Patents

Literature

97results about How to "Meet drying requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

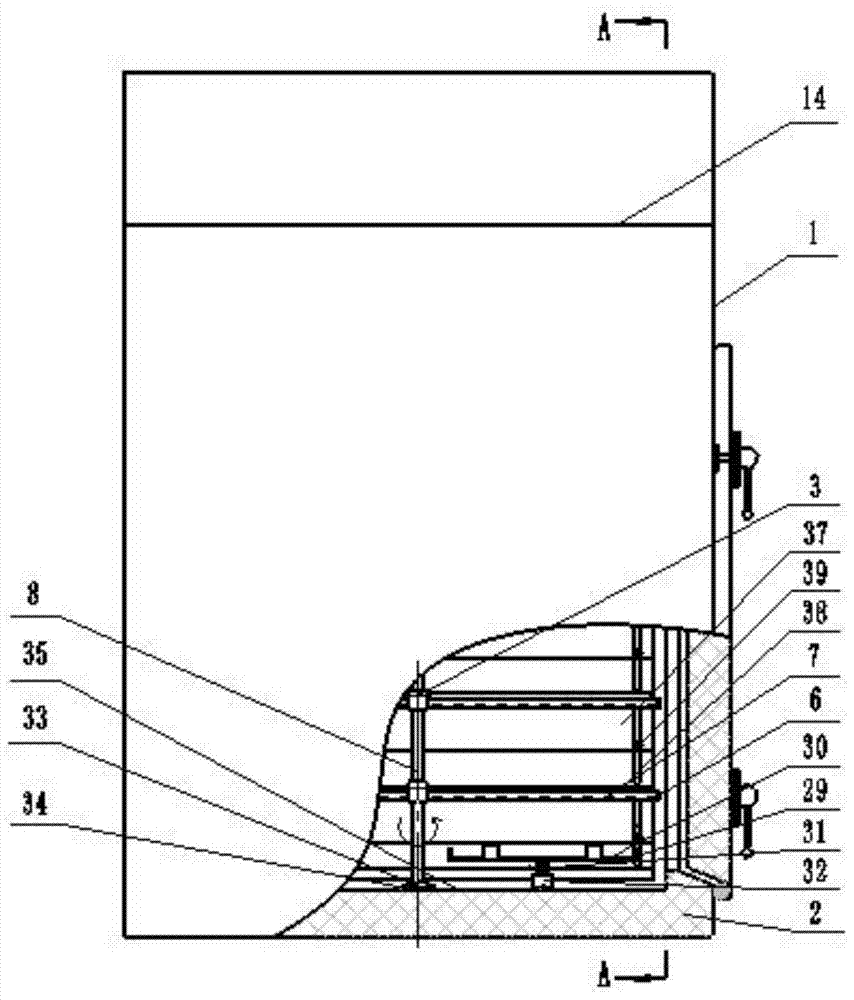

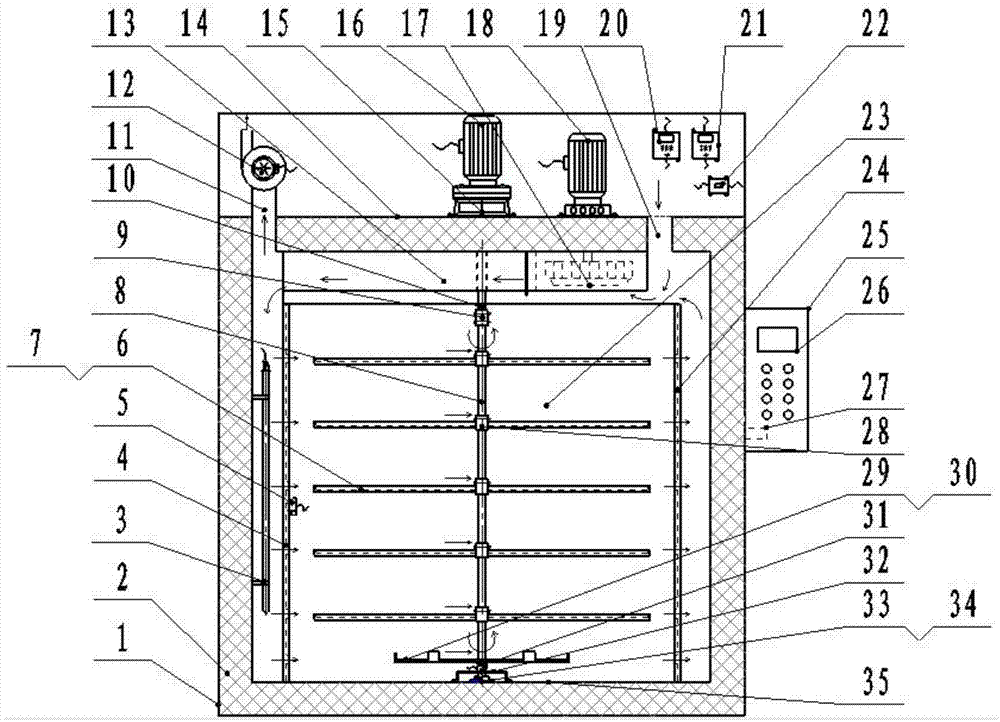

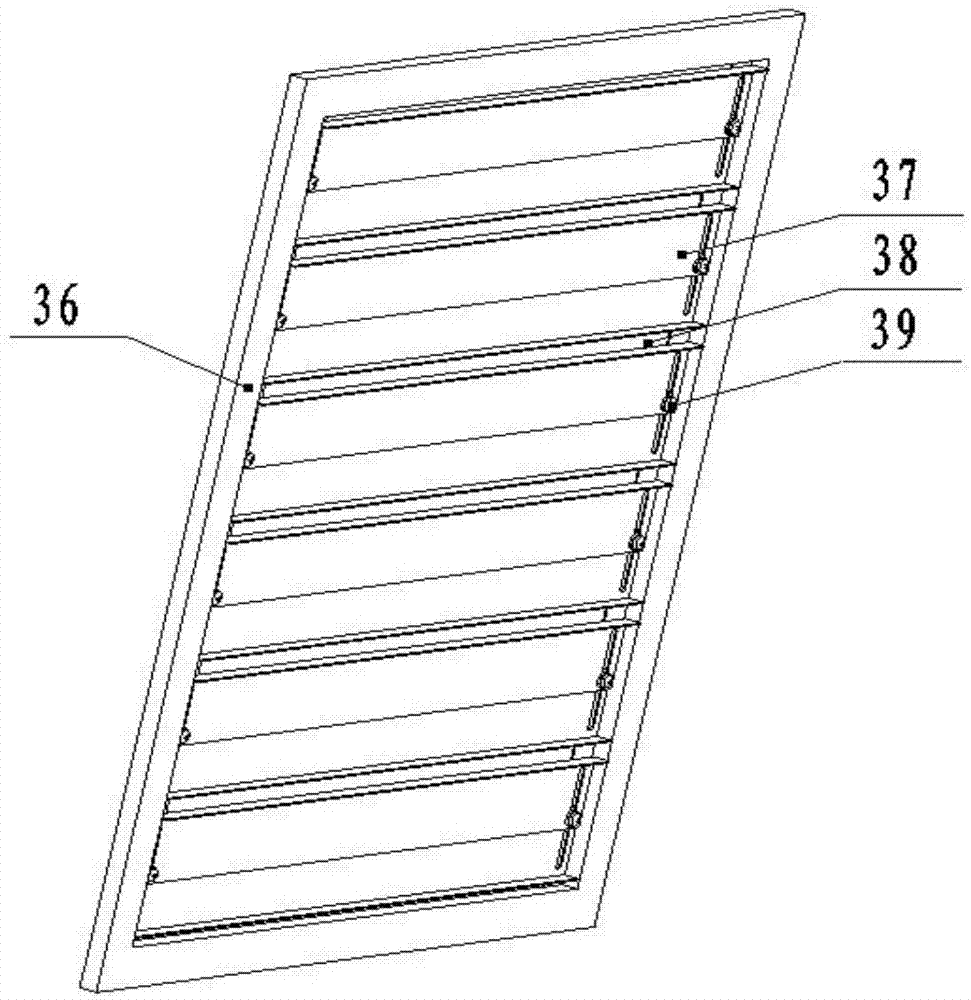

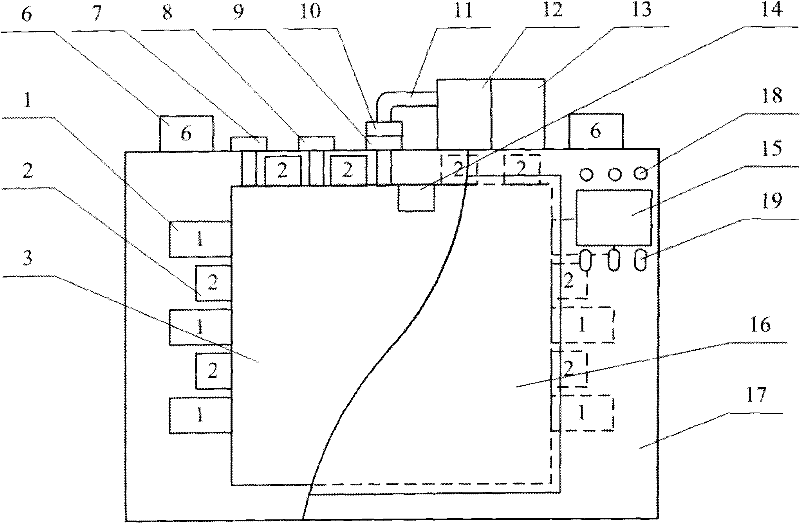

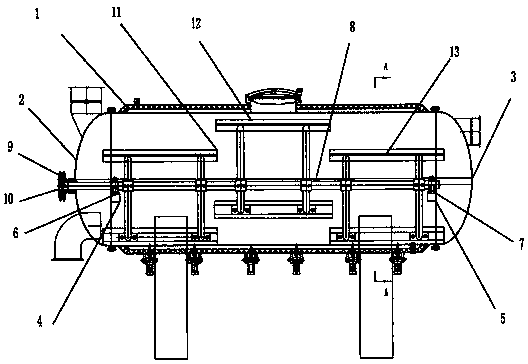

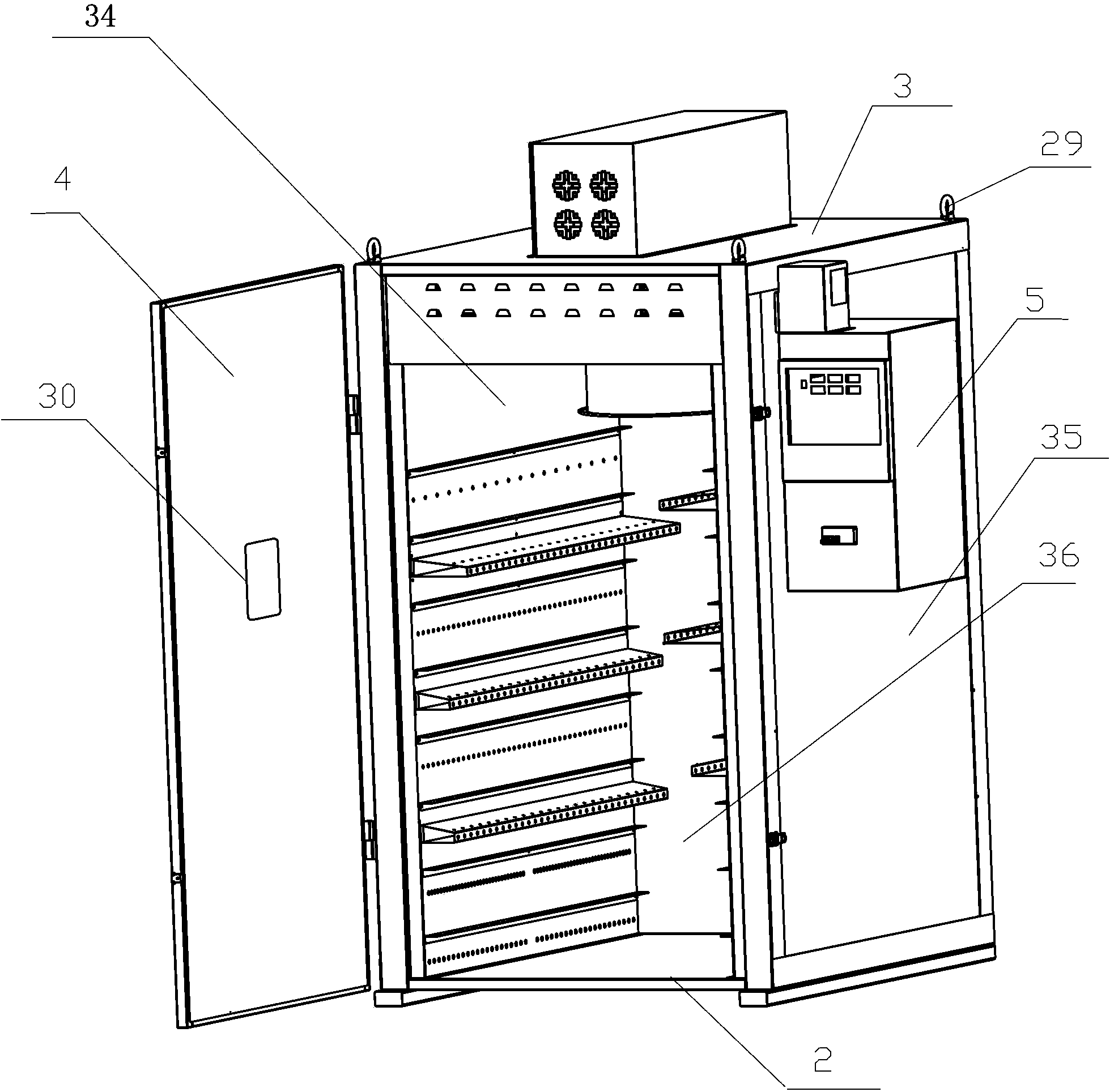

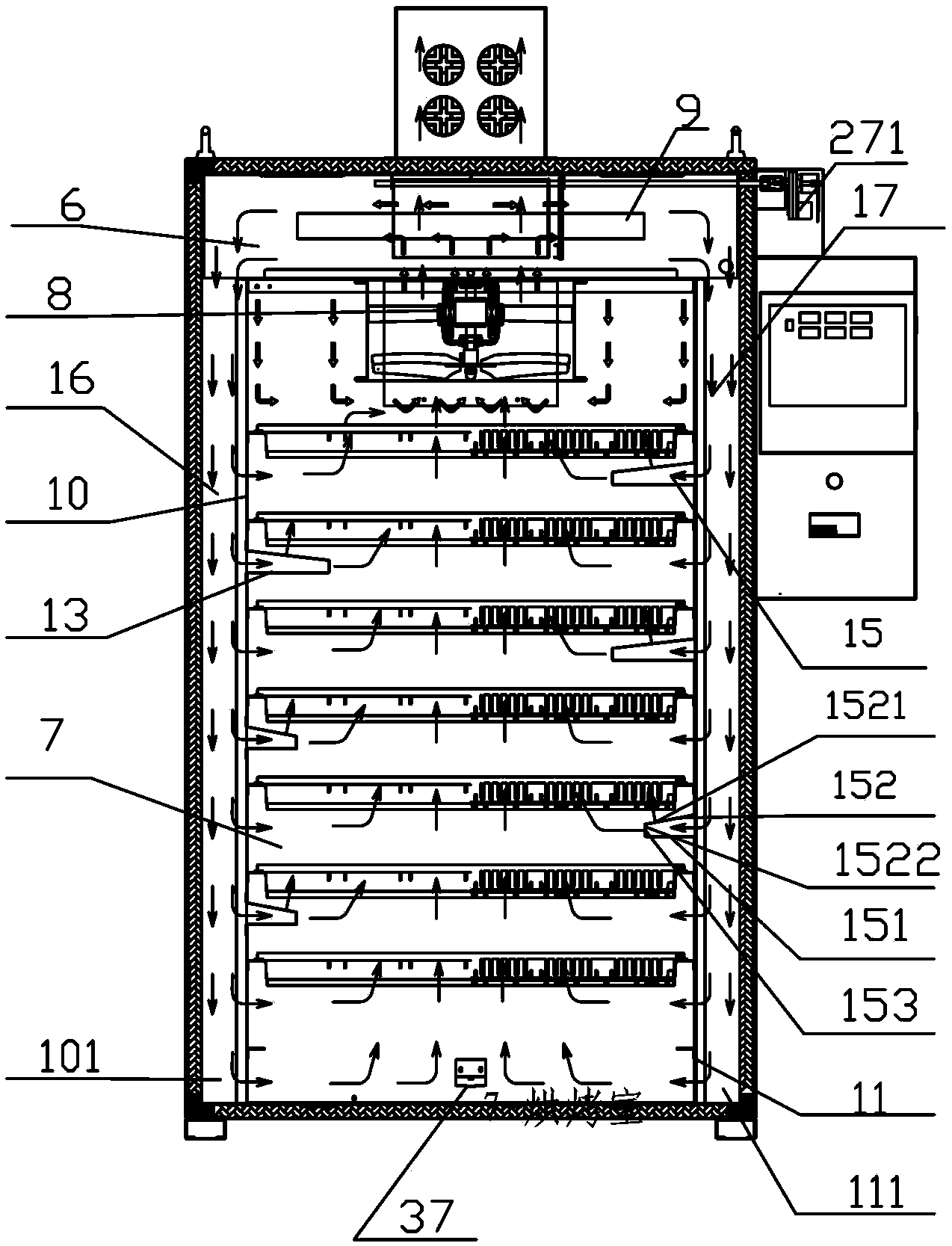

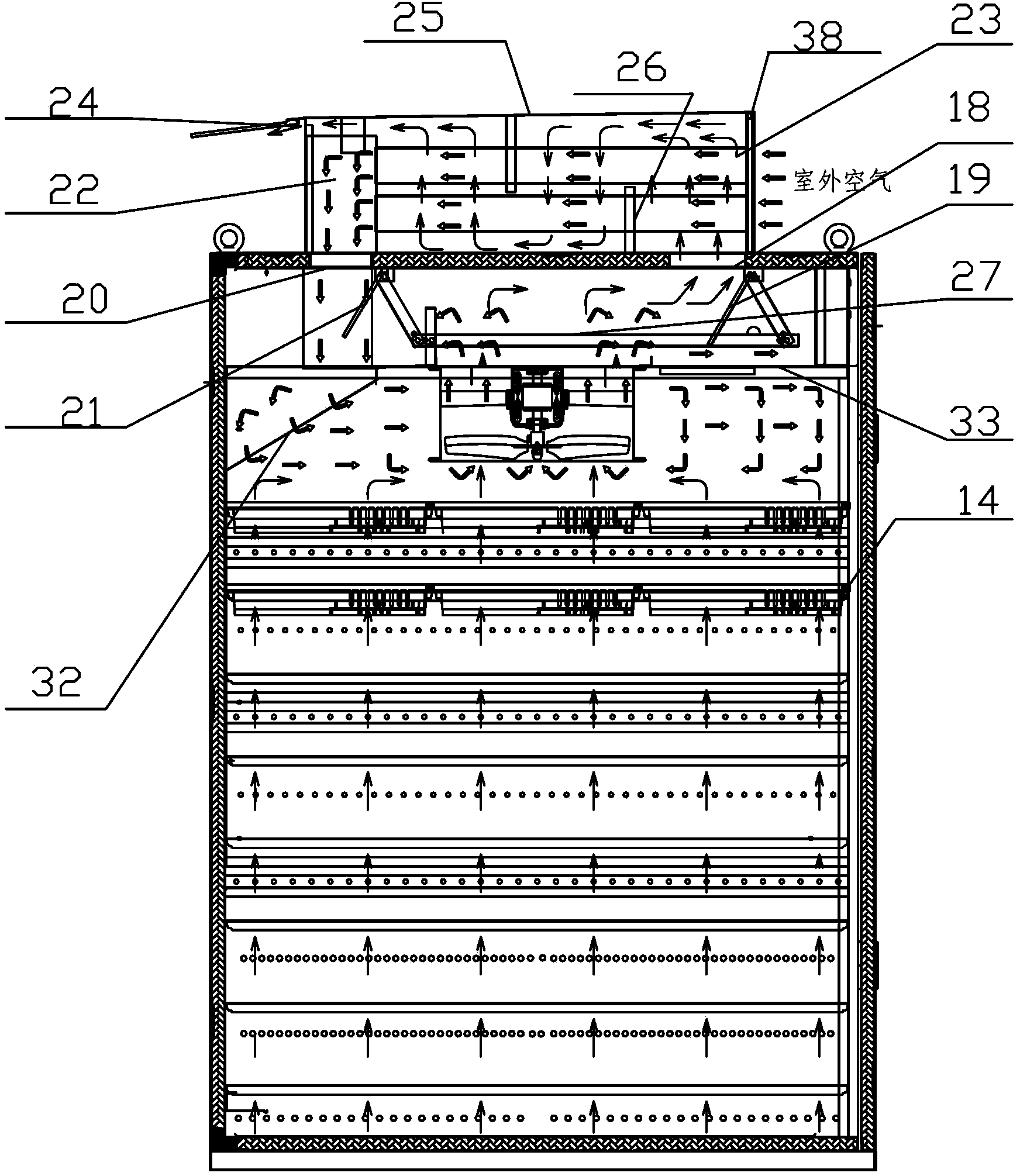

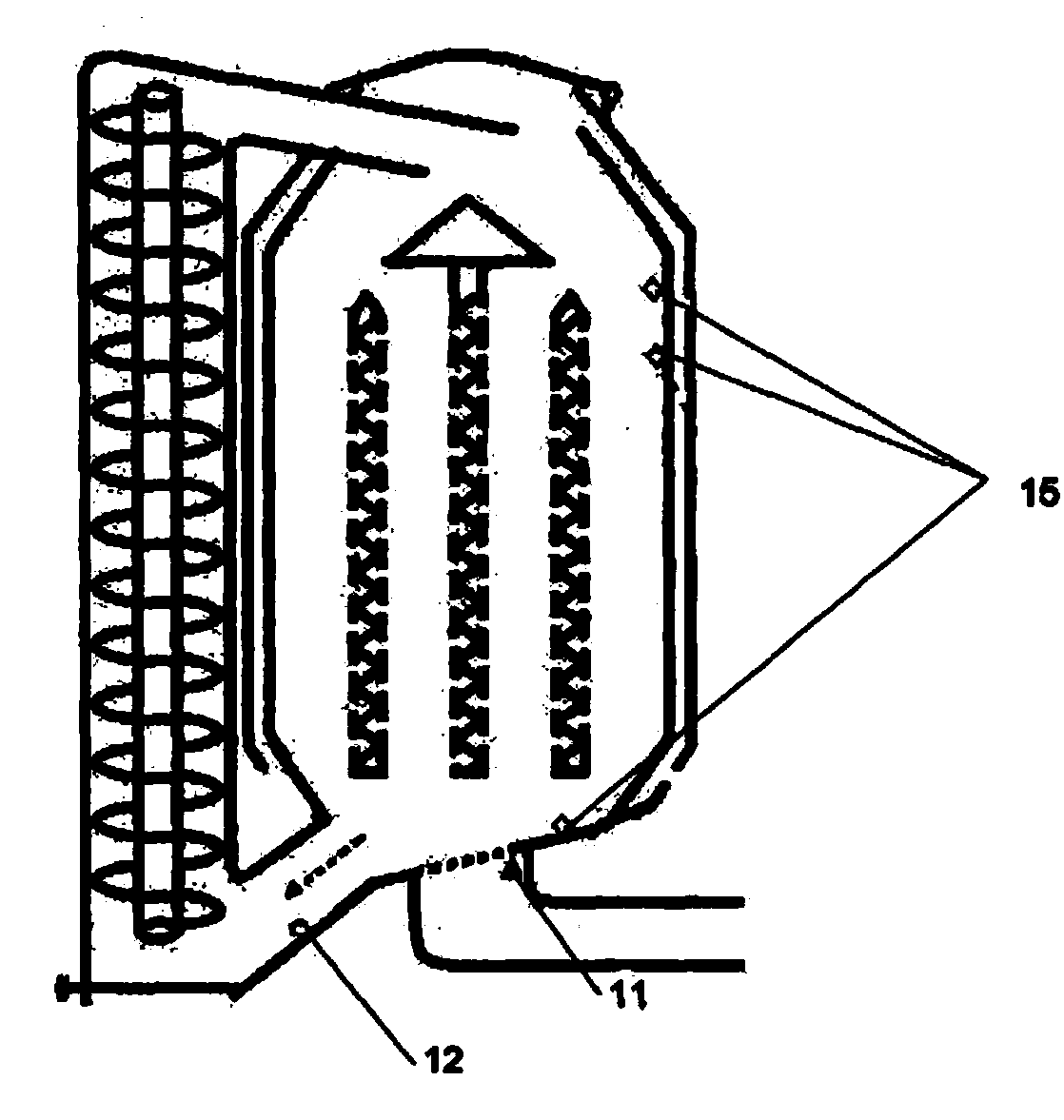

Rotary disk type air jet impact drying machine

InactiveCN103673563AEasy to manufacture and installLow costDrying gas arrangementsDrying solid materialsJet flowAutomatic control

