Method of manufacturing glass substrate for magnetic disk, method of manufacturing magnetic disk, and polishing apparatus of glass substrate for magnetic disk

a technology of glass substrate and magnetic disk, which is applied in the direction of base layer manufacturing, edge grinding machines, manufacturing tools, etc., can solve the problems of inconvenient formation of portions, thermal asperity trouble, read error, etc., and achieve high processing accuracy, high polishing speed, and low inner diameter tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

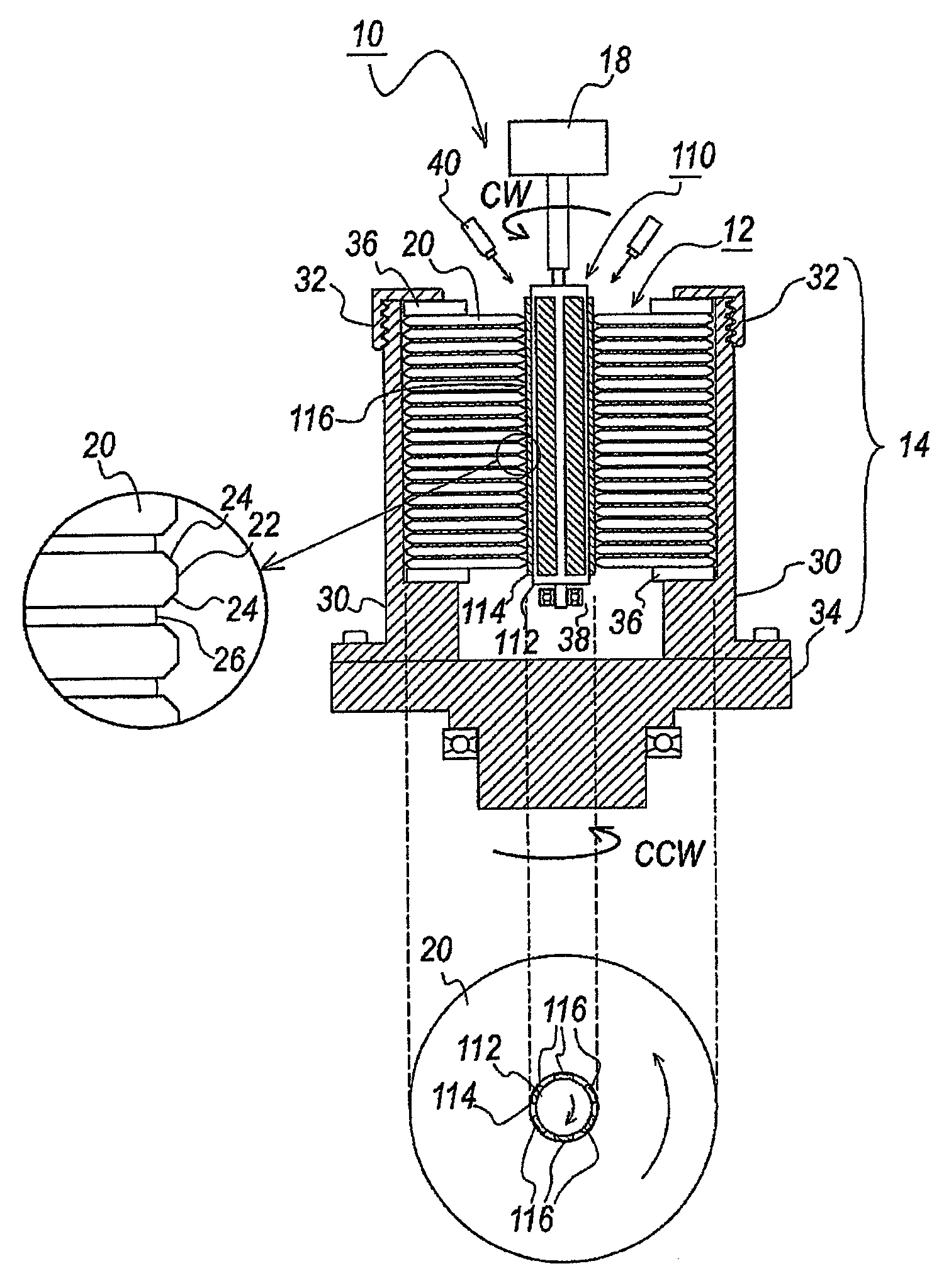

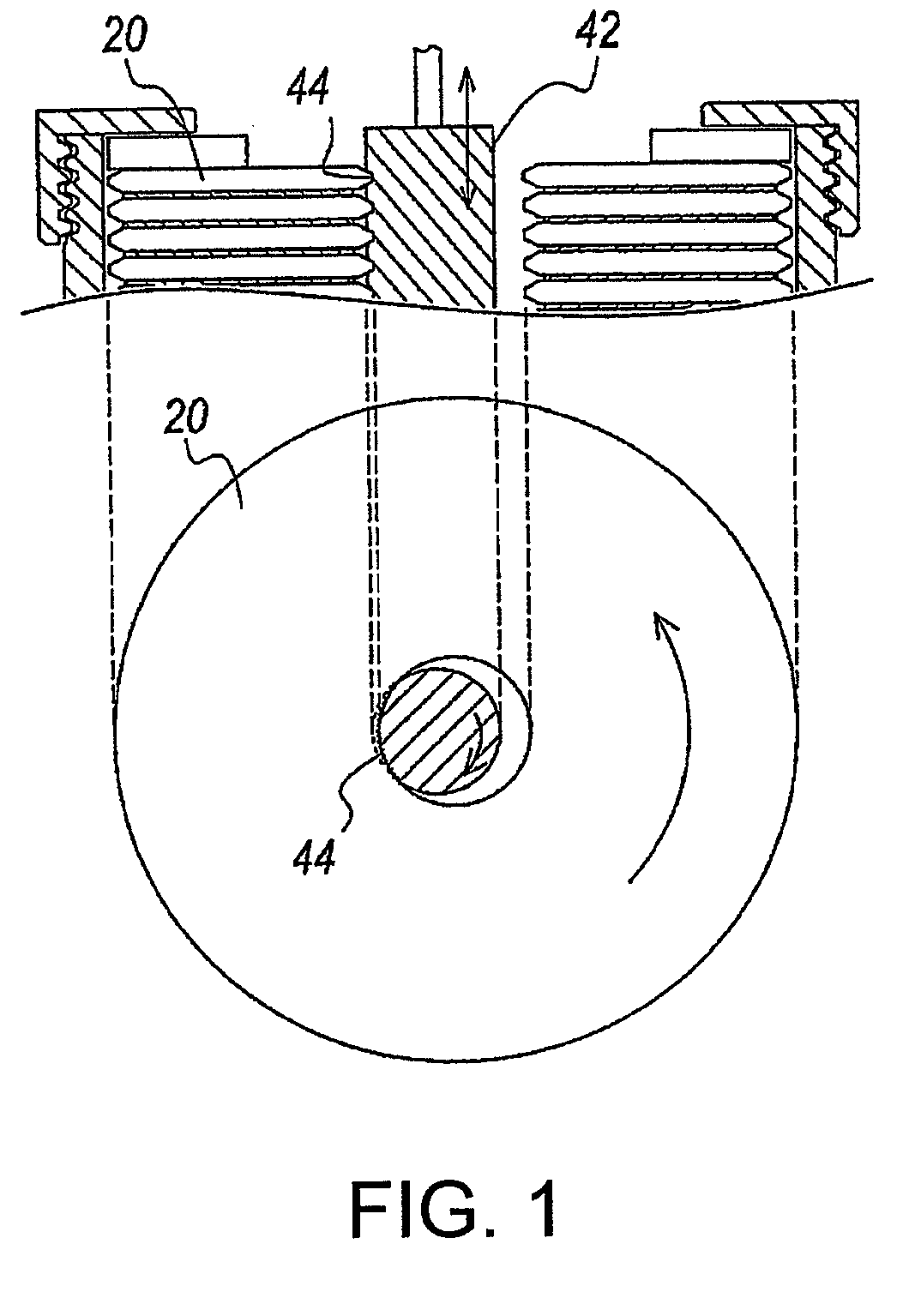

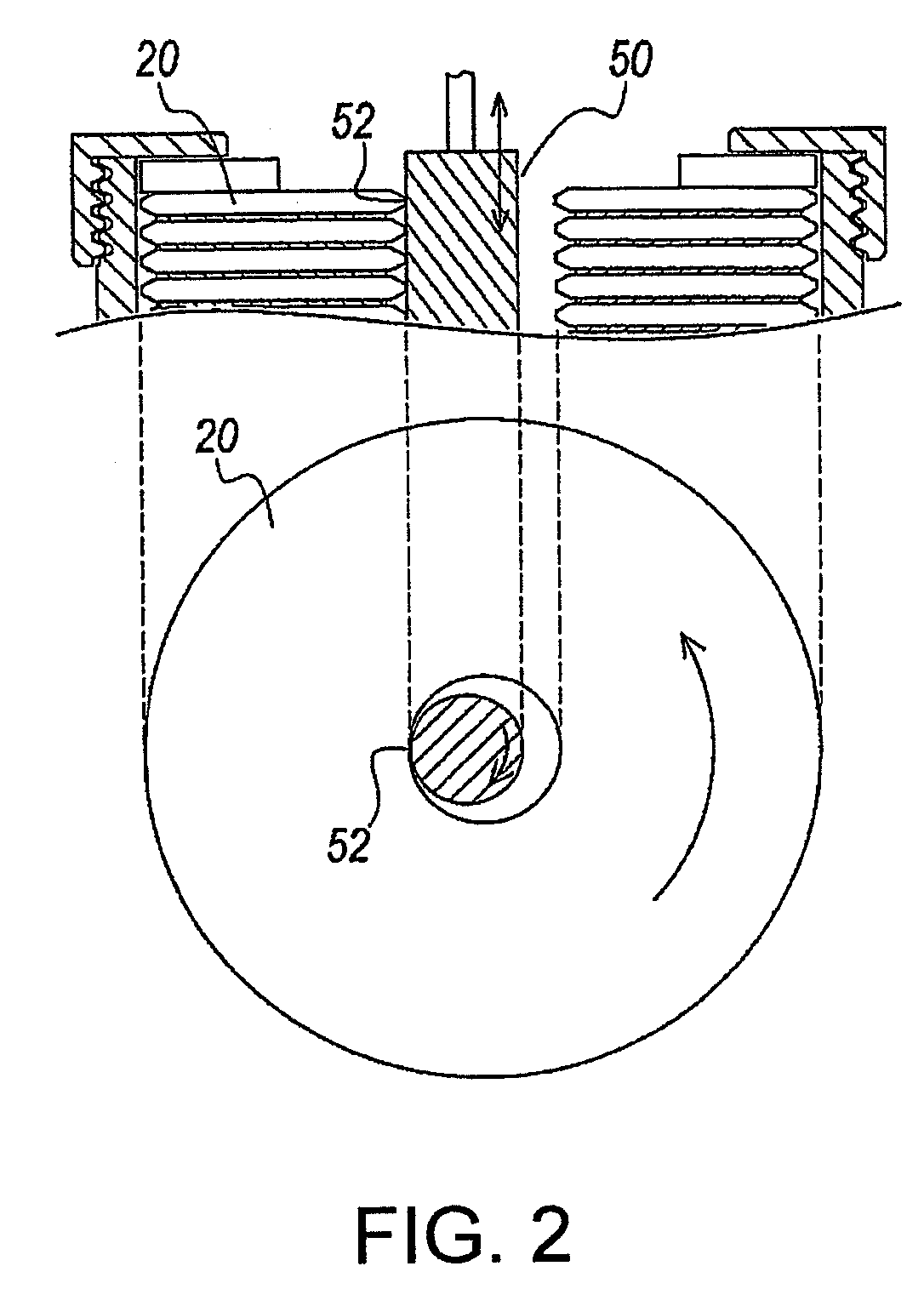

Method used

Image

Examples

example 1

[0116]In the example, a glass substrate for a magnetic disk and a magnetic disk were manufactured through the following steps. Particularly, in an end face polishing step, the polishing method according to the embodiment is used.

