Patents

Literature

147results about How to "Increase drying temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent hot-air drying control device

InactiveCN103123215AReduce energy consumptionReduced dehumidification loadDrying gas arrangementsEngineeringAir blower

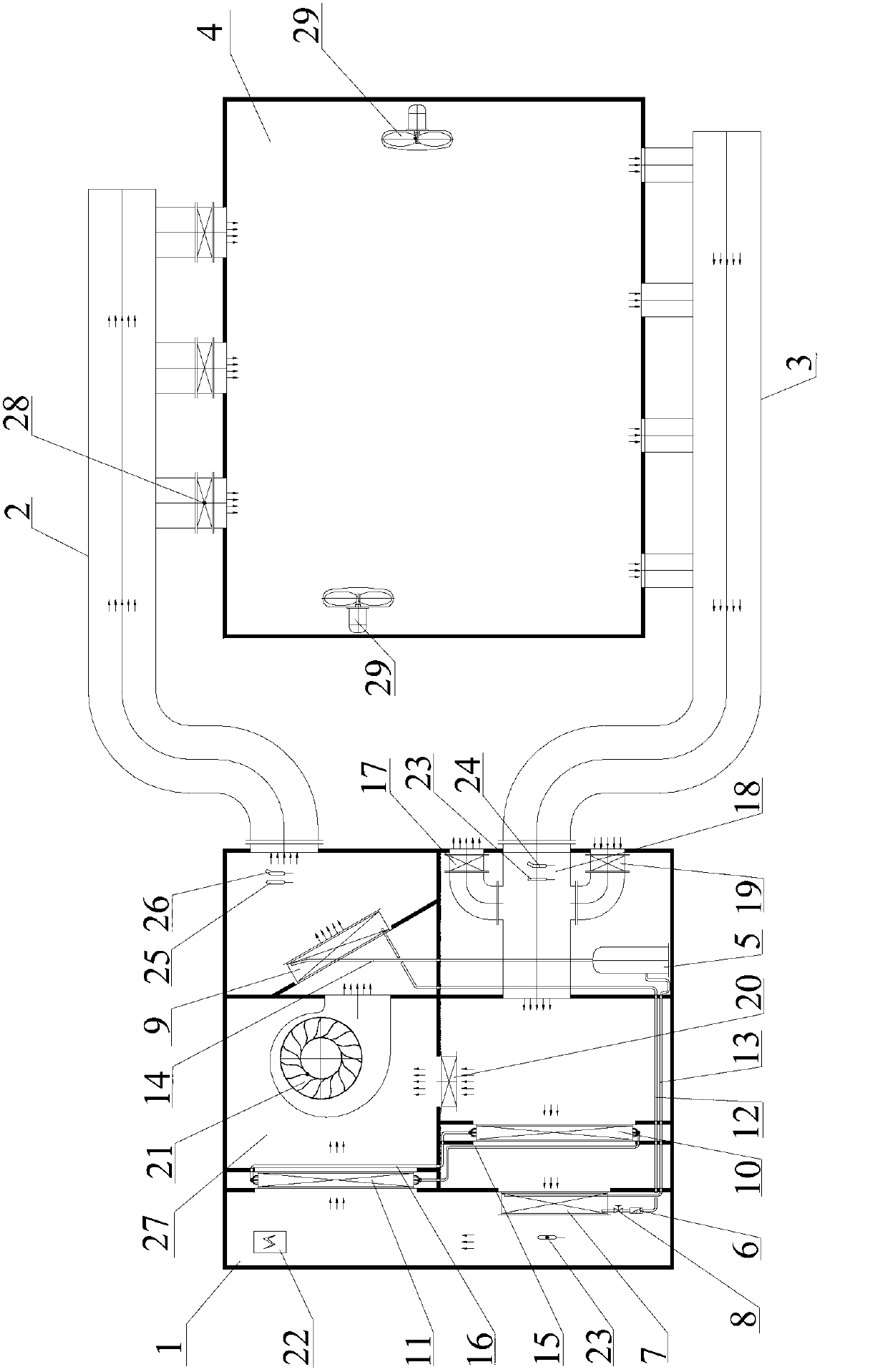

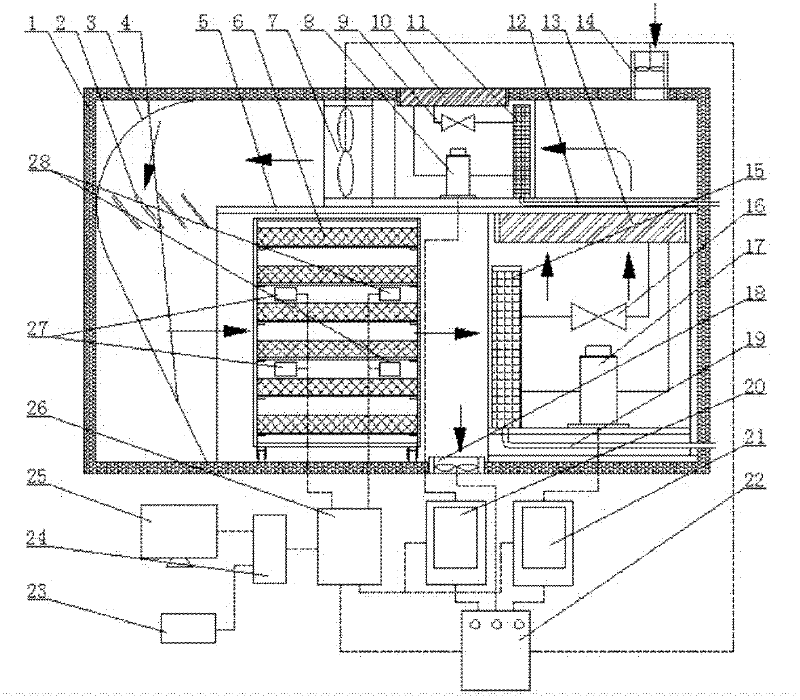

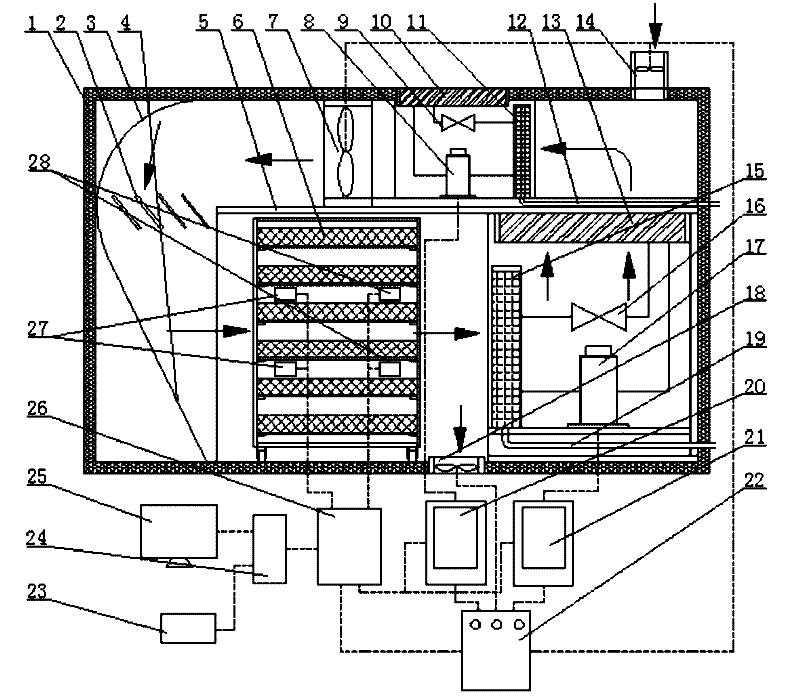

The invention discloses an intelligent hot-air drying control device which comprises a heat exchange box and a drying chamber, wherein he heat exchange box is separated into multiple spaces, and the drying chamber is connected with the heat exchange box through an air supplying main pipe and a general air return pipe. A heat pump dehumidifying and heating system, a heat pipe return heat exchange system, a hot air circulating system and an intelligent control system are arranged in the heat exchange box. The heat pump dehumidifying and heating system which is composed of a compressor, a drying filter, a dehumidifying evaporator, a throttle valve and a heating condenser. The heat pipe return heat exchange system is composed of a heat pipe evaporator and a heat pipe condenser. The hot air circulating system is composed of a high-pressure refrigerant liquid connecting pipe, a low-pressure refrigerant return gas connecting pipe, a high-pressure refrigerant gas connecting pipe, a liquid refrigerant connecting pipe, a gas refrigerant connecting pipe, an air exhaust regulating valve, a mixed air box, a fresh air regulating valve, a secondary air flow regulating valve and an air blower assembly. The intelligent control system is composed of the a temperature sensor, a humidity sensor, a hot air temperature sensor and a hot air humidity sensor, wherein the temperature sensor, the humidity sensor, the hot air temperature sensor and the hot air humidity sensor are connected in the various systems. The intelligent hot-air drying control device can regulate the temperature and the humidity of drying air automatically and improve the material drying efficiency.

Owner:孙应真

Direction reduction and electric furnace smelting-separation preparation process of vanadium-titanium magnetite cold bound pellet

The cooled agglomerated carbon-contained pellet prepared with vanadium titano magnetite concentrate and opposite direct reduction with former pellet comprises: mixing the concentrate, reducer and bonding agent, drying, grinding, and pelletizing to obtain the cooled agglomerated carbon-contained pellet drying and sieving into the reduction furnace with reducer for reduction atmosphere; loading the reduced pellet into electric furnace to melt and separate the iron liquid, V, Ti and Cr. This invention is fit to the pellet on wide application temperature and low energy consumption, has well efficiency and low running cost, and can also extract V, Ti Fe and Cr from electric furnace with high yield and obvious environmental protection.

Owner:鲜帆 +2

Welding-resistant low-alkaline ink for developing and photosenstive imaging

InactiveCN1390898AGood glossHigh glossInksPhotosensitive materials for photomechanical apparatusAcrylateOligomer

A weld-resistant ink for weakly alkaline developing and photosensitive imaging of PCB contains modified acrylate as photosensitive oligomer (50-70 wt.%), epoxy resin (10-20), multifunctional acrylate (5-20), optical trigger (5-15), filler (7.5-30), pigment (0.5-1) and silica oil. Its advantages are high resistance to high temp (260 deg.C or more) and lustre, and not discolouring and dropping off.

