Magnetic tunnel junction with improved tunneling magneto-resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

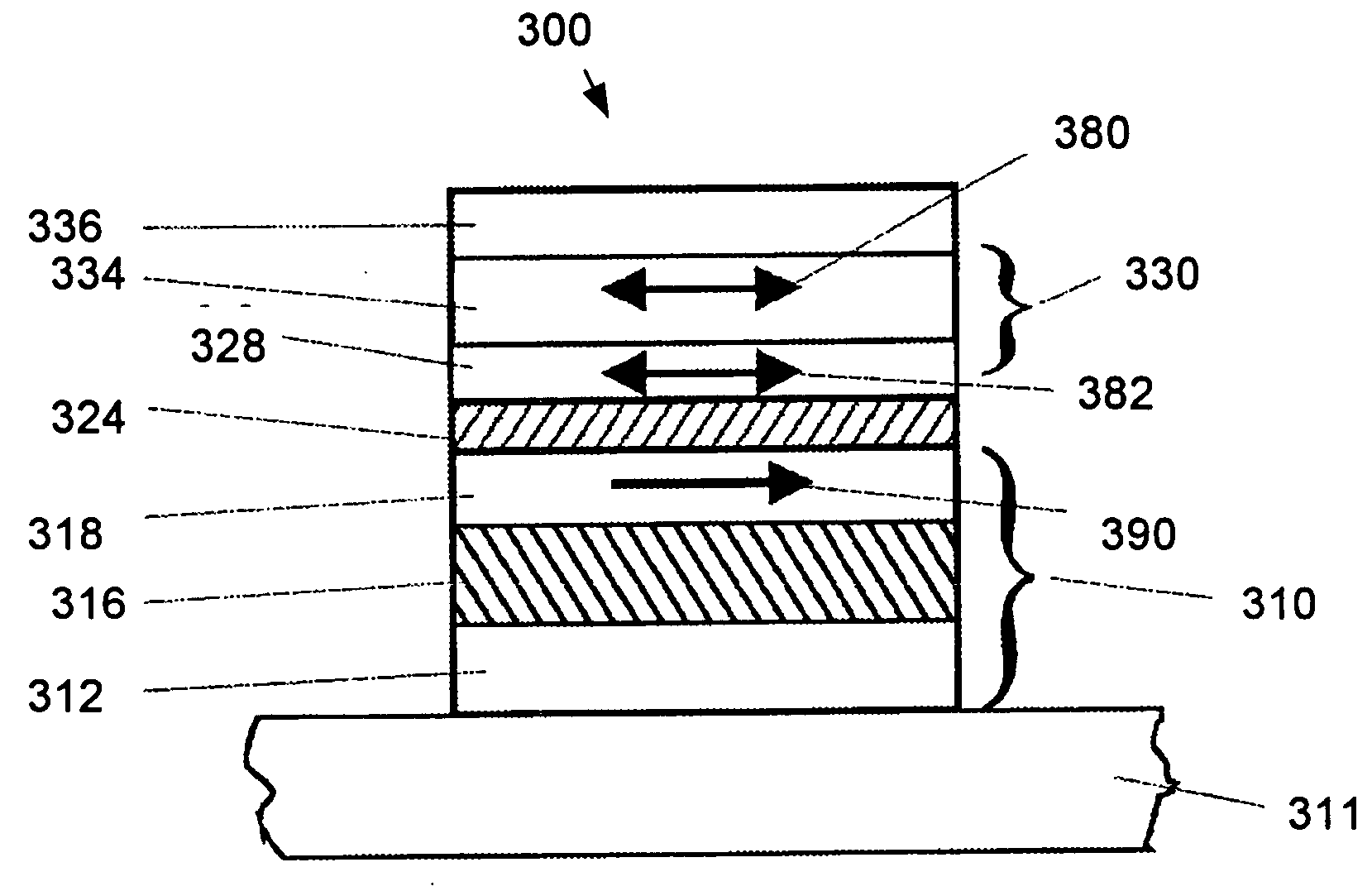

Embodiment Construction

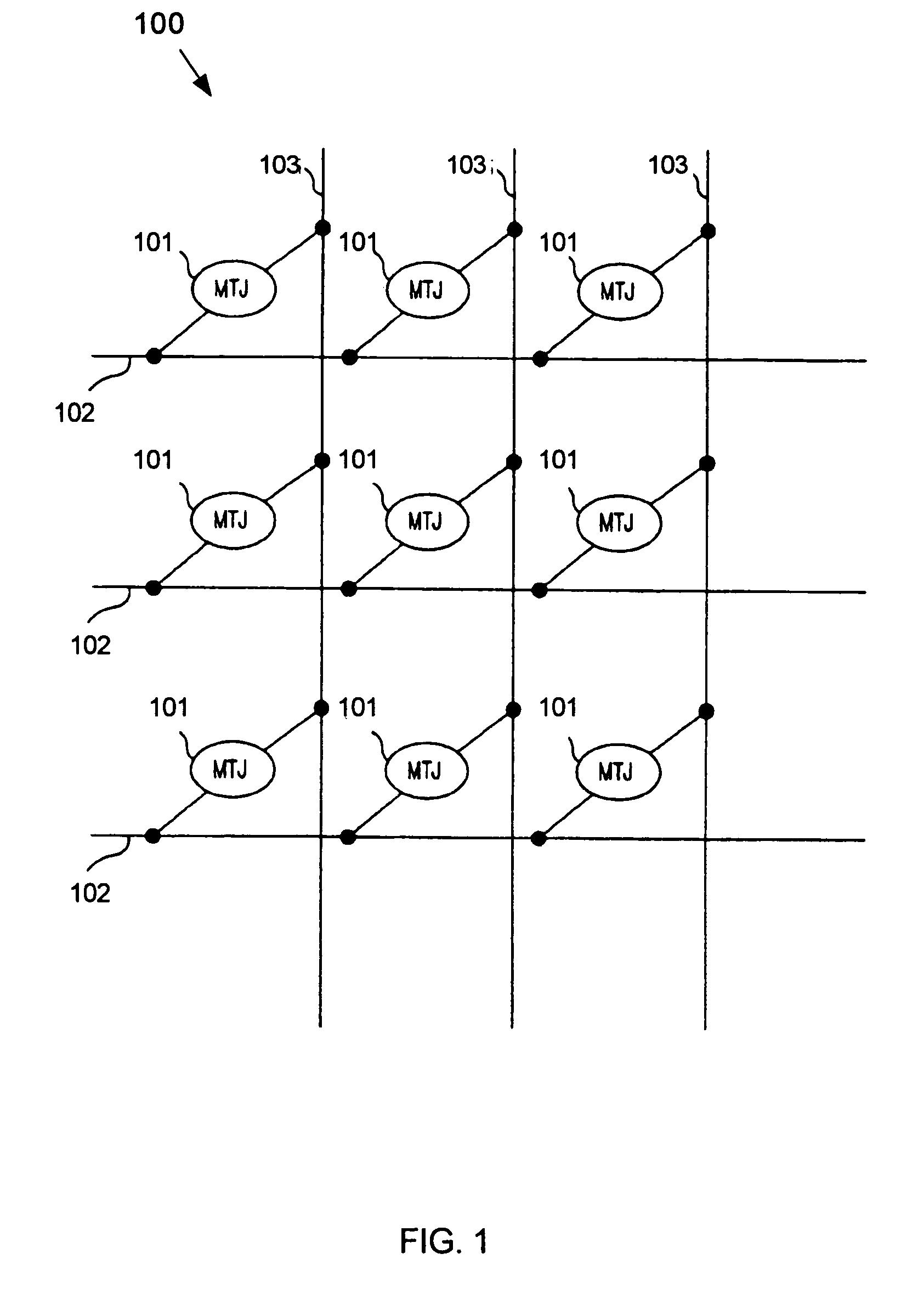

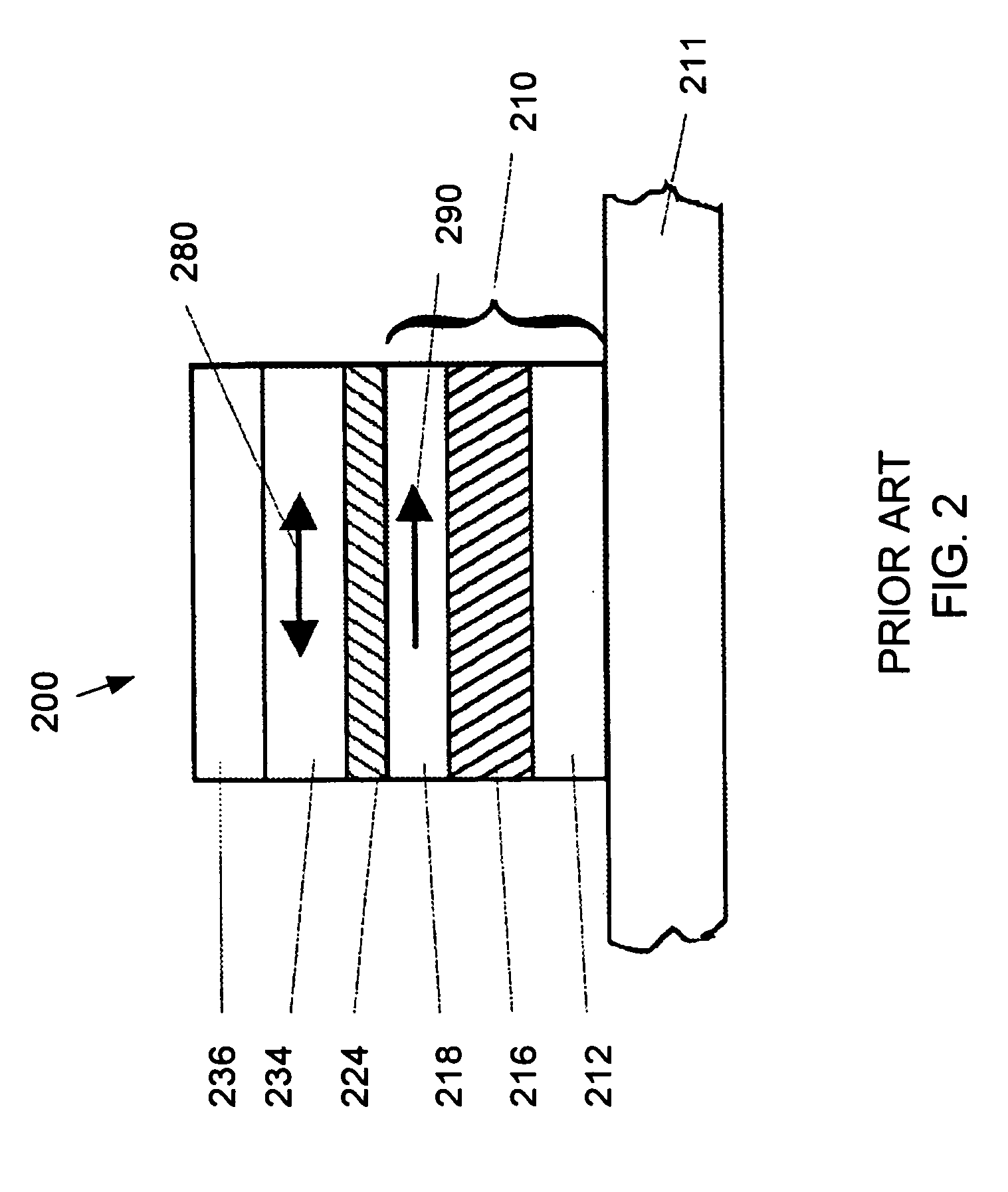

[0035] The present invention provides MTJ structures having Al2O3 tunnel barriers exhibiting TMR of nearly 70%. According to the present invention, one layer of an MTJ element is formed from the class of ferromagnetic (FM) materials of the form CoFeX or CoFeXY in which the dopants X and Y are chosen from B, Hf, Zr, C, Be, Si, Ge, P and Al, or combinations of two or more of these elements. Use of a thin interface layer of CoFe along with these CoFeX and CoFeXY alloys significantly enhances the TMR of an MTJ element according to the present invention. The enhanced TMR values together with excellent magnetic-switching characteristics (high AQF values) make CoFeX and CoFeXY alloys with CoFe interface layers extremely attractive for MRAM applications as well as other applications, for example, magnetic recording read heads, in which high TMR values are needed in comparatively low magnetic fields. The layers of an MTJ device according to the present invention show very good thermal stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com