Patents

Literature

869results about How to "Improve the overall coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

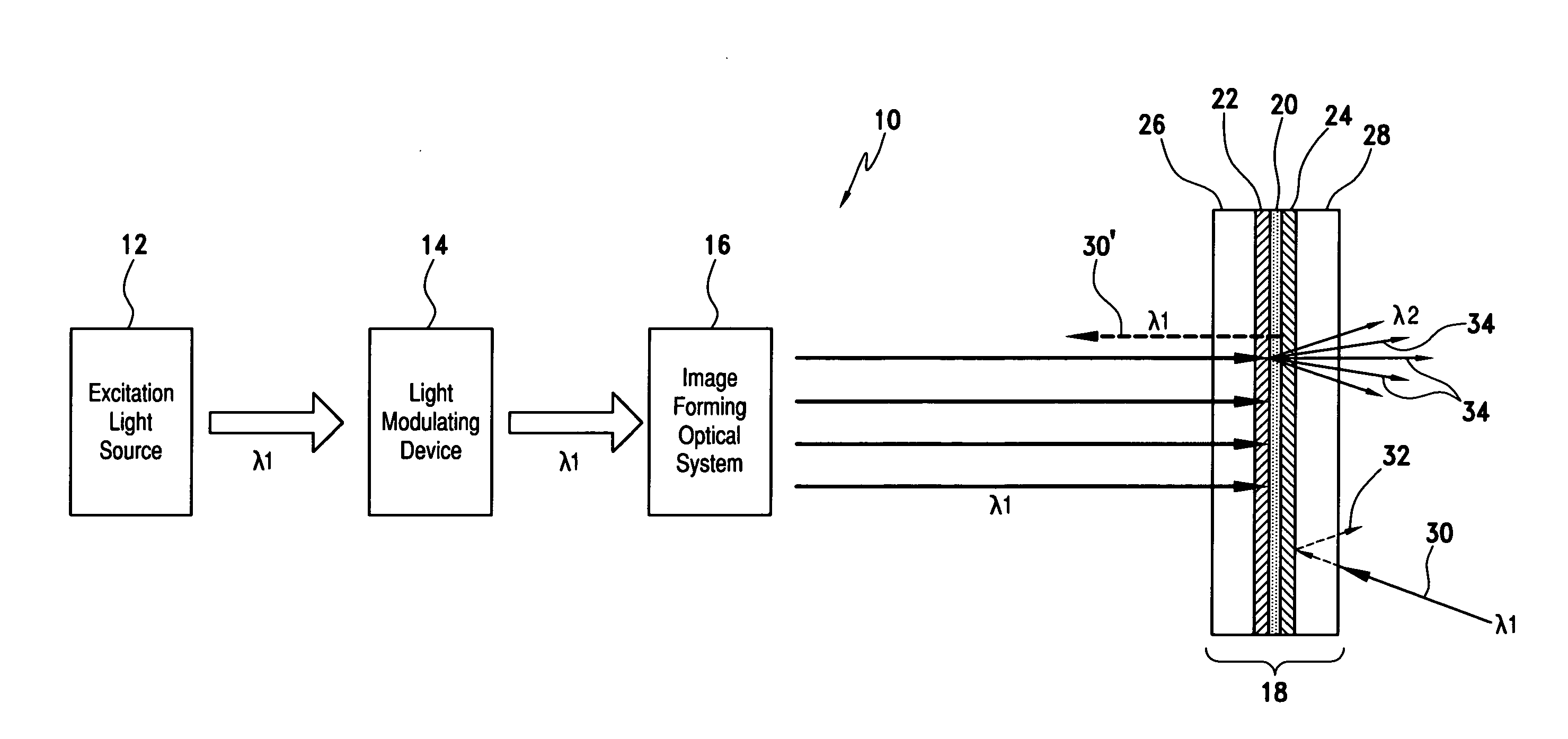

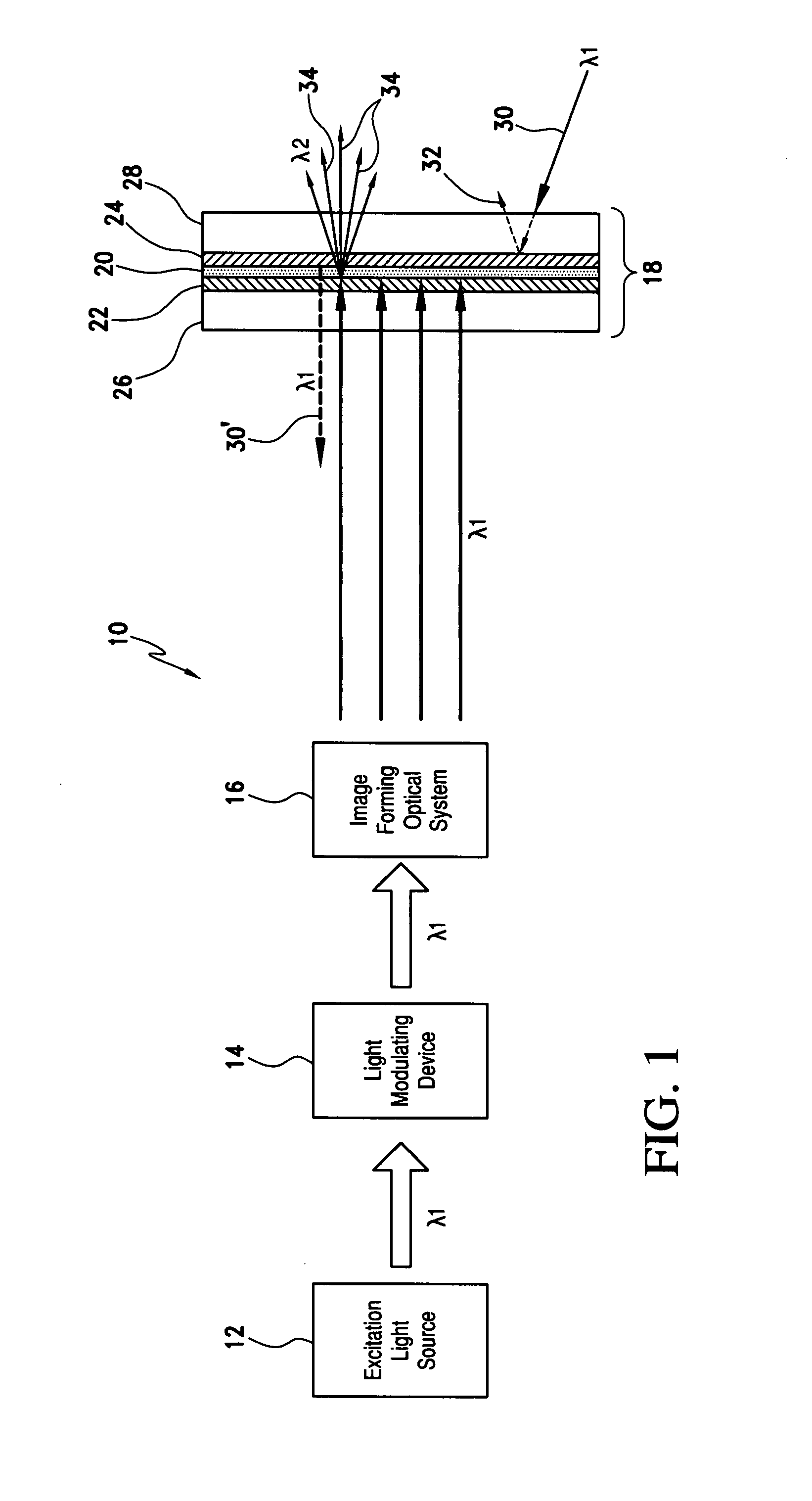

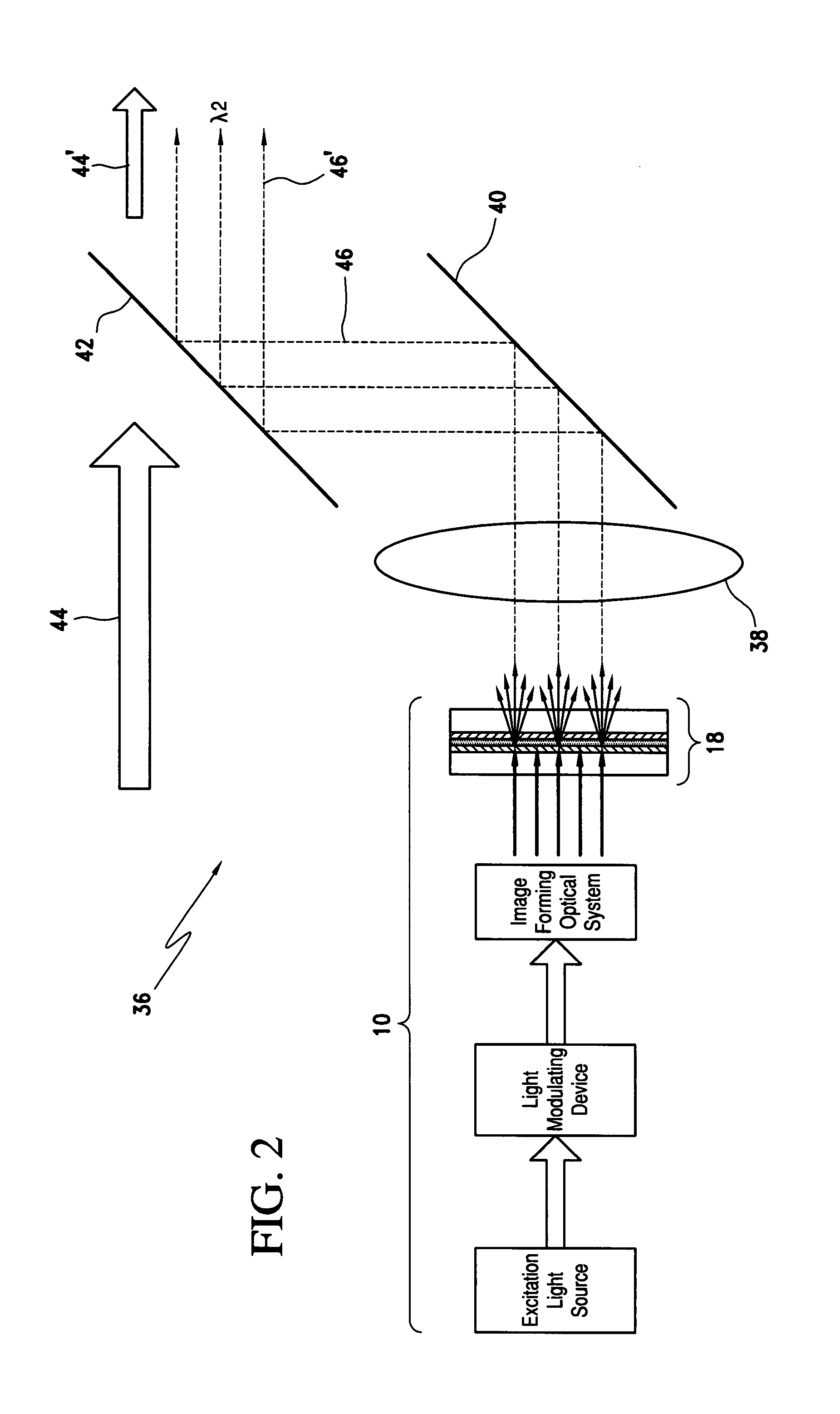

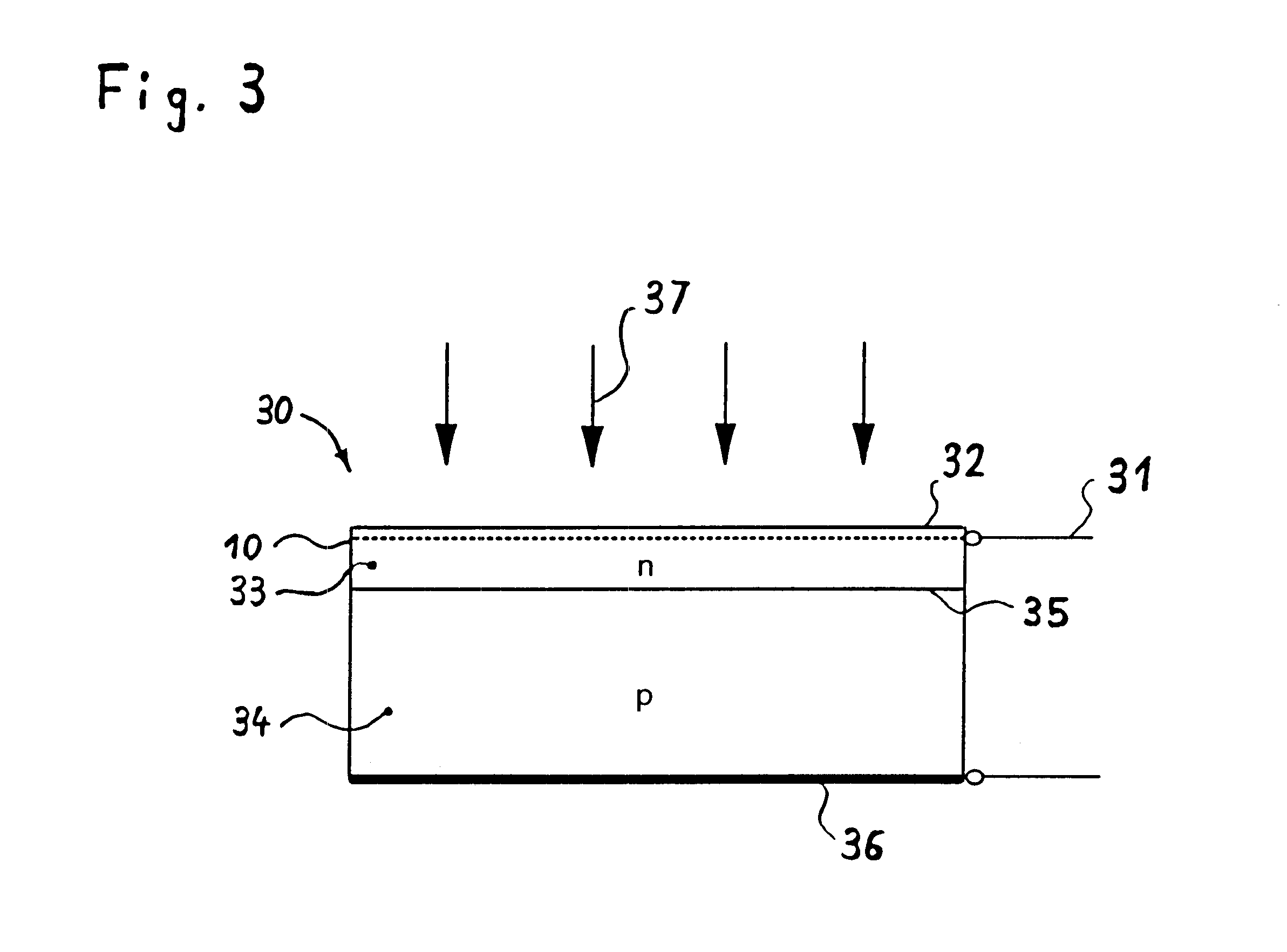

Phosphor screen and displays systems

InactiveUS7733571B1Good optical performanceImprove cooling effectOptical filtersNon-linear opticsPhosphorFluorescence

A phosphor screen for image forming including phosphor material being excitable by light in a wavelength λ1. The phosphor screen receives an optical image from an image forming optical system and produces the optical image at a second wavelength λ2. The phosphor screen includes a phosphor layer comprising the phosphor material. A short-pass reflective coating is positioned on a first side of the phosphor layer. The short-pass reflective coating transmits the wavelength λ1 and reflects the wavelength λ2. A long-pass reflective coating is positioned on a second side of the phosphor layer. The long-pass reflective coating transmits the wavelength λ2 and reflects the wavelength λ1. A first substrate is positioned over the short-pass reflective coating. The first substrate is formed of optically clear and thermal conductive material. A second substrate is positioned over the long-pass reflective coating. The second substrate is formed of long-pass absorptive optical filter material that transmits the wavelength λ2 and absorbs wavelength λ1 from ambient light to prevent the phosphor layer from being excited by the ambient light. The phosphor screen may alternatively be used for a direct-view visual display apparatus. These principles can also be utilized for backlighting and general illumination applications.

Owner:ROCKWELL COLLINS INC

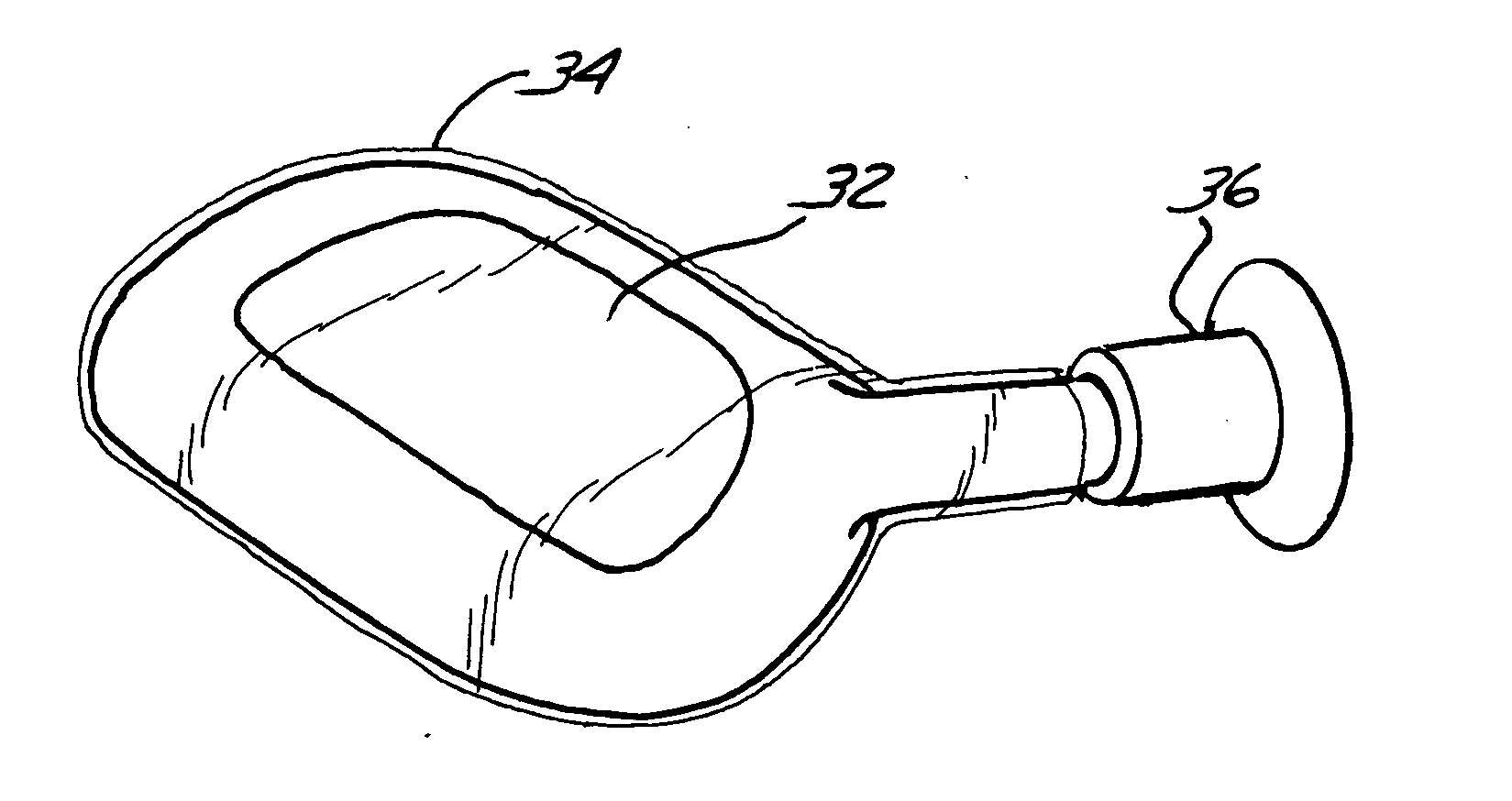

Knee joint prosthesis

InactiveUS20050043808A1Eliminate the effects ofImprove propertiesImpression capsAnkle jointsTissue repairProsthesis

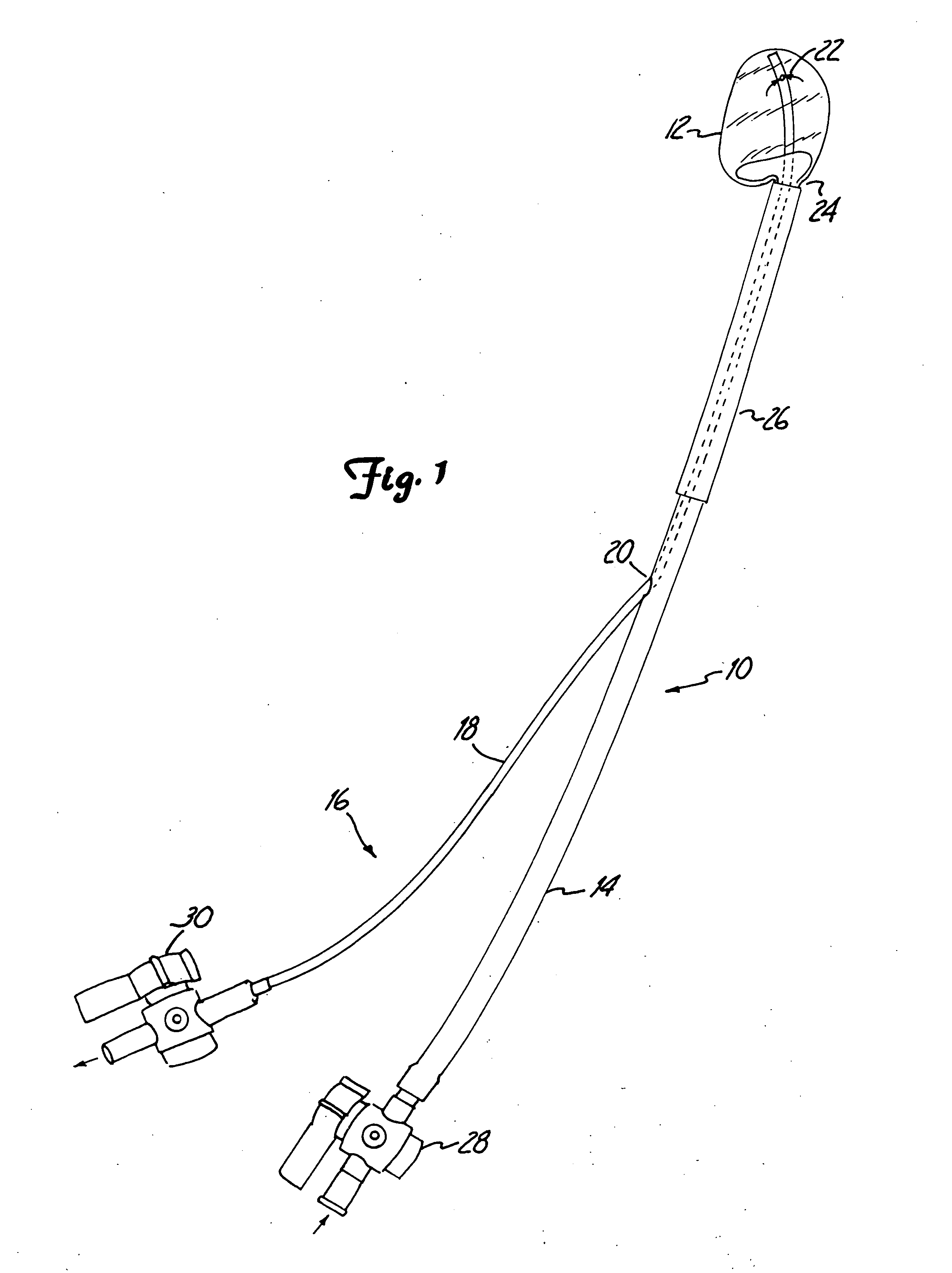

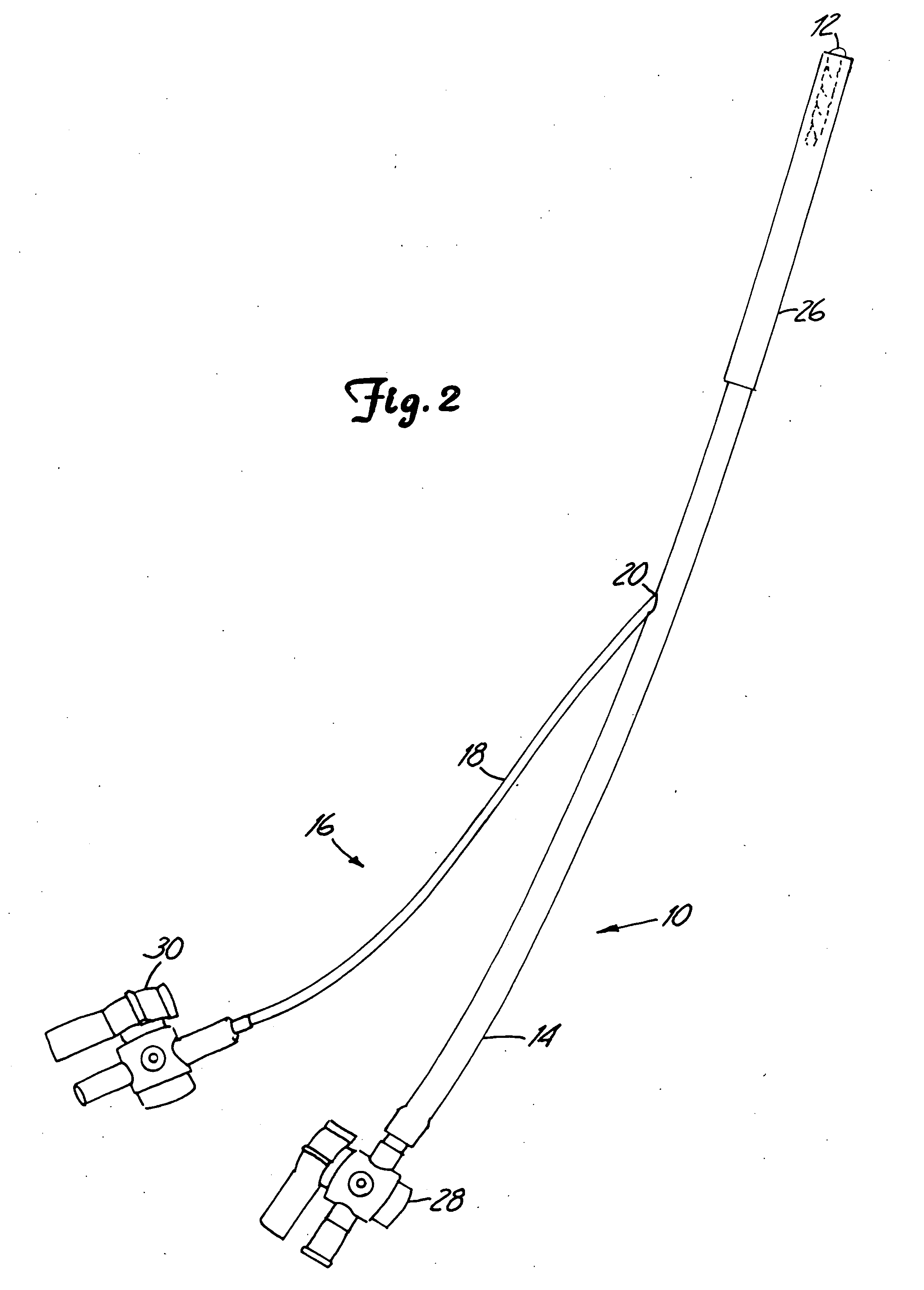

A method, and related composition and apparatus for repairing a tissue site. The method involves the use of a curable polyurethane biomaterial composition having a plurality of parts adapted to be mixed at the time of use in order to provide a flowable composition and to initiate cure. The flowable composition can be delivered using minimally invasive means to a tissue site and there fully cured provide a permanent and biocompatible prosthesis for repair of the tissue site. Further provided are a mold apparatus, e.g., in the form of a balloon or tubular cavity, for receiving a biomaterial composition, and a method for delivering and filling the mold apparatus with a curable composition in situ to provide a prosthesis for tissue repair.

Owner:ADVANCED BIO SURFACE

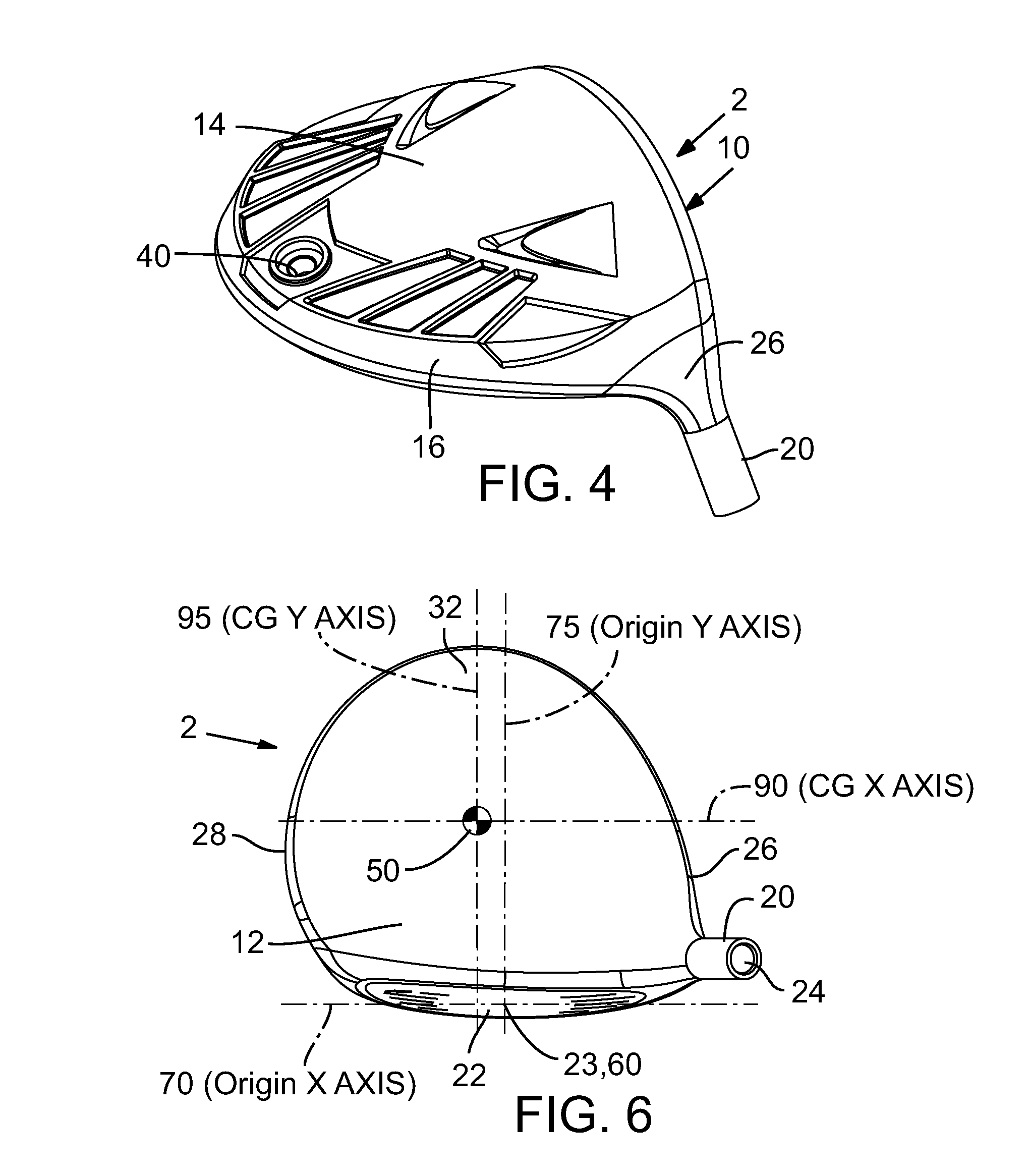

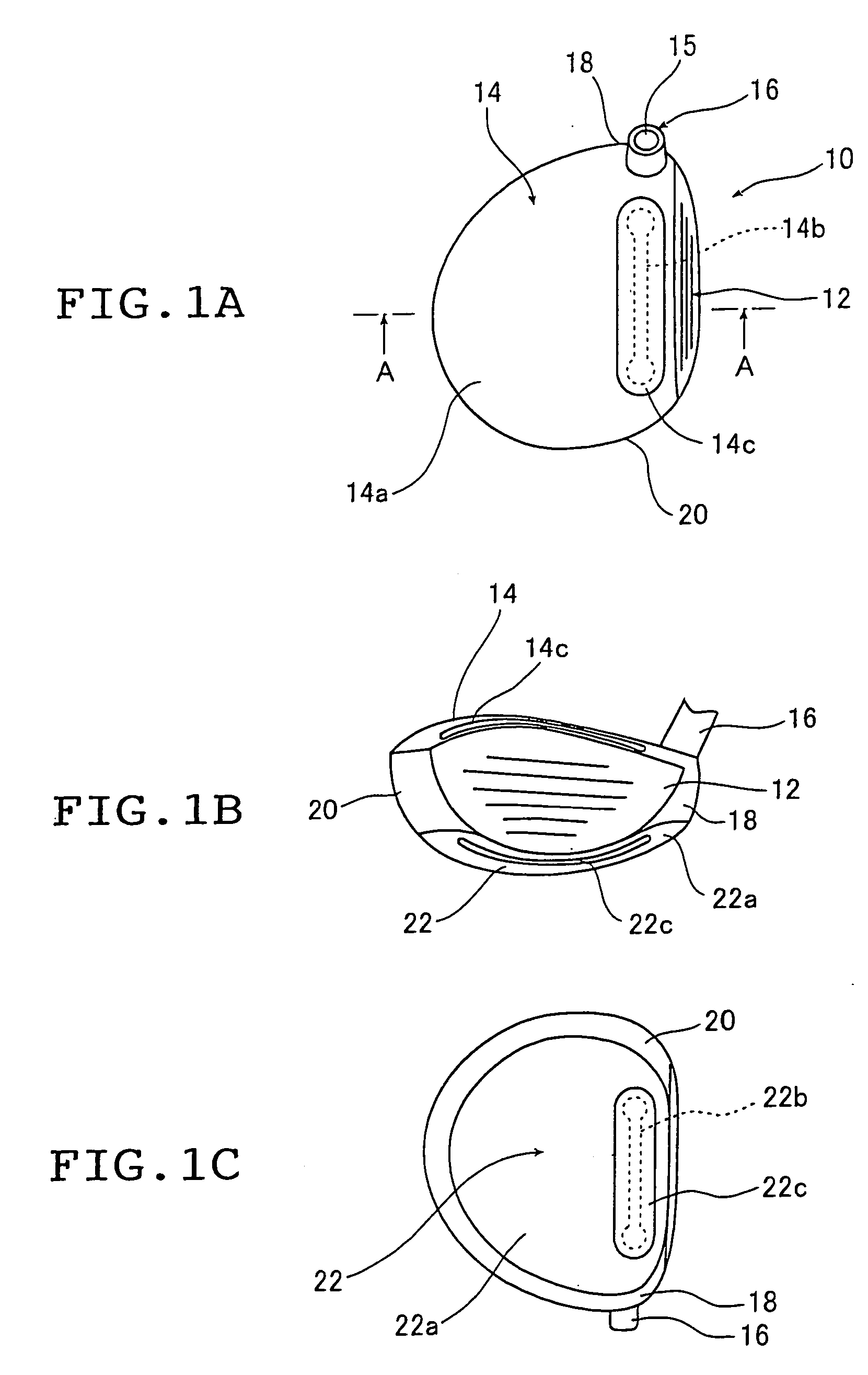

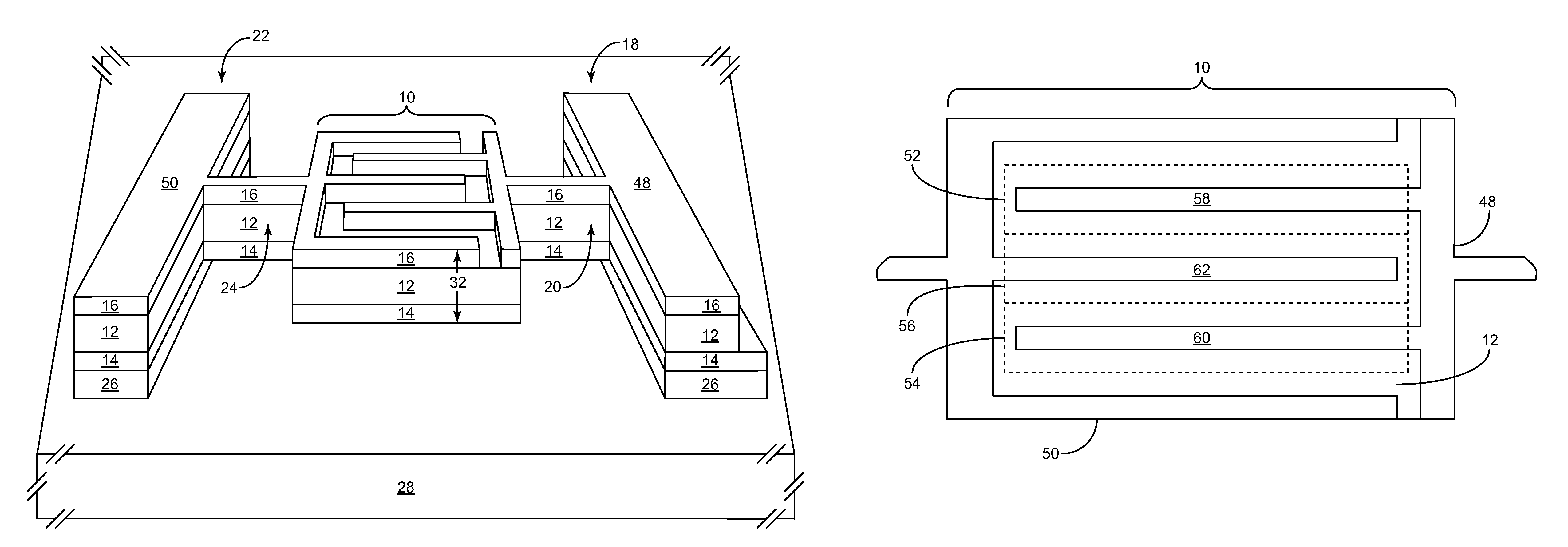

Fairway wood center of gravity projection

ActiveUS8900069B2Improved forgivenessImproved ballspeedGolf clubsRacket sportsCoefficient of restitutionGravity center