Owner:广州市乃天精密电子器材有限公司 +1

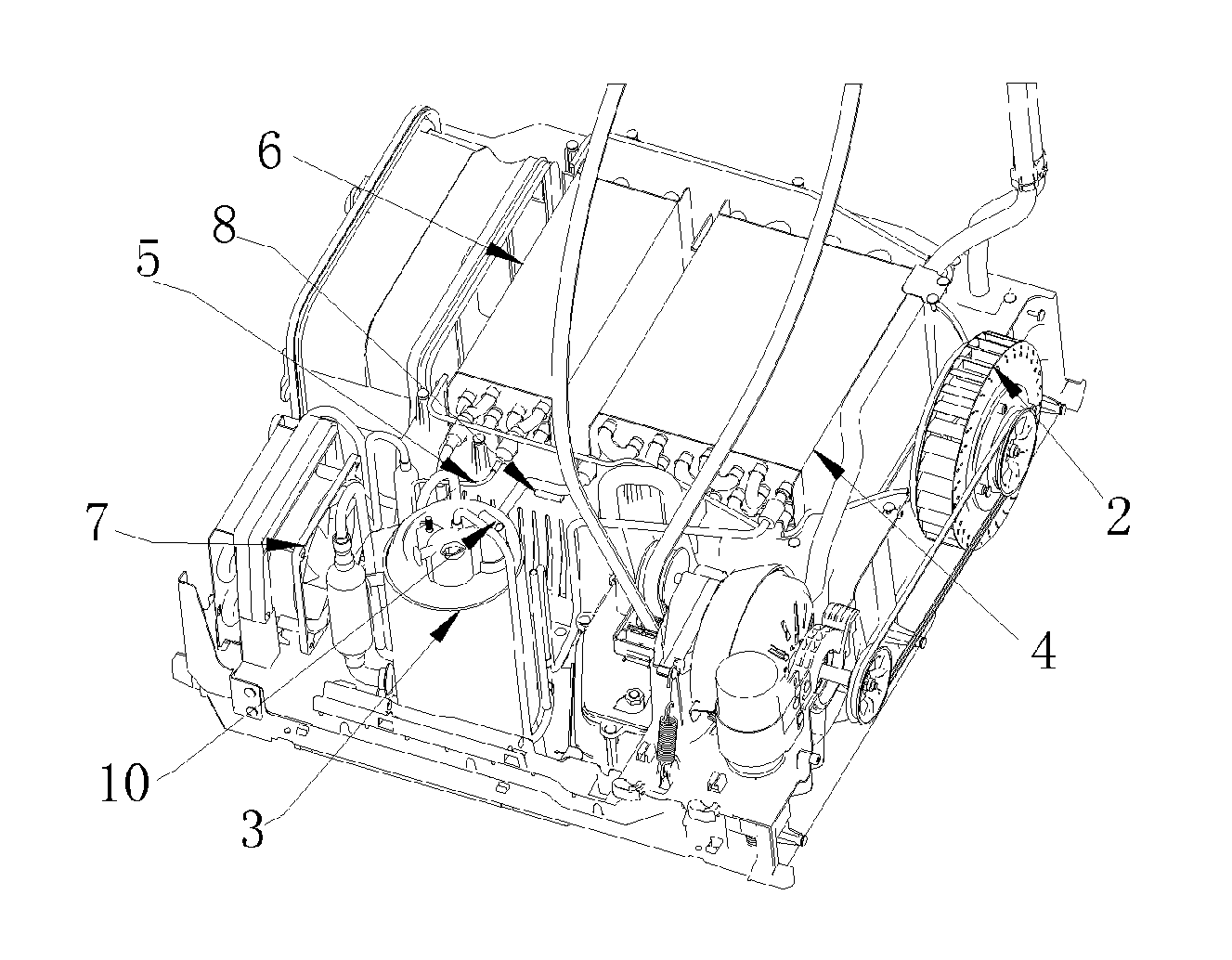

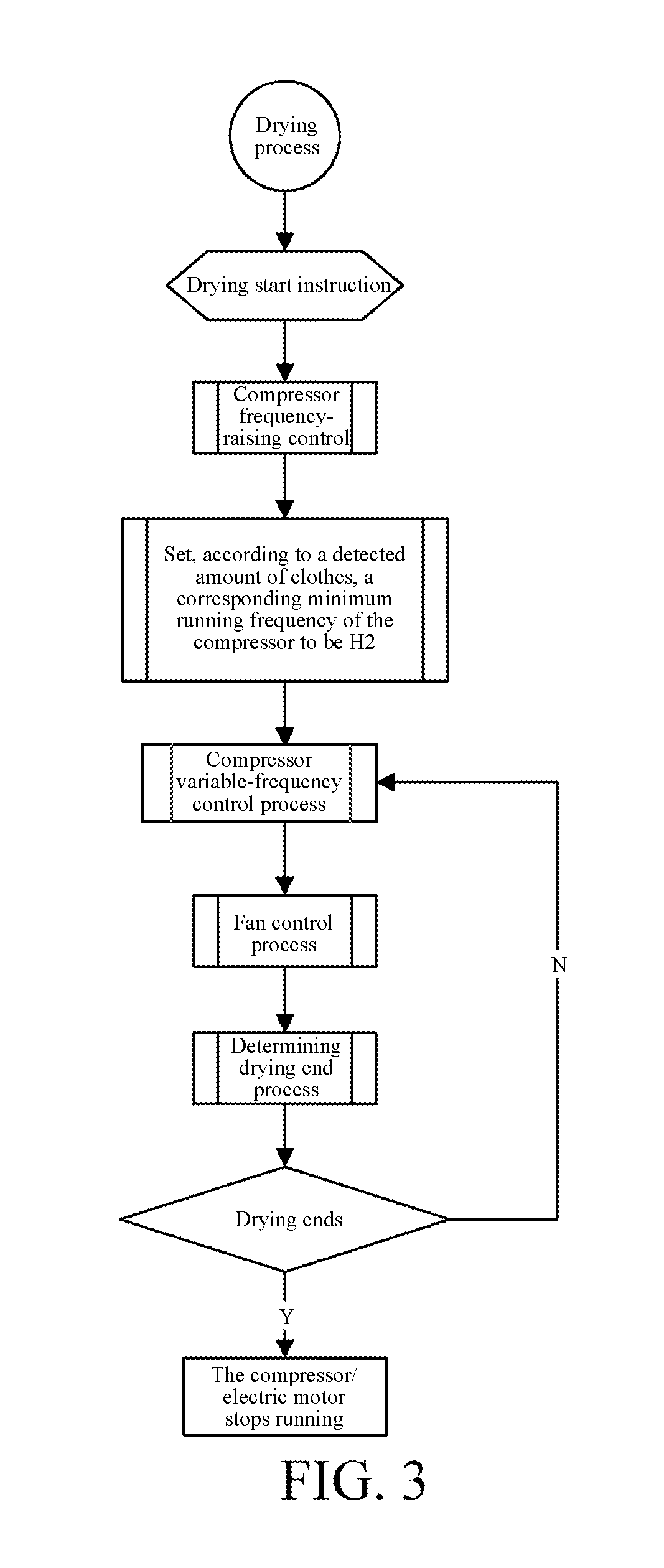

Clothes dryer control method

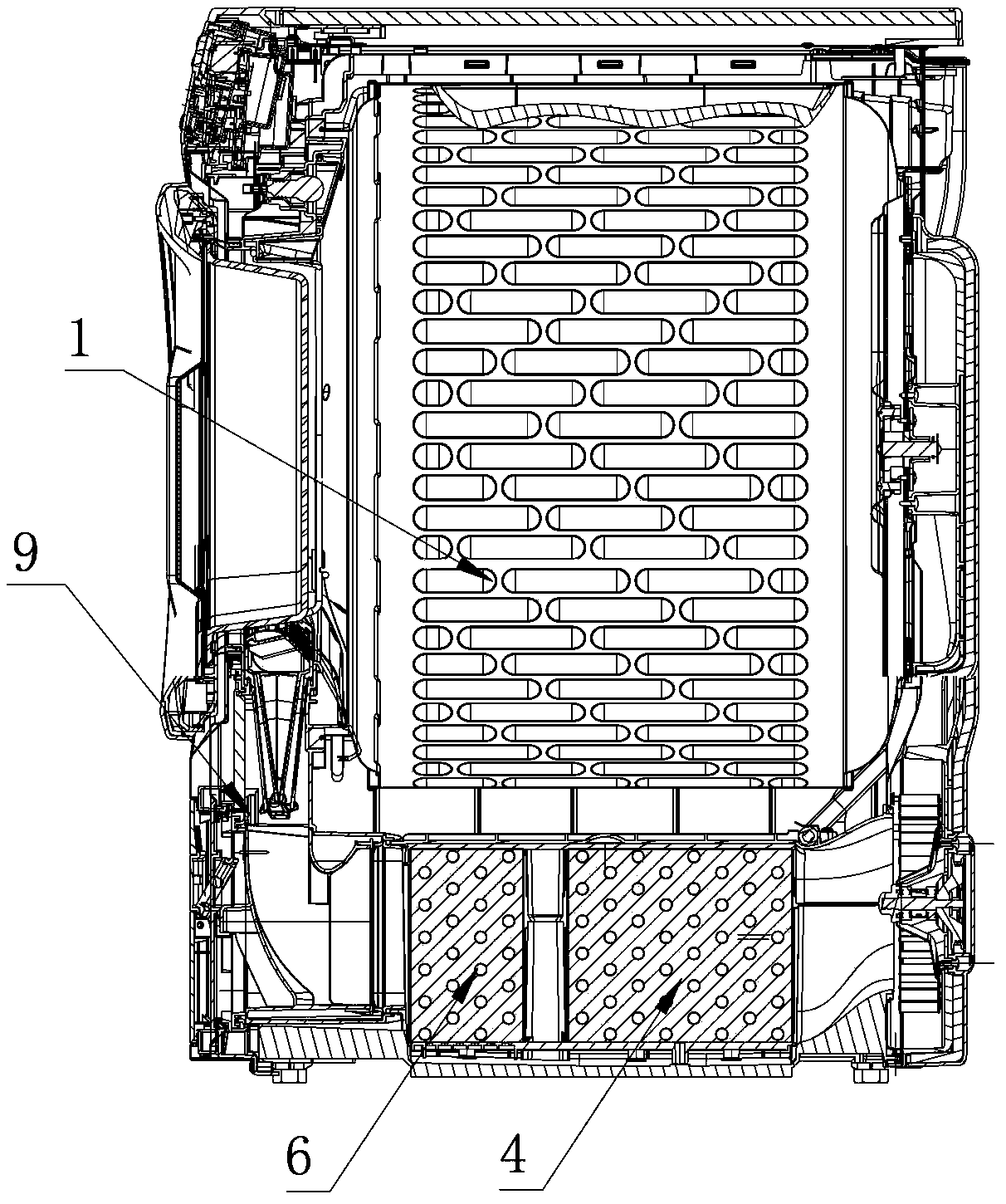

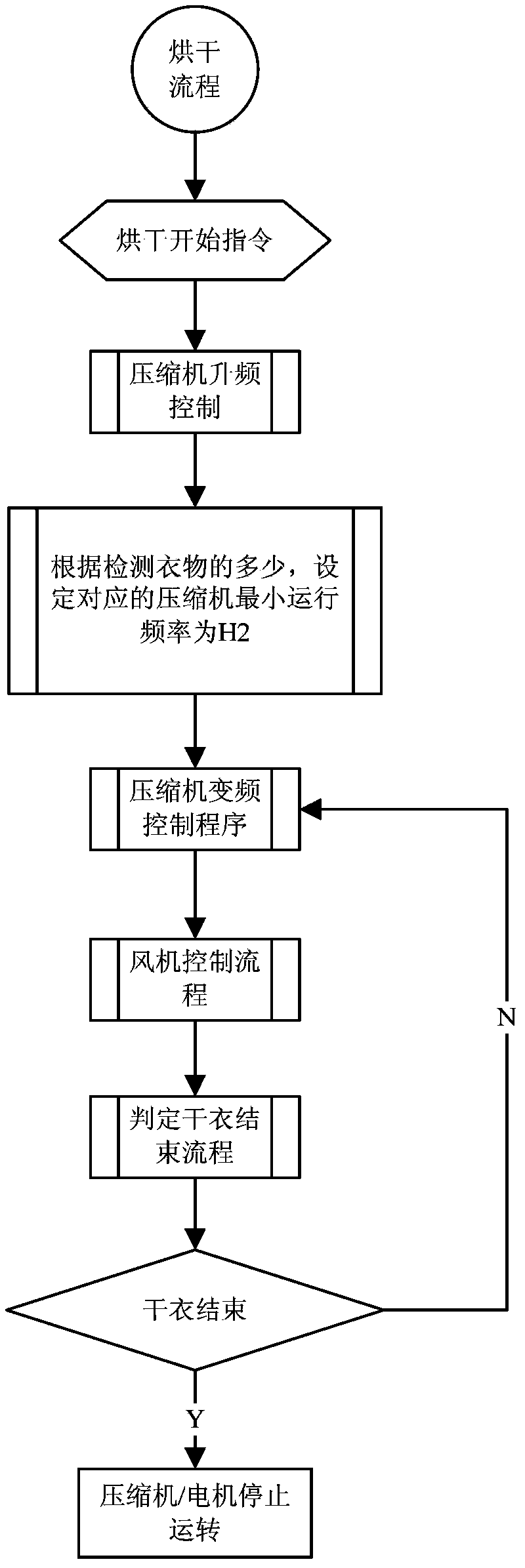

ActiveCN104120591AIncrease the minimum operating frequencyIncrease drying temperatureTextiles and paperHome appliance efficiency improvementProcess engineeringLaundry

Disclosed is a control method for a laundry dryer. The laundry dryer is a heat-pump laundry dryer, and a compressor is a variable-frequency compressor. According to the amount of laundry, a minimum running frequency of the compressor is set, and the more the laundry is, the greater the set minimum running frequency is. Specifically, when laundry drying is started, the amount of laundry is detected, and according to the detected information, a minimum running frequency, corresponding to the information, of the compressor, is invoked, and a minimum running frequency of the compressor of the current laundry drying process is set. In the improved control method for a compressor in a heat-pump laundry dryer of the present invention, when there is a large amount of laundry, a set minimum running frequency of the compressor is increased, so as to increase the drying temperature inside the cylinder, shorten the drying duration, and eventually achieve a more desirable laundry drying effect; when there is a small amount of laundry, because the laundry is relatively loose, the moisture inside the laundry can easily evaporate, and through comprehensive comparison of the power consumption and drying efficiency of the compressor, a low minimum running frequency of the compressor can be set, thereby lowering energy consumption in comparison.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

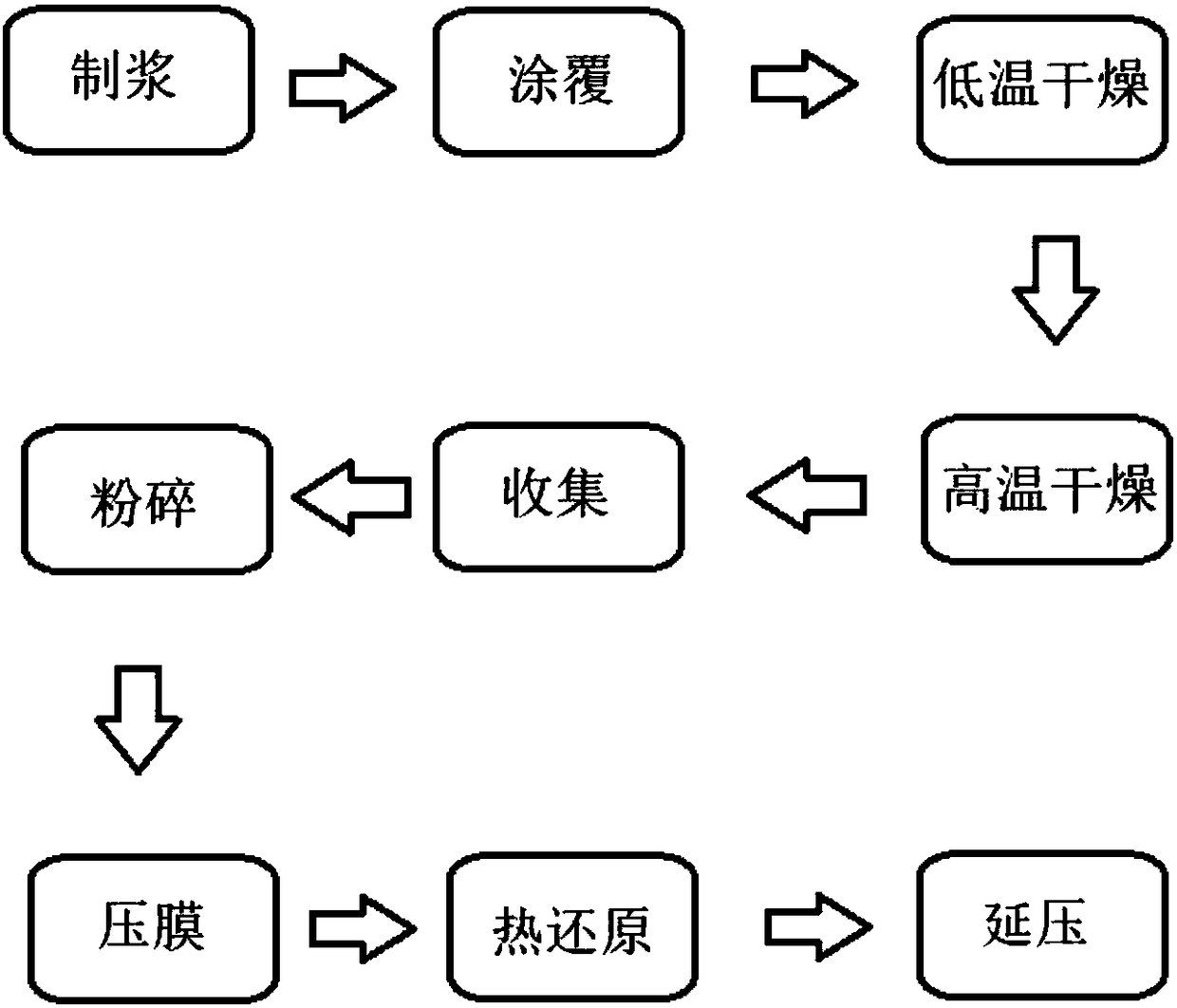

Graphene heat-conducting film as well as preparation method and production equipment thereof

ActiveCN109467078AEasy to separate and collectFunctional group reductionGrapheneHeat conductingSlurry

The invention provides a graphene heat-conducting film as well as a preparation method and production equipment thereof. The preparation method comprises the following steps: with graphene oxide as aprecursor, coating a tape with graphene oxide slurry, drying, and collecting the dried graphene oxide; grinding the dried graphene oxide, and pressing into a film; performing heat treatment on the pressed film so as to form a graphene film; and pressing again, thereby obtaining the graphene heat-conducting film disclosed by the invention.

