Patents

Literature

333 results about "Tunnel magnetoresistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

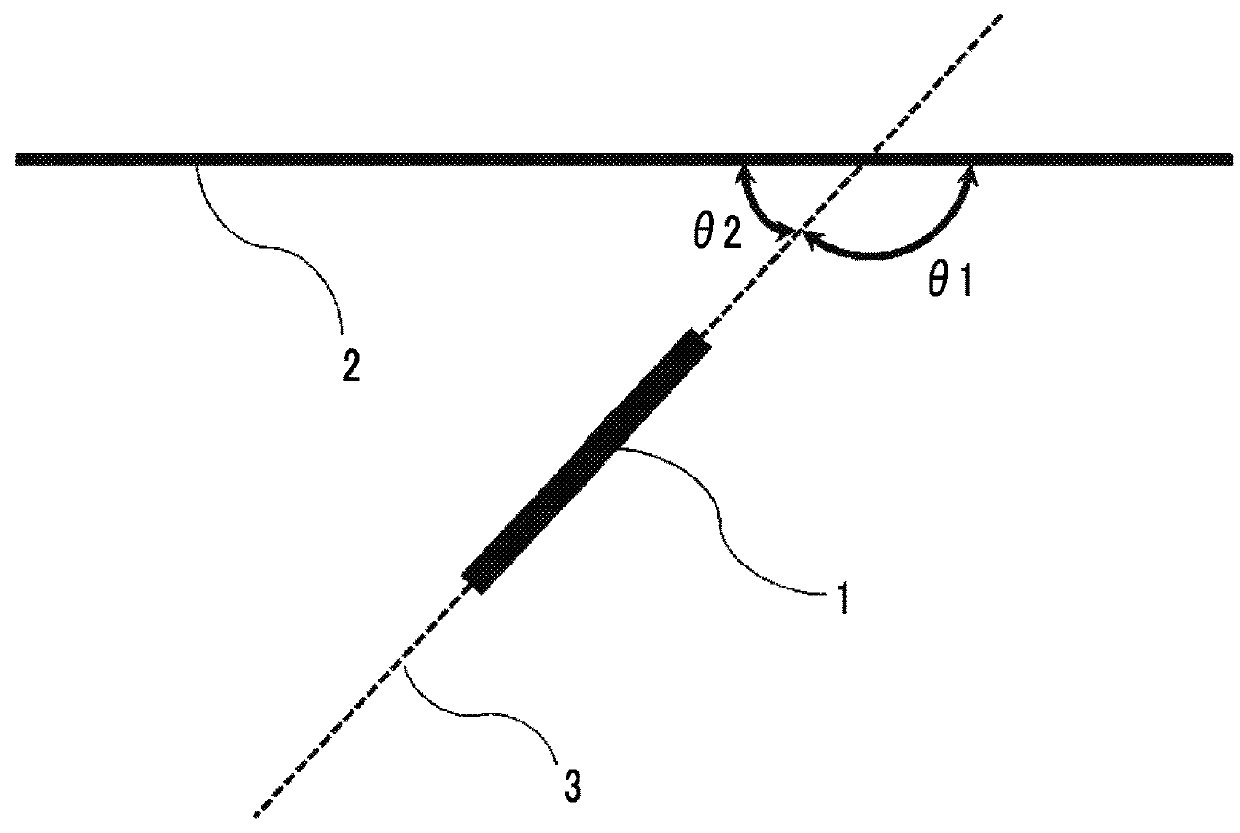

Tunnel magnetoresistance (TMR) is a magnetoresistive effect that occurs in a magnetic tunnel junction (MTJ), which is a component consisting of two ferromagnets separated by a thin insulator. If the insulating layer is thin enough (typically a few nanometres), electrons can tunnel from one ferromagnet into the other. Since this process is forbidden in classical physics, the tunnel magnetoresistance is a strictly quantum mechanical phenomenon.

