Patents

Literature

201results about How to "Good conversion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based rust conversion paint and preparation method thereof

InactiveCN105062245AGood conversion effectImprove corrosion resistanceAnti-corrosive paintsWater basedEmulsion

The invention discloses a water-based rust conversion paint and a preparation method thereof. For an existing rust conversion coating, a commonly used rust converting agent is acidic, and an acidic condition is required for an iron rust conversion process. The acidic rust converting agent can damage the stability of a commonly used alkaline emulsion. The water-based rust conversion paint comprises the components of, by mass, 30-47 parts of an aqueous polymer emulsion, 2-12 parts of a rust converting agent, 3-17 parts of a coloring pigment, 3-20 parts of an anti-rust pigment, 4-8 parts of a filler, 0.1-0.5 part of a deforming agent, 0.1-1 part of a dispersing agent, 0.5-4 parts of a film coalescing aid, 0.1-2 parts of an emulsion stabilizer, 0.1-0.5 part of a thickeners, 0.1-0.5 part of a mildew preventive, and 10-35 parts of water. The paint has good stability, and excellent rust layer conversion effect. A coating formed with the paint has good corrosion resistance. The paint is suitable for steel rusty surface rust conversion and corrosion prevention, and is mainly used as a primer.

Owner:STATE GRID CORP OF CHINA +2

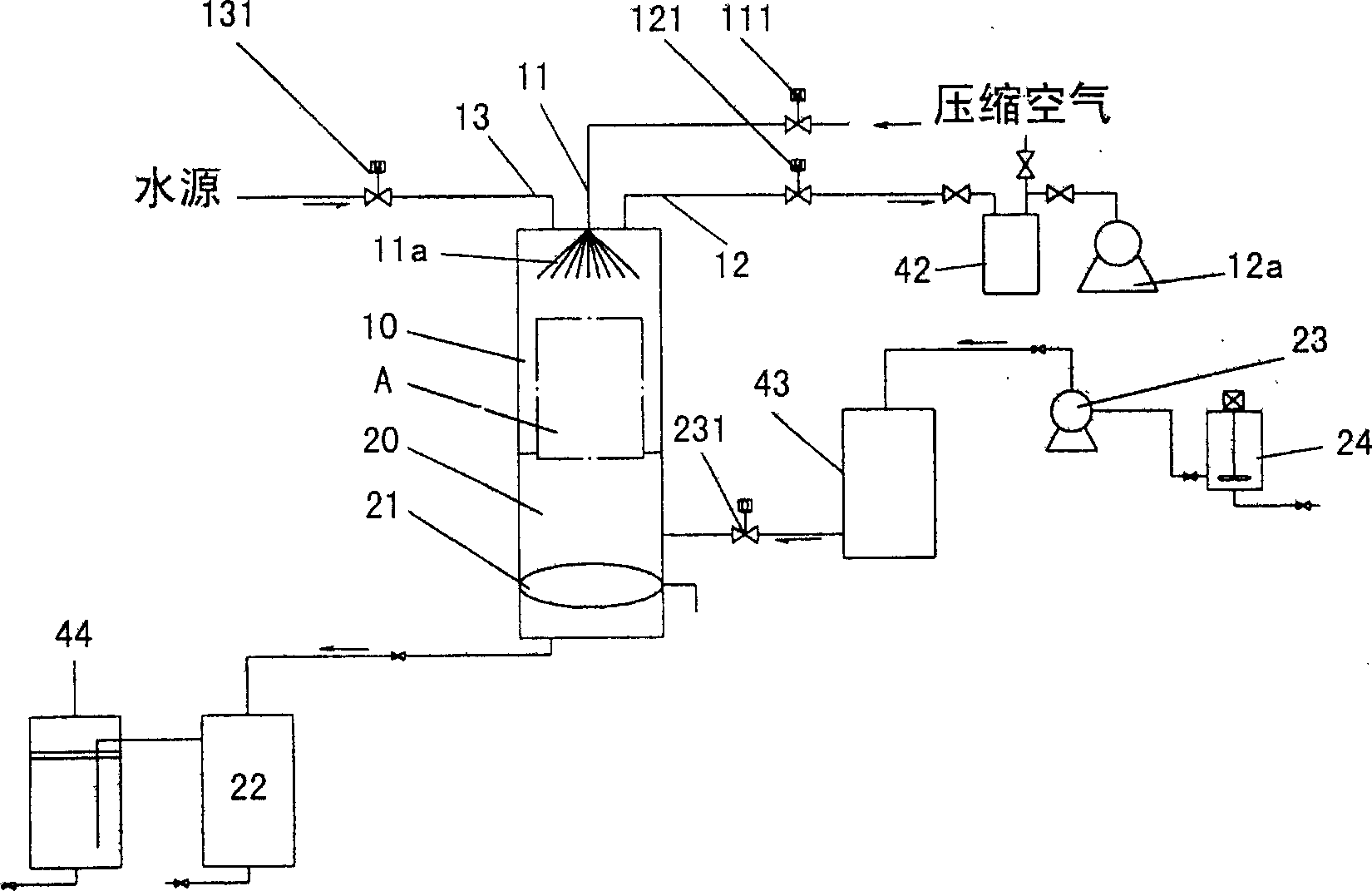

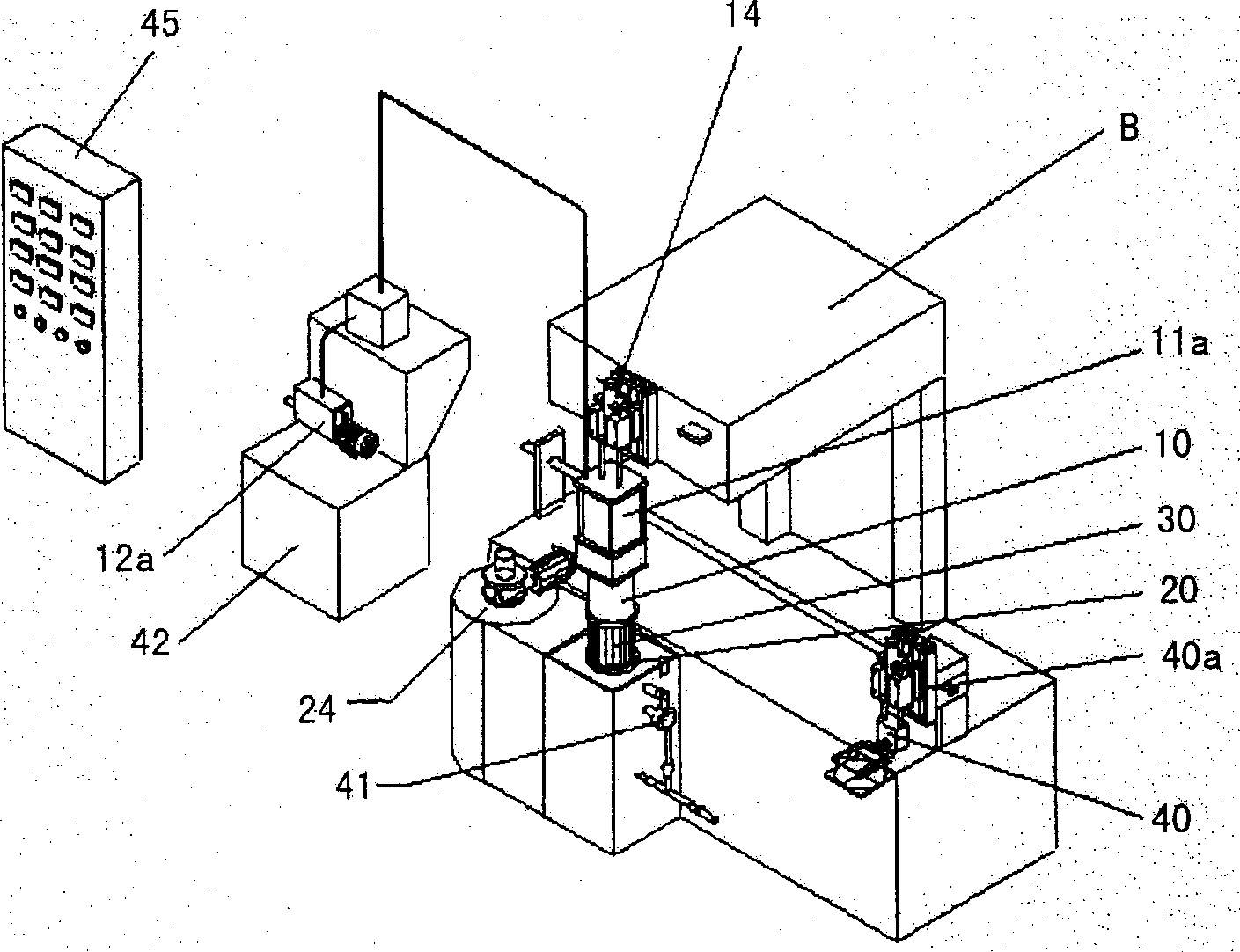

Method and equipment for coating slurry layer on cellular carrier of ceramics

InactiveCN1660508AImprove efficiencyControl thicknessLiquid surface applicatorsCoatingsAutomatic controlPositive pressure

A process for coating the slurry on the surface of cellular ceramic carrier inclues such steps as arranging the cellular ceramic carrier to a particular working position by automatic fixture, sealing it, delivering the slurry via tube, negative-pressure coating, and positive-pressure scavenge to remove excessive slurry.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

