Patents

Literature

950results about "Base layer manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

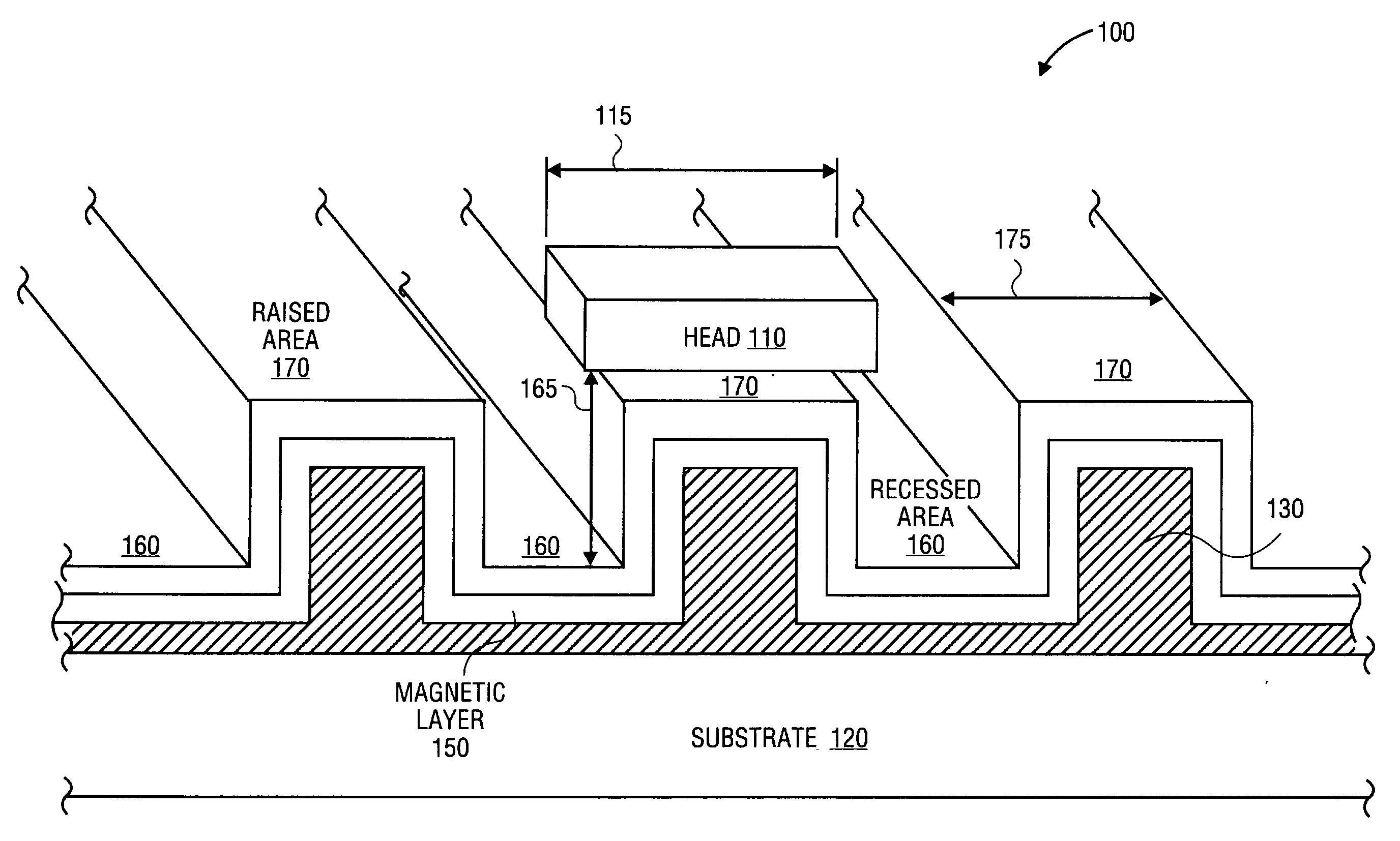

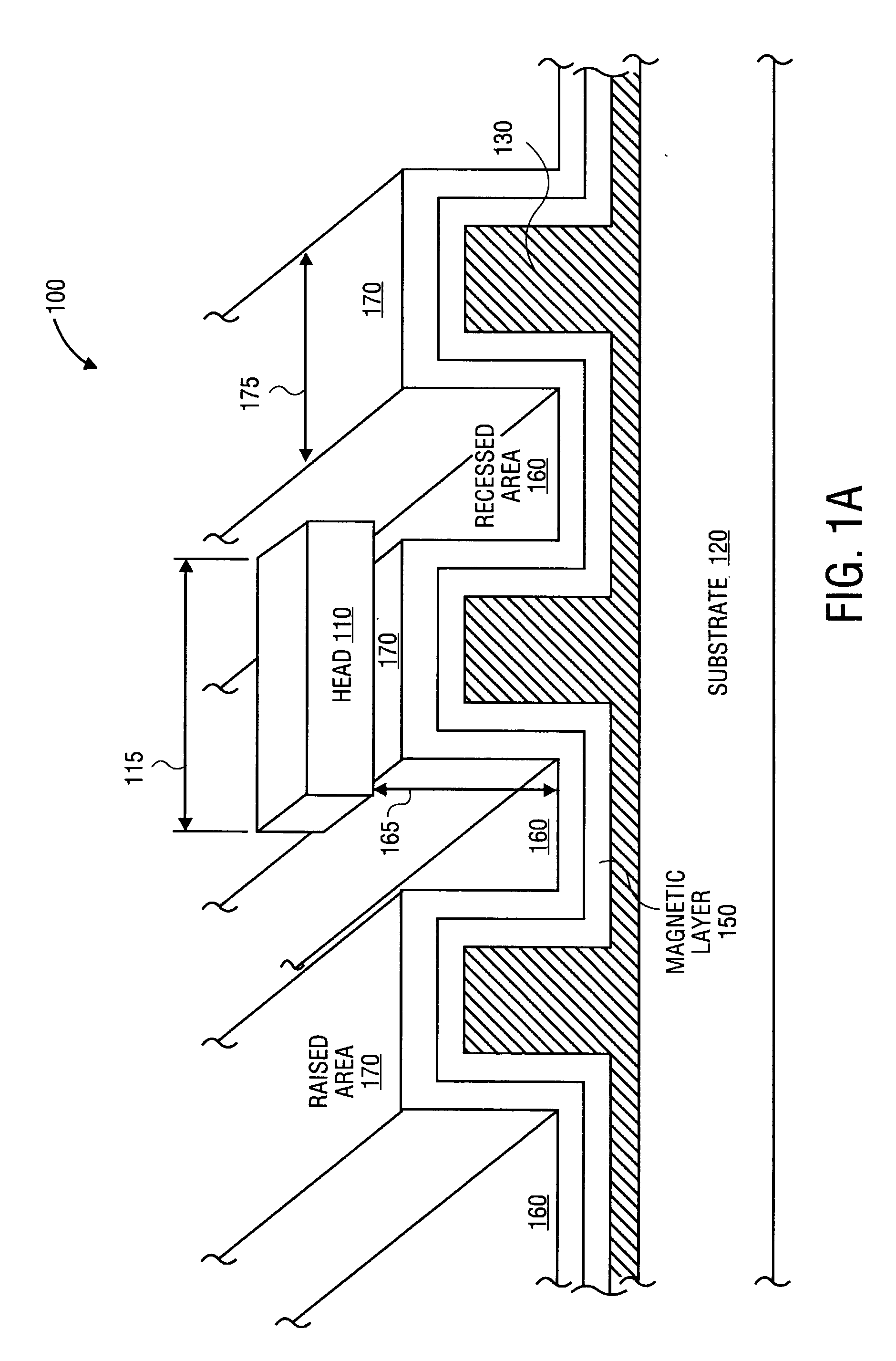

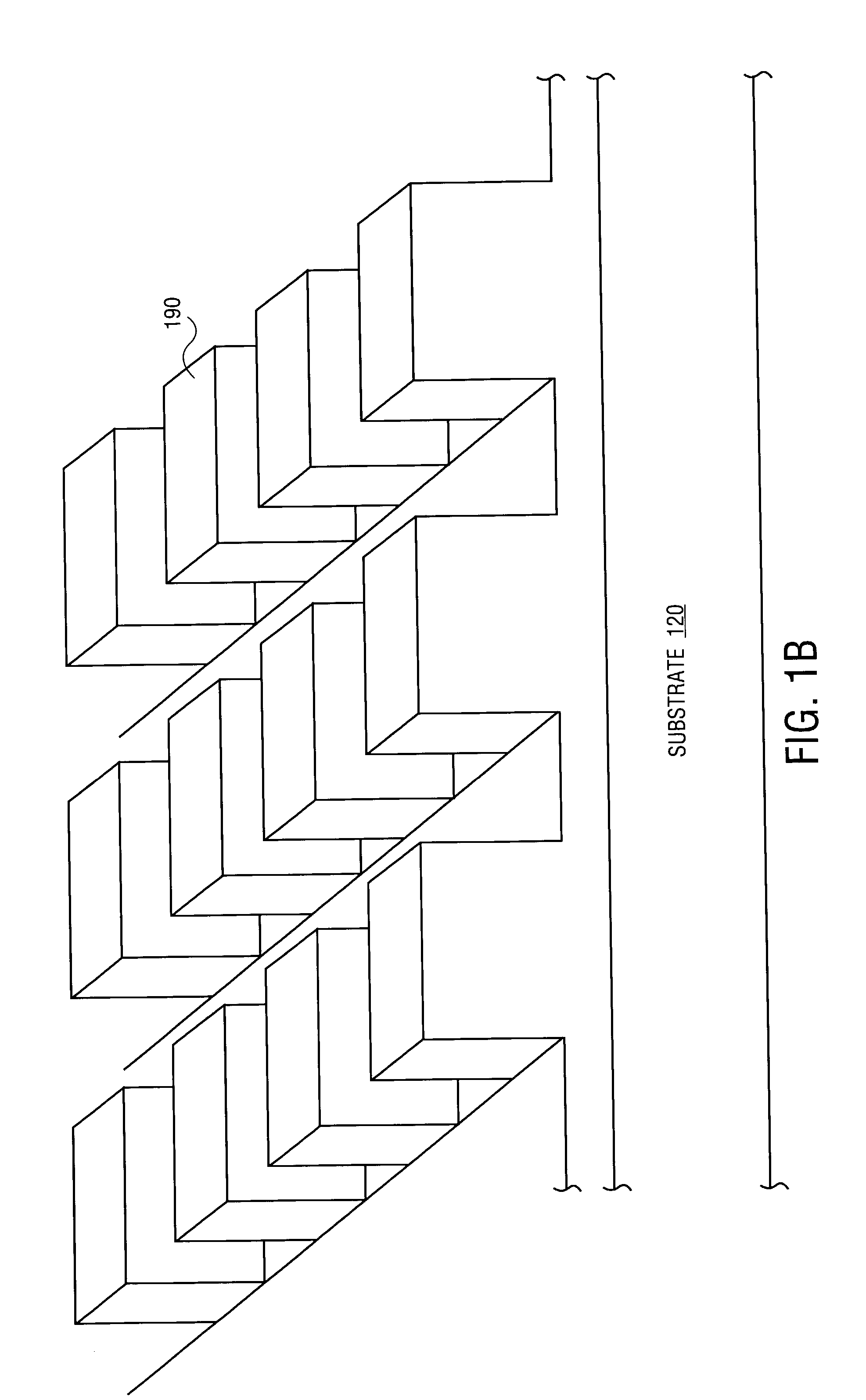

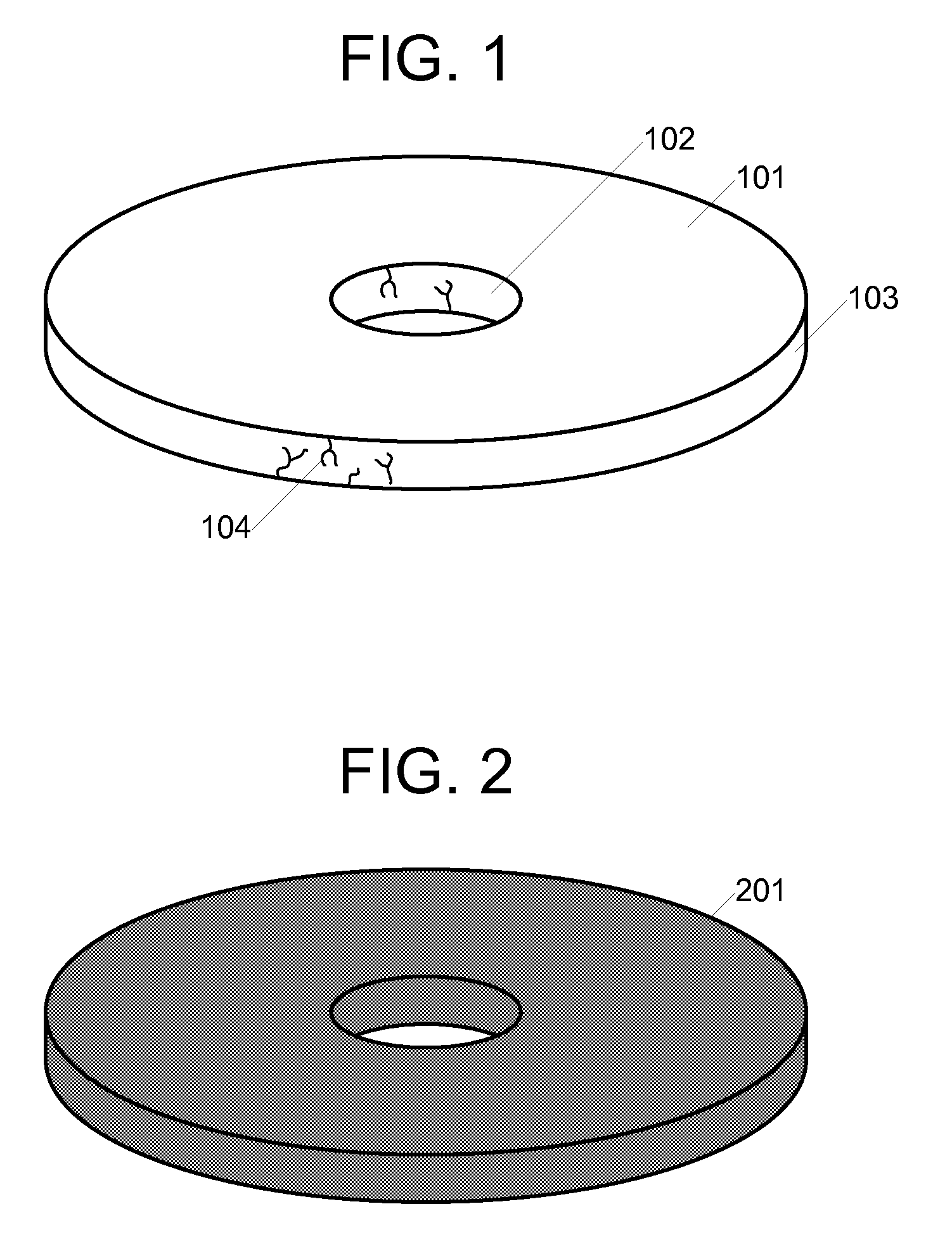

Magnetic discrete track recording disk

InactiveUS20050036223A1Protective coatings for layersBase layers for recording layersComputer science

Owner:KOMAG

Magnetic tape

Provided is a magnetic tape in which ferromagnetic powder included in a magnetic layer is ferromagnetic hexagonal ferrite powder having an activation volume equal to or smaller than 1,600 nm3, the magnetic layer includes one or more components selected from the group consisting of fatty acid and fatty acid amide, and an abrasive, a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %, and a tilt cos θ of the ferromagnetic hexagonal ferrite powder with respect to the surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

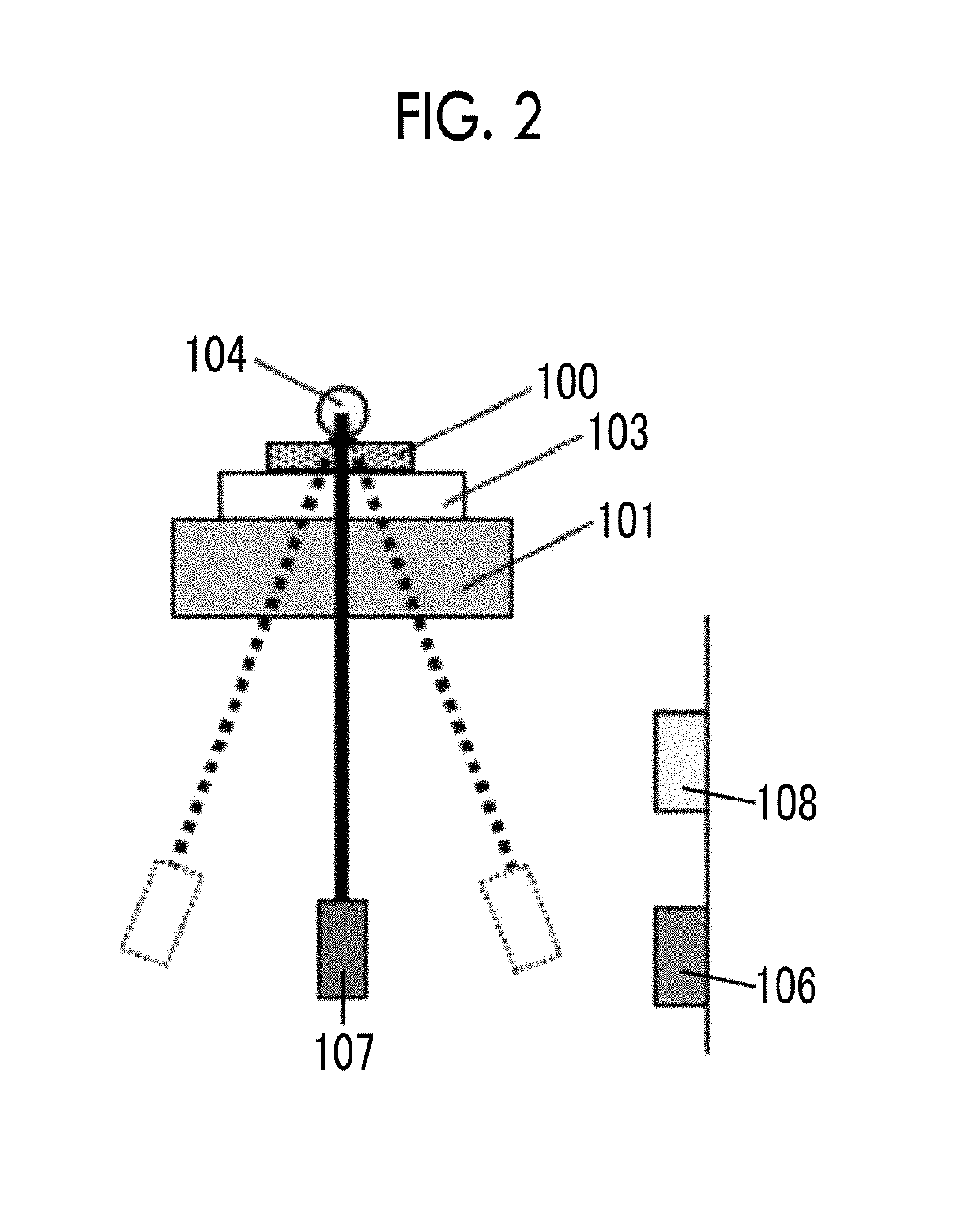

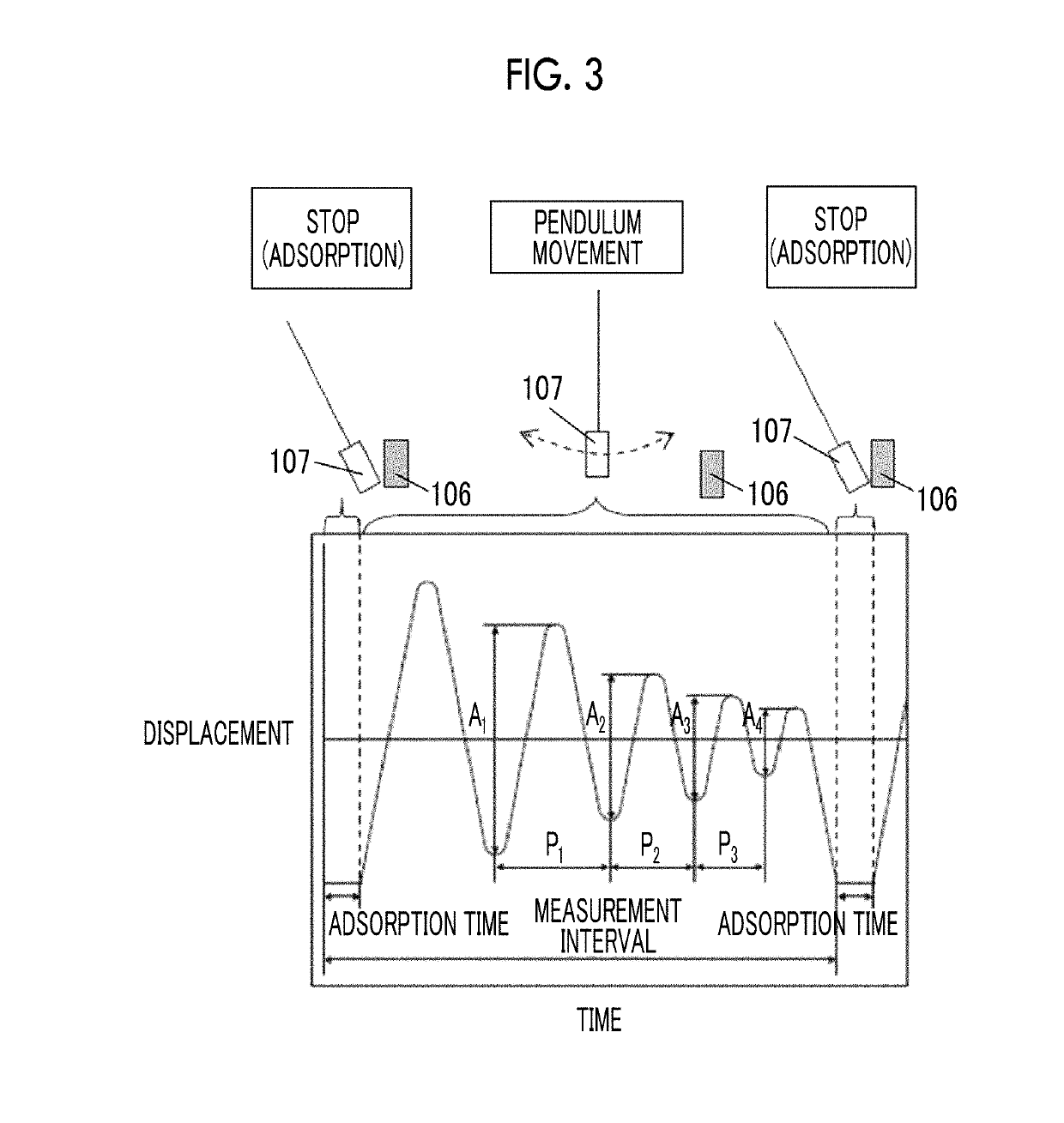

Magnetic recording medium and magnetic recording and reproducing device

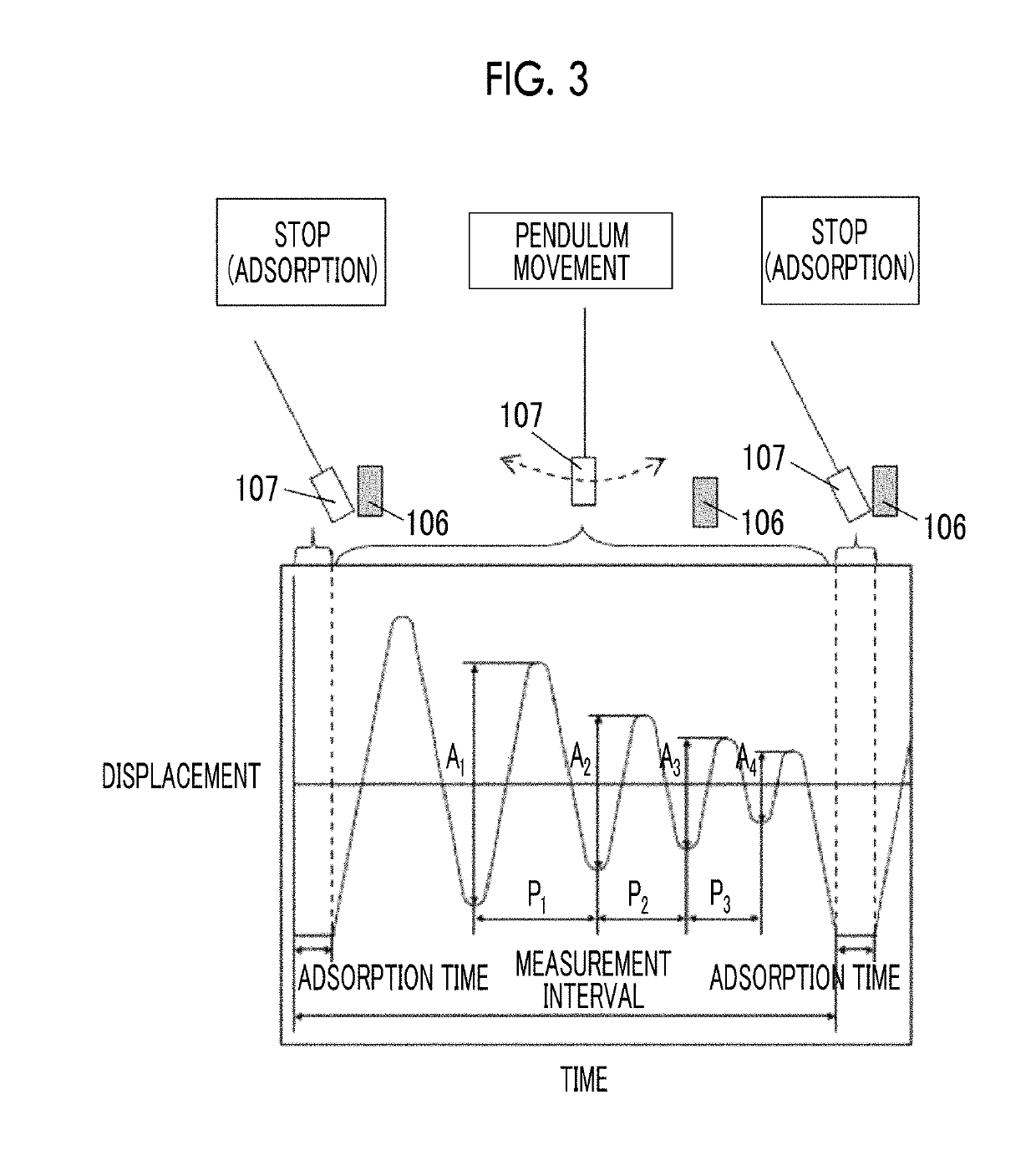

ActiveUS20190103131A1Excellent electromagnetic conversion characteristicAvoid it happening againDisposition/mounting of recording headsMagnetic materials for record carriersIn planeX-ray

Provided are a magnetic recording medium, in which a magnetic layer includes ferromagnetic hexagonal ferrite powder, a binding agent, and an oxide abrasive, an intensity ratio Int(110) / Int(114) obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio of the magnetic recording medium is 0.65 to 1.00, a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding a surface of the magnetic layer is equal to or smaller than 0.050, and an average particle diameter of the oxide abrasive obtained from a secondary ion image obtained by irradiating the surface of the magnetic layer with a focused ion beam is 0.04 μm to 0.08 μm, and a magnetic recording and reproducing device including this magnetic recording medium.

