Patents

Literature

654results about How to "Convey evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

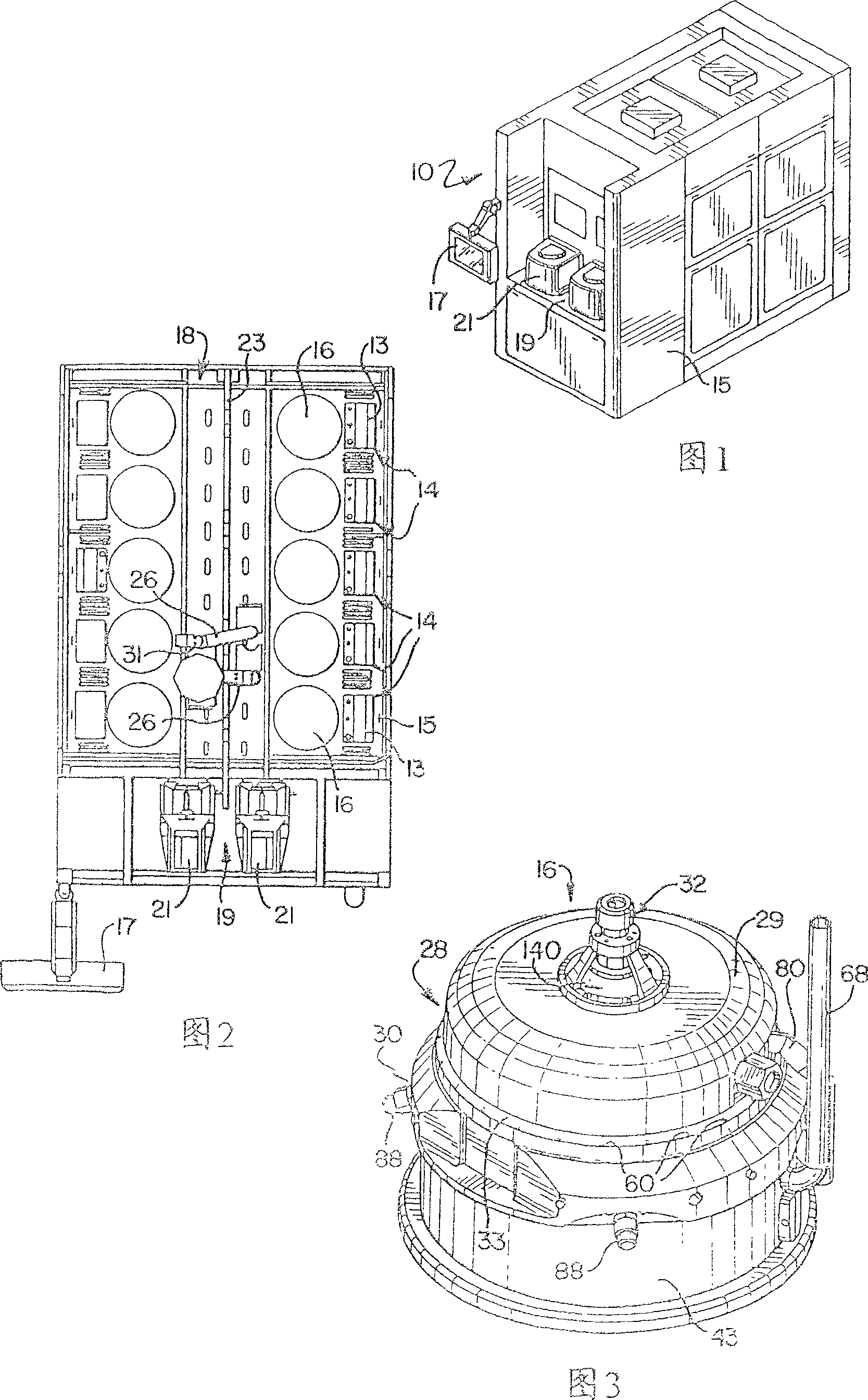

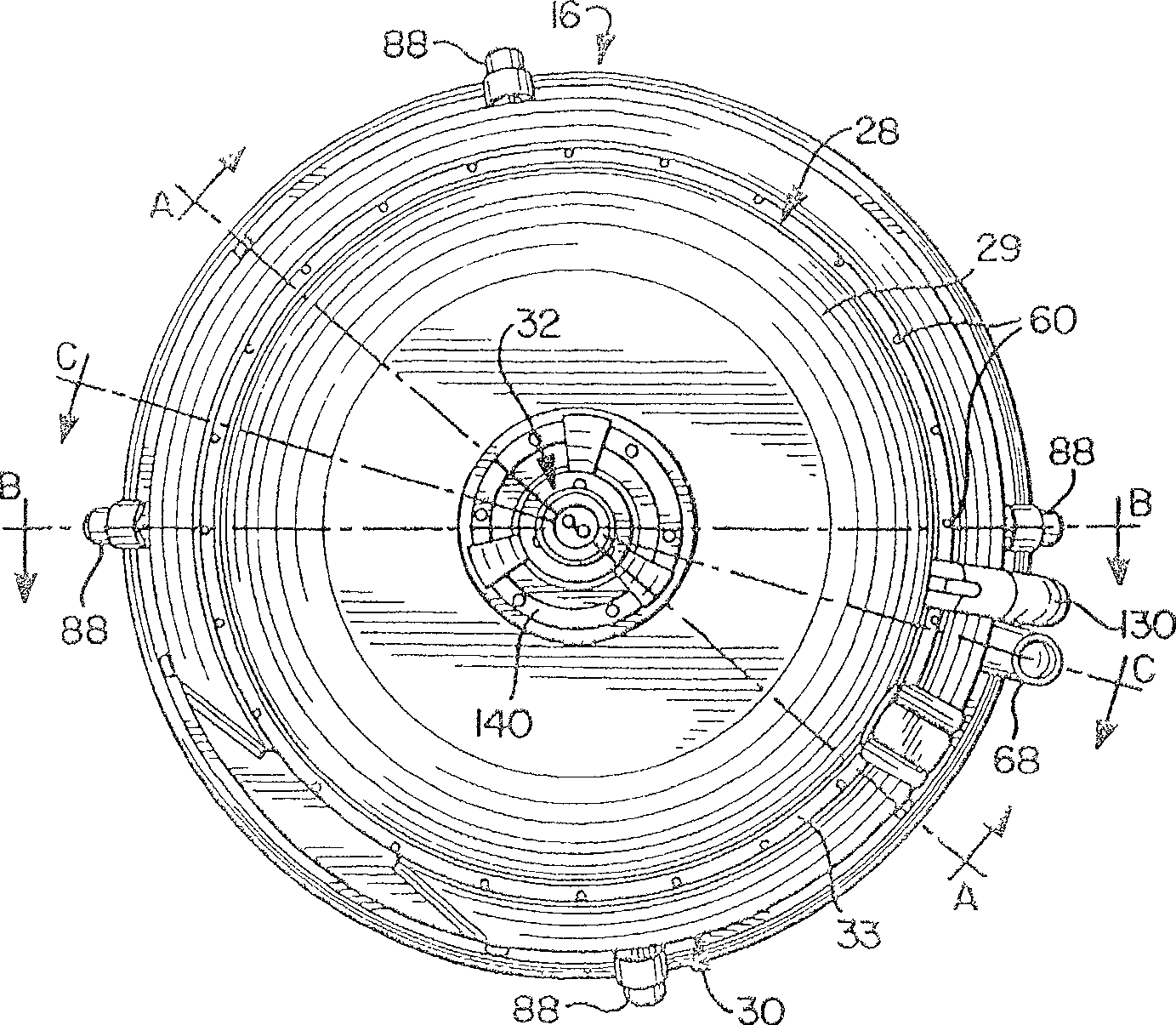

Mail sorting and distributing transfer system

InactiveUS7378610B2Reliable transmissionSmooth circulationControl devices for conveyorsSeparation devicesTransfer systemEngineering

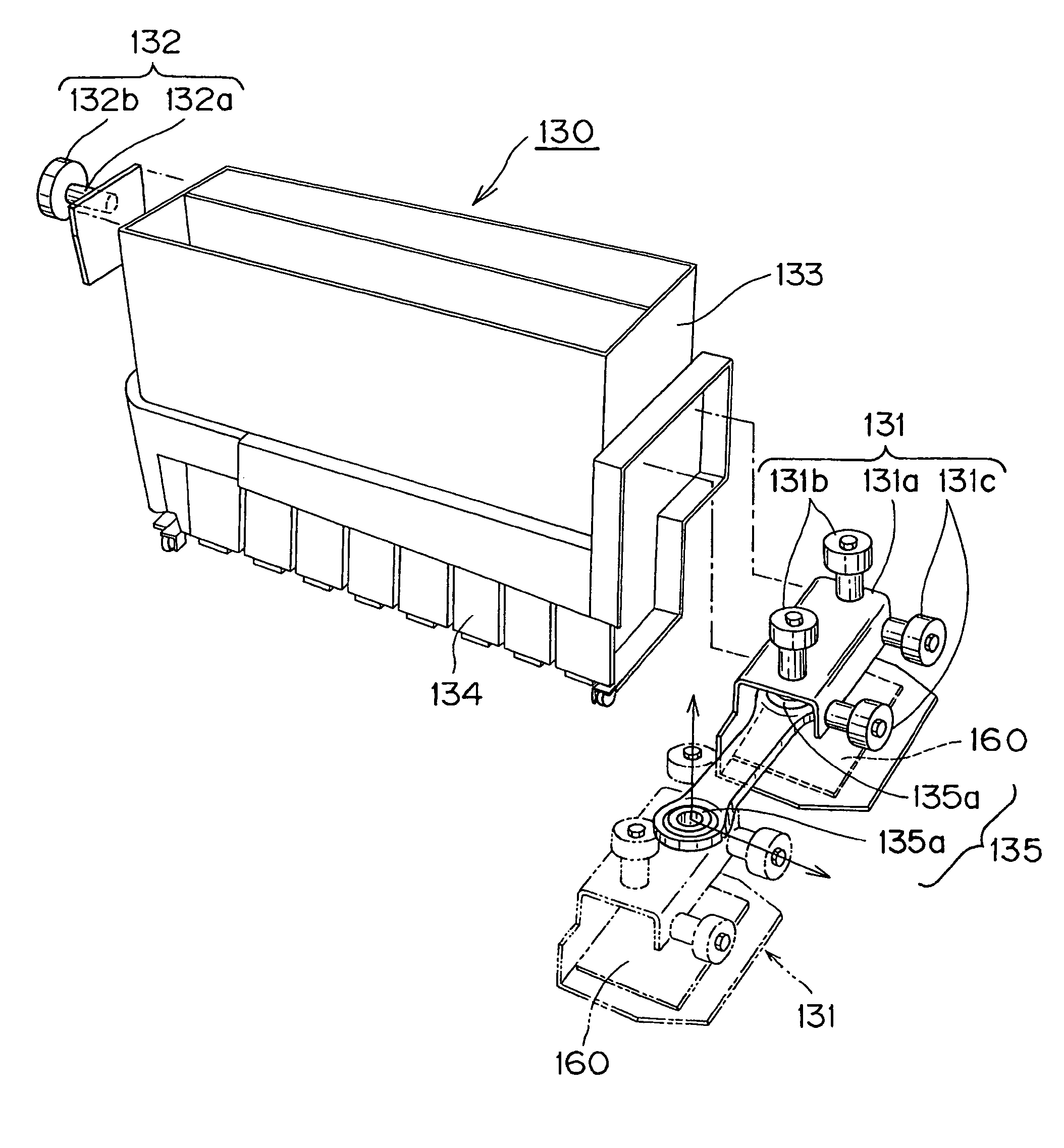

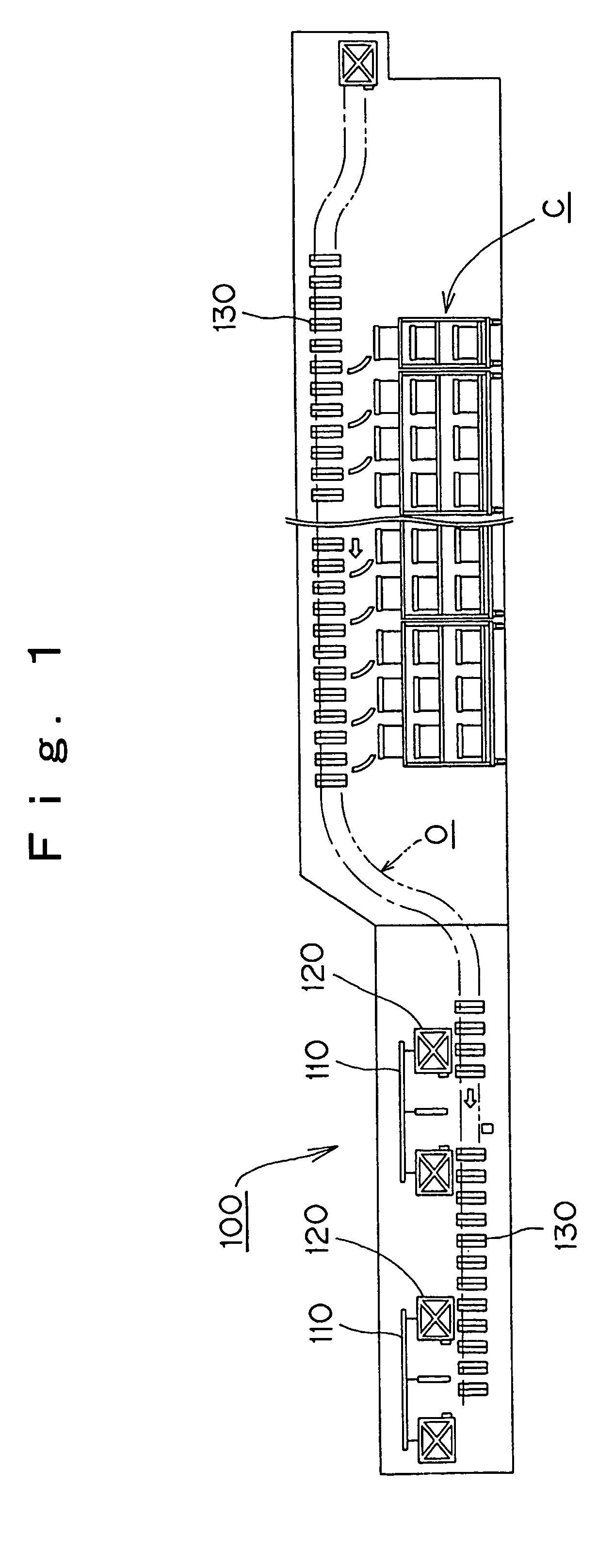

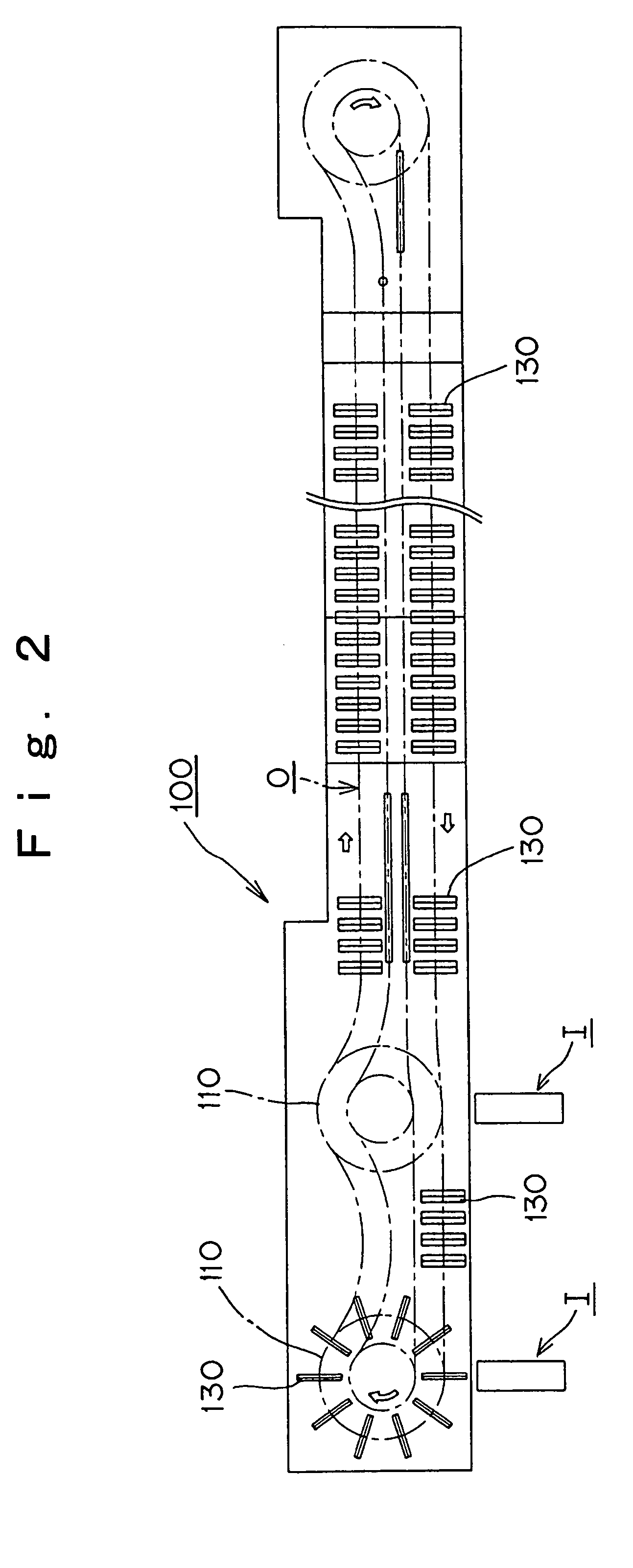

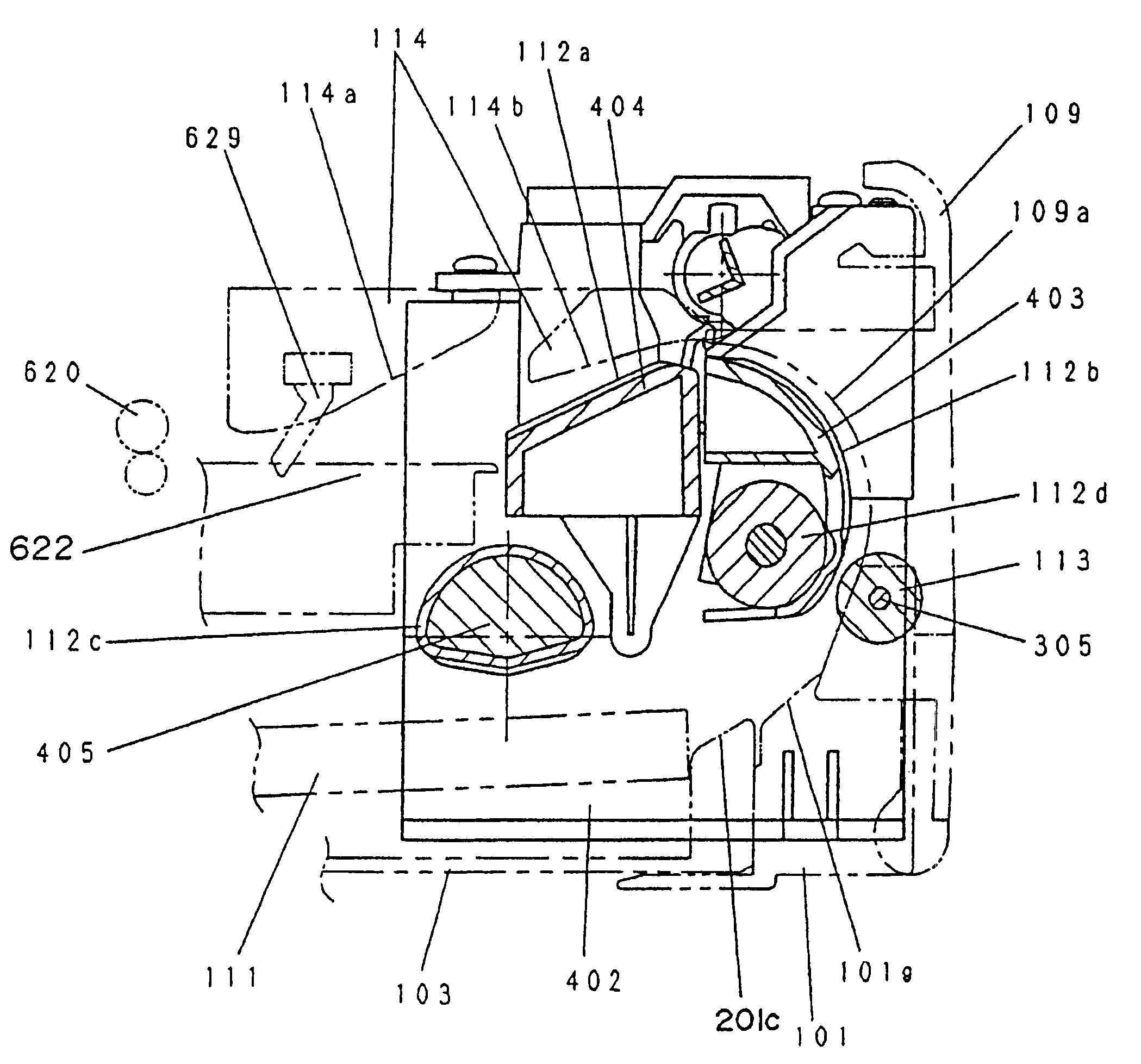

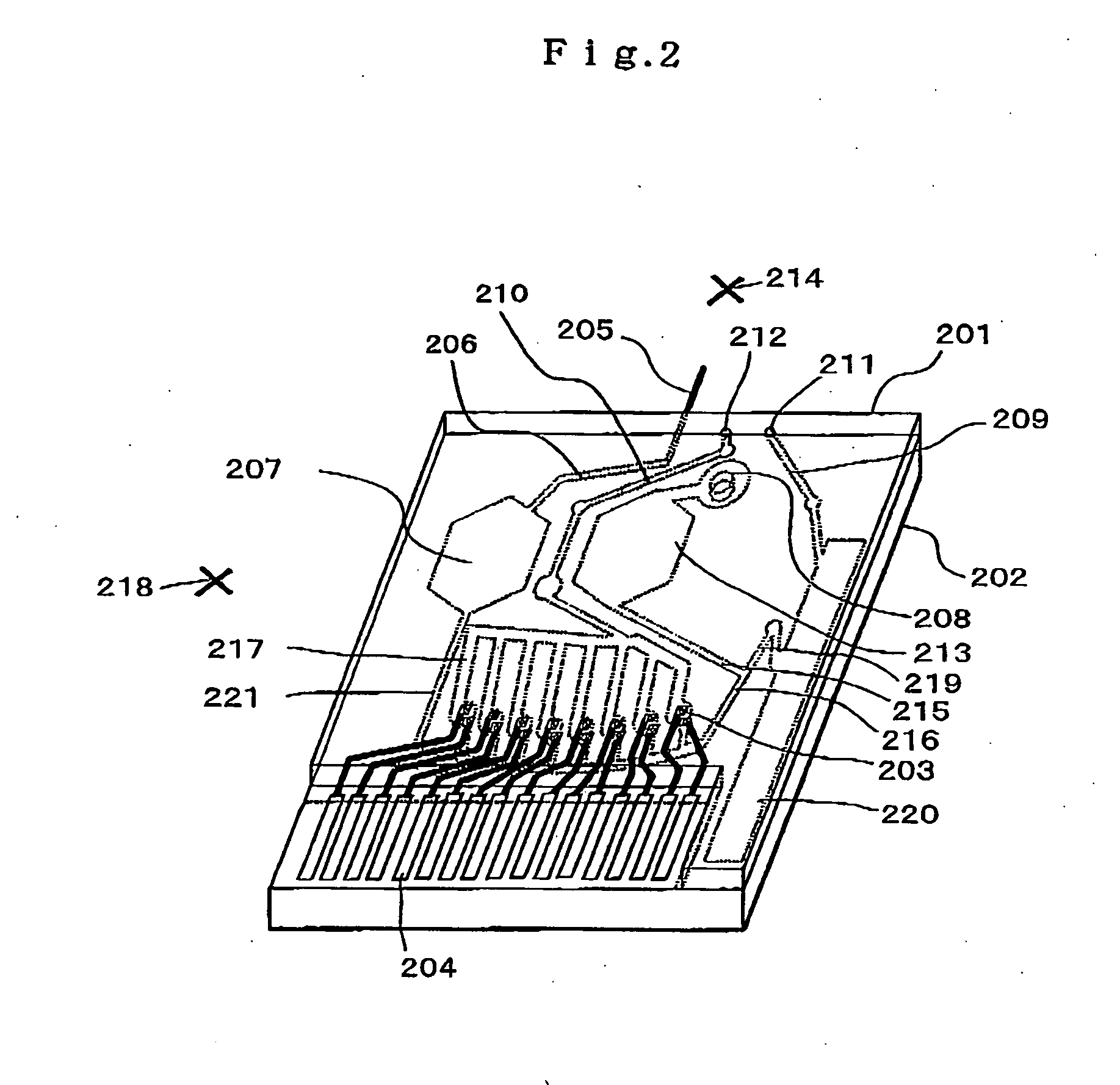

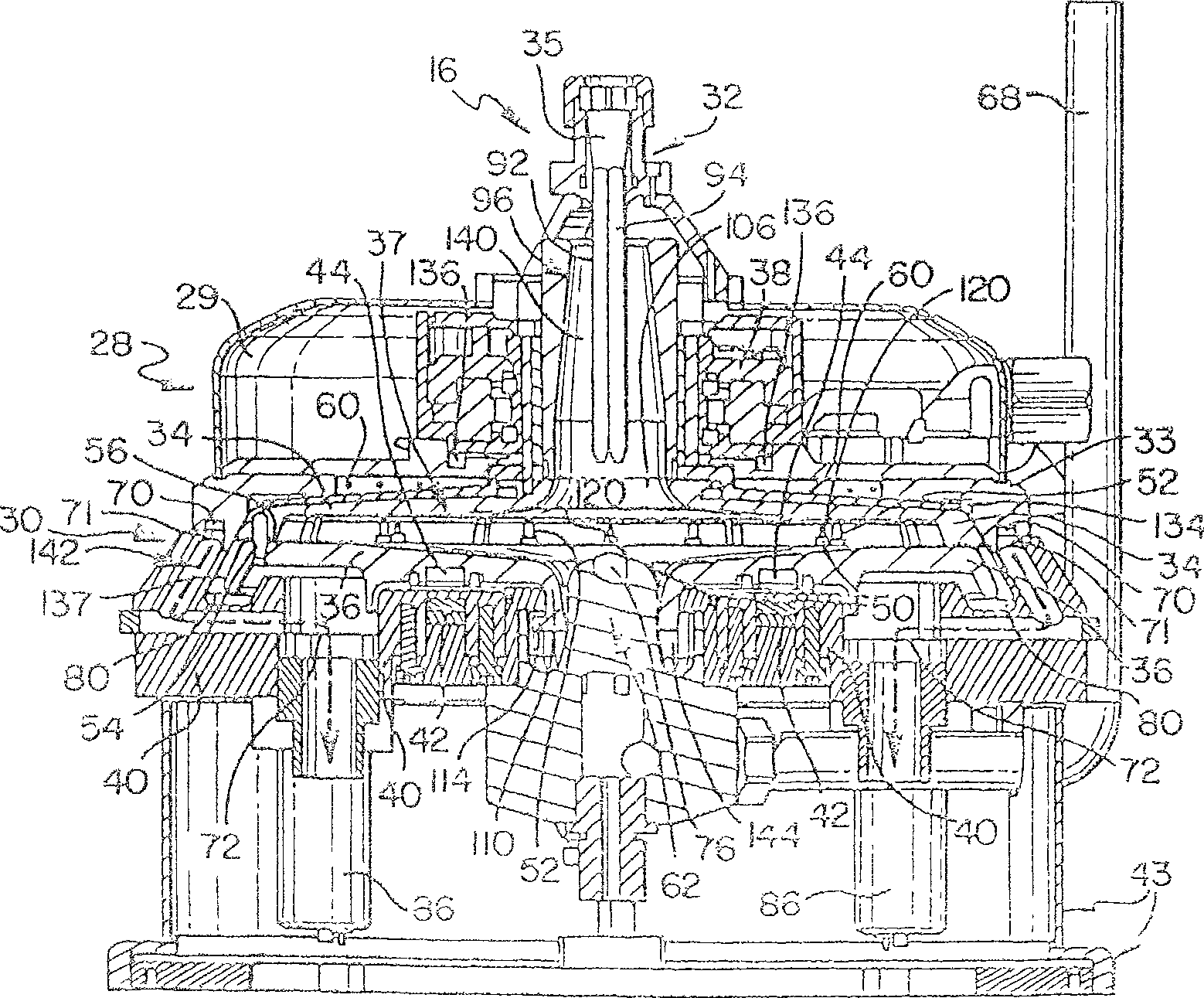

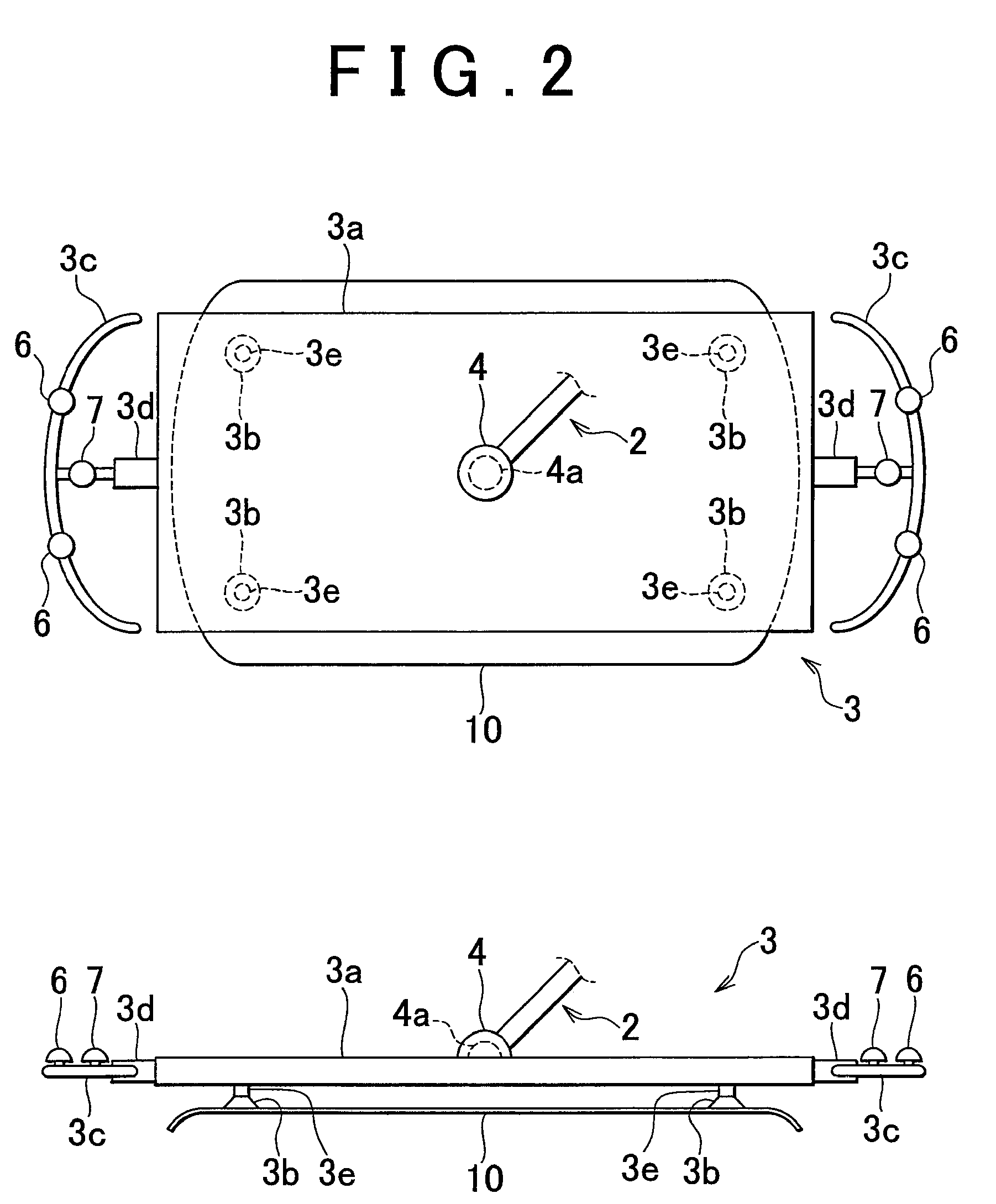

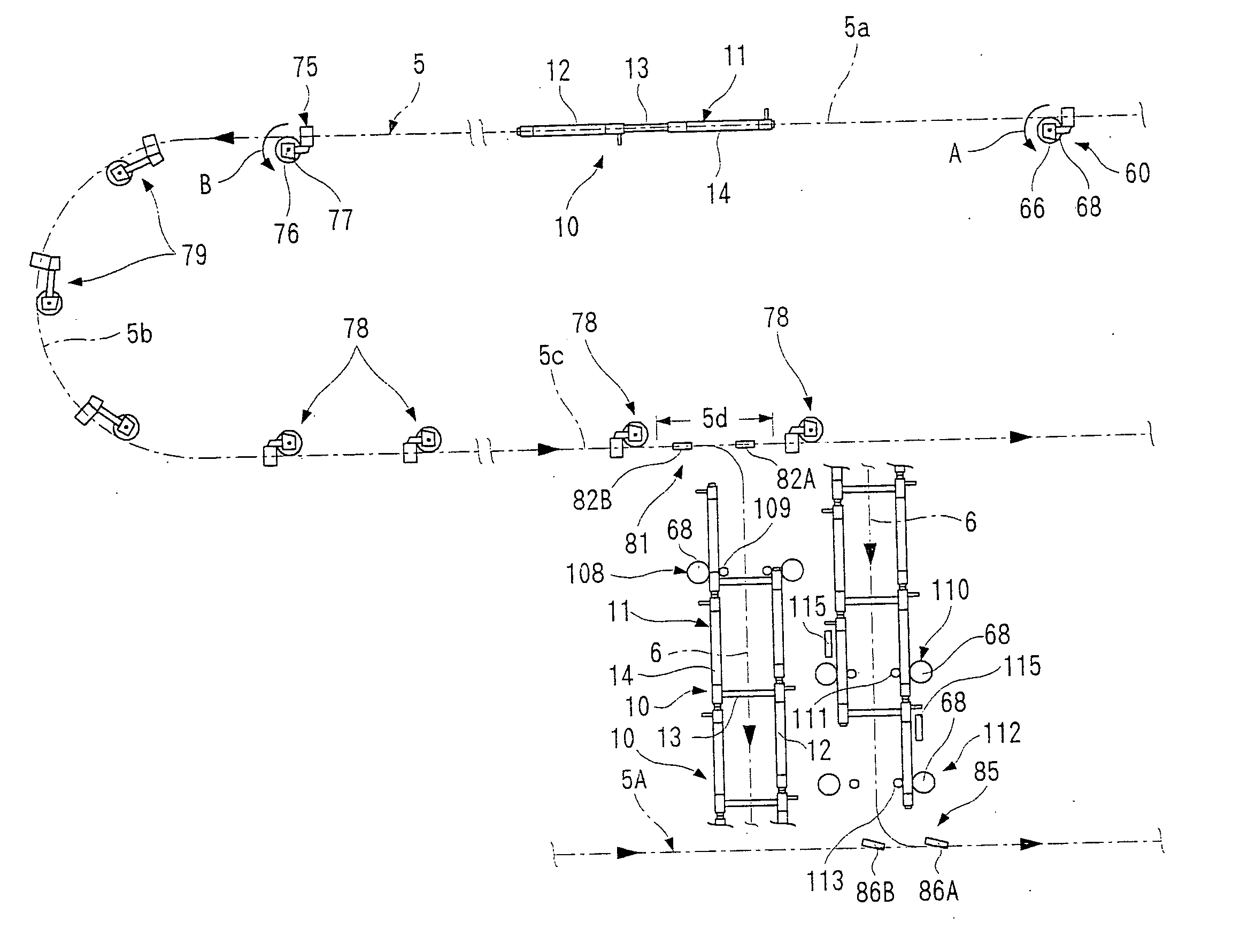

A mail sorting and distributing transfer system, which smoothly conveys mail on a mail sorting line having a compound curve whose line is not in a plane, but is three-dimensional, whereby the mail can be reliably transferred to a conveyor basket and conveying power savings are achieved. The system 100 receives mail in a transfer basket 120 hung at an outer circumferential edge of a mail sorting and distributing turn table 110 and transfers the mail through a transfer port 122 to a conveyor basket 130, which circulates on a mail sorting line O. The conveyor basket 130 includes an inner circumferential side carriage 131 and an outer circumferential side carriage 132, which respectively travel on an inner circumferential side rail 142 and an outer circumferential side rail 143 of the mail sorting line O while hanging a basket body 133 by both sides in a carried state.