Owner:CHANGZHOU FUXI TECH CO LTD

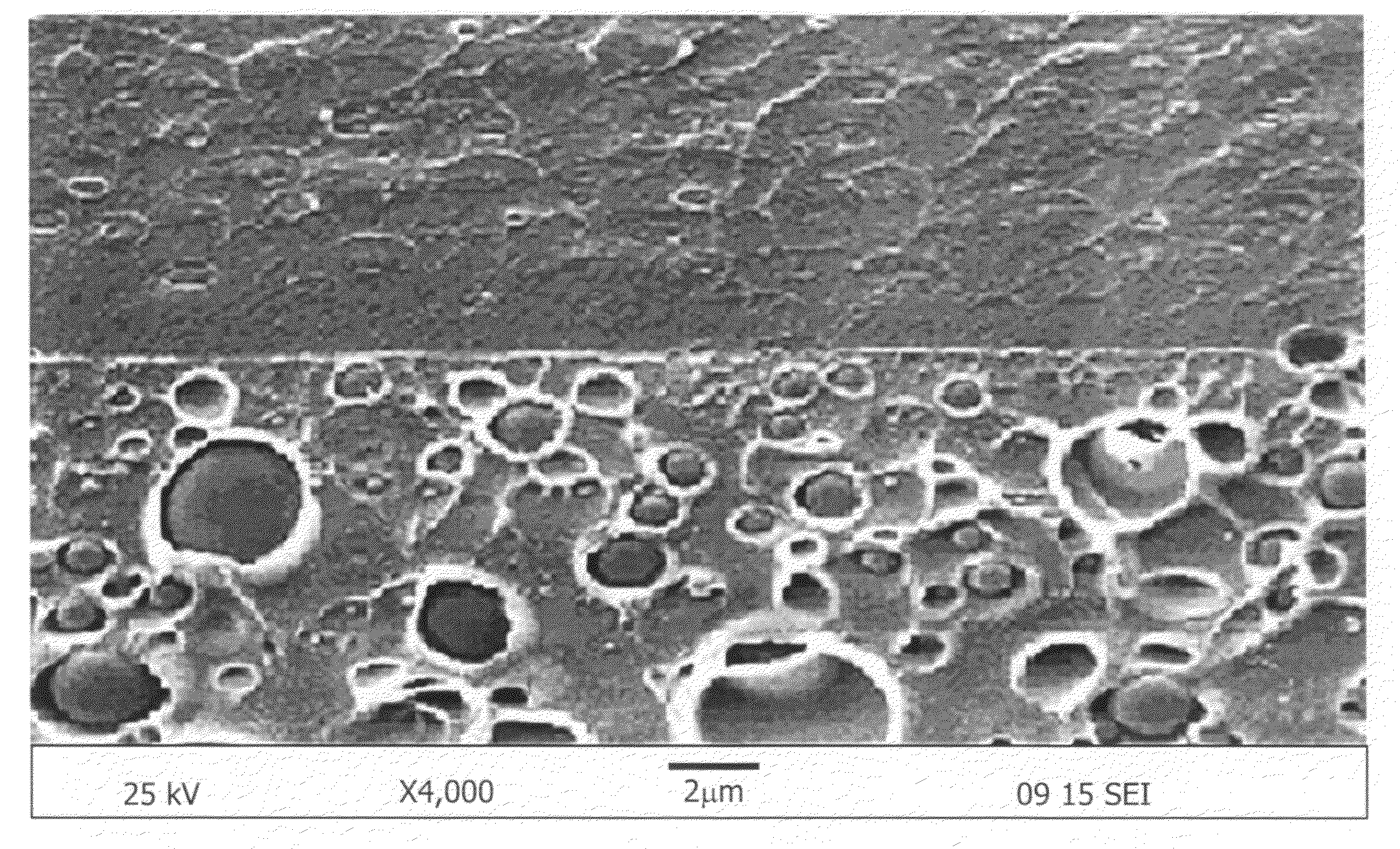

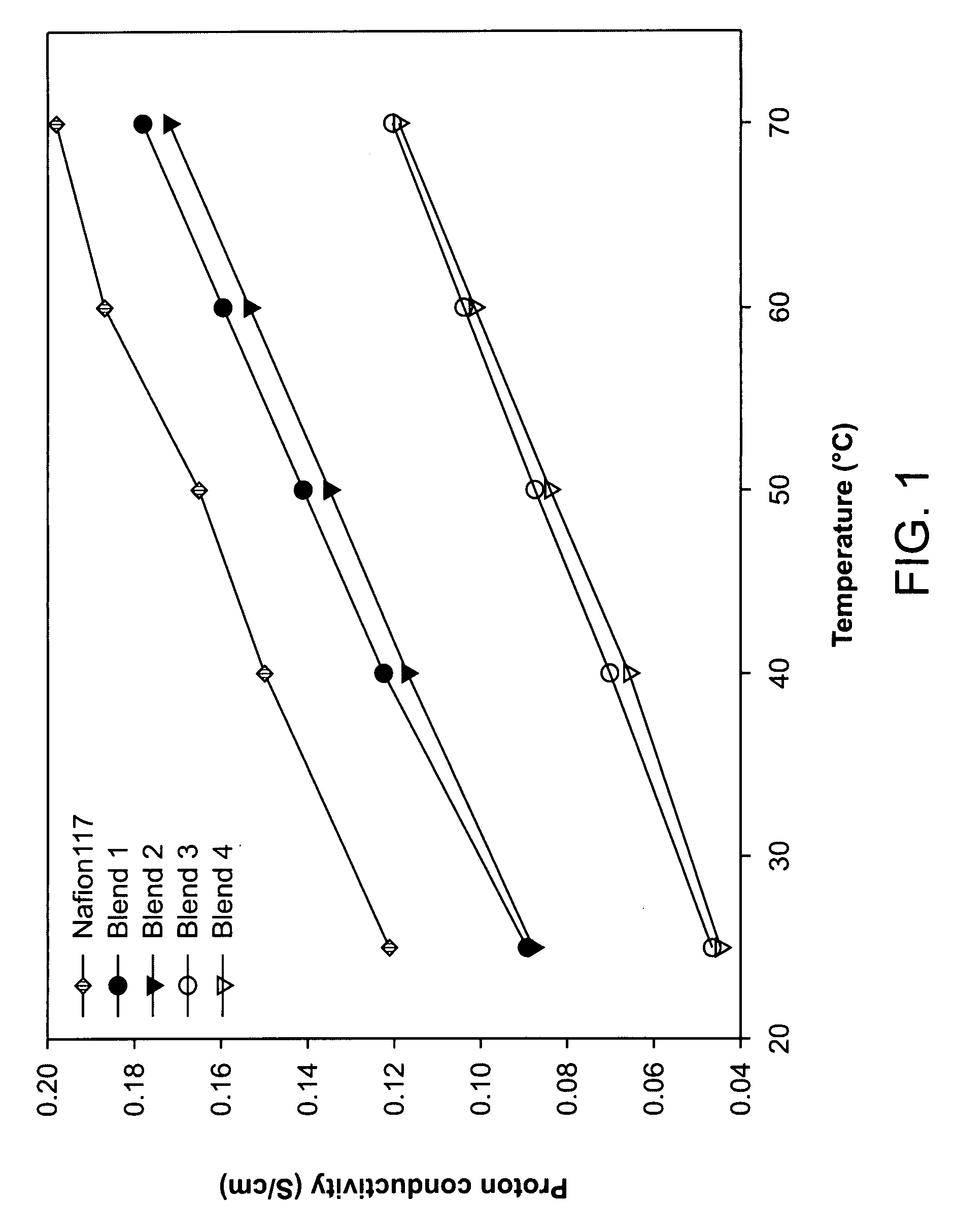

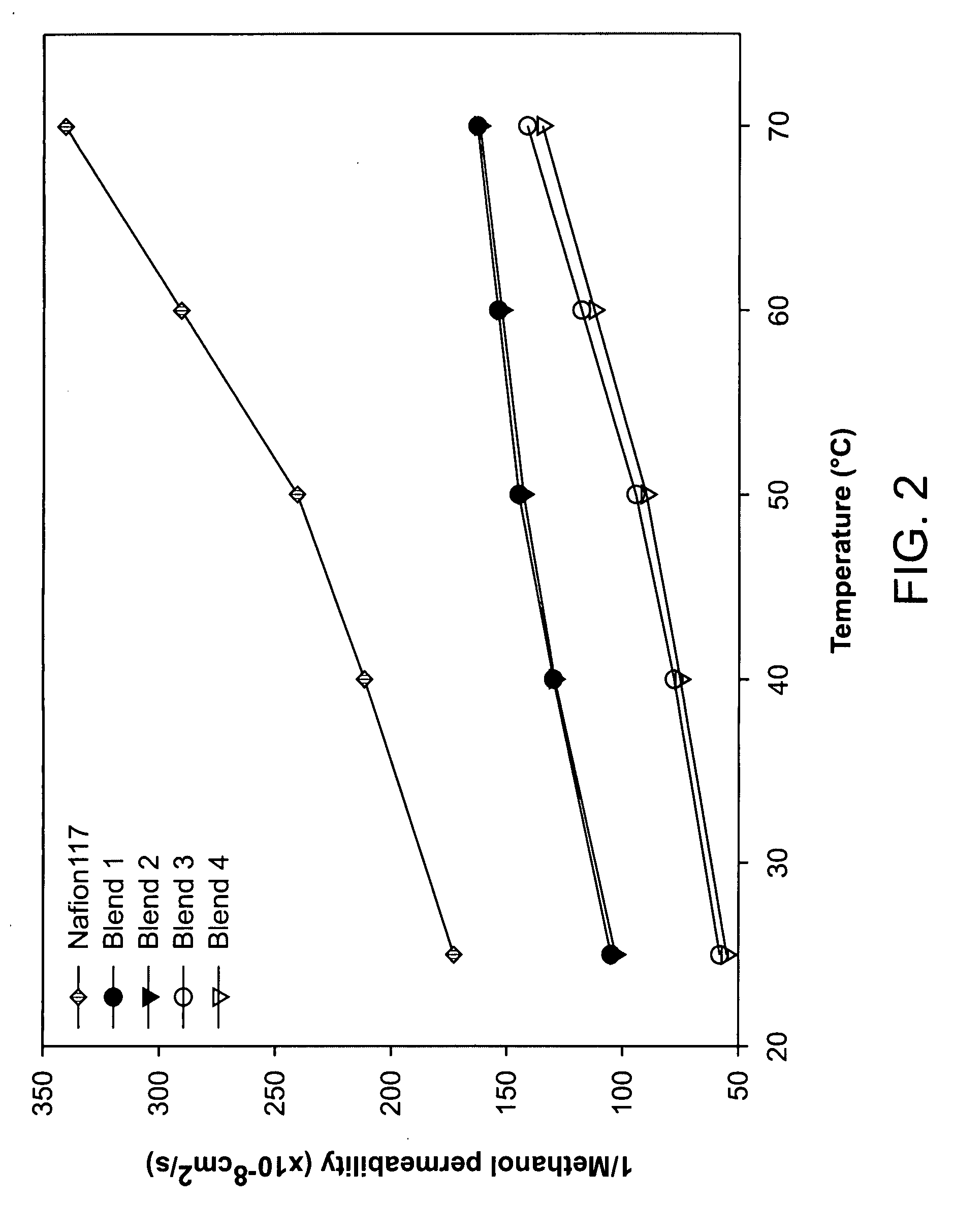

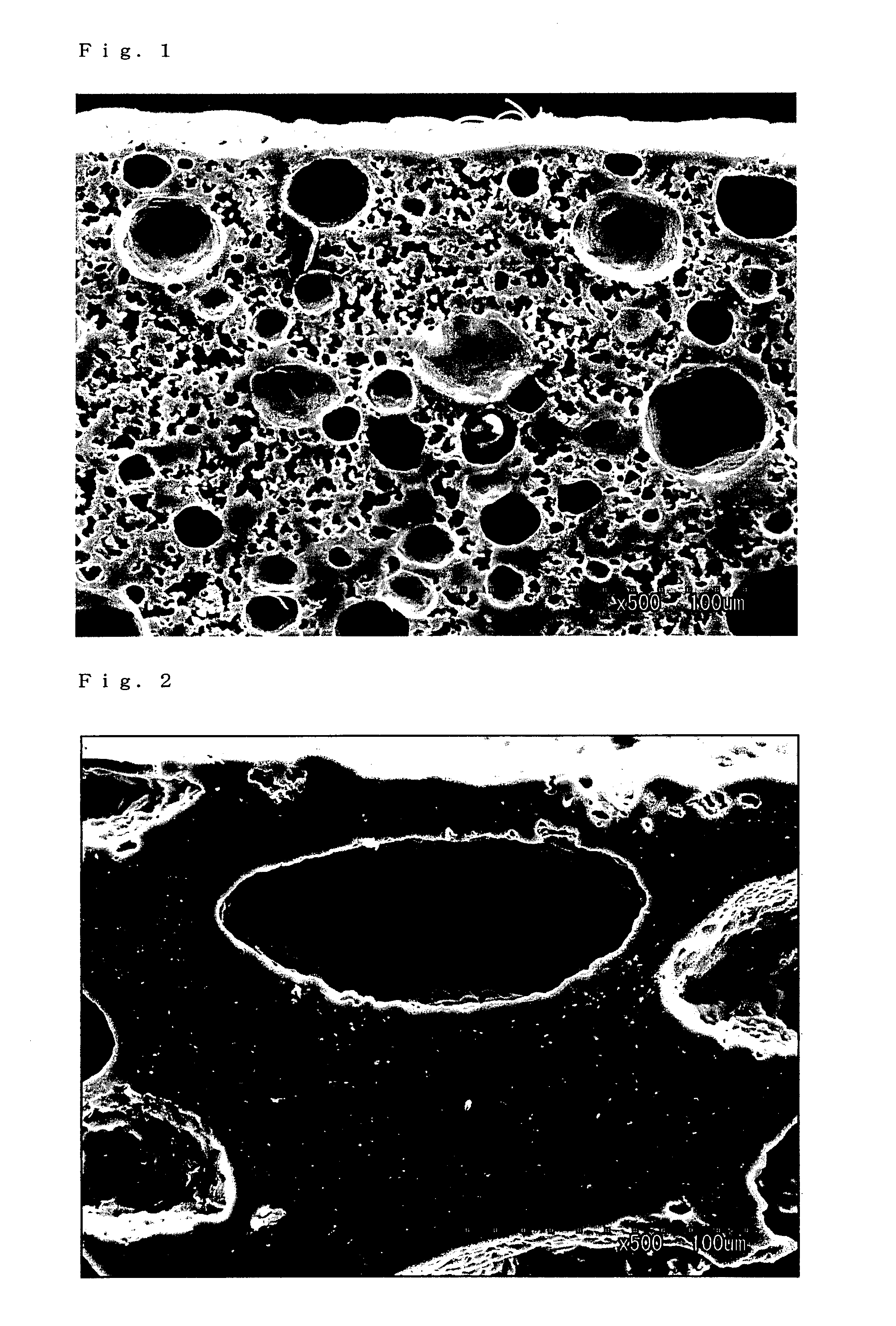

Polymer blend membranes for fuel cells and fuel cells comprising the same

InactiveUS20080241626A1High proton conductivityImprove proton conductivitySolid electrolytesFinal product manufactureChemistryMethanol

The present invention relates to polymer blend membranes of sulfonated and nonsulfonated polysulfones, methods for the preparation the membrane, and fuel cells comprising the same. The blend membranes can be obtained by varying drying condition and concentration of casting solution. The membranes have improved methanol barrier property, proton conductivity and membrane selectivity.

Owner:KOREA ADVANCED INST OF SCI & TECH

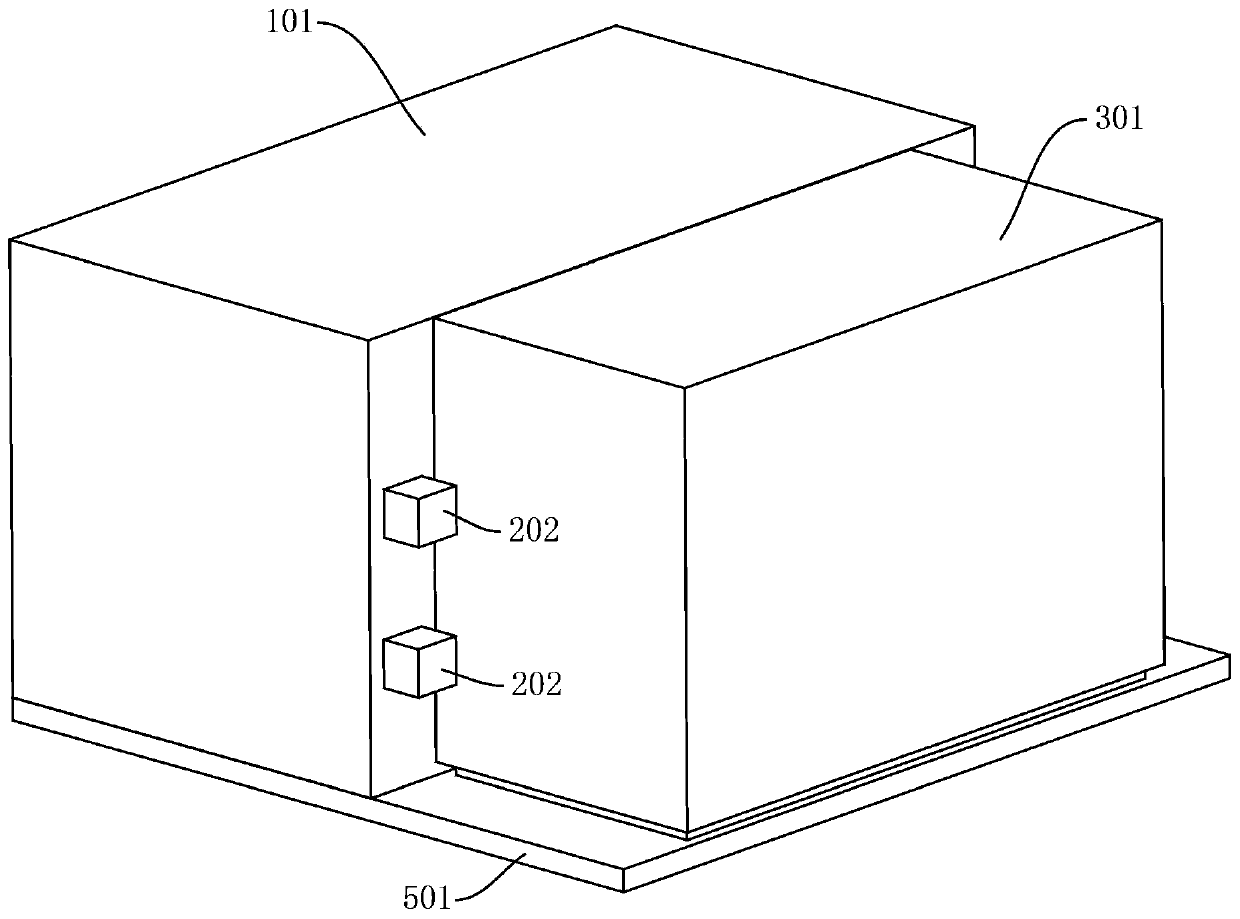

Heat pump drying device

InactiveCN102410709AFast high temperature dryingHigh quality low temperature dryingDrying gas arrangementsDrying solid materialsControl systemProcess engineering

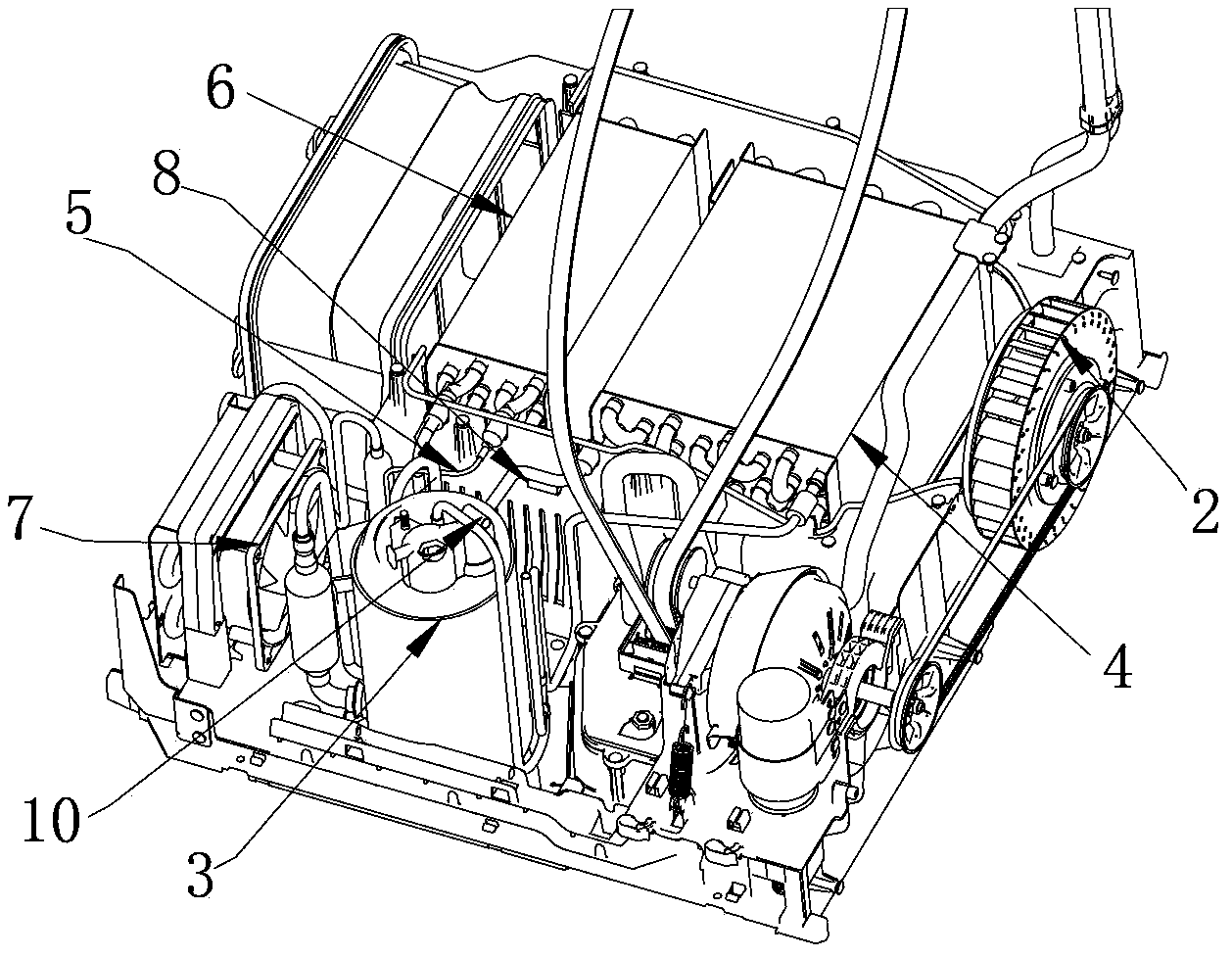

The invention discloses a heat pump drying device, which comprises a drying box and a control system, wherein the drying box comprises a shell and an air inlet fan, a dehumidifying heat pump, a main fan, a material shelf, an air outlet fan and a heating heat pump which are arranged in the shell; when an air inlet and an air outlet are closed, the dehumidifying heat pump, the main fan, the material shelf, the heating heat pump and the dehumidifying pump are communicated in sequence, and a circulating path of a drying medium is formed in the shell; when the air inlet and the air outlet are opened, the air outlet, the dehumidifying heat pump, the main fan, the material shelf and the air outlet are communicated in sequence to form a one-way circulating path of the drying medium; and an air path between the main fan and the material shelf is arc-shaped, and an inclined air deflector is arranged in the air path. The heat pump drying device can not only realize high-temperature drying but also realize low-temperature drying and can meet temperature and humidify requirements of the same product at different drying stages; and the air path for communicating the main fan with the material shelf and the air deflector is improved, therefore airflow vortex is reduced, and drying quality and speed are increased.

Owner:SOUTH CHINA UNIV OF TECH

Production method of formaldehyde-free non-ironing shirt

ActiveCN102808322AShort production processSimple process controlFibre treatmentFormaldehyde freeProcess control

The invention relates to a production method of a formaldehyde-free non-ironing shirt. The production process is as follows: spraying of finishing liquid, drying, stereoscopic molding, shaping of a drying tunnel, and dehumidifying and dampening, wherein the drying temperature is set to be 80 DEG C to 90 DEG C, and the humidity is controlled to be 30-50%; in the stereoscopic molding step, a stereoscopic combined type press process is adopted, the temperature is controlled to be 140 DEG C to 160 DEG C the time is controlled to be 1-2min, and force of 6-10 kg / cm<2> is applied; and in the step of shaping of the drying tunnel, the design of circular blowing and heat insulation as well as a band-type drying tunnel of a ternary-form gradually-heated system are adopted, the shaping temperature of different segments is set to be 110 DEG C to 140 DEG C, 130 DEG C to 160 DEG C and 150 DEG C to180 DEG C, and the total shaping time is 3-6min. The non-ironing shirt produced by the invention is free from formaldehyde and belongs to a real formaldehyde-free non-ironing shirt, the production process flow is short, the process control is simple, the production reproducibility is good, and the product quality is stable.

