Patents

Literature

30results about How to "High crystal retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Y molecular sieve modification method

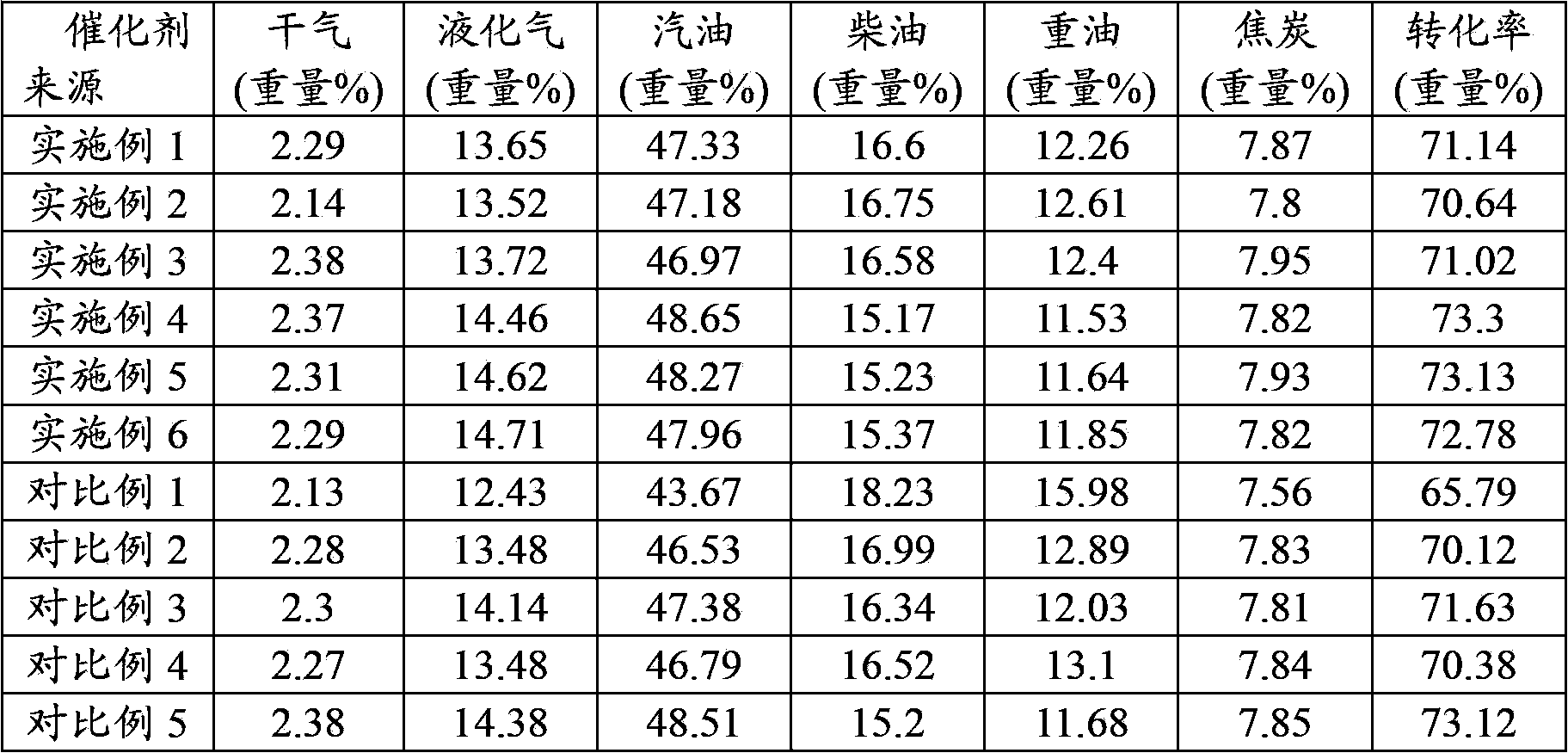

ActiveCN1803612ASmall cell constantHigh crystal retentionCatalyst carriersMolecular sieve catalystsMolecular sieveDistilled oil

The invention relates to a modifying method for Y molecular sieve, which comprises: using industrial NaY molecular sieve as material for ammonium exchange, baking deeply; then, adding surfactant during dealumination with acid. This invention obtains HY molecular sieve with high SiO2 / Al2O3(9~15) and crystallinity, improves secondary pores and acid structure compared with the industrial NaY, and fits to be carrier for hydrotreating catalyst for heavy distilled oil.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