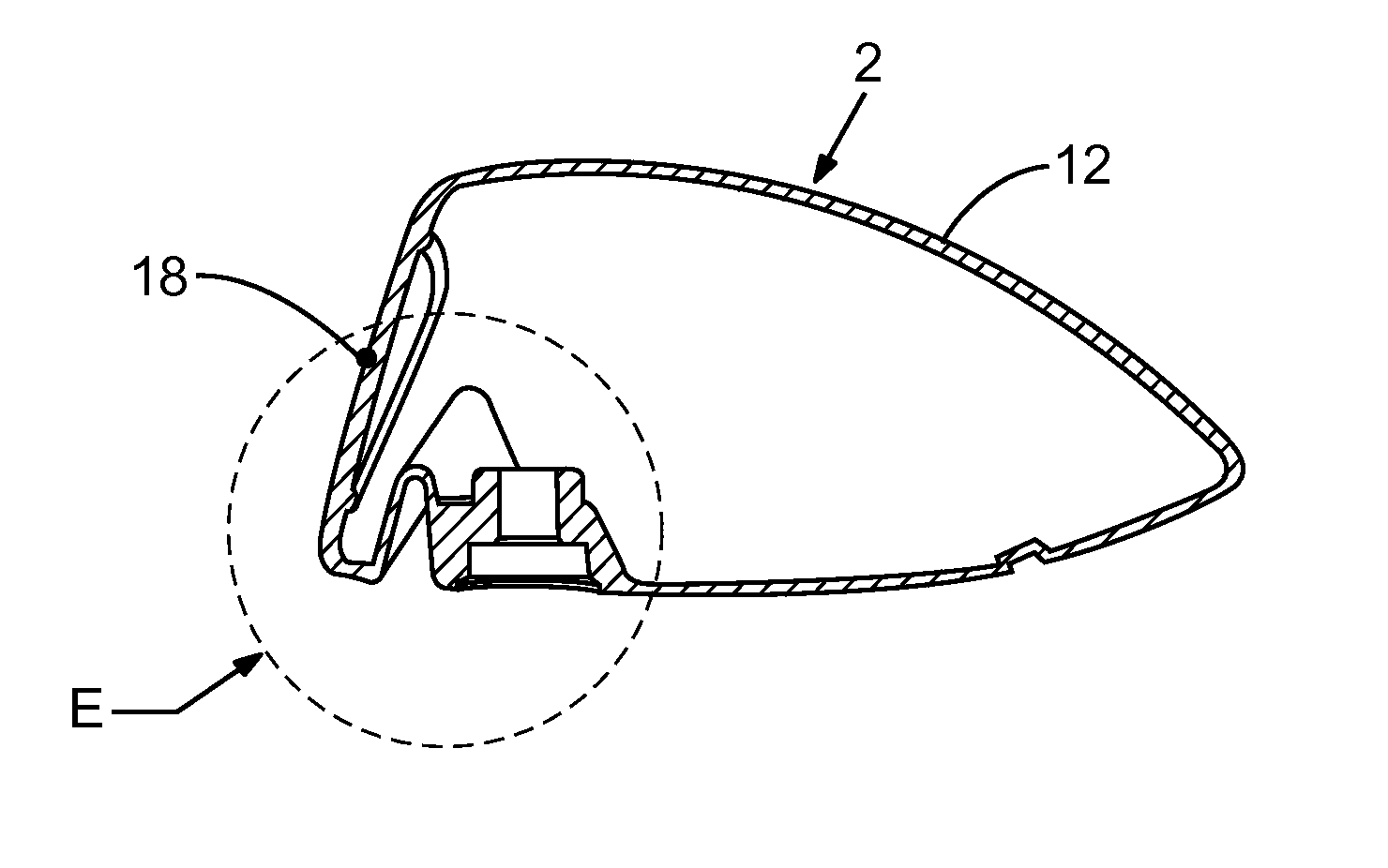

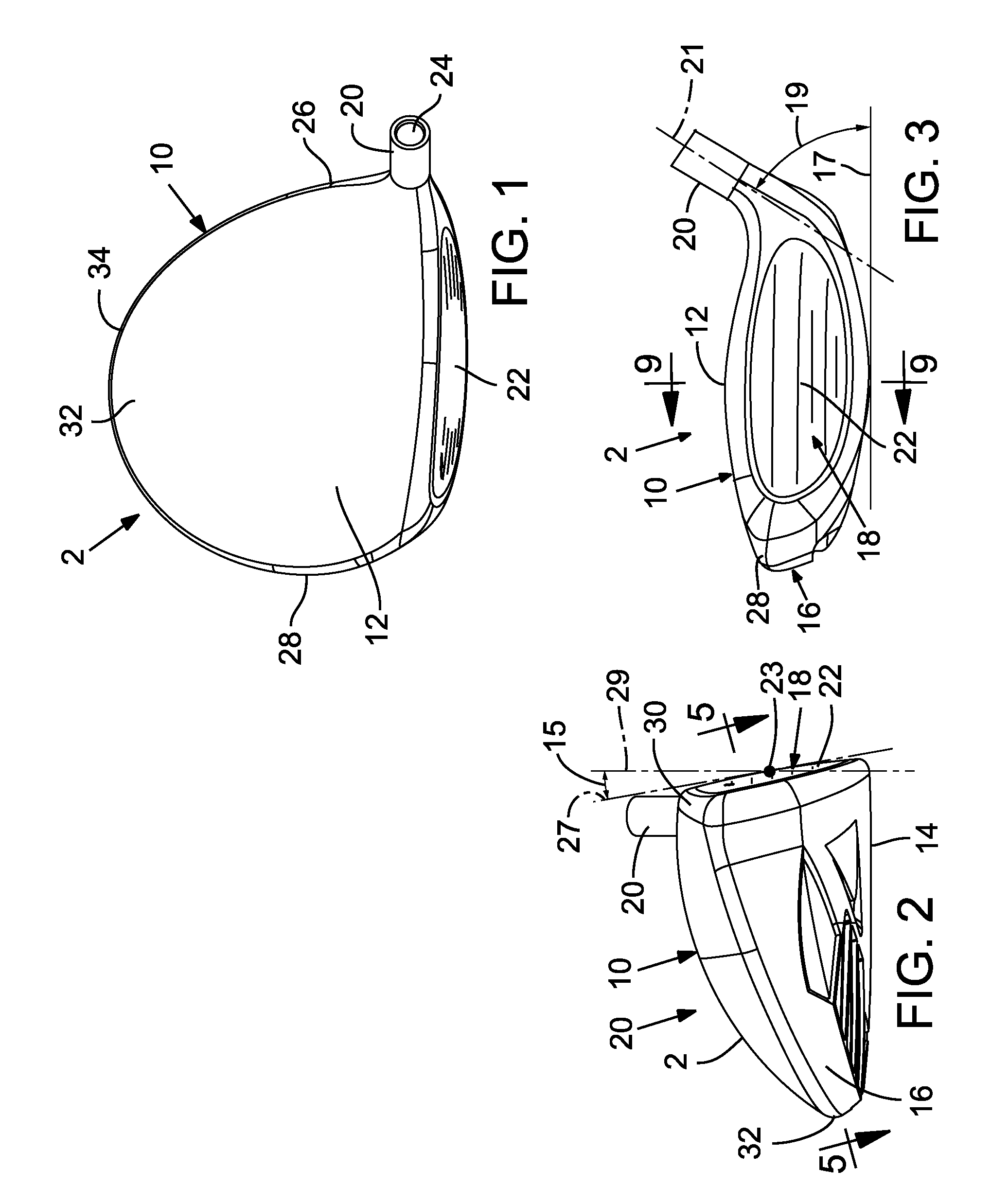

A golf club head includes a body defining an interior cavity. The body includes a sole positioned at a bottom portion of the golf club head, a crown positioned at a top portion, and a skirt positioned around a periphery between the sole and crown. The body has a forward portion and a rearward portion. The club head includes a face positioned at the forward portion of the body. The face defines a striking surface having an ideal impact location at a golf club head origin. Embodiments include club heads for a fairway wood that at least one of a high moment of inertia, a low center-of-gravity, a thin crown and a high coefficient of restitution.

Owner:TAYLOR MADE GOLF

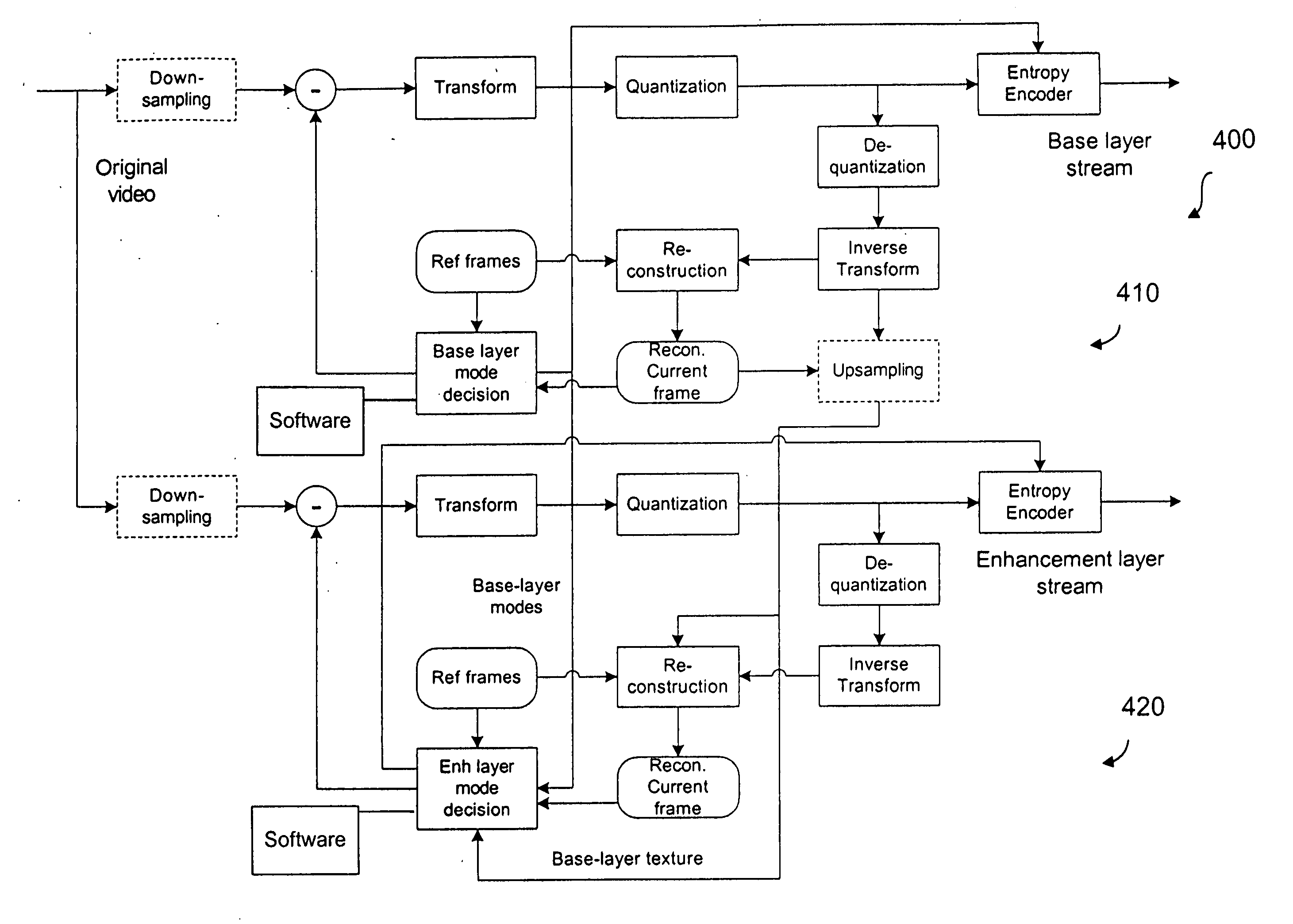

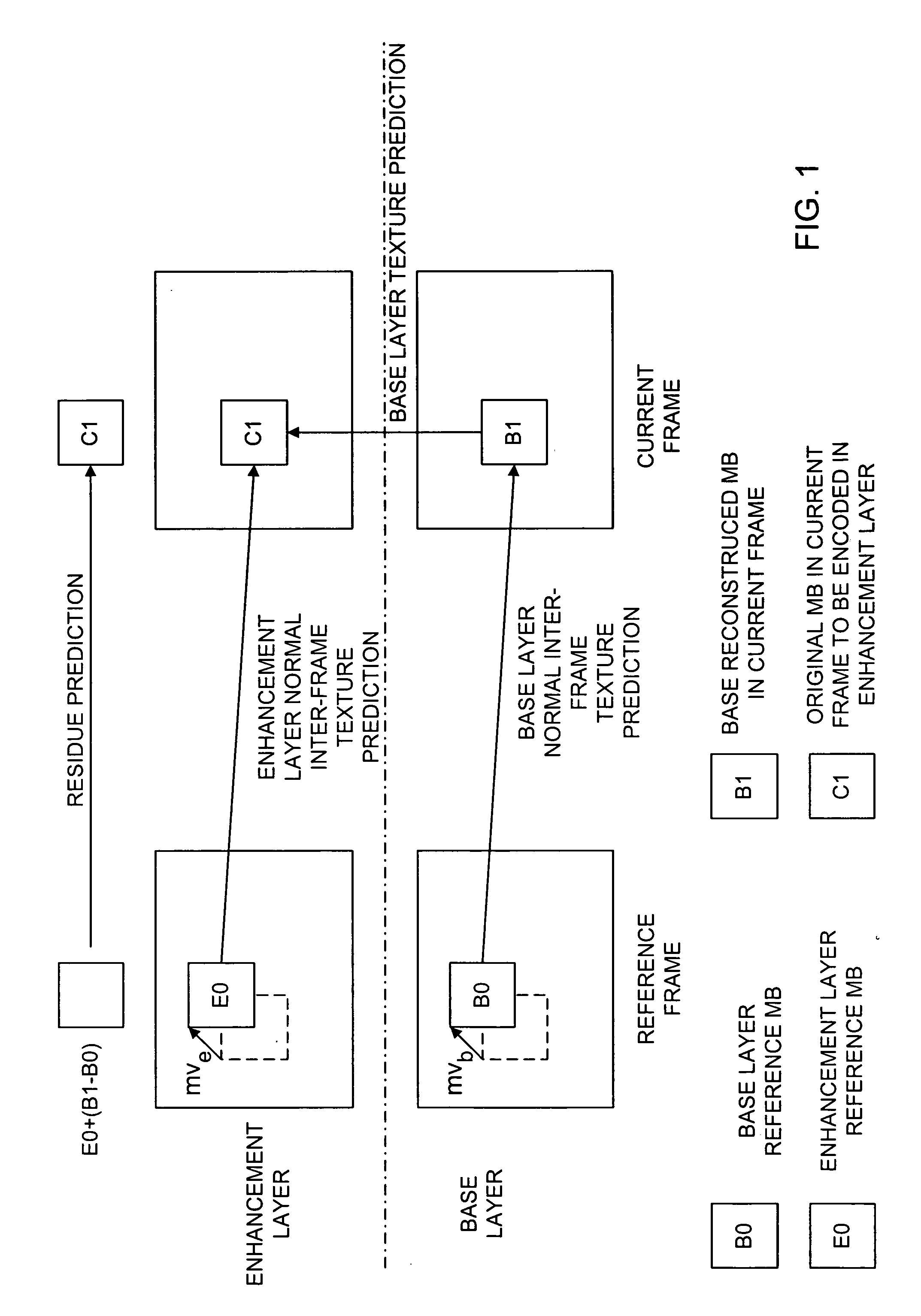

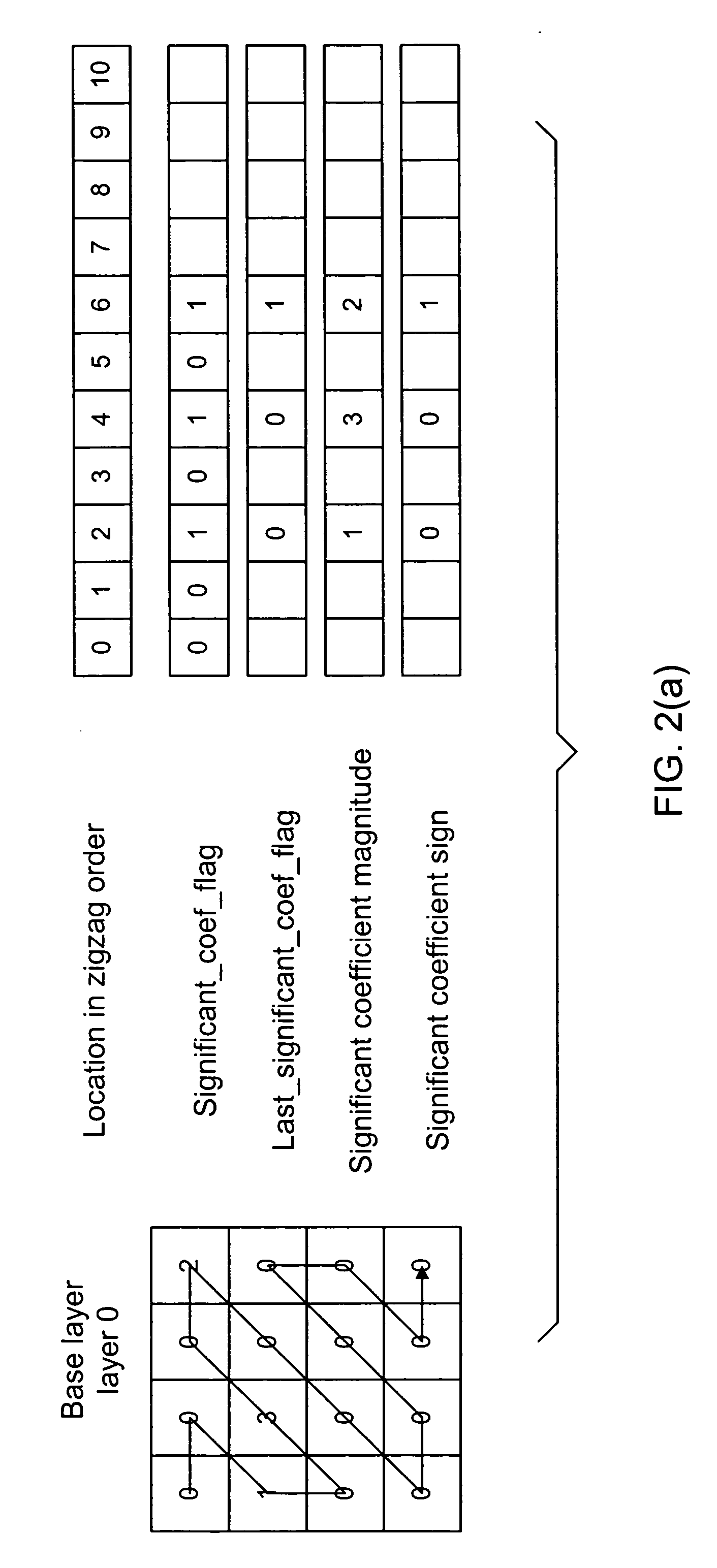

Inter-layer coefficient coding for scalable video coding

InactiveUS20060153294A1Pixel predictorImprove the overall coefficientColor television with pulse code modulationColor television with bandwidth reductionInter layerComputer architecture

A scalable video coding method and apparatus for coding a video sequence, wherein the coefficients in the enhancement layer is classified as belonging to a significant pass when the corresponding coefficient in the base layer is zero, and classified as belonging to a refinement pass when the corresponding coefficient in the base layer is non-zero. For coefficients classified as belonging to the significance pass, an indication is coded to indicate whether the coefficient is zero or non-zero, and if the coefficient is non-zero, coding an indication of the sign of the coefficient. A last_significant_coeff_flag is used to indicate the coding of remaining coefficients in the scanning order can be skipped. For coefficients classified as belonging to the refinement pass, a value to refine the magnitude of the corresponding coefficient in the base layer is coded, and if the coefficient is non-zero, a sign bit may be coded.

Owner:NOKIA CORP

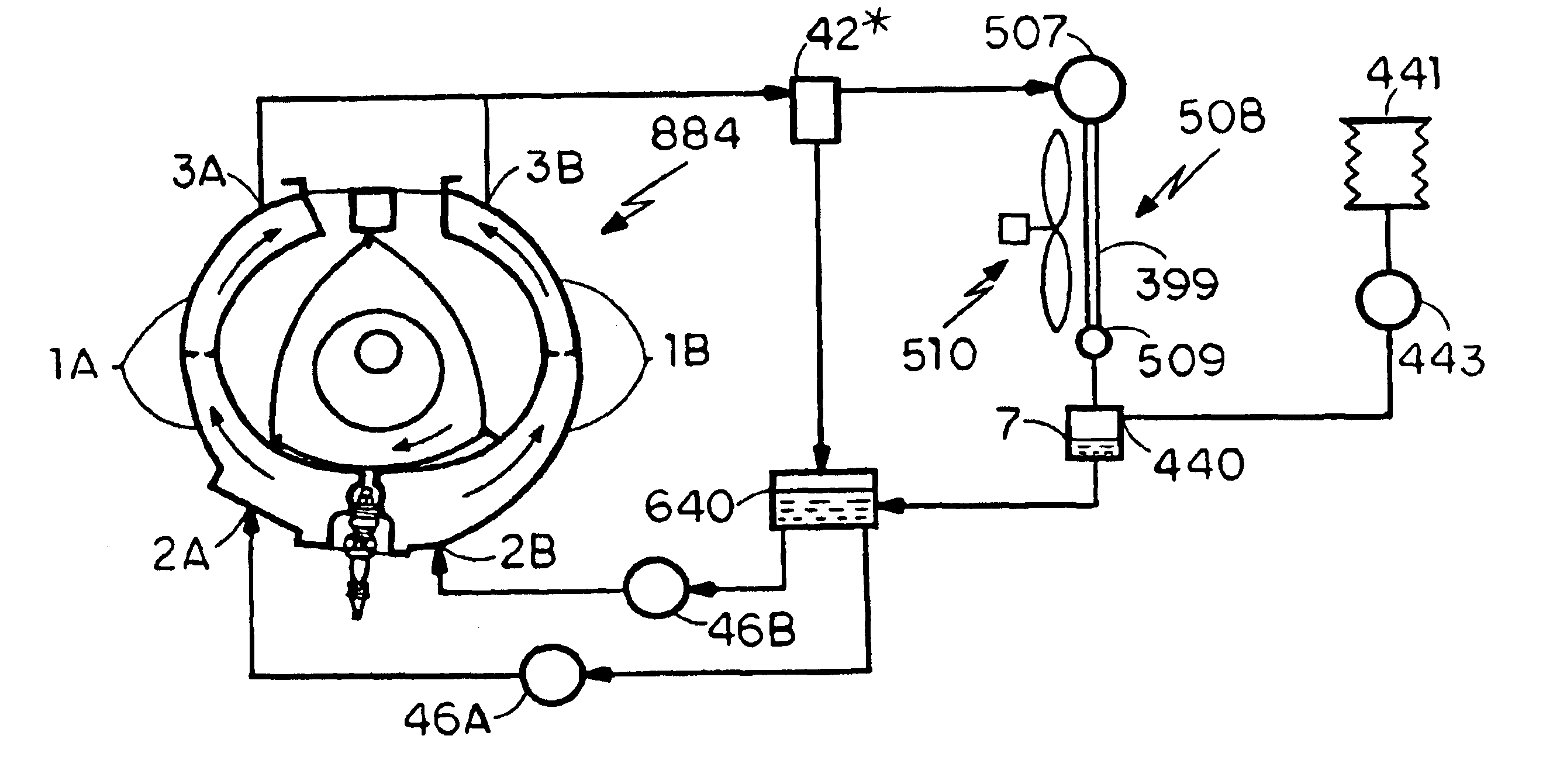

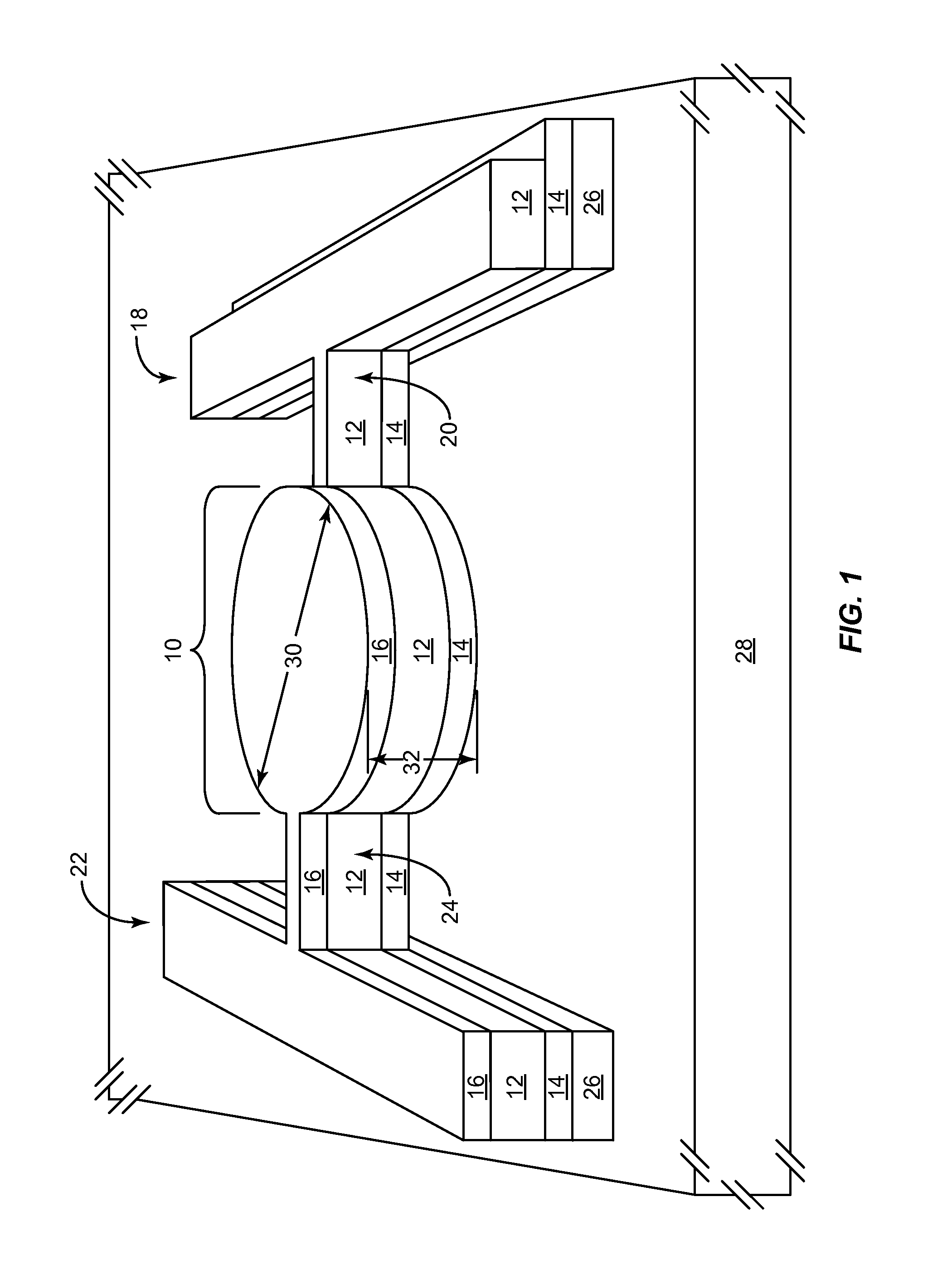

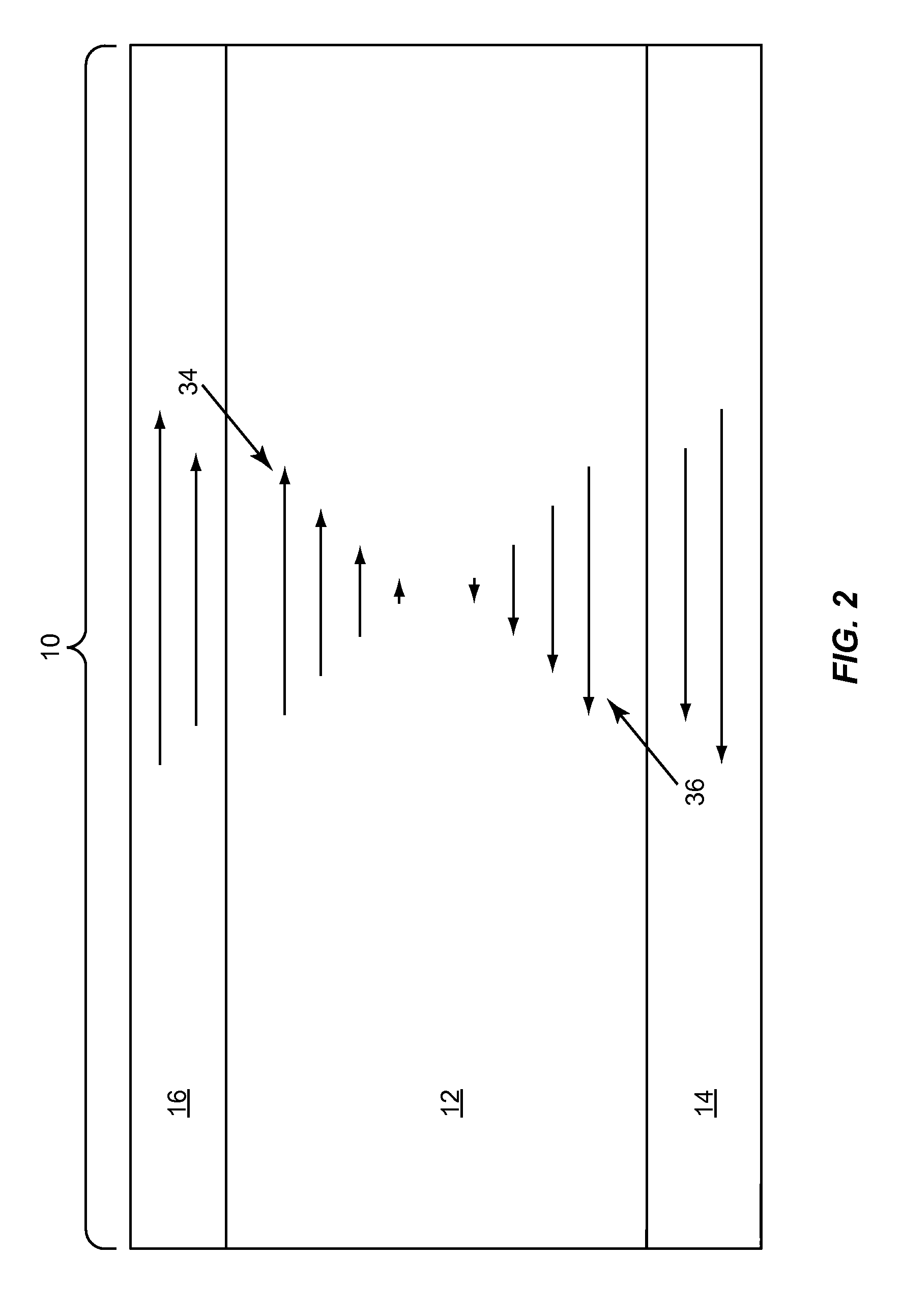

Two-phase heat-transfer systems

InactiveUS6866092B1Prevent freezingImprove the overall coefficientLiquid coolingCasingsLiquid jetInternal pressure

Various techniques are disclosed for improving airtight two-phase heat-transfer systems employing a fluid to transfer heat from a heat source to a heat sink while circulating around a fluid circuit, the maximum temperature of the heat sink not exceeding the maximum temperature of the heat source. The properties of those improved systems include (a) maintaining, while the systems are inactive, their internal pressure at a pressure above the saturated-vapor pressure of their heat-transfer fluid; and (b) cooling their internal evaporator surfaces with liquid jets. FIG. 43 illustrates the particular case where a heat-transfer system of the invention is used to cool a piston engine (500) by rejecting, with a condenser (508), heat to the ambient air; and where the system includes a heat-transfer fluid pump (10) and means (401-407) for achieving the former property.

Owner:MOLIVADAS STEPHEN

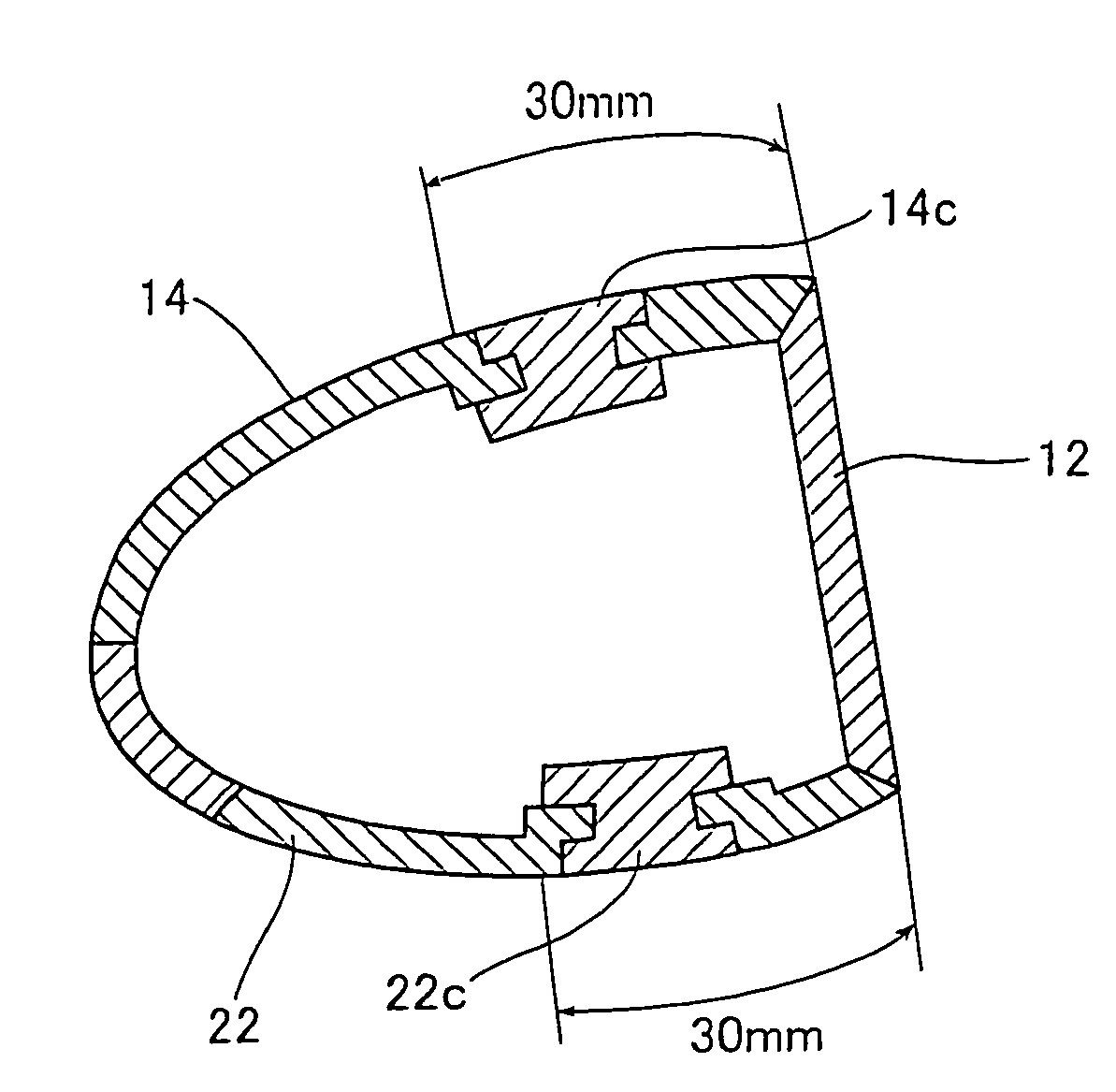

Hollow golf club head

InactiveUS7470201B2Improve the overall coefficientIncrease distanceGolf clubsRacket sportsPlastic materialsMetallic materials

A golf club head of the present invention includes a face portion having an impact surface that impacts a golf ball and is made from a metallic material, and a crown portion, a heel portion, a sole portion, and the toe portion that are adjacent to the face portion. In at least two portions from among the crown portion, the heel portion, the sole portion, and the toe portion, at least one from among dissimilar metallic materials that differ from the metallic material of the impact surface and fiber reinforced plastic materials is used in regions along ends that are adjacent to the face portion, within a range of 30 mm from the adjacent ends. Thereby, the golf club has a structure that easily deforms with respect to golf ball impacts, and the face portion deforms more than conventional face portions. The coeffecient of restitution of a struck golf ball therefore increases, the initial velocity of the golf ball increases, and the carry distance increases.

