Patents

Literature

2523 results about "Steaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steaming is a method of cooking using steam. This is often done with a food steamer, a kitchen appliance made specifically to cook food with steam, but food can also be steamed in a wok. In the American southwest, steam pits used for cooking have been found dating back about 5,000 years. Steaming is considered a healthy cooking technique that can be used for many kinds of food.

Black tea and production technology

The invention discloses a production technology for black tea with stronger tea fragrance, more mellow taste and darker liquor color. The production technology is characterized by comprising the following steps of: primarily processing raw black tea; removing impurities and screening; humidifying and steaming tea; piling, steaming and shaping; drying or floating and drying; and packaging. The produced brick tea has the advantages of black brown or russet brown color and luster, zero smoke fat pollution, pure and lofty tea perfume, mellow taste, orange red or orange yellow liquor color, red-yellow brightness, eurotium cristatum filled in brick tea, and full grains. The production technology is simple, convenient in implementing, safe and environment-friendly. The produced black tea is smoke-free and harmless, is fragrant and fine-quality and is a real environment-friendly healthy beverage.

Owner:湖北省赵李桥茶厂有限责任公司

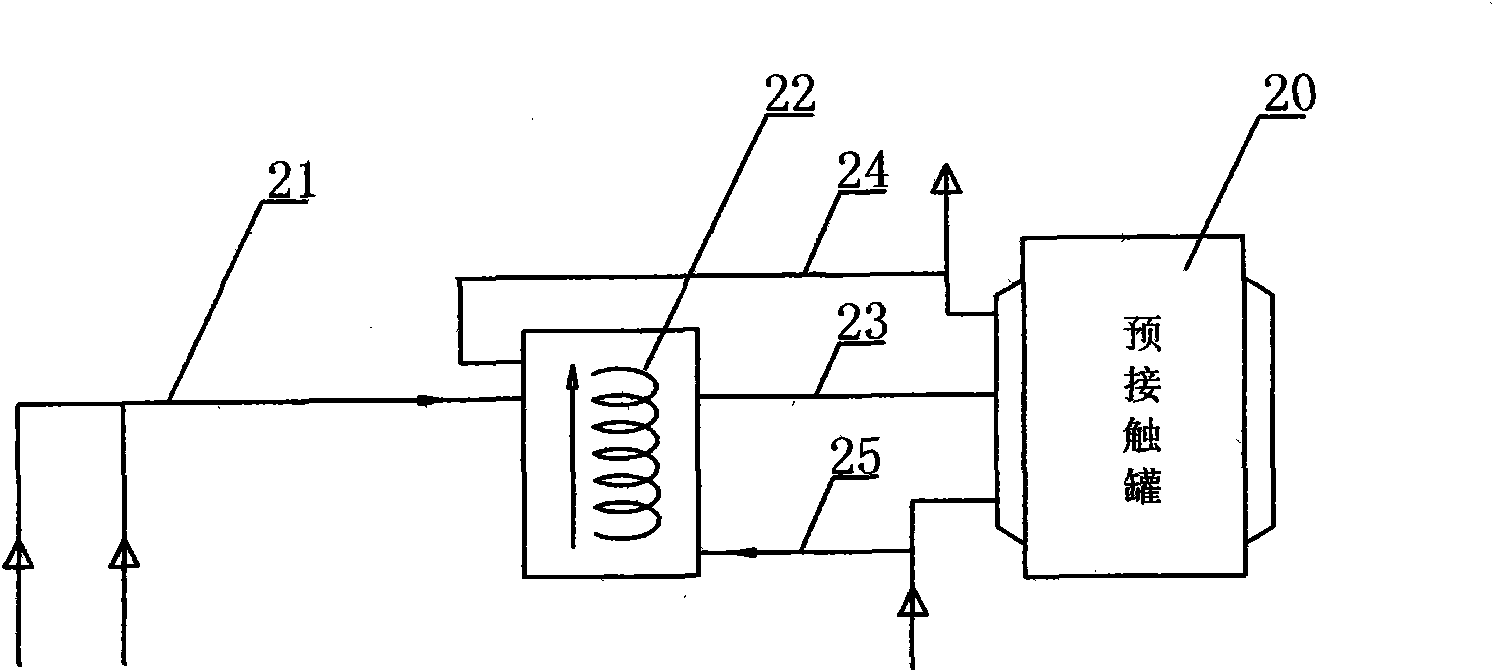

Delayed-boosting electric pressure cooker control method and delayed-boosting electric pressure cooker

InactiveCN106820951ASolve the problem of poor cooking effectEntrance smoothPressure-cookersTemperature controlEngineering

A delayed-boosting electric pressure cooker control method comprises the steps that delayed starting temperature and safe starting temperature are set, wherein the delayed starting temperature is lower than the safe starting temperature; a delayed starting temperature control unit is arranged, the temperature of a temperature sensor is detected, the delayed starting temperature control unit begins to perform delayed timing after the delayed starting temperature is reached and sends out a delayed finishing signal when delaying finishes; after the delayed finishing signal sent out by the delayed starting temperature control unit is received, and a controller controls and closes an air outlet channel of an electric pressure cooker. The delayed-boosting electric pressure cooker control method has the advantages that after rice boiled by the electric pressure cooker is boiling, part of steam in the cooker is discharged out, the rice in the cooker is continuously boiling in a half-high-pressure state so that the rice can rapidly absorb moisture in the half-high-pressure state, an air outlet is closed to make the pressure in the cooker rise after set time is reached, then outage is performed to achieve heat-insulating rice steaming, the cores of cooked rice are cooked well, and the rice is tough and chewy and is smooth in the mouth.

