Respiratory type solid-state fermentation method and fermentation tank

A solid-state fermentation and fermenter technology, applied in solid-phase fermentation bioreactors, fermentation, bioreactor/fermenter combinations, etc., can solve the problems of controversial impact on production efficiency, reduced production efficiency, and impact on growth and metabolism. Achieve the effect of improving fermentation level, increasing evaporation and increasing overall reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

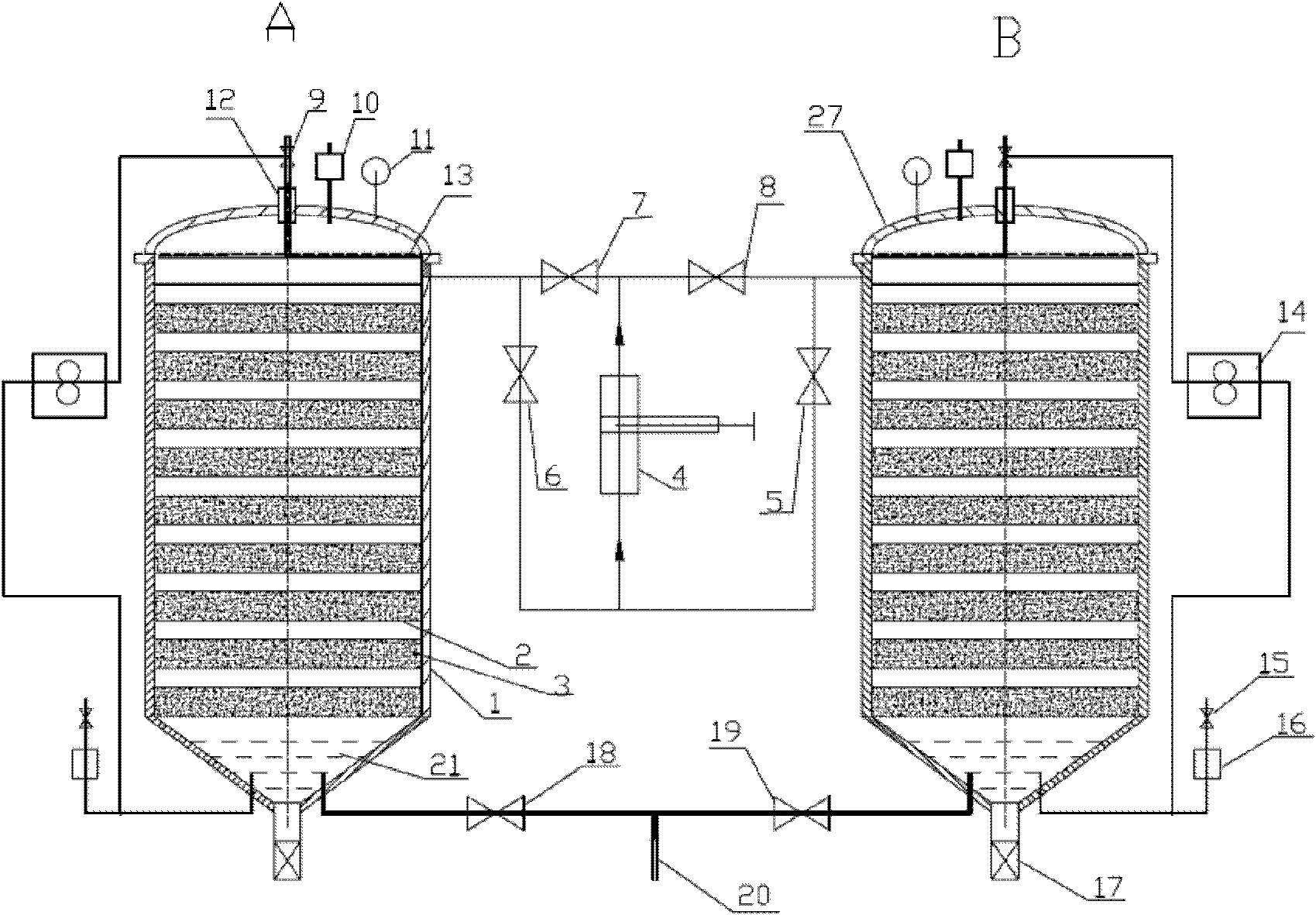

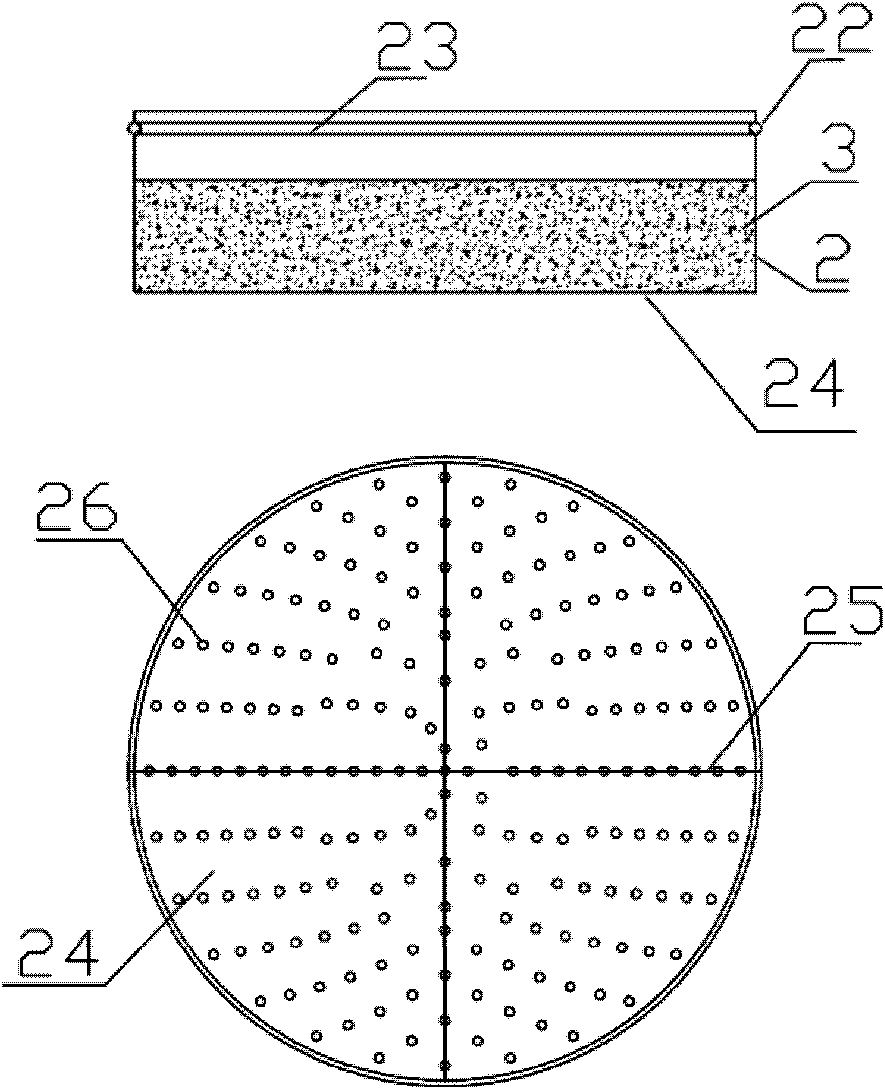

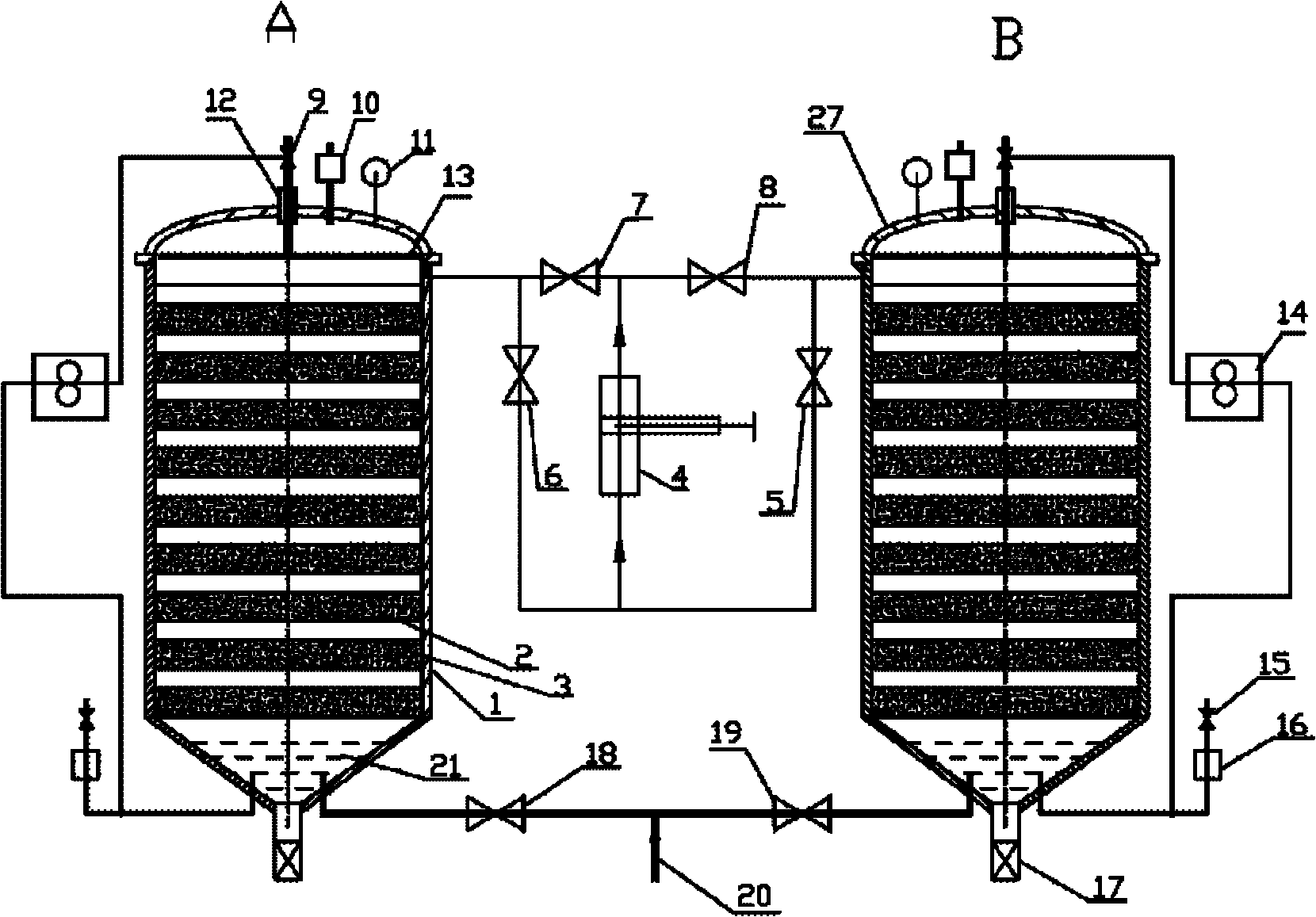

[0024] Production of cellulase by fermenting Trichoderma reesei in a breathing solid-state fermenter.

[0025] A fermenter with a height-to-diameter ratio of 1:2, a diameter of 1.5m, and a cylinder height of 3m is used, with a volume of 5.3m 3 . The taper angle at the bottom of the tank is chosen to be 150°, and the taper volume is 0.118m 3 , can be used to store a certain quality of sterile water for air humidity regulation. The height of the tray is 15cm, and the number of tray layers is 20. The used substratum of solid-state fermentation is steam-exploded corn stalk and