Owner:THE YOKOHAMA RUBBER CO LTD

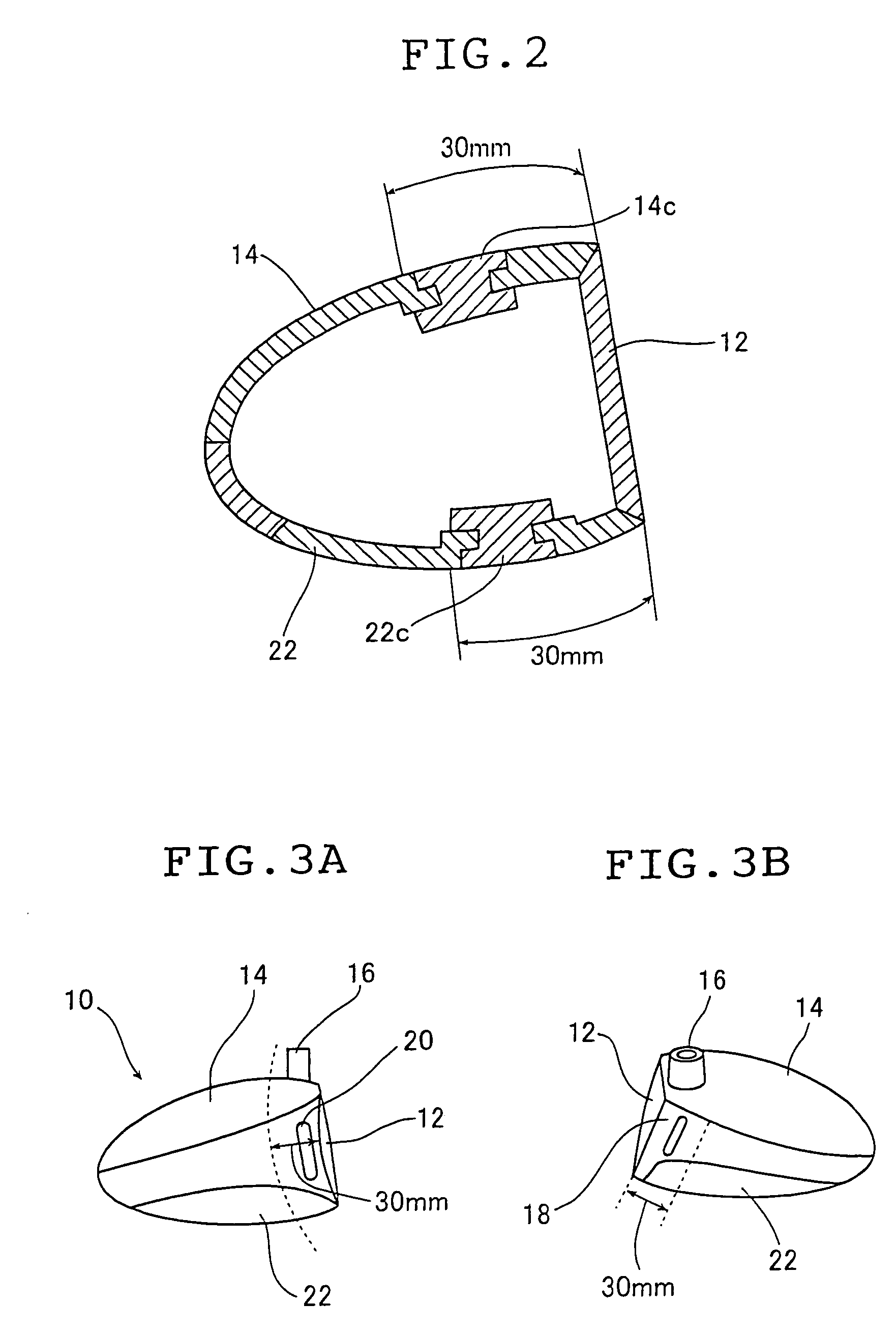

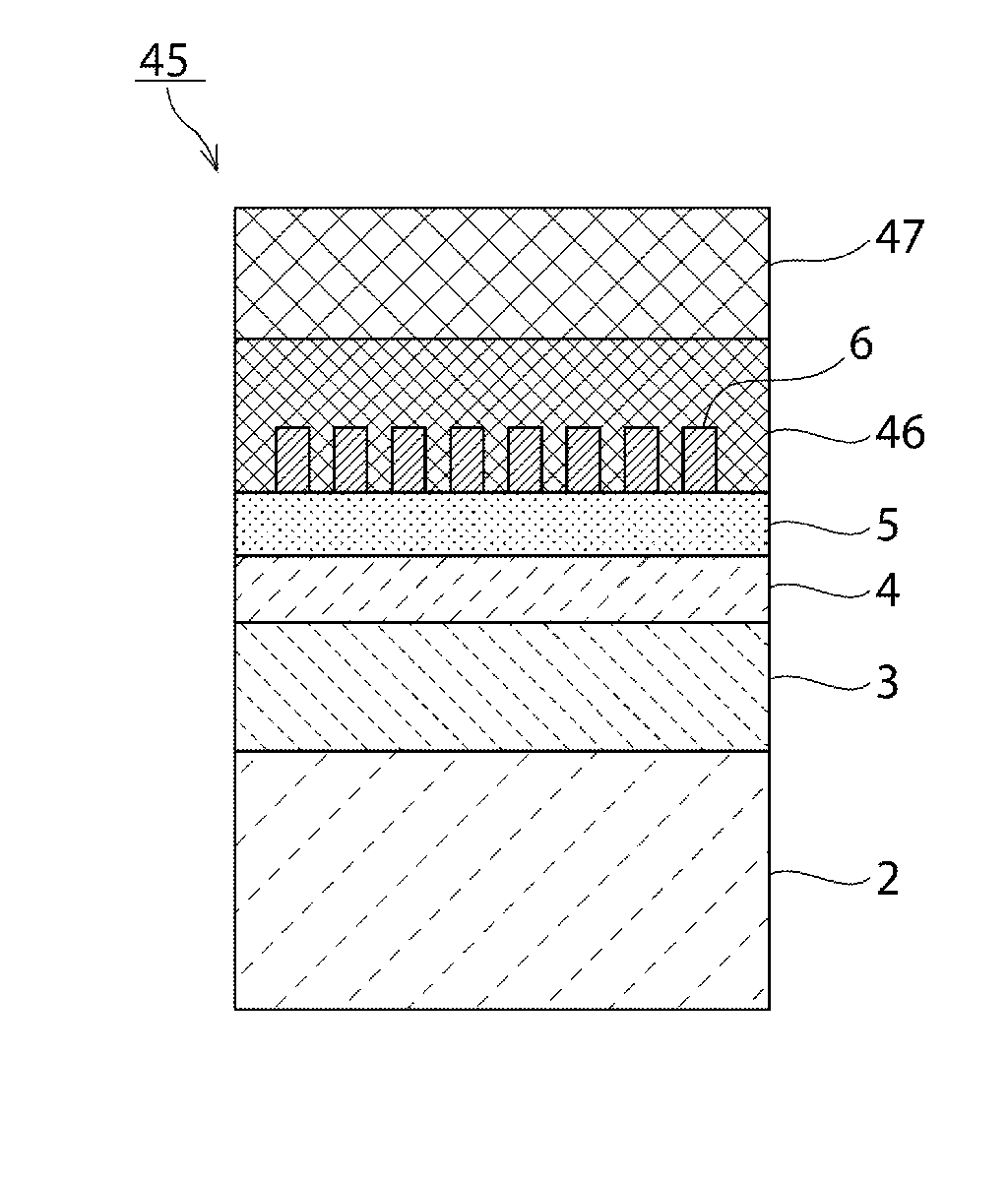

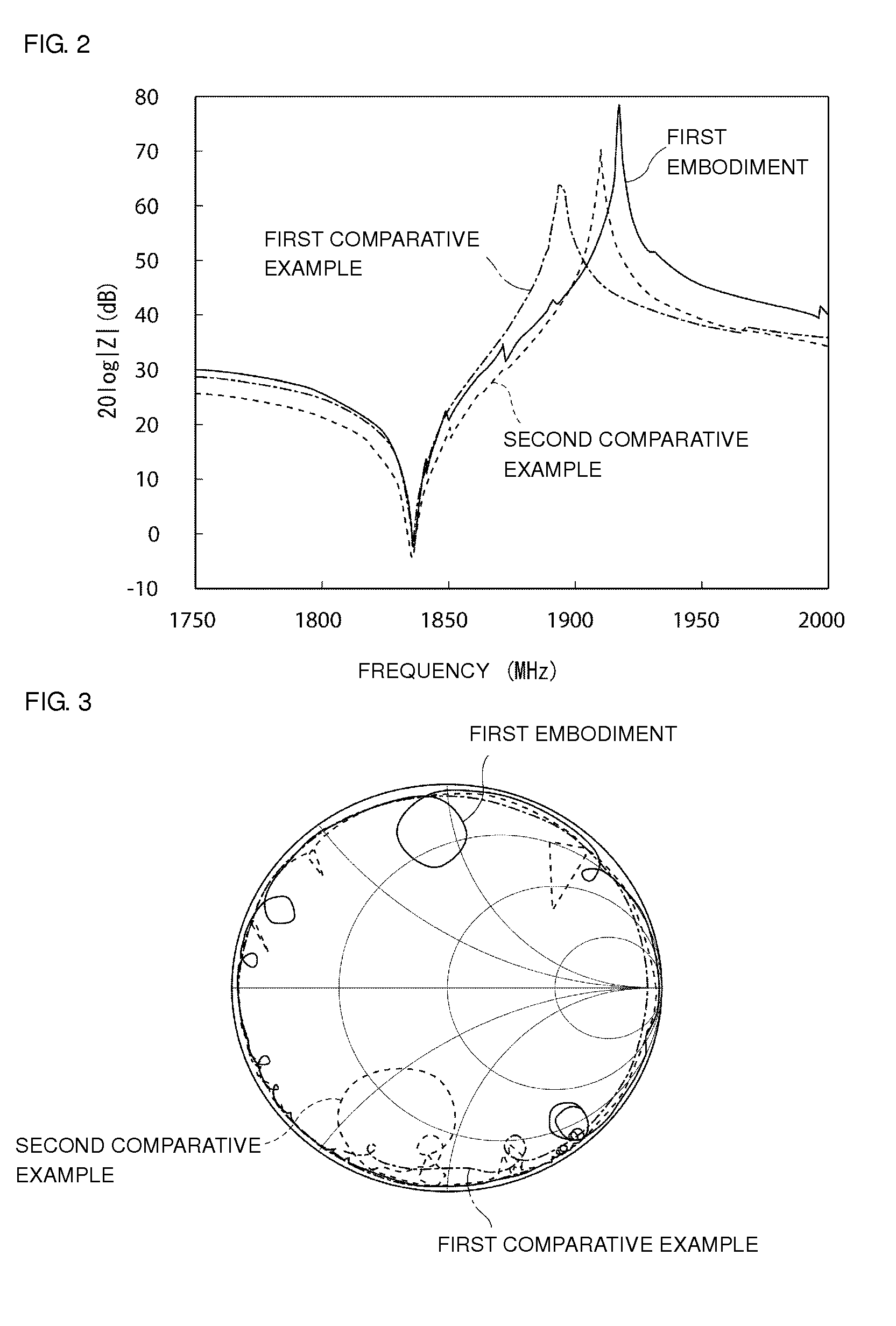

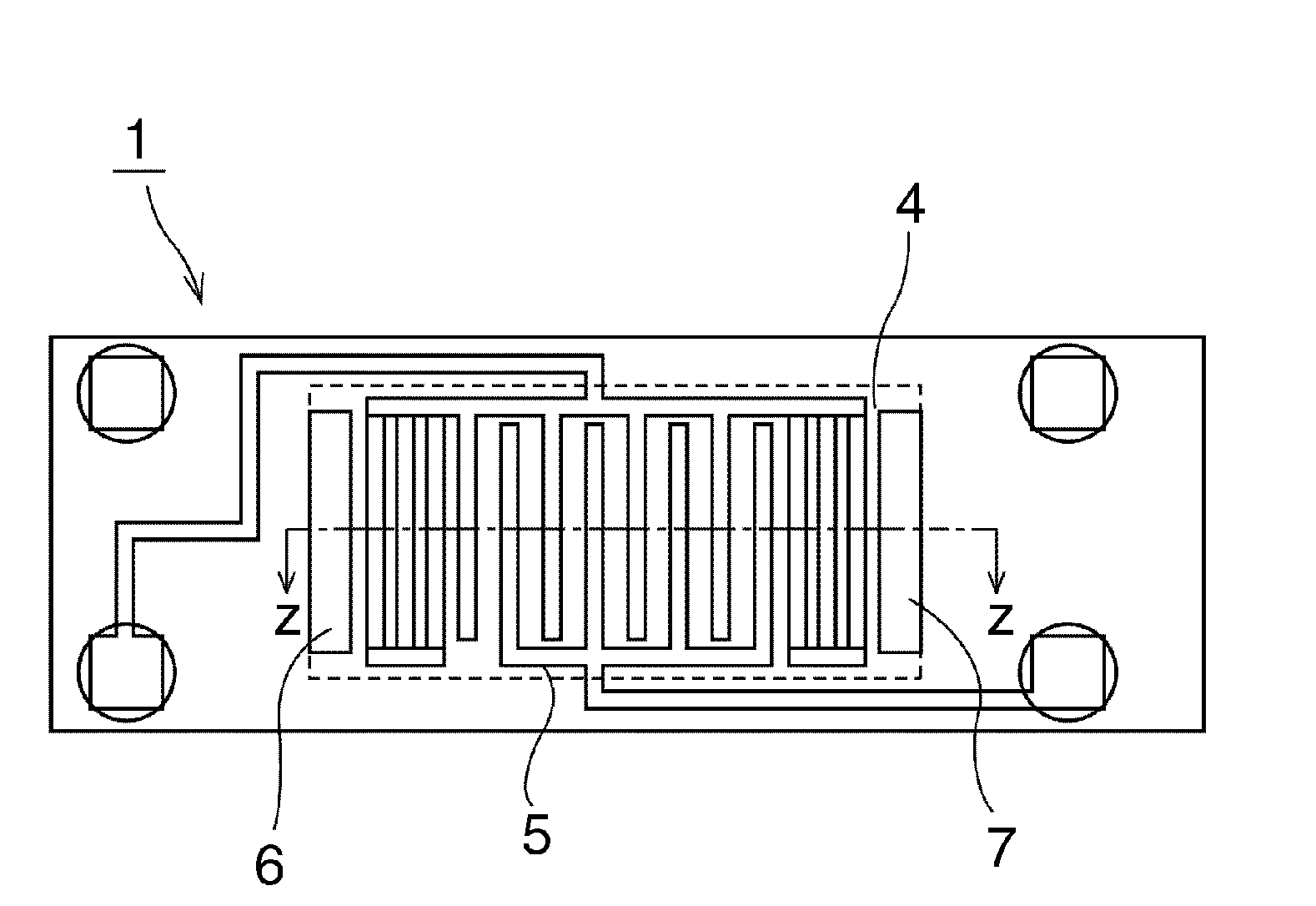

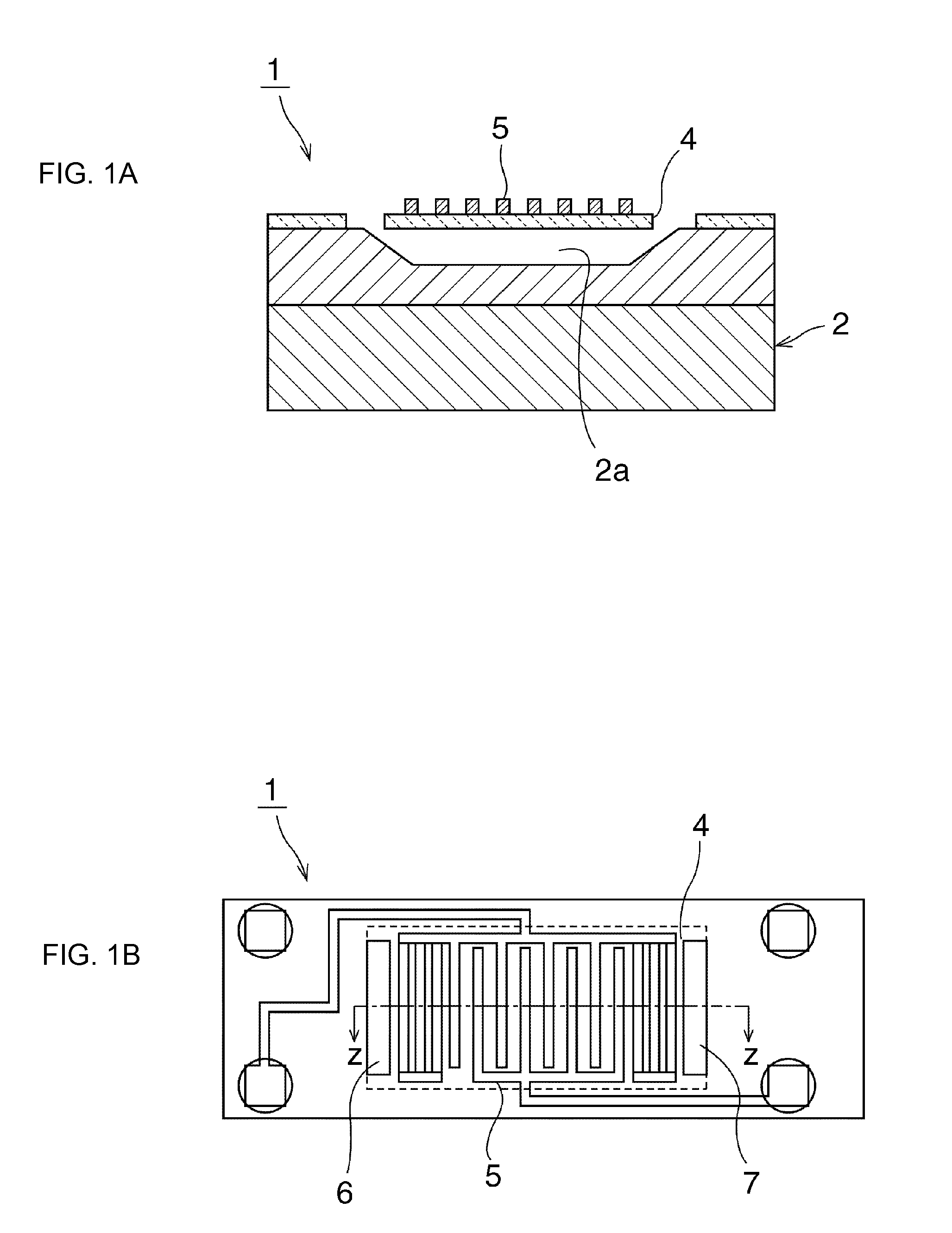

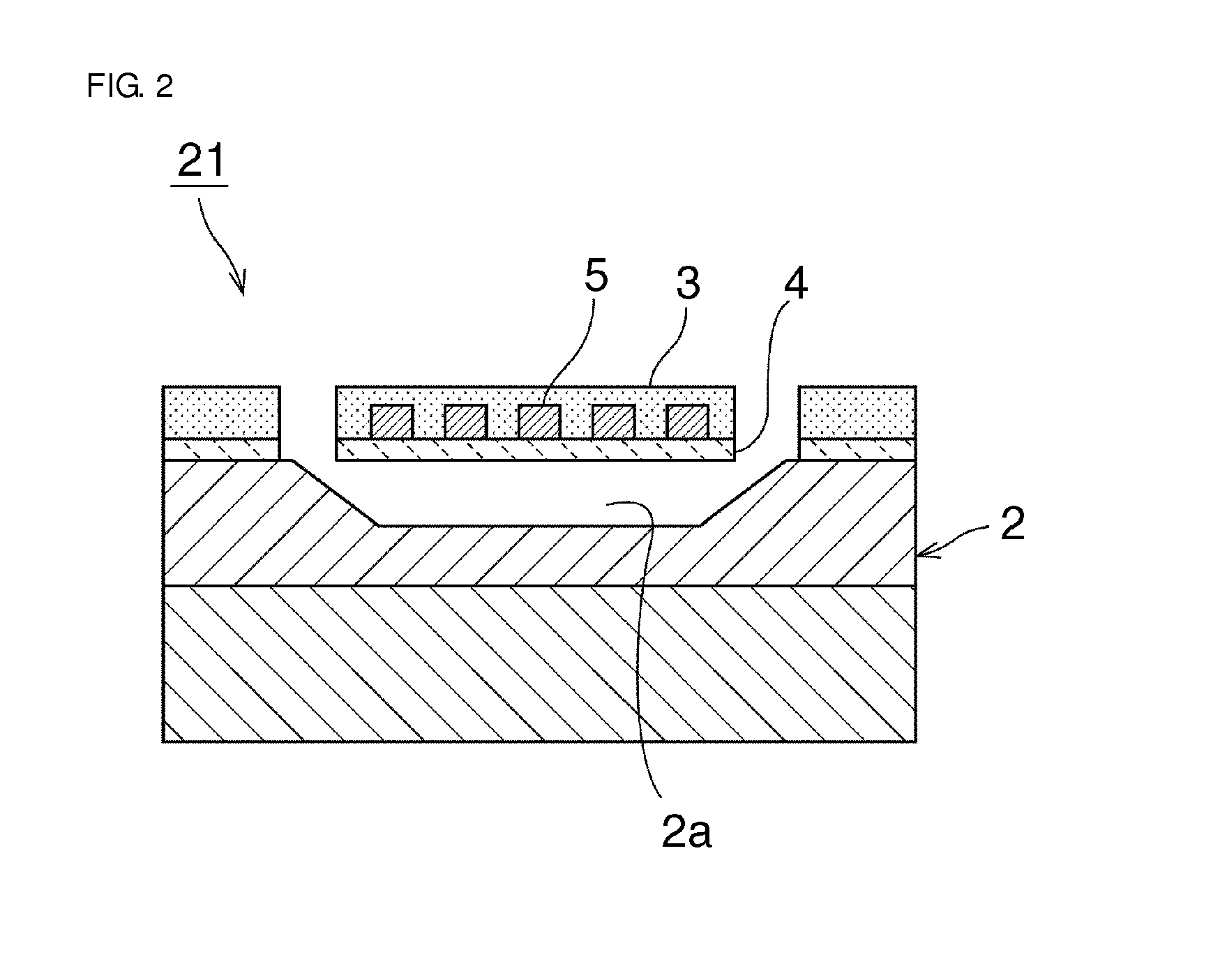

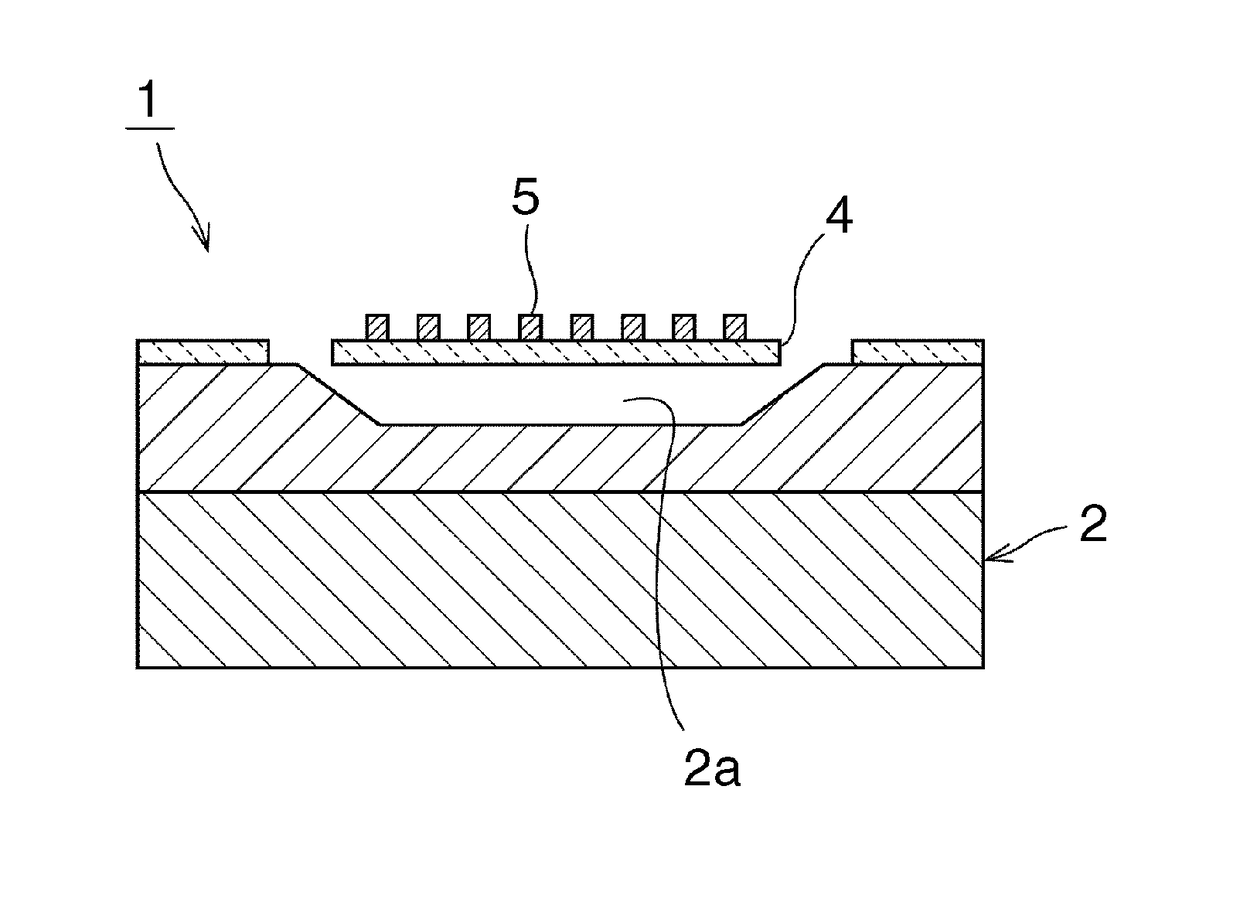

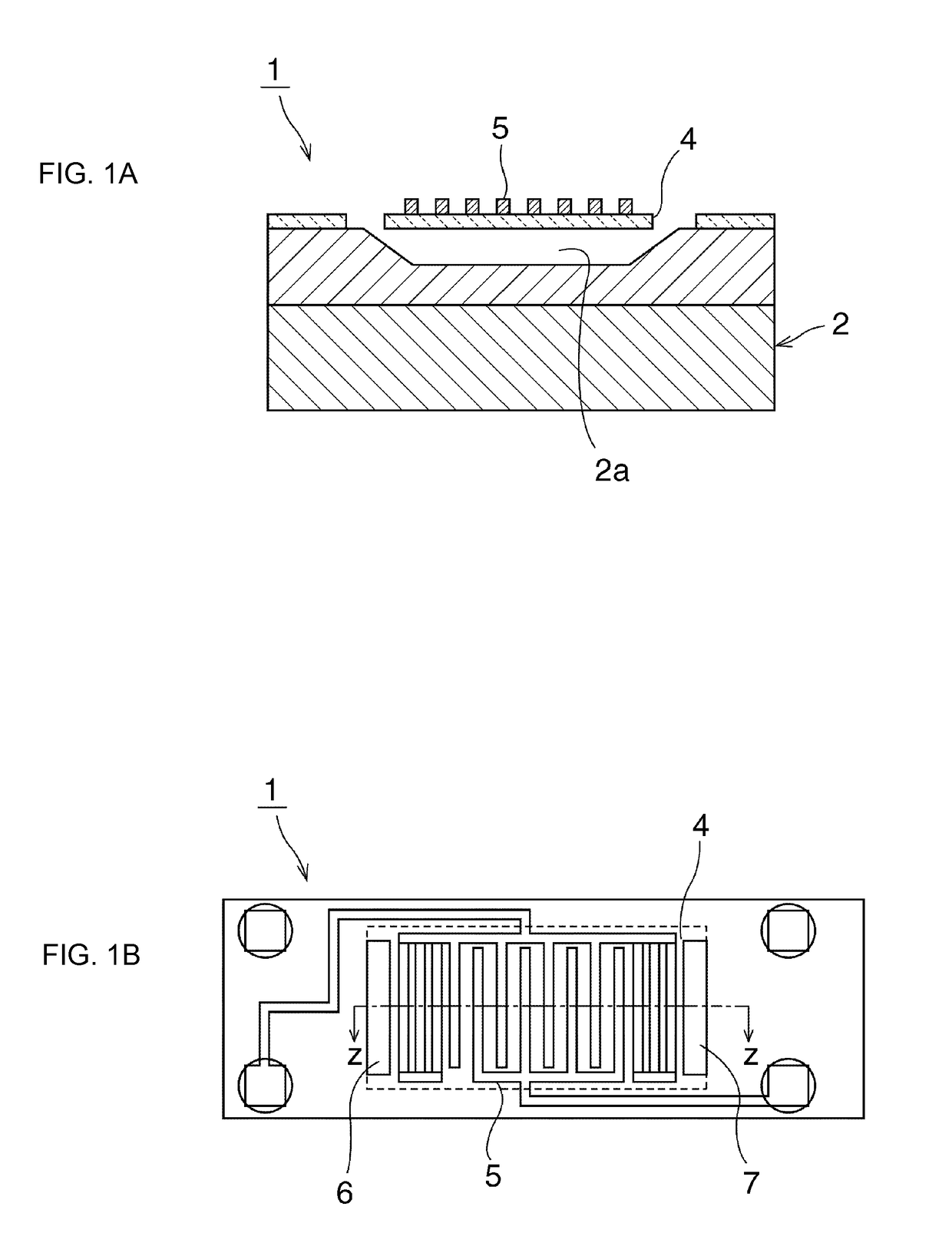

Elastic wave device and method for manufacturing the same

ActiveUS20130285768A1Recover piezoelectricityImprove featuresImpedence networksSpeed of soundElectrode

An elastic wave device includes a supporting substrate, a high-acoustic-velocity film stacked on the supporting substrate and in which an acoustic velocity of a bulk wave propagating therein is higher than an acoustic velocity of an elastic wave propagating in a piezoelectric film, a low-acoustic-velocity film stacked on the high-acoustic-velocity film and in which an acoustic velocity of a bulk wave propagating therein is lower than an acoustic velocity of a bulk wave propagating in the piezoelectric film, the piezoelectric film is stacked on the low-acoustic-velocity film, and an IDT electrode stacked on a surface of the piezoelectric film.

Owner:MURATA MFG CO LTD

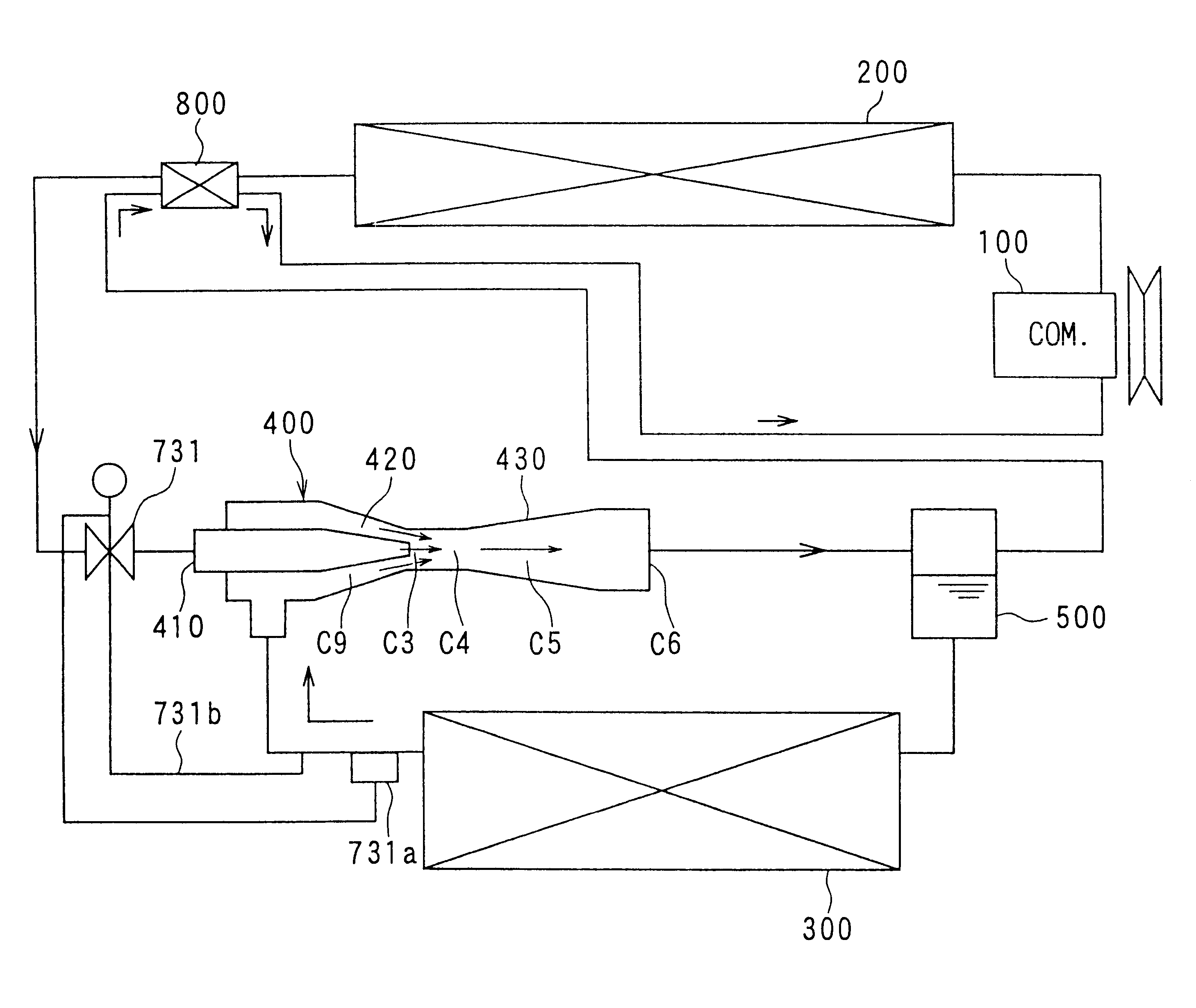

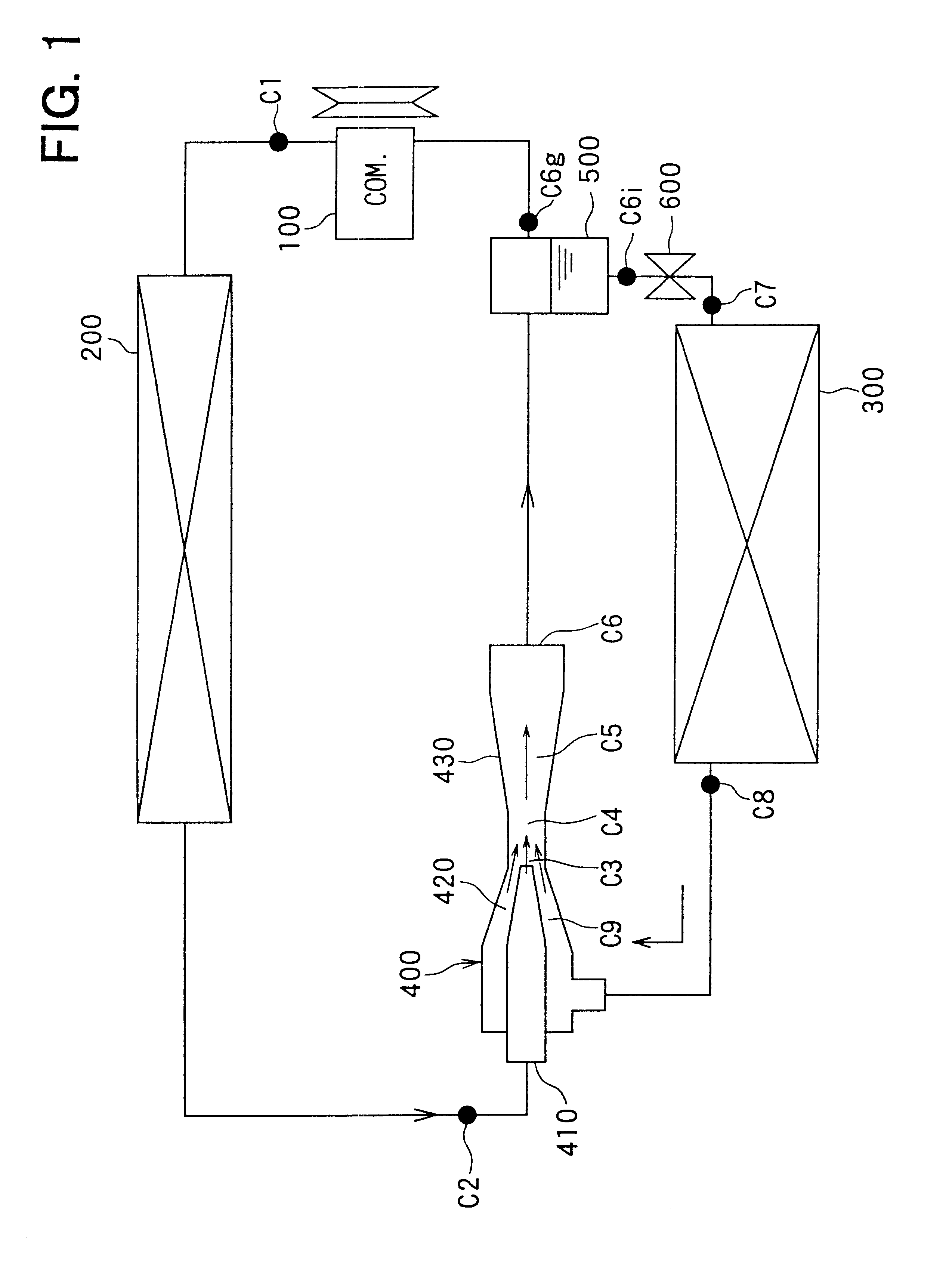

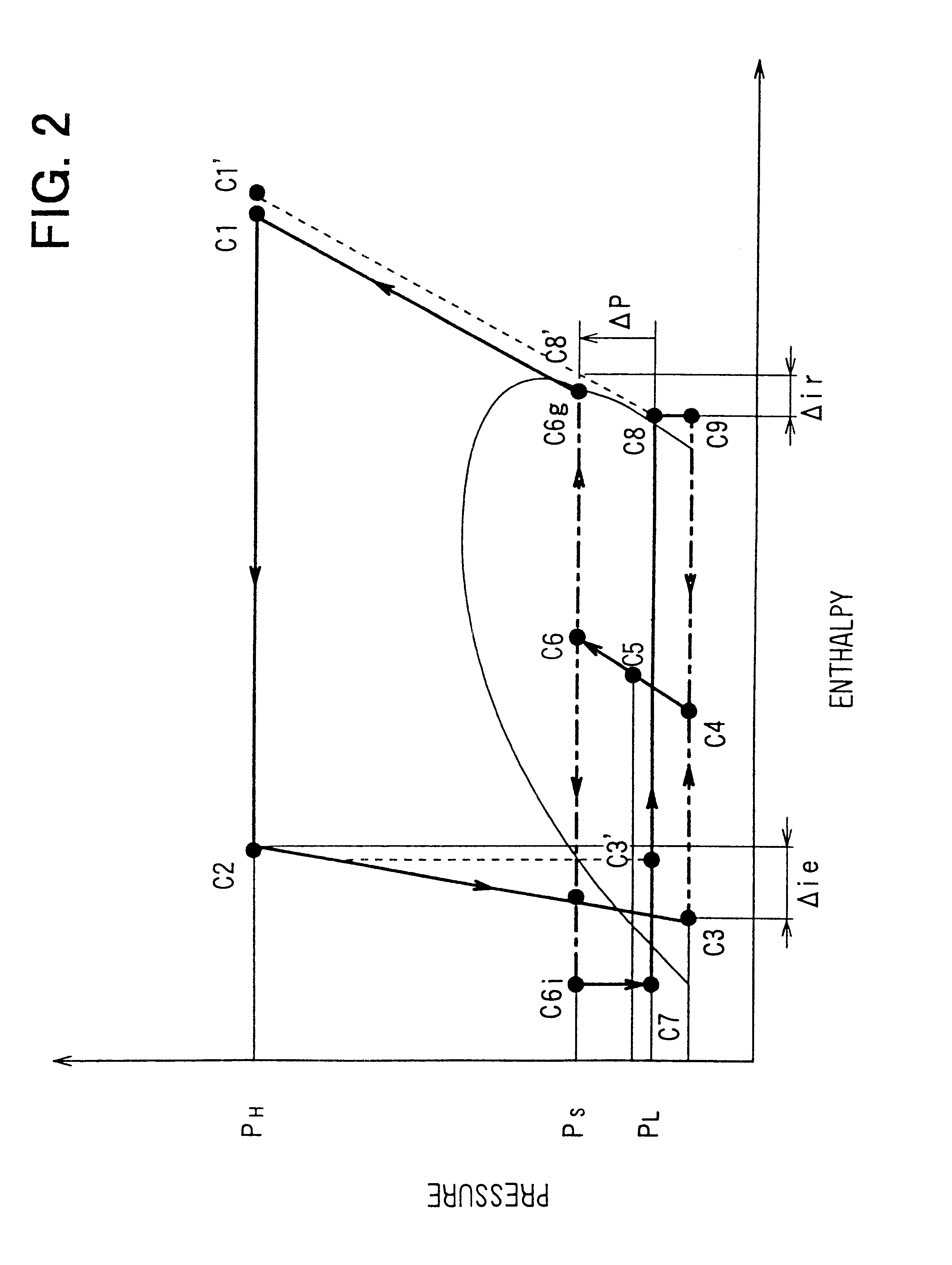

Ejector cycle system with critical refrigerant pressure

InactiveUS6477857B2Recover energyReduce power consumptionCompression machines with non-reversible cycleEvaporators/condensersEngineeringPressure difference