Owner:TSUBAKIMOTO CHAIN CO

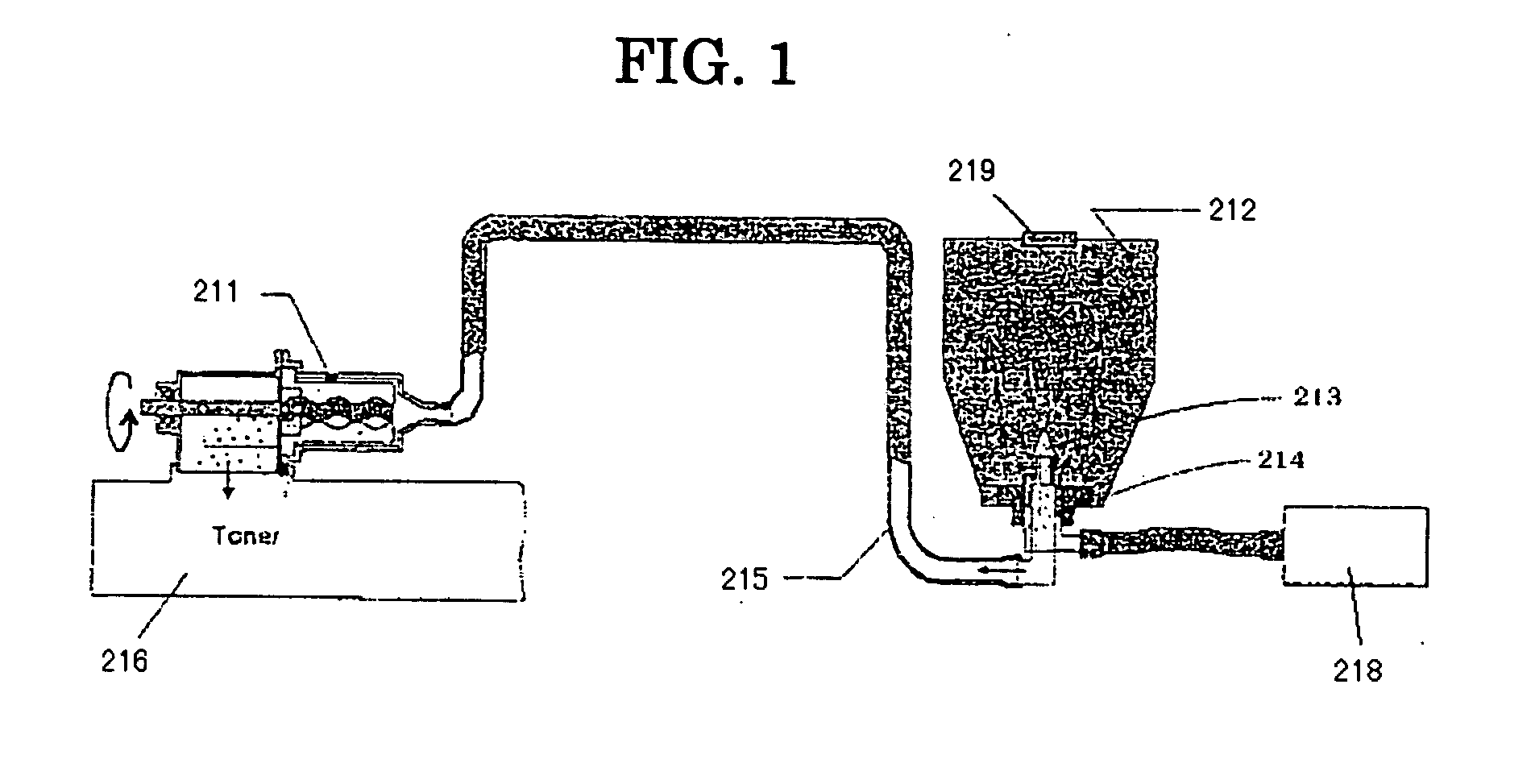

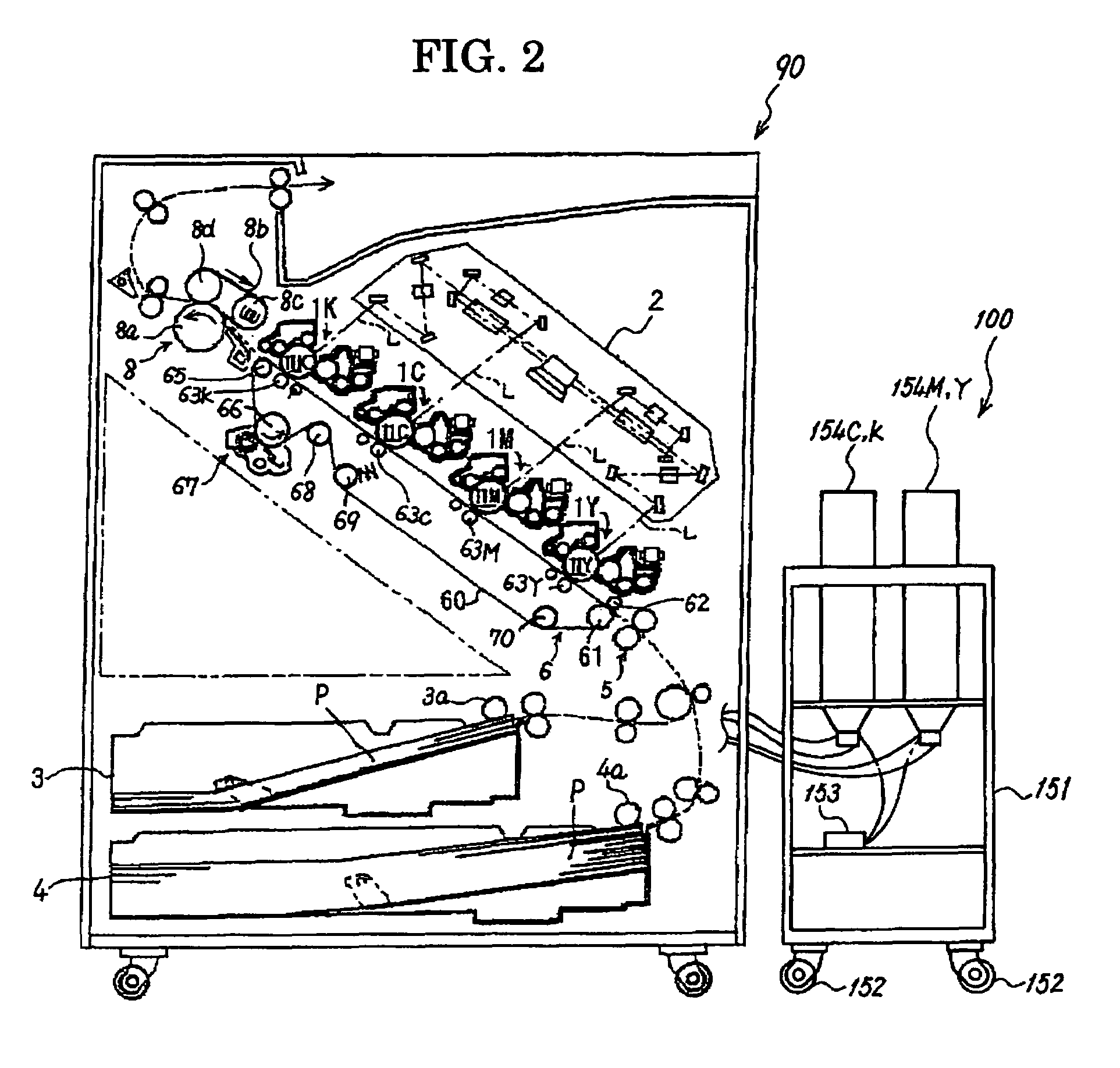

Toner supplying device, toner supplying process, image forming apparatus, and image forming process

InactiveUS20050244193A1Convey evenlyImprove liquidityElectrographic process apparatusImage formationVolumetric Mass Density

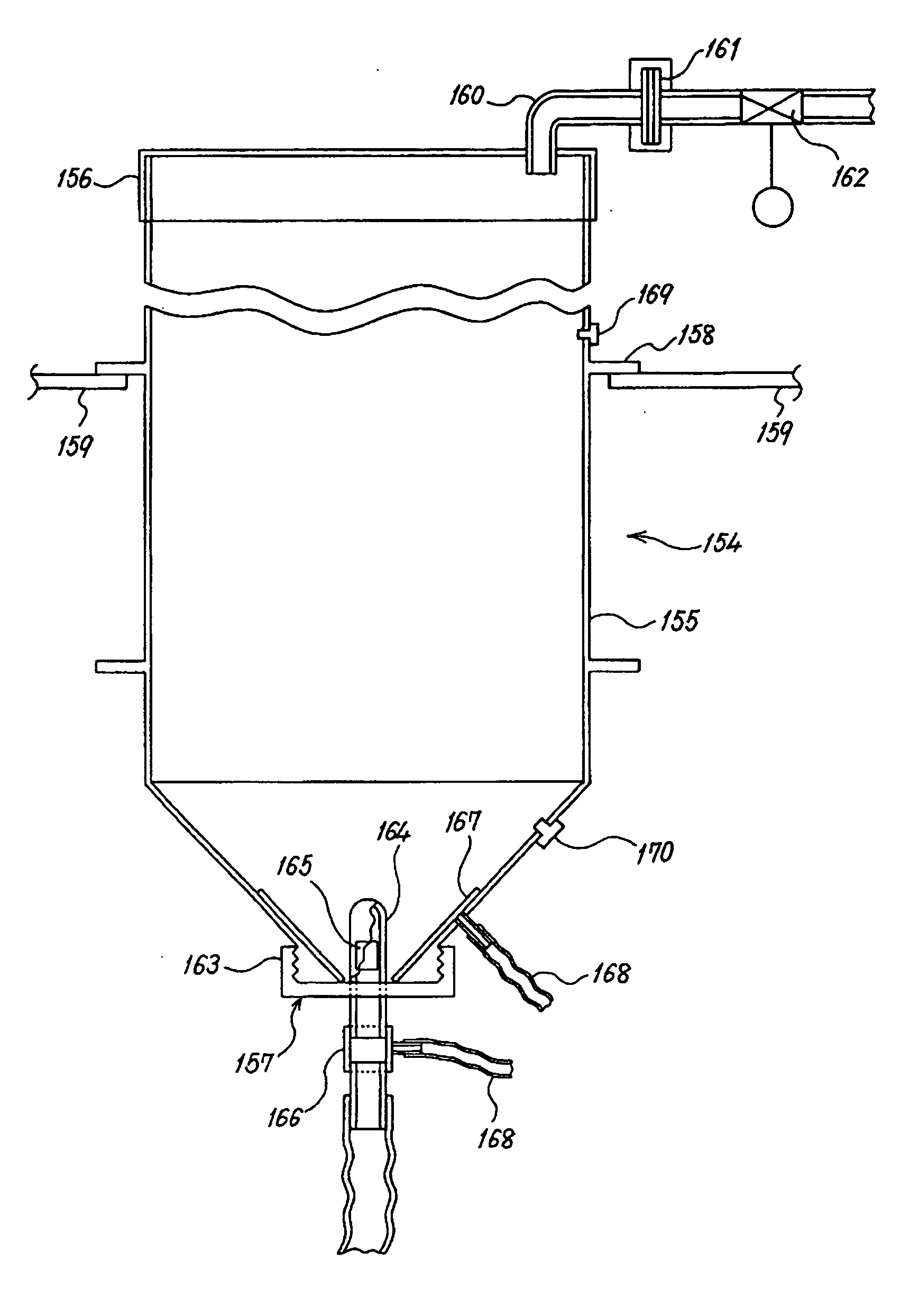

The object of the present invention is to provide toner supplying devices, toner supplying processes, and the like that control the bulk density of the mixture of toner and gas more efficiently thereby the fluidity of the mixture is enhanced, and the high fluidity may be maintained for a long period. The object is attained by a toner supplying device that comprises a toner containing portion configured to store a toner, a toner outlet configured to discharge the toner from the toner containing portion, a conveying pipe configured to convey the toner, and a gas feeding unit configured to feed a gas, wherein the toner supplying device supplies the toner from the toner containing portion to an image forming unit of an image forming apparatus, a porous member is disposed near the toner outlet, and the gas is fed into the toner containing portion through the porous member.

Owner:RICOH KK

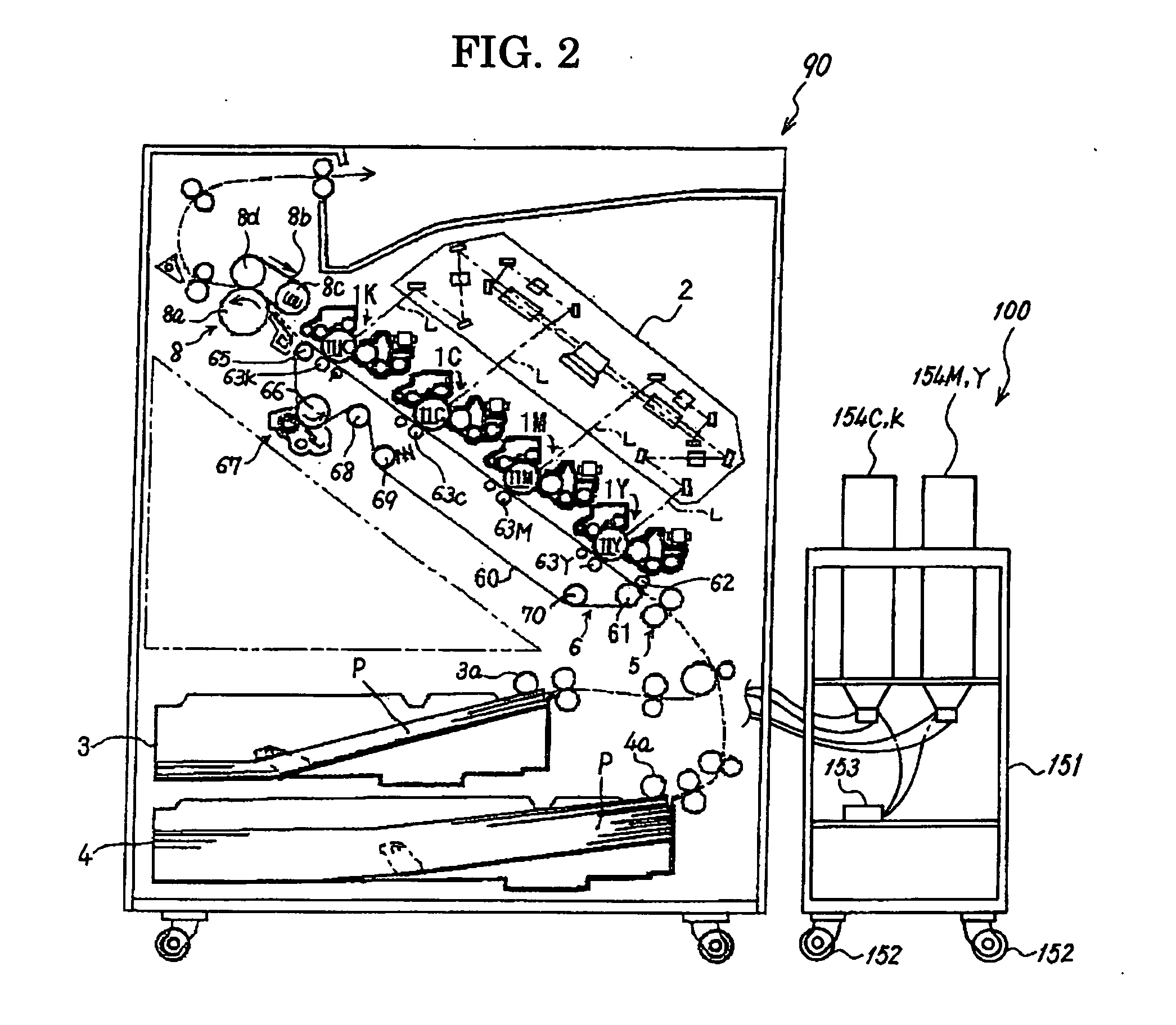

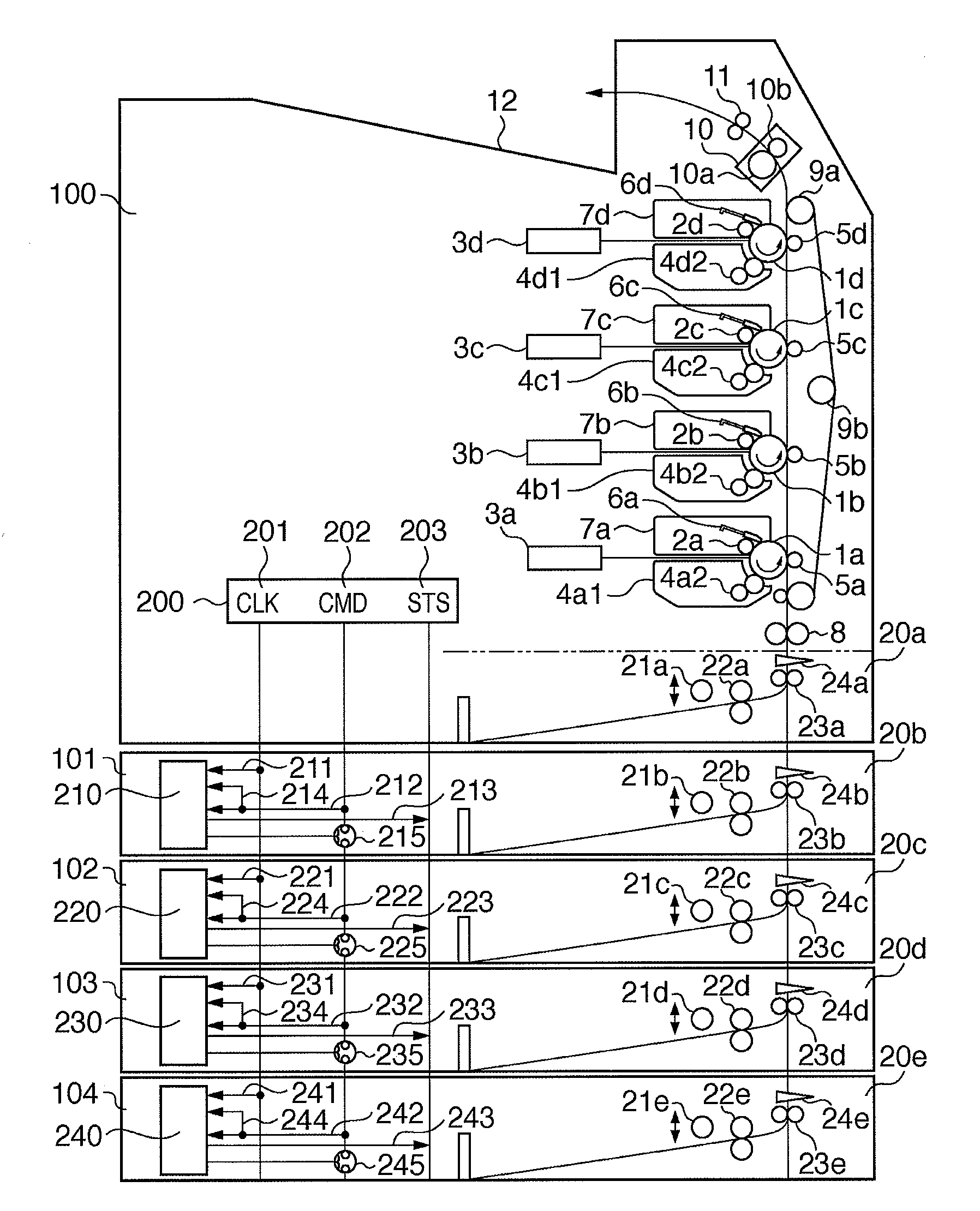

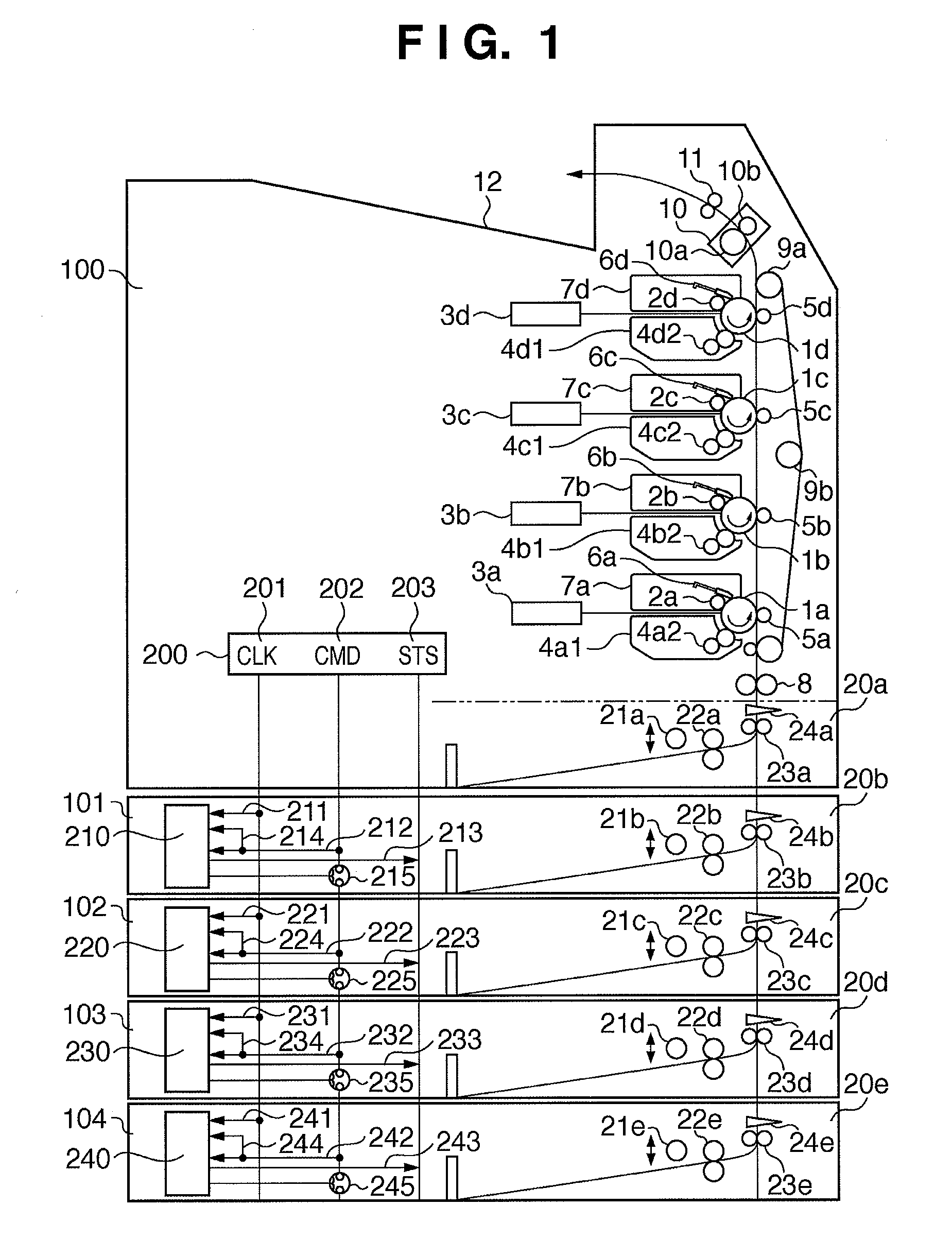

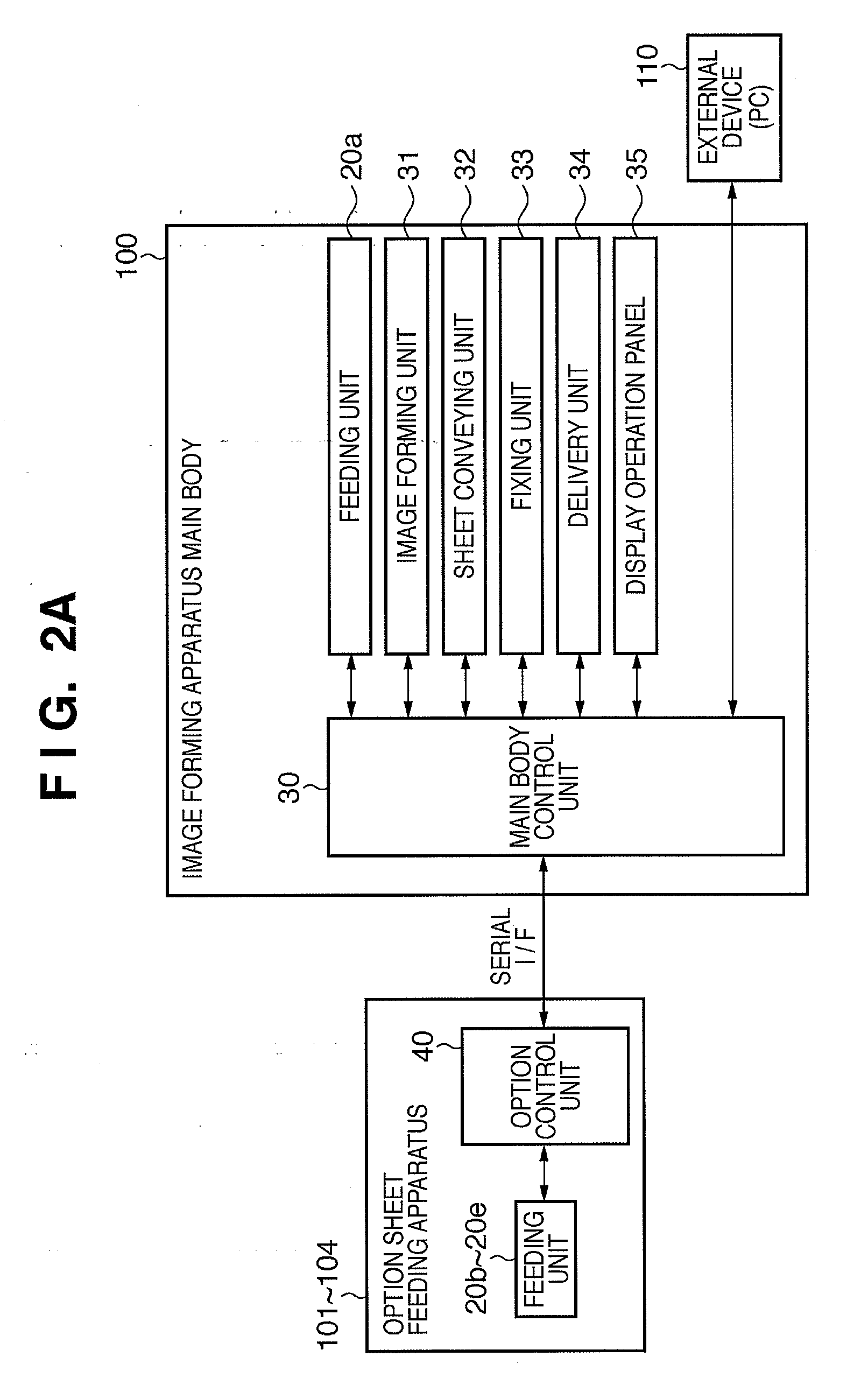

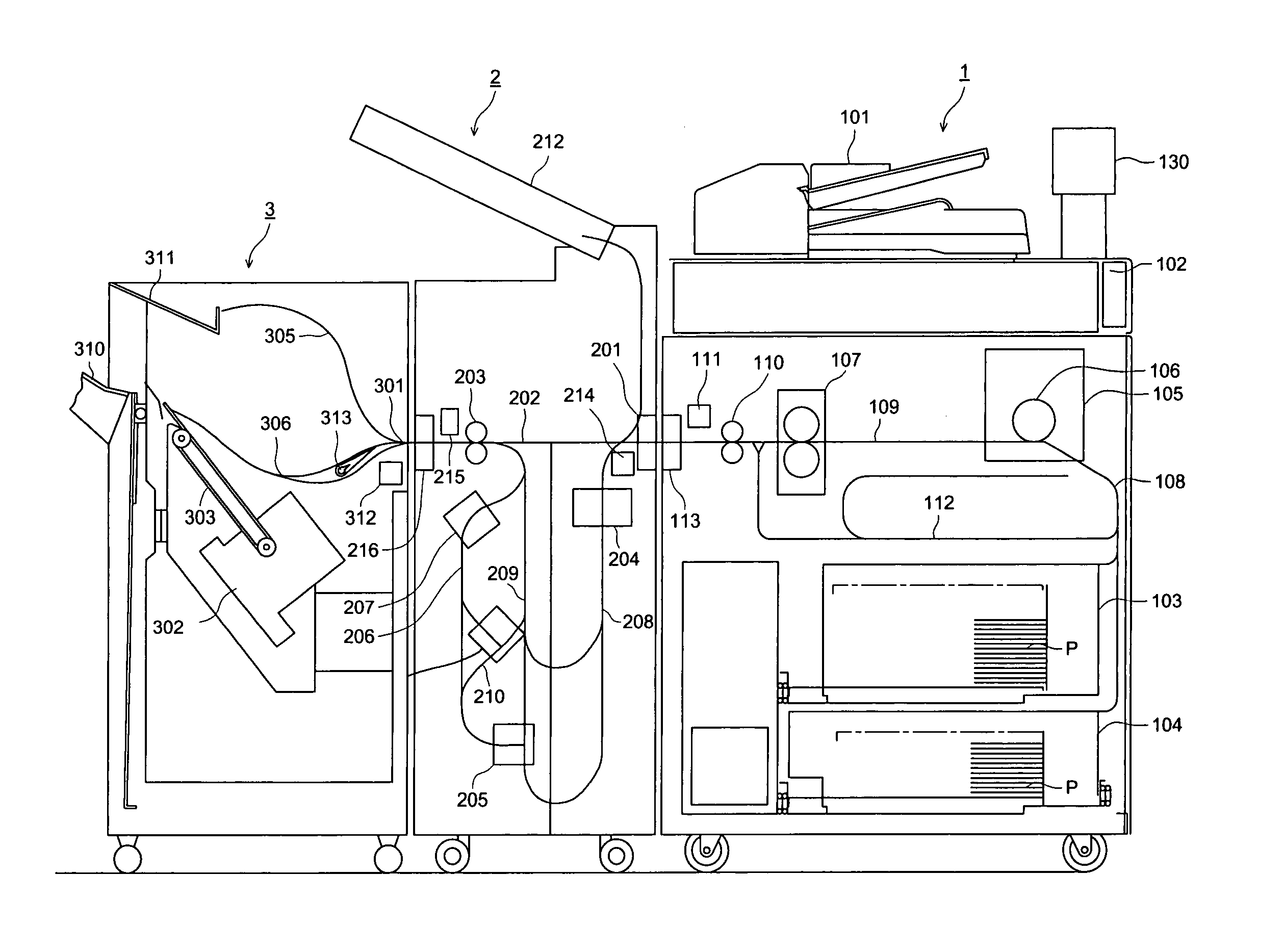

Image forming apparatus

ActiveUS20100020354A1Power consumption be suppressConvey evenlyElectrographic process apparatusArticle feedersControl optionEngineering

This invention provides an image forming apparatus capable of smoothly controlling option apparatuses while suppressing power consumed by conveyance, compared to a conventional technique. To achieve this, the control unit of the image forming apparatus issues a control instruction by serial communication via a common communication line to drive not all but two or more option apparatuses at once.

