Patents

Literature

296results about How to "Raise the level of fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

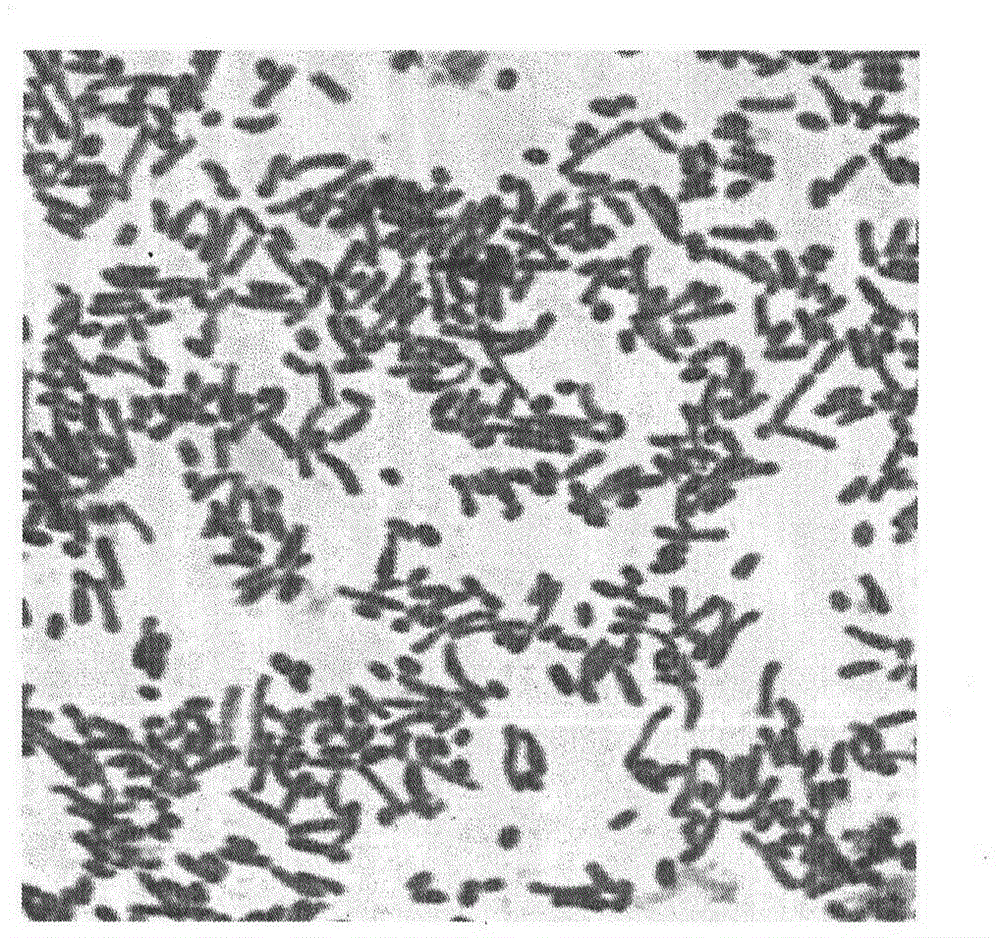

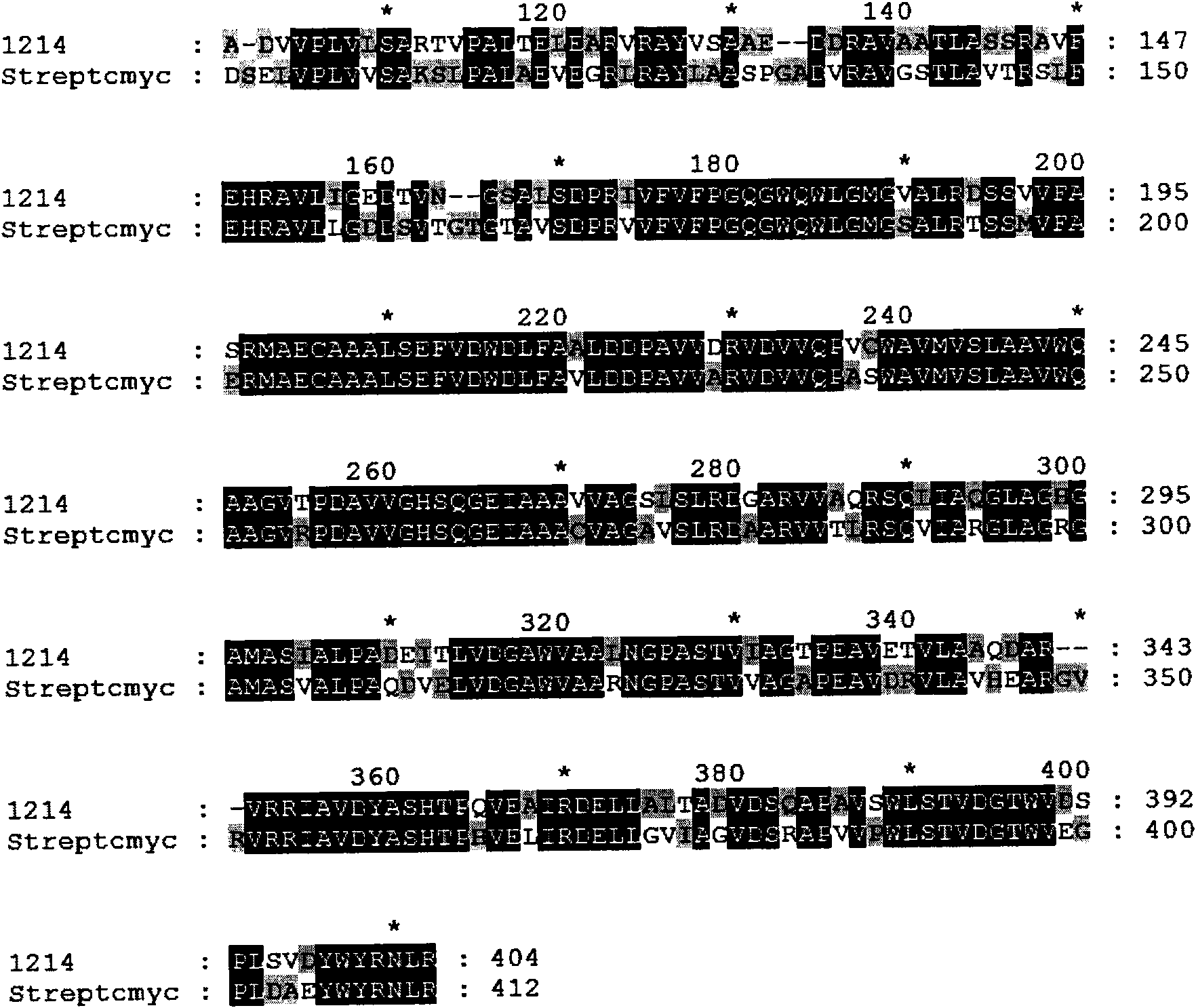

High-yield strain streptomyces lydicus, breeding and fermentation thereof

ActiveCN101693881AProduction keeps accumulatingGrowth and reproduction are not affectedBacteriaMutant preparationStreptomycesMicrobiology

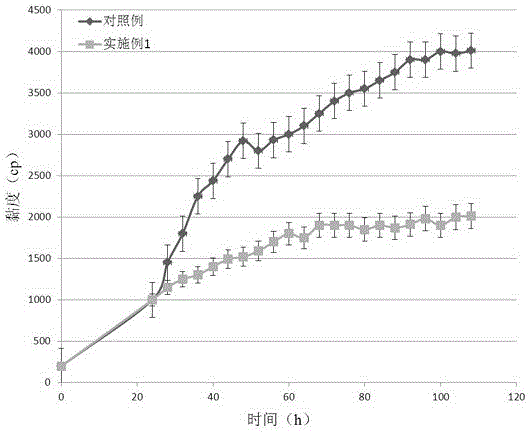

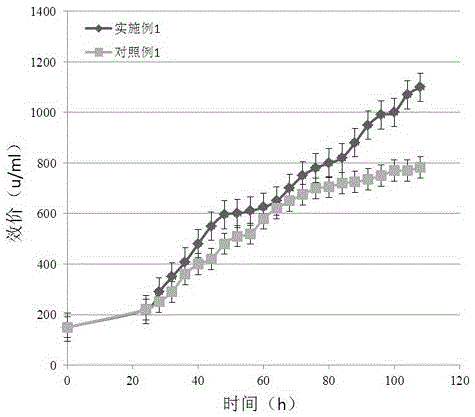

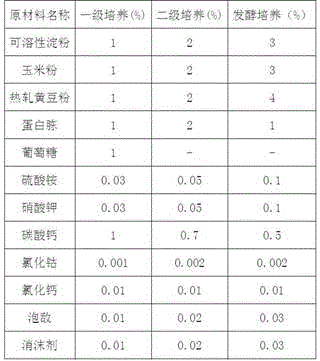

The invention discloses a high-yield strain streptomyces lydicus, as well as breeding and fermentation thereof. The fermentation of the high-wield stain streptomyces lydicus E9 CGMCC No.3075 comprises the following steps: (1) preparation of a shake flask, seeds and a fermentation medium; (2) shake flask culture; (2) seed culture; (4) fermentation pot culture: leading a seed culture liquid in a fermentation pot filled with the fermentation medium and culturing for 24-96 hours to obtain a high-wield stain streptomyces lydicus E9 fermentation liquor under the condition of ventilating, stirring, temperature of 25-35 DEG C, and pH of 4-9; and carrying out ultrasonication for 20-40 min. The strain of the invention can generate large quantity of substances with antimycotic activity in the fermentation liquor, and the fermentation liquor has evident inhibiting effect on rhizoctonia solani; and the bacterial inhibition rate of the fermentation liquor which is diluted by 50 times reaches above 97.8% after 48 hour fermentation.

Owner:TIANJIN UNIV

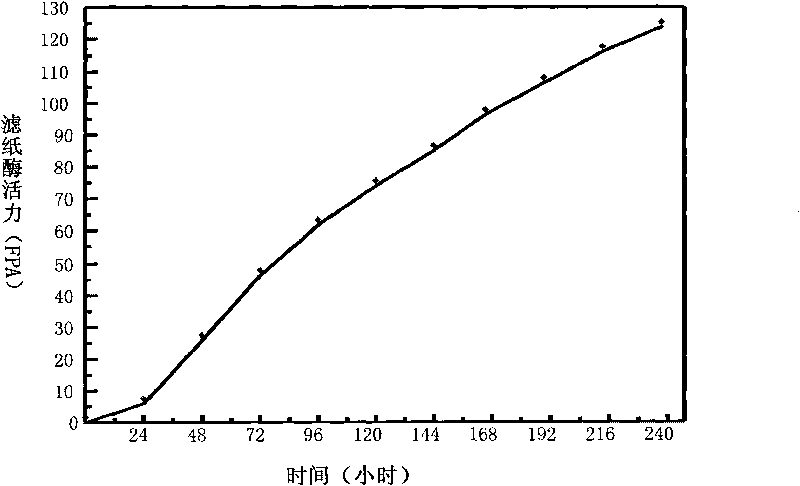

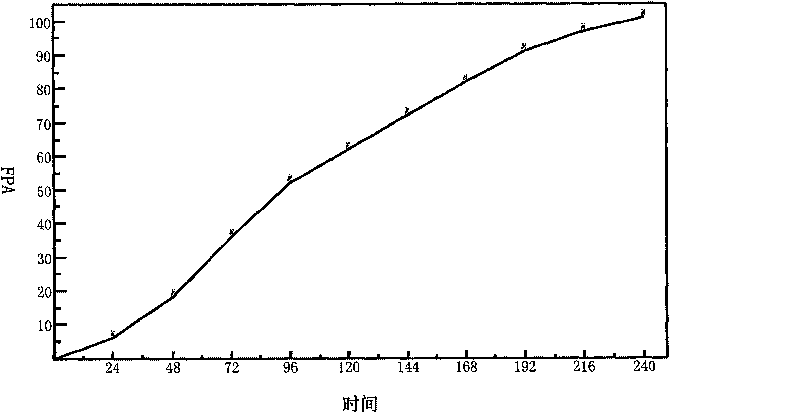

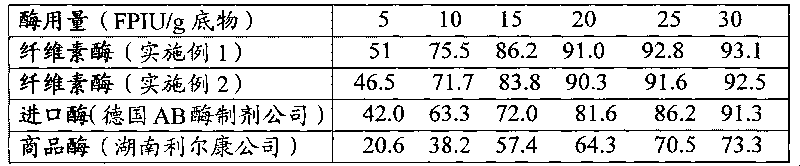

Method for efficiently producing cellulase

InactiveCN101735993AIncrease vitalityPromote formationMicroorganism based processesEnzymesMetaboliteSugar

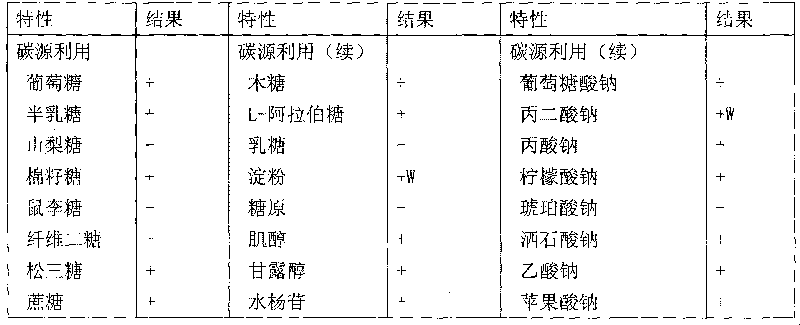

The invention provides a method for producing cellulase, which comprises the following steps of: inoculating Trichoderma reesei to a fermentation medium; fermenting for 60 to 90 hours, and then starting feed-batch culture; feeding a culture medium when a pH value of a fermentation liquor is more than 4.8 in the process of the feed-batch culture; stopping feeding the culture medium when the pH value of the fermentation liquor is less than 4.5; and stopping fermenting when the total fermentation time reaches 192 to 240 hours. The method integrates an insoluble carbon source and a soluble carbon source to collaboratively induce expression of cellulase genes. The method achieves coordinated balance in the process of growing strains and forming a target metabolic product through the feed-batch culture, solves the problems existing in the process for producing the cellulase by merely taking cellulose or soluble sugar as an inducer, effectively improves fermentation level of the cellulase; and the obtained cellulase has high degradation performance to cellulose substrates.