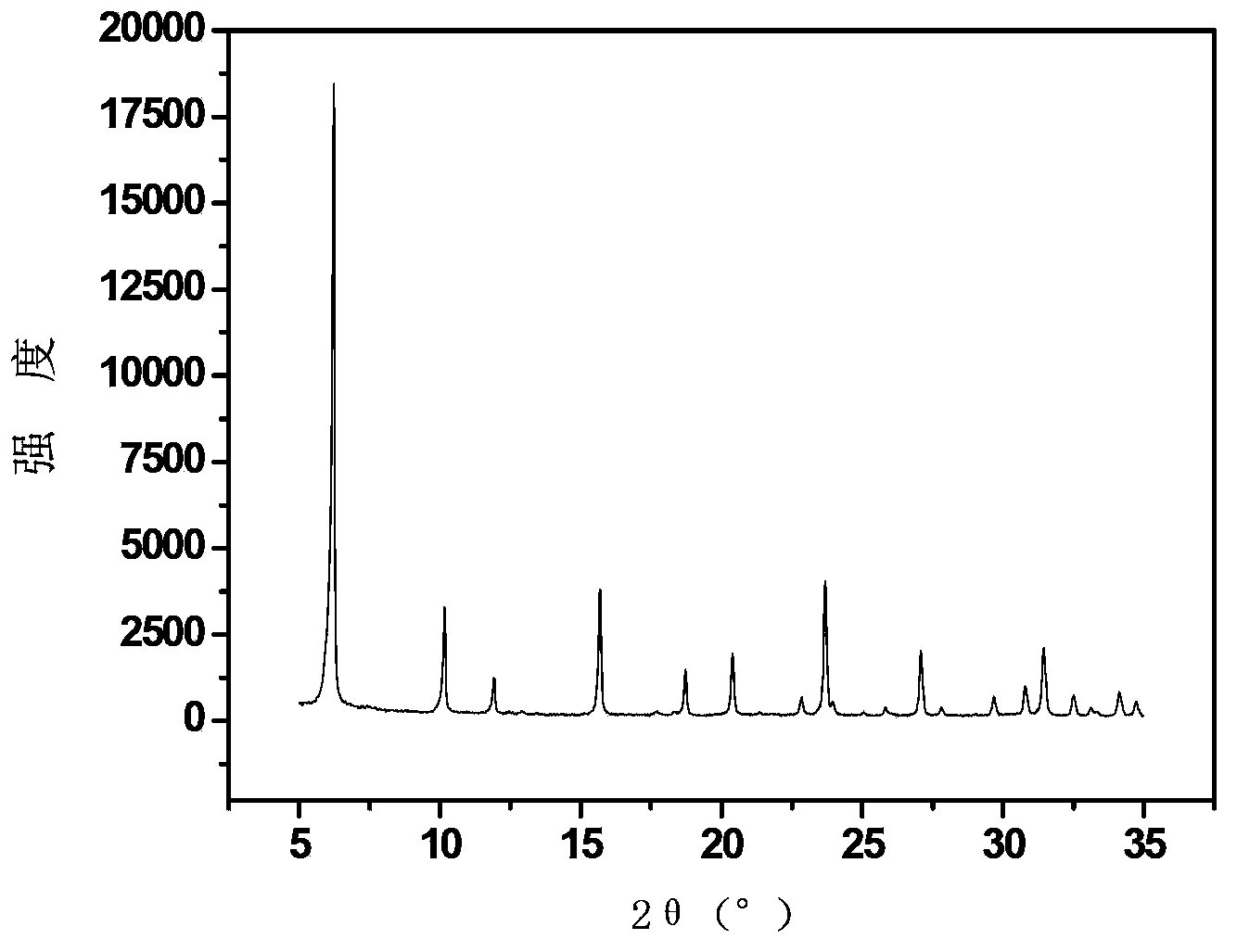

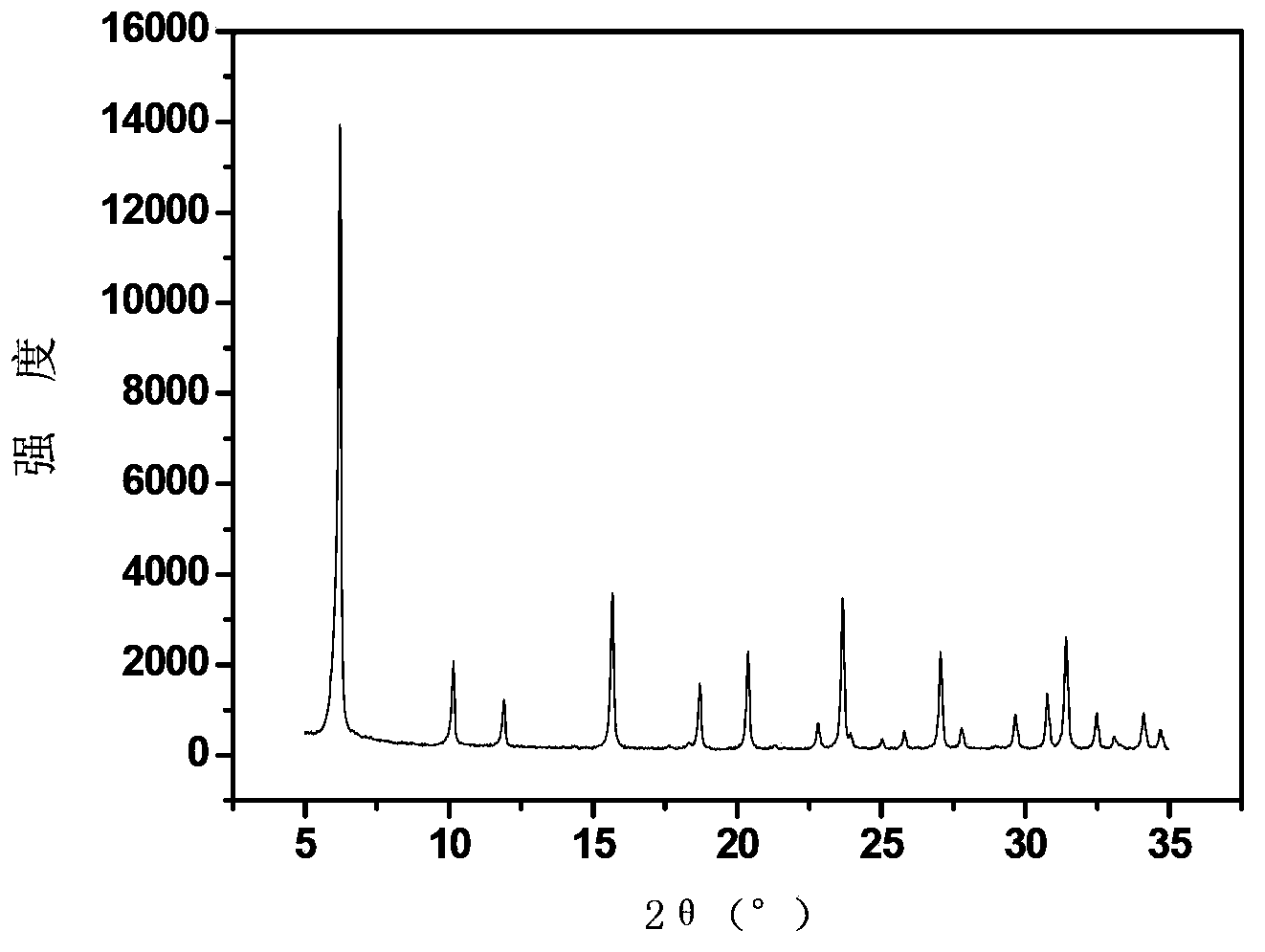

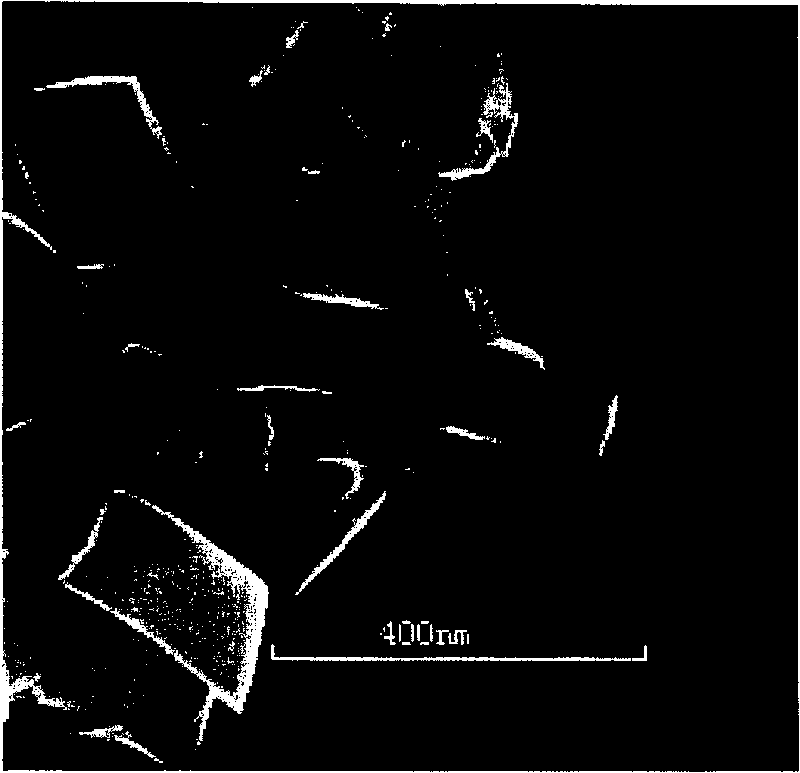

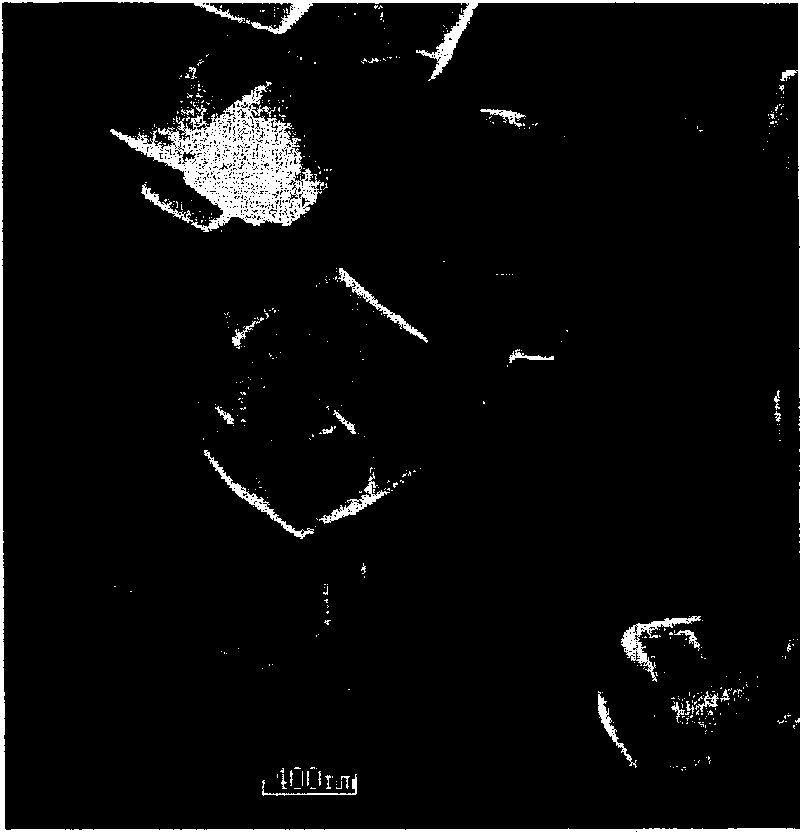

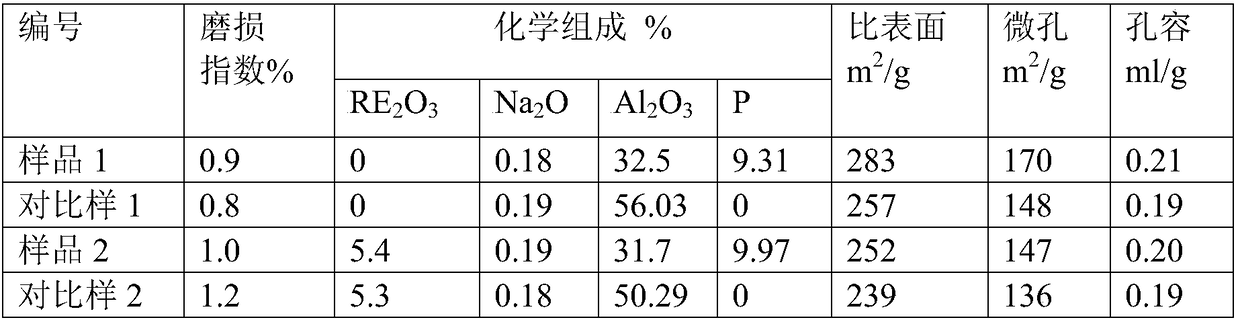

Small crystal grain Y-shaped molecular sieve and preparation method thereof

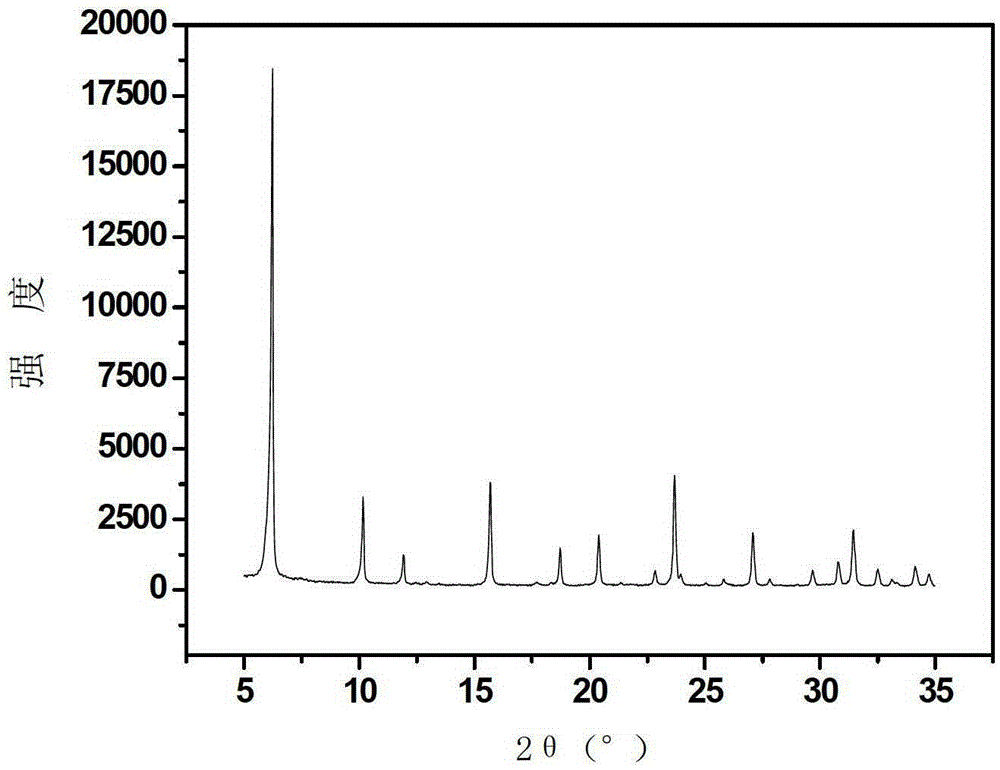

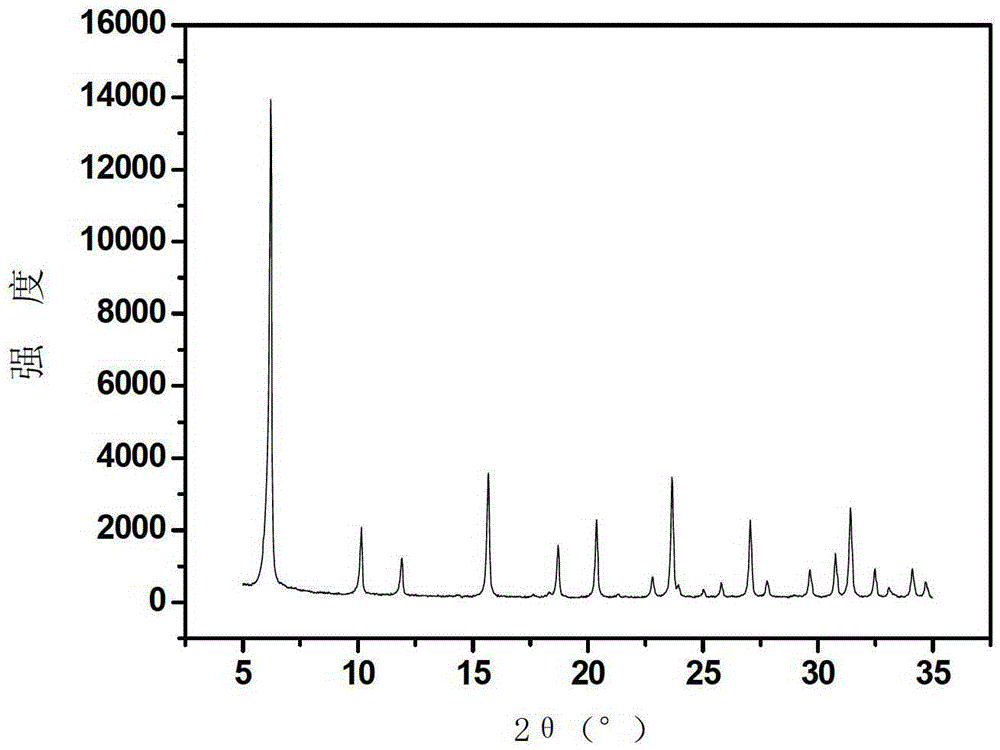

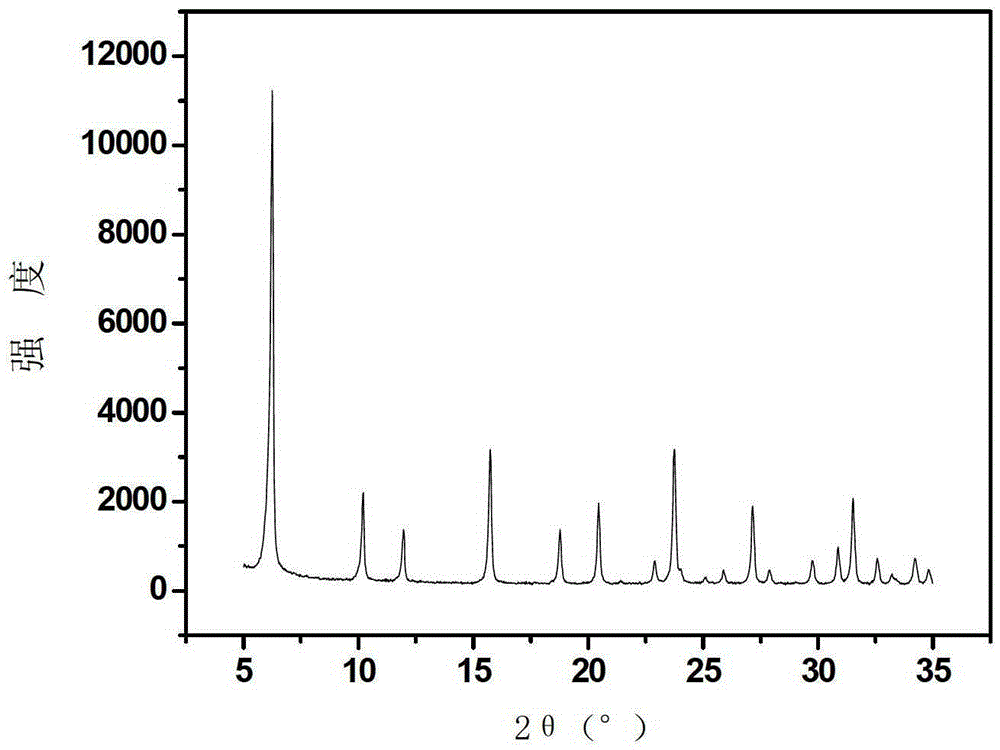

ActiveCN101723400AGuaranteed skeleton continuityReduce collapseFaujasite aluminosilicate zeoliteOxygenFluosilicates

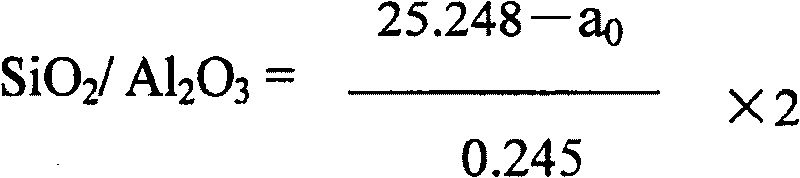

The invention discloses a small crystal grain Y-shaped molecular sieve and a preparation method thereof. The small crystal grain Y-shaped molecular sieve has the following properties that: the molar ratio of SiO2 / Al2O3 is 5.0-20.0; the average diameter of crystal grains is 100 to 700nm; the crystallization reservation degree is over 95 percent; and the weight percentage of sodium oxide is less than or equal to 0.1 percent. The small crystal grain Y-shaped molecular sieve takes a small crystal grain NaY molecular sieve with good thermal stability and hydrothermal stability as a raw material, has a high silicon-aluminum ratio, good stability and a uniform framework, namely a silicon-aluminum structure, can uniformly remove aluminum and supplement silica in an ammonium exchanging and ammonium fluosilicate dealuminizing and silica-supplementing process, guarantees the framework continuity of the molecular sieve product, decreases the probability of framework structure collapse, and furthest reserves the integrity of the product, namely the silicon-aluminum-oxygen structure so that the product has very high crystallization reservation degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