Owner:DENSO CORP

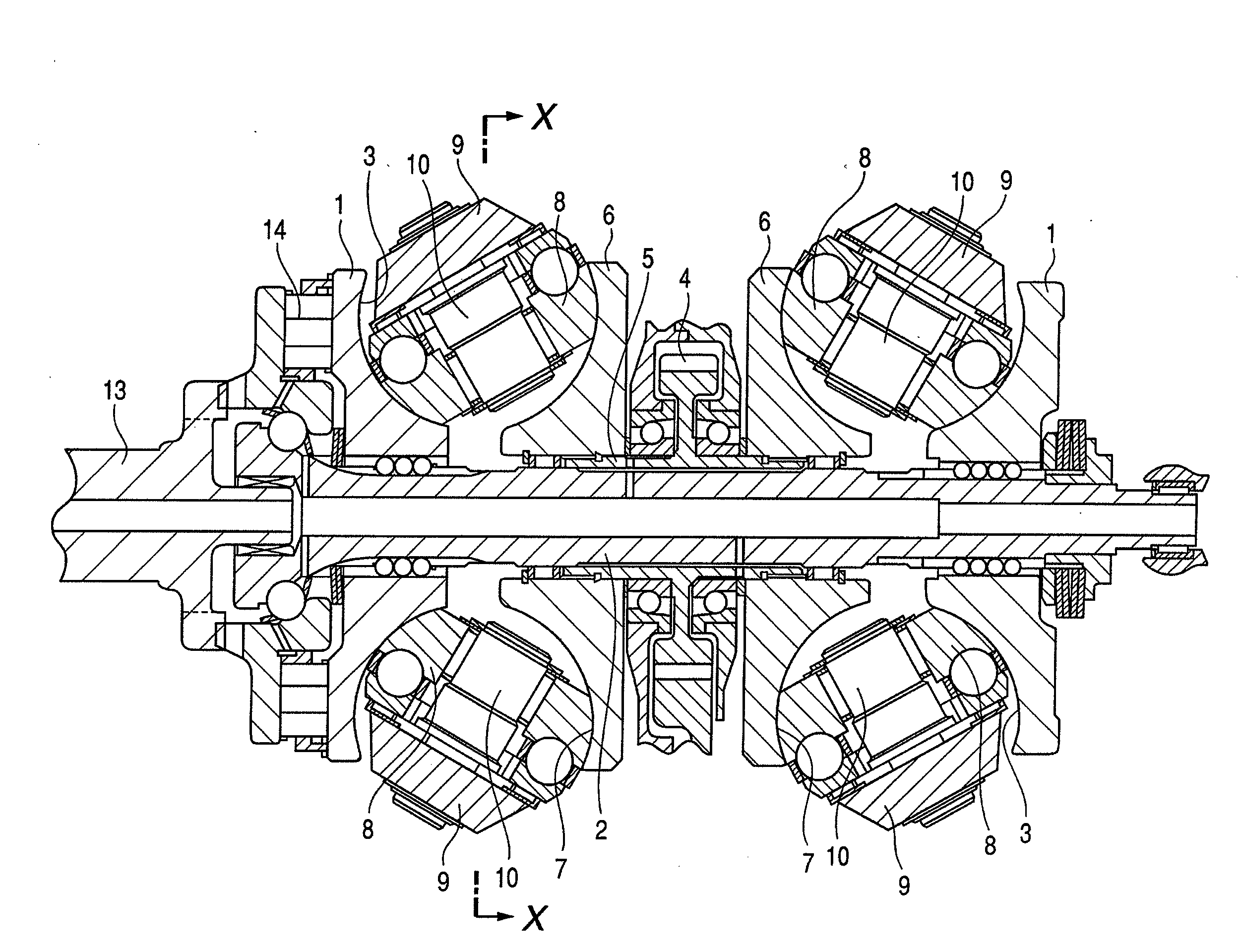

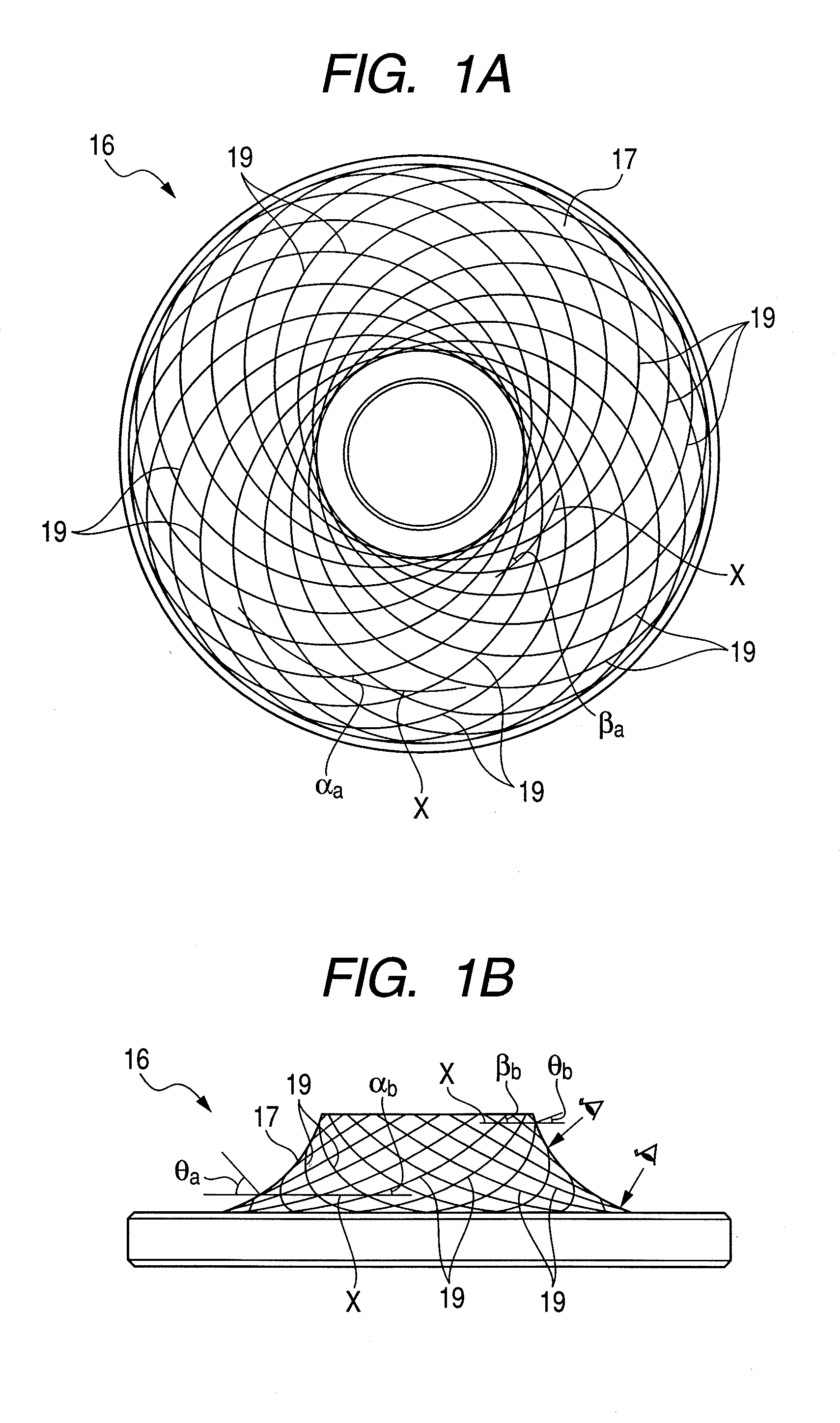

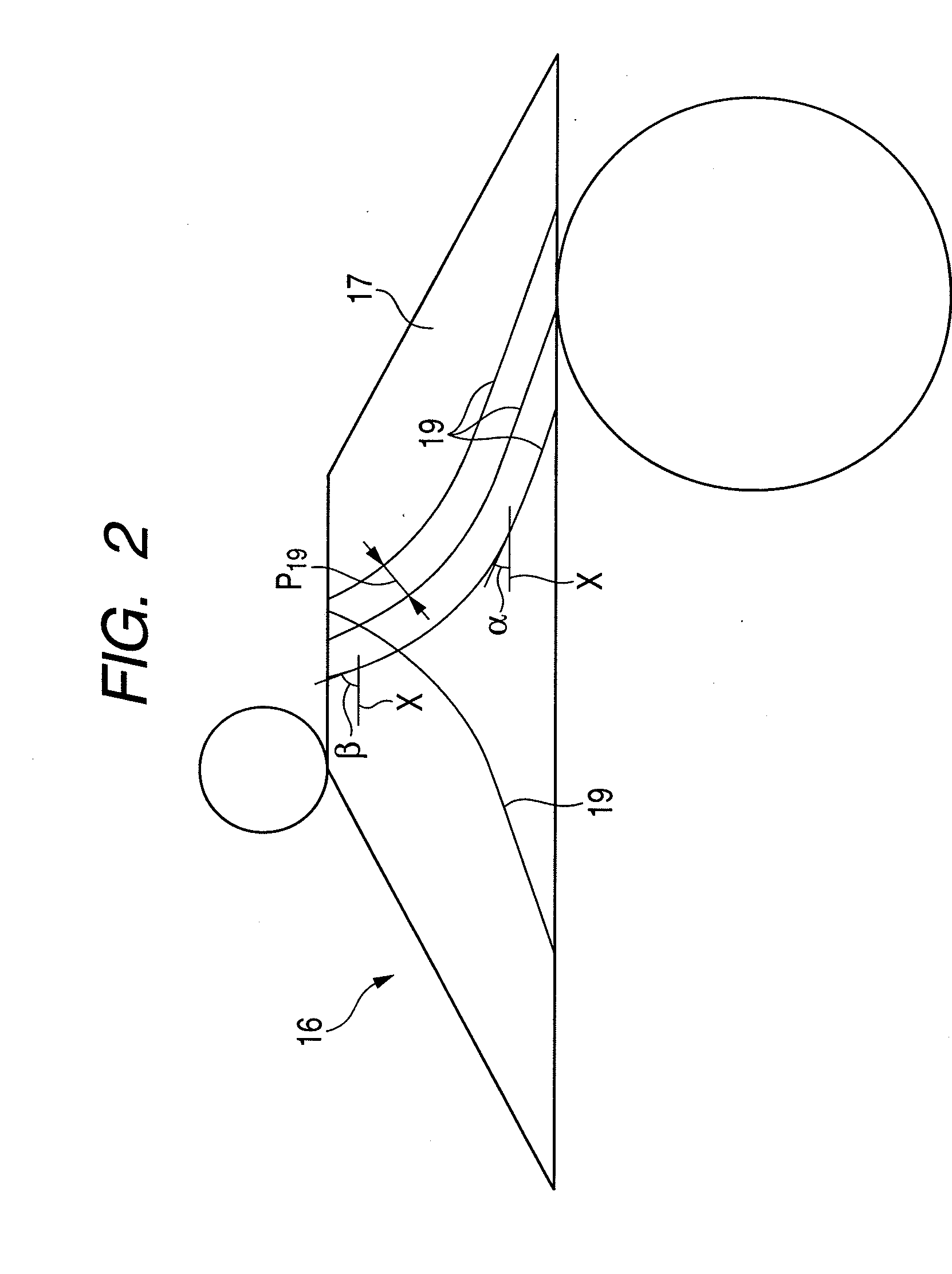

Toroidal continuously variable transmission

ActiveUS20080305920A1Low costReduce processing costsMetal-working apparatusGear wheelsEngineeringGear ratio

Power roller-side concave grooves are opposed to disk-side concave grooves 19, 19 so as to have angles therebetween in a rolling contact area between a peripheral surface of the power roller and a one-side surface 17 of a disk 16 in an axial direction regardless of a transmission gear ratio of a toroidal continuously variable transmission. Accordingly, the disk-side concave grooves 19, 19 are formed so as to have angles with respect to a circumferential direction of the disk 16 when viewed from a normal direction relative to the one-side surface 17 in the axial direction. Meanwhile, the power roller-side concave grooves are formed into a concentric shape (or a spiral shape) about a central shaft of the power roller. As a result, it is possible to prevent a decrease of a contact area in the rolling contact area regardless of the transmission gear ratio.

Owner:NSK LTD

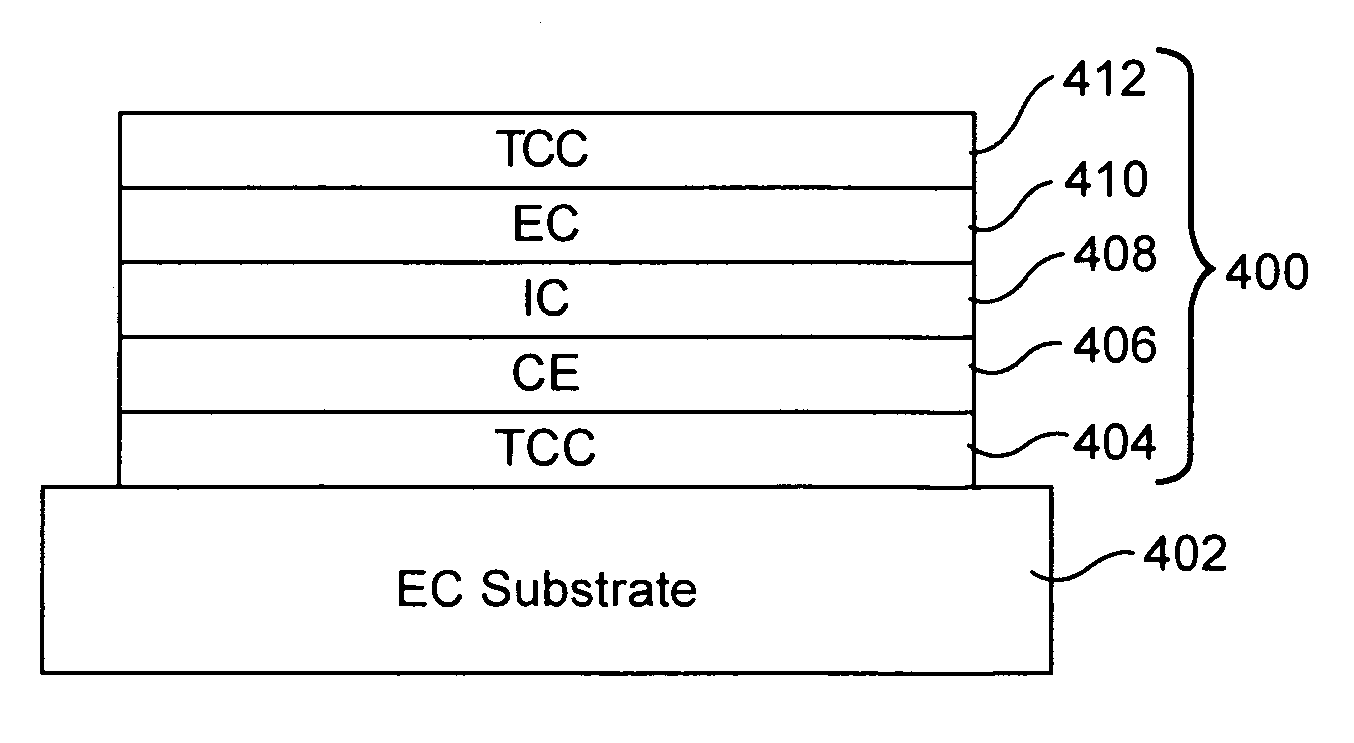

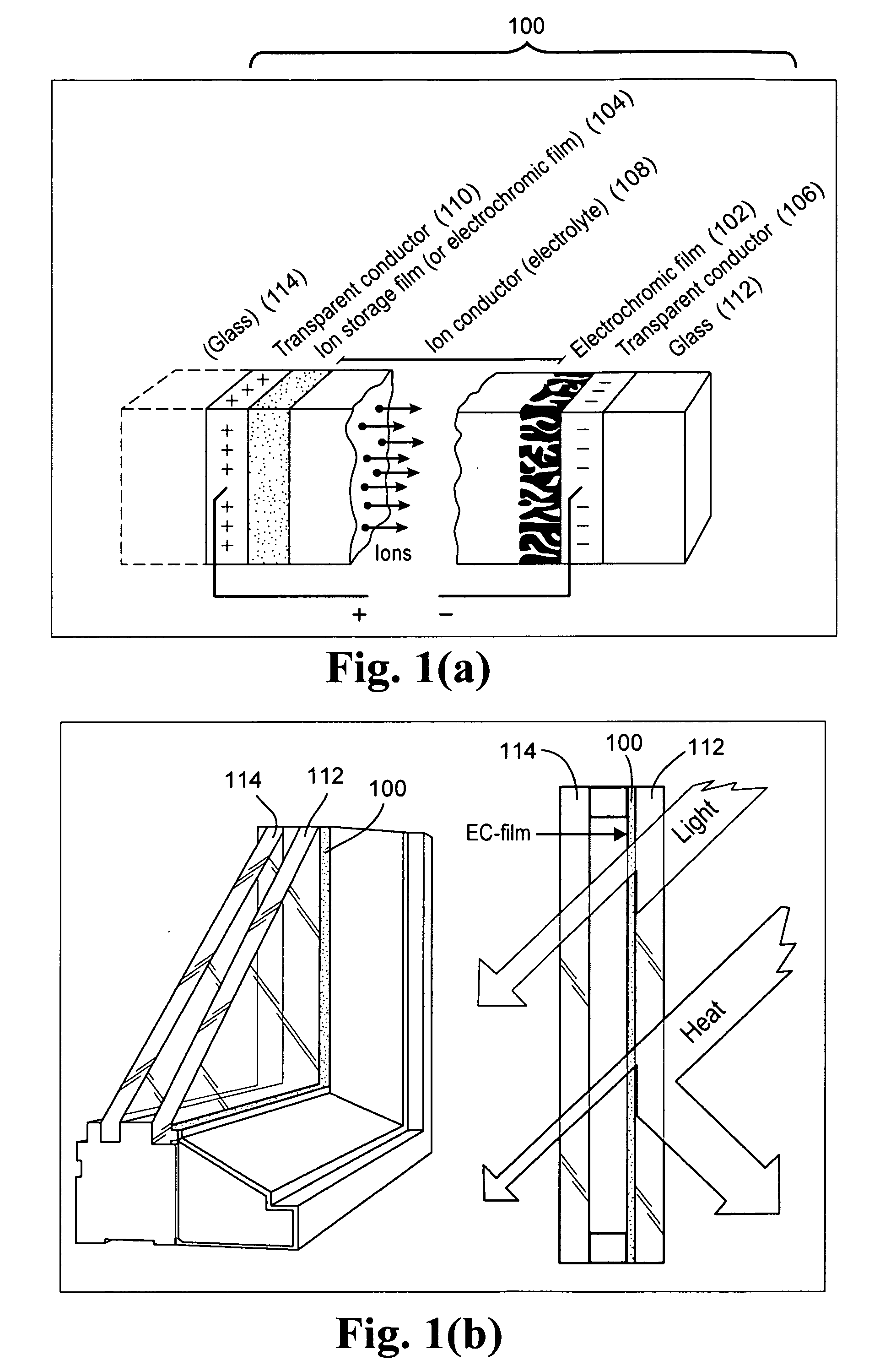

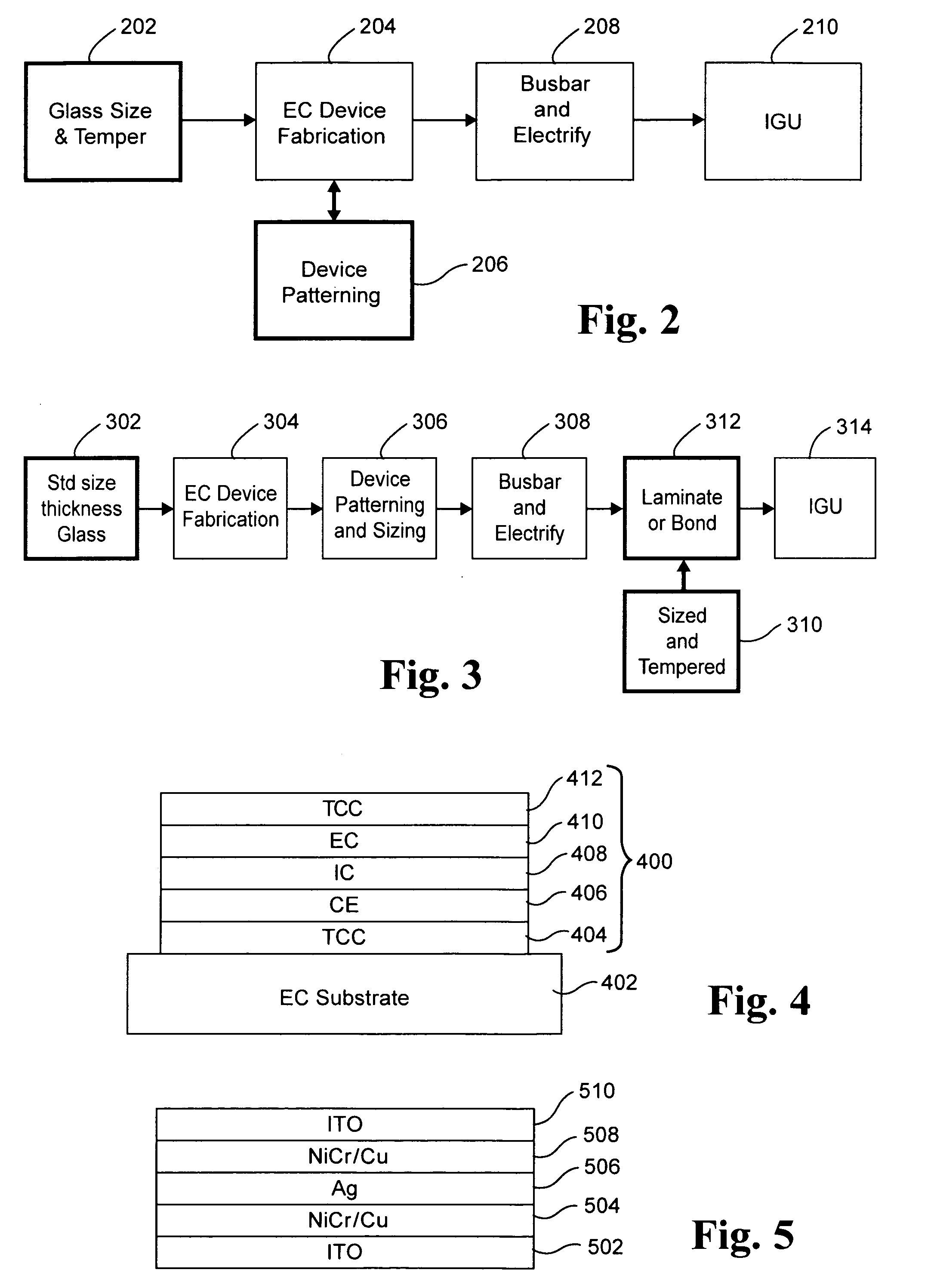

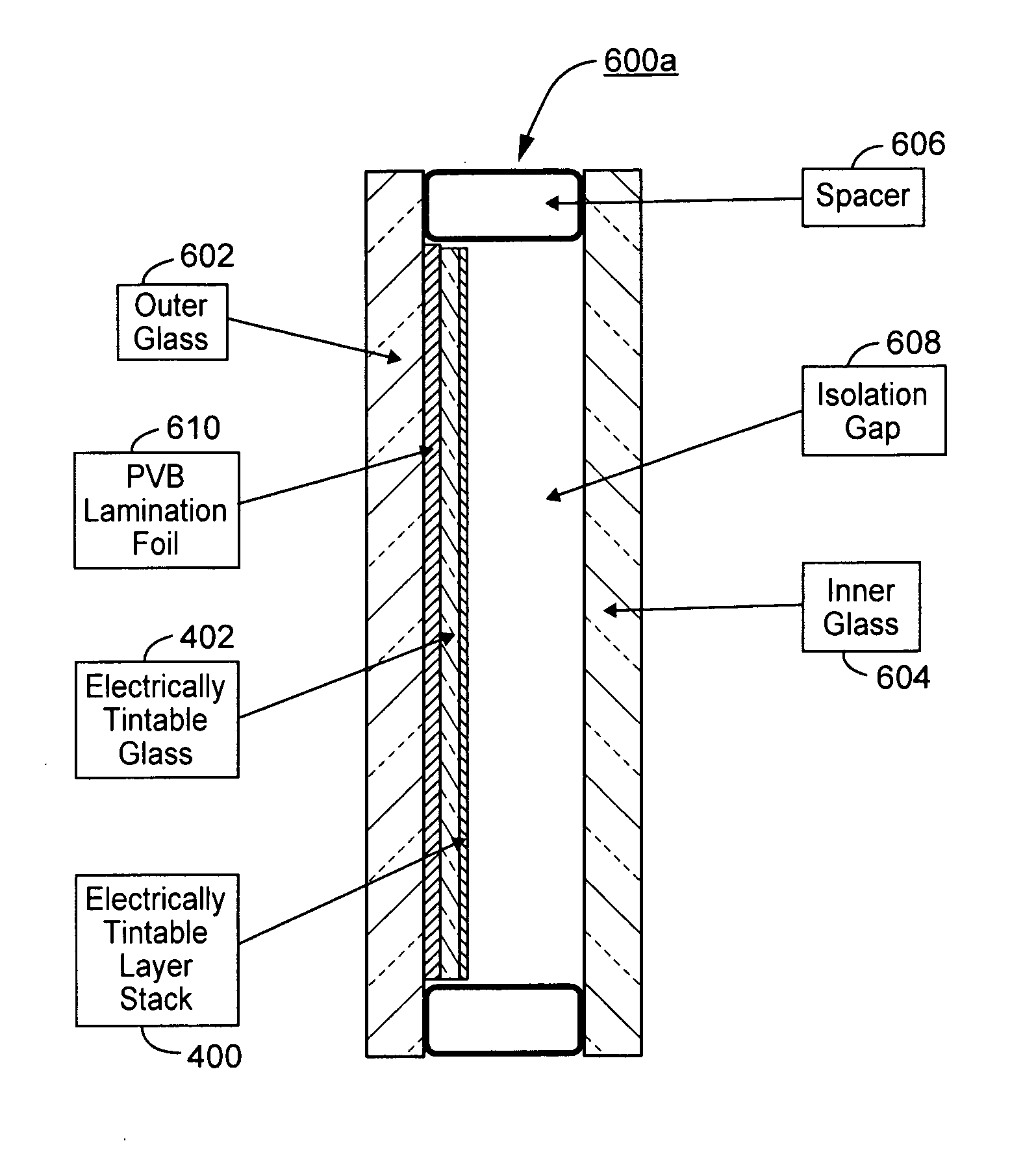

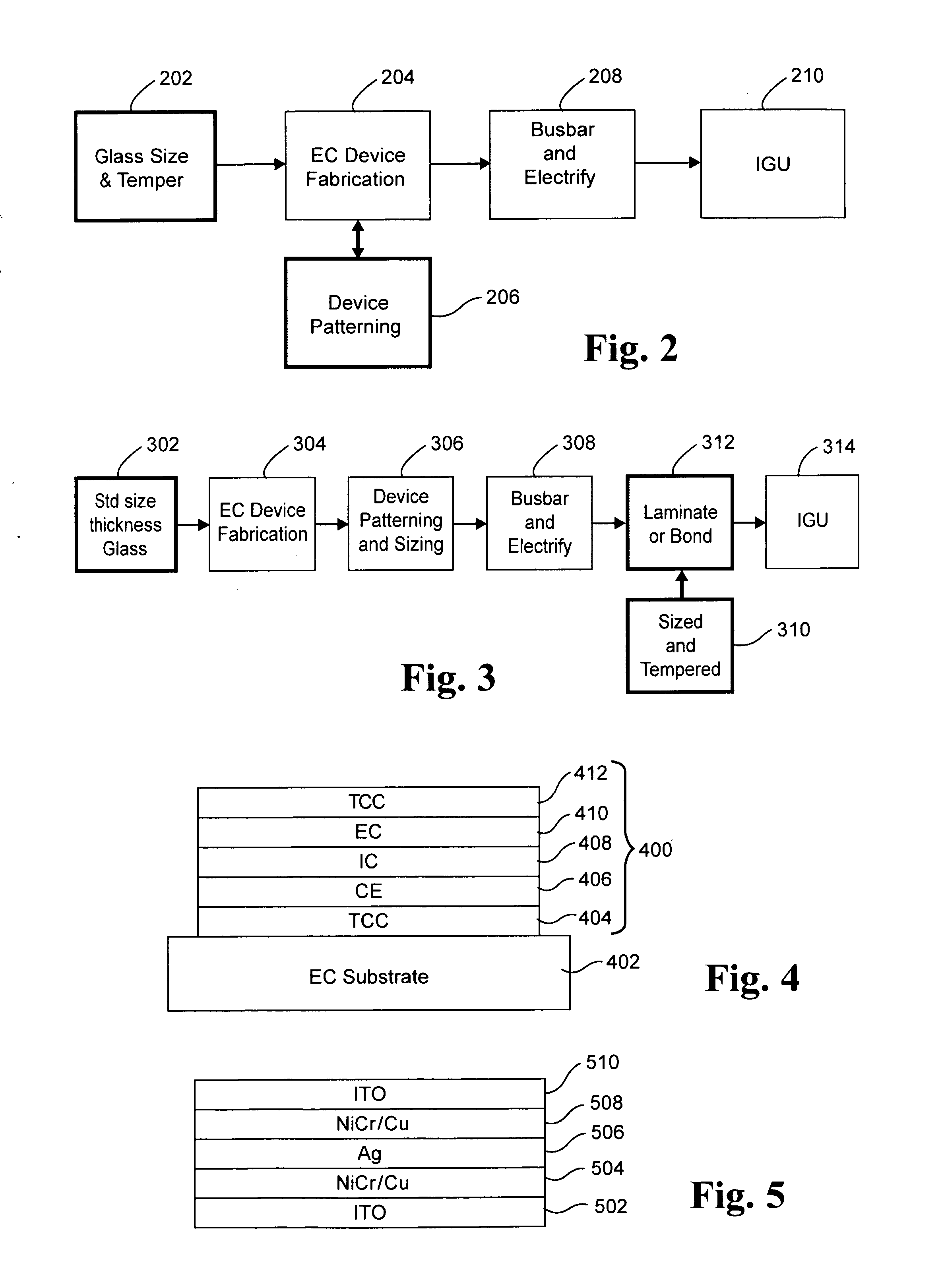

Electrochromic devices, assemblies incorporating electrochromic devices, and/or methods of making the same

ActiveUS20110048614A1Great visible transmissionGood lookingLamination ancillary operationsLight protection screensElectricityProcess integration

Certain example embodiments of this invention relate to electrochromic (EC) devices, assemblies incorporating electrochromic devices, and / or methods of making the same. More particularly, certain example embodiments of this invention relate to improved EC materials, EC device stacks, high-volume manufacturing (HVM) compatible process integration schemes, and / or high-throughput low cost deposition sources, equipment, and factories.

Owner:GUARDIAN GLASS LLC

Magnetic recording medium and process for producing the same

InactiveUS20070231606A1Improve the overall coefficientHead contaminationMaterials with cobaltRecord information storageMetal powderCobalt

A magnetic recording medium comprising a substrate and a magnetic layer containing ferromagnetic metal powder and a binder, wherein the ferromagnetic metal powder contains iron, cobalt and form 2 to 20 atom % of yttrium based on a total of iron and cobalt contained in the ferromagnetic metal powder and has an average length of 50 nm or smaller, and the magnetic recording medium has a test value of at least 100 passes in a magnetoresistive head resistance reduction test performed as defined herein.

Owner:FUJIFILM CORP

Electrochromic devices, assemblies incorporating electrochromic devices, and/or methods of making the same

ActiveUS20110051221A1Great visible transmissionGood lookingLight protection screensGlass/slag layered productsElectricityProduction rate

Certain example embodiments of this invention relate to electrochromic (EC) devices, assemblies incorporating electrochromic devices, and / or methods of making the same. More particularly, certain example embodiments of this invention relate to improved EC materials, EC device stacks, high-volume manufacturing (HVM) compatible process integration schemes, and / or high-throughput low cost deposition sources, equipment, and factories.

Owner:GUARDIAN GLASS LLC

Elastic wave device and manufacturing method for same

ActiveUS20140152145A1Easily realizeSmall sizePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksEngineeringEuler angles

An elastic wave device includes a support layer with a through-hole or a recess opened at an upper surface thereof, a piezoelectric thin film arranged on the support layer to extend above the recess or the through-hole of the support layer, and an IDT electrode defined on at least one of upper and lower surfaces of the piezoelectric thin film in a region of the piezoelectric thin film, the region extending above the recess, or the through-hole. A secondary mode of a plate wave, which contains a U1 component as a main component, is utilized. The piezoelectric thin film is made of LiTaO3, and Euler angles (φ, θ, ψ) of the LiTaO3 fall within specific ranges.

