Patents

Literature

465 results about "Process integration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process integration is a term in chemical engineering which has two possible meanings.

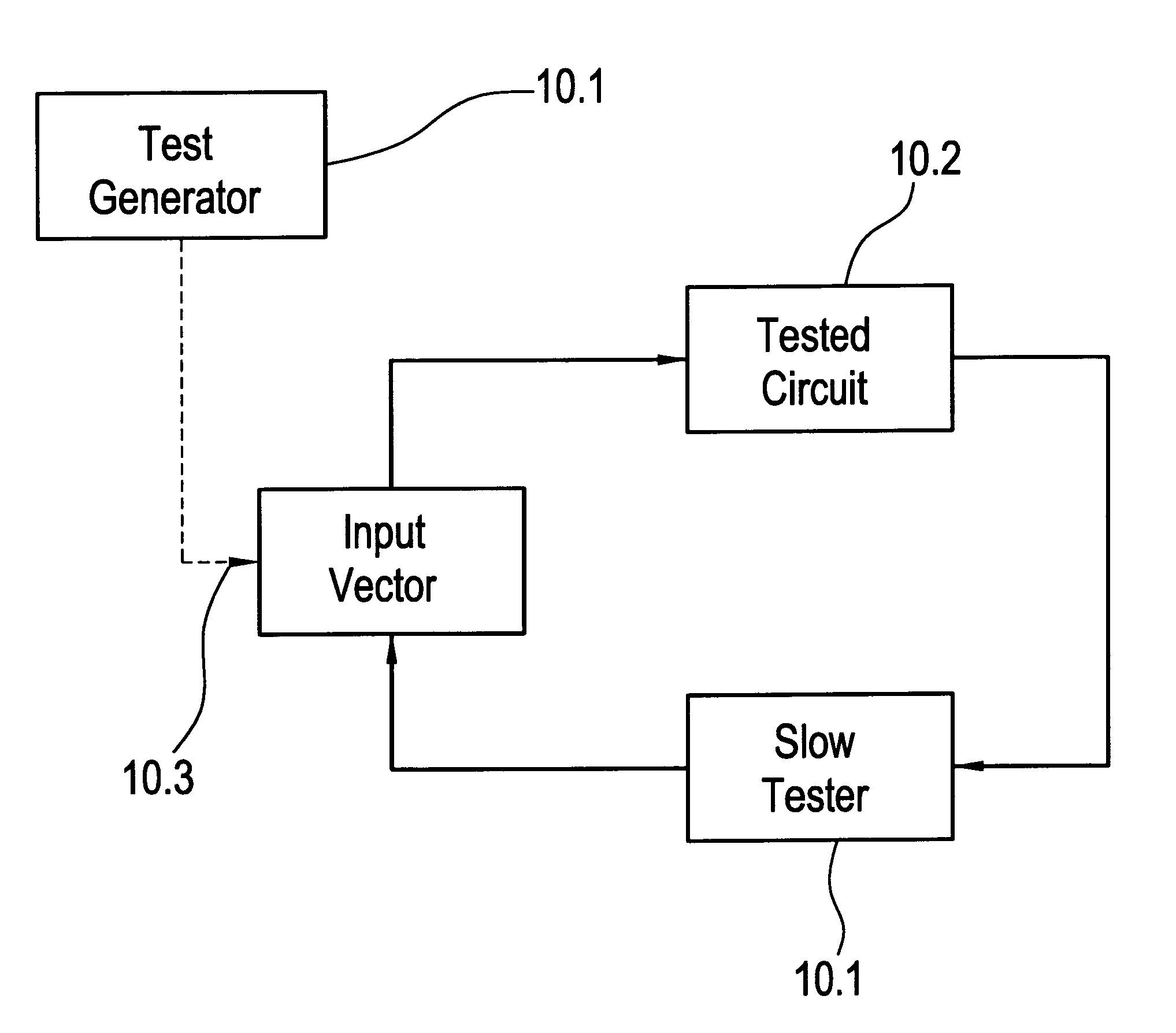

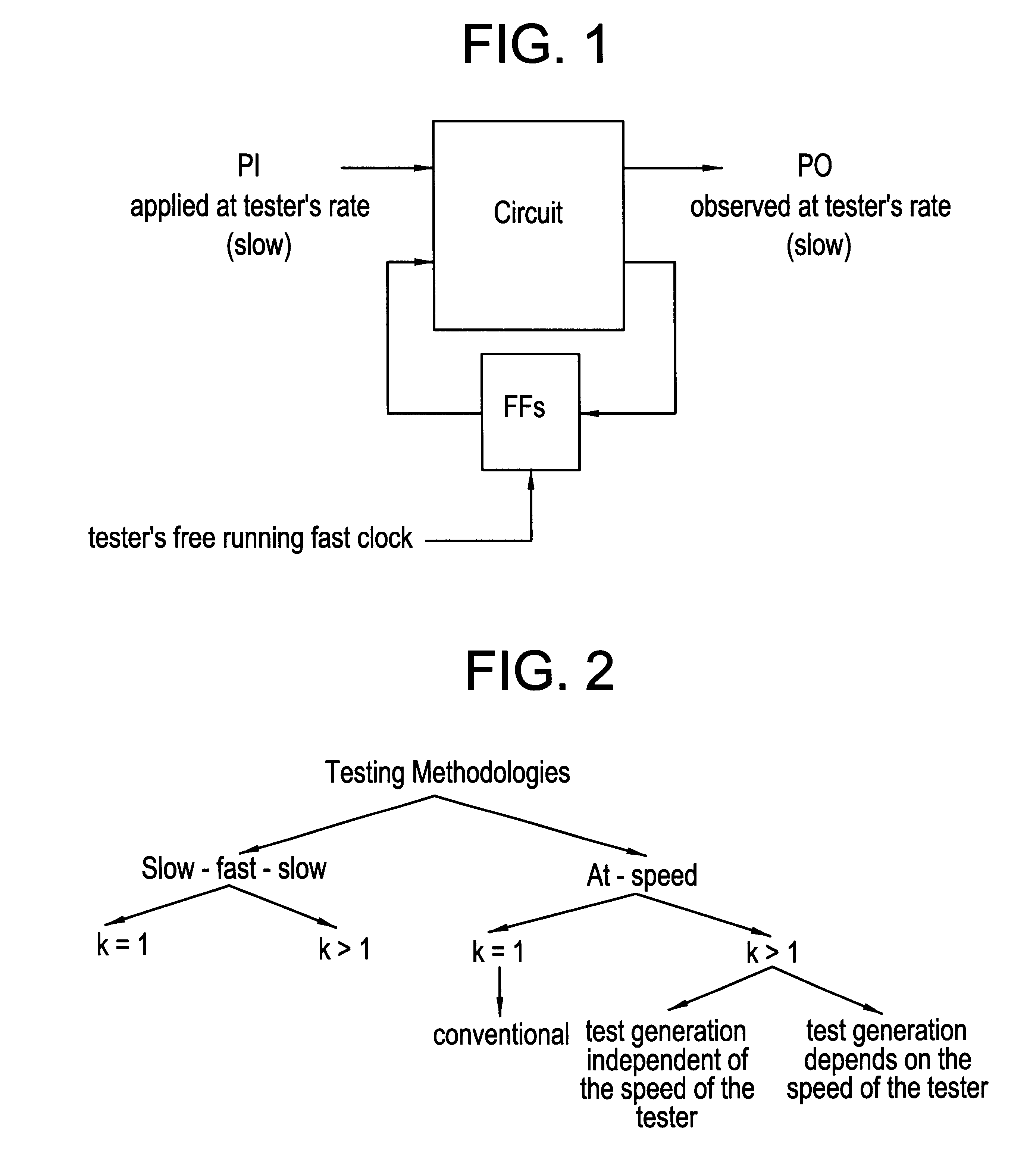

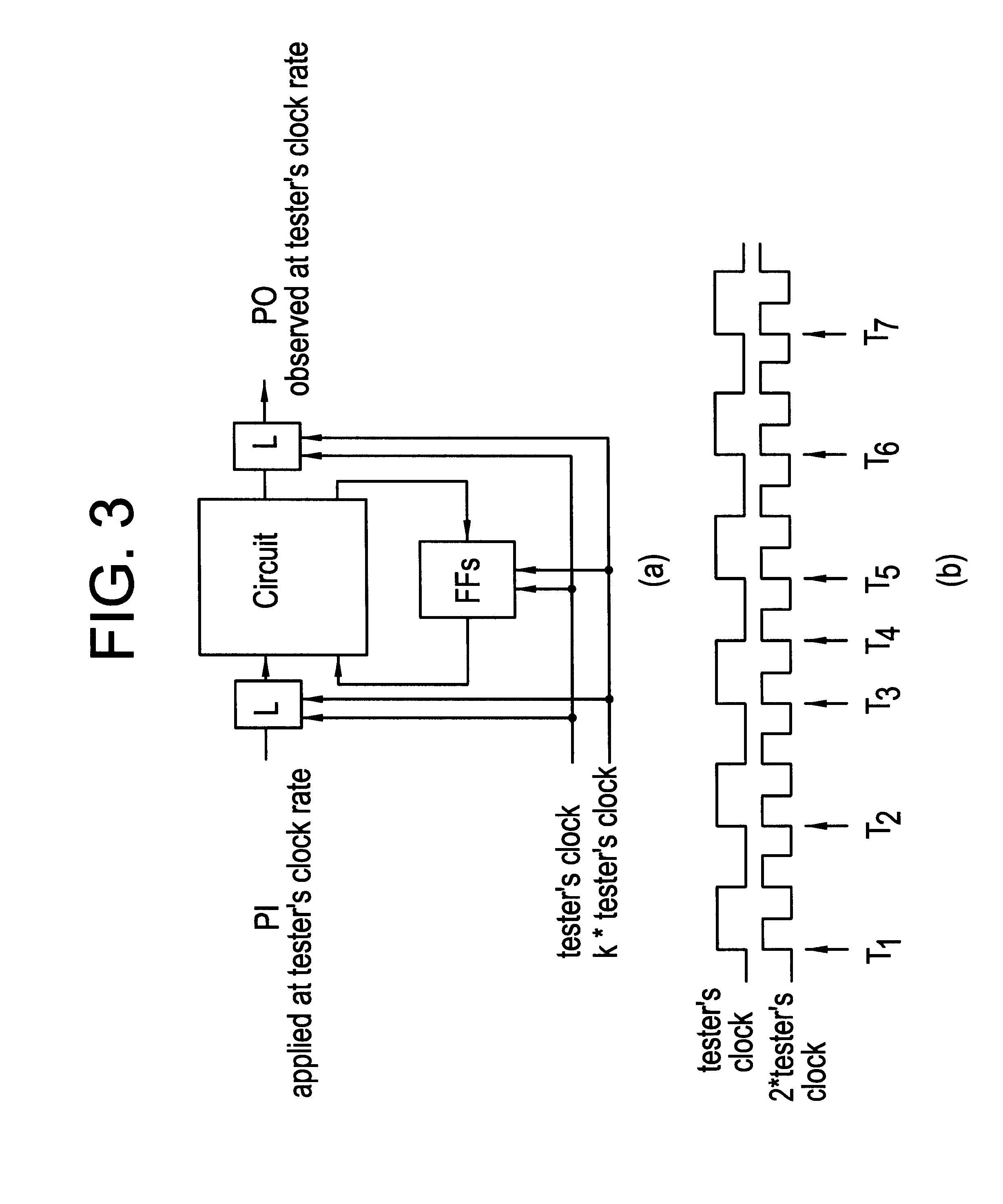

System and method for testing high speed VLSI devices using slower testers

InactiveUS6345373B1Shorten application timeLow fault coverageDigital circuit testingError detection/correctionGeneration processFault coverage

At-speed strategies for testing high speed designs on slower testers. At-speed testing schemes is provided that integrates the tester's speed limitations with the test generation process. Due to constraints placed at the test generation process, these schemes might result in a reduced fault coverage. To increase the fault coverage and reduce the test application time, the slow-fast-slow and at-speed strategies can be combined for testing high speed designs on slower testers. A slow tester that uses test vectors that are generated while taking into account the speed of the tester.

Owner:NEC CORP +1

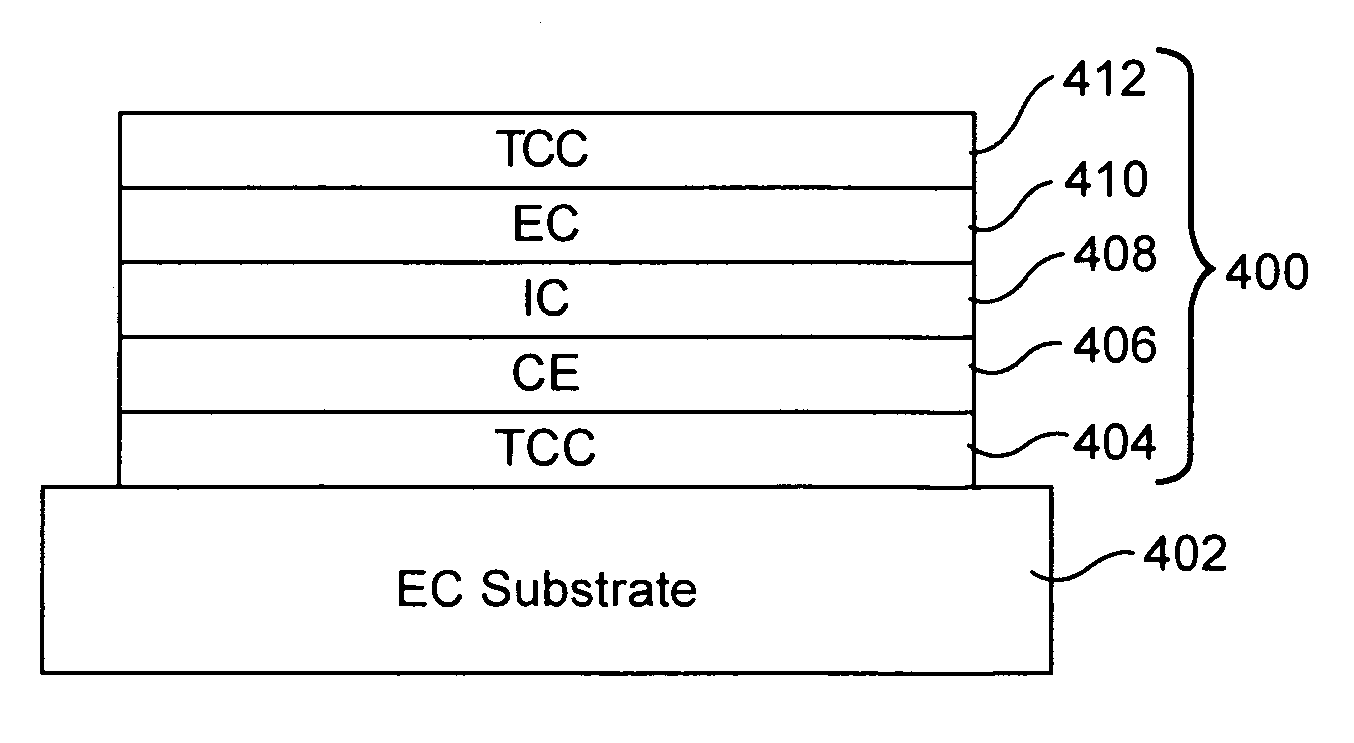

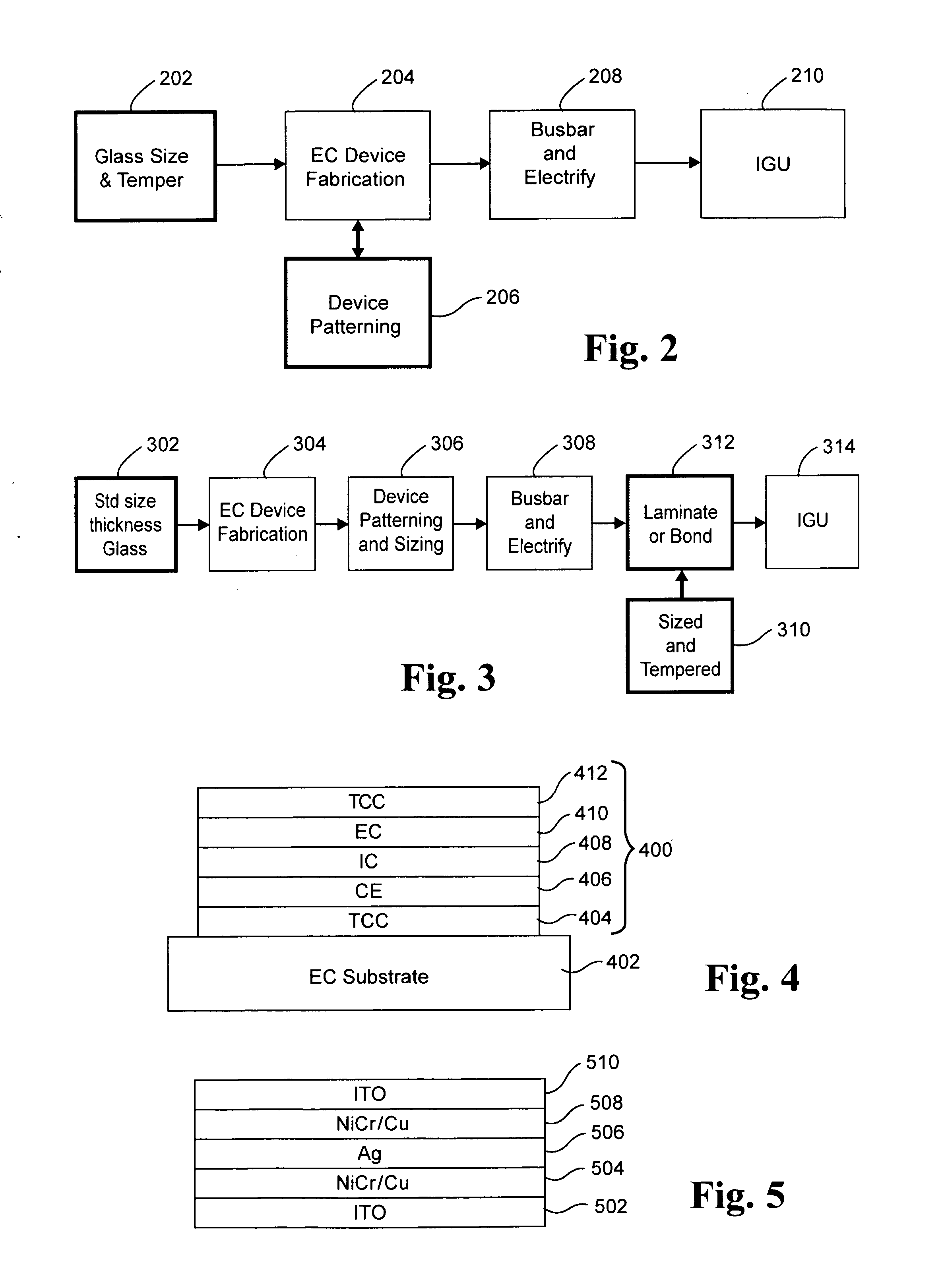

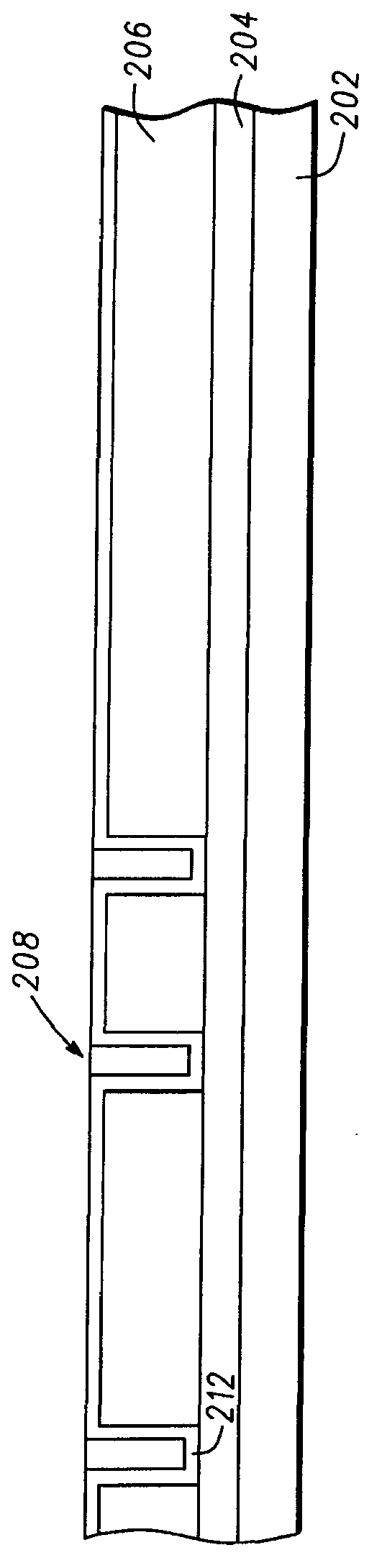

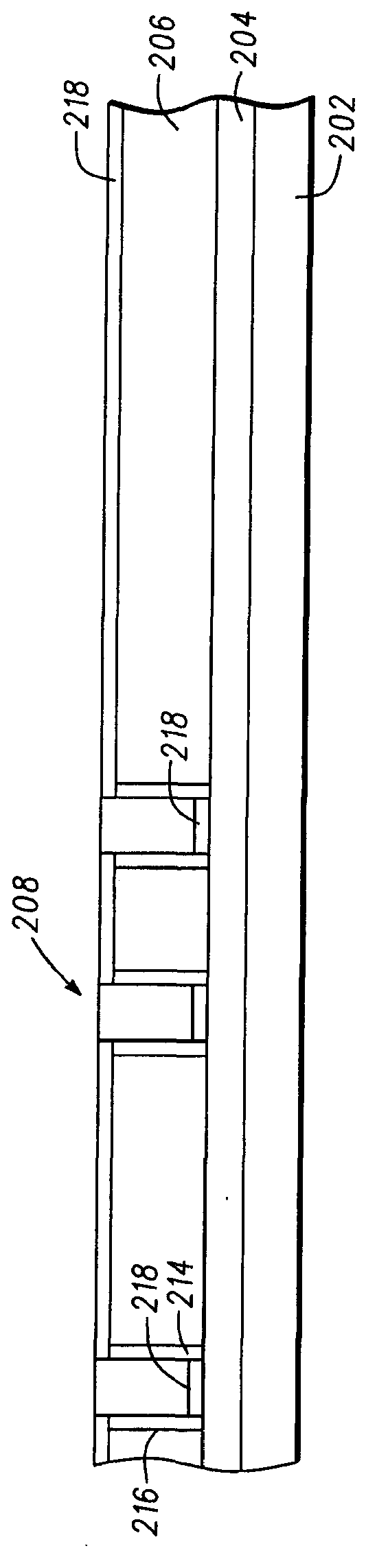

Electrochromic devices, assemblies incorporating electrochromic devices, and/or methods of making the same

ActiveUS20110048614A1Great visible transmissionGood lookingLamination ancillary operationsLight protection screensElectricityProcess integration

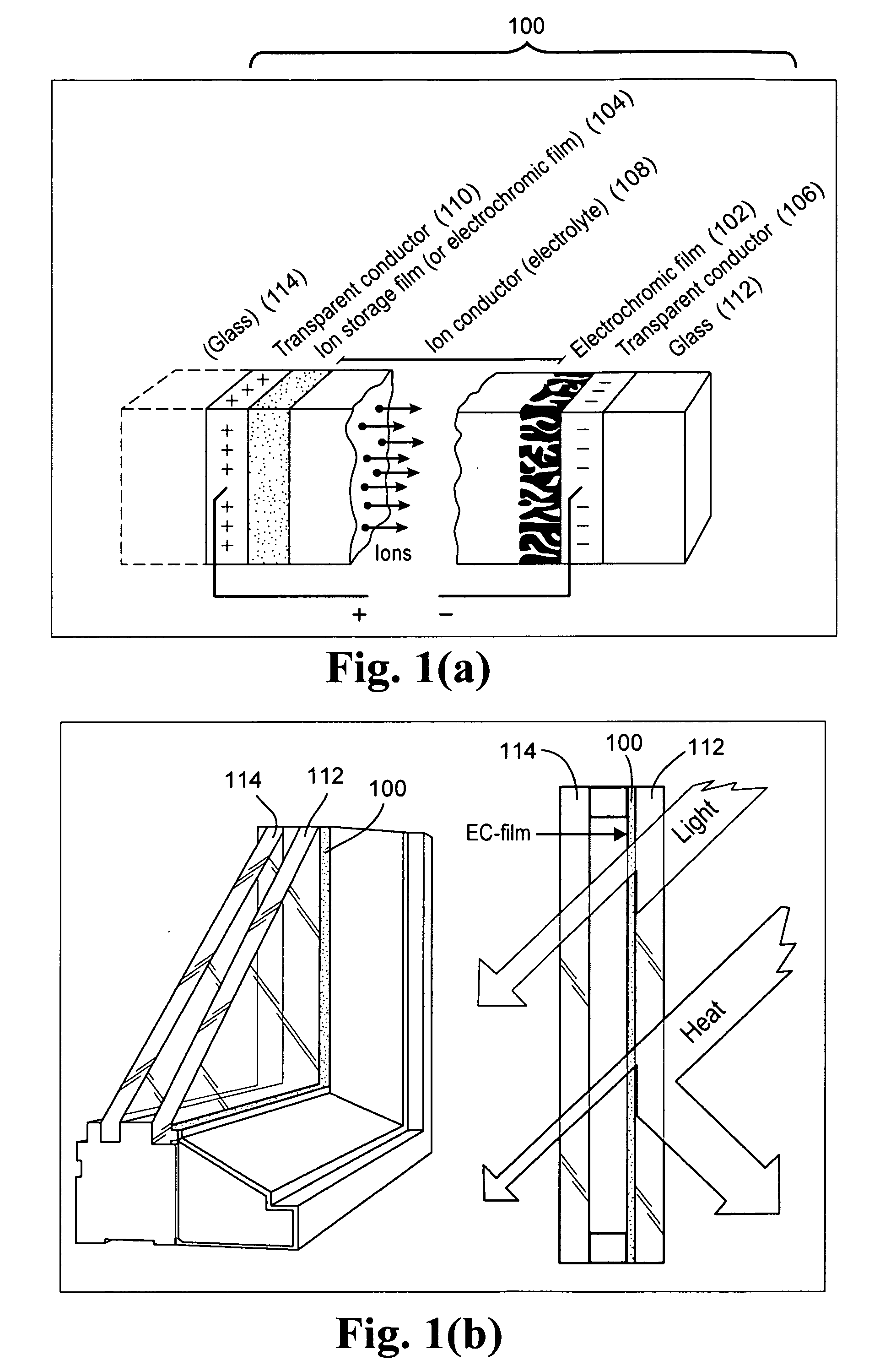

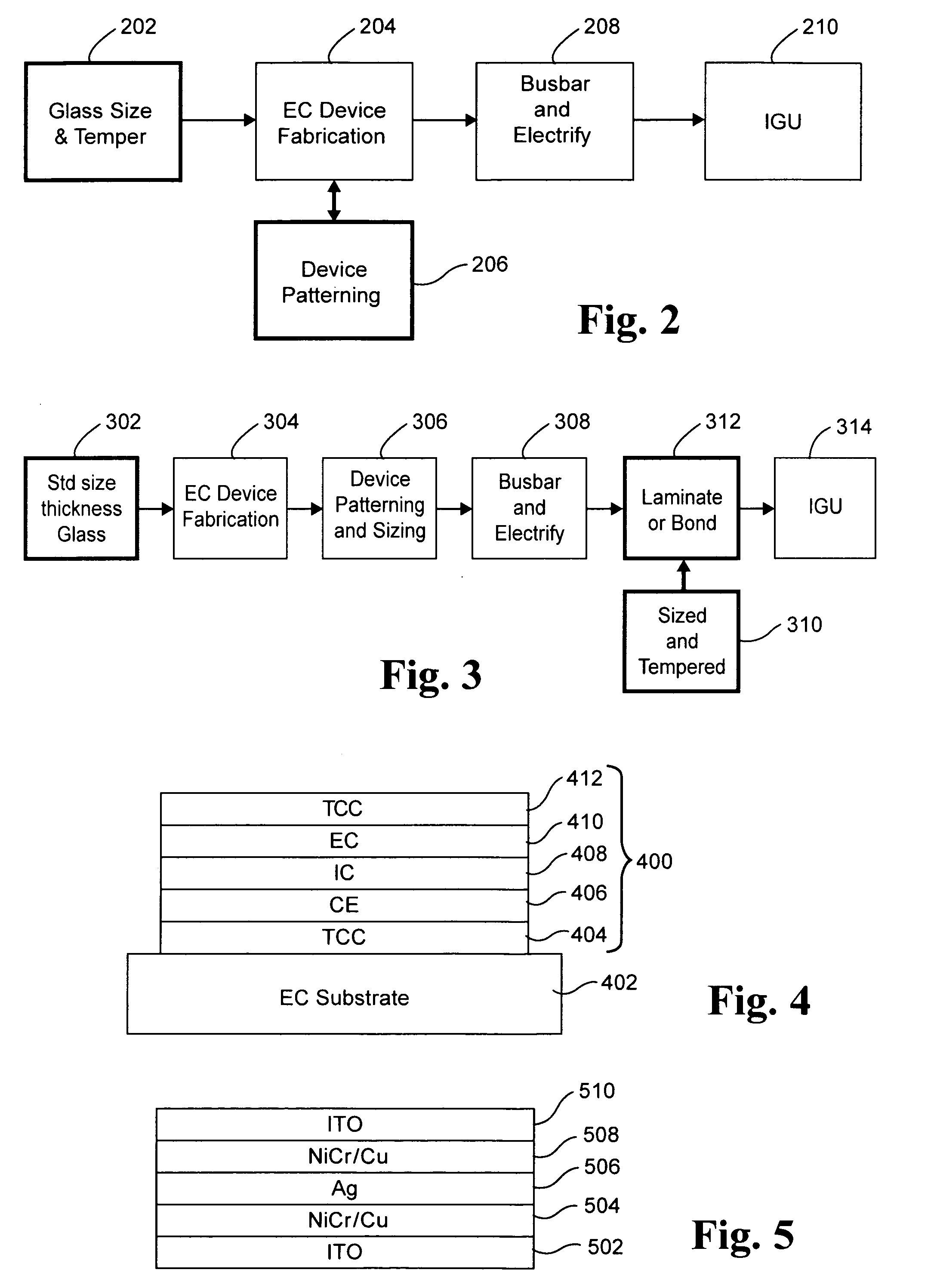

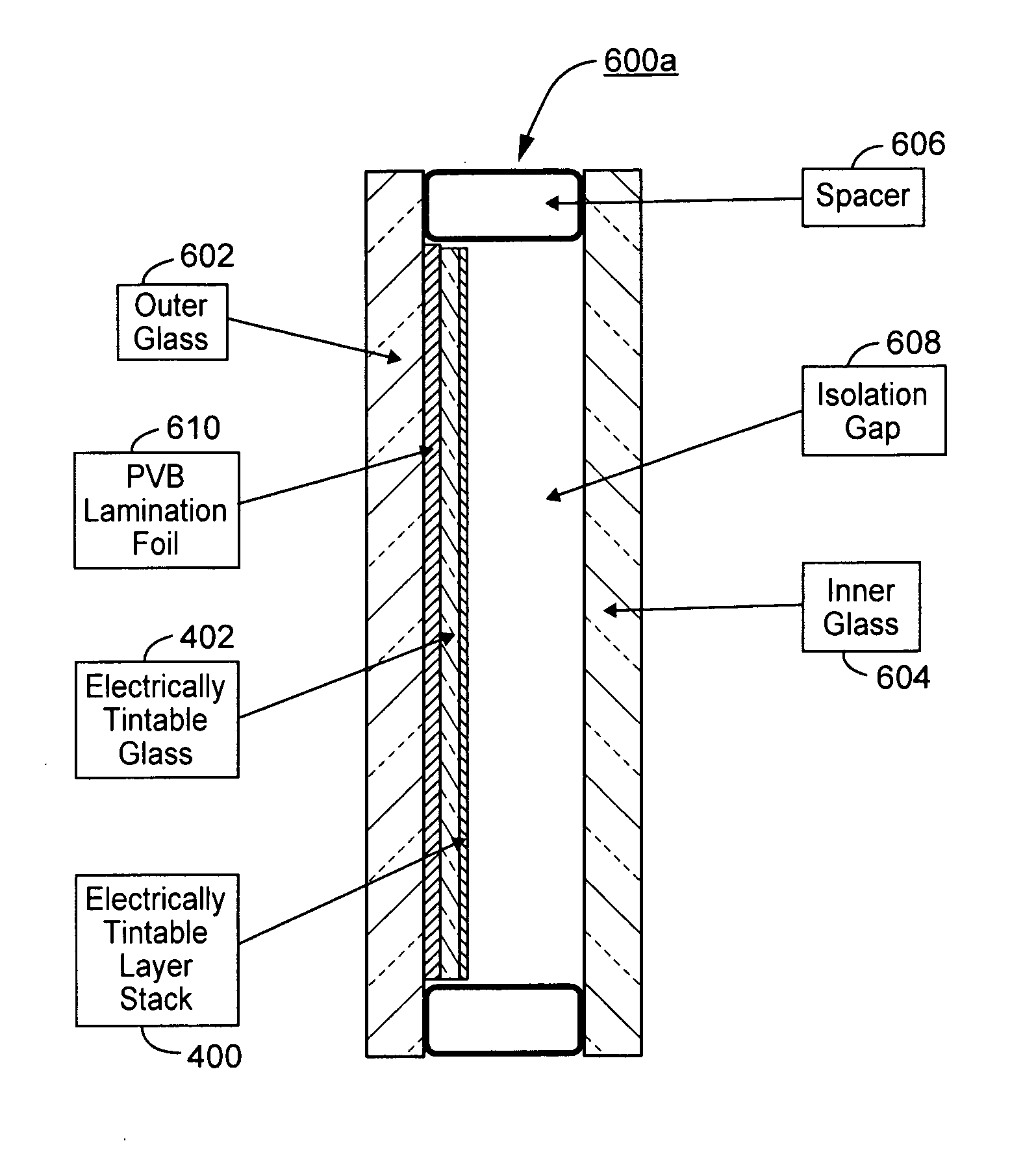

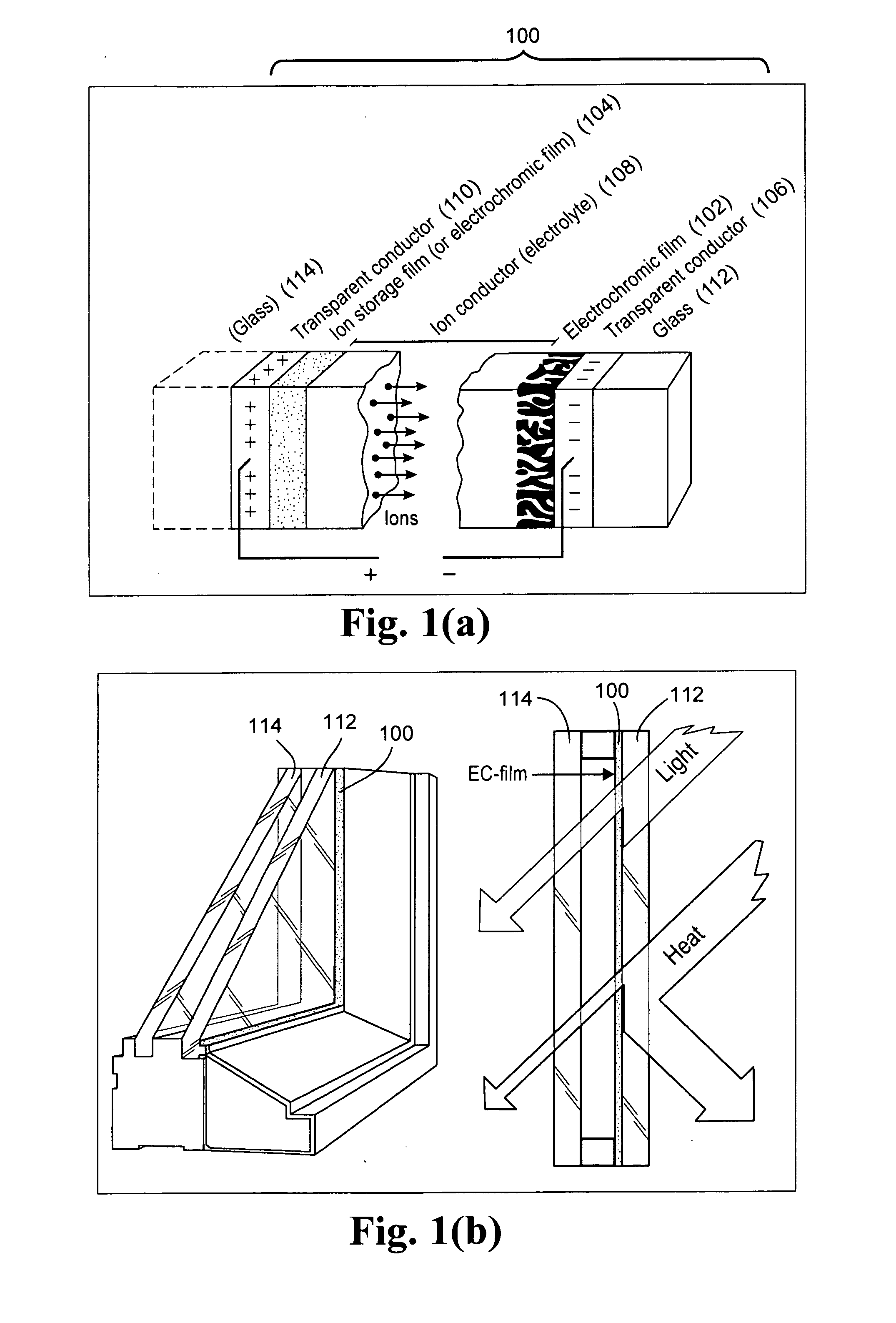

Certain example embodiments of this invention relate to electrochromic (EC) devices, assemblies incorporating electrochromic devices, and / or methods of making the same. More particularly, certain example embodiments of this invention relate to improved EC materials, EC device stacks, high-volume manufacturing (HVM) compatible process integration schemes, and / or high-throughput low cost deposition sources, equipment, and factories.