Owner:ZHEJIANG UNIV

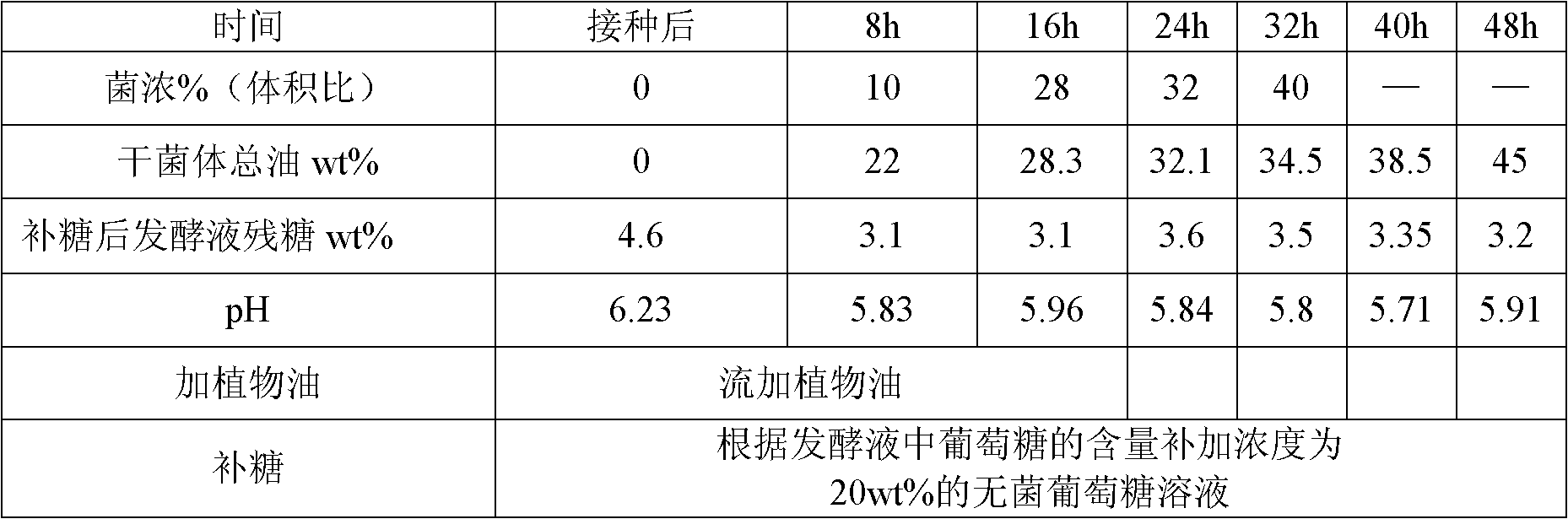

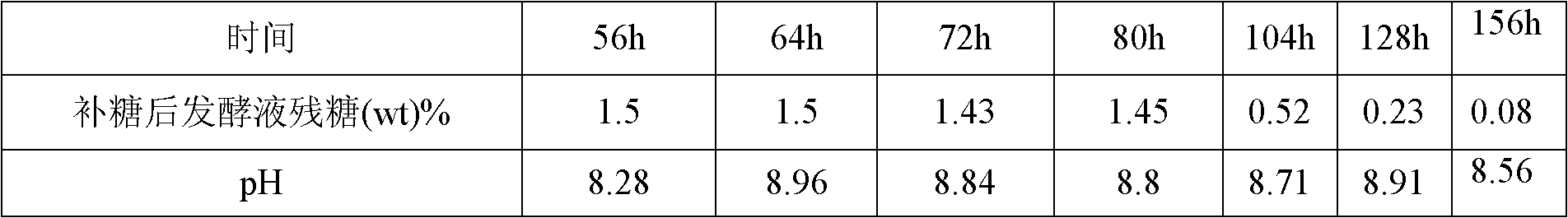

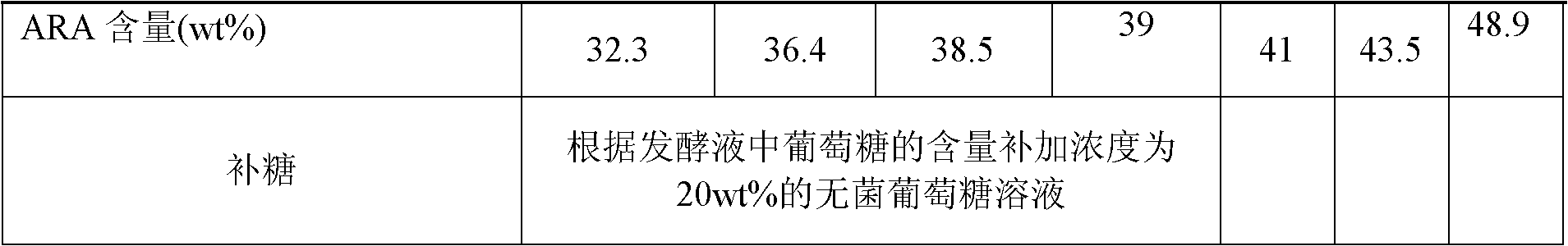

Industry method for producing arachidonic acid grease by using mortierella alpine

InactiveCN102925502AEffective controlSimplified Fermentation RecipeMicroorganism based processesFermentationBiotechnologyCulture fluid

The present invention provides an industry method for producing arachidonic acid grease by using mortierella alpine. The method is characterized by comprising the following steps: activating an original strain; carrying out seed culture; carrying out seed enlarge culture; and carrying out fermentation culture, wherein the fermentation culture comprises an initial fermentation stage, the seed enlarge culture liquid is inoculated in a fermentation tank to carry out stirring culture, glucose and edible oil are supplemented according to the situation, the initial fermentation stage is completed when bacterial concentration of the fermentation broth achieves 40% (by ??volume) and the dried mycelium total oil achieves 40 wt%, a post-fermentation stage starts, the fermentation broth is cooled to a temperature of 23-27 DEG C, sterile ammonia water is concurrently added to adjust the pH value to 8-9, standing fermentation is performed while the glucose content is controlled, the post-fermentation stage is completed when the arachidonic acid content is higher than 45 wt%, and the obtained fermentation broth is subjected to a fermentation treatment to obtain the grease containing the arachidonic acid. The industry method has the following characteristics that: a fermentation formula is simplified, specific yield of the arachidonic acid can be 10 gARA / L fermentation broth through the specific process control, a process is simple and easy to control, and industrial production is achieved.

Owner:CABIO BIOTECH WUHAN CO LTD

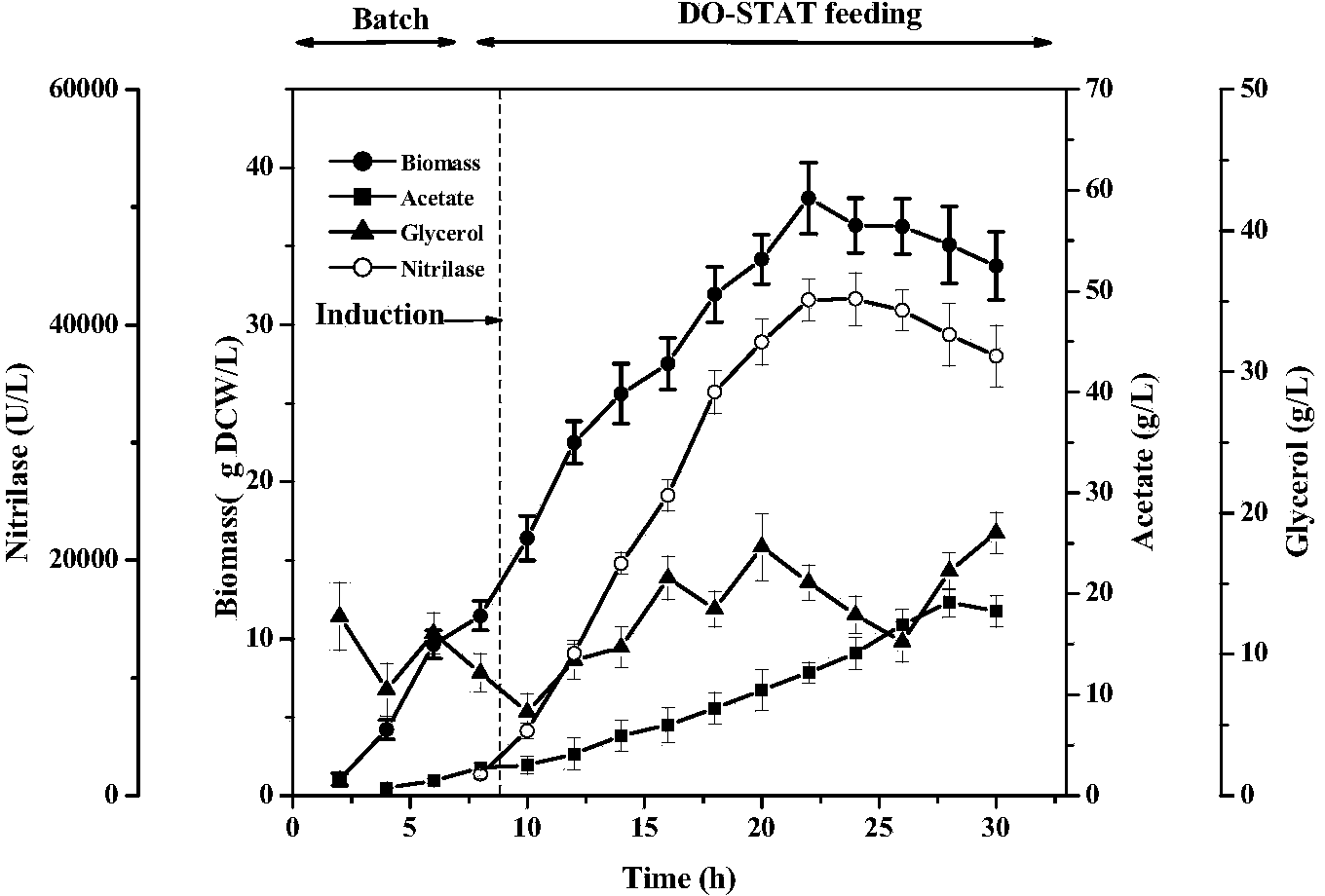

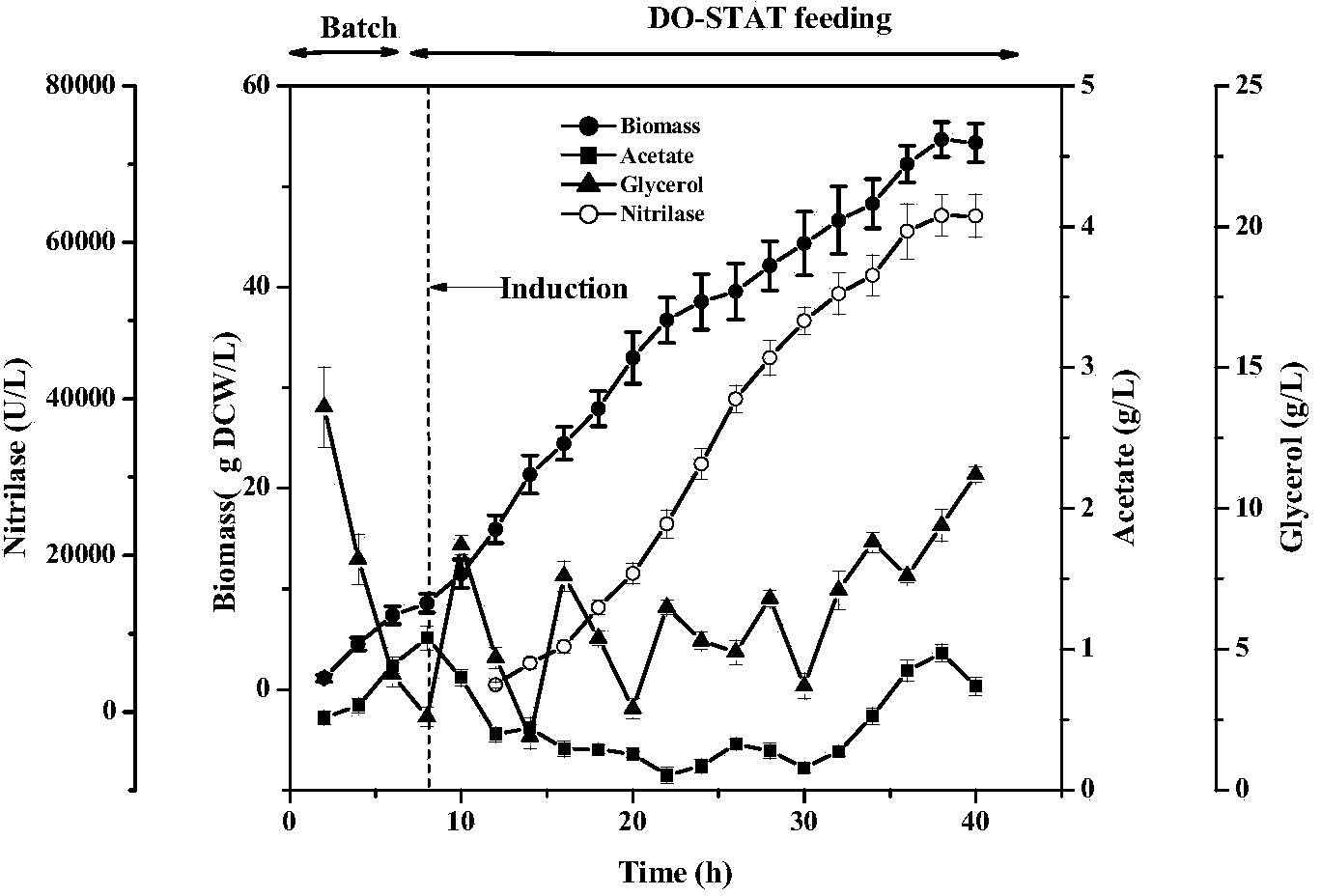

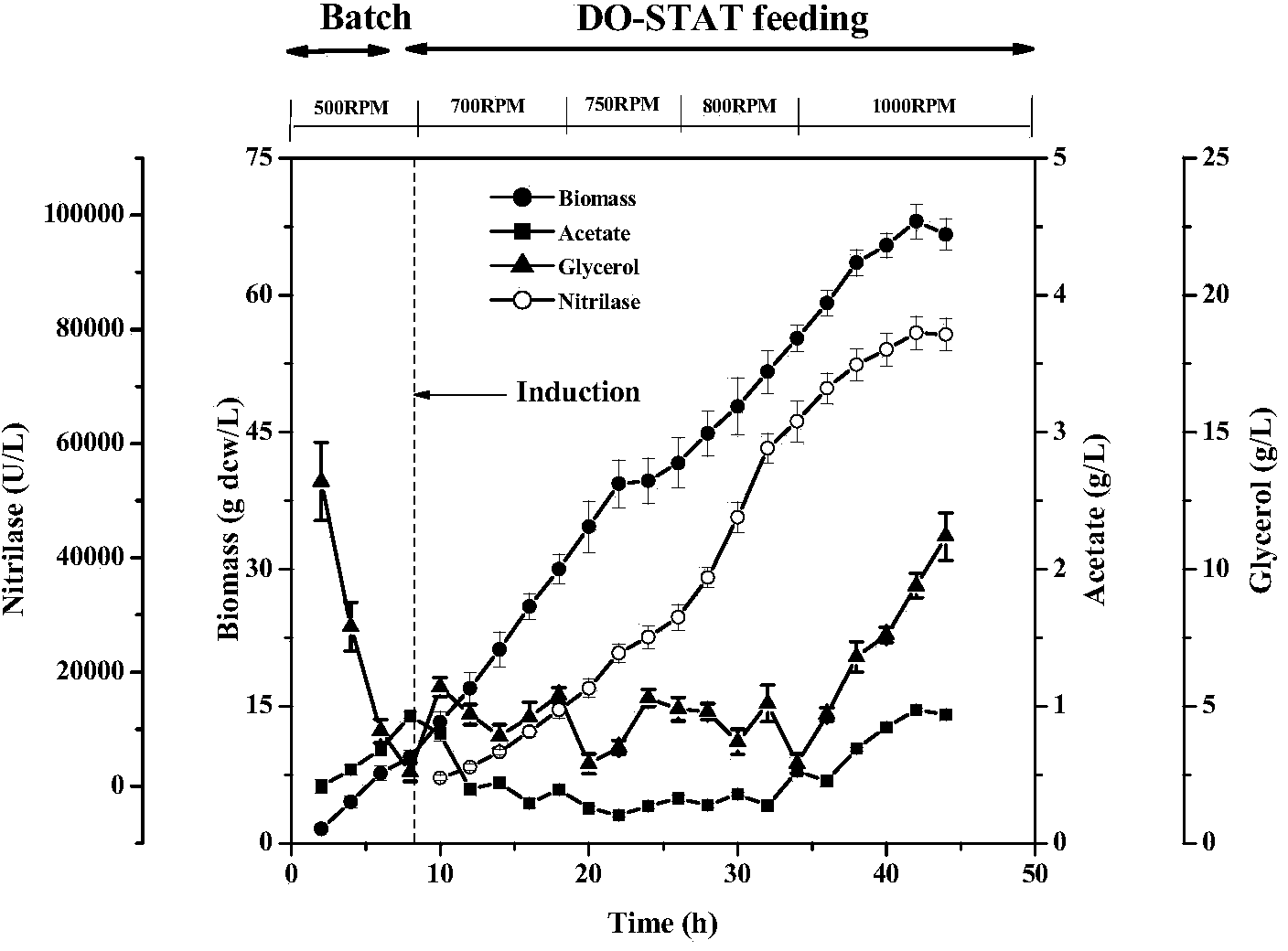

High-density fermentation method of engineering bacteria containing nitrilase

InactiveCN104212785APrevention of waste and other disadvantagesControl growth rateHydrolasesMicroorganism based processesEscherichia coliHigh concentration

The invention discloses a high-density fermentation method of engineering bacteria containing nitrilase. The method adopts a novel recombinant Escherichia coli fermentation and supplementary material culture medium formula, and uses a method of DO-STAT coupling step-by-step induction and gradual increase of the speed stage by stage. The method not only meets the need for mixing power in the culture process with biomass increase, effectively controls the growth rate of thalli, and prevents disadvantages of produced acid accumulation caused by fast growth of thalli, feedback inhibition and culture medium waste. In addition, the induced mode of batch-by-batch lactose supplement addition avoids the high viscosity of the fermentation broth caused by high concentration of lactose, resulting in resistance of oxygen transfer and mass transfer, but also improves the induction strength. The high-density fermentation technology of the invention increase the biomass of recombinant Escherichia coli from 10.35g DCW / L to 70g DCW / L, volume enzyme activity from 18205U / L to 103530U / L, and the fermentation level by 4.7 times.

Owner:ZHEJIANG UNIV OF TECH

Efficient biochemical fulvic acid preparing process

The efficient biochemical fulvic acid preparing process is to utilize, enrich and culture humic acid producing bacteria and auxiliary bacteria existing in nature to form specific fulvic acid producing bacteria. The fermented material includes crop stalks, saw dust and other agricultural and forest waste and some inorganic nutrient components as well as fulvic acid producing bacteria, and through controlling nutrients compounding ratio, water content, temperature, humidity and other technological parameters, fulvic acid is produced through directional fermentation. The present invention has the advantages of short fermentation period, low cost, high fulvic acid content, high product quality and easy control of the production process. The fermented product contains great amount of fulvic acid, amino acid, nucleic acid and other matters, and may be used widely in plantation, stockbreeding, aquiculture, industrial fermentation, medicine, pesticide and other industry.