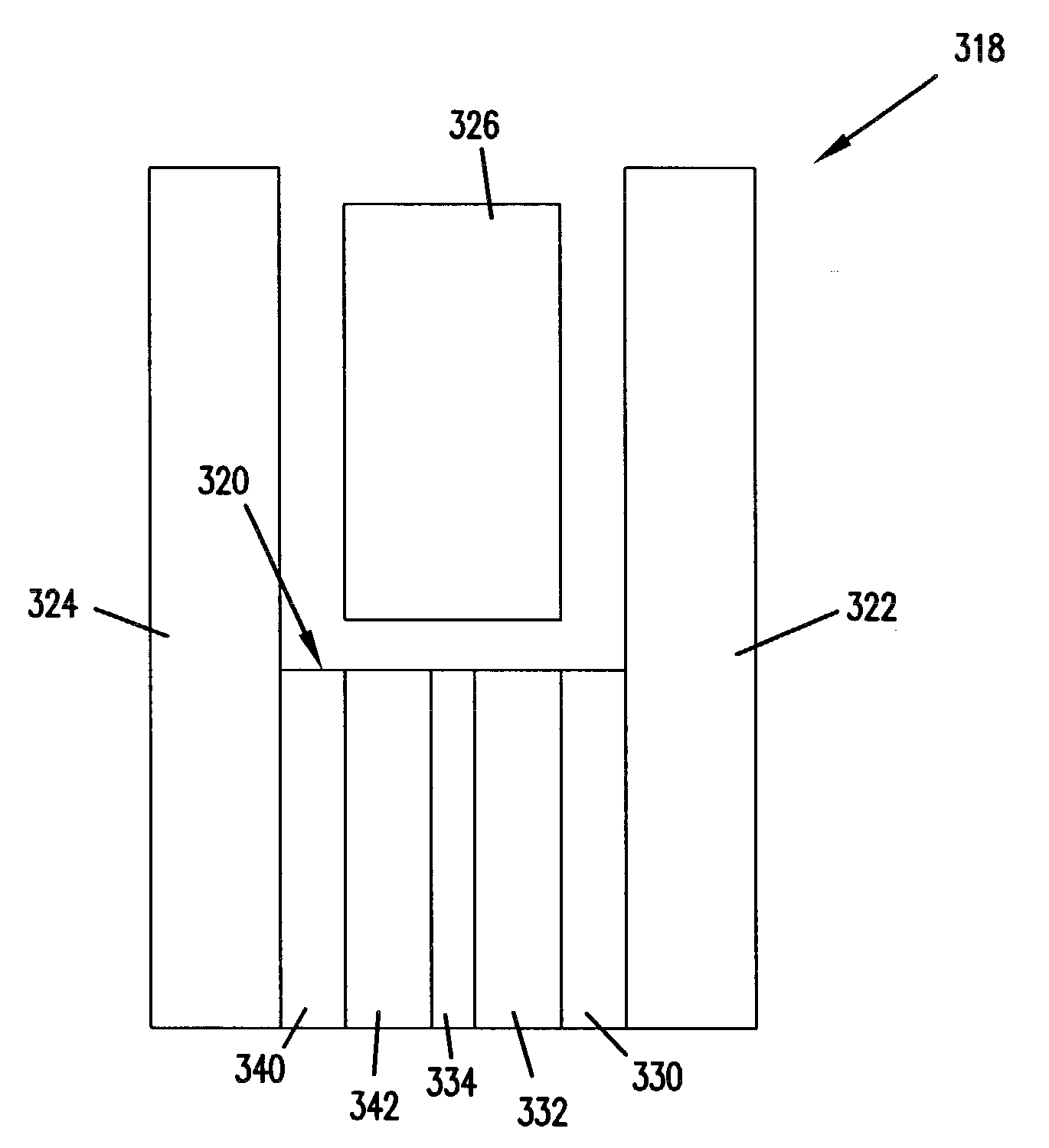

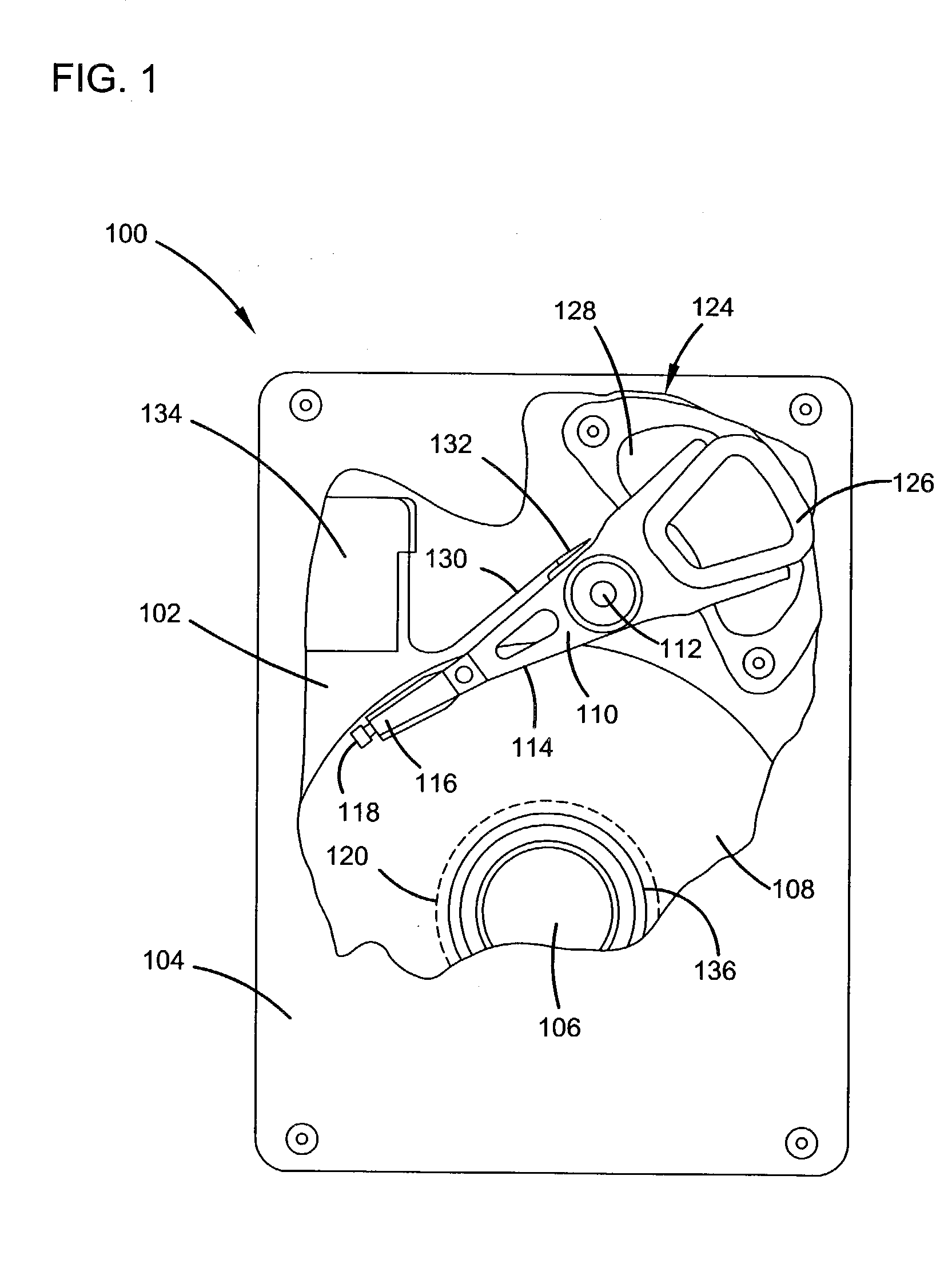

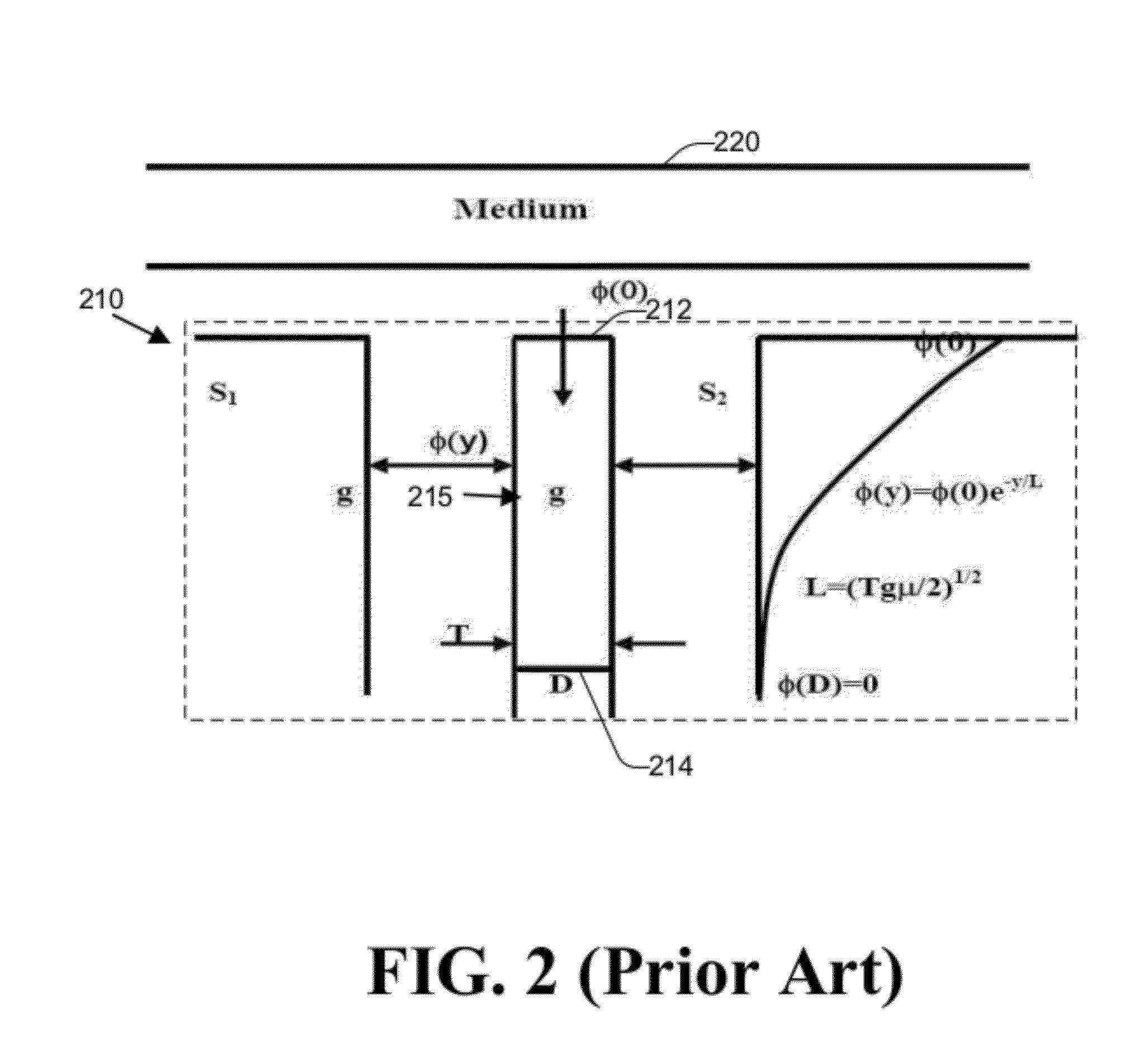

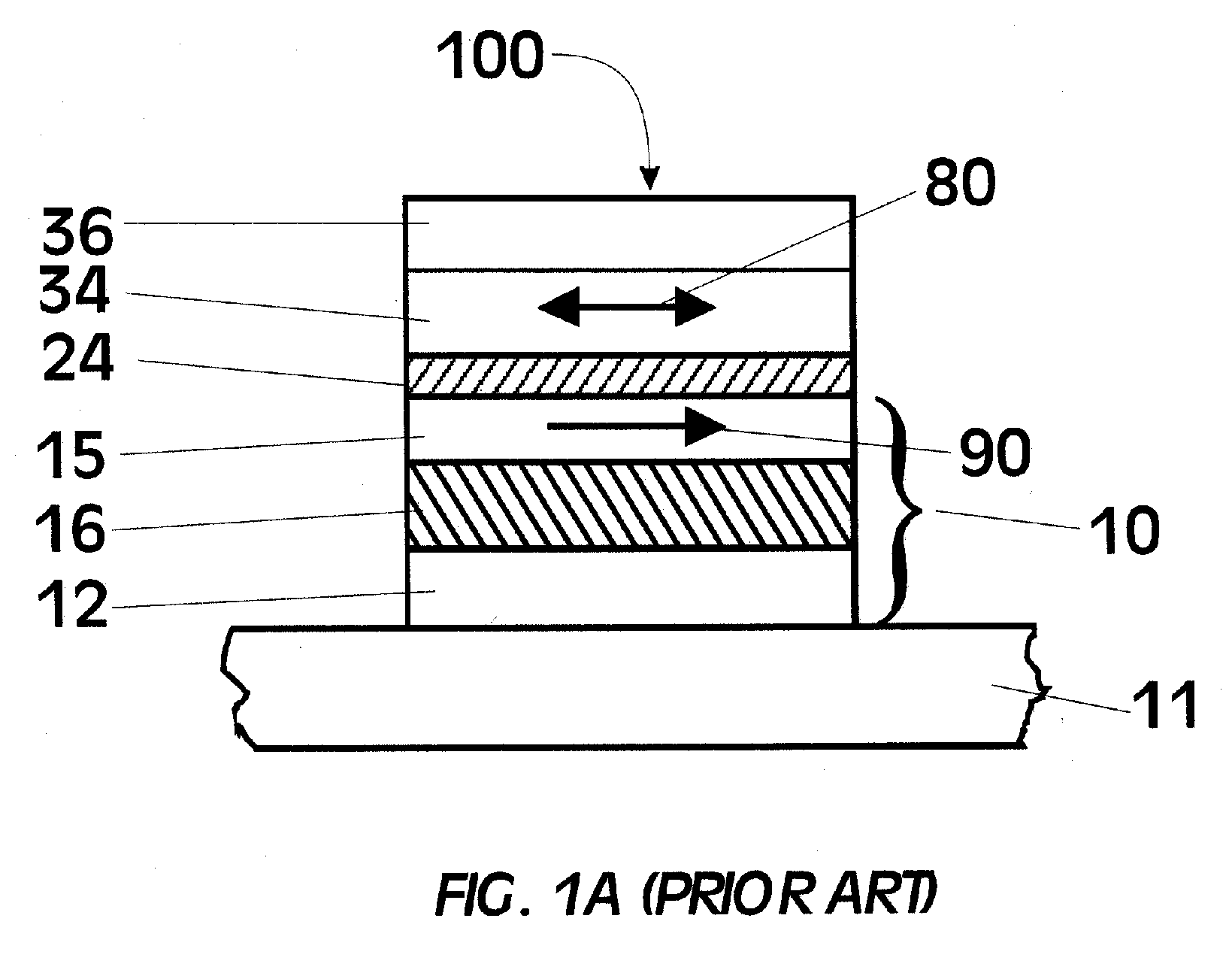

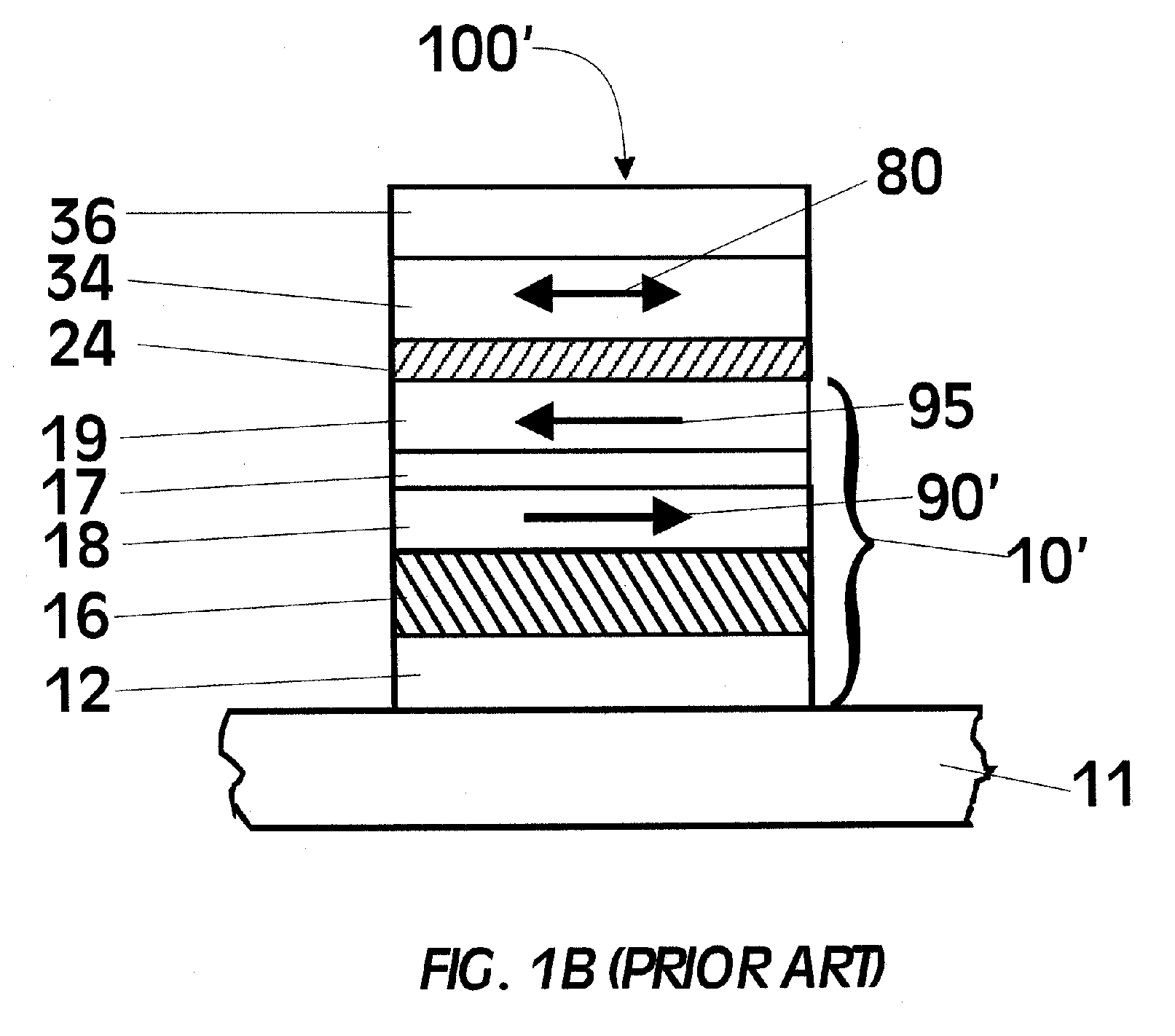

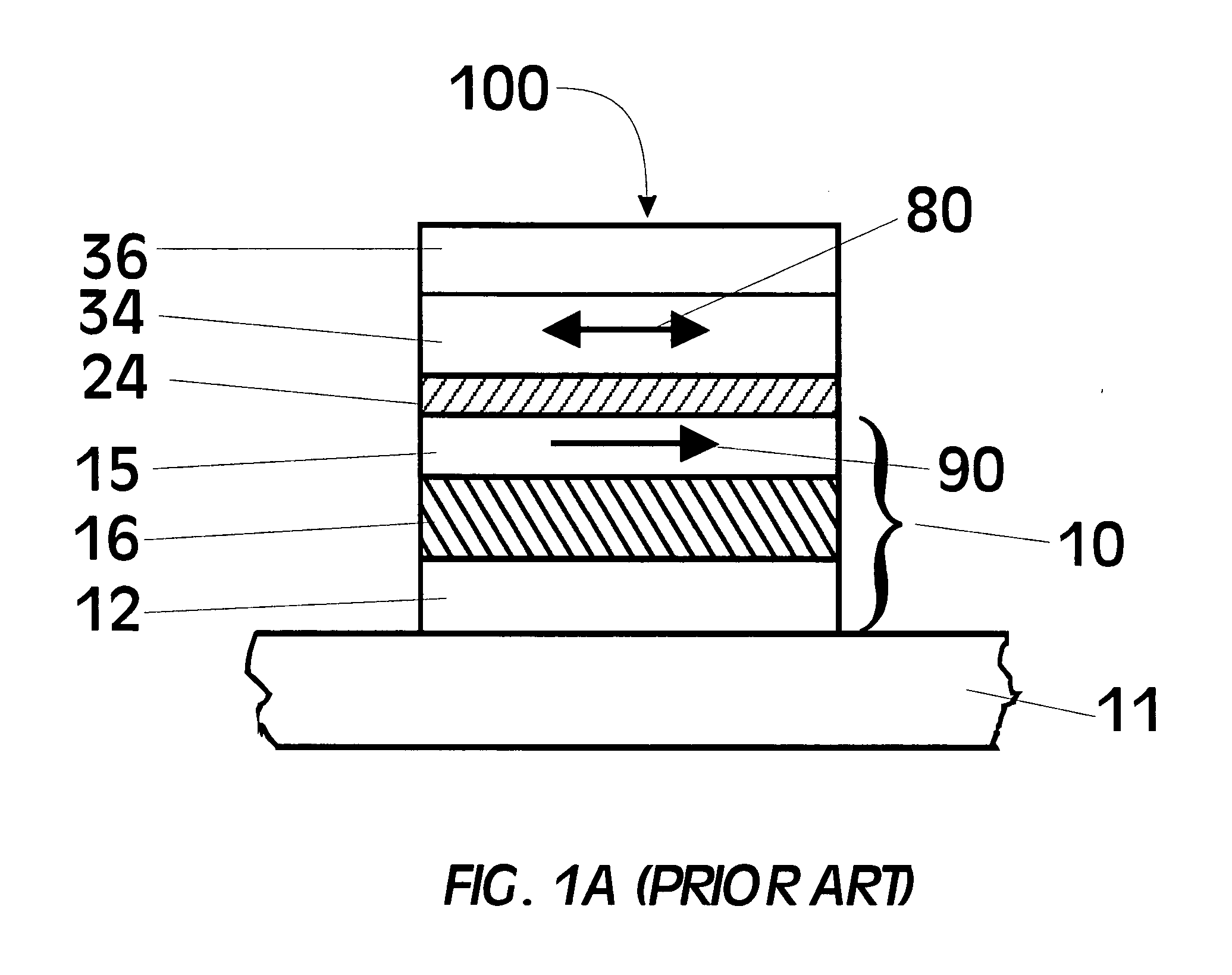

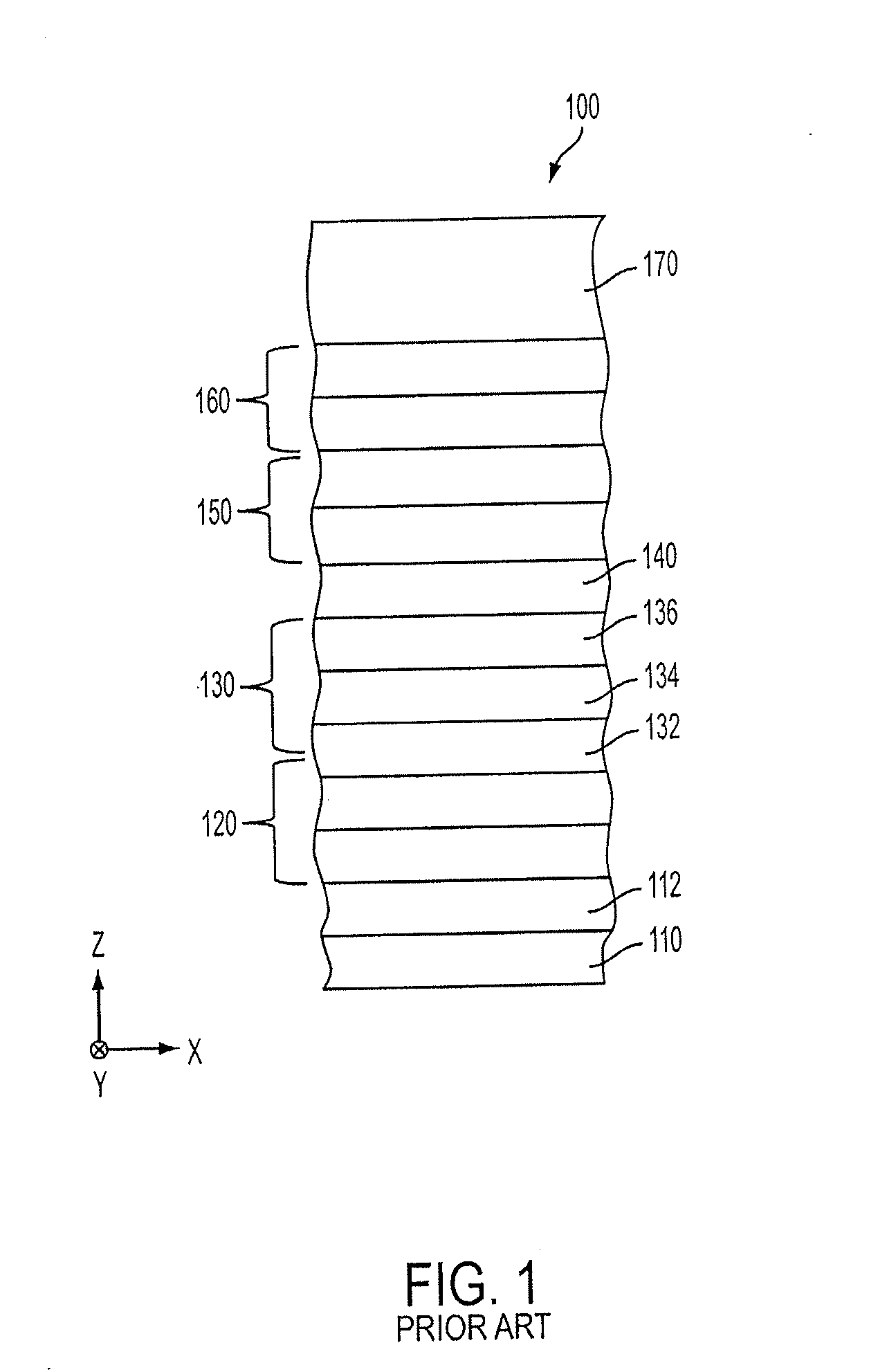

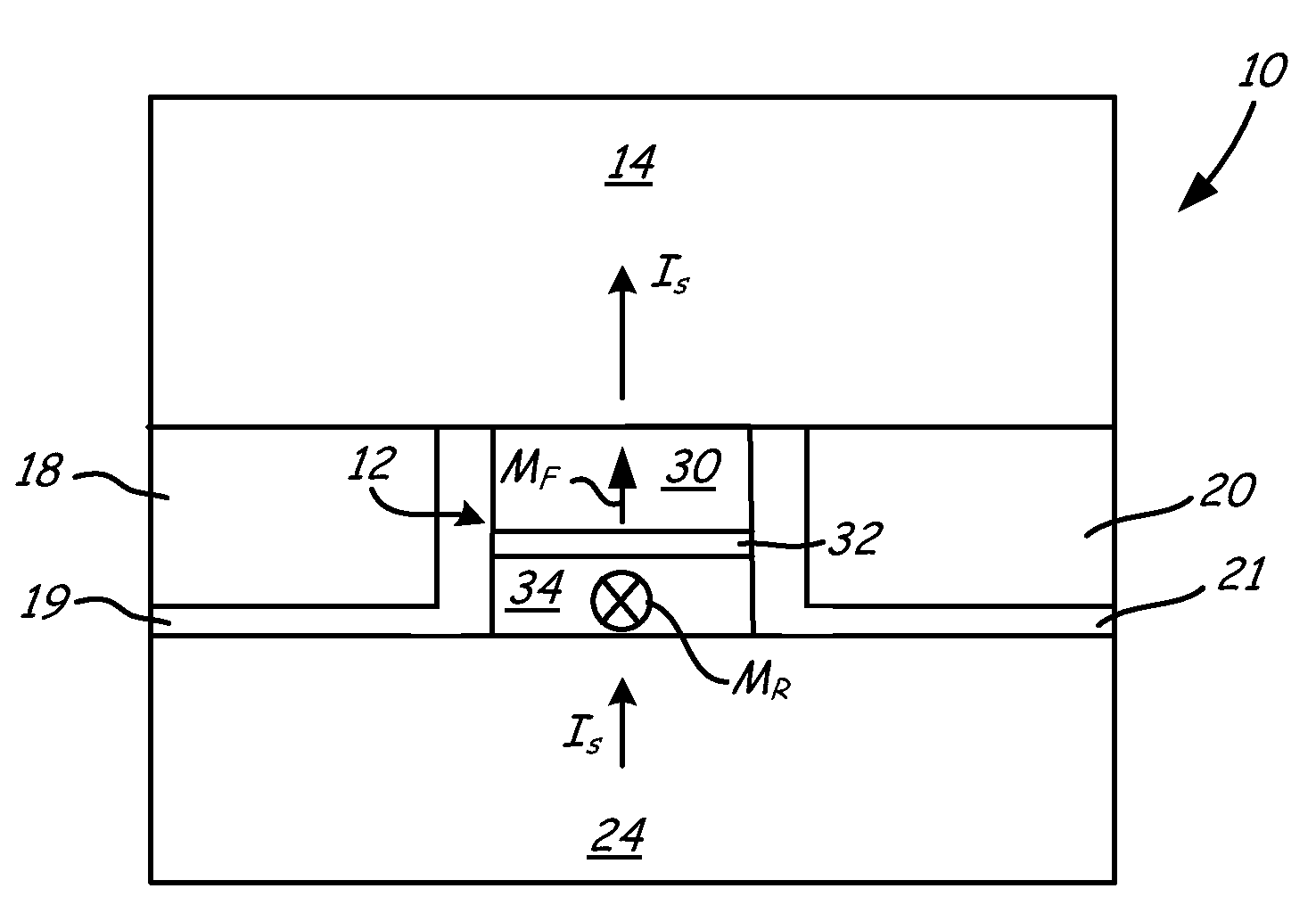

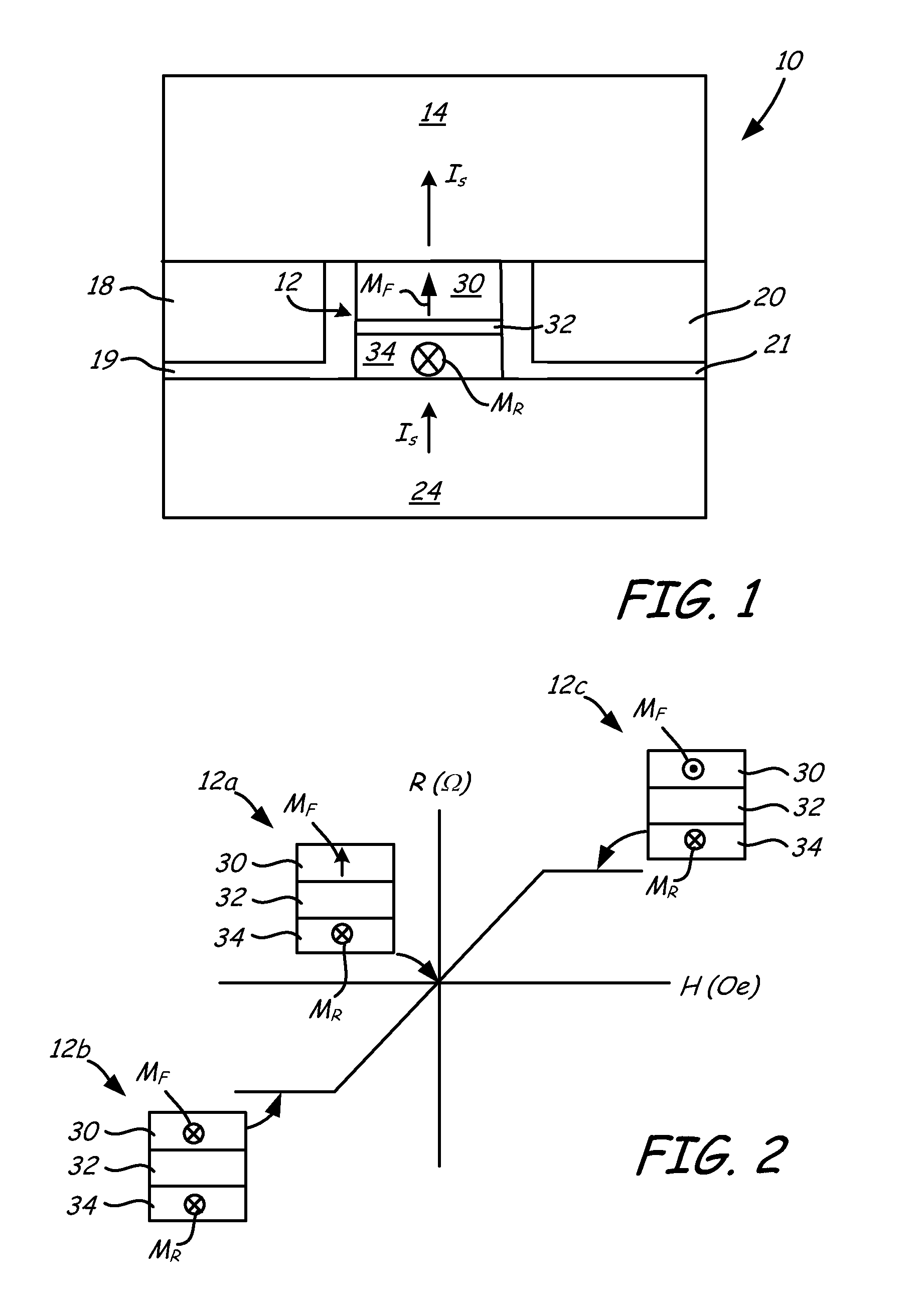

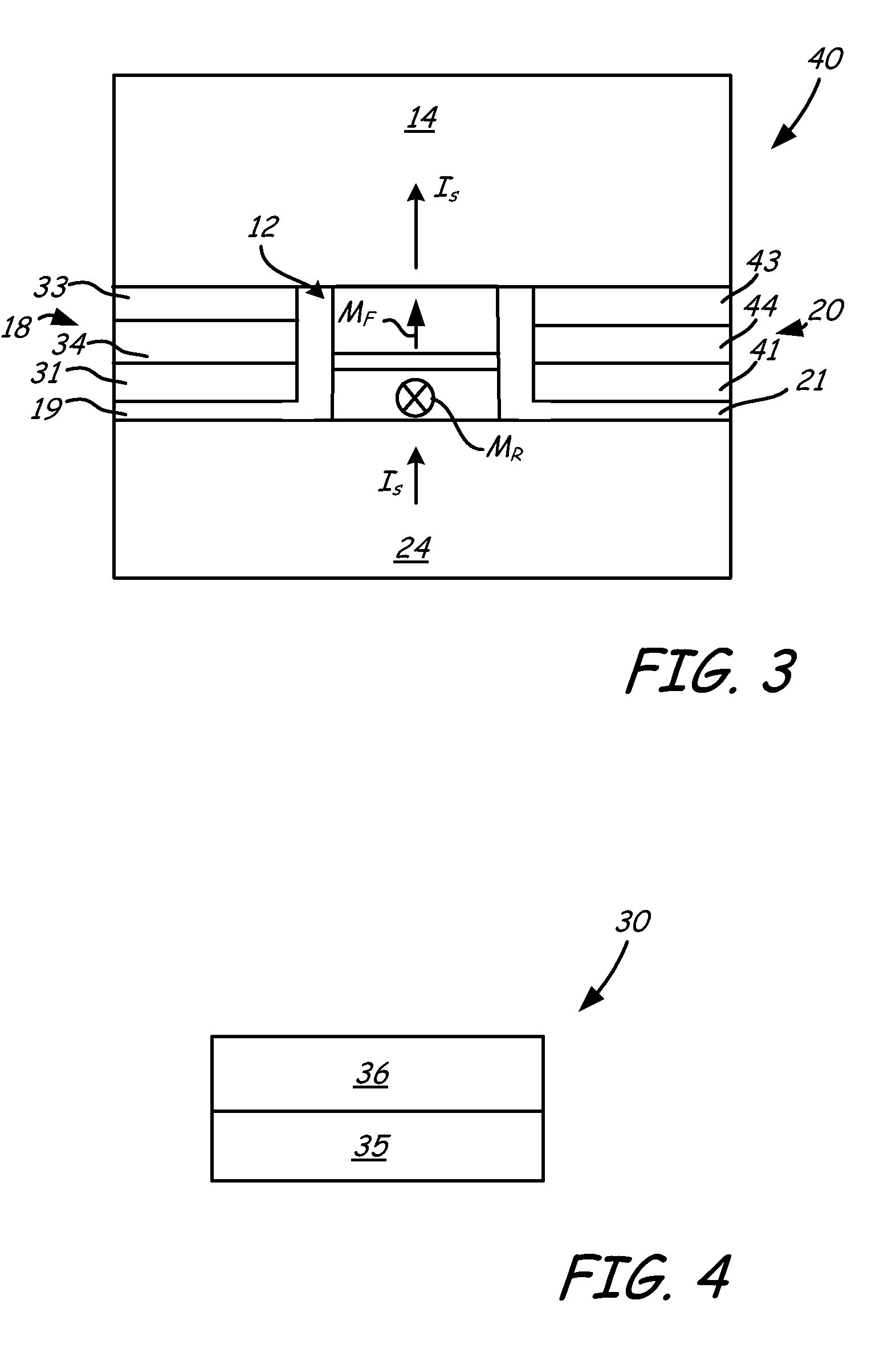

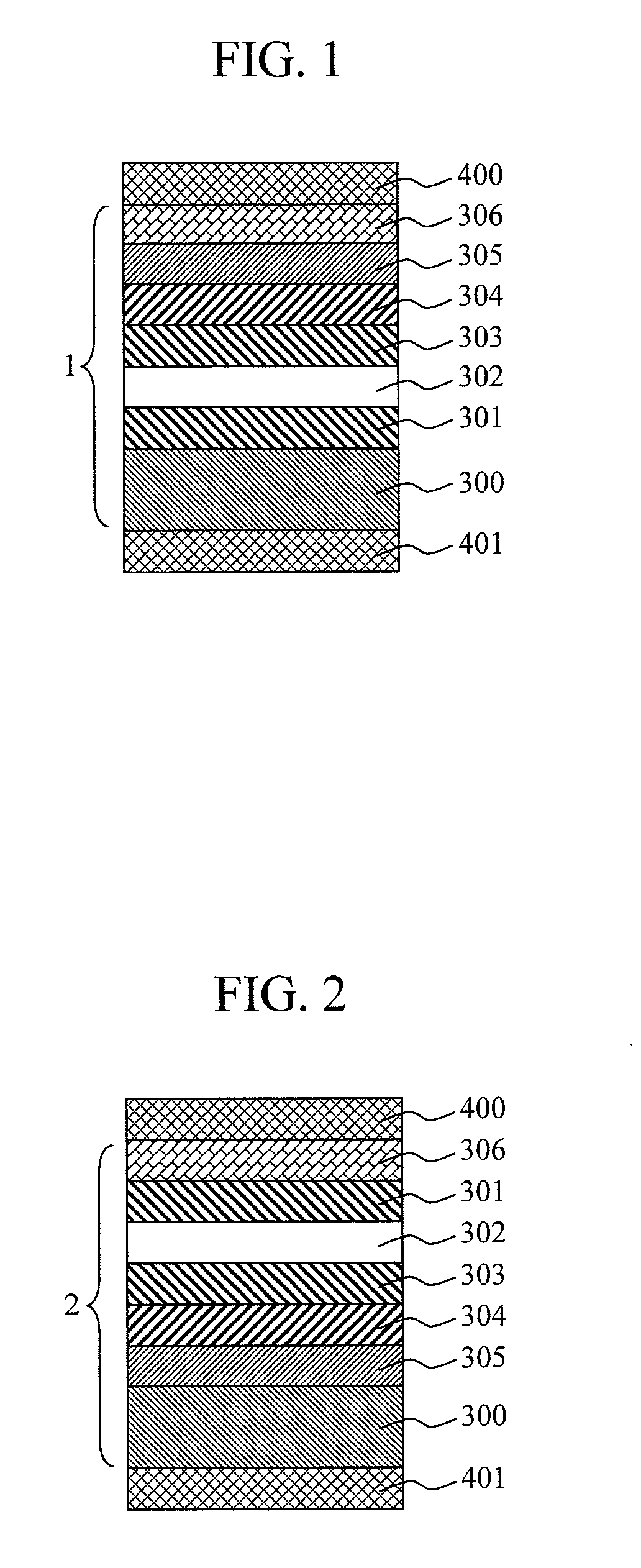

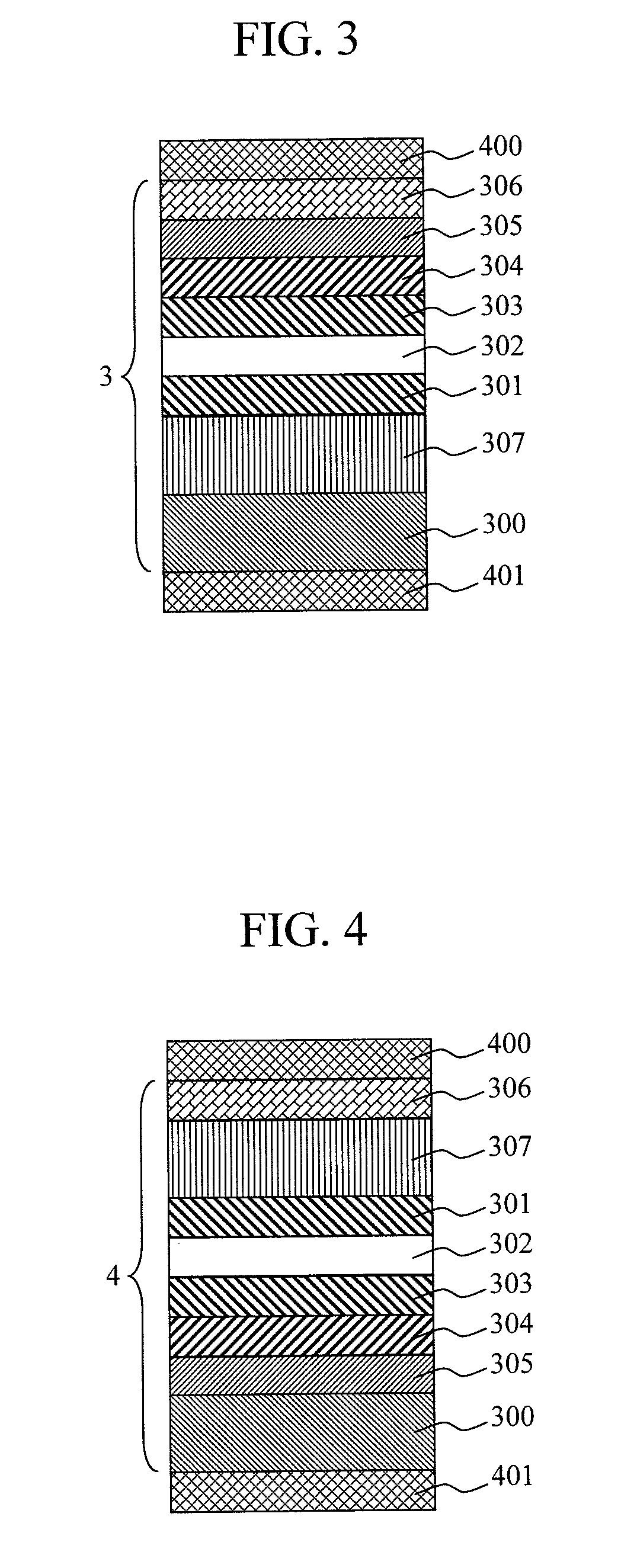

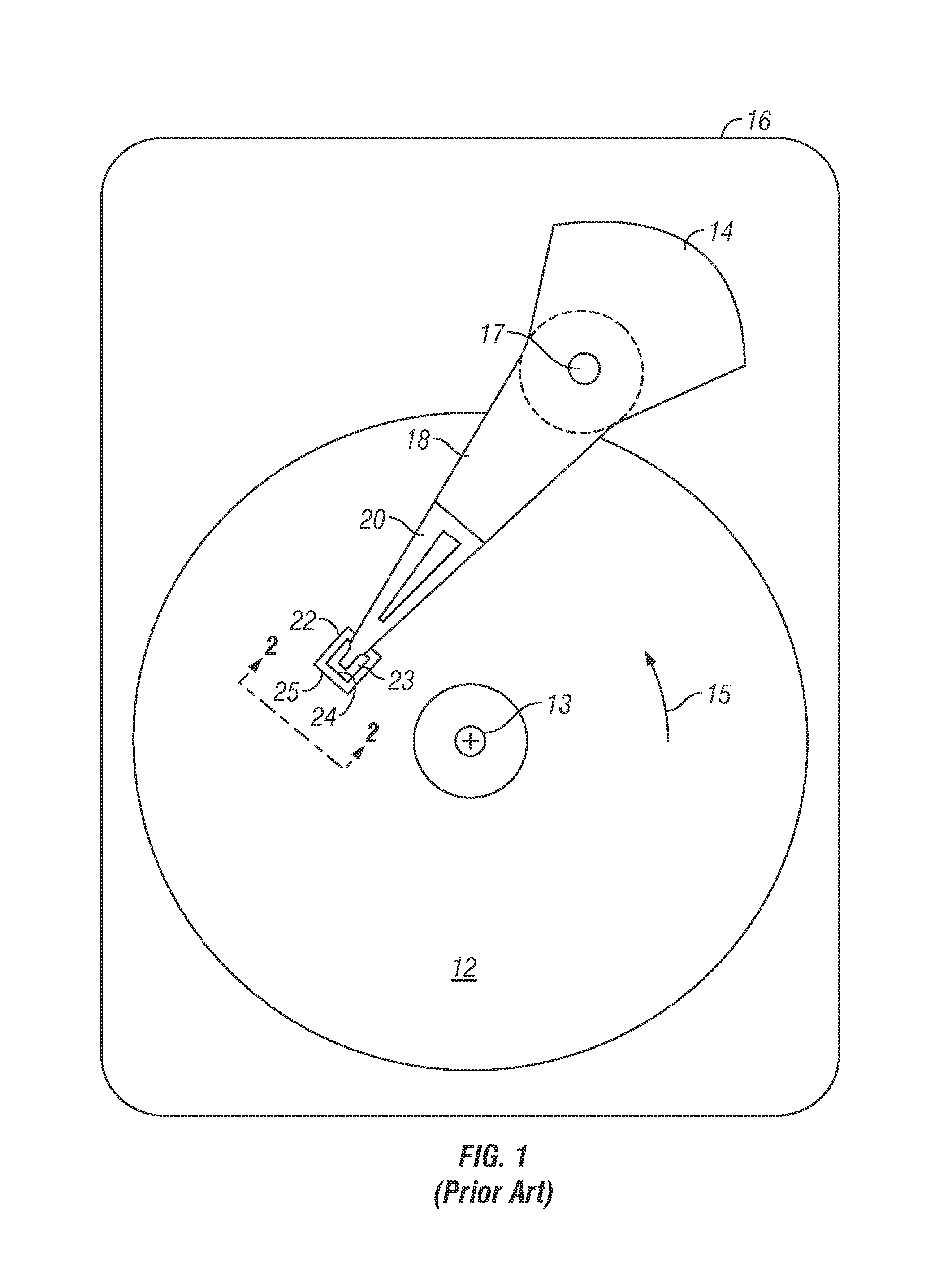

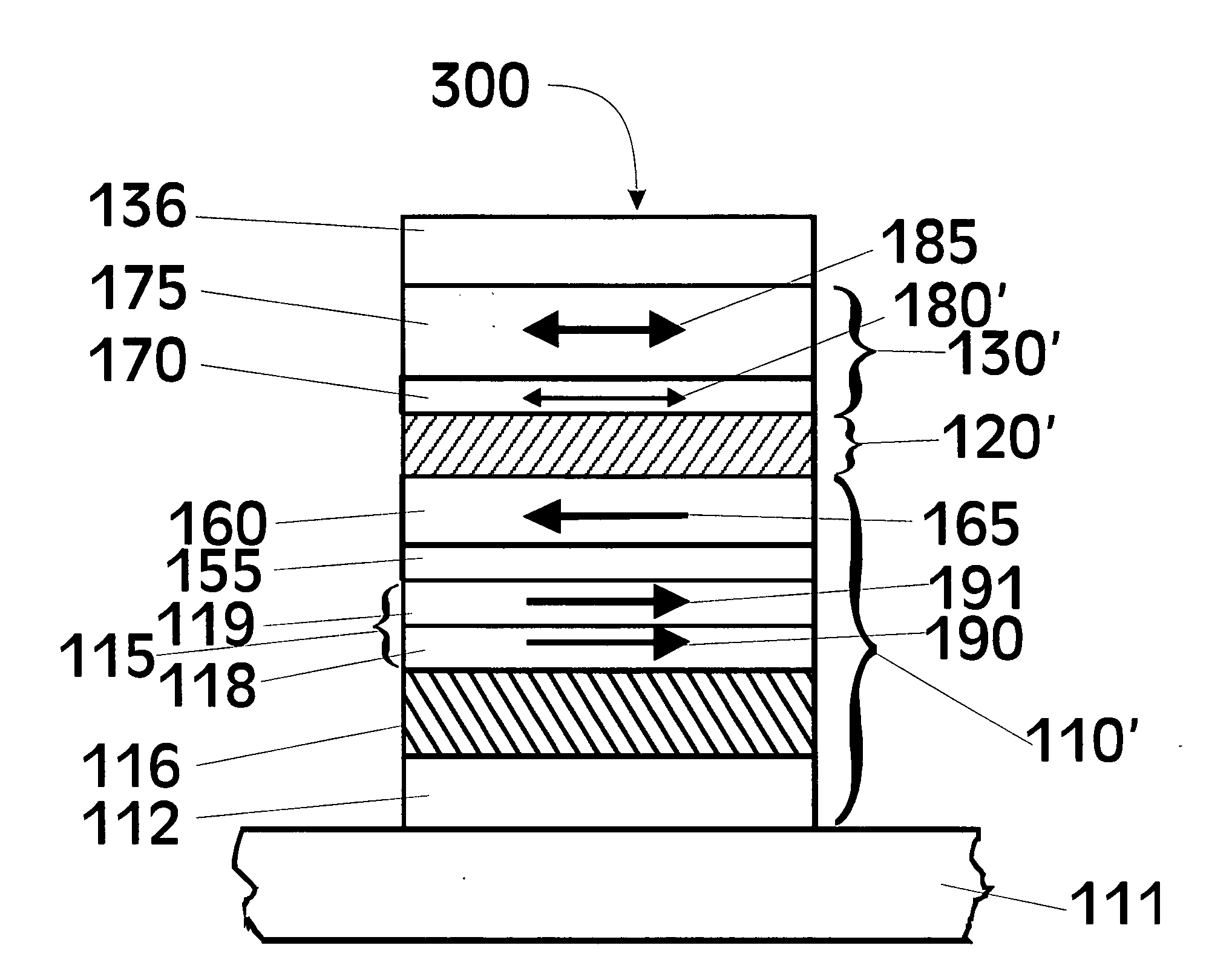

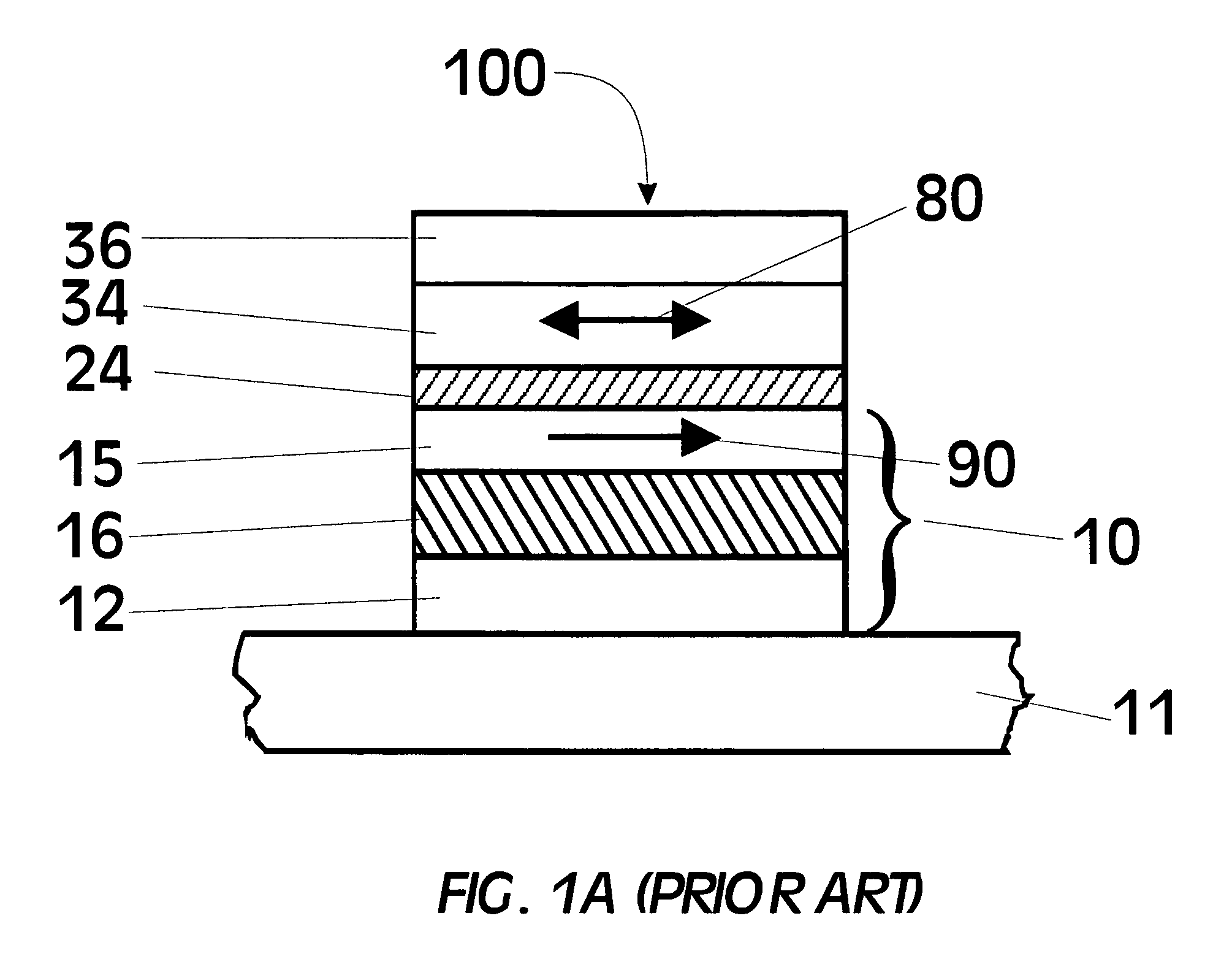

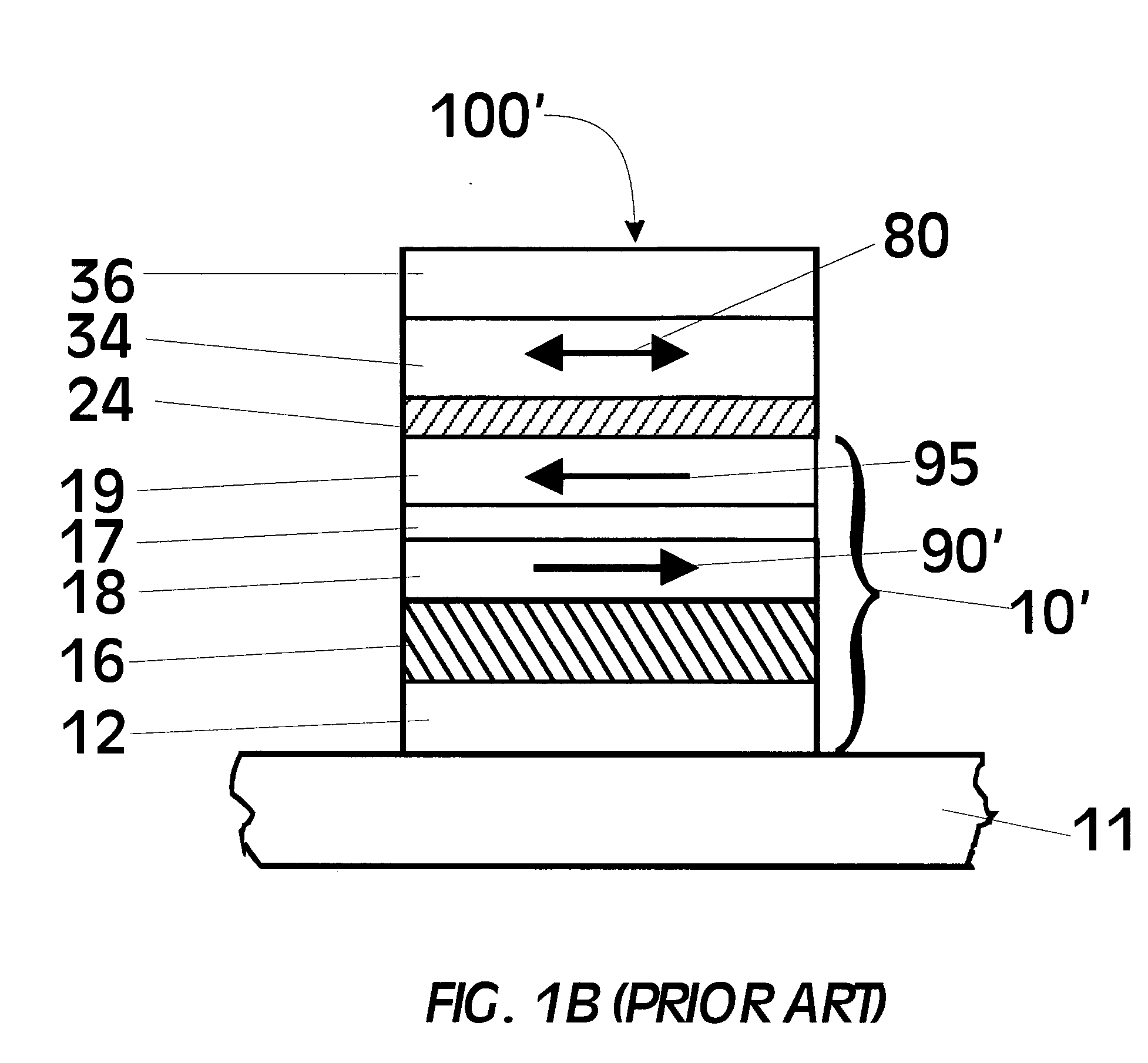

Structure to achieve sensitivity and linear density in tunneling GMR heads using orthogonal magnetic alignments

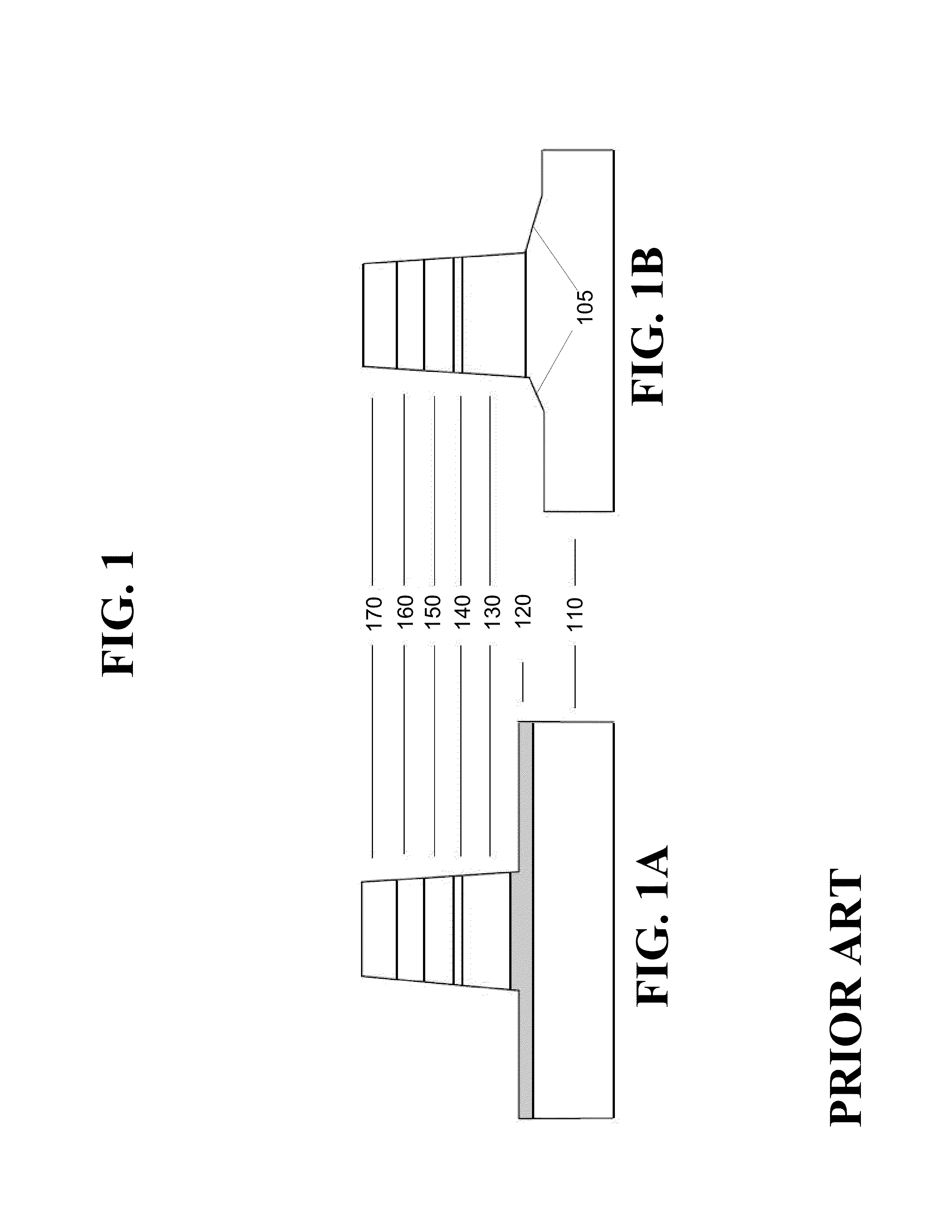

ActiveUS7035062B1Increase linear densityHigh sensitivityNanomagnetismNanoinformaticsMagnetic reluctanceMagnetization

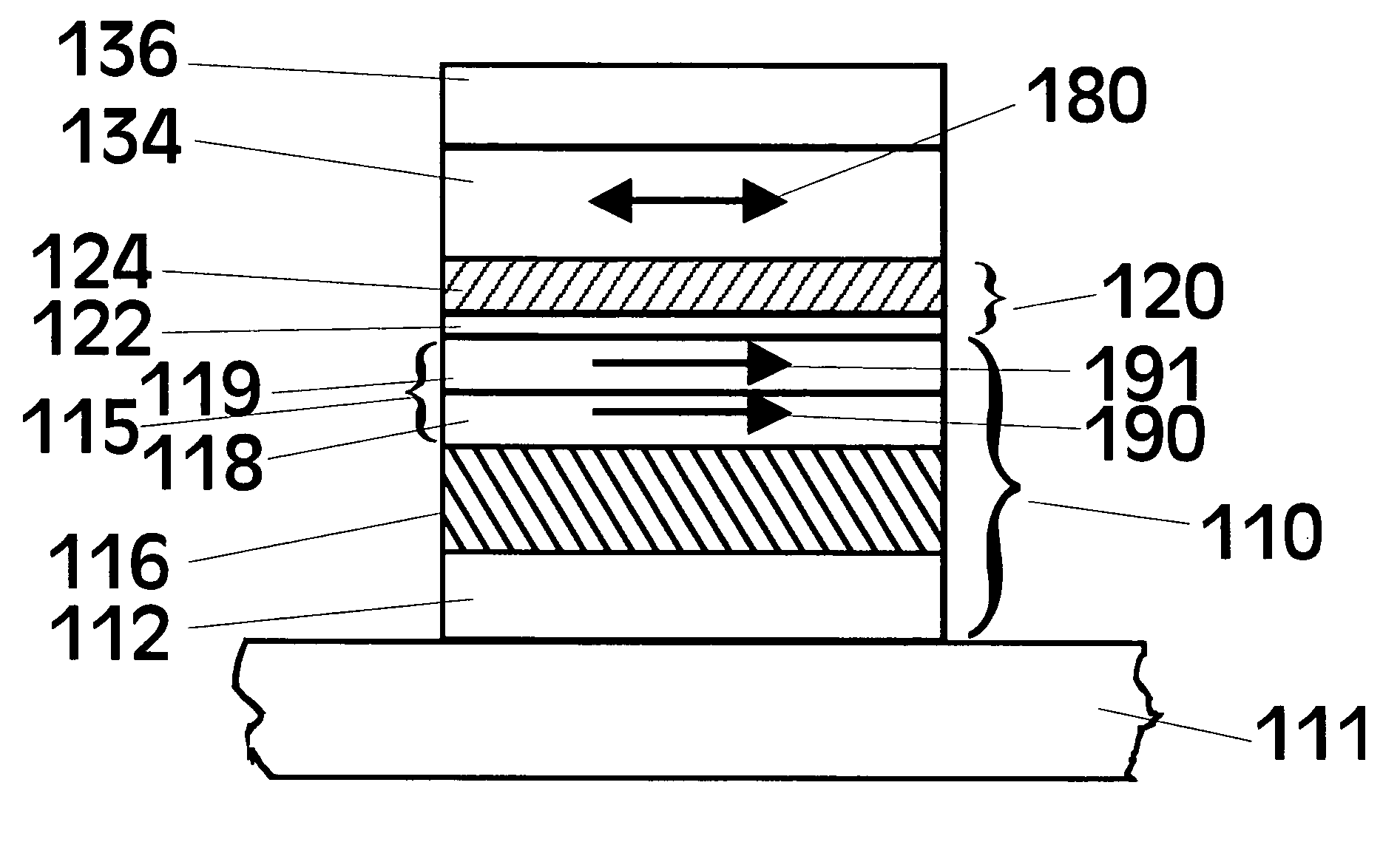

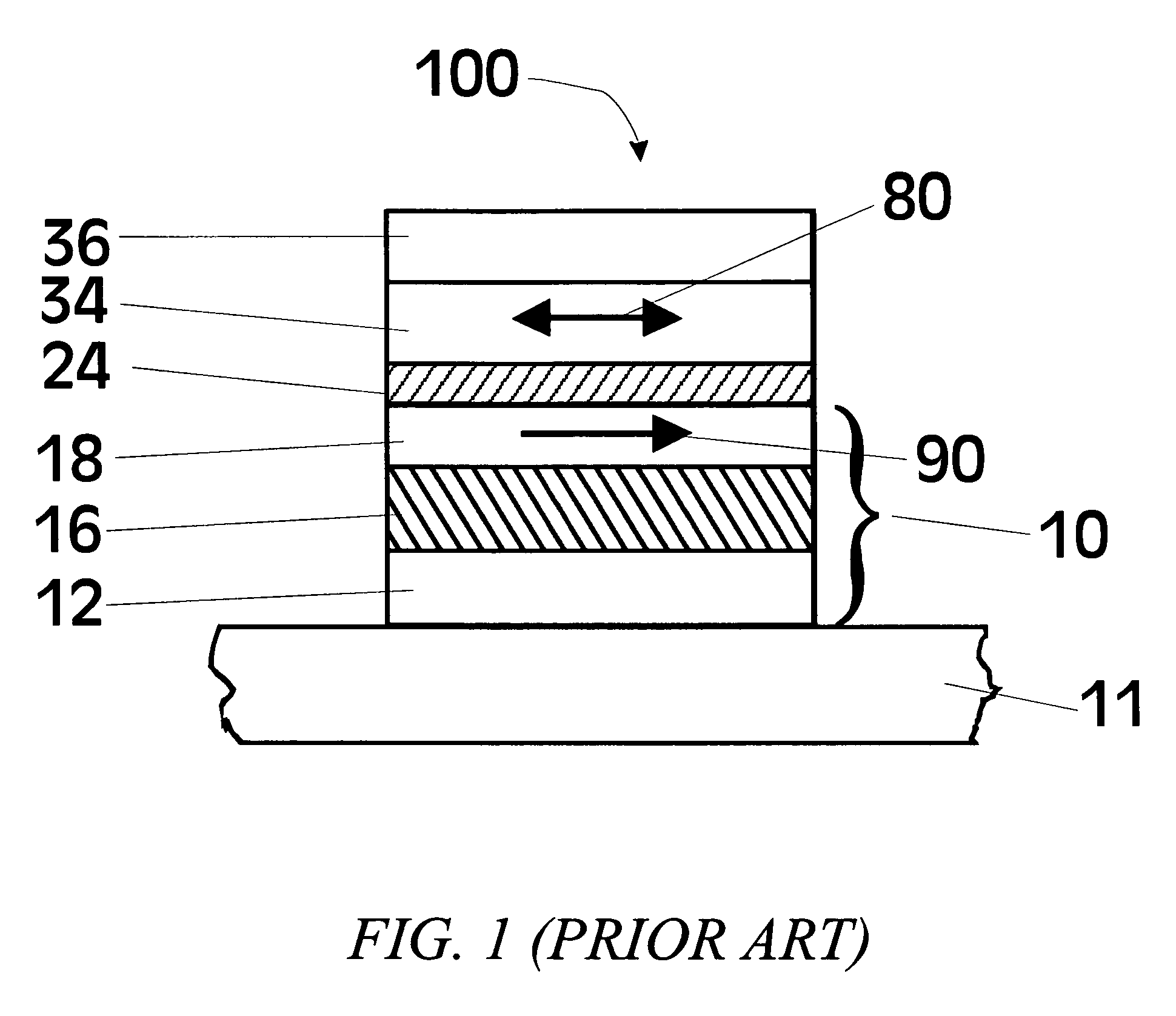

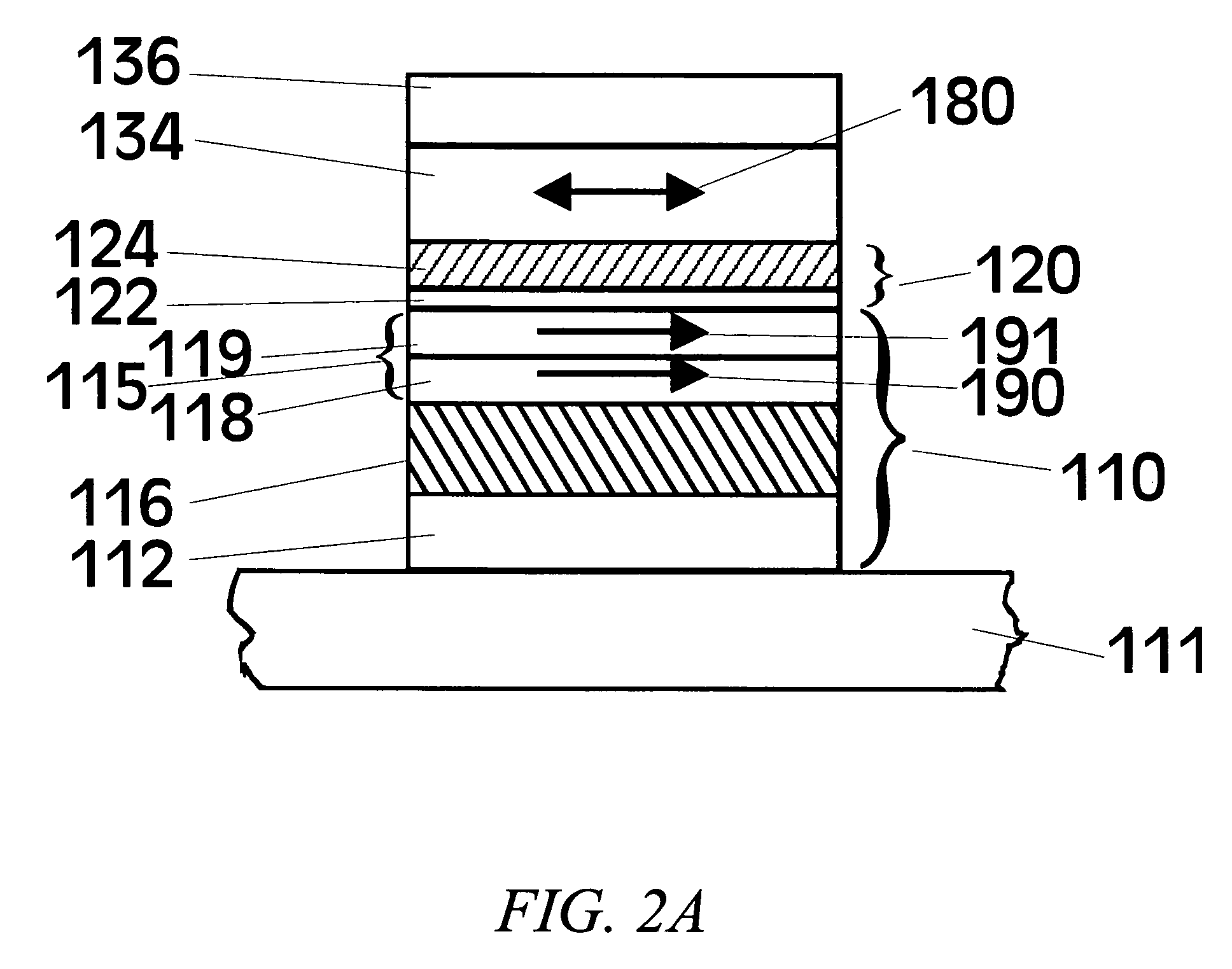

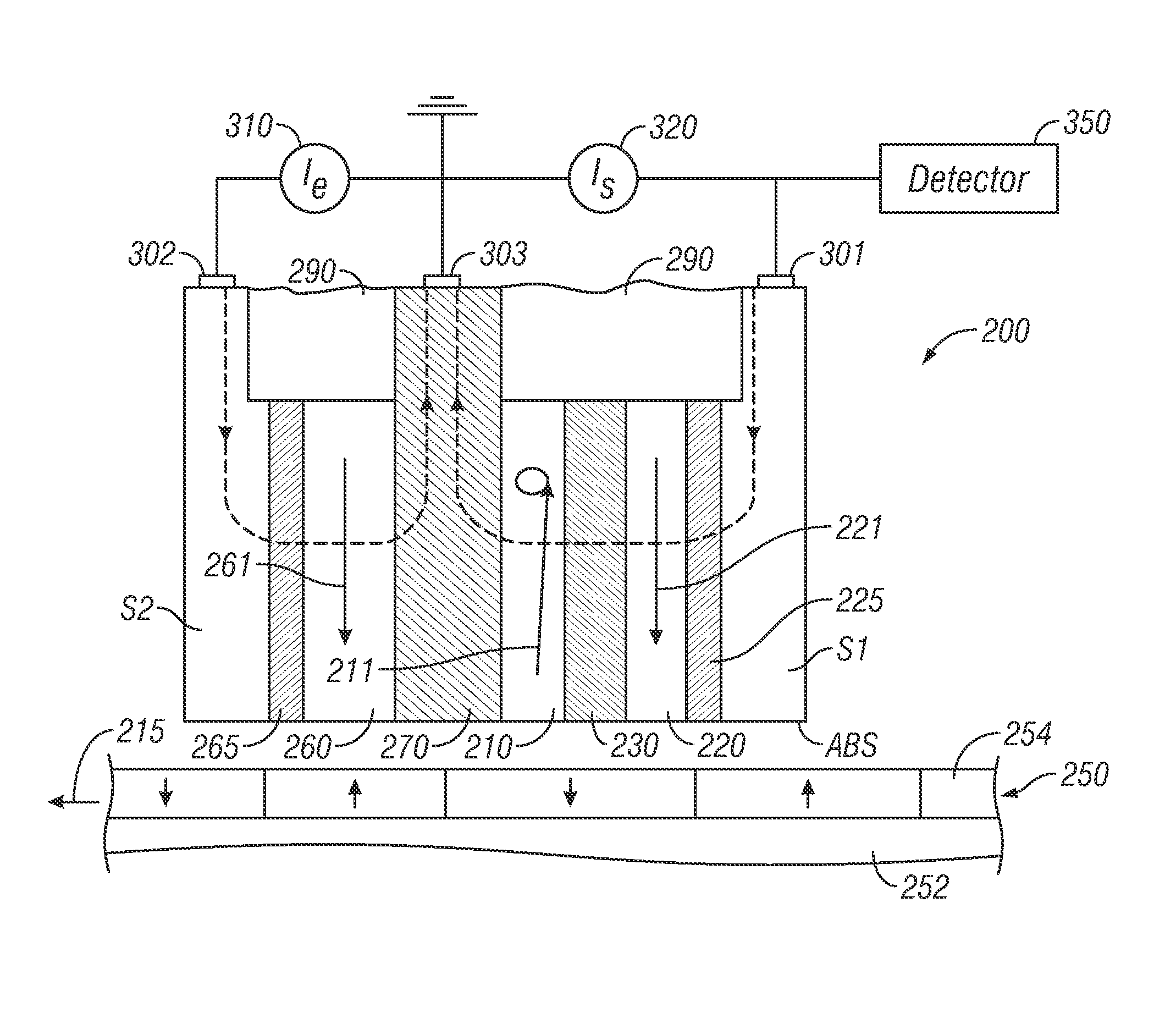

The present invention provides a tunneling magneto-resistive read sensor structure that improves sensitivity and linear density of the sensor structure. The sensor includes first and second electrodes and a stack positioned between the electrodes. The stack includes first and second free layers with magnetization orientations that are biased relative to each other. A tunneling barrier (insulating layer) or non-magnetic metal spacer is positioned between the first and second free layers. A sense current is passed between the first and second free layers of the stack. The amount of current passing through the first and second free layer changes based upon the orientation of the first and second free layers relative to each other.