Owner:GUARDIAN GLASS LLC

Electrochromic devices, assemblies incorporating electrochromic devices, and/or methods of making the same

ActiveUS20110051221A1Great visible transmissionGood lookingLight protection screensGlass/slag layered productsElectricityProduction rate

Certain example embodiments of this invention relate to electrochromic (EC) devices, assemblies incorporating electrochromic devices, and / or methods of making the same. More particularly, certain example embodiments of this invention relate to improved EC materials, EC device stacks, high-volume manufacturing (HVM) compatible process integration schemes, and / or high-throughput low cost deposition sources, equipment, and factories.

Owner:GUARDIAN GLASS LLC

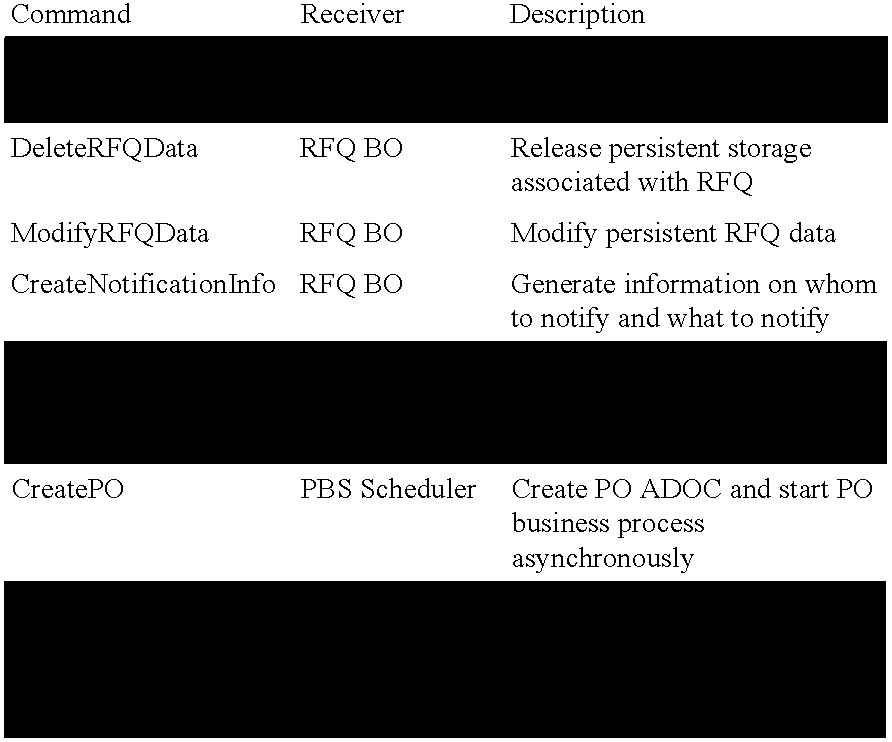

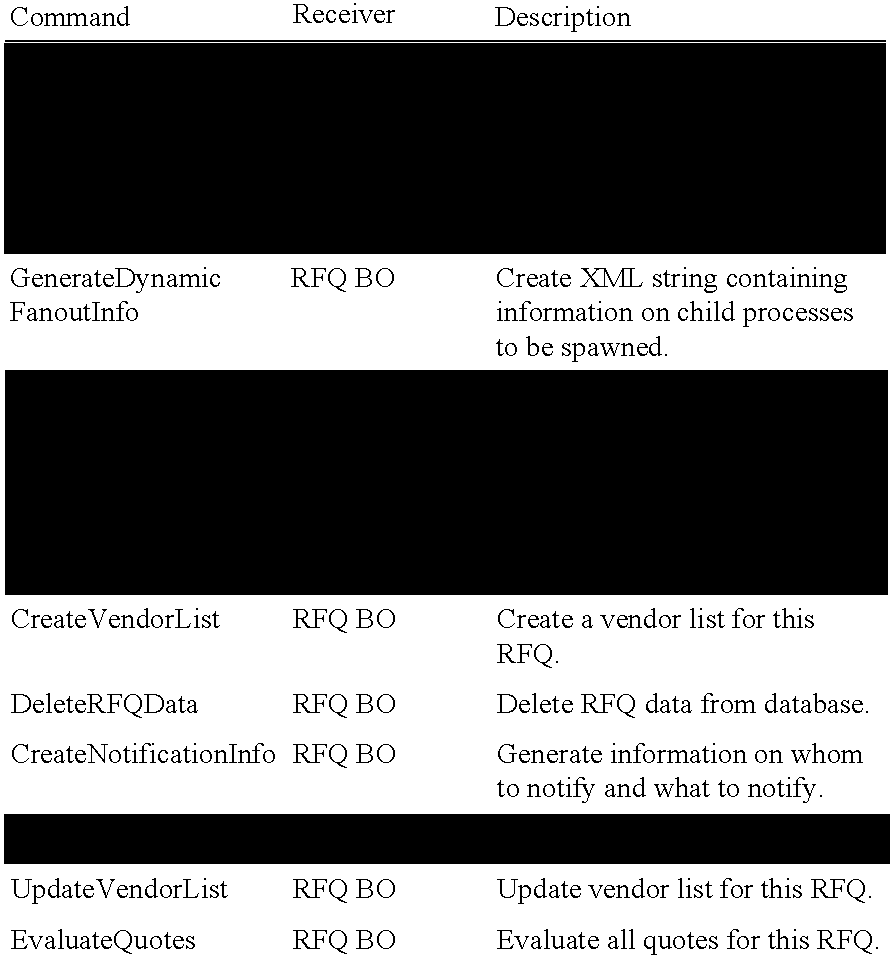

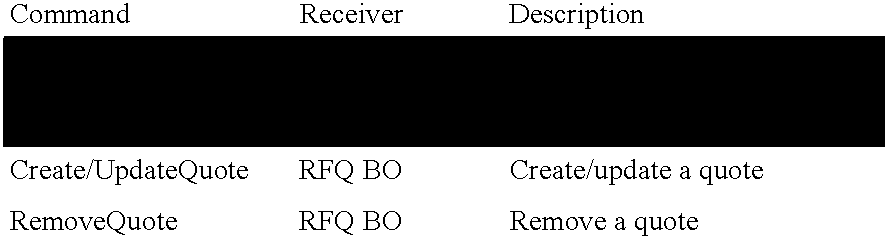

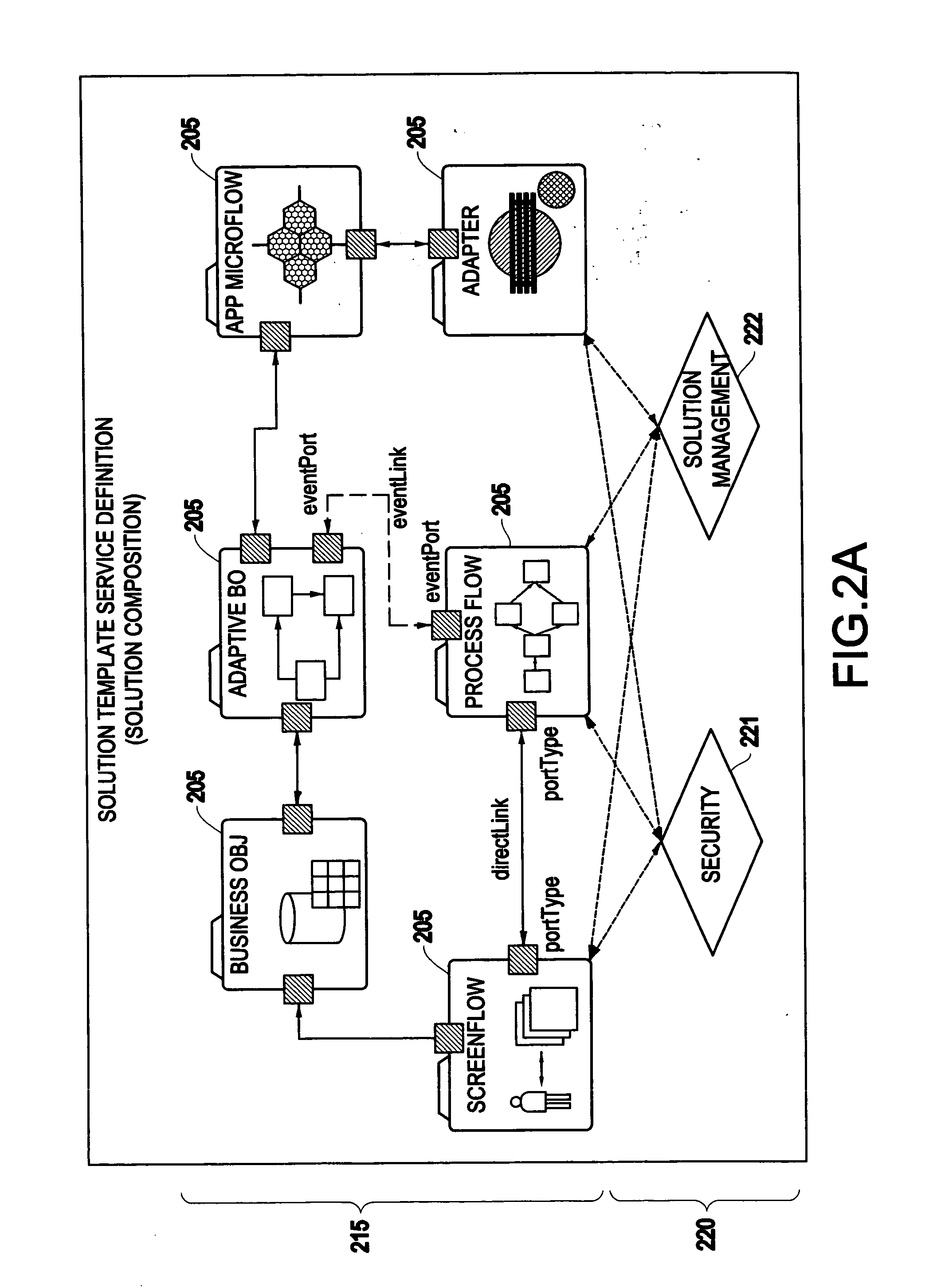

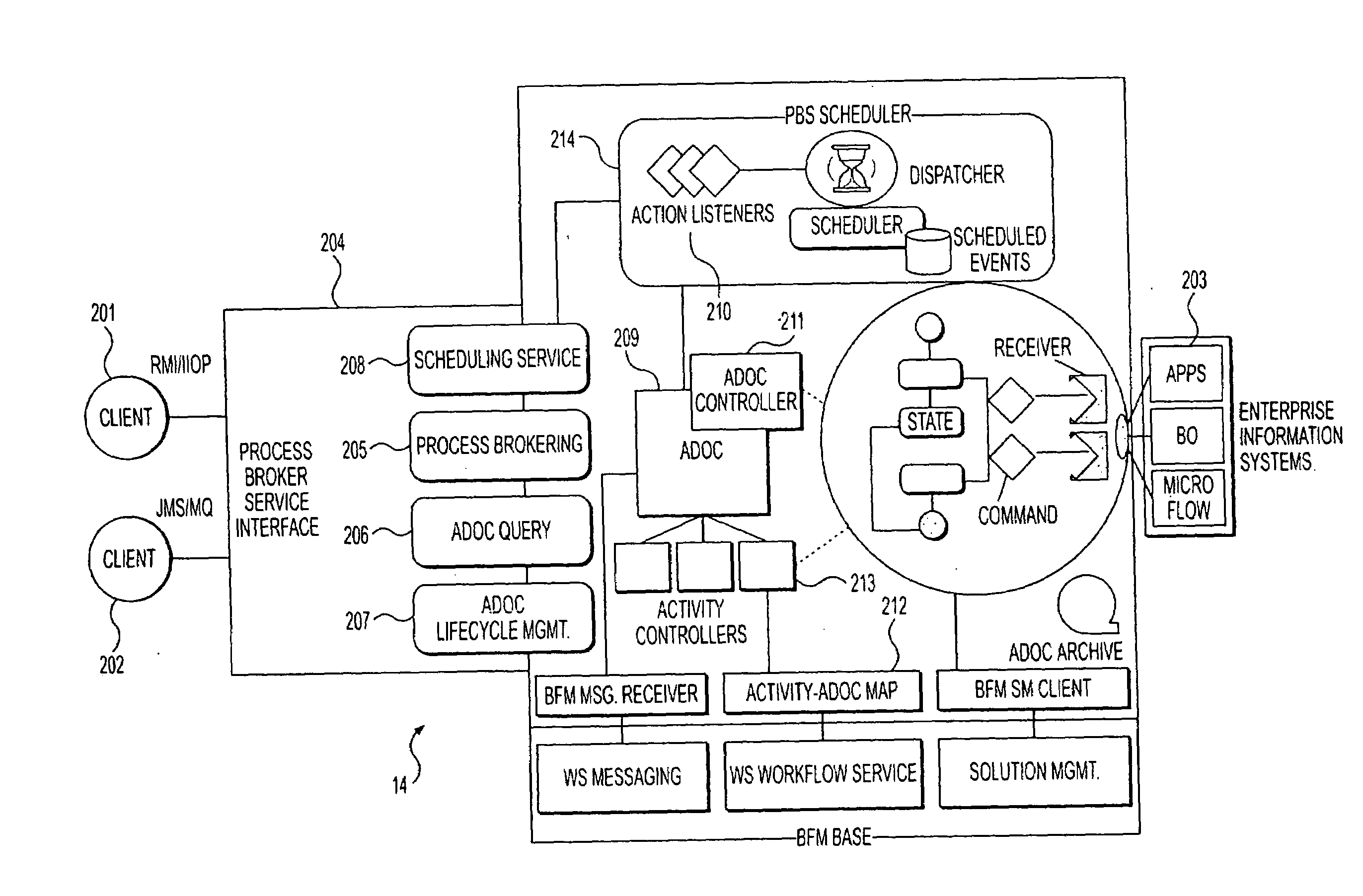

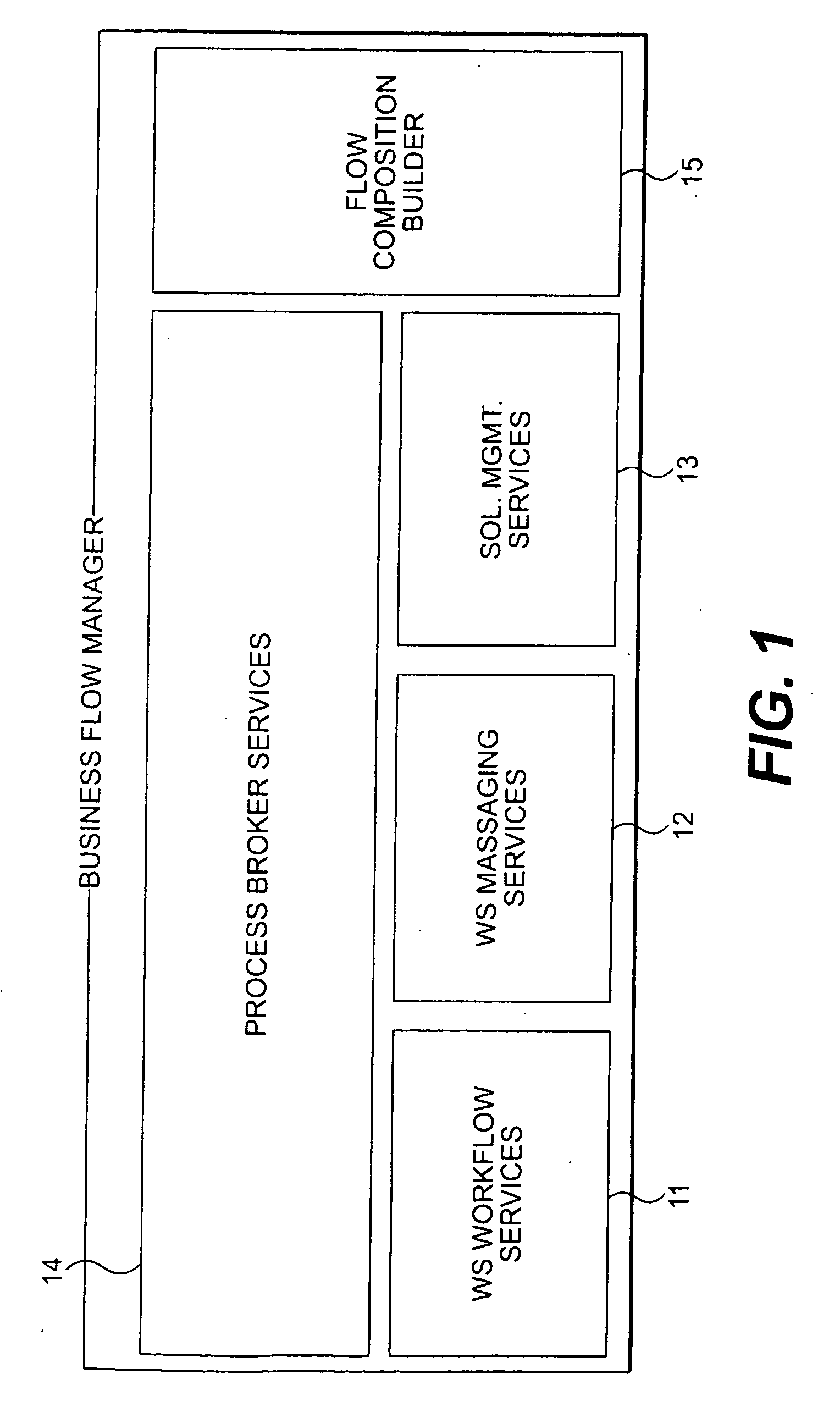

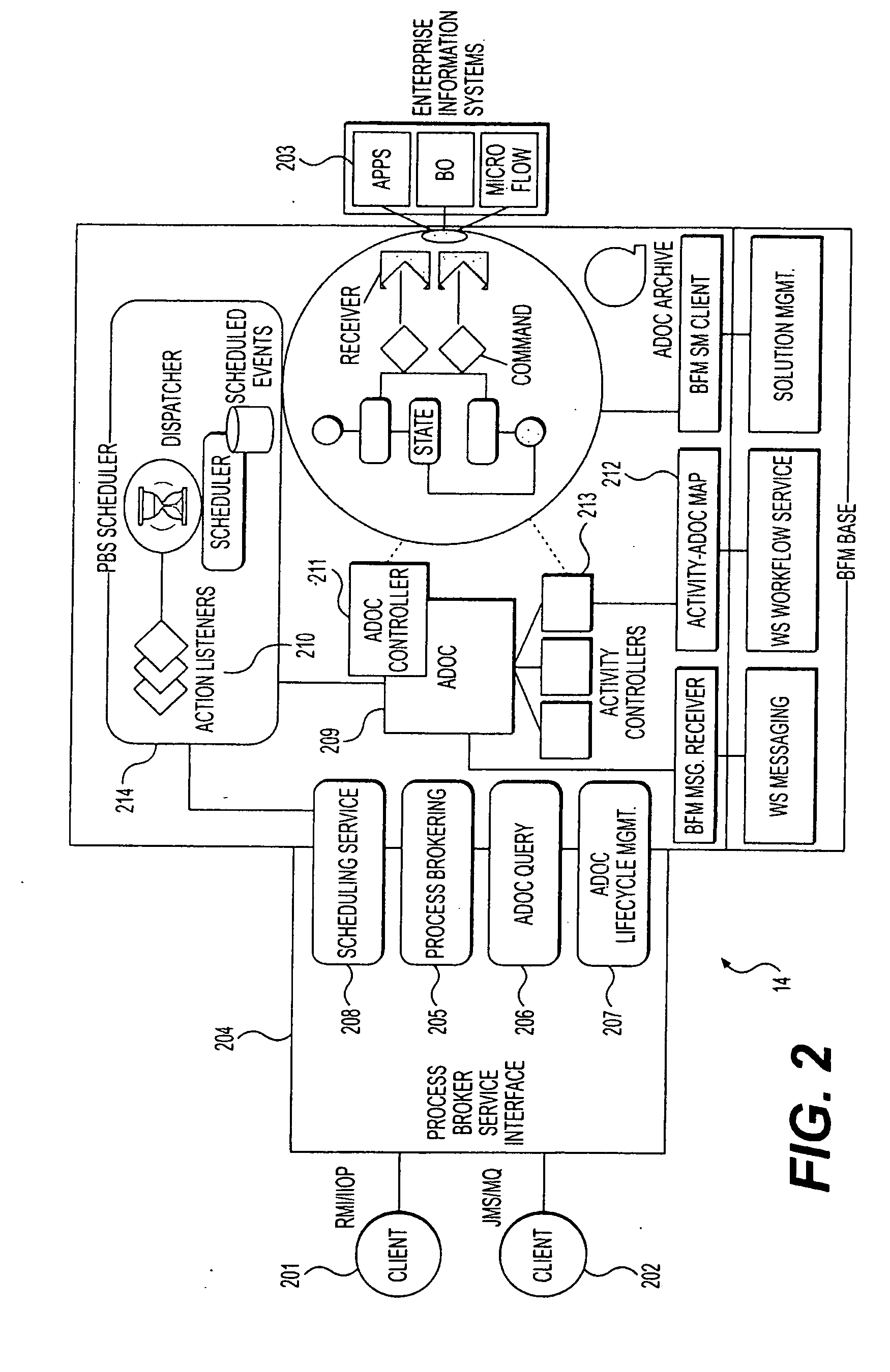

Method and system for process brokering and content integration for collaborative business process management

InactiveUS20030187743A1FinanceMultiple digital computer combinationsApplication softwareBusiness process management

Process Brokering Services (PBS) are implemented though the concept of Adaptive Documents to facilitate electronic commerce (e-commerce). PBS provides a single point of process control over the various fragmented execution flows and brings together the elements for process integration (views, content, flows) in a unified, scalable architecture on an industry standard platform. The two principal functions of the PBS are brokering of multiple business processes encapsulated in various back-end systems including workflow engines and business applications, and aggregating content from multiple enterprise information systems in the business context and managing the shared access to this based on the roles of the participants. The dynamic services provided by PBS are accessible to clients through the PBS Interface.

Owner:IBM CORP

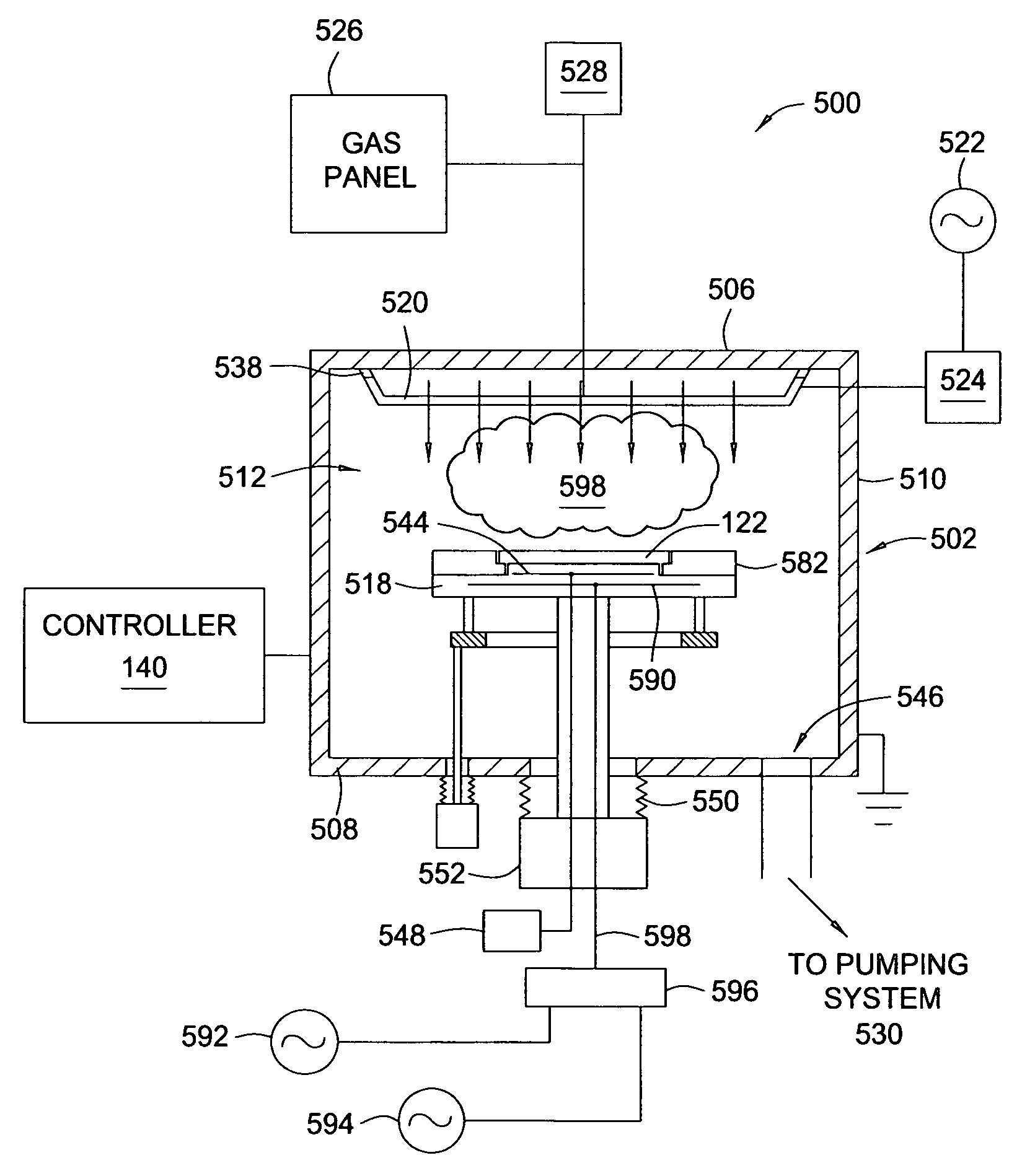

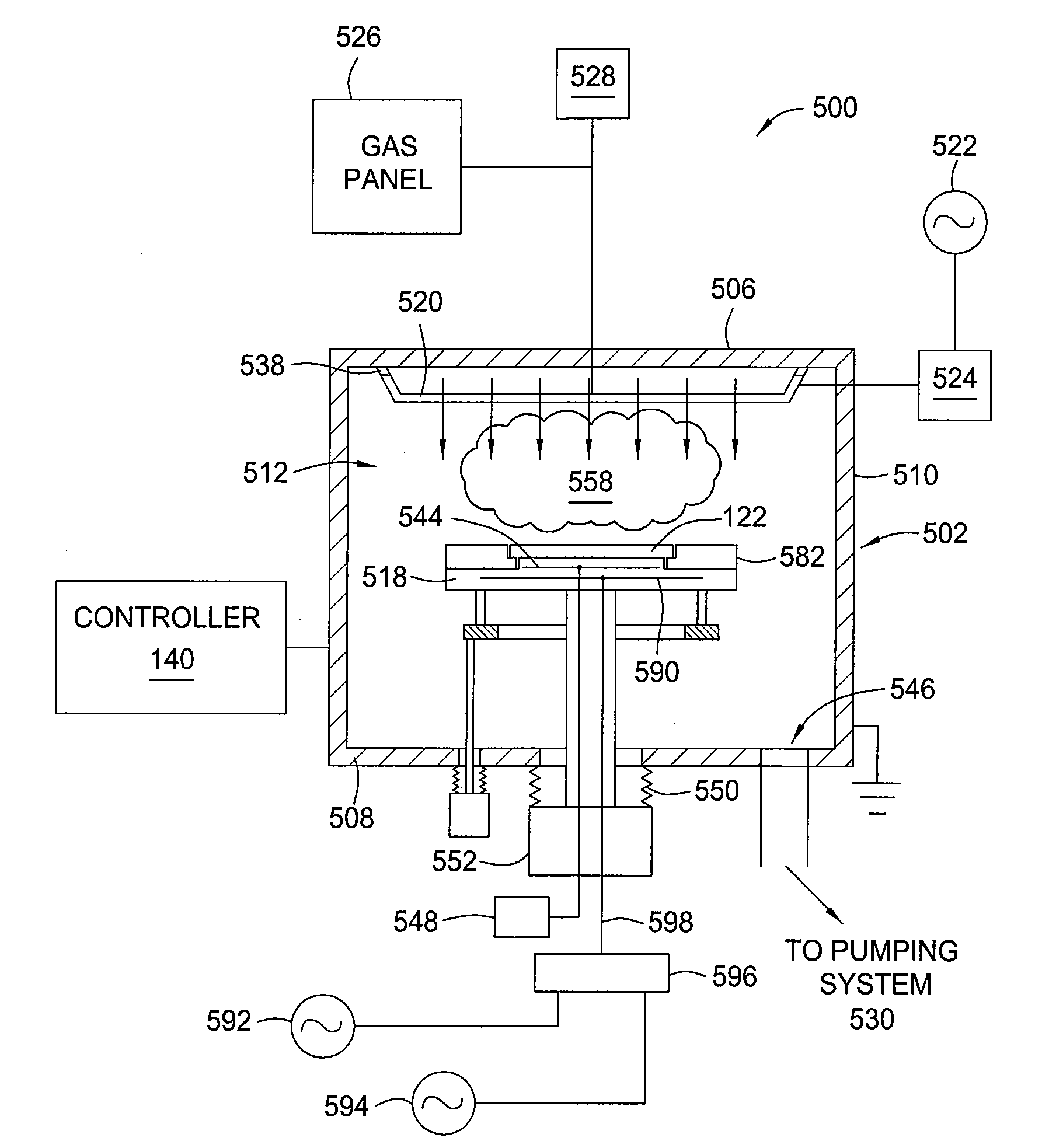

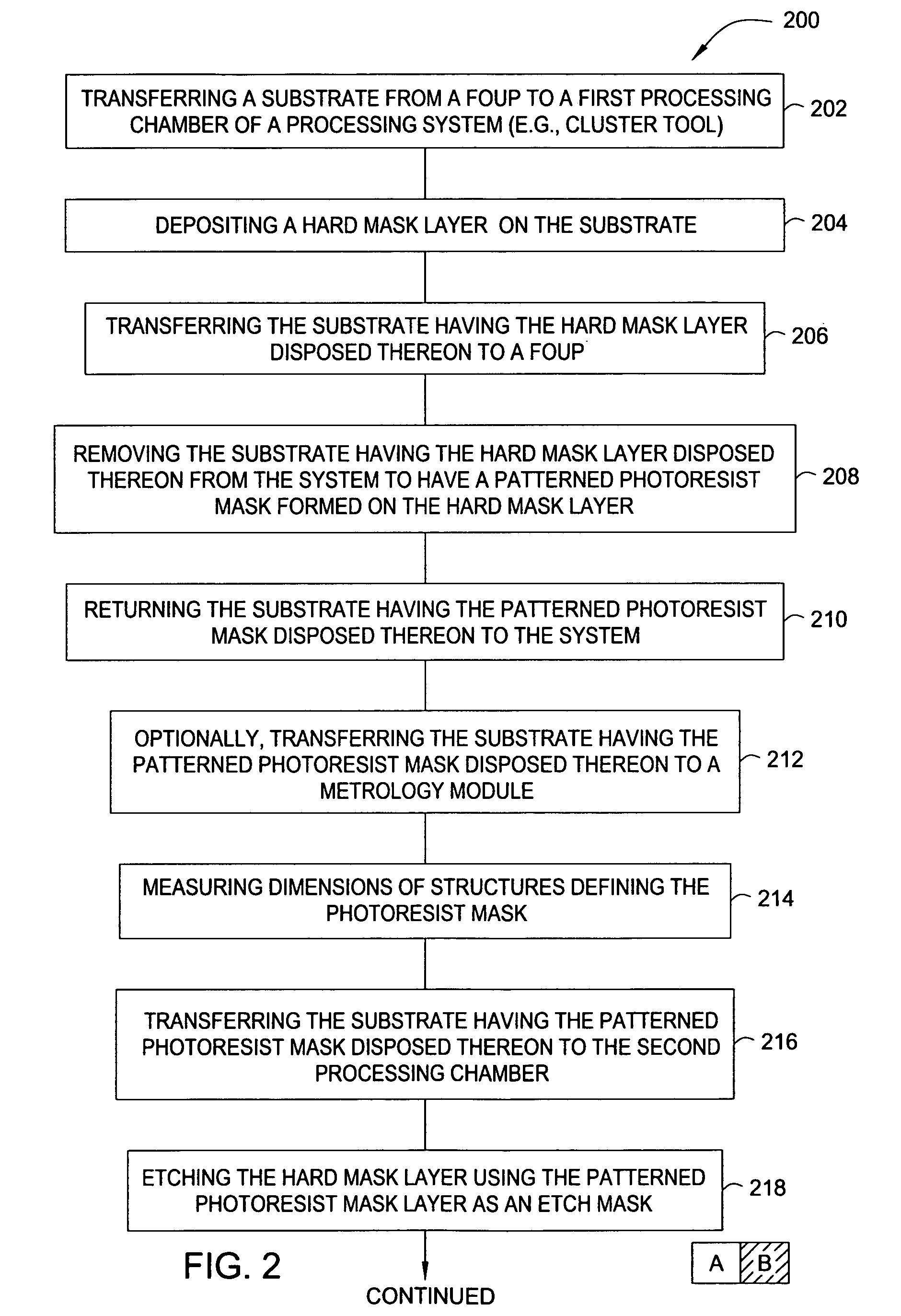

Chemical vapor deposition chamber with dual frequency bias and method for manufacturing a photomask using the same

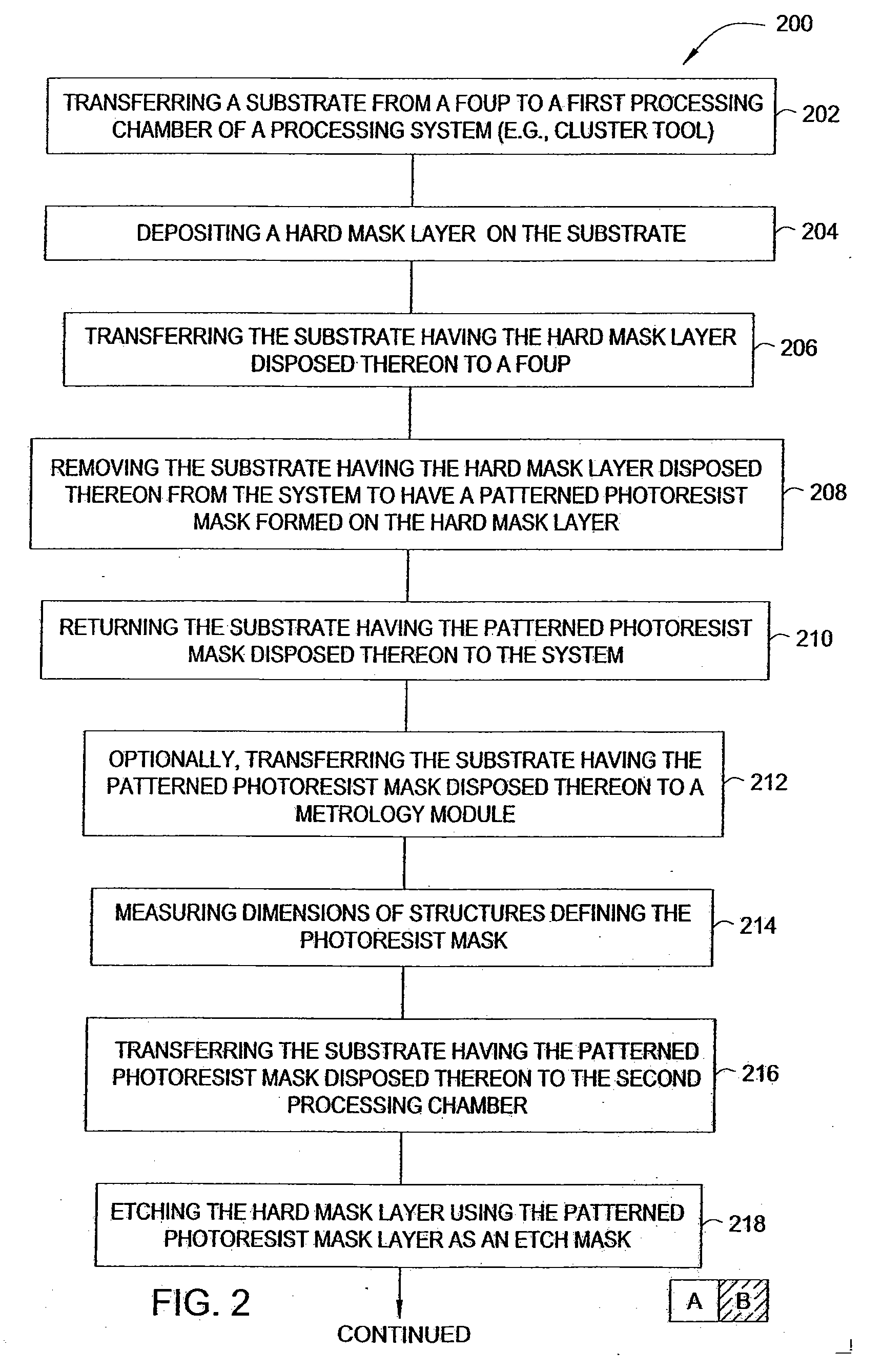

A method and apparatus for process integration in manufacture of a photomask are disclosed. In one embodiment, a cluster tool suitable for process integration in manufacture of a photomask including a vacuum transfer chamber having coupled thereto at least one hard mask deposition chamber and at least one plasma chamber configured for etching chromium. In another embodiment, a method for process integration in manufacture of a photomask includes depositing a hard mask on a substrate in a first processing chamber, depositing a resist layer on the substrate, patterning the resist layer, etching the hard mask through apertures formed in the patterned resist layer in a second chamber; and etching a chromium layer through apertures formed in the hard mask in a third chamber.