Owner:CANON KK

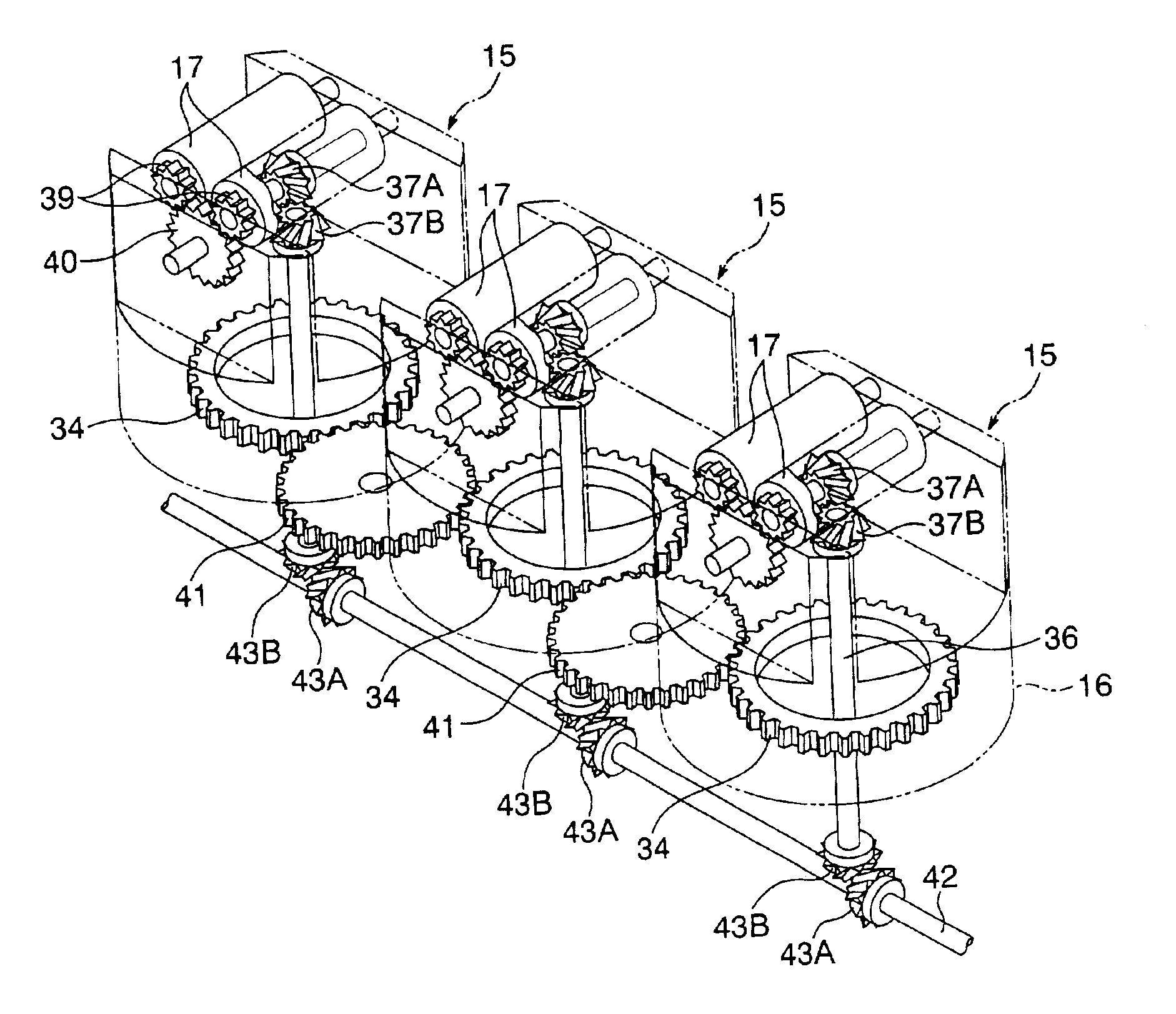

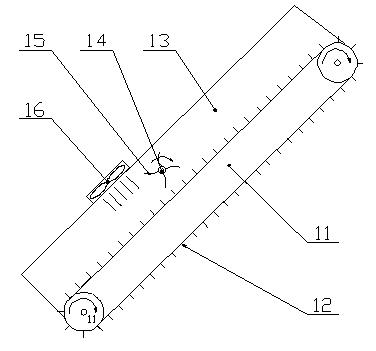

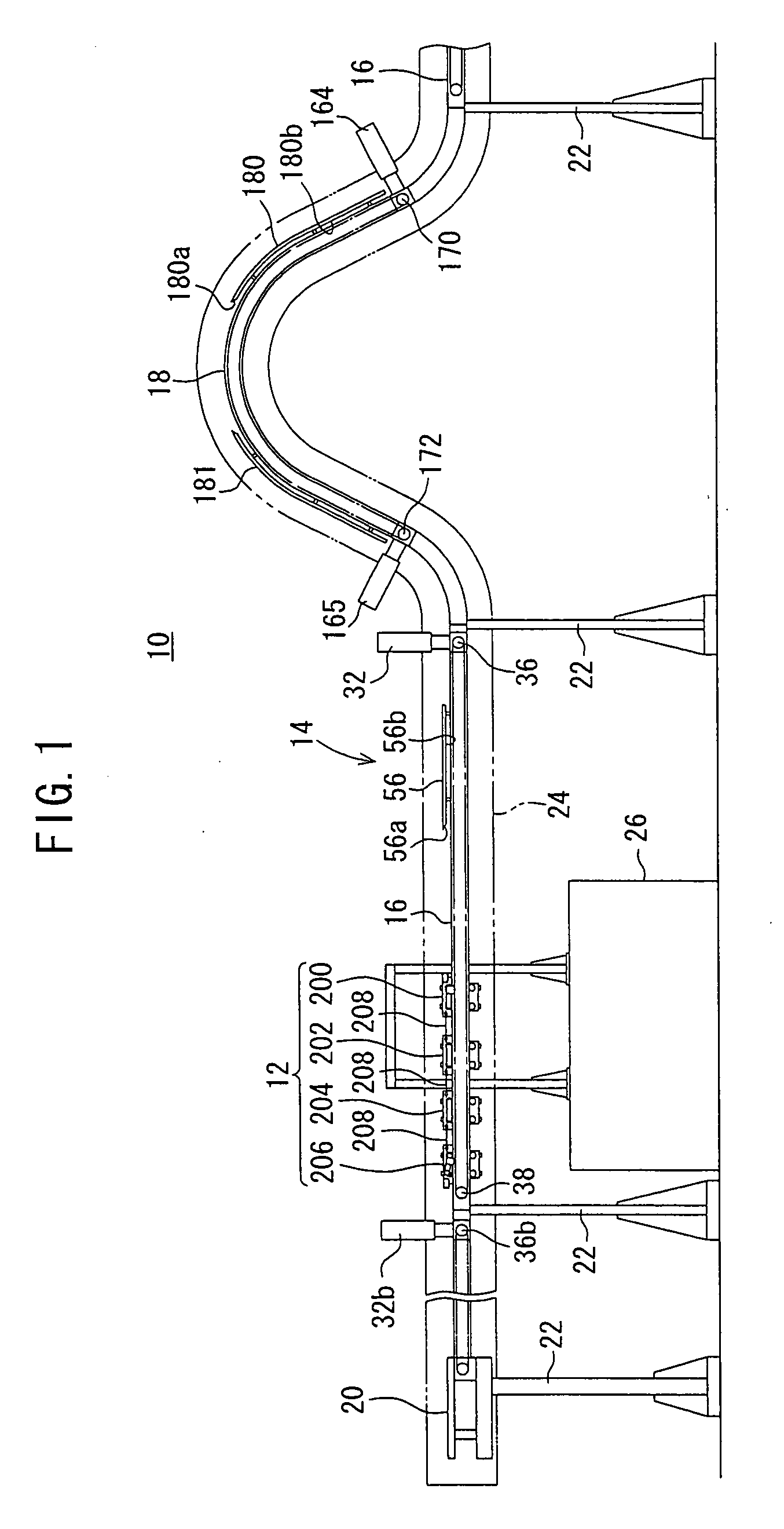

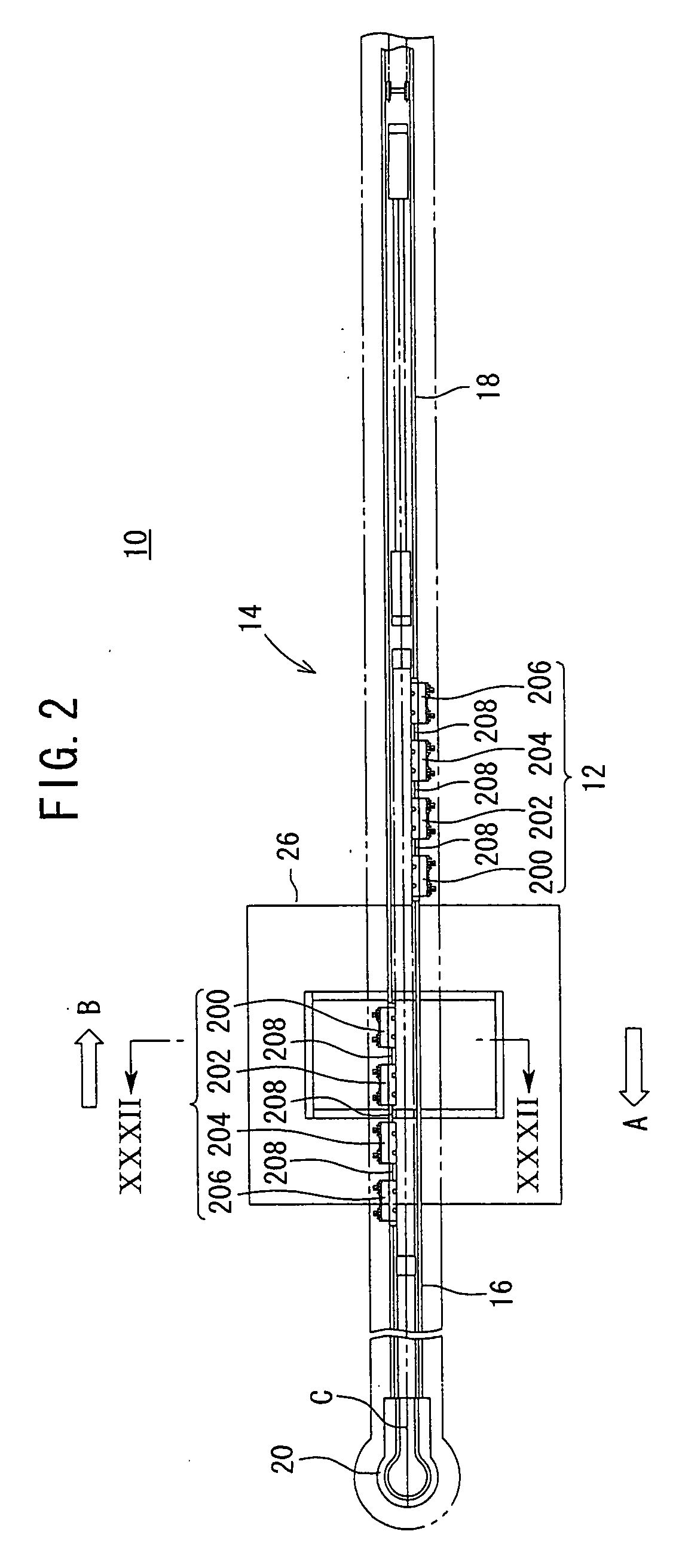

Conveying apparatus and conveying system

InactiveUS6889815B2Efficiently transmitSmoothly conveyPackagingStorage devicesEngineeringMechanical engineering

There are disclosed a conveying apparatus and a conveying system in which a force is efficiently transmitted to an article so as to smoothly convey the article in an arbitrary direction. In each of feed portions 15 provided at a conveying apparatus 10, 11 of the invention, a twist gear 34 is mounted on a twist base 16, and is disposed below feed rollers 17, and therefore the degree of freedom of the configurations of the twist gear 34 and feed rollers 17 are higher as compared with a conventional construction in which a feed roller is provided within a twist gear. Therefore, a compact design of the twist gear 34 can be achieved, and also the feed portions 15 and 15 can be disposed closer to each other as compared with the conventional construction. And besides, a large-size design of the feed rollers 17 can be achieved, so that an area of contact of the feed rollers 17 with the article can be increased. As a result, the force can be efficiently transmitted to the article 90 from each of feed portions so as to smoothly convey the article in an arbitrary direction.

Owner:ASAHI SEIKI INDUSTRIES +1

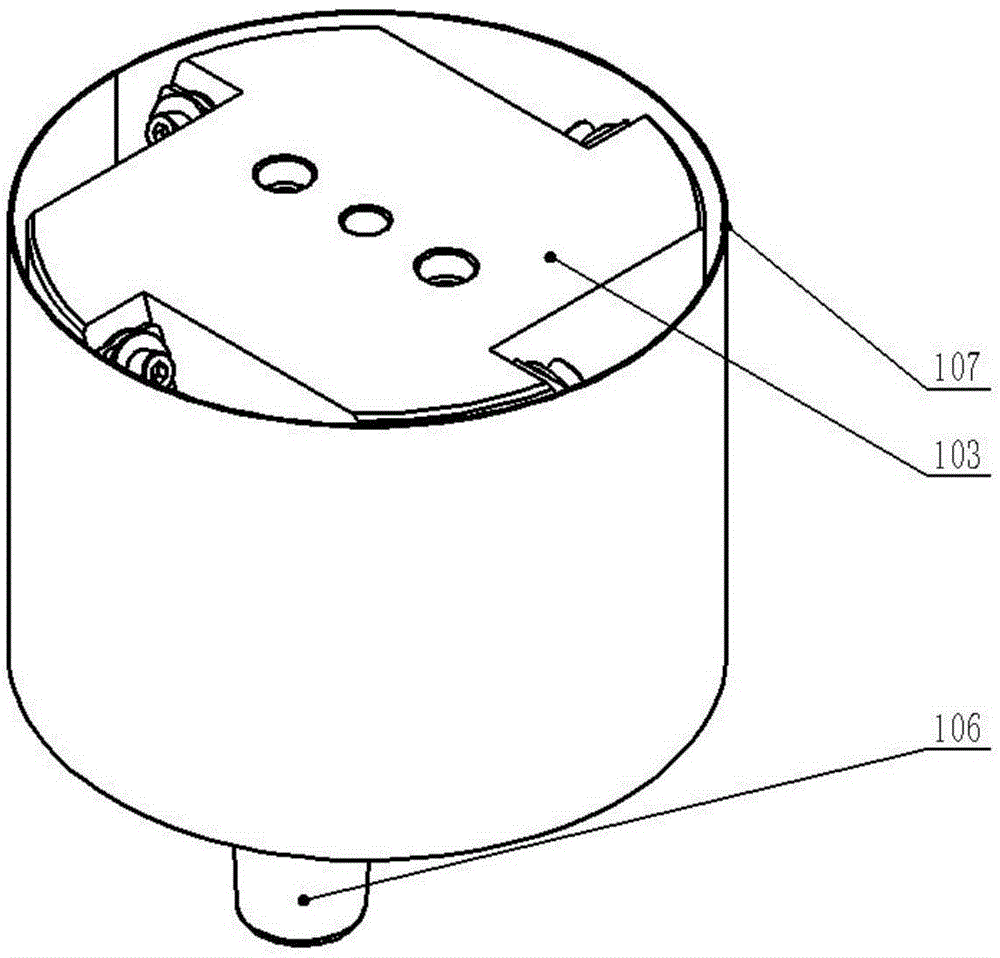

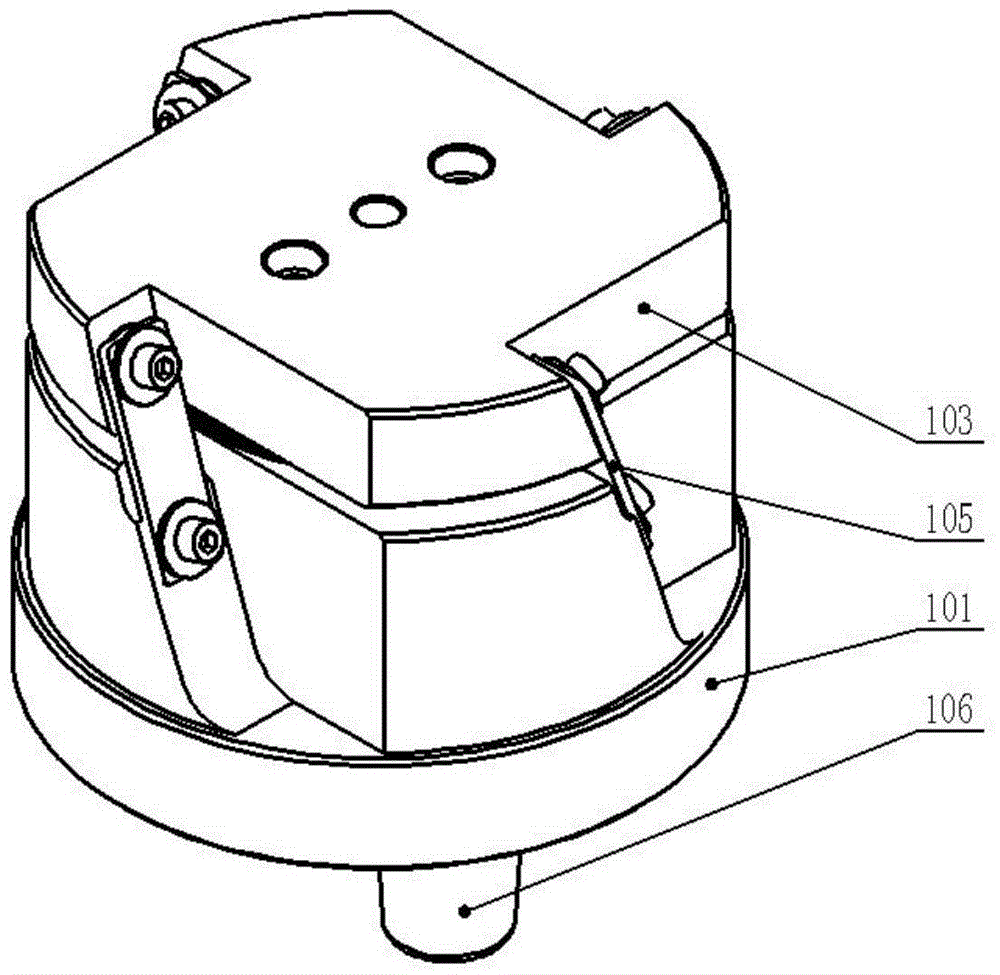

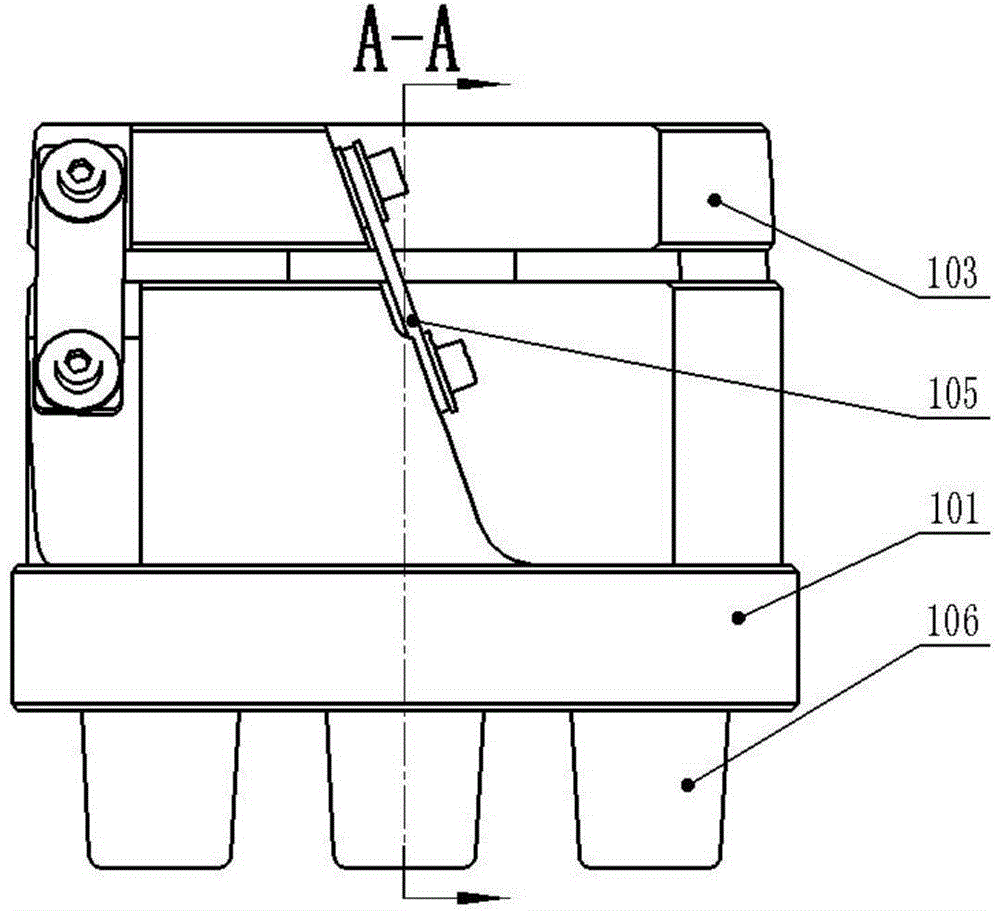

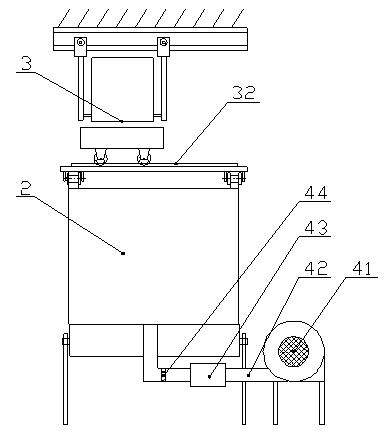

Automatic light adhesive material feeding vibration hopper

InactiveCN104444132AContinuous deliveryConvey evenlyJigging conveyorsConveyor partsEngineeringMechanical engineering

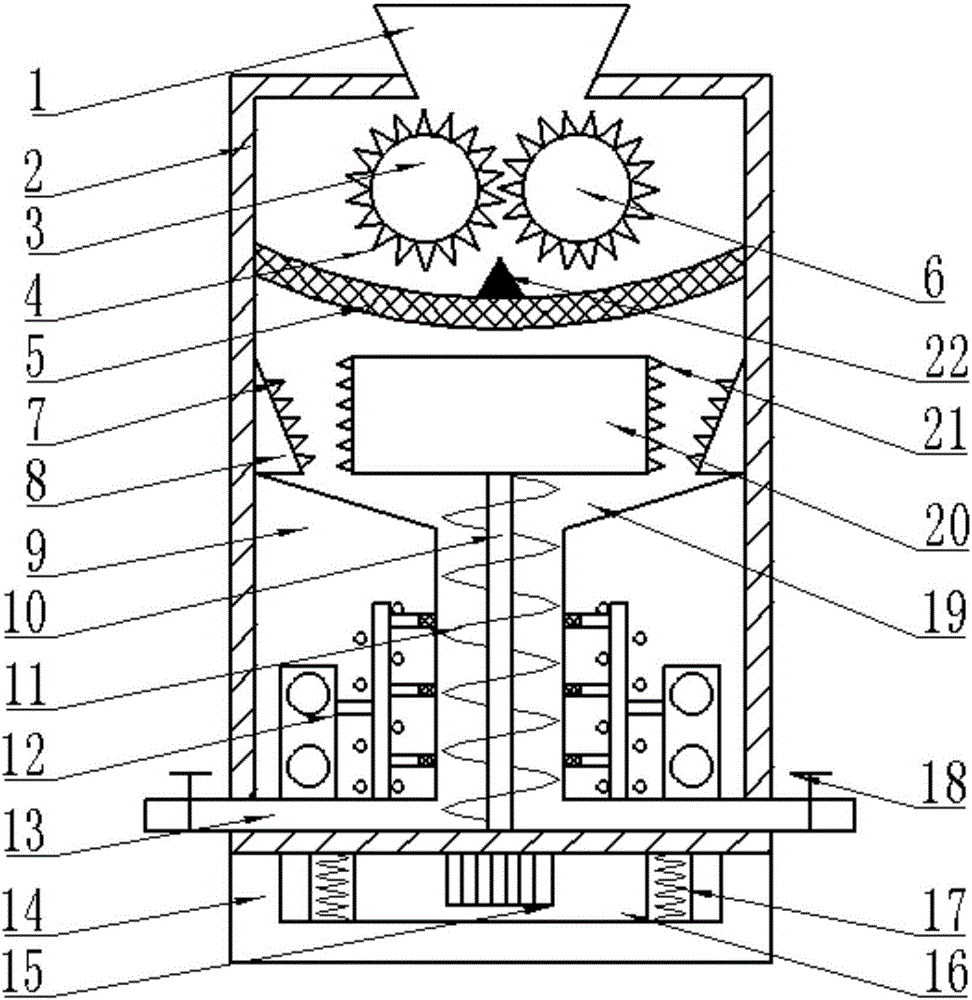

The invention discloses an automatic light adhesive material feeding vibration hopper which comprises a main magnetic vibration machine and a material tray. The vibration hopper generates electromagnetic force through an electromagnetic coil of the main magnetic vibration machine, the material tray with vibration plate springs is stimulated to vibrate, boosting nuts in the material tray vibrate and ascend along a spiral feeding rail, light adhesive materials in the material tray are cyclically boosted to transmit along the feeding rail, and in the discharging stage, air blowing pipes are used for blowing air in an oriented mode, so that the materials are finally conveyed. The air blowing pipes located accurately are used in cooperation with the boosting nuts, so that the light adhesive materials are automatically and rapidly fed in order. According to the automatic light adhesive material feeding vibration hopper, structural design is reasonable, certain universality is achieved, the materials which are adhesive, low in mass, small in inertia and the like can be continuously and evenly conveyed to the position to be machined, the conveying speed is high, work efficiency is improved, and production cost is reduced.

Owner:SOUTHEAST UNIV

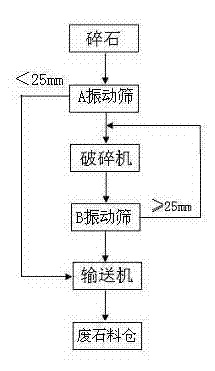

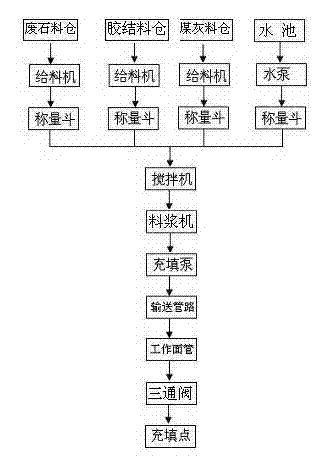

Filling method and system of coal mine goaf

ActiveCN102865101AImprove protectionAvoid missingMaterial fill-upMining engineeringPulverized fuel ash

The invention relates to a filling method and system of coal mine goaf. The filling system comprises a filling bin, a feeder, a weighing hopper, a stirrer, a slurry machine, a filling pump, a delivering pipeline, a working face pipe and a tee pipe, wherein the filling bin is respectively connected with the inlet of the stirrer through the feeder and the weighing hopper; and the outlet of the stirrer is connected to a filling point through the slurry machine, the filling pump, the delivering pipeline and a tee valve. The filling method comprises the steps that barren rocks with granularity of less than 25mm, a cementing agent, pulverized fuel ash and water are delivered to the weighing hopper through the feeder for weighing; the barren rocks, the cementing agent and the pulverized fuel ash are mixed in a mass ratio of 1:(0.22-0.80):(0.35-0.57), and are added with water to produce slurry in a mass concentration of between 70 and 83 percent through the stirrer; and the slurry is delivered to the filling point for filling through the slurry machine, the filling pump, the delivering pipeline, the working face pipe and the tee valve. According to the filling method and system, the sources of filling materials can be enlarged, the filling substance strength and durability can be increased, the filling material can be delivered to the filling point and uniformly filled by delivering and filling in a slurry state, and the filling effect can be improved.

