Method and device for selecting cocoon before reeling silkworm cocoon

A technology for selecting cocoons and silkworm cocoons, applied in the direction of cleaning/classifying silkworm cocoons, which can solve the problems of time-consuming, labor-intensive, dusty, etc., and achieve the effects of ensuring physical health, reducing labor intensity, and shortening the process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

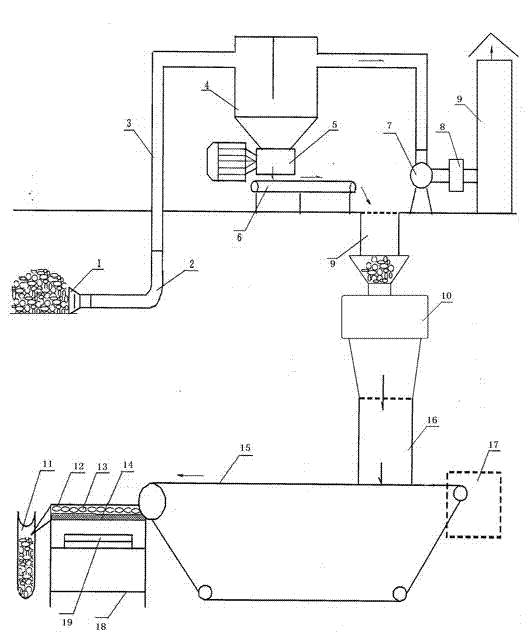

[0024] figure 1 see in:

[0025] The cocoon selection process and equipment before cocoon reeling are as follows: after the suction fan 7 is turned on, the cocoons are sucked from the cocoon suction plate 1, and after passing through the conveying hose 2, the conveying pipe 3 and the shut-off box 4, the shut-off fan 5 starts, and the cocoons fall into the Conveyor belt 6, dust is sucked by suction fan 8, through filter 8, gas discharges chimney 9, and the silkworm cocoon that falls into conveyer belt 6 enters cocoon peeling machine 10 and then to feeding cocoon box 16, carries out light cocoon selection.

[0026] The device for cocoon selection by light, it comprises the feeding cocoon box 16, the transmission device 17 and the conveyor belt 15 of the existing cocoon selection machine. One end is equipped with a light cocoon selection device; the light cocoon selection device includes a bracket 18, a glass 14 (with frosted glass), a lighting lamp 19 (with a 20w fluorescent la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com