Owner:陆一铭

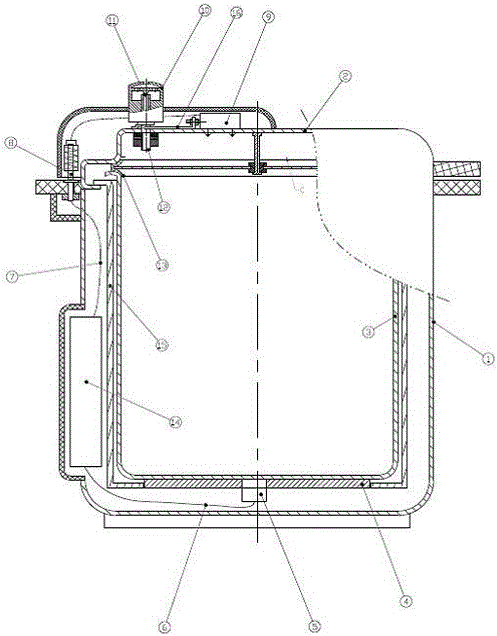

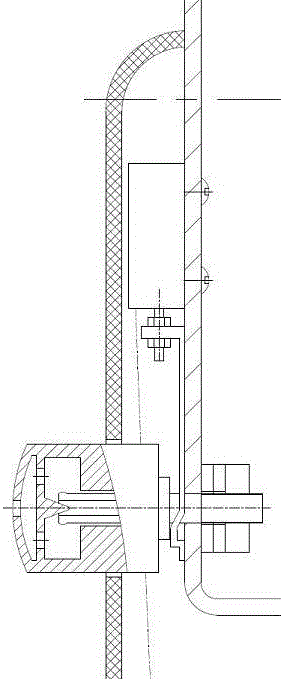

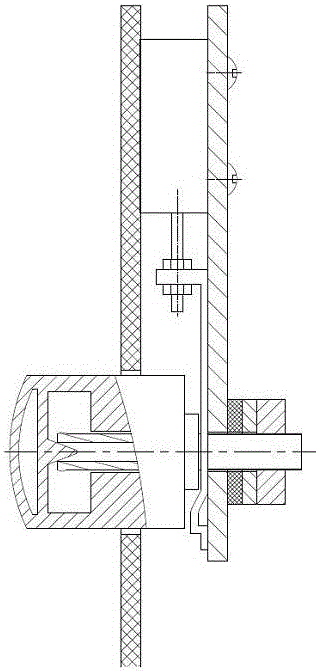

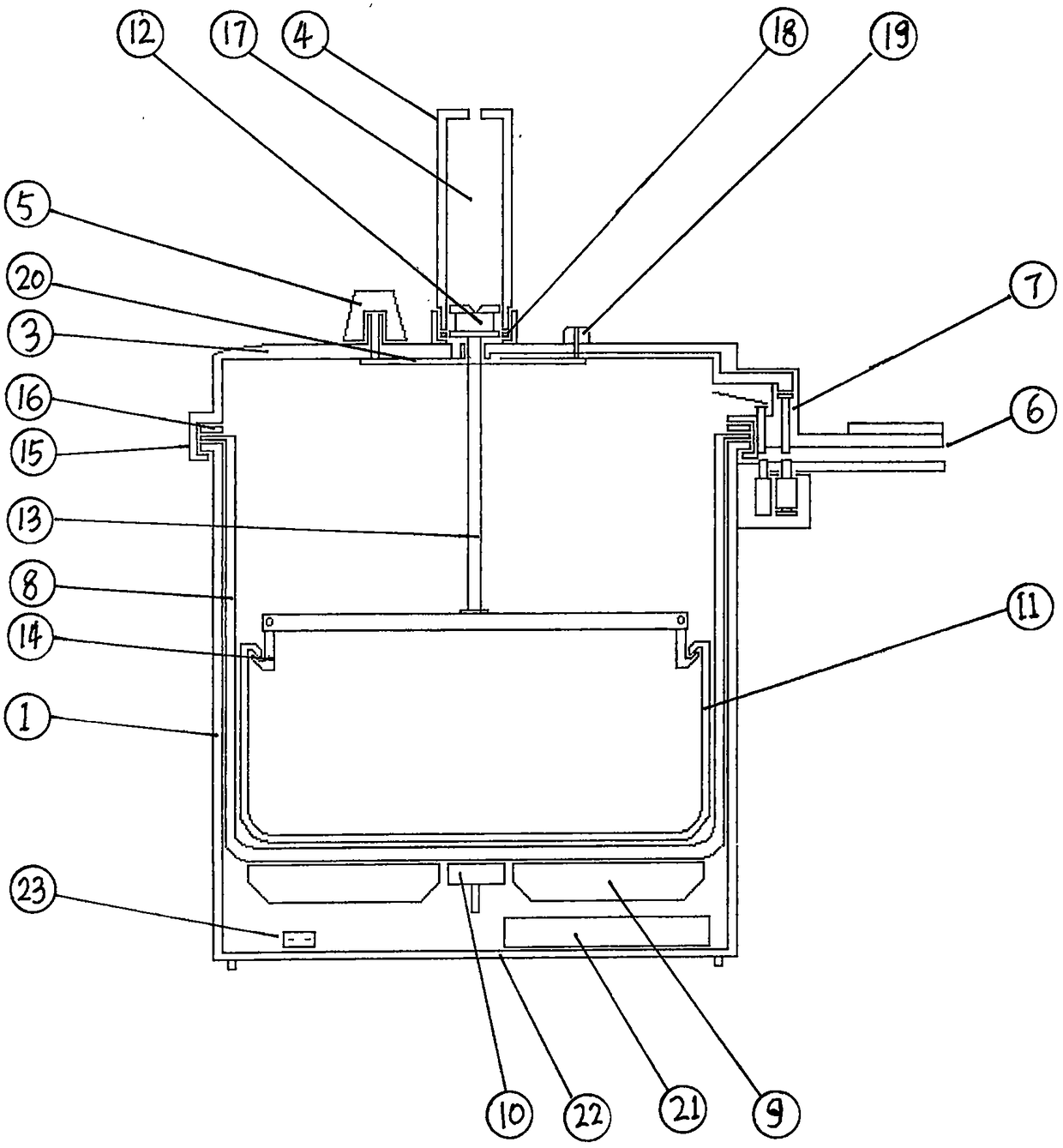

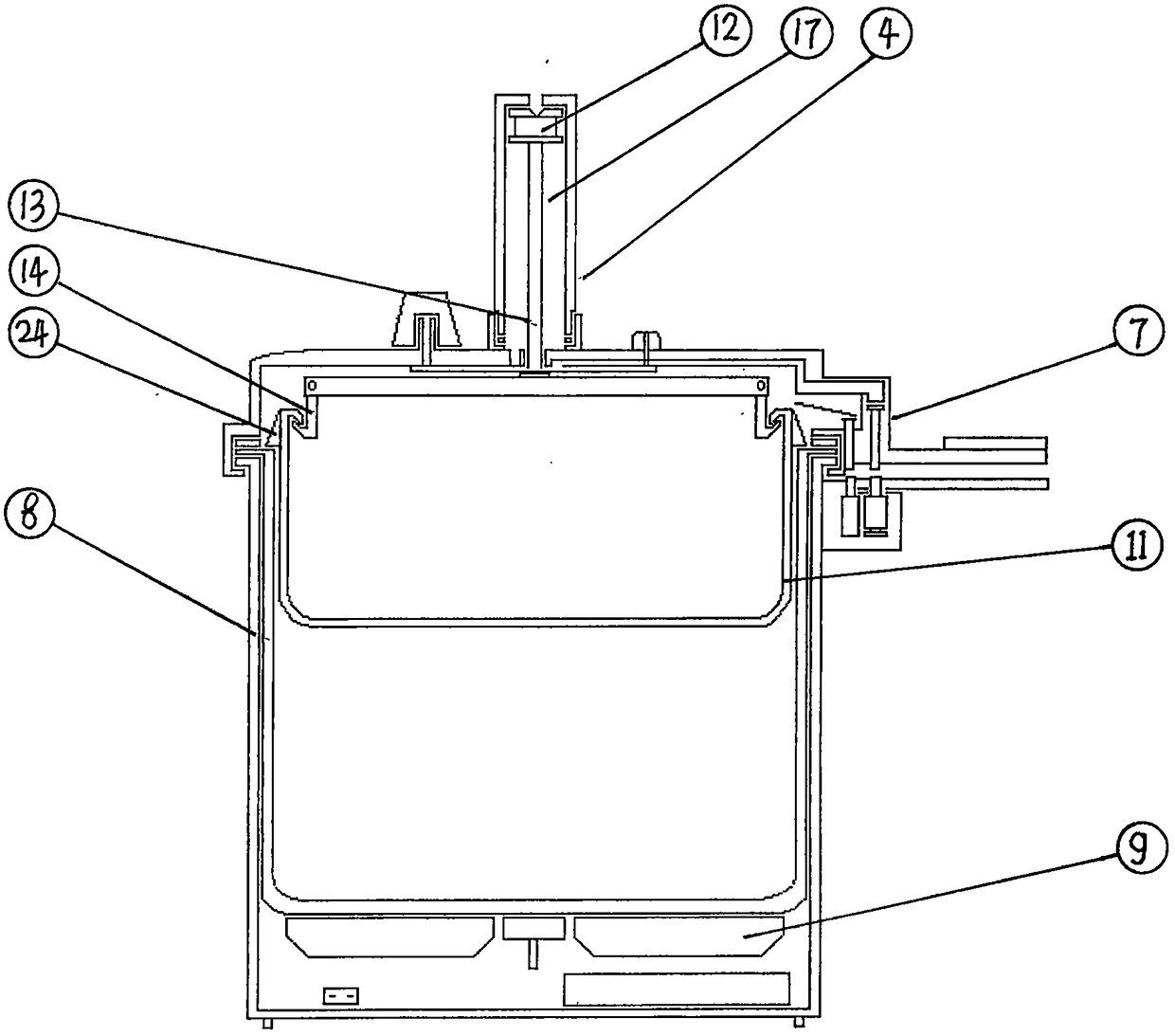

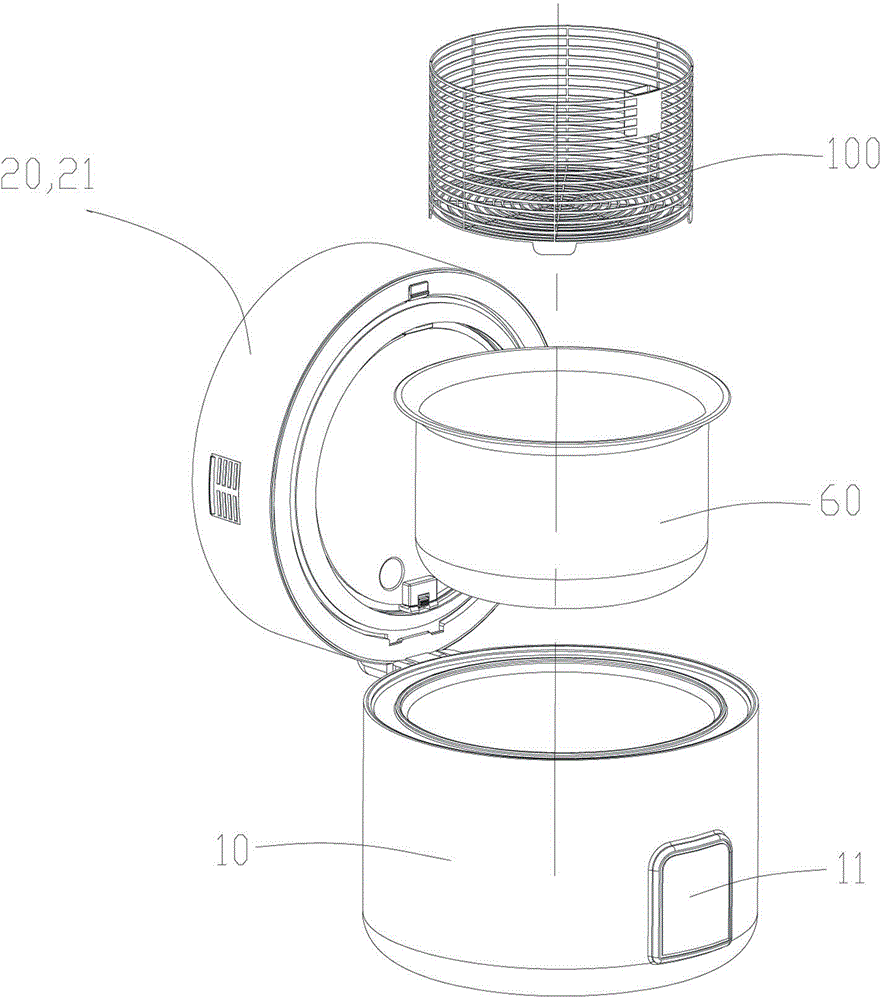

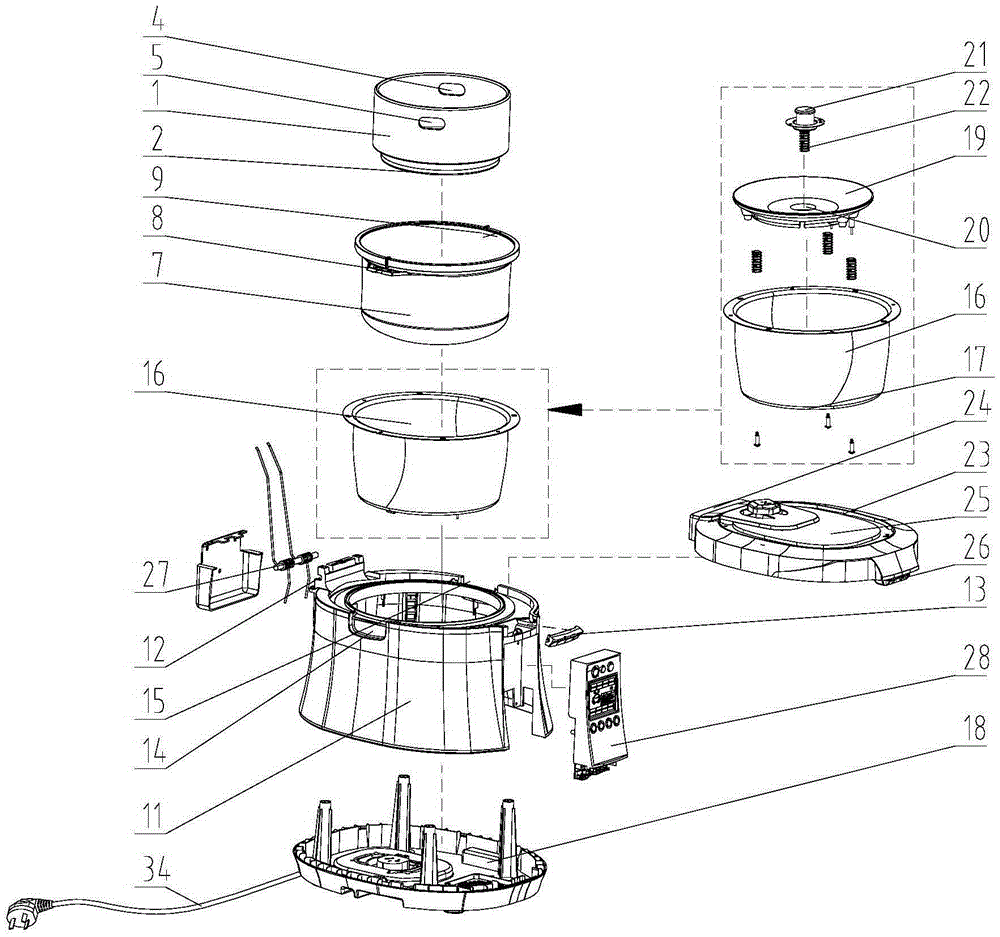

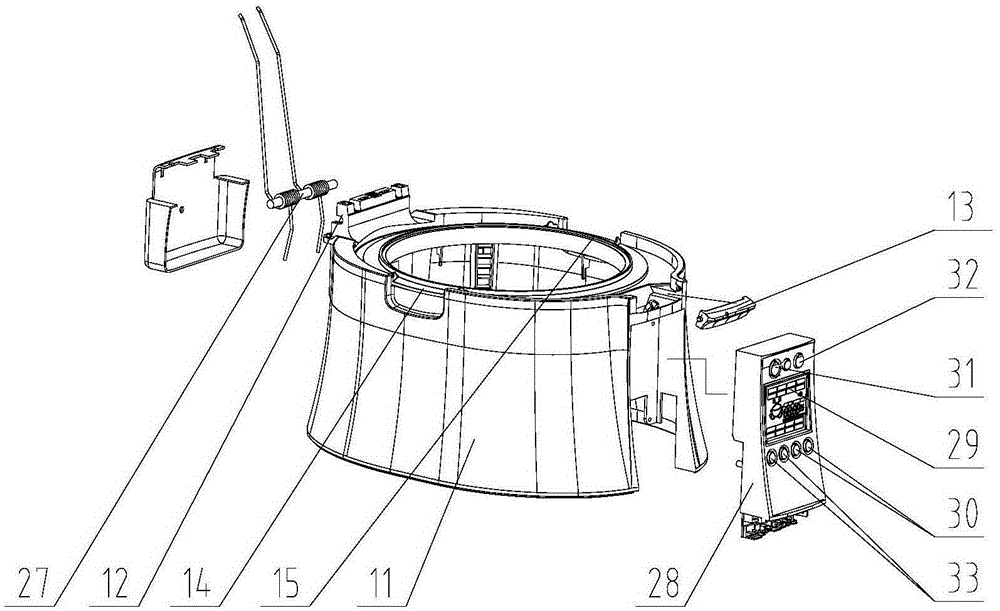

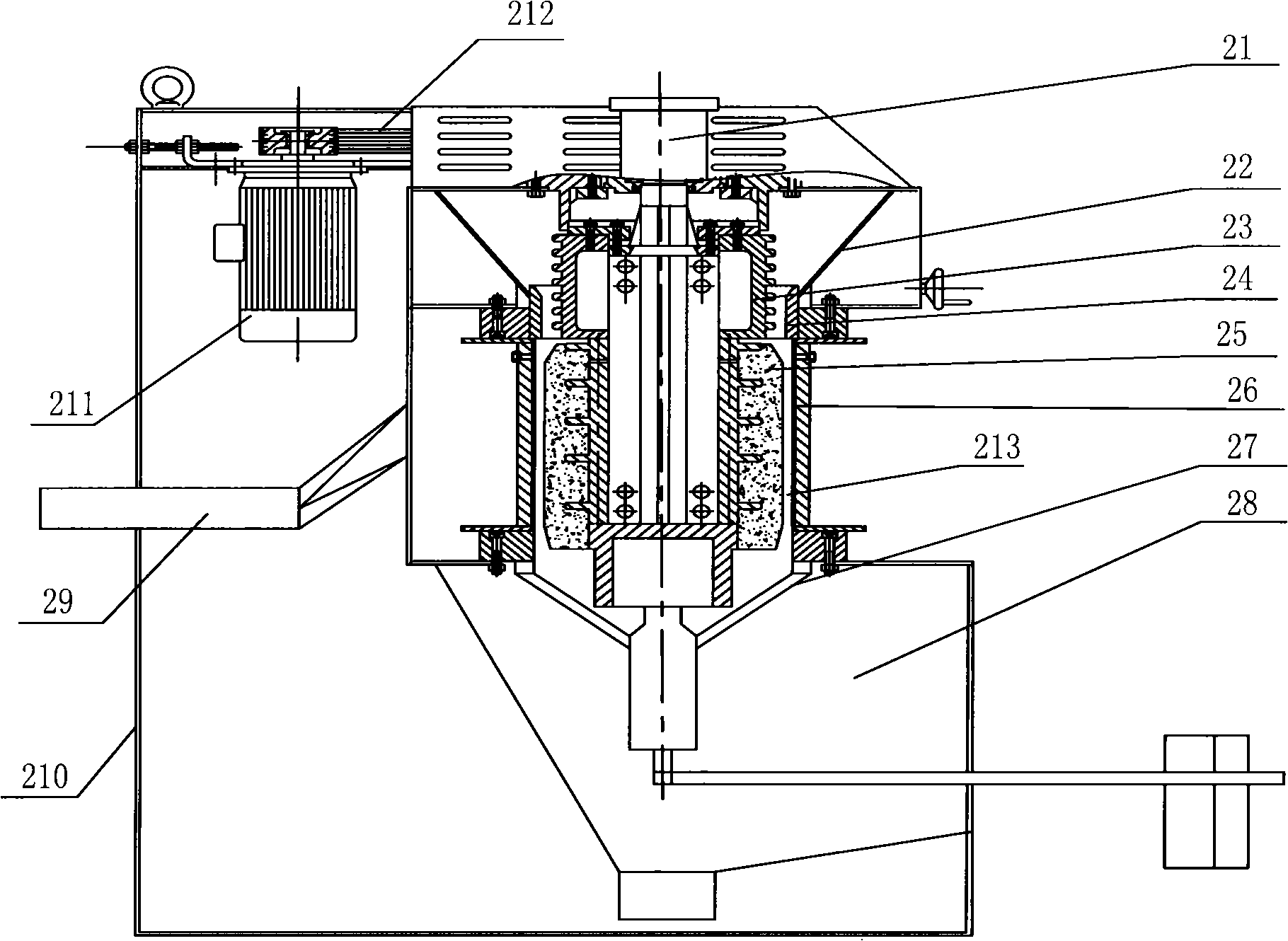

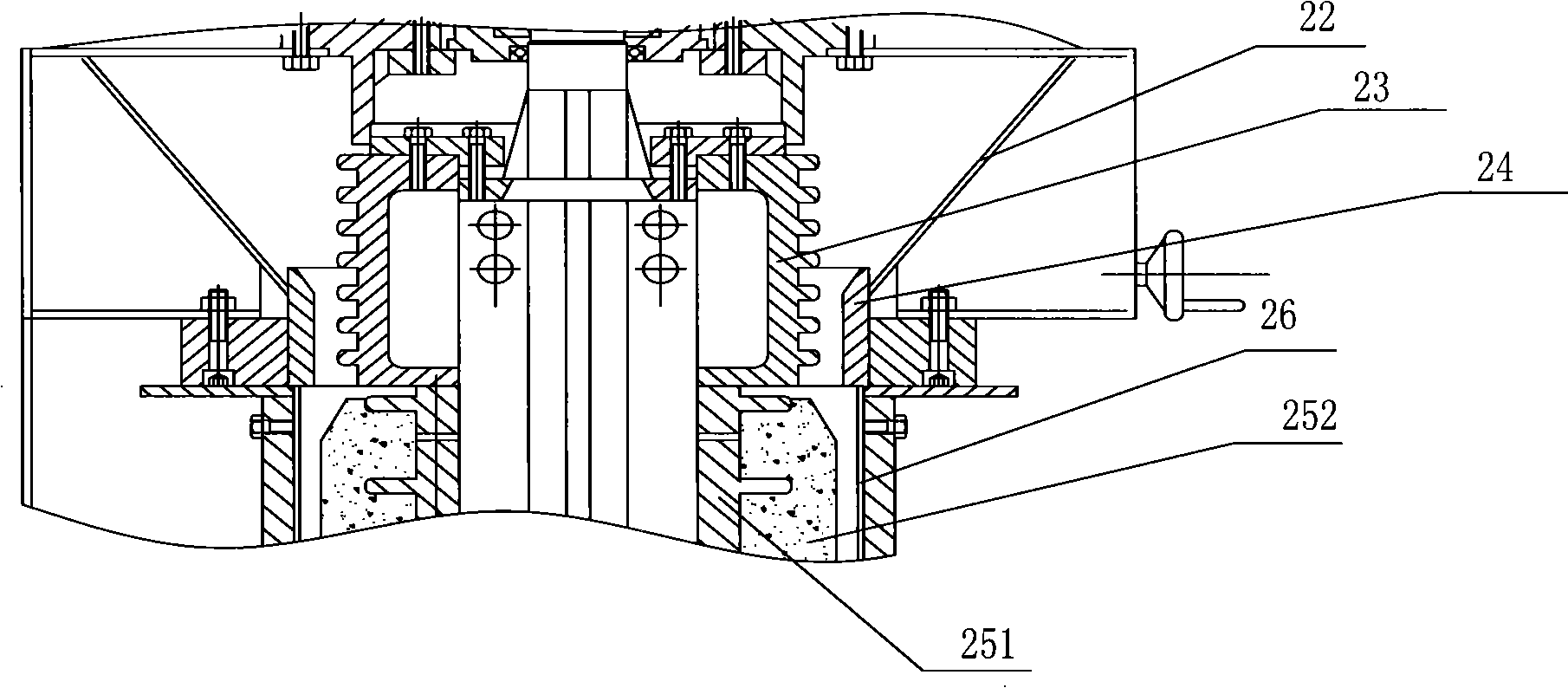

Water-filtering type high-pressure rice steamer

InactiveCN108497914AReduce viscosityNo cakingSteam cooking vesselsPressure-cookersWater filterEngineering

The invention relates to the fields of electric cookers and pressure cooker, and in particular to equipment for implementing water-filtering type rice steaming. According to a water-filtering type high-pressure rice steamer, an electric heating tray is arranged on a base plate of a pot body; a high-pressure inner body is arranged in the pot body; a rice steaming basket is arranged in the high-pressure inner body; a pressure piston lifting device is arranged on a top cap; an air cylinder and a piston are arranged in the pressure piston lifting device; and a piston and a hook are connected to alifting rod. During working of the equipment (the rice steamer), water and rice in the pot body are heated via the electric heating tray, so that a purpose of cooking rice can be achieved; an exhaustchannel in a gas control component is closed via a controller when the water in the pot body is heated to 100 DEG C, and meanwhile, a piston in the air cylinder is pushed to move upwards through high-pressure gas which is generated as the water in the pot body is continuously heated; the rice steaming basket is lifted upwards under the actions of the lifting rod and the hook, and rice, which is cooked by 70%, is filtered out from the water via the rice steaming basket and the rice is well cooked through high-pressure steam and heat energy generated from the water body; therefore, a purpose ofhigh-pressure water-filtering type rice steaming is achieved.