Owner:河北充填采矿技术有限公司

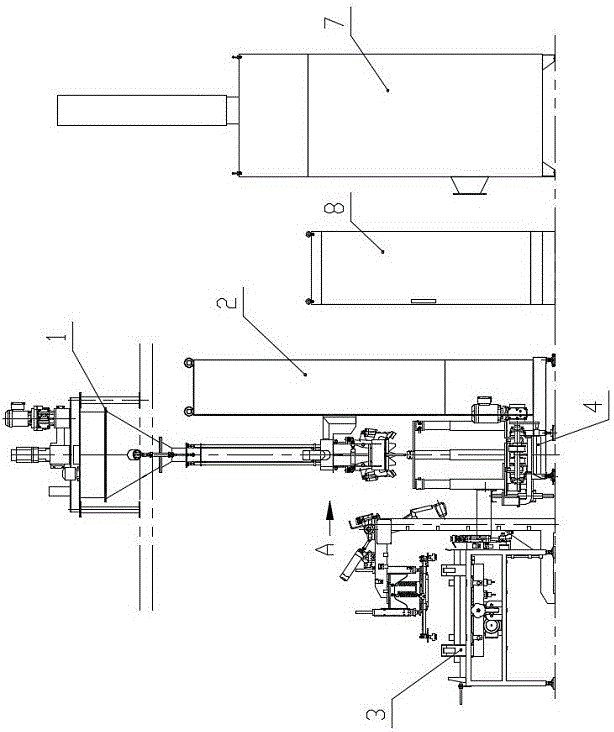

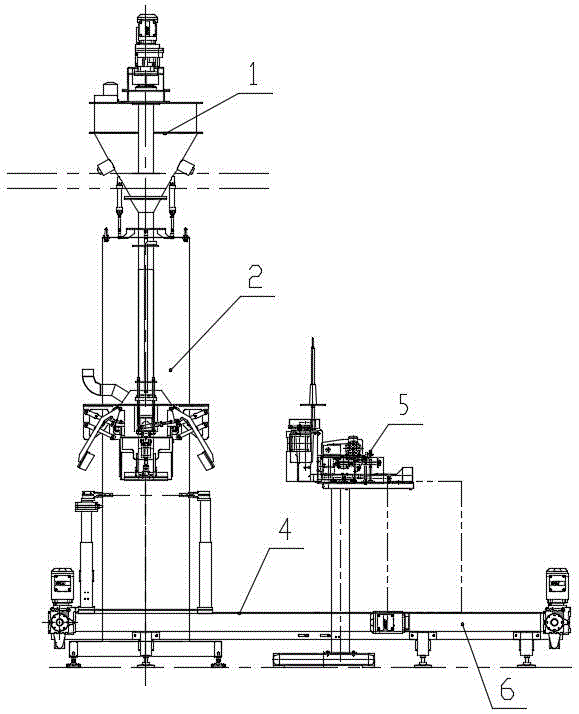

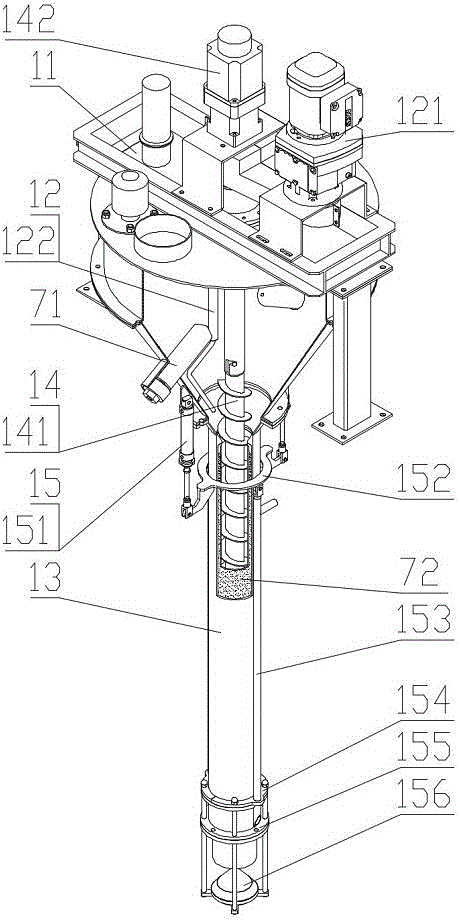

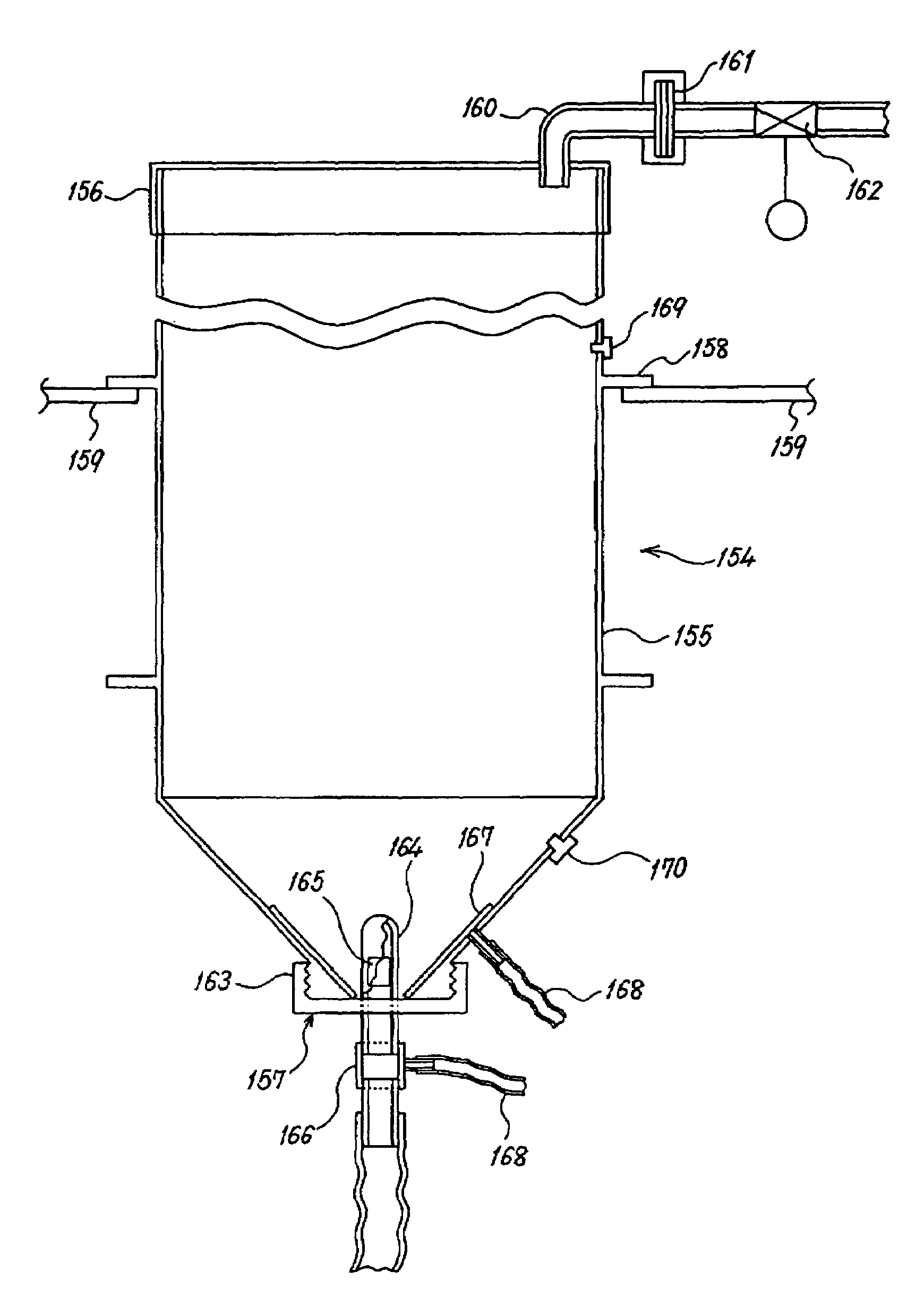

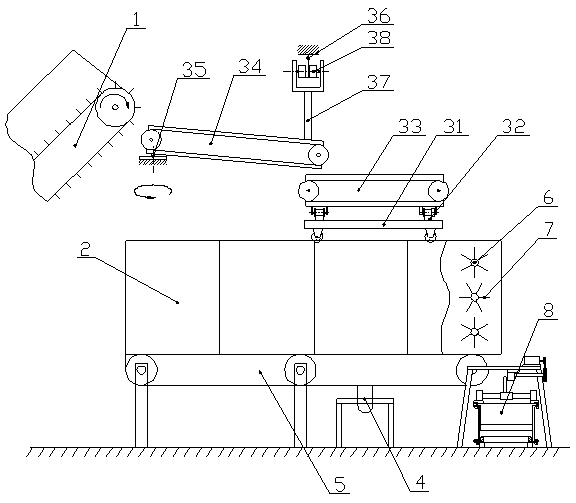

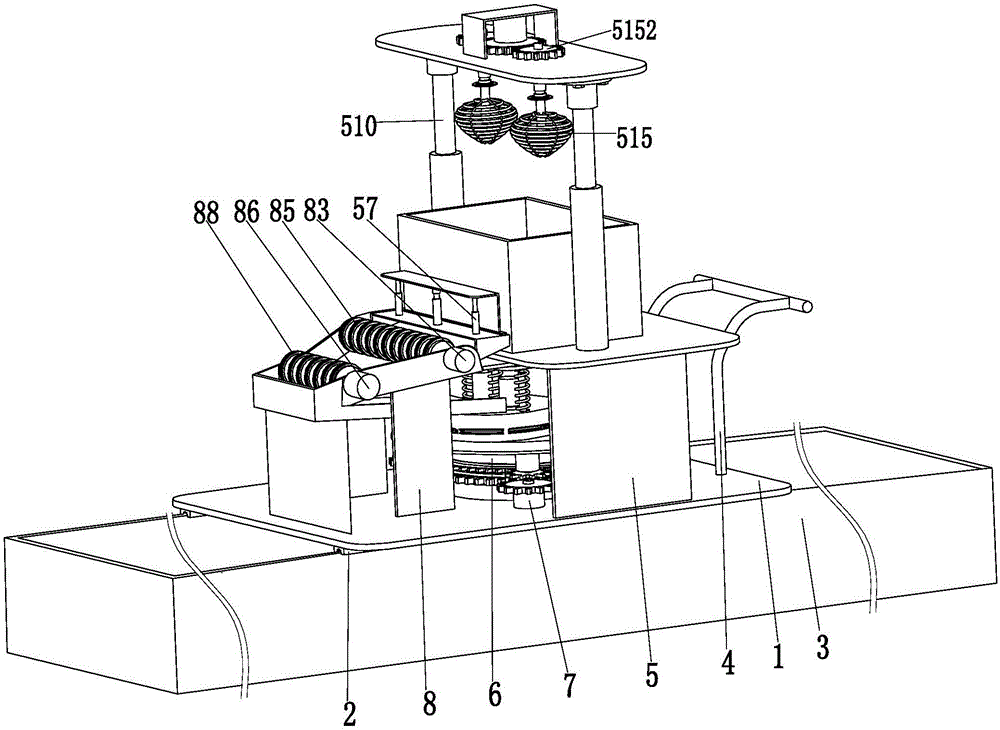

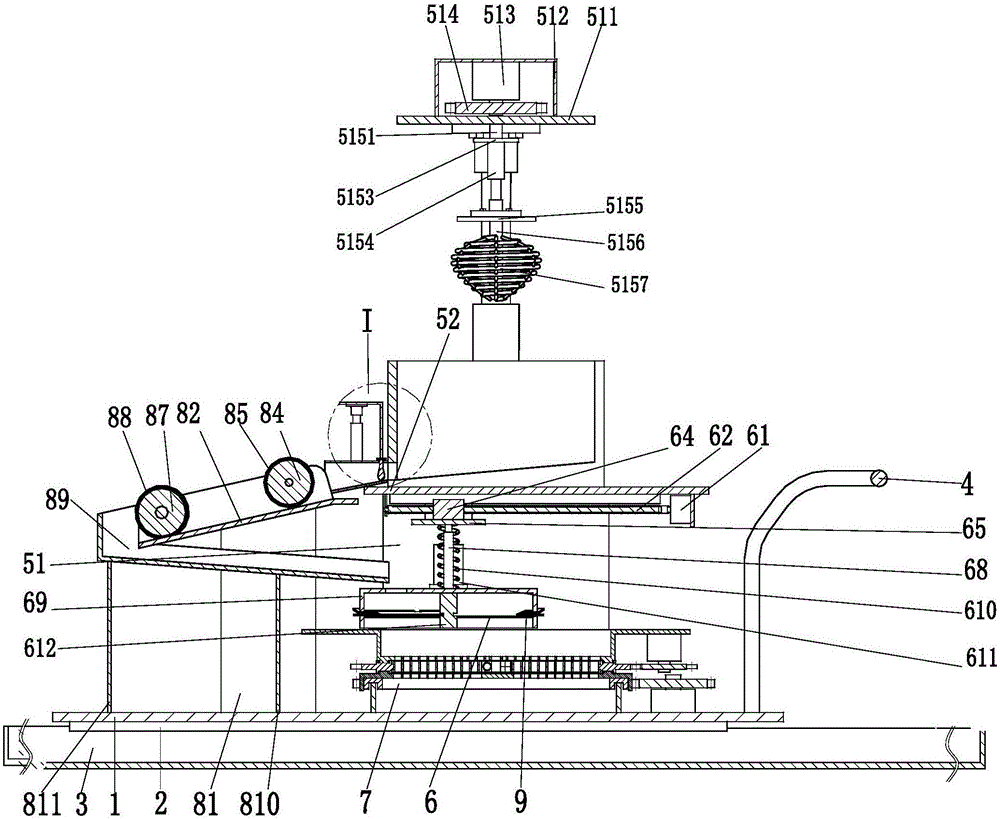

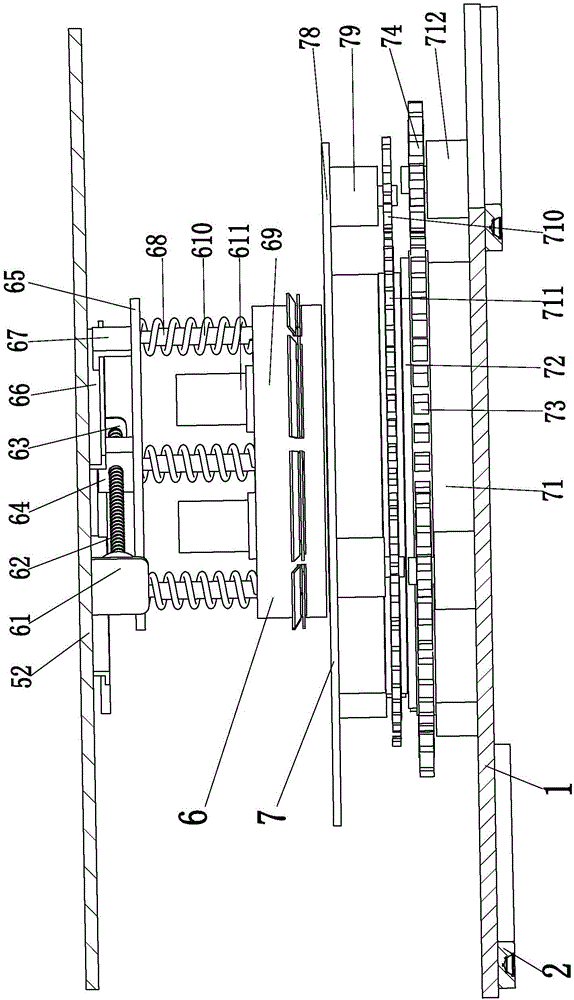

Full-automatic powder packaging system

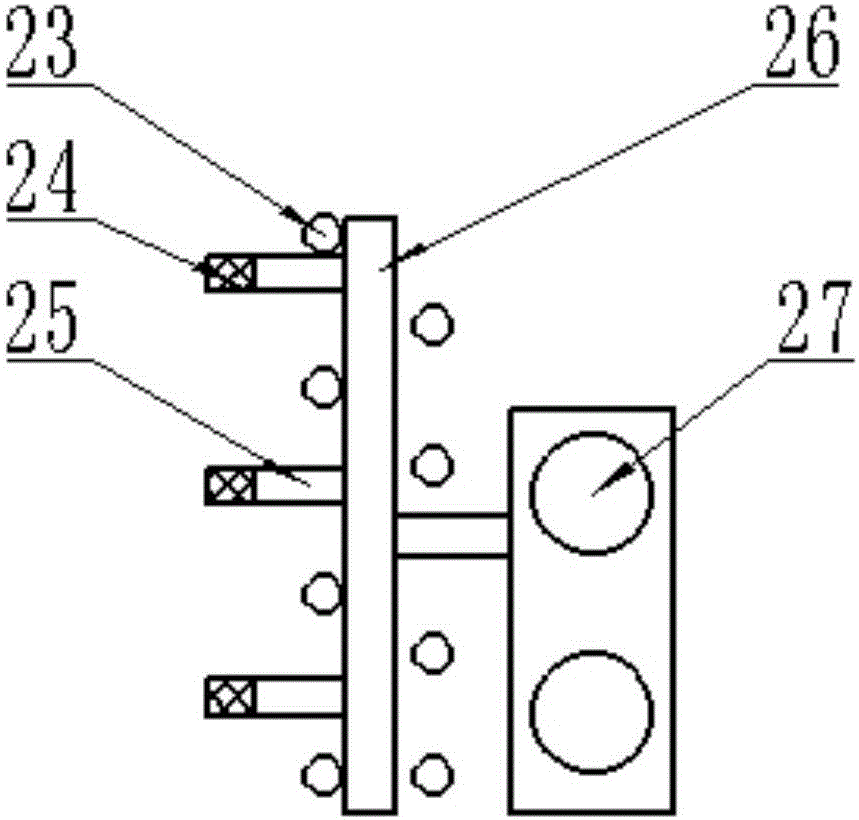

The invention discloses a full-automatic powder packaging system. The full-automatic powder packaging system comprises a screw filling device (1), a lifting bag clamping and weighing device (2), an automatic bagging device (3), a clamping, transferring and conveying device (4), a bag sewing device (5), a finished product transfer device (6), a powder recycling device (7) and an electronic control device (8). The lifting bag clamping and weighing device comprises a weighing mechanism (24) and a duckbill bag clamping mechanism (25) which can ascend and descend synchronously. A discharging cylinder (13) is sleeved with the duckbill bag clamping mechanism. The duckbill bag clamping mechanism clamps a packaging bag and ascends before filling operation so that a movable material door (156) can be located at the bottom in the packaging bag, the duckbill bag clamping mechanism gradually descends synchronous with ascending of the material level in the filling operation process, and the weighting mechanism conducts weighing at the same time. By the adoption of the full-automatic powder packaging system, powder materials can be weighed precisely, packaging bags are sealed and conveyed, and the full-automatic powder packaging system is especially suitable for premise metering and automatic packaging of extremely fine powder materials.

Owner:SAIMO ELECTRIC

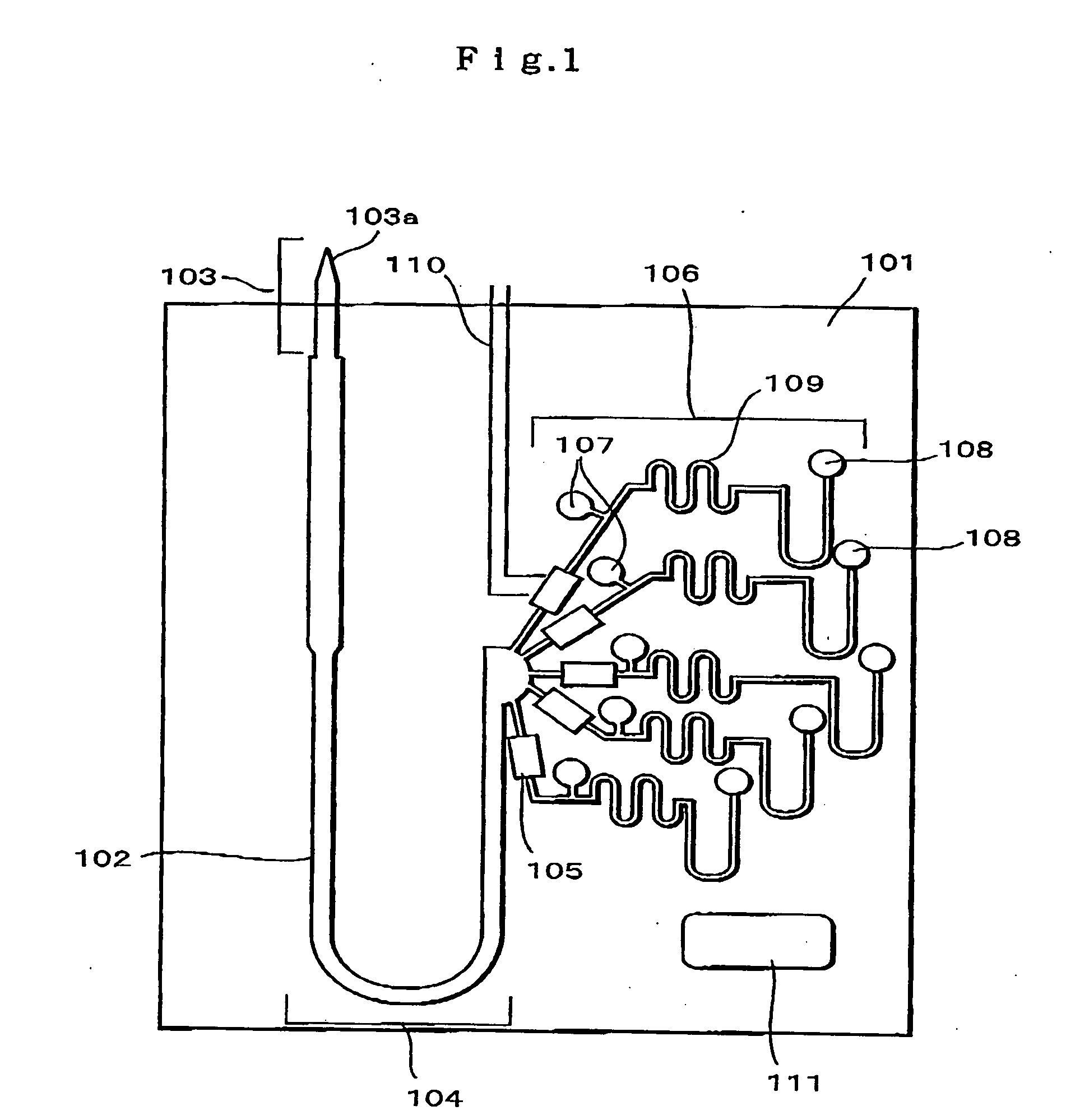

Inductively-coupled plasma torch

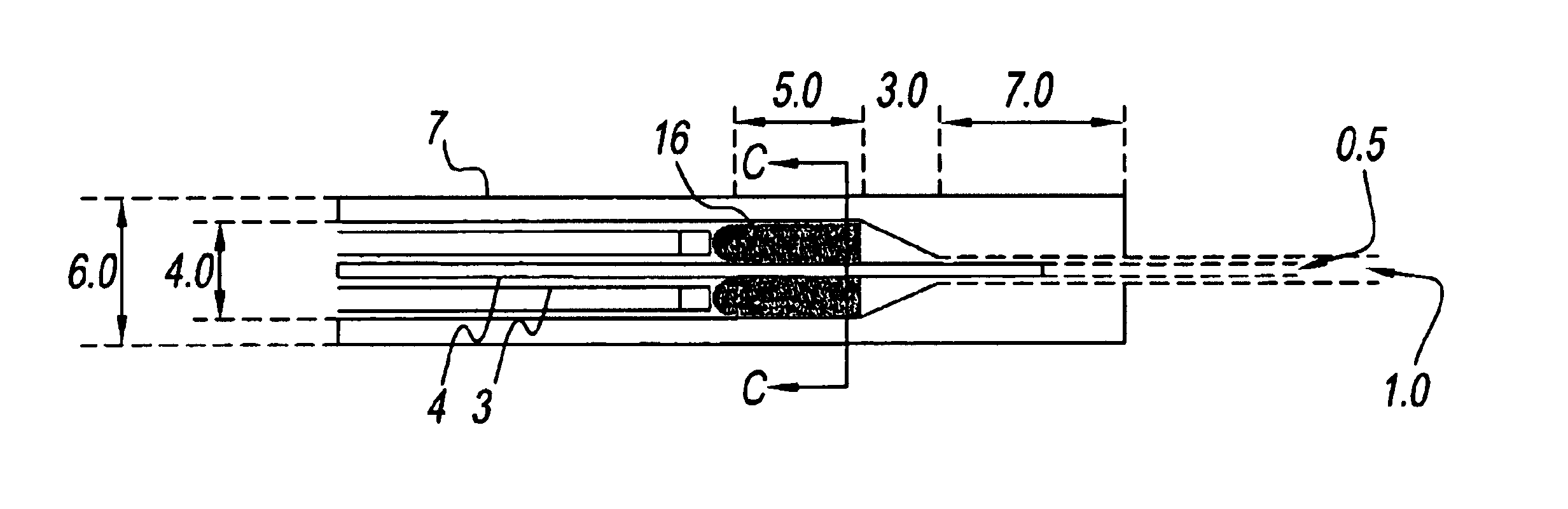

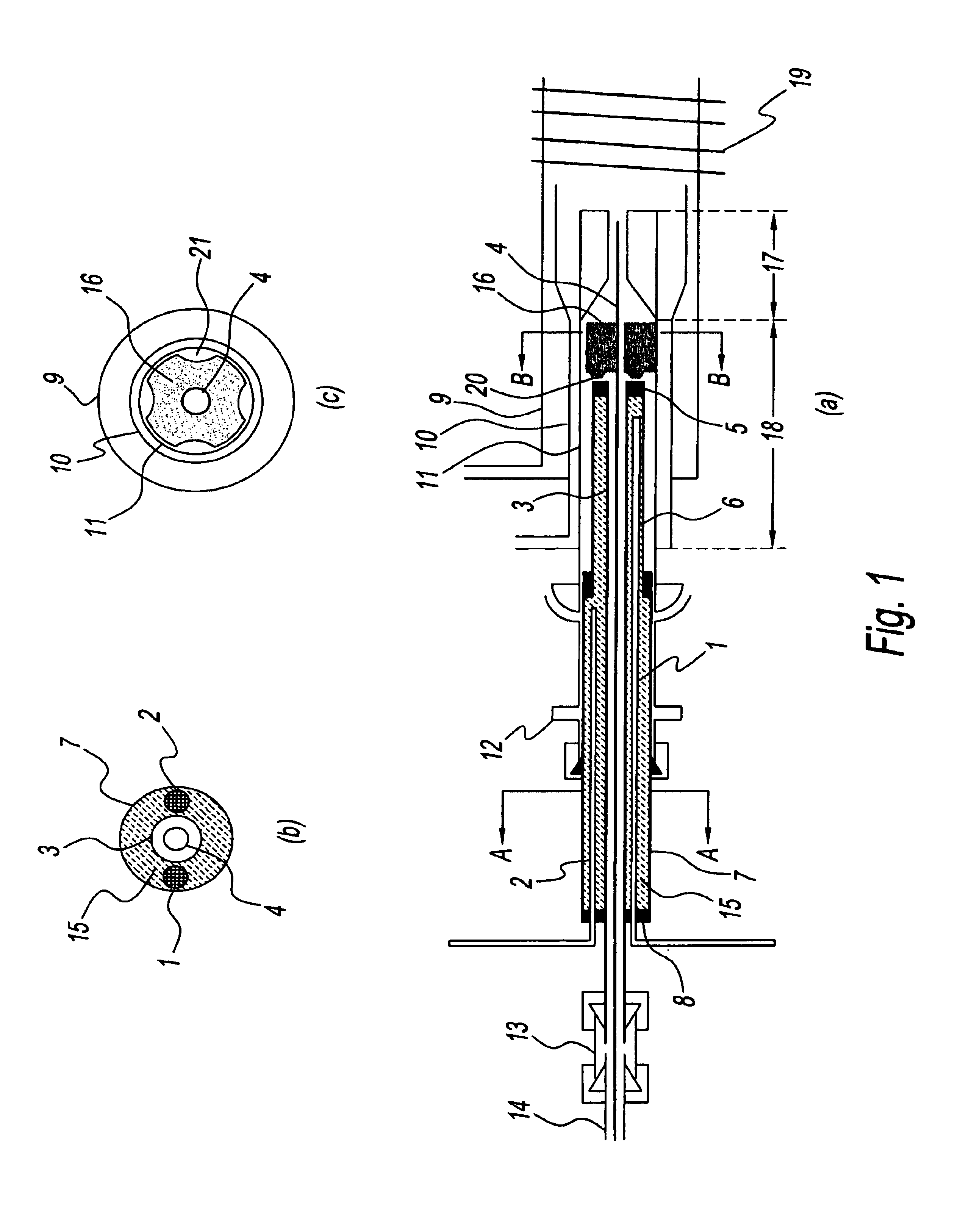

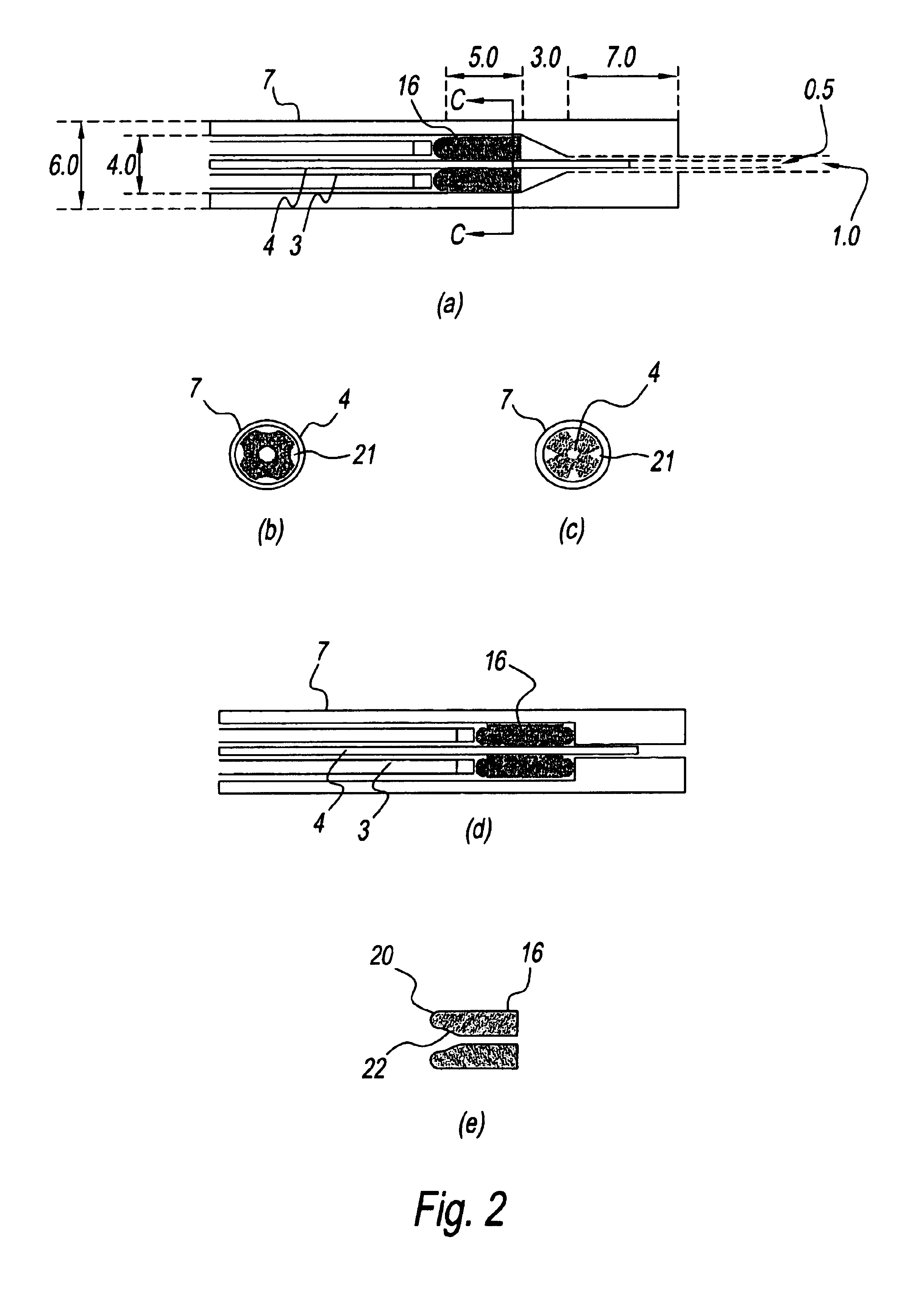

InactiveUS6936787B2Convey evenlyPrecise positioningComponent separationMaterial analysis by electric/magnetic meansTorchEngineering

An inductively-coupled plasma torch capable of holding a capillary tube coaxially with an injector tube and conveying make-up gas smoothly is provided. The inductively-coupled plasma torch of the present invention includes a guide which is held near the end portion of the injector tube, and has a through hole for holding the capillary tube coaxially with the injector tube, and means for conveying make-up gas.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

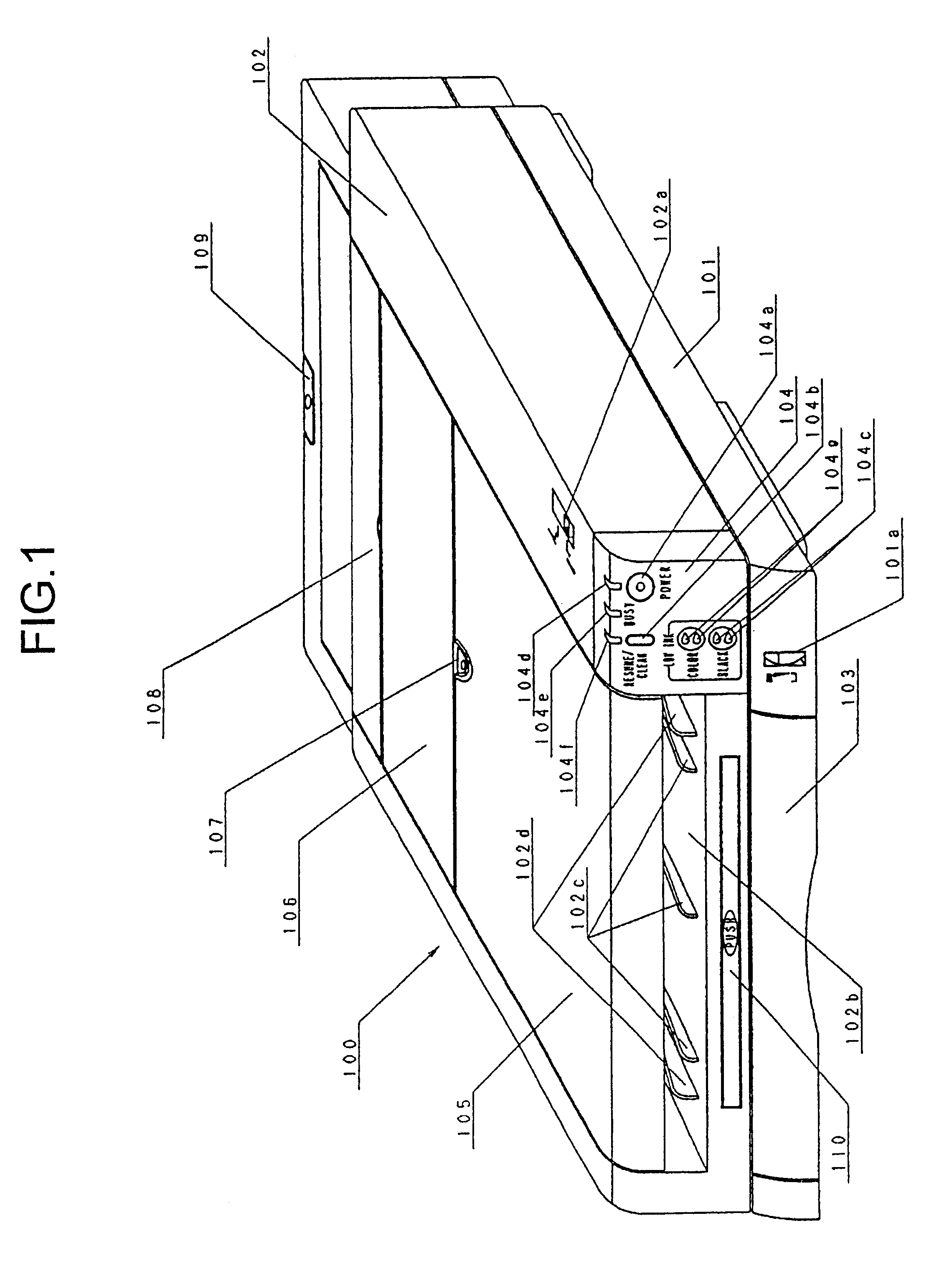

Sheet feeding apparatus and image processing apparatus

Present invention relates to a sheet feeding apparatus for conveying a sheet from a feeding roller to an image processing section, comprising an intermediate conveyance roller disposed between the feeding roller and the image processing section, a drive source providing a rotary drive force to the intermediate conveyance roller, an intermediate conveyance roller moving mechanism for moving the intermediate conveyance roller to be projecting in a sheet conveyance route so as to be conveyable of the sheet when the drive source is driven in one rotational direction and to be escaping from the sheet conveyance route when the drive source is driven in the other rotational direction and an intermediate conveyance roller normally feeding mechanism for rotating the intermediate conveyance roller in only one sheet feeding direction notwithstanding of the rotational direction of the drive source.

Owner:CANON KK

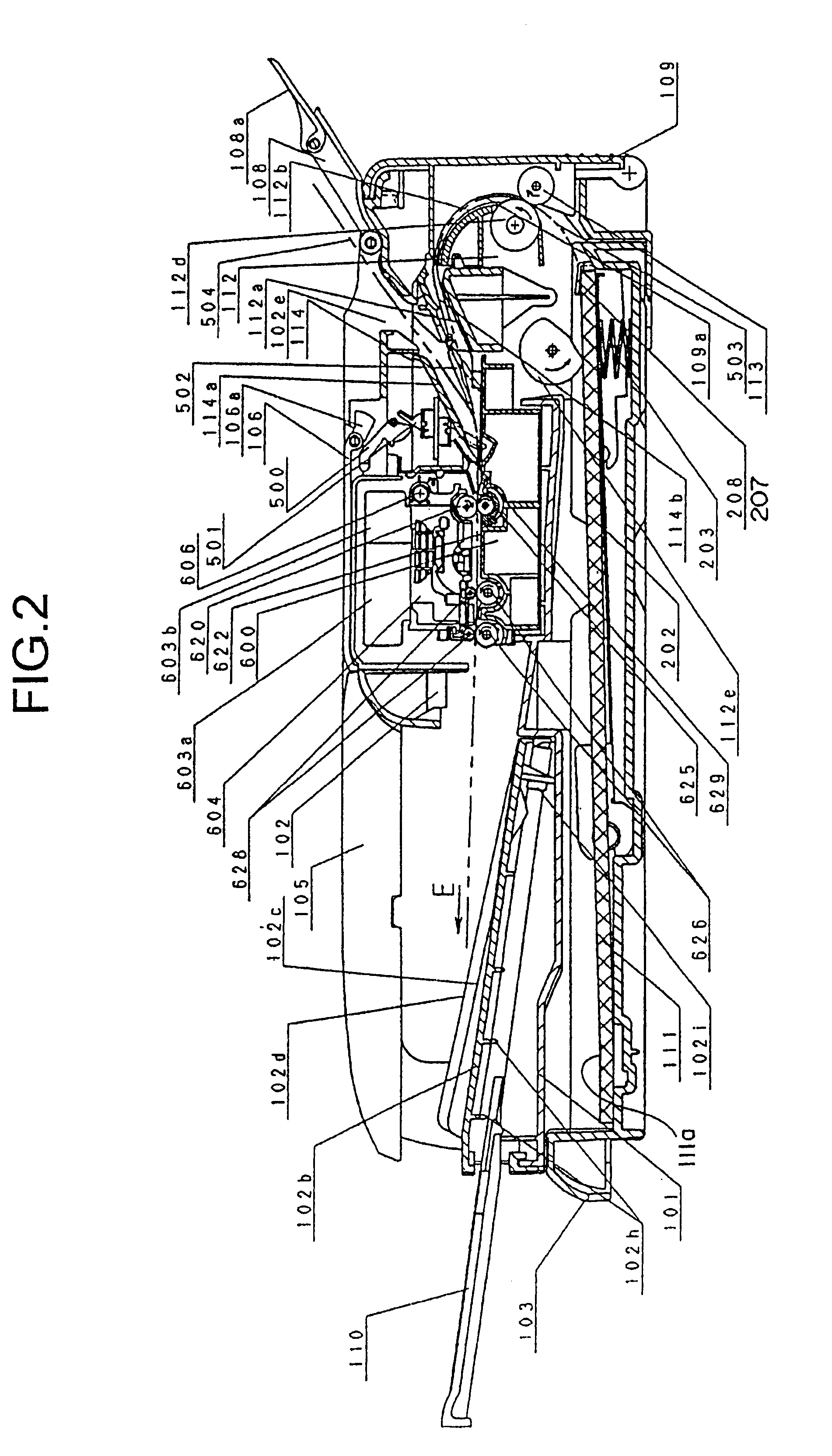

Finisher with increased conveyance speed

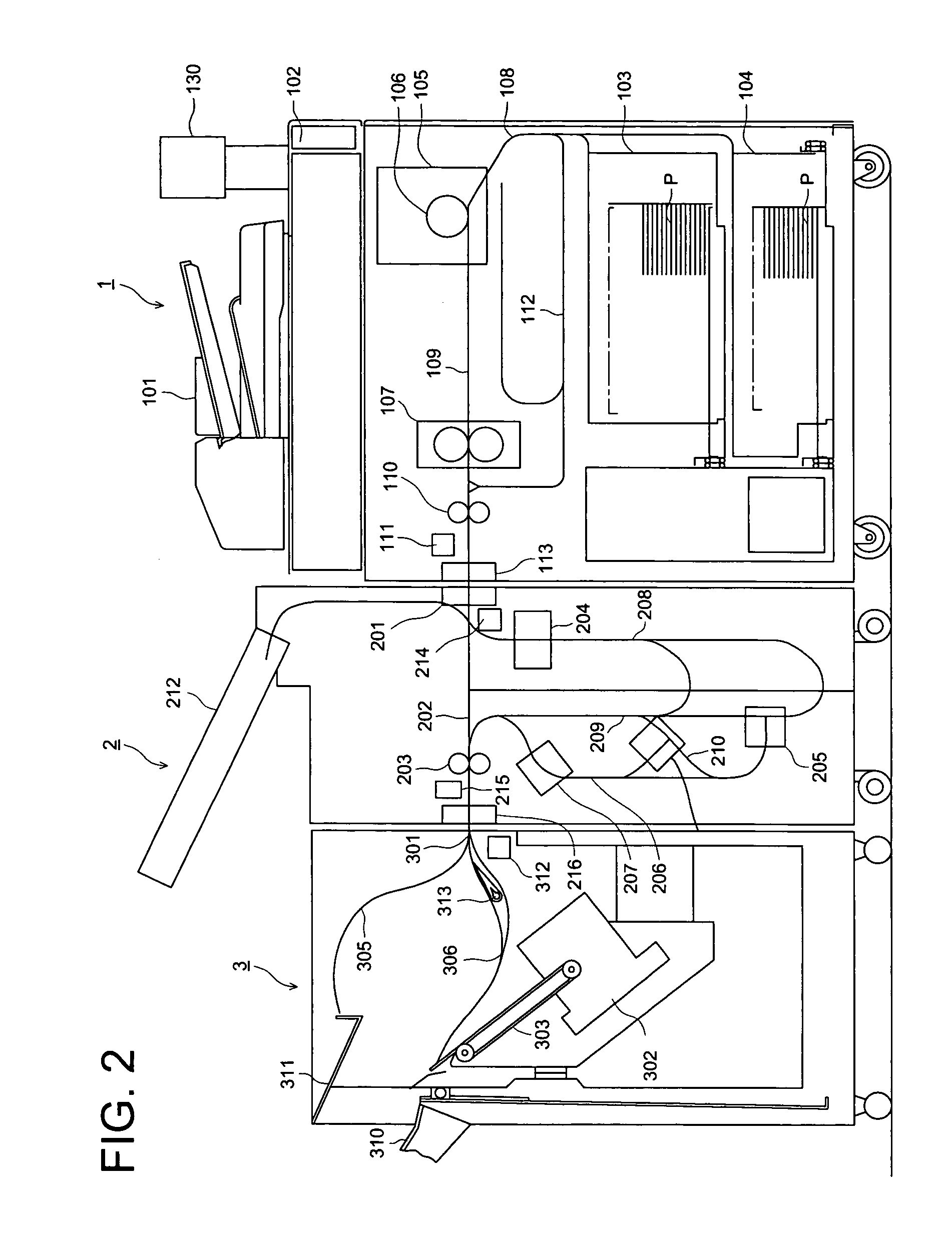

ActiveUS7175173B2Reduce incidenceEasy to controlElectrographic process apparatusArticle feedersEngineeringPaper sheet

An image forming system includes: an image forming apparatus capable of conveying a recording sheet at a predetermined speed; at least one finisher capable of conveying the sheet eject from the image forming apparatus at a prescribed speed to process the sheet; and a controller for changing a conveyance speed of the recording sheet in the finisher to be higher than that of the sheet in the image forming apparatus.

Owner:KONICA MINOLTA BUSINESS TECH INC

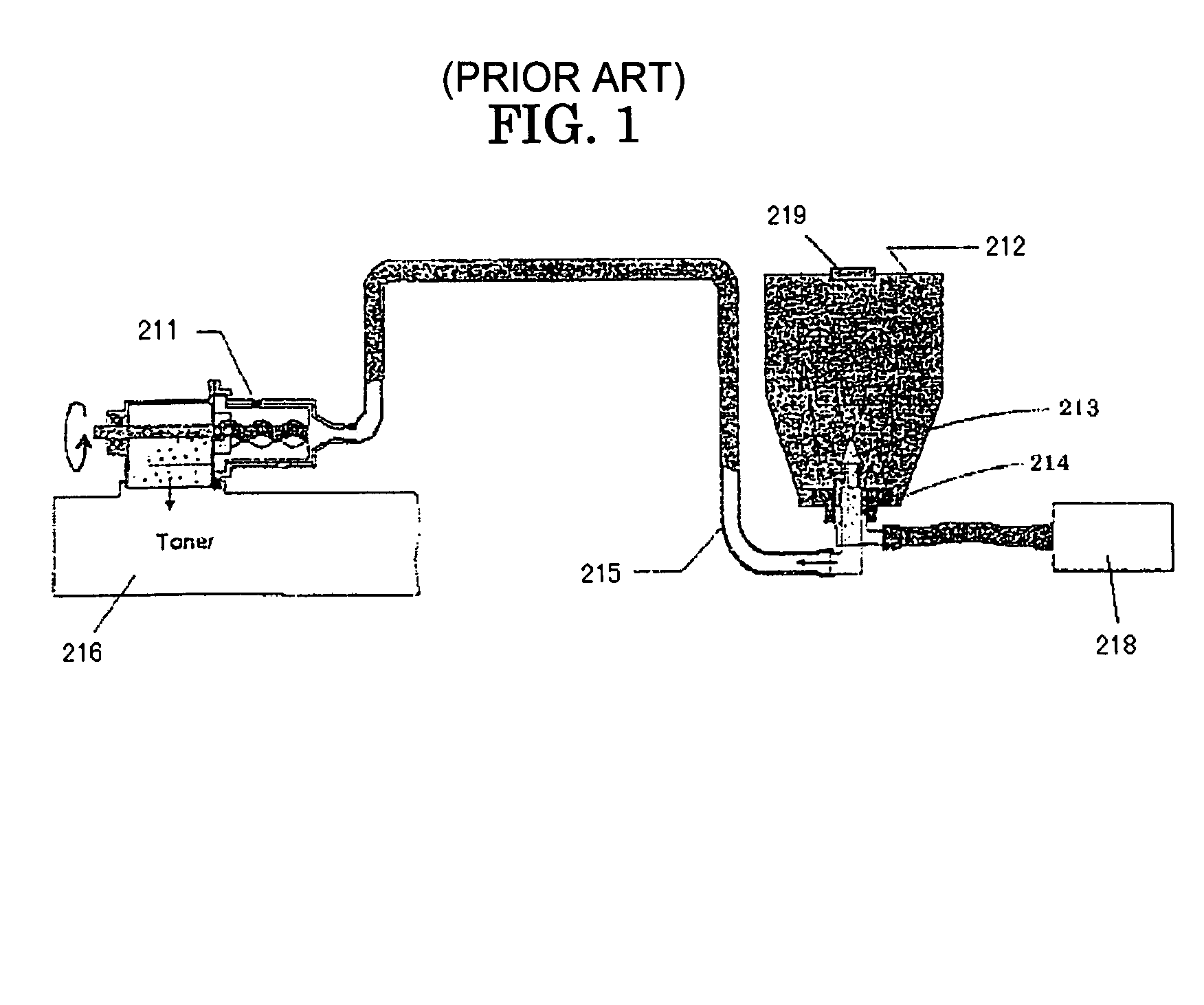

Toner supplying device, toner supplying process, image forming apparatus, and image forming process

InactiveUS7283772B2Convey evenlyImprove liquidityElectrographic process apparatusImage formationEngineering

The present invention provides toner supplying devices, toner supplying processes, and the like that control bulk density of a mixture of toner and gas efficiently thereby enhancing the fluidity of the mixture, and maintaining the high fluidity for a long period. The invention includes a toner supplying device that has a toner containing portion configured to store a toner, a toner outlet configured to discharge the toner from the toner containing portion, a conveying pipe configured to convey the toner, and a gas feeding unit configured to feed a gas. The toner supplying device supplies the toner from the toner containing portion to an image forming unit of an image forming apparatus. A porous member is disposed near the toner outlet, and the gas is fed into the toner containing portion through the porous member.

