Patents

Literature

77 results about "Distilled oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molecularly distilled fish oil is purified by a process that maintains a low temperature and mild handling conditions. Distillation is a purification and concentration method by which the substances of interest evaporate, travel a distance, and condense on a separate surface.

Y molecular sieve modification method

ActiveCN1803612ASmall cell constantHigh crystal retentionCatalyst carriersMolecular sieve catalystsMolecular sieveDistilled oil

The invention relates to a modifying method for Y molecular sieve, which comprises: using industrial NaY molecular sieve as material for ammonium exchange, baking deeply; then, adding surfactant during dealumination with acid. This invention obtains HY molecular sieve with high SiO2 / Al2O3(9~15) and crystallinity, improves secondary pores and acid structure compared with the industrial NaY, and fits to be carrier for hydrotreating catalyst for heavy distilled oil.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

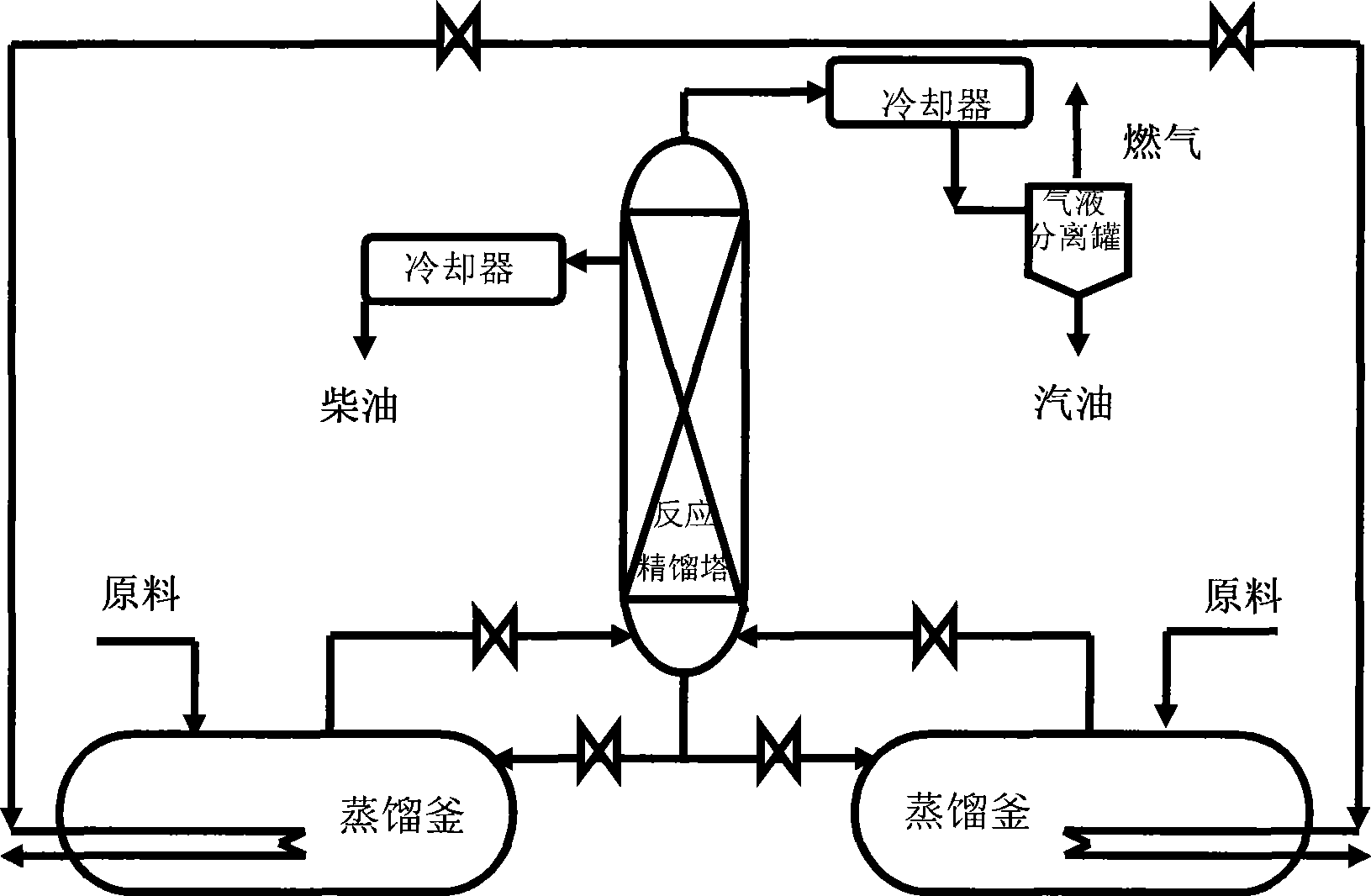

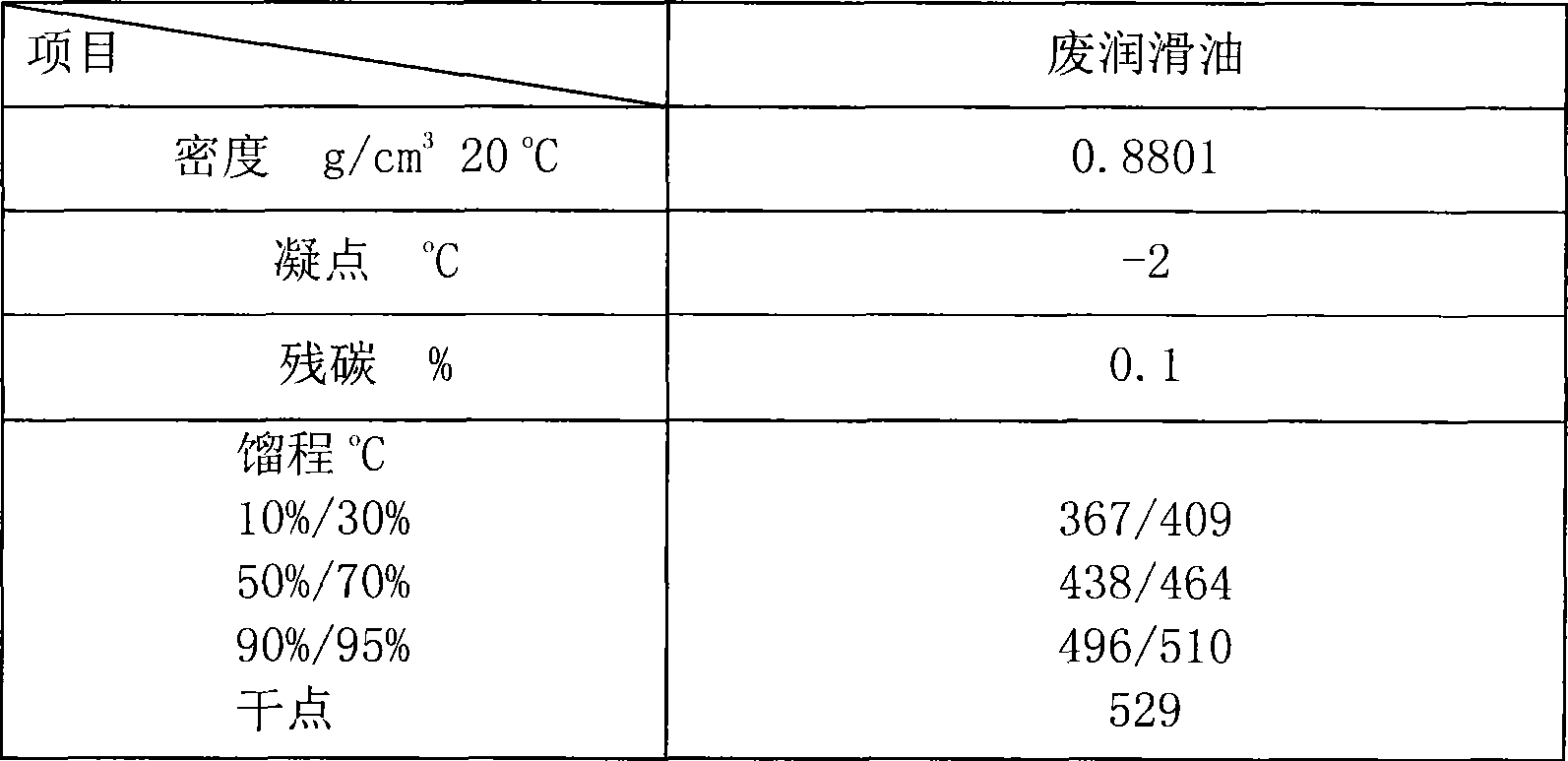

Method for producing petrol and diesel oil by recycling waste lubricant oil

ActiveCN101475870ASimple processLow costHydrocarbon distillationLubricant compositionDistilled oilGas phase

The invention relates to a method for producing gasoline and diesel fuel through resource utilization of waste lubricant oil, which belongs to the technical field of environmental protection and energy resources. The method comprises: integrally performing the vapor phase catalytic cracking process on molecular sieve / alumina catalyst of the waste lubricant oil and the fractionation and separation process of reaction products in a reaction fractionator; injecting crude waste oil into a distillation kettle, and adopting waste residue and fuel gas generated during conversion of the waste lubricant oil for heating, wherein the temperature of the distillation kettle is controlled to be between 250 and 500 DEG C; making distilled oil gas enter the reaction fractionator which is filled with the molecular sieve / alumina catalyst for reaction and rectification when the distillation kettle is heated to 250 DEG C, wherein the ratio of the catalyst to oil is controlled to be between 1 and 20; and cutting the oil into the gasoline and the diesel fuel according to the distilled temperature, wherein fuel gas generated by reaction and residual cinder can be used for heating the distillation kettle, and generated fuel gas can be used for heating the distillation kettle. The method has the advantages of wide range of raw materials, normal-pressure reaction and separation, simple technological flow, high conversion and selectivity of products, long service life of the catalyst, comprehensive utilization of the fuel gas and the cinder, no secondary pollution, large operating flexibility of a production apparatus, and small investment.

Owner:DALIAN UNIV OF TECH

Middle-pressure hydrocracking method for producing aviation kerosene and low-freezing point diesel

ActiveCN103059985AThe method flow is simpleLow investment costTreatment with hydrotreatment processesDistilled oilMixed materials

The invention discloses a middle-pressure hydrocracking method for producing aviation kerosene and low-freezing point diesel. The method comprises the steps that a single-section serial one-time passing flow is adopted under a middle pressure condition; the heated material and hydrogen enter a hydrotreatment reactor; reaction effluent enters a hydrocracking reactor without separation, and reacts under the existence of a hydrocracking catalyst; the generated reaction effluent is subjected to oil-gas separation and then cyclically used after being compressed by the obtained hydrogen-rich gas; the obtained liquid is distilled to obtain a little of pyrolytic naphtha; and a large part of product is middle distilled oil fraction. By adopting the method provided by the invention, 3# aviation kerosene and low-freezing point diesel meeting the GC6537-2006 standard are prepared from light wax oil or a mixed material of the light wax oil and FCC light cycle oil under the middle pressure condition. The method disclosed by the invention is simple in flow, low in operating cost, and low in device investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation of distilled oil

A process for hydrogenating fraction oil features that the raw fraction oil is directly contacted with hydrocatalyst at 330-400 deg.C, 3-8 MPa of hydrogen pressure and 0.5-2.0 / hr for reaction, and the resultant substance is cooled and separated to obtain diesel oil and less naphtha. Said hydrocatalyst is composed of active metal component chosen from VIII or VIB family and the alumina-zeolite mixture as carrier. Its advantages are high output rate, high hexodecane number and low density and sulfur content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of preparing and separating epichlorohydrin by chloropropene epoxidation

ActiveCN101016280AHigh energy consumptionLong processOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyDistilled oil

The invention discloses an epoxidizing method of epoxy chloropropane through chloropropene, which comprises the following steps: adopting excessive chloropropene to produce epoxy chloropropane directly under phosphotungstic acid quaternaries as catalyst and alkyl phenol polyoxyethylene ester as adjuvant catalyst and hydrogen peroxide solution as oxidant to reflux; cooling reactant; recycling solid-phased catalyst; distilling oil phase of reacting liquid to recycle residual chloropropene; decompressing; distilling; obtaining the purified product.

