Patents

Literature

1600 results about "Magneto resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

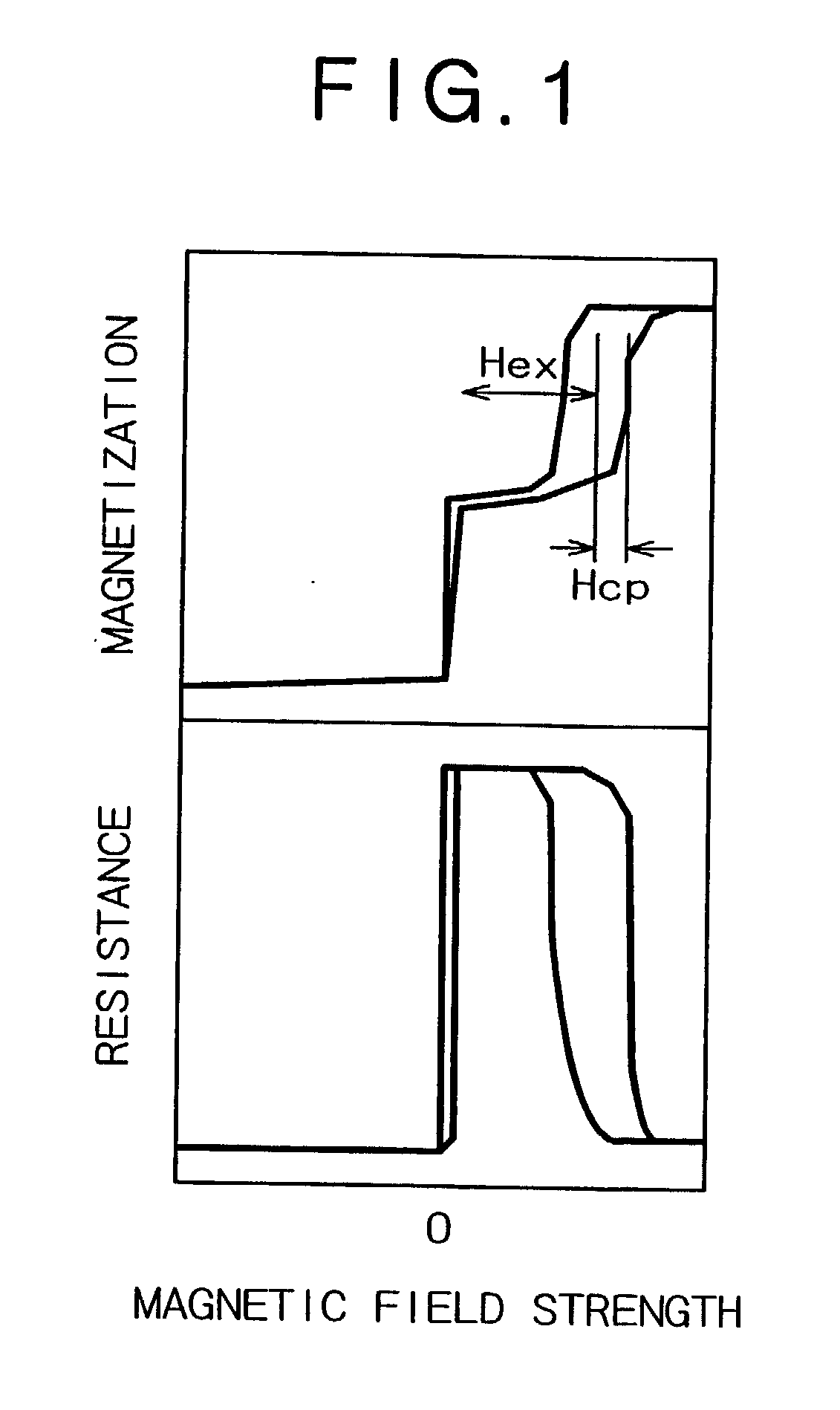

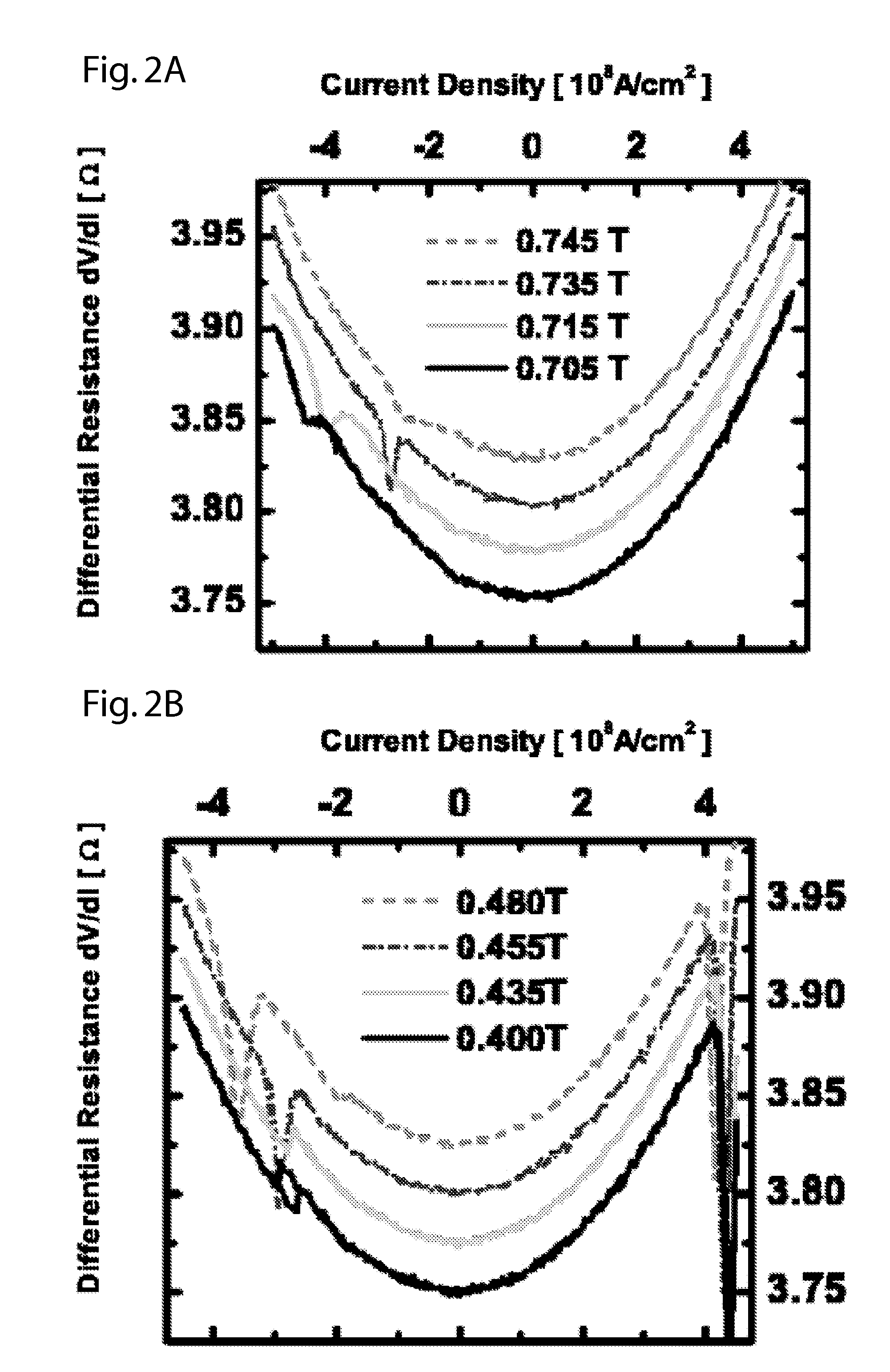

This effect is called magneto resistance, discovered by Sir William Thomson. Three types of magneto resistance effect: Giant magneto resistance, Extraordinary magneto resistance and tunnel magneto resistance. The characteristic curve shows the dependency of resistance on the magnetic field strength.

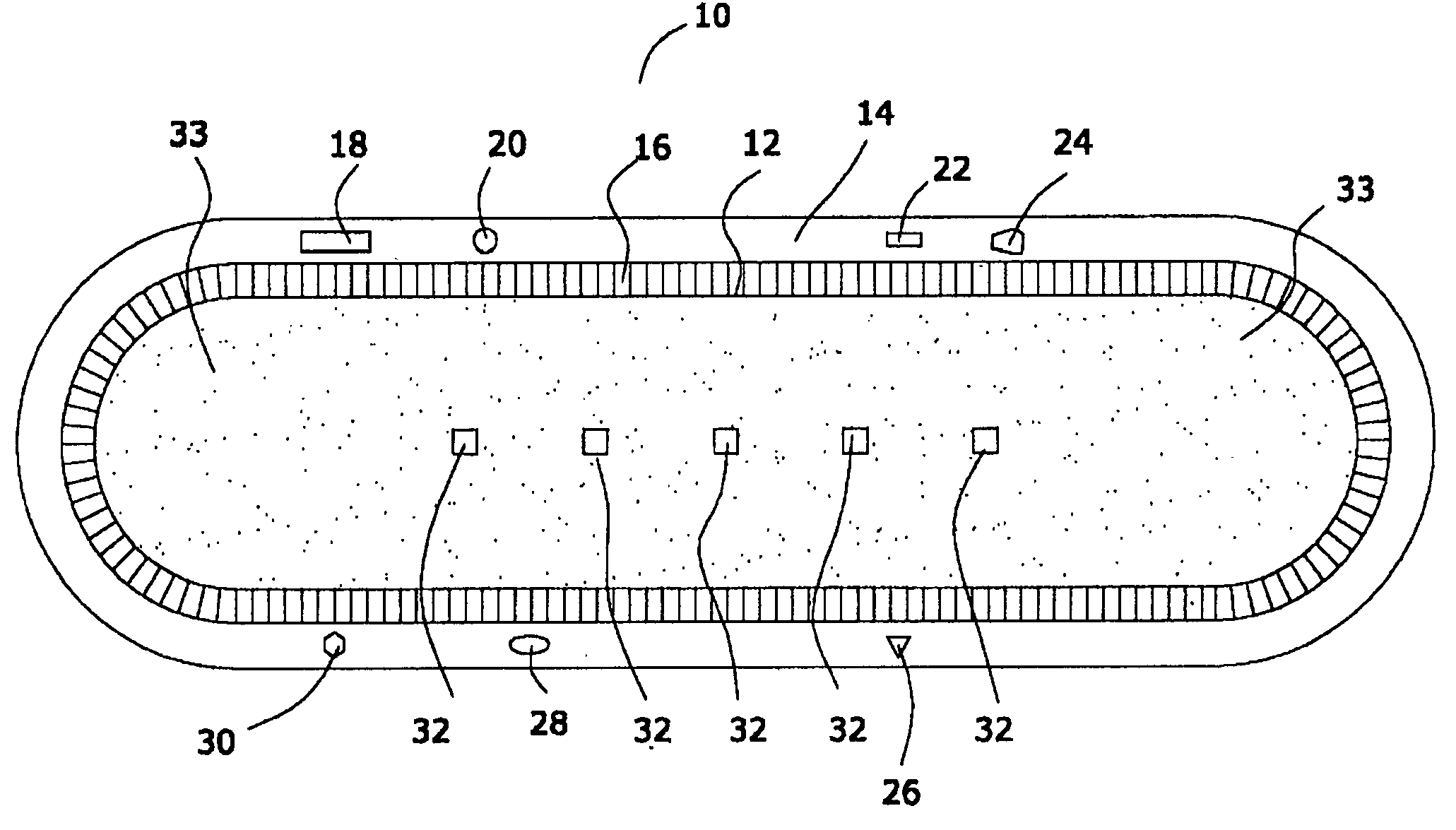

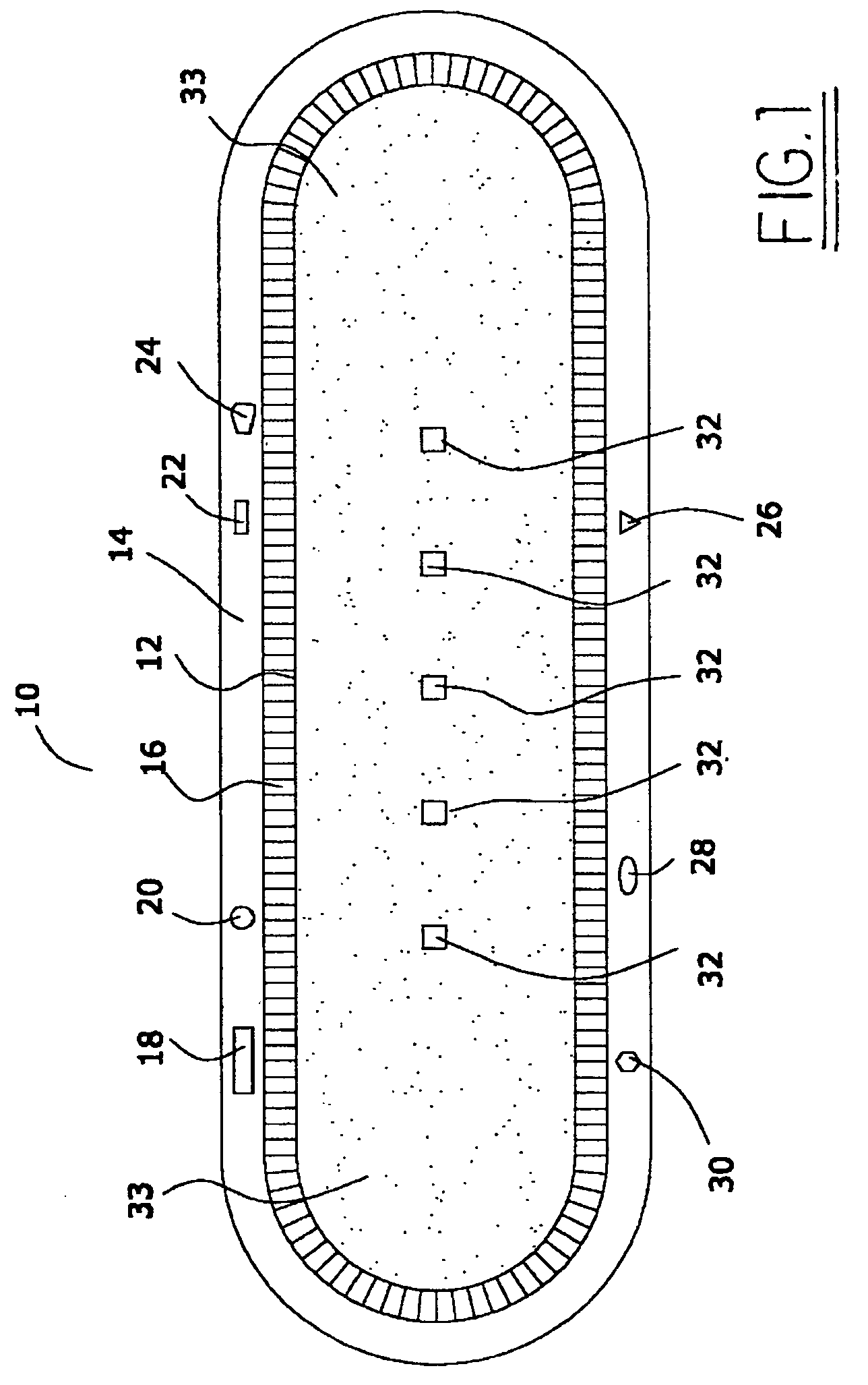

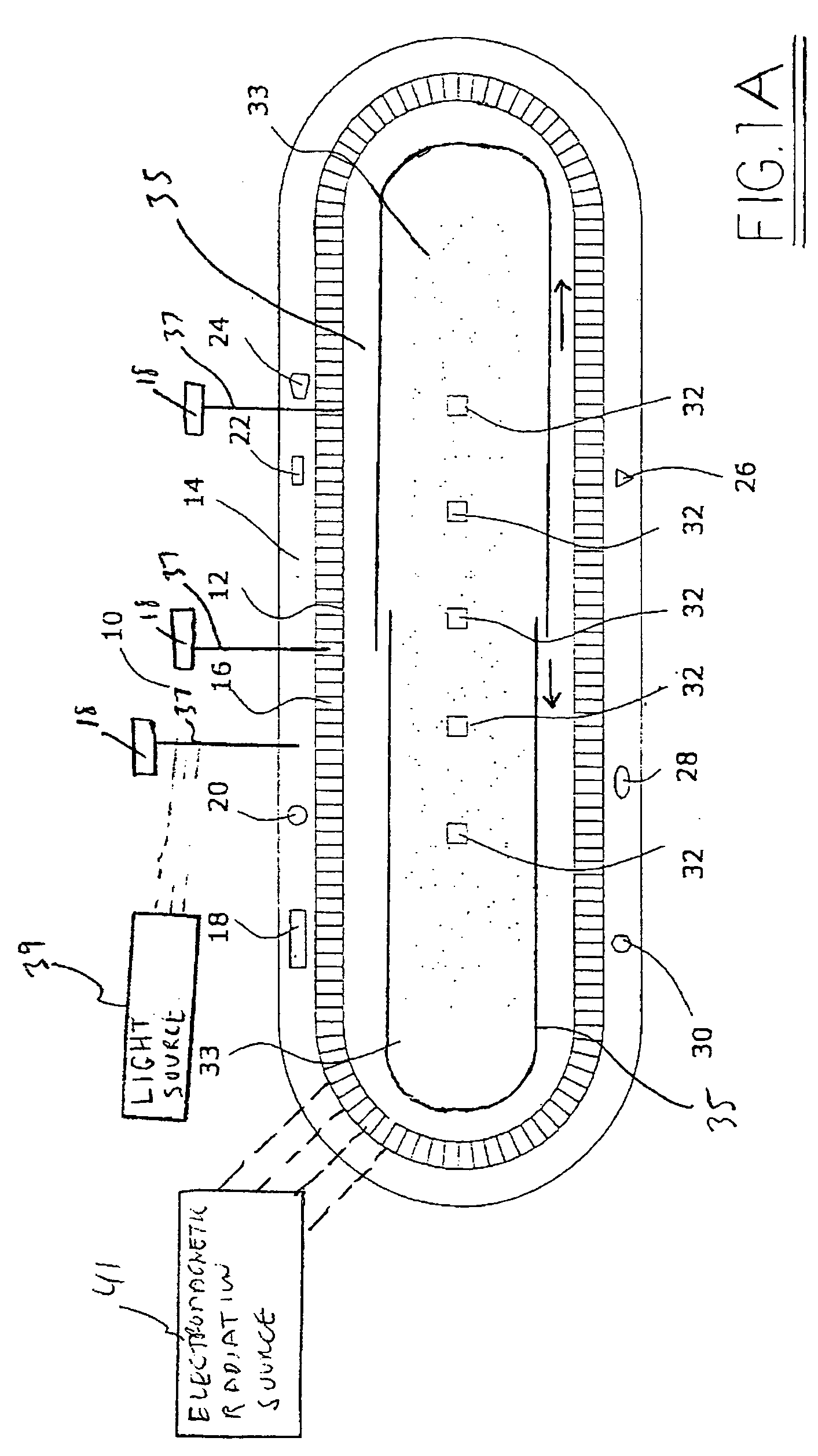

Medical device with low magnetic susceptibility

InactiveUS20050079132A1Batteries circuit arrangementsElectrotherapyMagnetic susceptibilityCoherence length

An assembly with a substrate, nanomagnetic material and magetoresistive material. The nanomagnetic material has a saturation magentization of from about 2 to about 3000 electromagnetic units per cubic centimeter; and it contains nanomagnetic particles with an average particle size of less than about 100 nanometers. The average coherence length between adjacent nanomagnetic particles is less than 100 nanometers.

Owner:BIOPHAN TECH

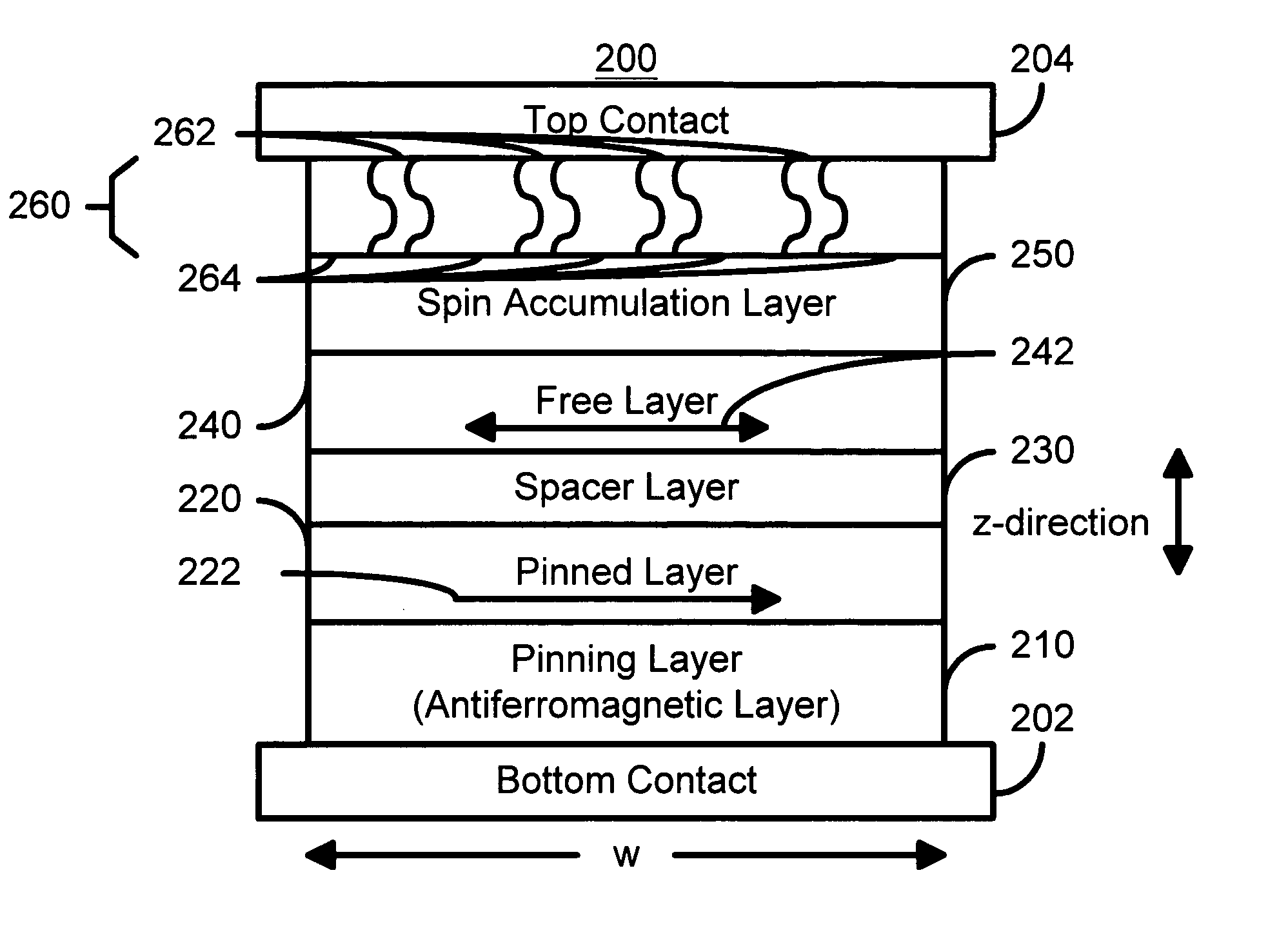

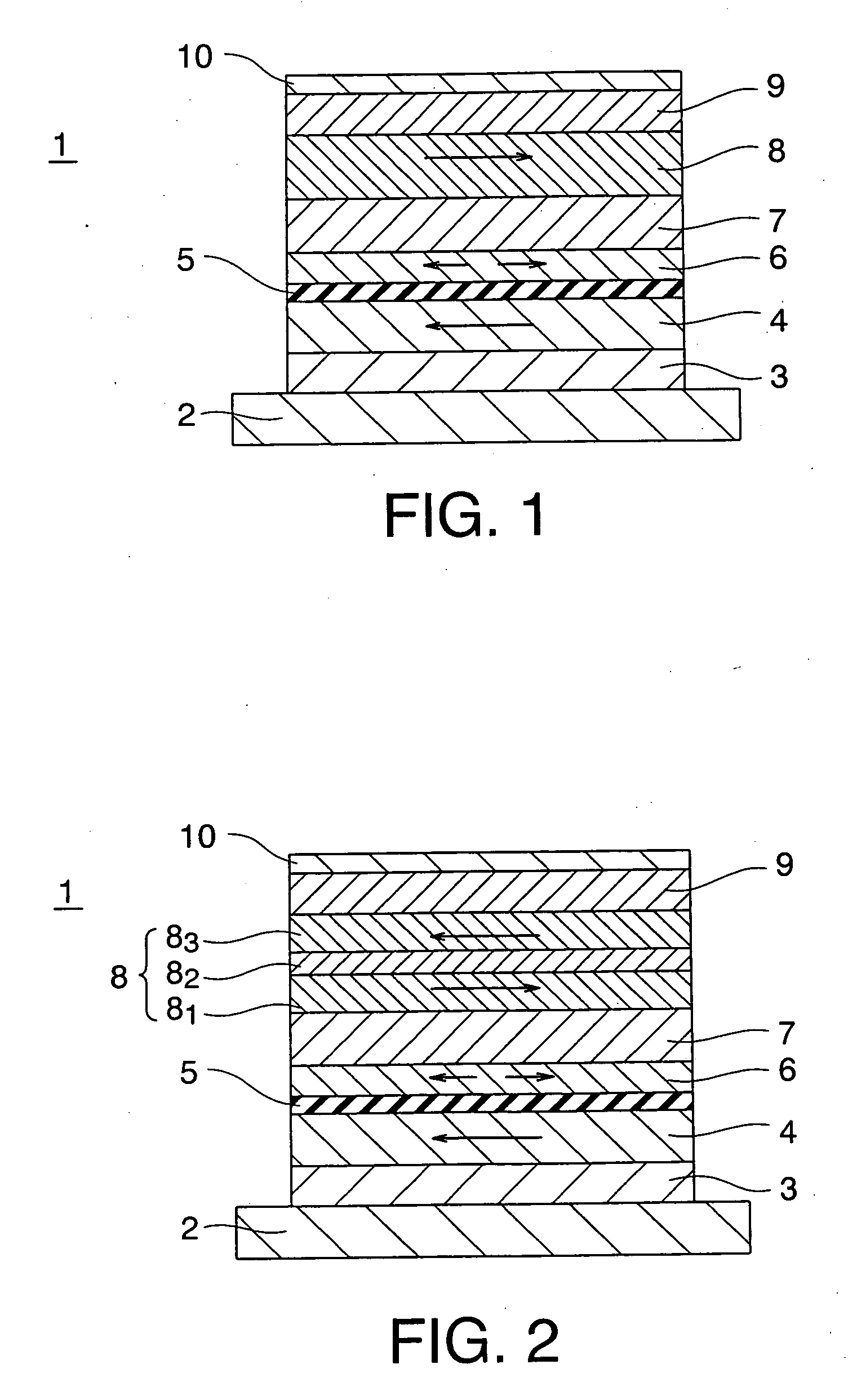

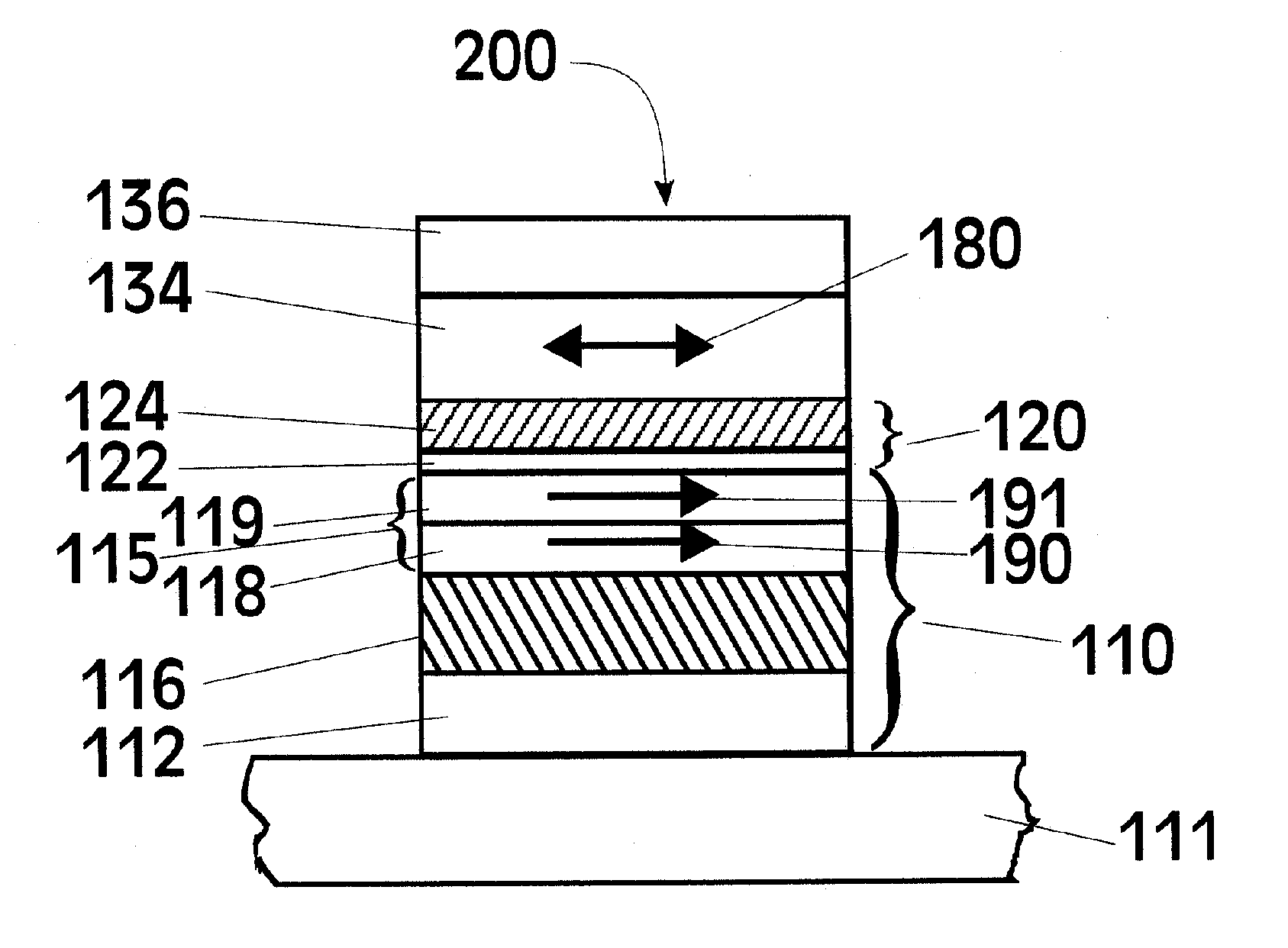

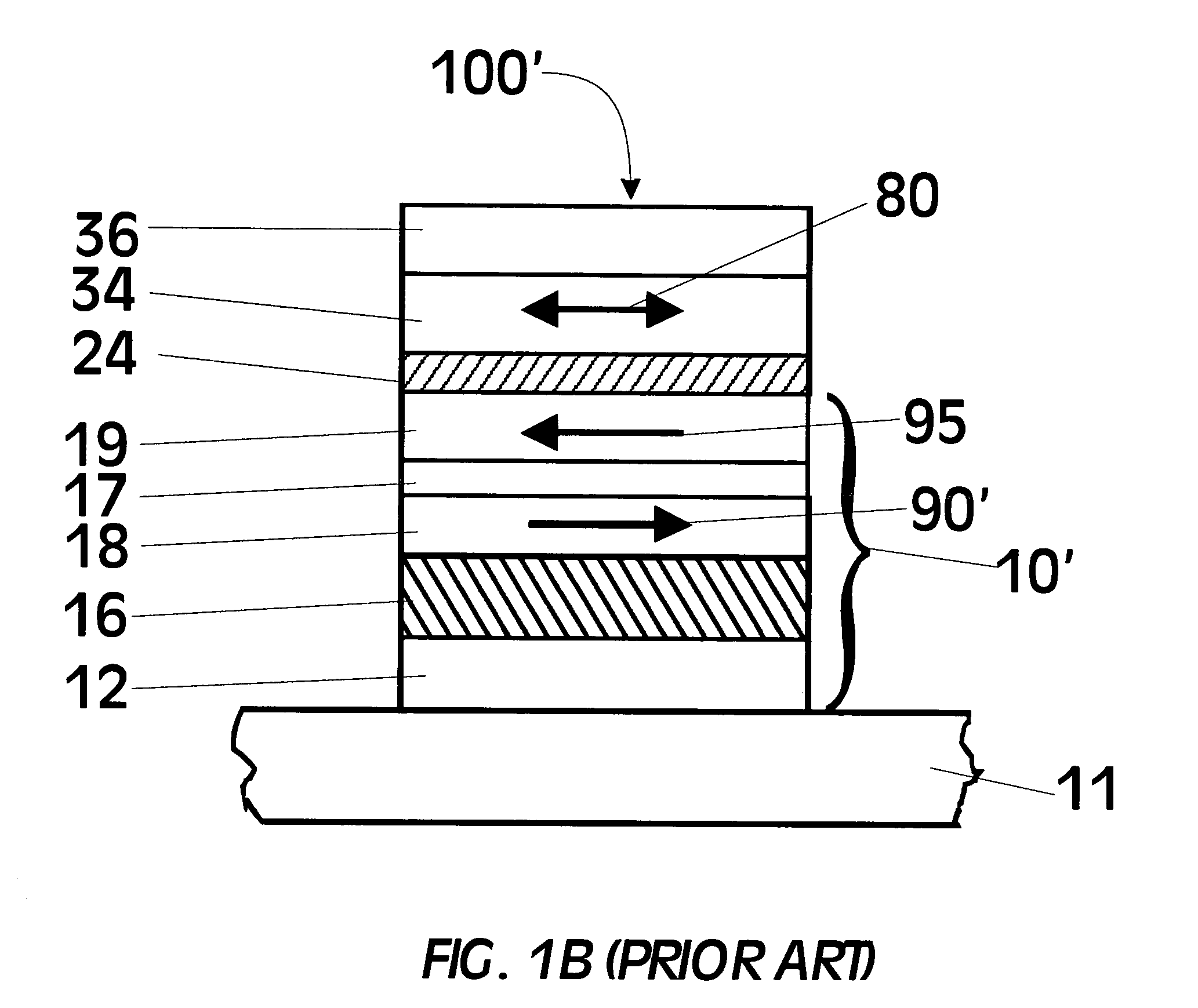

Spin barrier enhanced magnetoresistance effect element and magnetic memory using the same

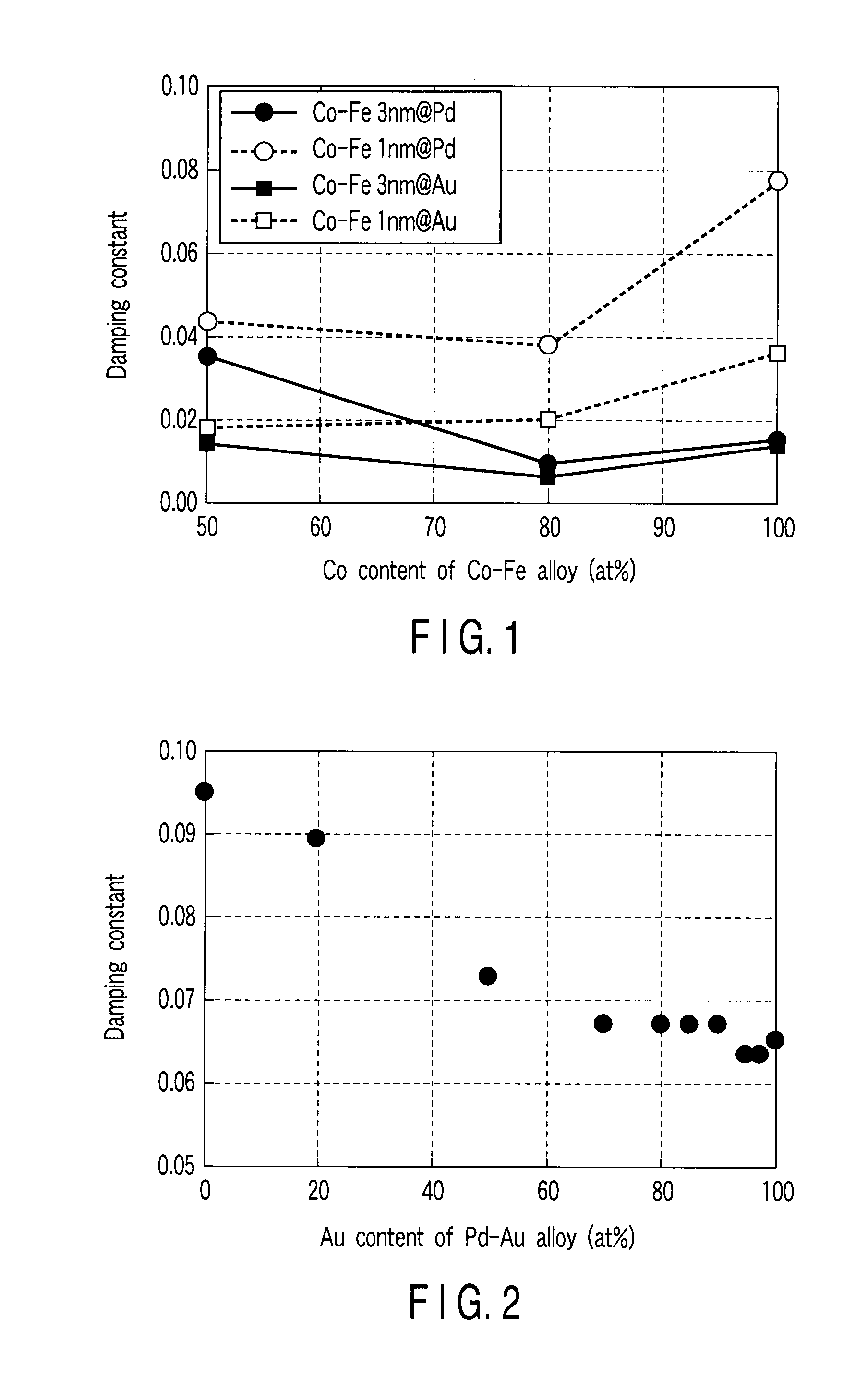

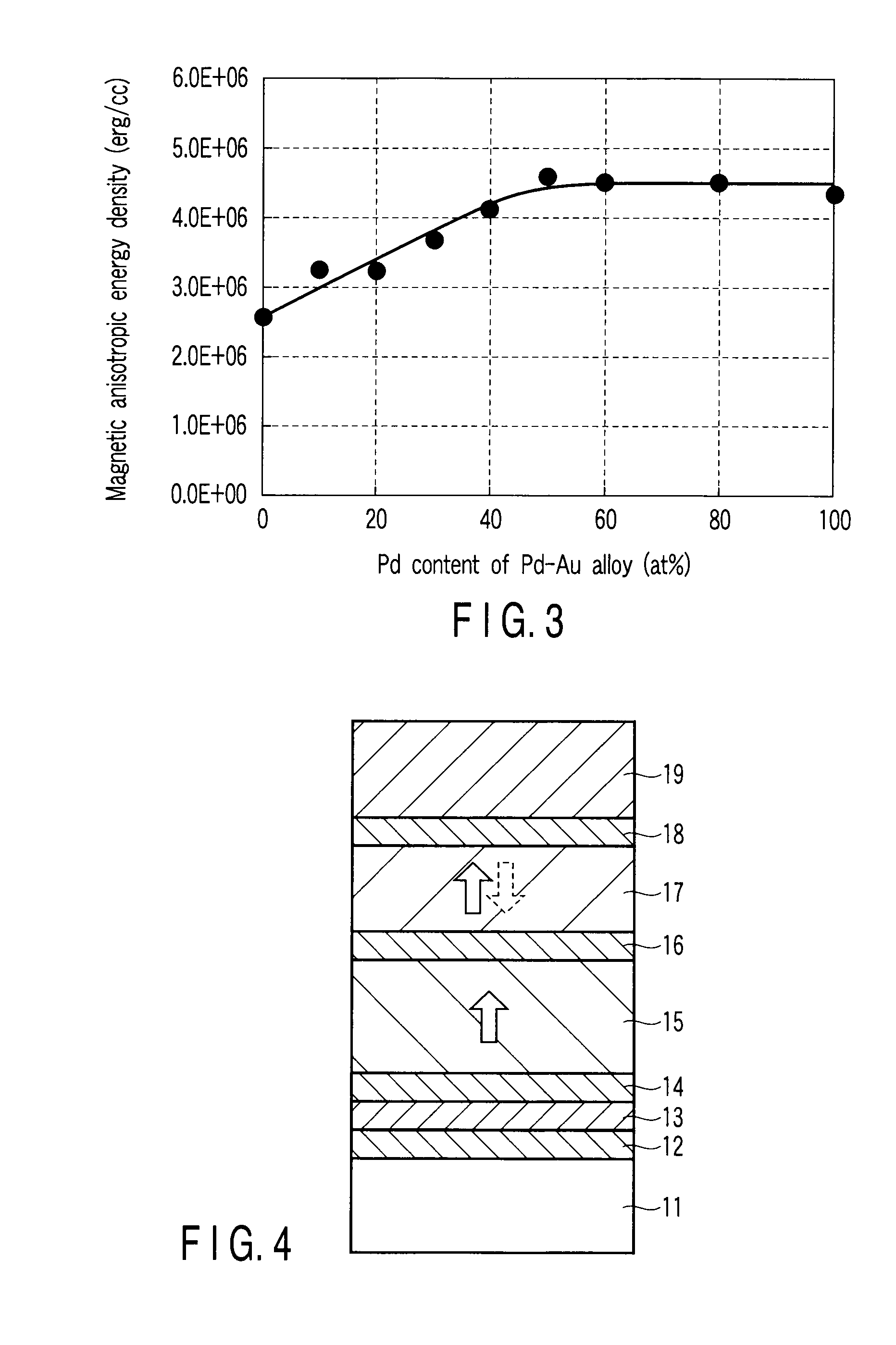

ActiveUS7088609B2Reduce outer surfaceHigh areal resistanceNanomagnetismMagnetic-field-controlled resistorsDamping constantMagnetic memory