Owner:APPLIED MATERIALS INC

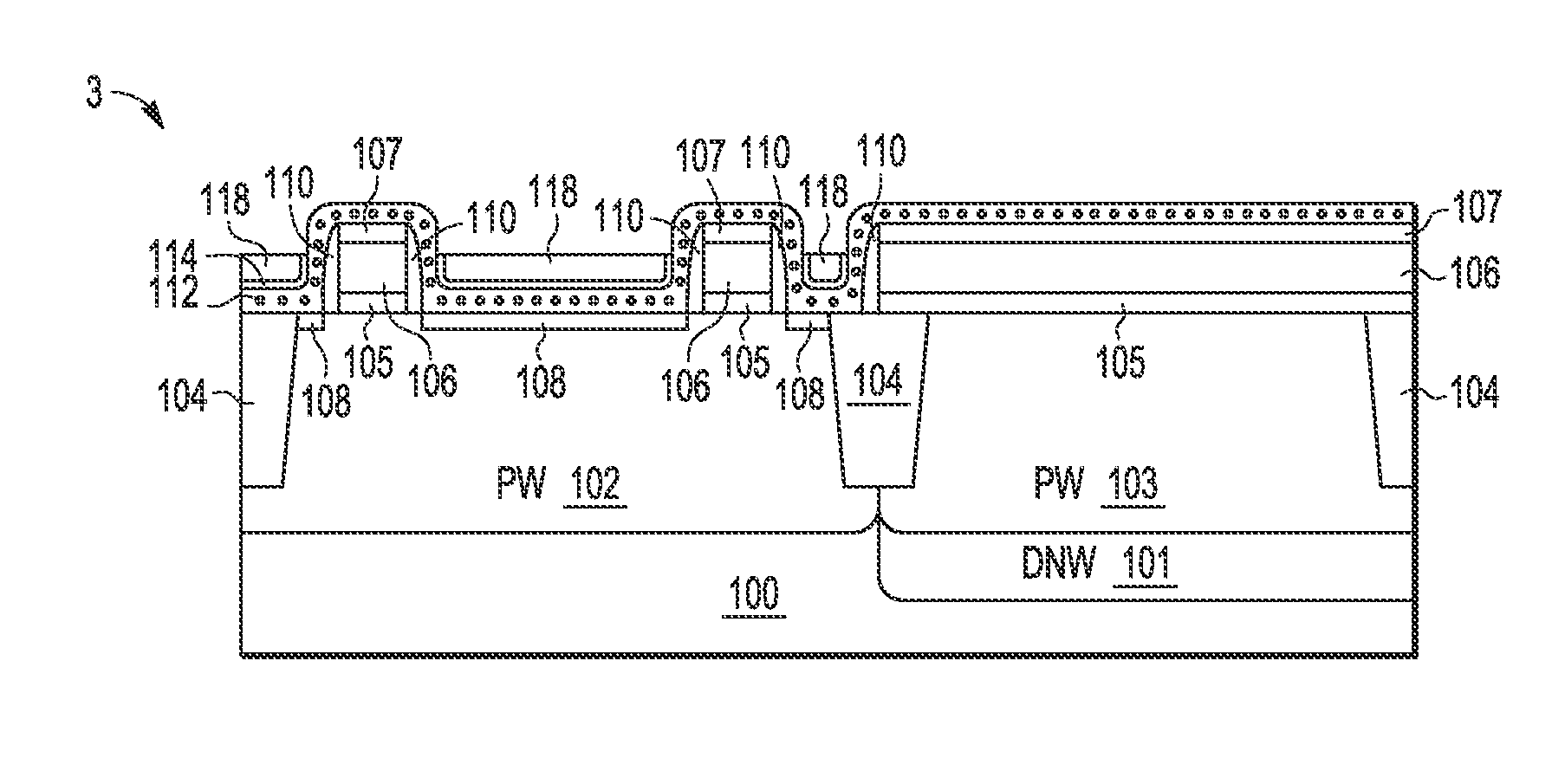

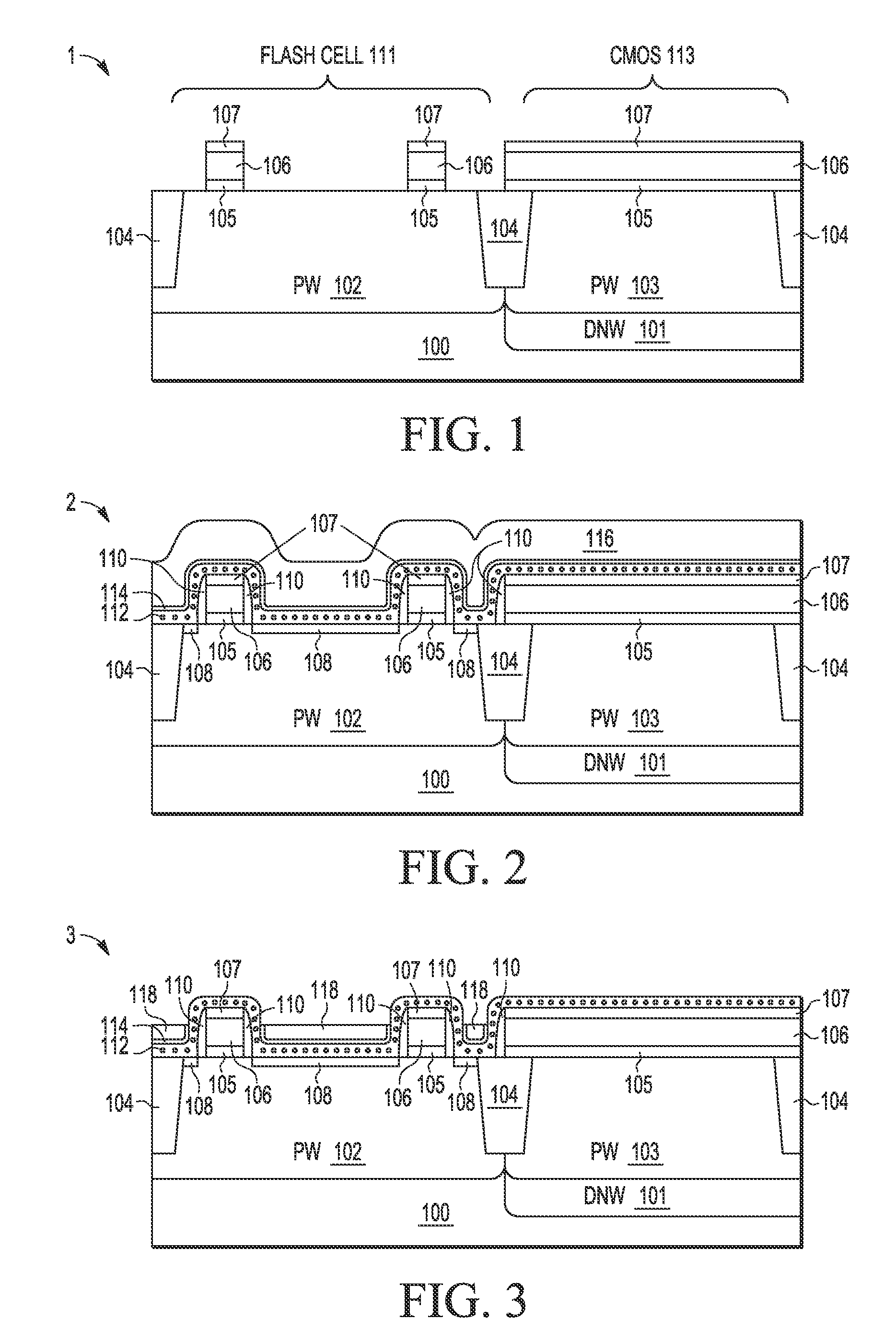

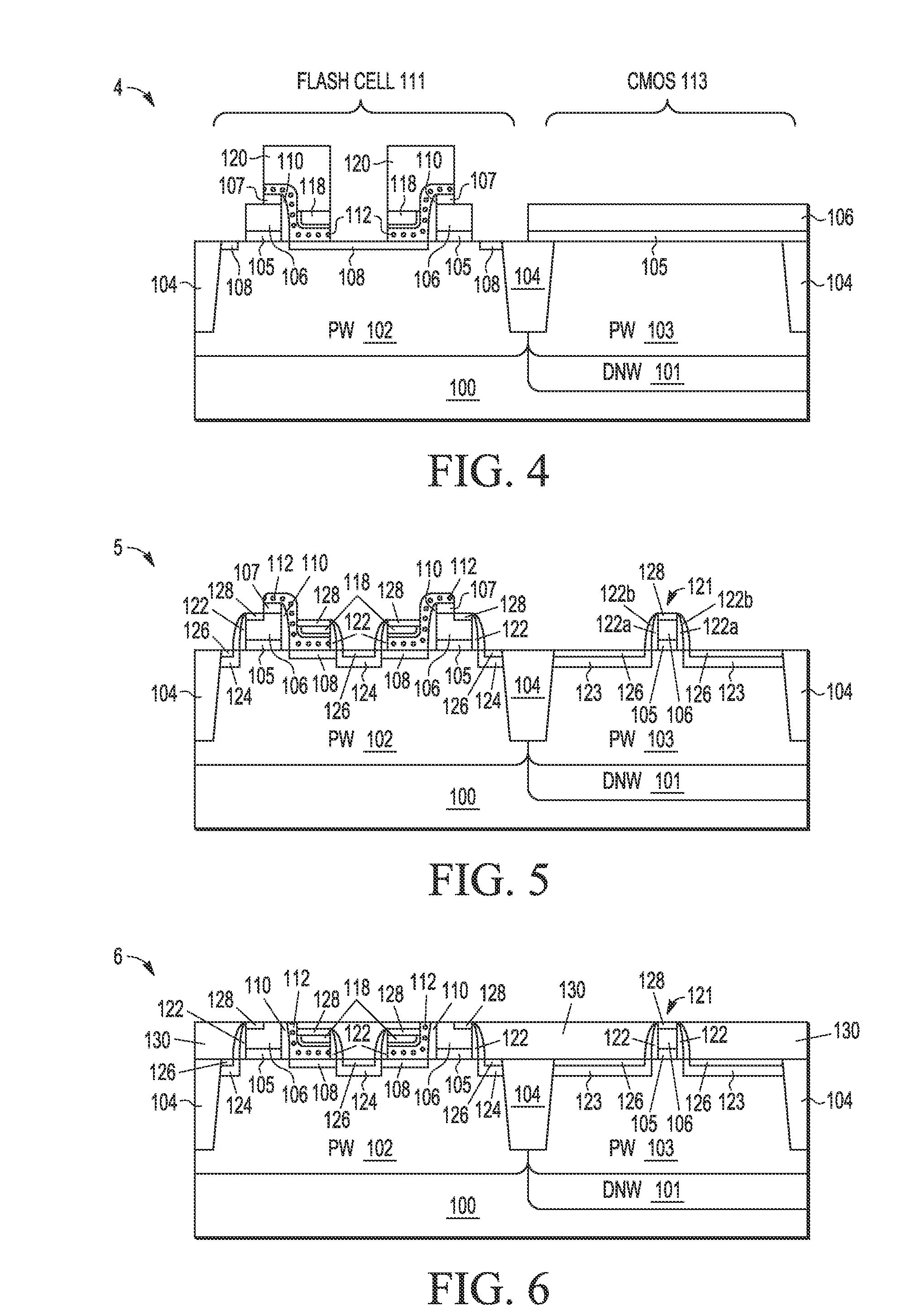

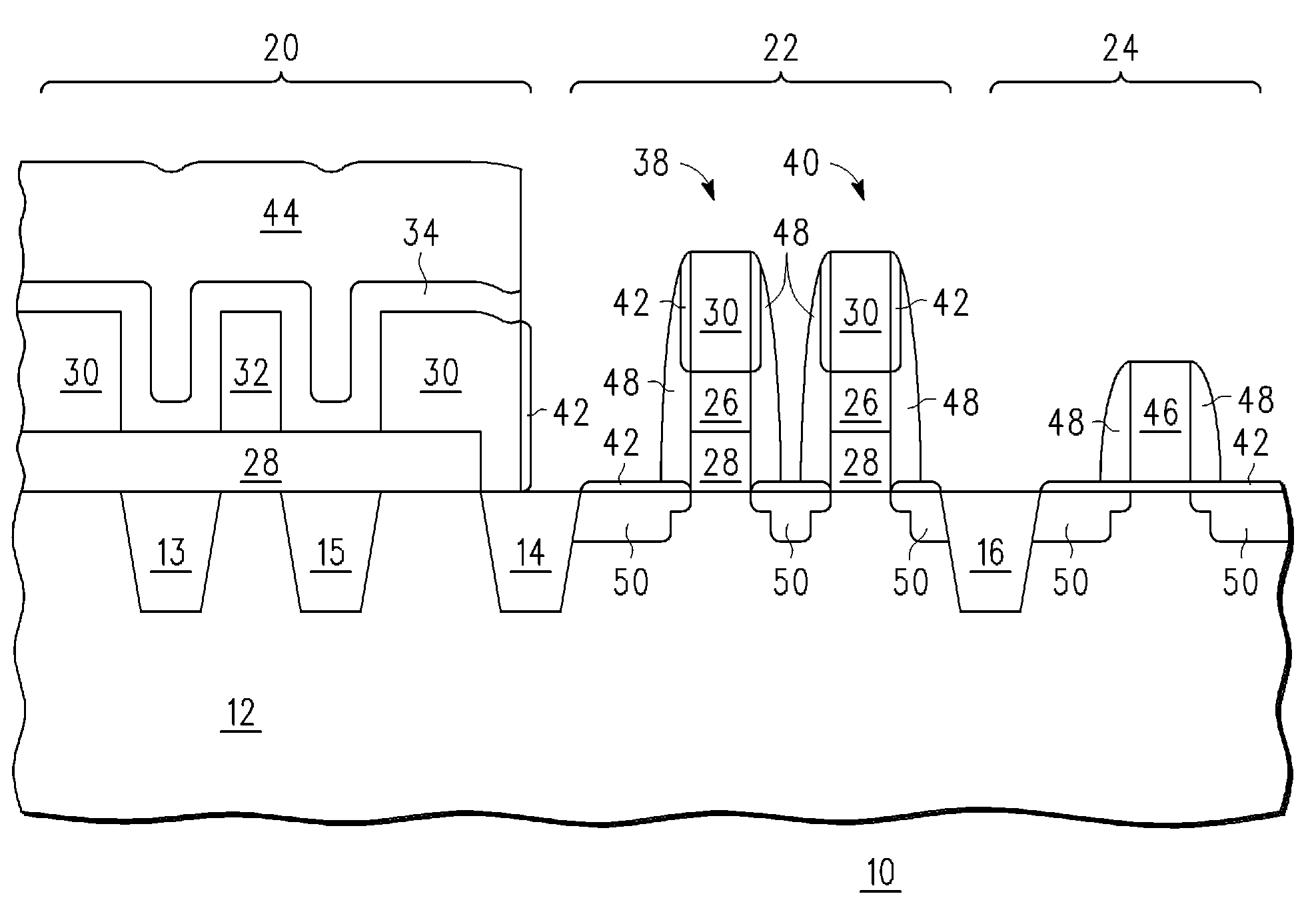

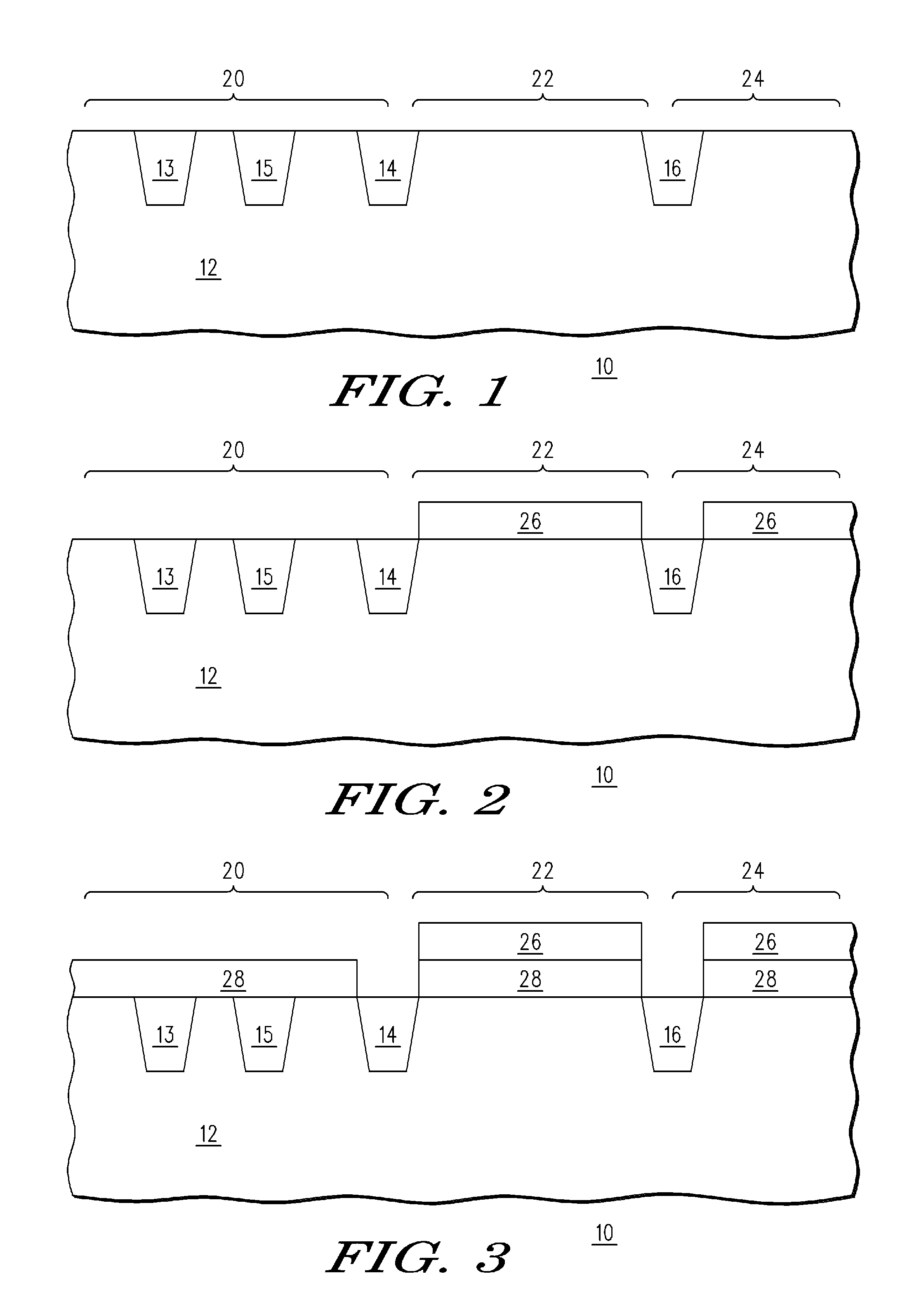

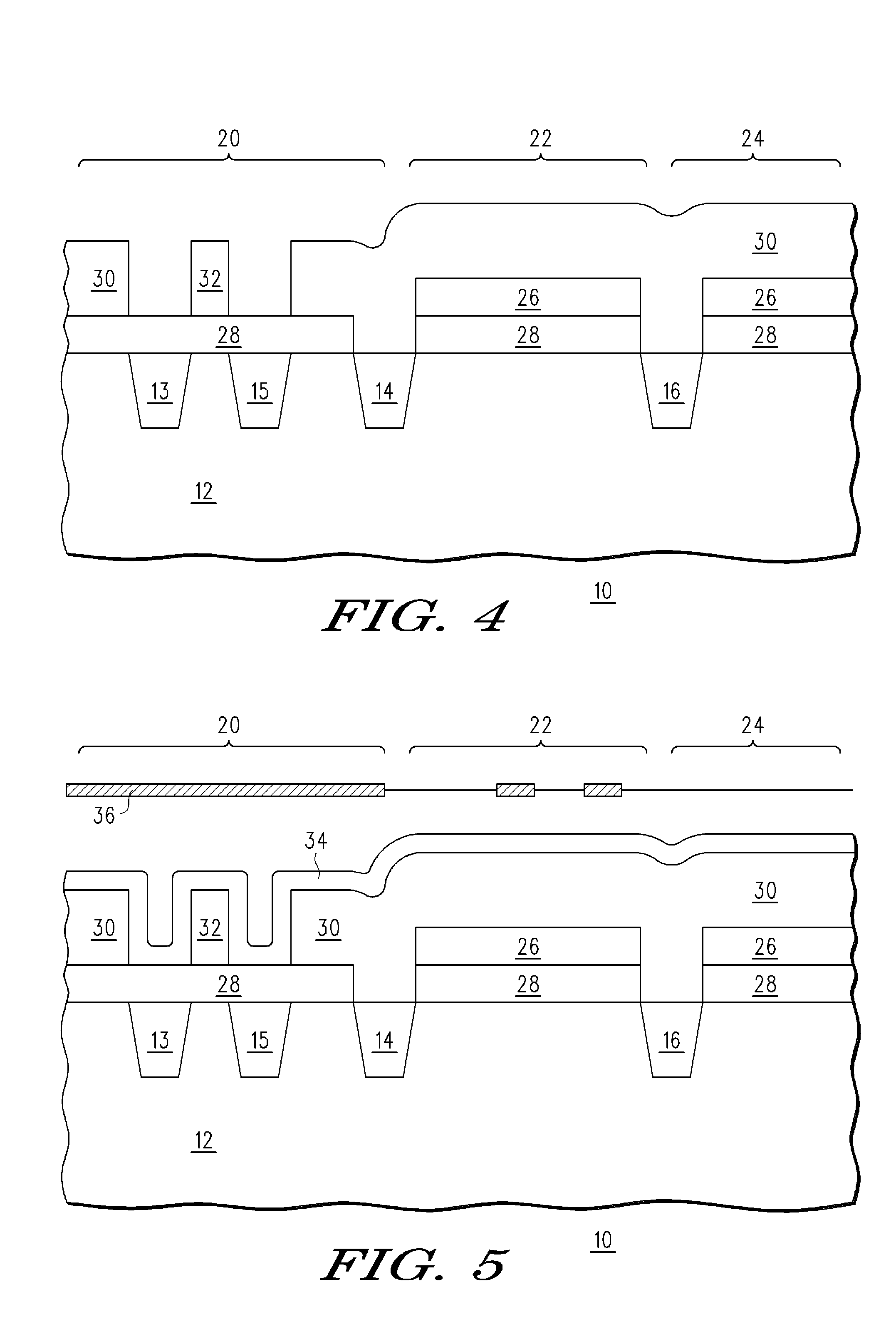

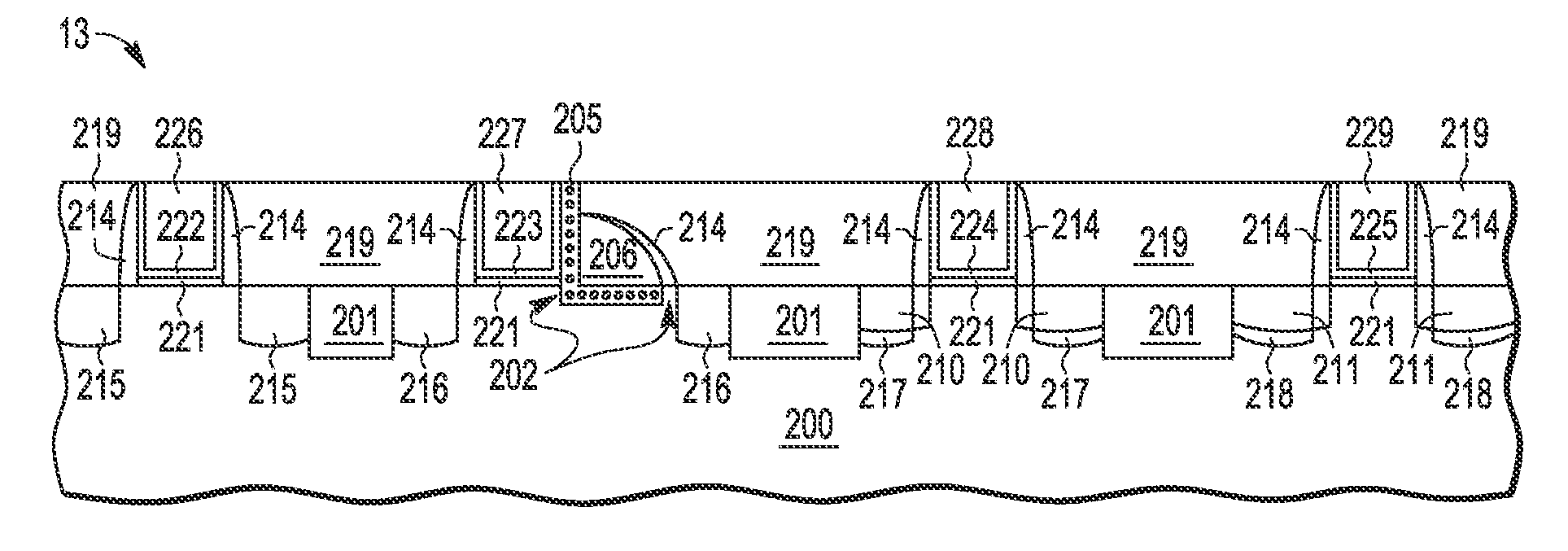

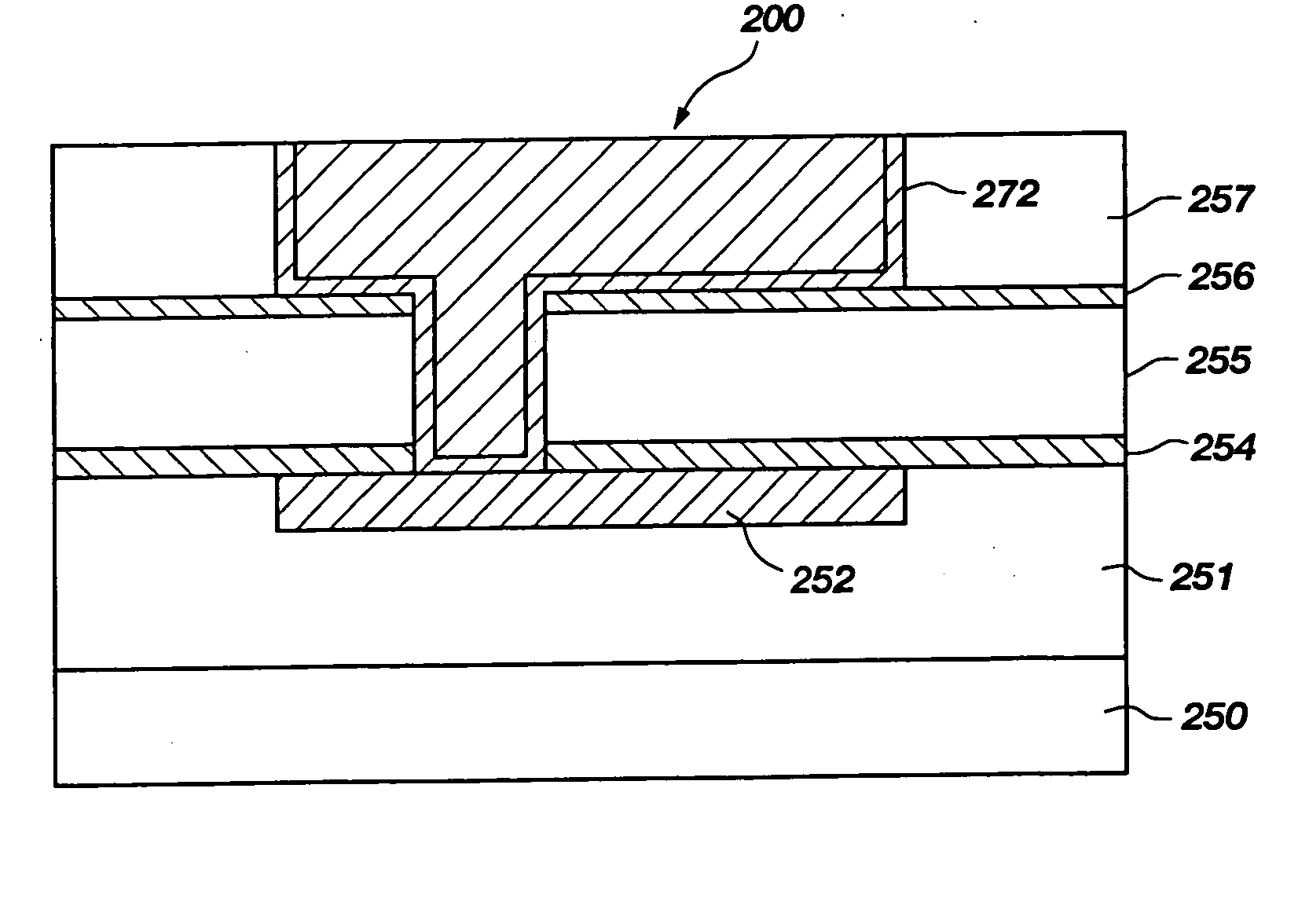

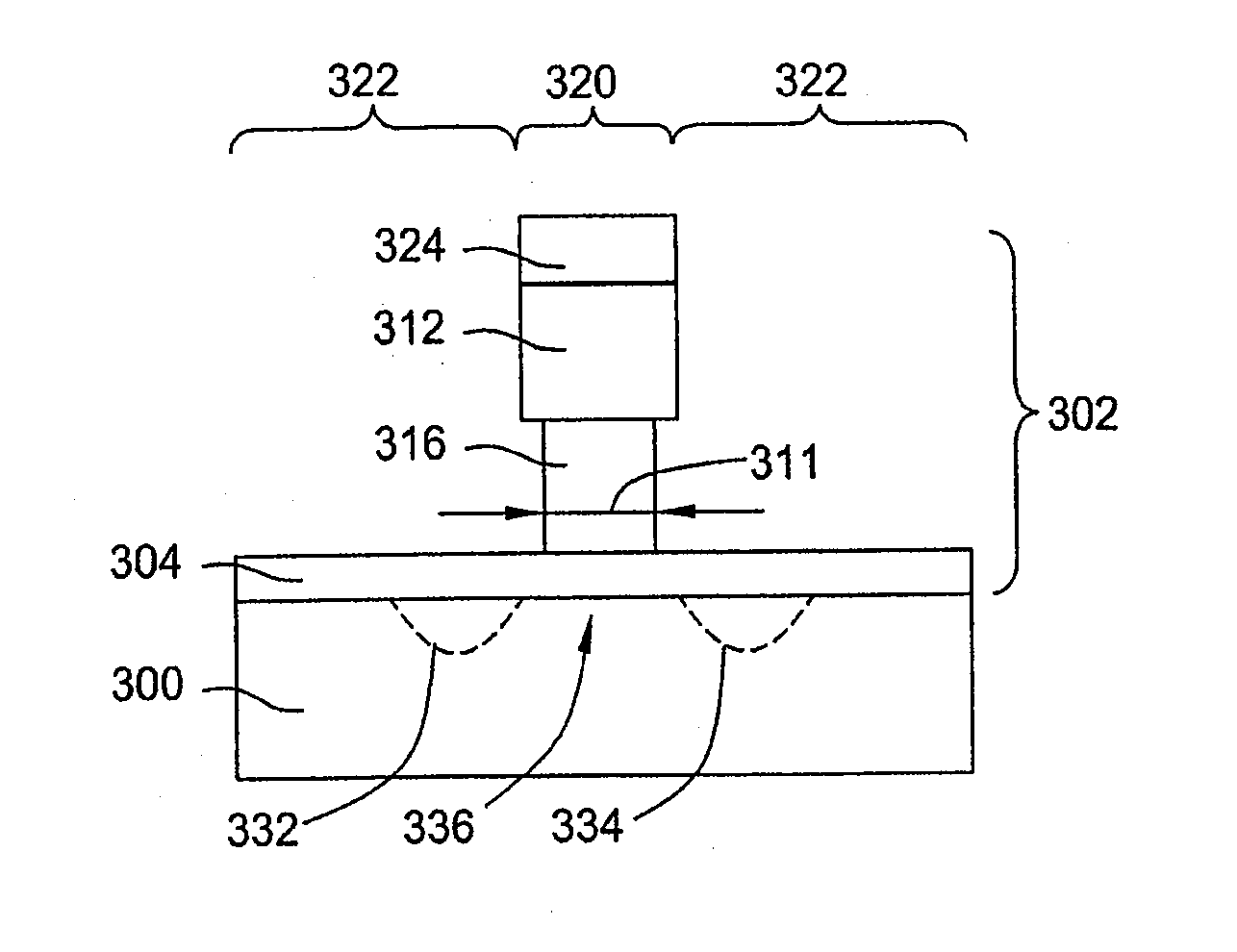

Nonvolatile Memory Bitcell With Inlaid High K Metal Select Gate

ActiveUS20150041875A1Solid-state devicesSemiconductor/solid-state device manufacturingDielectricProcess integration

A process integration is disclosed for fabricating non-volatile memory (NVM) cells having recessed control gates (118, 128) on a first substrate area (111) which are encapsulated in one or more planar dielectric layers (130) prior to forming in-laid high-k metal select gates and CMOS transistor gates (136, 138) in first and second substrate areas (111, 113) using a gate-last HKMG CMOS process flow without interfering with the operation or reliability of the NVM cells.

