Patents

Literature

160results about "Coating by liquid dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

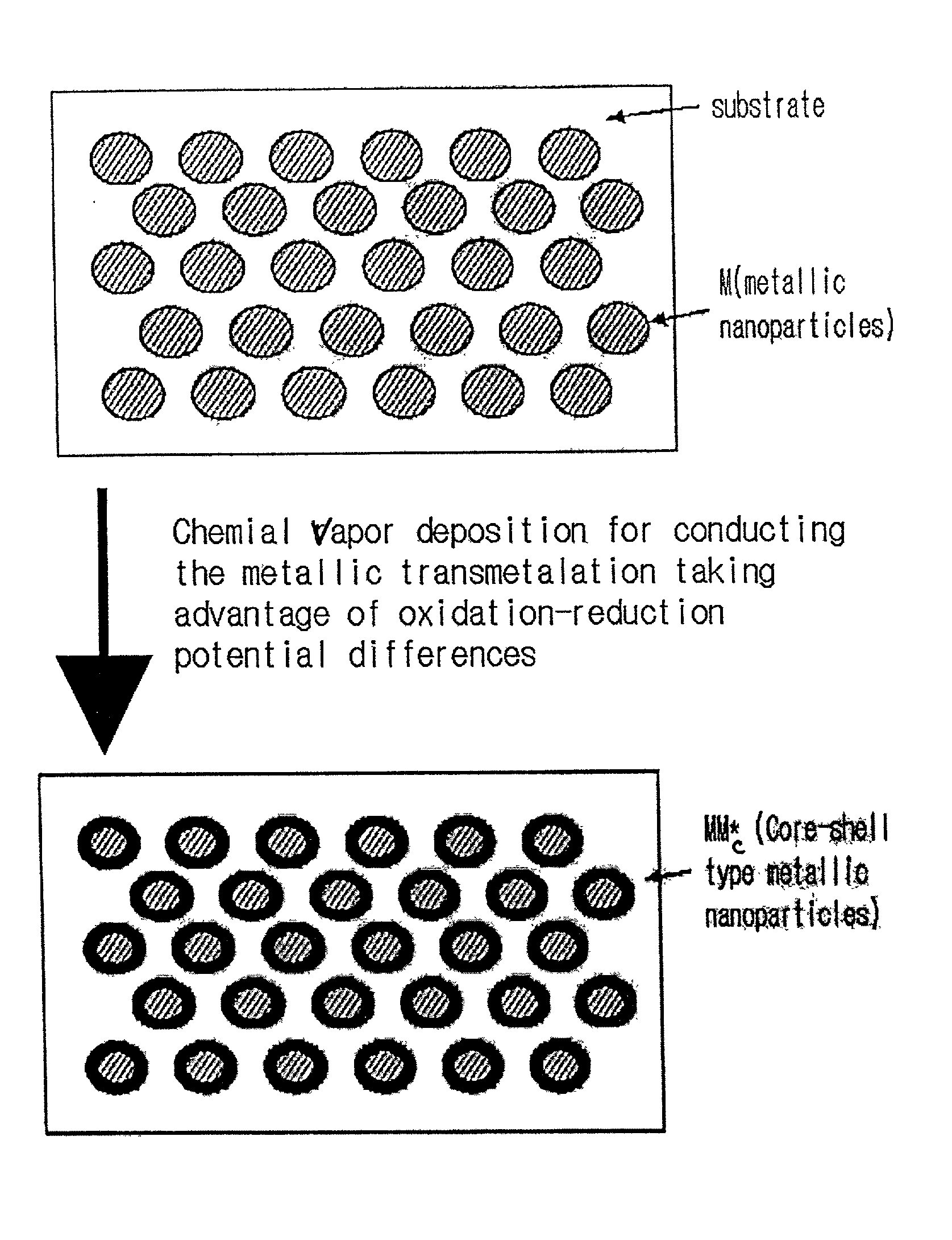

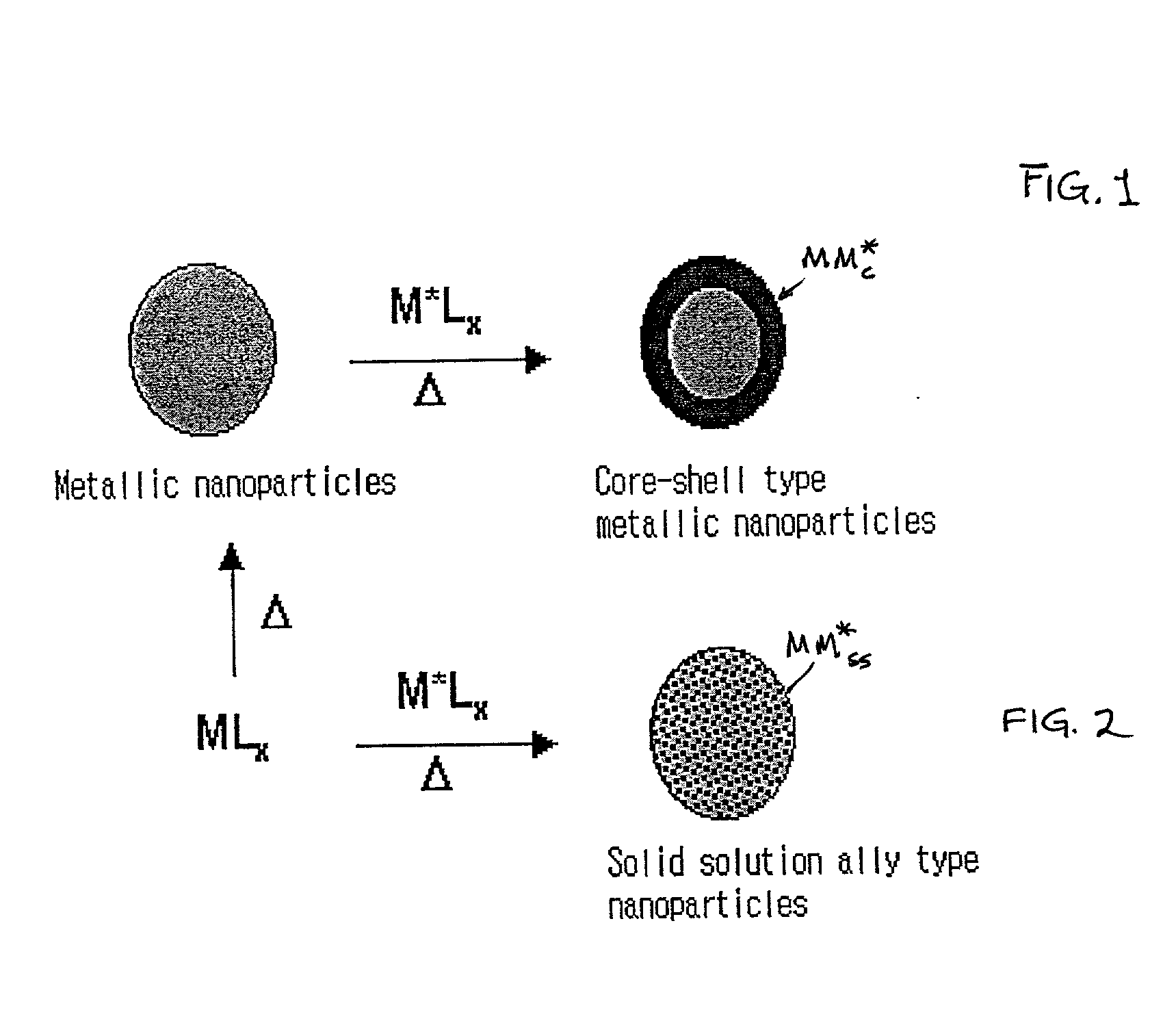

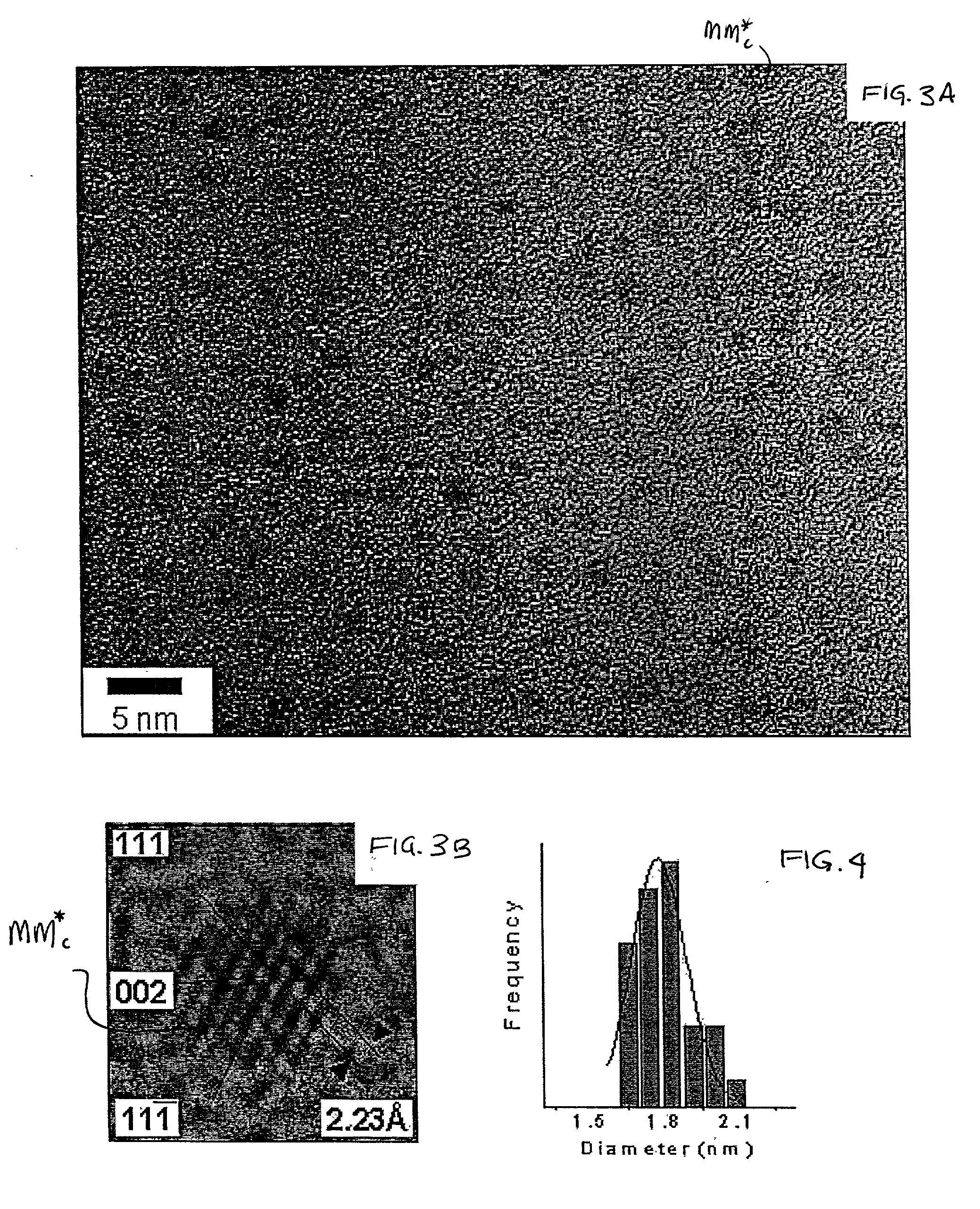

Method for synthesis of core-shell type and solid solution alloy type metallic nanoparticles via transmetalation reactions and applications of same

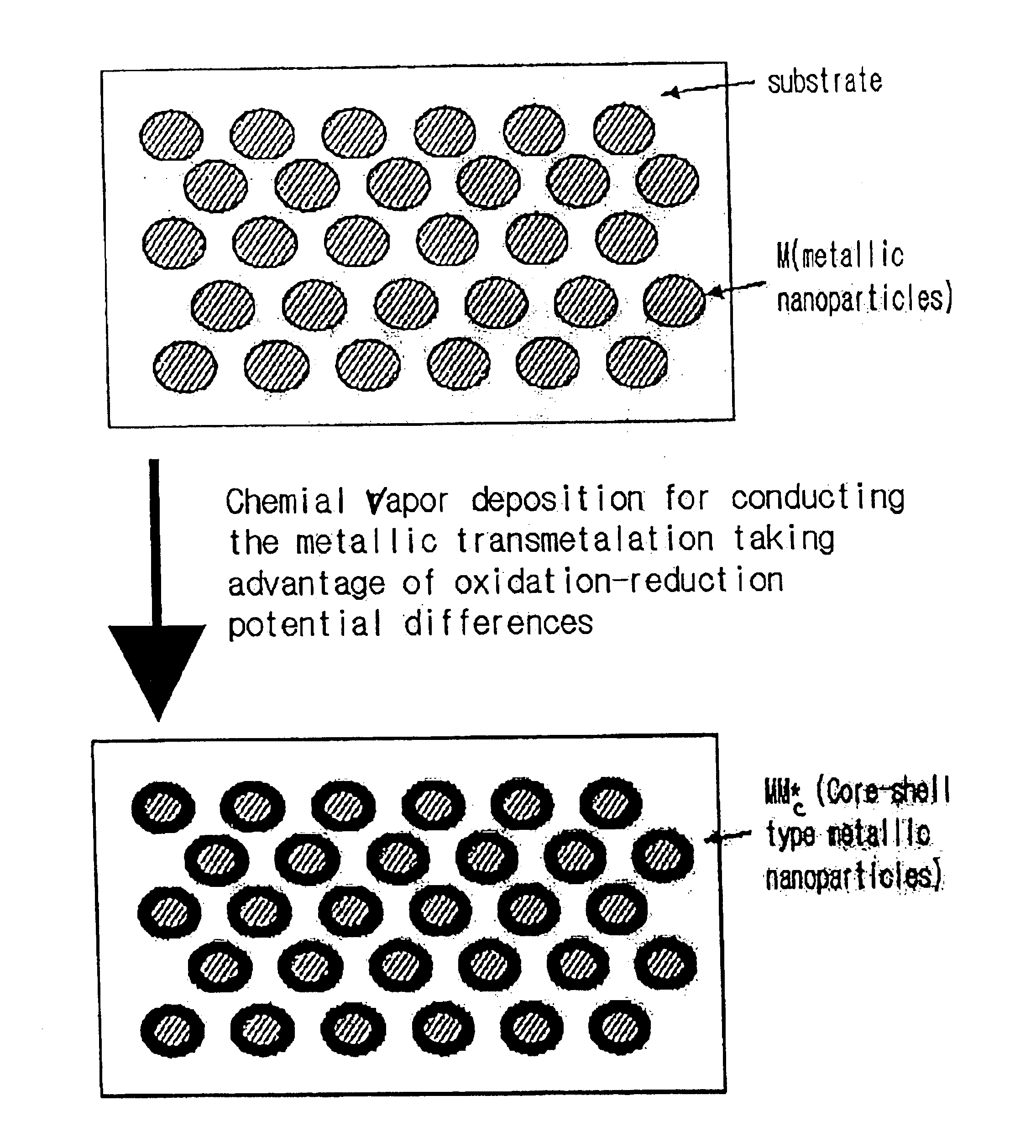

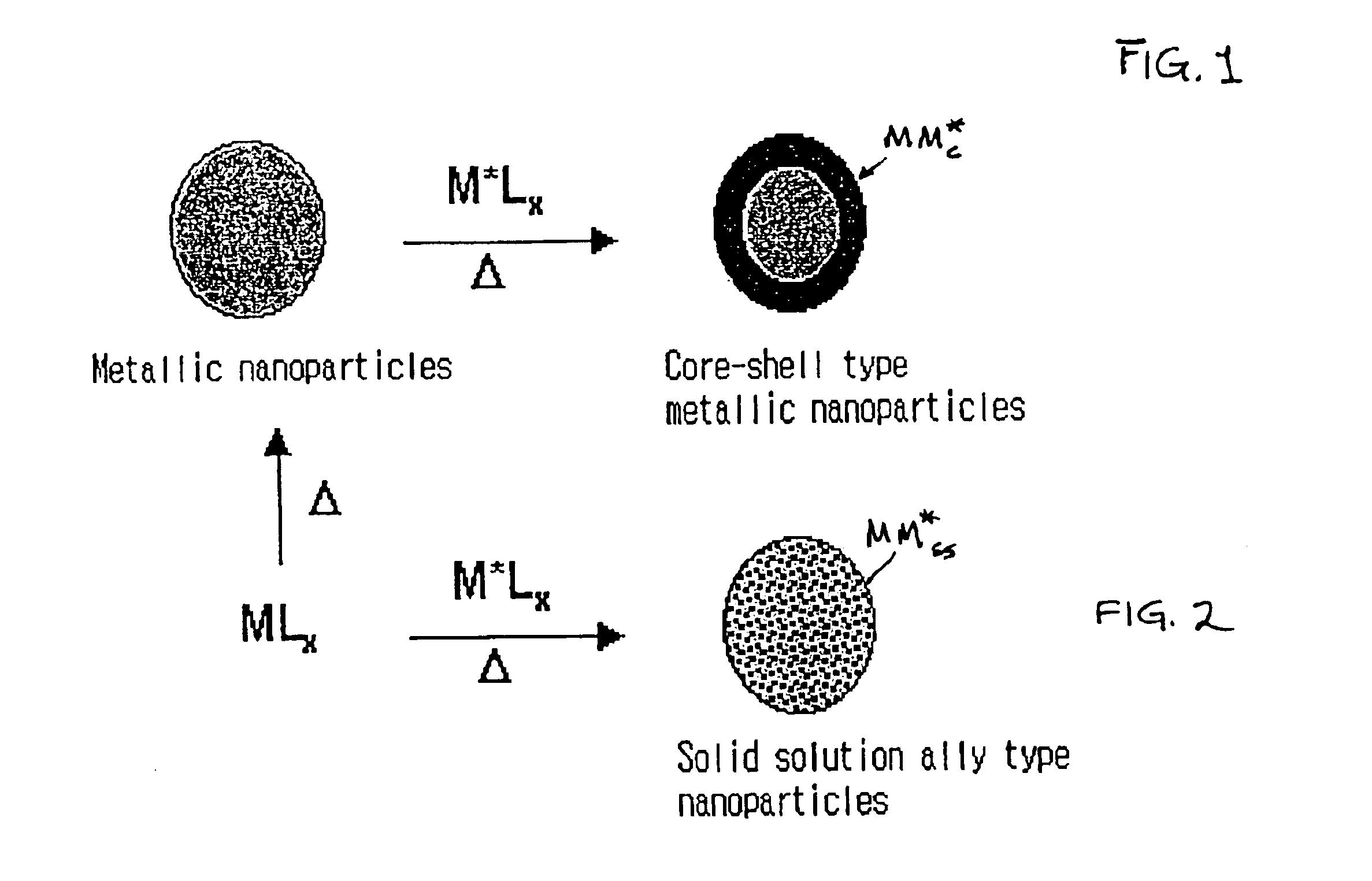

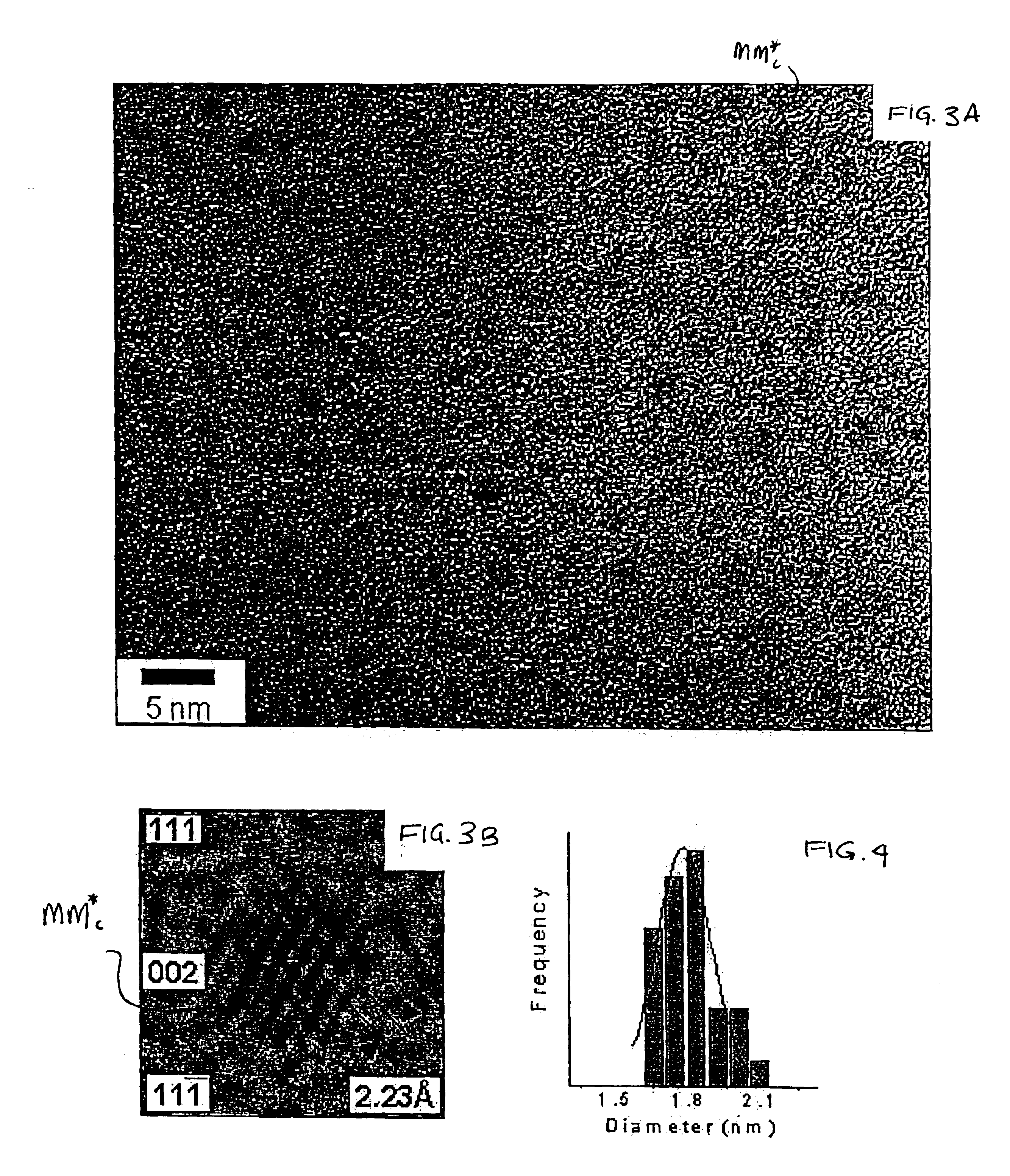

Disclosed is a method for producing core-shell type metallic nanoparticles involving (i) providing a dispersion of a first metal as nanoparticles in an appropriate organic solvent; (ii) providing a solution of a metallic precursor containing a second metal in an appropriate organic solvent, in which the second metal has a reduction potential higher than that of the first metal; and (iii) combining the dispersion from (i) and the solution from (ii) together to carry out the transmetalation reaction of the first and second metals, thereby forming core-shell type metallic nanoparticles.

