Patents

Literature

84results about "Silk cocoons cleaning/classifying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silk producing method

The invention relates to a silk producing method which comprises the steps of: high-temperature direct steaming: processing silkworm cocoons with saturated steam in an direct steaming chamber or a direct steaming device, wherein the direct steaming temperature is 100 DEG C, the direct steaming time is 8 to 10 minutes; standing: standing the directly-steamed silkworm cocoons at a normal temperature for 18 to 26 hours; vacuum infiltration: infiltrating the stood silkworm cocoons by utilizing a vacuum infiltration method to subject the silkworm cocoons to absorbing water, wherein the infiltration water temperature is 35 DEG C to 40 DEG C, the infiltration time is 5 to 10 minutes, and the vacuum degree is 0.05 to 0.1 Mpa (megapascal); cocoon cooking: cooking the silkworm cocoons subjected to vacuum infiltration in a cocoon cooking device; silk reeling: dissociating cocoon filaments of the cooked silkworm cocoons at a temperature of 40 DEG C, and utilizing sericin to glue and connect the cocoon filaments to form raw silk; and post-reeling which includes steps of roughness removal, small reel silk sheet balancing, small reel vacuum moisture absorption, rereeling, large reel silk sheet balancing, arranging and the like. The silk producing method enables the neatness of the raw silk to be relatively high by utilizing high-temperature direct steaming and vacuum infiltration.

Owner:杭州金利丝业有限公司

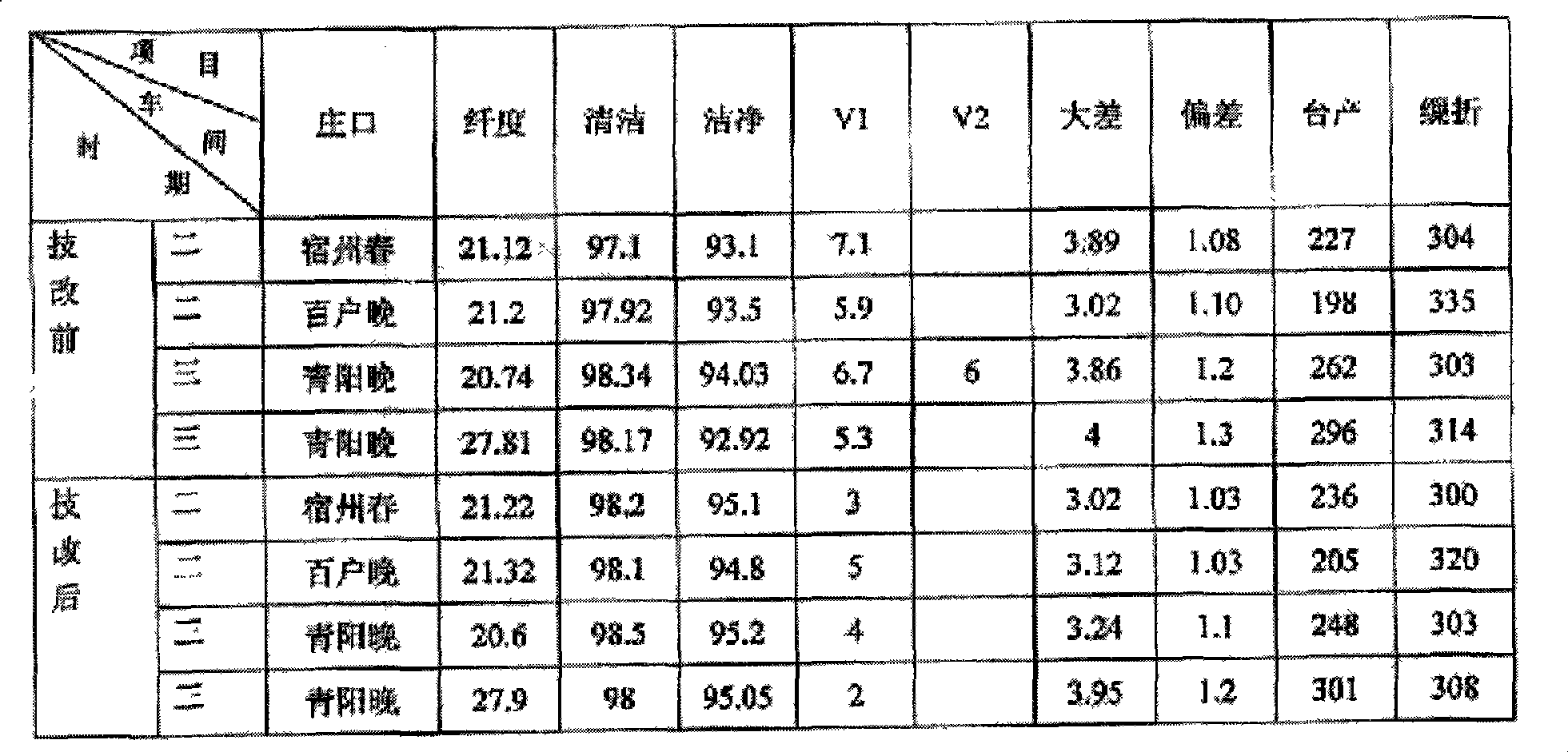

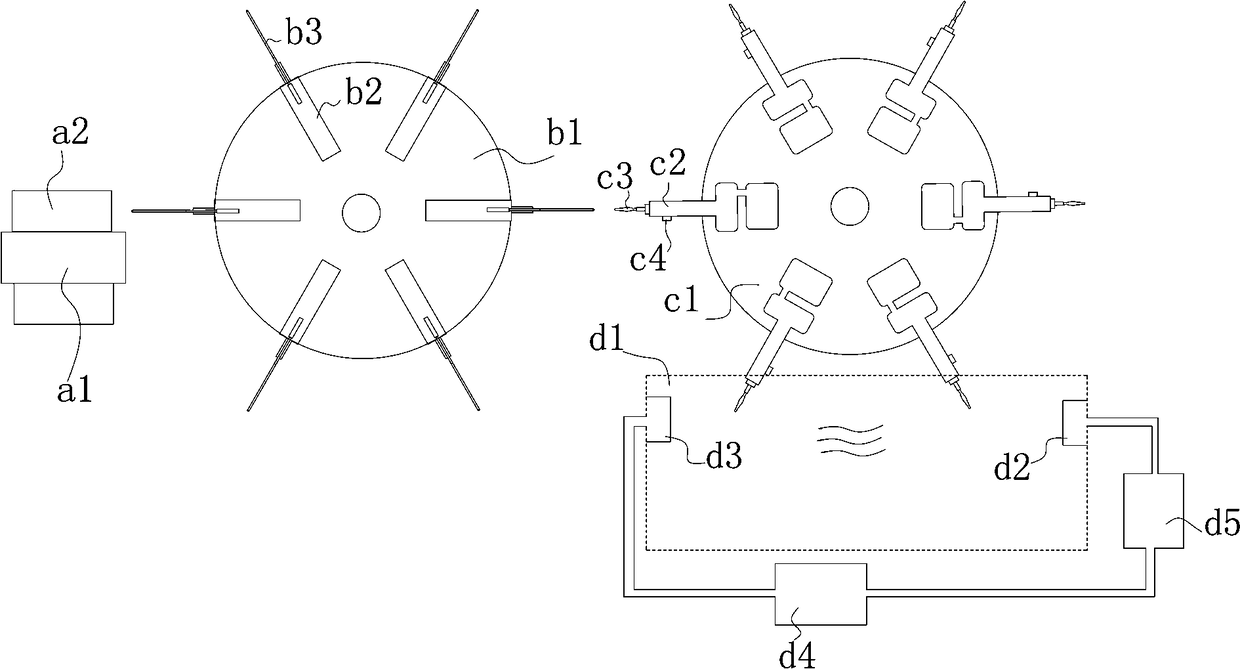

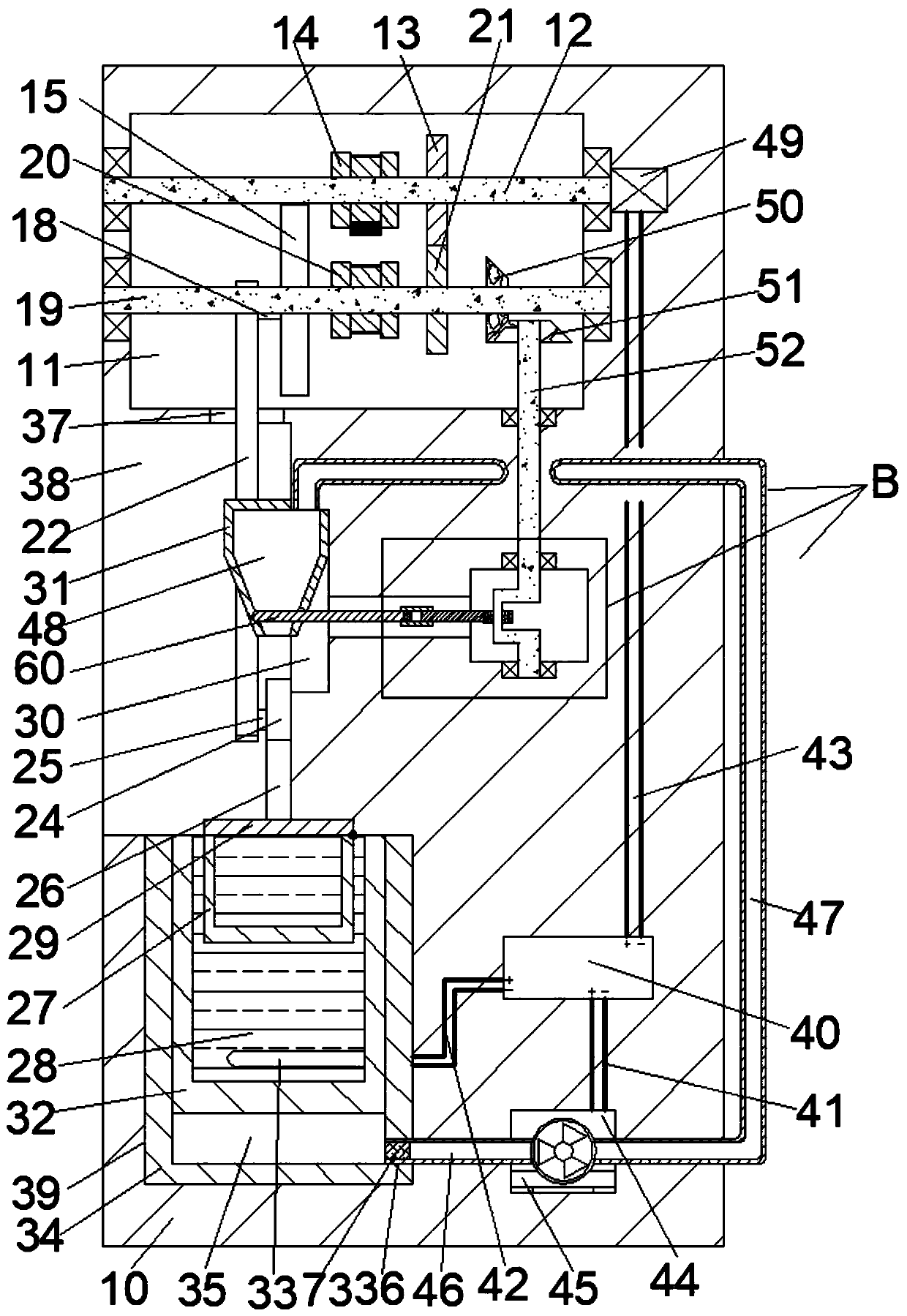

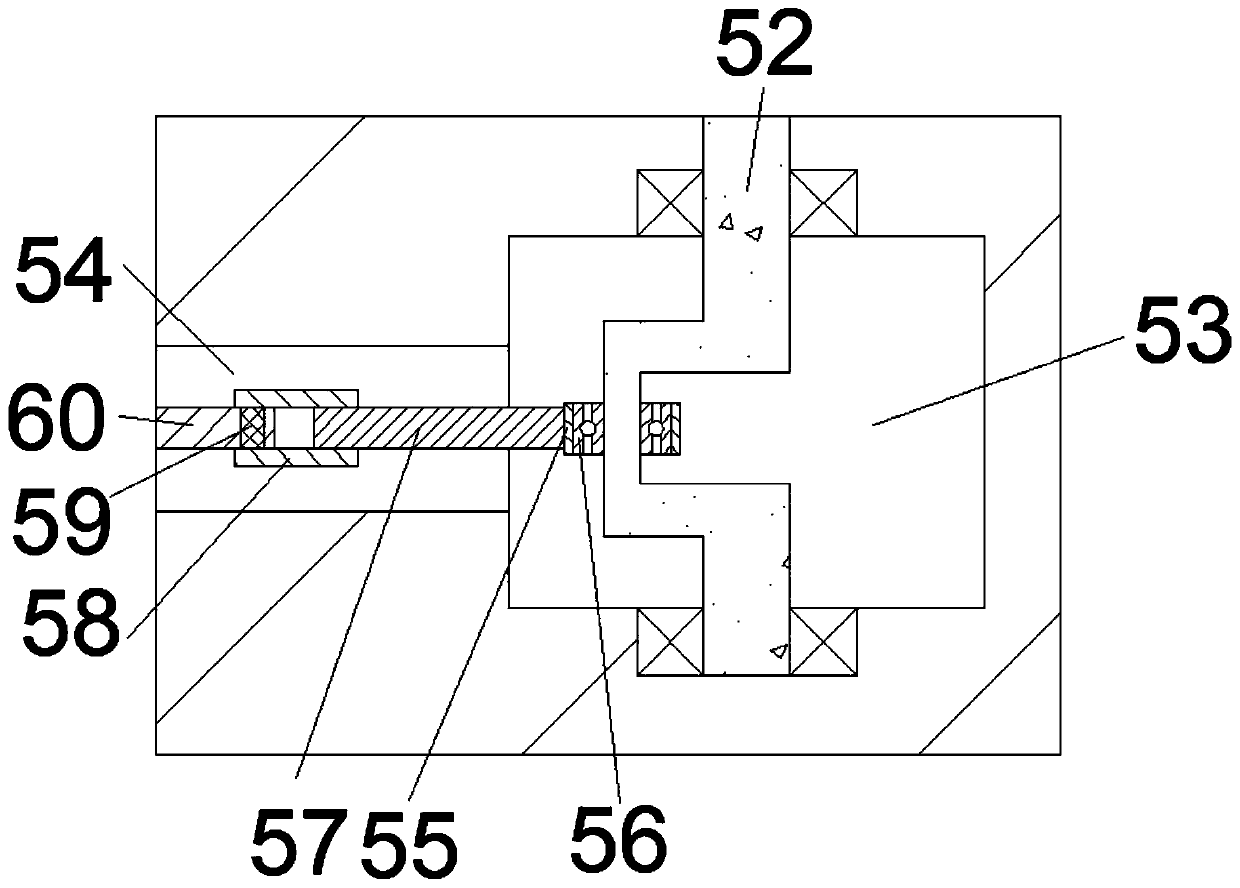

Production facility and production process for 6A grade white steam filature

InactiveCN101413144AReduce consumptionStable cocoonSilk reelingSilk cocoons cleaning/classifyingPulp and paper industryHigh pressure