Owner:NXP USA INC

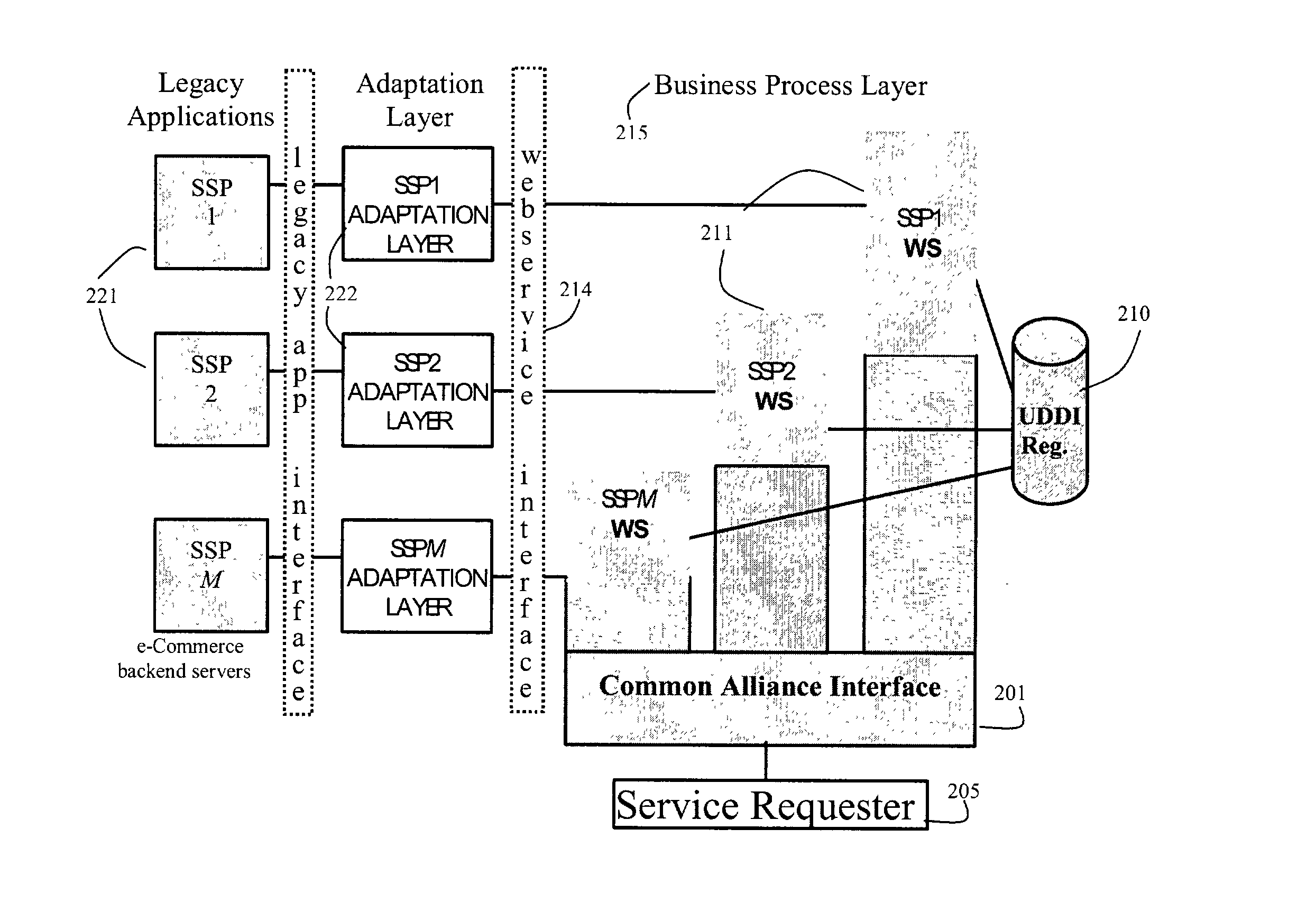

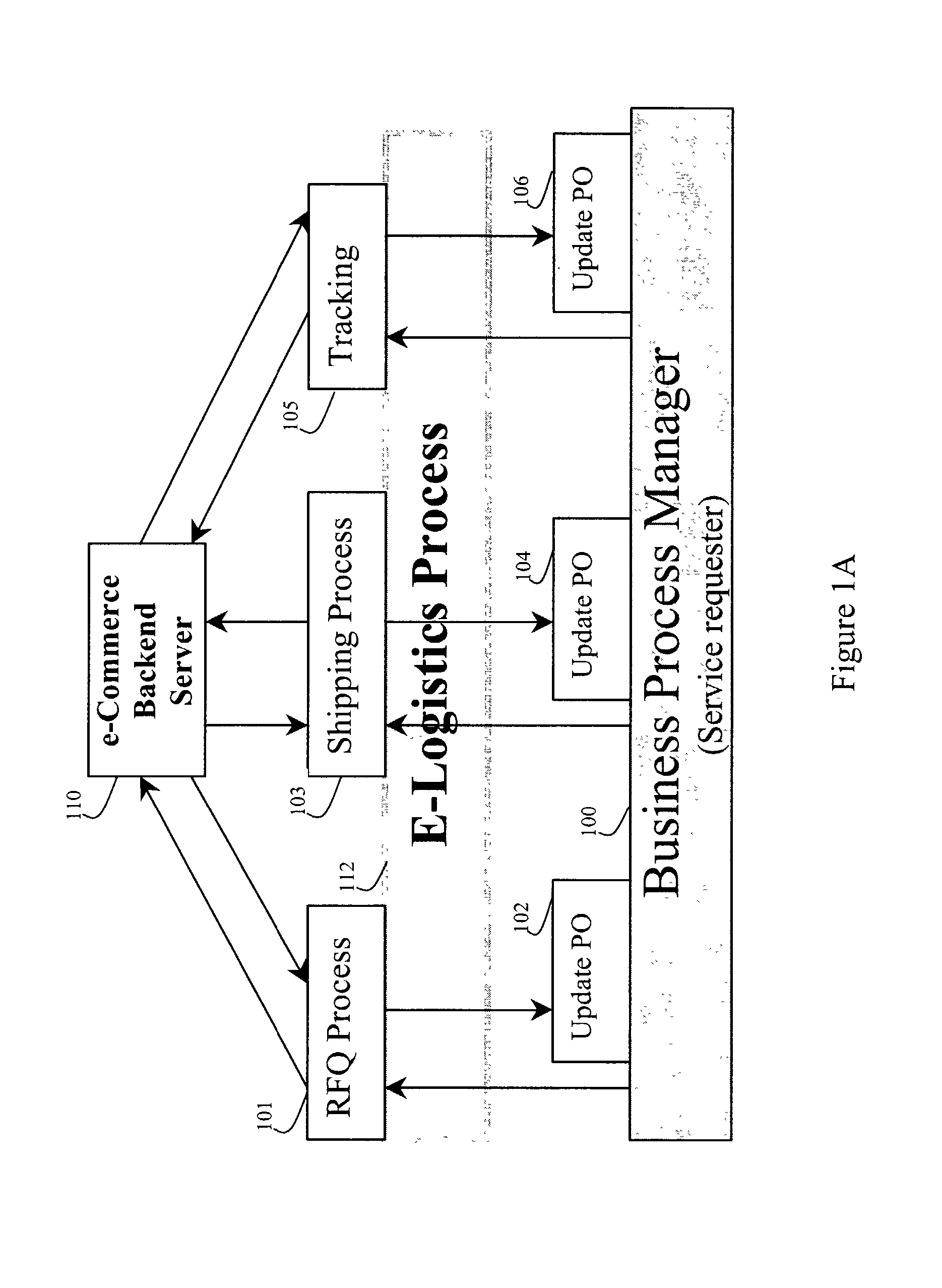

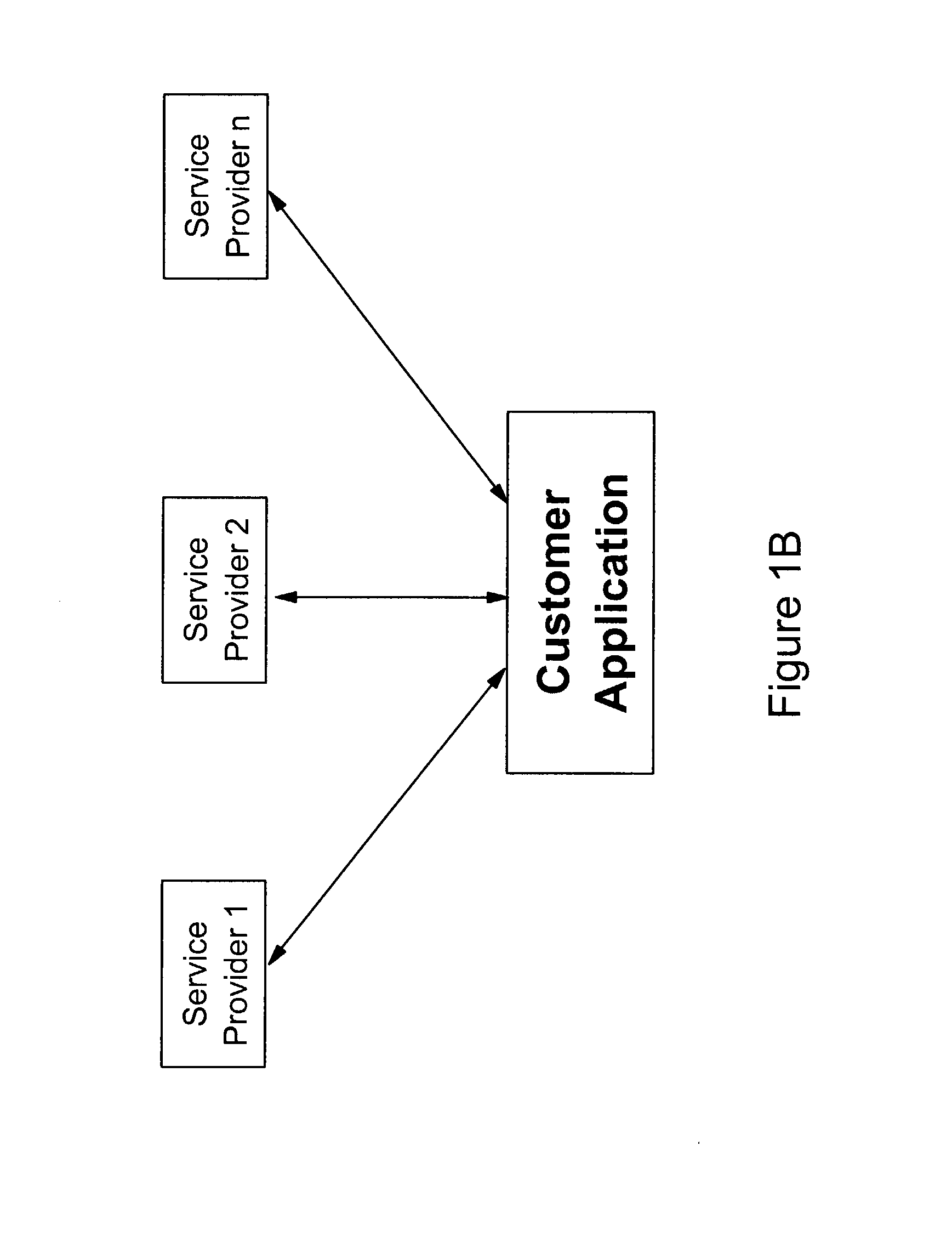

Method and system for integrating e-Logistics processes into a user/provider interface using Web Services

InactiveUS20030191677A1Avoiding high cost and complexityImprove efficiencyResourcesLogisticsLogistics managementProcess integration

A system and method for providing specified electronic commerce services to users, in particular e-Logistics services, services which are available in the marketplace from a variety of service providers whose electronic commerce systems are incompatible. There is provided a user / customer interface to the specified electronic commerce services, called a Common Alliance Interface, and a distinct interface for service providers of the specified electronic commerce services. Between the two interfaces is a business process layer which integrates one or more components of the specified electronic commerce services, these integrated components thereby being transparent to users. The service provider obtains access to users of the Common Alliance Interface by updating entries in a UDDI registry. There is further provided a service template which the service provider can modify to provide an adaptation layer between their legacy application and the business process layer. There is disclosed a business process layer of e-Logistics services comprised of RFQ, shipping and tracking processes.

Owner:IBM CORP

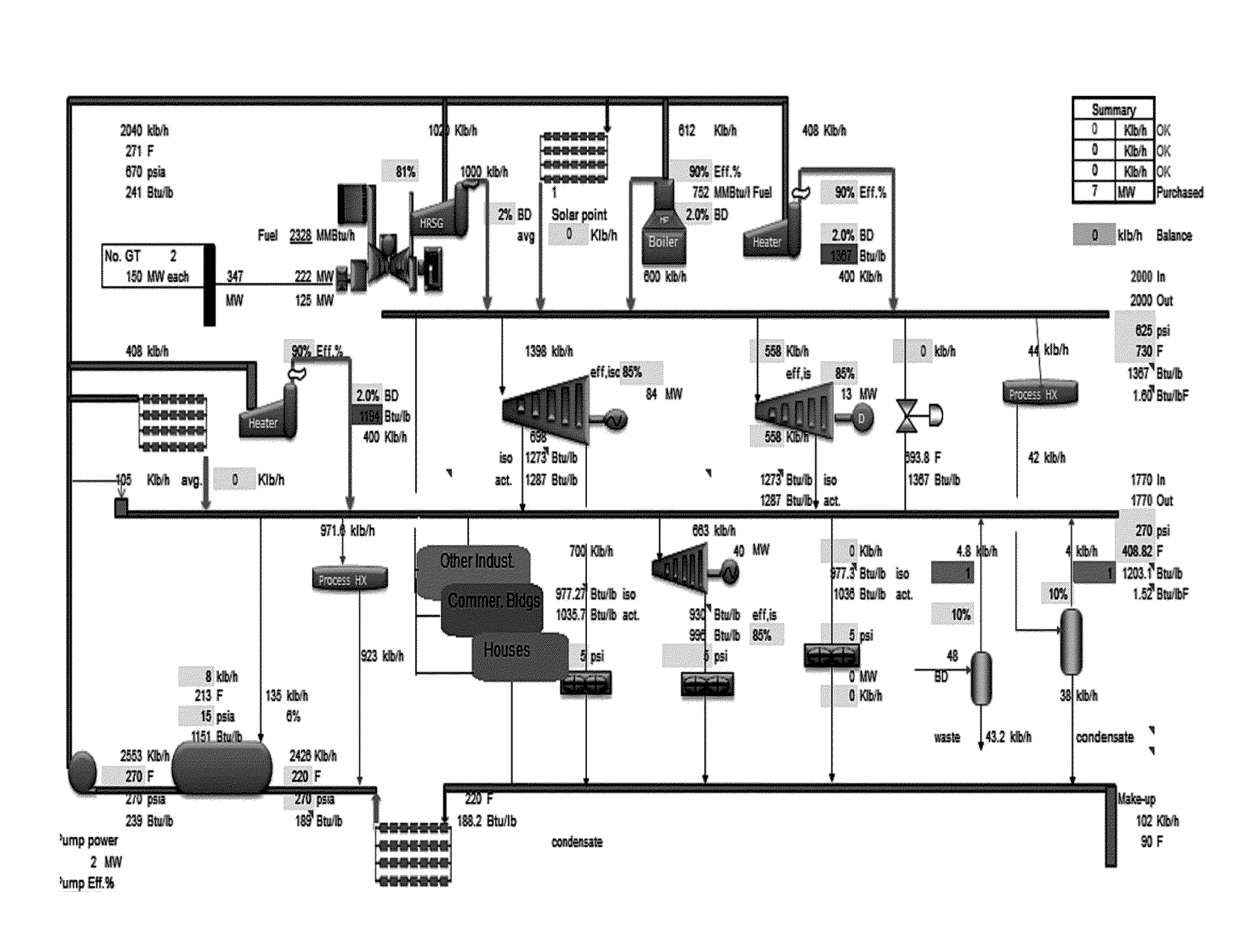

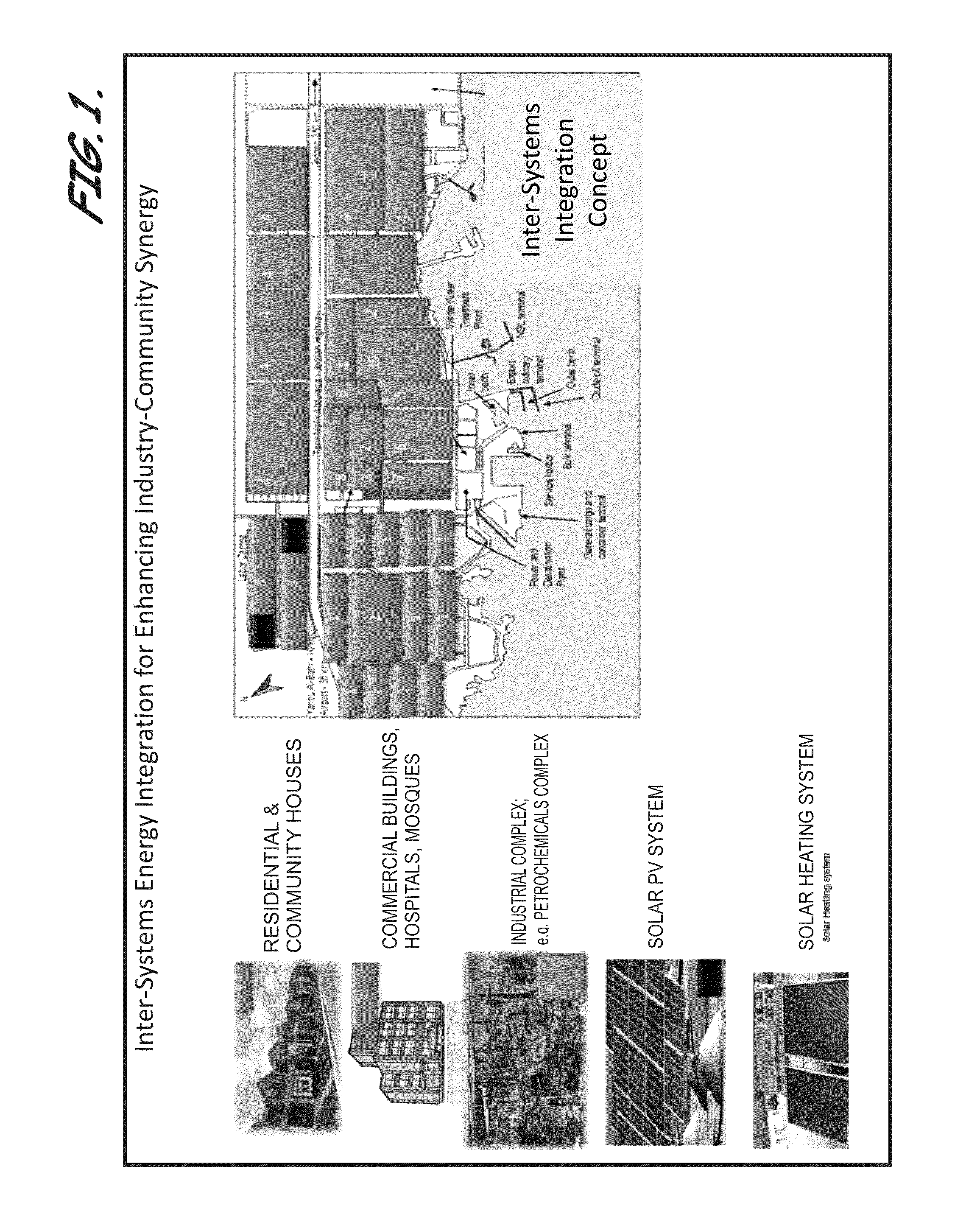

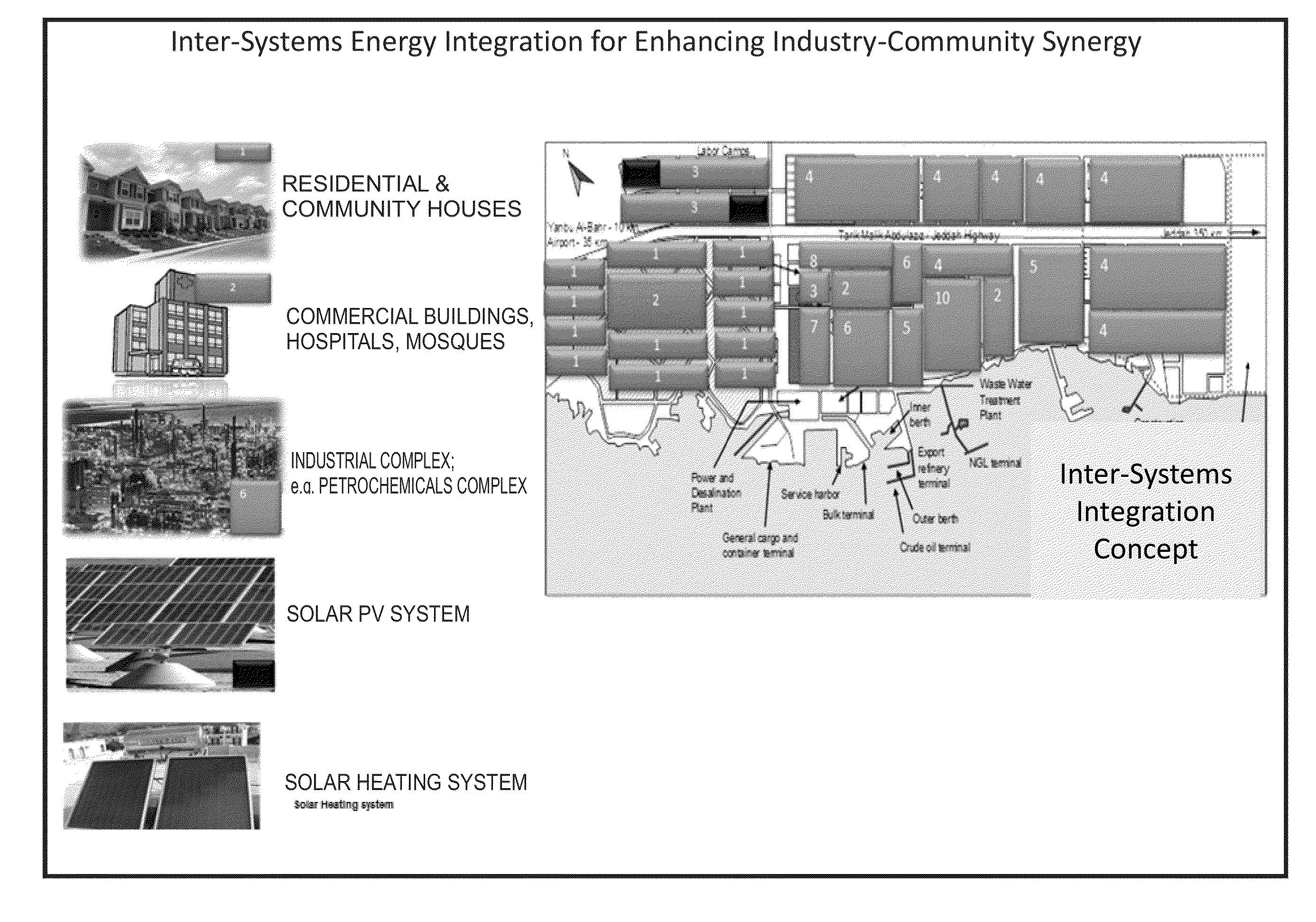

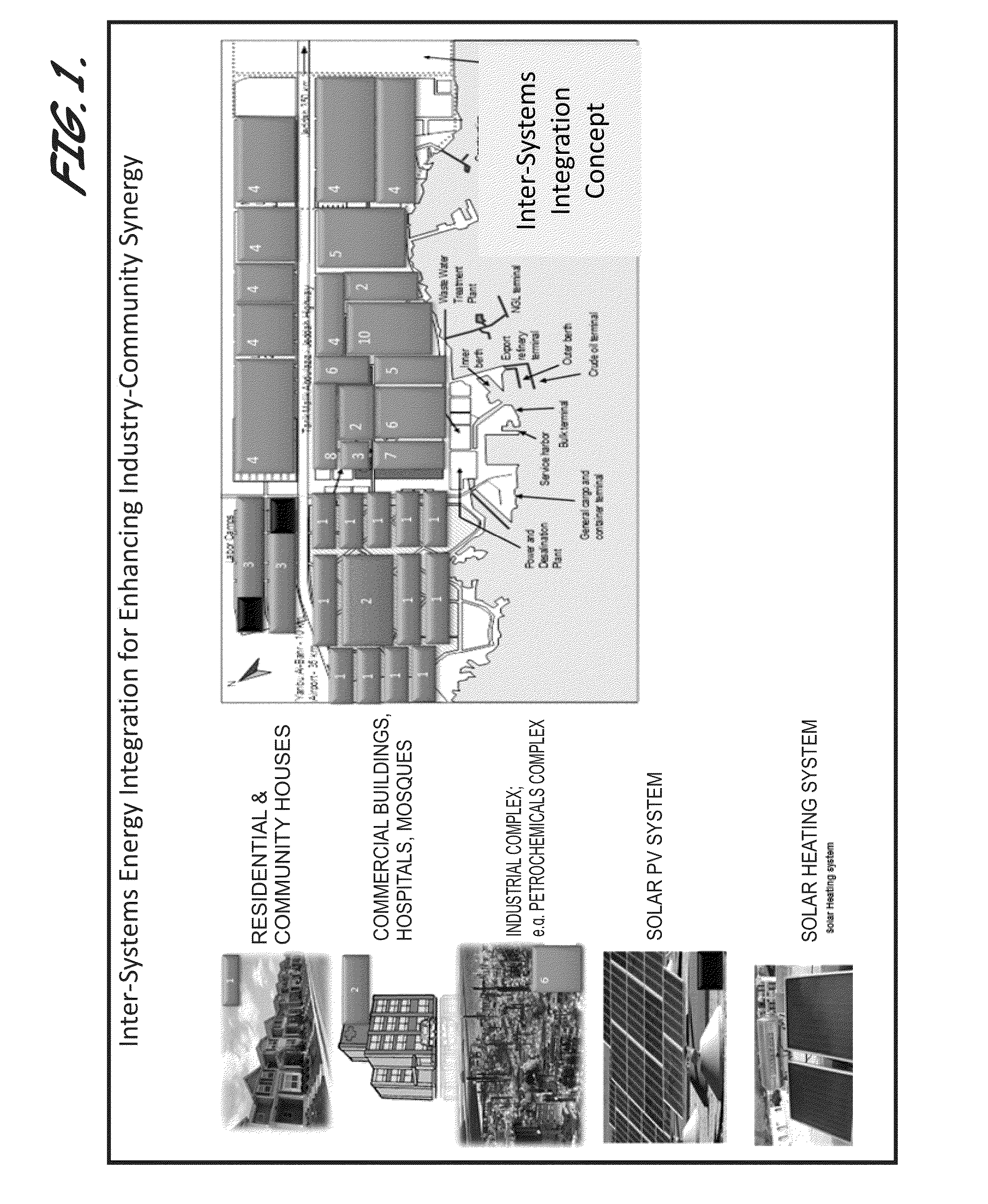

Methods For Enhanced Energy Efficiency Via Systematic Hybrid Inter-Processes Integration

ActiveUS20130231909A1Improve energy efficiencyReducing greenhouse gas emissionDesign optimisation/simulationSpecial data processing applicationsSites treatmentSystems design

Methods for systematically providing enhanced energy efficiency of mega industrial sites and synergy with the adjacent community through advanced hybrid inter-systems energy integration targeting and solutions generation to achieve desired best levels of energy consumption and greenhouse gas emissions reduction, are provided. An exemplary method includes identifying a plurality of possible inter-processes integration energy consumption targets for a plurality of possible inter-processes energy integration combinations between a plurality of functional areas of a mega industrial site, selecting an energy-efficient inter-processes integration energy consumption target, identifying the combination of the plurality of possible inter-processes energy integration combinations providing for the energy efficient inter-processes integration energy consumption target, generating a plurality of technically viable industrial site inter-processes heat exchange system design alternatives, and identifying the technically viable industrial site inter-processes heat exchange system design substantially providing for optimal total waste heat recovery between the respective functional areas.

Owner:SAUDI ARABIAN OIL CO

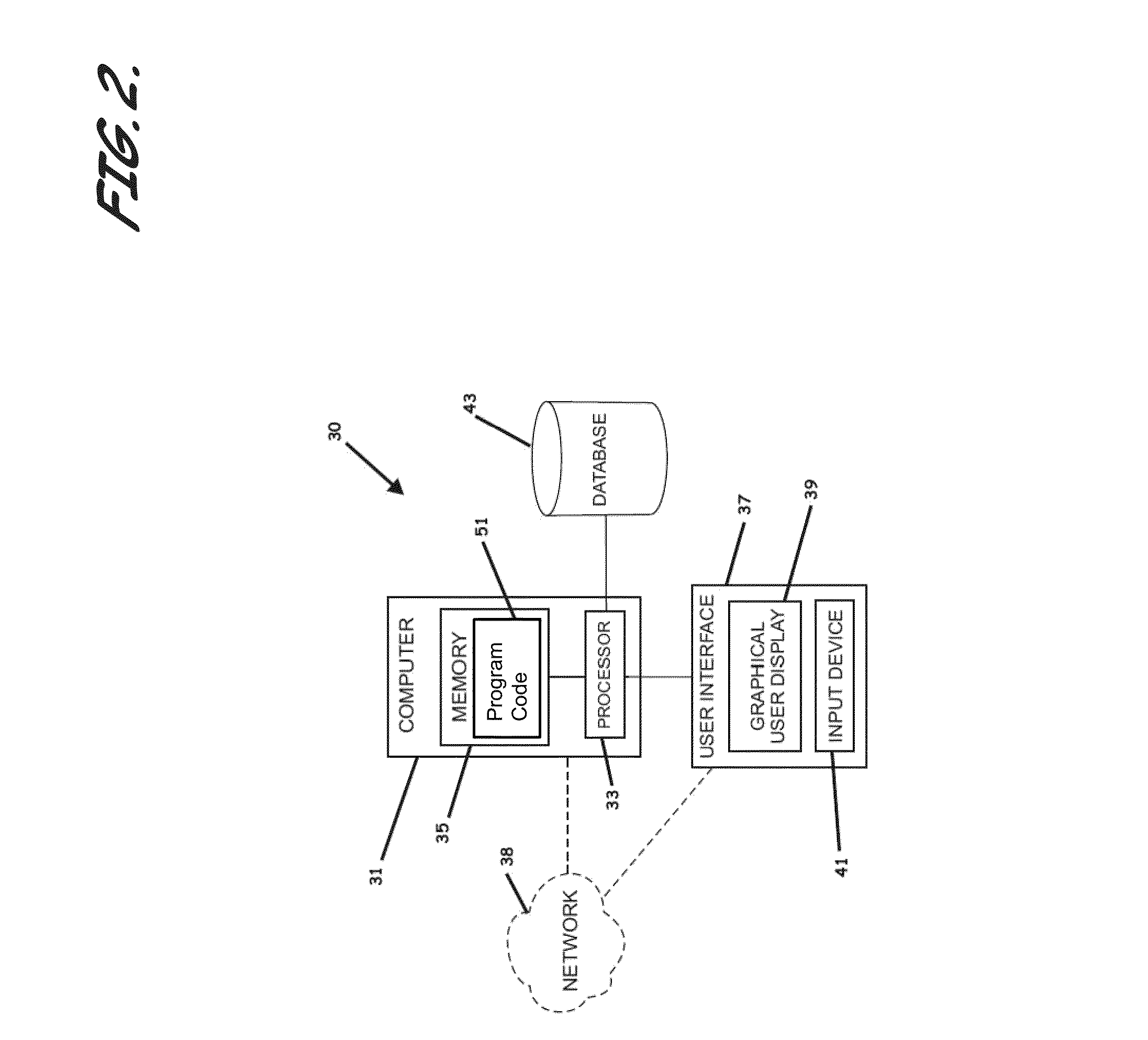

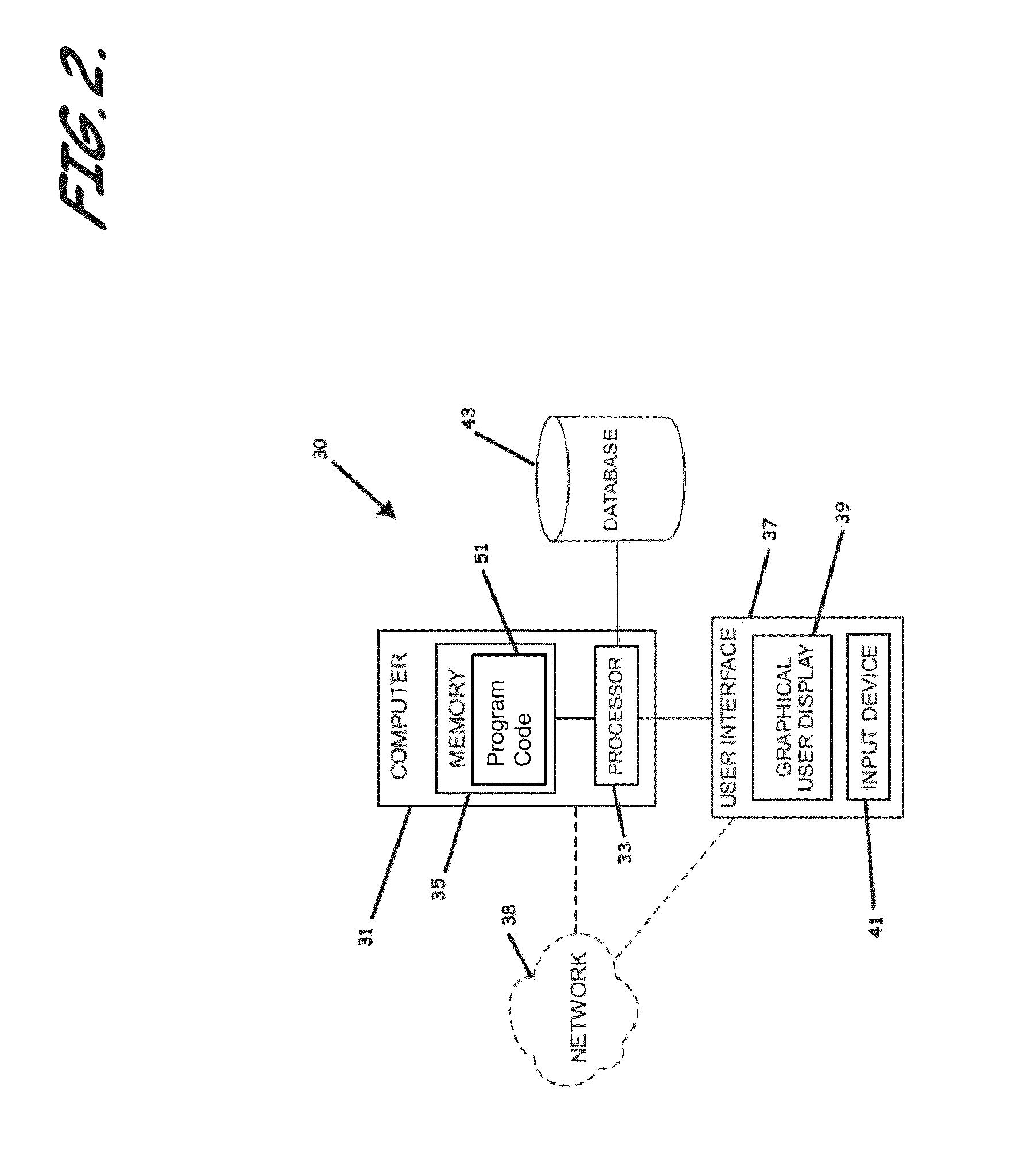

Systems, Computer Readable Media, and Computer Programs For Enhancing Energy Efficiency Via Systematic Hybrid Inter-Processes Integration

ActiveUS20130238154A1Improve energy efficiencyReducing greenhouse gas emissionMechanical power/torque controlLevel controlSystems designProcess integration

Systems, computer readable media, and program code for systematically providing enhanced energy efficiency of mega industrial sites and synergy with the adjacent community through advanced hybrid inter-systems energy integration targeting and solutions generation to achieve desired best levels of energy consumption and greenhouse gas emissions reduction, are provided. An exemplary system includes a computer and computer readable code for performing the operations of determining possible inter-processes integration energy consumption targets, selecting an energy-efficient inter-processes integration energy consumption target, determining the inter-processes energy integration combination providing for the energy efficient inter-processes integration energy consumption target, generating a plurality of technically viable industrial site inter-processes heat exchange system design alternatives, and assisting a user to identify the technically viable industrial site inter-processes heat exchange system design substantially providing for optimal total waste heat recovery between the respective functional areas.

Owner:SAUDI ARABIAN OIL CO

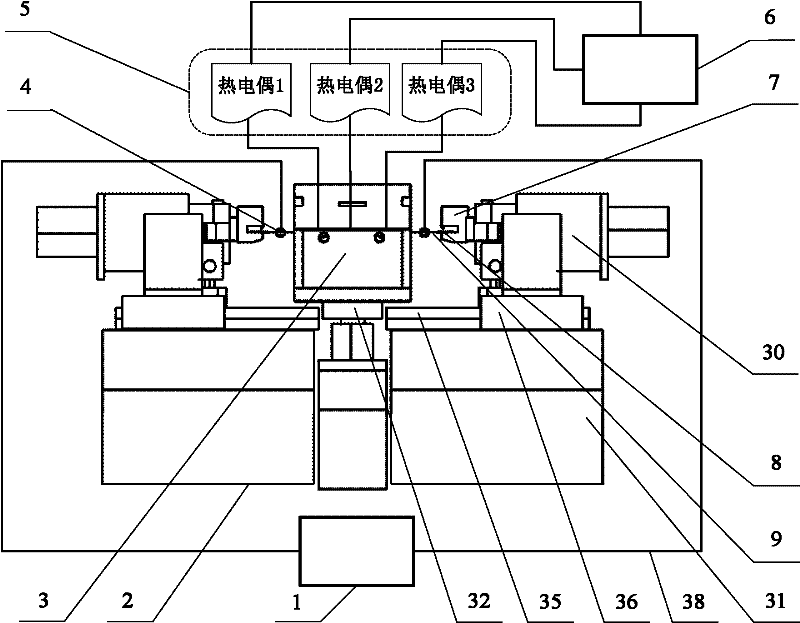

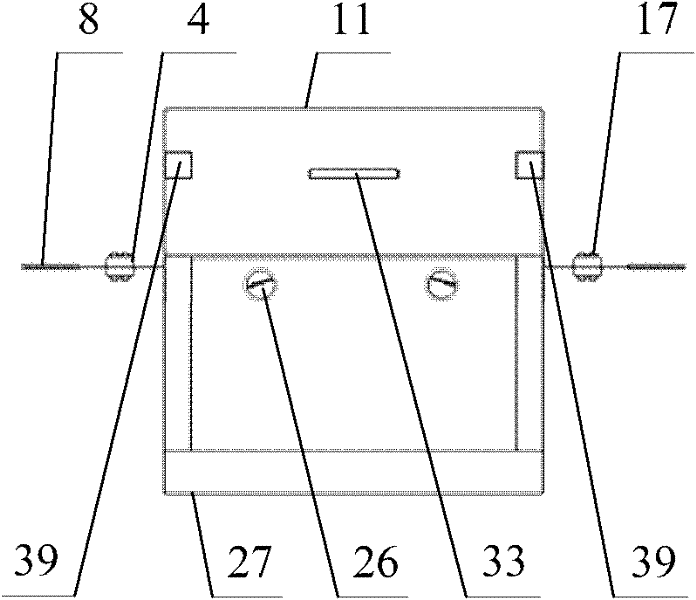

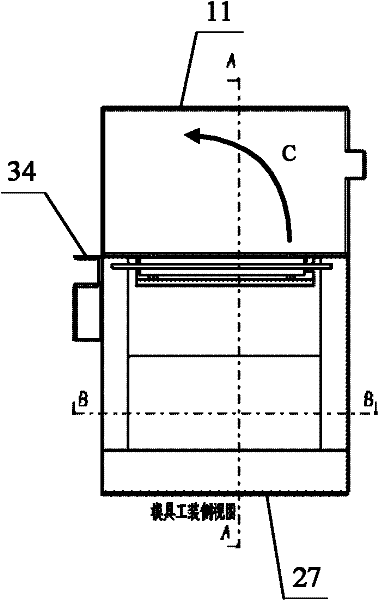

Hot forming tool of titanium alloy thin-wall part and machining method of hot forming tool

ActiveCN102500675AViscoplastic deformation facilitatesAvoid lostShaping toolsTemperature controlProcess integration

The invention provides a hot forming tool of a titanium alloy thin-wall part, comprising five parts, namely stretching equipment, a mould device, a blank, a power supply system and a temperature control system, wherein the mould device is arranged on a central worktable of the stretching equipment; the blank passes through a side wall crack of the mould device; an insulating and heat-insulation cushion layer is used for insulating the blank, a clamp of the stretching equipment, the surface of a mould and a tool of the mould; the power supply system is switched on to electrify an electrode clamping plate and generate a current in the blank; the blank is heated and the temperature of the blank is measured and controlled by the temperature control system; and after the temperature of the blank reaches a target temperature, the part is formed on the surface on the mould by the blank in an adhered manner through carrying out hot forming processes successively including stretching, covering, stretching, heat preservation and creep deformation and the like on the stretching equipment. A machining method of the hot forming tool of the titanium alloy thin-wall part comprises eight steps. According to the invention, the heating efficiency, the process integration, the material formation and the formation precision of the titanium alloy thin-wall part in manufacture are greatly improved, so that the hot forming tool of the titanium alloy thin-wall part and the machining method of the hot forming tool have a practical value and a popularization value.

