Method for producing petrol and diesel oil by recycling waste lubricant oil

A technology for waste lubricating oil, gasoline and diesel oil, applied in lubricating compositions, petroleum industry, hydrocarbon distillation, etc., can solve the problems of low product grade, poor economic benefit, secondary pollution, etc., achieve wide raw material range, reduce consumption, improve conversion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

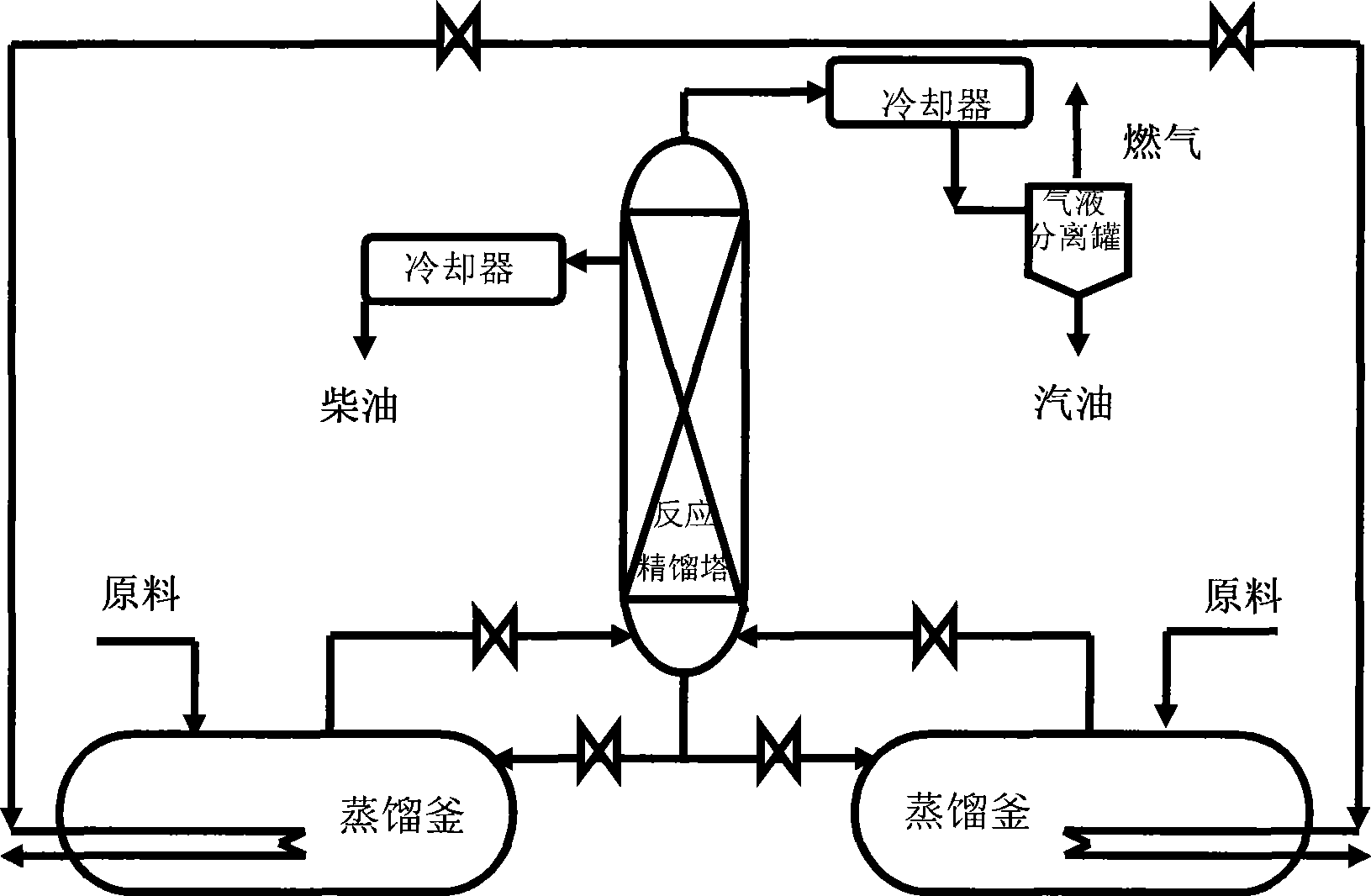

Method used

Image

Examples

Embodiment 1

[0023] Catalyst A is composed of alumina containing 30% ZSM-5 and 10% beta zeolite, and a columnar product of 2.0-3.0 mm can be obtained by bonding and molding, with a length of 3-8 mm, a bulk density of 0.65-0.80 g / ml, and a strength greater than 40 N / m mm. The product has high activity and good carbon resistance, has good stability, and is suitable for the largest volume of diesel products.

[0024] Catalyst B is composed of alumina containing 30% Y zeolite, 20% ZSM-5 and 10% Beta zeolite, and a columnar product of 1.8-2.5mm is obtained by bonding molding, with a length of 3-8mm and a bulk density of 0.70-0.85g / ml , the strength is greater than 40N / mm. The product has high activity and moderate impact resistance. It is suitable for deep conversion of waste lubricating oil and reduces the freezing point effect of diesel products.