Owner:RICOH KK

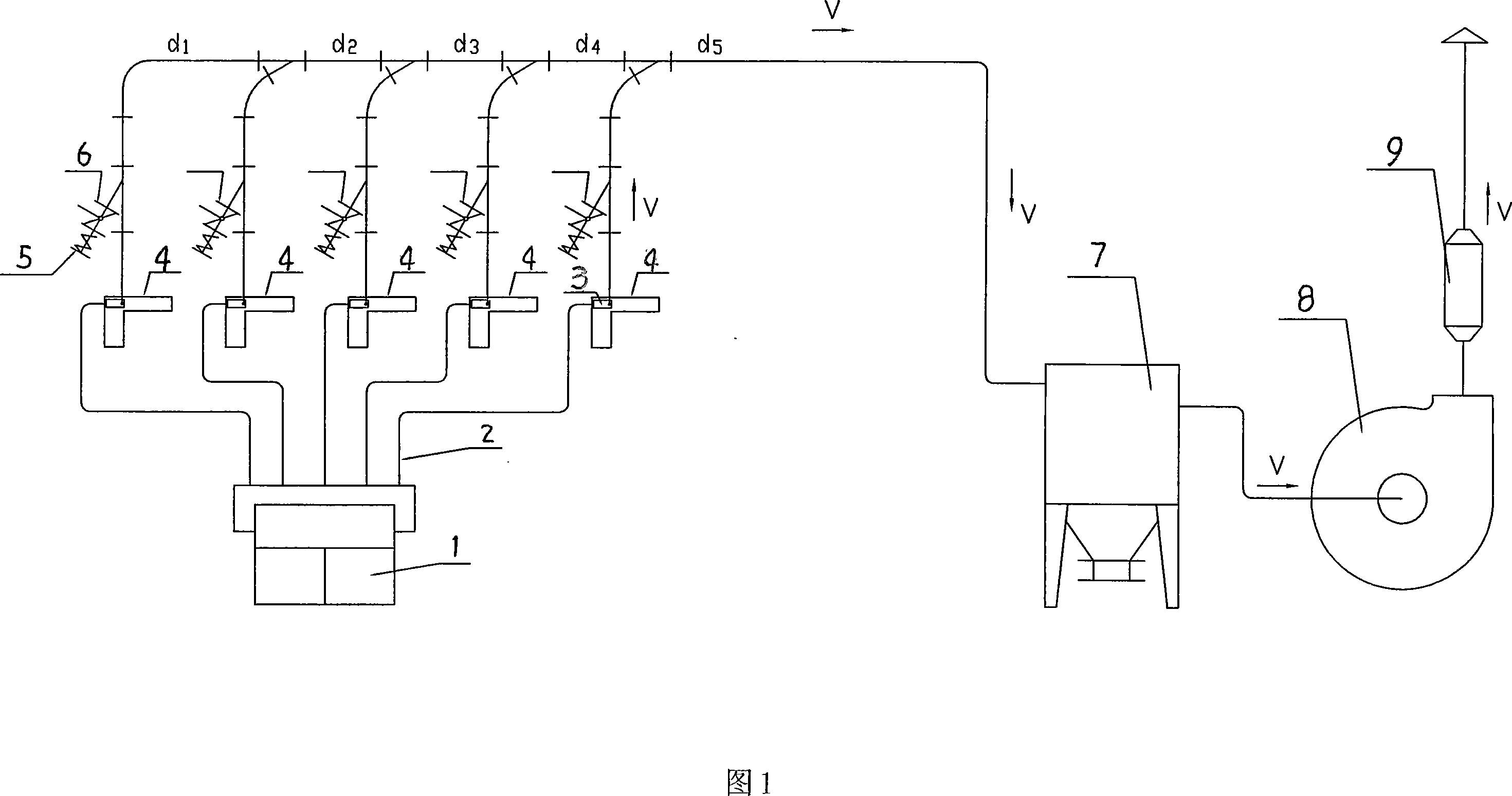

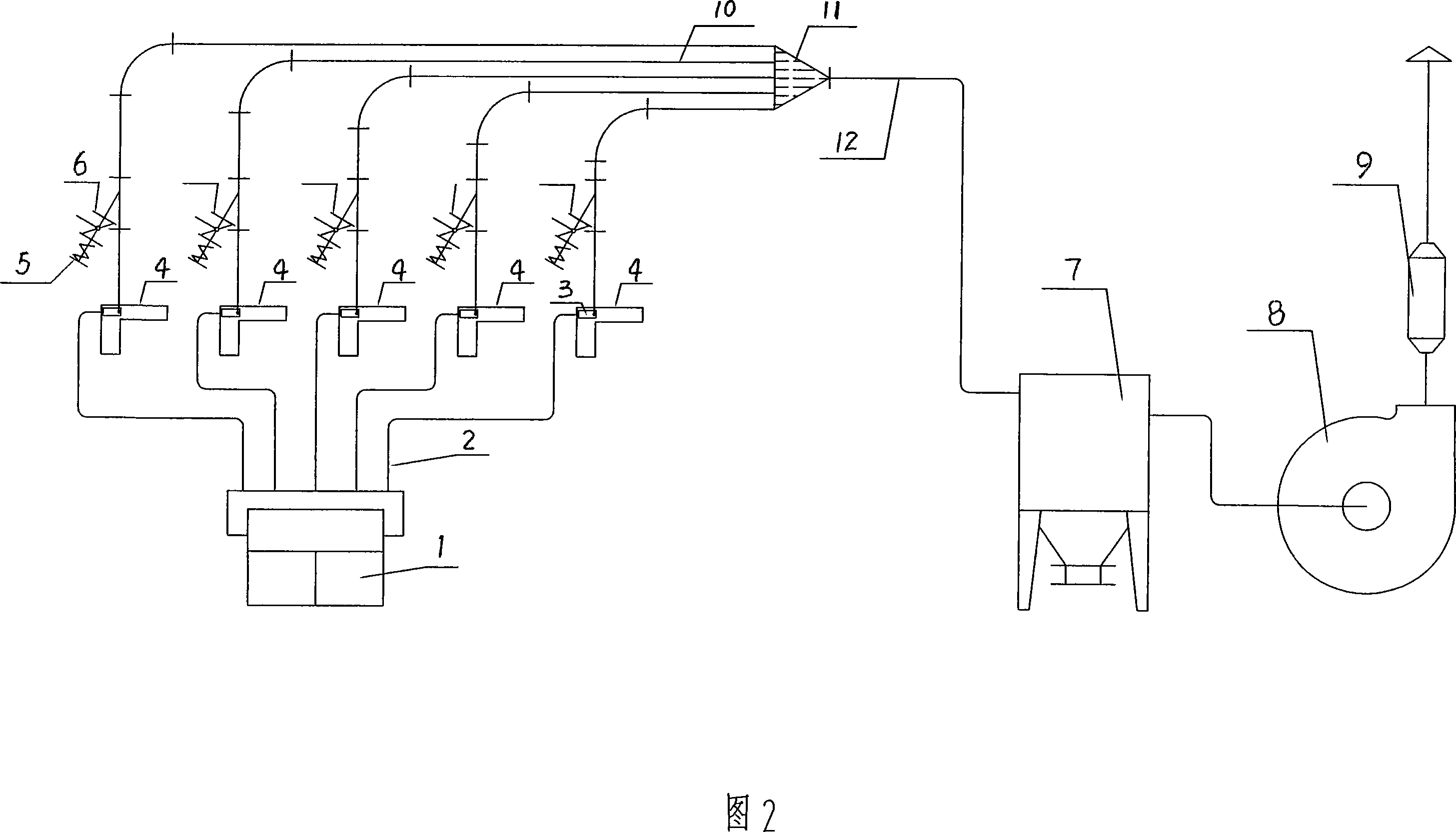

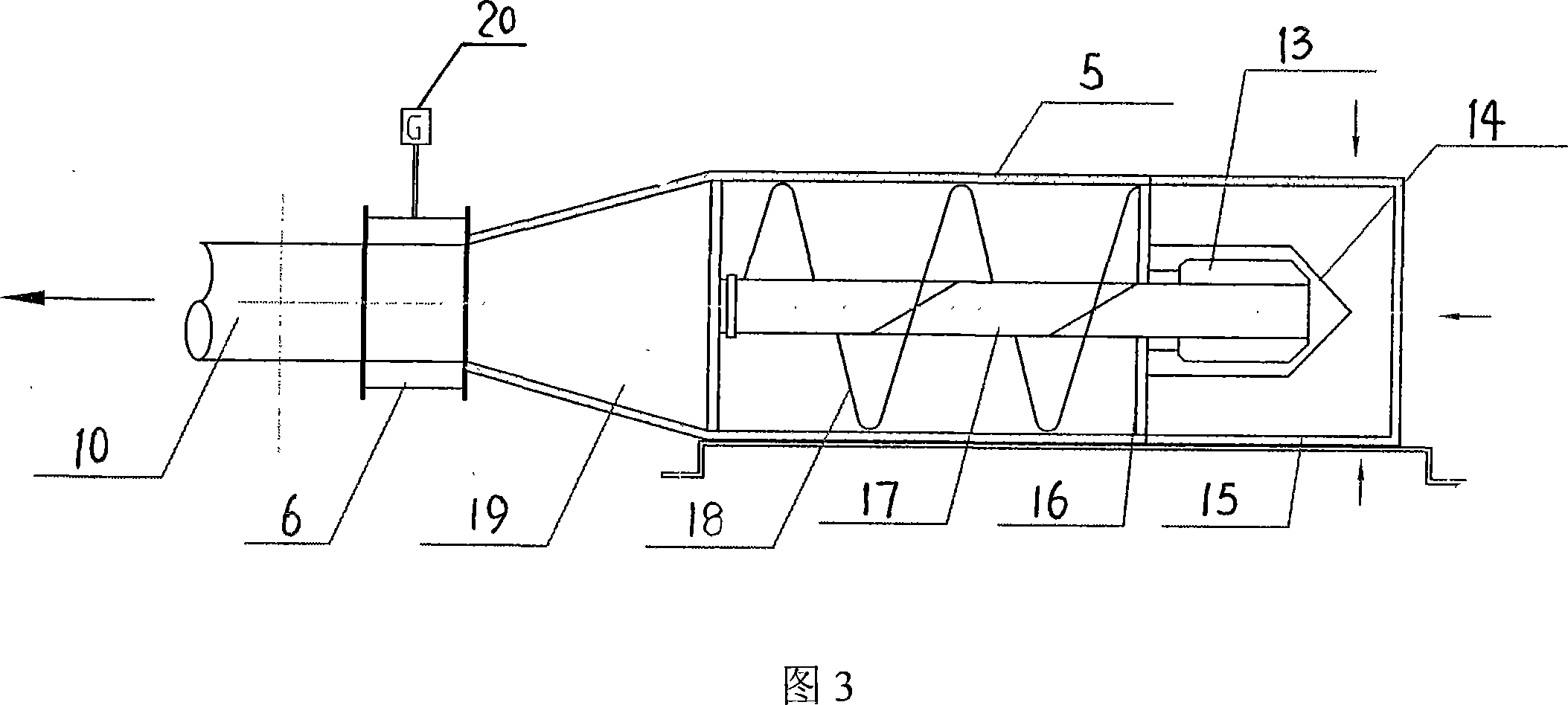

Binary isogram replacing constant-speed pneumatic conveying method

ActiveCN101134531ADampen wild swingsGuaranteed uptimeCigarette manufactureBulk conveyorsMaterial consumptionWorking set

The binary equivalent substitution constant speed pneumatic conveying process for multiple branch pipe negative pressure dilute phase pneumatic conveying system features that in a working set possessing branch pipes with pneumatic valve and damper and when some branch pipe is cut off suddenly, each of the other branch pipes inside the system is equivalently supplemented with corresponding air quantity and wind pressure. The process can convey material reliably and fluently in balance with minimized physical and chemical damage, and reach the aims of lowering material consumption, lowering cost and raising product quality.

Owner:邝勇兴

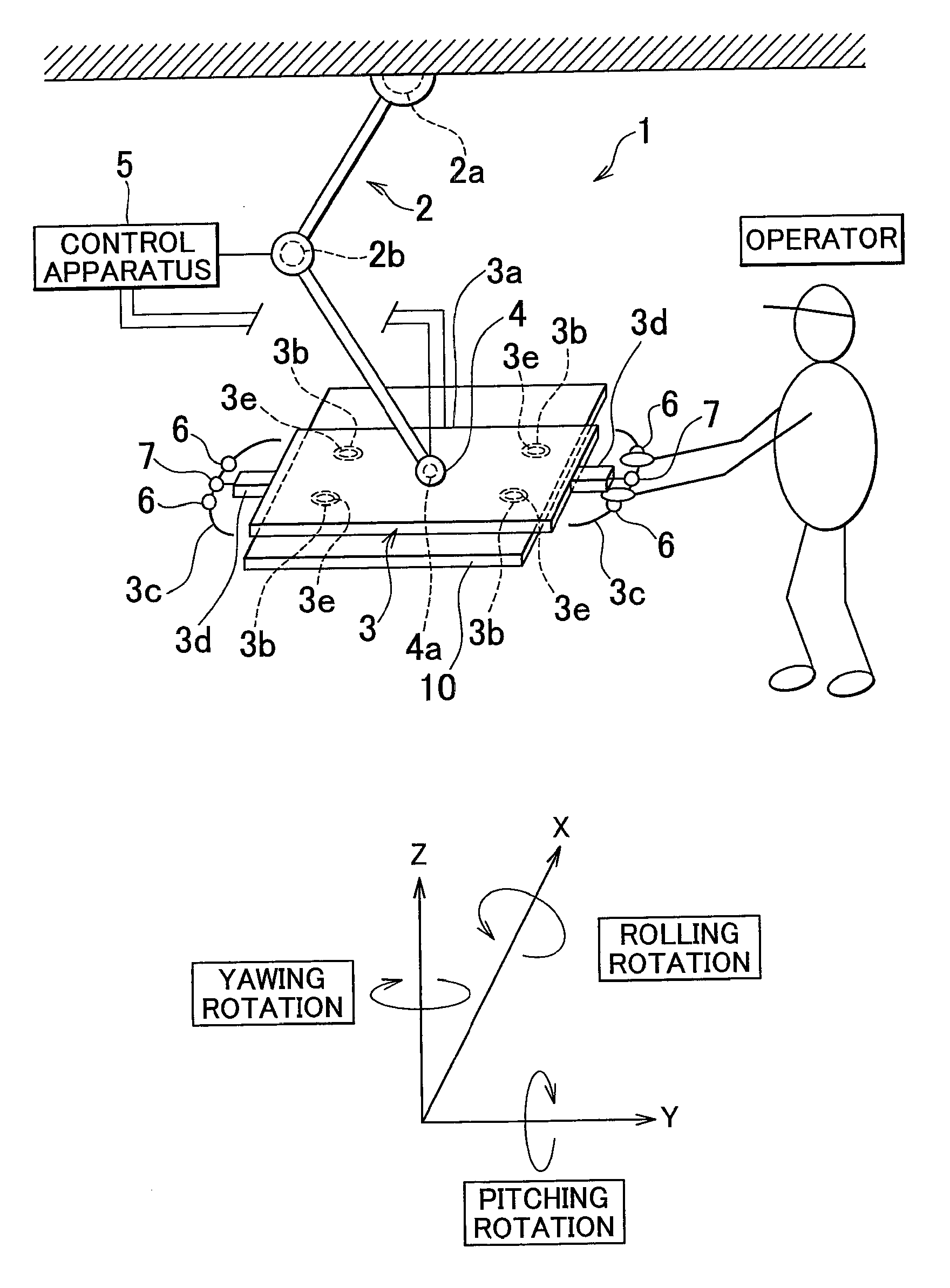

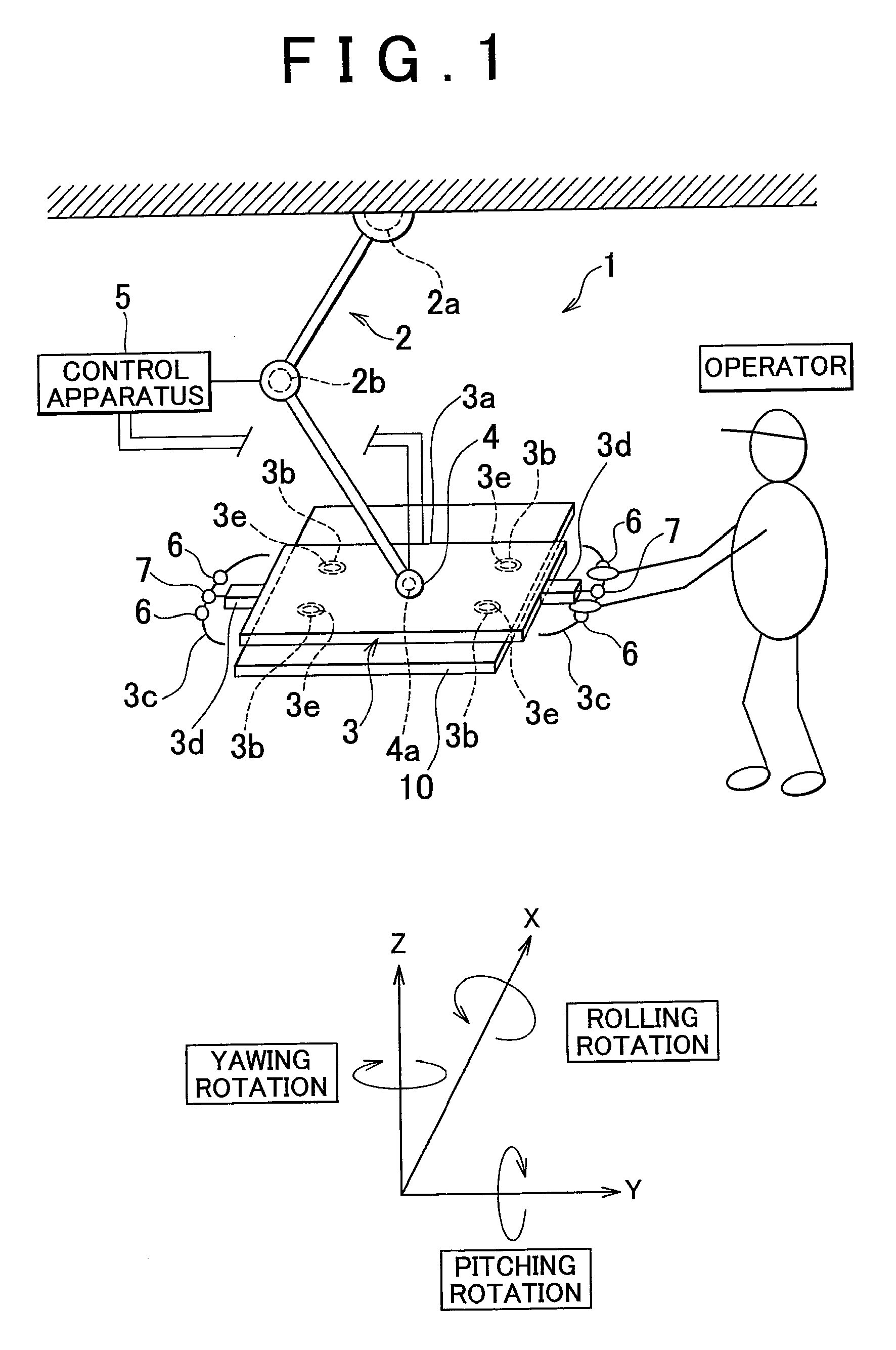

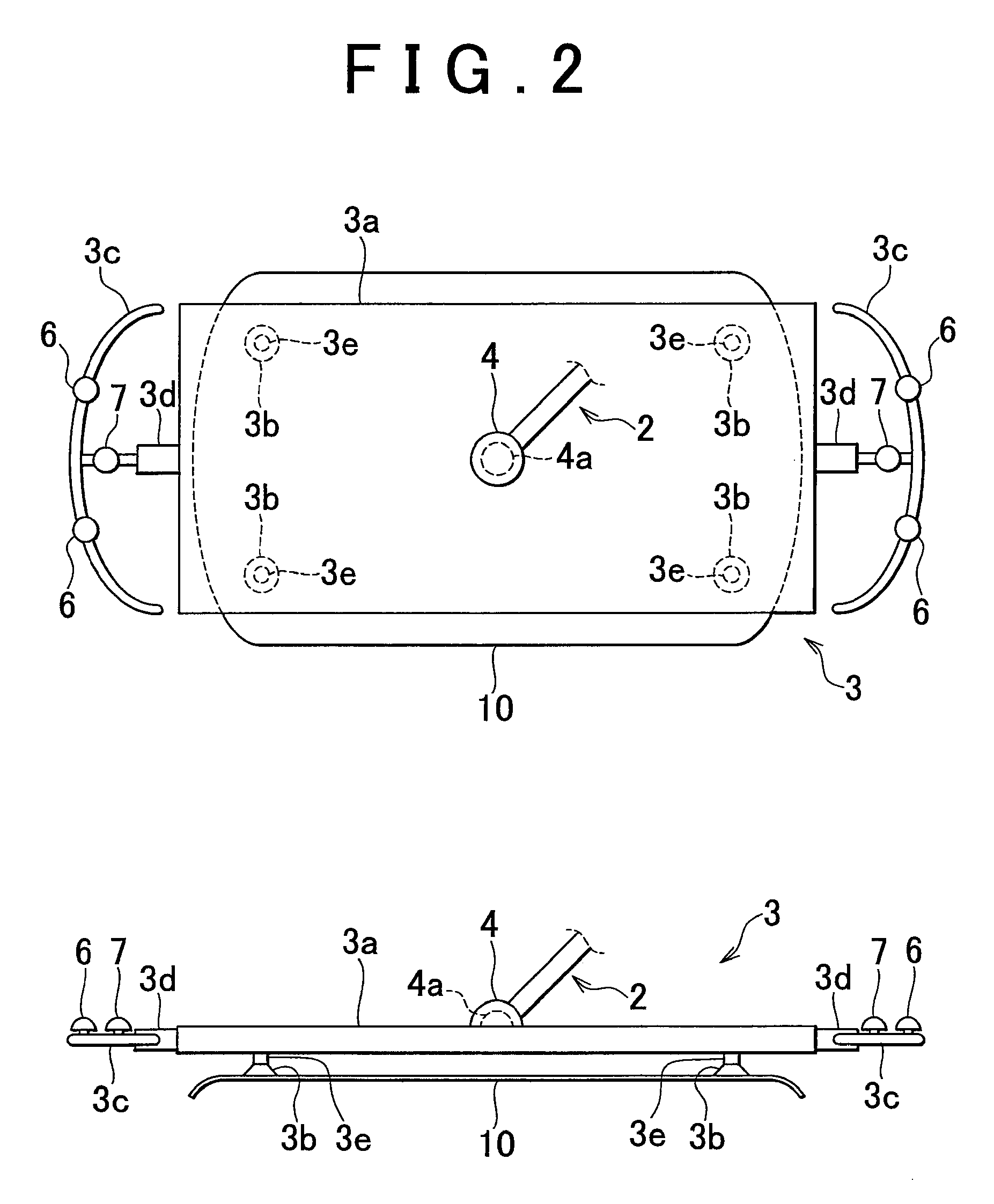

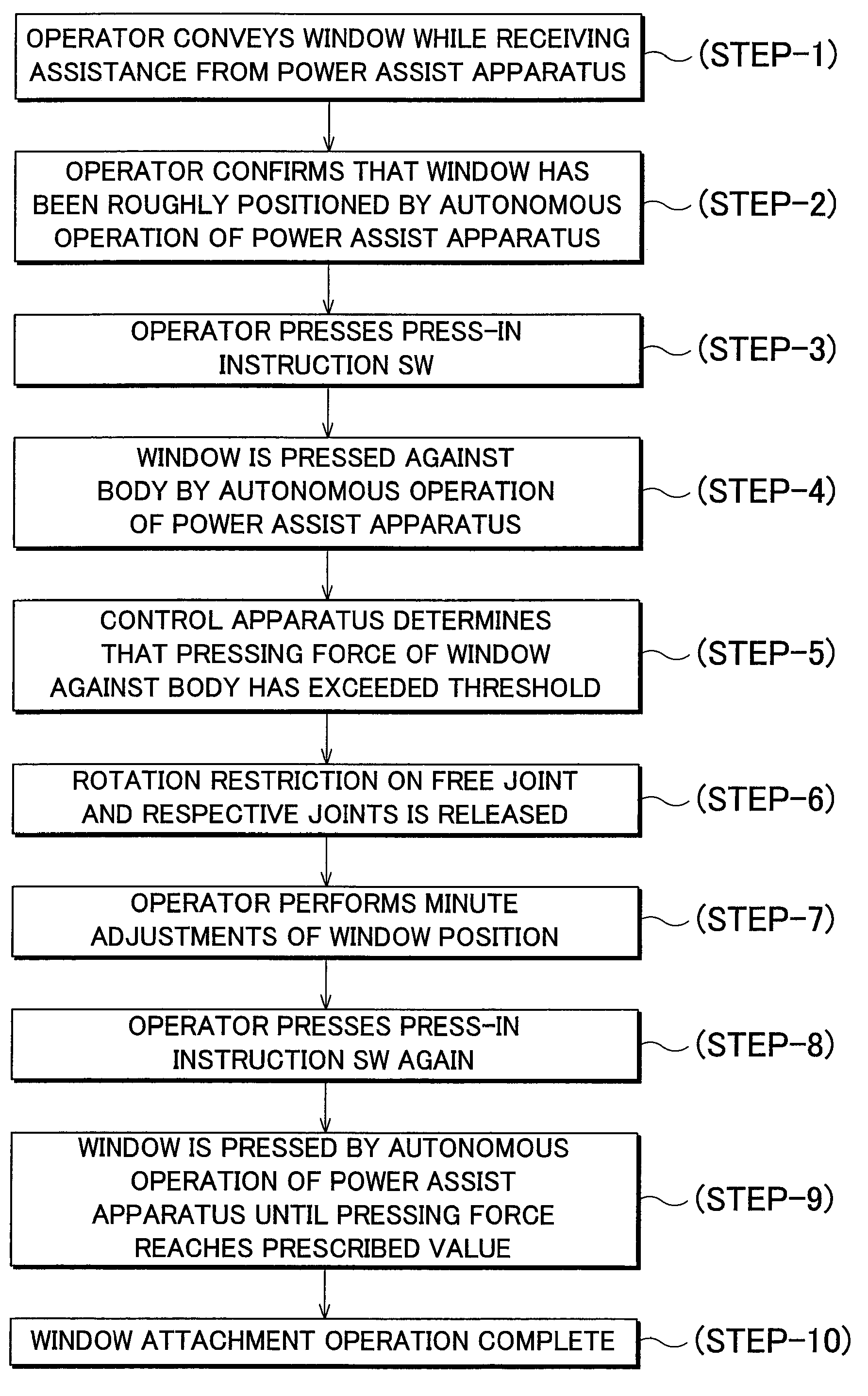

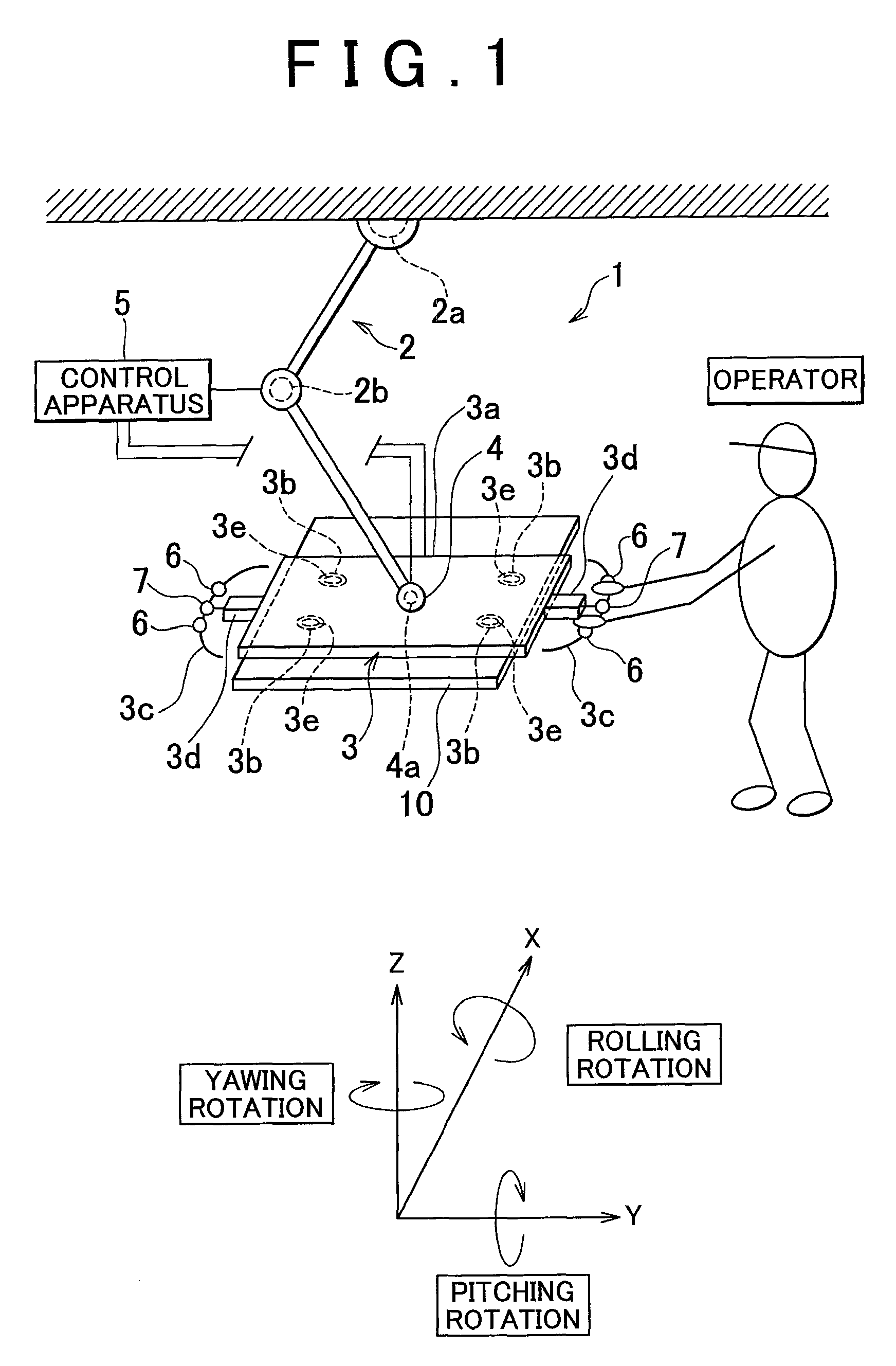

Power assist apparatus and control method thereof

ActiveUS20090216378A1Precise positioningImprove efficiencyProgramme-controlled manipulatorDigital data processing detailsEngineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