Owner:王明中

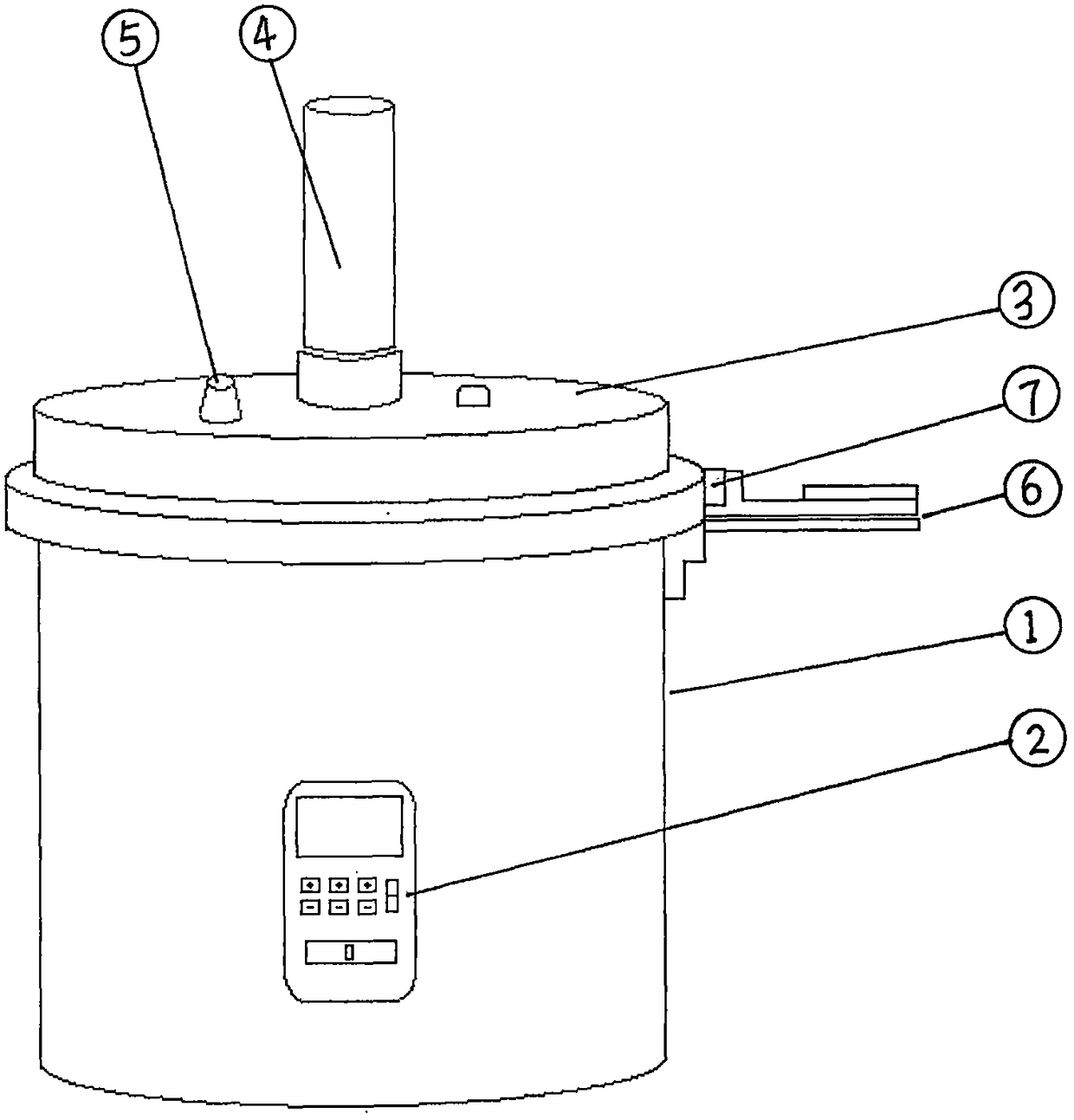

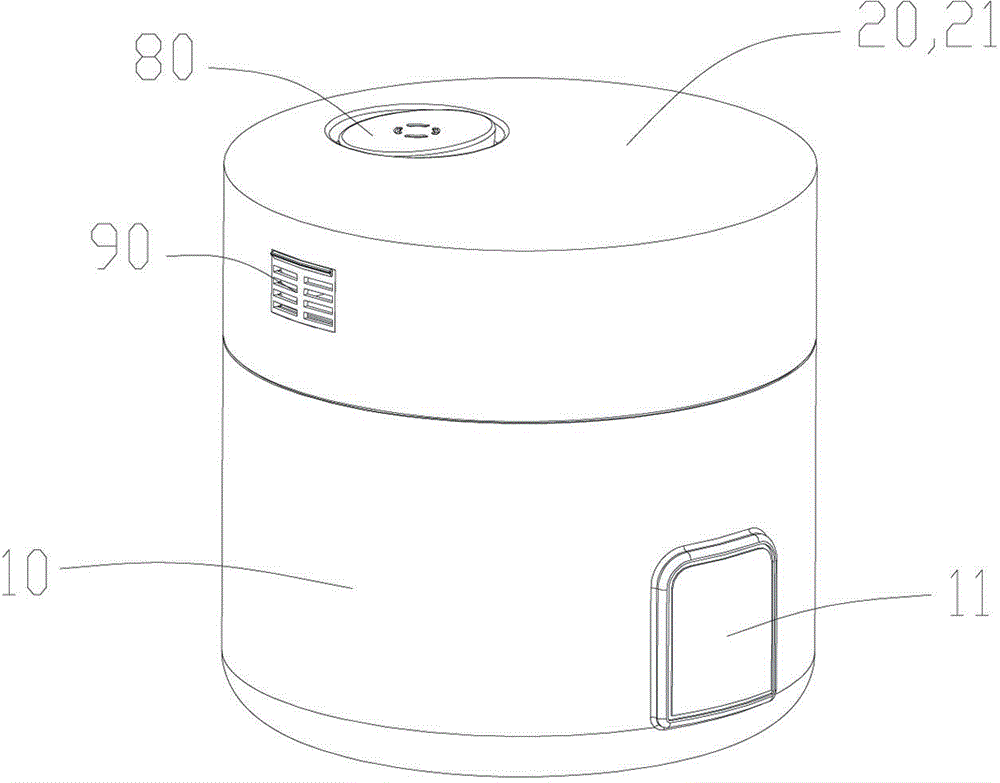

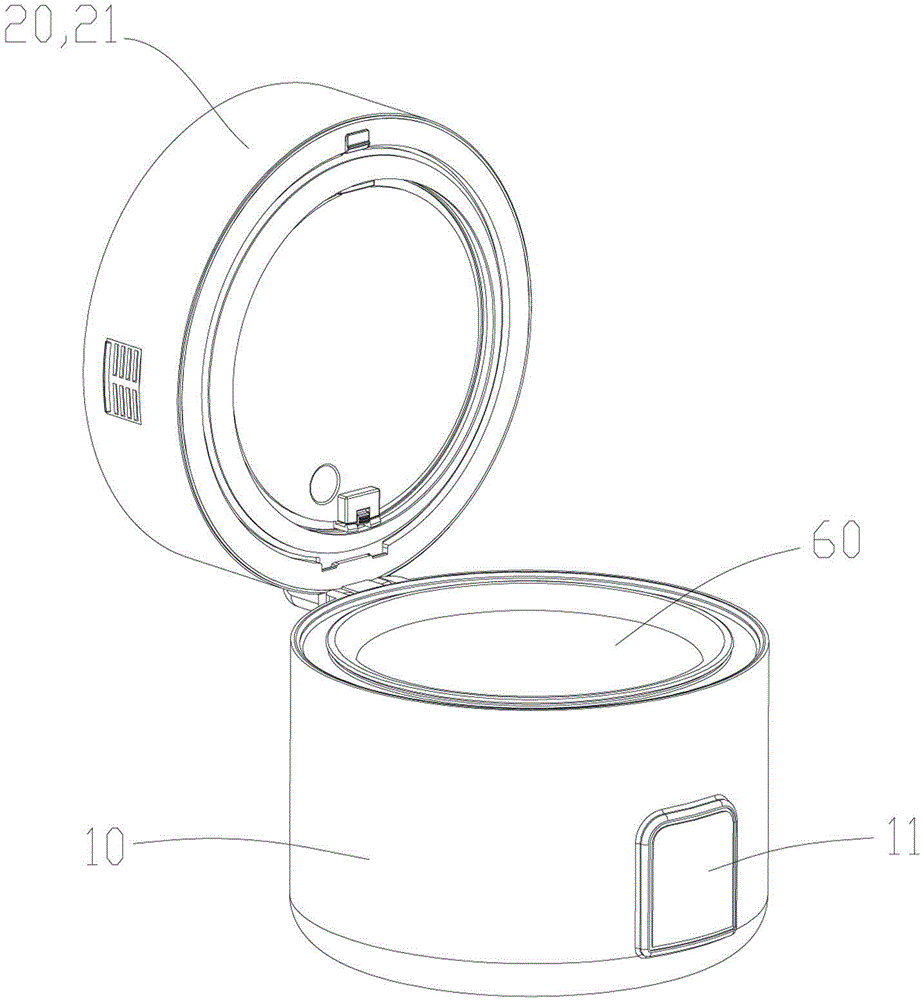

Electric caldron with baking function

InactiveCN104586233AEasy to useLow costCooking-vessel lids/coversRoasters/grillsTemperature controlEngineering

The invention relates to an electric caldron with a baking function. Based on a traditional electric caldron structure that an electric heating assembly (70) and a temperature control device are installed at the bottom of a caldron body (10), an inner caldron (60) is arranged inside the caldron body (10), a caldron cover assembly (20) is arranged at the upper portion, and a fan assembly (30) and a second electric heating assembly (40) are particularly installed in the caldron cover assembly (20) of the electric caldron, the electric caldron has the function of baking foods accordingly. The electric caldron can be used for baking or stewing the foods, and can also be used as the electric heating assembly (70) for supplying heat from the bottom during baking. By means of the electric caldron, the functions of boiling, stewing, steaming and the like can be achieved; and the baking function of an air fryer in the prior art can be achieved. When the baking function is used, an upper heating body and a lower heating body can work at the same time, and therefore the baking effect is good.

Owner:LIANCHUANG SANJIN ELECTRIC APPLIANCE SHENZHEN

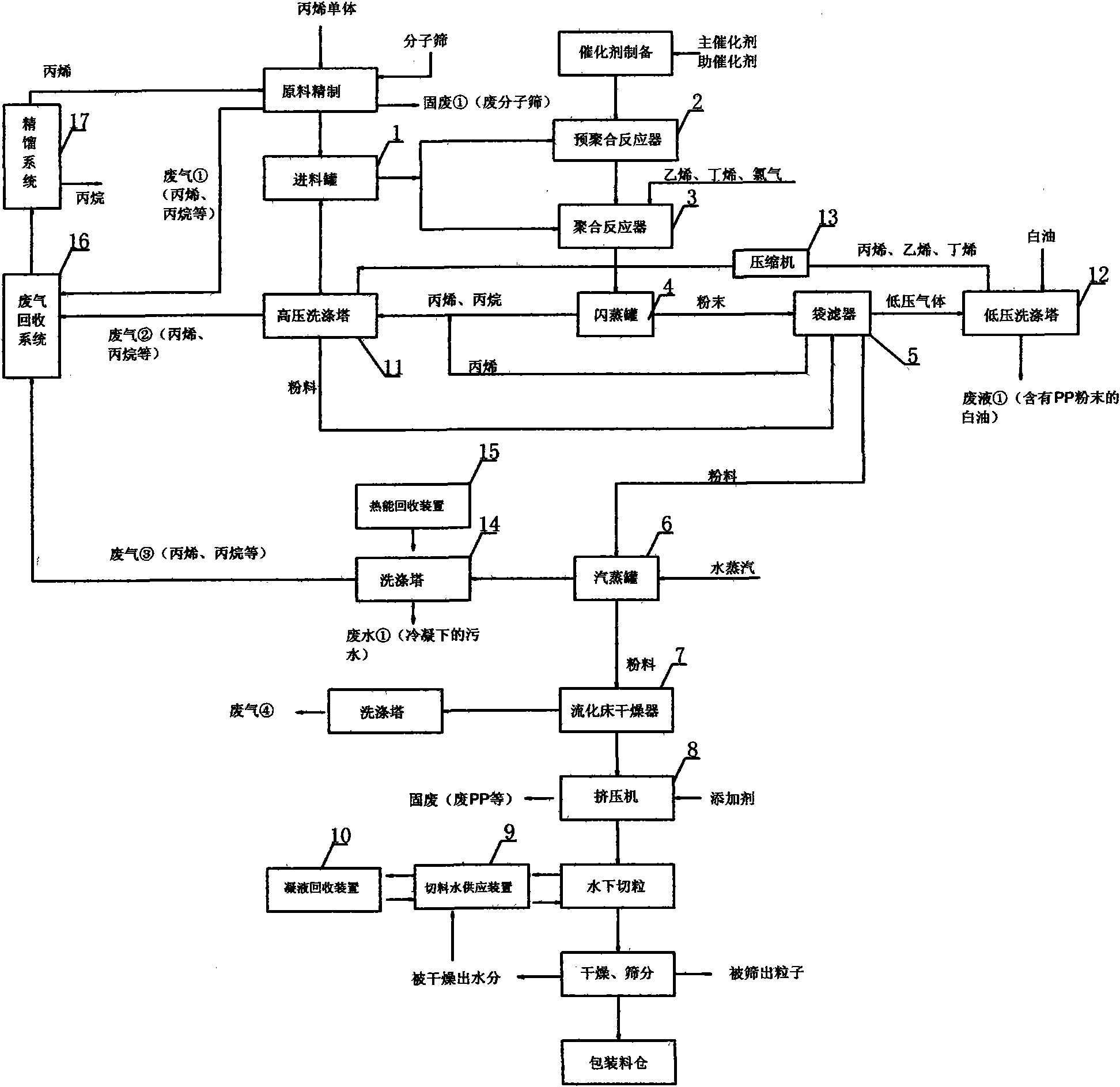

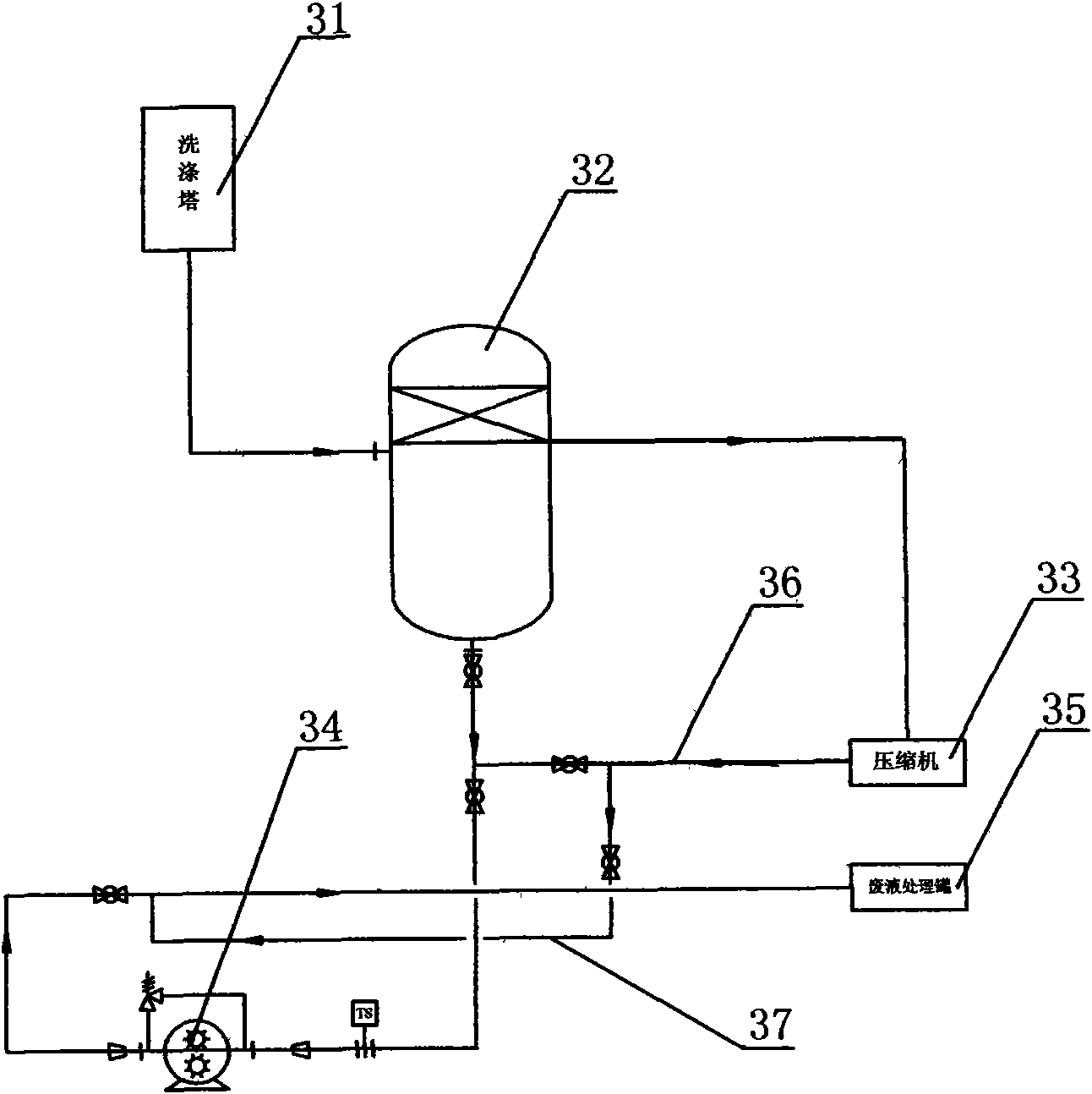

Production method of polypropylene and device thereof

The invention discloses a production method of polypropylene with an English name of Polypropylene (short for PP) and a device thereof, belonging to the technical field of polymer synthesis. The production method comprises the steps of: prepolymerization, polymerization-flash vaporization, degasification-steaming, drying-extruding, granulating-product package and the like. By optimizing the technique steps and parameters of prepolymerization, polymerization, flash vaporization, degasification, steaming, drying, extruding, granulating and the like, the invention improves the utilization ratio of raw materials, simultaneously adds a waste gas and waste liquor recovery system creatively, adds a heat recovery system of a washing tower, uses recovered heat for heating grease, and improves heat utilization ratio; the setting of powder and condensate recovery device improves production efficiency and reduces production cost; a standby water tank is added for granulating and water supply, thus preventing machine stopping caused by fault of the water tank and improving production efficiency; and the improvement of gas-exiting pipelines and exhaust pipelines eliminates potential safety hazard, saves cost and has good environment protection.

Owner:ZHEJIANG SHAOXING SANJIN PETROCHEM

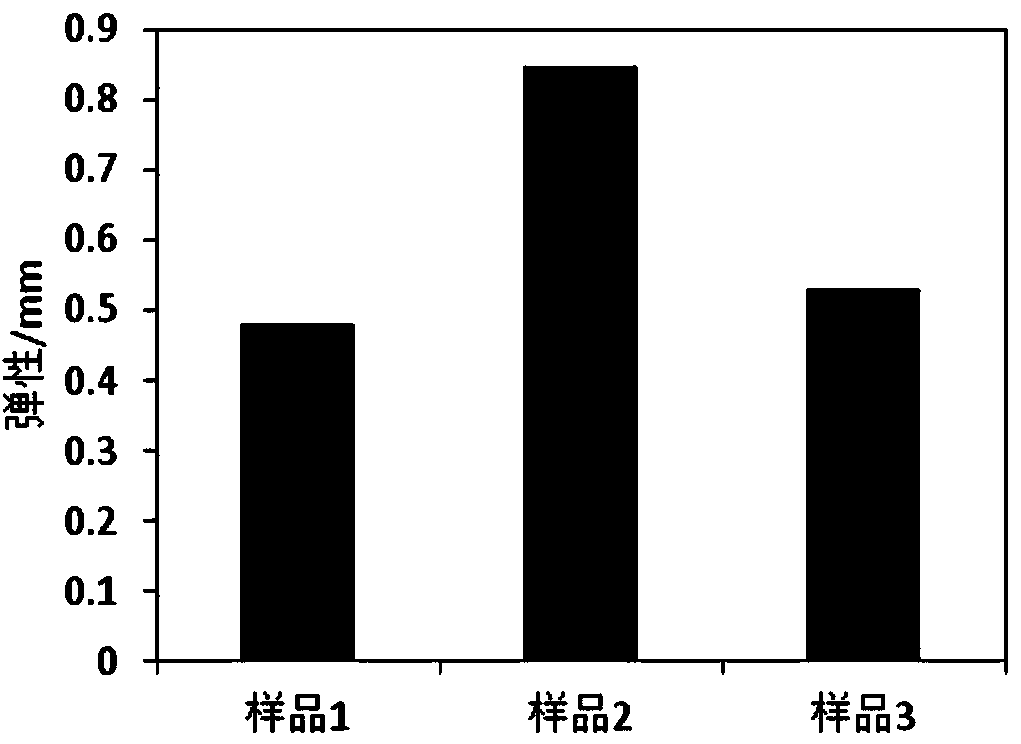

High-count smooth double-faced wool and production process thereof

The invention discloses high-count smooth double-faced wool which is double-layer texture structure cloth with upper portion and lower portion connected. The front texture of the high-count smooth double-faced wool is 2 / 2 twill, and the back texture of the cloth is 2 / 2 herringbone. A production process of the high-count smooth double-faced wool includes: respectively performing loose fiber dying on wool fibers, dacron fibers and modal fibers, then performing full sliver mixing, and spinning the mixed fibers into 20 / 1 and 24 / 1 yarns with an open-end spinning mode; weaving the high-count smooth double-faced wool cloth on a rapier loom through yarns; and performing blank checking, mending, reviewing, hemming, wool washing, dehydration, milling, wool jigging, dehydration, rotary width drying, wool steaming, fluffing, shearing, squeezing, burring galling, rolling, drying, polishing, polishing shearing, wool steaming and finish inspection on the weaved cloth to manufacture finished products. The high-count smooth double-faced wool is full in hand feeling, elastic, natural and gentle in gloss, and smooth and ordered in villus, cannot cause bottom explosion and depilation, and is rich and smooth in hand feeling and suitable for manufacturing high-grade clothing.