Owner:BALING PETRO CHEM CO LTD SINOPEC +1

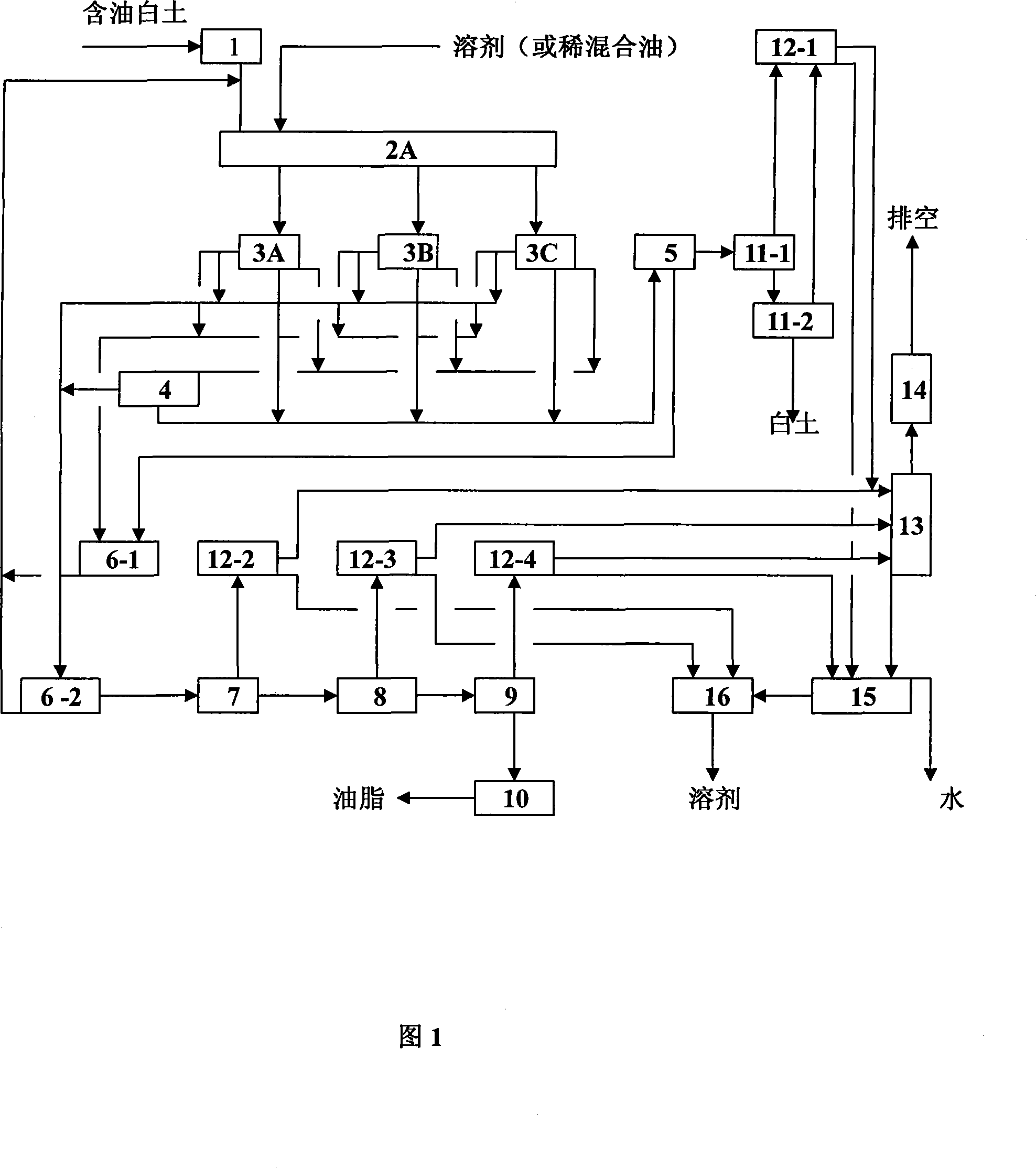

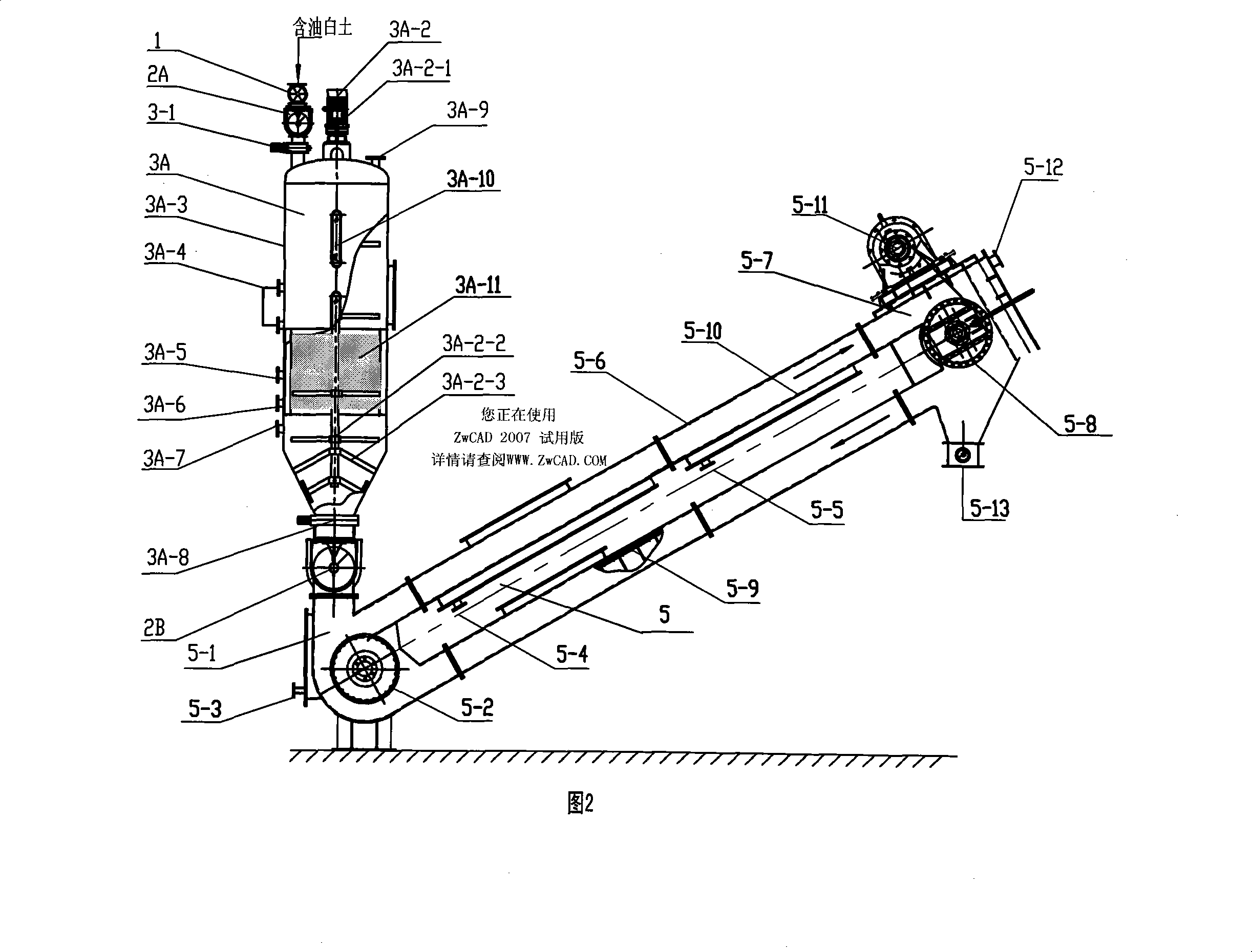

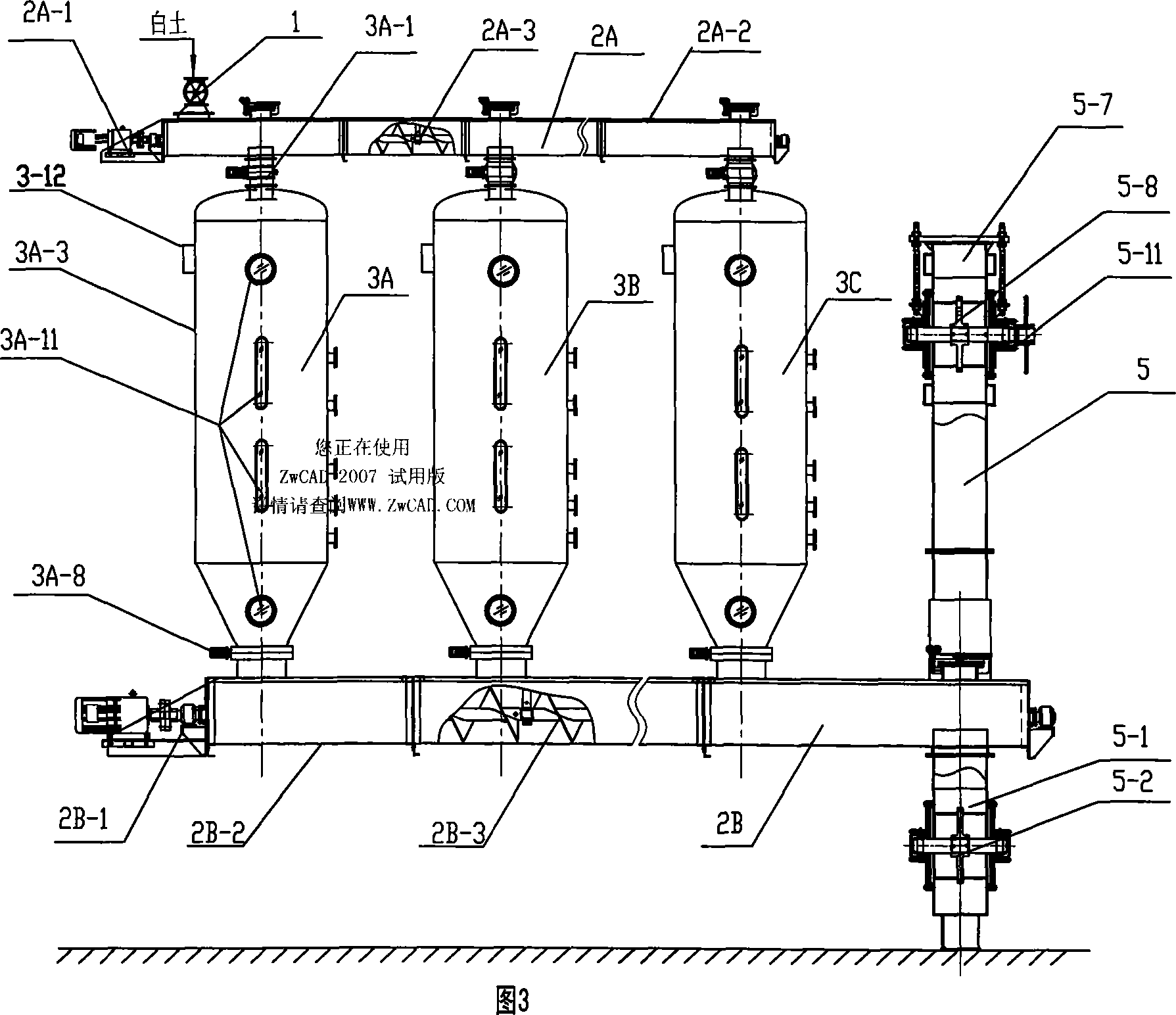

Technique for distilling oil from waste carclazyte by extraction method and device thereof

InactiveCN101186861ALow viscosityFacilitated DiffusionFatty oils/acids recovery from wasteFatty substance recoveryChemical industryVegetable oil

The invention relates to a technique to extract oils and fats in waste bentonite by solvent extraction directly and devices thereof. Processing steps are to preheat the waste bentonite with oils and the solvent to 50-55DEG C respectively, drop the waste bentonite with oils and the solvent into extracting machine with putting-down trap valve in ration, extract the mixed oils with the oils and fats and the solvent after at least twice immersions, feed the turbid mixed oils with the solvent into the mixed oils tank, and the mixture is dropped into evaporators for evaporating after settling down again, then filterable oils with standard quality can be recycled. After extracting from the net bucket detearing conveyors and exsolution from desolventizer, the purer waste bentonite can be achieved. The solvent air can be reused after condensating water and recycling. The invention is simple in technology, distinct in device, lower in production cost, and high in extraction efficiency, which is safe, reliable energy-conservational and environment-friendly. The invention with highly economic and social value applies to not onlythe petroleum chemical industry, but also the treatment of the waste bentonite in the vegetable oil processing industry.