Owner:FUJIFILM CORP

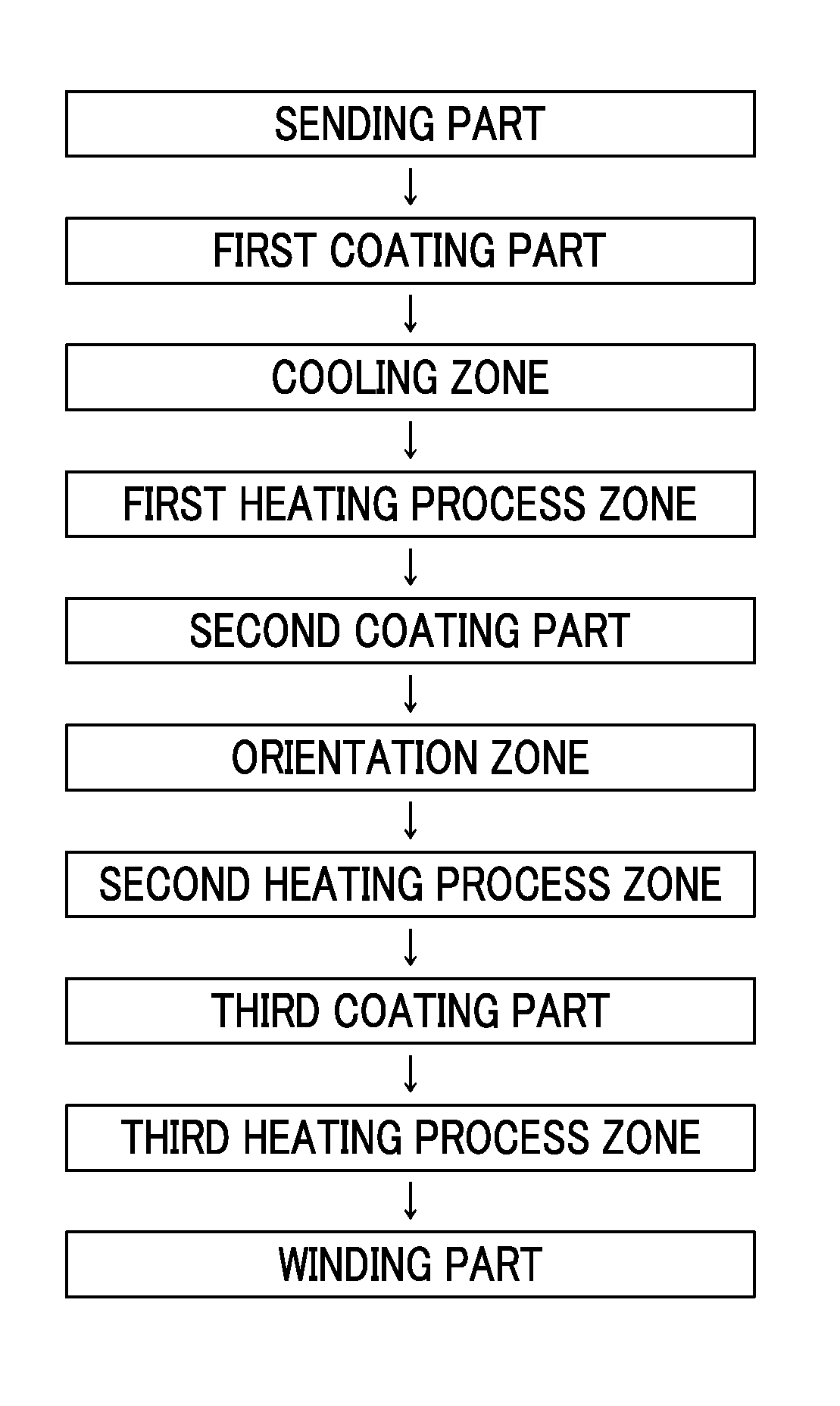

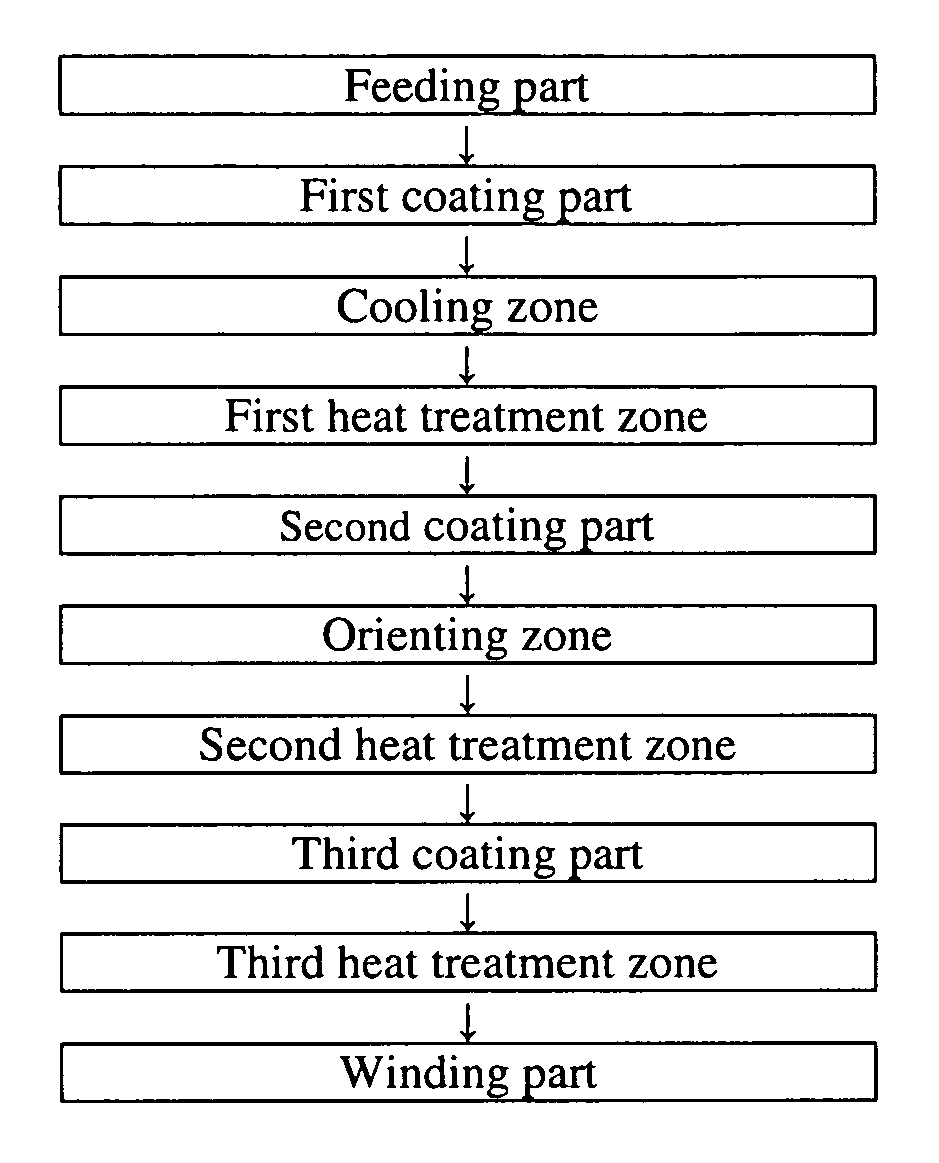

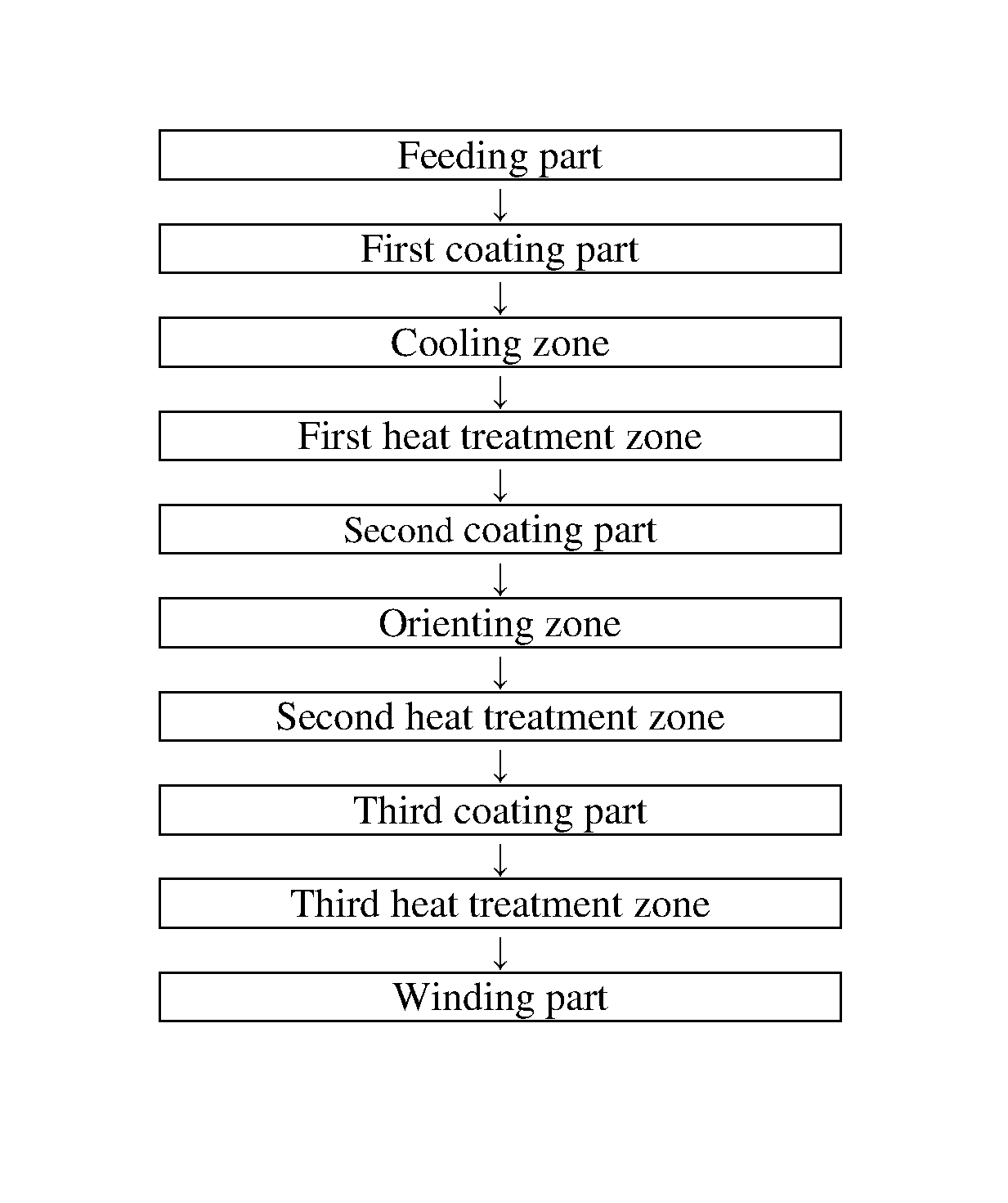

Magnetic tape and method of manufacturing the same

ActiveUS9711174B2Reduce thicknessIncrease recording capacityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm; at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on a surface on the magnetic layer side of the magnetic tape is greater than or equal to 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS9721605B2Avoid it happening againImprove the immunityBase layers for recording layersRecord information storageMedicineMagnetic tape

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a quantity of components selected from the group consisting of a fatty acid and a fatty acid amide per unit area of the magnetic tape among components that are extracted from a surface on the magnetic layer side of the magnetic tape is less than or equal to 15.0 mg / m2, and a concentration of carbon, C, that is obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on the surface on the magnetic layer side of the magnetic tape is greater than or equal to 50 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20170221517A1Good electromagnetic propertiesCompromise running stabilityMagnetic materials for record carriersBase layers for recording layersMagnetic tapeOptoelectronics

The magnetic tape has a magnetic layer and a backcoat layer, wherein, each of the magnetic layer and backcoat layer contains a fatty acid ester, the Ra measured on the magnetic layer side surface is less than or equal to 2.8 nm, the difference between the spacing measured by optical interferometry on the magnetic layer side surface after and before vacuum heating is greater than 0 nm but less than or equal to 8.0 nm, the FWHMbefore on the backcoat layer side surface is greater than 0 nm but less than or equal to 10.0 nm, the FWHMafter on the backcoat layer side surface is greater than 0 nm but less than or equal to 10.0 nm; and the difference between the spacing measured on the backcoat layer side surface after and before vacuum heating is greater than 0 nm but less than or equal to 8.0 nm.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20170032812A1Increase the lengthReduce thicknessRecord information storageMaterials with non-metallic substancesMagnetic tapeNon magnetic

The magnetic tape has a magnetic layer containing ferromagnetic powder and binder on one surface of a nonmagnetic support, and has a backcoat layer containing nonmagnetic powder and binder on the other surface thereof, wherein the magnetic layer contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide; the backcoat layer has a thickness of less than or equal to 0.30 μm and contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a magnetic layer side C—H derived C concentration is greater than or equal to 45 atom %; and a backcoat layer side C—H derived C concentration is greater than or equal to 35 atom %.

Owner:FUJIFILM CORP

Apparatus and method for improving chamfer quality of disk edge surfaces with laser treatment

A carbon dioxide laser is used as a non-mechanical means for smoothing and polishing the as-cut chamfer surface at the edge of the disk. Applying laser radiation to the glass surface causes transient melting and resolidification. Due to surface tension effects, the glass resolidifies to produce a surface that is significantly smoother than it was before irradiation. If scratches or abrasive marks are present on the glass surface prior to irradiation, the irradiation process "polishes out" these defects as long as they are not too deep. At a wavelength near 10 mum, the penetration depth of the radiation into the glass is approximately 1 mum. Therefore, scratches and defects of this order of magnitude are eliminated. The quality of the resulting modified chamfer surface is far superior to the original mechanically ground and polished surface.

Owner:WESTERN DIGITAL TECH INC

Magnetic tape and method of manufacturing the same

ActiveUS20160189740A1Avoid it happening againImprove the immunityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a quantity of components selected from the group consisting of a fatty acid and a fatty acid amide per unit area of the magnetic tape among components that are extracted from a surface on the magnetic layer side of the magnetic tape is less than or equal to 15.0 mg / m2, and a concentration of carbon, C, that is obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on the surface on the magnetic layer side of the magnetic tape is greater than or equal to 50 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS9704527B2Increase coefficient of frictionReduced stabilityRecord information storageMetals or alloysMagnetic tapeNon magnetic

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20160247530A1Improve running stabilityReduce coefficient of frictionRecord information storageMetals or alloysMagnetic tapeTotal thickness

The magnetic tape has on one surface of a nonmagnetic support a magnetic layer containing ferromagnetic powder and binder, and on the other surface of the nonmagnetic support, a backcoat layer containing nonmagnetic powder and binder, wherein the total thickness of the magnetic tape is less than or equal to 4.80 μm, the backcoat layer contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide, and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on a surface on the backcoat layer side of the magnetic tape ranges from 35 to 60 atom %.

Owner:FUJIFILM CORP

Magnetic tape and magnetic recording and reproducing device

ActiveUS20190103130A1Excellent electromagnetic conversion characteristicAvoid it happening againDisposition/mounting of recording headsMagnetic materials for record carriersMagnetic tapeViscoelasticity

Provided are a magnetic tape, in which a magnetic layer includes a ferromagnetic powder, a binding agent, and an oxide abrasive, ΔSFD in a longitudinal direction of the magnetic tape calculated by Expression 1, ΔSFD=SFD25° C.−SFD−190° C., is equal to or smaller than 0.50, a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding a surface of the magnetic layer is equal to or smaller than 0.050, and an average particle diameter of the oxide abrasive obtained from a secondary ion image obtained by irradiating the surface of the magnetic layer with a focused ion beam is 0.04 μm to 0.08 μm, and a magnetic recording and reproducing device including this magnetic tape.