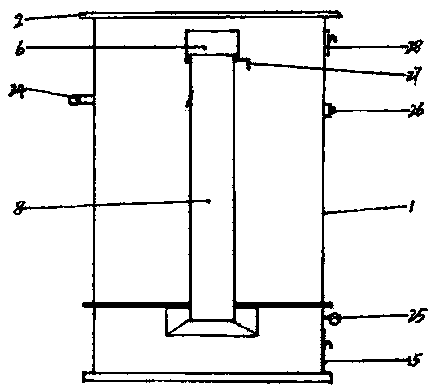

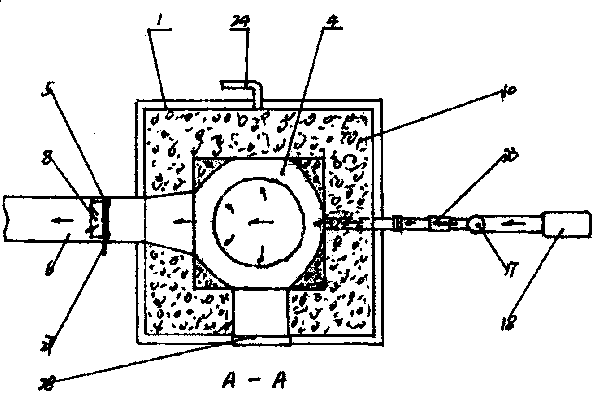

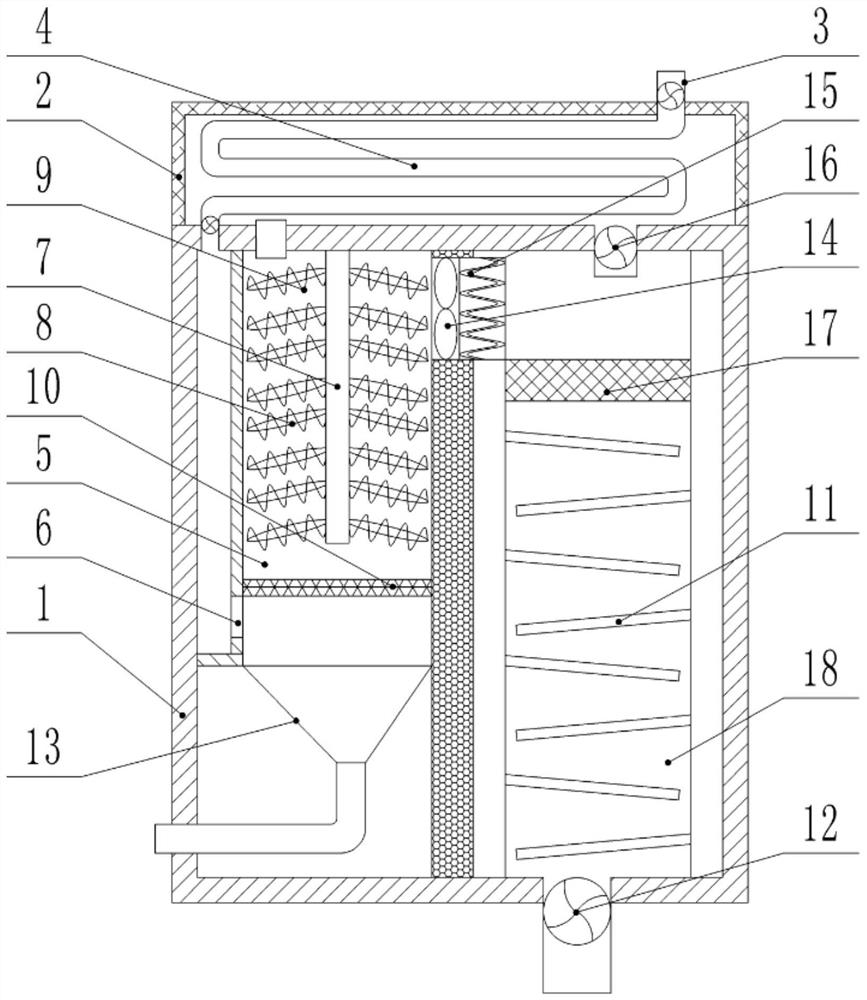

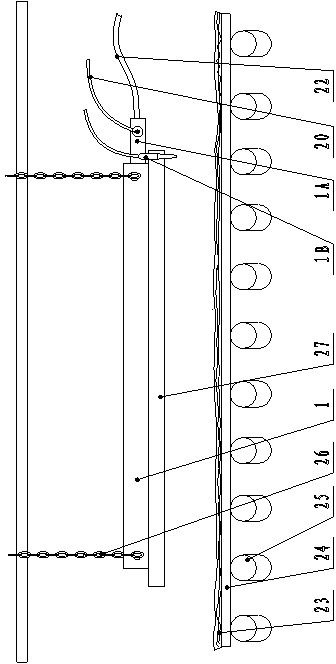

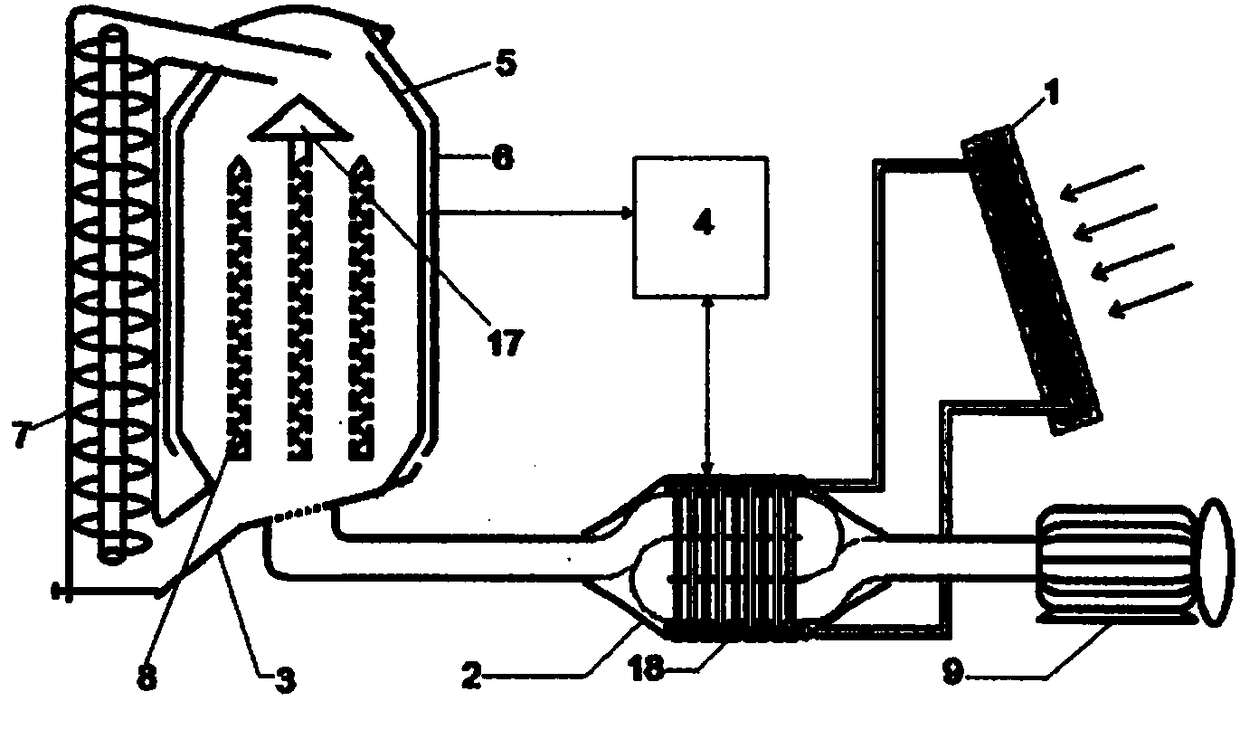

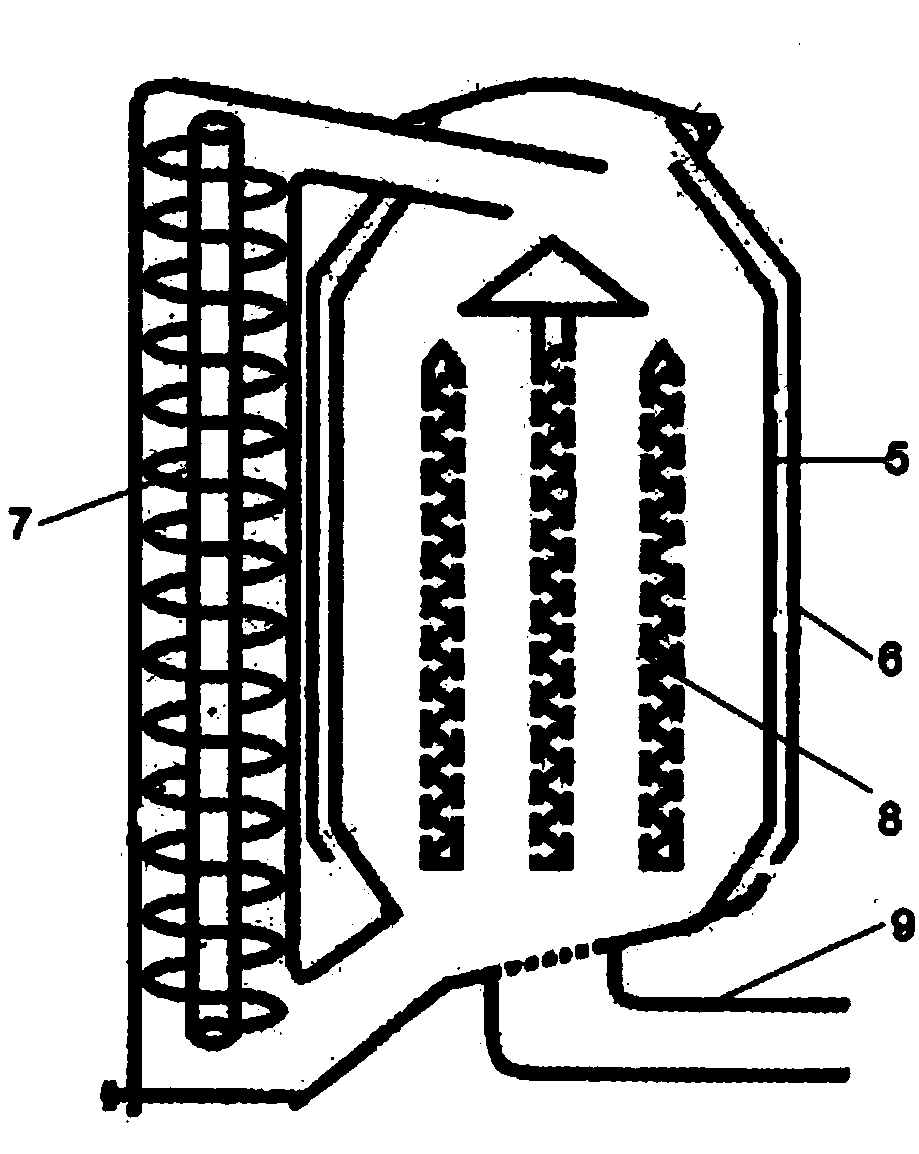

The invention belongs to the technical field of agricultural product processing, and particularly relates to a rotary disk type air jet impact drying machine. The rotary disk type air jet impact drying machine comprises an air flow circulation system, a rotary disk system, a weighing system and an automatic control system. In the drying process, hot air flow with certain pressure is jetted into a drying chamber (23) through an adjustable strip-shaped air flow jet (38), multiple layers of round material racks (6) evenly distributed in the drying chamber (23) in the axial direction of a rotary material shaft (8) carry a material disk (7) to rotate in the horizontal plane, the rotary disk system can conduct drying in a rotation speed changing and rotation mode changing mode and the weighing system can indicate the drying condition of materials. The rotary disk type air jet impact drying machine solves the problems that an existing air jet impact drying machine is limited in carrying capacity, hard to meet the drying requirements of batch agricultural materials and high in manufacturing cost, and air flow adjustment is inconvenient; meanwhile, the rotary disk type air jet impact drying machine can realize the batch-type drying process of drying-tempering-drying-tempering, improve the drying efficiency, and lower the running energy consumption of the rotary disk system, and is high in automation degree and good in material adaptability.