Owner:苏州优布纺织科技有限公司

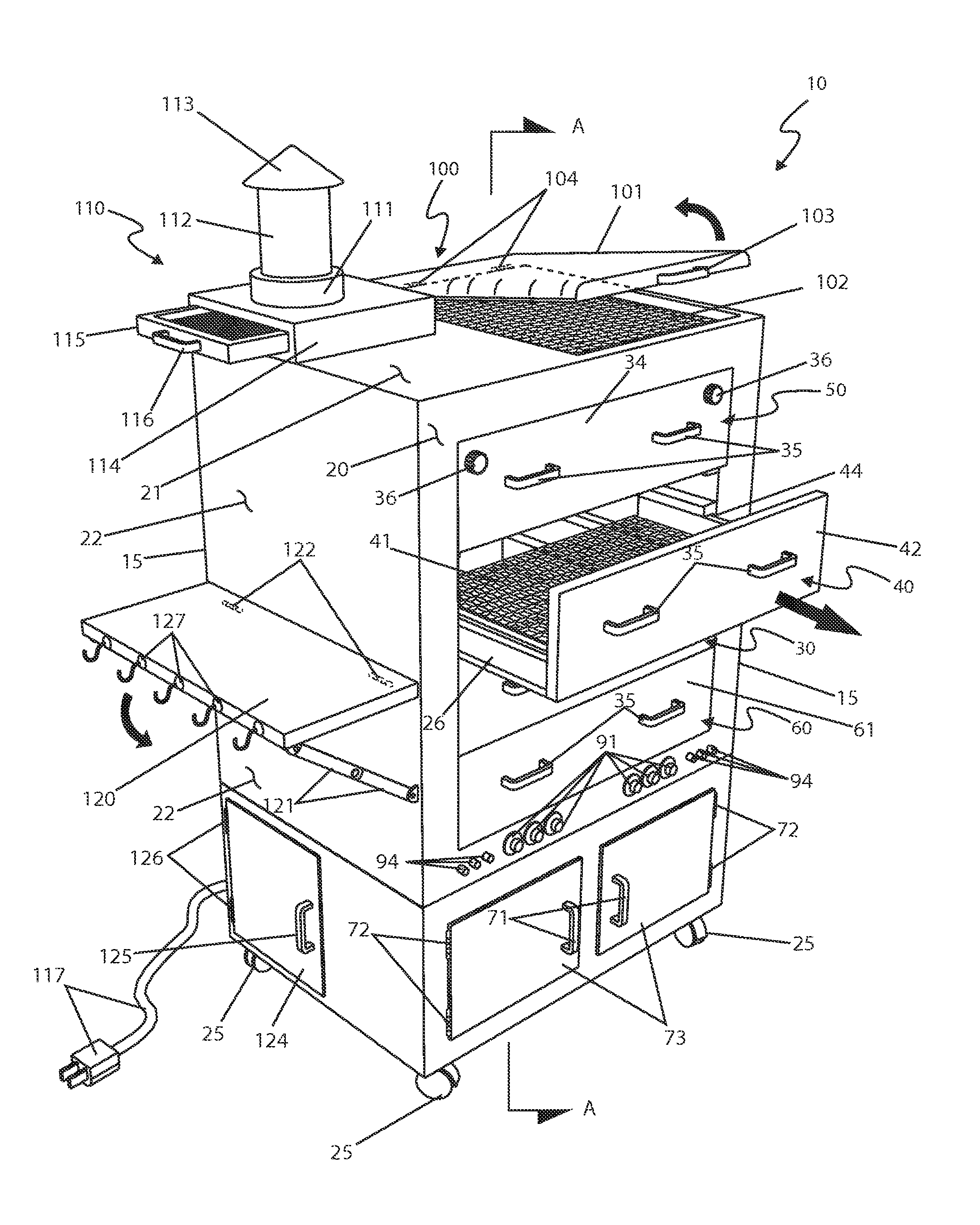

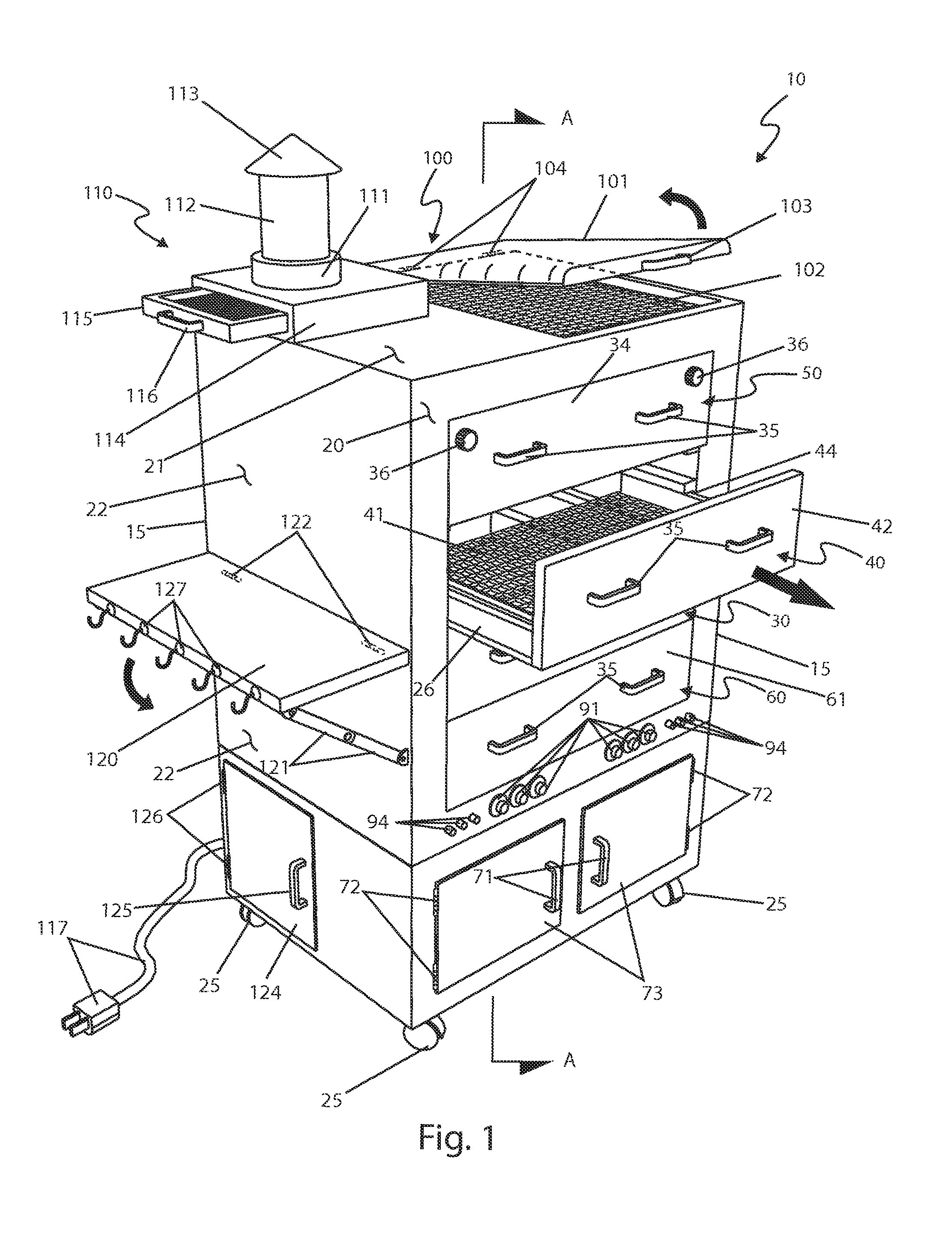

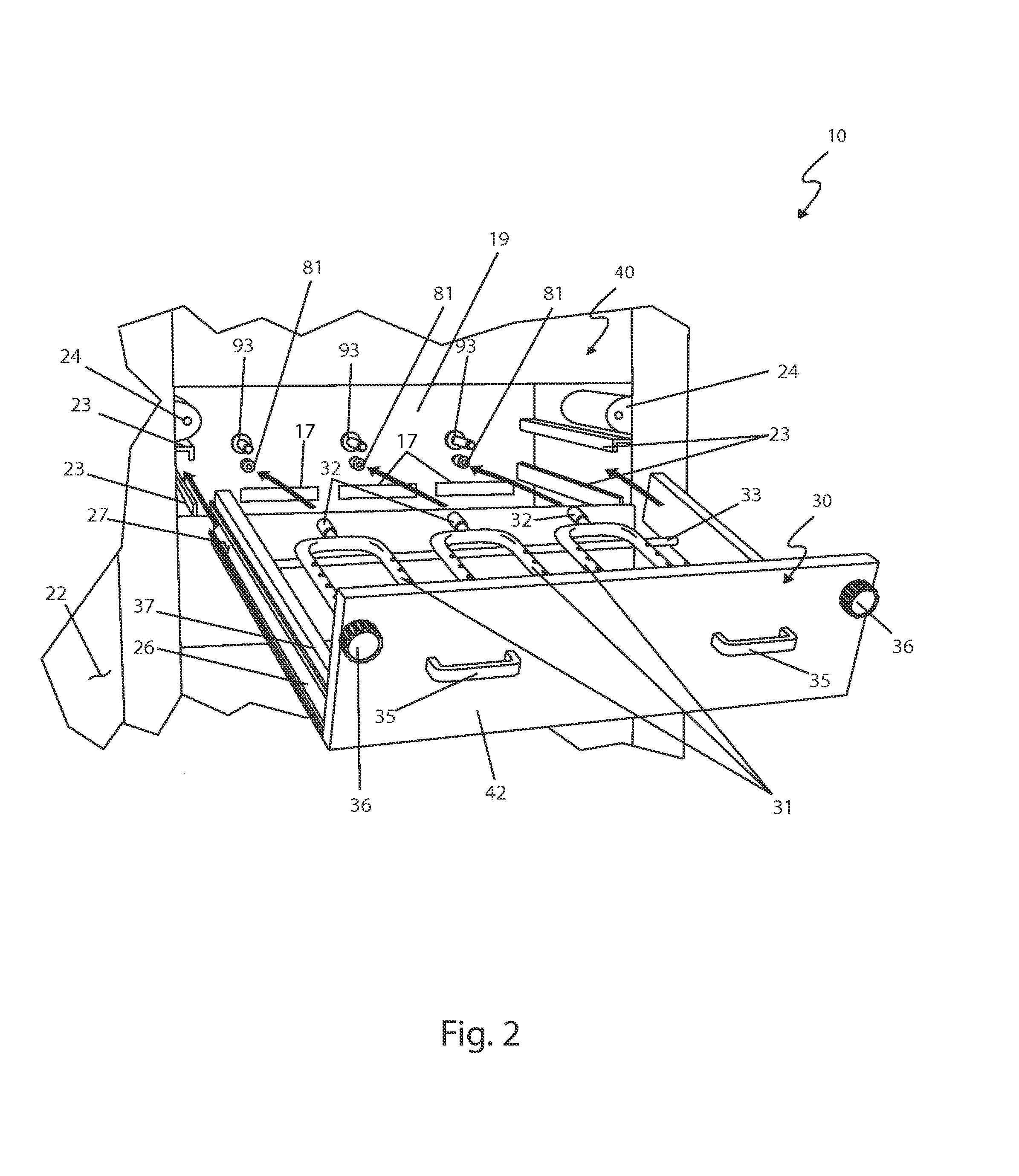

Residential flame broiler

InactiveUS8490614B1Avoid enteringEffective top and bottom cooking meanStoves/ranges foundationsLighting and heating apparatusCombustorBroiler chick

The invention discloses a gas grill with multiple enhancements to allow for easy grilling of foods, subsequent clean-up, and replacement of parts. In lieu of a top-opening lid, the apparatus provides a plurality of removable and insertable drawers, comprising a plurality of burner units, a plurality of grill trays, and a drip tray located in a vertical configuration therein a base unit. All drawers are interchangeable as desired. A storage compartment is located on the bottom directly below the drip tray and an exhaust assembly is located on the top for directing smoke away from the apparatus. The invention is adaptable to propane or natural gas. Additional drawers and burner assemblies are provided and may be used for charcoal or wood burning, bun or food warming, and water steaming. All drawers are easily removable on slides with a safety catch system for easy care and cleaning.

Owner:GREGORY MICHAEL S

Method for preparing low fats fishbone leisure food

InactiveCN101176561AMeet health requirementsImprove processing levelFood preparationSnack foodHuman health

The utility model relates to a preparation method of a fishbone snack food with low fat, which belongs to the technical field of the snack food handling. The utility model uses fishbone, which is the leftovers in the marine product processing as material; after rinsing, fishy smell removal, washing, curing, embrittlement, and flavour treating, the fishbone is made into the fishbone snack food product with low fat. The utility model can cure the fishbone adequately by means of the autoclave steaming; and then removes the moisture content by means of the microwave to embrittle the products. Themethod gets rid of the deep fry, has low fat, can meet the requirements of the human health adequately. The method of preparing the fishbone snack food with low fat for filling calcium is easy and quick, and is very good for improving the processing level of the farm products, the livestock products and the marine products in our country, and can bring along great economic benefits. The utility model uses the castoff as material to reduce the production cost, and prepares new products.

Owner:JIANGNAN UNIV

Salt-free pad steam continuous dyeing method for active dye

InactiveCN101200859AFor quick replacementGood reproducibilityDyeing processLiquid/gas/vapor textile treatmentTextile printerSalt free

The present invention relates to a continuous saltless pad-steam dyeing method with reactive dyes, which belongs to the novel technical field of textile printing and dyeing. After being singed, desized, boiled, bleached and mercerized, the half-finished product of cellulosic fibre woven fabric is dyed in the process of the continuous dyeing technique of padding, steam fixation, water washing, soaping, water washing and drying by the reactive dyes. The half-finished product of the preprocessed cellulosic fibre woven fabric is produced by pad dyeing, steaming and water washing, wherein, dyeing solution is composed of M reactive dyes, leveling agent, fixation alkali agent and water, and the mixture ratio is as follows: M reactive dyes: 0.01 percent to 10 percent, leveling agent: 0.1 percent to 0.2 percent, fixation alkali agent: 1.5 percent to 4 percent, and water: balance. The method is different from the conventional continuous dyeing technique of padding, drying, padding and steaming, which uses reactive dyes, and also different from the shortened wet-steaming technique with reactive dyes. On the conventional continuous padding machine, the novel method can fulfill the whole process of reactive dyeing without a hot-air padding machine and only with a developing and soaping range, thus greatly saving energy and reducing cost.

Owner:SHANXI CAIJIA PRINTING & DYEING

Production method of fish scale collagen

ActiveCN1628540AEasy to packEasy to storeProtein composition from fishAquatic productNutrient solution

The invention provides a production method of fish scale collagen which comprises, selecting high grade fish scale as raw material for pre-processing, removing glutinous substance and other impurity on fish scale surface, drying, deliming, degreasing, high-pressure catalytic steaming, extracting liquid form low molecular protein peptide fish scale collagen.

Owner:WEIHAI YUWANG GROUP +1

Chicken meat powder and its production method

The present invention relates to fowl product and is especially one kind of chicken powder and its production process. The chicken paste is produced with chicken breast, and through high pressure steaming, milling slurry, enzymolysis with proteinase, adding fixings and heat reaction, high pressure homogenizing, spray drying, cooling, sieving and packing. The the chicken powder is rich in taste and may be used as material for chicken bouillon powder, chicken seasoning, biscuit, instant noodles, puffing food, nutritious food and meat product.

Owner:广东富农生物科技股份有限公司

Moisture-absorption sweat-drainage worsted fabric and method for producing the same