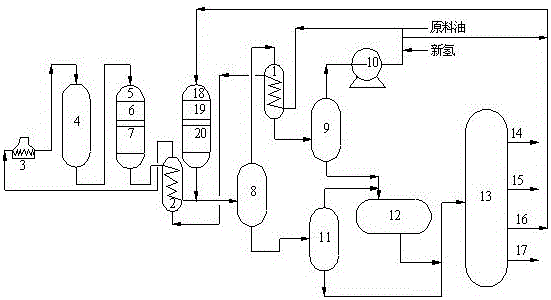

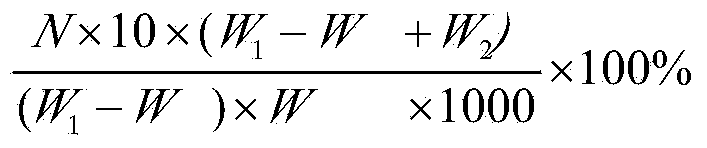

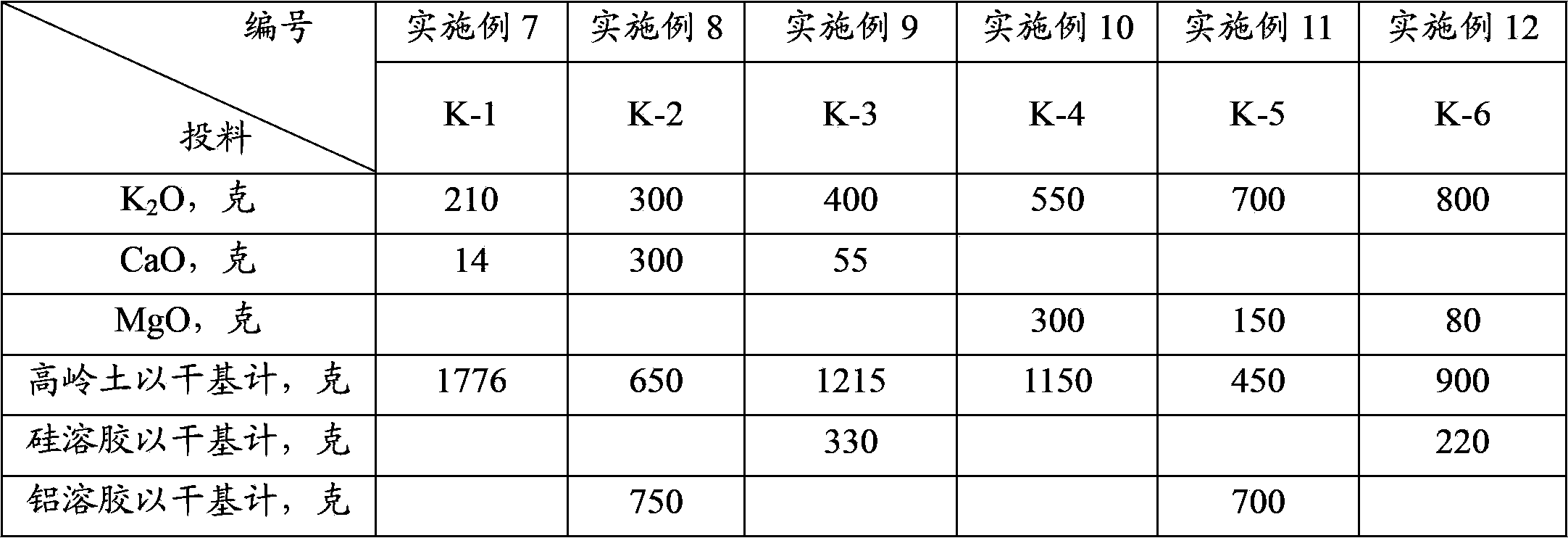

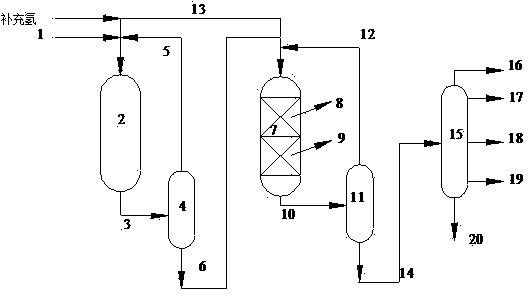

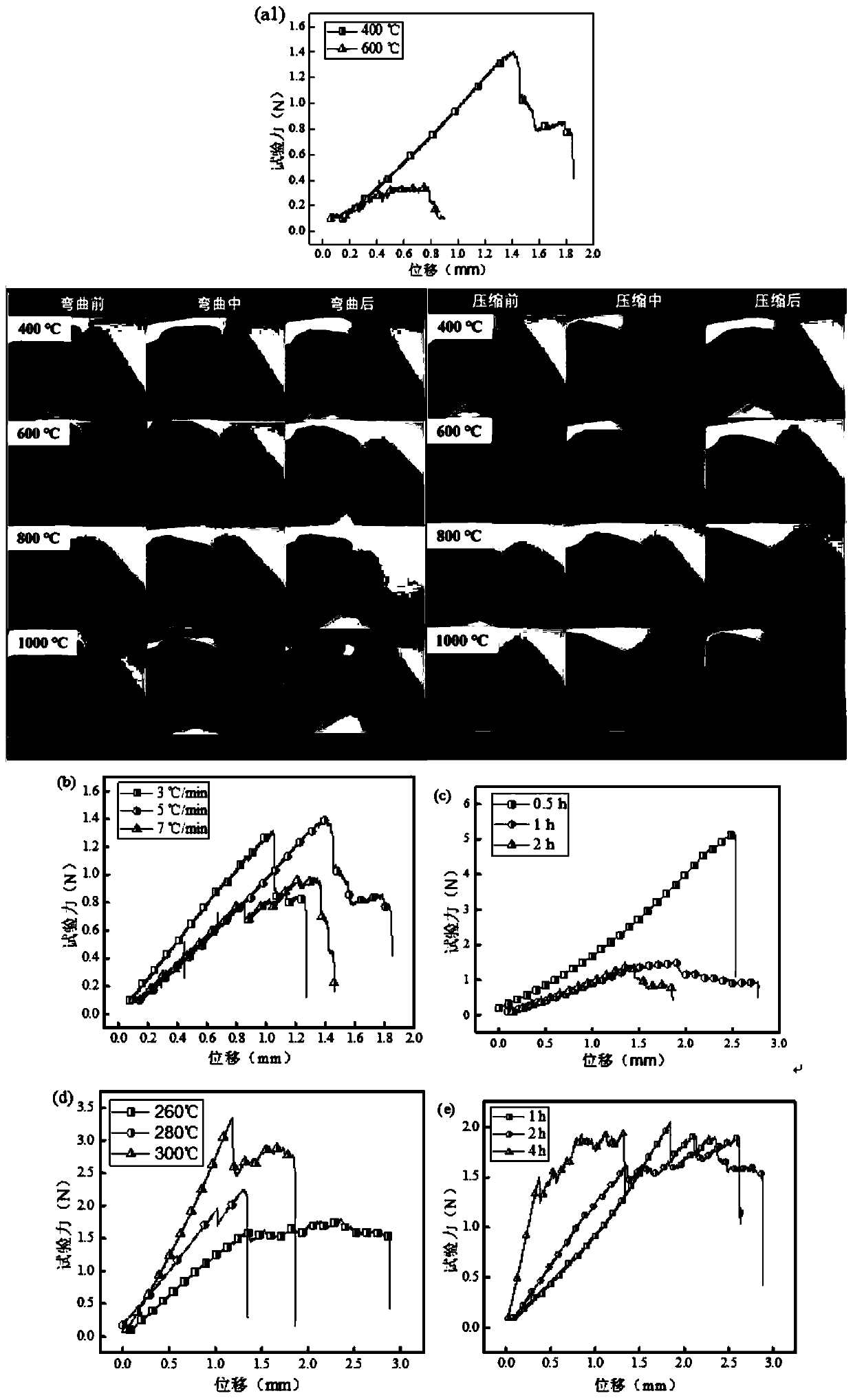

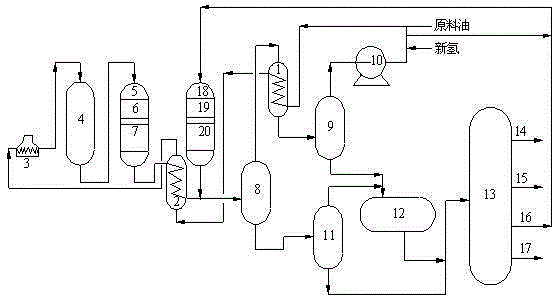

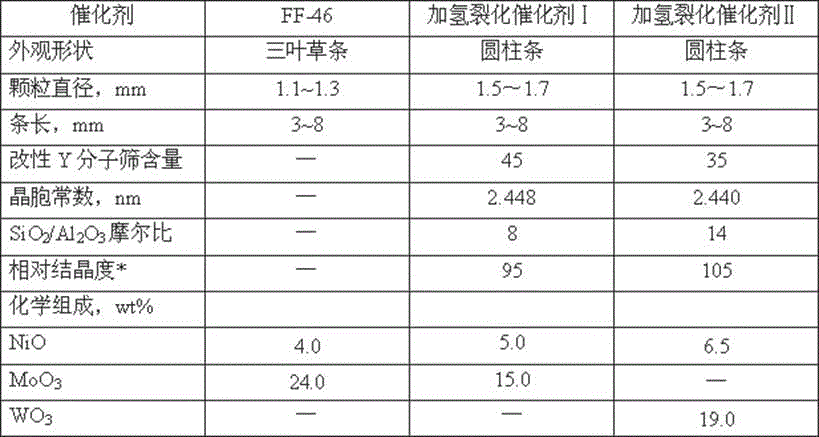

A hydrocracking method with low energy consumption and high yield of high-quality chemical raw materials

ActiveCN105018139BReduce consumptionSave engineering investmentTreatment with hydrotreatment processesMolecular sieveHydrogen

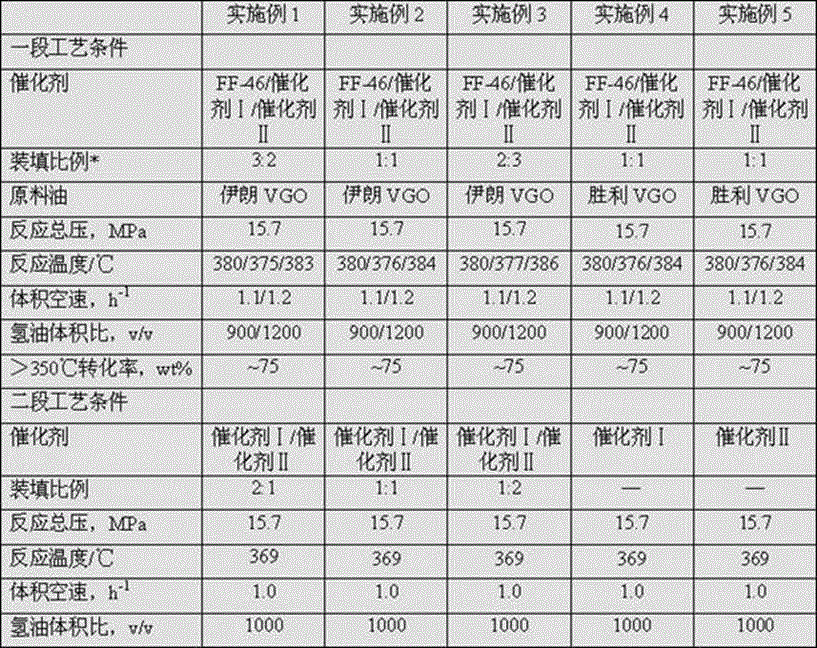

The invention discloses a hydrocracking method of low-nergy-onsumption productive high-quality chemical raw materials. After raw oil and hydrogen are mixed, the obtained mixture is subjected to heat transfer for two times and then passes through a heating furnace, the obtained object is sequentially subjected to hydrorefining and then passes through a first cracking reaction area, the obtained product is separated so as to obtain middle distillate, the middle distillate enters a second cracking reaction area to crack, wherein the first cracking reaction area is at least filled with two cracking catalysts, a catalyst I is filled in the upstream part, and a catalyst II is filled in the downstream part; and the catalyst I contains 30-70% of modified Y molecular sieve, the catalyst II contains 15-50% of modified Y molecular sieve, and the content of the modified Y molecular sieve in the catalyst I is 10-30% higher than the content of the modified Y molecular sieve in the catalyst II. In the method disclosed by the invention, a high-temperature and high-pressure countercurrent heat transfer technology and a hydrocracking catalyst grading technology are organically combined, and through the comprehensive utilization of hydrocracking reaction heat, while the selectivity of catalysts is maintained, the product quality is enhanced, and the construction investment and the energy consumption of operation are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

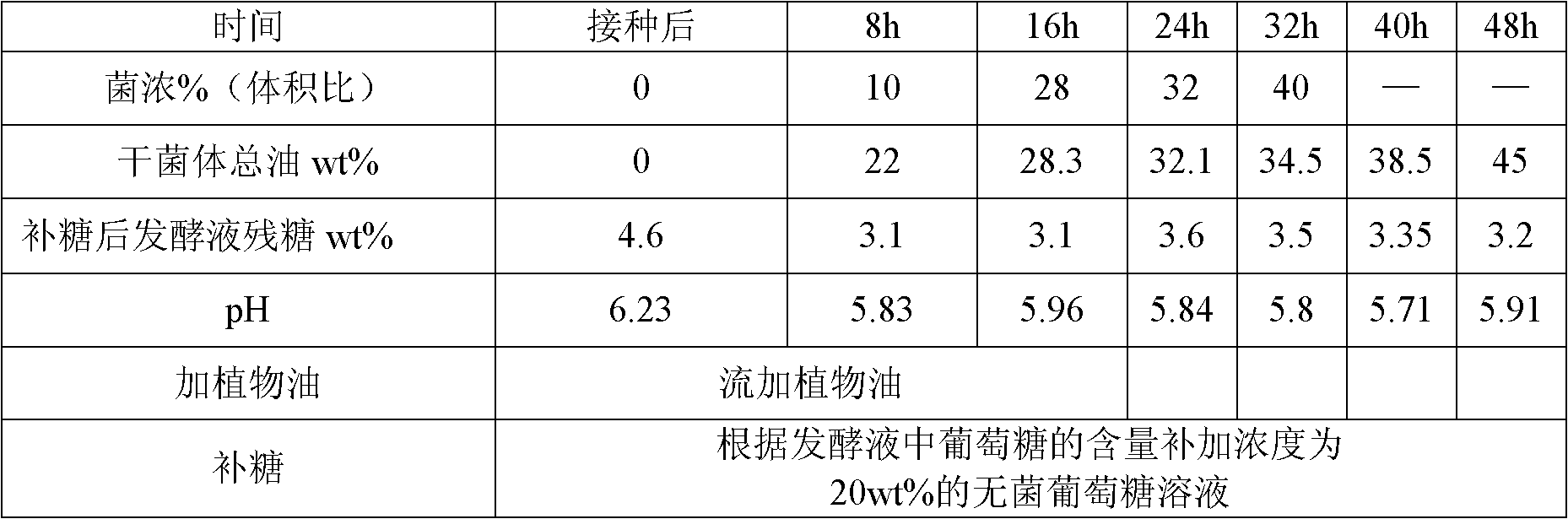

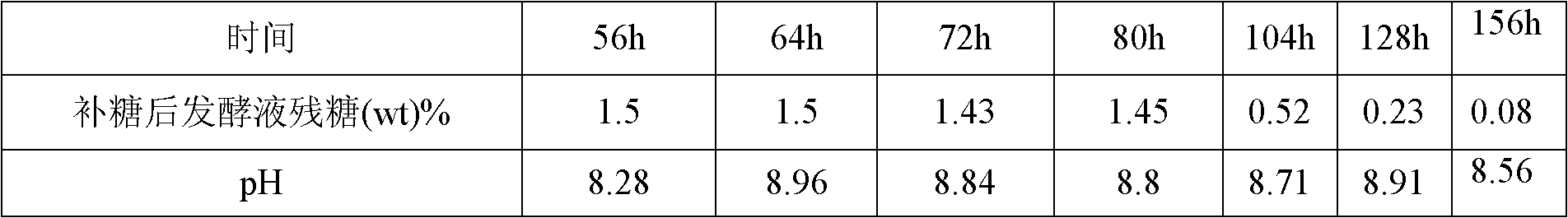

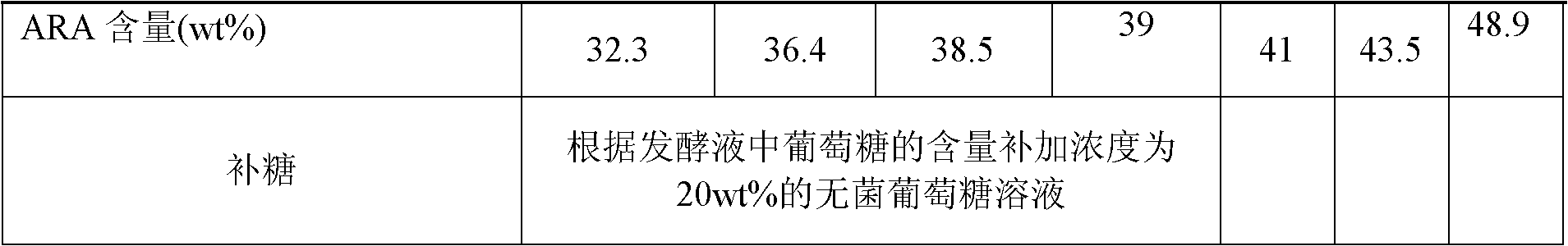

Industry method for producing arachidonic acid grease by using mortierella alpine

InactiveCN102925502AEffective controlSimplified Fermentation RecipeMicroorganism based processesFermentationBiotechnologyCulture fluid

The present invention provides an industry method for producing arachidonic acid grease by using mortierella alpine. The method is characterized by comprising the following steps: activating an original strain; carrying out seed culture; carrying out seed enlarge culture; and carrying out fermentation culture, wherein the fermentation culture comprises an initial fermentation stage, the seed enlarge culture liquid is inoculated in a fermentation tank to carry out stirring culture, glucose and edible oil are supplemented according to the situation, the initial fermentation stage is completed when bacterial concentration of the fermentation broth achieves 40% (by ??volume) and the dried mycelium total oil achieves 40 wt%, a post-fermentation stage starts, the fermentation broth is cooled to a temperature of 23-27 DEG C, sterile ammonia water is concurrently added to adjust the pH value to 8-9, standing fermentation is performed while the glucose content is controlled, the post-fermentation stage is completed when the arachidonic acid content is higher than 45 wt%, and the obtained fermentation broth is subjected to a fermentation treatment to obtain the grease containing the arachidonic acid. The industry method has the following characteristics that: a fermentation formula is simplified, specific yield of the arachidonic acid can be 10 gARA / L fermentation broth through the specific process control, a process is simple and easy to control, and industrial production is achieved.

