Patents

Literature

59results about How to "Reduced chance of splashing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

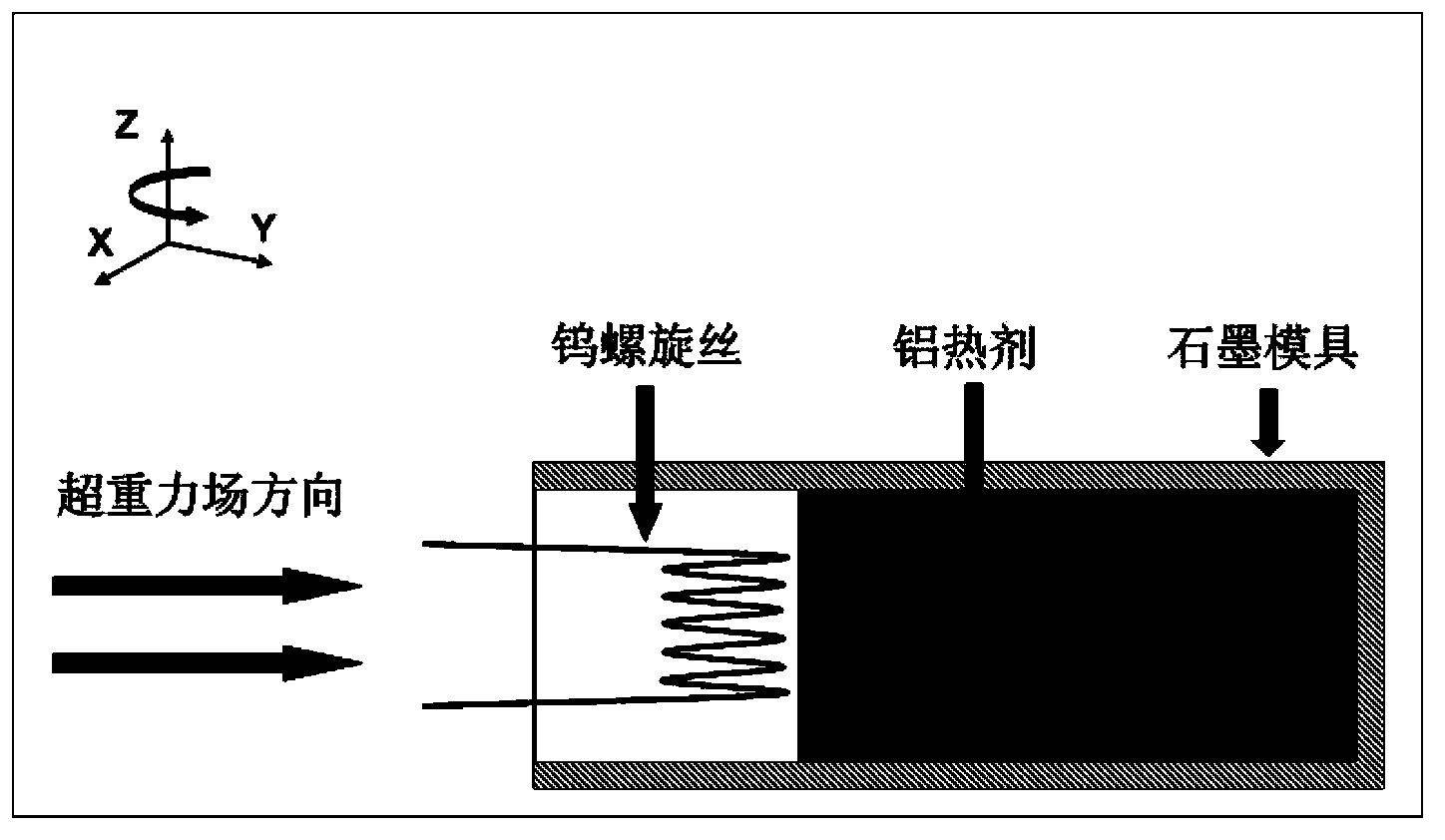

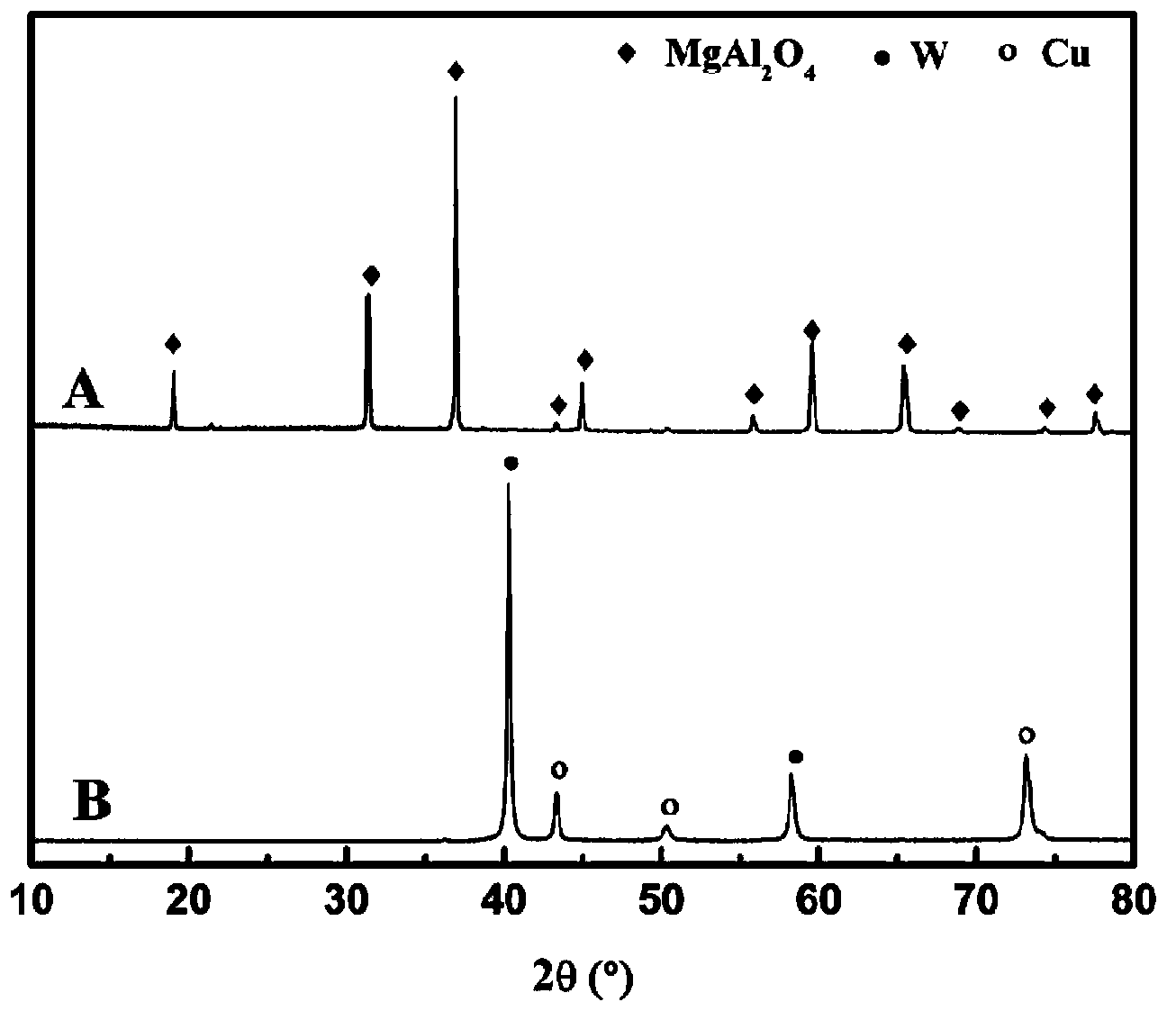

Thermite for hypergravity-assisted combustion synthesis of copper-based composite material

The invention belongs to the technical field of combustion synthesis preparation, and in particular relates to a thermite for hypergravity-assisted combustion synthesis of a copper-based composite material. According to the thermite provided by the invention, the formula employs a CuO powder with particle size in gradient distribution and an Al powder with particle size in gradient distribution, combustion rate and heat release amount in the preparation of the copper-based composite material is controlled by adding a Cu2O powder, a Cu powder, a MgO powder and a CaF2 powder, so as to realize stability and controllability of thermit reaction in the supergravity field. The thermite provided by the invention has the advantages of low sputtering rate, high heat release amount, stability and controllability, and is suitable for hypergravity-assisted combustion synthesis of various copper-based composite materials.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

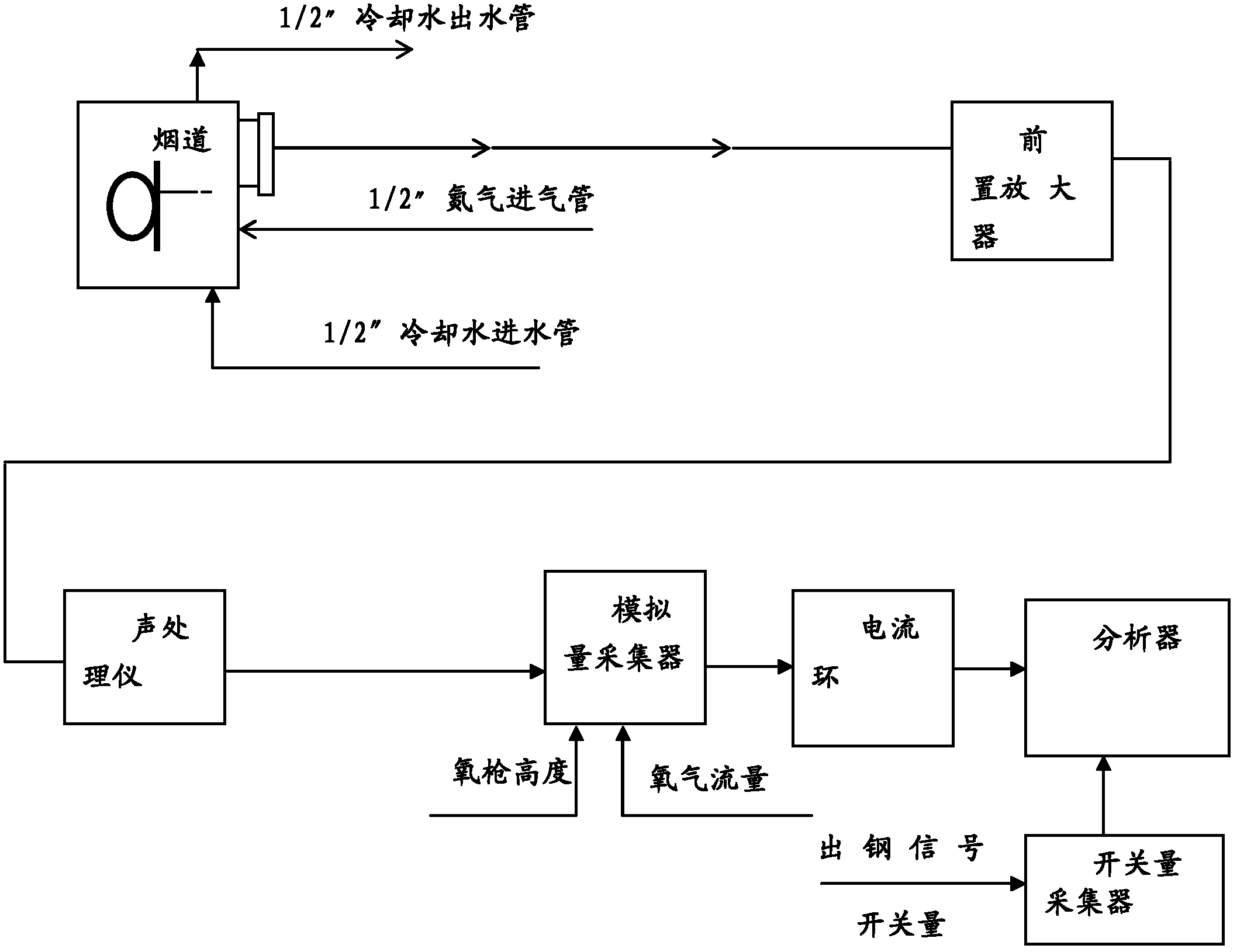

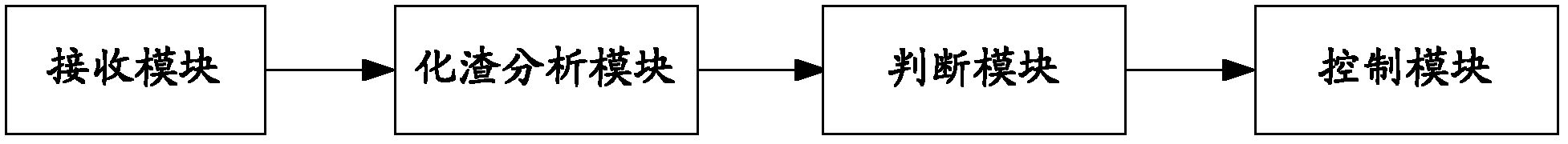

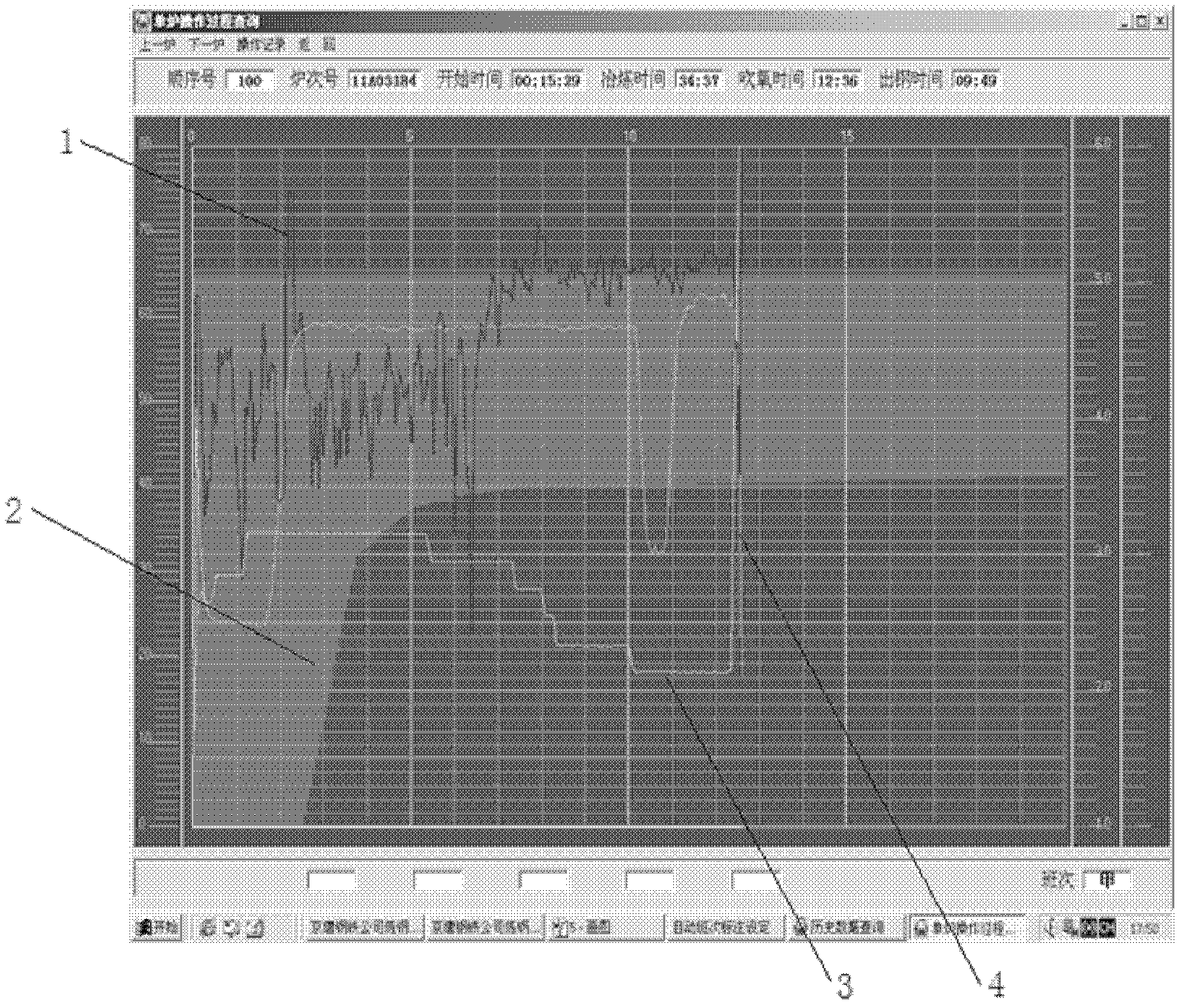

Sonar slagging analysis apparatus and method based on flue sound picking

The invention provides a sonar slagging analysis apparatus based on flue sound picking. The apparatus comprises a noise acquisition device, an analog quantity gatherer and an analyzer. The invention also provides a sonar slagging analysis method based on flue sound picking. The method comprises the following steps: acquiring noise information at a platform flue sampling opening; acquiring oxygen lance height information and oxygen flow information; and analyzing slagging situation according to the noise information, the oxygen lance height information and the oxygen flow information. The sonar slagging analysis apparatus and the sonar slagging analysis method based on flue sound picking provided in the invention can detect and process noise generated in the process of slagging of an oxygen converter, monitor the situation of changing of slag, display a variation curve of sound intensity in the slagging process and guidance information and operation records related to operation on a color monitor of a computer, forecast abnormal furnace conditions like splashing, redrying, etc., and provide visual and striking scientific guidance and management information for operation personnel in front of the converter.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

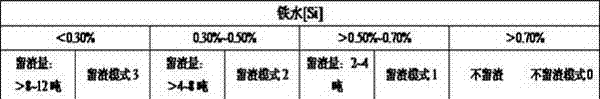

Automatic steelmaking and slag-leaving operation method for converter

The invention discloses an automatic steelmaking and slag-leaving operation method for a converter. The method comprises the following steps: (1) collecting the FeO content, and lower furnace molten iron ingredients in an end-point slag of the furnace by a secondary computer system; (2) adding a modifier for regulating the slag according to the FeO content in the slag, and protecting the furnace by slag splashing, wherein the slag splashing time is over 5 minutes; (3) determining the residual sludge amount according to the content of the lower furnace molten iron [Si], and automatically matching corresponding residual slag mode number by the system; (4) automatically matching an execution parameter of a corresponding end-point carbon target value according to the residual slag mode number and the residual slag mode group number subdivided by the corresponding end-point carbon target value; (5) carrying out related calculation on a secondary system steelmaking model, automatically generating an oxygen smelting step and a charging list, and transmitting to a primary system to implement. By adopting the automatic steelmaking and slag-leaving operation method, large splashing when the molten iron is blended can be effectively prevented, automatic steelmaking under the residual slag mode is achieved, consumption of a solvent and a steel material is reduced, and the production efficiency is improved.