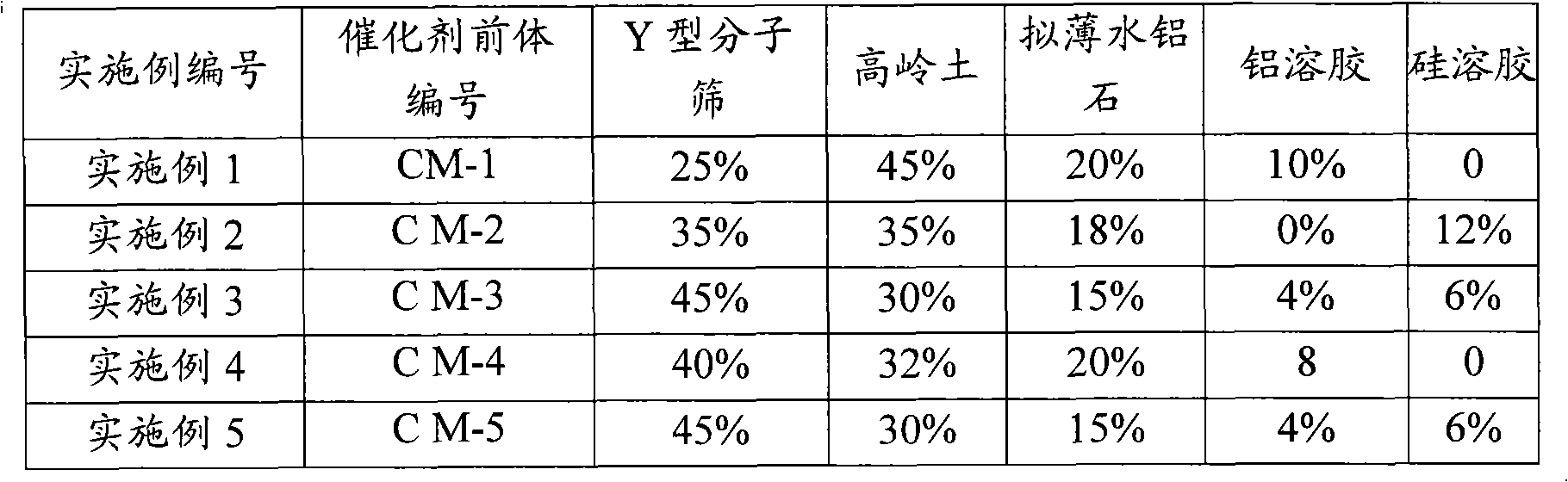

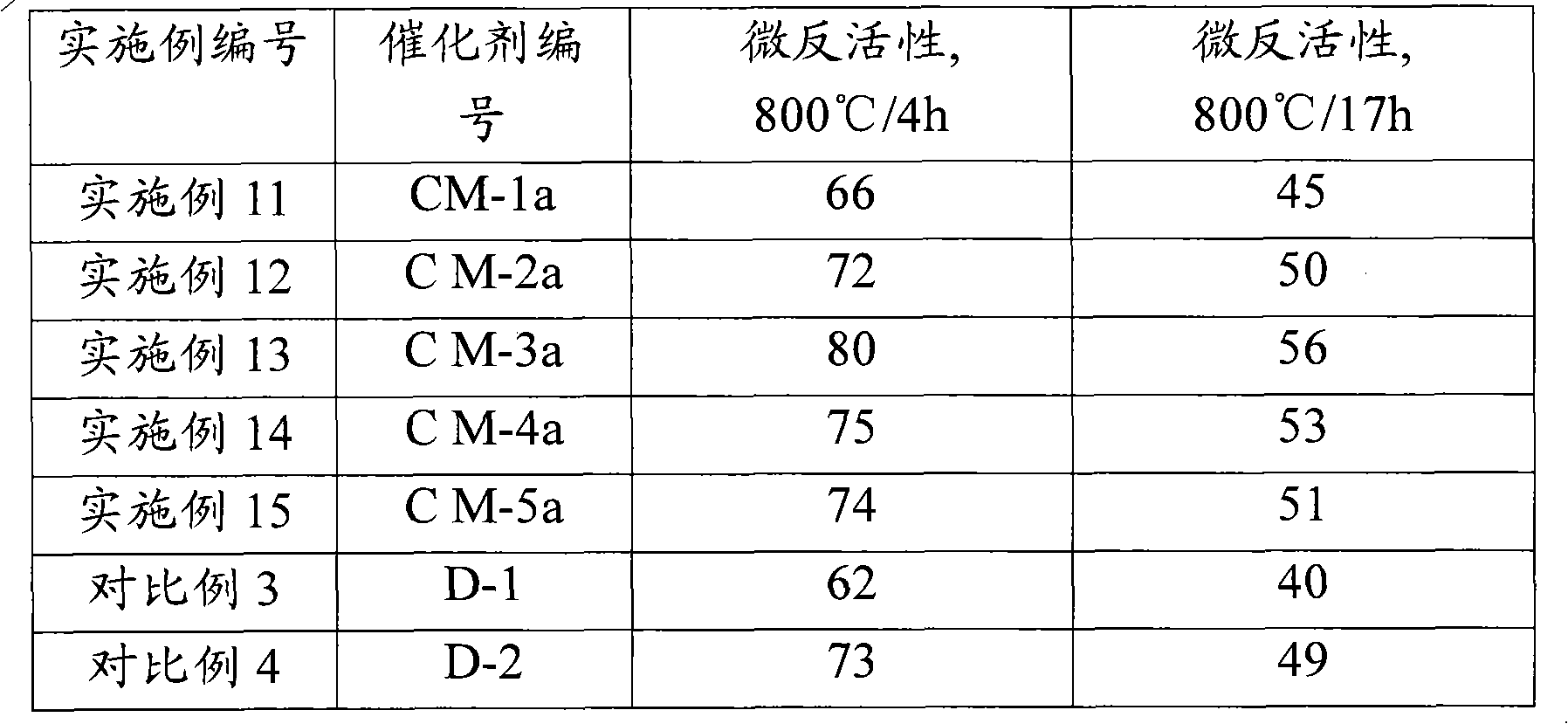

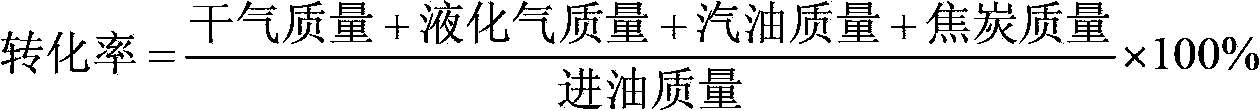

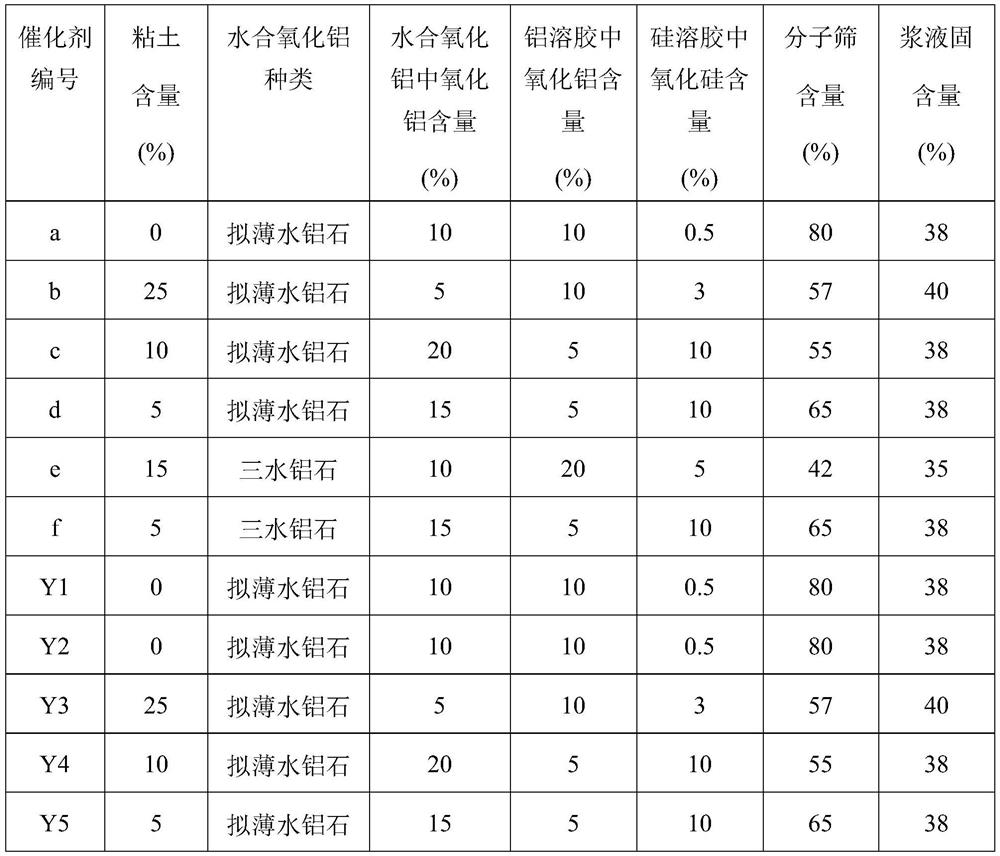

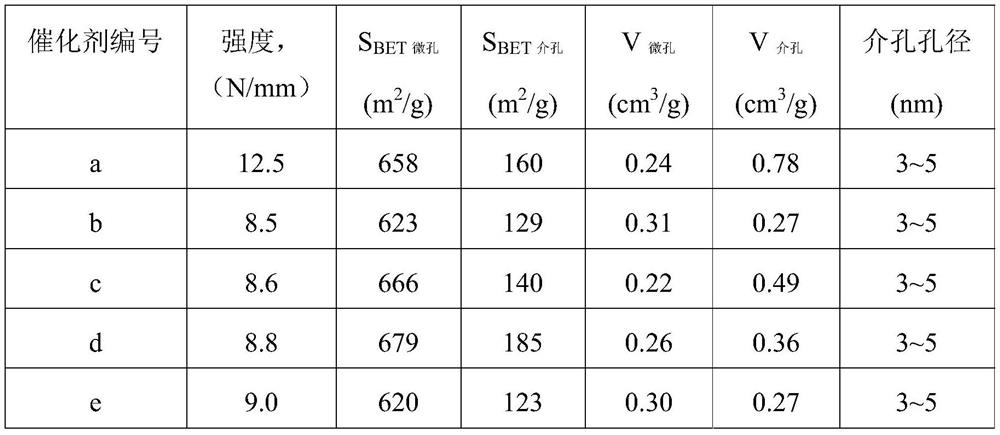

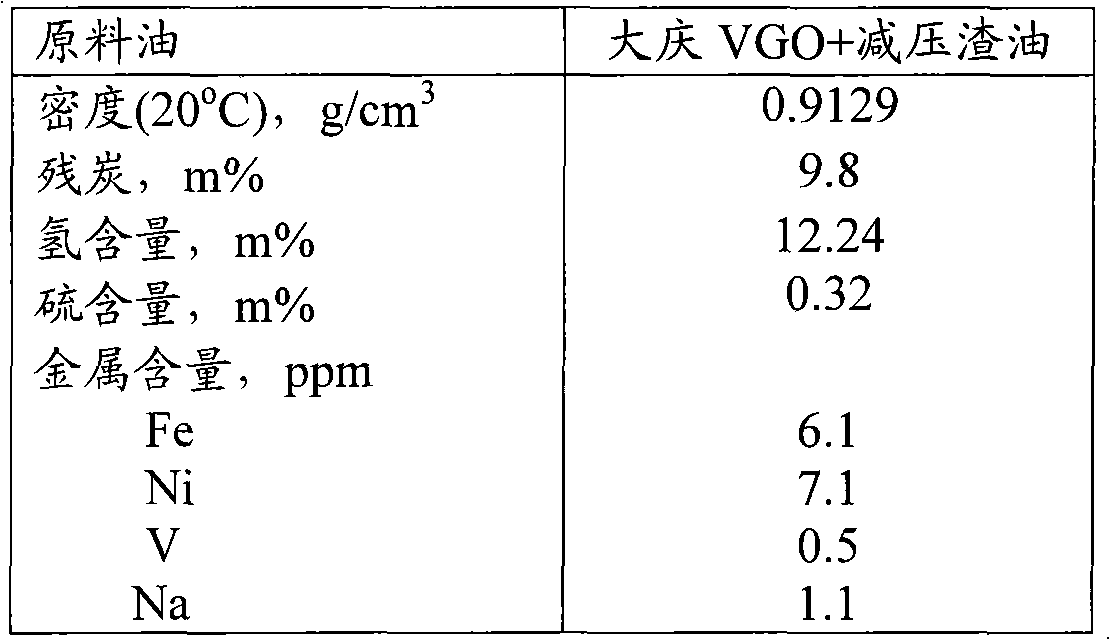

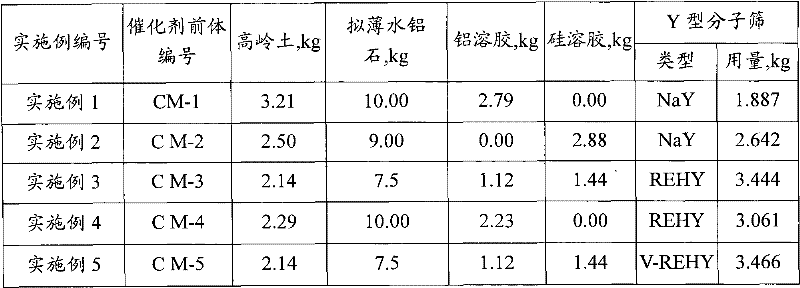

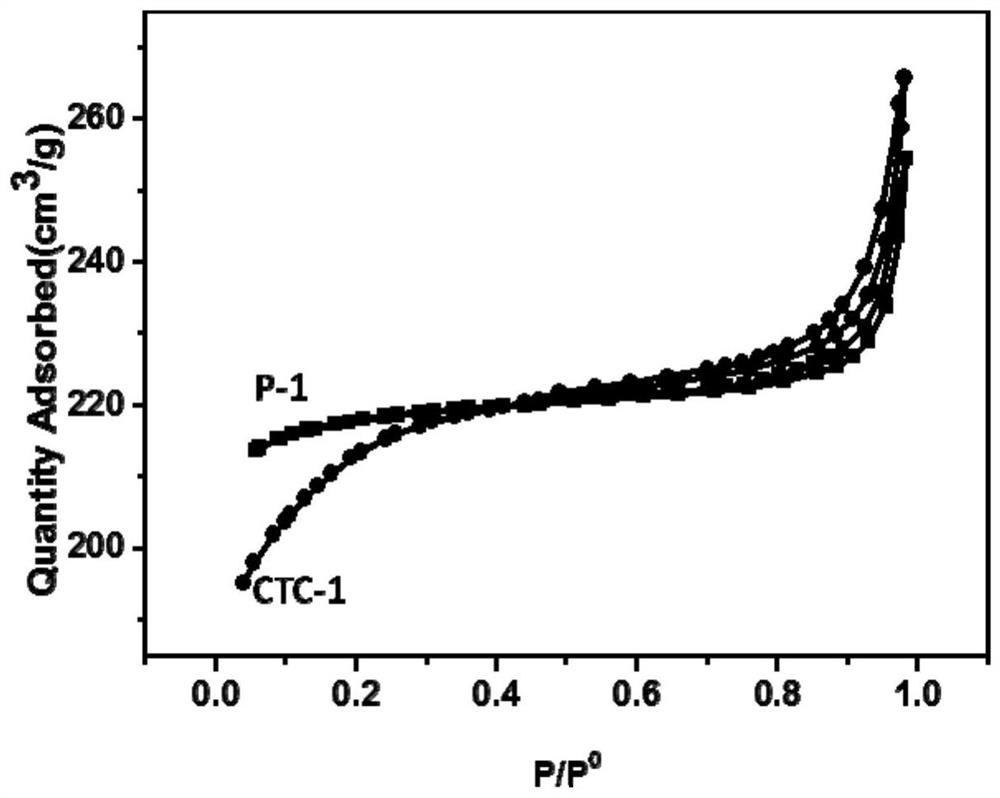

Cracking catalyst and preparation method thereof

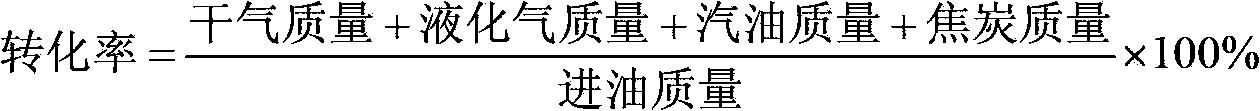

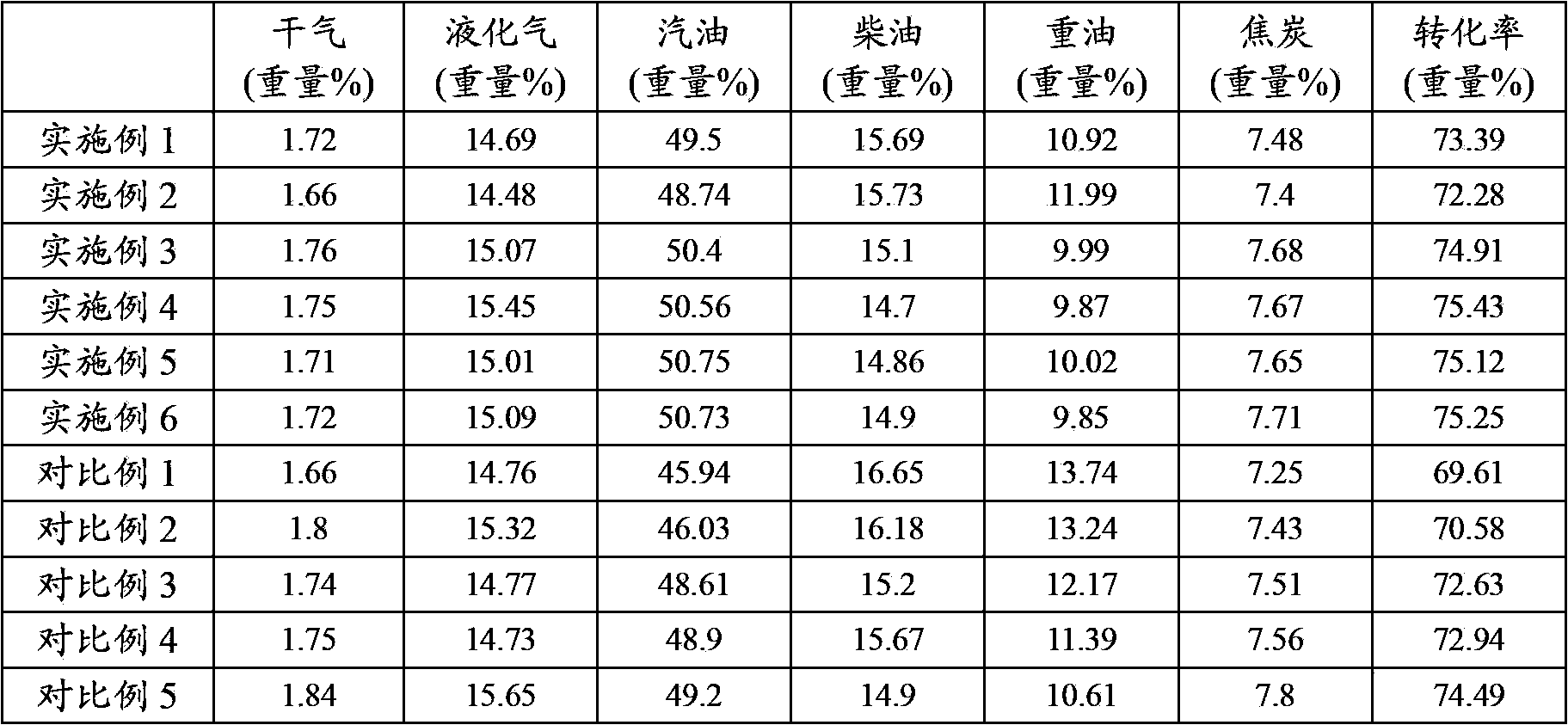

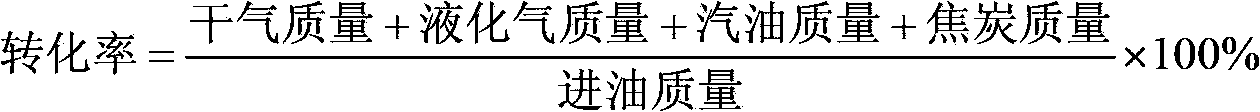

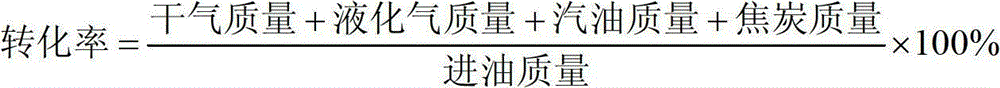

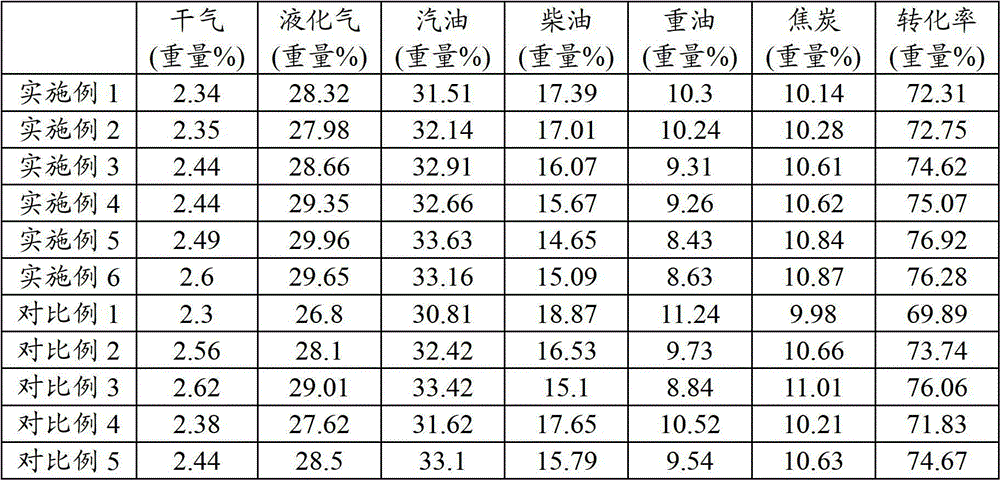

ActiveCN102029177AHigh ratio of silicon to aluminumHigh crystallinityCatalytic crackingMolecular sieve catalystsMolecular sieveSulfur