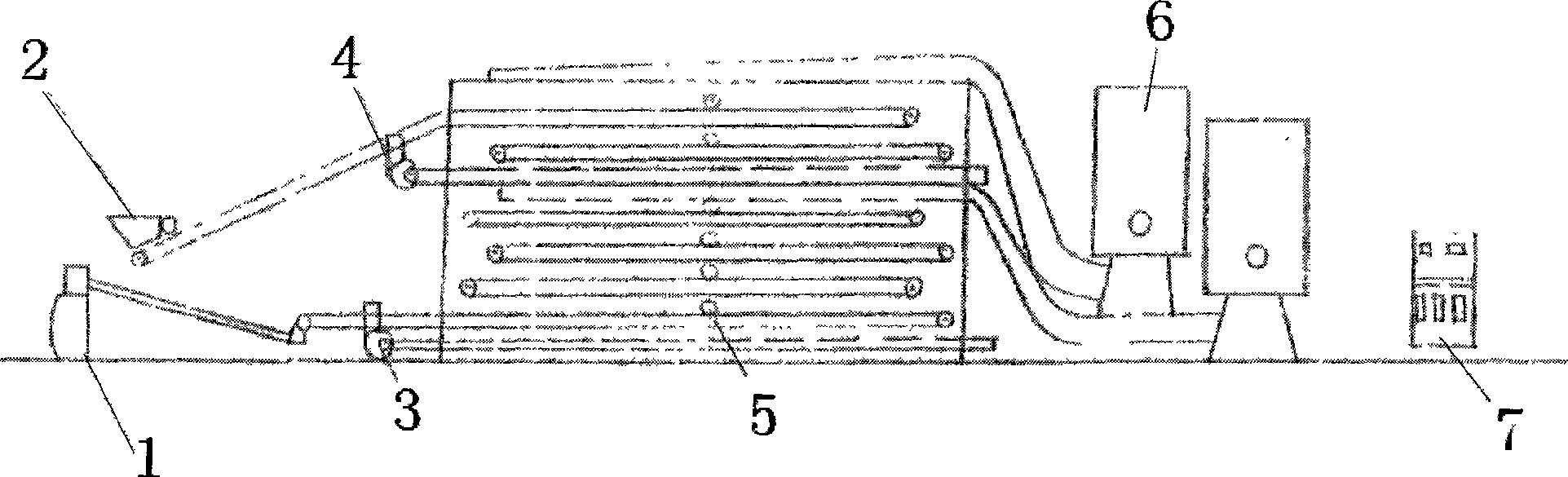

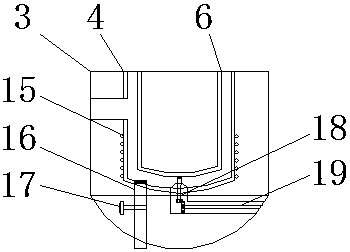

The invention discloses a device for producing a 6A-level white steam filature. According to the sequence of a production process, the device comprises a cocoon drying device, a cocoon assorting device, a cocoon cooking device, a self-silk-reeling device, a silk re-reeling device and the like, wherein the cocoon drying device is provided with a fresh cocoon water ratio detecting device. The technical proposal provided by the invention can effectively solve the following problems: the stable quality of the cocoon is hard to ensure in the production process of cocoon drying by the production technology of the 6A-level white steam filature; the air pressure and the temperature in a digester room are hard to control in the production process of cocoon cooking; and the production process of the white steam filature is lack of monitoring, has low automation level, poor quality stability of the product and the like. At the same time, the technical proposal ensures the stability of the cocoon quality, improves the reelability percentage and the cleanliness index, and promotes the inner layer sericin adhering point to separate instantly to swell at low temperature and at high pressure to the utmost extent; besides, outer surface sericin does not generate dissolving and melting, thus the technical proposal reduces dropped threads in middle and inner layers, reduces the consumption of raw materials, and strengthens the implementation of on-line monitoring in the processes of production and processing at the same time.

Owner:HUANGSHAN HUASHENG SILK GROUP

Method for preparing high grade sexual silk

InactiveCN101054731AImprove silk yieldSilk reelingSilk cocoons cleaning/classifyingFiberUltraviolet lights

The present invention discloses a process for preparing high-quality gender cocoon fibre. Said process comprises the following steps: adopting breeded fluorescent cocoon color to judge breed variety of gender silkworm under ultraviolet light source, respectively measuring sizes of female / male silkworm cocoon and thickness of cocoon layer after separating female silkworm cocoon from male silkworm cocoon, adjusting the cocoon drying technological conditions according to determination of conventional technological condition for cocoon drying and cocoon boiling, wherein for female cocoon, the reducing dry temperature is adjusted to 3-10 DEG C and the shortening reduced speed dry time is adjusted to 0.5-.5 hours, for male cocoon, the prolonging reduced speed dry time is adjusted to 0.5-.5 hours; regulating the technological conditions for cocoon boiling, for female cocoon, the prolonging boiling setting time is 1-3 minutes, for male cocoon, the shortening boiling debug time is 1-3 minutes; then, reeling silks at an auto cocoon cooking machine or an auto fiber-fixed reeling machine to manufacture male silkworm bast silk with a gradation of 6A and female silkworm bast silk with a gradation of 5A-6A. The obtained bast silks is one or two gradations higher than the male / female mixing bast silk, and then realizes the batch silk reeling of cocoon fibre, with high quality.

Owner:SUZHOU UNIV

Negative ion mulberry silk floss production method

InactiveCN106245118AEasy to operateReduce labor intensitySilk cocoons cleaning/classifyingAnimal materialInternational standardEngineering

Owner:GUANGXI YIZHOU BAIXINGRENJIA TEXTILES CO LTD

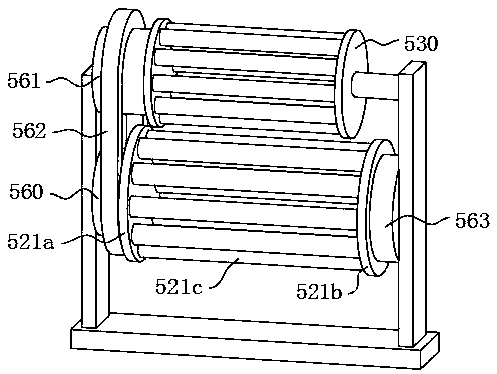

Transfer type silkworm cocoon separation device

InactiveCN101507961ATo prevent the situation of falling into the channel at the same timeSimple structureSilk cocoons cleaning/classifyingGradingEngineeringMechanical engineering

Owner:NANJING UNIV OF SCI & TECH +1

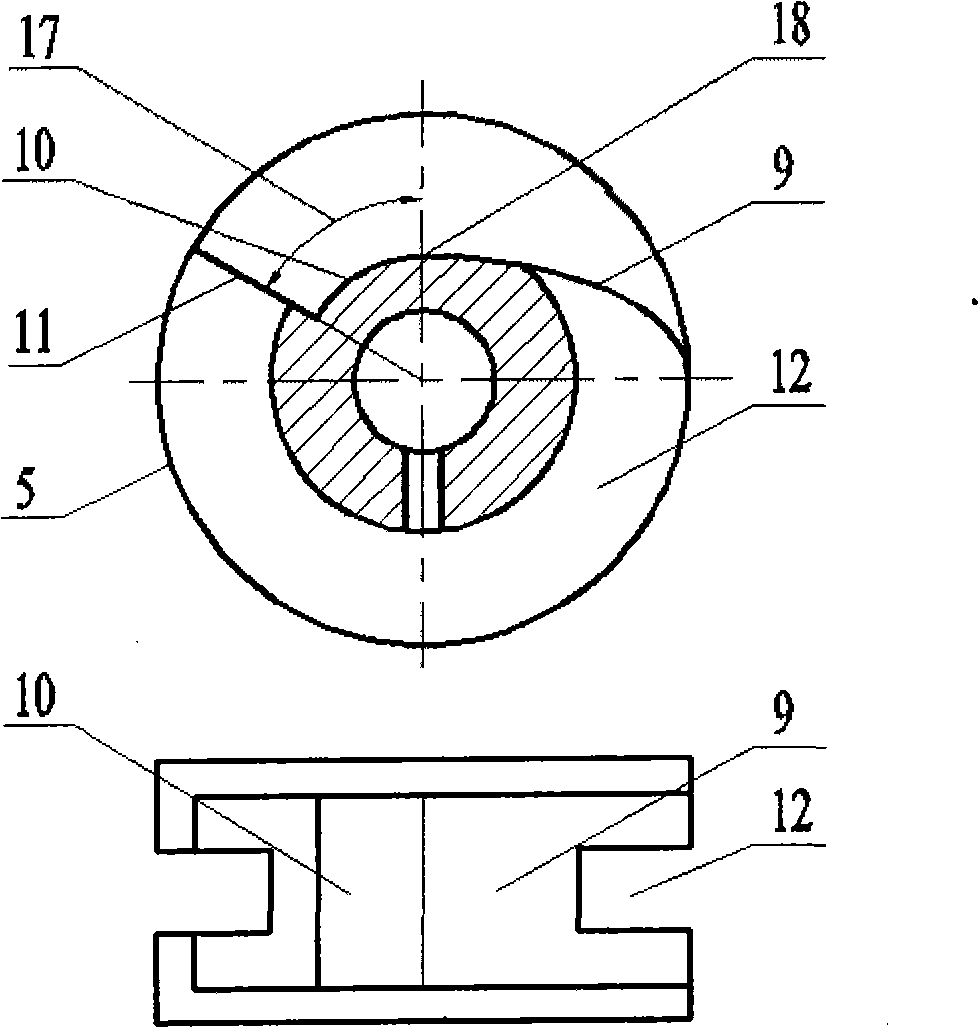

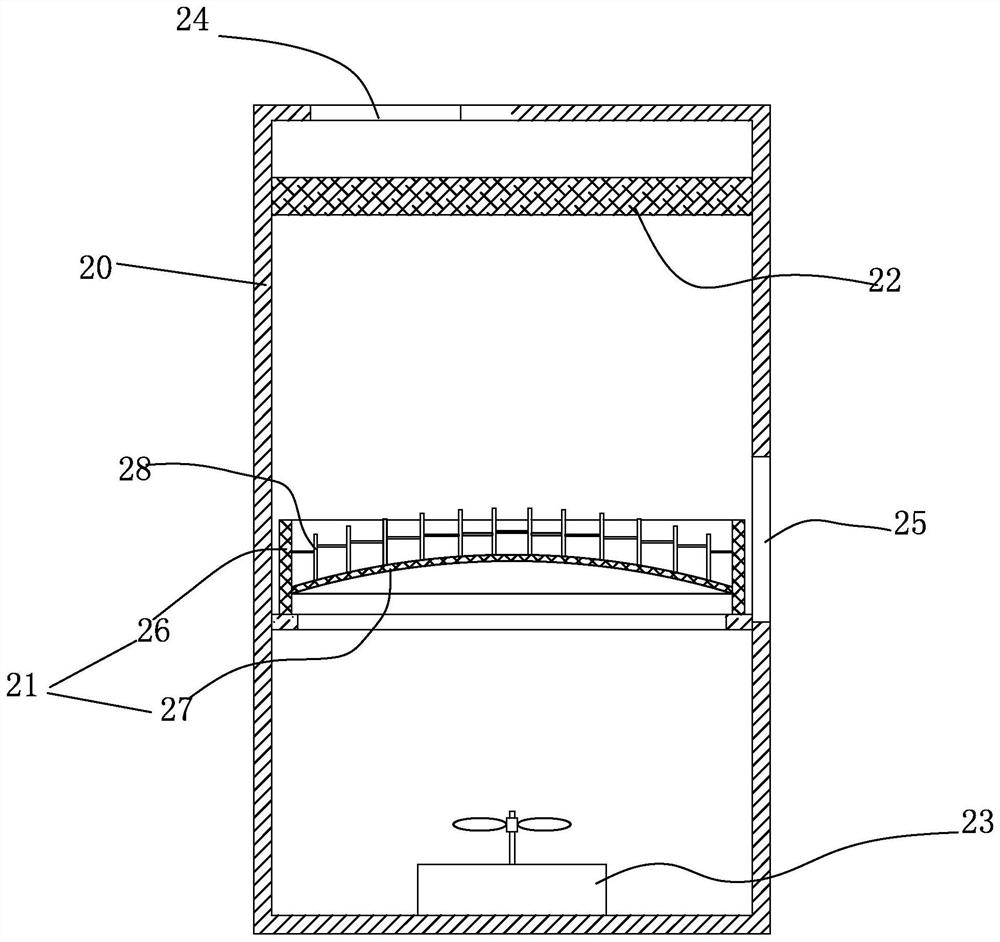

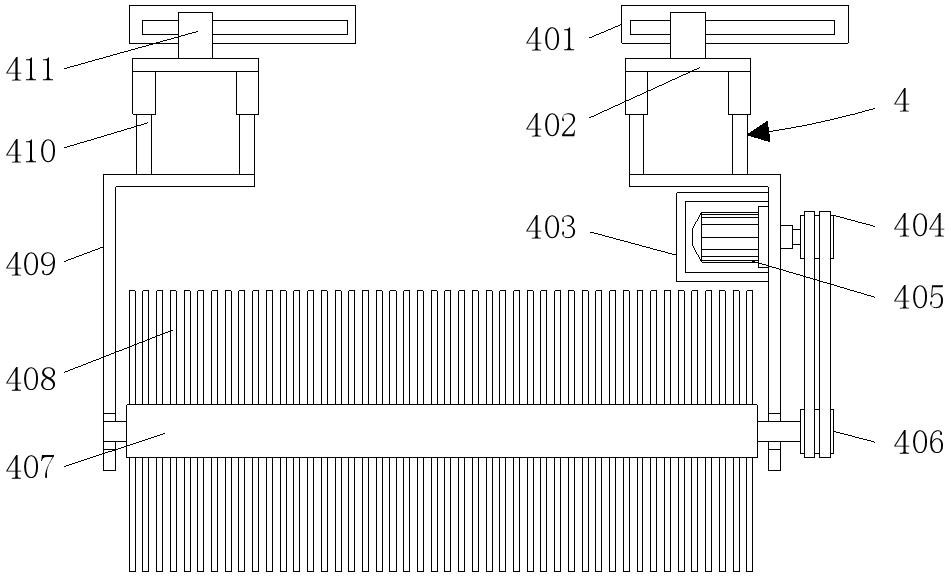

Rolling water-spray cocoon cooking machine

InactiveCN103451744ASpit water evenlyIncrease the areaSilk cocoons cleaning/classifyingSILK SERICINProcess engineering

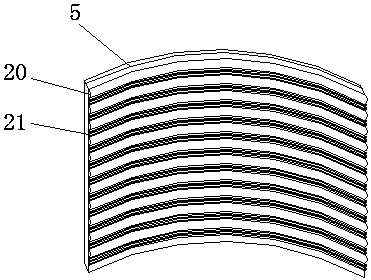

The invention discloses a rolling water-spray cocoon cooking machine comprising a conveyor belt used for conveying cocoon cages, and a housing enclosing the conveyor belt. The housing is provided with an inner cavity capable of accommodating materials. The housing includes a cocoon feed part, a preheating part, a cooking part, a regulating part and a cocoon discharge part sequentially along the conveying direction of the conveyor belt. The cooking part locates at one end of the conveyor belt. A cooking chamber encloses roll shafts at the ends of the conveyor belt. The cooking chamber includes an upper cooking chamber, a middle cooking chamber and a lower cooking chamber according to the end structure of the conveyor belt. The rolling water-spray cocoon cooking machine has the advantages that intra-layer and inter-layer sericin in cocoons can be swelled evenly and cleanliness of raw silk is improved.