Owner:范生安 +1

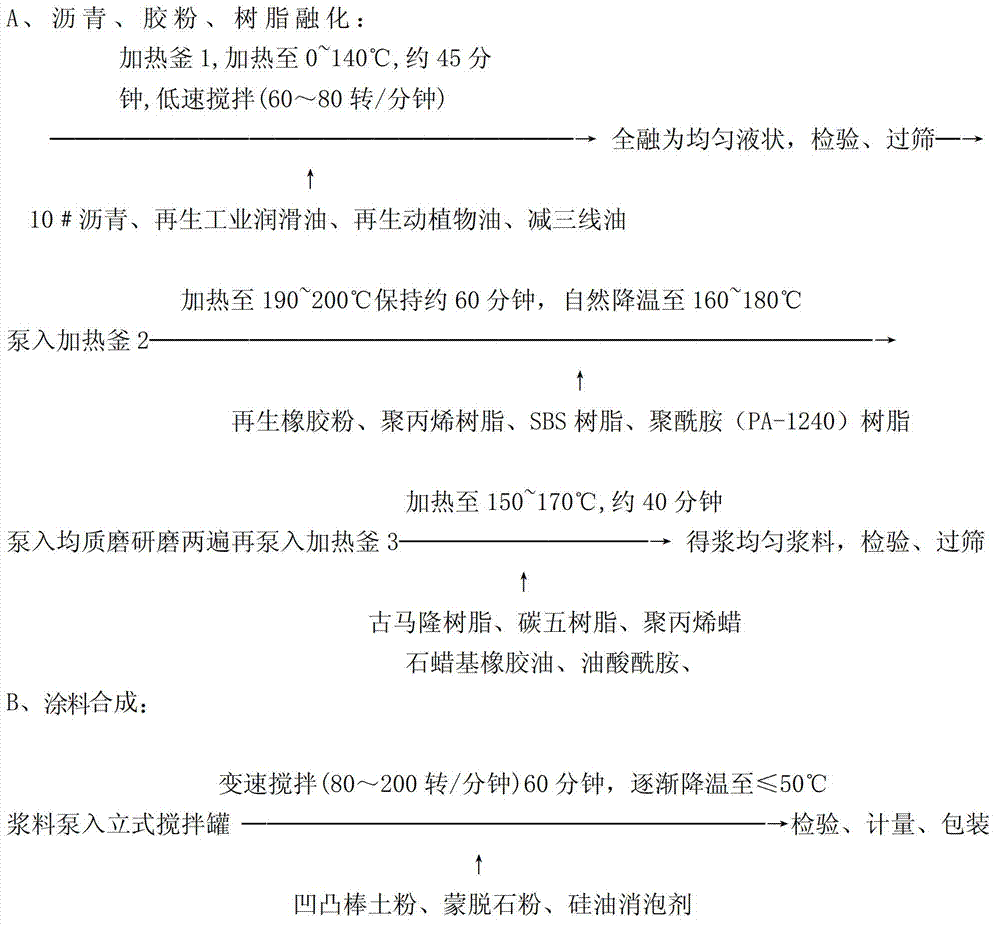

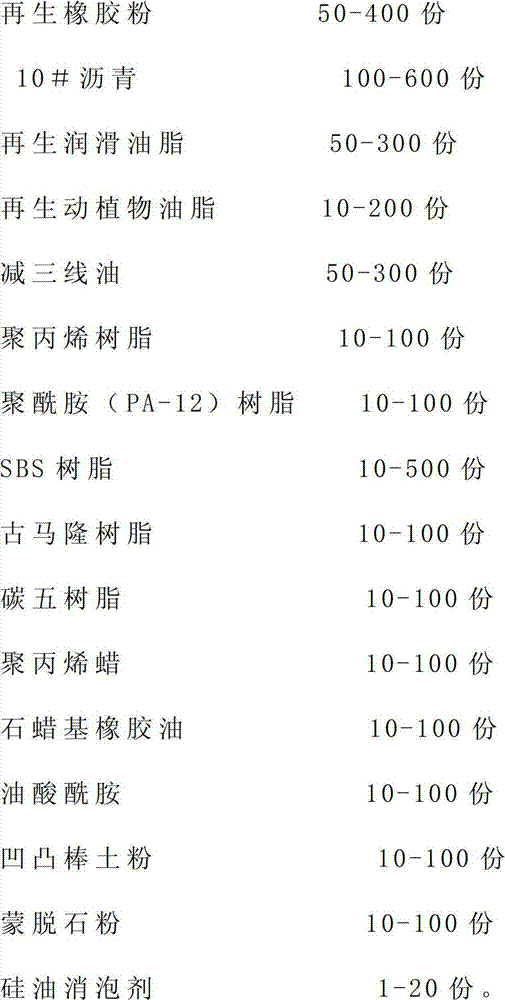

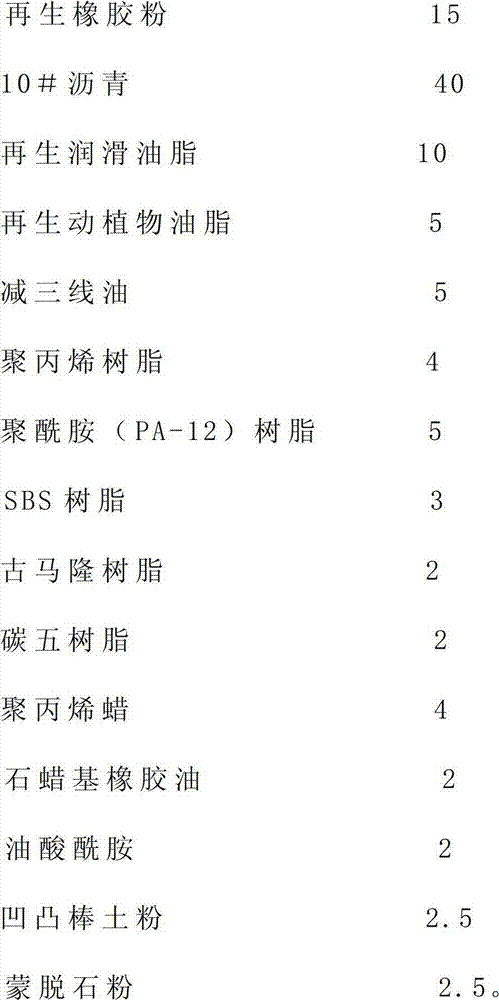

Non-solidifying rubber asphalt building waterproof coating

InactiveCN102925058AReduce pollutionImprove stabilityReclaimed rubber coatingsPolyamide coatingsDistilled oilFlora

The invention discloses a non-solidifying (wriggling) rubber asphalt building waterproof coating and belongs to the field of chemical material building. The coating is prepared by processing the following raw materials: 50-400 parts of regenerated rubber powder, 100-600 parts of 10# asphalt, 50-300 parts of regenerated lubricating grease, 10-200 parts of regenerated flora and fauna grease, 50-300 parts of tertiary-distilled oil, 10-100 parts of polypropylene resin, 10-100 parts of polyamide (PA-12) resin, 10-500 parts of styrene butadiene styrene (SBS), 10-100 parts of coumarone resin, 10-100 parts of carbon 5 resin, 10-100 parts of polypropylene wax, 10-100 parts of paraffin base rubber oil, 10-100 parts of oleamide, 10-100 parts of attapulgite powder, 10-100 parts of smectite and 1 part to 20 parts of silicone oil defoamer. Inspections show that technical indexes of the non-solidifying (wriggling) rubber asphalt building waterproof coating are superior to JC / T864-2008 national material building industry standard of the 'polymer emulsion building waterproof coating', and stability and aging resistance of the coating are greatly improved.

Owner:刘力

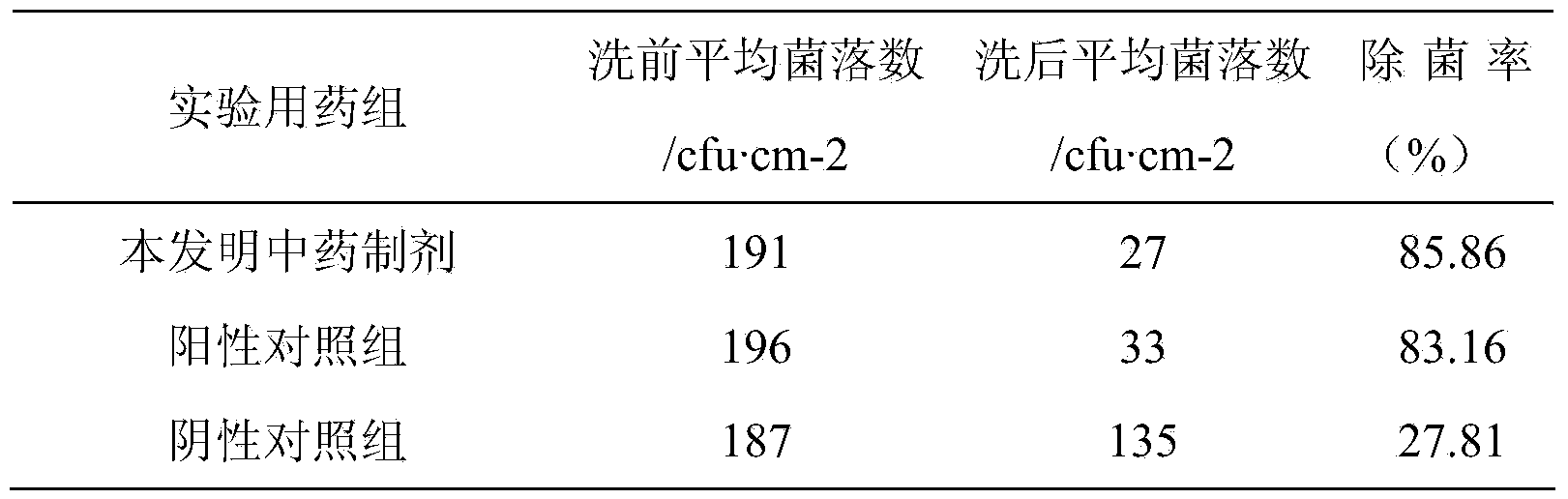

Sterilizing and odor-removing soap and preparation method thereof

InactiveCN103468443AImprove the bactericidal effectMoisturize the skinSoap detergents with organic compounding agentsSkin careBiotechnologyDistilled oil

The invention discloses a sterilizing and odor-removing soap and preparation method thereof, belonging to the field of sanitary articles. The sterilizing and odor-removing soap is prepared by mixing the following components in parts by weight: 8-10 parts of castor oil, 8-10 parts of palm oil, 10-15 parts of olive oil, 5-10 parts of Chinese hawthorn seed distilled oil, 2-3 parts of sodium hydroxide, 4-6 parts of purified water, 2-5 parts of powdered carbon, 0.5-1 part of peppermint extract, 0.5-1 part of honeysuckle extract, 0.2-0.5 part of bamboo vinegar, 0.2-0.5 part of citric acid, 1-2 parts of perfume compound for soap and 0.2-0.3 part of ethylenediaminetetraacetic acid disodium salt. The sterilizing and odor-removing soap and the preparation method thereof are reasonable in formulation and simple in technology; the plant herb extracts with effects of bacteria resistance and bacteriostasis and the powdered carbon and the bamboo vinegar which have the effects of sterilization and health care are added into the soap, so that the soap is remarkable in effects of sterilizing and removing odor, and does not have stimulation to the skin.

Owner:上海超领日化产品有限公司

Method for pre-processing neodymium iron boron wire cutting waste oil sludge

InactiveCN102912112AEasy to operateEasy temperature controlEnvironmental resistancePretreatment method

The invention relates to a method for pre-processing neodymium iron boron wire cutting waste oil sludge, belonging to the filed of rare earth recycle. The method comprises the following steps: distilling oil sludge after neodymium iron boron wire cutting at 50-100 DEG C at 10-300rpm with 0.01-0.1MPa, and carrying out acid dissolution, edulcoration, extraction separation, deposition and ignition on remaining products after distillation to obtain rear earth oxide, namely pouring the oil sludge after neodymium iron boron wire cutting in a revolving bottle for distillation by controlling the temperature, the air pressure and the rotary speed, and carrying out acid dissolution, edulcoration, extraction separation, deposition and ignition on remaining products after distillation to obtain rear earth oxide. The waste is oxidized and roasted when pre-processing is unnecessary; and the method is free of dust air pollution and is beneficial to environmental protection.