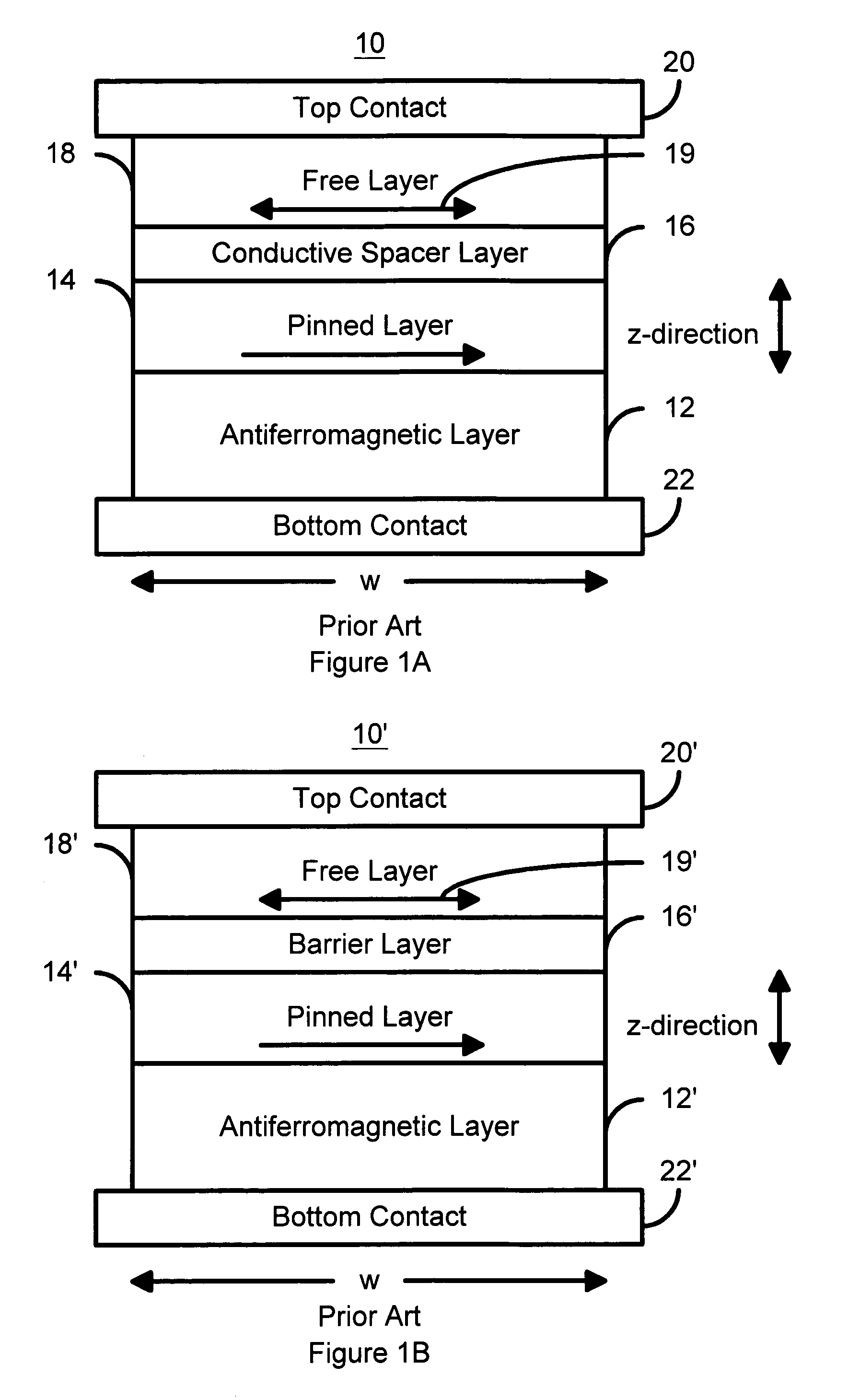

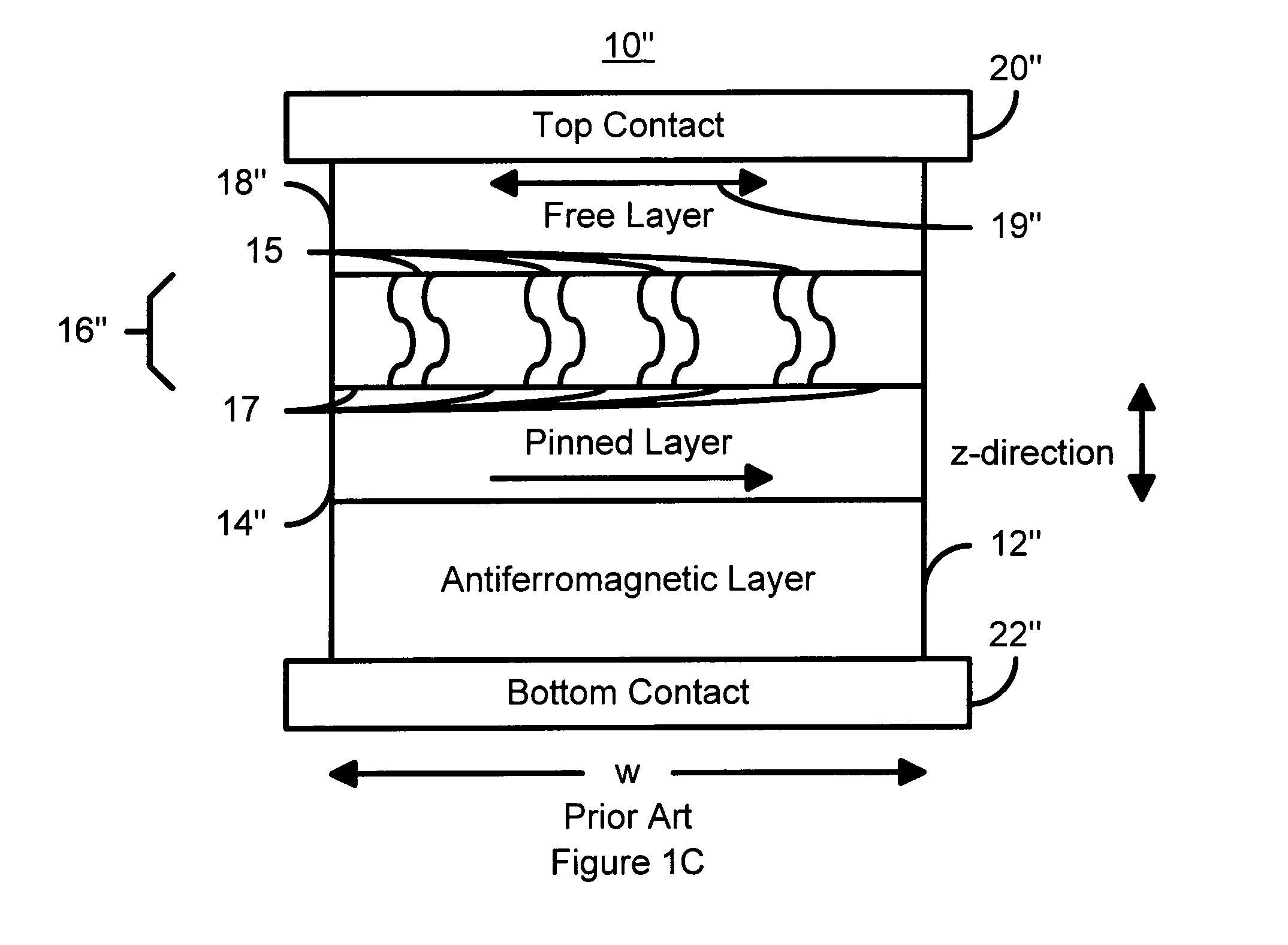

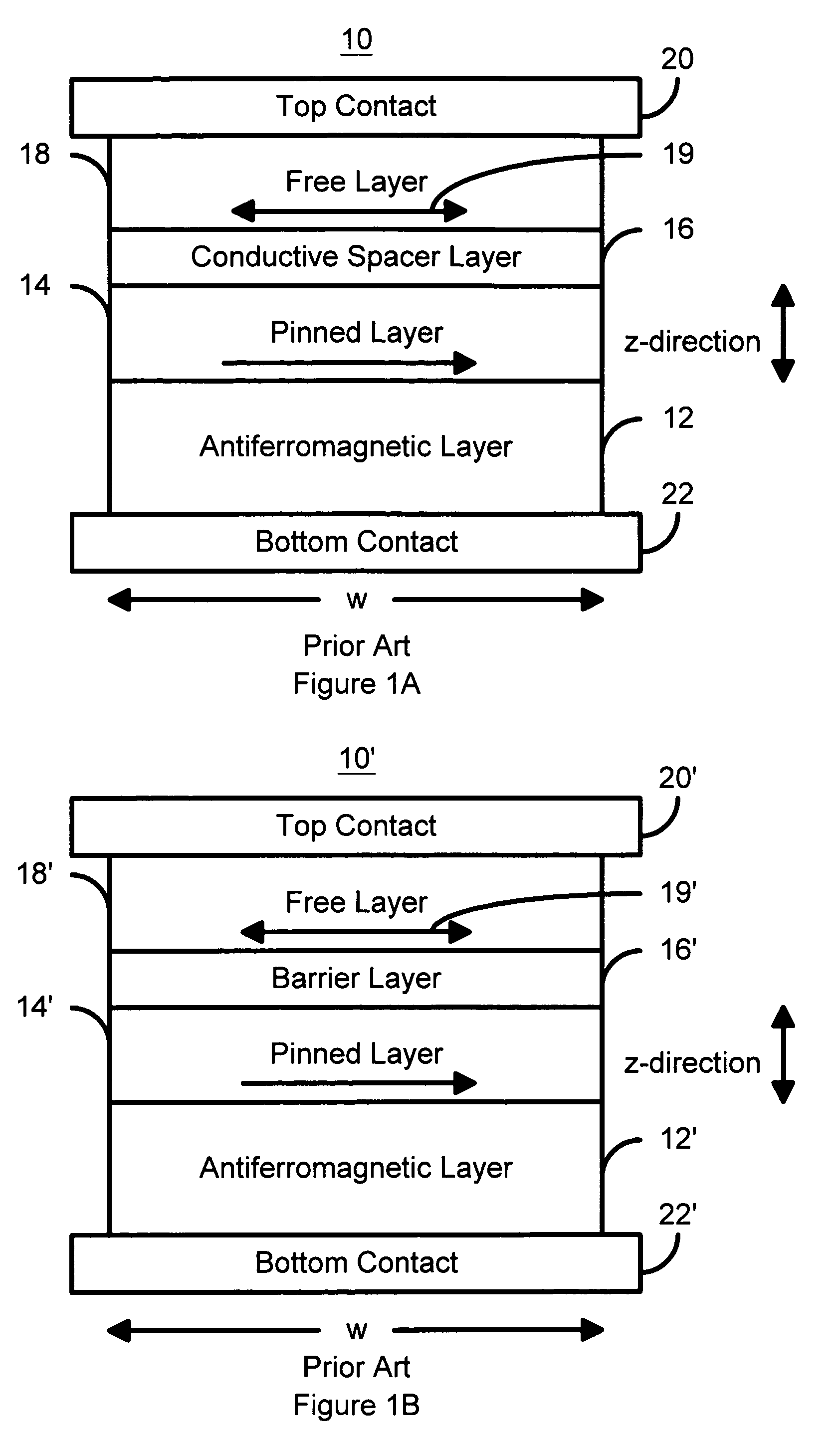

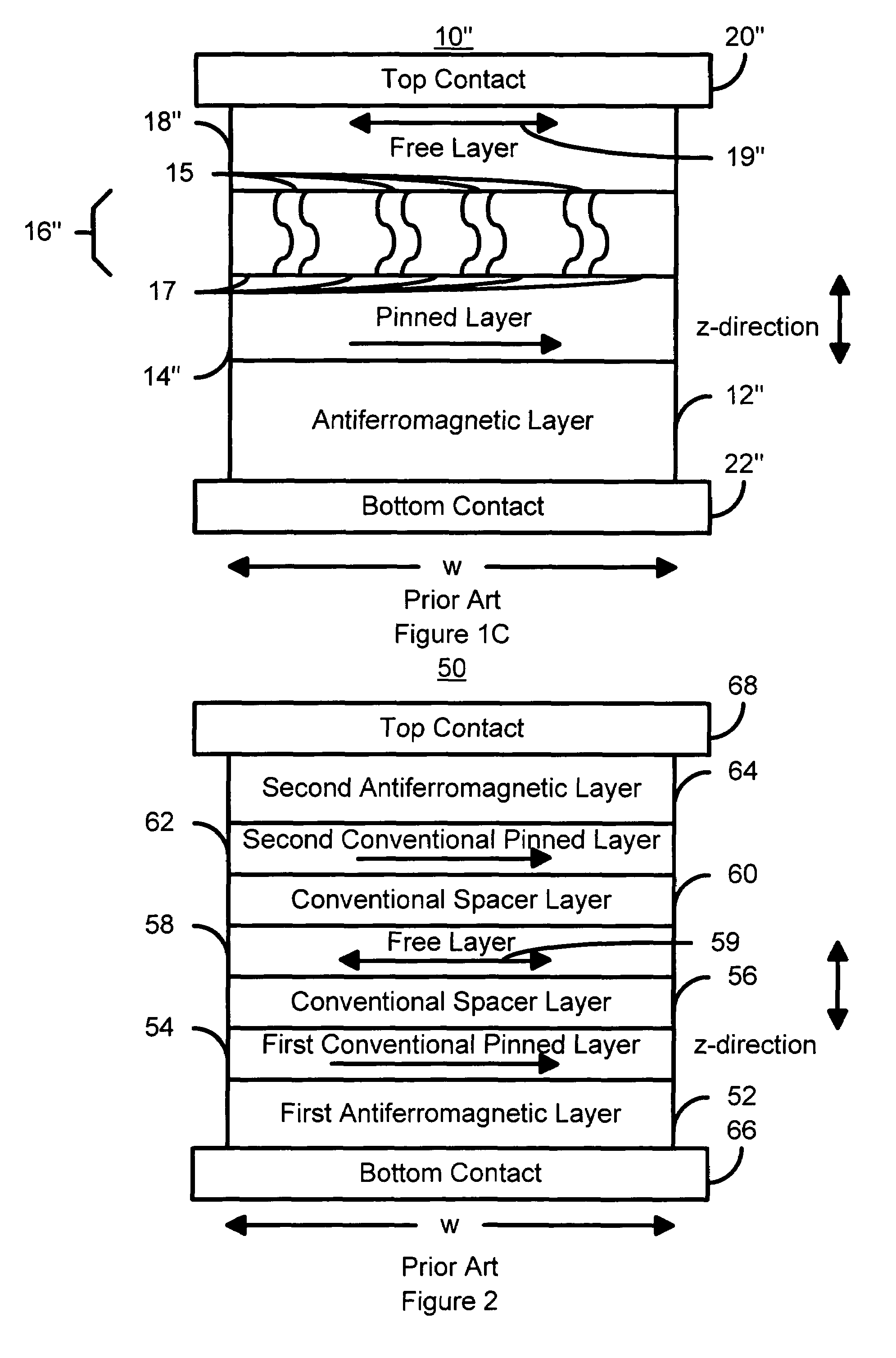

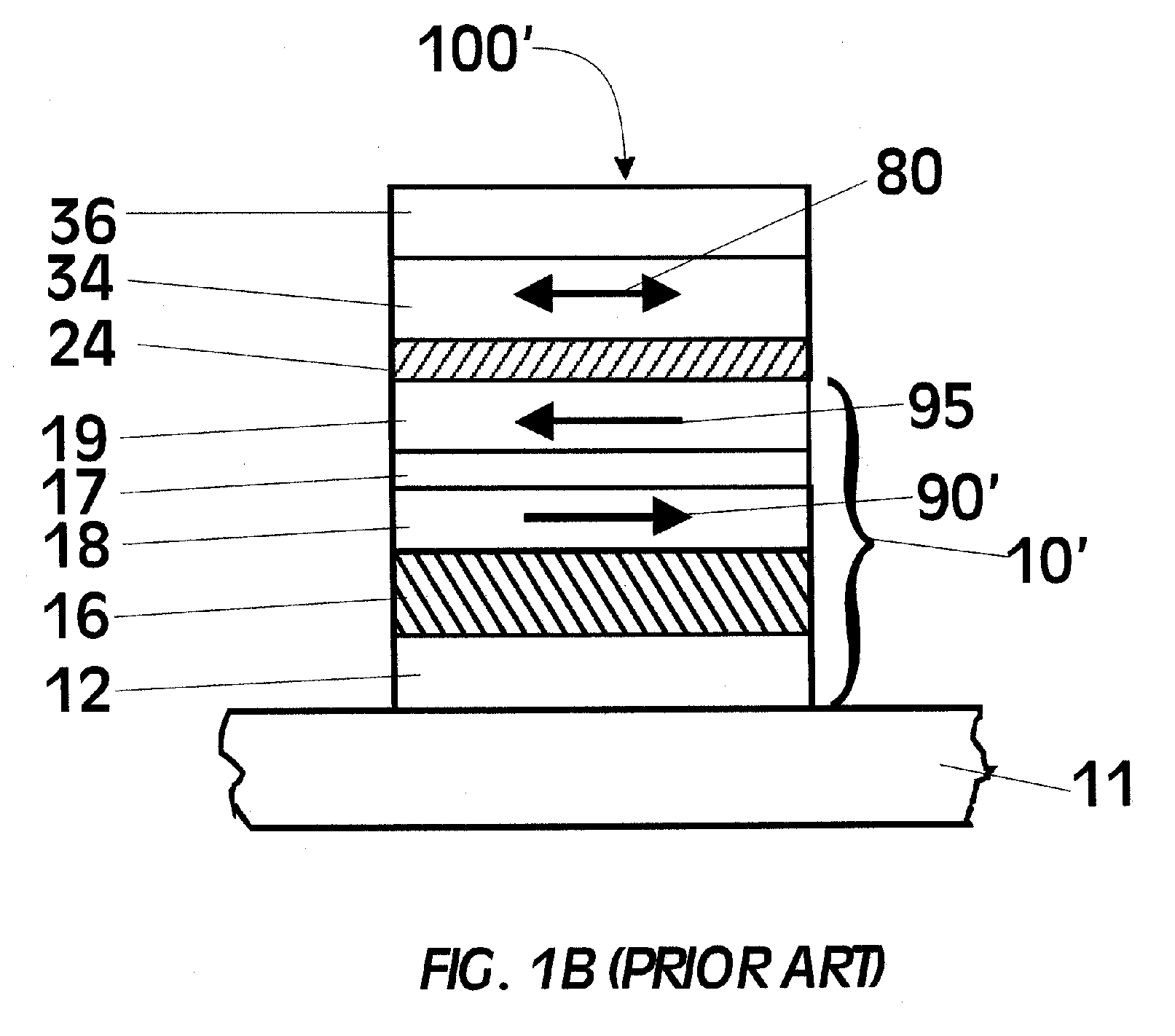

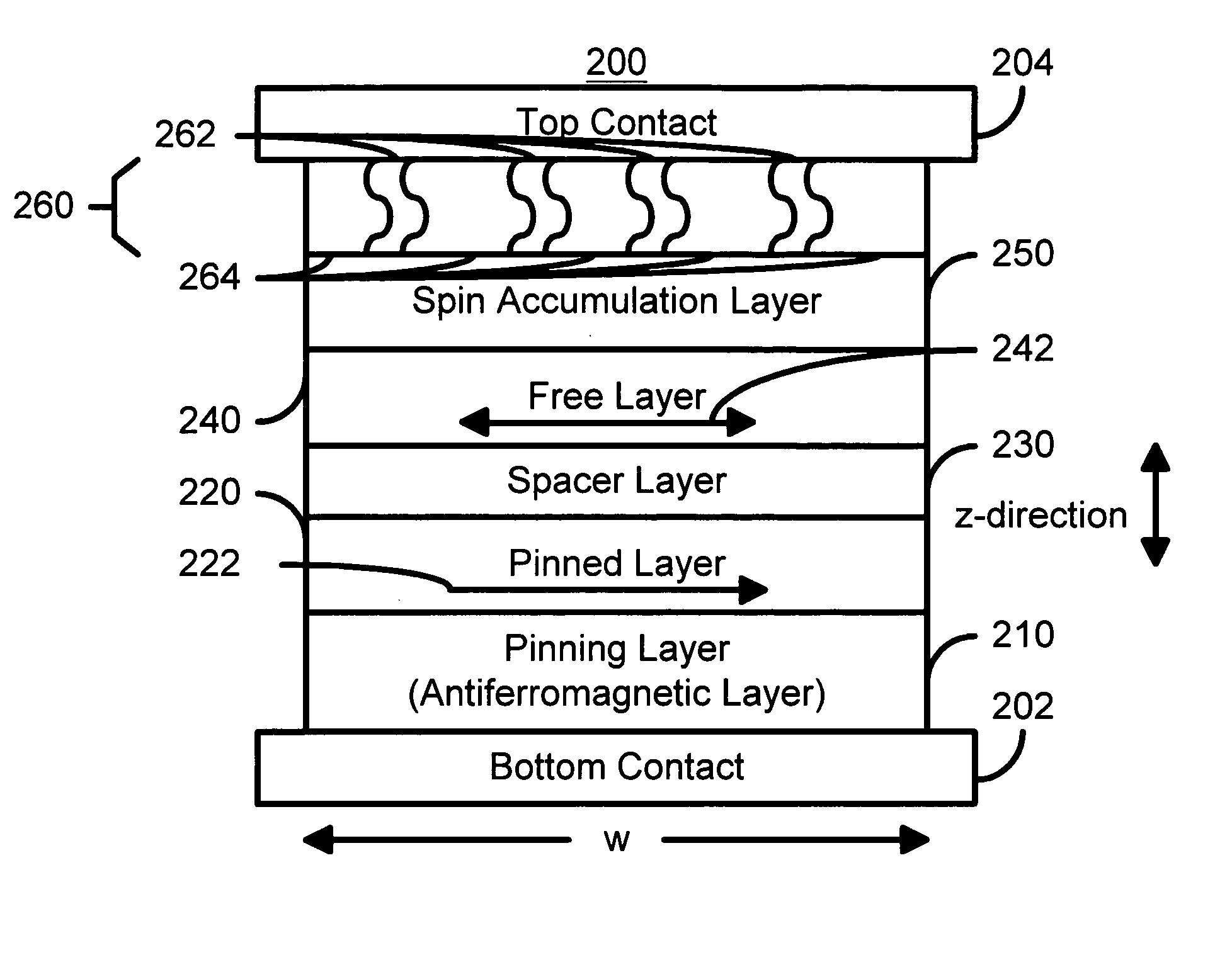

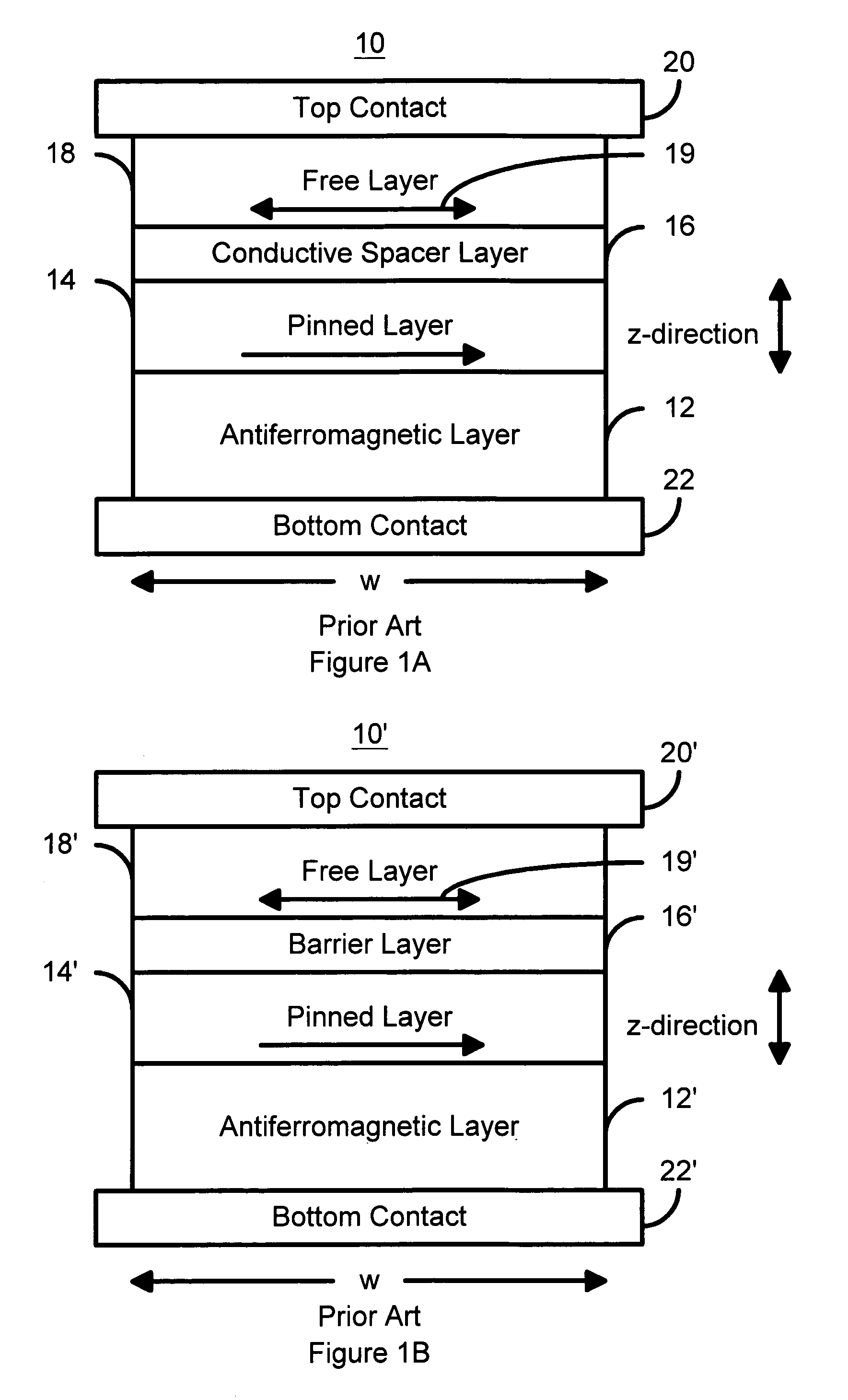

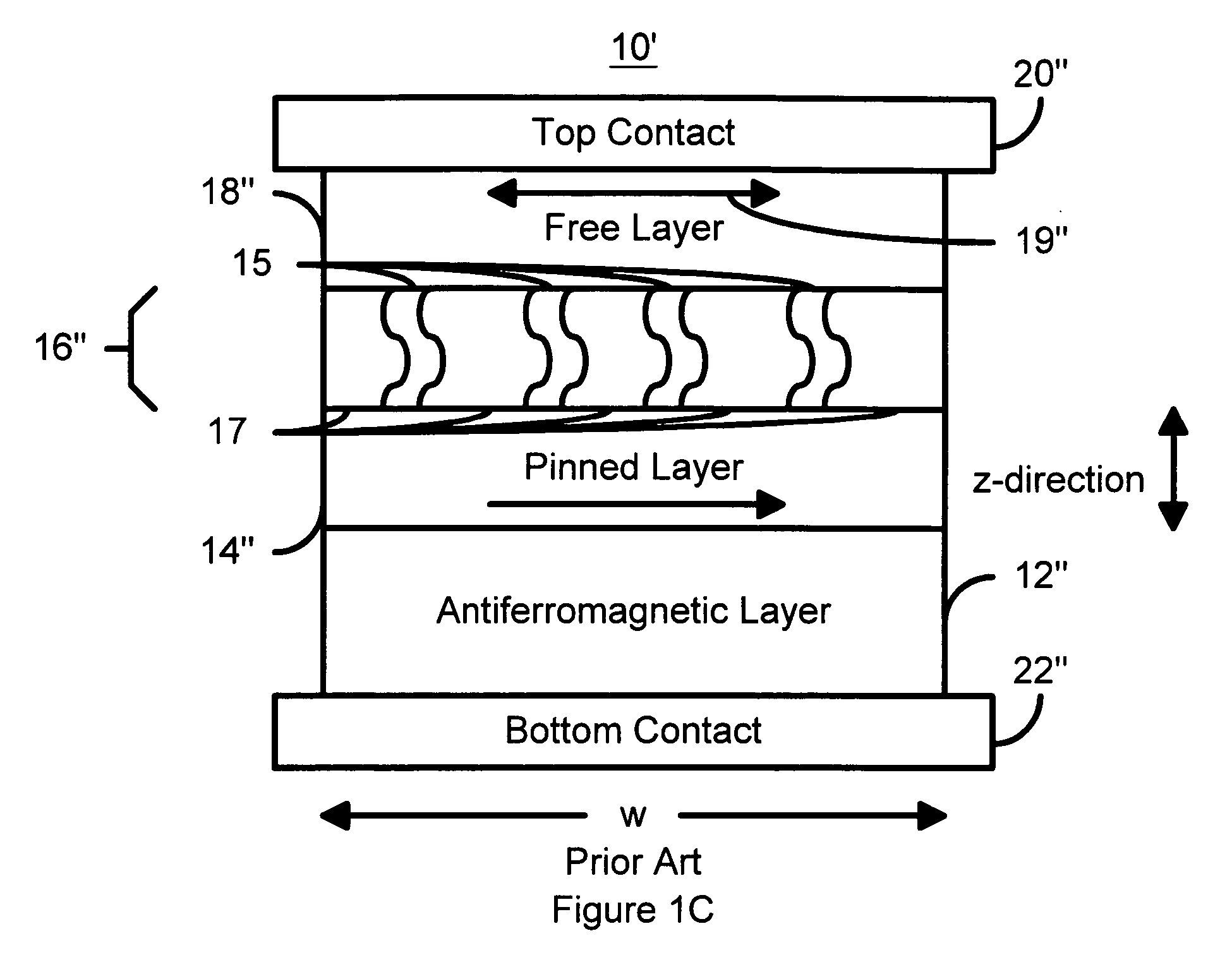

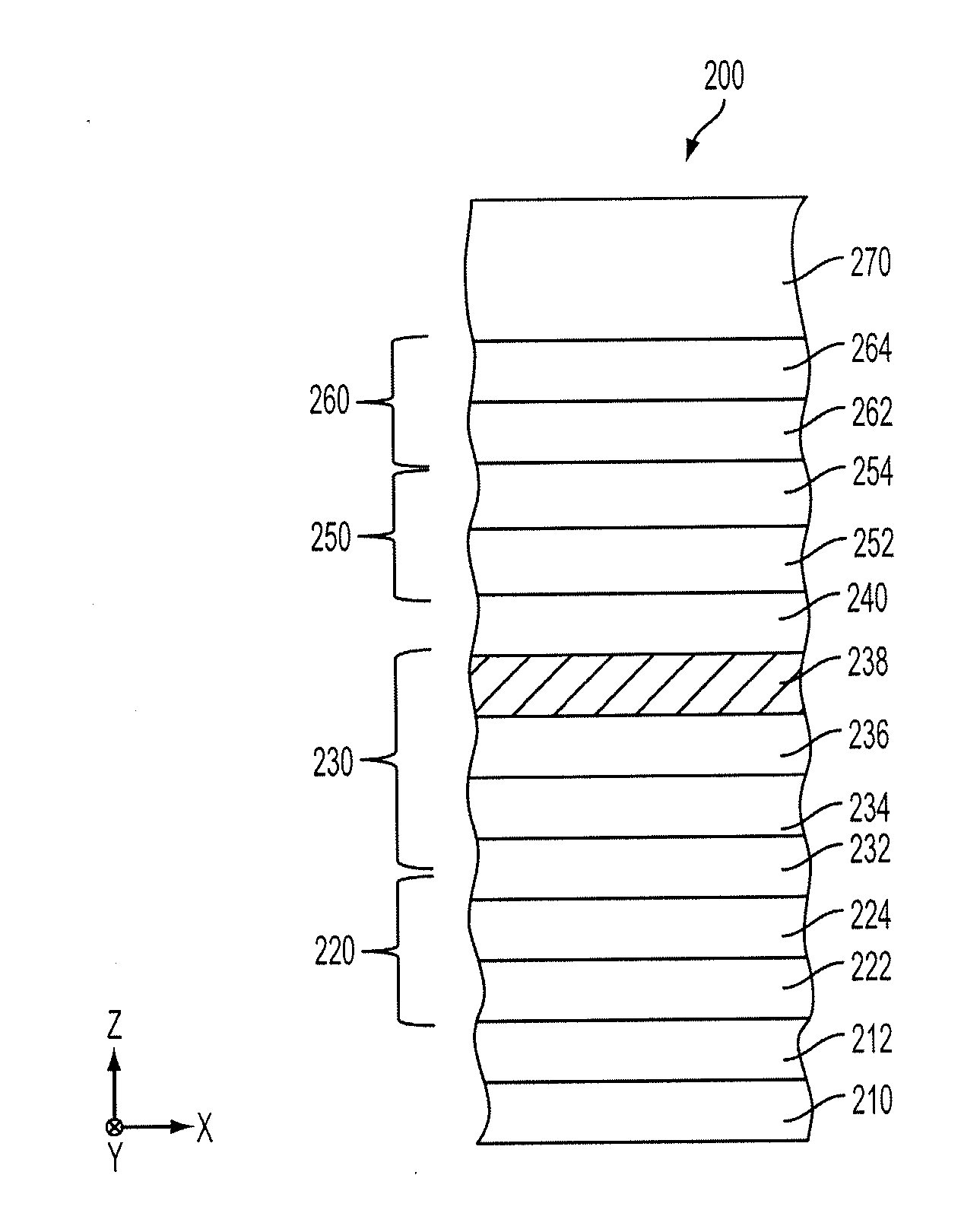

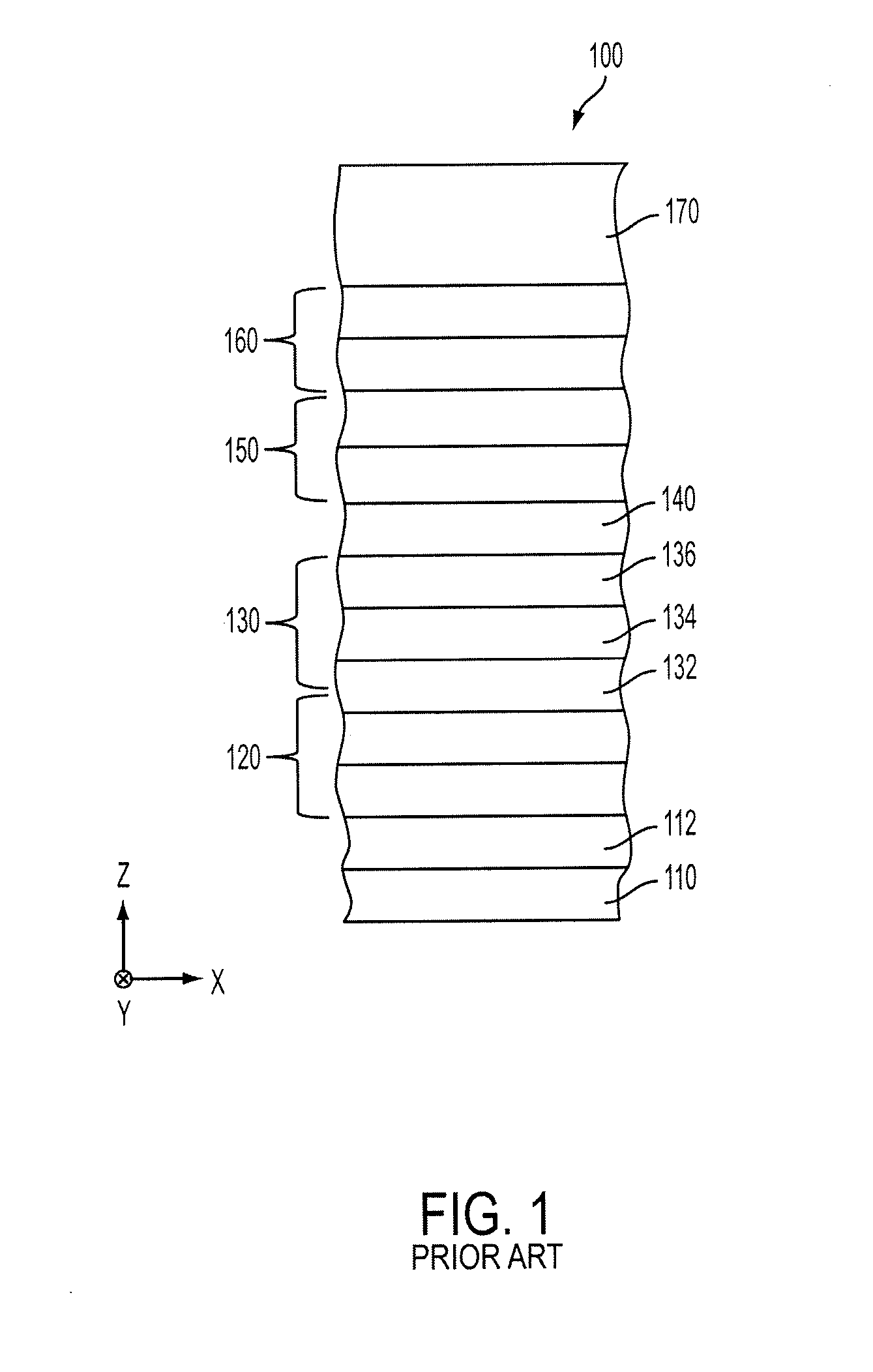

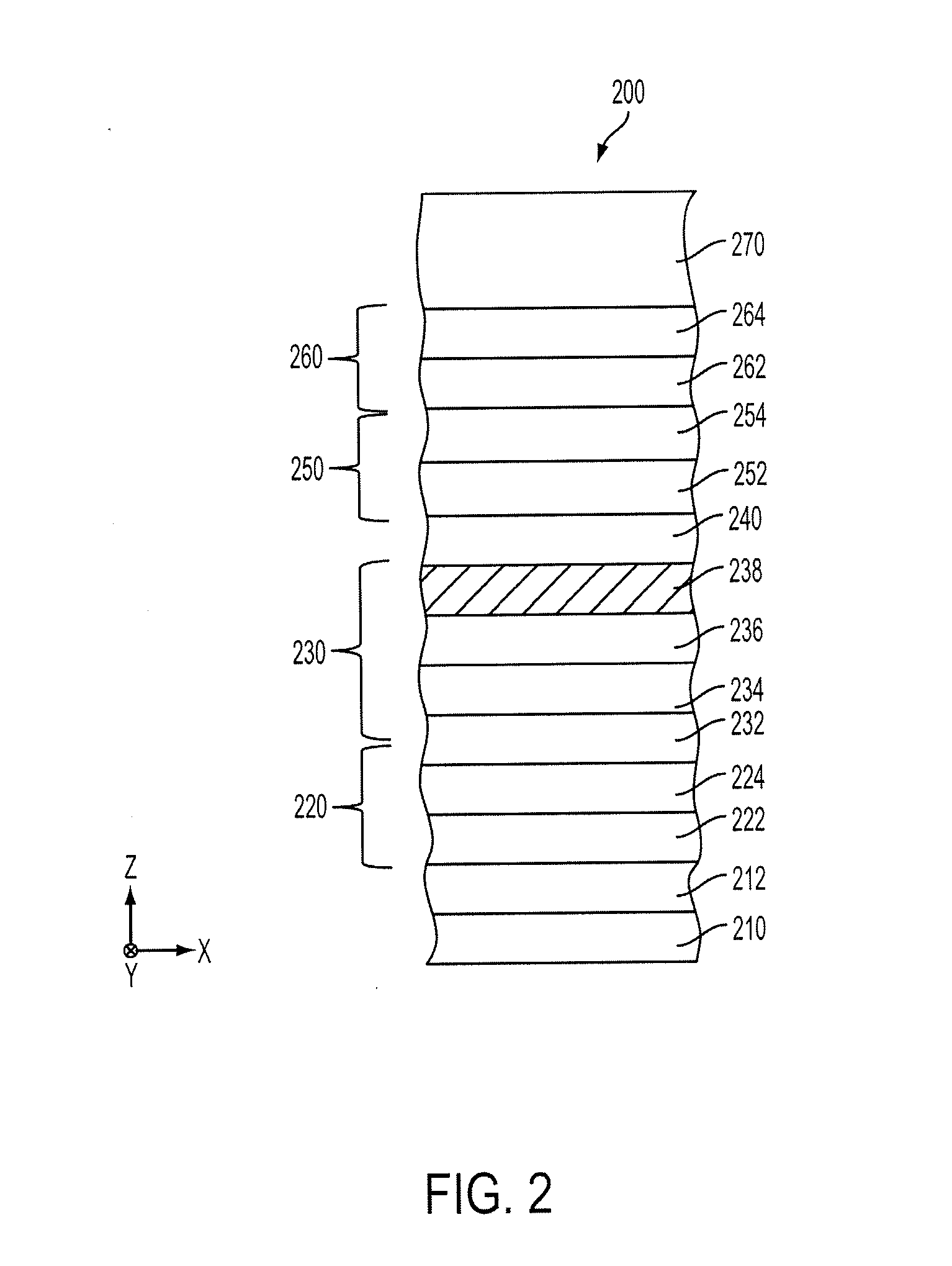

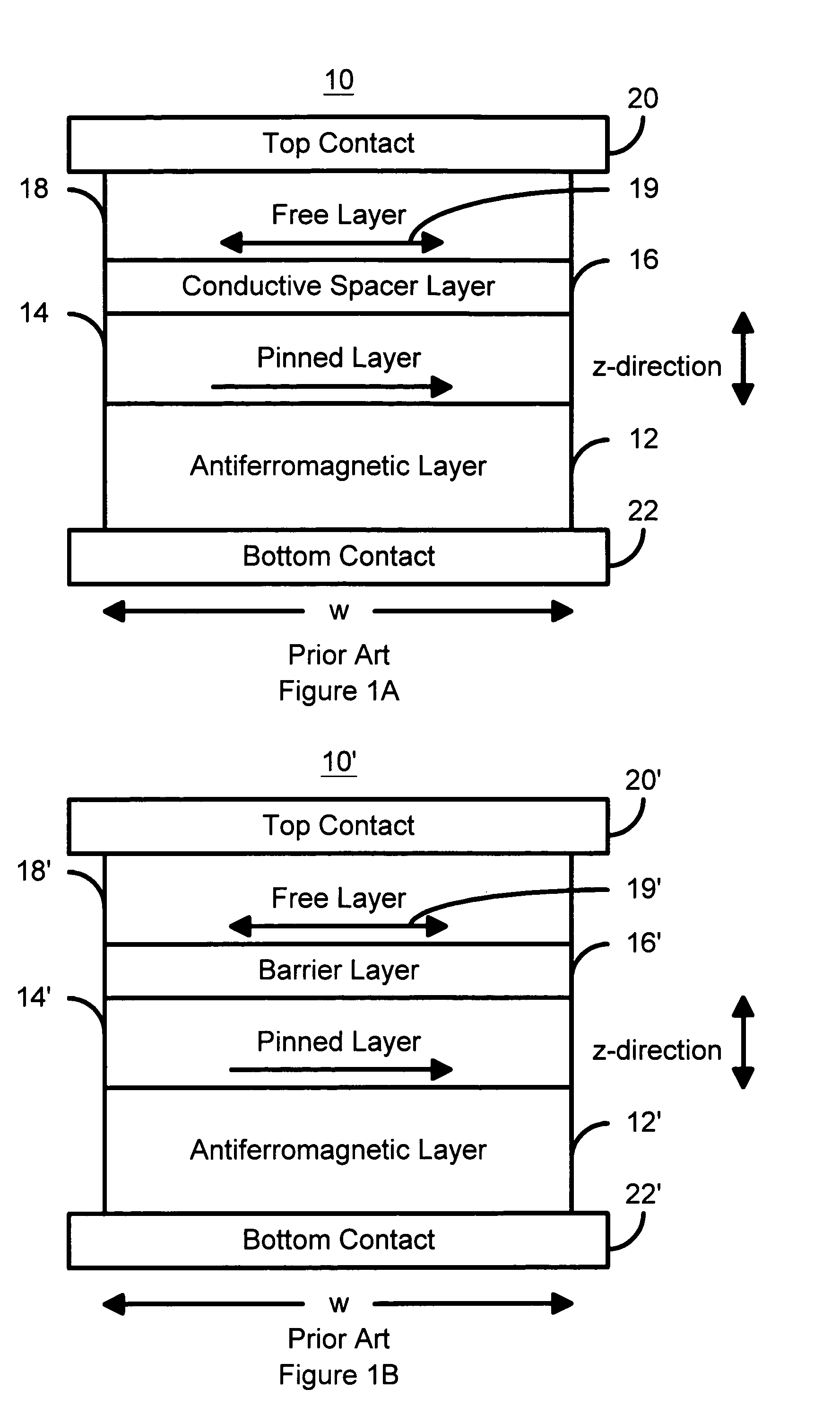

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes pinned, spacer, free, and spin barrier layers. The spacer layer is nonmagnetic and resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The free layer resides between the spacer layer and the spin barrier layer. The spin barrier layer is configured to reduce an outer surface contribution to a damping constant of the free layer. In one aspect, the spin barrier layer has a high areal resistance and may substantially eliminate spin pumping induced damping. In another aspect, the magnetic element also includes a spin accumulation layer between the spin barrier and free layers. The spin accumulation layer has a high conductivity, preferably being metallic, and may have a long spin diffusion length.

