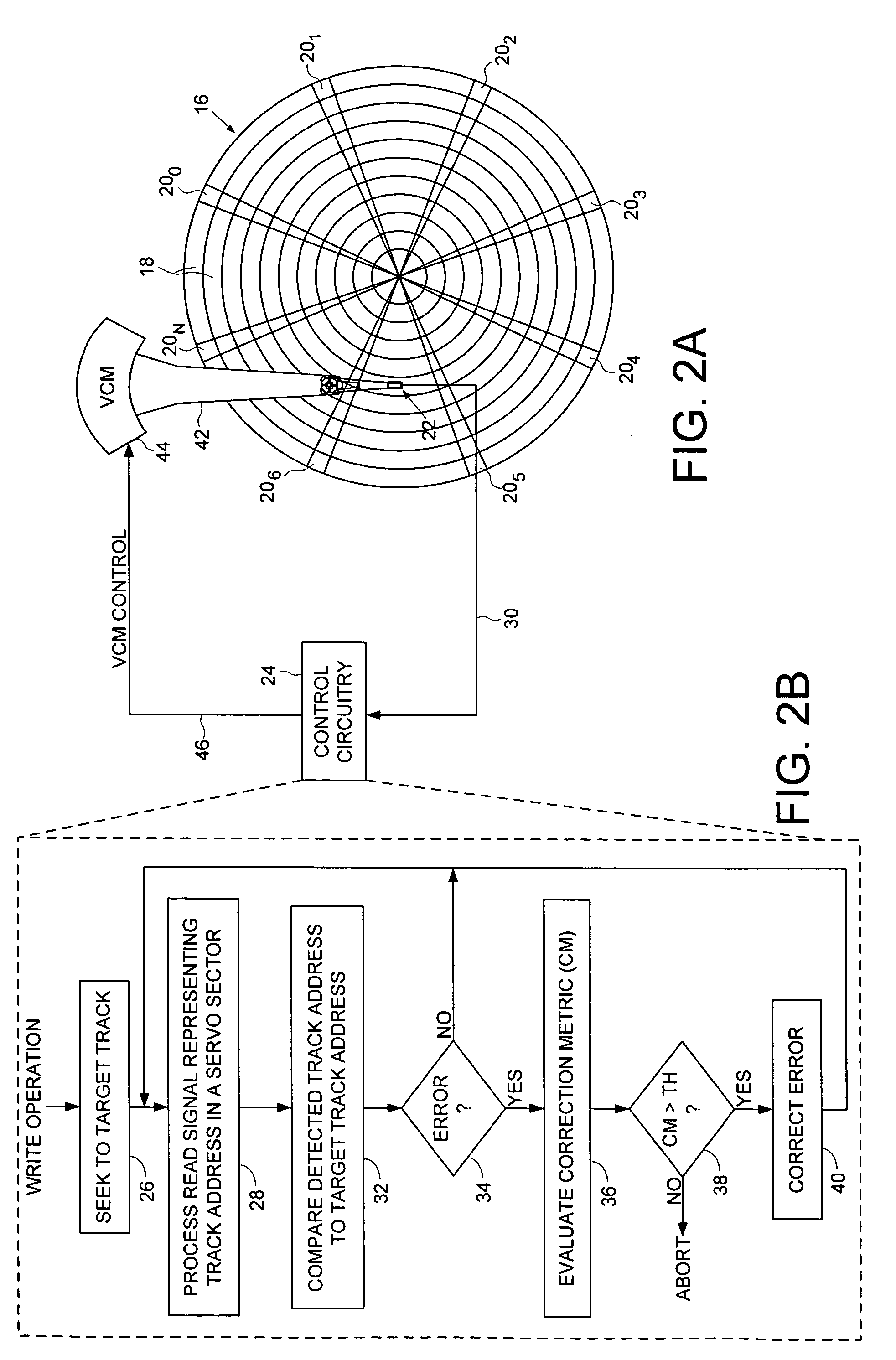

Disk drive correcting track address during a write operation

InactiveUS7369343B1Recording carrier detailsRecord information storageControl theoryComputer hardware

A disk drive is disclosed comprising a head actuated over a disk having a plurality of servo tracks, wherein each servo track comprises a plurality of servo sectors and each servo sector comprises a track address. A read signal from the head representing a first track address in one of the servo sectors is processed in order to generate a detected track address which is compared to a first target track address to obtain a first track address error. A correction metric is generated representing a likelihood that the first track address error was caused by a detection error, and if the correction metric exceeds a threshold, the detected track address is corrected in response to the first track address error, and the write operation is continued. If the correction metric does not exceed the threshold, the write operation is aborted.

Owner:WESTERN DIGITAL TECH INC

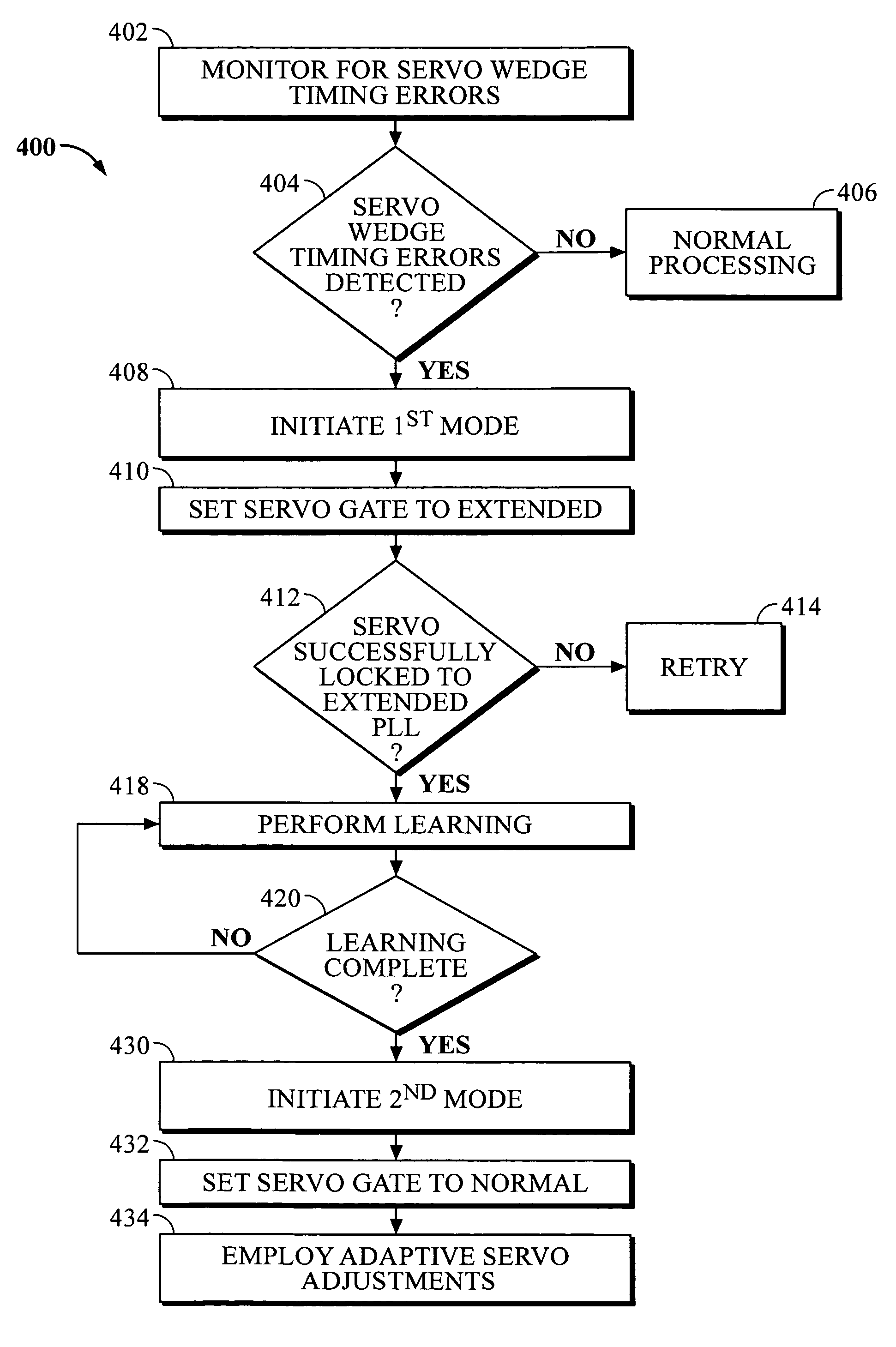

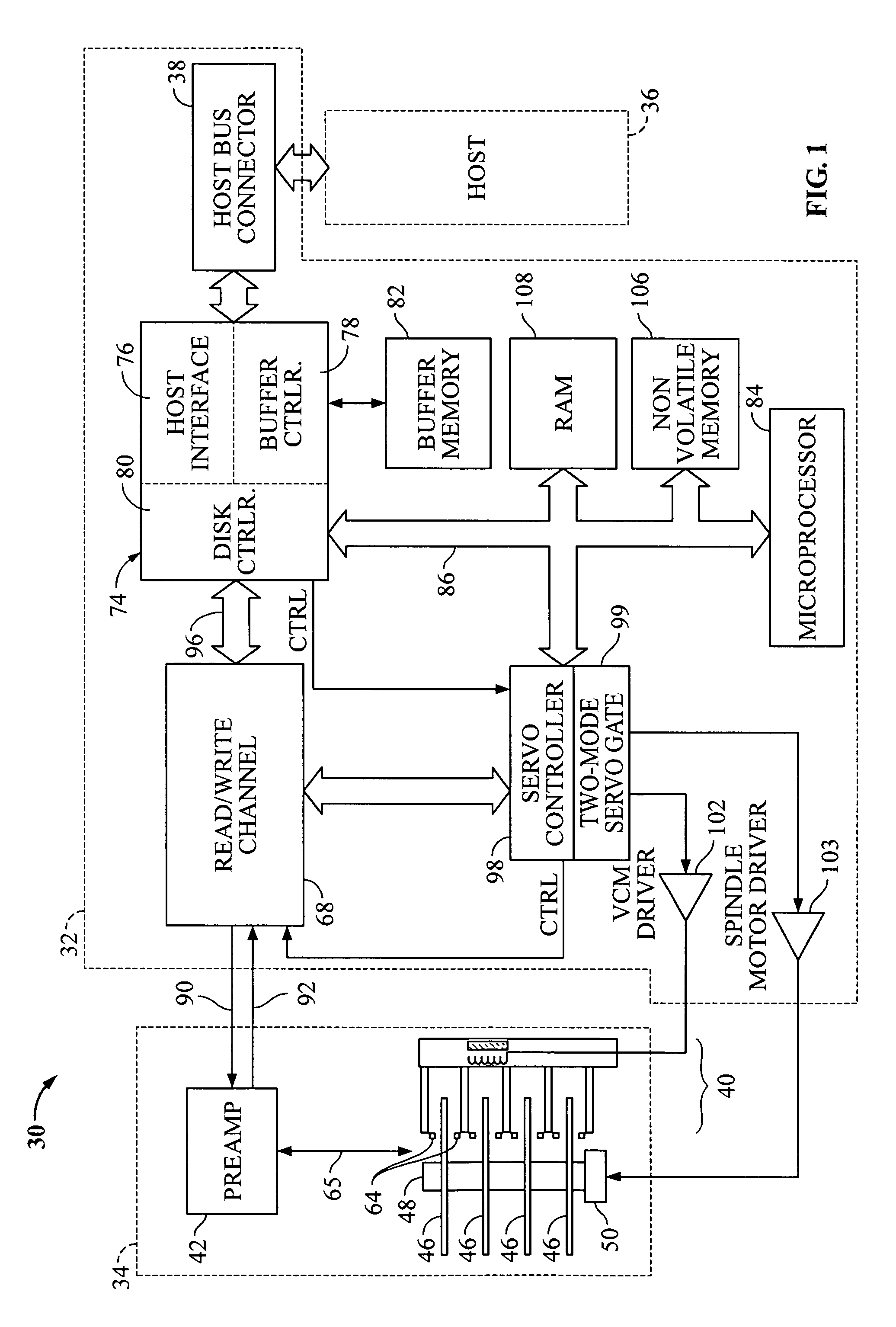

Disk drive servo controller utilizing an extended servo header

InactiveUS7057836B1Record information storageAlignment for track following on disksControl signalControl theory

A disk drive includes a moveable head and a disk having a circumferential track which includes a plurality of servo wedges. The servo wedges are spaced sequentially around a circumference of the circumferential track. Each servo wedge includes an extended servo header. The disk drive includes a servo controller to perform track following with the moveable head. The servo controller compensates for servo wedge timing errors due to eccentricity associated with the servo wedges of the circumferential track by implementing: a first mode in which the servo controller locks to the extended servo header of a servo wedge and performs servo wedge timing error learning to characterize servo wedge timing errors and a second mode to adapt servo control signals of the servo controller based on the characterized servo wedge timing errors of the first mode in order to dynamically compensate for the eccentricity associated with the servo wedges.