Owner:FUJIFILM CORP

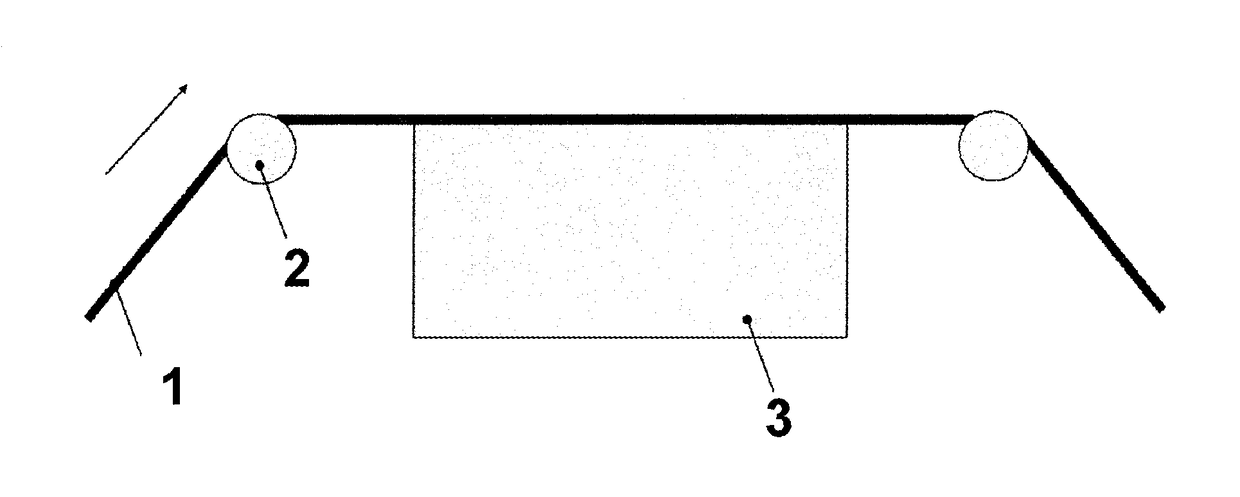

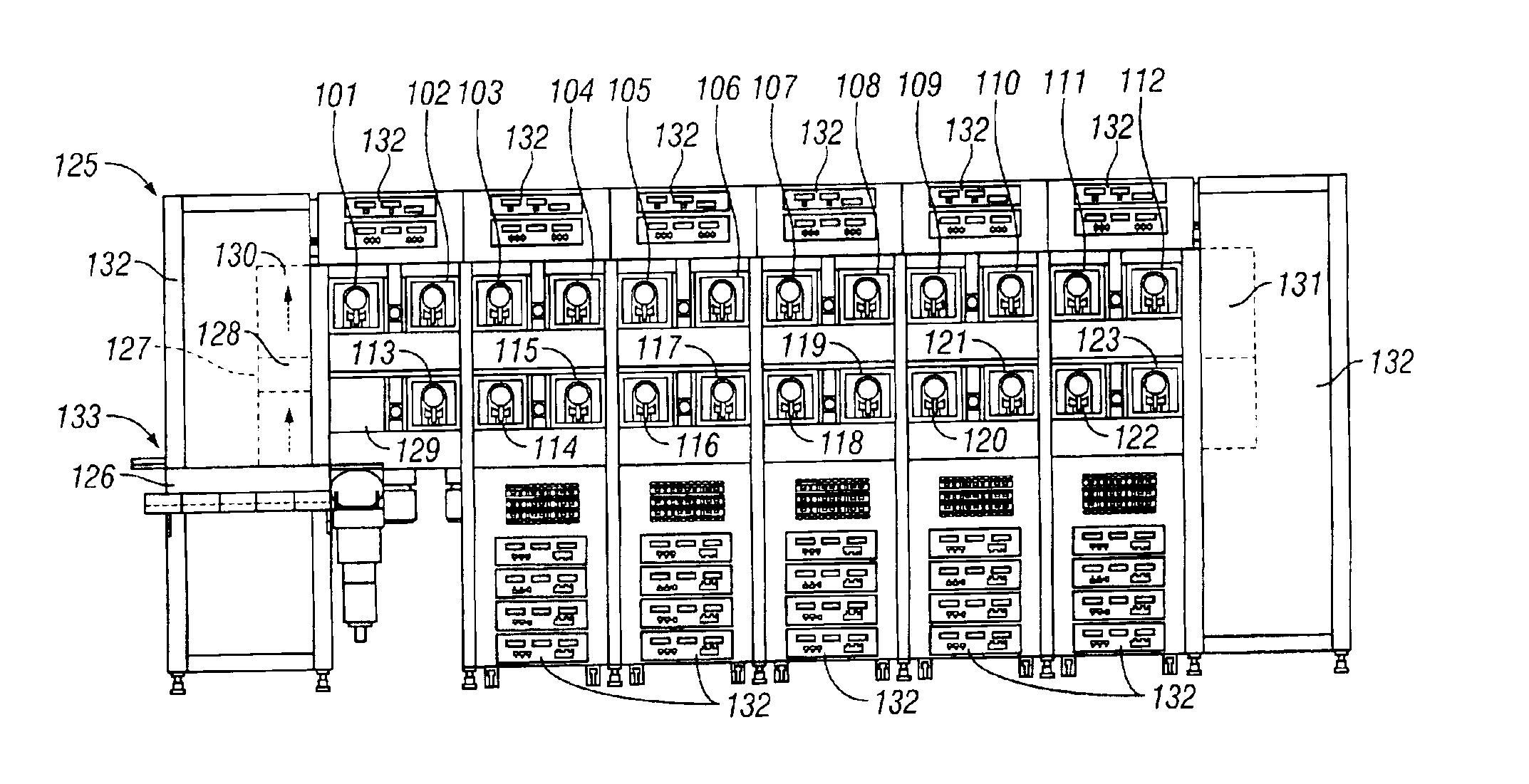

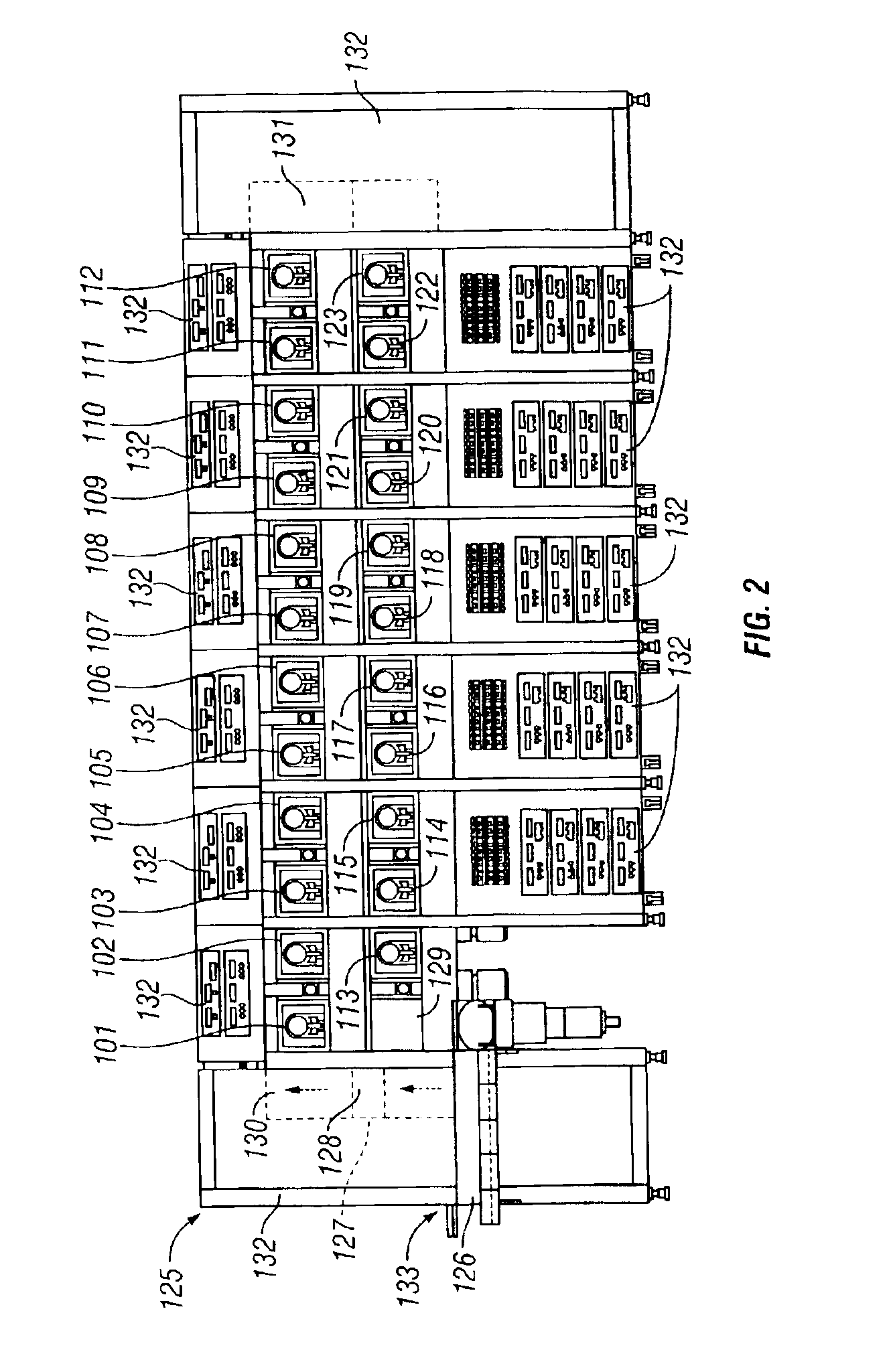

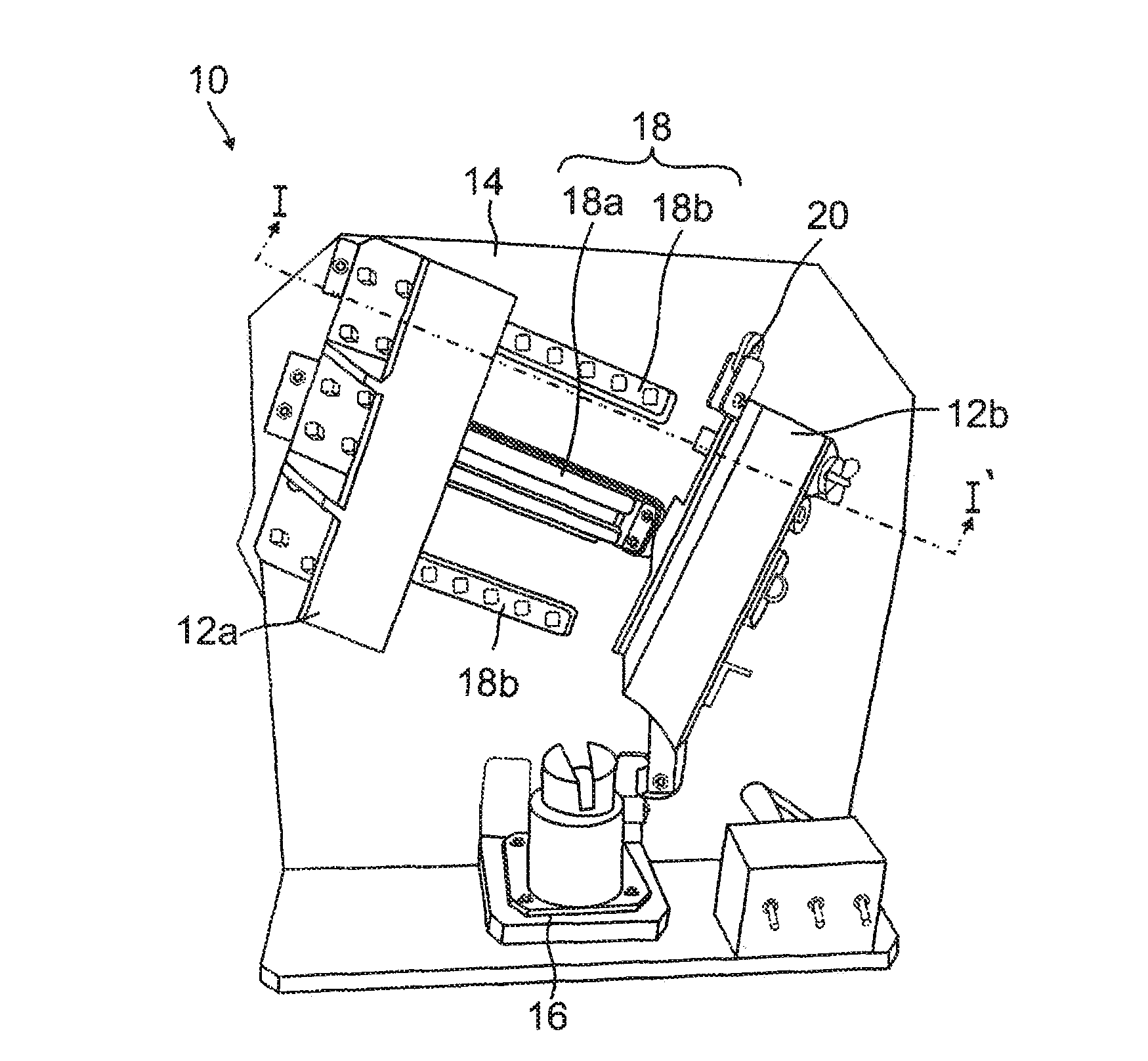

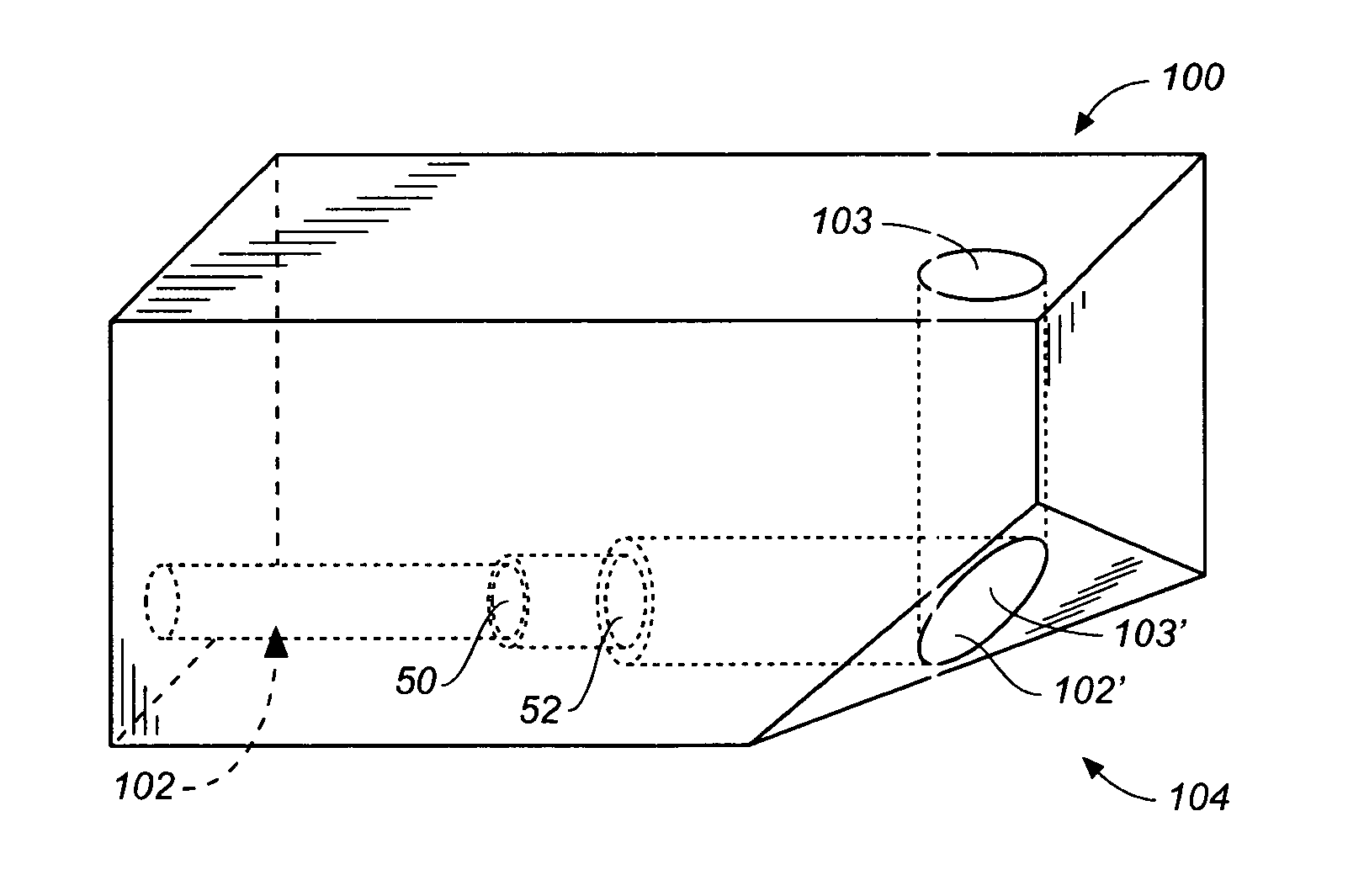

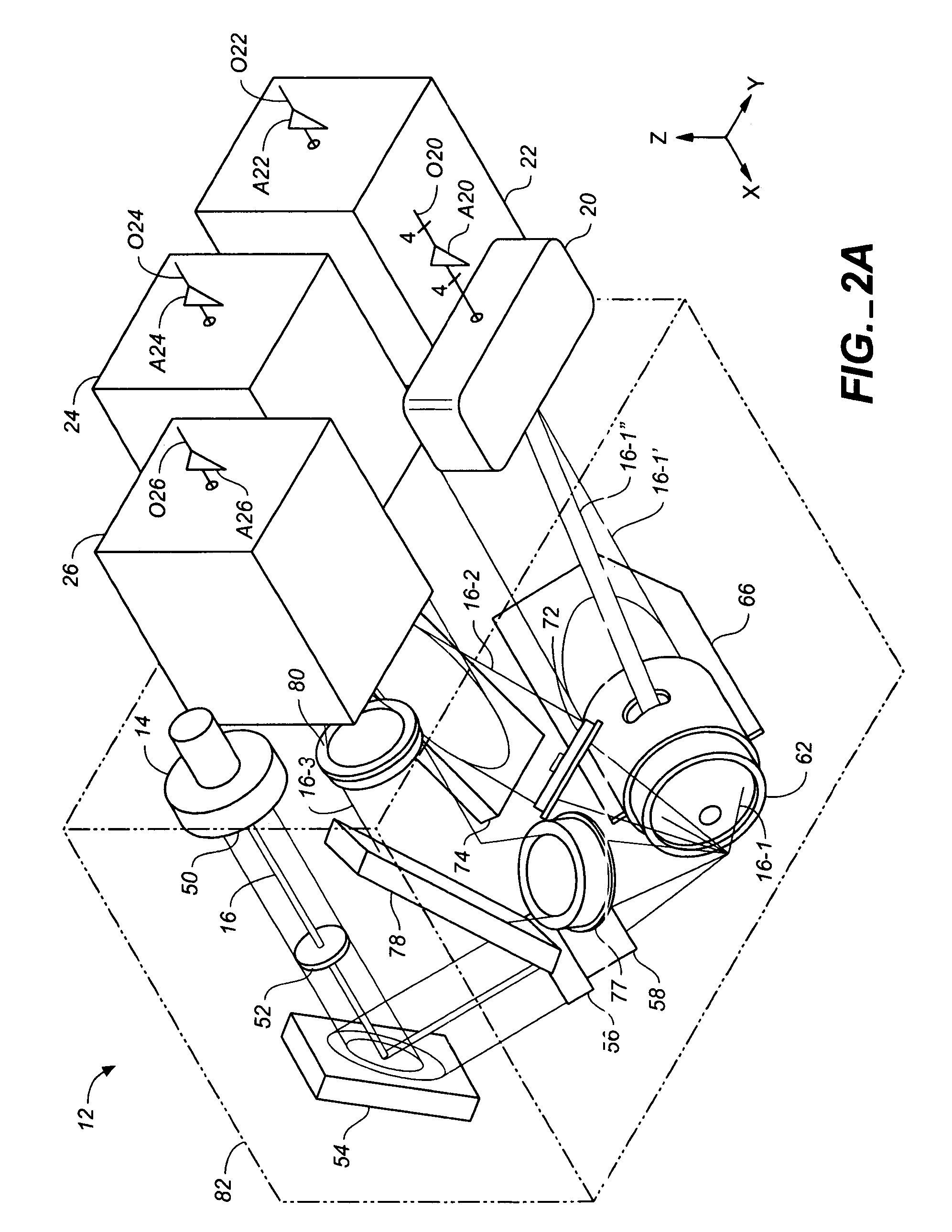

Disk coating system

InactiveUS6919001B2Improve throughputSmall footprintVacuum evaporation coatingSemiconductor/solid-state device manufacturingCoating systemEngineering

There is described a disk processing and manufacturing equipment in which the processing chambers are stacked on top of each other and in which the disks move through the system on disk carriers which are adjustable to take disks of varying sizes. The disks enter the system through a load zone and are then installed into disk carriers. They move in the carriers sequentially through processing chambers at one level and then move to the other level in a lift or elevator. At this other level, the disks again move sequentially through the system on that level and then exit at an unload zone.

Owner:INTEVAC

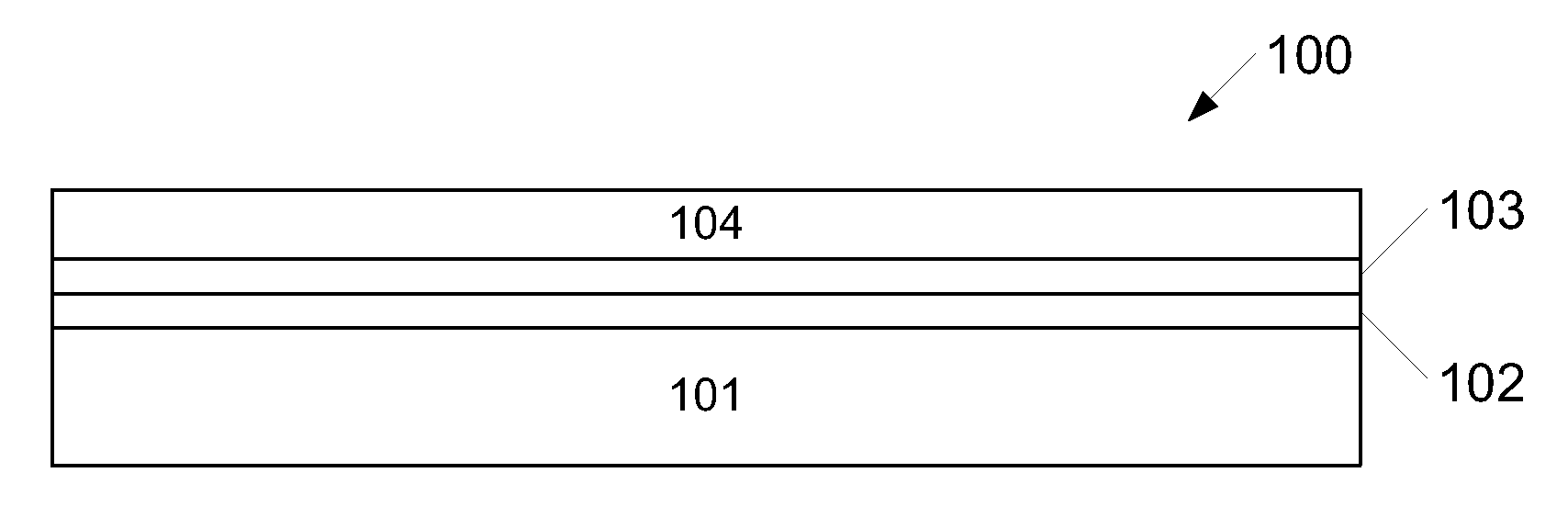

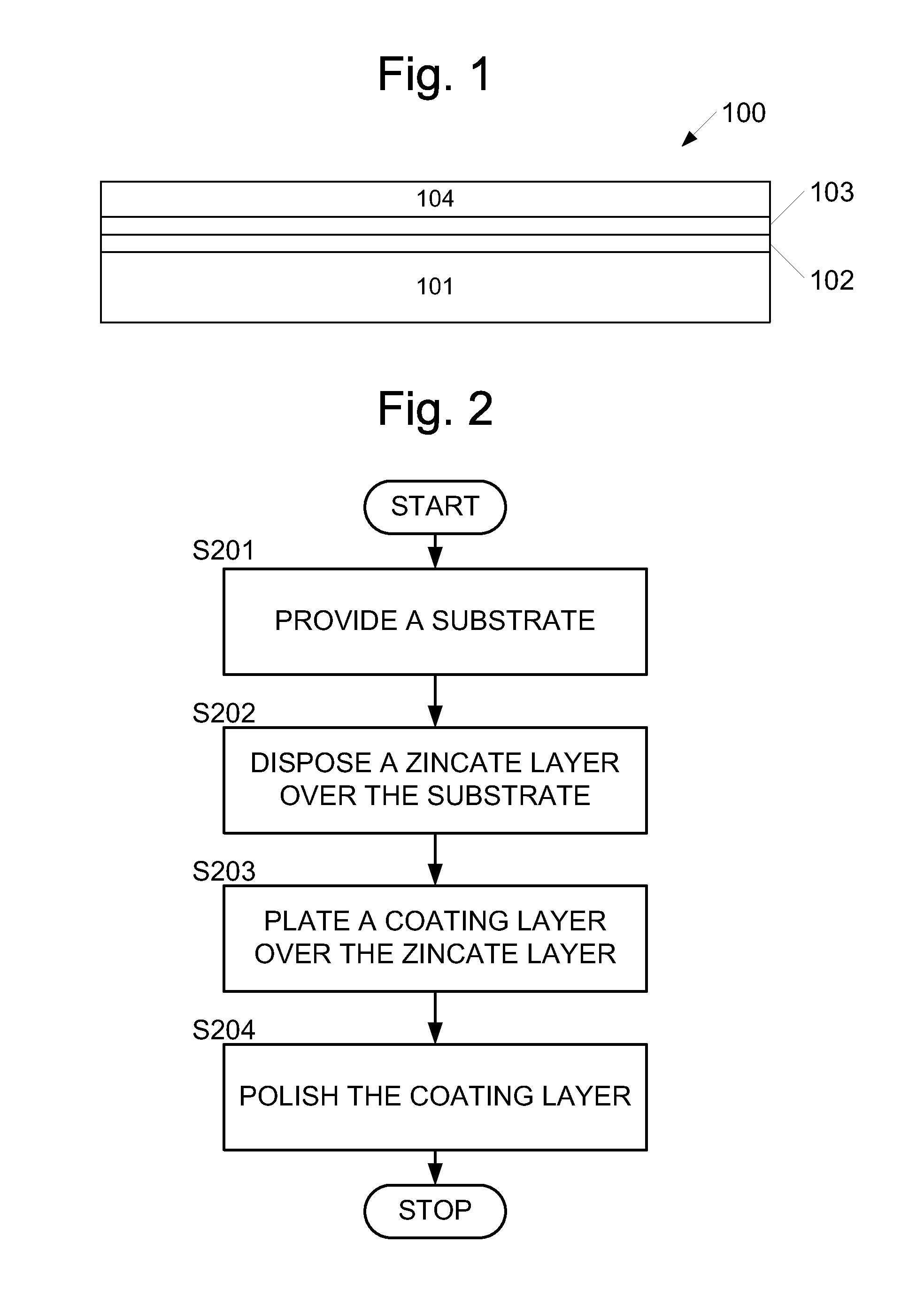

Electroless coated disks for high temperature applications and methods of making the same

ActiveUS8404369B2Improve thermal stabilityMagnetic materials for record carriersMagnetic layer production by platingHard disc driveAlloy

A disk for a hard disk drive is provided. The disk comprises a substrate comprising aluminum, and a coating layer disposed over the substrate. The coating layer comprises an alloy of Ni, X1 and X2, wherein X1 comprises one or more elements selected from the group consisting of Ag, Au, B, Cr, Cu, Ga, In, Mn, Mo, Nb, Pb, Sb, Se, Sn, Te, W, Zn and Zr, and wherein X2 comprises either B or P, and wherein X1 and X2 do not comprise the same elements.

Owner:WESTERN DIGITAL TECH INC

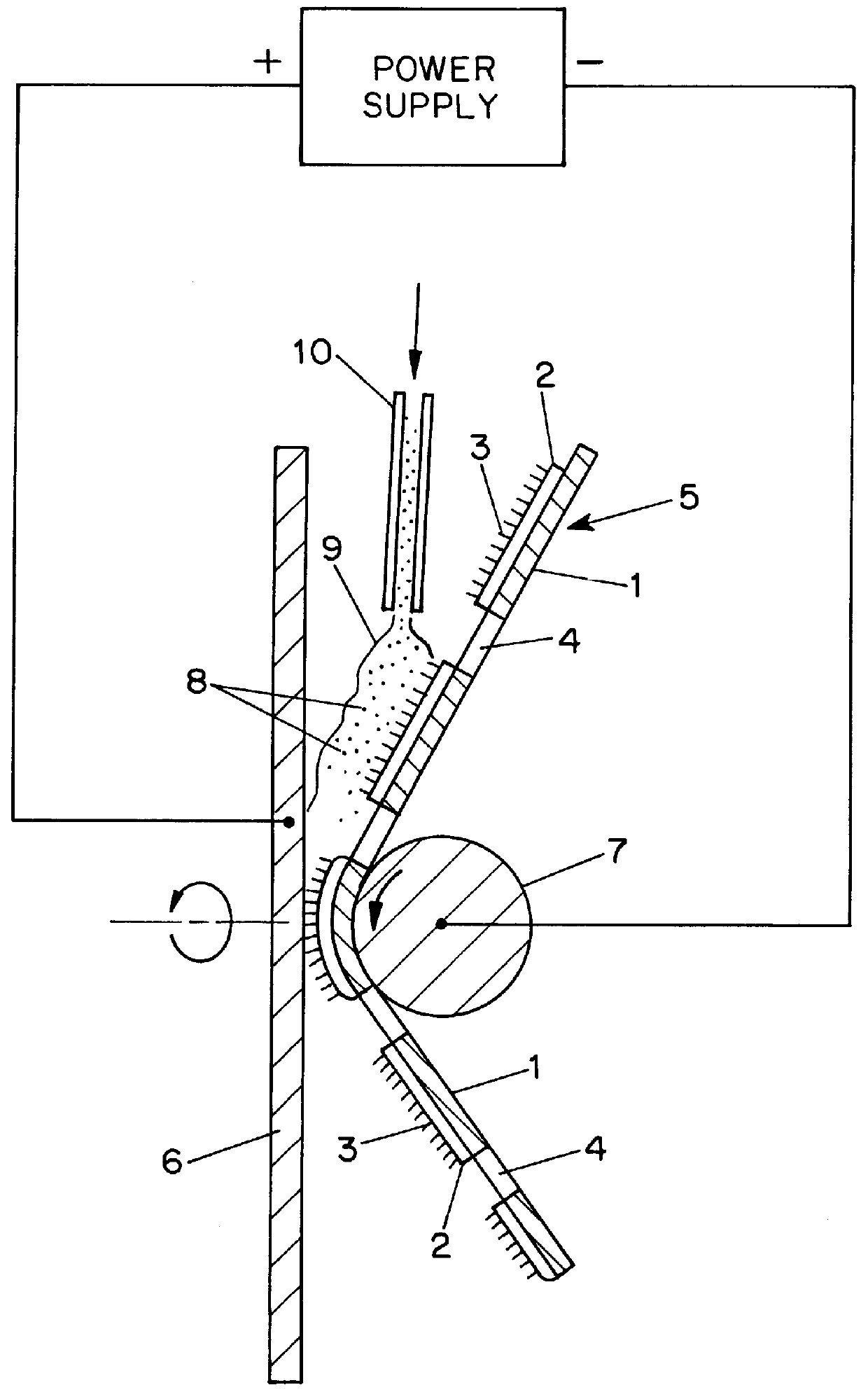

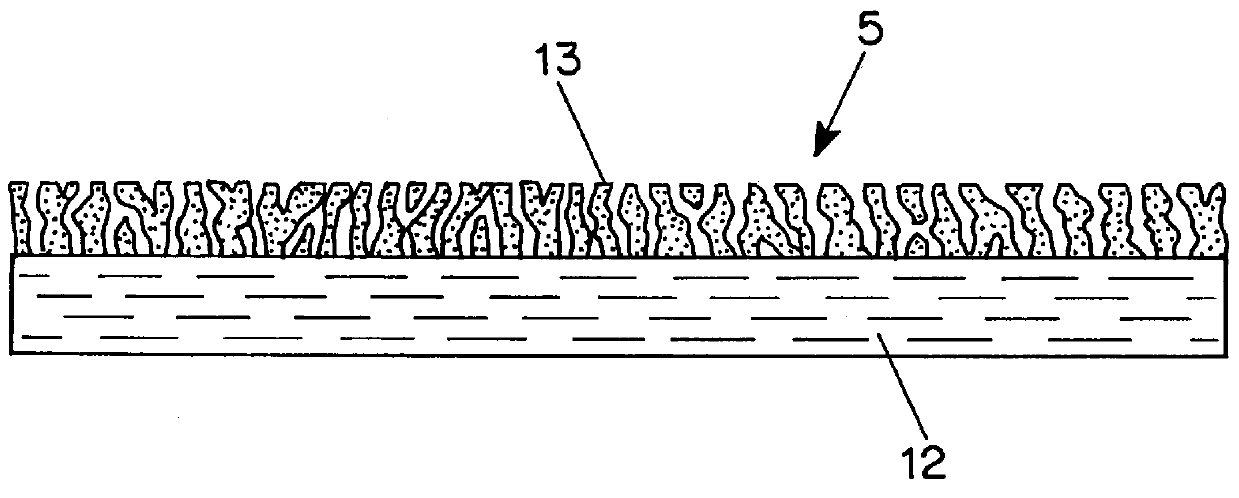

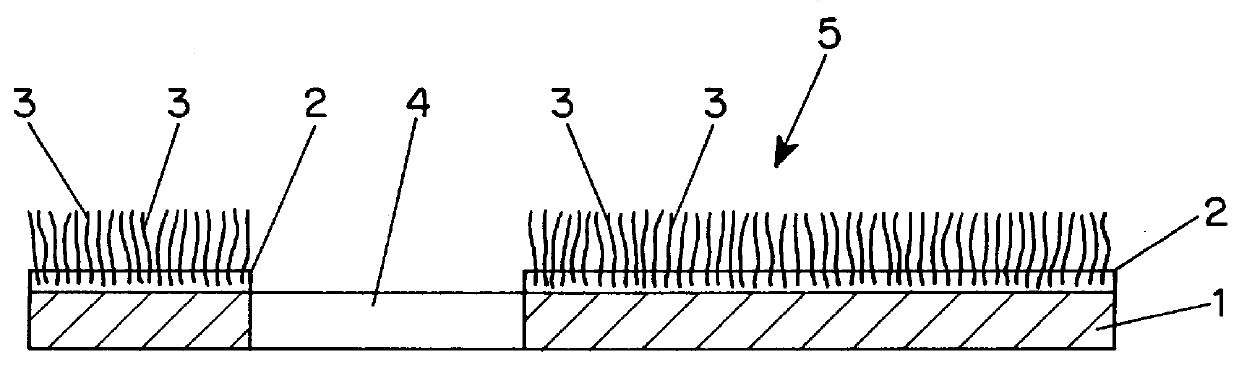

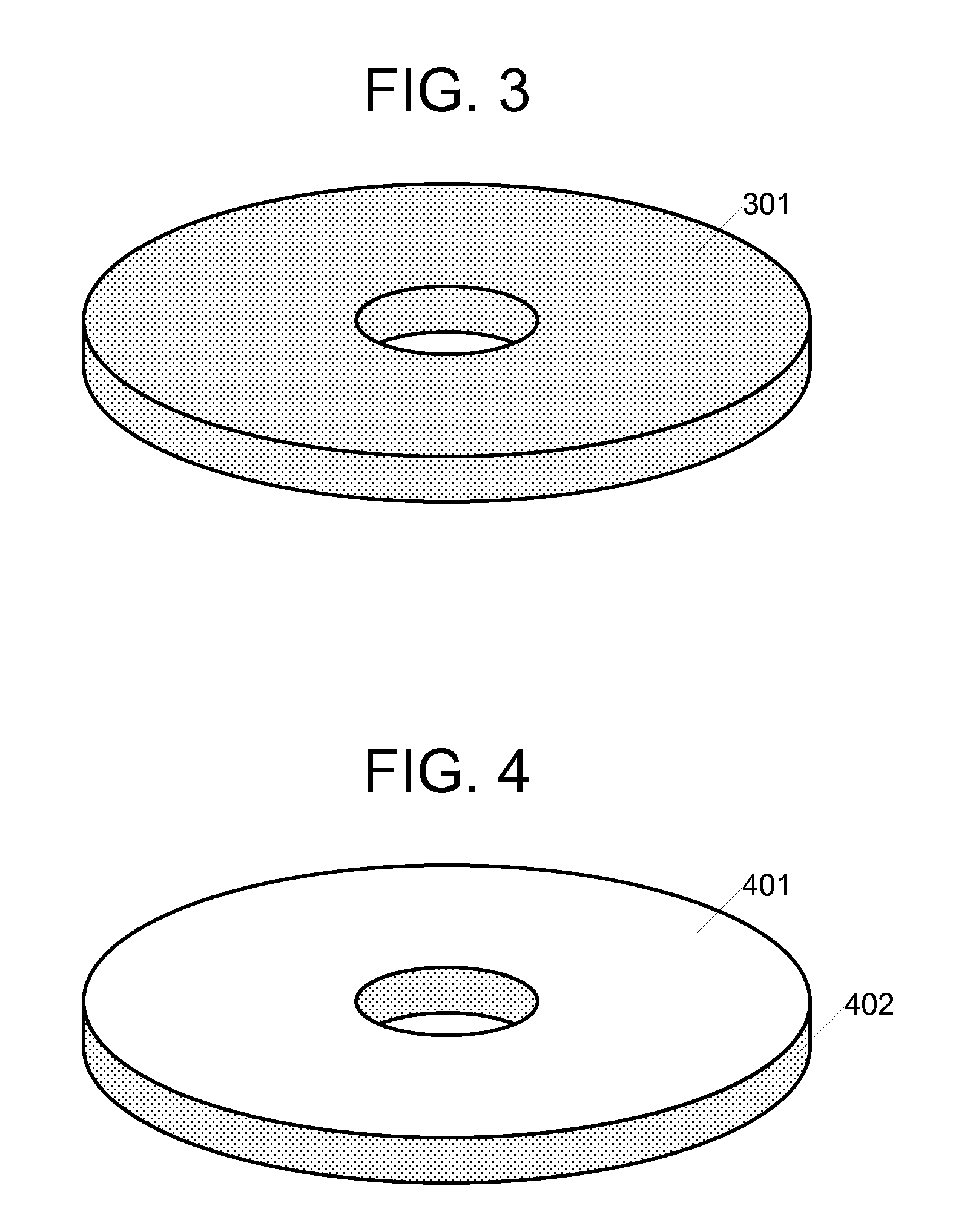

Combination electrolytic polishing and abrasive super-finishing method

InactiveUS6074284AHigh surface finishEfficient supplyBelt grinding machinesAbrasion apparatusFiberElectrolytic agent

An abrasive super-finishing method for workpieces, such as metallic thin-film magnetic discs, employs a polishing / texturing material having a backing, such as synthetic resin film or woven material or non-woven cloth, and a layer which can hold abrasive grains on the backing, such as flocked fibre or a porous polymer foam, on one surface of the backing. An electrolytic solution in which abrasive grains are suspended is supplied to the polishing / texturing material to conduct polishing or texturing of the workpiece surfaces. The workpiece is connected to an anode and a pressure roller or a cathode bar is connected to a cathode. A voltage is applied between the workpiece and the pressure roller or cathode bar to conduct simultaneously electrolytic polishing and abrasive polishing / texturing.

Owner:UNIQUE TECH INT PTE

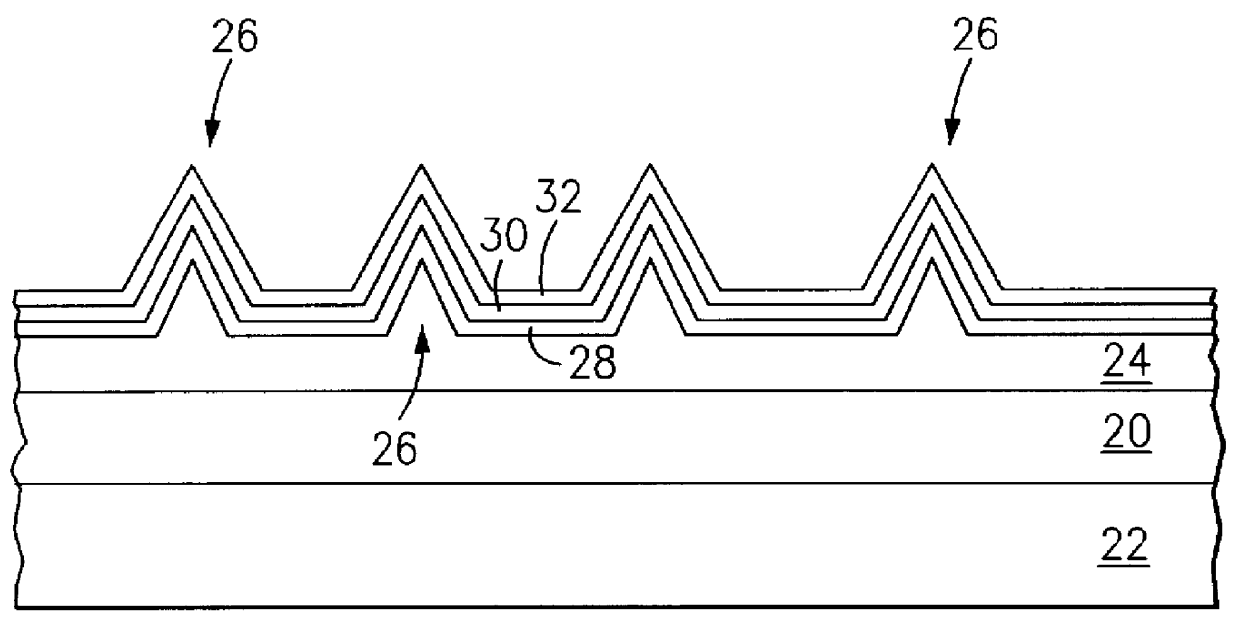

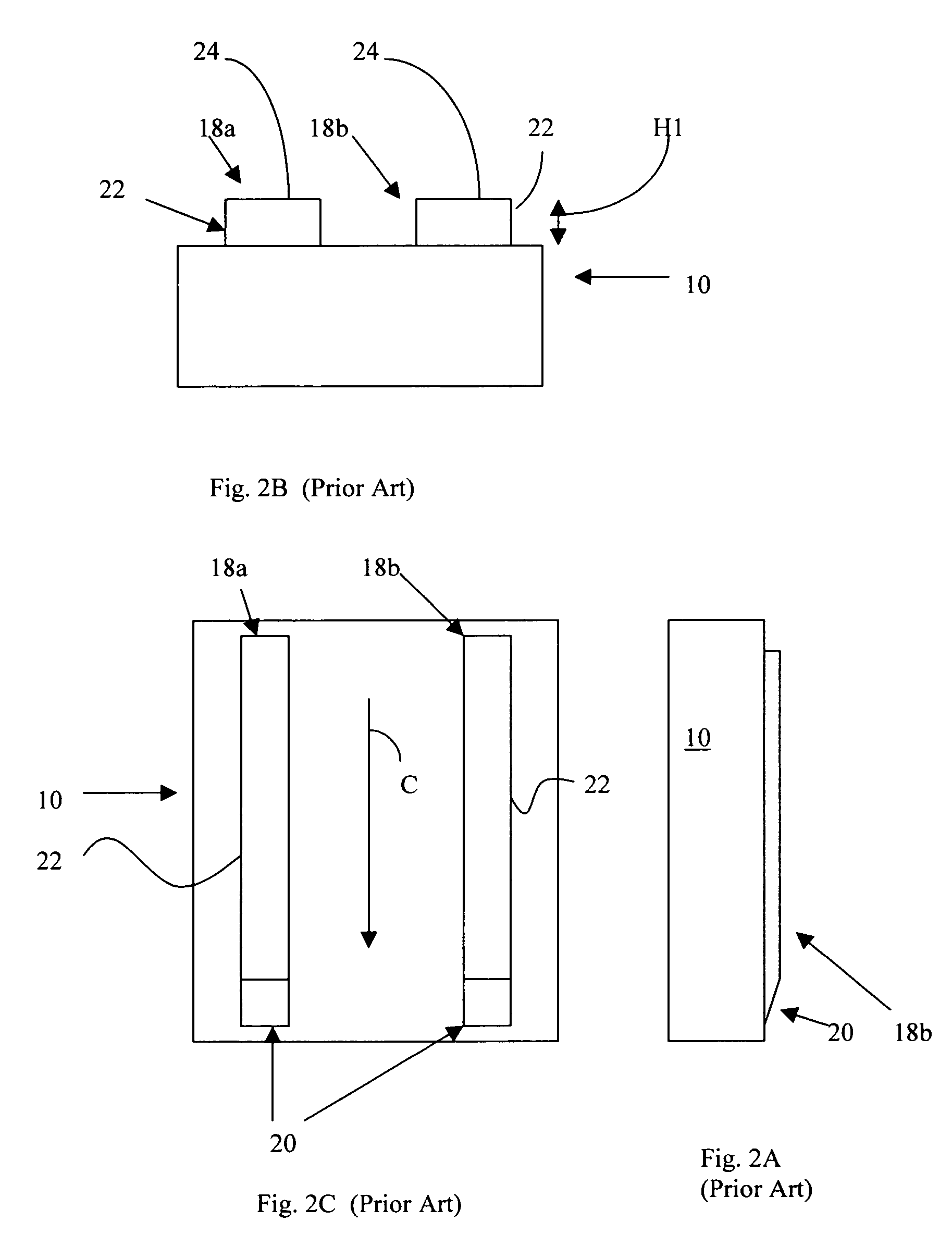

Laser textured magnetic disk comprising NiNb

A method for manufacturing a magnetic disk comprises the steps of depositing NiP (20) on a substrate (22); depositing NiNb (24) on the NiP; and laser texturing the NiNb. "Sombrero" shaped texture features are more easily formed on the substrate / NiP / NiNb structure than a substrate / NiP structure. The disk is completed by depositing an underlayer (e.g. sputtered Cr or NiP), a magnetic layer (e.g. a Co alloy) and a protective overcoat (e.g. by hydrogenated carbon).