Owner:SEAGATE TECH LLC

Magnetic etch-stop layer for magnetoresistive read heads

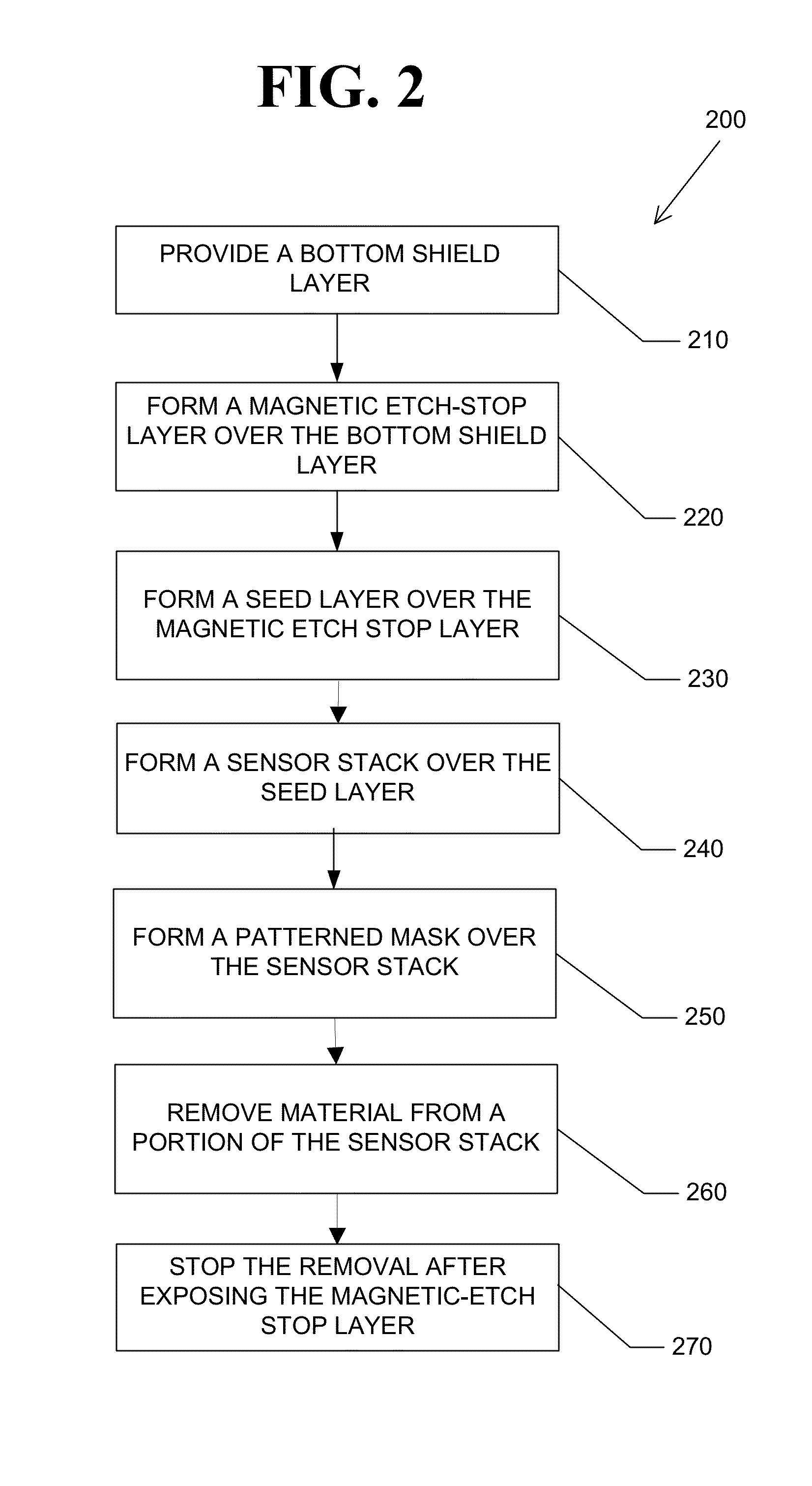

ActiveUS8611055B1Soft magnetic propertyReduce spacingRecord information storageManufacture of flux-sensitive headsEngineeringMask layer

A method of producing a magnetoresistive read head and a tunneling magnetoresistive read head produced thereby are disclosed. A shield layer is provided. A magnetic etch-stop layer is formed over the shield layer, where the magnetic etch-stop layer comprises a nonmagnetic metal and a soft magnetic material with overall property still being magnetically soft. A sensor stack is formed over the magnetic etch-stop layer. A patterned mask layer is formed over the sensor stack. Material from a portion of the sensor stack not covered by the patterned mask is removed.

Owner:WESTERN DIGITAL TECH INC

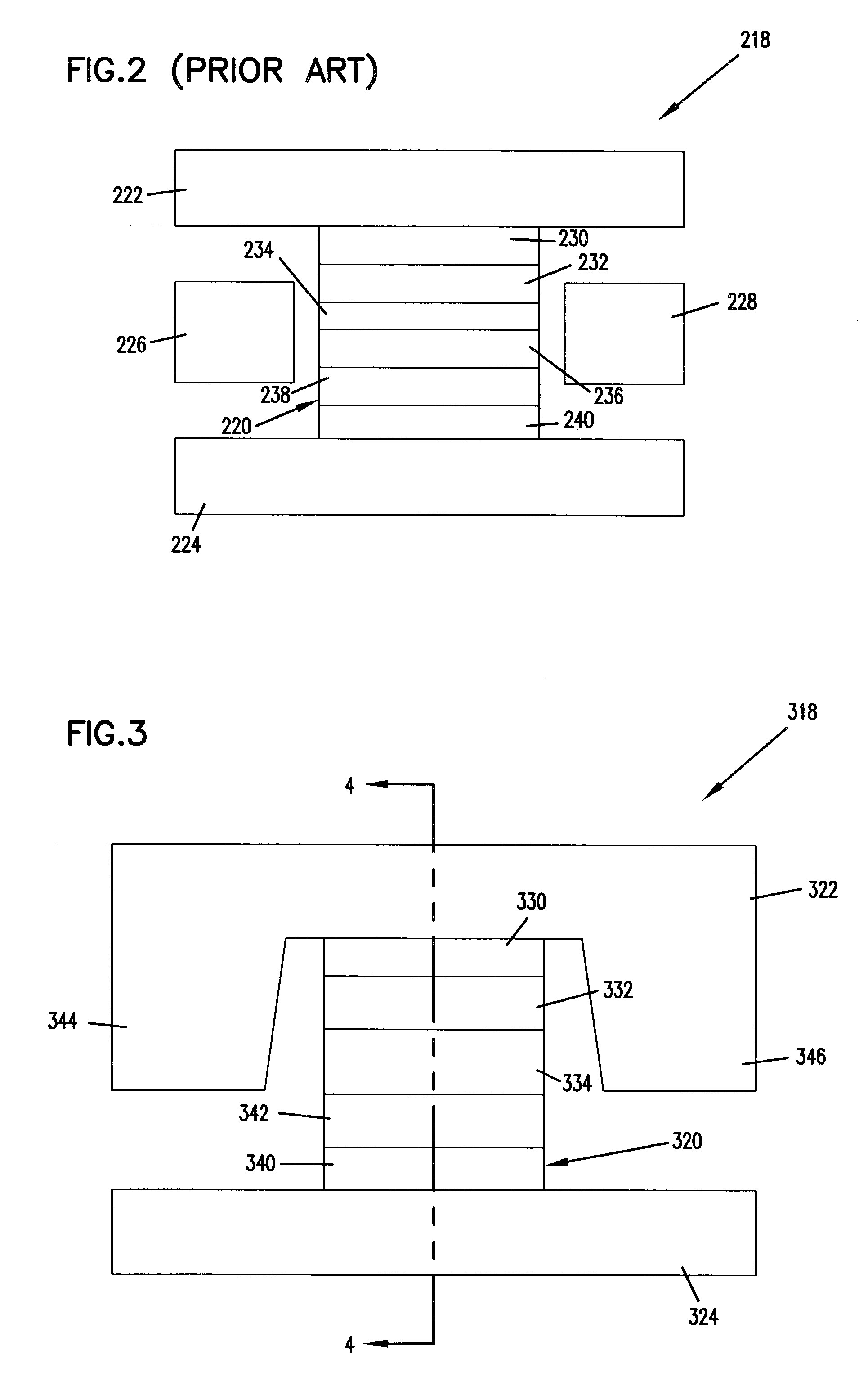

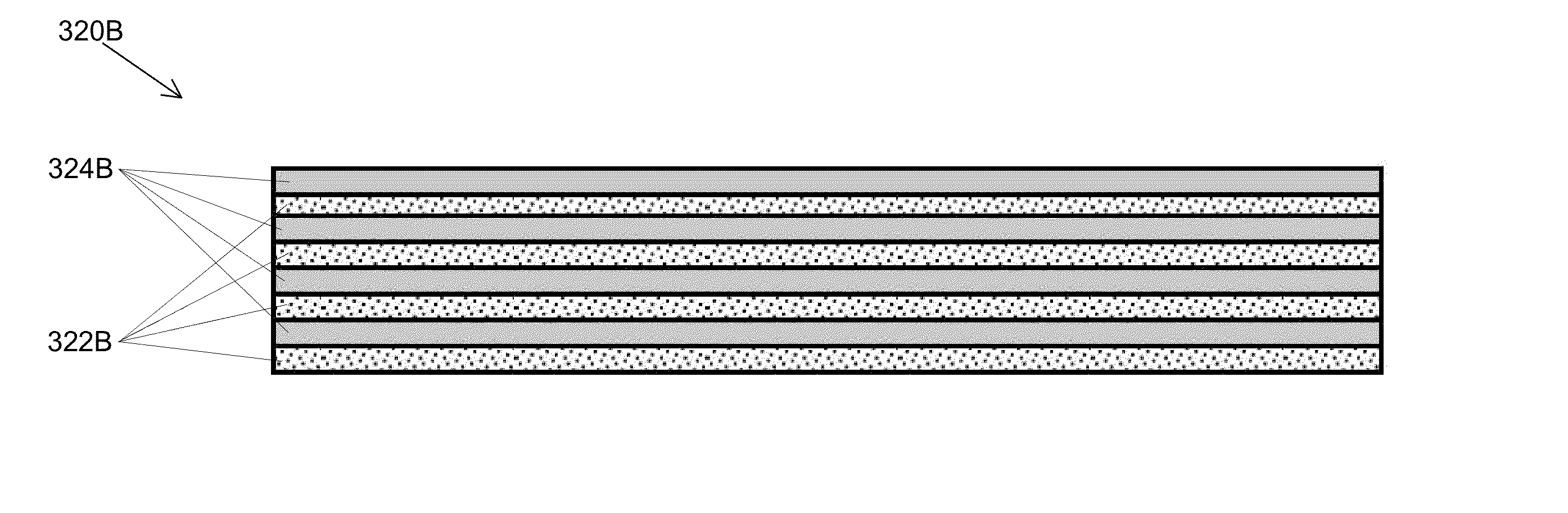

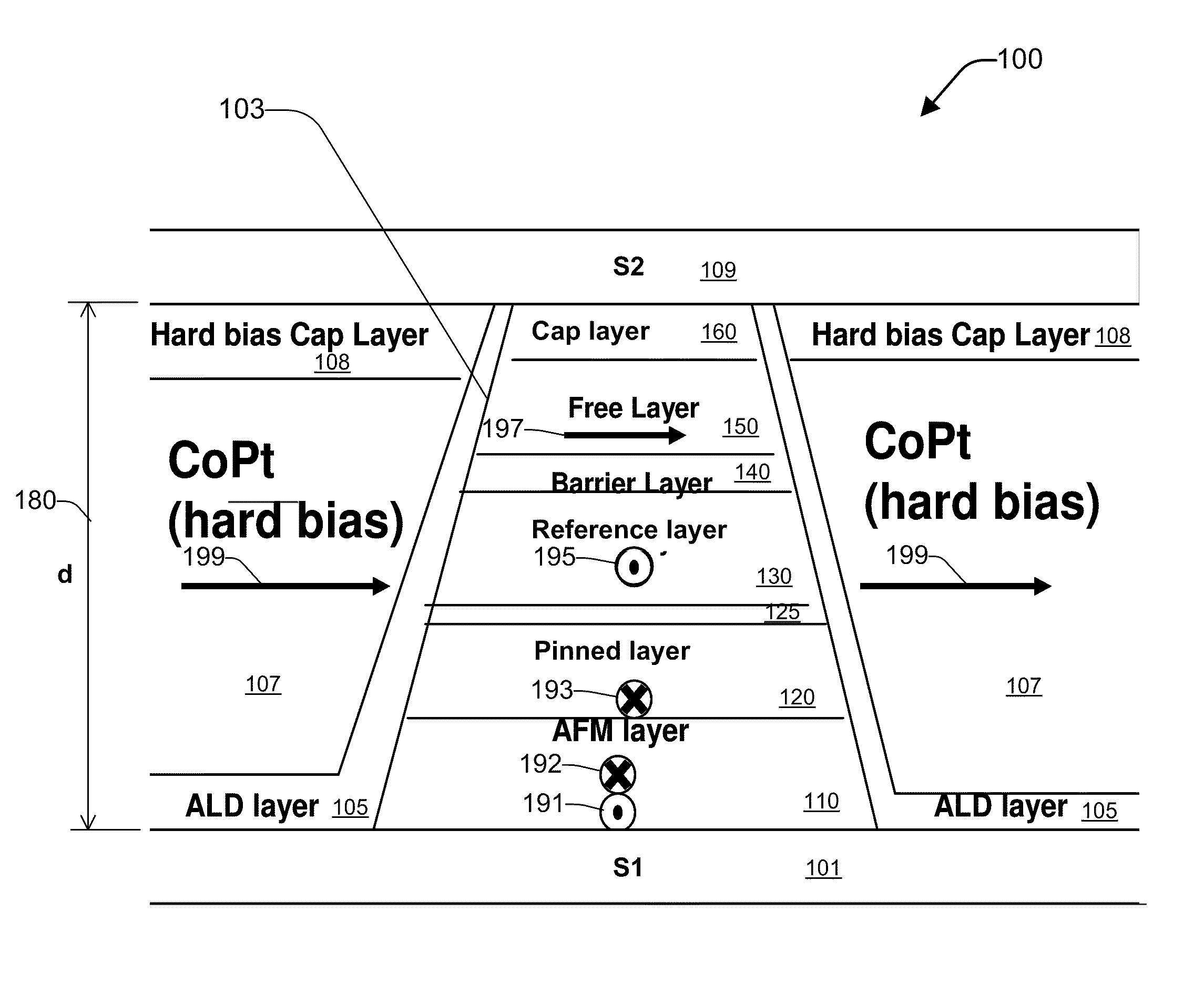

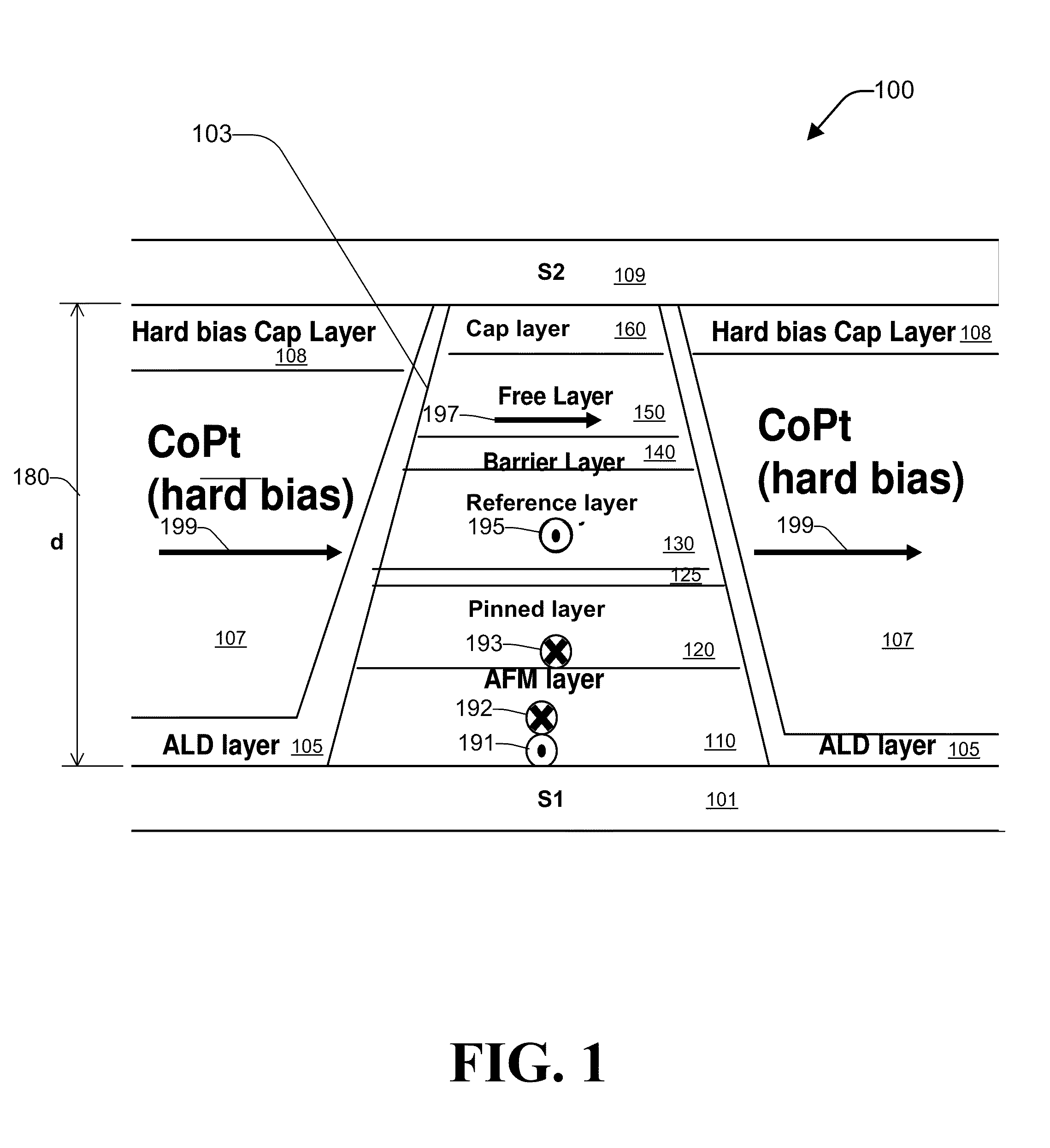

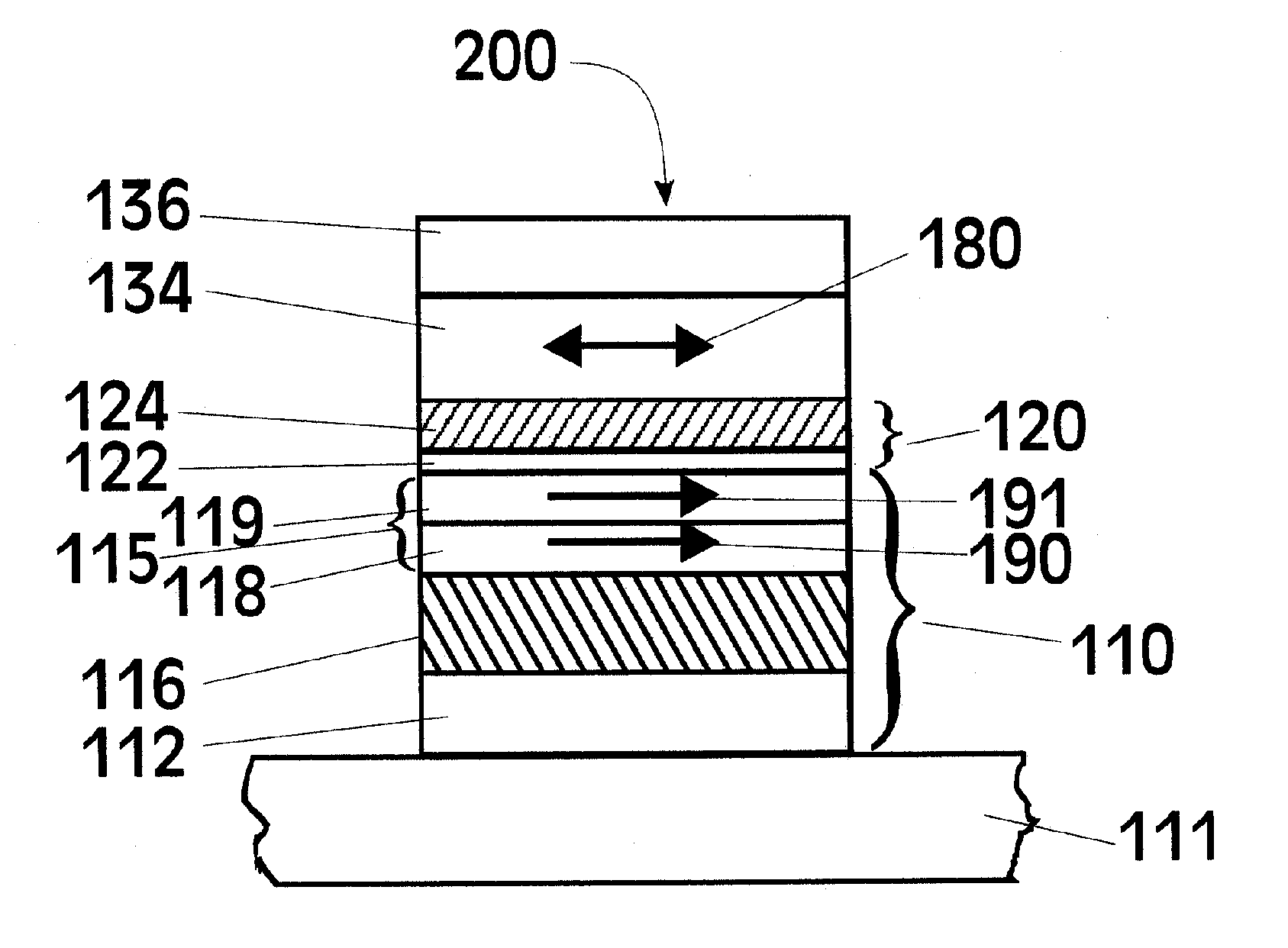

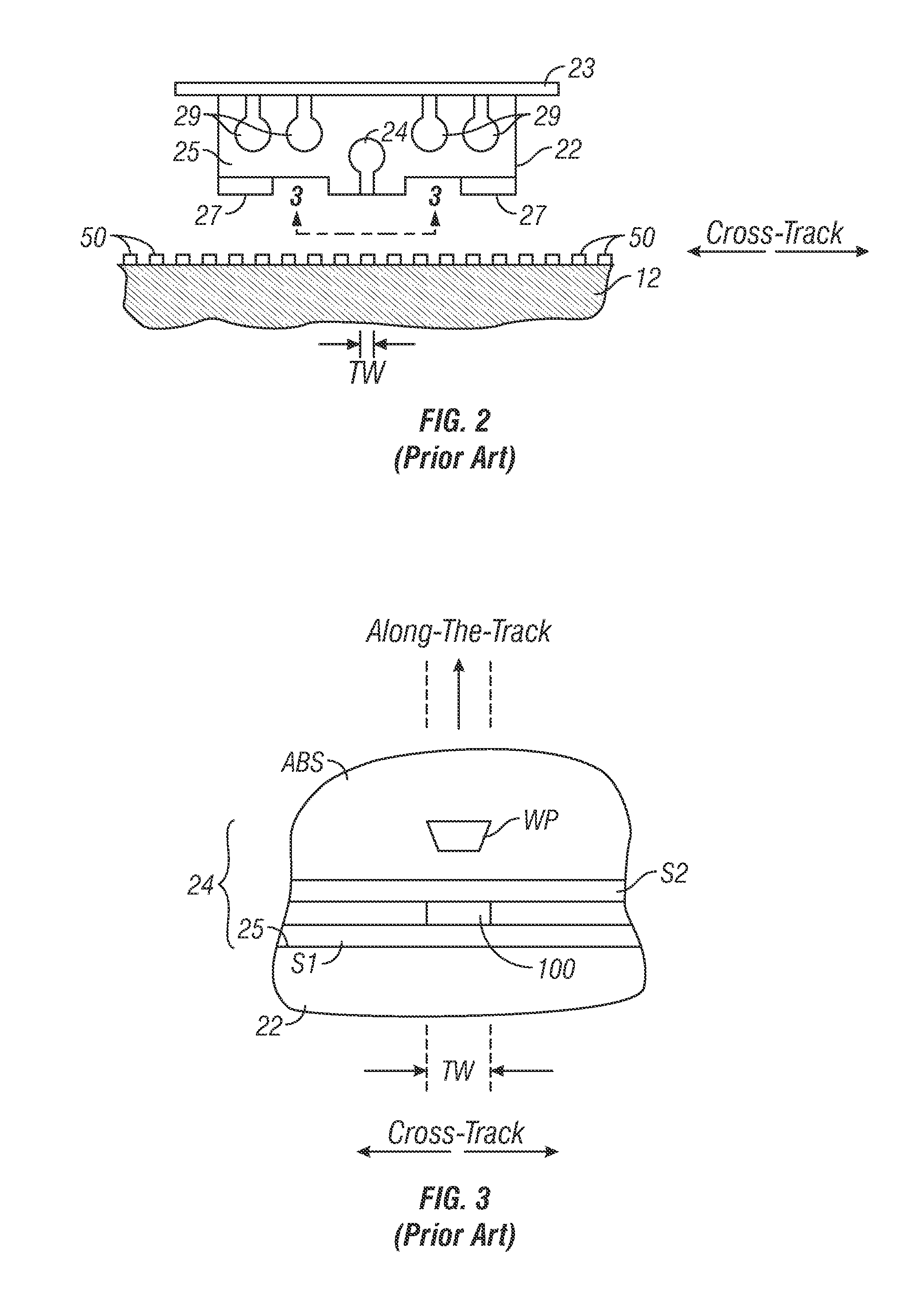

TMR read head structures with differential stripe heights

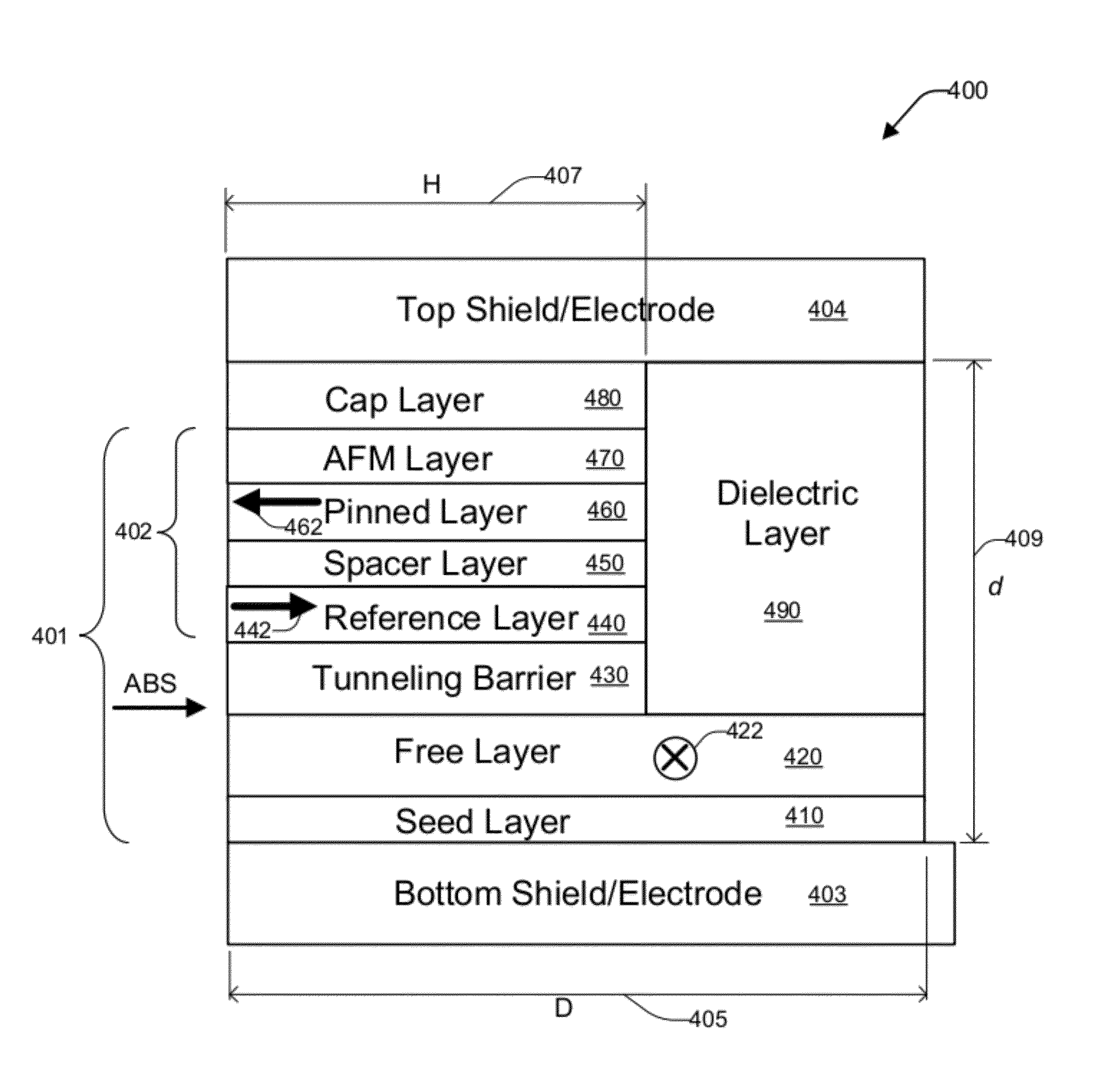

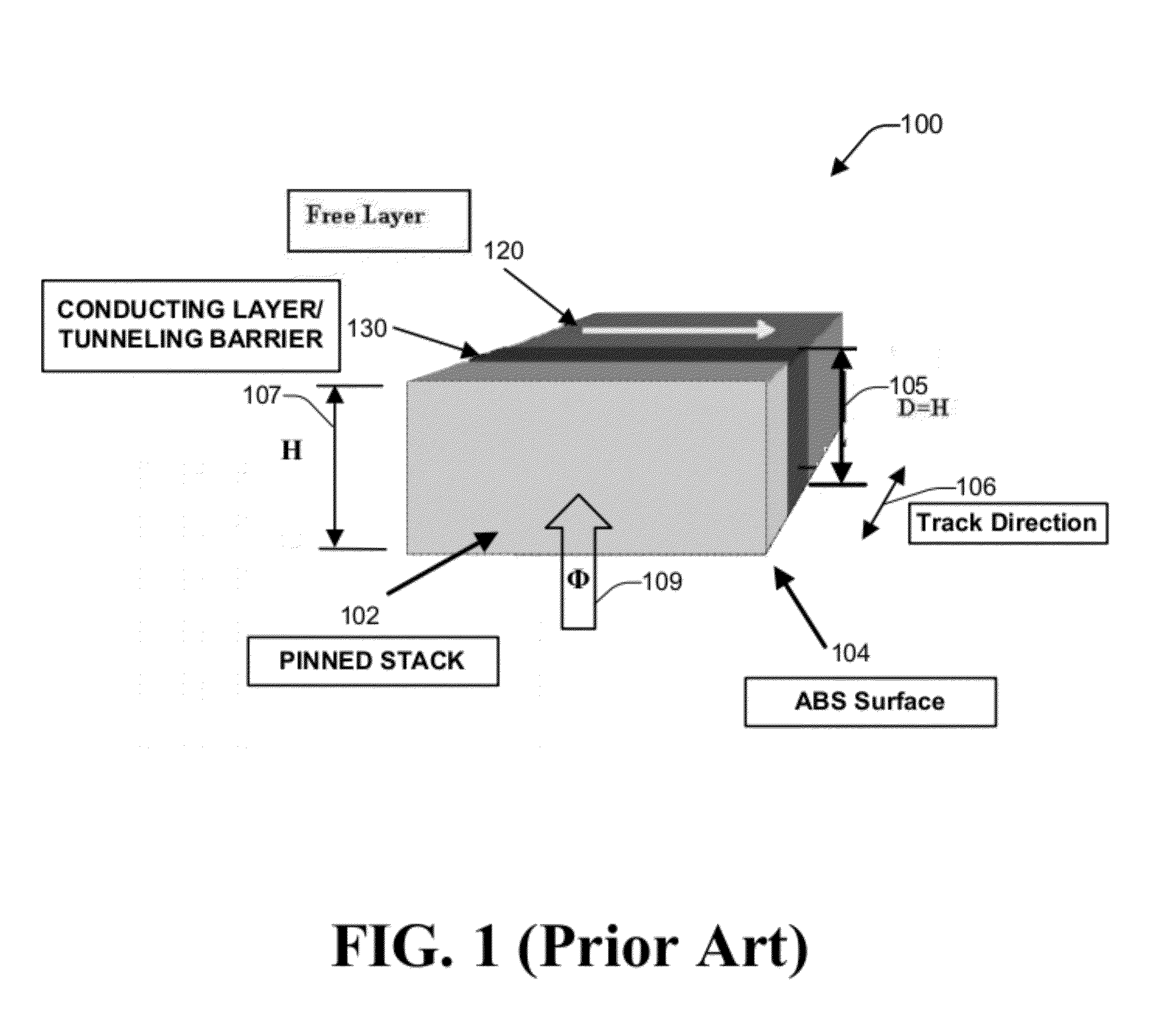

InactiveUS8194366B1Magnetic measurementsMagnetic-field-controlled resistorsMagnetic layerElectrical and Electronics engineering

A tunneling magnetoresistance (TMR) read head and a method of producing the same are disclosed. A free layer having a free layer stripe height is provided, the free layer having a first side and a second side. A tunneling barrier layer is formed adjacent to the first side of the free layer, the tunneling barrier layer having a first side and a second side, the second side of the tunneling barrier layer facing the first side of the free layer. A pinned stack is formed adjacent to the first side of the tunneling barrier layer. The pinned stack comprises at least one magnetic layer having a current path stripe height that is less than the free layer stripe height.