Owner:新余钢铁股份有限公司

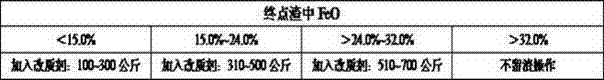

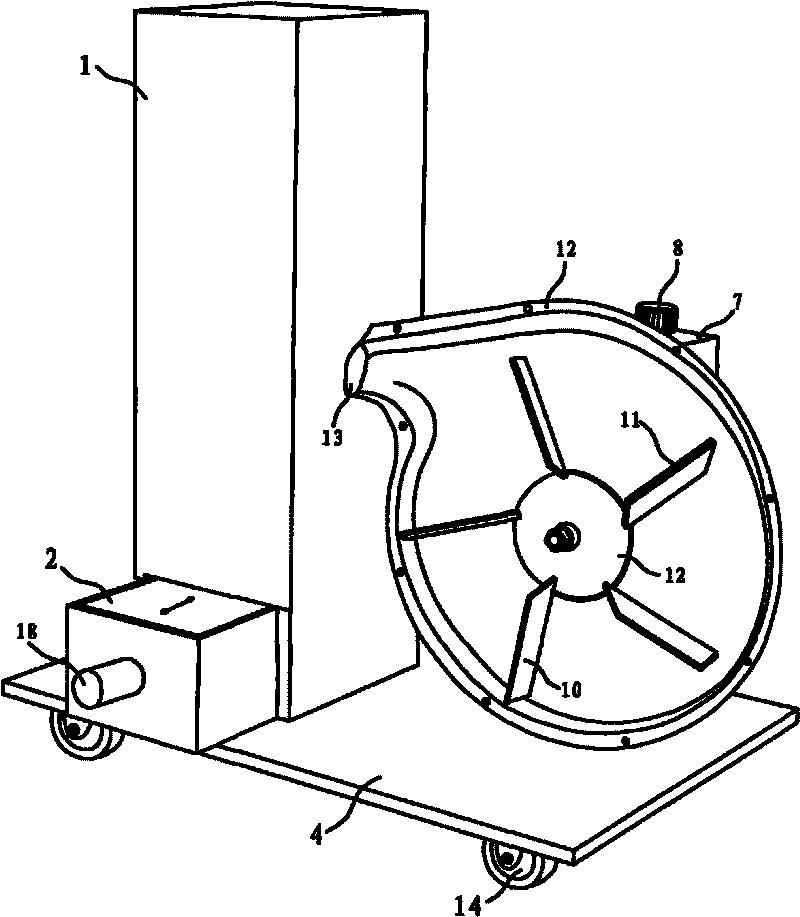

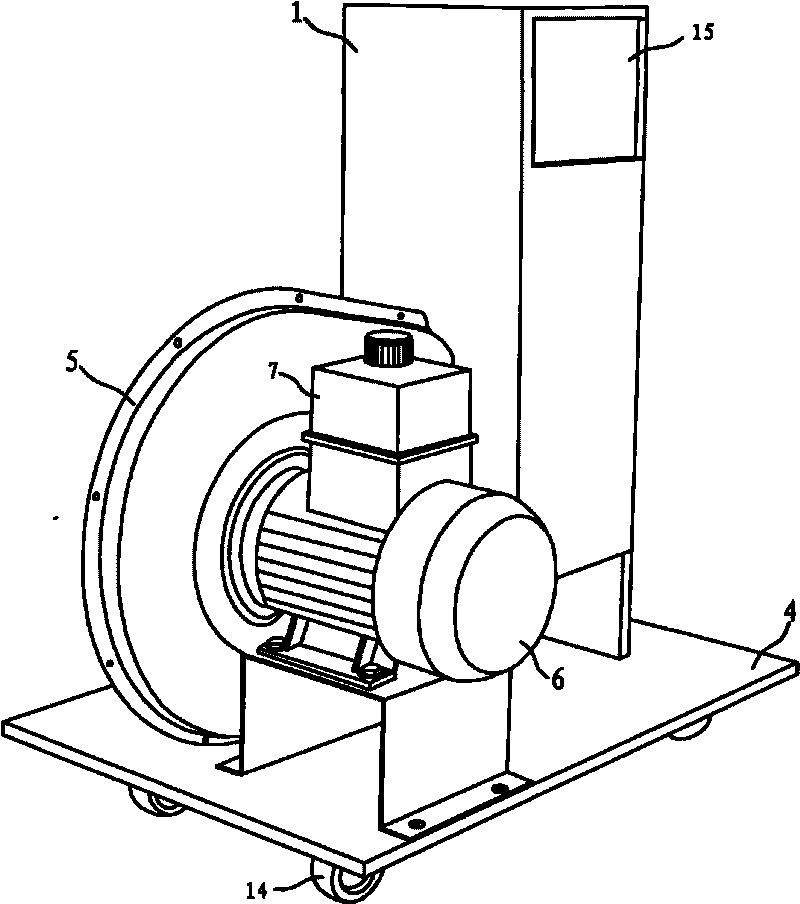

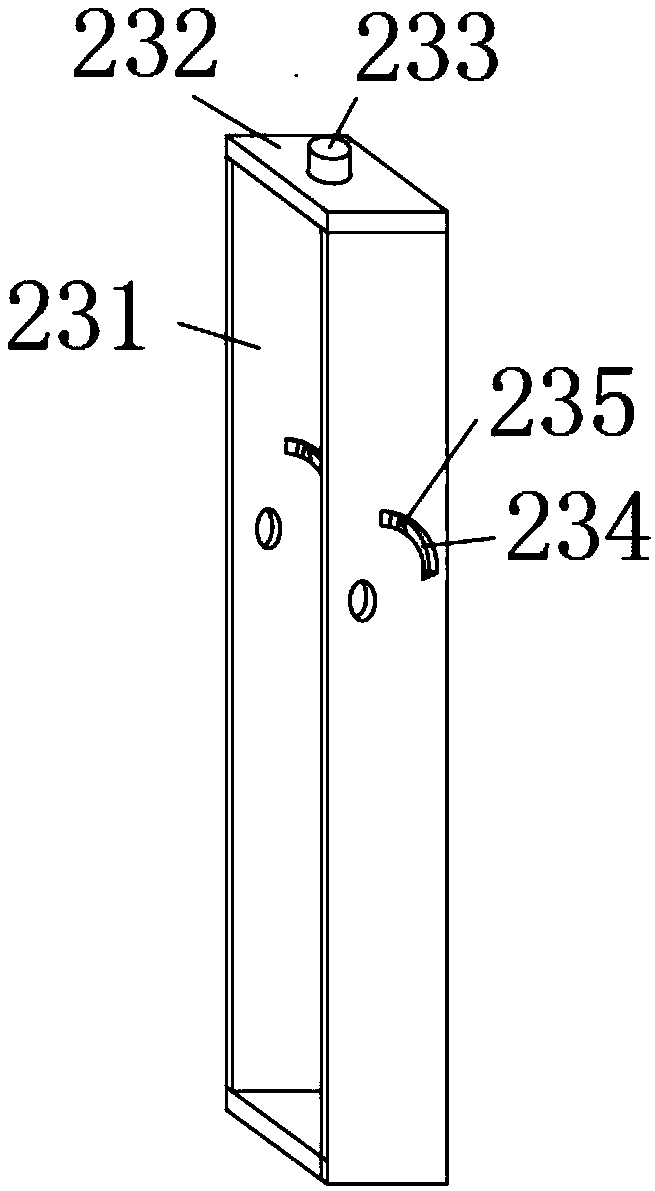

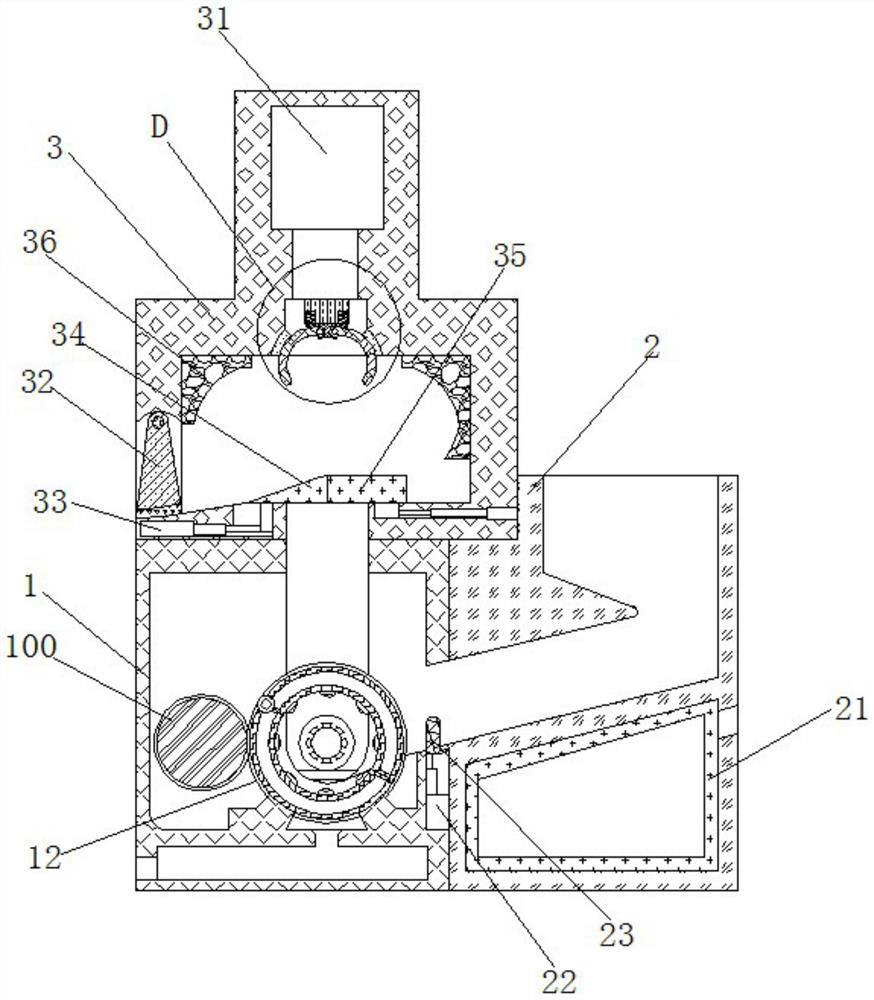

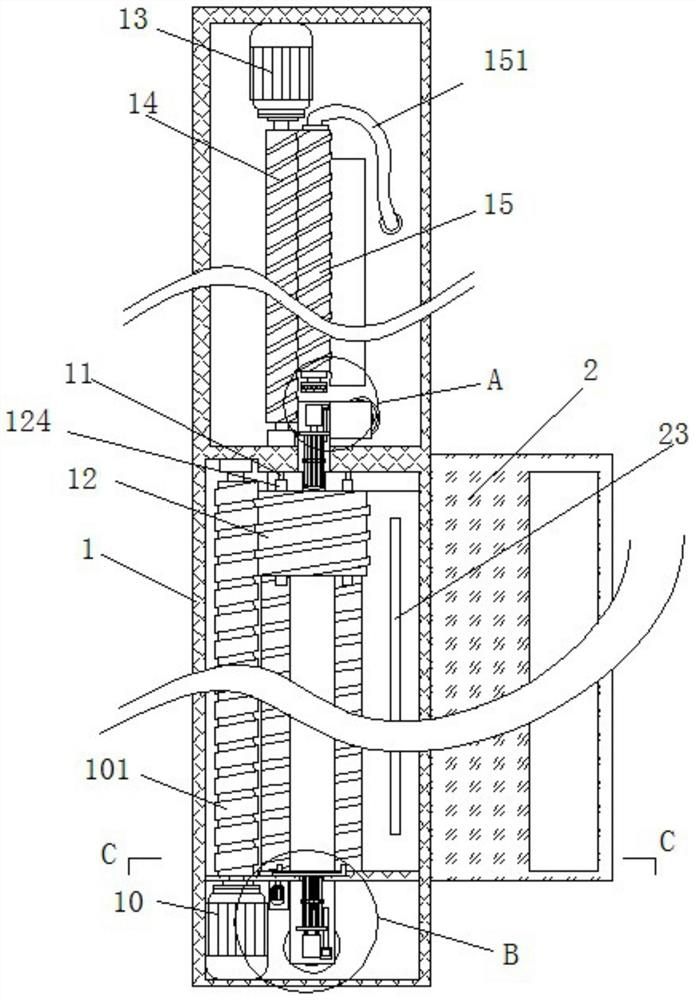

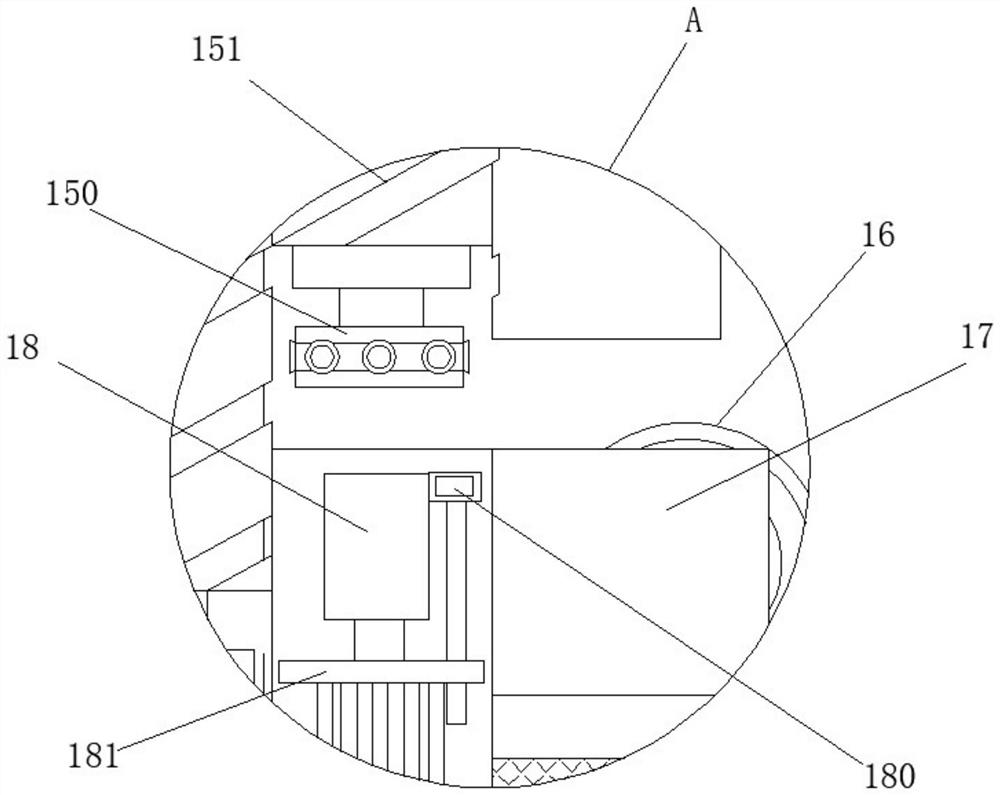

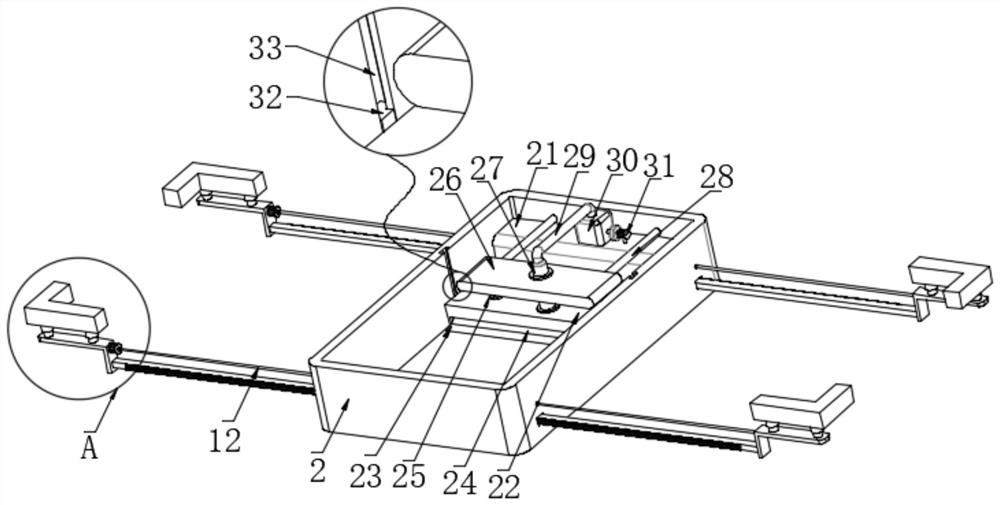

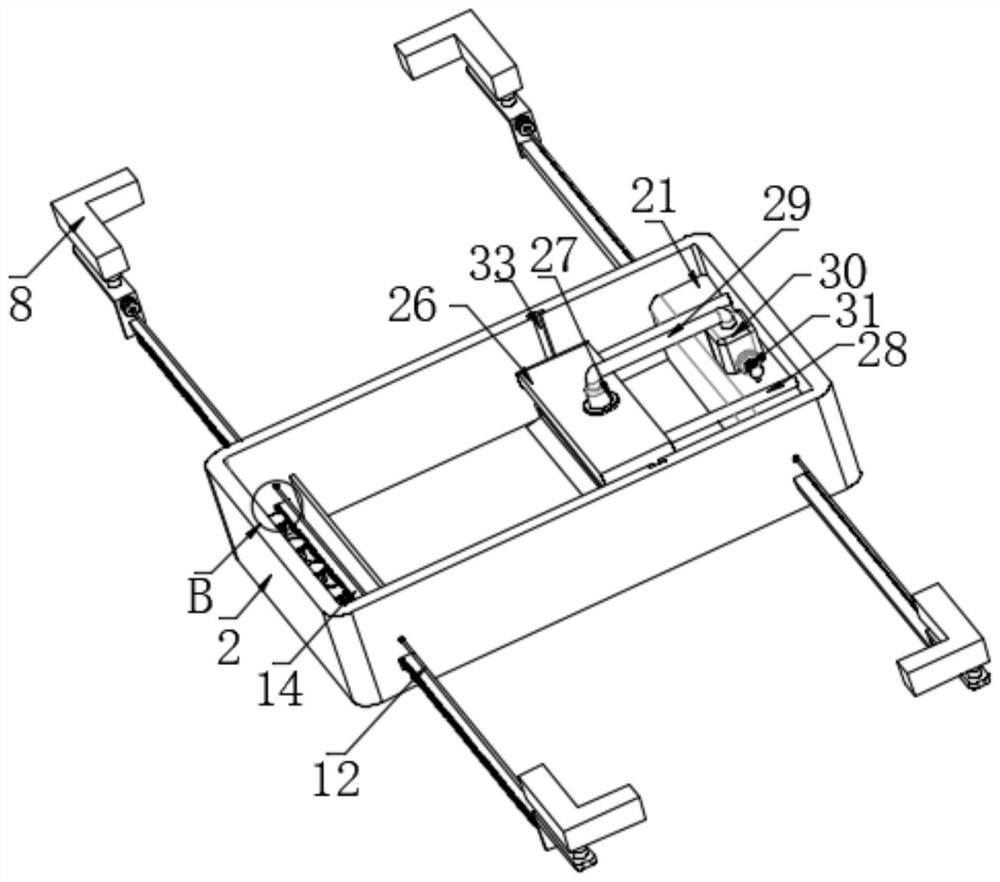

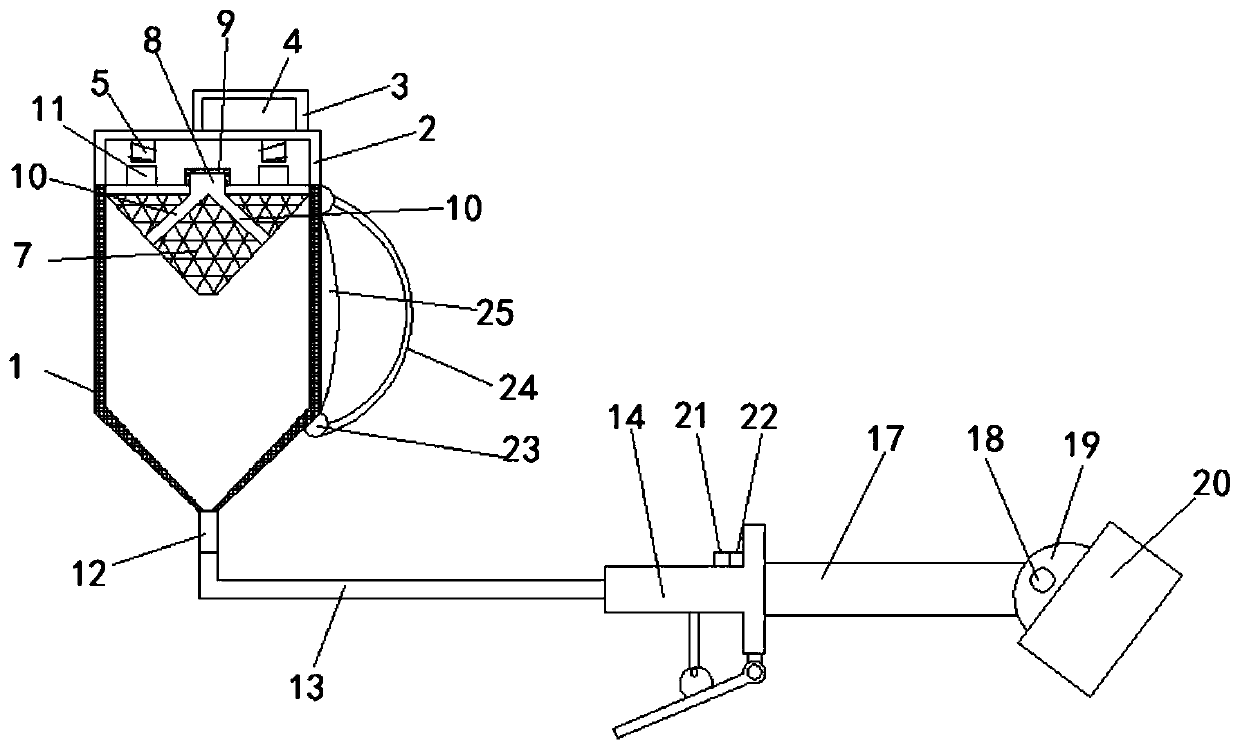

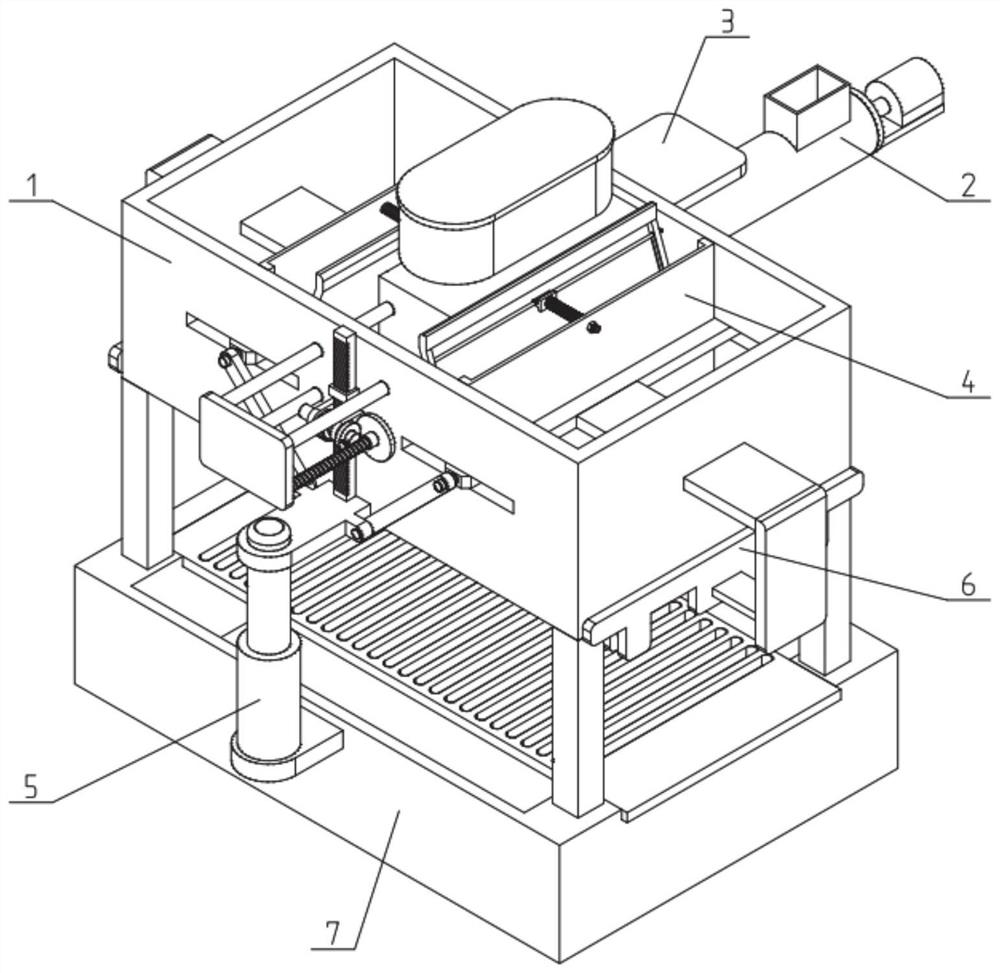

Single wheat/rice plant threshing device

The invention relates to a single wheat / rice plant threshing device comprising a centrifugal fan type thresher, a separating container and a mounting base. The centrifugal fan type thresher comprises a power mechanism, impellers, a volute casing and a wheat / rice ear inlet bucket. The impellers are arranged in the volute casing in a matching way and is connected with the rotating shaft of the power mechanism; the volute casing is provided with an air inlet and an air outlet, wherein the air inlet is butted with the wheat / rice ear inlet bucket, and the air outlet is communicated with the middle part of the separating container; the included angle Alpha between the air outlet direction and the horizontal direction is more than or equal to -30 DEG and less than or equal to 30 DEG; a wheat / rice bran discharge opening is arranged on the top of the separating container; and a movable wheat / rice kernel collecting slot which is matched with the separating container in shape is arranged at the bottom of the separating container. The single wheat / rice plant threshing device has novel and compact structure, small volume, light weight, low manufacturing cost, high threshing ratio, high intactness keeping ratio, high cleaning ratio, low breaking ratio, low retaining and adulterating ratio and low splashing ratio, has no dead corner for the residual and less wheat / rice kernel flow and collision link, is easy to use, consumes less power and can ensure the high purity and the high quality of the wheat / rice kernels and the material.

