Industry method for producing arachidonic acid grease by using mortierella alpine

A technology of arachidonic acid and Mortierella alpina, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of low mass percentage concentration and limited sources of arachidonic acid, and achieve the promotion of The ability to transform arachidonic acid, improve the dissolved oxygen level, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Activation of the original strain: inoculate the Mortierella alpina strain preserved in an amber tube on a PDA slant medium, cultivate it at 28±1°C for 8 days, select a PDA medium plate with vigorous growth of hyphae and spores, and remove the The hyphae and spores on the culture medium are made into spore suspension with sterile water;

[0032] 2. Seed culture: inoculate the spore suspension in the shake flask culture medium, shake and culture at 28±1°C for 48h, the shaking speed of the shaker is 200±20 rpm, the mass of the main raw material components in the liquid culture medium The percentage is glucose 4%, peptone 1%, yeast extract 3%, matrix distilled water, pH value is 7.2;

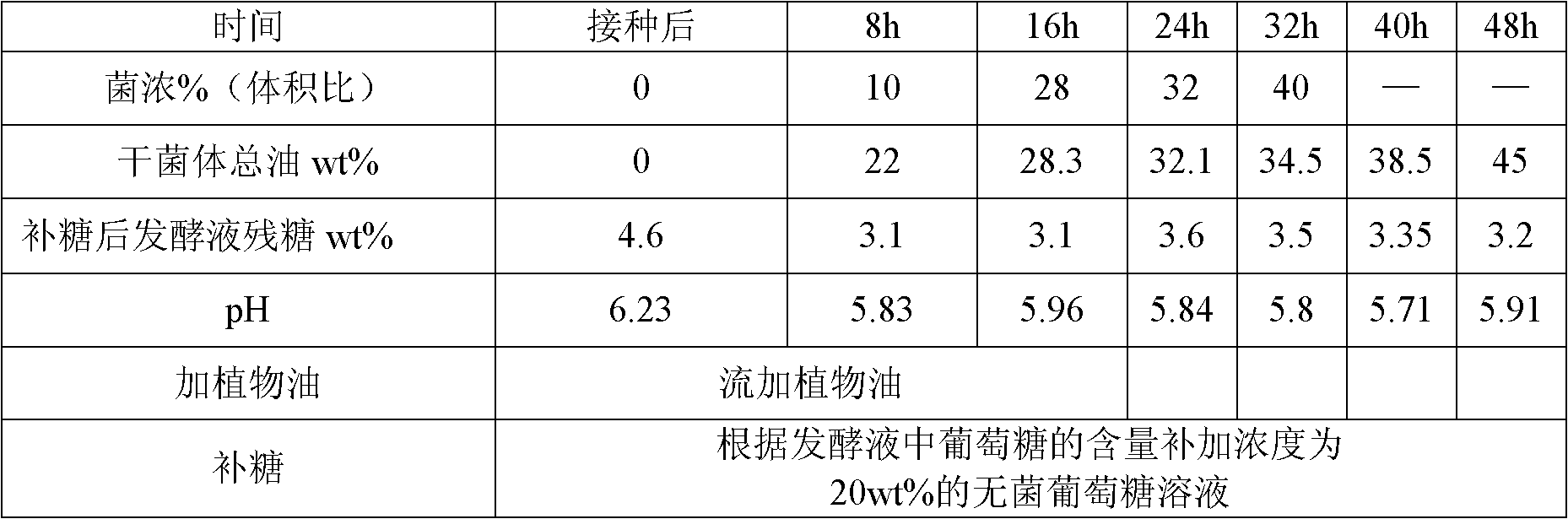

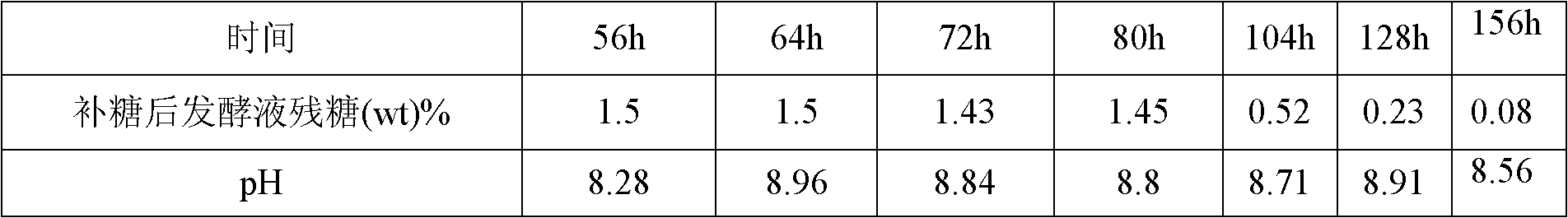

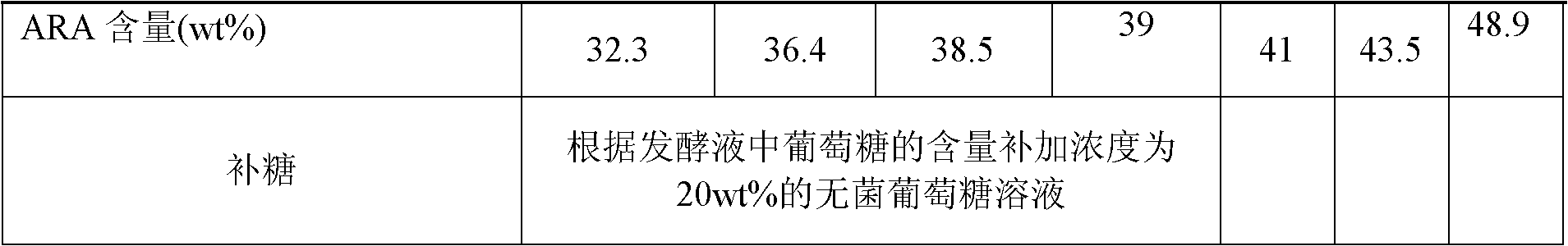

[0033] 3 seed expansion cultivation: the final fermenter volume is 50m 3 , so the selected seed pots are 10m 3 、1m 3 , inoculate 1.5L of shake flask seed fermentation liquid in step (2) to 1m 3 In the seed expansion fermenter, the mass percentages of the main raw material components i...

Embodiment 2

[0062] 1. Activation of the original strain: inoculate the Mortierella alpina strain preserved in an amber tube on a PDA slant medium, culture it at 28±1°C for 9 days, select a PDA medium plate with vigorous growth of hyphae and spores, and remove it. The hyphae and spores on the culture medium are made into spore suspension with sterile water;

[0063] 2. Seed culture: inoculate the spore suspension in the shake flask culture medium, shake and culture at 28±1°C for 48h, the shaking speed of the shaker is 200±20 rpm, the mass of the main raw material components in the liquid culture medium The percentage is glucose 5%, peptone 1.5%, yeast extract 2%, matrix distilled water, pH value is 7.0;

[0064] 3 seed expansion cultivation: the final fermenter volume is 200m 3 , so the seed tanks are 50m respectively 3 、5m 3 , 500L, inoculate 1L shake flask seed fermentation liquid in the seed expansion fermenter of 500L, cultivate 24h under the temperature of 30 ± 2 ℃, the bacterium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com