Owner:郭伟光

Fermentation production method based on epothilone B metabolic pathways

InactiveCN103243134ARaise the level of fermentationReduce fermentation costsMicroorganism based processesFermentationBiotechnologyAlcohol

The invention discloses a fermentation production method based on epothilone B metabolic pathways and belongs to the technical field of fermentation engineering. The method comprises the following steps of: 1) inoculating Sorangium cellulosum into an M26 culture medium, carrying out shake cultivation to obtain a seed solution; 2) inoculating the seed solution into fermentation liquor containing resin, carrying out shake culturing for 72-120 hours at 25-35 DEG C, adding a precursor and small molecular substances into the fermentation liquor containing resin; and 3) filtering the fermentation liquor after the culture is finished, collecting the resin, washing the resin and oscillating and extracting with methyl alcohol to obtain extract liquor containing the epothilone B. According to the invention, the precursor and small molecular substances related to the biosynthetic pathways obtained by screening are added into the fermentation liquor, and the constructive metabolism pathways of the epothilone B are disturbed, so that the excellent bacterial strain gives full play to the ability of anabolism and the fermentation level of the epothilone B is improved greatly, thus the fermentation cost is reduced and the commercial process of the anti-cancer drug is promoted.

Owner:SHAANXI UNIV OF SCI & TECH

Compound biochar-based slow-release fertilizer and application method thereof

InactiveCN106518529APromote growthImprove adsorption capacityBio-organic fraction processingExcrement fertilisersMoisture capacityFermentation

The invention discloses compound biochar-based slow-release fertilizer and an application method thereof and mainly relates to the field of biochar-based fertilizer. A preparation method of the compound bio-carbon-based slow-release fertilizer comprises mixing agricultural rice straws and wood shavings, preparing char, adding sodium selenite into the char to obtain biochar, mixing pig manure and chicken manure, carrying out fermentation on the pig manure and chicken manure, carrying out metal passivation treatment to obtain manure-based fertilizer, further fermenting the biochar and the manure-based fertilizer, and adding diatomite into the fermentation product for modification to obtain slow release fertilizer granules. In use, preferably, the slow-release fertilizer granules are applied to the field according to a ratio of 256 kg per mu, and a field moisture capacity measured value is kept in a range of 70% to 80% in the whole growth period. The compound biochar-based slow-release fertilizer can meet the demand of nitrogen and phosphorus in the early stage and the whole period of rice seedling, has sufficient and lasting fertilizer effects, prevents the effects of heavy metals, improves the soil environment, inhibits methylmercury, and can produce high-yield good-quality selenium-rich rice.

Owner:BENGBU COLLEGE

Genetic engineering strain for producing phenazine-1-carboxylic acid and application of genetic engineering strain

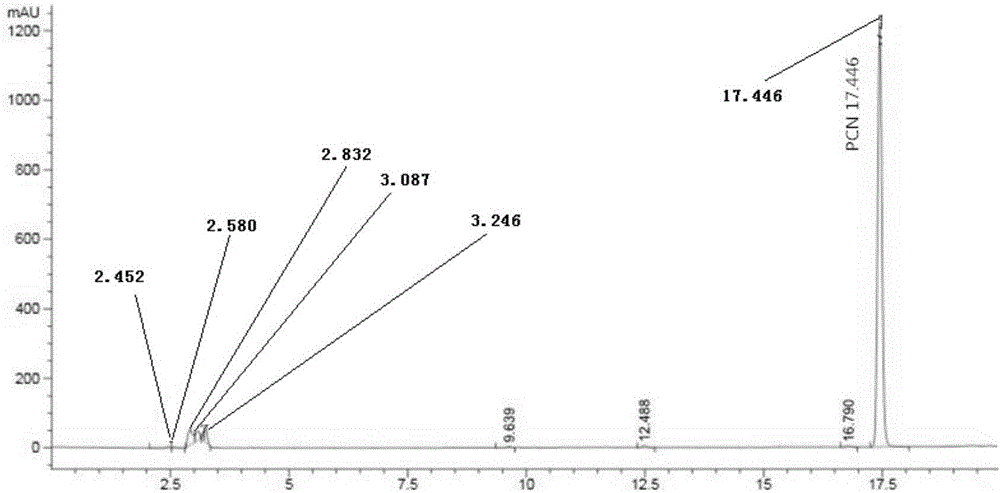

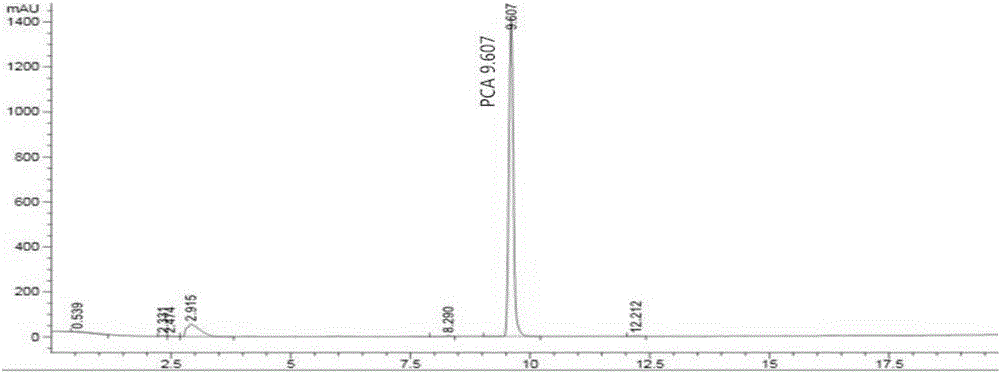

InactiveCN105087455ARaise the level of fermentationRaw materials are easy to obtainBiocideBacteriaFungicideSecondary metabolite

The invention discloses a genetic engineering strain for producing phenazine-1-carboxylic acid, which is produced by taking pseudomonas chlororaphis as a culture, as well as application of the genetic engineering strain; the genetic engineering strain is obtained by knocking out a phzH gene in pseudomonas chlororaphis genome. The genetic engineering strain for producing phenazine-1-carboxylic acid is finally prepared by deleting the phzH gene in the genome of the strain by virtue of insertion mutation or marker-less deletion from pseudomonas chlororaphis HT66 CCTCC NO: M2013467 which can naturally secrete phenazine-1-formamide as well as derivatives of the pseudomonas chlororaphis so as to convert a secondary metabolite from the phenazine-1-formamide into the phenazine-1-carboxylic acid. The invention also discloses a preparation method and a detection method of the fungicide.

Owner:SHANGHAI JIAO TONG UNIV

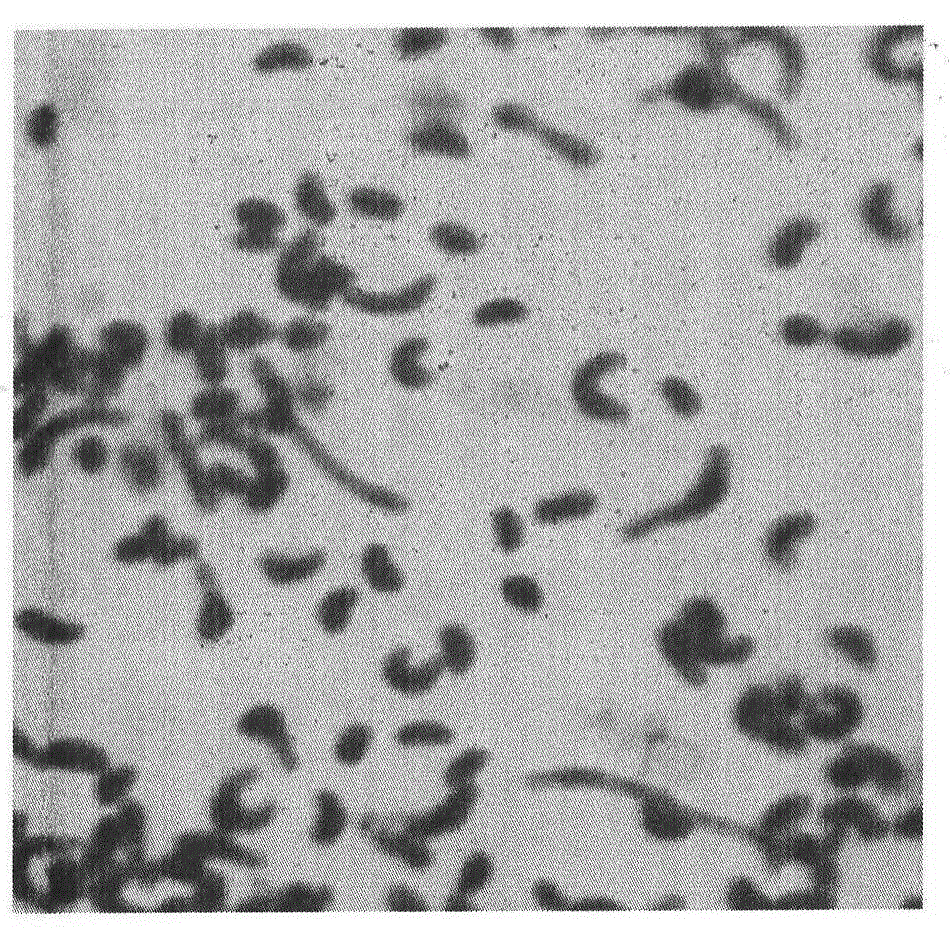

Coenzyme Q10 fermentation process and control strategy

ActiveCN104561154AReduce volatilityRaise the level of fermentationMicroorganism based processesFermentationRhodobacter sphaeroidesRhodobacter

The invention provides a coenzyme Q10 fermentation process and a control strategy. Rhodobacter sphaeroides fermentation is adopted to produce coenzyme Q10, a specific operation method of coenzyme Q10 fermentation is provided, a process regulation and control standard is created, through bacterial type change in observation of the fermentation process, the bacterial type transition period is taken as a basis for judging time and amplitude for process parameter adjustment, the fermentation level of the coenzyme Q10 is greatly improved, the production level is stabilized, and the fermentation cost is reduced.

Owner:INNER MONGOLIA KINGDOMWAY PHARMA +1

Method for producing tetracycline by fermentation of streptomyces aureus

ActiveCN103602714AReduce contentEasy to sterilizeMicroorganism based processesFermentationSucroseOxygen

The invention relates to a method for producing tetracycline by fermentation of streptomyces aureus. The method comprises the following steps: slant spore culture, seed culture and fermentation culture of the streptomyces aureus, and is characterized in that dextrin, sucrose, corn pulp, hydrolyzed soybean meal and other medium-effect carbon-nitrogen sources are adopted to replace original late-effect carbon-nitrogen sources; by reducing the contents of starch and bean flour in an original fermentation culture medium and combining with a formula of a mixture in the fermentation process and adjustment of a replenishing method and placing part of the nitrogen sources in the fermentation culture medium into material replenishment in the fermentation process, the concentration of the culture medium in the fermentation process is effectively controlled, the oxygen dissolution condition in the early stage of fermentation is improved, the final residue of the culture medium of fermentation is controlled by material replenishment, the material consumption is reduced, and the emission of solid wastes is reduced; the metabolism velocity in exponential growth phase in the fermentation process of the tetracycline is effectively controlled, the abnormal situations that a fermentation solution turns red and becomes sour and the like in the fermentation process are reduced, and the fermentation level is improved.

Owner:NINGXIA QIYUAN PHARMA

Method for producing cellulase by using induction and regulation of substrate

InactiveCN103045566ARaise the level of fermentationAvoid the decline of enzyme production capacityMicroorganism based processesEnzymesTrichoderma virideChemistry

The present invention provides a method for producing cellulase by using induction and regulation of substrate. Trichoderma viride is used as cellulase-producing bacteria. A soluble carbon source A and insoluble straw microcrystalline cellulose are used as an inducer for regulating metabolic processes. High active cellulase is produced by controlling medium composition, pH regulation, ventilation ratio, inducer adding manner and the like. The method provided by the present invention plays a significant role on improving cellulase activity, and reducing application cost of cellulose; is strong in operability; has no pollution as developing and utilizing straw and other natural cellulosic resources; is an effective means to promote the industrialization of straw ethanol; and has broad application prospects.

Owner:河南天冠纤维乙醇有限公司

Method for efficiently producing vitamin K2 by flavobacterium

InactiveCN103290077ARaise the level of fermentationEasy to useMicroorganism based processesFermentationVitamin K2Biotechnology

The invention discloses a method for efficiently producing vitamin K2 by flavobacterium. High-producing strains are bred by means of composite mutagenesis through a low-energy ion beam and a low-temperature plasma after original strains of the flavobacterium are activated on culture media, fermentation units of the high-producing strains are increased by 50-100% through preliminary screening and shake flask fermentation secondary screening of an analog flat plate with the vitamin K2, intracellular vitamin K2 is dissolved to an extracellular environment by adding surface active agents when the flavobacterium is fermented, and the yield of the vitamin K2 is improved by 50-200%. By the aid of the method, the fermentation level of the vitamin K2 can be greatly improved, high-efficiency biosynthesis of the vitamin K2 is realized, large-scale industrialized fermentation of the vitamin K2 is possible, and the method is convenient to use.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