Owner:BEIHANG UNIV

Chemical vapor deposition chamber with dual frequency bias and method for manufacturing a photomask using the same

InactiveUS20070119373A1Electric discharge tubesSemiconductor/solid-state device manufacturingDual frequencyResist

A method and apparatus for process integration in manufacture of a ask are disclosed. In one embodiment, a cluster tool suitable for process integration in manufacture of a photomask including a vacuum transfer chamber having coupled thereto at least one hard mask deposition chamber and at least one plasma chamber configured for etching chromium. In another embodiment, a method for process integration in manufacture of a photomask includes depositing a hard mask on a substrate in a first processing chamber, depositing a resist layer on the substrate, patterning the resist layer, etching the hard mask through apertures formed in the patterned resist layer in a second chamber; and etching a chromium layer through apertures formed in the hard mask in a third chamber.

Owner:APPLIED MATERIALS INC

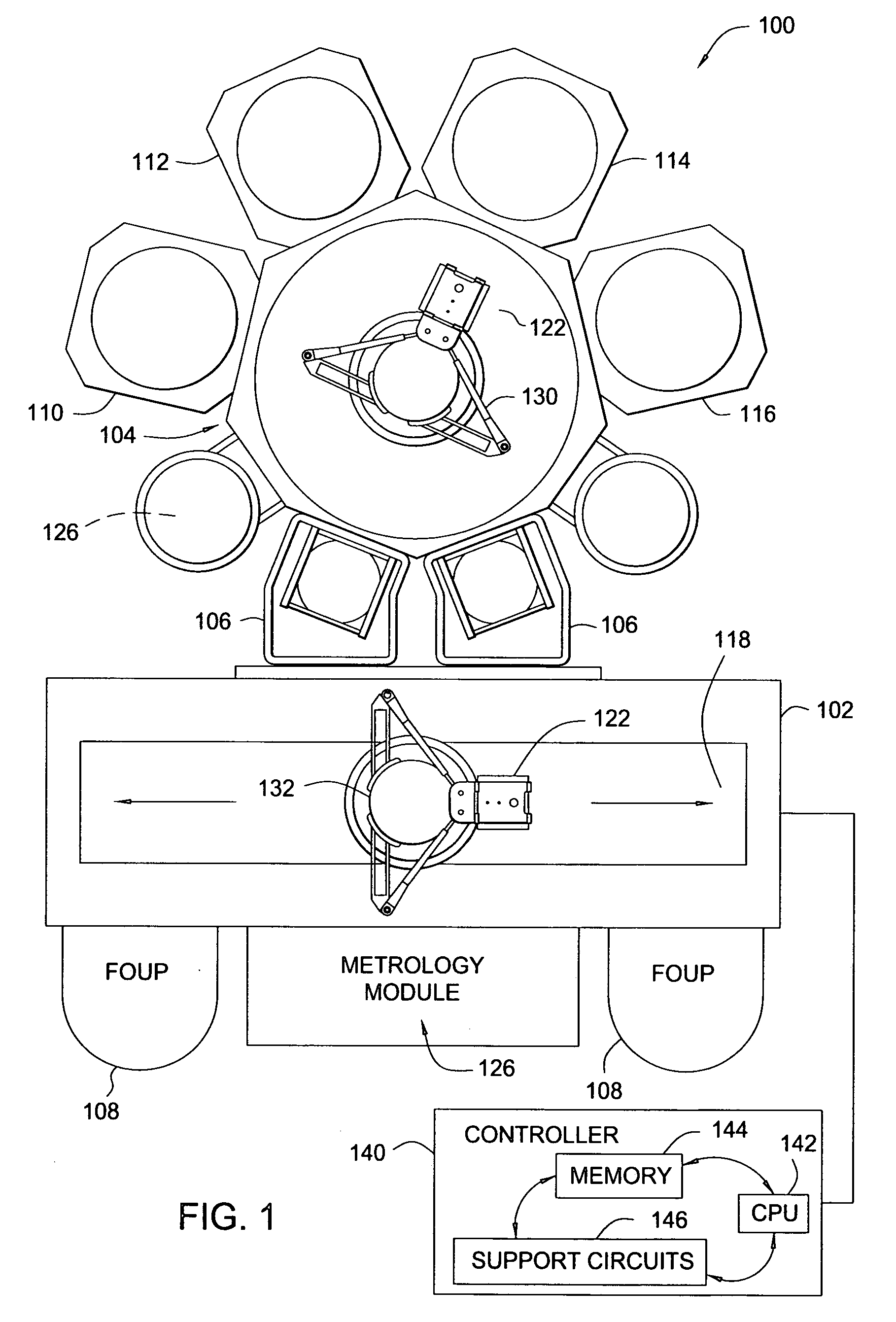

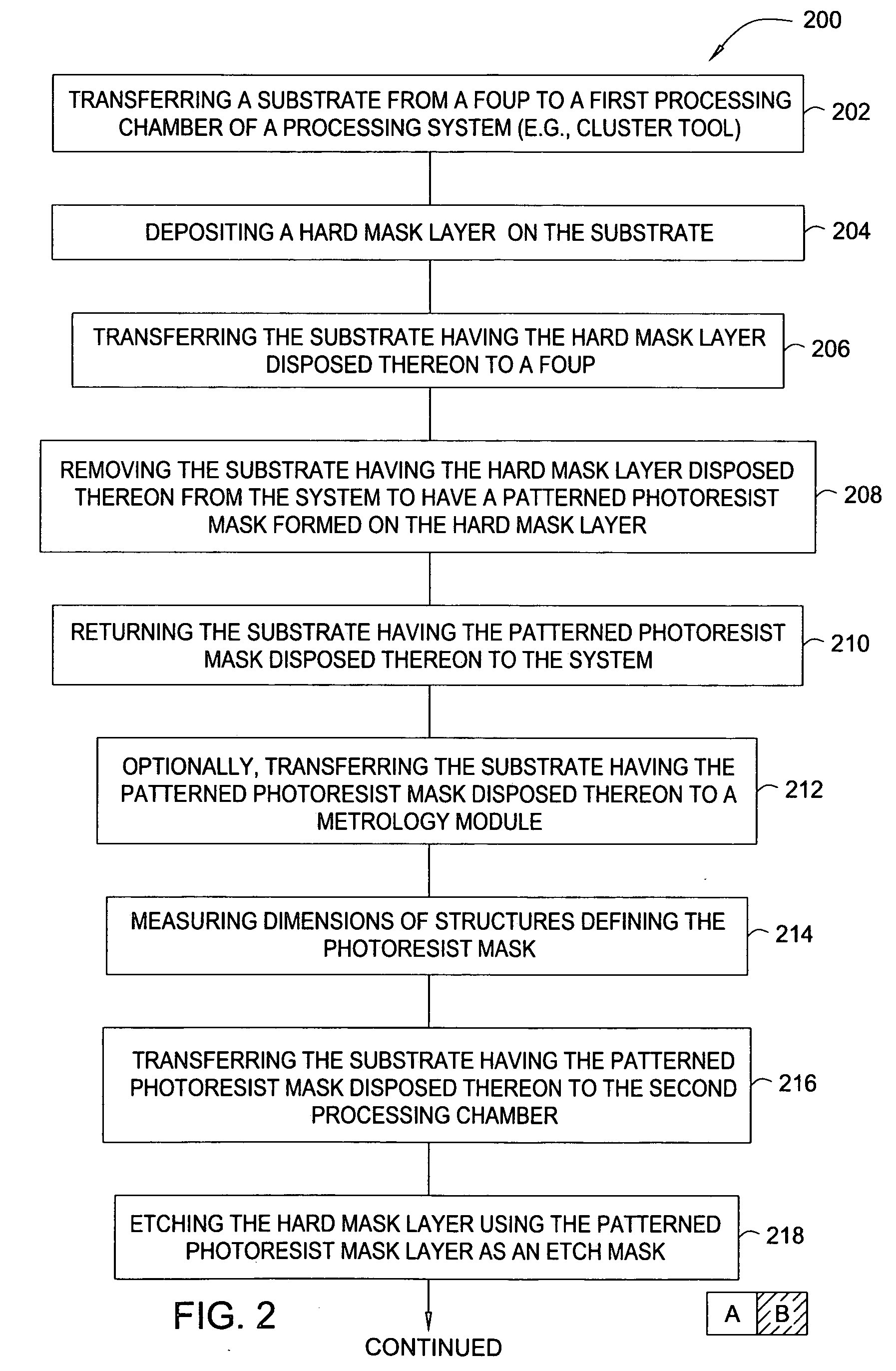

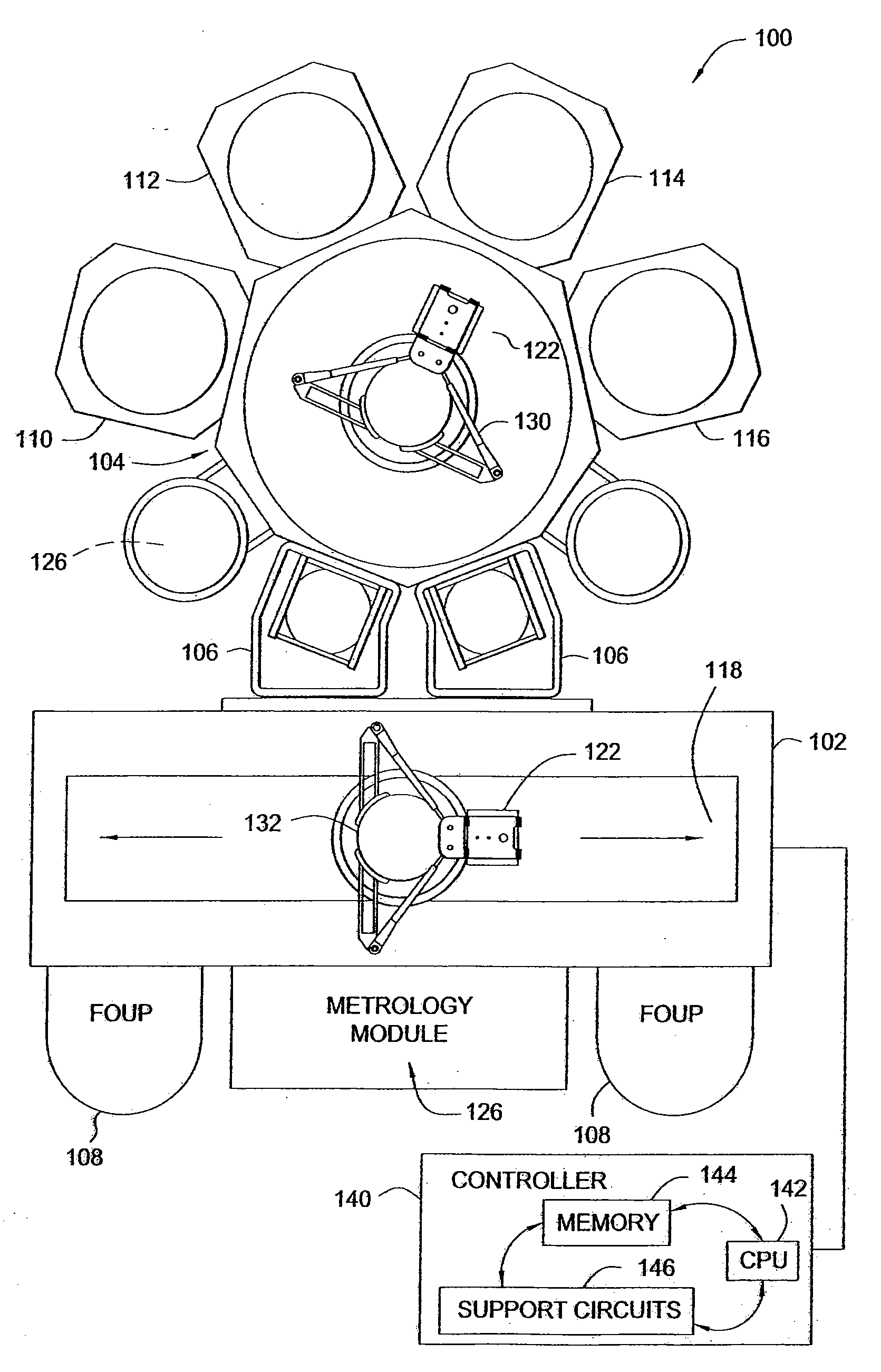

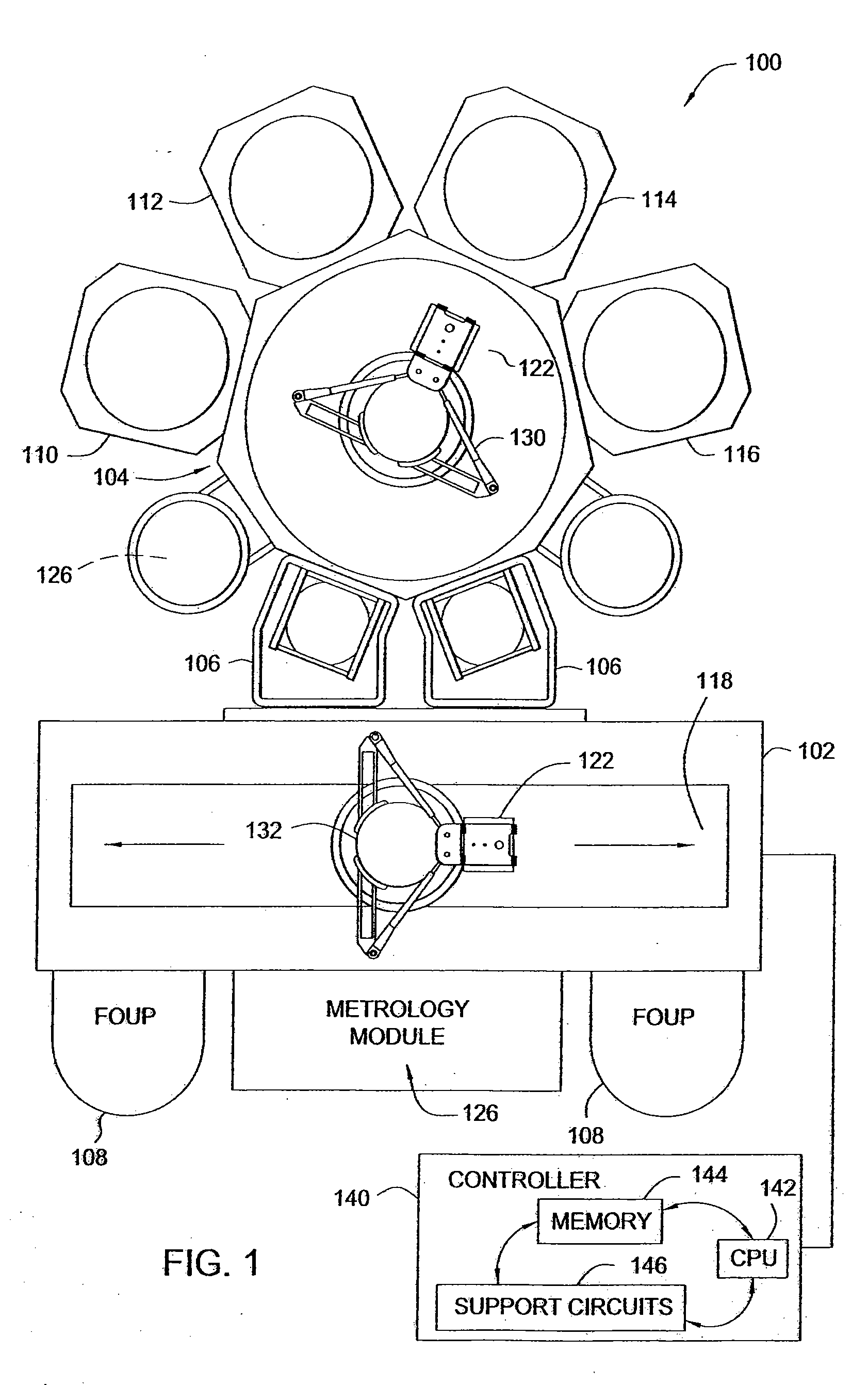

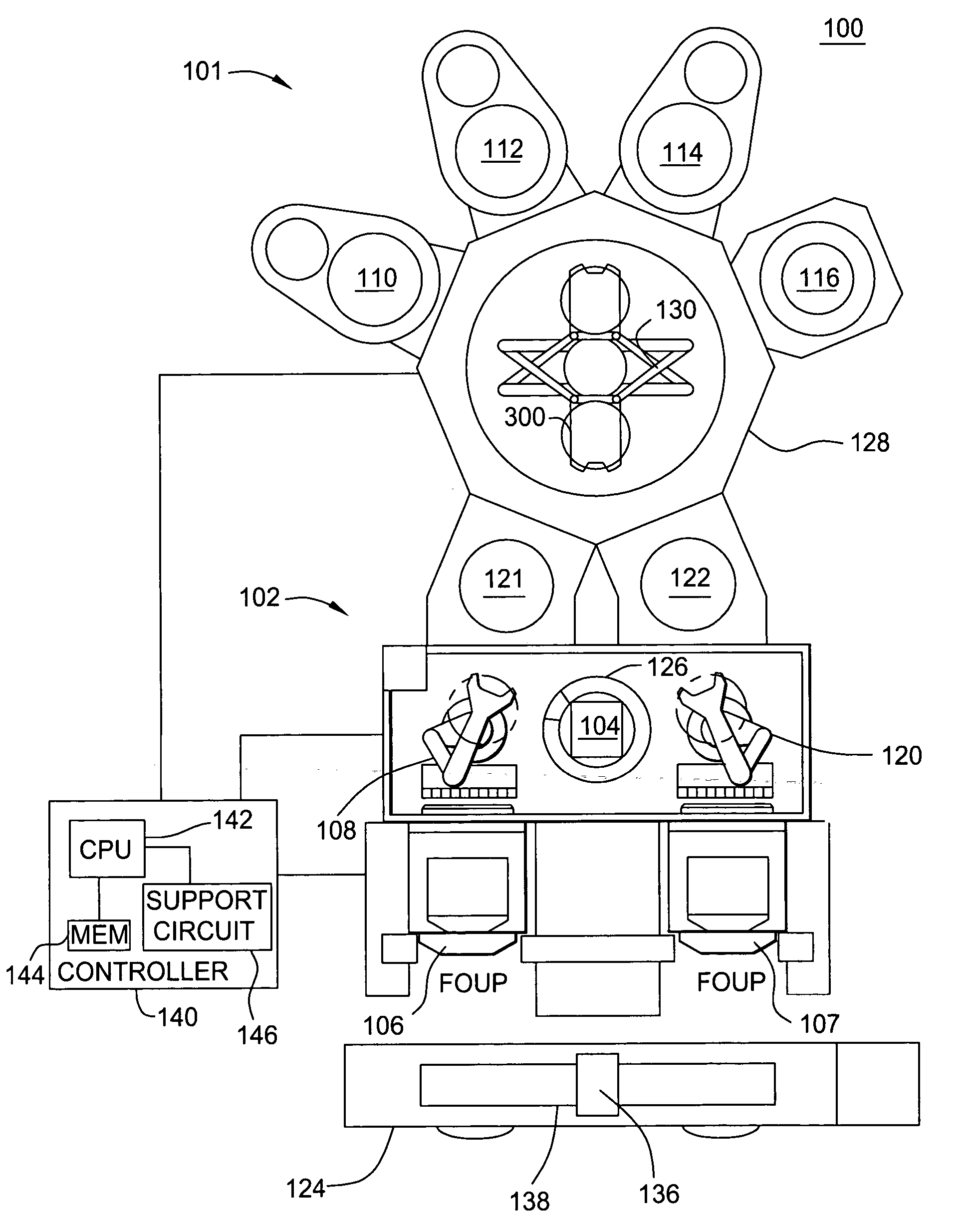

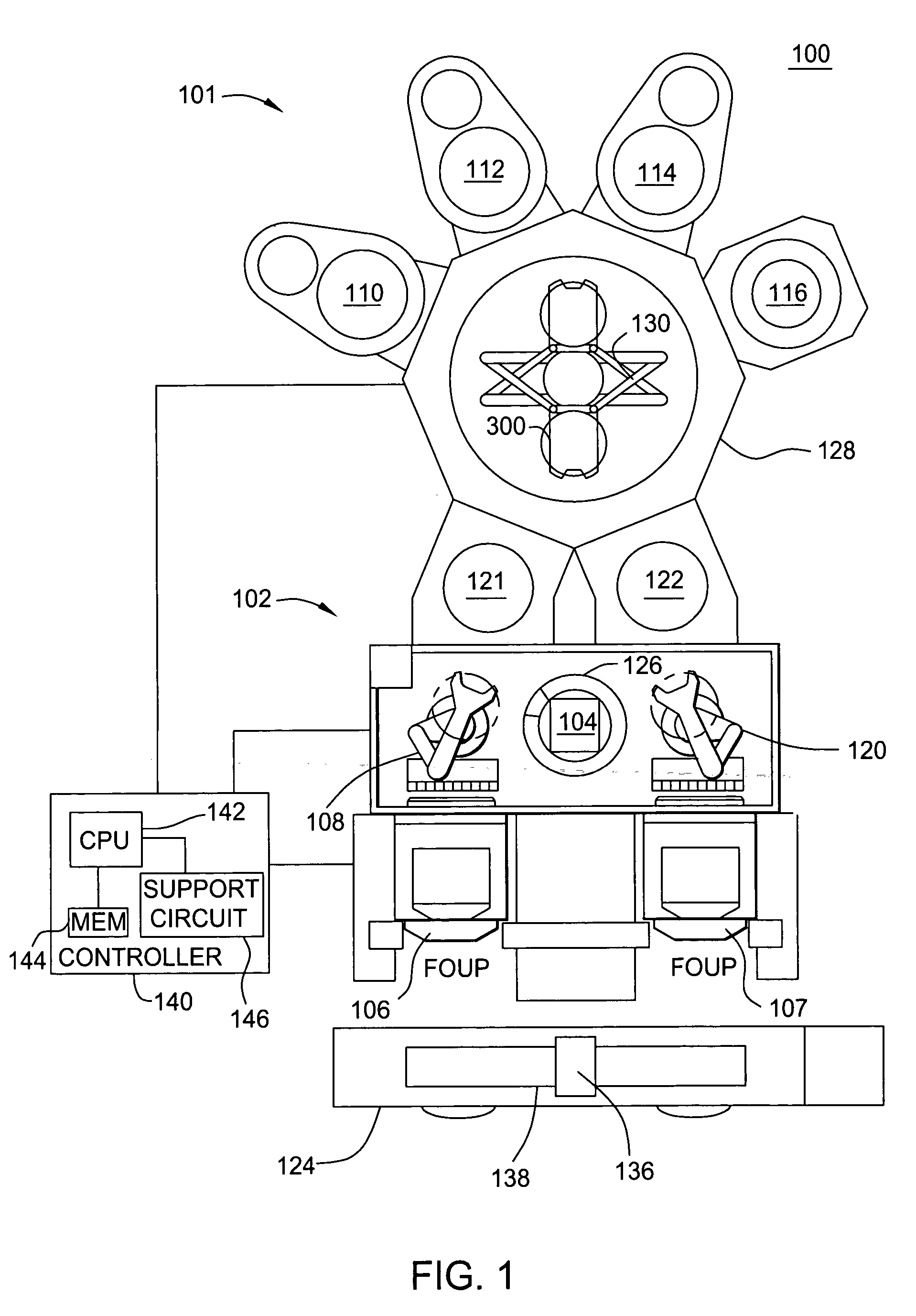

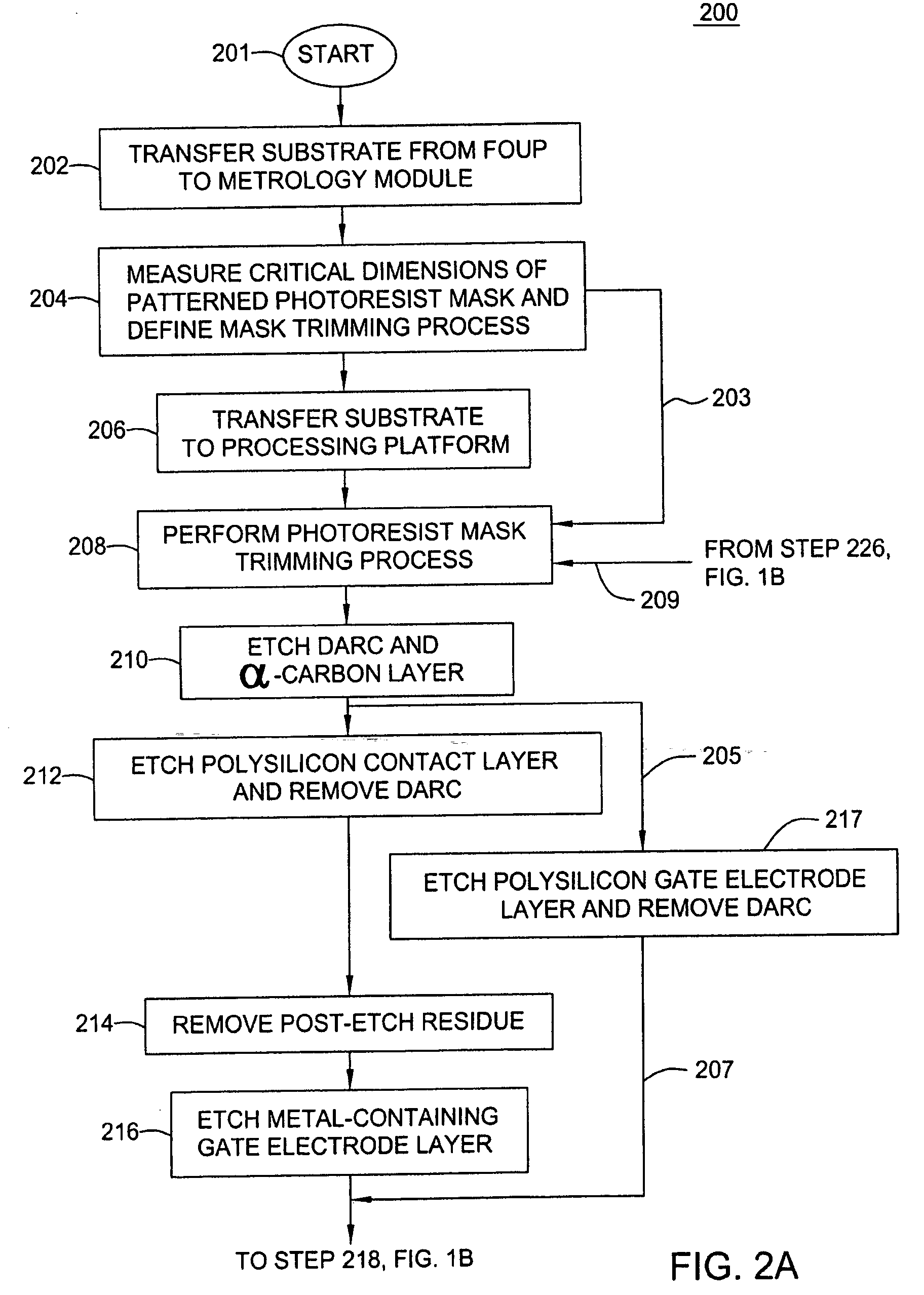

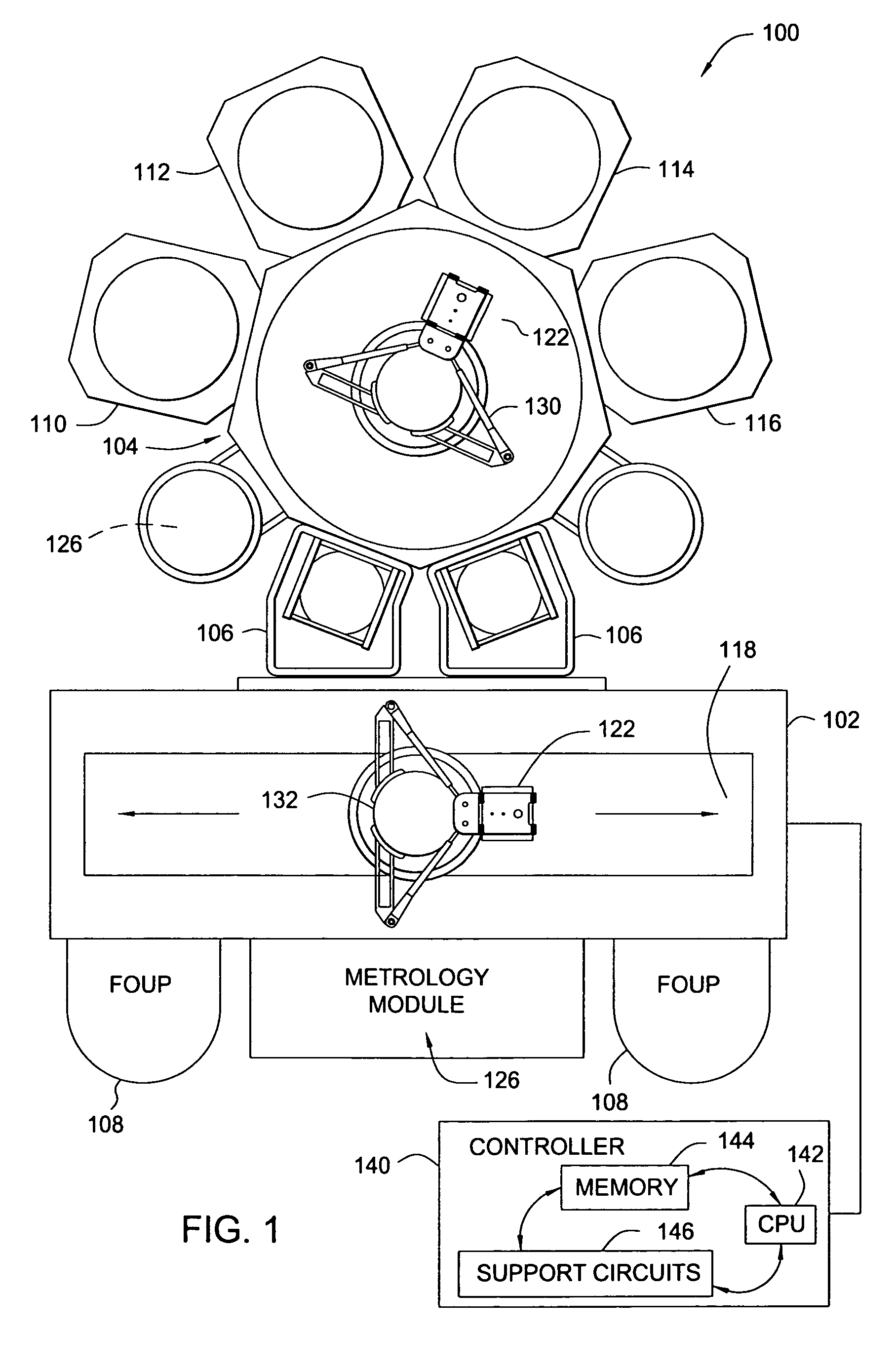

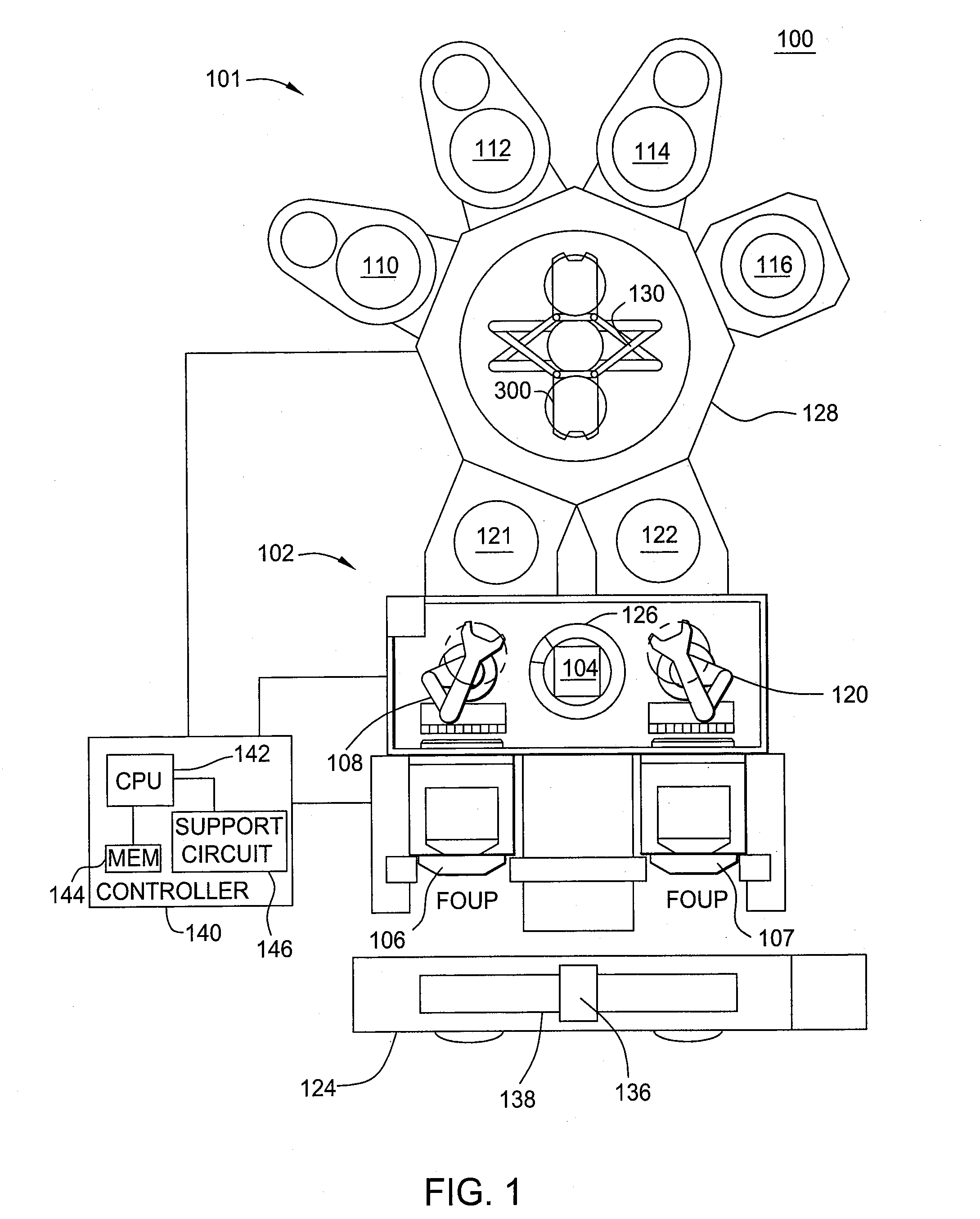

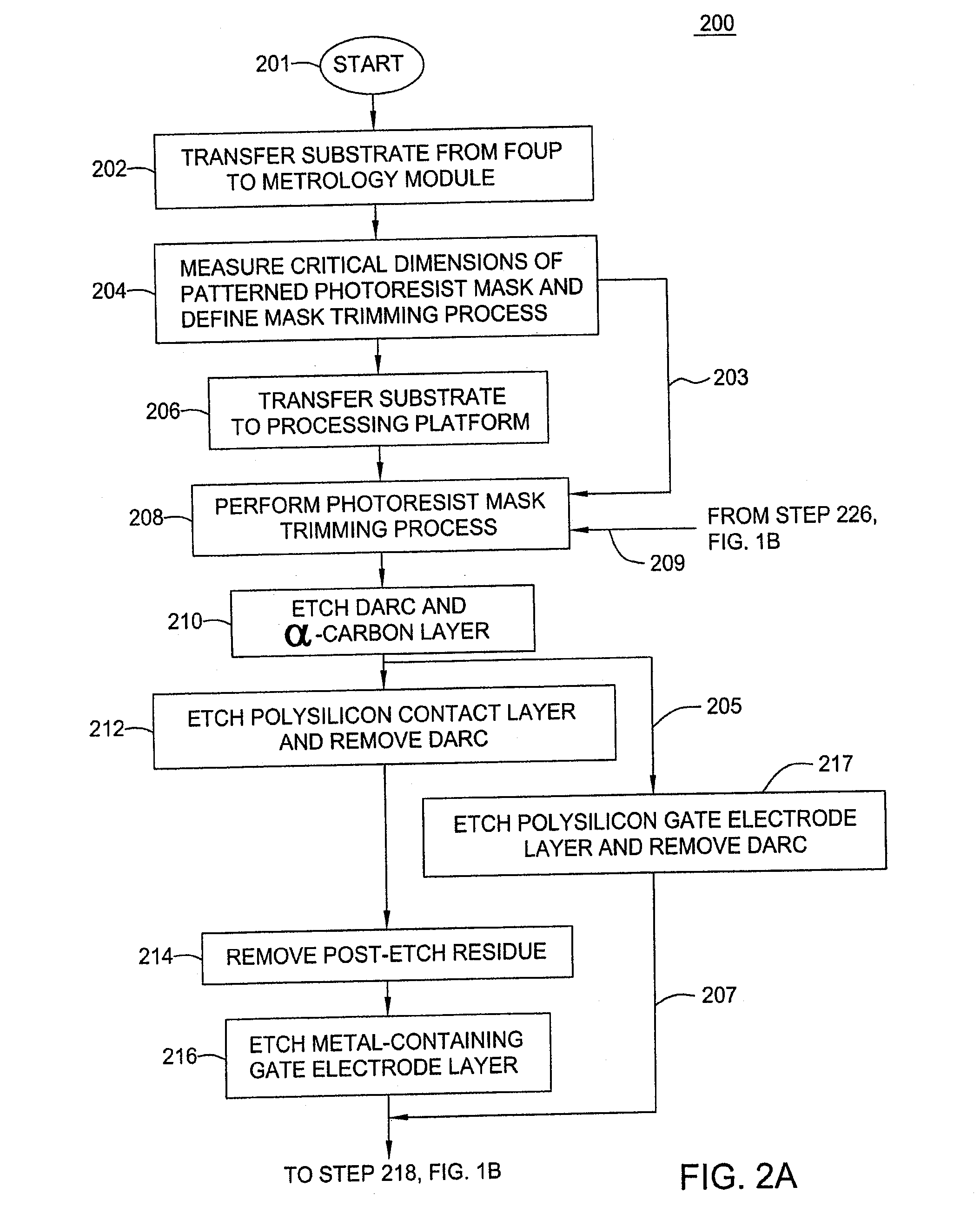

Cluster tool and method for process integration in manufacture of a gate structure of a field effect transistor

InactiveUS20060021702A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess integrationMetrology

A method and apparatus for process integration in manufacture of a gate structure of a field effect transistor are disclosed. The method includes assembling an integrated substrate processing system having a metrology module and a vacuumed processing platform to perform controlled and adaptive plasma processes without exposing the substrate to a non-vacuumed environment.