Owner:SAMSUNG SEMICON

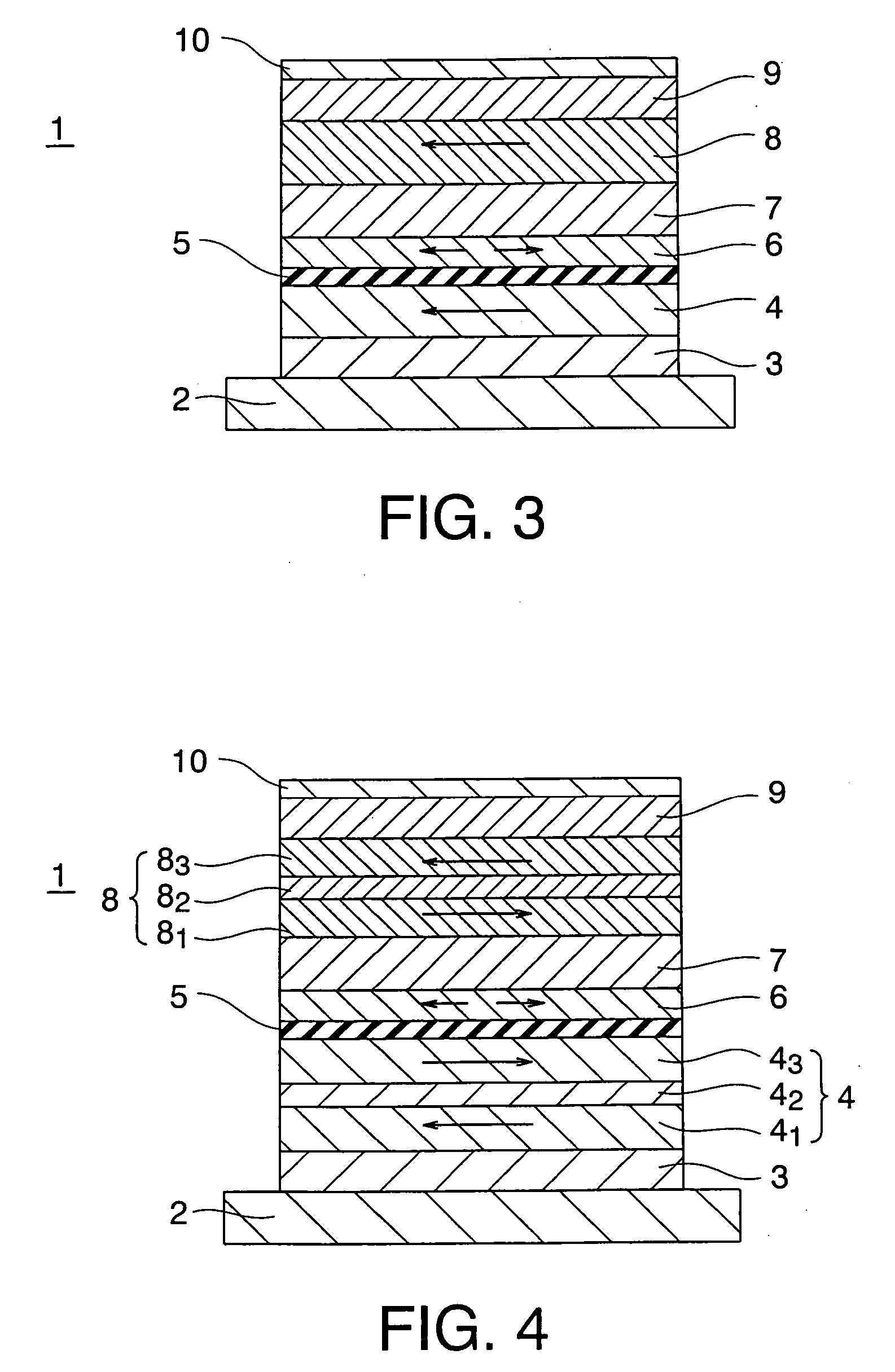

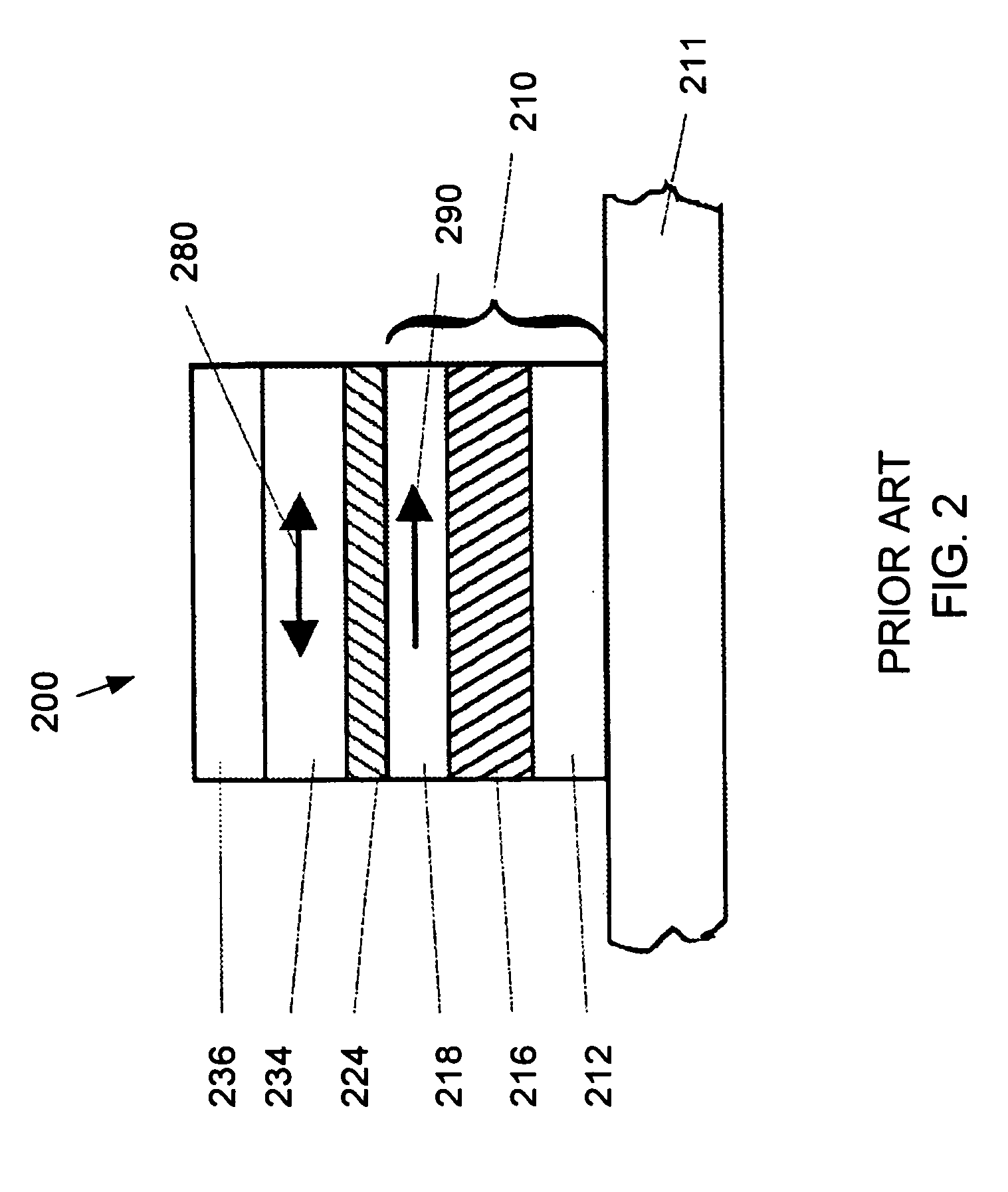

Spin barrier enhanced dual magnetoresistance effect element and magnetic memory using the same

ActiveUS7057921B2Reduce outer surfaceHigh areal resistanceNanomagnetismMagnetic-field-controlled resistorsDamping constantMagnetic memory

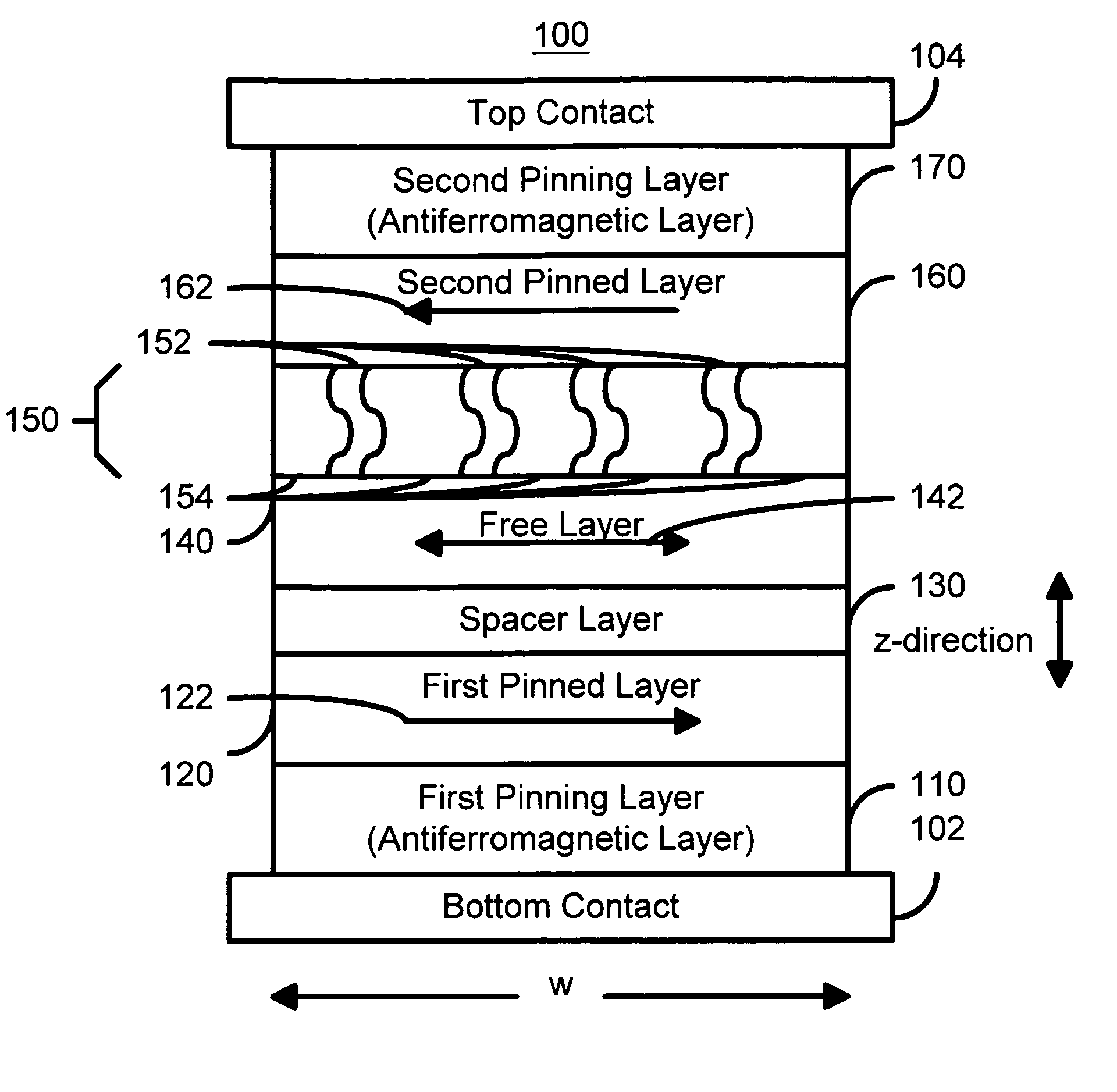

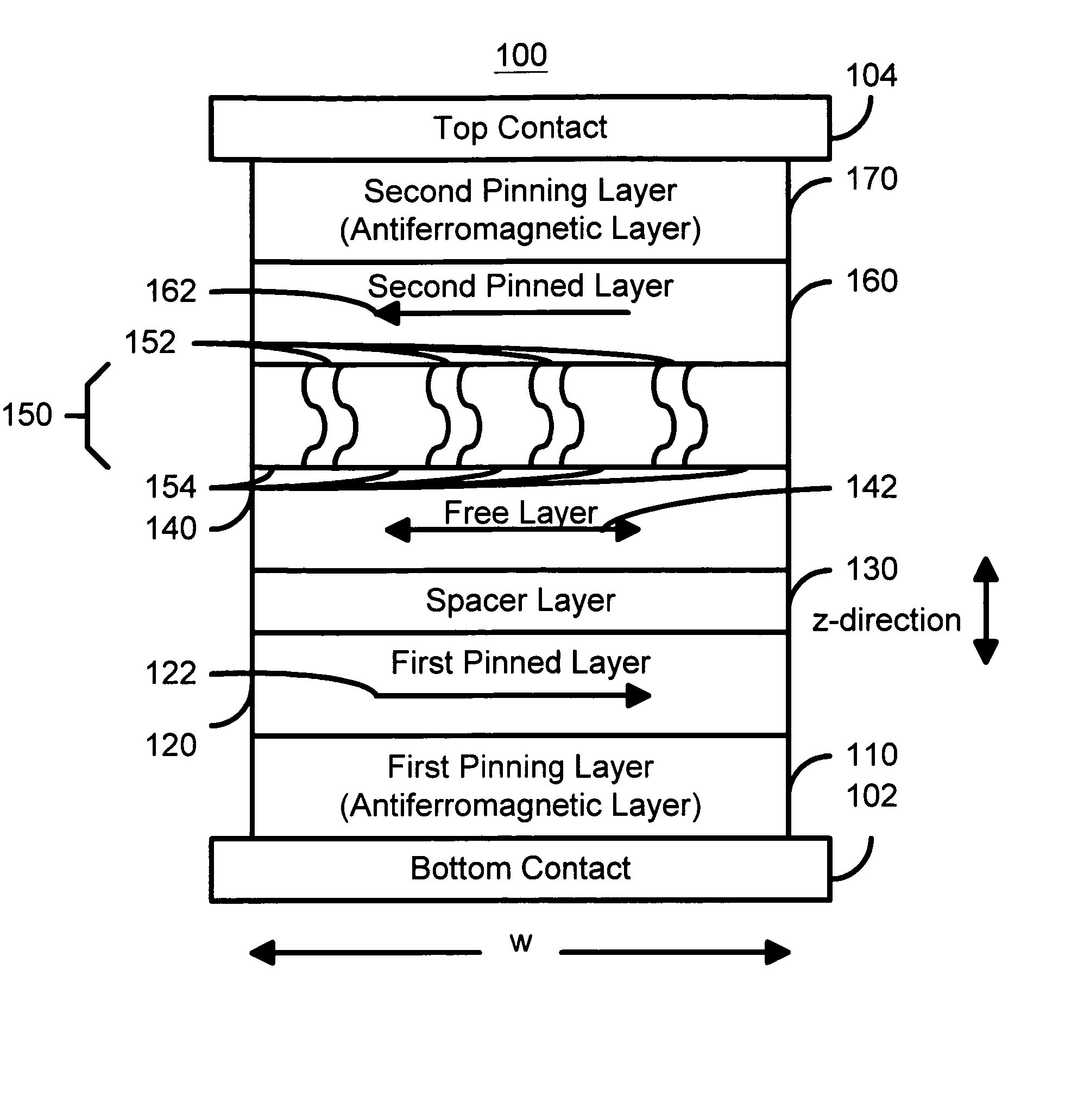

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes first pinned, spacer, free, spin barrier, and second pinned layers. The spacer layer is nonmagnetic and resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The free layer resides between the spacer and spin barrier layers. The spin barrier layer is between the free and second pinned layers. The spin barrier layer is configured to reduce an outer surface contribution to the free layer damping constant. In one aspect, the spin barrier layer has a high areal resistance and may substantially eliminate spin pumping induced damping. In another aspect, the magnetic element also includes a spin accumulation layer between the spin barrier and free layers. The spin accumulation layer has a high conductivity and may have a long spin diffusion length.

Owner:SAMSUNG SEMICON

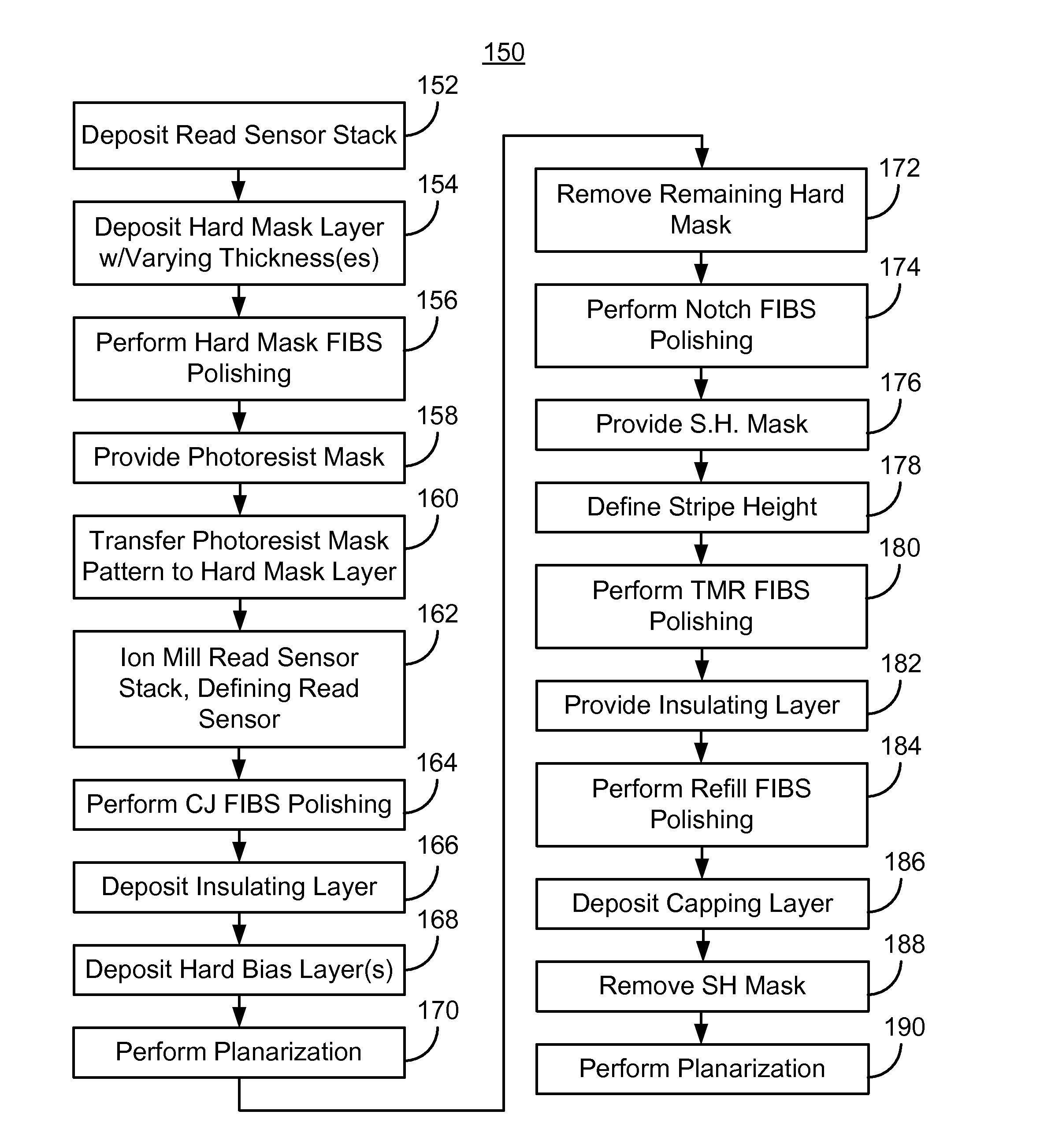

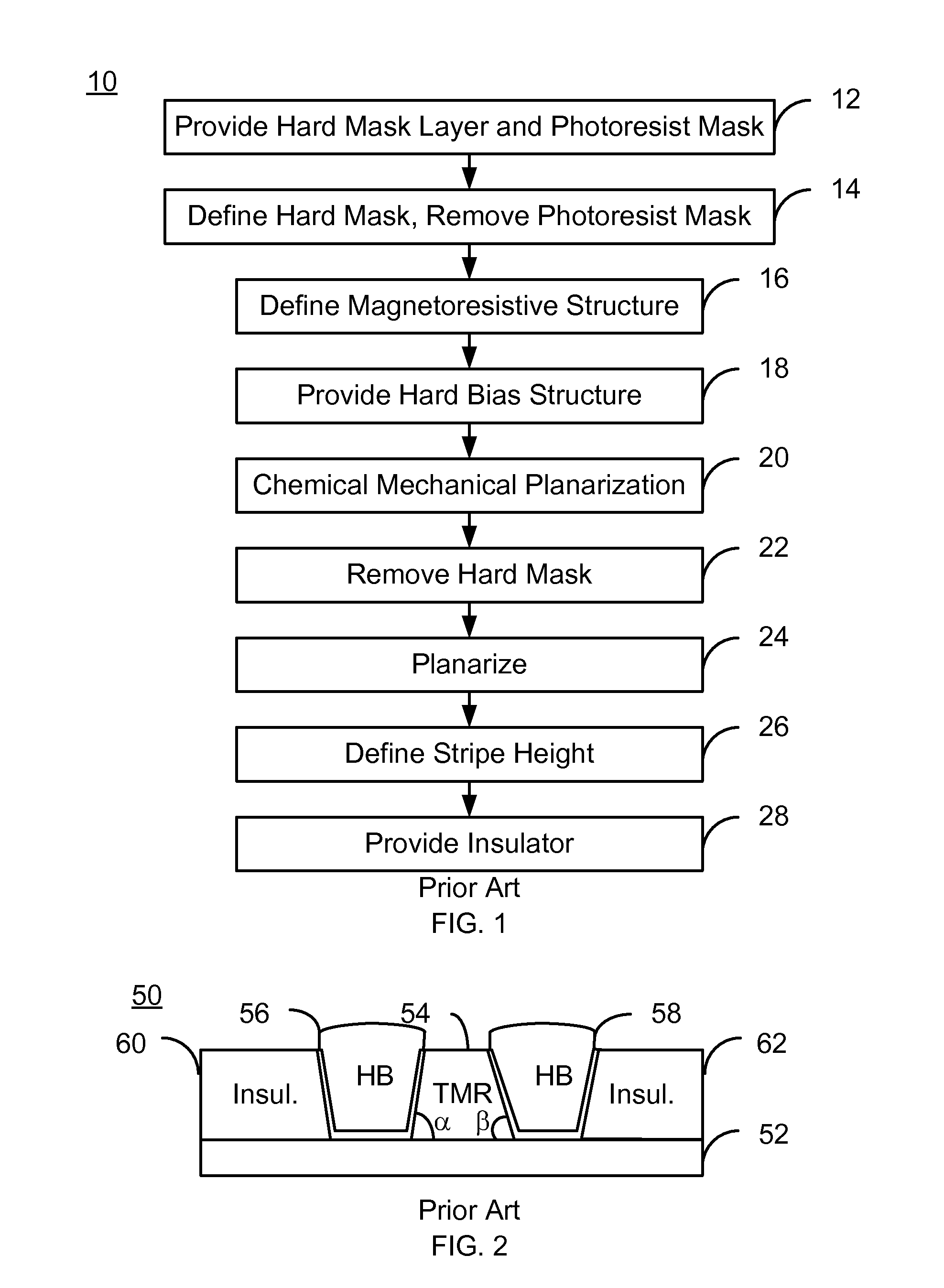

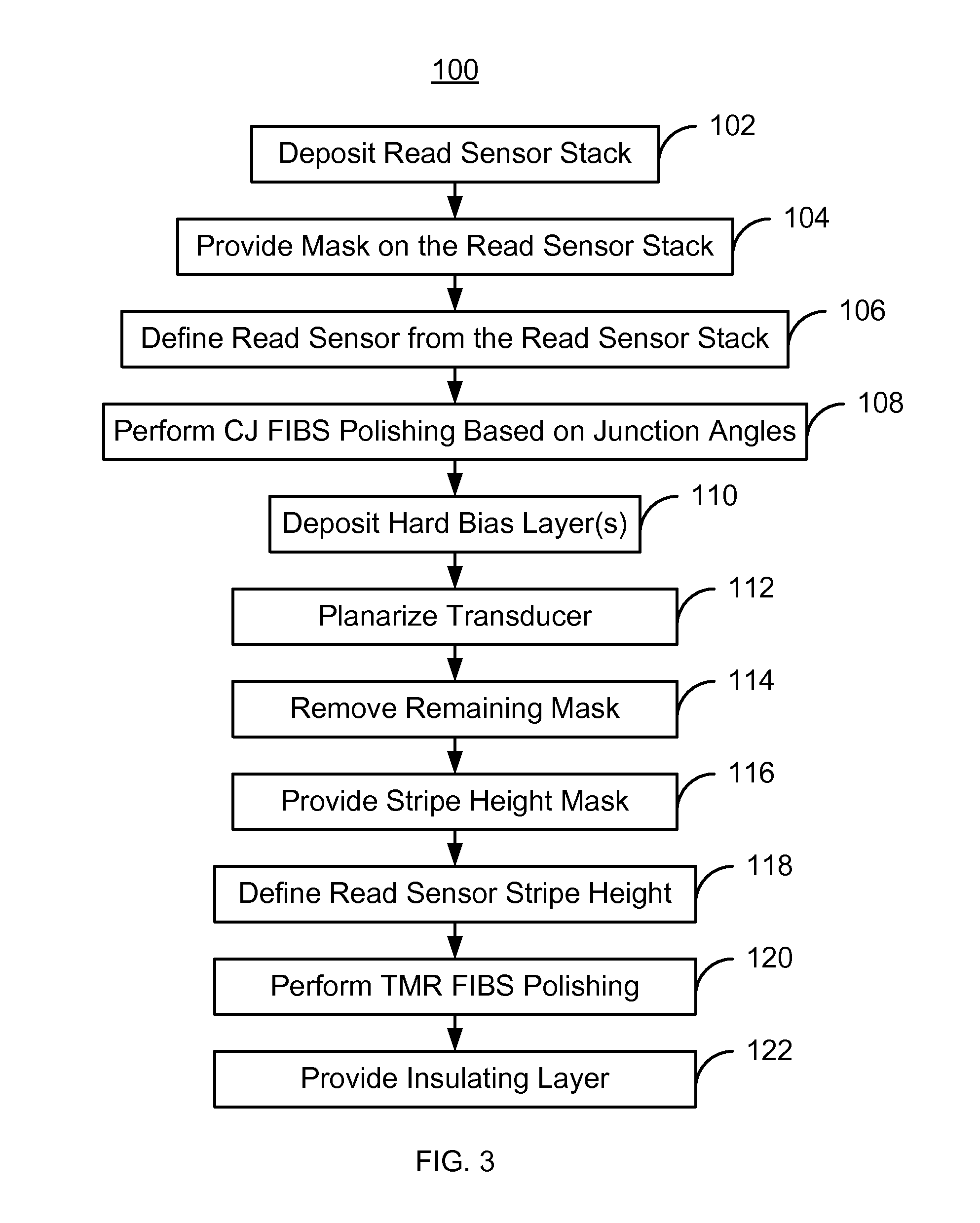

Method and system for providing a read sensor in a magnetic recording transducer using focused ion beam scan polishing

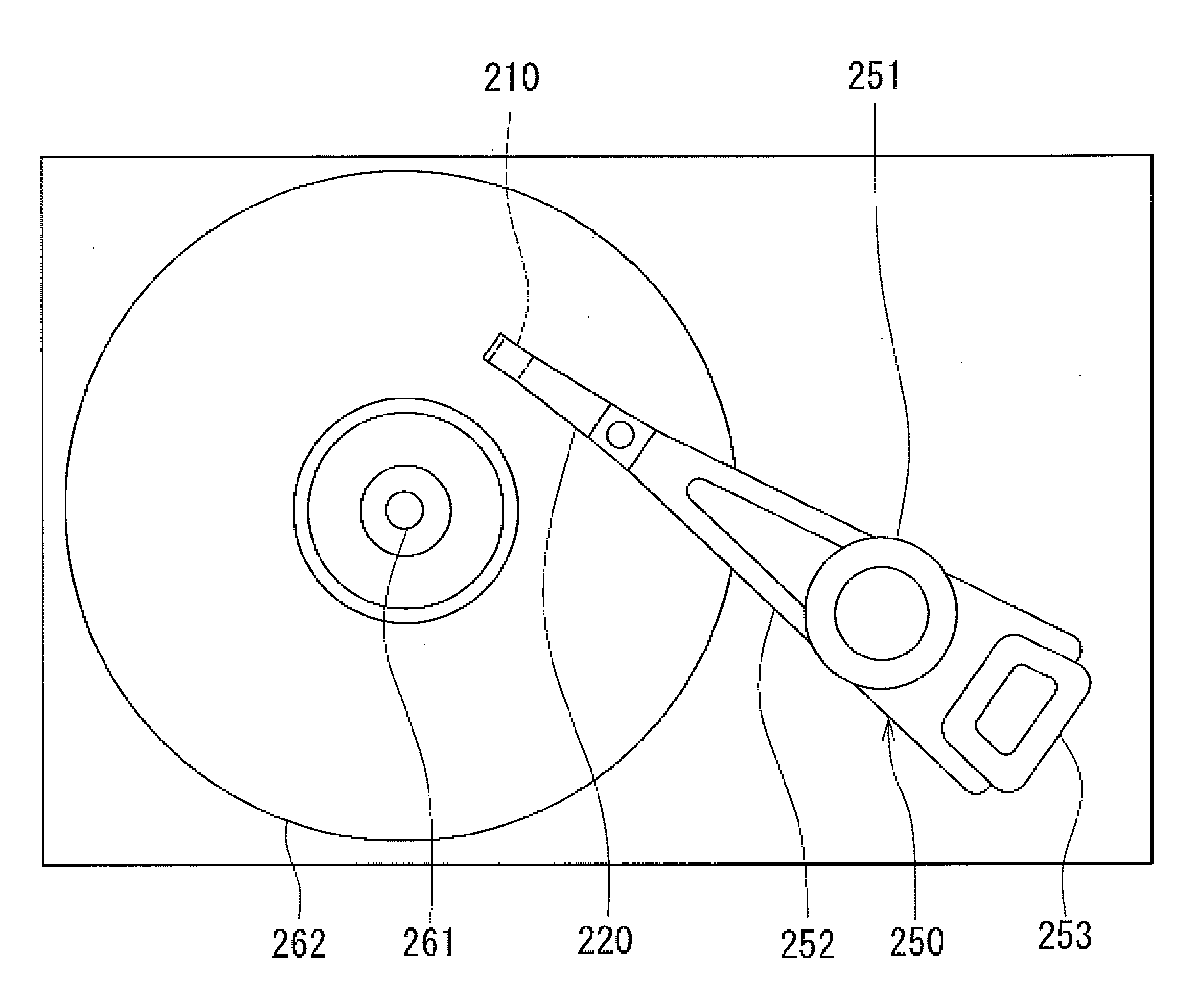

InactiveUS8480911B1Decorative surface effectsSemiconductor/solid-state device manufacturingSoftware engineeringIon beam

A read sensor for a read transducer is fabricated. The read transducer has field and device regions. A read sensor stack is deposited. A mask covering part of the stack corresponding to the read sensor is provided. The read sensor having inboard and outboard junction angles is defined from the stack in a track width direction. A critical junction (CJ) focused ion beam scan (FIBS) polishing that removes part of the read sensor based on the junction angles is performed. A hard bias structure is deposited and the transducer planarized. A remaining portion of the mask is removed. A stripe height mask covering part of the read sensor and hard bias structure in a stripe height direction is provided. The read sensor stripe height is defined. A tunneling magnetoresistance (TMR) FIBS polishing that removes part of the stack in the field region is performed. An insulating layer is provided.