Owner:SUZHOU UNIV

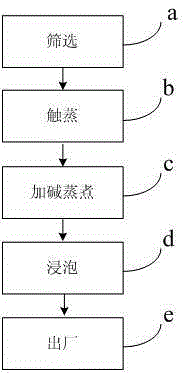

White steam filature production technology

InactiveCN105316774AIncrease elasticityImprove smoothnessSilk reelingSilk cocoons cleaning/classifyingEngineeringMechanical engineering

The invention relates to a white steam filature production technology. The technology includes the following steps that husks of dried cocoons are completely stripped through a cocoon stripping machine, unusable filature cocoons are removed through sorting and cleaning, yellow-spotted cocoons, decayed cocoons, inside-stained cocoons, cocoons pressed by cocooning frames and double cocoons are removed, and then good cocoons are metered; the quantitatively bagged cocoons are fed into a direct steaming process, wherein the direct steaming process comprises three stages, it is required to keep the pressure within 5-8 Mpa, the temperature within 70-90 DEG C and the time being 5 h at the first stage, it is required to keep the pressure within 8-10 Mpa, the temperature within 90-110 DEG C and the time being 12 h at the second stage, and it is required to keep the pressure within 5-8 Mpa, the temperature within 70-90 DEG C and the time being 6 h at the third stage; the outer layers of the cocoons are cooked thoroughly for more than half an hour through a vacuum infiltration cocoon cooking machine, and after the cocoons are cooked thoroughly, it is needed to add soap powder and a small amount of cleanser essence till the pH is measured to be 9.5-10 through pH test paper; the cocoons are placed in a stainless steel container and soaked in hydrogen peroxide for more than half an hour; delivery is performed.

Owner:HUZHOU DACHENG TEXTILE

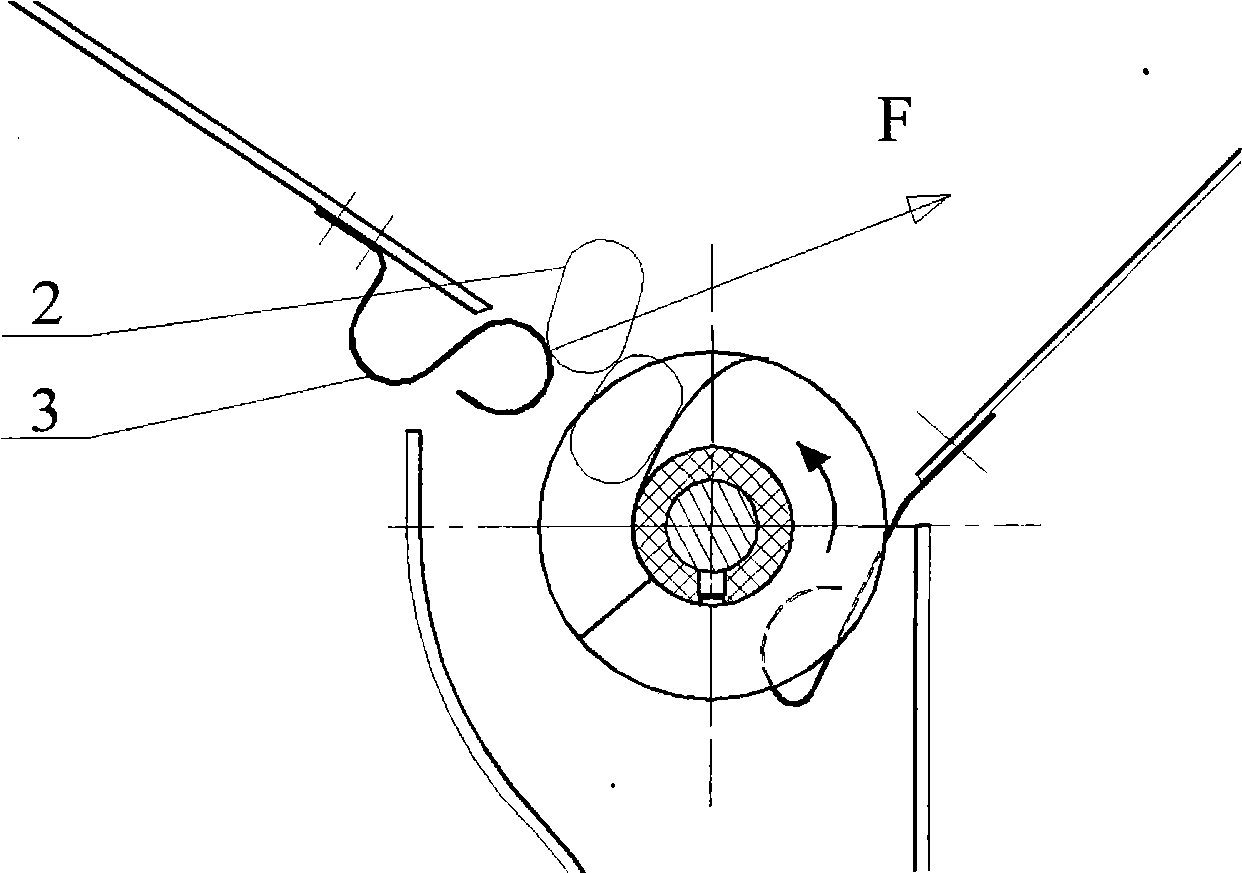

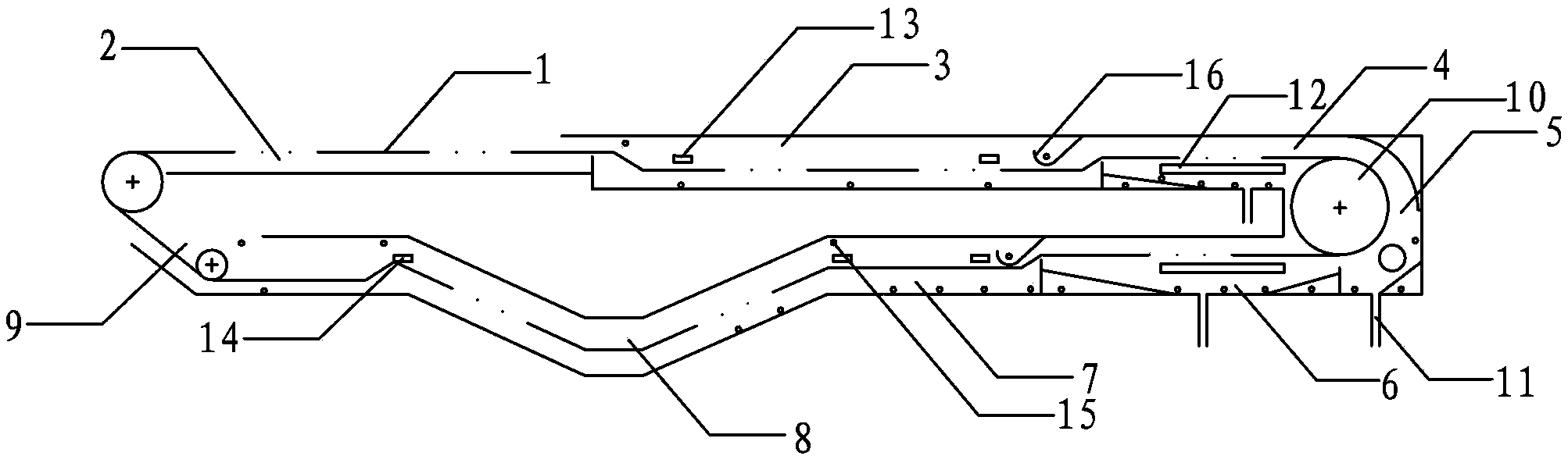

Slope vibrating separator

InactiveCN101838854AEasy to separateSimple structureSilk cocoons cleaning/classifyingState of artEngineering

The invention relates to a filature machine, in particular to a slope vibrating separator, which mainly solves the technical problems existing in the prior art that a separation mechanism realizes the separation of cocoons without end and thin shelled cocoons by using a wing wheel and a circular grid stick drum which rotate in different directions, the separation effect is not obvious and the like. The slope vibrating separator comprises a frame (1) and is characterized in that a downward inclined first vibrating plate (2) is arranged on the frame (1), a first cam (3) is arranged on the frame below the first vibrating plate, the first cam is connected with a driving device, a recycle bin (4) for recycling the thin shelled cocoons is arranged below the first vibrating plate, a delivery device (5) for delivering the cocoons without end is arranged at the front of the first vibrating plate, and a clearance (6) for dropping out the thin shelled cocoons is arranged at the front of the first vibrating plate.