Owner:HENAN AGRICULTURAL UNIVERSITY

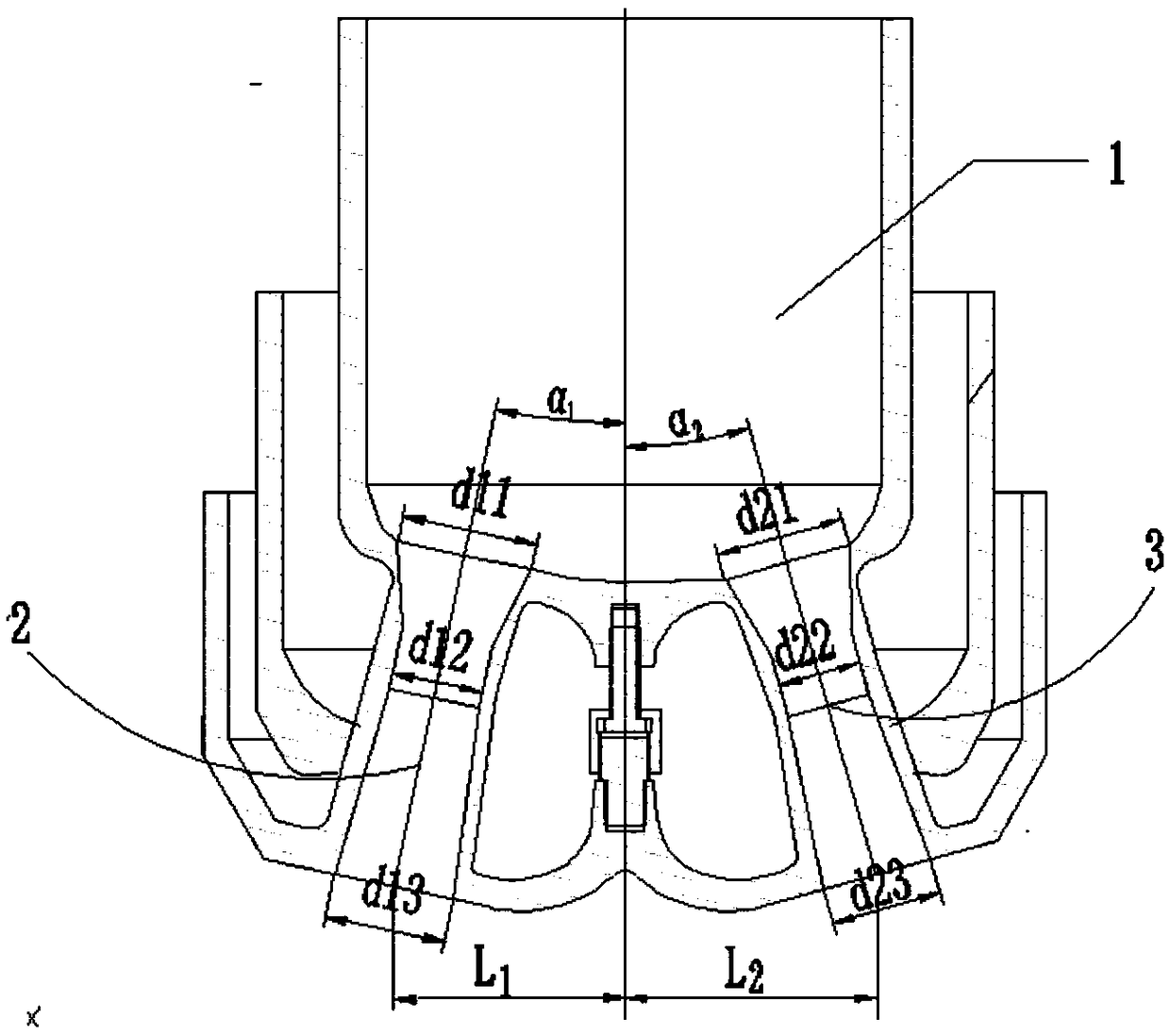

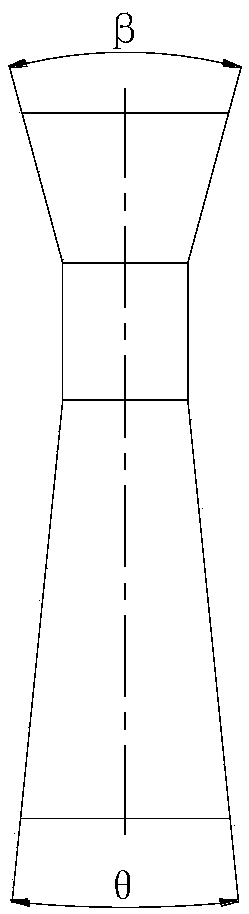

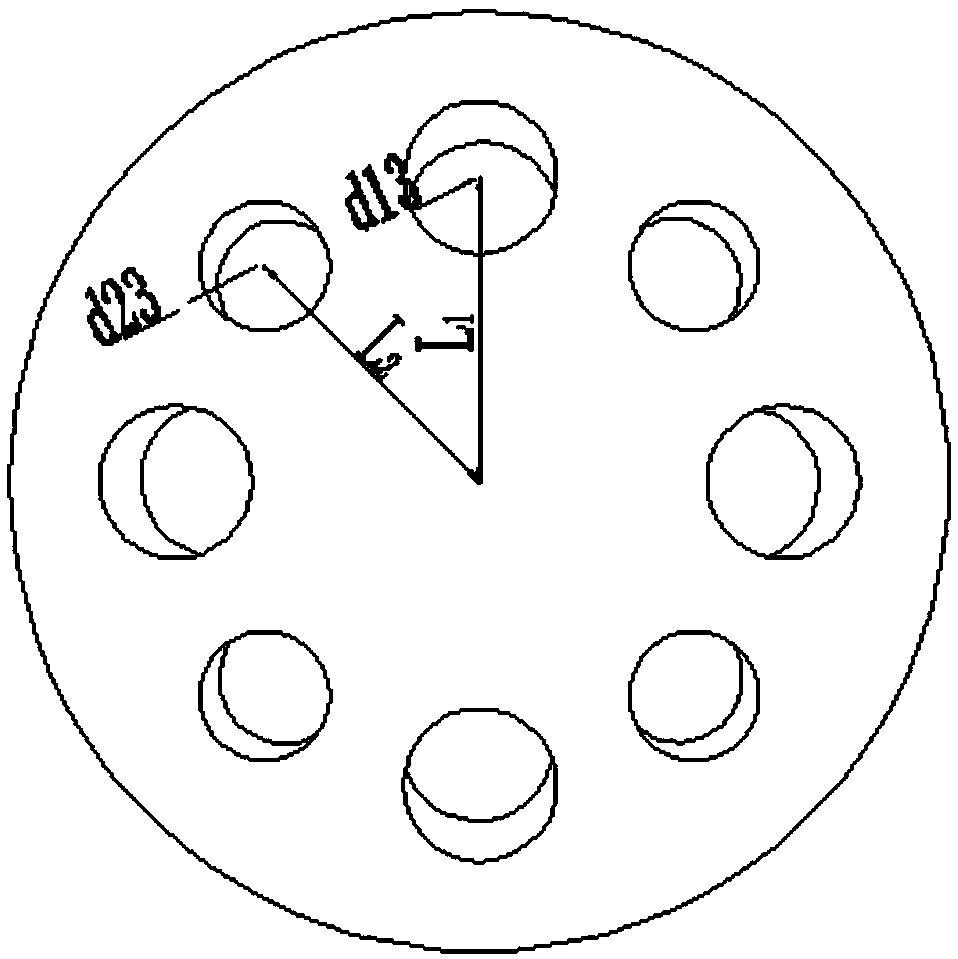

Single-runner dual-structure oxygen lance spraying head and blowing technology

PendingCN108642234AHigh strengthImprove the impact effectManufacturing convertersHead coolingEngineering

The invention relates to a single-runner dual-structure oxygen lance spraying head which comprises an oxygen inlet, laval pipe main holes and laval pipe auxiliary holes. The laval pipe main holes andthe laval pipe auxiliary holes are arranged alternatively; and the single-runner dual-structure oxygen lance spraying head is characterized in that the laval pipe main holes are small in flare angle and large in hole diameter, and the laval pipe auxiliary holes are large in flare angle and small in hole diameter. In the blowing process, the main hole jet flow strength is improved, the impact effect and the stirring strength of spraying head jet flows to a molten bath are strengthened, and the main hole spraying head jet flow core zone distance is lengthened. Auxiliary hole jet flows effectively buffer the main hole jet flow damping, the molten bath area is obviously increased, and the slugging effect is obvious; and the fusion distance of all jet flows in the furnace is obviously increased, the coverage possibility is greatly reduced, the splash rate is obviously reduced under the main and auxiliary hole coordinated work, gaps between columns are increased, the cooling water flow is better increased, the spraying head cooling effect is obvious, and the service life of the spraying head is prolonged.