Owner:SUQIAN BAOZITOU GARMENTS TECH

Heat Pump Laundry Dryer and a Method for Operating a Heat Pump Laundry Dryer

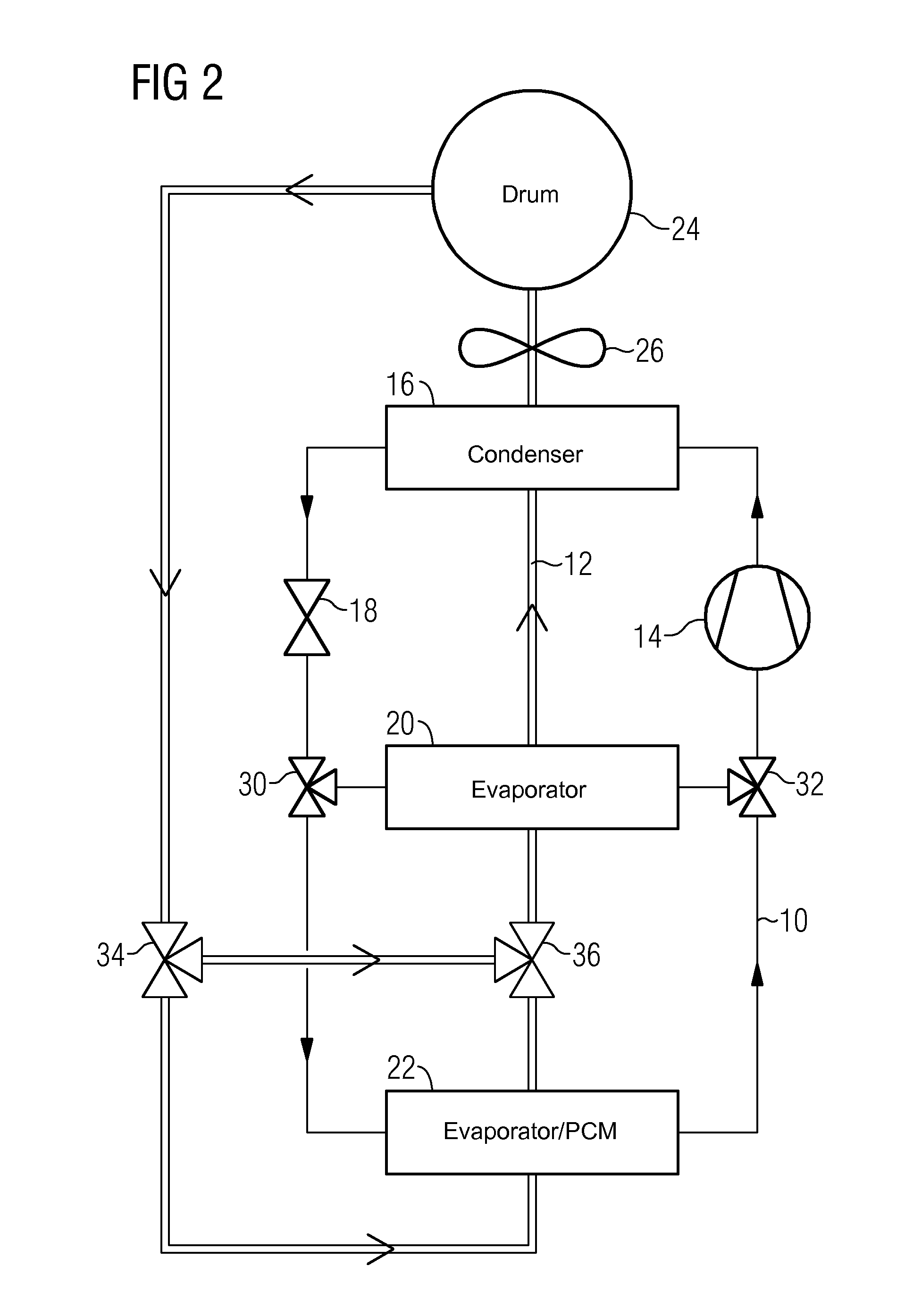

InactiveUS20120210597A1Increase air temperatureIncrease drying temperatureDrying solid materials with heatDrying gas arrangementsEngineeringCooling down

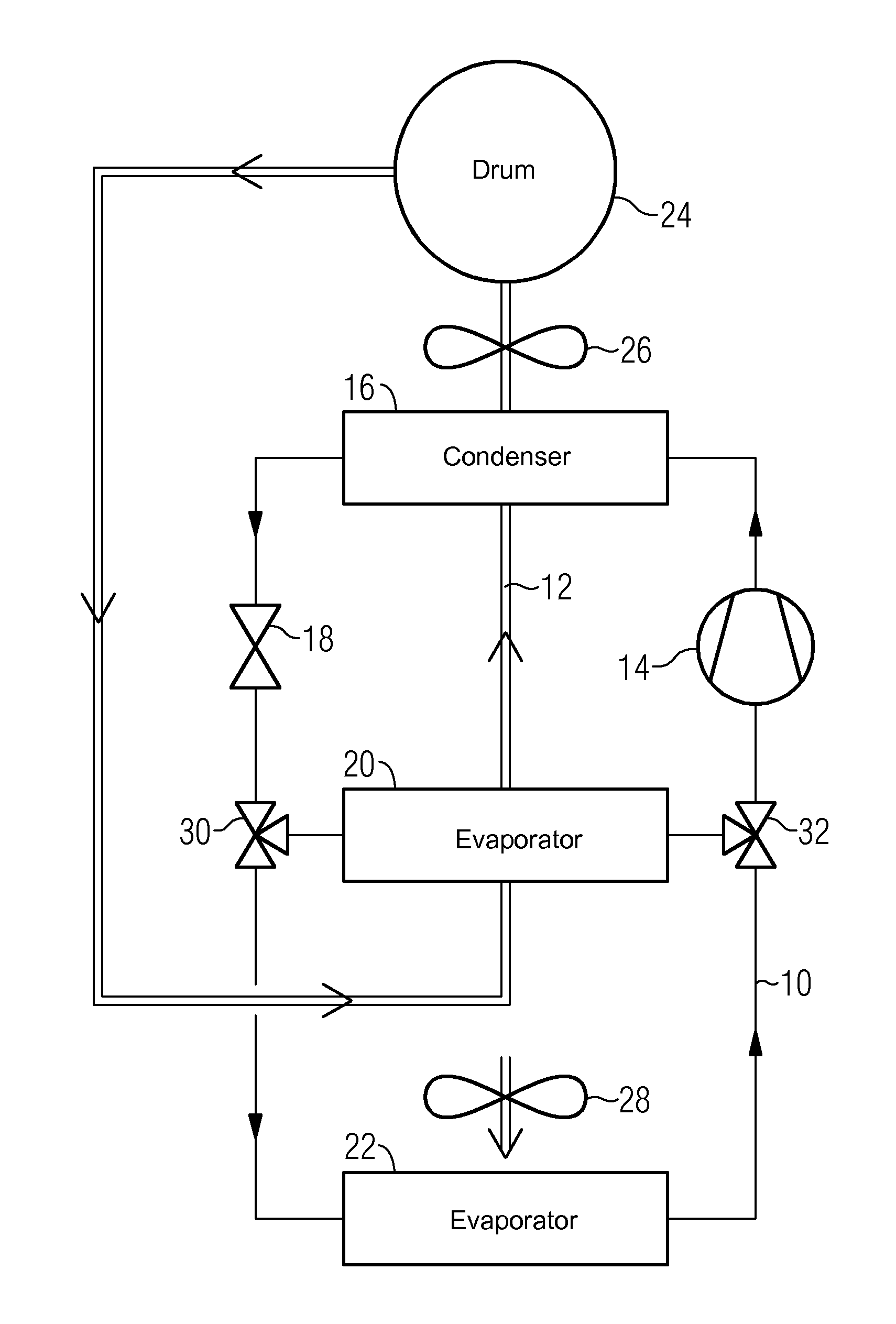

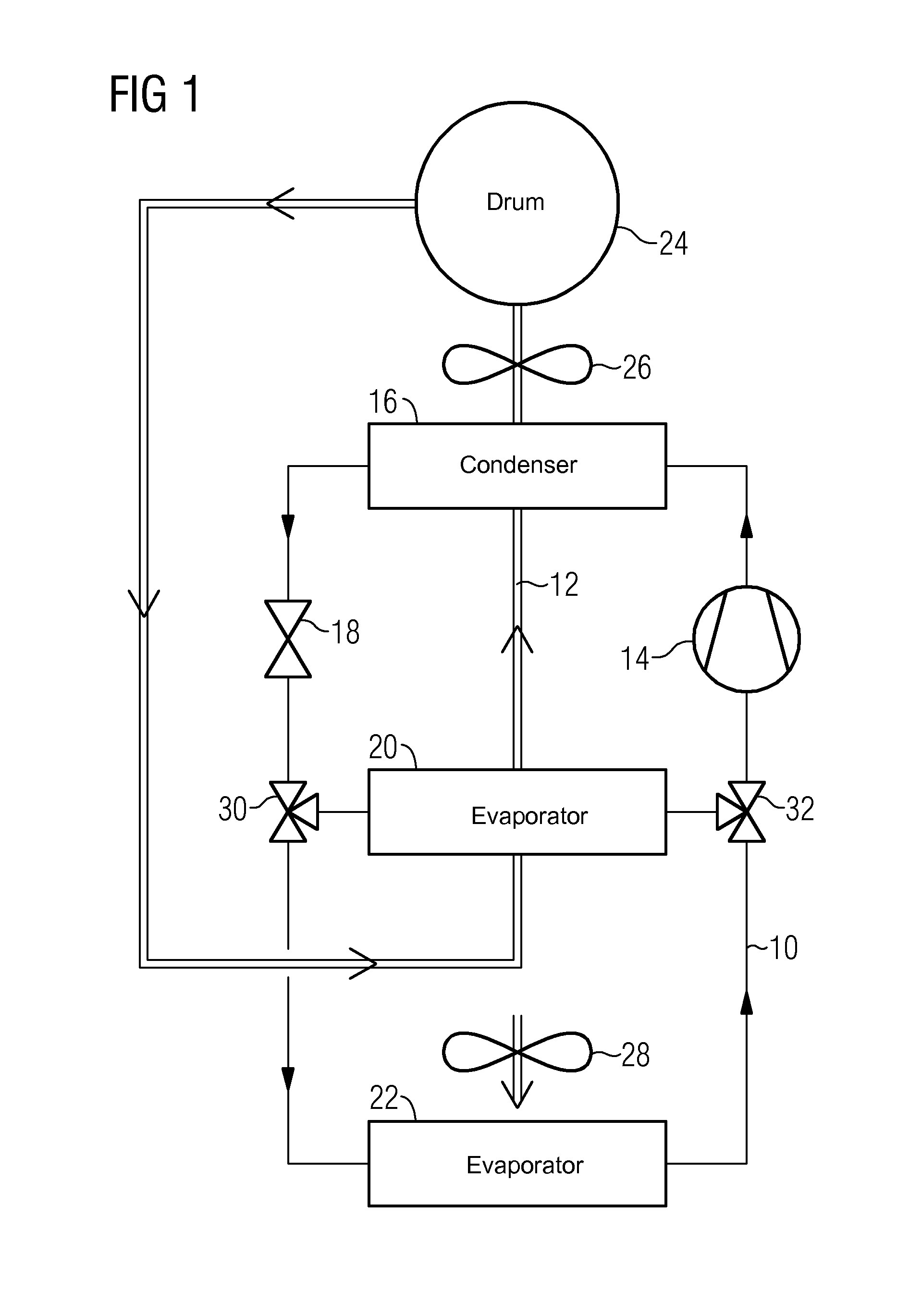

A heat pump system of a laundry dryer comprises a closed refrigerant circuit (10) and a drying air circuit (12). The refrigerant circuit (10) includes a compressor (14), a condenser (16), an expansion device (18) and a main evaporator (20). The air stream circuit includes the main evaporator (20), the condenser (16), a laundry drum and at least one fan (26). The refrigerant circuit (10) and the air stream circuit are thermally coupled by the condenser (16) and the main evaporator (20). The condenser (18) is a heat exchanger provided for heating up the air stream and cooling down the refrigerant. The main evaporator (20) is a heat exchanger provided for cooling down the air stream and heating up the refrigerant. At least one additional evaporator (22) is arranged in parallel to the main evaporator (20), and is switchably connected to the refrigerant circuit (10).

Owner:ELECTROLUX HOME PROD CORP NV

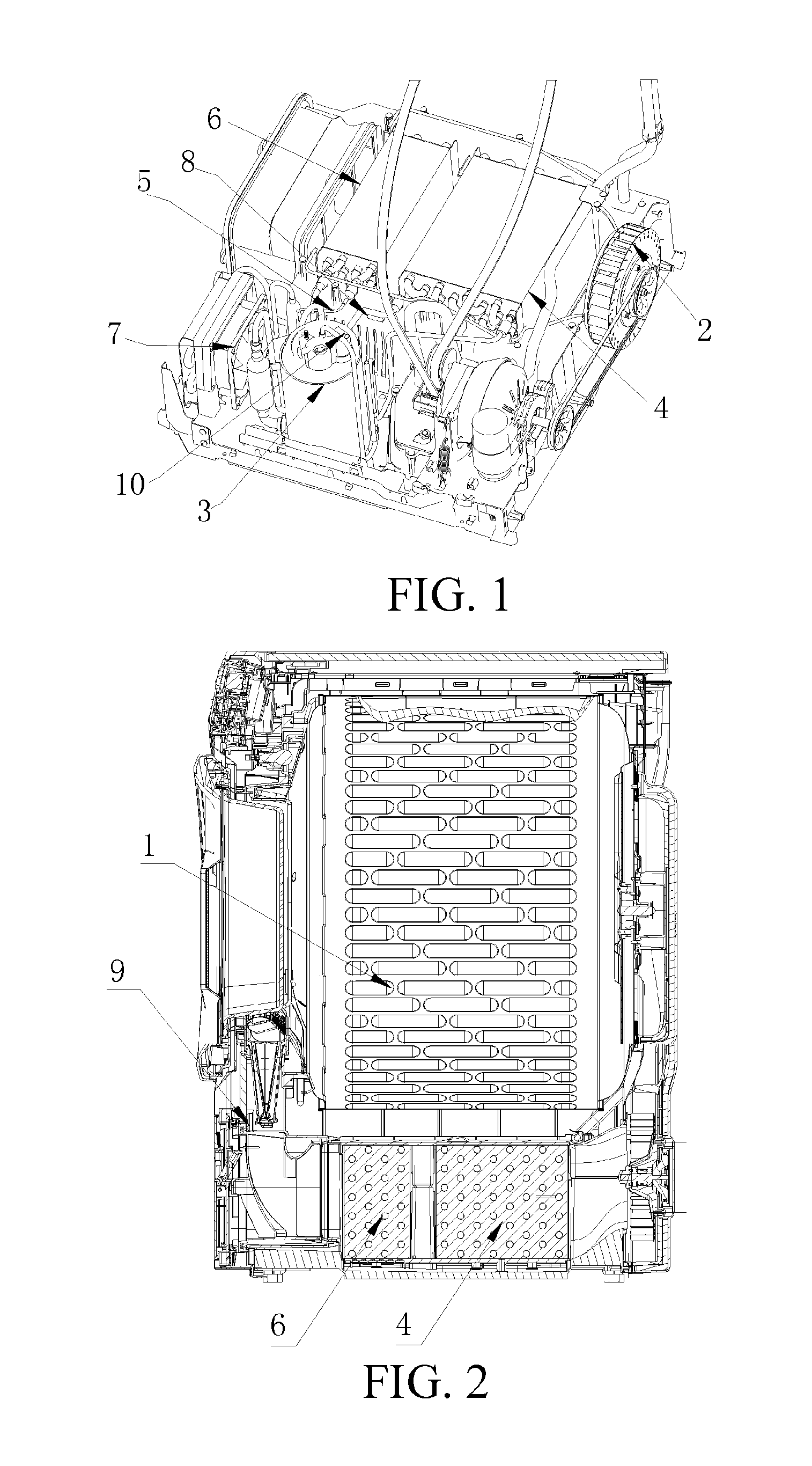

Control method for laundry dryer

ActiveUS20160040350A1Reduce power consumptionIncrease drying temperatureDrying solid materials with heatTextiles and paperProcess engineeringLaundry

The present invention relates to a control method for a laundry dryer. The laundry dryer is a heat-pump type laundry dryer and a compressor of the laundry dryer is a variable-frequency compressor. The control method includes setting a minimum running frequency of the compressor according to an amount of clothes to be dried, where the more the clothes are, the larger the set minimum running frequency is. Specifically, when laundry drying is started, the amount of the clothes being dried is detected. According to the detected information, a minimum running frequency of the compressor, corresponding to the information, is invoked, and the minimum running frequency of the compressor in the current laundry drying process is set.