Owner:WESTERN DIGITAL TECH INC

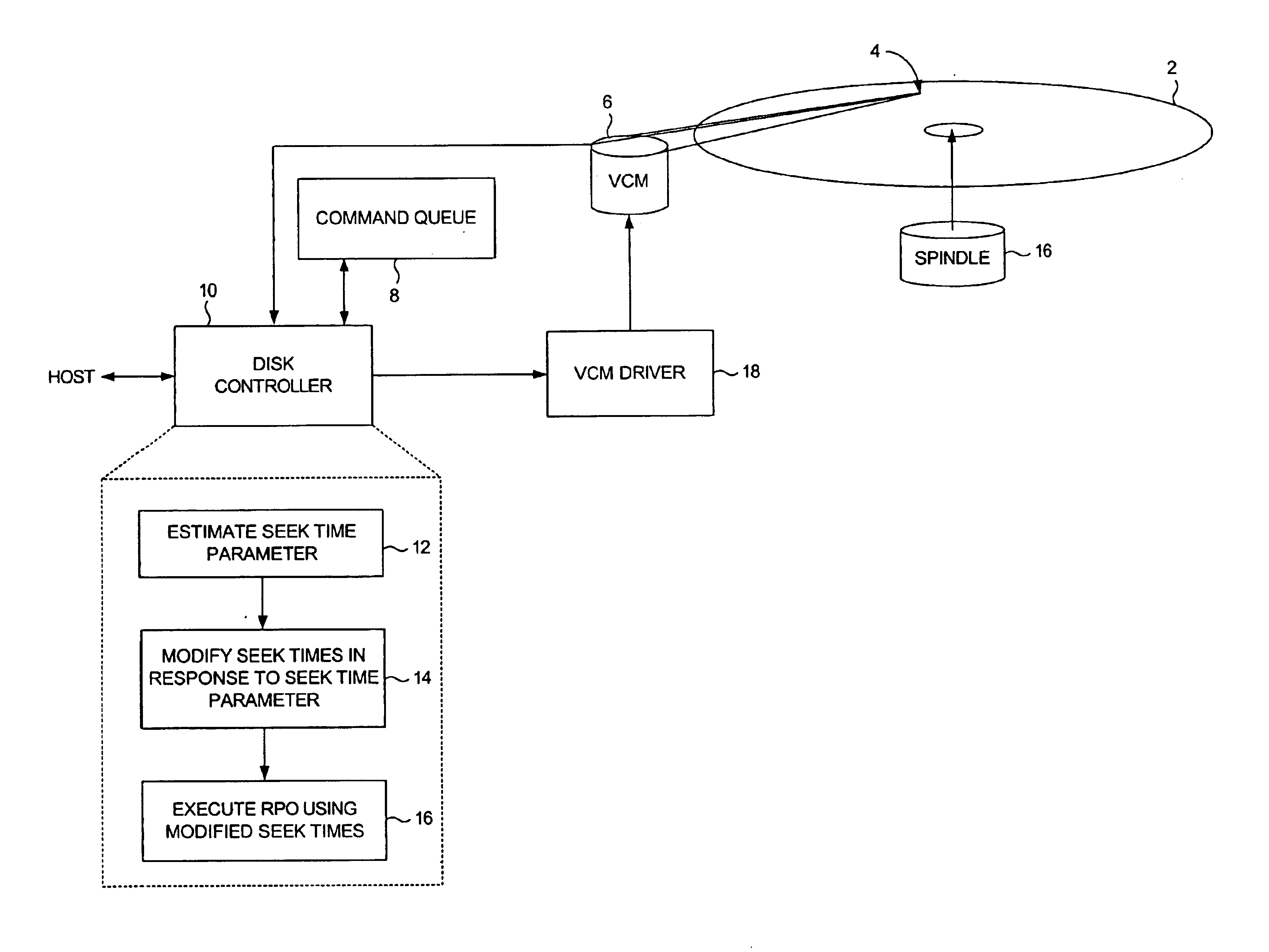

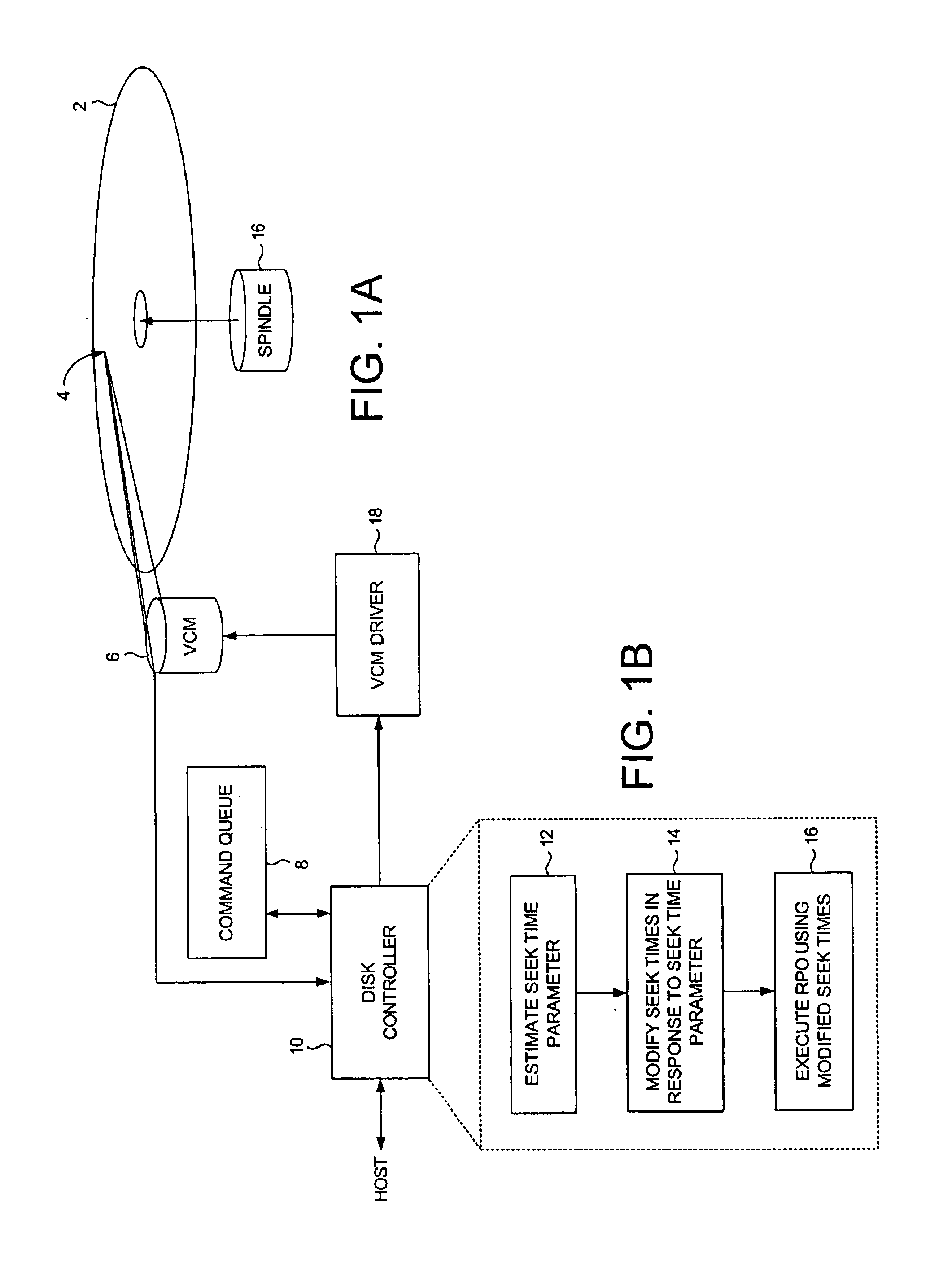

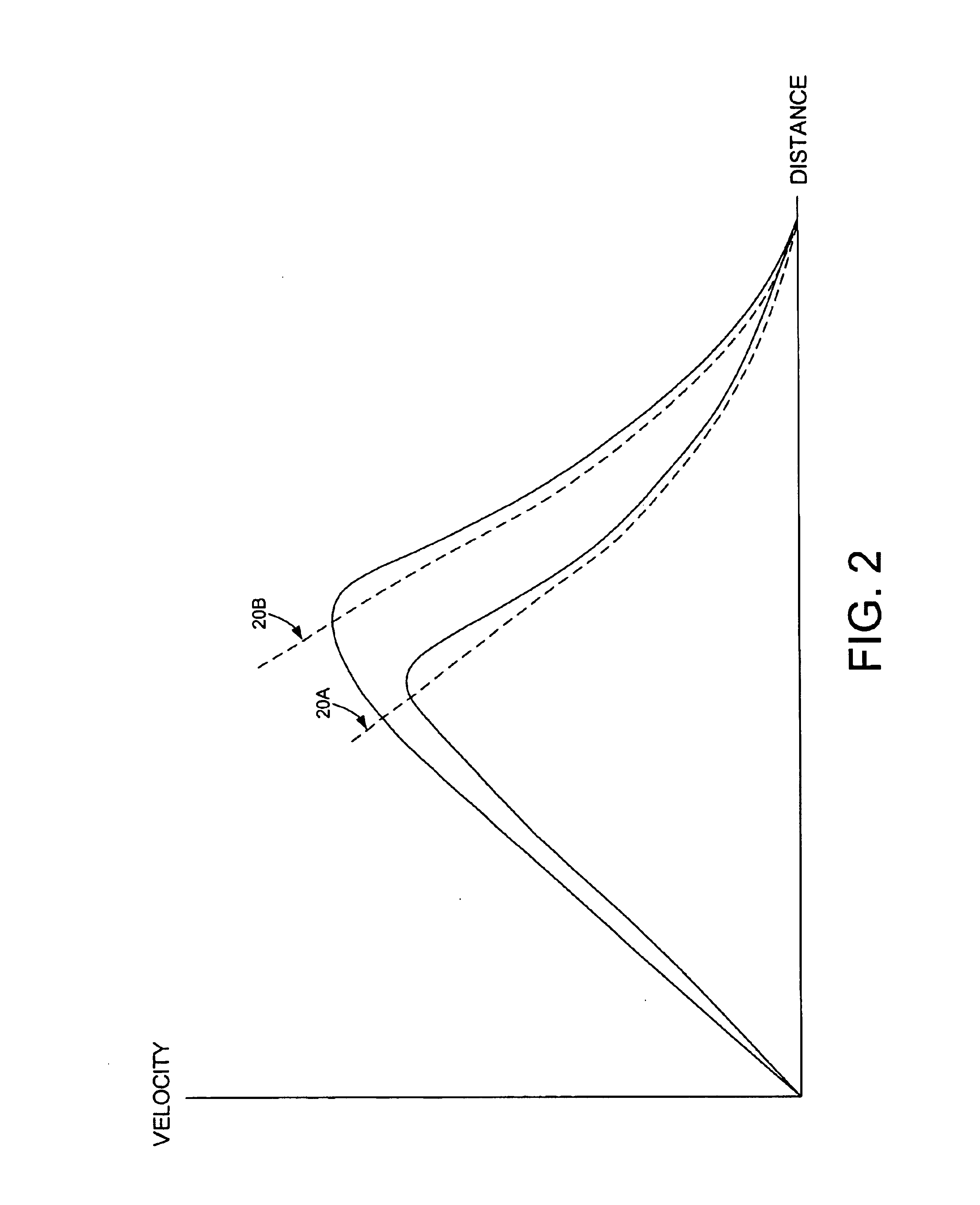

Disk drive modifying estimated seek times for a rotational position optimization algorithm based on change in estimated seek time parameter

A disk drive is disclosed comprising a disk, a head, and a voice coil motor (VCM) for actuating the head over the disk. The disk drive executes a rotational position optimization (RPO) algorithm to select a next command to execute relative to an estimated seek time computed for each command in a command queue. A seek time parameter is estimated and a seek time delta computed in response to the estimated seek time parameter. The seek time delta is added to a nominal estimated seek time to generate a modified estimated seek time for each command in the command queue, thereby optimizing the RPO algorithm.