Owner:UNIV OF SCI & TECH LIAONING

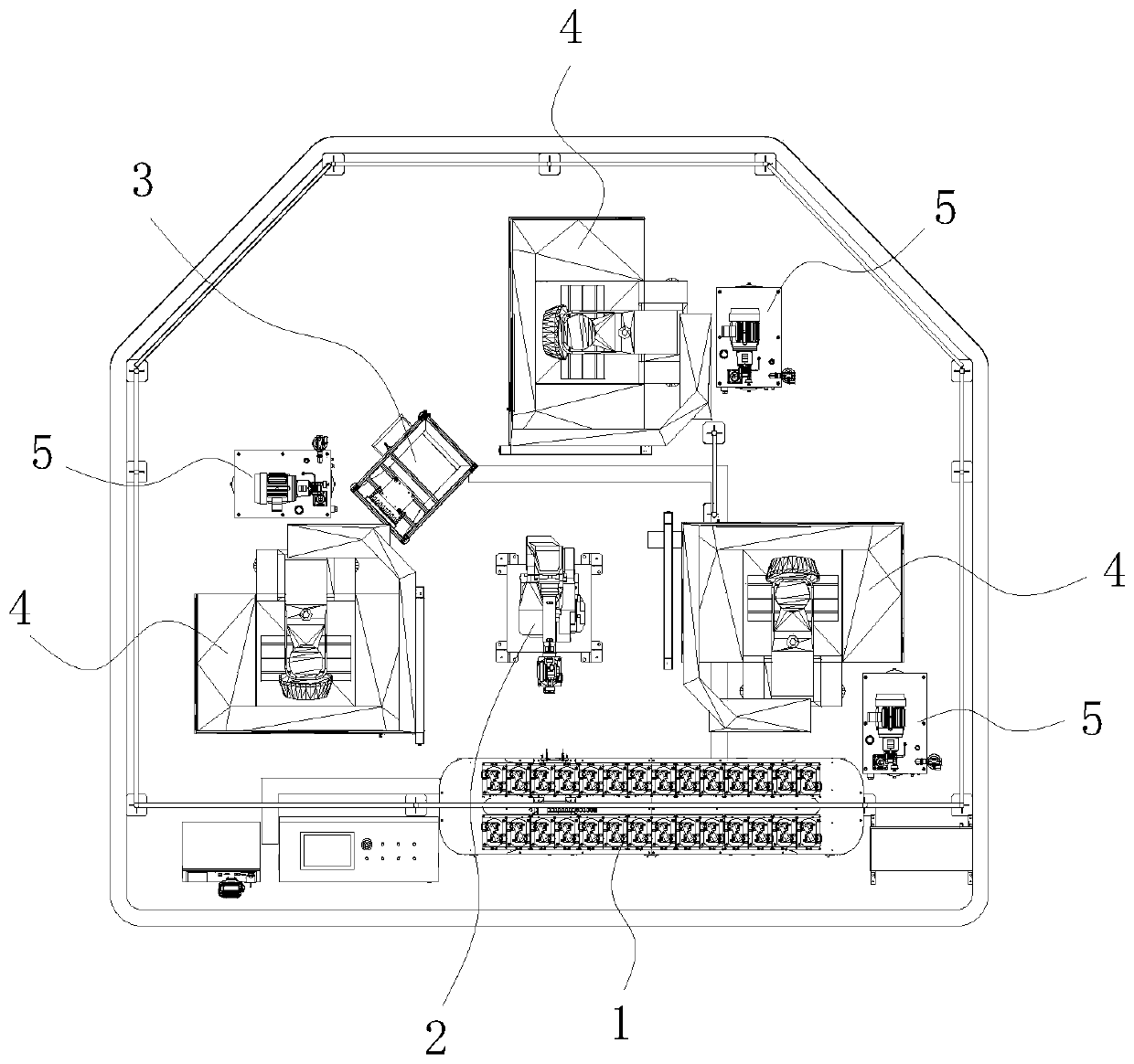

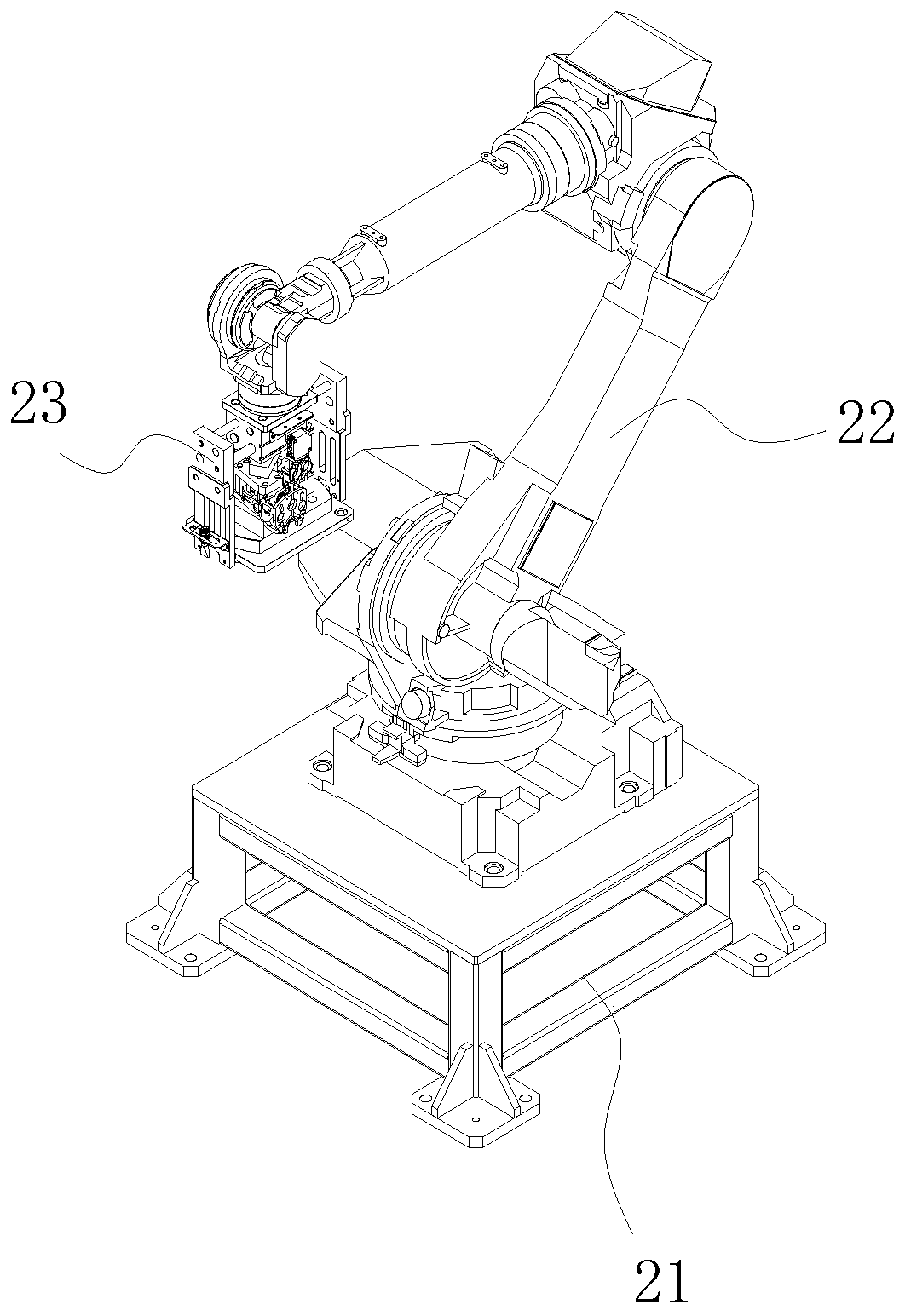

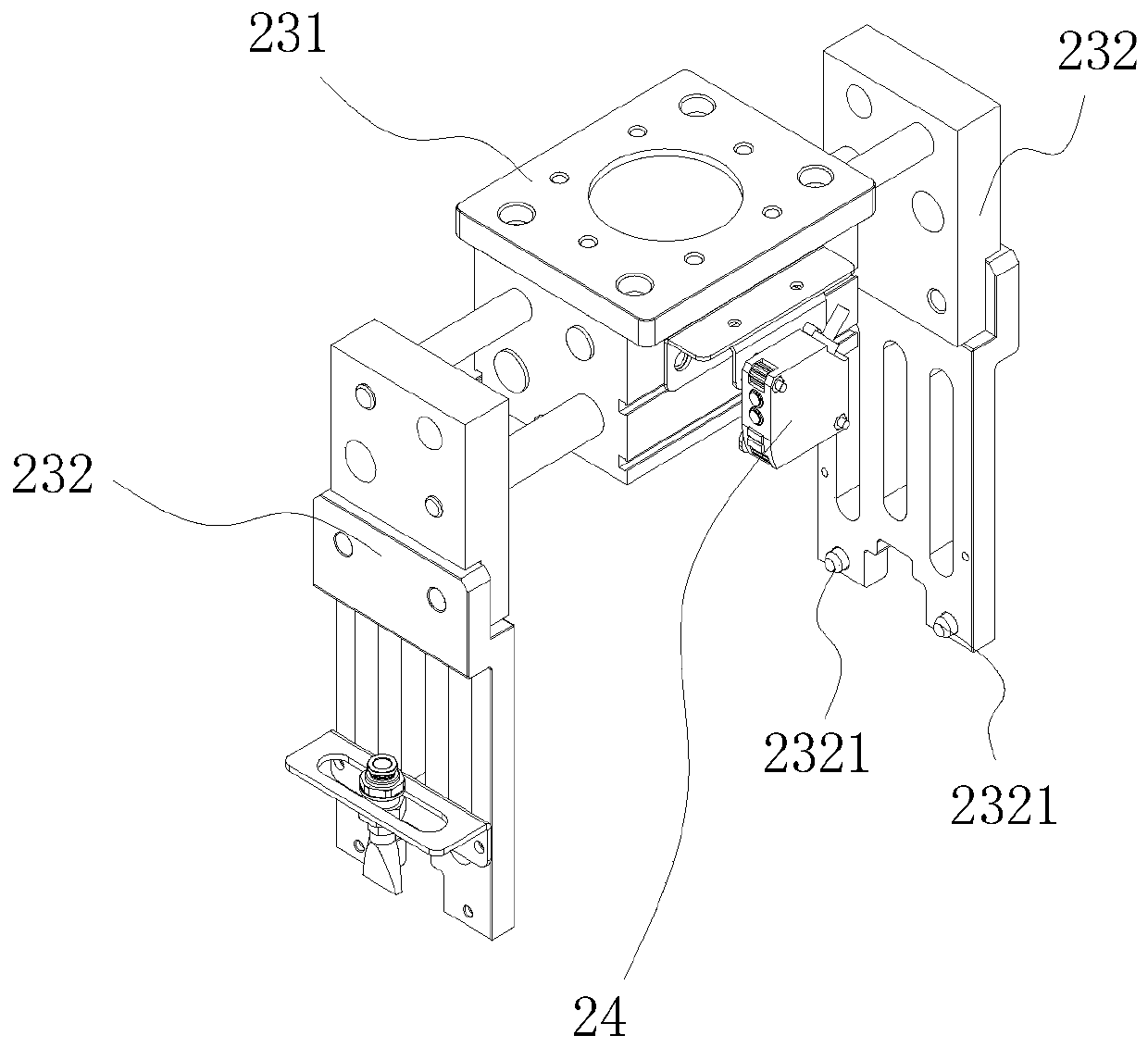

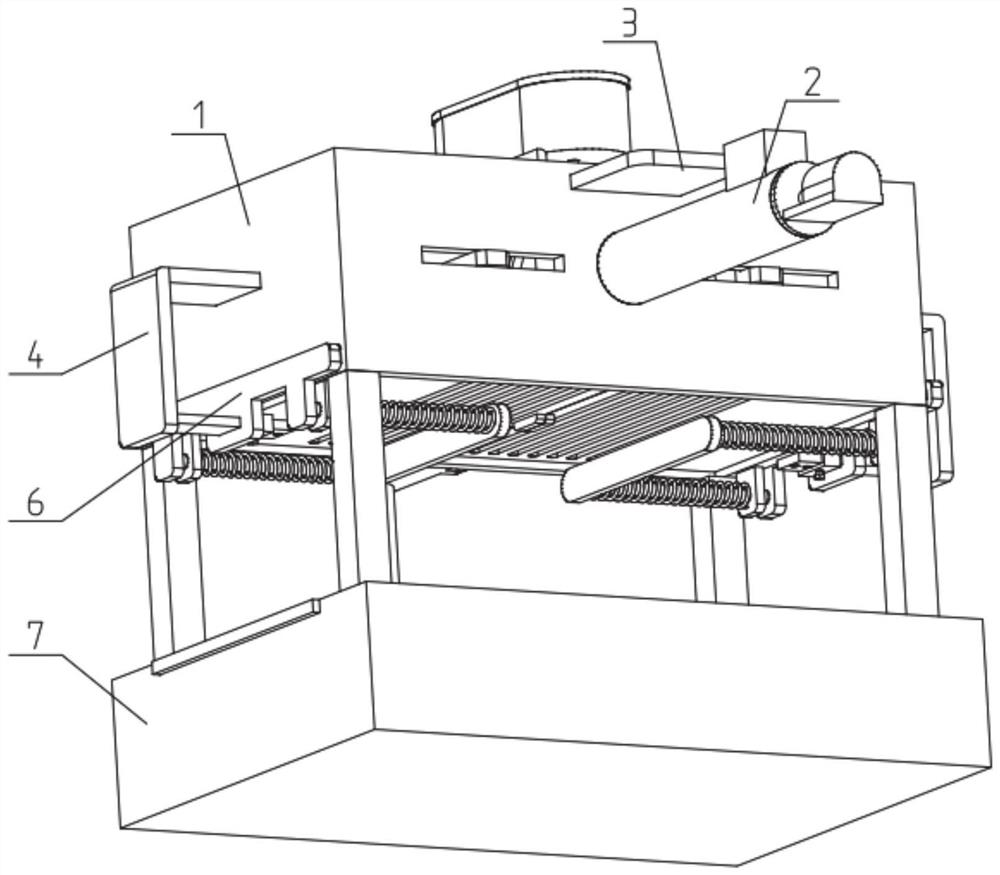

Small-batch multispecies automatic production line device and machining method thereof

ActiveCN111482848AHigh degree of automationSolve technical problems of repeated processingCleaning using liquidsMetal working apparatusNumerical controlProduction line

The invention discloses a small-batch multispecies automatic production line device. The small-batch multispecies automatic production line device comprises a feeding table, a robot device, a cleaningmachine and numerical control equipment, wherein the feeding table is used for conveying machined parts; the robot device is used for clamping the machined parts from the feeding table and is furtheradjacent to the feeding table; and the cleaning machine and the numerical control equipment are arranged on the periphery of the robot device. Due to the fact that the small-batch multispecies automatic production line device disclosed in the invention is provided with a cleaning table, the defect that products still need to be manually cleaned after the machined parts are machined in the prior art is overcome, the robot device can accurately clamp the machined parts through the small-batch multispecies automatic production line device, and thus machining errors are reduced. The small-batch multispecies automatic production line device further has the beneficial effect of being capable of machining production of the different machined parts and the effect of preventing scraps from splashing in the machining process. The invention further discloses a machining method of the automatic production line device. The machining method is applied to machining of the machined parts through theautomatic production line device.

Owner:杭州纳志机器人科技有限公司

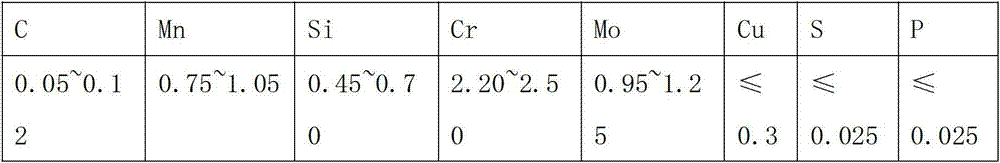

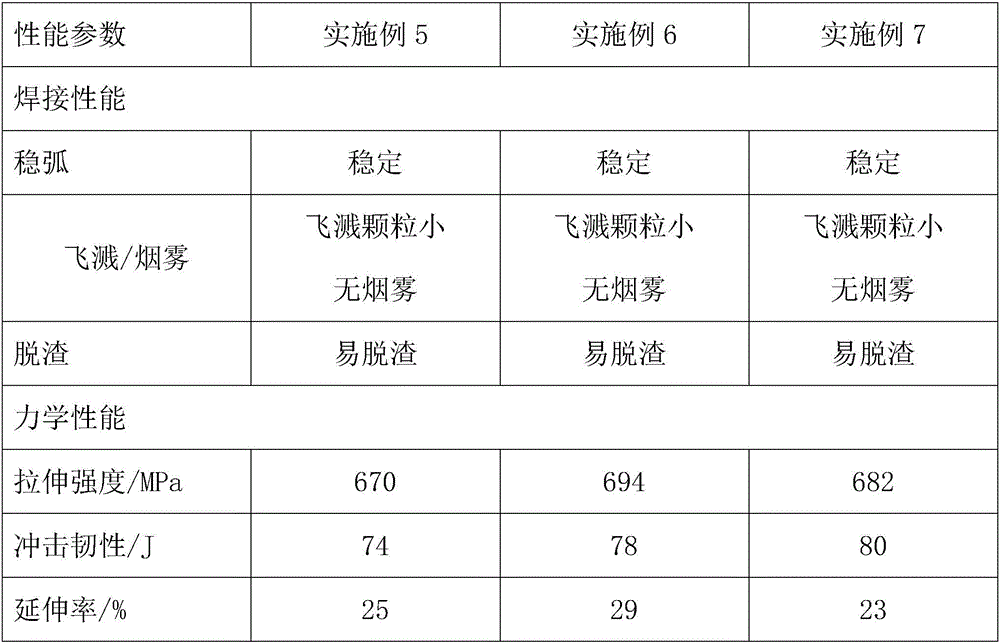

T/P91 steel electrode and manufacturing method thereof

InactiveCN103111774AArc stabilizationReduced chance of splashingWelding/cutting media/materialsSoldering mediaNiobiumWeight coefficient

The invention discloses a T / P91 steel electrode manufacturing method. An R40 welding wire is used as a core wire. Medical powder comprises, by weight percentage, marble 31-35, fluorite 26-29, titanium dioxide 4-7, quartz 1-2, mica 1-2, chromium metal 13-15, atomization nickel powder 1-2, ferrotitanium 7-9, ferromolybdenum 1-2, ferroniobium 0.5-1, ferrovanadium 1-2, and vanadium-nitrogen alloy 1-2. After the powder is mixed in a drying mode, water glass is added according to a ratio of 3:1 and is mixed with the powder in a wet mode, and suppression is carried out after uniform stirring is carried out. Electrode coating weight coefficient is controlled to be 0.95-1.0, cracking of a coating after being dried is avoided, the compression environmental temperature is over 20 DEG C, the products are placed into a drying box after being dried for 3 hours, and is dried for 2 hours when temperature is 100 DEG C, 125 DEG C per hour is risen into 450 DEG C, and then furnace cooling of the products is carried out after being warmed for two hours. The steel electrode is good in welding process performance, little in splatter, low in smoke amount, and attractive in appearance of weld. All the performances can reach foreign imported similar steel electrode technological level. Production cost is greatly reduced.

Owner:天津诚信达金属检测技术有限公司

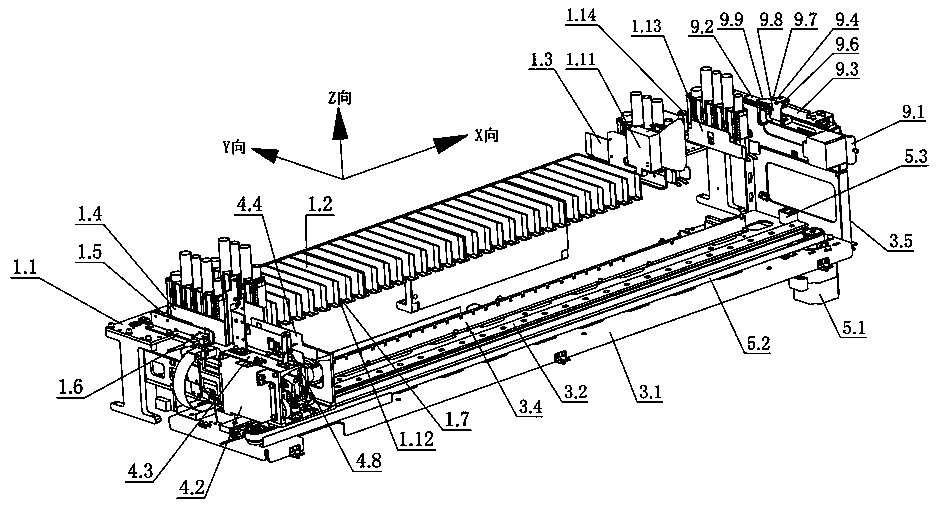

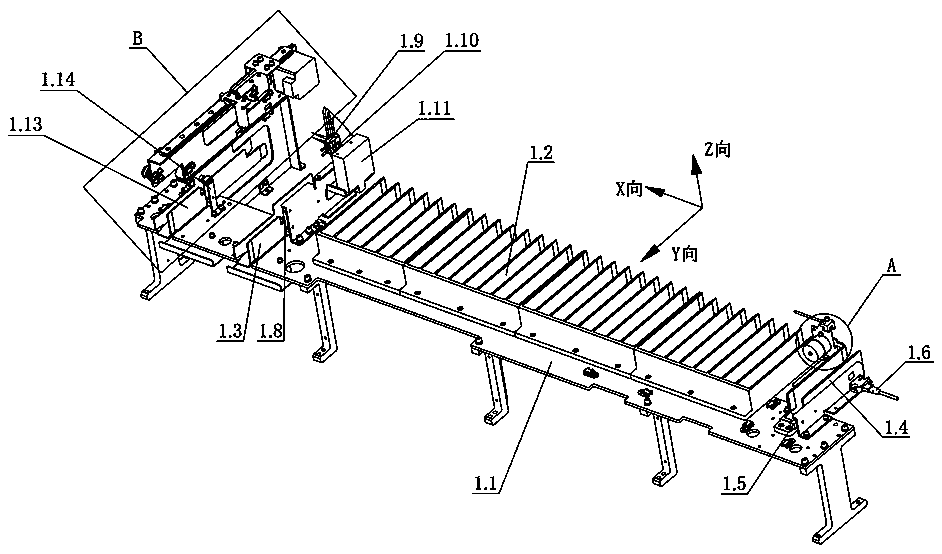

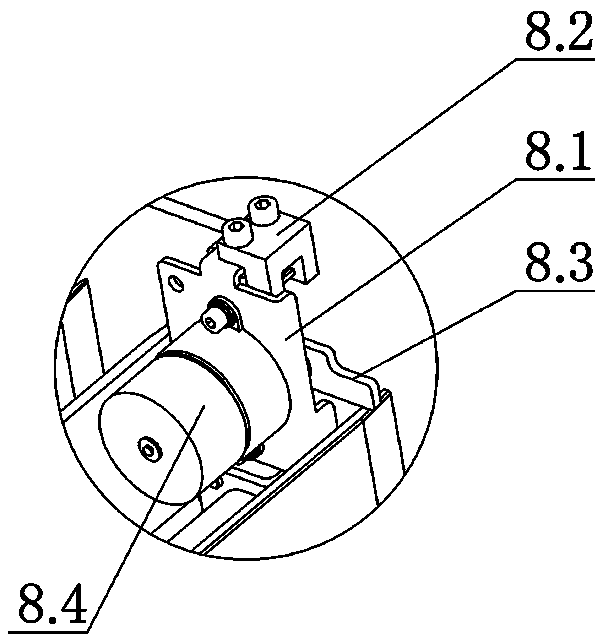

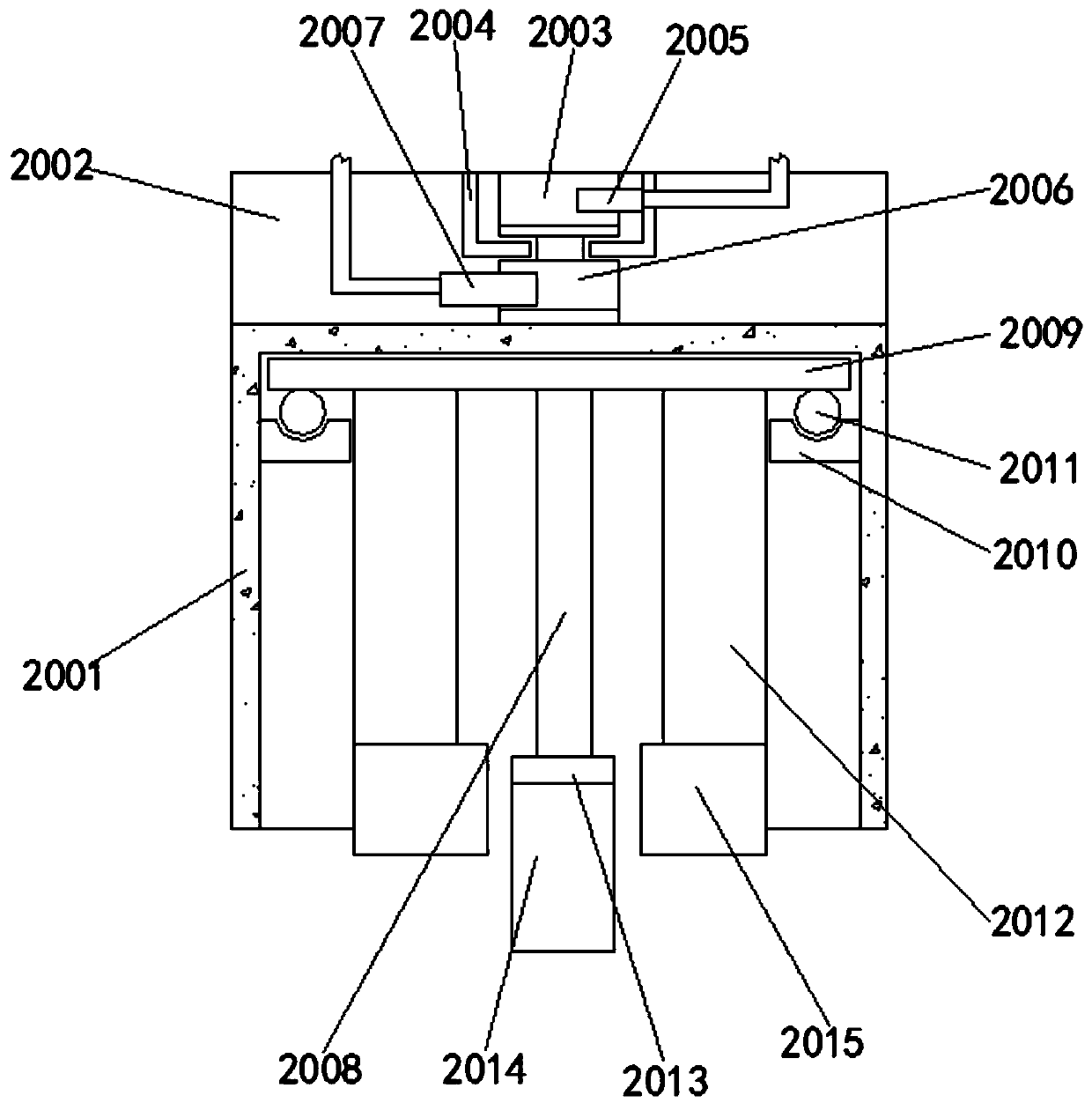

Sample caching and handling system with emergency treatment and repetition measurement functions

PendingCN109444442AEnsure efficient operationImprove diagnostic efficiencyMaterial analysisEmergency treatmentContamination

The invention discloses a sample caching and handling system with emergency treatment and repetition measurement functions. The sample caching and handling system with the emergency treatment and repetition measurement functions comprises a caching unit and a handling unit, wherein the caching unit comprises a caching area, a linking area and an emergency treatment area, wherein the emergency treatment area is provided with a sample frame emergency treatment tank; the handling unit comprises an X-axis installation plate; a first sliding block assembly is arranged on the X-axis installation plate; side plates are perpendicularly arranged on two sides of a Y-axis installation plate on the first sliding block assembly; two Y-axis guiding plates and a support plate on the top parts of the sideplates form a sample frame guiding tank for handling a sample frame; a second sliding block assembly is slidably arranged on the Y-axis installation plate; a pushing hand mechanism is arranged on thesecond sliding block assembly; a pushing hand of the pushing hand mechanism upwards extends out of the sample frame guiding tank. According to the sample caching and handling system with the emergency treatment and repetition measurement functions provided by the invention, the full-automatic sample feeding of an in vitro diagnosis analysis meter can be realized, the analysis meter can run efficiently, and the diagnosis efficiency is improved; the stability of samples during the handling process can be ensured, the cross contamination caused by liquid splashing is avoided, and the accuracy ofa sample result is ensured.