Owner:WESTERN DIGITAL TECH INC

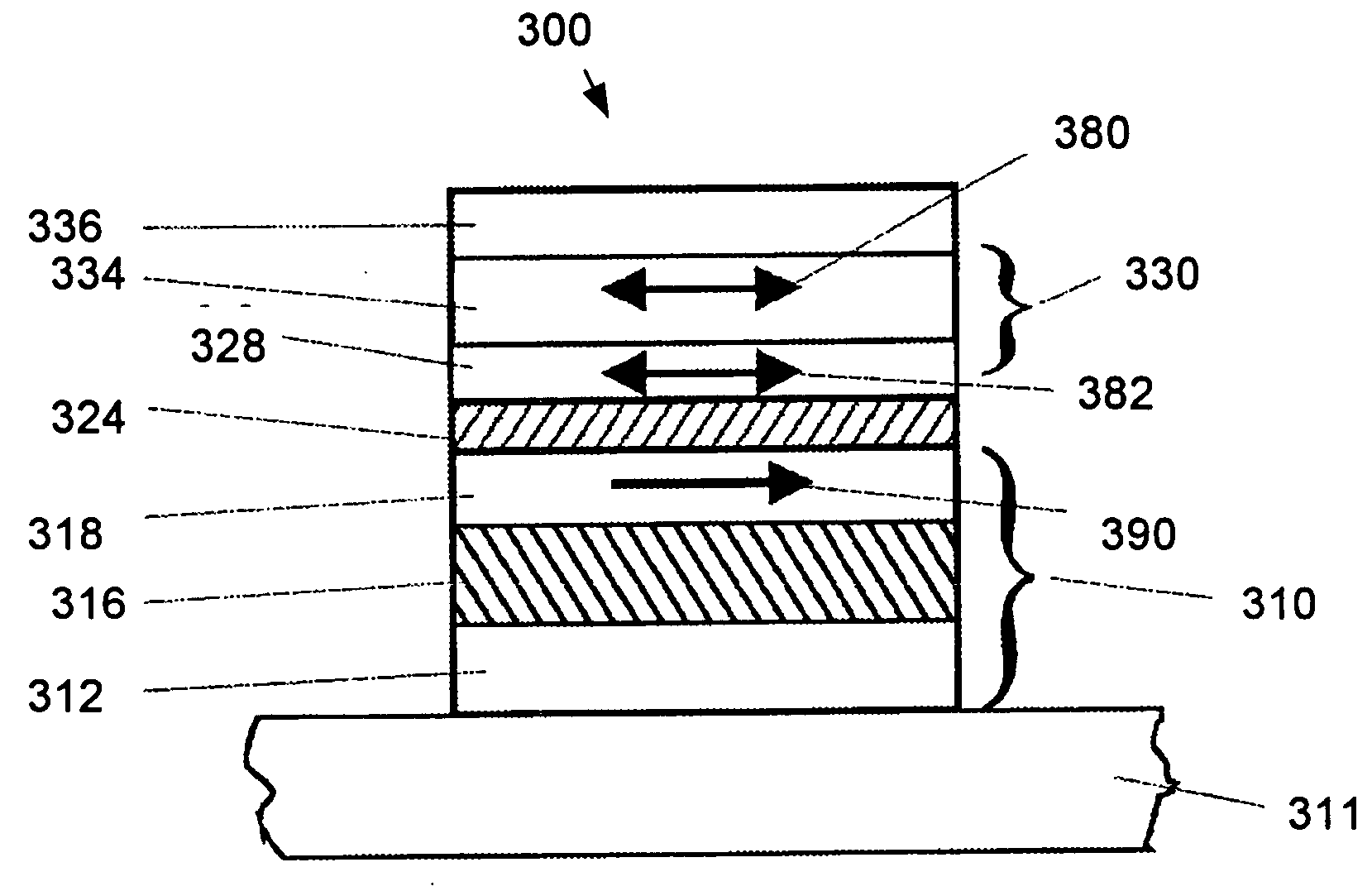

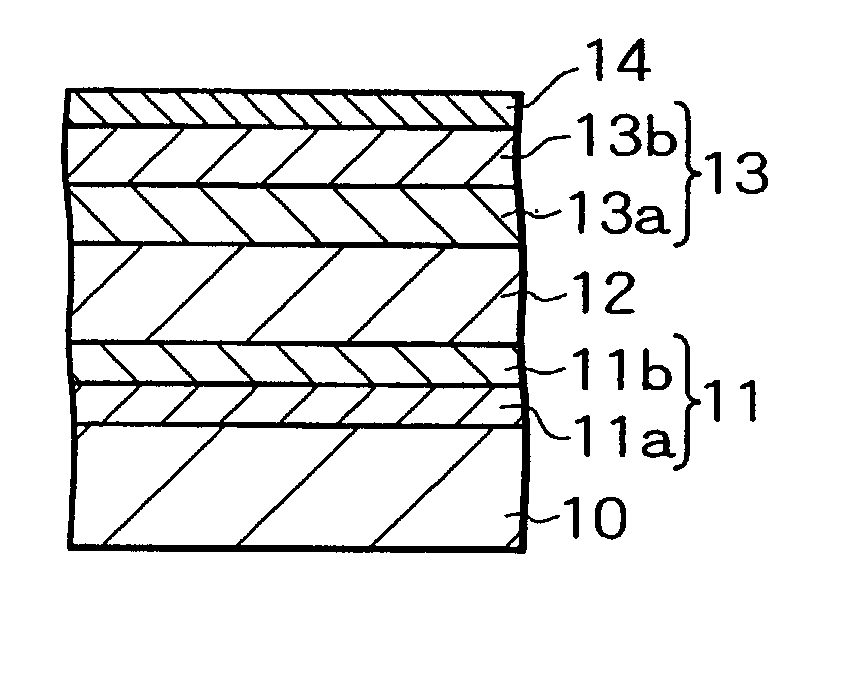

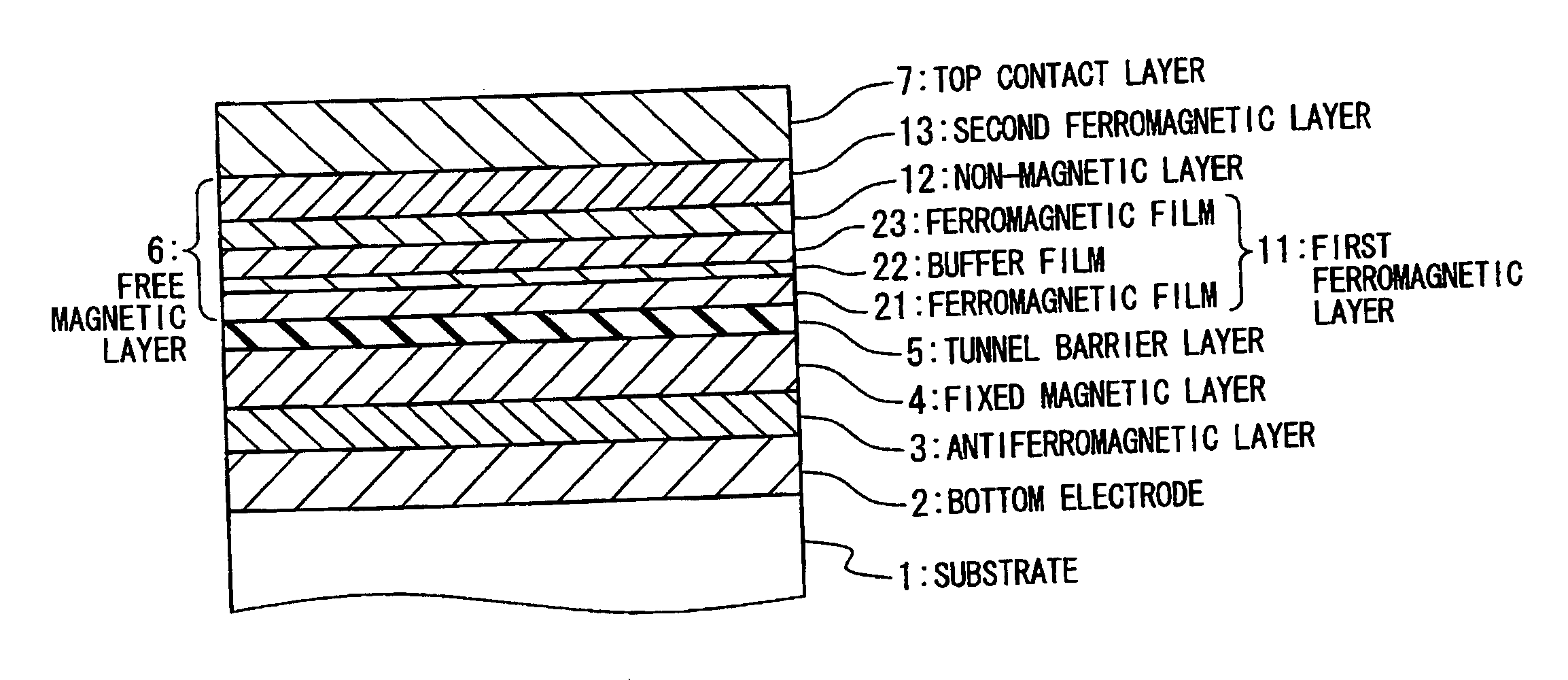

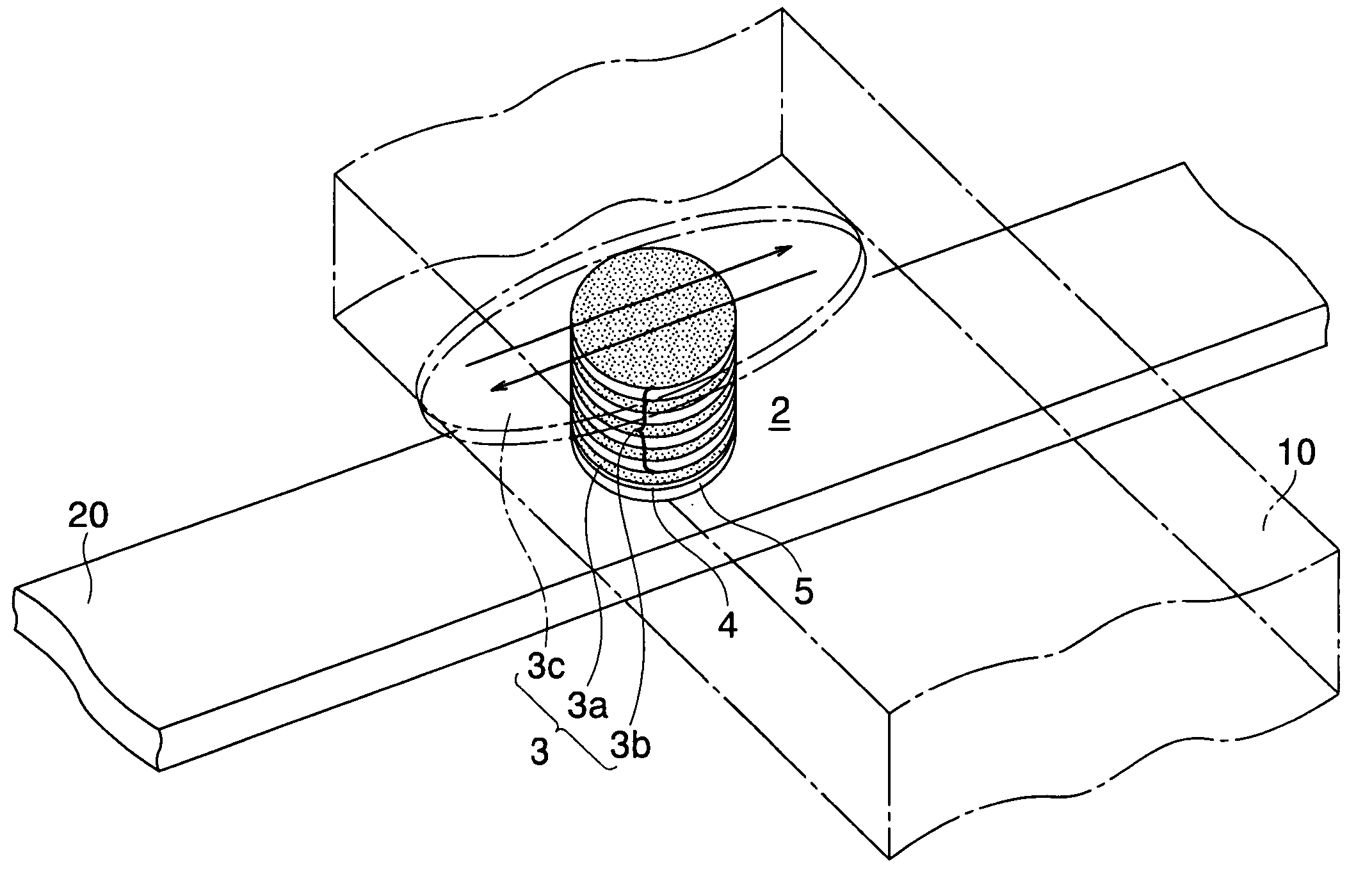

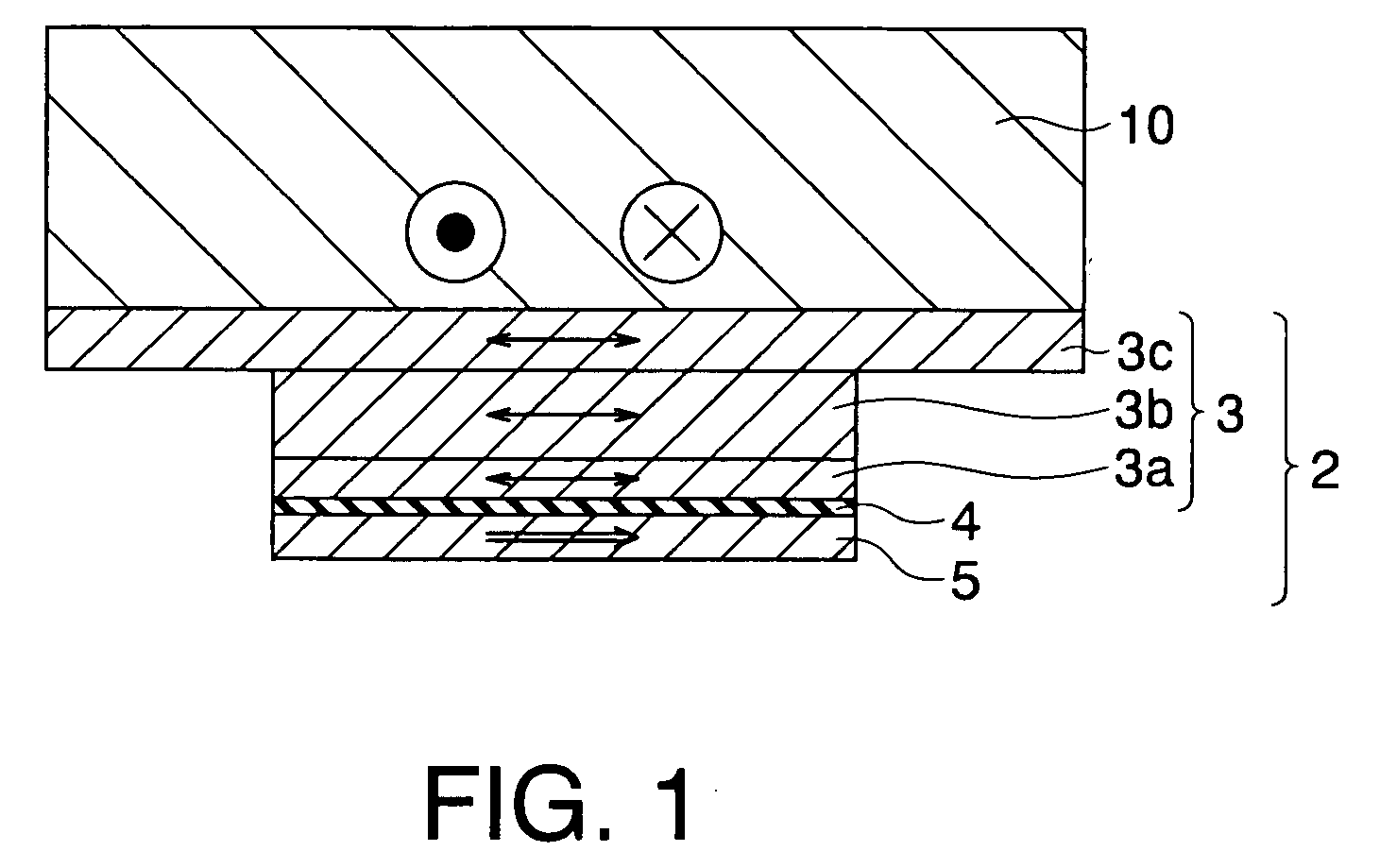

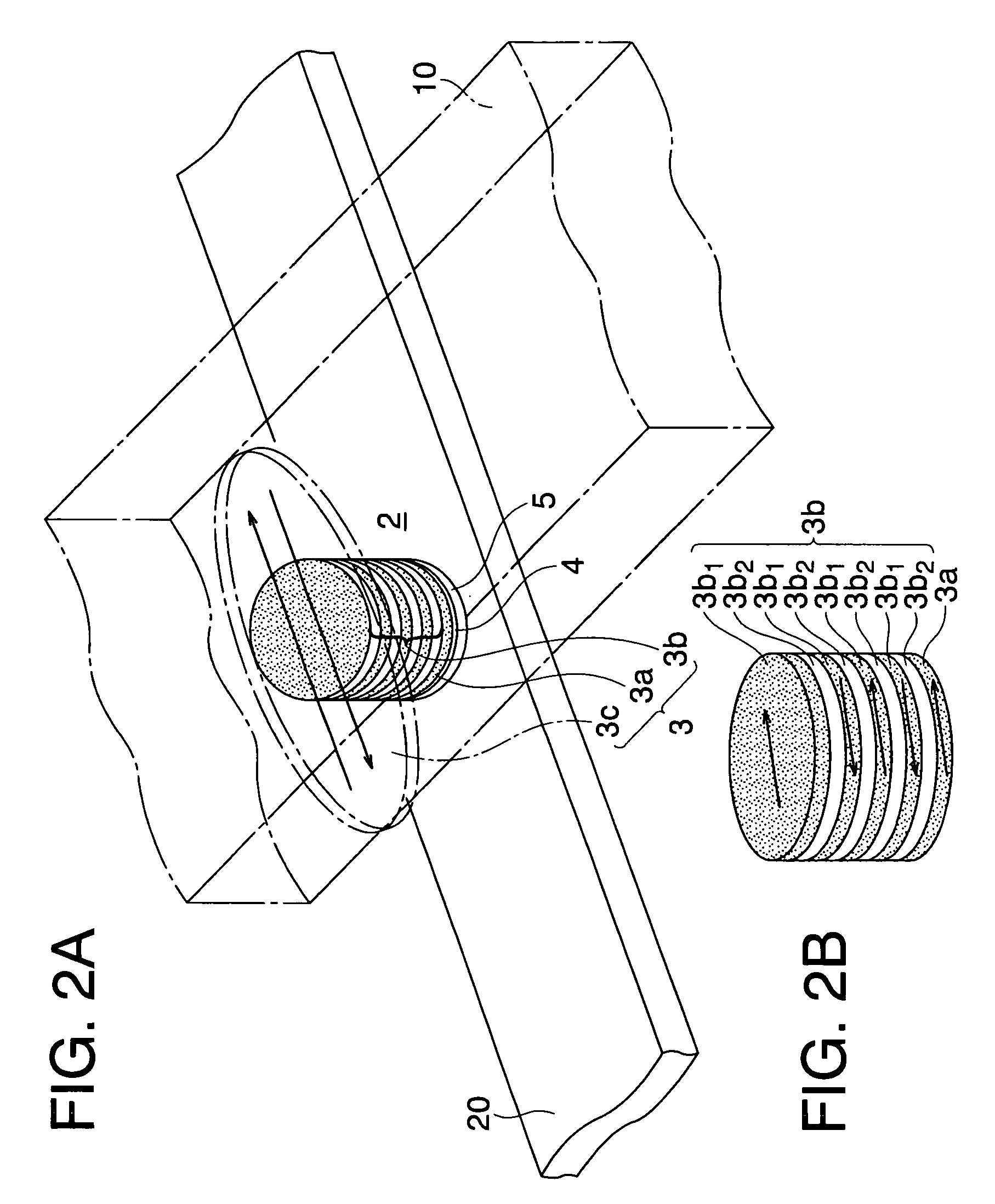

Magneto-resistance effect element and magnetic memory

InactiveUS20060227465A1Lower average currentNanomagnetismMagnetic-field-controlled resistorsMagnetizationMagnetic memory

It is possible to reduce a current required for spin injection writing. A magneto-resistance effect element includes: a first magnetization pinned layer; a magnetization free layer; a tunnel barrier layer; a second magnetization pinned layer whose direction of magnetization is pinned to be substantially anti-parallel to the direction of magnetization of the first magnetization pinned layer, and; a non-magnetic layer. When the second magnetization pinned layer is made of ferromagnetic material including Co, material for the non-magnetic layer is metal including at least one element selected from the group consisting of Zr, Hf, Rh, Ag, and Au; when the second magnetization pinned layer is made of ferromagnetic material including Fe, material for the non-magnetic layer is metal including at least one element selected from the group consisting of Rh, Pt, Ir, Al, Ag, and Au; and when the second magnetization pinned layer is made of ferromagnetic material including Ni, material for the non-magnetic layer is metal including at least one element selected from the group consisting of Zr, Hf, Au, and Ag.

Owner:KK TOSHIBA

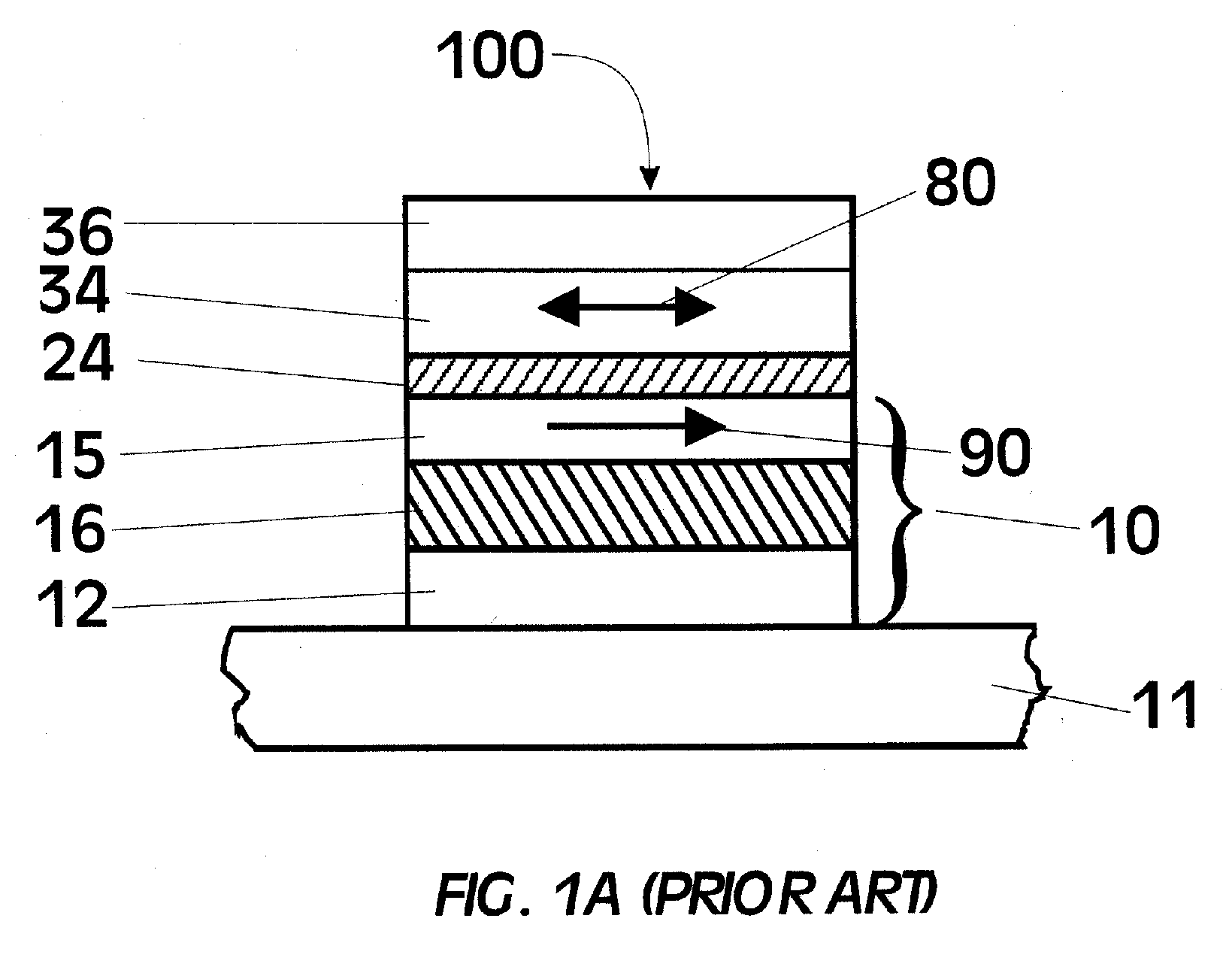

Magnetic tunnel junction with improved tunneling magneto-resistance

InactiveUS20050110004A1Improve featuresNanostructure applicationNanomagnetismInterface layerMagnetic memory

A magnetic tunnel element that can be used, for example, as part of a read head or a magnetic memory cell, includes a first layer formed from an amorphous material, an amorphous tunnel barrier layer, and an interface layer between the first layer and the tunnel barrier layer. The interface layer is formed from a material that is crystalline when the material is in isolation from both the first layer and the tunnel barrier layer. Alternatively, the thickness of the interface layer is selected so that the interface layer is not crystalline. The first layer is formed from at least one material selected from the group consisting of amorphous ferromagnetic material, amorphous ferrimagnetic materials, and amorphous non-magnetic materials. The interface layer is formed from a material selected from the group consisting of a ferromagnetic material and a ferrimagnetic material.

Owner:GLOBALFOUNDRIES INC

Magnetic Tunnel Junctions Using Amorphous Materials as Reference and Free Layers

ActiveUS20060098354A1Improve barrier propertiesImprove performanceNanomagnetismNanoinformaticsBoronTunnel junction

Magnetic tunnel junctions are constructed from a MgO or Mg—ZnO tunnel barrier and amorphous magnetic layers in proximity with, and on respective sides of, the tunnel barrier. The amorphous magnetic layer preferably includes Co and at least one additional element selected to make the layer amorphous, such as boron. Magnetic tunnel junctions formed from the amorphous magnetic layers and the tunnel barrier have tunneling magnetoresistance values of up to 200% or more.

Owner:IBM CORP

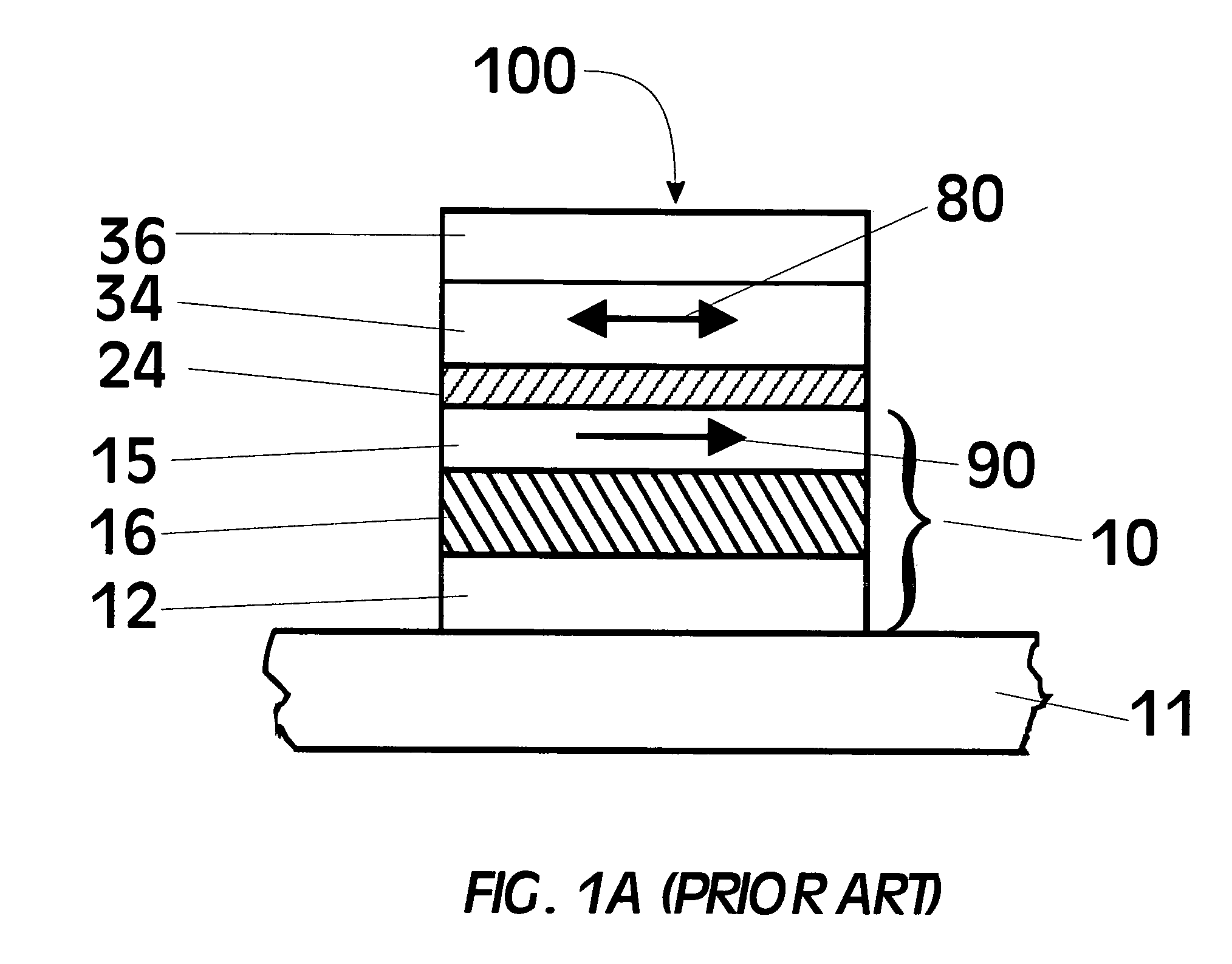

Spin barrier enhanced magnetoresistance effect element and magnetic memory using the same

ActiveUS20050254287A1Reduce outer surfaceHigh areal resistanceNanomagnetismMagnetic-field-controlled resistorsDamping constantMagnetic memory

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes pinned, spacer, free, and spin barrier layers. The spacer layer is nonmagnetic and resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The free layer resides between the spacer layer and the spin barrier layer. The spin barrier layer is configured to reduce an outer surface contribution to a damping constant of the free layer. In one aspect, the spin barrier layer has a high areal resistance and may substantially eliminate spin pumping induced damping. In another aspect, the magnetic element also includes a spin accumulation layer between the spin barrier and free layers. The spin accumulation layer has a high conductivity, preferably being metallic, and may have a long spin diffusion length.

Owner:SAMSUNG SEMICON

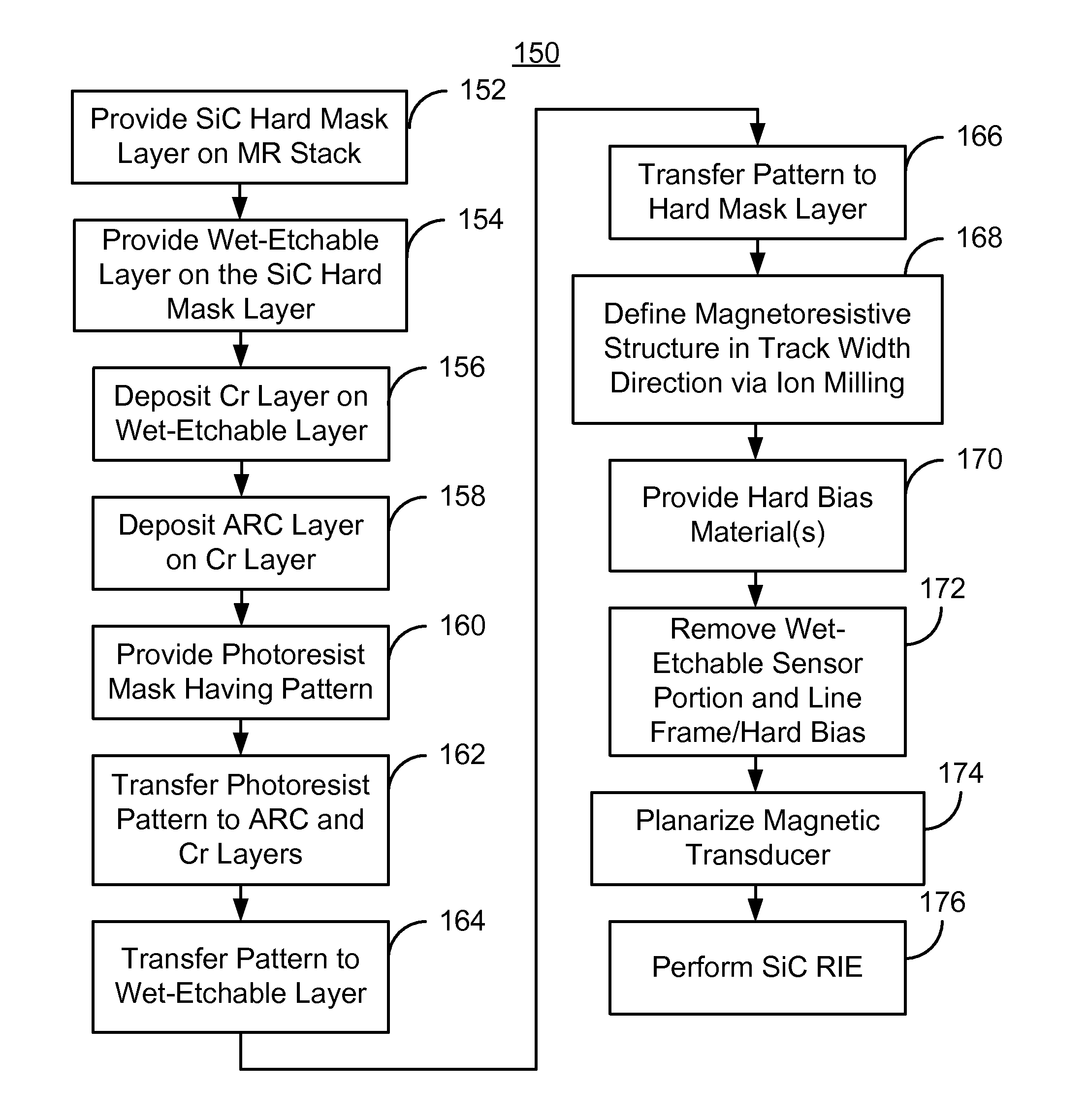

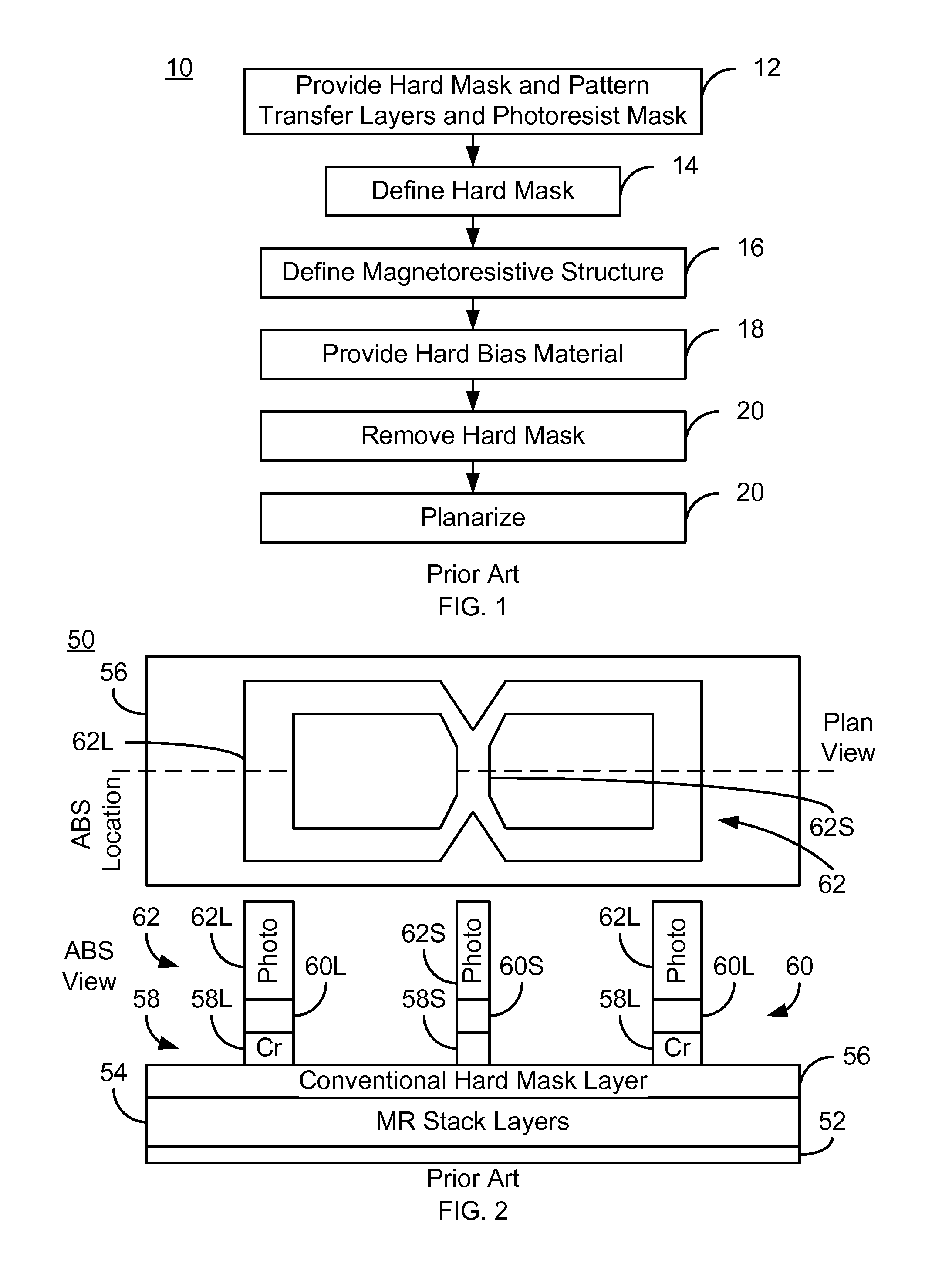

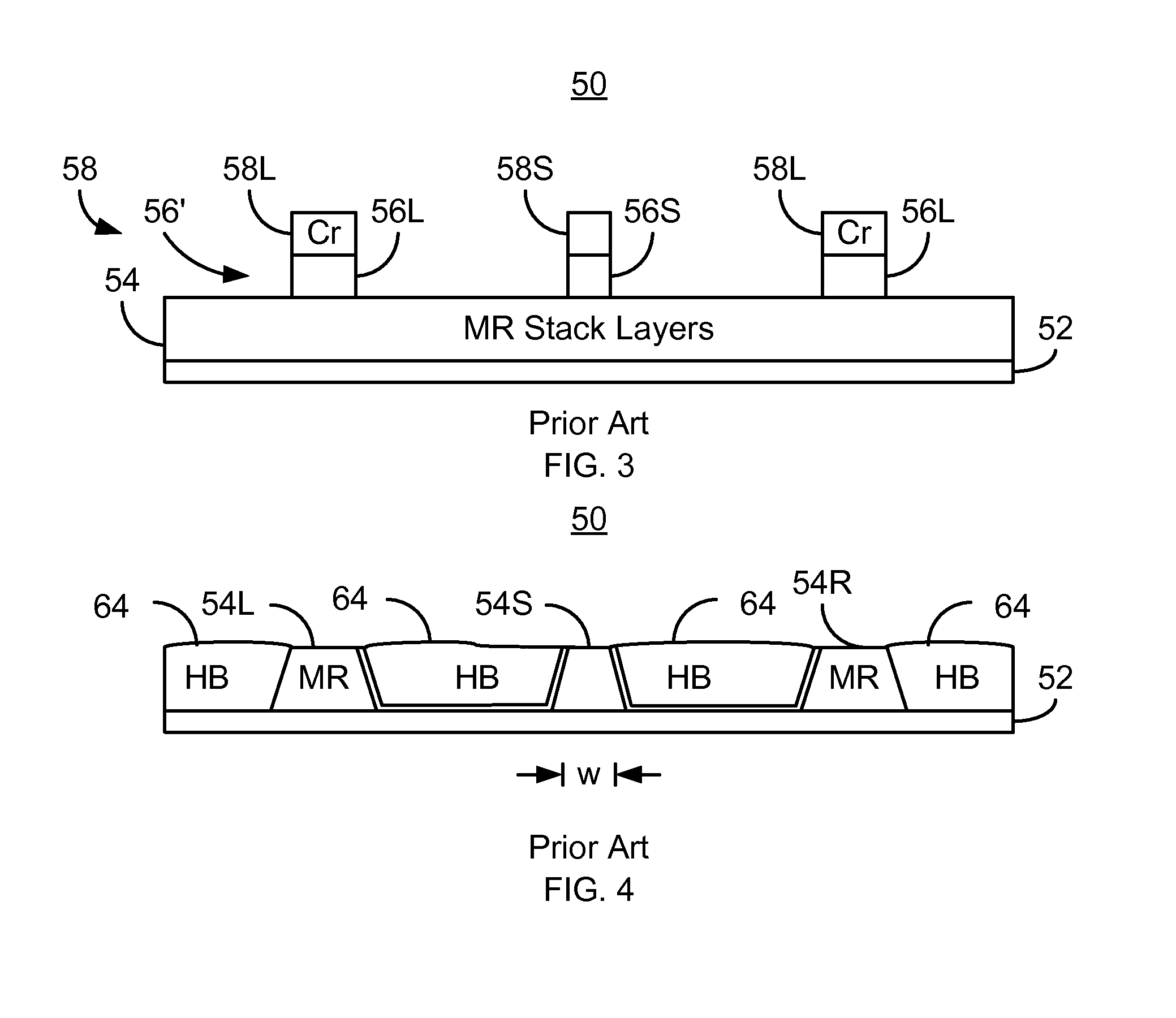

Method and system for providing a magnetic recording transducer using a line hard mask and a wet-etchable mask

A method and system for fabricating a magnetic transducer is described. The transducer has device and field regions, and a magnetoresistive stack. Hard mask layer and wet-etchable layers are provided on the magnetoresistive stack and hard mask layer, respectively. A hard mask and a wet-etchable mask are formed from the hard mask and the wet-etchable layers, respectively. The hard and wet-etchable masks each includes a sensor portion and a line frame. The sensor portion covers part of the magnetoresistive stack corresponding to a magnetoresistive structure. The line frame covers a part of the magnetoresistive stack in the device region. The magnetoresistive structure is defined in a track width direction. Hard bias material(s) are then provided. Part of the hard bias material(s) is adjacent to the magnetoresistive structure in the track width direction. The wet-etchable sensor portion and line frame, and hard bias material(s) thereon, are removed.

Owner:WESTERN DIGITAL TECH INC

Exchange coupling film, magneto-resistance effect device, magnetic head, and magnetic random access memory

A foundation layer increasing adhesive properties to a substrate, another foundation layer controlling orientation of an antiferromagnetic layer, the antiferromagnetic layer including a disordered alloy of IrMn, a pinning layer, and a cap protection layer are formed in the order on the substrate. The pinning layer includes two layers having an exchange coupling giving layer which exchange-couples to the antiferromagnetic layer and an exchange coupling enhancement layer which enhances the exchange coupling, the exchange coupling giving layer is made of a ferromagnetic material including Co or a Co100-XFeX alloy (O<=X<25) having face-centered cubic structure. The exchange coupling enhancement layer is made of Fe or a Co100-YFeY alloy (25<=Y<=100) having body-centered cubic structure.