Owner:KOREA ADVANCED INST OF SCI & TECH

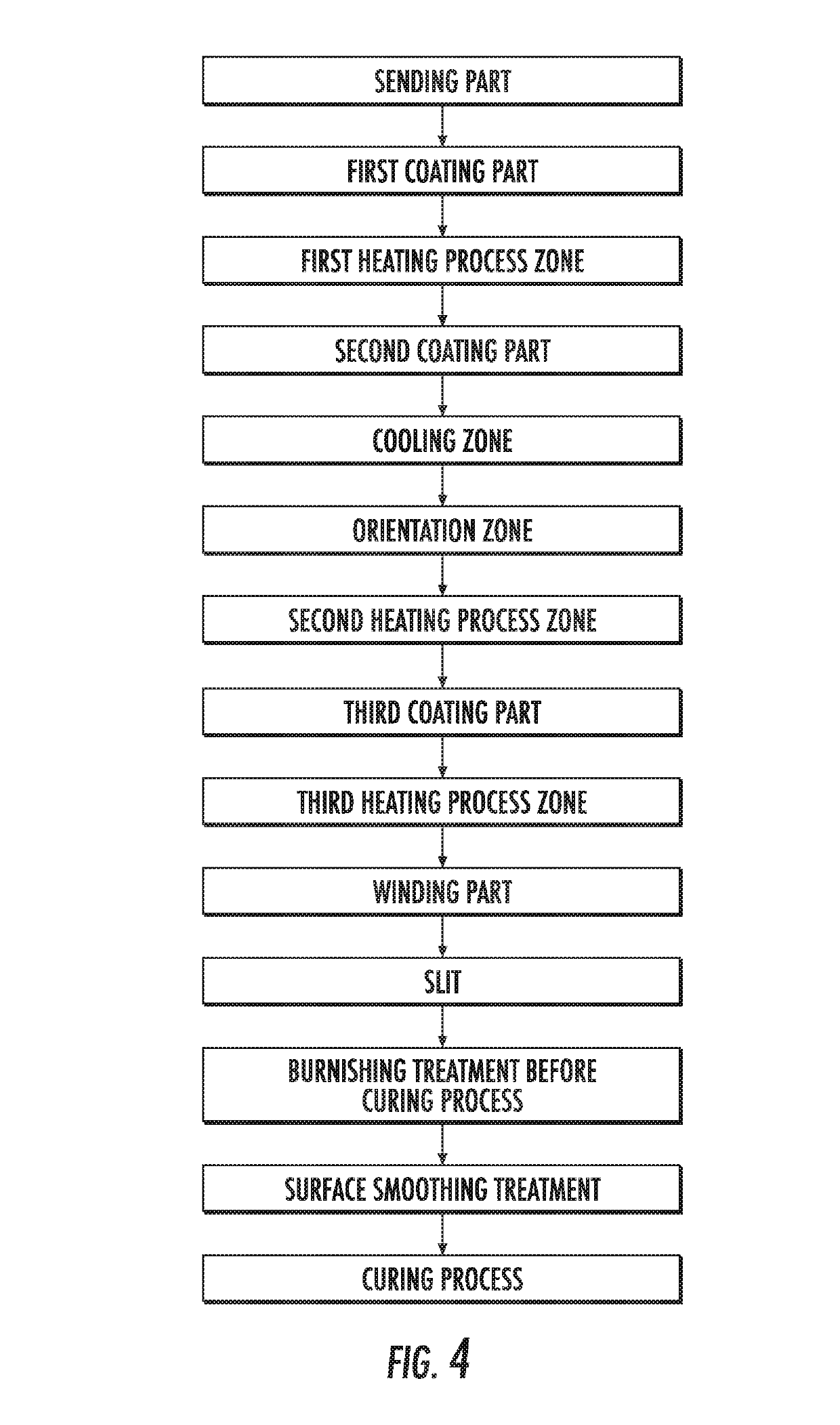

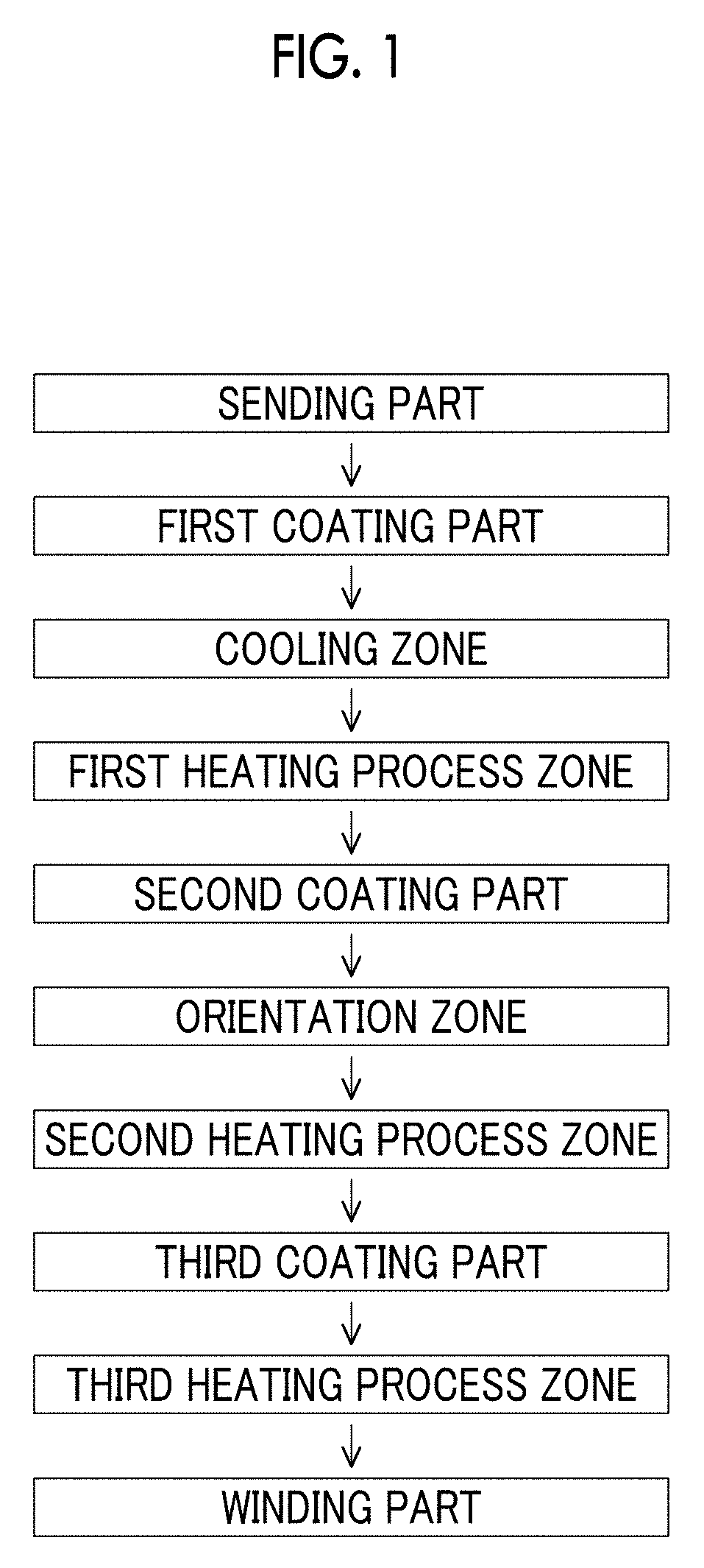

Method of manufacturing hexagonal ferrite magnetic powder, magnetic recording medium and method of manufacturing the same

ActiveUS20120244387A1Good dispersionReduce dispersion loadMagnetic materials for record carriersIron organic compoundsMagnetic liquidsSolvent

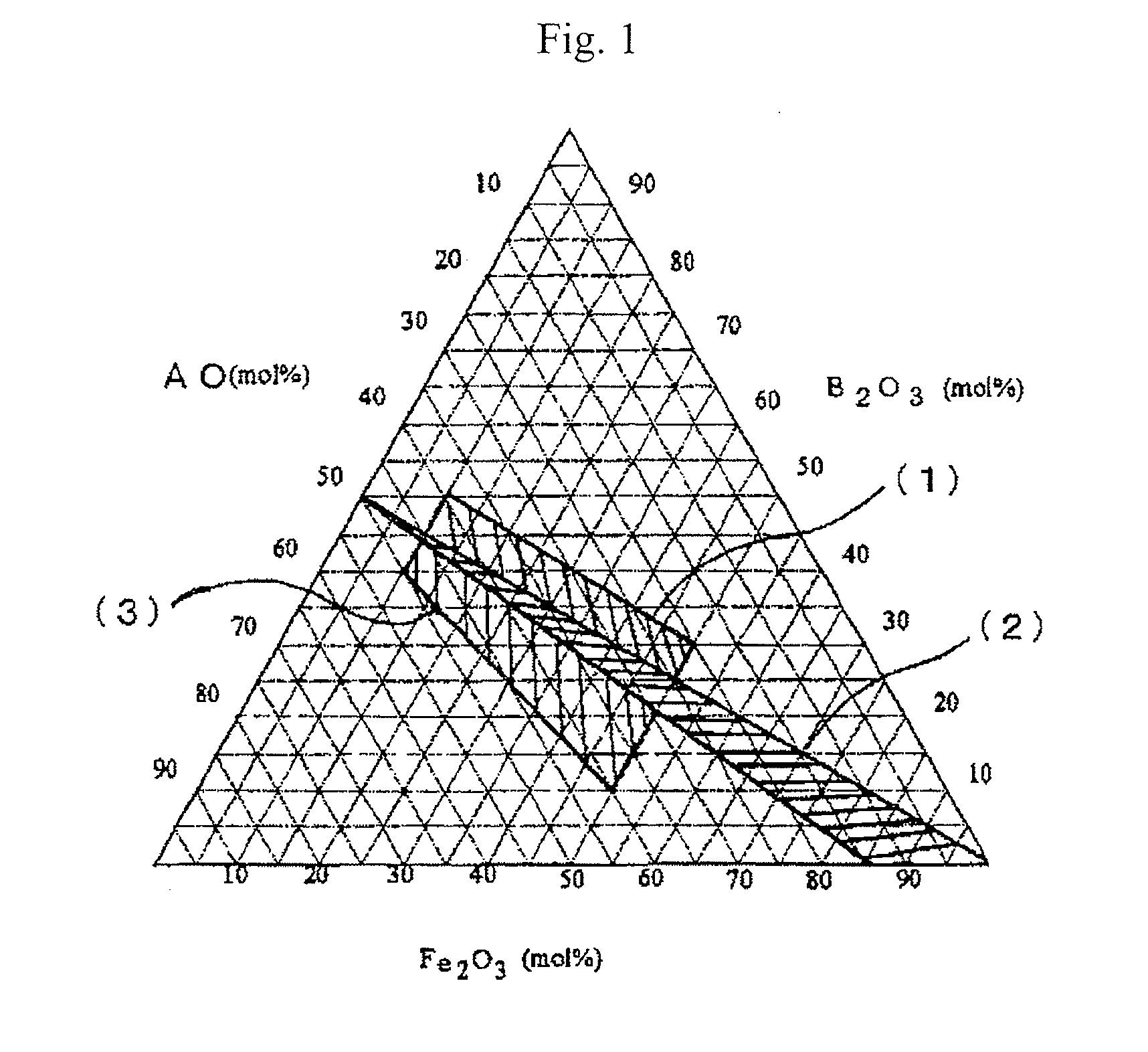

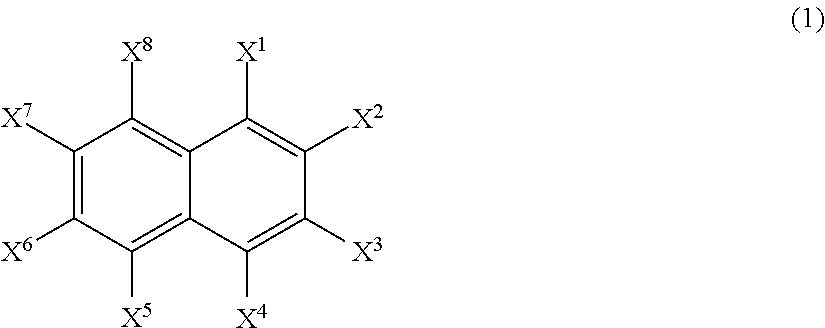

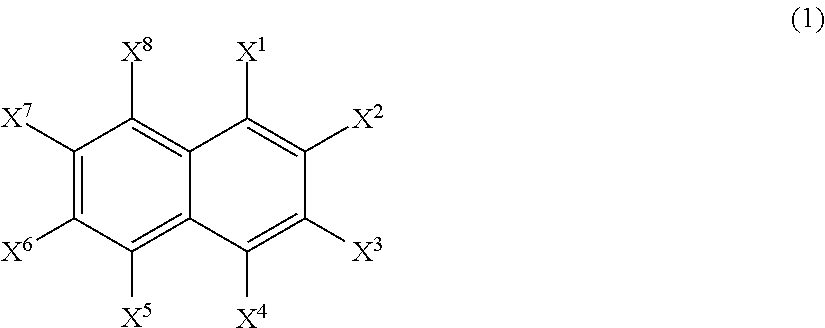

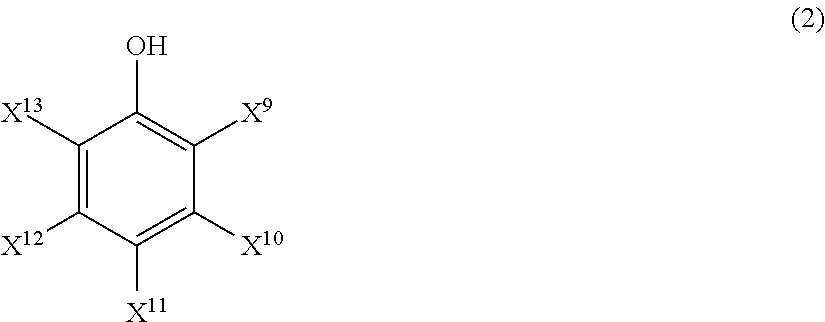

An aspect of the present invention relates to a method of manufacturing hexagonal ferrite magnetic powder. The method of manufacturing hexagonal ferrite magnetic powder comprises wet processing hexagonal ferrite magnetic particles obtained following acid treatment in a water-based solvent to prepare an aqueous magnetic liquid satisfying relation (1) relative to an isoelectric point of the hexagonal ferrite magnetic particles: pH0−pH*≧2.5, wherein, pH0 denotes the isoelectric point of the hexagonal ferrite magnetic particles and pH* denotes a pH of the aqueous magnetic liquid, which is a value of equal to or greater than 2.0, adding a surface-modifying agent comprising an alkyl group and a functional group that becomes an anionic group in the aqueous magnetic liquid to the aqueous magnetic liquid to subject the hexagonal ferrite magnetic particles to a surface-modifying treatment, and removing the water-based solvent following the surface-modifying treatment to obtain hexagonal ferrite magnetic particles.