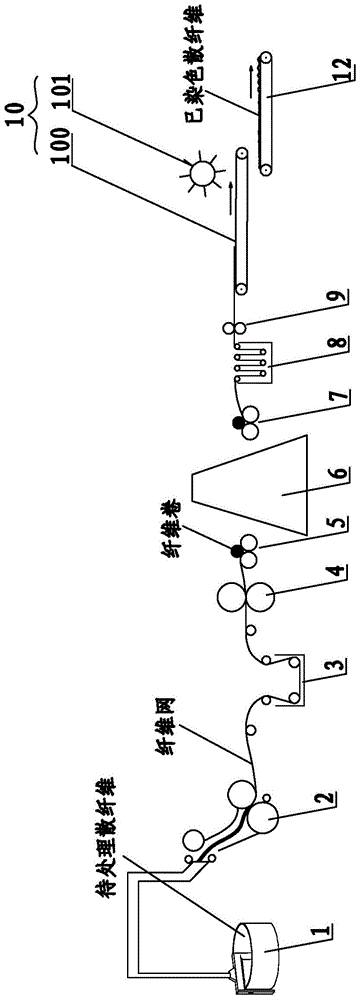

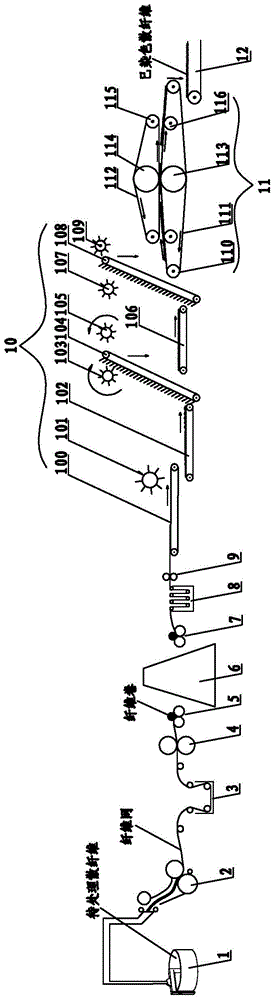

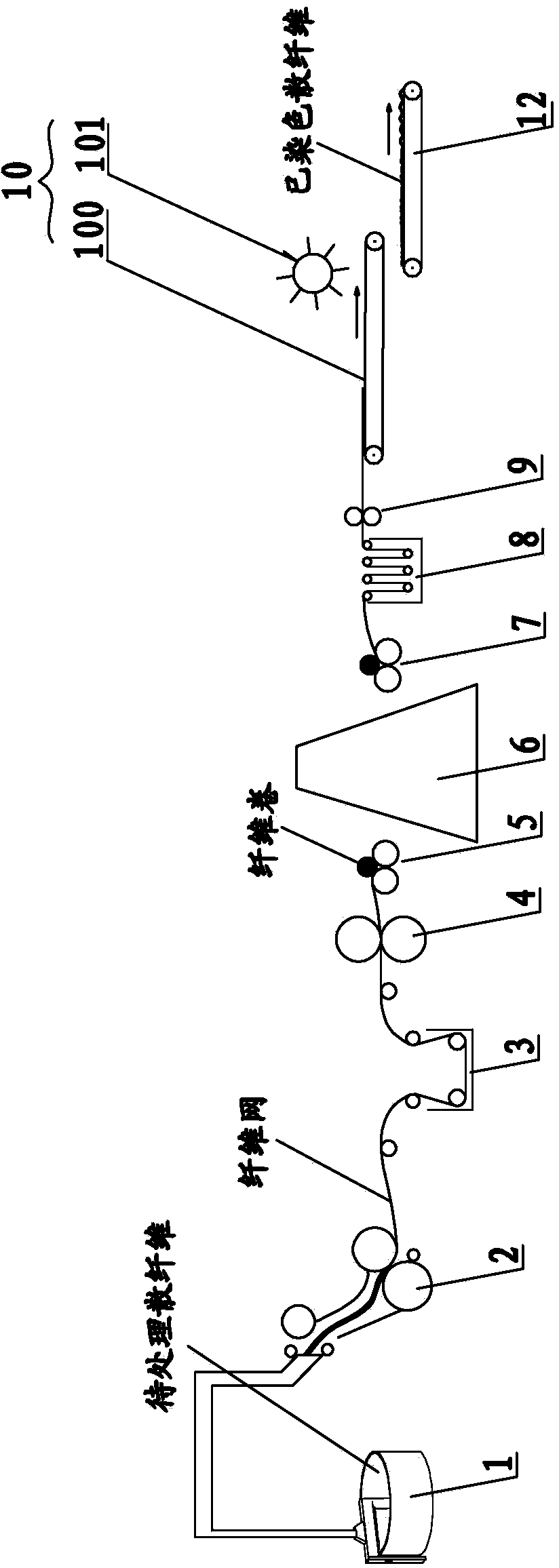

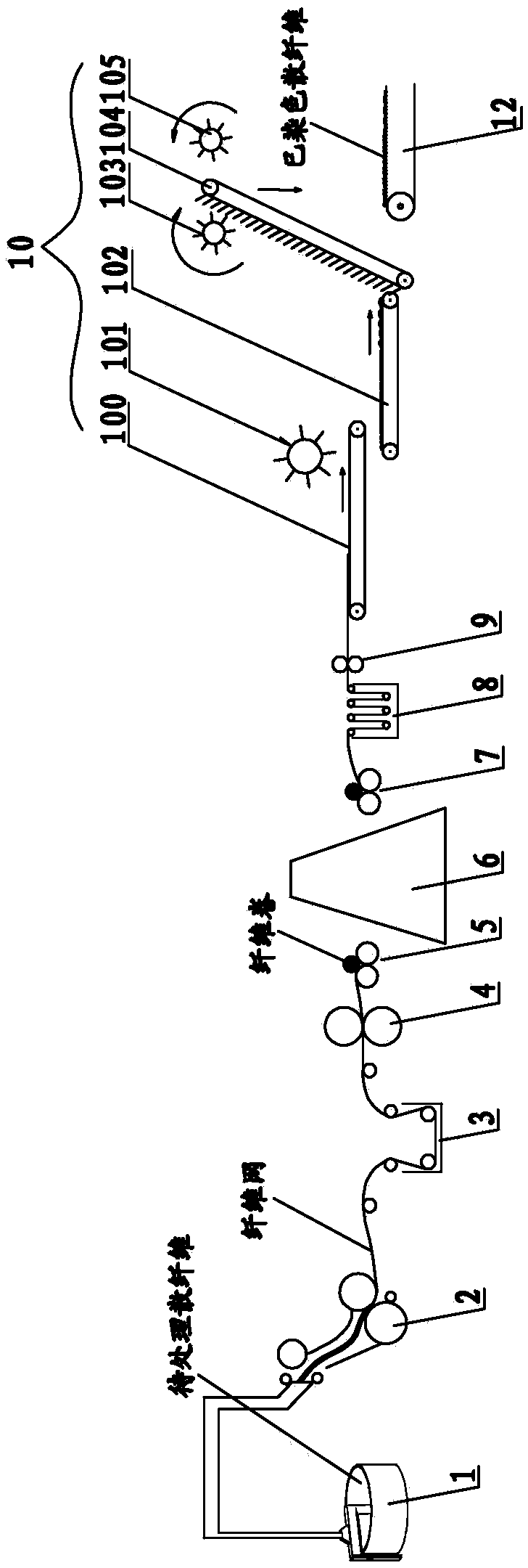

Automatic green tea leaf storing and withering production line

ActiveCN102524445ASimple structureLow costPre-extraction tea treatmentProduction lineEconomic benefits

The invention relates to an automatic green tea leaf storing and withering production line. the production line is characterized by comprising a green tea leaf lifting and conveying mechanism for feeding material at a start end, wherein the upper end of the green tea leaf lifting and conveying mechanism leads to a green tea leaf storage box blanking mechanism arranged above a green tea leaf storage box, a humidifying device is arranged beside the green tea leaf storage box and leads to the inner cavity of the box from the bottom of the green tea leaf storage box, a conveyor belt is arranged at the bottom of the green tea leaf storage box, a plurality of rotating shafts are arranged vertically side by side on one side of the discharge end of the green tea leaf storage box, a shifting rod for spreading green tea leaves is arranged on each rotating shaft, a green tea leaf vibrating conveying mechanism is arranged below the discharge end side of the green tea leaf storage box, the discharge end of the green tea leaf vibrating conveying mechanism leads to an energy-saving green tea leaf withering device through a lifter to perform withering and cooling. The production line is simple inwhole structure, low in manufacturing cost, can implement flow line production of tea leaves, can improve the automation degree of early-state processing of tea leaves and can reduce workload and improve production capacity on the condition that the quality of tea leaves is ensured; therefore, higher economic benefit is created for enterprises.

Owner:DABUTONG TEA IND FUJIAN

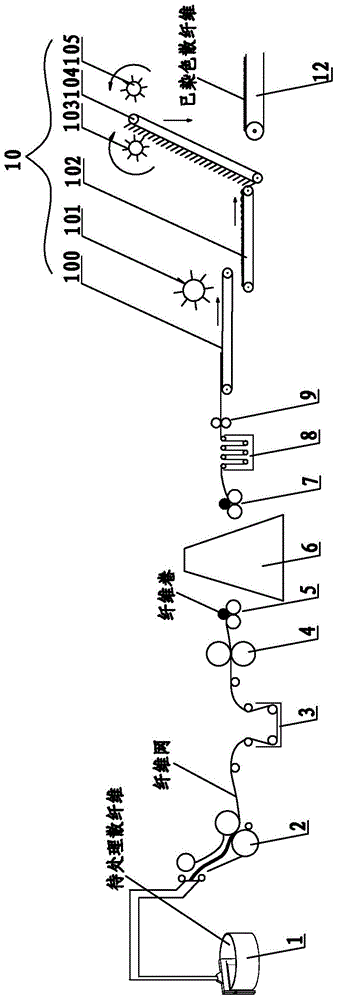

Loose fiber dyeing process

ActiveCN103911782AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberPolymer science

The invention relates to a loose fiber dyeing process and belongs to technical field of fiber dyeing. The process sequentially includes: grabbing cotton, forming nets, soaking, mangling, forming rolls, cold piling, unrolling, washing, squeezing, splitting, spreading and drying. Squeezed loose fibers are fed to the spreading procedure after splitting, the loose fibers are squeezed at the squeezing force of 3-15kg / cm<2> under the premise of not damaging the fibers, the squeezed dyed fibers are directly fed through a lower conveying belt to an eight-cage dryer or a loose fiber high-frequency dryer for drying. By the process, the defects that continuous production cannot be performed and machining efficiency is low in conventional technologies are overcome, the defects that of uneven dyeing, low drying efficiency, large energy consumption and the like when the loose fibers are dried in a net structure are overcome, fiber damage is low during processing, and the quality of the finished fibers is guaranteed.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

High-pressure continuous dense-phase biomass powder conveying device with height of delivery outlet adjustable

InactiveCN101863383AContinuous and stable deliveryConvey evenlyBulk conveyorsCombustionProcess engineering

The invention discloses a high-pressure continuous dense-phase biomass powder conveying device with the height of a delivery outlet adjustable, which comprises a storage silo, at least two feeding silos and a delivery silo. The principle is that the two transitional feeding silos are arranged between the storage silo and the delivery silo, are respectively provided different air ducts communicated with a main air pipeline and can control the interactive and continual feeding to the delivery silo according to the time sequence through changing the pressure difference between the two feeding silos, so that the level in the delivery silo is maintained no lower than the low level, thereby realizing the continuous and stable conveying of biomass powder to gasification equipment. The device is mainly applied in the biomass powder pressurization and gasification plant and the continuous combustion device of the biomass powder, no blockage can occur to the conveying process, and the biomass powder is conveyed continuously, smoothly and uniformly with low pulsation. Therefore, the conveying device satisfies the requirements for pressurization and gasification of the biomass powder.

Owner:合肥天焱绿色能源开发有限公司

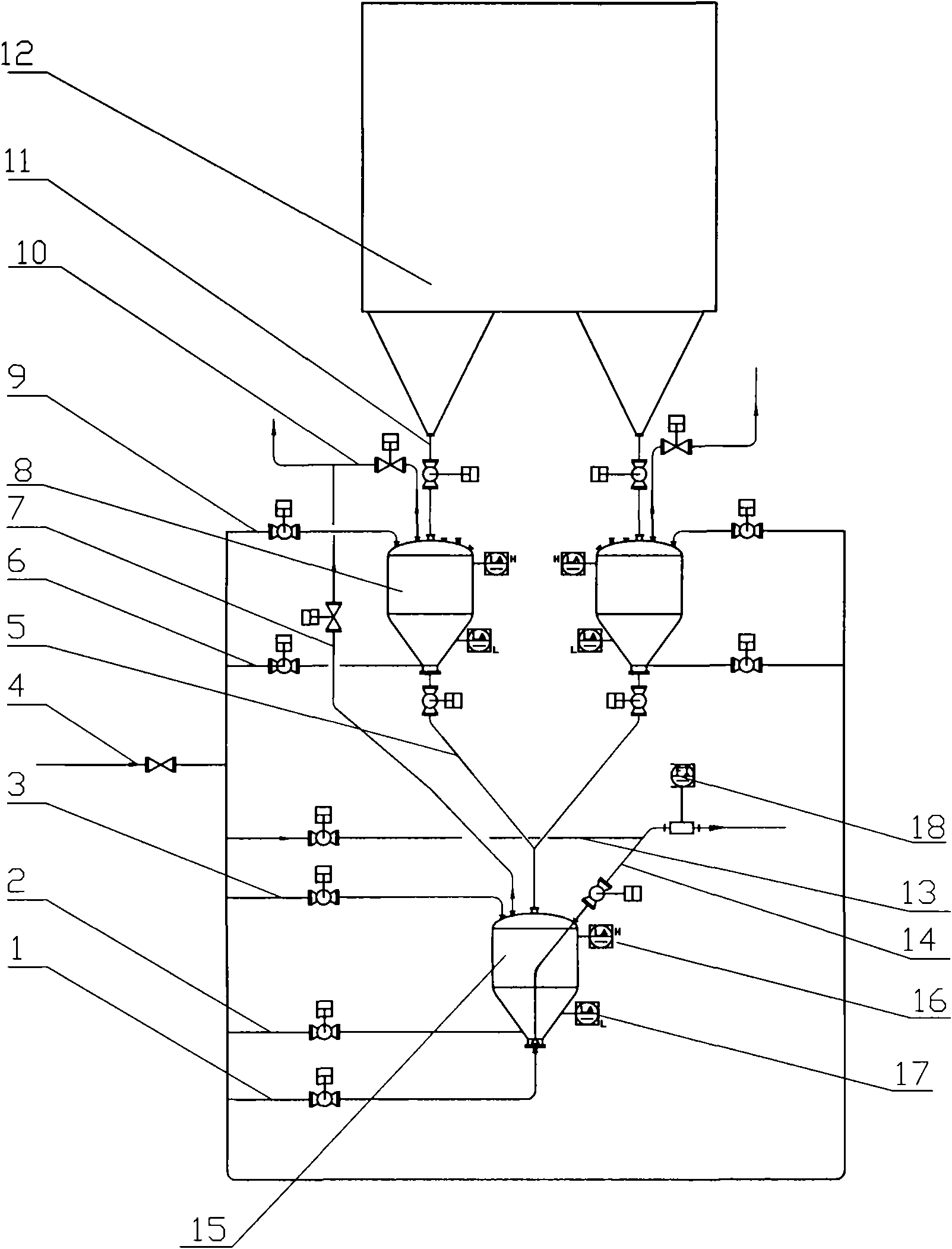

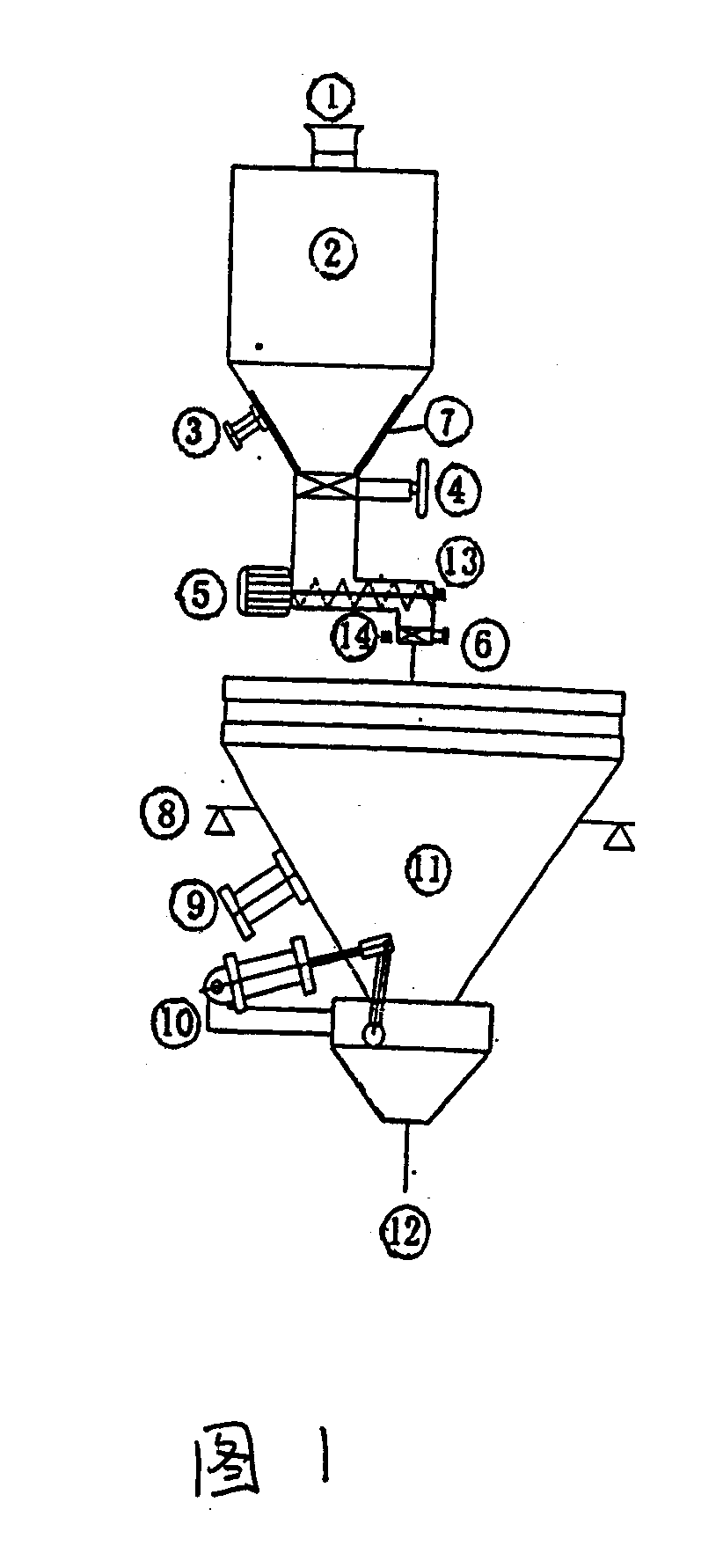

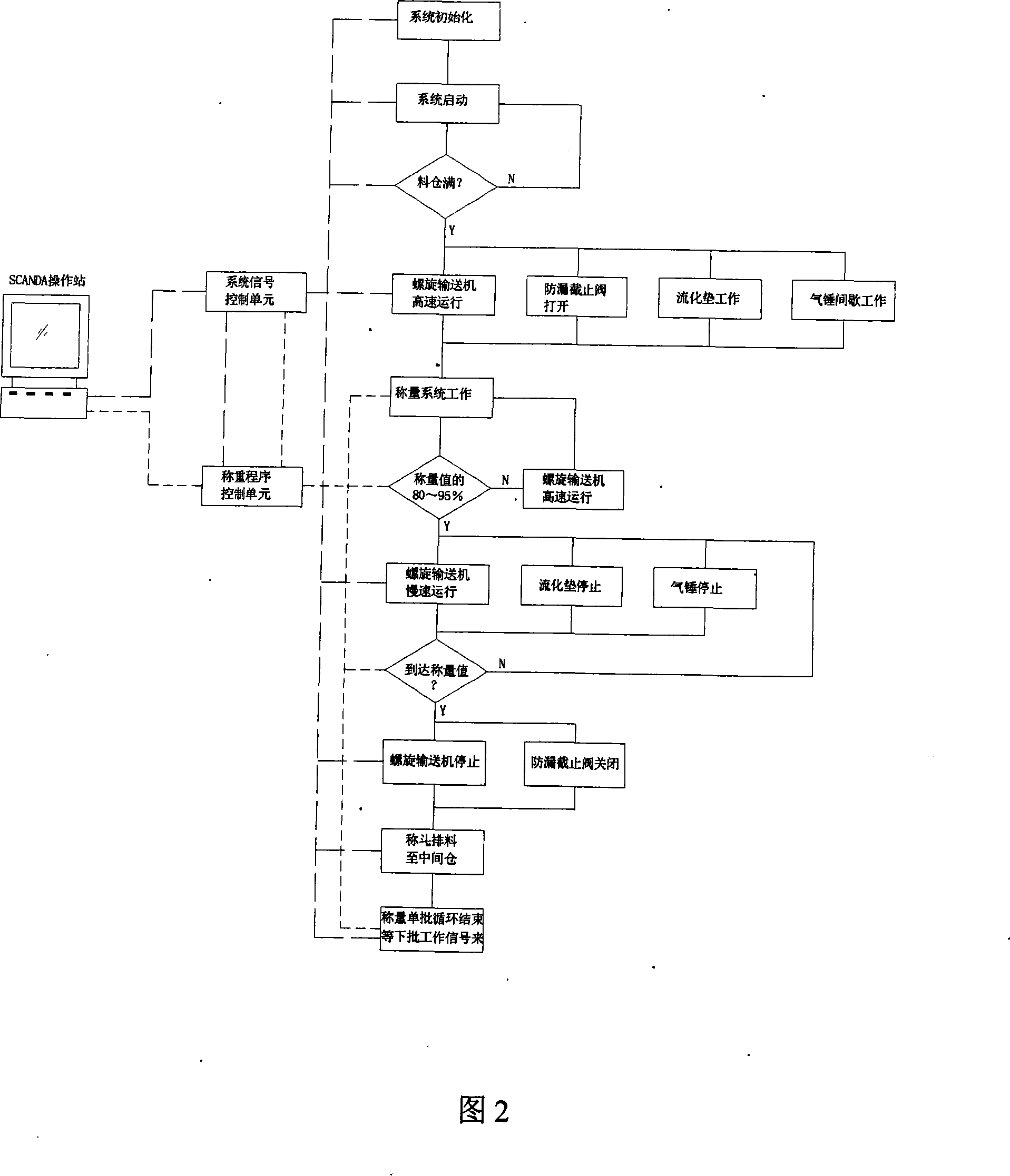

Device and method for micro-control of batches weighing device precision

InactiveCN101251408AConvey evenlyAdjustable speedWeighing apparatus with automatic feed/dischargeMaster stationEngineering

The invention relates to a micro-control device and a control method for the accuracy of an batch weighing device. Because the batches of substrate glass are characterized in a plurality of varieties, big difference between the proportions of the batches, high requirement on the error accuracy and high speed requirement on the batching efficiency, the invention consists of a series of mechanisms such as a fluidization cushion, a screw conveyor, a leakage proof stop valve, etc. on the base of meeting the requirements of the batch production process flow. An electrical system is adopted for the weighing control, and the control unit and a master station signal controller adopt the scheme of time sharing and synchronous scanning treatment, thereby meeting the fast-response requirement of the batch weighing device, the stability of the systematic adjustment and the accuracy of the batch weighing.

Owner:陕西彩虹电子玻璃有限公司

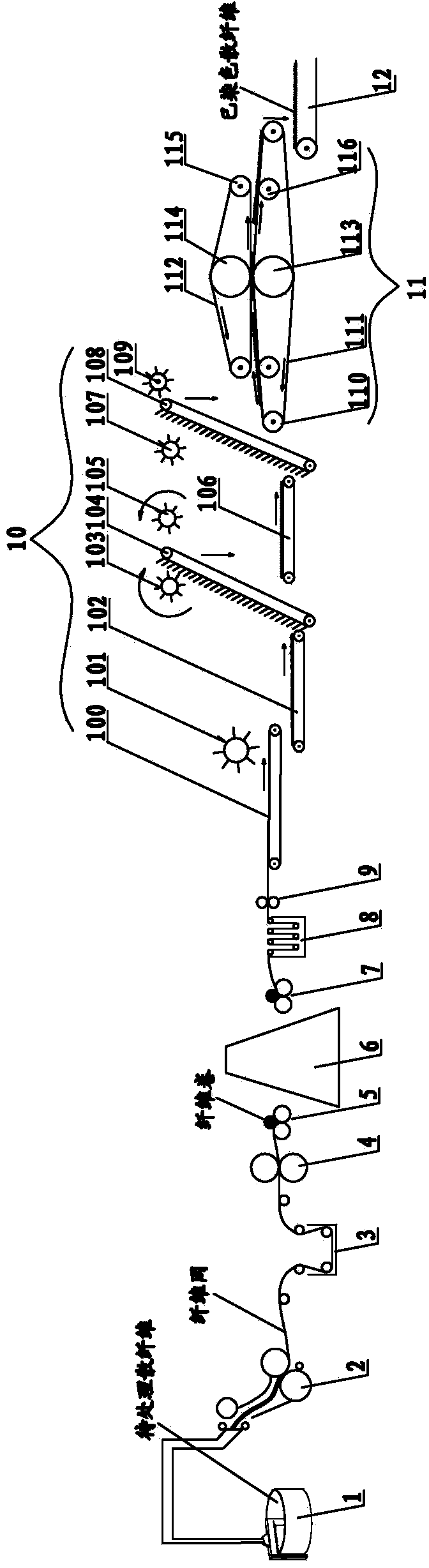

Loose stock dyeing device

ActiveCN103882637AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberProcess efficiency

The invention relates to a loose stock dyeing device and belongs to the technical field of stock dyeing devices. The loose stock dyeing device comprises a cotton grabbing device, a net forming device, a steeping device, a mangle device, a coiling device, a cold-batch fixation device, a uncoiling device, a washing device, a squeezing device, a splitting device and a drying device, wherein the cotton grabbing device, the net forming device, the steeping device, the mangle device, the coiling device, the cold-batch fixation device, the uncoiling device, the washing device, the squeezing device, the splitting device and the drying device are sequentially arranged. A loose stock net after squeezing is sent to the splitting device to be split and sent to the drying device to be dried. According to the technical scheme, the defects that continuous production cannot be performed and processing efficiency is low in the prior art are overcome, and the defects that dyeing is uneven, drying efficiency is low and energy consumption is large in drying loose stock with a net-shaped structure are overcome. In the processing process, stock damage is little, and the quality of finished stock products is ensured.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

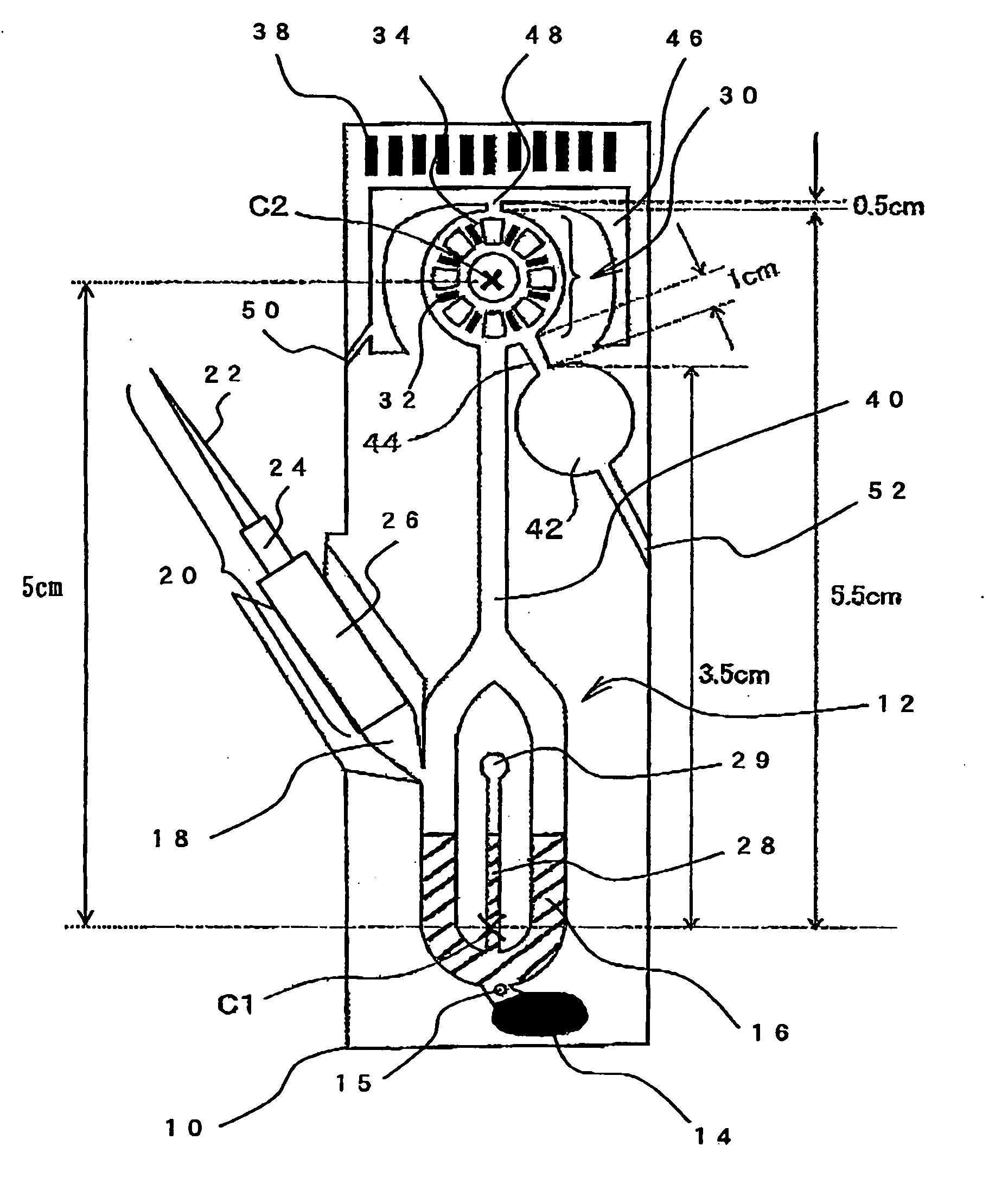

Blood Analysis Apparatus and Blood Analysis Method

InactiveUS20080028821A1Improve accuracyHigh precision analysisSpecific gravity using centrifugal effectsMaterial analysis by optical meansLow speedCentrifugation

A corpuscle / plasma separating part is disposed at the lower end of the substrate, and a sensor part connected to the corpuscle / plasma separating part is disposed at the upper end of the substrate, with a calibration solution reservoir being disposed on the lower side of the sensor part, and a calibration solution waste reservoir being disposed on the upper side of the sensor part. A first centrifugal axis is located upper to the corpuscle fraction storing part and lower to the plasma fraction storing part of the corpuscle / plasma separating part, while a second centrifugal axis is located within or close to the sensor part. Conveyance and discharge of the calibration solution can be carried out by performing centrifugation around the first centrifugal axis which is distant from the sensor part at a low speed of rotation, so that the centrifugal force exerted on the sensors would be small. During the centrifuge operation at a high speed of rotation for the separation of blood corpuscles, centrifugation can be performed around the second centrifugal axis so that the centrifugal force exerted on the sensors is small. Centrifuge operation allows separation of the blood corpuscles and blood plasma, and conveyance of the blood plasma and the calibration solution, as Well as certain discharge of the calibration solution from the sensors, thereby allowing precise analysis. Any damage in the sensors due to strong centrifugal force during the separation of blood corpuscles and blood plasma can be prevented.

Owner:NAT INST FOR MATERIALS SCI

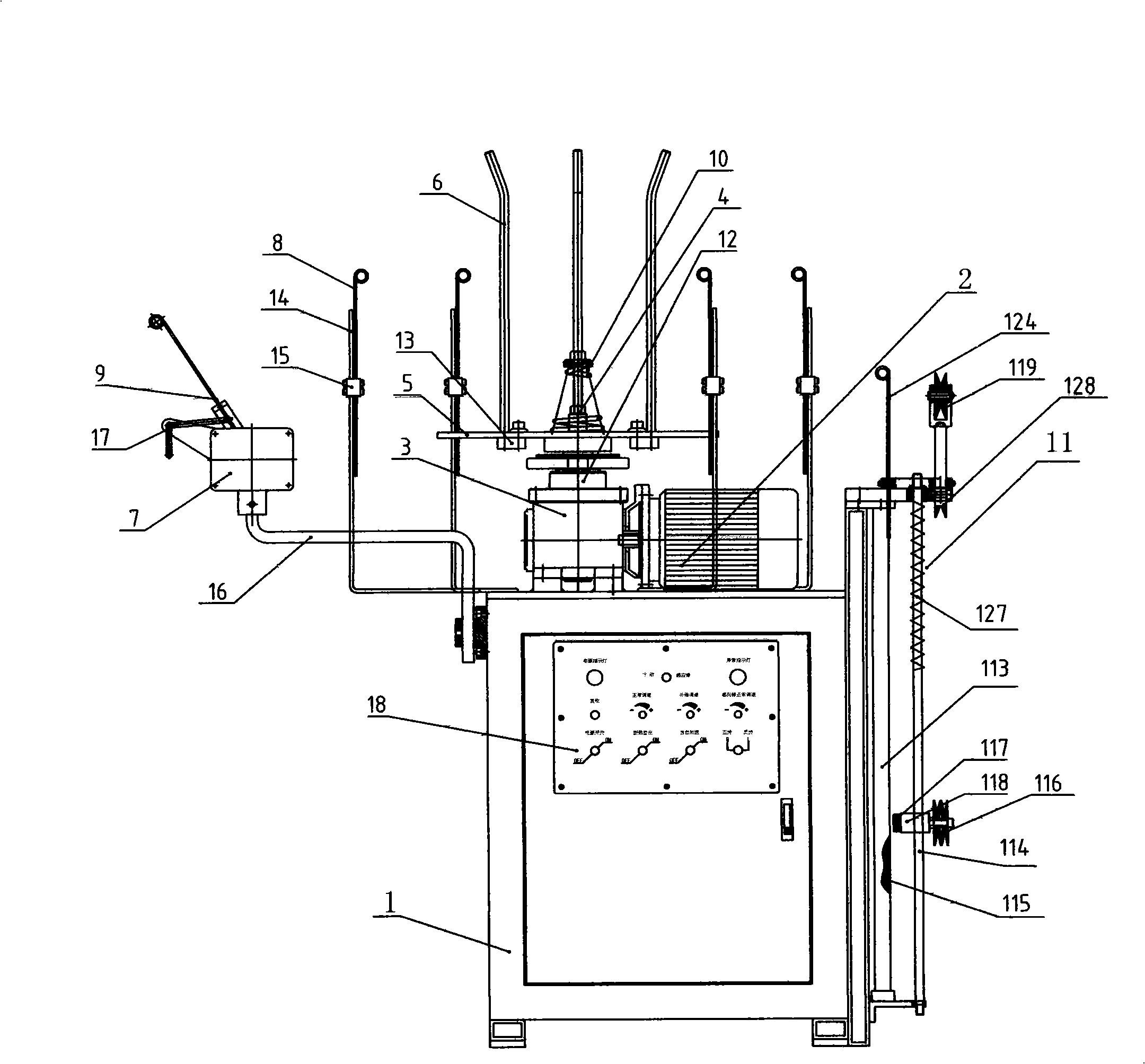

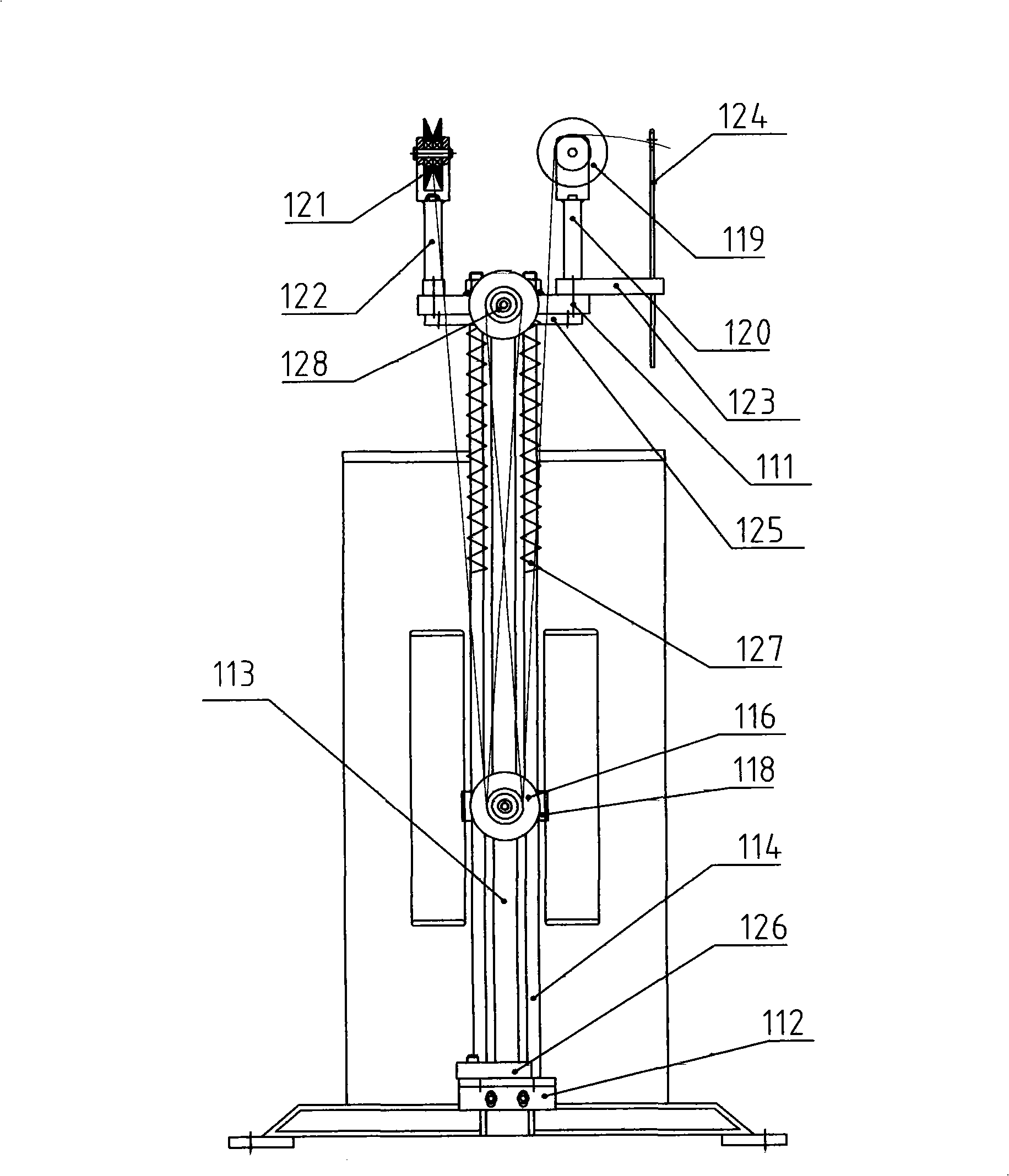

Dual-purpose automatic wire feeding machine

The invention discloses a dual-purpose automatic wire feeding machine which comprises a box body and a motor which is arranged at the box body. The motor is connected with a reducer. A spindle is connected with the reducer. A tray for accommodating wires is arranged at the spindle. A wire retaining rod is arranged at the tray. The wire retaining rod can maintain and limit the middle position of the wires on the tray. A travel switch for controlling the motor and a plurality of treading rods for guiding the direction of the wires are also arranged at the box body. A switch pulling rod is arranged on the travel switch. A conical spiral compression spring for accommodating fine wires is also arranged at the spindle. A magnetic induction pulley wire feeding mechanism for guiding and transporting the fine wires is arranged on a lateral side of the box body. With the structure adopted, the dual-purpose automatic wire feeding machine can use both the contact control technology of the travel switch for automatically transporting wires which are longer than 0.5mm and the magnetic non-contact control technology for transporting wires which are 0.1-0.5mm stably, rapidly and uniformly.