Owner:NEC CORP

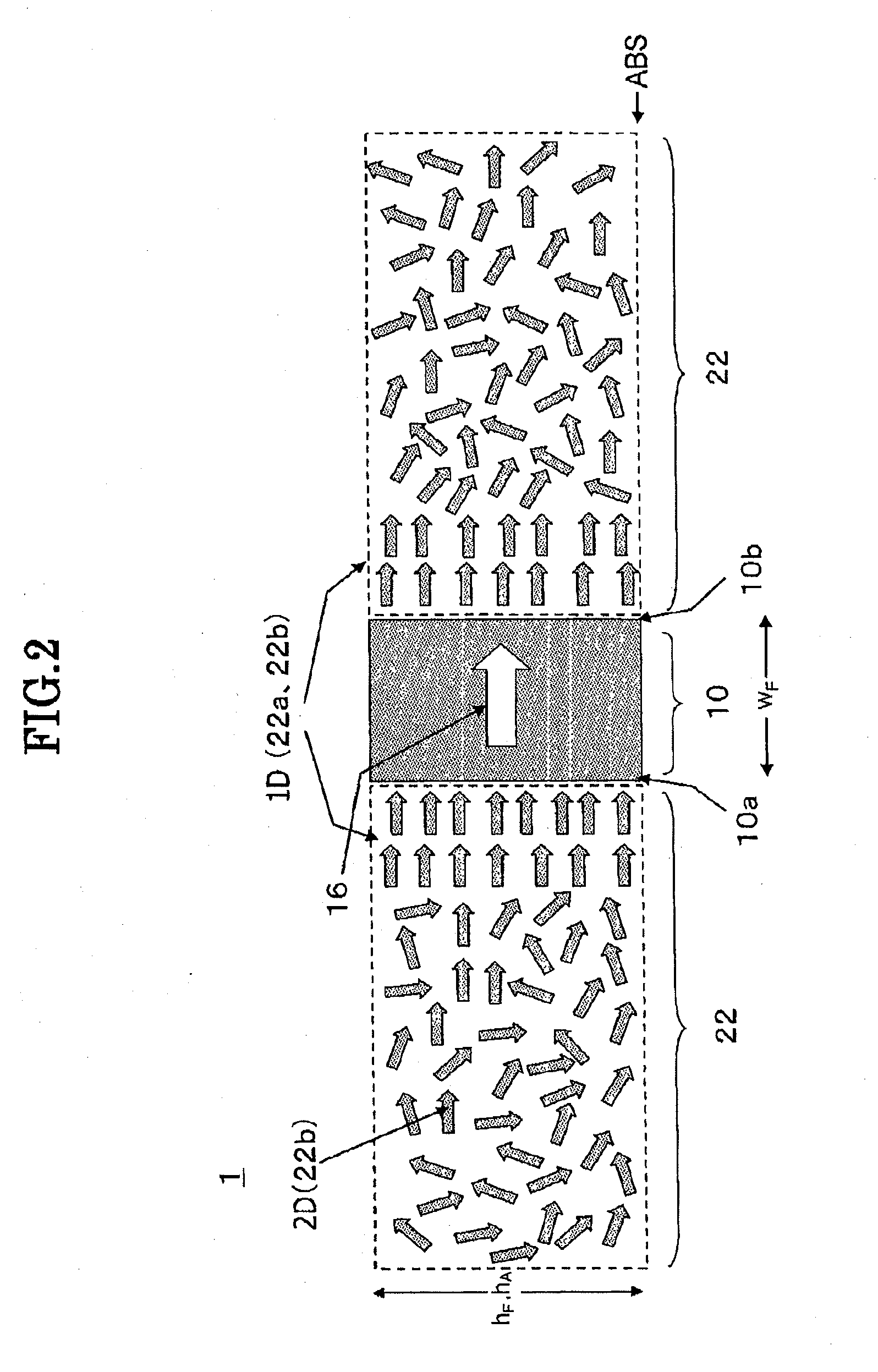

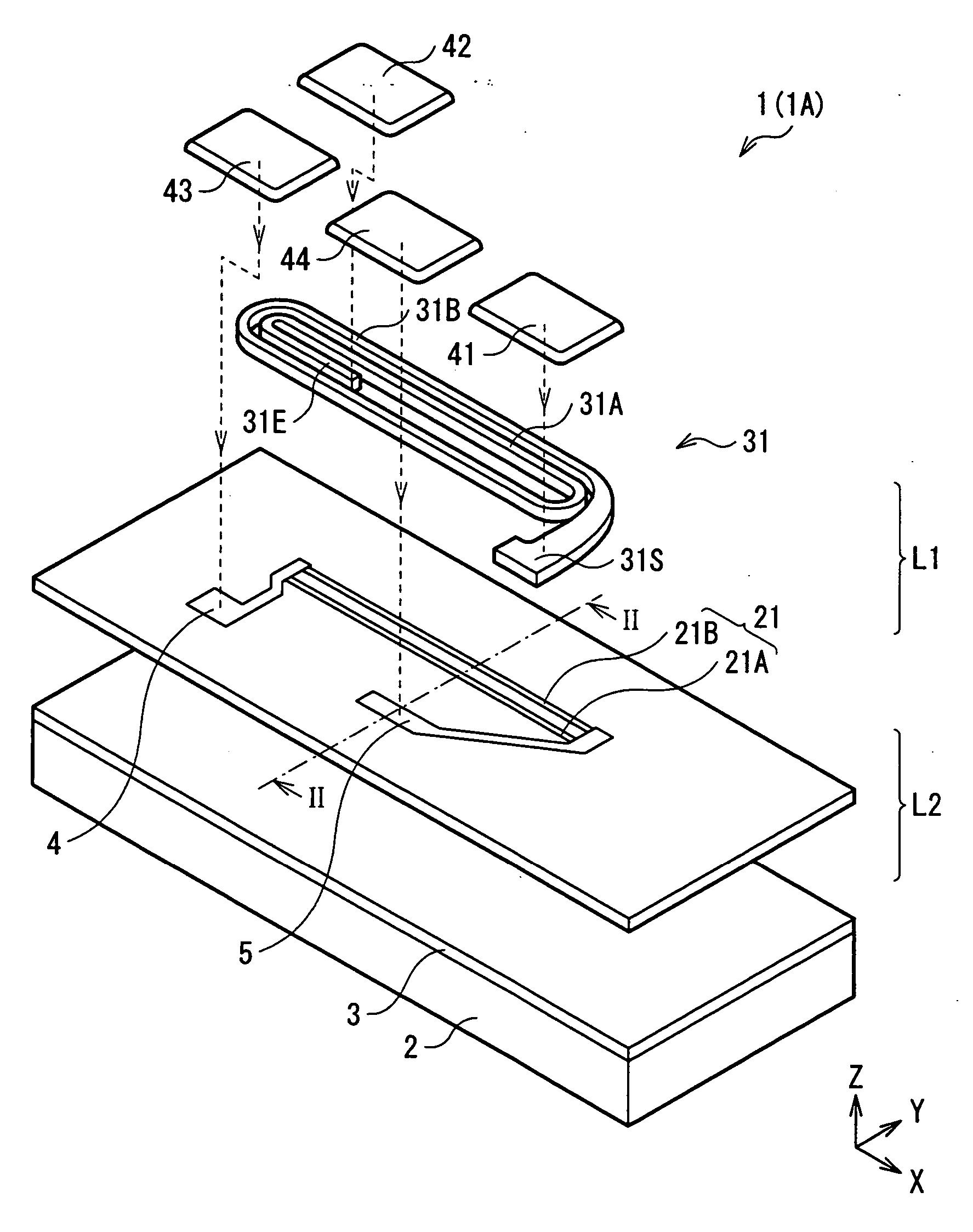

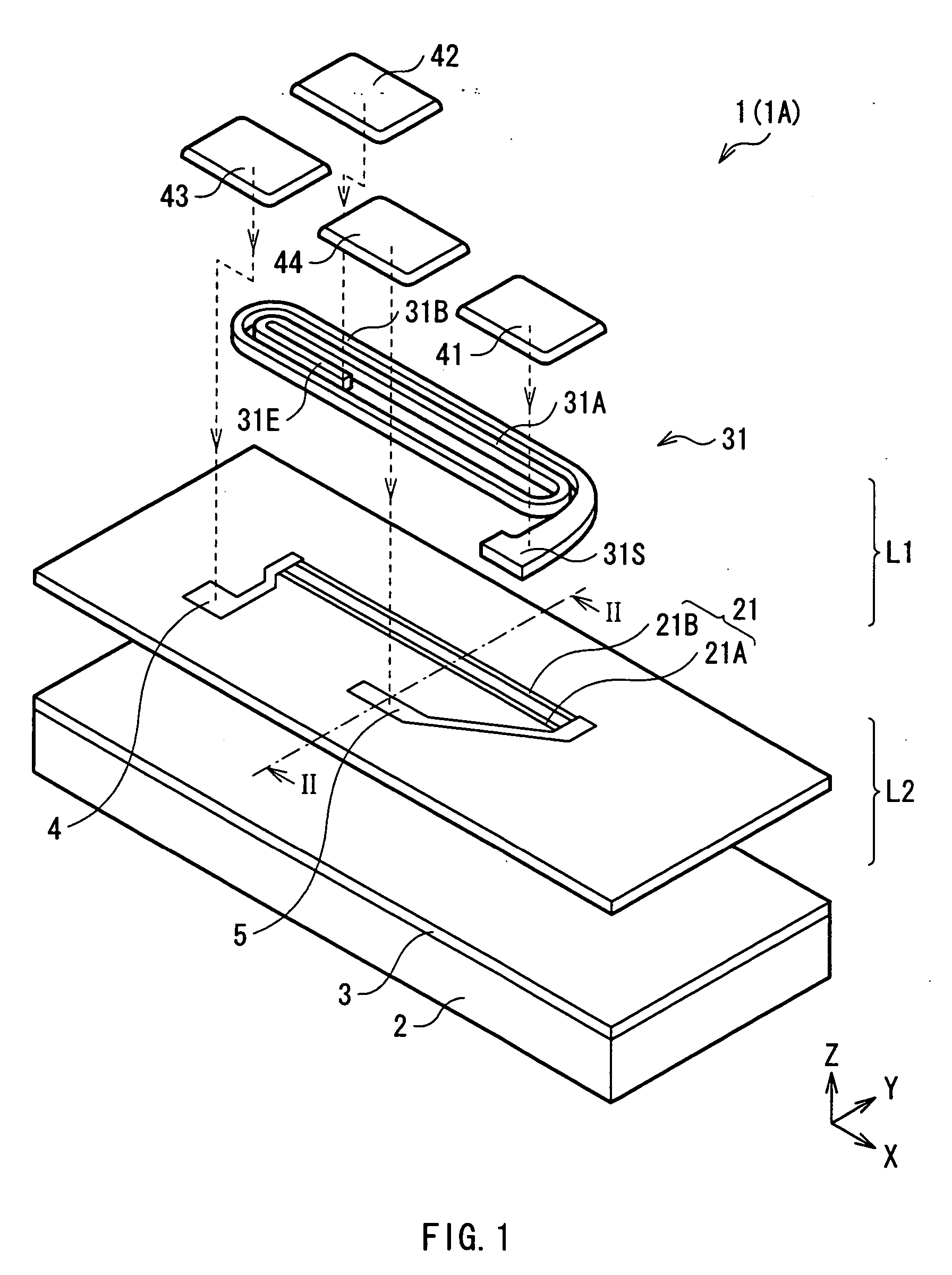

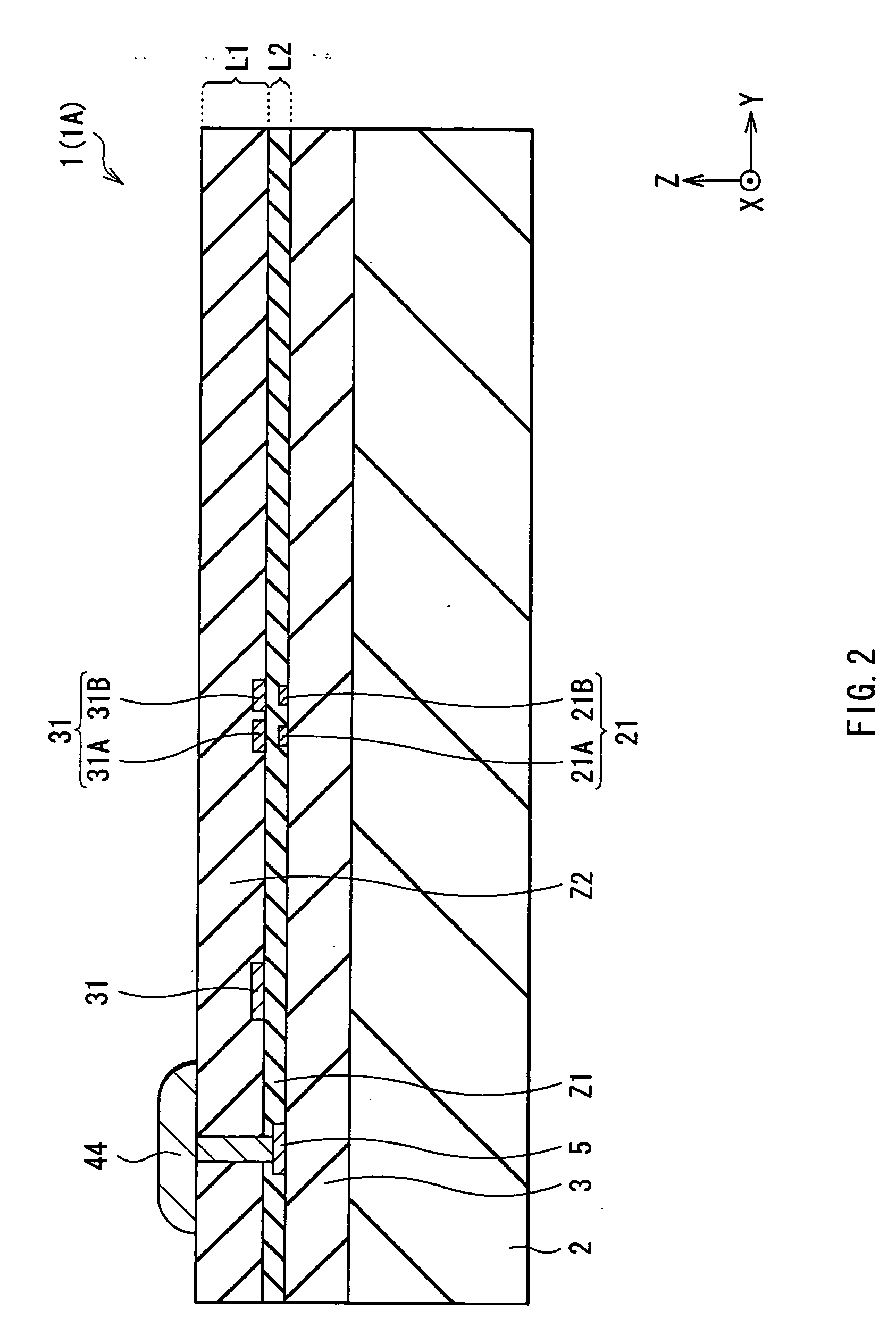

Magnetic sensor stack body, method of forming the same, film formation control program, and recording medium

ActiveUS20110032645A1Good effectEnhance layeringMagnetic measurementsDecorative surface effectsElectrical resistance and conductanceFerromagnetism

The present invention is directed to align crystal c-axes in magnetic layers near two opposed junction wall faces of a magnetoresistive element so as to be almost perpendicular to the junction wall faces. A magnetic sensor stack body has, on a substrate, a magnetoresistive element whose electric resistance fluctuates when a bias magnetic field is applied and, on sides of opposed junction wall faces of the magnetoresistive element, field regions including magnetic layers for applying the bias magnetic field to the element. The magnetoresistive element has at least a ferromagnetic stack on a part of an antiferromagnetic layer, and width of an uppermost face of the ferromagnetic stack along a direction in which the junction wall faces are opposed to each other is smaller than width of an uppermost face of the antiferromagnetic layer in the same direction.

Owner:CANON ANELVA CORP

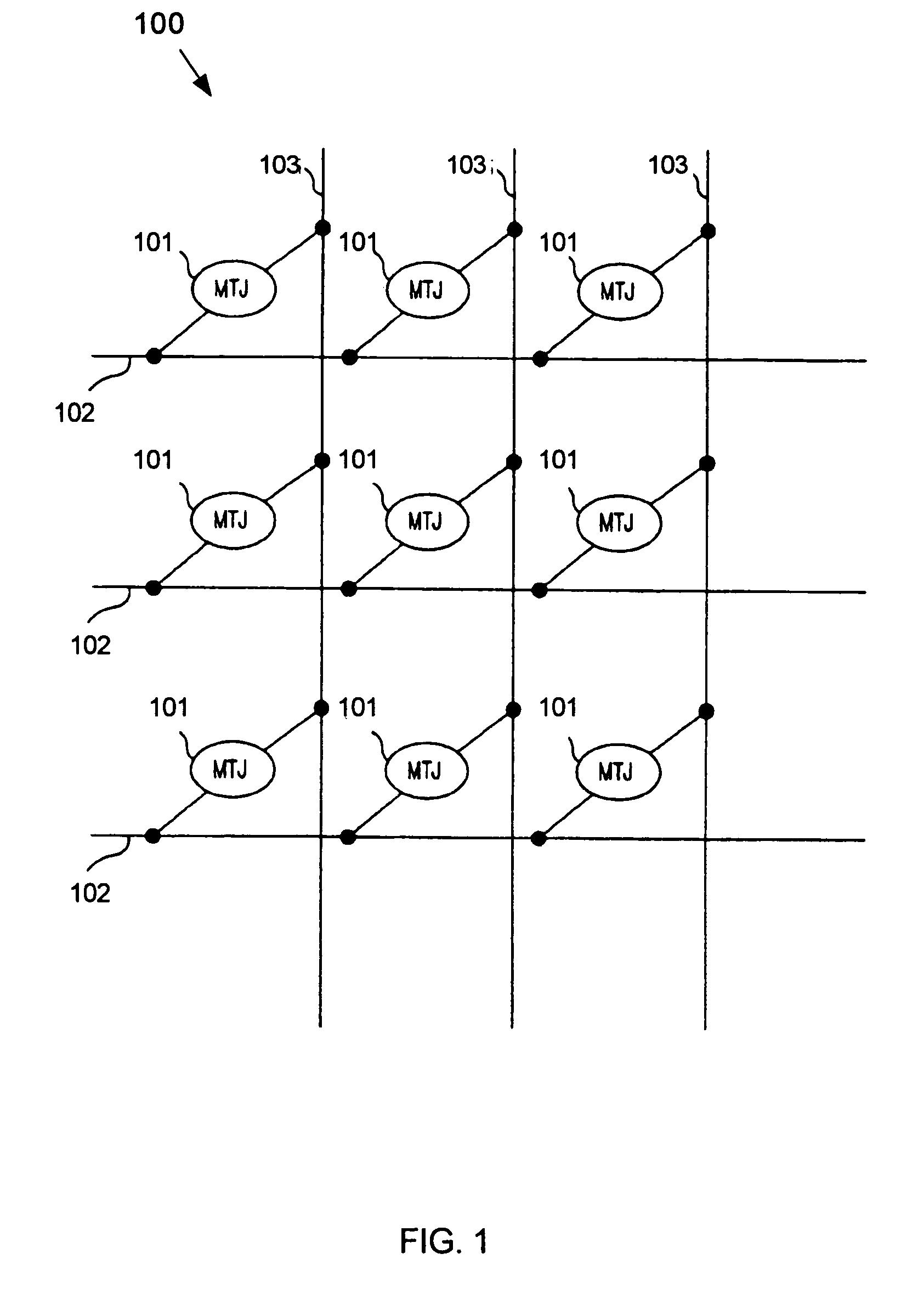

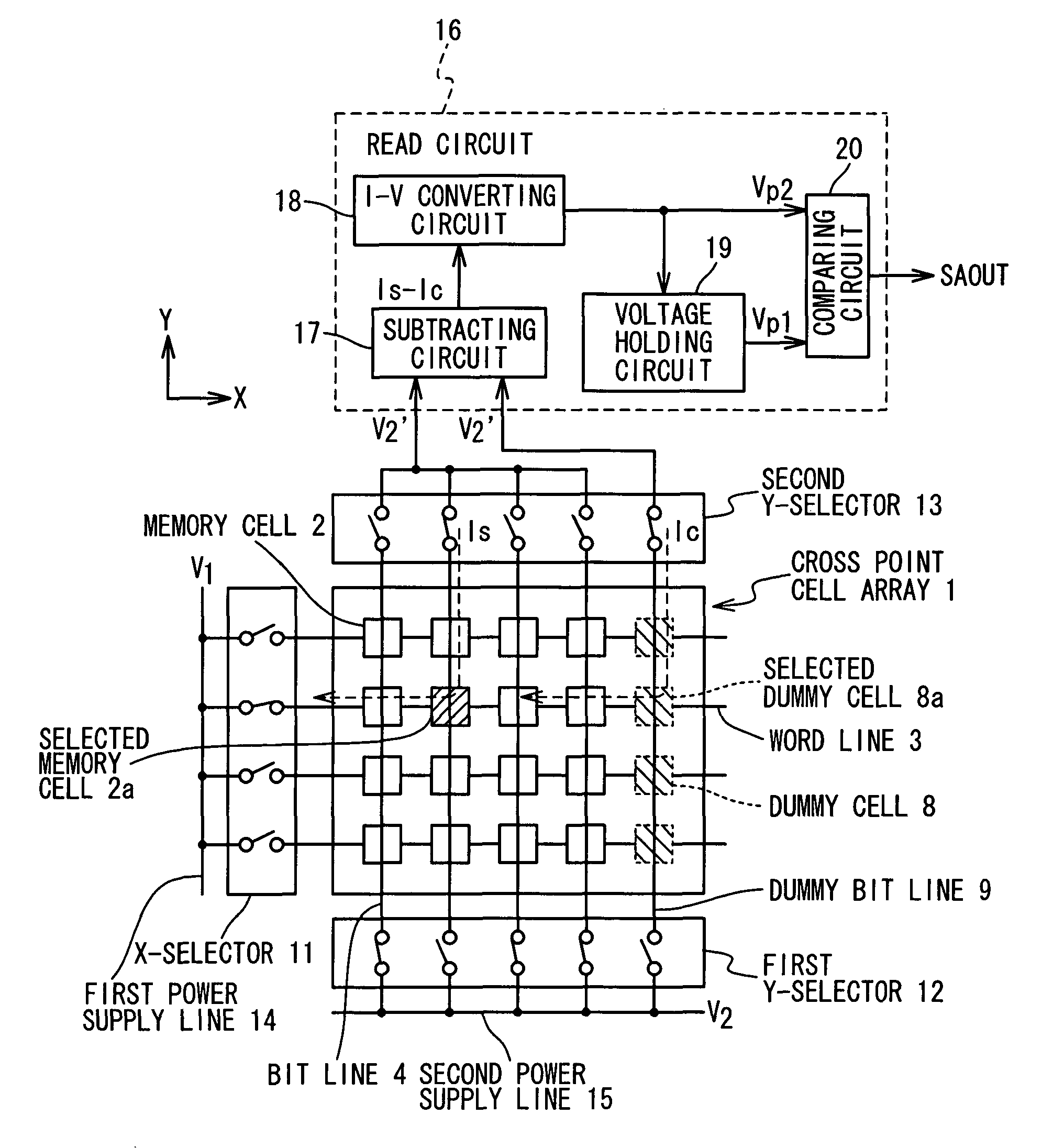

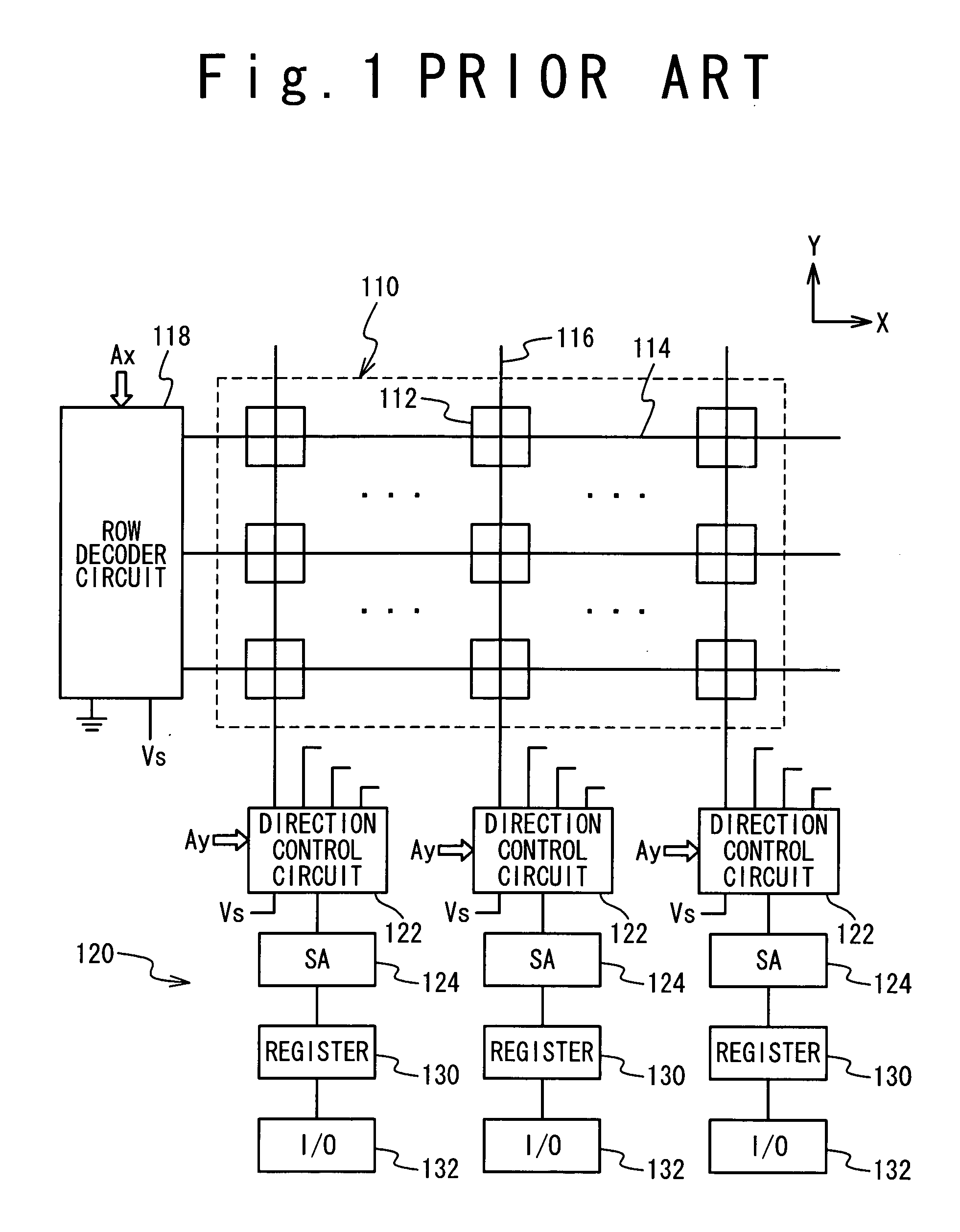

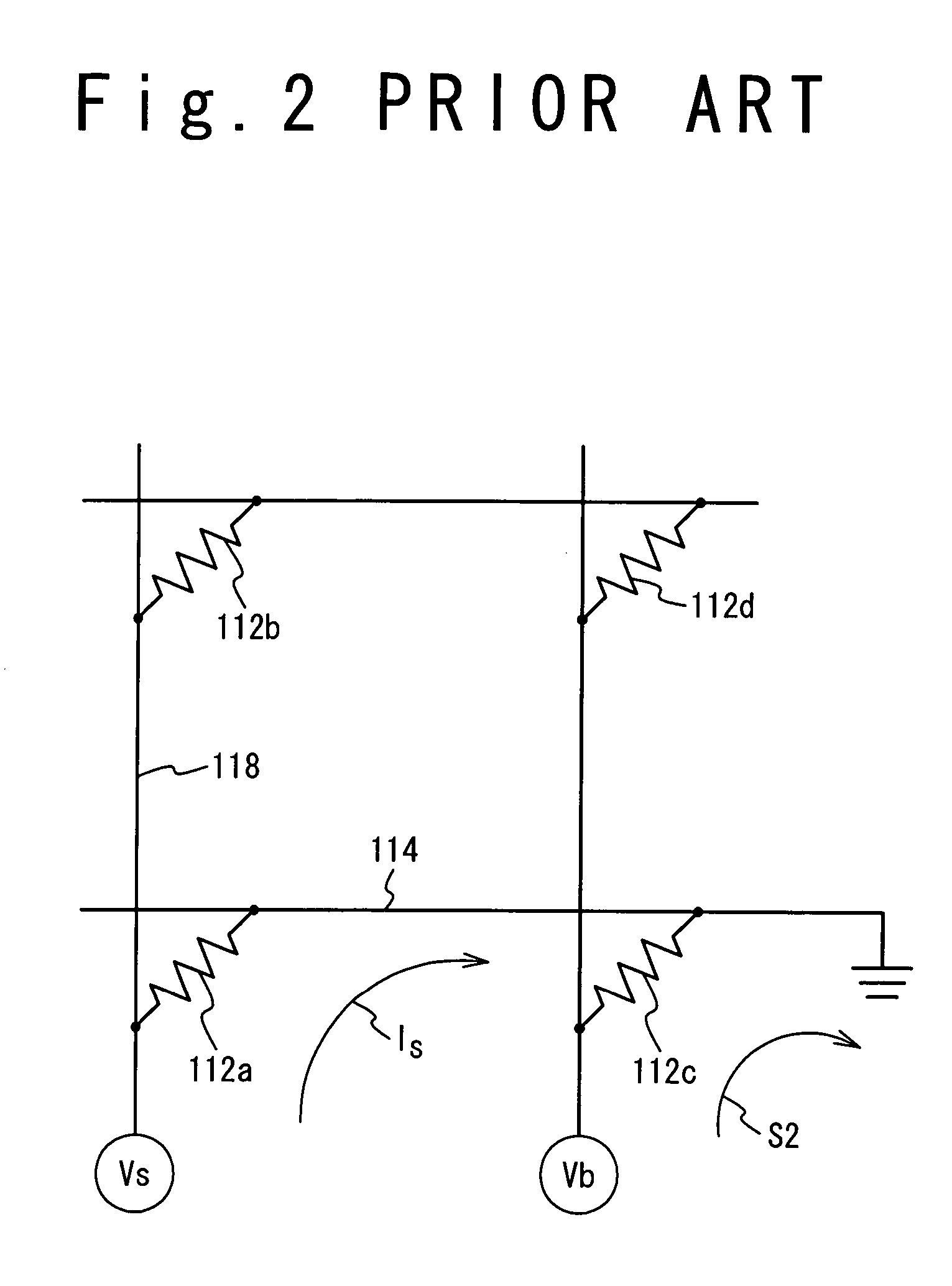

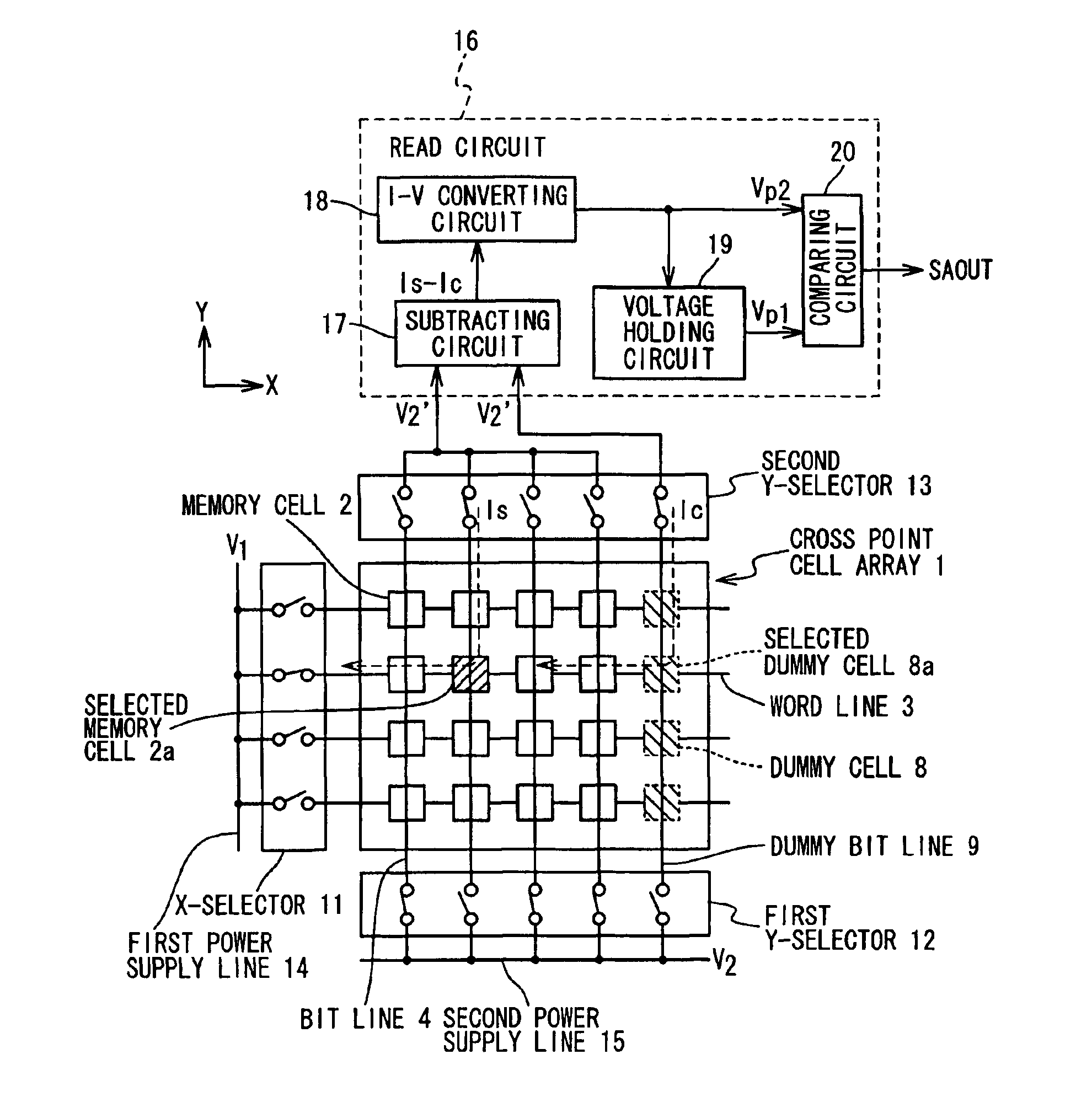

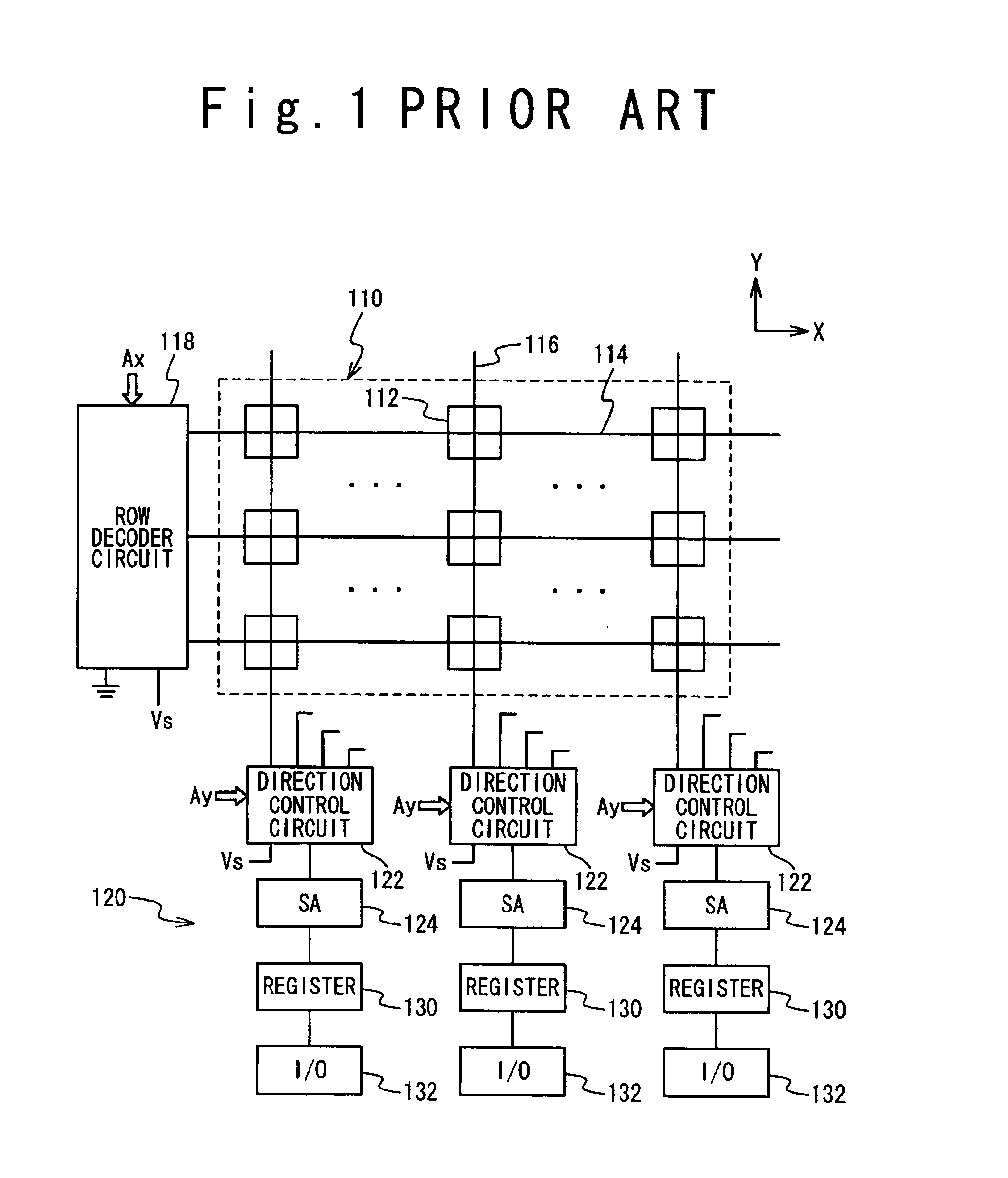

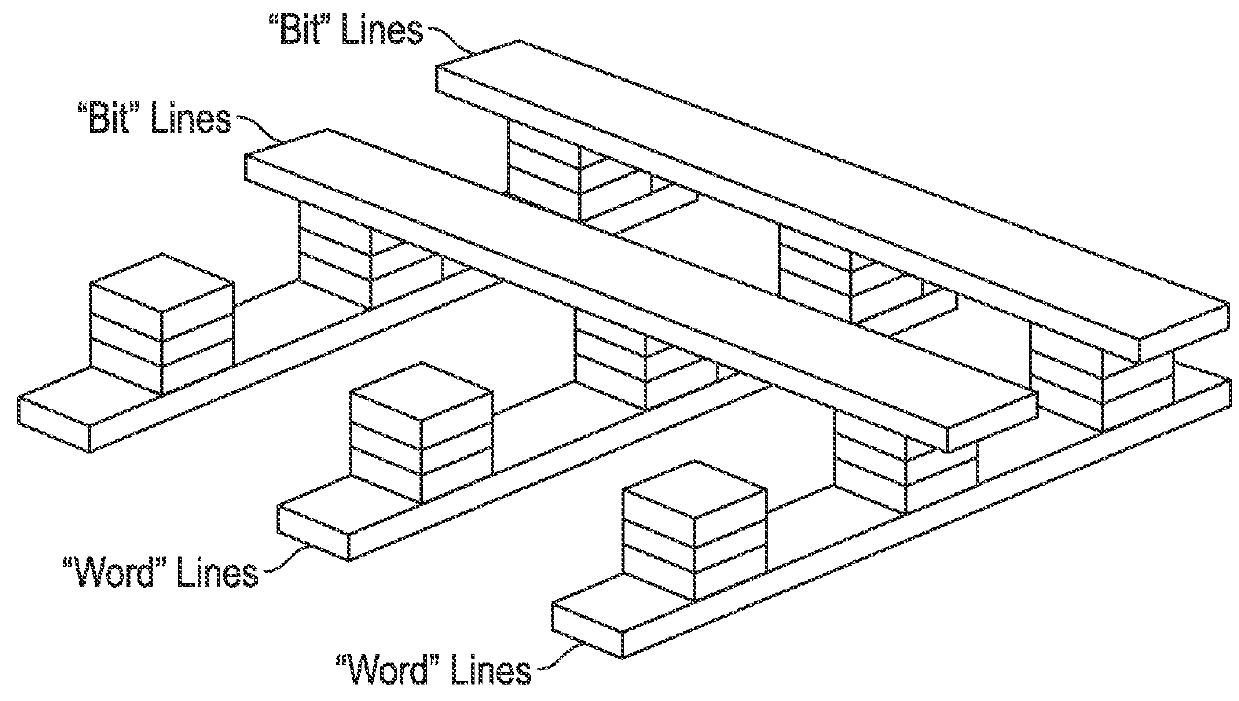

Magnetic random access memory

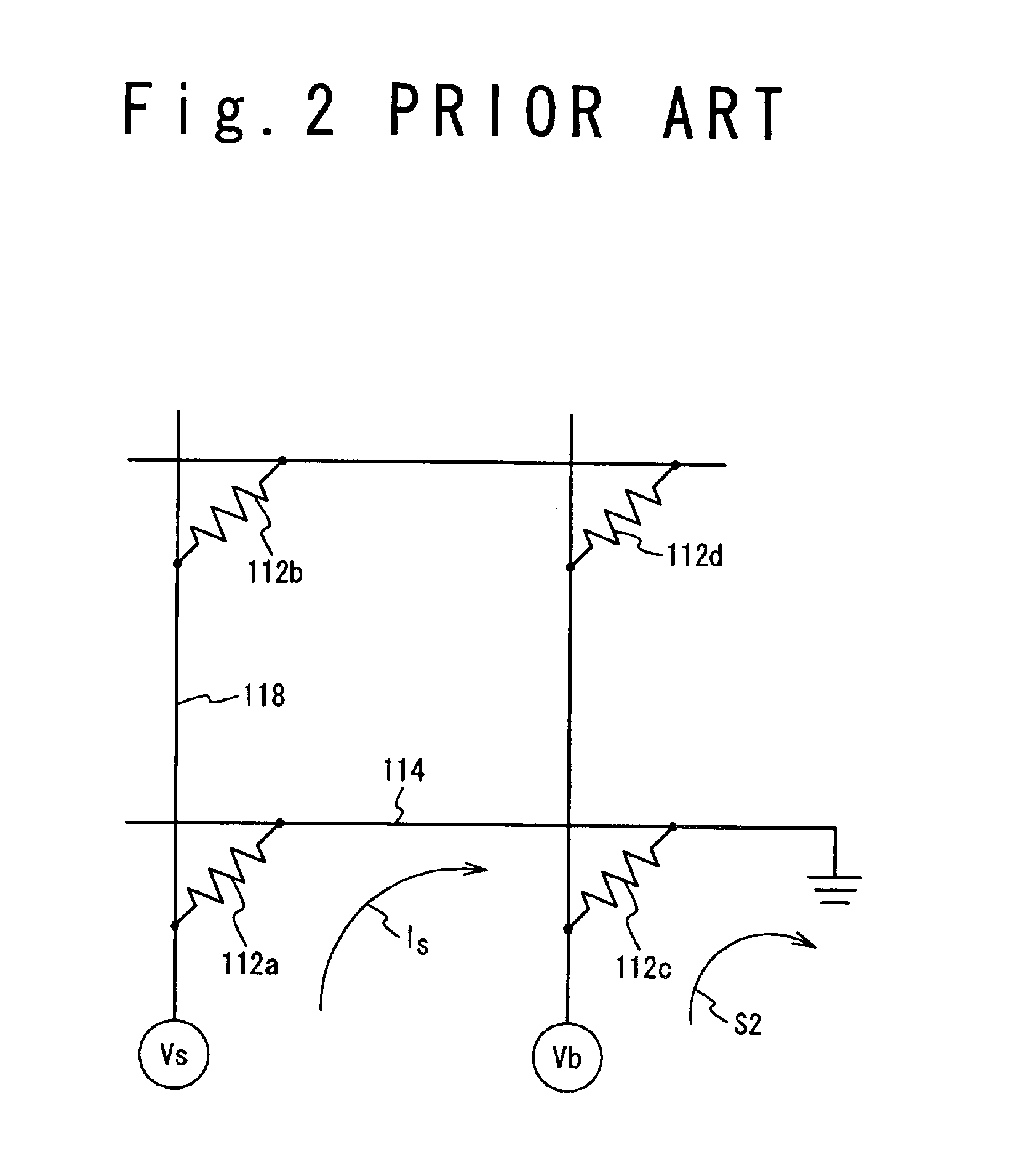

In a magnetic random access memory, a cross point cell array of memory cells is arranged in a matrix of columns and rows, and each of the memory cells has a magneto-resistance element. A column of dummy memory cells is provided, and each of the dummy memory cells has a magneto-resistance element. Word lines are provided for the rows of the memory cells and the dummy memory cells, respectively, and bit lines are provided for the columns of the memory cells, respectively. A dummy bit line is provided for the column of dummy memory cells. A read circuit is connected with the cross point cell array and the dummy bit line.