Owner:AOYANG GRP CO LTD

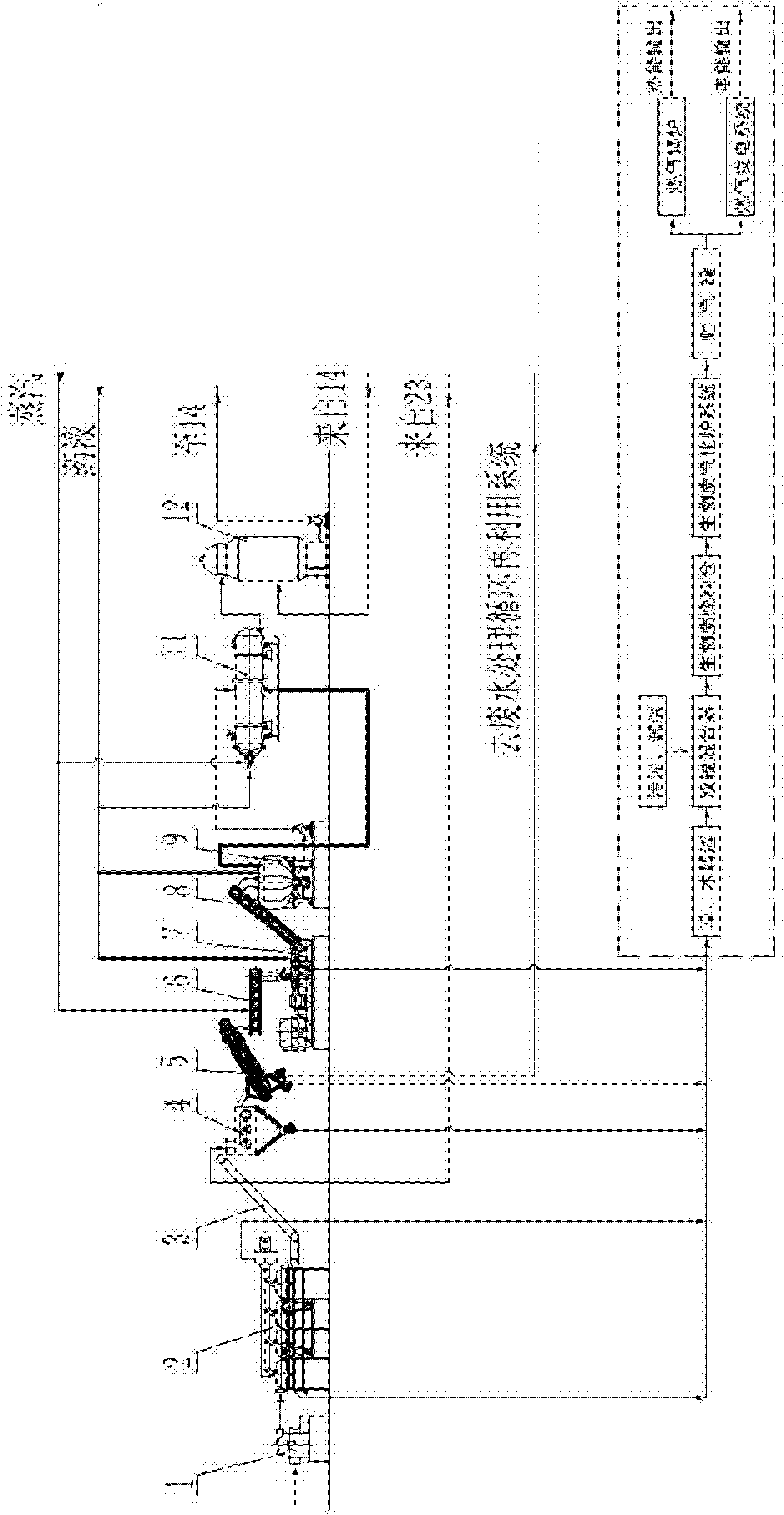

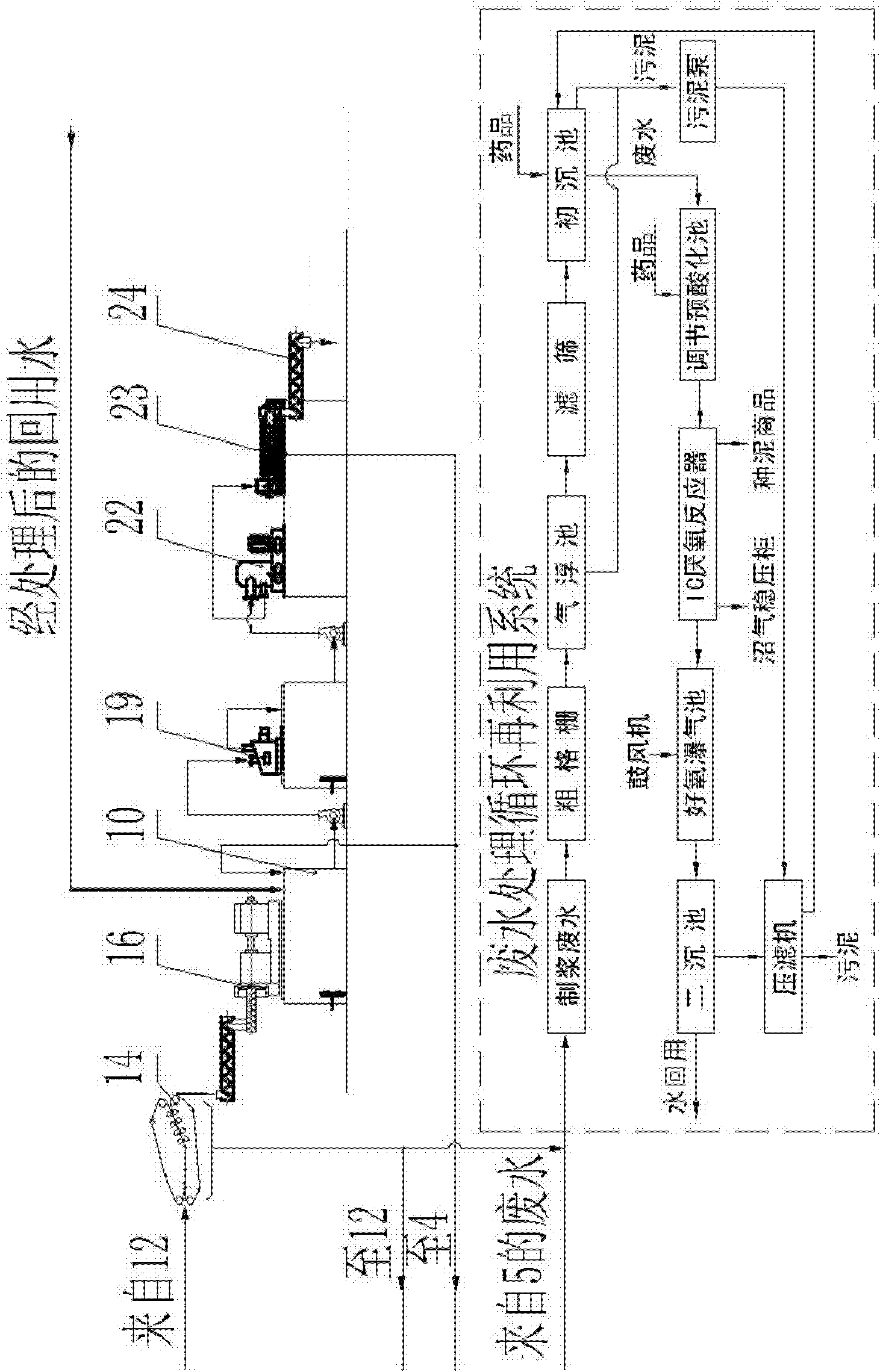

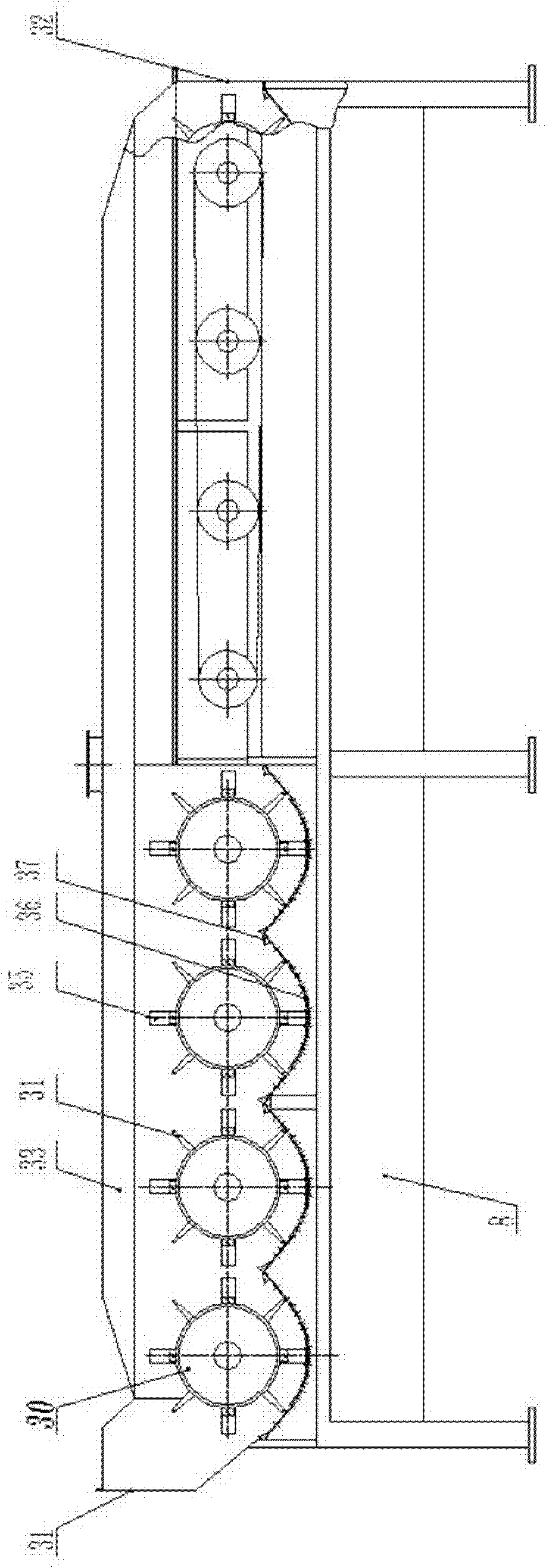

Environmentally-friendly paper making and pulping technique and system with high yield

InactiveCN102242512AReduce adverse effectsImprove wettabilityPretreatment with water/steamPretreatment with alkaline reacting compoundsFiberBlack liquor

The application of the invention provides an environmentally-friendly paper making and pulping technique with high yield, which comprises a raw material preprocessing stage, a physical fibrillation impregnating processing stage, an impregnating, steaming and bleaching three-section integrated pulping stage and a thickening and dewatering processing stage. An environmentally-friendly paper making and pulping system with high yield realizing the pulping technique comprises a stock cutter, a hammering and fibrillation screening dust remover, a washing dust remover, dewatering conveying equipment, a spiral steaming conveyor, a crashing, extruding and impregnating machine, a stirring and impregnating cabin, a pump pipe and a discharge pipe of a high-enriched steaming, bleaching and pulping all-in-one machine, wherein the pump pipe is connected to the high-enriched steaming bleaching pulping all-in-one machine; the discharge pipe of the high-enriched steaming, bleaching and pulping all-in-one machine is connected to a pulp cabin; the pump pipe of the pulp cabin is connected with a thickening and dewatering machine; the thickening and dewatering machine is output to the high-enriched pulping machine; the output of the high-enriched pulping machine is connected with a screening purifier and a thickening and squeezing machine in sequence. In the invention, the problems of high pollution, high energy consumption, serious shortage of paper making raw material and the like in present pulping and paper making industry can be solved fundamentally; rich plant fiber in the nature can be used, and the technical purposes of efficient bleaching, high yield, no black liquor and low energy consumption can be realized.

Owner:李刚荣 +1

Silk producing method

The invention relates to a silk producing method which comprises the steps of: high-temperature direct steaming: processing silkworm cocoons with saturated steam in an direct steaming chamber or a direct steaming device, wherein the direct steaming temperature is 100 DEG C, the direct steaming time is 8 to 10 minutes; standing: standing the directly-steamed silkworm cocoons at a normal temperature for 18 to 26 hours; vacuum infiltration: infiltrating the stood silkworm cocoons by utilizing a vacuum infiltration method to subject the silkworm cocoons to absorbing water, wherein the infiltration water temperature is 35 DEG C to 40 DEG C, the infiltration time is 5 to 10 minutes, and the vacuum degree is 0.05 to 0.1 Mpa (megapascal); cocoon cooking: cooking the silkworm cocoons subjected to vacuum infiltration in a cocoon cooking device; silk reeling: dissociating cocoon filaments of the cooked silkworm cocoons at a temperature of 40 DEG C, and utilizing sericin to glue and connect the cocoon filaments to form raw silk; and post-reeling which includes steps of roughness removal, small reel silk sheet balancing, small reel vacuum moisture absorption, rereeling, large reel silk sheet balancing, arranging and the like. The silk producing method enables the neatness of the raw silk to be relatively high by utilizing high-temperature direct steaming and vacuum infiltration.

Owner:杭州金利丝业有限公司

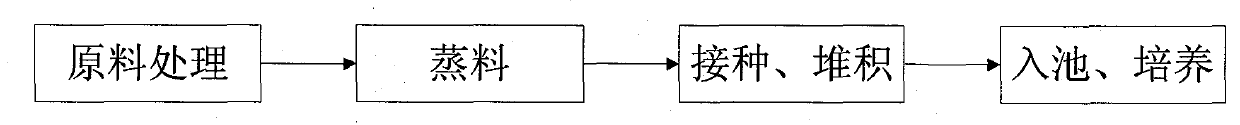

Method for preparing low-alcohol light type red yeast rice wine

ActiveCN103789144AReduce drunkennessMake drinking more funAlcoholic beverage preparationBiotechnologyRed yeast rice

The invention relates to a method for brewing low-alcohol light type red yeast rice wine. According to the method, a tan-fan-method mature fermented mash is formed through sticky rice steaming, wheat koji and red yeast rice adding, jar entering and saccharification, stirring and cooling and fermentation; a lin-fan-method mature fermented mash is formed through sticky rice steaming, rhizopus rice flour and red yeast rice flour adding, hole forming and saccharification, yeast adding and fermentation; the tan-fan-method mature fermented mash and the lin-fan method mature fermented mash are merged and bred, and squeezing and clarification, component adjustment, alcohol content dropping through flash, high-temperature sterilization, jar filling and aging, blending and sterilization are performed on the mature fermented mash to obtain the low-alcohol light type red yeast rice wine brewed through a new technology. Compared with a traditional brewing technology, by the utilization of the new technology, the fermentation period is shortened, the productivity is high, and the low-alcohol light type red yeast rice wine which is good in flavor is brewed. The low-alcohol light type red yeast rice wine serves as brewed wine which is low in alcohol, low in sugar and good in flavor and conforms to the ideas of modern wine consumption, environmental protection and health, the high-grade low-alcohol light type red yeast rice wine is developed, and the method has practical significance and application prospects for improving economic benefits of enterprises.

Owner:FUJIAN NORMAL UNIV

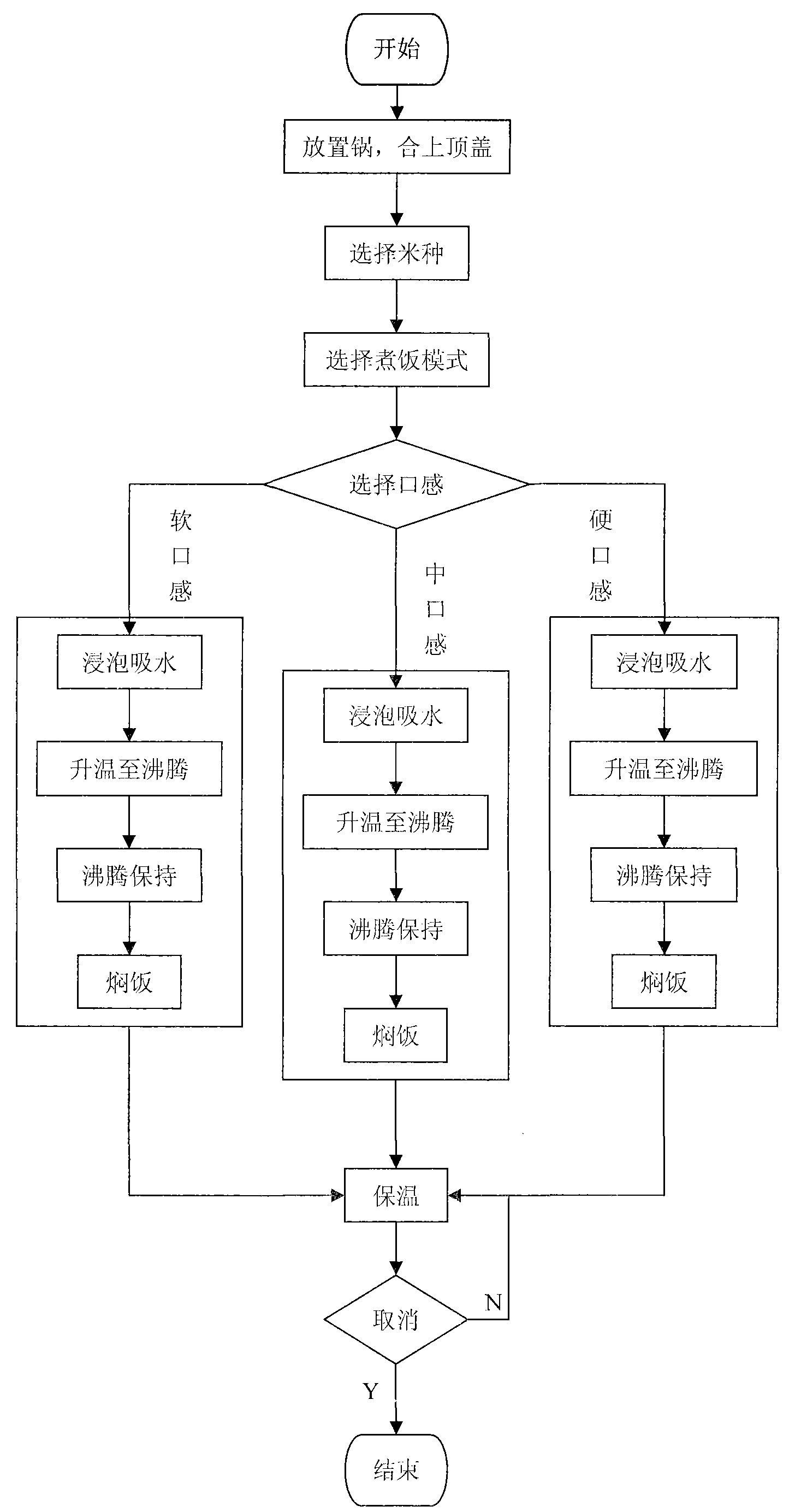

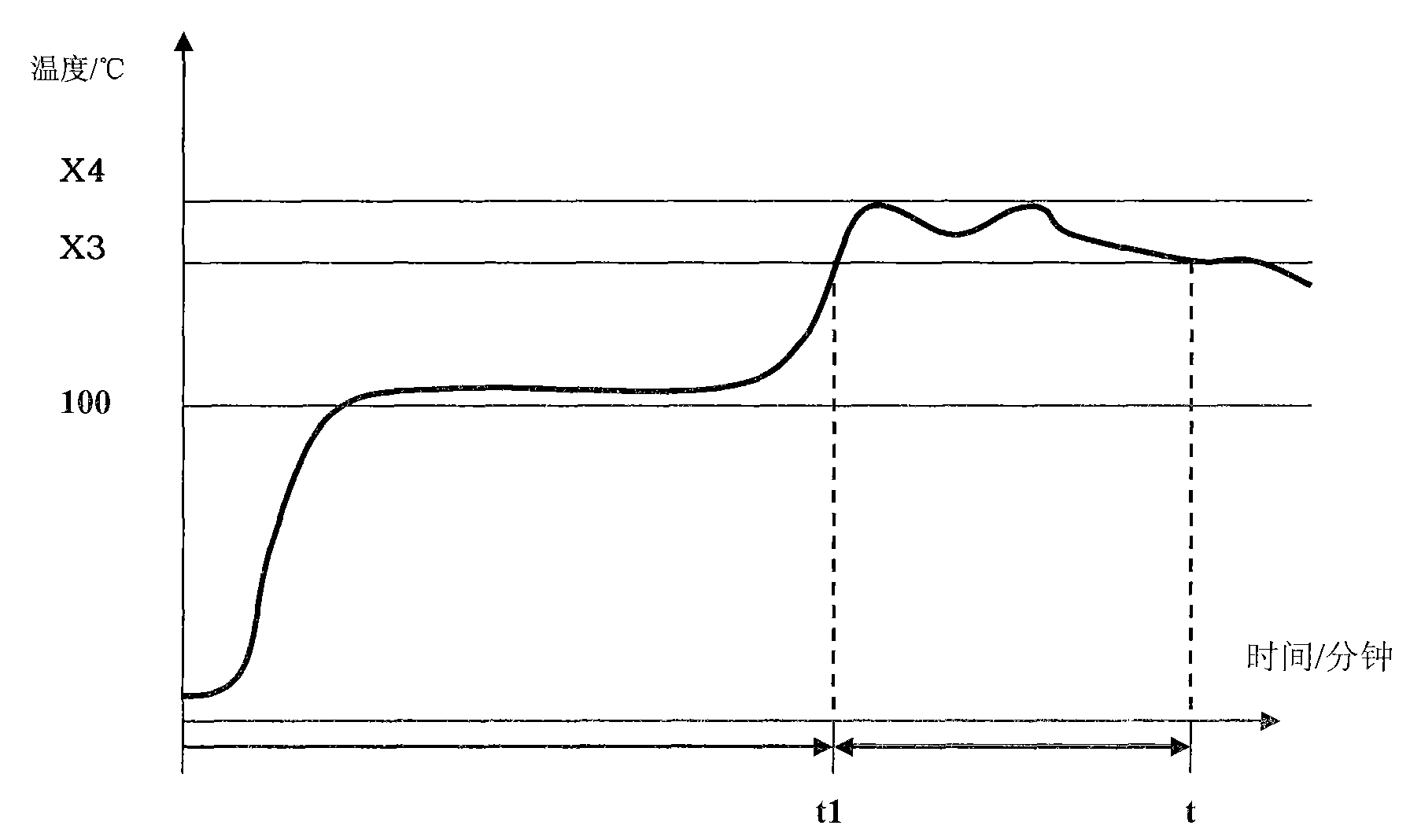

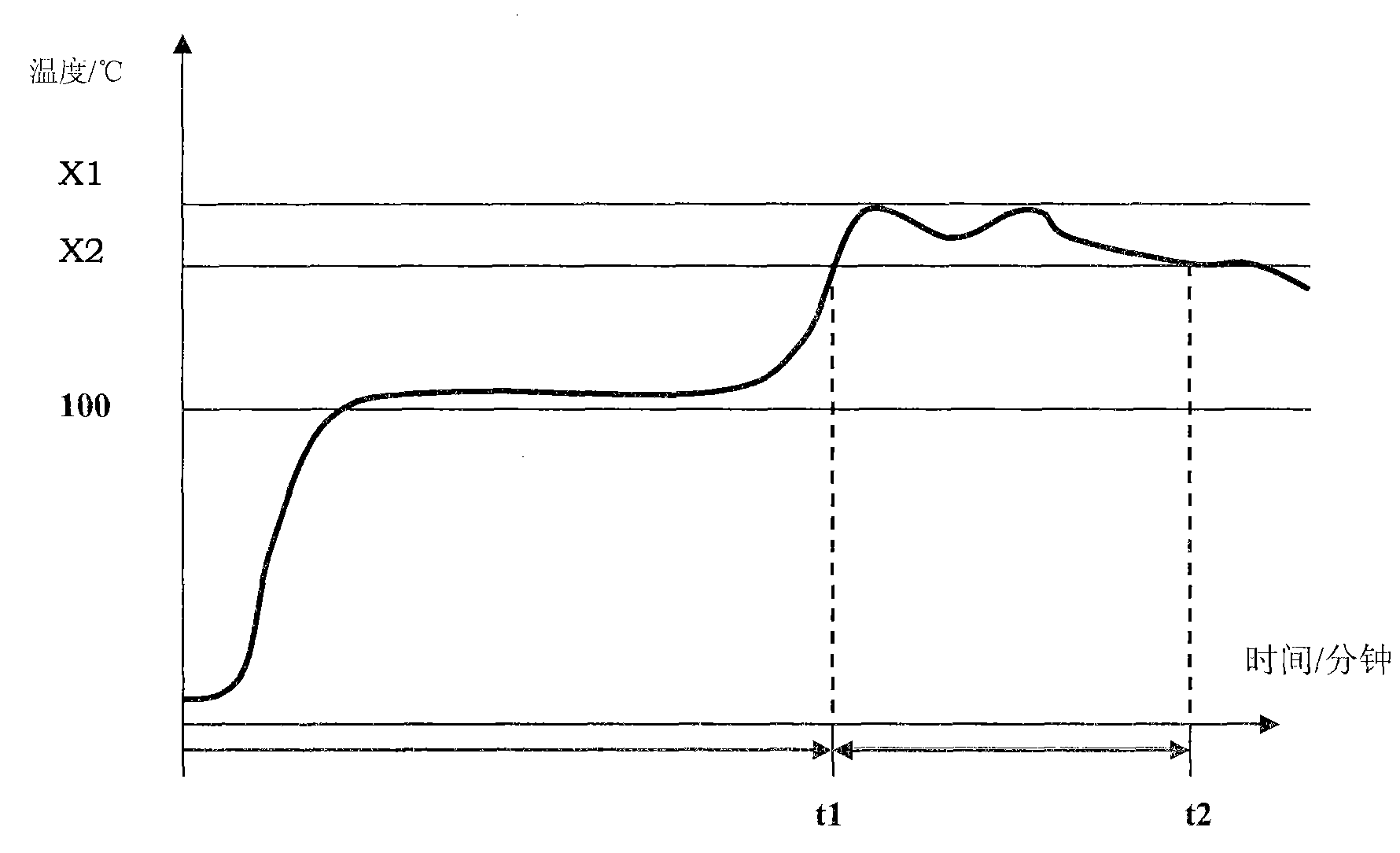

Method for controlling rice steaming and boiling of electric rice cooker

ActiveCN101587330ARaise the temperature gradientFully gelatinizedProgramme control in sequence/logic controllersWarming devicesRice dishesTemperature difference