Owner:ZHEJIANG OMNIPOTENT SPRING MACHINE

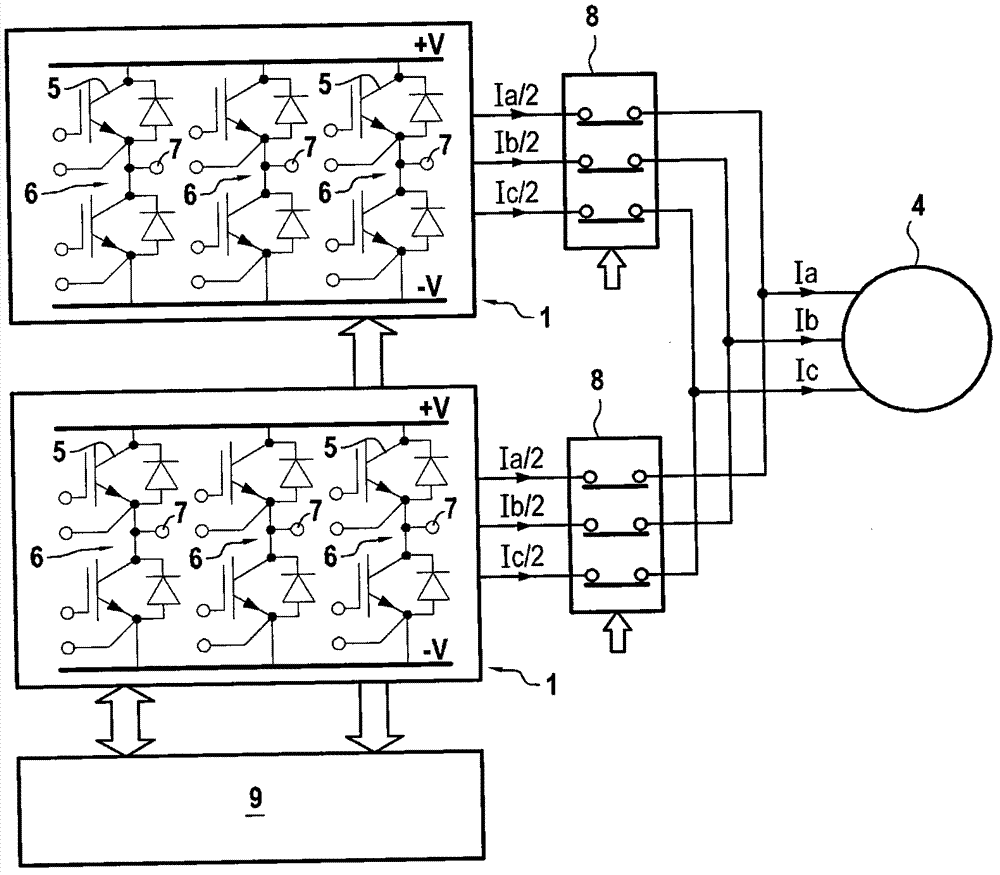

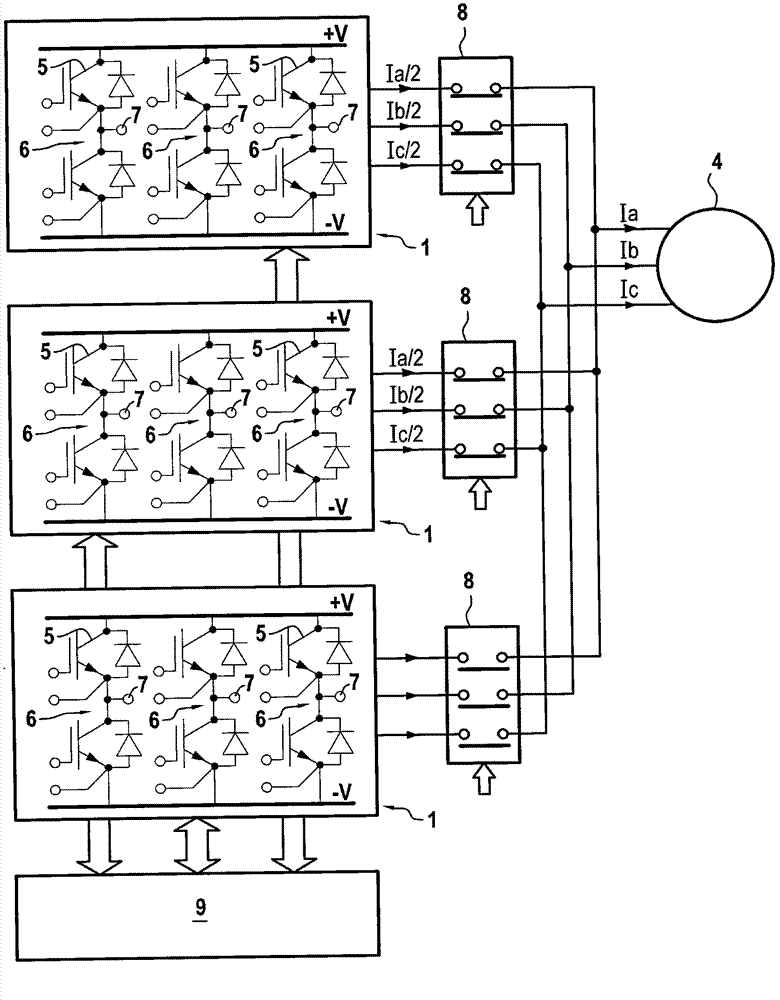

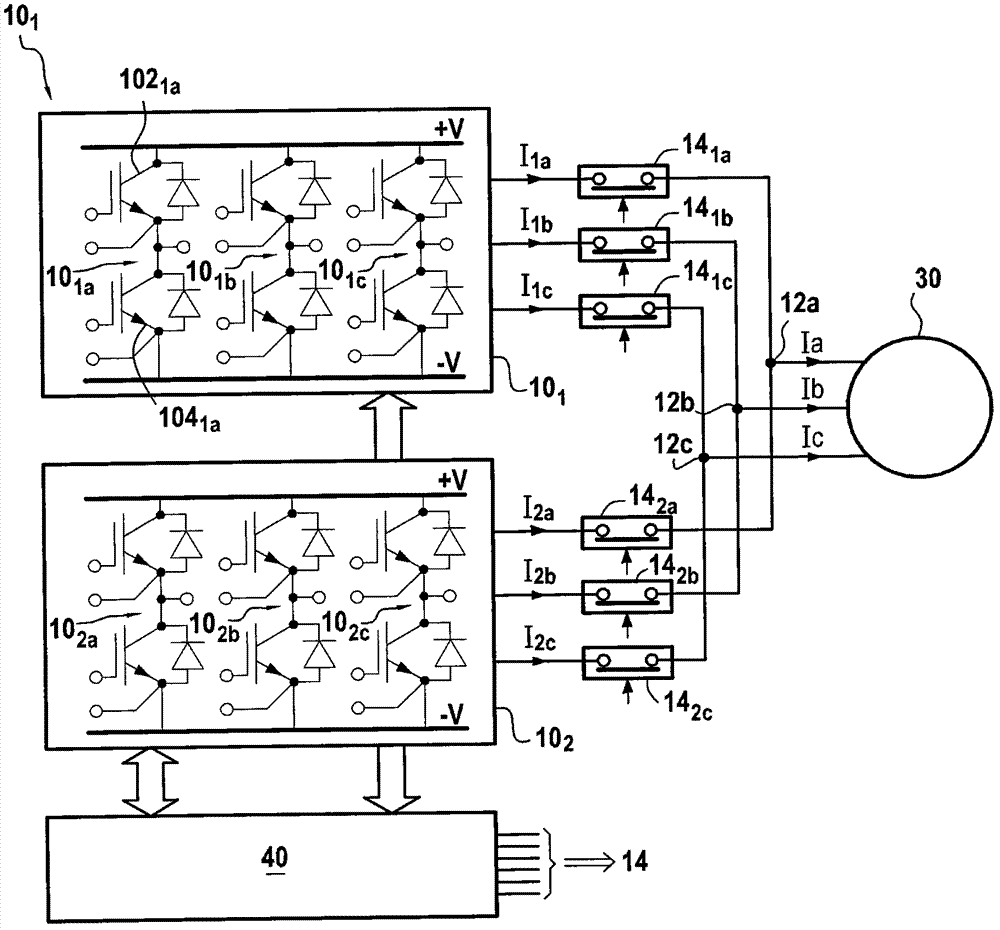

Method and device for controlling a polyphase electrical machine

ActiveCN102771042AConvey evenlyMitigationElectric motor controlAc-dc conversionPhase currentsSwitched current

The invention relates to a polyphase electrical machine (30), which is controlled by means of at least two inverters in parallel (101, 102), wherein each inverter has branches (101a, 101b, 101c, 102a, 102b, 102c), in a number equal to the number of phases of the machine, and is controlled by pulse width modulation (PWM). In response to the detection of a defective inverter branch (102a), the latter is isolated, and the phase in question is supplied with power by the or each other corresponding inverter branch (101a). The control by PWM is modified so as to make the power switches of said or each other branch (101a) consecutively conductive without switching when, in absolute value form, the strength of the current for the phase in question (1a) is greater than or equal to a threshold between 80% and 120% of (n-1) Imax / n, where n is the number of inverters and Imax is the maximum strength of the phase current. It is thus possible to maintain generation of substantially sine wave voltage over each phase while preventing overrated voltage in the power switches so that, in the event of a defect, said switches can switch currents with higher amplitudes than during normal operation.

Owner:LABINAL POWER SYST

Workpiece processing system

InactiveCN100487855CReduce cross contaminationEasy to handleLiquid surface applicatorsSemiconductor/solid-state device manufacturingParticulatesRotor magnets

A system for handling workpieces includes a handling head assembly and a base assembly. The treatment head assembly has a treatment head and an upper rotor. The base assembly has a base and a lower rotor. The base and the lower rotor have magnets, wherein the upper rotor can engage the lower rotor by magnetic force generated by the magnets. The joined upper and lower rotors form a processing chamber in which semiconductor wafers are positioned for processing. A treatment fluid for treating the workpiece is introduced into the treatment chamber, optionally as the treatment head rotates the workpiece. Additionally, airflow around and through the processing chamber is controlled to reduce particulate additions to the workpiece.

Owner:APPLIED MATERIALS INC

Smashing and drying device for rubber production

InactiveCN106738484ADry comprehensiveReduce vibrationPlastic recyclingDrying gas arrangementsDrive motorShock absorber

The invention provides a smashing and drying device for rubber production. The smashing and drying device comprises a box body, a smashing device, two drying chambers and a motor chamber, wherein a feed hopper and discharge pipes are arranged on the box body; the smashing device comprises a left smashing roller, a right smashing roller, side plates and an intermediate plate; the left smashing roller and the right smashing roller are arranged on the upper end of the interior of the box body; smashing teeth are arranged on the left smashing roller and the right smashing roller; a rotating shaft is arranged between the two drying chambers; a drying device is arranged in each drying chamber; a discharge channel is formed among the drying chambers and the intermediate plate; each drying device comprises heating pipes, a main pipe and blowers; the motor chamber is arranged at the lower end of the box body; a base is arranged at the lower end of the motor chamber; a drive motor and two shock absorbers are arranged in the motor chamber; the base is fixed to the bottom end of the box body in a welding manner; and a spring is arranged in each of the shock absorbers. The smashing and drying device disclosed by the invention is capable of performing thorough smashing to obtain uniform smashed particles, drying and absorbing shock.