Owner:AUTOBIO LABTEC INSTR CO LTD

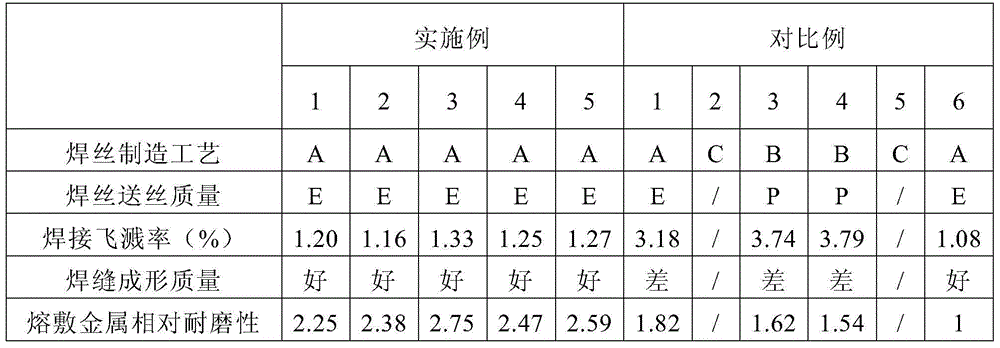

Gas shielded flux-cored welding wire for vertical mill grinding roller bead welding composite manufacture and preparation method thereof

ActiveCN106141503AReduce work hardeningExcellent wire feedingArc welding apparatusWelding/cutting media/materialsHigh carbonManganese

The invention discloses a gas shielded flux-cored welding wire for vertical mill grinding roller bead welding composite manufacture and a preparation method thereof. The welding wire is composed of aferrite stainless steel band and powder wrapped in the ferrite stainless steel band, wherein the powder accounts for 25-28% of the total weight of the welding wire. The powder comprises, by weight, 60.0-65.0% of high carbon ferro-chrome, 12.0-15.0% of chromium carbide, 5.8-6.0% of graphite, 1.0-2.0% of metal manganese powder, 4.0-4.5% of carbonizing silica powder, 1.0-2.0% of aluminum magnesium alloy, 0.2-0.5% of zircon sand, 0.5-1.5 of cryolite, 0.5-1.5% of sodium fluoride, 0.5-1.5% of lithium carbonate, and the balance iron powder. The preparation method comprises the following steps of manufacturing the ferrite stainless steel band with the thickness of 0.4 mm and the width of 10 mm into a U shape; adding the powder into the U-shaped groove; after the U-shaped groove heals up, conducting six times of continuous drawing reducing in sequence; finally conducting mechanical cleaning on the surface of the welding wire; and obtaining the phi 1.2mm gas shielded flux-cored welding wire forgrinding roller bead welding composite manufacture. The vertical mill grinding roller bead welding composite manufacture can be achieved by adopting the welding wire, the welding processing performance of the welding wire is excellent, little welding smoke is produced, the operation is flexible, and a bead welding layer is high in abrasive resistance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Method for directly smelting high-titanium molten iron by using converter

InactiveCN102816887AReduce consumptionLow costManufacturing convertersProcess efficiency improvementSludgeTitanium

The invention discloses a method for directly smelting high-titanium molten iron by using a converter, which comprises the following steps of: (1) adding magnetic separation slag and sludge balls in the earlier stage of converting so as to promote vanadium titanium molten iron to scum more quickly in the earlier stage; (2) converting by a method of low lance position and large flow of oxygen, and weakening the temperature echelon and the concentration gradient of a converter molten pool, so that pig iron, the magnetic separation slag and the sludge balls are quickly melted in the earlier stage; (3) strongly stirring, so that after FeO in the magnetic separation slag and the sludge balls are melted, the magnetic separation slag and the sludge balls as well as slagging raw materials form furnace slag; and (4) reducing the content of iron oxide of the slag, and weakening the foaming tendency of the slag to prevent foam splashing. The method provided by the invention has the following advantages: (1) the vanadium titanium molten iron is directly smelted in the converter without extracting vanadium and titanium from the molten iron; (2) the plashing is favorably reduced, the converter protection effect by slag splashing is improved, the stability of smelting of the converter is improved, and the splashing rate of the converter is reduced; and (3) the resource recycling rate is increased, the consumption of iron and steel materials is reduced and the cost is reduced. The method is suitable for iron and steel smelting enterprises.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

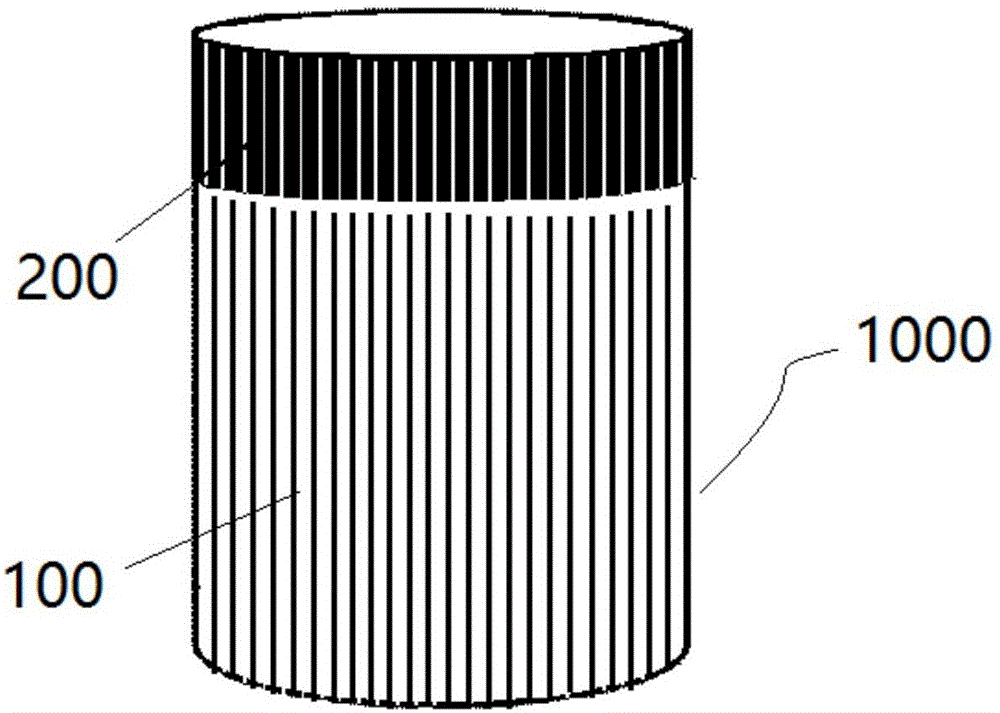

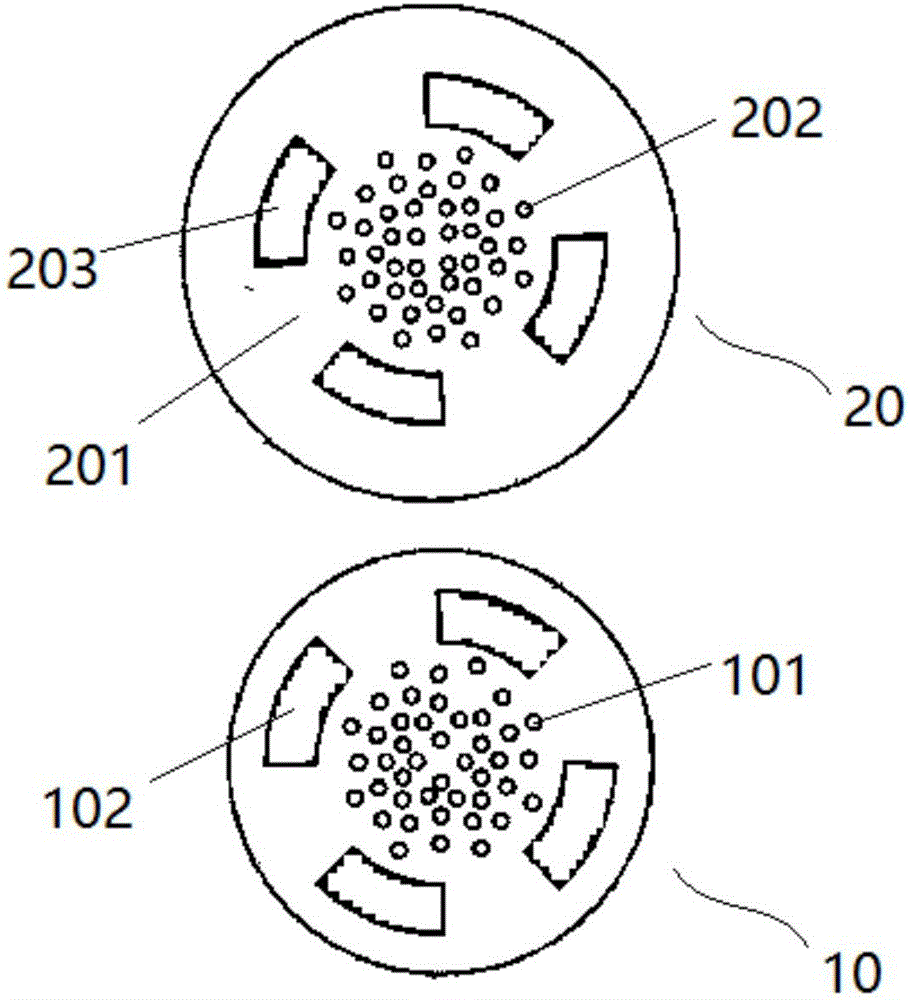

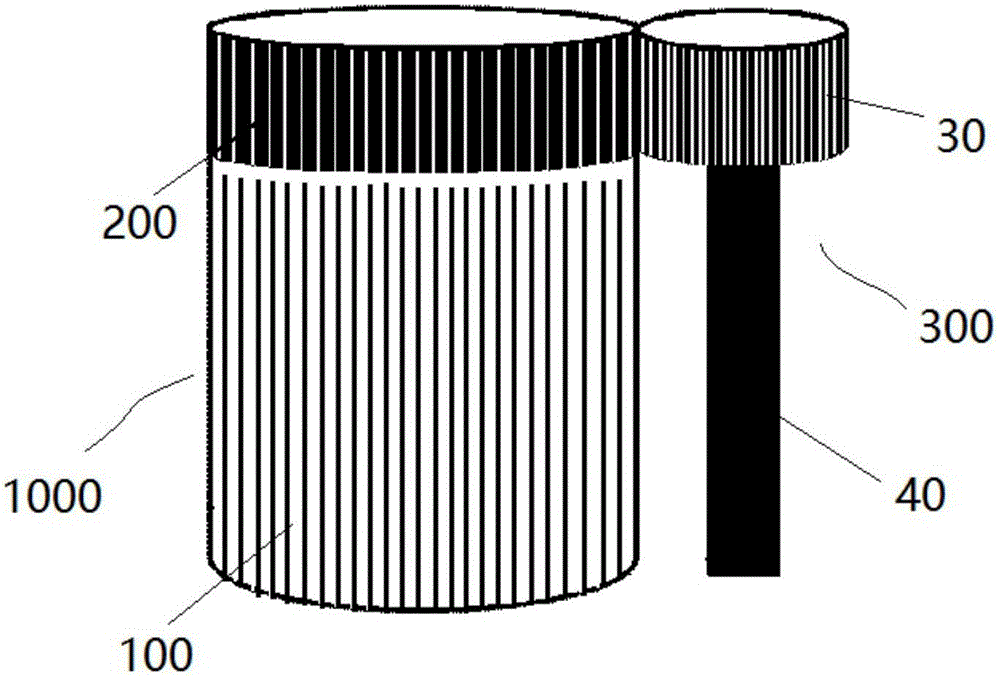

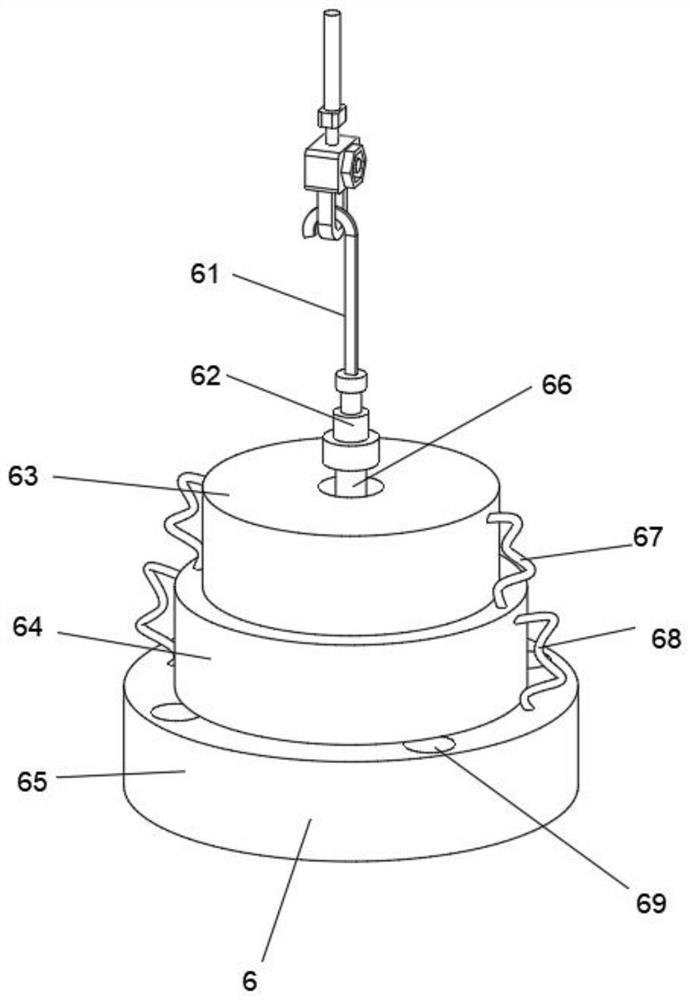

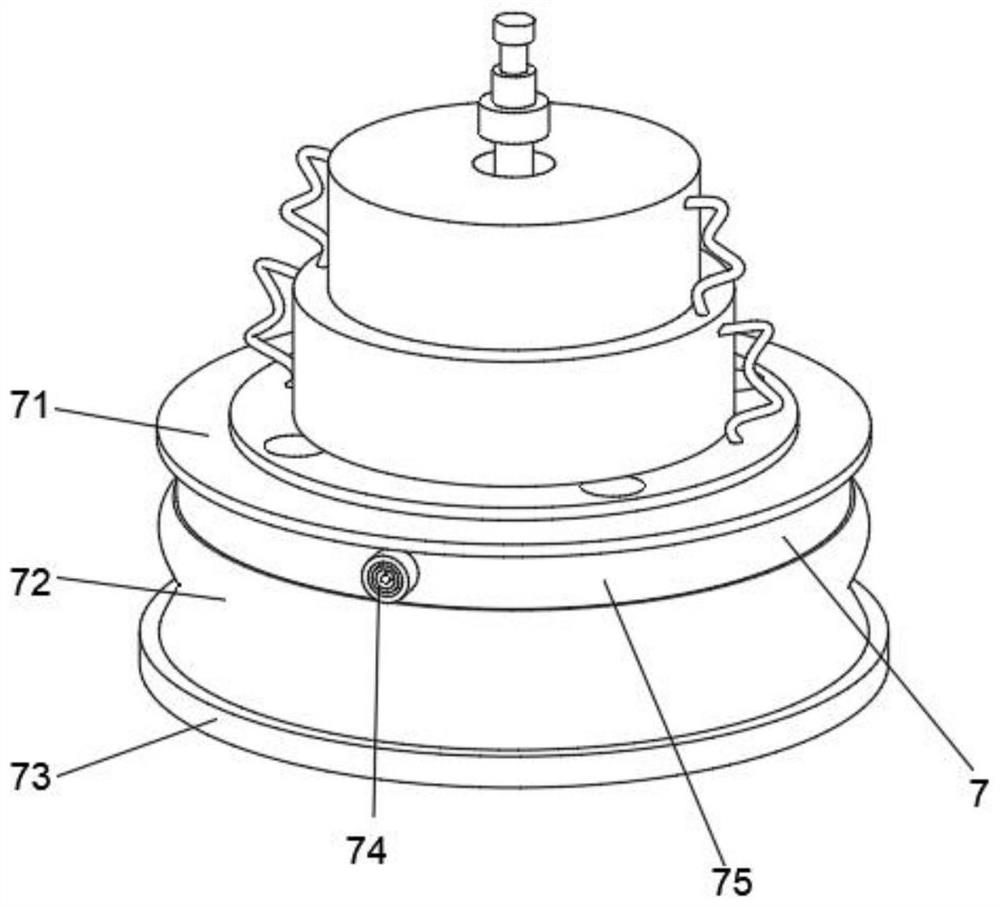

Crucible device

InactiveCN107177821AEvenly heatedReduced chance of splashingVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention provides a crucible device. The crucible device comprises a container body and a cover plate module. The cover plate module is detachably connected to the upper end of the container body in a covering mode. The cover plate module comprises an inner cover plate and an outer cover plate. One of the inner cover plate and the outer cover plate is provided with a plurality of vent holes and at least one evaporation plating through hole, and the other one is provided with at least one sheltering part capable of sheltering the evaporation plating through holes. Each sheltering part can shelter the at least one evaporation plating through hole. Moreover, the inner cover plate and the outer cover plate can rotate relatively so as to enable the sheltering parts to completely cover the evaporation plating through holes or enable the sheltering parts and the evaporation plating through hole to be staggered. By adopting the crucible device, splashed evaporation plating materials can be reduced; pollution to a crucible cavity and material waste can be avoided; the quality of finished evaporation plated products can be improved; and the cost can be saved.