Owner:MURATA MFG CO LTD

Sustained release medicinal compositions

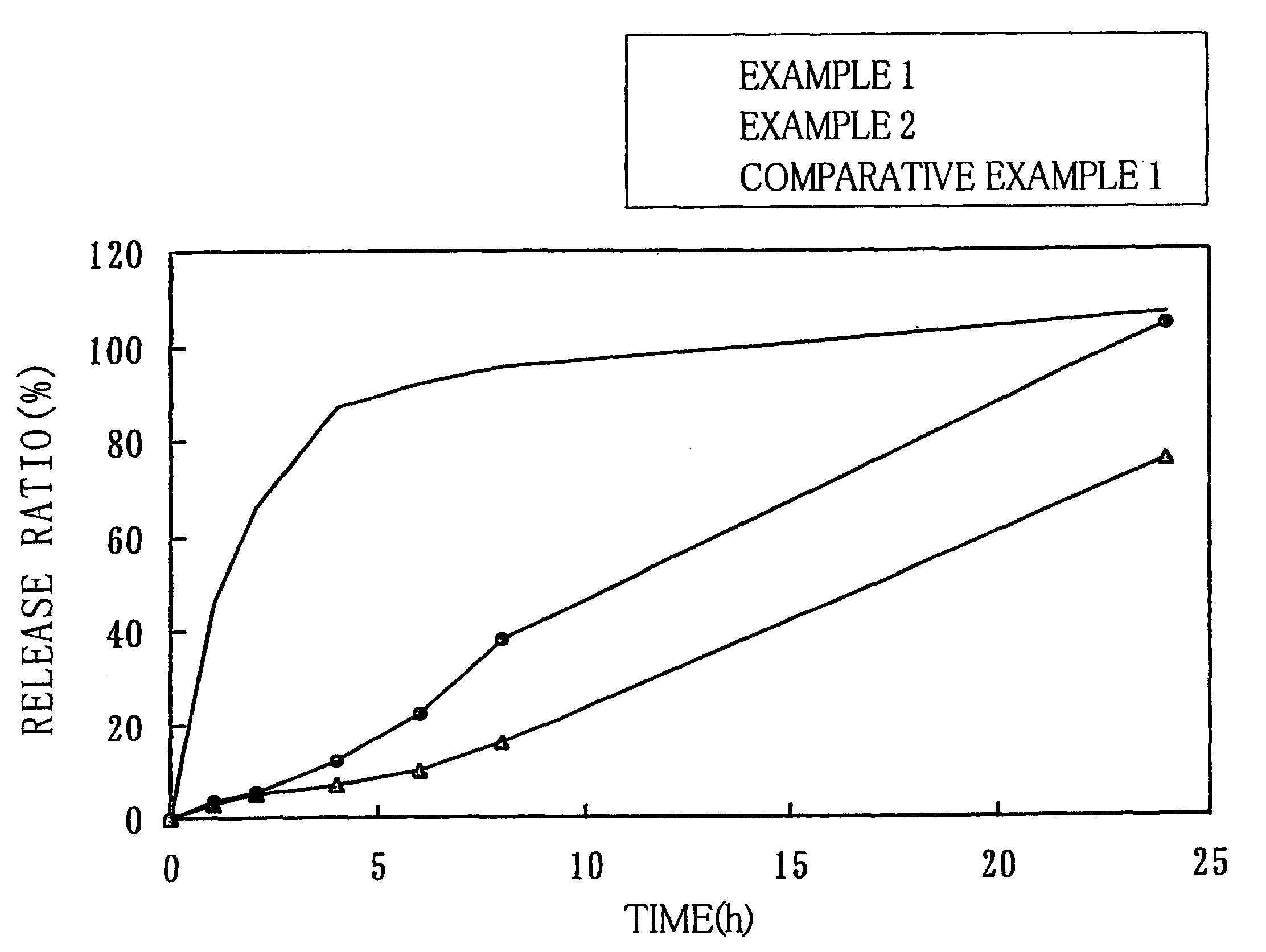

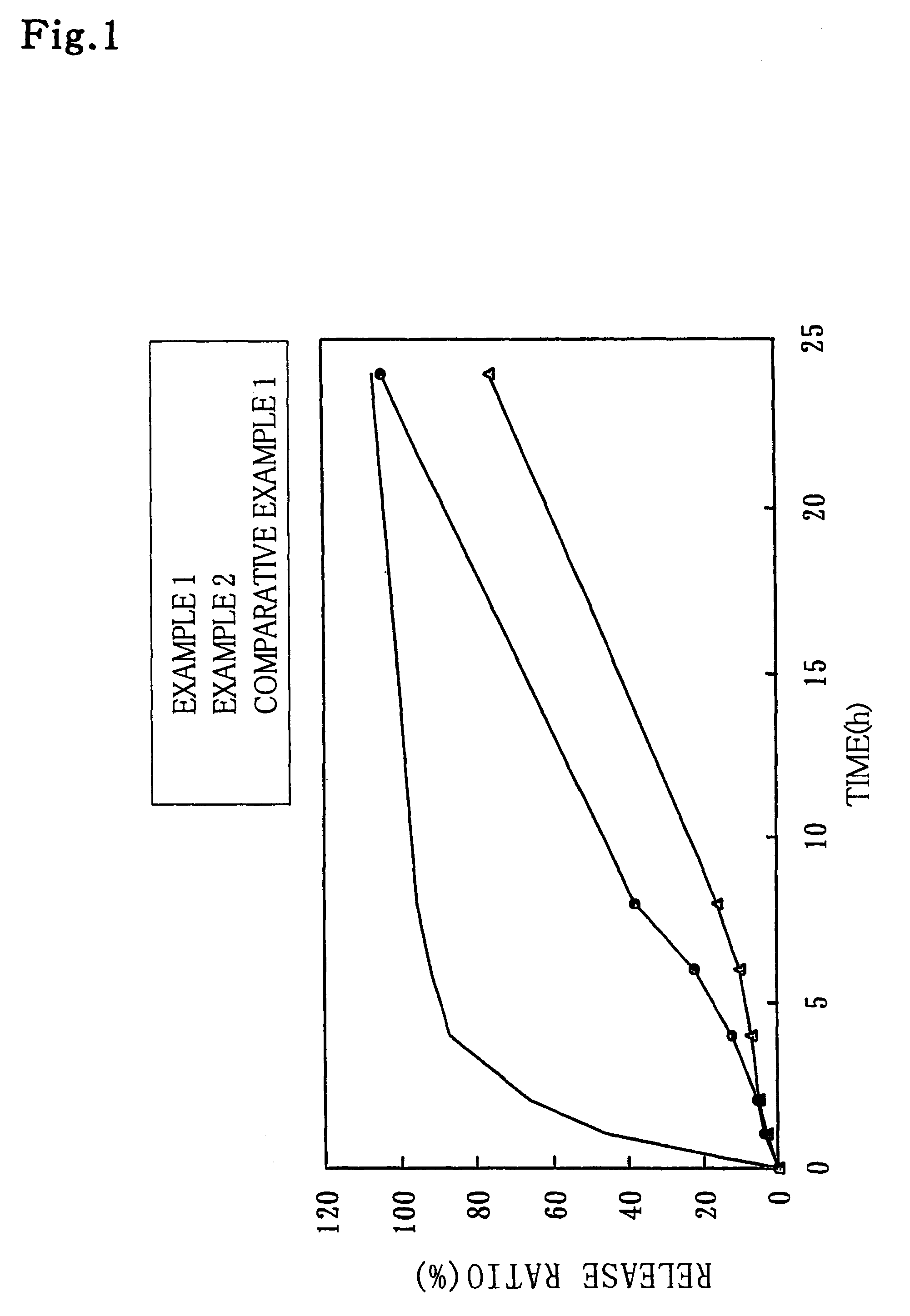

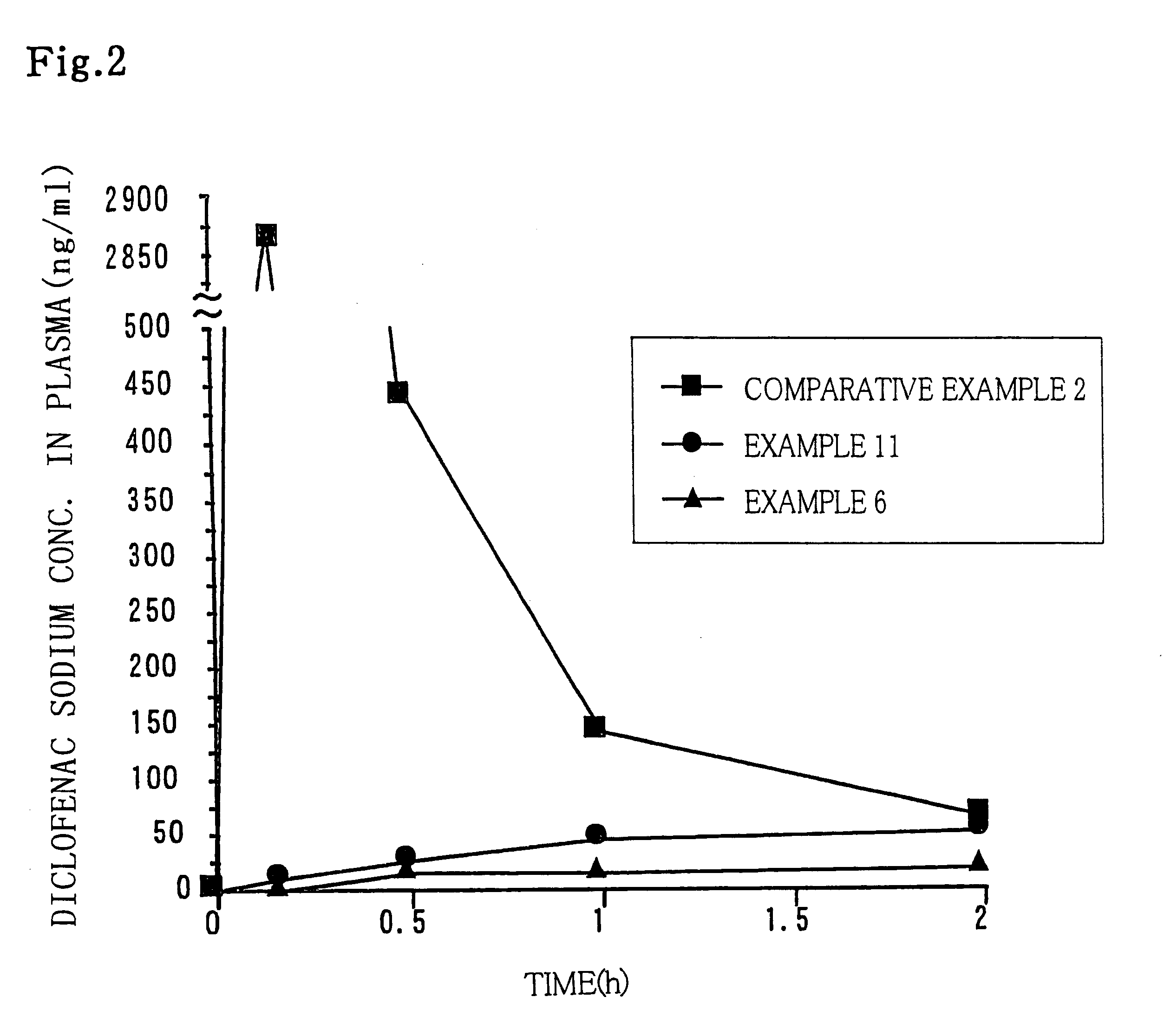

InactiveUS6328979B1Improve hydrophobicityGood sustained release effectElcosanoid active ingredientsAerosol deliverySolubilityAcid derivative

The present invention relates to sustained-release pharmaceutical compositions for ionic pharmaceutically active substances (excluding ionic prostanoic acid derivatives) containing ionic compounds having opposite charges to those of the active substances and increasing hydrophobicity of the active substances. More specifically, the invention relates to sustained-release pharmaceutical compositions comprising the ionic pharmaceutically active substances and the ionic compounds having opposite charges to those of the active substances and increasing hydrophobicity of the active substances that contain hydrophobic groups in the molecule thereof. The pharmaceutical composition of the invention can exhibit excellent sustained release effect of the active substance, irrespective of water solubility possessed by the ionic pharmaceutically active substances.

Owner:ASTELLAS PHARMA INC

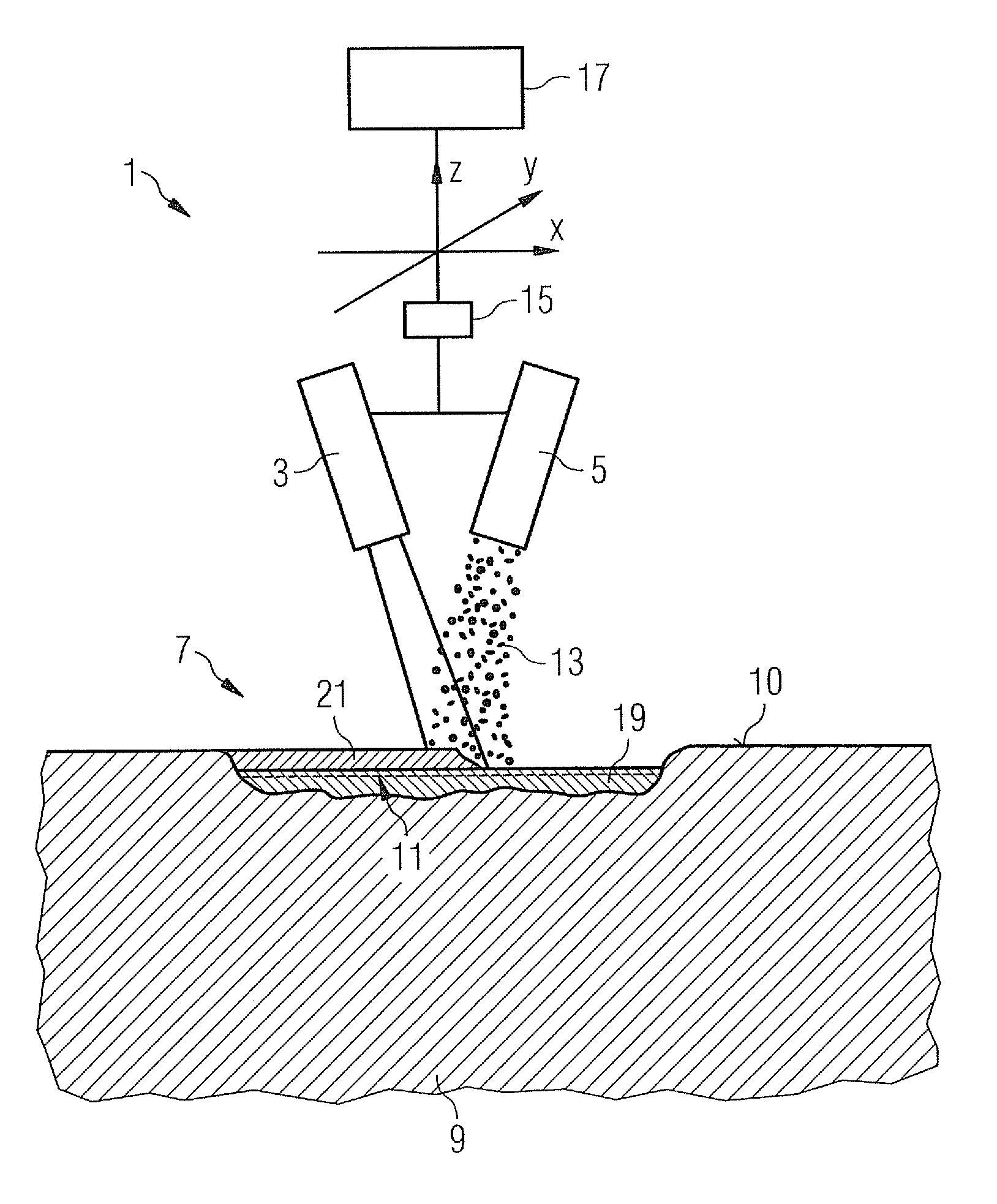

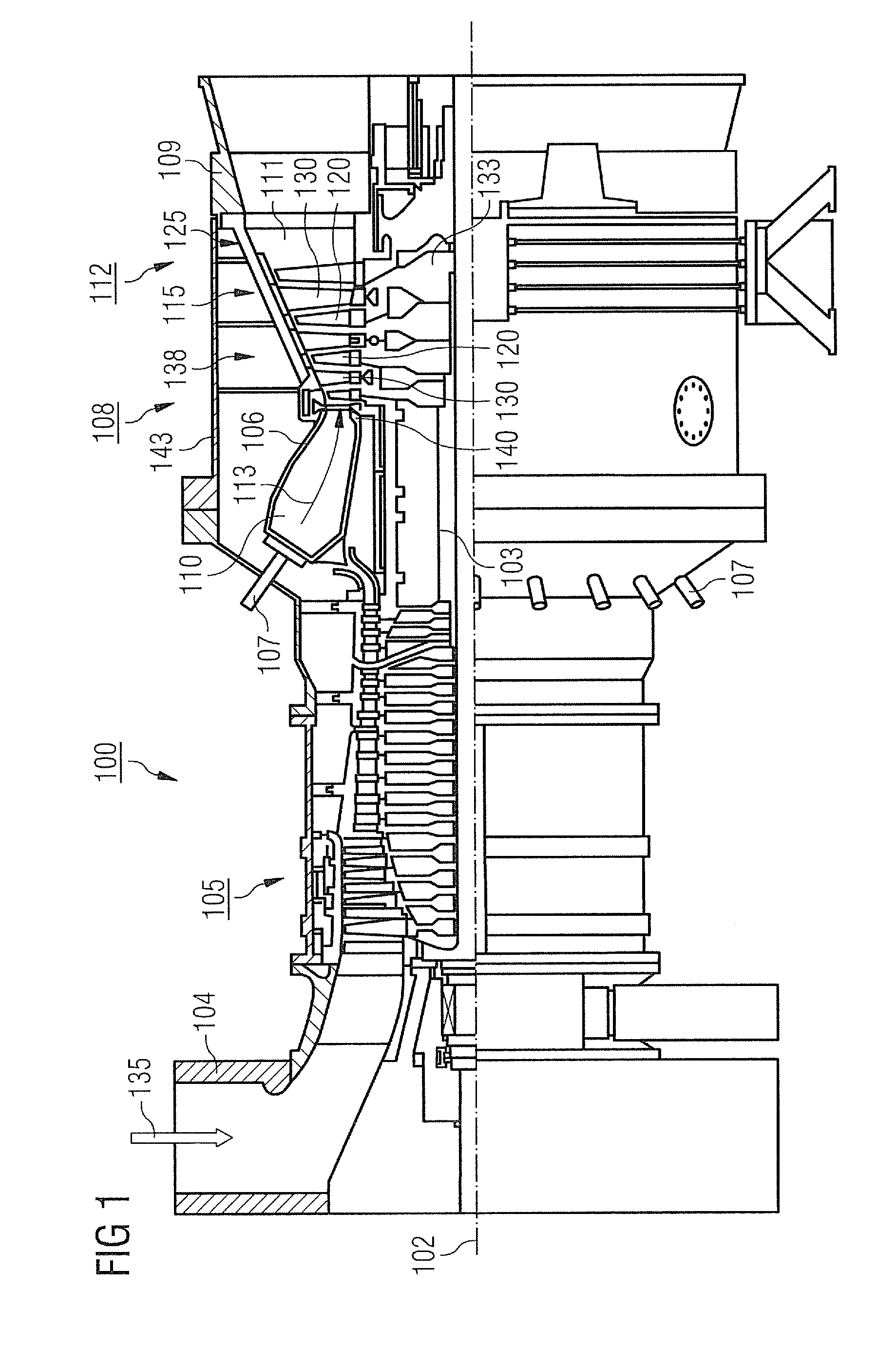

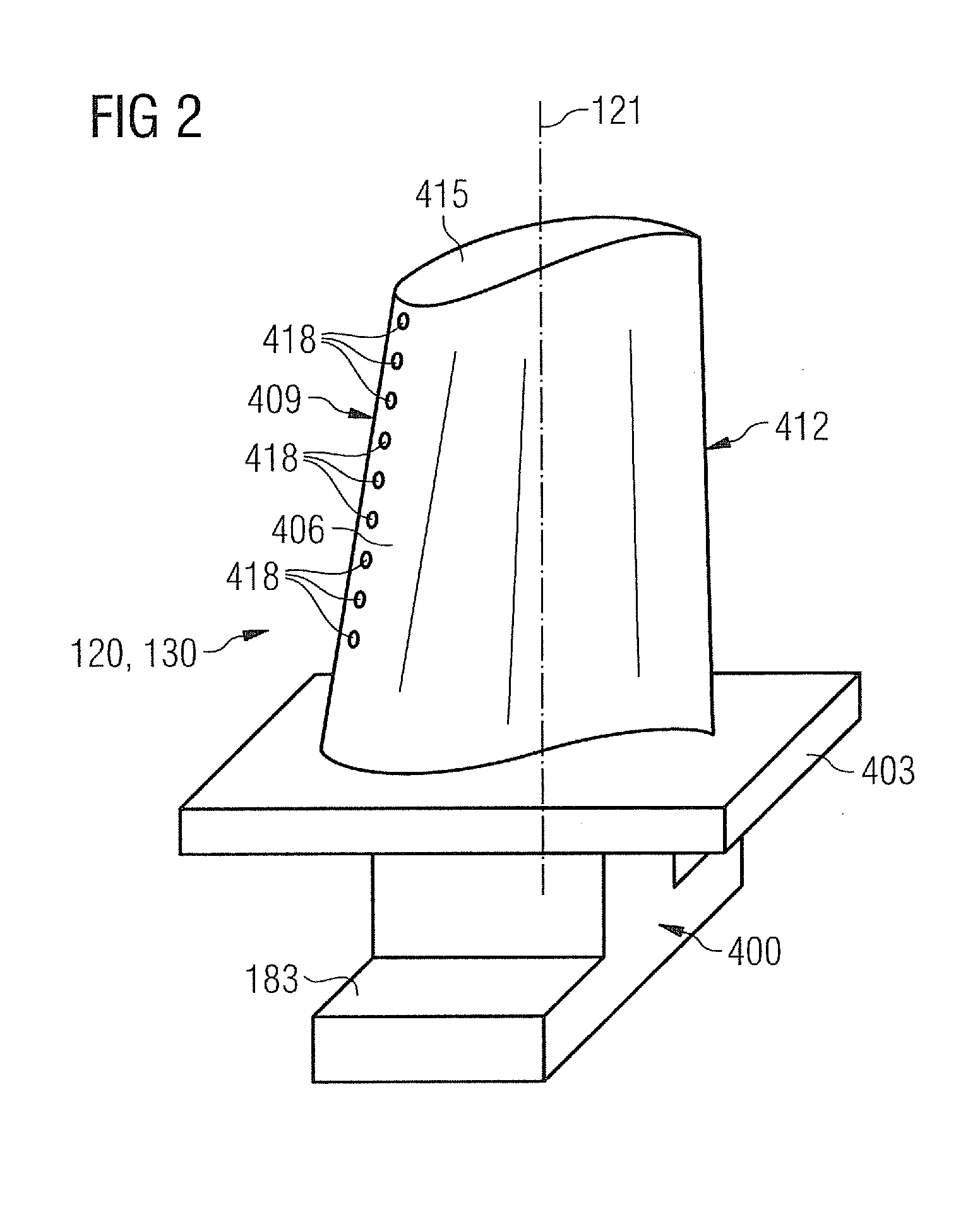

Method for welding workpieces made of highly heat-resistant superalloys, including a particular mass feed rate of the welding filler material

InactiveUS20120267347A1Improve cooling effectIncrease chanceTurbinesEngine manufactureHeat resistanceRelative motion

A welding method for welding workpieces made of highly heat-resistant superalloys is provided. The method includes generating a heat input zone on the workpiece surface by means of a heat source, feeding welding filler material into the heat input zone by means of a feeding device, and generating a relative motion between the heat source and the feeding device on one hand and the workpiece surface on the other hand by means of a conveying device. Furthermore, according to the welding method, the mass feed rate is ≦350 mg / min.

Owner:SIEMENS AG +1

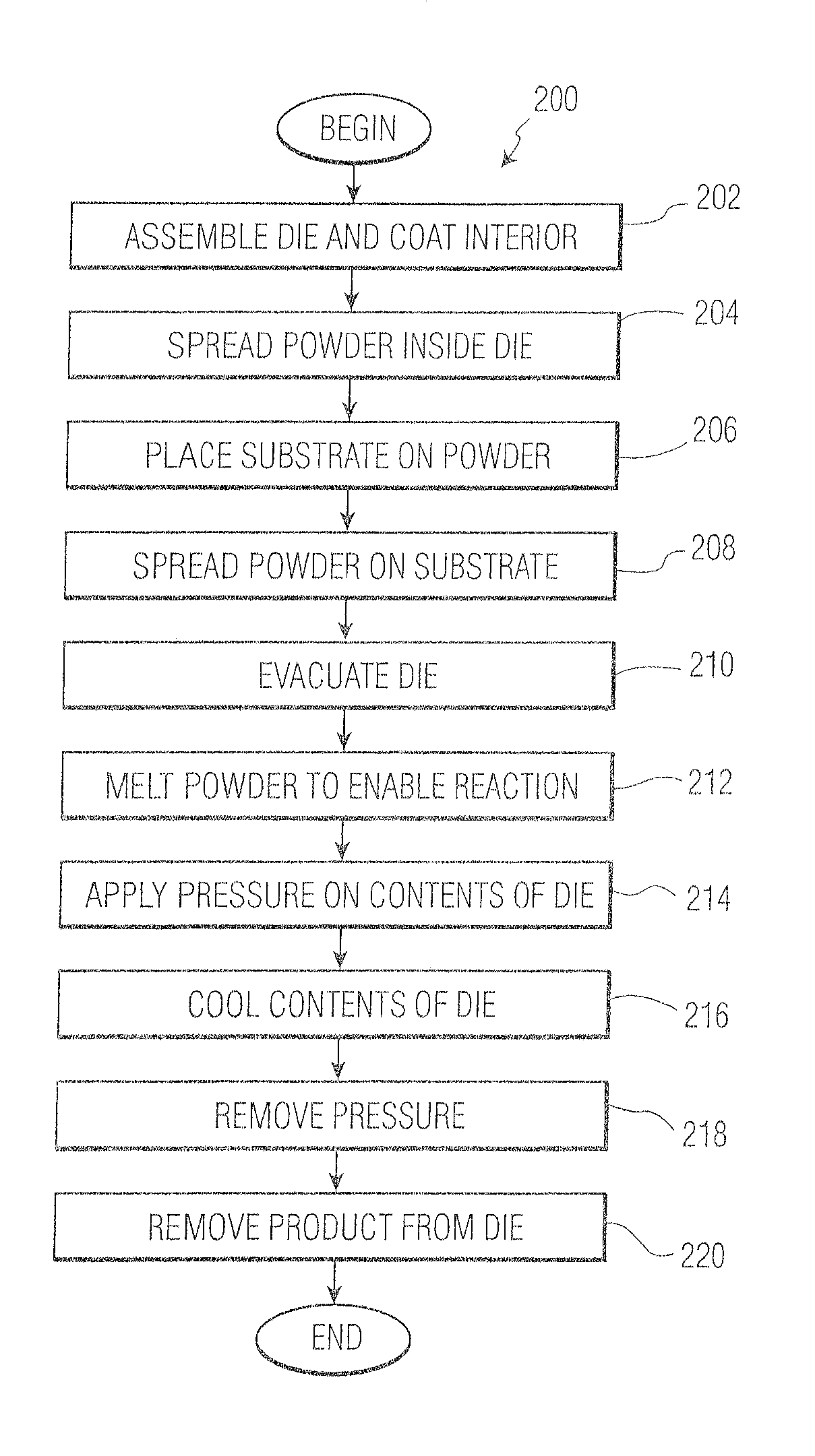

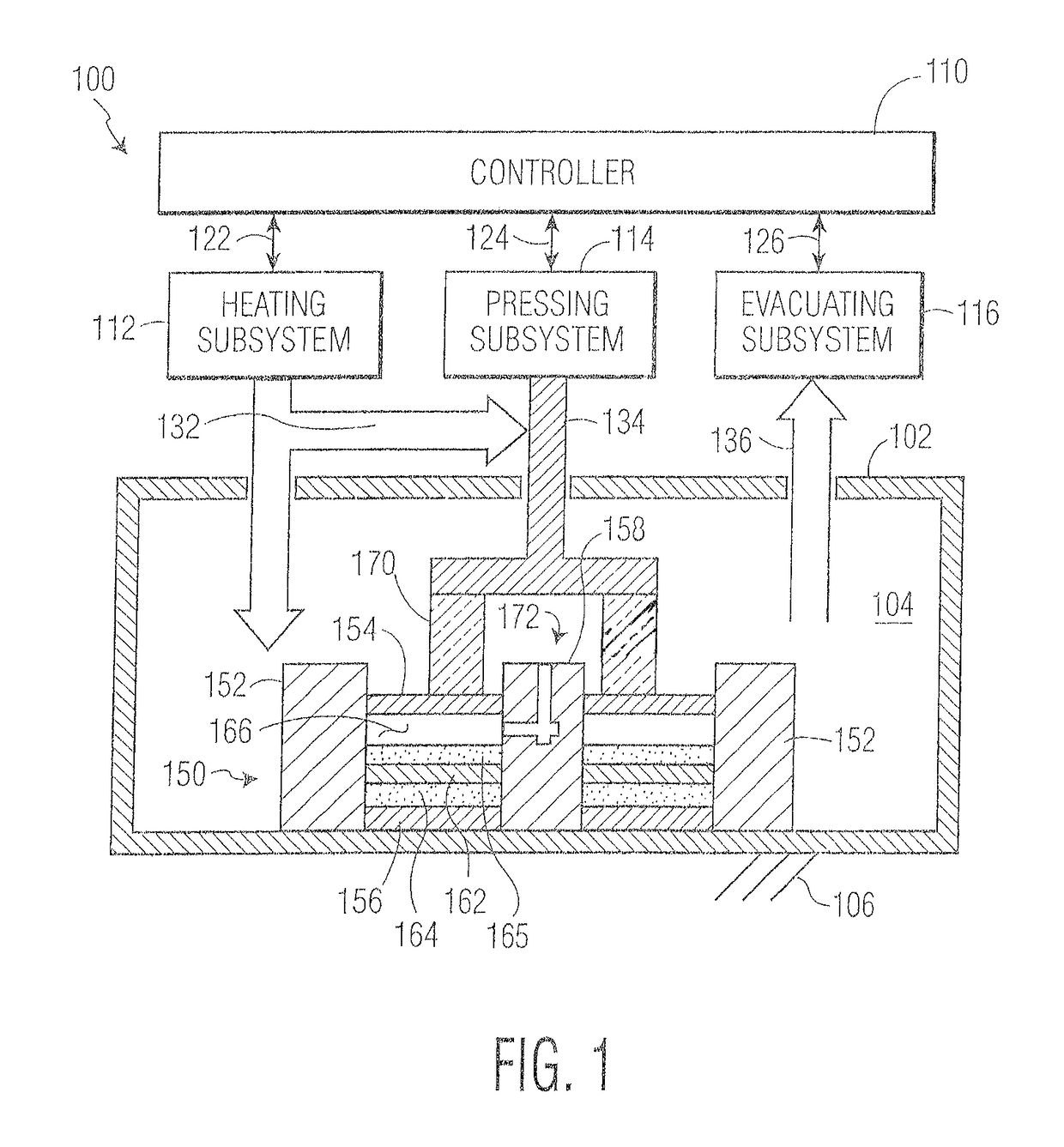

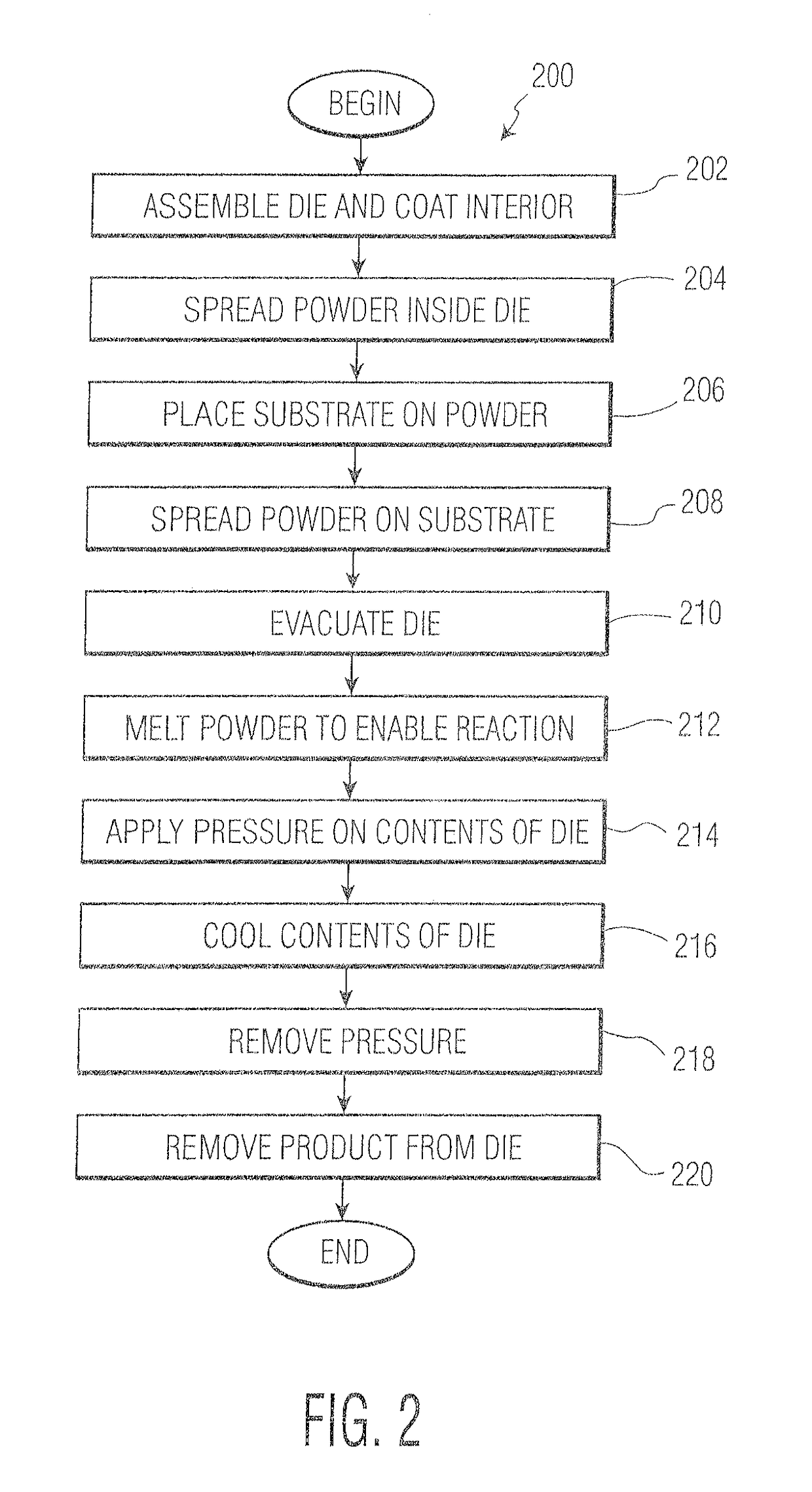

Systems and methods for forming a layer onto a surface of a solid substrate and products formed thereby

InactiveUS9933031B2Increase capacityImprove the overall coefficientBlade accessoriesBraking discsMetal matrix compositeSolid substrate

A method for forming a vehicular brake rotor involving loading a shaped metal substrate with a mixture of metal alloying components and ceramic particles in a dieheating the contents of the die while applying pressure to melt at least one of the metal components of the alloying mixture whereby to densify the contents of the die and form a ceramic particle-containing metal matrix composite coating on the metallic substrate; and cooling the resulting coated product.