Owner:CABIO BIOTECH WUHAN CO LTD

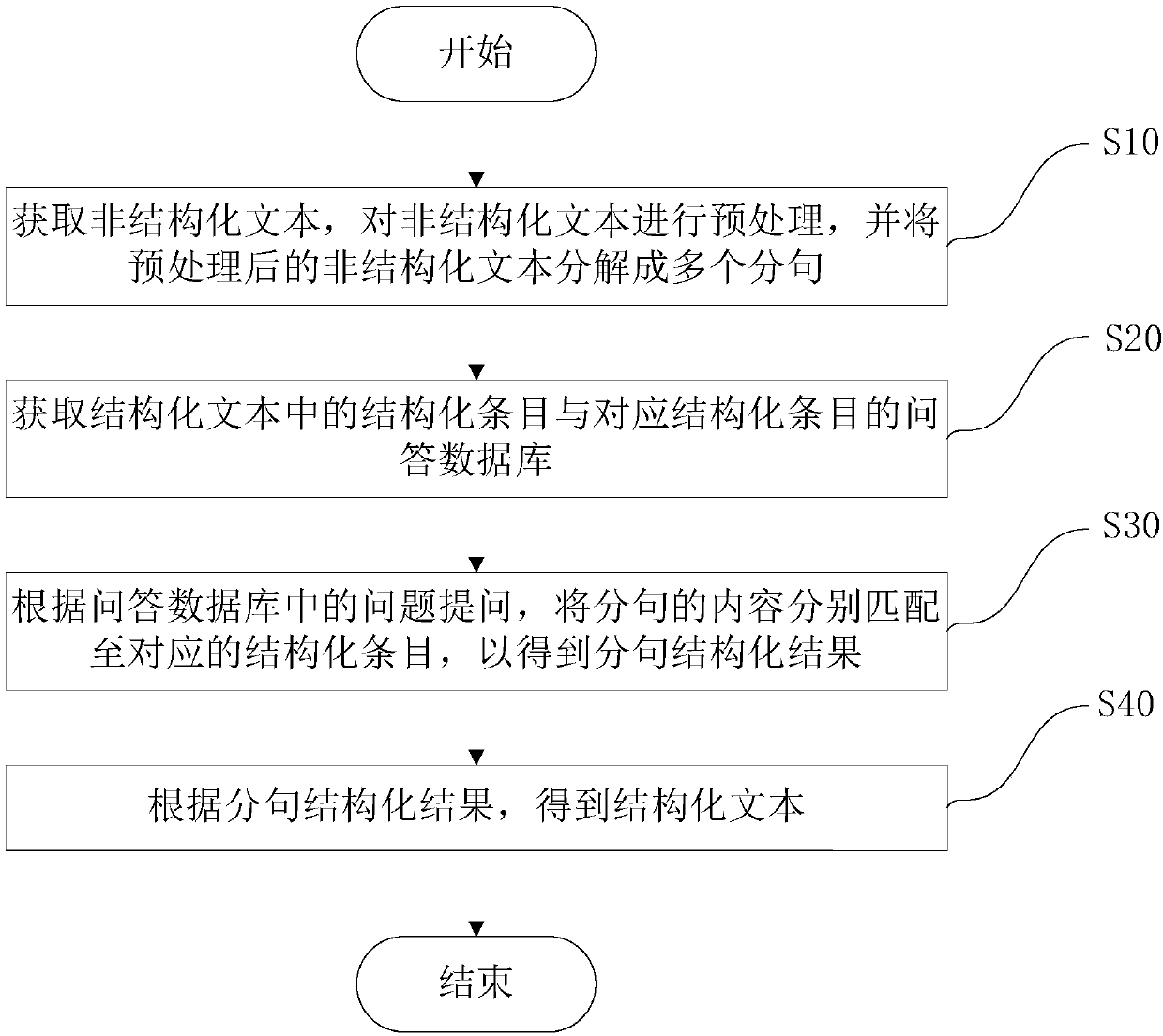

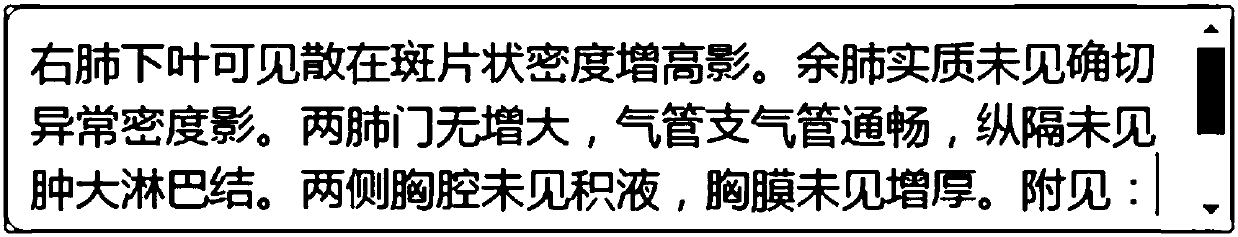

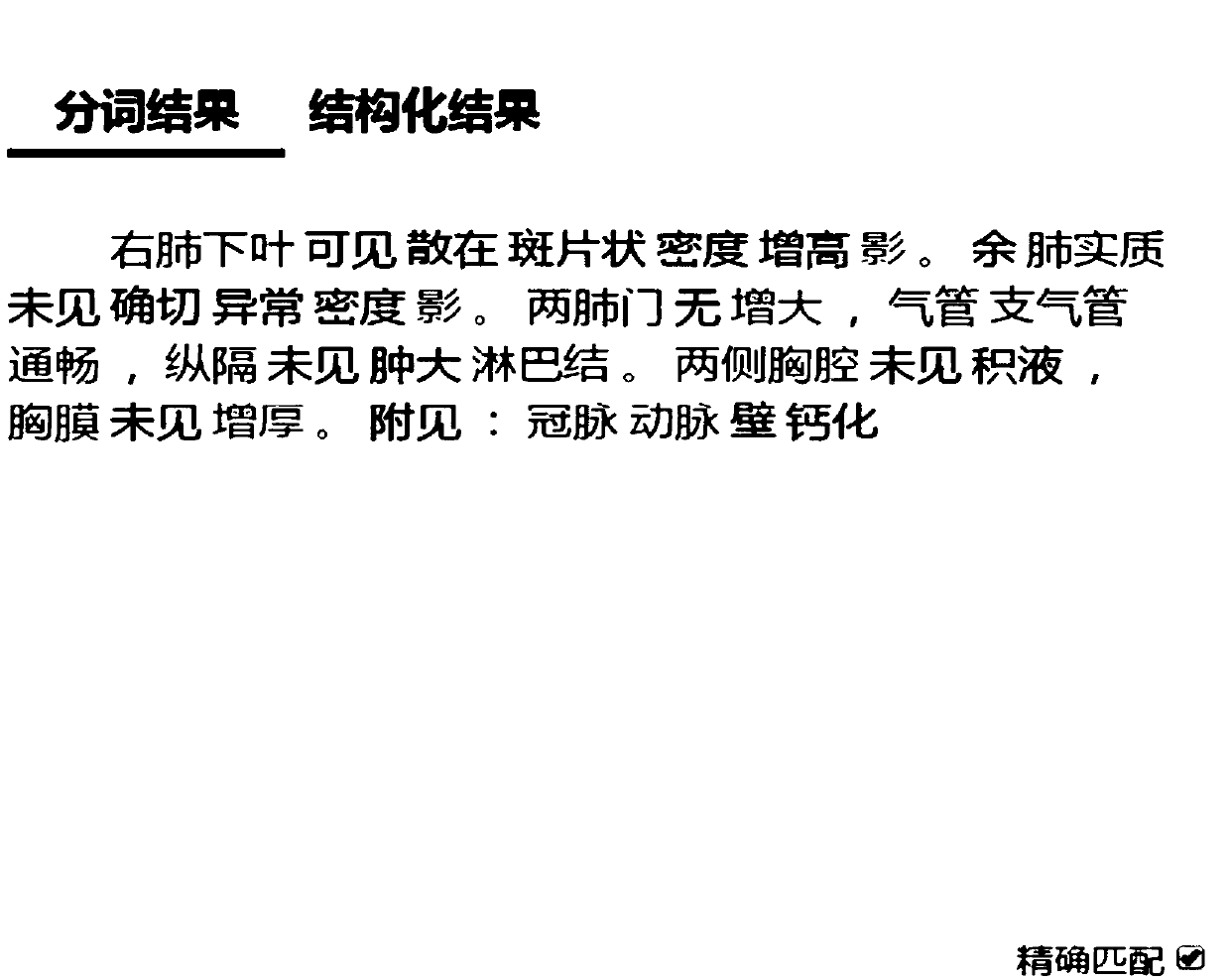

Text structuring method, device and system and nonvolatile storage medium

ActiveCN107729392AGood conversion effectImprove accuracyNatural language data processingSpecial data processing applicationsQuestions and answersData library

The invention relates to a text structuring method, device and system and a nonvolatile storage medium. The method comprises the steps that an unstructured text is obtained and preprocessed, and the preprocessed unstructured text is disaggregated into multiple sub-clauses; structured items in the structured text and question and answer databases corresponding to the structured items are acquired;questions are put according to questions in the question and answer databases, the content of the sub-clauses is matched to the corresponding structured items respectively, and a sub-clause structuring result can be obtained; according to the sub-clause structuring result, a structured text is obtained. According to the text structuring method, device and system and the nonvolatile storage medium,the question and answer databases are combined, unstructured text information can be completely converted into structured information, the conversion effect is good, the accuracy is high, sub-clausesstructuring processing is carried out through two LSTM networks, diversified expression manners in a free text can be processed, and good robustness is achieved.

Owner:GUANGZHOU WOMEN AND CHILDRENS MEDICAL CENTER +1

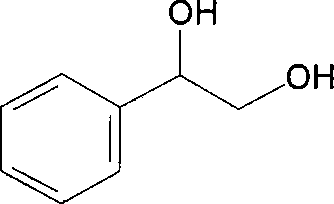

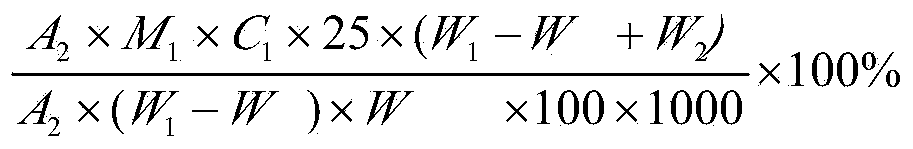

Method for preparing (R)-styrene glycol by employing asymmetric conversion of recombinant strain

ActiveCN101230363APromote conversionIncrease cell massBacteriaMicroorganism based processesEscherichia coliKetone

The invention relates to a method of using recombinant strain to asymmetrically transform and manufacture (R)-phenyl glycol, which belongs to the field of biological catalytic asymmetric transforming technique. The invention inserts the (R)-specific alcohol dehydrogenase gene rcr into the vector pET21c to construct a recombinant plasmid pET-RCR which is transformed to the E.coli to construct the recombinant plasmid E.coli BL21 / pET-RCR. The recombinant strain has the capability of asymmetrically catalyzing the 2-hydroxy phenyl ethyl ketone into (R)-phenyl ethylene glycol. Under optimized reaction condition, the 2.5-10 percent isopropanol is added to pH 8.0 Tris-HCL buffer as an auxiliary substrate, the 0.1-0.4g / ml recombinant cell solution is used for transforming the 0.5-5g / L 2-hydroxy phenyl ethyl ketone substrate for 48h, the product (R)-phenyl ethylene glycol with optical purity of 80-100 percent e.e. and productive rate of 70 to 100 percent is finally gained. The invention not only provides an effective way to manufacture (R)-phenyl ethylene glycol, but also makes sense for developing the biological catalyst for the chiral transformation.

Owner:JIANGNAN UNIV

Microbial strain for preparing androstenedione and application thereof

ActiveCN103382445AAbundant resourcesLow priceBacteriaMicroorganism based processesMicroorganismSterol

The invention discloses a microbial strain for preparing androstenedione. The collection number of the microbial strain is CCTCC NO:M2012522. The preparation of androstenedione by the utilization of the strain comprises the following steps: A, primary seeding tank fermentation: inoculation amount of the strain is 0.5-1.5%, and cultivation is carried out at 160-200rpm and at 0.03-0.07MPa for 30-42h; B, secondary seeding tank fermentation: inoculation amount of the strain is 8-12%, and cultivation is carried out under the same conditions for 20-30h; C, fermentation tank fermentation for conversion to generate androstenedione: inoculation amount of the strain is 10-14%, and cultivation is carried out under the conditions of 27-35 DEG C and 0.03-0.07MPa; and D, termination of conversion: sterol is lower than 0.5%, pH is 8.9-9.0, discharging, heating to 90-100 DEG C and keeping for 30-50min, cooling to 30-50 DEG C, stopping stirring and standing for 4-6h. The invention provides a high-efficiency fermentation strain of mycobacterium. Meanwhile, a surfactant, soya-bean oil and a broth are used to form a two-way system. The fermentation technology is improved, and feeding amount of raw materials and conversion rate of microorganisms are greatly raised.