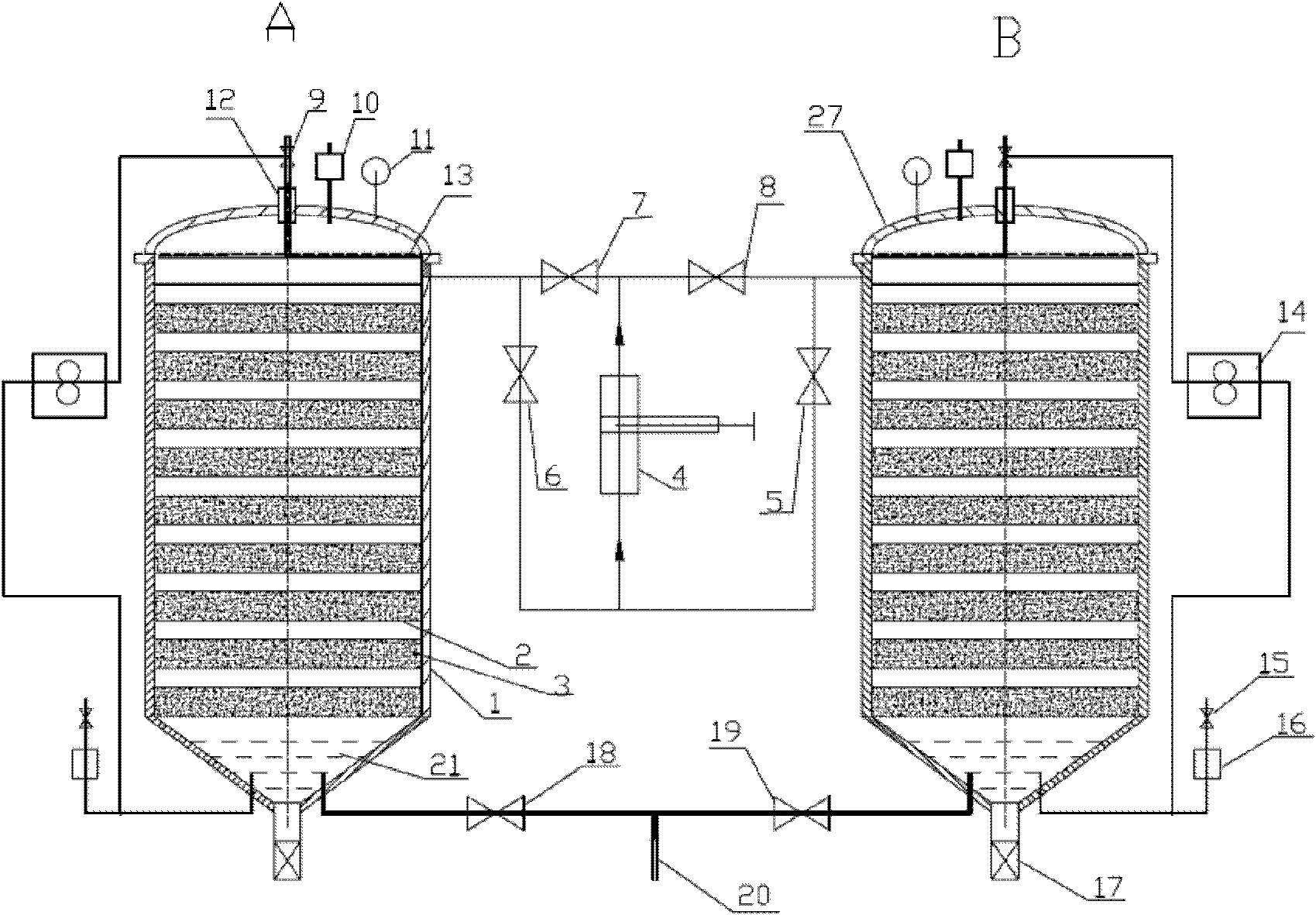

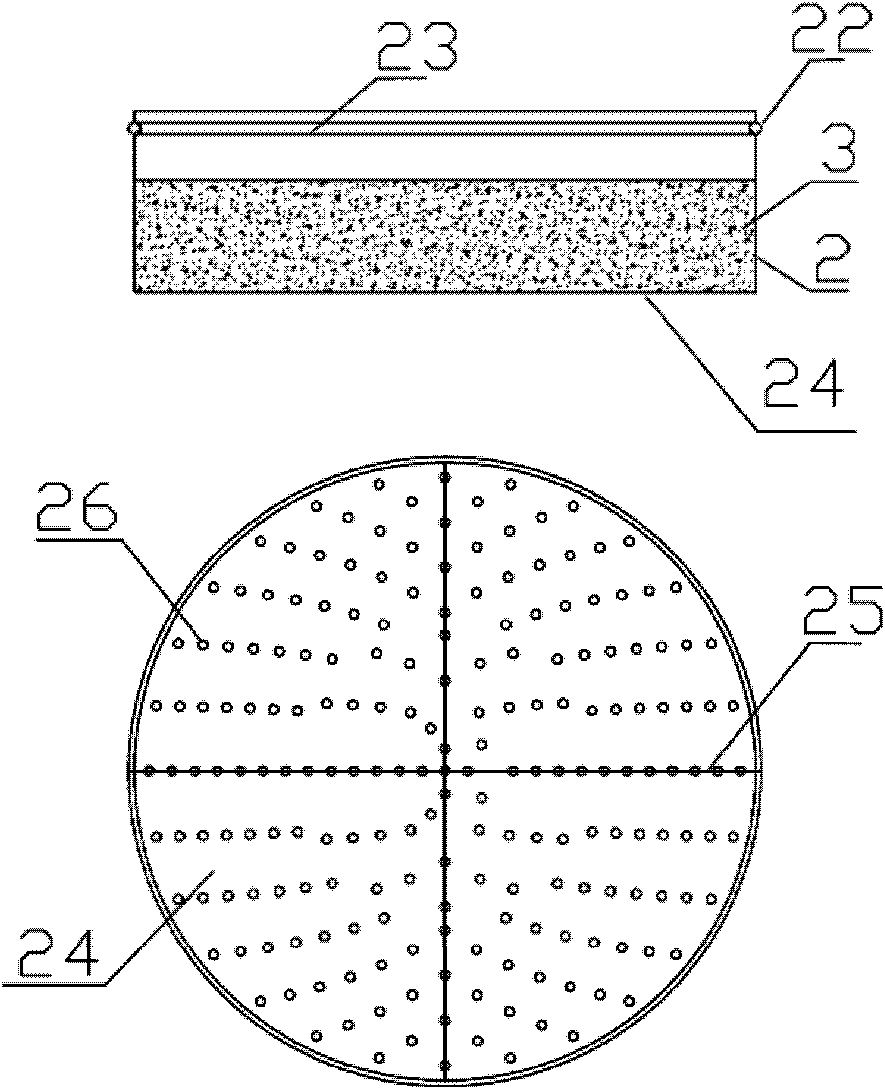

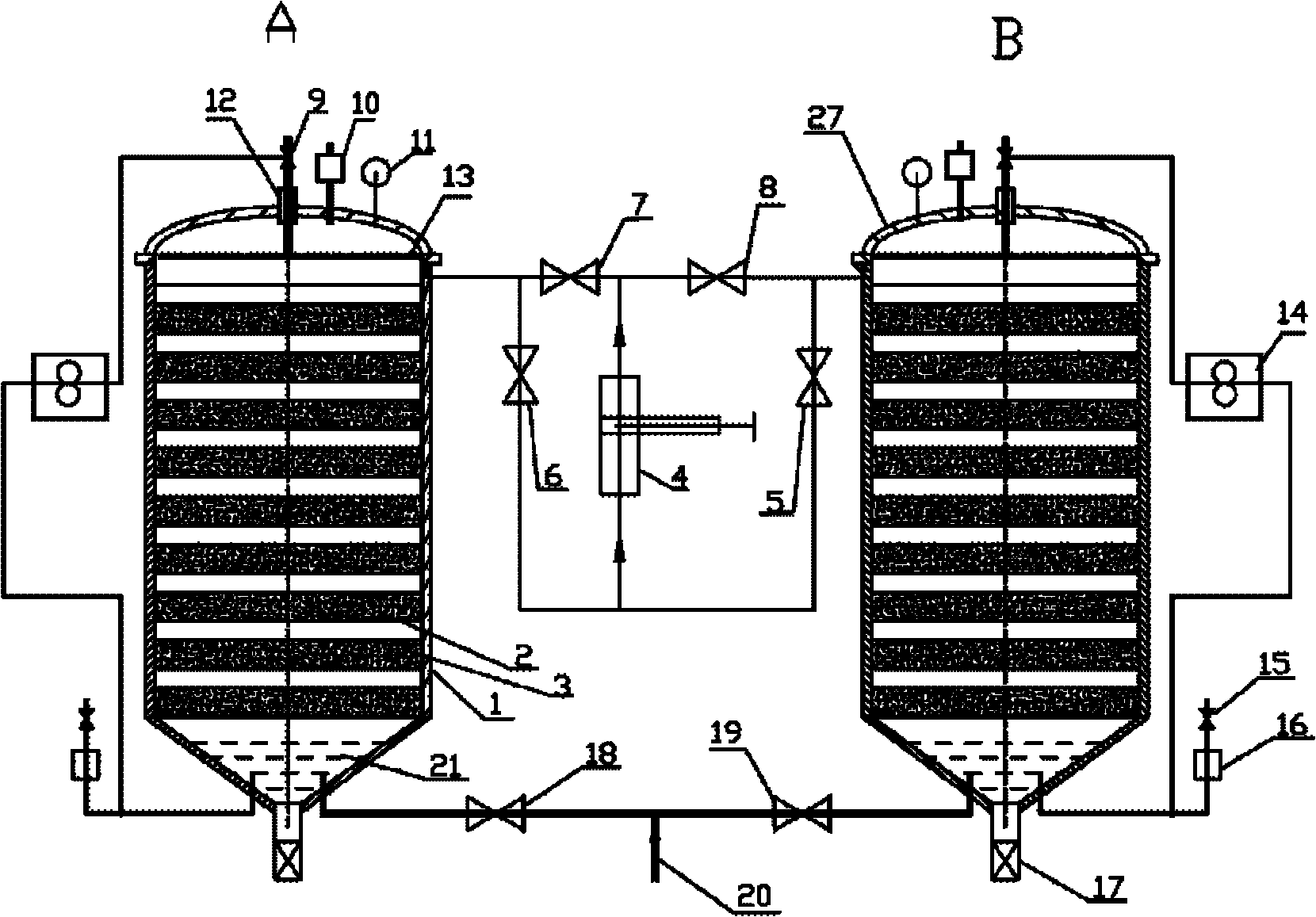

Respiratory type solid-state fermentation method and fermentation tank

InactiveCN102191276ASimple structureImprove reliabilityBioreactor/fermenter combinationsBiological substance pretreatmentsInternal pressureFresh air

The invention discloses a respiratory type solid-state fermentation method and a fermentation tank. The fermentation tank structurally comprises double pressure-bearable tank bodies, a respiratory type air charging and discharging system and a liquid circulating system. In a fermentation process, the respiratory type air charging and discharging system is used for alternatively sucking an air part form one tank body and charging the air part into the other tank body, then the fermentation tank undergoing air suction sucks in fresh air, the tank body undergoing air charging rapidly discharges air, and thus, the two tank bodies charge and discharge air alternatively. The design disclosed by the invention ensures that waste air in the tank bodies can be completely discharged, and the evaporation of moisture in a culture medium can be accelerated and the heat generated in the fermentation process can be taken way in time in an air discharging process. Microorganisms are periodically stimulated due to the periodical changes of internal pressure of a reactor, so that the growth of the microorganisms is favorably promoted.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

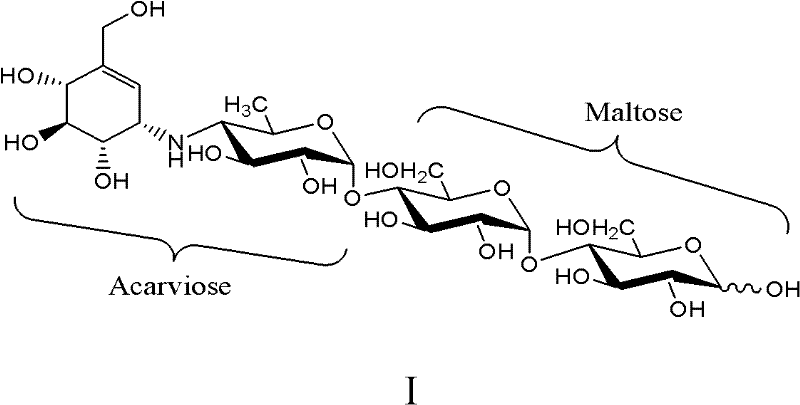

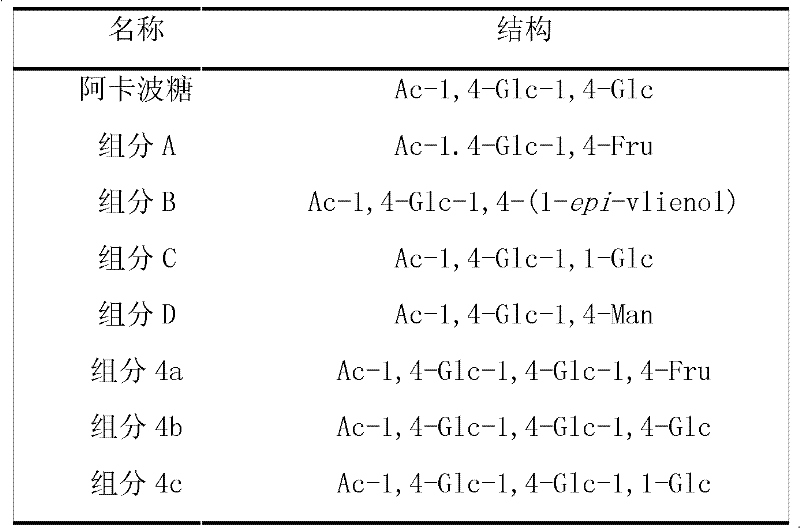

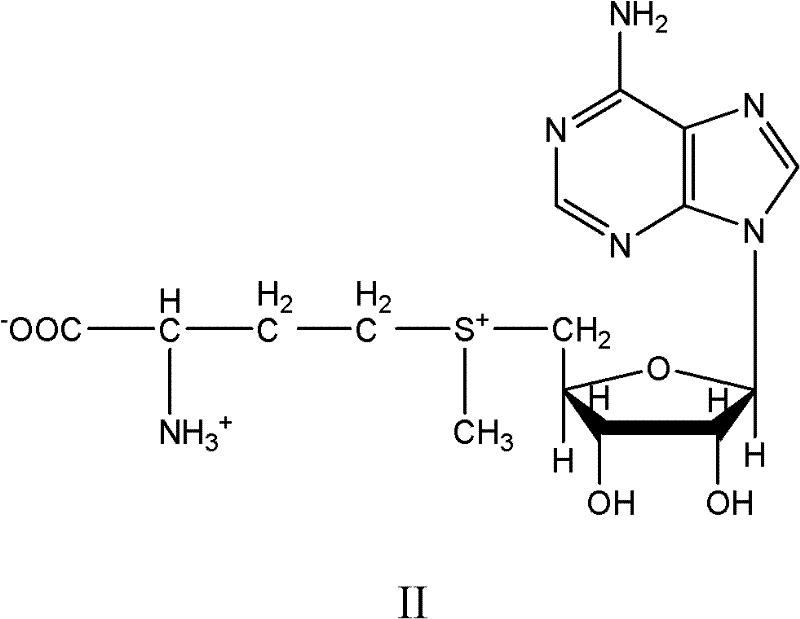

Method for synthesizing acarbose through microbial fermentation

ActiveCN102399837ARaise the level of fermentationImprove fermentation titerMicroorganism based processesFermentationBiotechnologyInorganic salts

The invention discloses a method for synthesizing acarbose through microbial fermentation, which comprises the following steps that acarbose producing strains CCTCC NO: M 209022 are inoculated to a fermentation culture medium containing carbon sources, nitrogen sources and inorganic salt applicable to all strains, the fermentation culture is carried out for 96 to 192hours at 20 to 32 DEG C, afterthe fermentation is completed, the obtained fermentation liquid is extracted and separated, and the acarbose is obtained. The method is characterized in that the fermentation culture is carried out for 0 to 60h, and water solution of ademetionine is added, so the ademetionine concentration in the fermentation culture medium is 1 to 300 mu mol / L. Through the supplementary addition of the ademetionine in the acarbose fermentation process, the fermentation level of the acarbose is improved.

Owner:ZHEJIANG UNIV OF TECH +2

Fermentation process capable of improving production level of recombinant human collagen

ActiveCN106119322AIncrease the rate of biosynthesisRaise the level of fermentationConnective tissue peptidesFungiPichia pastorisSodium pyruvate

The invention discloses a fermentation process capable of improving the production level of recombinant human collagen. The fermentation process comprises the following steps: firstly inoculating a Pichia pastoris strain liquid into a sterilized fermentation culture medium, fermentatively culturing for 14 to 18 hours, refilling methanol to carry out induction expression, simultaneously adding sodium pyruvate to the fermentation culture medium, wherein the sodium pyruvate is added in an amount of 0.01 to 10 g / L. In the fermentation process, the sodium pyruvate is added in the methanol-induced expression stage, so that the biosynthesis rate of the recombinant human collagen is improved; a continuous feed-batch way is adopted, so that the biosynthesis rate of the recombinant human collagen is further improved, and the fermentation time is shortened; meanwhile, the expression quantity of the recombinant human collagen is increased, the fermentation level is increased by more than 20%, and the production cost is reduced; the fermentation process is especially suitable for industrialized mass production of recombinant human collagen, and can bring huge practical application value for industrial production.