Owner:BEIJING UNIV OF TECH

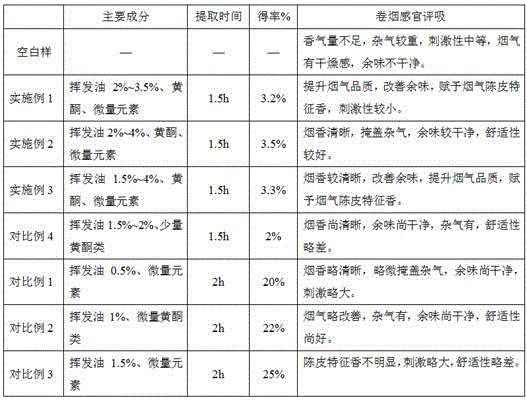

Preparation method of essential oil of tangerine peel and application of essential oil of tangerine peel in cigarettes

InactiveCN106244330AResolution statusSolve solubilityTobacco preparationTobacco treatmentAdditive ingredientTangerine Peel

The invention discloses a preparation method of essential oil of tangerine peel, including: crushing tangerine peel, distilling, separating oil and water, and distilling secondarily. The essential oil of tangerine peel obtained herein has high contents of main ingredients such as flavone, volatile oils and alkaloids, the preparation process is simple, the operability is high, the cost is low, the purity of the essential oil is high, and the whole production process is efficient and suitable for industrial implementation; in addition, the essential oil of tangerine peel prepared herein can be applied to cigarettes to improve smoking aftertaste of cigarettes, special natural flavor is imparted to the cigarettes, and smoke quality is improved.

Owner:YUNNAN YANGRUI TECH GRP

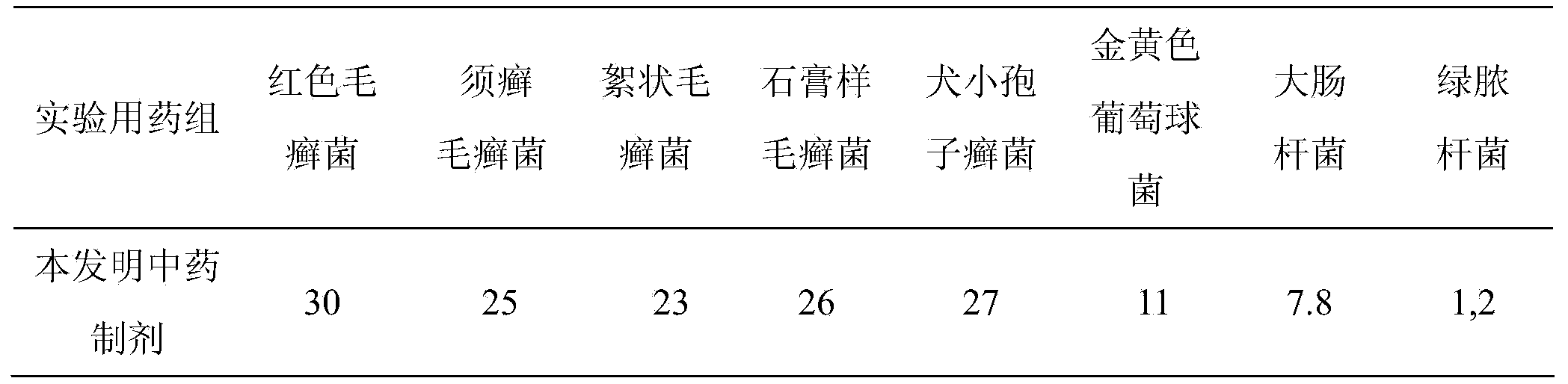

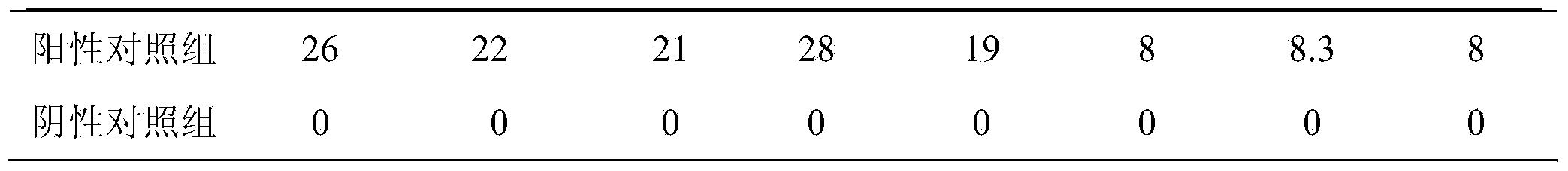

Application of traditional Chinese medicine preparation in preparation of medicines for treating dermatophytosis

InactiveCN104107237ASafeLow recurrence rateAntimycoticsDermatological disorderBeriberiUse medication

The invention relates to a novel application of a traditional Chinese medicine preparation in preparation of medicines for treating dermatophytosis. Active substances of the traditional Chinese medicine preparation are prepared from the following raw materials: 5 parts of Chinese hawthorn seed dry distilled oil, 20 parts of Chinese hawthorn seed dry distilled liquid, 25 parts of Tween -80 and 50 parts of deionized water. The clinical test and animal pharmacodynamic test prove that the traditional Chinese medicine preparation can treat patients suffering from dermatophytosis and is high in effective rate, and therefore a new medication choice is provided for clinical test.

Owner:SHANDONG BUCHANG SHENZHOU PHARMA

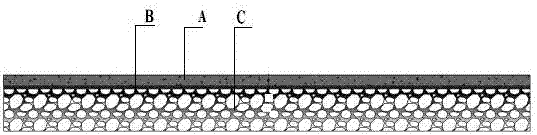

Maintenance construction method of asphalt road surface solid permeability wearing layer

ActiveCN108003639AFast constructionRepair early diseaseIn situ pavingsBuilding insulationsDistilled oilRoad surface

The invention discloses a maintenance construction method of an asphalt road surface solid permeability wearing layer. The construction method includes the following steps that the spreading amount ofa solid permeability agent is surveyed; a road surface is cleaned; the road surface is pre-processed; the solid permeability agent is sprayed; a wearing layer is spread; manual trimming is carried out; preliminary maintenance is carried out. According to the maintenance construction method, the solid permeability agent is demulsified immediately after being atomized or smeared on the original road surface, heavy cycloparaffin distilled oil rapidly infiltrates to restore old asphalt performance, early diseases of the original asphalt road surface are repaired, and meanwhile a matrix asphalt and tackifier mixture is left on the road surface to form a binding layer. A solid permeability layer is formed by the repaired original asphalt road surface and the binding layer. The maintenance construction method is high in construction speed and efficiency.

Owner:江苏瑞文戴尔交通科技有限公司

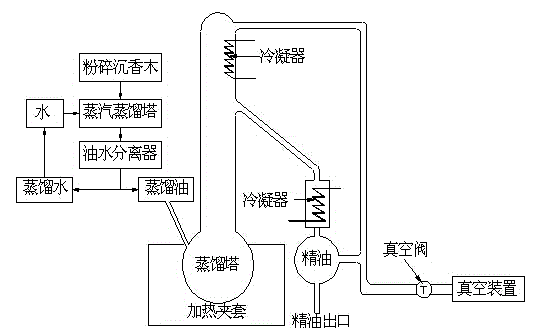

Method for preparing aquilaria essential oil

InactiveCN104946396AImprove liquidityAvoid breakingEssential-oils/perfumesDistilled oilDistilled water

Owner:聂超

Synthesis technology for 2, 4, 6-trimethylbenzene acetyl chloride

ActiveCN102633626ASolve the problem of low qualitySimple methodOrganic compound preparationCarboxylic compound preparationDistilled oilOil phase

The invention relates to a synthesis technology for 2, 4, 6-trimethylbenzene acetyl chloride, comprising the following steps of: putting thionyl chloride, a catalyst and 2, 4, 6-trimethylbenzene acetic acid into a reaction kettle in batches, and controlling temperature to carry out reaction; and after the reaction, distilling (high vacuum) in a heating way in the reaction kettle, and acquiring a final product. The preparation method of the 2, 4, 6-trimethylbenzene acetic acid can comprise the following steps of: carrying out chloromethylation reaction by taking trimethylbenzene, formaldehyde and concentrated hydrochloric acid as raw materials, adding toluene to extract after reacting, and washing to obtain a toluene solution of 2, 4, 6-trimethyl benzyl chloride; taking the toluene solution of 2, 4, 6-trimethyl benzyl chloride and the sodium cyanide as raw materials, adding a phase transfer catalyst, reflowing in a heating way to carry out cyanation reaction, washing by adding water after reacting, distilling oil phase to recover toluene and mesitylene, and rectifying to obtain 2, 4, 6-trimethylbenzene acetonitrile; and hydrolyzing the 2, 4, 6-trimethylbenzene acetonitrile, centrifuging to obtain a 2, 4, 6-trimethylbenzeneacetic acid crude product, and optionally selecting and carrying out the aftertreatment to obtain the 2, 4, 6-trimethylbenzeneacetic acid. The content of the 2, 4, 6-trimethylbenzene acetyl chloride synthesized by the method disclosed by the invention is more than or equal to 98.0%, and the content of the 2, 4, 6-trimethylbenzene acetonitrile is less than or equal to 0.5%.

Owner:SUQIAN COSMOS CHEM +1

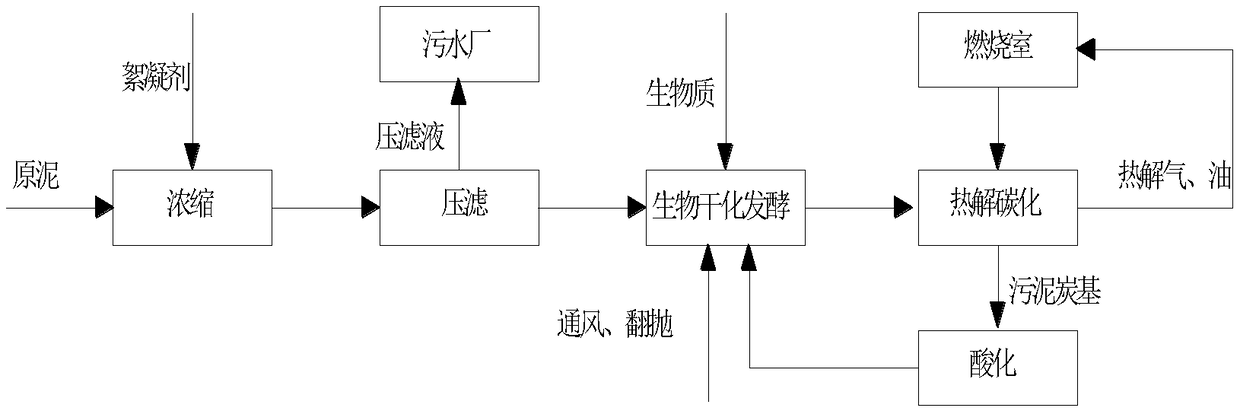

Sludge treatment method

InactiveCN108558179AShorten the timeReduce energy consumptionSludge treatment by thermal conditioningSludge treatment by pyrolysisDistilled oilCombustion chamber

The invention discloses a method for coupling sludge drying and carbonizing based on organisms. The method comprises the steps of S1, adding original sludge from a sewage plant into a flocculating agent which accounts for 1-3%o of the oven-dry weight of the sludge for concentration, and using a belt filter press to filter-press the concentrated sludge to obtain filter cake and a filtrate; S2, adding pulverized straw of which the moisture content is 10-35% into the filter-cake sludge obtained in S1, fully mixing the materials to obtain a mixture, and draining the obtained filtrate to the sewageplant for treatment, wherein the mixing ratio of biomass of the sludge to biomass of the pulverized straw is (2-4):1; S3, adding a microbial agent which accounts for 3-6%o of the oven-dry weight of the mixture into the mixture obtained in S2 for mixing, and fermenting and drying a to-be-dried material pile obtained after mixing to obtain biological dried sludge; S4, placing the biological dried sludge obtained in S3 into a carbonizing furnace for carbonization for 20-40 min to obtain carbonized sludge, and conducting pyrolysis to obtain gas and distilled oil; activating the obtained carbonized sludge, afterwards, mixing the carbonized sludge back into a sludge biological drying and fermenting bin for mixed fermenting, introducing the obtained pyrolysis gas and oil into an incinerator or asecondary combustion chamber of an incinerator system for combustion, and then introducing combusted exhaust gas into the carbonizing furnace.