Owner:FUJIFILM CORP

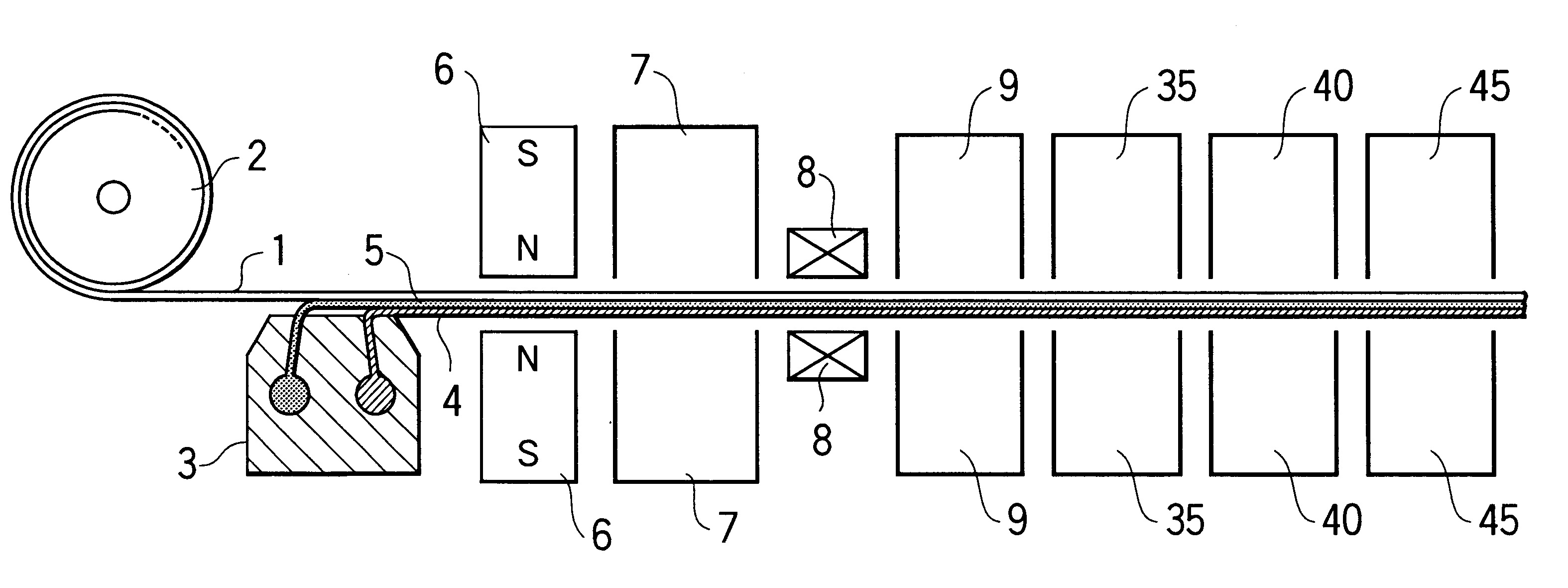

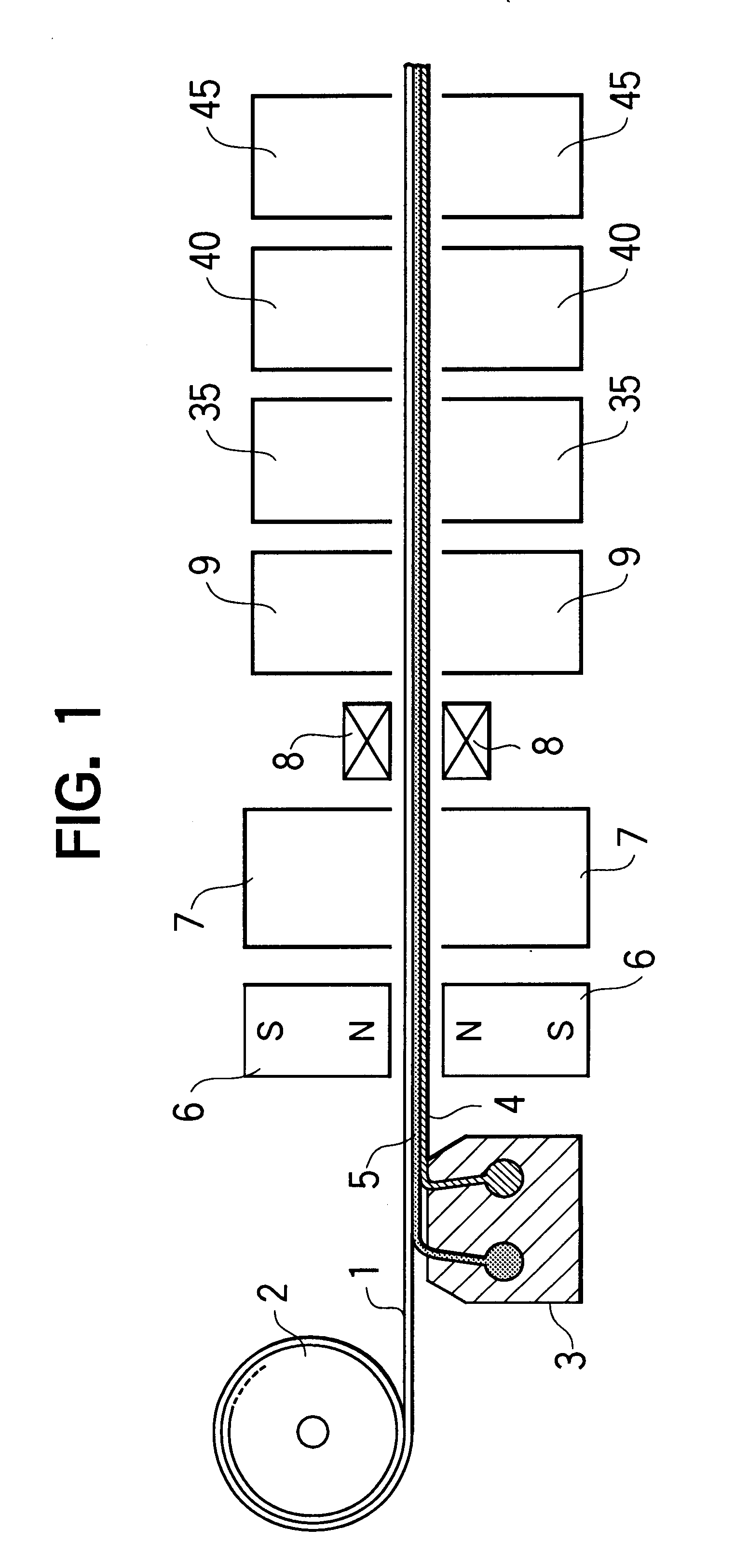

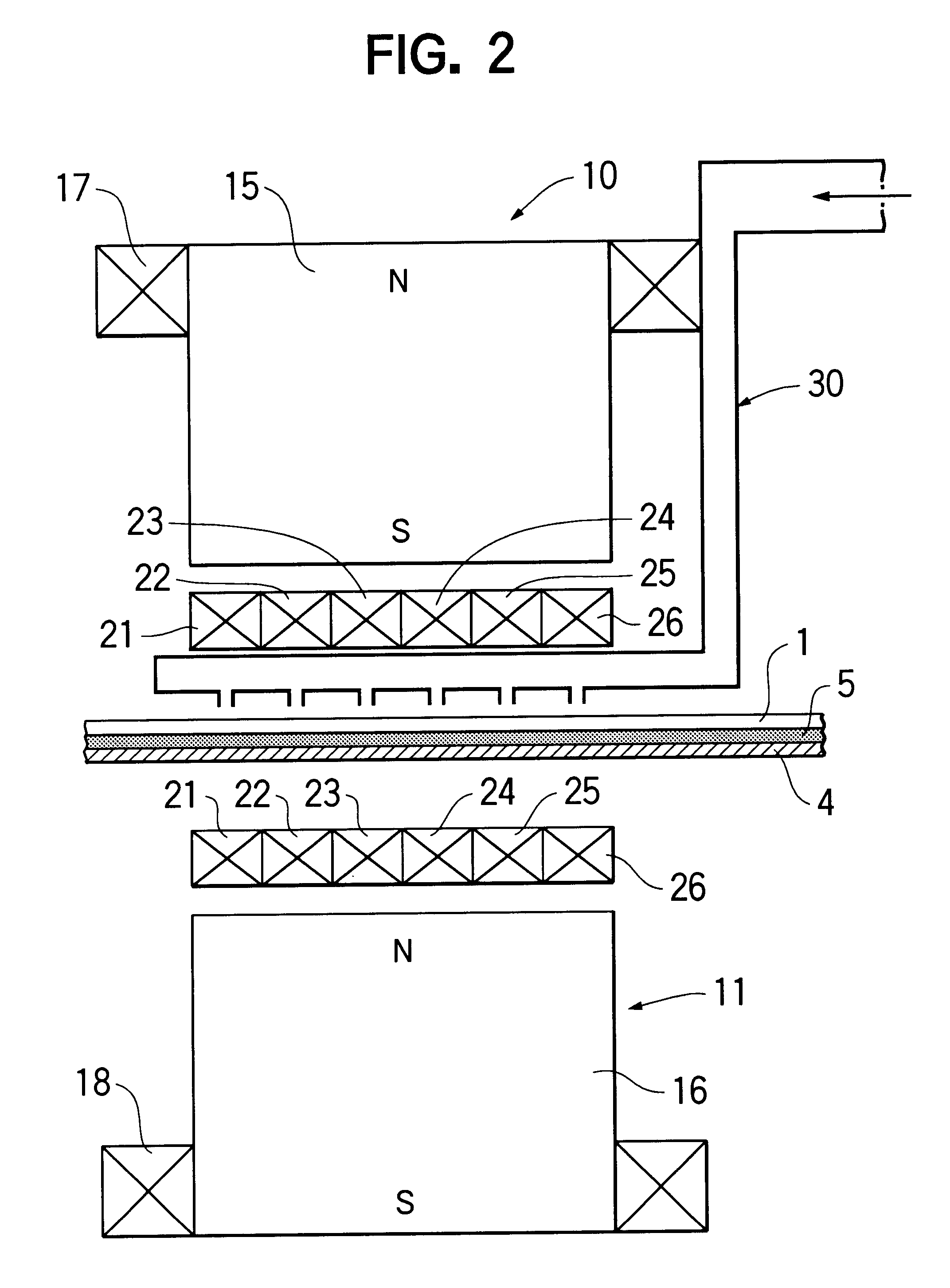

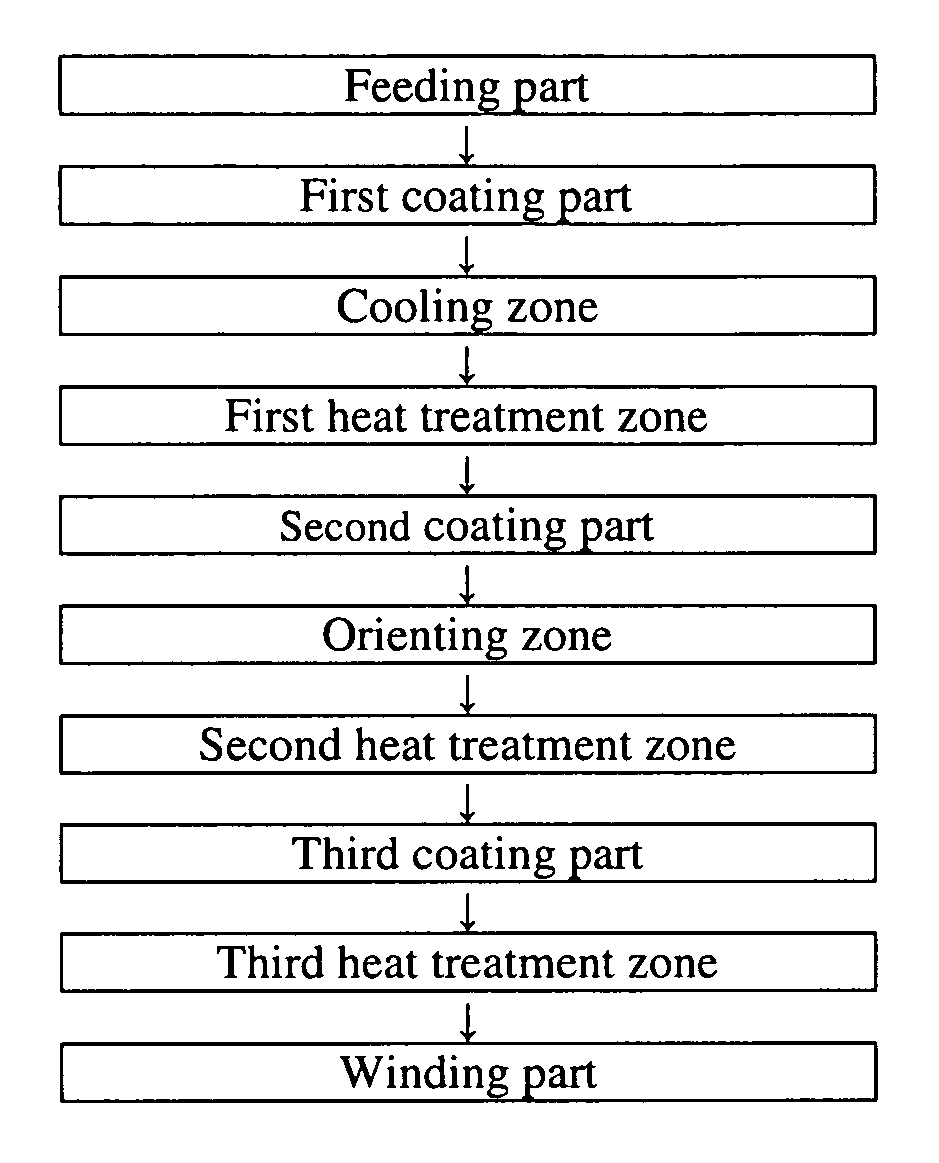

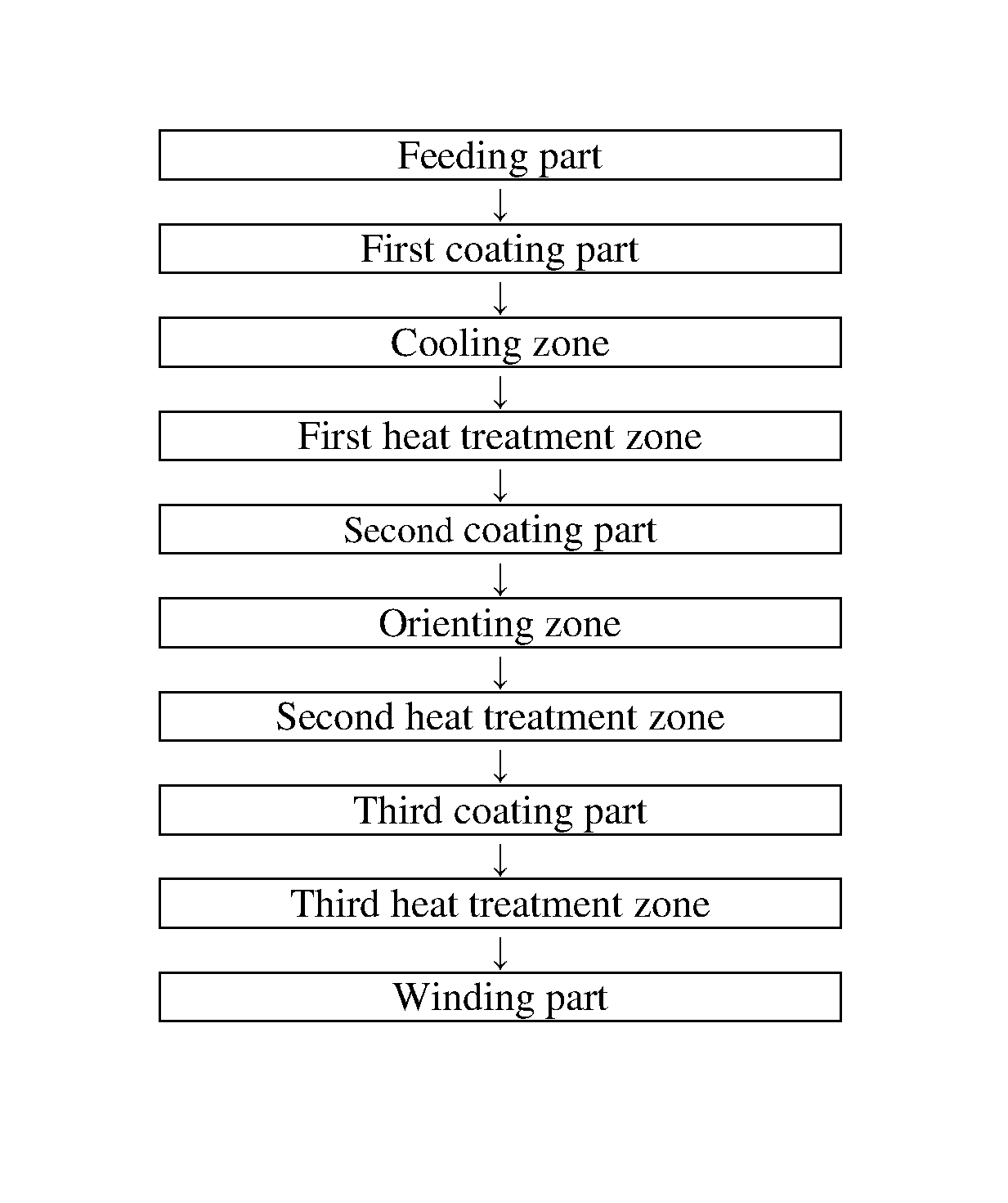

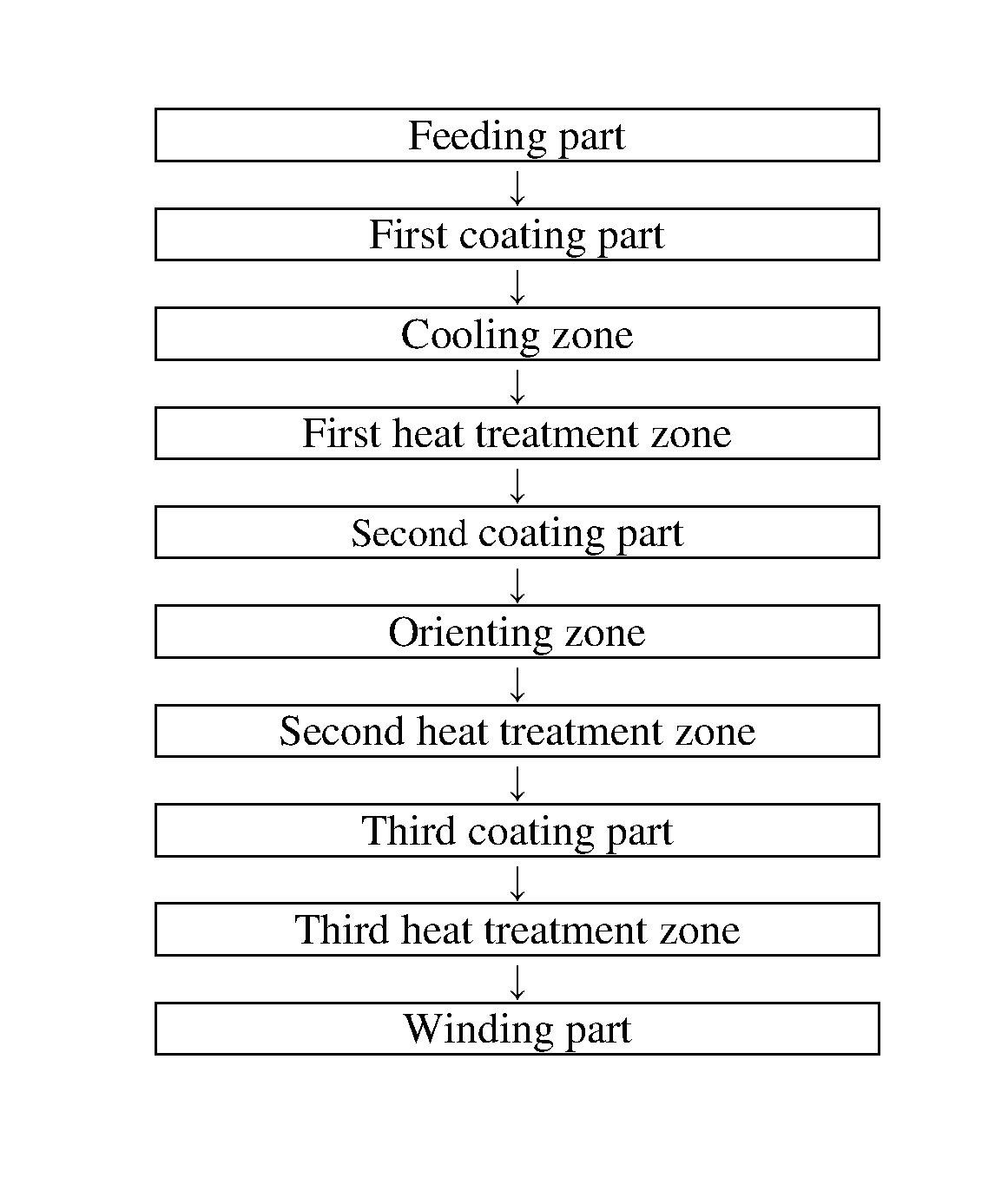

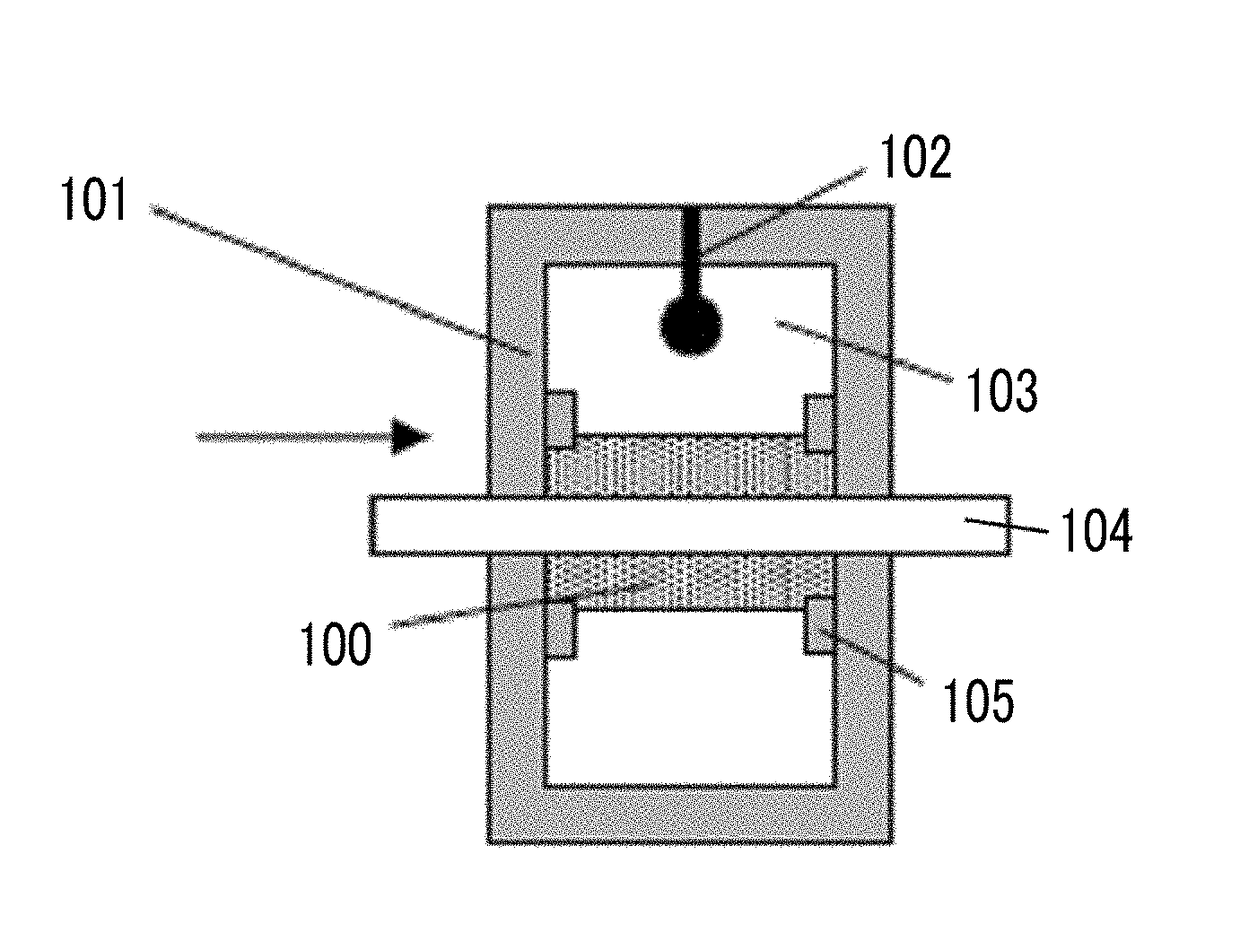

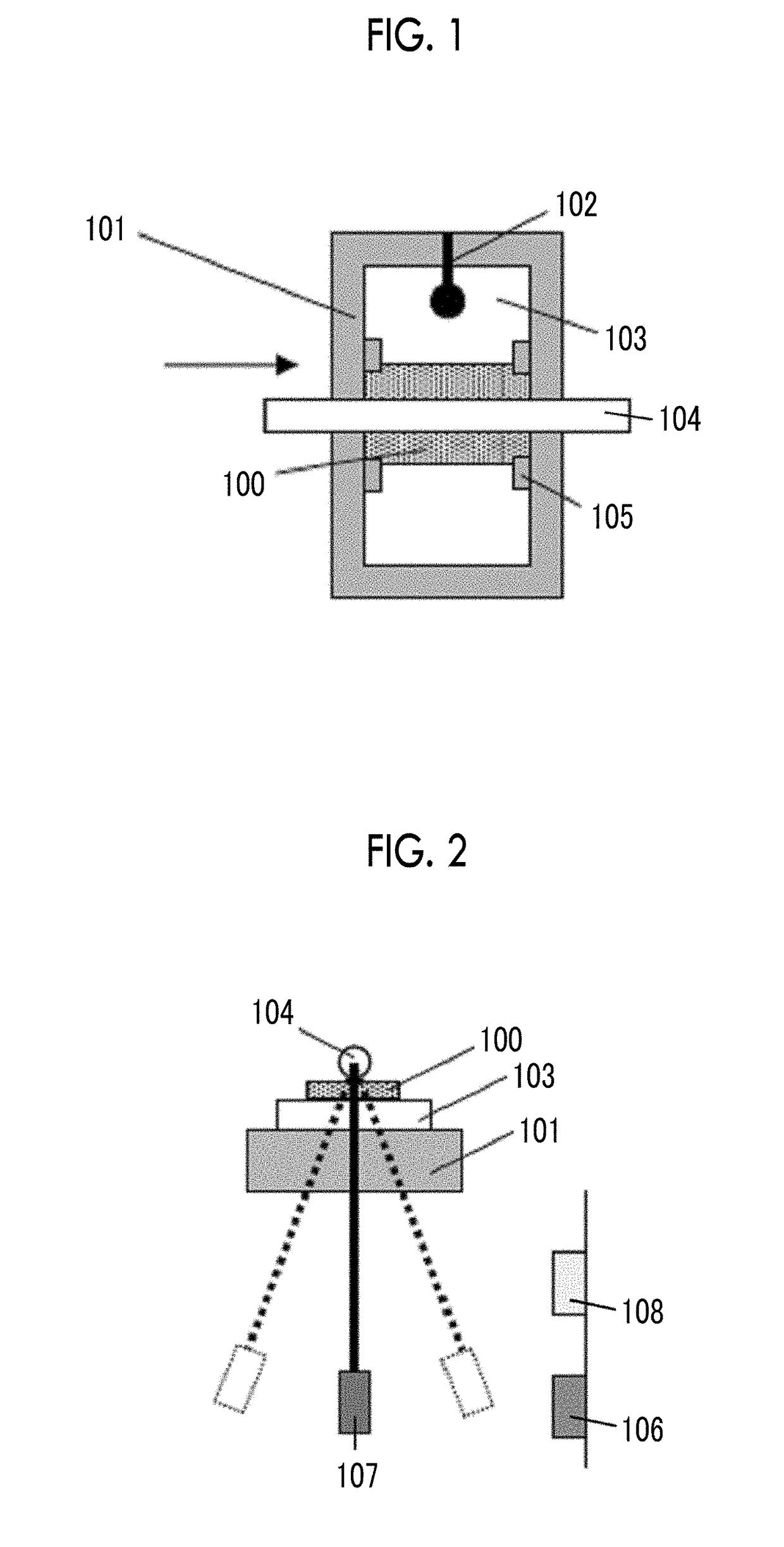

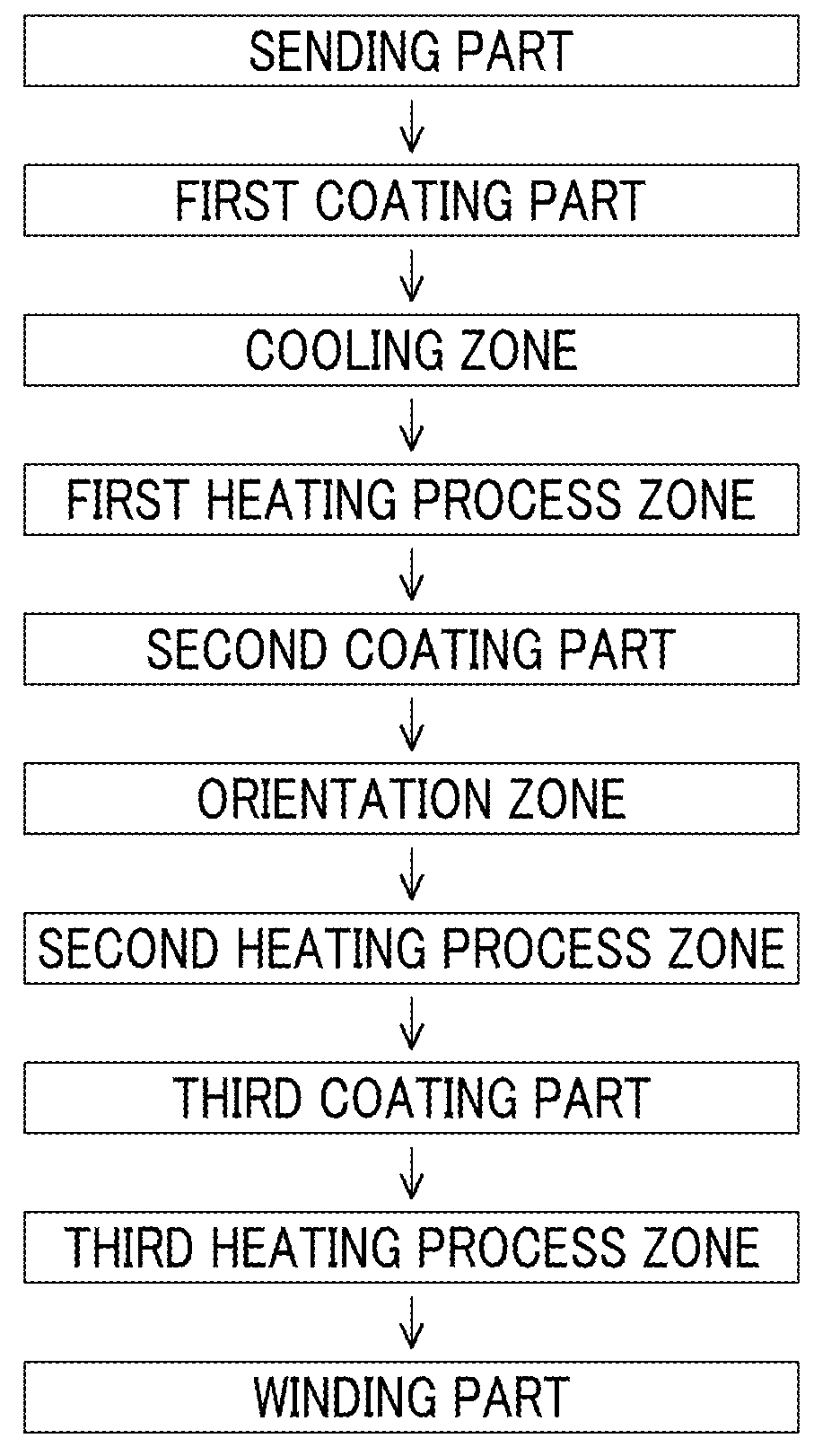

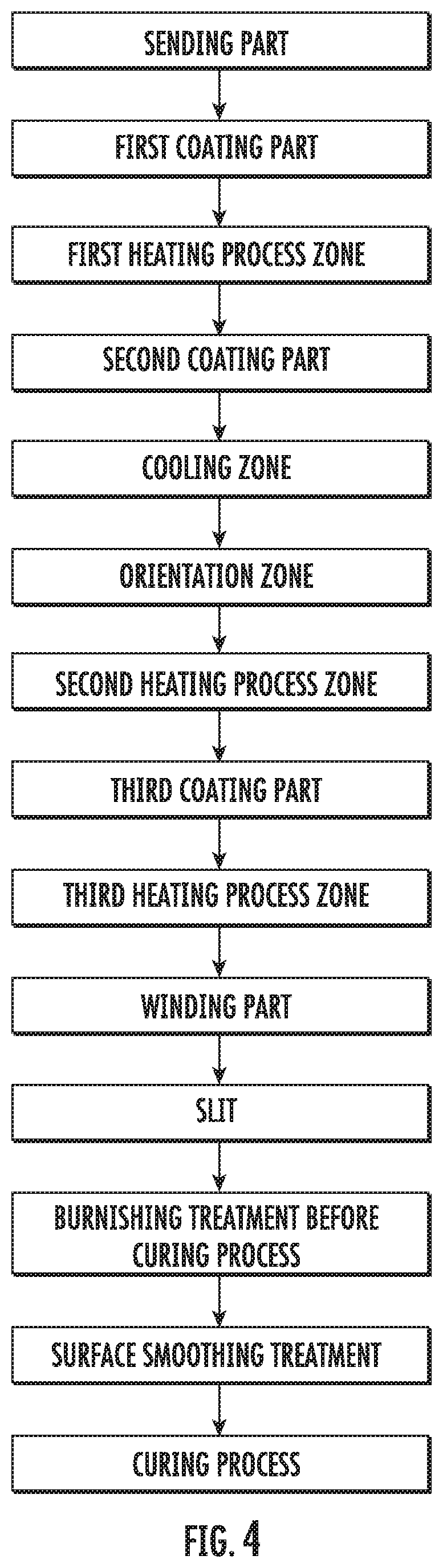

Method and apparatus for manufacturing magnetic recording medium

InactiveUS6261647B1Raise the ratioIncreased durabilityCoating by liquid dispersionMagnetic materialsEngineeringNon magnetic

A method for manufacturing a magnetic recording medium includes steps of forming a magnetic layer containing magnetic powder particles on a web-like non-magnetic support being continuously transported in one direction and applying a magnetic field to the magnetic layer by a plurality of magnets in such a manner that an angle of the magnetic field applied to the magnetic layer to the transporting direction of the non-magnetic support in a plane perpendicular to a surface of the magnetic layer and parallel to the transporting direction of the non-magnetic support gradually increases in the transporting direction of the non-magnetic support, thereby orienting the magnetic powder particles in an oblique direction with respect to the surface of the magnetic layer. According to this method, it is possible to orient magnetic powder particles in a desired direction with respect to the surface of a magnetic layer and to manufacture a magnetic recording medium having a high squareness ratio without increasing the size of the apparatus.

Owner:FUJIFILM CORP +1

Method for synthesis of core-shell type and solid solution alloy type metallic nanoparticles via transmetalation reactions and applications of same

Disclosed is a method for producing core-shell type metallic nanoparticles involving (i) providing a dispersion of a first metal as nanoparticles in an appropriate organic solvent; (ii) providing a solution of a metallic precursor containing a second metal in an appropriate organic solvent, in which the second metal has a reduction potential higher than that of the first metal; and (iii) combining the dispersion from (i) and the solution from (ii) together to carry out the transmetalation reaction of the first and second metals, thereby forming core-shell type metallic nanoparticles.

Owner:KOREA ADVANCED INST OF SCI & TECH

Magnetic tape and method of manufacturing the same

ActiveUS9711174B2Reduce thicknessIncrease recording capacityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm; at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on a surface on the magnetic layer side of the magnetic tape is greater than or equal to 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS9721605B2Avoid it happening againImprove the immunityBase layers for recording layersRecord information storageMedicineMagnetic tape

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a quantity of components selected from the group consisting of a fatty acid and a fatty acid amide per unit area of the magnetic tape among components that are extracted from a surface on the magnetic layer side of the magnetic tape is less than or equal to 15.0 mg / m2, and a concentration of carbon, C, that is obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on the surface on the magnetic layer side of the magnetic tape is greater than or equal to 50 atom %.

Owner:FUJIFILM CORP

Magnetic recording medium and method of manufacturing the same

ActiveUS20130260179A1Excellent characteristicsImprove running stabilityRecord information storageCoating by liquid dispersionNon magneticMaterials science

An aspect of the present invention relates to a magnetic recording medium, which comprises a nonmagnetic layer containing a nonmagnetic powder and a binder and a magnetic layer containing a ferromagnetic powder and a binder in this order on a nonmagnetic support, wherein the nonmagnetic layer has a thickness of equal to or less than 300 nm; a composite elastic modulus as measured on a surface of the magnetic layer ranges from 6.0 to 8.0 GPa; the magnetic layer comprises an abrasive with a specific surface area by BET method ranging from 14 m2 / g to 40 m2 / g; and a surface abrasive occupancy on a surface of the magnetic layer ranges from 0.2% to 2%.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same, and magnetic recording device

ActiveUS20120243120A1Improve thermal stabilityImprove signal-to-noise ratioMagnetic materials for record carriersFilamentary/web record carriersDemagnetizing fieldMagnetic tape