Owner:CHINA AGRI UNIV

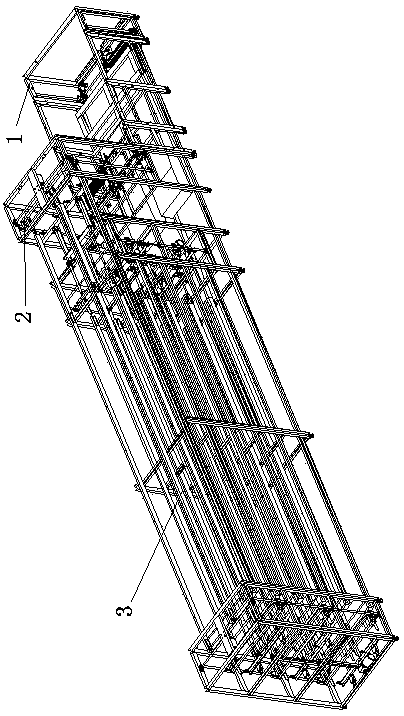

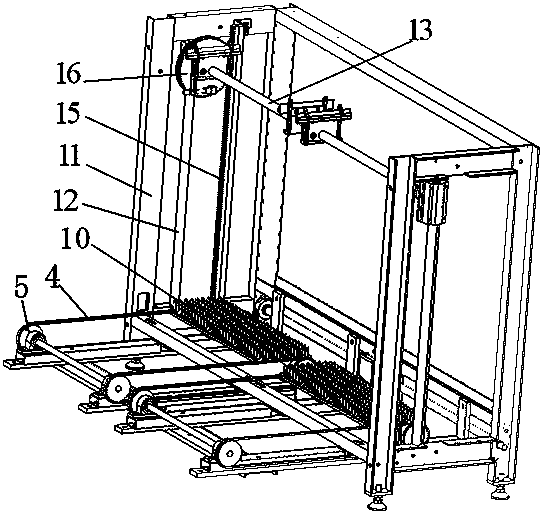

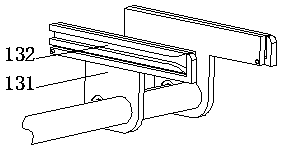

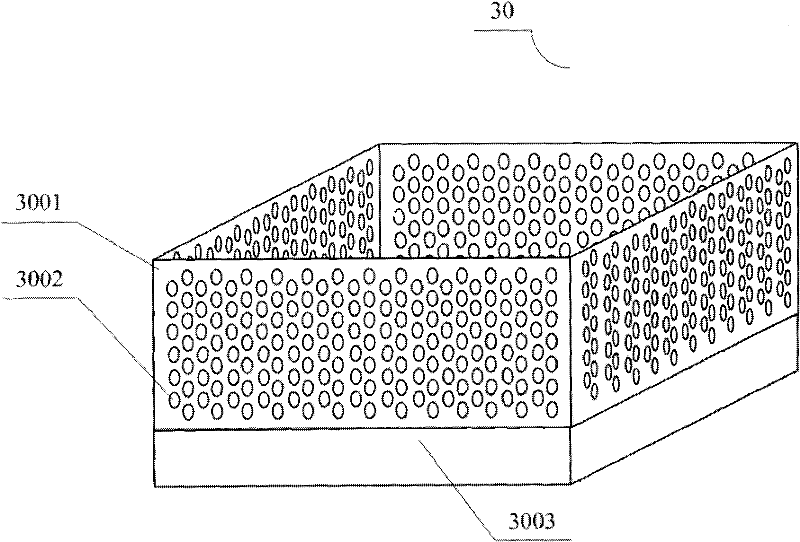

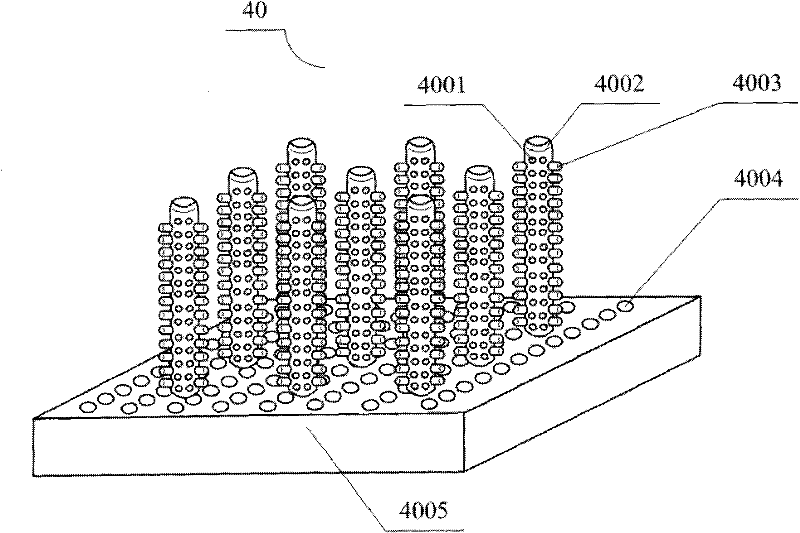

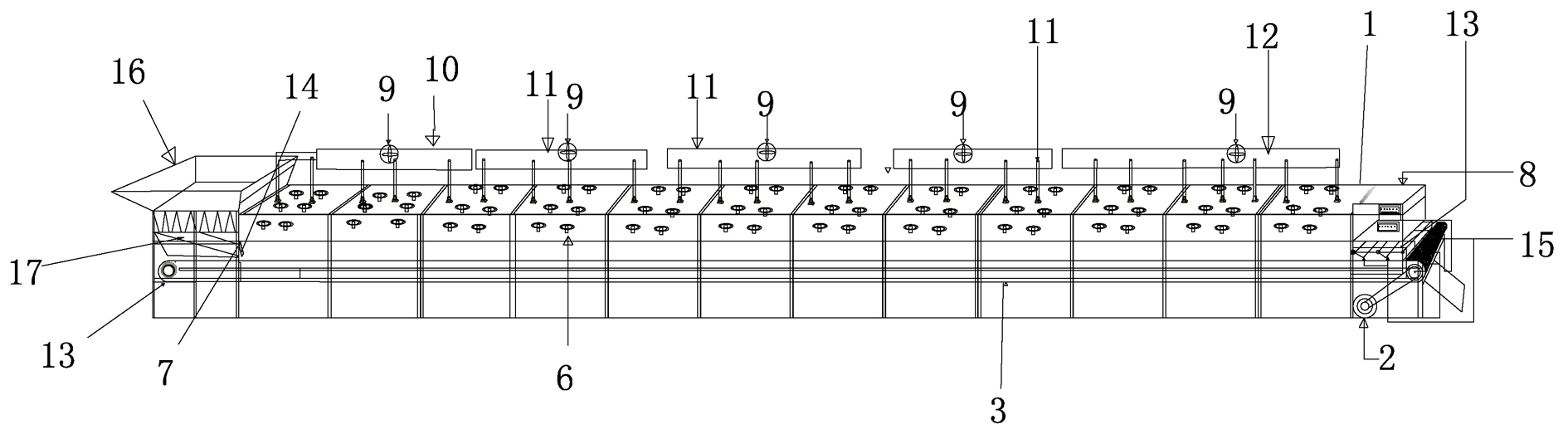

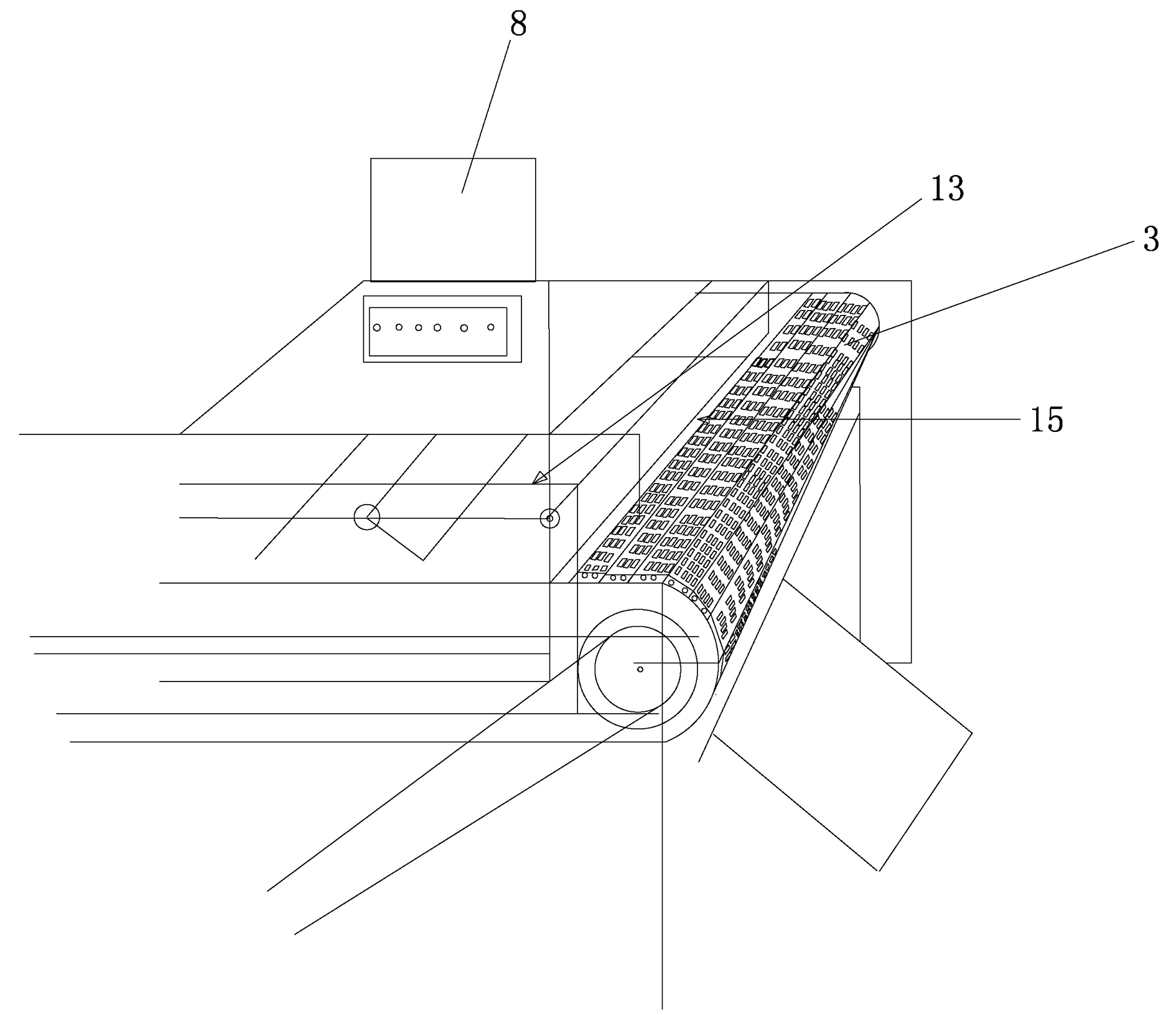

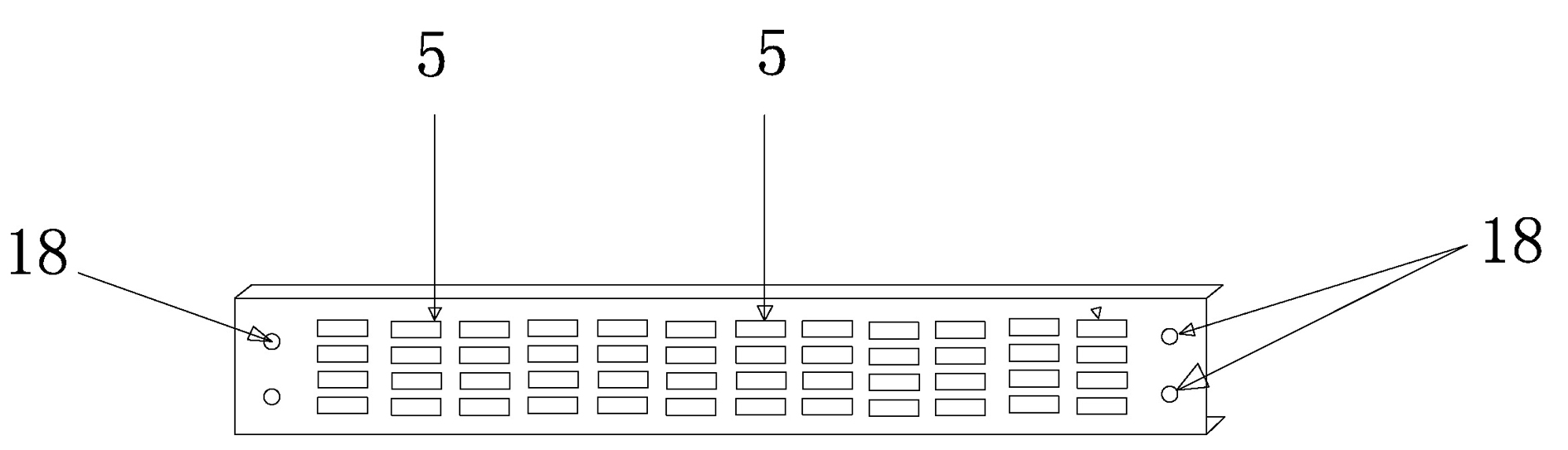

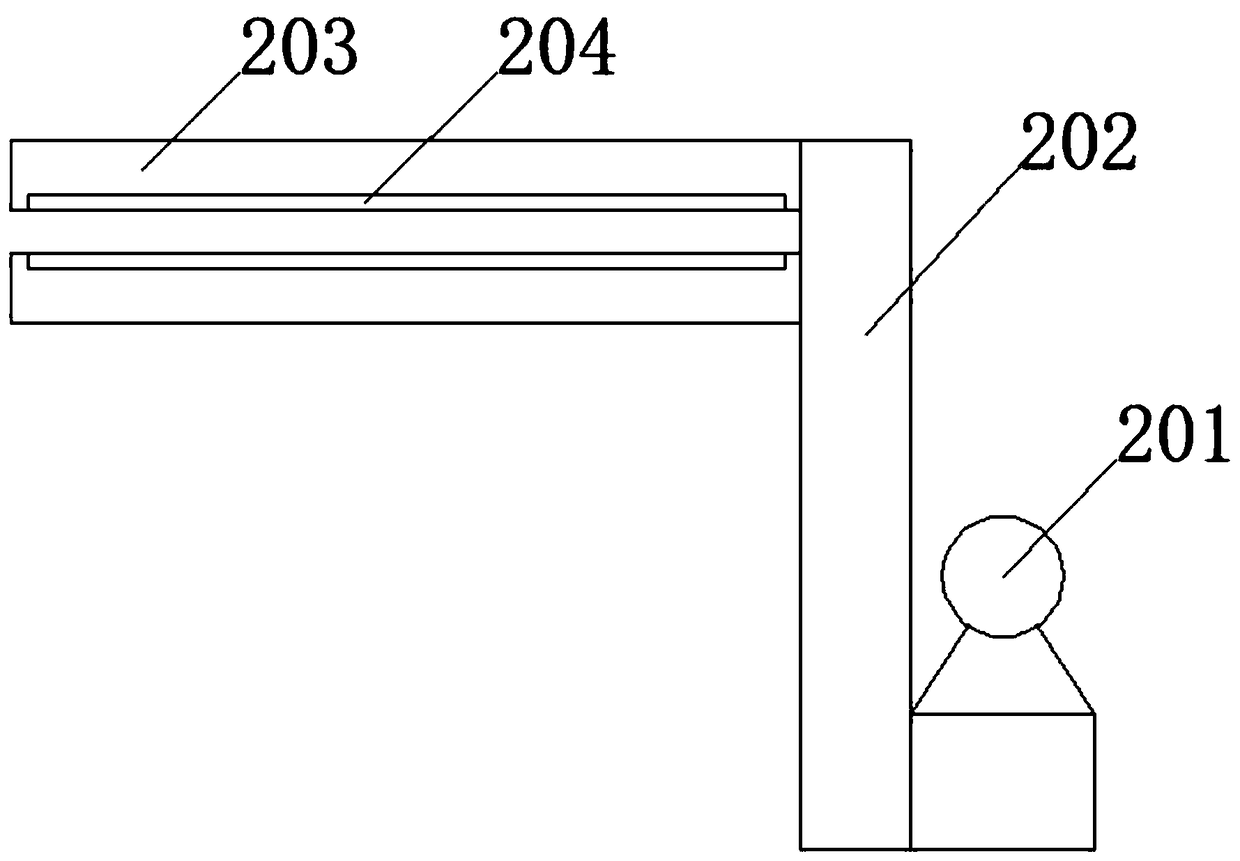

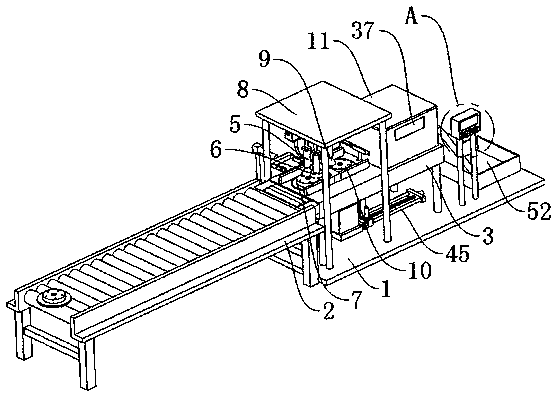

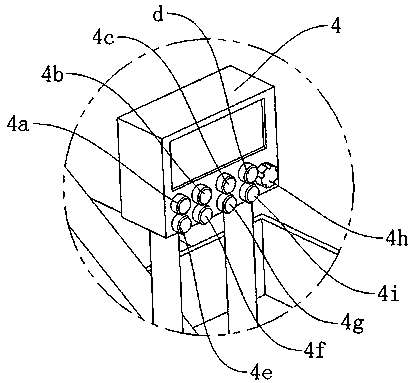

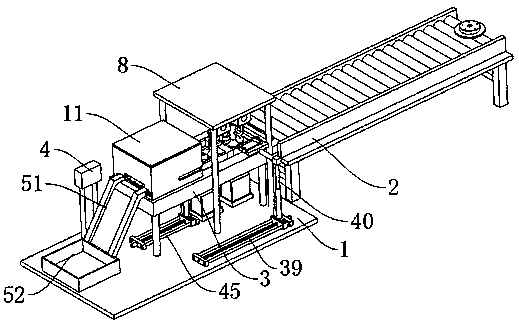

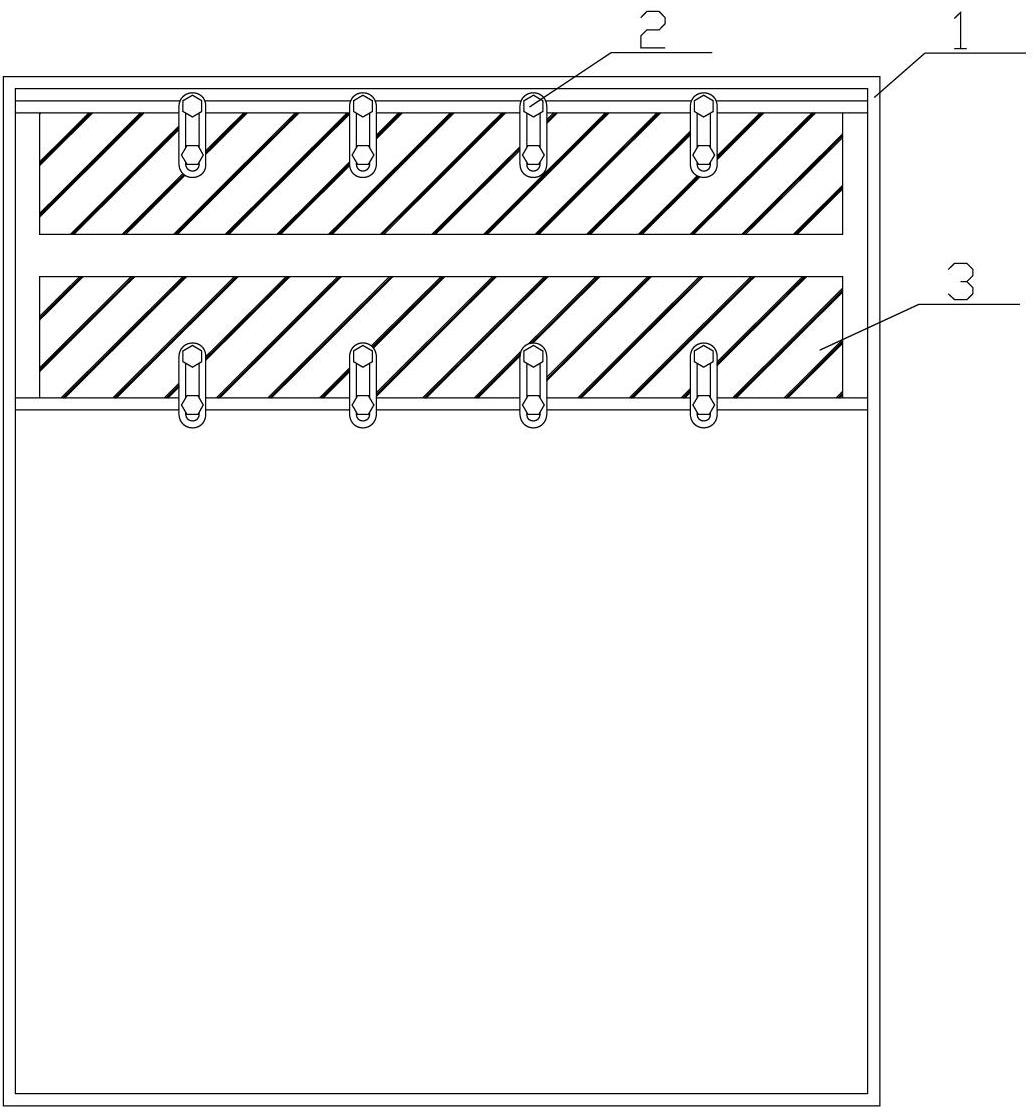

Capsule production line equipment

ActiveCN104044904AOvercome shockOvercome large vibrationConveyor partsMechanical conveyorsProduction lineSynchronism

The invention discloses capsule production line equipment, which comprises a slab overturning mechanism, a circulating capsule drying device and a slab lifting mechanism, wherein the lifting mechanism drives the slab to overturn stably, the service lives of a gear and a rack are long, no compact or noise is generated during an overturning process, the lifting mechanism does not need to stop to wait for a slab to be pushed into a clamping groove, the slab enters the clamping groove automatically, the slab conveying time is saved, the continuity of a production line is better, and the processing efficiency of the capsule production line is improved; the defect that the slab can only be pushed in when a slab lifting device descends to the lowest position is overcome by the slab lifting mechanism, at least two slabs can be lifted at a time, and the work efficiency of the capsule production line is greatly improved; the occupied space of the circulating capsule drying device is smaller, the utilization rate is high, lead screws at each layer move synchronously, and slab pushing mechanisms at multiple layers can be driven by one motor, so that resources are saved, and the synchronism of each slab pushing mechanism is ensured.

Owner:XINCHANG HONGHAI MACHINERY

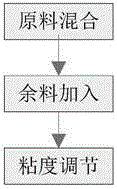

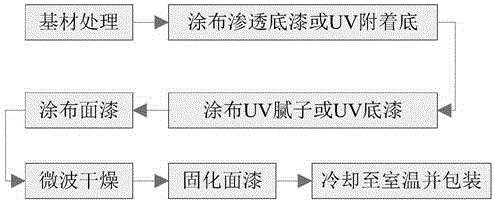

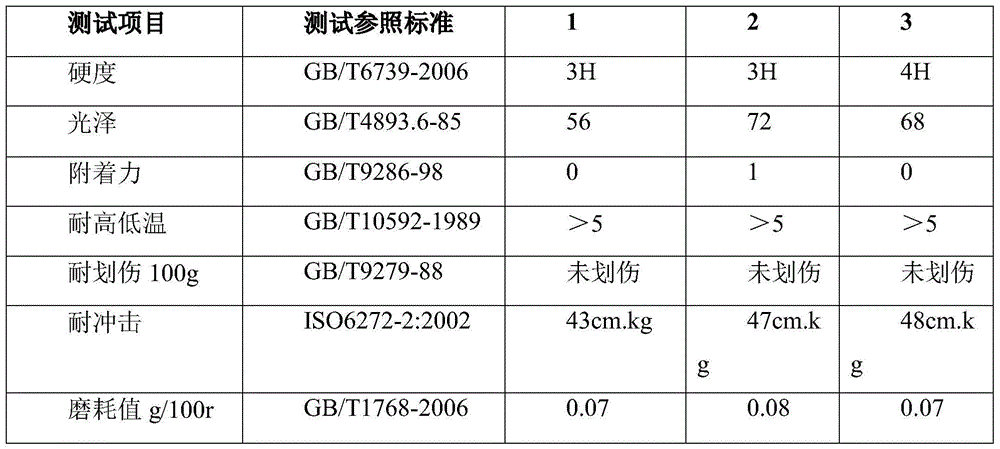

Aqueous UV wood paint, preparation method and application technology thereof

InactiveCN105860792AInhibition releaseGuaranteed to be environmentally friendlyPretreated surfacesPolyurea/polyurethane coatingsHardnessWear resistance

The invention discloses an aqueous UV wood paint. The aqueous UV wood paint comprises the following components: 20-40% of aqueous polyurethane resin, 20-60% of aqueous UV resin, 0.2-0.6% of an antifoaming agent, 0.2-0.8% of a leveling agent, 0.2-0.8% of a wetting agent, 0.2-0.8% of a thickening agent, 0.2-0.8% of an initiator, 0.2-0.8% of a dispersant, 0.2-0.8% of matting powder, 5-40% of water, and 0.2-0.5% of a handfeel auxiliary agent. The invention also discloses a preparation method of the aqueous UV wood paint and an application technology thereof. The aqueous UV wood paint has the advantages of good environmental protection performance, strong adhesive force, high hardness, good wear resistance and coin scratching-resistant performance. The preparation method has the advantage of simple operation, by employing a microwave drying method, the drying speed is fast, drying requirement of a thicker coating can be satisfied, the production efficiency is high, and the aqueous UV wood paint is quit suitable for industrial production.

Owner:HUNAN BANFERT NEW MATERIALS TECH

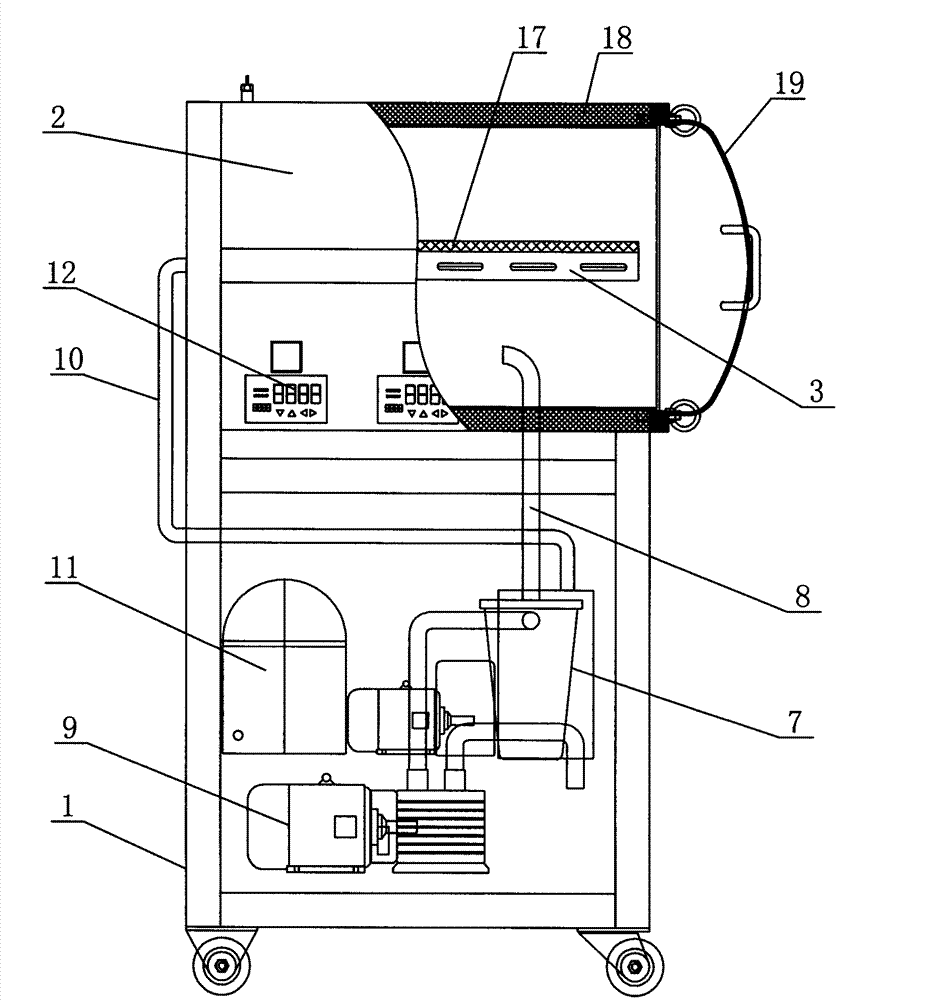

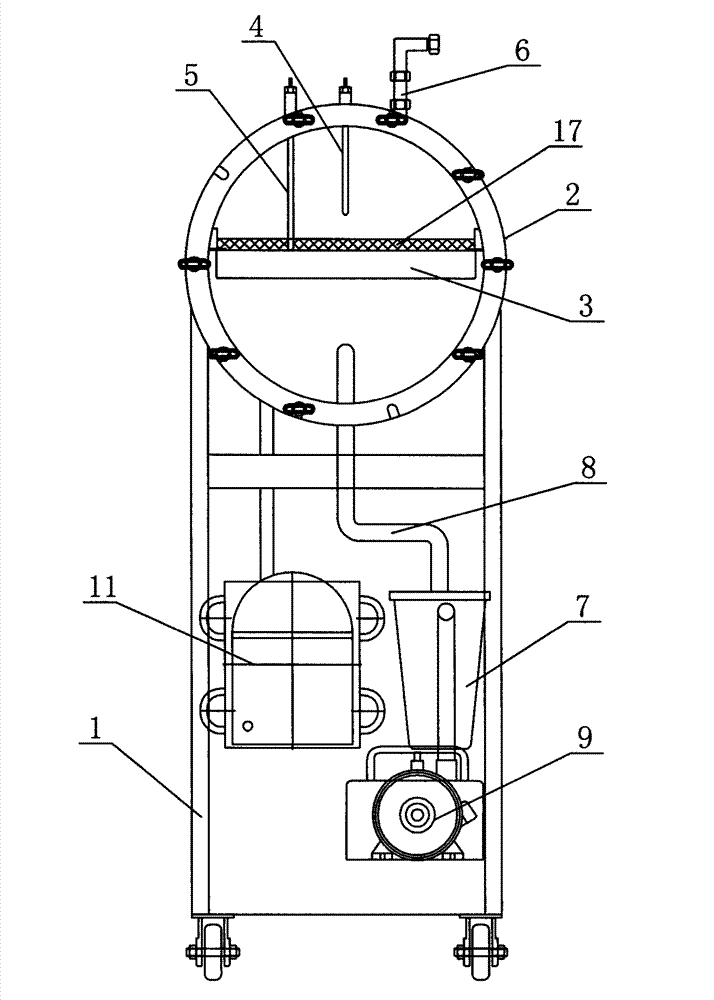

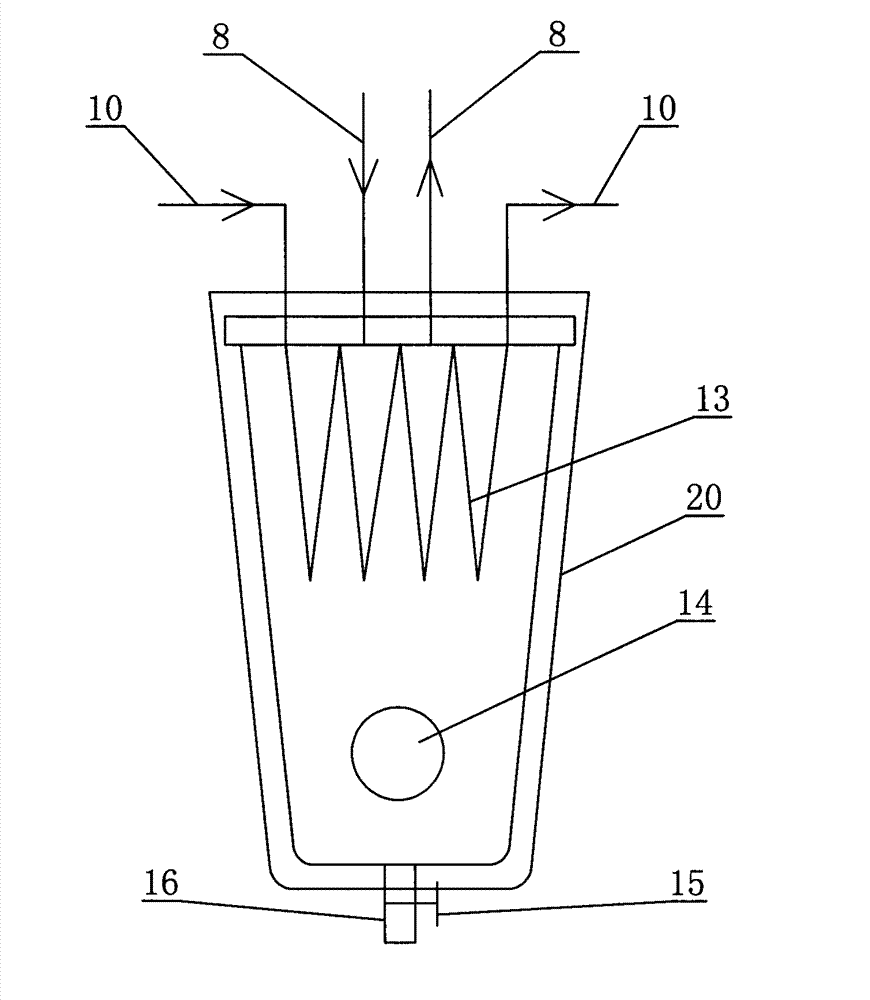

Low-temperature negative pressure drying method and device for textile materials and textiles

InactiveCN102175071AOvercoming the bottleneck of the relatively long isokinetic drying phaseFast drying processDrying using combination processesDrying machines with local agitationResonant cavityMicrowave

The invention discloses a low-temperature negative pressure drying method and a low-temperature negative pressure drying device for textile materials and textiles. The device comprises a microwave source, a temperature sensor, a resonant cavity, an air-cooled or water-cooled device, a vacuum sensor, an air release valve, a humidity sensor, an air extraction valve, an air extraction pipeline, a vacuum pump, a vacuum pump motor, a stirrer, a panel, a controller, a shielding sealing door, a shell, an indicating lamp, a switch, a scattered article drying box and a cheese drying bracket; and the scattered textile materials or textiles are put into the scattered article drying box, or cheeses are stacked on the cheese drying bracket and then put into the resonant cavity, and the dried articles are heated and dried under the low-temperature negative pressure working condition. Relatively long bottleneck at the uniform velocity drying stage when single microwave is used for drying can be effectively overcome, over drying is avoided, and the whole drying process is quick and energy-saving; and the method and the device can particularly meet the drying requirements of special animal fibers, artificial fibers, synthetic fibers and like and the products thereof with special temperature requirements.