Owner:WESTERN DIGITAL TECH INC

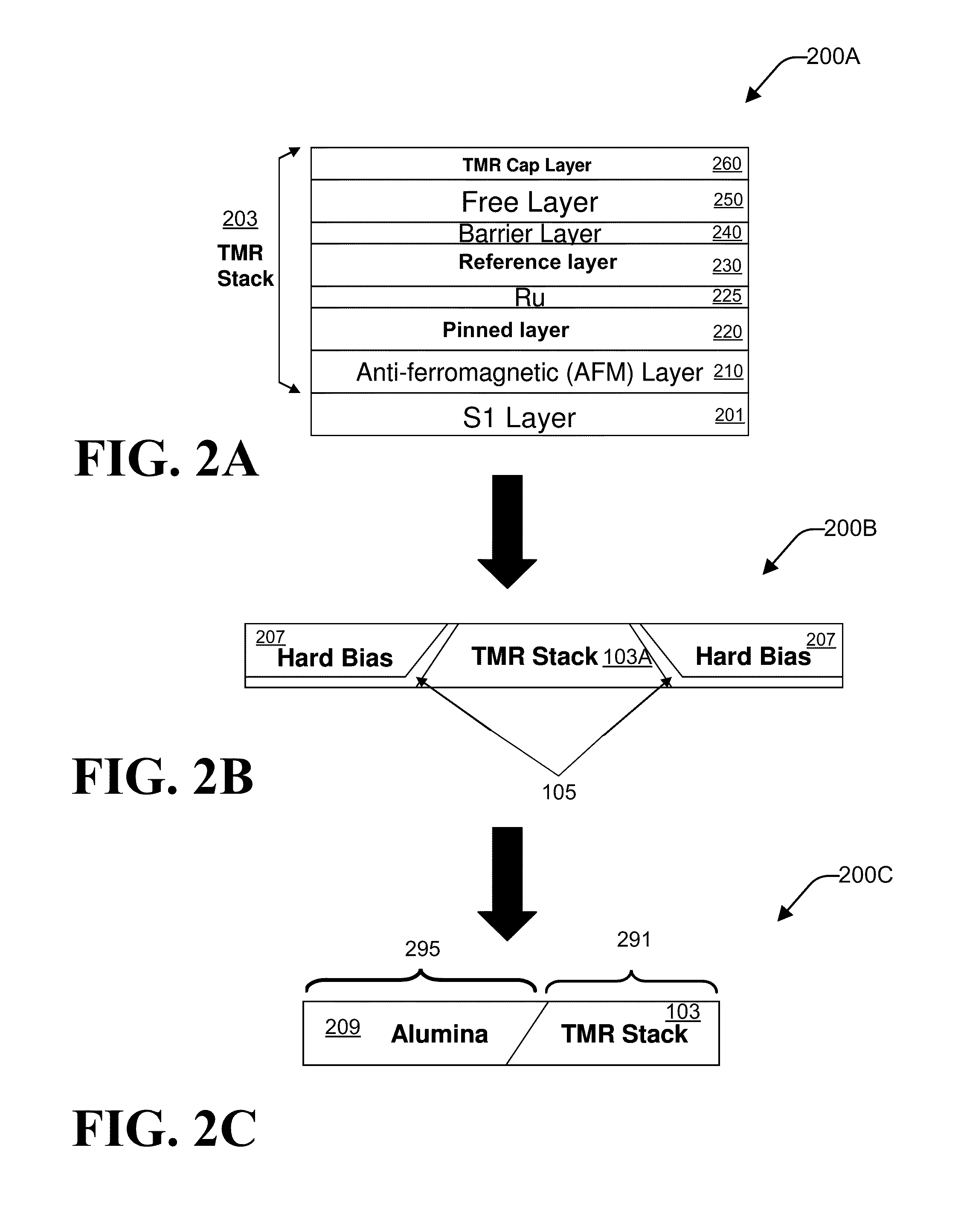

Method of fabricating a tunneling magnetoresistive (TMR) reader

A method of fabricating a tunneling magnetoresistance (TMR) reader is disclosed. A TMR structure comprising at least one ferromagnetic layer and at least one nonmagnetic insulating layer is provided. A first thermal annealing process on the TMR structure is performed. A reader pattern definition process performed on the TMR structure to obtain a patterned TMR reader. A second thermal annealing process is performed on the patterned TMR reader.

Owner:WESTERN DIGITAL TECH INC

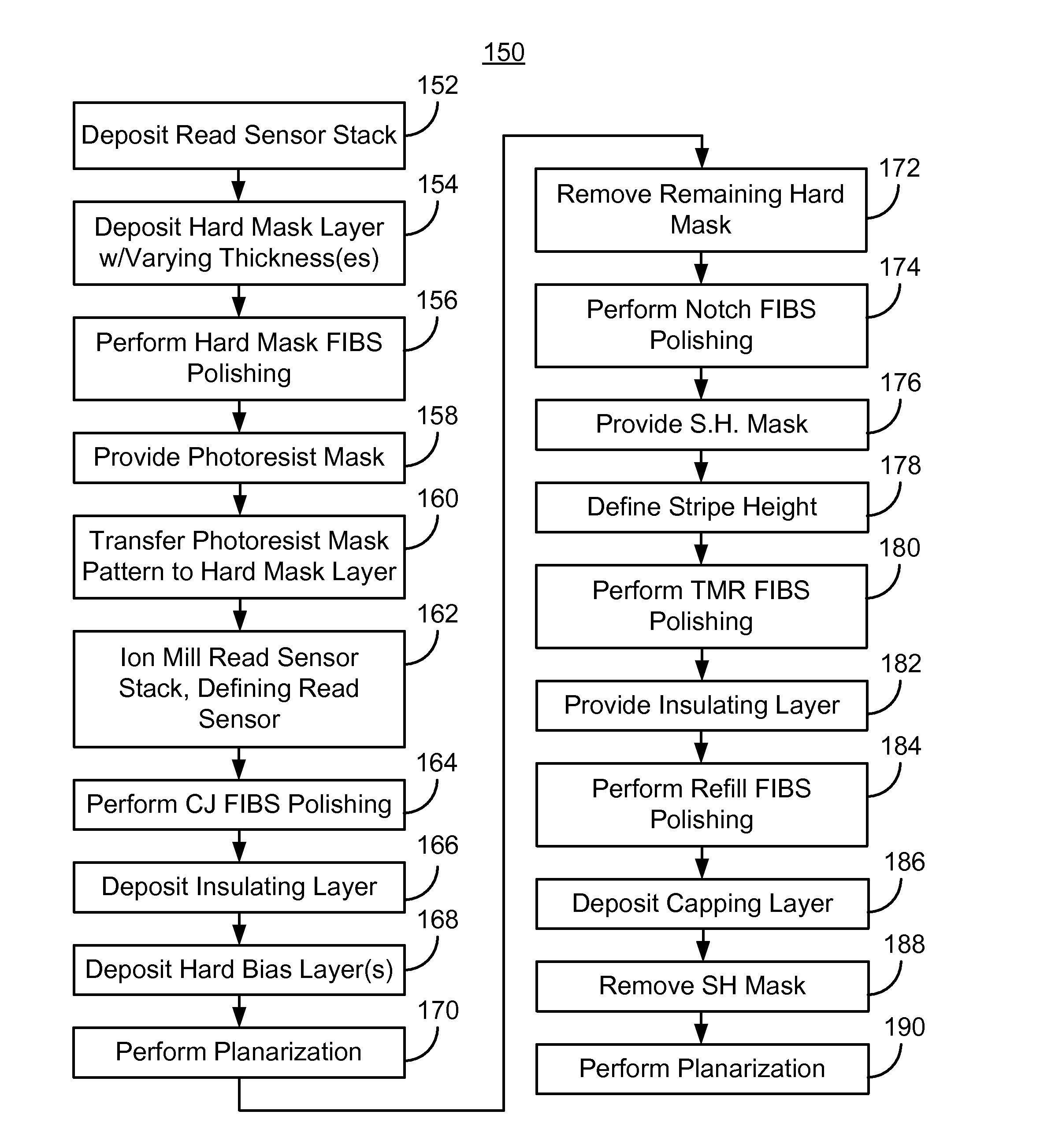

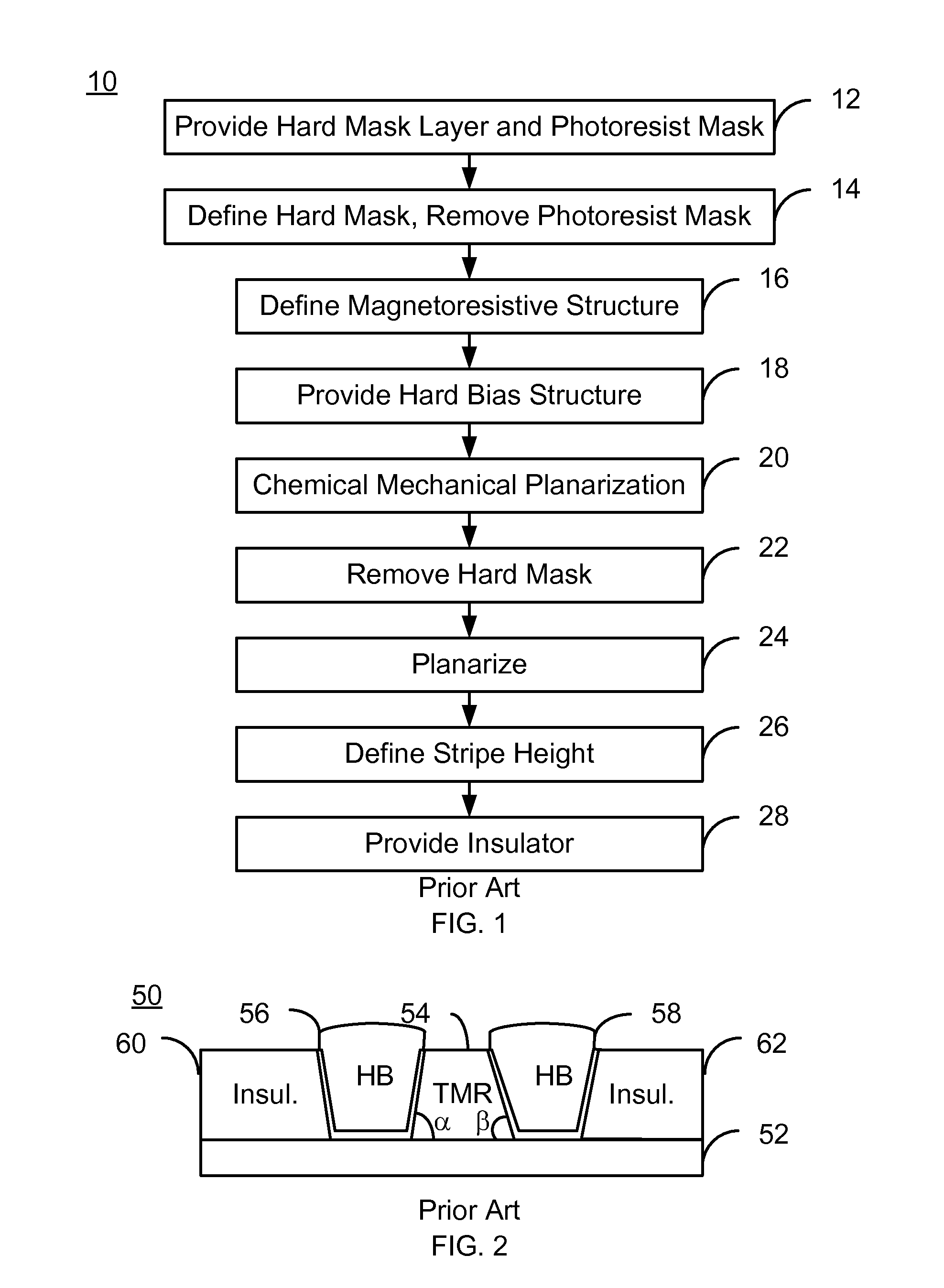

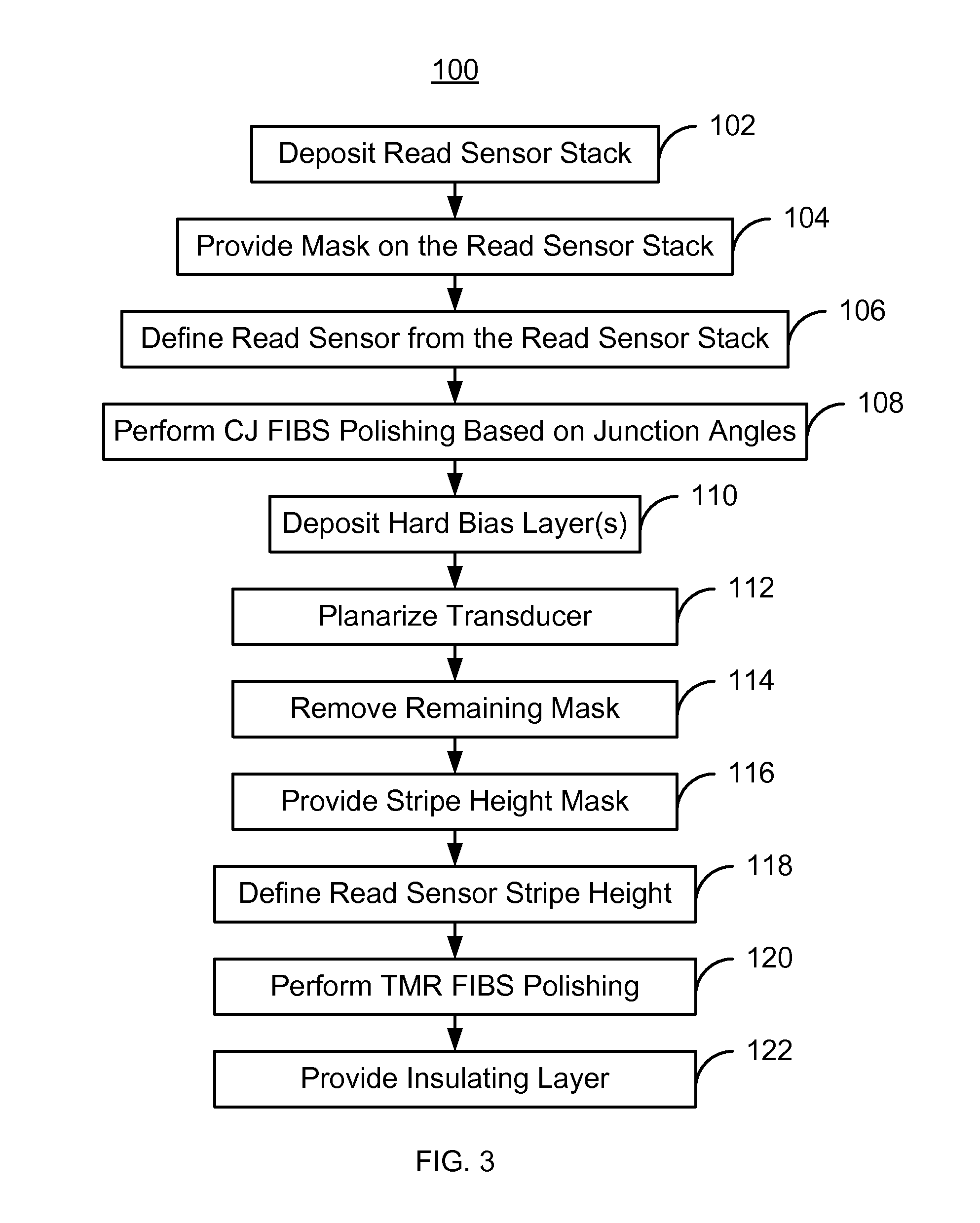

Method and system for providing a read sensor in a magnetic recording transducer using focused ion beam scan polishing

InactiveUS8480911B1Decorative surface effectsSemiconductor/solid-state device manufacturingSoftware engineeringIon beam

A read sensor for a read transducer is fabricated. The read transducer has field and device regions. A read sensor stack is deposited. A mask covering part of the stack corresponding to the read sensor is provided. The read sensor having inboard and outboard junction angles is defined from the stack in a track width direction. A critical junction (CJ) focused ion beam scan (FIBS) polishing that removes part of the read sensor based on the junction angles is performed. A hard bias structure is deposited and the transducer planarized. A remaining portion of the mask is removed. A stripe height mask covering part of the read sensor and hard bias structure in a stripe height direction is provided. The read sensor stripe height is defined. A tunneling magnetoresistance (TMR) FIBS polishing that removes part of the stack in the field region is performed. An insulating layer is provided.

Owner:WESTERN DIGITAL TECH INC

Magnetic Tunnel Junctions Using Amorphous Materials as Reference and Free Layers

ActiveUS20060098354A1Improve barrier propertiesImprove performanceNanomagnetismNanoinformaticsBoronTunnel junction

Magnetic tunnel junctions are constructed from a MgO or Mg—ZnO tunnel barrier and amorphous magnetic layers in proximity with, and on respective sides of, the tunnel barrier. The amorphous magnetic layer preferably includes Co and at least one additional element selected to make the layer amorphous, such as boron. Magnetic tunnel junctions formed from the amorphous magnetic layers and the tunnel barrier have tunneling magnetoresistance values of up to 200% or more.

Owner:IBM CORP

Method of forming a barrier layer of a tunneling magnetoresistive sensor

InactiveUS6841395B2Prevent electrostatic dischargeMagnetic and TMR propertyNanostructure applicationNanomagnetismIon beamXenon

Owner:GLOBALFOUNDRIES INC

Mg-Zn oxide tunnel barriers and method of formation

ActiveUS7252852B1Not diminishing spin polarizationImprove performanceNanomagnetismMagnetic measurementsOxygenZinc

ZnMg oxide tunnel barriers are grown which, when sandwiched between ferri- or ferromagnetic layers, form magnetic tunnel junctions exhibiting high tunneling magnetoresistance (TMR). The TMR may be increased by annealing the magnetic tunnel junctions. The zinc-magnesium oxide tunnel barriers may be incorporated into a variety of other devices, such as magnetic tunneling transistors and spin injector devices. The ZnMg oxide tunnel barriers are grown by first depositing a zinc and / or magnesium layer onto an underlying substrate in oxygen-poor (or oxygen-free) conditions, and subsequently depositing zinc and / or magnesium onto this layer in the presence of reactive oxygen.

Owner:IBM CORP

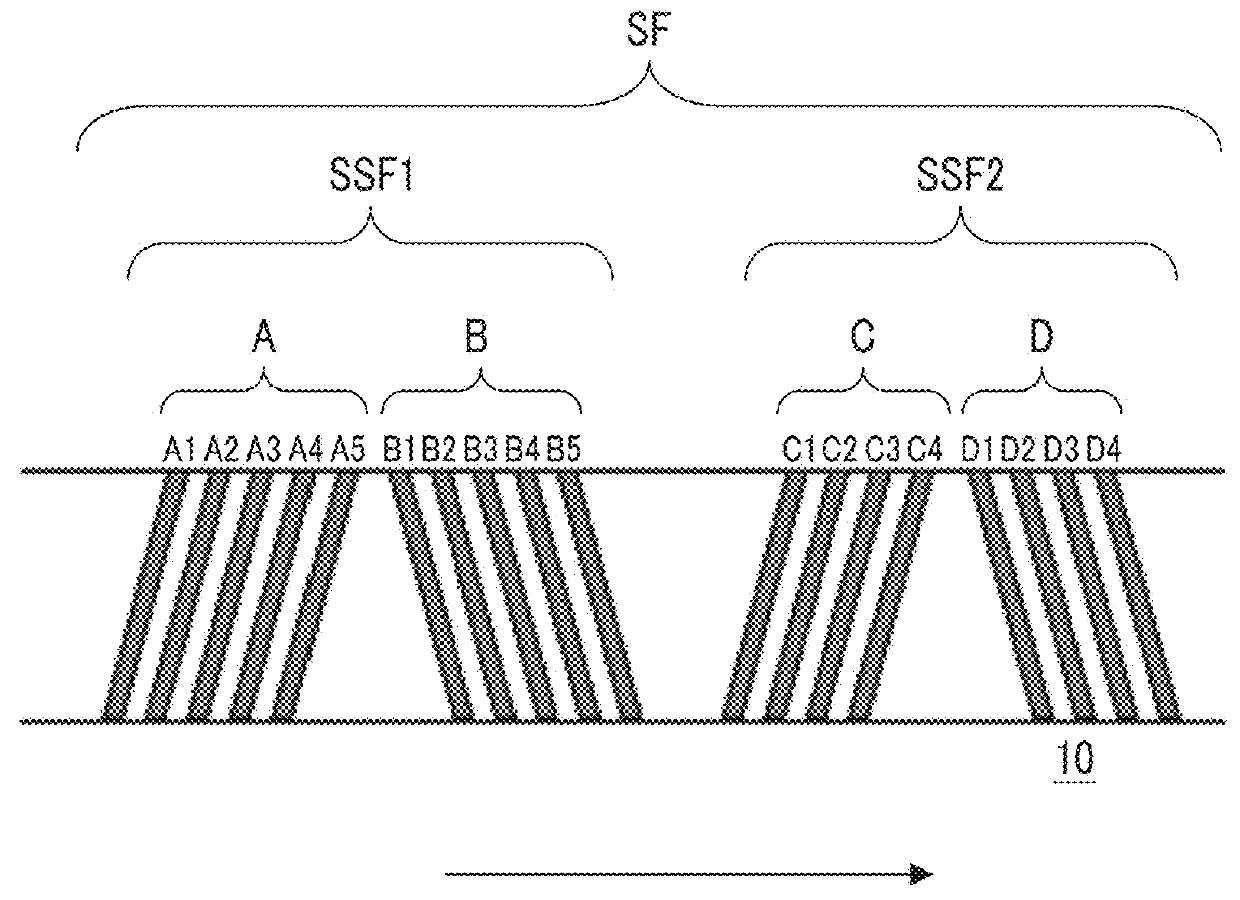

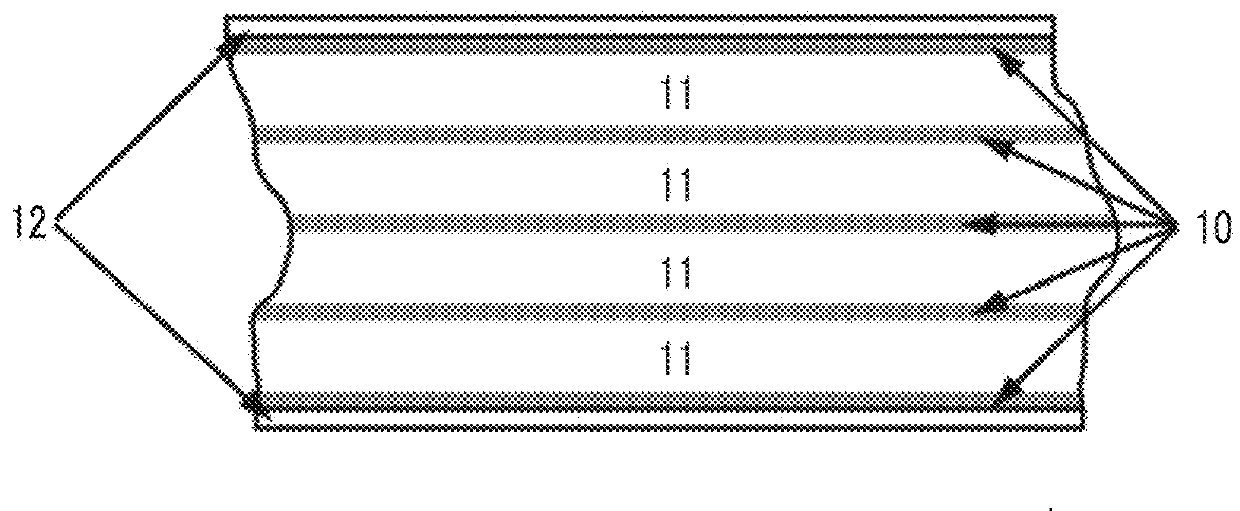

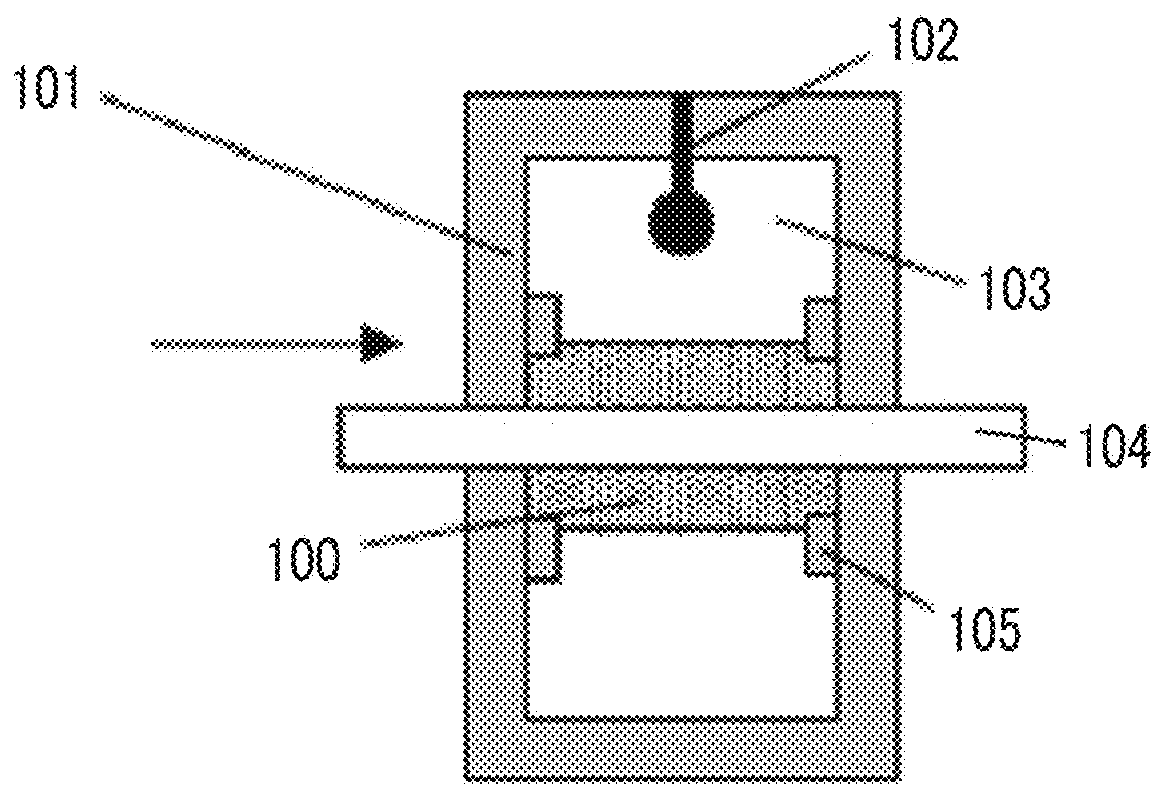

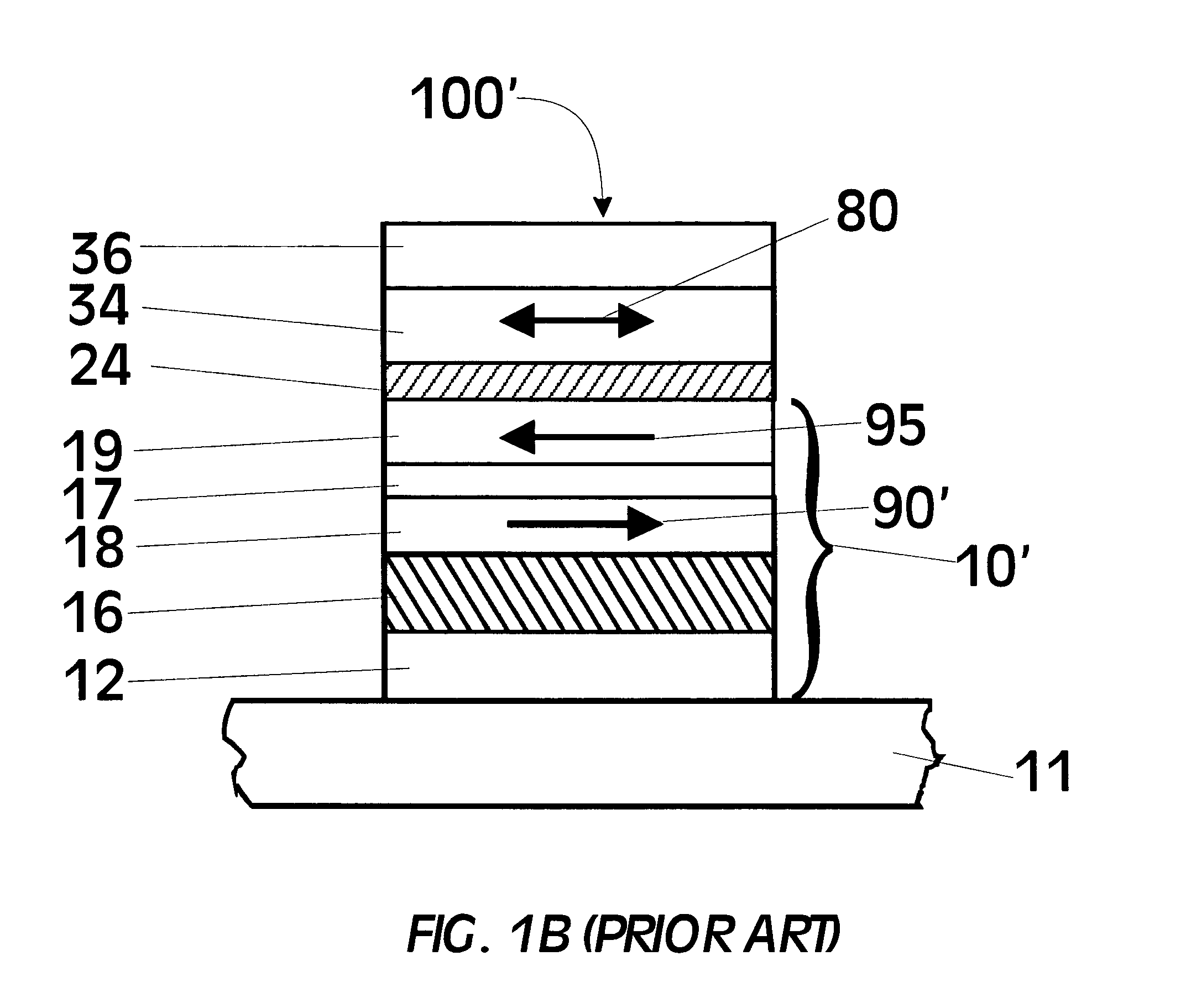

Magnetic tape device and head tracking servo method

ActiveUS9972351B1Avoid it happening againImprove accuracyAlignment for track following on tapesRecord information storageMagnetic tapeEngineering