Embodiment 2

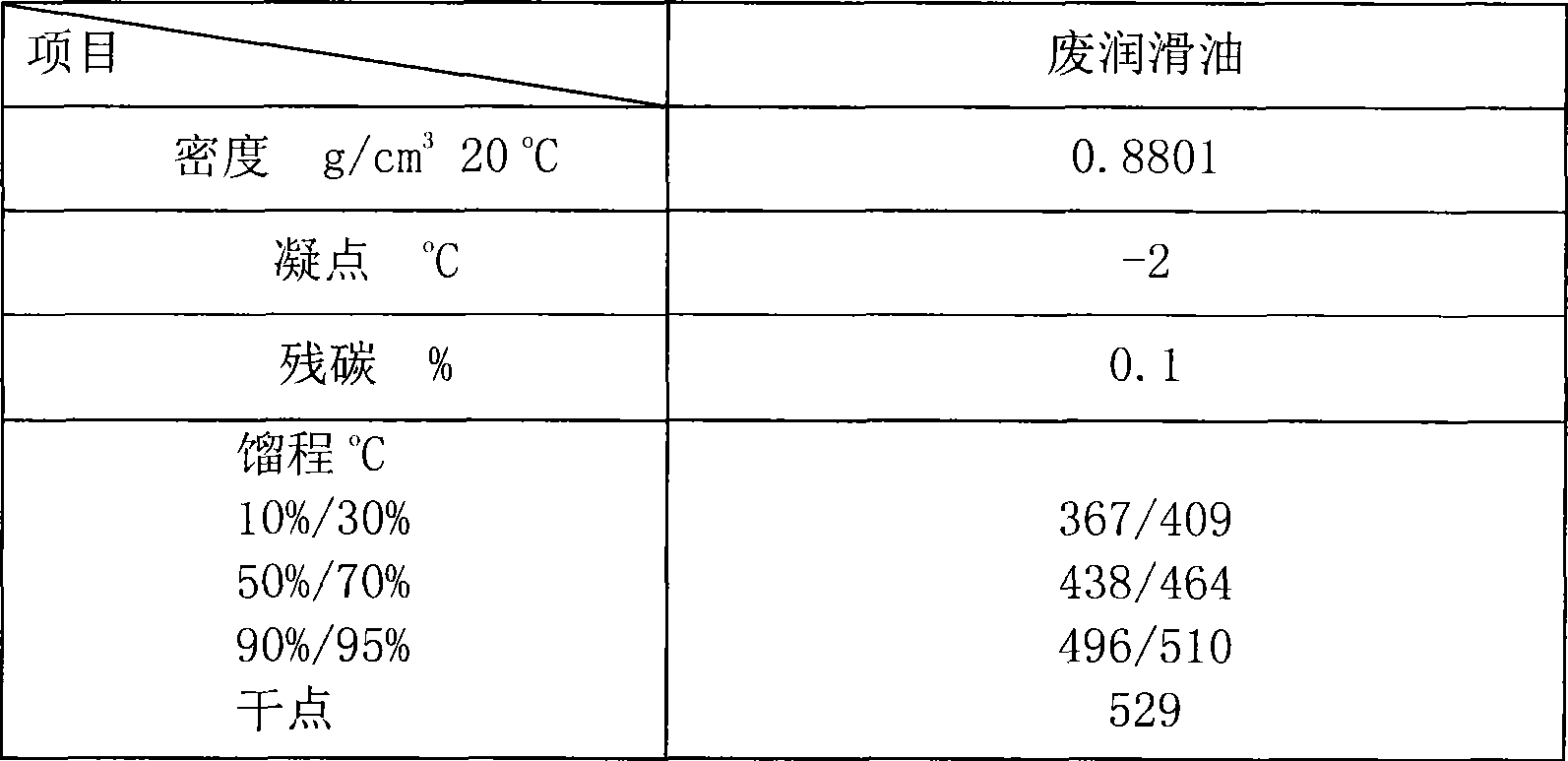

[0026] The properties of waste lubricating oil are shown in Table 1. It can be seen from the table that the raw materials of waste lubricating oil have higher density and lower freezing point, so the production of light diesel oil needs to crack and isomerize high-boiling alkanes in order to achieve the purpose of light weight and depressing pour point. At the same time, gas cannot be produced by excessive cracking, which will affect the yield of liquid products.

[0027] Table 1 Properties of waste lubricating oil raw materials

[0028]

Embodiment 3

[0030] Using waste lubricating oil as raw material, adopting catalyst A and catalyst B to utilize the technical scheme of the present invention to produce light oil (gasoline and diesel oil) results on laboratory kilogram-level devices.

[0031] Table 2 Reaction process conditions and product composition

[0032] Catalyst A Catalyst B Process conditions

[0033] It can be seen from Table 2 that under the condition of solvent-oil ratio of 1:10, catalyst A has a light oil yield of 90.00%, a total liquid yield of 94.54%, and a light oil density of 0.827g / cm 3 , The freezing point of light oil is -13°C, which is -11°C lower than the freezing point of raw materials. Under the condition of catalyst oil ratio of 1:10, the light oil yield of Catalyst B is 90.14%, the total yield is 94.94%, and the light oil density is 0.825g / cm 3 , The freezing point of light oil is -16°C, which is -14°C lower than the freezing point of raw materials. The above results show that Ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com