Process integration of a single chip three axis magnetic field sensor

A magnetic field sensor, magnetic field component technology, applied in the direction of the magnetic field control resistor, the size/direction of the magnetic field, the components of the electromagnetic equipment, etc., can solve the problems of chip-level packaging difficulties, large vertical expansion, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following detailed description is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any theory presented in the preceding background or the following detailed description.

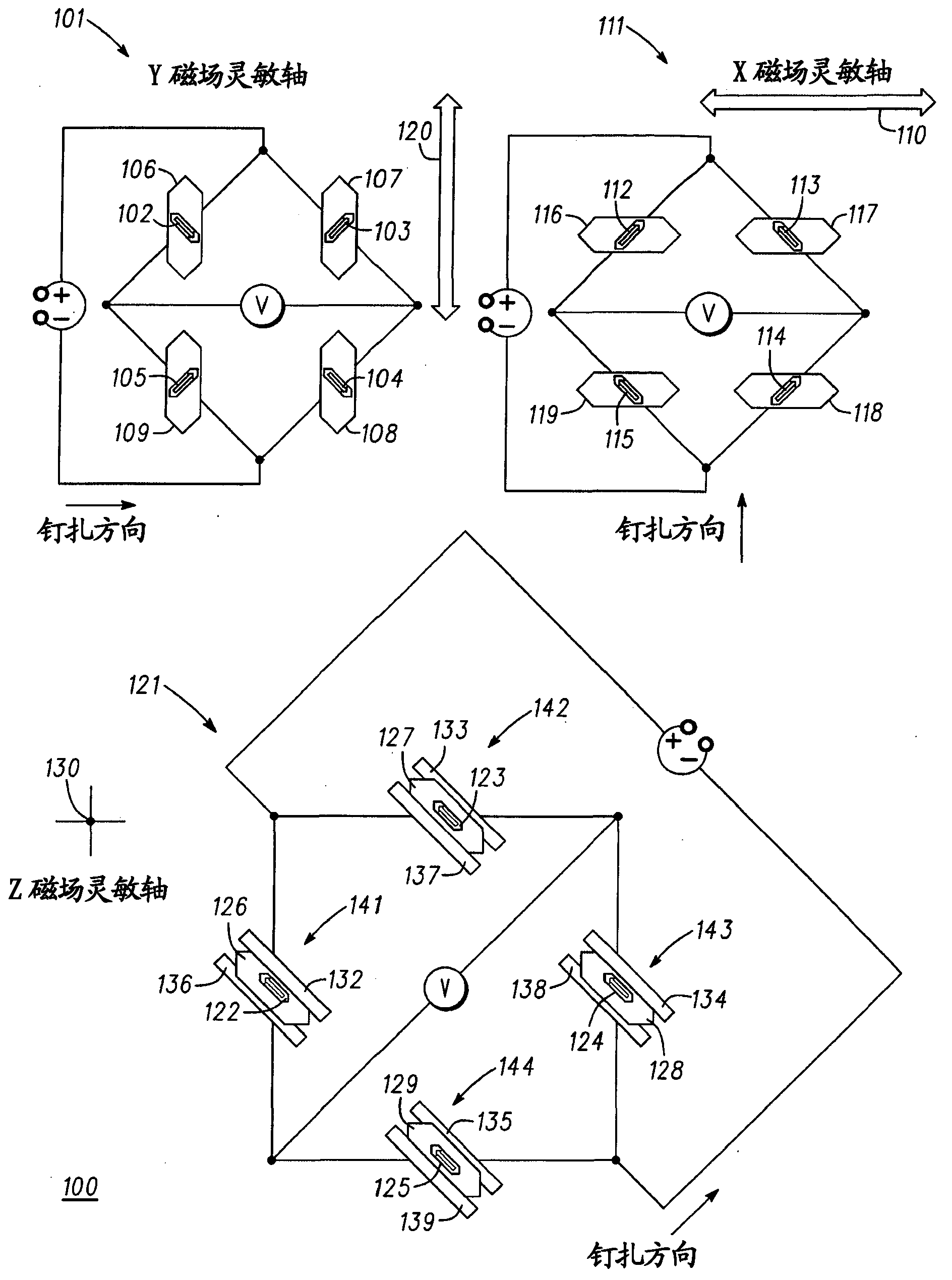

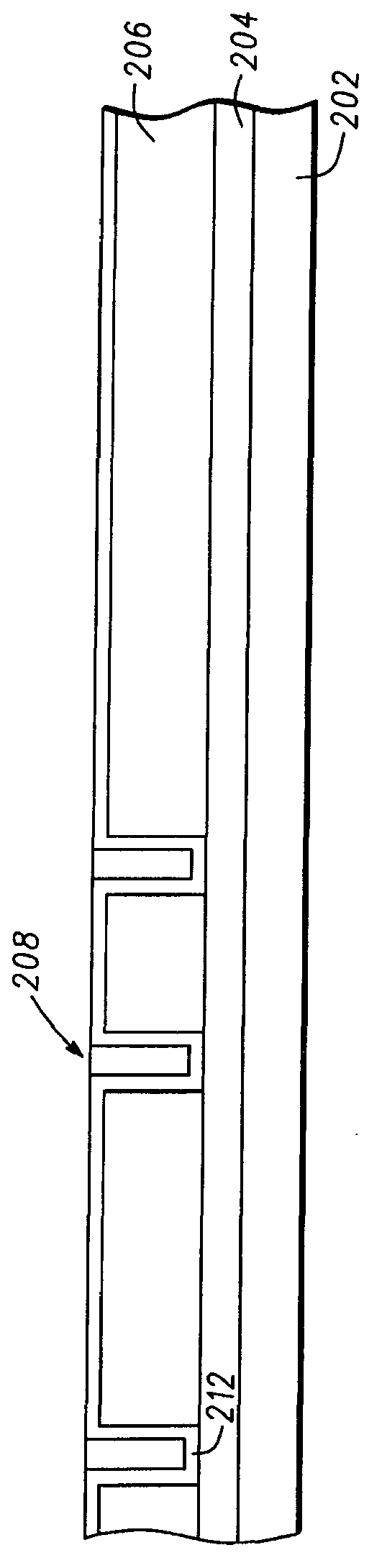

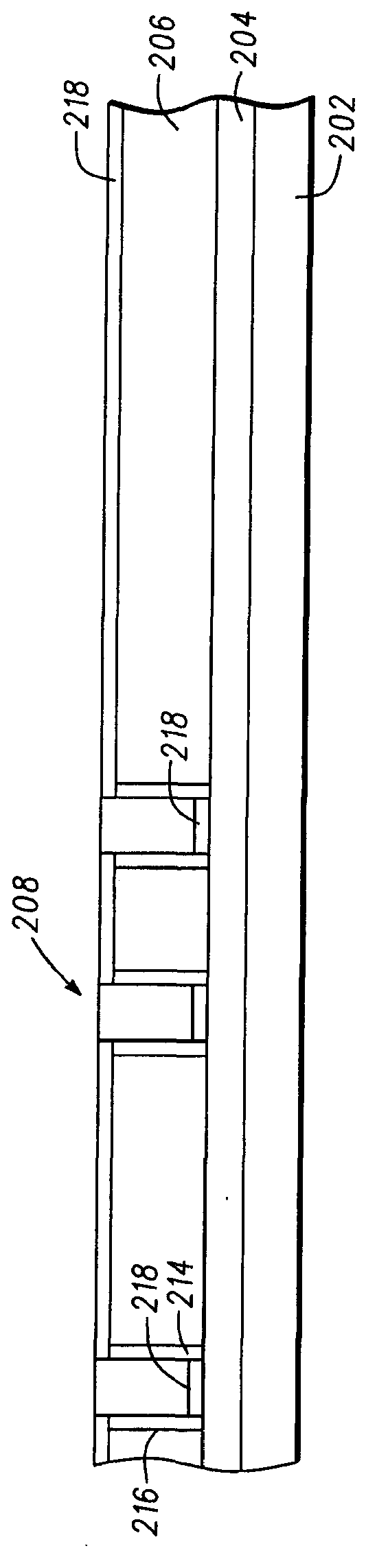

[0018] High aspect ratio vertical strips (flux guides) by integrating magnetically permeable material (typically having a magnetic permeability greater than 100, more preferably greater than 1000, such as nickel-iron alloy (NiFe)) , and the edges of the vertical bars terminate in close proximity to opposite edges and opposite sides of the magnetic sensing element, allowing part of the vertical (Z-axis) magnetic field to enter the plane of the sensing element (X-Y plane). Magnetic permeability is the degree of magnetization a material acquires in response to an applied magnetic field. These flux guides act to capture the magnetic flux from the Z component of the applied magnetic fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com