Owner:FUJIFILM CORP

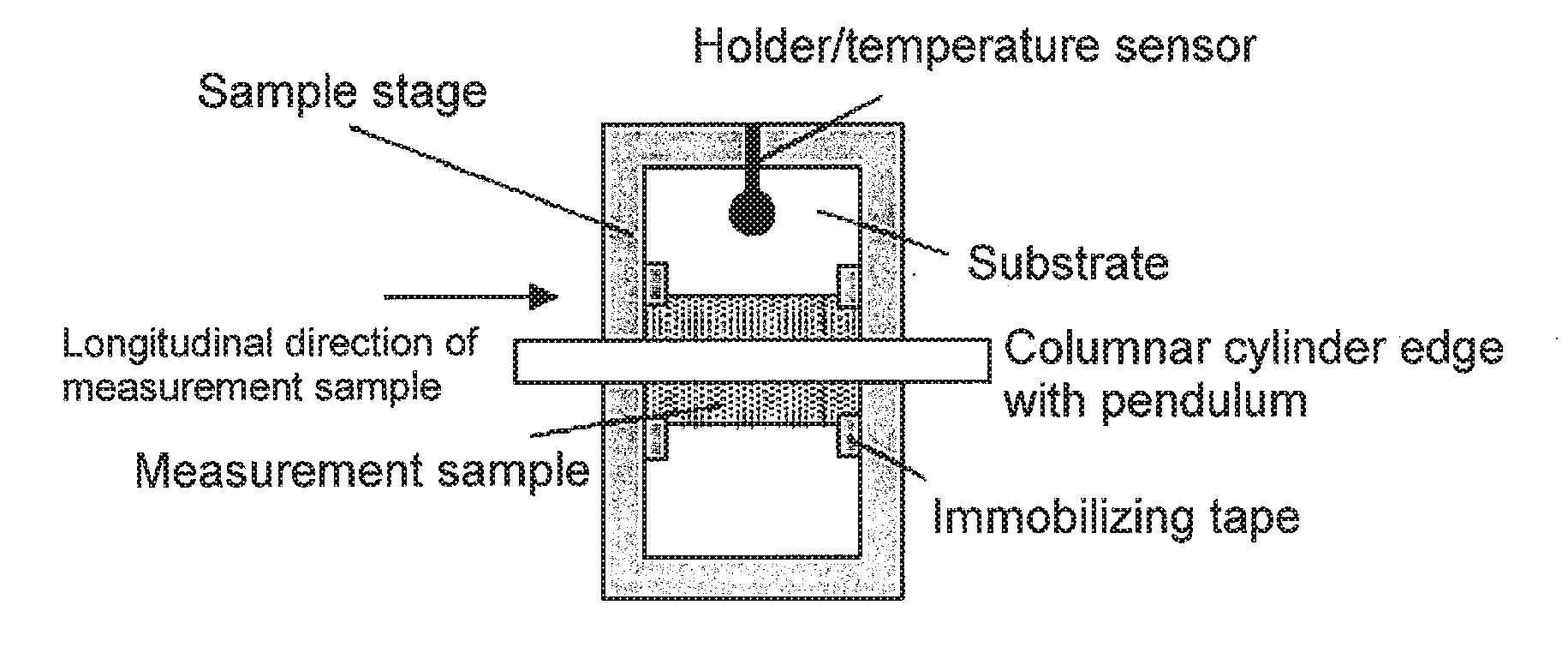

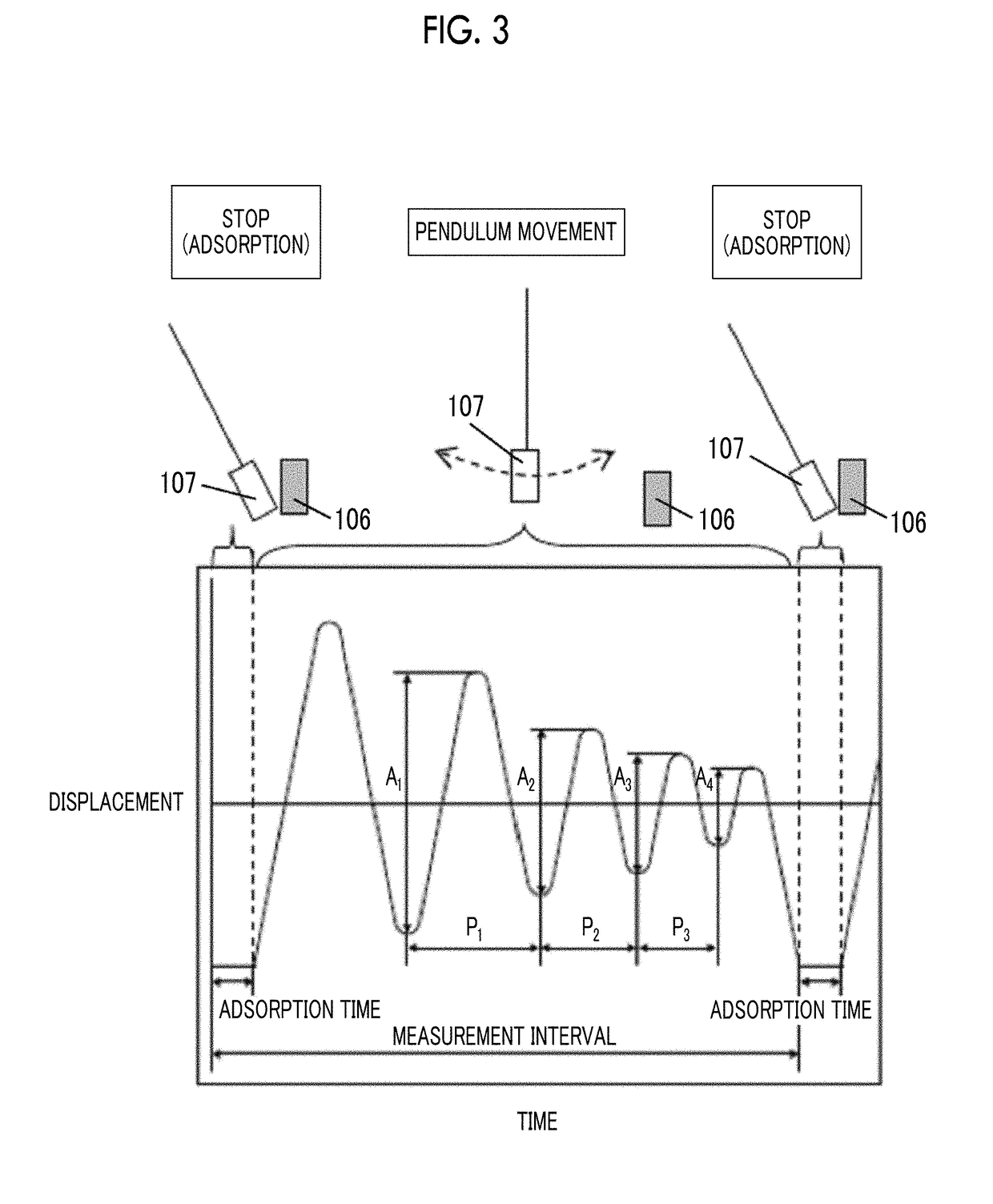

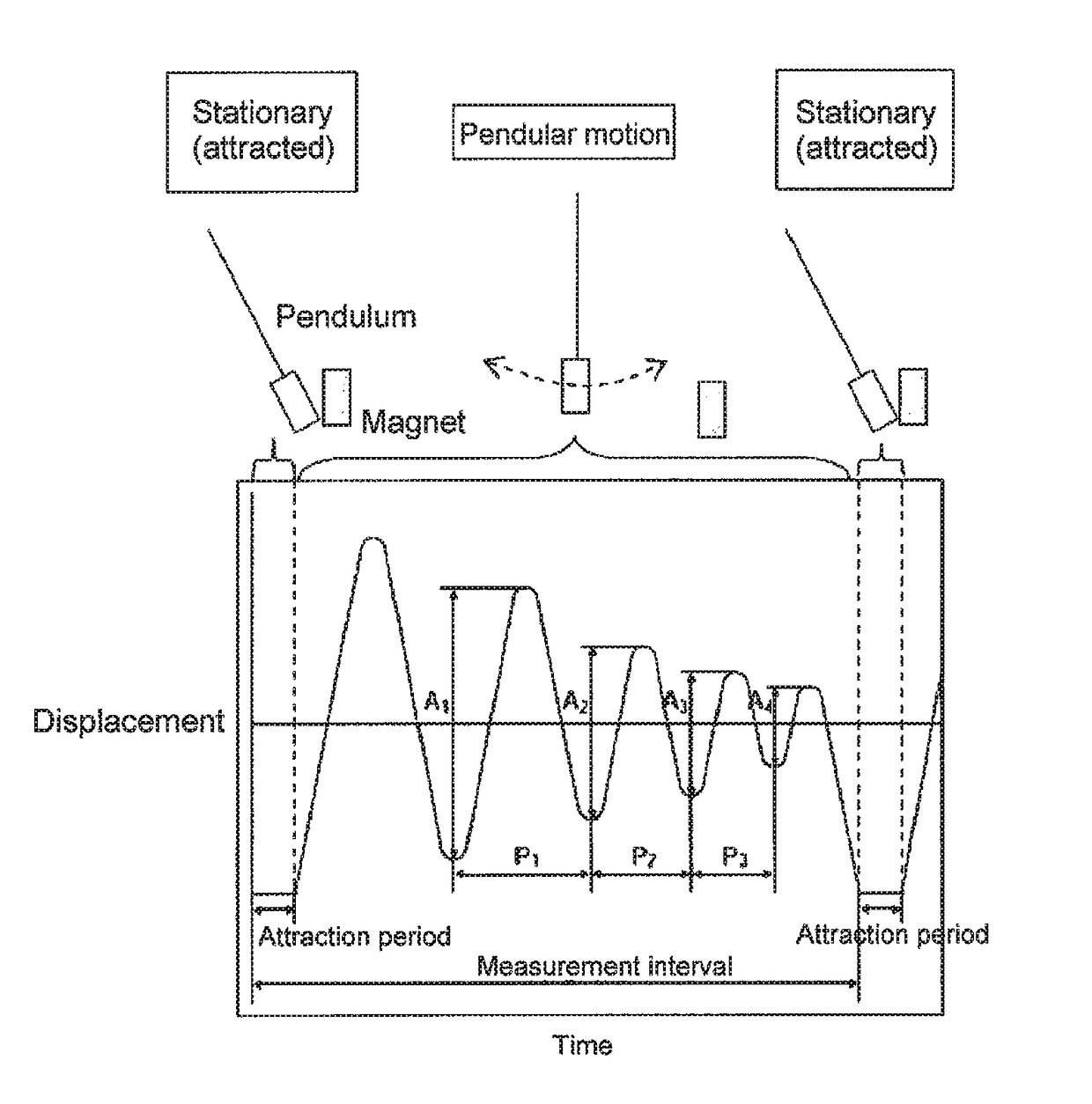

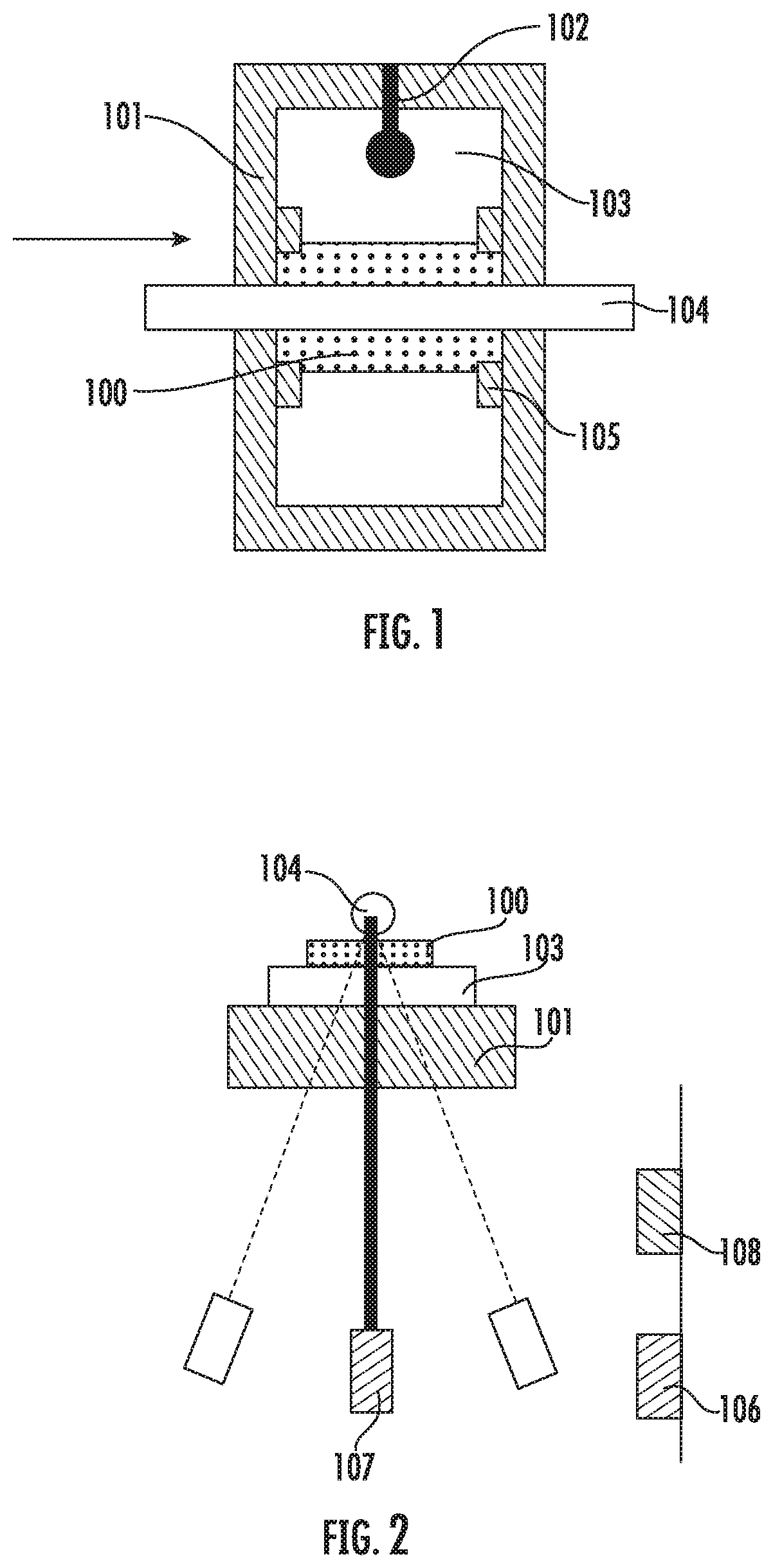

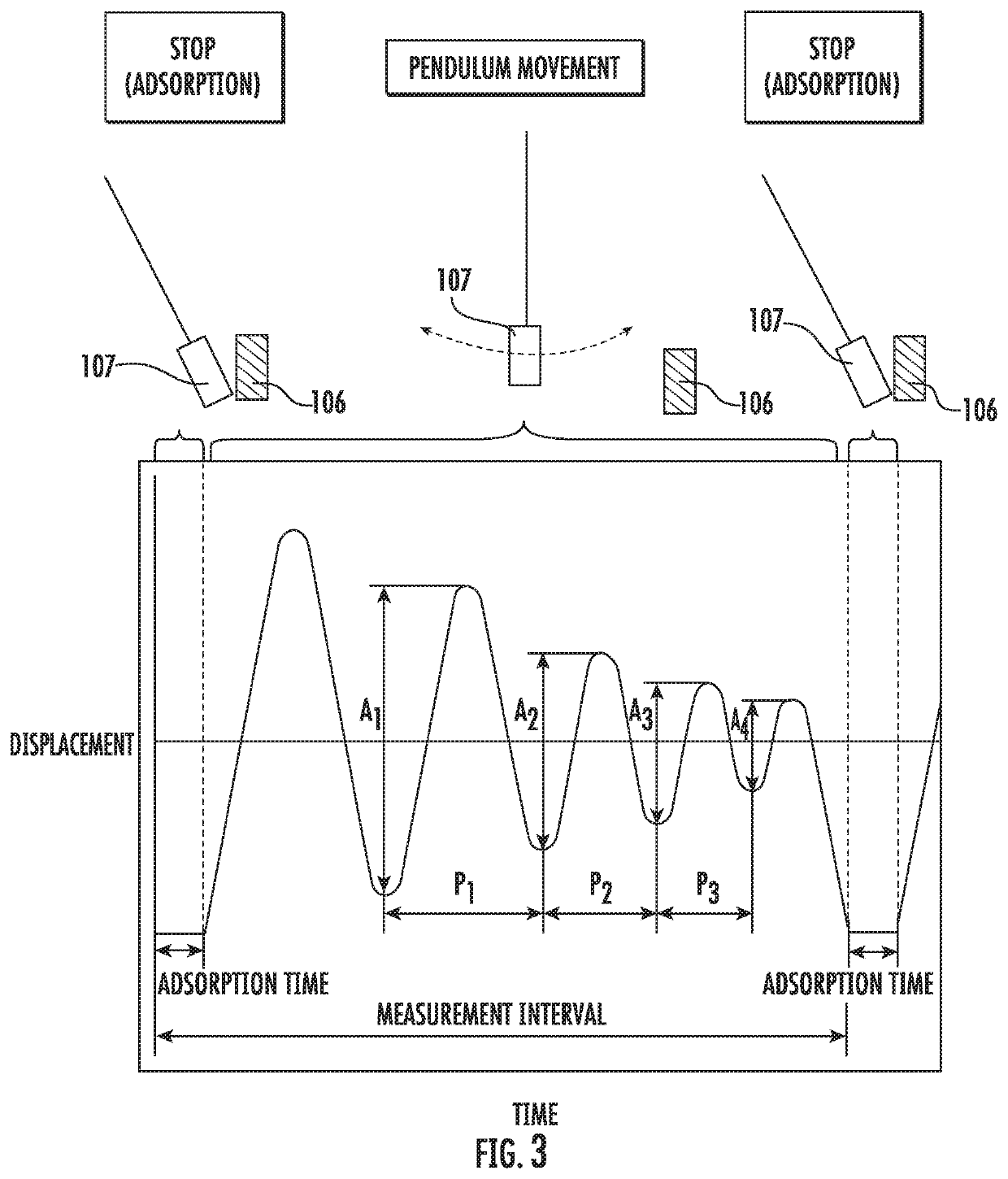

Magnetic tape having controlled surface properties of the magnetic layer and method of manufacturing the same