Owner:KOMAG

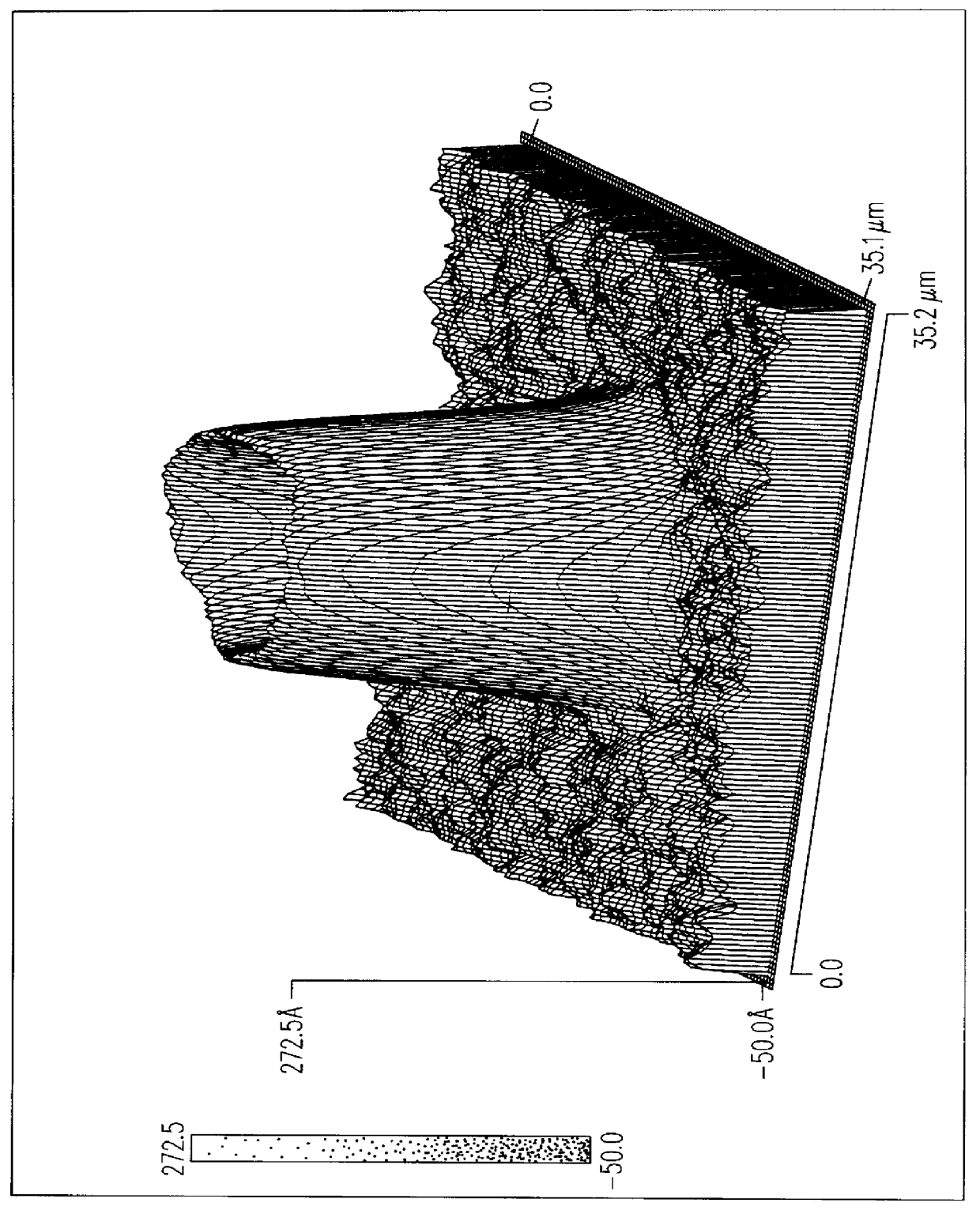

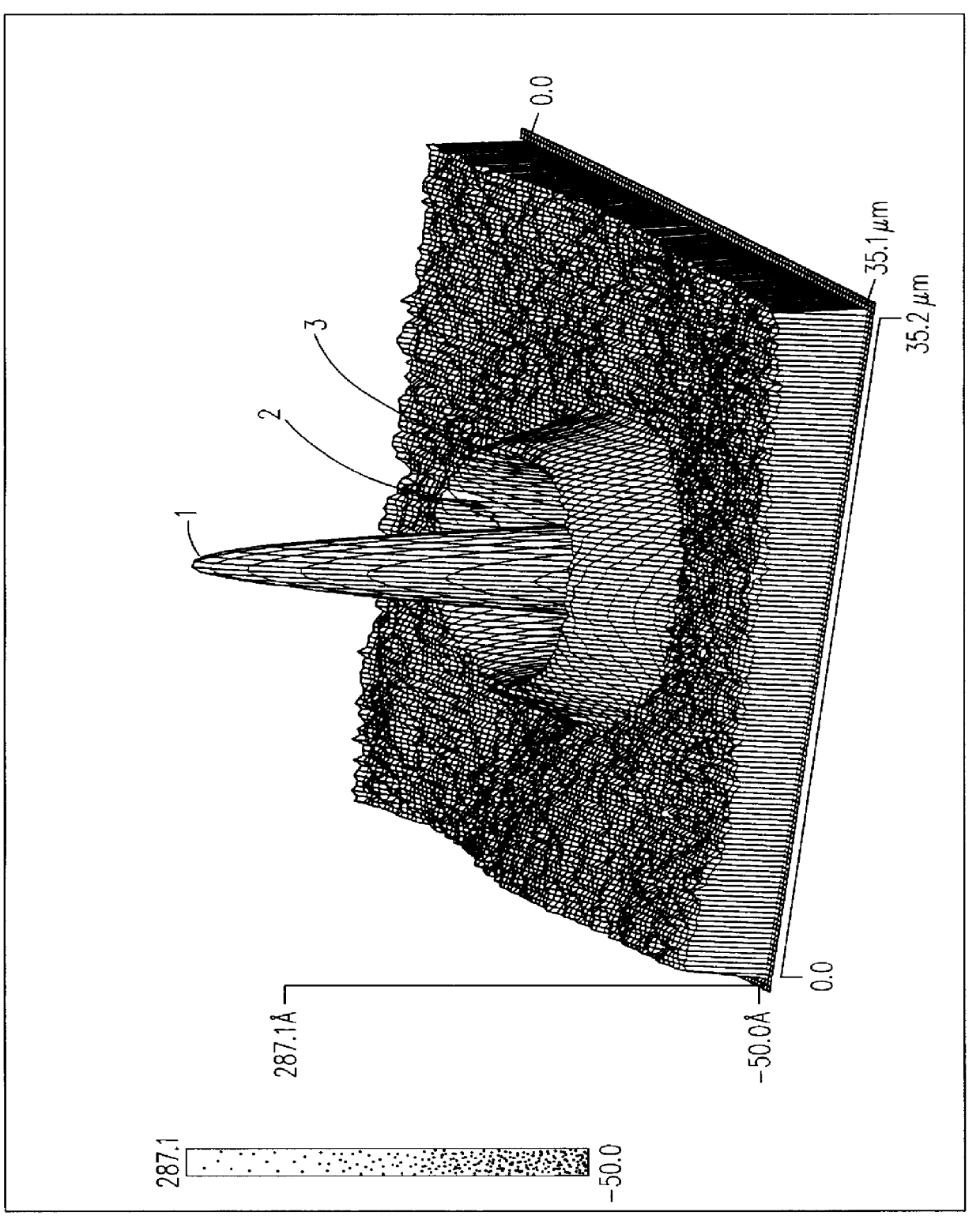

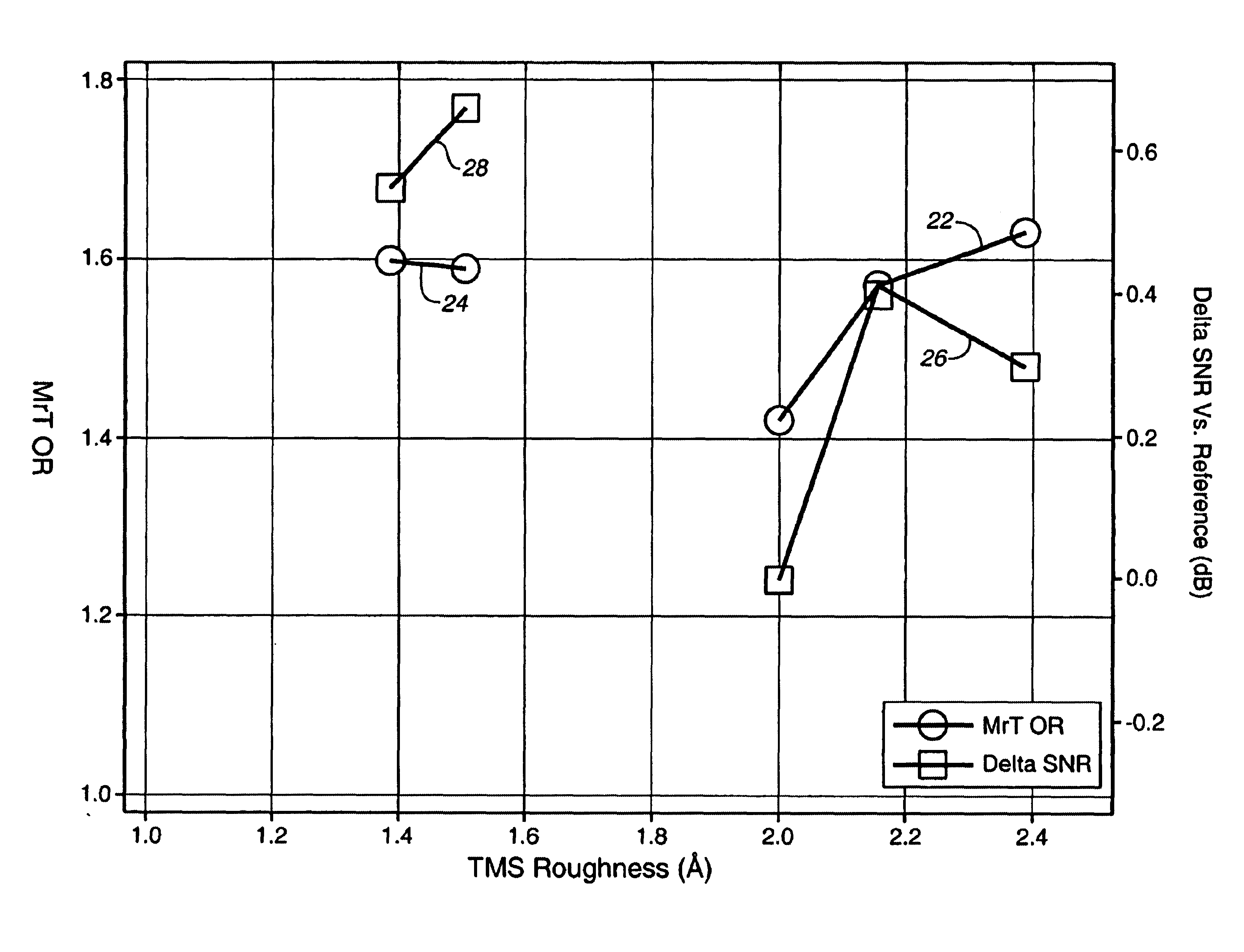

Texturing of magnetic disk substrates

InactiveUS6972135B2Uniform particle sizeLarge low-frequencyMagnetic materials for record carriersBase layers for recording layersNanometreMaterials science

A method for texturing a substrate for a magnetic disk comprises abrading the substrate using nano-sized diamond particles (e.g. having a diameter less than or equal to 20 nm). A magnetic layer is then deposited over the substrate. Even when the texture is extremely smooth (e.g. less than about 2.2 ÅRa), the disk still exhibits good Hc and MrT orientation ratios, SNR and PW50.

Owner:WD MEDIA

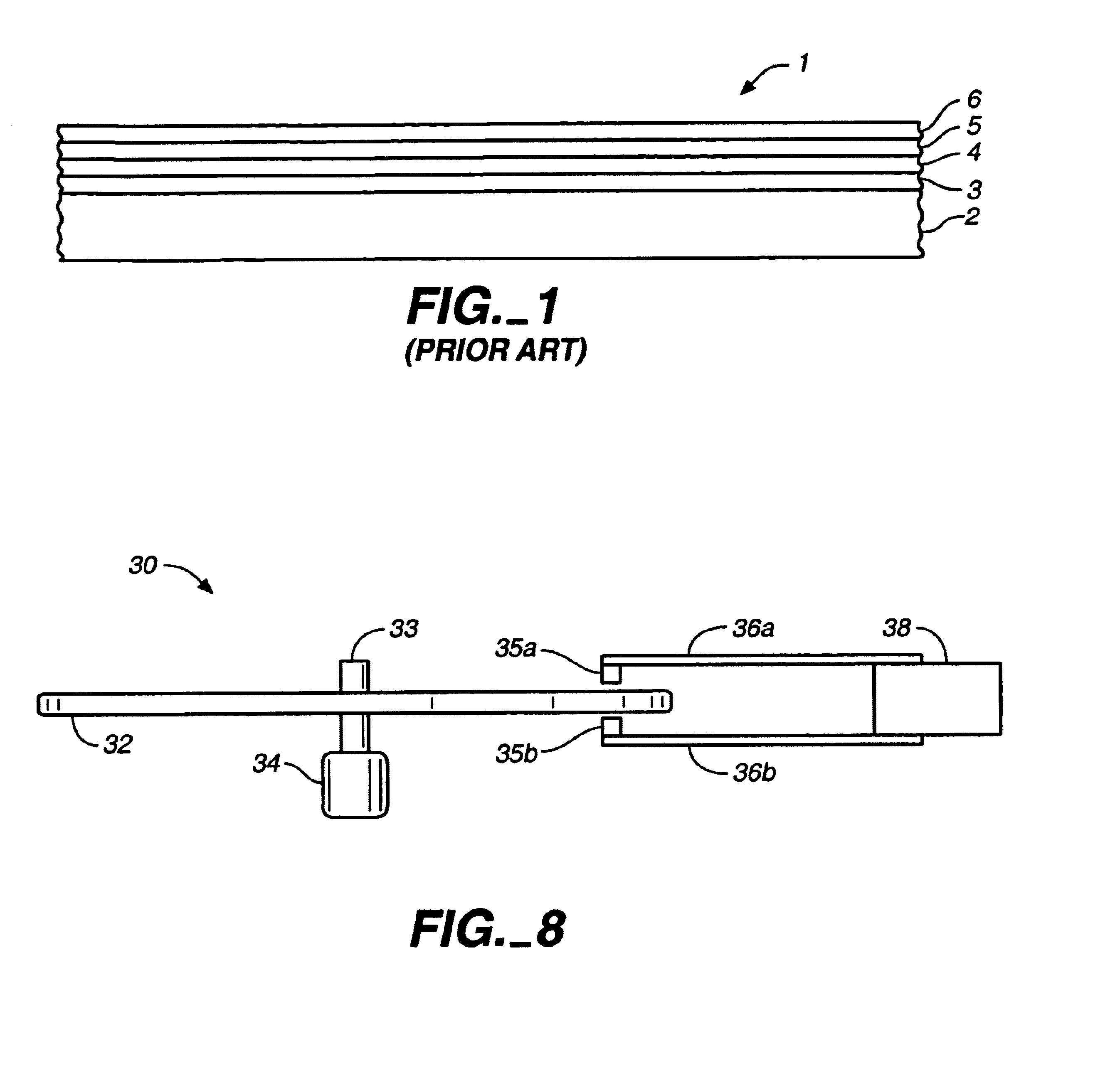

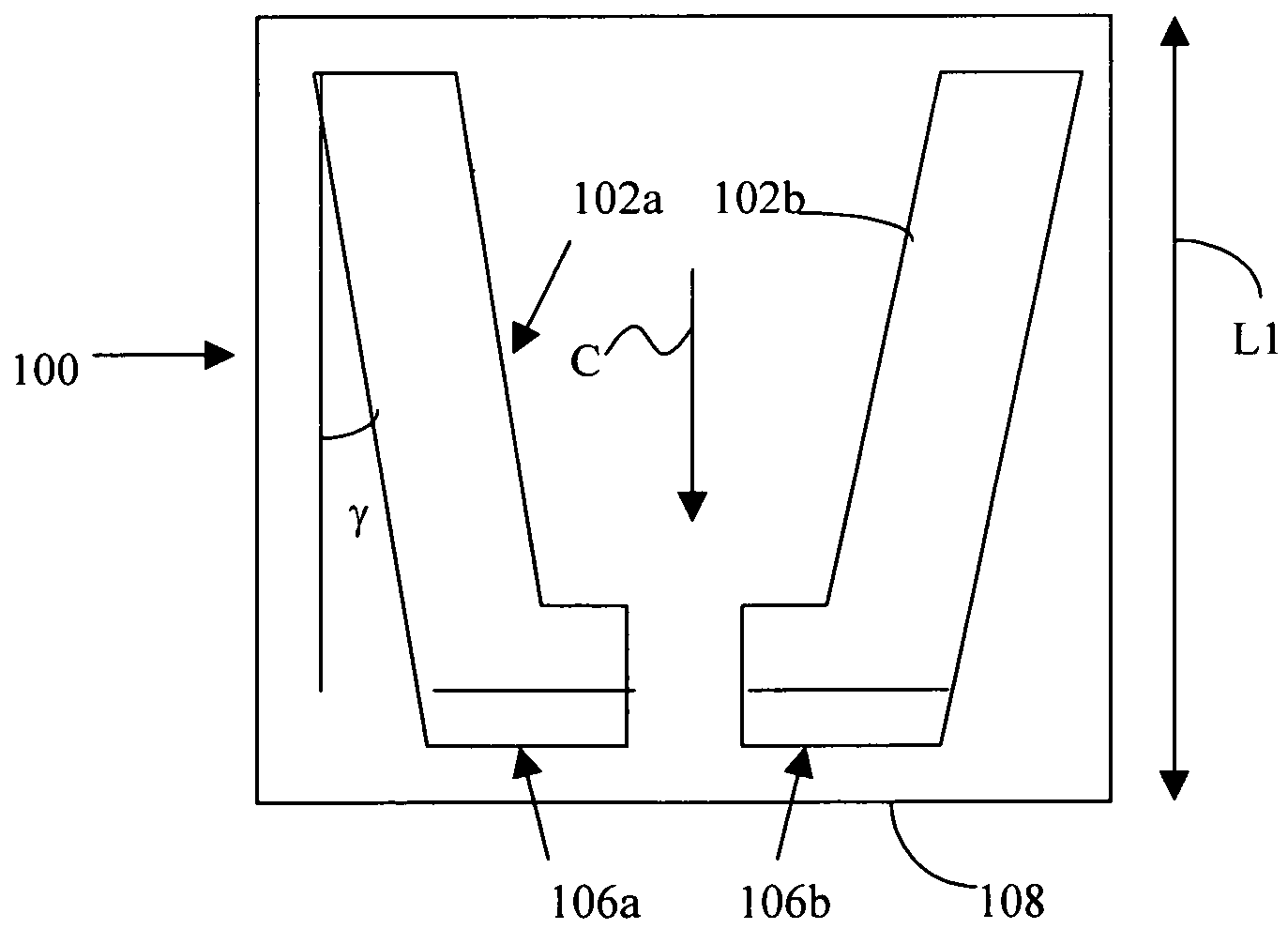

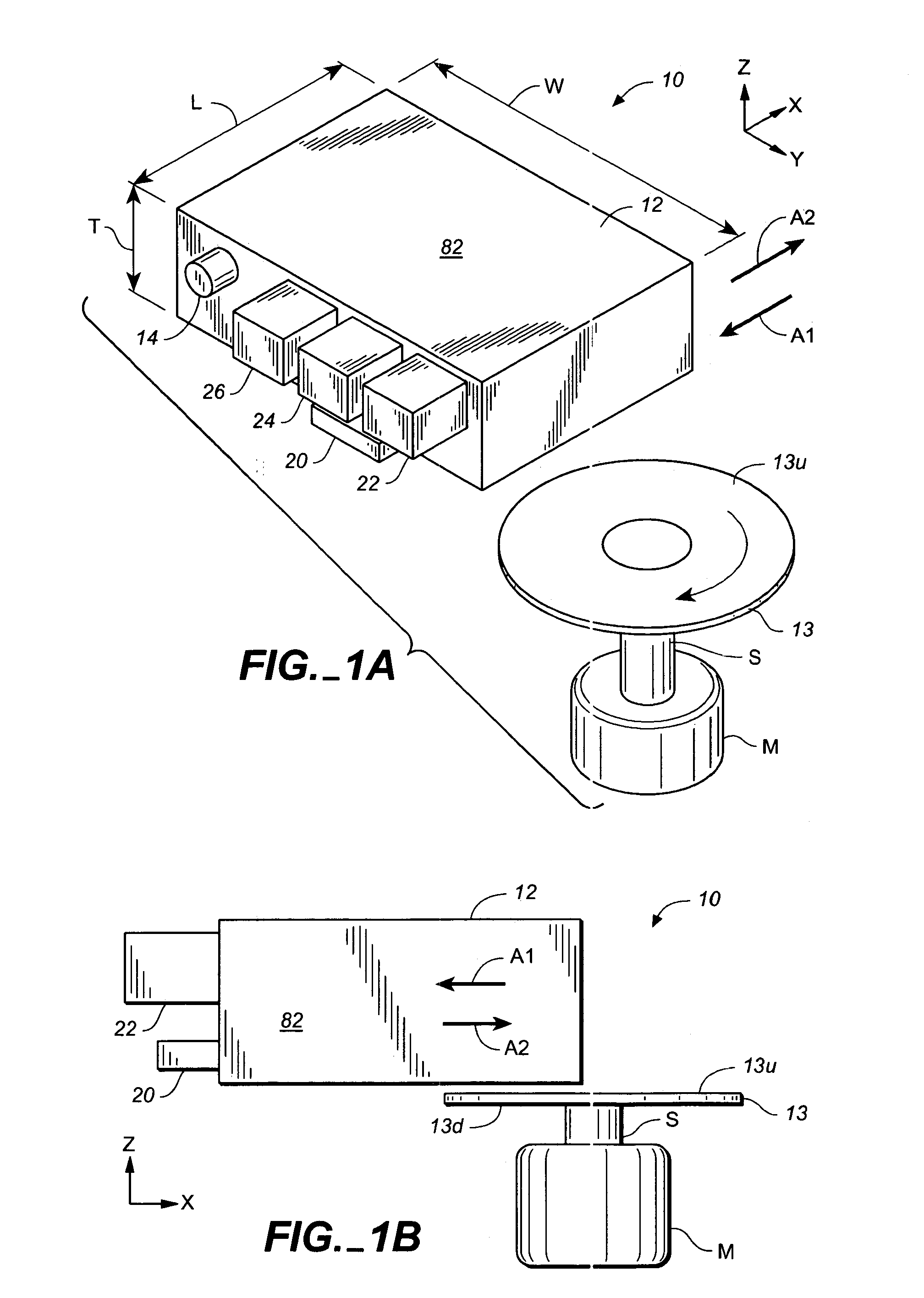

Burnishing head

InactiveUS7314404B2Less time for to recoverIncrease heightRevolution surface grinding machinesFluid-dynamic spacing of headsEngineeringMechanical engineering

A burnishing head comprises at least two rails, each rail having an inner wall and an outer wall. The outer walls are at an angle relative to one another and relative to a central axis of the burnishing head. This angle permits the burnishing head to exhibit improved recovery time if it contacts a disk being burnished. The rail walls are vertical, and the corner between the rail walls and the top surface of the rails is sharp.

Owner:WESTERN DIGITAL TECH INC +1

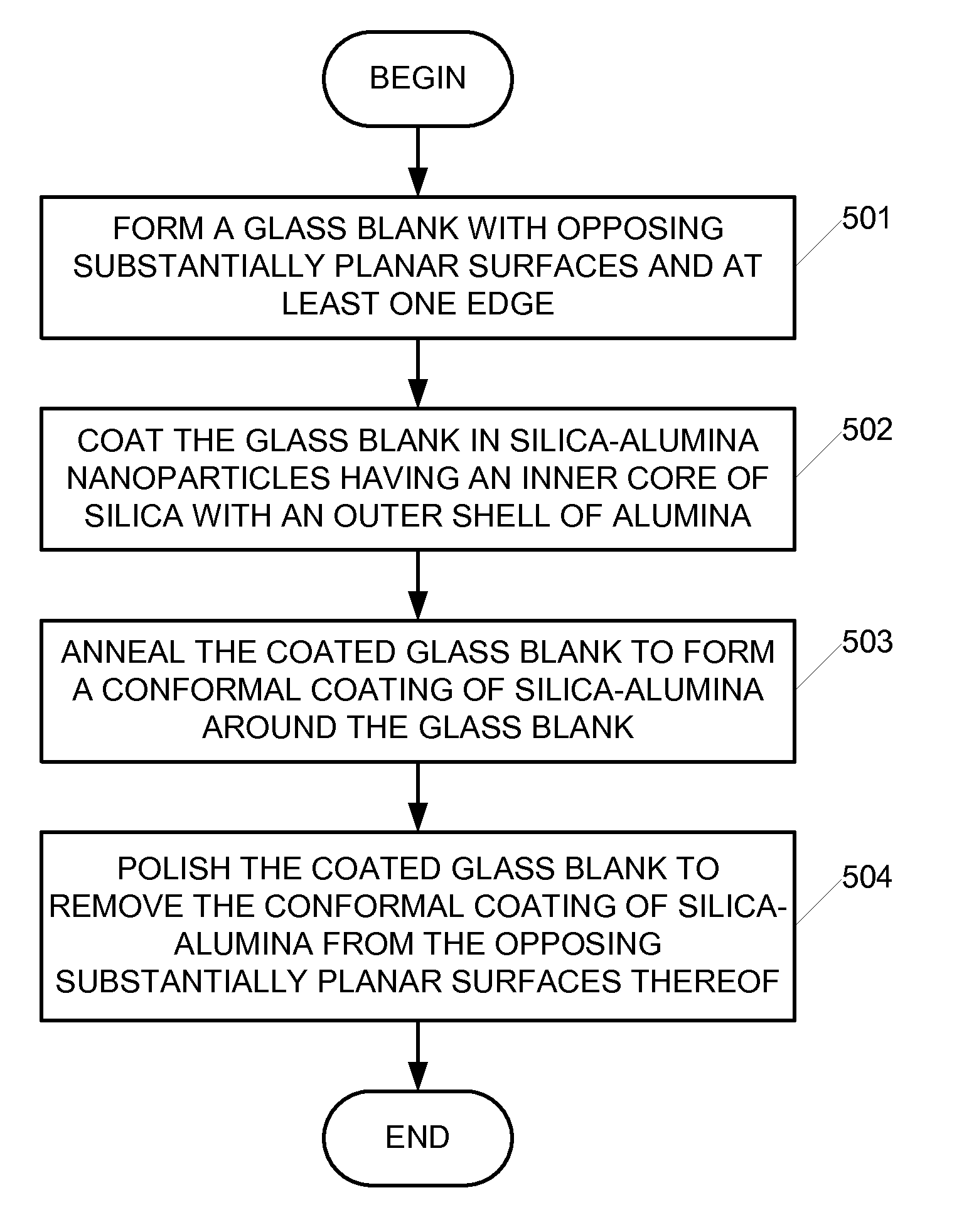

Glass substrates and methods of annealing the same

ActiveUS8206789B2Improve fracture resistanceDisc-shaped record carriersMagnetic materials for record carriersNanoparticleConformal coating

A method for forming a glass substrate comprises the steps of forming a glass blank with opposing substantially planar surfaces and at least one edge, coating the glass blank in silica-alumina nanoparticles, the silica-alumina nanoparticles comprising an inner core of silica with an outer shell of alumina, annealing the coated glass blank to form a conformal coating of silica-alumina around the glass blank, and polishing the coated glass blank to remove the conformal coating of silica-alumina from the opposing substantially planar surfaces thereof.

Owner:WESTERN DIGITAL TECH INC

Texturing of magnetic disk substrates

InactiveUS20050142990A1Uniform particle sizeLarge low-frequencyBase layers for recording layersBelt grinding machinesNanometreMaterials science

A method for texturing a substrate for a magnetic disk comprises abrading the substrate using nano-sized diamond particles (e.g. having a diameter less than or equal to 20 nm). A magnetic layer is then deposited over the substrate. Even when the texture is extremely smooth (e.g. less than about 2.2 Å Ra), the disk still exhibits good Hc and MrT orientation ratios, SNR and PW50.