Owner:NEC CORP

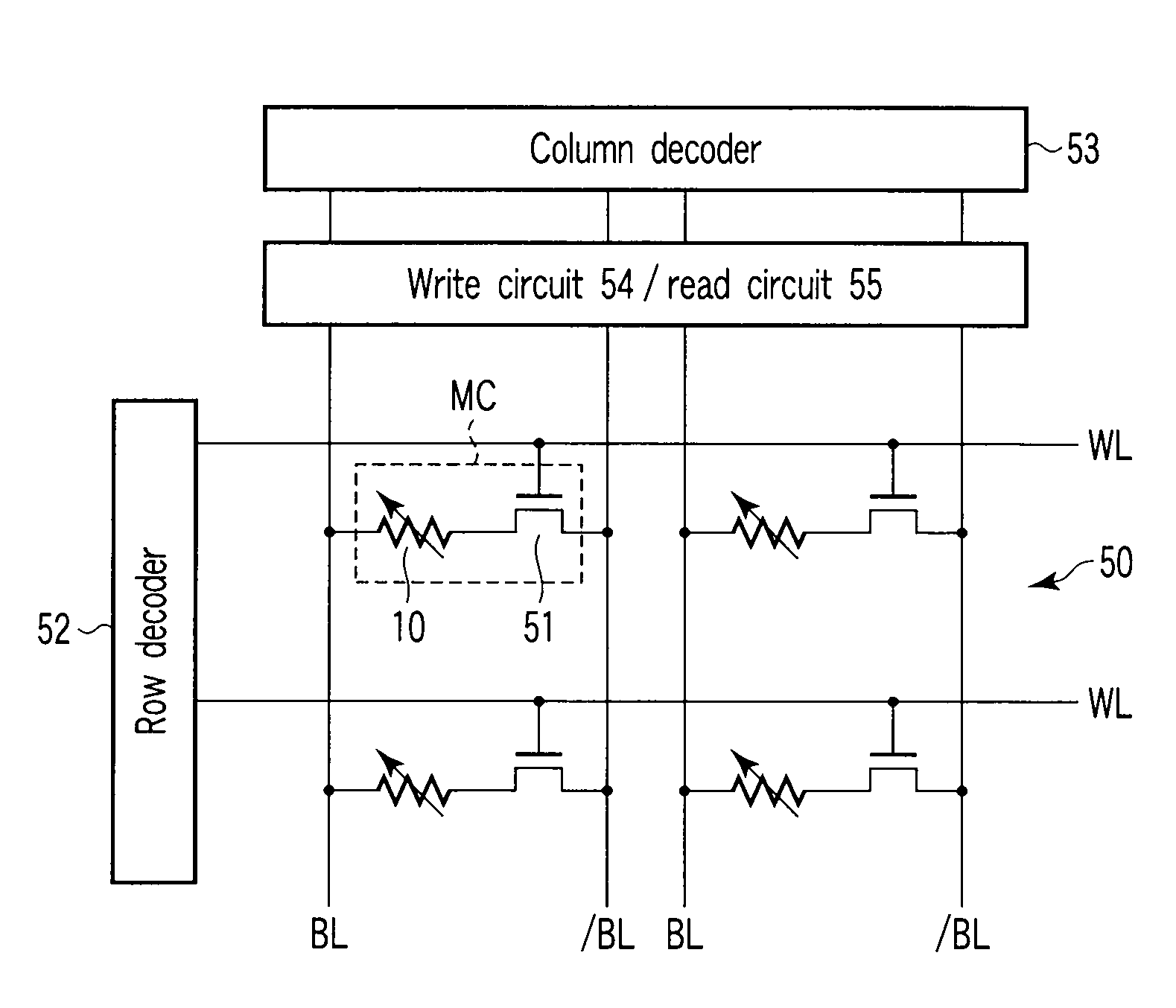

Magnetoresistive element and magnetic memory

A magnetoresistive element includes a first reference layer having magnetic anisotropy perpendicular to a film surface, and an invariable magnetization, a recording layer having a stacked structure formed by alternately stacking magnetic layers and nonmagnetic layers, magnetic anisotropy perpendicular to a film surface, and a variable magnetization, and an intermediate layer provided between the first reference layer and the recording layer, and containing a nonmagnetic material. The magnetic layers include a first magnetic layer being in contact with the intermediate layer and a second magnetic layer being not in contact with the intermediate layer. The first magnetic layer contains an alloy containing cobalt (Co) and iron (Fe), and has a film thickness larger than that of the second magnetic layer.

Owner:KIOXIA CORP

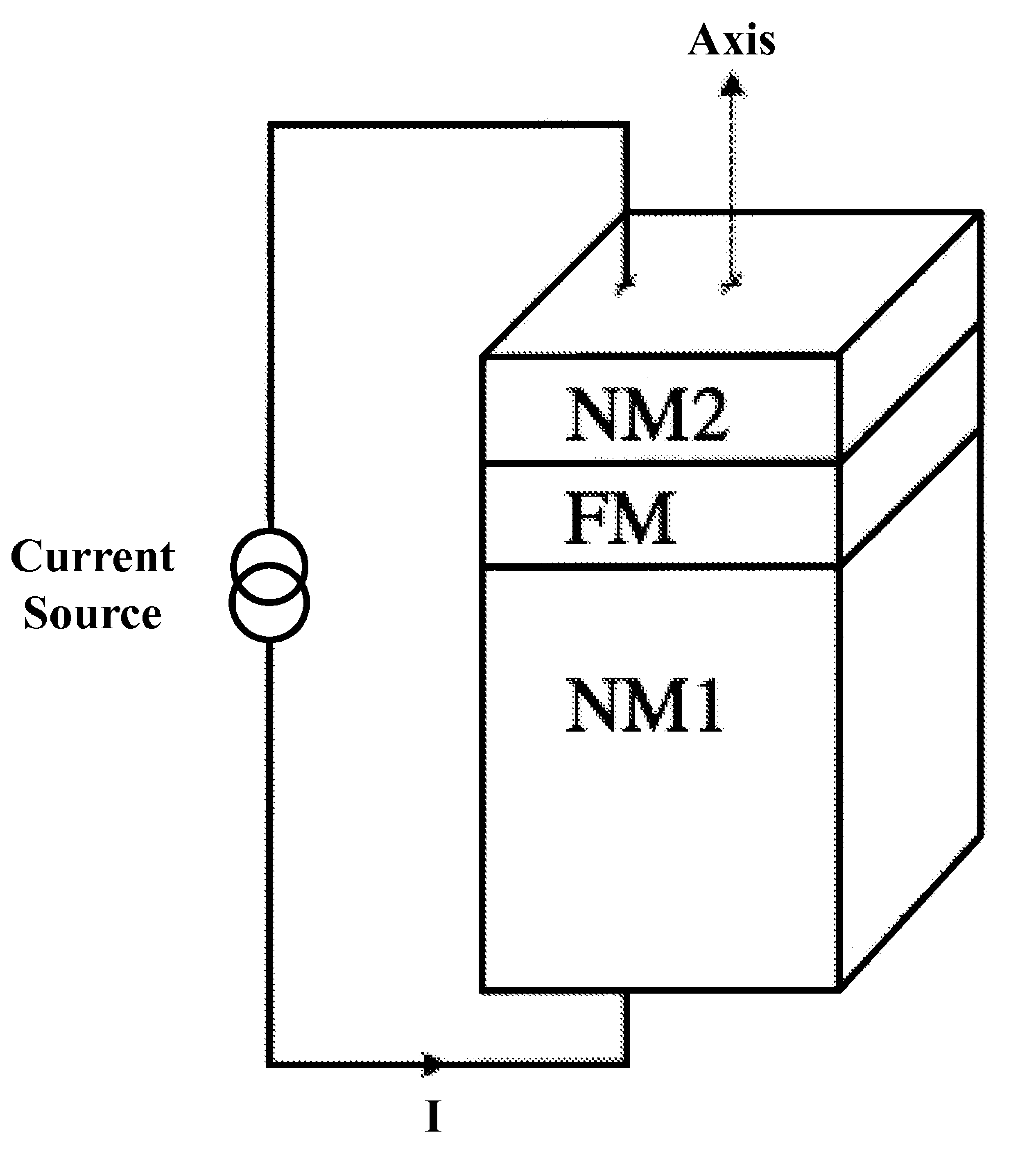

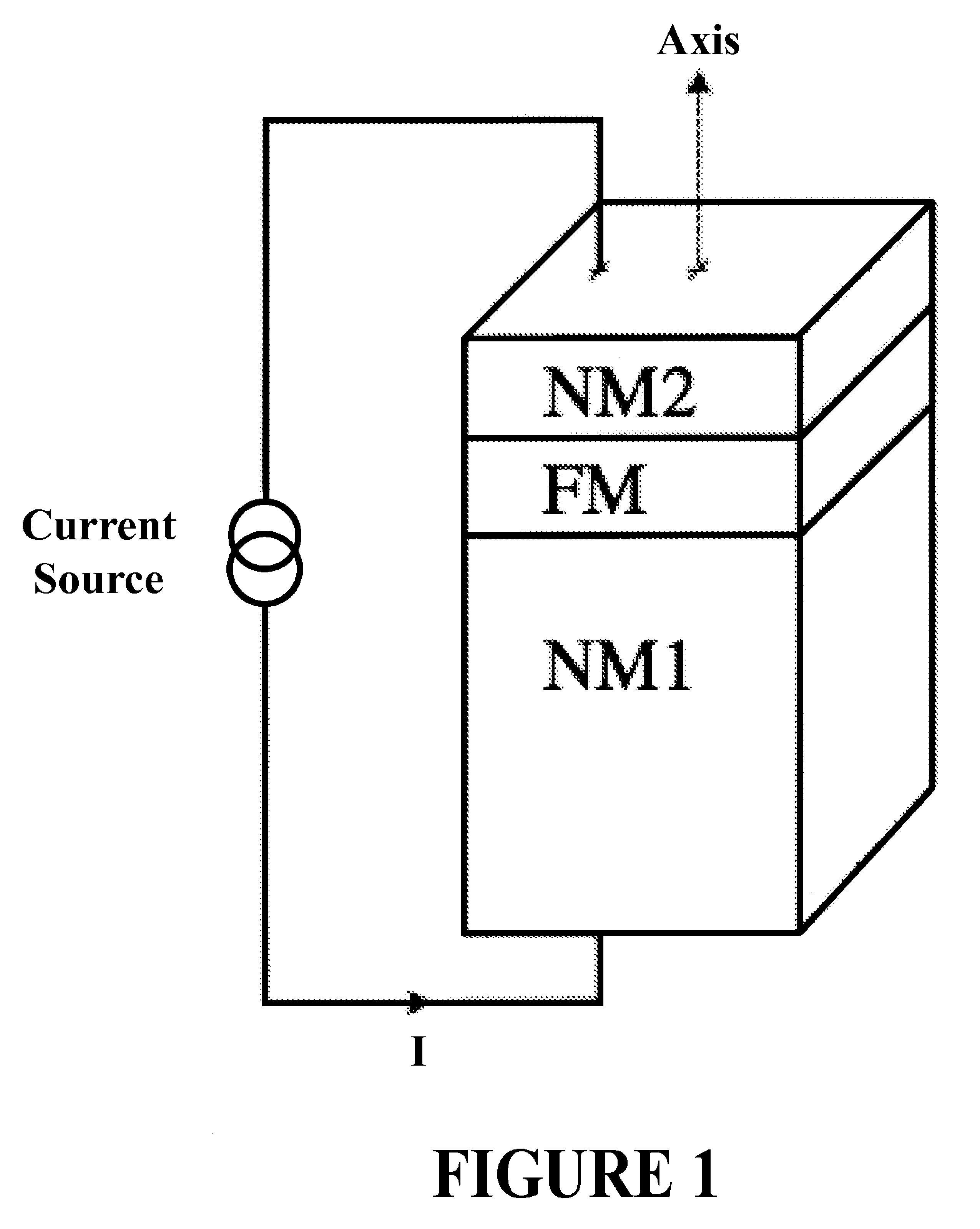

Electronic devices based on current induced magnetization dynamics in single magnetic layers

InactiveUS7986544B2Magnetic-field-controlled resistorsDigital storageInformation processingMagnetization dynamics

The present invention generally relates to magnetic devices used in memory and information processing applications, such as giant magneto-resistance (GMR) devices and tunneling magneto-resistance devices. More specifically, the present invention is directed to a single ferromagnetic layer device in which an electrical current is used to control and change magnetic configurations as well as induce high frequency magnetization dynamics. The magnetic layer includes full spin-polarized magnetic material, which may also have non-uniform magnetization. The non-uniform magnetization is achieved by varying the shape or roughness of the magnetic material. The present invention may be used in memory cells, as well as high frequency electronics, such as compact microwave sources, detectors, mixers and phase shifters.

Owner:NEW YORK UNIV

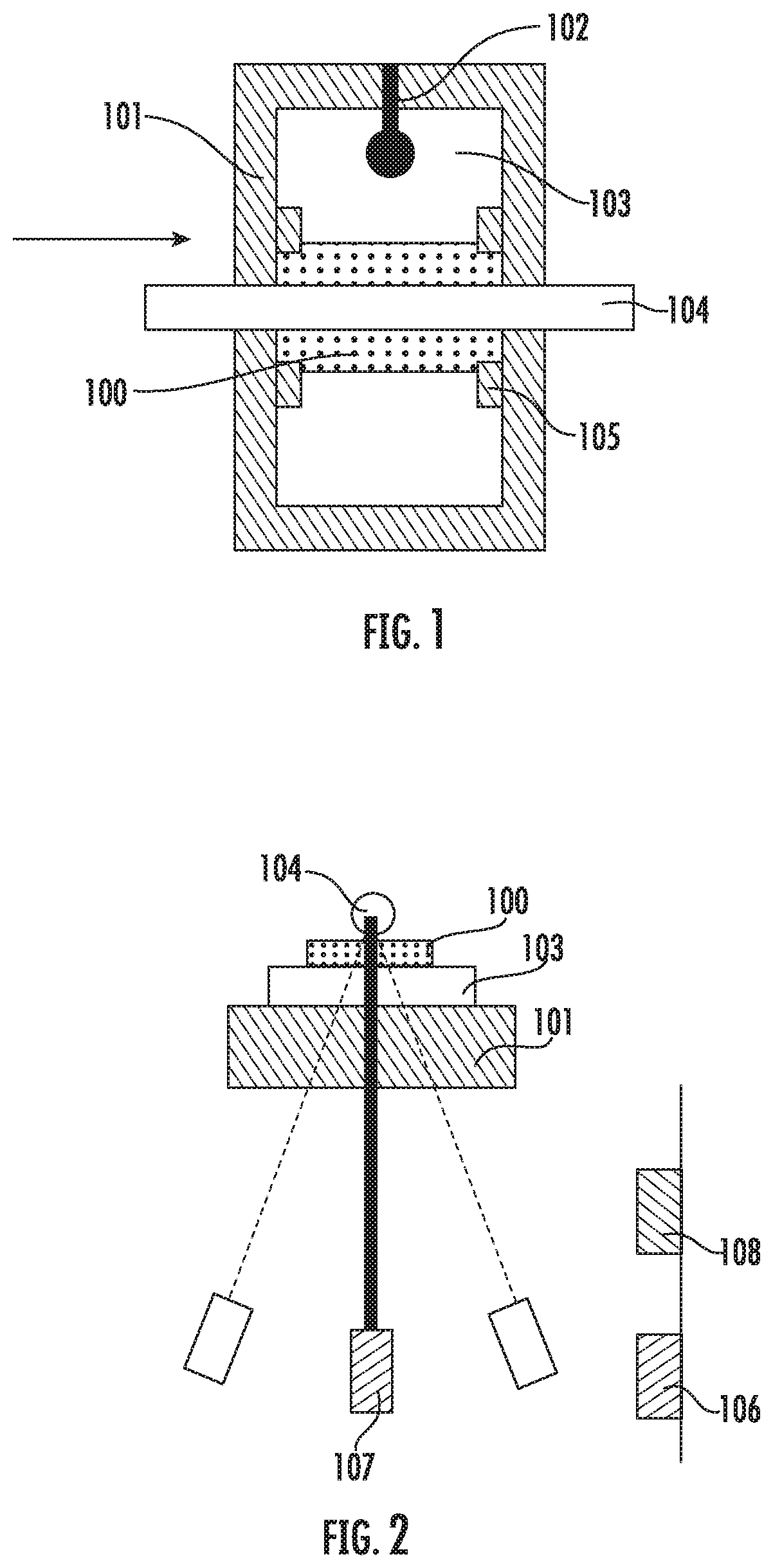

Magnetic recording medium and process for producing the same

InactiveUS20070231606A1Improve the overall coefficientHead contaminationMaterials with cobaltRecord information storageMetal powderCobalt

A magnetic recording medium comprising a substrate and a magnetic layer containing ferromagnetic metal powder and a binder, wherein the ferromagnetic metal powder contains iron, cobalt and form 2 to 20 atom % of yttrium based on a total of iron and cobalt contained in the ferromagnetic metal powder and has an average length of 50 nm or smaller, and the magnetic recording medium has a test value of at least 100 passes in a magnetoresistive head resistance reduction test performed as defined herein.

Owner:FUJIFILM CORP

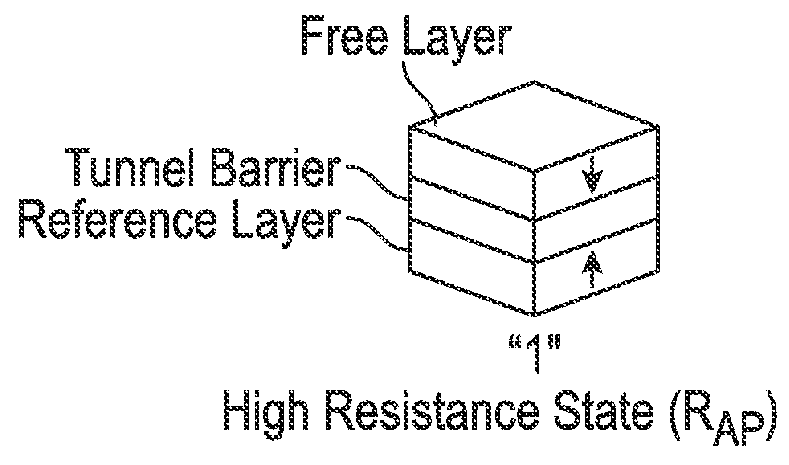

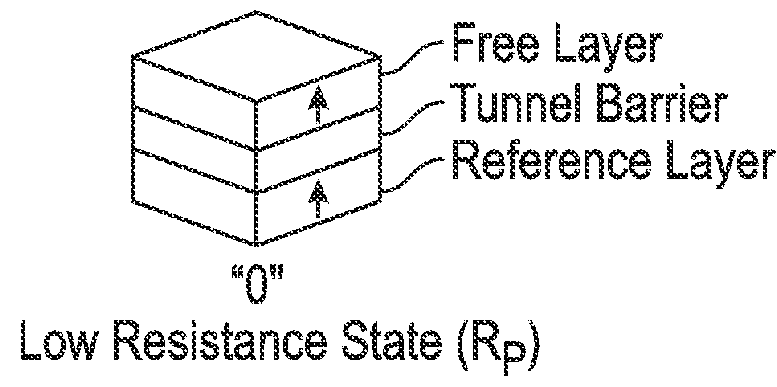

Magnetic tunnel junction for MRAM device

InactiveUS20150279904A1Improve performanceSwitching currentMagnetic-field-controlled resistorsSolid-state devicesTantalum nitrideSoftware engineering

A magnetoresistive random-access memory device with a magnetic tunnel junction stack having a significantly improved performance of the free layer in the magnetic tunnel junction structure. The memory device includes an antiferromagnetic structure and a magnetic tunnel junction structure disposed on the antiferromagnetic structure. The magnetic tunnel junction structure includes a reference layer and a free layer with a barrier layer sandwiched therebetween. Furthermore, a capping layer including a tantalum nitride film is disposed on the free layer of the magnetic tunnel junction structure.

Owner:SPIN MEMORY INC

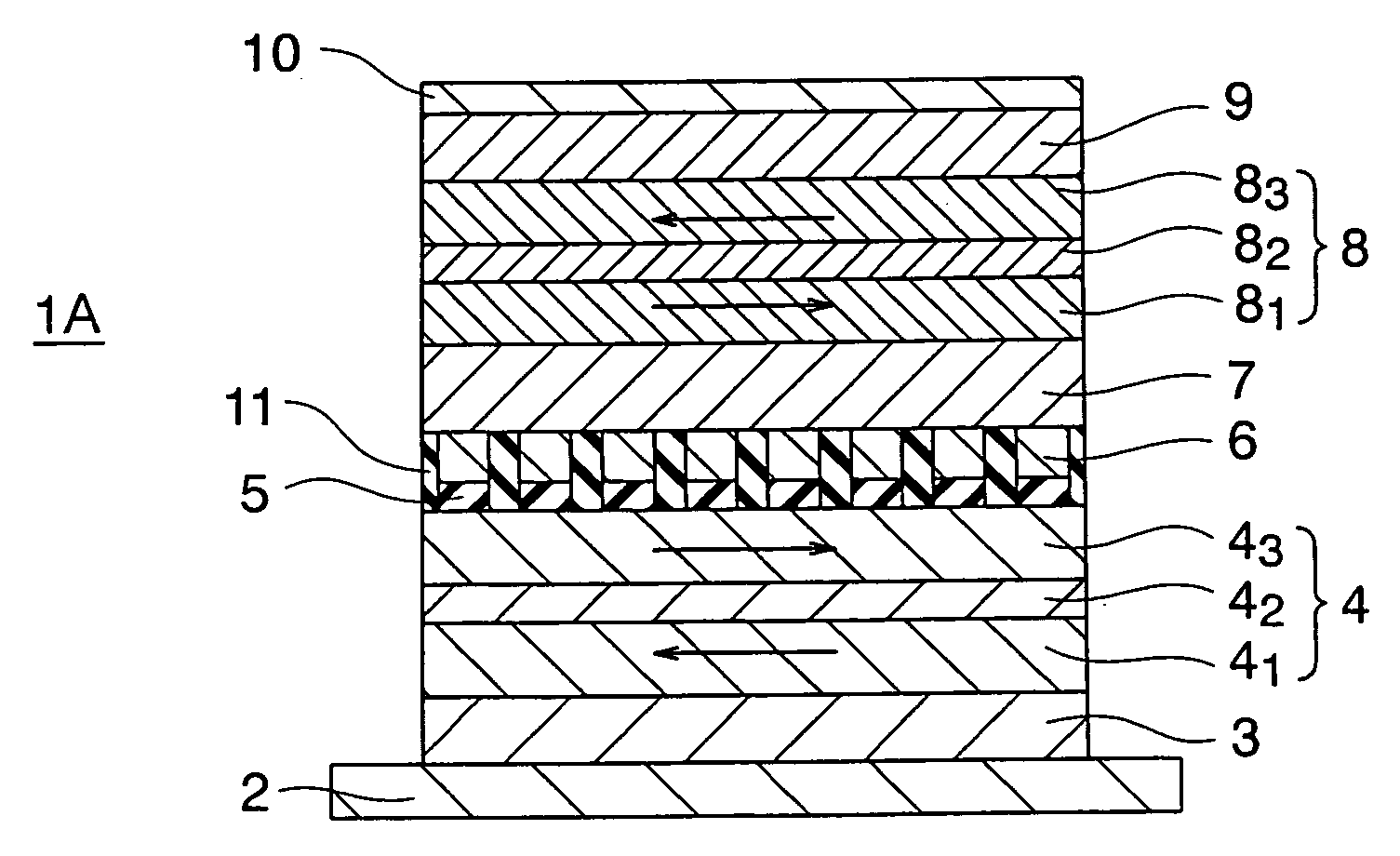

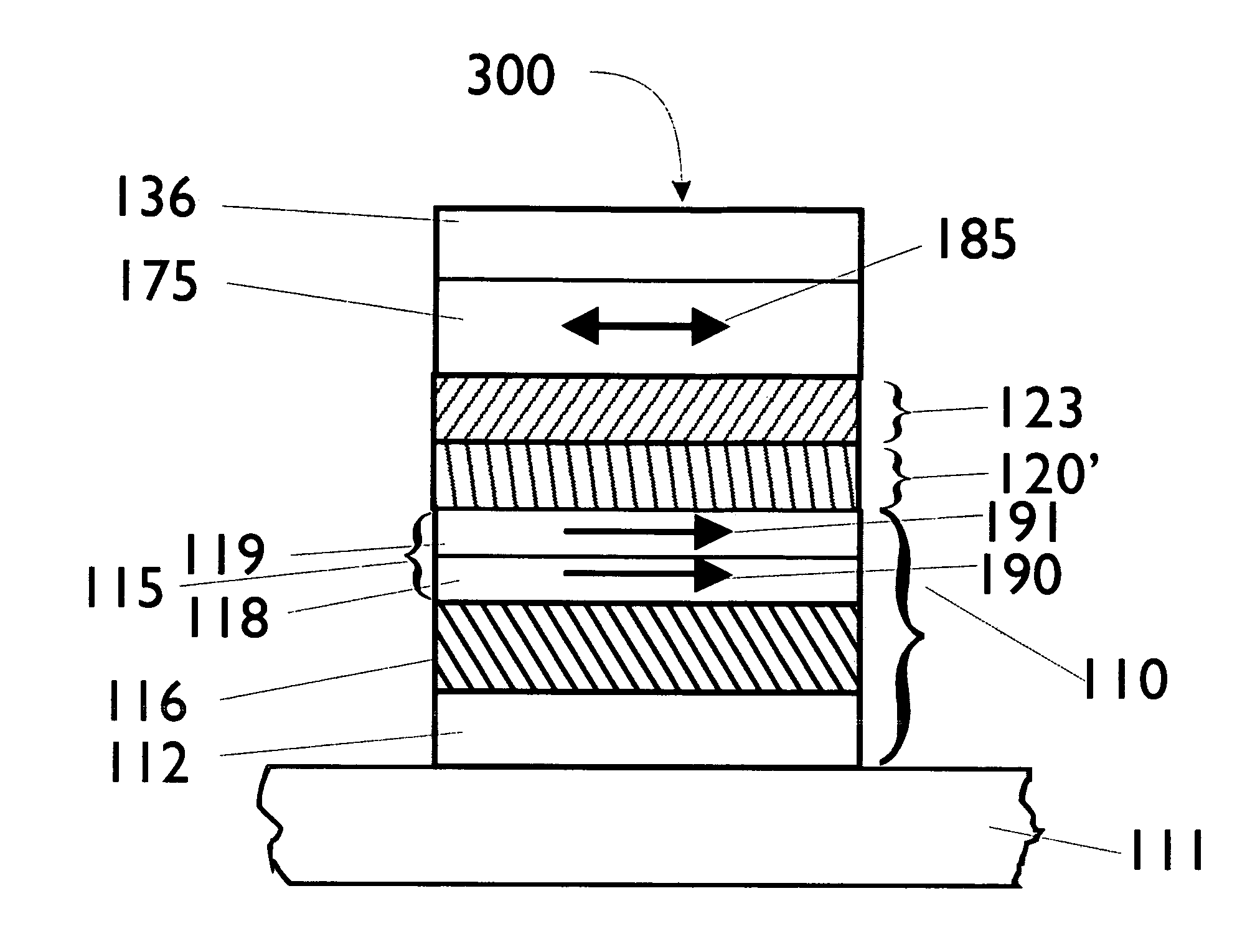

Spin barrier enhanced dual magnetoresistance effect element and magnetic memory using the same

ActiveUS20050254286A1Reduce outer surfaceHigh areal resistanceNanomagnetismMagnetic-field-controlled resistorsDamping constantMagnetic memory

A method and system for providing a magnetic element that can be used in a magnetic memory is disclosed. The magnetic element includes first pinned, spacer, free, spin barrier, and second pinned layers. The spacer layer is nonmagnetic and resides between the pinned and free layers. The free layer can be switched using spin transfer when a write current is passed through the magnetic element. The free layer resides between the spacer and spin barrier layers. The spin barrier layer is between the free and second pinned layers. The spin barrier layer is configured to reduce an outer surface contribution to the free layer damping constant. In one aspect, the spin barrier layer has a high areal resistance and may substantially eliminate spin pumping induced damping. In another aspect, the magnetic element also includes a spin accumulation layer between the spin barrier and free layers. The spin accumulation layer has a high conductivity and may have a long spin diffusion length.

Owner:SAMSUNG SEMICON

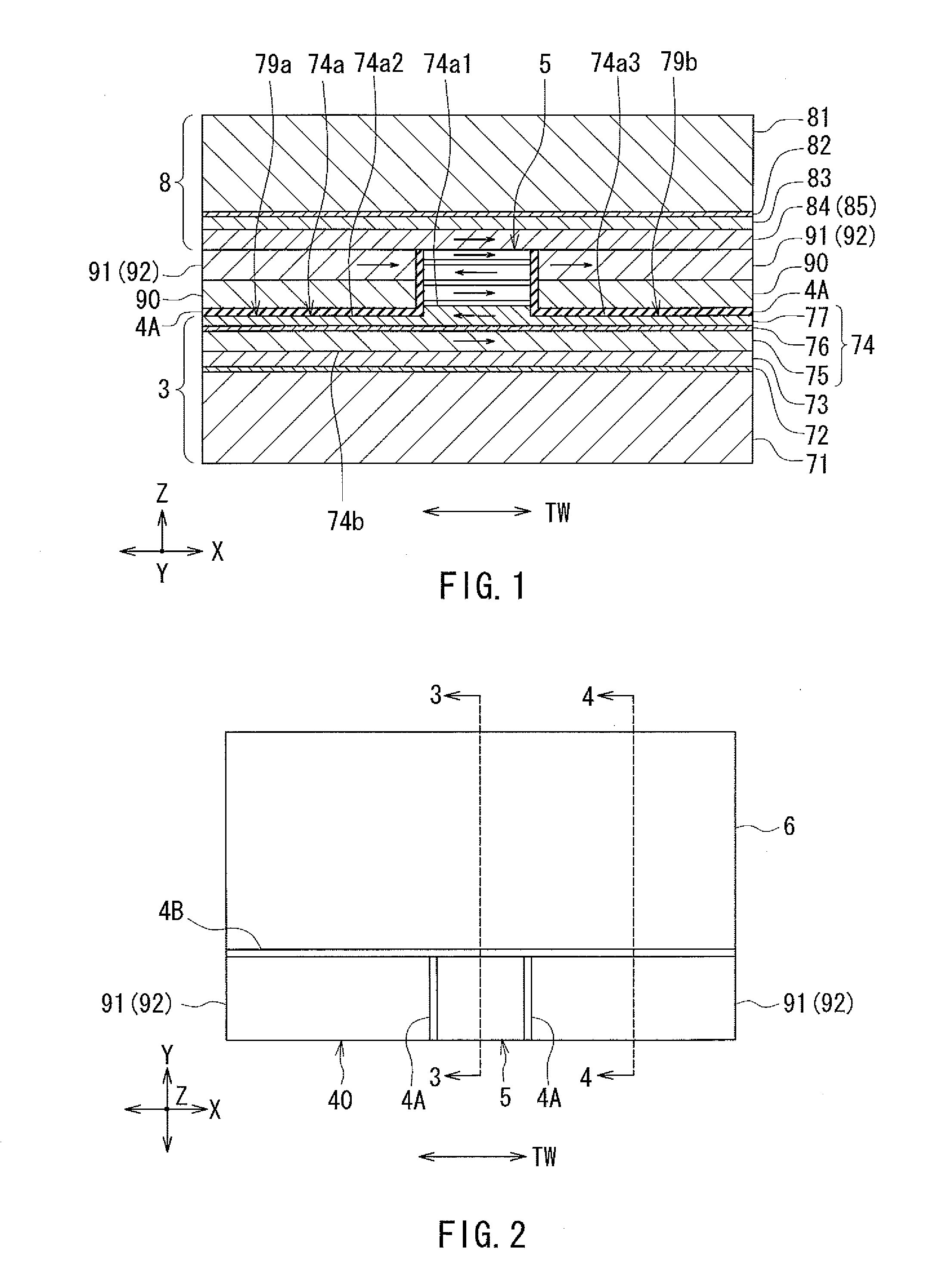

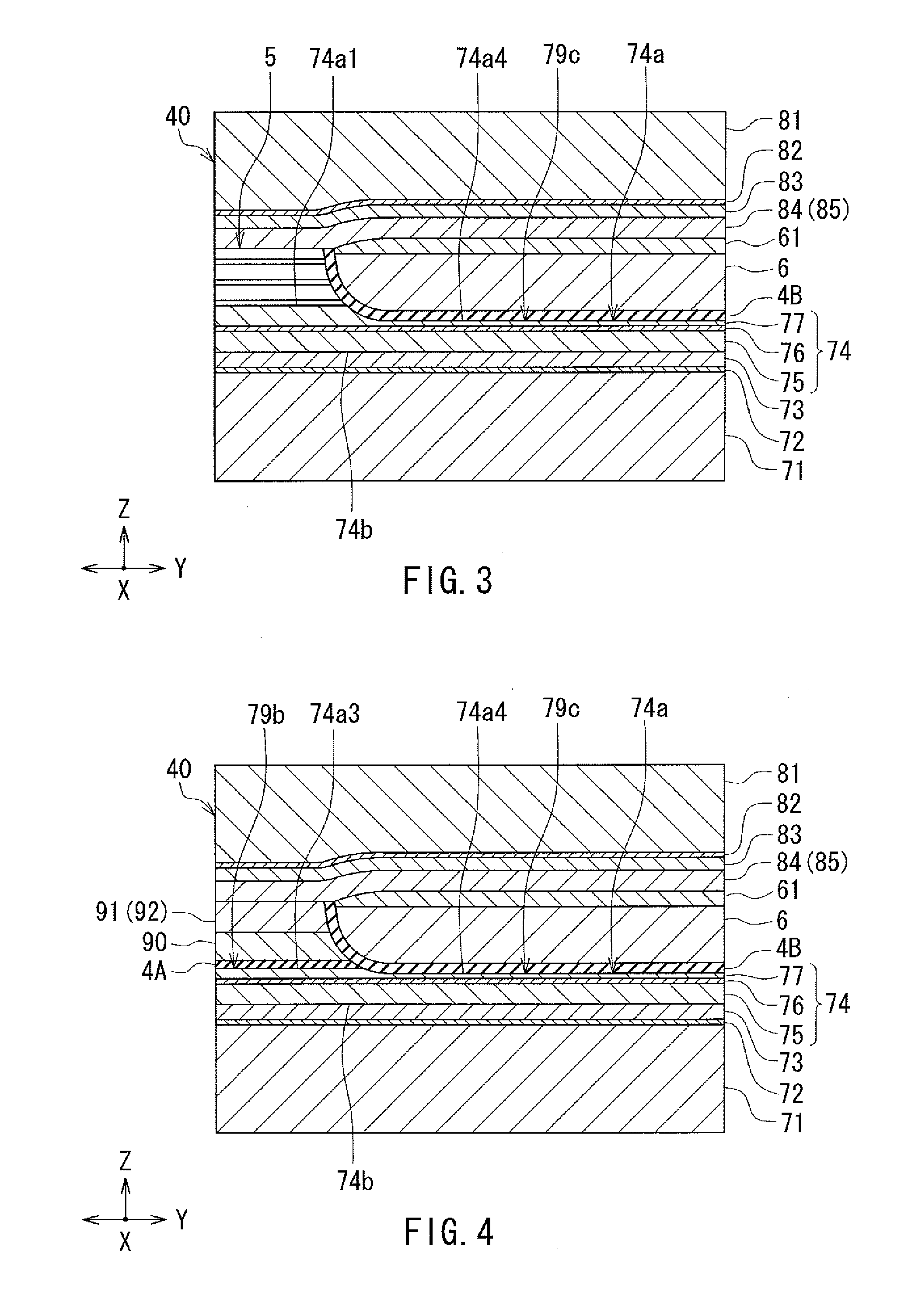

Magnetoresistive element having a pair of side shields

An MR element includes an MR stack disposed between first and second main shield portions, and a pair of side shields disposed on opposite sides of the MR stack in the track width direction. The first main shield portion includes a first exchange coupling shield layer that is exchange-coupled to a first antiferromagnetic layer. The second main shield portion includes a second exchange coupling shield layer that is exchange-coupled to a second antiferromagnetic layer. The MR stack includes a spacer layer, and first and second free layers with the spacer layer therebetween. The direction of magnetization of the first free layer is controlled by the first exchange coupling shield layer. The direction of magnetization of the second free layer is controlled by the second exchange coupling shield layer. Each side shield includes at least one shield-coupling magnetic layer that is in contact with and magnetically coupled to one of the first and second exchange coupling shield layers.

