Aluminium alloy mold drying device for beret

A drying device and aluminum alloy technology, which is applied to hats, hat products, applications, etc., can solve problems such as uneven heating, achieve the effect of solving curly hair and scorched hair, uniform heating, and increased drying temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

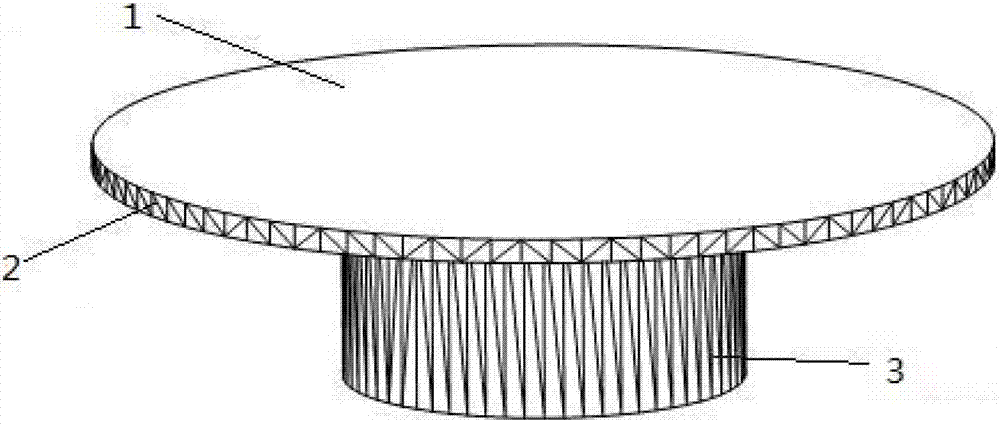

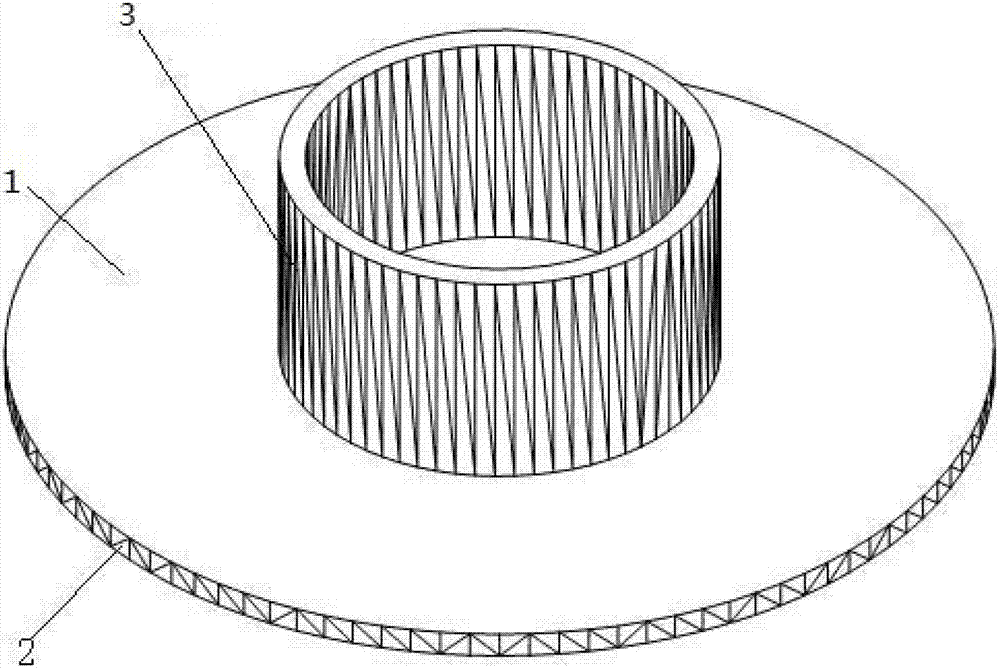

[0022] Such as figure 1 As shown, the beret aluminum alloy mold drying device of the present invention includes a tray 1 and an iron column 3, the iron column 3 is installed in the middle of the tray 1, the iron column 3 is a hollow iron column, and the tray 1 is provided with a certain thickness The edge 2; the thickness of the edge 2 is 2cm-5cm, preferably 3cm.

[0023] Tray 1 is an aluminum profile tray with good thermal conductivity, so that the beret can be heated evenly during the drying process, thus solving the phenomenon of curls and burnt hairs during the drying process.

[0024] During use, the beret is placed on the tray 1, and the brim of the hat is inlaid on the tray 1 along the edge 1, and then the fixed beret is followed by the mold as follows figure 1 Put them together in the oven as s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com