Owner:HOMOLA ANDREW

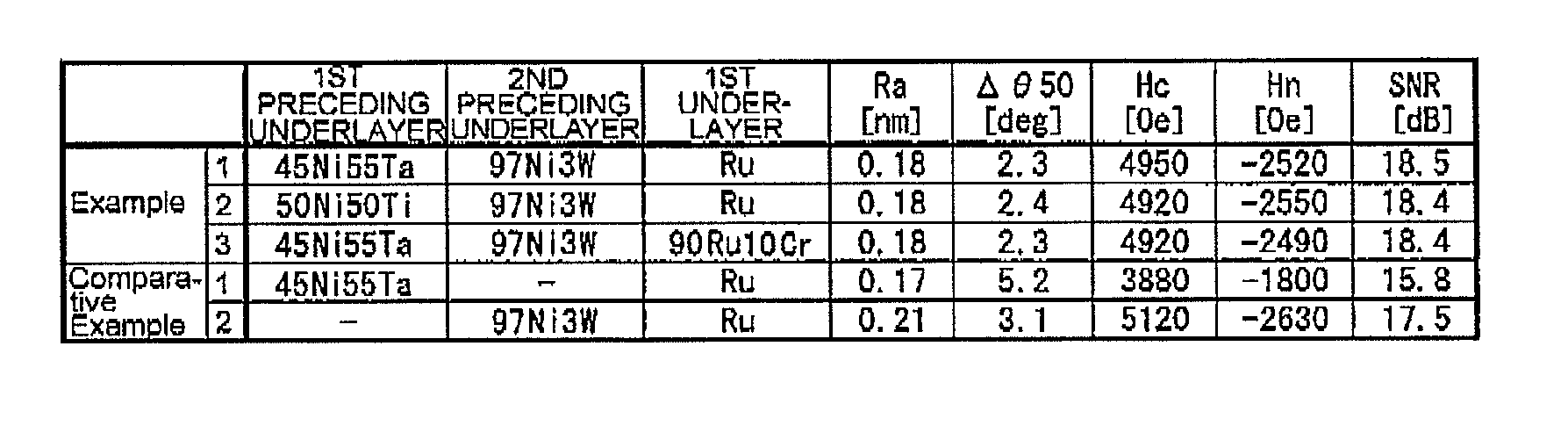

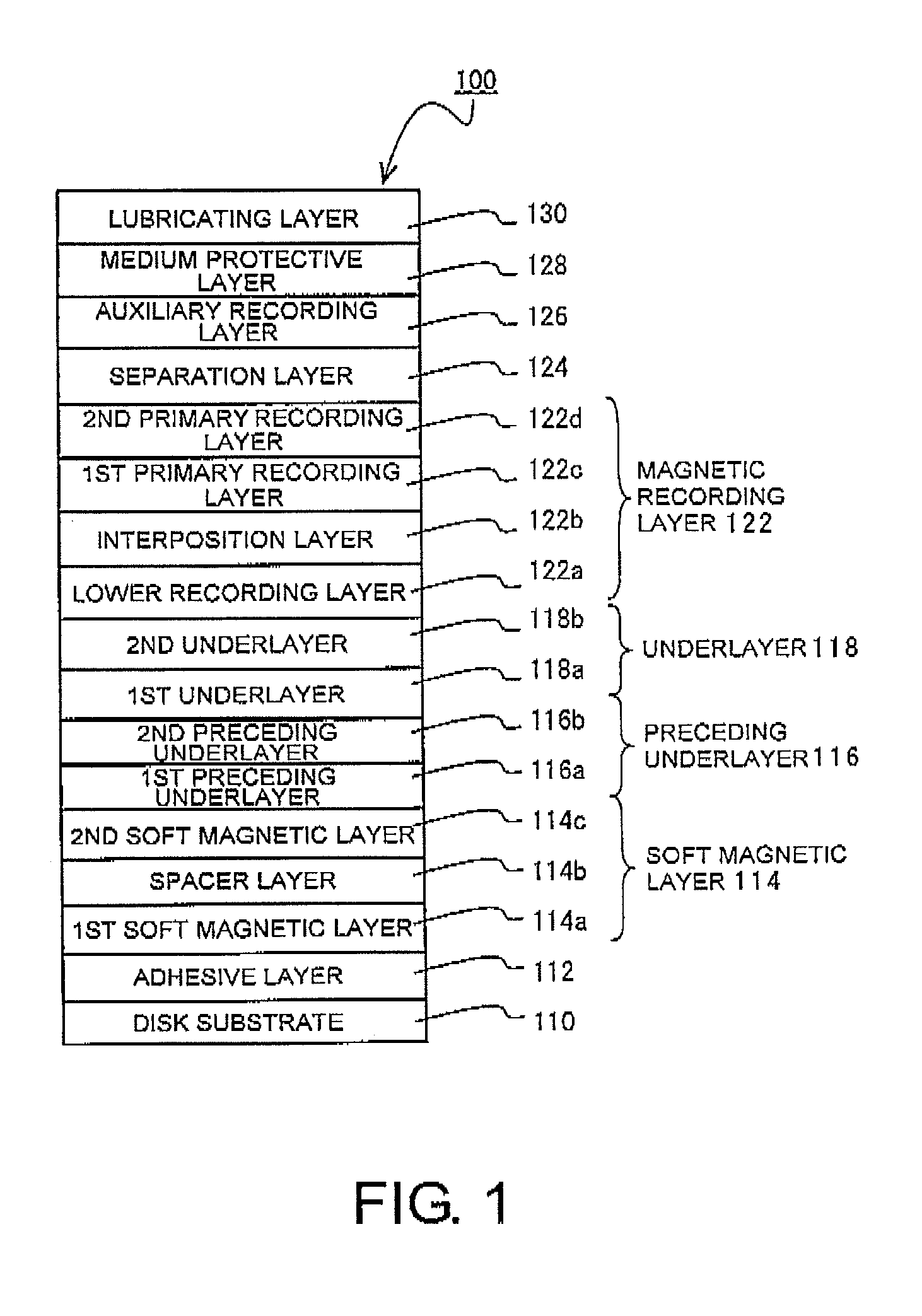

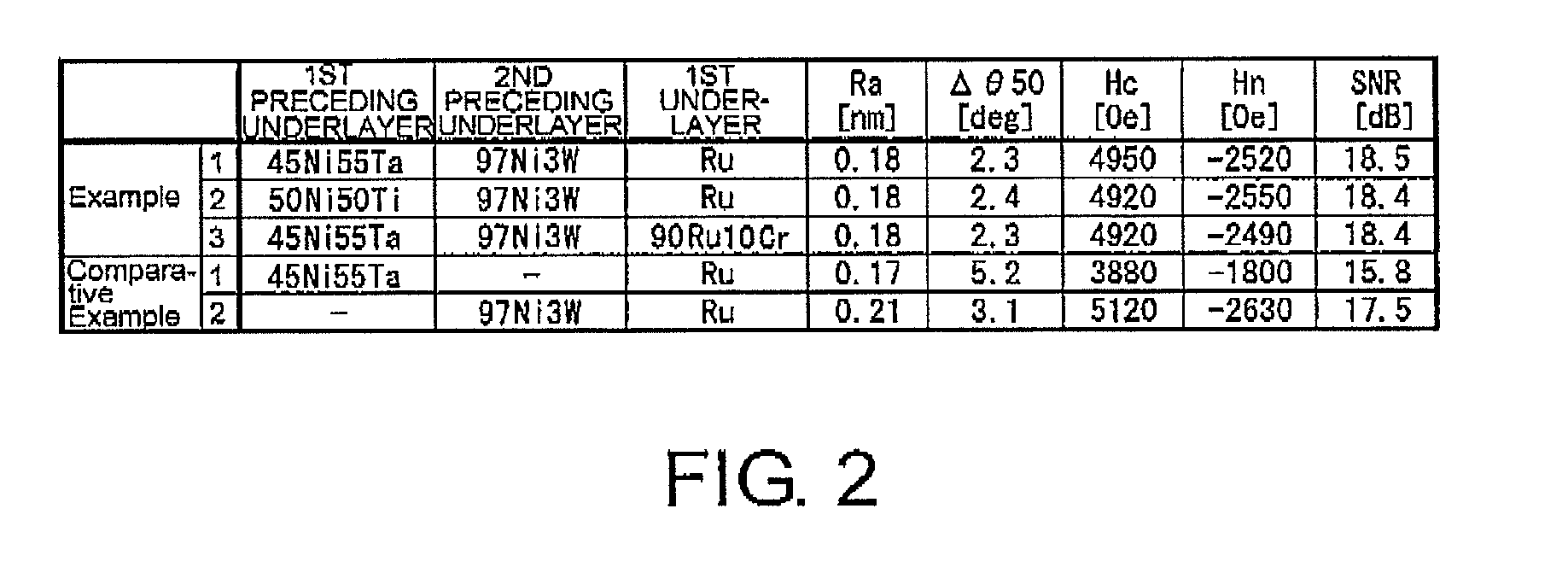

Perpendicular magnetic recording medium and method of manufacturing the same

ActiveUS8431258B2Reduce roughnessCrystallinity is disorderedRecord information storageDisk carriersCrystal orientationOptoelectronics

A perpendicular magnetic recording medium comprises a magnetic recording layer that records a signal, an underlayer formed of Ru or Ru compound below the magnetic recording layer, a non-magnetic layer formed of a non-magnetic material below the underlayer to control crystal orientation of the underlayer, a soft magnetic layer provided below the non-magnetic layer, and a substrate on which the magnetic recording layer, the underlayer, the non-magnetic layer, and the soft magnetic layer are formed. The non-magnetic layer comprises a first non-magnetic layer formed above the soft magnetic layer and a second non-magnetic layer formed above the first non-magnetic layer. The first non-magnetic layer is formed of amorphous Ni compound while the second non-magnetic layer is formed of crystalline Ni or crystalline Ni compound.

Owner:WESTERN DIGITAL TECH INC

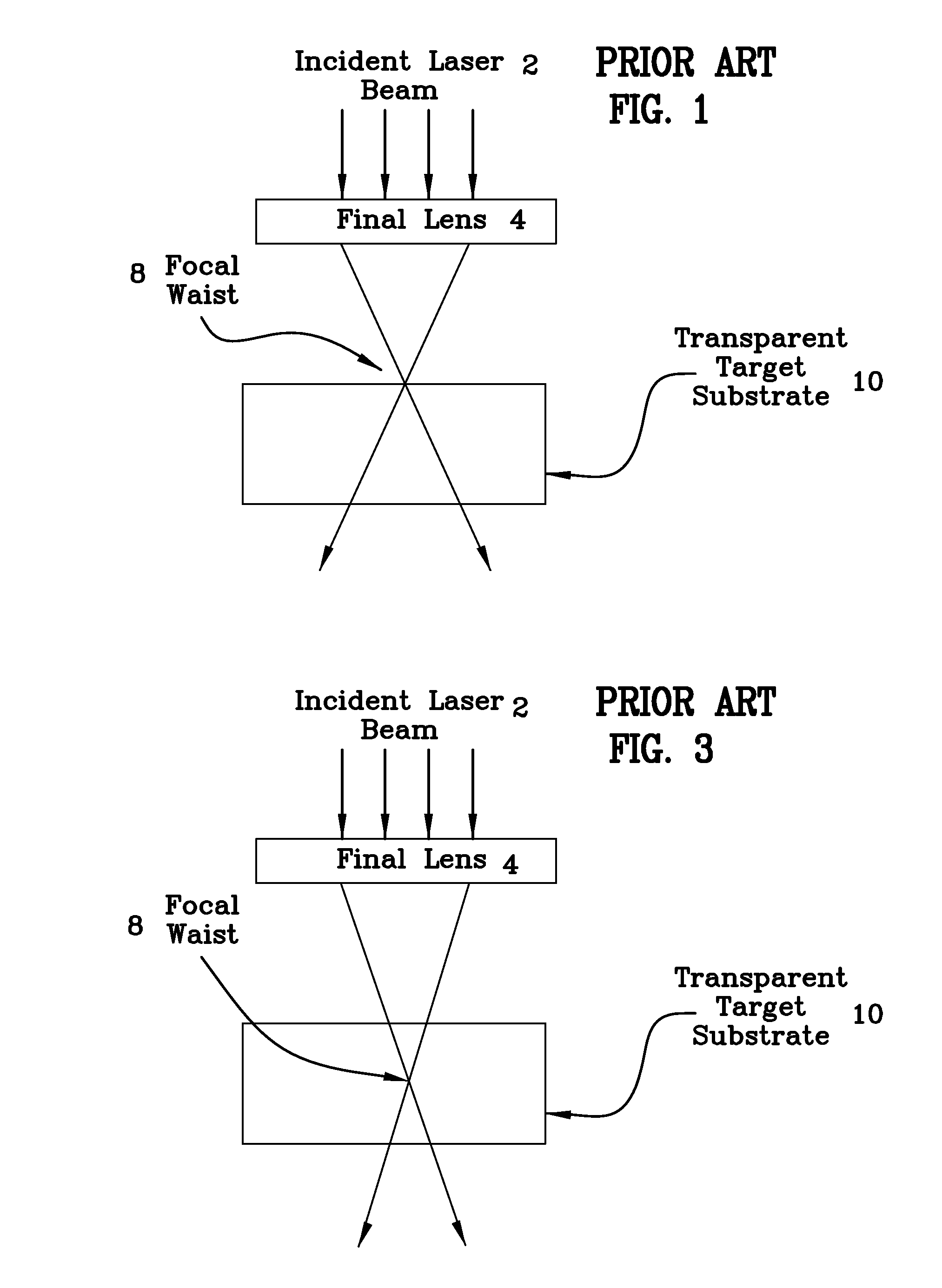

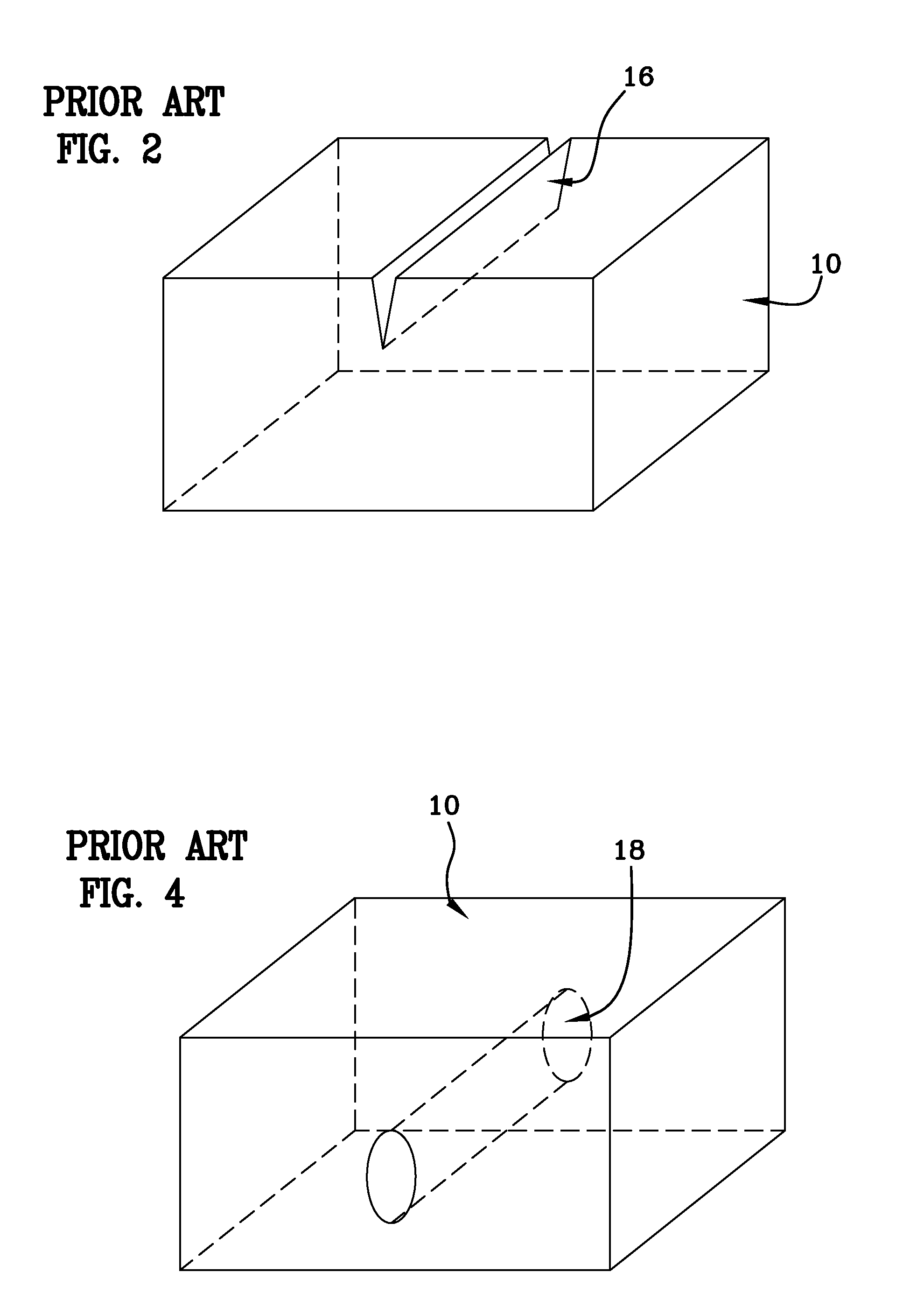

Method of fabricating a glass magnetic hard drive disk platter using filamentation by burst ultrafast laser pulses

ActiveUS20150118522A1Reduce manufacturing costExtreme precisionMagnetic materials for record carriersGlass furnace apparatusHard disc driveNon ablative

A non-ablative method and apparatus for making an economical glass hard disk (platter) for a computer hard disk drive (HDD) using a material machining technique involving filamentation by burst ultrafast laser pulses. Two related methods disclosed, differing only in whether the glass substrate the HDD platter is to be cut from has been coated with all the necessary material layers to function as a magnetic media in a computer's hard drive. Platter blanks are precisely cut using filamentation by burst ultrafast laser pulses such that the blank's edges need not be ground, the platter's geometric circularity need not be corrected and there is no need for further surface polishing. Thus the platters can be cut from raw glass or coated glass. As a result, this method reduces the product contamination, speeds up production, and realizes great reductions in the quantity of waste materials and lower production costs.

Owner:ROFIN SINAR TECH

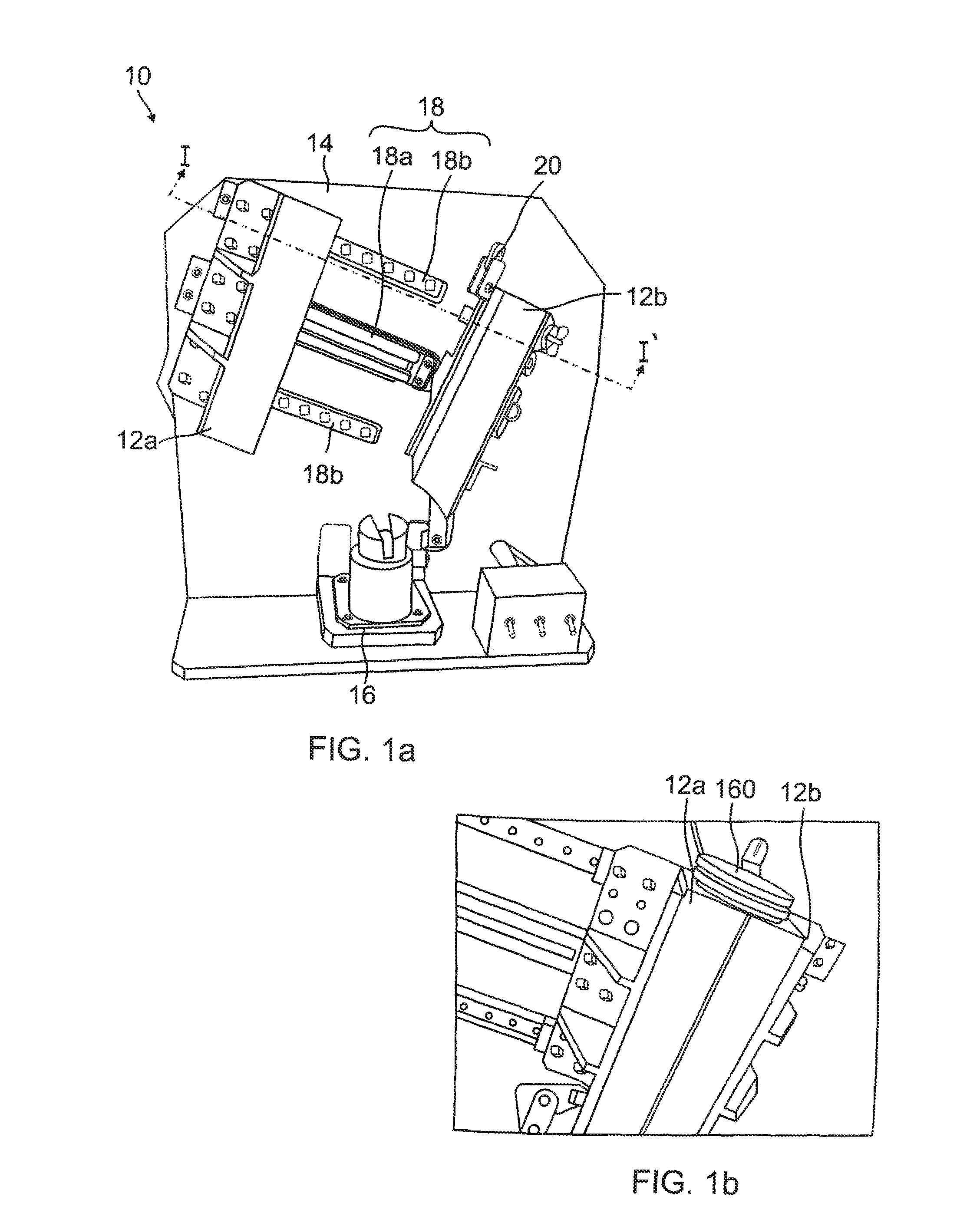

Disk stacking method and apparatus

InactiveUS8556566B1Avoid damageReduce the overall diameterFilament handlingPile receiversEngineeringMagnetic disks

Aspects of embodiments of the present invention are directed toward a method of stacking disk-shaped substrates for polishing without using a centering shaft and an apparatus for implementing the method. A stack of disk-shaped substrates can be concentrically aligned without contacting the inside circumferential surfaces of the disk-shaped substrates by applying pressure to the outside edges of the disk-shaped substrates in different lateral directions.