Owner:BOE TECH GRP CO LTD

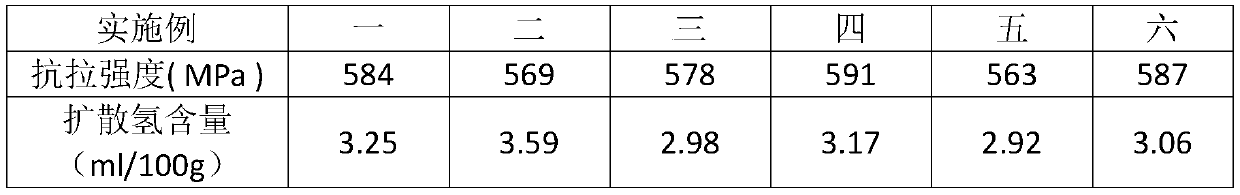

Novel self-shielded flux-cored wire for submerged arc welding

ActiveCN110293330AGood welding performanceLow diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaWeld seamRutile

The invention provides a novel self-shielded flux-cored wire for submerged arc welding. The self- shielded flux-cored wire is characterized in that liquid slag completely covers electric arcs, moltendrops and molten pools in the welding process, and the self-shielded flux-cored wire comprises a metal sheath and a flux core, wherein the metal sheath is an N6 nickel strip, and the neutral fluoride-rutile slag system is taken as a basic slag system of the flux core. The formula of the flux core comprises the following components of, in mass percent, 10%-35% of rutile, 20%-40% of fluoride, 10%-20% of manganese powder, 3%-10% of aluminum powder, 5%-15% of molybdenum powder, 0%-5% of chromium powder and balance iron powder. According to the flux-cored wire, electric arc combustion is stable inthe welding process, the phenomenon of arc breaking is avoided, the spatter rate is low, the forming performance of welding seams is good, the tensile strength of welded joints is up to 550 Mpa, the diffusible hydrogen content of the joints is lower than 5 ml / 100 g, and the standard of ultra-low hydrogen welding materials is reached.

Owner:HARBIN INST OF TECH AT WEIHAI +1

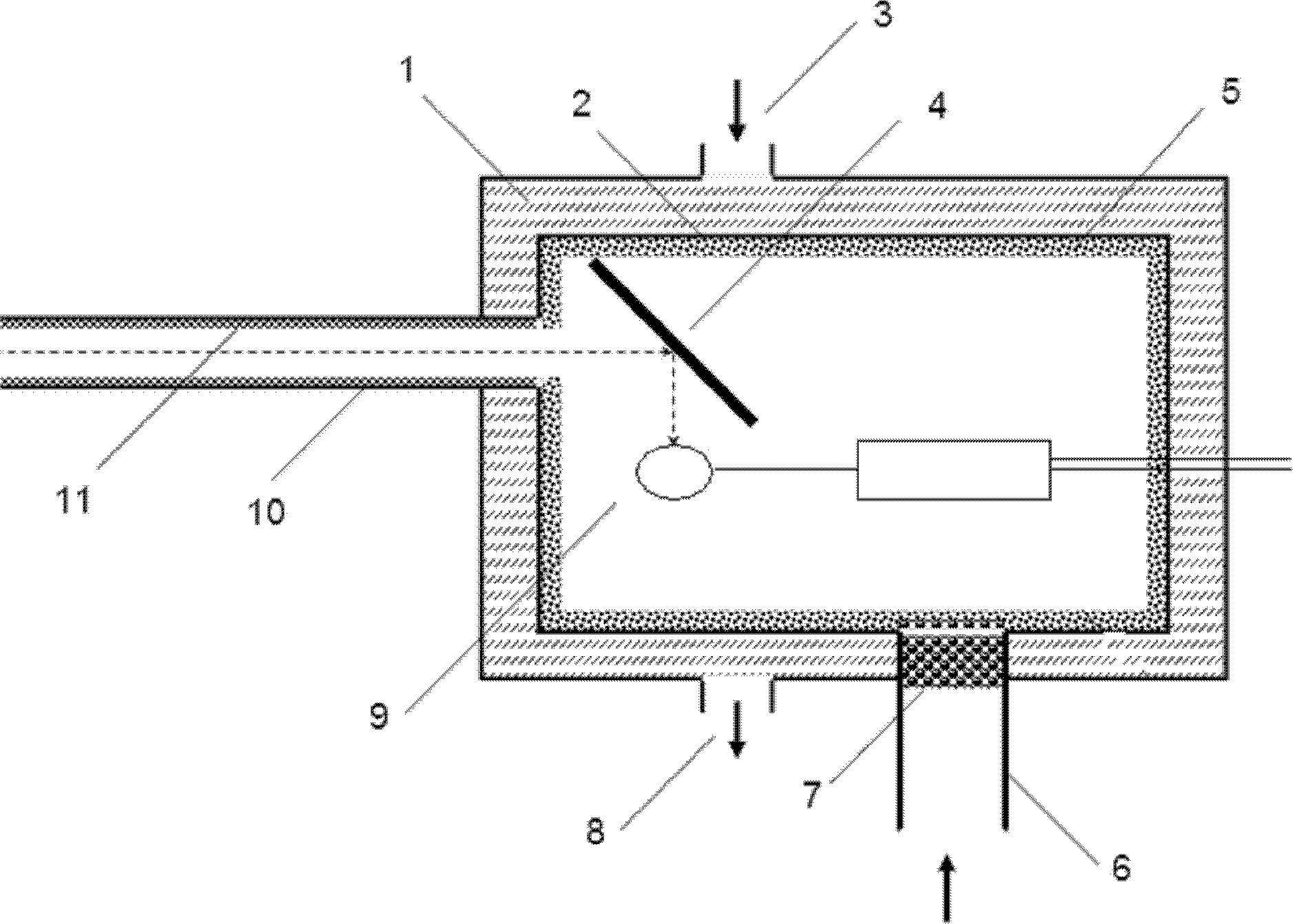

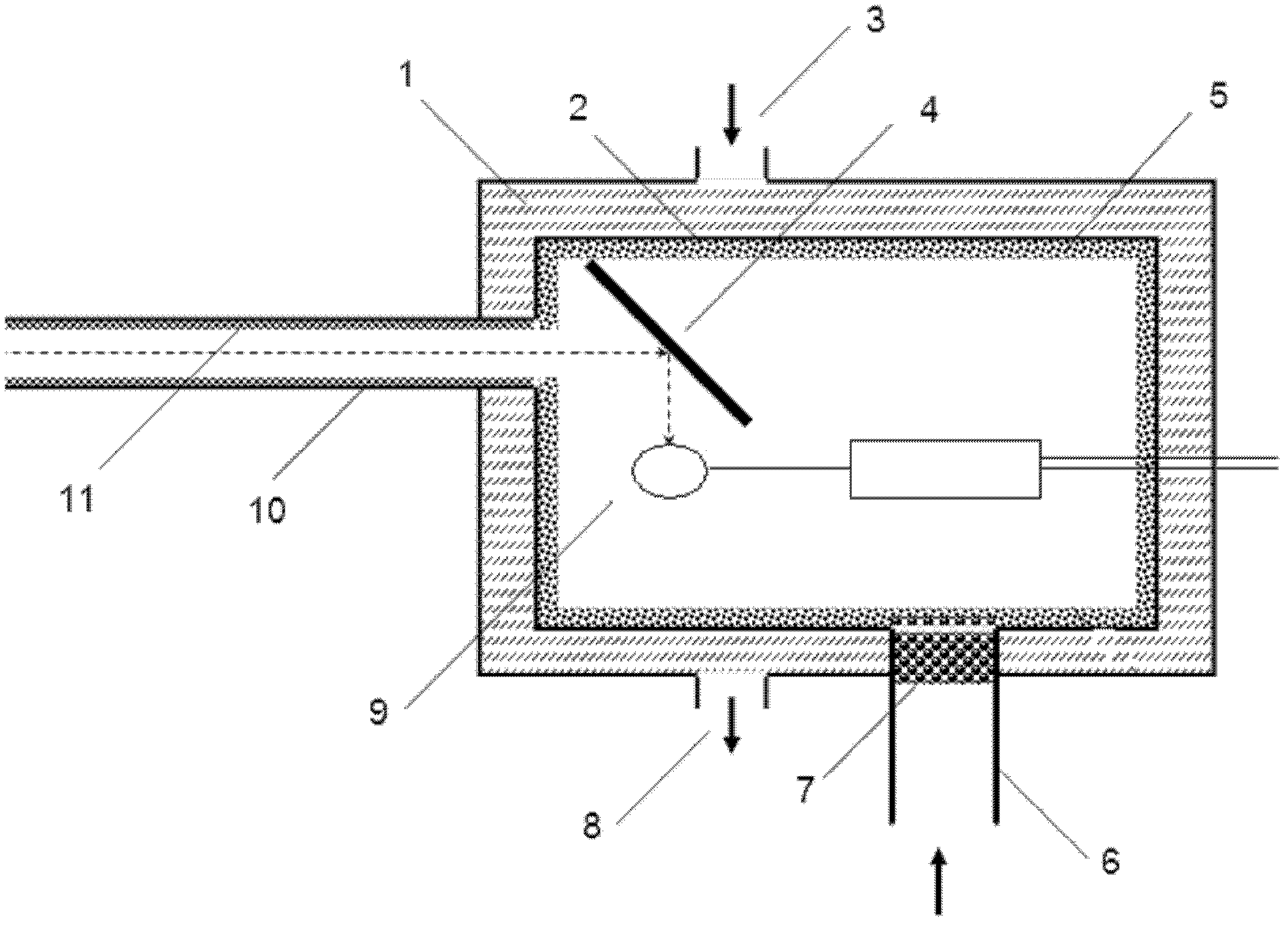

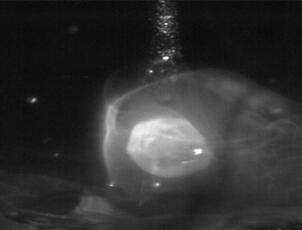

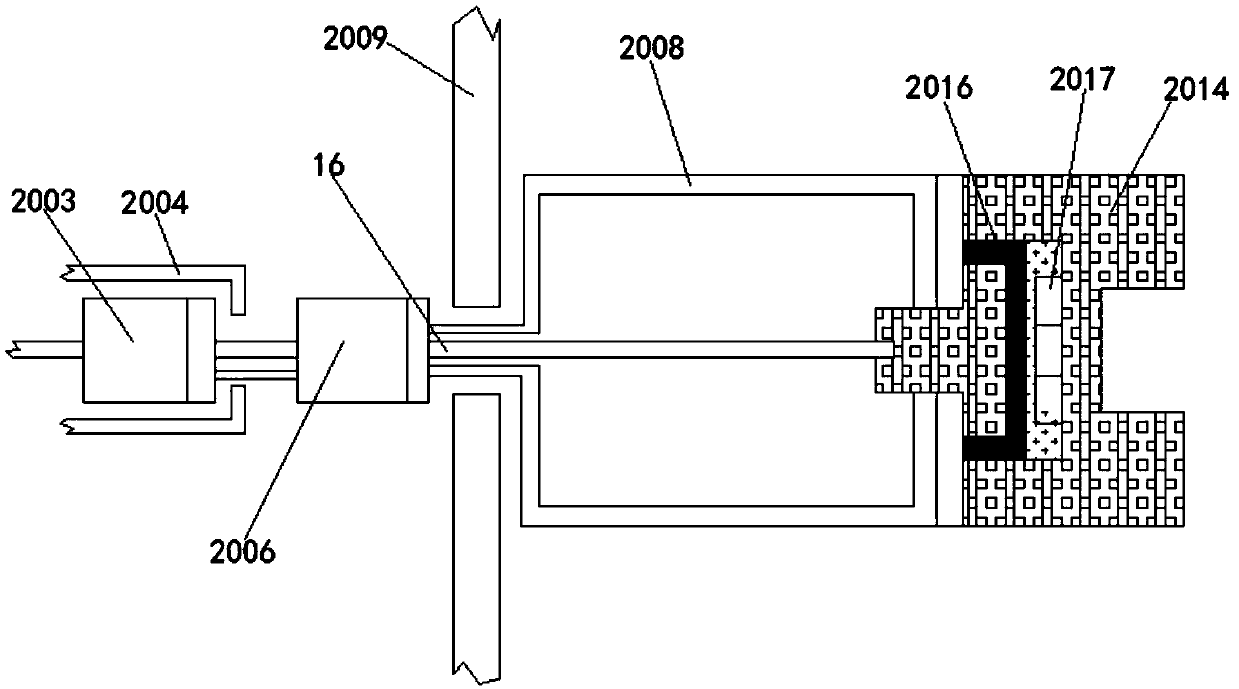

Audio-frequency noise acquisition apparatus arranged at slagging furnace mouth of converter

InactiveCN102495139AAvoid enteringWill not cause interferenceResponse signal detectionAcquisition apparatusCentral line placement

The invention relates to an audio-frequency noise acquisition apparatus arranged at a slagging furnace mouth of a converter, and the apparatus is used in a noise analysis system. The apparatus comprises an acquisition box and a pickup arranged in the acquisition box; a circulating water drum is arranged out of the acquisition box, one side of the acquisition box is provided with a directing steel pipe that is communicated with a cavity in the acquisition box, the acquisition box is also provided with an air inlet which is used for conveying air into the acquisition box, and a sound filter is provided at the air inlet; a reflecting plate which is used for reflecting sound and absorbing thermal radiation is arranged in the acquisition box at a position opposite to the center line of the directing steel pipe, the reflecting plate and the center line of the directing steel pipe forms an included angle, and the pickup is located on a symmetric line of the center line of the directing steel pipe, with the normal of a reflection plane being a symmetrical axis of the symmetric line and the center line of the directing steel pipe. According to the invention, interference of ambient noise is effectively avoided, thermal radiation on the pickup is reduced, and flue dust and corrosive gas are prevented from entering into the acquisition box; therefore, it is guaranteed that the acquisition box can accurately and stably acquire slagging noise at a furnace mouth, accuracy of an analysis system of a slagging state during steel-making of a converter is improved, possibility of occurrence of splashing is substantially lowered down, and steel-making efficiency is enhanced.

Owner:SHANDONG JIANZHU UNIV

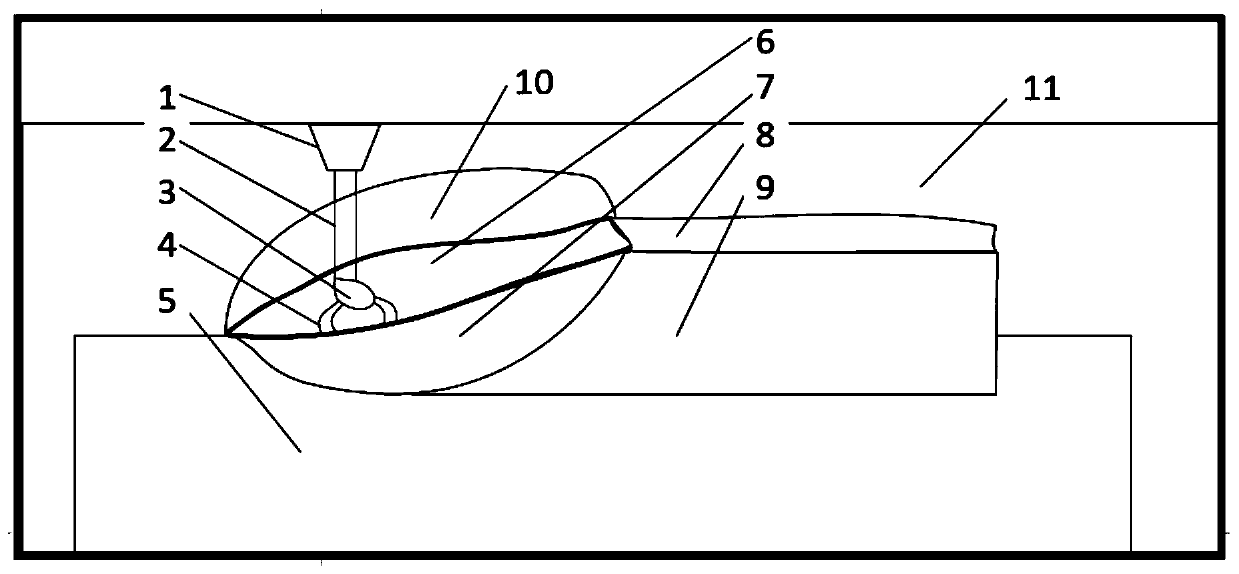

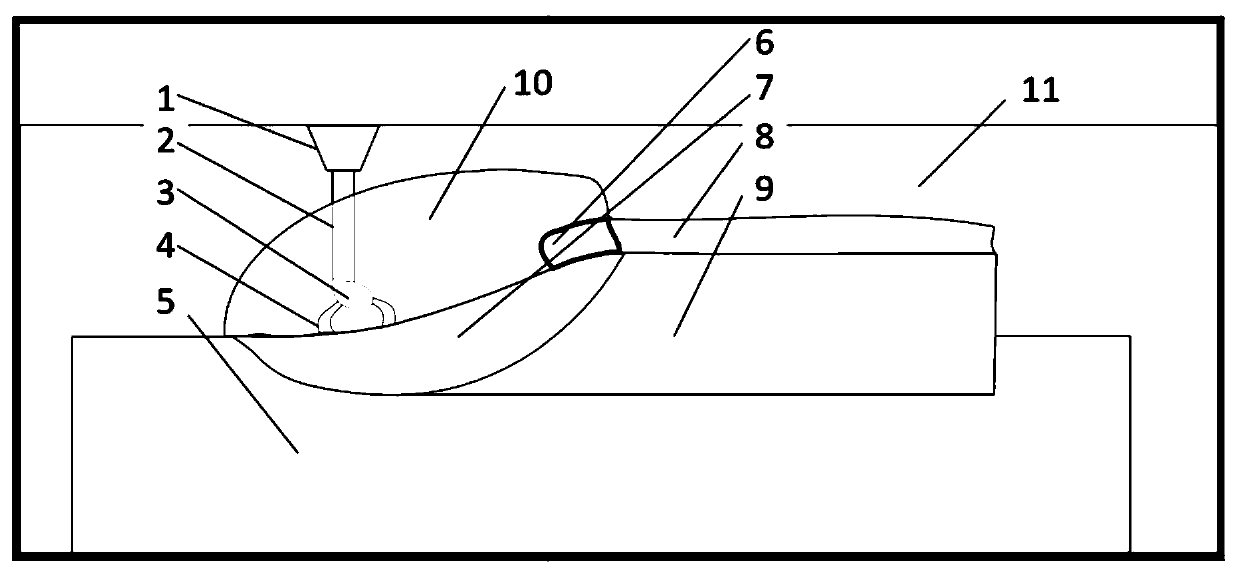

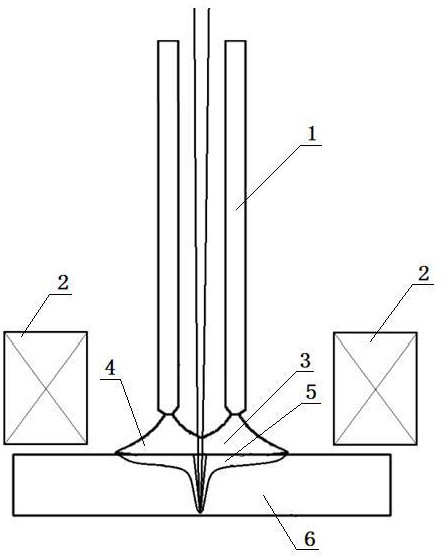

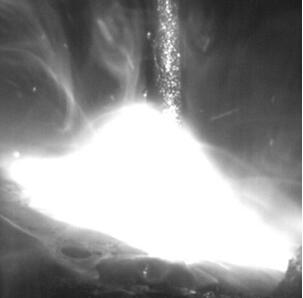

Ultrahigh-power laser and hollow tungsten electrode hybrid welding method based on magnetic rotation control technology

PendingCN112775551AIncrease energy densityReduce distractionsLaser beam welding apparatusMagnetic rotationThick plate

The invention discloses an ultrahigh-power laser and hollow tungsten electrode hybrid welding method based on a magnetic rotation control technology. At present, in ultrahigh-power laser medium and thick plate welding, the welding process is extremely unstable due to the too violent heat energy conversion effect, and the welding problems that air holes and splashing easily occur, forming is difficult to control and the like are solved. The method is characterized in that a hollow tungsten electrode (1) is included, ultrahigh-power laser penetrates through a center hole of the hollow tungsten electrode to form a coaxial composite laser beam (3), an annular inductance coil or permanent magnet (2) is arranged above a welding test plate (6), the inductance coil or permanent magnet and an electric arc (4) at the bottom of the hollow tungsten electrode form a longitudinal magnetic field, the laser beam penetrates through the electric arc and a molten pool (5), the longitudinal magnetic field can directionally rotate the electric arc, and the rotating electric arc and the laser beam are formed to be combined and jointly act on a welding spot area. The ultrahigh-power laser and hollow tungsten electrode hybrid welding method based on the magnetic rotation control technology is provided.