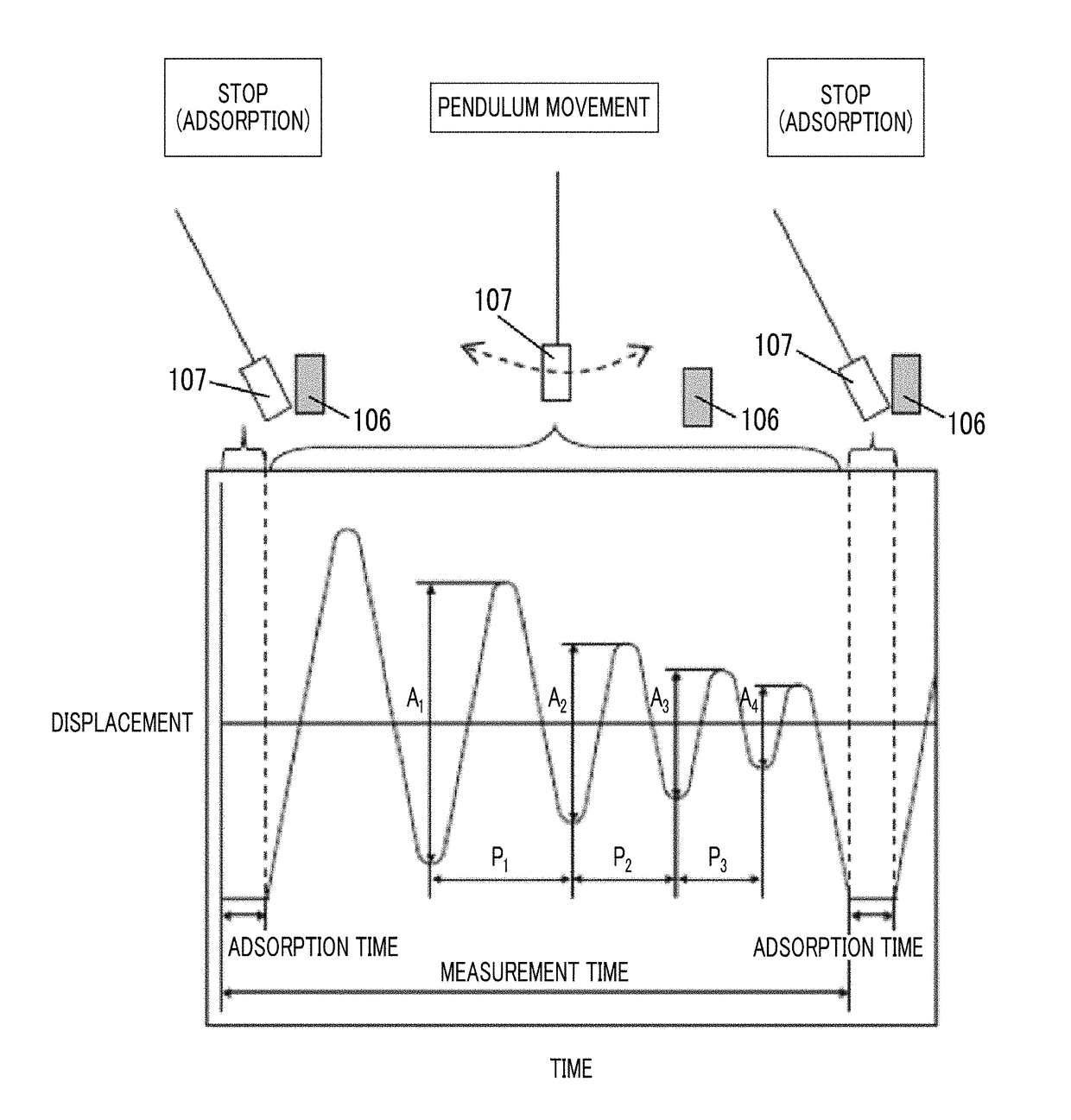

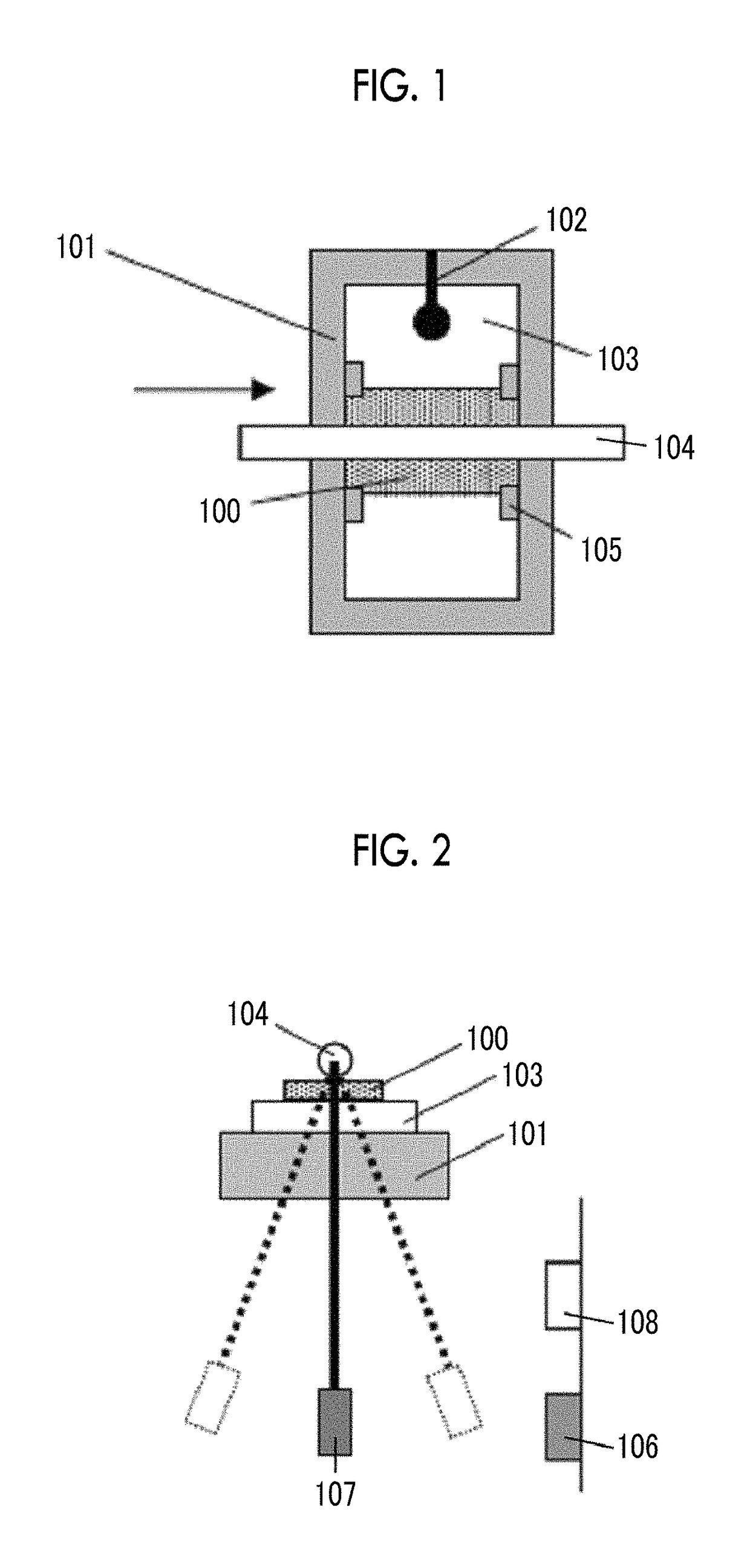

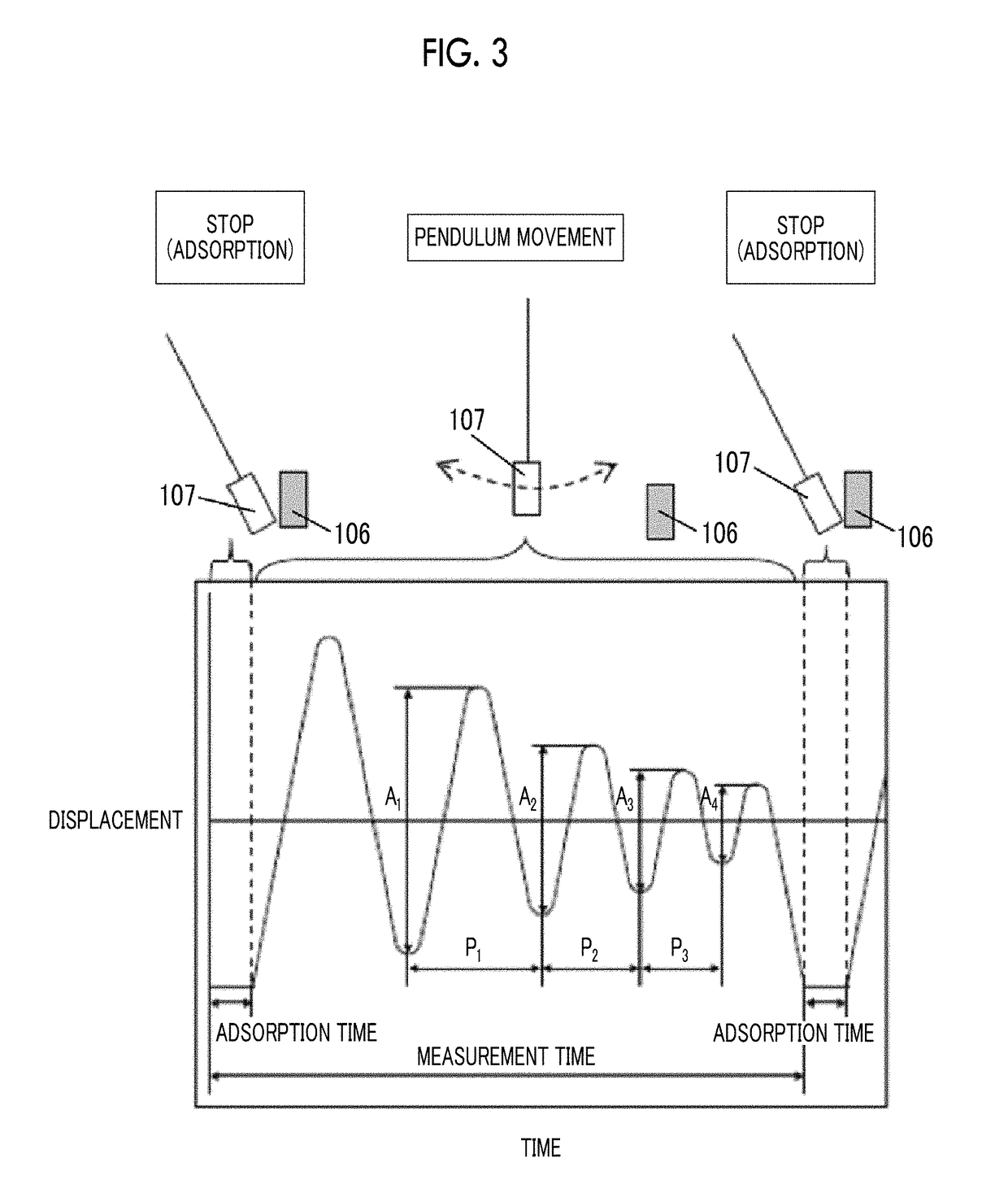

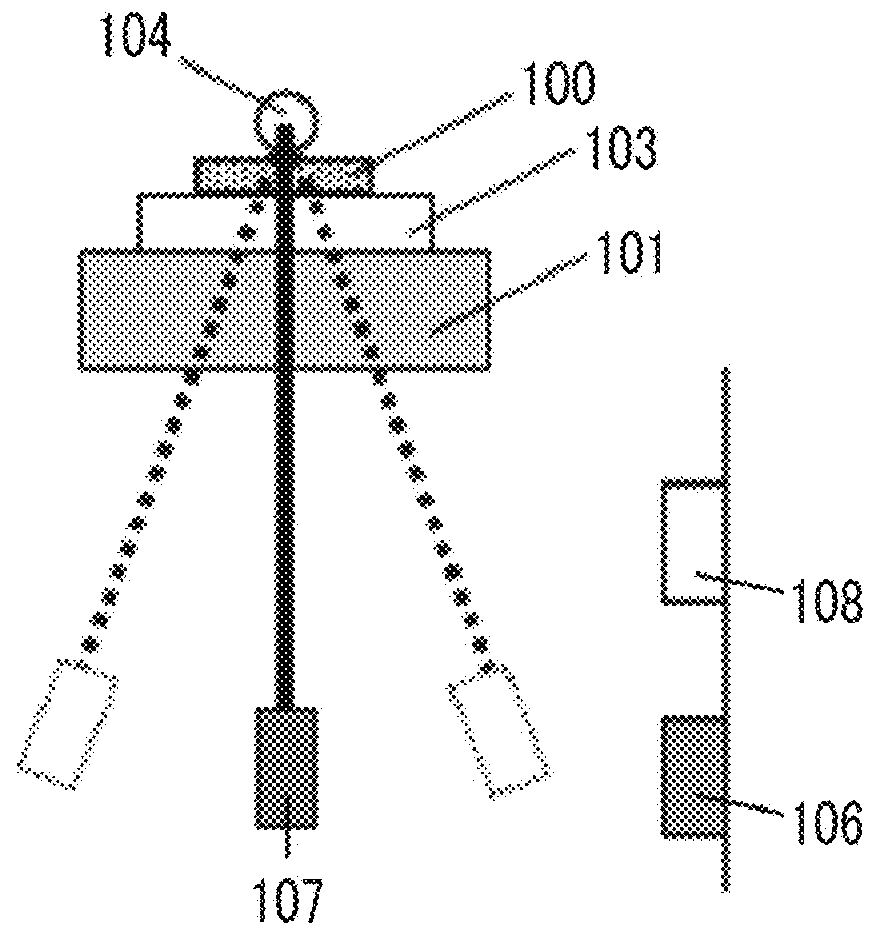

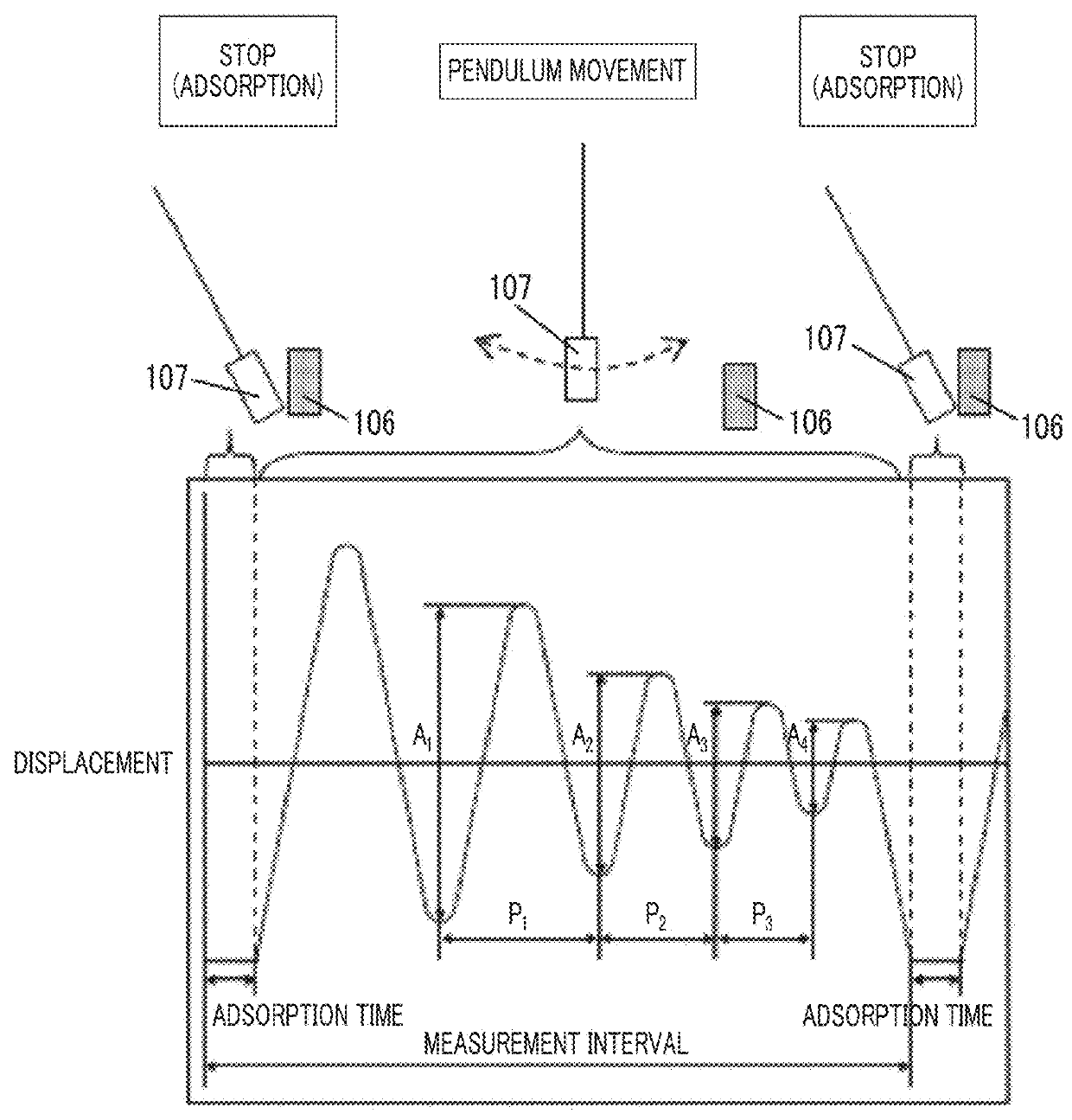

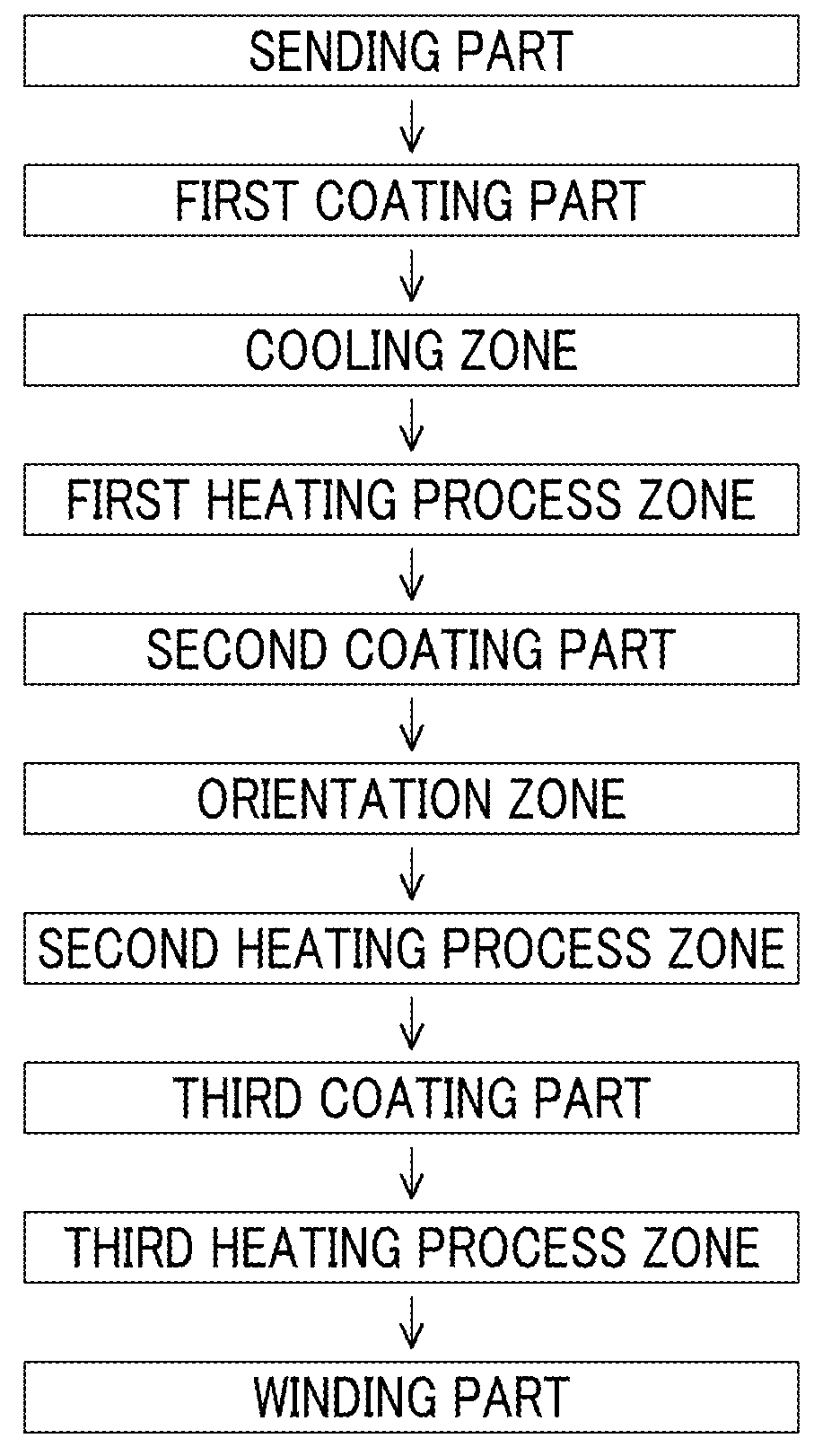

The magnetic tape device including: a magnetic tape; and a servo head, in which the servo head is a magnetic head including a tunnel magnetoresistance effect type element as a servo pattern reading element, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the magnetic layer includes a servo pattern, and logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding a surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

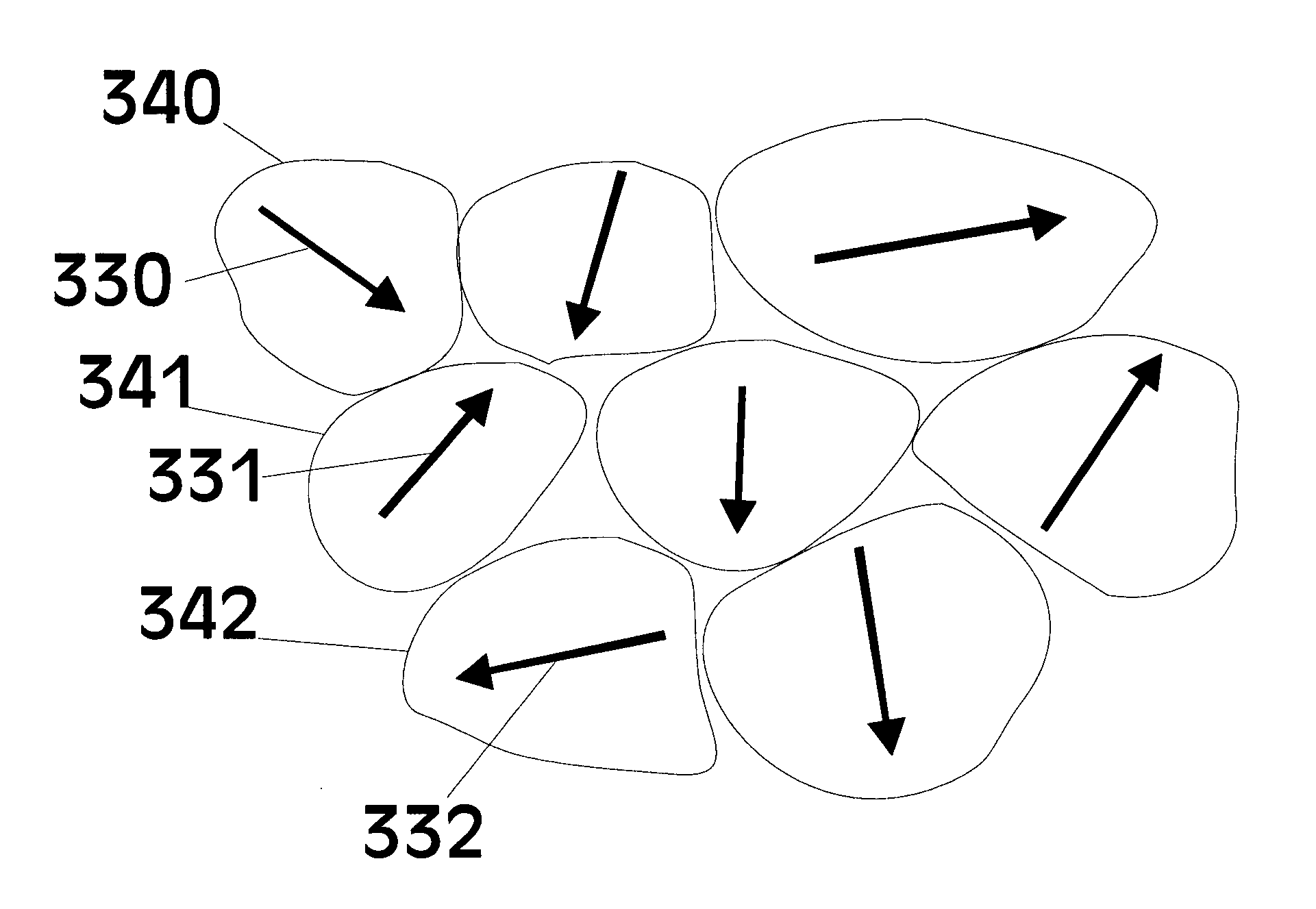

InactiveUS20180182427A1Avoid it happening againAvoiding characteristicFilamentary/web record carriersTape carriersMagnetic tapeElectron microscope

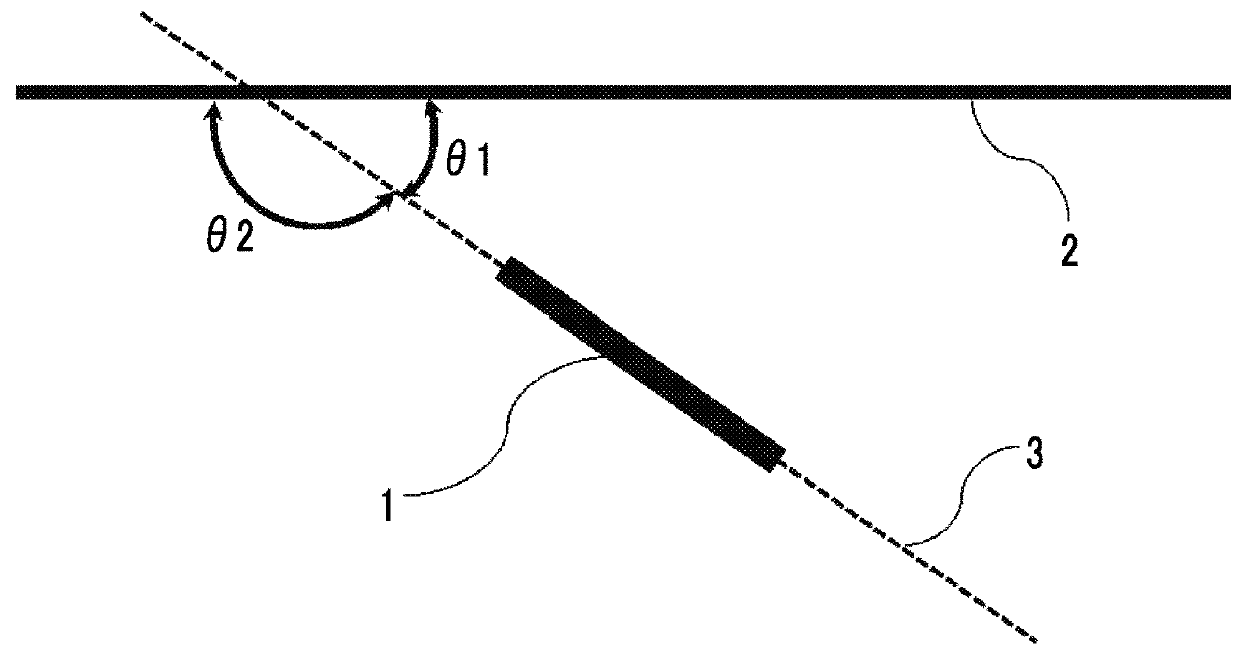

The magnetic tape device includes: a magnetic tape; and a reproducing head, in which a magnetic tape transportation speed of the magnetic tape device is equal to or lower than 18 m / sec, the reproducing head is a magnetic head including a tunnel magnetoresistance effect type element as a reproducing element, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic hexagonal ferrite powder, non-magnetic powder, and a binding agent on the non-magnetic support, and a tilt cos θ of the ferromagnetic hexagonal ferrite powder with respect to a surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 0.95.

Owner:FUJIFILM CORP

Magnetic tape device and head tracking servo method

ActiveUS20180182417A1Avoid it happening againImprove accuracyAlignment for track following on tapesRecord information storageMagnetic tapeEngineering

The magnetic tape device includes: a magnetic tape; and a servo head, in which a magnetic tape transportation speed of the magnetic tape device is equal to or lower than 18 m / sec, the servo head is a magnetic head including a tunnel magnetoresistance effect type element as a servo pattern reading element, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the magnetic layer includes a servo pattern, and a coefficient of friction measured regarding a base portion of a surface of the magnetic layer is equal to or smaller than 0.30.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180182425A1Avoid it happening againReduce resistanceMaterials with ironRecord information storageMagnetic tapeEngineering

The magnetic tape device includes: a magnetic tape; and a reproducing head, in which the reproducing head is a magnetic head including a tunnel magnetoresistance effect type element as a reproducing element, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, and logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180182429A1Avoid it happening againAvoiding characteristicMagnetic materials for record carriersBase layers for recording layersMagnetic tapeX-ray

The magnetic tape device includes: a magnetic tape; and a reproducing head, in which a magnetic tape transportation speed of the magnetic tape device is equal to or lower than 18 m / sec, the reproducing head is a magnetic head including a tunnel magnetoresistance effect type element as a reproducing element, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the magnetic layer includes one or more components selected from the group consisting of fatty acid and fatty acid amide, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %.

Owner:FUJIFILM CORP

High performance magnetic tunnel barriers with amorphous materials

ActiveUS20060003185A1Improve barrier propertiesImprove performanceNanomagnetismNanoinformaticsTunnel junctionMagnetic layer

A magnetic tunneling element is constructed from a MgO or Mg—ZnO tunnel barrier and an amorphous magnetic layer in proximity with the tunnel barrier. The amorphous magnetic layer includes Co and at least one additional element selected to make the layer amorphous. Magnetic tunnel junctions formed from the amorphous magnetic layer, the tunnel barrier, and an additional ferromagnetic layer have tunneling magnetoresistance values of up to 200% or more.

Owner:IBM CORP

Magnetic tape device and head tracking servo method

ActiveUS20190130936A1Improve accuracyExact reproductionAlignment for track following on tapesRecord information storageMagnetic tapeEngineering

Owner:FUJIFILM CORP

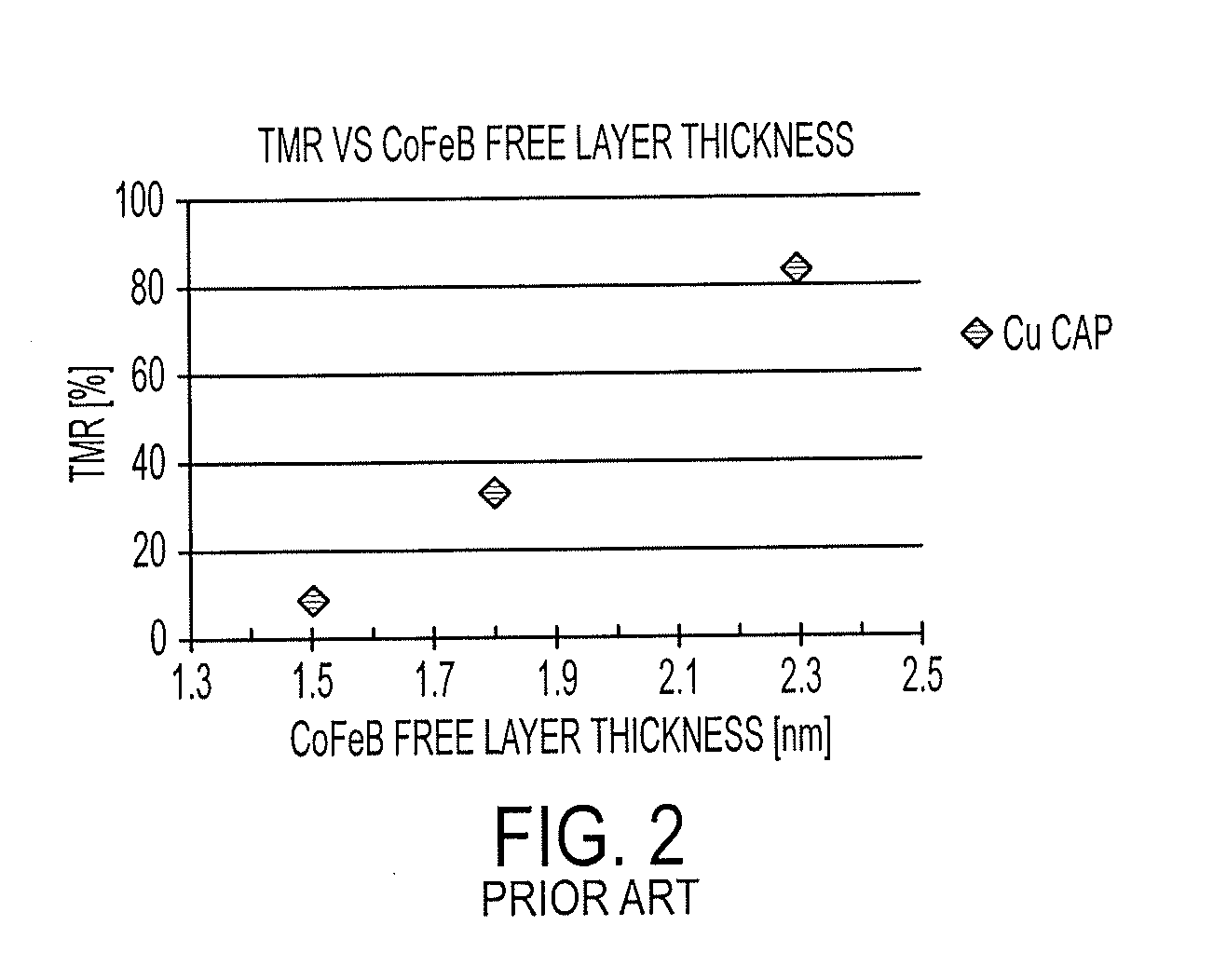

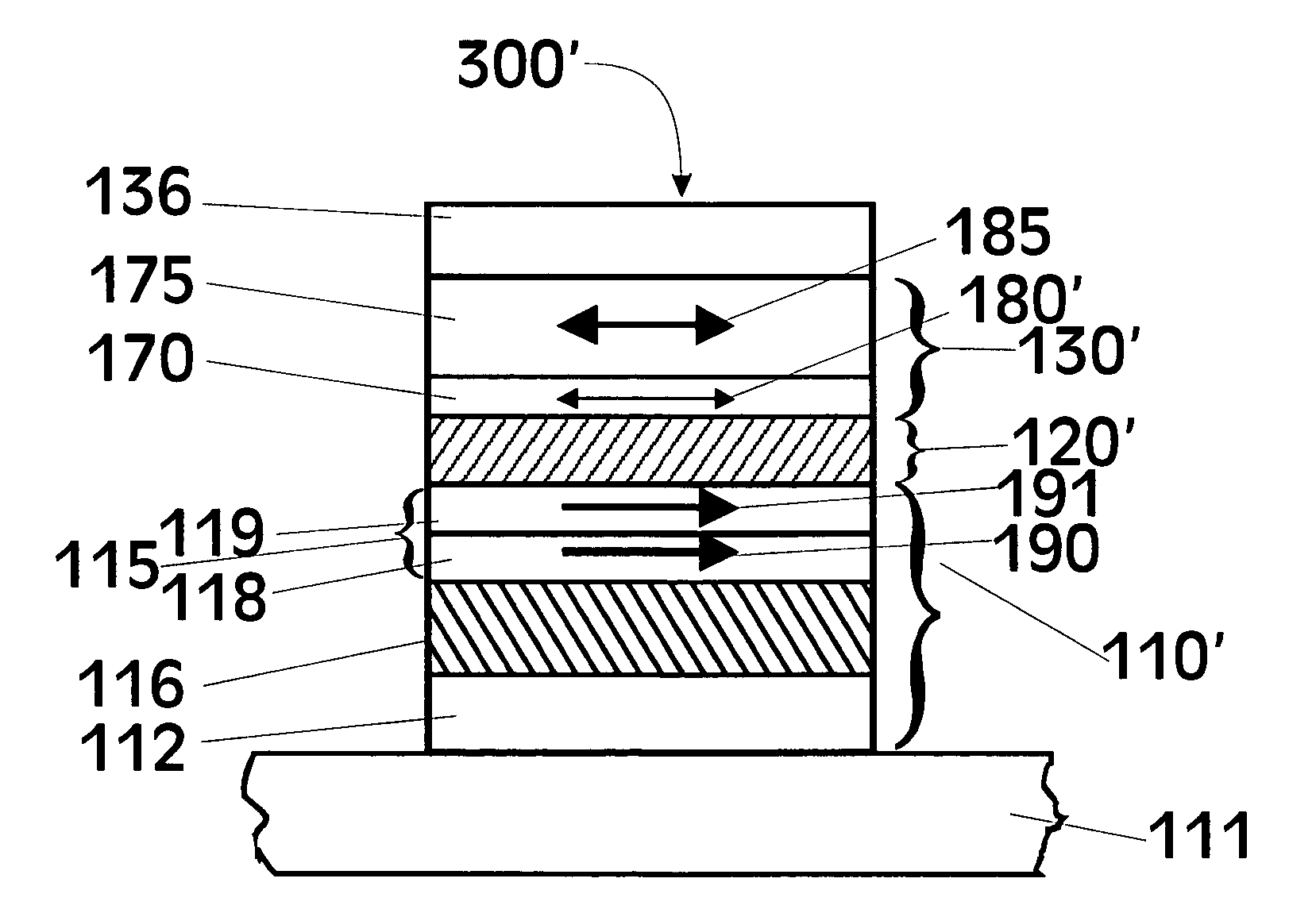

Magnetic tunnel junction structure for MRAM device

ActiveUS20160087193A1Increase TMR valueOptimized free layer magnetic propertiesNanomagnetismSolid-state devicesTantalum nitridePolarizer

A magnetic tunnel junction stack is provided that includes nonmagnetic spacer layers between the free layer and the polarizer layer formed from magnesium oxide and tantalum nitride materials that balance the spin torques acting on the free layer. The design provided enables a deterministic final state for the storage layer and significantly improves the tunneling magnetoresistance value and switching characteristics of the magnetic tunnel junction for MRAM applications.

Owner:INTEGRATED SILICON SOLUTION CAYMAN INC

Magnetic tape device and magnetic reproducing method

InactiveUS20180182426A1Avoid it happening againAvoiding characteristicFilamentary/web record carriersRecord information storageMagnetic tapeNon magnetic

The a magnetic tape device includes: a magnetic tape; and a reproducing head, in which a magnetic tape transportation speed of the magnetic tape device is equal to or lower than 18 m / sec, the reproducing head is a magnetic head including a tunnel magnetoresistance effect type element as a reproducing element, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, and a contact angle with respect to 1-bromonaphthalene measured regarding a surface of the magnetic layer is 48.0° to 53.0°.

Owner:FUJIFILM CORP

High performance magnetic tunnel barriers with amorphous materials

ActiveUS7270896B2High spin polarization valueEasy to manufactureNanomagnetismNanoinformaticsTunnel junctionMagnetic layer

A magnetic tunneling element is constructed from a MgO or Mg—ZnO tunnel barrier and an amorphous magnetic layer in proximity with the tunnel baffler. The amorphous magnetic layer includes Co and at least one additional element selected to make the layer amorphous. Magnetic tunnel junctions formed from the amorphous magnetic layer, the tunnel barrier, and an additional ferromagnetic layer have tunneling magnetoresistance values of up to 200% or more.