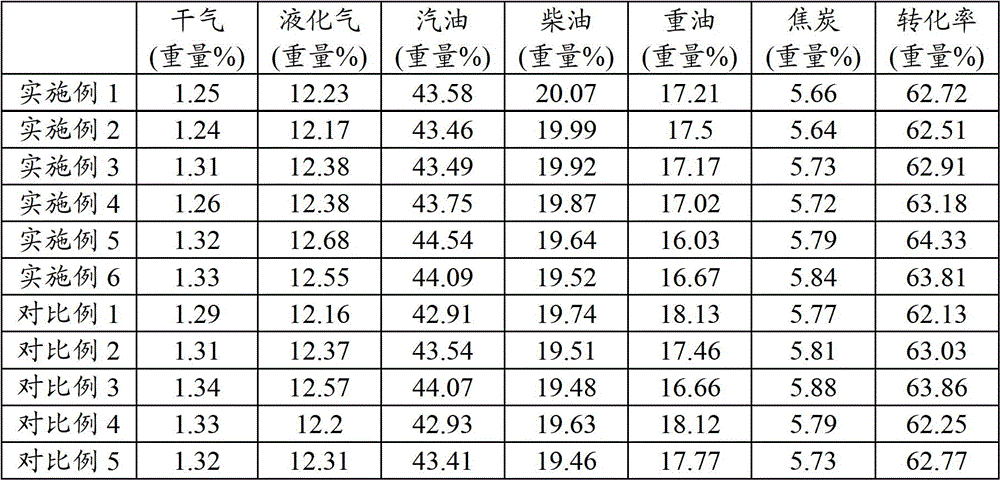

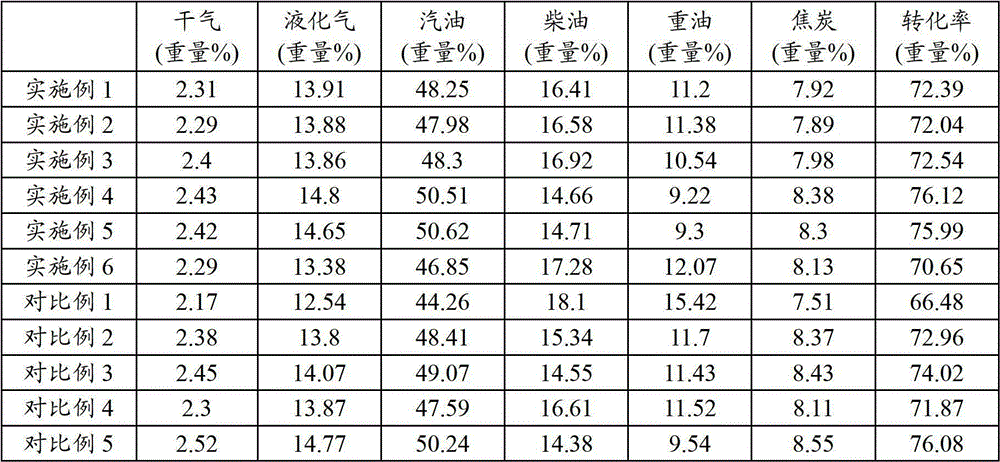

The invention relates to a preparation method of a cracking catalyst, which comprises: raw materials and water are mixed to prepare a slurry solution by utilizing the catalyst containing a Y type molecular sieve and a silicon vector; the slurry solution is dried to obtain a catalyst precursor; the catalyst precursor is baked; and a contact reaction is carried out on the catalyst precursor and an acidic ammonium salt solution. The preparation method of the cracking catalyst can enhance the crystallization retaining degree of the Y type molecular sieve in the catalyst and the stability of the catalyst. The catalyst prepared by utilizing the method is used for the catalytic cracking of heavy oil and has the advantages of strong conversion capability of the heavy oil, high yield of gasoline, and low sulphur content in the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthetic method for NaY zeolite with high silica-alumina ratio

ActiveCN104118885AHigh crystallinityMild preparation temperatureFaujasite aluminosilicate zeoliteHigh silicaSilicon

The invention provides a synthetic method for NaY zeolite with a high silica-alumina ratio. The method comprises the main steps: according to the proportioning requirement of a directing agent to uniformly mix a silicon source, an aluminium source and water, and ageing at 15 DEG C-60 DEG C for 0.5-120 h, so as to prepare the directing agent; according to the proportioning requirement of a gel reaction mixture to adding the directing agent and an alkaline solution into a silicone source at 10 DEG C-90 DEG C, stirring for 1 h-80 h, and stirring uniformly to obtain the gel reaction mixture; performing crystallization on the gel reaction mixture at 80-120 DEG C for 10-50 h, and then filtering, washing and drying to prepare NaY zeolite. The method does not employ a template, the preparation of the directing agent is mild in temperature, NaY zeolite with high crystallization degree and the high silica-alumina ratio is synthesized at a relatively short crystallization time. Also the method is capable of replacing conventional production technology without changing current apparatuses for industrial production, and has great important meaning on improving performances of catalytic cracking catalysts.

Owner:PETROCHINA CO LTD +1

Catalytic cracking catalyst and preparation method thereof

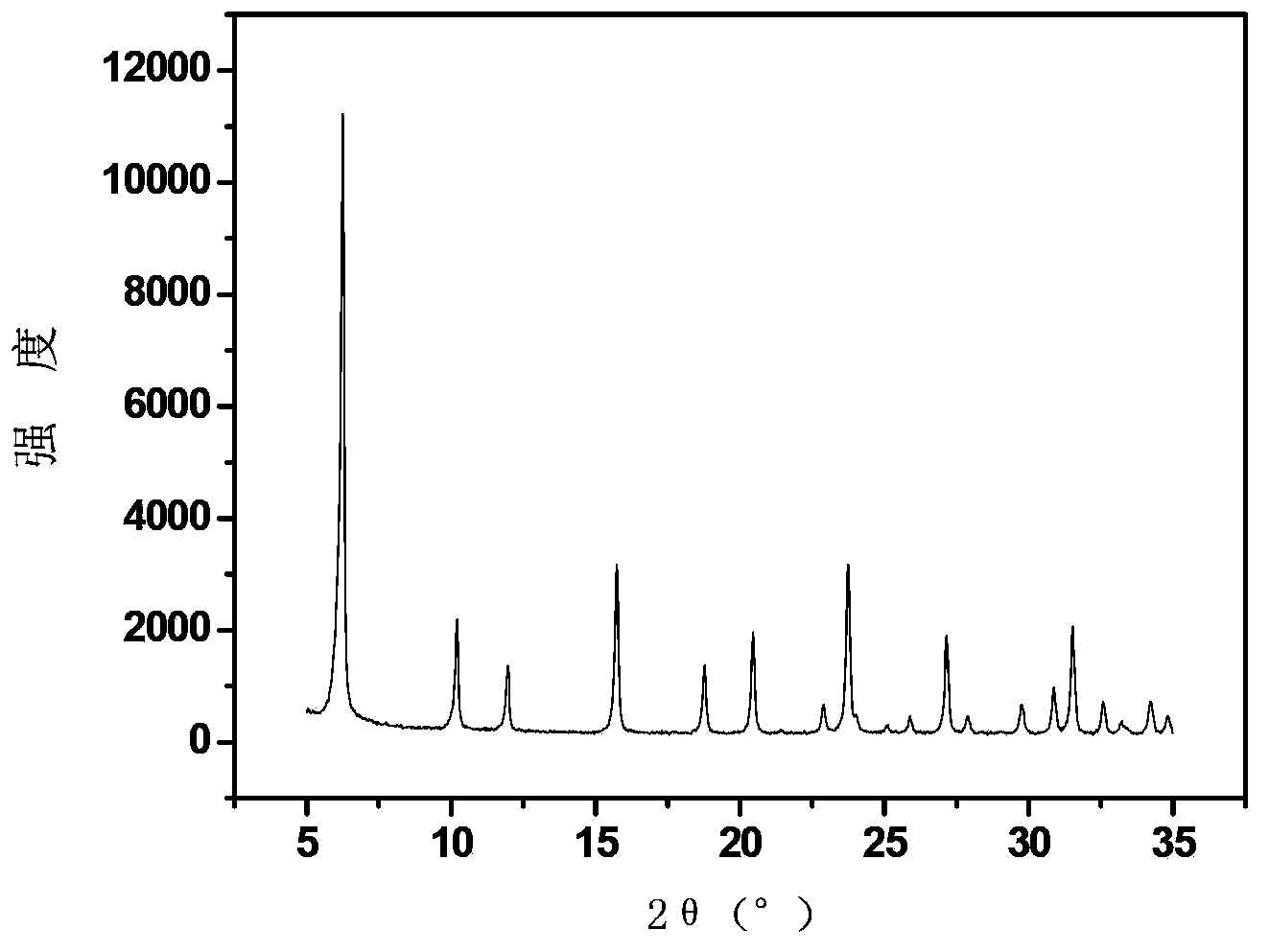

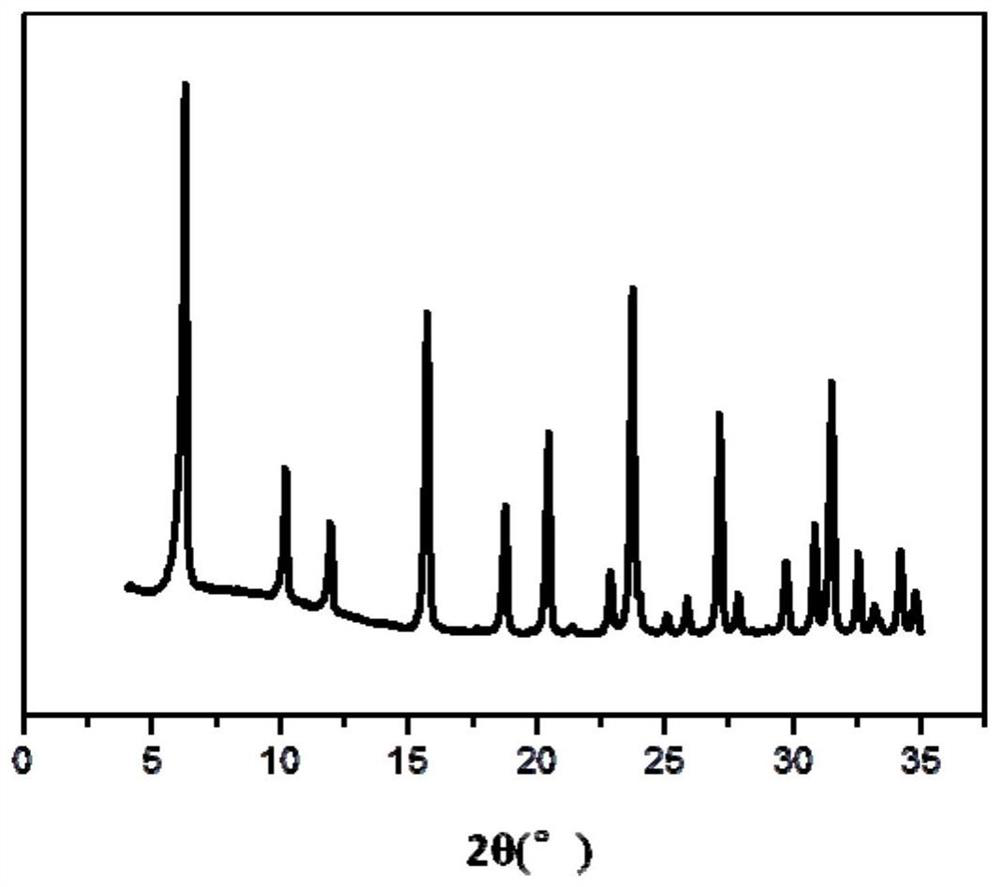

ActiveCN103657711AIncrease profitSave resourcesCatalytic crackingMolecular sieve catalystsAdhesiveGas phase

The invention relates to a catalytic cracking catalyst and a preparation method. The catalytic cracking catalyst contains a cracking activity component, clay and an adhesive, wherein the cracking activity component a first Y-type molecular sieve, a second Y-type molecular sieve and a third Y-type molecular sieve; the first Y-type molecular sieve is a rare-earth Y-type molecular sieve, the rare-earth content in the first Y-type molecular sieve is 10-25 wt% on the basis of rare-earth oxides, the cell constant is 2.440-2.472nm, the crystallinity is 35-65%, the silicon / aluminum atomic ratio in the framework is 2.5-5.0, and the product of the ratio (I1 / I2) of 2theta=11.8+ / -0.1 degree peak intensity I1 to 2theta=12.3+ / -0.1 degree peak intensity I2 in an X-ray diffraction pattern and the rare-earth weight percent in the molecular sieve on the basis of rare-earth oxides is greater than 50; the second Y-type molecular sieve is a rare-earth-containing gas-phase overstable Y-type molecular sieve; and the third Y-type molecular sieve is a rare-earth-containing DASY molecular sieve. The preparation method comprises the following steps: preparing a slurry containing the cracking activity component, adhesive and clay, and carrying out spray drying. The catalyst has higher conversion rate and gasoline yield, and can reduce the consumption of the molecular sieves, thereby lowering the cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN103657702AIncrease profitSave resourcesCatalytic crackingMolecular sieve catalystsAdhesiveX-ray

The invention relates to a catalytic cracking catalyst and a preparation method. The catalytic cracking catalyst contains a cracking activity component, a mesoporous silicon-aluminum material, clay and an adhesive, wherein the cracking activity component comprises a rare-earth Y-type molecular sieve; and the rare-earth content in the Y-type molecular sieve is 10-25 wt% on the basis of rare-earth oxides, the cell constant is 2.440-2.472nm, the crystallinity is 35-65%, the silicon / aluminum atomic ratio in the framework is 2.5-5.0, and the product of the ratio (I1 / I2) of 2theta=11.8+ / -0.1 degree peak intensity I1 to 2theta=12.3+ / -0.1 degree peak intensity I2 in an X-ray diffraction pattern and the rare-earth weight percent in the molecular sieve on the basis of rare-earth oxides is greater than 50. The preparation method comprises the following steps: preparing a mixed slurry containing the cracking activity component, mesoporous silicon-aluminum material, adhesive and clay, and carrying out spray drying. Compared with the prior art, the rare-earth-containing Y-type molecular sieve is matched with the mesoporous silicon-aluminum material, so that the catalyst has higher thermal and hydrothermal stability and higher heavy oil cracking capacity, and can reduce the consumption of the molecular sieves in the catalyst, thereby lowering the catalyst production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

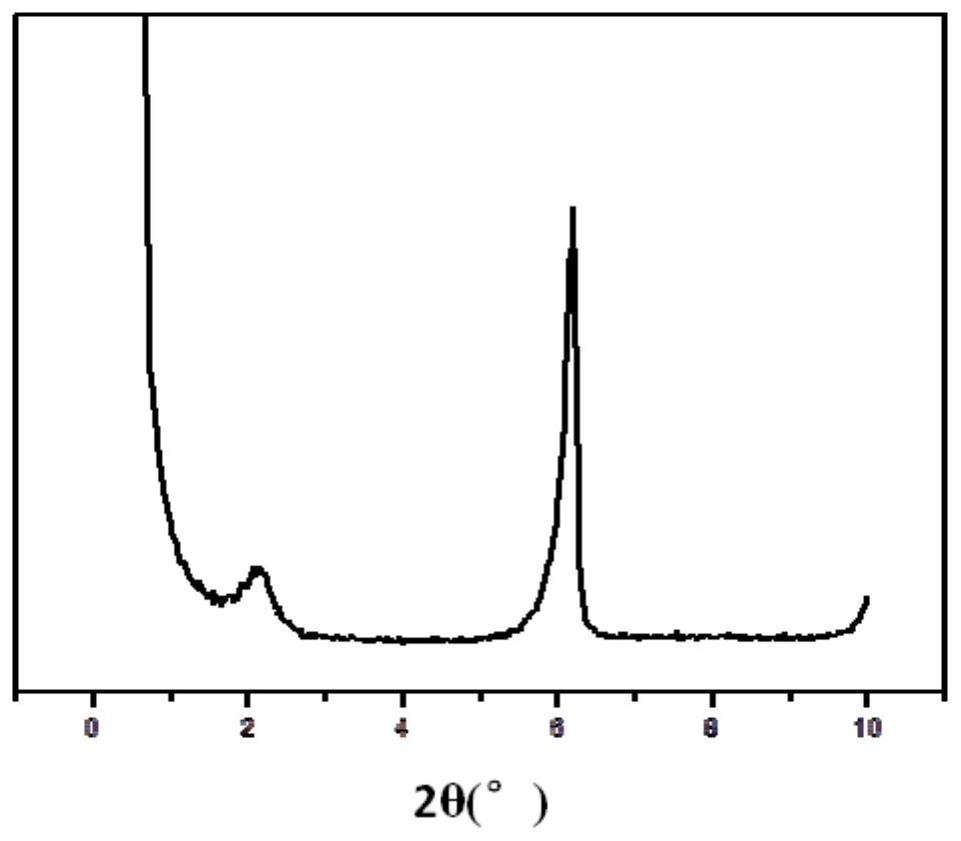

Modified Y molecular sieve having regular mesopore-micropore, and preparation method thereof

ActiveCN109665539AOvercome the disadvantage of not easy to separateImprove connectivityFaujasite aluminosilicate zeoliteMolecular sieveSieve

The present invention relates to a modified Y molecular sieve having regular mesopore-micropore, and a preparation method thereof, wherein the molar ratio of the skeleton SiO2 / Al2O3 of the modified Ymolecular sieve is 5.0-6.0, the specific surface area of the mircopore is 400-600 m<2> / g, the pore volume of the micropore is 0.25-0.35 cm<3> / g, the specific surface area of the mesopore is 30-200 m<2> / g, the pore volume of the mesopore is 0.07-0.85 cm<3> / g, the pore size of the mesopore is 2.0-6.0 nm, and based on the total weight of the modified Y molecular sieve, the sodium oxide content in themodified Y molecular sieve is not more than 0.1 wt%. According to the present invention, the mesopore is introduced while the micropore of the Y molecular sieve is retained, and the mesopore and themicropore have connectivity so as to easily achieve the macromolecule diffusion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst carrier and preparation method thereof