Owner:HUBEI GONGTONG BIOLOGICAL SCI & TECH

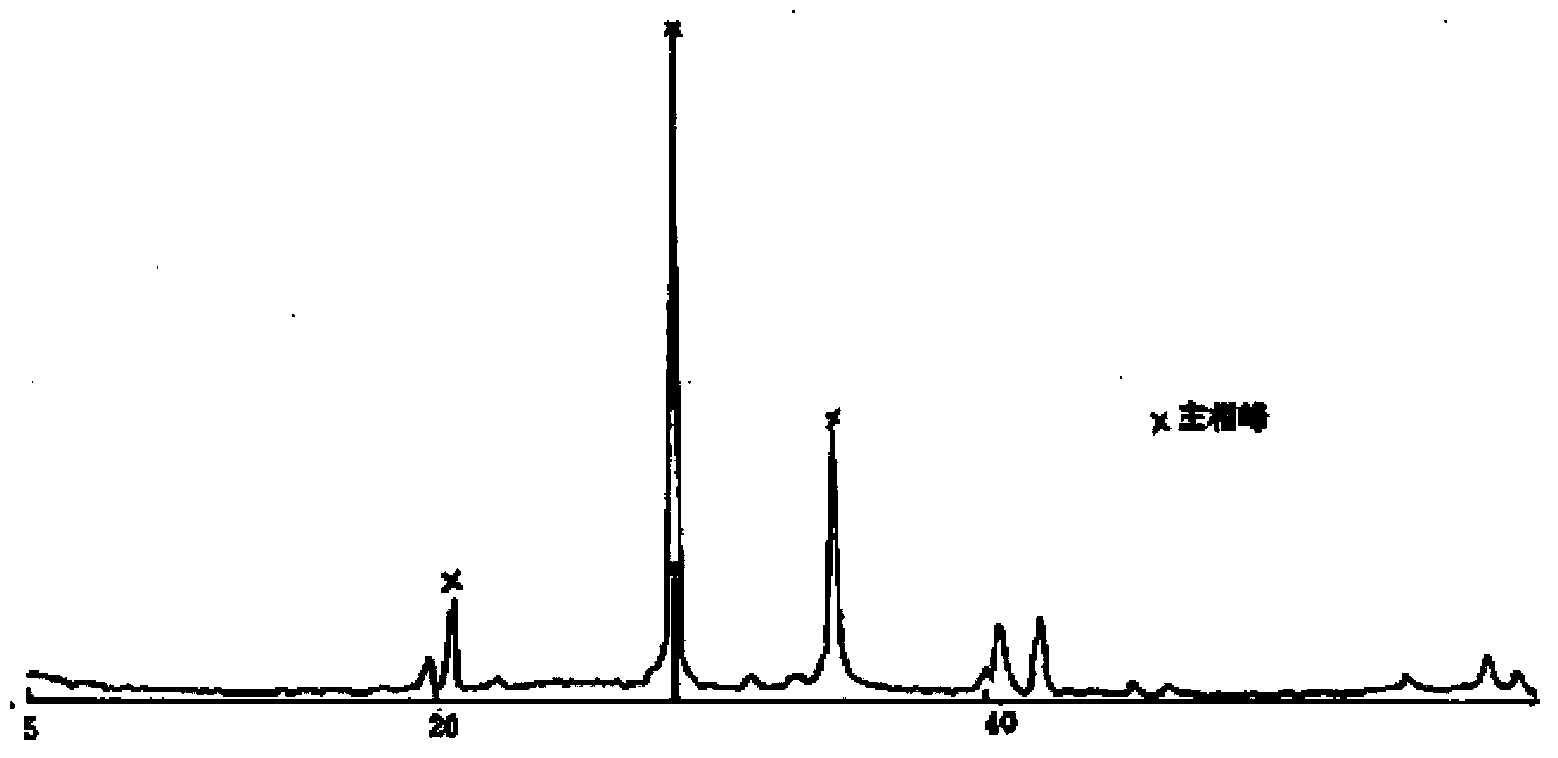

Hydrocracking method of high-yield high-quality chemical raw material

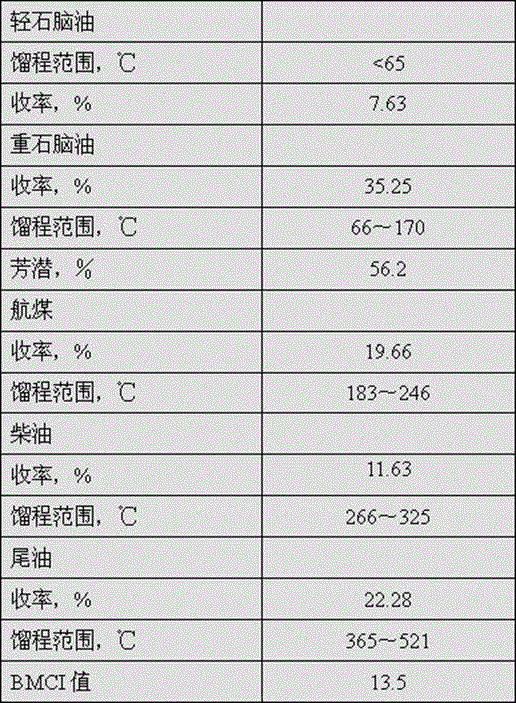

ActiveCN103773452AGood choiceFang QiangaoTreatment with hydrotreatment processesMolecular sievePetroleum naphtha

The invention discloses a hydrocracking method of a high-yield high-quality chemical raw material. According to the hydrocracking method comprises following steps: raw oil and hydrogen are subjected to hydrofinishing and are delivered through a first cracking reaction zone successively, and middle fraction oil is obtained via separation, and is delivered to a second cracking reaction zone for cracking; the first cracking reaction zone comprises two cracking catalysts, an upper zone is filled with a catalyst I, and a lower zone is filled with a catalyst II; the catalyst I comprises 30 to 70% of modified Y molecular sieve; the catalyst II comprises 15 to 50% of modified Y molecular sieve; and the content of the modified Y molecular sieve in the catalyst I is 10 to 30% higher than that in the catalyst II. Acid center of the catalyst I matches hydrogenation center, and the catalyst I possesses excellent heavy naphtha selectivity; and the catalyst II possesses excellent aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components into smaller molecules so as to distribute in heavy petroleum fractions. The two catalysts are combined, so that demands of the high-yield high-quality chemical raw material are satisfied.

Owner:CHINA PETROLEUM & CHEM CORP +1

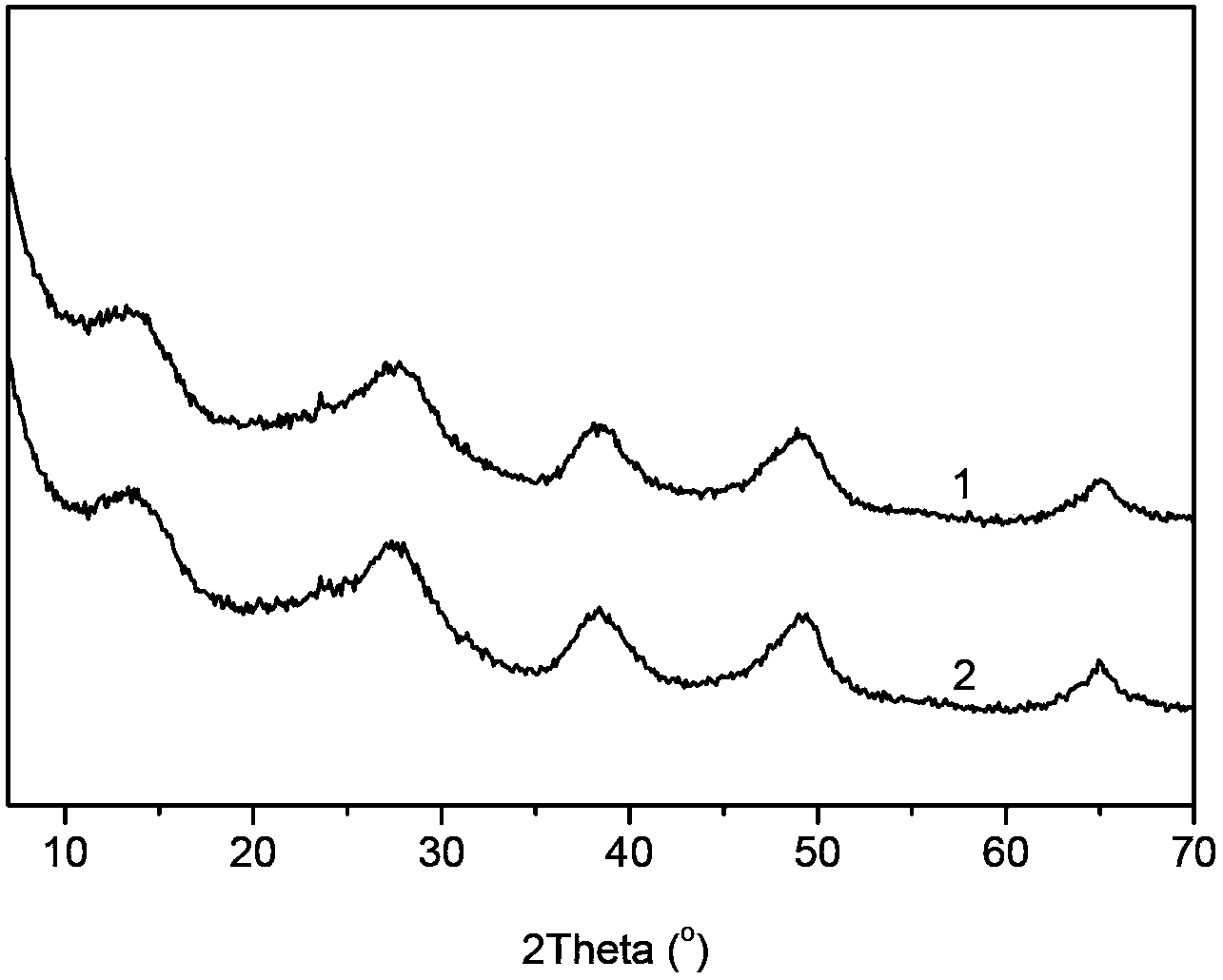

Multifunctional catalysis composition

ActiveCN103566962AGood catalytic coke gasification abilityLower gasification temperatureCatalytic crackingMolecular sieve catalystsBoehmiteOxide

A multifunctional catalysis composition comprises 1-50wt% of a mesoporous aluminosilicate material, 1-40wt% of a gasification active component, 1-60wt% of a cracking active component, 0-70wt% of clay and 5-97wt% of a heatproof inorganic oxide matrix, wherein the mesoporous aluminosilicate material has a phase structure of pseudo-boehmite, has an anhydrous chemical expression formula of (0-0.3)Na2O.(40-90)Al2O3.(10-60)SiO2 by weight of oxide, and has a specific surface area of 200-400m<2> / g, a pore volume of 0.5-2.0mL / g, an average aperture of 8-20nm and a most probable aperture of 5-15nm The catalysis composition can reduce the gasification temperature of the cracking gasification conversion of hydrocarbon oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Two-stage hydrocracking method used for producing high-quality chemical raw materials

ActiveCN103773462AReduce the impactIncrease hydrogen partial pressureTreatment with hydrotreatment processesMolecular sieveLiquid product

The invention discloses a two-stage hydrocracking method used for producing high-quality chemical raw materials. The two-stage hydrocracking method comprises following steps: (1) raw material oil is mixed with hydrogen, and an obtained mixture is subjected to hydrofinishing reaction; (2) a refining reaction product is subjected to gas-liquid separation; (3) an obtained liquid product and hydrogen are subjected to hydrocracking reaction, and are contacted with a catalyst I and a catalyst II successively, wherein molecular sieve content of the catalyst I and molecular sieve content of the catalyst II are different; and (4) a hydrocracking effluent is subjected to separation and fractionation so as to obtain a plurality of hydrocracking products. The molecular sieve content of the hydrocracking catalyst I is higher, acid center of the hydrocracking catalyst I matches hydrogenation center, and the hydrocracking catalyst I possesses excellent heavy naphtha selectivity; and the catalyst II possesses excellent aromatic hydrocarbon transformative capacity, and is capable of transforming aromatic hydrocarbons in heavier components of the raw material oil into smaller molecules so as to distribute in heavy petroleum fractions. The two hydrocracking catalysts with different molecular sieve contents are combined, so that aromatic hydrocarbon potential content of heavy naphtha is increased, and tail oil BMCI value is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-use functional fertilizer and preparation method thereof

ActiveCN103922855AAdjustable pHImprove adsorption capacityFertilizer mixturesSophocarpidineAdditive ingredient

The invention discloses a multi-use functional fertilizer and a preparation method thereof, and belongs to the technical field of fertilizers, and the multi-use functional fertilizer can be used for solving the problems of short fertilizer effect, single fertilizer effect, single function and easiness in causing land hardening and desertification. The fertilizer is prepared by fermenting nitrogen phosphorus and potassium, Chinese herbal medicine ingredients, sophocarpidine, humic acid, medium trace elements, biological bacteria and polypeptides, wherein the medium trace elements are calcium, magnesium, sulfur and silicon as well as iron, boron, manganese and zinc, and have the same amount; the Chinese herbal medicine ingredients are platycodon grandiflorum, lycoris radiate, nerium indicum, equisetum arvense, equisetum ramosissimum, elderberries, ailanthuses, xanthium sibiricum and polygonatum sibiricum. According to the fertilizer, the phenomena of soil hardening, deterioration, dysbacteriosis and the like caused by multi-year application of chemical fertilizers can be reduced and the root nutrient adsorption, transportation, storage and conversion capability is facilitated; after the fertilizer is applied, the yield of vegetables and the like can be increased by 20%-30%, the yield of fruit trees can be increased by 10%-20%, and the yield of economic crops such as peanuts and cotton can be increased by 10%-15%.