Owner:SHANGHAI ZHONGFANG BAODA TEXTILE INTELLIGENT INSTR +2

Processing method of rheum officinale baill

InactiveCN101991658AMeet drying requirementsSimple methodPlant ingredientsCooking & bakingEngineering

The invention discloses a processing method of rheum officinale baill, which is characterized in that corks are removed from the collected fresh rheum officinale baill, rootlets are cut off, the main root stock is cut into short segments of 6-8cm, the segments are uniformly spread out and are fed into a drying room, the temperature is controlled to 40-50 DEG C for 48 hours for baking for first time, meanwhile, moisture is pumped, and then the segments are taken out for 72-80 hours for cooling, and then are fed into the drying room again, the temperature is controlled to 50 DEG C for baking for second time for 24 hours. In the invention, a two-section low-temperature baking mode is adopted, time and energy are saved and the cost is low; the method is simple, standard and easy, the water content of the dried rheum officinale baill is less than 8.0 percent, effective contents of the rheum officinale baill can not be damaged and the appearance thereof is smooth.

Owner:镇巴县春茂中药材开发有限责任公司

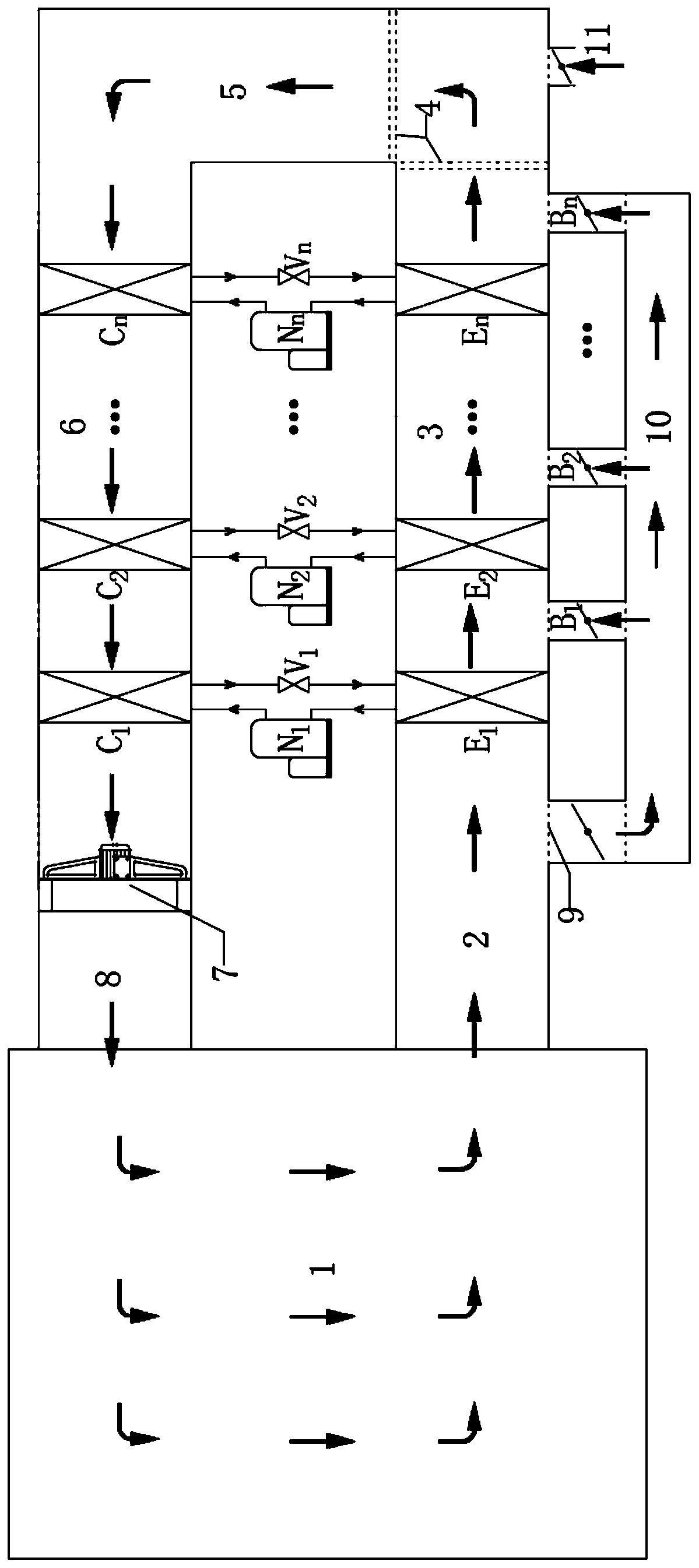

Drying method and drying device for supercapacitor

InactiveCN103745840AImprove drying efficiencyService life is not affectedDrying/impregnating machinesSupercapacitorNitrogen

The invention relates to the capacitor manufacture field, and is to provide a drying method and drying device for a supercapacitor. The drying method for the supercapacitor comprises the following steps: (1) putting the supercapacitor to a drying chamber arranged in a drying furnace; (2) extracting the air in the drying chamber until the vacuum degree is lower than 1 pa; (3) filling nitrogen to the drying chamber; (4) heating the drying furnace for 2-5 hours until the temperature reaches 120-200 DEG; (5) extracting the nitrogen in the drying chamber until the vacuum degree is lower than 1 pa; (6) keeping the vacuum degree in the drying chamber to be lower than 1 pa, and meanwhile, holding the temperature of the drying furnace to be 120-200 DEG for 5-10 hours and performing drying; and (7) filling the nitrogen into the drying chamber, opening the drying furnace and the drying chamber, and taking out the supercapacitor which has been dried. The drying efficiency of the drying method for the supercapacitor is high; the drying effect is good without influencing the service life; and the drying device of the drying method for the supercapacitor is simple in structure and is capable of satisfying the drying requirements.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

Device and method for generating clean coal by means of quick total sulfur treatment of coal

The invention relates to a device and a method for generating clean coal by means of quick total sulfur treatment of coal. Total sulfur in raw coal is subjected to low-temperature negative-pressure treatment by means of vacuum negative pressure combined with microwave heating to quickly remove evaporable harmful substances in the raw coal, and pyrite in the coal is quickly translated into pyrrhotite and troilite which are higher in paramagnetism by means of microwave irradiation so as to be convenient to remove more effectively in subsequent magnetic separation. The device and the method can be also applied to heating, drying and removal of evaporable harmful substances in industries of textile, dyeing, printing, food, medicine, chemical engineering, mining, papermaking and the like, such as quick removal of harmful substances like formaldehyde contained in textiles and garments and dimethylbenzene contained in artificial boards.

Owner:SHANGHAI ZHONGFANG BAODA TEXTILE INTELLIGENT INSTR +2

Intelligent multilevel inverter microwave and optical wave crawler speed-regulating tunnel type coal drying device

InactiveCN102012153AIntegrity guaranteedWarranty requirementsDrying solid materials with heatDrying machines with progressive movementsMicrowaveMetal-halide lamp

The invention relates to an intelligent multilevel inverter microwave and optical wave crawler speed-regulating tunnel type coal drying device, which comprises a tunnel type box and a metal crawler connected to a variable frequency motor, wherein the metal crawler is formed by splicing a plurality of crawler slots; each crawler slot is provided with a plurality of orderly arrayed small holes; a microwave magnetron set and an optical wave metal halide lamp set are arranged above the metal crawler in the tunnel type box; and the coal is dried through the microwave and optical wave. The invention has the advantages that a microcomputer control system can ensure that the coal is not broken and cracked under the condition of microwave drying technique, which meets the drying demand of cleanly produced coal, decreases the energy consumption and is free from pollution.

Owner:洪正中

Multi-stage heat pump drying and dehumidifying system with bypass pipeline

ActiveCN107642925AGood dehumidification performanceLower pressure ratioDrying gas arrangementsEfficient regulation technologiesAir volumeEngineering

The invention belongs to the technical field of hot air drying of agricultural and sideline products, and discloses a multi-stage heat pump drying and dehumidifying system with a bypass pipeline. Thesystem comprises a control unit, a main air channel and a drying chamber which is used for containing to-be-dried materials; an air supply inlet for introducing air and an air exhaust outlet for discharging the air are formed in the drying chamber; the two ends of the main air channel are communicated with the air supply inlet and the air exhaust outlet respectively, and the main air channel is internally provided with a main blower, a dehumidifying chamber, a water baffler and a heating chamber, wherein the dehumidifying chamber, the water baffler and the heating chamber are sequentially arranged in the air flow direction; the multi-stage heat pump drying and dehumidifying system further comprises a multi-stage heat pump unit and the bypass pipeline which is communicated with the dehumidifying chamber, and multi-stage heating and multi-stage humidifying are achieved. Compared with a single-stage heat pump drying system, the pressure ratio of a compressor is reduced, the efficiency ofthe compressor is improved, and the air volume control based on the bypass pipeline effectively adjusts the humidifying performance of the system, so that the system has a wider adjusting range.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

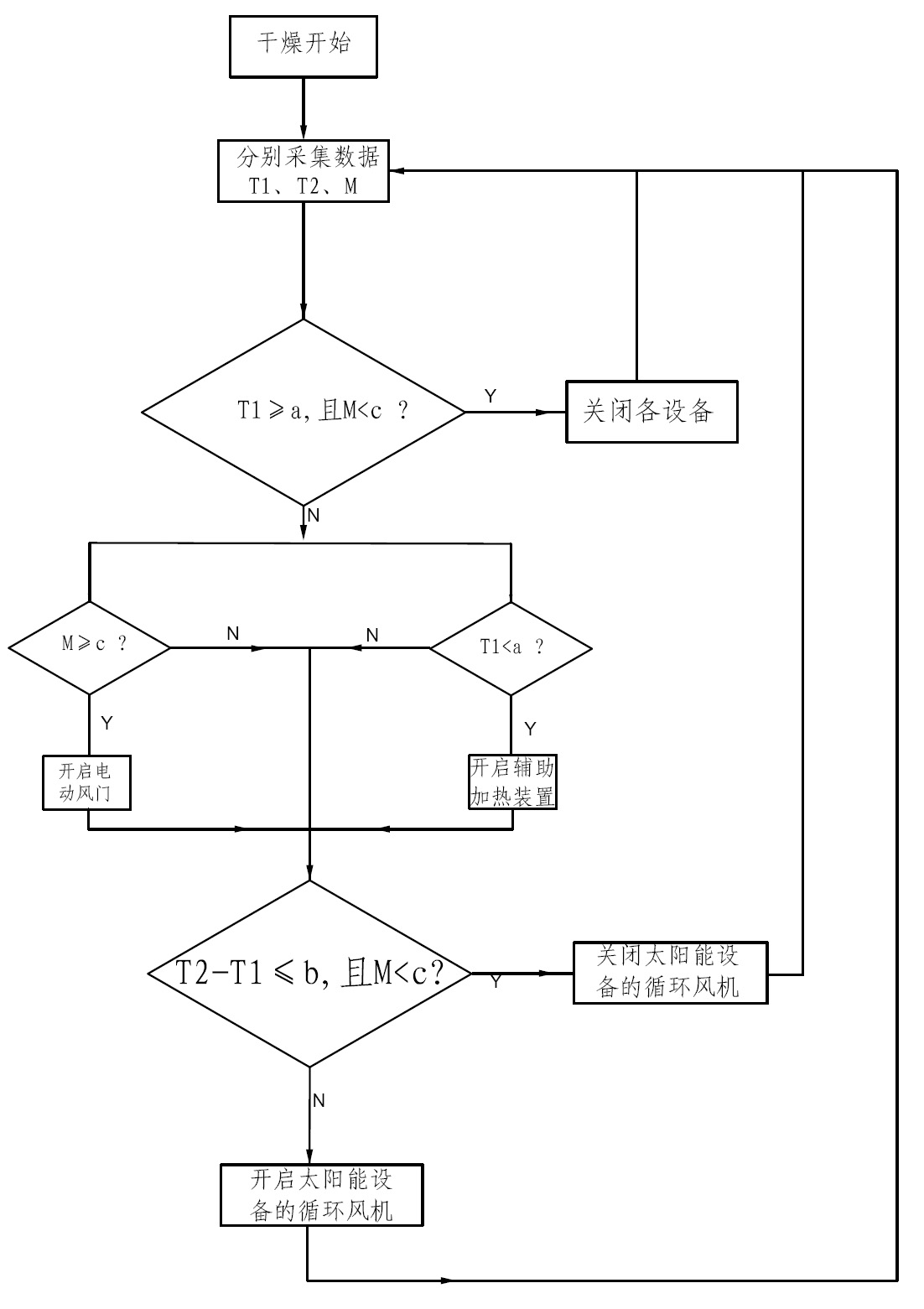

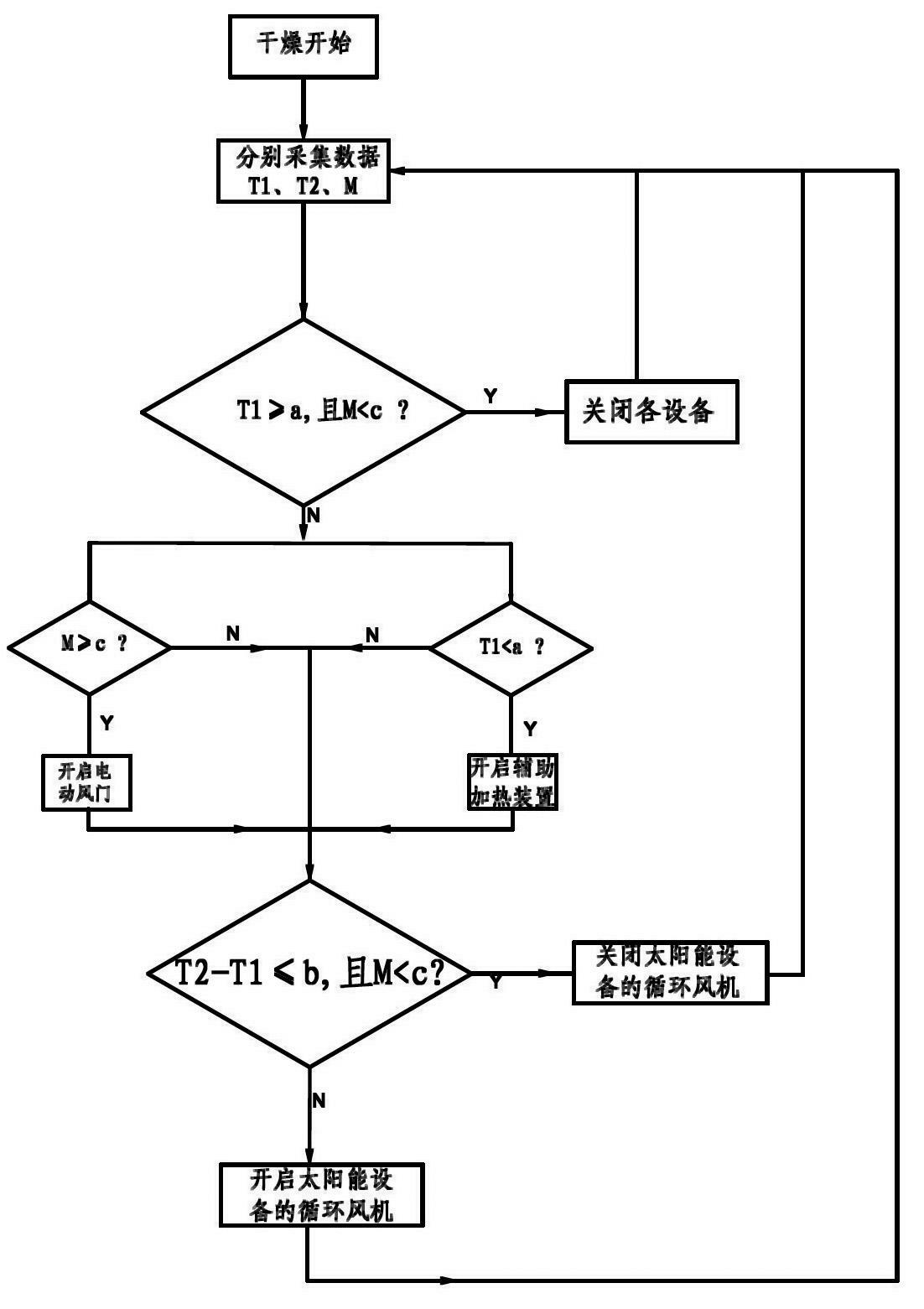

Method for controlling temperature and humidity of solar drying room precisely

InactiveCN102607252AEasy to monitorPrecise temperature controlDrying gas arrangementsSolar dryingRoom temperature

The invention discloses a method for controlling temperature and humidity of a solar drying room precisely, which includes the following steps: A. collecting room temperature T1 of the drying room, air outlet temperature T2 of a solar air heat collector and room temperature M of the drying room; B. judging whether T1 is not smaller than a first set value a, judging if M is smaller than a second set value c, and if T1 is not smaller than the first set value a and M is smaller than the second set value c, closing a solar heat collecting device, an auxiliary heating device and an electric air door of a dehumidifier, and executing the step A repeatedly; otherwise entering next step; C. judging whether T2-T1 is not larger than a third set value b, judging whether M is smaller than a set value c simultaneously, and if T2-T1 is not larger than the third set value b and M is smaller than the set value c, a circulating fan is closed, the solar heat collecting device does not work, and the step A is repeated; otherwise entering next step; and D. starting the circulating fan, exchanging air of the drying room through the solar heat collecting device, and repeating the step A. The method for controlling the temperature and the humidity of the solar drying room precisely judges outdoor and indoor humidity timely, achieves linkage control of all drying devices, and can precisely control the temperature and the humidity in the drying room.

Owner:SHENZHEN COMMONPRAISE SOLAR

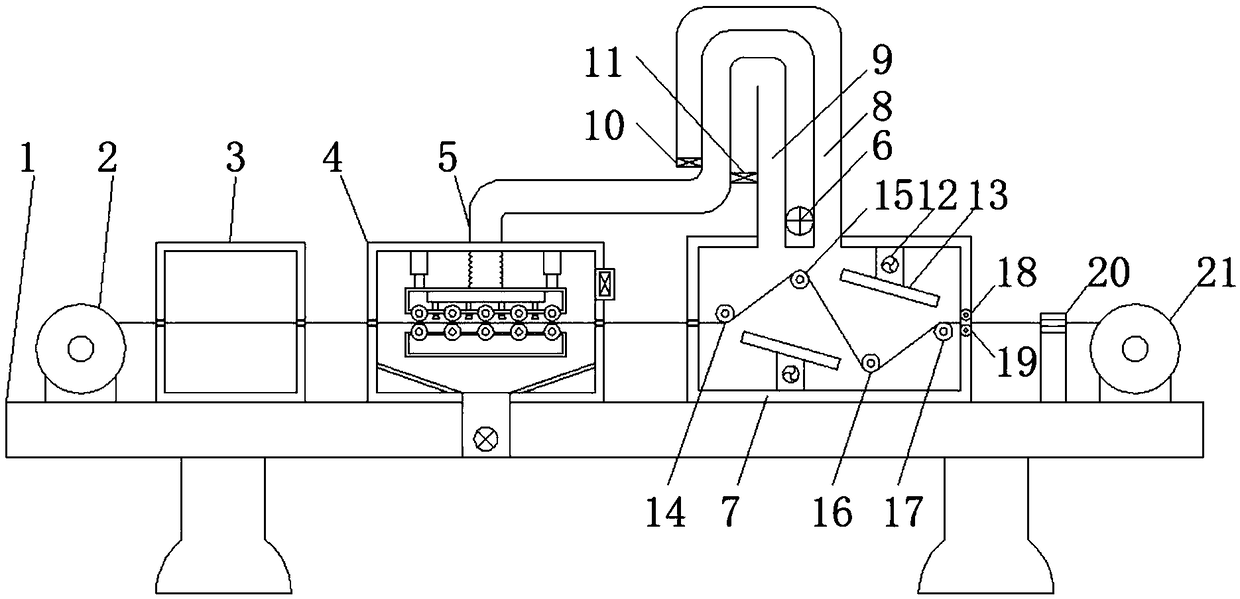

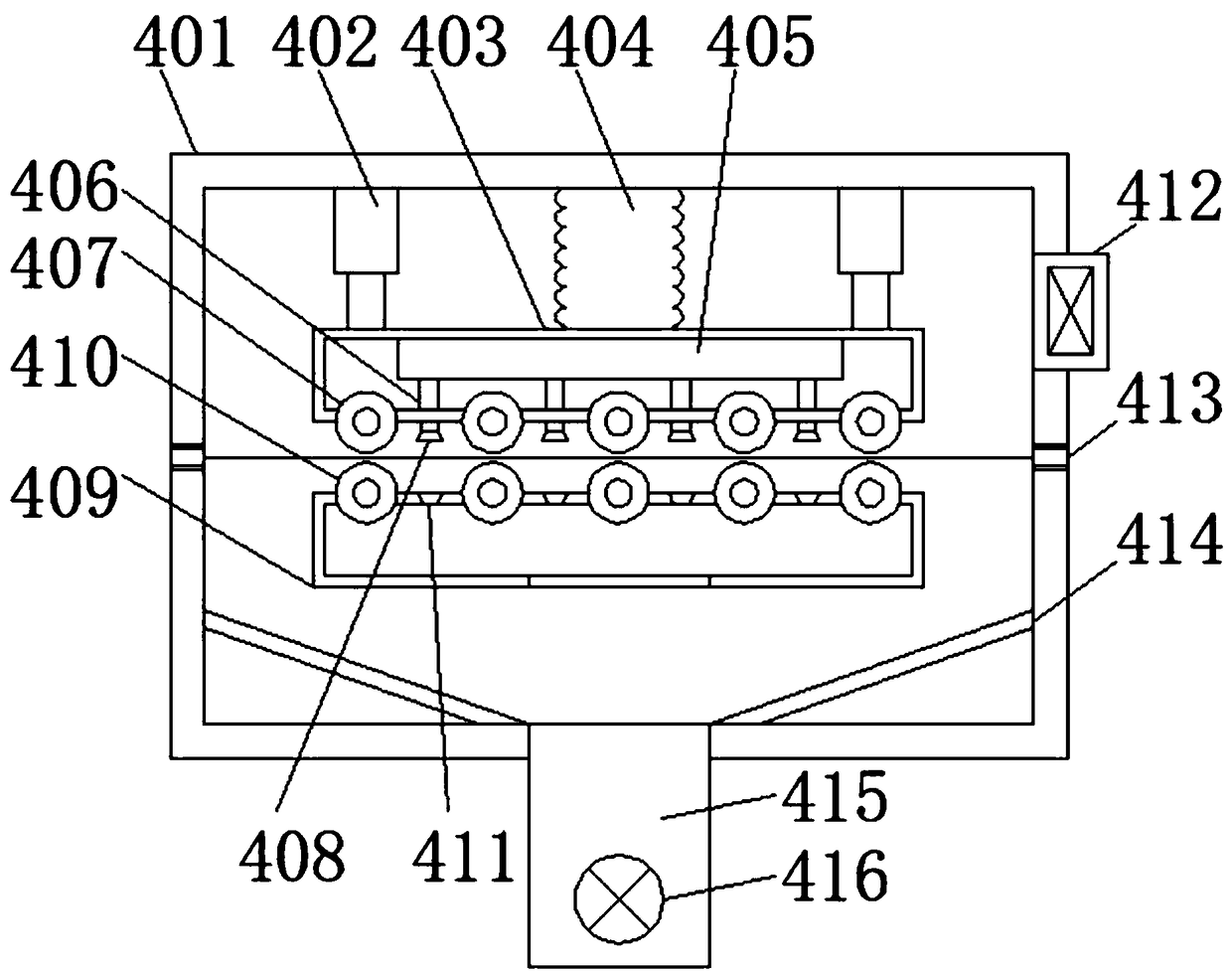

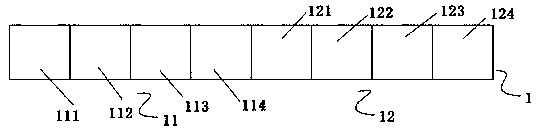

Long gauze drying device with pre-drying

InactiveCN108895801AFully dryAchieve drynessDrying gas arrangementsDrying machines with progressive movementsLaboratory ovenEngineering

The invention provides a long gauze drying device with pre-drying, which relates to the technical field of the long gauze drying device. Which is provided with a pre-drying long gauze drying device, including the rack, A feeding rotating shaft is movably installed on the left side of the top of the rack, A cooking device is fixedly installed on the top of the rack, a pre-drying device is fixedly installed on the top of the rack, an air inlet pipe is fixedly installed on the top of the pre-drying device, an air inlet port is arranged on the right side port of the air inlet pipe, and an oven isfixedly installed on the top of the rack. Which is provided with a pre-drying long gauze drying device, contacting the drying air with waste heat in the drying device with the air inlet pipe connectedto the pre-drying device through the first air duct and the second air duct, In this way, the waste heat inside the drying device can be transferred to the pre-drying device for pre-drying the long gauze, and the long gauze can be pre-dried while being extruded by the upper pressing shaft and the lower pressing shaft, so that the long gauze can be dried more fully and thoroughly.