Owner:WESTERN DIGITAL TECH INC

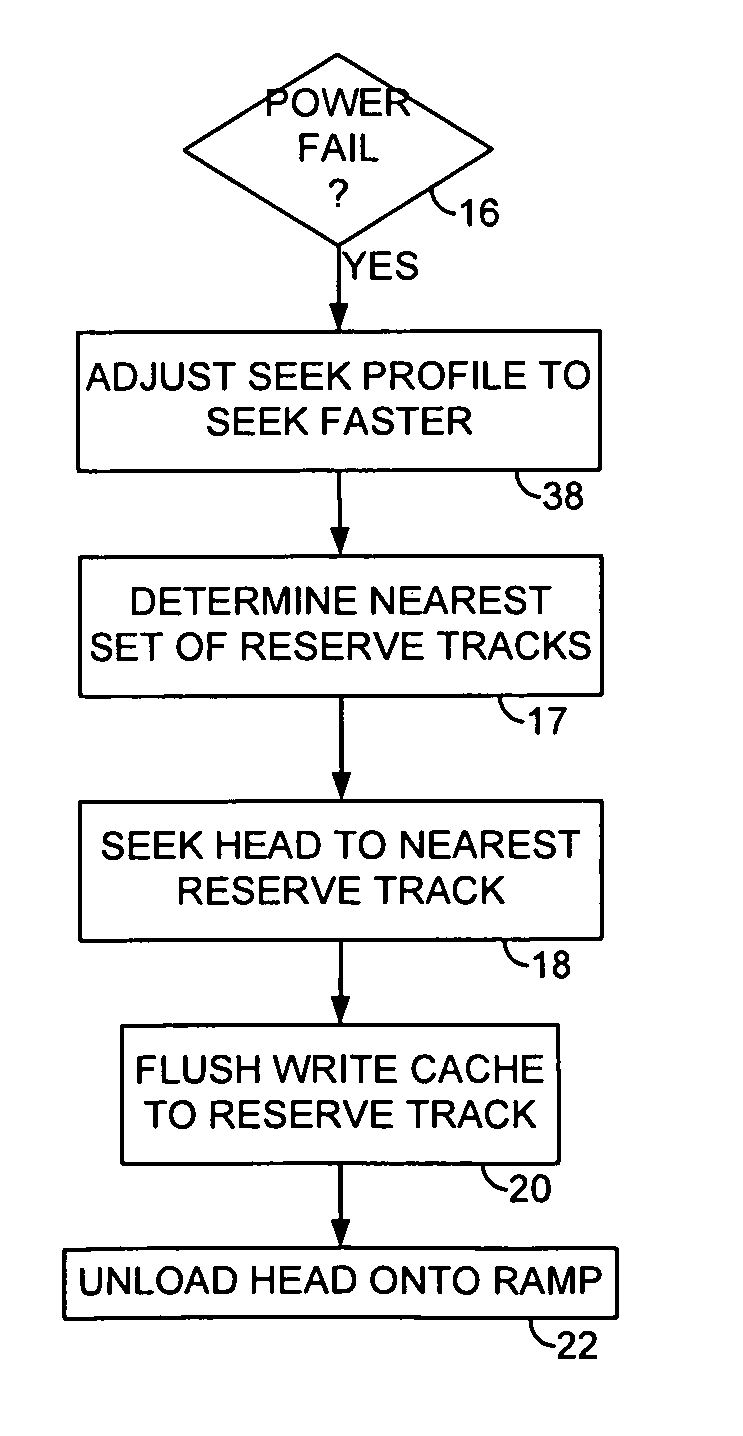

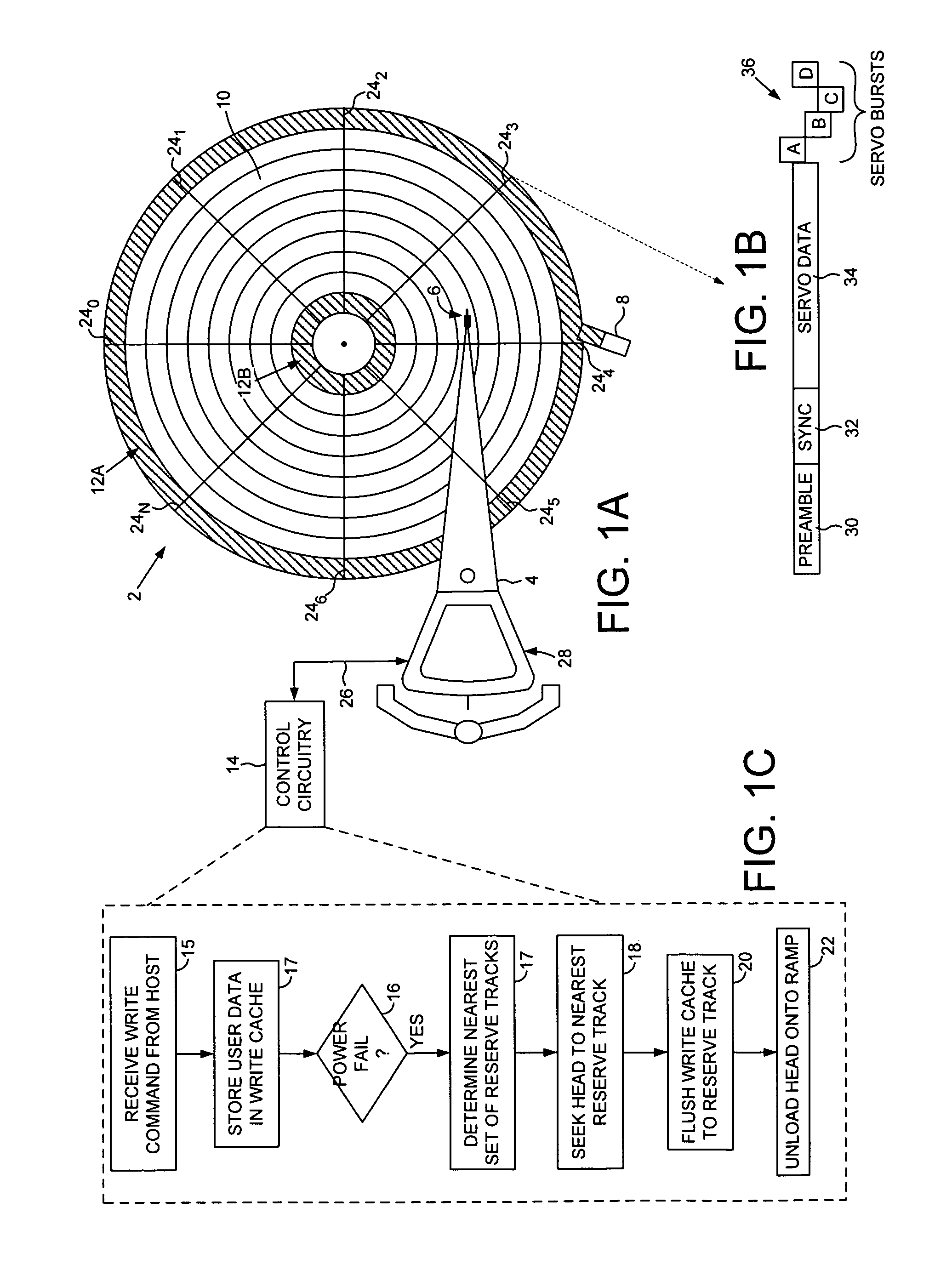

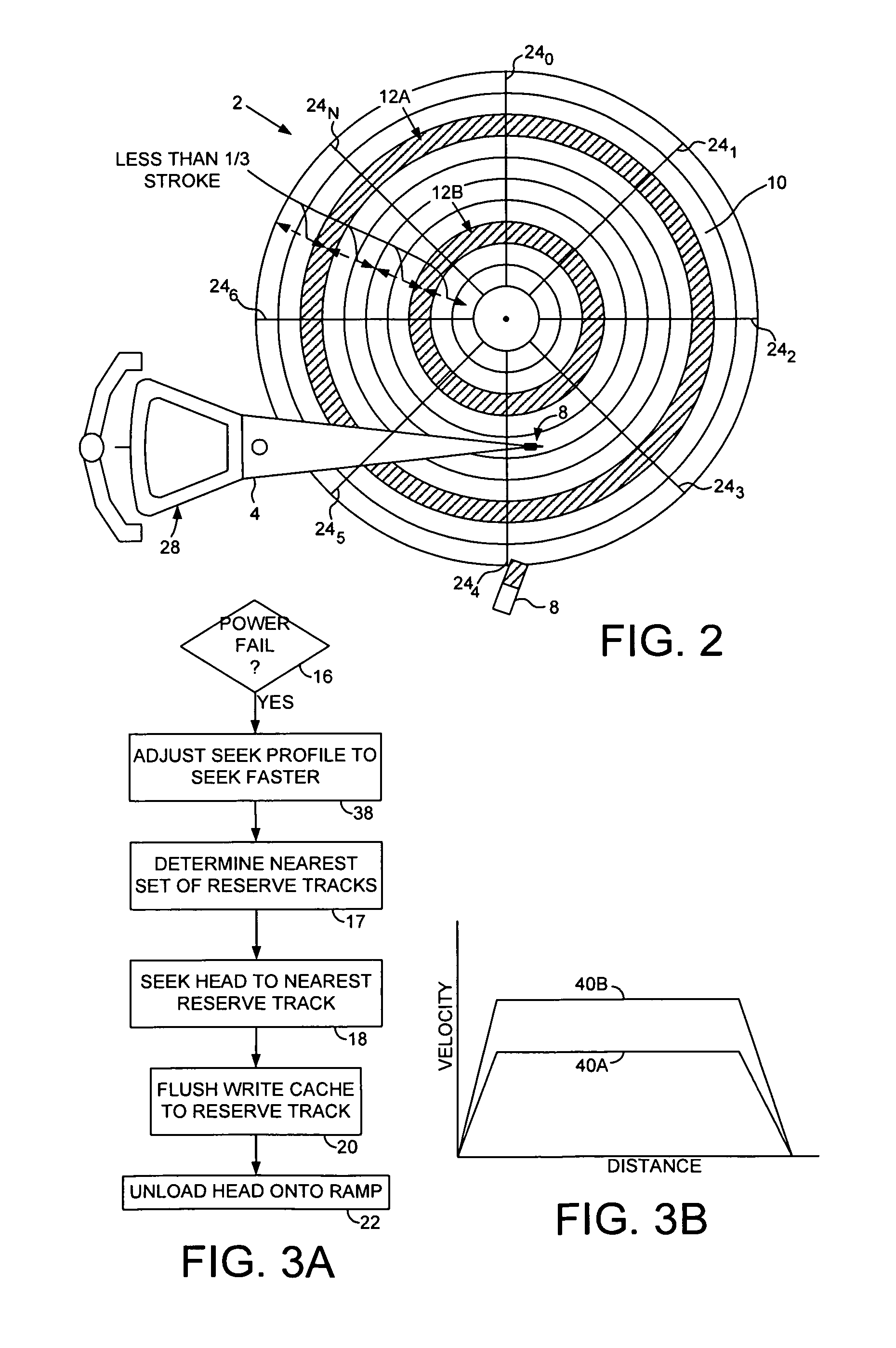

Disk drive flushing write cache to a nearest set of reserved tracks during a power failure

ActiveUS7800856B1Driving/moving recording headsRecord information storageParallel computingData storing

Owner:WESTERN DIGITAL TECH INC

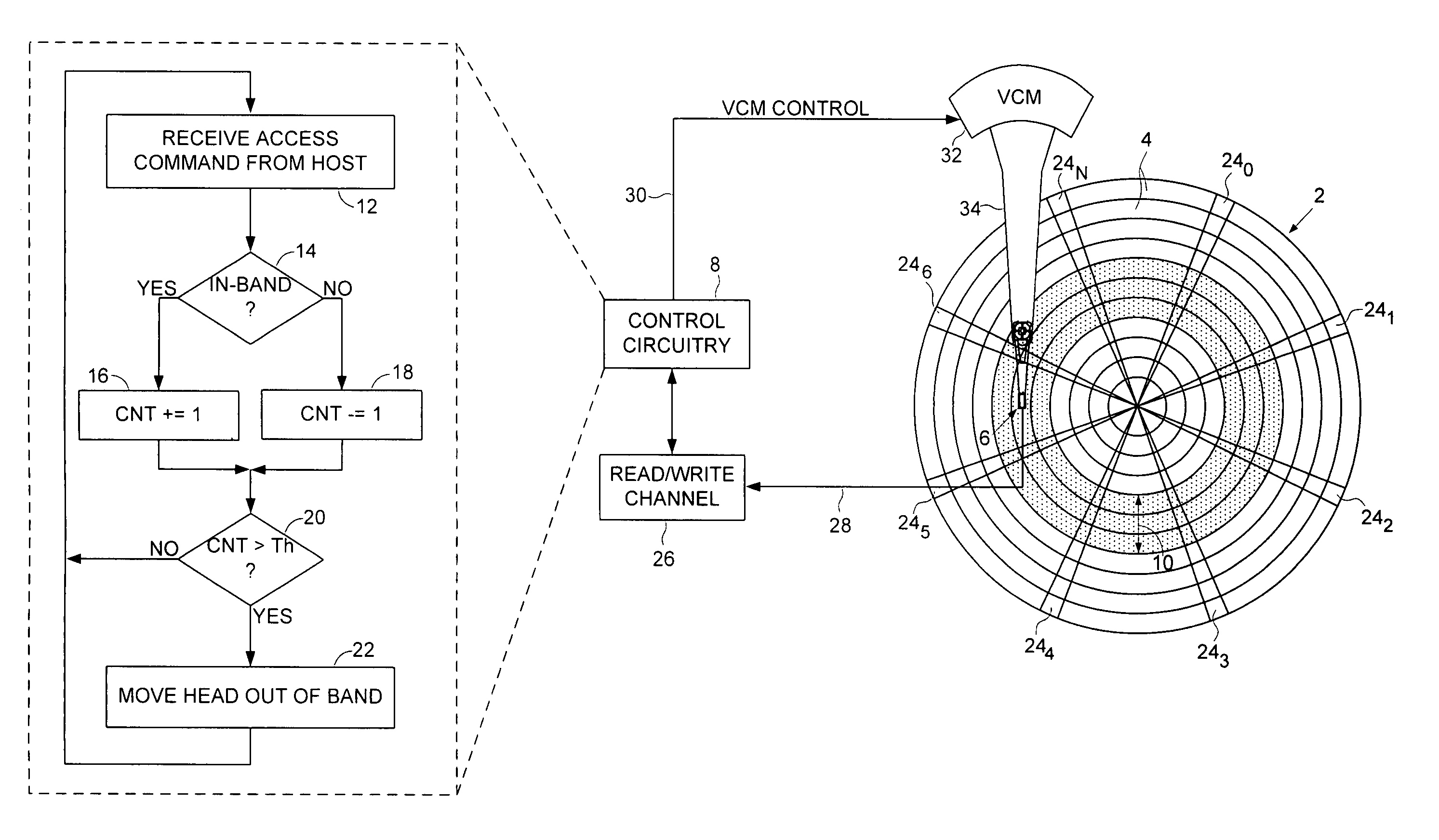

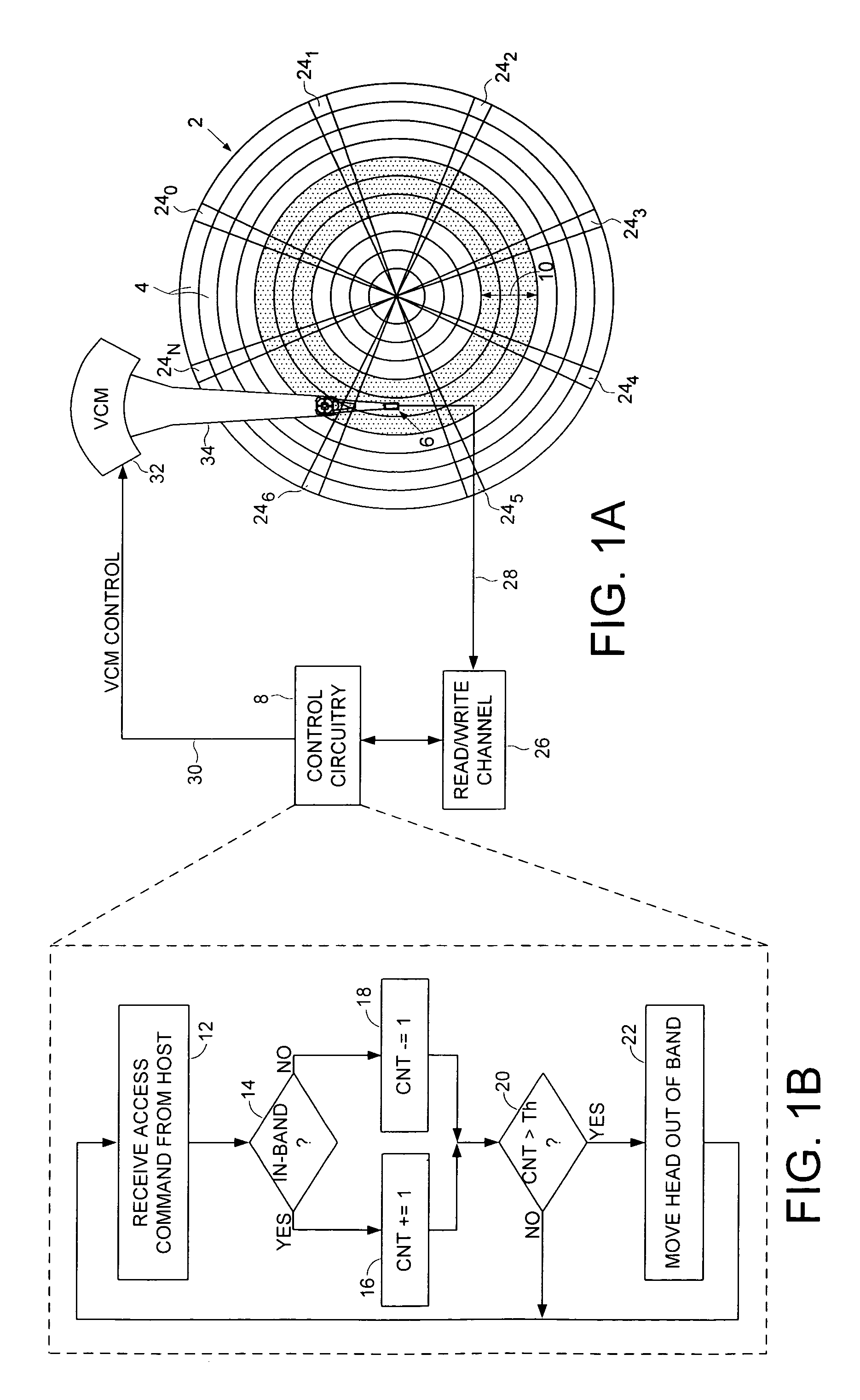

Disk drive implementing wear prevention in a high frequency access band of tracks

ActiveUS7149046B1Facilitate wear preventionManufacture head surfaceDriving/moving recording headsControl circuitComputer science