Owner:HARBIN WELDING INST LTD

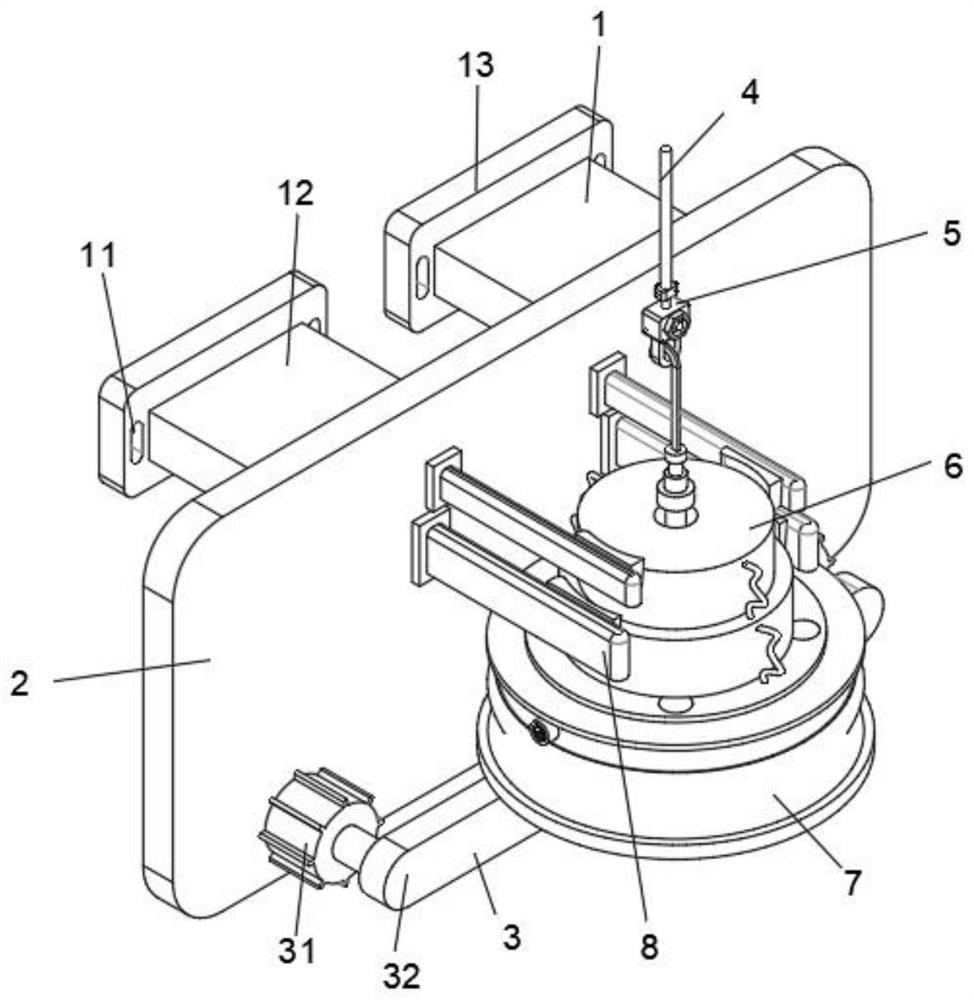

Construction method of highway soft foundation

PendingCN112854179AImprove efficiencyImprove construction efficiencyRoadwaysSoil preservationArchitectural engineeringStructural engineering

The invention relates to the technical field of soft foundation construction, and particularly relates to a construction method of a highway soft foundation. The highway soft foundation comprises a mounting plate, a connecting mechanism, a traction rope, an auxiliary supporting mechanism, an anti-splashing mechanism and a limiting mechanism, wherein the connecting mechanism is connected with the mounting plate, and the mounting plate is connected with a crane through the connecting mechanism; the lower end of the traction rope is connected with a detacher, and the traction rope is connected with a winding roller of the crane; the auxiliary supporting mechanism is connected with the mounting plate; the anti-splashing mechanism is connected with a rammer mechanism; and the limiting mechanism is connected with the mounting plate. The construction device at the highway soft foundation has the advantage of improving the construction efficiency.

Owner:安徽东冶地质勘查技术有限公司

Semi-steel smelting constant-pressure constant lance steelmaking method

ActiveCN106011362AReduce process dry-outReduce splashManufacturing convertersSteelmakingSmelting process

The invention relates to a semi-steel smelting constant-pressure constant lance steelmaking method, and belongs to the technical field of semi-steel smelting. The semi-steel smelting constant-pressure constant lance steelmaking method is provided to reduce the process lance position fluctuation in order to fundamentally reduce the TFe content of final slag. A slagging system is optimized, and corundum slag is used to carry out early slagging and process slag adjustment in order to reach semi-steel smelting rapid slagging and reduce process drying. The TFe content and splash are fundamentally reduced through constant-pressure constant lance operation without special slag modifying treatment. The method has the advantages of simplicity in operation, low cost, reduction of the drying and splashing probability in the semi-steel smelting process, stationary process, and realization of control of the TFe content of the final slag within 17%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Flux-cored wire capable of improving welding performance and preparation method of flux-cored wire

InactiveCN112296551AExtend the droplet transfer periodImprove self-protection performanceWelding/cutting media/materialsSoldering mediaAl powderSlag (welding)

The invention discloses a flux-cored wire capable of improving welding performance and a preparation method of the flux-cored wire. The preparation method comprises the steps that a mixture of fluorinated graphene and titanium carbide powder is added into an original slag-free self-protection flux-cored wire, and the mixture is prepared from following components in percentage by mass: 6.5% of Mg powder, 35% of Fe powder, 2.0% of Al powder, 11.5% of Cr powder, 3.0% of V powder and 0.05% of the mixture prepared from fluorinated graphene and titanium carbide. Compared with the prior art, the flux-cored wire of the scheme has the beneficial effects that the molten drop transition period of the welding wire is prolonged, the metallurgical reaction behavior is intensified, and therefore, the self-protection effect of the welding wire is further optimized; the splashing rate after improvement is relatively low; and the action effect on a molten pool is enhanced, slag splashing behaviors are relatively few, the deposition efficiency is improved, a certain influence is achieved on macroscopic forming of a weld joint, and the abrasion resistance and the oxidation resistance are enhanced. Thewelding wire is prevented from being affected with damp, and air pores are reduced; and the flux-cored wire has the effects of refining grains, improving the weld joint hardness and improving the impact toughness.

Owner:JIANGSU UNIV OF SCI & TECH

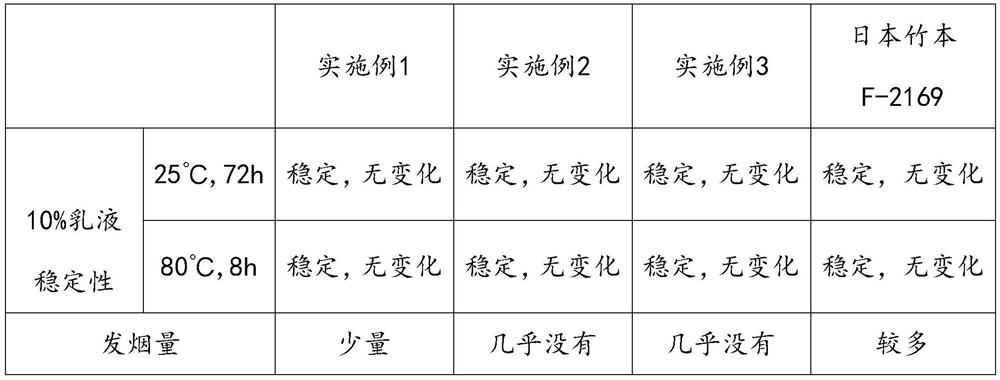

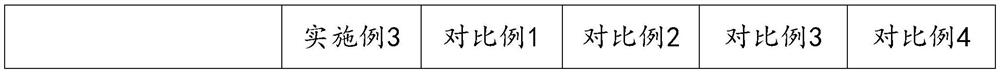

Spinning oil for polyester staple fibers and preparation method of spinning oil

ActiveCN113308765AHigh flash pointImprove smoothnessSynthetic polymer filament chemical after-treatmentPolyesterPolymer science

The invention relates to the technical field of oil for synthetic fiber processing, and provides spinning oil for polyester staple fibers and a preparation method of the spinning oil. The spinning oil comprises the following raw materials in parts by weight of 6-12 parts of dodecylamine polyoxyethylene ether, 4-8 parts of decyl monomethylol dimethyl ammonium chloride, 6-12 parts of iso-tridecanol, 64-76 parts of castor oil polyoxyethylene ether, 1.2-1.6 parts of a coupling agent, 5-10 parts of octyl stearate, 2-4 parts of an anti-splashing agent, 12-20 parts of an emulsifier and 2-4 parts of a penetrant. The problems that in the prior art, spinning oil is poor in heat resistance and splashing resistance are solved.

Owner:福建合利新材料科技有限公司

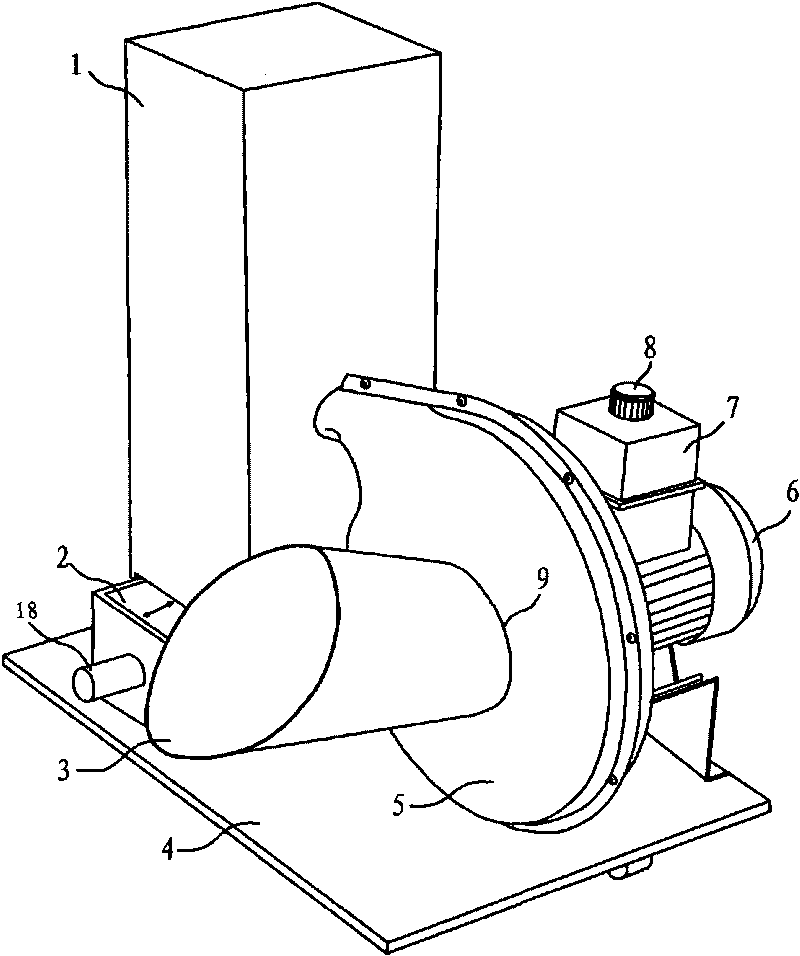

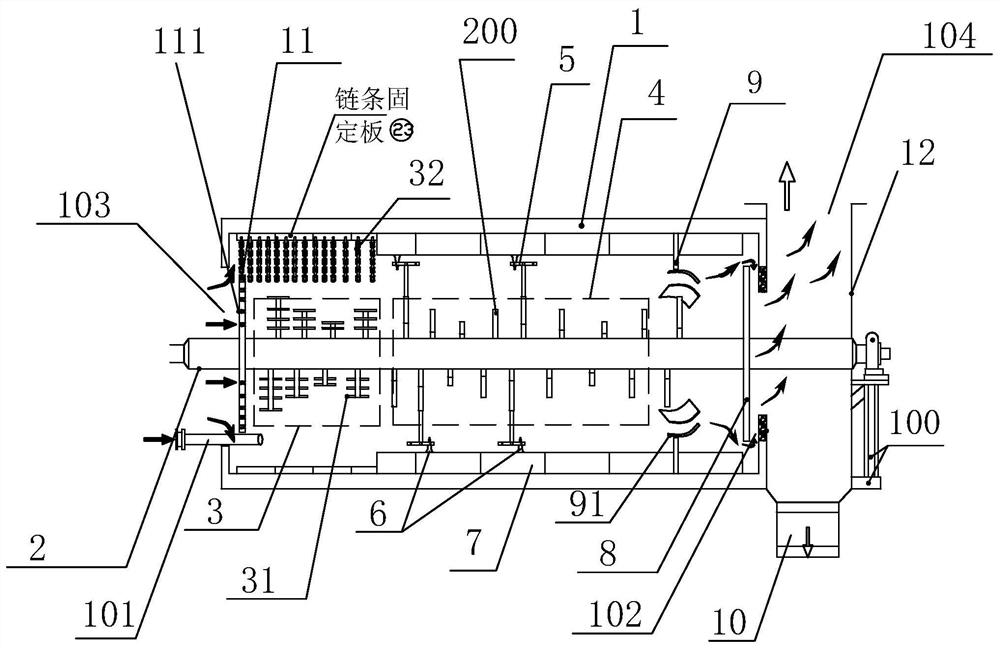

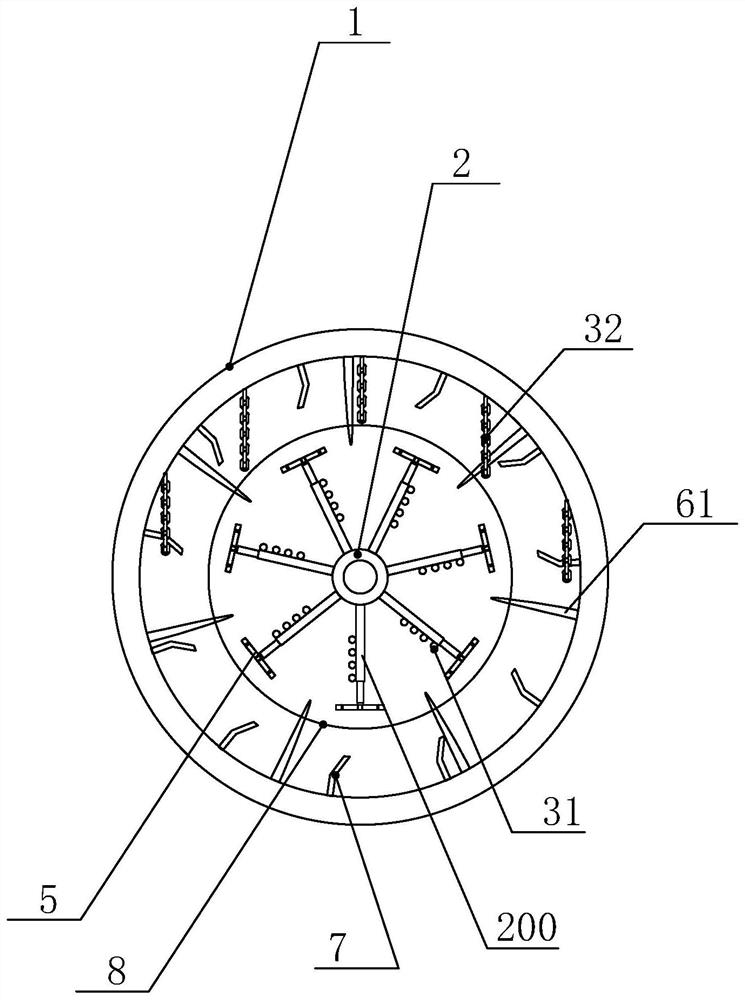

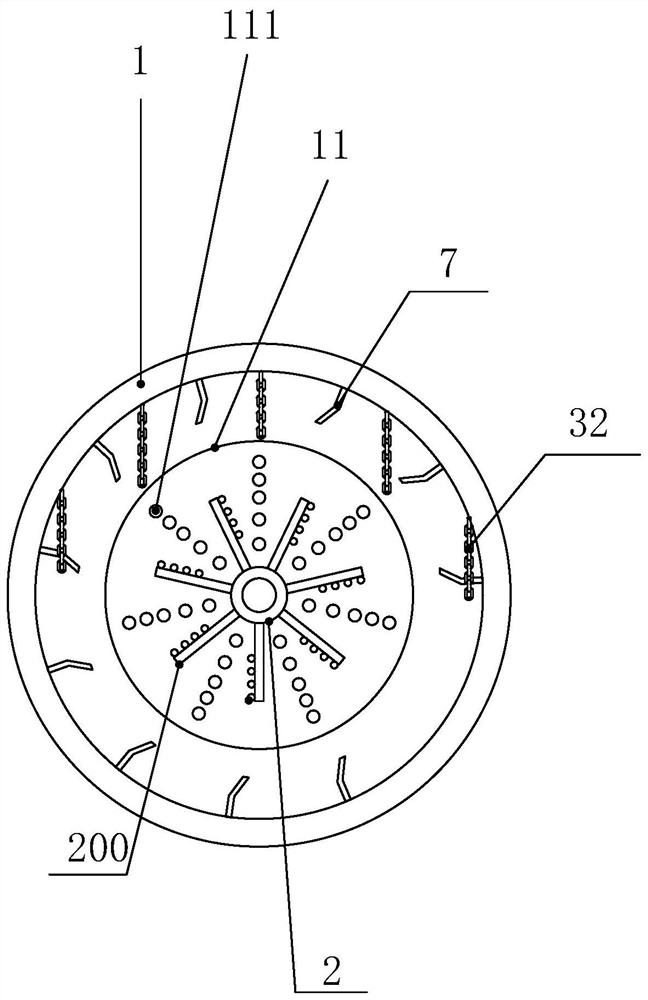

Sludge crushing and drying device

ActiveCN112794615AGuaranteed joint effectImprove articulationSludge treatment by de-watering/drying/thickeningGrain treatmentsSludgeEngineering

The invention discloses a sludge crushing and drying device which comprises a machine base; a drying rotary drum is transversely arranged on the machine base, an inner rotating shaft is arranged in the drying rotary drum, a stirring pushing rod assembly is arranged on the inner rotating shaft in the radial direction, and the stirring pushing rod assembly comprises a pushing section and a fine crushing section in the extending direction of the inner rotating shaft; and a material inlet is formed in one end, close to the pushing section, of the drying rotary drum, a hot smoke inlet is formed above the material inlet, and a fine crushing rotary wheel is arranged at the tail end of the stirring pushing rod in the fine crushing section. The stirring pushing rod arranged in the length direction of the drying rotary drum is divided into the pushing section and the fine crushing section, refining and labor division are achieved, the fine crushing rotary wheel at the tail end of the fine crushing section is used for fully crushing sludge in a cementing stage, the treatment effect of a sludge crushing and drying device is effectively improved, the drying efficiency is improved, and the service life of equipment is prolonged.