Owner:HANGZHOU TIANFENG TEXTILE MACHINERY

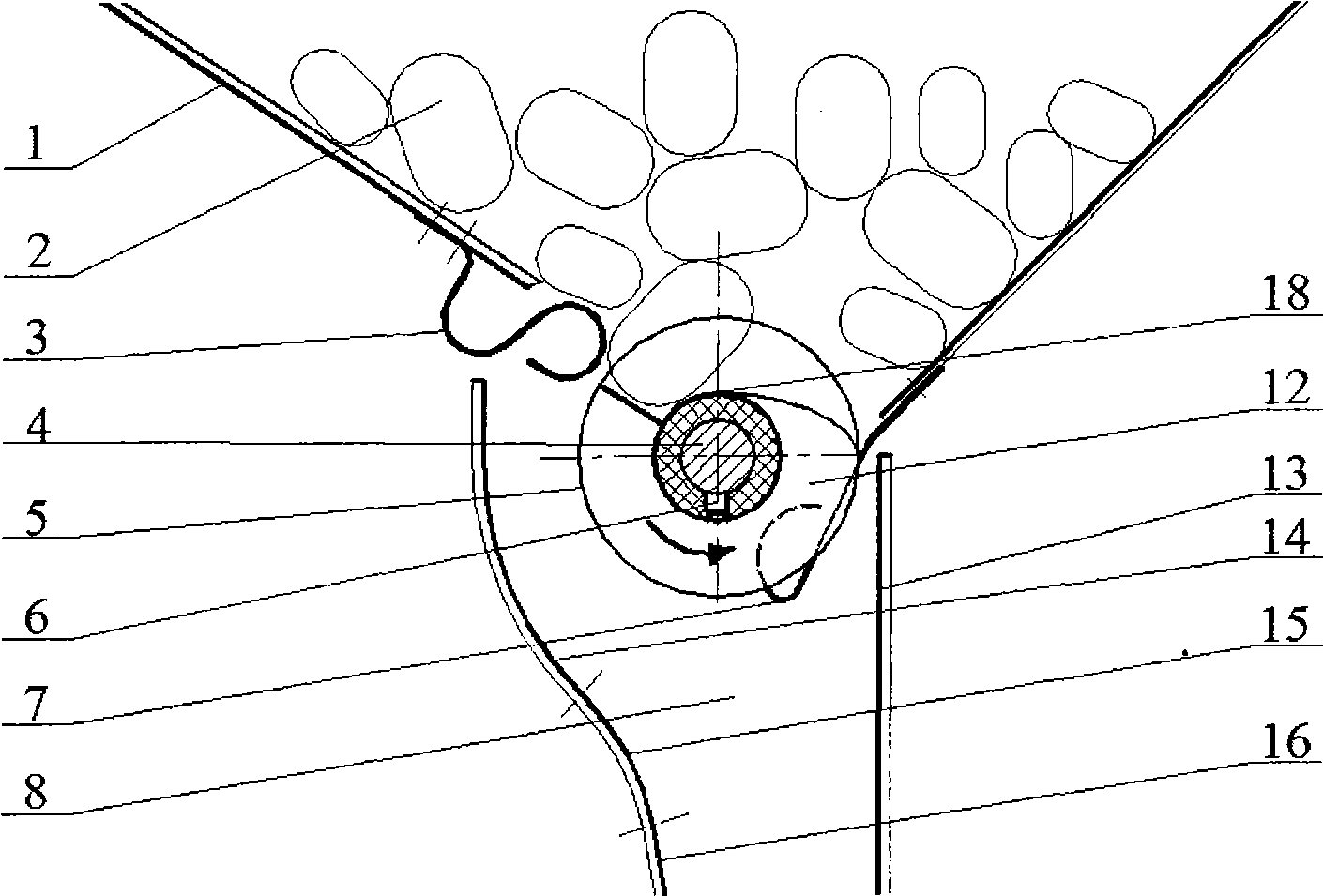

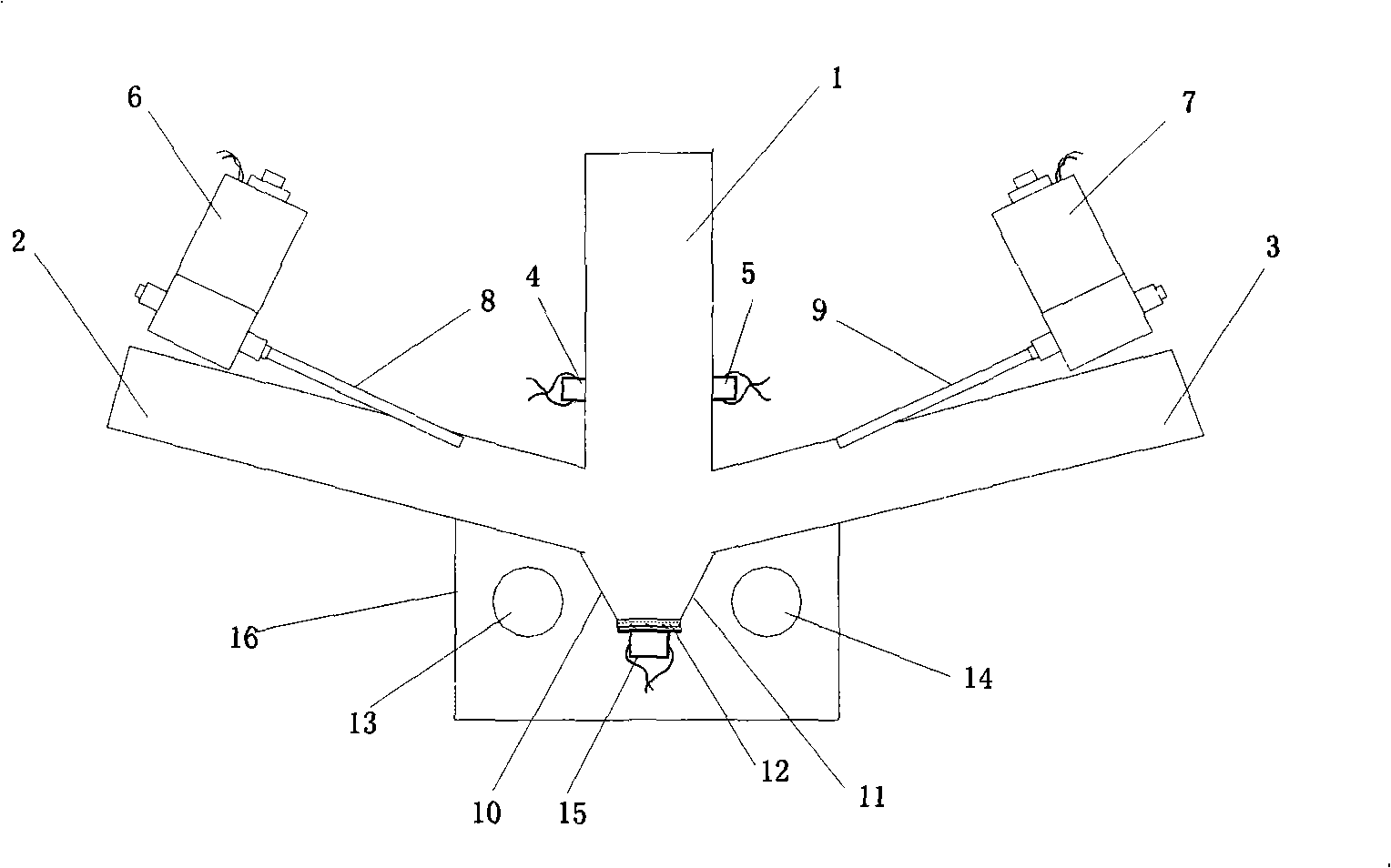

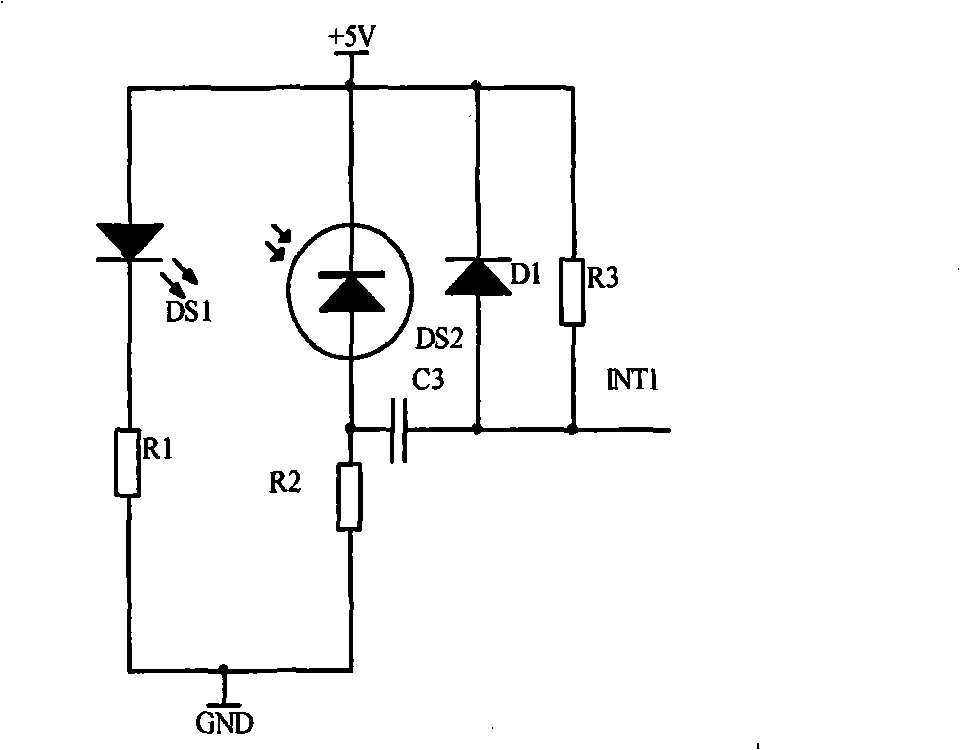

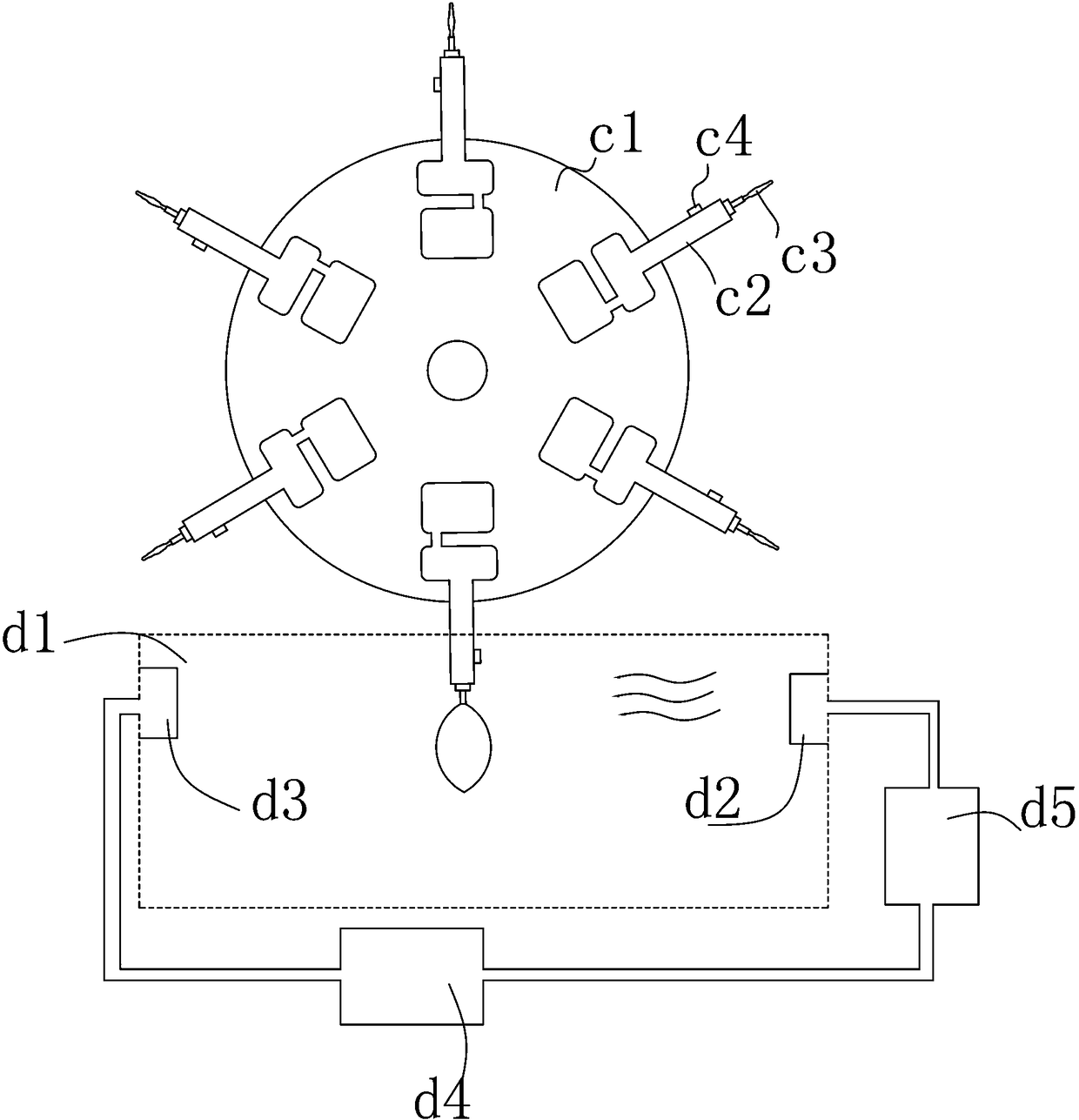

Automatic male and female sorting apparatus for cocoons judged by fluorescence color

InactiveCN101403142AImprove accuracyImprove efficiencySilk cocoons cleaning/classifyingFluorescence/phosphorescenceInlet channelFluorescence

The invention relates to an automatic male and female sorting device for judging sexes of cocoons by fluorescent color and belongs to the technical field of textile and silk producing. The device comprises a cocoon inlet channel and an adjusting and controlling circuit; the side wall of the cocoon inlet channel is provided with a light sensor, and the lower end of the cocoon inlet channel faces an activation cavity; the side wall of the activation cavity is provided with an ultraviolet filter, and the bottom of the activation cavity is provided with a yellow filter; the outer side of the ultraviolet filter is provided with an ultraviolet source, and a photosensitive element is arranged below the yellow filter; the two sides above the large end of the activation cavity form a cocoon outlet channel, the upper wall of the cocoon outlet channel is provided with an air pipe, and an air outlet of the air pipe faces the activation cavity; the output end of the light sensor is connected with the trigger end of the adjusting and controlling circuit, the output end of the photosensitive element is connected with the signal input end of the adjusting and controlling circuit, and two controlling and outputting ends of the adjusting and controlling circuit are respectively connected with two electromagnetic valves. According to scientific sorting principle, judging sexes of cocoons can be completed automatically with high accuracy and efficiency, thus creating conditions for ensuring sorting quality and reducing sorting cost and laying foundation for producing high-quality raw silk later.

Owner:JIANGSU SOHO INTERNATIONAL GROUP CORPORATION +1

Cocoon overturning, stripping and washing integrated machine with ditch groove

ActiveCN108728908AImprove efficiencyUniform thicknessSilk cocoons cleaning/classifyingAnimal husbandryPunchingMating

The invention discloses a cocoon overturning, stripping and a washing integrated machine with ditch groove, and comprises a transmission device for conveying silkworm cocoons, a punching device for perforating the silkworm cocoons, a tweeze taking out device for taking out the silkworm cocoons, an expansion device which is matched with the taking out device and expands the silkworm cocoons, a water washing device for washing the silkworm cocoons; after punching and taking, the overturning is realized through the mating of the expansion structure, and then is cleaned in a water pool after beingturned over, integrally finished with high efficiency; washing during the stretching process on the balloon sleeve, not only is the thickness of the opening even and is not easy to break while stretching, but also the water washing efficiency is high.