The invention relates to a method for controlling the rice steaming and boiling of an electric rice cooker, which comprises the following steps: (1) confirming the boiling maintenance time t and the boiling maintenance temperature X of the electric rice cooker according to different rice kinds and mouth feeling; (2) starting the electric rice cooker and soaking, dewatering, heating and boiling rice according to a set procedure; (3) achieving the boiling maintenance temperature X= 130-165 DEG C after time t1=15-35 min and maintaining boiling in the electric rice cooker for the maintenance time t=6-10 min; and (4) cooking the rice after achieving the maintenance time t. The invention provides the method for controlling the rice steaming and boiling of the electric rice cooker, which controls the temperature and the time in the process of boiling maintenance, improves a temperature difference between the electric rice cooker and rice boiling, enables the rice to be fully gelatinized and enables water to be fully vaporized and absorbed by rice grains, thereby boiling the rice with high quality.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

Preparation method of detoxified gingko tea

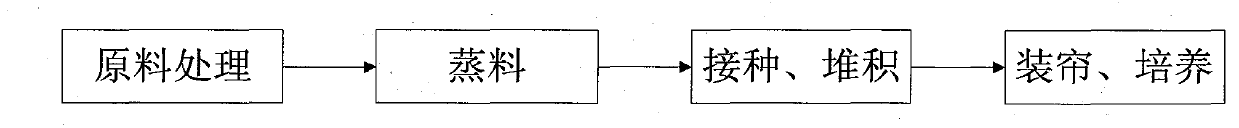

ActiveCN104286247AWith health functionHigh content of functional ingredientsPre-extraction tea treatmentBrickFermentation starter

The invention discloses a preparation method of detoxified gingko tea. The preparation method comprises the following steps: 1) preparing a fermenting agent, namely, separating eurotium cristatum from Fuzhuan dark tea and preparing a solid pure strain fermenting agent; 2) pretreating gingko leaves, namely, cleaning the gingko leaves, removing impurities, slitting and carrying out fixation, cooling and twisting after fixation so as to obtain raw tea; 3) blending and carrying out pile fermentation, namely, blending the raw tea of which the impurities are removed with dark raw tea, and carrying out pile fermentation on the blended tea leaves after primary steaming; 4) inoculating, namely, adding the solid pure strain fermenting agent into the tea leaves after pile fermentation and secondarily steaming and inoculating; 5) briquetting and fermenting: compressing the inoculated tea leaves into tea bricks, and putting the tea bricks into a fermentation chamber for fermenting; and 6) dehydrating and packaging: dehydrating the fermented tea bricks and dehydrating, and packaging the dehydrated tea bricks directly. The method not only can be used for effectively retaining active substances benefiting to human bodies, but also can be used for reducing the content of ginkgolic acid; the detoxified gingko tea is safe and reliable in quality, and is suitable for large-scale production and popularization.

Owner:葛振刚

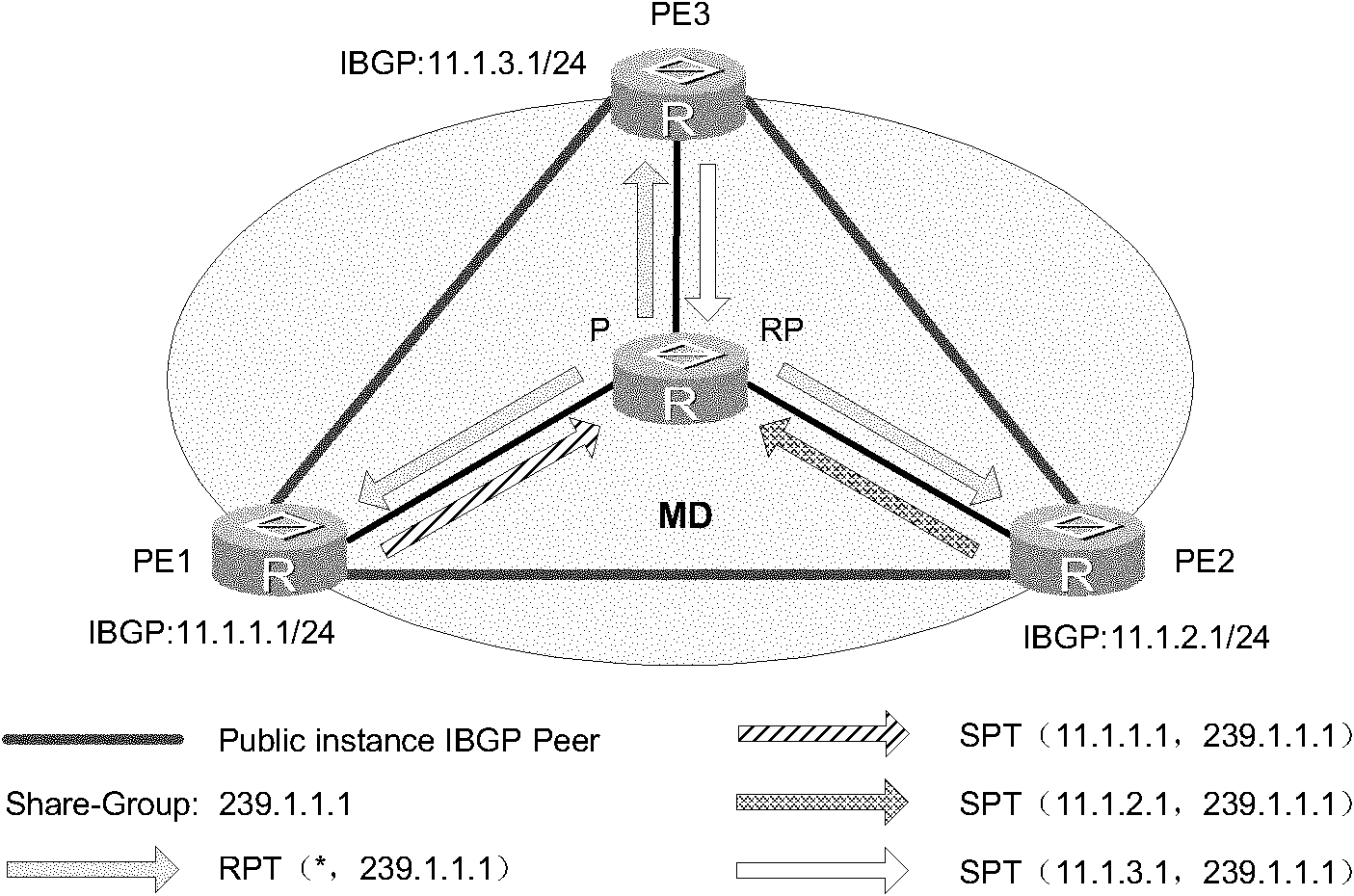

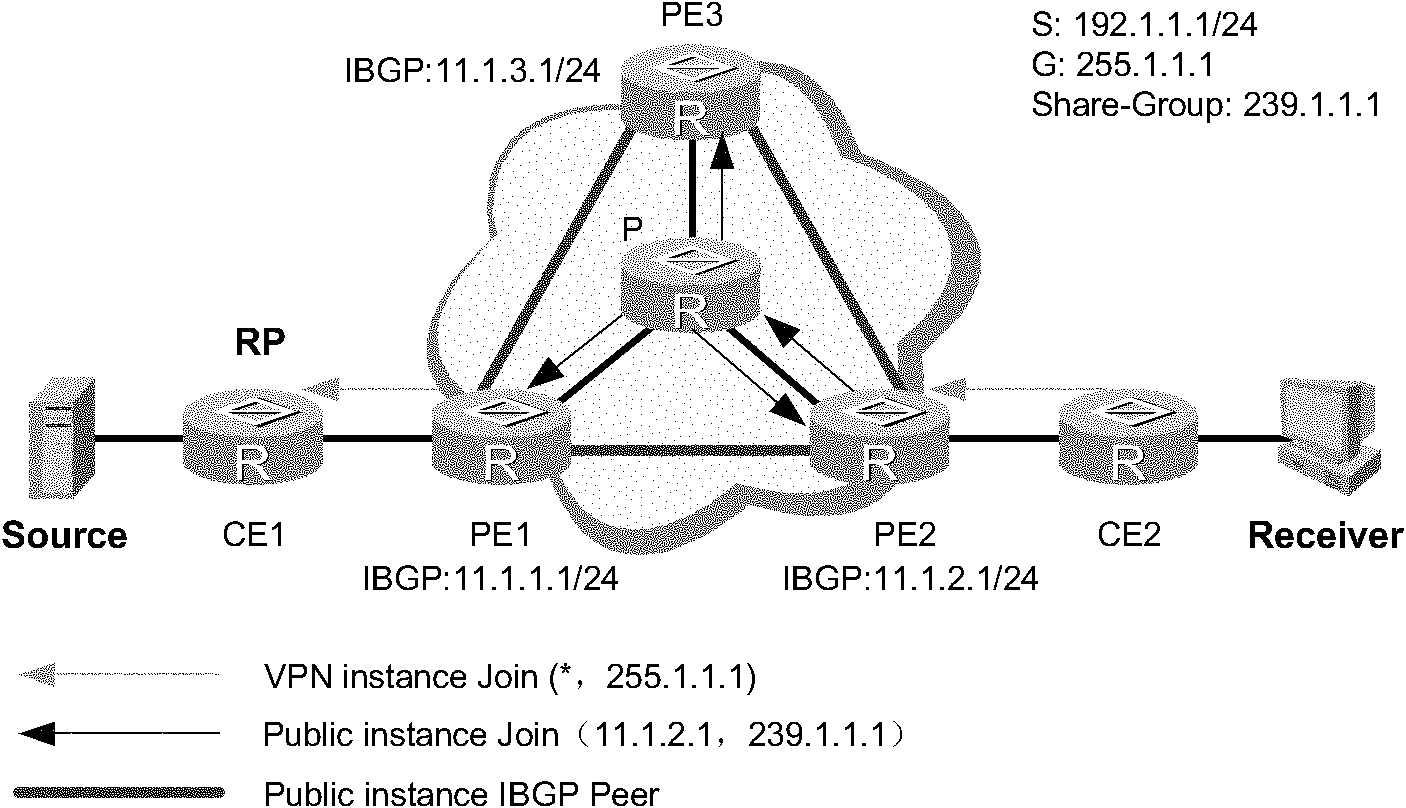

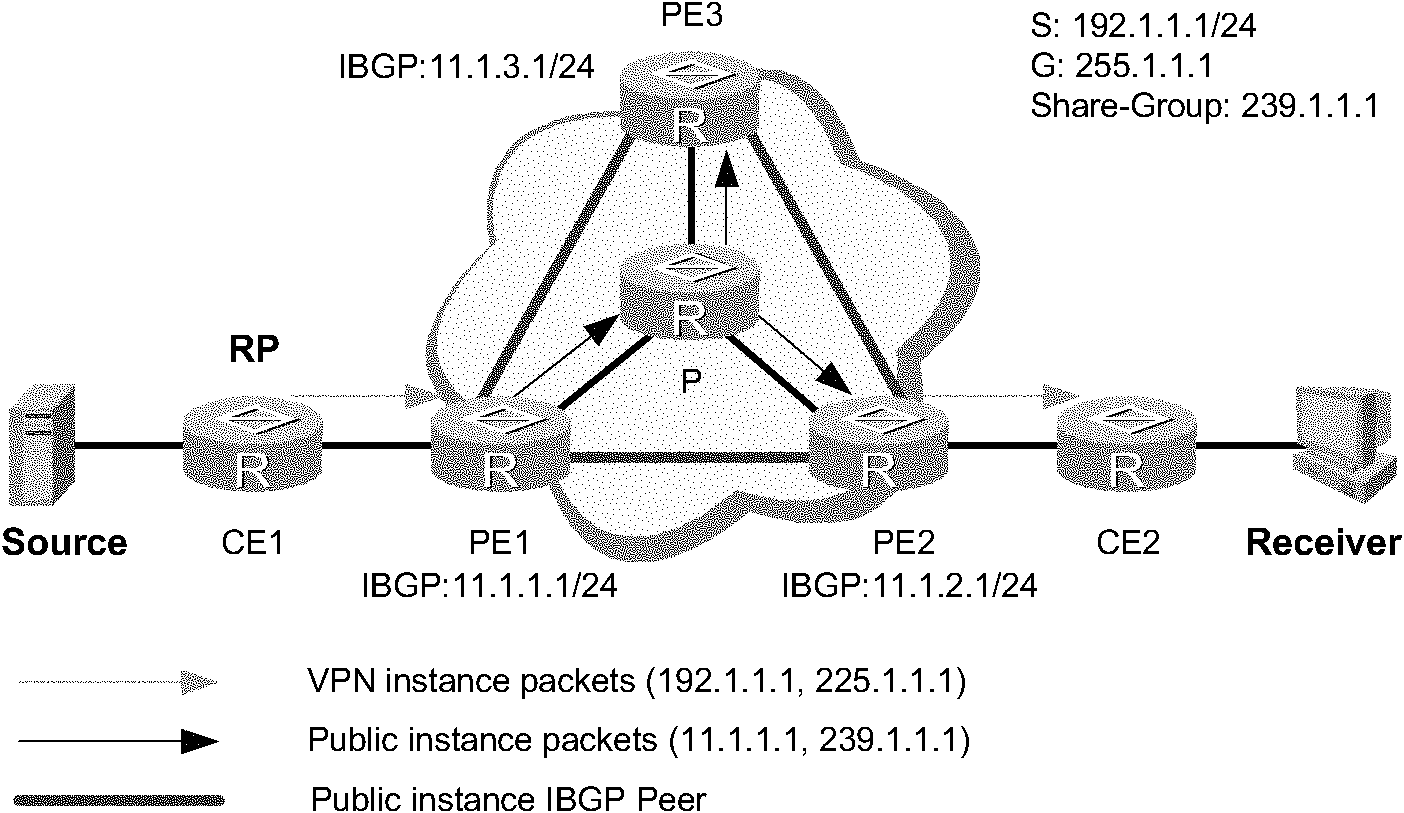

Method, device and system for establishing switching multicast distribution tree

ActiveCN102137000AThere will be no problem of packet lossSpecial service provision for substationNetworks interconnectionDistribution treePacket loss

The embodiment of the invention discloses a method for establishing a switching multicast distribution tree (a public network forwarding tunnel) in a multicast virtual private network (VPN). In the method, a provider edge (PE) at a source end sends a switching message containing a switching group address to a downlink PE along a share-multicast distribution tree (share-MDT), wherein the switching message is used for establishing the switching multicast distribution tree; and a register message is sent to a rendezvous point (RP) in a public network before multicast streaming on the share-MDT starts to switch so as to trigger the RP in the public network and the PE at the source end to establish the switching multicast distribution tree with a PE at a receiving end. The embodiment of the invention also provides a corresponding device and system. By using the method, the switching multicast distribution tree can be established before the multicast streaming is switched to the switching multicast distribution tree from the share-MDT, thus the problem of packet loss of the multicast steaming can be avoided in the process of switching the multicast streaming to the switching multicast distribution tree from the share-MDT.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Manufacturing method of folium mori tea

The invention discloses a manufacturing method of folium mori tea. The manufacturing method comprises steps of leaf picking, treatment, caging, green steaming, enzyme deactivation, rubbing, drying, spreading for cooling and screening. The manufacturing method disclosed by the invention is simple in manufacturing and easy to operate; the folium mori tea made using the manufacturing method is clear and bright, fragrant and sweet, fresh and mellow and tasty and refreshing when being brewed using hot water; particularly a novel beverage is provided for the middle-aged and aged people who are not suitable for drinking tea, so that certain health-care effects are provided for the middle-aged and aged people while having the tea; and the tea is beneficial for health maintenance, health care and life prolonging when being drunk frequently.

Owner:洪双应

Buring free, steaming free bearing building blocks or bricks prepared from tailing sand of iron ore, and manufacturing process

InactiveCN1727301ASolve pollutionSolve the damageSolid waste managementClaywaresBrickPortland cement

A load-bearing building block or brick is prepared from iron ore tailings (20-40 Wt%), broken stone (40-60), powdered coal ash (10-30), Portland cement (9.9-20) and water-reducing agent (0.1-1). Its making technology without calcining and steaming is also disclosed.