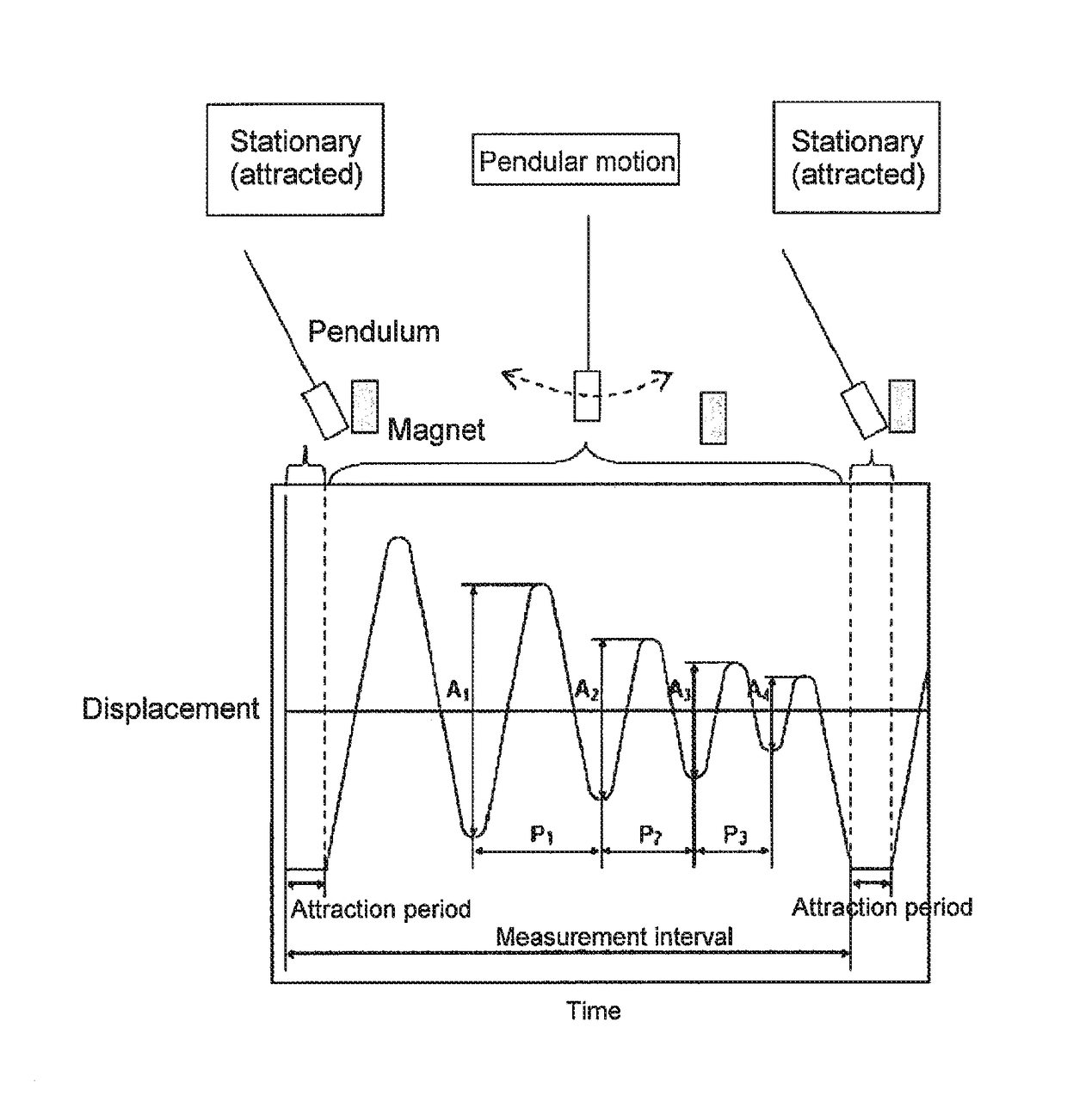

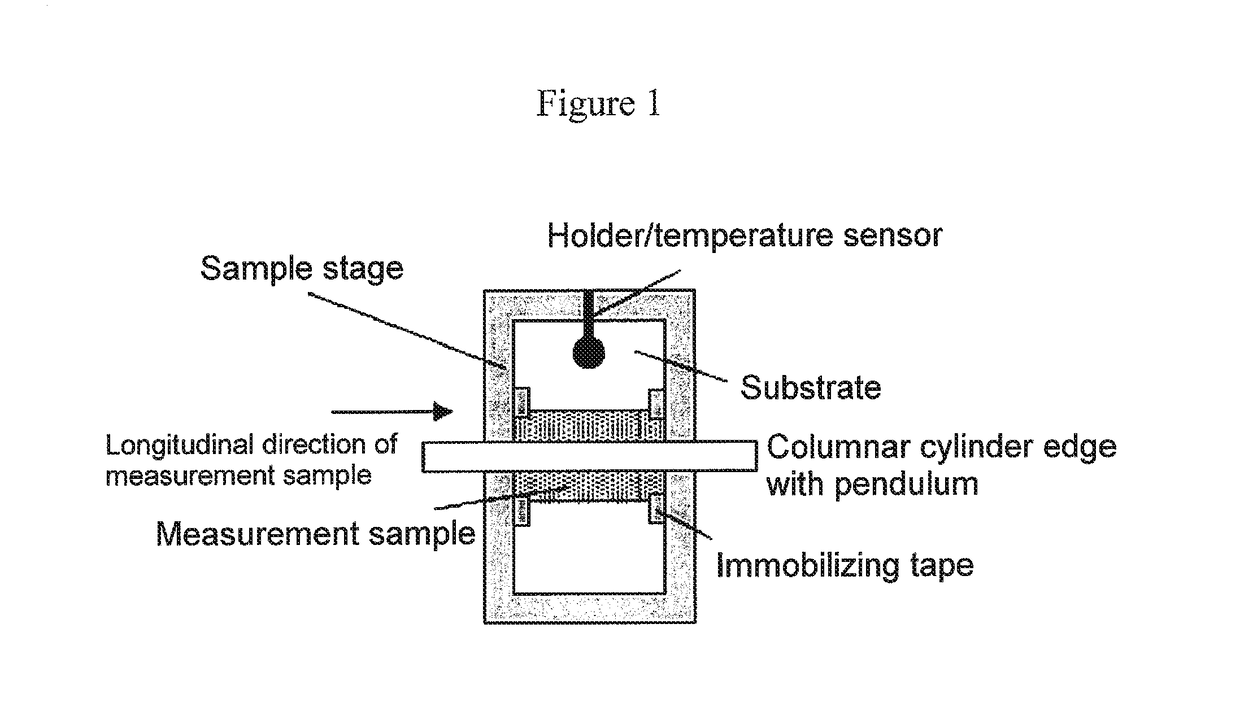

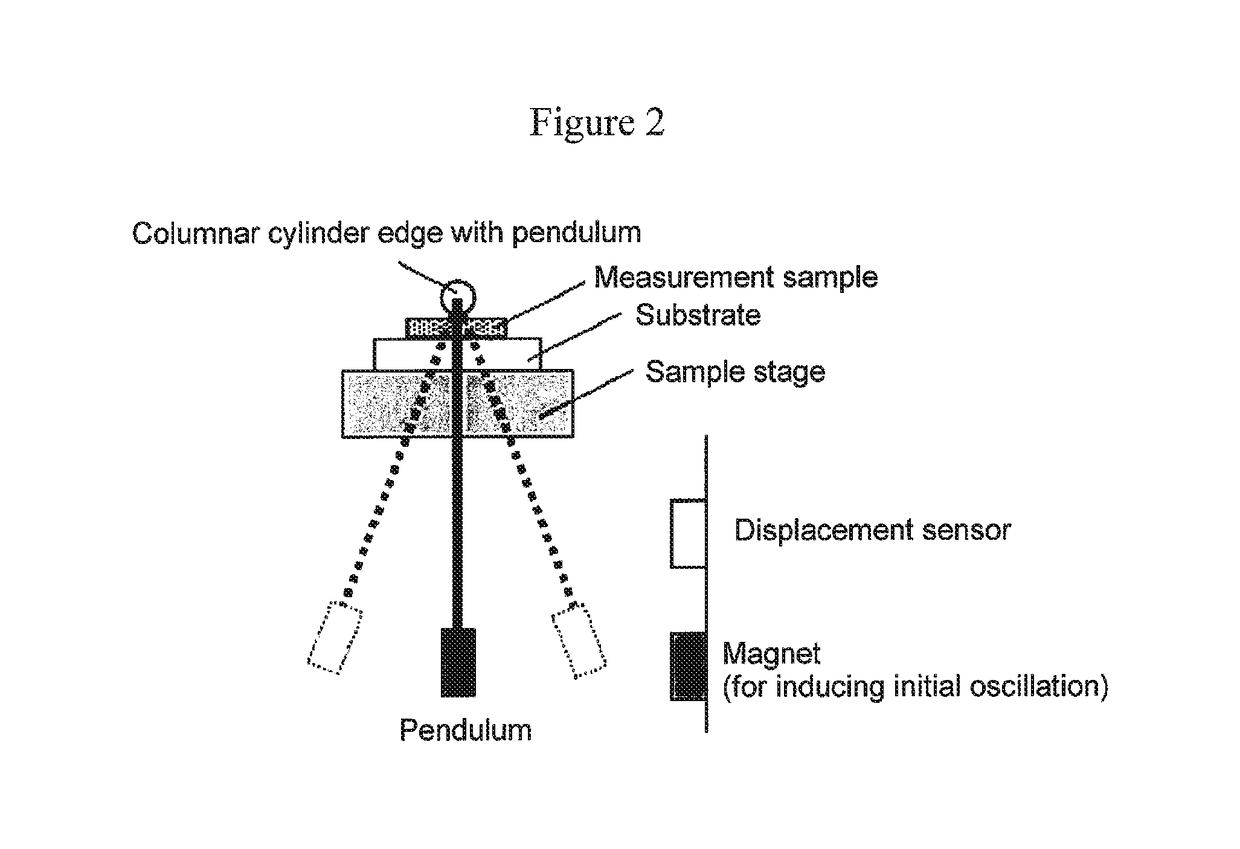

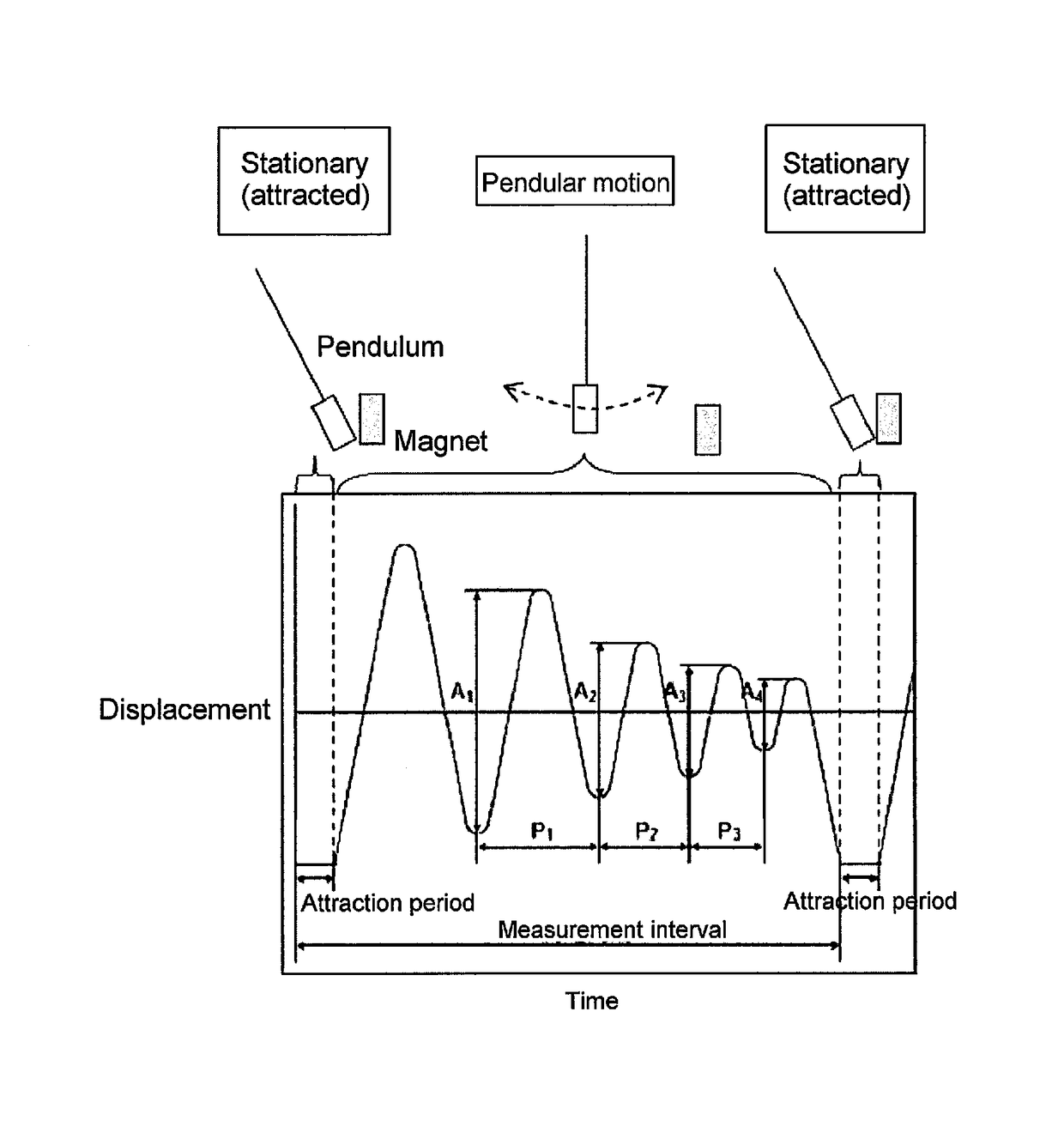

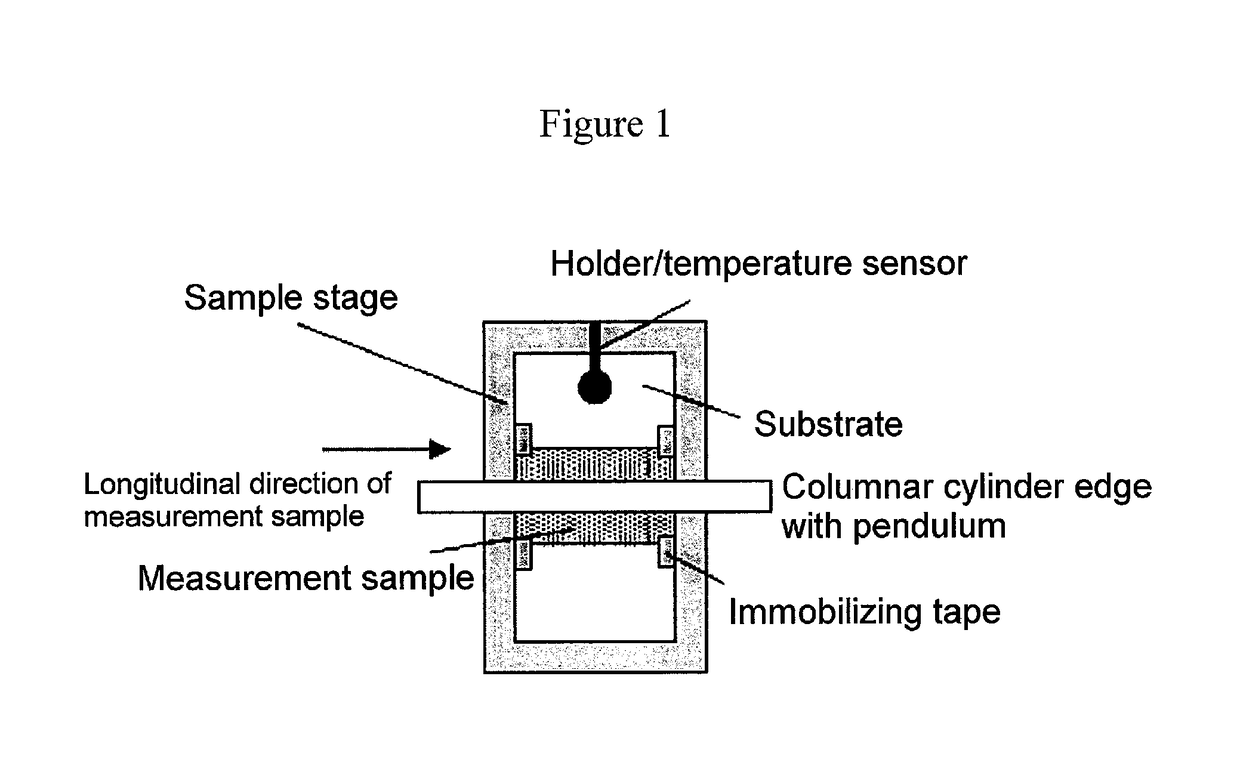

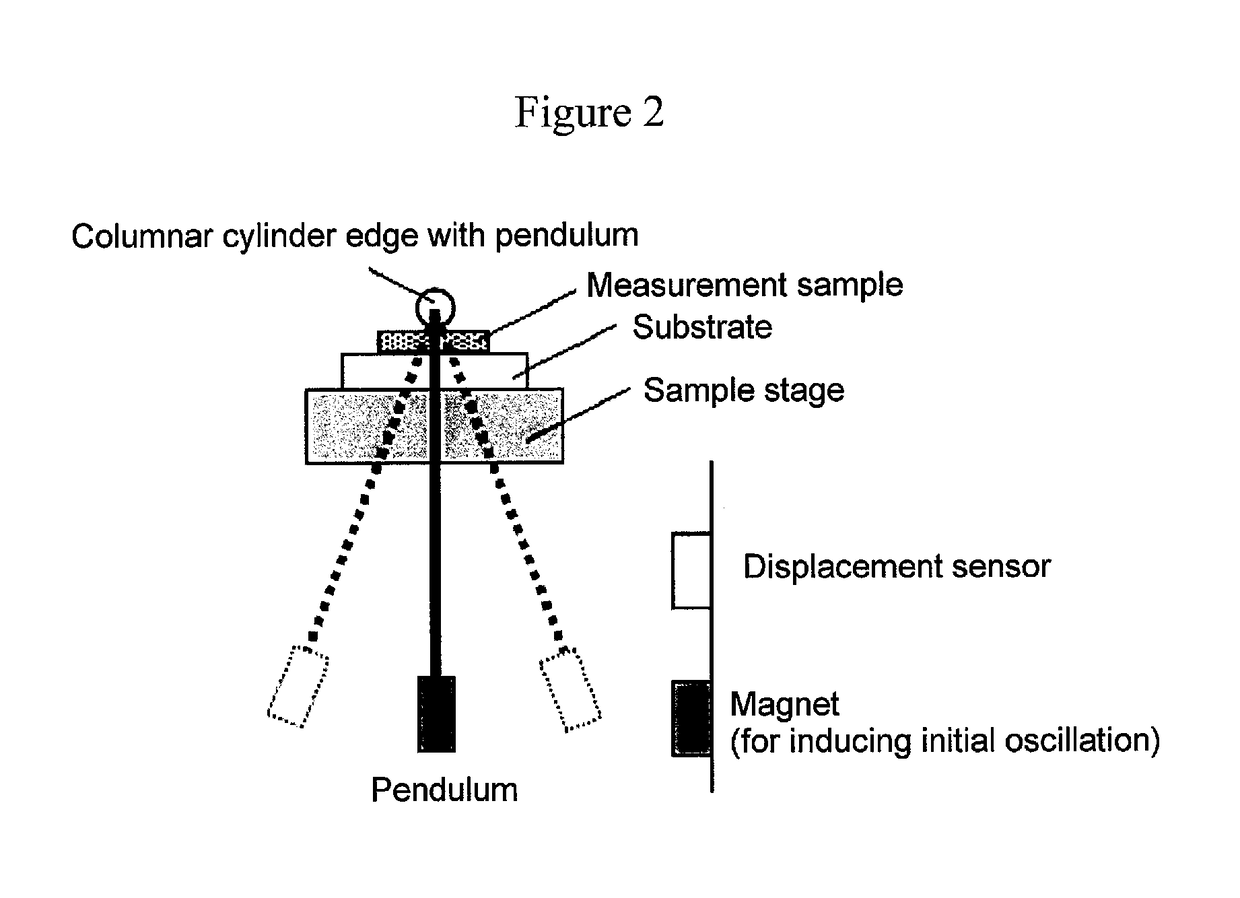

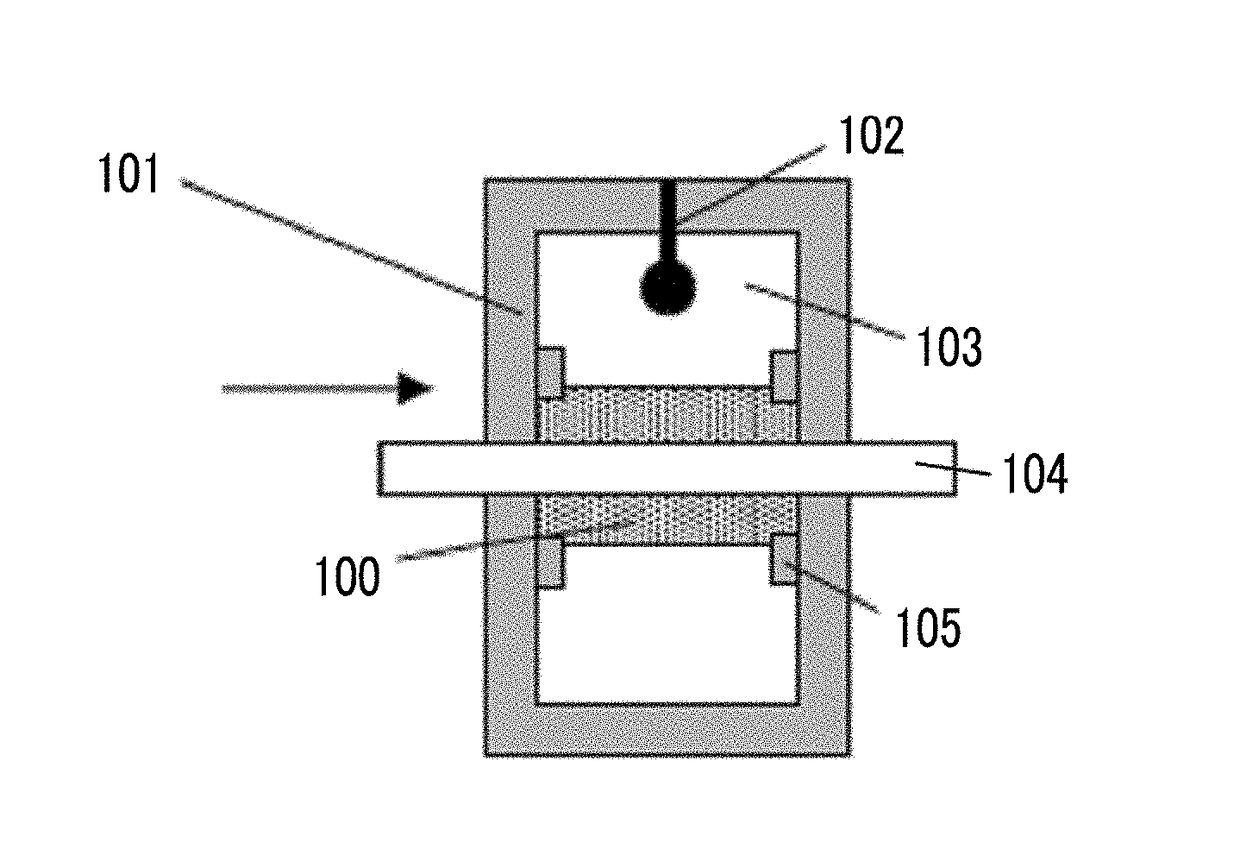

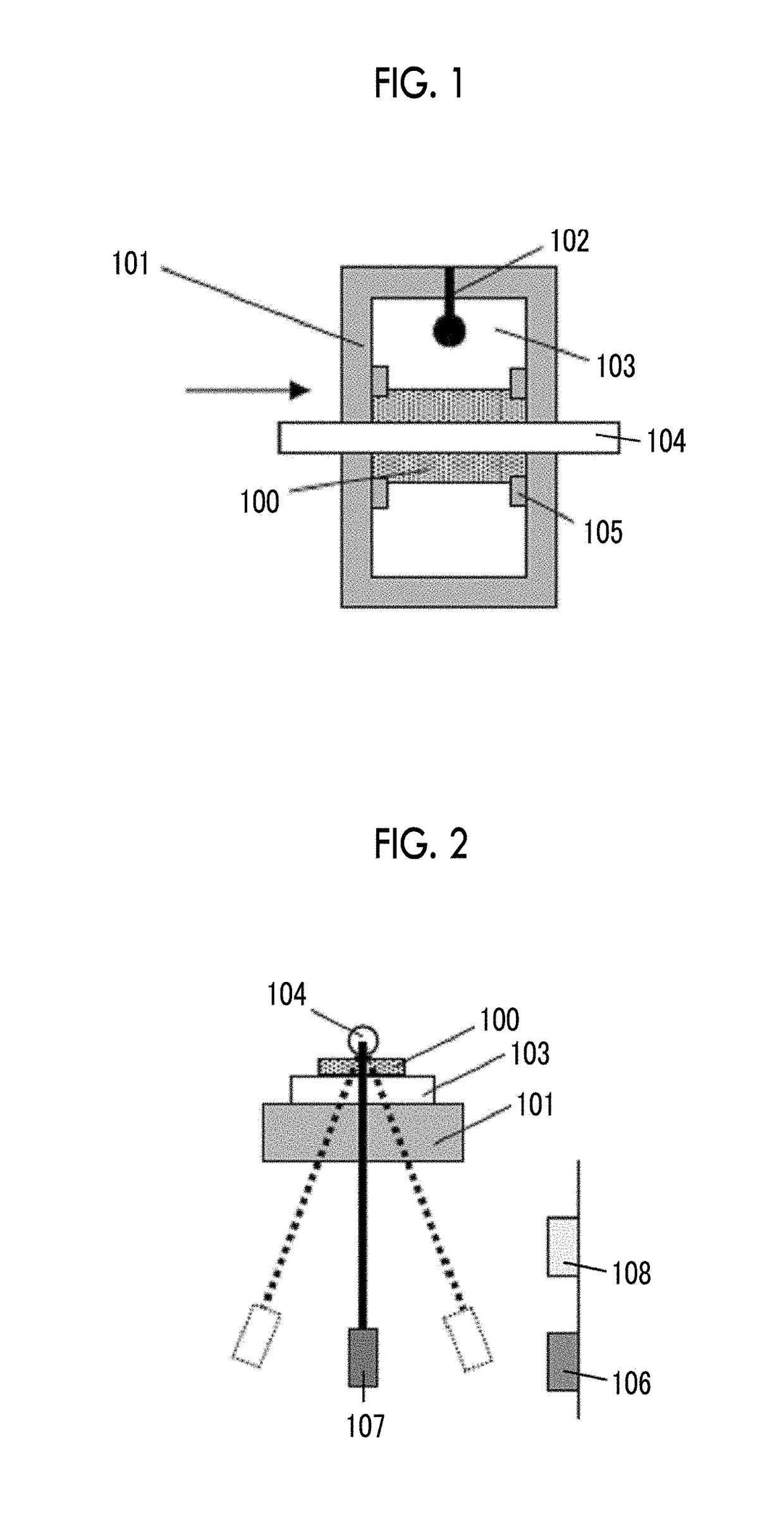

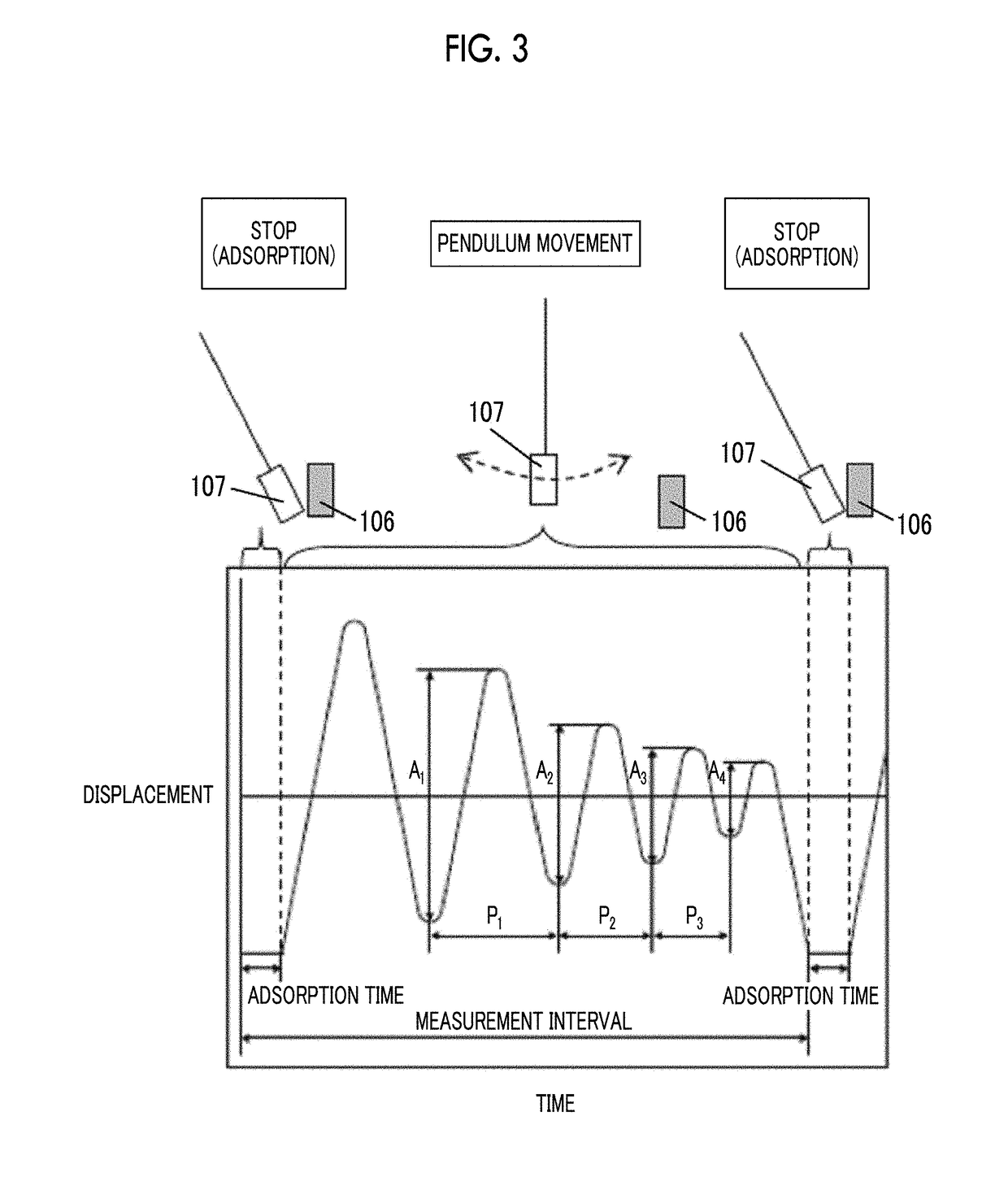

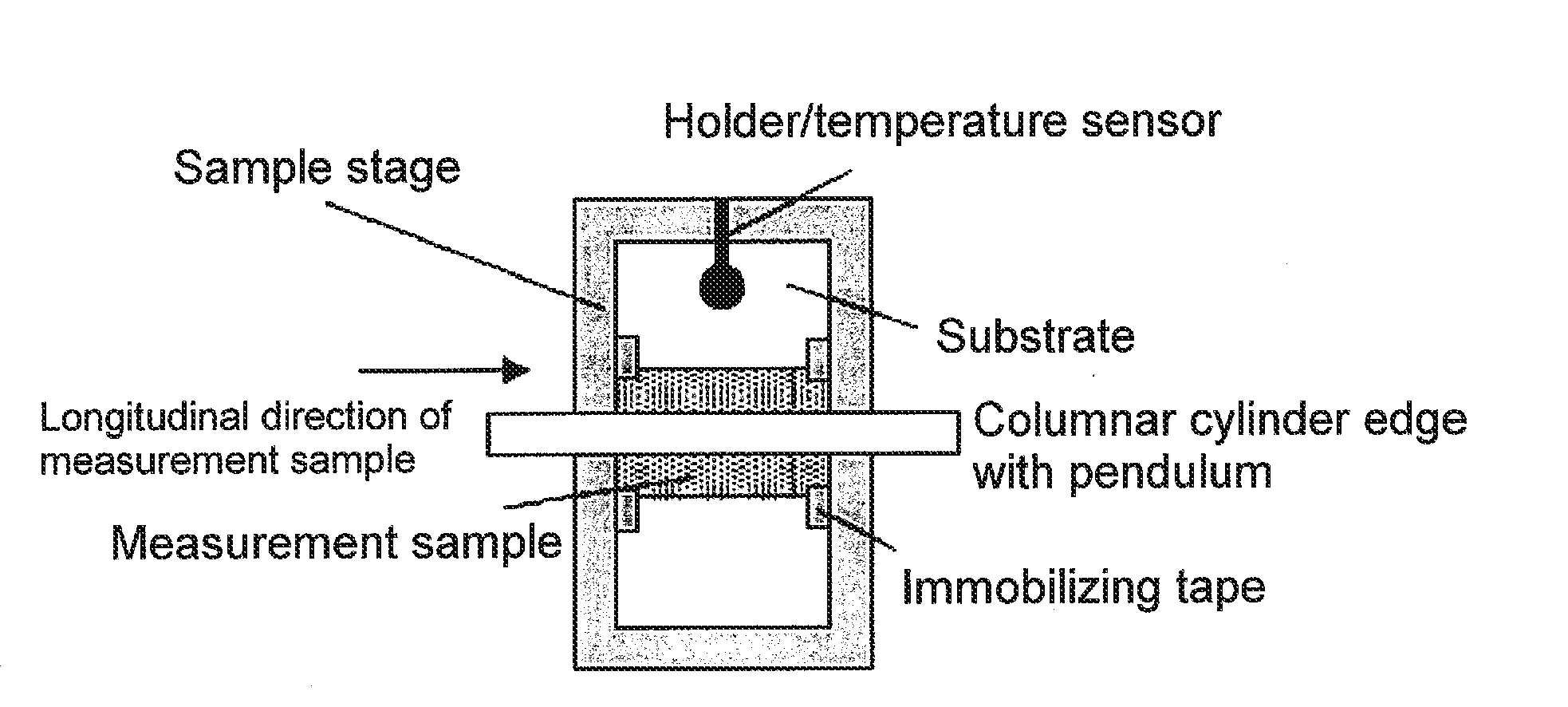

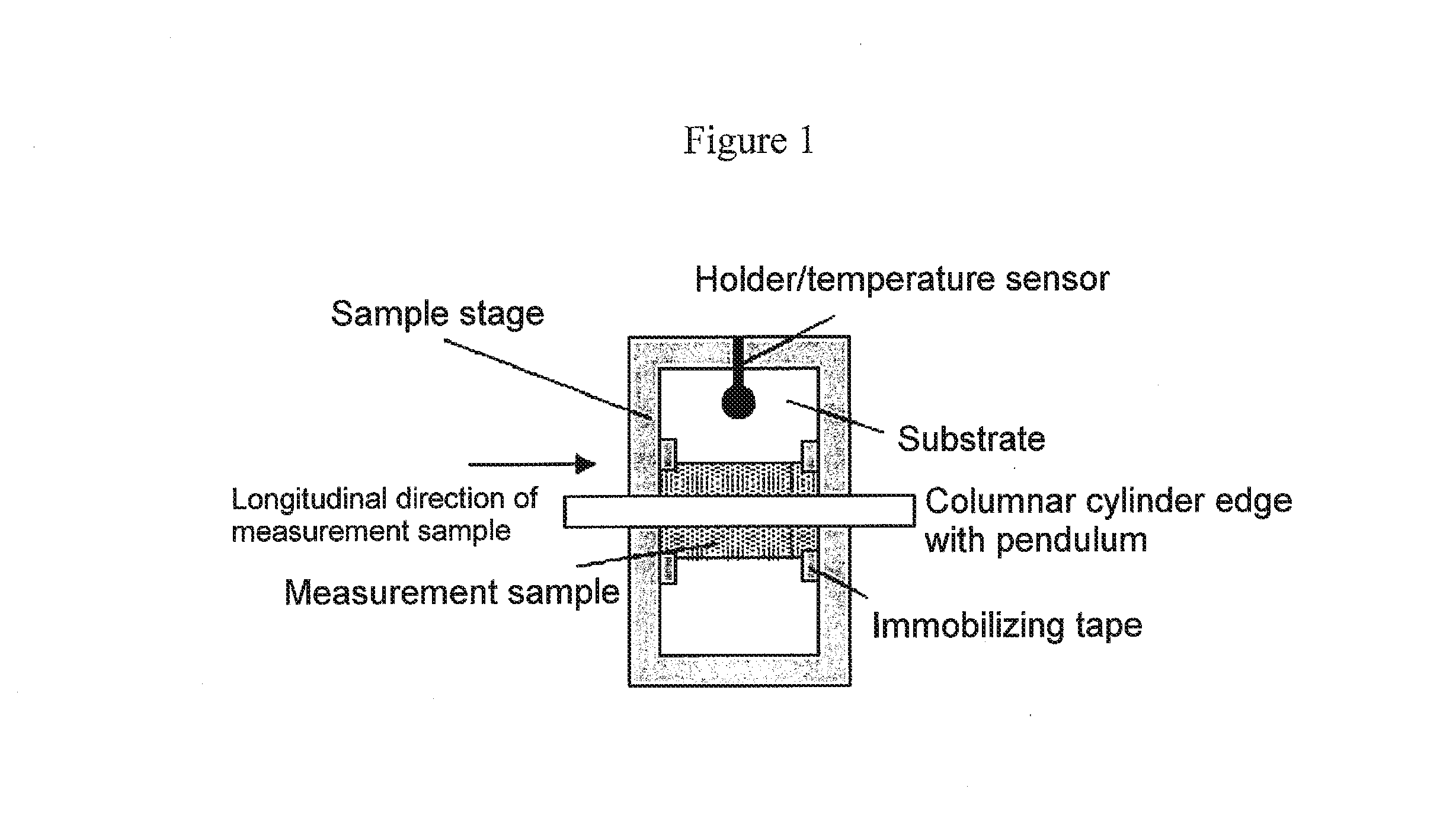

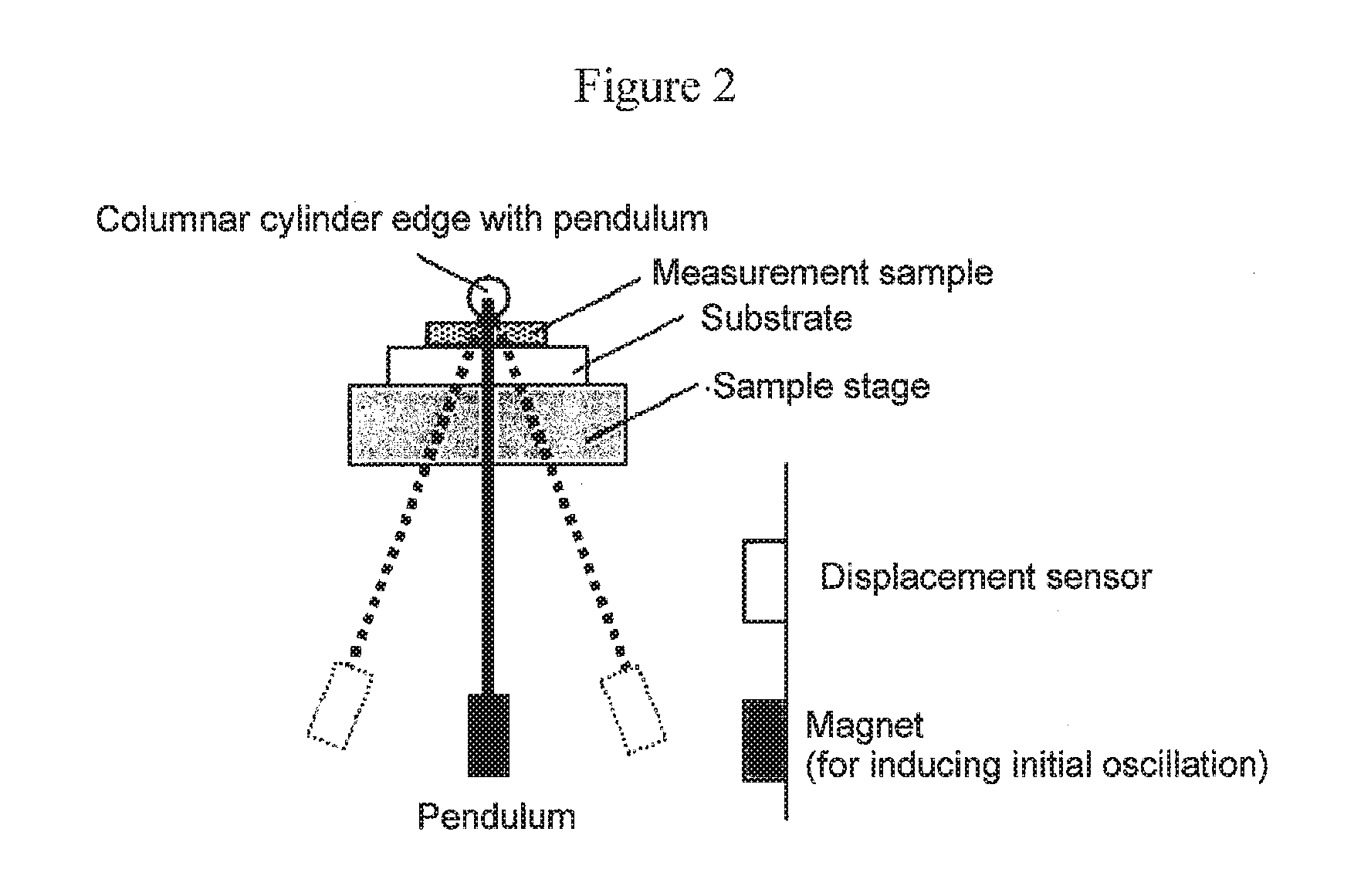

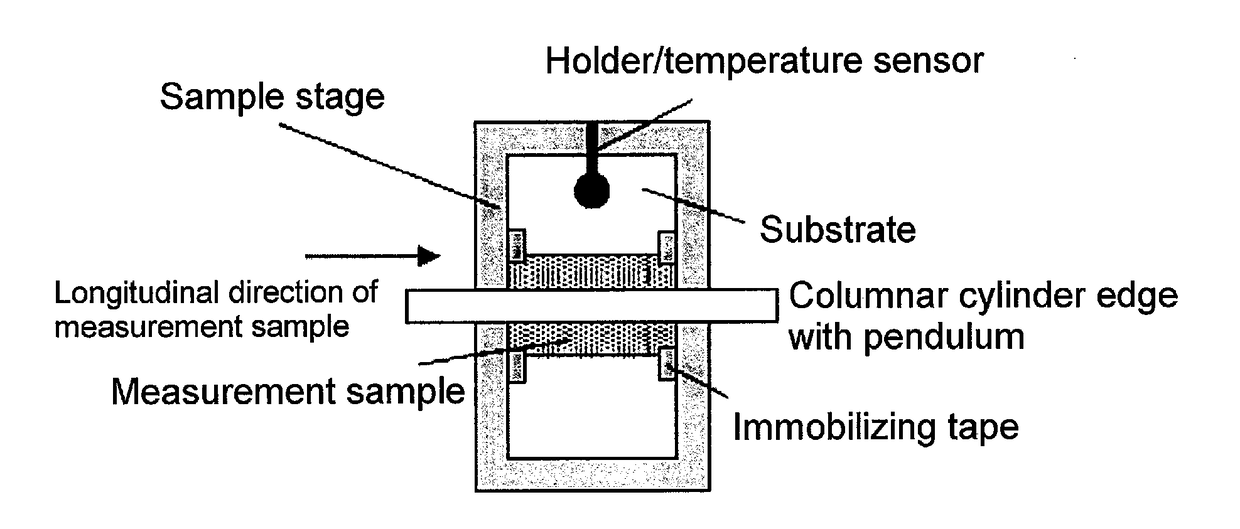

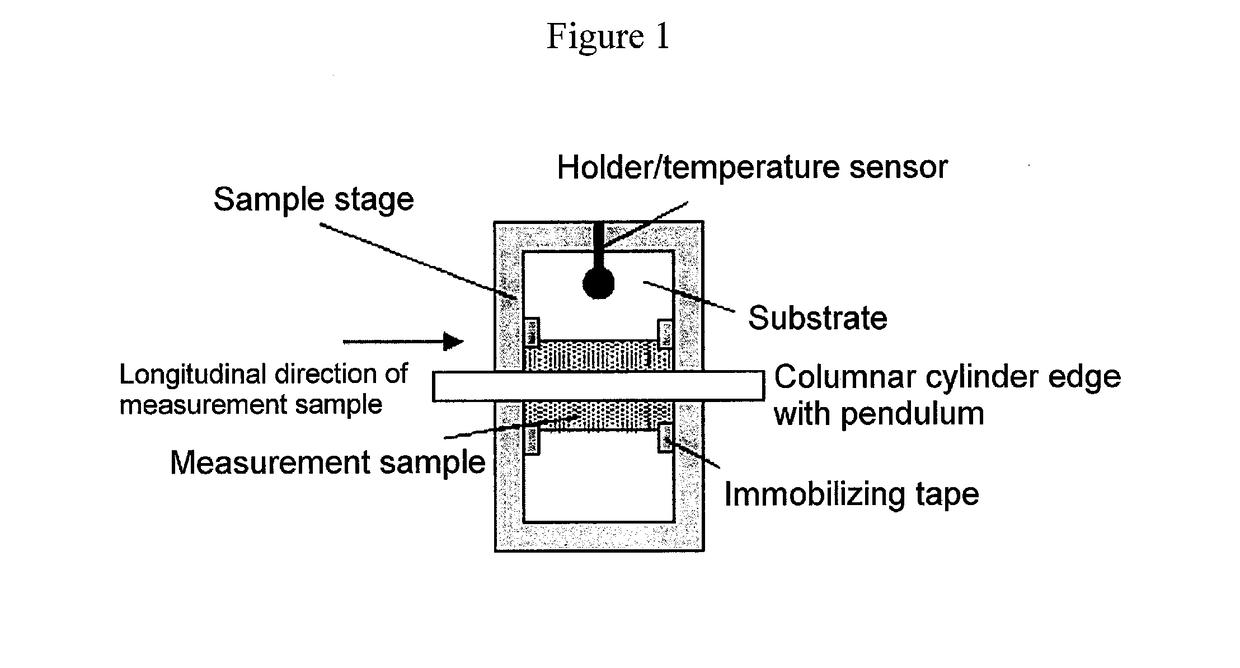

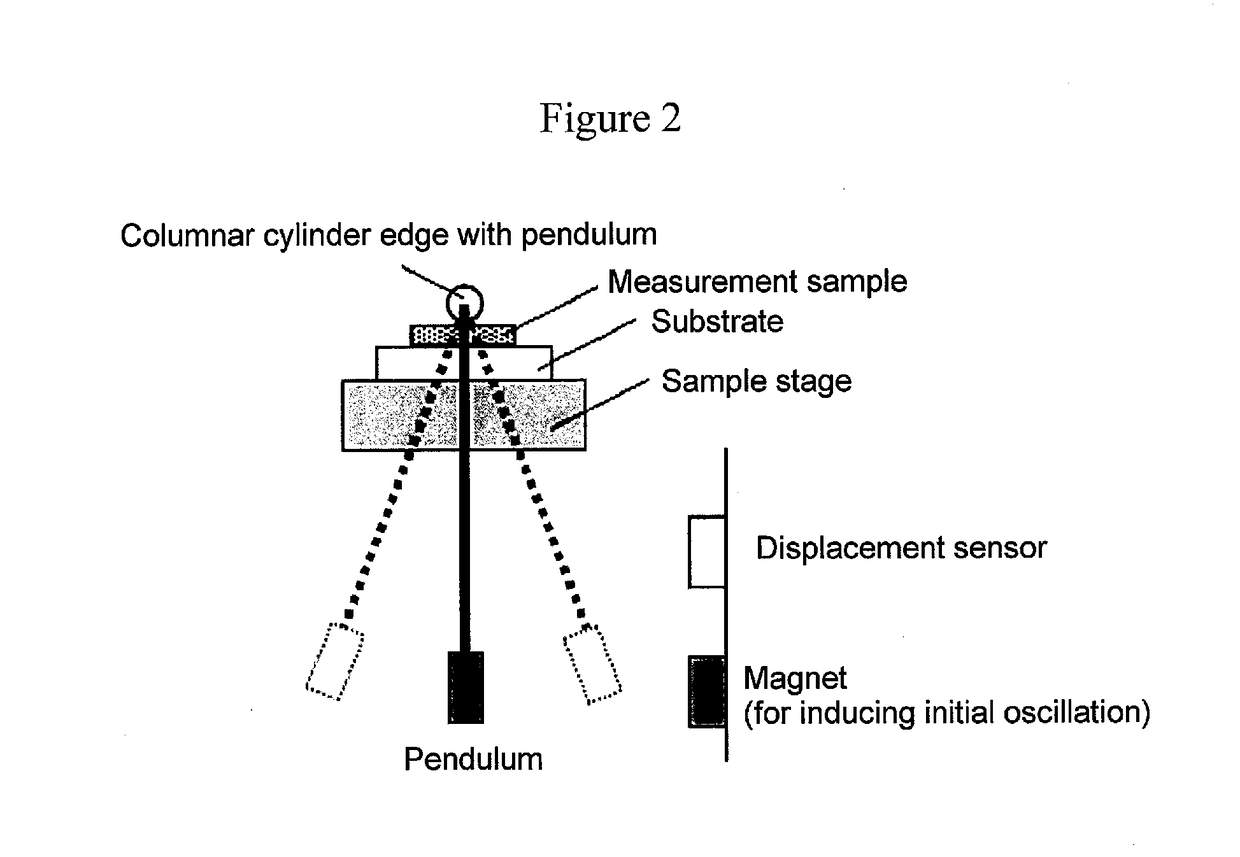

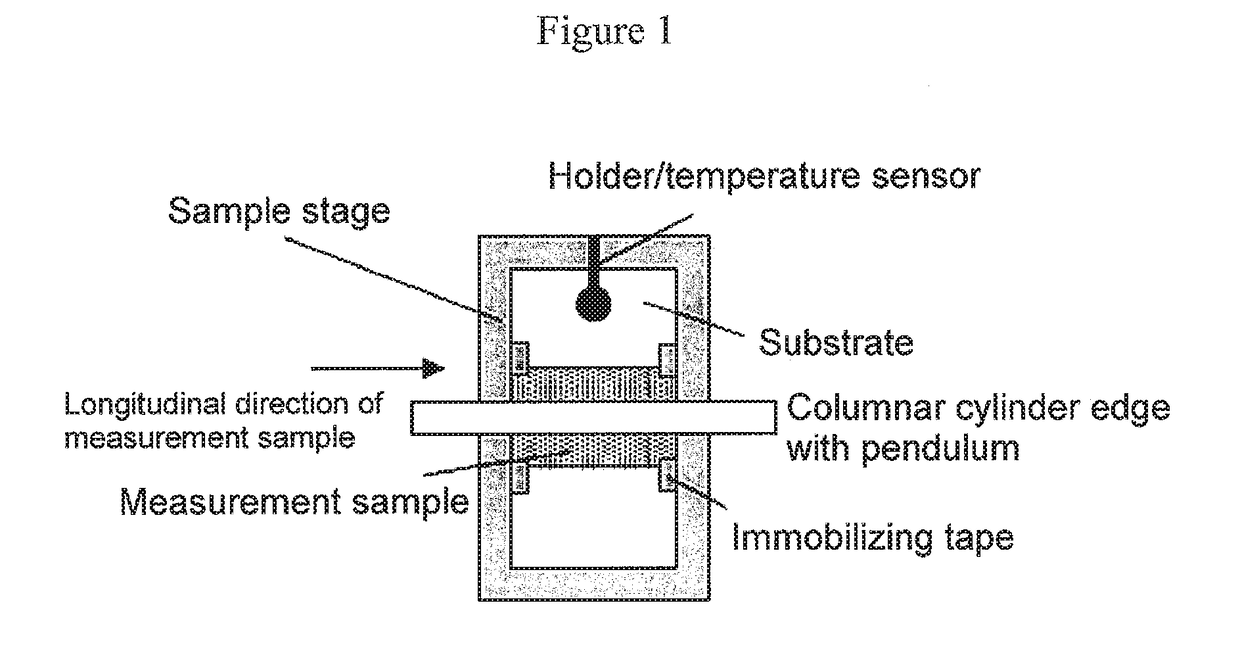

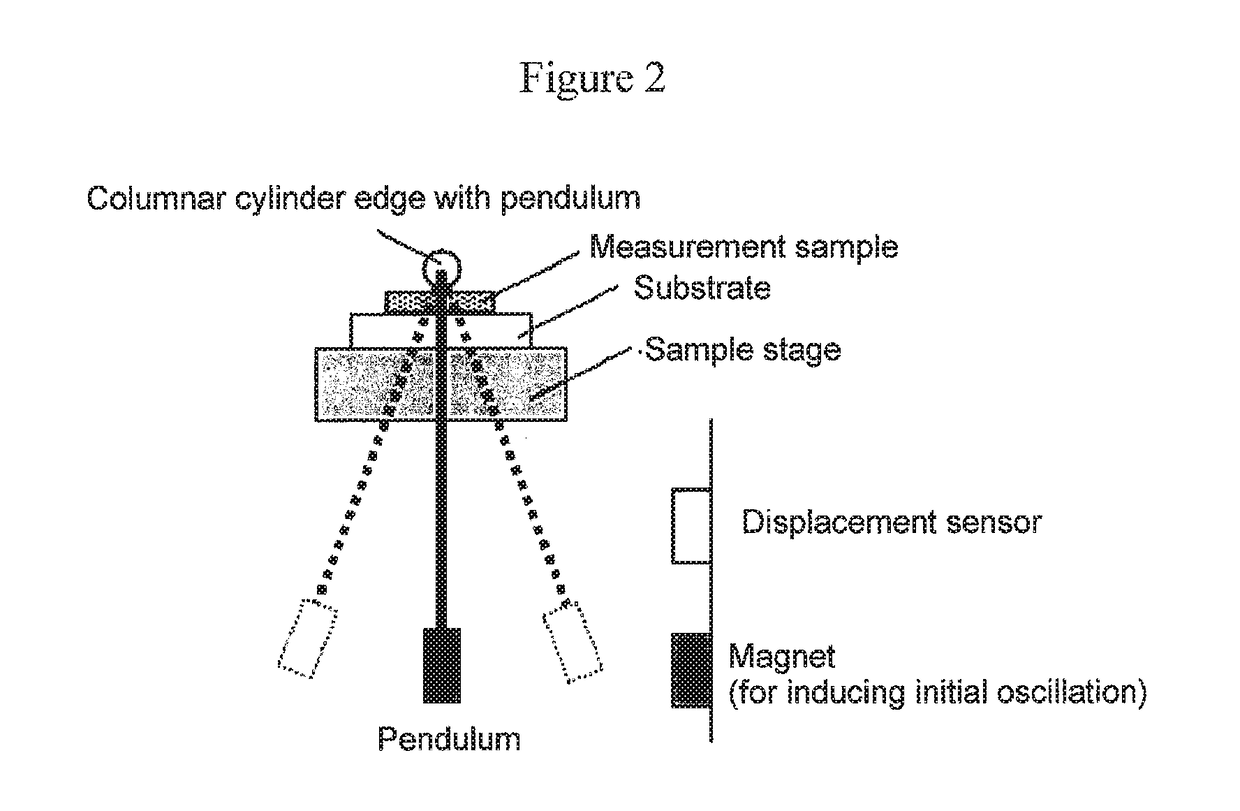

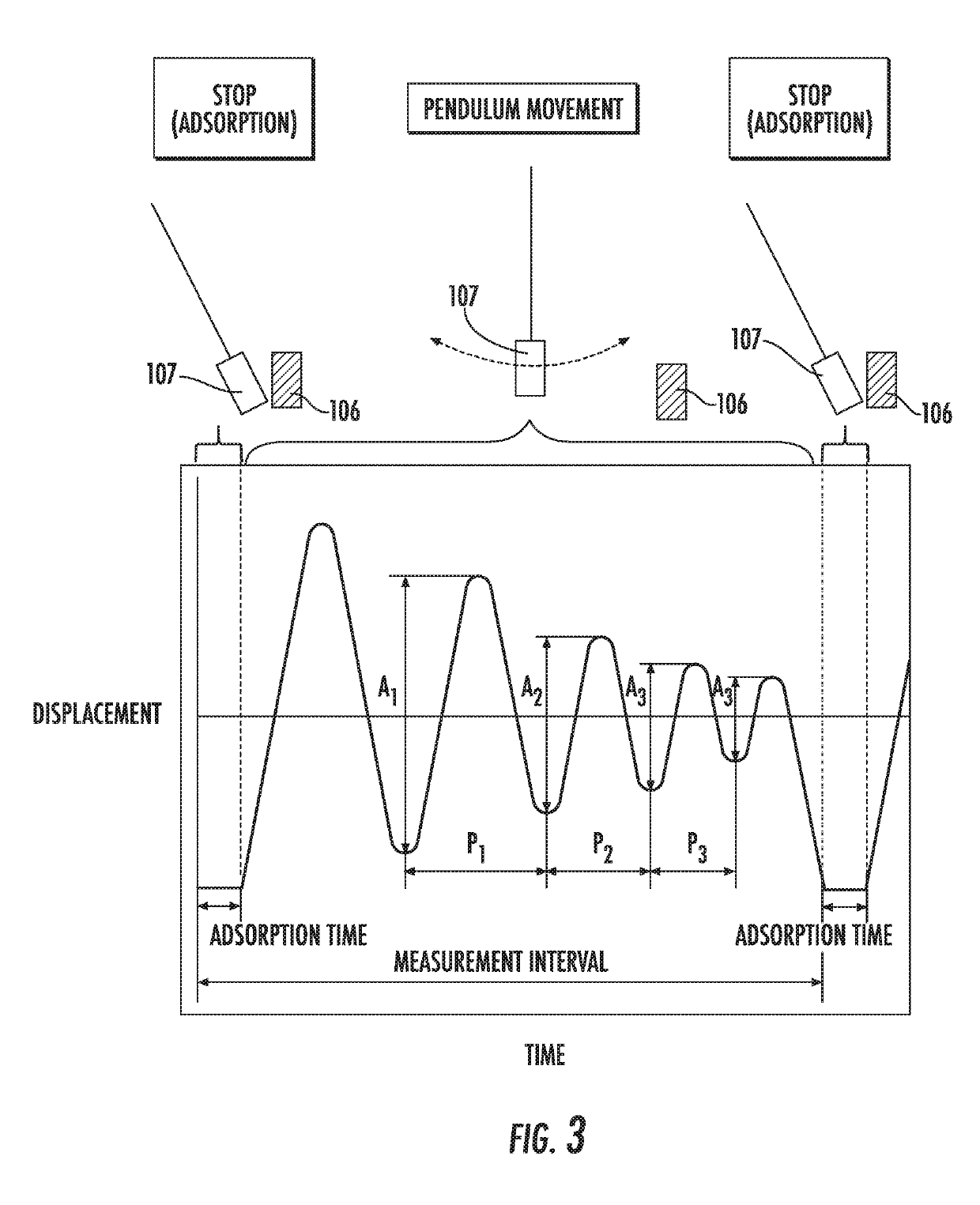

The magnetic tape has a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support, and has a magnetic layer containing ferromagnetic powder and binder on the nonmagnetic layer, wherein the combined thickness of the magnetic layer and the nonmagnetic layer is less than or equal to 0.80 μm; and the logarithmic decrement as determined by a pendulum viscoelasticity test on the surface on the magnetic layer side of the magnetic tape is less than or equal to 0.050 and the coefficient of friction as measured on a base portion of the surface on the magnetic layer side is less than or equal to 0.35.

Owner:FUJIFILM CORP

Magnetic tape having controlled surface properties of the magnetic layer and method of manufacturing the same

ActiveUS10026434B2Improve surface smoothnessImprove featuresRecord information storageTape carriersMagnetic tapeSurface roughness

Owner:FUJIFILM CORP

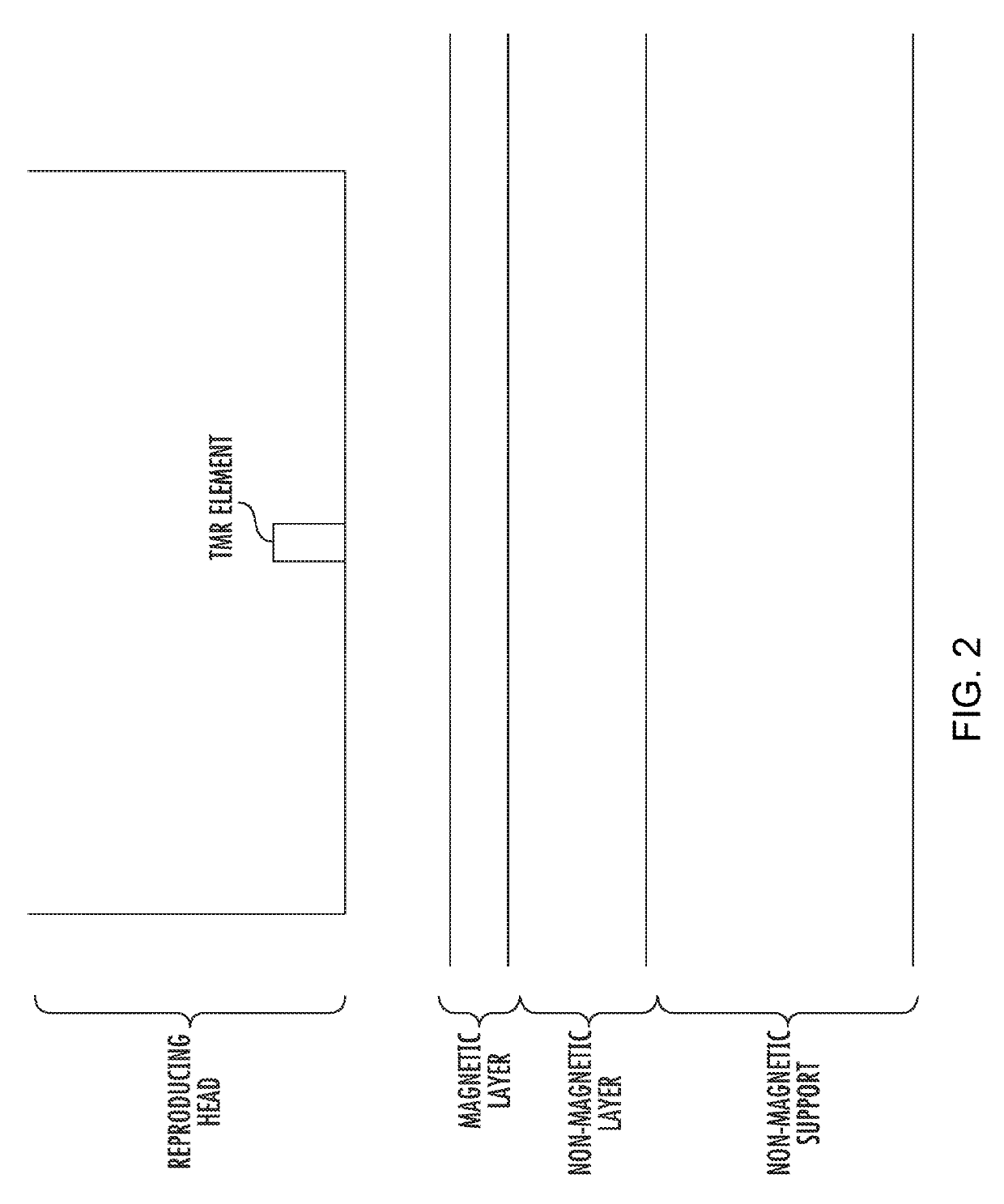

Magnetic tape device and magnetic reproducing method

ActiveUS20180240478A1Improve smoothnessImprove surface smoothnessMagnetic materials for record carriersBase layers for recording layersIn planeX-ray

The magnetic tape device includes a TMR head as a reproducing head; and a magnetic tape which includes a non-magnetic support, and a magnetic layer including ferromagnetic hexagonal ferrite powder and a binding agent on the non-magnetic support, an XRD intensity ratio (Int(110) / Int(114)) of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, and a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

The magnetic tape has a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support, and has a magnetic layer containing ferromagnetic powder and binder on the nonmagnetic layer, wherein the combined thickness of the magnetic layer and the nonmagnetic layer is less than or equal to 0.80 μm; and the logarithmic decrement as determined by a pendulum viscoelasticity test on the surface on the magnetic layer side of the magnetic tape is less than or equal to 0.050 and the coefficient of friction as measured on a base portion of the surface on the magnetic layer side is less than or equal to 0.35.