Method of Manufacturing a Perpendicular Magnetic Disc

a perpendicular magnetic disk and manufacturing method technology, applied in the field of perpendicular magnetic disk manufacturing, can solve the problems of low coating strength, low coating strength, and invite a decrease in the reliability of the perpendicular magnetic disk, and achieve the effect of improving reliability and high snr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

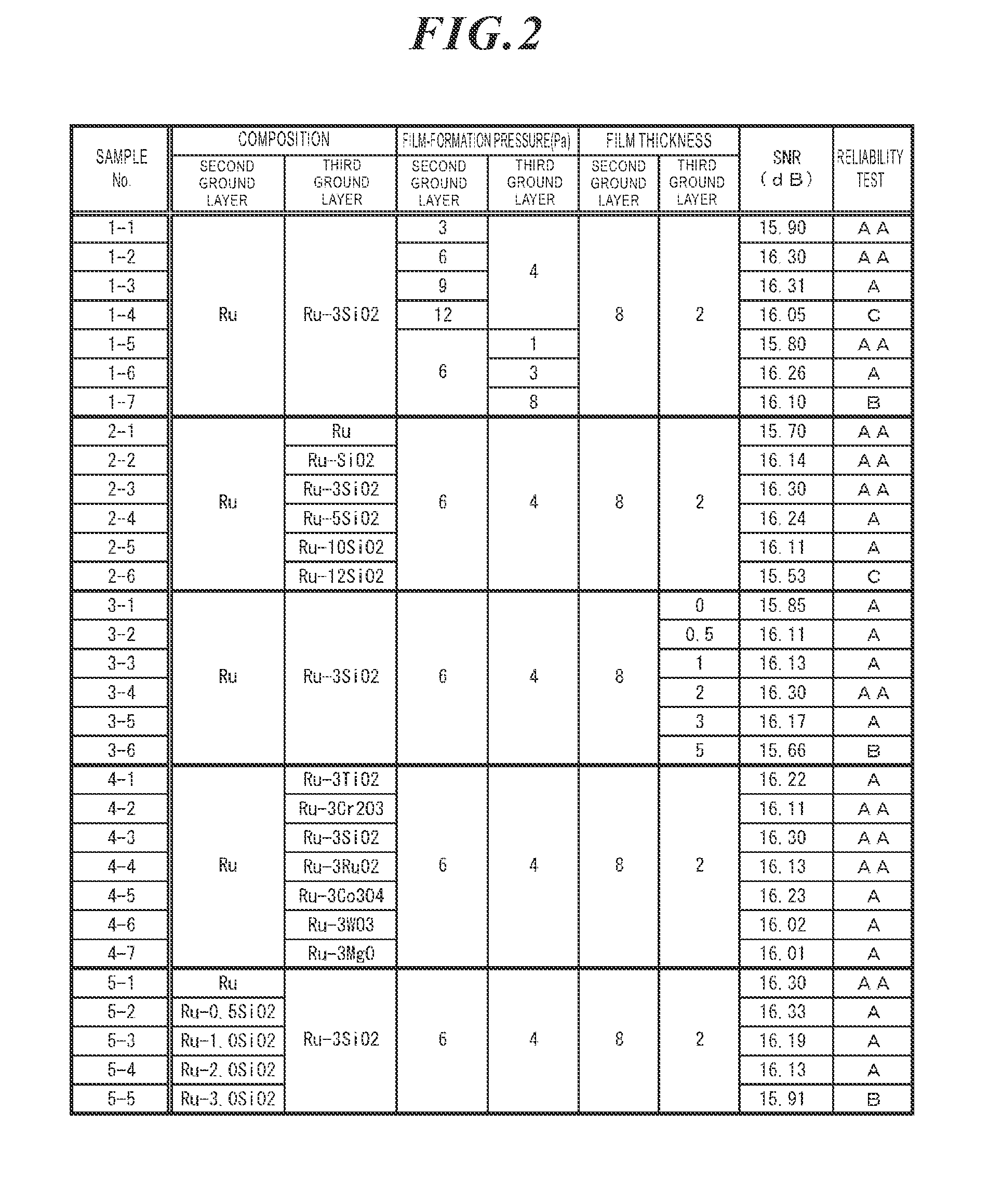

[0055]To confirm effectiveness of the above-structured perpendicular magnetic disk 100 manufactured by using the manufacturing method described above, description is made by using samples as examples below. FIG. 2 is a drawing for comparing and describing various components as being changed. Here, it can be said that reliability of the perpendicular magnetic disk 100 means durability thereof, in other words. Therefore, in reliability tests shown in FIG. 2, scratch tests by a needle, which are durability evaluation tests, were adopted, and evaluations were made in four steps, with “AA” when an abrasion mark in the scratch tests has a depth smaller than 0.5 nm, “A” when the depth is equal to or larger than 0.5 nm and smaller than 1.0 nm, “B” when the depth is equal to or larger than 1.0 nm and smaller than 3.0 nm, and “C” when the depth is equal to or larger than 3.0 nm.