Owner:ZHEJIANG ZHUJI JUYUAN BIOTECHNOLOGY CO LTD

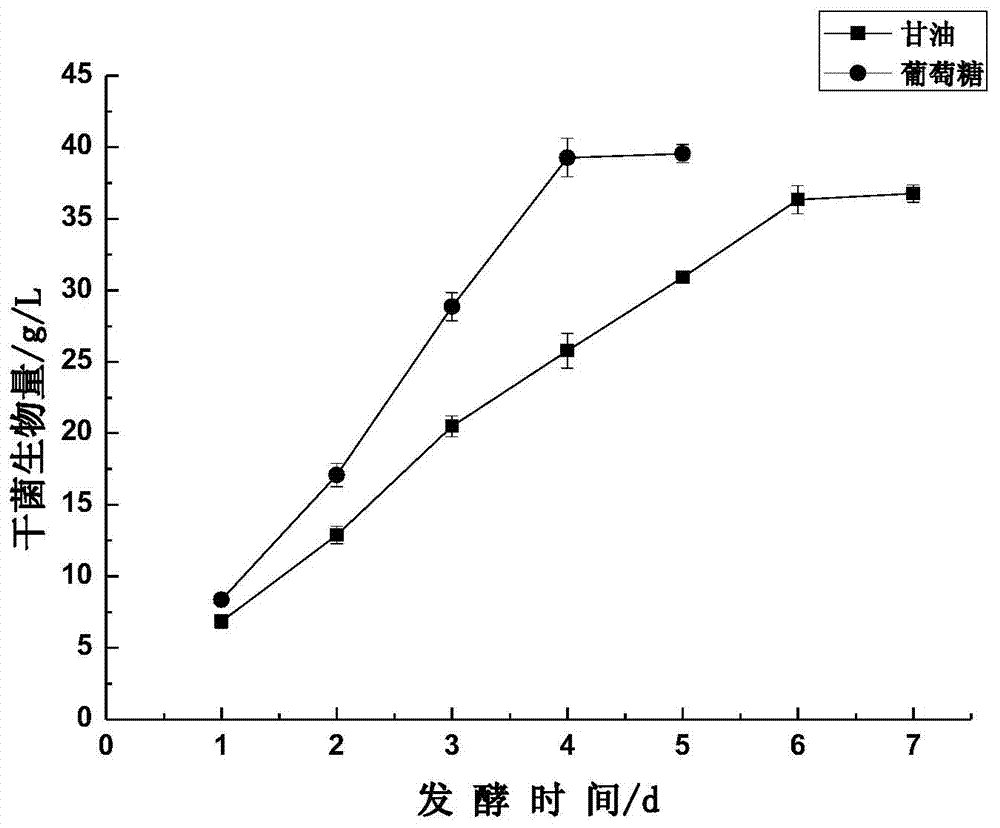

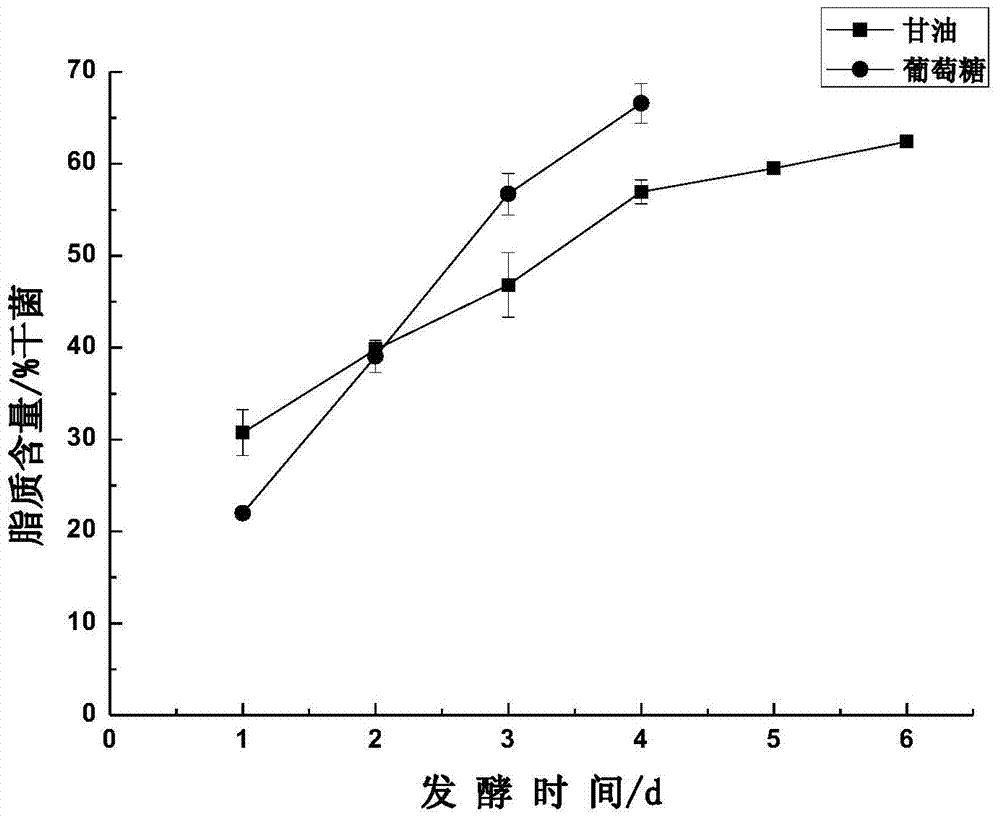

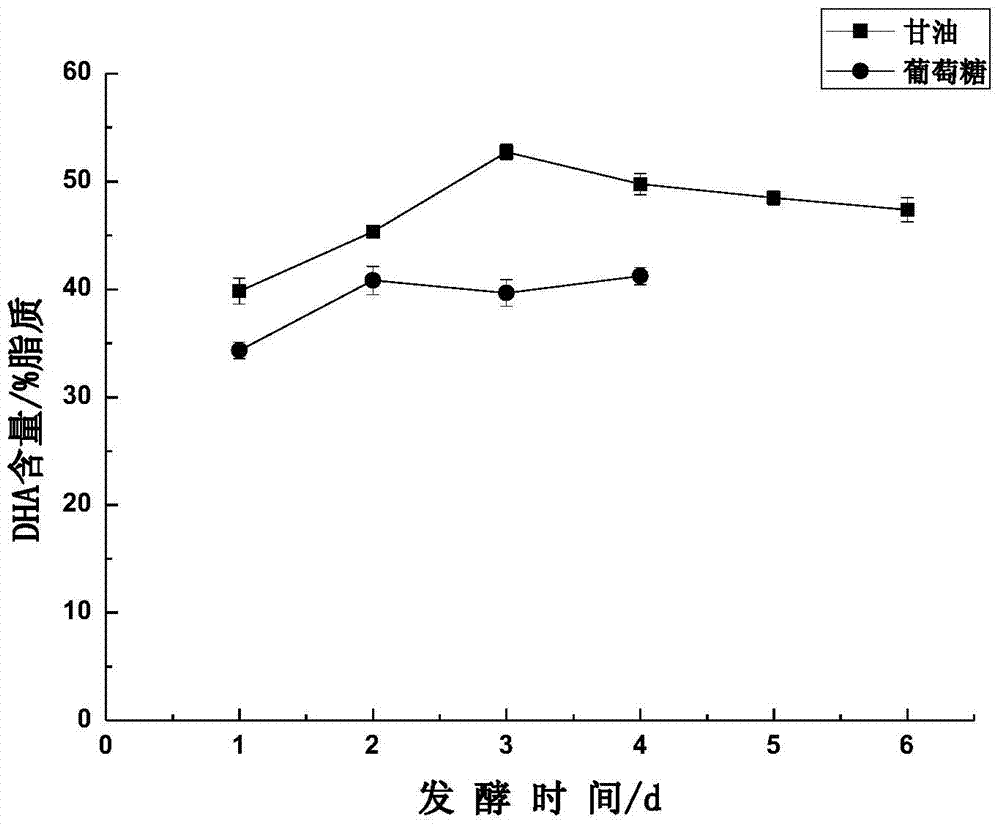

Method for producing DHA (Docosahexaenoic Acid) by fermenting schizochytrium limacinum via mixed carbon source

InactiveCN103937843APromote the development of industrializationRaise the level of fermentationMicroorganism based processesFermentationBiotechnologyGlycerol

The invention discloses a method for producing DHA (Docosahexaenoic Acid) by fermenting schizochytrium limacinum via a mixed carbon source. The method comprises the following steps: culturing a schizochytrium limacinum seed solution by utilizing a seed medium; inoculating the schizochytrium limacinum into a fermentation medium of a single glucose carbon source or the mixed carbon source of glucose and glycerol; and replenishing the glycerol or the mixed carbon source of the glucose and the glycerol when the surplus quantity of the glucose in the fermentation medium is 1% to 5% of the total weight of the original glucose. The method has the beneficial effects that not only are the advantages of rapid growth speed and high total lipid content of the schizochytrium limacinum fermented by the single glucose carbon source absorbed, but also the characteristic of high DHA content of the schizochytrium limacinum fermented by the single glycerol carbon source is realized, so that the utilization rate of substrates is increased; the fermentation level of the DHA is improved; relatively high algal oil quality is ensured at the same time. Thus, the method is very favorable for promoting the industrialization development of producing the DHA by fermenting the schizochytrium limacinum.

Owner:JIANGNAN UNIV

Production method for microbial germ powder

ActiveCN102352329AHigh viable countImprove the fermentation coefficientBacteriaMicroorganism based processesBiotechnologyCold treatment

The invention discloses a production method for microbial germ powder, which has the technical steps that: the heat treatment is carried out on proper production seeds after primary seed culture at the treatment temperature being 60 to 90 DEG C for 5 to 60 minutes, the heat treatment is carried out after secondary seed culture, the heat treatment and the cold treatment are carried out after tertiary seed culture, then, the materials are inoculated into a liquid culture medium and is cultured for 16 to 36 hours in a fermentation tank, a liquid culture medium and / or alkali are / is supplemented into the fermentation tank in real time according to the real-time data dynamically detected in the fermentation culture process, germ sledge is obtained after fermentation liquid is separated, the germ sledge is uniformly mixed with absorbing agents, and germ powder is obtained after the crushing and the sieving. The method has the advantages that the viable count of the fermentation liquid is greatly improved, the fermentation factor and the yield are high, the energy consumption is low, the cost is low, the product quality standard is improved, microbes realize the synchronously growth in the fermentation culture process of the seeds after the heat treatment and cold treatment, the viable count of the obtained germ powder is high, the spore mature speed is high, the spore conversion rate is high, the fermentation level is high, and the viable germ yield and the survival rate are high.

Owner:远大生命科学(重庆)有限公司

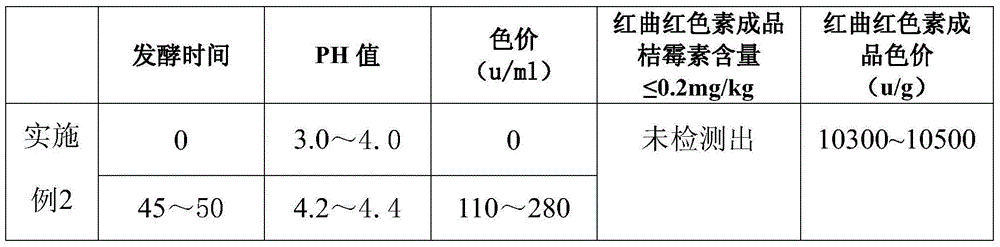

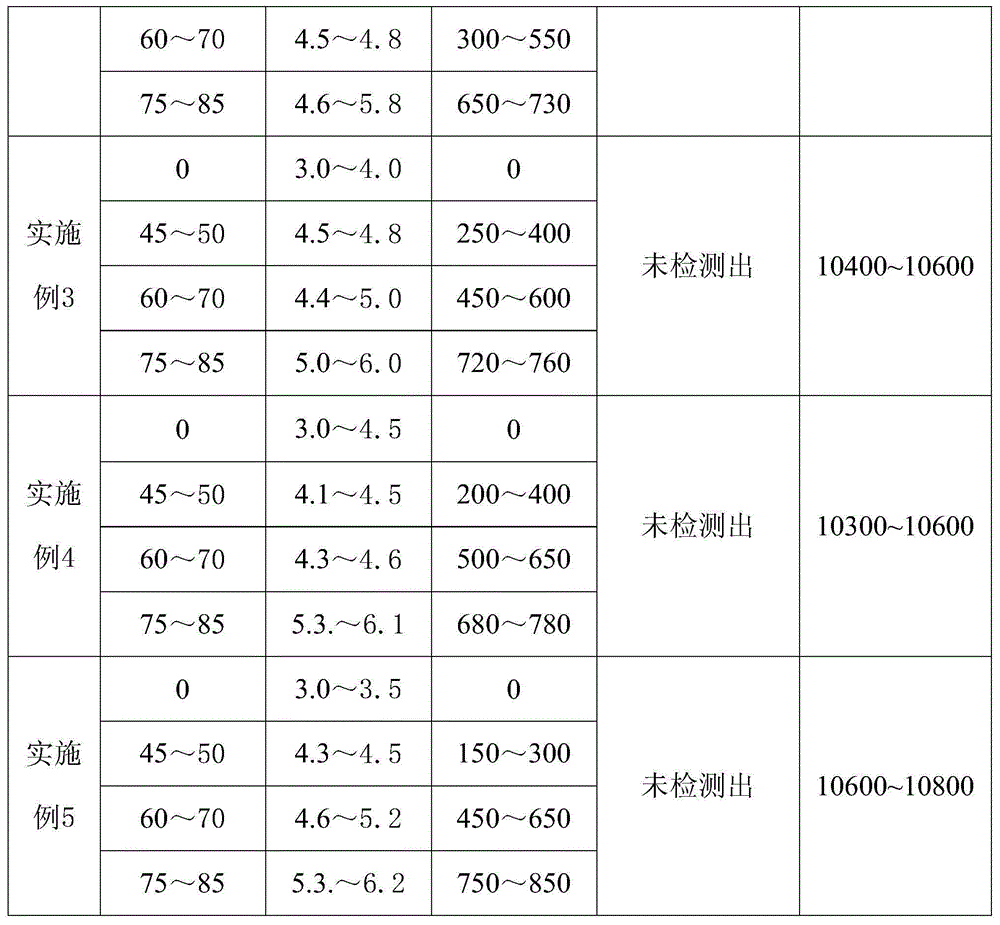

Liquid state fermentation lower citrinin and high color value monascus red pigment preparing method and product

ActiveCN104893983AGood biological propertiesLarge amount of inoculationFungiMutant preparationMicroorganismMonascus anka

The invention discloses Monascus anka Yang YZ 301 and a cultivation method thereof, wherein the microbial preservation number of the Monascus anka Yang YZ 301 is CGMCC9707. The invention further discloses a method for preparing lower citrinin and high color value monascus red pigment through liquid state fermentation of the Monascus anka Yang YZ 301. The method includes the first step of strain breeding, the second step of seed cultivation and enlarged cultivation, and the third step of liquid state fermentation, extraction and purification, spray drying and the like. The strains are the Monascus anka Yang YZ 301 obtained by cultivation, repeated UV mutagenesis and repeated isolation and screening of Monascus anka Nakazawa et Sato YZ201 developed by the Tianyi Biological Fermentation Technology Co., Ltd in Dongguan. The invention further discloses a lower citrinin and high color value monascus red pigment product obtained through the preparing method. The provided strains are excellent, and the technology is reasonable and stable. The obtained product is high in yield and stable in quality. The content of citrinin in the product is not more than 0.2 mg / kg (calculated by unit color value of 500 mu / g), and the color value of monascus red pigment ranges from 10,300 mu / g to 10,800 mu / g.