Owner:APPLIED MATERIALS INC

Integrated biorefineries for production of sugars, fermentation products, and coproducts

InactiveUS20140356915A1Minimize cooling water requirementRequires minimizationChemical industryBiofuelsSolventMonomer

Processes are described for fractionating lignocellulosic biomass into cellulose, hemicellulose, and lignin, comprising fractionating lignocellulosic biomass in the presence of a solvent for lignin (such as ethanol), a hydrolysis catalyst (such as sulfur dioxide), and water, to produce a liquor containing hemicellulose, cellulose-rich solids, and lignin; hydrolyzing the hemicellulose to produce hemicellulosic monomers; saccharifying the cellulose-rich solids to produce glucose; recovering the hemicellulosic monomers and the glucose, separately or in a combined stream, as fermentable sugars; and fermenting the fermentable sugars to a fermentation product having a higher normal boiling point than water. Process integration of mass and / or energy is disclosed in many specific embodiments. The fermentation product may include an organic acid, an alcohol, a diol, or combinations thereof.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC

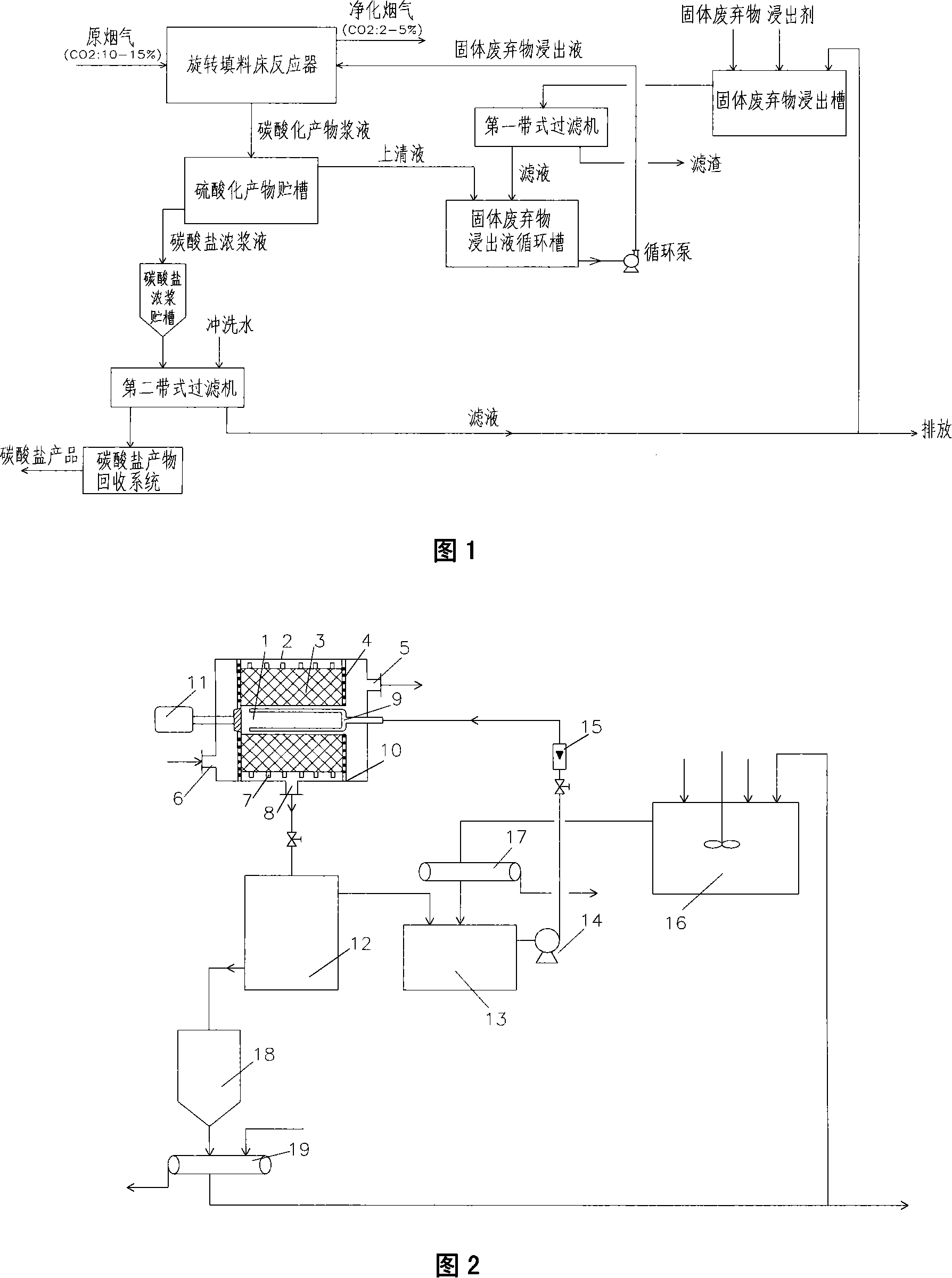

Method and device for fixing CO2 in stack gas by solid castoff carbonatation

InactiveCN101219330AIncrease mass transfer absorption rateIncrease carbon sequestration capacityDispersed particle separationBy chemical separationProcess integrationCentrifugal force

The invention provides a technique method for integrating coupling in-situ CO2 through utilizing a plurality of processes such as CO2 absorbing separation, carbonation fixation and solid wastes recovery in stack gas and a device thereof. A supergravity rotating packing bed reactor is used for intensifying transmission and multi-phase reacting process through utilizing powerful centrifugal force generated by the high-speed rotary packing bed, which is a breakthrough technology and can strengthen order of magnitude to the transmitting process of liquidoid-controlled CO2, etc., thus greatly improving mass transfer absorption rate of the CO2.

Owner:SOUTHEAST UNIV

Cluster tool and method for process integration in manufacturing of a photomask

InactiveUS20070026321A1Improve photomask fabricationMinimal financial investmentDecorative surface effectsPhotomechanical apparatusResistProcess integration

A method and apparatus for process integration in manufacture of a photomask are disclosed. In one embodiment, a cluster tool suitable for process integration in manufacture of a photomask including a vacuum transfer chamber having coupled thereto at least one hard mask deposition chamber and at least one plasma chamber configured for etching chromium. In another embodiment, a method for process integration in manufacture of a photomask includes depositing a hard mask on a substrate in a first processing chamber, depositing a resist layer on the substrate, patterning the resist layer, etching the hard mask through apertures formed in the patterned resist layer in a second chamber; and etching a chromium layer through apertures formed in the hard mask in a third chamber.

Owner:APPLIED MATERIALS INC

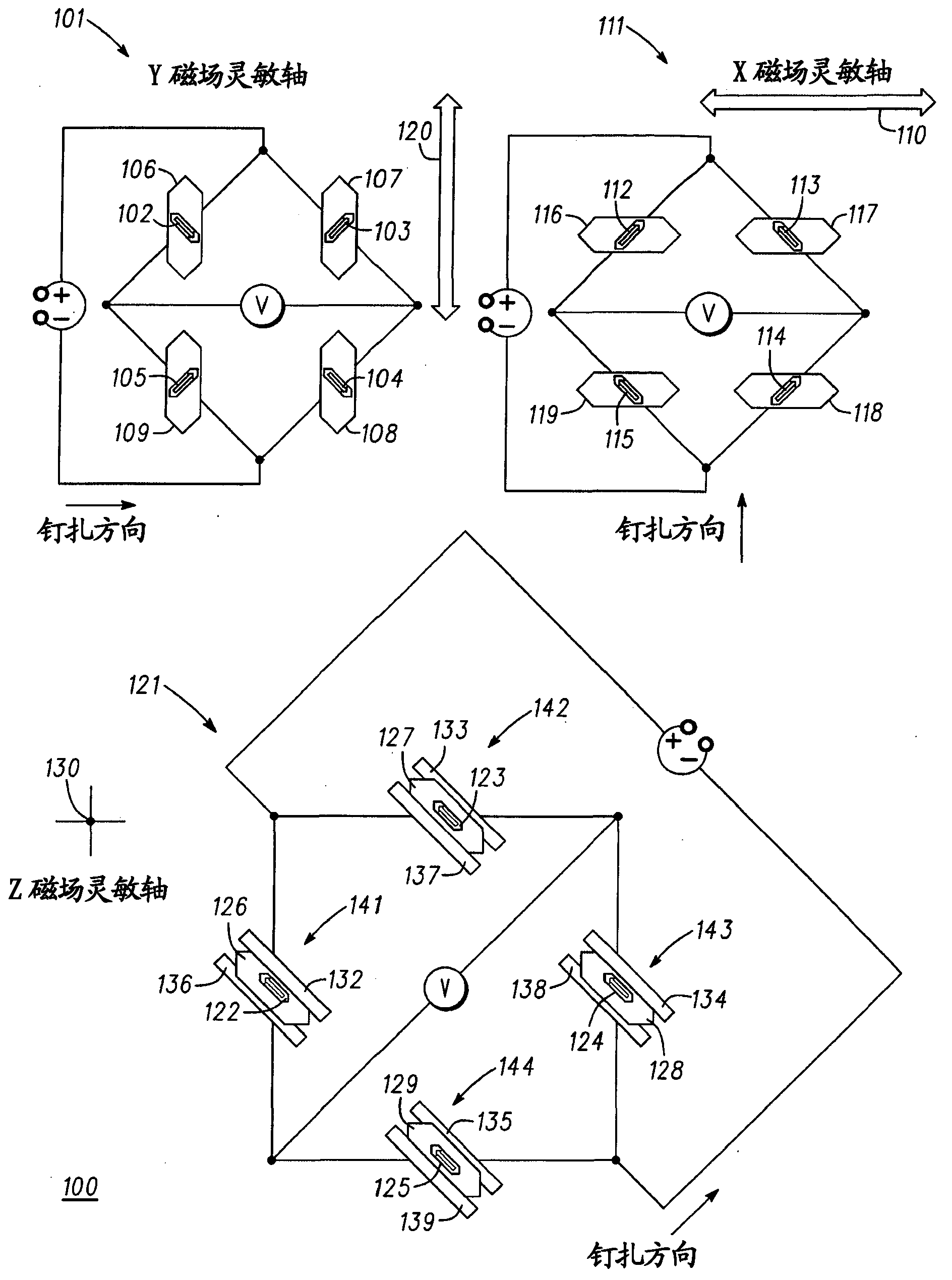

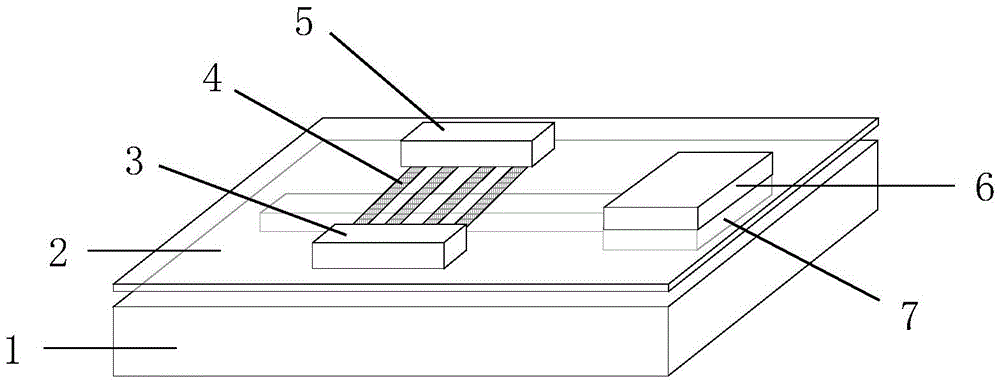

Process integration of a single chip three axis magnetic field sensor

A semiconductor process integrates three bridge circuits, each include magnetoresistive sensors coupled as a Wheatstone bridge on a single chip to sense a magnetic field in three orthogonal directions. The process includes various deposition and etch steps forming the magnetoresistive sensors and a plurality of flux guides on one of the three bridge circuits for transferring a ''Z'' axis magnetic field onto sensors orientated in the XY plane.

Owner:EVERSPIN TECHNOLOGIES

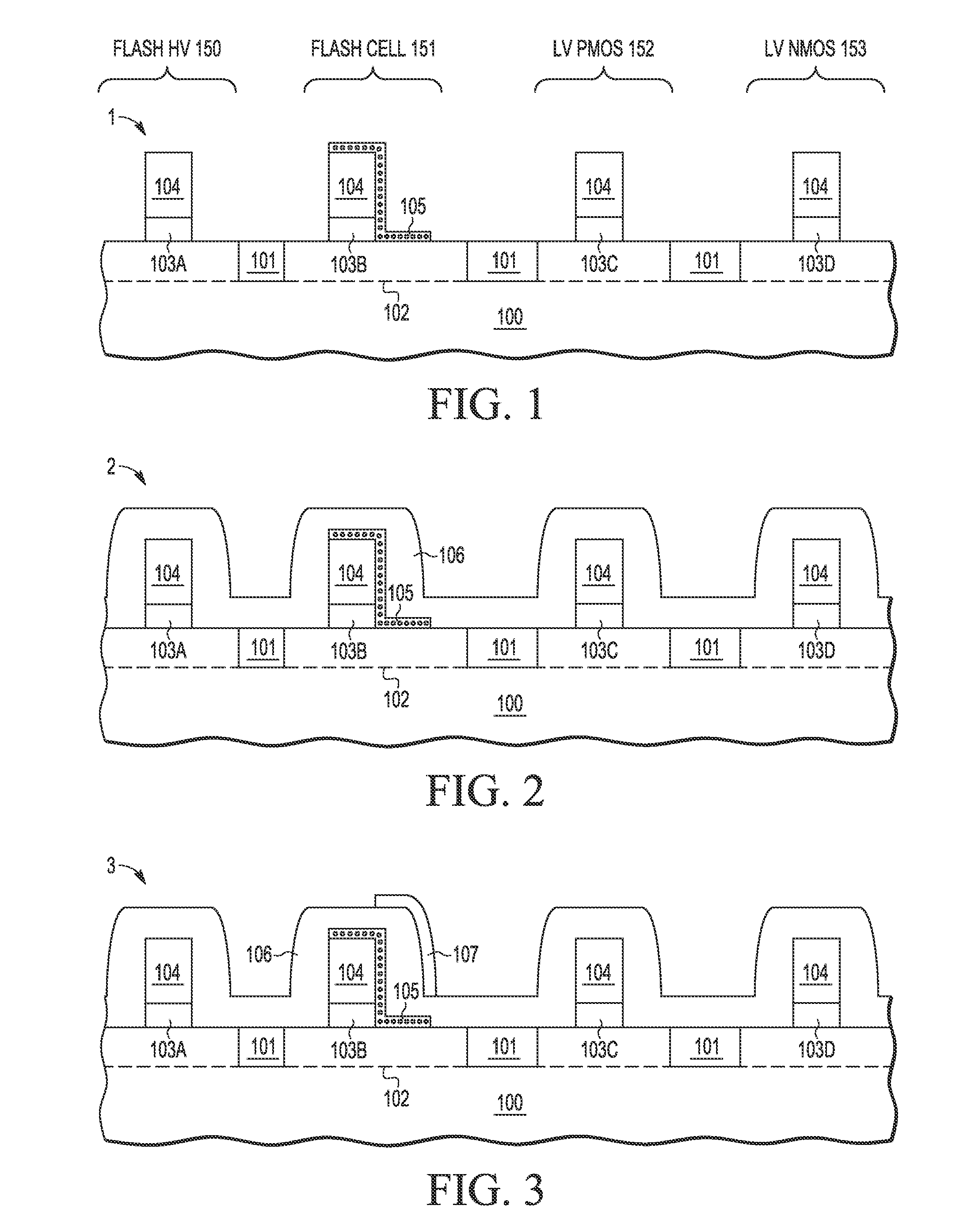

Method for process integration of non-volatile memory cell transistors with transistors of another type

A method for making a semiconductor device having non-volatile memory cell transistors and transistors of another type is provided. In the method, a substrate is provided having an NVM region, a high voltage (HV) region, and a low voltage (LV) region. The method includes forming a gate dielectric layer on the HV and LV regions. A tunnel oxide layer is formed over the substrate in the NVM region and the gate dielectric in the HV and LV regions. A first polysilicon layer is formed over the tunnel dielectric layer and gate dielectric layer. The first polysilicon layer is patterned to form NVM floating gates. An ONO layer is formed over the first polysilicon layer. A single etch removal step is used to form gates for the HV transistors from the first polysilicon layer while removing the first polysilicon layer from the LV region.

Owner:NORTH STAR INNOVATIONS

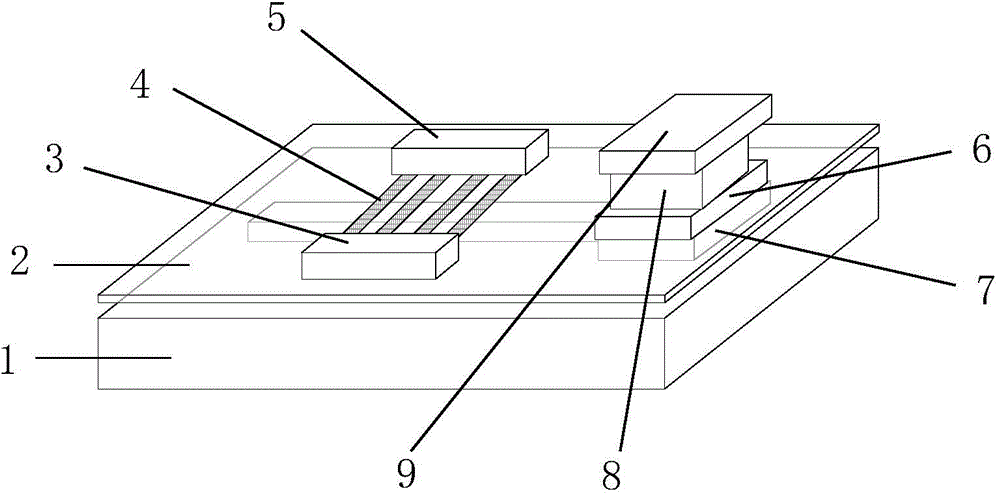

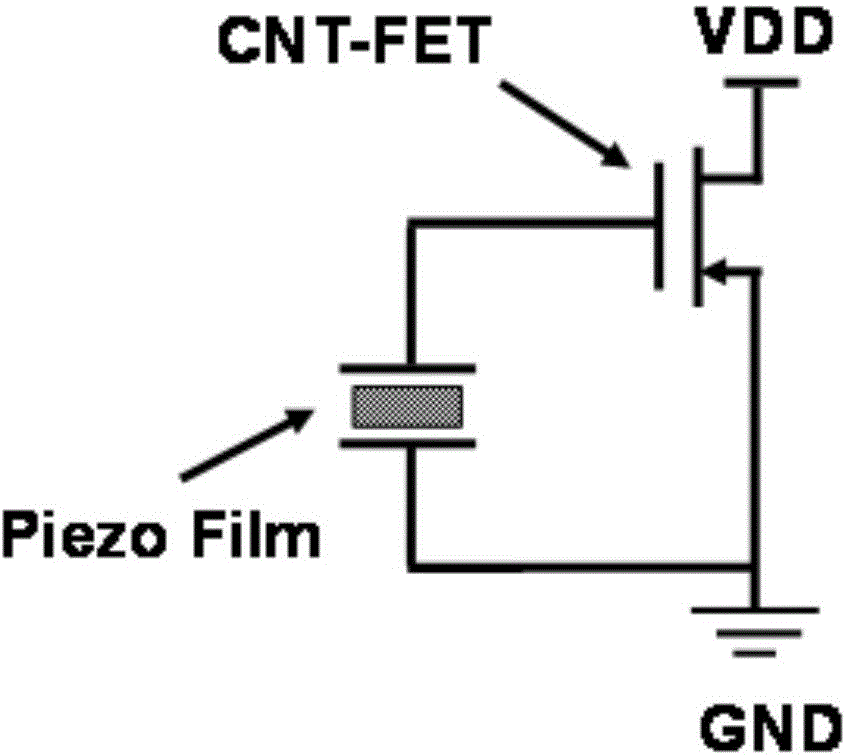

Flexible active strain or pressure sensor structure and preparation method

ActiveCN104613861AHigh carrier mobilityHigh sensitivitySemiconductor/solid-state device manufacturingForce measurement using piezo-electric devicesProcess integrationCarbon nano tube field effect transistor

The invention discloses a flexible active strain or pressure sensor structure and a preparation method. A carbon nano-tube transistor serves as a flexible active field effect transistor, flexible piezoelectric thin film material is used for preparing a piezoelectric strain or pressure sensor unit, and process integration is carried out on a piezoelectric sensor and the grid electrode of the active field effect transistor so as to amplify and output piezoelectric sensing signals through the carbon nano-tube field effect transistor. The flexible active strain or pressure sensor structure and the preparation method guarantee the high sensitivity of the piezoelectric sensor when realizing the active control for the flexible strain or pressure sensor; the flexible active strain or pressure sensor structure and the preparation method provide a very convenient implementation method for the large-scale application of the sensor.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

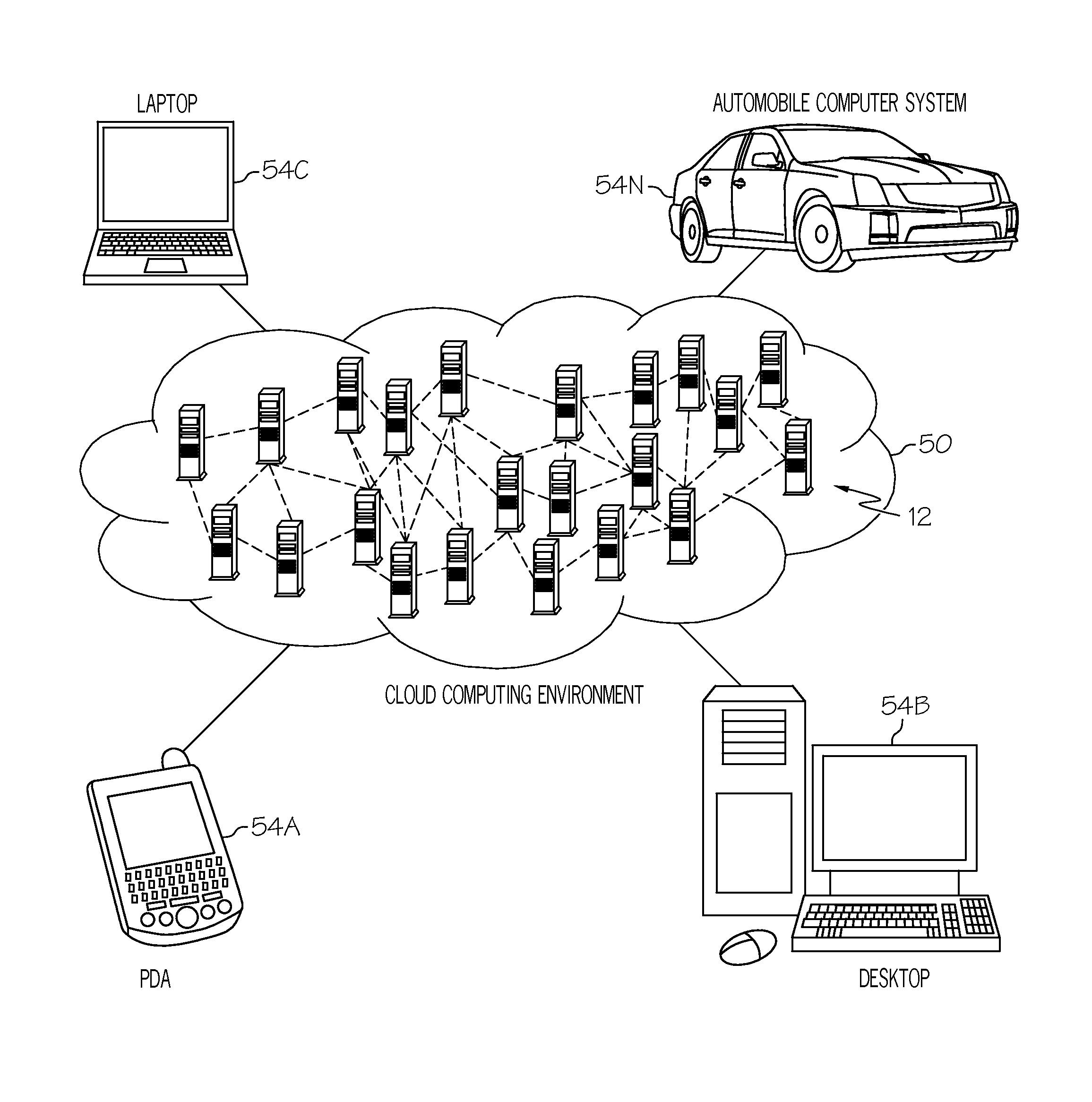

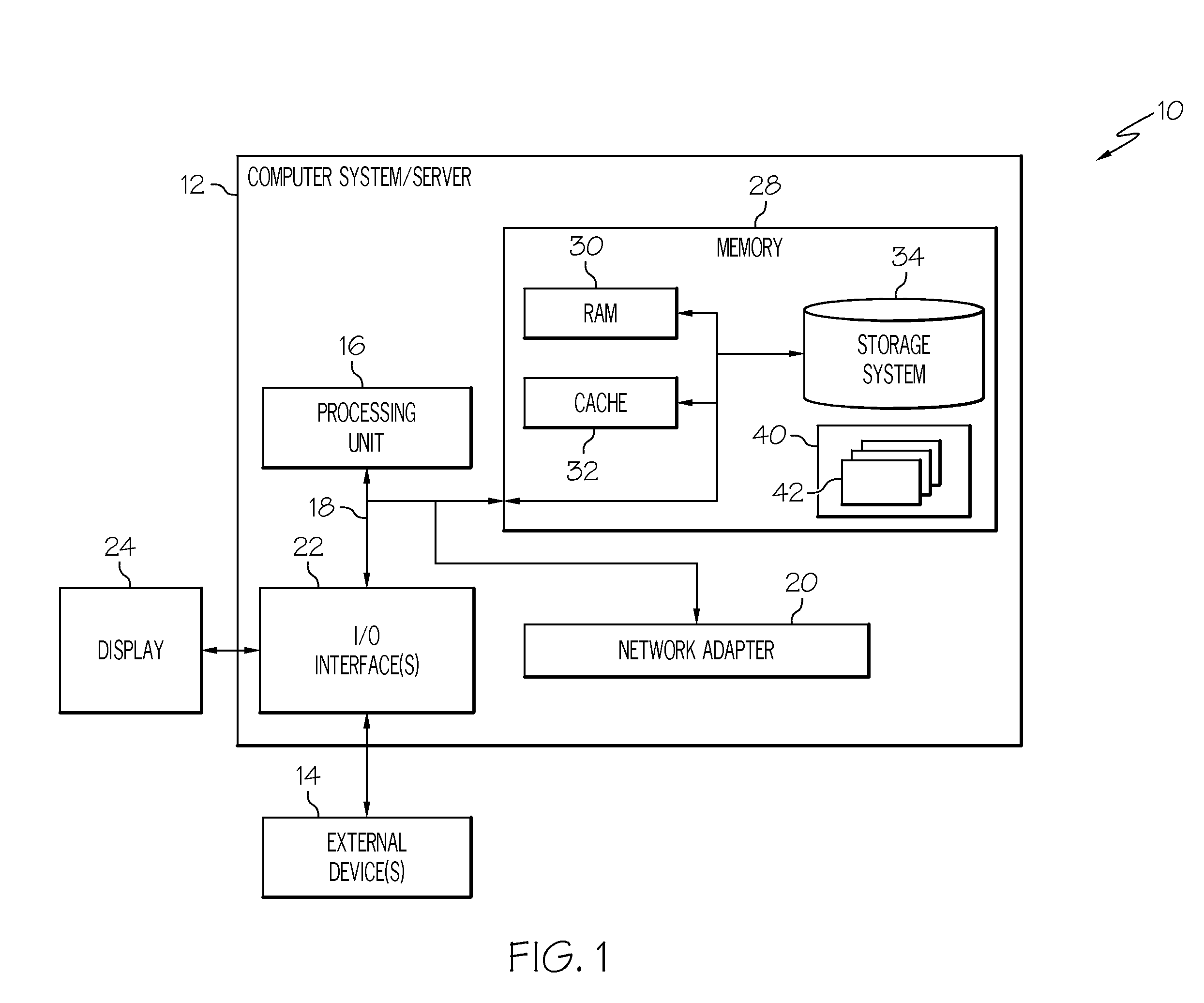

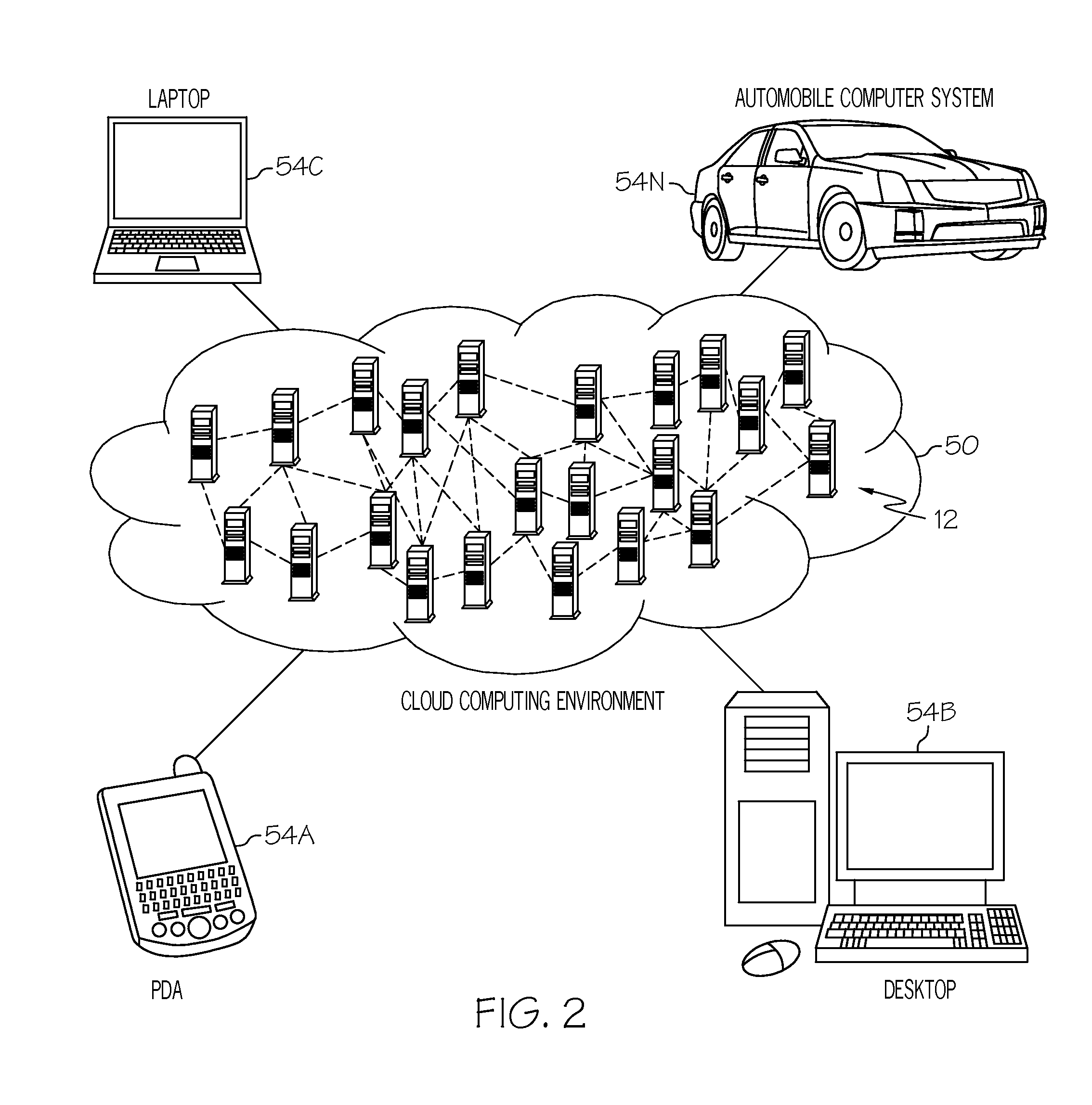

Resource planning and data interchange functionality within a cloud computing environment

The present invention provides technology neutral process integration (Cloud Resource Planning), and optimization methodology leveraging a business meta-schema format Cloud Data Interchange (CDI) to integrate, enable, and invoke Cloud services. One example is that the present invention provides a management layer at the process level. There can be multiple Cloud implementations / types within a govern enterprise—perhaps utilizing different infrastructure (e.g., hardware of one supplier versus that of another) or different areas of functionality (computing services, storage services, etc). This disclosure provides an abstraction or ‘resource planning’ layer above these core services such that a customer does not have to have knowledge or choose different Cloud types and / or understand or choose each underlying service. As such, it provides a ‘one stop’ portal.