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20160189740A1Avoid it happening againImprove the immunityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a quantity of components selected from the group consisting of a fatty acid and a fatty acid amide per unit area of the magnetic tape among components that are extracted from a surface on the magnetic layer side of the magnetic tape is less than or equal to 15.0 mg / m2, and a concentration of carbon, C, that is obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on the surface on the magnetic layer side of the magnetic tape is greater than or equal to 50 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20170053671A1Increase recording capacityReduce thicknessTape carriersRecord information storageMagnetic tapeNon magnetic

The magnetic tape has a magnetic layer containing ferromagnetic powder and binder on the surface on one side of a nonmagnetic support and has a backcoat layer containing nonmagnetic powder and binder on the surface on the other side of the nonmagnetic support, wherein the backcoat layer is less than or equal to 0.30 μm in thickness; and the logarithmic decrement as determined by a pendulum viscoelasticity test on the surface on the backcoat layer side of the magnetic tape is less than or equal to 0.060.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20180301165A1Improve surface smoothnessImprove featuresTape carriersRecord information storageMagnetic tapeSurface roughness

The magnetic tape has a magnetic layer containing ferromagnetic powder and binder on a nonmagnetic support, wherein the centerline average surface roughness Ra as measured on the surface on the magnetic layer side of the magnetic tape is less than or equal to 1.8 nm, and the logarithmic decrement as determined by a pendulum viscoelasticity test on the surface on the magnetic layer side of the magnetic tape is less than or equal to 0.050.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducting method

ActiveUS20180240476A1Lower the resistance valueImprove smoothnessMagnetic materials for record carriersBase layers for recording layersMagnetic force microscopeMagnetic tape

The magnetic tape device includes a magnetic tape; and a reproducing head, in which the reproducing head is a TMR head, a center line average surface roughness Ra measured regarding a surface of the magnetic layer of the magnetic tape is equal to or smaller than 2.0 nm, a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050, and a ratio (Sdc / Sac) of an average area Sdc of a magnetic cluster of the magnetic tape in a DC demagnetization state and an average area Sac of a magnetic cluster of the magnetic tape in an AC demagnetization state measured with a magnetic force microscope is 0.80 to 1.30.