Owner:佛山市真红生物技术有限公司

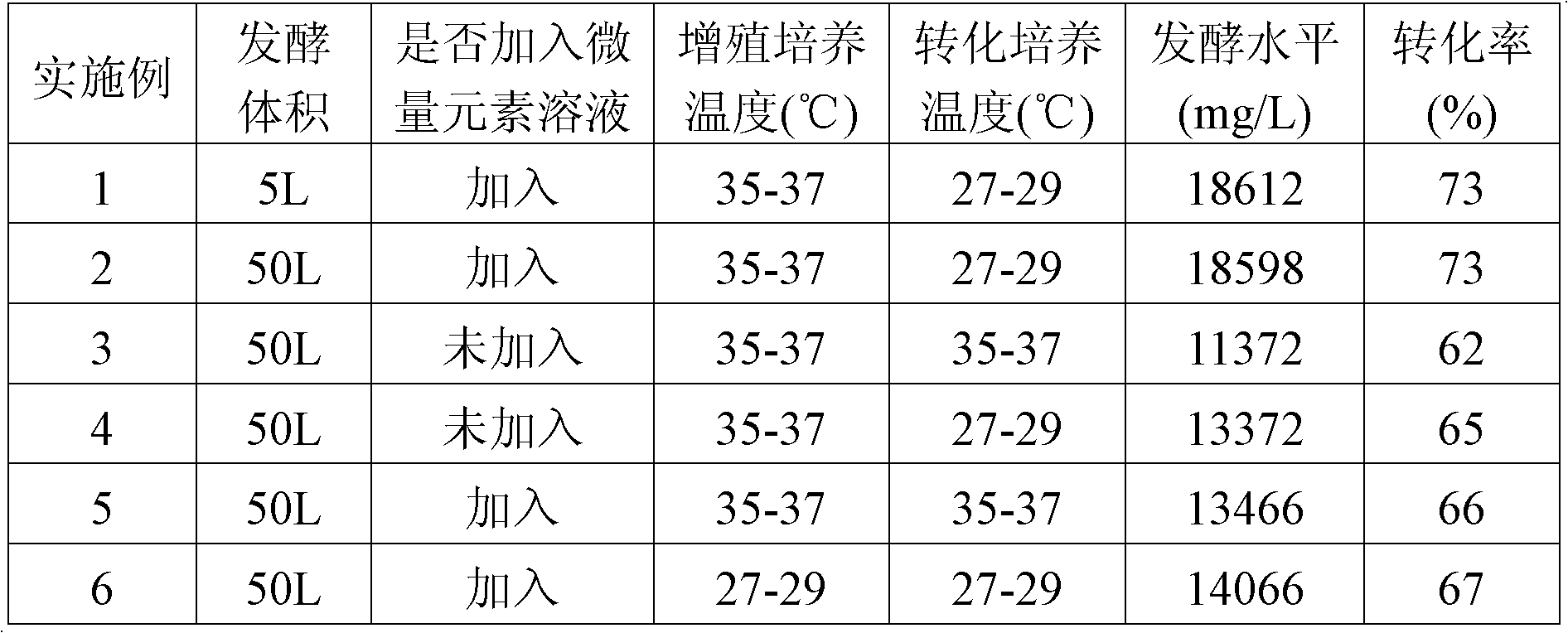

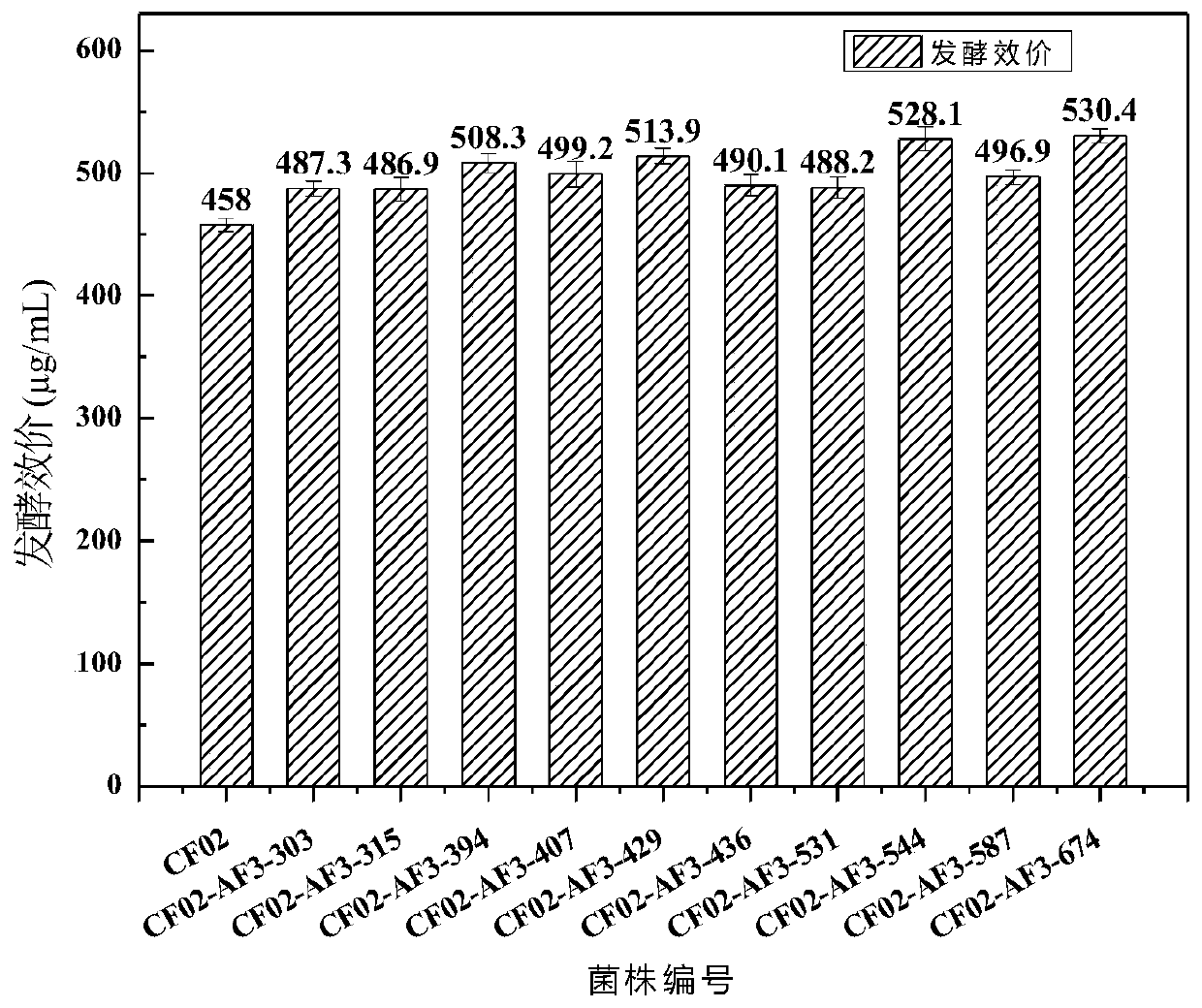

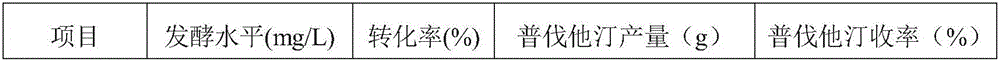

Fermentation process for producing pravastatin by transforming compactin by using actinomadura yumaense

ActiveCN102757986AImprove conversion abilityRaise the level of fermentationMicroorganism based processesFermentationMicroorganismTrace element

The invention discloses a fermentation process for producing pravastatin by transforming compactin by using actinomadura yumaense. According to the fermentation process based on the conventional fermentation process, the transformation ability of the microbial substrate and the fermentation level of the pravastatin are improved by adding trace element solution into a fermentation culture medium and utilizing the effect of the trace elements completely; the transformation ability of the microbial transformation bacteria-actinomadura yumaense on the compactin and the fermentation level of the pravastatin are effectively improved by controlling the culture temperature of the actinomadura yumaense and the transformation temperature of the compactin by using actinomadura yumaense; and the fermentation level is far higher than that of the prior art. The fermentation process is simple and convenient to operate, low in cost and suitable for large-scale production.

Owner:GUANGDONG BLUE TREASURE PHARMA

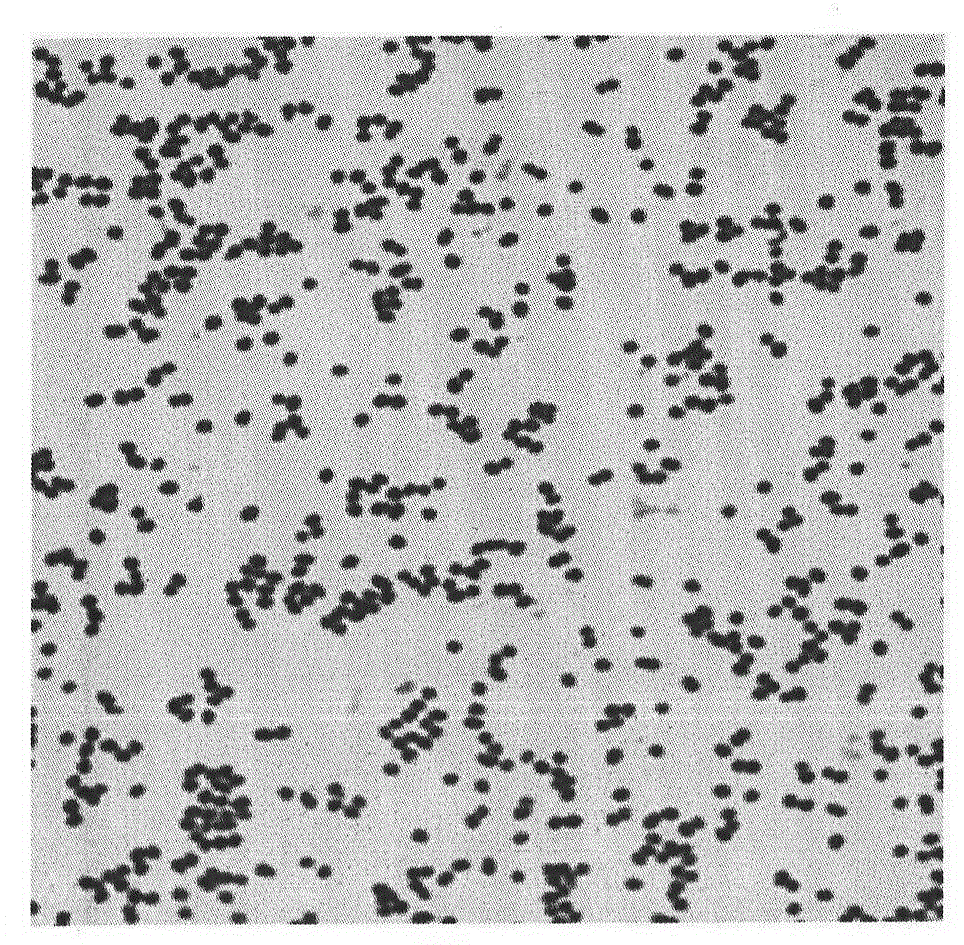

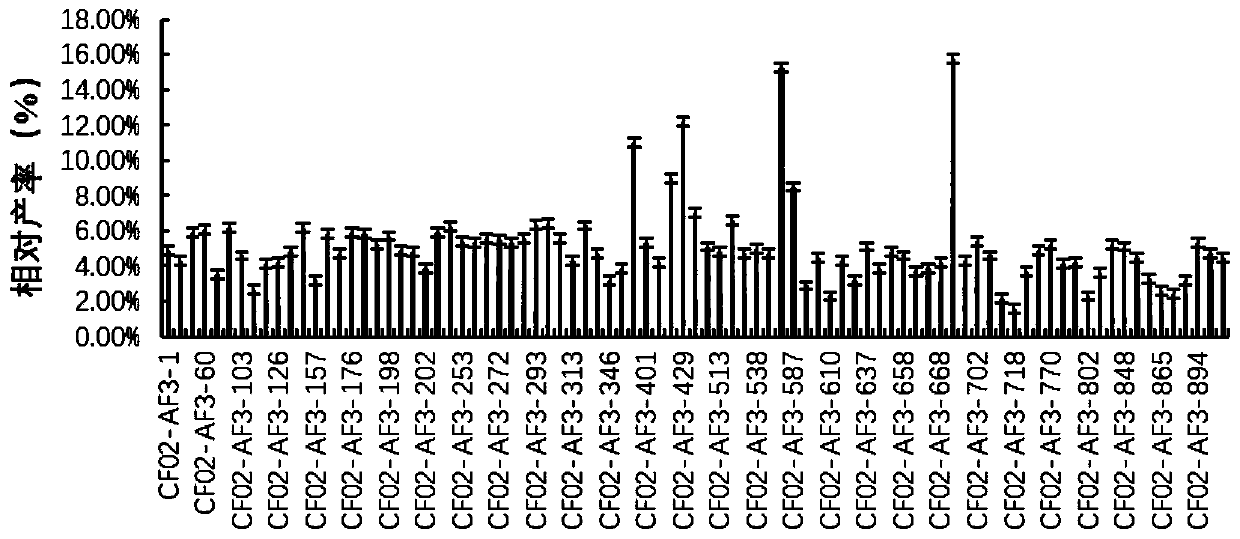

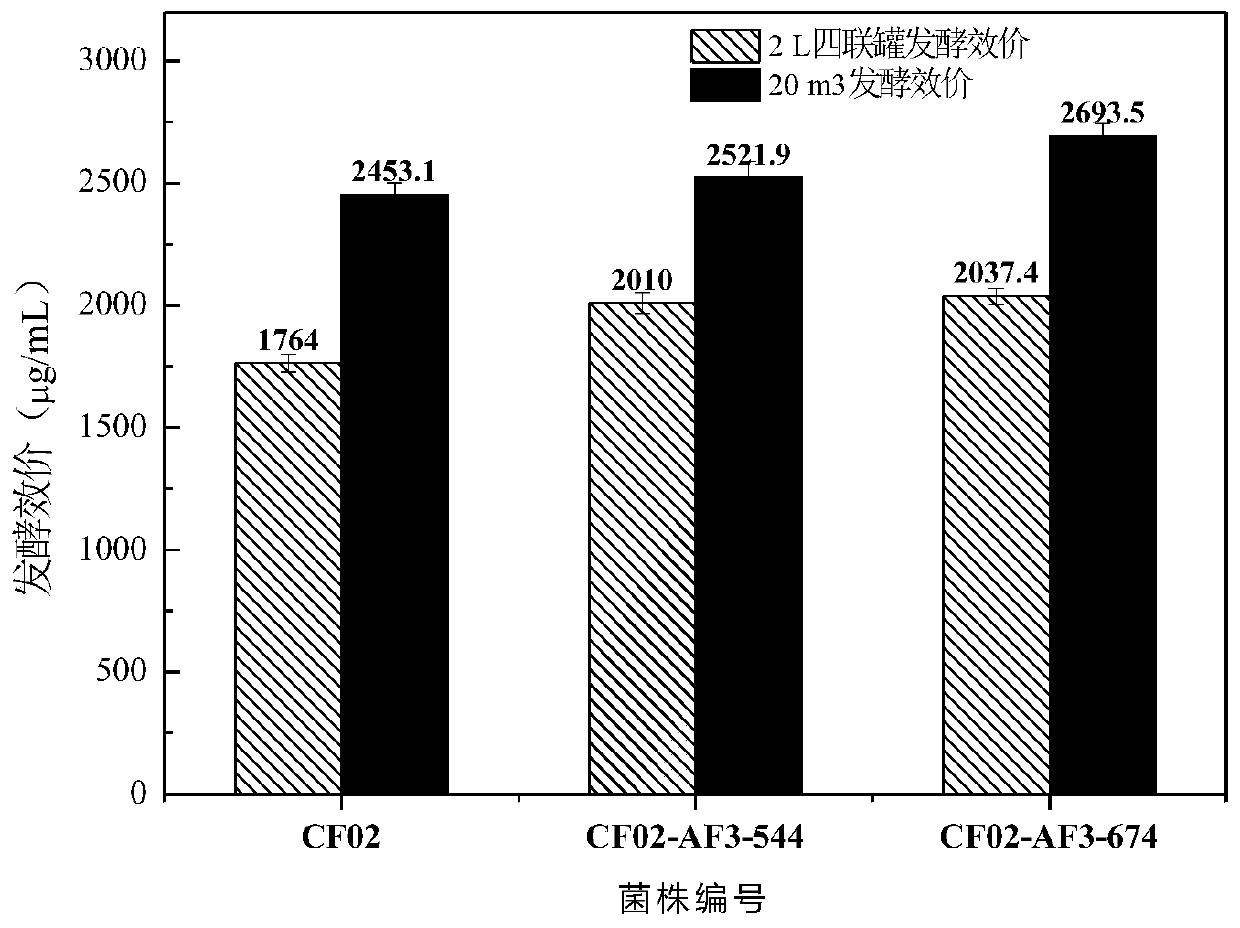

High-yield coenzyme Q10 rhodobacter sphaeroides and mutation breeding and application thereof

ActiveCN109762757AQuadruple resistantIncrease productionBacteriaMicroorganism based processesBacteroidesHigh-Throughput Screening Methods

The invention provides high-yield coenzyme Q10 rhodobacter sphaeroides and mutation breeding and application thereof, and relates to the field of microbial mutation breeding. Strains screened by spacemutagenesis are used as starting bacteria and subjected to plasma mutagenesis at normal pressure and room temperature. The high-yield coenzyme Q10 rhodobacter sphaeroides are obtained after multi-resistance screening, high-throughput screening and step-by-step amplification verification, and are deposited in China General Microbiological Culture Collection Center with the deposit number of CGMCCNo. 16625. The average titer of a mutant strain of the rhodobacter sphaeroides can reach 2694[mu] / mL according to 20m<3> fermentation production verification, and the yield of the coenzyme Q10 is significantly improved. In addition, the strain has quadruple resistance and broad application prospects.