Owner:WESTERN DIGITAL TECH INC

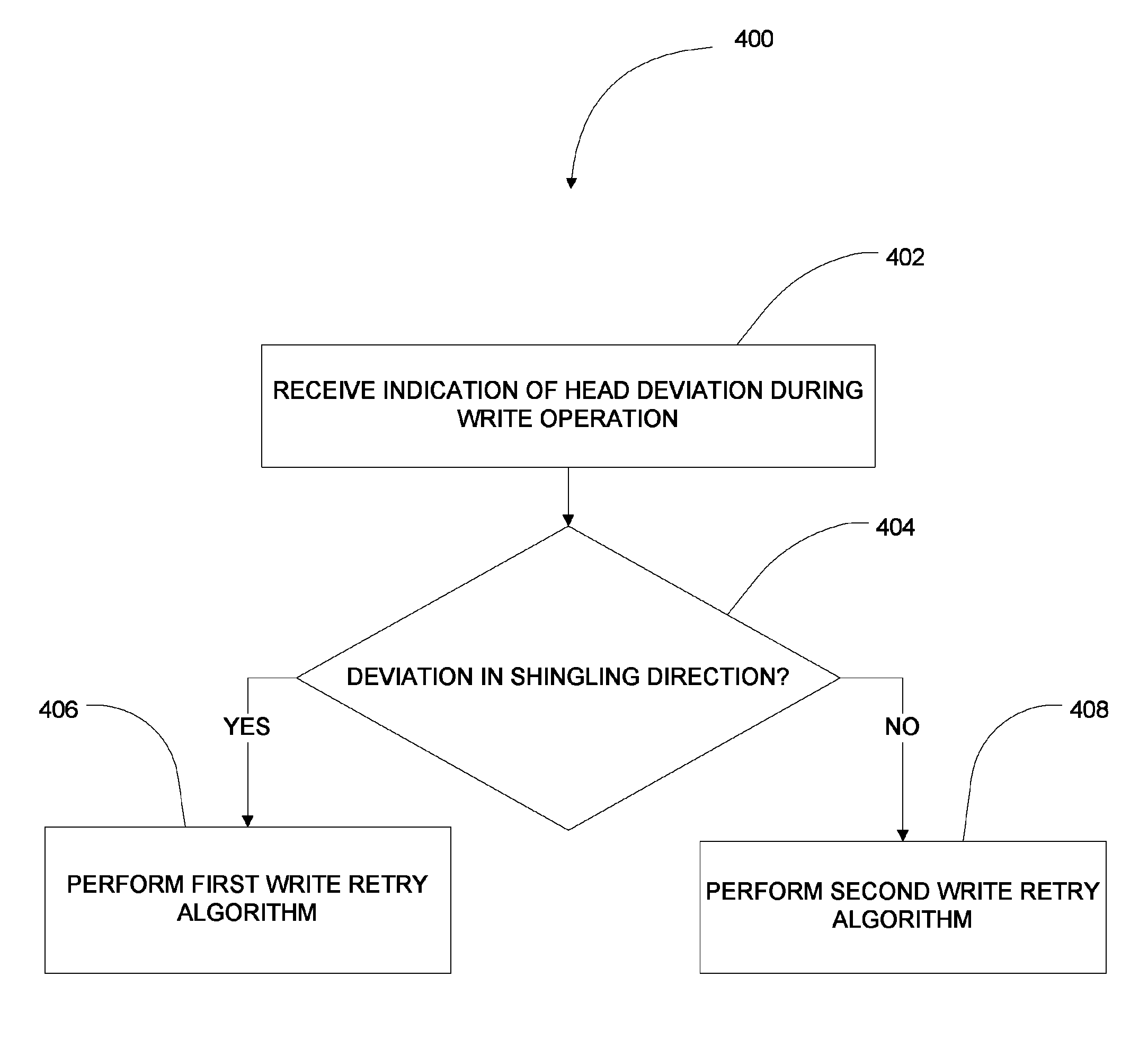

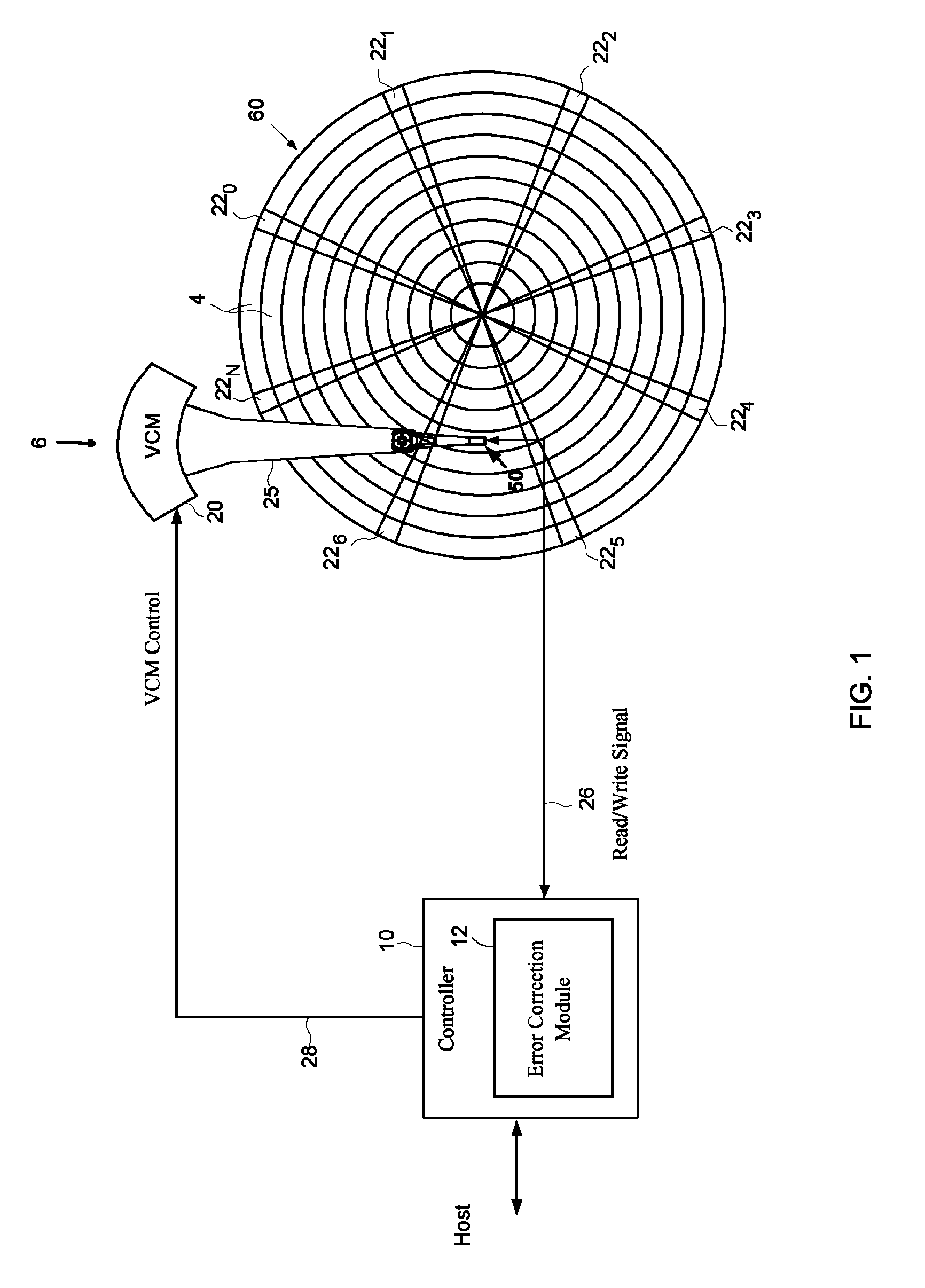

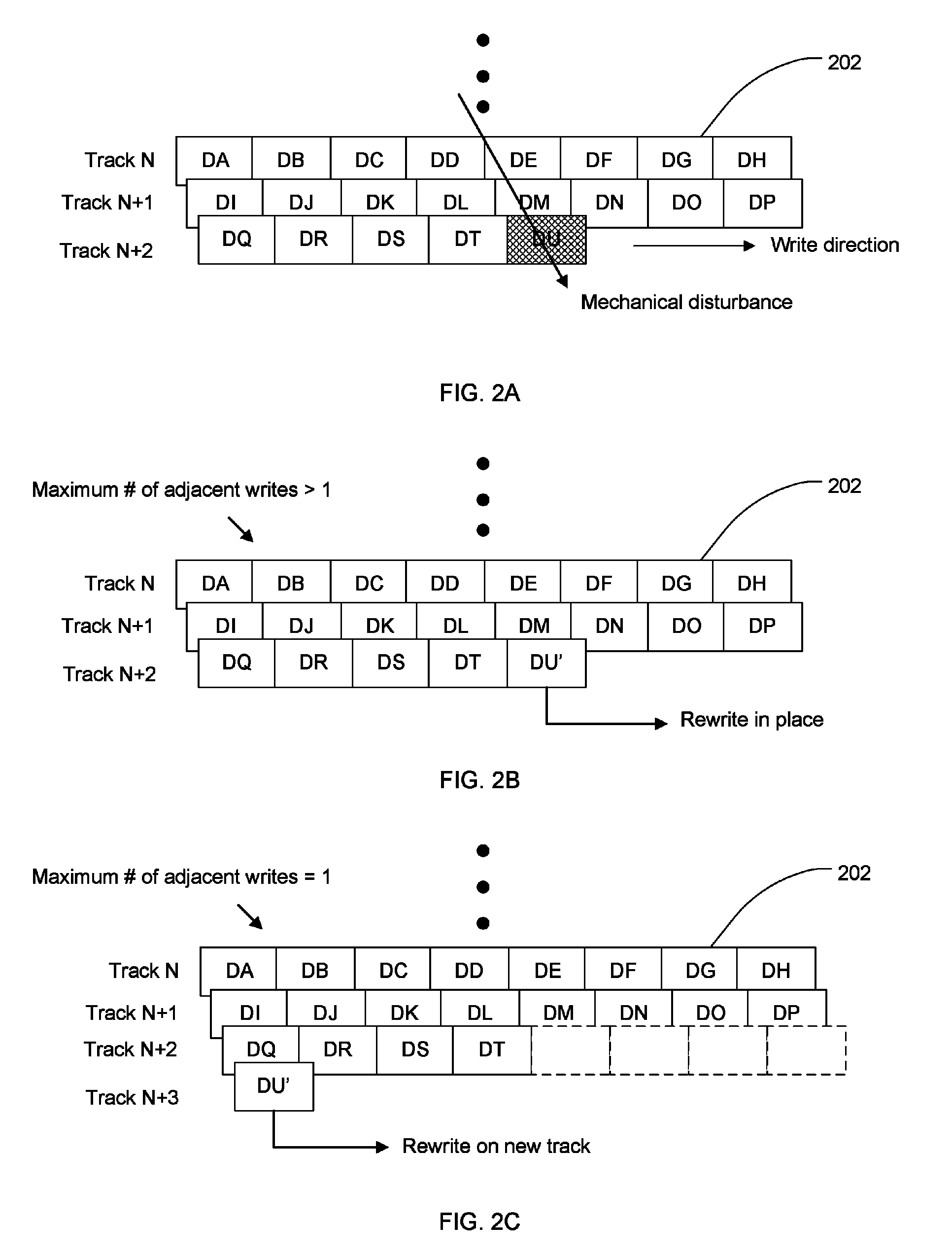

Directional write retry for shingled disk drive application

Owner:WESTERN DIGITAL TECH INC

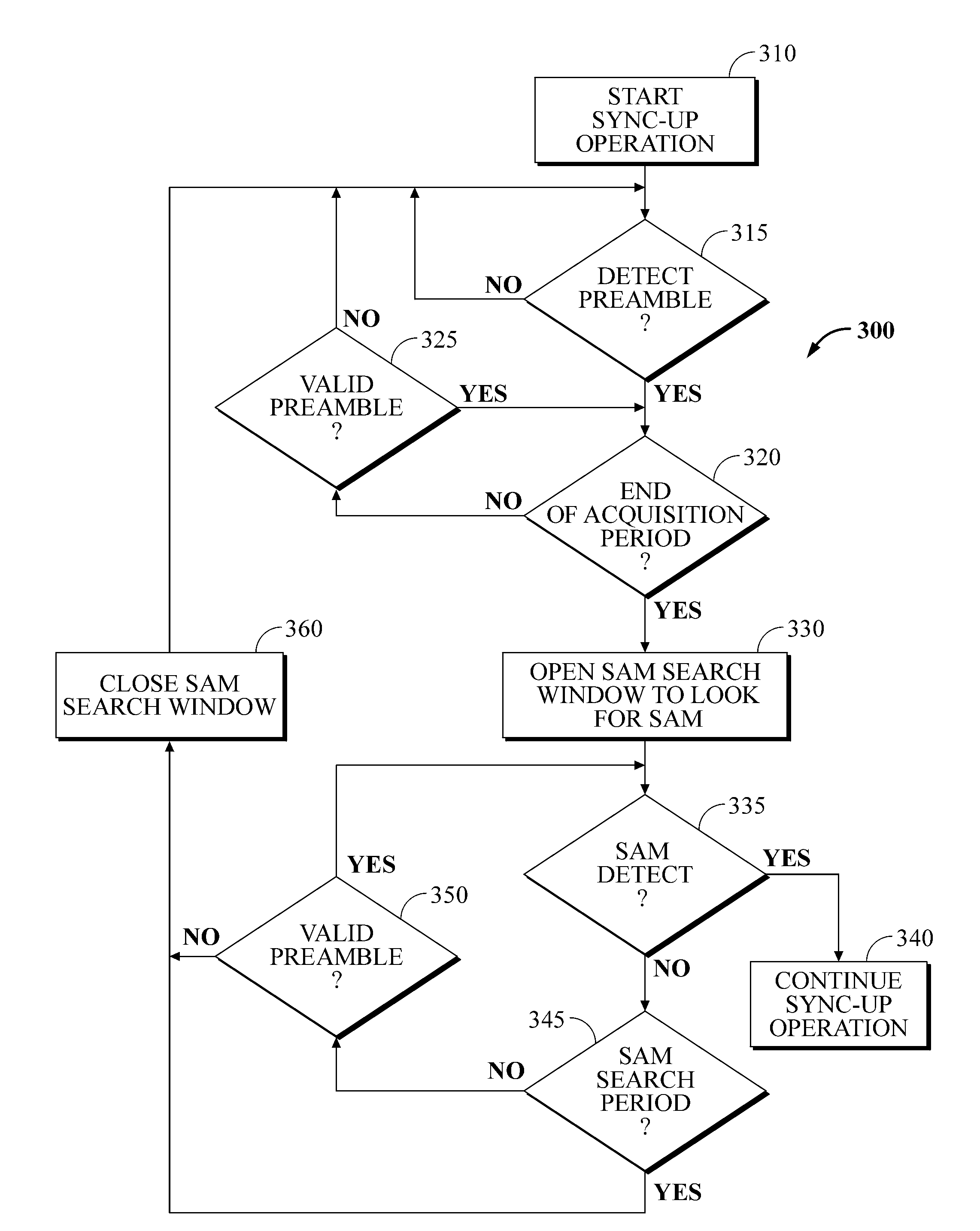

Detecting a servo address mark (SAM) in a servo field sync-up operation

ActiveUS8159768B1Record information storageAlignment for track following on disksControl theoryPreamble

A method for detecting a servo address mark (SAM) of a servo sector of a disk of a disk drive during a servo field sync-up operation is disclosed. The method includes: detecting a start of a preamble; opening a SAM search window to detect the SAM; and continuing to detect the presence of the preamble during a SAM search time period. Further, the method discloses that: if the preamble is detected, the SAM search window is continued; and if the preamble is not detected, and the SAM is not detected, the SAM search window is closed.