Owner:HAIER GRP CORP +1

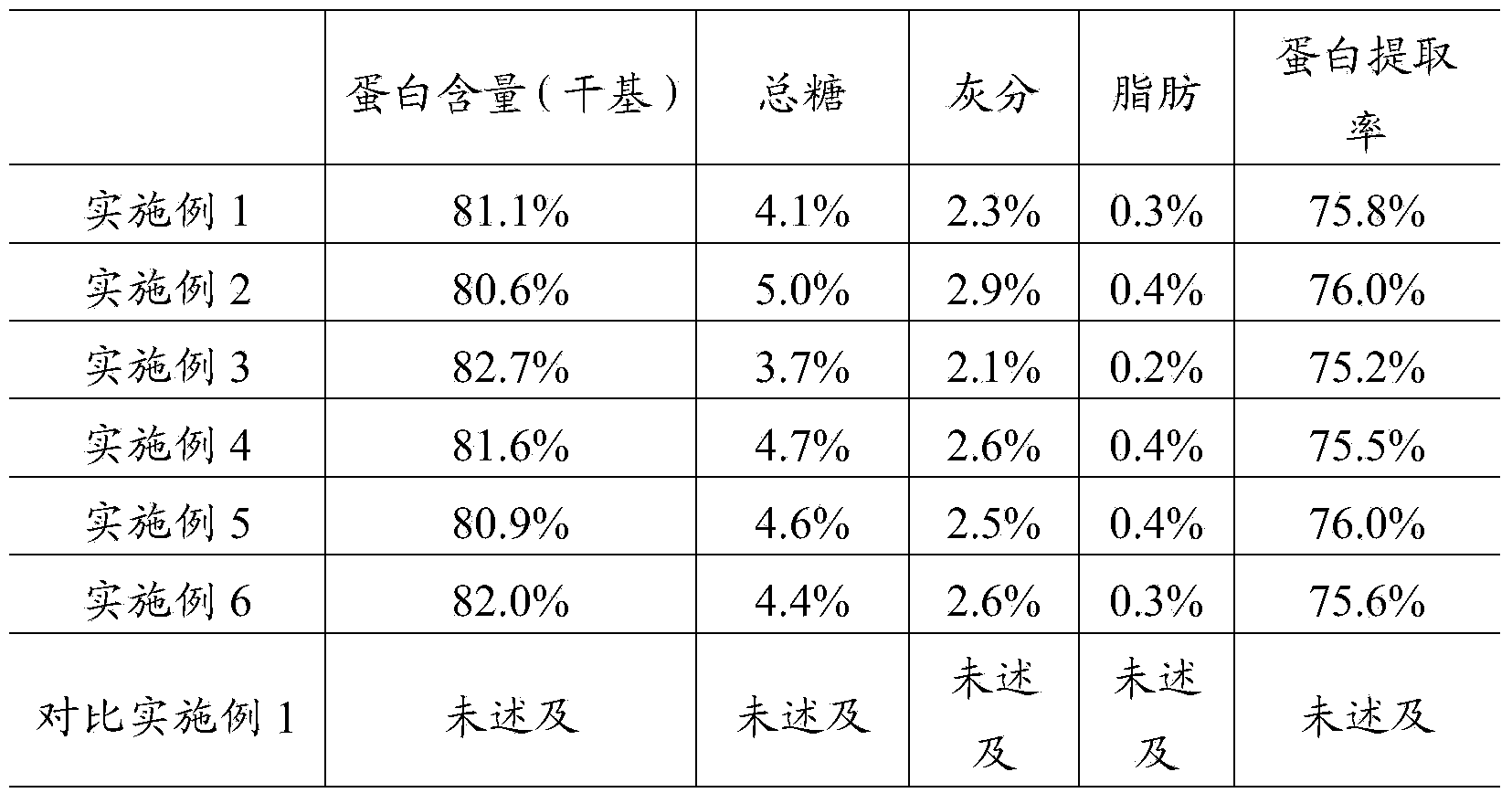

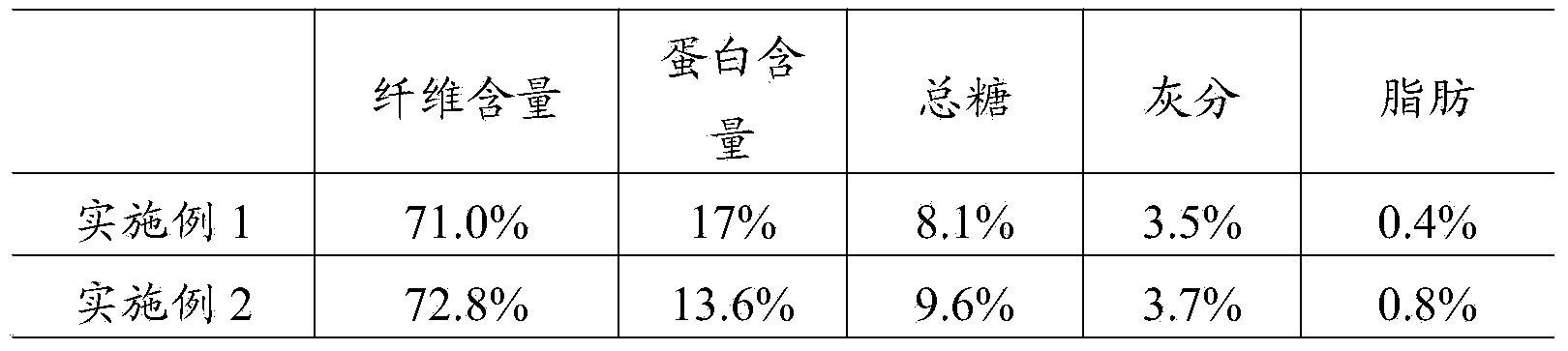

High-purity rice bran protein and rice bran fibers and preparation method thereof

The invention relates to high-purity rice bran protein and rice bran fibers, and further relates to a preparation method of the high-purity rice bran protein and the rice bran fibers. The preparation method includes the steps of raw material pretreatment, first size mixing and enzyme reaction, second size mixing and enzyme reaction, separate washing, drying and the like. According to the method, through superfine grinding and amylase and cellulose hydrolyzing, components of defatted rice bran are effectively separated, a whirlcone is utilized to conduct the washing treatment, and therefore separate washing efficiency is greatly improved. Compared with spray drying, flash drying equipment is utilized, investment is saved by about 40%, operating cost is saved by about 35%, in rice bran protein products, the protein content is over 80%, the ash content is below 3%, the fat content is below 0.5%, the protein extraction ratio is over 75%, and in rice bran fiber products, the fiber content is over 70%, the ash content is below 4%, and the fat content is below 1%. The high-purity rice bran protein and the rice bran fibers all can be widely applied to the field of health food, nutritious food and the like, and additional value of rice deep processing is greatly improved.

Owner:格乐瑞(无锡)营养科技有限公司

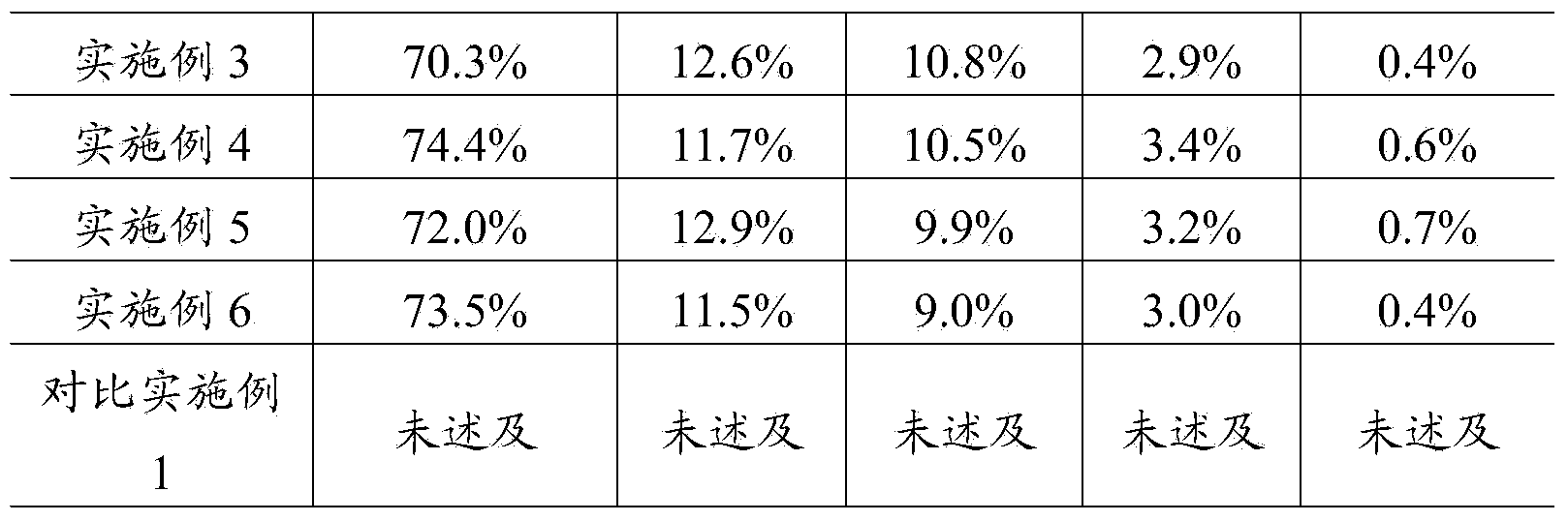

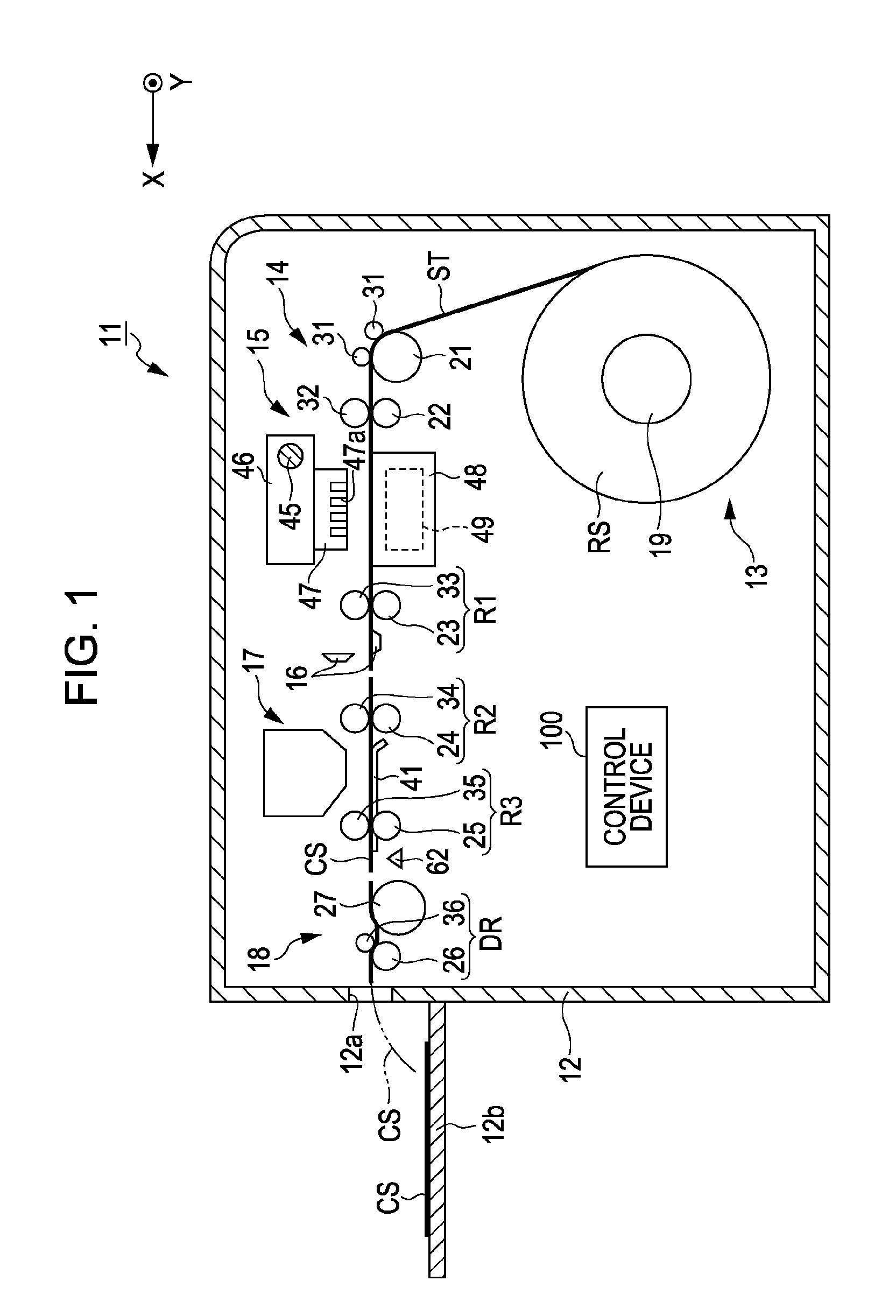

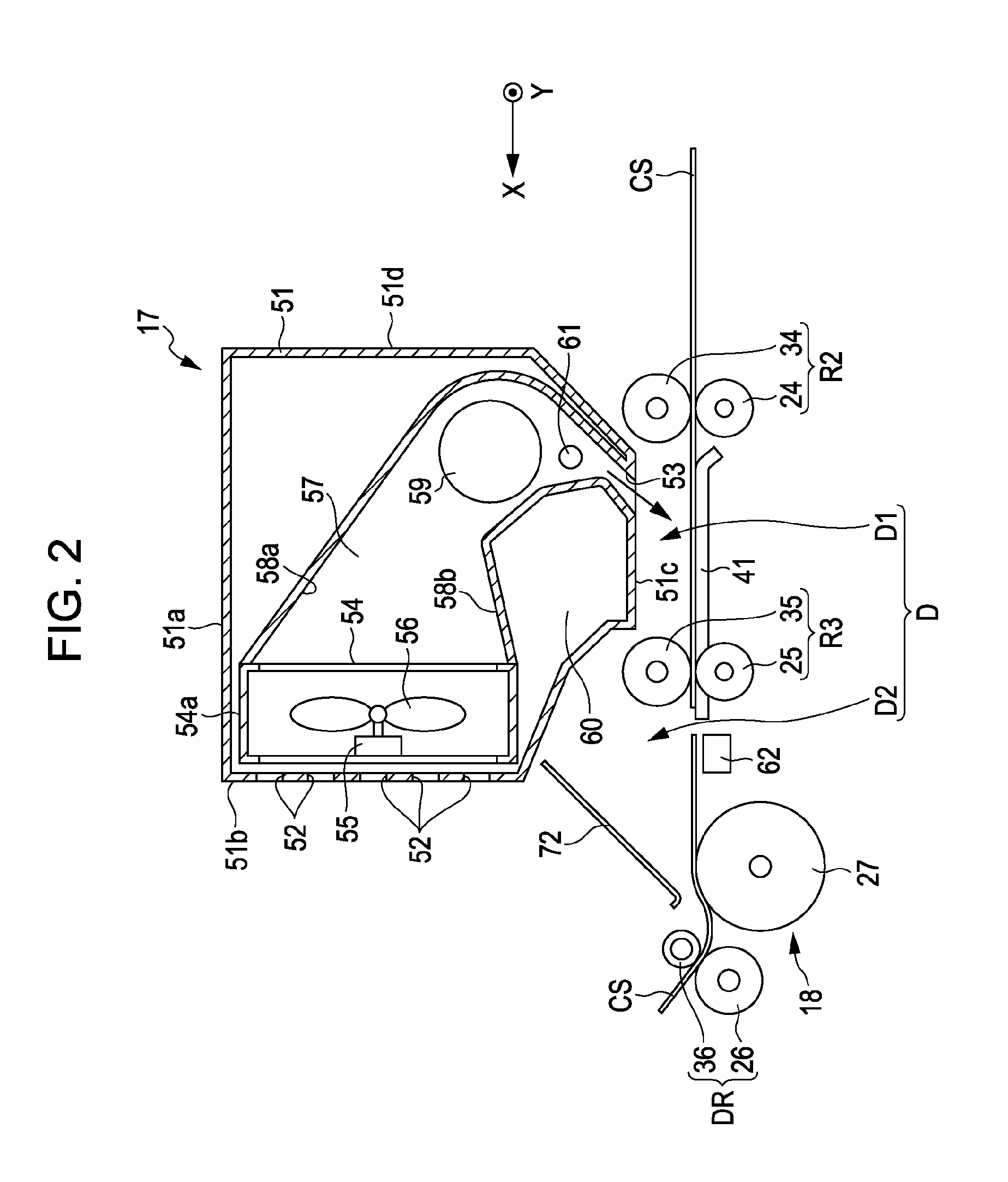

Printing apparatus

ActiveUS20130057629A1Keep dryIncrease drying temperatureOther printing apparatusEngineeringMechanical engineering

A printing apparatus includes a transport unit that transports a printing medium to a downstream side of a transport direction, a printing head that performs printing on the printing medium, a drying unit that performs a drying process on the printing medium in the course of a transport path of the printing medium, a transport roller that is disposed further to the downstream side in the transport direction than the drying unit, a de-curl roller that pinches the printing medium with the transport roller, and a curl correcting unit that corrects the curl of the printing medium, and the de-curl roller is positioned at a de-curl position of pinching the printing medium with the transport roller at the time of increasing the temperature of the drying unit to a predetermined temperature.

Owner:SEIKO EPSON CORP

Paper printing method for fibrous and leather materials

ActiveCN102597364AGood effectReduce drainage loadWater-repelling agents additionDuplicating/marking methodsFiberAdhesive

Disclosed is a paper printing method for fibrous and leather materials characterized by having: a step wherein printing paper is obtained by applying a mixed paste comprising a water-soluble synthetic binder, a natural adhesive, and an auxiliary agent to base paper, which is then dried to obtain paper for printing, onto which a dye ink is printed; a step wherein the printing paper is bonded to a fibrous or leather material and fixed using pressure / heat; and a step wherein the printing paper is removed after a dye fixing process is carried out while the printing paper is fixed to the fibrous or leather material. Further disclosed are the paper for printing and the printing paper used in the paper printing process, and the fibrous and leather materials characterized by being printed on in the paper printing process.

Owner:山本眩士

Preparation method of trehalose anhydrous

ActiveCN104262413ASolve technical problems that are difficult to get rid ofKeep drySugar derivativesDispersed particle separationChromatographic separationHigh concentration

The invention relates to a preparation method of trehalose anhydrous. The preparation method comprises the following step: by adopting a trehalose reaction solution prepared from high-concentration malt syrup by enzymatic conversion as a raw material, performing processes such as enzymolysis and impurity removal, activated carbon decolorization, ion exchange, simulated moving bed chromatographic separation and belt-type vacuum continuous drying and dehydration to prepare series products containing trehalose anhydrous with the purity of 50-99.5wt% so as to meet the special requirements of trehalose anhydrous as a drying agent in different fields of drying. A trehalose anhydrous production process disclosed by the invention is simple and low in cost, and can be used for saving energy and reducing consumption in a production process.