Owner:IBM CORP

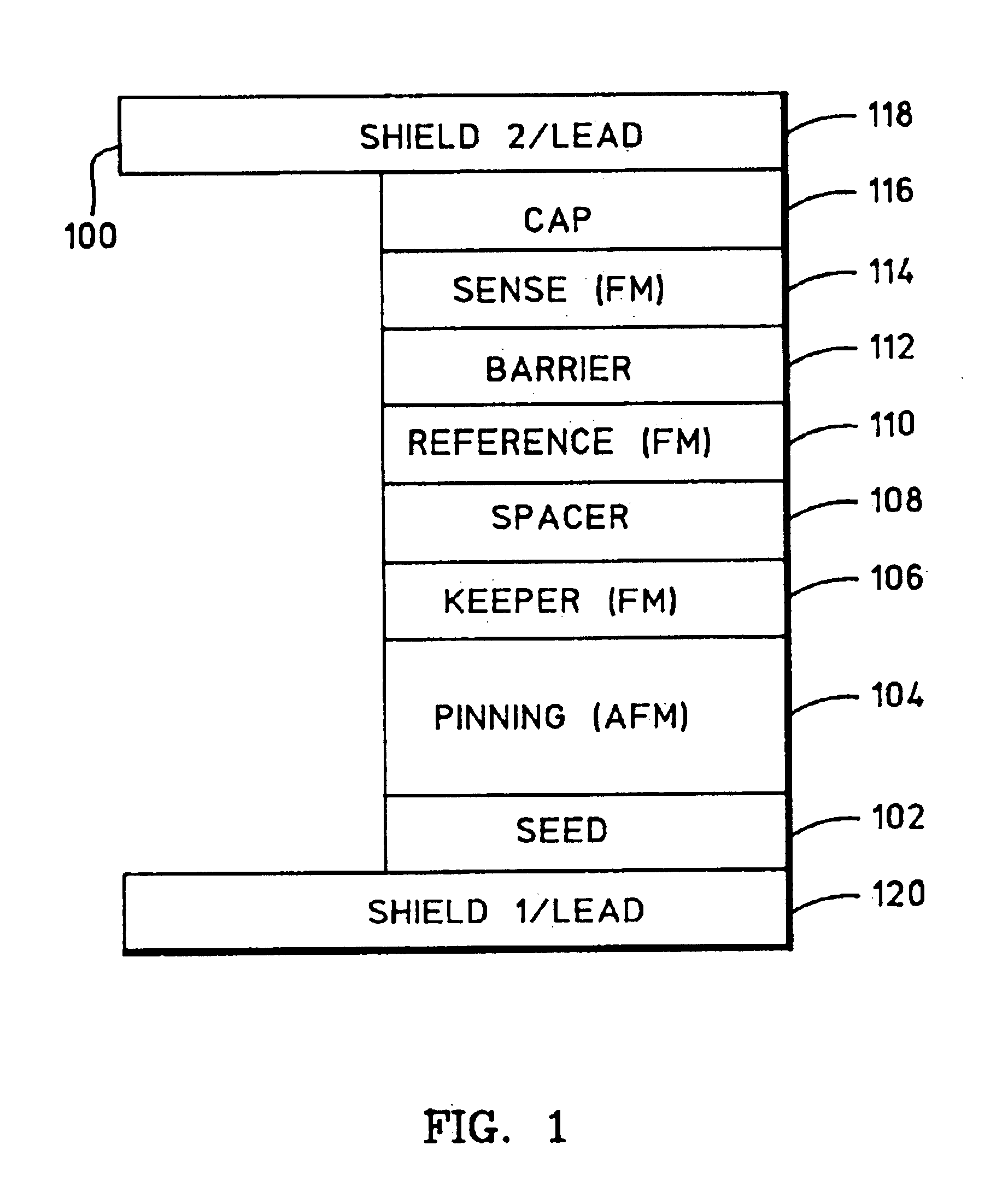

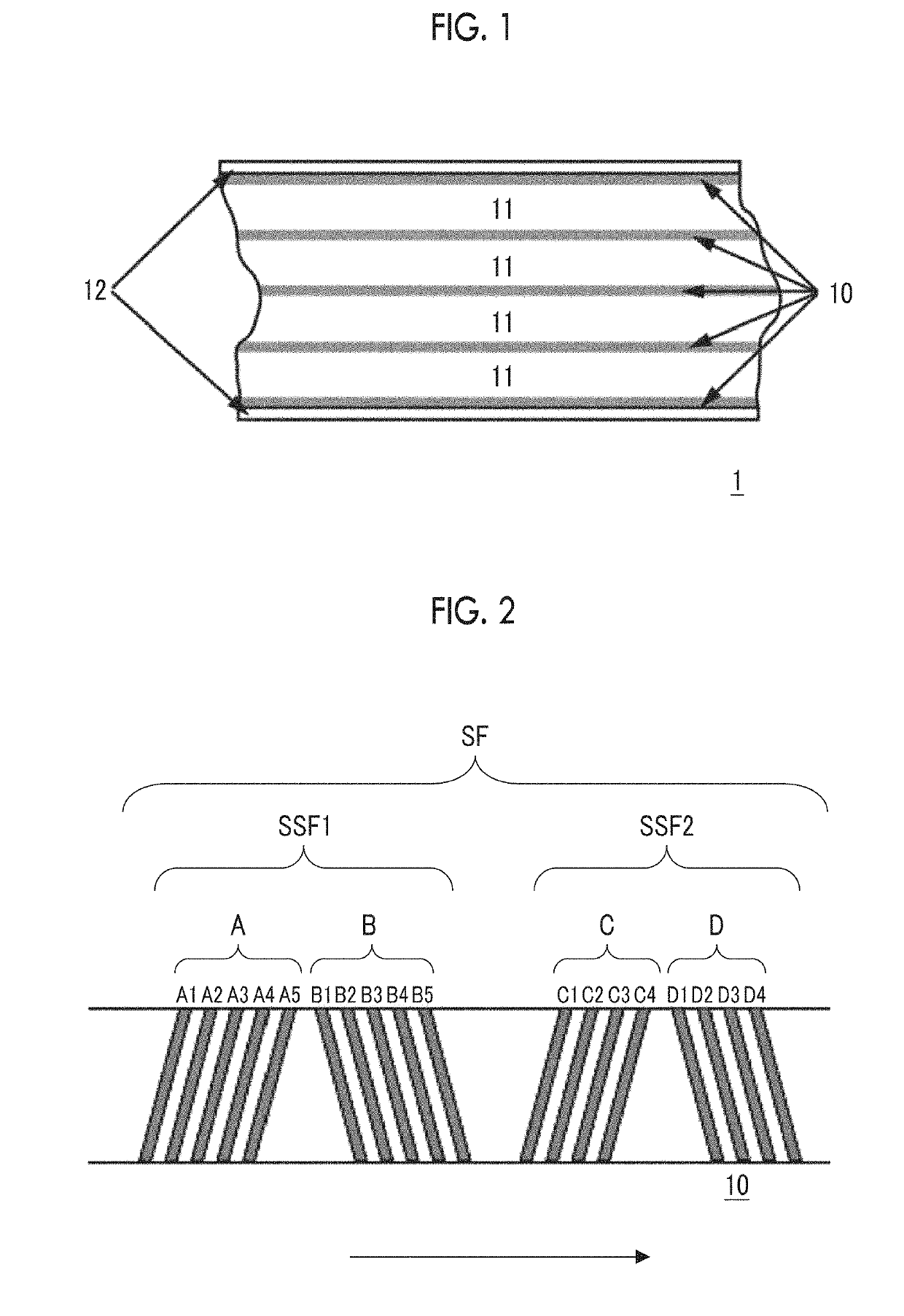

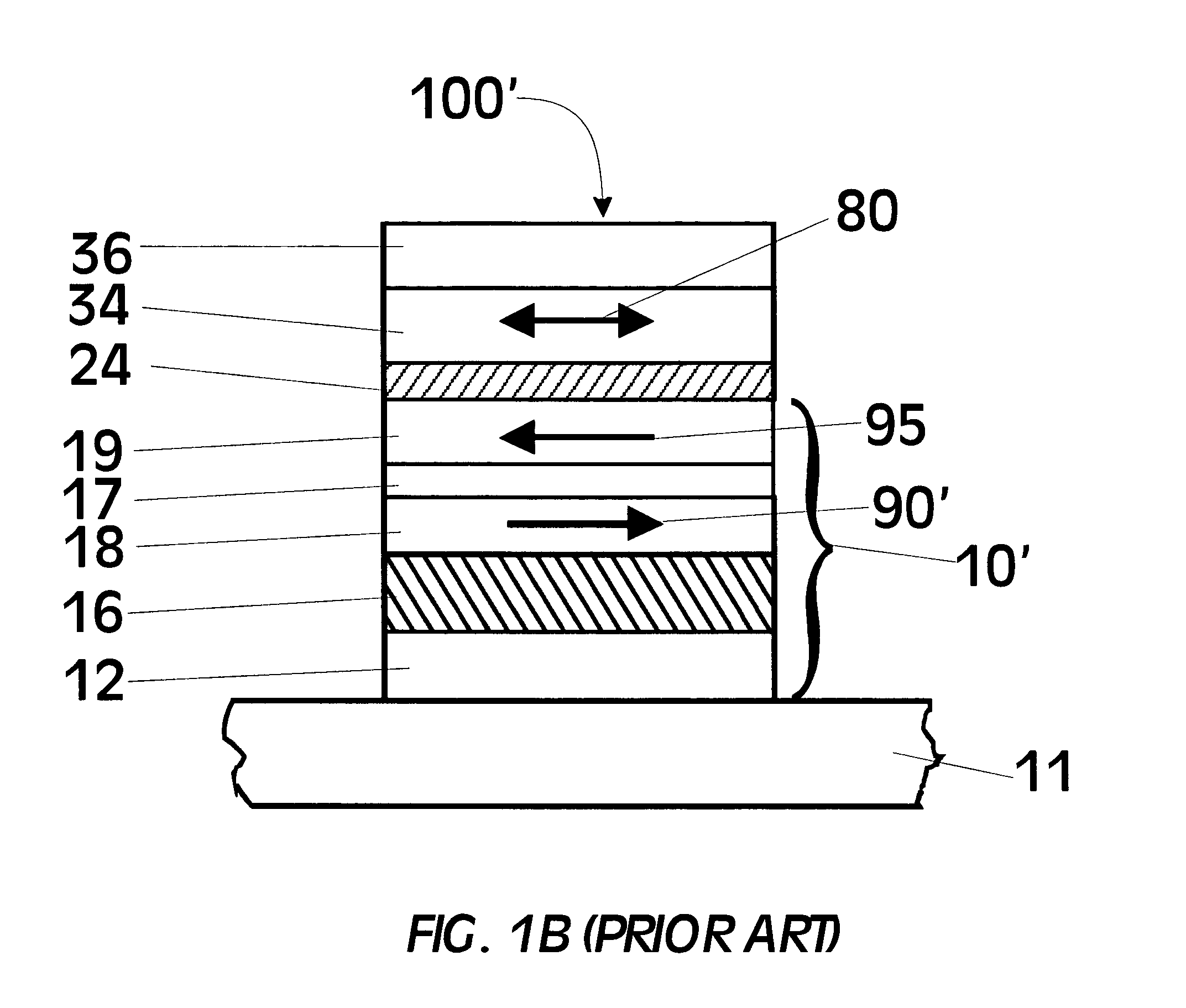

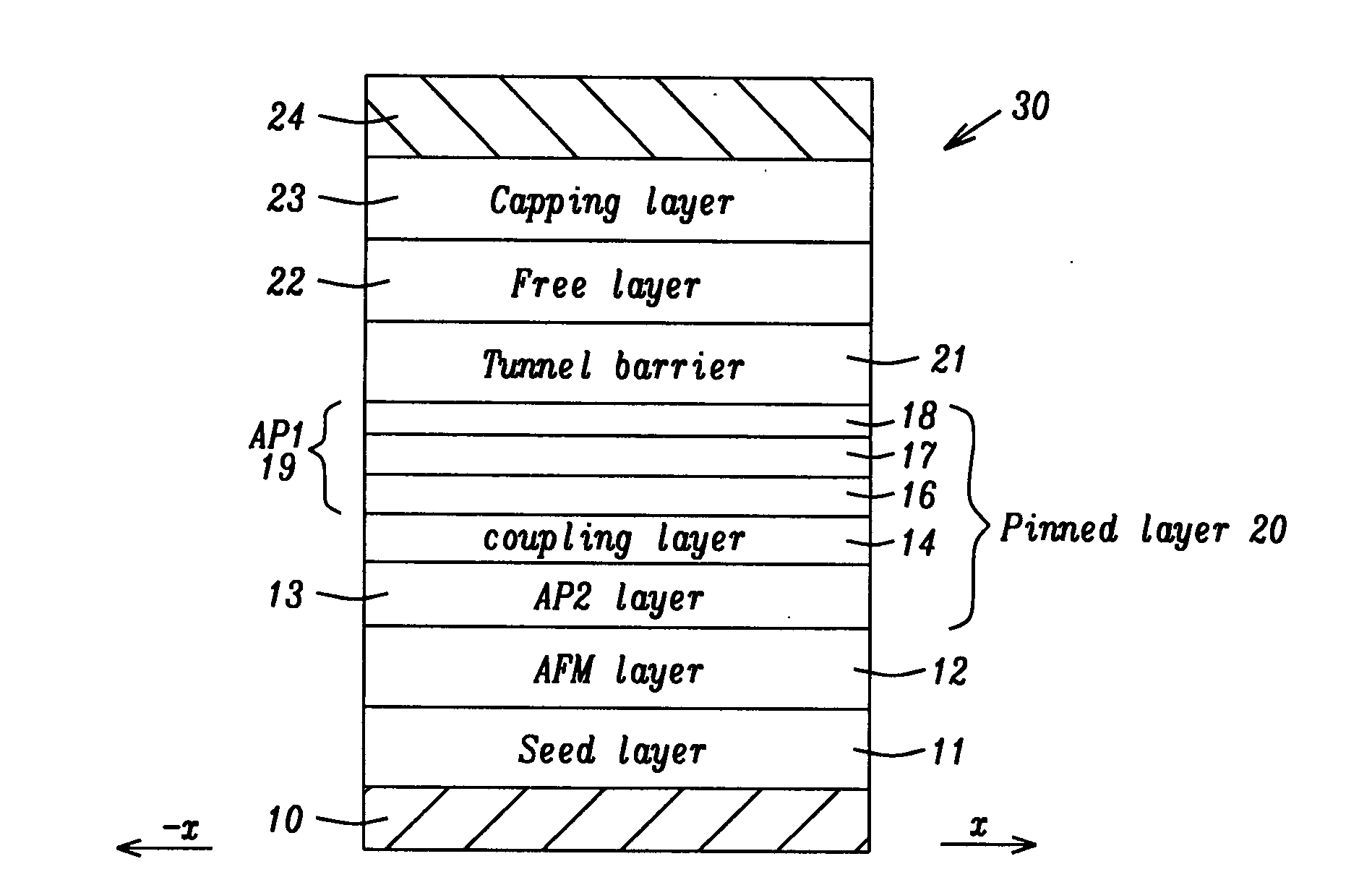

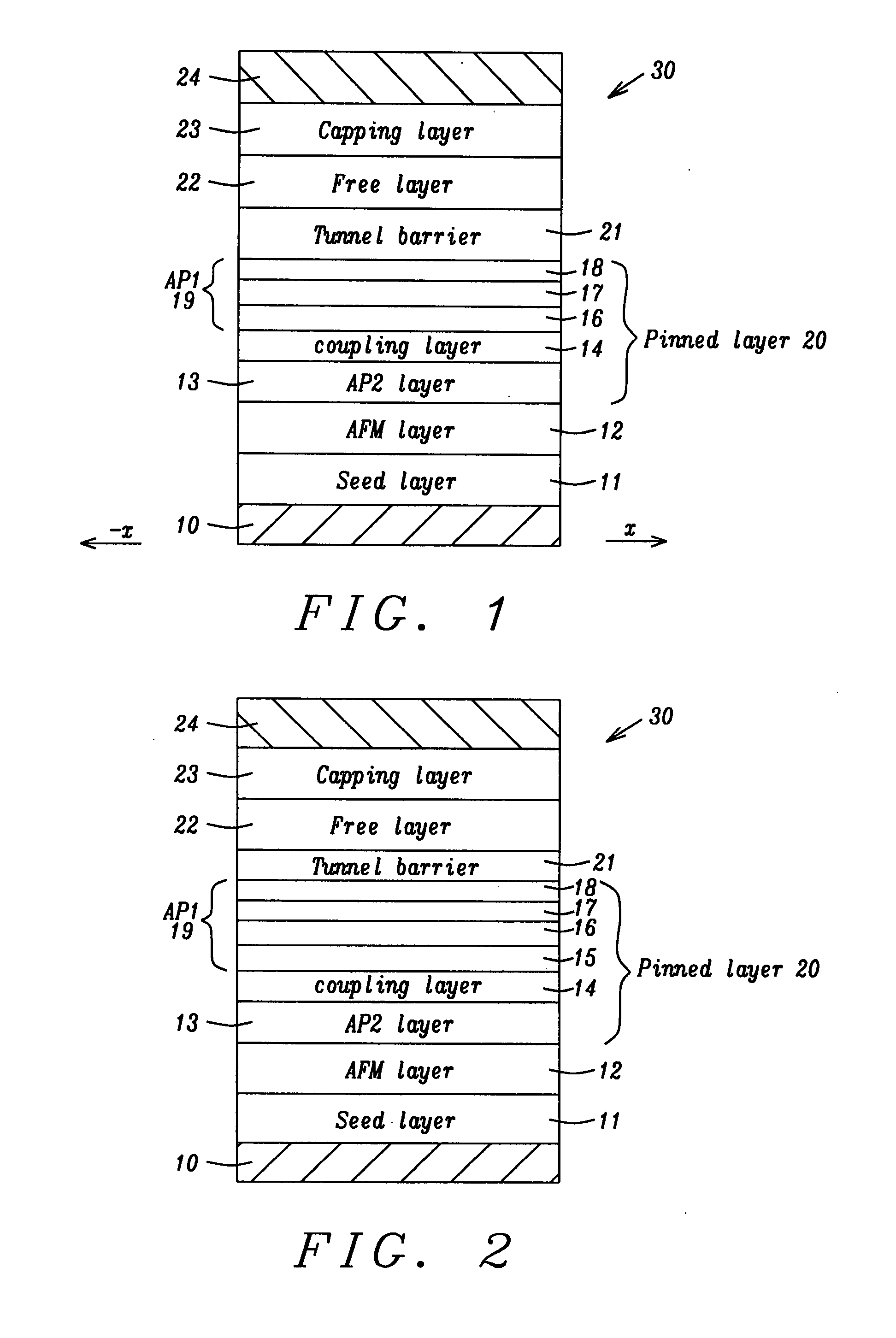

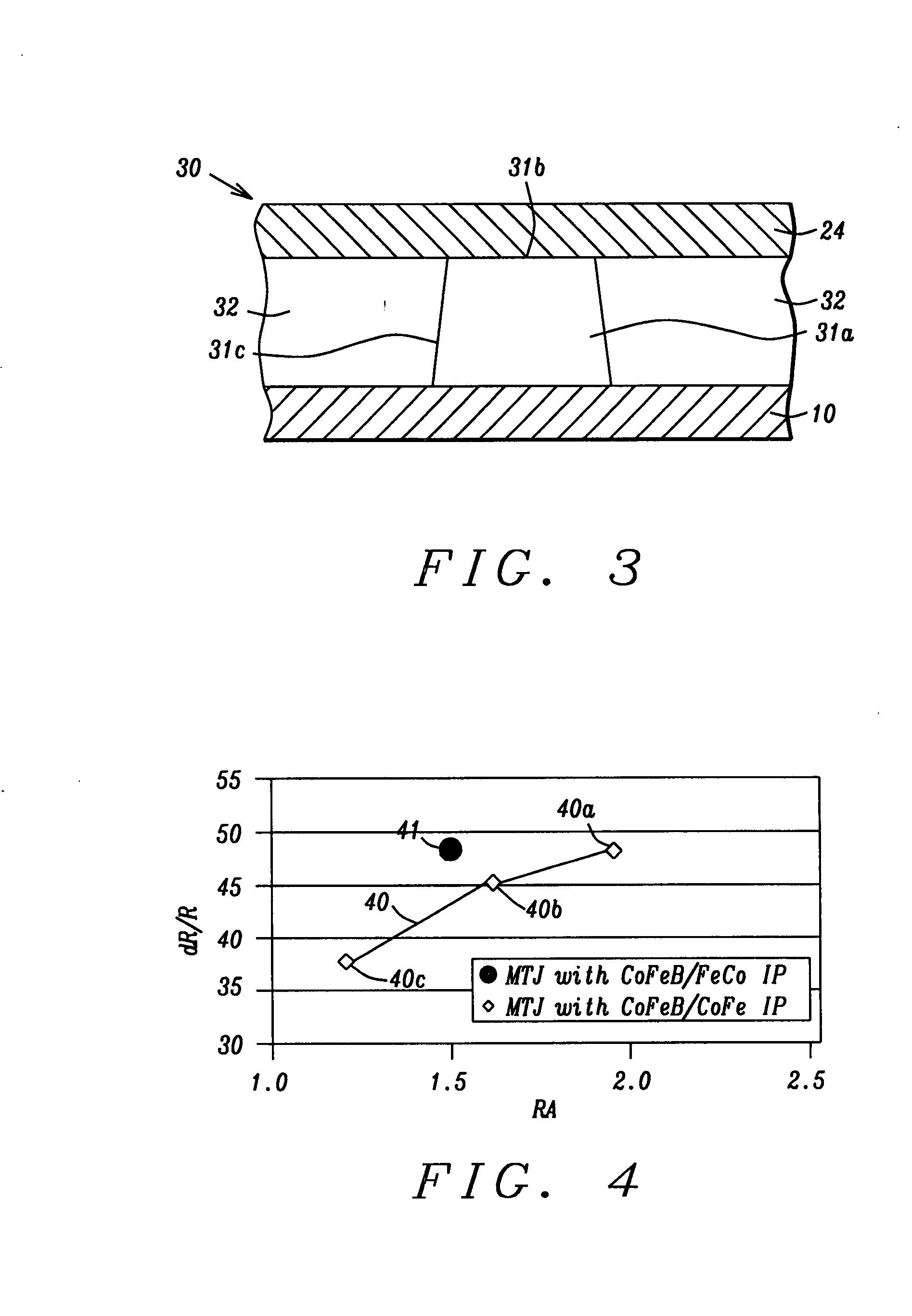

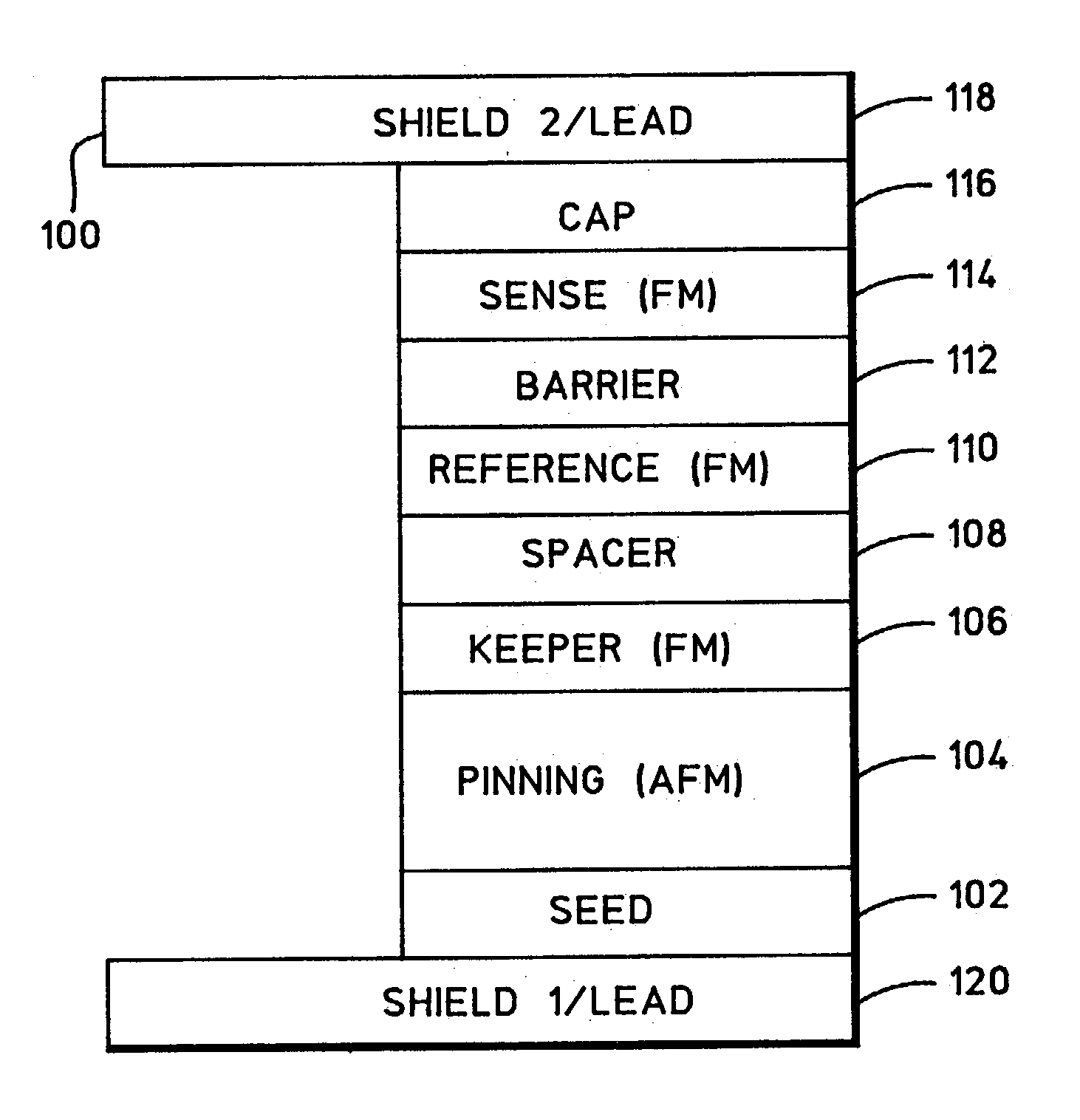

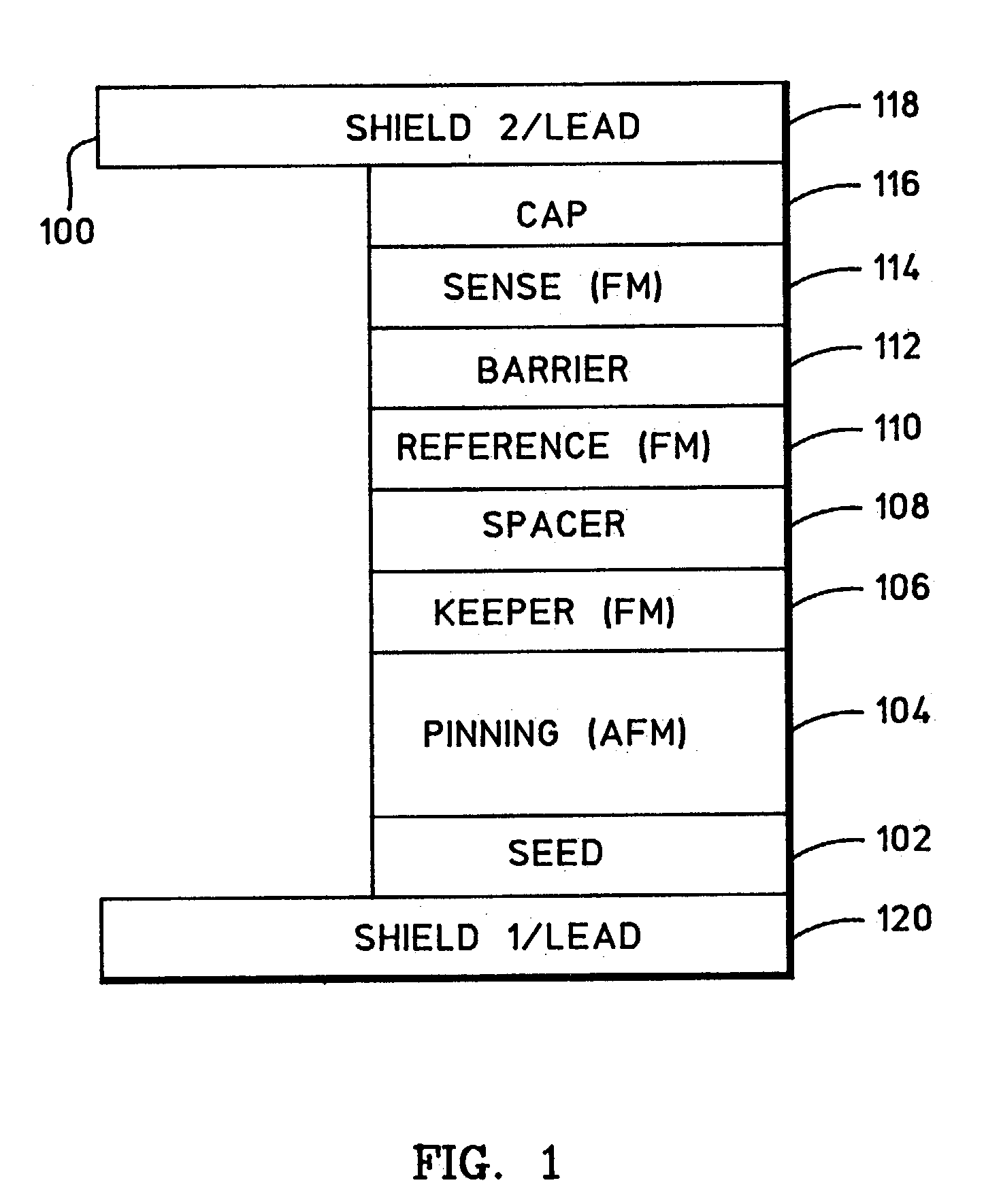

Low resistance tunneling magnetoresistive sensor with composite inner pinned layer

A high performance TMR sensor is fabricated by employing a composite inner pinned (AP1) layer in an AP2 / Ru / AP1 pinned layer configuration. In one embodiment, there is a 10 to 80 Angstrom thick lower CoFeB or CoFeB alloy layer on the Ru coupling layer, a and 5 to 50 Angstrom thick Fe or Fe alloy layer on the CoFeB or CoFeB alloy, and a 5 to 30 Angstrom thick Co or Co rich alloy layer formed on the Fe or Fe alloy. A MR ratio of about 48% with a RA of <2 ohm-um2 is achieved when a CoFe AP2 layer, MgO (NOX) tunnel barrier, and CoFe / NiFe free layer are used in the TMR stack. Improved RA uniformity and less head noise are observed. Optionally, a CoFe layer may be inserted between the coupling layer and CoFeB or CoFeB alloy layer to improve pinning strength and enhance crystallization.

Owner:HEADWAY TECH INC

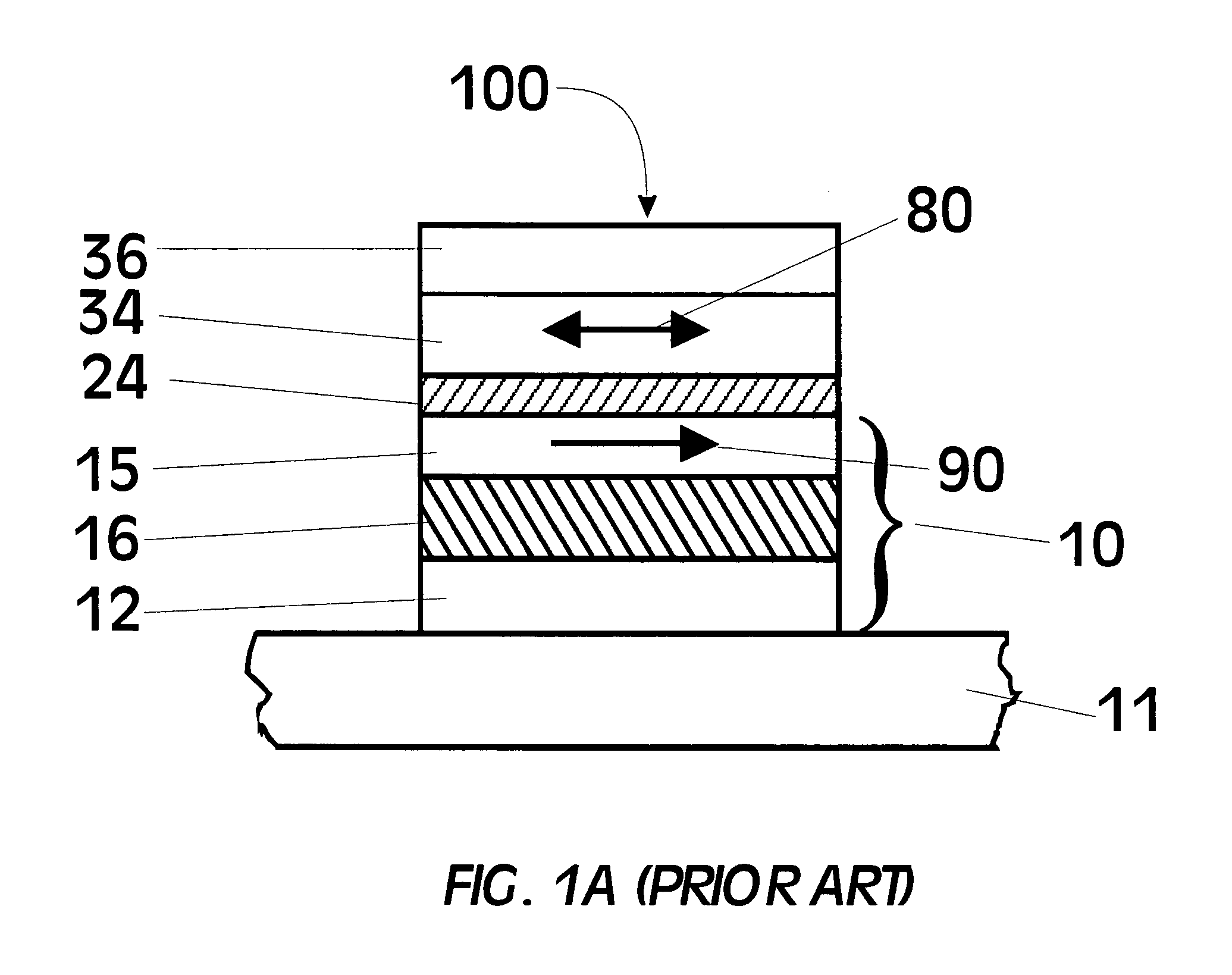

Magnetic sensor with perpendicular anisotrophy free layer and side shields

ActiveUS20110007429A1Increase the areaMagnetic measurementsMagnetic-field-controlled resistorsPerpendicular anisotropyMagnetization

A tunneling magneto-resistive reader includes a sensor stack separating a top magnetic shield from a bottom magnetic shield. The sensor stack includes a reference magnetic element having a reference magnetization orientation direction and a free magnetic element having a free magnetization orientation direction substantially perpendicular to the reference magnetization orientation direction. A non-magnetic spacer layer separates the reference magnetic element from the free magnetic element. A first side magnetic shield and a second side magnetic shield is disposed between the top magnetic shield from a bottom magnetic shield, and the sensor stack is between the first side magnetic shield and the second side magnetic shield. The first side magnetic shield and the second side magnetic shield electrically insulates the top magnetic shield from a bottom magnetic shield.

Owner:SEAGATE TECH LLC

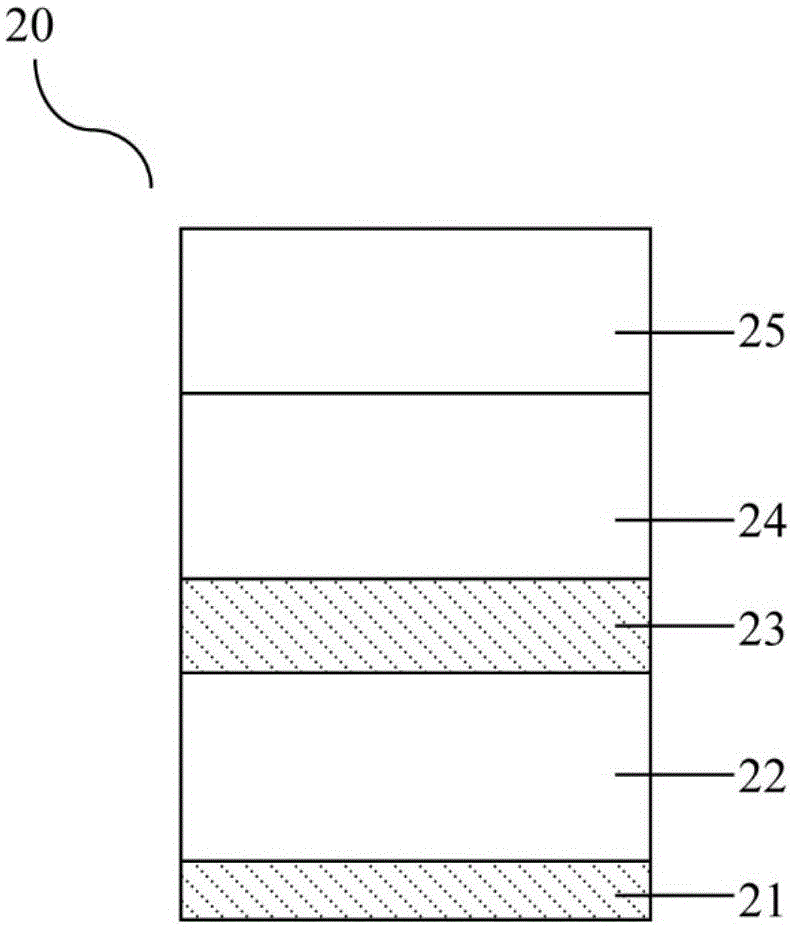

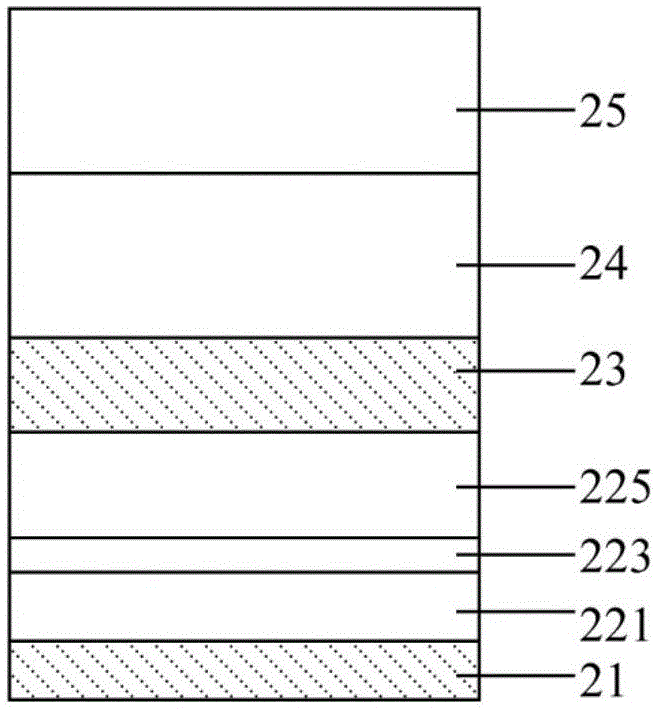

Magnetoresistive Element, Magnetic Memory Cell and Magnetic Random Access Memory Using the Same

ActiveUS20100034014A1Improve thermal stabilityLong retention timeMagnetic-field-controlled resistorsSolid-state devicesSpin-transfer torqueRandom access memory

Provided is a high-speed and ultra-low-power-consumption nonvolatile memory having a high temperature stability at a zero magnetic field. In a tunnel magnetoresistive film constituting a nonvolatile magnetic memory that employs a writing method using a spin-transfer torque, an insulating layer and a nonmagnetic conductive layer are stacked above a ferromagnetic free layer.