(1) Shaping Step and First Lapping Step

[0117]First, melted alminosilicate glass was molded into a disk shape by direct press using an upper mold, a lower mold, and a sleeve mold, so that amorphous plate-like glass was obtained. As the alminosilicate glass, glass for chemical strengthening was used. In addition to direct press, the disk-like glass substrate for a magnetic disk may be obtained by cutting sheet glass, which is formed by a down draw method or float method, by a grinding stone. As the alminosilicate glass, chemical strengthening glass was used, which mainly contains SiO2 of 58 to 75 wt %, Al2O3 of 5 to 23 wt %, Li2O of 3 to 10 wt %, and Na2O of 4 to 13 wt %.

[0118]Next, both main surfaces of the plate-like glass were subjected to lapping to be for...

example 2

[0152]A glass substrate for a magnetic disk was manufactured in the same way as in the example 1 except for performing a chemical strengthening step before an end face polishing step in the descried manufacturing method. Removal depth of the inner circumferential end face in the end face polishing step was 4 μm, and inner diameter circularity of the glass substrate was 3 μm after the end face polishing step. A magnetic disk was manufactured in the same way as in the example by using the glass substrate for a magnetic disk. The magnetic disk was subjected to a glide test, as a result, hit or crush was not found. Furthermore, a reproducing test was performed using a magnetoresistive head, as a result, false operation caused by thermal asperity was not found in reproducing.

[0153]While the preferred embodiment of the invention was described with reference to accompanying drawings hereinbefore, it will be appreciated that the invention was not limited to such embodiment. It is obvious th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| removal depth | aaaaa | aaaaa |

| Ra | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com