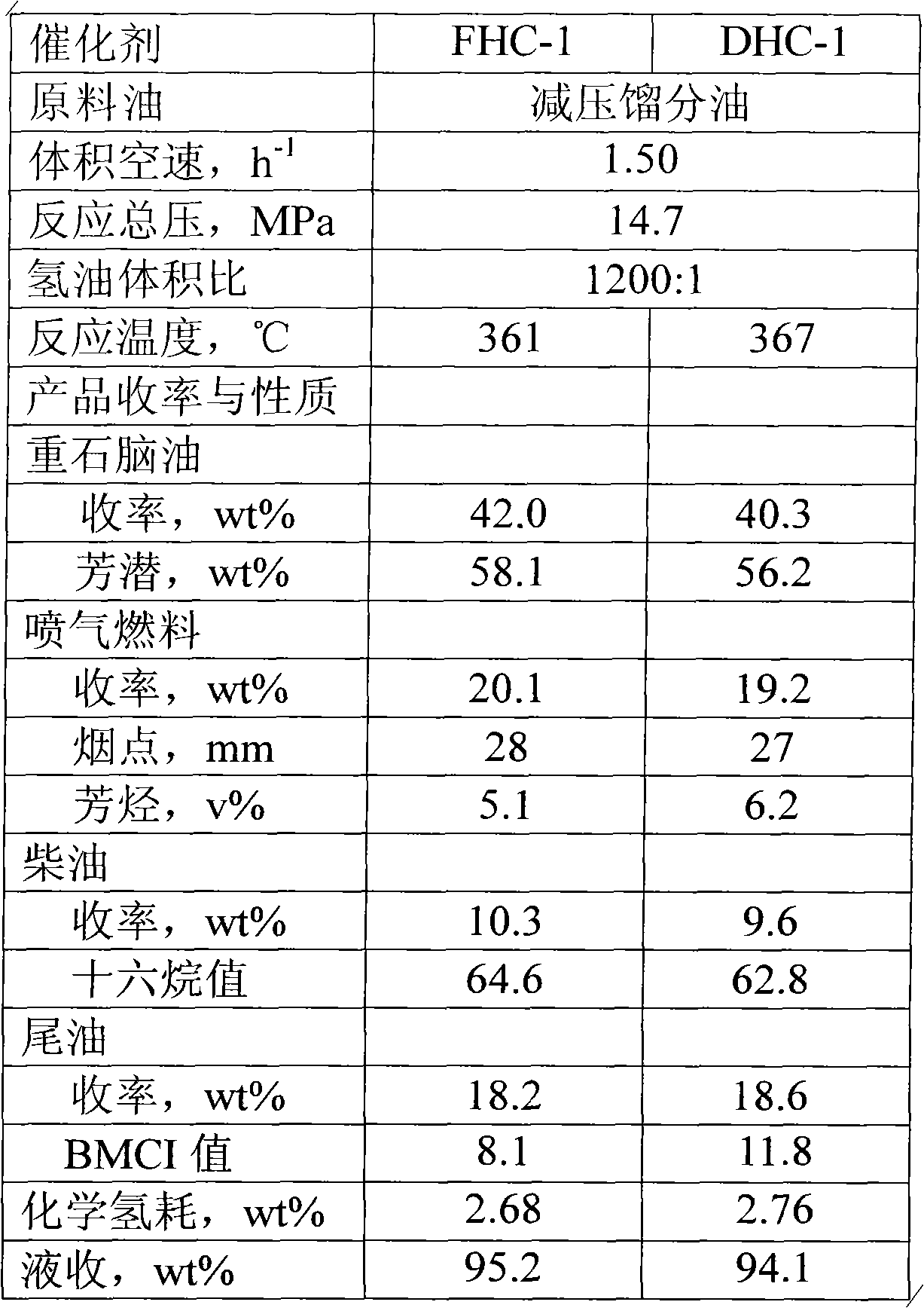

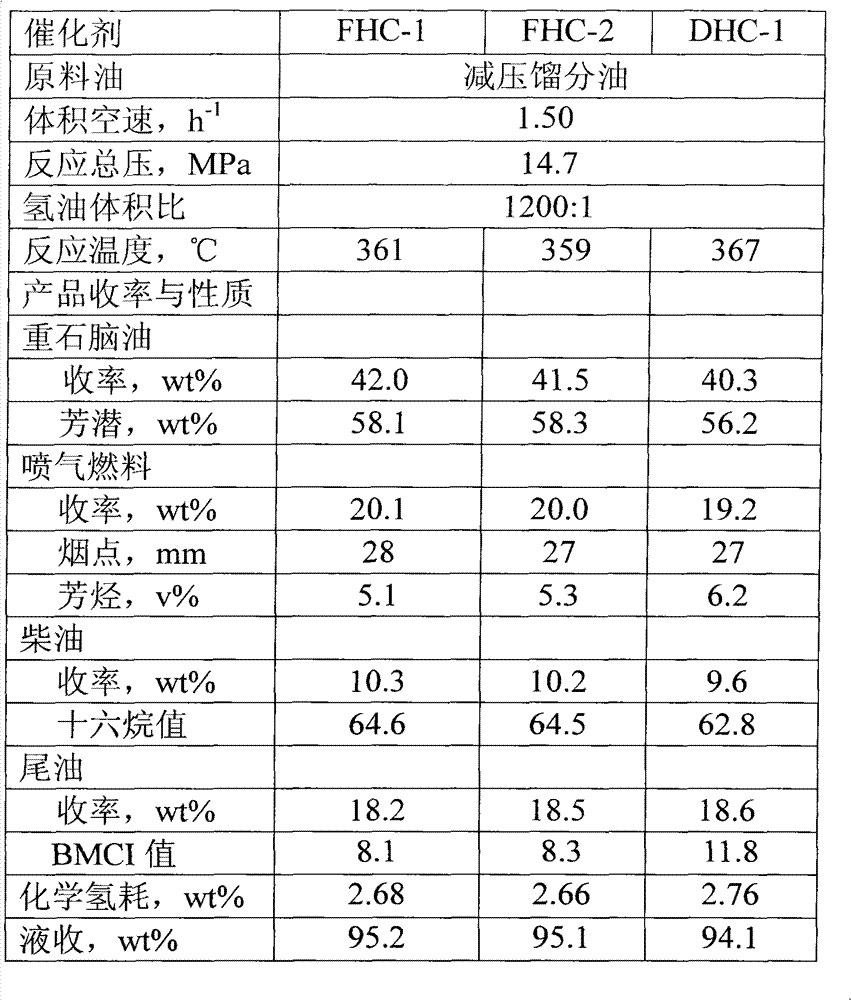

ActiveCN102049307AHigh crystallinityPreserve integrityCatalyst carriersMolecular sieve catalystsMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The carrier consists of a small crystal particle Y-shaped molecular sieve and alumina, wherein the small crystal particle Y-shaped molecular sieve has high crystallinity, high ratio of silicate to aluminium, continuous and stable framework structure and smooth pores. A hydrocracking catalyst prepared from the carrier has the characteristics of high catalytic activity, high heavy naphtha selectivity, high potential aromatic hydrocarbon content, low bureau of mines correlation index (BMCI) value of hydrocracking tail oil and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

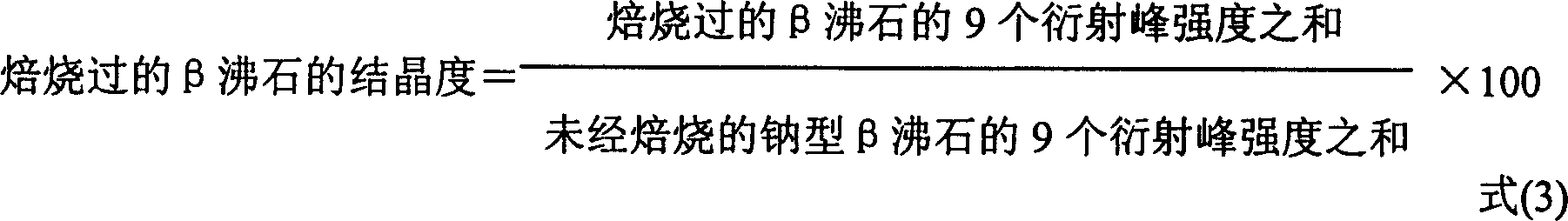

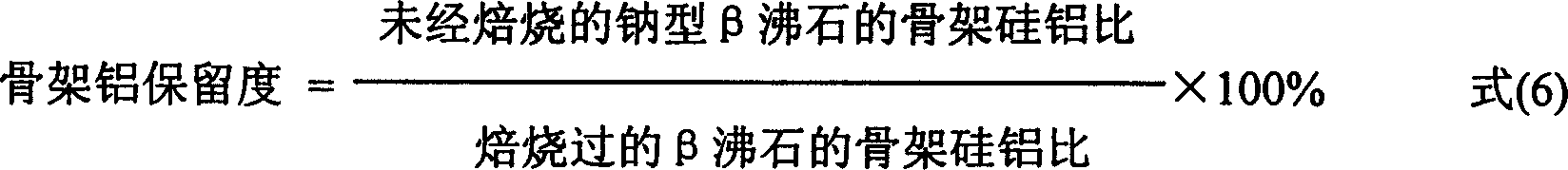

Method for removing organic amine from beta-zoolite

InactiveCN1443710AHigh crystal retentionReduce heatCrystalline aluminosilicate zeolitesAir atmosphereChemistry

The present invention relates to a method for removing organic amine from beta-zeolite. It is aimed at mainly resolving the problems of previous techniques which are complex in operation and unsafe of whose zeolite skeleton aluminium is easy to lose. Said invention utilzies the adoption of direct four-stage roasting technical scheme in the air atmosphere so as to better resolve the above-mentioned problems. Said four-stage roasting process is as follows: first stage, roasting for 0.5-4.0 hr. at 110-180 deg.C; second stage, roasting for 1.0-6.0 hr. at 230-300 deg.C; third stage, roasting for 0.5-6.0 hr at 360-430 deg.C and fourth stage, roasting for 2.0-10.0 hr. at 530-580 deg.C.