Owner:江西美宝利实业有限公司

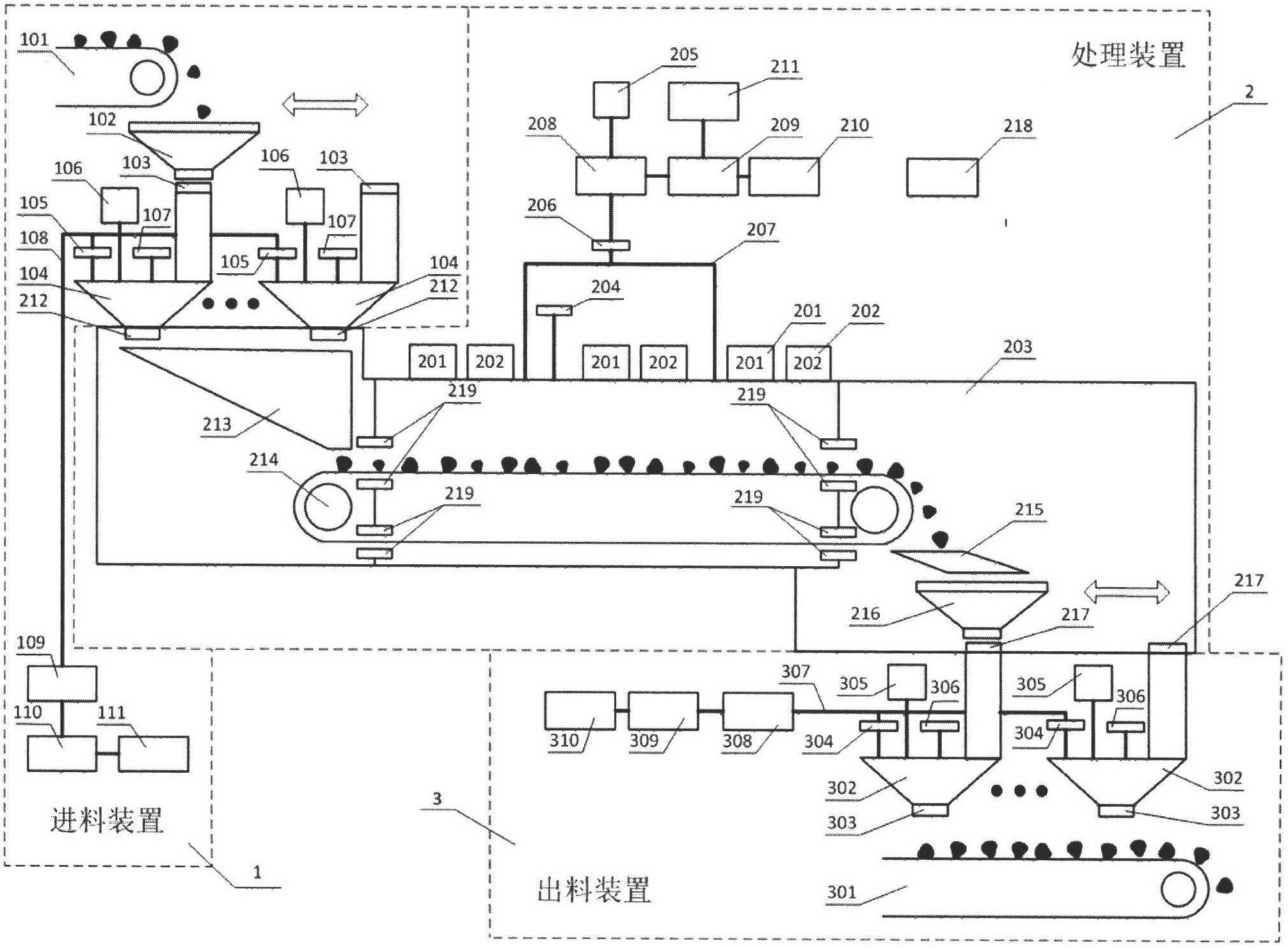

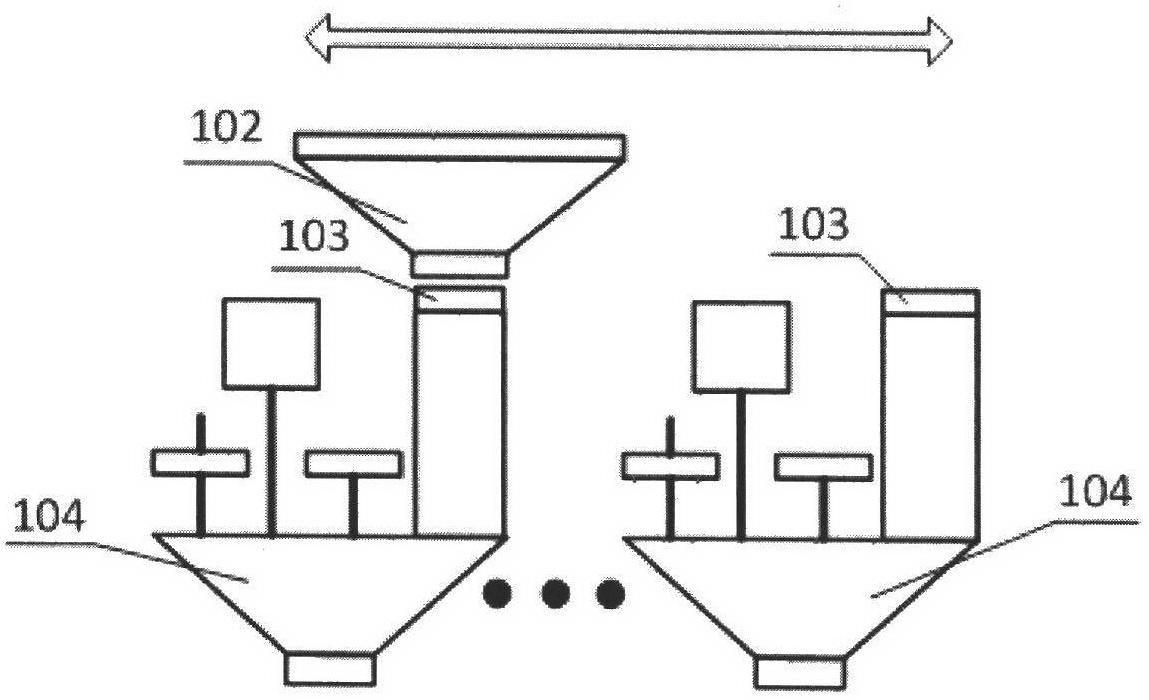

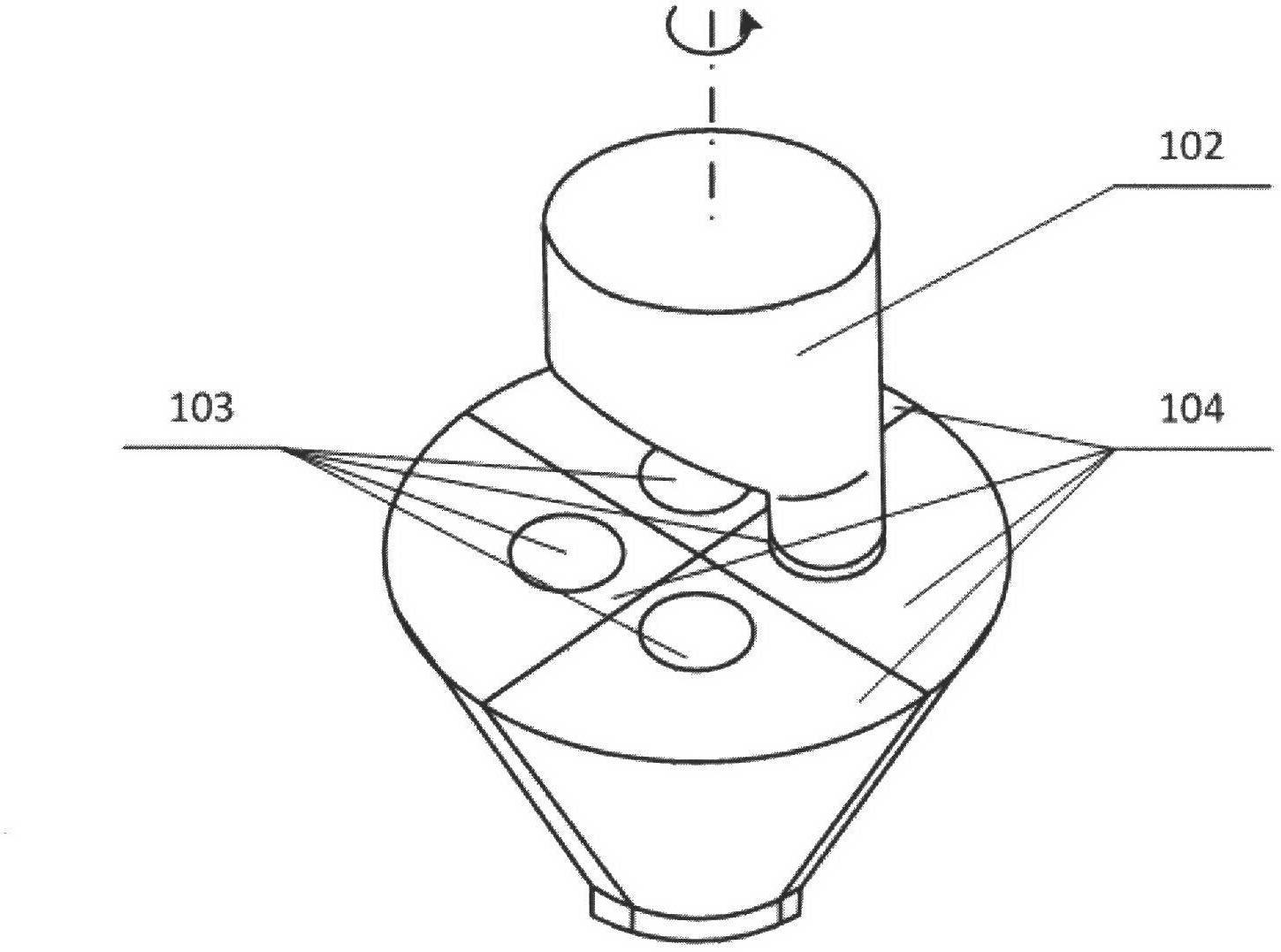

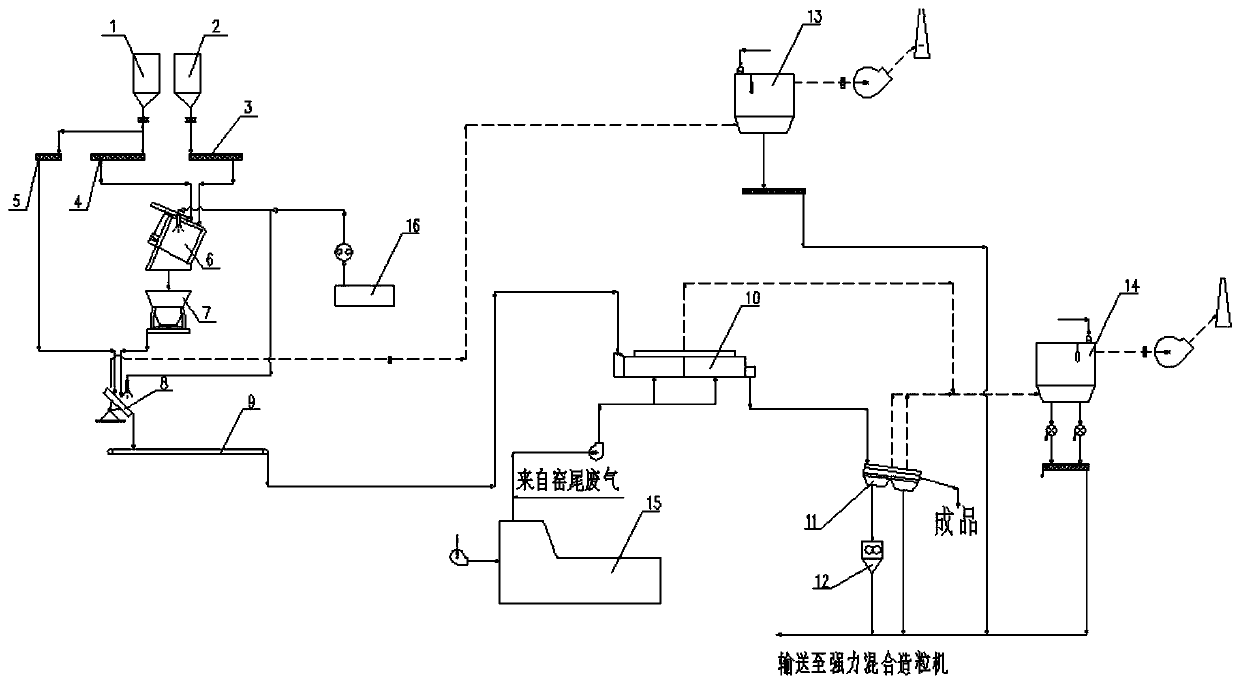

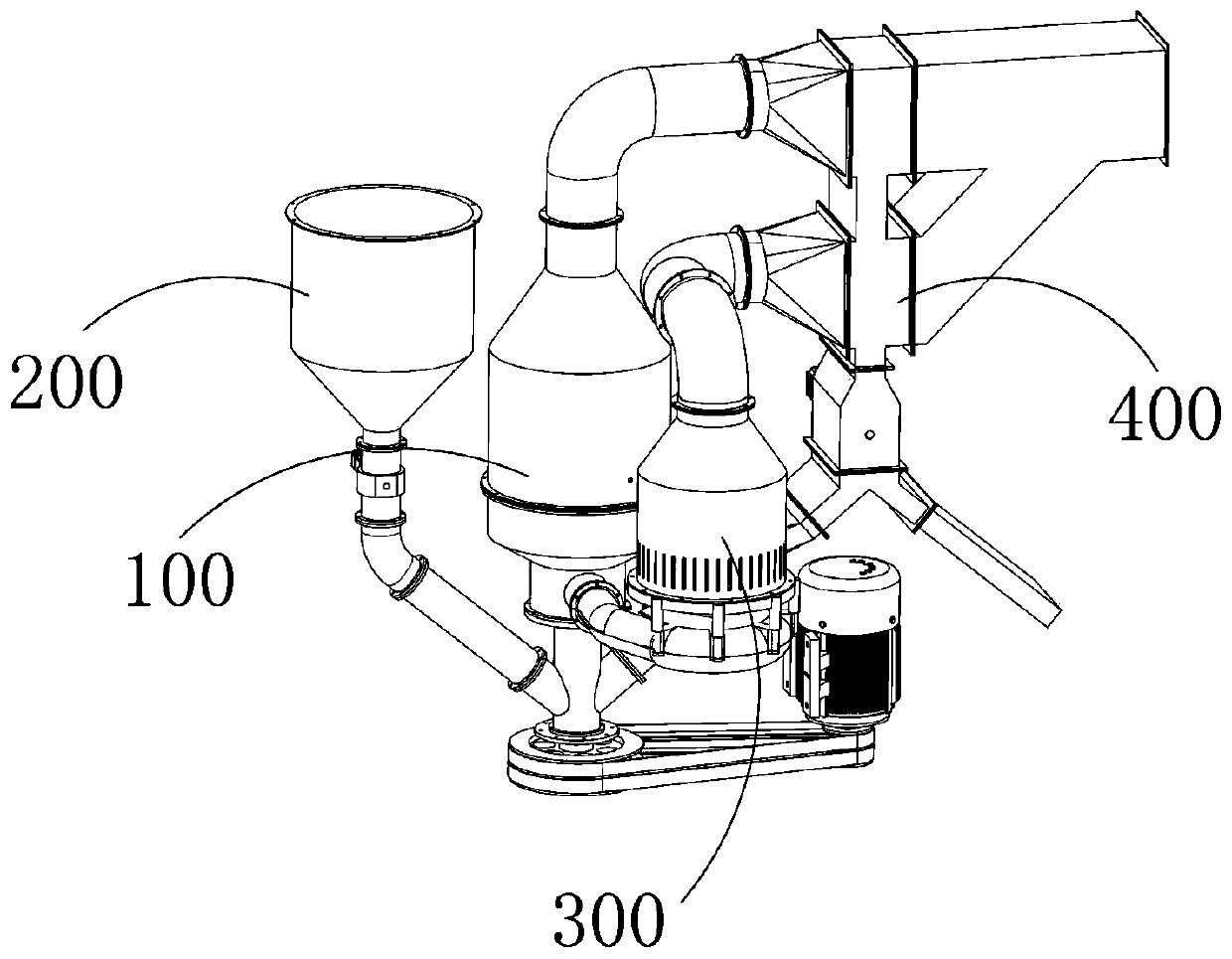

Mineral source soil conditioner granulation process and device

PendingCN111318229ASimple processGood mixing effectGranulation in rotating dishes/pansGranulation in stationary drums/troughsMineralogyMoisture

The invention relates to a mineral source soil conditioner granulation process and device. The granulation process comprises the following steps: (1) raw material proportioning; (2) micro-granulation:forming uniform micro-particles with the moisture content of 10-12% and the particle size of 0.2-0.5 mm through strong mixing granulation; (3) micro-particle storage; (4) disc granulation: forming particles with the moisture content of 11-13% and the particle size of 2-3mm through disc granulation; the granulating device comprises a storage bin, a strong mixing granulator, a micro-particle storage bin, a disc granulator, a drying machine and a vibrating screen which are connected in sequence; and a stirring device and a scraper are arranged in a granulator cylinder of the strong mixing granulator. According to the process, a process of combining strong mixing micro-granulation and disc granulation is adopted, so that the material mixing uniformity is increased, the use ratio of a granulation additive is reduced, the balling rate reaches 85% or above and is improved by 35%, the moisture of disc granules is reduced, single-stage drying is adopted, and the process flow and equipment investment are simplified.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

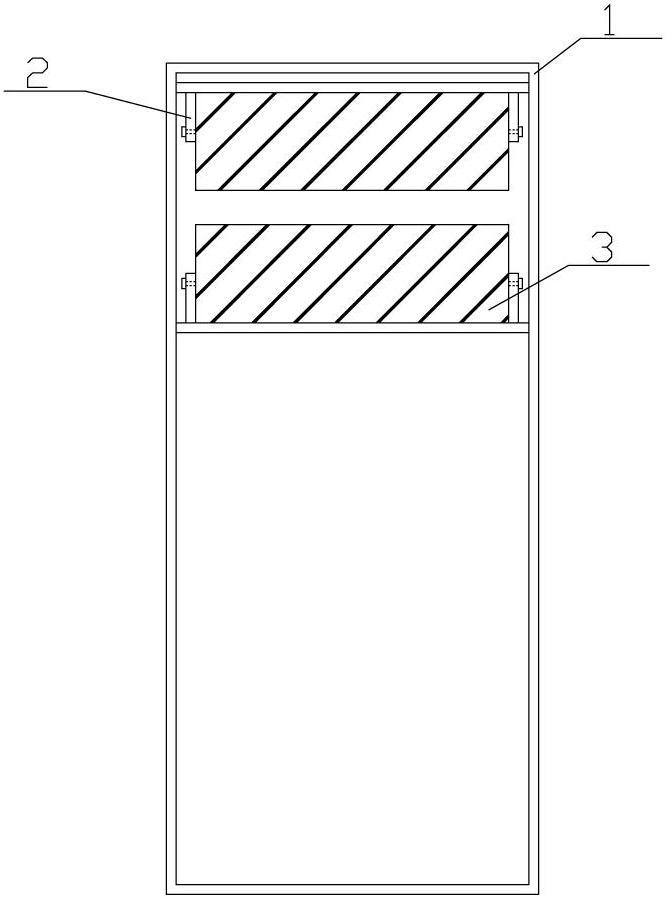

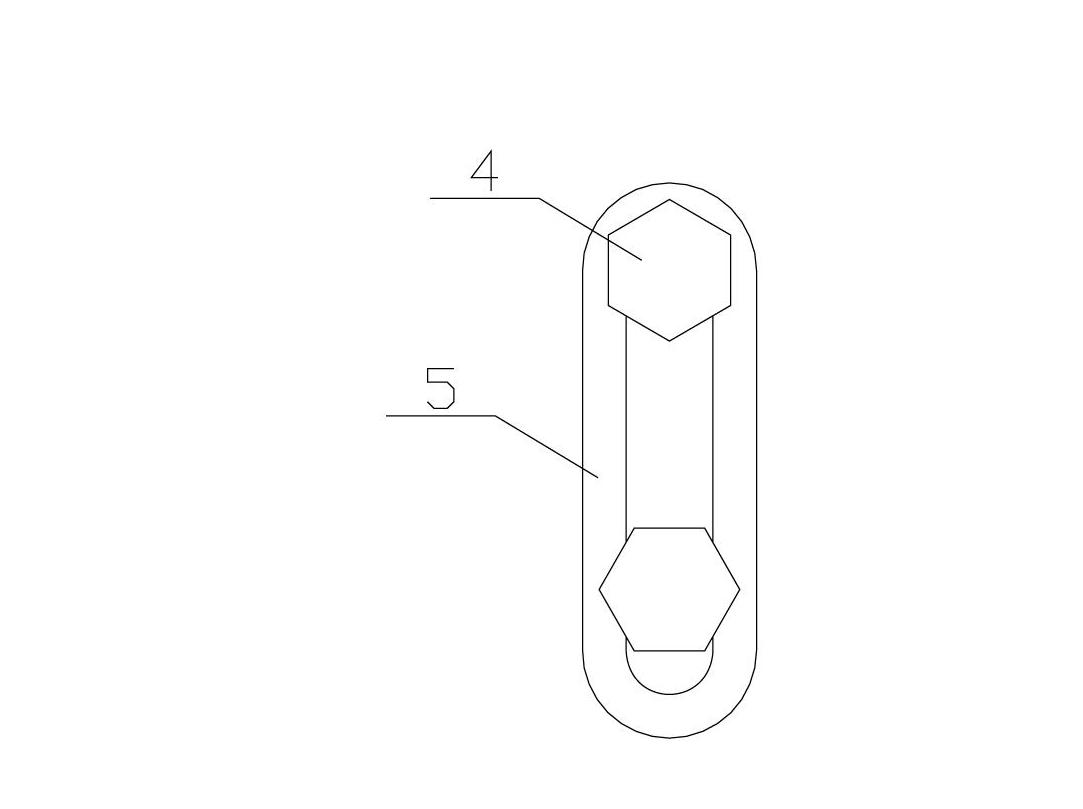

Maintenance equipment suitable for automobile brake disc after renovation

ActiveCN110237963AShorten maintenance timeReduce waiting timeCleaning using toolsSpray boothsElectricityElectric heating

The invention relates to the technical field of automobile part machining, in particular to maintenance equipment suitable for an automobile brake disc after renovation. The maintenance equipment comprises a base and a conveyor, and further comprises a workbench, a controller, a cleaning mechanism, a paint spraying mechanism and a drying mechanism; the cleaning mechanism comprises a cleaning assembly, a wiping assembly and a first rotating assembly; the paint spraying mechanism comprises a paint spraying assembly and a second rotating assembly; and the drying mechanism comprises a protective cover and four electric heating plate. According to the maintenance equipment suitable for the automobile brake disc after the renovation, the maintenance time of the automobile brake disc after renovation is shortened, the solidification speed of automobile paint is increased, and the maintenance efficiency is improved; meanwhile, the maintenance is more comprehensive and the effect is better, and the maintenance cost is reduced; and an observation window is designed, so that the drying process is transparent, the drying condition of the automobile paint is observed through the observation window in real time, and the drying temperature is adjusted by matching with an adjusting function of a knob switch to meet the drying requirements of different automobile paint and different temperatures.