Owner:BAOLINGBAO BIOLOGY

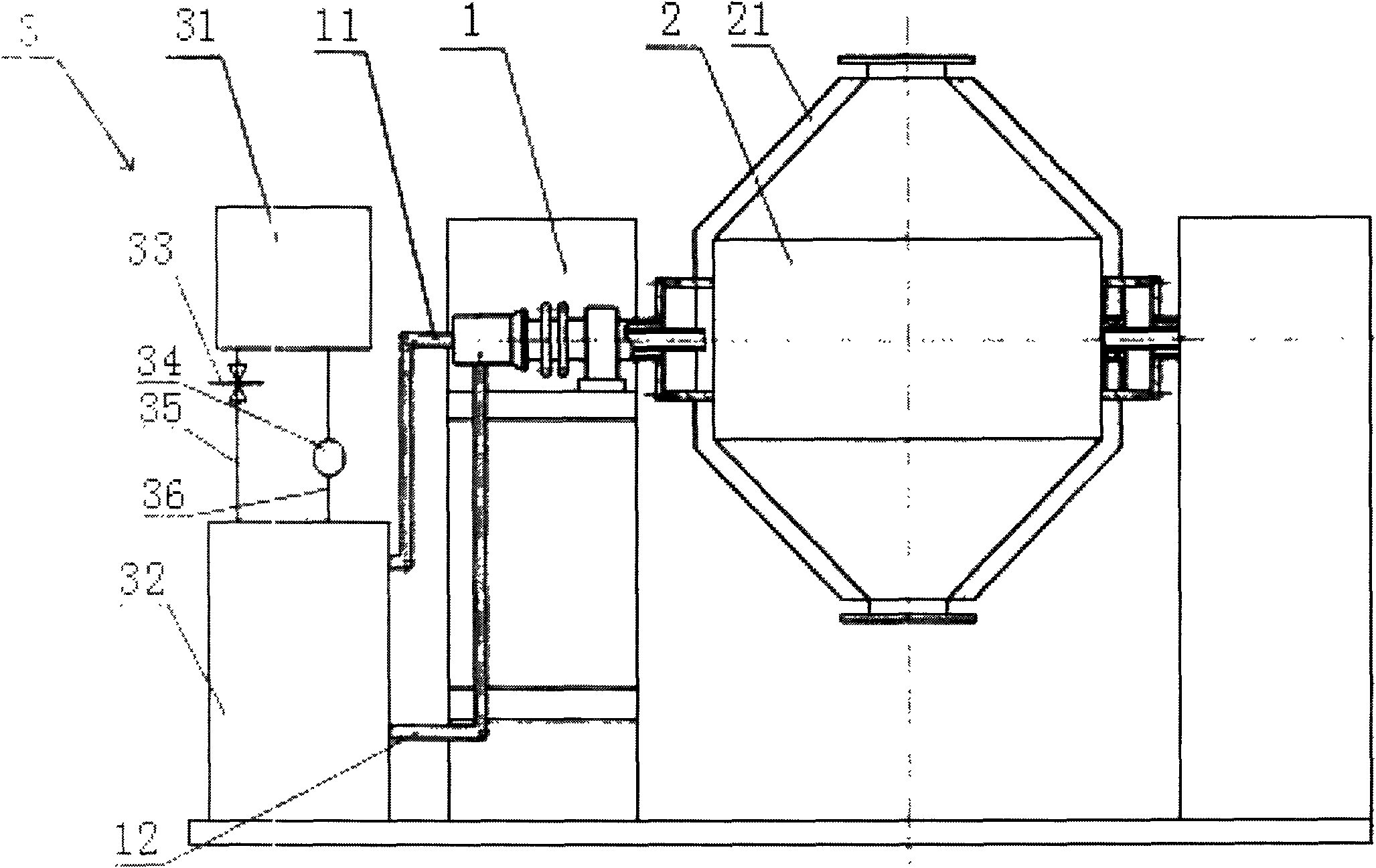

Double-cone rotary vacuum drier

InactiveCN102735030AIncrease drying temperatureShorten drying timeDrying using combination processesDrying machines with non-progressive movementsHeat conductingProcess engineering

The invention relates to a double-cone rotary vacuum drier which comprises a base, a double-cone cylinder and a heat supply device, wherein the double-cone cylinder is provided with a jacket; the base is provided with a heat source inlet and a heat source outlet which are communicated with the interior of the jacket and are connected with the heat supply device by pipes; and the heat supply device is a heat-conducting oil heat supply device. The double-cone rotary vacuum drier can achieve higher drying temperature within shorter time as the heat-conducting oil is adopted as the heating source of the double-cone rotary vacuum drier, thus effectively improving the working efficiency.

Owner:金伟均

Technical method for paint decoration on surface of pencil

InactiveCN103952036AVolatile fastFast volatilization ratePolyester coatingsMethyl acetateEthyl acetate

The invention discloses a technical method for paint decoration on the surface of a pencil. A solvent such as methyl acetate, ethyl acetate and acetone with high volatilization rate is selected in the preparation process of a paint, matt powder is added to enable the paint to be more rapidly volatilized, and meanwhile, the drying temperature and the air flow velocity are increased to ensure that the surface dry time of the paint is shortened from 60s to 10s, so that the thickness of a film painted every time can be increased from 10mu m to 15mu m, and the covering power of the paint is also enhanced; and due to the increment of the thickness of the film, the painting times can be correspondingly reduced from 10 to 6, and finally, the production efficiency is increased by 30-40%.

Owner:AXUS STATIONERY (SHANGHAI) CO LTD

High-temperature-resistant colored pencil core and preparation method thereof

ActiveCN103937330AImprove temperature resistanceIncrease drying temperaturePencil leadsAdhesiveFlexural strength

The invention discloses a high-temperature-resistant colored pencil core which comprises the following components in parts by weight: 40-70 parts of clay, 5-15 parts of constitution raw material, 5-20 parts of pigment powder, 1-12 parts of wax, 1-10 parts of grease, 1-8 parts of adhesive and 10-40 parts of water. The invention also discloses a preparation method of the high-temperature-resistant colored pencil core. The modified cellulose and modified synthetic wax are adopted to increase the high temperature resistance of the mixture and enhance the temperature of the drying oven, thereby shortening the lead drying time to less than 12 hours, greatly shortening the time of the whole technique and enhancing the production efficiency. The vacuum core extrusion technique is adopted to enhance the density of the lead core, thereby enhancing the flexural strength of the lead core, the core tip stress of the penpoint, lowering the breaking rate of in the sharpening process and improving the wear resistance of the pencil; and the appearance of the lead core is more smooth, and the quality of the product is upgraded.

Owner:AXUS STATIONERY (SHANGHAI) CO LTD

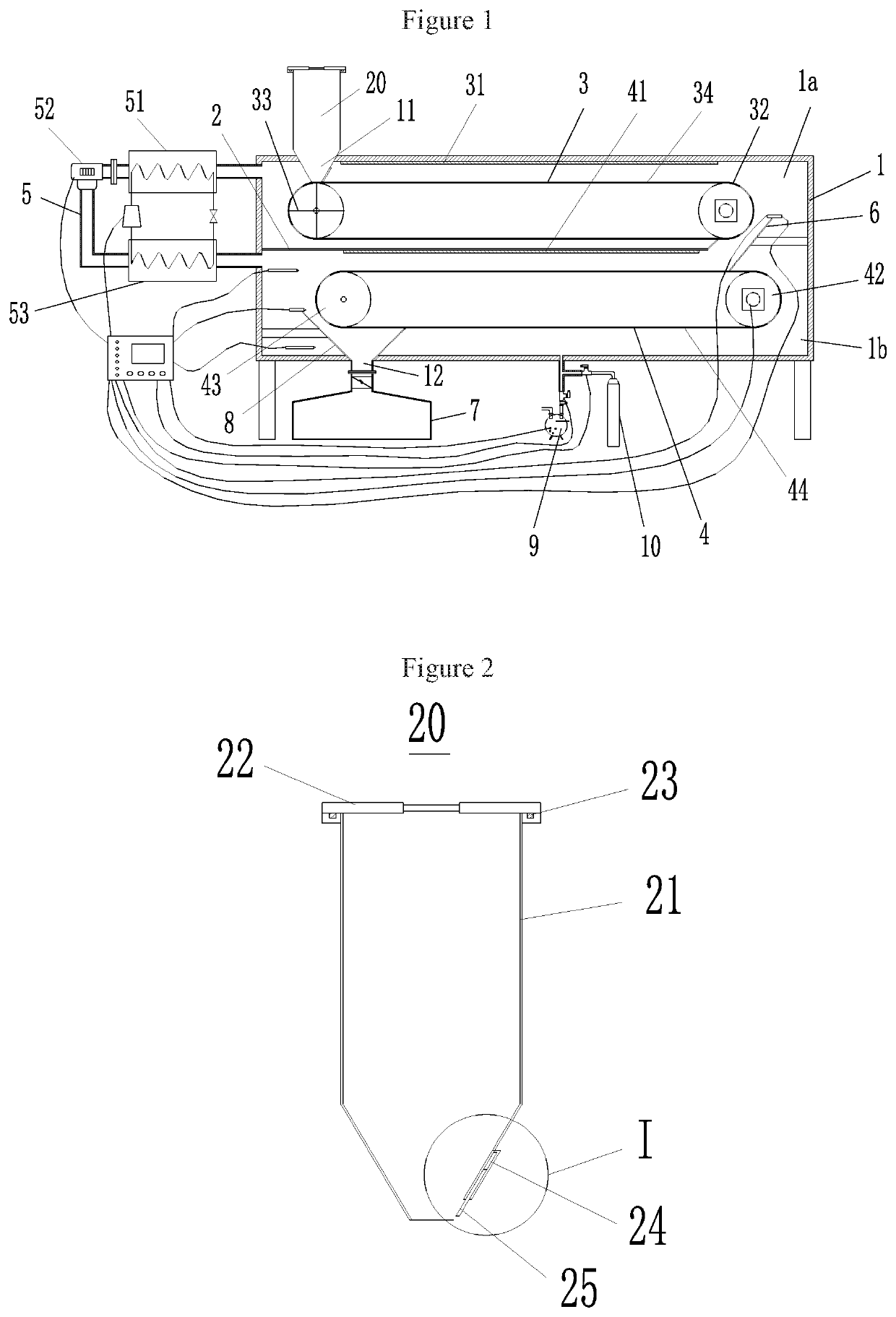

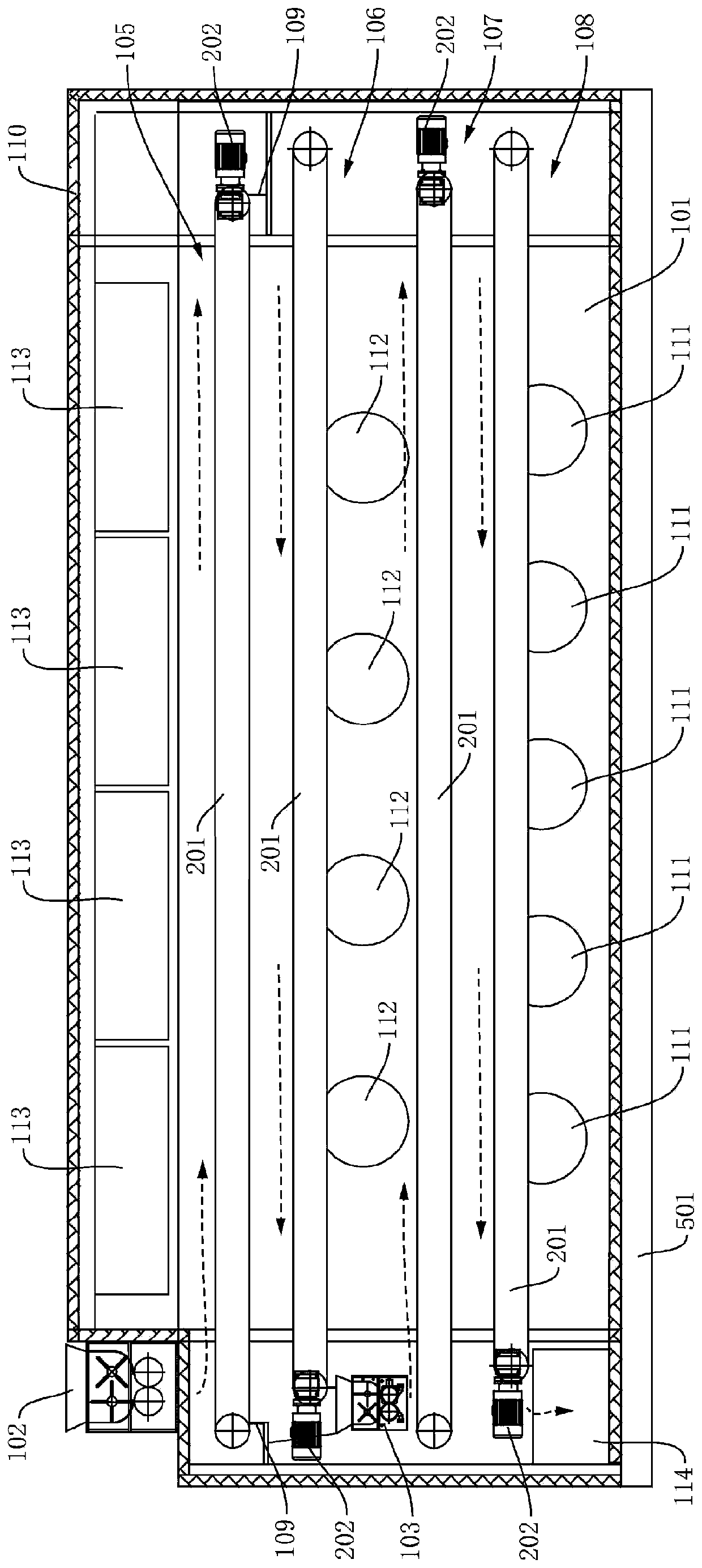

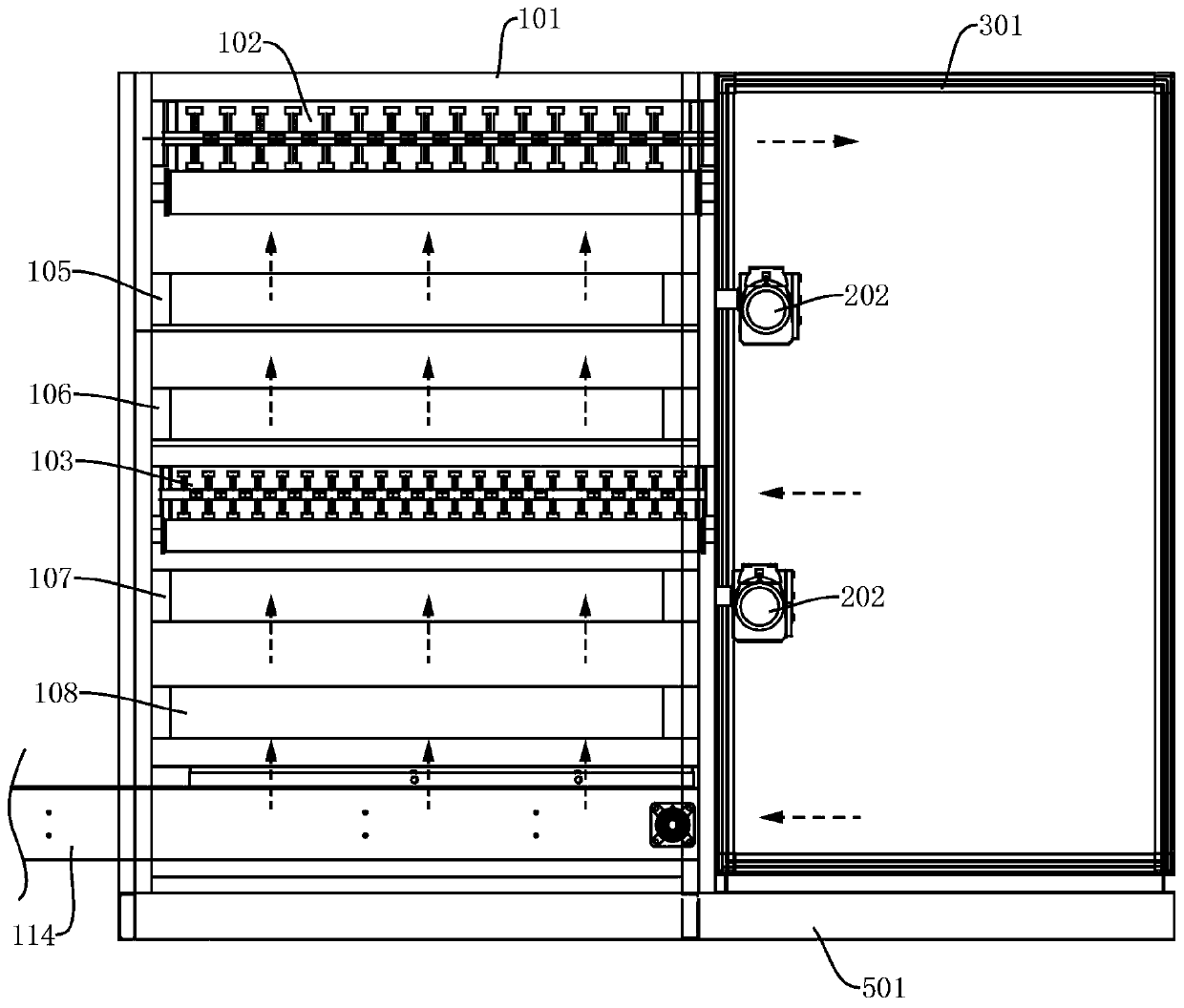

Continuous drying apparatus for bee pollen and related drying method

ActiveUS20210293479A1Increase drying speedImprove product qualityHeat pumpsDrying solid materials with heatBiotechnologyBee products