Owner:ATS MER LLC

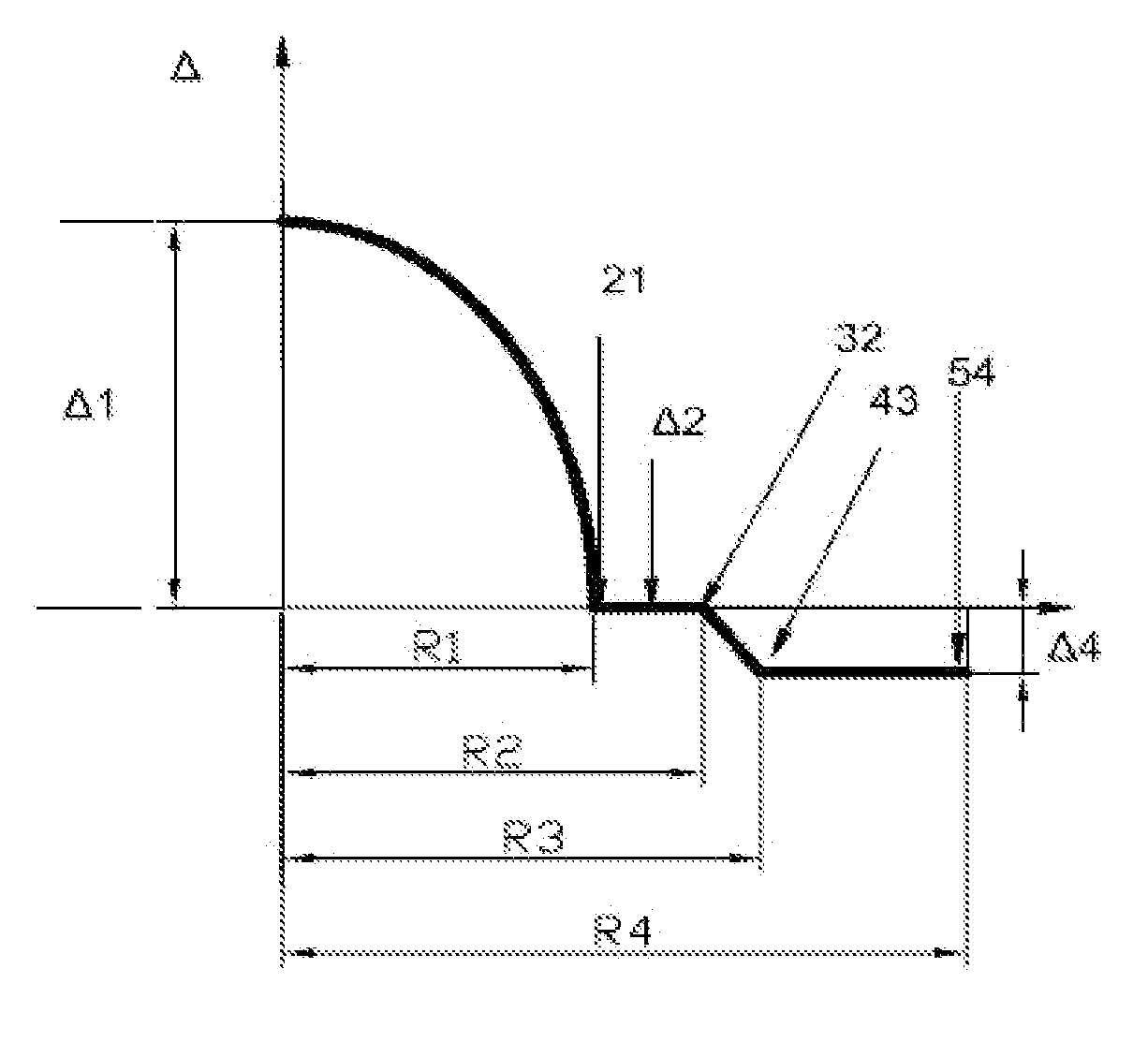

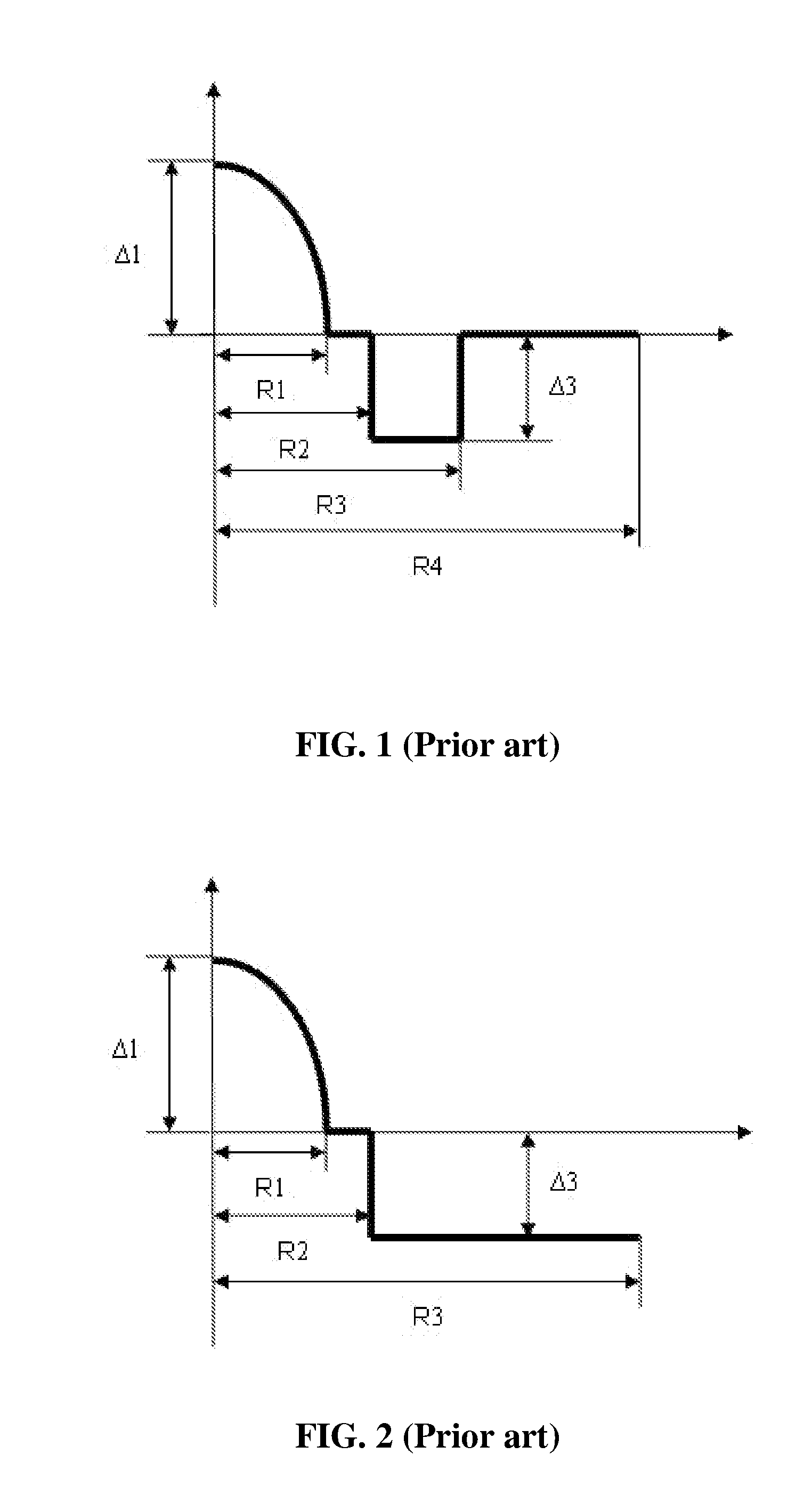

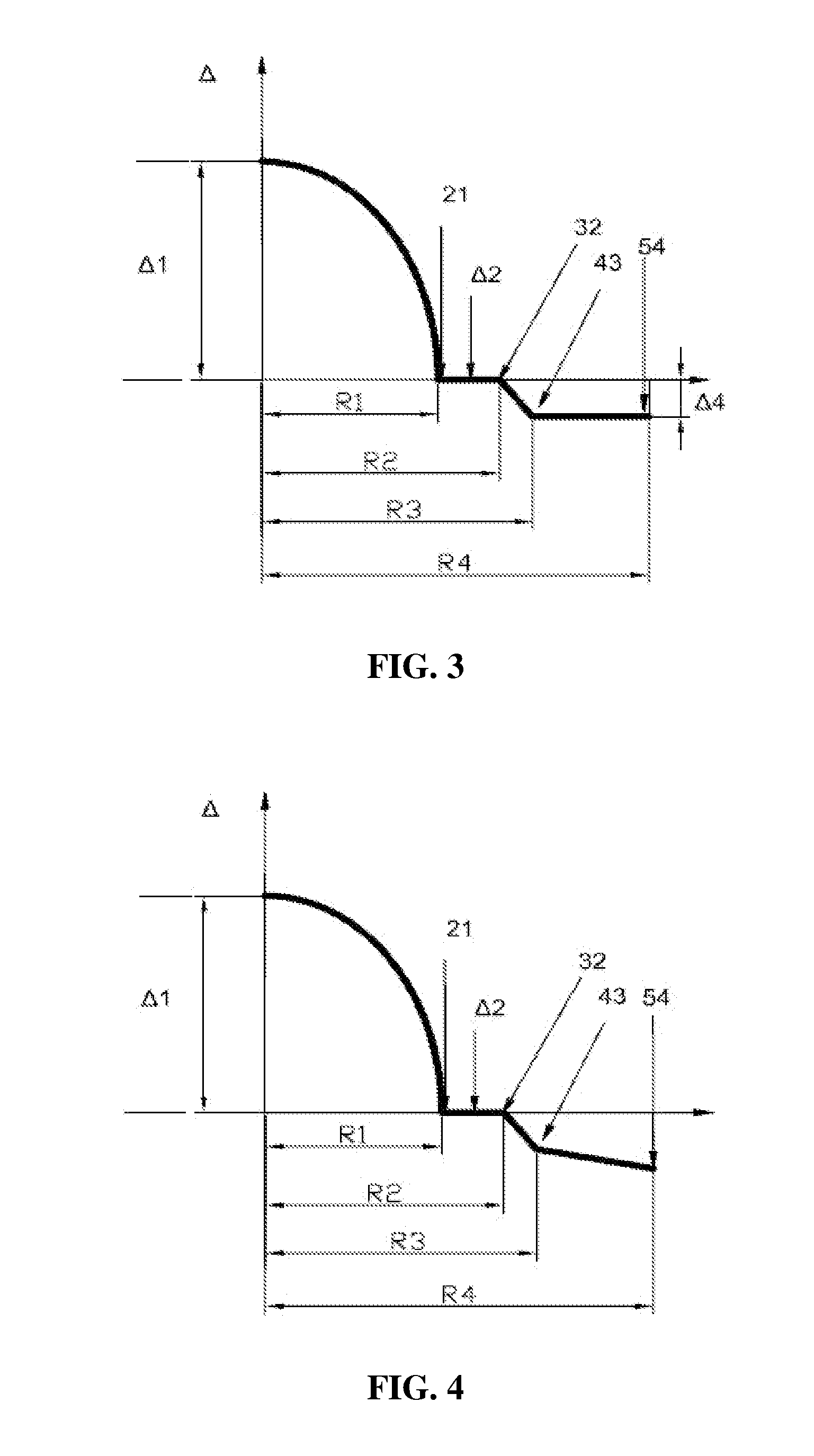

Multi-mode bending-resistant fiber and production method thereof

ActiveUS20110044596A1High mechanical reliabilityEasy to useOptical fibre with graded refractive index core/claddingOptical articlesMedicineRelative refractive index

A multimode fiber including a core and a cladding. The core has a radius (R1) of 24-26 μm, the refractive index profile thereof is a parabola, and the maximum relative refractive index difference (Δ1) is 0.9-1.1%. The cladding surrounds the core and includes from inside to outside an inner cladding, a middle cladding, and an outer cladding; a radius (R2) of the inner cladding is 1.04-1.6 times that of the core, and a relative refractive index difference (Δ2) thereof is −0.01-0.01%; the middle cladding is a graded refractive index cladding whose radius (R3) is 1.06-1.8 times that of the core, and a relative refractive index difference thereof is decreased from Δ2 to Δ4; and a radius (R4) of the outer cladding is 2.38-2.63 times that of the core, and a relative refractive index difference (Δ4) thereof is between −0.20 and −0.40%. The invention reduces the additional bending loss of the fiber, improves the bending resistance and mechanical properties, basically eliminates the internal stress, and ensures the service life even working for a long term under the condition of low radius. The method for producing the fiber is simple, effective, and suitable for mass production.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

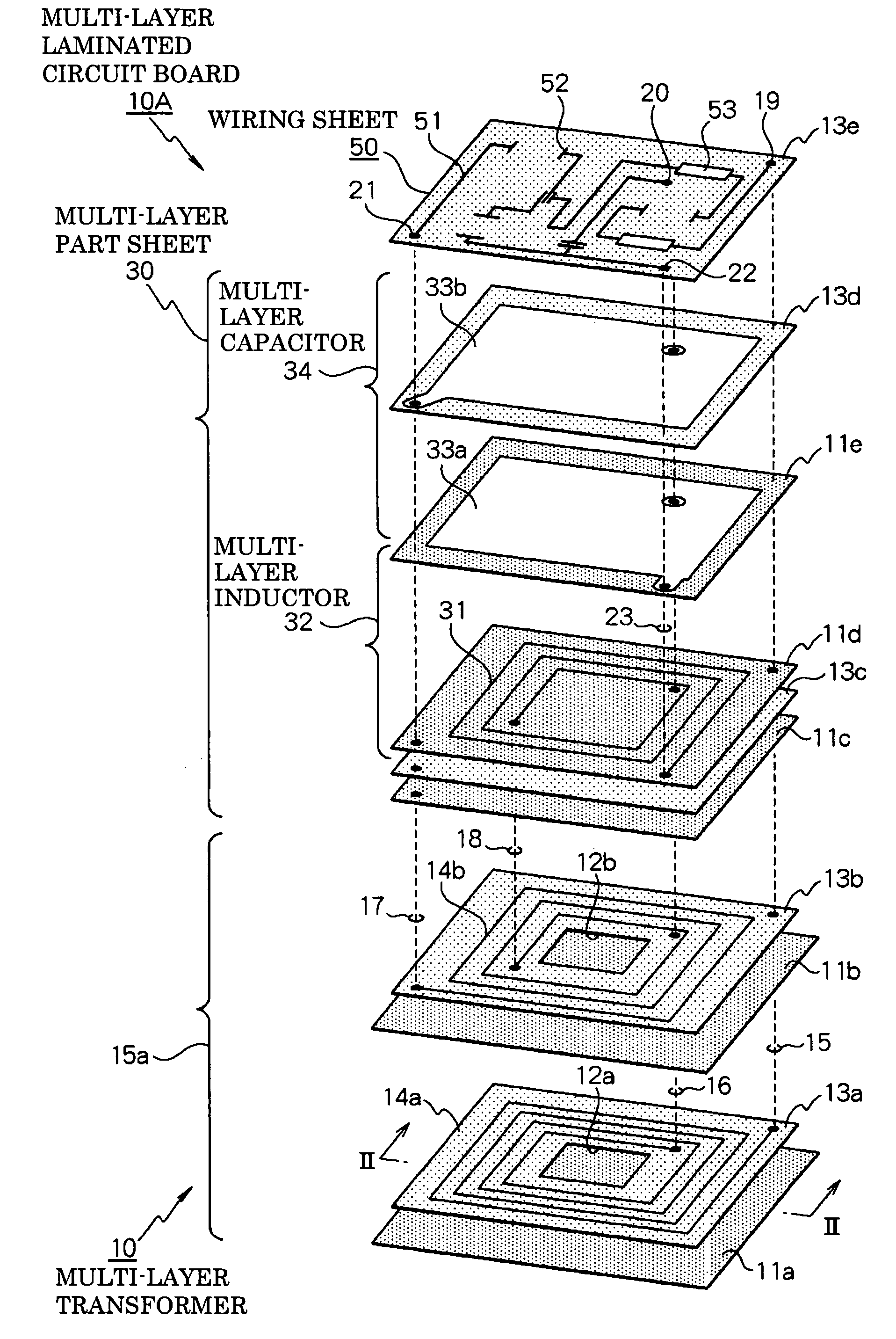

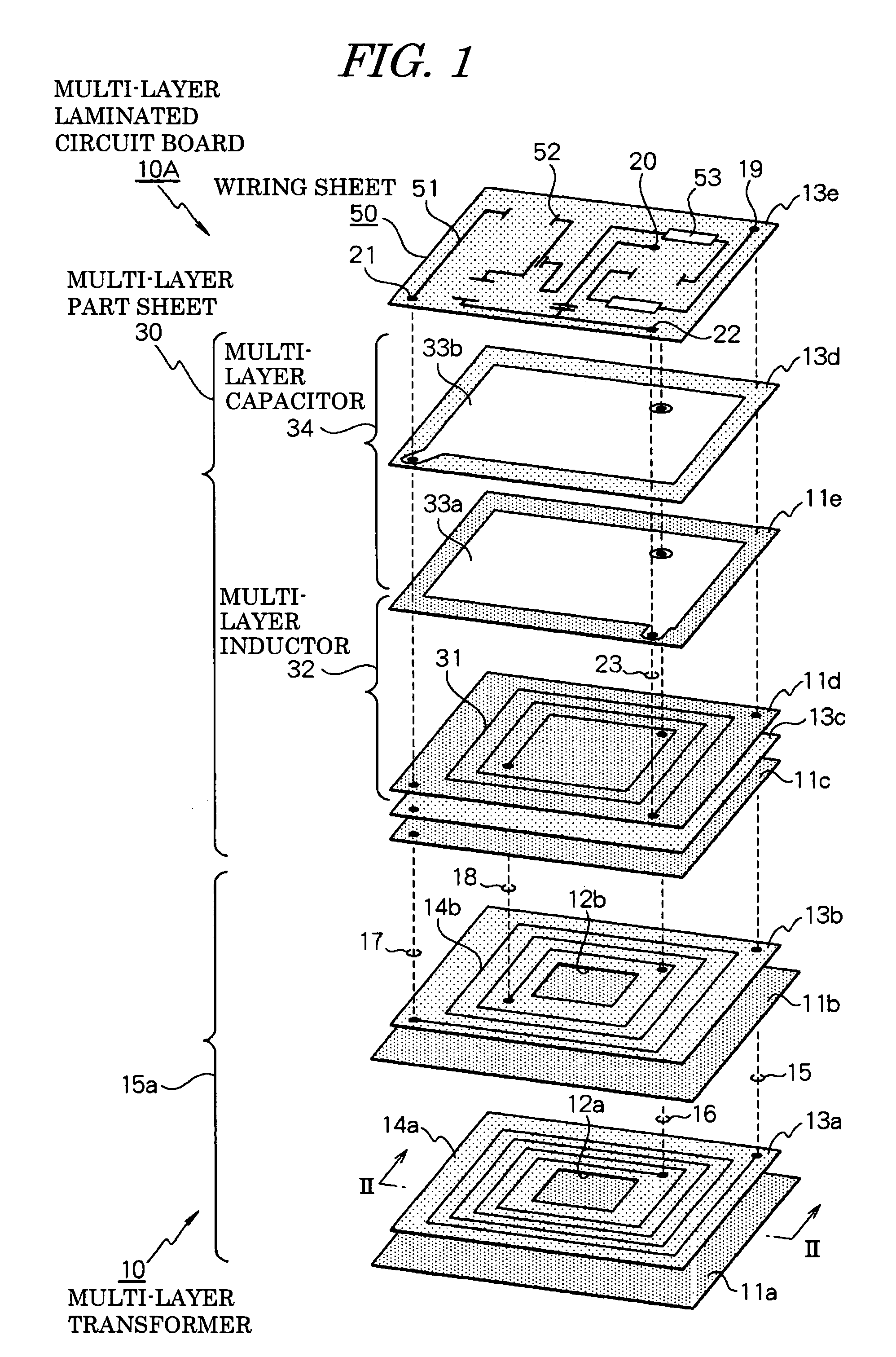

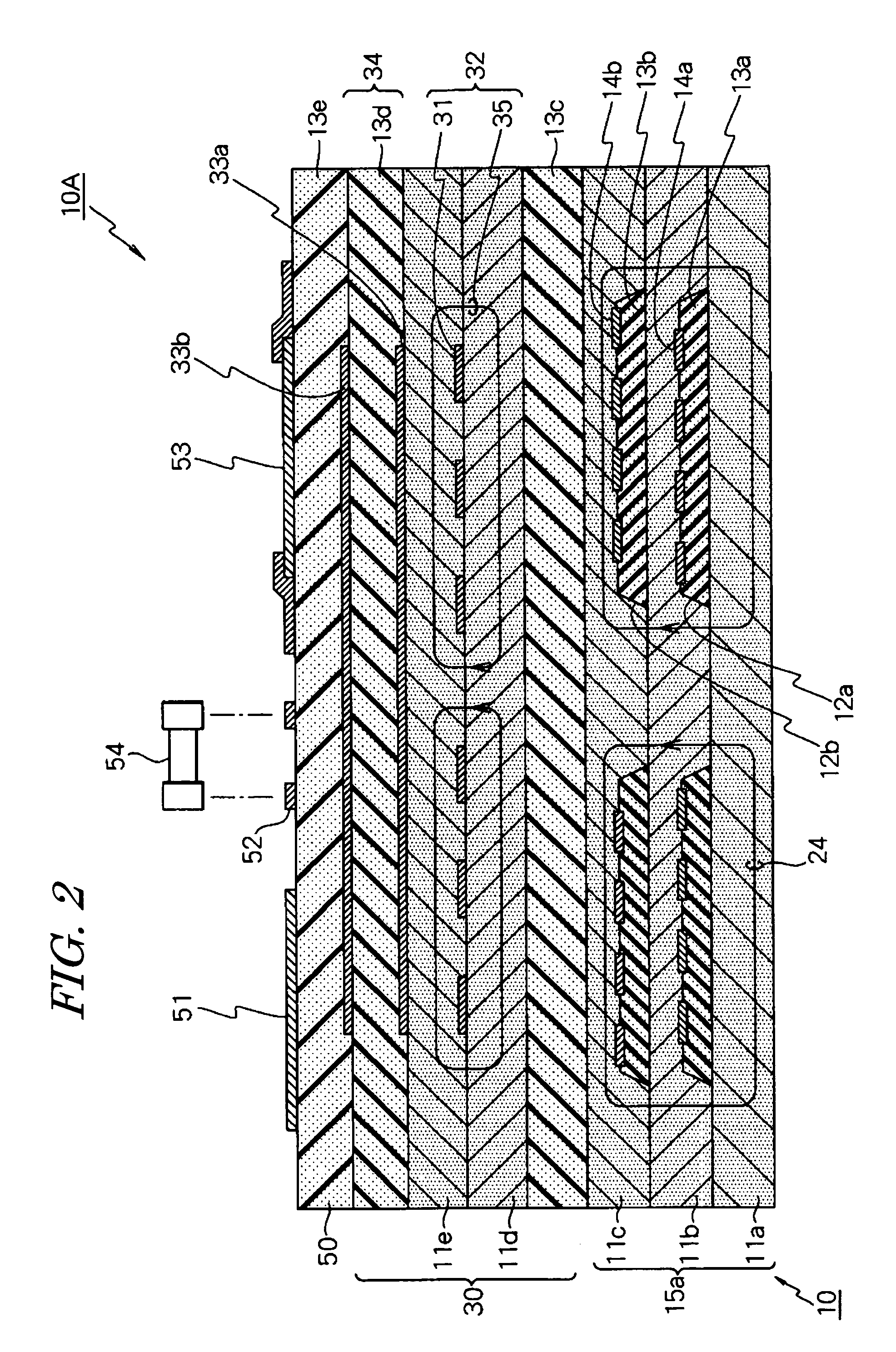

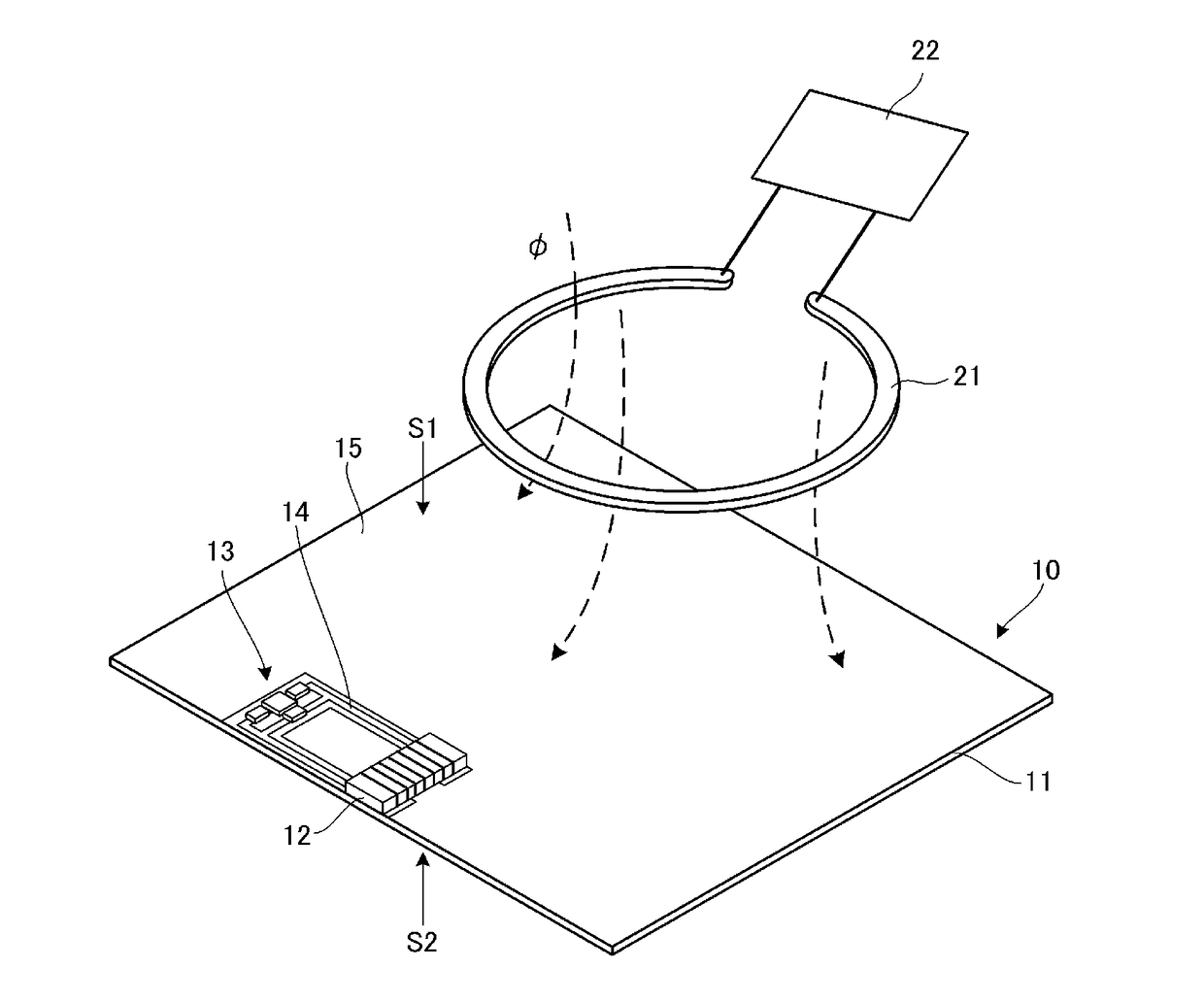

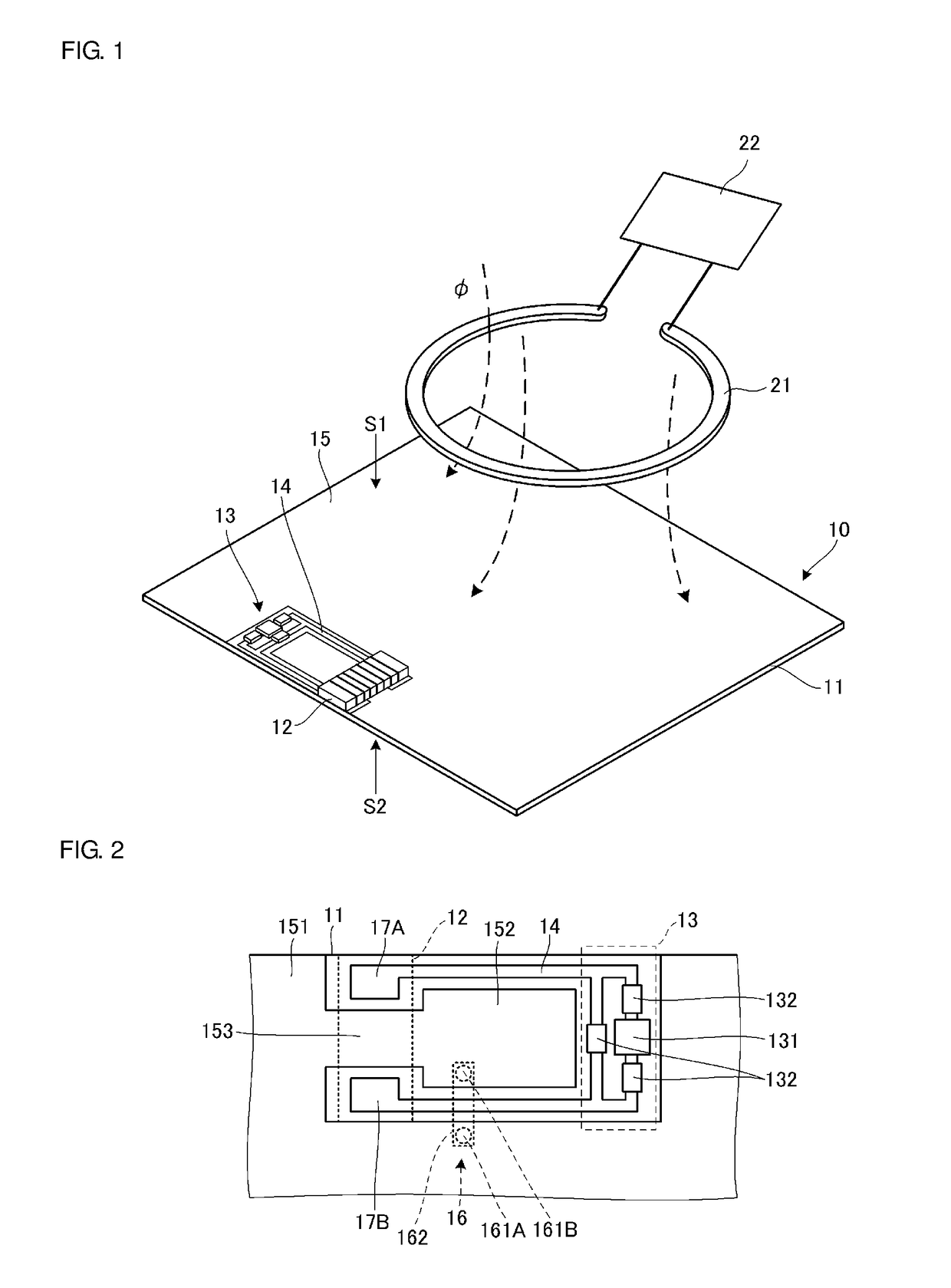

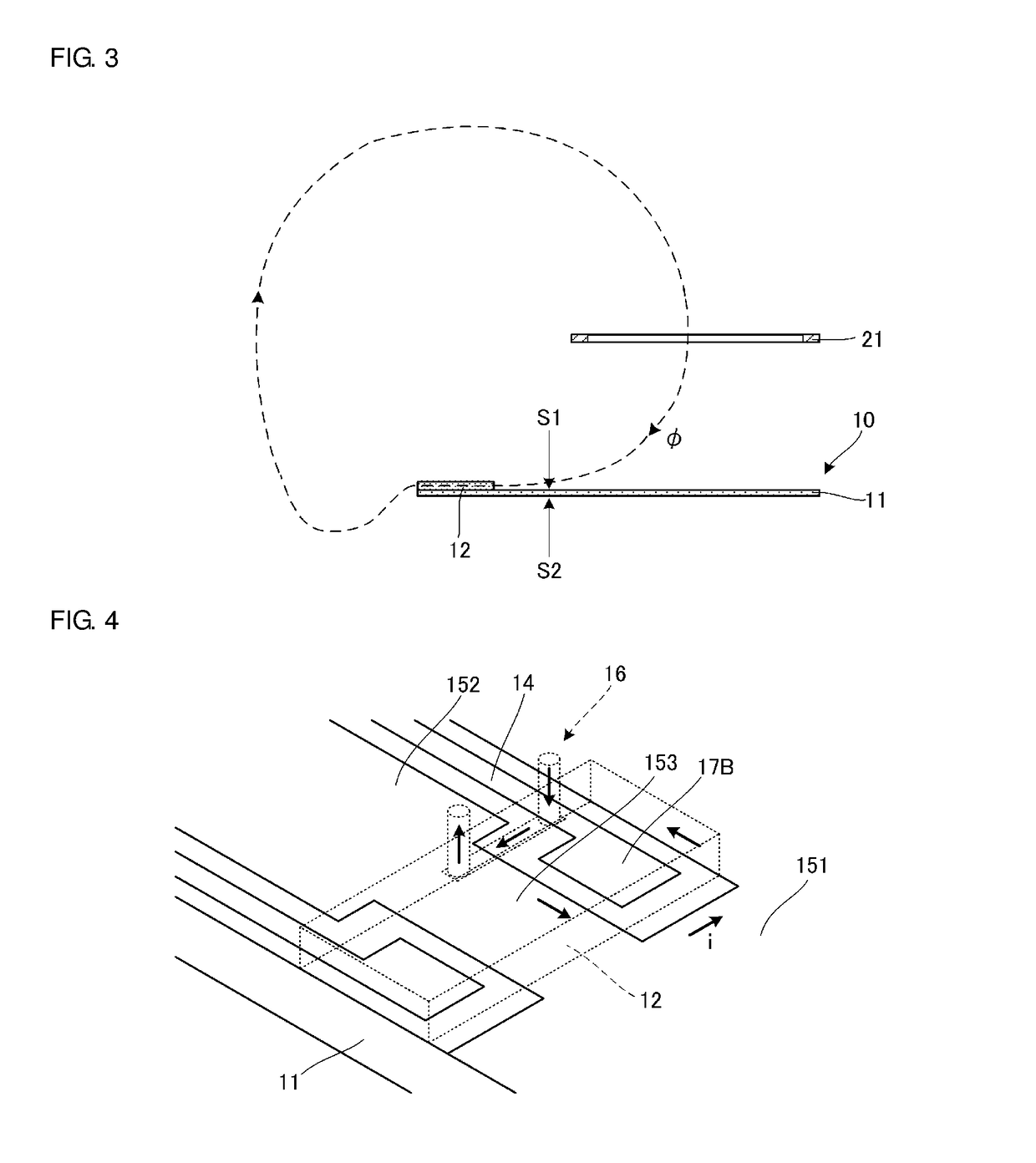

Multilayer laminated circuit board

InactiveUS20070030659A1Improvement in magnetic saturation characteristicEasy to manufactureTransformers/inductances coils/windings/connectionsElectrical connection printed elementsTransformerEngineering

A multi-layer laminated circuit board 10A of the present invention is formed by laminating together a multi-layer transformer 10, a multi-layer part sheet 30 formed with a multi-layer part, and a wiring sheet 50 formed with a circuit pattern. The multi-layer transformer 10 is incorporated into the multi-layer laminated circuit board 10A, and therefore a package for the multi-layer transformer 10 is omitted, and the wiring between the multi-layer transformer 10 and other components is reduced to a minimum.

Owner:TAMURA KK

Method for manufacturing a vibrating MEMS circuit

ActiveUS9369105B1Low temperature coefficientAccurate shapePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectromechanical coupling coefficientCrystal orientation

A method for making a micro-electro-mechanical systems (MEMS) vibrating structure is disclosed. The MEMS is supported by a MEMS anchor system and includes a single-crystal piezoelectric thin-film layer that has a specific non-standard crystal orientation, which may be selected to increase an electromechanical coupling coefficient, decrease a temperature coefficient of frequency, or both. The MEMS vibrating structure may have dominant lateral vibrations or dominant thickness vibrations. The single-crystal piezoelectric thin-film layer may include Lithium Tantalate or Lithium Niobate, and may provide MEMS vibrating structures with precise sizes and shapes, which may provide high accuracy and enable fabrication of multiple resonators having different resonant frequencies on a single substrate.

Owner:QORVO US INC

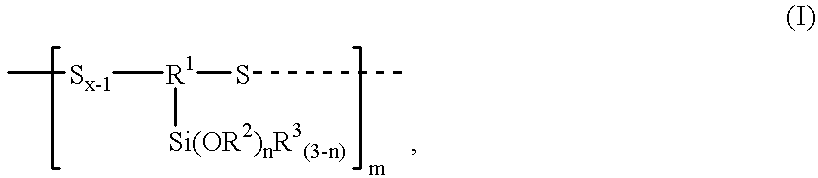

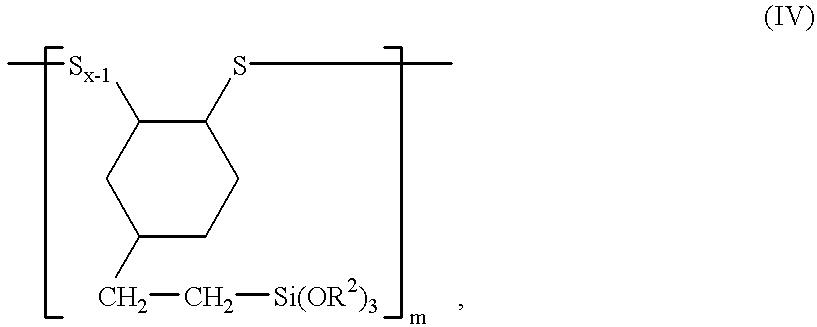

Reinforcement additives

InactiveUS6268421B1Simple methodImprove the overall coefficientAlkali metal halidesSpecial tyresUnsaturated hydrocarbonSulfur containing

The invention concerns reinforcement additives consisting of oligomeric and / or polymeric sulfur-containing organoorganooxysilanes, perhaps other unsaturated hydrocarbon-containing organoorganooxysilanes and reinforcing semiactive, active, and / or highly active carbon blacks, common in rubber, their production, and the use of the additives in perhaps silicatically filled vulcanizable rubber mixtures and compositions and in plastic mixtures or in carbon black dispersions.