Owner:TDK CORPARATION

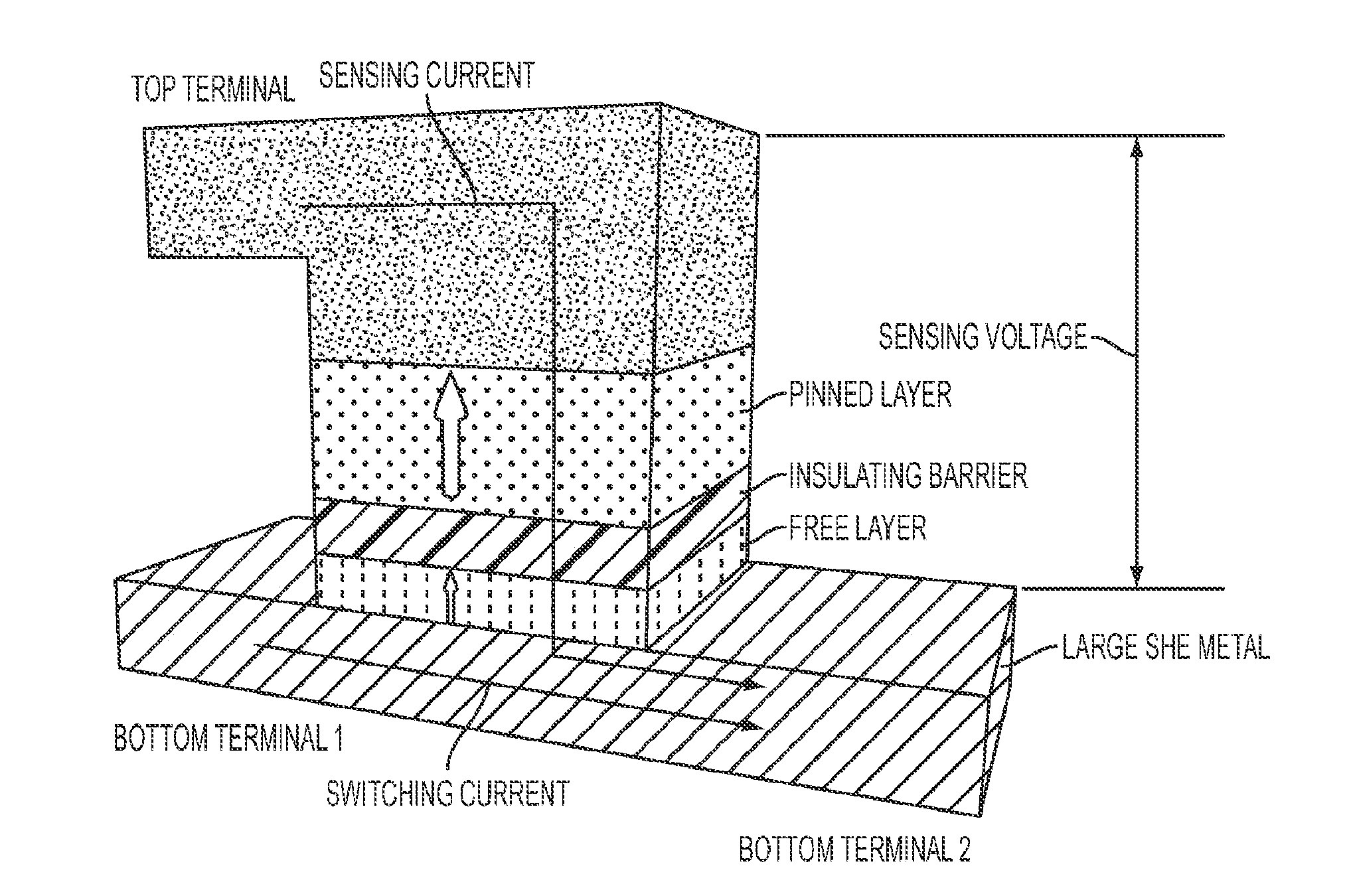

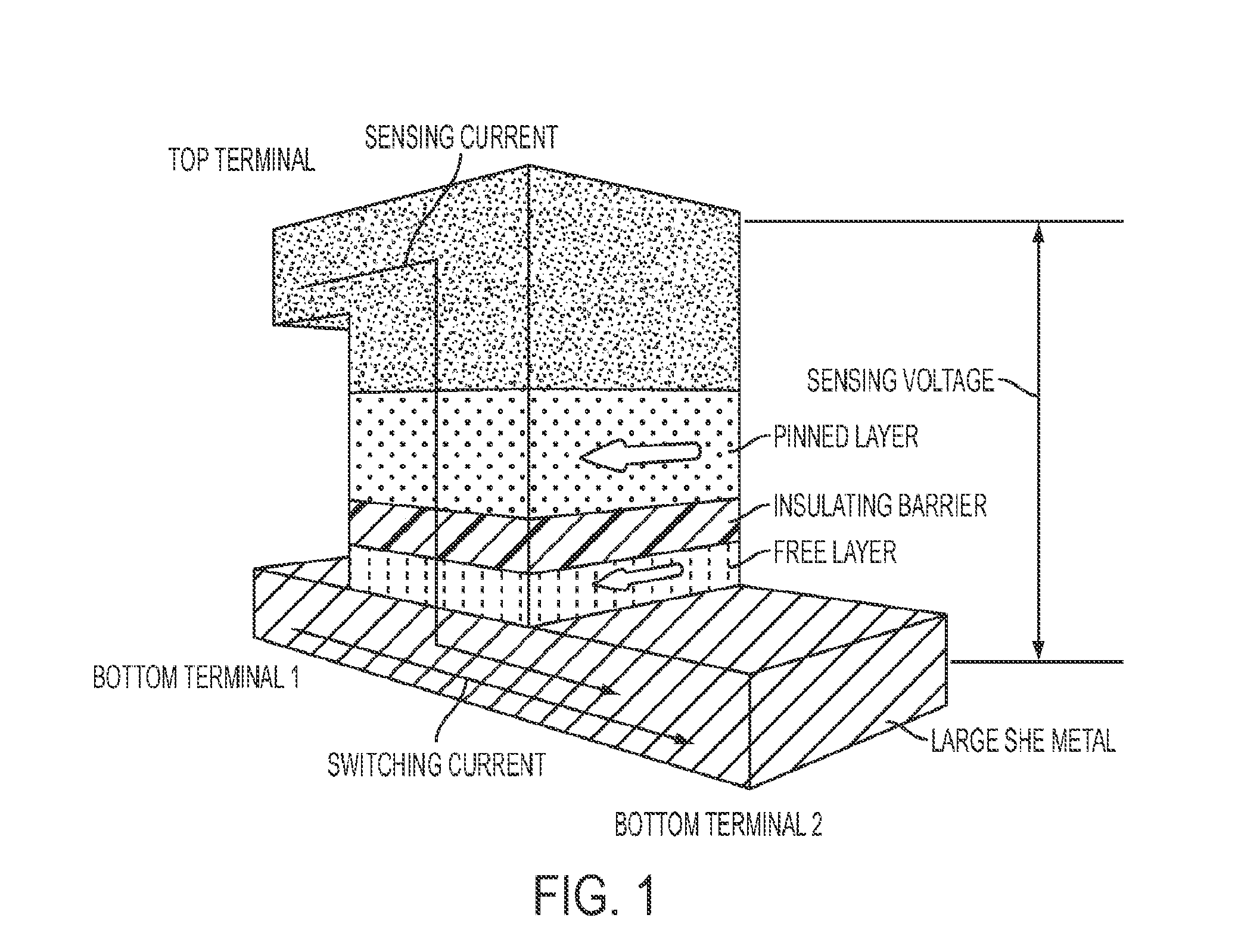

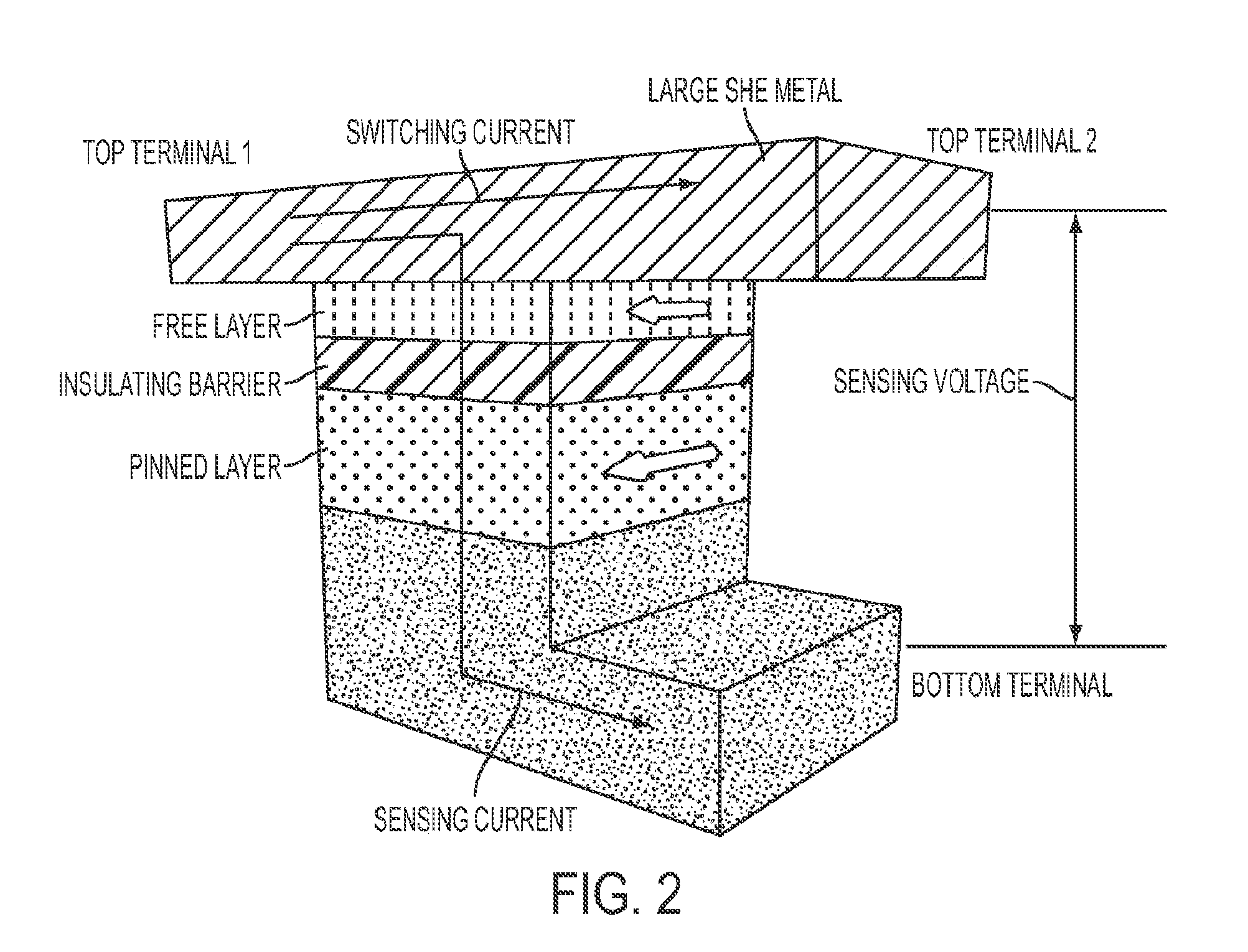

Spin hall effect magnetic apparatus, method and applications

ActiveUS20150348606A1Improve efficiencySmall costRead-only memoriesDigital storageElectrical conductorSpin Hall effect

Owner:CORNELL UNIVERSITY

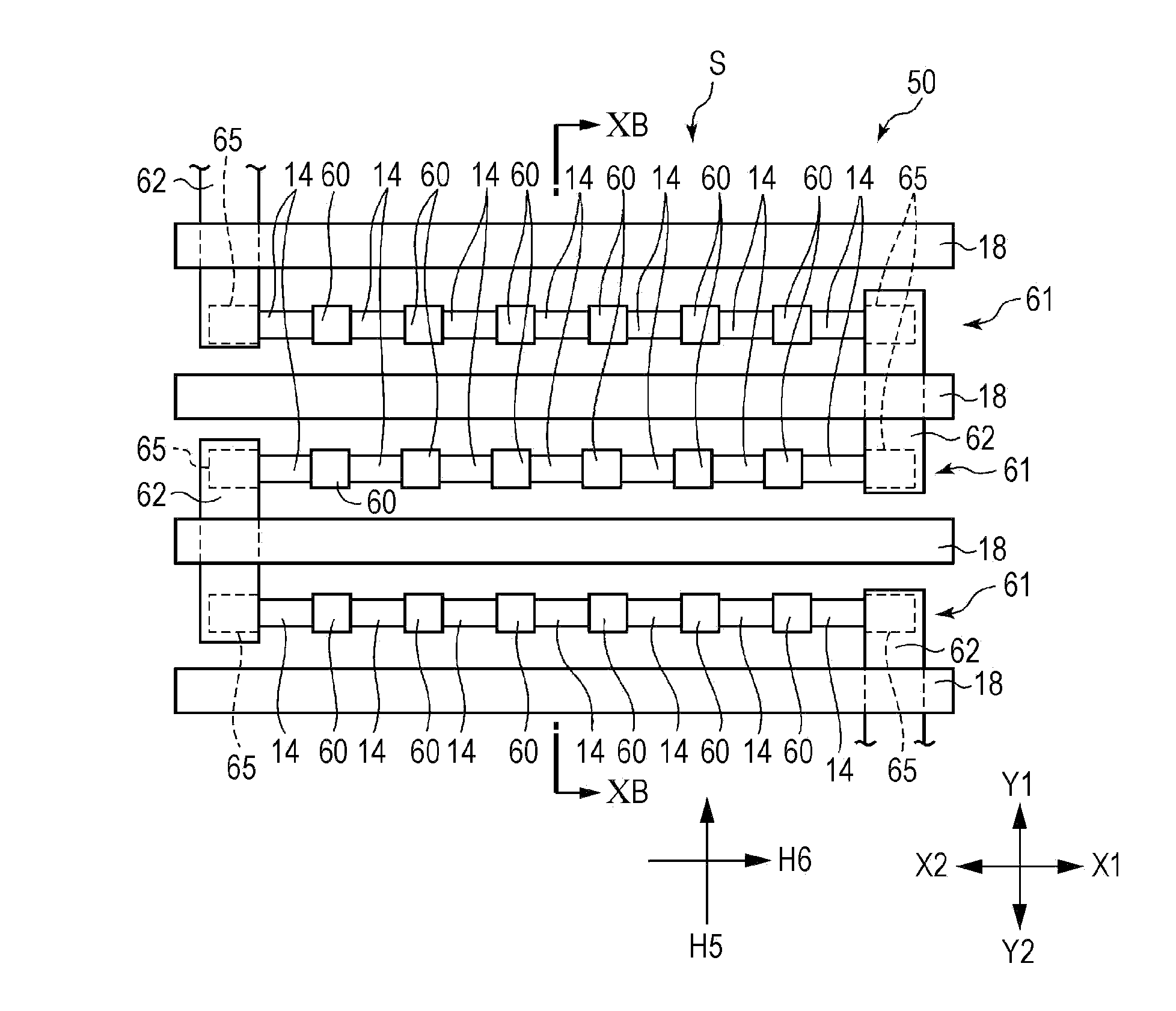

Magnetic sensor

ActiveUS20120200292A1Simple configurationLow costNanomagnetismMagnetic-field-controlled resistorsMagnetizationPerpendicular magnetic field

A magnetic sensor includes magnetoresistive elements and a soft magnetic body. The magnetoresistive elements have multi layers including a magnetic layer and a nonmagnetic layer on a substrate, and exert a magnetoresistance effect. The soft magnetic body is electrically disconnected with the magnetoresistive elements, and converts a vertical magnetic field component from the outside into a magnetic field component in a horizontal direction so as to provide the magnetoresistive elements with the horizontally converted magnetic field component. The magnetoresistive elements have a pinned magnetic layer having a fixed magnetization direction and a free magnetic layer having a variable magnetization direction. The free magnetic layer is stacked on the pinned magnetic layer with a nonmagnetic layer interposed between the free magnetic layer and the pinned magnetic layer. The magnetization directions of the pinned magnetic layers of the magnetoresistive elements are the same direction. The magnetoresistive elements form a bridge circuit.

Owner:ALPS ALPINE CO LTD

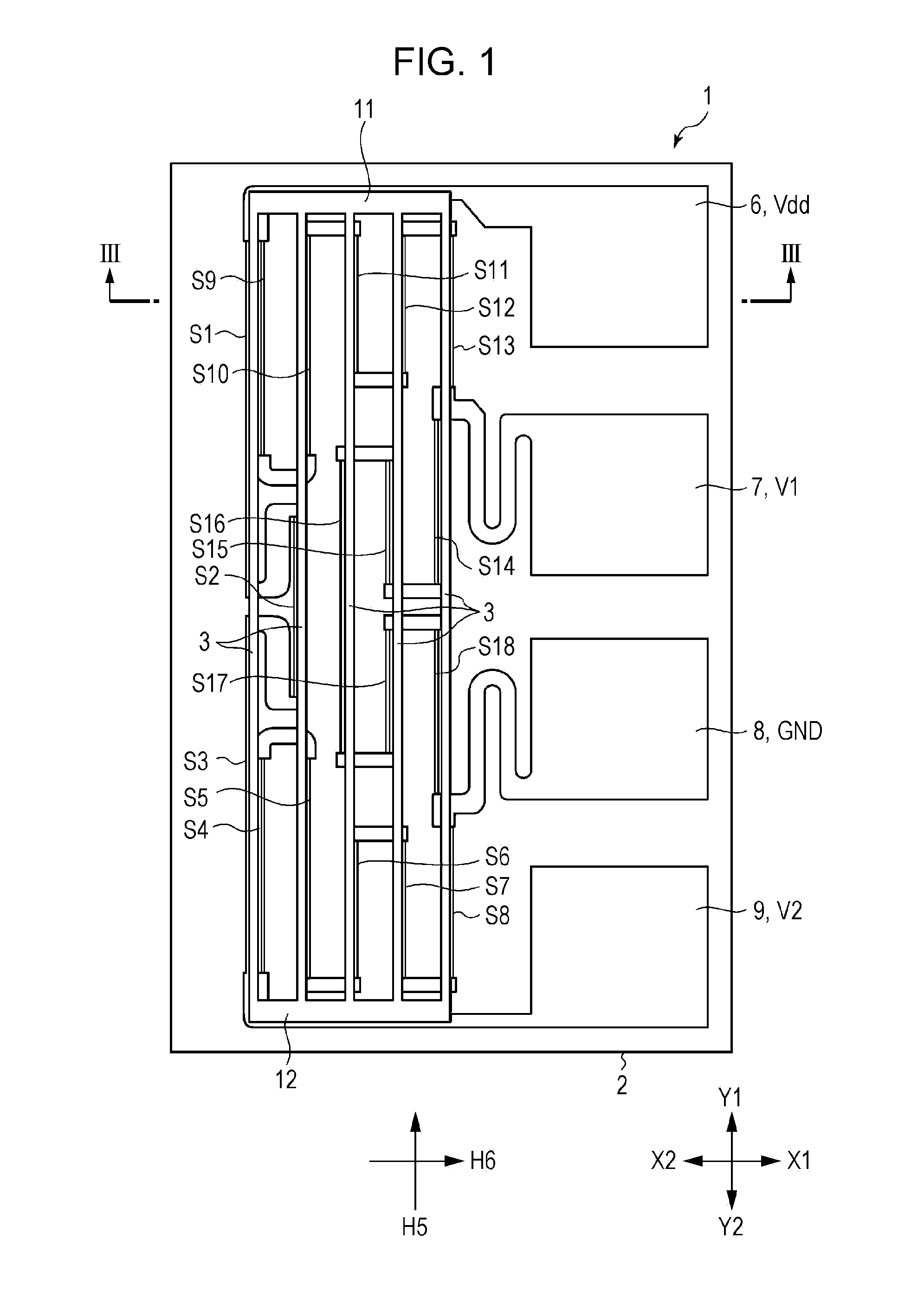

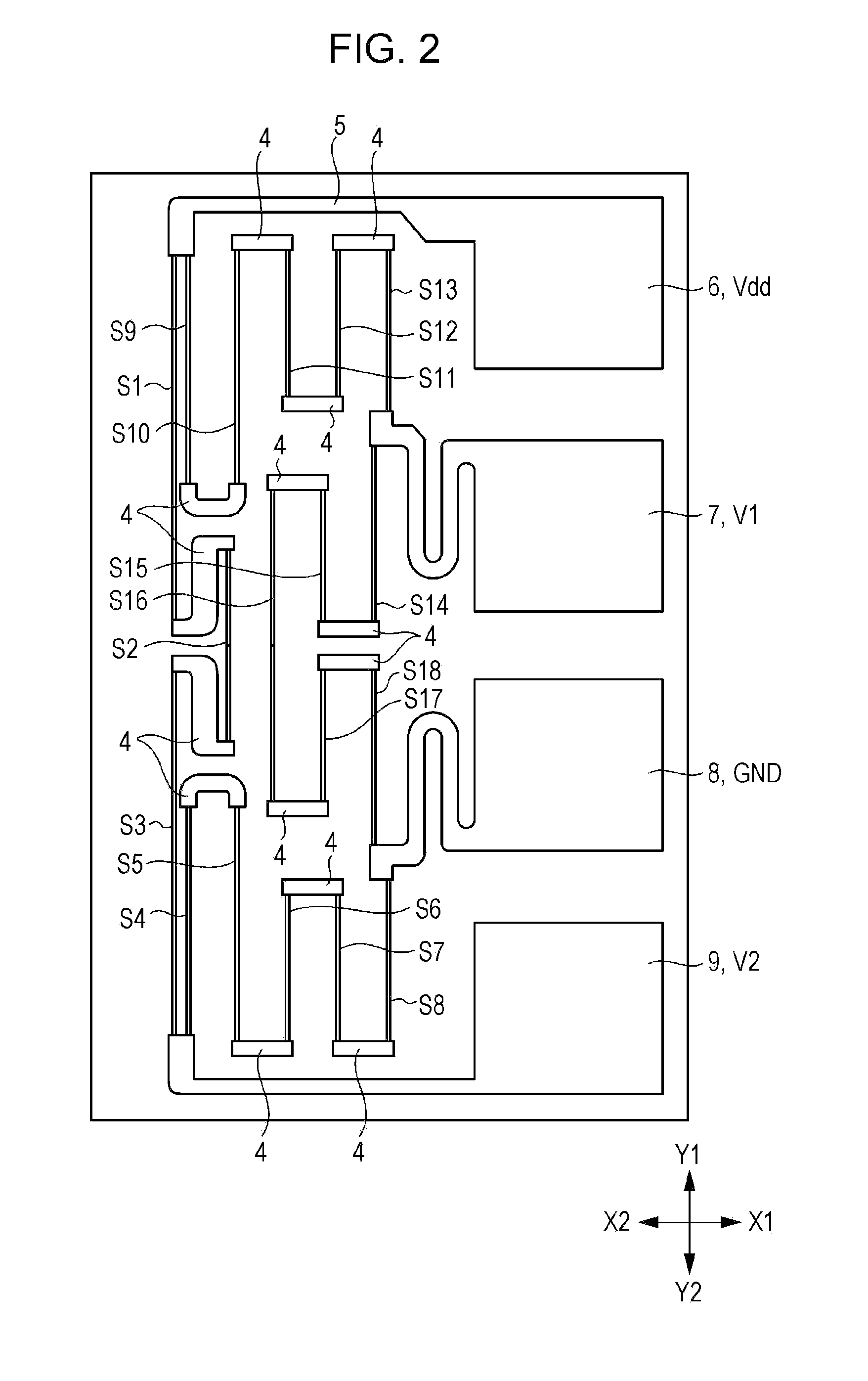

Current sensor

ActiveUS20060170529A1Reduced dimensionStrong applicationMagnetic-field-controlled resistorsSolid-state devicesElectrical resistance and conductanceMagnetic reluctance

A current sensor that is compact can detect with high sensitivity and high accuracy a magnetic field generated by a current. The current sensor has a thin film coil including turn portions extending in an X-axis direction at a second layer, and a first magnetoresistive element which includes element patterns disposed at a first layer in areas corresponding to the turn portions, the resistance value of which varies according to a magnetic field generated by a current detected of from 10 to 50 mA flowing through the turn portions. The distance between each turn portion and each element pattern is from 0.4 to 1.0 μm. Each cross-sectional area at the turn portions is from 0.4 to 3.0 μm2. This permits efficient detection of a magnetic field without the influence of heat generated from the thin film coil.

Owner:TDK CORPARATION

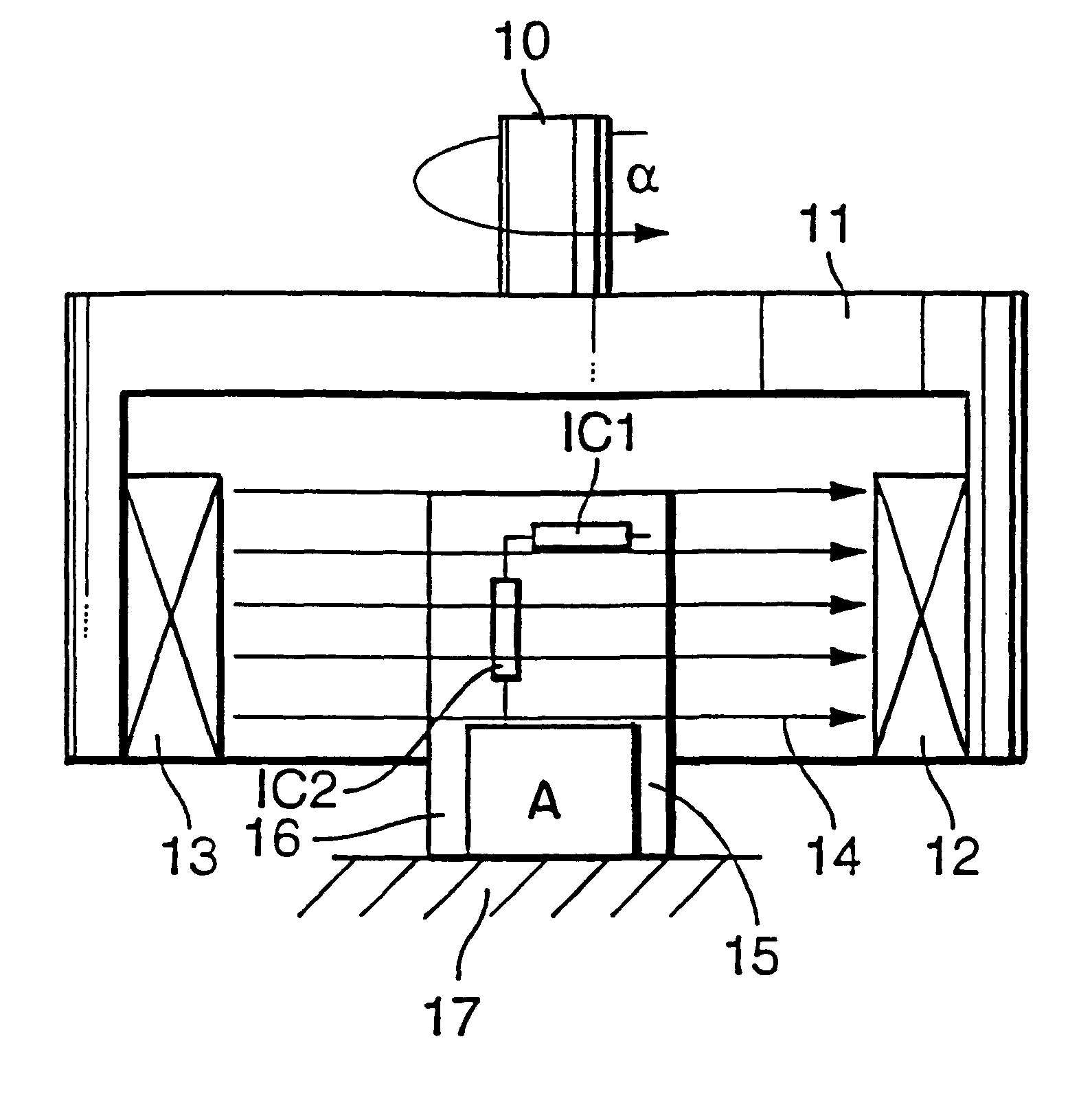

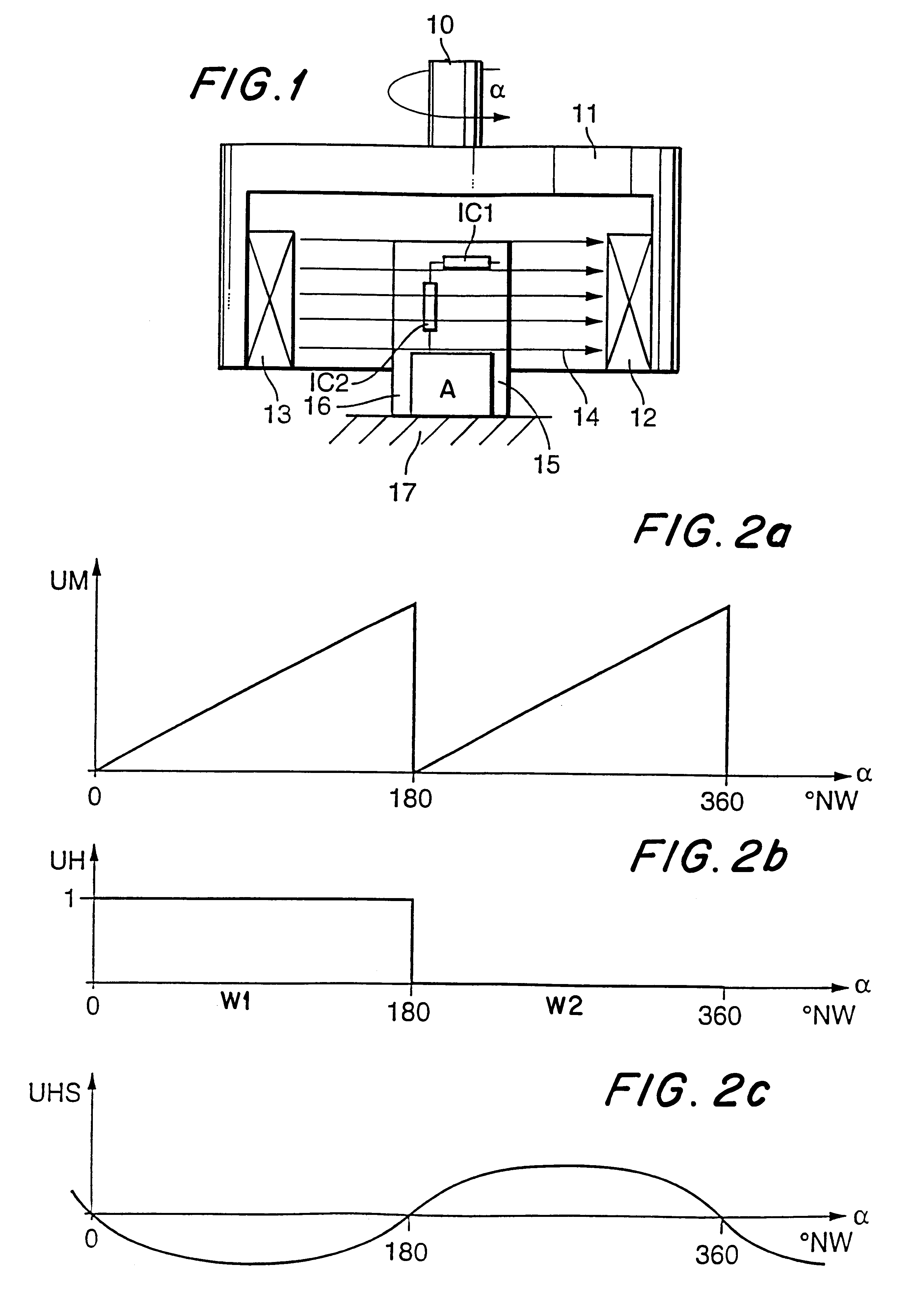

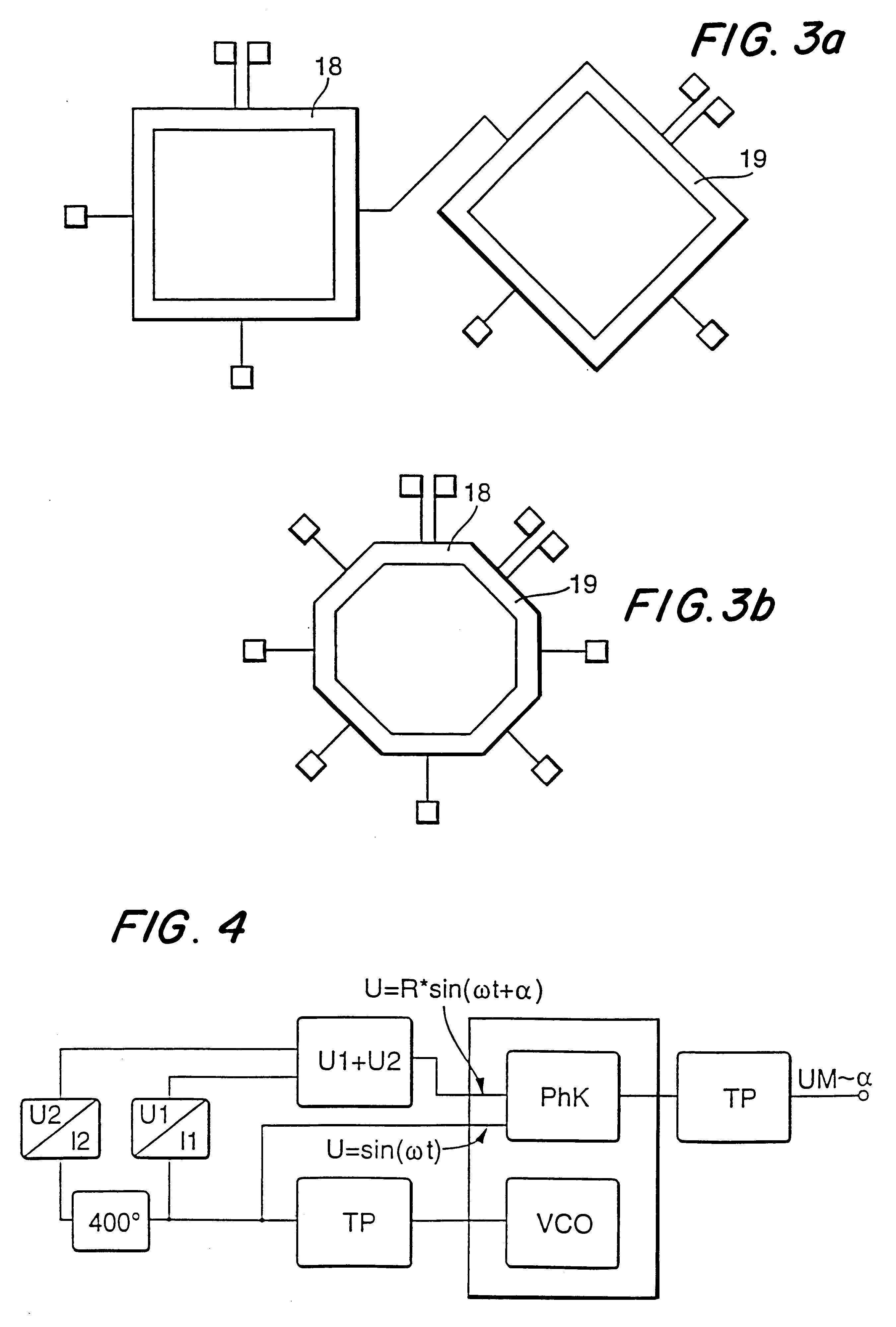

Non-contact system for detecting an angle of rotation

InactiveUS6212783B1Angles/taper measurementsElectric ignition installationAngular orientationInternal combustion engine

The arrangement for contactless determination of an angular position of a rotatable element, such as a camshaft of an internal combustion engine, which includes a magnet arranged to rotate with the rotatable element; a magnetic field sensor stationary in relation to the rotatable element and including a first sensor element (IC1) and a second sensor element (IC2), wherein the first sensor element generates a first output signal linearly dependent on an angle between the magnetic field and the magnetic field sensor according to a magnetoresistive effect, whereby the first output signal has respective values between 0° and 180° that repeat between 180° and 360°, and the second sensor element generates a second output signal having a high value between 0° and 180° and a low value between 180° and 360° according to a Hall effect; and an evaluation circuit (A) for analyzing output signals of both sensor elements to determine the angular position of the rotatable element between 0° and 360°. The evaluating circuit finds that the absolute angular position is either of two angular orientations spaced 180° from each other only from the signal from the first sensor element and selects one of them as the absolute angular position according to the second output signal.

Owner:ROBERT BOSCH GMBH

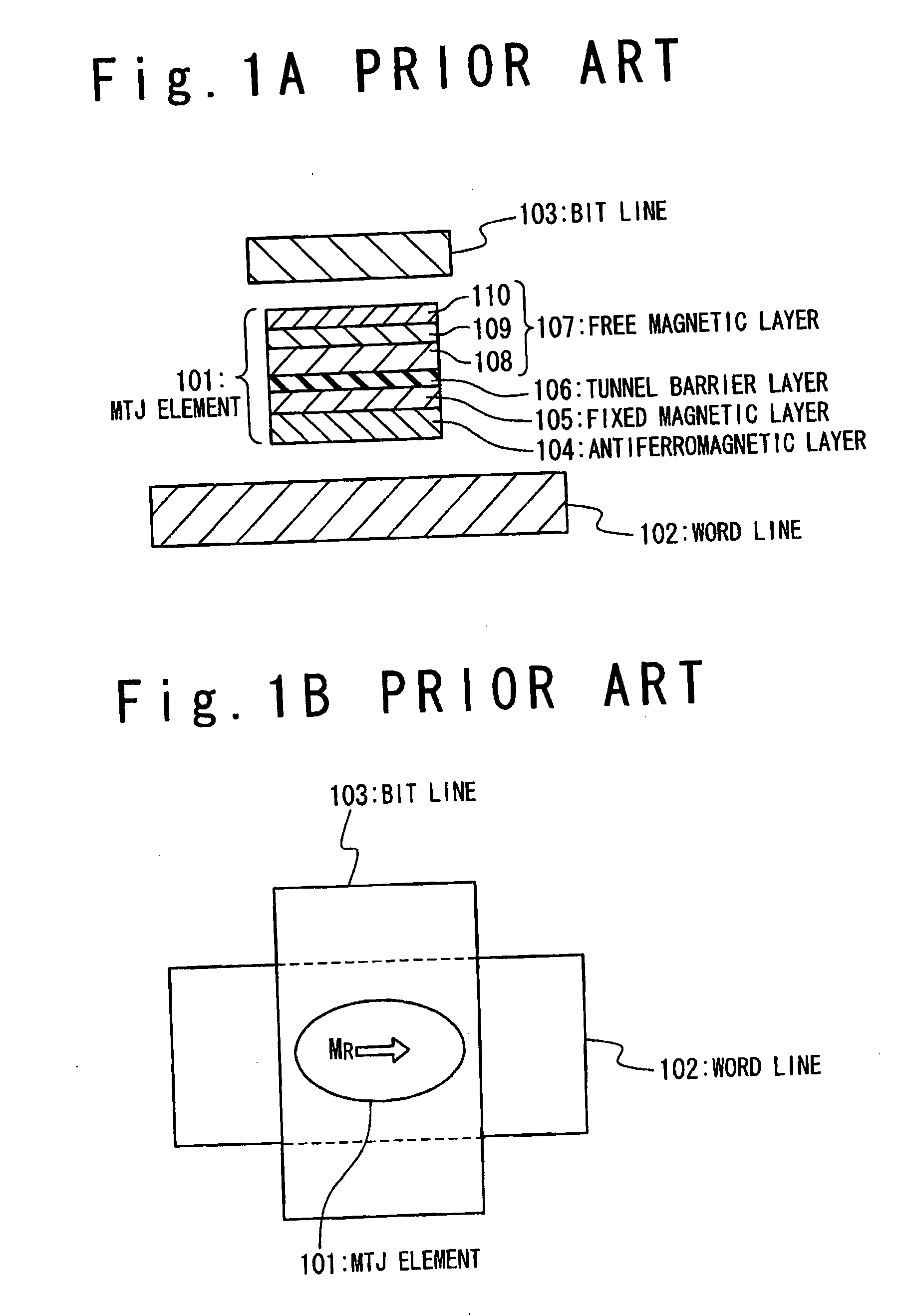

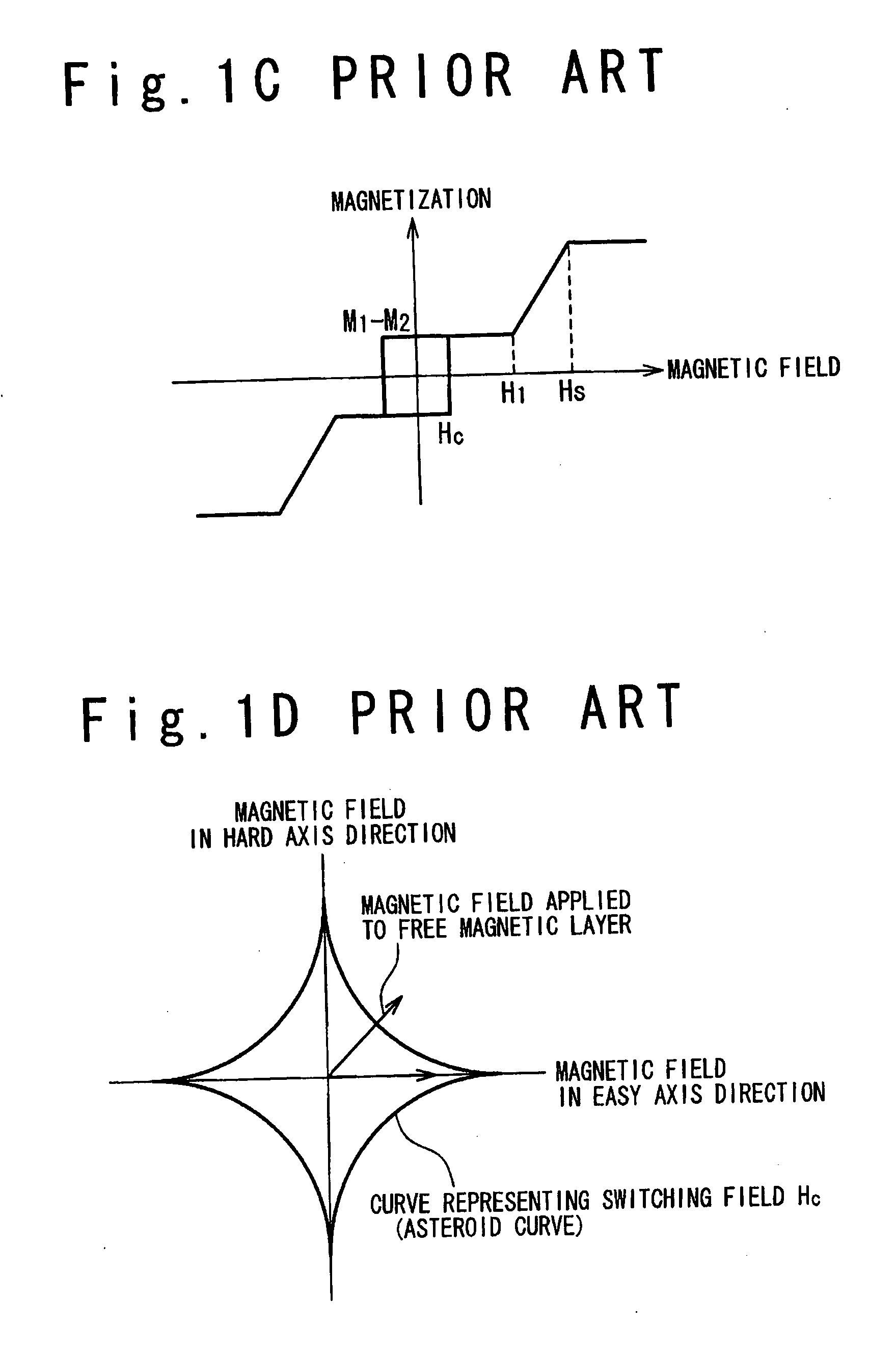

Magnetic random access memory including a cell array having a magneto-resistance element

InactiveUS6885579B2Improve reliabilityMagnetic-field-controlled resistorsSolid-state devicesBit lineComputer architecture

In a magnetic random access memory, a cross point cell array of memory cells is arranged in a matrix of columns and rows, and each of the memory cells has a magneto-resistance element. A column of dummy memory cells is provided, and each of the dummy memory cells has a magneto-resistance element. Word lines are provided for the rows of the memory cells and the dummy memory cells, respectively, and bit lines are provided for the columns of the memory cells, respectively. A dummy bit line is provided for the column of dummy memory cells. A read circuit is connected with the cross point cell array and the dummy bit line.