Owner:NANJING WONDUX ENVIRONMENTAL PROTECTION TECH CO LTD

Pressing method of black pearl sunflower seed oil

InactiveCN105273826AImprove oil yieldStrong aromaFatty-oils/fats refiningFatty-oils/fats productionDistilled oilHydrogen

The invention relates to the technical field of edible oil processing, in particular to a pressing method of black pearl sunflower seed oil. Black pearl sunflower seeds are kept for 20-22 min under the pressure of 0.15-0.18 MPa in the microwave power of 32-35 W / g, the pressure is reduced immediately until the black pearl sunflower seeds are in the vacuum state, the black pearl sunflower seeds are kept for 12-15 min in the vacuum state, rolled and shelled, the shelled black pearl sunflower seeds are repeatedly pressed for 30-40 min, crude oil and pressed residues are obtained, the pressed residues are crushed, water is added, the volume ratio of water to the pressed residues is 1:3, the PH (potential of hydrogen) is adjusted to 5, papain is added for enzymolysis, enzymolysis residues are reserved and dried until the water content is lower than 10%, the enzymolysis residues are fed to a steam generator and distilled at the steam temperature of 100-120 DEG C under the pressure of 0.022-0.025 MPa until no clear oil droplets flow out of effluent, distillation is stopped, and distilled oil is obtained; the crude oil and the distilled oil liquid are mixed and introduced into the steam generator to be distilled at the steam temperature of 130-150 DEG C under the pressure of 0.035-0.038 MPa until no clear oil droplets flow out of effluent, and distillation is stopped.

Owner:CHUZHOU YINSHI GREASE CO LTD

Reducing the odor of oil components by means of adsorption with polymeric adsorbing agents

Owner:COGNIS IP MANAGEMENT GMBH

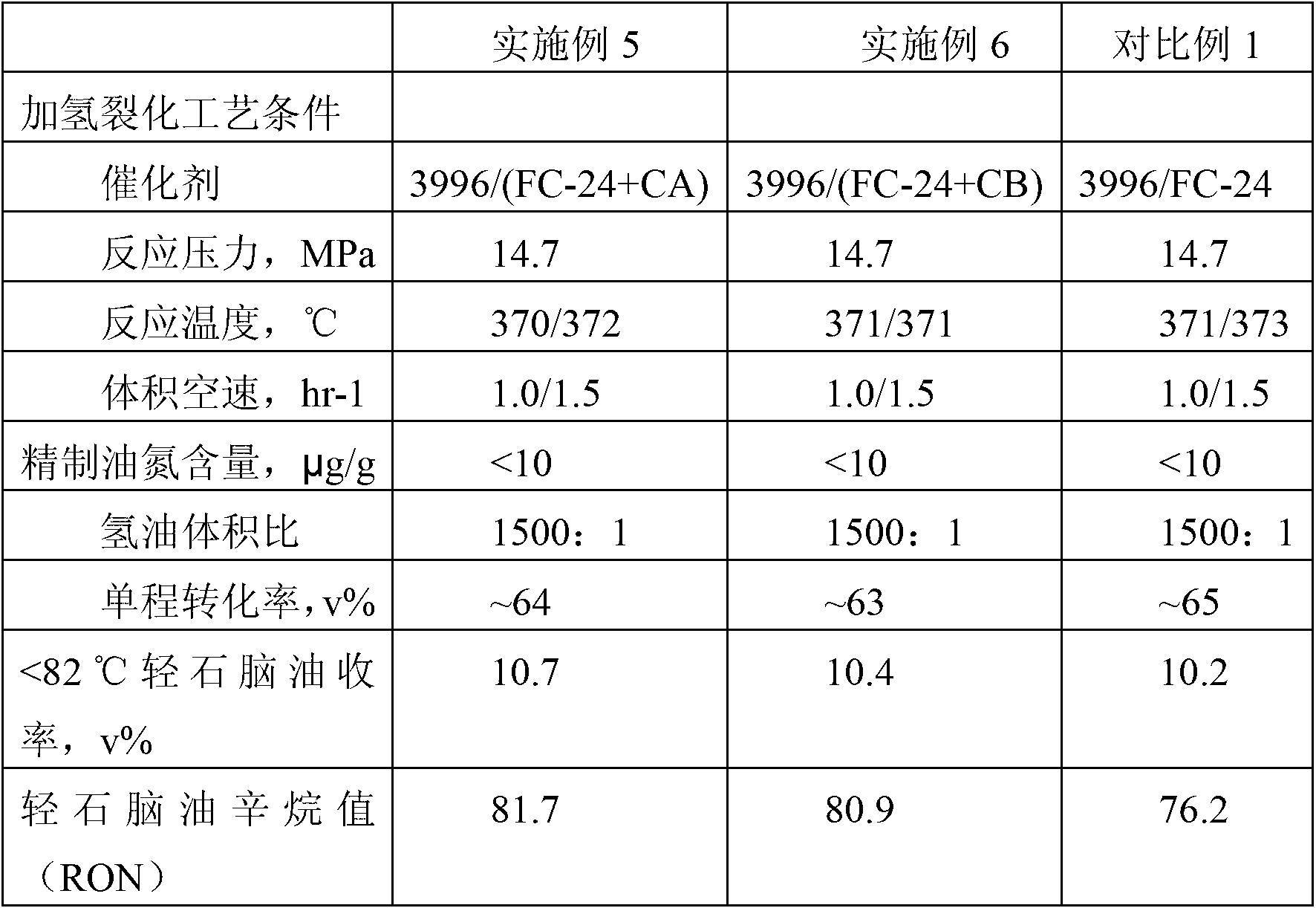

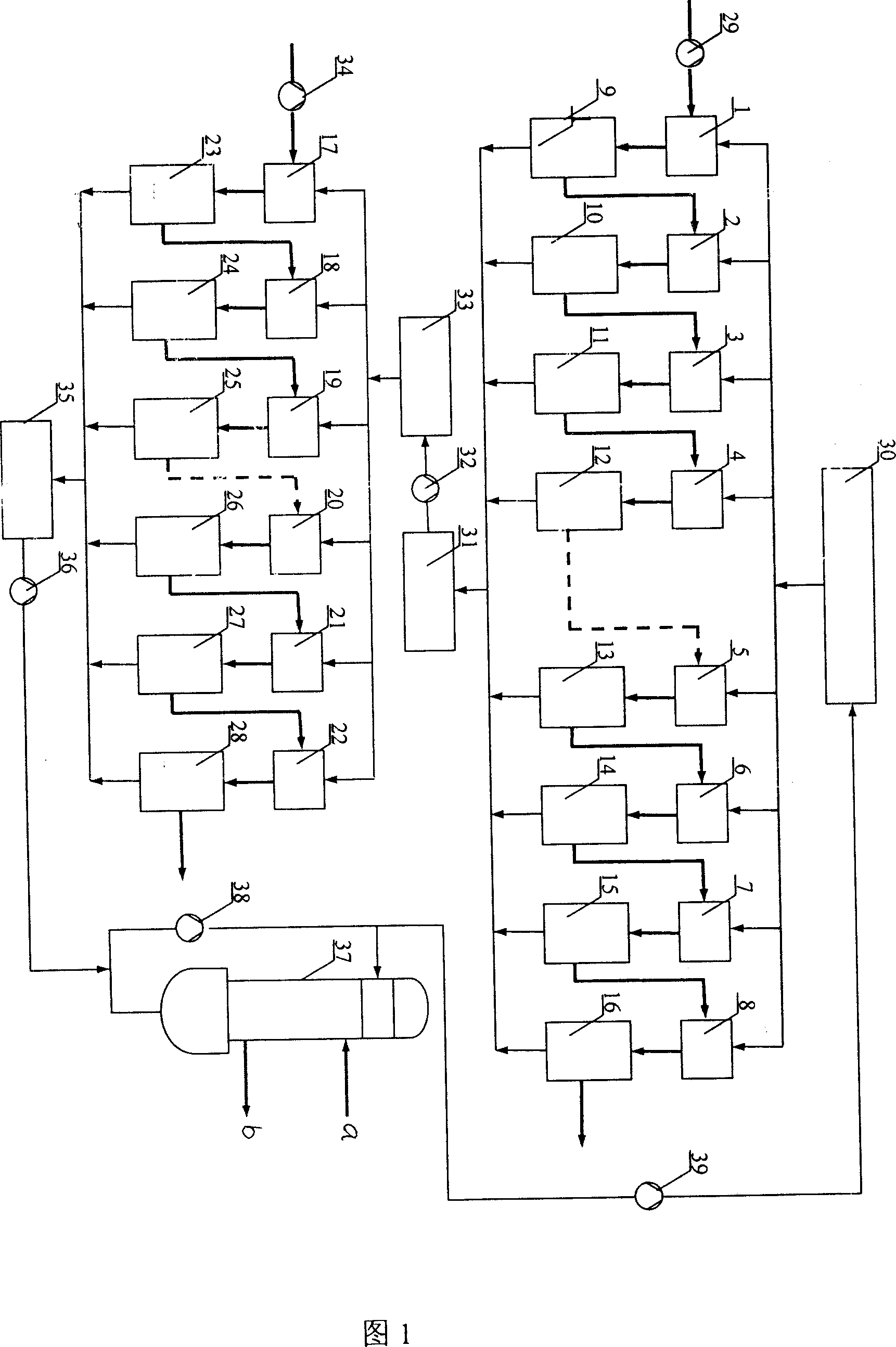

Hydrocracking method for preparation of high-octane naphtha

ActiveCN103071527AMolecular sieve catalystsTreatment with hydrotreatment processesMolecular sieveDistilled oil

The invention discloses a hydrocracking method for preparation of high-octane naphtha. The method comprises the following steps: (1), in a first reactor, heavy distilled oil conducts hydrofining reaction under the catalysis of hydrofining catalyst; (2), products generated during hydrofining reaction enter a second reactor, at the upper layer of the second reactor, the products generated during hydrofining reaction conduct hydrocracking reaction under the catalysis of hydrocracking catalyst, and the products during hydrocracking reaction enter the lower layer of the second reactor and conduct cracking and isomerization reaction under the catalysis of the catalyst containing composite molecular sieve; and (3), the products generated during cracking and isomerization reaction are separated, so that the high-octane naphtha is obtained. The method has the advantages that the raw material adaptability is strong, the process is simple, the product quality is good, and the octane of light naphtha is high.