Owner:DEGUSSA AG

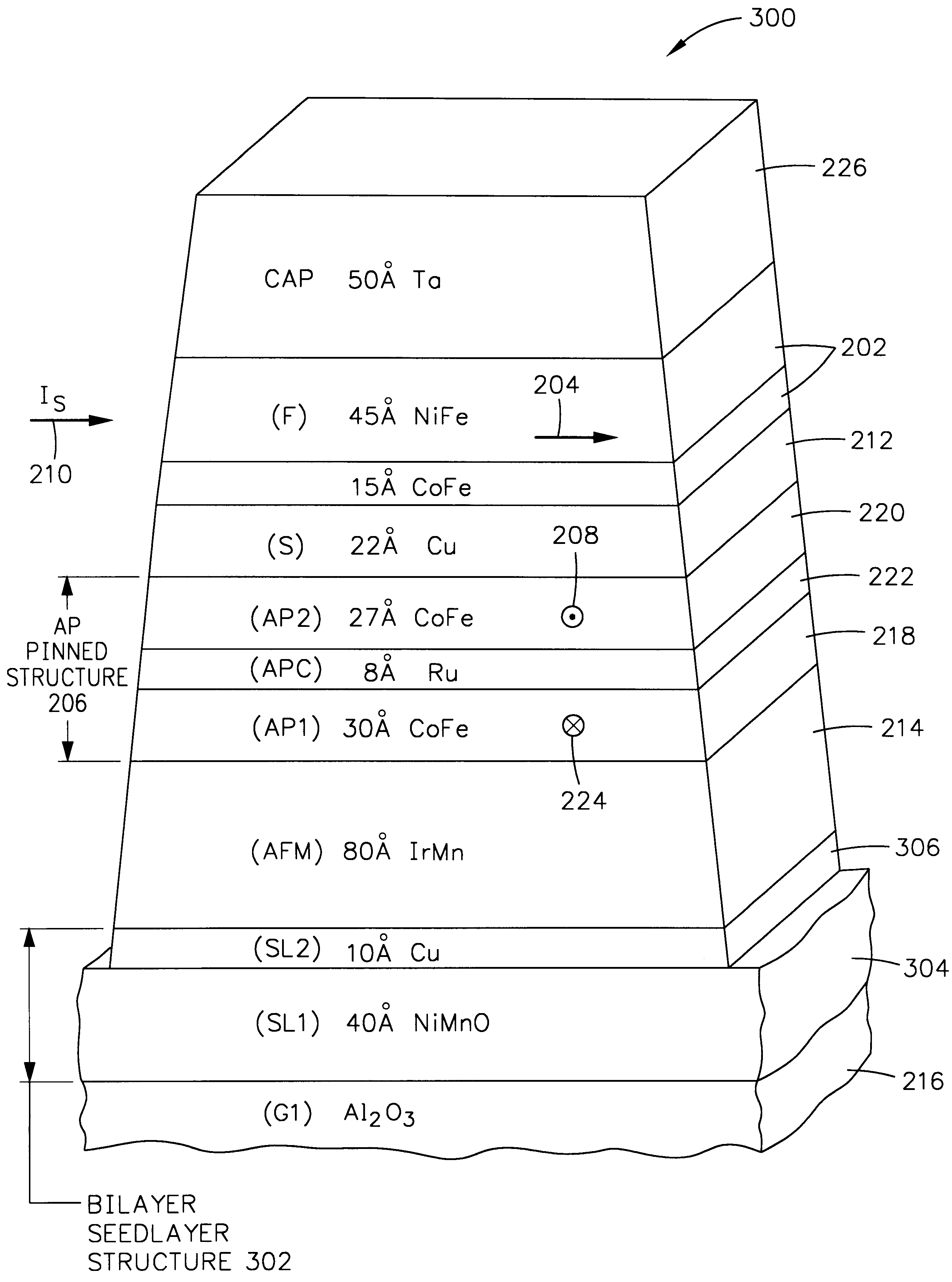

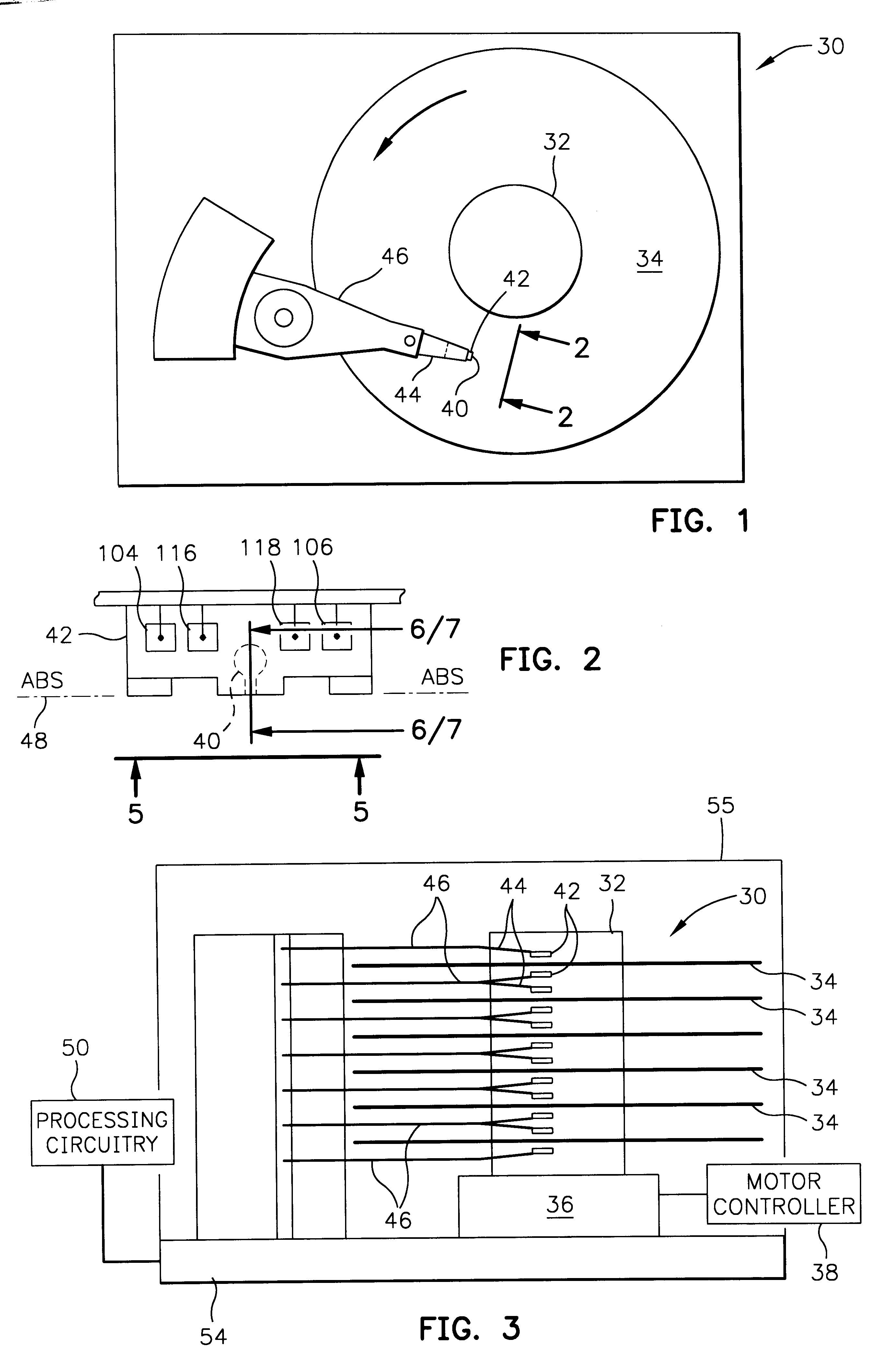

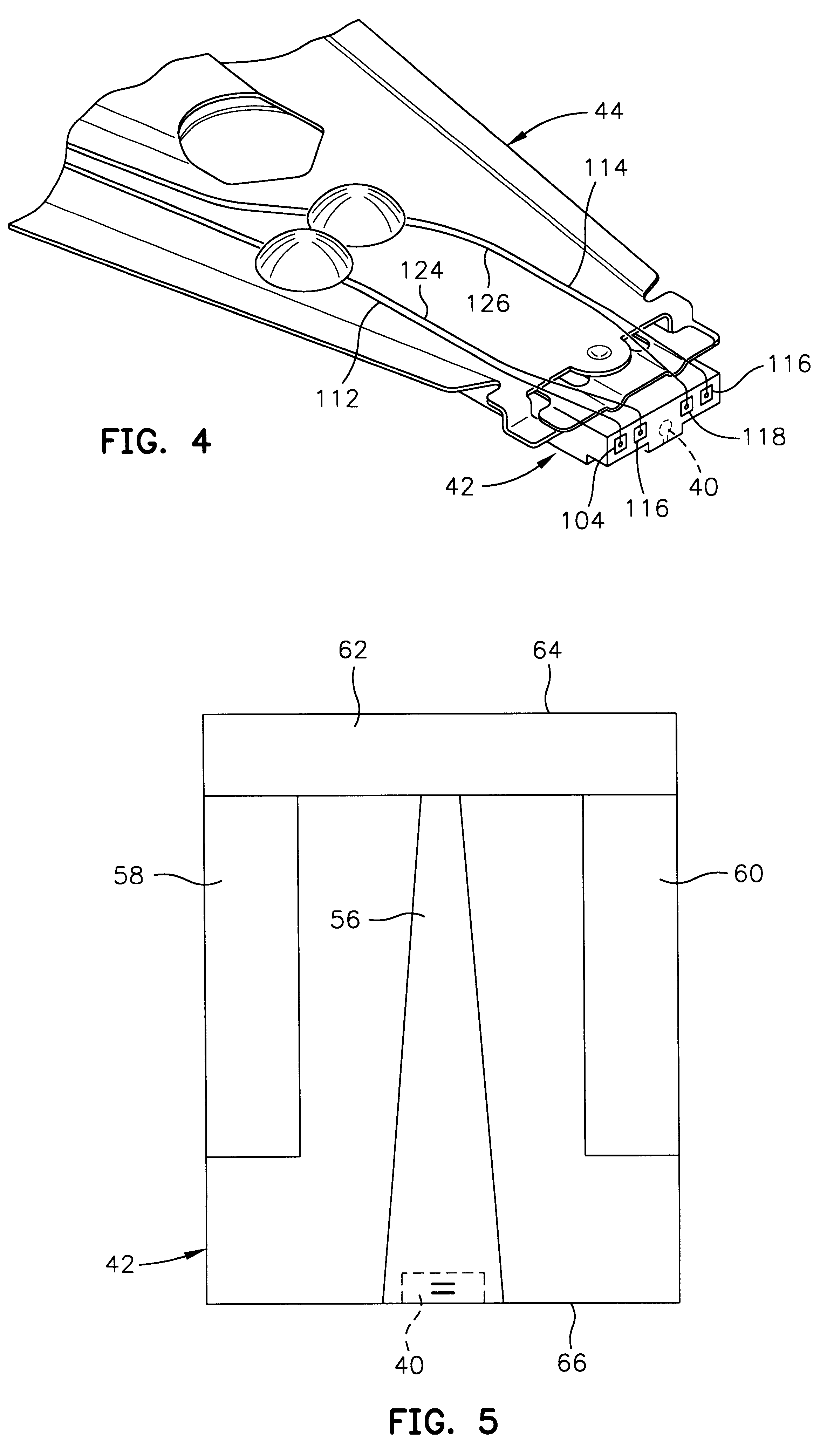

Seed layer structure for spin valve sensor

InactiveUS6208492B1Increase the gapImprove thermal stabilityNanomagnetismNanoinformaticsManganese oxideNickel

A bilayer seed layer structure is employed between a first read gap layer and a spin valve sensor for increasing the magnetoresistive coefficient (dr / R). In a bottom spin valve sensor the bilayer seed layer structure is located between the first read gap layer and a pinning layer and in a top spin valve sensor the bilayer seed layer structure is located between the first read gap layer and the free layer. The pinning layer is preferably iridium manganese (IrMn). The bilayer seed layer structure includes a first seed layer which is a metallic oxide and a second seed layer that is a nonmagnetic metal. A preferred embodiment is a first seed layer of nickel manganese oxide (NiMnO) and a second seed layer of copper (Cu).

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Elastic wave device and manufacturing method for same

ActiveUS9748923B2Lower electrode resistanceImprove featuresImpedence networksEngineeringPiezoelectric thin films

An elastic wave device includes a support layer with a through-hole or a recess opened at an upper surface thereof, a piezoelectric thin film arranged on the support layer to extend above the recess or the through-hole of the support layer, and an IDT electrode defined on at least one of upper and lower surfaces of the piezoelectric thin film in a region of the piezoelectric thin film, the region extending above the recess, or the through-hole. A secondary mode of a plate wave, which contains a U1 component as a main component, is utilized. The piezoelectric thin film is made of LiTaO3, and Euler angles (φ, θ, ψ) of the LiTaO3 fall within specific ranges.

Owner:MURATA MFG CO LTD

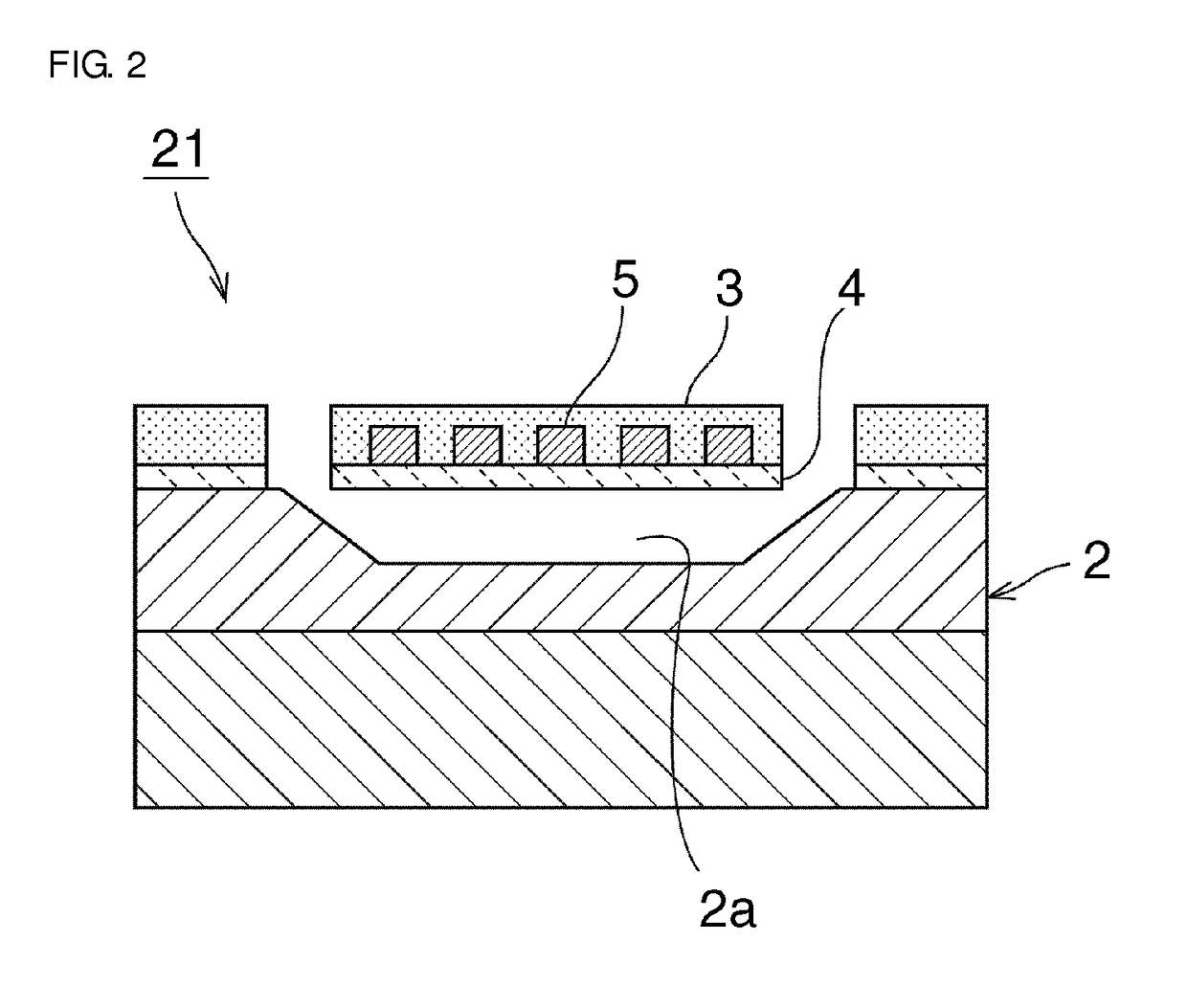

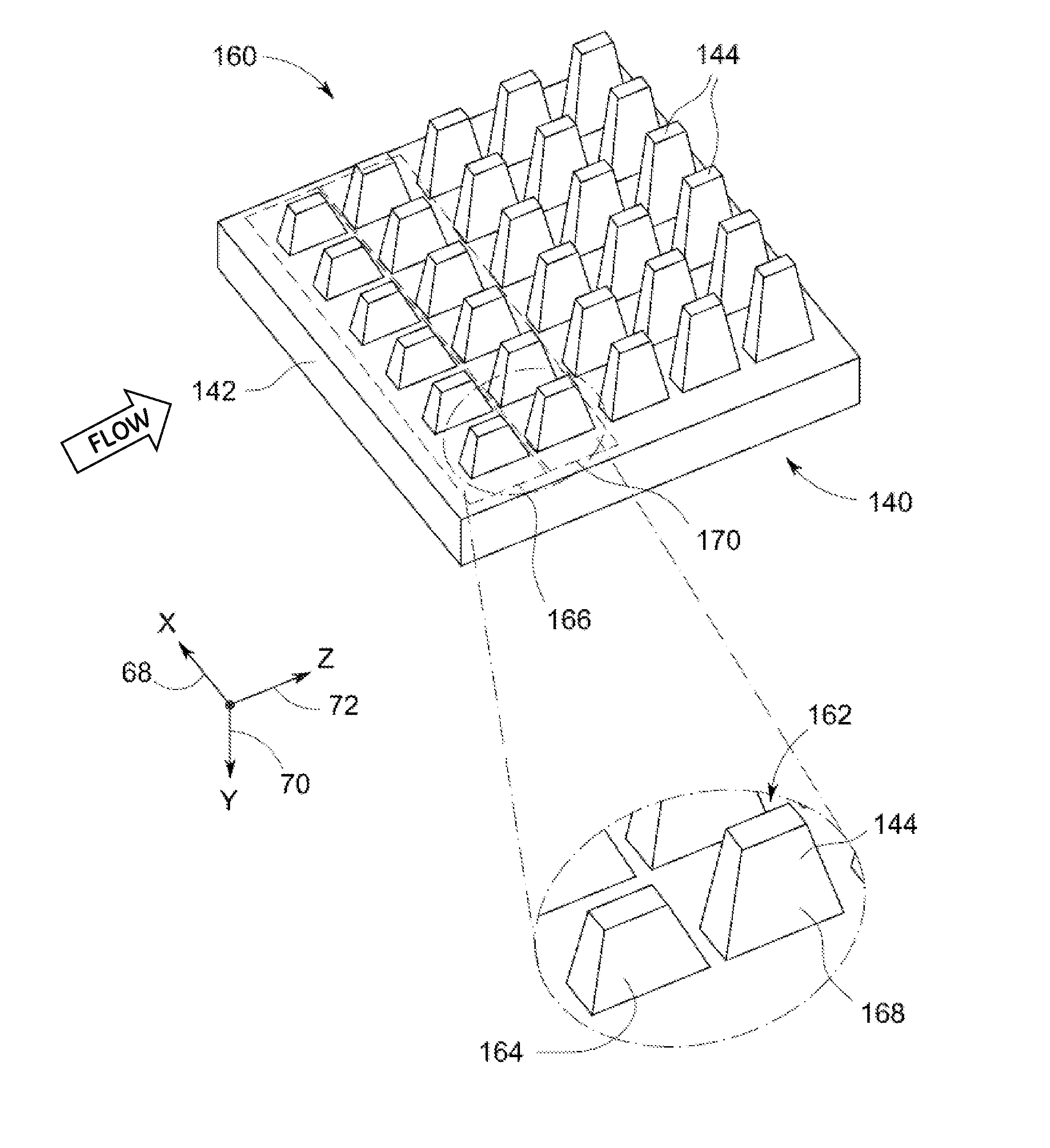

Air-cooled engine surface cooler

ActiveUS20140027102A1Improve heat transfer performanceIncreasing turbulence levelEngine fuctionsTurbine/propulsion engine coolingSurface coolingEngineering

A surface cooler comprises a plate-like layer and a plurality of spaced-apart fins extending substantially perpendicular from an uppermost layer of the plate-like layer. The plurality of fins defining a plurality of air flow paths. The plurality of spaced-apart fins are configured to augment heat transfer of the surface cooler by increasing the turbulence levels of a fluid flowing through the airflow paths by promoting increased mixing with a resulting increase in the heat transfer coefficient of the surface cooler. A method of forming the surface cooler and an engine including the surface cooler.

Owner:GENERAL ELECTRIC CO

Laser processing of a locally heated target material

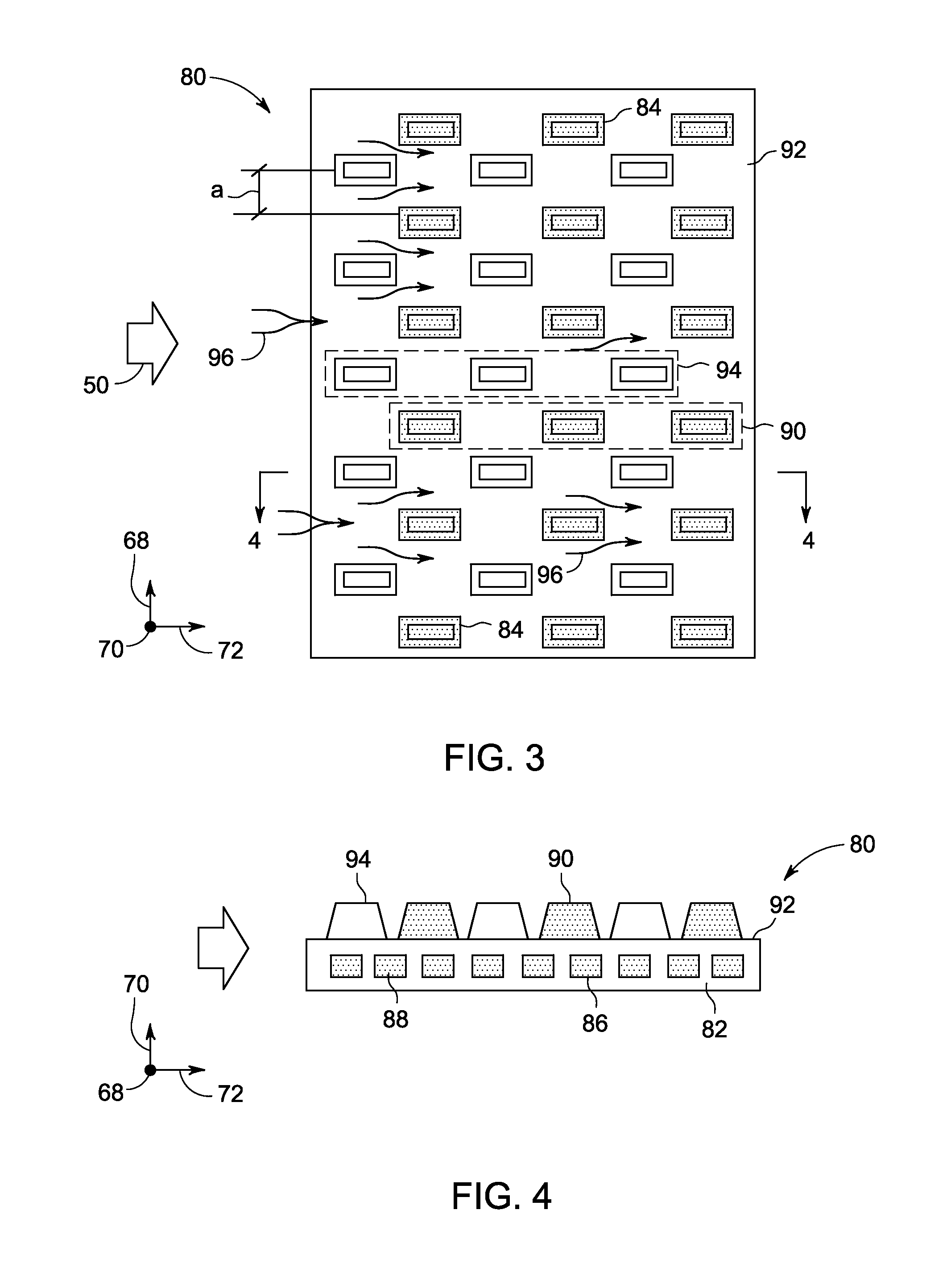

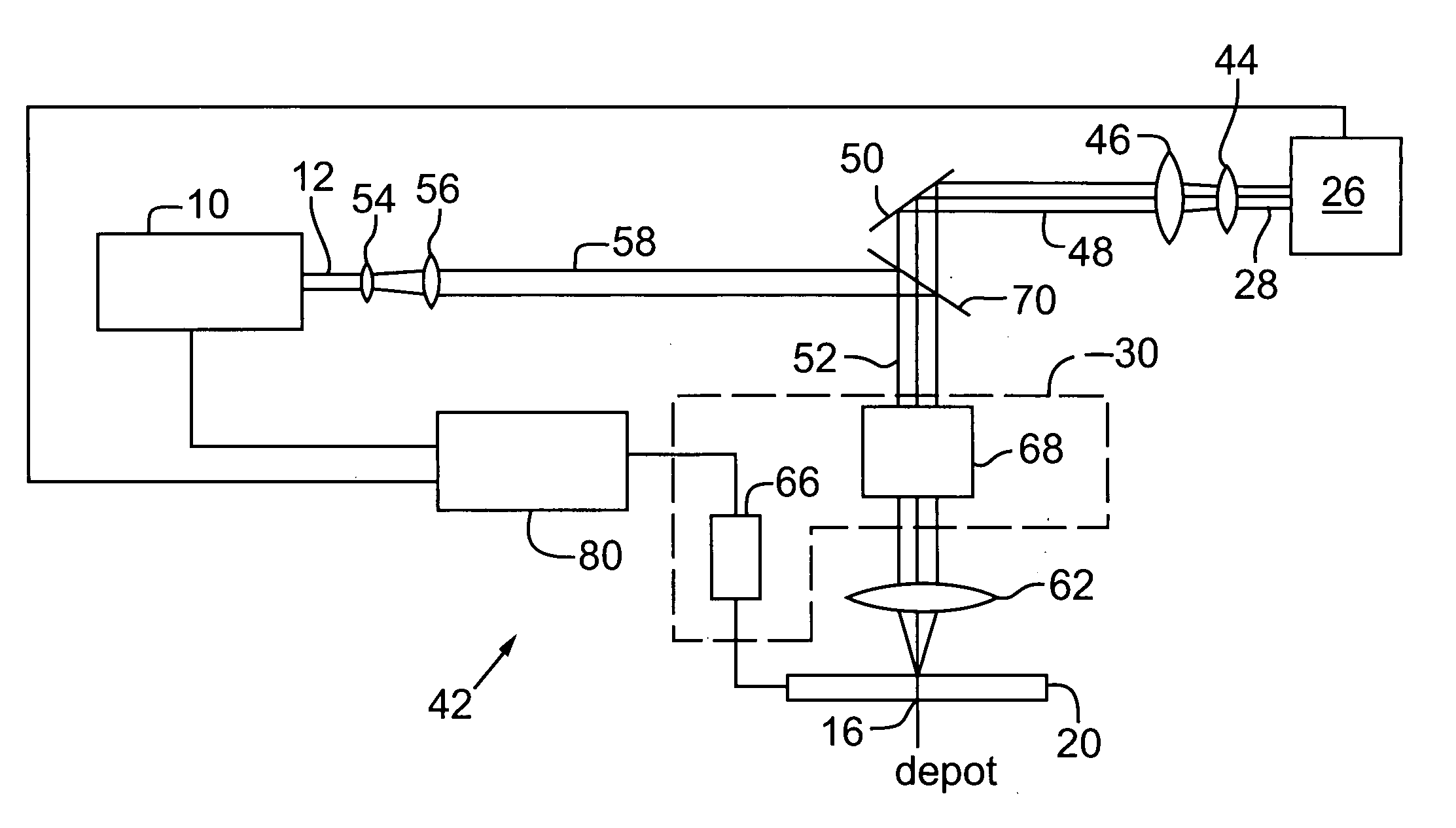

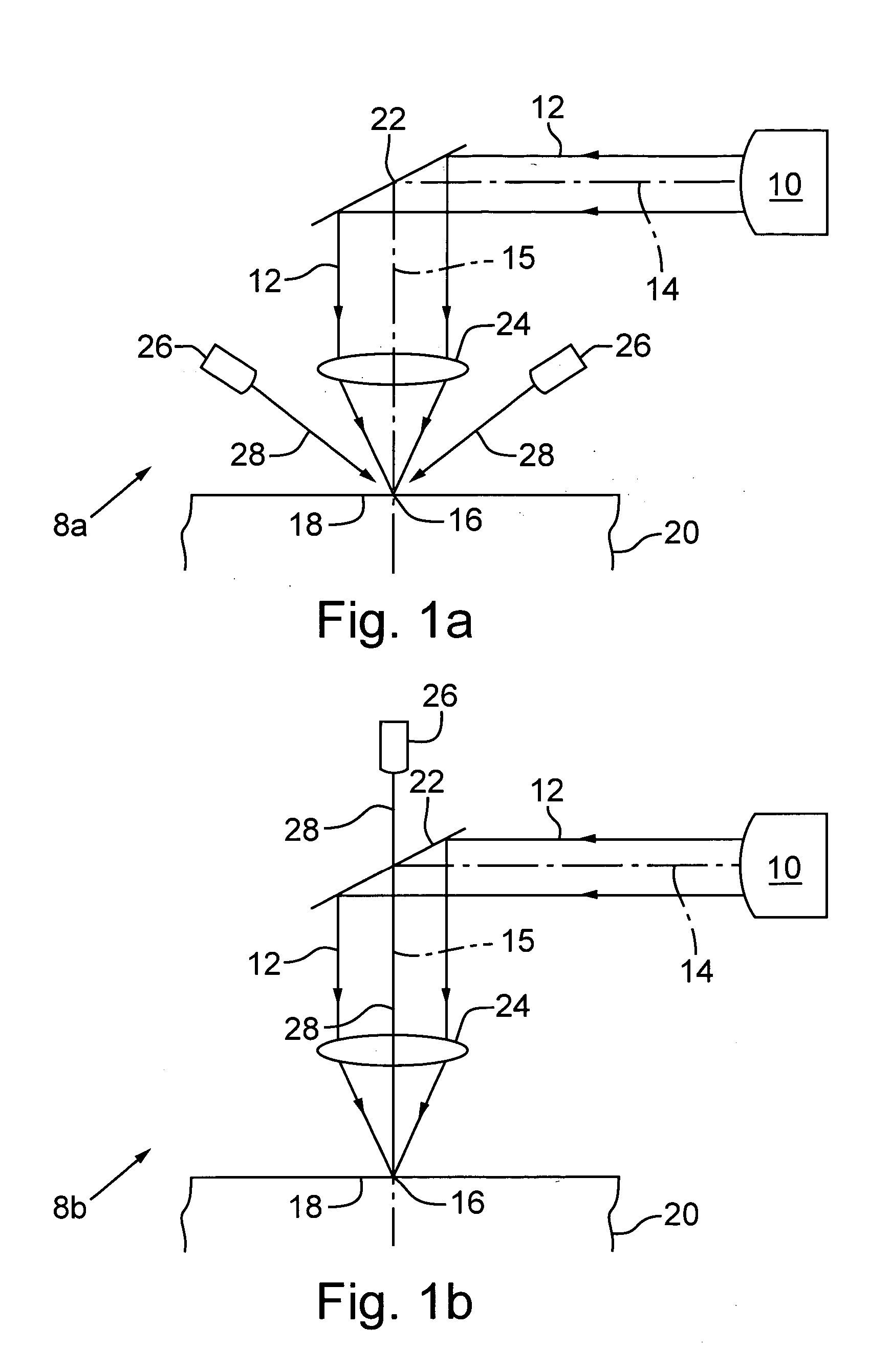

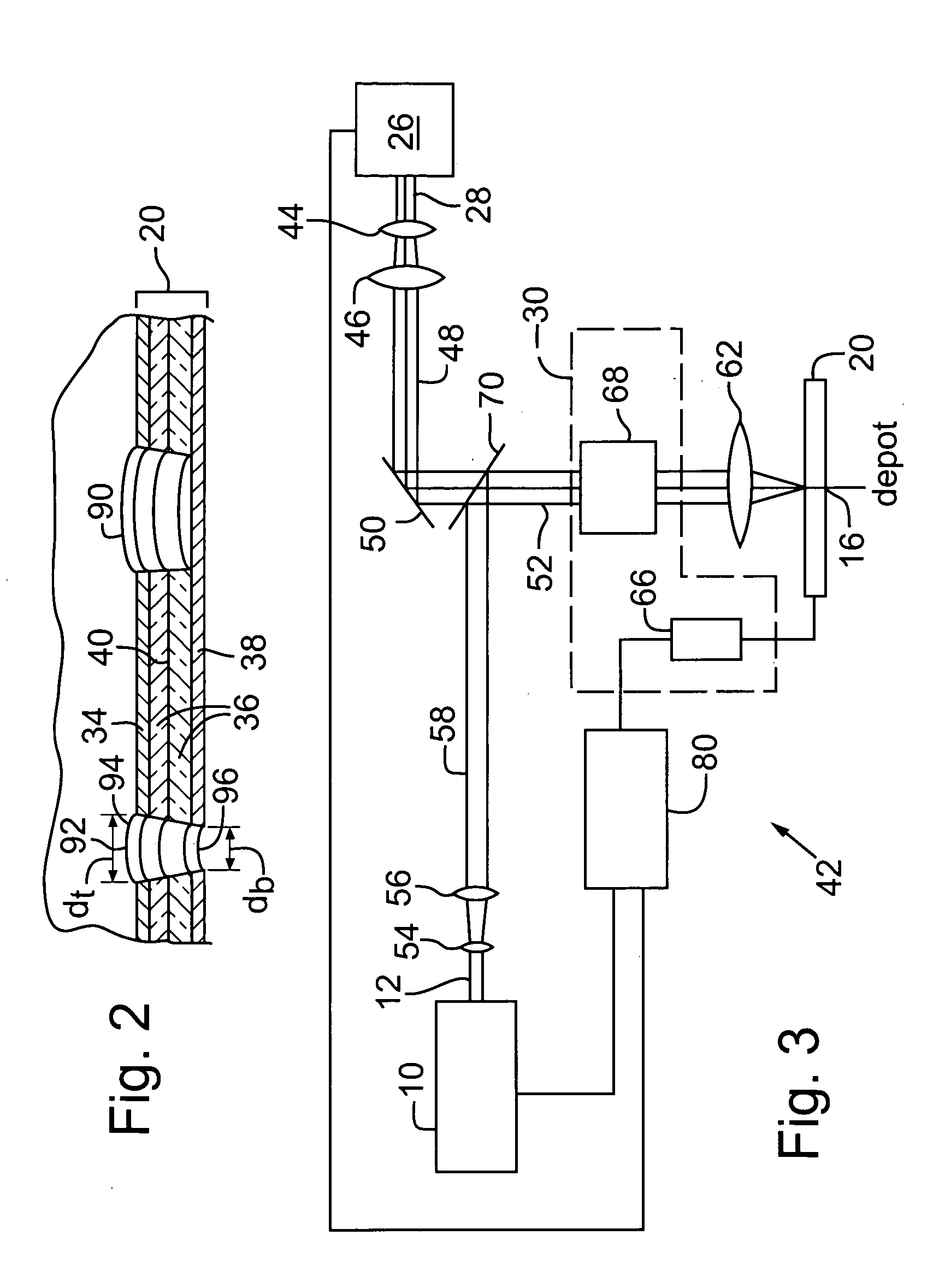

InactiveUS20050087522A1Improve efficiencyIncrease speedPrinted circuit manufactureWelding/soldering/cutting articlesThermal energyLaser processing

A method and laser system effect rapid removal of material from a workpiece by applying heating energy in the form of a light beam to a target location on the workpiece to elevate its temperature while maintaining its dimensional stability. When the target portion of the workpiece is heated, a laser beam is directed for incidence on the heated target location. The laser beam preferably has a processing laser output that is appropriate to effect removal of the target material from the workpiece. The combined incidence of the processing laser output and the heating energy on the target location enables the processing laser output to remove a portion of the target material at a material removal rate that is higher than the material removal rate achievable when the target material is not heated.

Owner:ELECTRO SCI IND INC

Thermal interface structure and process for making the same

InactiveUS20060208354A1Low costImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesCarbon nanotubeElectronic component

A thermal interface structure (10, 20) is provided for a highly conductive thermal interface between an electronic component and a cooling device for dissipating heat generated by the electronic component. The thermal interface structure includes a matrix (12, 22) and a plurality of carbon nanotubes (14, 24) incorporated in the matrix. The matrix is generally made from a phase change material. A method for making a thermal interface structure is also provided.