Owner:SHENGTAI BIOENG CO LTD OF JILIN WANTONG PHARMACY GRP CO

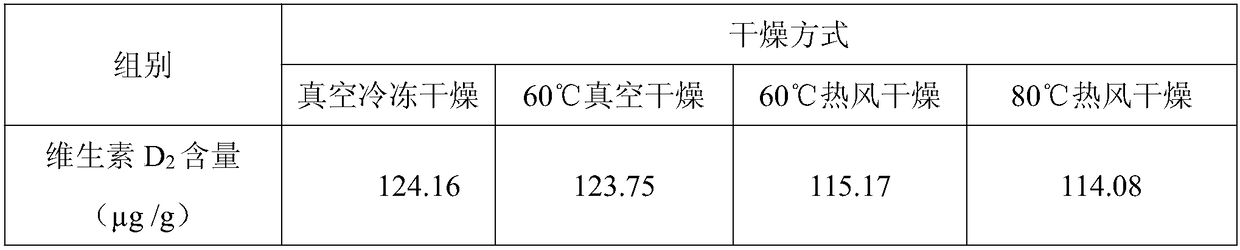

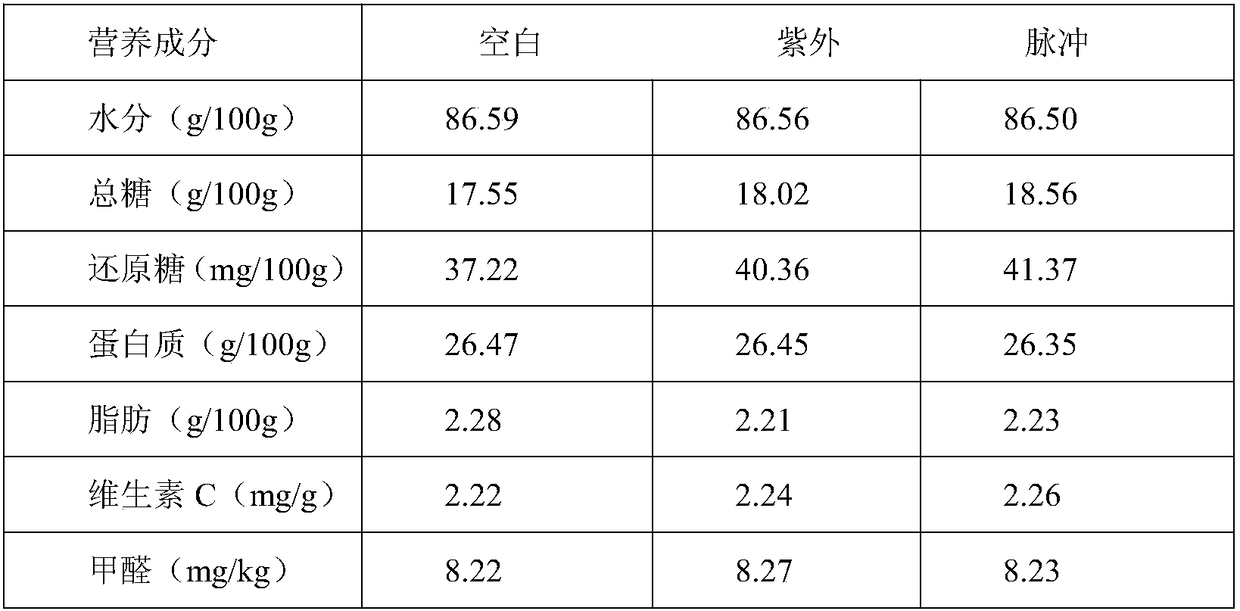

Method for increasing vitamin D2 in edible mushrooms

InactiveCN108185408AOther quality effectsDoes not cause changes in color and shapeFood scienceVitamina D2Edible mushroom

The invention provides a processing method for increasing vitamin D2 in edible mushrooms. The processing method comprises the following steps of performing radiation treatment on the edible mushroomsby pulse glare, wherein the spectral of pulse glare consists of UV-A of which the wavelength is 315nm-400nm, UV-B of which the wavelength is 280nm-315nm and UV-C of which the wavelength is 200nm-280nm. According to the processing method disclosed by the invention, the pulse glare treatment is adopted, so that the situation that ergosterol in the edible mushrooms is converted into vitamin D2 can bequickly promoted, and the effect of the processing method is far better than that of ultraviolet radiation; and before the pulse glare treatment is performed, the edible mushrooms are cut into slices, so that the conversion rate of the ergosterol can be obviously increased, and the browning reaction degree of fruiting bodies cannot be increased.

Owner:陈麒宇

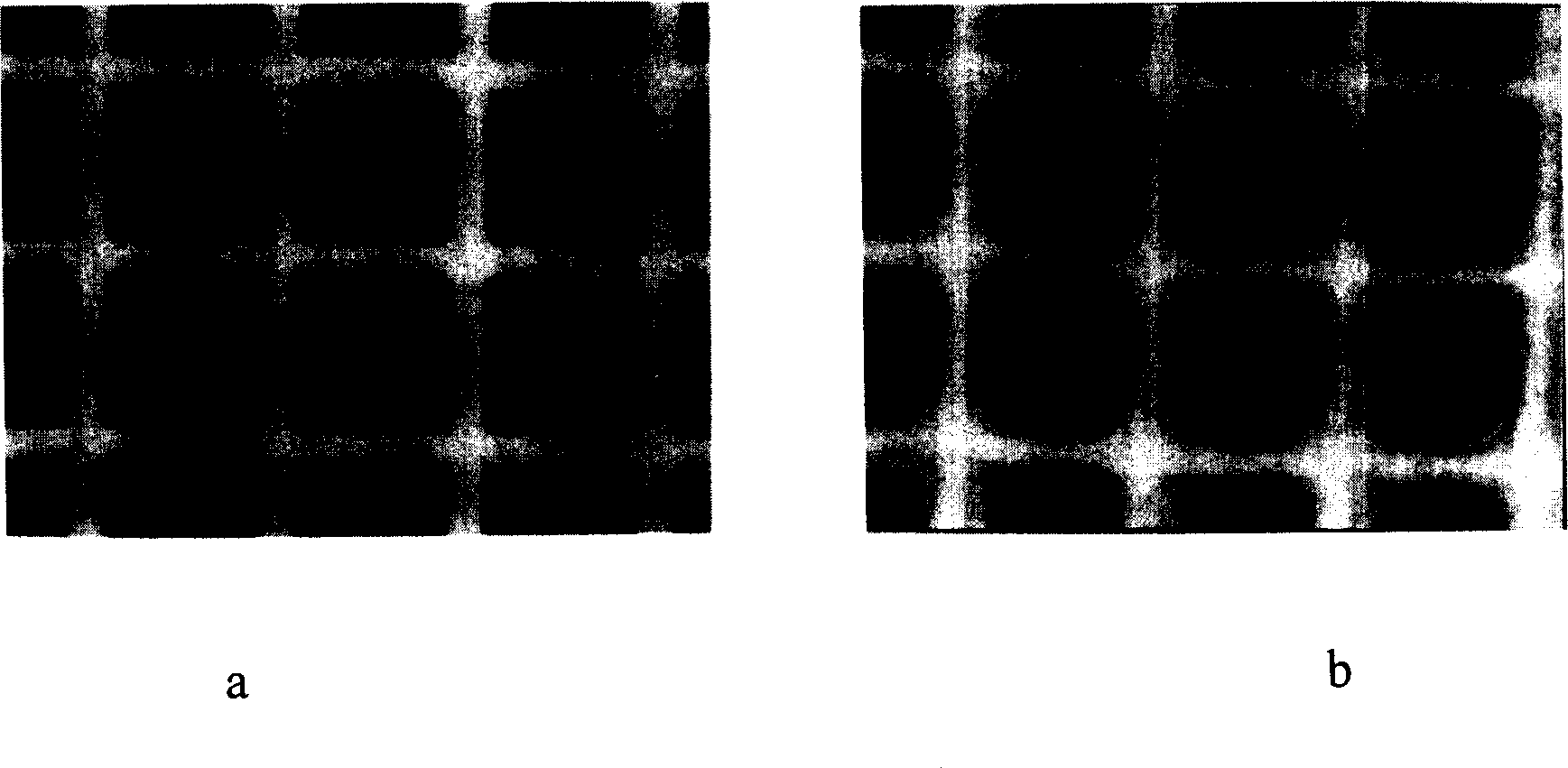

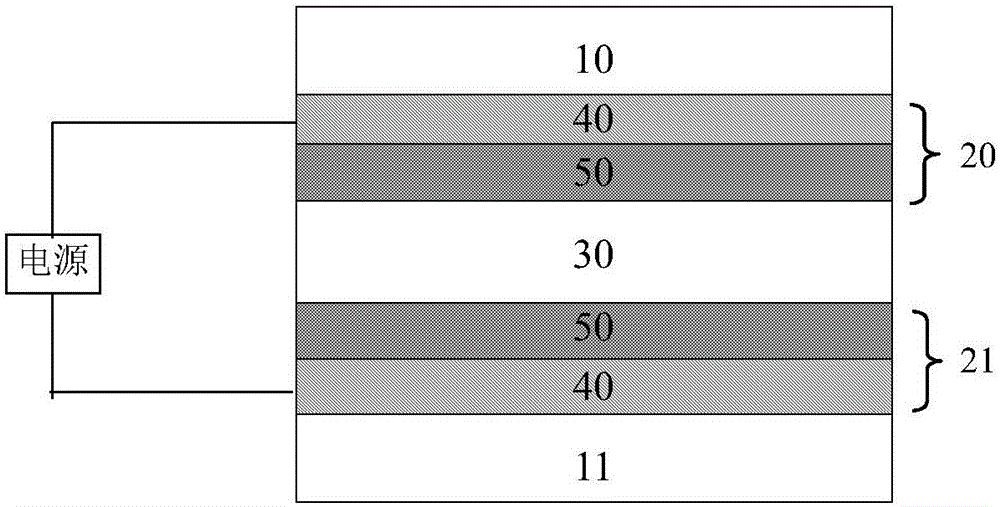

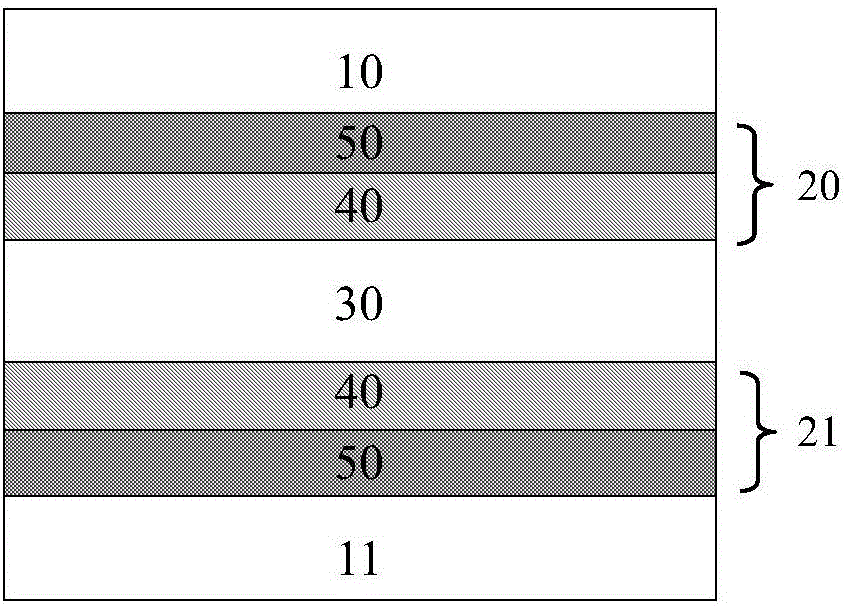

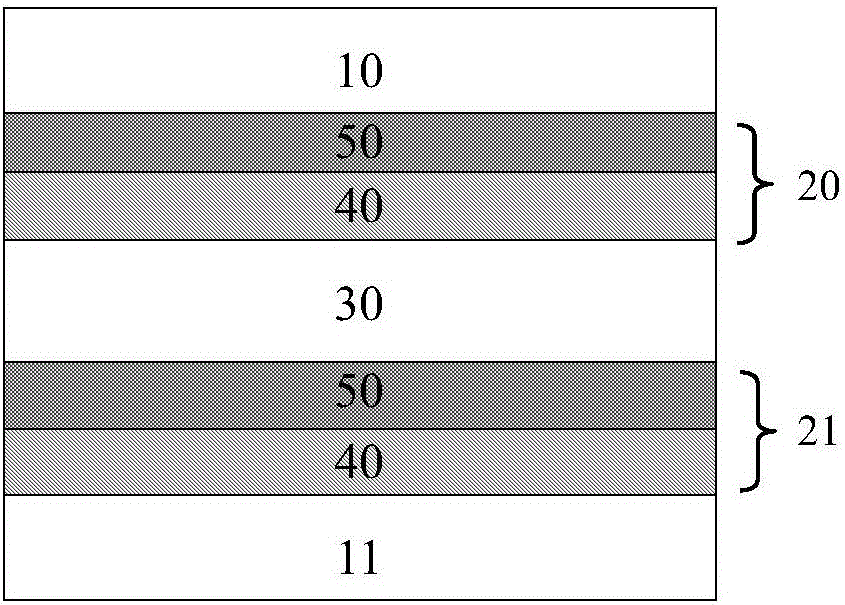

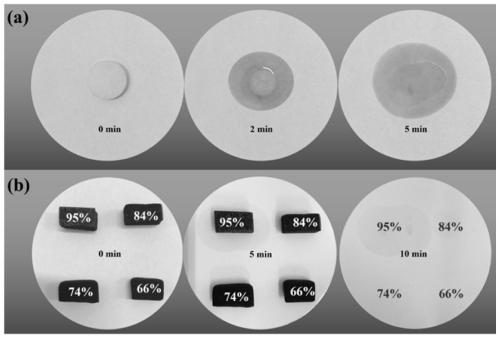

Polymer-dispersed liquid crystal light dimming device

InactiveCN106154617ARealize the purpose of dimmingSimple structureNon-linear opticsMicro structureRefractive index

The invention discloses a polymer-dispersed liquid crystal light dimming device. The polymer-dispersed liquid crystal light dimming device comprises an upper transparent base material, a first function layer, a polymer-dispersed liquid crystal layer, a second function layer and a lower transparent base material which are sequentially arranged. The first function layer and the second function layer comprise conducting layers, at least one function layer comprises a micro structure layer, the polymer-dispersed liquid crystal layer has capacity that the optical refractive ratio can be converted from n1 to n2 in voltage driving, the particle diameter of liquid crystal particles is smaller than 100nm, the refractive ratio of the micro structure layer is n, and the n is equal to n1 or n2. The refractive ratio of the polymer-dispersed liquid crystal layer can be changed by controlling a switch of a power supply. Due to refractive ratio difference between the micro structure layer and the polymer-dispersed liquid crystal layer, a transparent state can be achieved when the refractive ratios are the same, and a foggy state can be achieved when the refractive ratios are different; thus, the transparent state can be changed to a foggy state, and the purpose of dimming light is achieved. The polymer-dispersed liquid crystal light dimming device is simple in structure, easy for industrial production and good in converting effect, and the fog scale can be adjusted at will according to need.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Ecological restoration method for geological collapse area

The invention provides an ecological restoration method for a geological collapse area. The ecological restoration method comprises the following steps that gangue is employed as fillers to fill into a collapse area and then the area is flattened by a bulldozer; the gangue layer is solidly pressed by a road roller; a soil coating layer is paved on the gangue layer; the soil coating layer is formed by 30 to 60wt% of sludge, 30 to 50wt% of gangue and 10 to 30wt% of coal ash; surface soil layer with thickness of 0.3 to 0.5cm is paved on the soil coating layer; the surface soil layer is formed by loess, coal ash, sludge, ureaformaldehyde, bacterial manure and polyacrylamide with proper proportions; and at last, Chinese pines, Populus davidiana and leguminosae trees are mixedly planted on the surface soil layer. By the use of the method, productivity of reconstructed soil can be restored and enhanced in short time, soil environment quality can be improved and soil ecological system can be restored; and the method is simple and easy to operate.