Owner:WESTERN DIGITAL TECH INC

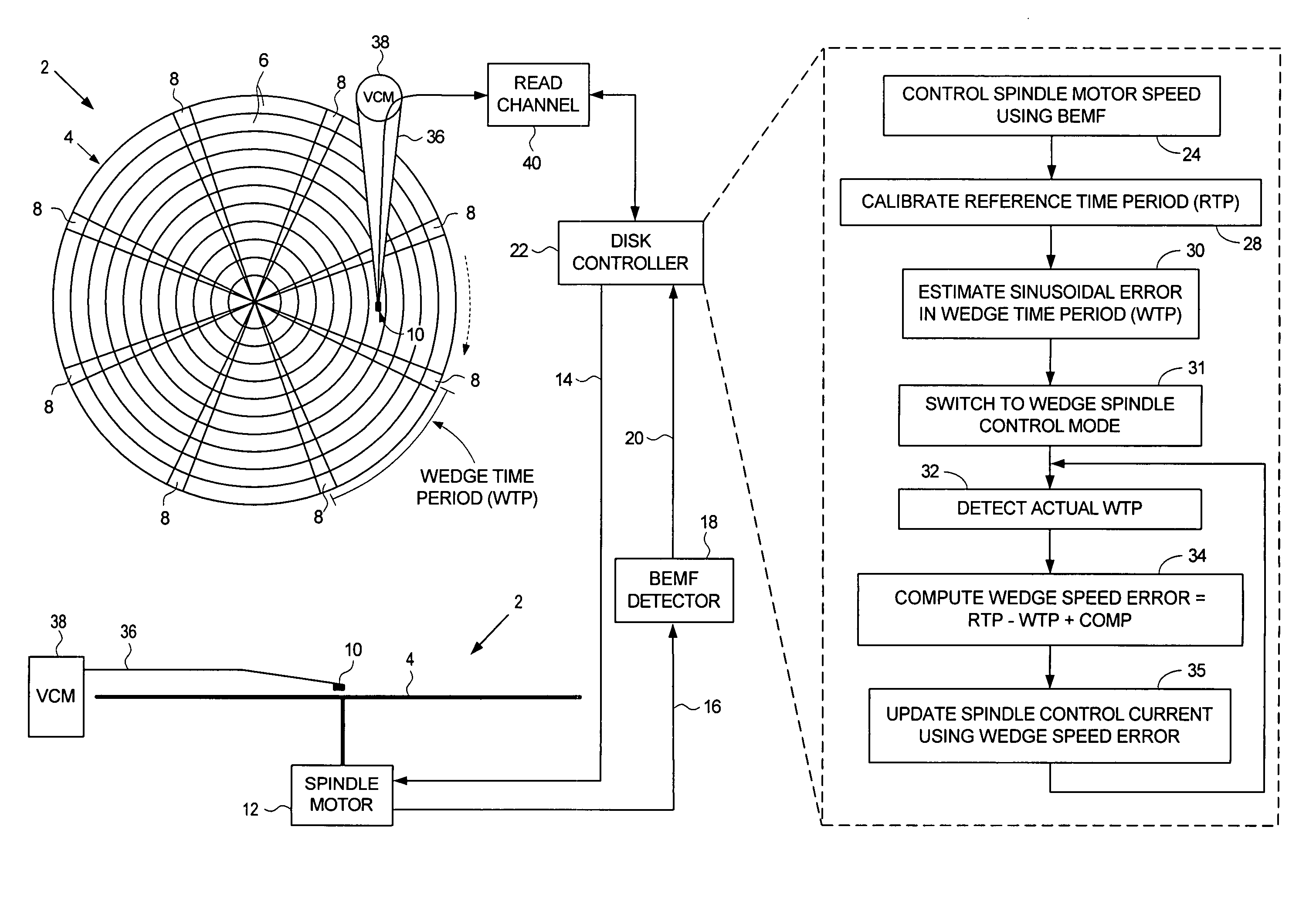

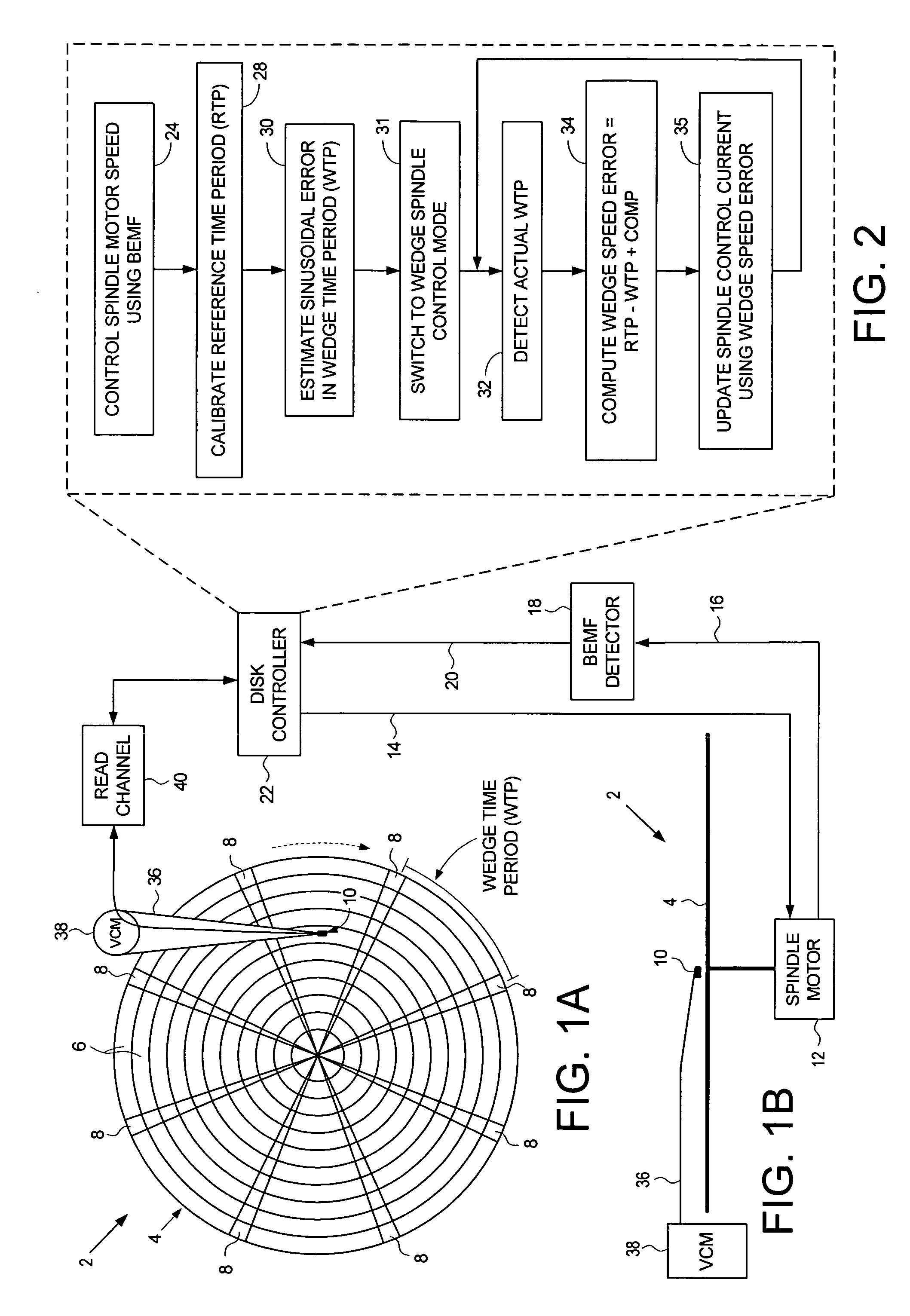

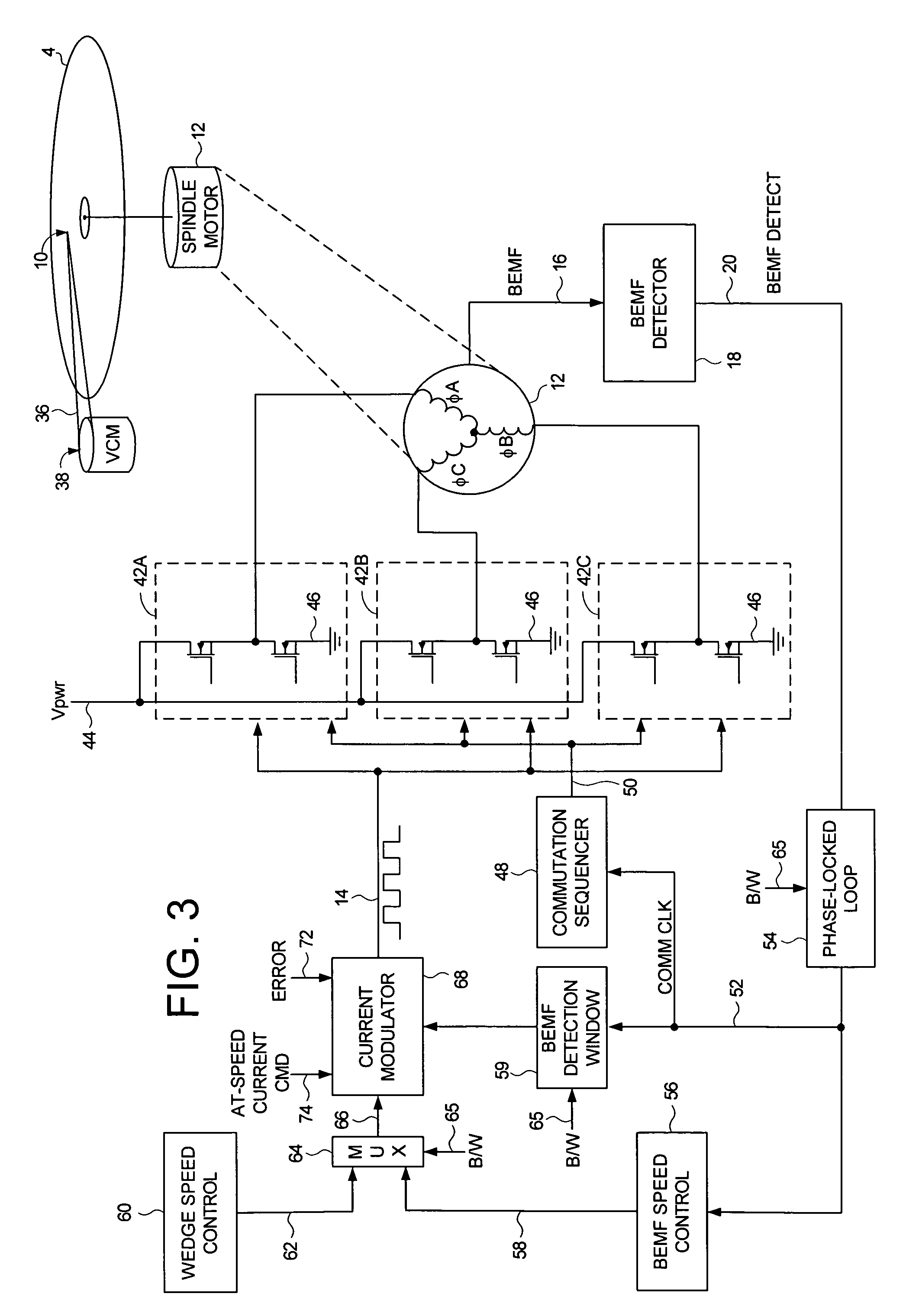

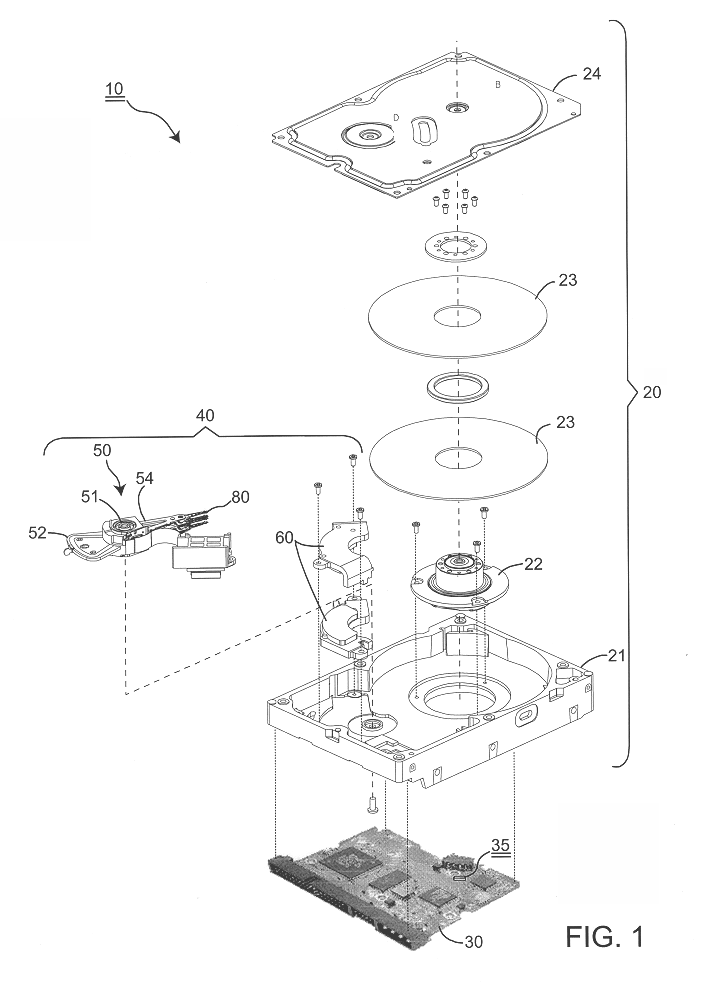

Disk drive employing wedge spindle speed control with eccentricity compensation

A disk drive is disclosed wherein a BEMF speed error is measured during a BEMF spindle speed control mode, and a spindle control current is updated in response to the BEMF speed error to drive the disk at an operating speed. A reference time period (RTP) is calibrated, and a sinusoidal error in a wedge time period (WTP) due to eccentricity in the disk rotating is estimated to generate an eccentricity compensation value. After switching to a wedge spindle speed control mode, an actual WTP is detected and a wedge speed error is generated in response to the RTP, the detected actual WTP, and the eccentricity compensation value. The disk is then maintained at the operating speed by updating the spindle control current in response to the wedge speed error.