Owner:ANYANG IRON & STEEL GRP +1

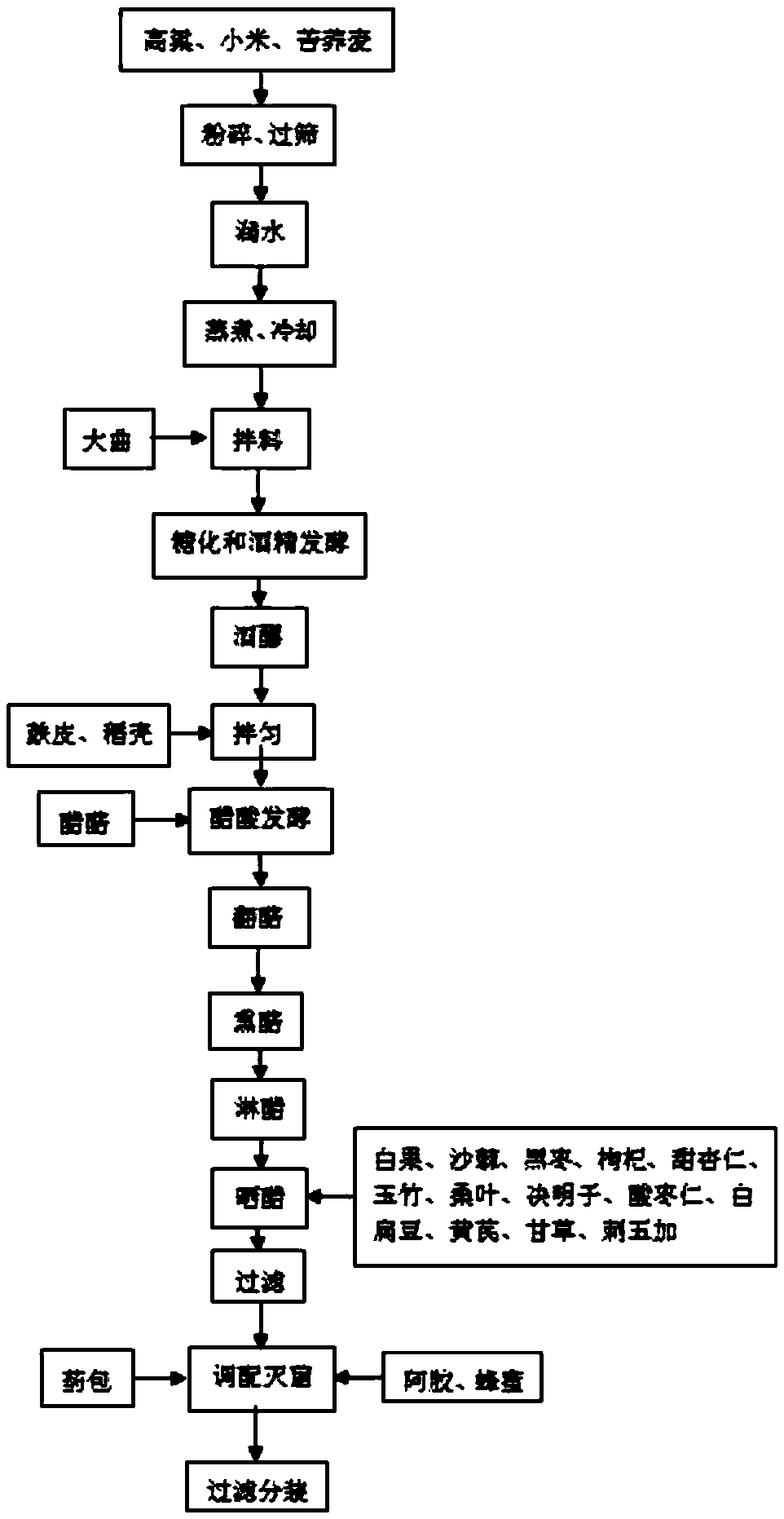

Health care vinegar and brewing process thereof

ActiveCN105505732AIncrease profitIncrease concentrationDigestive systemUnknown materialsAdditive ingredientPlant Sources

The invention provides health care vinegar and a brewing process thereof. The brewing process of the health care vinegar comprises the following steps of material steaming, saccharification, alcoholic fermentation, acetic fermentation, solid-substrate fermentation conducted through fumigation, vinegar spraying, ageing, blending and sterilization. In order to guarantee mellow and normal mouthfeel of the health care vinegar, the solid state fermentation mode is adopted in the production process; medicine-and-food homologous materials which are from different sources are added at different stages of ageing and vinegar decoction separately, and sufficient release and utilization of nutritional ingredients of the medicine-and-food homologous materials are guaranteed. The medicine-and-food homologous materials of the plant source are subjected to smashing treatment, then added at the vinegar sunning and ageing stages and reutilized at the vinegar decoction stage, so that the raw material utilization rate is raised; the materials of the animal source are added at the vinegar decoction stage, and it is guaranteed that efficacy and mouthfeel of the materials are not destroyed. The health care vinegar prepared through the preparation method is suitable for being eaten by people in different physique conditions, the physique conditions can be improved when the vinegar is eaten for a long time, and a good health care function is achieved.

Owner:TIANJIN UNIV OF SCI & TECH

Method for preparing fungal polysaccharide

The invention discloses a method for preparing fungi polysaccharide, namely a multi-stage dissolvent-cycle dynamic-thermal-reflux extraction condensation method. The method comprises the technological steps of raw material crushing, mixing with a solvent, extraction, condensation, deposition in alcohol, filtering and drying so as to obtain a finished product. The method for preparing fungi polysaccharide integrates extraction, condensation, solvent recovery and the like together, and is completely carried out in an enclosed system, without any bad occurrence of escaping, steaming, leakage and dripping, etc. The production practice shows that the method can shorten the extraction cycle by 50 percent to 85 percent so as to improve the production rate; the ration between raw material to solvent can be reduced to 1:3-8 (as the traditional method has a ration between raw material and solvent higher than 1:20), and the amount of an extractant used can also be saved by 25 percent to 80 percent; primary / secondary steam can be put into fullplay and cooling water is saved so that the effect of energy conservation is very significant. Compared with the traditional method, the method can save 30 percent to 70 percent of steam amount; and the medical material does not need to be crushed finely, which is favorable to the further operation. The method can be largely applied to the development and production of the fungi polysaccharide and other related polysaccharides or natural medical materials.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

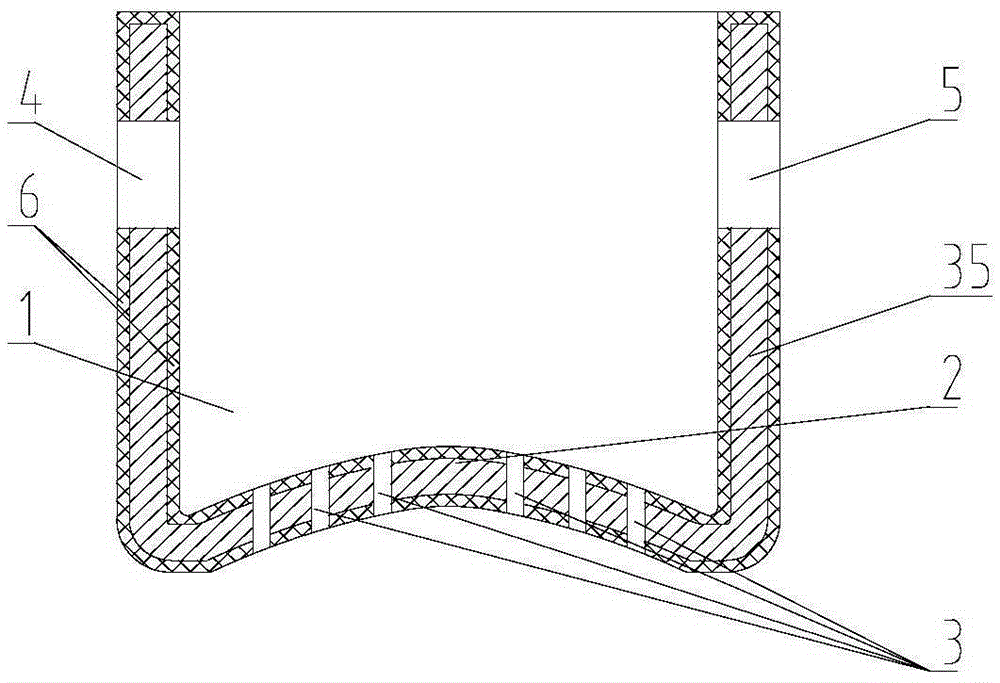

Low-temperature steaming and baking type food heating device

ActiveCN105286491ARetain nutrientsEasy to separateSteam cooking vesselsRoasters/grillsElectricityControl system

The invention belongs to the technical field of household appliances, and relates to a low-temperature steaming and baking type food heating device for health preservation. The main structure comprises an inner pot concave bottom with a structure formed by an inner pot bottom raised towards a pot opening direction, wherein the inner pot concave bottom is provided with gas-liquid holes; the upper part of an inner pot side wall is provided with a left hand support and a right hand support; the inner and outer surfaces of an inner pot are provided with first medical stone films with the thickness of 0.1-0.5mm by spraying or sintering; the inner and outer surfaces of an outer pot are sprayed with medical stone films with the thickness of 0.1-0.5mm; an anti-scald left handle and an anti-scald right handle are fixed at relative positions at two sides of the outer pot side wall by using screws; a display screen, a temperature regulating key, indicator lights, a switching key and a time control key are arranged on a control system respectively; the control system is in electric information connection with a heating base plate and a temperature limiter and controls the conduction time and temperature to ensure that the heating temperature is controlled within 90 DEG C; and the nutritional ingredients in food materials are effectively retained, solid food materials and soup are separated quickly and completely, waterless dry steaming can be performed, the structural design is reasonable, the manufacturing process is simple, and the application is environment-friendly.

Owner:青岛好恩酷国际贸易有限公司

Low-gelatinization-degree staple food regenerated rice and processing technology thereof

ActiveCN103766735ALow degree of gelatinizationGreat tasteFood shapingFood dryingAdditive ingredientCorn flour

The invention discloses low-gelatinization-degree staple food regenerated rice and a processing technology thereof. The raw materials of the regenerated rice comprise main ingredients and auxiliary materials, wherein the main ingredients are one or more of broken rice flour, potato powder and corn flour; the auxiliary materials are one or two of yam flour and lotus root powder. The processing technology of the regenerated rice comprises the following steps: crushing the raw materials, adding water for tempering, extruding and granulating, performing surface hardening treatment and drying, wherein the step of extruding and granulating comprises the sub-steps: uniformly adding the materials subjected to water adding and tempering into a twin screw extruder, controlling the temperature of a compression section, a feeding section and a metering section of an extruder and a rotating speed of a screw rod, performing extrusion melting on the materials, molding by virtue of a die head, and cutting into the shape of rice grains by virtue of a cutter; the drying step comprises the sub-step of drying the materials in the shape of rice grains subjected to the surface hardening treatment into the moisture content of 10-13 percent by adopting three-section gradient hot air. The regenerated rice is easy to form, and the processed staple food regenerated rice is low in gelatinization degree, low in swelling degree, low in crack rate, low in broken rice rate, uniform in rice grains, boiling-resistant and steaming-resistant and good in taste.

Owner:WUHAN POLYTECHNIC UNIVERSITY

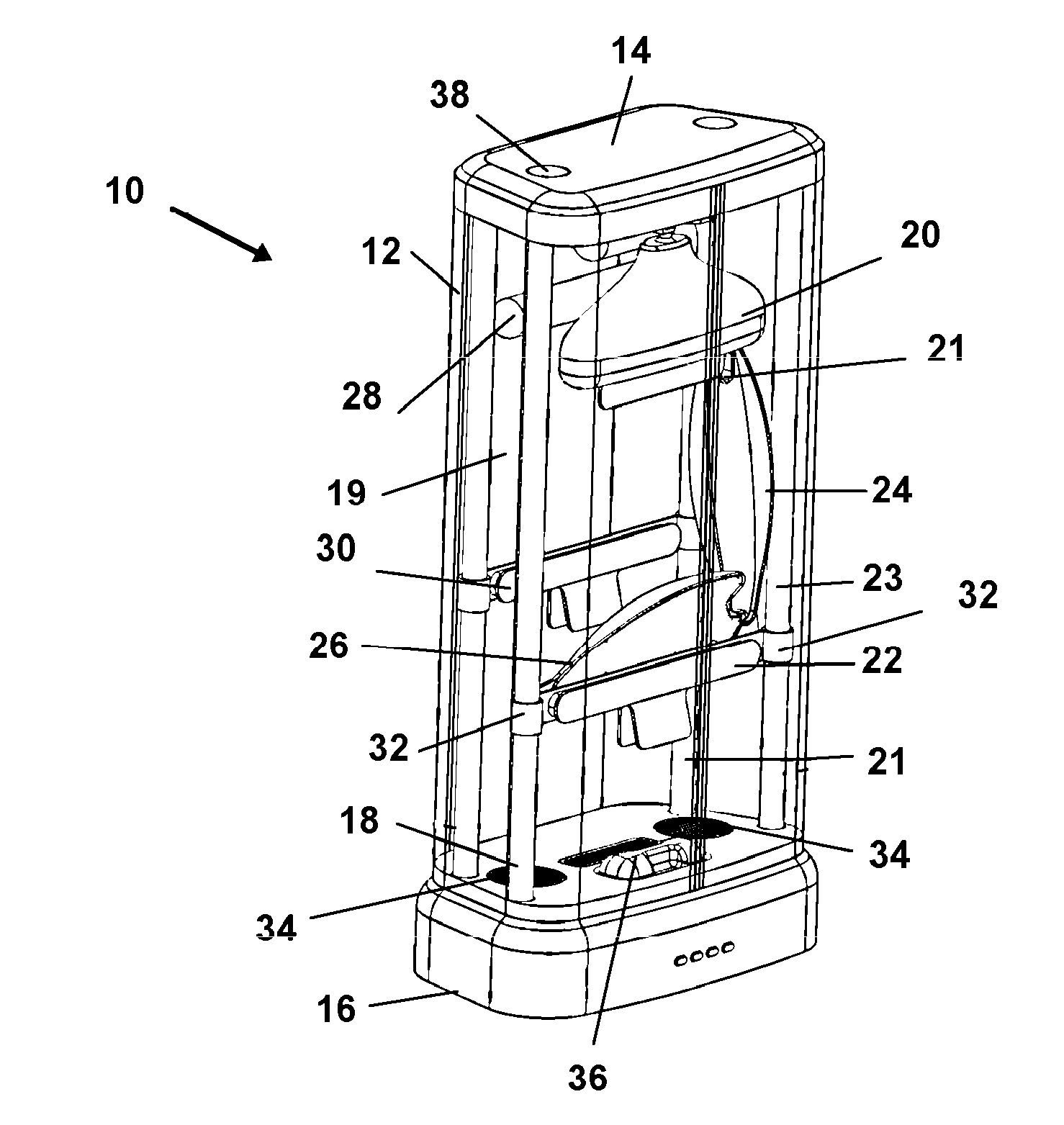

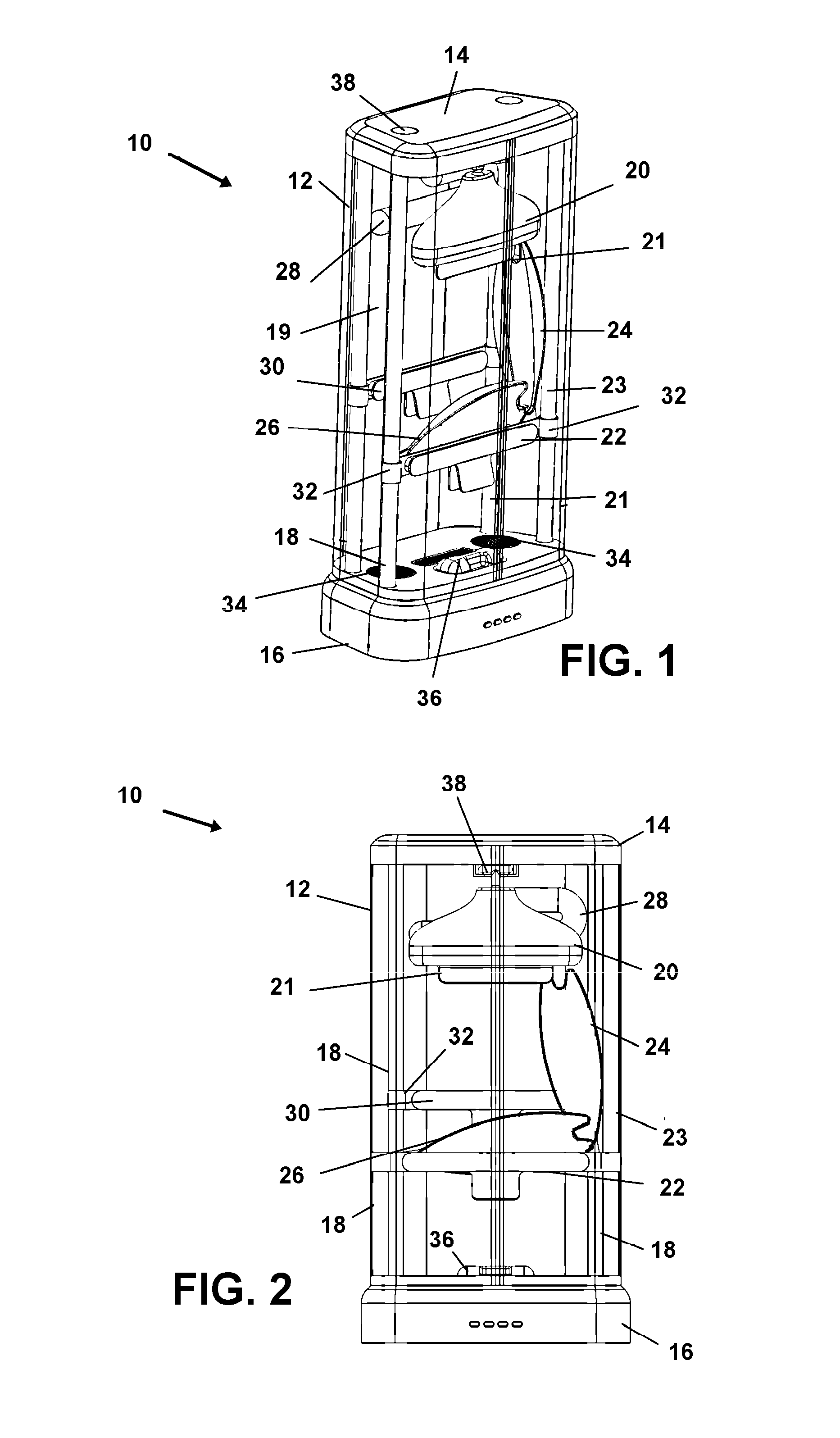

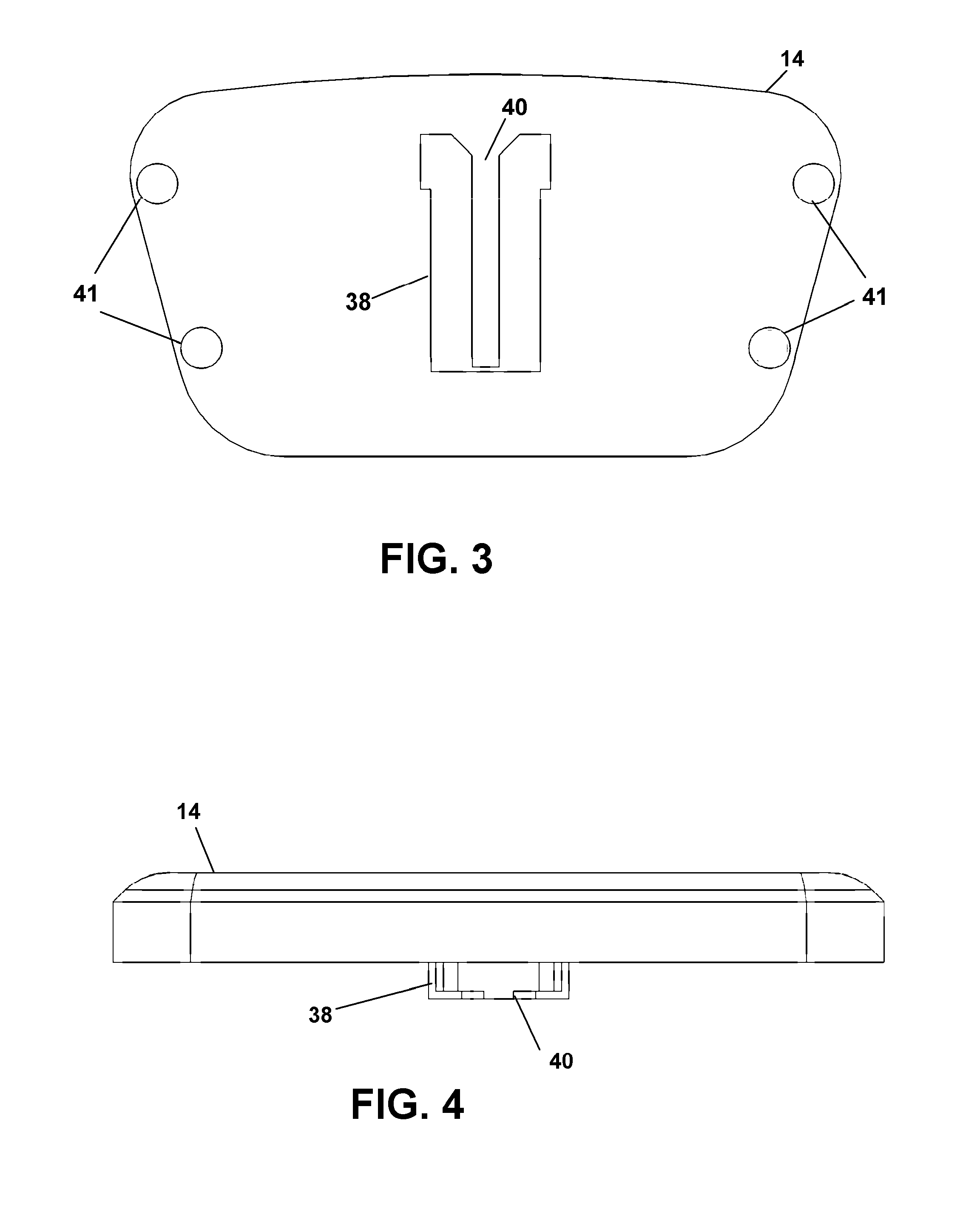

Portable Garment Steaming System

InactiveUS20120018461A1More compact storage or transportationMaintenanceIroning apparatusTextile shapingEngineeringSteaming

A clothing de-wrinkling device which employs clips to hold shirts and pants at two points and expose the fabric surfaces to steam communicated to a closed enclosure. The clips when engaged will hold the fabric of the shirts or pants taught and thereby increase the de-wrinkling of the steam. Also provided are shirt sleeve engagement members which will hold the two side portions of shirt sleeves taught during exposure to steam.