Owner:SUZHOU GOLD MANTIS GREEN LANDSCAPE LIMITED

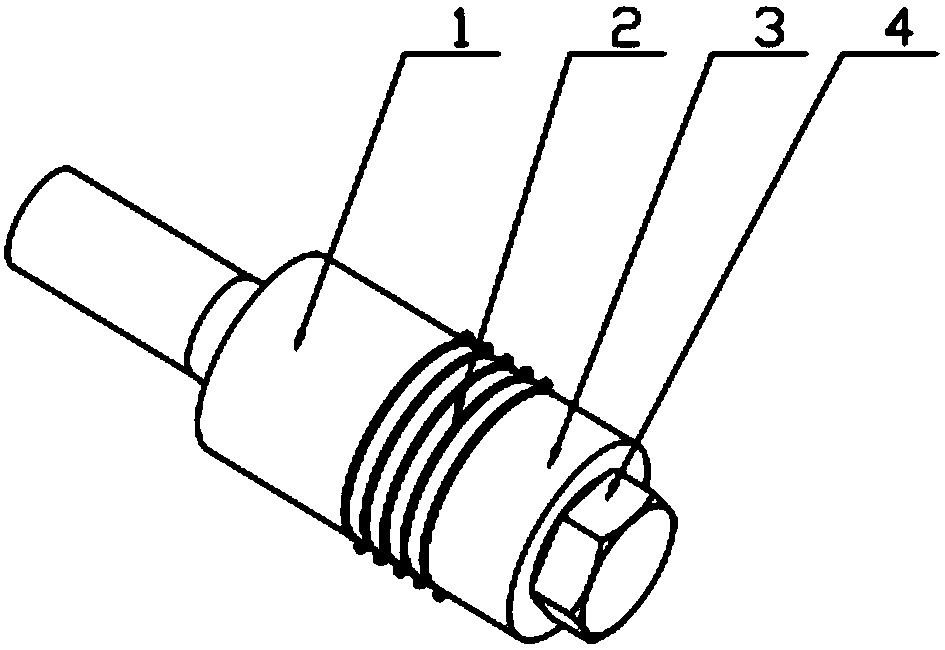

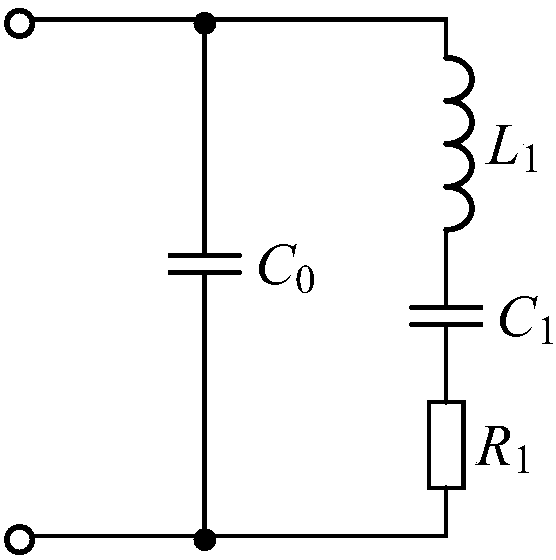

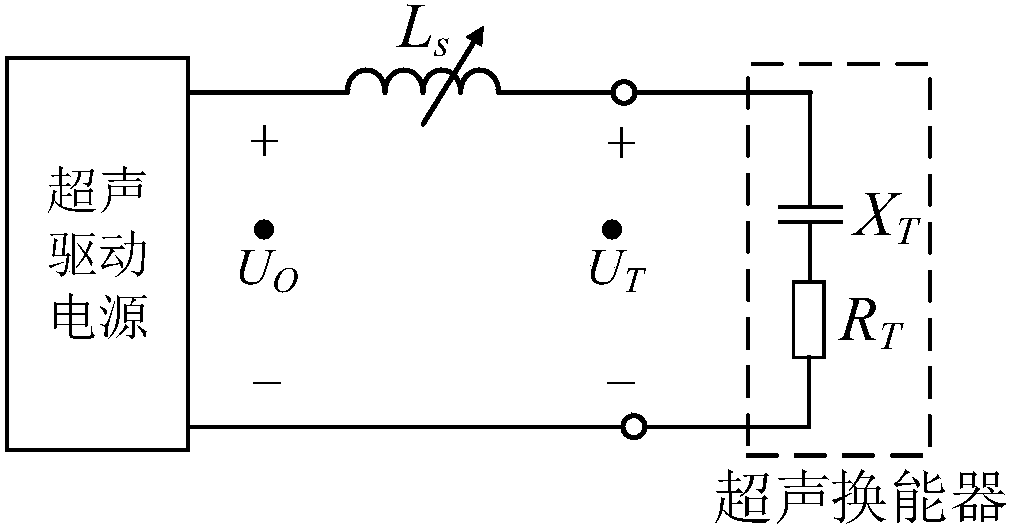

Ultrasonic transducer excitation frequency selection method

ActiveCN108566114AGood conversion effectLarge amplitudePiezoelectric/electrostriction/magnetostriction machinesElectrical resistance and conductanceCritical condition

The invention provides an ultrasonic transducer excitation frequency selection method. The method comprises the steps that as for the ultrasonic transducer to be processed, the frequency sweep range of the ultrasonic transducer is determined according to the parameters of the ultrasonic transducer; the resistance and reactance values of the ultrasonic transducer under each frequency node are acquired according to each frequency node within the frequency sweep range; the screening critical condition used for screening the working frequency of the ultrasonic transducer is determined according tothe resistance and reactance values of each frequency node within the frequency sweep range; and at least one frequency node is selected out of the frequency sweep range to act as the working frequency of the excitation ultrasonic transducer according to the screening rules and the screening critical condition. The ultrasonic transducer and the external matching inductance are enabled to generatecoupling resonance by the excitation frequency of the ultrasonic transducer selected by the method so as to achieve the optimal conversion effect from electric energy to mechanical energy, the amplitude is maximum and vibration is stable.

Owner:BEIHANG UNIV

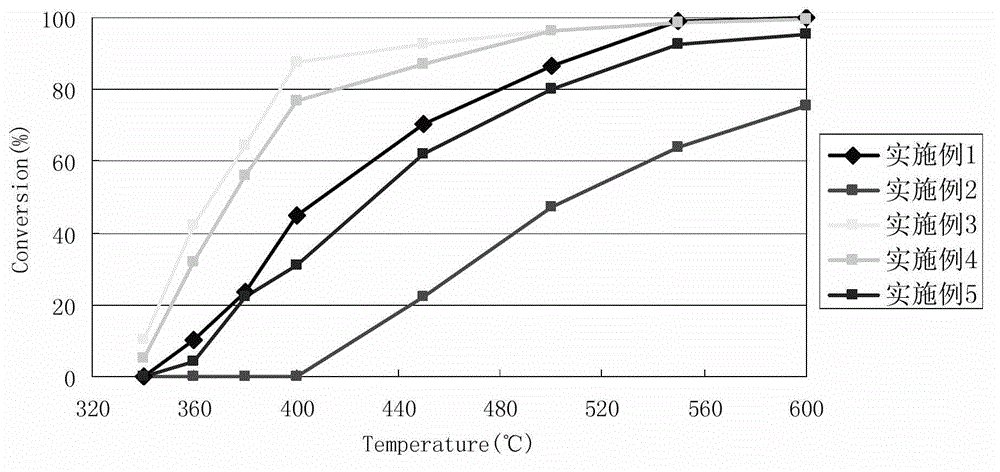

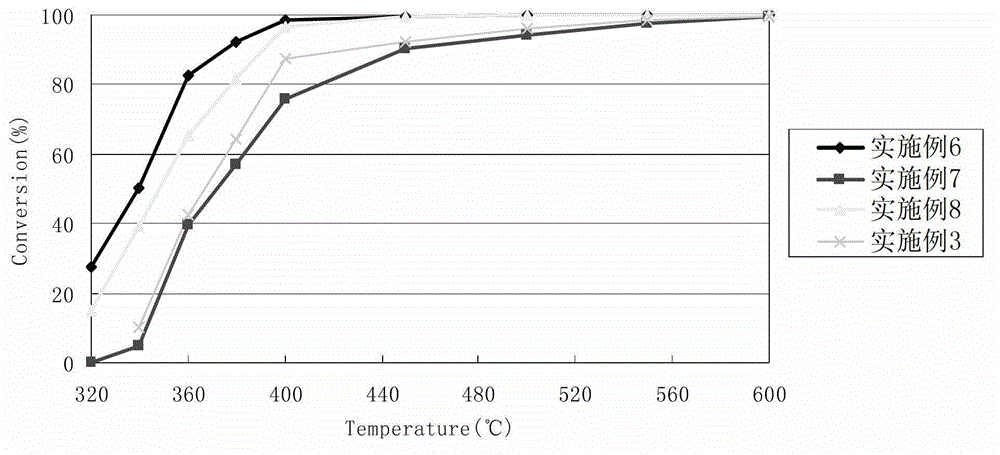

Catalyst suitable for processing tail gas of lean-burn natural gas vehicle and preparation method thereof

ActiveCN102974343AEasy to preparePracticalDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMischmetalRare earth

The invention discloses a catalyst suitable for processing the tail gas of a lean-burn natural gas vehicle and a preparation method thereof. The catalyst is prepared through the following steps of: loading rare earth metal on a carrier gamma-AL2O3, painting precious metal, and drying and calcining carrier gamma-AL2O3 coated with the precious metal, wherein the precious metal is Pt and / or Pd, and the rare earth metal is Zr, Y, La and / or Ce; the weight percentage of the precious metal is 2.0%, wherein the weight ratio of Pt to Pd is (1-0):(0-1); and the weight percentage of the rare earth metal Zr is 10%, the weight percentage of the rare earth metal Y is 0-10%, the weight percentage of the rare earth metal La is 0-10%, and the weight percentage of the rare earth metal Ce is 0-10%. The preparation method of the catalyst, which is disclosed by the invention, has the advantages of simplicity, easiness in controlling the preparation process conditions, and high practicability. Through the detection, the catalyst has favorable CH4 conversion performance, and has a favorable effect in processing the tail gas of lean-burn natural gas vehicles so as to enable the tail gas to meet various corresponding national standards and requirements.

