Additive-reinforced hematite magnetization roasting method

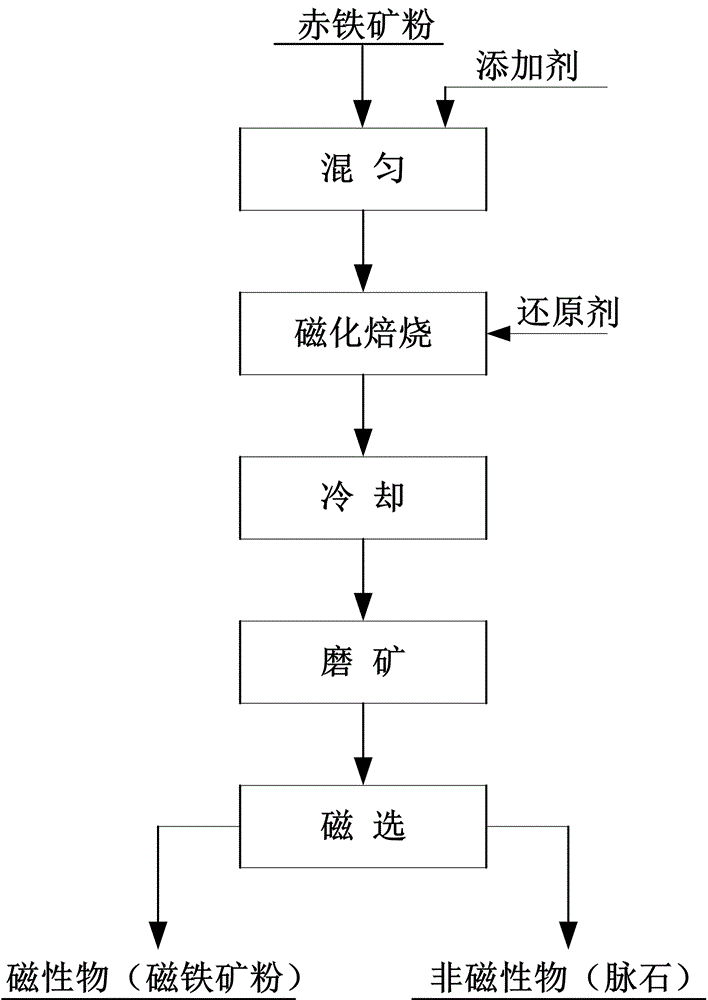

A technology of magnetized roasting and hematite, which is applied in mineral processing and metallurgy fields, can solve the problems of shortening roasting time and low conversion efficiency, and achieves the effects of easy acquisition, high iron recovery rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Magnetite concentrate with a fineness of ≤100 mesh is used as an additive, added to the hematite powder with a fineness of ≤50 mesh and fully mixed, and the additive is loaded on the surface of the hematite particle by using the agglomeration performance of the ore powder particles. Crystal seeds form mixed ore powder; wherein the mass ratio of magnetite concentrate and hematite powder is 0.1:10; the iron grade of magnetite concentrate is 70.5%, and the iron grade of hematite is 31%;

[0029] Using a gas reducing agent as the medium, place the mixed ore powder in a fluidized reduction retention tank, and perform magnetization roasting in a suspension state at a roasting temperature of 500°C and a roasting time of 5 minutes to obtain roasted ore; the gas reducing agent is CO , the superficial flow velocity of the gas reducing agent is 0.1m / s during the suspension state magnetization roasting;

[0030] Quenching and cooling the roasted ore water to normal temperature, the...

Embodiment 2

[0033] Method is with embodiment 1, and difference is:

[0034] (1) The mass ratio of magnetite concentrate to hematite powder is 0.5:10; the iron grade of magnetite concentrate is 54%, and the iron grade of hematite is 34%;

[0035] (2) Using the gas reducing agent as the medium, place the mixed ore powder in the fluidized reduction residence tank, and carry out magnetization roasting in suspension state, the roasting temperature is 600°C, and the roasting time is 0.5min, to obtain the roasted ore; the gas The reducing agent is H 2 , the superficial flow velocity of the gas reducing agent is 0.3m / s during the suspension state magnetization roasting;

[0036] (3) The iron grade of magnetite powder is 66.7%, the conversion rate of hematite to magnetite is 92% (calculated after deducting the amount of magnetite in additives), and the recovery rate of iron is 89% (calculated after deducting the amount of magnetite in additives). calculated from the amount of iron ore).

[0037...

Embodiment 3

[0039] Method is with embodiment 1, and difference is:

[0040] (1) The mass ratio of magnetite concentrate to hematite powder is 1:10; the iron grade of magnetite concentrate is 43%, and the iron grade of hematite is 33%;

[0041] (2) Using the gas reducing agent as the medium, place the mixed ore powder in the fluidized reduction retention tank, and carry out magnetization roasting in suspension state, the roasting temperature is 550°C, and the roasting time is 2 minutes, to obtain the roasted ore; the gas reduction The agent is water gas, and the superficial flow velocity of the gas reducing agent is 0.2m / s when the suspension is magnetized and roasted;

[0042] (3) The iron grade of magnetite powder is 67.2%, the conversion rate of hematite to magnetite is 97% (calculated after deducting the amount of magnetite in additives), and the recovery rate of iron is 95% (calculated after deducting the amount of magnetite in additives). calculated from the amount of iron ore).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com