Owner:CHINA PETROLEUM & CHEM CORP +1

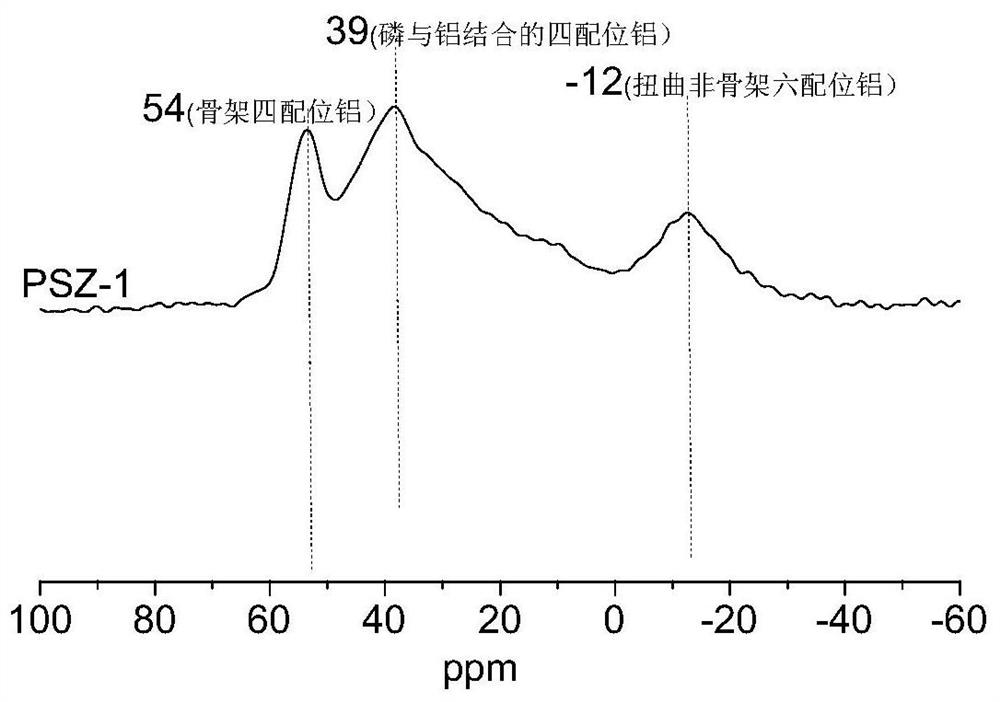

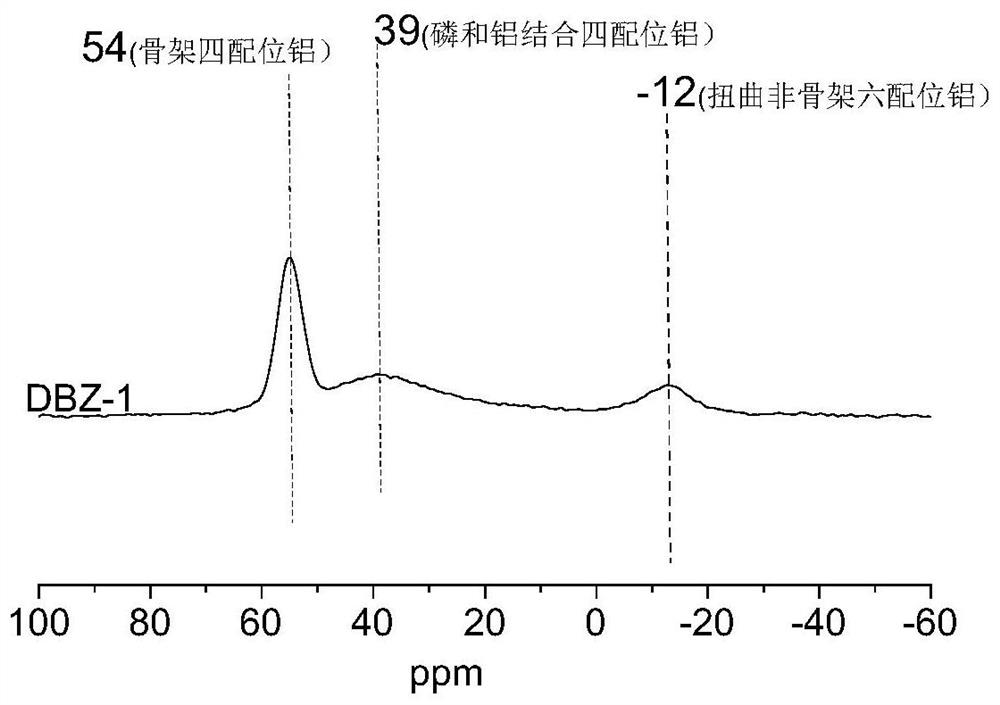

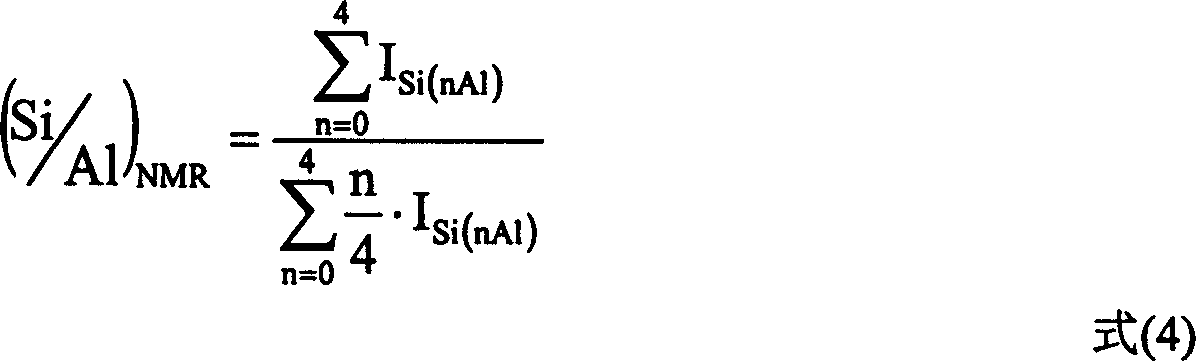

Phosphorus-modified ZSM-5 molecular sieve and preparation method thereof

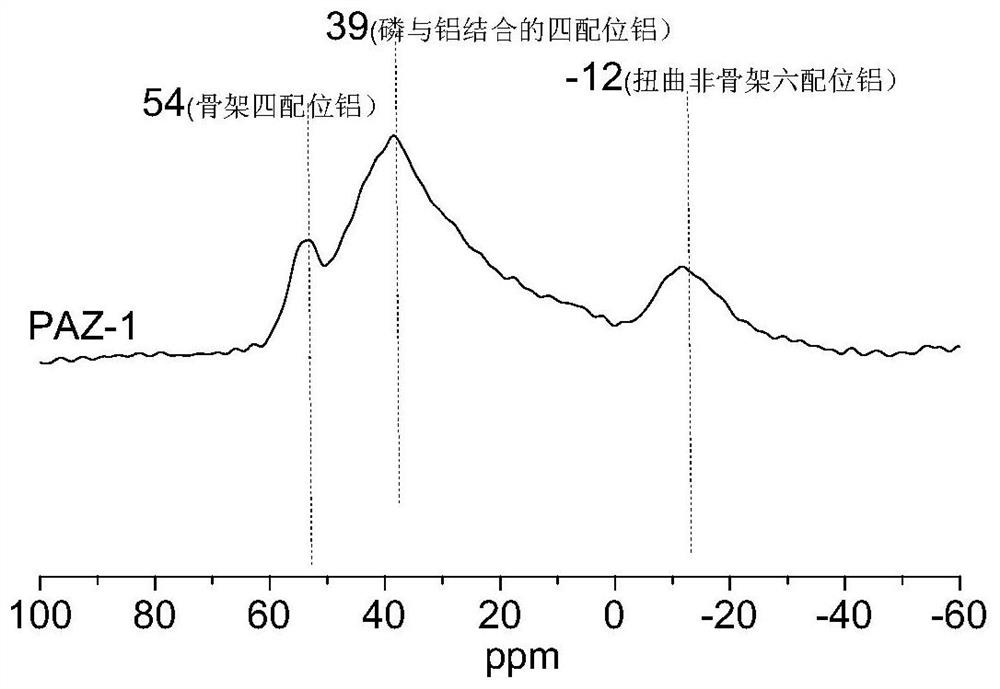

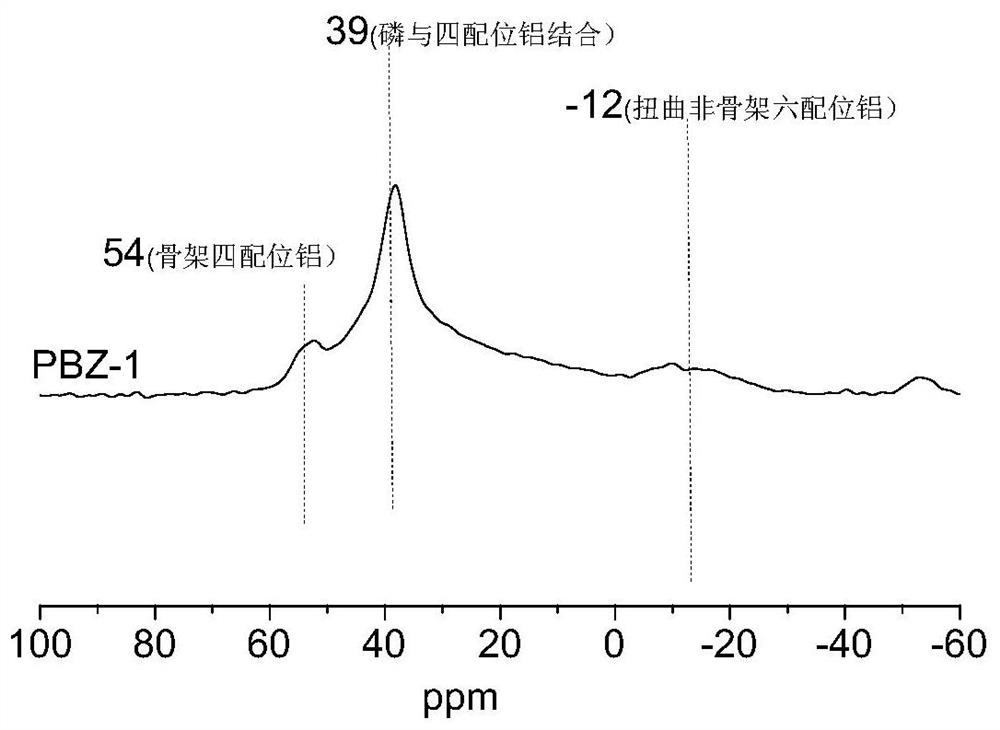

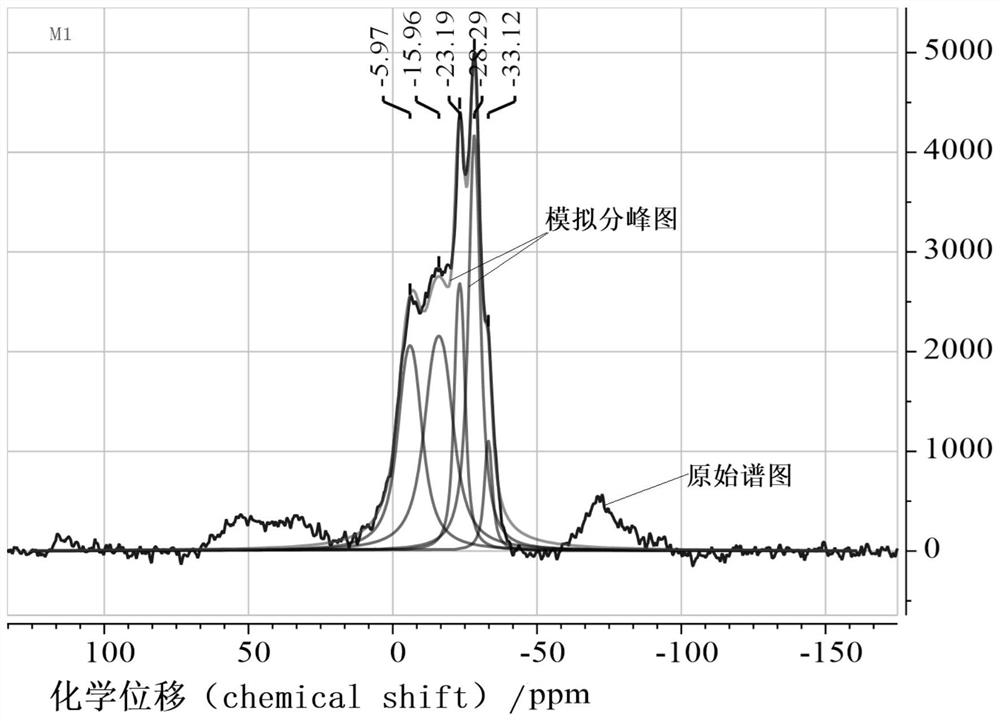

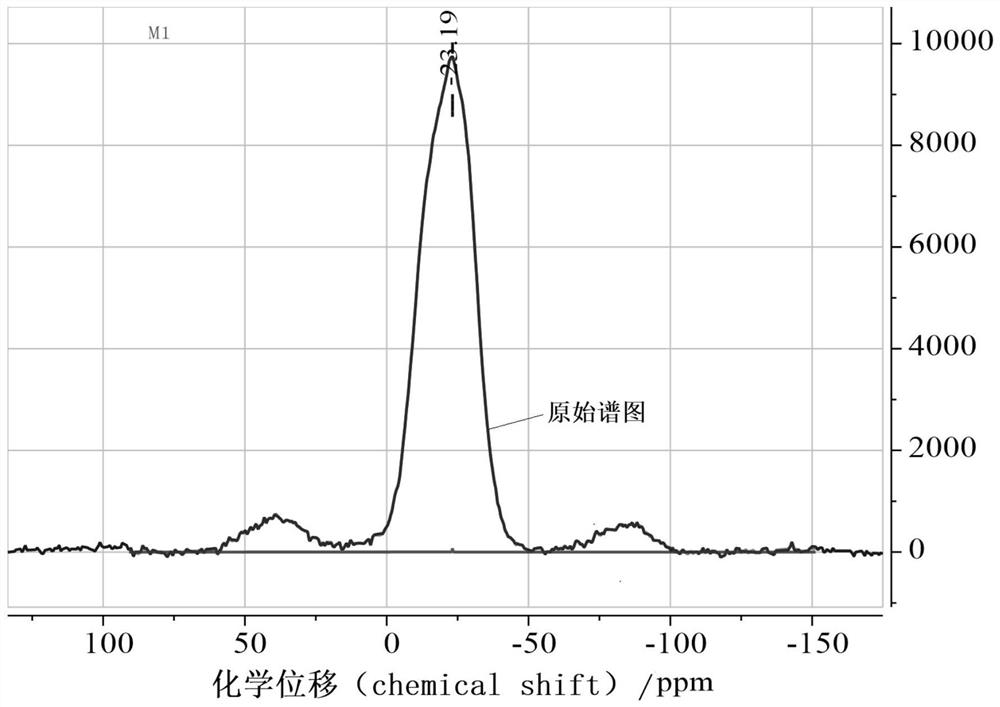

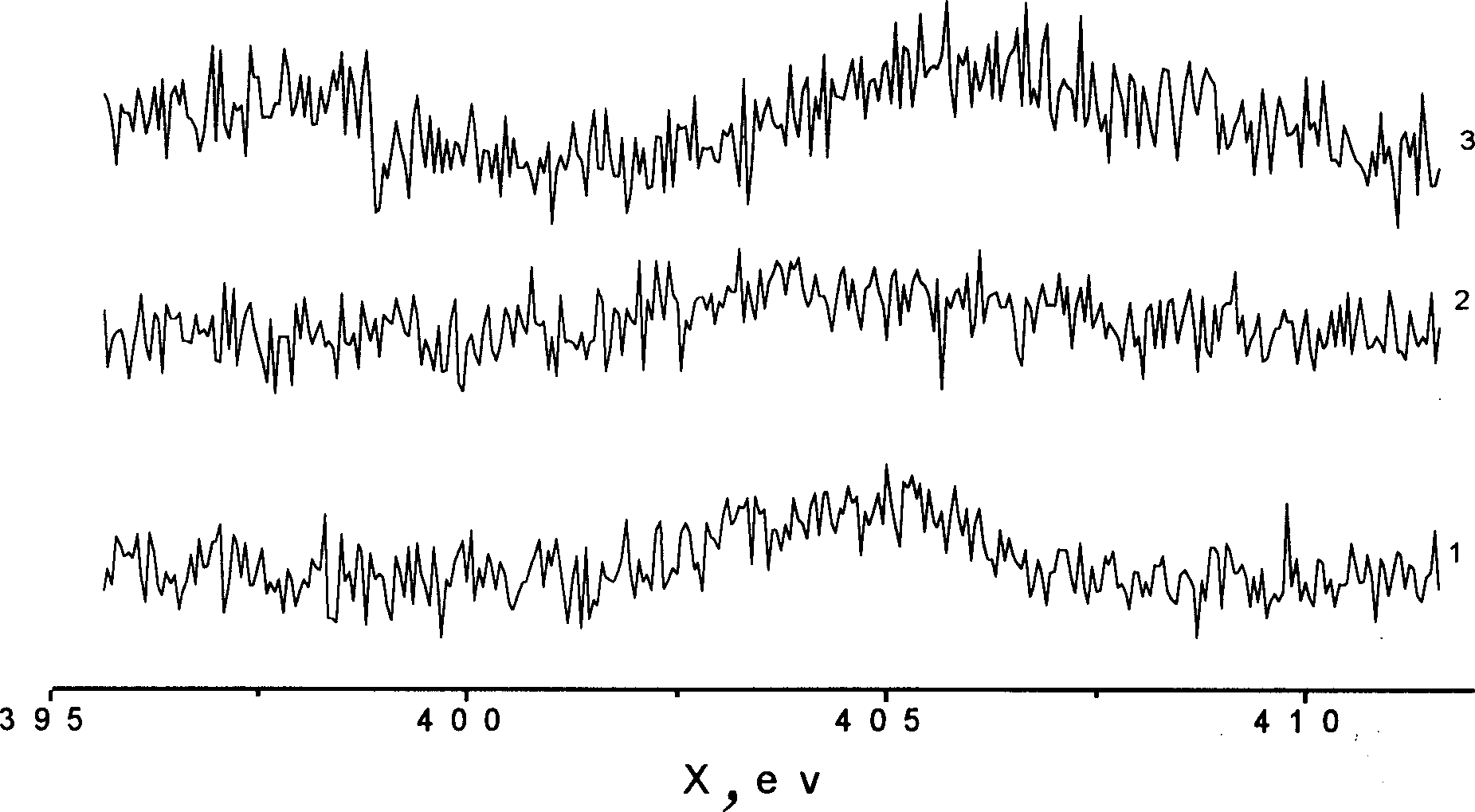

ActiveCN113526520APromote migrationGood hydrothermal stabilityMolecular sieve catalystsBulk chemical productionMolecular sieveAlkene

The invention discloses a phosphorus modified ZSM-5 molecular sieve. In 27Al MAS-NMR, the ratio of the resonance signal peak area with the chemical shift of 39 + / - 3 ppm to the resonance signal peak area with the chemical shift of 54 + / - 3 ppm is greater than or equal to 1. The phosphorus-modified ZSM-5 molecular sieve is prepared by carrying out phosphorus modification treatment on a hydrogen type ZSM-5 molecular sieve by adopting a phosphorus-containing compound solution through an impregnation method; and carrying out hydrothermal roasting treatment under the atmosphere environment of externally applying pressure and externally adding water. Phosphorus in the molecular sieve is fully coordinated with framework aluminum, and the framework aluminum is fully protected, so that the molecular sieve has good hydrothermal and active stability and meanwhile has more excellent cracking conversion rate and higher low-carbon olefin yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for removing organic amine from beta-zeolite

InactiveCN1199858CEfficient removalInhibition of dealuminationCrystalline aluminosilicate zeolitesAir atmosphereCalcination

The invention relates to a method for removing organic amines in beta zeolite, which mainly solves the problems of troublesome operation, unsafe operation or easy loss of zeolite framework aluminum in the prior art. The present invention preferably solves this problem by adopting the technical scheme of direct four-stage roasting in an air atmosphere. The four-stage roasting process is as follows: the first stage is fired at 110-180°C for 0.5-4.0 hours, and the second stage is fired at 230-300°C. ℃ for 1.0 to 6.0 hours, the third stage for 0.5 to 6.0 hours at 360 to 430°C, and the fourth stage for 2.0 to 10.0 hours at 530 to 580°C. The method of the present invention can be used in the industrial preparation of zeolite beta.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN103657700AHigh thermal and hydrothermal stabilityImprove structural stabilityCatalytic crackingMolecular sieve catalystsAdhesiveX-ray

The invention relates to a catalytic cracking catalyst and a preparation method. The catalytic cracking catalyst contains a cracking activity component, clay and an adhesive, wherein the cracking activity component comprises a rare-earth Y-type molecular sieve; and the rare-earth content in the Y-type molecular sieve is 10-25 wt% on the basis of rare-earth oxides, the cell constant is 2.440-2.472nm, the crystallinity is 35-65%, the silicon / aluminum atomic ratio in the framework is 2.5-5.0, and the product of the ratio (I1 / I2) of 2theta=11.8+ / -0.1 degree peak intensity I1 to 2theta=12.3+ / -0.1 degree peak intensity I2 in an X-ray diffraction pattern and the rare-earth weight percent in the molecular sieve on the basis of rare-earth oxides is greater than 50. The preparation method comprises the following steps: preparing a mixed slurry containing the cracking activity component, adhesive and clay, carrying out spray drying, washing and drying. Compared with the prior art, the rare-earth-containing Y-type molecular sieve has higher structural stability and activity stability; and the catalyst has higher thermal and hydrothermal stability, and can reduce the consumption of the molecular sieves in the catalyst, thereby lowering the catalyst production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for preparing the small crystal grain NaY molecular screen

ActiveCN101007639BGood hydrothermal stabilityHigh crystal retentionFaujasite aluminosilicate zeoliteMolecular sieveSilica gel

The invention discloses a making method of NaY molecular sieve with small grain size, which comprises the following steps: synthesizing guide agent; forming silicon aluminium gel; aging under 10-85 deg.c for 5-50h; adding additive with molar rate of Al2O3 and silicon-aluminium gel at 0.1-1000; crystallizing; recycling product; selecting the additive from one or more of amorphous SiO2, Al2O3, Al2O3primer, ZrO2, AlPO4, TiO2, alumina silica gel and clay.