Owner:SINOCAT ENVIRONMENTAL TECH

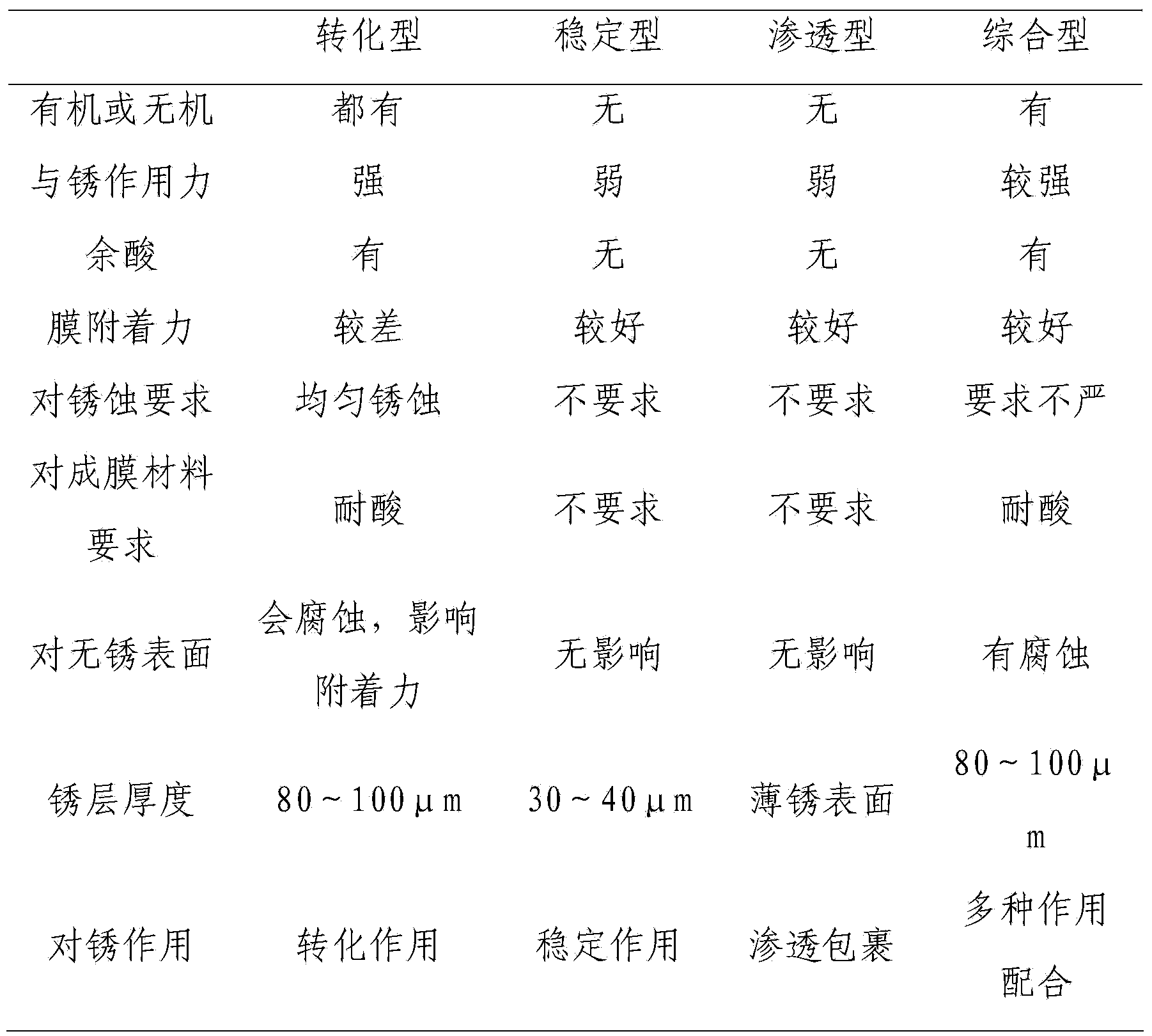

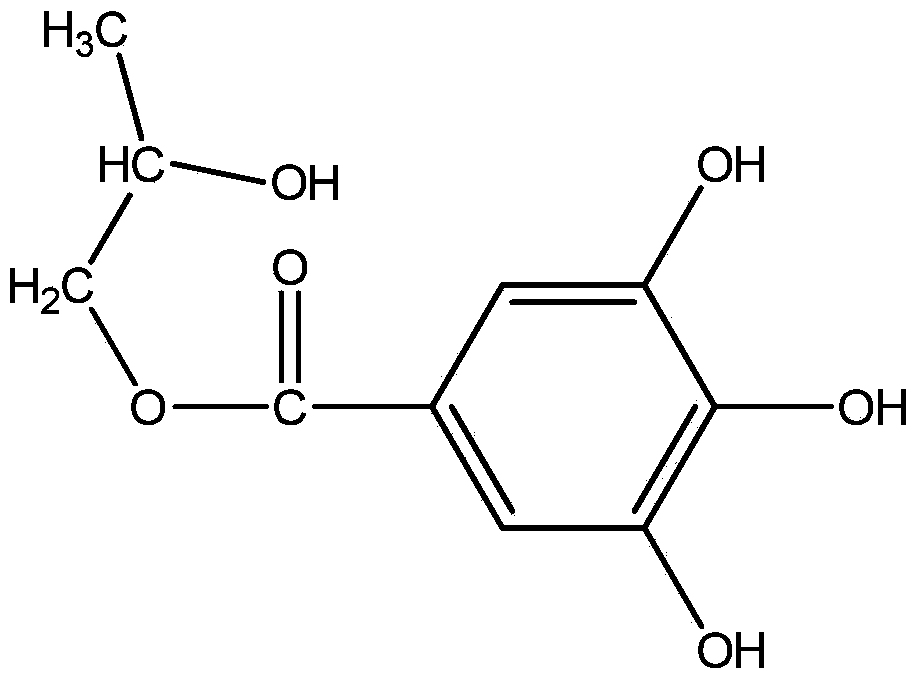

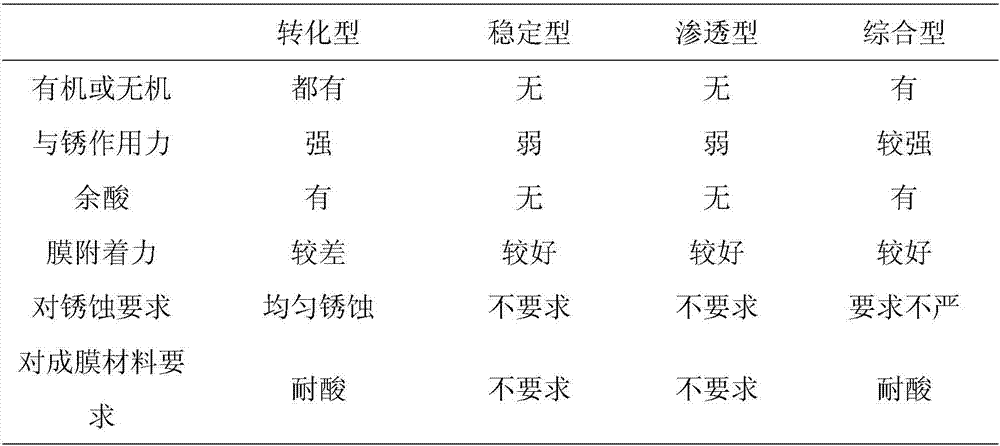

Rust transforming agent and preparation method thereof, water-based iron rust conversion coating and preparation method thereof

InactiveCN103849862AImprove water resistanceImprove stabilityAnti-corrosive paintsMetallic material coating processesWater basedGallic acid ester

The invention belongs to the technical field of a metal anti-corrosion coating, and particularly relates to a rust transforming agent and a preparation method thereof, a water-based iron rust conversion coating and a preparation method thereof. The rust transforming agent comprises a step of synthesizing 2-hydroxypropyl 3,4,5-trihydroxybenzoic acid by taking a gallic acid, 1,2-propylene glycol and a p-toluenesulfonic acid as initial raw materials, wherein the rust transforming agent contains 18.5-26.7% of gallic acid, 66.6-74% of 1,2-propylene glycol, and 6.6-7.5% of p-toluenesulfonic acid; the water-based iron rust conversion coating is prepared from a vinylidene chloride composite polymer emulsion, ethylene glycol butyl ether, filling slurry prepared in the step (1) and the rust transforming agent. The prepared rust transforming agent disclosed by the invention is good in water tolerance, strong in stability, and good in matching property with a water paint and an oil paint.

Owner:SHANDONG UNIV OF SCI & TECH

Method for improving tobacco stalk quality by combining steam explosion and anaerobic treatment technology

InactiveCN101933655AFluffy structureImprove the smoke effectTobacco preparationTobacco treatmentProcess engineeringAnaerobic microorganisms

The invention discloses a method for improving tobacco stalk quality by combining steam explosion and anaerobic treatment technology. The method comprises the following steps of: performing steam explosion on tobacco stalks by using a steam exploder; placing the exploded tobacco stalks in a sealed container, adding anaerobic microorganisms into the container and forming an anaerobic environment in the container to perform anaerobic treatment by vacuuming or filling the container with an inert gas; taking the tobacco stalks out of an anaerobic treatment container and quickly dehydrating at the low temperature to control water content to be about 20 to 30 percent; and finally slicing the dehydrated tobacco stalks for the production of cigarette. The method can improve the amount of the tobacco stalk added during the production of the cigarette on the premise of not influencing the aesthetic quality of the cigarette, so that the cigarette cost is effectively reduced.

Owner:CHINA TOBACCO CHUANYU IND

SWSR-8 pressurization sulfur recovery process

ActiveCN105947992AEmission reductionReduce sizeEnergy inputSulfur preparation/purificationSulfurFlue gas

The invention belongs to the field of sulfur recovery, and particularly relates to an SWSR-8 pressurization sulfur recovery process. The process comprises the steps that acid gas enters a sulfur making furnace, H2S is subjected to a high-temperature Claus reaction and converted into sulfur, and sulfur enters a two-stage converter to conduct two stage catalytic conversion for recovering sulfur; sulfur making tail gas enters a hydrogenation reactor, under the action of a hydrogenation catalyst, SO2 and COS are reduced to H2S through hydrogenation hydrolysis, reduced H2S gas is absorbed with an MDEA solution, and after purified tail gas recovers heat through incineration, flue gas is exhausted to the atmosphere through a chimney, wherein the pressure of acid gas entering the sulfur making furnace ranges from 90 kPa(g) to 120 kPa(g), and the pressure of the sulfur making furnace ranges from 90m kPa(g) to 120 kPa(g). The pressure of cooling and heat exchange equipment such as a sulfur making waste heat furnace, a first stage sulfur condenser, a second stage sulfur condenser, a third stage sulfur condenser, a steam generator and a tail gas waste heat boiler is higher than that in the prior art, the total heat transfer coefficient is increased, the occupied area is decreased, catalytic and absorption reactions can be conducted conveniently, the sulfur recovery rate is increased, and SO2 discharge is reduced.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

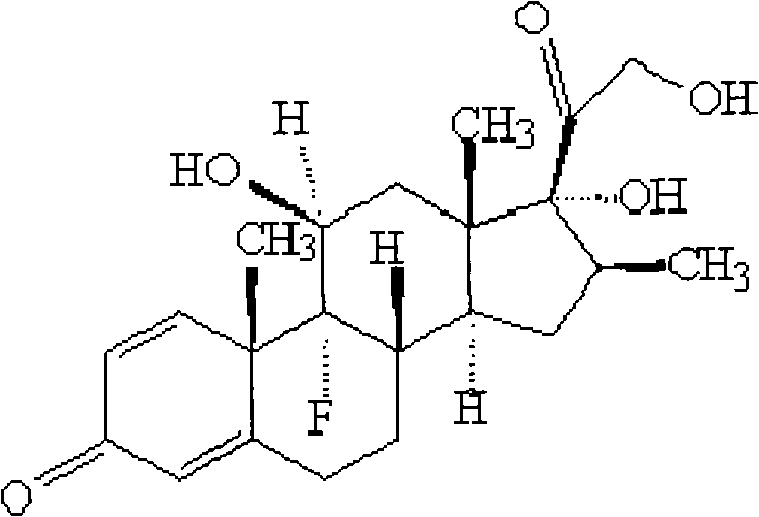

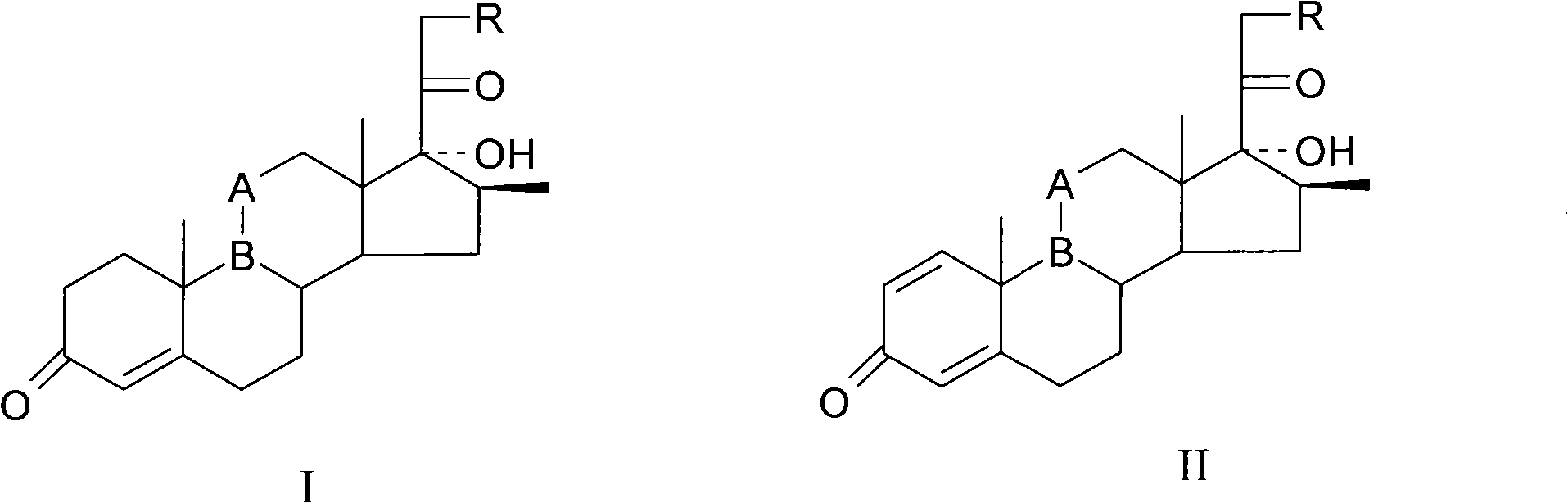

Preparation process of betamethasone intermediate

InactiveCN102071240AHigh yieldQuality improvementMicroorganism based processesFermentationCompound (substance)Betamethasone

The invention discloses a preparation process of a compound shown in a formula II. The compound is prepared from a compound shown in a formula I by biological fermentation and dehydrogenation, and in the processes of biological fermentation and dehydrogenation, an inert grinding material is added in fermentation liquid. In the invention, the fermentation manner is improved under a condition of using a common arthrobacter simplex strain; and a proper amount of inert grinding material is added in the fermentation liquid so that the yield and the quality of a compound product (namely a betamethasone intermediate) in the formula II are improved under the condition that the feeding concentration is maintained to be over 0.5%, and the production cost of betamethasone is reduced. In addition, no chemical solvent is used in the preparation process, and thus the cost for auxiliary materials is saved.

Owner:ZHEJIANG XIANJU PHARMA

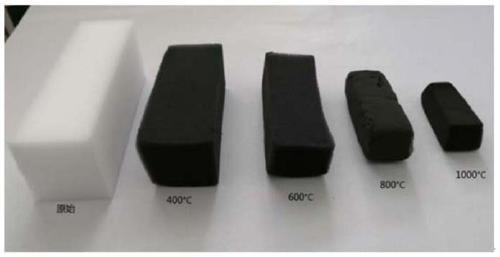

Phase-change composite material with photo-thermal conversion function and preparation method thereof

ActiveCN110257019AGood size controlEasy to processSolar heating energyOther chemical processesDecoyThermal energy storage

The invention discloses a phase-change composite material with a photo-thermal conversion function and a preparation method thereof, and belongs to the cross field of phase-change energy storage and energy conversion. The multifunctional phase change composite material is prepared by combining Ti2O3 nano particles with a heat storage phase change material for the first time, so that a photo-thermal conversion function is expected to be provided on the basis of phase-change heat storage and temperature control functions, and the carbon foam-based phase-change composite material which is is easy to cut and process, has a controllable appearance size, has light weight and flexibility, and has photo-thermal conversion performance is provided. Due to the three-dimensional porous carbon foam matrix of the phase change composite material, the phase-change material can be stably stored, and the storage capacity can be regulated and controlled. The phase-change composite material has excellent photo-thermal conversion and temperature adjusting functions and can be used in the aspects of heat energy storage and release, thermal insulation, photo-thermal conversion, infrared stealth and infrared decoy of military equipment, and the like.