Owner:AZIZIAN HOVIK +1

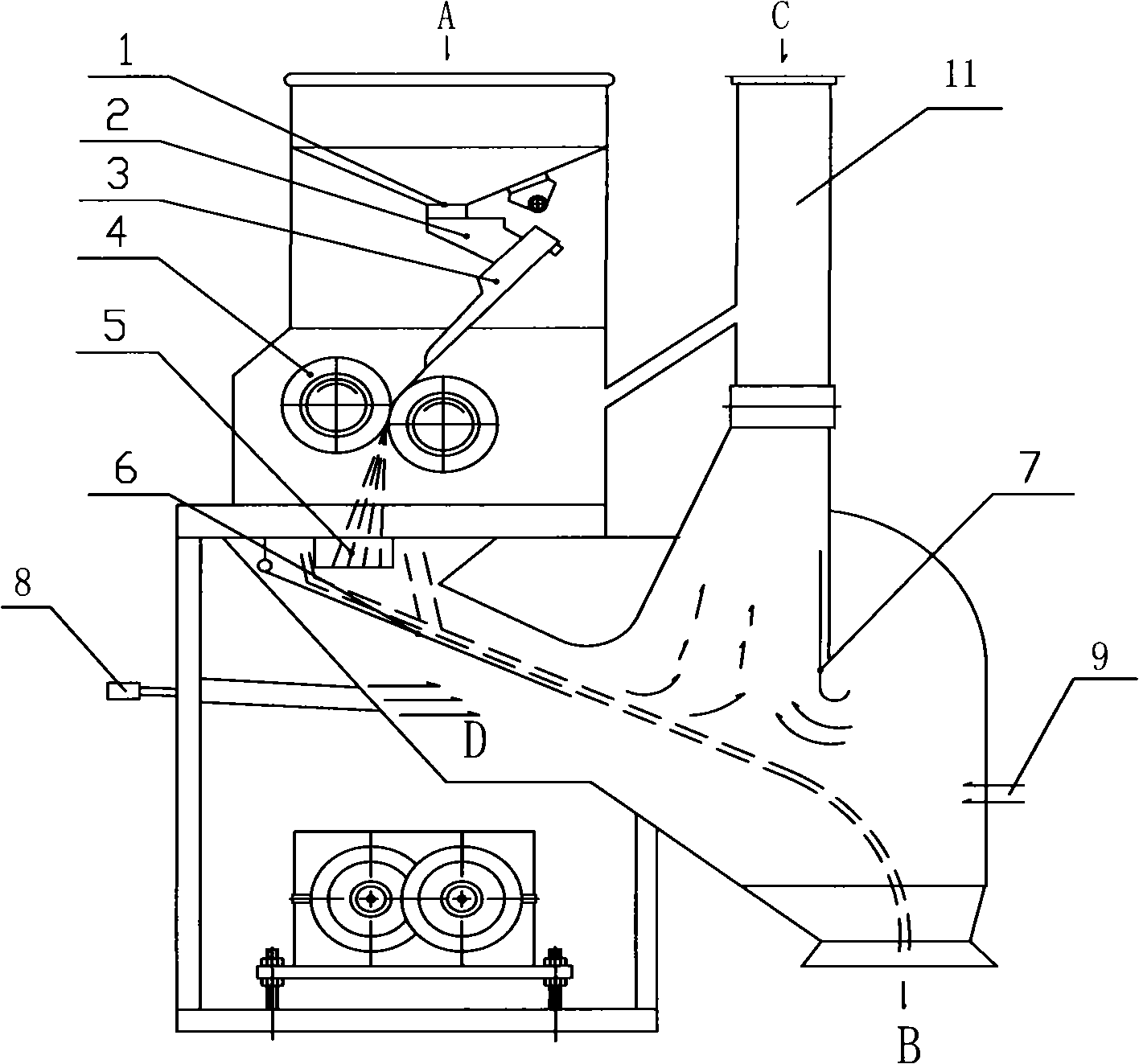

Oat barking equipment and barking method

ActiveCN101264459AShort preparation timeFragrant smellGrain huskingGrain polishingNutritive valuesSkin effect

The invention discloses an oat pelt puller and the skinning method. The pelt puller comprises a frame, a feeding assembly, a propeller, a sand drum assembly and a power unit; which is characterized in that: the whole components are arranged on the frame; the propeller is arranged in the feeding assembly, the propeller is connected with the momentum output terminal of the power unit, the lower end of the propeller passes through the exit end of the feeding assembly and is connected with the sand drum assembly, a sand plate is correspondingly arranged on the periphery of the sand drum assembly, a skinning chamber forms between the sand plate and the sand drum assembly, the distance between the sand plate and the sand drum assembly is 1 to 10mm, the lower end of the skinning chamber is a discharge opening. The pelt puller has the advantages of simple combination, high efficiency, good skinning effect, and no damage to oat grain, the obtained oat without peel has the advantages of ability to be used for cooked congee, rice steaming, short process time, ability to direct edible, moderate mouthfeel, fragrant odor, high nutritive value, suitability for traditional food habits of Asian, satisfaction for the diversification requirements for oats food edible mood.

Owner:SANZHULIANG ZAOZHUANG FOOD BEVERAGE CO LTD

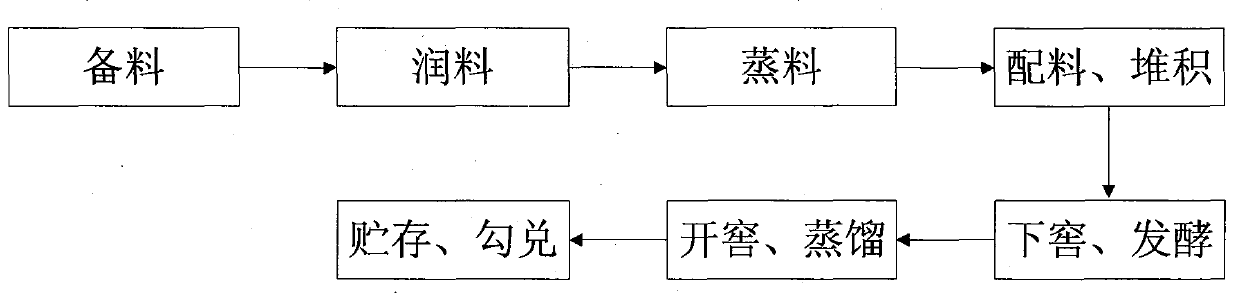

Brewing method for maotai-flavor white spirit

The invention discloses a brewing method for a maotai-flavor white spirit. The brewing method comprises steps of material preparation, material humectation, material steaming, material proportioning, accumulation, cellaring fermentation, taking out from the cellar, distillation, storage and blending. In the method, sorghum and wheat are employed as raw materials for brewing. Aspergillus kawachii mouldy bran, saccharomycetes mouldy bran and bacterium mouldy bran are employed as spirit yeasts for brewing of a maotai-flavor white spirit. Because spirit yeasts called daqu are replaced by mouldy bran, required grain dosage for brewing is decreased, production cost is lowered, fermentation cycle is shortened, and liquor yield is raised.

Owner:GUIZHOU BIJIE BICHUN WINE

Method for preparing dry day-lily buds

InactiveCN101911963AIncrease powerIncrease productionFruits/vegetable preservation by heatingFruits/vegetable preservation by dehydrationFlavorFood additive

The invention discloses a method for preparing dry day-lily buds. The method comprises the following steps of: fixing day-lily buds; removing green from the day-lily buds, roasting and / or airing the day-lily buds; inspecting the dry day-lily buds; packaging the inspected dry day-lily buds; and putting the packaged dry day-lily buds in storage. The method is characterized in that: the fixing step comprises the following specific steps of: scattering picked fresh day-lily buds on a steaming sieve, wherein scattering thickness is between 150 and 200 millimeters; racking the steaming sieve; pushing the steaming sieve into a steam box; introducing steam into the steam box; controlling temperature in the steam box to be between 50 and 65 DEG C; steaming for 5 to 8 minutes; and opening the door of the steam box to take the steaming sieve out. Compared with the prior art, the method has the advantages that: 1) any food additive does not need to be added in a fixing process and the dry day-lily buds have a natural color, natural taste, natural flavor and sweet taste; 2) day-lily bud drying rate is increased by 2 percent by steam fixation and the growth rate of market prices is increased by 13 percent; and 3) the day-lily buds processed by the steam fixation are accordant with food quality standard, do not cause any pollution, are truly green food and are well appreciated by customers.

Owner:湖南吉祥食品有限公司

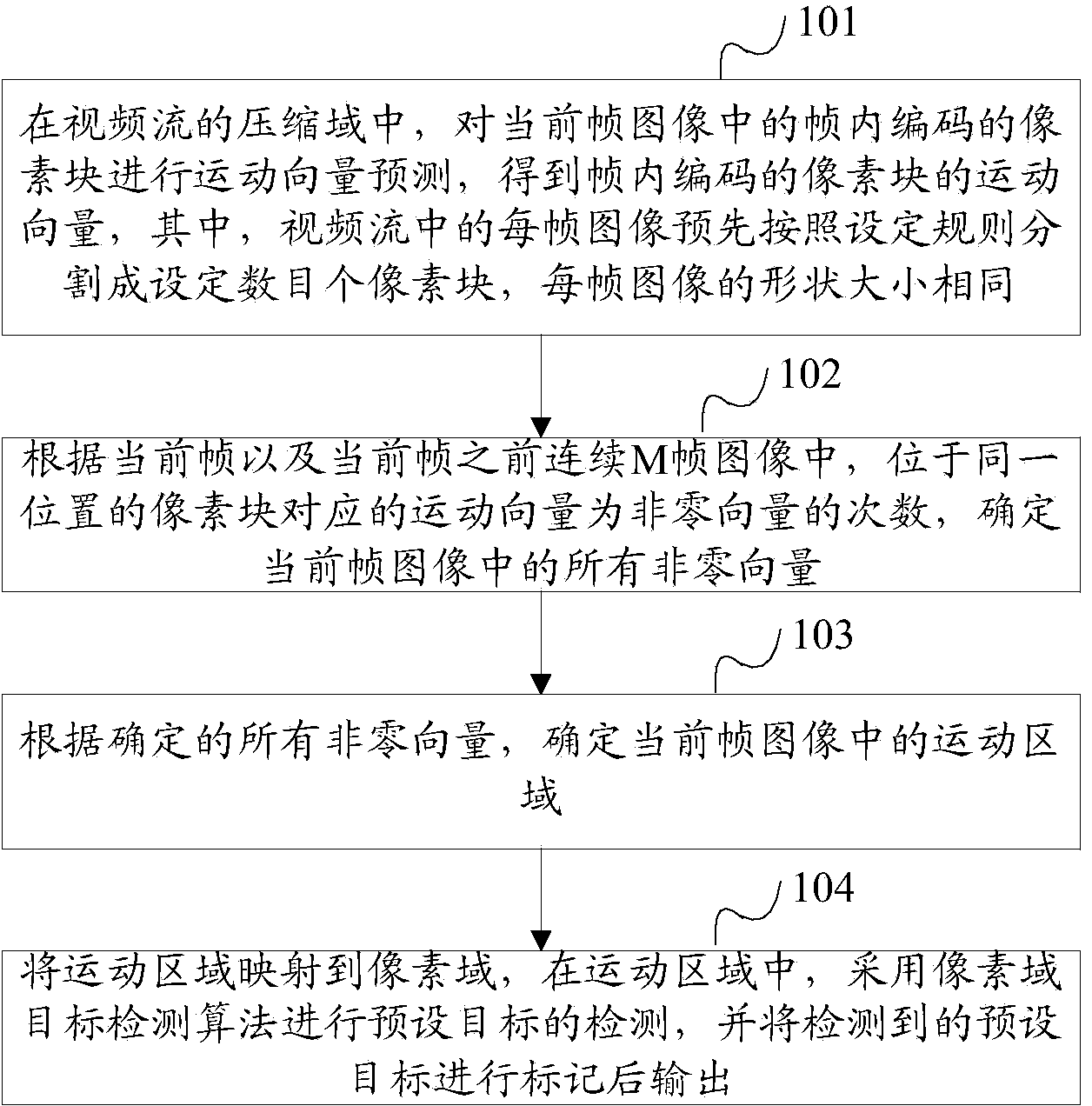

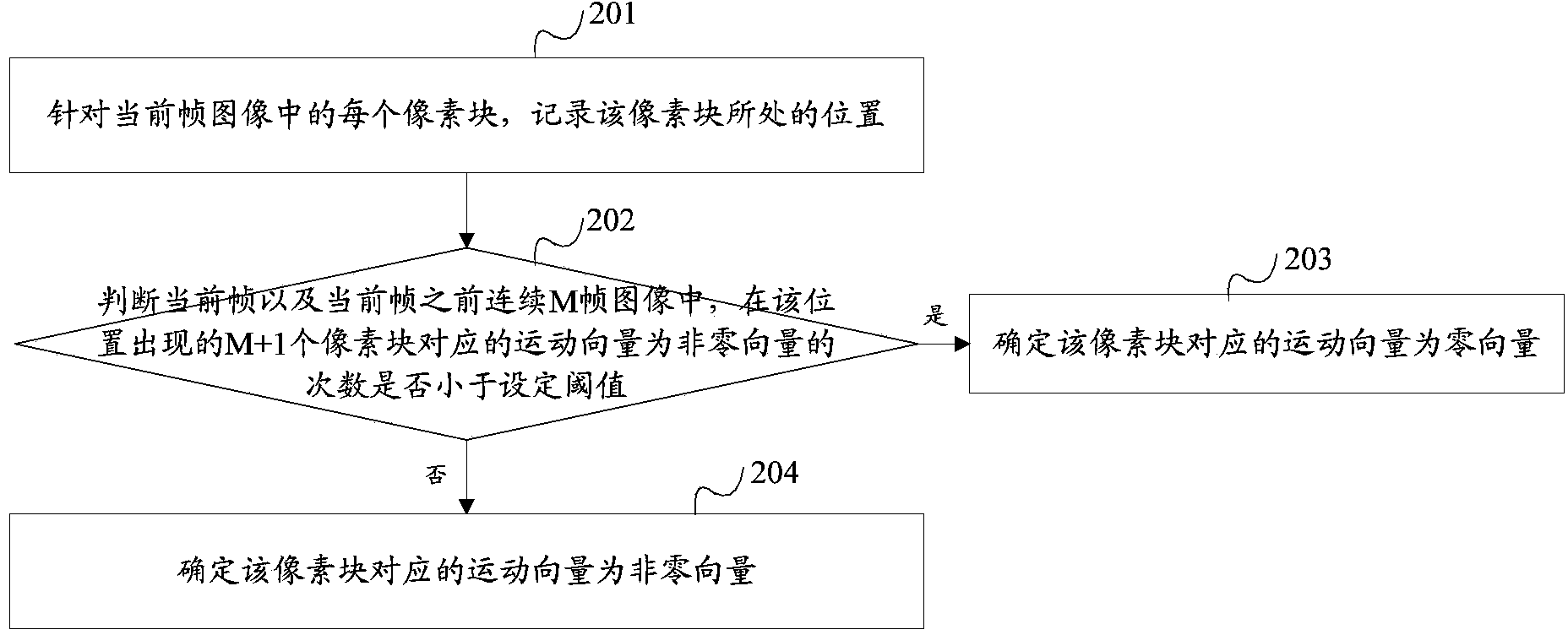

Motion object detection method and device

The invention provides a motion object detection method and device. The method comprises the steps that in a compressed domain of video streaming, motion vector prediction is performed on pixel blocks of an intra-frame code in a current frame of image, so that motion vectors of the pixel blocks of the intra-frame code are obtained, wherein each frame of image in the video steaming is divided into a set number of pixel blocks according to setting rules in advance, and the sizes of all frames of images are equal; according to the frequency that motion vectors corresponding to pixel blocks located at the same position are non-vanishing vectors in the current frame of image and the continuous M frames of images before the current frame of image, all non-vanishing vectors in the current frame of image are determined; according to all the determined non-vanishing vectors, a motion area in the current frame of image is determined; the motion area is mapped into a pixel domain, in the motion area, preset targets are detected based on the pixel domain target detection algorithm, and the detected preset targets are indicated and then output. According to the motion object detection method and device, the accuracy of target detection can be improved, and the speed of target detection can be increased.

Owner:CHINA SECURITY & FIRE TECH GRP +1

Tartary buckwheat tea and production method thereof

InactiveCN101449726AReasonable drynessImprove immunityTea substituesFood preparationMedicineSteaming

The invention relates to bitter-buckwheat tea with health care and medical function and a method of producing the same, which is prepared by mixing tartary buckwheat 99% and Astragalus root 1%, through vrushing, soaking, heat steaming, drying, rolling, wind selecting, magnetic separating, parching, finally packaging, drunk by human.

Owner:雎明杰

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com