Owner:CHINA PETROLEUM & CHEM CORP +1

Y molecular sieve modification method

ActiveCN100572275CSmall cell constantHigh crystal retentionCatalyst carriersMolecular sieve catalystsMolecular sieveCrystallinity

The invention relates to a modification method of Y molecular sieve. The method is characterized in that surfactants are added in the acid dealumination process, that is, industrial NaY molecular sieves are used as raw materials through ammonium exchange, and after deep roasting, acid dealumination is carried out under the protection of surfactants, and a higher SiO2 / Al2O3 ( 9-15) HY molecular sieves while maintaining high crystallinity. Compared with industrial NaY molecular sieves, the secondary pores of the molecular sieve prepared by this method are greatly improved, and the acid structure is also further improved. Support for hydrotreating catalysts for heavy distillate oils.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

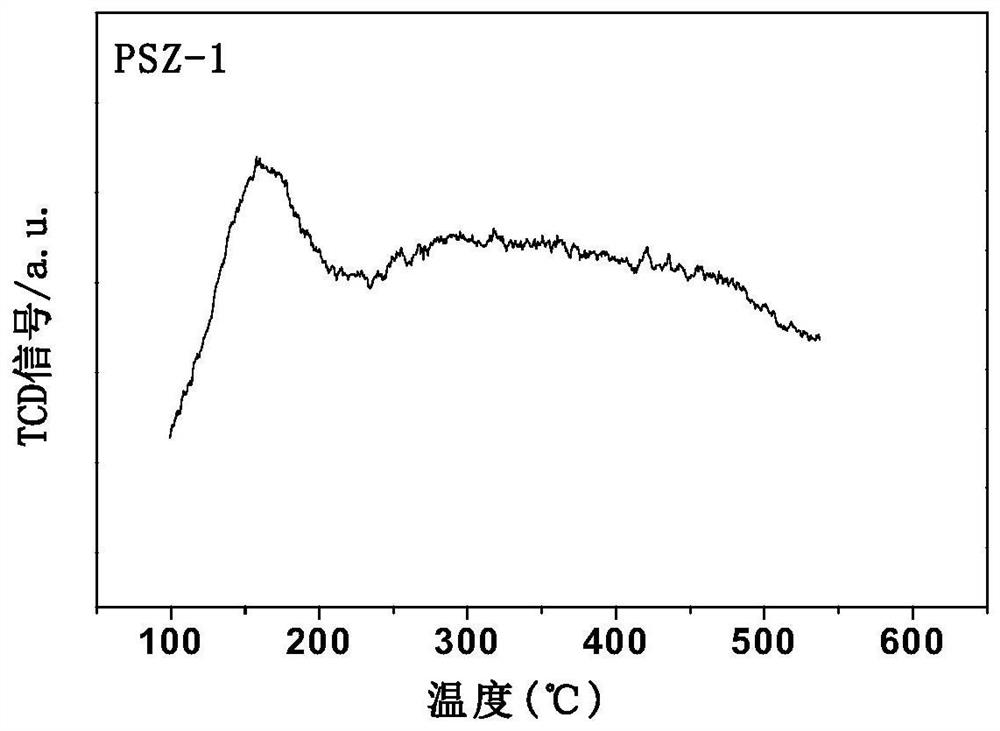

Phosphorus-containing hierarchical pore ZSM-5 molecular sieve and preparation method thereof

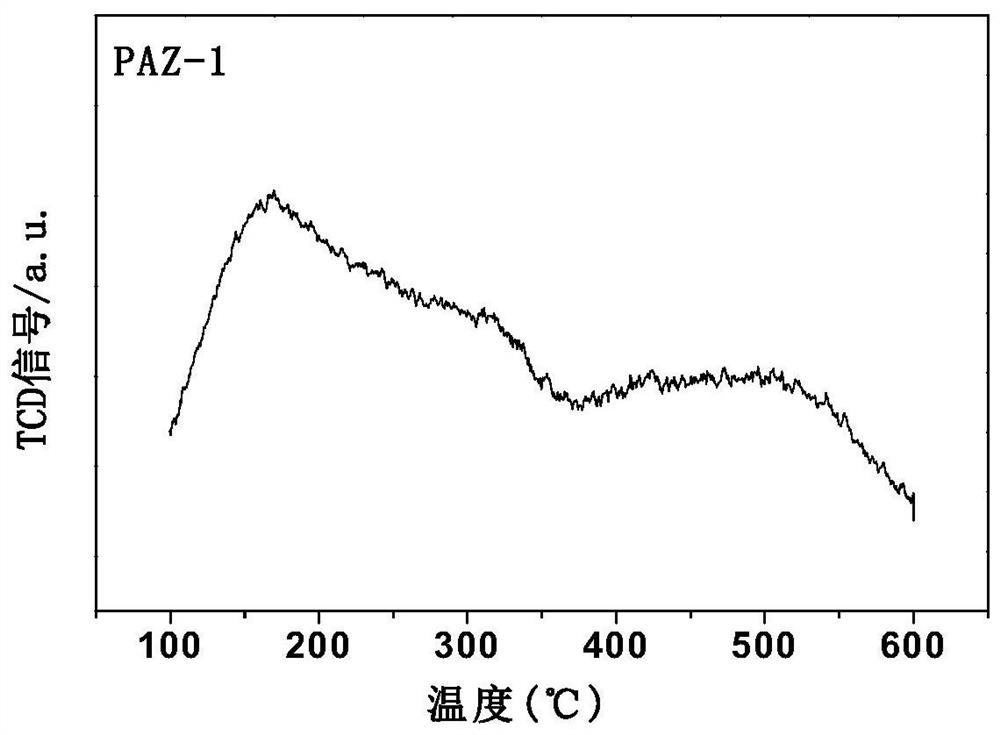

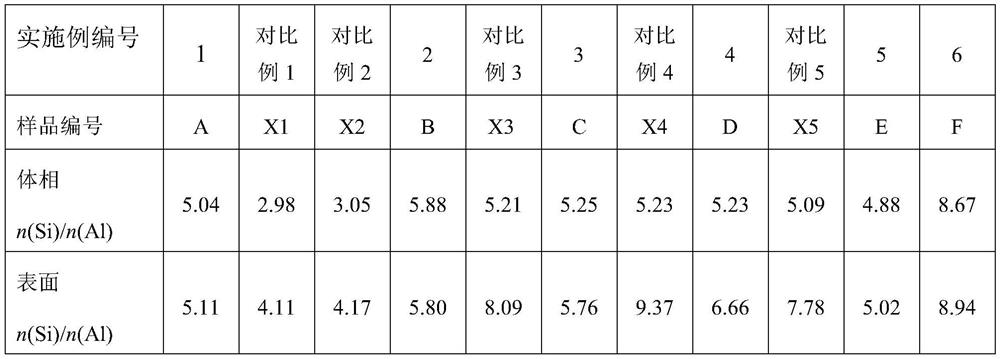

ActiveCN113526519AFully protectedGood hydrothermal stabilityMolecular sieve catalystsMolecular sieve catalystMolecular sieveWater vapor

The invention discloses a phosphorus-containing hierarchical pore ZSM-5 molecular sieve, which is characterized in that in surface XPS elemental analysis, n1 / n2 is less than or equal to 0.08, n1 represents the mole number of phosphorus, and n2 represents the total mole number of silicon and aluminum. Based on an NH3-TPD atlas after 17h of hydrothermal aging under the conditions of 800 DEG C and 100% water vapor, the proportion of the central peak area of the strong acid at the desorption temperature of 200 DEG C or above to the central peak area of the total acid is greater than or equal to 45%, and the strong acid center retention degree is relatively high. The molecular sieve is capable of increasing the yield of low-carbon olefins and increasing the yield of high-added-value products in liquefied gas production.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of synthetic method of high silicon aluminum ratio nay zeolite

ActiveCN104118885BHigh catalytic activityIncrease productionFaujasite aluminosilicate zeoliteHigh silicaSilicon

The invention provides a synthetic method for NaY zeolite with a high silica-alumina ratio. The method comprises the main steps: according to the proportioning requirement of a directing agent to uniformly mix a silicon source, an aluminium source and water, and ageing at 15 DEG C-60 DEG C for 0.5-120 h, so as to prepare the directing agent; according to the proportioning requirement of a gel reaction mixture to adding the directing agent and an alkaline solution into a silicone source at 10 DEG C-90 DEG C, stirring for 1 h-80 h, and stirring uniformly to obtain the gel reaction mixture; performing crystallization on the gel reaction mixture at 80-120 DEG C for 10-50 h, and then filtering, washing and drying to prepare NaY zeolite. The method does not employ a template, the preparation of the directing agent is mild in temperature, NaY zeolite with high crystallization degree and the high silica-alumina ratio is synthesized at a relatively short crystallization time. Also the method is capable of replacing conventional production technology without changing current apparatuses for industrial production, and has great important meaning on improving performances of catalytic cracking catalysts.

Owner:PETROCHINA CO LTD +1

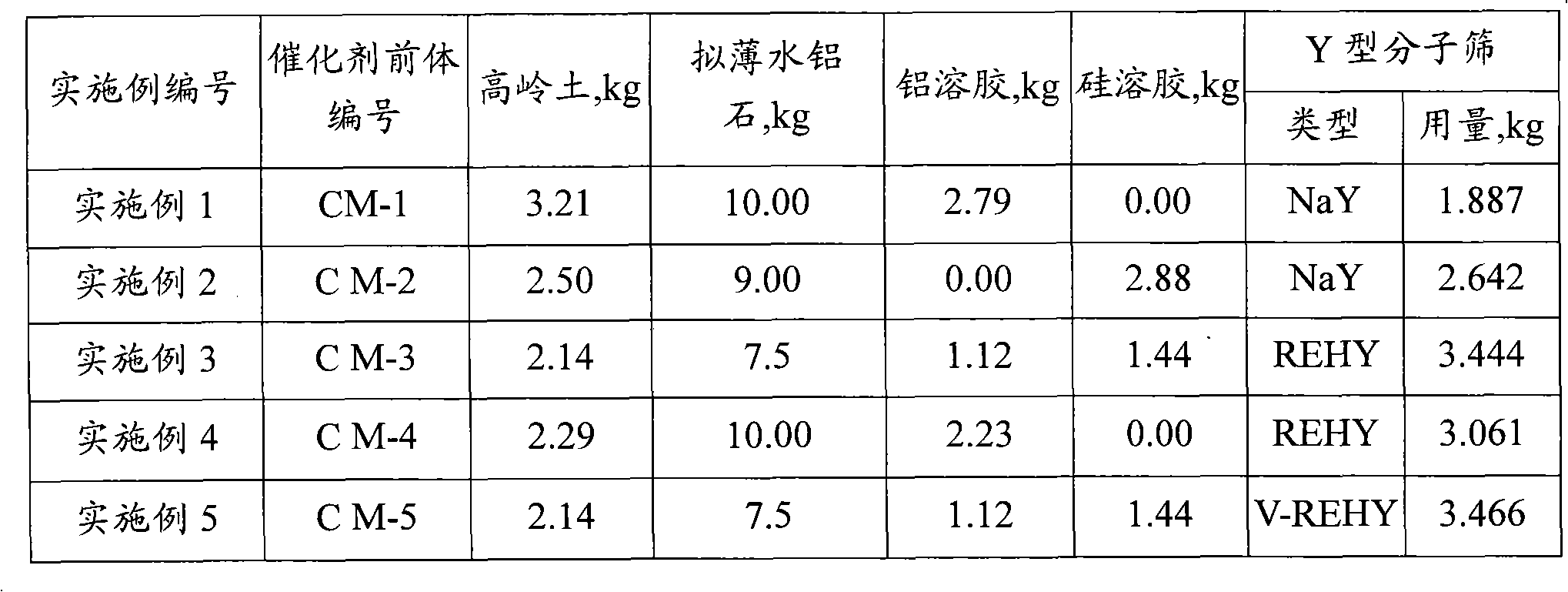

Catalyst containing Y-type molecular sieve and preparation method thereof

ActiveCN112808296AImprove connectivityFacilitated DiffusionMolecular sieve catalystsBulk chemical productionMolecular sieveAlkaline earth metal

The invention provides a preparation method of a catalyst containing a Y-type molecular sieve, the catalyst is obtained by mixing, kneading, extruding and rolling mixed slurry of the Y-type molecular sieve, alumina sol, pseudo-boehmite, silica sol, clay, acid and water, the Y-type molecular sieve is an NH4Y molecular sieve prepared by carrying out ammonium exchange treatment on a NaY molecular sieve, and the NH4Y molecular sieve is a Y-type molecular sieve prepared by carrying out ammonium exchange treatment on the NH4Y molecular sieve. And contacting the obtained NH4Y molecular sieve with a salt solution containing alkali metal ions and / or a salt solution containing alkaline earth metal ions, filtering, washing, drying, carrying out hydrothermal aging on the obtained product, contacting with an acid solution, and recovering the product, wherein the alkali metal is selected from rubidium and cesium, and the alkaline earth metal is selected from strontium and barium.

Owner:CHINA PETROLEUM & CHEM CORP +1

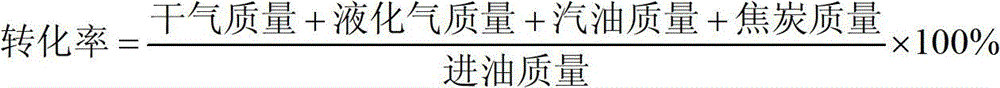

Catalytic cracking catalyst for producing low-carbon olefin and application thereof

ActiveCN102430422BImprove wear resistanceGood conversion effectCatalytic crackingMolecular sieve catalystsMolecular sieveHydrotalcite

The invention discloses a catalytic cracking catalyst for producing low-carbon olefin. The catalyst consists of 0.5-15 parts by weight of particles A and 1 part by weight of particles B, wherein the particles A include 10-85 percent by weight of aluminum binder, 15-60 percent by weight of molecular sieve and 0-75 percent by weight of clay based on the total weight of the particles A; the molecular sieve is MFI zeolite or MFI zeolite and Y type zeolite; the clay is one or more of montmorillonoid, diatomite, halloysite, soapstone, sepiolite, attapulgite, hydrotalcite and bentonite; and the particles B include 20-80 percent by weight of rectorite and 20-80 percent by weight of silicon oxide binder in terms of silicon oxide based on the total weight of the particles B. The catalyst provided by the invention has high olefin yield and excellent wear resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cracking catalyst and preparation method thereof

ActiveCN102029177BHigh ratio of silicon to aluminumHigh crystallinityCatalytic crackingMolecular sieve catalystsMolecular sieveSulfur

The invention relates to a preparation method of a cracking catalyst, which comprises: raw materials and water are mixed to prepare a slurry solution by utilizing the catalyst containing a Y type molecular sieve and a silicon vector; the slurry solution is dried to obtain a catalyst precursor; the catalyst precursor is baked; and a contact reaction is carried out on the catalyst precursor and an acidic ammonium salt solution. The preparation method of the cracking catalyst can enhance the crystallization retaining degree of the Y type molecular sieve in the catalyst and the stability of the catalyst. The catalyst prepared by utilizing the method is used for the catalytic cracking of heavy oil and has the advantages of strong conversion capability of the heavy oil, high yield of gasoline, and low sulphur content in the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst and preparation method thereof

ActiveCN102049282BGuaranteed continuityReduce collapseMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation activity metals and a carrier consisting of a modified small crystal particle Y-shaped molecular sieve and alumina, wherein the small crystal particle Y-shaped molecular sieve has the following properties: the SiO2 / Al2O3 molar ratio is 10.0-120.0, the average diameter of the crystal particles is 100-700nm, the cell parameter is 2.436-2.445nm, sodium oxide is less than or equal to 0.1 weight percent, and the crystal retention rate is over 95 percent. The hydrocracking catalyst has the characteristics of high catalytic activity, high heavy naphtha selectivity, high potential aromatic hydrocarbon content, low bureau of mines correlation index (BMCI) value of hydrocracking tail oil and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN103657712BIncrease profitSave resourcesCatalytic crackingMolecular sieve catalystsAdhesiveX-ray

The invention relates to a catalytic cracking catalyst and a preparation method. The catalyst contains a cracking activity component, a mesoporous silicon-aluminum material, clay and an adhesive, wherein the cracking activity component comprises a Y-type molecular sieve and an MFI-structure molecular sieve; the Y-type molecular sieve comprises a first Y-type molecular sieve; and the rare-earth content in the first Y-type molecular sieve is 10-25 wt% on the basis of rare-earth oxides, the cell constant is 2.440-2.472nm, the crystallinity is 35-65%, the silicon / aluminum atomic ratio in the framework is 2.5-5.0, and the product of the ratio of 2theta=11.8+ / -0.1 degree peak intensity I1 to 2theta=12.3+ / -0.1 degree peak intensity I2 in an X-ray diffraction pattern and the rare-earth weight percent in the molecular sieve on the basis of rare-earth oxides is greater than 50. The preparation method comprises the following steps: preparing a mixed slurry containing the cracking activity component, mesoporous silicon-aluminum material, adhesive and clay, carrying out spray drying, washing and drying. The catalyst has higher conversion rate and liquefied gas yield, and can reduce the consumption of the molecular sieves in the catalyst, thereby lowering the catalyst production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN105854927BSimple processReduce manufacturing costCatalytic crackingMolecular sieve catalystsAdhesiveReaction temperature

The invention discloses a catalytic cracking catalyst. The catalytic cracking catalyst is prepared from, by weight, 20-45 parts of active components, 35-45 parts of clay and 10-45 parts of adhesive. The adhesive is calculated based on oxide, and the adhesive is phosphorus silica-alumina gel. The invention further discloses a preparation method of the catalytic cracking catalyst. The preparation method includes the steps that the clay and deionized water are mixed and pulped to be fully uniform, the active components and the adhesive are added into pulp, mixing and stirring are conducted, spray drying and pelleting are conducted after acidification, and a head product is obtained; the head product is calcined at the set temperature, a calcined product is obtained, and the cauterant decrease of the calcined product is controlled; the calcined product and silicon tetrachloride are subjected to a contact reaction at a set ratio, the reaction temperature is controlled at the set temperature, the product is washed, filtered and dried after the reaction is completed, and the catalytic cracking catalyst is obtained. According to the catalyst, multiple times of exchange and calcination of the active components are not needed, and the process is simple and environmentally friendly. The adopted phosphorus silica-alumina gel is good in adhesion, no acid gas is generated in the calcination process, equipment is prevented from being corroded, and the energy consumption and the production cost of the catalyst are reduced.