Owner:嘉兴市迅程信息技术有限公司

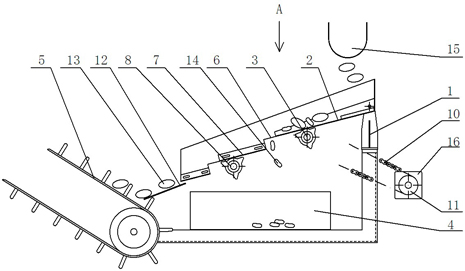

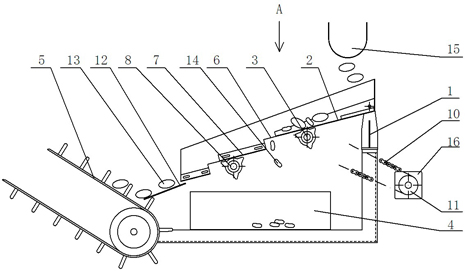

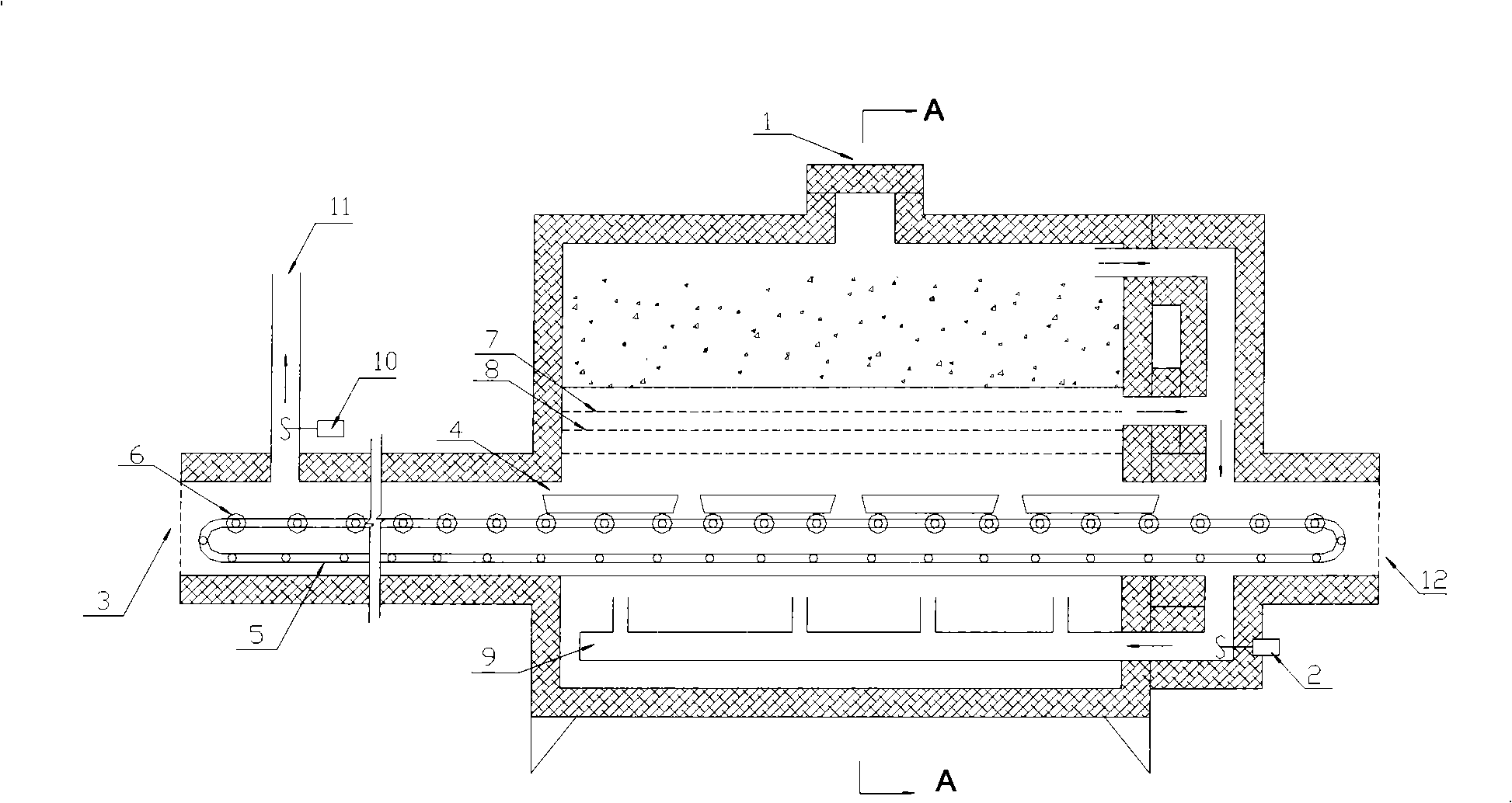

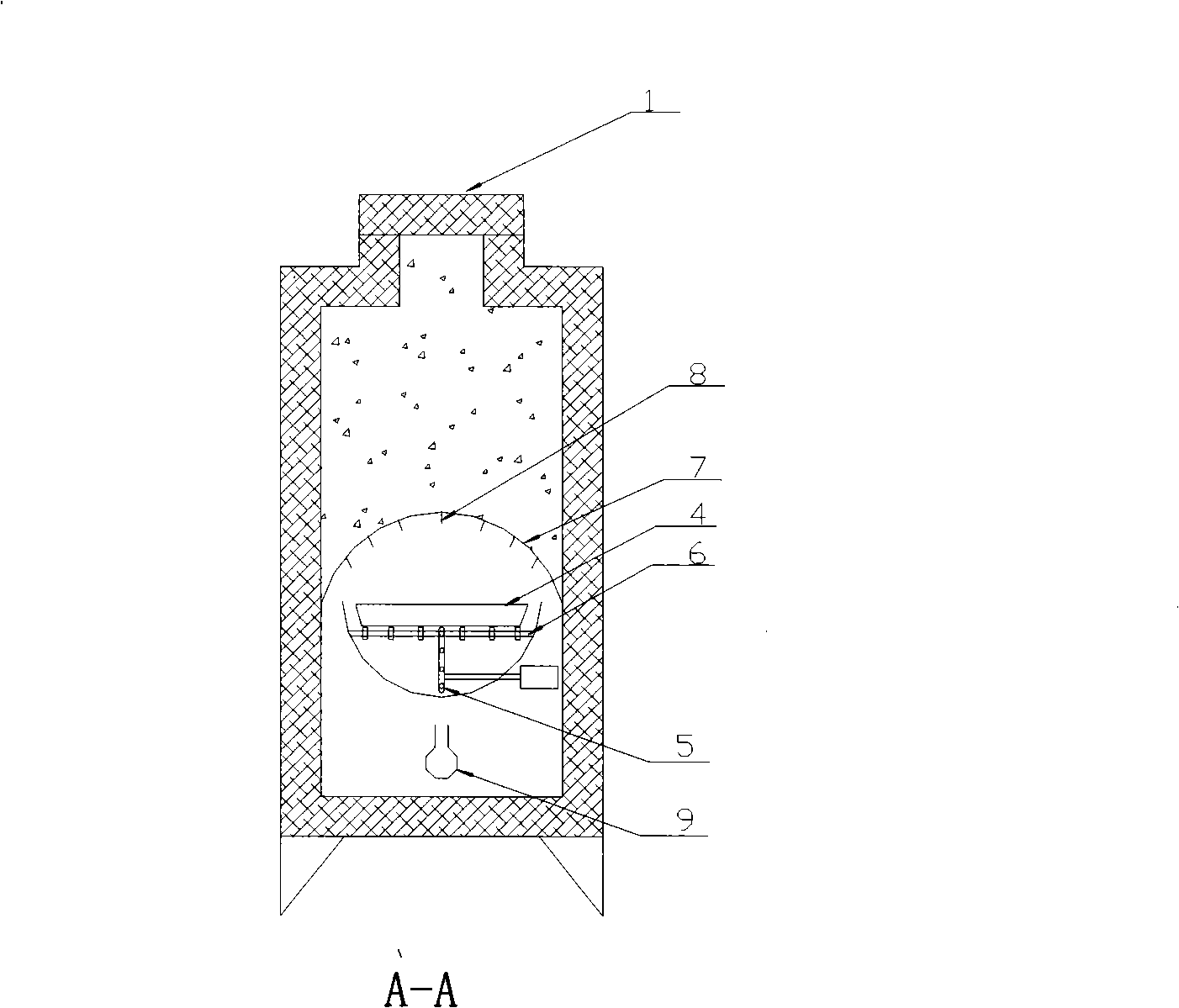

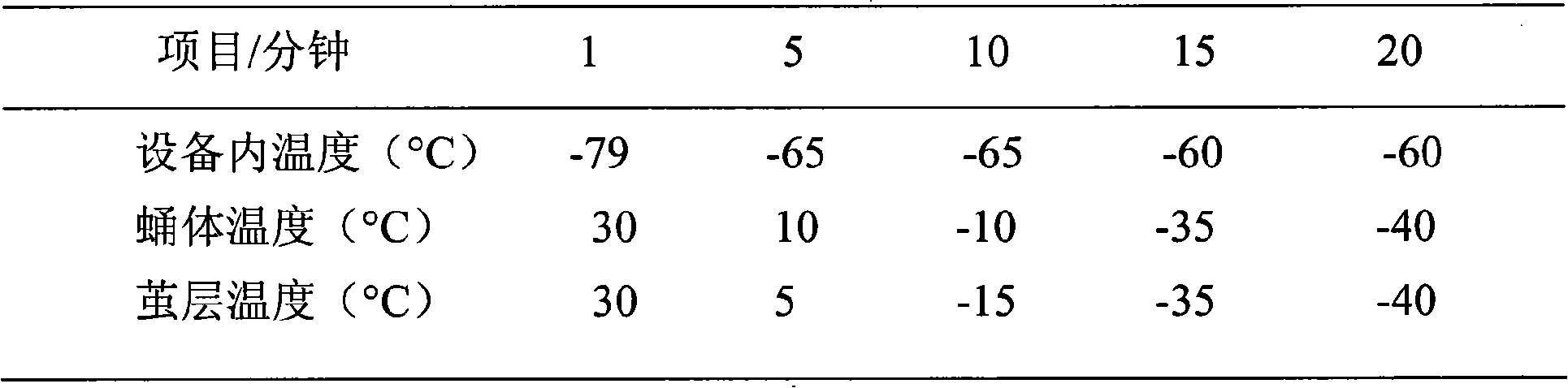

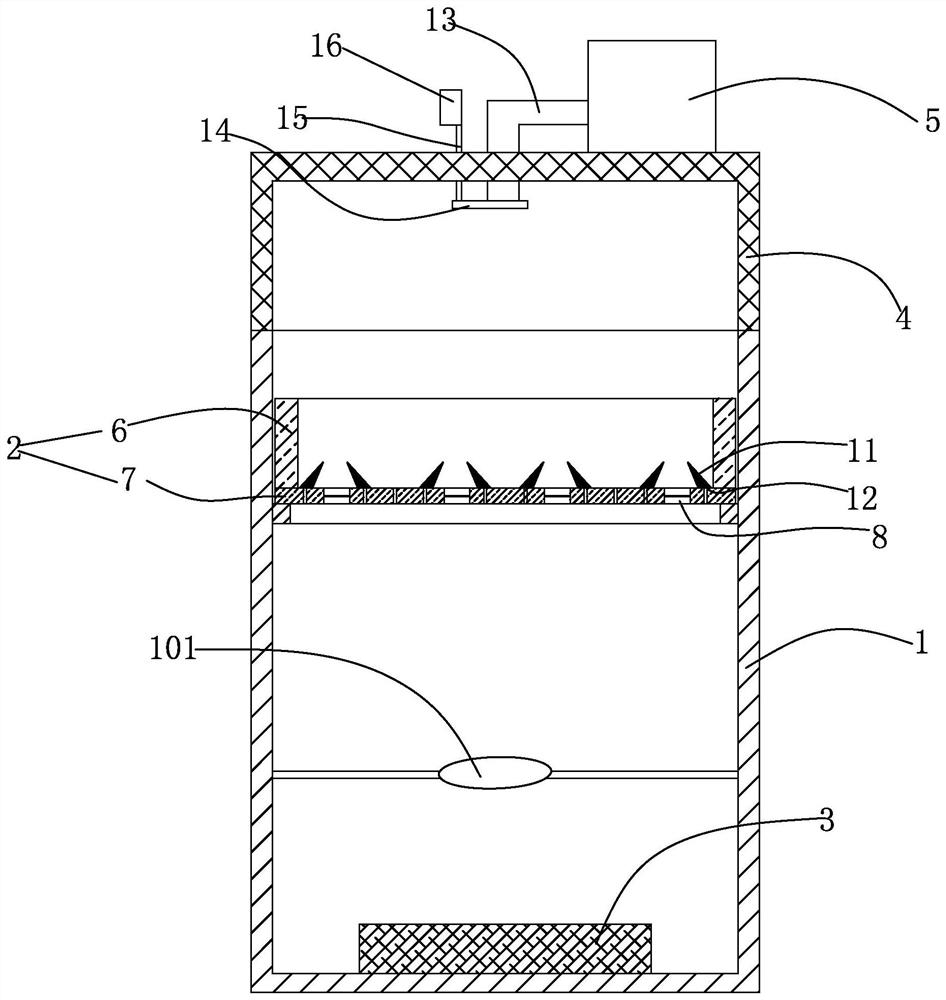

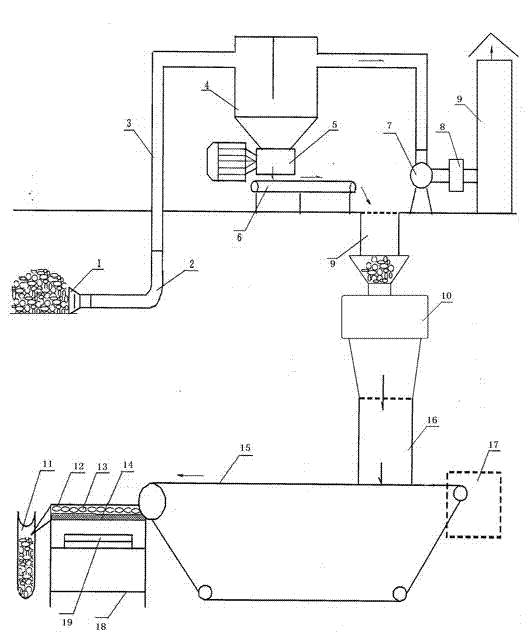

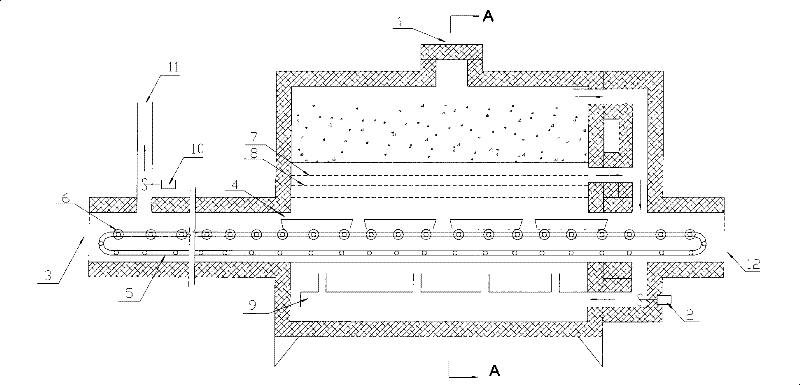

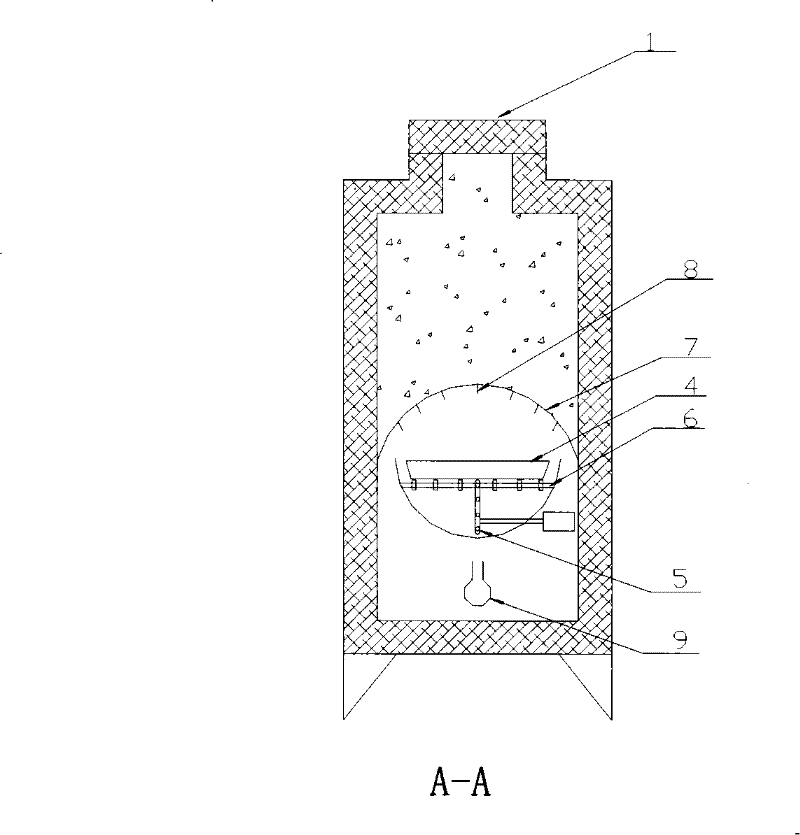

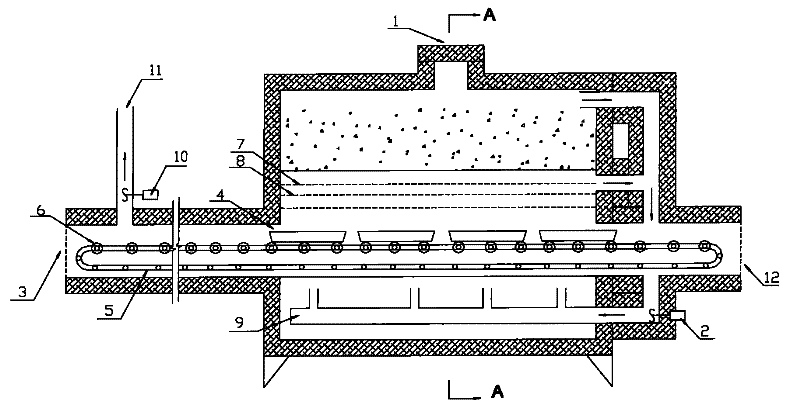

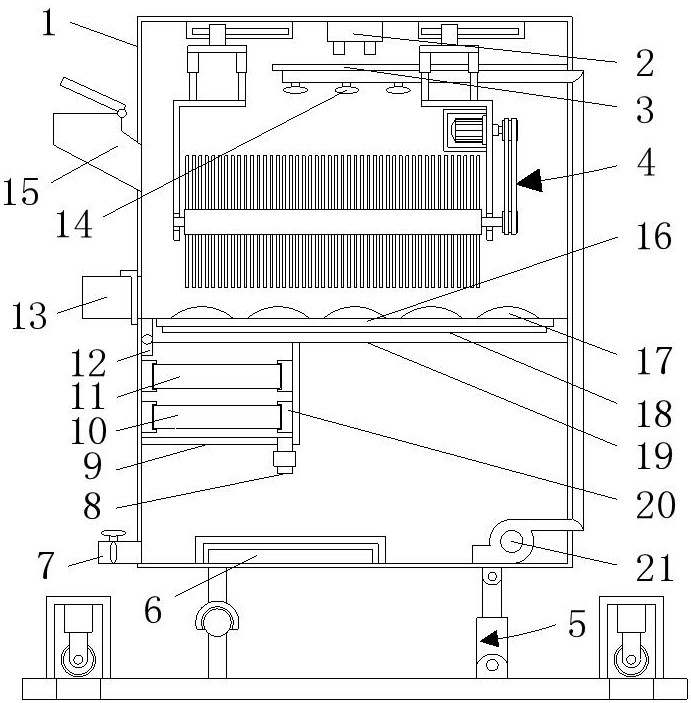

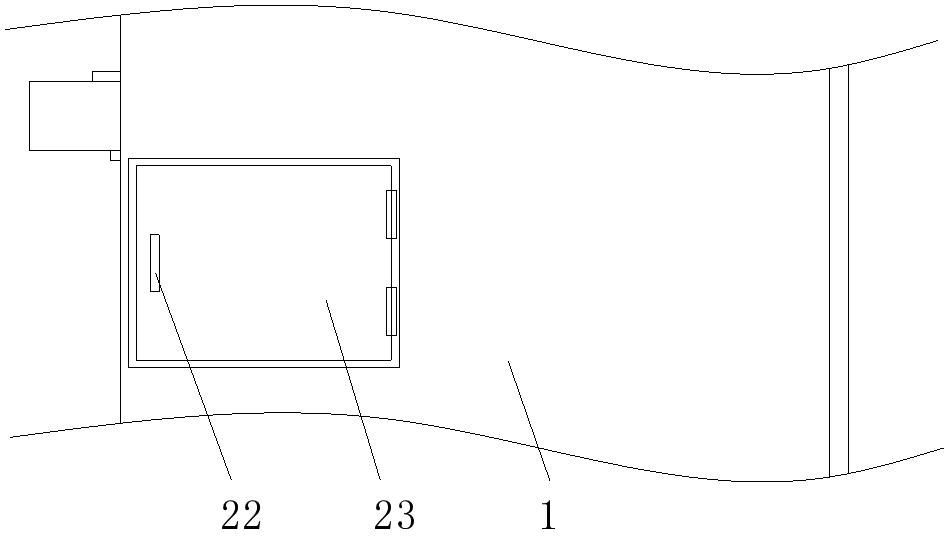

Method and equipment of cultivated silkworm fresh cocoon quick-freezing for cocoon suffocation

ActiveCN101328617ALittle impact on qualityImprove qualitySilk cocoons cleaning/classifyingDry iceNatural state

The invention provides a quick freezing pupa killing method for fresh silkworm cocoons, particularly comprising the following steps that: solid dry ice is taken as a cold source to absorb heat of the fresh silkworm cocoons, and simultaneously carbon dioxide obtained through sublimation of the dry ice is taken as the cold source to blow over the fresh silkworm cocoons and exchange heat with the fresh silkworm cocoons so as to make the temperature of the fresh silkworm cocoons reduced to below a given temperature and maintain for a period of time. The invention simultaneously provides a device for realizing the method, comprising an insulated cabinet body and an endless apron, wherein, a cold source cabinet body is arranged on the upper part of the insulated cabinet body, and the solid dry ice is arranged inside the cabinet body; the bottom of the cold source cabinet body is provided with a heat exchange plate; a cold blast pipe is arranged on the lower side of the endless apron, and an opening of the cold blast pipe faces to the endless apron; the cold blast pipe is communicated with the cold source cabinet body; and a fan is arranged on an inlet end of the cold blast pipe. By adoption of the method and the device, the pupa killing production cycle can be obviously shortened and the labor efficiency can be obviously improved; moreover, because pupae are killed at a low temperature, fresh cocoon shells and pupal cells maintain natural state, thereby the quality of the fresh cocoon shells and the pupal cells is slightly influenced and good-quality raw materials are provided for the silk reeling technique and deep-processing of fresh pupae.