Owner:SHENZHOU BIOLOGY & TECH CO LTD +1

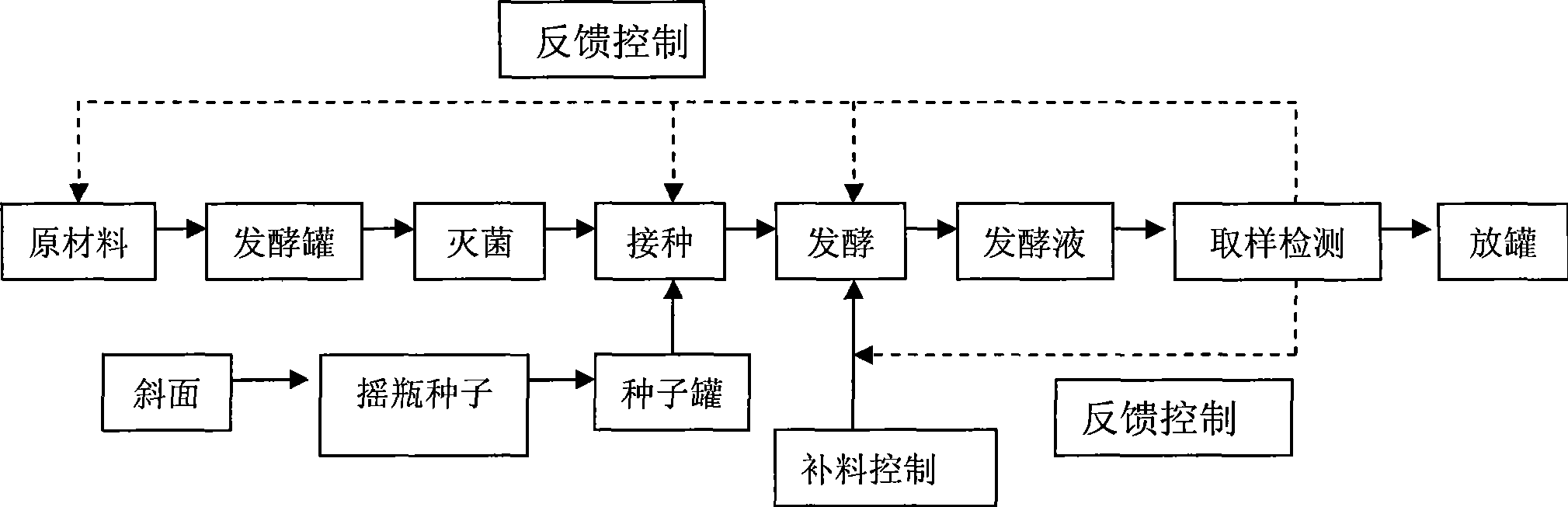

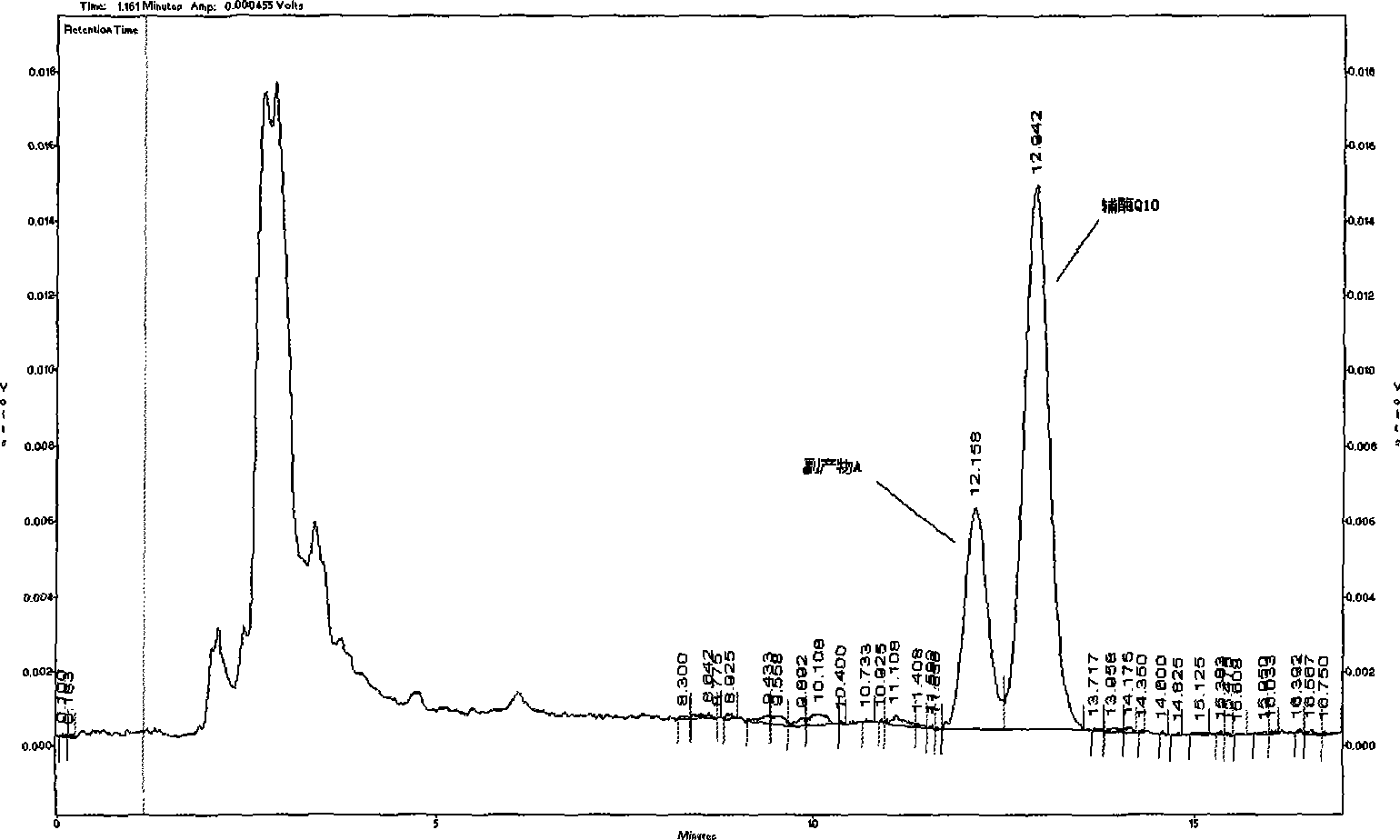

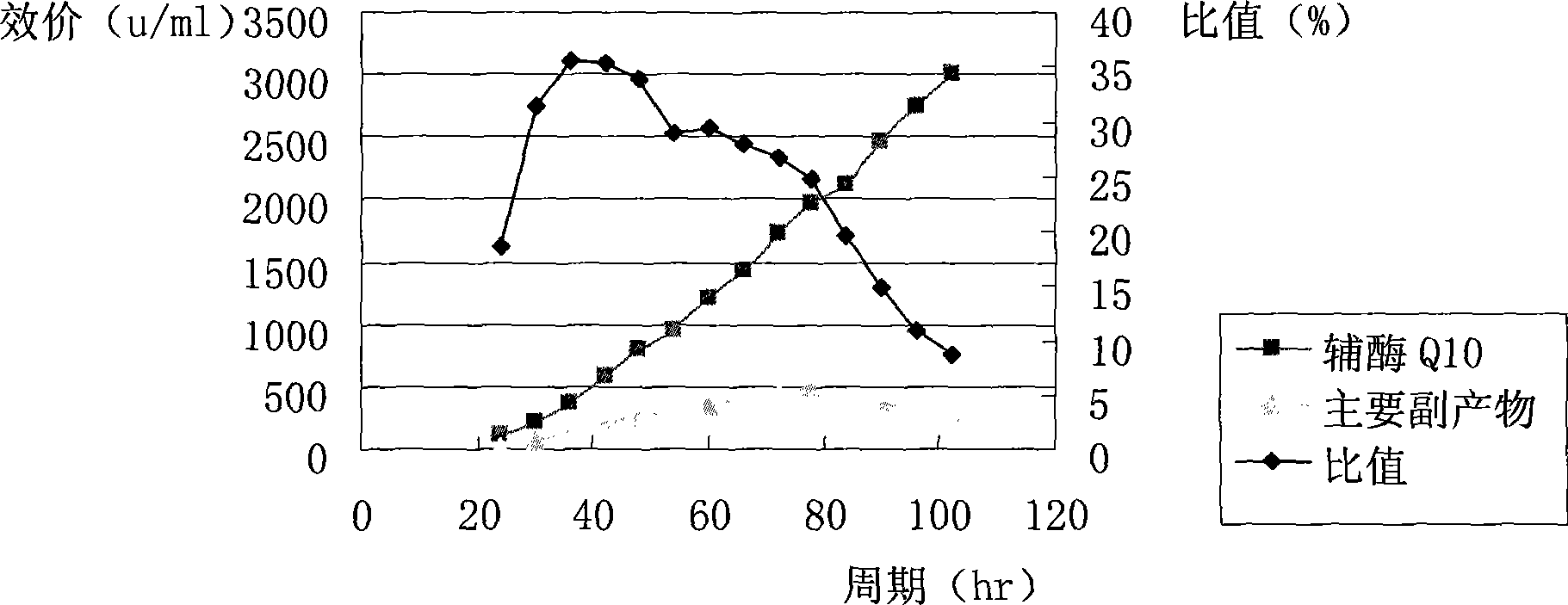

Production and fermentation process of coenzyme Q10

ActiveCN101519681ARaise the level of fermentationImprove time utilizationMicroorganism based processesFermentationMaterial consumptionCellular anabolism

The invention discloses a production and fermentation process of coenzyme Q10. On the premise that the fermentation quality of the coenzyme Q10 is retained, according to the synthesis rate of the main byproduct 5-demethoxylation coenzyme Q10 in the bacteria metabolism process of the coenzyme Q10 as well as the content change thereof, the feedback adjustment is performed on the initial reaction of metabolism, and the speed restriction action is acted on the anabolism, therefore, the feedback adjustment is performed on the accumulation of the product coenzyme Q10 in the cell, the fermenting level of the coenzyme Q10 is greatly promoted through the optimization to the concentration of the main substrate in the fermenting formula and through the optimization control to the stirring rotational speed during the fermenting process and can be improved to above 3000 u / ml, the determination of the optimal time for pot laying improves the utilization ratio of time of the production of the coenzyme Q10 in the cell, the fermentation cost is reduced, and the consumption of the fermenting raw material is greatly reduced.

Owner:YIDU HEC BIOCHEM PHARMA

Process for producing beta-thymidine through microbiological fermentation method

InactiveCN105950689AReduce the number of fermentation stagesShort processMicroorganism based processesFermentationMicroorganismMicrobiology

The invention discloses a process for producing beta-thymidine through a microbiological fermentation method. The process is characterized in that a strain culturing process, a seed culturing process and a fermental culturing process are carried out to obtain a fermenting liquid. According to the process, the fermenting conditions are optimized; the fermenting grades are decreased; in addition, the process is easily controlled; the formula of a culture substrate is adjusted; the fermenting cost is reduced. The process has the beneficial effects that the process is simple, the fermenting grades are decreased, the process is stable and easily controlled, the cost is low, and industrial production is facilitated.

Owner:焦作健康元生物制品有限公司

Method for improving yield of fermentation of epsilon-polylysine

InactiveCN102154392AHigh positive mutation rateRaise the level of fermentationMutant preparationMicroorganism based processesEpsilon-PolylysineMicrowave

The invention provides a method for improving yield of fermentation of epsilon-polylysine. In the method, a microwave and dithyl sulfate combined mutation induction method is used to obviously improve the forward mutation of Streptomyces albulus CGMCC4.121 to obtain a high-yield strain for producing epsilon-polylysine by fermentation. Results show that the shake flask fermentation level of the epsilon-polylysine is improved from 0.60g / L to 0.85g / L.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

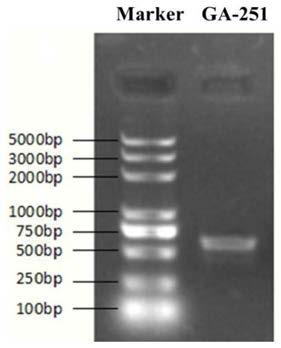

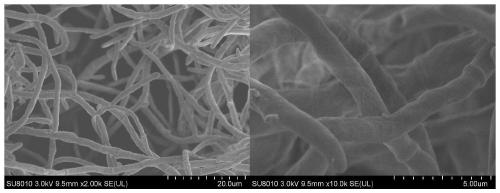

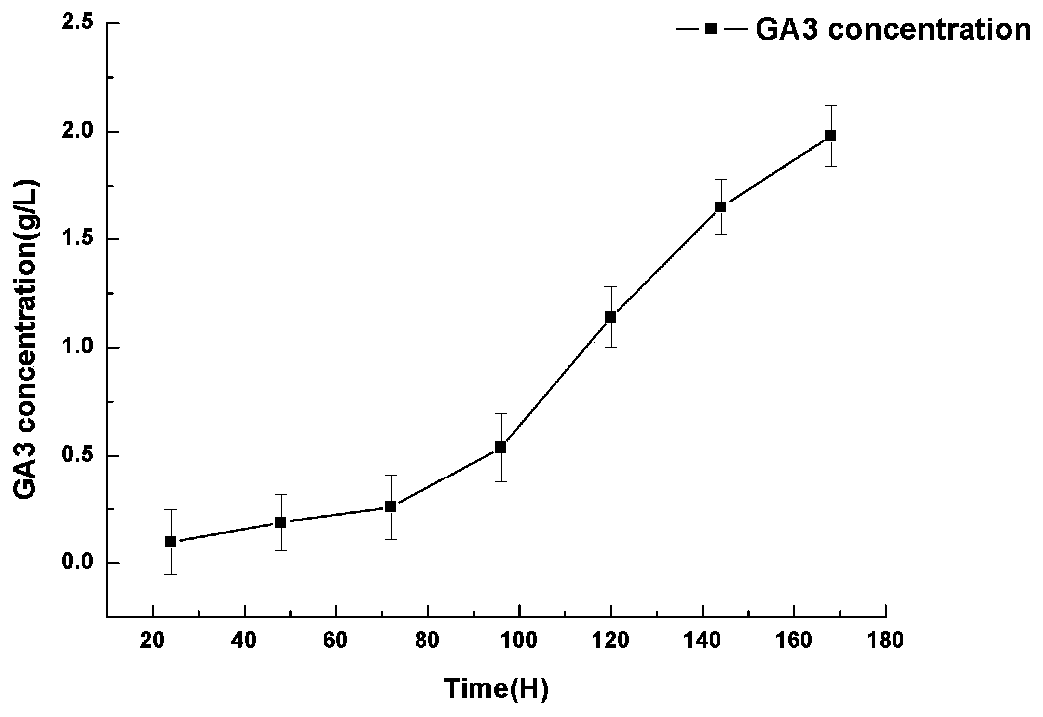

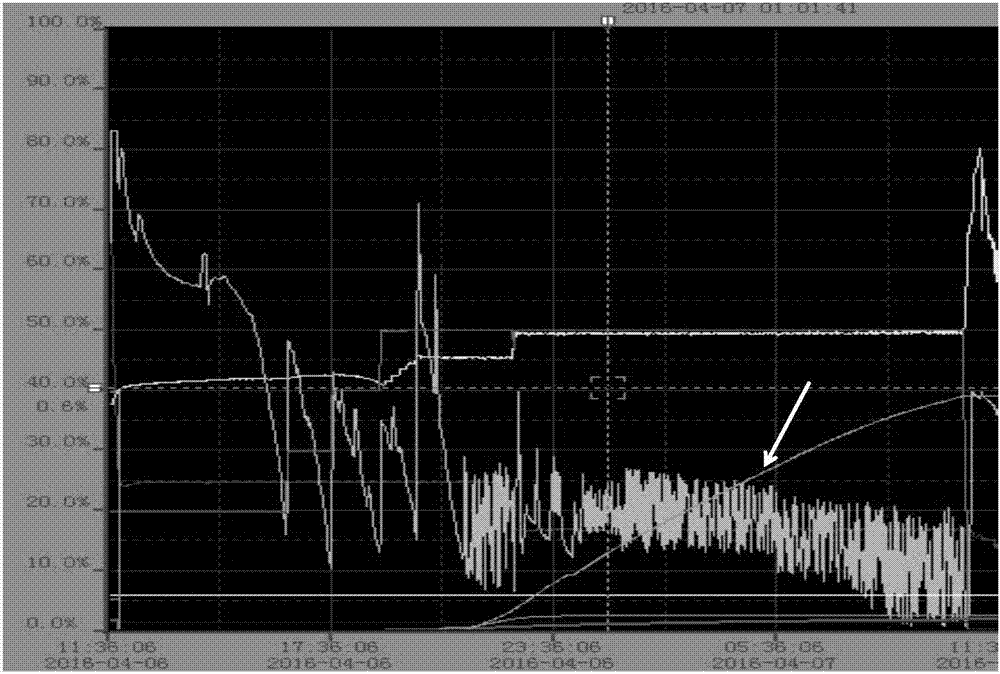

Gibberella fujikuroia mutant strain with high yield of gibberellin GA3 and applications thereof

ActiveCN110042061AIncrease profitRaise the level of fermentationFungiMicroorganism based processesBiotechnologyFusarium fujikuroi

The invention discloses Fusarium fujikuroi GA-251 and applications thereof, wherein the Fusarium fujikuroi GA-251 is a Gibberella fujikuroia mutant strain and has high yield of gibberellin GA3. The Fusarium fujikuroi GA-251 is preserved in China Center for Type Culture Collection, wherein the address is Wuhan University, Wuhan, China, the postal code is 430072, the preservation number is CCTCC NO:M 2019201, the preservation date is March 25th, 2019. The strain is obtained by carrying out radiation composite mutagenesis on protoplasts through lithium chloride and cobalt 60, and gibberellin GA3production of the strain is improved by 20%. The method has the advantages of high titer and easy extraction of the final product, and overcomes the defects of low fermentation titer and high cost oforiginal processes.