Owner:郑州吉音动漫科技有限公司

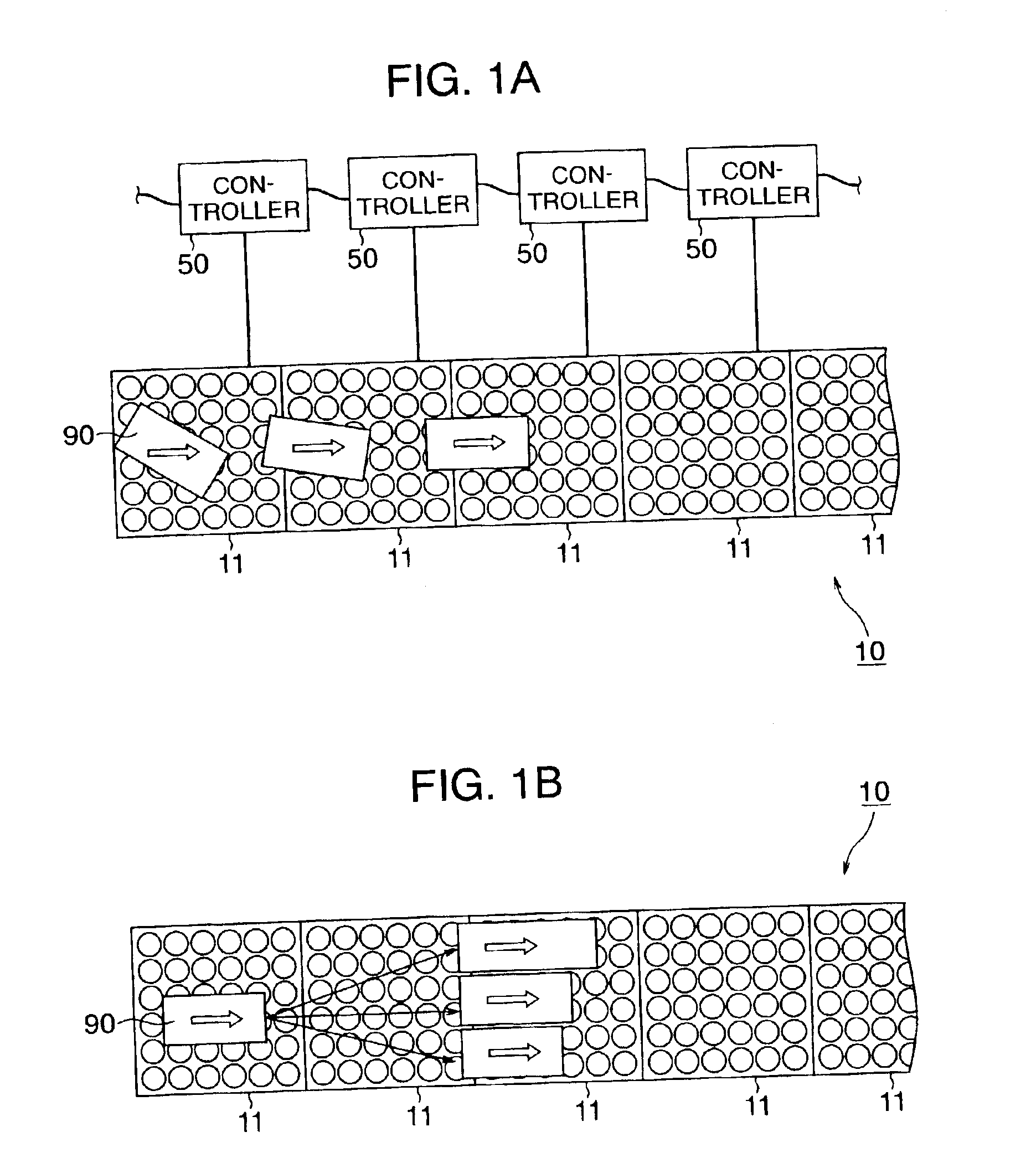

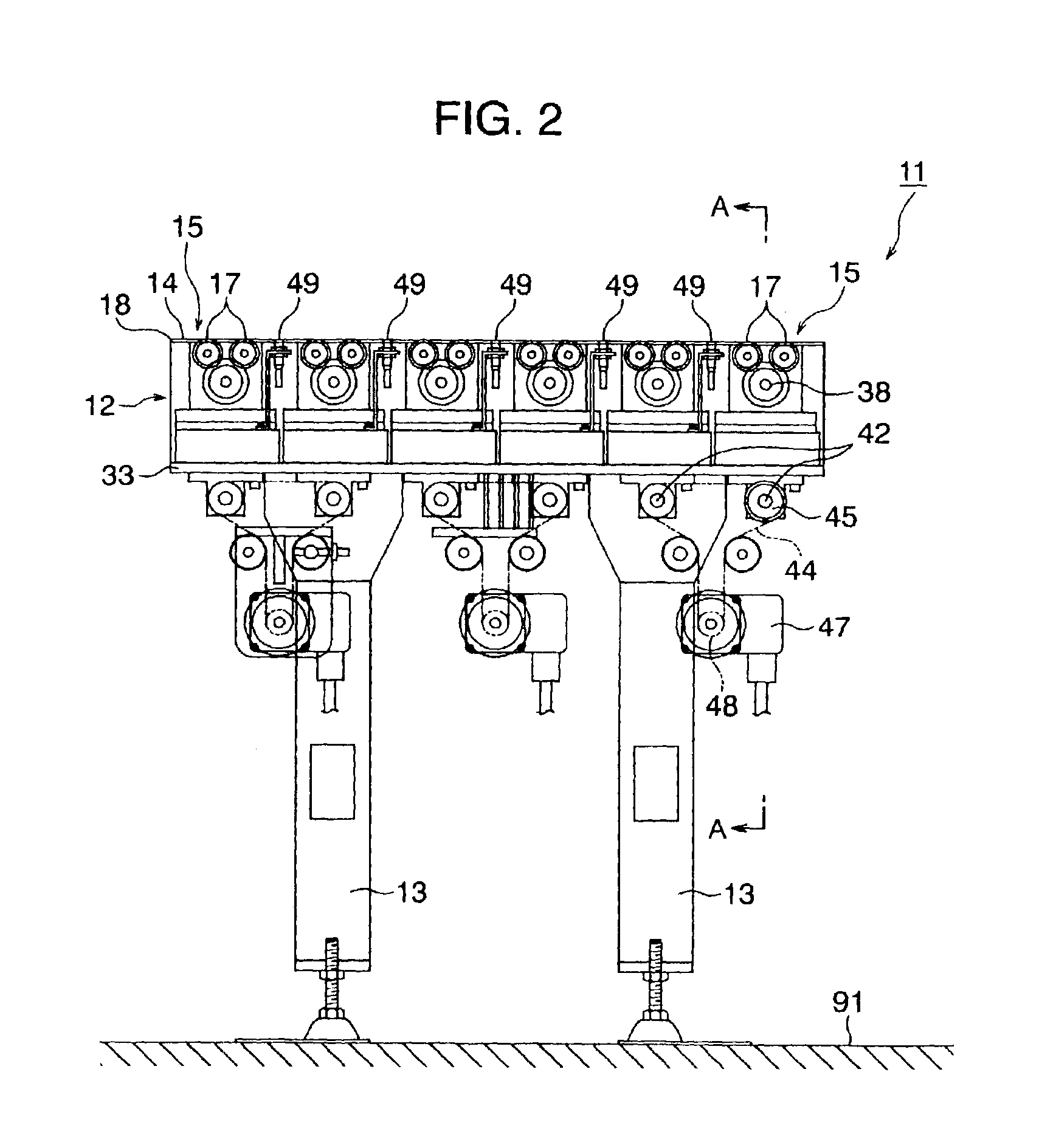

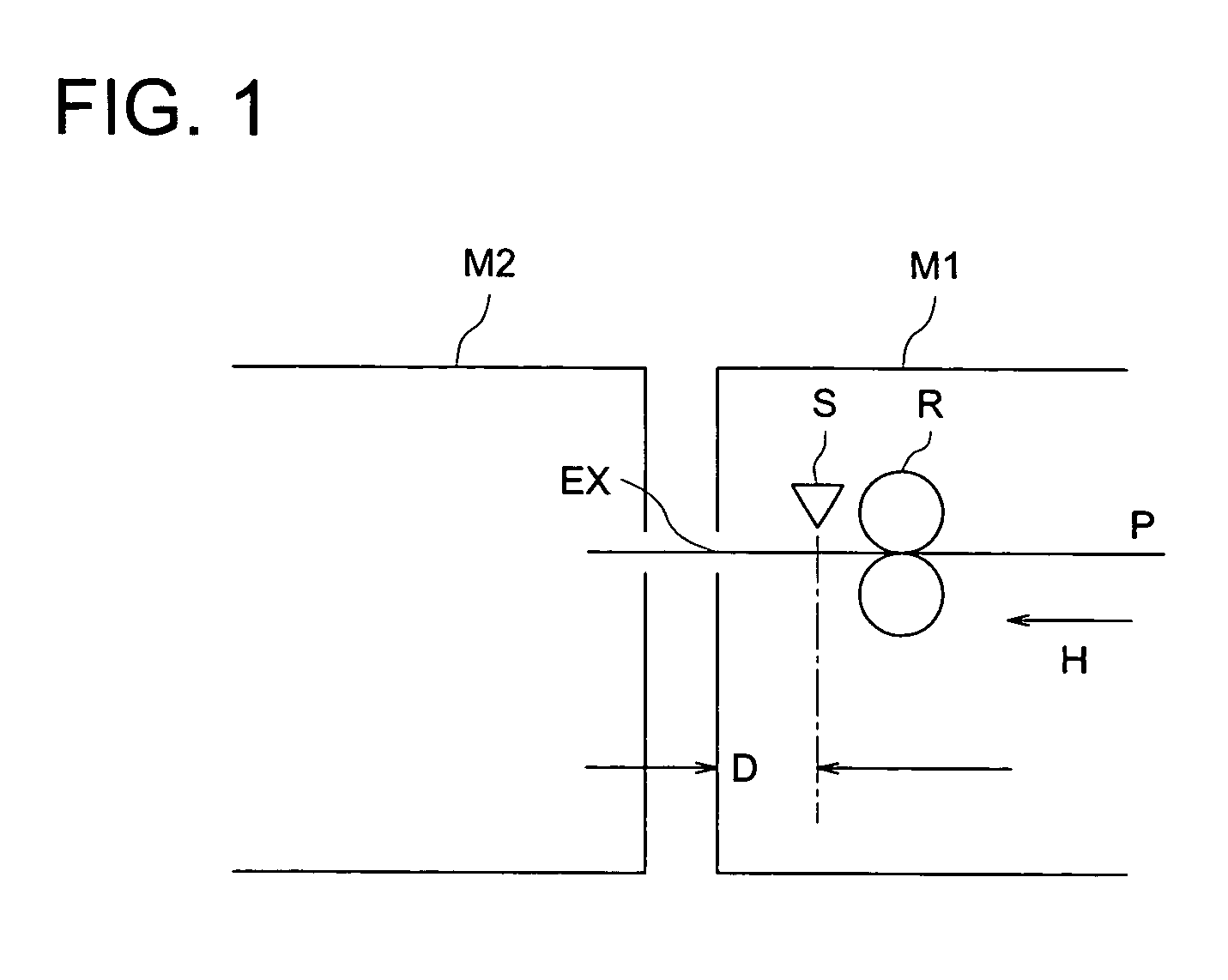

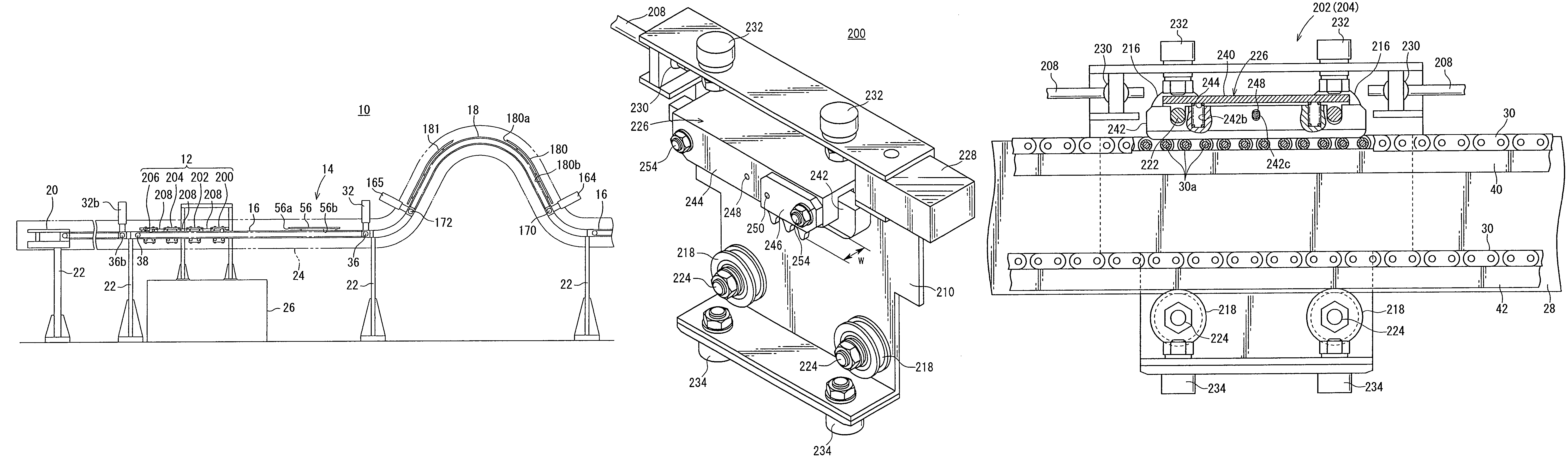

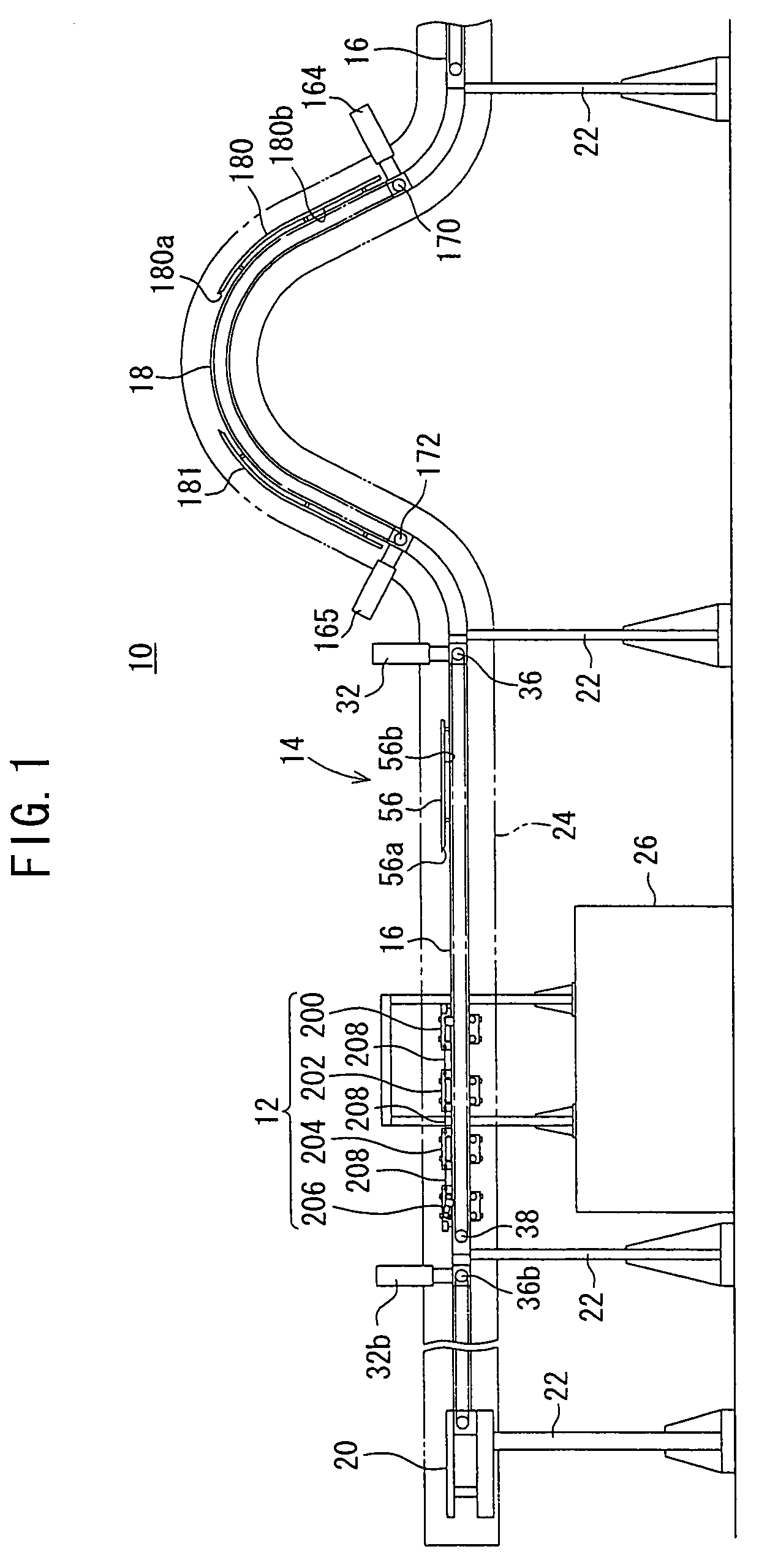

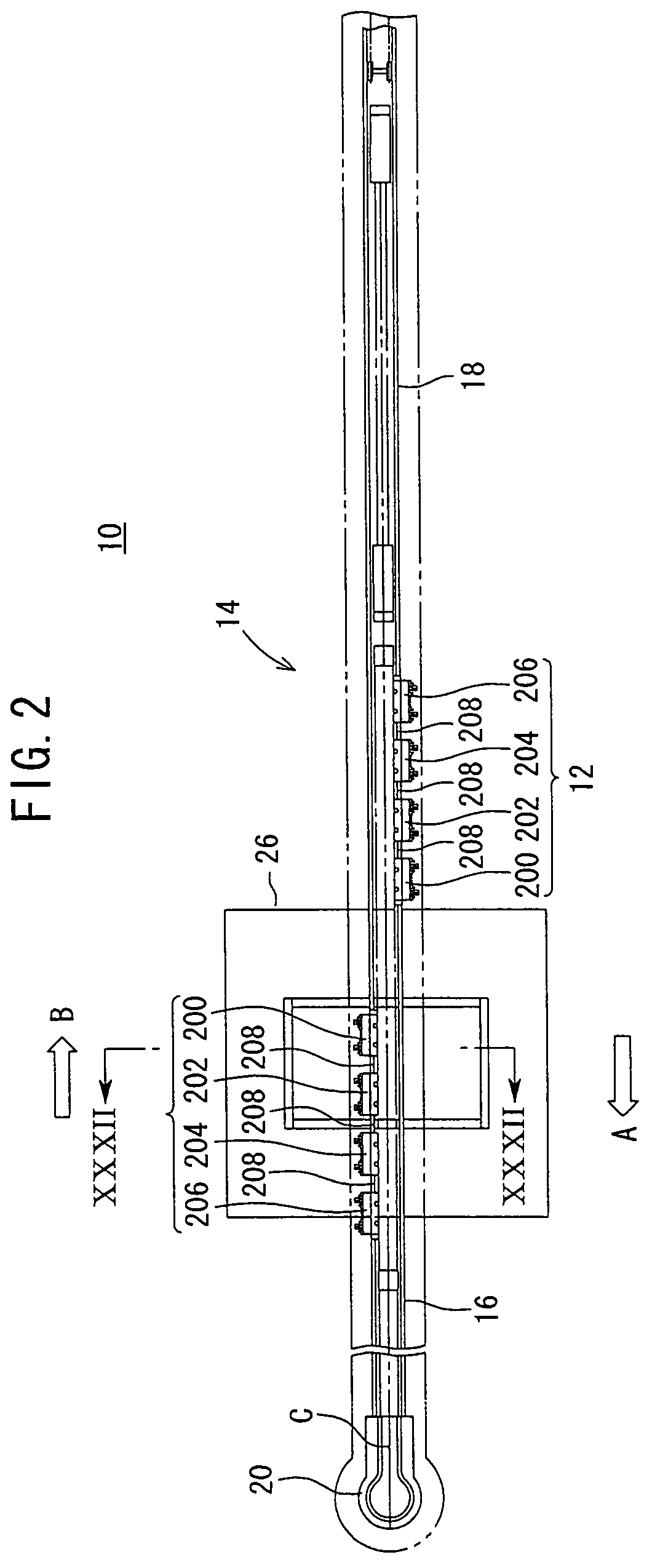

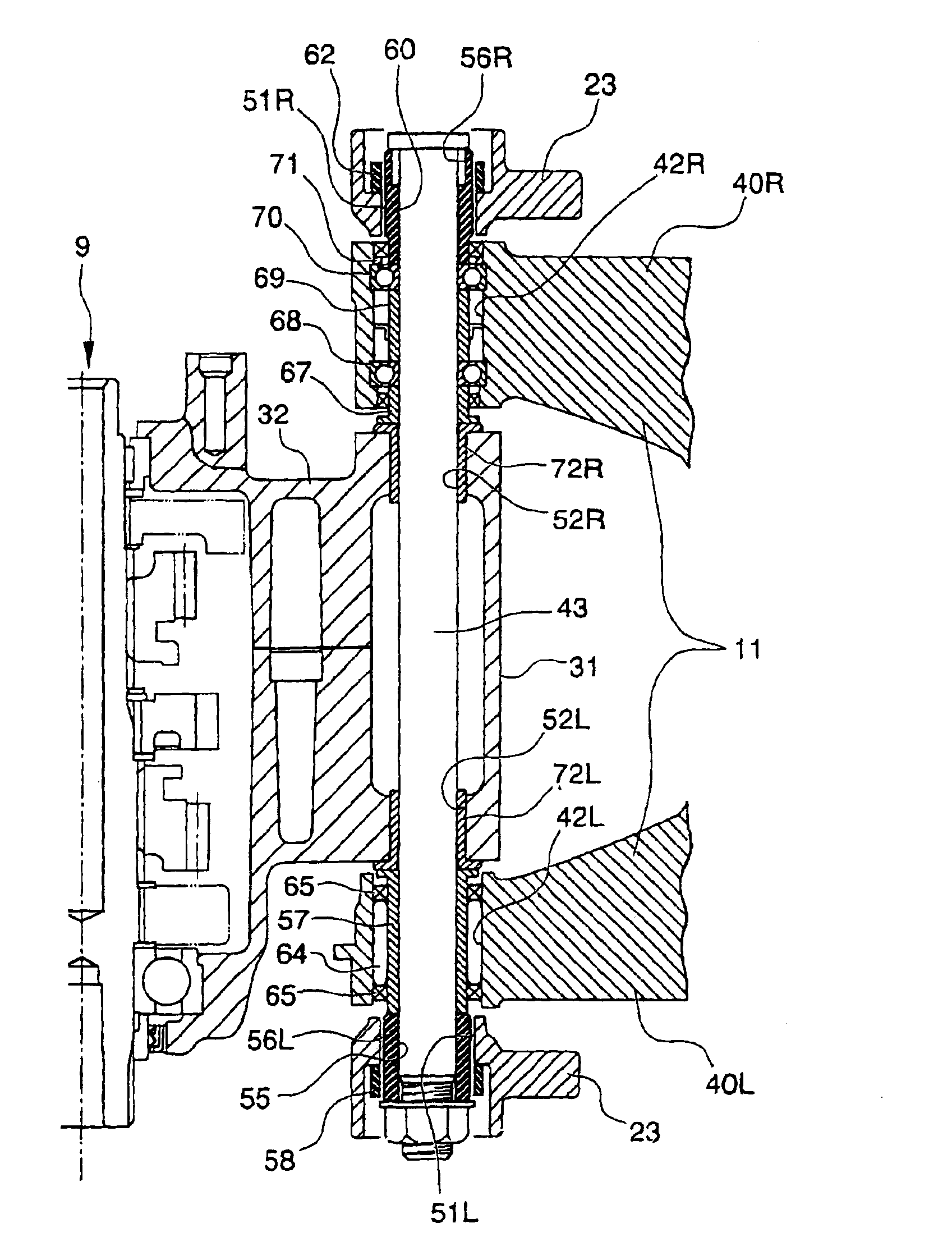

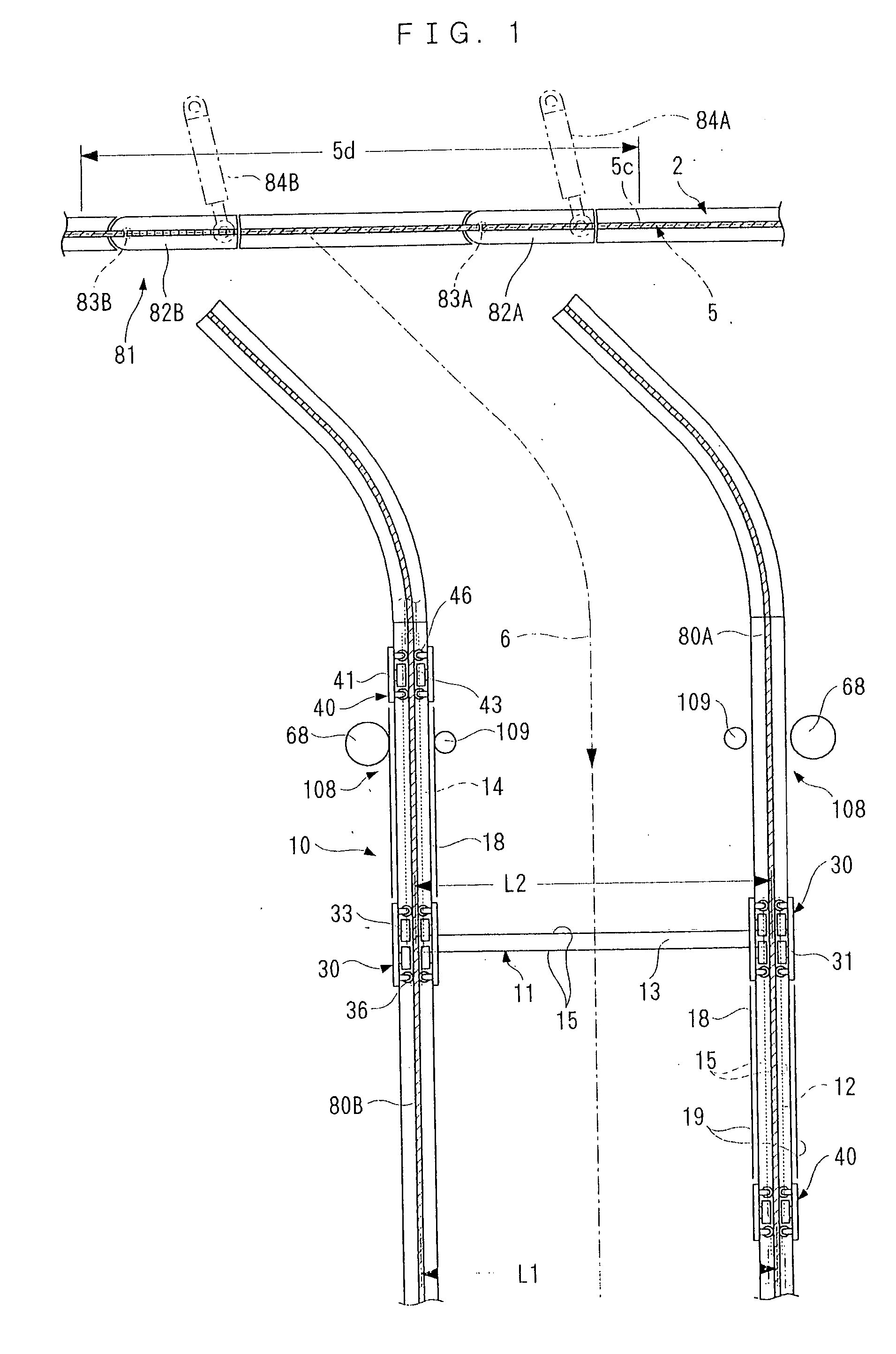

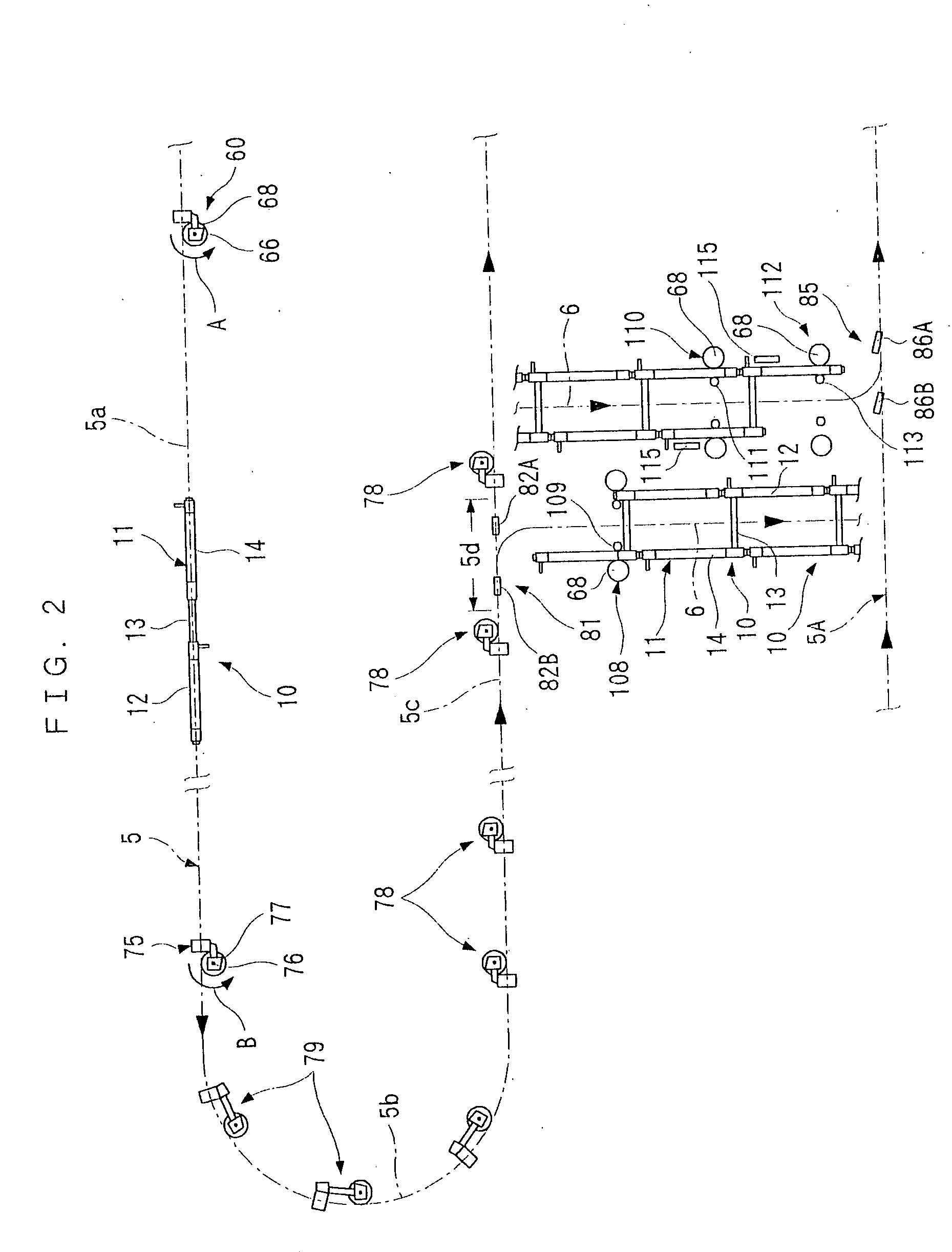

Conveyance system

InactiveUS20060060450A1Easy passConvey evenlyTrain hauling devicesTramway railsMechanical engineeringDelivery system

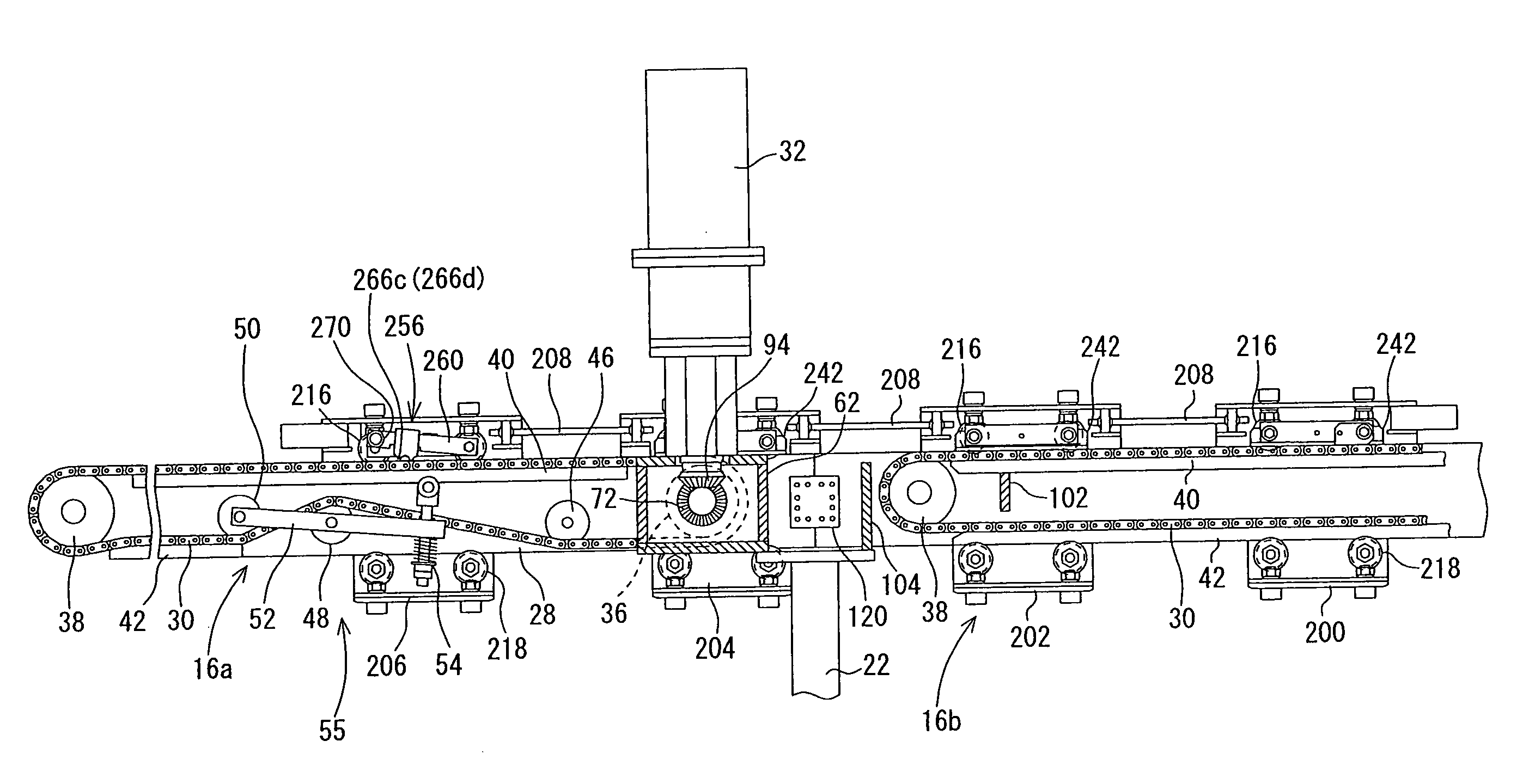

A conveyance system, wherein dividable horizontal conveyance units are connected to each other through joint plates and a support post and rails of the horizontal conveyance units are connected to each other without any step and clearance. A joint conveyance carriage assembly is conveyed by a force applied thereto from annular chains of the horizontal conveyance units through chain presser plates. When the rearmost one of the chain presser plates leaves the annular chain of the horizontal conveyance unit, the chain presser plate of the headmost first conveyance carriage reaches the annular chain of the horizontal conveyance unit and the joint conveyance carriage assembly is continuously conveyed.

Owner:HONDA MOTOR CO LTD +1

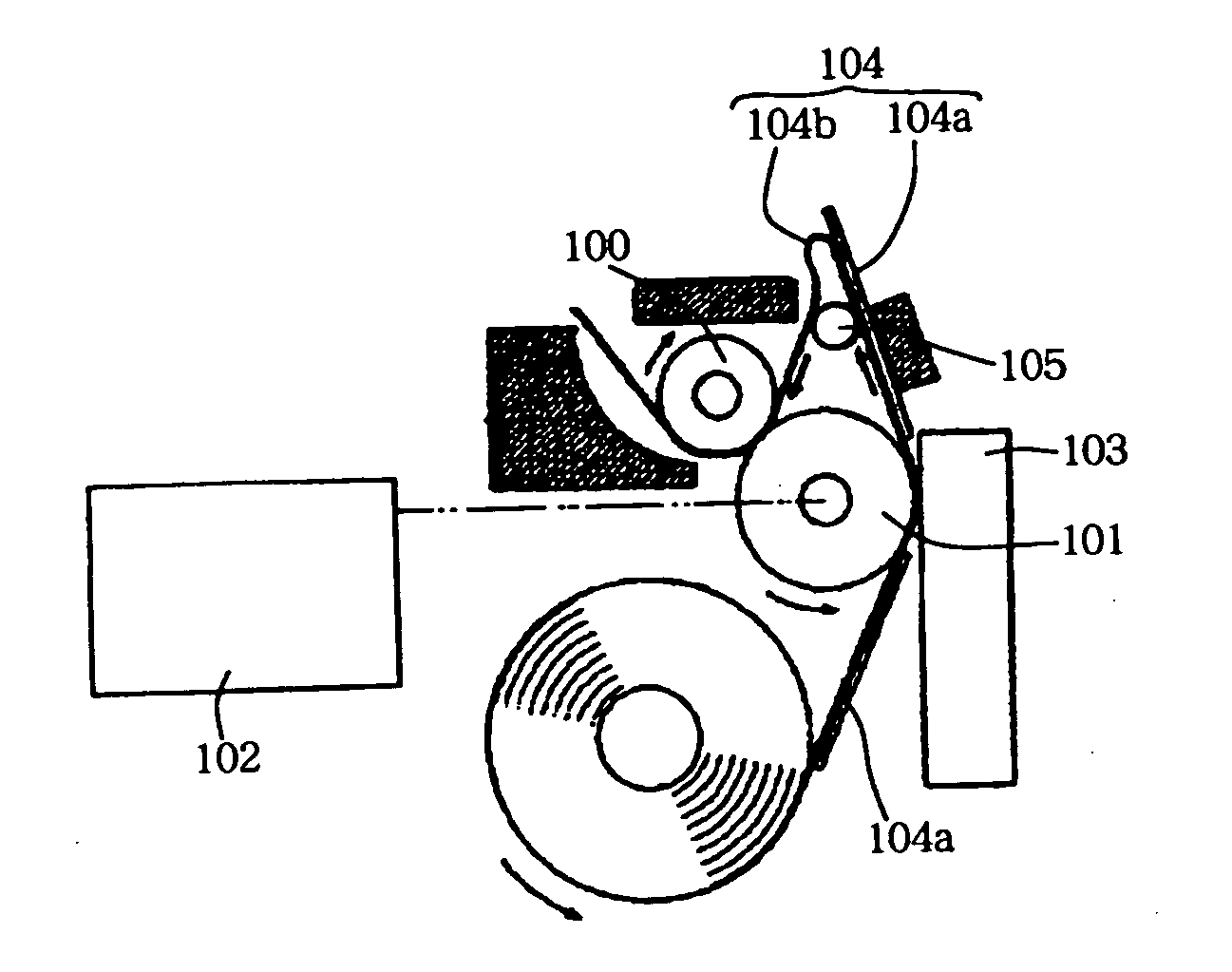

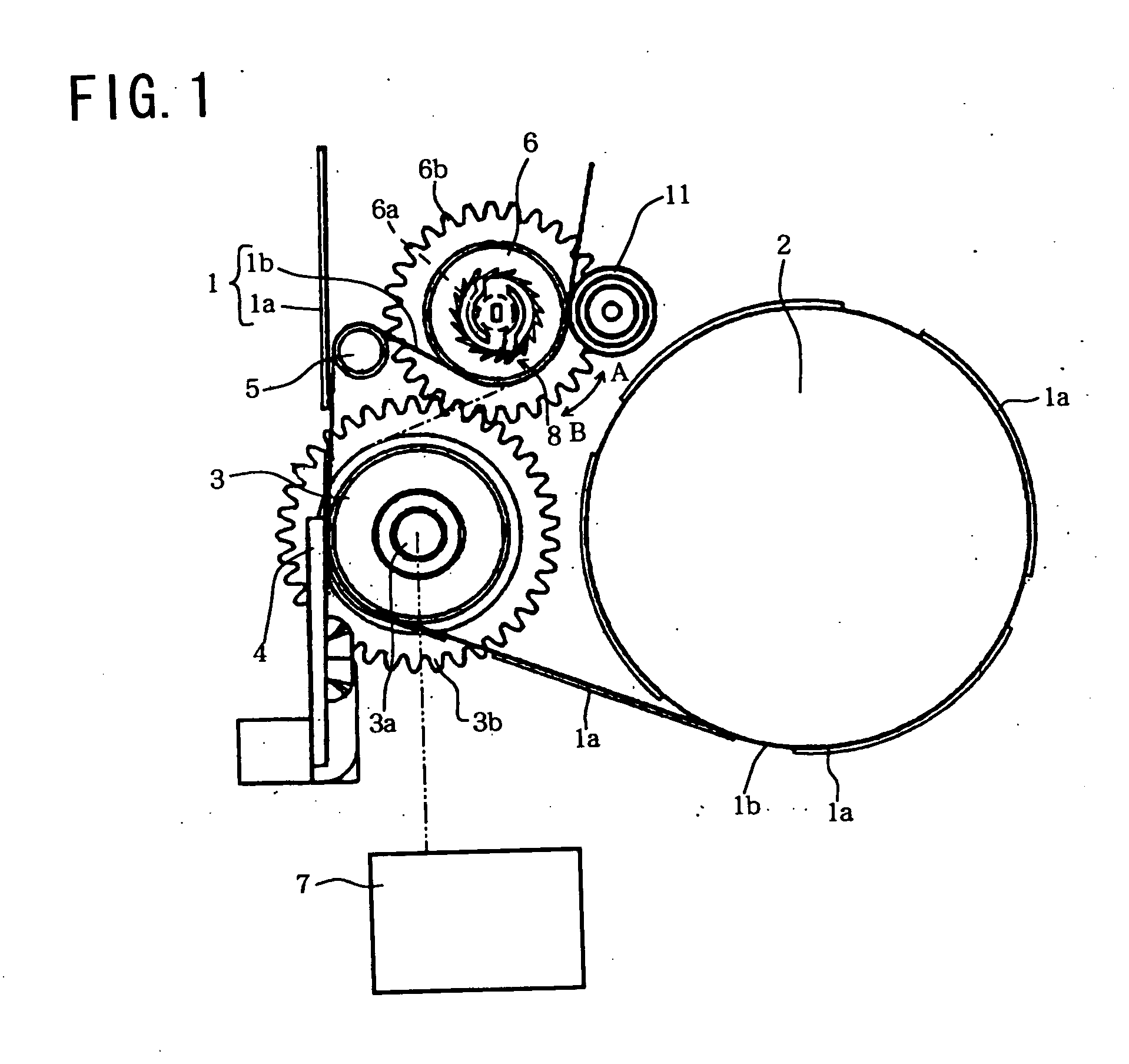

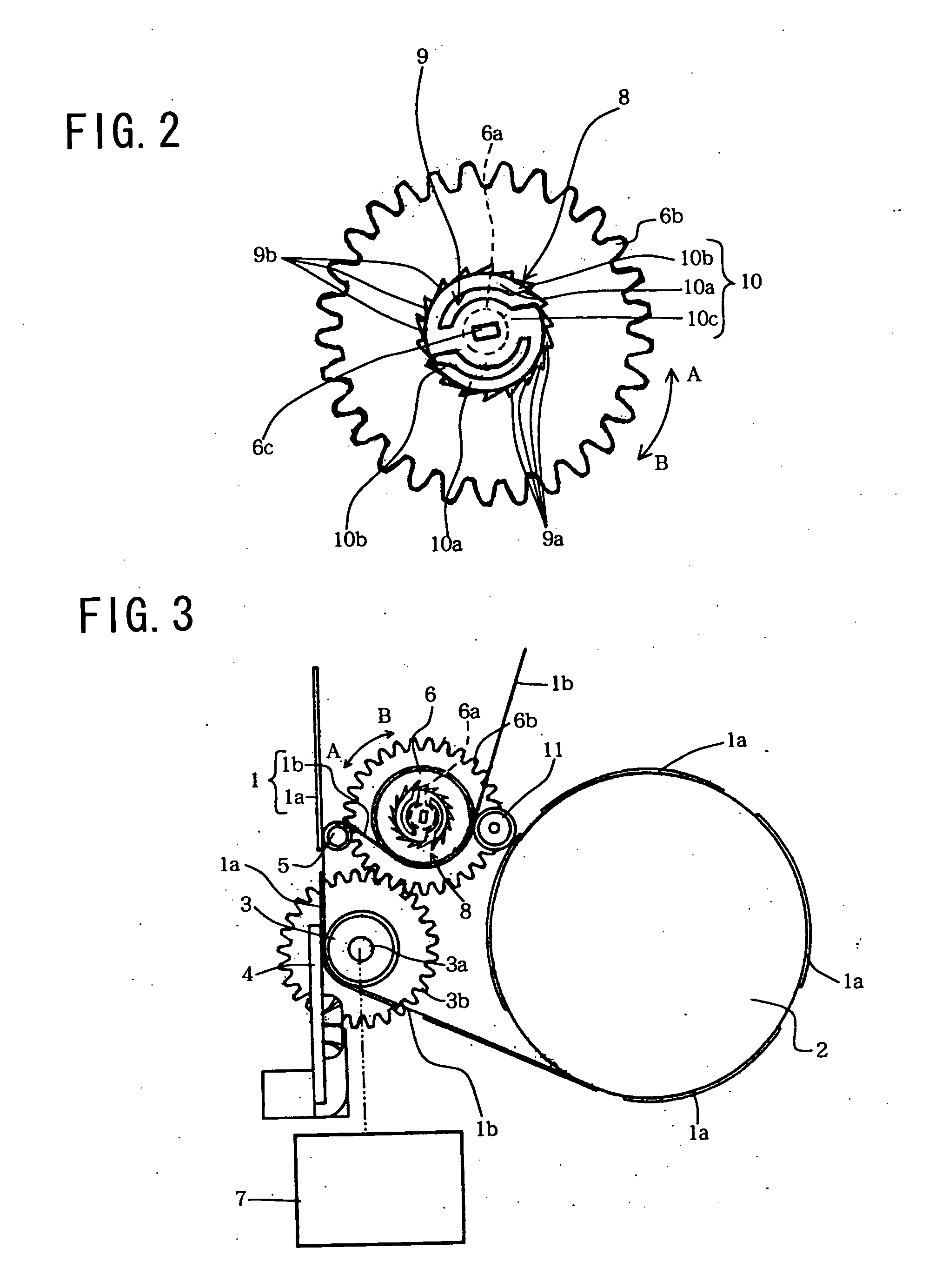

Label conveying apparatus and label printer having the same

InactiveUS20060056900A1Suppress errorConvey evenlyScreen printersOther printing apparatusLeading edgeEngineering

A motor (7) rotates a platen roller (3) so as to convey a continuous label sheet (1) drawn out from a roll member (2). A thermal head (4) generates heat at an appropriate timing in synchronism with the conveyance, thereby effecting recording on an adhesive label (1). The continuous label sheet (1) that has undergone recording is deflected along the outer periphery of a peeler bar (5), causing an adhesive label (1a) to peel off from a peeling paper (1b). The peeling paper (1b) from which the adhesive label (1a) has been peeled off reaches the outer periphery of a peeling paper conveying roller (6). Torque is transmitted via an accelerating wheel train composed of a platen roller driving gear (3b) and a conveying roller driving gear (6b), whereby the peeling paper conveying roller (6) conveys the peeling paper (1b) at a greater conveying capacity than the platen roller (3). The continuous label sheet (1) (peeling paper (1b)) advances while being constantly applied with a force pulling it from the leading edge side (downstream side), whereby no slack develops in the continuous label sheet (1) as it is conveyed.

Owner:SEIKO INSTR INC

Integrated processing equipment of dry lime powder for breeding silkworms

ActiveCN106830717AImprove crushing efficiencyReduce labor intensityGrain treatmentsAnimal husbandryEngineeringIntegrated processing

The invention relates to integrated processing equipment of dry lime powder for breeding silkworms. The integrated processing equipment comprises a bottom plate, wherein an annular opening structure is arranged at the lower end of the bottom plate; two sliding rails are symmetrically mounted at the lower end of the bottom plate; a crushing mechanism with adjustable height is mounted on the bottom plate; a screening mechanism is mounted at the lower end of the crushing mechanism; a quantifying mechanism is mounted in the middle of the upper end face of the bottom plate; the quantifying mechanism is located just below the screening mechanism; a conveying and grinding mechanism is mounted at the front end of the bottom plate; the crushing mechanism, the conveying and grinding mechanism, the screening mechanism and the quantifying mechanism are matched to finish an integrated processing process of the dry lime powder. By adopting the integrated processing equipment provided by the invention, the difficulties in an existing silkworm breeding and mulberry leaf water absorption process that the requirements of silkworms with different ages on dry lime powder grains are different, the dry lime powder grains need to be manually distinguished, manual scattering is not uniform, the labor intensity is great, the working efficiency is low and the like can be solved; an integrated function of crushing the dry lime powder, grinding, screening and quantitatively scattering can be realized.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

Conveyance system

InactiveUS7255220B2Convey evenlySimple structureTrain hauling devicesTramway railsMechanical engineeringDelivery system

A conveyance system, wherein dividable horizontal conveyance units are connected to each other through joint plates and a support post and rails of the horizontal conveyance units are connected to each other without any step and clearance. A joint conveyance carnage assembly is conveyed by a force applied thereto from annular chains of the horizontal conveyance units through chain presser plates. When the rearmost one of the chain presser plates leaves the annular chain of the horizontal conveyance unit, the chain presser plate of the headmost first conveyance carriage reaches the annular chain of the horizontal conveyance unit and the joint conveyance carriage assembly is continuously conveyed.

Owner:HONDA MOTOR CO LTD +1

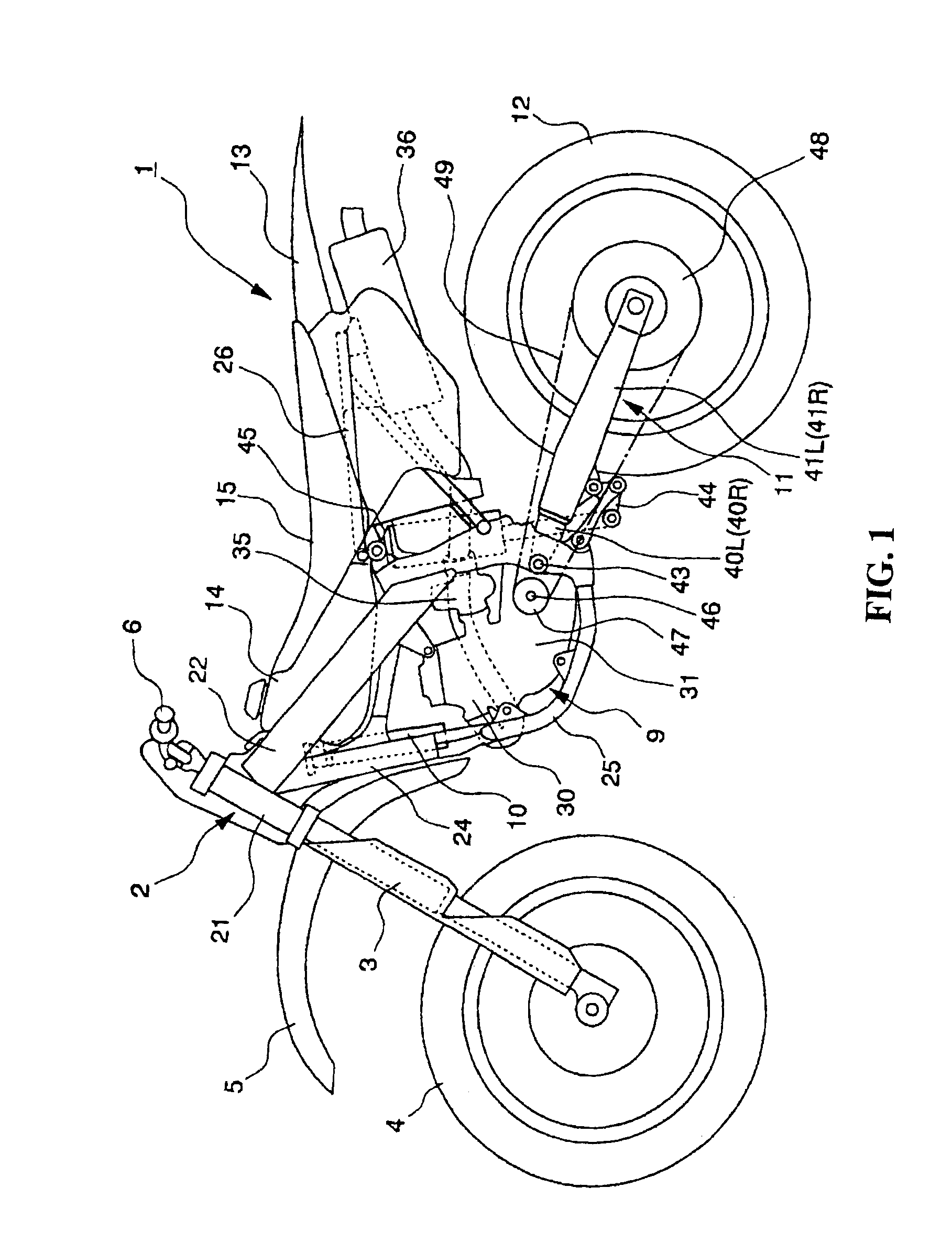

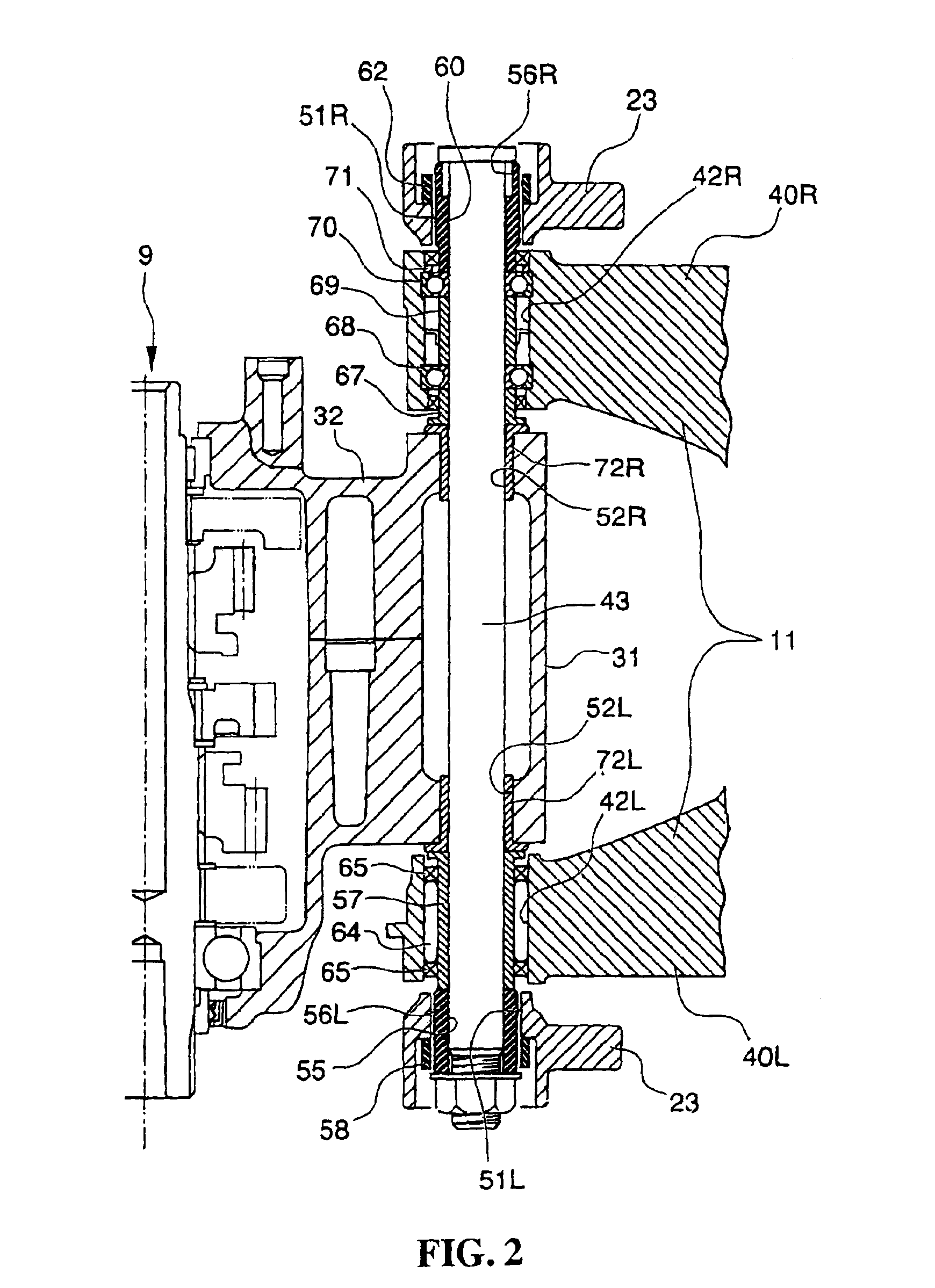

Structure of mounting rear fork in vehicle such as motorcycle

ActiveUS6913101B2Convey accuratelyImprove comfortPassenger cyclesChildren cyclesVehicle frameIn vehicle

A structure for mounting a rear fork in a vehicle, including a body frame having left and right pivot supporting holes; left and right arm portions of a rear fork having supporting holes which are coaxial with the right and the left pivot supporting holes of the body frame a pivot shaft penetrating the pivot supporting holes of said body frame and the supporting holes of the left and right arm portions of the rear fork, said rear fork being rotatively supported on the pivot shaft and being rotatable with respect to said body frame. A tapered cutout is provided on the end surface portion of the collar to be pressed into the pivot supporting hole of the engine, so as to allow the pivot shaft to deflect.

Owner:HONDA MOTOR CO LTD

Power assist apparatus and control method thereof

ActiveUS7953509B2Improve efficiencyHigh positioning accuracyProgramme-controlled manipulatorTemperatue controlEngineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

Conveyance apparatus using movable body

InactiveUS20050183620A1Simple structureEasy maintenanceTrain hauling devicesRailway tracksEngineeringMechanical engineering

A conveyance apparatus using movable bodies, in which a plurality of lateral travel rail members capable of supporting and guiding guided devices situated on a main rail are provided to the side of a prescribed region of the fixed path, in such a manner that a frame member provided with a supporting section assumes an orthogonal attitude or position with respect to a direction of travel, and the other frame members become aligned in the direction of travel, and causing the guided devices to branch off onto the lateral travel rail member group in the prescribed region. Thereby, spacing between the movable bodies in the lateral travel direction can be maintained readily by using a simple structure, and the group of movable bodies can be moved laterally in such a manner that there is no mutual contact between conveyed items.

Owner:DAIFUKU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com