wheat bran, and its mass ratio is 4: 1, and the inorganic salt solution of 2.5 times (mass ratio) is added after the two are thoroughly mixed, and the composition of inorganic salt solution is: (NH 4 ) 2 SO 4 , 15g / L; MgSO 4 , 6g / L; KH 2 PO 4 , 3g / L. The culture medium was sterilized at 121°C in a steaming tank for 40 minutes, and then inoculated with Trichoderma viride liquid seeds, and the inoculu...

Embodiment 2

[0029] Fermentation of Xanthomonas campestris CGMCC 1.1781 to produce xanthan gum in a breathing solid-state fermenter.

[0030] A fermenter with a height-to-diameter ratio of 1:1, a diameter of 2m, and a cylinder height of 2m is used, with a volume of 6.28m 3 . The taper angle at the bottom of the tank is chosen to be 120°, and the taper volume is 0.524m 3 , can be used to store a certain quality of medium. The height of the tray is 10cm, and the number of tray layers is 20. The medium used for solid-state fermentation is glucose 30g L -1 , NH 4 NO 3 1g L -1 , yeast powder 2g L -1 , MgSO 4 ·7H 2 O 0.25g L -1 、Na 2 HPO 4 0.1gL -1 , CaCO 3 3g L -1 .

[0031] Load the polyurethane foam block that side length is 0.5cm in the feed tray, and the height of packing is 6cm, and the space of 4cm is reserved on the top of the feed tray.

[0032] Open the tank cover 27, and the tray is hoisted into the reactor through the tray cross 25. Close the tank cover 27, feed sat...

Embodiment 3

[0034] Clarithromycin is produced by continuous solid-state fermentation of Streptomyces clavuligerus in the present invention.

[0035] A fermenter with a height-to-diameter ratio of 1:5, a diameter of 1m, and a cylinder height of 5m is used, with a volume of 3.93m 3 . The taper angle at the bottom of the tank is chosen to be 60°, and the taper volume is 0.453m 3, can be used to store a certain quality of medium. The height of the tray is 50cm, and the number of tray layers is 10. The medium used for solid-state fermentation is glycerol 12g / L, soybean flour extract 300ml / L, peptone 10g / L and KH 2 PO 4 0.8g / L.

[0036] Loading side length in the feed tray is a polyurethane foam block of 1cm, the height of the tray is 45cm, and there is a 5cm space on the top of the reserve tray.

[0037] The operation mode of the reactor for continuous fermentation is as follows: open the tank cover 27, and lift the tray through the tray cross 25 into the reactor. Close the tank cover 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com