Owner:蓝际智能装备(威海)有限公司

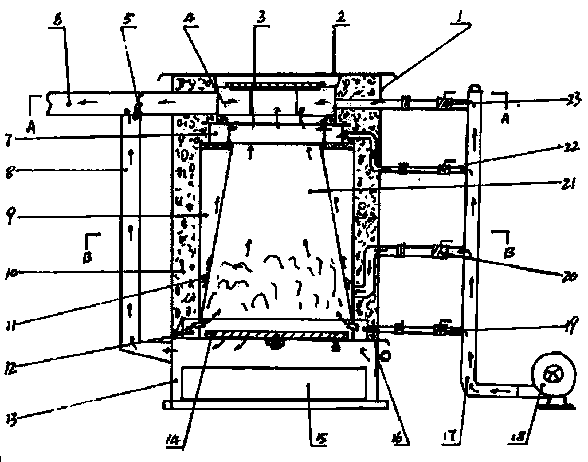

Energy-saving environment-friendly high-temperature hot air drying stove

InactiveCN104165457AMeet drying requirementsEnergy saving and emission reduction effectFood processingDrying gas arrangementsCombustion chamberEngineering

The invention discloses an energy-saving environment-friendly high-temperature hot air drying stove and belongs to stove type devices. The energy-saving environment-friendly high-temperature hot air drying stove is mainly formed by assembling a stove body, a high-temperature hot air radiating communicated pipe, various air pipes, various chambers, a medium-pressure draught fan and the like through welding. A stove plate cover is arranged on the stove body. The high-temperature energy storage chamber is arranged in the stove body. One of the two ends on the two sides of the high-temperature energy storage chamber is connected with a control valve air inlet pipe, and the other one of the two ends on the two sides of the high-temperature energy storage chamber is connected with the high-temperature hot air radiating communicated pipe. A feeding air inlet is formed in the front portion of the high-temperature energy storage chamber. The secondary oxygenation gasification chamber is located below the high-temperature energy storage chamber. One side of the secondary oxygenation gasification chamber is externally connected with another control valve air inlet pipe. A stove inner part combustion area is arranged below the secondary oxygen adding gasification chamber. The high-temperature heating chamber is arranged on the periphery of the stove inner part combustion area. An air discharge pipe is externally connected to the rear portion of the upper side of the high-temperature heating chamber. Another control valve air inlet pipe is externally connected to the lower side of the high-temperature heating chamber. The bottom oxygenation combustion chamber is located below the stove inner part combustion area. Another control valve air inlet pipe is connected to one side of the bottom oxygenation combustion area. The stove floor air inlet ignition chamber is connected to the lower portion of the stove body. One side of the stove floor air inlet ignition chamber is externally connected with a reverser combustion channel. All the air inlet pipes are communicated with a main air pipe. The medium-pressure draught fan is connected to a lower end opening of the main air pipe. The energy-saving environment-friendly high-temperature hot air drying stove is compact in structure, easy and safe to operate, easy to install and maintain, high in heat efficiency, high in heating speed, capable of consuming various kinds of fuel, and remarkable in energy conversation and emission reduction effect and has the drying function, the heating function, the temperature increasing function and the like.

Owner:余增辉

Machine for drying and sterilizing towels in bathroom by extrusion and dehydration

InactiveCN108577635ADry fastShorten drying timeDomestic applicationsRadiationHydraulic cylinderPulp and paper industry

The invention discloses a machine for drying and sterilizing towels in a bathroom by extrusion and dehydration. The machine comprises a box body, a hydraulic cylinder and an air heater, wherein a horizontal rotating plate is embedded in the top center of the box body, the lower lateral surface of a pressure plate is covered with water absorbing sponge, and a horizontal extruding screen is arrangedbelow the water absorbing sponge; a hanging rod for hanging a towel is fixedly mounted in a hanging rod groove; and a downward-sunken embedded groove is formed in the upper surface of a support plate, a plurality of drainage holes penetrating through the support plate of the box body are formed in the bottom of the embedded groove, and a horizontal support screen is fixedly mounted in the embedded groove. The extruding screen which can move up and down, and the support screen below the extruding screen can be used for extruding the towel between the extruding screen and the support screen toextrude the moisture in the towel, wherein a part of moisture is absorbed through the water absorbing sponge on the upper surface, and the other part of moisture flows into a collecting tank at the lower side, thereby quickly reducing the moisture in the towel, being convenient for quickly drying the towel by hot air and shortening the drying time of the towel.

Owner:王书铭

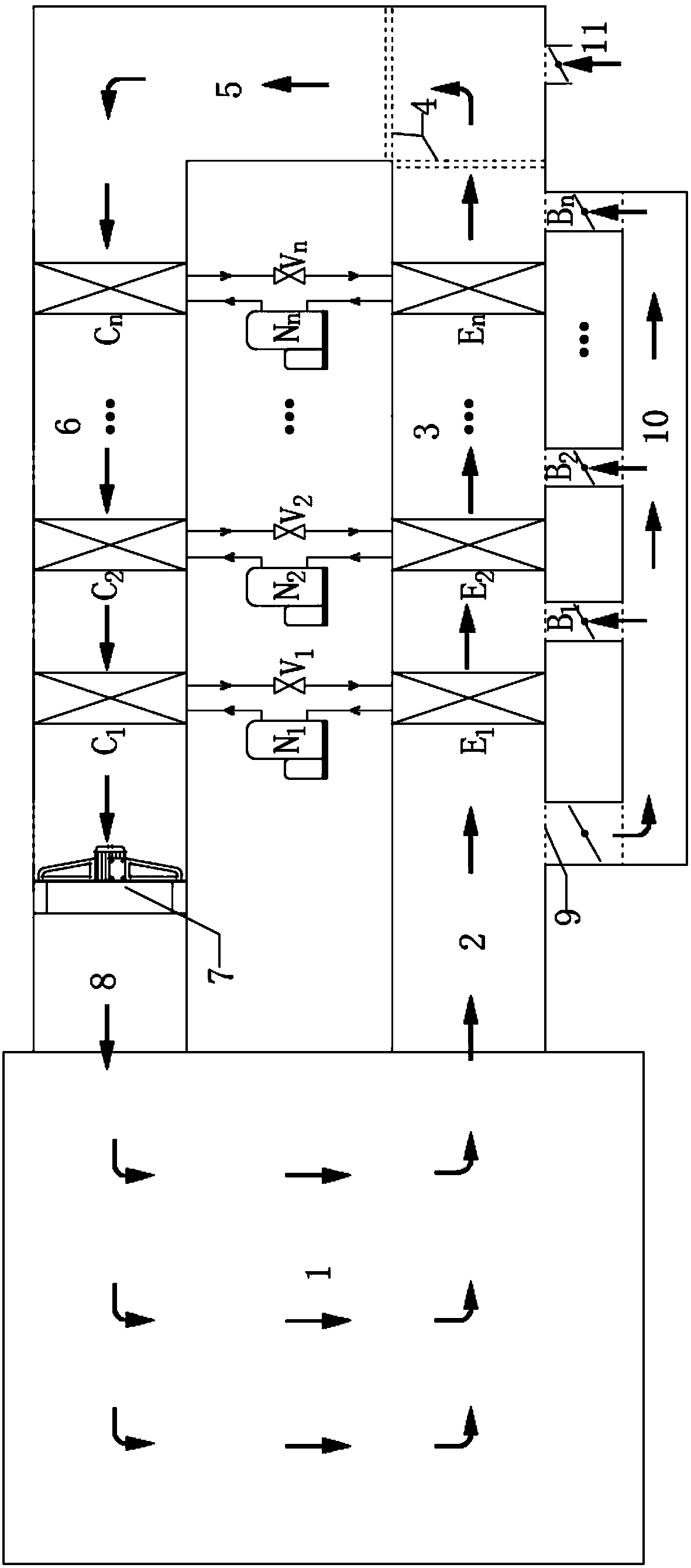

A multi-stage heat pump drying and dehumidification system with bypass pipeline

ActiveCN107642925BGuaranteed uptimeMeet drying requirementsMechanical apparatusDrying gas arrangementsAgricultural scienceAir volume

The invention belongs to the technical field of hot air drying of agricultural and sideline products, and discloses a multi-stage heat pump drying and dehumidification system with a bypass pipeline, comprising: a control unit, a main air duct and a drying room for placing materials to be dried, the drying room An air supply port for introducing gas and an air exhaust port for exhausting gas are provided; the two ends of the main air duct are respectively connected with the air supply port and the air exhaust port, and the main air duct is provided with a main fan and an air exhaust port. A dehumidification chamber, a water baffle, and a heating chamber are arranged in sequence along the airflow direction; it also includes a multi-stage heat pump unit and a bypass pipeline connected with the dehumidification chamber to realize multi-stage heating and multi-stage dehumidification. Compared with the single-stage heat pump drying system, the pressure ratio of the compressor is reduced, and the efficiency of the compressor is improved, and the air volume control based on the bypass pipeline can effectively adjust the dehumidification performance of the system, so that the system has a larger adjustment range.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

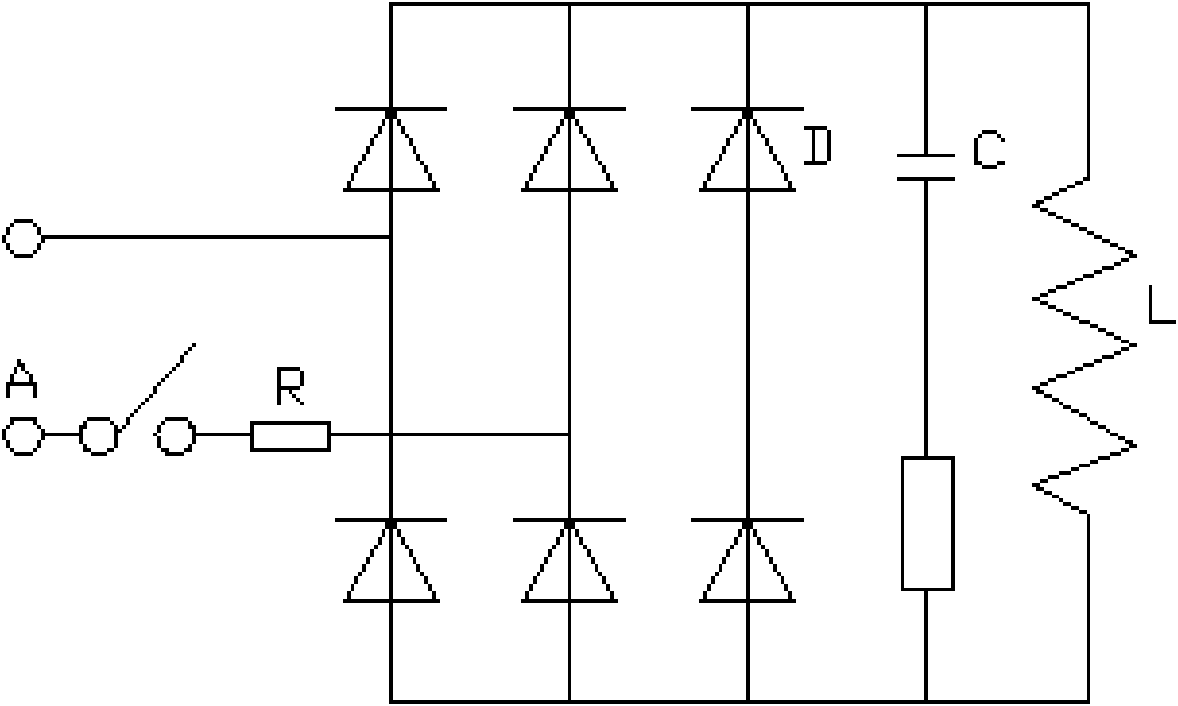

Hydraulic turbogenerator short circuit drying process

InactiveCN101552519AMeet drying requirementsEasy to operateManufacturing dynamo-electric machinesElectricityExcitation current

The invention relates to a generator servicing technology field, especially a hydraulic turbogenerator short circuit drying process. The invention is characterized in that the three phase of electricity generator is short-circuited artificially, droved to by hydroturbine, and generates greater current sufficient to make electricity generator windings exothermic by forming loop with short circuit point through the lower chi-potential of stator winding with small quantity of adjustable exciter current, and dries itself with the heat of windings. The invention has the advantage of simple operation, small attrition of electric energy during the drying procedure, high efficiency, great adjustable extent of electrical current, and can conform to the drying request of all kinds of electricity generator windings in middle and small hydraulic power plant.

Owner:HANGZHOU FUCHUNJIANG HYDROELECTRIC EQUIP

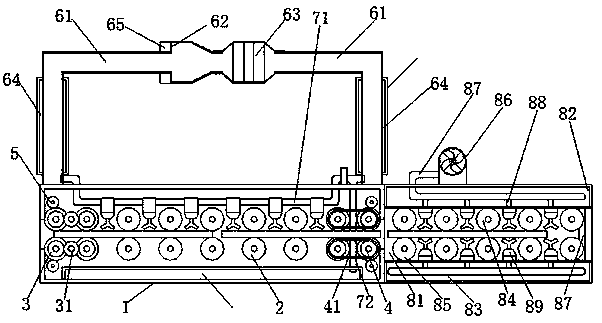

Drying device for drum printing machine

InactiveCN102673119AReduce wasteMeet drying requirementsPrinting press partsEngineeringPrinting press

The invention discloses a drying device for a drum printing machine. The drying device comprises ovens, a bracket for fixing and supporting the ovens, and a plurality of track components capable of adjusting the positions of the ovens, wherein the adjustable track components are fixed on the bracket; and the ovens are fixed on the adjustable track components. The device disclosed by the invention adopts a mounting mode that the ovens and the bracket are movably fixed, and the upper and lower ovens and a cloth surface needing to be dried can be adjusted so as to effectively control the effective distances between the front and back of the cloth surface and the corresponding ovens.

