Smashing and drying device for rubber production

A technology of drying device and pulverizing device, applied in the directions of drying gas arrangement, drying, drying machine, etc., can solve the problems of shortened mechanical service life, unevenness, easy loosening of screws, etc., to reduce vibration, improve service life, Dry full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

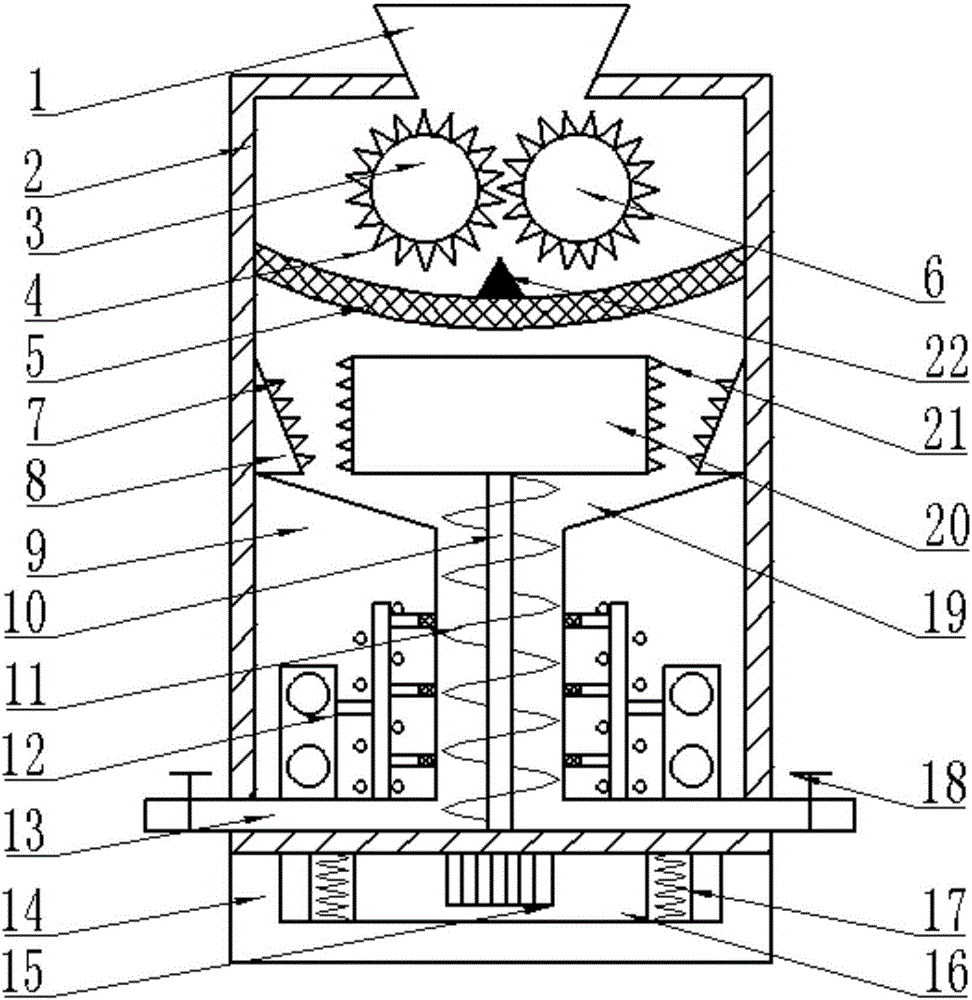

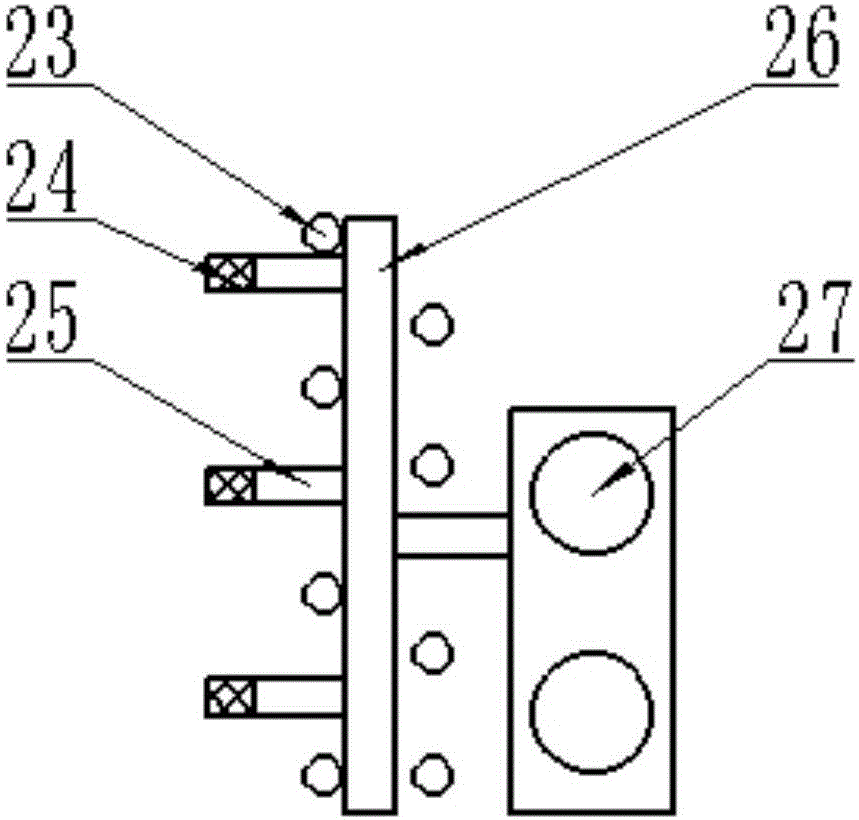

[0016] see Figure 1-2 , the present embodiment provides a crushing and drying device for rubber production, including a casing 2, a crushing device, a drying chamber 9 and a motor chamber 16; the casing 2 is provided with a feed hopper 1 and a discharge pipe 13; the The feed hopper 1 is conical and is arranged in the center of the upper end of the box body 2; the discharge pipe 13 is provided with two, arranged on the upper end of the motor chamber 16, and the discharge pipe 13 is provided with a valve 18; the crushing device includes The left crushing roller 3, the right crushing roller 6, the side plate 8 and the middle plate 20; Teeth 4; the side plates 8 are fixed on the left and right ends of the box body 2, two side plates 8 are provided with side crushing blades 7, and the side plates 8 are arranged in a triangular shape; the side crushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com