Owner:TOHOKU UNIV

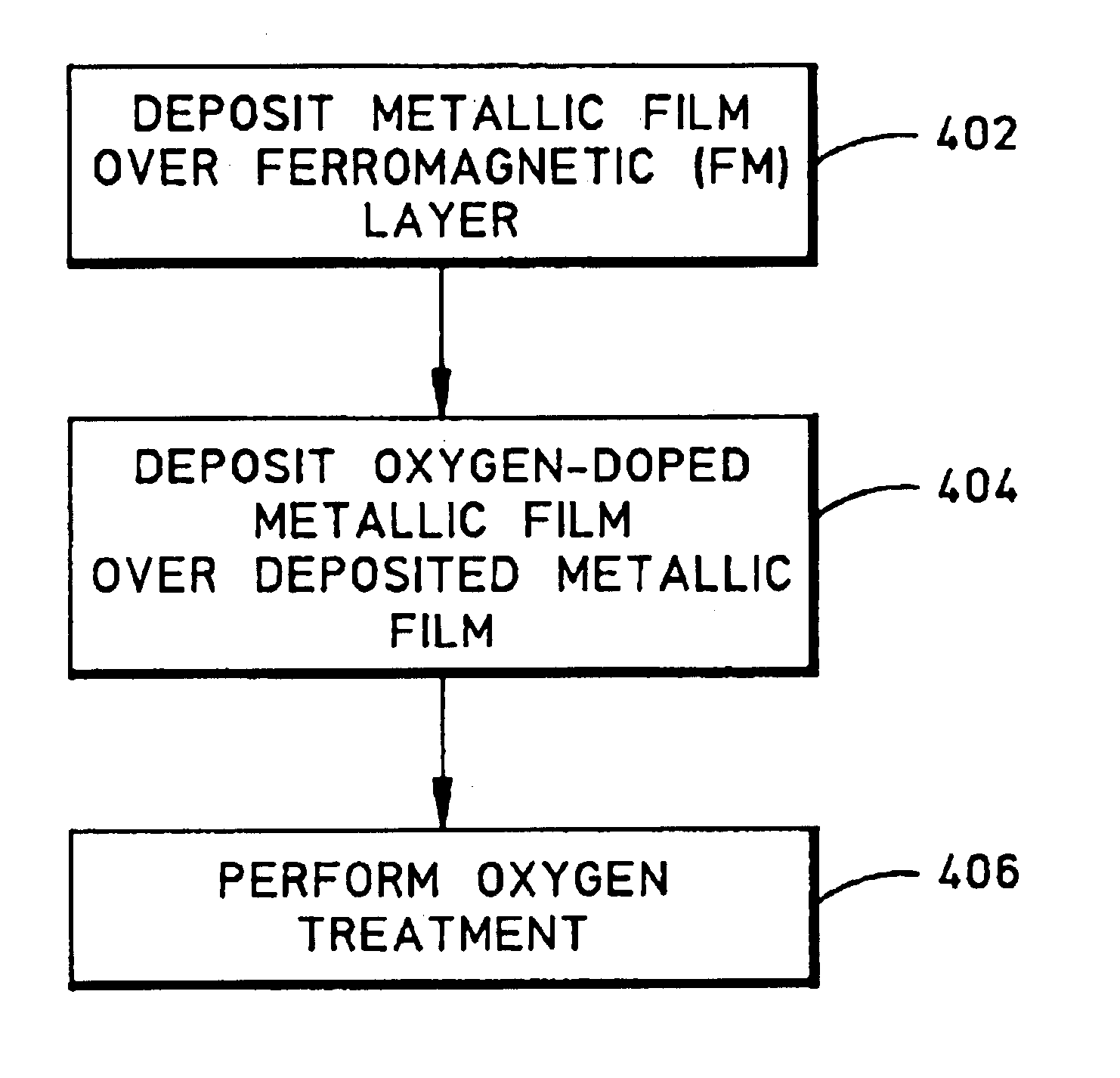

Method of forming a barrier layer of a tunneling magnetoresistive sensor

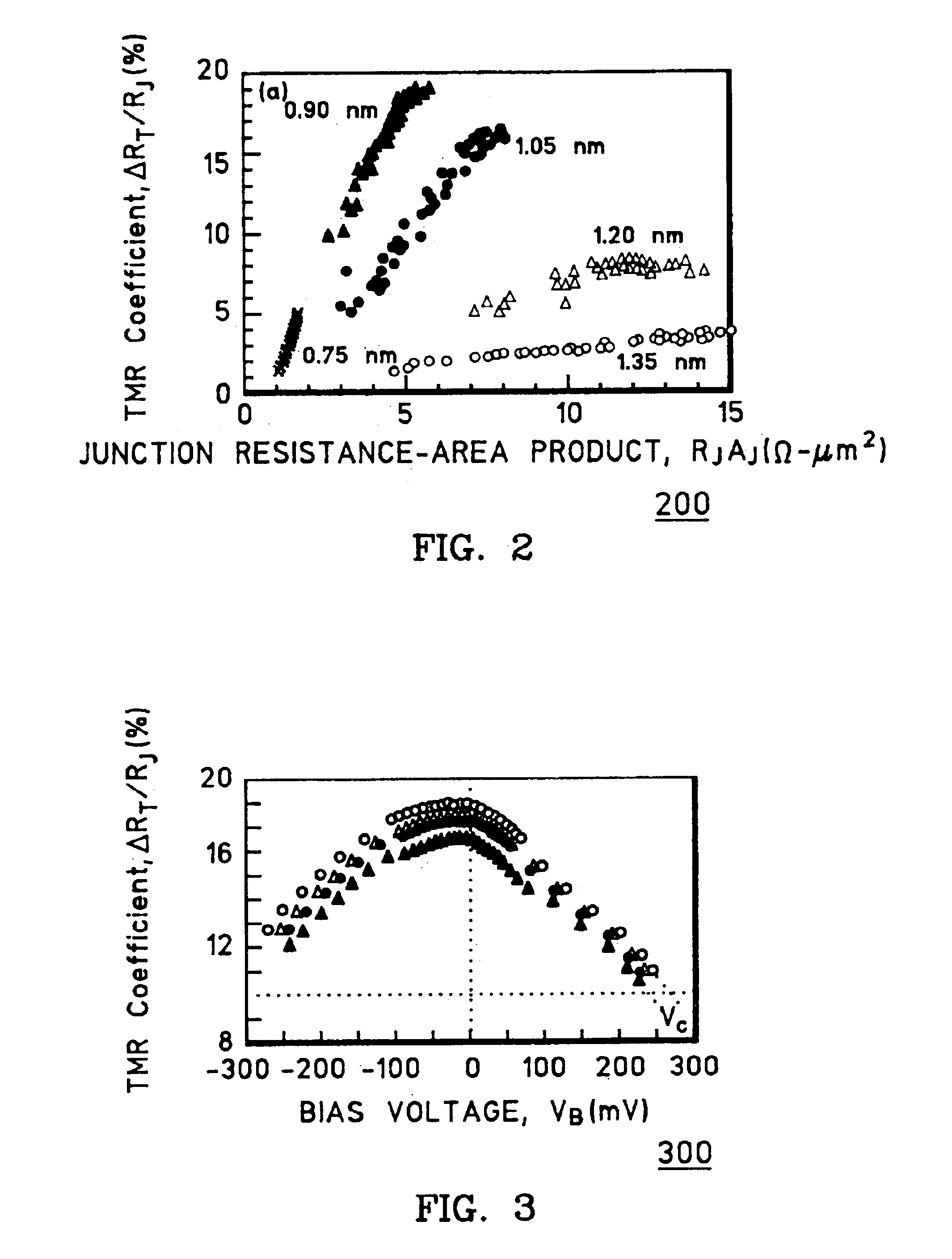

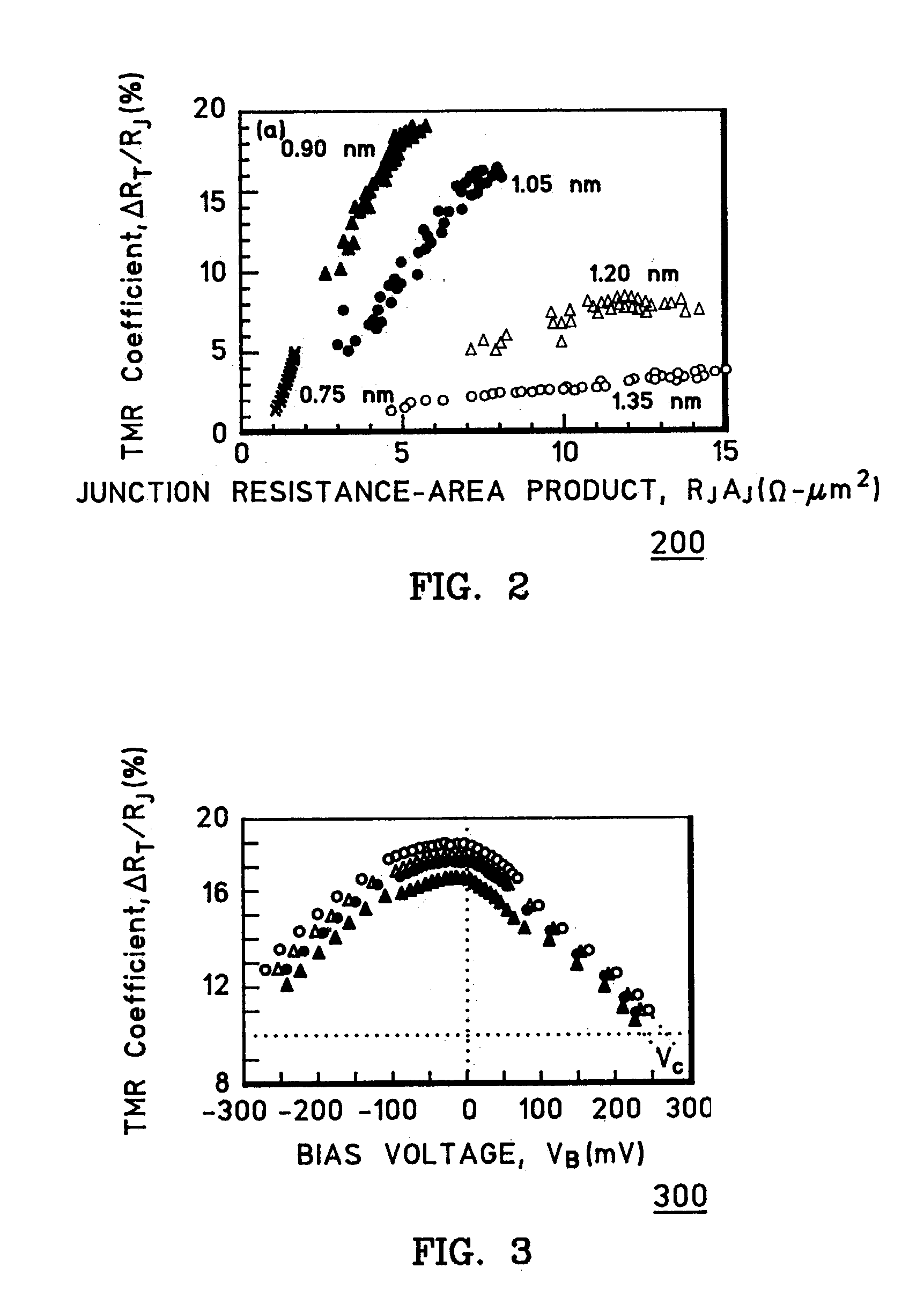

A fabrication process for a tunneling magnetoresistance (TMR) sensor is disclosed. In particular, a unique method of forming a barrier layer of the TMR sensor is utilized so that the TMR sensor exhibits good magnetic and TMR properties. In one particular example, the barrier layer is formed by depositing a metallic film in an argon gas in a DC magnetron sputtering module, depositing an oxygen-doped metallic film in mixed xenon and oxygen gases in an ion-beam sputtering module, and oxidizing these films in an oxygen gas in an oxygen treatment module. This three-step barrier layer formation process minimizes oxygen penetration into ferromagnetic (FM) sense and pinned layers of the TMR sensor and optimally controls oxygen doping into the barrier layer. As a result, the FM sense and pinned layers exhibit controlled magnetic properties, the barrier layer provides a low junction resistance-area product, and the TMR sensor exhibits a high TMR coefficient.

Owner:GLOBALFOUNDRIES INC

Method of forming a magnetic tunneling junction (MTJ) MRAM device and a tunneling magnetoresistive (TMR) read head

ActiveUS6960480B1Easy to controlSignificant exchangeNanostructure applicationNanomagnetismRandom access memoryThin layer

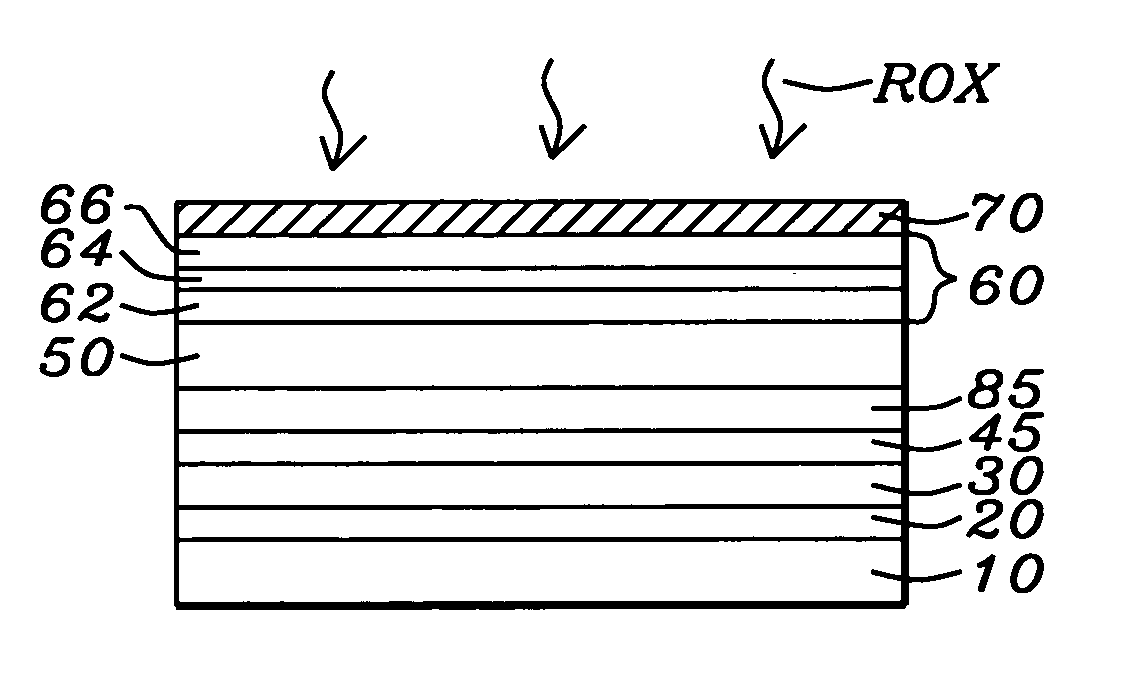

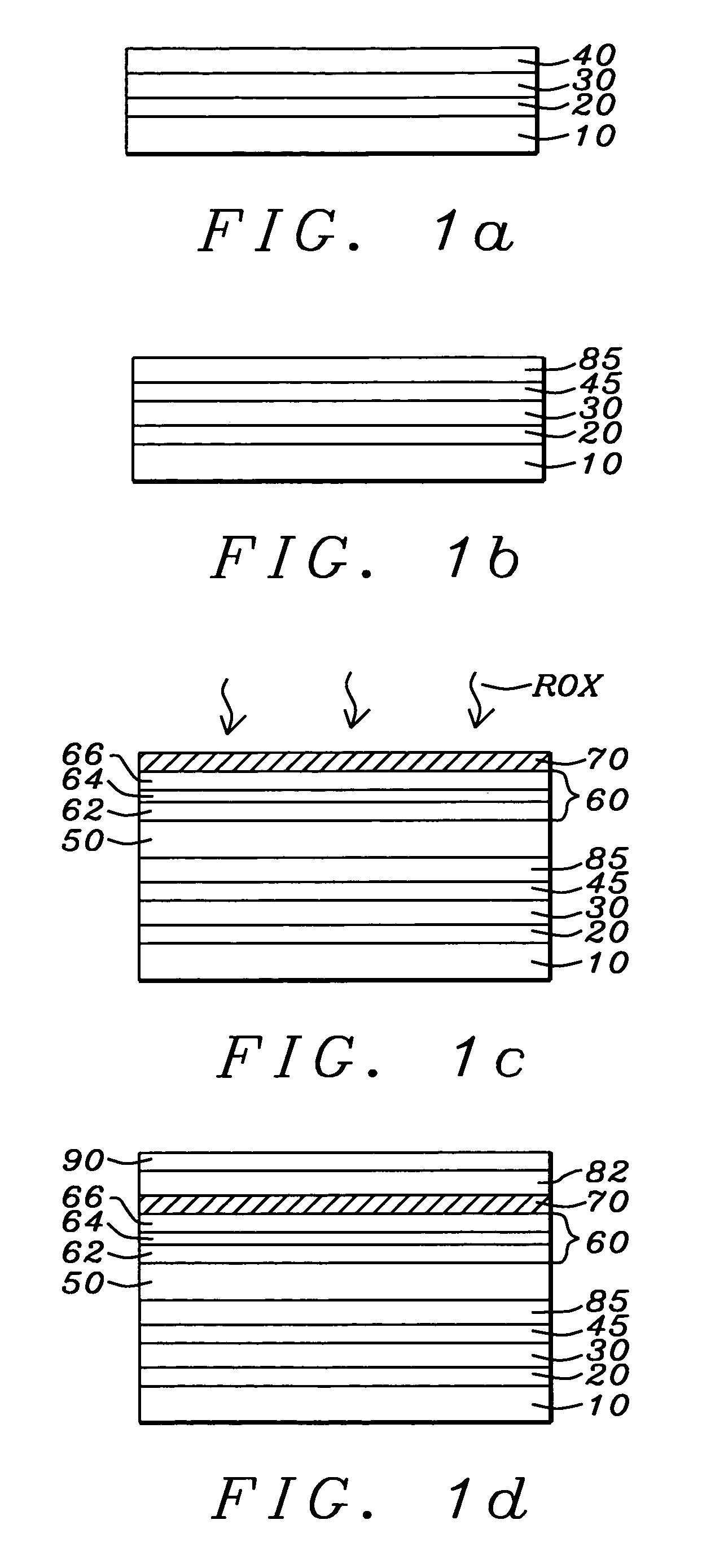

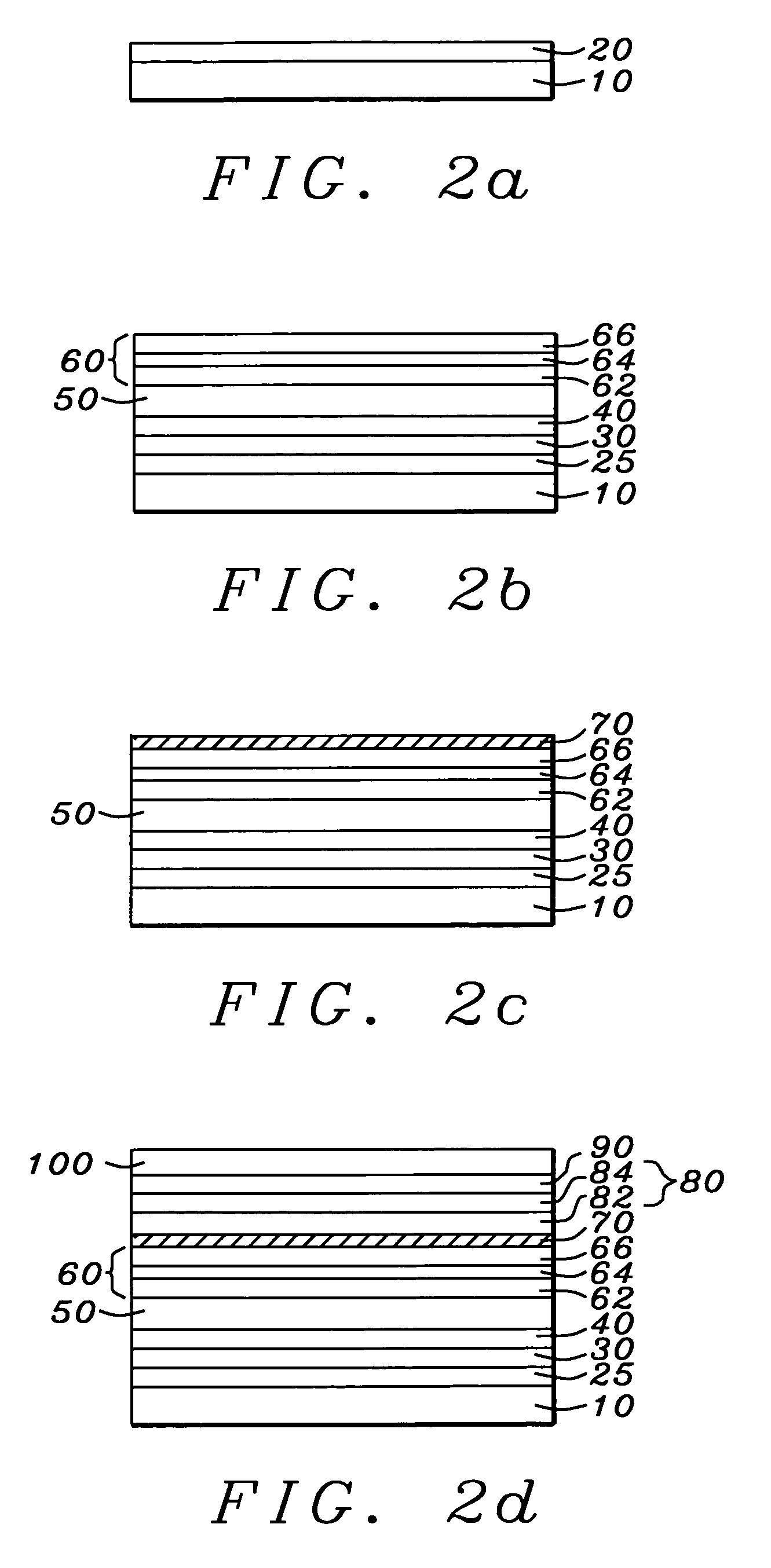

An MTJ (magnetic tunneling junction) device particularly suitable for use as an MRAM (magnetic random access memory) or a tunneling magnetoresistive (TMR) read sensor, is formed on a seed layer which allows the tunneling barrier layer to be ultra-thin, smooth, and to have a high breakdown voltage. The seed layer is a layer of NiCr which is formed on a sputter-etched layer of Ta. The tunneling barrier layer for the MRAM is formed from a thin layer of Al which is radically oxidized (ROX), in-situ, to form the layer with characteristics described above. The tunneling barrier layer for the read sensor formed from a thin layer of Al or a HfAl bilayer which is naturally oxidized (NOX), in situ, to form the barrier layer. The resulting device has generally improved performance characteristics in terms of GMR ratio and junction resistance.

Owner:APPLIED SPINTRONICS +1

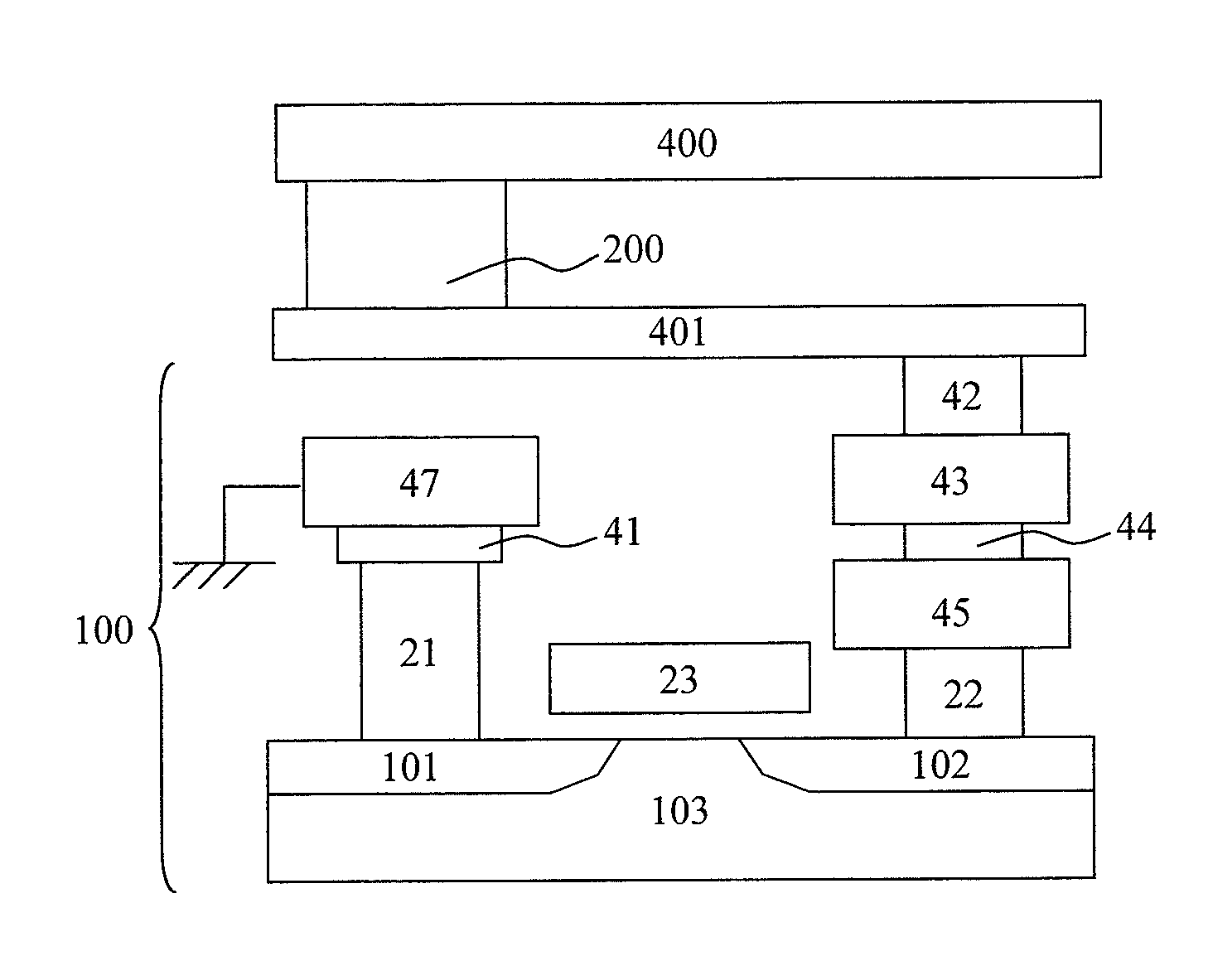

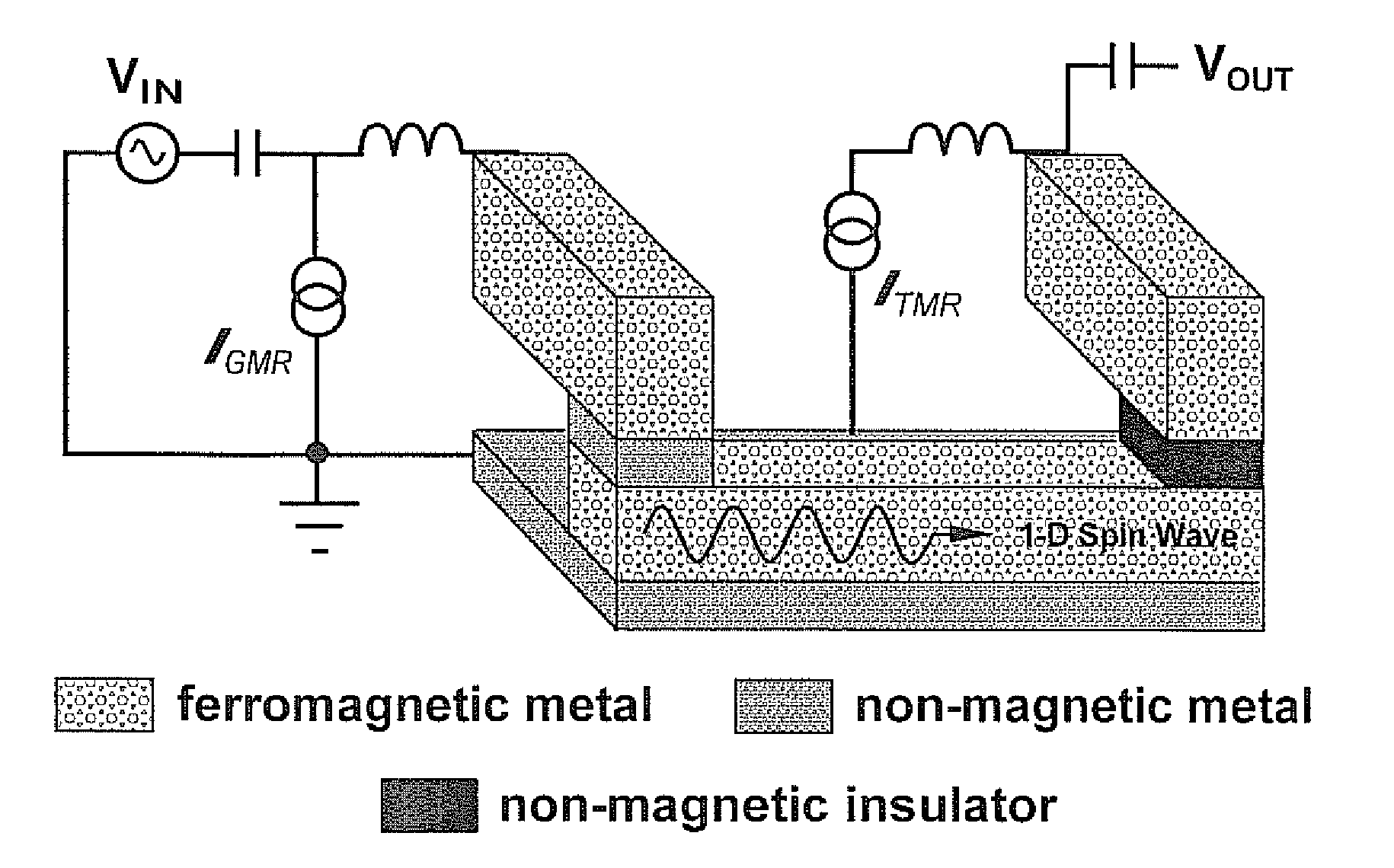

Three-terminal spin-torque oscillator (STO)