Owner:广东省蚕业技术推广中心 +3

Manufacturing process of lavender silk quilt

ActiveCN112410890AKeep pureThe production process is green and pollution-freeBed linenSilk cocoons cleaning/classifyingBiotechnologyEngineering

The invention discloses a manufacturing process of a lavender silk quilt, and belongs to the field of textile processing. According to the manufacturing process of the lavender silk quilt, fishy smellof silkworm cocoons after processing is completed does not exist any more. The manufacturing process sequentially comprises the following steps of S1, cocoon selection, wherein double cocoons are manually selected, the selected double cocoons are dried into dry cocoons by using a drying device; S2, cocoon cooking, wherein the dried cocoons are placed into water at the temperature of 25-35 DEG C,baking soda accounting for 2% of the weight of the water is added into the water, and cooking is performed for 60 minutes to 75 minutes; S3, cocoon steaming, wherein the cooked cocoons are placed in apeculiar smell removing device to be steamed, and a lavender material bag is arranged in the peculiar smell removing device; S4, soaking, wherein the cooked cocoons are soaked in clear water and cleaned; S5, drawing, wherein loosening and lengthening are performed on the soaked cocoons to form a strip net shape; and S6, quilt making, wherein silk is laid, folded, kneaded and pressed in a criss-cross arrangement mode, and the silk quilt is made.

Owner:JIAXING SHAOSHI HOME TEXTILE CO LTD

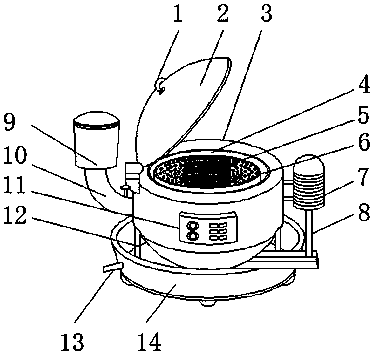

Deodorizing dewatering machine for silk processing

InactiveCN107557876AEasy to take outEasy to moveSilk cocoons cleaning/classifyingCentrifugationDrive shaft

The invention discloses a deodorizing and dehydrating machine for silk processing. The end is rotatably connected with a motor shaft, the motor shaft is rotatably connected with a fixed shaft through a driven shaft, a water outlet pipe is sleeved on one side of the chassis, and a heating hose is spirally connected to the bottom of the outer wall of the outer cylinder. The bottom end of the outer cylinder is provided with a drain pipe, the middle part of the drain pipe is clamped with a water stop valve, the inner wall of the inner cylinder is clamped with a hub plate, and the surface of the hub plate is provided with spacers and wires groove. The device of the invention uses the inner cylinder for centrifugal dehydration, and combined with the texture, the silk is centrifugally stuck in the wire groove, which is beneficial to the subsequent combing and threading, and the outer cylinder is used for heating with a heating hose to realize integrated boiling and deodorization inside, and the integration of deodorization and dehydration , reduce the circulation between processing procedures, and effectively reduce the consumption of manpower and material resources.

Owner:湖州宝成蚕业用品有限公司

Silkworm cocoon washing and air-drying device

InactiveCN106435749AWill not be damagedImprove cleaning efficiencySilk cocoons cleaning/classifyingElectric machineryEngineering

The invention relates to the field of silkworm cocoon washing equipment, and particularly relates to a silkworm cocoon washing and air-drying device. According to the technical scheme, the device comprises a washing tank and an air-drying tank, wherein the washing tank is provided with a washing drum, the washing drum is provided with a feeding hopper, the washing drum is provided with a bearing, the bearing is provided with a motor, the washing drum is provided with a stirring rod, the washing tank is provided with a water pipe, the water pipe is provided with a sprinkler head, the washing tank is connected with the air-drying tank, the air-drying tank is provided with a conveying belt, the air-drying tank is provided with an air pipe, the air pipe is provided with an air hole, the air-drying tank is provided with a collection hopper, and the air-drying tank is provided with a discharging opening. The silkworm cocoon washing and air-drying device makes up the defects in the prior art, and has the advantages of improving the silkworm cocoon washing efficiency, reducing the human resource waste, ensuring the silkworm cocoon quality and reducing the raw material waste.

Owner:六安市凯盛茧丝绢有限公司

Cocoon selection method before silkworm cocoon reeling silk

InactiveCN105154991AReduce labor intensityShort processSilk cocoons cleaning/classifyingEngineeringLight source

The invention discloses a cocoon selection method before silkworm cocoon reeling silk. The method comprises the following steps of (1) a vibrating sieving step, (2) a peeling cocoons step and (3) an optically selecting step, wherein in the first step, silkworm cocoons are placed on an inclined vibrating sieve and roughly sorted according to weights; silkworm cocoons under the sieve are collected; in the second step, waste silk outside the collected silkworm cocoons are peeled; the silkworm cocoons pass through light source; and qualified silkworm cocoons are collected according to light permeability. Three steps of vibrating screening, peeling and optical selection are employed to quickly achieve cocoon selection, so short operation technology process is achieved compared with a traditional way and labor intensity is reduced; and the method is simple and easy to operate.