Owner:FUJIFILM CORP

Magnetic tape having controlled surface properties of the backcoat layer and method of manufacturing the same

ActiveUS10026435B2Increase recording capacityReduce thicknessTape carriersRecord information storageMagnetic tapeNon magnetic

The magnetic tape has a magnetic layer containing ferromagnetic powder and binder on the surface on one side of a nonmagnetic support and has a backcoat layer containing nonmagnetic powder and binder on the surface on the other side of the nonmagnetic support, wherein the backcoat layer is less than or equal to 0.30 μm in thickness; and the logarithmic decrement as determined by a pendulum viscoelasticity test on the surface on the backcoat layer side of the magnetic tape is less than or equal to 0.060.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180182429A1Avoid it happening againAvoiding characteristicMagnetic materials for record carriersBase layers for recording layersMagnetic tapeX-ray

The magnetic tape device includes: a magnetic tape; and a reproducing head, in which a magnetic tape transportation speed of the magnetic tape device is equal to or lower than 18 m / sec, the reproducing head is a magnetic head including a tunnel magnetoresistance effect type element as a reproducing element, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the magnetic layer includes one or more components selected from the group consisting of fatty acid and fatty acid amide, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %.

Owner:FUJIFILM CORP

Magnetic recording medium

InactiveUS20060187589A1High reproductive outputHigh outputRecord information storageManufacture of flux-sensitive headsMetallurgyMicrometer

Provided is a magnetic recording medium capable of achieving high reproduction output in a short wavelength region. The magnetic recording medium comprises a nonmagnetic layer comprising a nonmagnetic powder and a binder and a magnetic layer comprising a ferromagnetic powder and a binder in this order on a nonmagnetic support. The magnetic layer has a squareness ranging from 0.6 to 1.0 in a perpendicular direction, and the magnetic recording medium is employed for recording a magnetic signal on the medium in a longitudinal direction at a linear recording density of equal to or greater than 300 Kbpi using a recording head with a gap length of equal to or less than 0.3 micrometer, and reproducing the magnetic signal using a magnetoresistive head with a shield spacing of equal to or less than 0.2 micrometer.

Owner:FUJIFILM CORP +1

Magnetic tape and method of manufacturing the same

ActiveUS20170186456A1Increase frictionImprove featuresRecord information storageTape carriersMagnetic tapeMagnetization

The magnetic tape has a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support and a magnetic layer containing ferromagnetic powder and binder on the nonmagnetic layer, wherein a fatty acid ester is contained in at least the magnetic layer, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, the ferromagnetic hexagonal ferrite powder has a crystallite volume as determined by X-ray diffraction analysis ranges from 1,000 nm3 to 2,400 nm3, and a ratio of the crystallite size Dx(107) obtained from a diffraction peak of a (107) plane to a particle size in a direction of an easy axis of magnetization DTEM as determined by observation with a transmission electron microscope, Dx(107) / DTEM, is greater than or equal to 1.1, and ΔSFD in a longitudinal direction of the magnetic tape as calculated with Equation 1: ΔSFD=SFD25° C.−SFD−190° C., ranges from 0.50 to 1.60.

Owner:FUJIFILM CORP

Nanoparticle coated material and production method of same

The invention provides a method of producing a nanoparticle coated material, comprising a support and a nanoparticle layer formed on the support, wherein the nanoparticle layer contains nanoparticles comprising a CuAu type or Cu3Au type hard magnetic ordered alloy, and wherein the method satisfies at least one of the following conditions (i) and (ii): (i) the method comprises the steps of forming a shielding layer on the support before forming the nanoparticle layer; and (ii) a step of forming the nanoparticle layer comprises: the steps of applying a coating liquid containing nanoparticles capable of forming a CuAu type or Cu3Au type hard magnetic ordered alloy phase on the support to form a coating film; and irradiating laser light on the coating film.

Owner:FUJIFILM CORP +1

Magnetic tape device and reproducing method employing TMR reproducing head and tape with characterized XRD intensity ratio

ActiveUS10546602B2Improve smoothnessImprove surface smoothnessMagnetic materials for record carriersBase layers for recording layersMagnetic tapeFerrite powder

The magnetic tape device includes a Tunneling Magnetoresistive (TMR) head as a reproducing head; and a magnetic tape which includes a non-magnetic support, and a magnetic layer including ferromagnetic hexagonal ferrite powder and a binding agent on the non-magnetic support, an XRD intensity ratio (Int(110) / Int(114)) of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, and a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

Method of preparing high orientation nanoparticle-containing sheets or films using ionic liquids, and the sheets or films produced thereby

InactiveUS7550520B2High magnetic anisotropyImprove signal-to-noise ratioNanostructure manufactureConductive materialNon solventMagnetite Nanoparticles

A method is provided for the preparation of nanomaterials, which involves the dissolution and / or suspension of a combination of (a) one or more resin substrate materials and (b) one or more magnetic nanoparticulate substances, in a medium made from one or more ionic liquids, to provide a mixture, and recovering the solid nanomaterial by combining the mixture with a non-solvent (solvent for the ionic liquids but not the other components), while also applying an electromagnetic field to the mixture during the recovering step to align the magnetic nanoparticulate substances, along with the use of the resulting nanomaterials to provide unique information storage media, particularly in the form of sheets or films.

Owner:UNIVERSITY OF ALABAMA +1

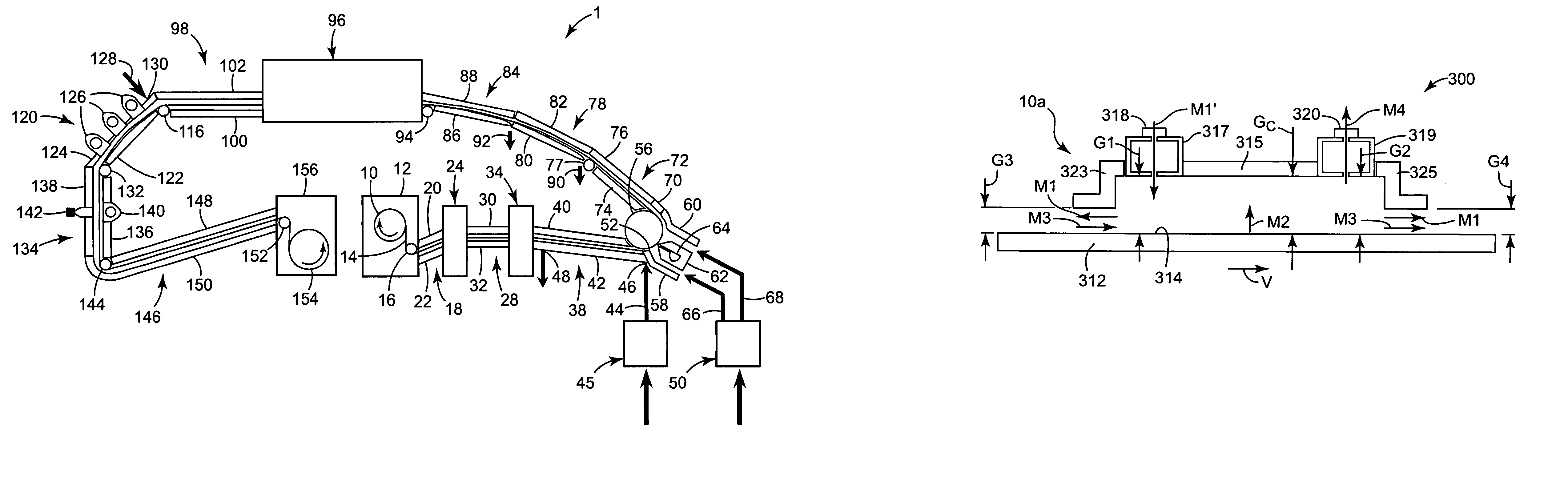

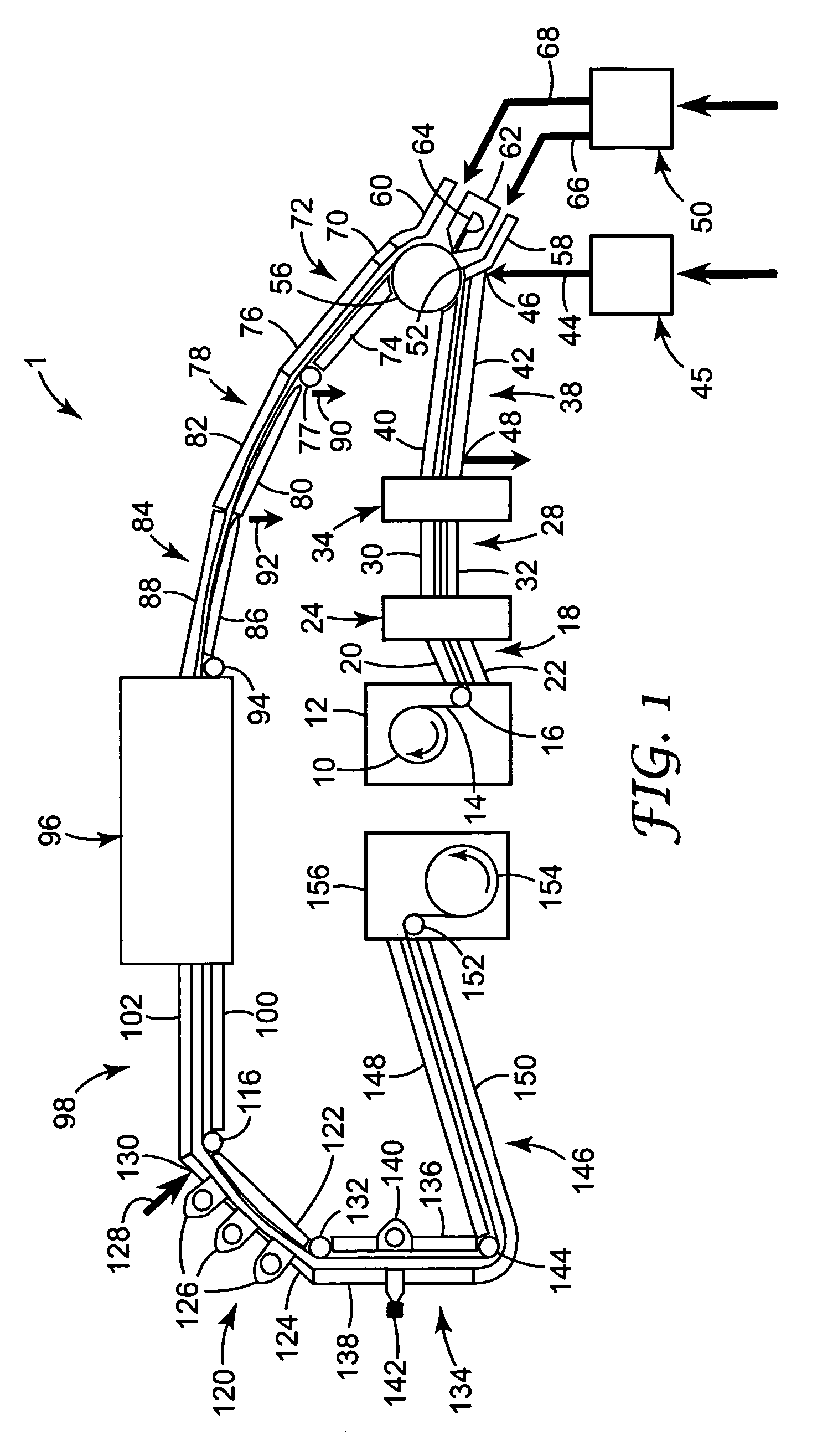

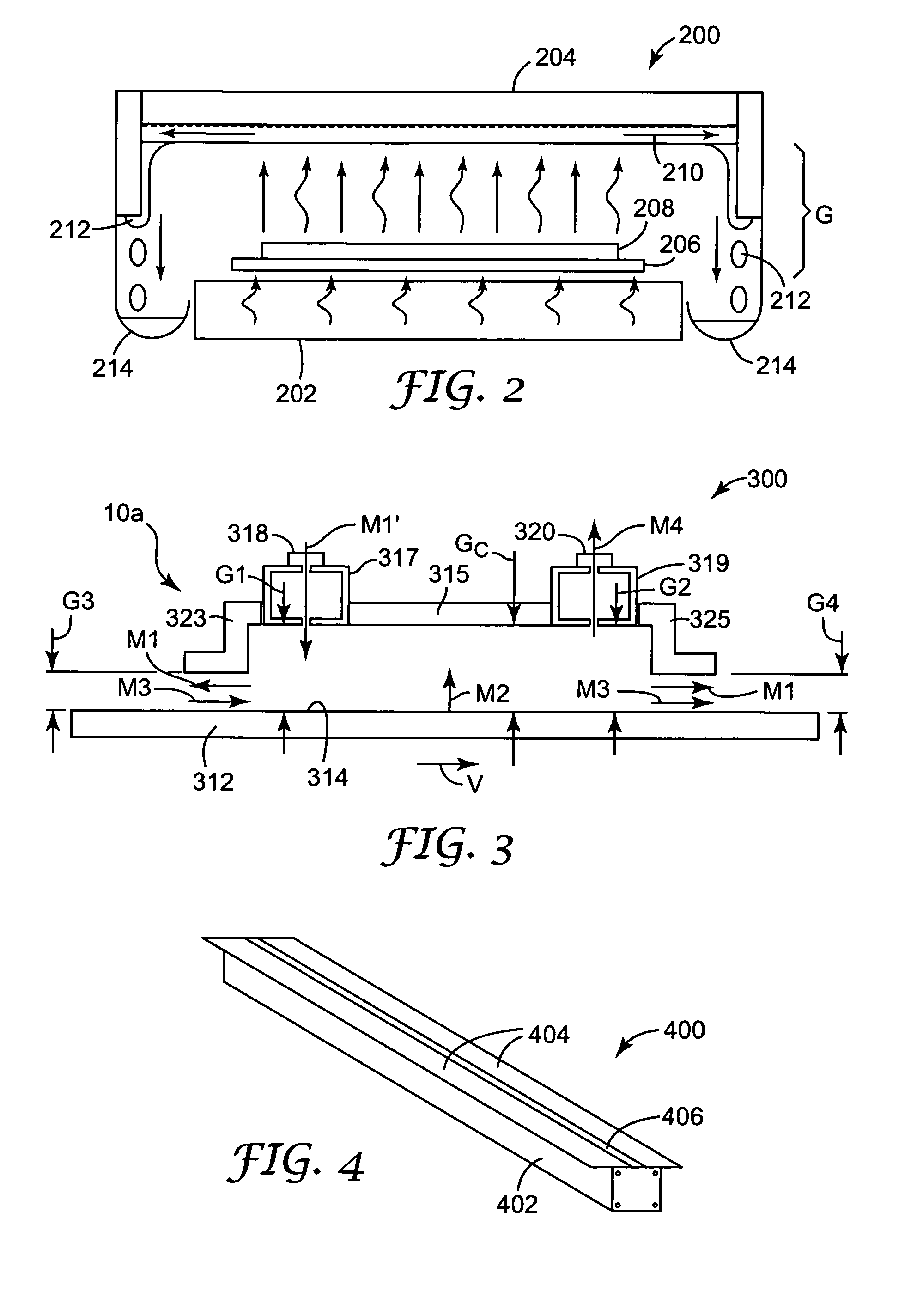

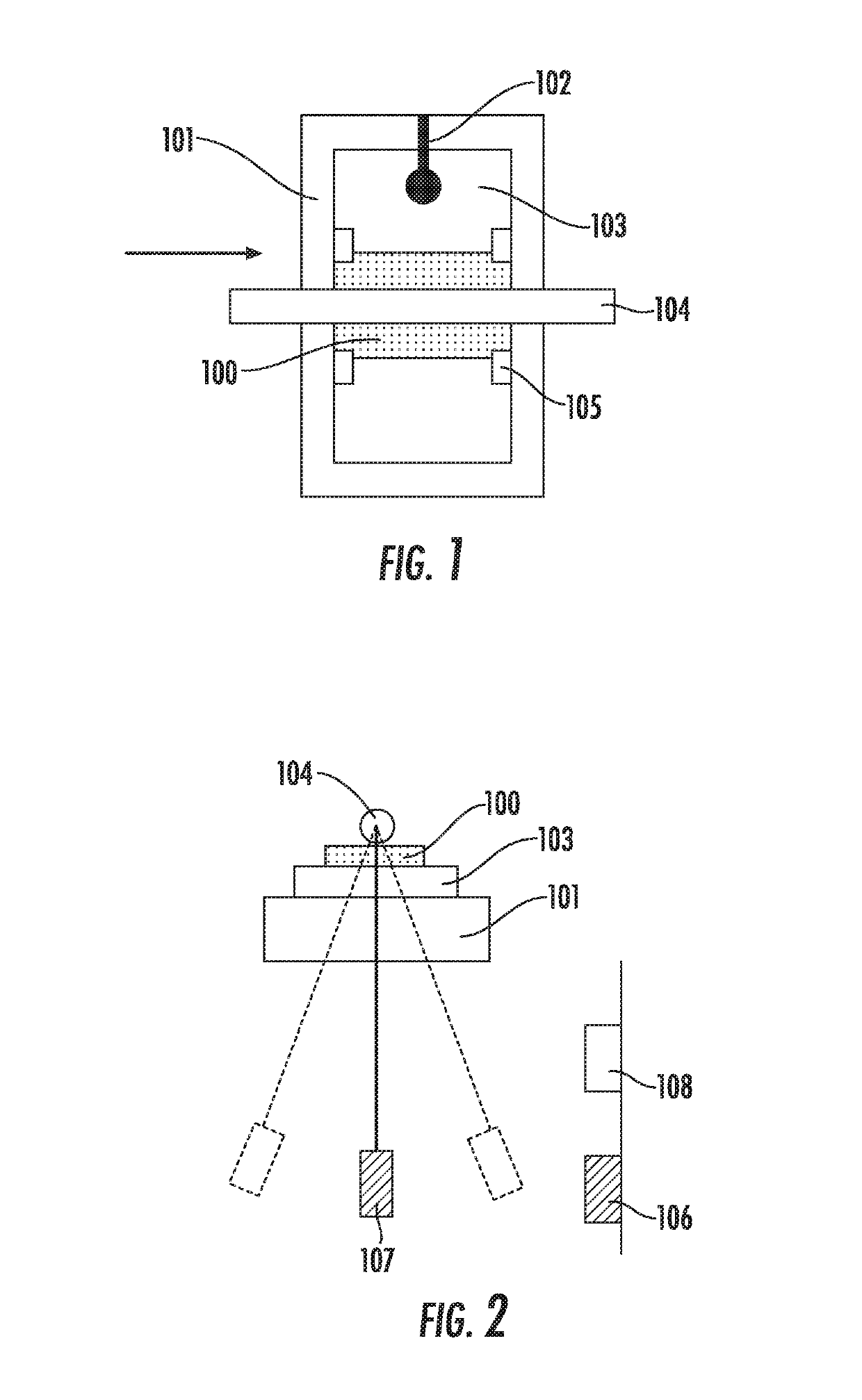

Coating process and apparatus

InactiveUS7032324B2Drying using combination processesDrying solid materials with heatEngineeringWeb handling

A web coating process and apparatus employing a coating applicator, dryer or curing station and web-handling equipment for conveying the web past the coating applicator and through the dryer. The web is enclosed from at least the coating applicator to the dryer or curing station in a close-coupled enclosure or series of close-coupled enclosures supplied with one or more streams of conditioned gas flowing at a rate sufficient to reduce materially the particle count or change materially a physical property of interest in a close-coupled enclosure.