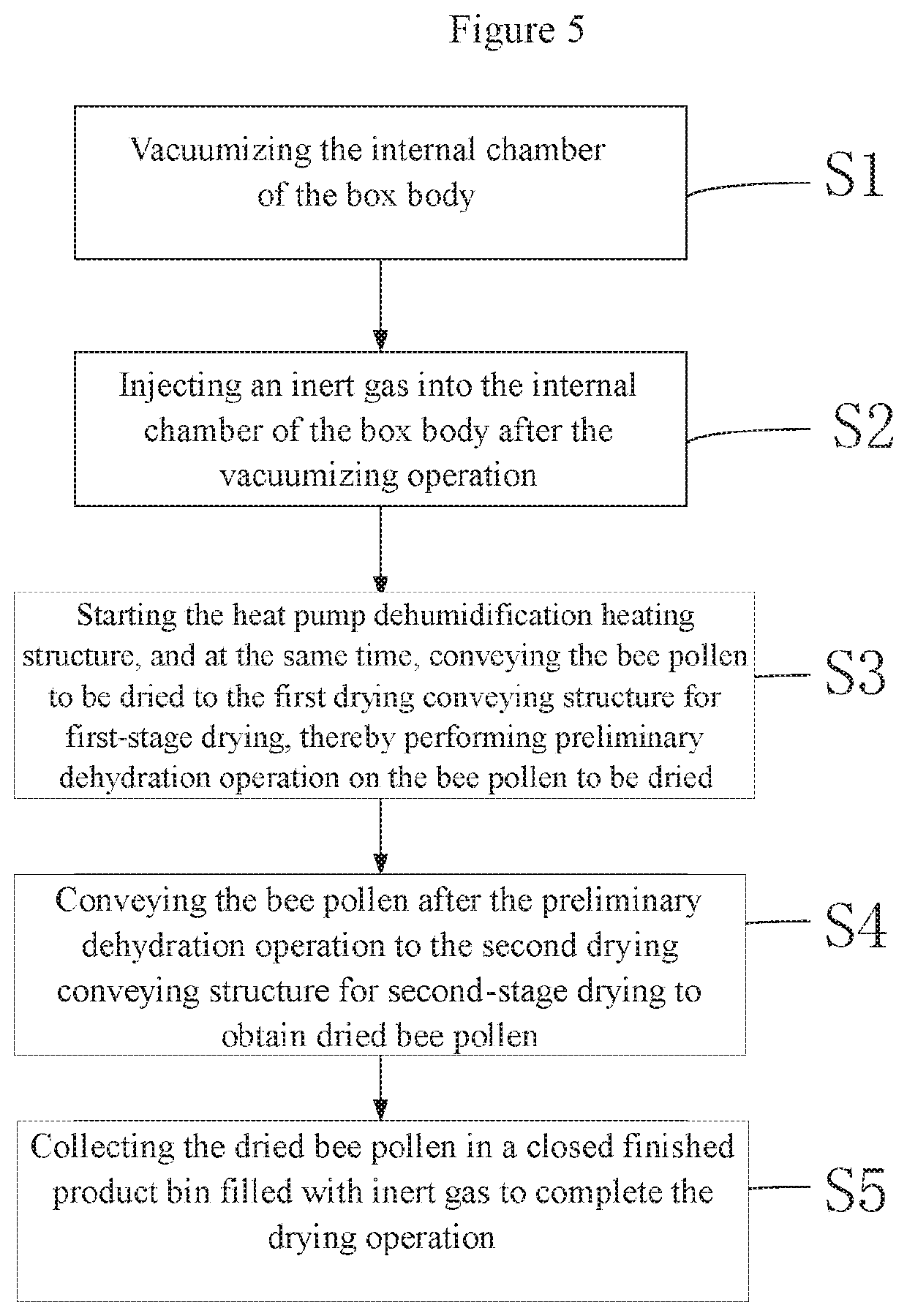

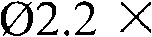

The present invention relates to the technical field of bee product processing, and discloses a continuous drying apparatus for bee pollen and related drying method. The continuous drying apparatus for bee pollen comprises: a box body; a first drying conveying structure; a second drying conveying structure; and a heat pump dehumidification heating structure. The continuous drying apparatus for bee pollen has the advantage of high drying efficiency.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

Method for preparing high-concentration round grainy potassium muriate

InactiveCN101289201AUniform particlesHigh strengthAlkali metal halide formation shapeGrain shapeScrap

The invention relates to a production method for potassium chloride with high concentration and rounded grain shape, which comprises the steps that: powdered potassium chloride with certain fineness in which the content of potassium oxide is 60 percent or more is added into a round granulating disc or a revolving drum granulator, potassium chloride saturated solution is sprayed according to certain proportion as granulation liquid phase for carrying out rounding beading granulation, and then drying and sieving are carried out to generate the rounded-grain-shaped potassium chloride. The content of kalium reaches 60 percent or more. The production method is characterized by simple operation technology, great production capability, wide scope of grain diameter of products, round grains, high intensity, and the like, and generates no waste during production, which has the advantages of energy saving and environmental protection, thereby having very wide market prospect.

Owner:汉枫缓释肥料有限公司

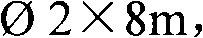

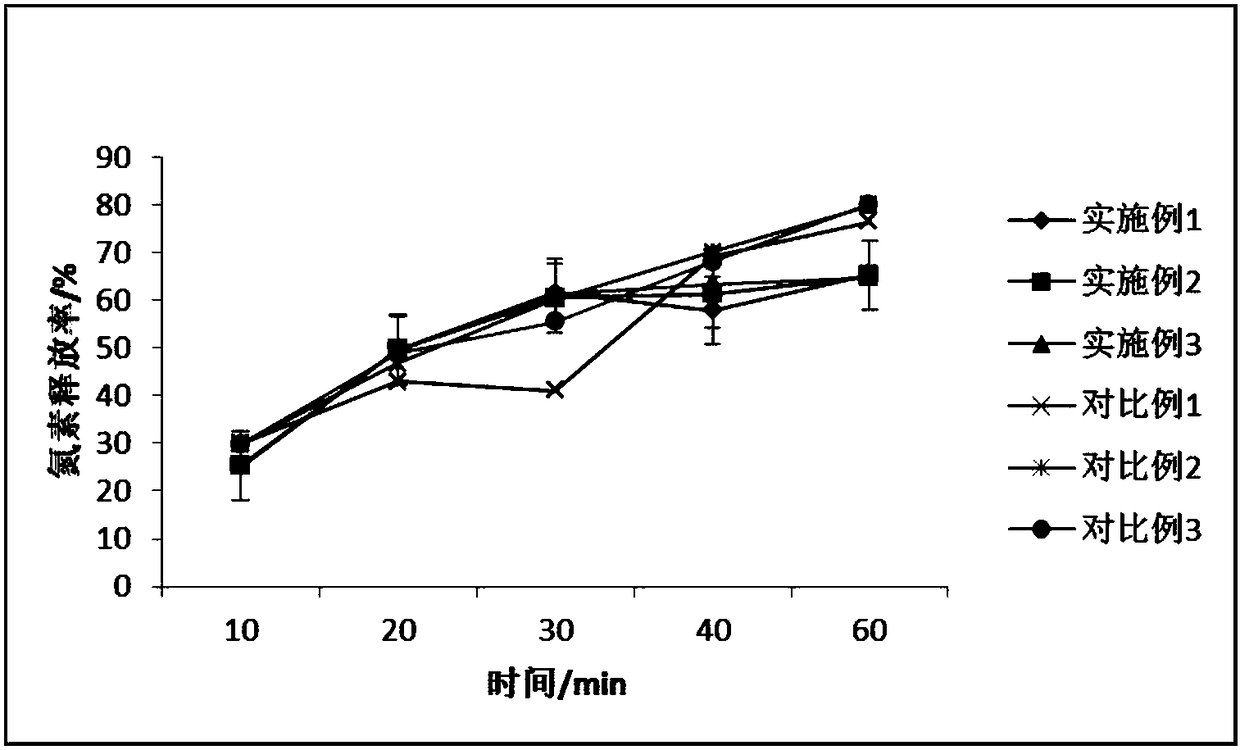

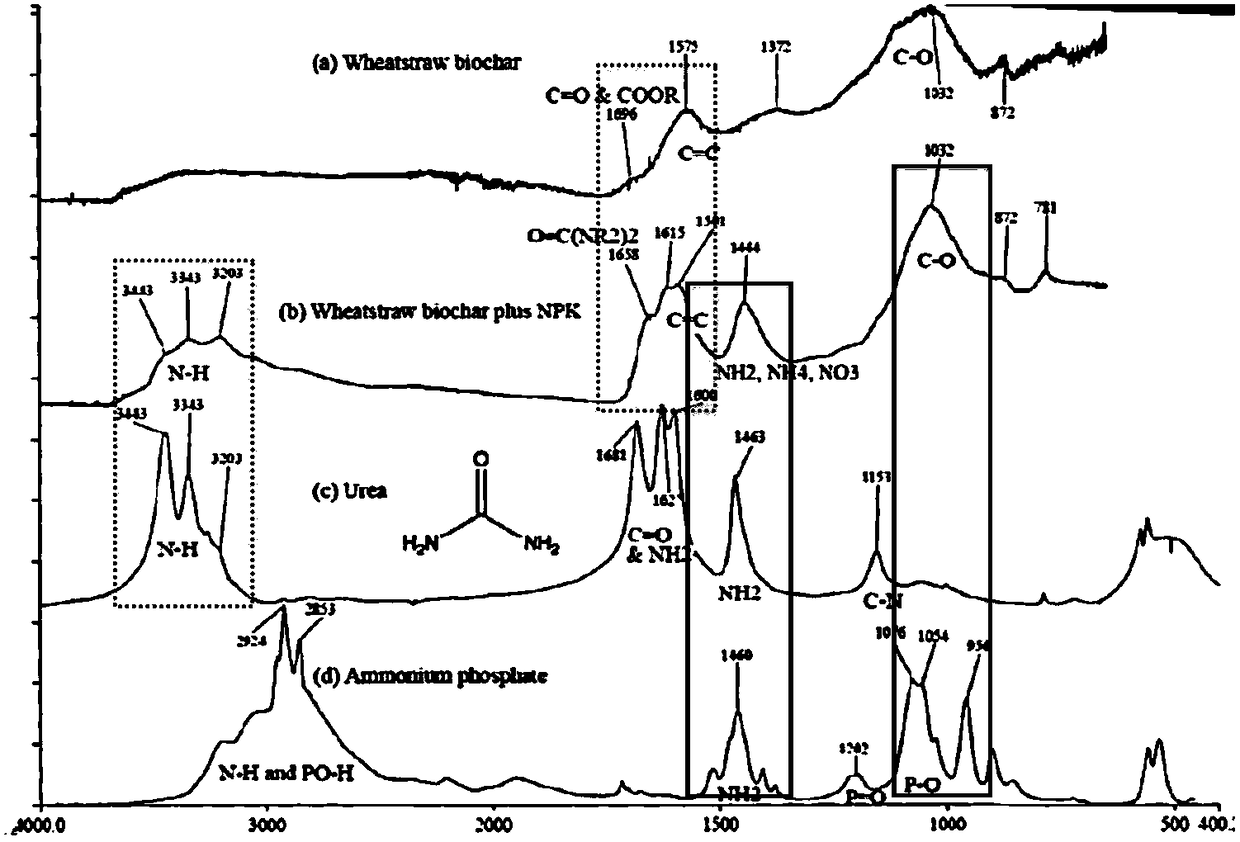

Biomass-charcoal basal fertilizer and preparation method therefor

InactiveCN108164330AImprove adhesionEasy to shapeCalcareous fertilisersAlkali orthophosphate fertiliserSodium BentoniteNutrient

The invention belongs to the technical field of agricultural fertilizers and particularly relates to a biomass-charcoal basal fertilizer and a preparation method therefor. The biomass-charcoal basal fertilizer is prepared from the following raw materials in parts by weight: 15-20 parts of biomass charcoal, 20-30 parts of urea, 20-30 parts of ammonium dihydrogen phosphate, 15-25 parts of potassiumsalt, 5-10 parts of bentonite and 1-5 parts of calcium sulfate. According to the preparation method for the biomass-charcoal basal fertilizer, a granulating process has physical and chemical double reactions, an amido bond of urea and a nitrogen-phosphorus bond of ammonium dihydrogen phosphate in the charcoal basal fertilizer are bonded to a charcoal group to change chemical shift under high-temperature steam reaction conditions, nutrients and a carbon skeleton are bonded to each other, the bonding among the raw materials is closer, and thus, the fertilizer effect is prolonged.

Owner:BEIJING SANJU GREEN ENERGY TECH CO LTD

Low-temperature drying device for high-water-content high-viscosity sludge

PendingCN110372172AIncrease moisture contentHigh viscosity sludgeSludge treatment by de-watering/drying/thickeningBusiness efficiencySludge

The invention relates to a low-temperature drying device for high-water-content high-viscosity sludge. The device comprises a drying chamber and a heat pump system communicating with the drying chamber; the drying chamber is provided with a material inlet strip cutting machine and a secondary strip cutting machine, the material inlet strip cutting machine is used for primary cutting of the sludgeconveyed into the drying chamber, and the secondary strip cutting machine is used for secondary cutting of the sludge during conveying of the sludge; and the heat pump system adopts a high-temperaturerefrigerant, and the heat pump system is used for heating and dehumidifying the drying chamber. According to the low-temperature drying device provided by the invention, secondary cutting is performed on the sludge, so that the forming effect of the cut strips is better, the cut strips are finer and no longer adhere to one another, and the drying effect of the sludge is greatly enhanced; and at the same time, the high-temperature refrigerant is adopted as a refrigerant, so that the drying device has a higher energy efficiency ratio and higher drying efficiency, and can satisfy drying treatment of the high-viscosity sludge with a water content of 60-85% and turn a sludge cake with a water content of 85% into sludge particles with a water content of 30% or less by one drying.

Owner:SCIMEE TECH & SCI CO LTD

Method for forming film, and film

InactiveUS20130183491A1Increase productivityHigh peel strengthLayered productsPretreated surfacesSolid contentAqueous dispersion

A method for forming a film, containing the following steps (1) to (4), and a film obtained by the method for forming a film: step (1): preparing an aqueous dispersion liquid containing (A) a hydrophilic functional group-containing resin, (B) an ammonium salt, and (C) a nonionic thickener, a mixed amount of the component (B) being from 0.25 to 10 parts by mass per 100 parts by mass of a solid content of the component (A); step (2): coating the aqueous dispersion liquid on at least one surface of a substrate to form a coated film; step (3): subjecting the coated film to a thermal gelation treatment to form a gelled film; and step (4): drying and solidifying the gelled film to form a film.

Owner:KURARAY CO LTD

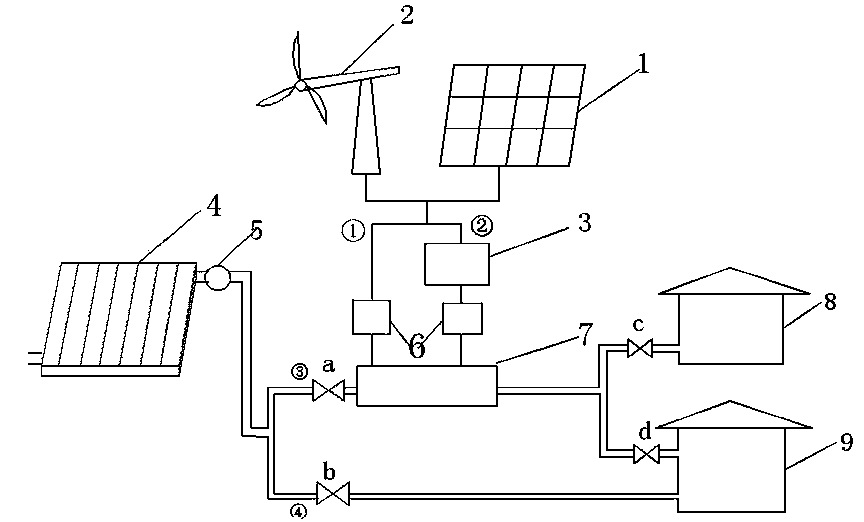

Heat pump drying and heating system powered by solar energy and wind energy in complementary mode

InactiveCN103727772AIncrease profitMeet electricity demandBatteries circuit arrangementsPV power plantsElectricityEngineering

A heat pump drying and heating system powered by solar energy and wind energy in a complementary mode comprises a solar photovoltaic module, a wind power generation system, a storage battery, an air heating collector, a draught fan, a heat pump, a controller, a drying chamber and a house, wherein the output end of the solar photovoltaic module and the wind power generation system is divided into two branches (I and II), the branch II is connected to the storage battery, the storage battery is connected with the heat pump through the controller, two branches of the heat pump are connected with the house and the drying chamber respectively, the branch I is directly connected with the heat pump through the controller, the air heating collector is divided into two branches (III and IV), the branch III is connected with the heat pump, and the branch IV is directly connected with the drying chamber. The heat pump drying and heating system powered by the solar energy and the wind energy in the complementary mode can generate electricity by combining the solar energy and the wind energy, effectively improve the comprehensive utilization rate of the solar energy and the wind energy, lower environmental pollution, achieve the purpose of continuously drying agricultural products, avoid the problem that the quality of the agricultural products is lowered due to manual airing, and provide a heat source for heat supply of the house.