Owner:IBM CORP

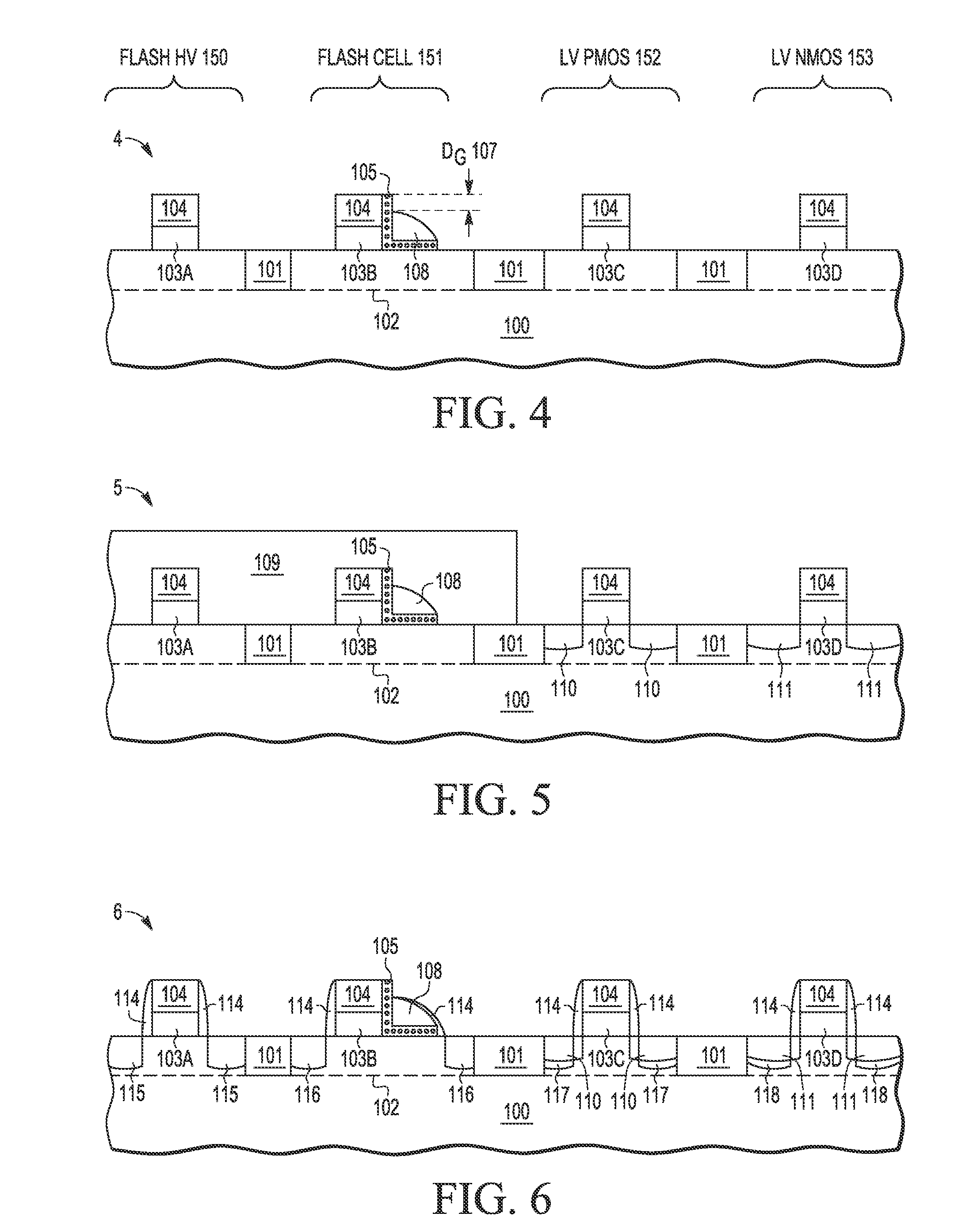

Split Gate Nanocrystal Memory Integration

A process integration is disclosed for fabricating non-volatile memory (NVM) cells having spacer control gates (108) along with a high-k-metal-poly select gate (121, 123, 127) and one or more additional in-laid high-k metal CMOS transistor gates (121, 124, 128) using a gate-last HKMG CMOS process flow without interfering with the operation or reliability of the NVM cells.

Owner:NXP USA INC

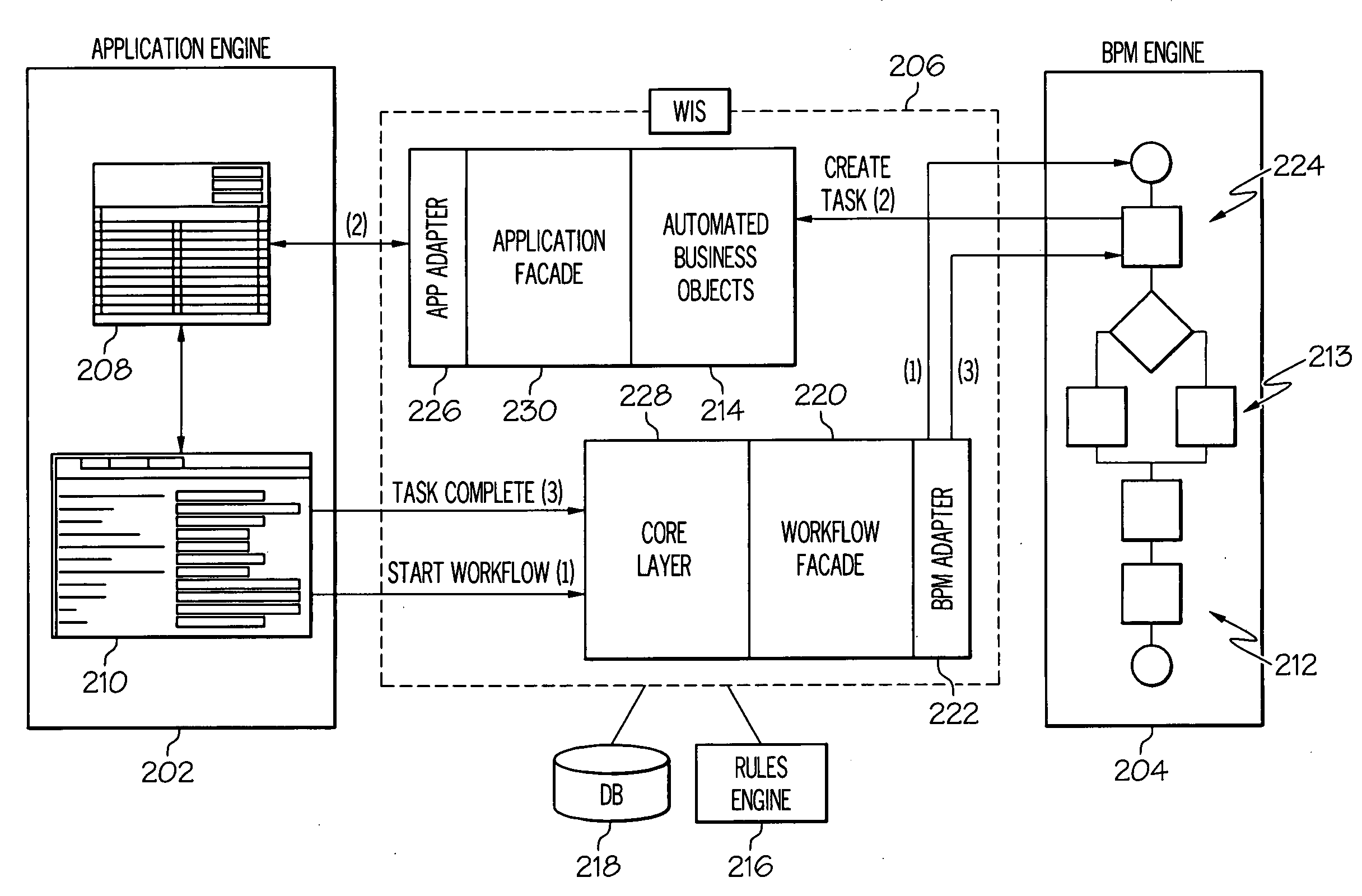

Application workflow integration subsystem

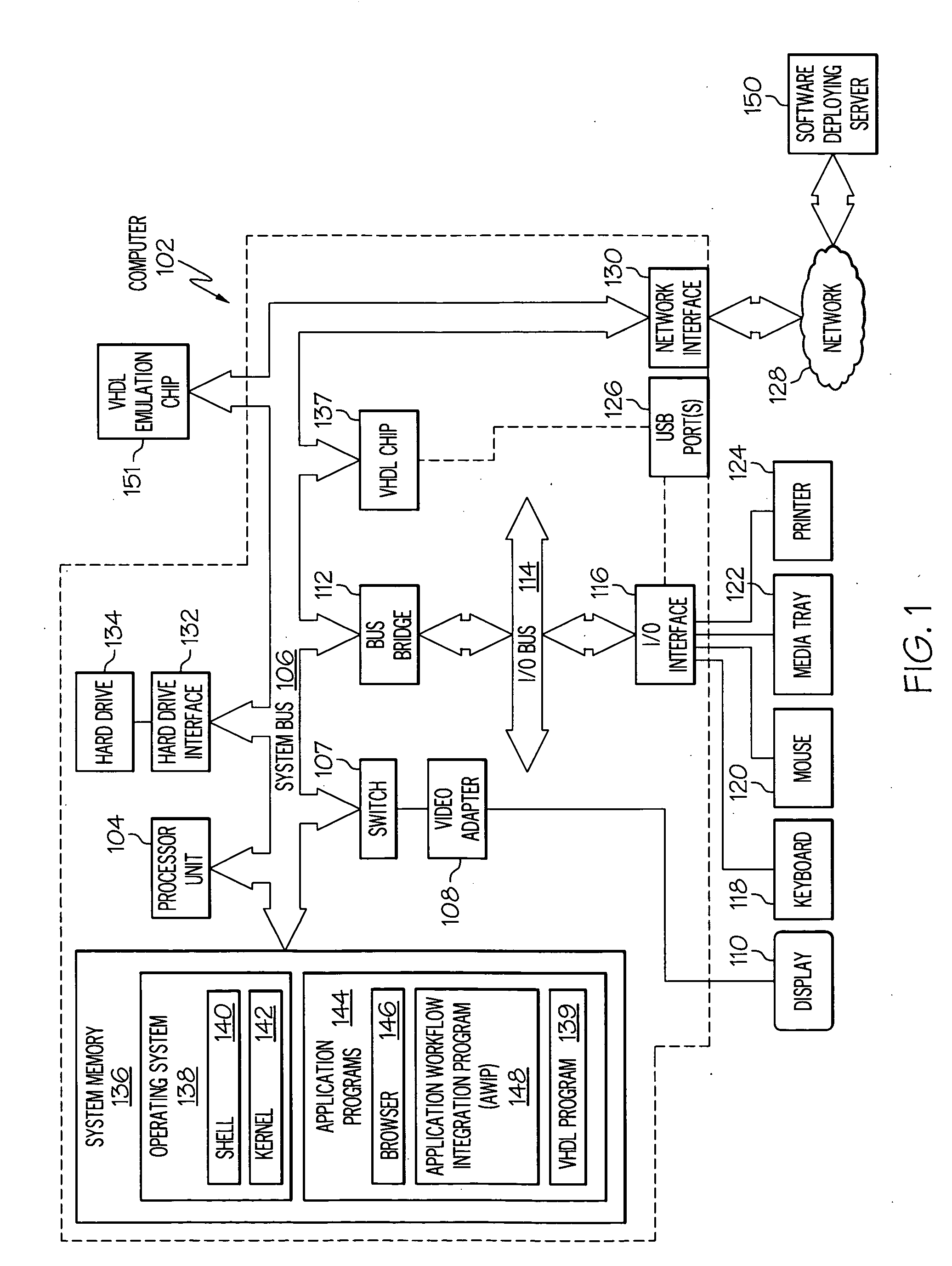

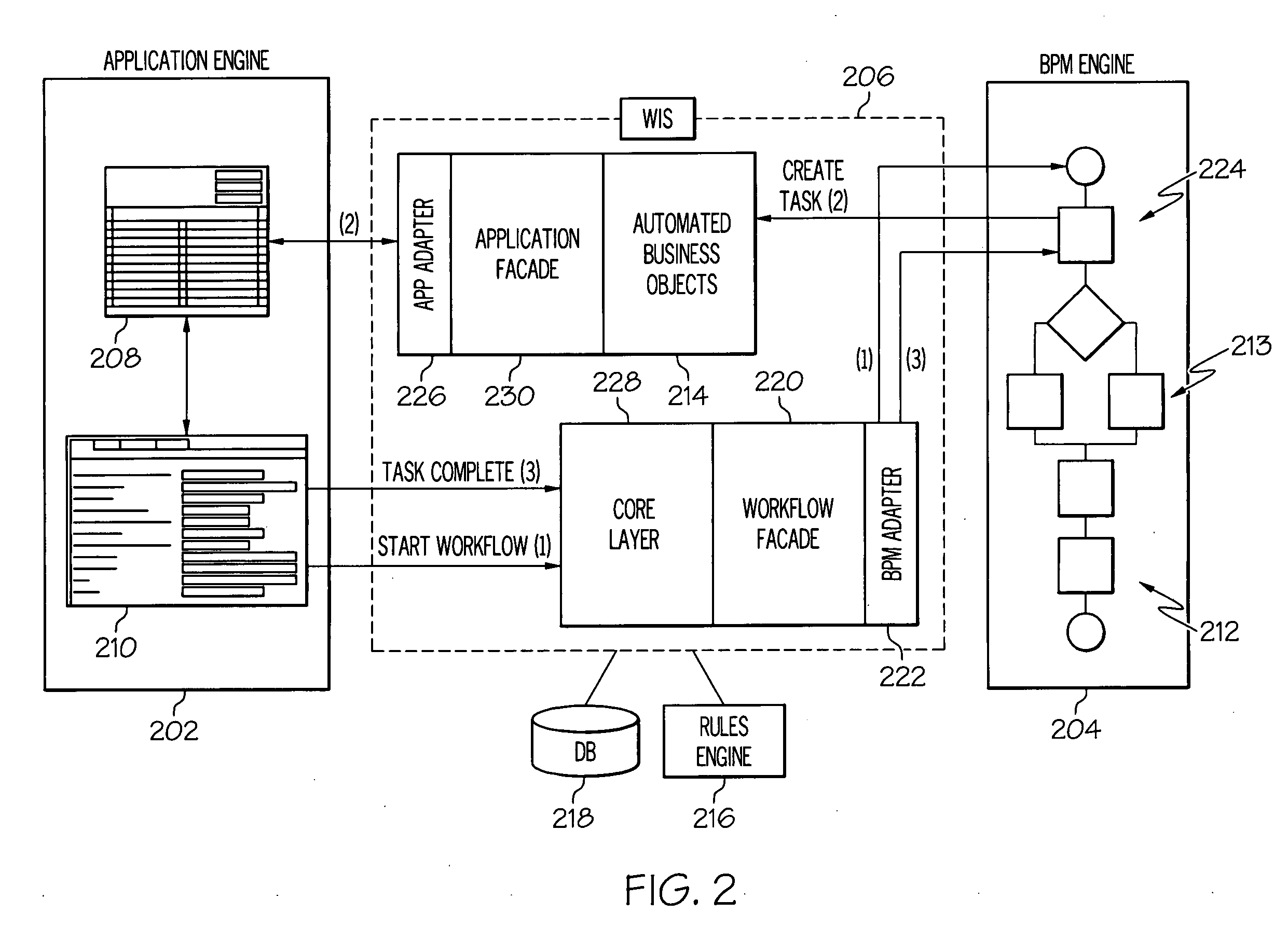

ActiveUS20100205616A1Easy to integrateMultiprogramming arrangementsProcess integrationSoftware engineering

A computer-implemented method, system and computer program product for integrating an application engine with processes depicted by a flow-chart created by a Business Process Management (BPM) engine are presented. Execution of a first application, which is generated by a first application engine, is initiated. The first application performs a first subtask that is depicted by a first component of a flow-chart that has been previously generated by the BPM engine. A Workflow Integration Subsystem (WIS), which provides an interface between the first application engine and the BPM engine, selects the flow-chart that contains the first subtask performed by the first application. The BPM engine calls other application engines to perform other subtasks that supplement the first subtask, such that the first subtask and the other subtasks combine to perform an entire task that is depicted by the flow-chart.

Owner:IBM CORP

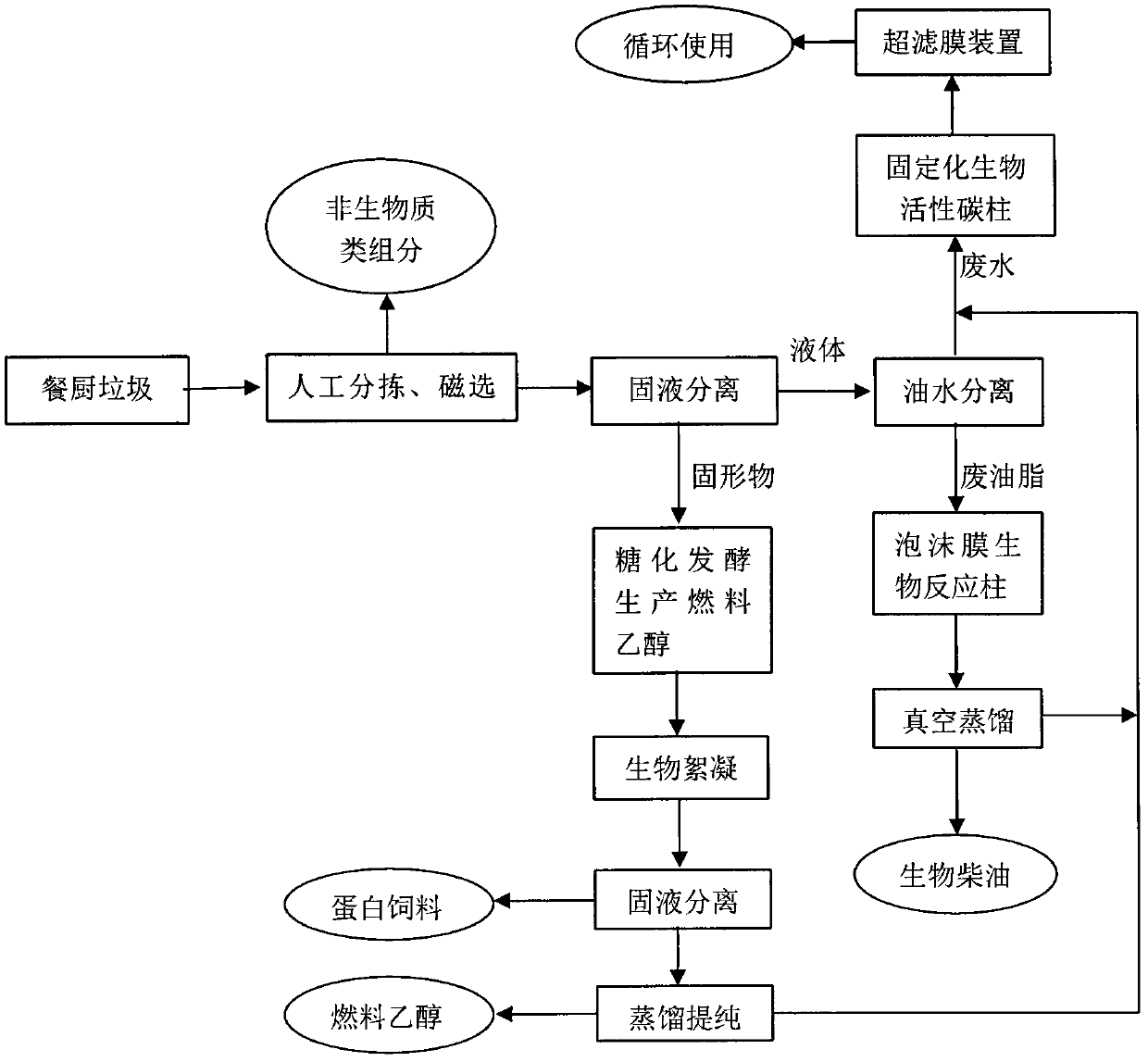

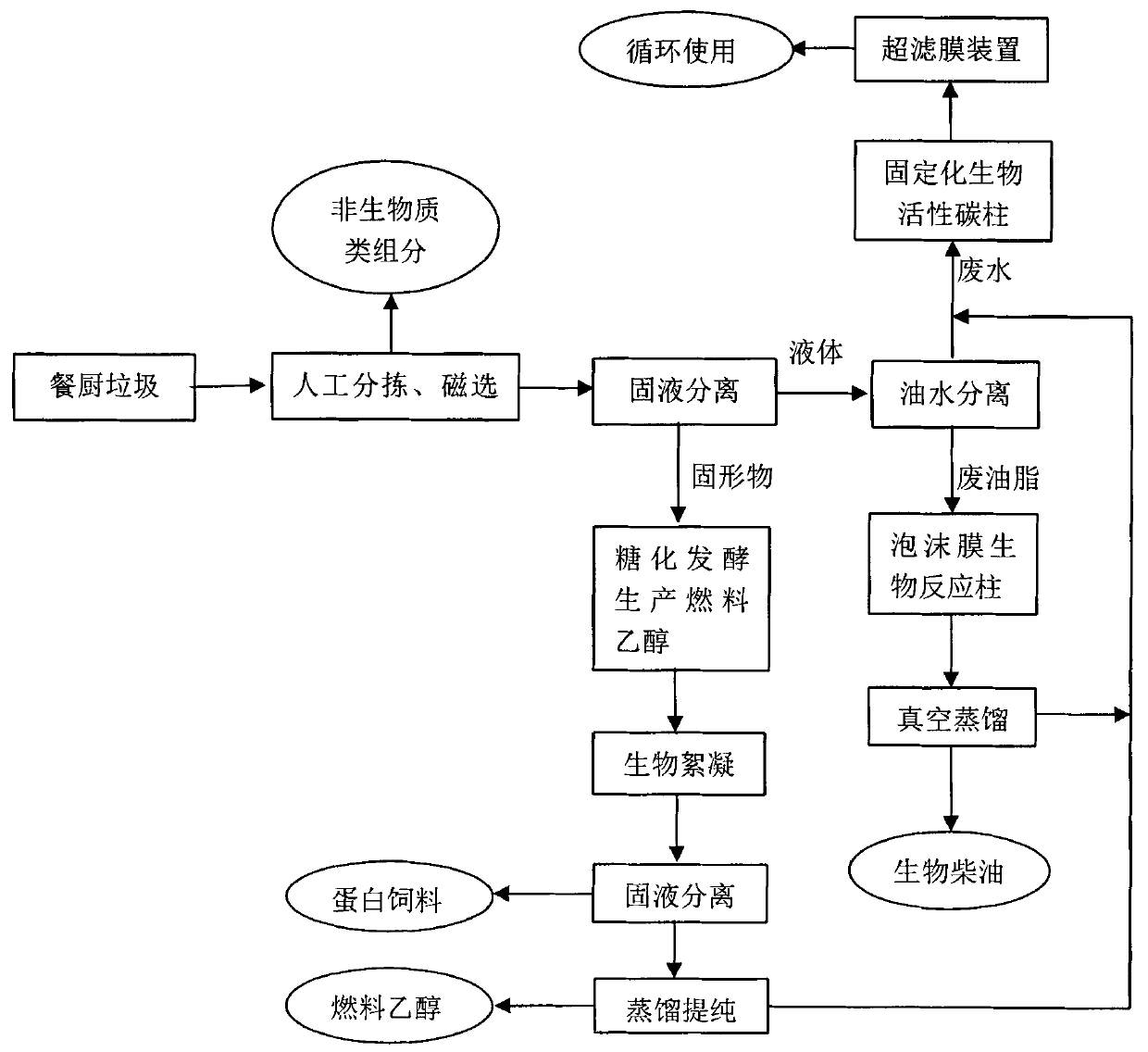

Full-biomass resource utilization method for kitchen waste

InactiveCN102553886AShorten fermentation timeOvercome the defects of single enzymatic hydrolysisFatty oils/acids recovery from wasteFatty acid esterificationOil and greaseResource utilization

The invention relates to a full-biomass resource utilization method for kitchen waste. The method comprises the following steps: sorting kitchen waste and then performing solid-liquid separation, performing oil-water separation on the liquid phase, grinding the solid phase and then producing fuel ethanol by complex enzyme preparation and multi-step hydrolysis, producing protein feeds from the solid residues and yeast after production purification, and performing transesterification on the separated waste oil to produce bio-diesel oil. The invention has the advantages that different components in the kitchen waste are transformed with high efficiency respectively by utilizing the process integration technology to produce fuel ethanol, bio-diesel oil, protein feeds and other products with high value added, so that the cost of kitchen waste treatment is reduced, and the economic benefits are improved; the operation process is mild, the energy consumption is reduced, and the process flow is environment-friendly; and the kitchen waste is turned into treasure, and the comprehensive waste reduction, resource and energy utilization can be achieved.

Owner:天津新生环境发展有限公司 +2

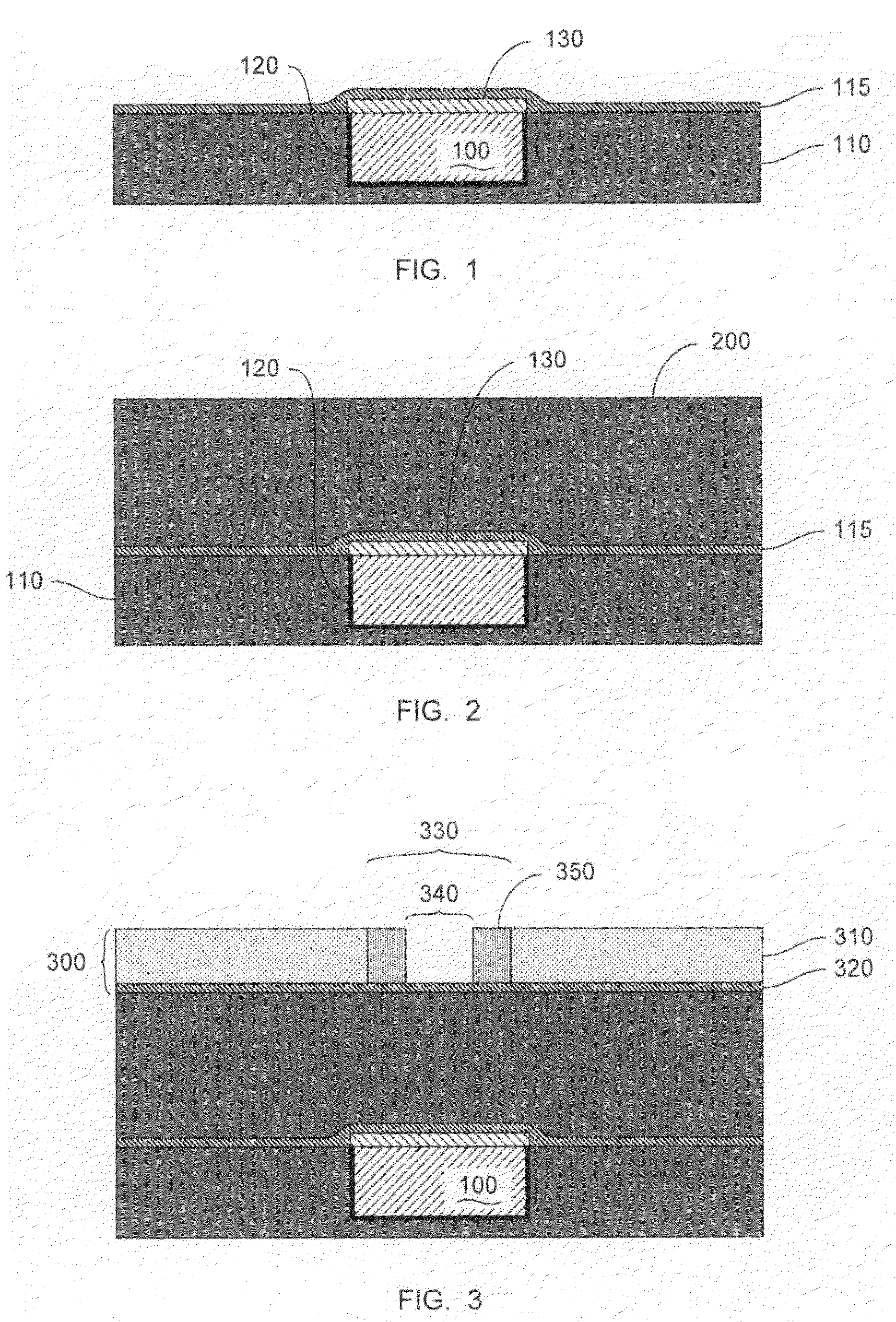

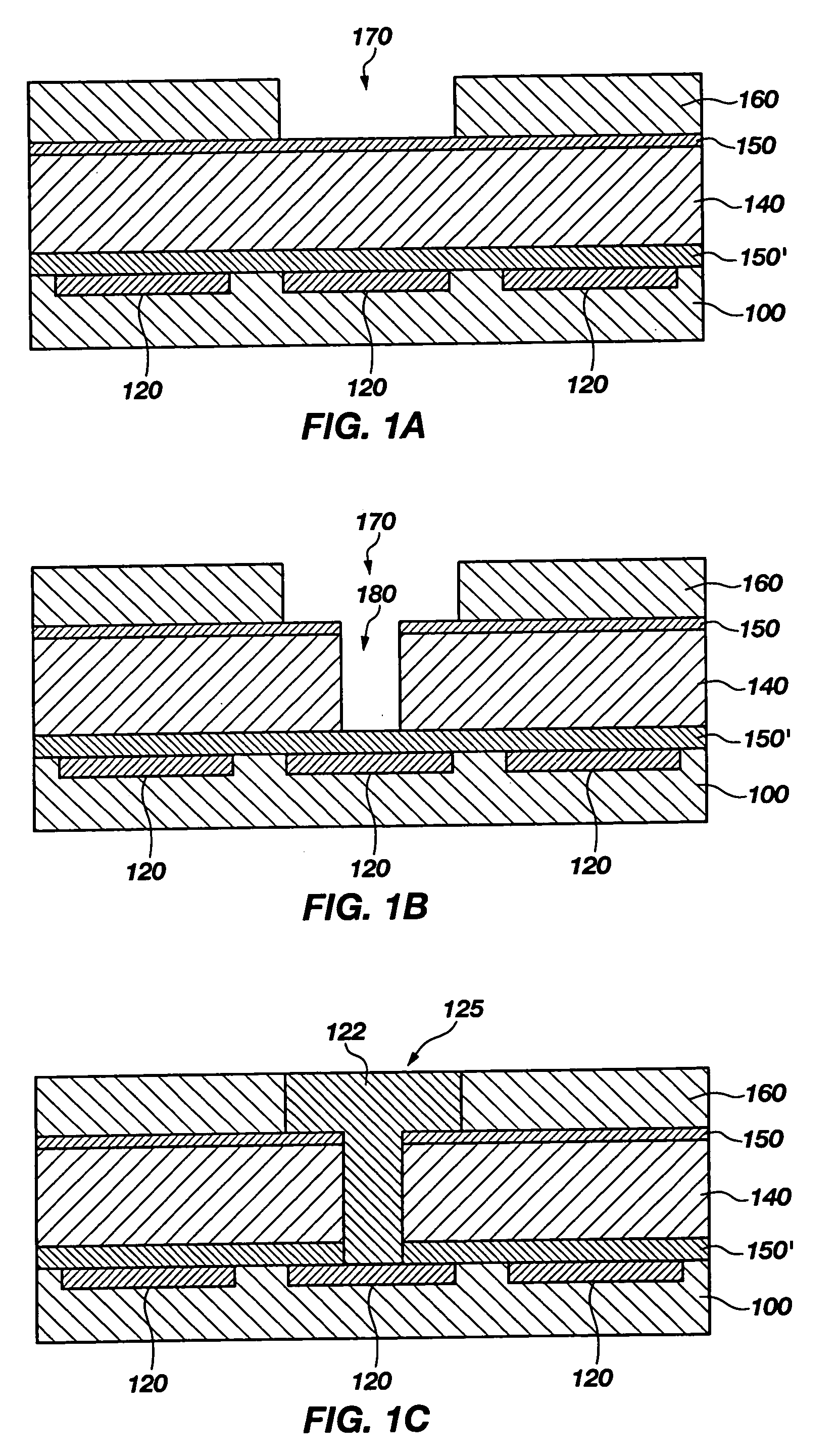

Process integration scheme to lower overall dielectric constant in BEoL interconnect structures

InactiveUS20080150138A1Semiconductor/solid-state device detailsSolid-state devicesProcess integrationEngineering

Back-End of Line (BEoL) interconnect structures, and methods for their manufacture, are provided. The structures are characterized by narrower conductive lines and reduced overall dielectric constant values. Conformal diffusion barrier layers, and selectively formed capping layers, are used to isolate the conductive lines and vias from surrounding dielectric layers in the interconnect structures. The methods of the invention employ techniques to narrow the openings in photoresist masks in order to define narrower vias. More narrow vias increase the amount of misalignment that can be tolerated between the vias and the conductive lines.

Owner:LAM RES CORP

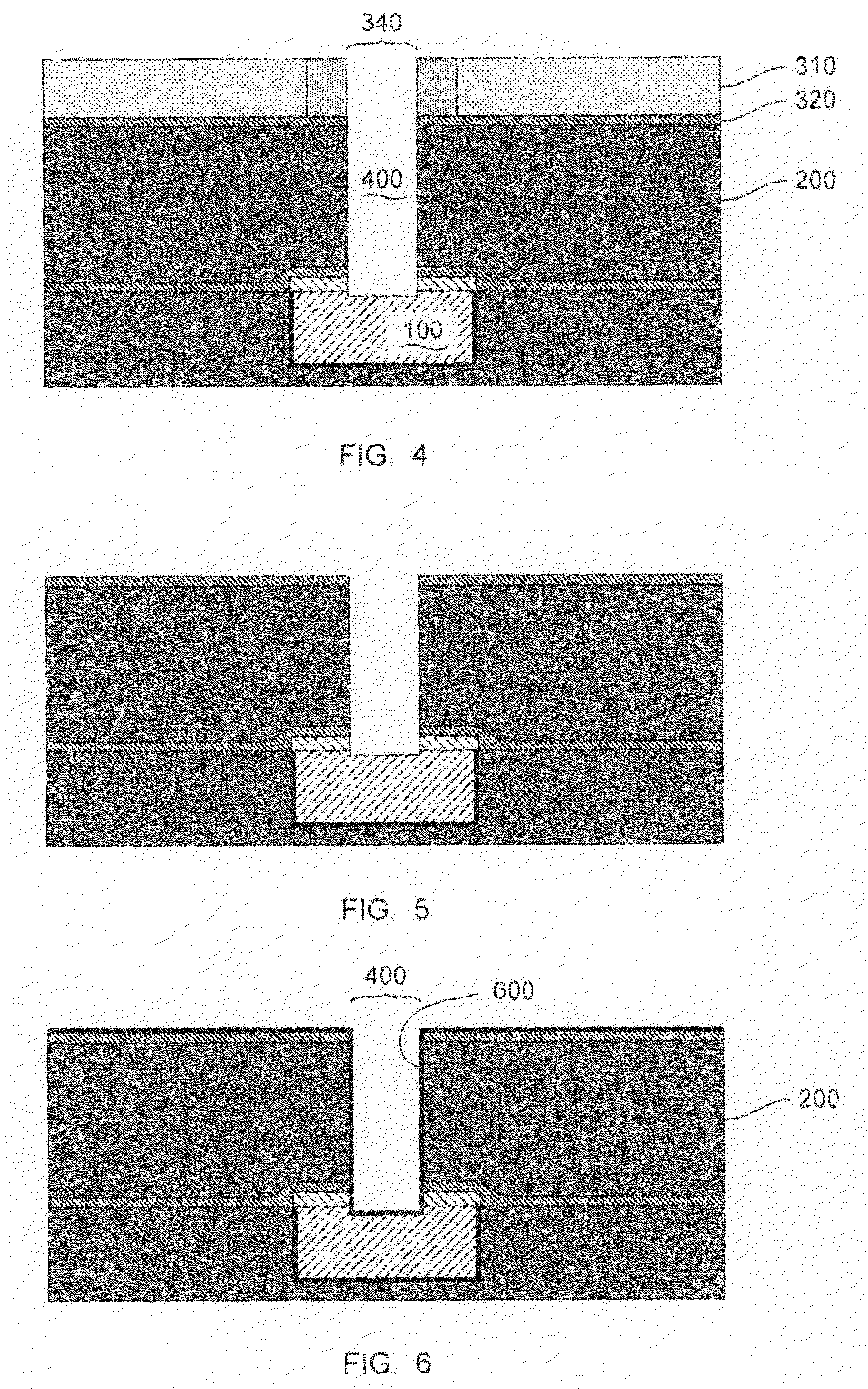

Methods for improving metal-to-metal contact in a via, devices made according to the methods, and systems including the same

ActiveUS20050170642A1Compromise reliabilityMinimize exposureSemiconductor/solid-state device manufacturingState of artProcess integration

In damascene process integration, a reducing plasma is applied after the etch stop or barrier layer is opened over a copper layer. Currently known methods for opening barrier layers suffer from the disadvantage that they cause at least some of the underlying copper to oxidize to copper oxide.. Because copper oxide is selectively removed by subsequent wet cleaning, voids can form where damaged copper (e.g., copper oxide) is removed, thus compromising the reliability of metal-to-metal contact in vias. The present invention advantageously overcomes this and other disadvantages of the prior art through the use of a hydrogen plasma following the barrier layer opening step, which repairs damaged copper (e.g., reduces copper oxide to copper), thus preventing and / or diminishing defects in metal-to-metal contacts in vias and concomitantly improving the reliability of the same.