Owner:CHINA NAT OFFSHORE OIL CORP +3

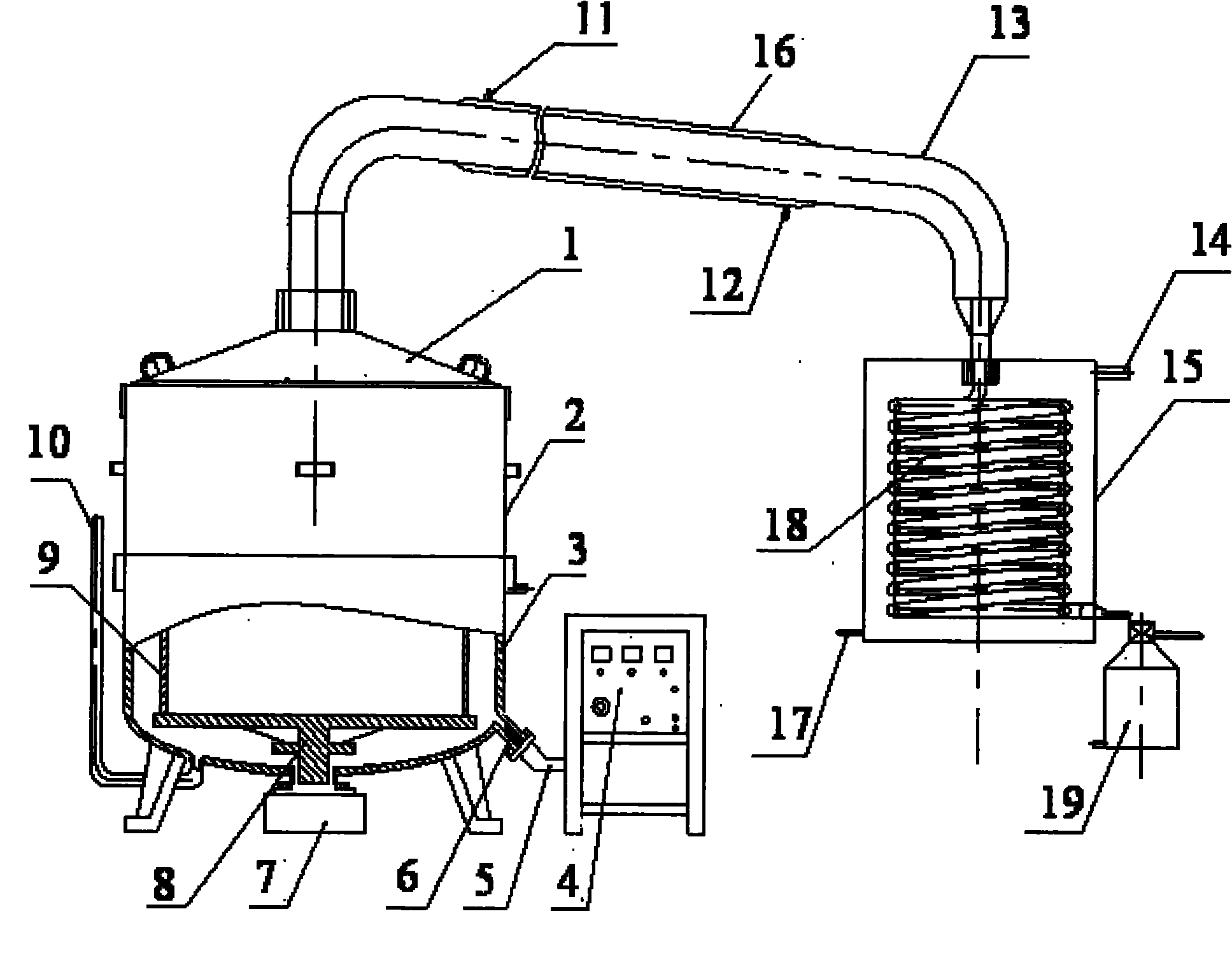

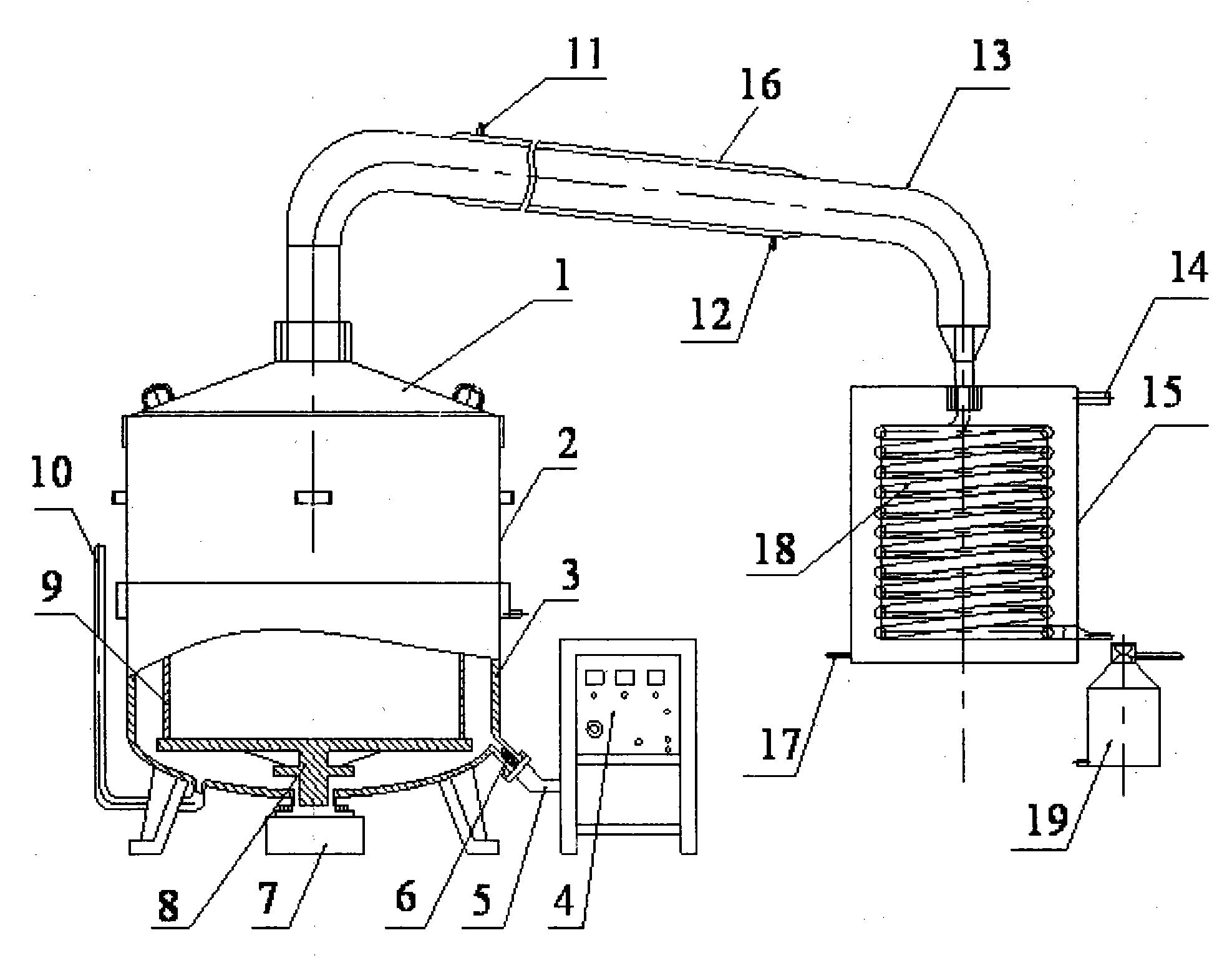

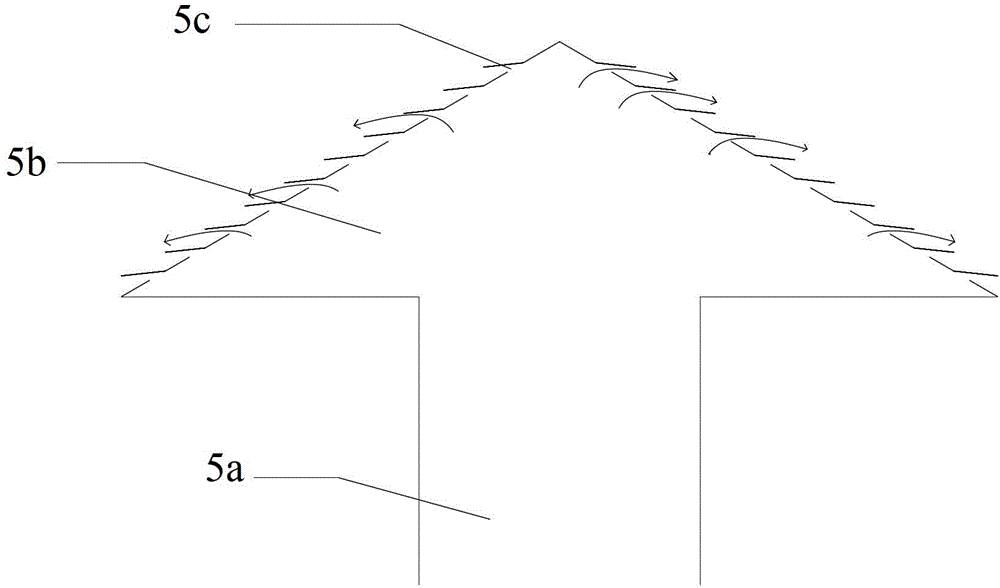

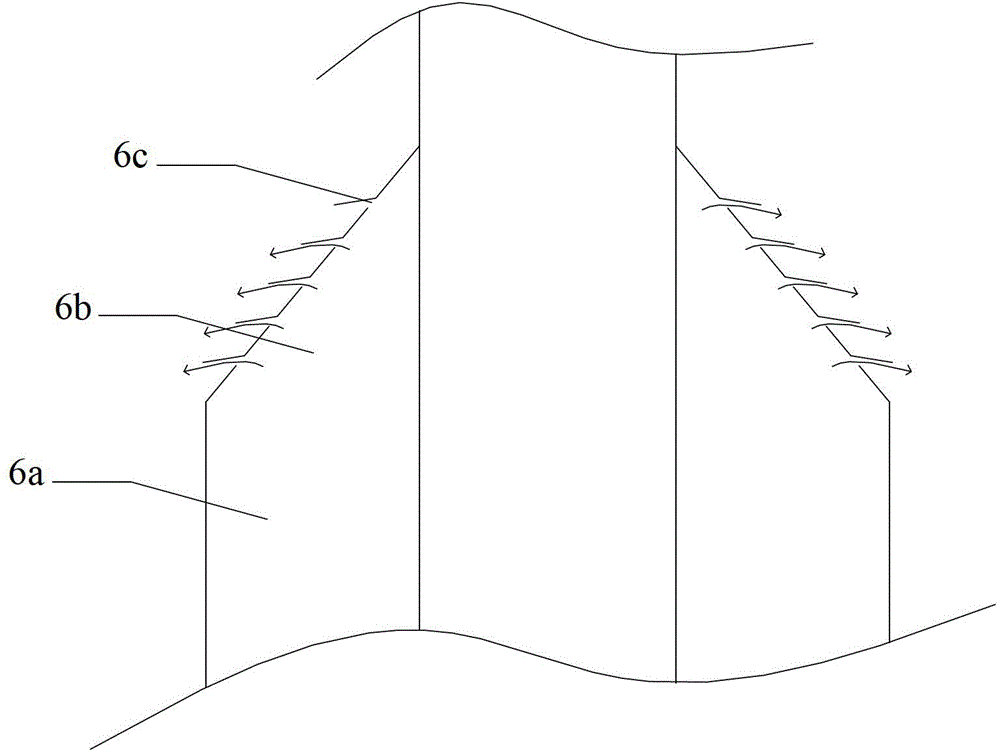

Linalool crude oil extraction device

InactiveCN101912762AImprove distillation oil extraction rateIncrease distillation rateOrganic compound preparationHydroxy compound preparationDistilled oilEngineering

The invention discloses a linalool crude oil extraction device. An upper pot body is in coaxially sealed connection with a lower pot body; a charging barrel is coaxially arranged in the lower pot body; the bottom end of the charging barrel is connected with a rotating device through a rotary tray; the lower end of the side wall of the lower pot body is connected with a steam pipe and a microwave waveguide tube respectively; the microwave waveguide tube is connected with a microwave power generator; the upper end of the upper pot body is connected with a pot lid; the top end of the pot lid is connected with one end of a condensing coil in a cooling tank through a cooling pipe; the other end of the condensing coil is connected with a crude oil gathering tank; a water outlet and a water inlet are reserved at the upper side end and lower side end of the cooling tank correspondingly and respectively; and the outer wall of the cooling pipe is connected with an annular cooling pipe. The device of the invention has the technical advantages of increasing the distilling oil extraction efficiency and the distilling speed of linalool crude oil, along with simple structure and convenient use.