Owner:GUIZHOU KAILIN GRP CO LTD

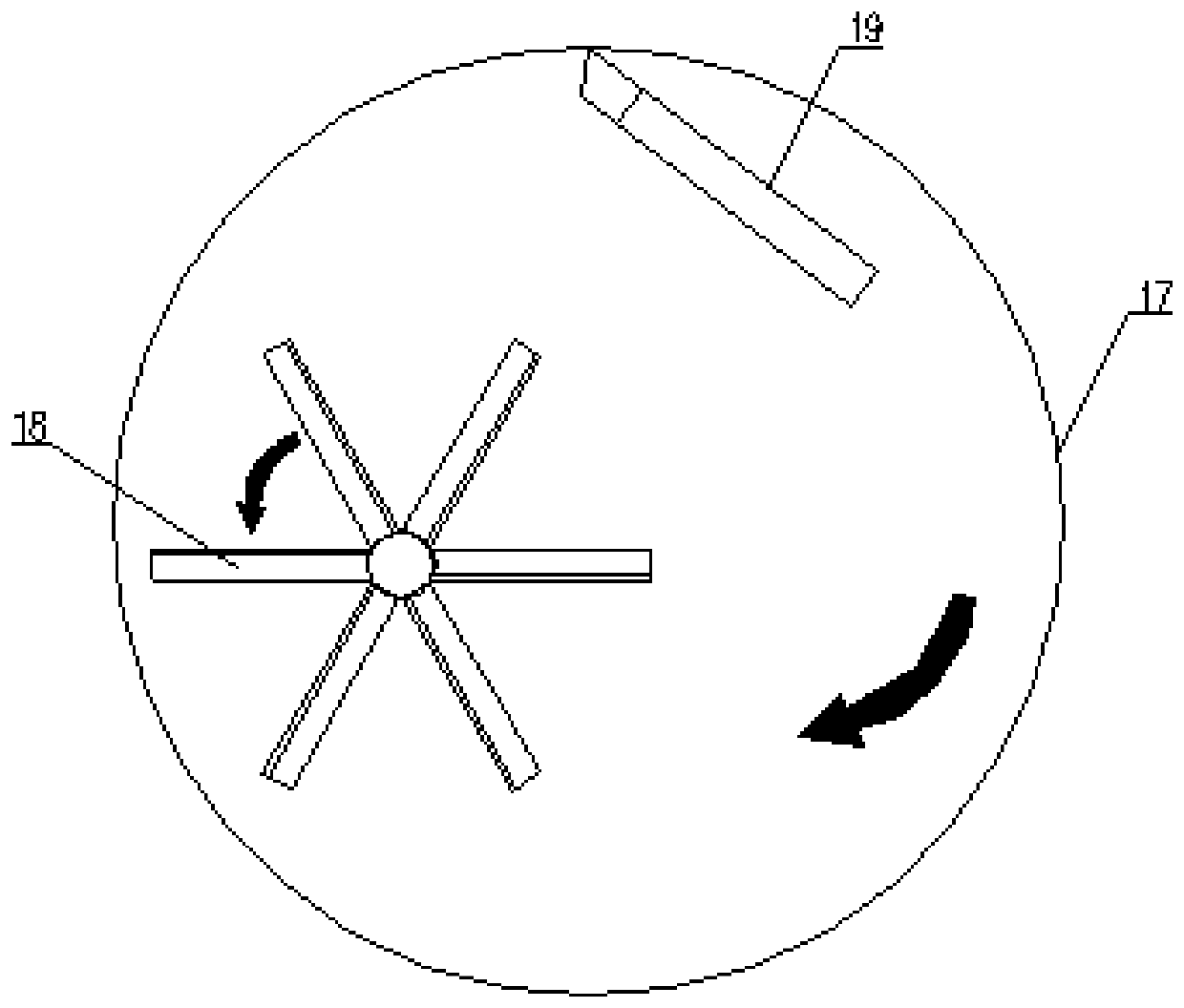

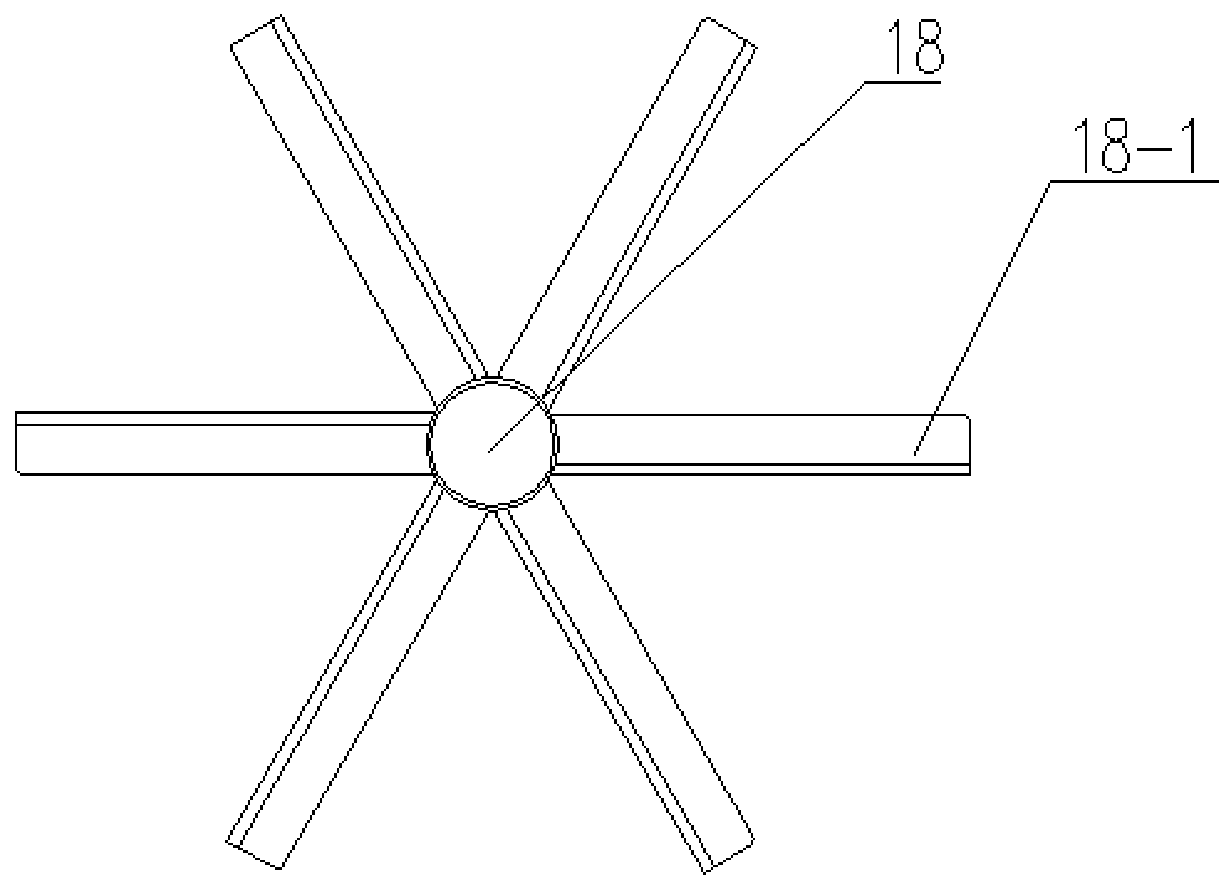

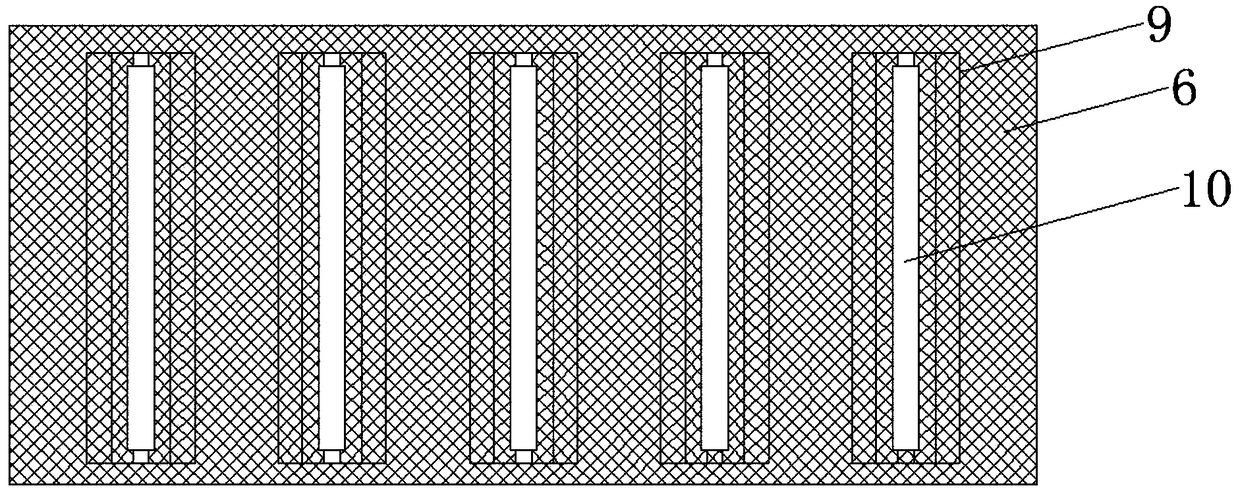

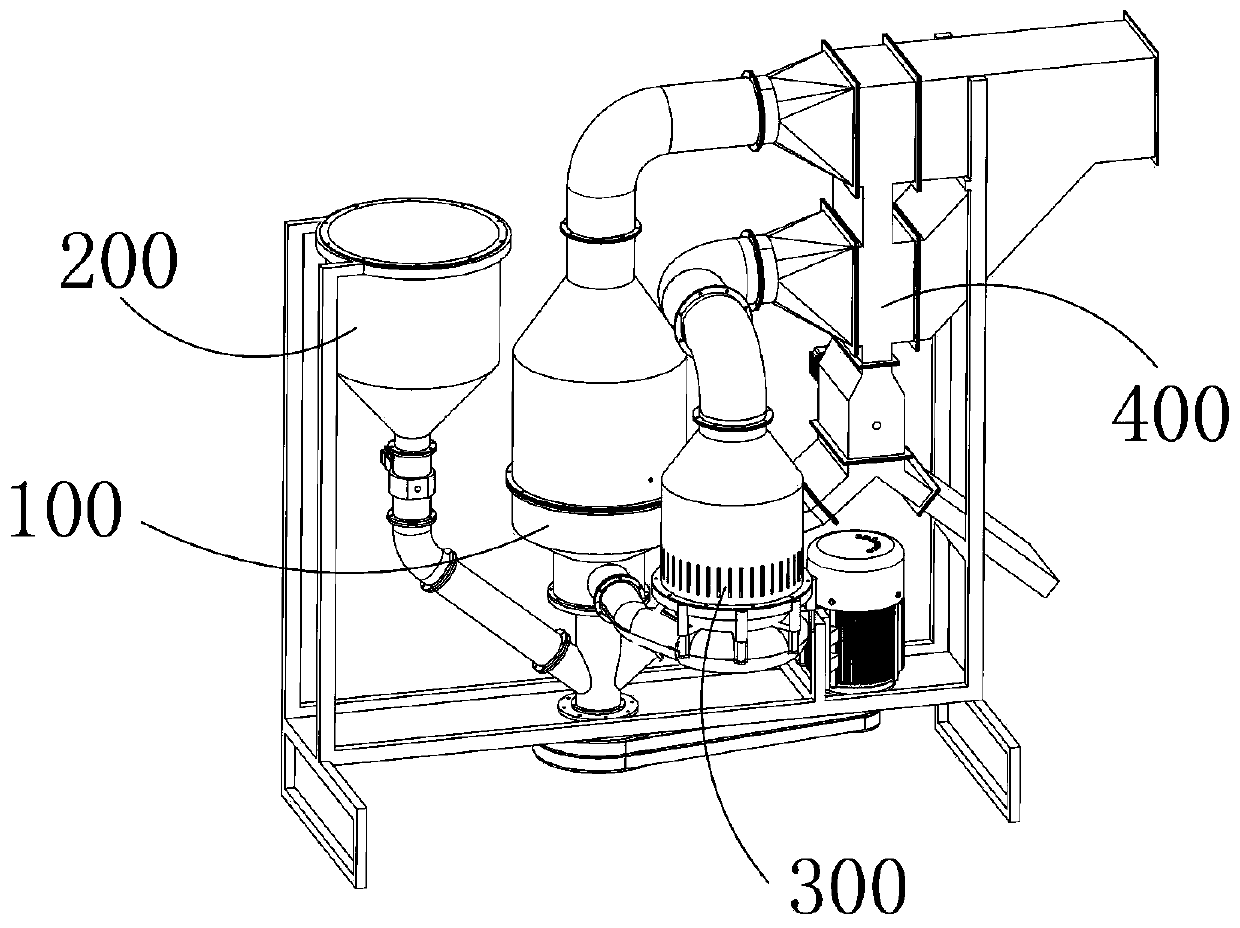

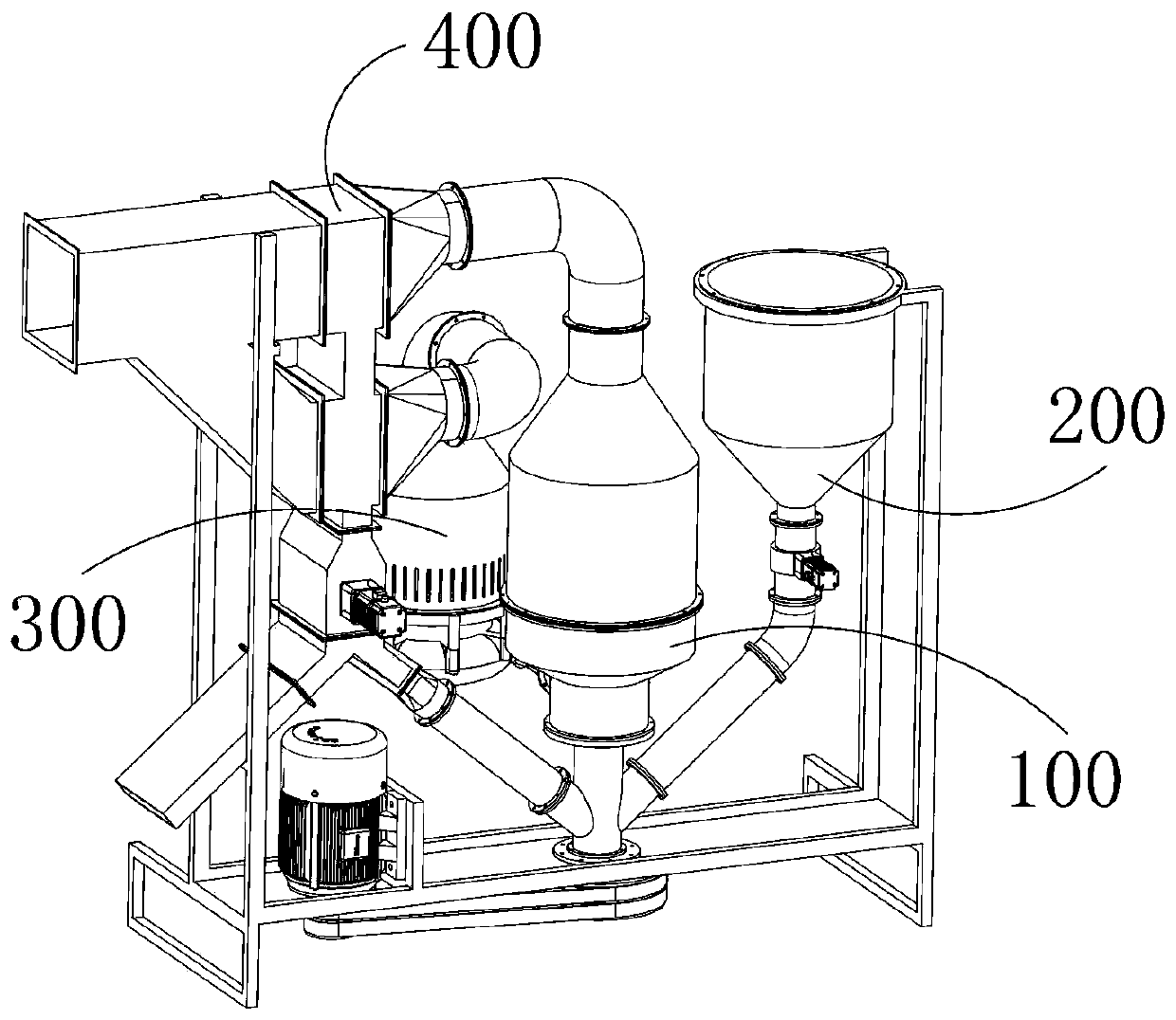

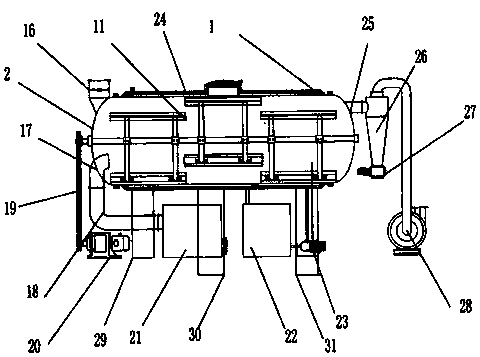

Internal circulation dryer applied to drying and dehumidifying rice and other grains

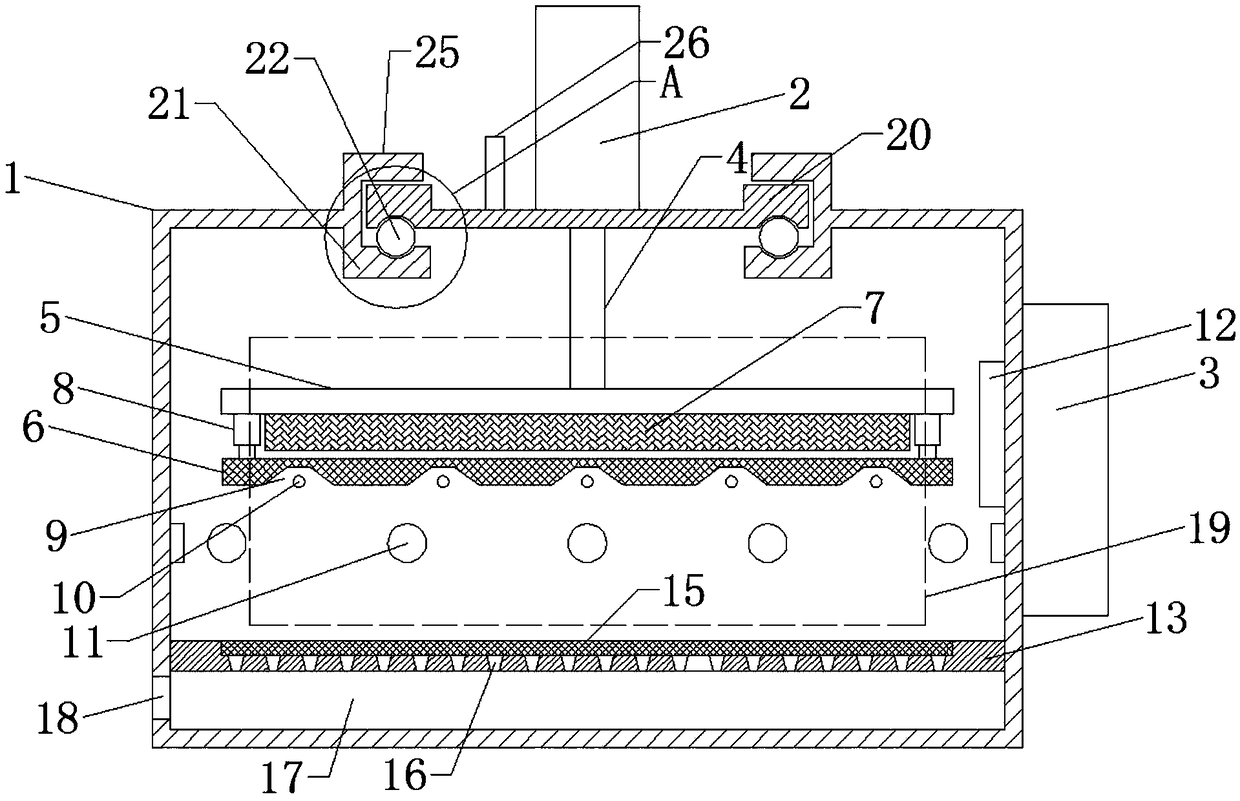

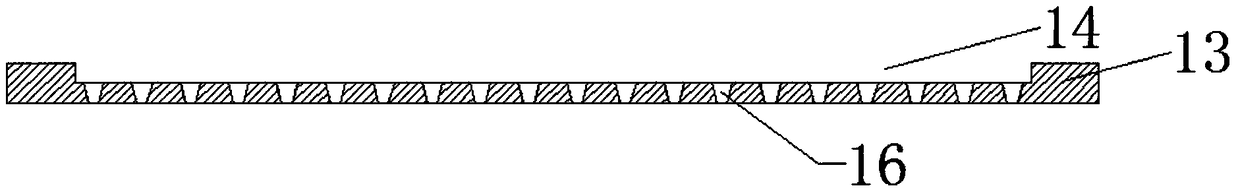

PendingCN110521771AMeet drying requirementsCompliant with Drying RequirementsDrying gas arrangementsSeed preservation by dryingHOTAIREngineering

The invention provides an internal circulation dryer applied to drying and dehumidification rice and other grains. The internal circulation dryer comprises a mounting frame body, wherein an overturning and drying device, a feeding mechanism, an air blowing mechanism and a circulating discharging mechanism are mounted on the mounting frame body; the feeding mechanism is used for conveying grains into the overturning and drying device; the air blowing mechanism is used for providing air flow for overturning and drying, the overturning and drying device is used for heating air and conducting hotair overturning and drying treatment on grains with the air as a drying source, and the circulating discharging mechanism is used for receiving the dried grains and conveying the dried grains back tothe overturning and drying device or conveying the dried grains away. The grains are conveyed into a drying tank; hot air is blown into the drying tank in a uniform dispersing and rotating mode through cooperation of a flow stabilizing body and an air direction changing piece, so that grains are dried in the drying tank in a suspension overturning mode, the drying efficiency and effect are better,and the dried grains can be cooled by the first discharging mechanism through the circulating discharging mechanism.

Owner:祝磊

Furniture water paint drying system

ActiveCN110044139AAvoid energy wasteSpeed up evaporationDrying solid materials with heatWood treatment detailsLacquerEngineering

The invention provides a furniture water paint drying system. The furniture water paint drying system comprises a drying chamber and is characterized in that the drying chamber comprises a microwave heating chamber and a hot air convection heating chamber, and the microwave heating chamber and the hot air convection heating chamber are sequentially arranged; the microwave heating chamber comprisesa first microwave heating chamber, a second microwave heating chamber, a third microwave heating chamber and a fourth microwave heating chamber, and the first microwave heating chamber, the second microwave heating chamber, the third microwave heating chamber and the fourth microwave heating chamber are sequentially arranged; the hot air convection heating chamber comprises a first jet flow area,a second jet flow area, a first air convection area and a second air convection area, and the first jet flow area, the second jet flow area, the first air convection area and the second air convection area sequentially arranged; and the microwave heating chamber is a low-temperature area, and the hot air convection heating chamber is a high-temperature area. Compared with traditional heating anddrying by an oven, the heating and drying efficiency of the furniture water paint drying system is improved by dozens of times, more water is discharged from each heating and drying process, even thewater which is not exhausted in the previous processes can be discharged, so that the drying of surface paint of the furniture is further guaranteed.

Owner:惠州左右家私有限公司

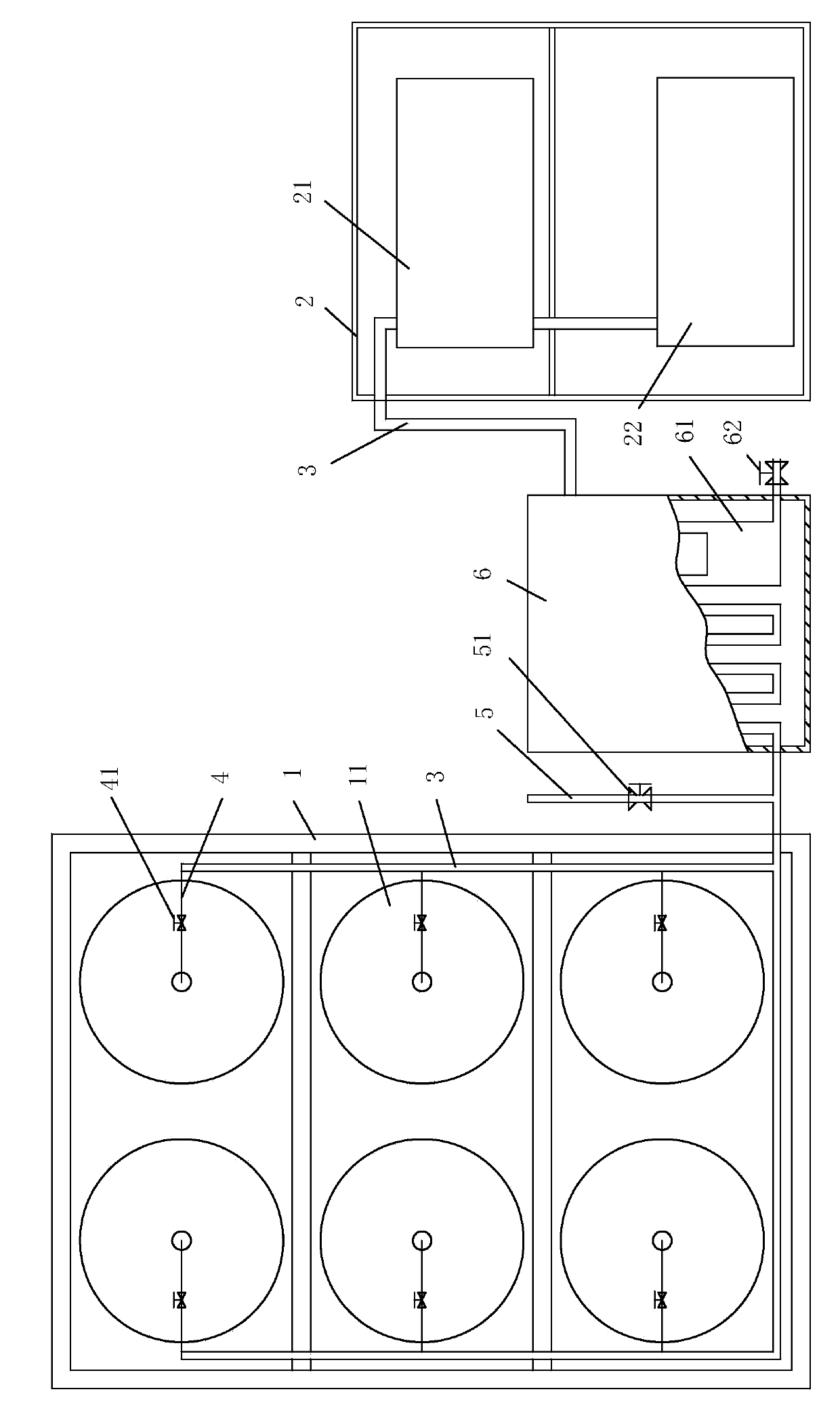

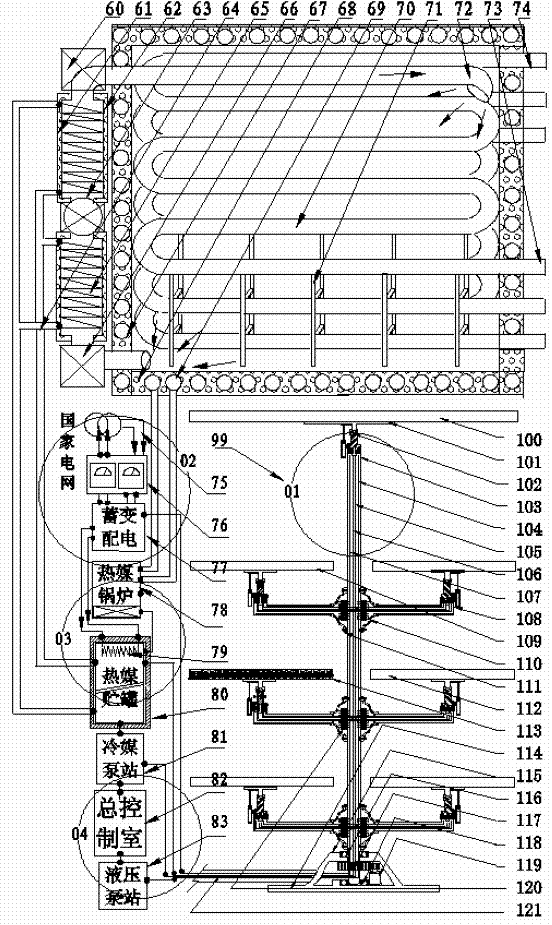

Solar vertical circulation dying room

InactiveCN103398562AImprove energy efficiencyLow running costSolar heating energySteam generation heating methodsThermodynamicsEngineering

The invention belongs to the field of solar energy, and particularly relates to a solar vertical circulation dying room. The solar vertical circulation dying room is composed of a solar system and a drying room system, and the solar system comprises a refrigerant type solar cantilever tower (99), a refrigerant type solar panel (113), a heating medium storage tank (80), a heating medium boiler (78) and an automatic power changeover switch (76). The drying room system comprises a dehumidifier A (60), a heating box (61), a heating box heat preservation layer (62), a heat pump fan (63), a heating medium loop (64), a heating medium coil pipe (65), a dehumidifier B (66), a drying room heat preservation layer (67), a steam loop (68), a steam coil pipe (69), a vertical bend type conveyor (70), a conveyor rack (71), a hot air pipe outlet (72), a drying material inlet (73) and a drying material outlet (74). The solar vertical circulation dying room is characterized in that the temperature ranging from 60 DEG C to 180 DEG C is adjustable, the capacity is selectable, steam, hot air and flowing drying materials are adopted in the solar vertical circulation dying room, and the solar vertical circulation dying room has good market prospects, saves energy and is environmentally friendly.

Owner:宁波市科技园区绿牌软包装技术贸易有限公司 +1

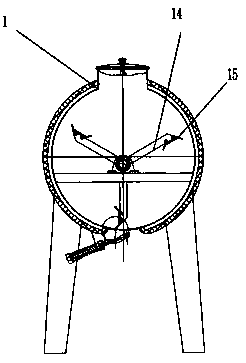

Sea buckthorn fruit slag stirring and drying tank body device and stirring and drying method

PendingCN108662876AAvoid lostMeet drying requirementsDrying gas arrangementsDrying machines with non-progressive movementsAutomatic controlSlag

The invention discloses a sea buckthorn fruit slag stirring and drying tank body device and a stirring and drying method. The problems that when existing equipment is used for drying small-particle materials of high density, the drying efficiency is low, and an exhaust structure is not scientific and reasonable are solved. The sea buckthorn fruit slag stirring and drying tank body device can be mainly divided into a stirring, throwing and scattering system, a hot-air sending and drying system, a damp air sucking system, a discharging system, a tank body heat preservation and heating system andan in-tank temperature and humidity monitoring system, and the systems can be controlled by an industrial personal computer. The tank body is internally provided with a temperature sensor and a humidity sensor. The industrial personal computer controls the in-tank temperature by collecting signals of the sensors through an automatic control program and switches between material throwing and scattering and damp air suction through the signals sent by the humidity sensor. The drying efficiency is improved, the cost is lowered, and the drying quality of the materials is improved.

Owner:山西省林业科学研究院

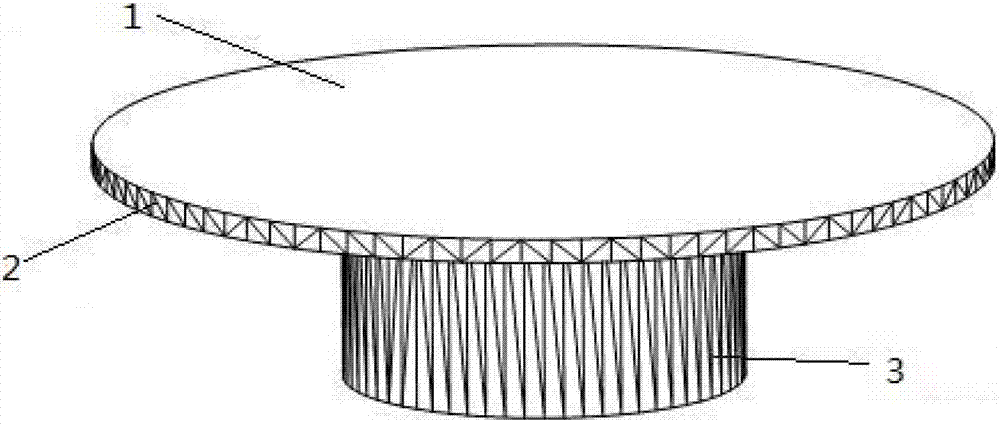

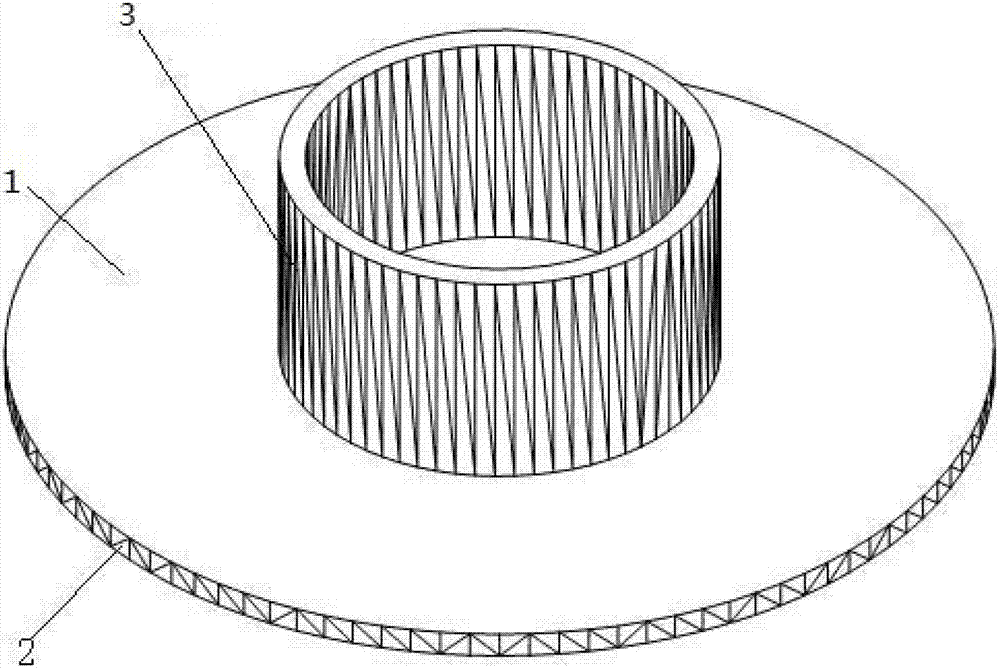

Aluminium alloy mold drying device for beret

The invention belongs to the technical field of production of berets and particularly relates to an aluminium alloy mold drying device for a beret. The drying device comprises a tray and a pillar mounted in the middle of the tray, wherein the round pillar is a hollow round pillar; the tray is provided with an edge with the thickness of 2cm-5cm, and preferably, the edge is 3cm in thickness; and the tray is an aluminum profile tray and the pillar is an iron pillar. By adopting the drying device, the drying temperature can be further increased in the drying process so as to meet the drying requirements of different products; the tray made of aluminum profile has excellent thermal conductivity, so that the beret can be uniformly heated in the drying process, and the problems that curling and coking are caused in the drying process are solved; and the drying device provided by the invention achieves the purpose of uniform heating of the beret in the drying process.