Owner:WESTERN DIGITAL TECH INC

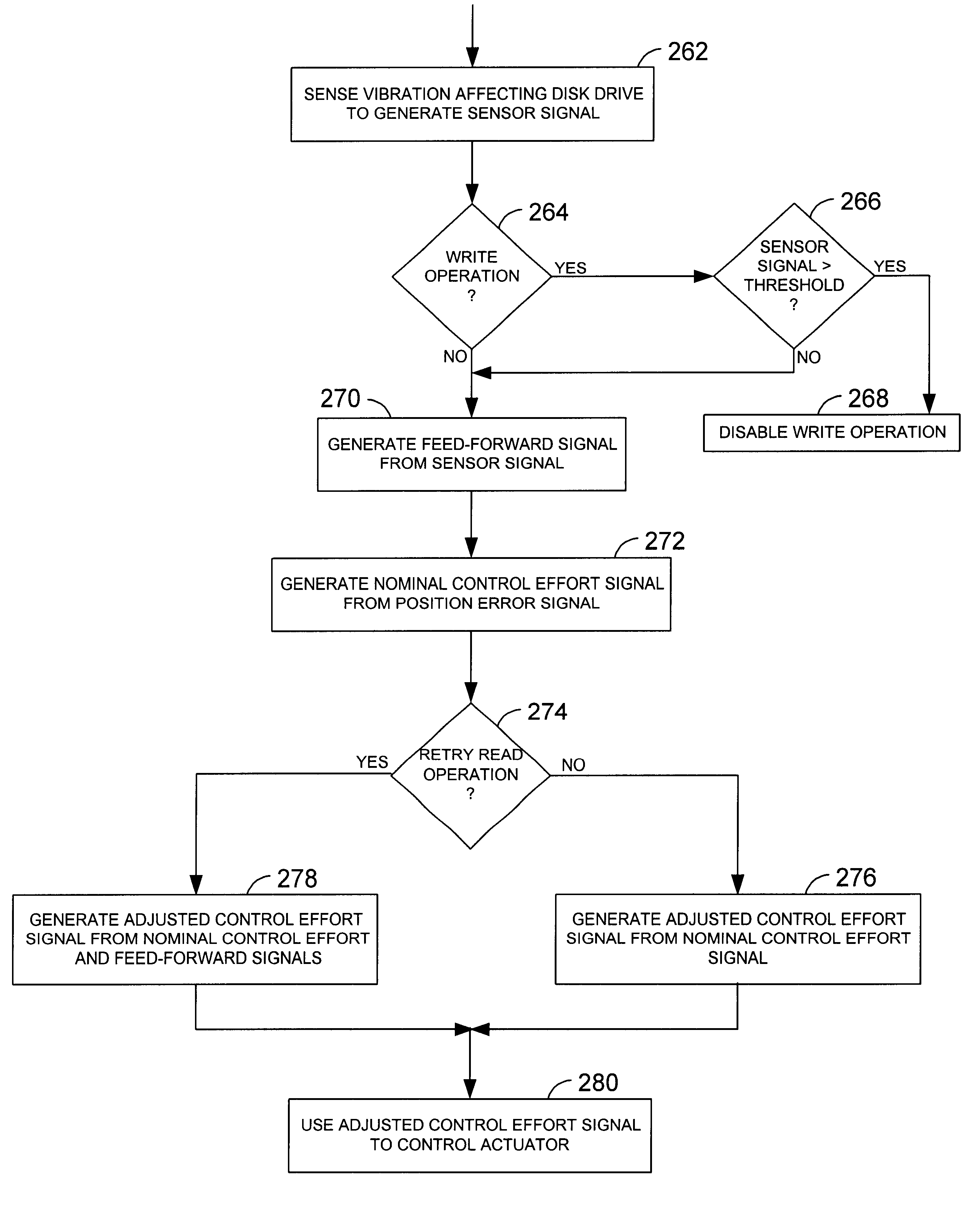

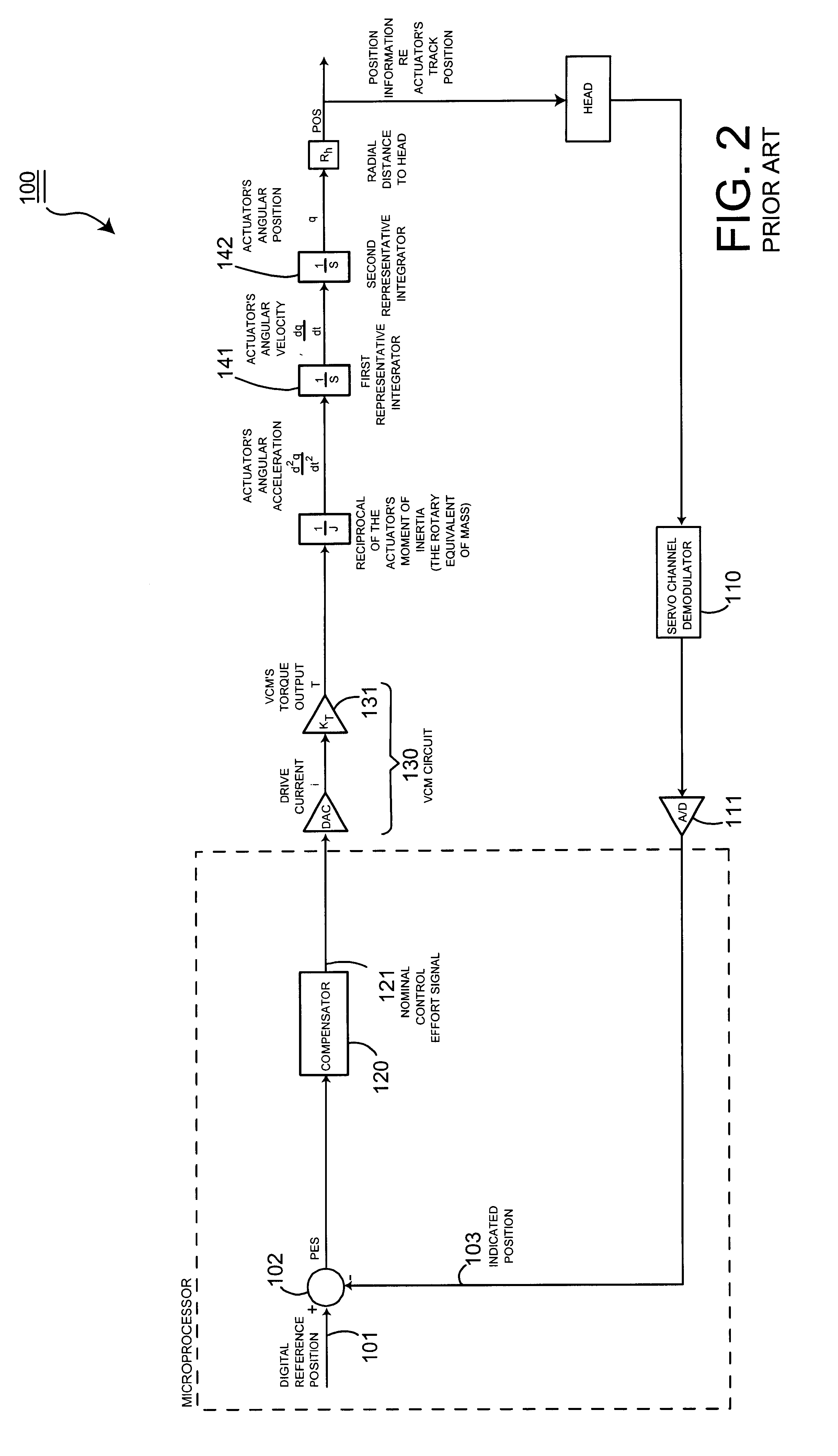

Disk drive employing adaptive feed-forward vibration compensation to enhance a retry operation

A disk drive is disclosed comprising a head, and an actuator, responsive to an adjusted control effort signal, for actuating the head radially over a disk. An adaptive feed-forward signal is generated in response to a vibration affecting the disk drive and combined with a nominal control effort signal to generate the adjusted control effort signal. During a normal read operation the feed-forward signal is substantially removed from the adjusted control effort signal, and during a retry read operation the feed-forward signal is included in the adjusted control effort signal.

Owner:WESTERN DIGITAL TECH INC

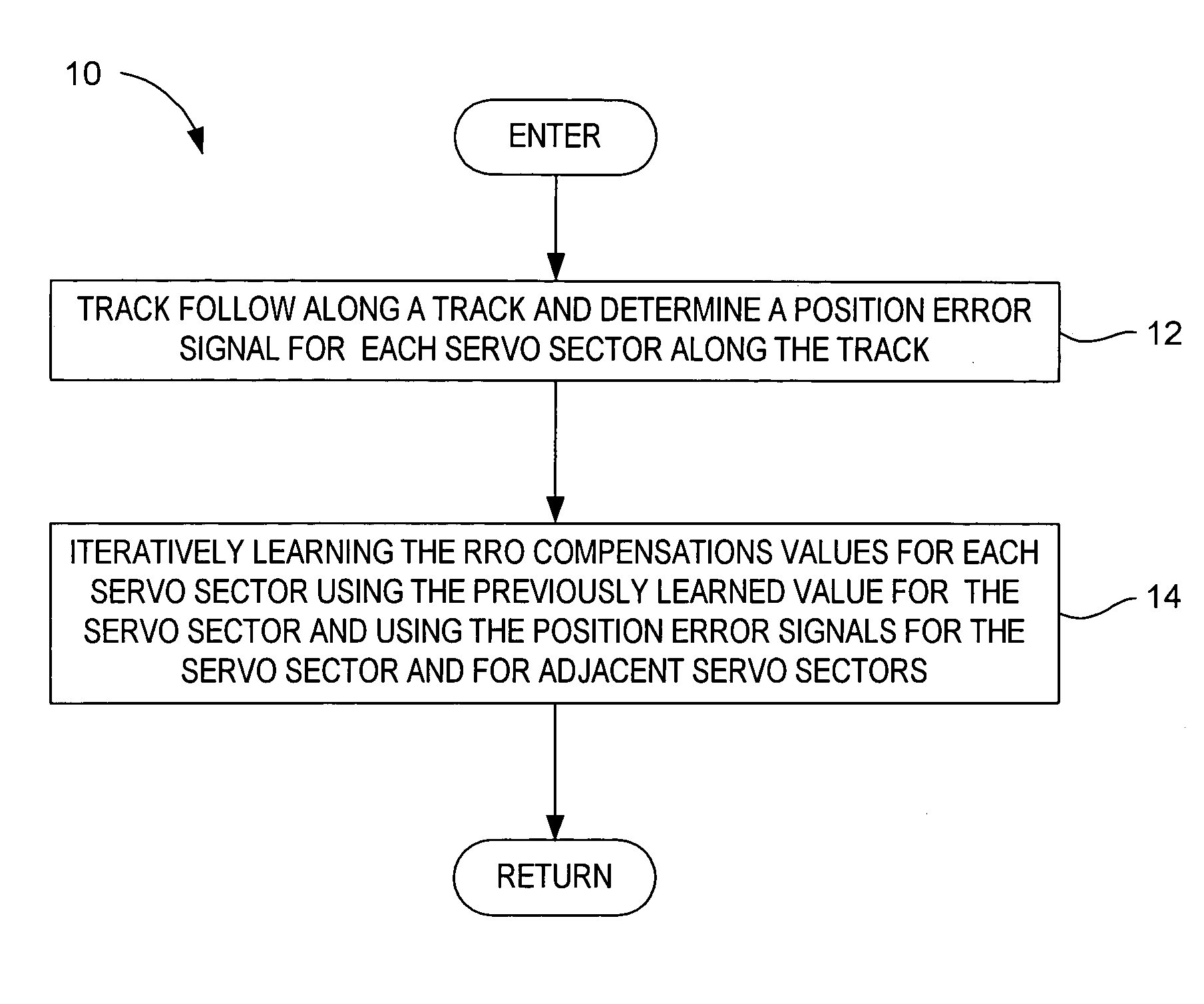

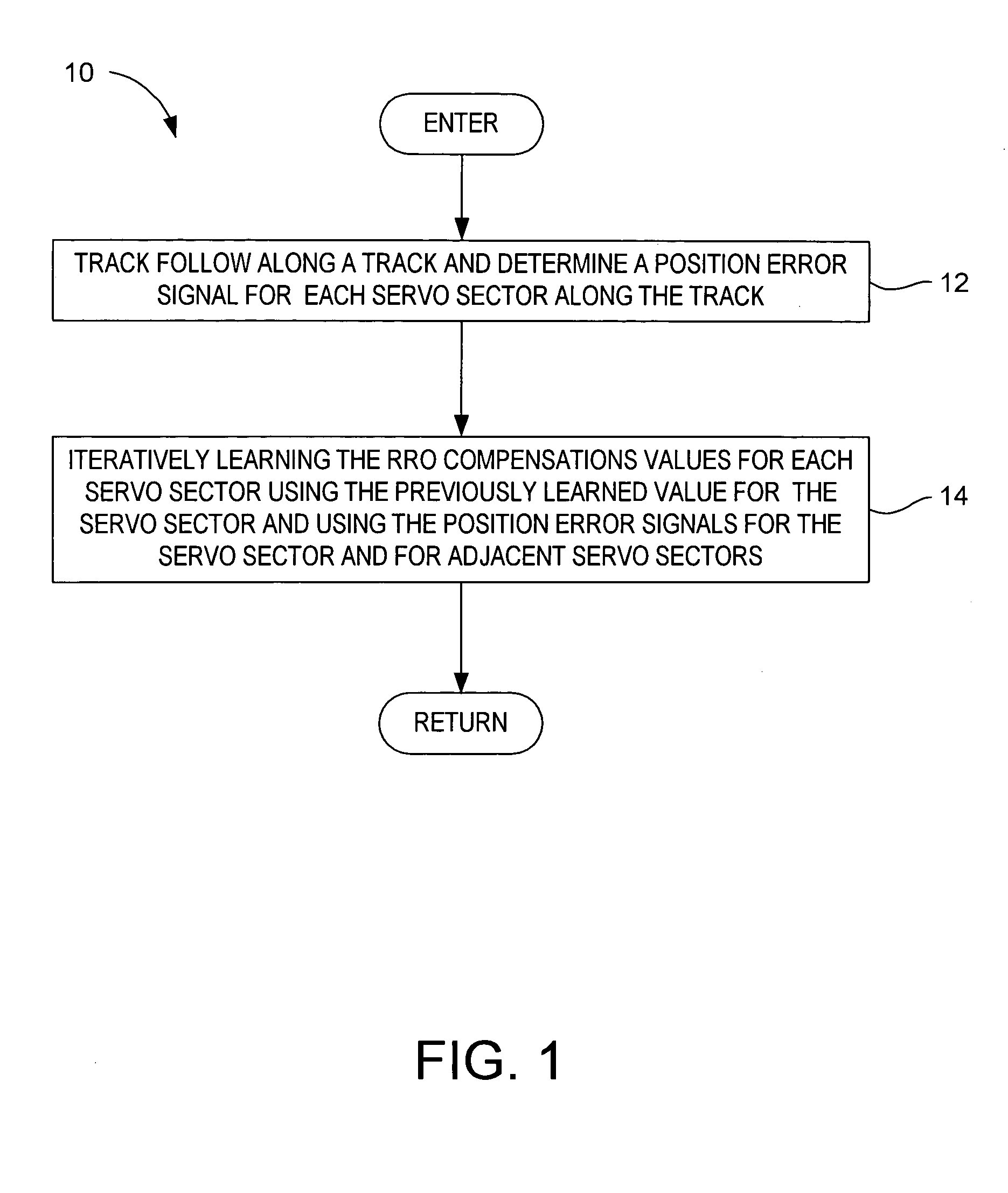

Method for iteratively determining repeatable runout cancellation values in a magnetic disk drive

InactiveUS6999267B1Record information storageAlignment for track following on disksValue setControl theory

The present invention may be embodied in a method of determining a repeatable runout (RRO) compensation value set for a data track on a magnetic disk in a disk drive. The track comprises a plurality of embedded sectors that define a circumferential path having RRO requiring compensation during data read and write operation. In the method, track following is performed along the track and a position error signal (PES) is determined for each servo sector. An RRO compensation value is iteratively learned for each servo sector using the previously learned value for the servo sector and using the PES for the servo sector and for adjacent servo sectors.