Owner:WD MEDIA

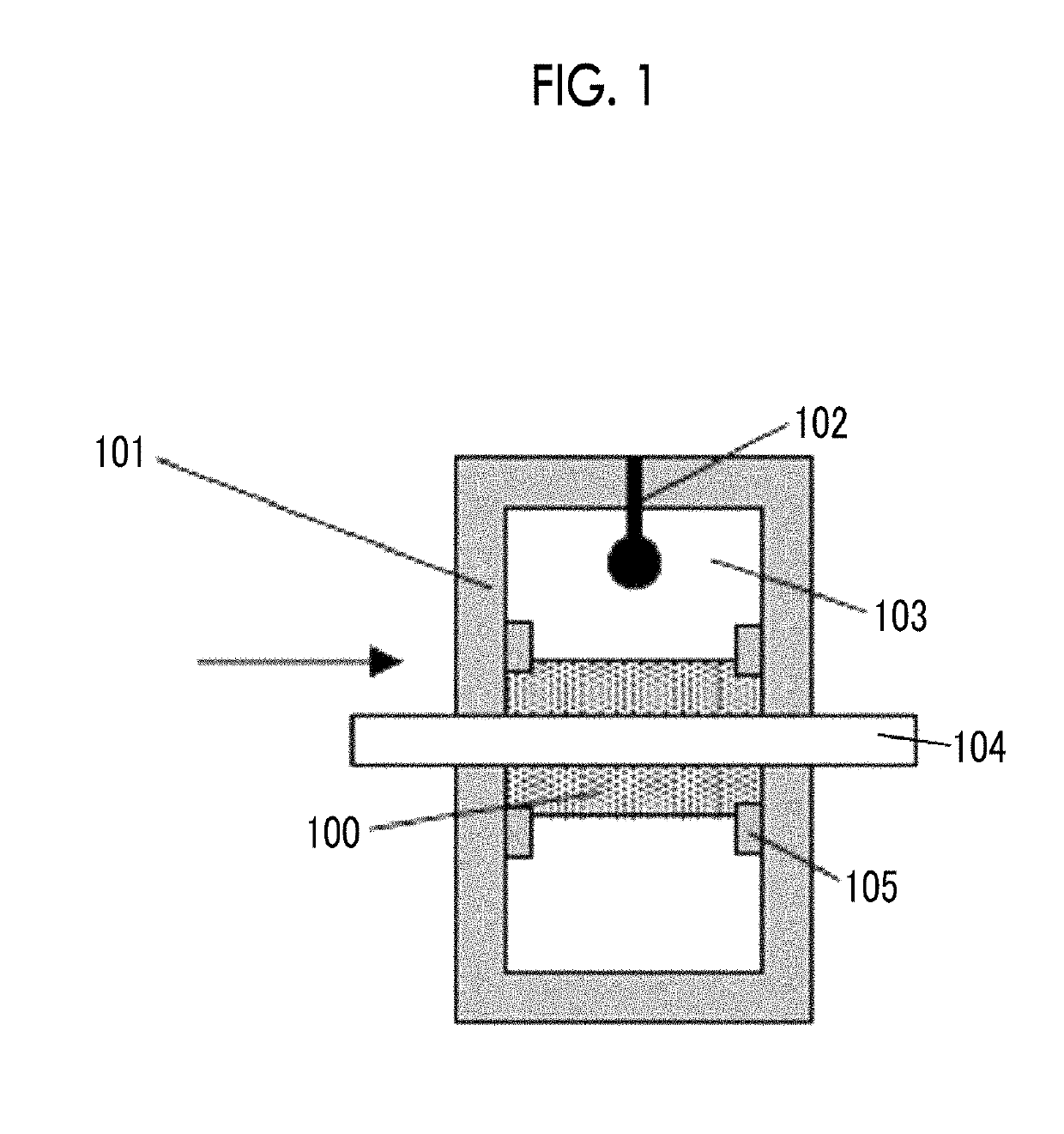

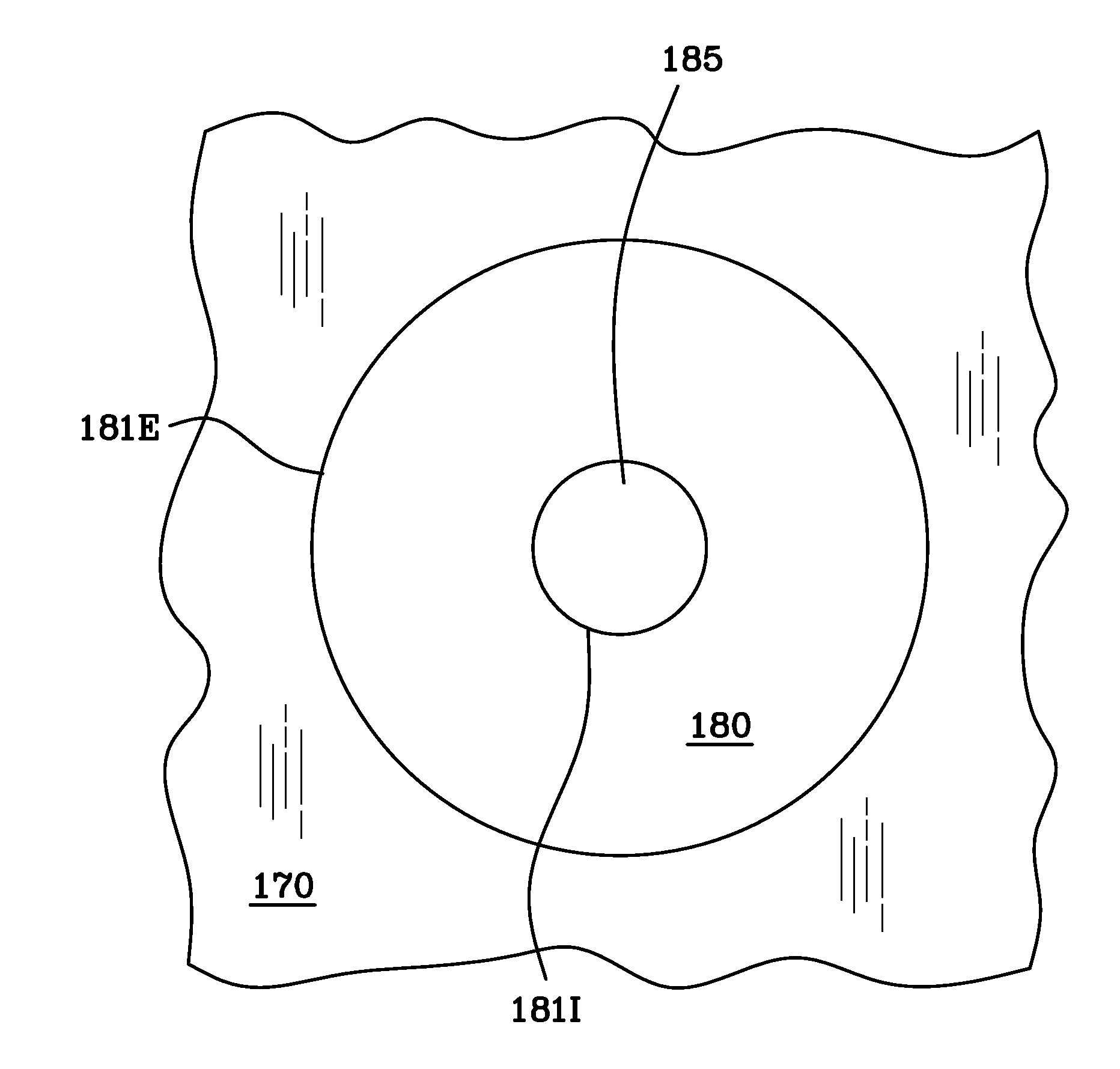

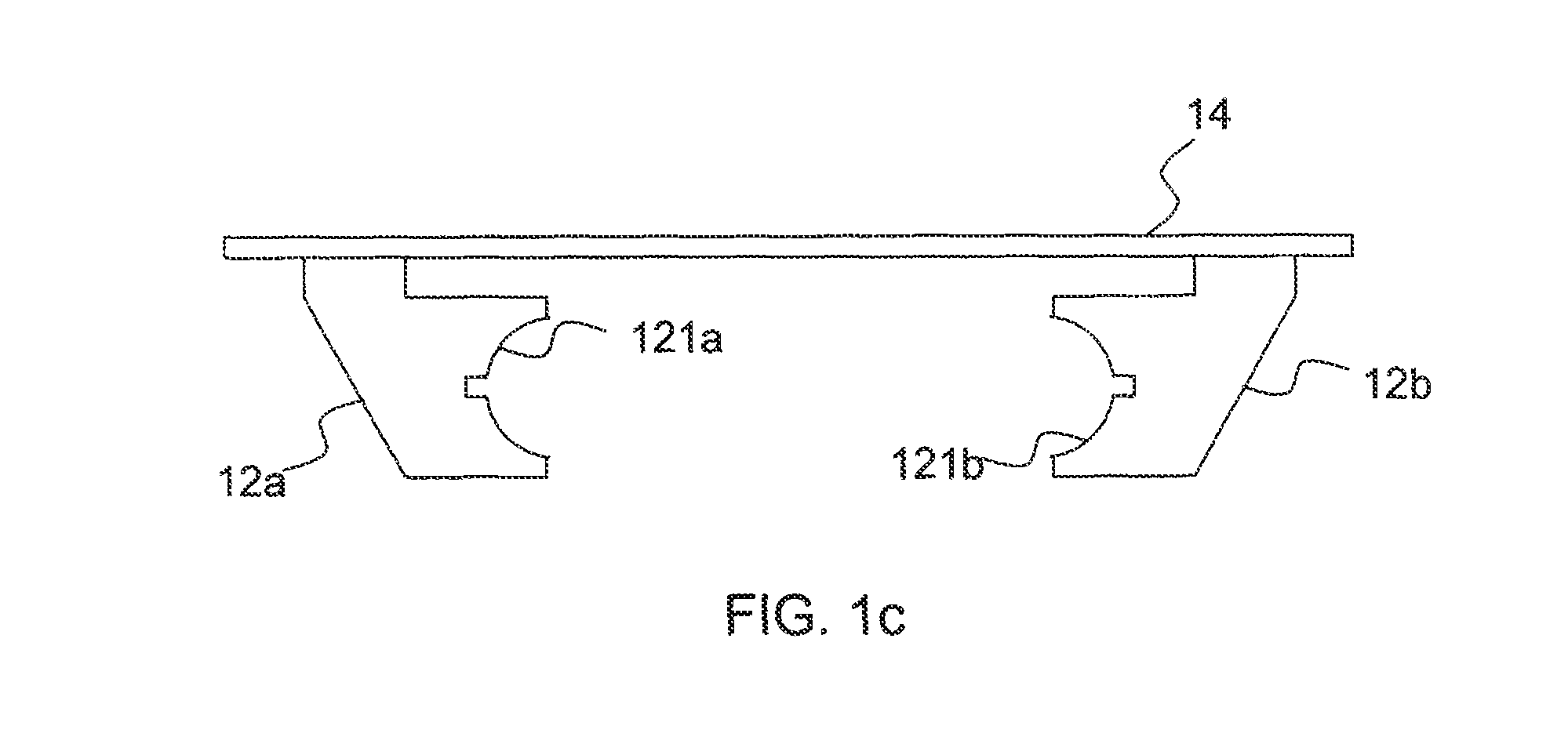

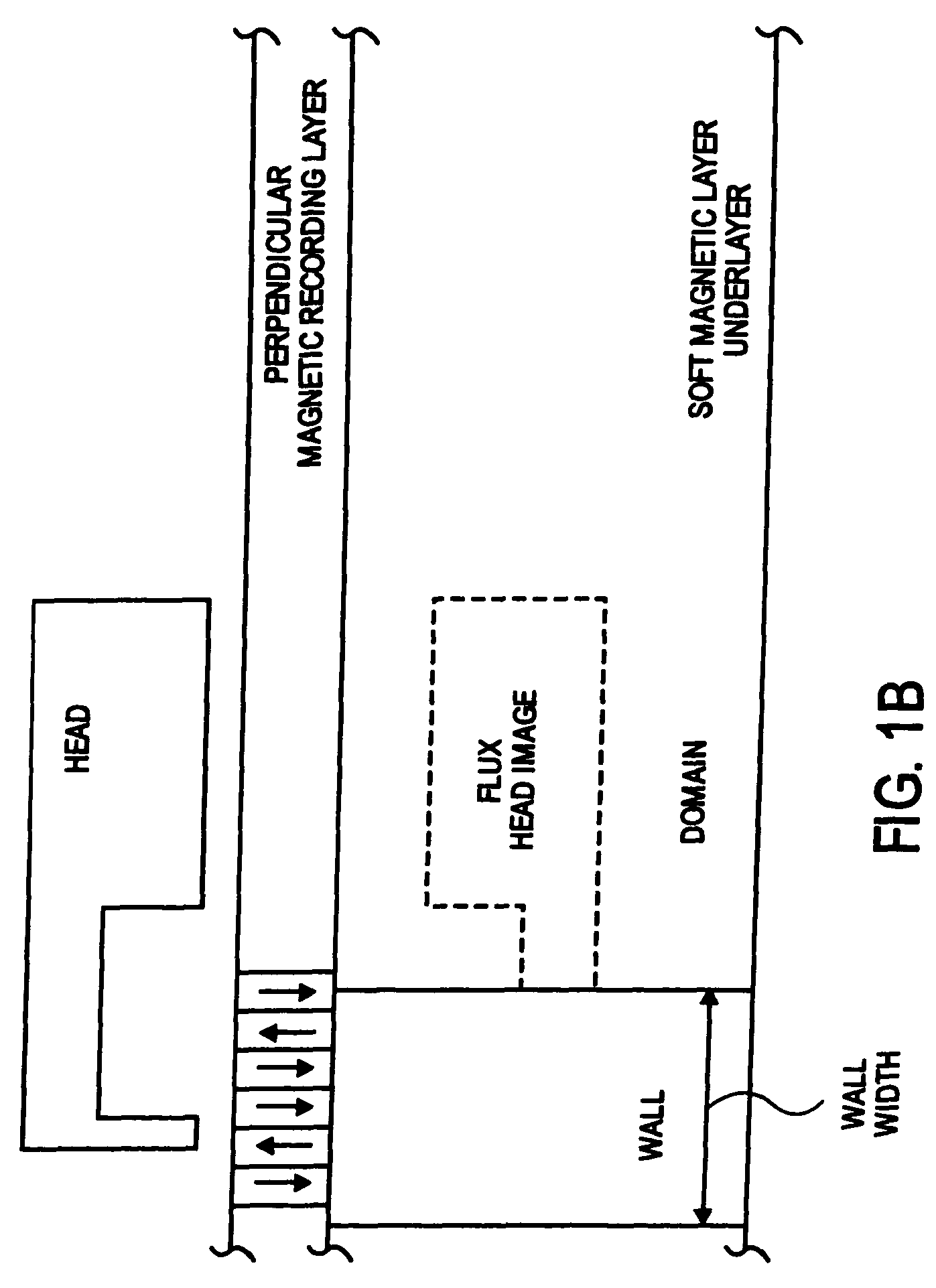

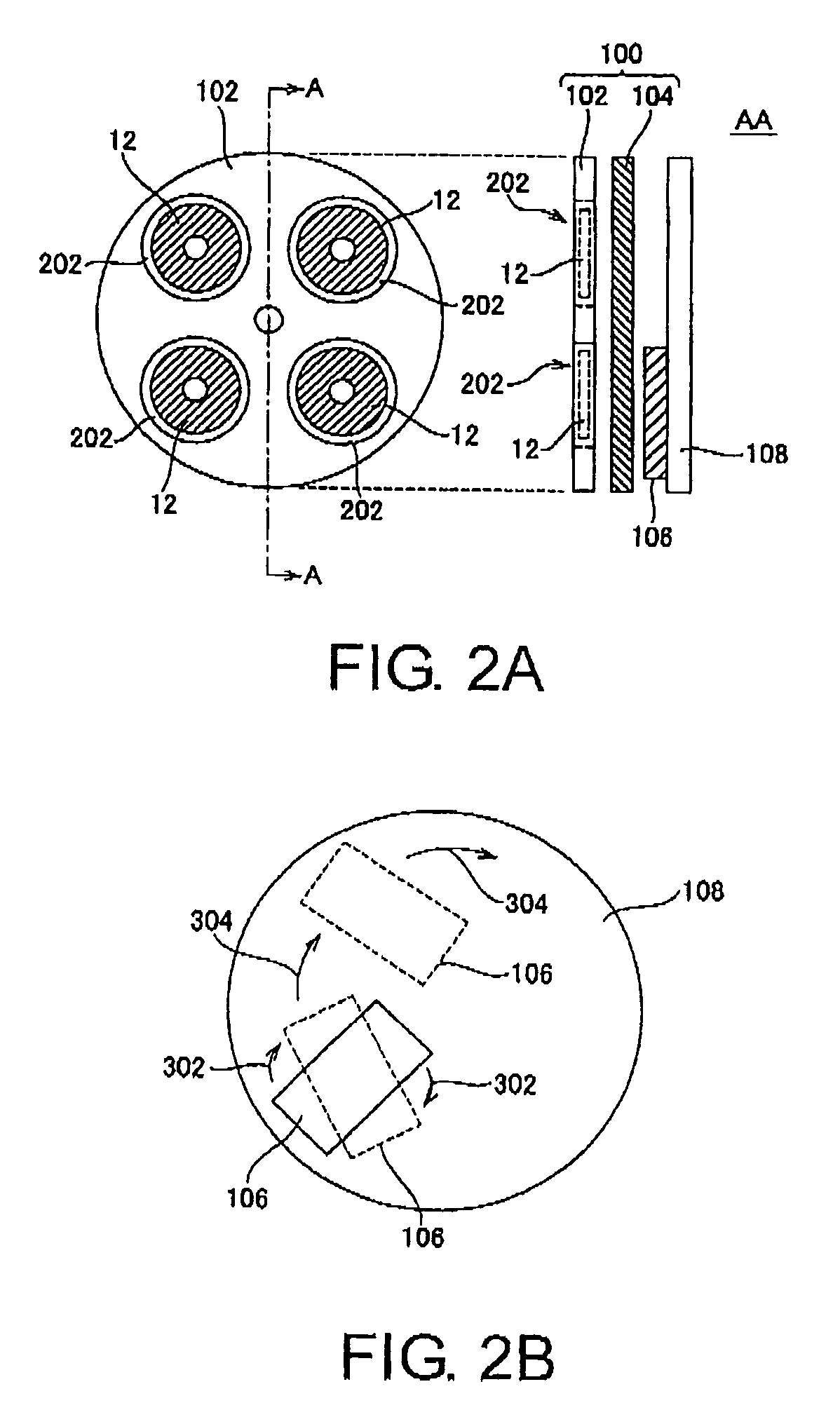

Radial magnetic field reset system for producing single domain soft magnetic underlayer on perpendicular magnetic recording medium

A radial magnetic field reset apparatus including a housing having a cavity with a soft magnet rod disposed at its center and a permanent magnet disposed around the cavity. The cavity and thickness of the soft magnet rod are sized to permit a cassette of disks to be inserted into the housing with the soft magnet rod disposed within the inner diameter holes of the disks contained in the cassette. The soft magnet rod at the center of the housing attracts the magnetic field generated by the permanent magnet, which results in a substantially uniform, radial magnetic field inside the housing.

Owner:WD MEDIA

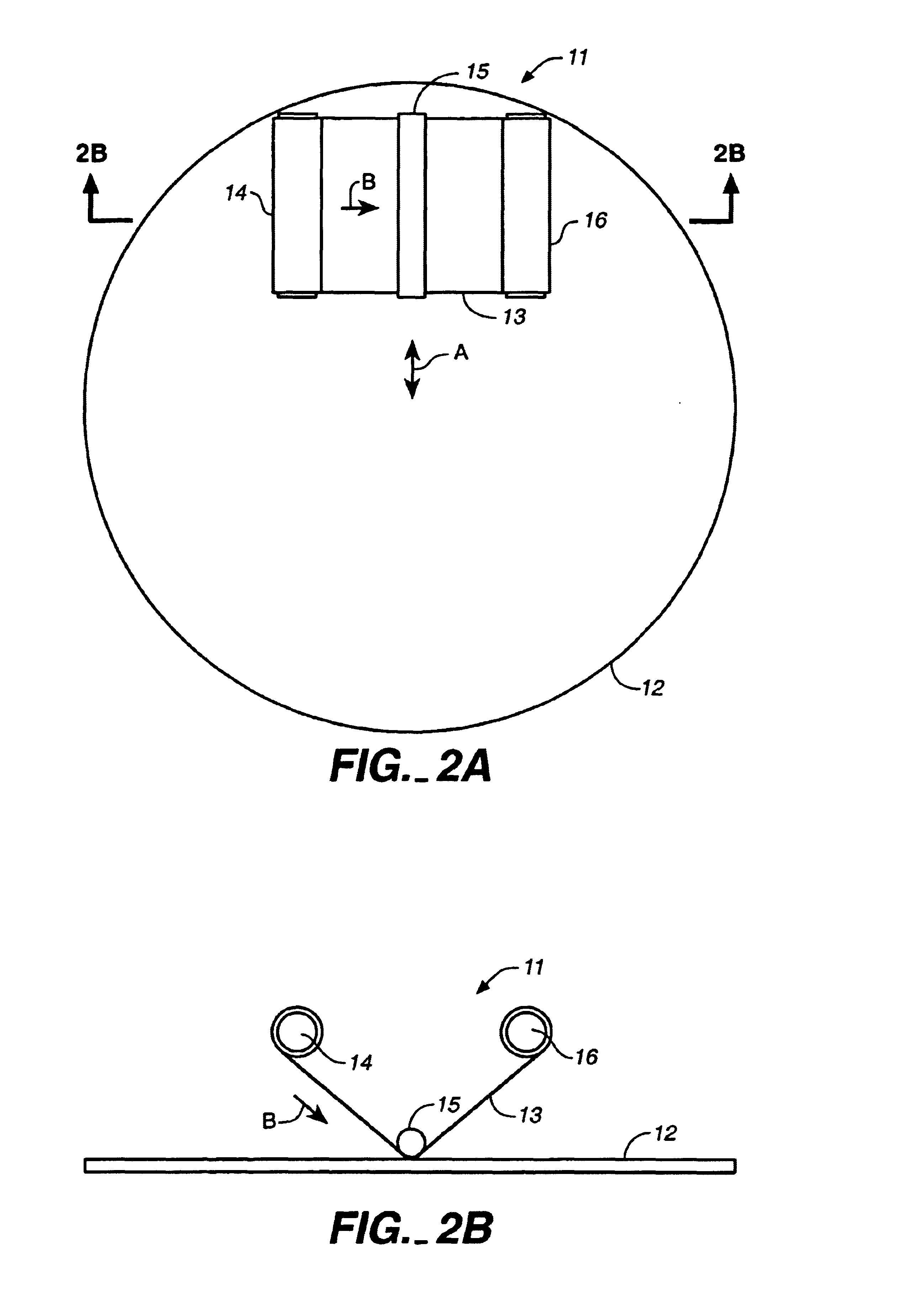

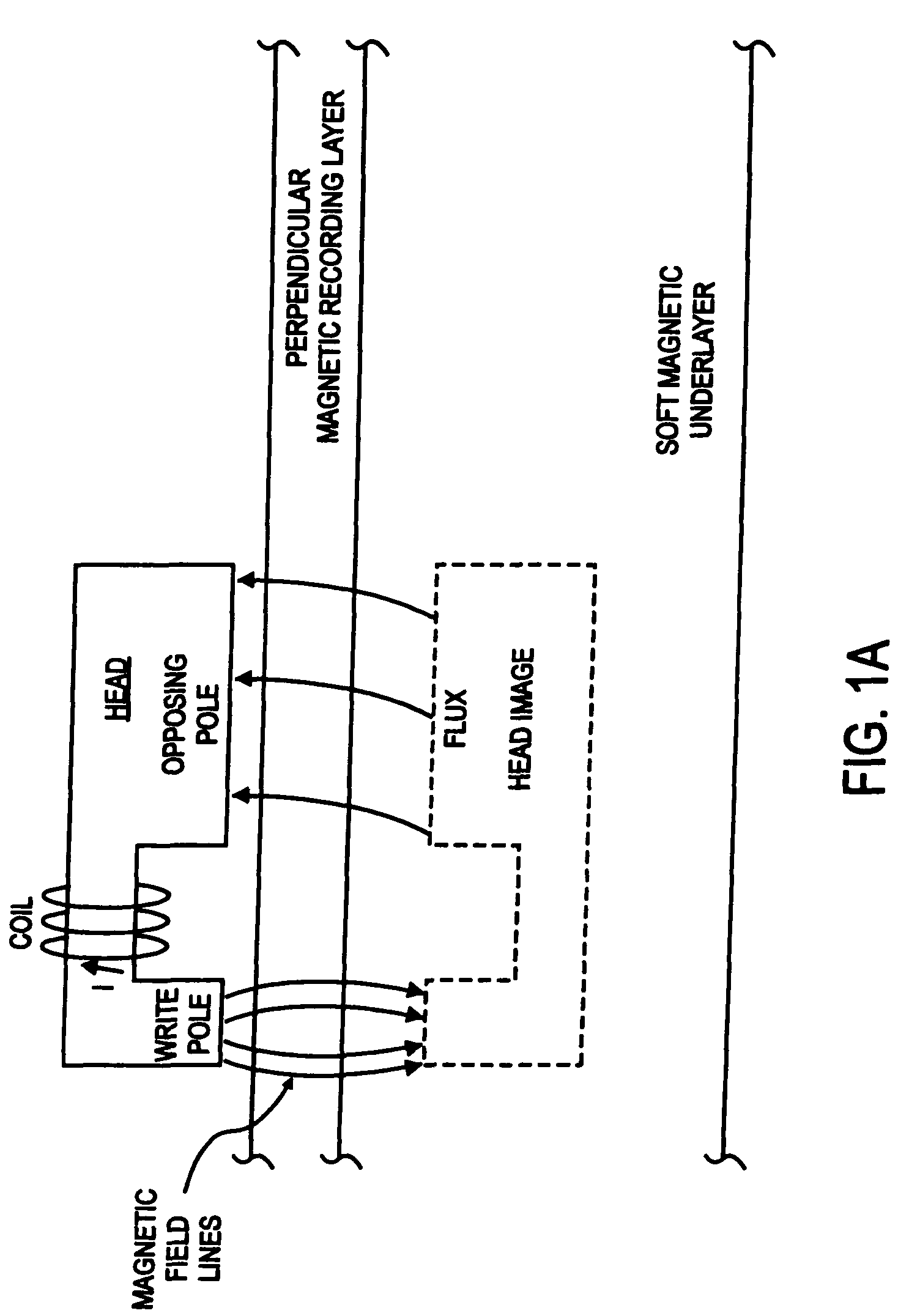

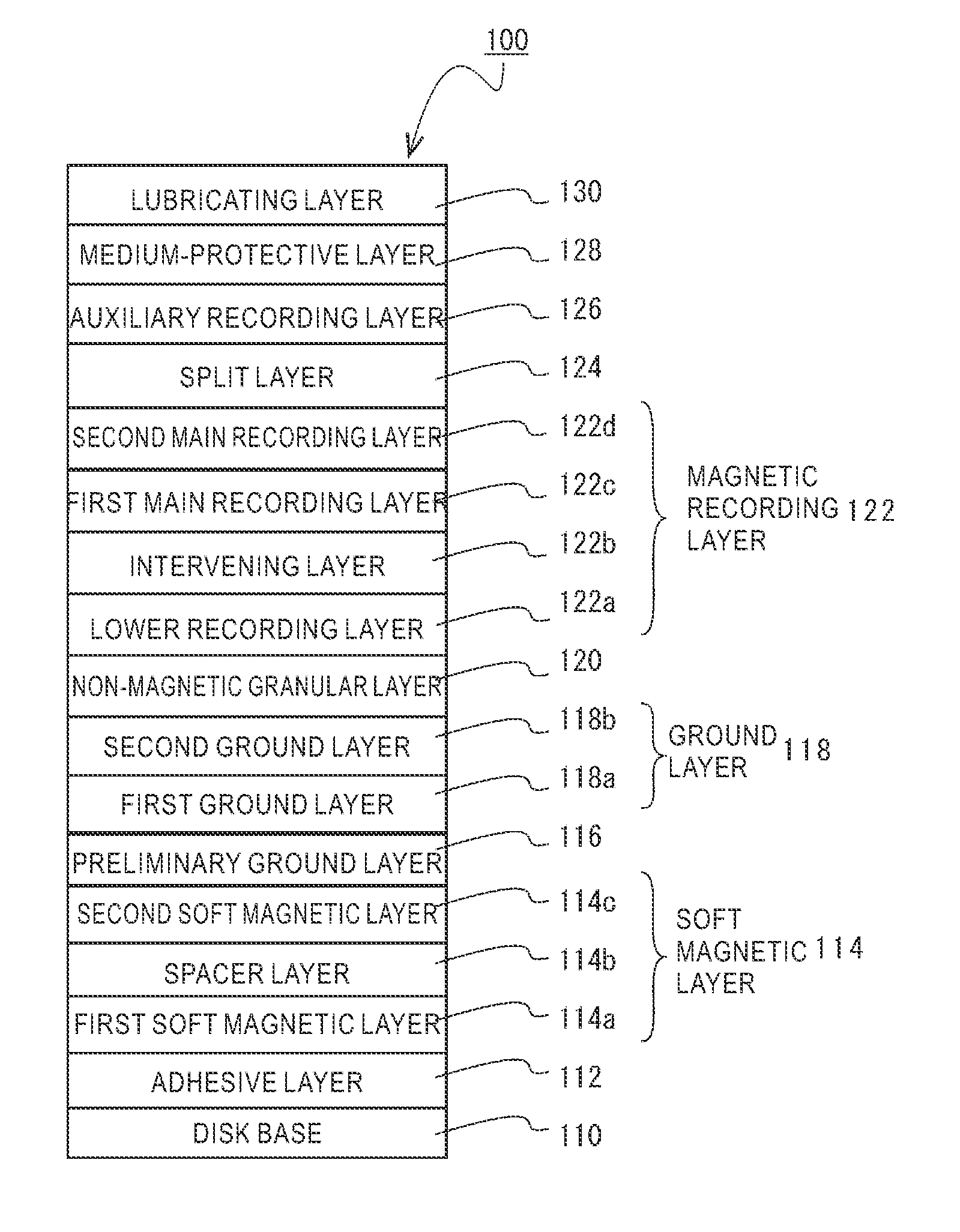

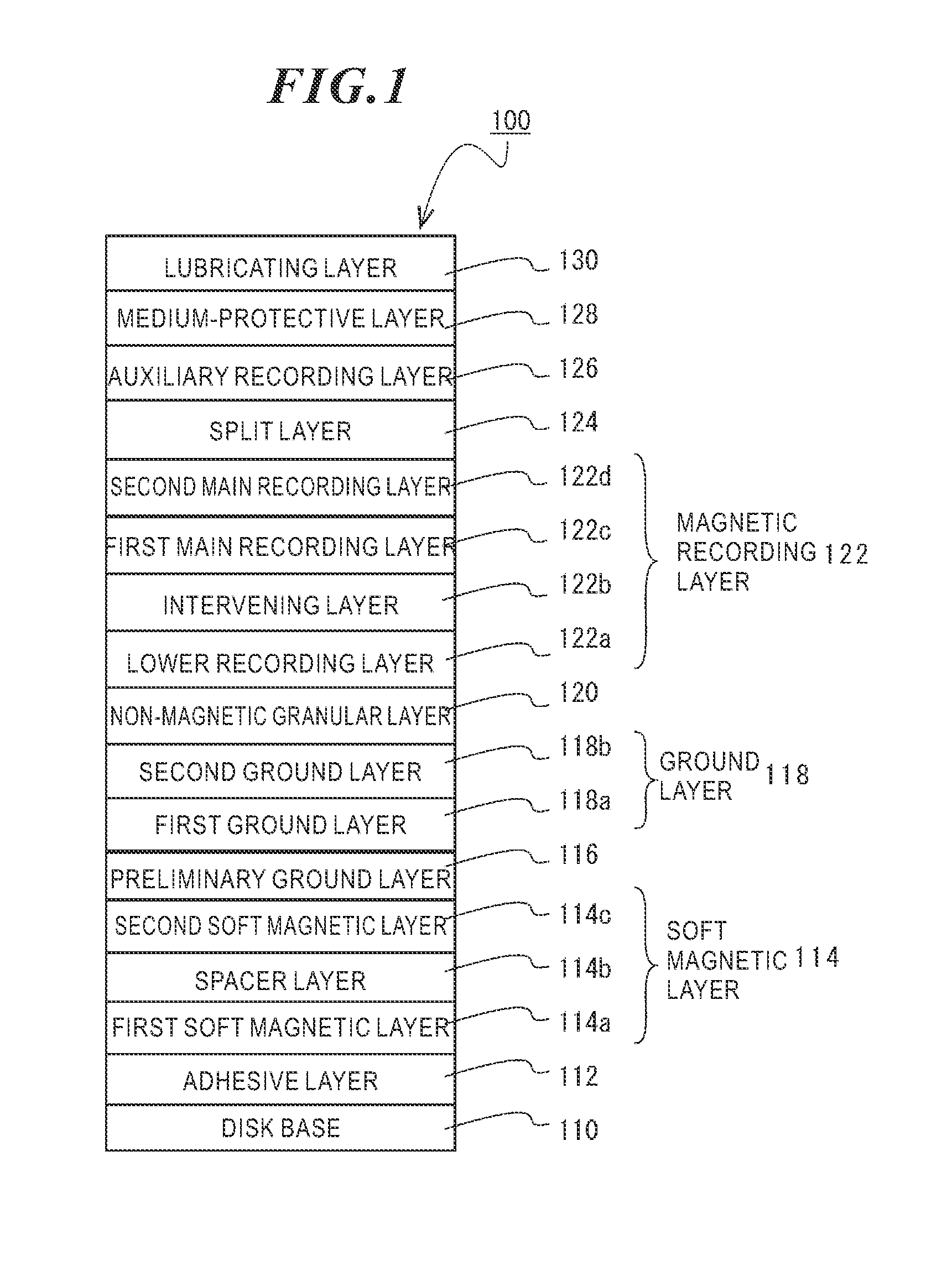

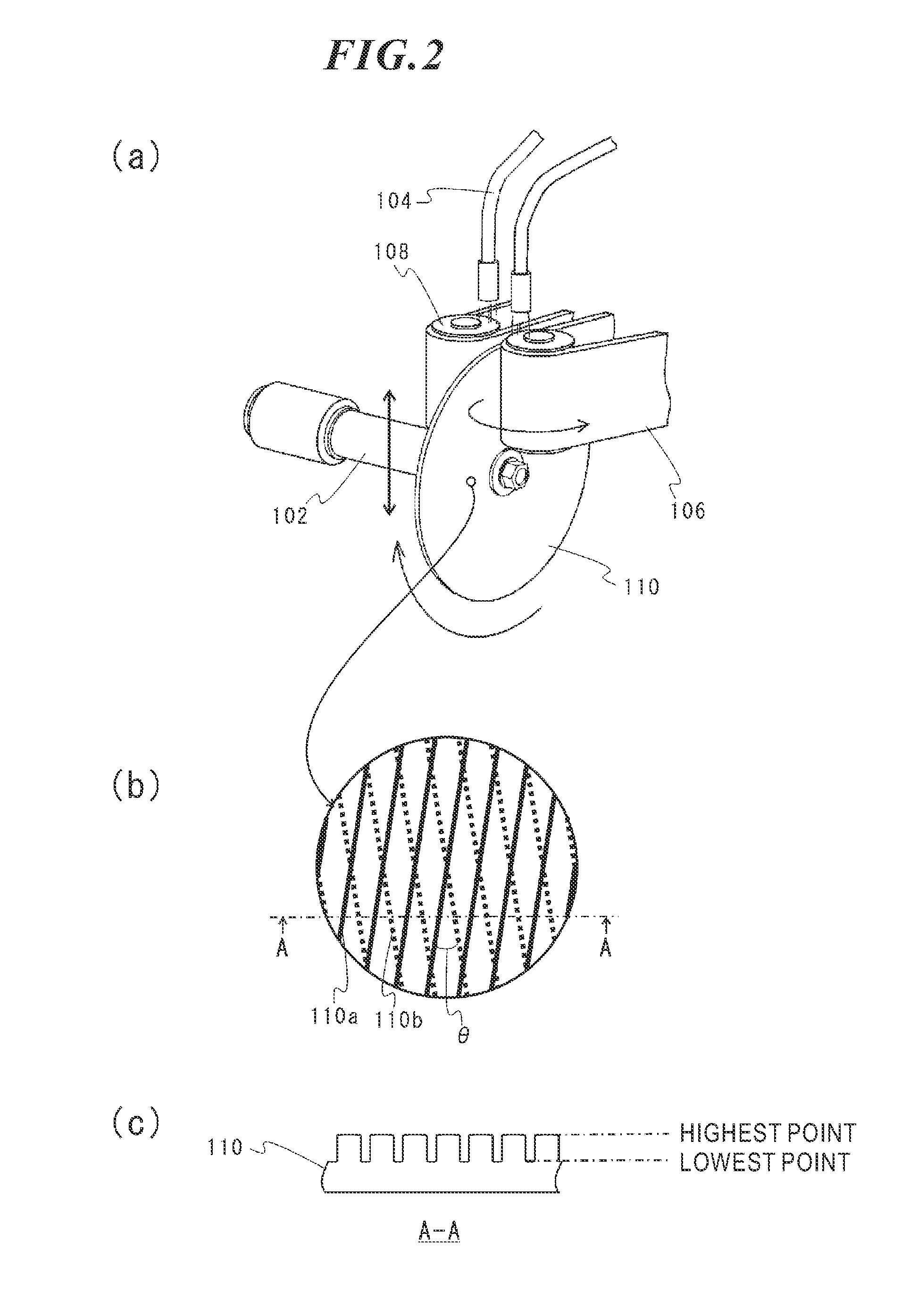

Perpendicular Magnetic Recording Media

ActiveUS20120140359A1Improve recording densityNarrow widthRecord information storageDisk carriersRecording layerRecording density