Owner:JIANGNAN UNIV

Dendrobium kudzu eucommia bark functional food

InactiveCN101444303AFully functionEasy to useDigestive systemImmunological disordersProtective drugsLung

The invention provides a dendrobium kudzu eucommia bark functional food, and relates to a health food which can offer auxiliary protection for chemical liver injury and improve immunity, in particular to a health care functional food which takes dendrobium as a monarch drug. The food is prepared by uniformly mixing dendrobium powder with granularity no less than 60 meshes, kudzu extractive with eucommia bark extractive, and the dendrobium powder, the kudzu extractive and the eucommia bark extractive are mixed by the following weight fraction: 6-10 parts of dendrobium, 1-3 parts of kudzu extractive, and 1-2 parts of eucommia bark extractive. The functional food is characterized in that a liver-protective drug which is homology of medicine and food, a drug of nourishing yin and varieties which have the function of tonifying yang are organically combined by a reasonable method to produce a health food with remarkable effects. The functional food has the efficacy of protecting liver, improving eyesight, moistening lung, nourishing stomach, and adjusting the equilibrium between yin and yang in human body, and can achieve the effect of notably improving chemical liver injury and a series of symptoms caused by low immunity.

Owner:王晶

Hydrocracking method of low-nergy-onsumption productive high-quality chemical raw materials

ActiveCN105018139AReduce consumptionSave engineering investmentTreatment with hydrotreatment processesMolecular sieveHydrogen

The invention discloses a hydrocracking method of low-nergy-onsumption productive high-quality chemical raw materials. After raw oil and hydrogen are mixed, the obtained mixture is subjected to heat transfer for two times and then passes through a heating furnace, the obtained object is sequentially subjected to hydrorefining and then passes through a first cracking reaction area, the obtained product is separated so as to obtain middle distillate, the middle distillate enters a second cracking reaction area to crack, wherein the first cracking reaction area is at least filled with two cracking catalysts, a catalyst I is filled in the upstream part, and a catalyst II is filled in the downstream part; and the catalyst I contains 30-70% of modified Y molecular sieve, the catalyst II contains 15-50% of modified Y molecular sieve, and the content of the modified Y molecular sieve in the catalyst I is 10-30% higher than the content of the modified Y molecular sieve in the catalyst II. In the method disclosed by the invention, a high-temperature and high-pressure countercurrent heat transfer technology and a hydrocracking catalyst grading technology are organically combined, and through the comprehensive utilization of hydrocracking reaction heat, while the selectivity of catalysts is maintained, the product quality is enhanced, and the construction investment and the energy consumption of operation are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water-based rust conversion priming paint and preparation method

InactiveCN107033686AImprove water resistanceImprove stabilityAnti-corrosive paintsWater basedEmulsion

The invention belongs to the technical field of metal anticorrosive coatings and relates to a water-based rust conversion priming paint and a preparation method. The water-based rust conversion priming paint comprises the components of, by weight, 30-60 parts of vinylidene chloride compound macromolecule emulsion, 20-40 parts of color filling slurry, 5-15 parts of 2-hydroxyl propyl-3,4,5-trihydroxybenzoic acid rust conversion agent, 0.05-0.1 part of antifoaming agent and 0.1-0.5 part of thickening agent. The rust conversion agent is good in water resistance, high in stability and excellent in matching with water-based and oil-based paints, and the workability, the conversion efficiency and the corrosion resistance are all relatively high.

Owner:SHANDONG UNIV OF SCI & TECH

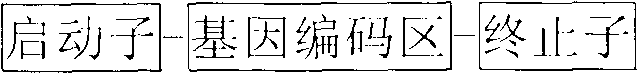

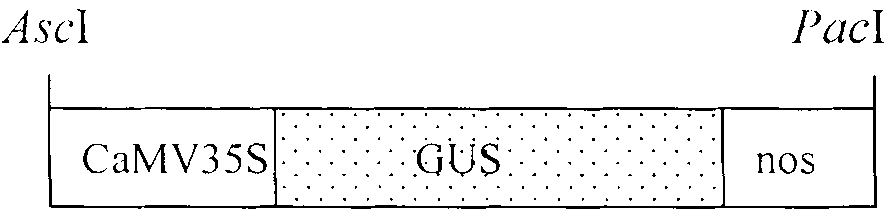

Method for quickly building genetic transformation regeneration system of grapes

InactiveCN103444524AImprove transgenic efficiencyShort conversion cycleHorticulture methodsPlant tissue cultureFluorescence microscopeSkin callus

The invention provides a method for quickly building a genetic transformation regeneration system of wine grape Riesling, and belongs to the technical field of transgenic breeding of grapes. The method is characterized by comprising the following steps: performing tissue culture to induce grape anther to obtain callus; subculturing and screening to obtain embryonic callus; with embryonic callus as a receptor, screening through a selective medium by an agrobacterium tumefaciens-mediated method to obtain resistant callus; and then regenerating a grape plant. Whether the gene gfp is expressed can be observed and reported by PCR (Polymerase Chain Reaction) verification and through a stereo fluorescence microscope, and a transformant also can be identified quickly, therefore, the grape transgenosis efficiency can be improved. Compared with the prior art, the method has the advantages that the culture medium has a good effect on culturing and screening, and achieves quick regeneration of a Riesling transgenic grape plant, thus the grape transgenosis efficiency is greatly improved, and the regeneration rate reaches 81%; the transformation cycle is short, the transgenic plant can be obtained within seven months; the transformant is greatly increased; the transformation rate can reach 63%.

Owner:TOBACCO RES INST HENAN ACADEMY OF AGRI SCI

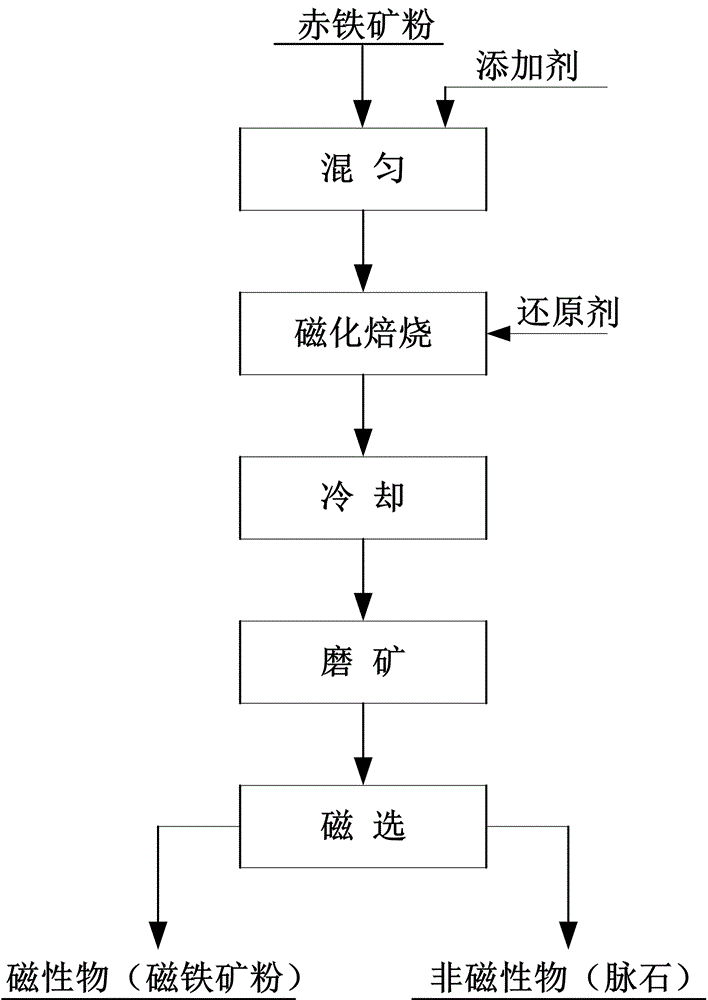

Additive-reinforced hematite magnetization roasting method

The invention provides an additive-reinforced hematite magnetization roasting method. The method includes the following steps that (1) magnetite concentrate serves as an additive and is added into hematite powder to be fully and uniformly mixed; (2), a gas reducing agent or a solid reducing agent serves as a medium to perform roasting on the mixed mineral powder; (3), water quenching cooling is performed till the normal temperature is reached, then ore grinding and magnetic separating are performed, and magnetite powder is obtained. The additive is easy to obtain, the magnetite concentrate in a mineral processing plant can be directly adopted, the iron recycling rate is high, any existing magnetization roasting equipment or procedure is not changed, and the additive-reinforced hematite magnetization roasting method has the advantages of being low in investment, simple in operation and economical and applicable.

Owner:NORTHEASTERN UNIV

Medicinal preparation for supplementing calcium, magnesium and vitamin D

A medicine for supplementing Ca, Mg and VD to human body is proportionally prepared from Ca preparation, Mg preparation and VD.

Owner:湖南泰尔制药股份有限公司

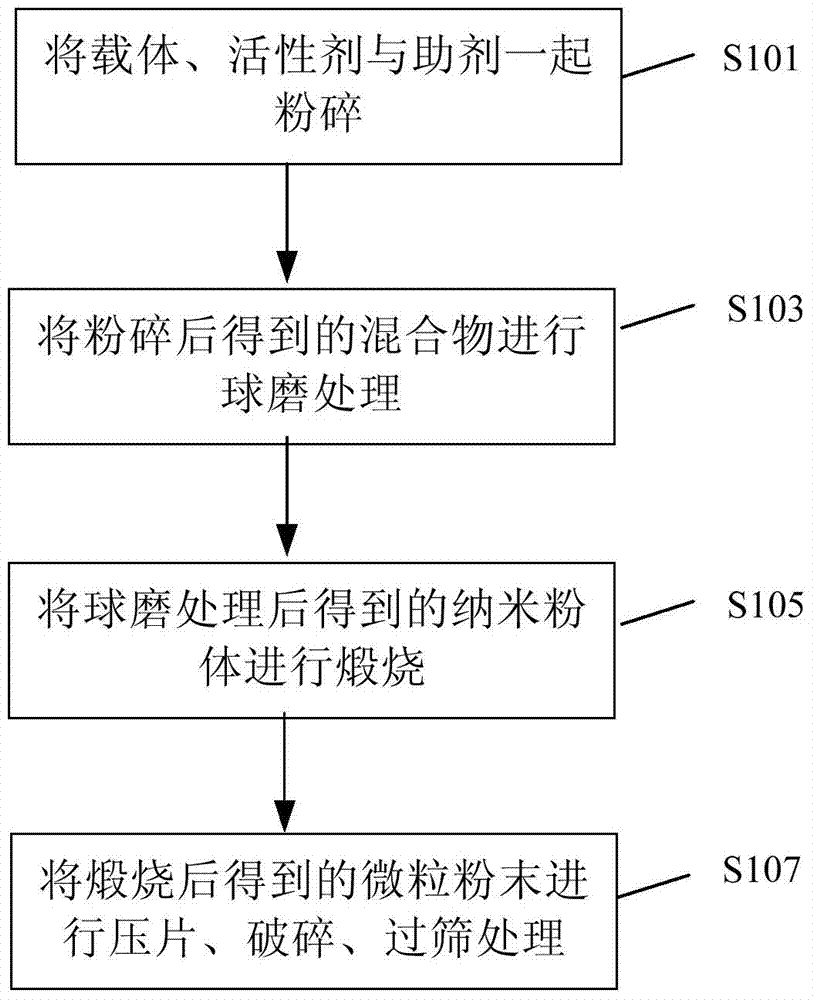

Low-temperature methane steam reforming catalyst and preparation method thereof

ActiveCN103611541AGood conversion effectReduce process stepsHydrogenCatalyst activation/preparationSteam reformingActive agent

The invention provides a preparation method for a low-temperature methane steam reforming catalyst. The preparation method comprises the following steps of crushing a carrier, an active agent and an auxiliary to obtain a mixture, wherein the active agent is a nickel-containing compound, and the auxiliary is nitrate; ball-milling the mixture to obtain nanometer powder; calcining the nanometer powder to obtain fine powder; tabletting the fine powder, crushing and sieving. According to the method, process steps are reduced, so that the process production time is remarkably shortened, and the production efficiency is improved; compared with other catalysts in the prior art, the methane steam reforming catalyst prepared by the method has a good conversion effect during methane steam reforming reaction.

Owner:ENN SCI & TECH DEV

Method for cleaning DNA transformation plant without choosing marker gene

InactiveCN101914571AShort conversion cycleRemove inhibitionOther foreign material introduction processesHorticulture methodsA-DNAGel electrophoresis

The invention discloses a method for cleaning a DNA transformation plant without choosing a marker gene. The method comprises the following steps of: 1), preparing a target gene expression frame: adopting an appropriate restriction enzyme to cut a constructed target gene expression frame DNA fragment from a plasmid vector according to the sequence character of the plasmid vector on which the target gene expression frame to be transferred is, and obtaining the target gene expression frame DNA by electrophoresing, separating, tapping and reclaiming a gel; 2), preparing a DNA particle vector suspension; 3), bombarding plant callus to transform the plant callus; 4), regenerating the plant; and 5), choosing transgenic plants. When the method is adopted to perform plant transgenosis, the influences of the selected marker gene and superfluous DNA sequences such as the plasmid vector frame DNA sequence on the transgenic plants and genetically modified foods can be overcome fundamentally, so that the transgenic plants without other superfluous DNAs except for the target gene expression frame are obtained.

Owner:CHINA NAT RICE RES INST +1

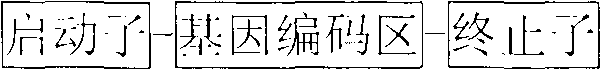

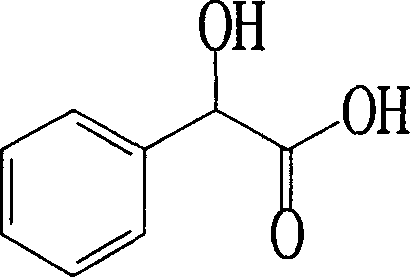

Process for preparing (R)-mandelic acid by microbial asymmetric resolution

InactiveCN1840671AGood conversion effectSimple compositionBacteriaMicroorganism based processesMicroorganismMandelic acid

The asymmetrical resolution method for (R)-mandelic acid comprises: screening the (Brevibacterium flavum) AS 1.818 for culture and full cell preparation; with racemic acid as substrate, catalytic converting to obtain the product with optical purity up to 90%e.e. This invention improves product optical purity and has important meaning for enzyme development and resolution.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com