Owner:RONGSHUI MIAO AUTONOMOUS COUNTY YULONG COCOON SILK

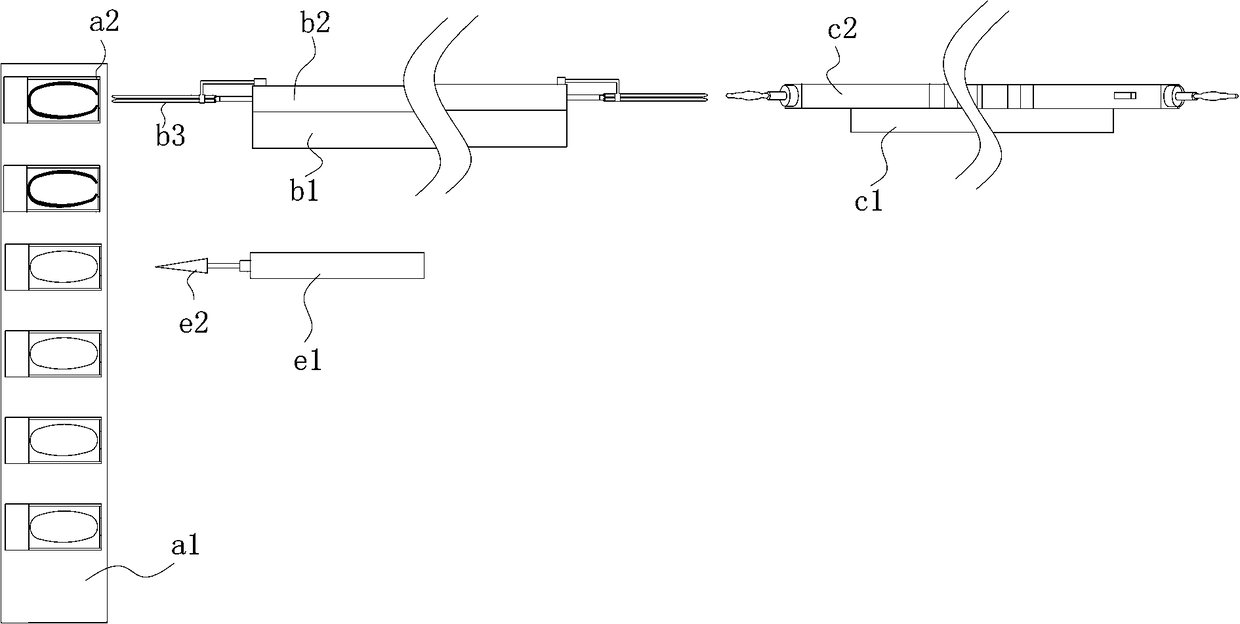

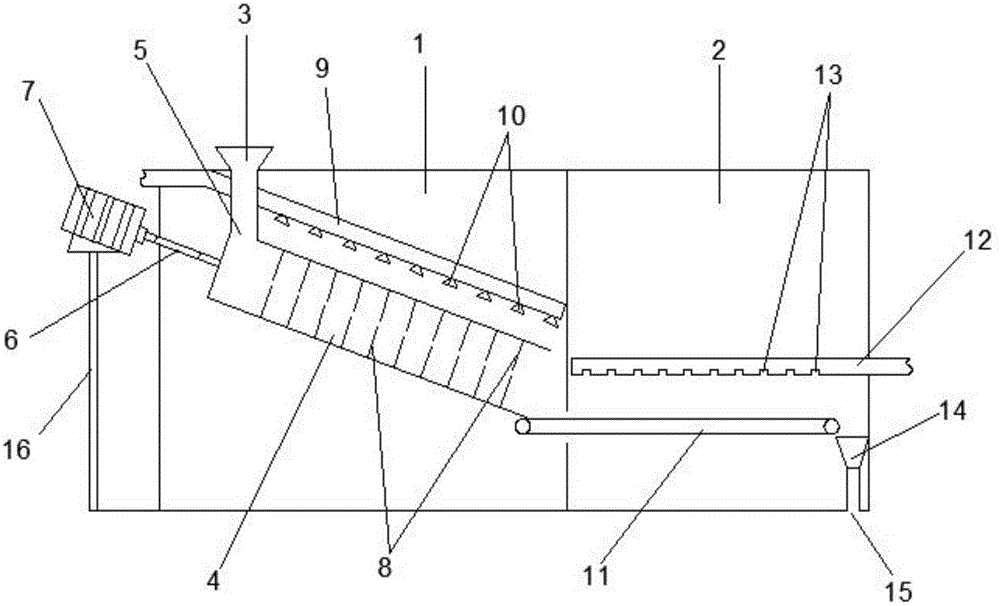

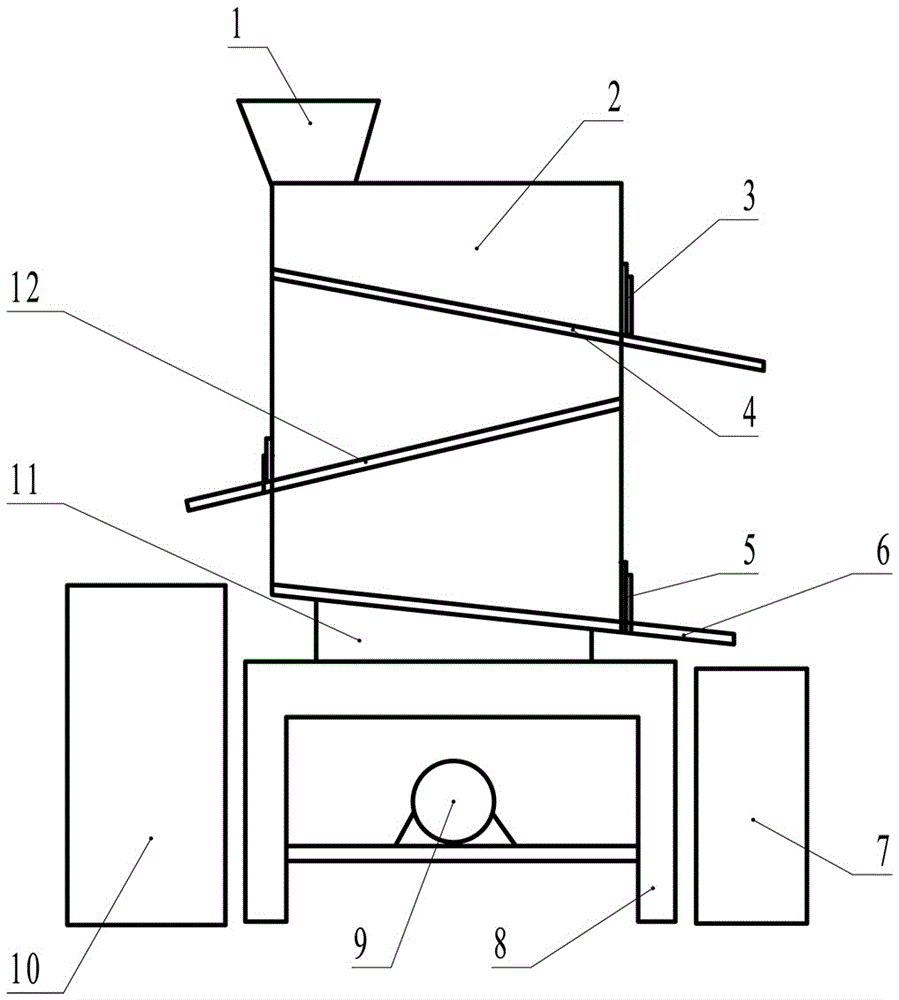

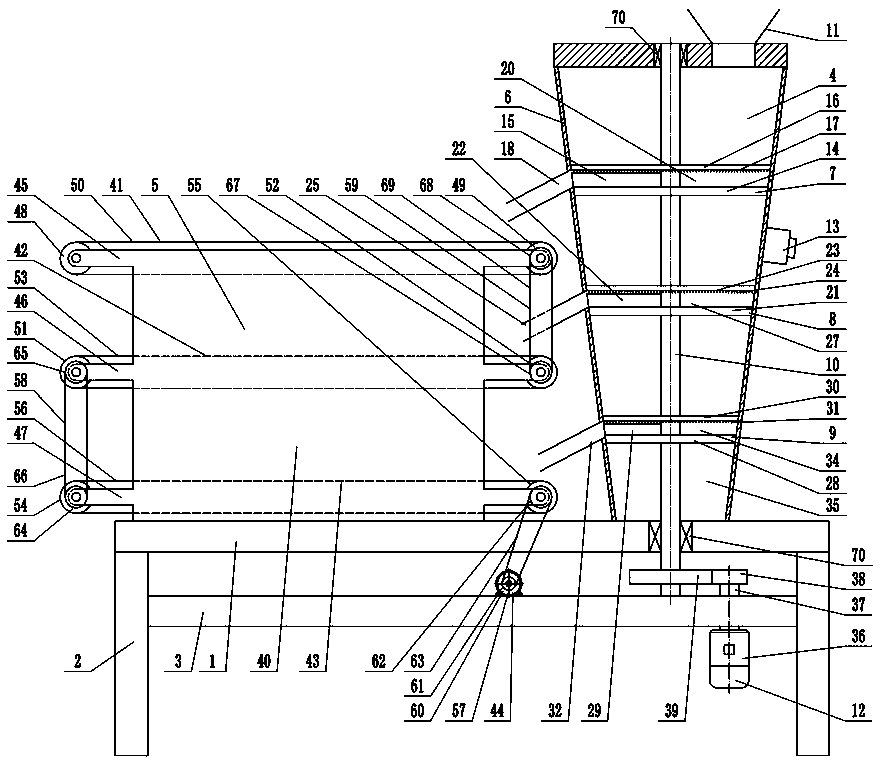

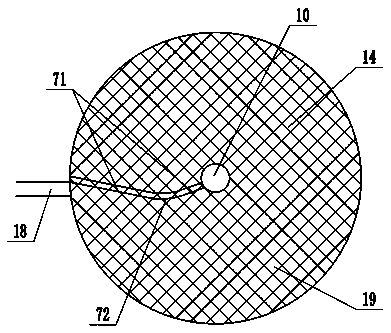

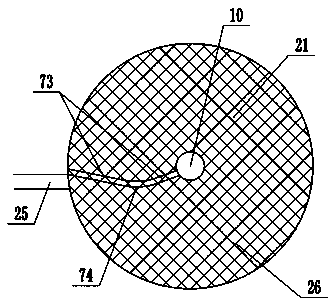

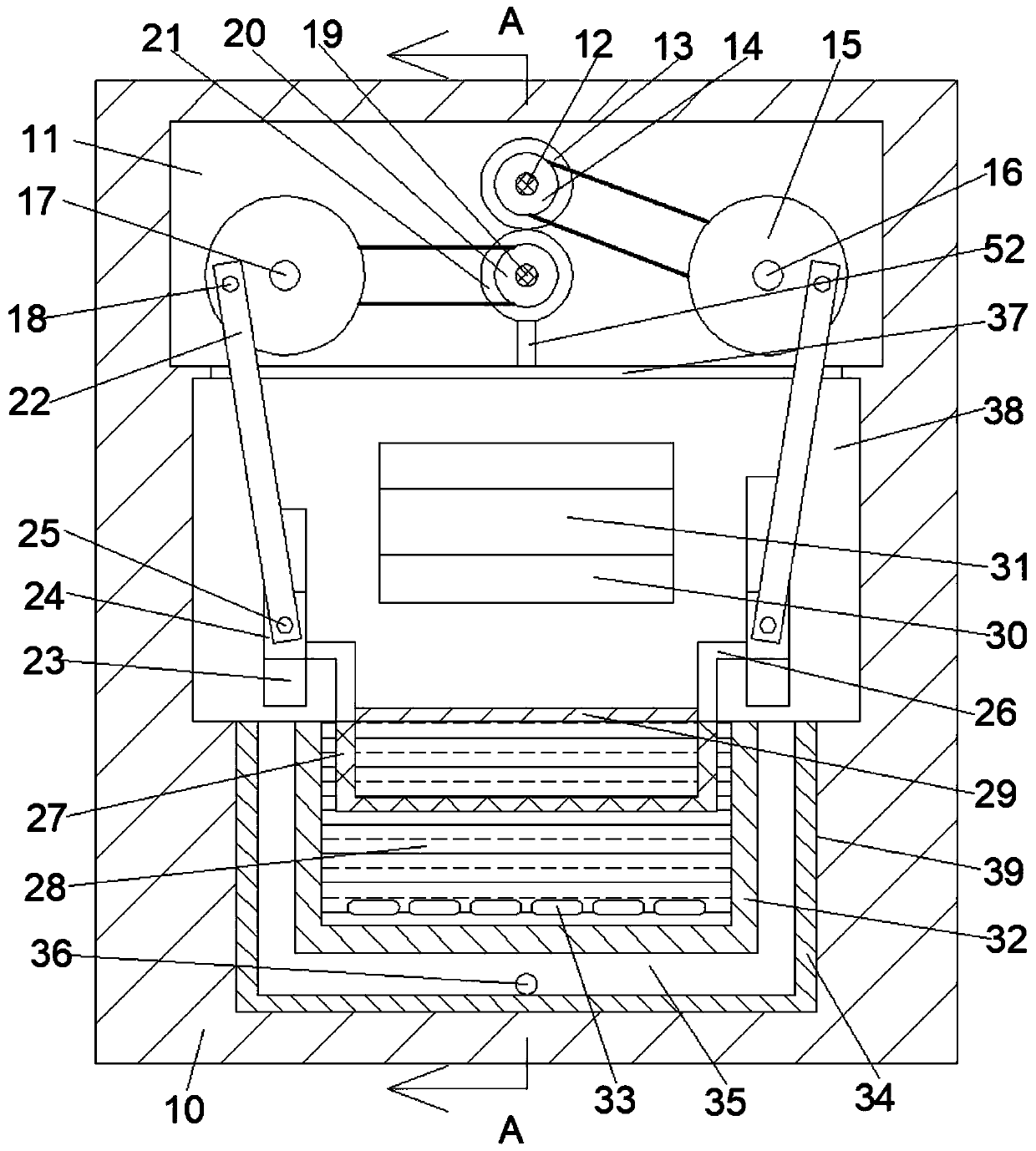

Method and device for selecting cocoon before reeling silkworm cocoon

ActiveCN102888660AReduce labor intensityGood ability to send cocoonsSilk cocoons cleaning/classifyingEngineeringWind power

The invention relates to a method and a device for selecting cocoons before reeling silkworm cocoons. The method is characterized by comprising the processes of sending cocoons by wind power, stripping cocoons and selecting cocoons under lights, and the device is characterized by comprising equipment for sending the cocoons by wind power, cocoon stripping equipment and cocoon selecting equipment under the lights, wherein the process of sending the cocoons by the wind power comprises that the purchased silkworm cocoons are sucked to a conveying pipe by virtue of a suction fan and the silkworm cocoons and dust are separated by virtue of an air sealing case; the process of stripping the cocoons process comprises that waste and disordered silks outside the silkworm cocoons are stripped and the dust in the cocoon stripping process is removed; and the process of selecting cocoon under the lights comprises that the silkworm cocoons which pass are observed through the surface of a transparent box body and good cocoons and light defective cocoons are selected under the condition of reflection of the lights. The cocoon selecting device provided by the invention is easy to operate, the quality of the silkworm cocoons which enter a reeling machine is guaranteed, the labor intensity of workers is lightened, and the dust can be sucked and discharged outside before the silkworm cocoons are stripped, so that the health of the workers is protected.

Owner:JIANGSU HUAJIA SILK +1

Cocoon cooking method capable of increasing cohesion times of fresh cocoon raw silk

InactiveCN107245762AImprove mechanical propertiesEfficient removalSilk cocoons cleaning/classifyingGamma rayEngineering

The invention belongs to the technical field of silkworm cocoon cooking, and in particular relates to a cocoon cooking method for increasing the cohesion times of fresh cocoons and raw silk, including sorting fresh cocoons, soaking in rice washing water, gamma ray irradiation, soaking in a cocoon cooking machine, cooking and adjusting several process. Compared with the prior art, the invention has the following advantages: by soaking the silkworm cocoons with rice-washing water, the stains on the surface of the silkworm cocoons can be effectively removed, and the surface of the silkworm cocoons can also be adsorbed while having a cleaning effect, and gamma rays are irradiated under the condition of negative pressure. , the peptide bond in the amorphous region in the cocoon is broken, the orientation of the cocoon molecules is reduced, and the water molecules can quickly enter the sericin molecules; in the dipping stage I and dipping stage II respectively, the corresponding aqueous solution enters the The gap between the sericin molecules weakens the intermolecular force, realizes the uniform softening of sericin, and at the same time enhances the mechanical properties of the raw silk.

Owner:HEFEI JUFENG THROWING

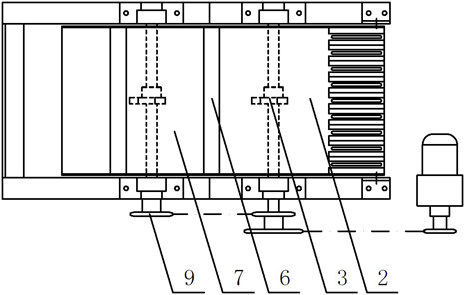

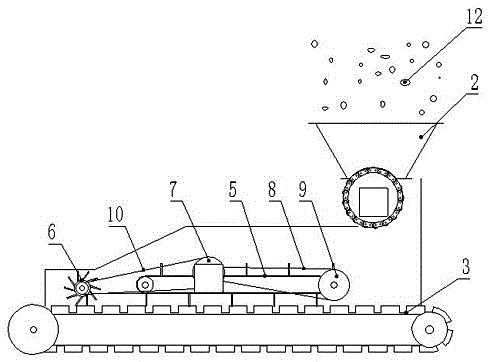

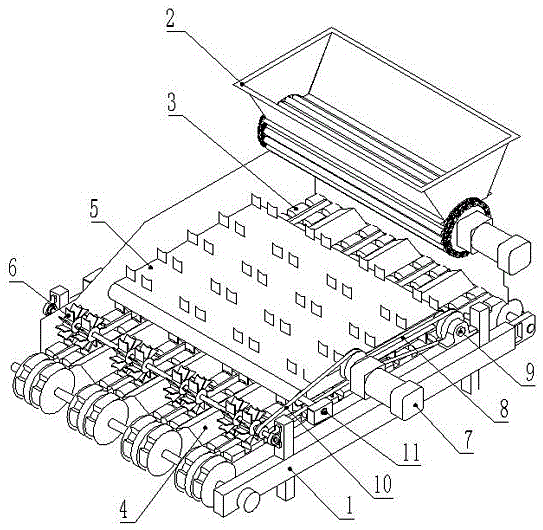

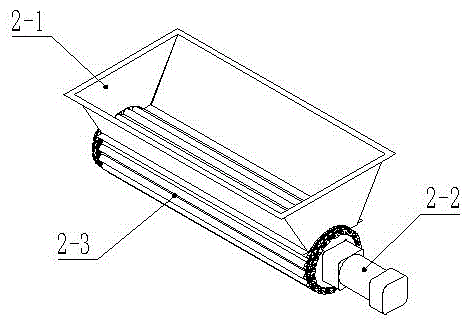

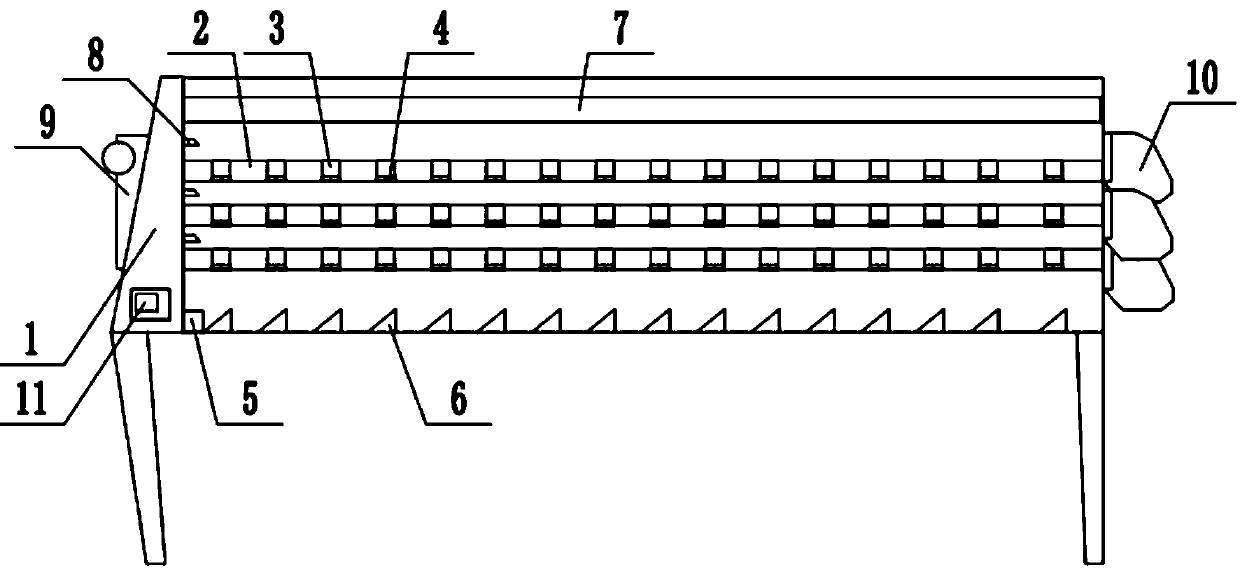

Silkworm cocoon separating method

The invention discloses a silkworm cocoon separating method and relates to the technical field of silkworm cocoon processing. The method comprises the steps that A, a first adjustable-speed motor and a second adjustable-speed motor are started; B, silkworm cocoons are placed in a discharging hopper and fall onto a conveyer belt through guide grooves of a discharging roller, the silkworm cocoons moving forward with the conveyer belt are scraped by scrapers on a lower separation scraper blade belt into a positioning groove of the conveyer belt, and the silkworm cocoons which are still on the surface of the conveyer belt after passing a separation scrape roller are scraped by shifting pieces on a rotary shaft of a rolling stripping roller into the positioning groove located on the back side; C, the silkworm cocoons in the positioning groove are separated one by one by the conveyer belt and delivered to the next procedure, so that silkworm cocoon separation is finished. Compared with the prior art, the method has the advantage that the problem that silkworm cocoons can not be separated orderly one by one can be solved.

Owner:LIUZHOU CHENGMING TECH CO LTD

Cocoon sorting machine

ActiveCN110644061AQuick checkAccurate detectionSilk cocoons cleaning/classifyingBeam splitterSoftware engineering

A cocoon sorting machine comprises a frame, cocoon sorting platforms, cocoon sorting slots, cocoon sorting slot retaining plates, a near-infrared light source, beam splitters, a receiver, high-pressure air nozzles, an air compressor, collection bags and a controller. By near-infrared spectroscopic analysis for cocoon shell weight detection, quick detection and accurate cocoon sorting are realizedthrough the near-infrared spectroscopic cocoon sorting machine. By adoption of the multiple beam splitters, each cocoon sorting platform can be completely covered by one light source, and accordinglycost saving is realized, and cocoon sorting efficiency is improved.

Owner:广西立盛茧丝绸有限公司

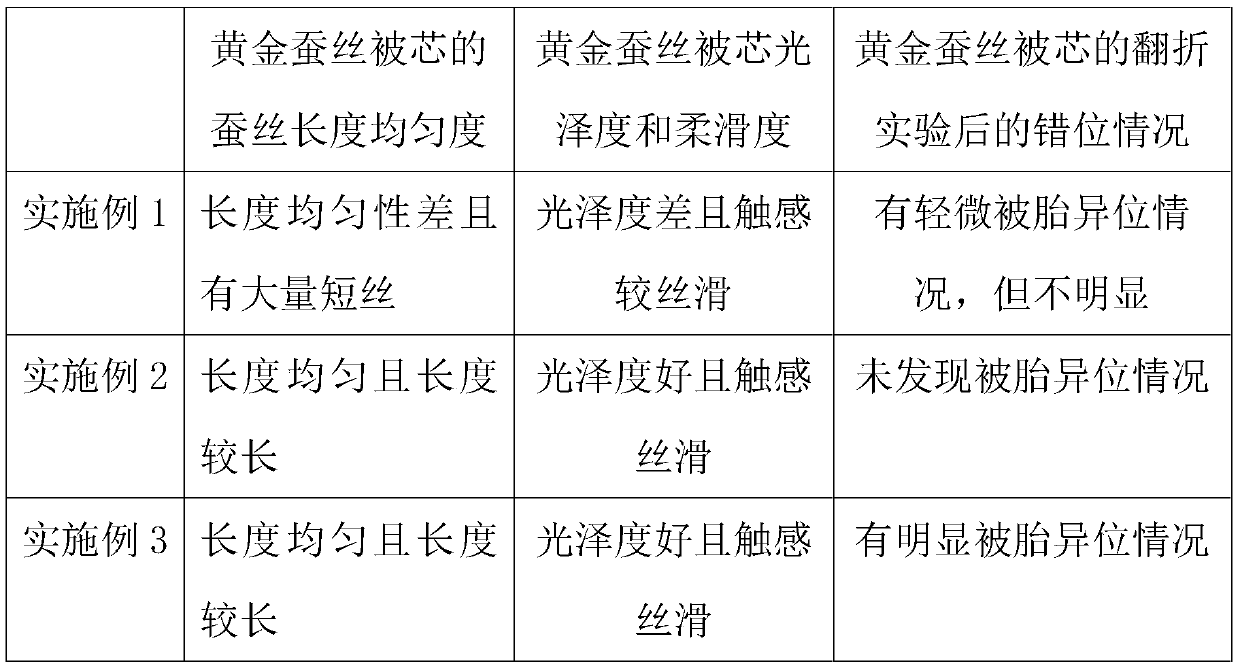

Making process of gold silk skin-nourishing quilt

InactiveCN110257924AFull penetrationAffect glossBed linenSilk cocoons cleaning/classifyingToughnessPermeation

Owner:江苏缔凡蚕丝科技创意园有限公司

Method and equipment of cultivated silkworm fresh cocoon quick-freezing for cocoon suffocation

ActiveCN101328617BLittle impact on qualityImprove qualitySilk cocoons cleaning/classifyingNatural stateDry ice

The invention provides a quick freezing pupa killing method for fresh silkworm cocoons, particularly comprising the following steps that: solid dry ice is taken as a cold source to absorb heat of the fresh silkworm cocoons, and simultaneously carbon dioxide obtained through sublimation of the dry ice is taken as the cold source to blow over the fresh silkworm cocoons and exchange heat with the fresh silkworm cocoons so as to make the temperature of the fresh silkworm cocoons reduced to below a given temperature and maintain for a period of time. The invention simultaneously provides a device for realizing the method, comprising an insulated cabinet body and an endless apron, wherein, a cold source cabinet body is arranged on the upper part of the insulated cabinet body, and the solid dry ice is arranged inside the cabinet body; the bottom of the cold source cabinet body is provided with a heat exchange plate; a cold blast pipe is arranged on the lower side of the endless apron, and anopening of the cold blast pipe faces to the endless apron; the cold blast pipe is communicated with the cold source cabinet body; and a fan is arranged on an inlet end of the cold blast pipe. By adoption of the method and the device, the pupa killing production cycle can be obviously shortened and the labor efficiency can be obviously improved; moreover, because pupae are killed at a low temperature, fresh cocoon shells and pupal cells maintain natural state, thereby the quality of the fresh cocoon shells and the pupal cells is slightly influenced and good-quality raw materials are provided for the silk reeling technique and deep-processing of fresh pupae.