Owner:YUNNAN NORMAL UNIV

Traditional Chinese herbal medicine drying equipment

InactiveCN105202869AGuaranteed qualityQuality improvementDrying solid materials with heatDrying gas arrangementsHerb medicineBiochemical engineering

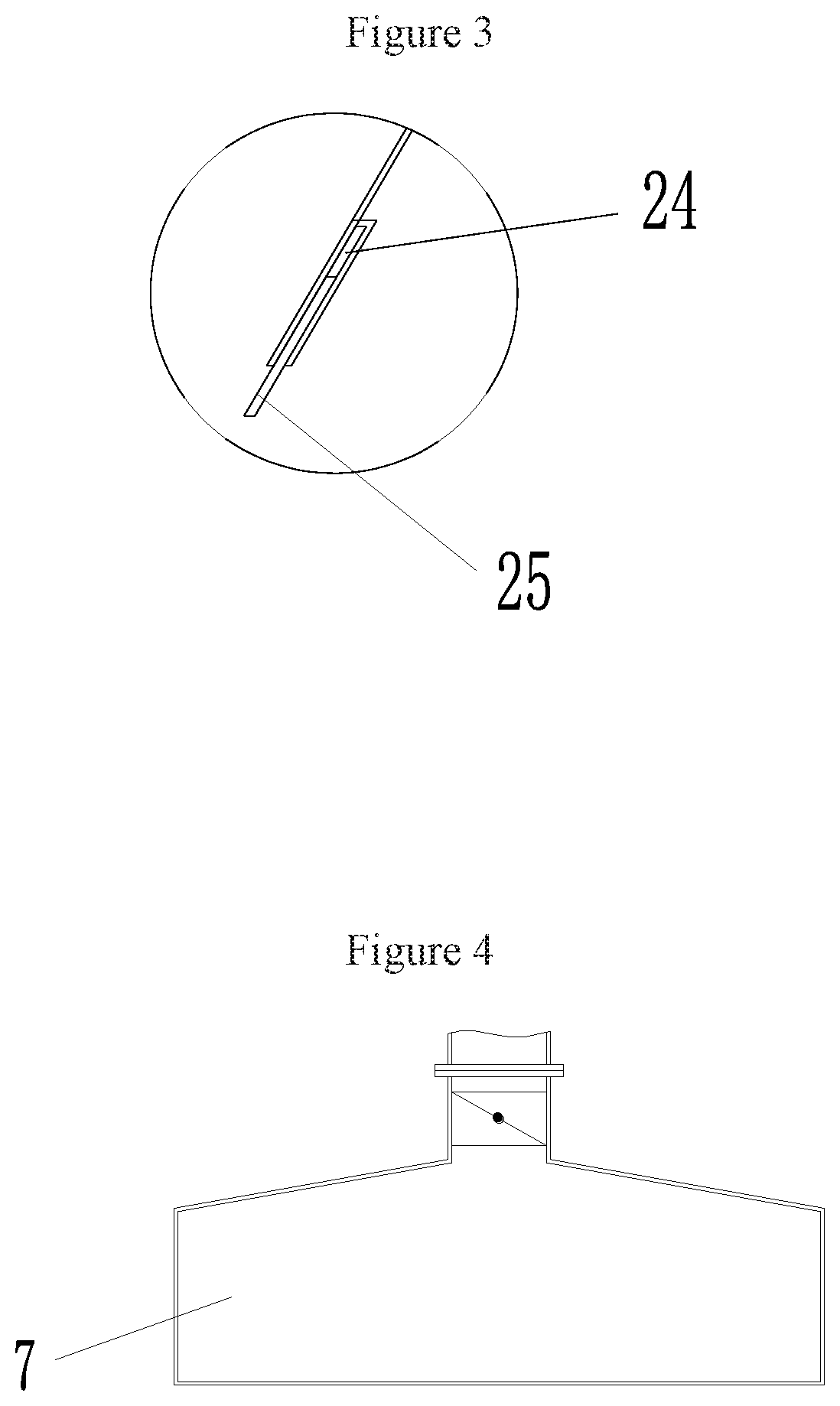

The invention provides traditional Chinese herbal medicine drying equipment, which comprises a drying tube body, wherein a drying round plate is arranged at the middle part of the drying tube body; the size of the drying round plate is matched with the inner wall of the drying tube body; a plurality of ventilation holes are uniformly formed in the drying round plate; the two side ends of the drying round plate are provided with a rotating shaft; the rotating shaft is rotationally connected with the inner wall of the drying tube body; a temperature sensor is arranged on the inner wall of the drying tube body; a filtering net plate is arranged on the upper end of the drying tube body; a waste material cover covers the filtering net plate; the top end of the waste material cover is communicated with a waste material pipe; a fixing ring is supported on the outer wall of the drying tube body; the lower end, supporting the fixing ring, is fixedly provided with a support rod; a discharging opening is formed right under the drying tube body; a heating box is connected onto the side wall of the lower end of the drying tube body through the air inlet pipe; the air inlet end of the heating box is connected with a blast blower; a controller is arranged on the outer wall of the heating box. The traditional Chinese herbal medicine drying equipment has the advantages that the structure is simple; the design is reasonable; medical materials can be sufficiently and uniformly dried; the temperature inside the tube body is controlled; the finished product quality and the finished product obtaining efficiency of the medical materials are improved.

Owner:成都米戈科技有限公司

Polymer composite coated slow release fertilizer

InactiveCN1948241ALong release periodAvoid breakingFertiliser formsFertilizer mixturesEmulsionPolymer adhesive

The present invention provides a kind of polymer composite coated type slow release granular fertilizer. Said fertilizer is formed from fertilizer core and its exterior coating layer, in which said coating layer includes: (a), high barrier polymer coating layer formed by adopting melt type and / or organic solution type polymer adhesive; and (b), polymer coating layer and / or sulfur-containing polymer mixture coating layer formed by adopting emulsion type polymer adhesive.

Owner:NANJING UNIV OF SCI & TECH

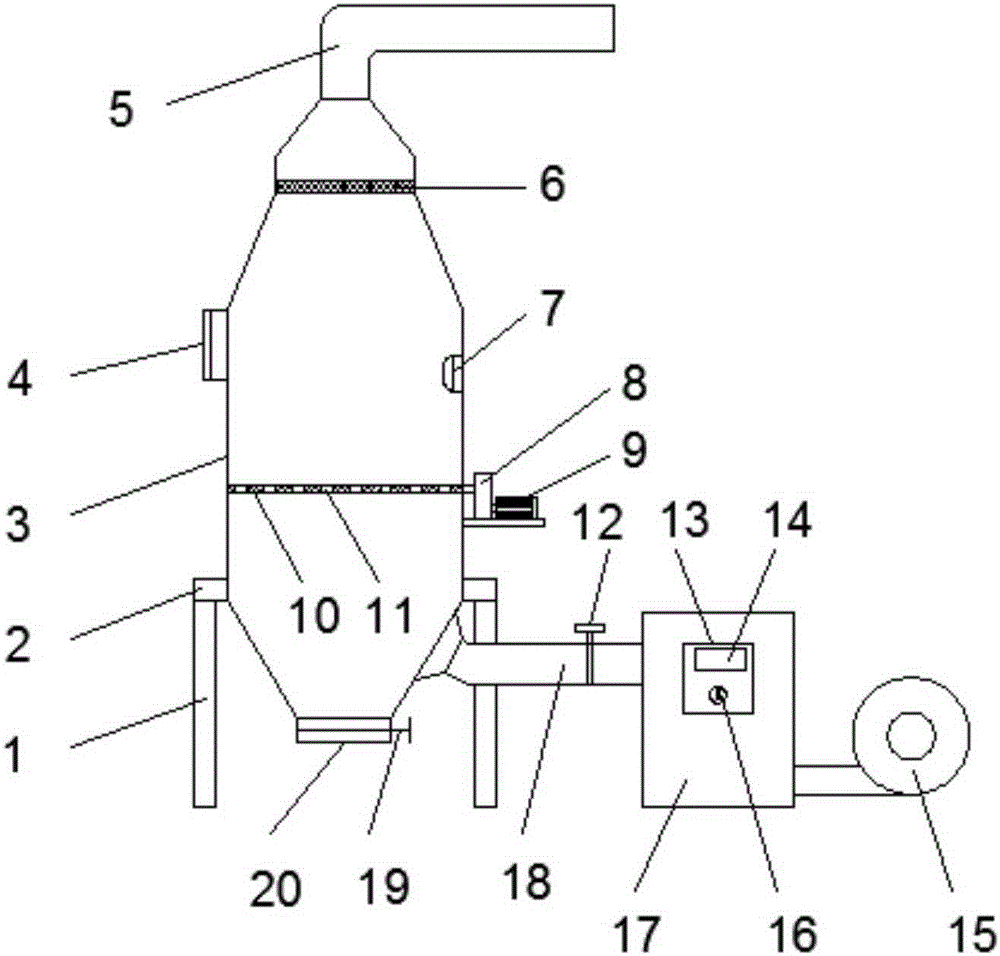

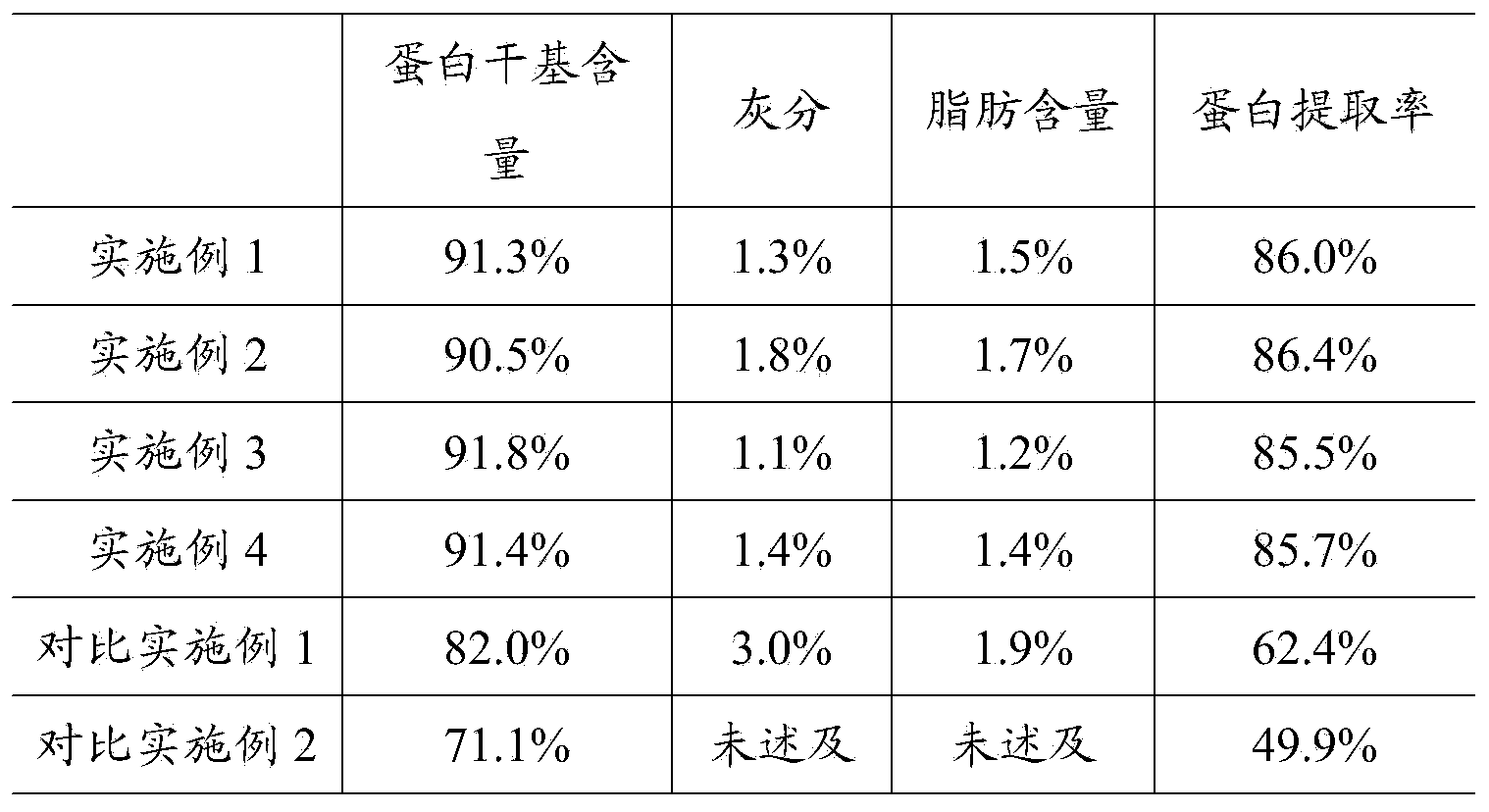

Preparation method of edible rice protein

ActiveCN103404688AImprove the efficiency of separation and washingSave washing waterVegetable proteins working-upCycloneFood sector

The invention relates to a preparation method of edible rice protein. The method comprises the following steps of pre-treating raw materials, crushing, mixing, reacting, separating and washing, drying and the like. According to the method provided by the invention, macromolecular dextrin in rice dreg is washed by using hot water before being aged; impurities in the rice dreg can be separated from protein which is not dissolved in water by crushing and a salt forming reaction of fat; then a cyclone is used for separating and washing so that the separating and washing efficiency is greatly improved; compared with flash drying and spray drying, the preparation method has the advantages that the equipment investment is saved by about 40% and the operation cost is saved by about 35%; the edible rice protein with the protein dry basis content more than 90%, fat content less than 2% and ash content less than 2% is obtained; the extraction rate of the rice protein is more than 85%; the obtained product can be widely applied in food industries, particularly infant foods; compared with a manner of using the raw material rice dreg as a feed, the preparation method has the advantage that the added value of products is greatly increased.

Owner:无锡新禾创工食品科技有限公司

Ca/Fe/GO/biomass charcoal, carbon-based slow-release fertilizer special for corn and application of carbon-based slow-release fertilizer

InactiveCN109809926AImprove adhesionFine grainClimate change adaptationAgriculture gas emission reductionSodium BentoniteSlag

The invention provides Ca / Fe / GO / biomass charcoal, carbon-based slow-release fertilizer special for corn and application of the carbon-based slow-release fertilizer, and belongs to the technical fieldof fertilizer. The Ca / Fe / GO / biomass charcoal is prepared by the following steps: mixing biomass raw material slag powder with calcium chloride, ferric chloride and graphene oxide, carbonizing the mixed material at 100 to 120 DEG C for 1 to 2hours and at 500 to 600 DEG C for 4 to 6 hours in sequence, and washing the carbonized product to be neutral to obtain modified biomass charcoal. The carbon-based slow-release fertilizer special for the corn is prepared from the following components in parts by weight: 15 to 20 parts of the modified biomass charcoal, 5 to 8 parts of calcium cyanamide, 35 to40 parts of superphosphate, 20 to 30 parts of potassium salt, 6 to 9 parts of plant ash, 5 to 10 parts of bentonite, 1 to 5 parts of calcium sulfate and 3 to 7 parts of a mushroom dreg composted material. The slow-release fertilizer provided by the invention is not easily broken, and the fertilizer effect is prolonged; when the slow-release fertilizer is applied in a corn planting process, the yield is increased by 5% or above and the soil structure can be improved.

Owner:QINGDAO AGRI UNIV

Processing method of polygonum multiflorum decoction piece with high content of stilbeneglycoside and free anthraquinone

The invention discloses a processing method of a polygonum multiflorum decoction piece with a high content of stilbeneglycoside and free anthraquinone. The processing method comprises the steps of cleaning, drying and slicing polygonum multiflorum, adding black soya bean juice concentrated liquid for thorough moistening, performing high pressure steaming and high-voltage electric field drying to form preliminarily processed polygonum multiflorum, repeating the thorough moistening, the steaming and drying for many times for the preliminarily processed polygonum multiflorum to form the radix polygonum multiflorum preparata decoction piece with a high active ingredient content and low toxicity. The traditional and modern technologies are combined; the toxicity of the polygonum multiflorum isreduced by processing for many times; the active ingredient content is increased via a modern high-pressure steaming technology and a high-voltage electric field drying technology; a curative effect of the prepared radix polygonum multiflorum preparata decoction piece is better than that of a radix polygonum multiflorum preparata decoction piece processed by the traditional technique; toxic and side effects of the decoction piece are lower than those of the decoction piece processed by a modern processing technique; and the prepared radix polygonum multiflorum preparata decoction piece is highin safety.

Owner:广东汇群中药饮片股份有限公司 +1

Substitute tea capable of removing heat and toxic materials, and preparation method of substitute tea

ActiveCN103918823AReduce moisture contentShorten drying timePre-extraction tea treatmentClimate change adaptationBitter gourdToxic material

The invention discloses substitute tea capable of removing heat and toxic materials which contains the following raw materials: dehydrated guava leaves, dried guava fruits, dried bitter gourd, tea leaves, liquorice, dehydrated stigma of corn, dehydrated roselle, pericarpium citri reticulatae, dehydrated stevia rebaudian, dehydrated semen cassia, chrysanthemum, dehydrated gynostemma pentaphylla, dehydrated lotus leaf, pink rose, broadleaf holly leaf and the like, wherein the raw materials are dehydrated and dried till the water content is controlled to be 5%-8%. In addition, the invention further discloses a preparation method of the substitute tea. The preparation method comprises the following steps: selecting fresh tea material, cleaning the fresh tea material, finishing, blanching, cooling, carrying out vacuum dewatering under variable pressures, drying with combination of solar energy and dehumidification, grinding raw materials, mixing and stirring, packing with small filter-bags. The technical solution provided by the invention overcomes the defects in the traditional series substitute tea processing methods, energy consumption and production cost are reduced, influences of weather are avoided, the drying is fast, the product quality is good, and the product meets the national standard related to food hygiene.

Owner:GUANGZHOU QINGXIANG AGRI PROD CO LTD

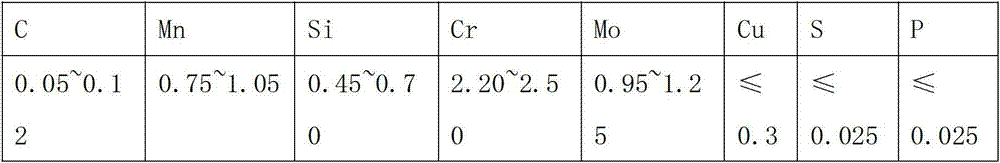

T/P91 steel electrode and manufacturing method thereof

InactiveCN103111774AArc stabilizationReduced chance of splashingWelding/cutting media/materialsSoldering mediaNiobiumWeight coefficient

The invention discloses a T / P91 steel electrode manufacturing method. An R40 welding wire is used as a core wire. Medical powder comprises, by weight percentage, marble 31-35, fluorite 26-29, titanium dioxide 4-7, quartz 1-2, mica 1-2, chromium metal 13-15, atomization nickel powder 1-2, ferrotitanium 7-9, ferromolybdenum 1-2, ferroniobium 0.5-1, ferrovanadium 1-2, and vanadium-nitrogen alloy 1-2. After the powder is mixed in a drying mode, water glass is added according to a ratio of 3:1 and is mixed with the powder in a wet mode, and suppression is carried out after uniform stirring is carried out. Electrode coating weight coefficient is controlled to be 0.95-1.0, cracking of a coating after being dried is avoided, the compression environmental temperature is over 20 DEG C, the products are placed into a drying box after being dried for 3 hours, and is dried for 2 hours when temperature is 100 DEG C, 125 DEG C per hour is risen into 450 DEG C, and then furnace cooling of the products is carried out after being warmed for two hours. The steel electrode is good in welding process performance, little in splatter, low in smoke amount, and attractive in appearance of weld. All the performances can reach foreign imported similar steel electrode technological level. Production cost is greatly reduced.

Owner:天津诚信达金属检测技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com