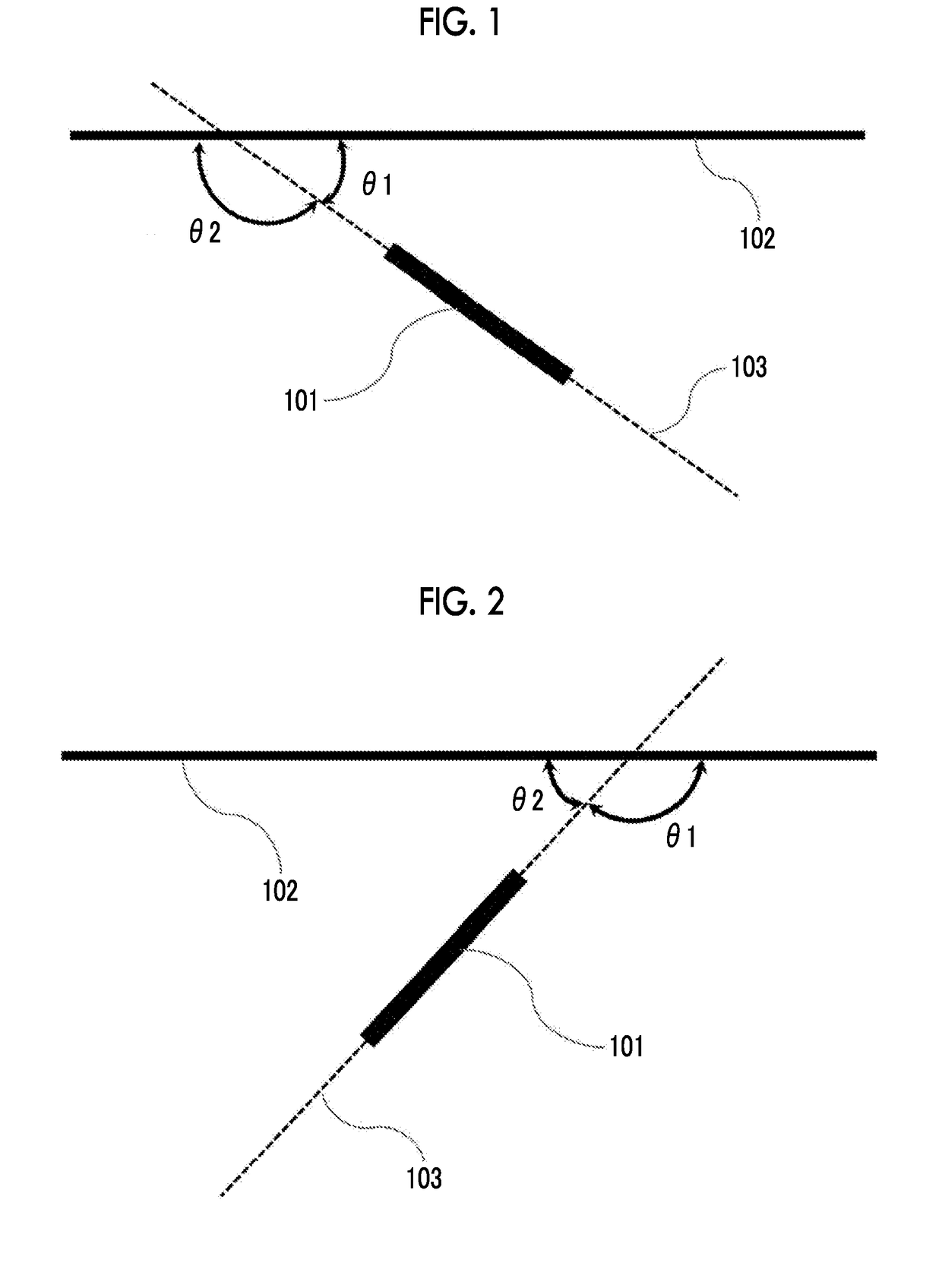

[Summary][Problem] An object is to provide a perpendicular magnetic recording medium in which a narrower track width is achieved by enhancing an exchange coupling magnetic field Hex of a soft magnetic layer so that a higher recording density can be achieved.[Solution] A perpendicular magnetic recording medium according to the present invention is configured to include a magnetic recording layer 122 that records a signal, and a soft magnetic layer 114 provided below the magnetic recording layer, on a base 110 on a main surface of which textures are formed, wherein the textures includes first textures 110a that is linear rails in a certain direction, and second textures 110b that are trails intersecting at a predetermined angle with the first textures; and the angle of intersection between the first textures and the second textures is 10° or less.

Owner:WESTERN DIGITAL TECH INC

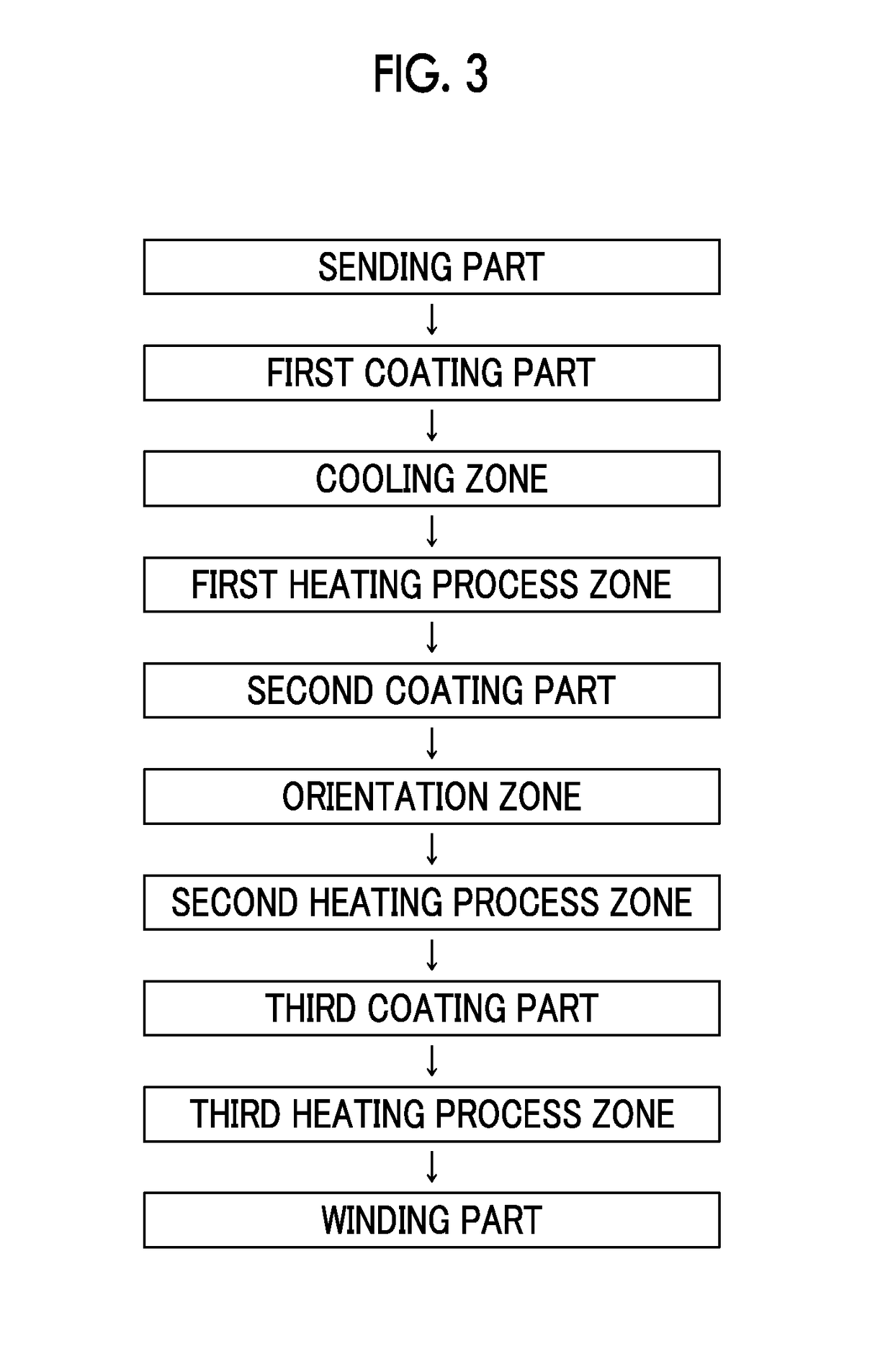

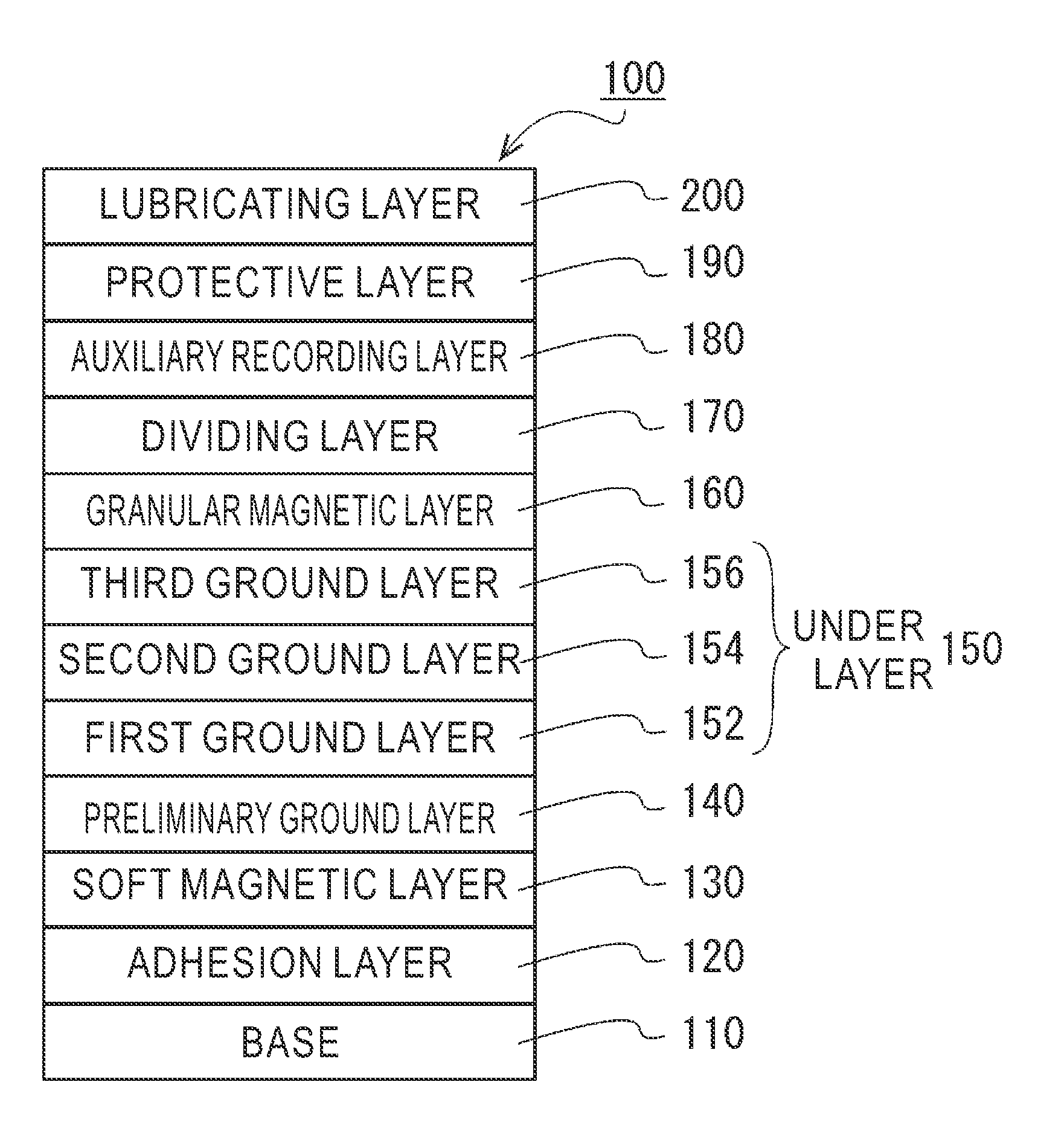

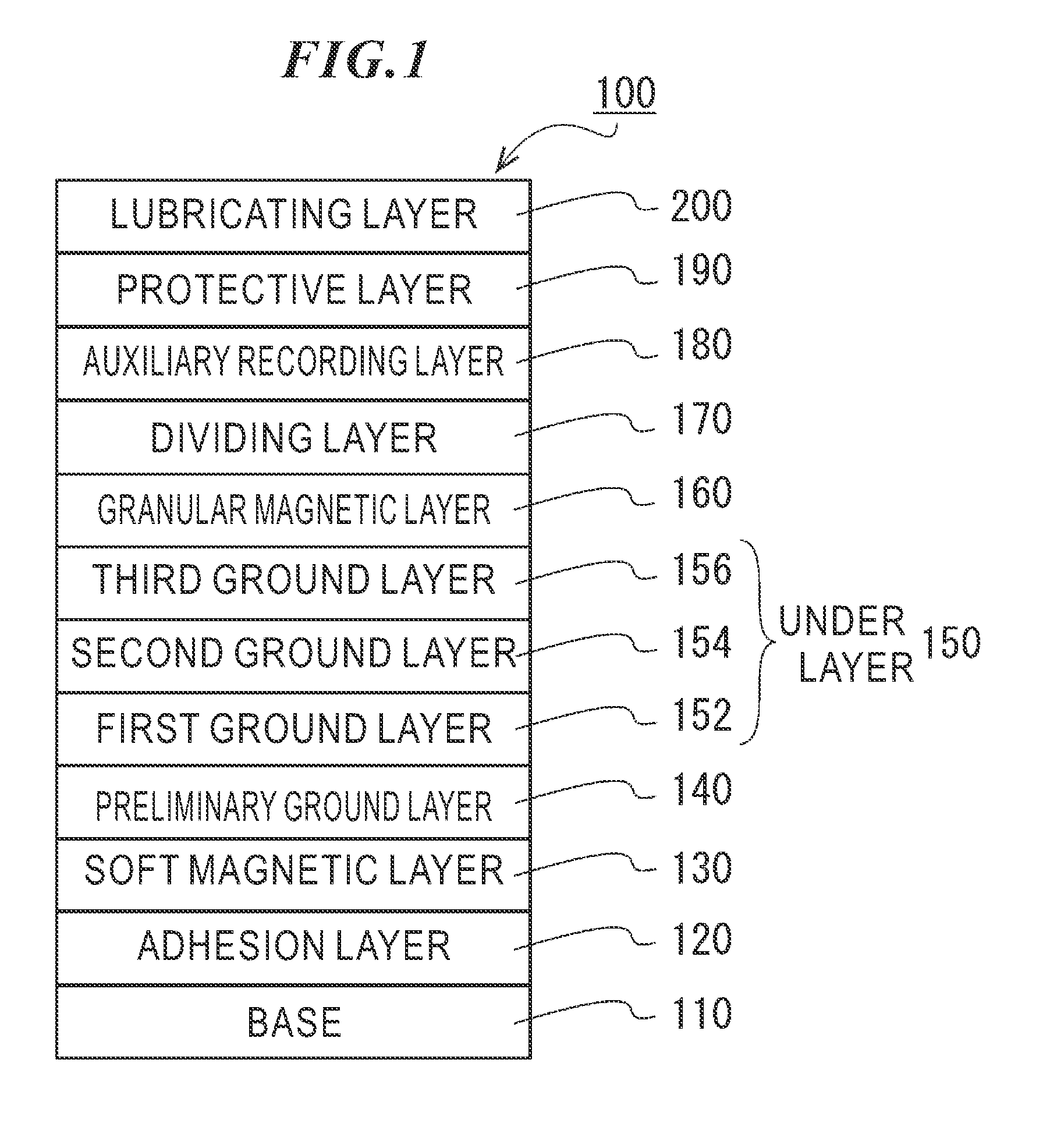

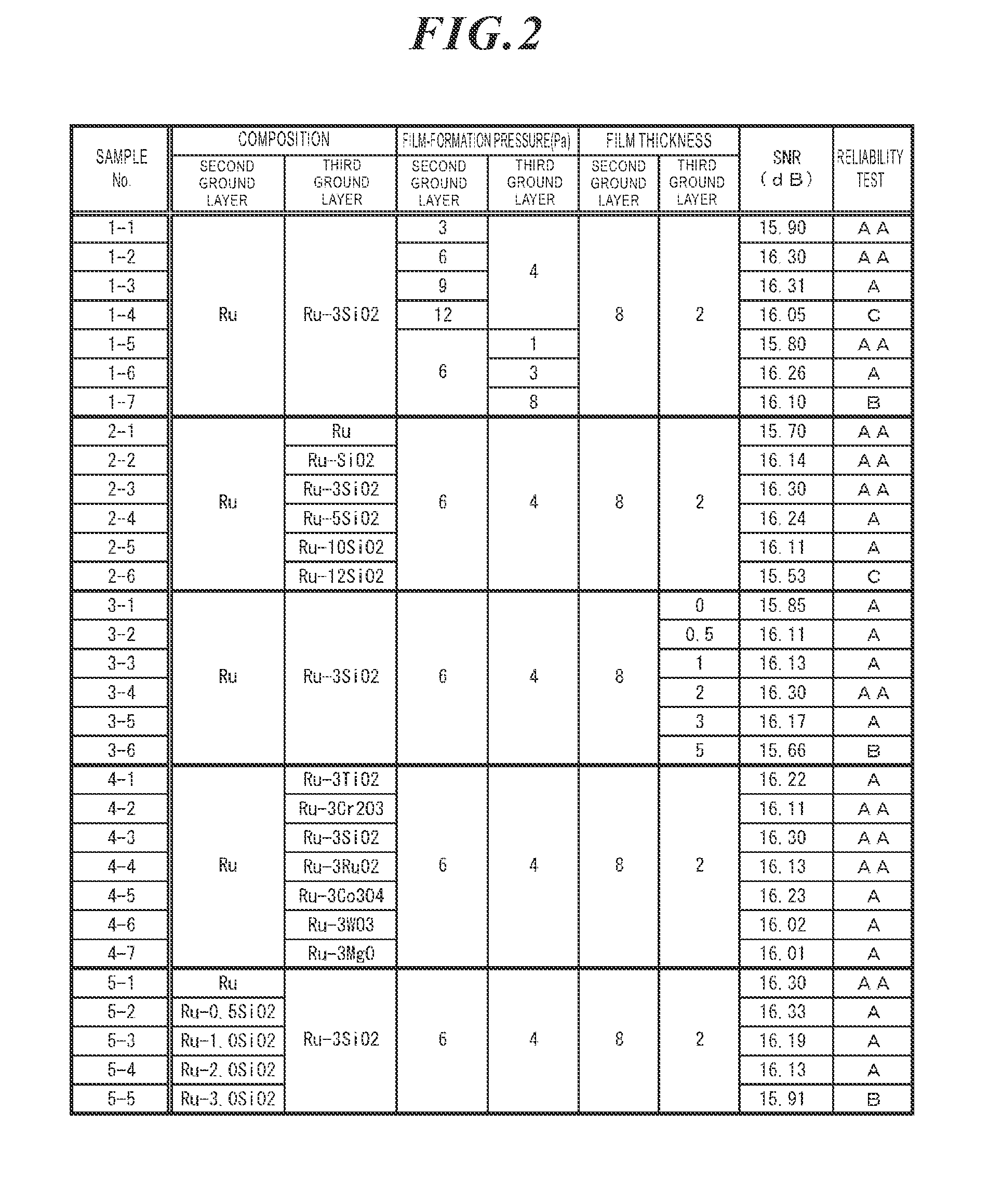

Method of Manufacturing a Perpendicular Magnetic Disc

InactiveUS20120207919A1Improve reliabilityImprove signal-to-noise ratioPretreated surfacesRecord information storageAlloyNon magnetic

A method of manufacturing a perpendicular magnetic disk comprises forming, on a base, a film of a first ground layer made of Ru or a Ru alloy at a first pressure, forming, on the first ground layer, a film of a second ground layer made of Ru or a Ru alloy at a second pressure higher than a first pressure, forming, on the second ground layer, a film of a third ground layer having Ru or a Ru alloy as a main component and an oxide as an accessory component at a third pressure higher than the first pressure and lower than the second pressure, and forming, on a layer above the third ground layer, a film of a granular magnetic layer in which a non-magnetic substance having an oxide is segregated around magnetic particles having an CoCrPt alloy grown in a columnar shape to form a grain boundary.

Owner:WD MEDIA SINGAPORE PTE

Magnetic disk and magnetic disk manufacturing method

InactiveUS7993497B2Magnetic materials for record carriersVacuum evaporation coatingMagnetic anisotropyGroup element

In a magnetic disk having at least a glass substrate, a plurality of underlayers formed over the glass substrate, and a magnetic layer formed over the plurality of underlayers, at least one of the underlayers is an amorphous underlayer containing a VIa group element and carbon and, given that the remanent magnetization in a circumferential direction of the disk is Mrc and the remanent magnetization in a radial direction of the disk is Mrr, the magnetic disk has a magnetic anisotropy in which Mrc / Mrr being a ratio between Mrc and Mrr exceeds 1.