Owner:NEC CORP

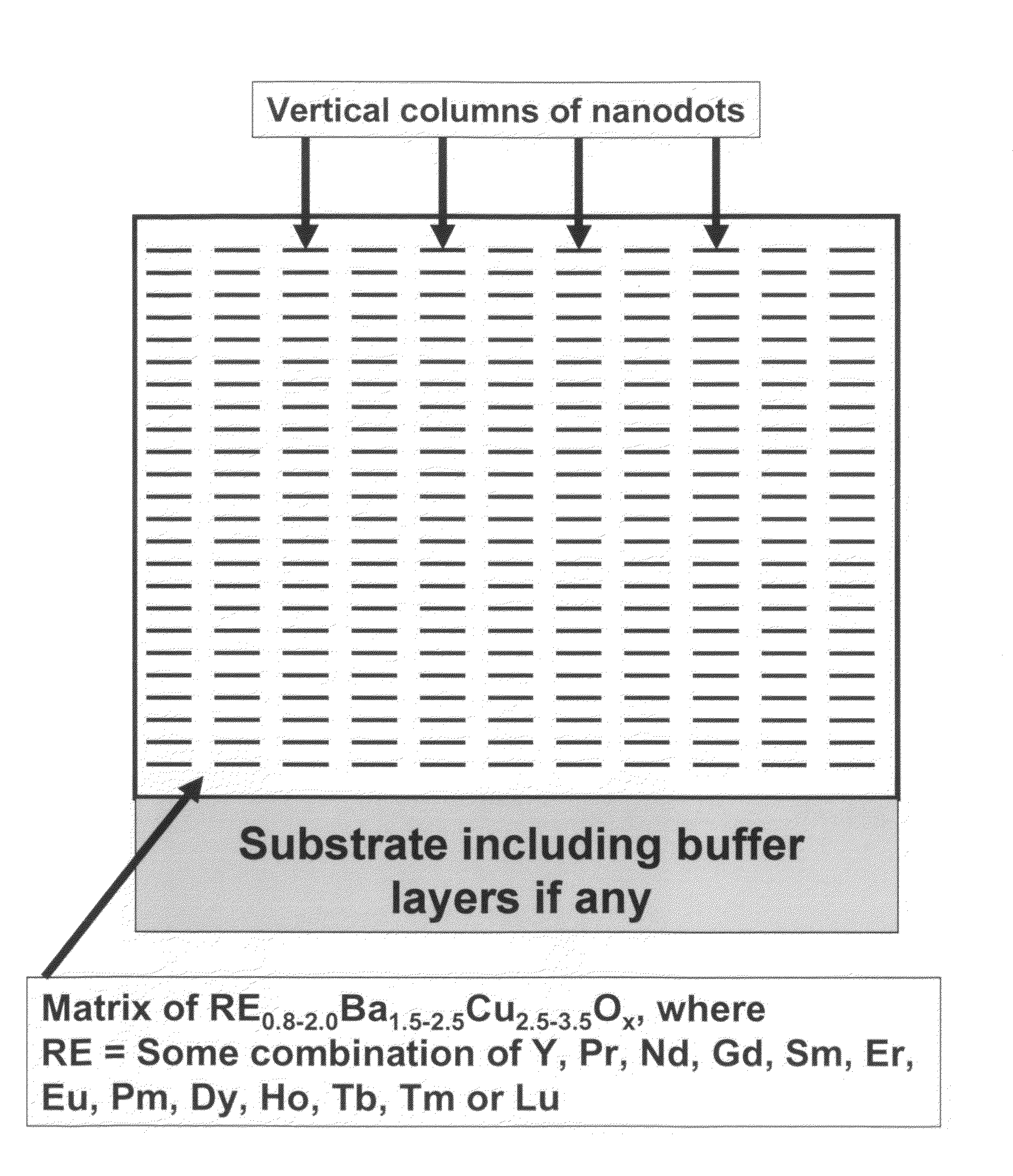

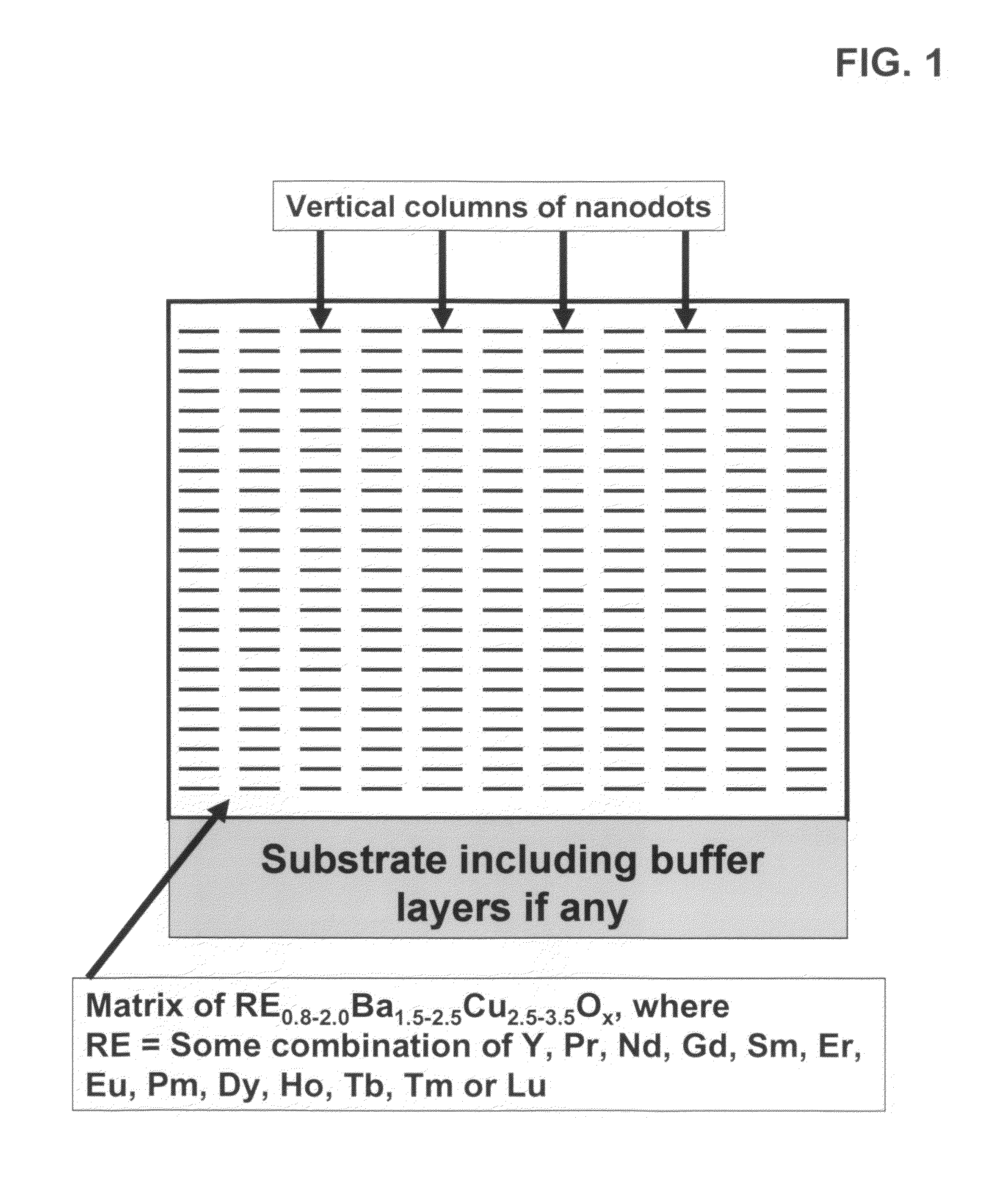

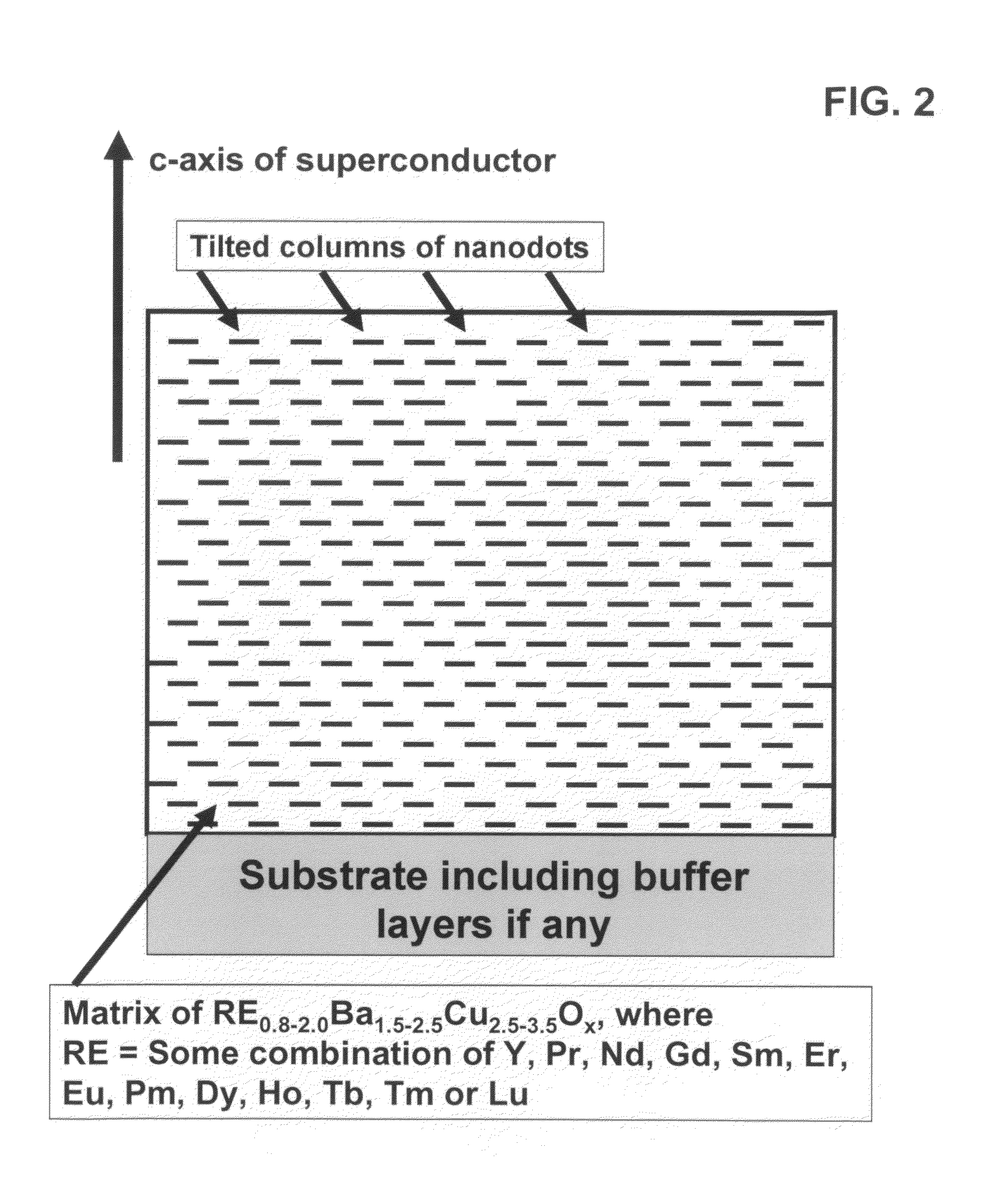

High performance devices enabled by epitaxial, preferentially oriented, nanodots and/or nanorods

ActiveUS20080176749A1Improve performanceSuperconductors/hyperconductorsGalvano-magnetic material selectionNanodotPhotoluminescence

Novel articles and methods to fabricate same with self-assembled nanodots and / or nanorods of a single or multicomponent material within another single or multicomponent material for use in electrical, electronic, magnetic, electromagnetic, superconducting and electrooptical devices is disclosed. Self-assembled nanodots and / or nanorods are ordered arrays wherein ordering occurs due to strain minimization during growth of the materials. A simple method to accomplish this when depositing in-situ films is also disclosed. Device applications of resulting materials are in areas of superconductivity, photovoltaics, ferroelectrics, magnetoresistance, high density storage, solid state lighting, non-volatile memory, photoluminescence, thermoelectrics and in quantum dot lasers.

Owner:GOYAL AMIT

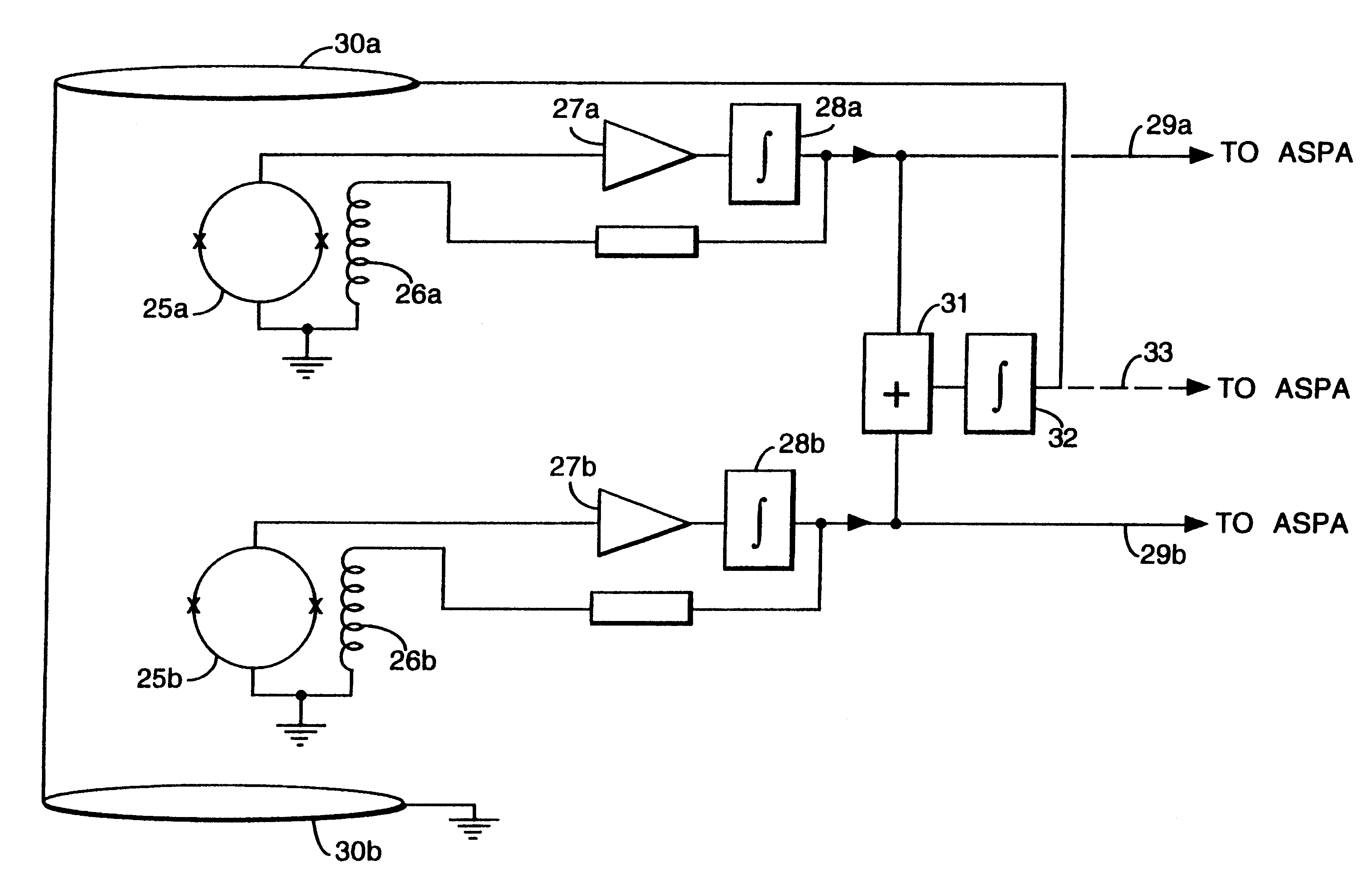

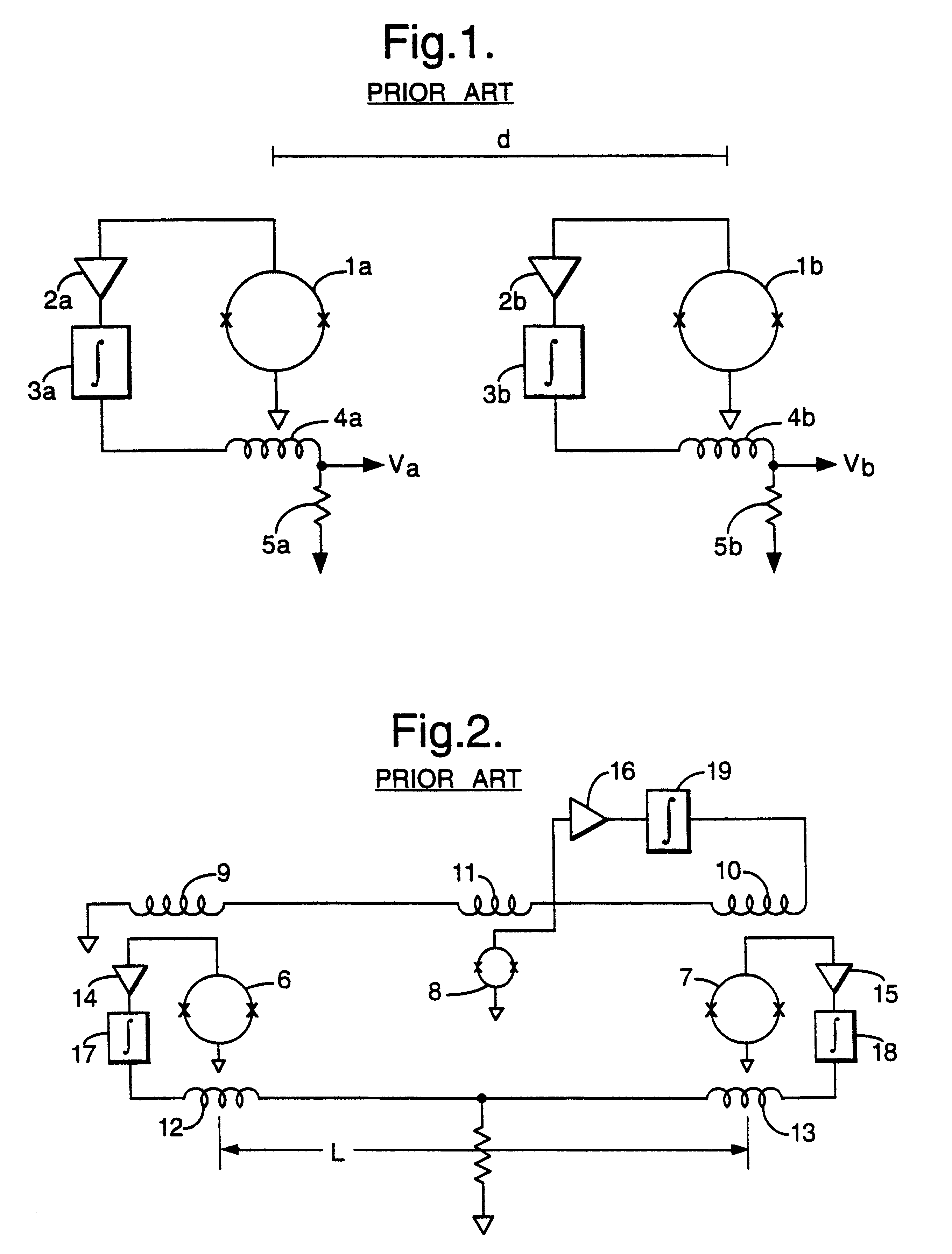

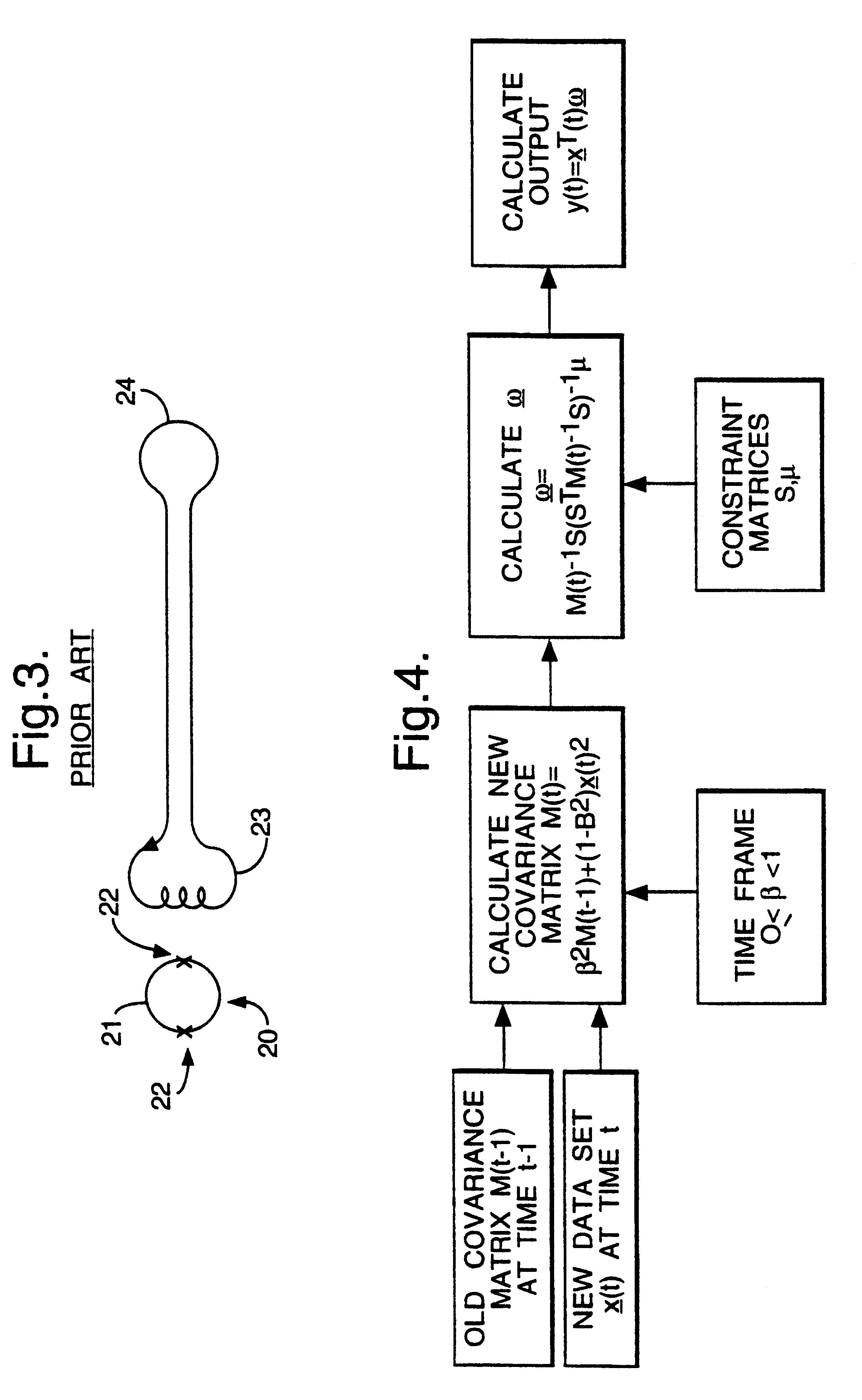

Magnetic gradiometer incorporating global feedback

InactiveUS6339328B1Minimizing energySufficient dynamic rangeMagnetic field measurement using flux-gate principleMagnetic field measurement using galvano-magnetic devicesMagnetic field gradientGradiometer

A gradiometer for measuring properties of a magnetic field and in particular, for measuring magnetic field gradient components, comprising at least two magnetic sensors wherein at least two of the magnetic sensors are arranged to sense the magnetic field component in substantially the same direction. The magnetic sensors may be super conducting quantum interference device (SQUID) magnetometers, Hall probes, flux gates or magneto-resistive magnetometers. The gradiometer also includes a computer processor loaded with an adaptive signal-processing algorithm, for performing adaptive signal balancing of the magnetometer outputs. In a preferred embodiment the gradiometer may comprise at least eight magnetometers in a three-dimensional arrangement, and a set of three orthogonal global feedback coils, one for each direction x, y, z, such that the five independent magnetic field gradient components may be measured. The gradiometer may also be used to measure second or higher order magnetic field gradient components.

Owner:QINETIQ LTD

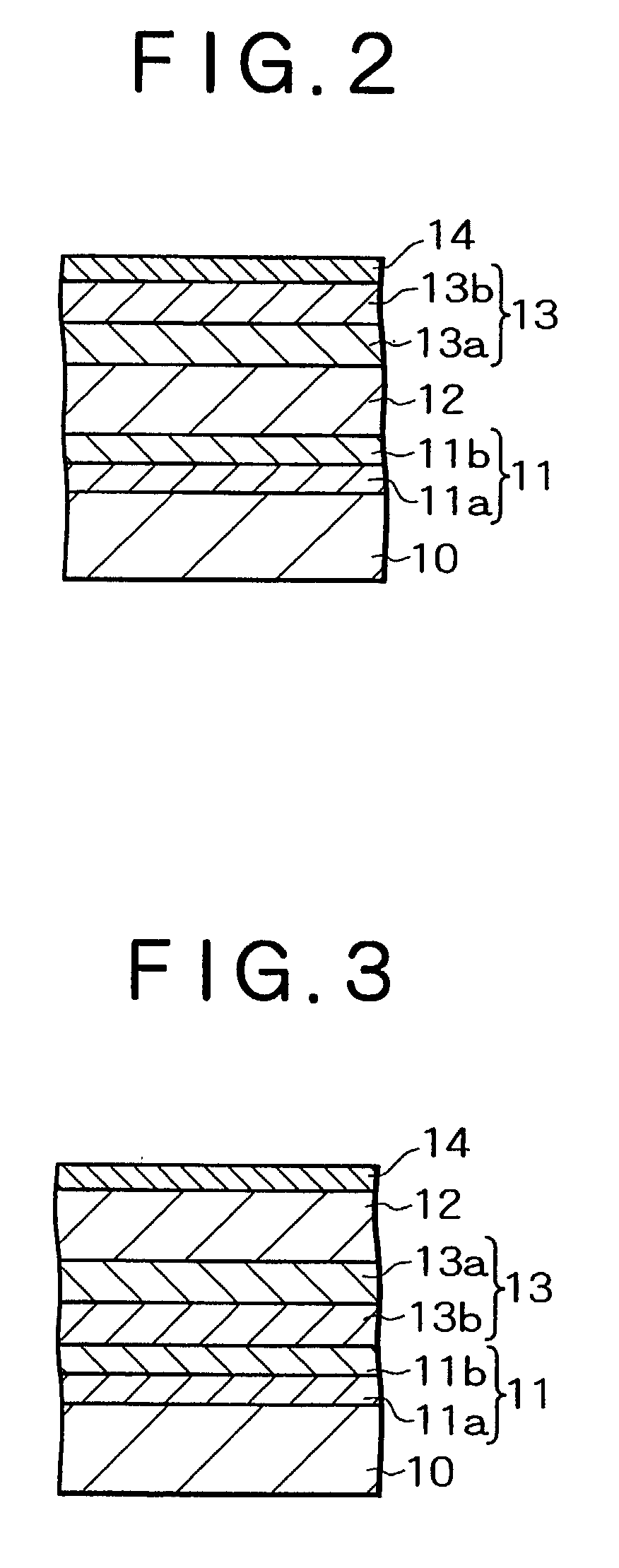

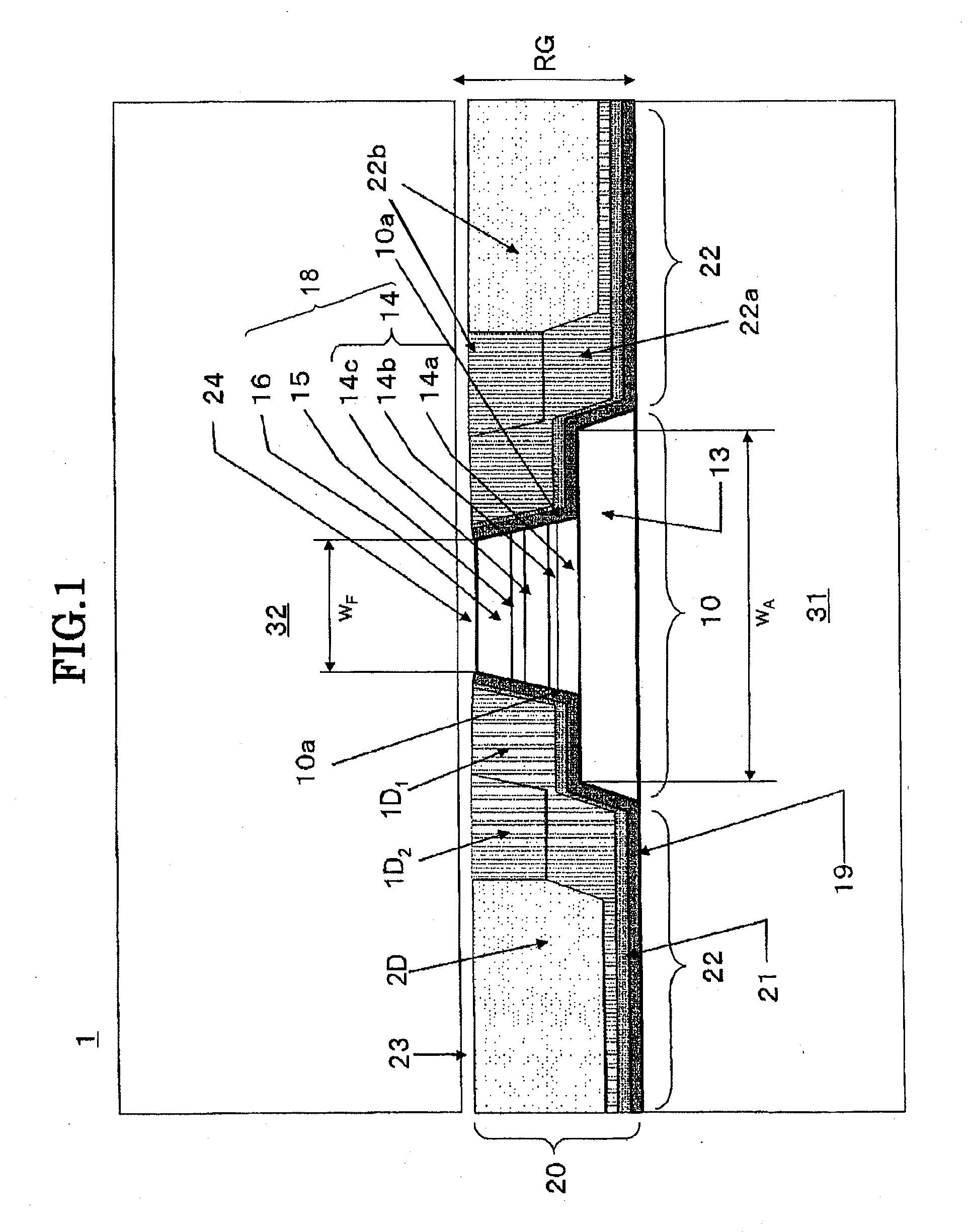

Magnetoresistance device including layered ferromagnetic structure, and method of manufacturing the same

InactiveUS20060180839A1Great exchange couplingRaise the ratioNanomagnetismMagnetic measurementsMagnetic reluctanceNon magnetic

A layered ferromagnetic structure is composed of a first ferromagnetic layer positioned over a substrate; a second ferromagnetic layer positioned over the first ferromagnetic layer; and a first non-magnetic layer placed between the first and second ferromagnetic layers. The top surface of the first ferromagnetic layer is in contact with the first non-magnetic layer. The first ferromagnetic layer includes a first orientation control buffer that exhibits an effect of enhancing crystalline orientation of a film formed thereon.

Owner:NEC CORP

Magnetic tunnel junctions including crystalline and amorphous tunnel barrier materials

Owner:INT BUSINESS MASCH CORP

Magneto-resistance effect element, magnetic memory and magnetic head

InactiveUS20040100855A1Reduce power consumptionImprove thermal stabilityNanomagnetismNanoinformaticsMagnetic memoryMagnetization

The magneto-resistance effect element includes: a first ferromagnetic layer serving as a magnetization fixed layer; a magnetization free layer including a second ferromagnetic layer provided on one side of the first ferromagnetic layer, a third ferromagnetic layer which is formed on an opposite side of the second ferromagnetic layer from the first ferromagnetic layer and has a film face having an area larger than that of the second ferromagnetic layer and whose magnetization direction is changeable by an external magnetic field, and an intermediate layer which is provided between the second ferromagnetic layer and the third ferromagnetic layer and which transmits a change of magnetization direction of the third ferromagnetic layer to the second ferromagnetic layer; and a tunnel barrier layer provided between the first ferromagnetic layer and the second ferromagnetic layer.

Owner:KK TOSHIBA

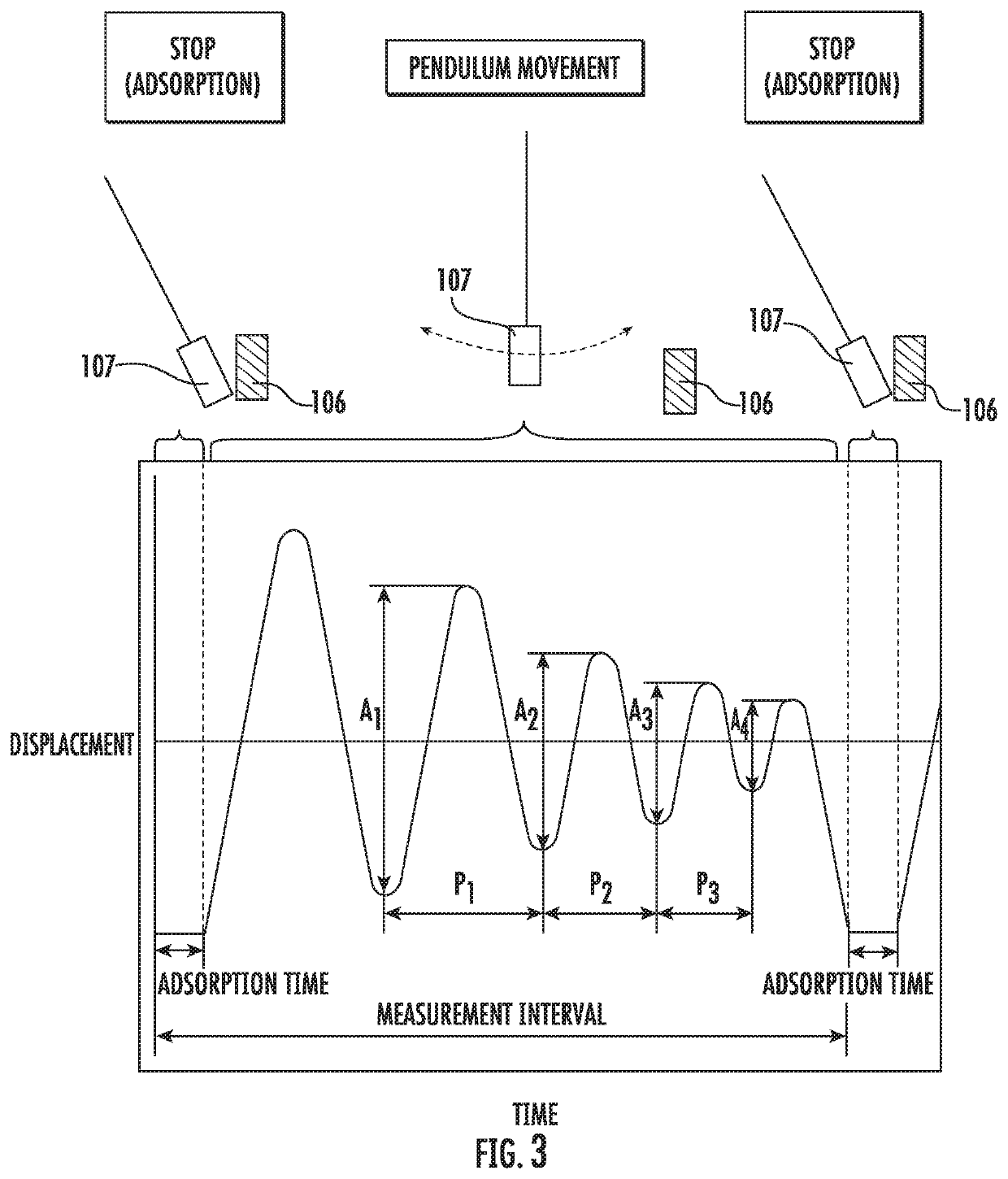

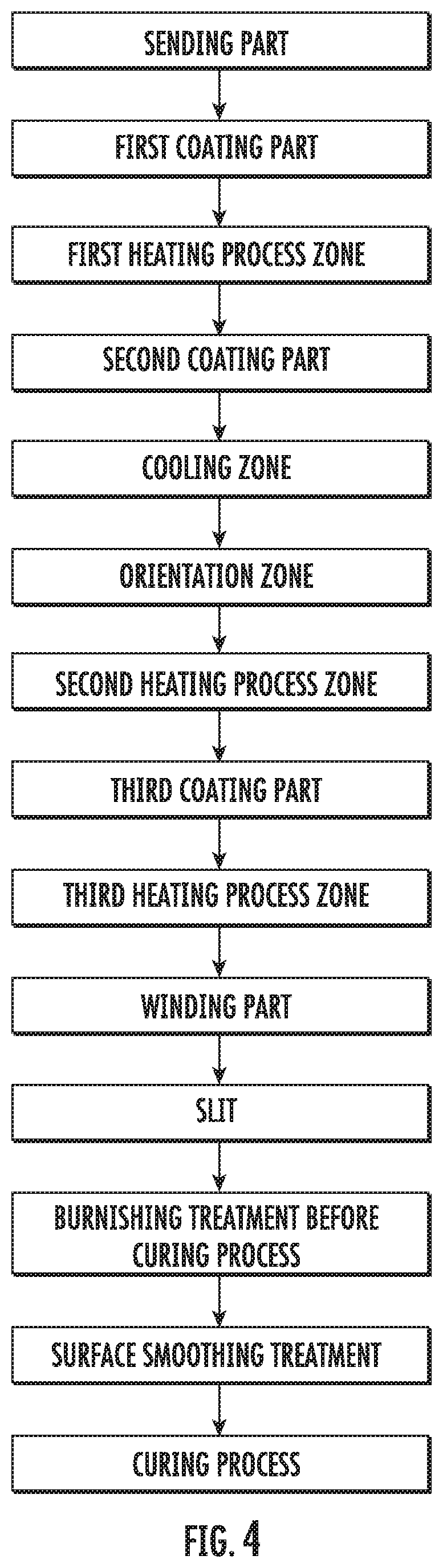

Magnetic tape device and reproducing method employing TMR reproducing head and tape with characterized XRD intensity ratio

ActiveUS10546602B2Improve smoothnessImprove surface smoothnessMagnetic materials for record carriersBase layers for recording layersMagnetic tapeFerrite powder

The magnetic tape device includes a Tunneling Magnetoresistive (TMR) head as a reproducing head; and a magnetic tape which includes a non-magnetic support, and a magnetic layer including ferromagnetic hexagonal ferrite powder and a binding agent on the non-magnetic support, an XRD intensity ratio (Int(110) / Int(114)) of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, and a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

Perpendicular spin transfer torque (STT) memory cell with double MgO interface and CoFeB layer for enhancement of perpendicular magnetic anisotropy

ActiveUS9337415B1Increase contentInhibited DiffusionMagnetic-field-controlled resistorsGalvano-magnetic material selectionSpin-transfer torqueMagnetic reluctance

A magnetic tunnel junction (MTJ) for use in a magnetoresistive random access memory (MRAM) has a CoFeB alloy free layer located between the MgO tunnel barrier layer and an upper MgO capping layer, and a CoFeB alloy enhancement layer between the MgO capping layer and a Ta cap. The CoFeB alloy free layer has high Fe content to induce perpendicular magnetic anisotropy (PMA) at the interfaces with the MgO layers. To avoid creating unnecessary PMA in the enhancement layer due to its interface with the MgO capping layer, the enhancement layer has low Fe content. After all of the layers have been deposited on the substrate, the structure is annealed to crystallize the MgO. The CoFeB alloy enhancement layer inhibits diffusion of Ta from the Ta cap layer into the MgO capping layer and creates good crystallinity of the MgO by providing CoFeB at the MgO interface.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com