Owner:QINGDAO RUNQIAN HI TECH CO LTD

A kind of catalytic cracking catalyst and preparation method thereof

ActiveCN103657700BHigh thermal and hydrothermal stabilityImprove structural stabilityCatalytic crackingMolecular sieve catalystsAdhesiveX-ray

The invention relates to a catalytic cracking catalyst and a preparation method. The catalytic cracking catalyst contains a cracking activity component, clay and an adhesive, wherein the cracking activity component comprises a rare-earth Y-type molecular sieve; and the rare-earth content in the Y-type molecular sieve is 10-25 wt% on the basis of rare-earth oxides, the cell constant is 2.440-2.472nm, the crystallinity is 35-65%, the silicon / aluminum atomic ratio in the framework is 2.5-5.0, and the product of the ratio (I1 / I2) of 2theta=11.8+ / -0.1 degree peak intensity I1 to 2theta=12.3+ / -0.1 degree peak intensity I2 in an X-ray diffraction pattern and the rare-earth weight percent in the molecular sieve on the basis of rare-earth oxides is greater than 50. The preparation method comprises the following steps: preparing a mixed slurry containing the cracking activity component, adhesive and clay, carrying out spray drying, washing and drying. Compared with the prior art, the rare-earth-containing Y-type molecular sieve has higher structural stability and activity stability; and the catalyst has higher thermal and hydrothermal stability, and can reduce the consumption of the molecular sieves in the catalyst, thereby lowering the catalyst production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

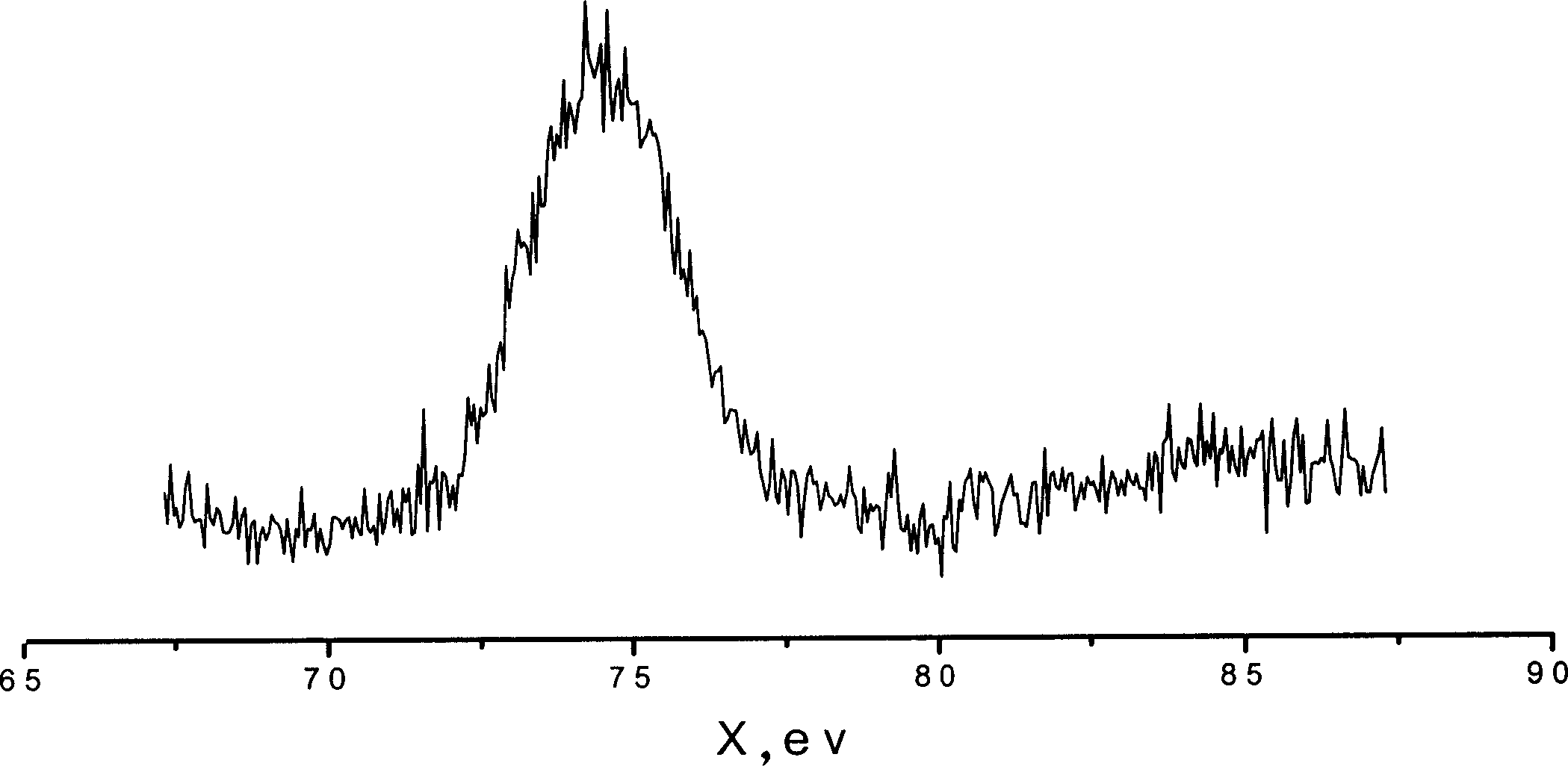

Phosphorus-containing faujasite and preparation method thereof

ActiveCN112811438AIncrease acidityReduce acidityFaujasite aluminosilicate zeoliteBulk chemical productionPhysical chemistryFaujasite

The invention provides phosphorus-containing faujasite and a preparation method thereof. The preparation method comprises the following step: carrying out a gas-solid phase reaction on dried sodium faujasite and mixed gas of silicon tetrachloride and phosphorus trichloride to obtain the phosphorus-containing faujasite. According to the phosphorus-containing faujasite prepared by the preparation method of the phosphorus-containing faujasite, phosphorus enters a zeolite framework, and the phosphorus-containing faujasite has the characteristics of high B acid content, high stability, high crystallinity, high silica-alumina ratio and low sodium content.

Owner:PETROCHINA CO LTD +1

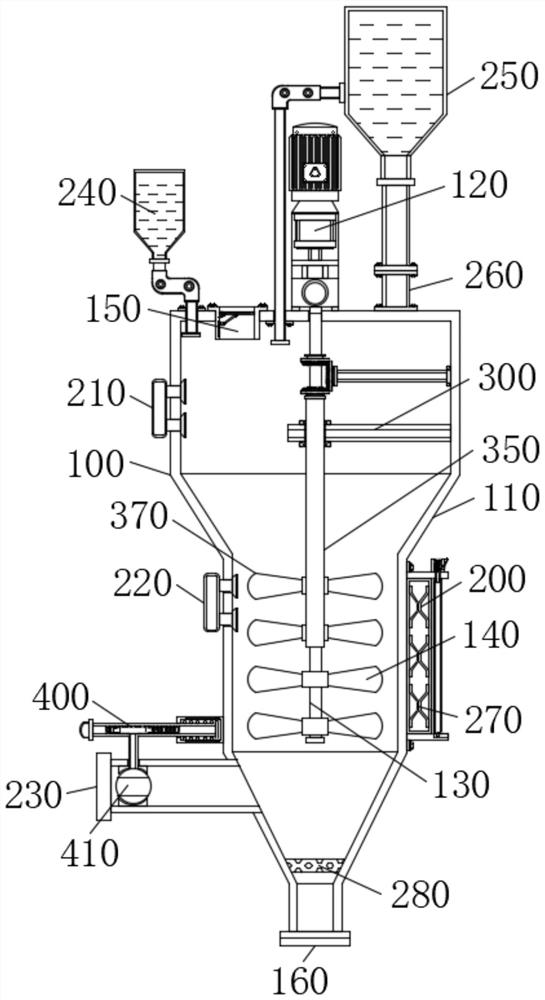

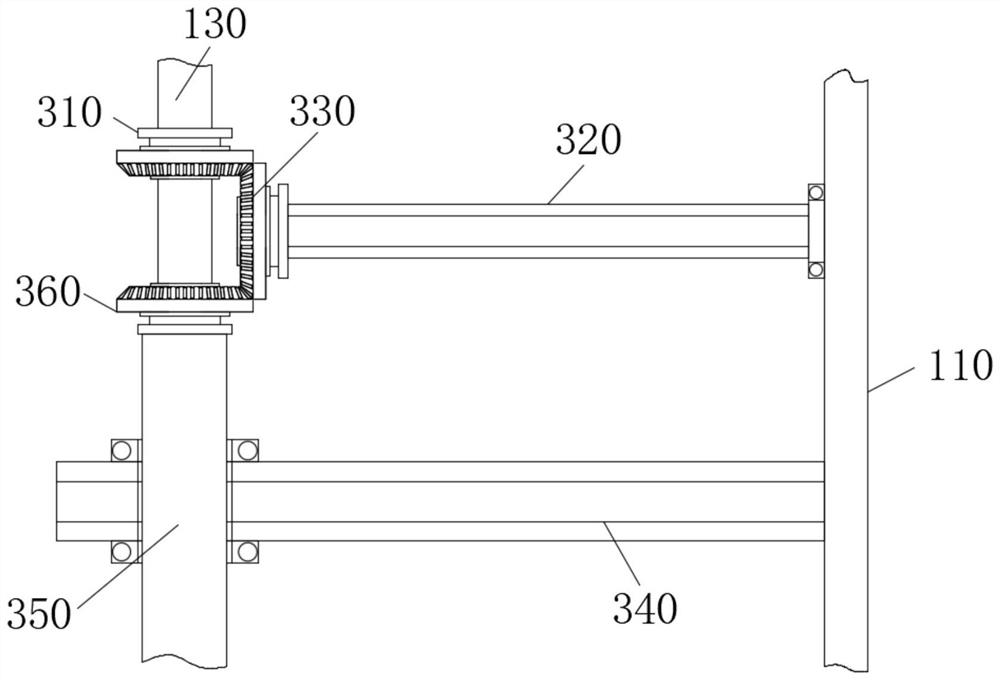

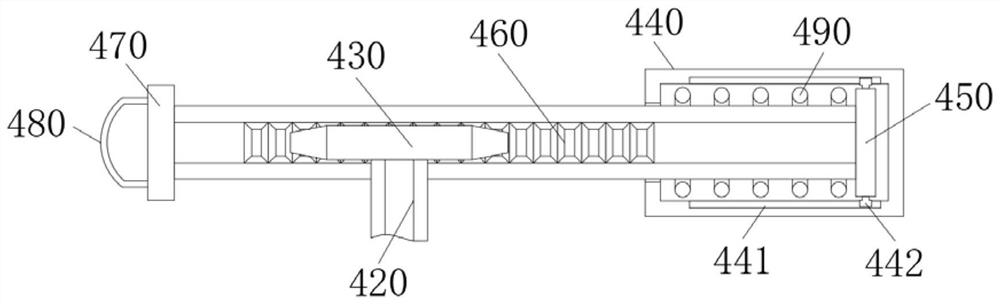

A device for modifying molecular sieve materials and its application method

ActiveCN111977664BHigh crystal retentionImprove hydrophobicityTransportation and packagingRotary stirring mixersMolecular sieveElectric machine

The invention discloses a molecular sieve material modification treatment device and a method for using the device, which comprises a device body, the device body includes a mixing device, and a control motor is fixedly connected to the top end of the mixing device, and an output shaft is fixedly connected to the bottom end of the control motor , the outer wall of the output shaft is fixedly connected with a first stirring blade, the top left side of the mixing device is fixedly connected with a molecular sieve feed port, the bottom end of the mixing device is fixedly connected with a discharge port, and the inside of the mixing device is provided with a separation mechanism, and the separation mechanism includes a first temperature sensor, the left end of the mixing device is fixedly connected with the first temperature sensor, the left end of the mixing device is fixedly connected with the second temperature sensor, and the left end of the mixing device is inserted with hot dry air and four Silicon chloride liquid import. The invention solves the problem of relatively low preparation rate of traditional molecular sieve silicon-alumina preparation equipment, and improves the preparation effect of the device.

Owner:山东荣创催化新材料有限公司 +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN103657711BIncrease profitSave resourcesCatalytic crackingMolecular sieve catalystsAdhesiveGas phase

The invention relates to a catalytic cracking catalyst and a preparation method. The catalytic cracking catalyst contains a cracking activity component, clay and an adhesive, wherein the cracking activity component a first Y-type molecular sieve, a second Y-type molecular sieve and a third Y-type molecular sieve; the first Y-type molecular sieve is a rare-earth Y-type molecular sieve, the rare-earth content in the first Y-type molecular sieve is 10-25 wt% on the basis of rare-earth oxides, the cell constant is 2.440-2.472nm, the crystallinity is 35-65%, the silicon / aluminum atomic ratio in the framework is 2.5-5.0, and the product of the ratio (I1 / I2) of 2theta=11.8+ / -0.1 degree peak intensity I1 to 2theta=12.3+ / -0.1 degree peak intensity I2 in an X-ray diffraction pattern and the rare-earth weight percent in the molecular sieve on the basis of rare-earth oxides is greater than 50; the second Y-type molecular sieve is a rare-earth-containing gas-phase overstable Y-type molecular sieve; and the third Y-type molecular sieve is a rare-earth-containing DASY molecular sieve. The preparation method comprises the following steps: preparing a slurry containing the cracking activity component, adhesive and clay, and carrying out spray drying. The catalyst has higher conversion rate and gasoline yield, and can reduce the consumption of the molecular sieves, thereby lowering the cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nitrogenous zeolite and preparing method thereof

InactiveCN1509815AHigh thermal stability and crystallization retentionHigh activityMolecular sieve catalystsCatalyst activation/preparationZSM-5 zeoliteNitrogen

A nitrogen-contained zeolite used as the active component of catalyst for catalytic cracking is a crystallized silicoaluminate containing nitrogen (0.01-5 wt%), and is prepared through mixing the ammonium nitrate with the zeolite chosen from Y zeolite, mordenite and ZSM-5 zeolite and heating at 50-600 deg.C for 0.1-15 hr. Its advantages are high thermal stability, activity and selectivity, and good crystal retention.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified y molecular sieve with regular meso-micropores and preparation method thereof

ActiveCN109665539BOvercome the disadvantage of not easy to separateImprove connectivityFaujasite aluminosilicate zeoliteMolecular sievePhysical chemistry

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN103657701BIncrease profitSave resourcesCatalytic crackingMolecular sieve catalystsAdhesiveX-ray

The invention relates to a catalytic cracking catalyst and a preparation method thereof. The catalyst contains a first Y-type molecular sieve, a second Y-type molecular sieve and a third Y-type molecular sieve, wherein the rare-earth content in the first Y-type molecular sieve is 10-25 wt%, the cell constant is 2.440-2.472nm, the crystallinity is 35-65%, the silicon / aluminum atomic ratio in the framework is 2.5-5.0, and the product of the ratio of 2theta=11.8+ / -0.1 degree peak intensity to 2theta=12.3+ / -0.1 degree peak intensity in an X-ray diffraction pattern and the rare-earth weight percent in the molecular sieve is greater than 50; the second Y-type molecular sieve is a magniferous overstable Y-type molecular sieve; and the third Y-type molecular sieve is a rare-earth-containing DASY molecular sieve. The preparation method comprises the following steps: preparing a mixed slurry containing the molecular sieves, an adhesive and clay, carrying out spray drying, washing and drying. The catalyst has higher conversion rate and diesel yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking catalyst and preparation method thereof

ActiveCN103657702BIncrease profitSave resourcesCatalytic crackingMolecular sieve catalystsMolecular sieveAdhesive

The invention relates to a catalytic cracking catalyst and a preparation method. The catalytic cracking catalyst contains a cracking activity component, a mesoporous silicon-aluminum material, clay and an adhesive, wherein the cracking activity component comprises a rare-earth Y-type molecular sieve; and the rare-earth content in the Y-type molecular sieve is 10-25 wt% on the basis of rare-earth oxides, the cell constant is 2.440-2.472nm, the crystallinity is 35-65%, the silicon / aluminum atomic ratio in the framework is 2.5-5.0, and the product of the ratio (I1 / I2) of 2theta=11.8+ / -0.1 degree peak intensity I1 to 2theta=12.3+ / -0.1 degree peak intensity I2 in an X-ray diffraction pattern and the rare-earth weight percent in the molecular sieve on the basis of rare-earth oxides is greater than 50. The preparation method comprises the following steps: preparing a mixed slurry containing the cracking activity component, mesoporous silicon-aluminum material, adhesive and clay, and carrying out spray drying. Compared with the prior art, the rare-earth-containing Y-type molecular sieve is matched with the mesoporous silicon-aluminum material, so that the catalyst has higher thermal and hydrothermal stability and higher heavy oil cracking capacity, and can reduce the consumption of the molecular sieves in the catalyst, thereby lowering the catalyst production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com