Owner:MICRON TECH INC

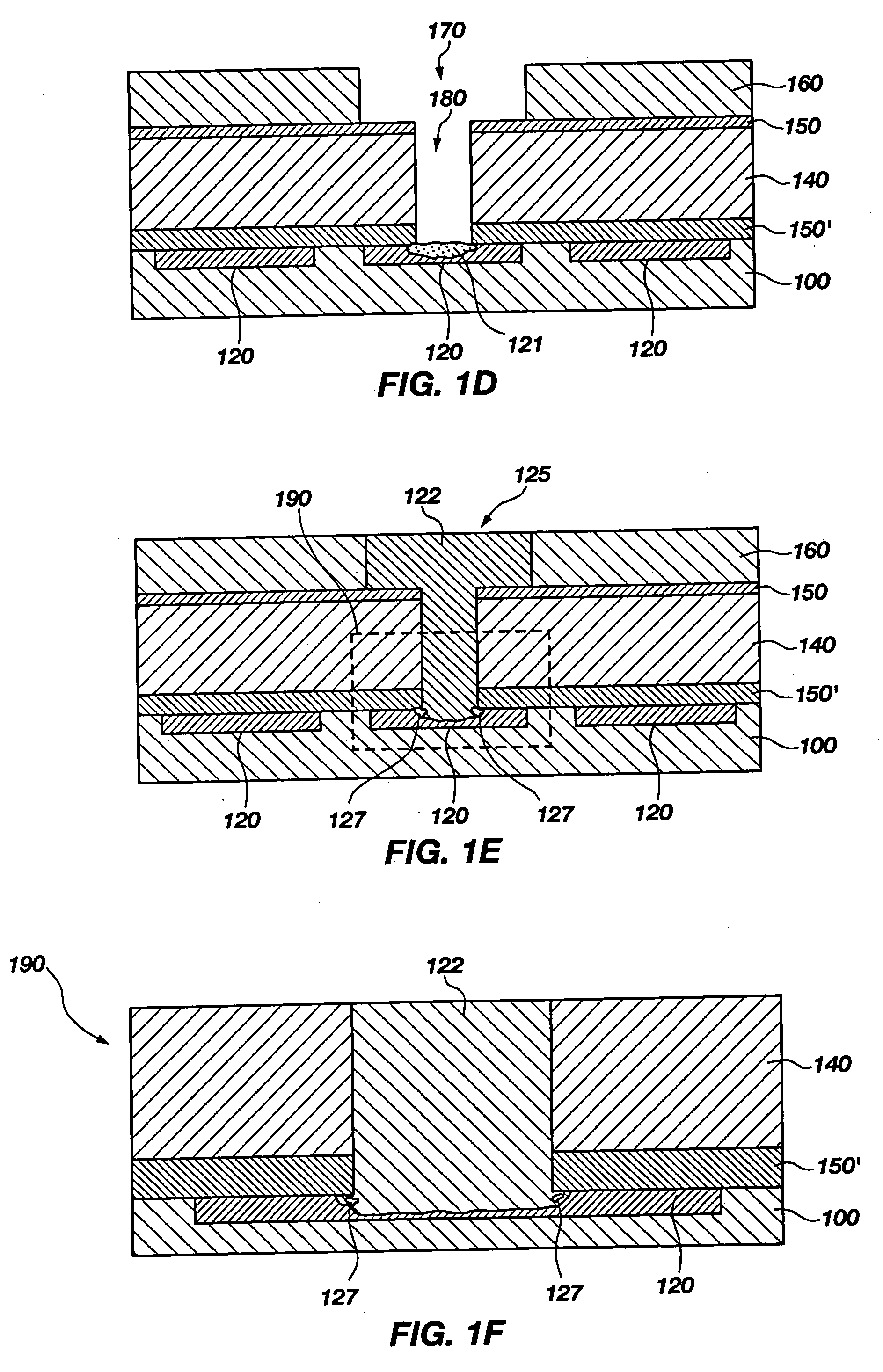

High-salt epoxy resin production waste-water film integrated salt recovery and biochemical treatment method

InactiveCN1850635ASolve the problem of high salinity alkaline wastewaterAdvanced technologySemi-permeable membranesMembranesHigh concentrationEpoxy

The invention discloses a membrane-process integration salt recovering and biochemical processing method for waste water from high-salinity epoxy resin production, purifying and splitting waste water, i.e. processing the washing waste waters of different salinities and concentrations, respectively: concentrating little amounts of waste water with high salinity and high concentration by membrance distillation integration technique and screening out salt; preprocessing large amounts of rinsing waste water with low salinity and low concentration of organic matters and then processing in a two-stage biochemical processing system, to meet the specified effluent standard. And it largely solves the problem of serious inhibition of high-salinity organic waste water to the biotreatment and adopts salt recovering and water recycling processes, and large amounts of waste heat can serve as a heat source of membrane distillation and the afterheat of the waste water can be used by the membrane distillation.

Owner:ZHEJIANG UNIV

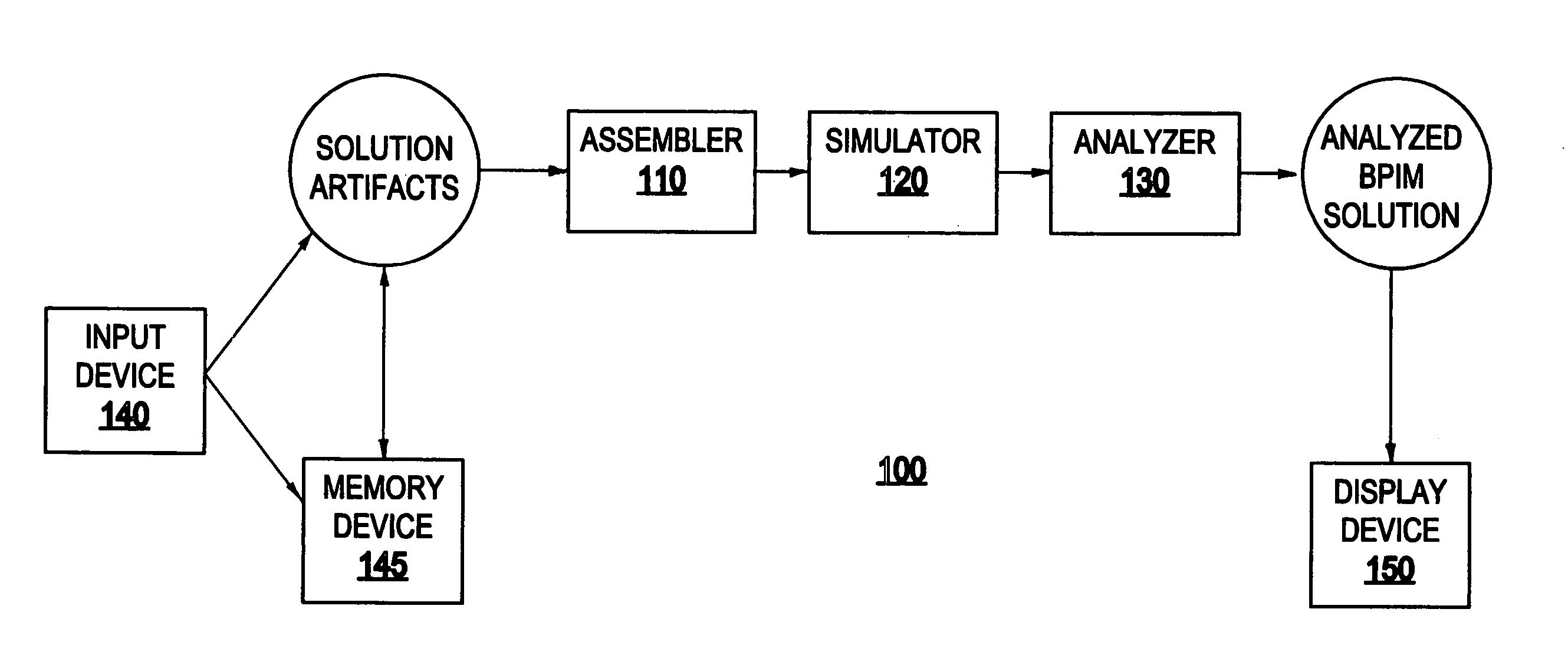

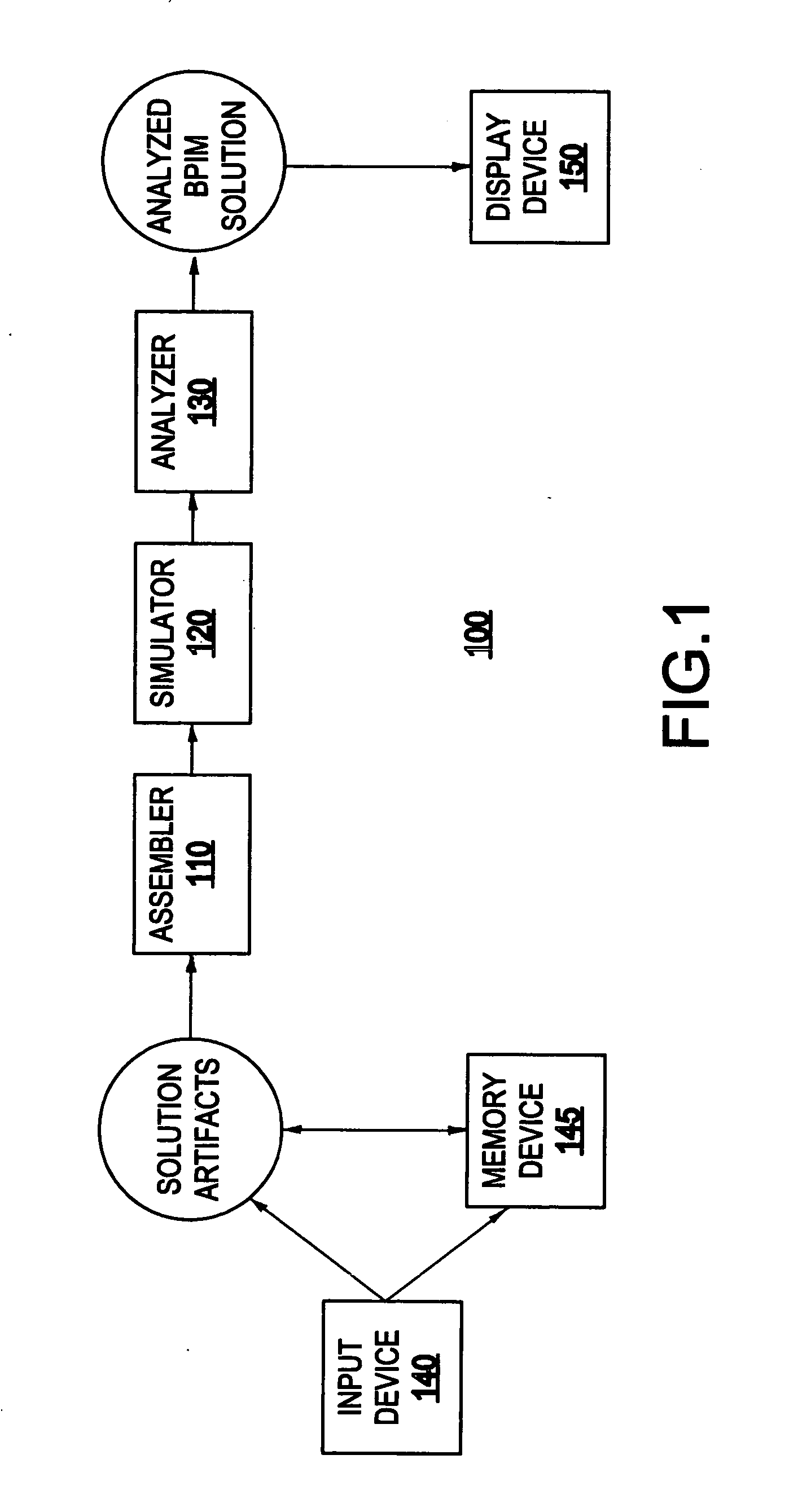

System and method for analyzing a business process integration and management (BPIM) solution

InactiveUS20050080609A1Efficient and effectiveSignificantly effectiveForecastingProgram controlProcess integrationBusiness process integration

A system for analyzing a business process integration and management (BPIM) solution includes an assembler which assembles a plurality of solution artifacts to form a platform independent solution template, a simulator which simulates an execution of a BPIM solution based on the platform independent solution template, and an analyzer for analyzing a performance of the BPIM solution.

Owner:IBM CORP

Cluster tool and method for process integration in manufacture of a gate structure of a field effect transistor

InactiveUS20070026547A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingProcess integrationMetrology

A method and apparatus for process integration in manufacture of a gate structure of a field effect transistor are disclosed. The method includes assembling an integrated substrate processing system having a metrology module and a vacuumed processing platform to perform controlled and adaptive plasma processes without exposing the substrate to a non-vacuumed environment.

Owner:APPLIED MATERIALS INC

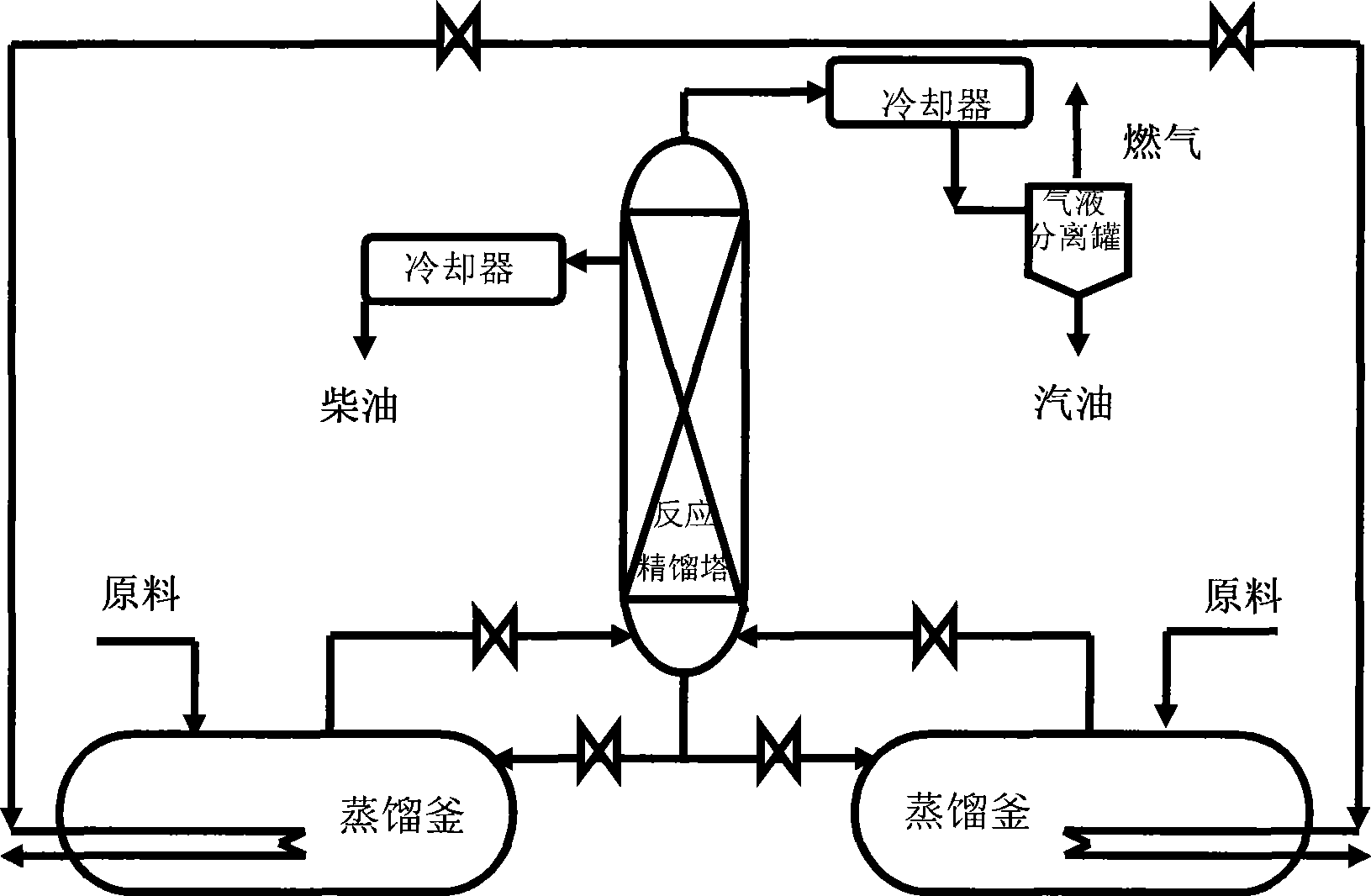

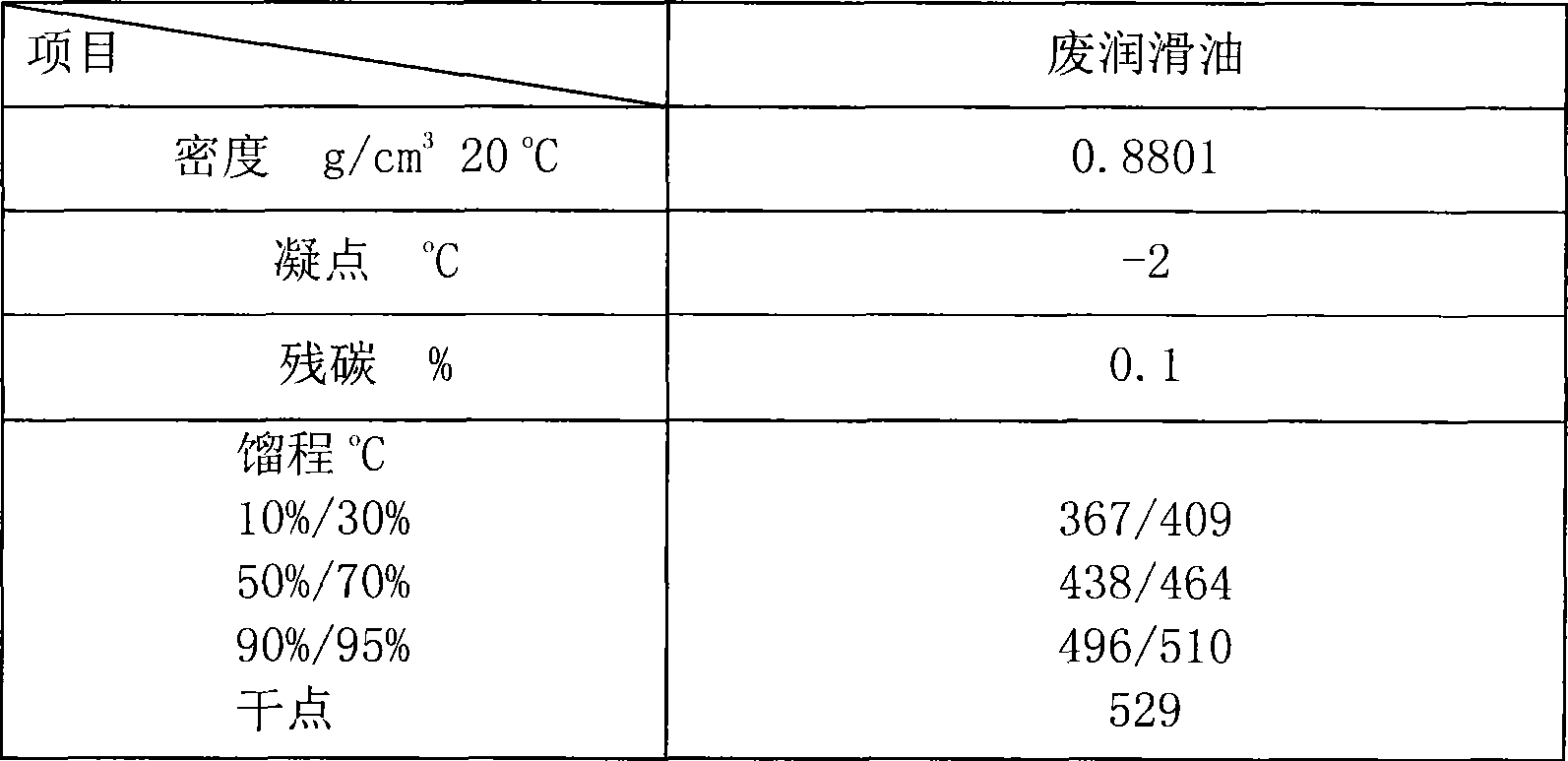

Method for producing petrol and diesel oil by recycling waste lubricant oil

ActiveCN101475870ASimple processLow costHydrocarbon distillationLubricant compositionDistilled oilGas phase

The invention relates to a method for producing gasoline and diesel fuel through resource utilization of waste lubricant oil, which belongs to the technical field of environmental protection and energy resources. The method comprises: integrally performing the vapor phase catalytic cracking process on molecular sieve / alumina catalyst of the waste lubricant oil and the fractionation and separation process of reaction products in a reaction fractionator; injecting crude waste oil into a distillation kettle, and adopting waste residue and fuel gas generated during conversion of the waste lubricant oil for heating, wherein the temperature of the distillation kettle is controlled to be between 250 and 500 DEG C; making distilled oil gas enter the reaction fractionator which is filled with the molecular sieve / alumina catalyst for reaction and rectification when the distillation kettle is heated to 250 DEG C, wherein the ratio of the catalyst to oil is controlled to be between 1 and 20; and cutting the oil into the gasoline and the diesel fuel according to the distilled temperature, wherein fuel gas generated by reaction and residual cinder can be used for heating the distillation kettle, and generated fuel gas can be used for heating the distillation kettle. The method has the advantages of wide range of raw materials, normal-pressure reaction and separation, simple technological flow, high conversion and selectivity of products, long service life of the catalyst, comprehensive utilization of the fuel gas and the cinder, no secondary pollution, large operating flexibility of a production apparatus, and small investment.

Owner:DALIAN UNIV OF TECH

Method and System for Process Brokering and Content Integration for Collaborative Business Process Management

Process Brokering Services (PBS) are implemented though the concept of Adaptive Documents to facilitate electronic commerce (e-commerce). PBS provides a single point of process control over the various fragmented execution flows and brings together the elements for process integration (views, content, flows) in a unified, scalable architecture on an industry standard platform. The two principal functions of the PBS are brokering of multiple business processes encapsulated in various back-end systems including workflow engines and business applications, and aggregating content from multiple enterprise information systems in the business context and managing the shared access to this based on the roles of the participants. The dynamic services provided by PBS are accessible to clients through the PBS Interface.

Owner:INT BUSINESS MASCH CORP

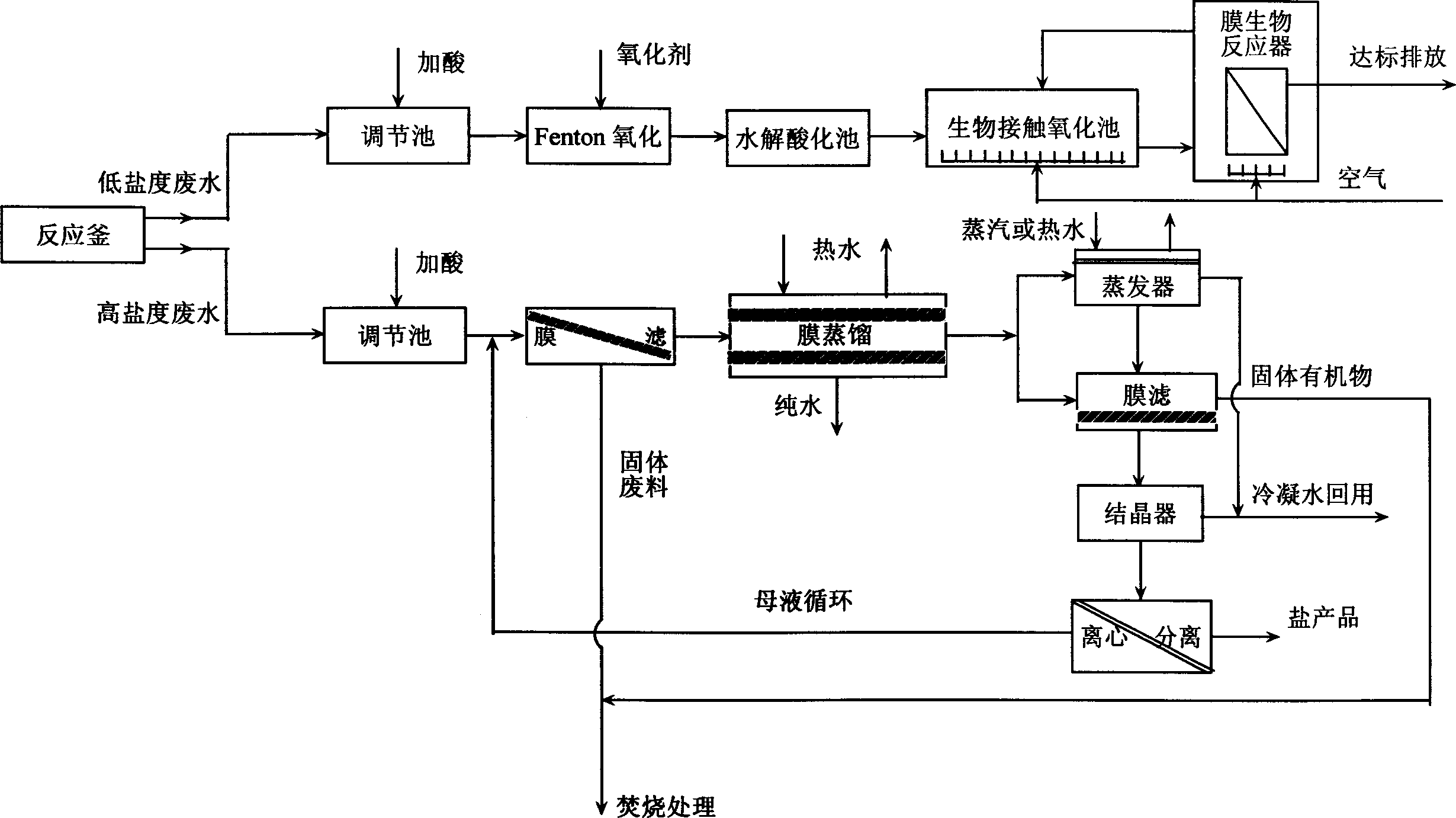

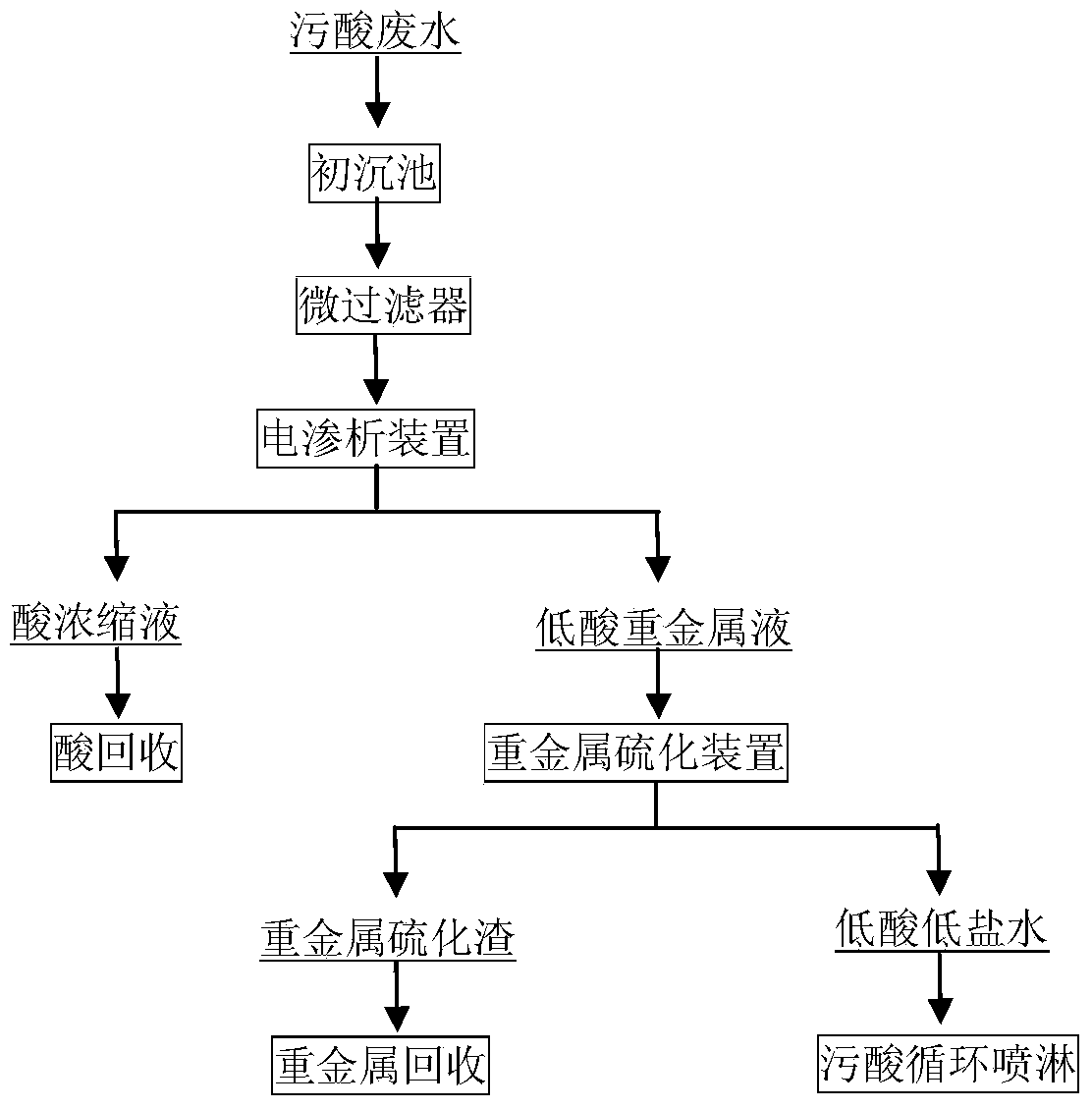

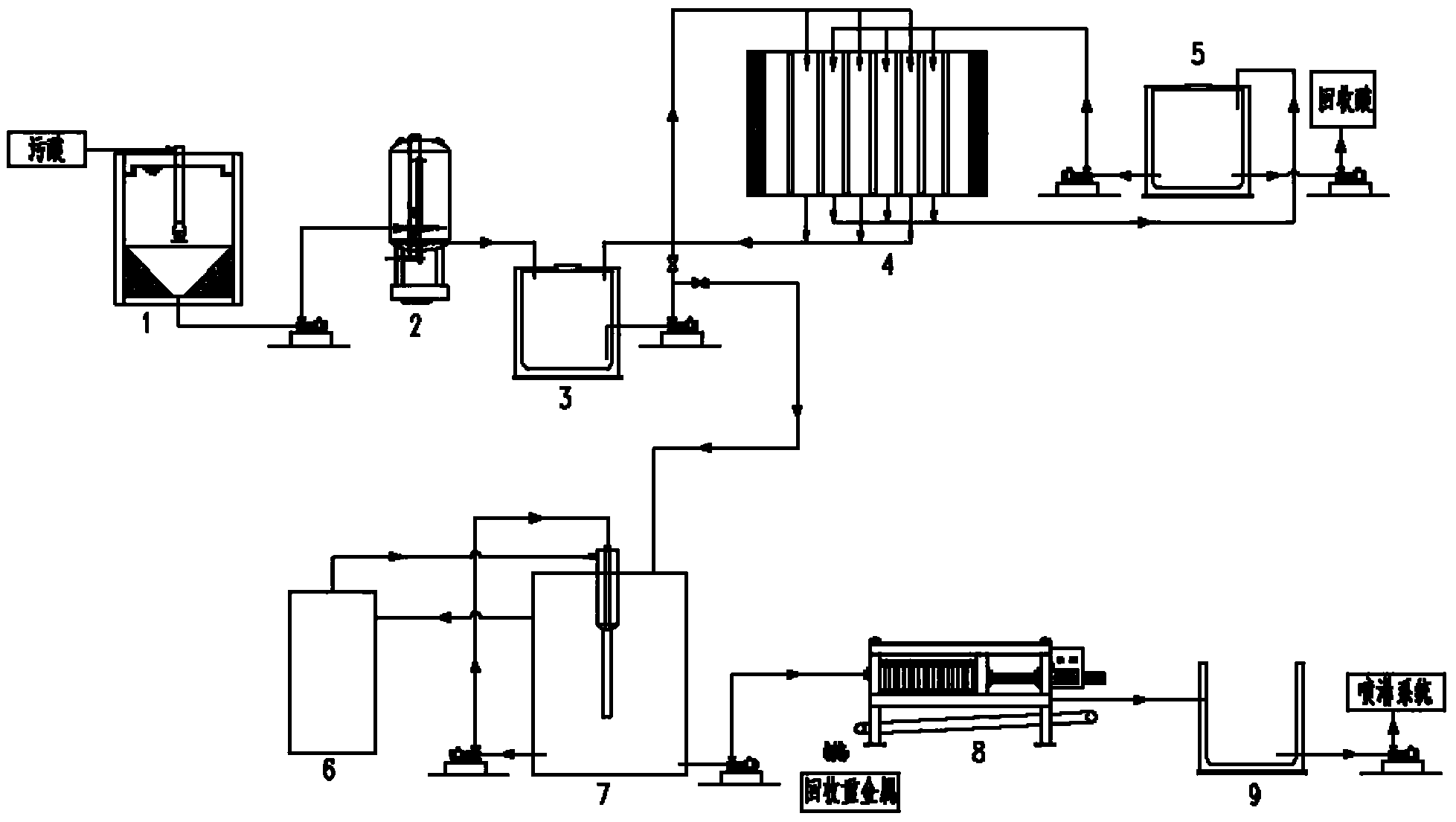

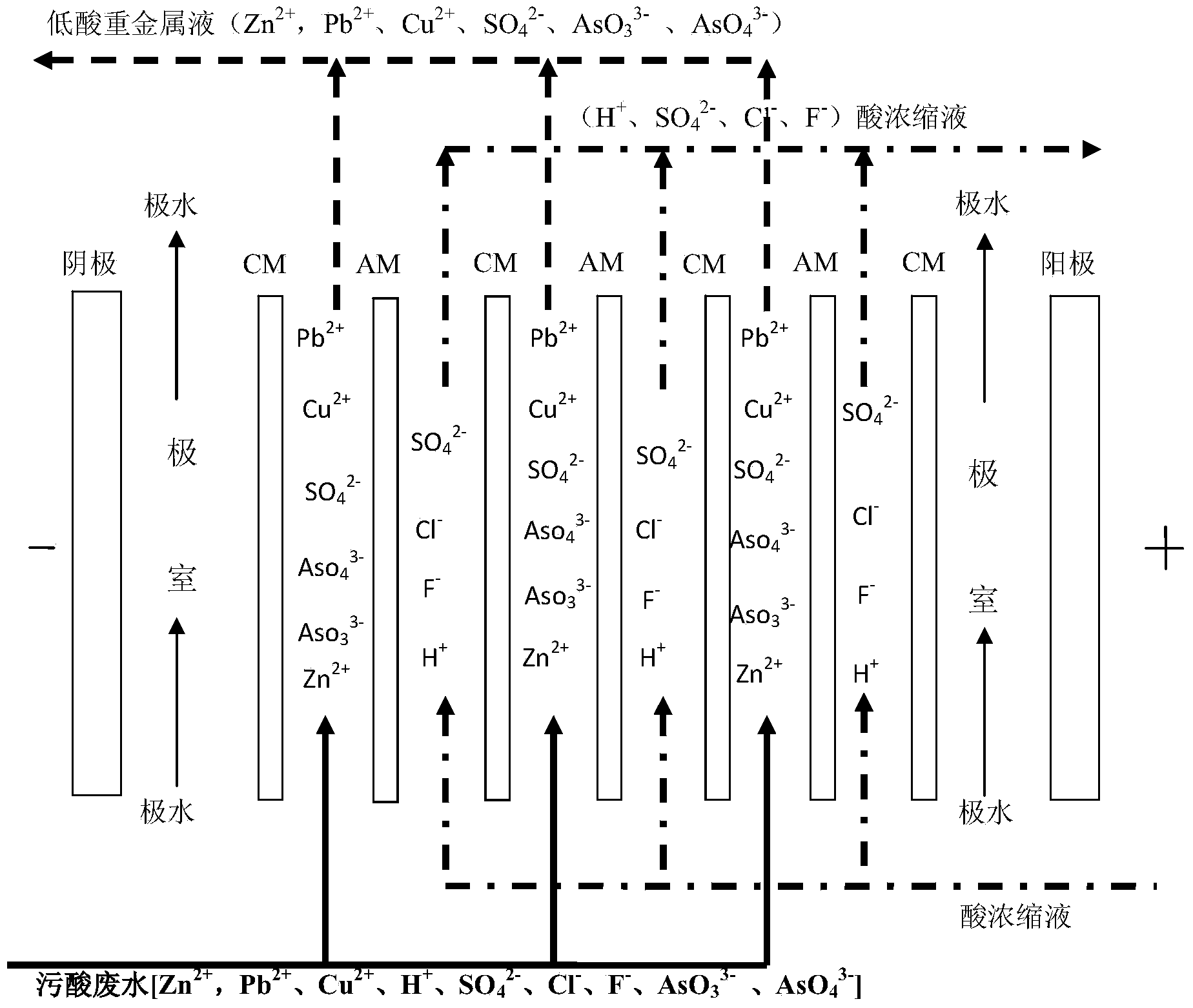

Heavy metal waste acid and wastewater resource recycling method and device

ActiveCN103553248APromote recoveryEfficient recyclingDispersed particle separationMultistage water/sewage treatmentLiquid wasteProcess integration

The invention discloses a heavy metal waste acid and wastewater resource recycling method and device. According to the method, acids in waste acid can be well separated through selection of anionic and cationic membranes in the electrodialysis process, heavy metal ions still remain in a waste acid solution, and the separated acid enters a concentration basin, has the acidity of over 8 percent and can be used for a sulfuric acid preparation process; the acidity of the treated waste acid is reduced to a pH value of over 3, valuable heavy metals in heavy metal-containing low-acidity waste liquor can be rapidly recovered by utilizing a hydrogen sulfide and jet process integration technology, and the recovery rate of the heavy metal ions is over 95 percent; the residual low-acidity low-salt wastewater can be recycled for a spraying system. According to the method, the heavy metal waste acid and wastewater can be treated at high efficiency, the phenomena that neutralization residues which are difficultly treated are generated and secondary pollution is caused in the process of neutralizing by adopting alkalis are avoided, high-quality sulfuric acid and heavy metals can be recovered, and more important, the adopted equipment and device are simple, convenient to operate and good in treatment effect.

Owner:CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com