Owner:蚌埠格识知识产权运营有限公司

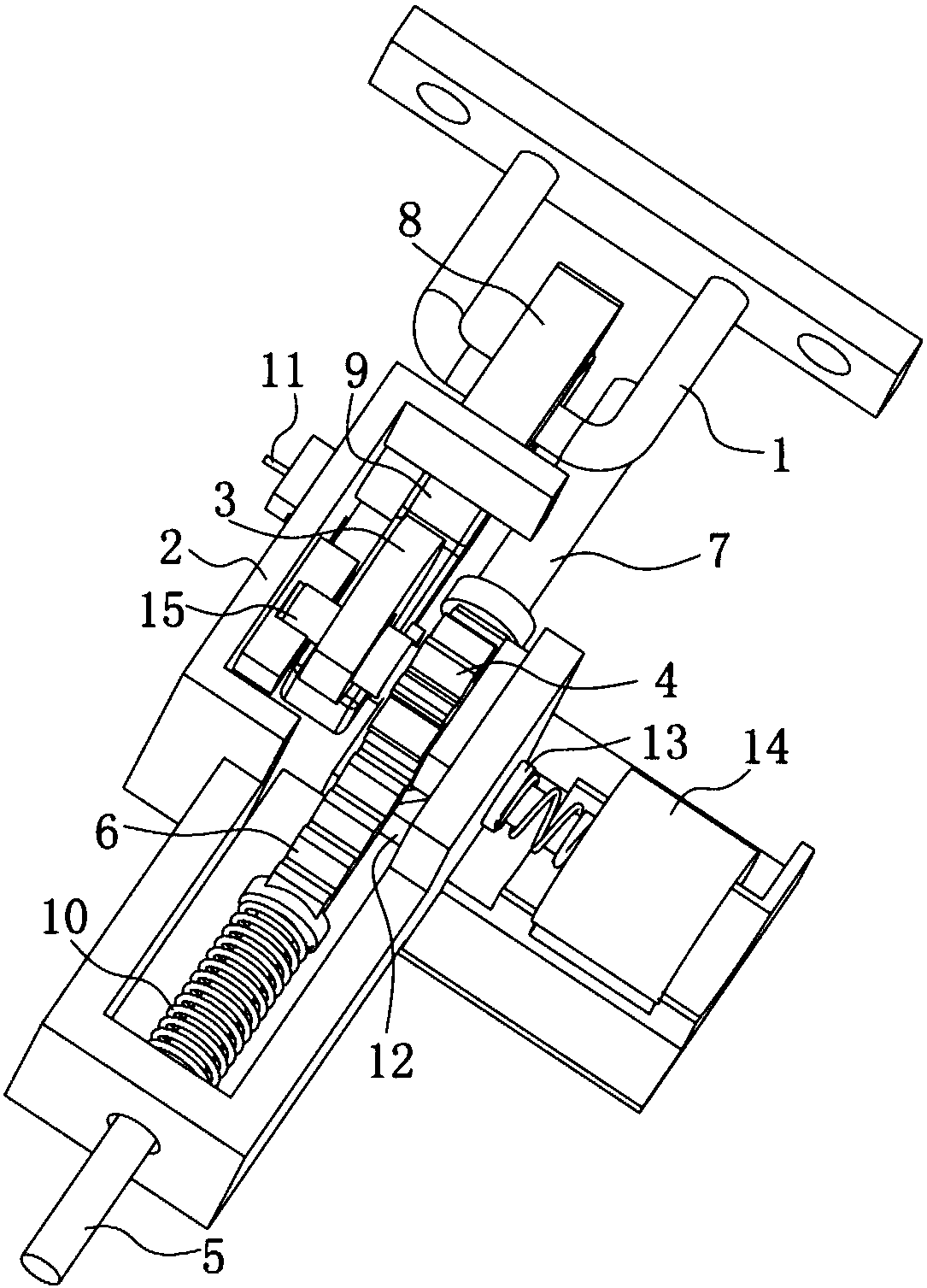

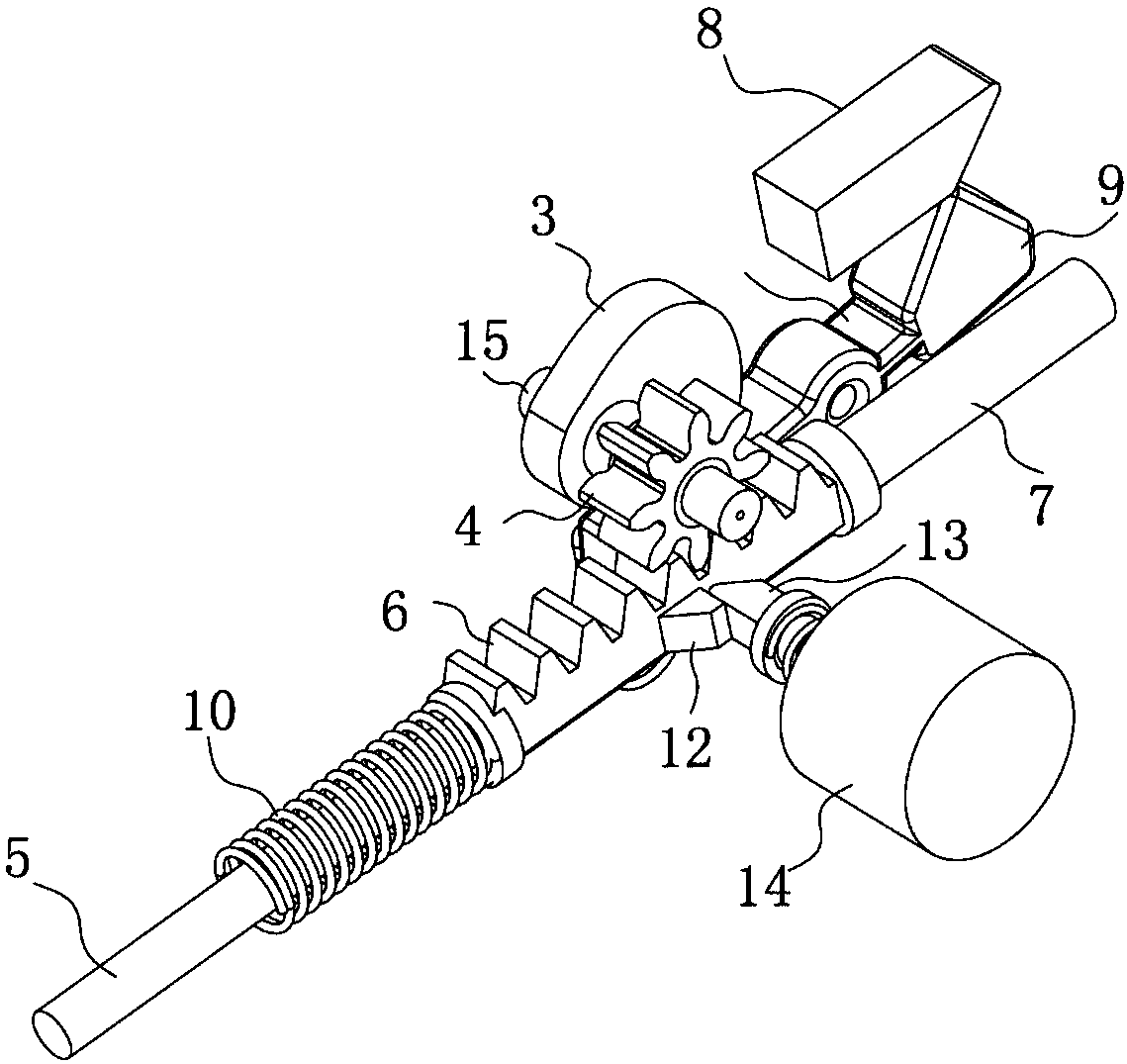

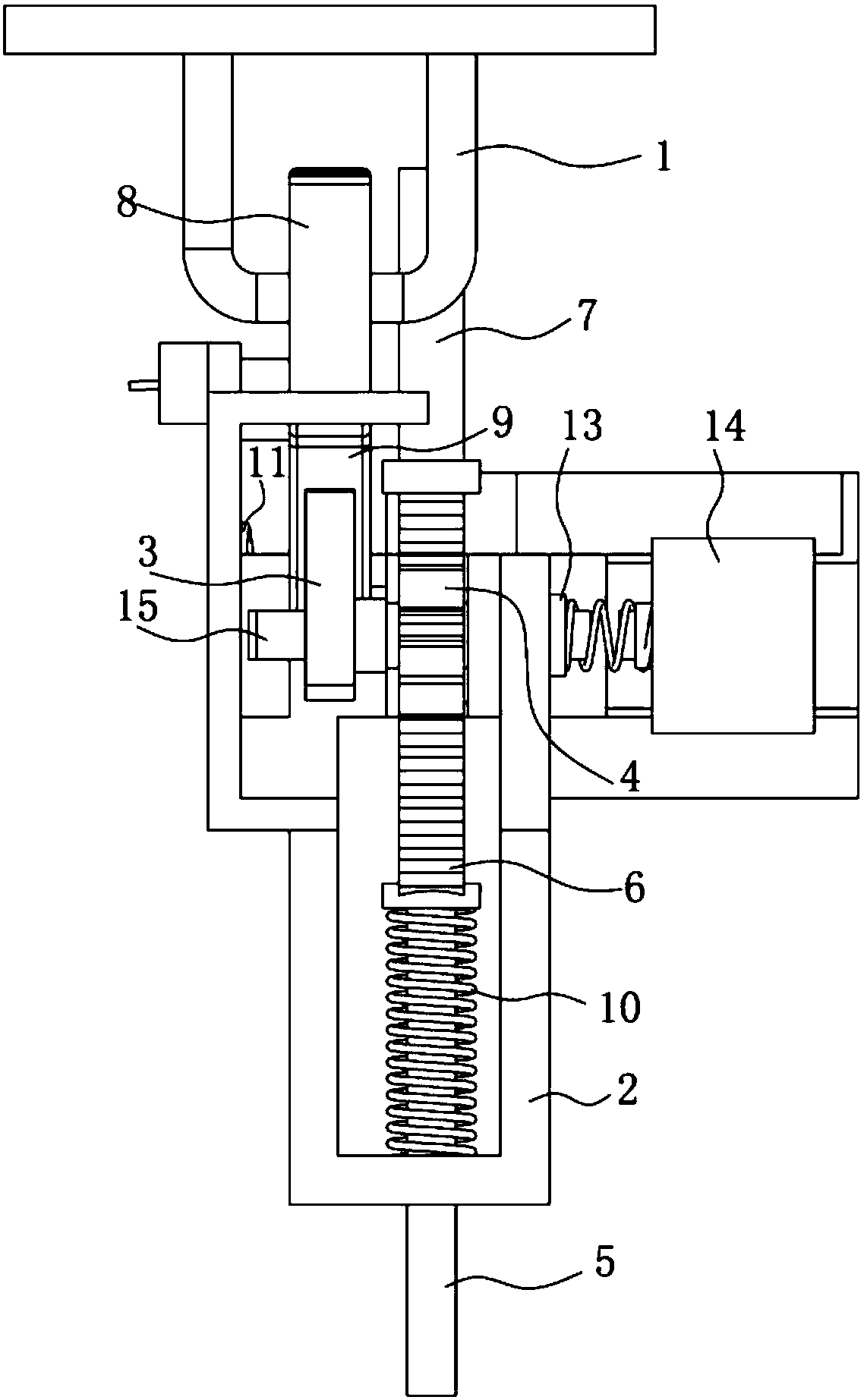

Automatic door lock of dish washing machine and dish washing machine

ActiveCN108661455ARealize automatic openingSimple structureTableware washing/rinsing machine detailsNon-mechanical controlsEngineeringCooperative work

The invention relates to an automatic door lock of a dish washing machine and the dish washing machine. The automatic door lock comprises an automatic lock head and a lock catch, wherein the automaticlock head is arranged on an inner container of the dish washing machine, the lock catch is arranged on a door body, and the automatic lock head comprises a machine frame and a lock head body; and a limiting mechanism, a release mechanism and a push-out mechanism are arranged in the machine frame, wherein the limiting mechanism is used for limiting the normal work of the push-out mechanism and therelease mechanism, the push-out mechanism can drive the release mechanism to unlock the lock head body, and the push-out mechanism is further used for pushing the door body so as to enable the door body to be separated from the inner container. According to the automatic door lock and the dish washing machine, the limiting mechanism is used for limiting the push-out mechanism to drive the releasemechanism to move, the push-out mechanism drives the release mechanism to unlock the lock head body, then the dish washing machine door lock can be automatically unlocked through cooperative work among all the mechanisms, and the drying requirement can be met through applying less heat in the drying process of the dish washing machine; and meanwhile, the automatic door lock is simple in structureand easy to detach and maintain.

Owner:QINGDAO HAIER DISHWASHER

Intelligent electric heating drier

InactiveCN102645095BUniform temperature distributionImprove the baking effectDrying gas arrangementsDrying chambers/containersCold airEngineering

Owner:XIAN SENWAS AGRI SCI & TECH

A heat pump device for sludge drying

ActiveCN109626788BUniform condensation and dehumidificationHeating evenlySludge treatment by de-watering/drying/thickeningSludgeHeater Rod

The present invention is a heat pump device for sludge drying, which includes a shell, and is characterized in that a heat recovery box is fixedly connected to the top of the shell, and the heat recovery box is arranged in a hollow cuboid structure, located on the In the heating chamber below the gas distribution plate two, a number of electric heating rods inclined downward are interlaced from top to bottom. The invention has compact structure and reasonable design. By setting the serpentine heat recovery pipe and the heat recovery box, the heat lost by the hot and humid air into the pipe can be effectively recovered, and the thermal efficiency utilization rate can be improved. Gas distribution plate 1, cooling plate and condensate net, uniformly condense and dehumidify the hot and humid air, preheat by setting electric heating wires, set gas distribution plate 2 in the heating and heating chamber, and set the tilt mutually staggered from top to bottom The downward electric heating rod evenly heats the dehumidified air, which is conducive to the stable operation of the heat pump drying and meets the sludge drying requirements.

Owner:天津五洲同创空调制冷设备有限公司

Ultrasonic-enhanced airflow drying system

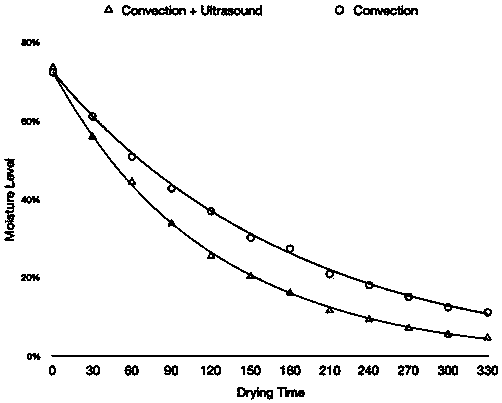

InactiveCN111387528AReduce consumptionImprove utilization efficiencyFood processingFood treatmentEngineeringConveyor belt

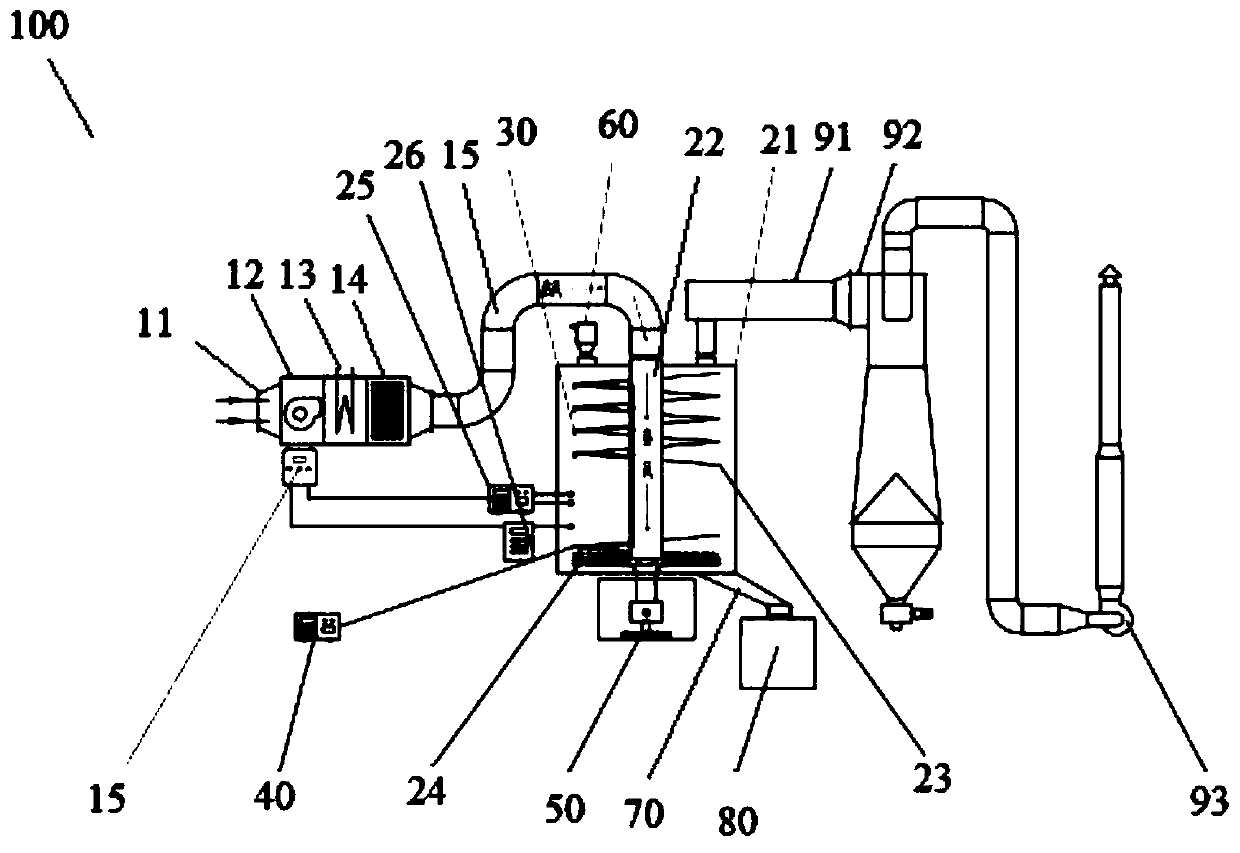

The invention provides an ultrasonic-enhanced airflow drying system. The system includes an air supply module, a drying chamber, ultrasonic transducers, an ultrasonic generator, a supporting base, a vacuum feeder, a material guide groove, a material collecting cabin and an air discharge module; the air supply module includes an air supply opening, a draught fan section, a heating section, a filtersection and an air supply pipeline; the drying chamber includes a chamber shell, a hollow cylinder vertically arranged in the center of the chamber shell and connected to the air supply pipeline, a conveyor belt arranged in a spiral shape around the hollow cylinder, and an air distribution device arranged at the bottom of the chamber shell and connected to the hollow cylinder; the ultrasonic transducers are fixedly arranged under the conveyor belt and closely attached to the conveyor belt; the ultrasonic generator is connected to the ultrasonic transducers through a cable; the supporting baseis arranged under the chamber shell and connected with the hollow cylinder; the vacuum feeder is connected to the top of the chamber shell; the material guide groove is connected to the bottom of thechamber shell; the material collecting cabin is connected to the material guide groove; and the air discharge module includes an air discharge channel connected to the top of the chamber shell, a cyclone separator connected to the air discharge channel and an induced draft fan connected to the cyclone separator.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Paper document vacuum drying machine

ActiveCN102901325ASimple structureEasy to operateDrying solid materials without heatPaper documentRefrigerated temperature

The invention relates to a paper document vacuum drying machine which comprises a machine frame and a vacuum tank installed at the upper portion of the machine frame. A horizontally-arranged plate-type heat exchanger, a temperature sensor and a pressure sensor are arranged in the vacuum tank, the lower portion of the machine frame is provided with a freezing-drying filter, the freezing-drying filter is respectively connected with the vacuum tank and a vacuum pump through air pipeline and respectively connected with the plate-type heat exchanger and a refrigerator assembly through Freon pipelines, and the temperature sensor, the pressure sensor, the vacuum pump and the refrigerator assembly are respectively connected with a controller installed on the machine frame. The paper document vacuum drying machine is simple in structure, convenient to operate, capable of quickly drying paper documents, good in drying effect, shirt in drying time and capable of effectively preventing harmful microorganisms, pests and water from damaging the paper documents, does not produce secondary damage to the documents and can meet the drying requirement of a large amount of mildewed, sticky and drowned documents.

Owner:山东齐元信息技术有限公司

Mineral powder drying method and drying device

ActiveCN104110951ALess investmentImprove drying efficiencyDrying machines with progressive movementsHeating arrangementPhysical chemistryElectromagnetic valve

The invention relates to a mineral powder drying method and drying device. Infrared radiators of the drying device are arranged in the direction of a conveying belt. Each infrared radiator is provided with a reflection cover, an electromagnetic valve and a non-contact temperature measurer, wherein the infrared radiator radiates mineral powder on the conveying belt, the electromagnetic valve is connected to an air inlet of the infrared radiator, the electromagnetic valve is connected with a gas branch pipe, and the gas branch pipe is communicated with a gas header pipe. The drying method comprises the steps that the dehydrated mineral powder passes through the drying device and is discharged to the conveying belt through a discharging opening, and the water content of the mineral powder ranges from 10% to 11%; infrared radiation is carried out on the mineral powder by all the gas infrared radiators in sequence under the infrared radiation effect of the gas infrared radiators, and the water content of the mineral powder is decreased to range from 8.5% to 9%; after the mineral powder is in the stable baking state, the surface temperature of the conveying belt ranges from 80 DEG C to 120 DEG C. According to the mineral powder drying method and drying device, the drying efficiency is high, and the drying equipment cost is low.

Owner:TAIYUAN IRON & STEEL GROUP

Intelligent cereal drying device based on solar energy

InactiveCN108244233AEfficient use ofImprove economic efficiencySolar heating energyFood processingIonSolar thermal collector

The invention relates to an intelligent cereal drying device based on solar energy. The intelligent cereal drying device consists of four parts of a vacuum pipe type solar energy heat collector, a heat exchanger, a gravity circulation type additional heating stock bin and a controller, wherein the gravity circulation type additional heating stock consists of inner walls, a housing, a spiral lifter, far infrared heating pipes, a blowing machine and a wind pipe; the controller consists of parts of a single-chip microcomputer, a temperature-detecting control circuit, a humidity detecting controlcircuit, a solar energy heat collector heat exchanging valve switching circuit, a keyboard and LCD display circuit, a pressure sensor and a circuit thereof, an alarm circuit, a far infrared compensating heater and a heating pipe piston valve; and the humidity detecting control circuit comprises a moisture-sensitive sensor; and the moisture-sensitive sensor is a zirconia moisture-sensitive sensor based on doping of metal ions.

Owner:韦德永

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com