Owner:WESTERN DIGITAL TECH INC

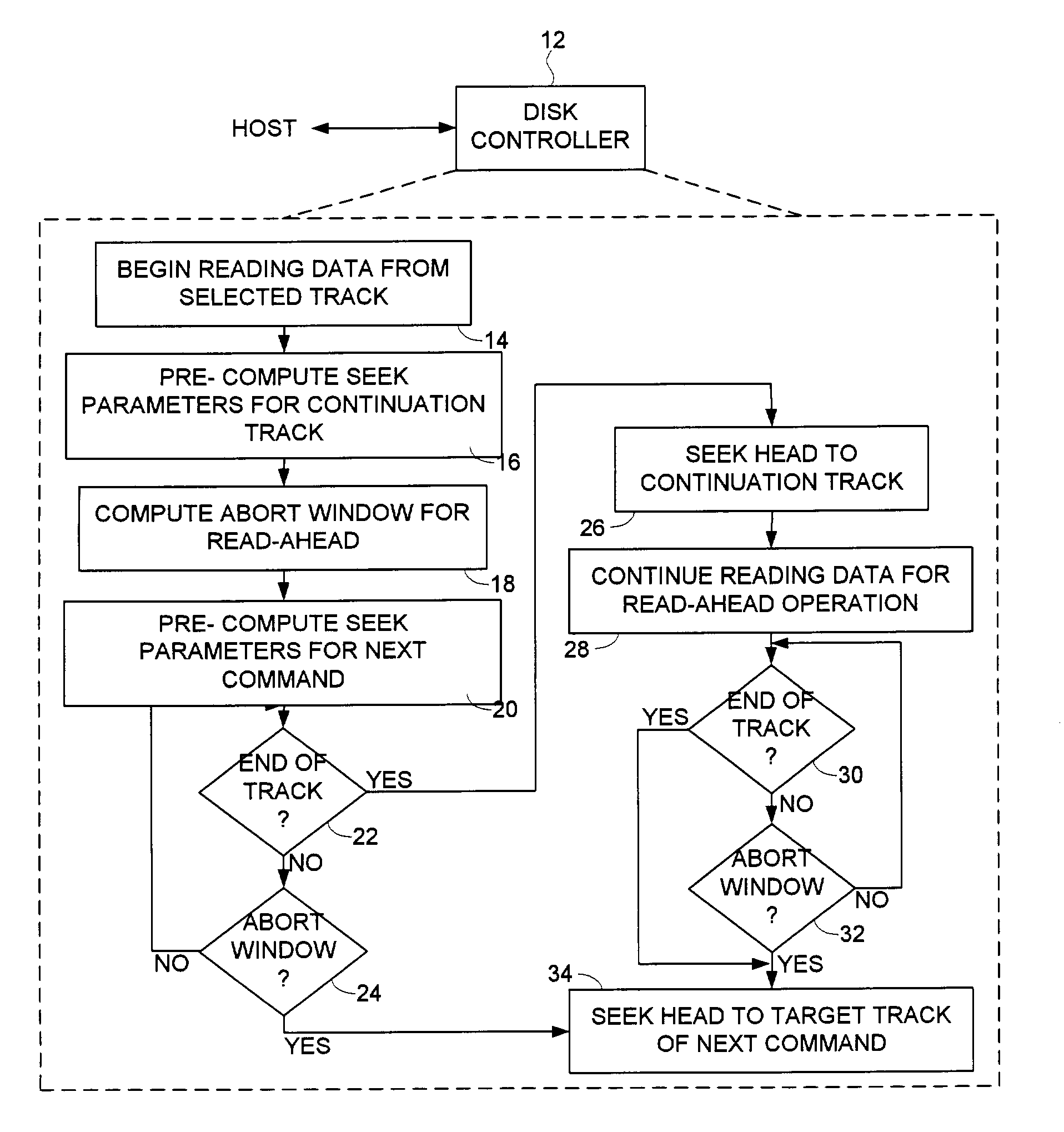

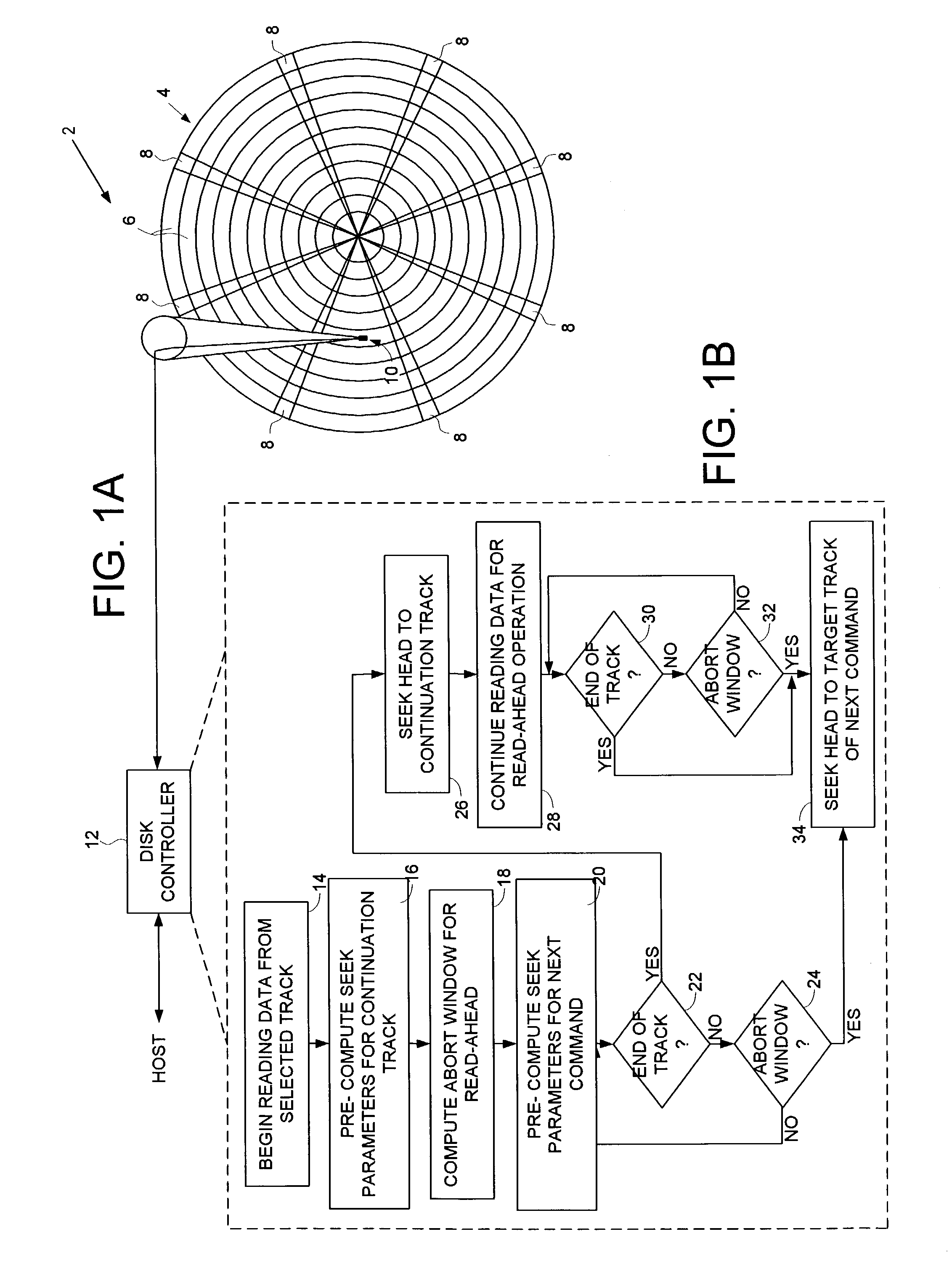

Disk drive pre-computing seek parameters for a continuation track and a next command to facilitate continuing a read-ahead or aborting the read-ahead

InactiveUS6965966B1Memory adressing/allocation/relocationRecord information storageContinuationControl theory

A disk drive is disclosed which pre-computes first seek parameters to seek to a continuation track storing read-ahead data, and second seek parameters to seek to a target track of a next command. An abort window is also computed for aborting a read-ahead operation early in order to seek to the target track of the next command. If the head enters the abort window, the disk drive is programmed with the second seek parameters to seek to the target track of the next command. If the read-ahead operation requires a seek to the continuation track prior to the head entering the abort window, the disk drive is programmed with the first seek parameters to seek to the continuation track.

Owner:WESTERN DIGITAL TECH INC

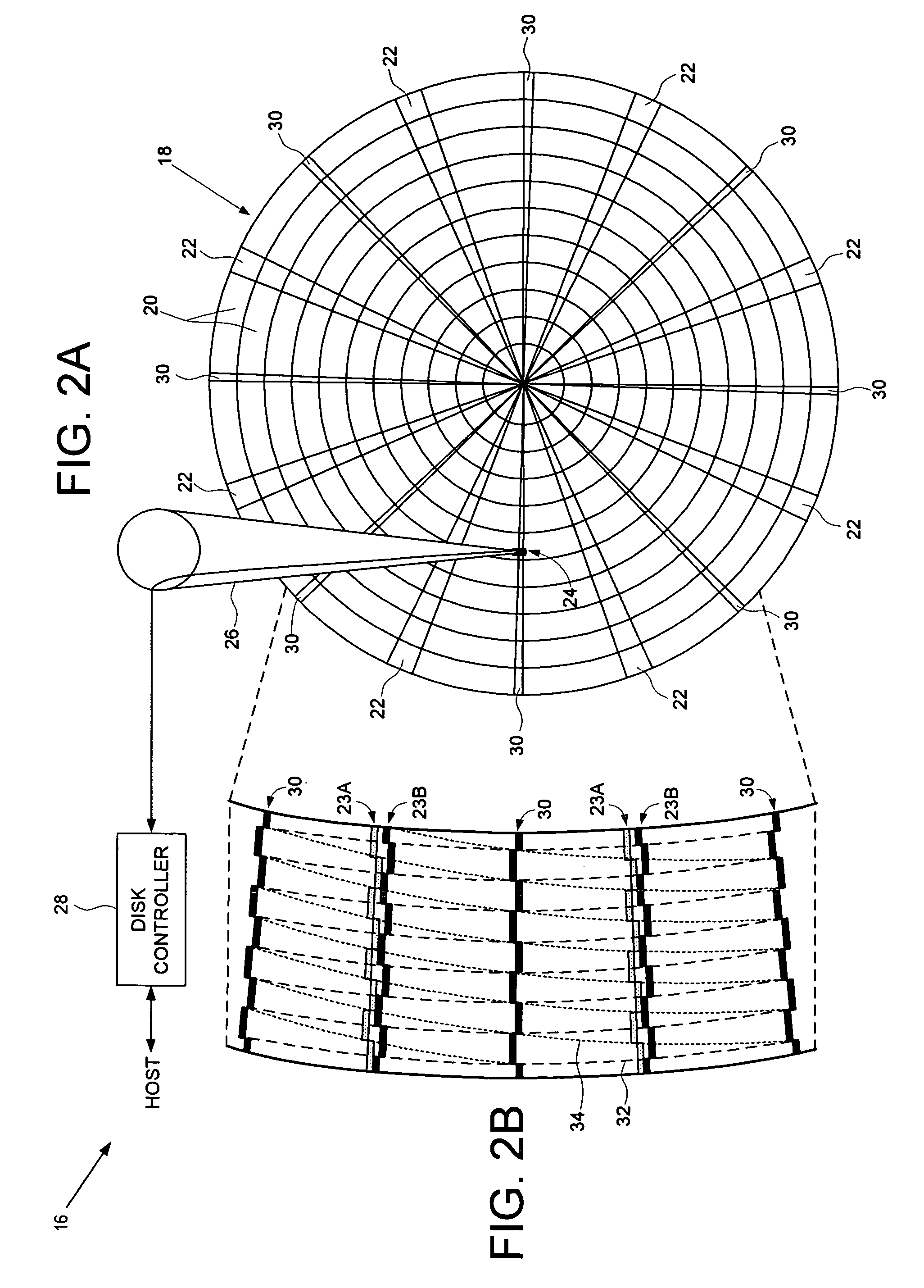

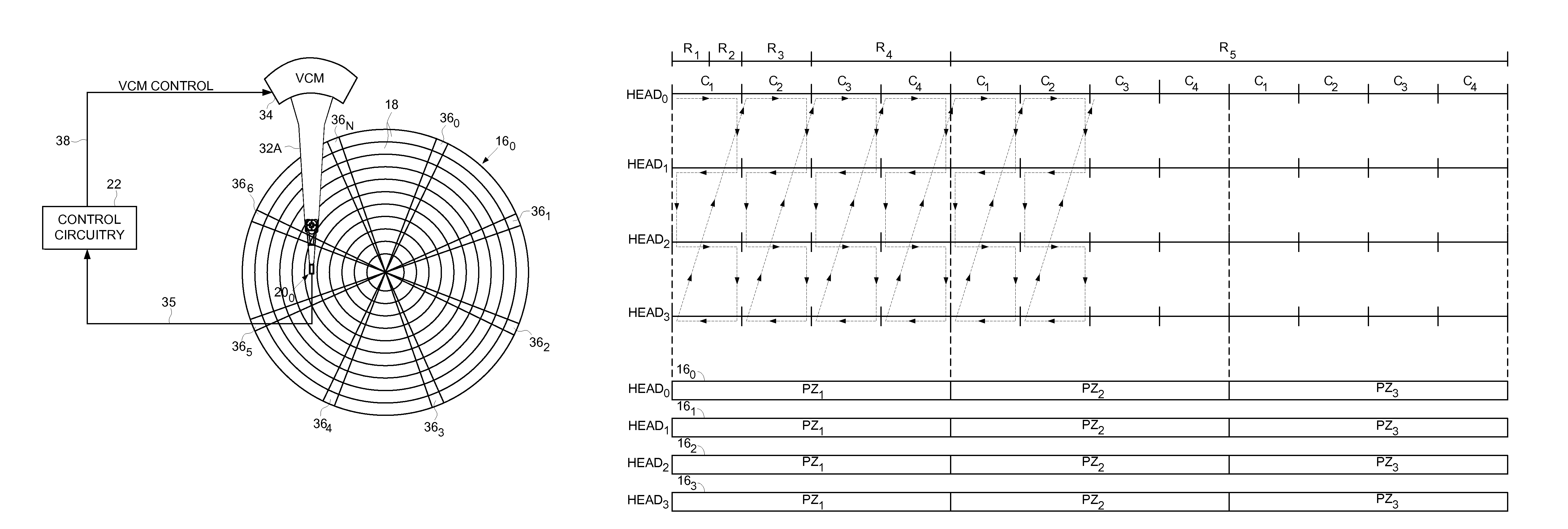

Disk drive reading servo sectors recorded at a relative offset on multiple disk surfaces to increase the servo sample rate

A disk drive is disclosed comprising a first disk surface and a second disk surface, wherein a first head is actuated radially over the first disk surface and a second head is actuated radially over the second disk surface. Each disk surface comprises a plurality of tracks, wherein each track comprises a plurality of data sectors for storing user data and N embedded servo sectors for storing servo data. The N embedded servo sectors on the tracks on the first disk surface are recorded at a physical angular offset from the N embedded servo sectors on the tracks on the second disk surface. While accessing a track on the first disk surface through the first head, the servo data on the first disk surface is read through the first head and the servo data on the second disk surface is read through the second head, thereby increasing the servo sample rate.