Owner:ZHEJIANG UNIV OF TECH

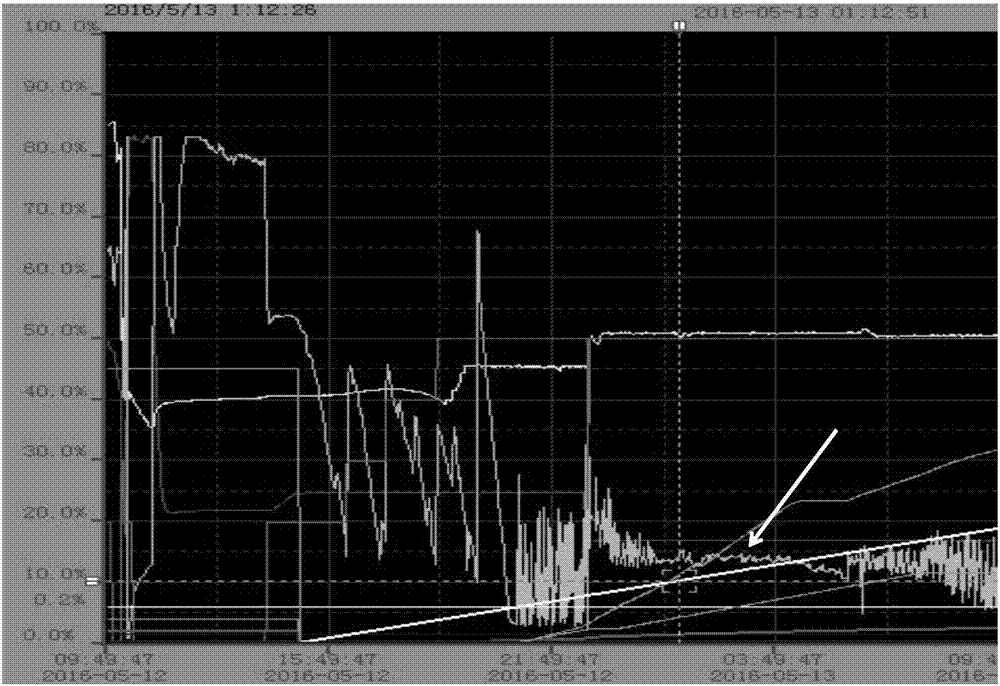

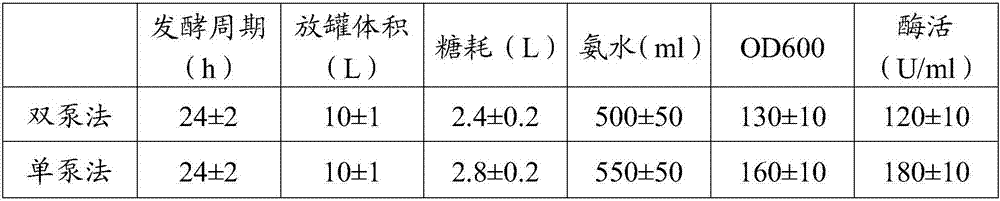

Dual-pump material feeding method and recombinant Escherichia coli fermentation method based on dual-pump material feeding method

ActiveCN107227287ARaise the level of fermentationShorten the timeBacteriaHydrolasesEscherichia coliMicroorganism

The invention relates to the technical field of microbial fermentation and particularly relates to a dual-pump material feeding method and a recombinant Escherichia coli fermentation method based on the dual-pump material feeding method. The dual-pump material feeding method utilizes a constant-speed material feeding pump and a dissolved oxygen-related pump to supplement materials to the fermentation broth. The method comprises starting the constant-speed material feeding pump, adjusting a glucose flow-addition rate of the constant-speed material feeding pump to less than consumption rate of the glucose in the fermentation broth, starting the dissolved oxygen-related pump, setting a related dissolved oxygen value, when the dissolved oxygen value of the fermentation broth is higher than the preset value of the dissolved oxygen-related pump, starting the dissolved oxygen-related pump to supplement materials, and when the dissolved oxygen value of the fermentation broth is less than the preset value of the dissolved oxygen-related pump, stopping the dissolved oxygen-related pump. The dual-pump material feeding method realizes fermentation of recombinant Escherichia coli and shortens a dissolved oxygen fluctuation range to 10%. After fermentation, the OD value of the fermentation broth is 160. The enzyme activity of the hydrolase expressed by the recombinant escherichia coli in fermentation broth is 180 U / ml. The recombinant Escherichia coli fermentation method greatly improves the fermentation level of Escherichia coli.

Owner:SHANDONG LUKANG PHARMA

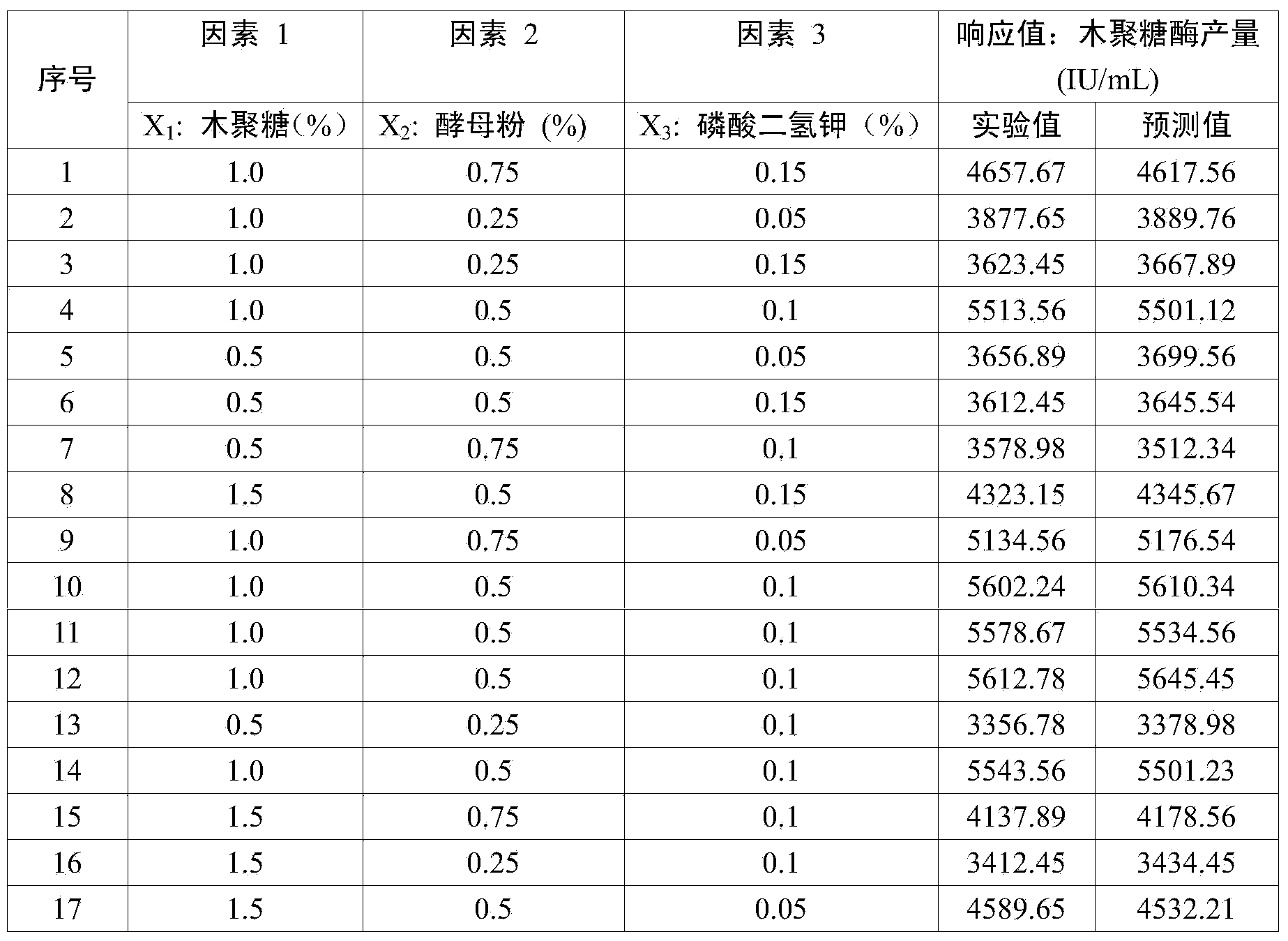

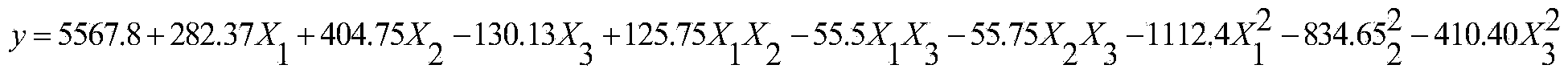

Bacillus sphaericus with high yield and high-temperature xylanase resistance and application thereof

ActiveCN104031860AMild culture conditionsEnrich relevant research contentBacteriaMicroorganism based processesMicrobiologyXylanase

The invention discloses a bacillus sphaericus with high yield and high-temperature xylanase resistance and an application thereof. The bacillus sphaericus is classified and named as Lysinibacillus sphaericus Xyn-1, and is collected in China Center for Type Culture Collection (CCTCC) on May, 5th, 2014 with the collection number CCTCCM2014183. The optimal fermentation enzyme production condition of a strain screening shake flask is determined by adopting a Plackett-Burman design and a response surface analysis method, and the fermentation level under the condition can reach 5678.5IU / mL. When the enzyme produced by fermentation of the strain is applied to degradation of plant hemicellulose, the xylobiose yield of the hemicellulose can reach over 60% through enzymolysis.

Owner:NANJING UNIV OF TECH

Material supplementing method for reducing viscosity of gentamicin C1a fermentation liquid

The invention relates to a material supplementing method for reducing viscosity of a gentamicin C1a fermentation liquid, and belongs to the field of fermentation engineering, in the whole fermentation process only control of supplementing of two materials of carbon and nitrogen is performed in the method, reducing sugar concentration in a fermentation pot is controlled in 1-20g / L, when the reducing sugar concentration is lower than 5g / L, a continuous flow adding method is used for supplementing the carbon, when the reducing sugar concentration is higher than 20g / L, the supplementing of the carbon is stopped, the rate for the supplementing of the carbon is adjusted according to real-time off-line determined reducing sugar concentration and fermentation liquid viscosity; amino nitrogen in the fermentation pot is controlled in 20-60mg / mL, when the amino nitrogen concentration is lower than 30mg / mL, the continuous flow adding method is used for supplementing the nitrogen, when the amino nitrogen concentration is higher than 60mg / mL, the supplementing of the nitrogen is stopped, and the rate for the supplementing of the nitrogen is adjusted according to real-time off-line determined amino nitrogen concentration and fermentation liquid viscosity. The method is simple in process, can obviously reduce the viscosity of the fermentation liquid and improve the oxygen transfer, and has an important effect on increasing of the yield of gentamicin.

Owner:HENAN RENHUA BIOTECH CO LTD

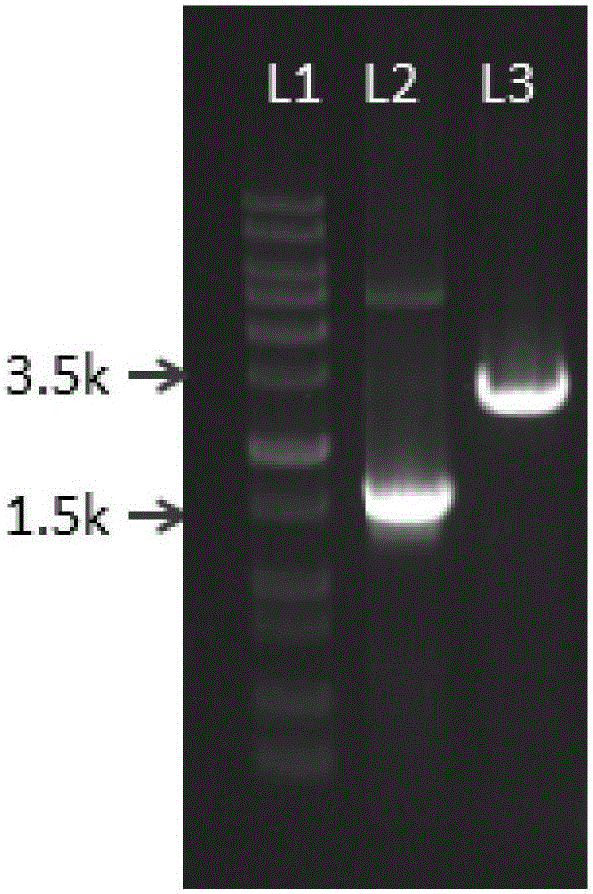

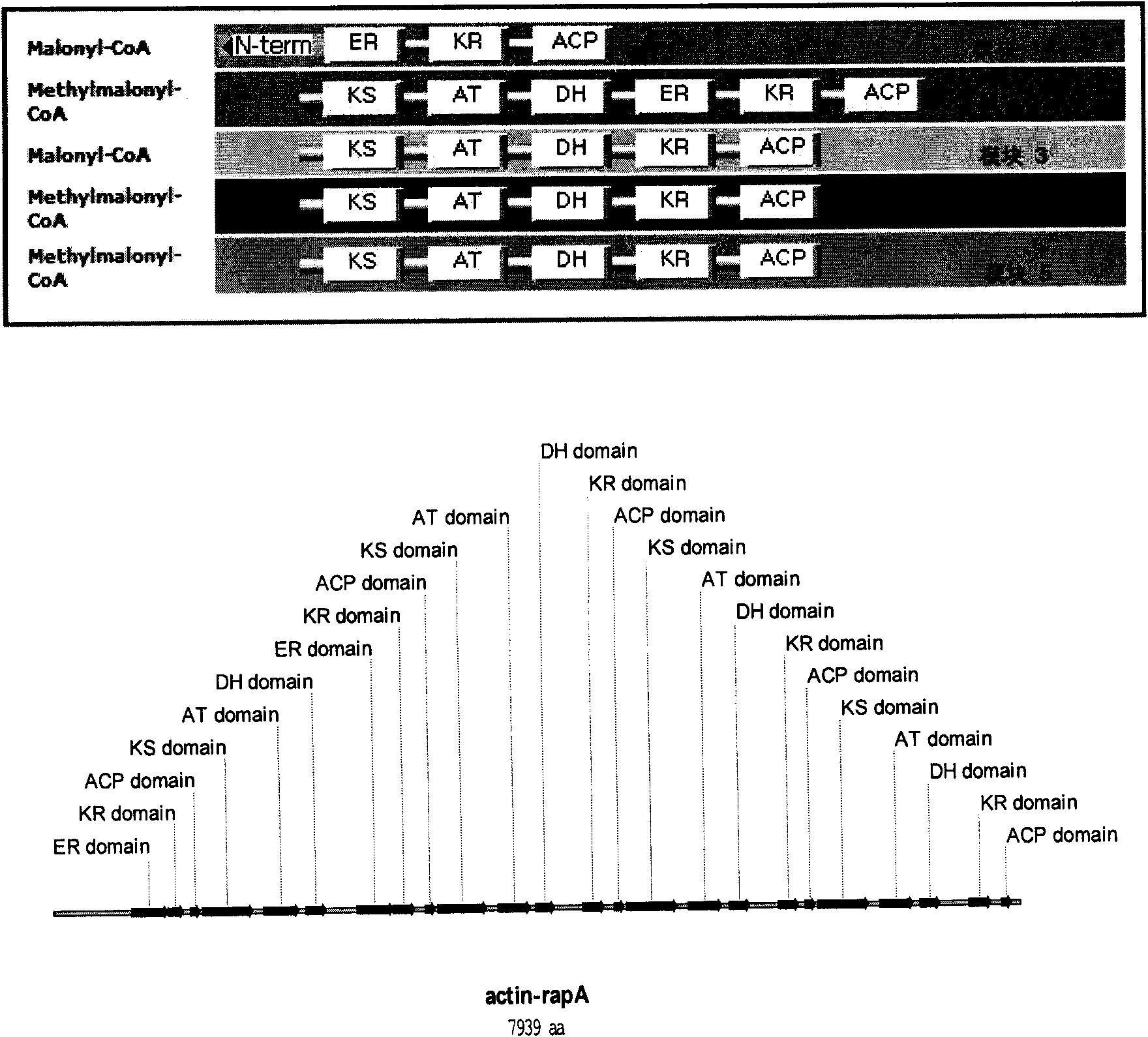

Rapamycin biosynthesis gene from actinoplanes, and separation method and application thereof

InactiveCN101886085AIncrease productionRaise the level of fermentationMicroorganismsMicrobiological testing/measurementNucleotideMicrobiology

The invention discloses a Rapamycin biosynthesis gene from antinoplanes, and a separation method and application thereof. The gene is a nucleotide sequence shown by SEQ ID NO:1.

Owner:SHANGHAI INST OF PHARMA IND CO LTD

Process for producing pravastatin on large scale

ActiveCN105821086ARealize large-scale productionRaise the level of fermentationBacteriaOrganic compound preparationMicroorganismOrganic solvent

The invention discloses a process for producing pravastatin on a large scale. The process comprises the steps of fermenting, extracting and refining, wherein a plant extracting solution composed of an exocarpium benincasae extracting solution and a water melon peel extracting solution is used in the fermentation process, drug resistance and the conversion capacity of microorganisms to the substrate compactin and the fermentation level of pravastatin are effectively improved, the yield of pravastatin is increased, and in the steps of extracting and refining, the pH value of the solution, types and dosage of organic solvent, extracting time and temperature, cooling operation and crystallization time are controlled strictly to ensure the yield and purity of pravastatin. The process is stable, cost is low, and large-scale industrial production of pravastatin is achieved.

Owner:GUANGDONG BLUE TREASURE PHARMA

Fermentation technology for industrially producing L-hydroxyproline through fermentation method

InactiveCN105506017ARaise the level of fermentationReduce manufacturing costFermentationMicrobiologyFermentation

Provided is a fermentation technology for industrially producing L-hydroxyproline through a fermentation method. The fermentation technology comprises the following steps that 1, a strain is cultured in a liquid culture medium, and a mature seed is obtained; 2, the mature seed is moved into the fermentation culture medium in a fermentation tank for fermentation and metabolism, and the L-hydroxyproline is produced. The fermentation technology is applied to production of the L-hydroxyproline through microbial fermentation, the fermentation level is improved, the production cost is reduced, and three-waste pollution is avoided.

Owner:TIANJIN JINGYE FINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com