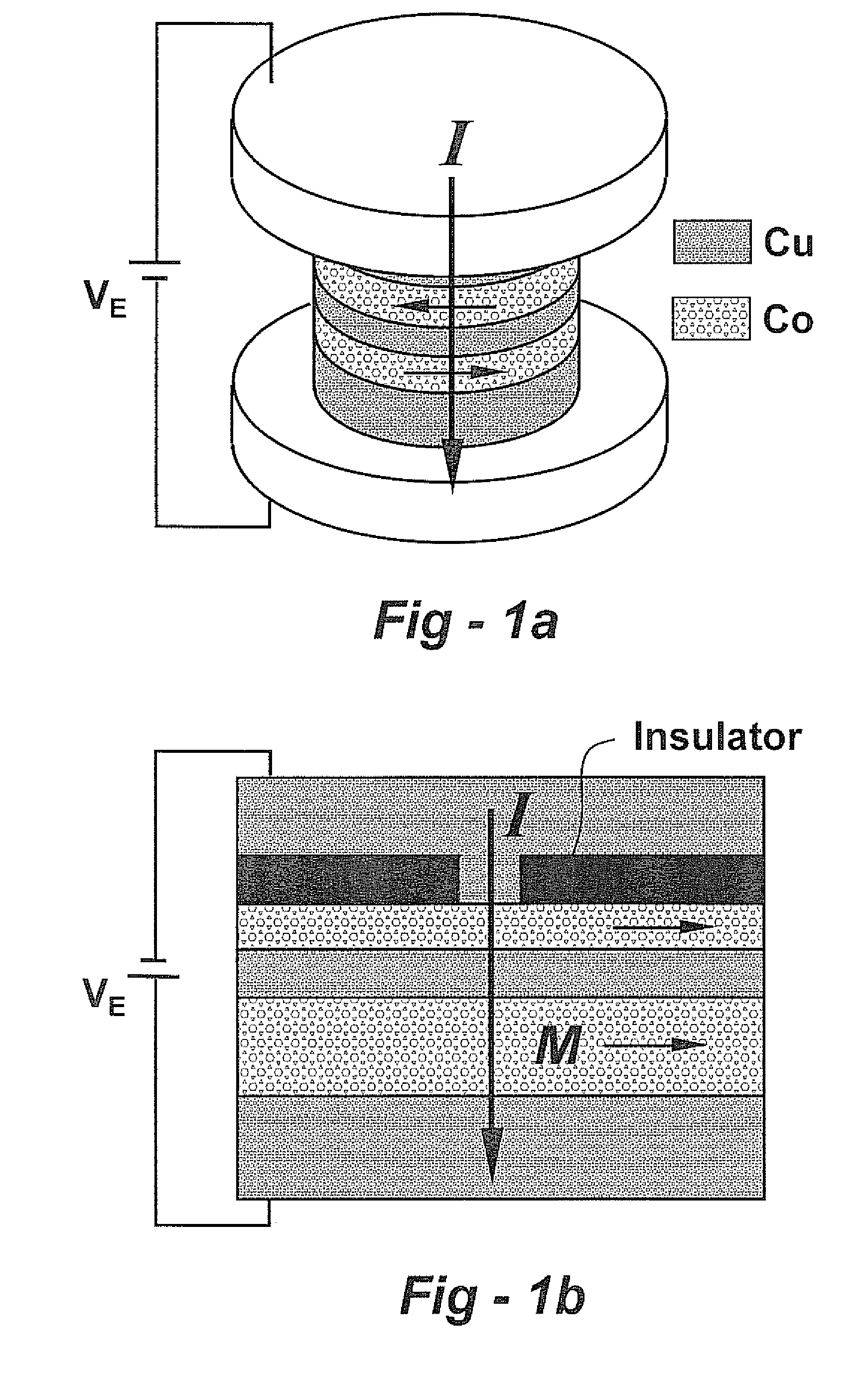

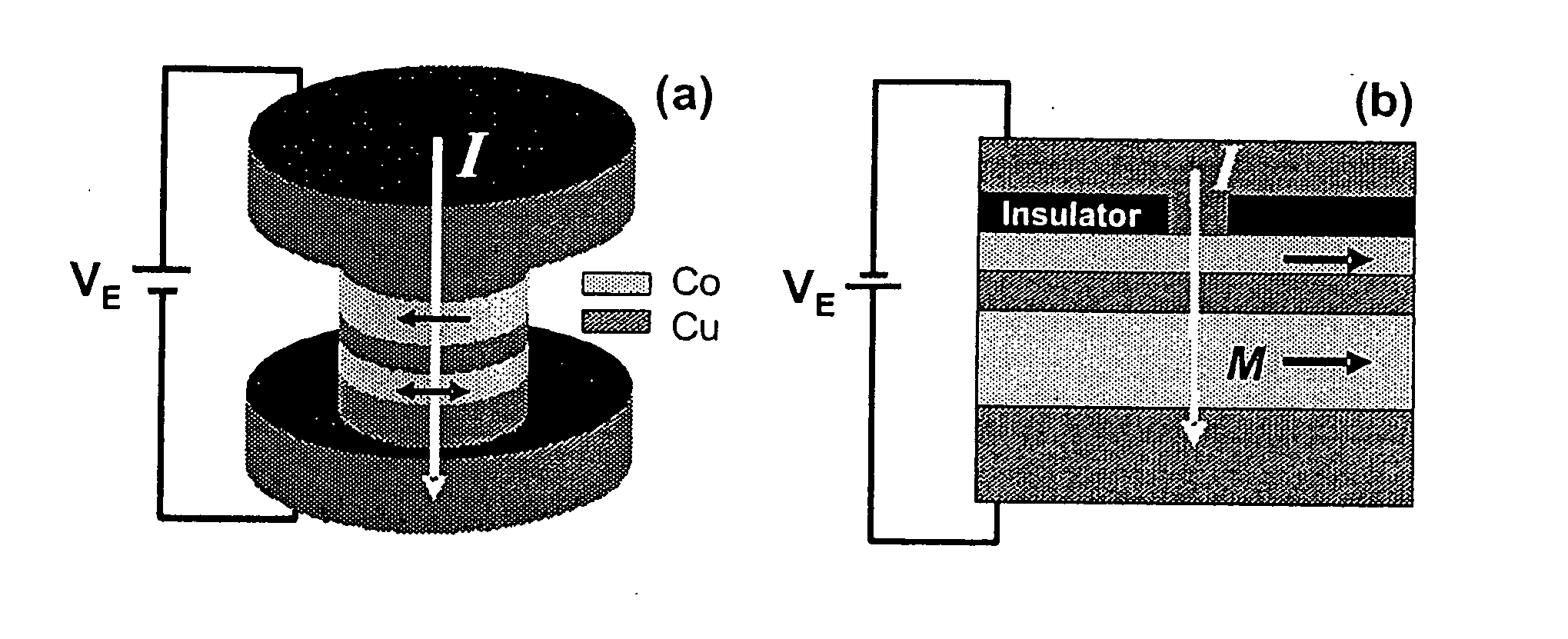

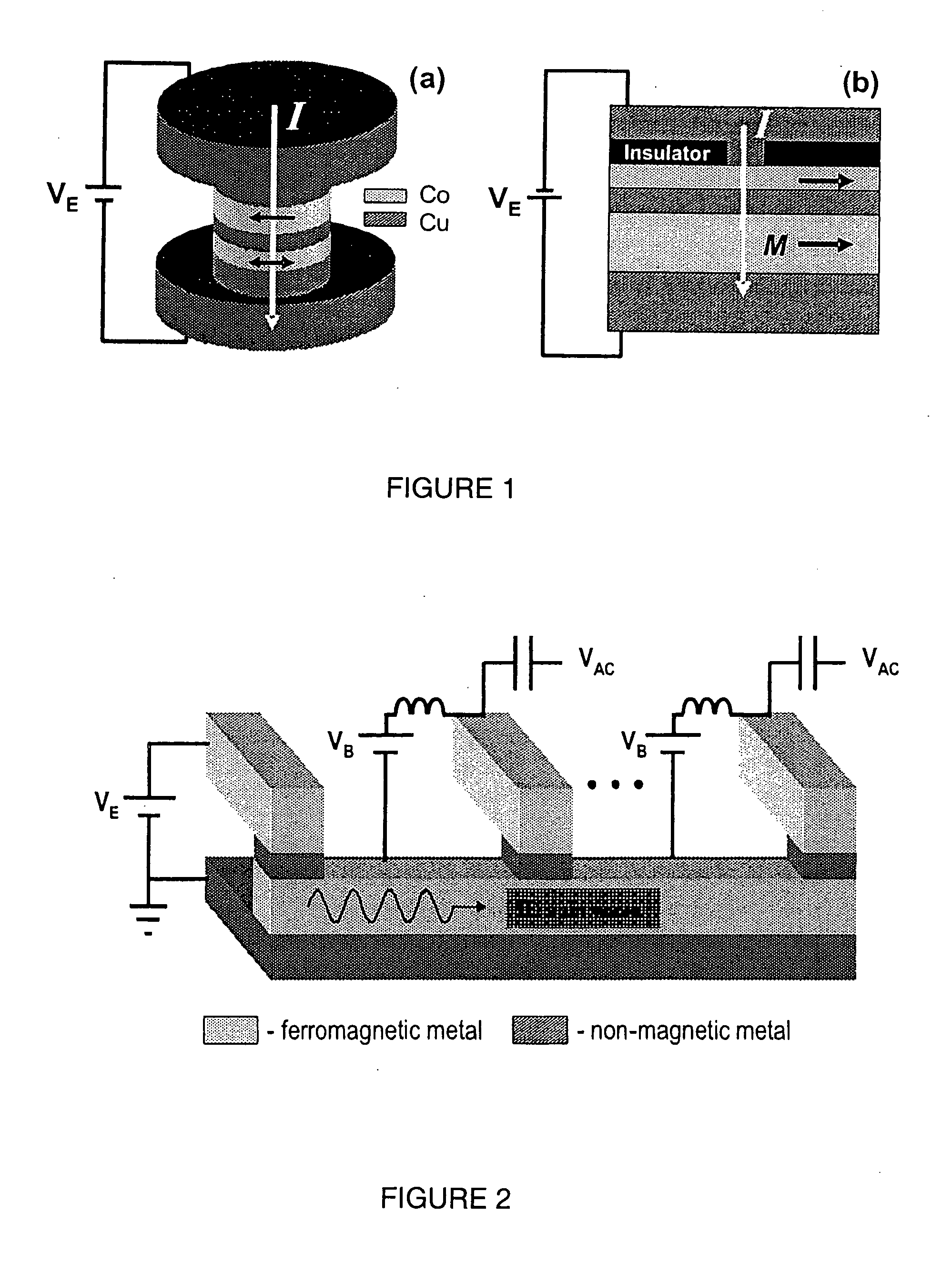

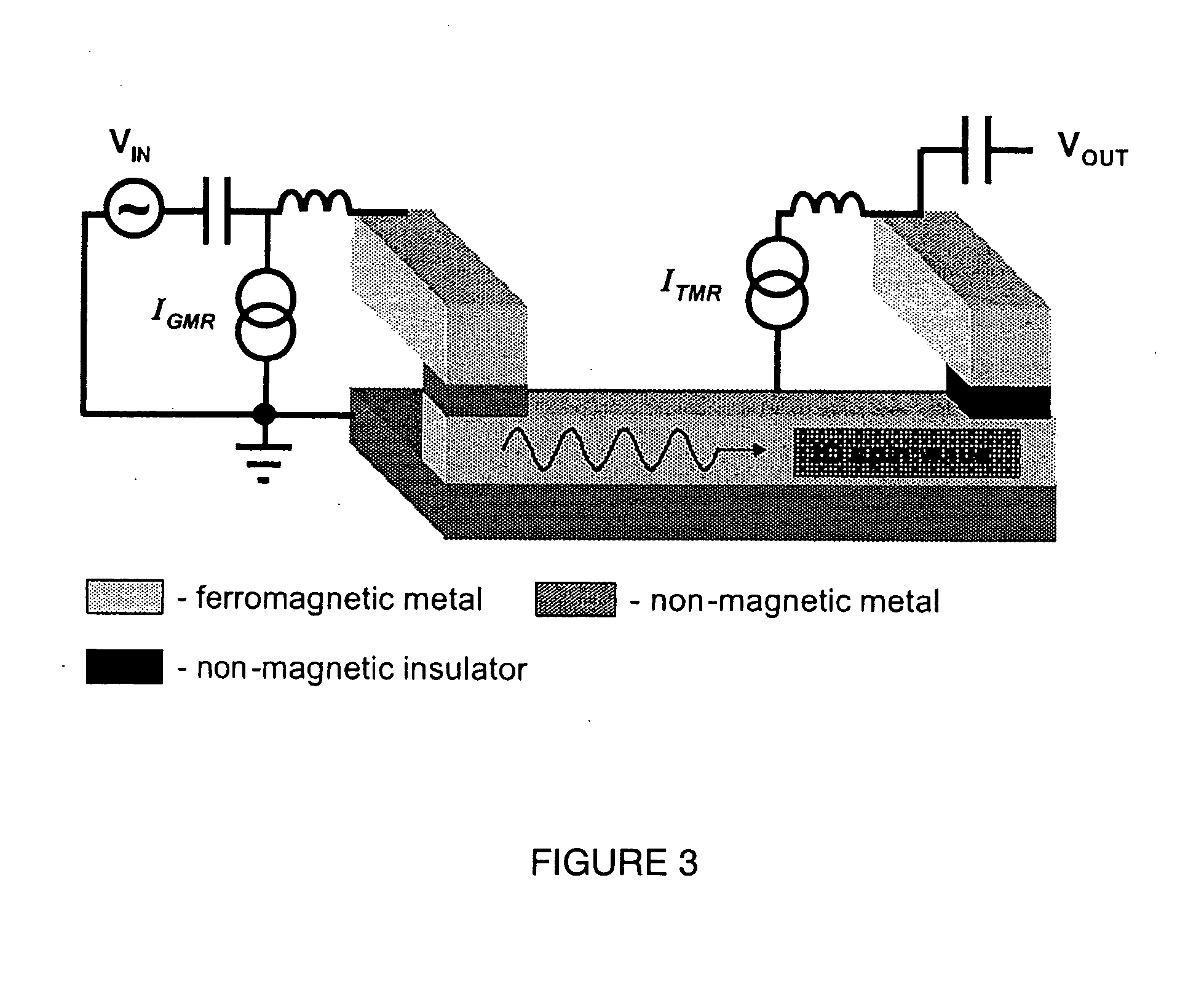

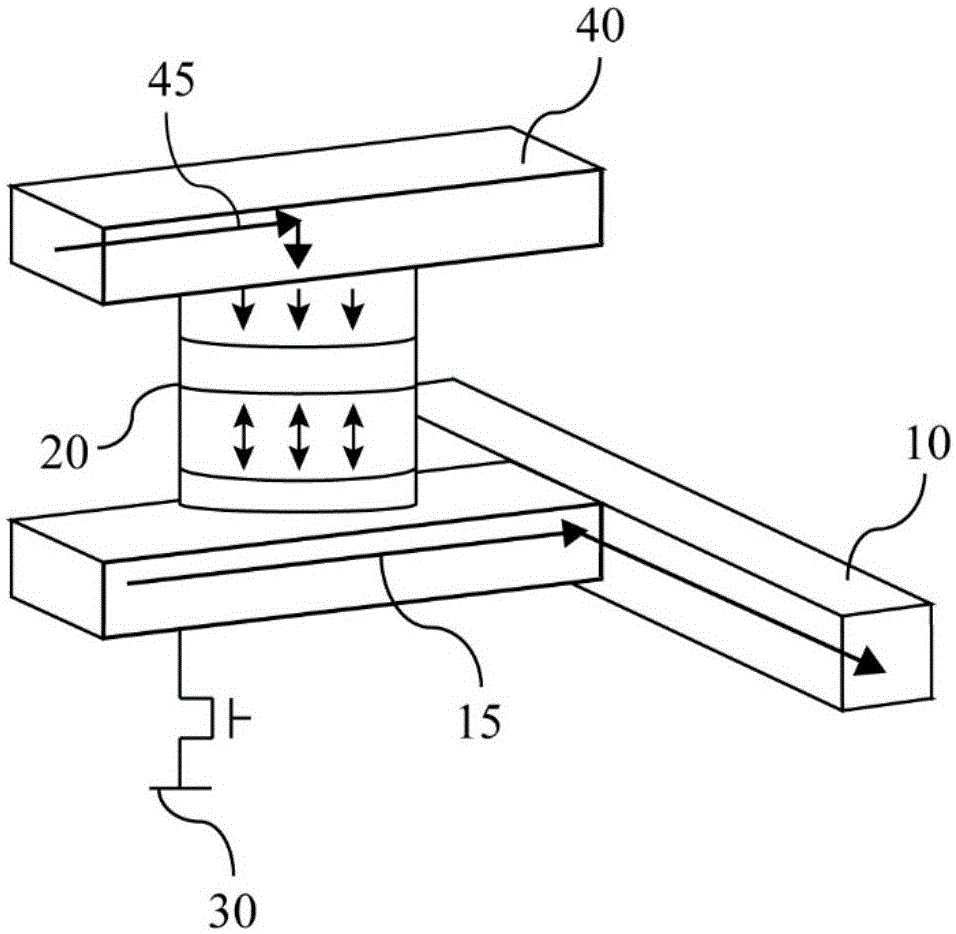

A spin-torque oscillator (STO) has a single free ferromagnetic layer that forms part of both a giant magnetoresistance (GMR) structure with a nonmagnetic conductive spacer layer and a tunneling magnetoresistance (TMR) structure with a tunnel barrier layer. The STO has three electrical terminals that connect to electrical circuitry that provides a spin-torque excitation current through the conductive spacer layer and a lesser sense current through the tunnel barrier layer. When the STO is used as a magnetic field sensor, the excitation current causes the magnetization of the free layer to oscillate at a fixed base frequency in the absence of an external magnetic field. A detector coupled to the sense current detects shifts in the free layer magnetization oscillation frequency from the base frequency in response to external magnetic fields.

Owner:WESTERN DIGITAL TECH INC

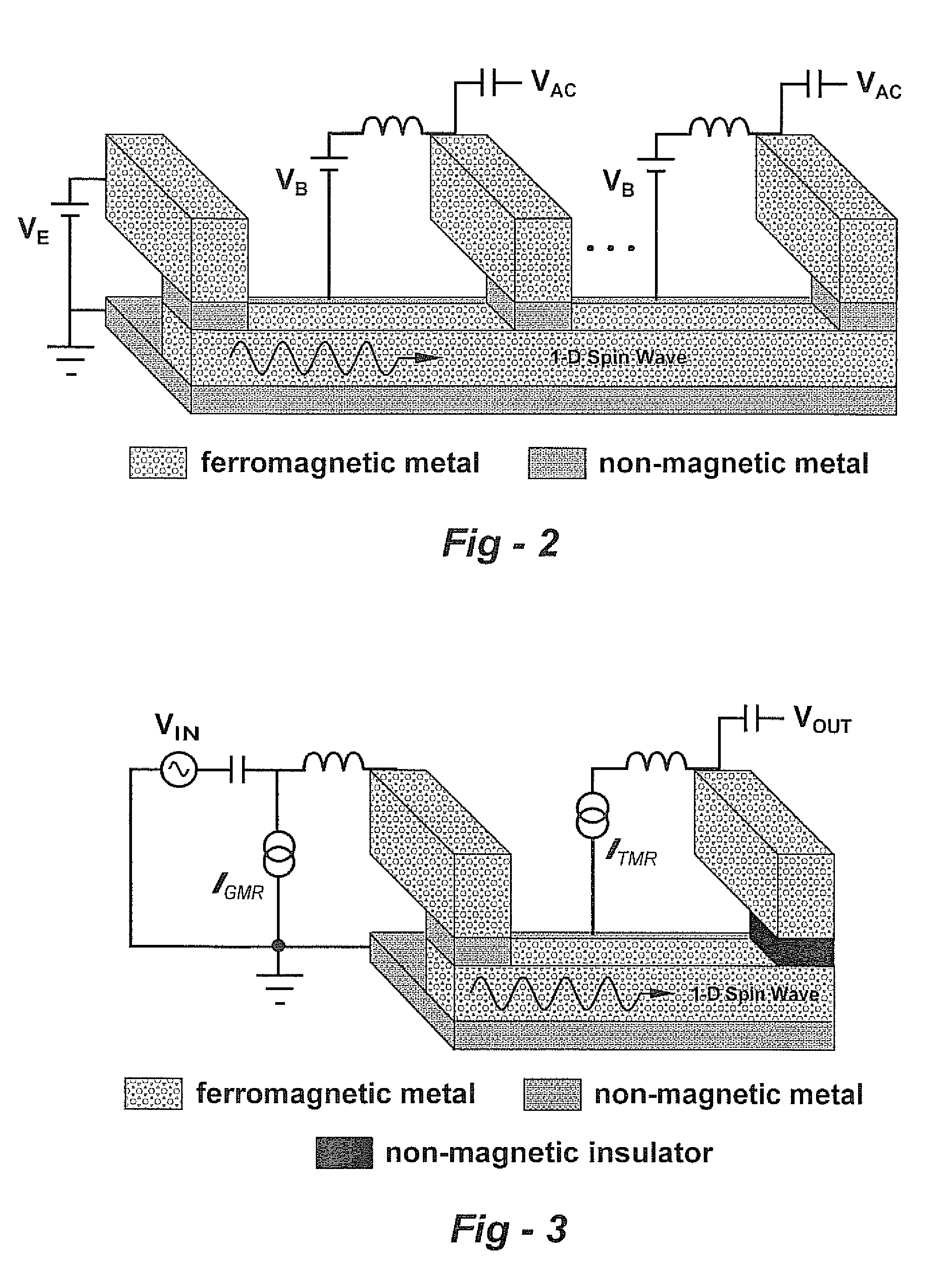

Spin-torque devices

ActiveUS7678475B2NanomagnetismMagnetic-field-controlled resistorsSemiconductor materialsMicrowave oscillators

Spin-torque devices are based on a combination of giant magnetoresistance (GMR) and tunneling magnetoresistance (TMR) effects. The basic structure has various applications, including amplifiers, oscillators, and diodes. For example, if the low-magnetoresistance (GMR) contact is biased below a critical value, the device may function as a microwave-frequency selective amplifier. If the GMR contact is biased above the critical value, the device may function as a microwave oscillator. A plurality of low- and high-magnetoresistance contact pairs may be induced to oscillate in a phase-locked regime, thereby multiplying output power. The frequency of operation of these devices will be tunable by the external magnetic field, as well as by the direct bias current, in the frequency range between 10 and 100 GHz. The devices do not use semiconductor materials and are expected to be exceptionally radiation-hard, thereby finding application in military nanoelectronics.

Owner:NANOSC AB

Magnetic tunnel barriers and associated magnetic tunnel junctions with high tunneling magnetoresistance

ActiveUS20080062581A1Improve performanceHigh spin polarization valueNanomagnetismMagnetic measurementsOxygen contentTunnel junction

Magnetic tunneling devices are formed from a first body centered cubic (bcc) magnetic layer and a second bcc magnetic layer. At least one spacer layer of bcc material between these magnetic layers exchange couples the first and second bcc magnetic layers. A tunnel barrier in proximity with the second magnetic layer permits spin-polarized current to pass between the tunnel barrier and the second layer; the tunnel barrier may be either MgO and Mg—ZnO. The first magnetic layer, the spacer layer, the second magnetic layer, and the tunnel barrier are all preferably (100) oriented. The MgO and Mg—ZnO tunnel barriers are prepared by first depositing a metallic layer on the second magnetic layer (e.g., a Mg layer), thereby substantially reducing the oxygen content in this magnetic layer, which improves the performance of the tunnel barriers.

Owner:IBM CORP

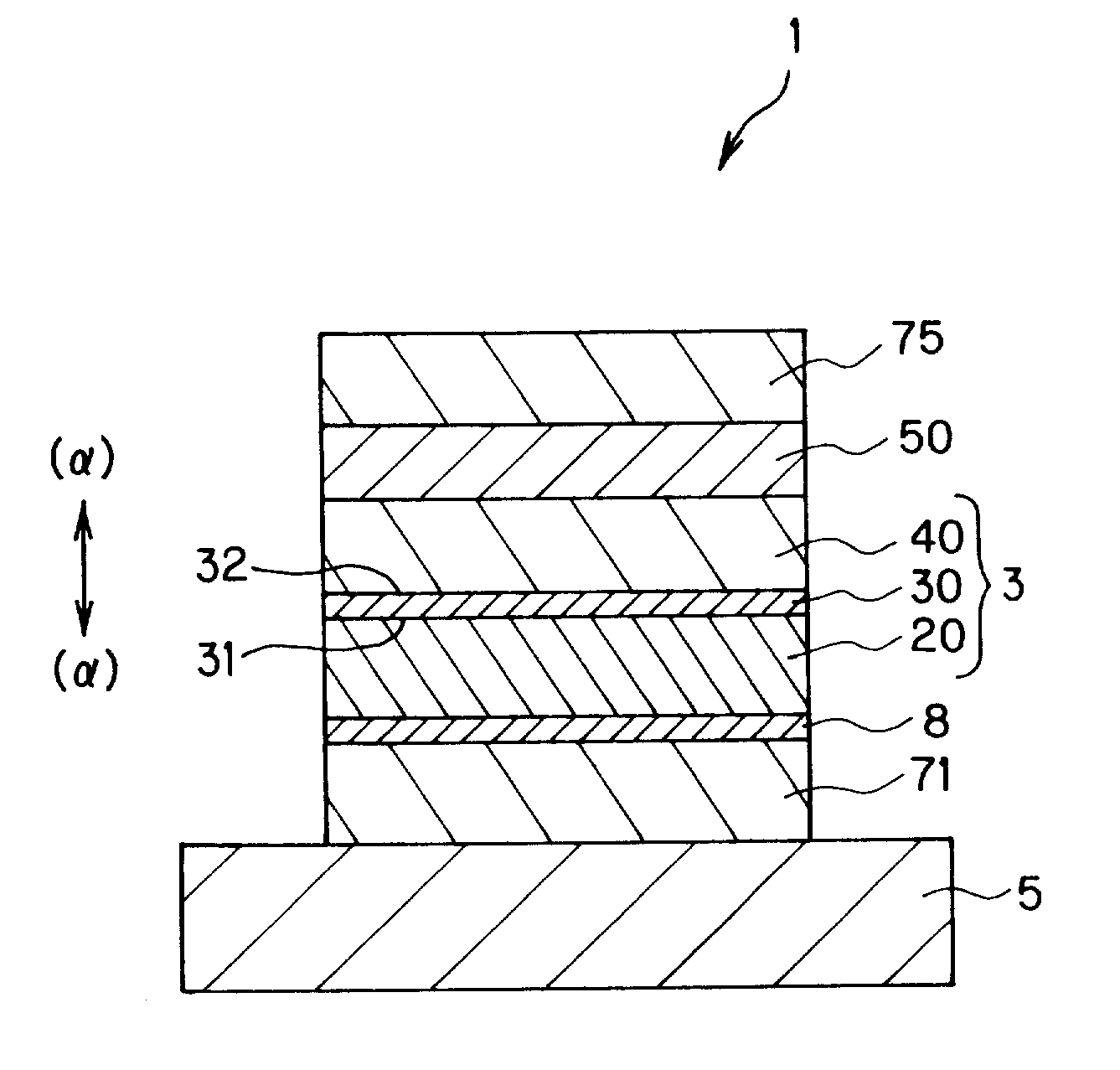

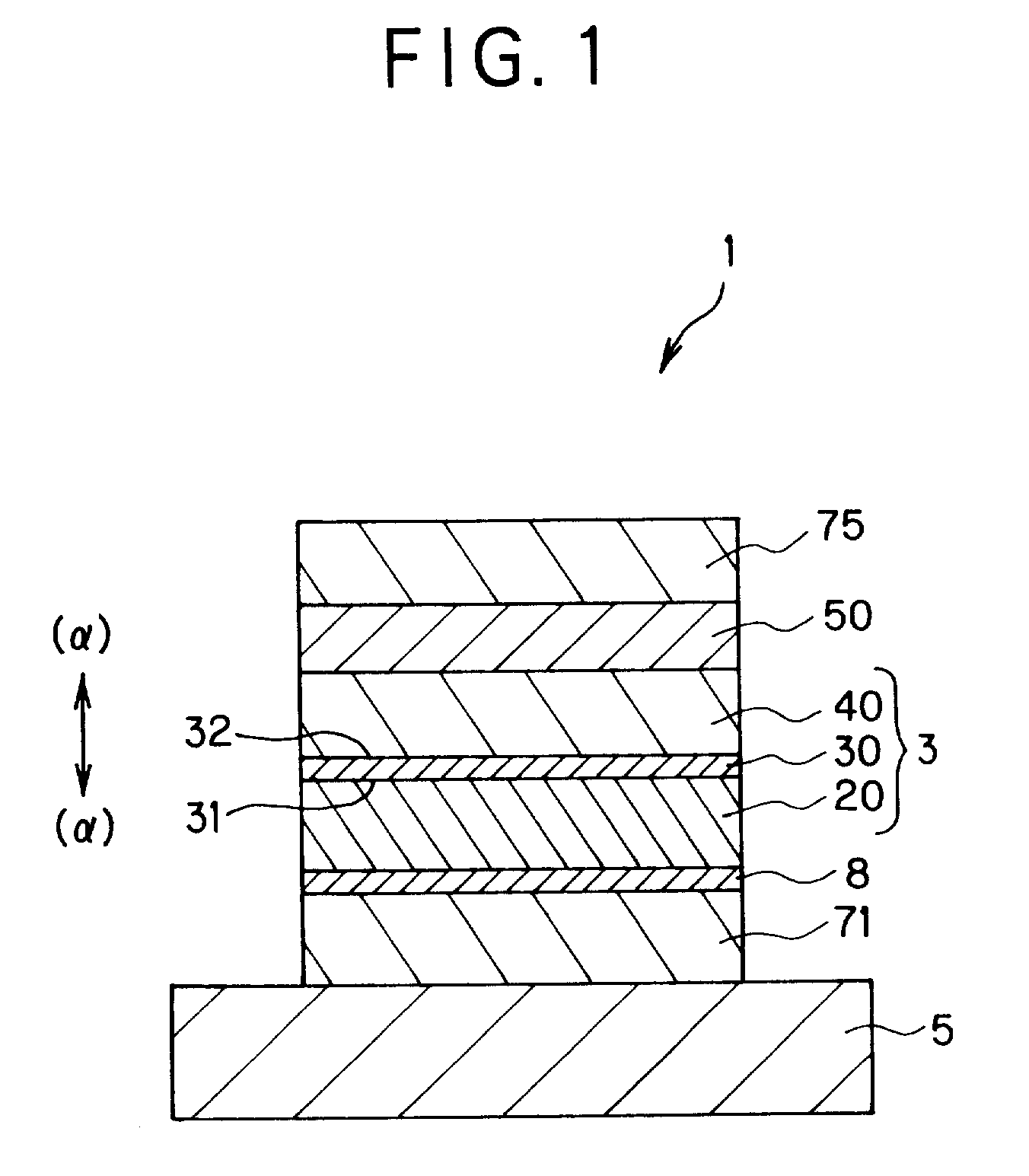

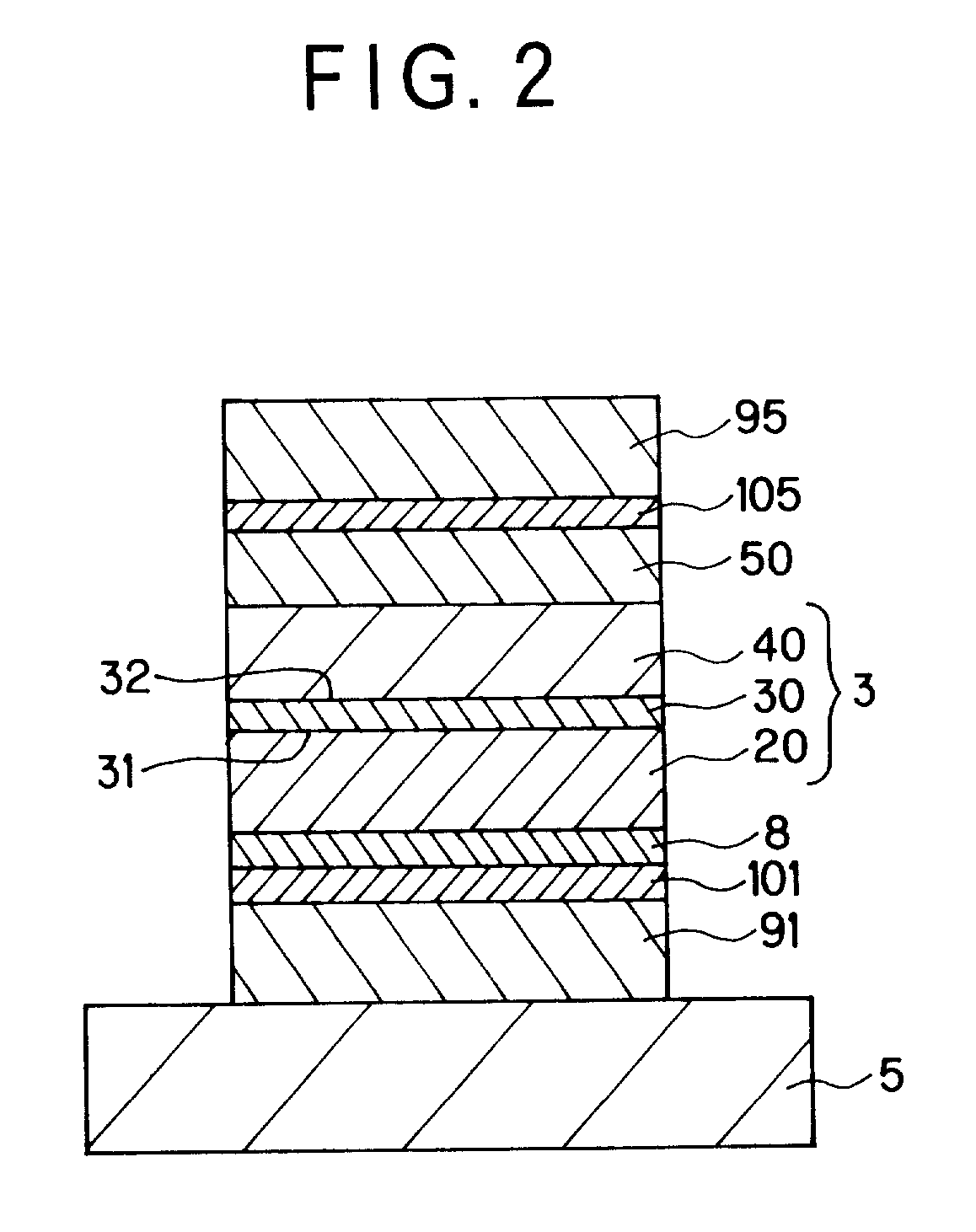

Tunnel magnetoresistance effect element

InactiveUS6483675B1Disposition/mounting of recording headsMagnetic measurementsSurface roughnessCondensed matter physics

In a tunnel magnetoresistance effect element comprising a tunnel multilayered film having a tunnel barrier layer, a ferromagnetic free layer and a ferromagnetic pinned layer such that the tunnel barrier layer is held between the ferromagnetic free layer and the ferromagnetic pinned layer, three indexes representing a surface roughness state of the tunnel barrier layer are set such that Ra<=1 nm, Rmax<=10 nm and Rrms<=1.2 nm, wherein Ra is one of the three indexes and representing the center line average roughness, Rmax is one of the three indexes and representing the maximum height, and Rrms is one of the three indexes and representing the standard deviation roughness. Thus, the tunnel magnetoresistance effect element exhibits improved characteristics, particularly, a large head output.

Owner:TDK CORPARATION

Spin-torque devices

ActiveUS20070259209A1Increase output powerNanomagnetismMagnetic-field-controlled resistorsSemiconductor materialsMicrowave oscillators

Spin-torque devices are based on a combination of giant magnetoresistance (GMR) and tunneling magnetoresistance (TMR) effects. The basic structure has various applications, including amplifiers, oscillators, and diodes. For example, if the low-magnetoresistance contact is biased below a critical value, the device may function as a microwave-frequency selective amplifier. If the low-magnetoresistance contact is biased above the critical value, the device may function as a microwave oscillator. A plurality of low- and high-magnetoresistance contact pairs may be induced to oscillate in a phase-locked regime, thereby multiplying output power. The frequency of operation of these devices will be tunable by the external magnetic field, as well as by the direct bias current, in the frequency range between 10 and 100 GHz. The devices do not use semiconductor materials and are expected to be exceptionally radiation-hard, thereby finding application in military nanoelectronics.

Owner:NANOSC AB

Double-barrier structure based magnetic memory device

InactiveCN105161613AImprove thermal stabilityPerpendicular magnetic anisotropy strengtheningMagnetic-field-controlled resistorsSolid-state devicesHigh resistanceMetallic materials

A double-barrier structure based magnetic memory device is disclosed. The double-barrier structure is used to strengthen perpendicular magnetic anisotropy or tunnel magnetoresistance ratio of a magnetic tunnel junction; meanwhile, a three-port device based on a spin orbit torque is formed by combination of metal wire at the bottom; the double-barrier structure of the magnetic memory device comprises a metal oxide barrier layer, a free layer formed by ferromagnetic metal and the other metal oxide barrier layer; a reference layer formed by the ferromagnetic metal and a covering layer formed by non-magnetic metal are deposited on the top of the structure in sequence; the top of the structure is connected with a peripheral circuit through a metal electrode; and the wire at the bottom is formed by metal materials with a larger hall angle and used for data writing. By introducing the double-barrier structure into the magnetic memory device based on the spin orbit torque, the adverse effect on the data writing caused by too high resistance can be effectively avoided, and the thermal stability and the tunnel magnetoresistance ratio of the device are improved; and the good property of the STT-MRAM is maintained by the device, and the double-barrier structure based magnetic memory device is quite suitable for industrial production.

Owner:BEIHANG UNIV

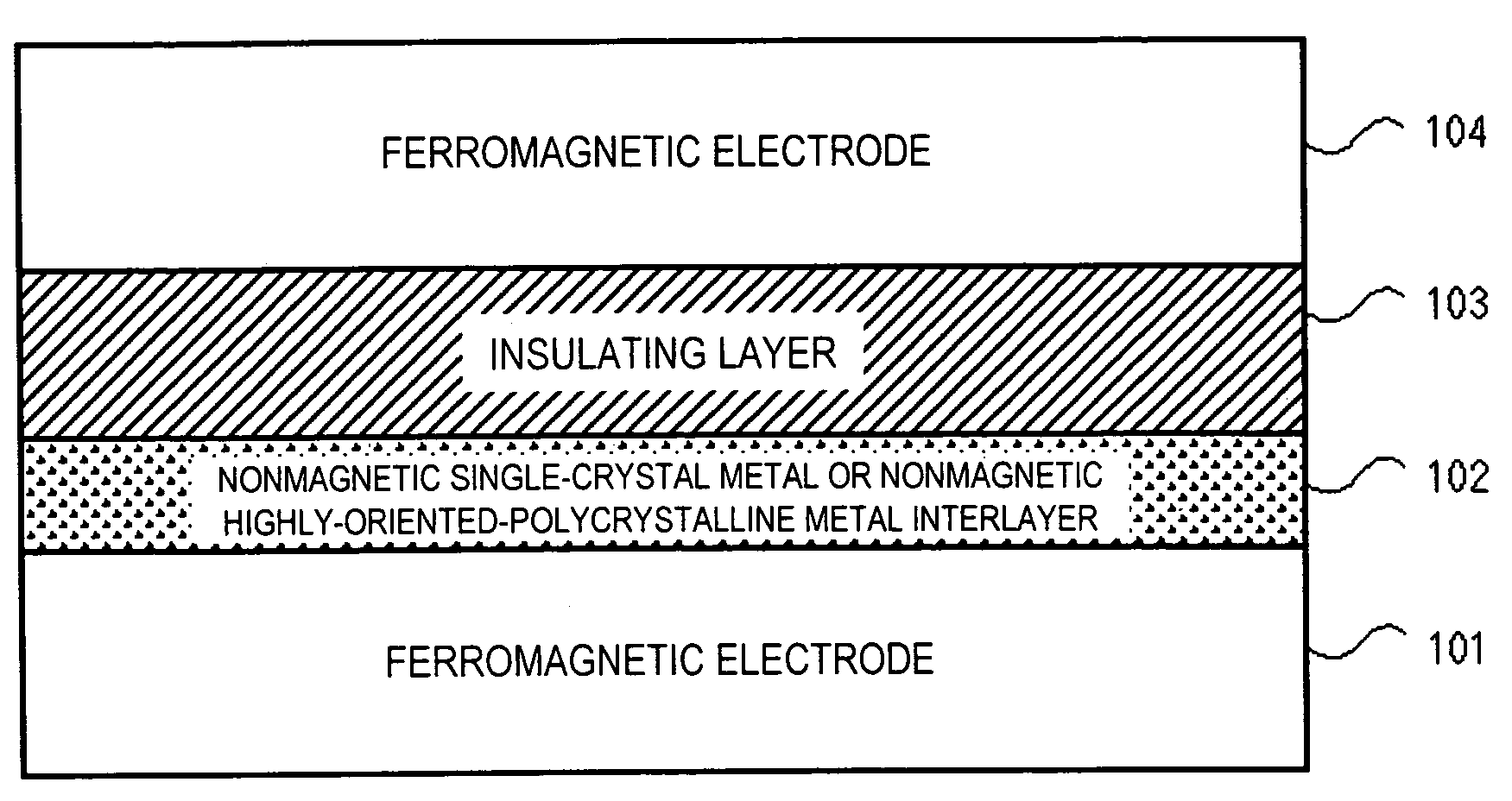

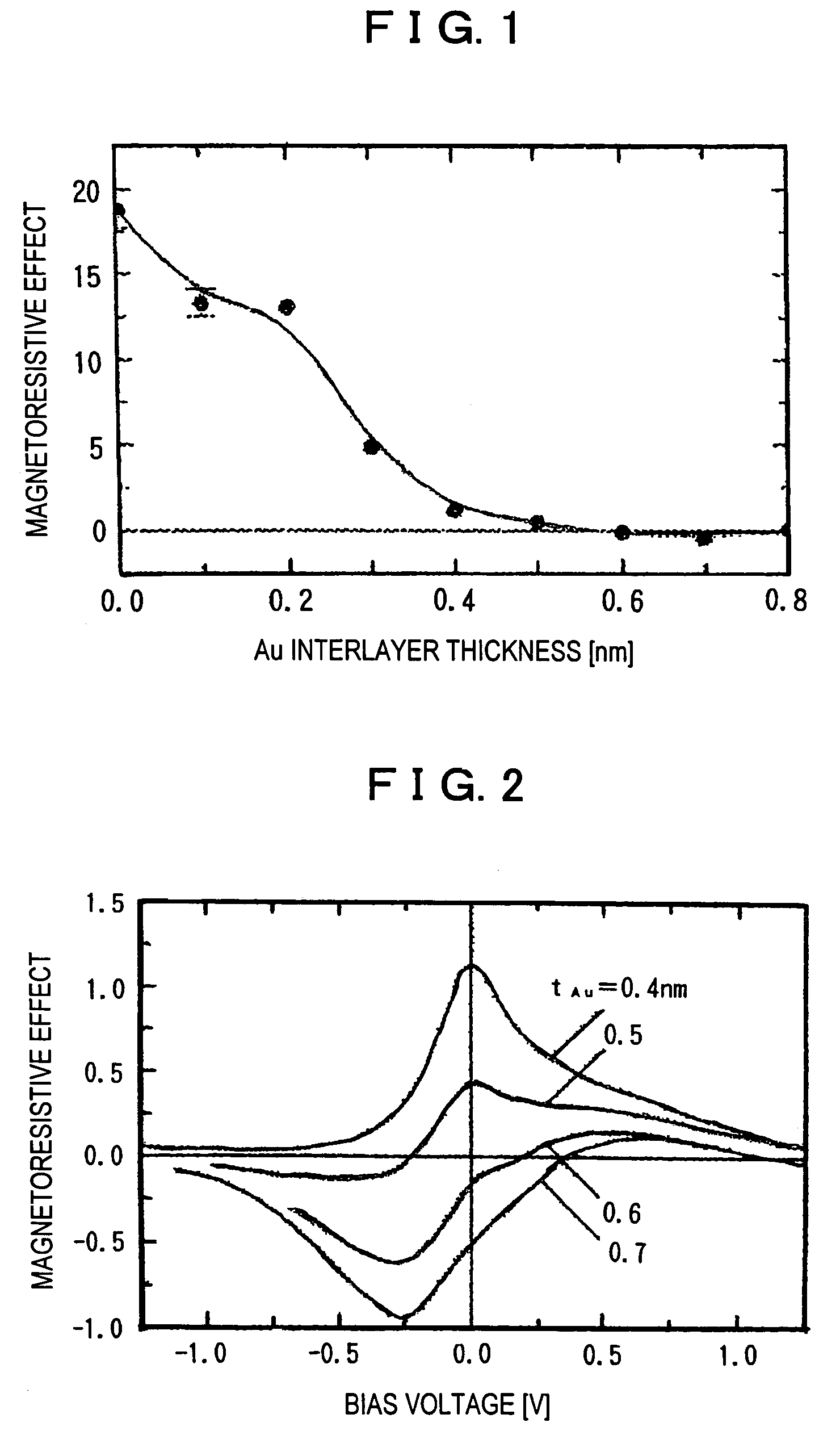

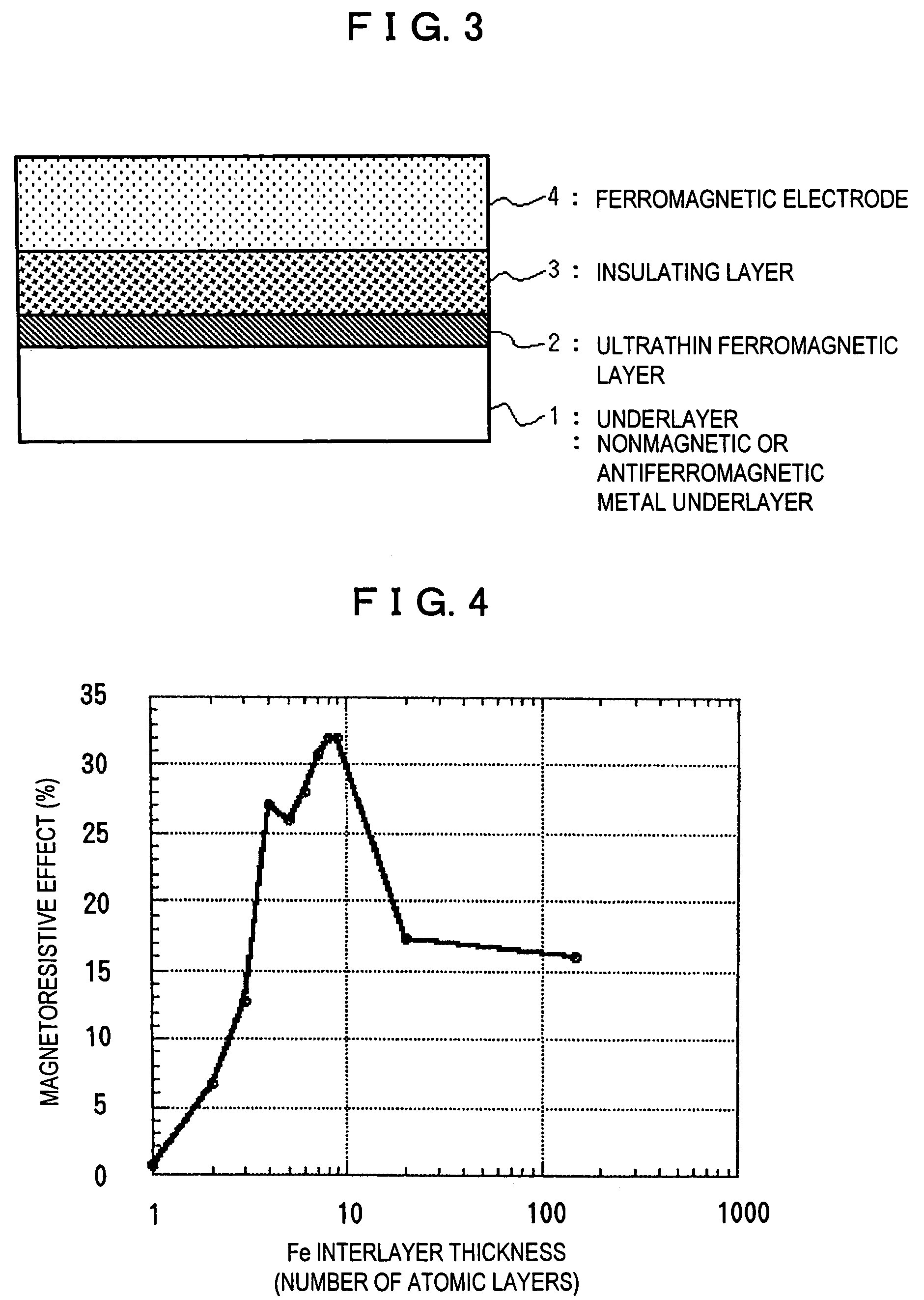

Tunnel magnetoresistance element

InactiveUS7220498B2Electron scattering of a nonmagnetic interlayer is preventedGood effectNanomagnetismNanoinformaticsChemical compositionMagnetic reluctance

By varying only the thickness of a known material having superior magnetic characteristics to increase spin polarization without changing the chemical composition, a tunnel magnetoresistive element capable of producing a larger magnetoresistive effect is provided. The tunnel magnetoresistive element includes an underlayer (nonmagnetic or antiferromagnetic metal film); an ultrathin ferromagnetic layer disposed on the underlayer; an insulating layer disposed on the ultrathin ferromagnetic layer; and a ferromagnetic electrode disposed on the insulating layer.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com