Owner:WD MEDIA SINGAPORE PTE

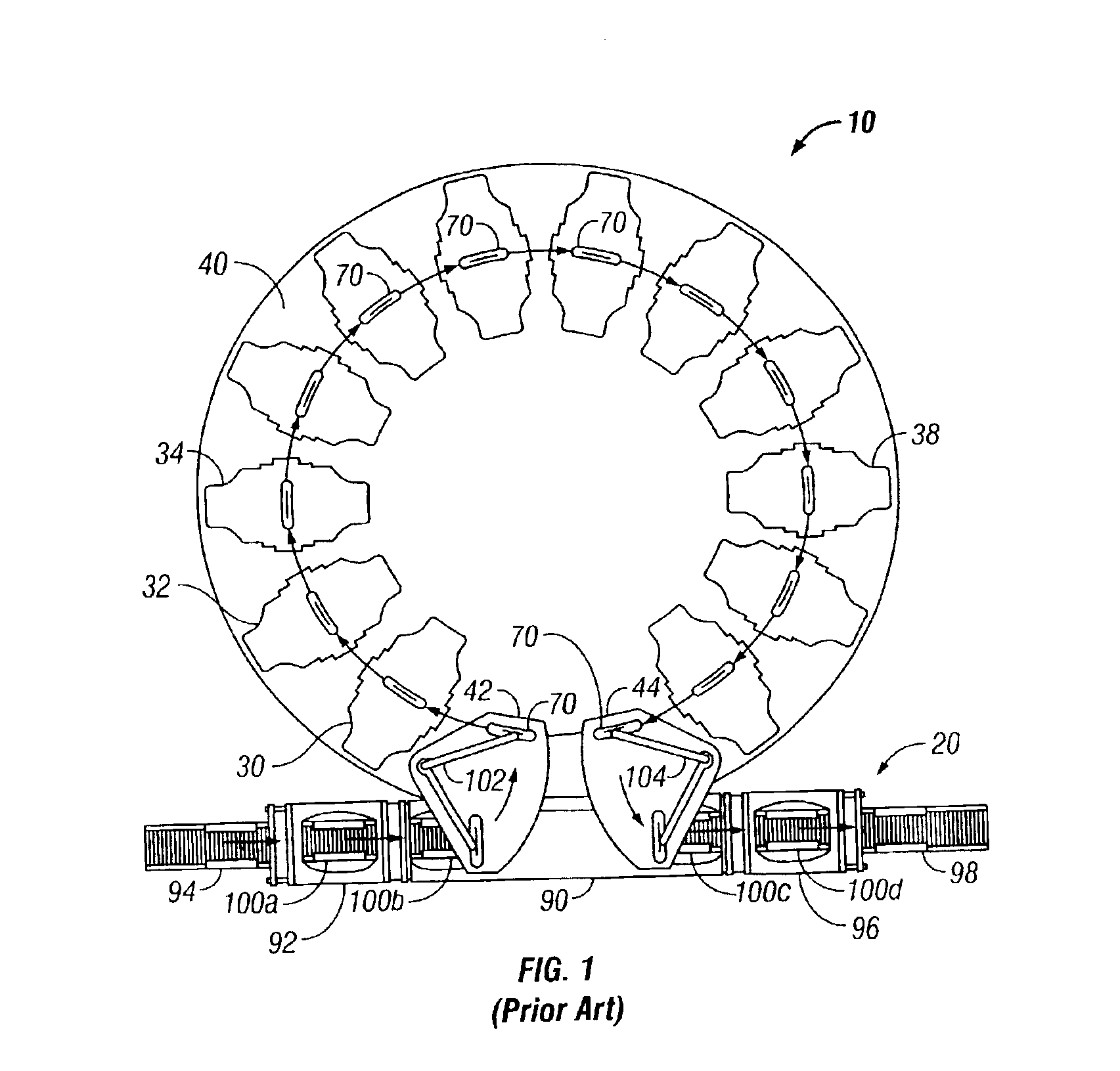

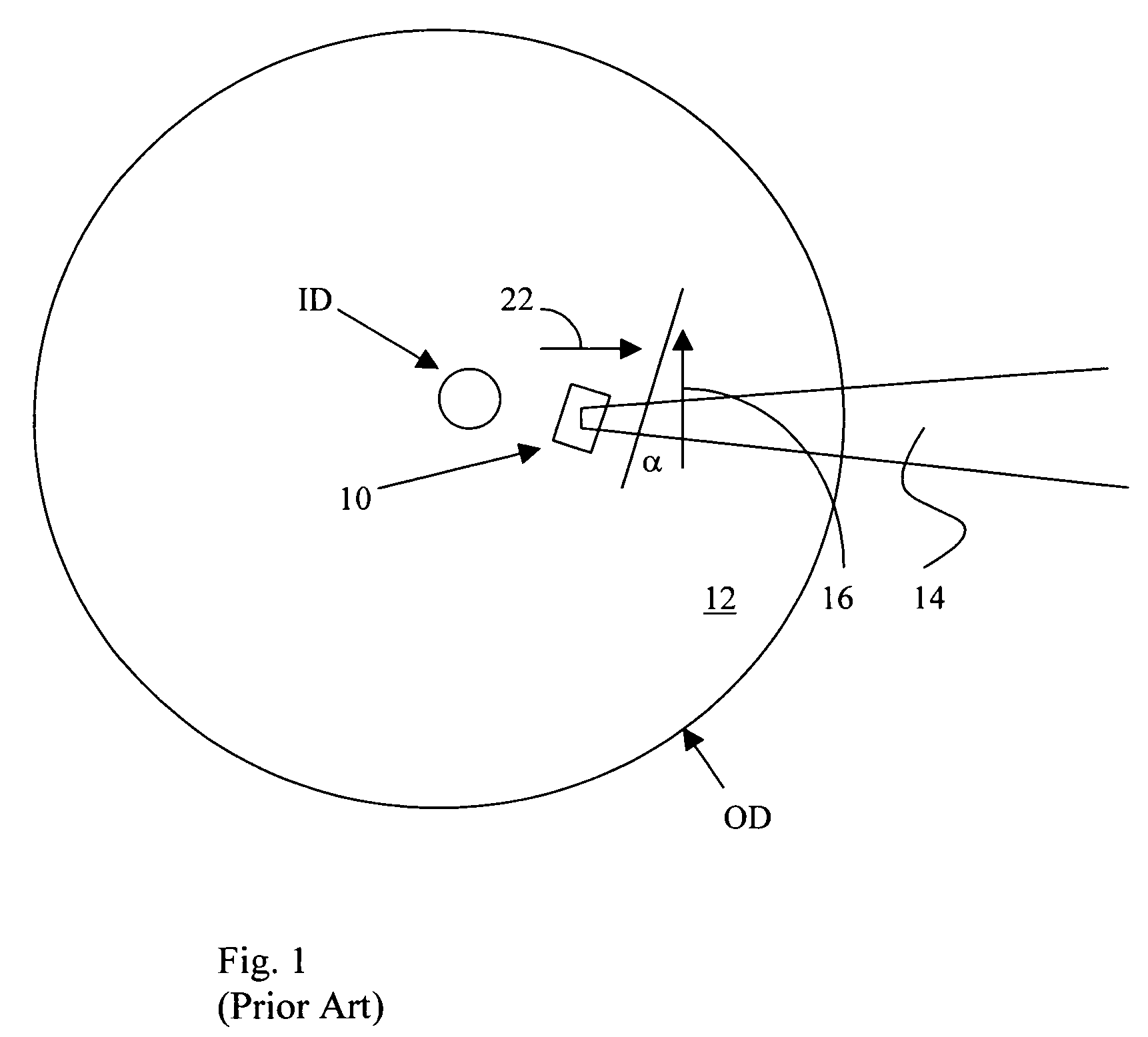

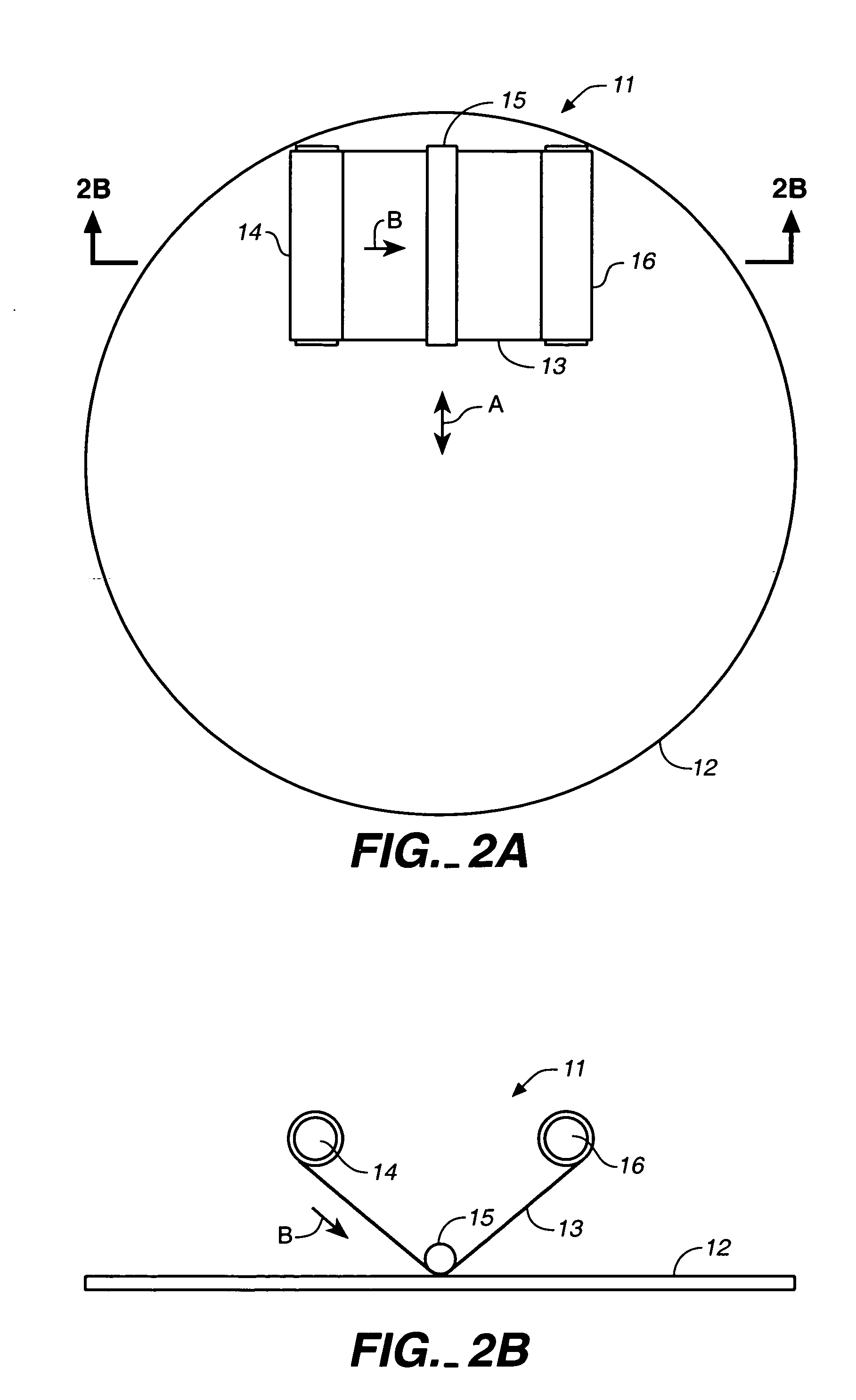

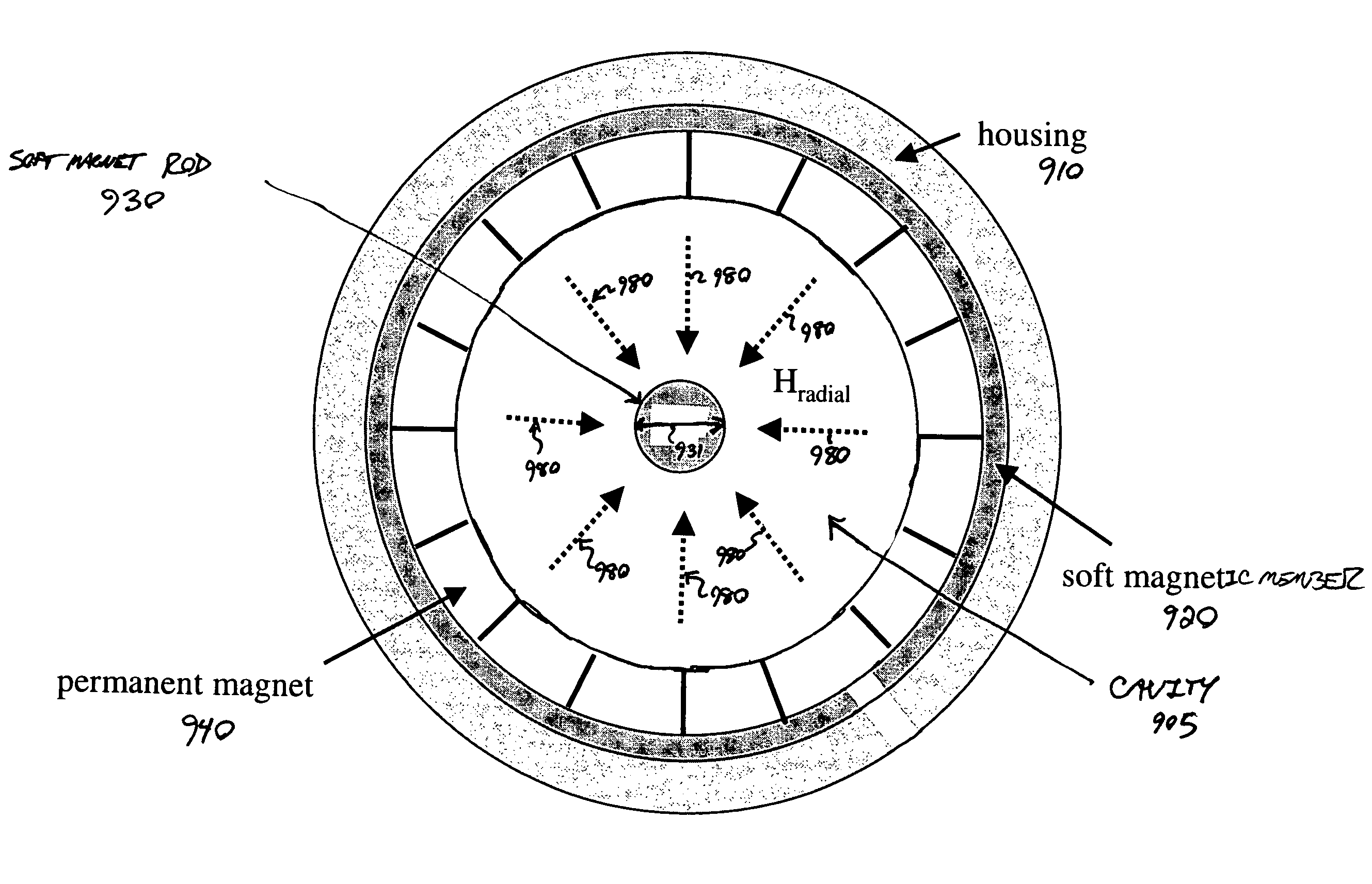

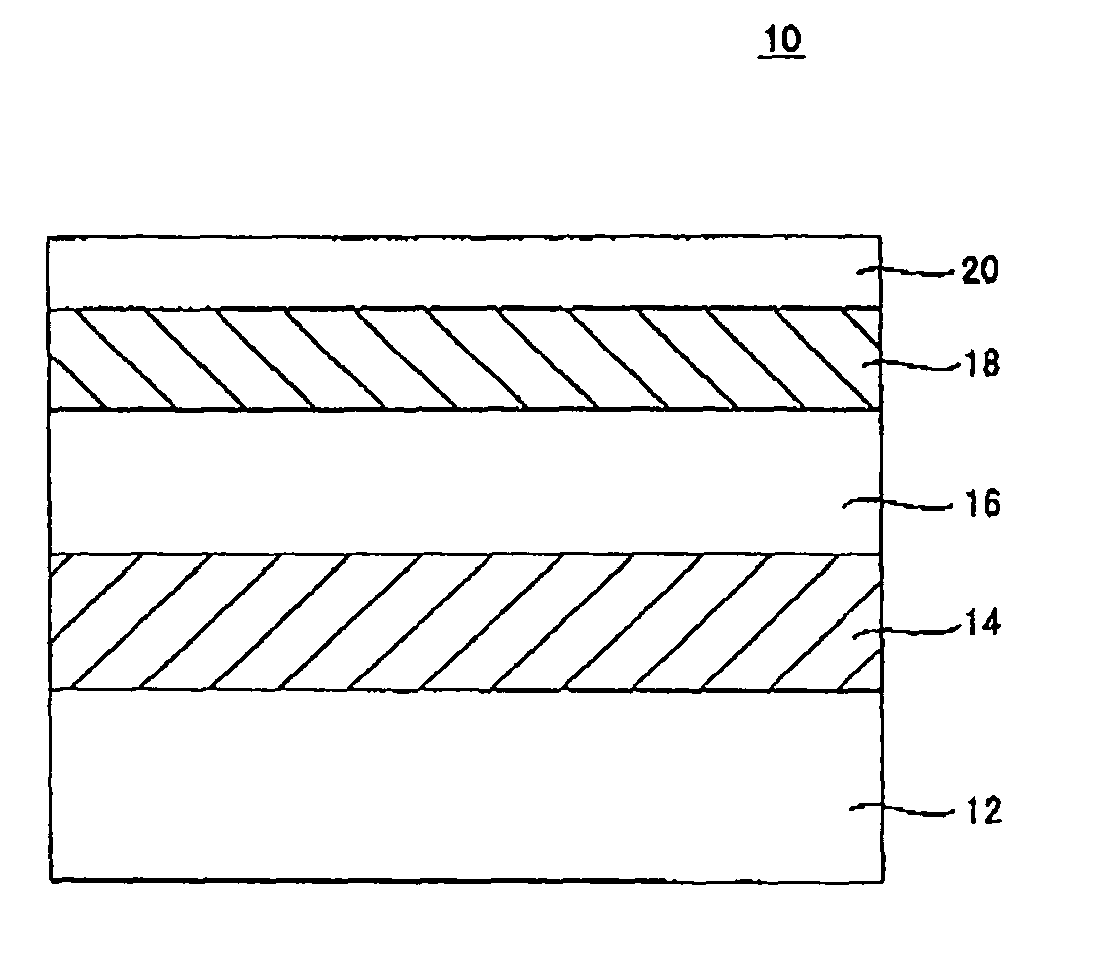

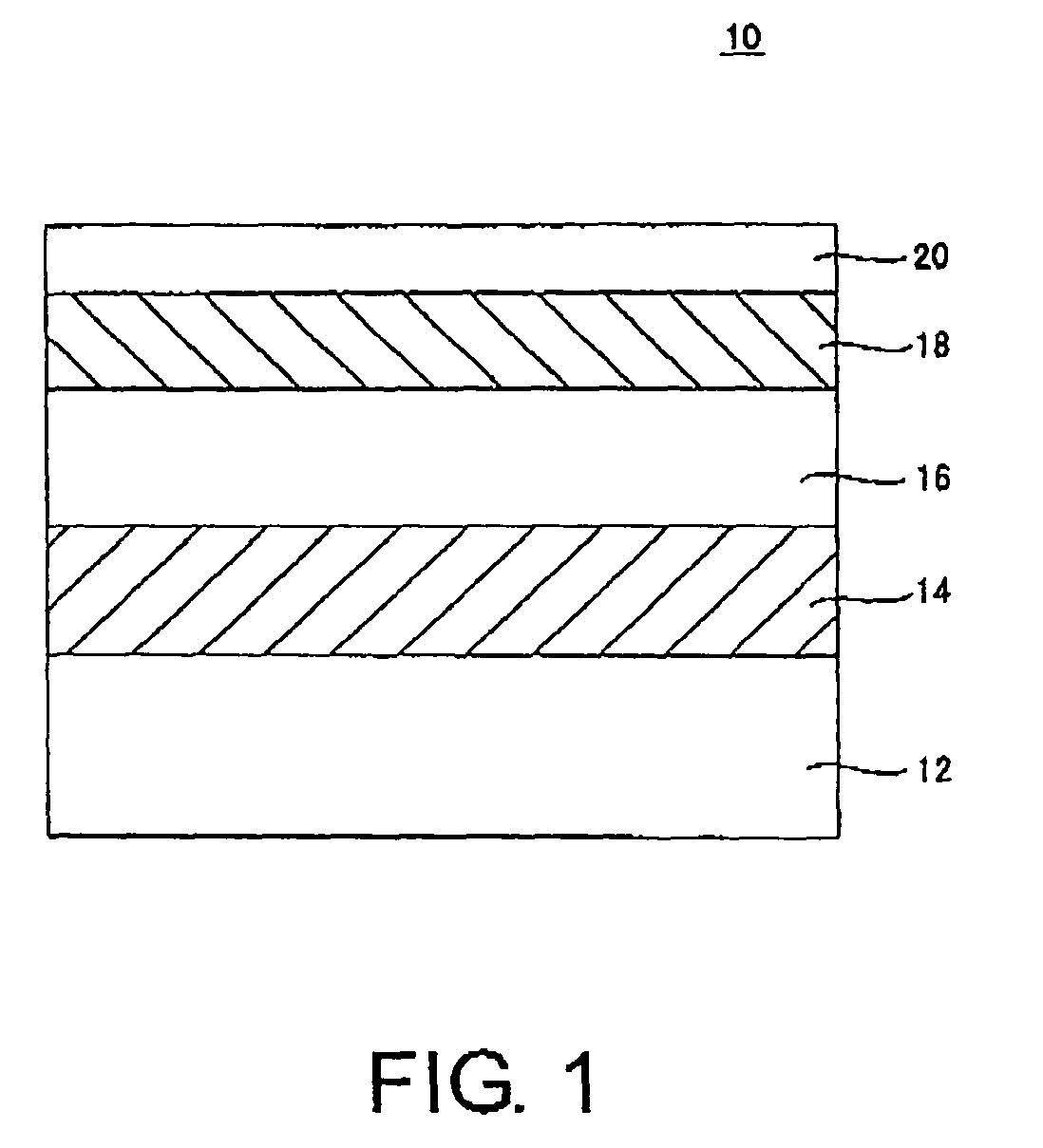

Magnetic recording medium having soft magnetic layer and perpendicular magnetic recording layer

InactiveUS7983003B2Suppress noiseEasy to controlCombination recordingRecord information storageHard disc driveMagnetization

A perpendicular magnetic recording medium 10 adapted to be mounted in a perpendicular magnetic recording type hard disk drive and including a disk-shaped disk base 12, a soft magnetic layer 14 formed on the disk base 12, and a perpendicular magnetic recording layer 16 formed on the soft magnetic layer 14, wherein, at respective portions of the soft magnetic layer 14, directional distribution of easy magnetization axes of magnetic particles included In each of the respective portions is isotropic with respect to respective directions in the main surface of the soft magnetic layer 14.

Owner:WD MEDIA SINGAPORE PTE

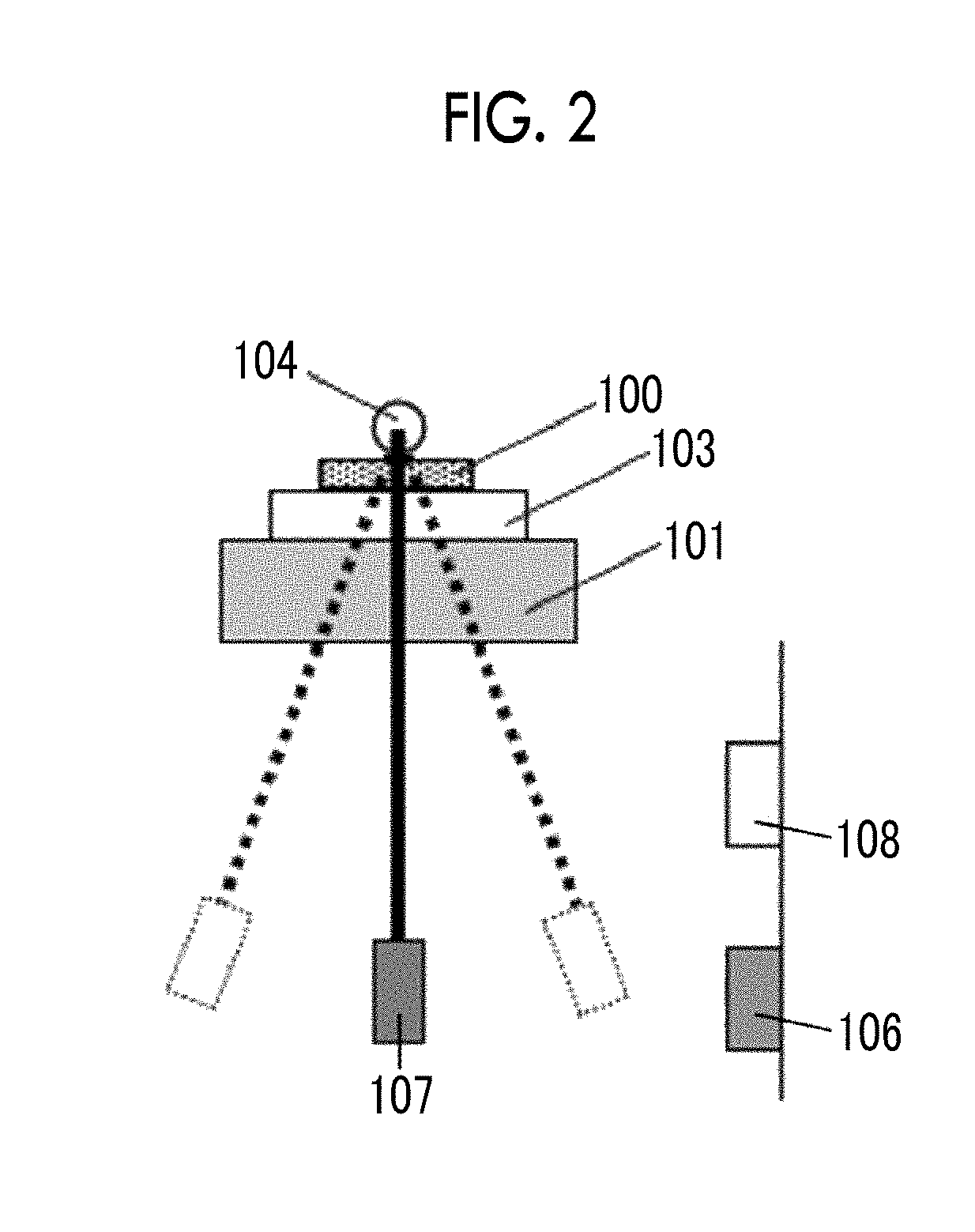

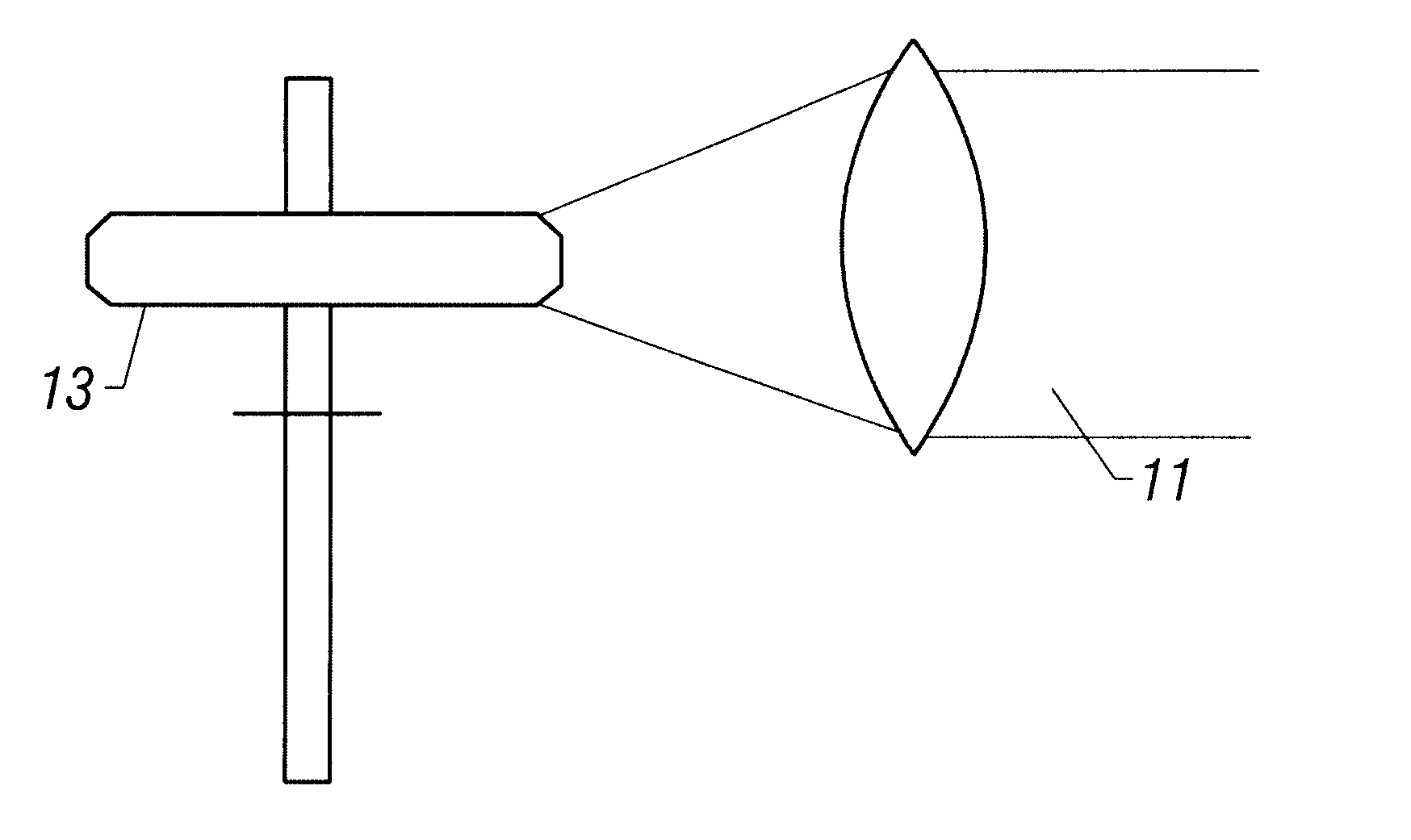

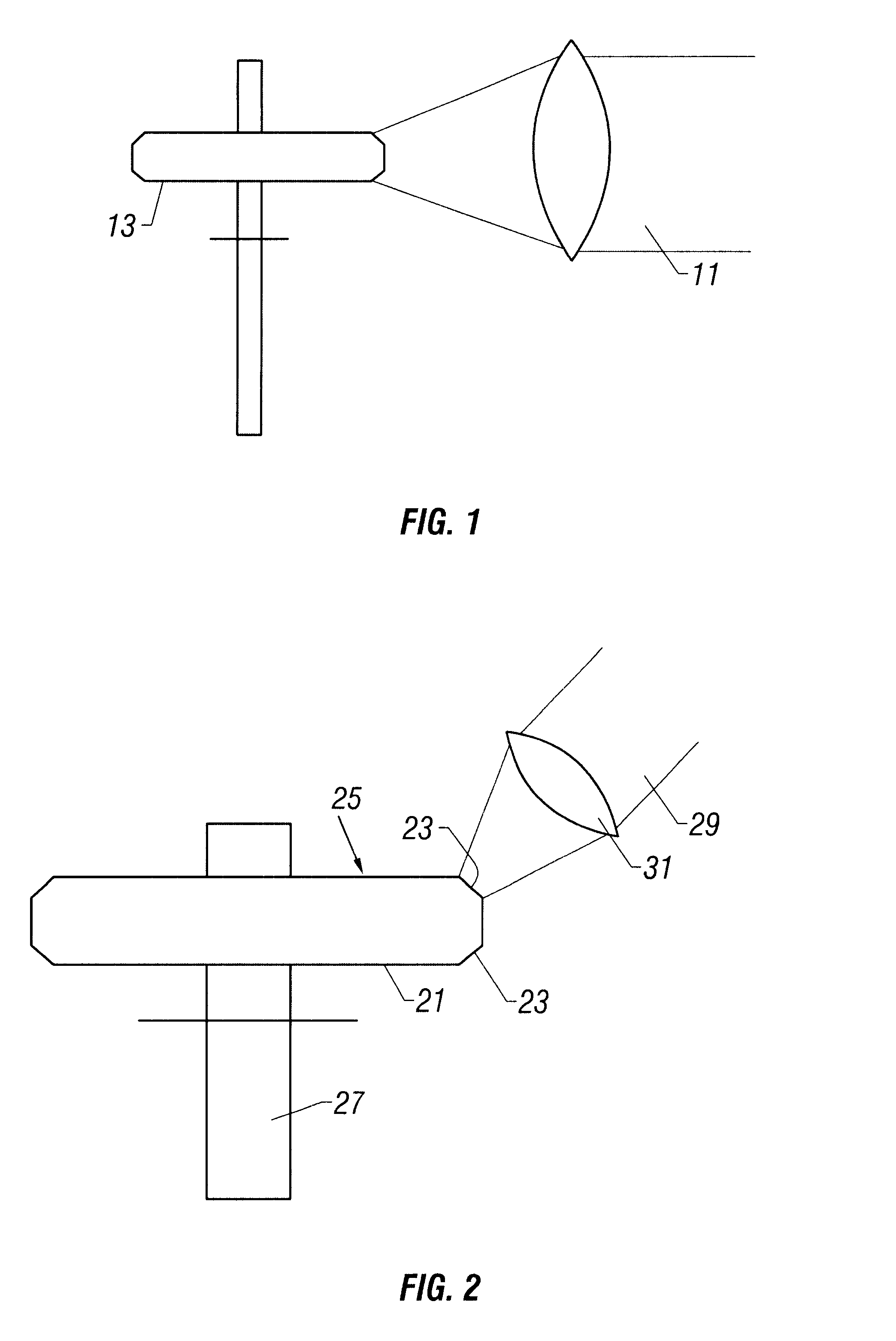

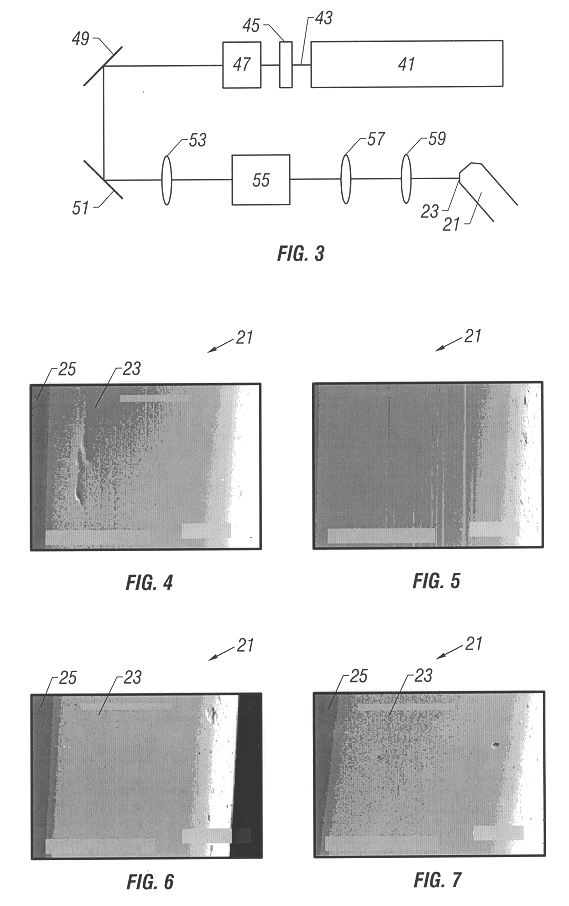

Test head for optically inspecting workpieces

InactiveUS7302148B2Reduce stray lightReduce and eliminate diffracted lightScattering properties measurementsOptically investigating flaws/contaminationOptical testLaser light

An optical test head comprises a block of material with a plurality of optical paths extending therethrough. At least one of the optical paths is an input optical path for receiving laser light and holding a lens for focusing the laser light on a workpiece that is proximate the head. At least another of the optical paths is an output path for receiving light that is reflected off of the workpiece and providing that light to a detector. (In one embodiment, several detectors are provided to direct specularly reflected light, narrow angle scattered light, wide angle scattered light and back scattered light to associated detectors.) Other optical elements can be affixed within or to the block of material. The test head can be used without requiring the individual optical elements to be aligned or adjusted.

Owner:WD MEDIA

Method of producing glass substrate for information recording medium

InactiveUS6332338B1Avoid deformationIncrease speedGlass drawing apparatusGlass forming apparatusProduction ratePoise

Disclosed is a process for producing a glass substrate for an information recording medium by press-shaping a molten glass which gives a glass containing 0.1 to 30 mol % of TiO2, 1 to 45 mol % of CaO, 5 to 40 mol % of total of MgO and the above CaO, 3 to 30 mol % of total of Na2O and Li2O, 0 to 15 mol % of Al2O3 and 35 to 65 mol % of SiO2 and having properties of a liquidus temperature of 1,360° C. or lower and a viscosity of at least 10 poise in a shaping-allowable temperature range, or by preparing a preform formed of a glass which contains 0.1 to 30 mol % of TiO2, 1 to 45 mol % of CaO, 5 to 40 mol % of total of MgO and the above CaO, 3 to 30 mol % of total of Na2O and Li2O, 0 to 15 mol % of Al2O3 and 35 to 65 mol % of SiO2 and has properties of a liquidus temperature of 1,360° C. or lower and shaping the preform in the form of a disc by a re-heat pressing method. According to the above process, there can be mass-produced, with high productivity, high-quality glass substrates to be used for information recording media such as a magnetic disc, an optical disc, a magneto-optic disc, and the like.

Owner:HOYA CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com