Owner:NANCHANG UNIV

Method of extracting, distilling and separating sodium hydroxide in sodium aluminate solution in aluminum oxide producing process

InactiveCN1923694AIncrease productivityLower caustic ratioAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali metal oxides/hydroxidesDistilled oilAluminium hydroxide

The invention discloses a NaOH separating method from sodium aluminate solution through alumina based on aliphatic alcohol as extractant, which comprises the following steps: returning extracted liquid in the alumina manufacturing system; resolving seed; adopting resolving mother liquid or wash solution of aluminum hydroxide or water back extraction as extracting phase; returning water phase solution after back extraction in the alumina manufacturing system; distilling oil phase for extracting; circulating oil phase continuously.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Energy-saving environment-friendly fuel oil and preparation method thereof

InactiveCN104099141AHigh calorific valueImprove performanceLiquid carbonaceous fuelsOil and greaseEnvironmental resistance

The invention discloses energy-saving environment-friendly fuel oil and a preparation method thereof. The energy-saving environment-friendly fuel oil comprises the following components in parts by mass: 10-20 parts of biodiesel, 10-40 parts of coal oil, 20-40 parts of vegetable fat, 5-10 parts of microbial oil, 3-6 parts of vegetable oleic acid or ethanolamine, 10-25 parts of methanol and 10-40 parts of distilled oil, wherein the distilled oil is obtained by distilling used oil, and / or diesel oil and / or drainage oil. The fuel oil disclosed by the invention is high in heat value, stable in performance, clean in discharge, not easy to volatilize, non-toxic, smokeless and tasteless, and can fully meet ignition temperature requirements during use, waste oil can be reasonably treated, and the existing energy sources are saved.

Owner:DONGGUAN XIANGYANG CENTURY ENERGY

Composite fuel oil and preparation method thereof

InactiveCN105713682AHigh calorific valueImprove performanceLiquid carbonaceous fuelsOil and greaseMicrobial oil

The invention discloses composite fuel oil and a preparation method thereof. The composite fuel oil comprises components in parts by mass as follows: 5-15 parts of heavy oil, 10-40 parts of coal oil, 10-20 parts of coking light oil, 20-40 parts of vegetable oil, 5-10 parts of microbial oil, 3-6 parts of vegetable oleic acid or ethanolamine, 10-25 parts of methanol, 10-40 parts of distilled oil and 1-5 parts of additives, wherein the distilled oil is obtained from waste oil and / or diesel oil and / or illegal cooking oil through distillation, and the additives comprise a combustion improver, a dispersing agent and an anticorrosive agent. The composite fuel oil has the advantages of high heat value, stable performance and clean emission, is not prone to volatilization and is free of toxicity, smoke and odor, the requirement for ignition temperature in a use process can be met sufficiently, waste oil can be treated reasonably, and existing energy is saved.

Owner:NANJING LISHENG RECYCLE CO LTD

Hydrogenation of distilled oil

A process for hydrogenating fraction oil features that the raw fraction oil is directly contacted with hydrocatalyst at 330-400 deg.C, 3-8 MPa of hydrogen pressure and 0.5-2.0 / hr for reaction, and the resultant substance is cooled and separated to obtain diesel oil and less naphtha. Said hydrocatalyst is composed of active metal component chosen from VIII or VIB family and the alumina-zeolite mixture as carrier. Its advantages are high output rate, high hexodecane number and low density and sulfur content.

Owner:CHINA PETROLEUM & CHEM CORP +1

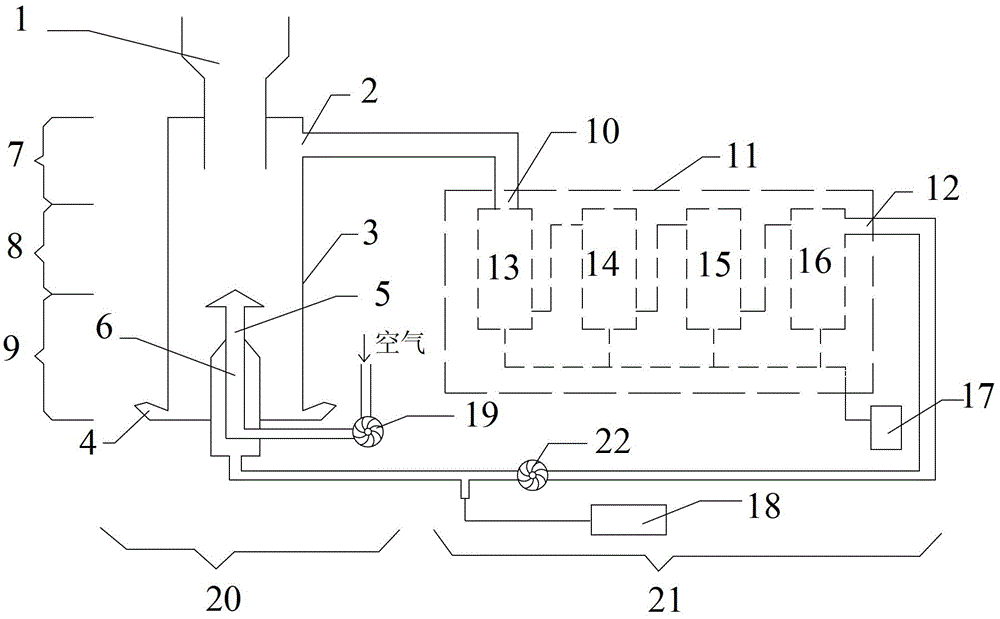

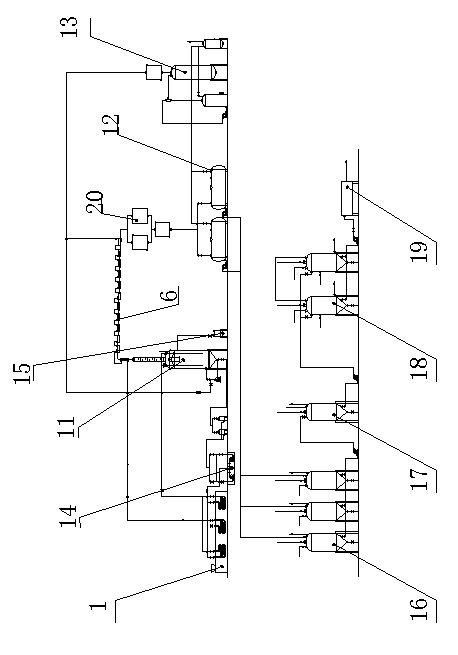

Oil shale dry distillation device and method

InactiveCN103146405ASimple structureImprove oil recoverySpecial form destructive distillationInlet channelDistilled oil

The invention relates to oil shale dry distillation device and method. The device comprises an internal combustion retort furnace, and an oil-gas separating device, wherein the internal combustion retort furnace is used for distilling oil shale particles; the oil-gas separating device is used for separating oil shale and gas in smoke generated after oil shale combustion; the internal combustion retort furnace comprises a feeding device, a smoke outlet, a furnace body, a slag discharge device, an air inlet channel and a gas inlet channel; the feeding device is arranged on the top of the internal combustion retort furnace; the smoke outlet is formed in the upper part of the internal combustion retort furnace; the slag discharge device is arranged at the bottom of the internal combustion retort furnace; and the air inlet channel and the gas inlet channel penetrate through the bottom of the internal combustion retort furnace. The oil shale dry distillation device is simple and reasonable in structure, high in oil yield, easy to industrially amplify, convenient to operate, low in production cost, and free of selectivity on grain size of the oil shale; and the oil shale of which the grain size is less than 120mm can be applied to the oil shale dry distillation device.

Owner:李伟

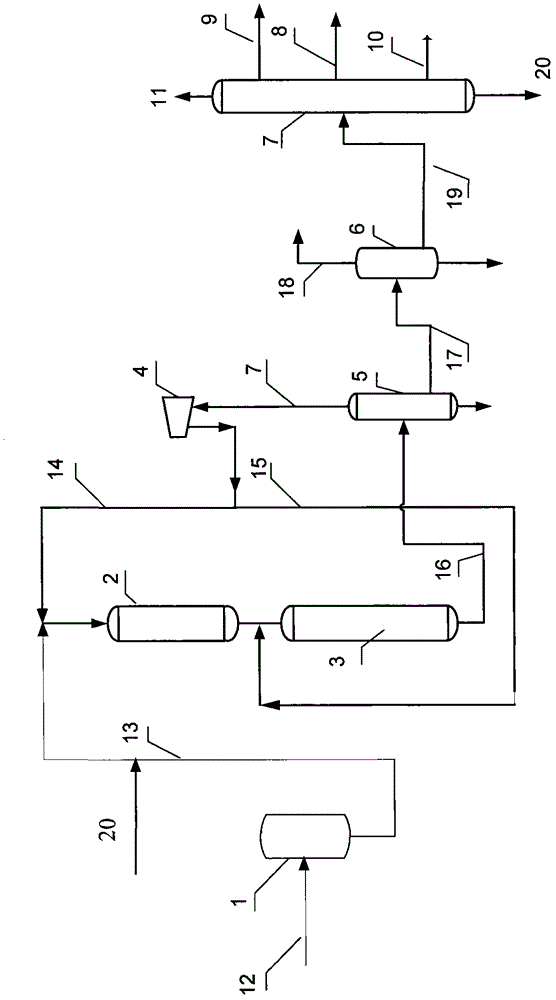

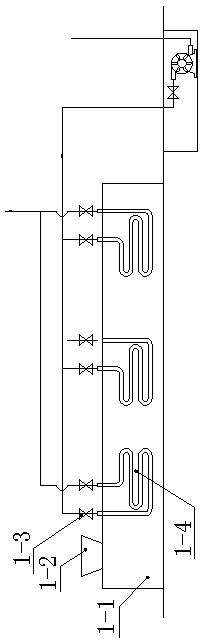

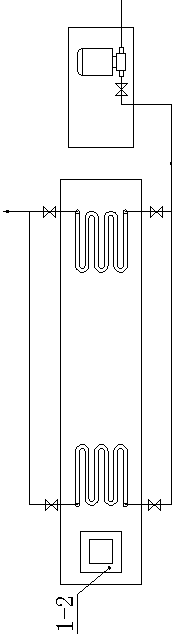

Tubular furnace and waste lubricating oil recovery device formed thereby

InactiveCN103343043AIncrease circulation spaceUniform heating rateLubricant compositionDistilled oilSlag

The invention discloses a tubular furnace and a waste lubricating oil recovery device. The tubular furnace comprises a furnace body which comprises a furnace head, a furnace body, a furnace tail, heating pipes and an exhaust device, wherein the heating pipes are transversely arranged in the furnace body in parallel and are connected with a control valve. The waste lubricating oil recovery device comprises the tubular furnace, wherein waste lubricating oil enters into the tubular furnace to be heated, and the heated oil enters into a distillation kettle to be divided into two parts, wherein one part of distilled oil enters into an oil storage tank and is acid-washed and alkali-washed, subjected to impurity removal by a white clay tank and filtered by a plate and frame filter to obtain light fuel oil. The other part is deslagged through a slag oil tank to obtain heavy fuel oil. The heating pipes of the tubular furnace are transversely arranged and the tubular furnace is connected with the distillation kettle through an oil pump. An overflow tank is connected to the distillation kettle. The heating pipes of the tubular furnace are transversely arranged, so that the furnace is not easy to coke. Compared with conventional single kettle production and vertical tubular furnace production, the fuel oil recovery device has the characteristics of anti-coking performance, large handling capacity and high oil yield.

Owner:SHANGQIU DONGHE SPECIAL EQUIP CO LTD

Production method of rubber filling oil excellent in stability

ActiveCN104560172AImprove stabilityFix stability issuesTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonDistilled oil

The invention relates to a production method of rubber filling oil excellent in stability. The production method comprises the following steps: sequentially charging decompression distilled oil of naphthenic crude oil and cycloalkane immediate crude oil, and light deasphalted oil into a hydro-treatment reaction area, a hydro-dewaxing reaction area and a hydro-refining reaction area; charging a hydro-refining product into an electromagnetic wave treatment area; removing a part of saturated polycyclic aromatic hydrocarbon under the irradiation of high-temperature electromagnetic wave; and charging a product which is obtained in the electromagnetic wave treatment area into a degumming unit to obtain a degummed fraction which is just the rubber filling oil product. The method disclosed by the invention has the advantages of improving the stability of the rubber filling oil without using noble metals for hydro-refining or adding additives, greatly simplifying the technological production procedures of the rubber filling oil and greatly reducing the device construction investment and the operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production process for producing biological diesel oil from vegetable oil

InactiveCN1928019AHigh puritySimple methodBiofuelsLiquid hydrocarbon mixture productionVegetable oilDistilled oil

The present invention provides process of producing biodiesel oil (fatty methyl ester) with vegetable oil fatty acid. The production process includes the following steps: 1. dewatering vegetable oil in a reaction tower at 80-120 deg.c and 0.3-0.5 KPa to obtain material oil with water content not more than 1.4 %; 2. heating the material oil at 320-340 deg.c in a heating furnace and distilling in a distilling tower at the temperature not lower than 310 deg.c for 1-2 hr; 3. fractioning the distilled oil and vapor in a rectifying tower and filtering the obtain biodiesel oil in a filtering tower; and 4. cooling the filtered biodiesel oil with cooling water at 30-50 deg.c to obtain biodiesel oil product. The production process has high conversion rate, less catalyst, less additives and other features.