Owner:广东省蚕业技术推广中心 +3

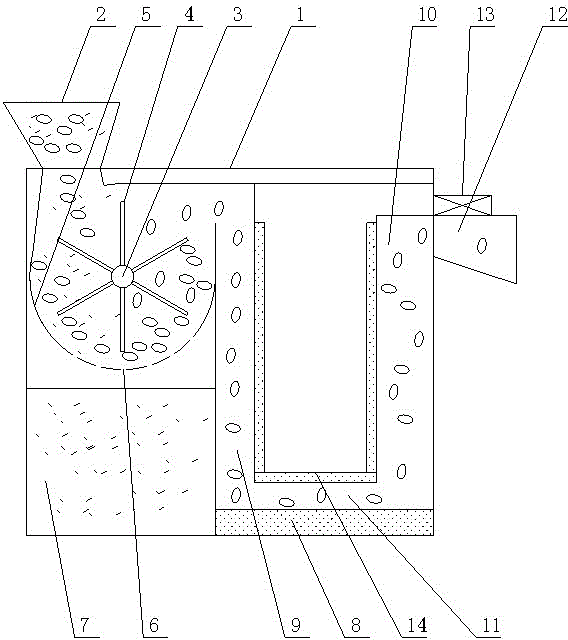

Silkworm cocoon purification and dehumidification equipment

InactiveCN104060332AImprove work efficiencyImprove the effect of impurity removalSilk cocoons cleaning/classifyingEngineeringImpurity

The invention discloses silkworm cocoon purification and dehumidification equipment which comprises a box body, wherein a silkworm cocoon inlet is formed in one side of the top of the box body; a diversion and purification component and a dehumidification channel are arranged in the box body; the diversion and purification component comprises a diversion purification roller, a plug flow plate and an external circular guide plate; the diversion purification roller drives the plug flow plate arranged in the external circular guide plate to rotate anticlockwise; the top of the external circular guide plate is connected with the silkworm cocoon inlet; an impurity outlet is formed in the bottom of the external circular guide plate; one side, far away from the silkworm cocoon inlet end, of the external circular guide plate, is connected with the dehumidification channel; a heating element is arranged at the bottom of the dehumidification channel; the dehumidification channel comprises a descending channel and an ascending channel; the top of the descending channel is connected with the external circular guide plate, and the bottom thereof is connected with that of the ascending channel; the top of the ascending channel is connected with a silkworm cocoon outlet; an induced draft fan is arranged on the silkworm cocoon outlet. The silkworm cocoon purification and dehumidification equipment has the following advantages: manual operation is replaced by machinery, so that the working efficiency is improved, the purification efficiency is high, labor force is reduced, and large-scale production can be affected.

Owner:杜银生

Silkworm cocoon sorting device

InactiveCN106435750ADeal with big damageSolve efficiency problemsSilk cocoons cleaning/classifyingEngineeringSieve

The invention discloses a silkworm cocoon sorting device which relates to the technical field of silkworm. The silkworm cocoon sorting device comprises a frame on which a vibrator with a vibrating box is mounted on the frame, the vibrator is driven by a motor provided on a frame chassis, the upper part of the vibrating box is provided with a hopper, a bottom board at the bottom of the vibrating box is arranged obliquely, and a large hole sieve plate and a small hole sieve plate are arranged obliquely from the top to the bottom of the vibrating box; a large cocoon discharge port is provided at the intersection position of the large hole sieve plate and the vibrating box, a qualified-size cocoon discharge outlet is arranged at the joint of the small hole sieve plate and the vibrating box, and a small cocoon discharge outlet is arranged at the bottom of the vibrating box. The large hole sieve plate and the small hole sieve plate form 15 to 30-degree included angle with the bottom plate and the horizontal level. The silkworm cocoon sorting device can solve the existing problem that high labor intensity of manual cocoon sorting can easily cause visual fatigue and have great harm to eyes of workers, and the problem of low efficiency.

Owner:广西环江意桐茧丝绸有限公司

Silk solidifying and degumming process

InactiveCN110387586APhenomenon that will not hardenHigh glossSilk cocoons cleaning/classifyingLiquid/gas/vapor removal by centrifugal forceEngineeringSericin

The invention discloses a silk solidifying and degumming process. The silk solidifying and degumming process comprises the steps as follows: (1) impurity removal of silkworm cocoons: impurity removalis performed by use of a silkworm cocoon shaker in combination with artificial selection; (2) scutching: silk floss sheets are prepared from silkworm cocoons after impurity removal, and the content ofsericin is determined for each batch of silk floss sheets; (3) degumming: the silk floss sheets are placed in a degumming treatment solution containing hydrogen peroxide, textile soap and sodium silicate; (4) sericin fixation: the silk floss sheets are placed in a sericin treatment solution containing a sericin fixing refining agent, a softening agent and tartaric acid; (5) cleaning: the silk floss sheets are cleaned with clear water and centrifugal dewatering is performed. The silk solidifying and degumming process can degum most sericin, so that part of sericin exists on the outer side of fibroin in the silk floss sheets, has a certain antibacterial function and cannot harden due to long-term use. Besides, the silk floss sheets contain the sericin and thus have good gloss and have a skin nourishing effect after long-term use.

Owner:ZHEJIANG CANYUAN HOME TEXTILE

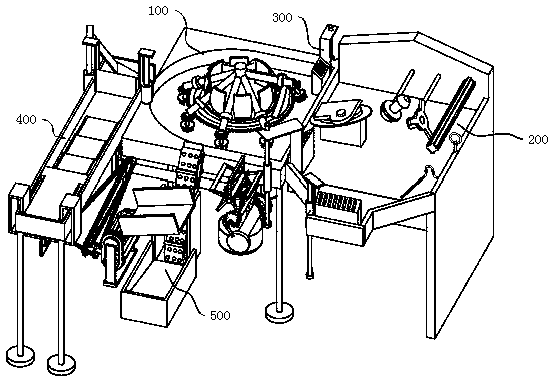

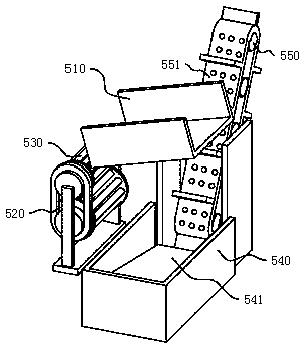

Pupa and cocoon separation recycling method

ActiveCN111593415AMeet the needs of modern productionNo manual operationSilk reelingSilk cocoons cleaning/classifyingProcess engineeringIndustrial engineering

The invention relates to a pupa and cocoon separation recycling method. The method comprises the following steps that silkworm pupas and silkworm cocoons conveyed out of a reeling machine are separated; and the separated silkworm pupas and silkworm cocoons are fed into an end groping apparatus to be subjected to end groping. According to the pupa and cocoon separation recycling method, manual operation is not needed, time and labor are saved, the separation recycling efficiency is high, the speed is uniform, and factory modern production needs can be well met.

Owner:岳西十行机械设备有限公司

Manufacturing process of skin-friendly silk quilt and silk quilt

InactiveCN111139538AGood skin affinityHas antibacterial propertiesBlanketBed linenPolymer scienceEngineering

The invention discloses a manufacturing process of a skin-friendly silk quilt and the silk quilt and relates to the field of home textiles. The manufacturing process comprises the following steps of manufacturing of ecological mulberry silk, manufacturing of a mulberry silk quilt smooth core and manufacturing of the silk quilt, wherein the manufacturing process of the silk quilt comprises the steps of firstly adding a layer of anti-silk-running gauze on each of the upper surface and the lower surface of the mulberry silk quilt smooth core to avoid silk running, then selecting a quilt cover made of brocade manufactured by using the ecological pure mulberry silk, finally sleeving the mulberry silk quilt smooth core into the selected quilt cover, and performing manual positioning, specifically, sewing edges first and then performing positioning by adopting a nine-needle or 12-needle positioning method. The skin-friendly ecological pure mulberry silk quilt is the silk quilt made by adopting the manufacturing process. The silk quilt has the advantages of being good in skin-friendly performance, antibacterial and antiallergic, capable of preventing skin diseases such as pruritus, and very beneficial to skin health.

Owner:何银春

Efficient silkworm cocoon cleaning device for spinning

InactiveCN113201795ATo achieve the effect of cleaningEasy to cleanWater/sewage treatment by irradiationSpecific water treatment objectivesSpinningPlasma generator

The invention discloses an efficient silkworm cocoon cleaning device for spinning. The device comprises a shell; a plasma generator is fixedly installed at the middle end of the top of an inner cavity of the shell; a cleaning mechanism is arranged at the top of the inner cavity of the shell; the cleaning mechanism comprises a sliding base, a first supporting plate, a first belt disc, a motor, a second belt disc, a cleaning roller, a cleaning brush, a second supporting plate, a first electric telescopic rod and a slider; the lower end of the inner cavity of the shell is fixedly connected with a second partition plate provided with protrusions and heating plates at the top in a staggered mode; the left end of the bottom of the second partition plate is fixedly connected with a first partition plate; the inner side of the first partition plate is fixedly connected with two groups of clamping seats; and the inner surfaces of the two groups of clamping seats are in clamped connection with a CPP composite filter element and a KDF filter layer respectively. According to the silkworm cocoon cleaning device, the cleaning mechanism, the second partition plate, the protrusions, the heating plates and the plasma generator are arranged, so that the silkworm cocoon cleaning effect of the device is effectively improved, and great use convenience is brought to people.

Owner:苏州市诚双纺织厂

Method for rinsing and decontaminating green cocoons

ActiveCN106637427AGuaranteed water absorptionFully absorbedSilk cocoons cleaning/classifyingComputer scienceStain

The invention discloses a method for rinsing and decontaminating green cocoons and relates to the technical field of silkworm cocoon processing. The method comprises the following steps: A, selecting cocoons; B, classifying; C, performing primary vibration; D, performing primary baking; E, performing secondary vibration; F, soaking; G, cleaning and performing secondary baking. Compared with the prior art, the method for rinsing and decontaminating green cocoons provided by the invention has the advantage that stains of the green cocoons can be completely cleaned.

Owner:广西江缘茧丝绸有限公司

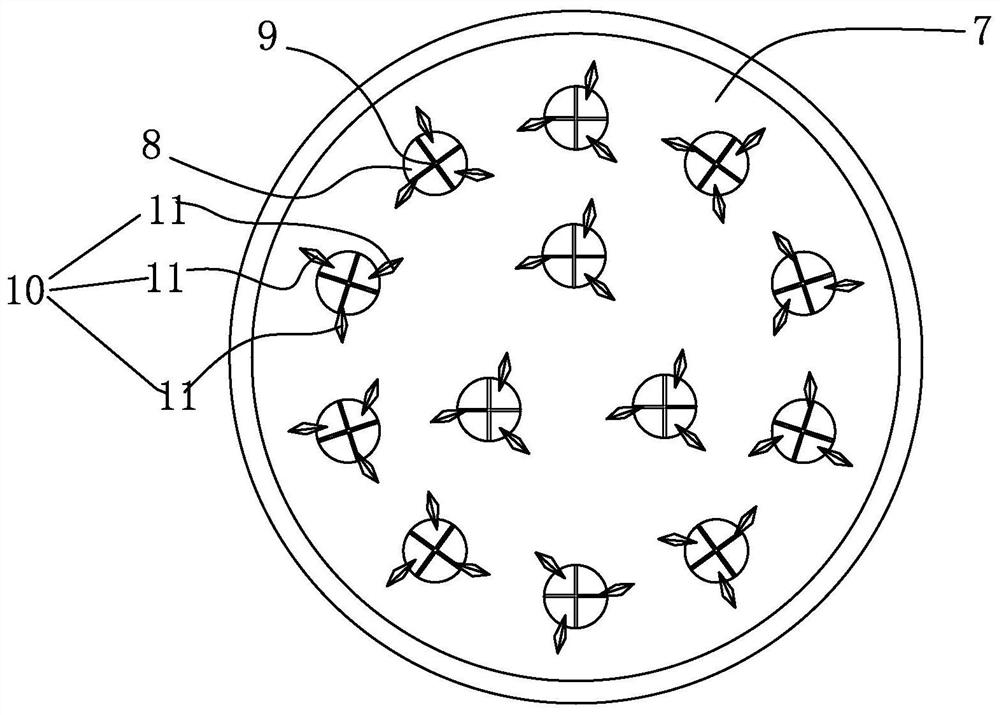

Cocoon stripper with screening function

PendingCN109881263AReduce wearHigh degree of engagementSilk cocoons cleaning/classifyingEngineeringControl theory

The invention provides a cocoon stripper with a screening function and belongs to the technical field of cocoon processing equipment. The cocoon stripper comprises a screening and cocoon stripping device and a screening and conveying device, wherein a first screening and cocoon stripping mechanism, a second screening and cocoon stripping mechanism and a third screening and cocoon stripping mechanism of the screening and cocoon stripping device are sequentially arranged in a cocoon feeding hopper from top to bottom; a first screening and cocoon stripping cavity is formed between a first cross-shaped cocoon stripping frame and a first screening disc of the first screening and cocoon stripping mechanism, a second screening and cocoon stripping cavity is formed between a second cross-shaped cocoon stripping frame and a first screening disc of the first screening and cocoon stripping mechanism, and a third screening and cocoon stripping cavity is formed between a third cross-shaped cocoon stripping frame and a third screening disc of the third screening and cocoon stripping mechanism, a collecting cavity is formed below the third screening disc, and the screening and conveying device comprises a first screening and conveying mechanism, a second screening and conveying mechanism, a third screening and conveying mechanism and a screening and conveying driving mechanism. The cocoon stripper not only can screen silkworm cocoons, but also can strip cocoon coats on the silkworm cocoons.

Owner:桐乡市腾飞家纺股份有限公司

Cleaning device for silkworm cocoons

ActiveCN110195262AQuality improvementIncrease profitSilk cocoons cleaning/classifyingTransmitted powerEngineering

The invention provides a cleaning device for silkworm cocoons. The device comprises a machine body, wherein a power chamber is fixed in the machine body, a power device is fixed in the power chamber,a soaking and filtering chamber is fixed in the inner wall of the lower side of the power chamber, a connecting rod hole is in communication with the portion between the soaking and filtering chamberand the power chamber, so that convenience is provided for the power device to transmit power into the soaking and filtering chamber, and a silkworm cocoon soaking device is fixed in the soaking and filtering chamber. Silkworm cocoons are a raw material of silk quilts and often used in daily life, in order to ensure the high quality of the silkworm cocoons and remove some surface dirt, people generally use a boiling cleaning method, and silkgrowers personally operate the process mostly at present, the operation is cumbersome, and the efficiency is low.

Owner:鹿寨古典桑蚕丝织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com