Owner:TSINGHUA UNIV +1

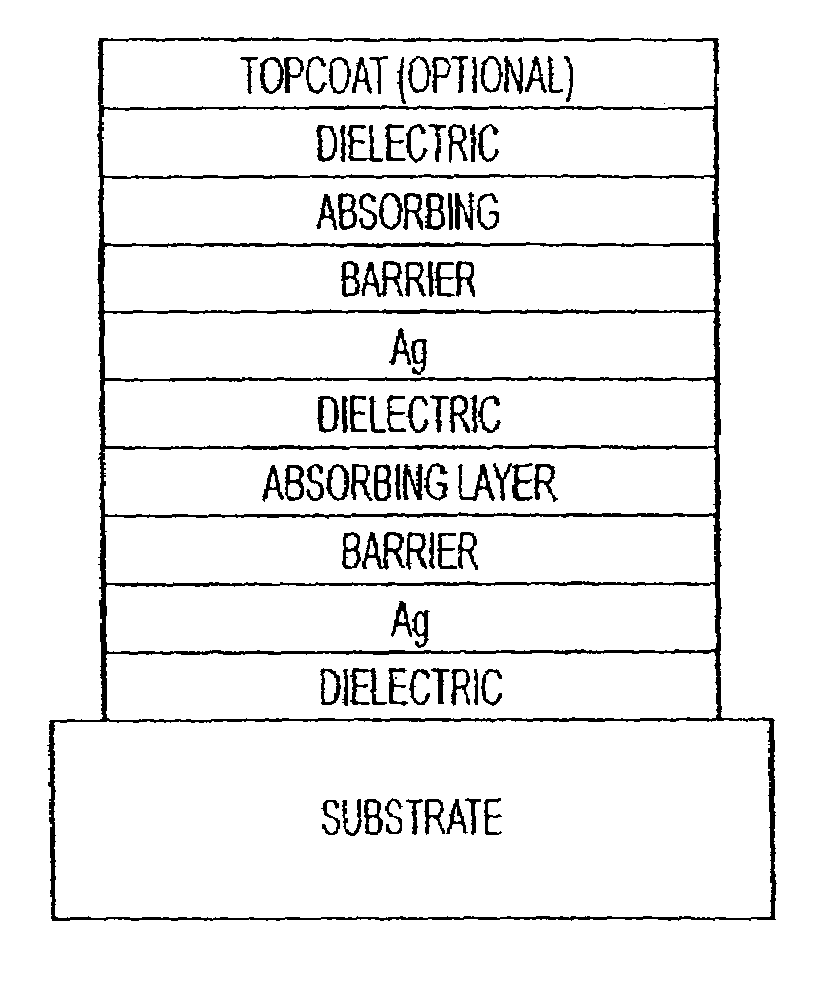

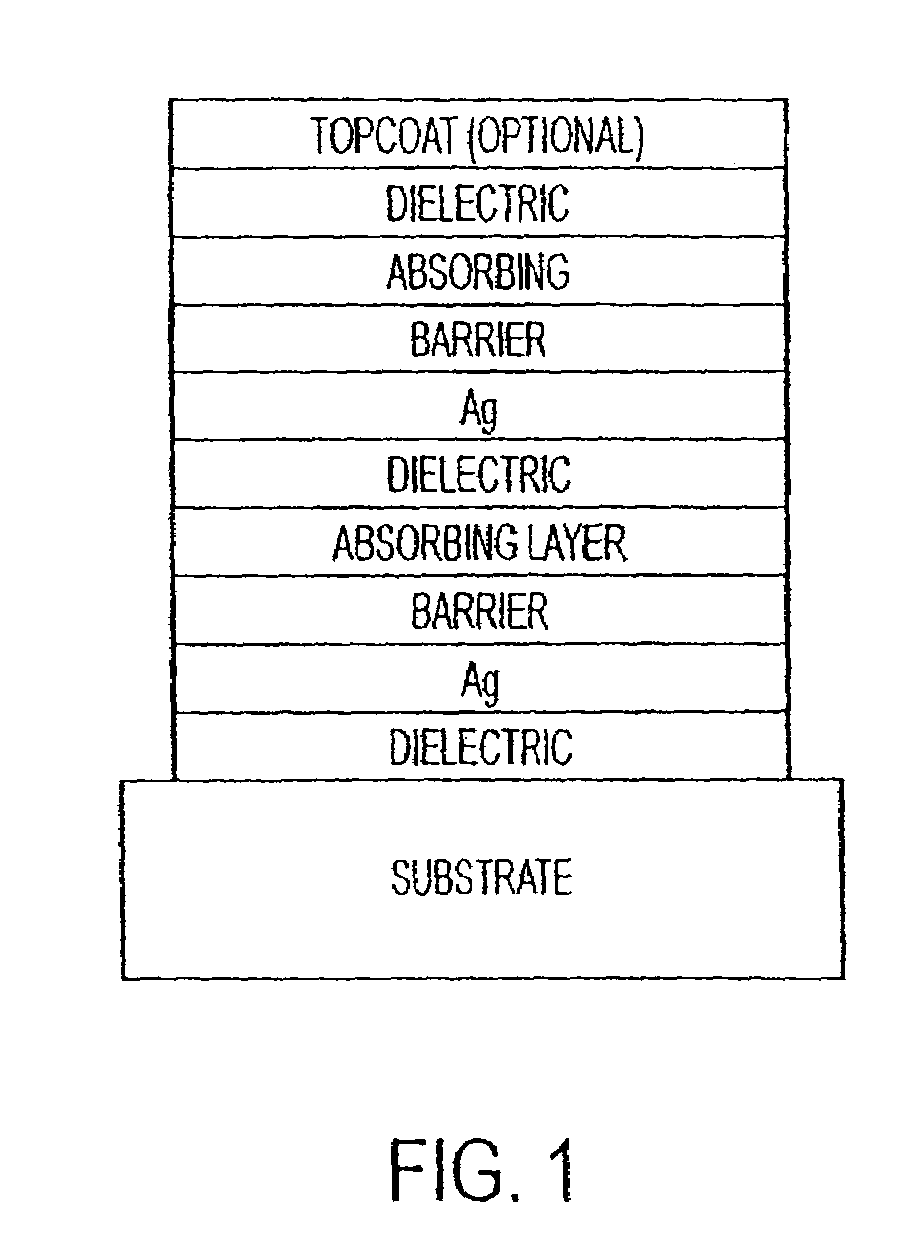

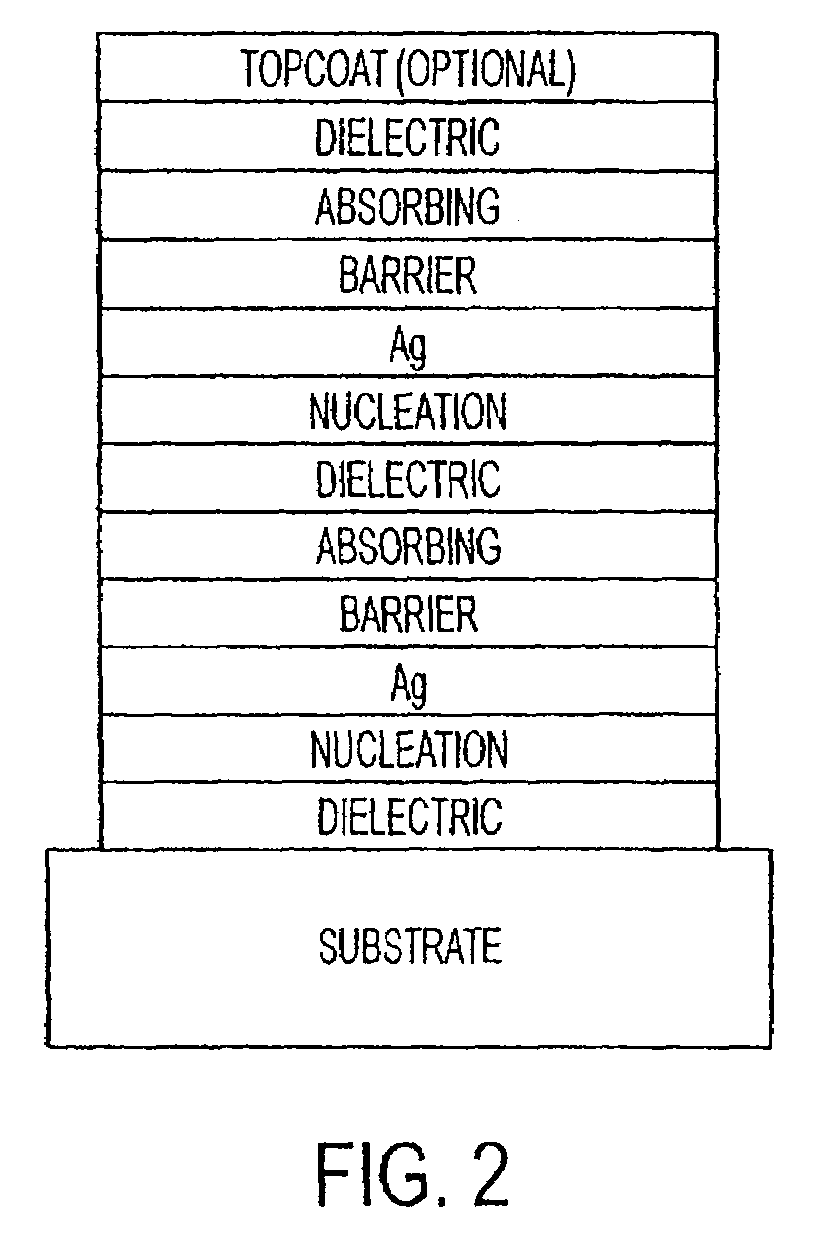

Low emissivity coating with low solar heat gain coefficient, enhanced chemical and mechanical properties and method of making the same

ActiveUS7659002B2Improve the overall coefficientIncreased durabilityGlass/slag layered productsCoatingsLow emissivityGain coefficient

Owner:CARDINAL CG

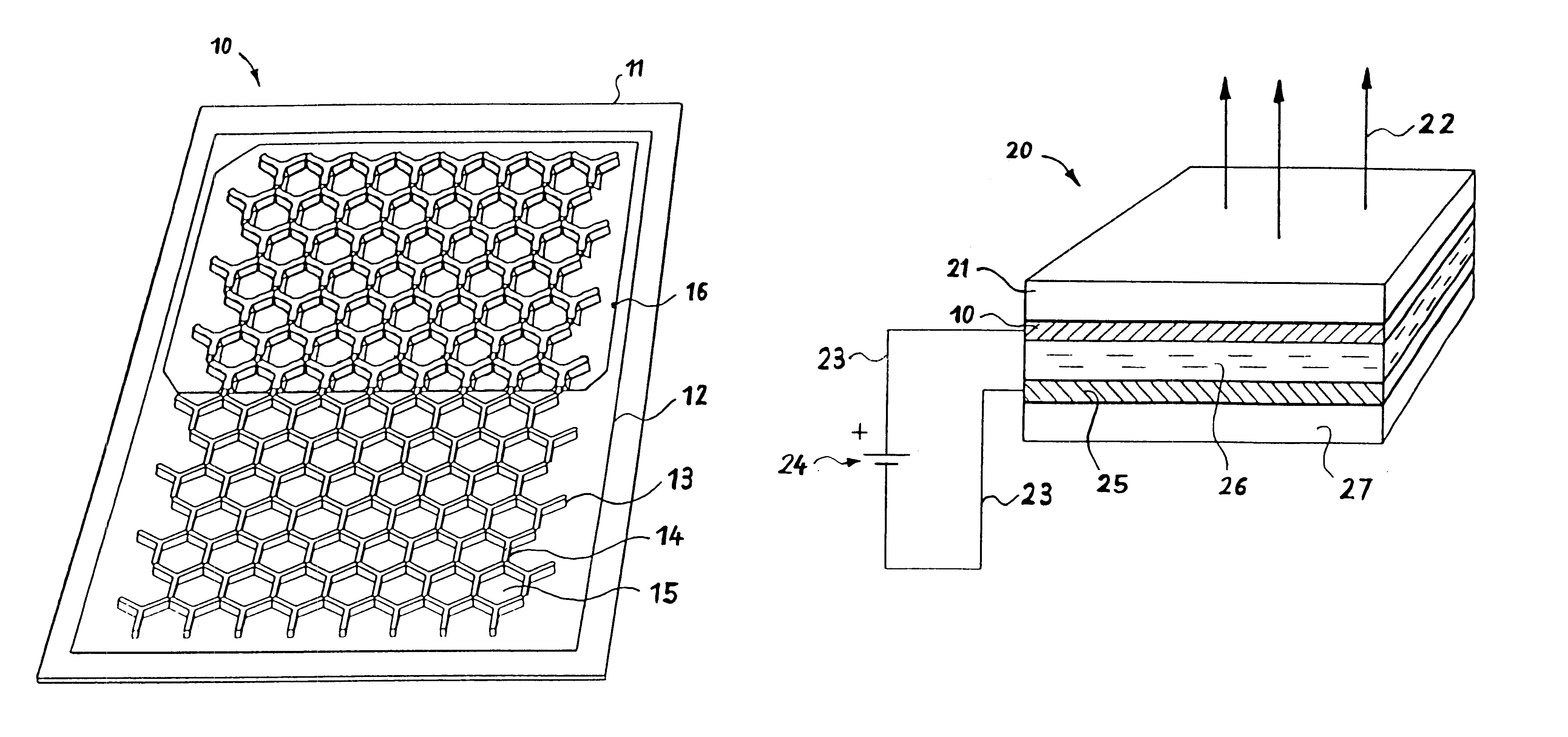

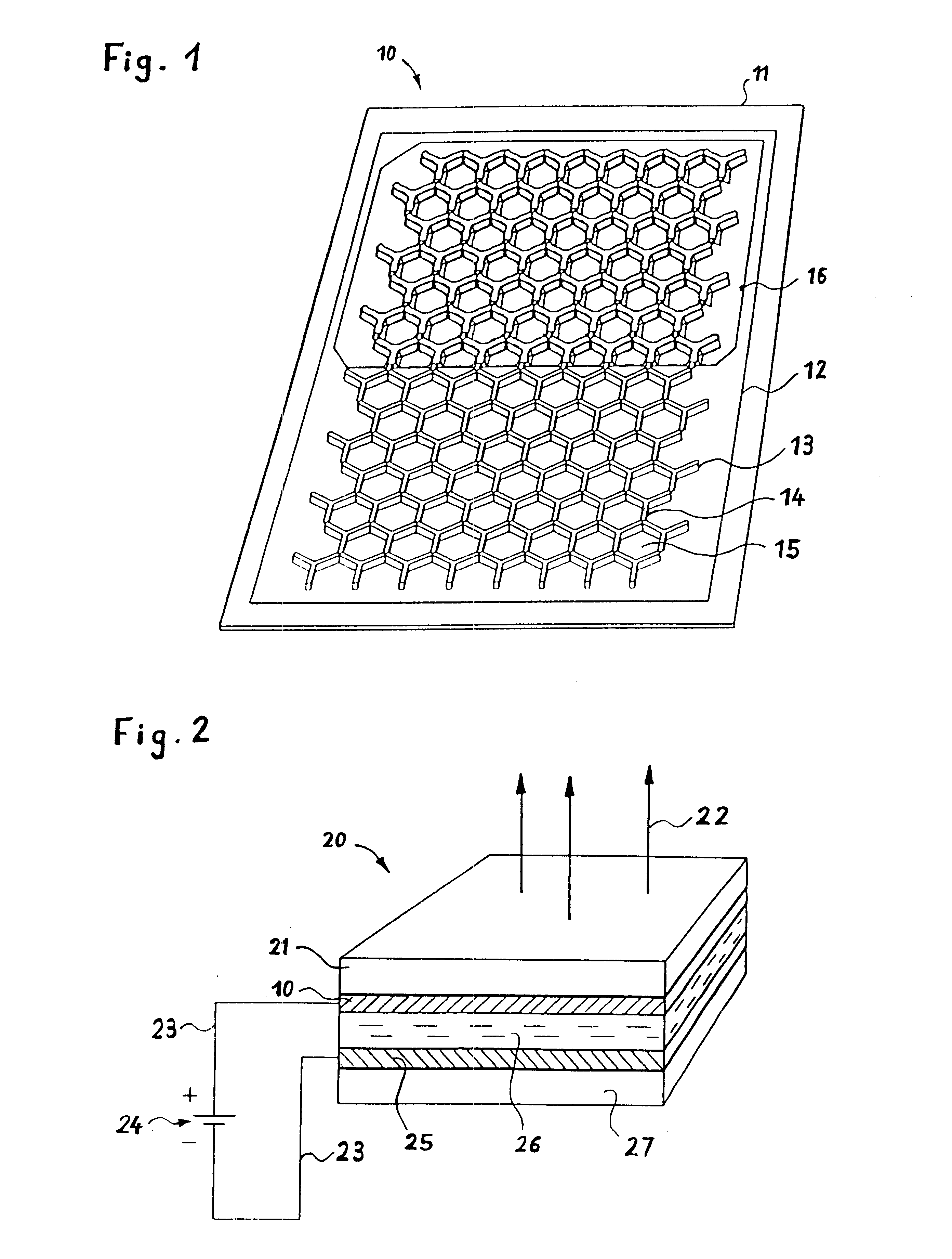

Electrode for use in electro-optical devices

InactiveUS6472804B2Improve conductivityWide adaptabilityMaterial nanotechnologyDischarge tube luminescnet screensForward scatterLength wave

An electrode for an electro-optical device is provided. Light is passing through this electrode which comprises a pattern of conductive elements. The elements have dimensions small compared to the wavelength of light, so that the electrode appear transparent. The light intensity distribution after having penetrated the electrode compared with the light intensity distribution before having penetrated the electrode is influenced by forward scattering.

Owner:AU OPTRONICS CORP

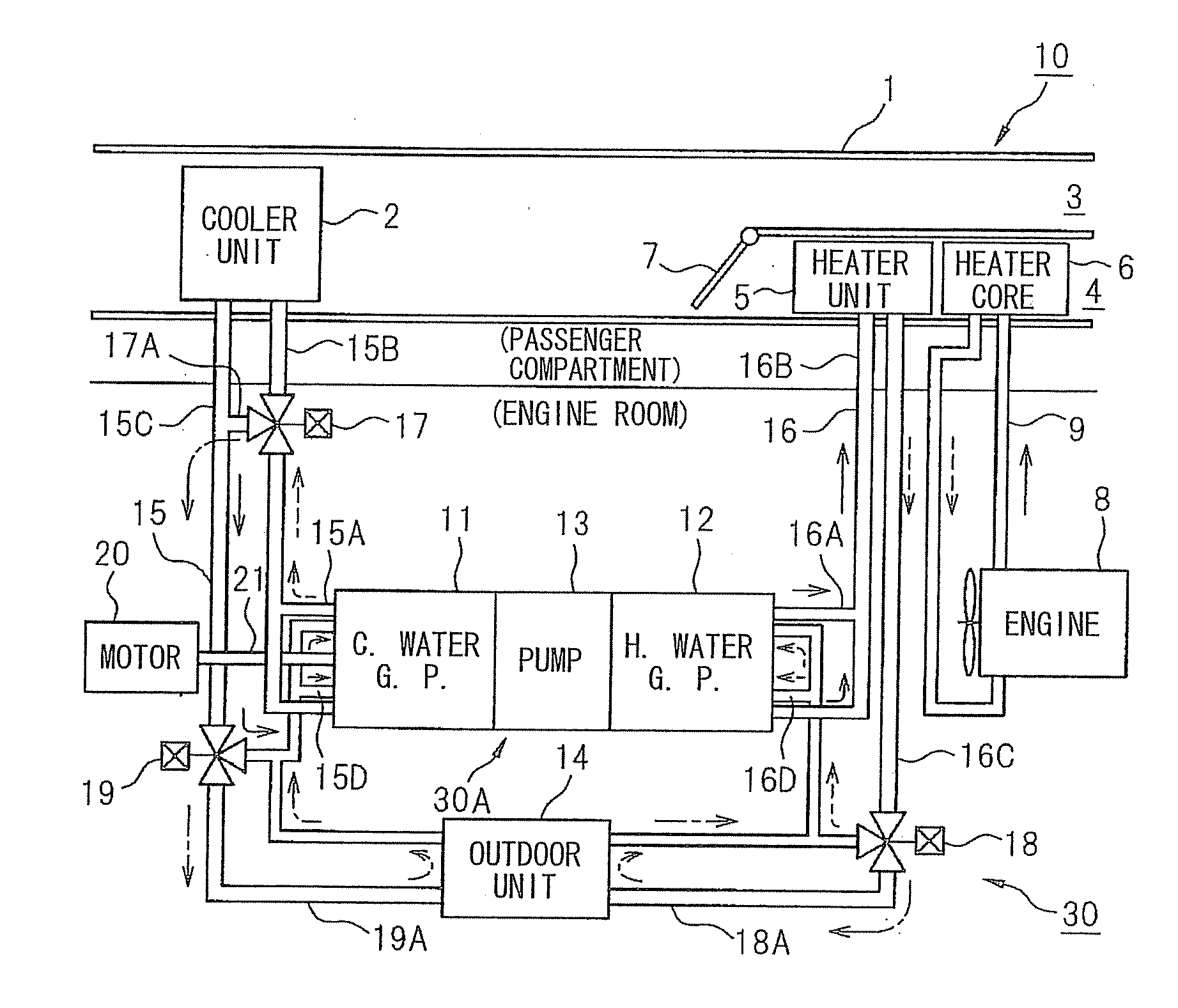

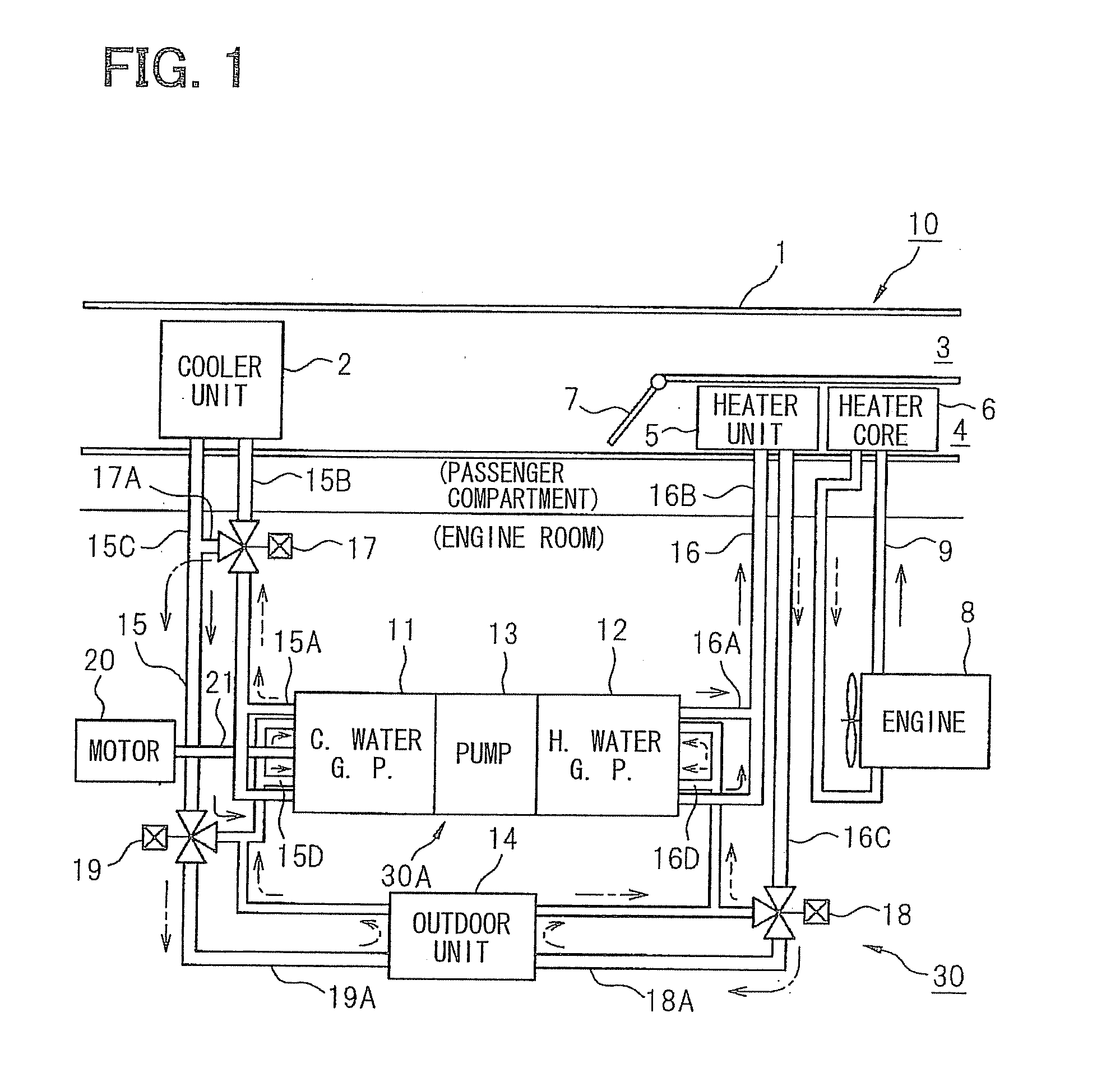

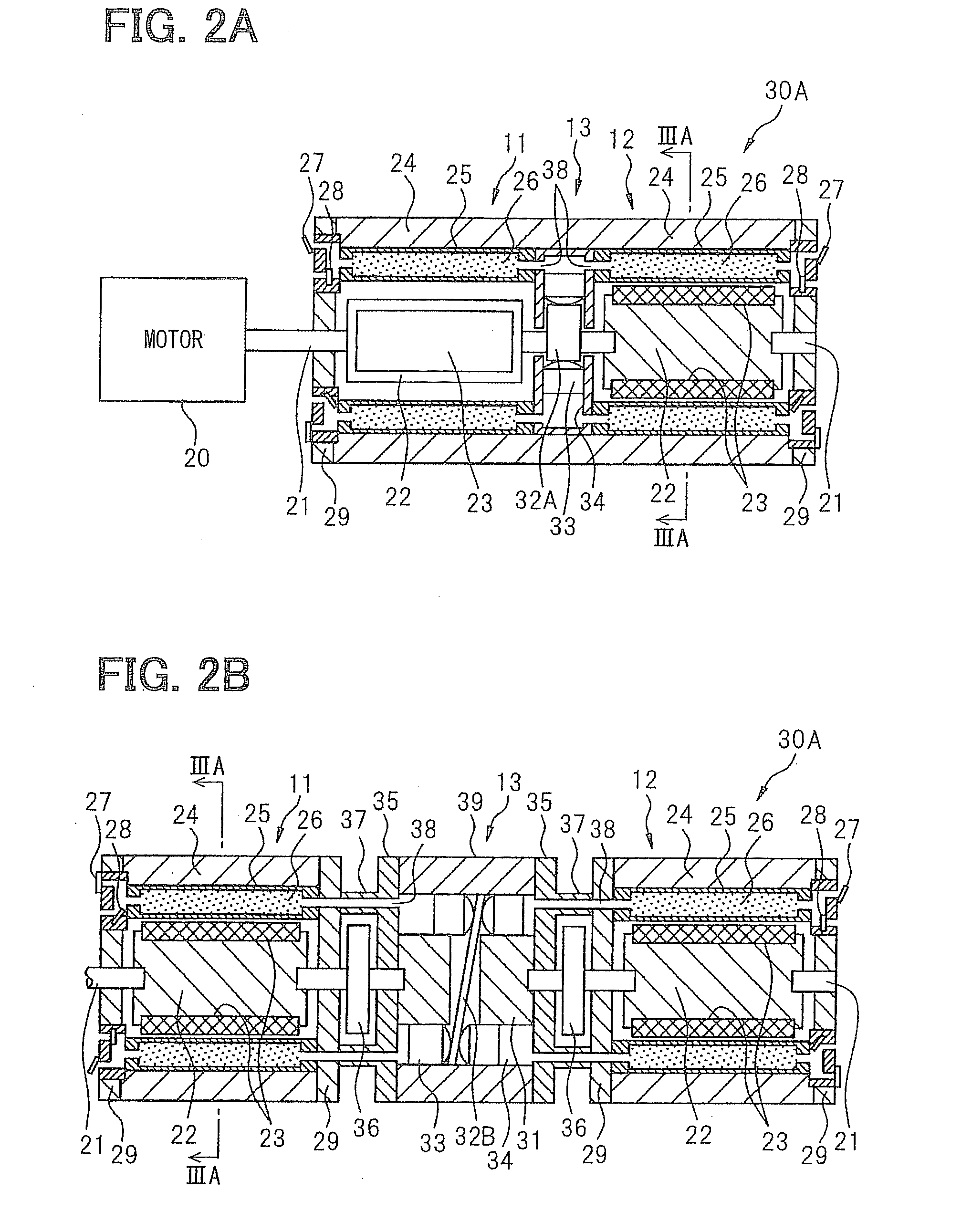

Magnetic heat pump system

ActiveUS20120272666A1Improvement factorImprove cooling effectEnergy efficient heating/coolingVehicle heating/cooling devicesTransport mediumEngineering

In a magnetic heat pump system, in which heat transport medium is heated or cooled by magnetocaloric effect material accommodated in a magnetic heat pump device. A material having a coefficient of thermal conductivity, which is higher than that of the heat transport medium, or a material having a specific heat or a volume specific heat, which is higher than that of the heat transport medium, is mixed in the heat transport medium. A coefficient of thermal conductivity of the heat transport medium is thereby increased so as to increase heating and / or cooling performance of the magnetic heat pump system.

Owner:DENSO CORP

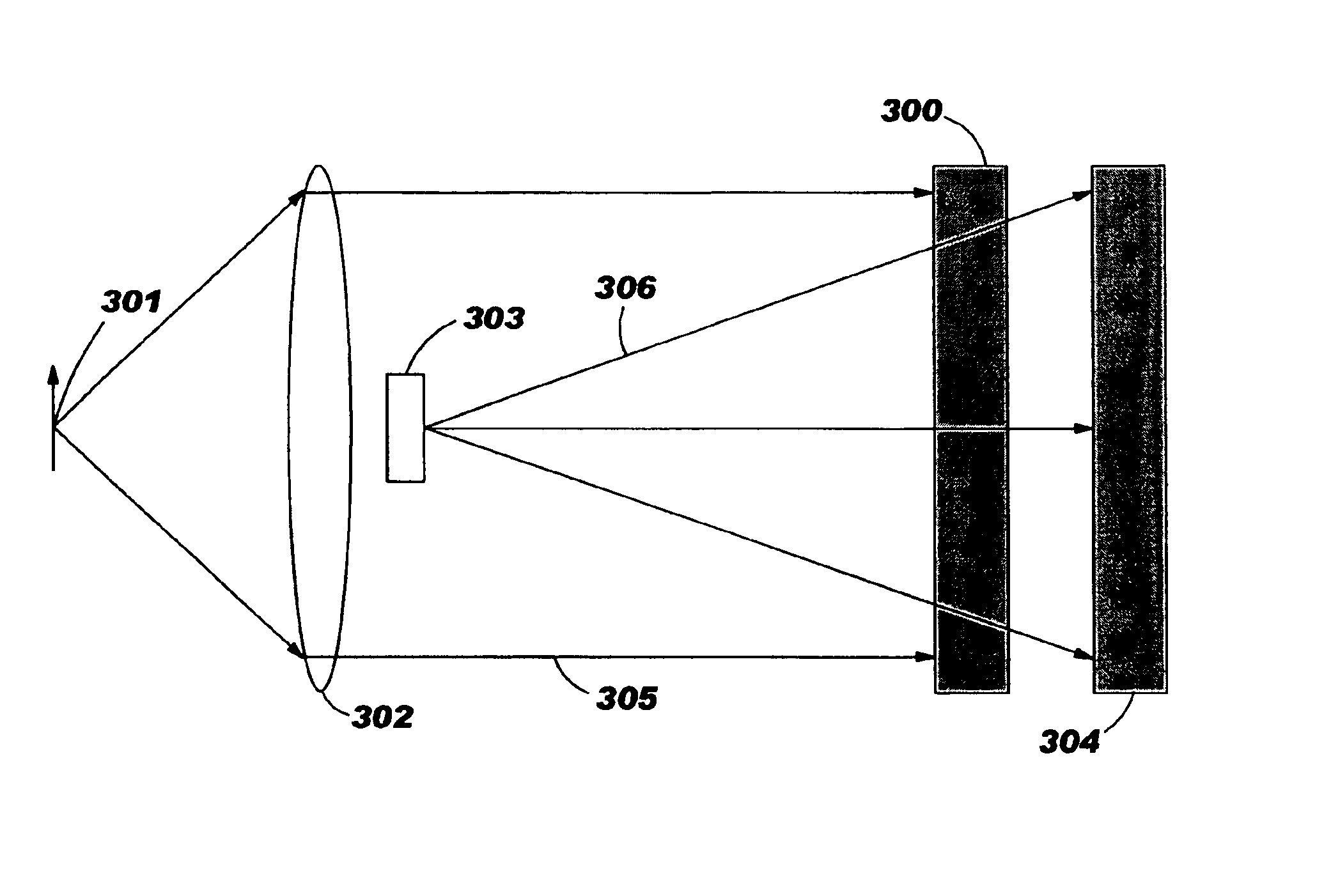

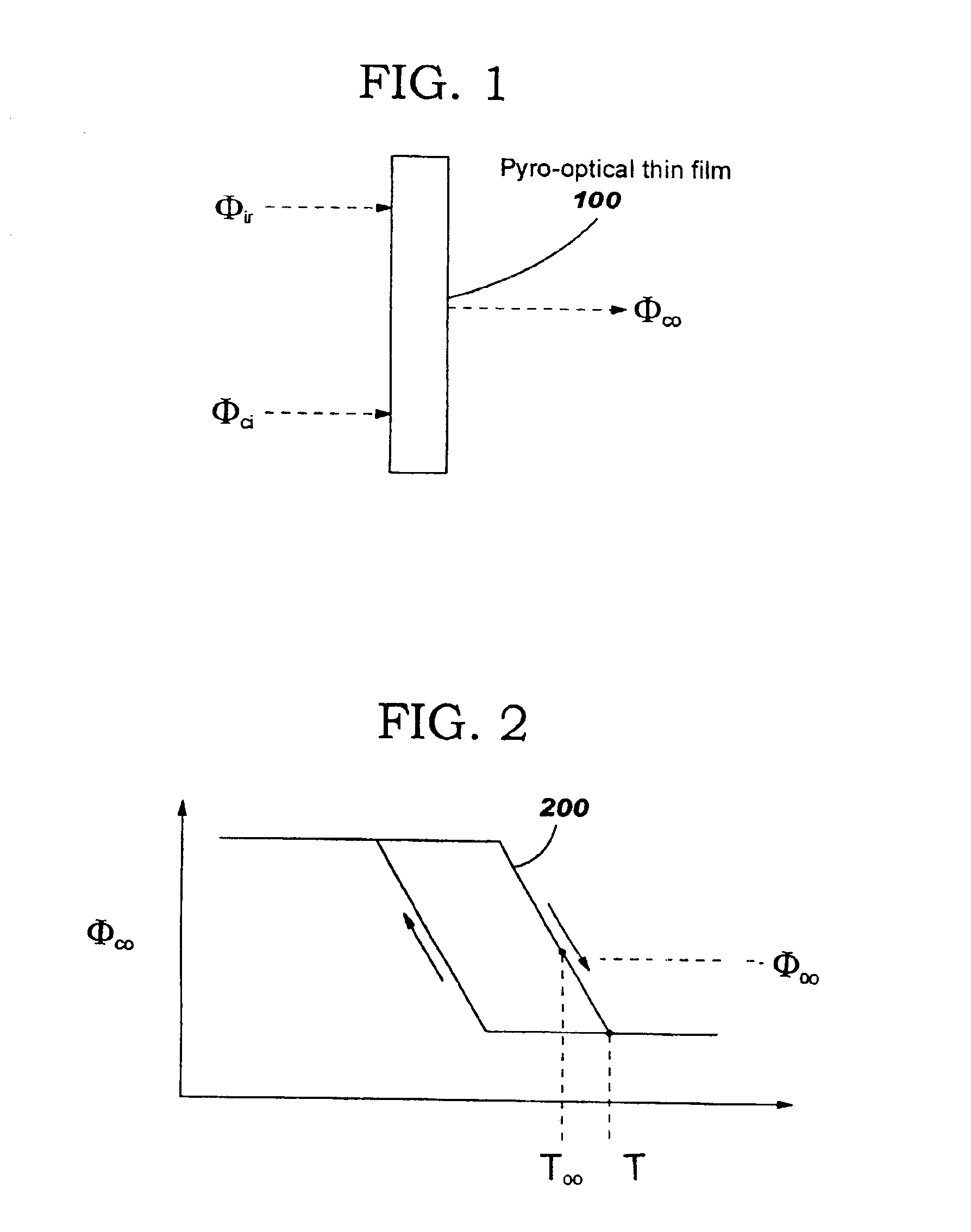

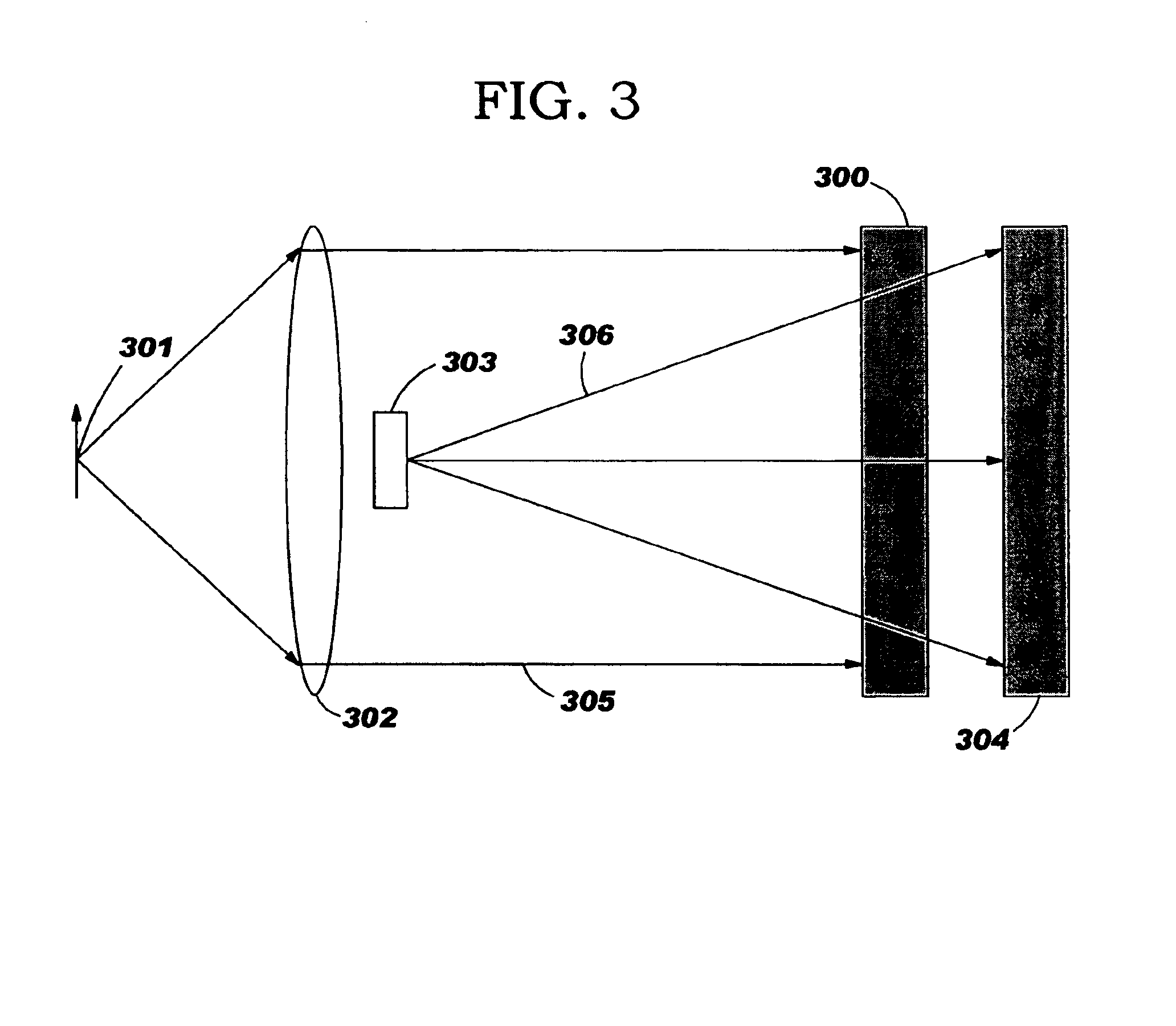

Radiation sensor with photo-thermal gain

InactiveUS6888141B2Increase temperatureImprove the overall coefficientRadiation pyrometryPhotometryTransmittanceRadiation sensor

A thermal sensor for low level radiation with built-in photo-thermal gain utilizing a thin film of pyro-optical material to modulate the reflectivity and / or transmission of a photonic carrier beam. The photonic carrier beam is modulated by the temperature of the pyro-optical film and detected by typically a silicon detector. A slight temperature increase of the pyro-optical film due to absorption of low level radiation increases the coefficient of absorption of the photonic carrier beam which in turn causes a further increase in temperature of the pyro-optical film. The photonic carrier beam provides power to increase the temperature of the pyro-optical film beyond the heating caused by the absorption of low level radiation alone. This thermal amplification effect provides a radiation sensor with photo-thermal gain.

Owner:MULTISPECTRAL IMAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com