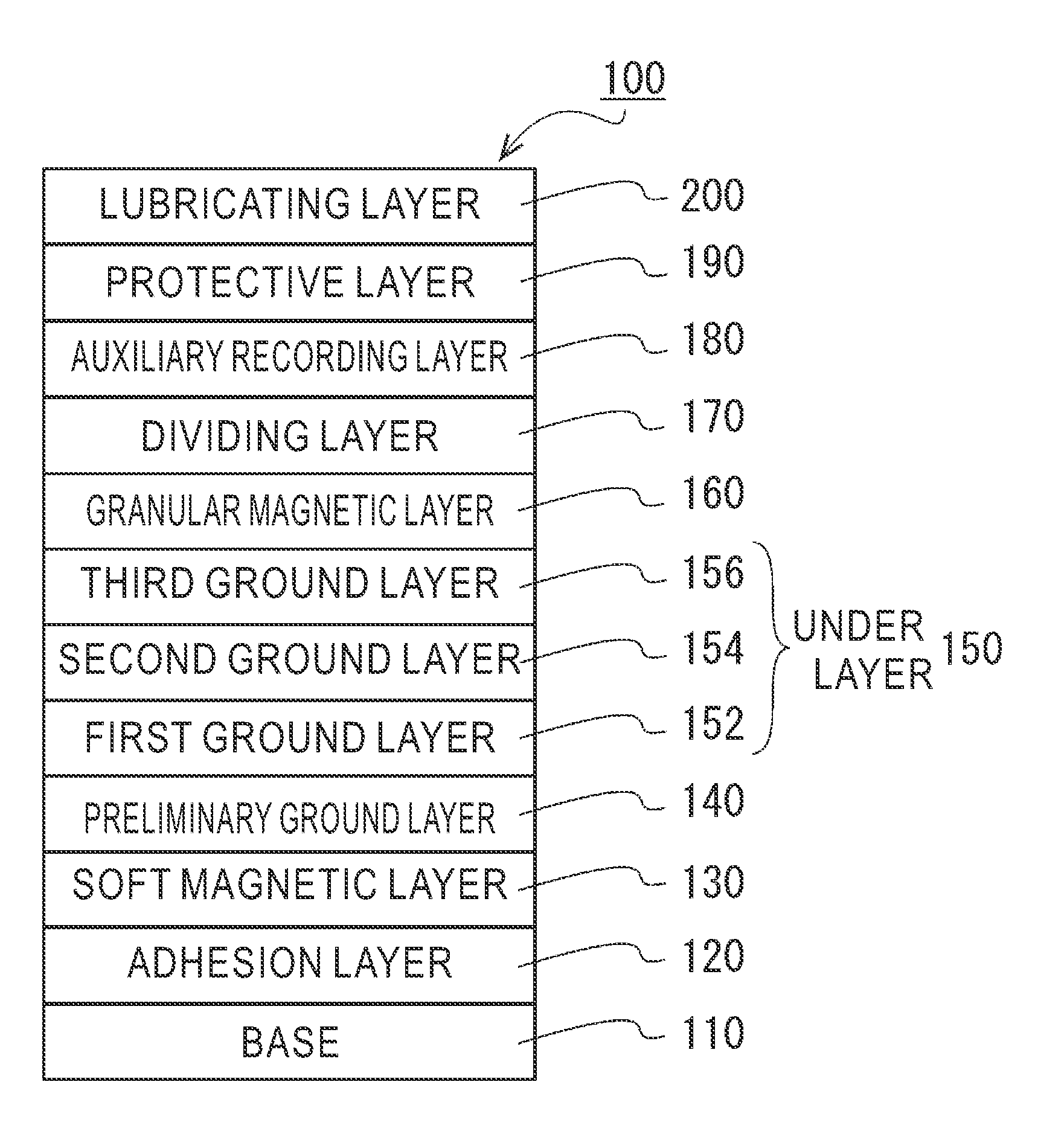

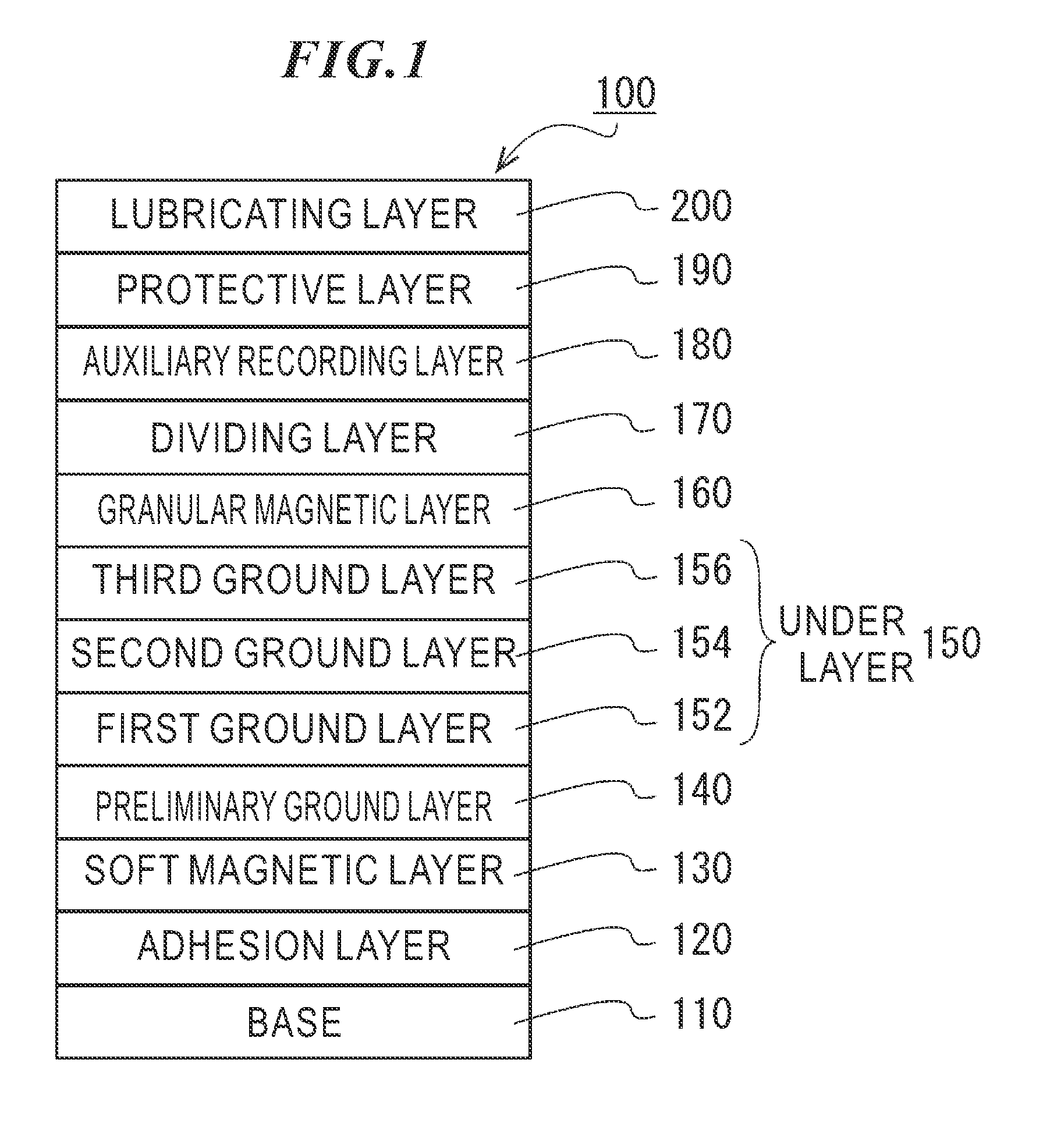

[0056]As an example, on the base 110, by using a vacuumed film forming device, films of the adhesion layer 120 to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com