Owner:孙文庆

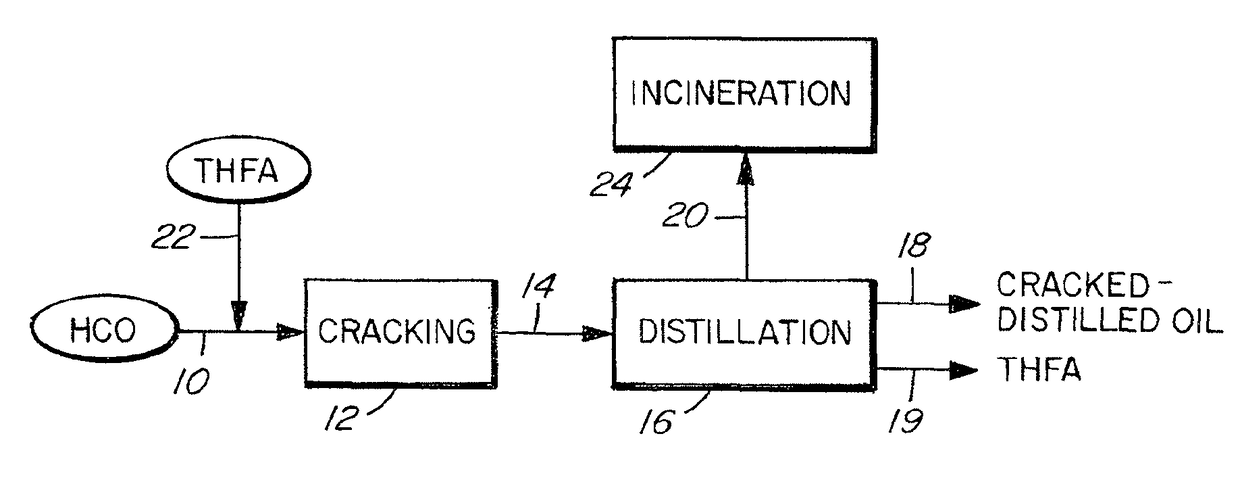

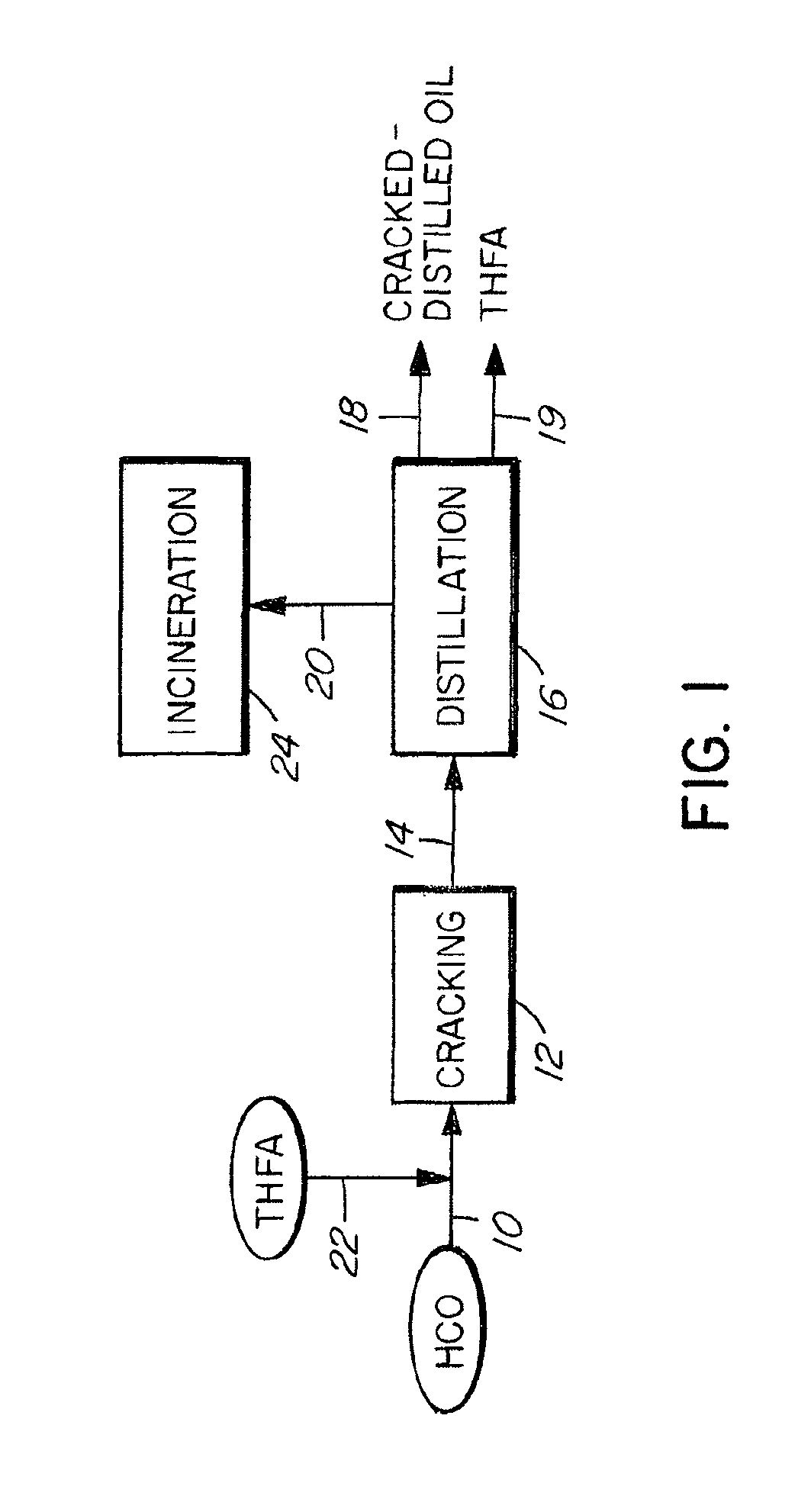

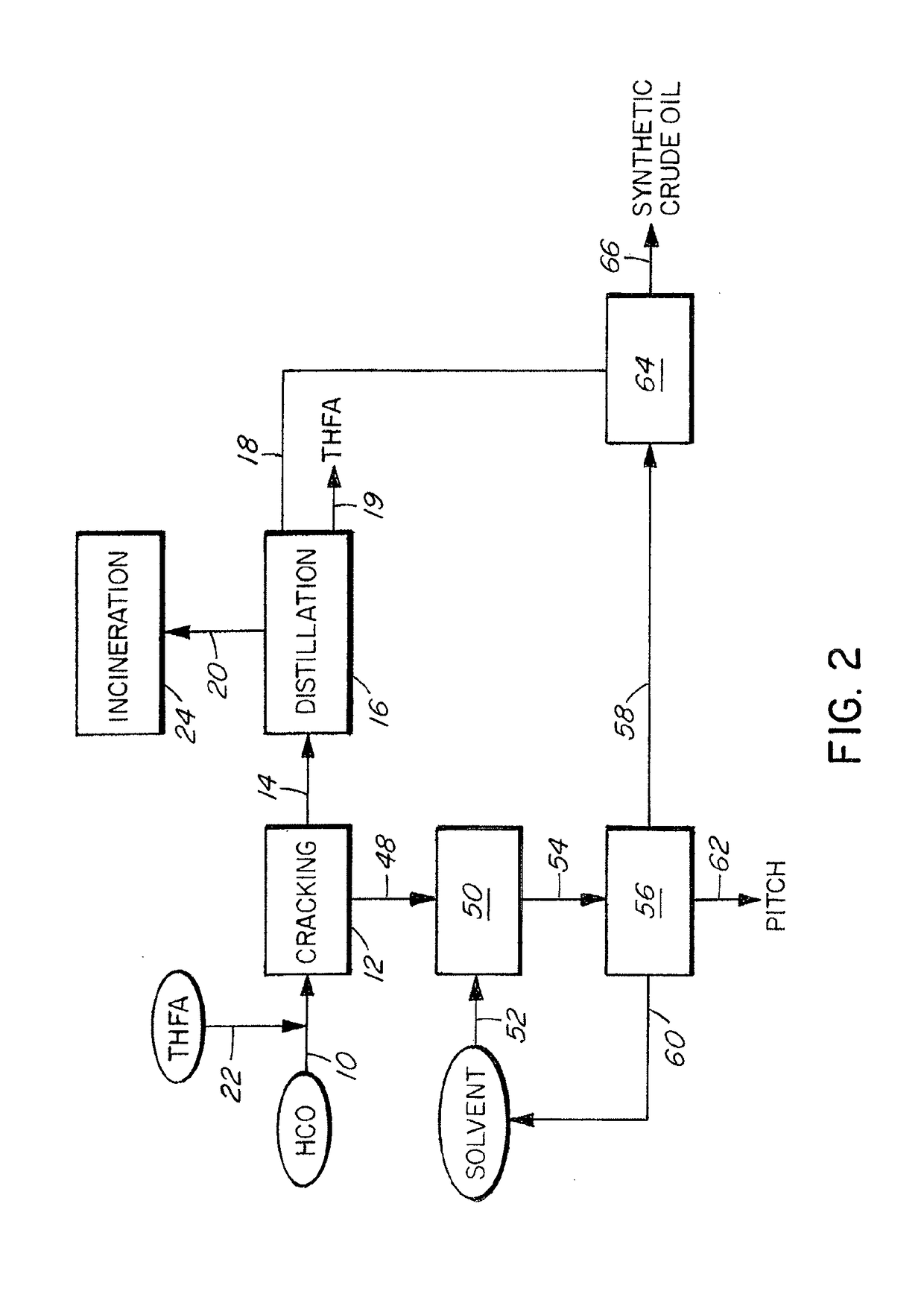

Method of upgrading heavy crude oil

ActiveUS9988584B2Prevent escapeThermal non-catalytic crackingHydrocarbon distillationAlcoholDistilled oil

Owner:CONSTABLE GEORGE ALEXANDER +1

Method and device for separating heavy aromatics from catalytic cracking oil slurry

InactiveCN104004540AHigh aromatic contentImprove product qualityTreatment with plural serial refining stagesTheoretical plateDistilled oil

The invention provides a method for separating heavy aromatics from catalytic cracking oil slurry. The method comprises the steps of a. carrying out reduced-pressure distilling on catalytic cracking oil slurry under the conditions of a temperature of 360-400 DEG C and a pressure of 1-3kPa and separating to obtain the distilled oil of which the temperature is 350-500 DEG C; and b. carrying out heavy aromatic extraction on the distilled oil at 60-110 DEG C by furfural with a weight ratio of furfural to distilled oil being (1-2.5) to 1 to obtain heavy aromatics and raffinate oil. The invention also provides a device for carrying out the method. The device comprises a vacuum tower and an extraction device, wherein the theoretical number of plates of the vacuum tower is 10-20 and the theoretical number of plates of the extraction device is 4-9.

Owner:嘉诚(福建)石油化工有限公司 +1

Method for coal tar hydrogenation for producing low solidifying point diesel oil

ActiveCN100558857CLittle impact on yieldIncreased yield impactLiquid hydrocarbon mixture productionTar working-up by distillationDistilled oilHydrogen

The invention relates to a method for producing diesel oil through hydrogenation modification, modification, isomerization and decondensation of coal tar. Separating coal tar into residual oil and distillate oil, using distillate oil as raw material, adopting a single-stage or series process flow, under suitable operating conditions, distillate oil raw material and hydrogen pass through the catalyst bed to obtain low freezing point diesel products And a small amount of naphtha products with low sulfur and nitrogen content. It is characterized in that the catalyst bed includes a hydrogenation treatment catalyst bed containing 0.5-<20wt% of zeolite beta. The key point of this technology is that it can directly provide high-quality diesel products with low freezing point and high cetane number, and at the same time provide a suitable technological route for the rational application of coal tar.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com