Owner:WESTERN DIGITAL TECH INC

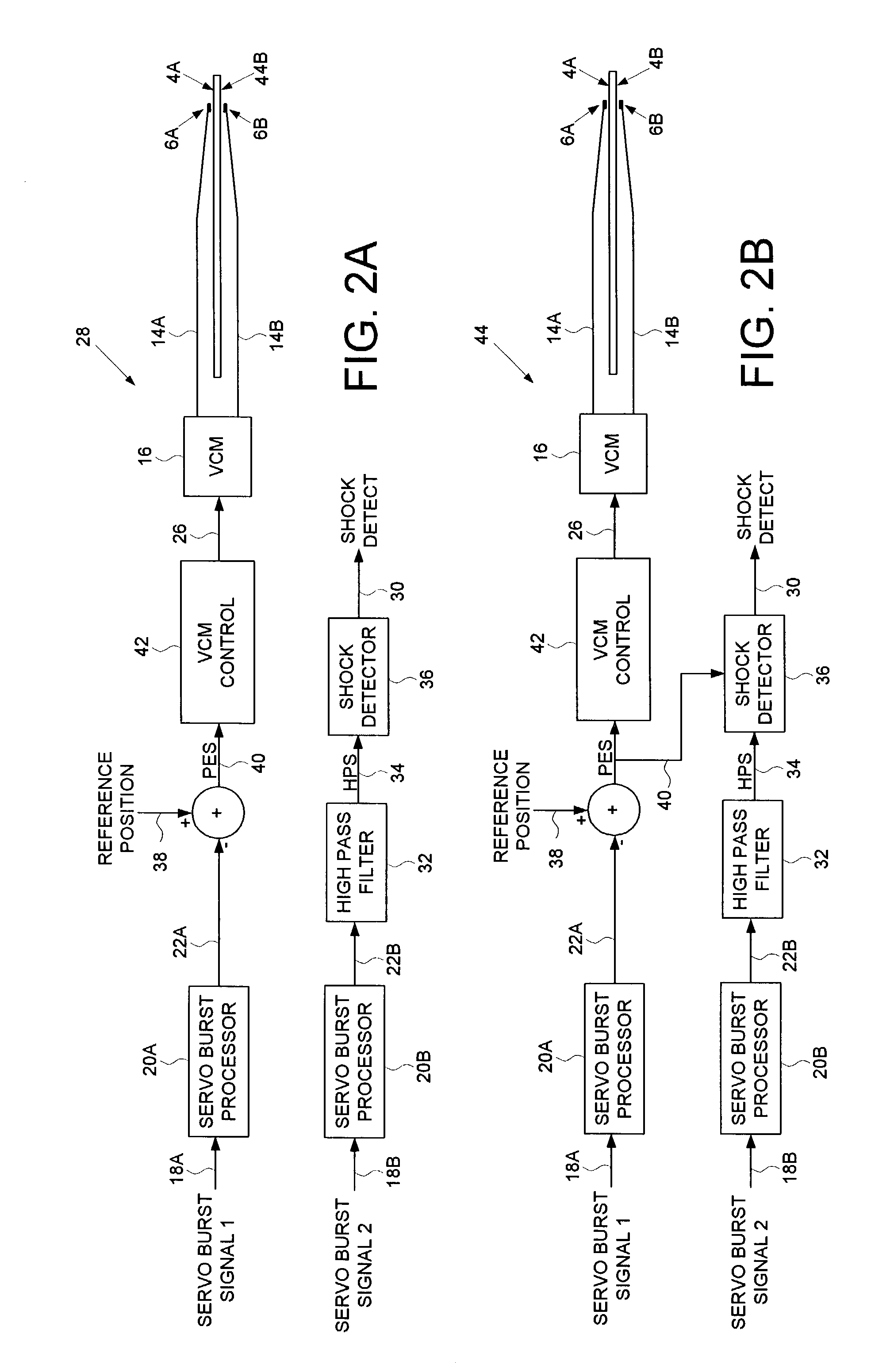

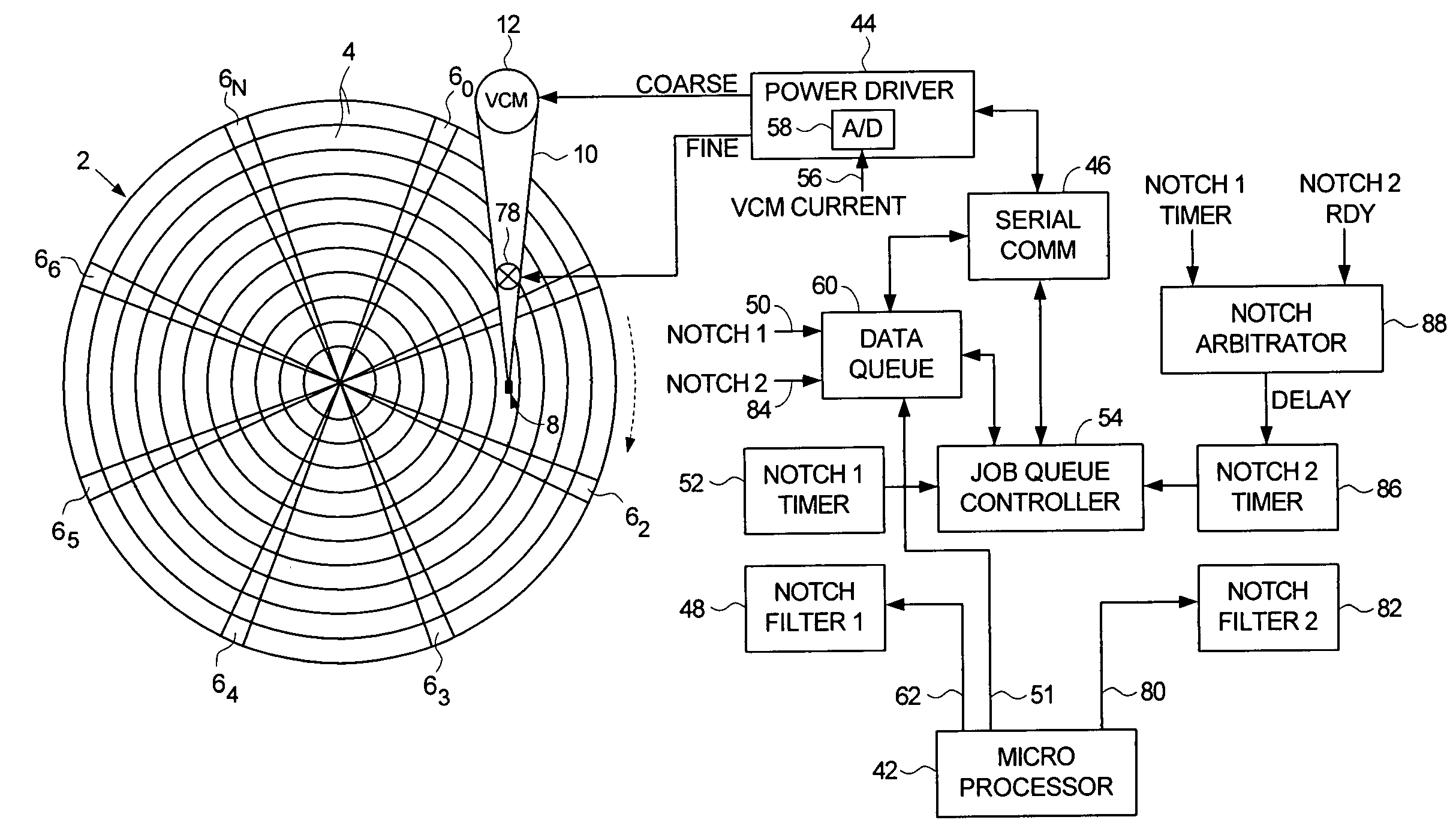

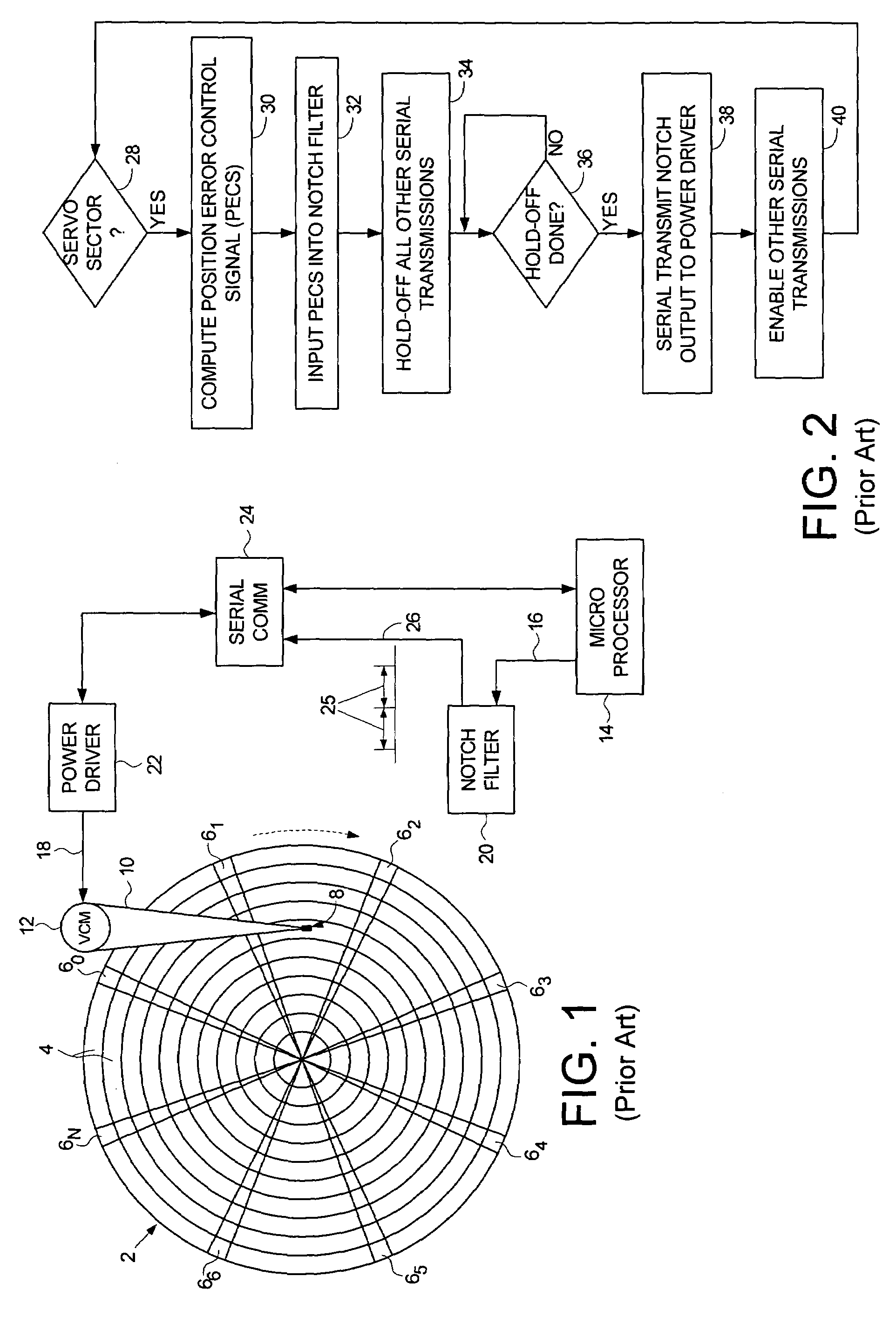

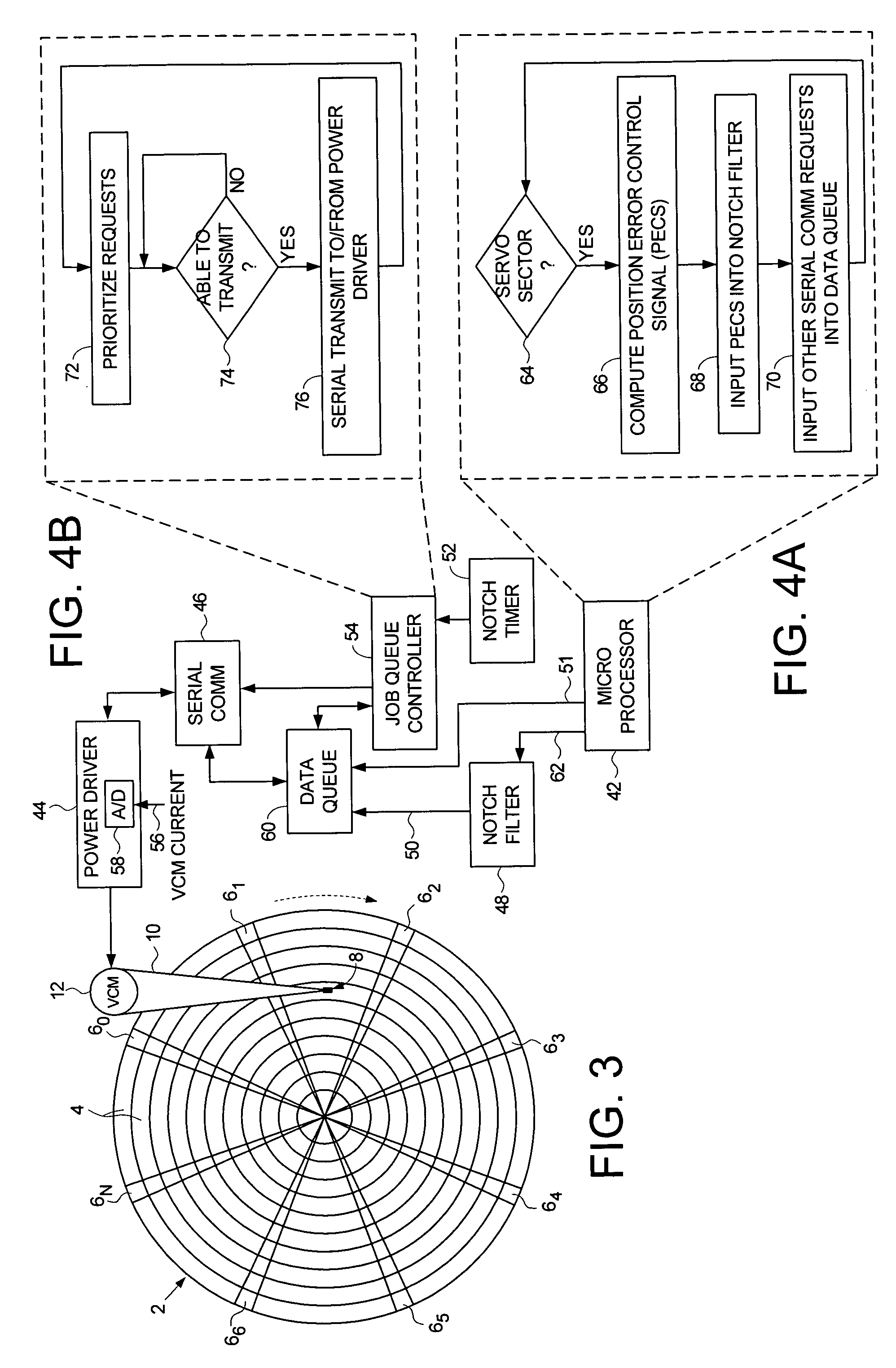

Disk drive using a timer to arbitrate periodic serial communication with a power driver

InactiveUS7106537B1Driving/moving recording headsFilamentary/web record carriersControl signalEngineering

A disk drive is disclosed comprising a microprocessor and a power driver for generating at least one actuator signal applied to the VCM actuator, wherein a serial communication circuit is used to communicate with the power driver. At least one control component periodically generates a control signal, wherein the control signal is transmitted at a substantially constant periodic interval using the serial communication circuit, and a timer times the periodic interval. A job queue controller queues and arbitrates serial communication requests to access the power driver using the serial communication circuit. The serial communication requests include a request to transmit the control signal and requests generated by the microprocessor. The job queue controller services a communication request generated by the microprocessor if the communication request can be serviced before the timer expires.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com