Owner:3M INNOVATIVE PROPERTIES CO

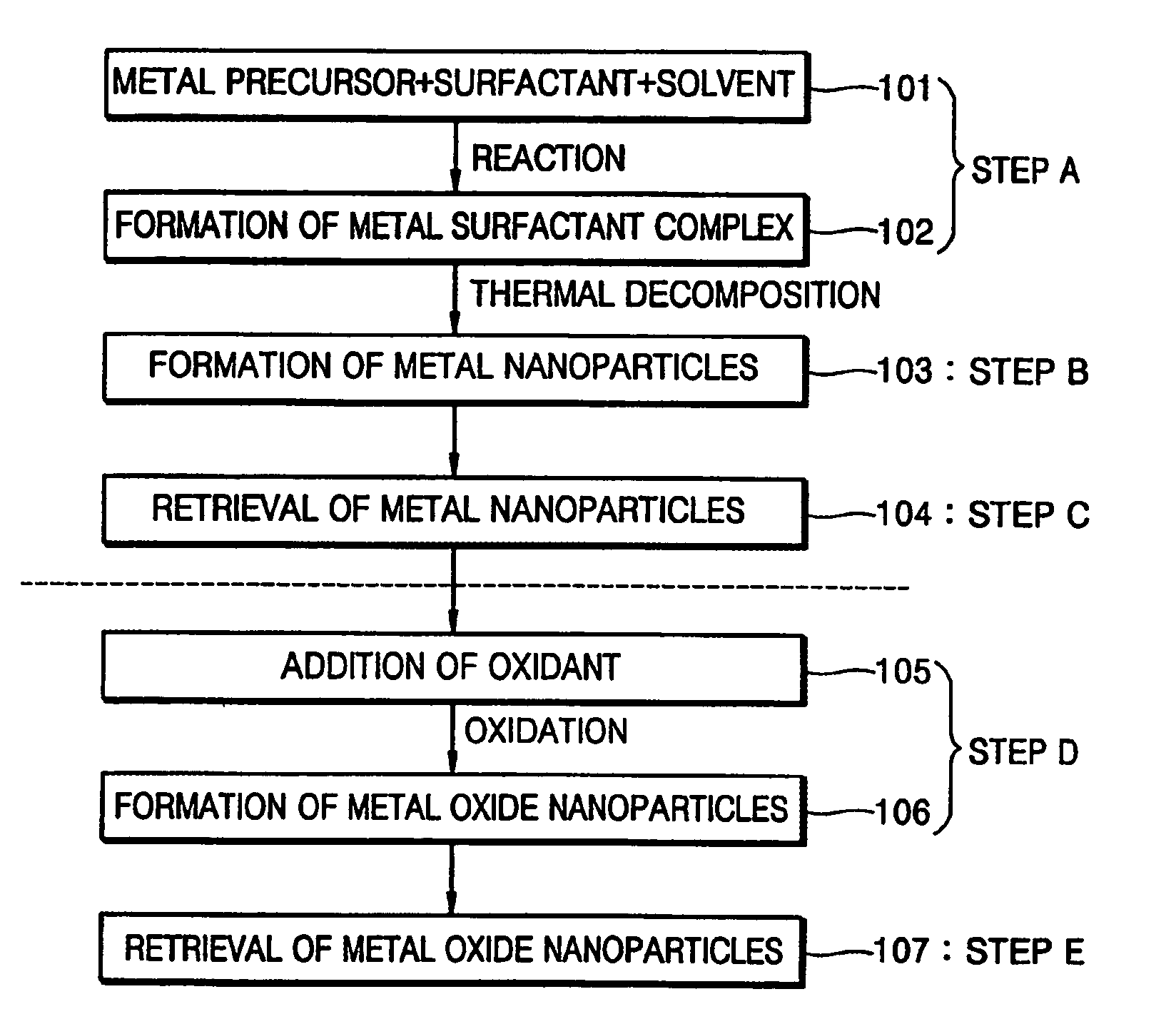

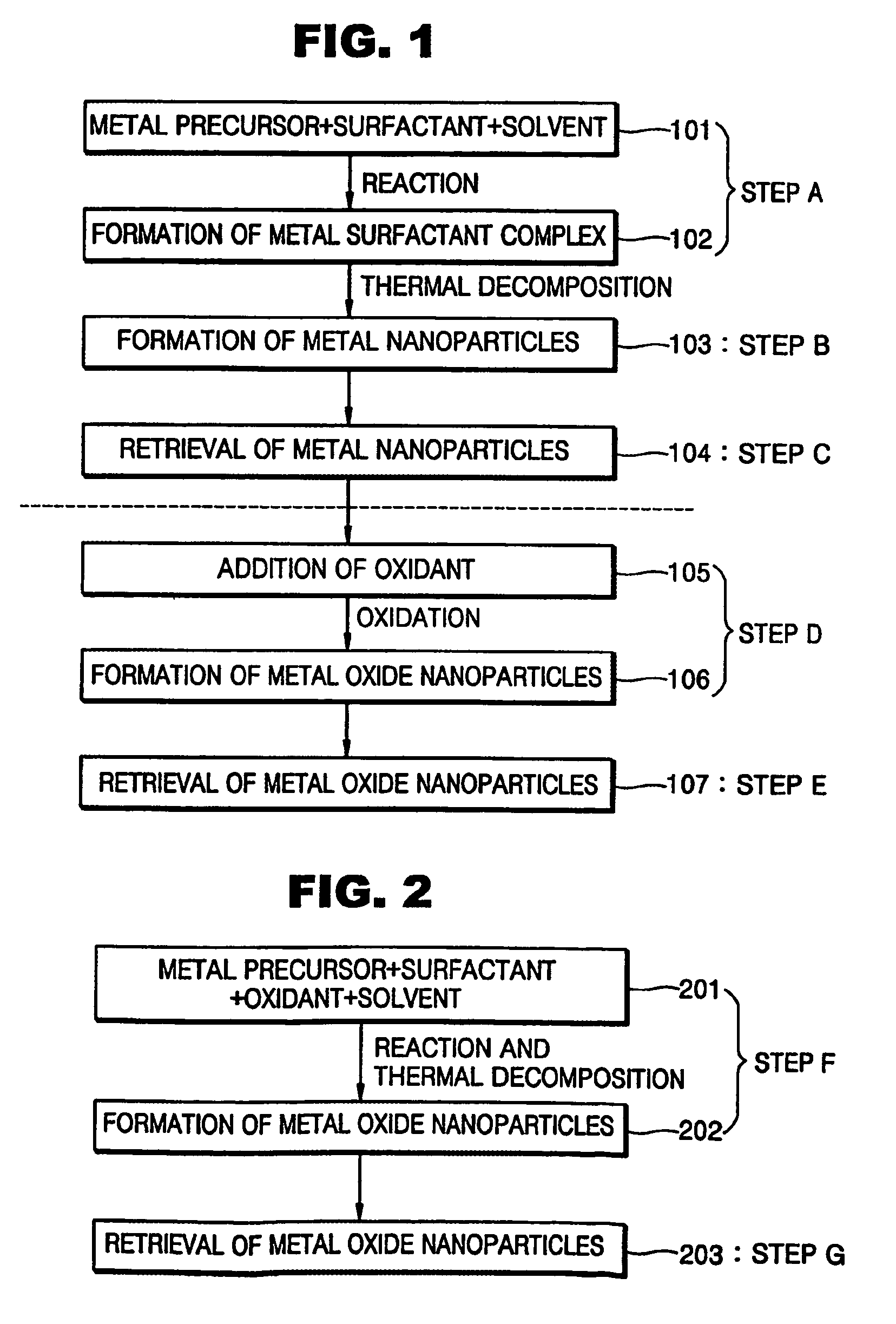

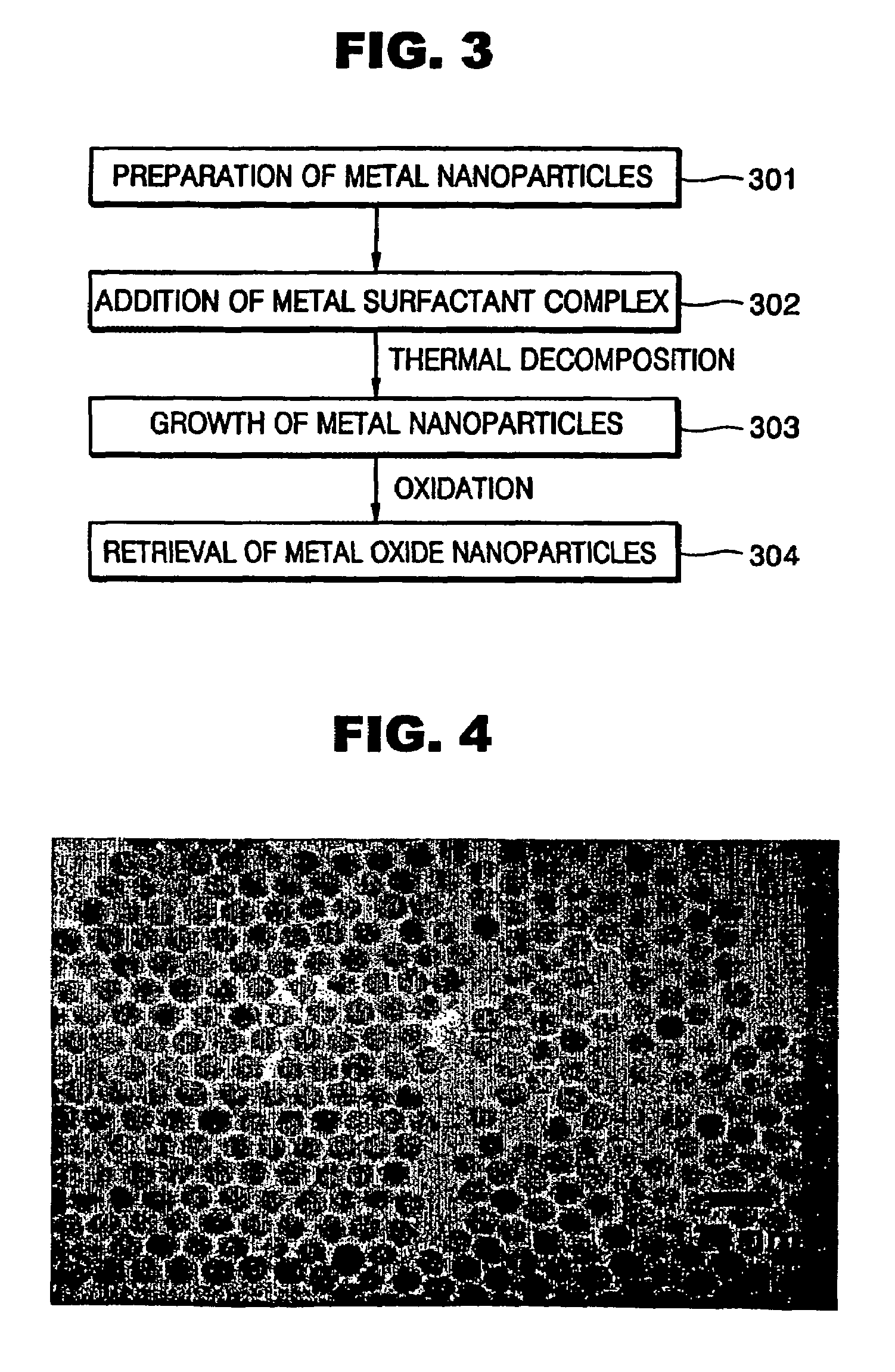

Synthesis of mono-disperse and highly crystalline nano-particles of metals, alloys, metal-oxides, and multi-metallic oxides without a size-selection process

InactiveUS7407527B2Sufficient reaction timeInduce precipitationMaterial nanotechnologyOxygen/ozone/oxide/hydroxideMetal oxide nanoparticlesSynthesis methods

A synthetic method of fabricating highly crystalline and monodisperse nanoparticles of metals, multi-metallic alloys, monometallic oxides and multi-metallic oxides without a size selection process are disclosed. A typical synthetic method comprises the steps of, synthesis of a metal surfactant complex from the reaction of a metal precursor and a surfactant, high temperature thermal decomposition of the metal surfactant complex to produce monodisperse metal nanoparticles, and completing the formation of synthesized metal, metal alloy or metal oxide nanoparticles by adding a poor solvent followed by centrifuging. For obtaining highly crystalline monodisperse nanoparticles, additional steps are necessary as described in the invention. The resulting nanoparticles have excellent magnetic property for many applications.

Owner:SEOUL NAT UNIV R&DB FOUND

Magnetic tape device and magnetic reproducting method employing TMR head and tape with characterized magnetic layer

ActiveUS10573338B2Increase resistanceReduce resistanceMagnetic materials for record carriersBase layers for recording layersMagnetic force microscopeMagnetic tape

Owner:FUJIFILM CORP

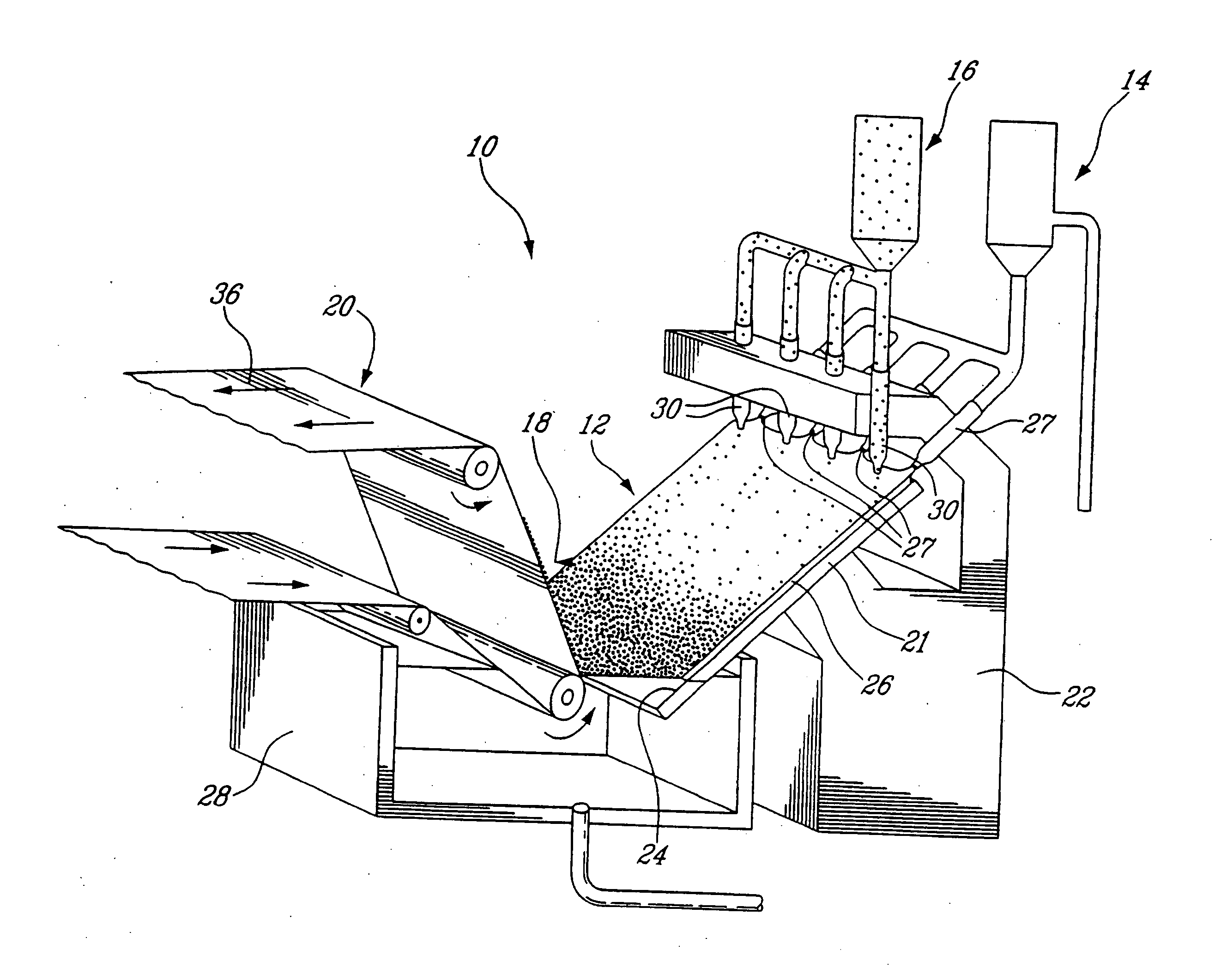

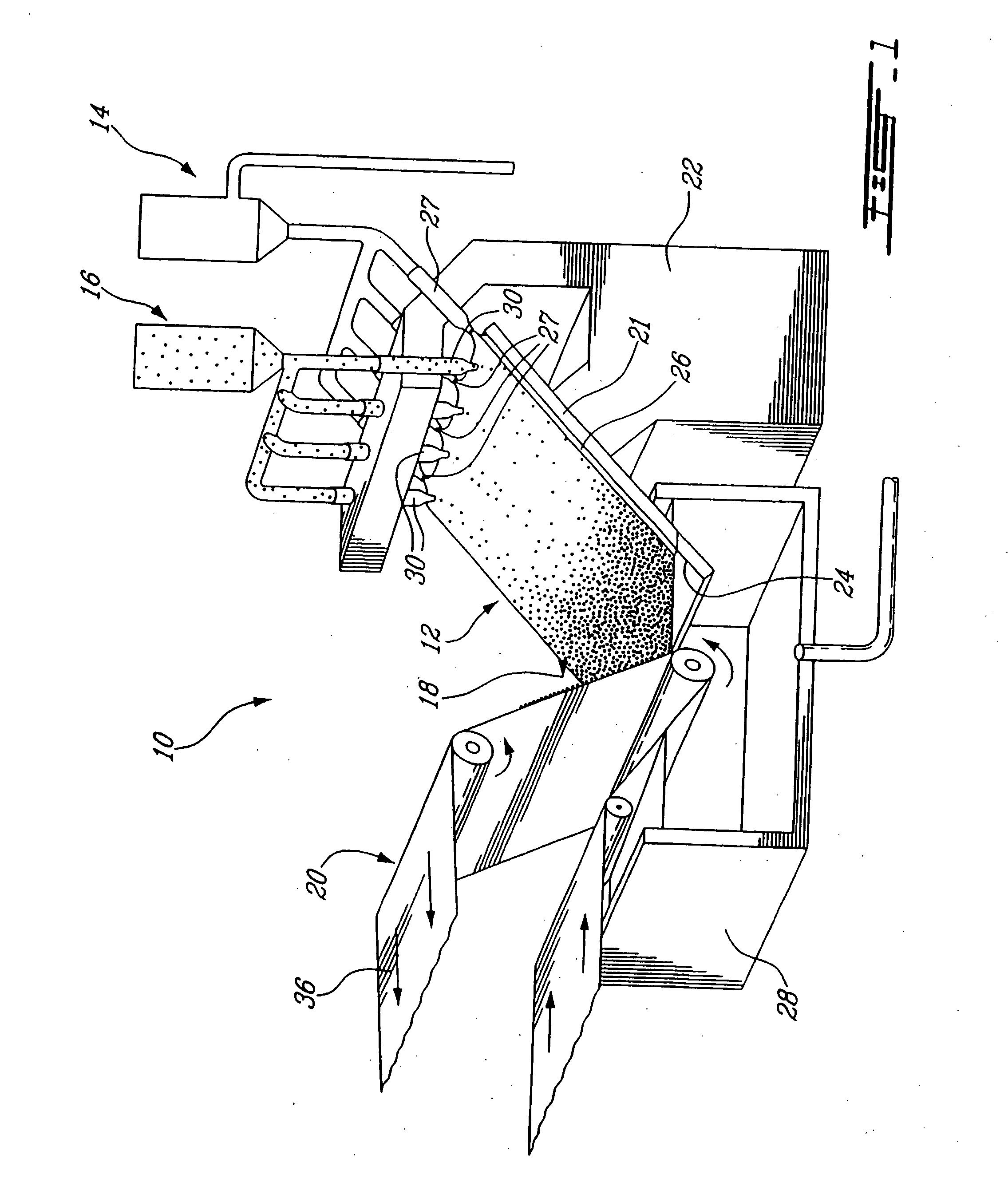

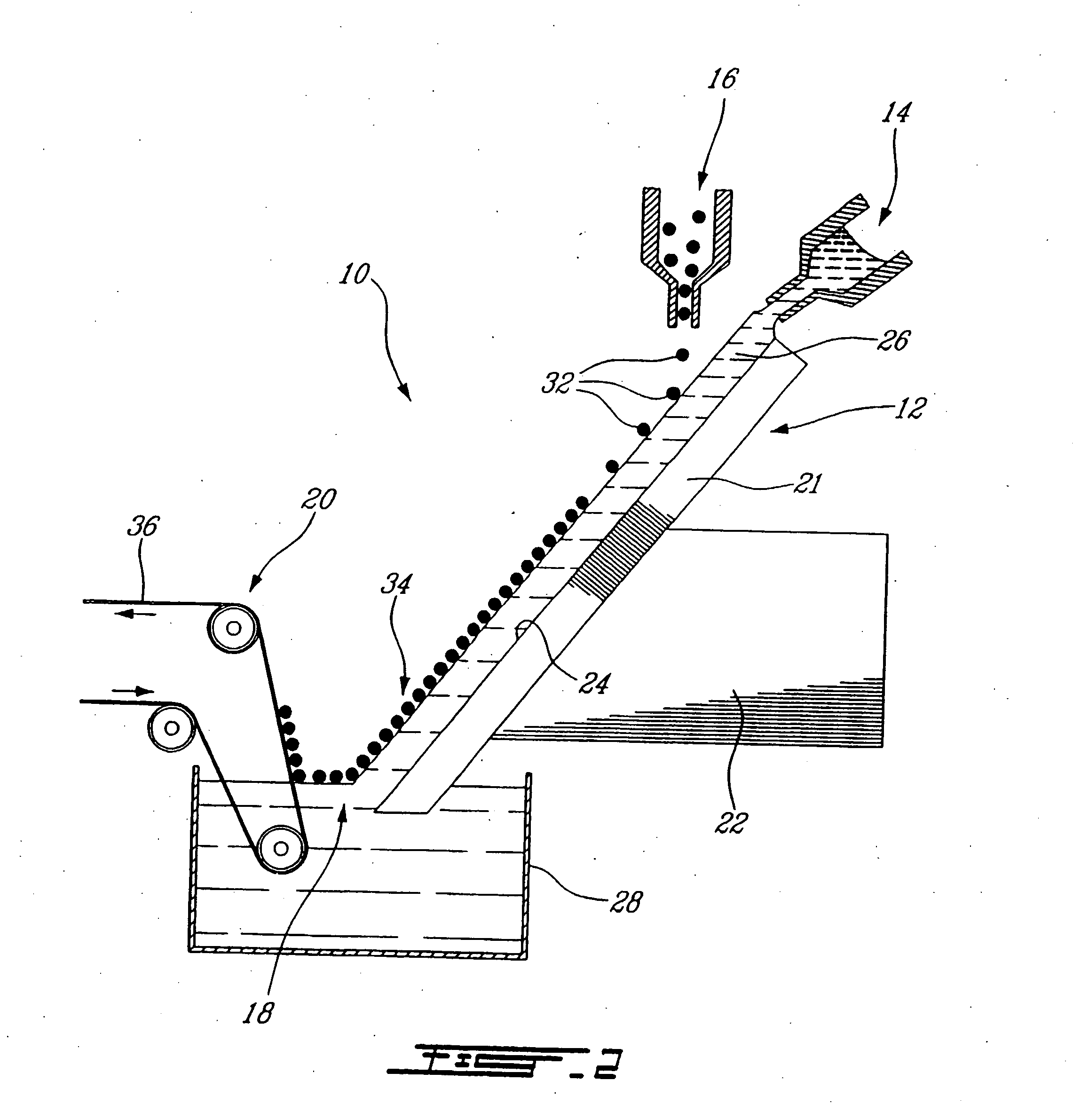

Method and apparatus for two dimensional assembly of particles

InactiveUS20050129867A1Provide flexibilityEasy production controlSemi-permeable membranesLiquid surface applicatorsThin layerEngineering

A method and an apparatus (10) for making thin layers from particles, wherein the particles are deposited on a carrier fluid flowing by gravity along a ramp (12) leading to a dam (18). The particles are held back at the bottom of the ramp (12), thereby causing the particles to be piled up one against the other in a monolayer configuration.

Owner:VERSATILIS

Magnetic tape device with magnetic tape having particular C-H derived C concentration and magnetic reproducing method

ActiveUS10438628B2Avoiding characteristicReduce resistanceMagnetic materials for record carriersBase layers for recording layersMagnetic tapeX-ray

The magnetic tape device includes: a magnetic tape; and a reproducing head, in which a magnetic tape transportation speed of the magnetic tape device is equal to or lower than 18 m / sec, the reproducing head is a magnetic head including a tunnel magnetoresistance effect type element as a reproducing element, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the magnetic layer includes one or more components selected from the group consisting of fatty acid and fatty acid amide, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %.

Owner:FUJIFILM CORP

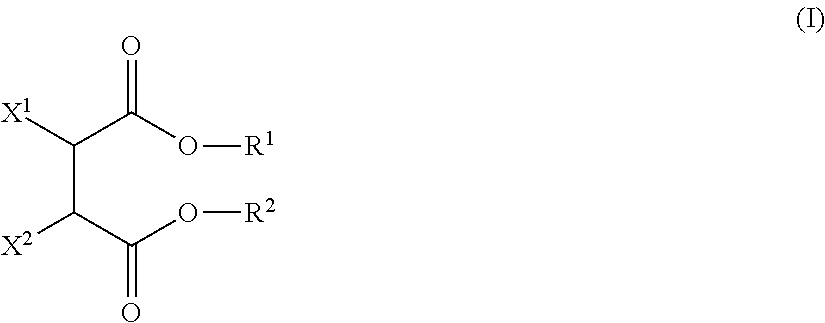

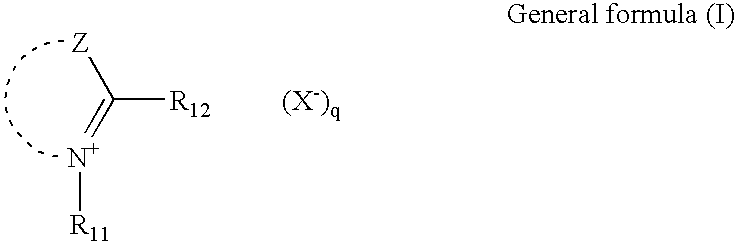

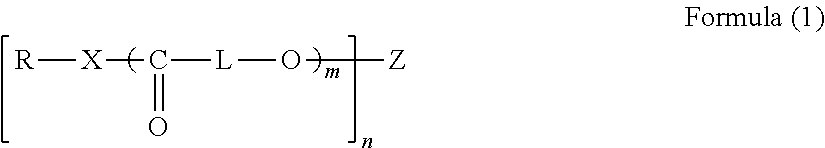

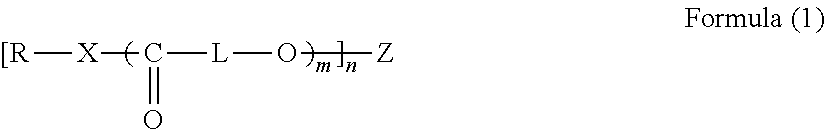

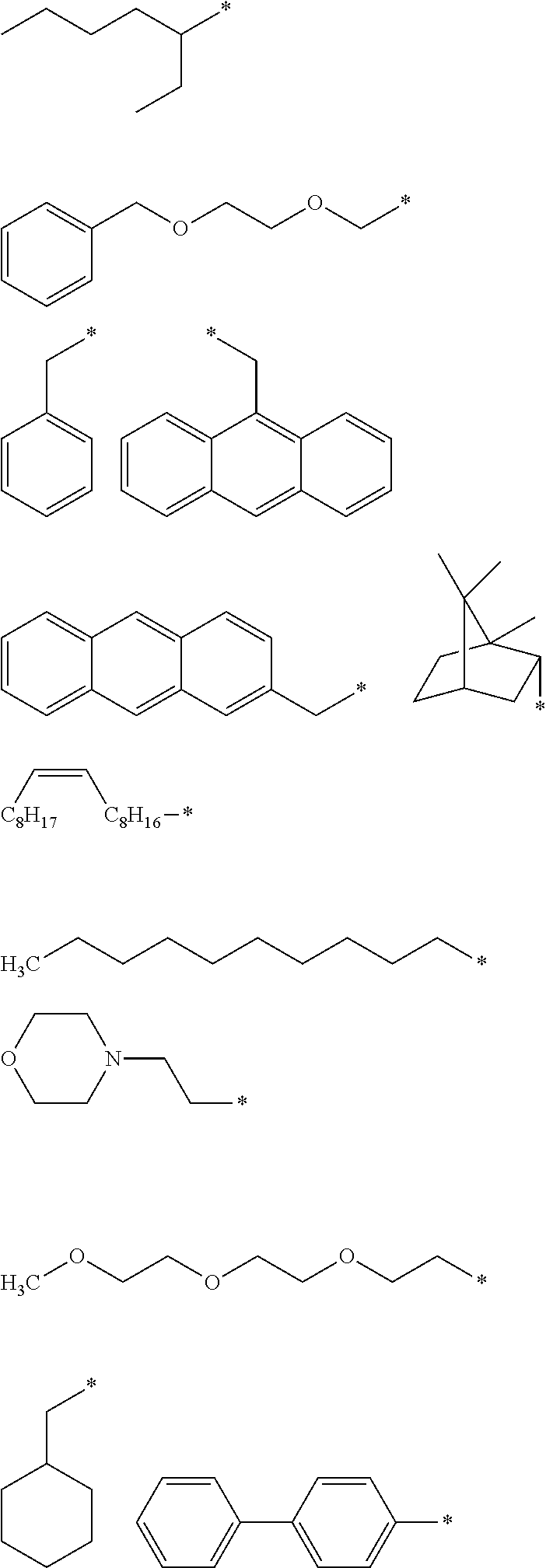

Metal oxide particle dispersion for manufacturing particulate magnetic recording medium, method of manufacturing magnetic layer-forming composition of particulate magnetic recording medium and method of manufacturing particulate magnetic recording medium

ActiveUS20170092316A1Avoid changeNovel featuresMagnetic liquidsRecord information storagePolyesterParticulates

The metal oxide particle dispersion for manufacturing a particulate magnetic recording medium contains metal oxide particles, solvent, and a polyester compound having one or more groups selected from the group consisting of a carboxyl group and a salt thereof, a phosphoric acid group and a salt thereof, a hydroxyl group and a nitrogen-substituted alkylene group, but substantially not containing ferromagnetic powder.

Owner:FUJIFILM CORP

Method of preparing high orientation nanoparticle-containing sheets or films using ionic liquids, and the sheets or films produced thereby

InactiveUS20060269695A1High magnetic anisotropyImprove signal-to-noise ratioNanostructure manufactureConductive materialNon solventMagnetite Nanoparticles

A method is provided for the preparation of nanomaterials, which involves the dissolution and / or suspension of a combination of (a) one or more resin substrate materials and (b) one or more magnetic nanoparticulate substances, in a medium made from one or more ionic liquids, to provide a mixture, and recovering the solid nanomaterial by combining the mixture with a non-solvent (solvent for the ionic liquids but not the other components), while also applying an electromagnetic field to the mixture during the recovering step to align the magnetic nanoparticulate substances, along with the use of the resulting nanomaterials to provide unique information storage media, particularly in the form of sheets or films.

Owner:UNIVERSITY OF ALABAMA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com