Owner:ZHEJIANG SANLIAN ENVIRONMENT MACHINERY EQUIP

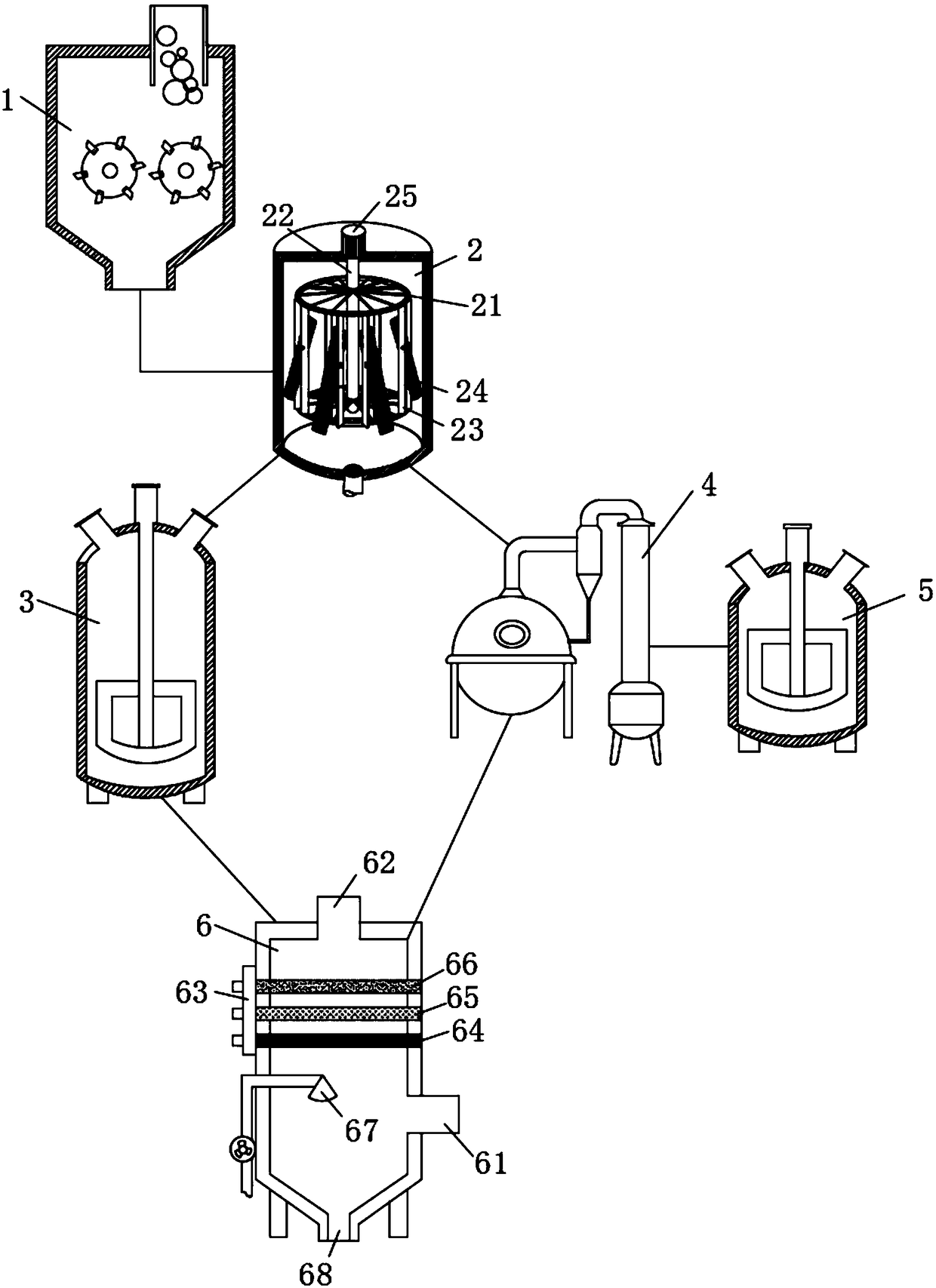

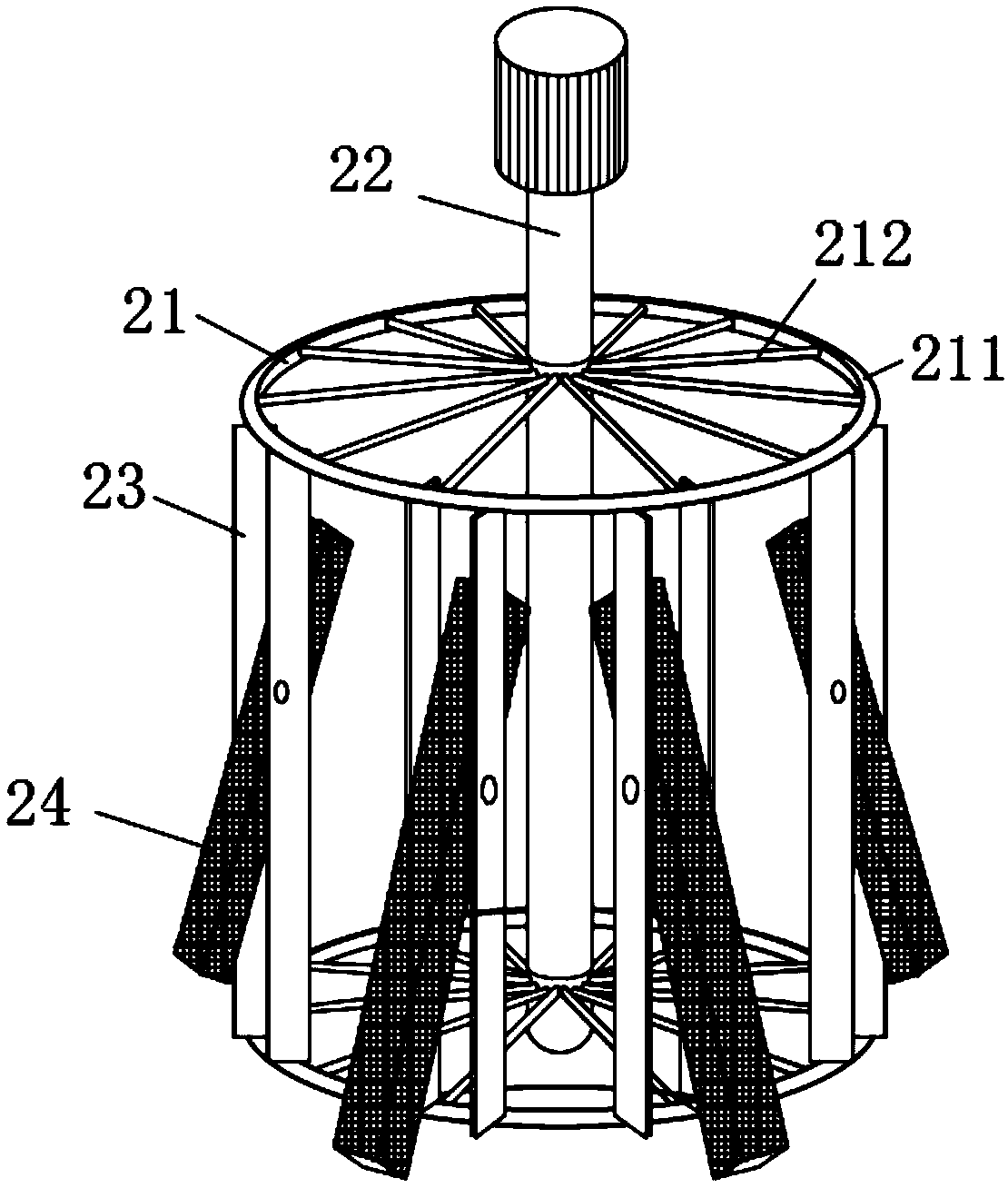

Environmental protection treatment equipment and method for improving rural ecological environment

ActiveCN109020632AIncrease profitReduced chance of splashingClimate change adaptationOrganic fertilisersEnvironmental resistanceEcological environment

The invention discloses environmental protection treatment equipment and method for improving the rural ecological environment. The method includes the steps of: sorting and impurity removal of ruralorganic waste; crushing: crushing the rural organic waste by a crusher; dehydration: putting the crushed organic material in dehydration equipment for dehydration, and dividing the material into solidwaste and waste liquid; solid waste fermentation: placing the solid waste in a first fermentation tank, adding a special microbial agent and conducting fermentation treatment; introducing the waste liquid into an evaporation and concentration tank for concentration and crystallization, then adding a special microbial agent and introducing the mixture into a second fermentation tank for fermentation; waste gas treatment: introducing the gases produced by the first fermentation tank and the second fermentation tank into deodorizing equipment for waste gas treatment, and introducing the waste liquid in the deodorizing equipment into the evaporation and concentration tank for concentration purification; finished product acquisition: mixing the fermentation products in the first fermentation tank and the second fermentation tank evenly, and performing after-ripening, thus obtaining an organic compost finished product. The equipment provided by the invention is convenient to use, improves the utilization efficiency of perishable waste, at the same time reduces probability of equipment damage, is convenient in operation, has strong practicability, and is easy to popularize and use.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

Paint spraying device capable of uniformly spraying paint and preventing paint from splashing for building pipe

InactiveCN113000272AReduced chance of splashingReduce exposurePretreated surfacesCoatingsElectric machineryStructural engineering

The invention relates to the technical field of pipe paint spraying, and discloses a paint spraying device capable of uniformly spraying paint and preventing the paint form splashing for a building pipe. The paint spraying device comprises a box body, a feeding box and a drying oven, wherein the feeding box and the drying oven are fixedly connected to the right side and the top end of the box body respectively, a first motor is fixedly arranged on the inner wall of the bottom of the box body, a first threaded rotating shaft is fixedly connected to the output end of the first motor, a paint spraying device body is in transmission connection with the outer ring of the right side of the first threaded rotating shaft, a feeder is fixedly connected to the inner wall of the box body, a second motor is fixedly arranged on the inner wall of the rear side of the bottom of the box body, a second threaded rotating shaft is fixedly connected to the output end of the second motor, and a feeding pipe is in transmission connection with the outer ring of the right side of the second thread rotating shaft. According to the device, the inner wall and the outer wall of the pipe is uniformly sprayed, the sprayed paint is prevented from splashing, the pipe can be dried, the situation that the non-dried paint is scratched is avoided, the continuity of pipe paint spraying operation is high, and the working efficiency of paint spraying is improved.

Owner:温州传顿机械科技有限公司

Low-dust environment-friendly alkaline carbon steel welding rod

InactiveCN106736039AImprove low temperature impact toughnessGood welding performanceWelding/cutting media/materialsSoldering mediaBrown iron oxideWollastonite

The invention discloses a low-dust environment-friendly alkaline carbon steel welding rod. The low-dust environment-friendly alkaline carbon steel welding rod comprises a welding core and a covering coating the surface of the welding core. The covering comprises, by weight, 15-35% of marble, 3-10% of barium carbonate, 2-7% of magnesite, 5-8% of feldspar, 10-20% of micaceous iron oxide, 3-15% of wollastonite, 2-12% of rutile, 3-10% of manganese sand, 1-2% of sodium alga acid, 1-2% of chalk and the balance iron powder. The low-dust environment-friendly alkaline carbon steel welding rod has the advantages that the micaceous iron oxide substitutes for fluorides, so that diffusible hydrogen content in weld metal is controlled effectively, low-temperature impact toughness of weld joints is enhanced, smoke is avoided in a welding process, and environmental pollution caused by welding is reduced.

Owner:天长市通联焊业有限公司

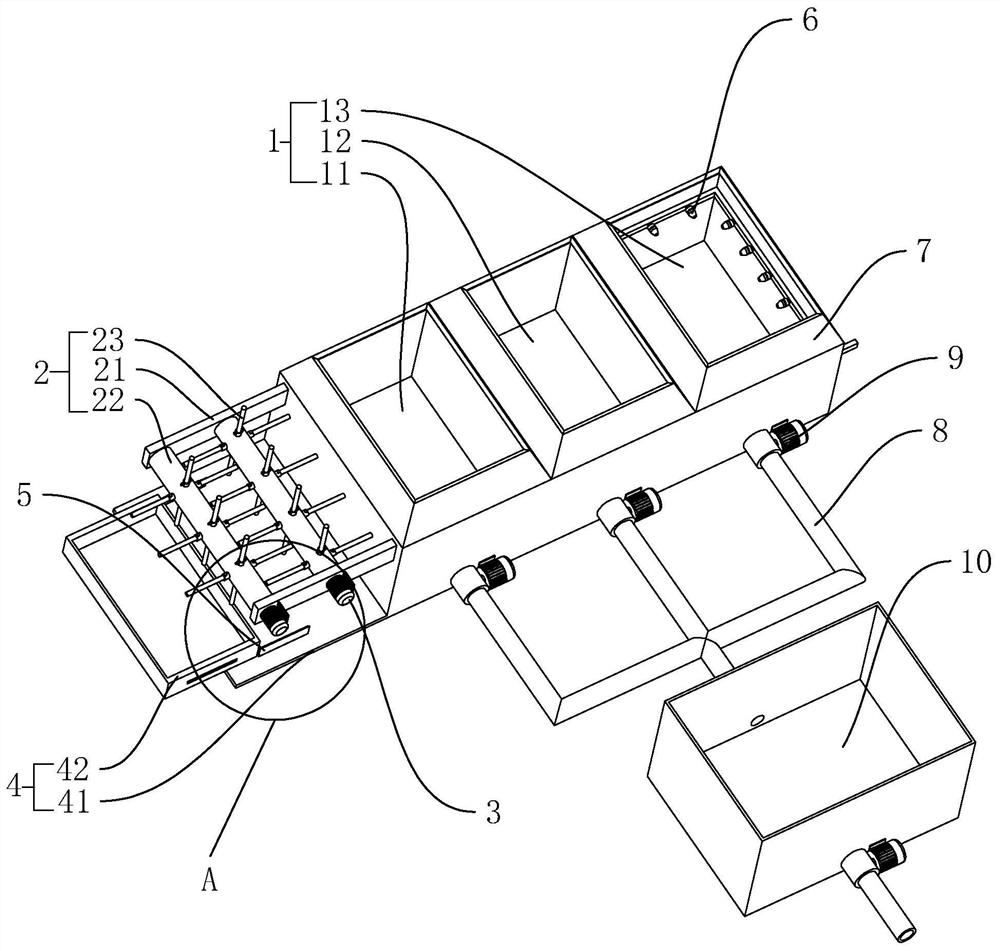

Pickling equipment and pickling method using equipment to produce steel plate

PendingCN111778512AImprove pickling efficiencyAvoid affecting the working environmentMechanical engineeringSteel plates

The invention relates to pickling equipment. The pickling equipment comprises a pool body; the pool body comprises a pickling pool and a cleaning pool integrally formed on one side of the pickling pool; an impurity removal mechanism is installed on one side of the pickling pool away from the cleaning pool; the impurity removal mechanism comprises two mounting racks, two rotating shafts and a plurality of flapping rods; the two mounting racks are both fixedly arranged at one side of the pickling pool away from the cleaning pool; the two rotating shafts are rotatably arranged between the two mounting racks; the plurality of flapping rods are uniformly arranged in the circumferential directions of the rotating shafts along the length directions of the rotating shafts; and actuators are installed on the mounting racks and used for driving the two rotating shafts to rotate in opposite directions. The pickling equipment provided by the invention has the effect of removing impurities on the surface of a steel plate before pickling, and improving the efficiency of pickling.

Owner:浙江协和陶瓷有限公司

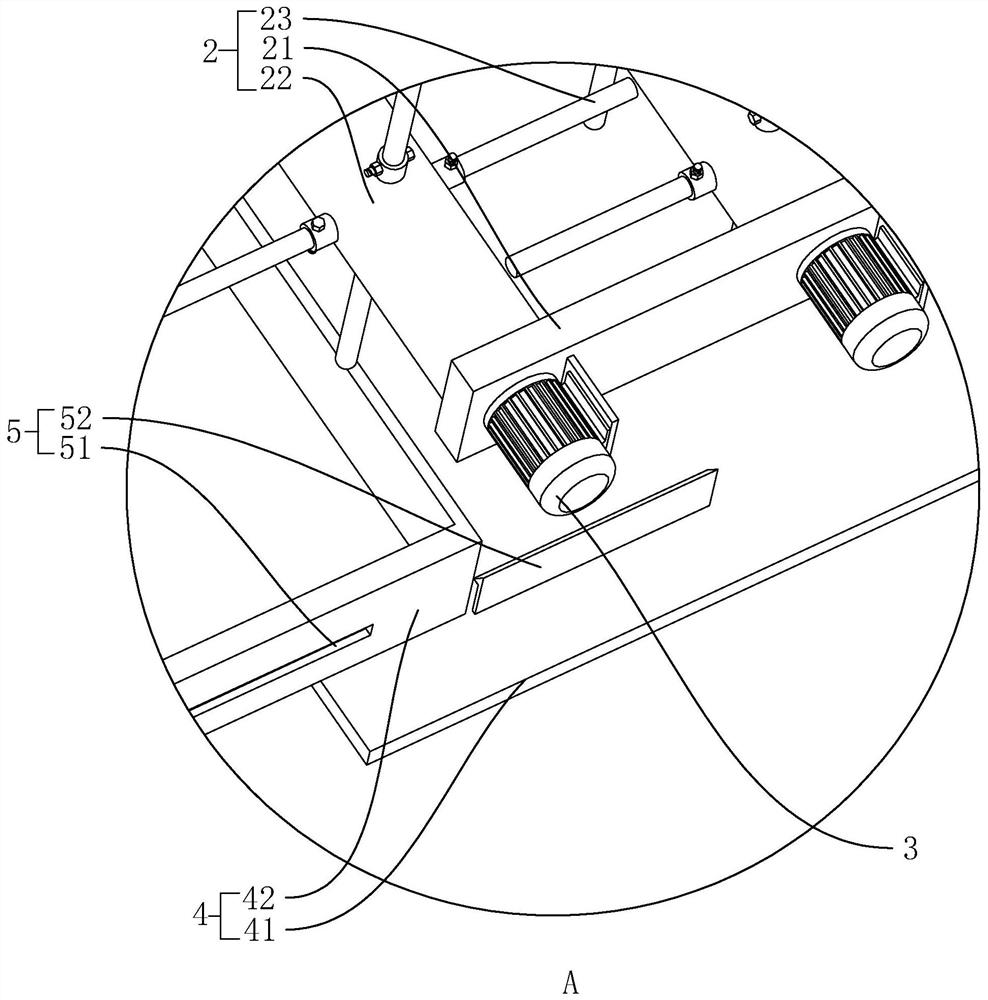

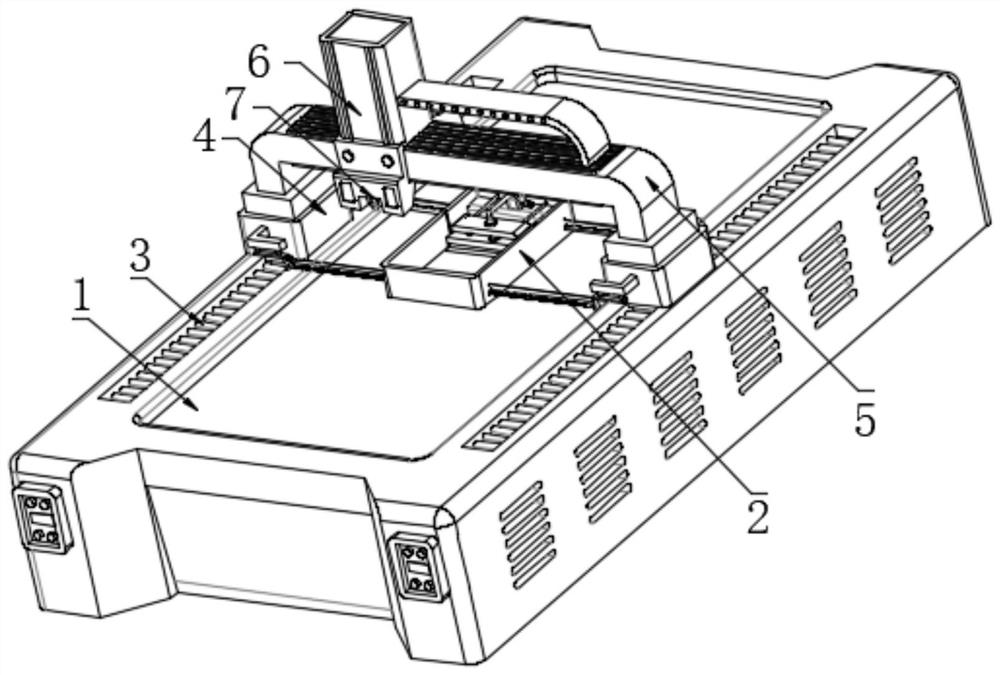

High-precision laser cutting machine for automobile sheet metal parts

PendingCN114523214AAchieve cleanupReduce the impactGrinding drivesGrinding machinesGear driveGear wheel

The invention discloses a high-precision laser cutting machine for automobile sheet metal parts, and particularly relates to the technical field of laser cutting machines, the high-precision laser cutting machine comprises a cutting machine table body and a protective frame, two guide sliding rails are arranged on the upper surface of the cutting machine table body, and guide moving frames are arranged on the inner walls of the guide sliding rails; the upper surfaces of the two guide moving frames are fixedly connected with the lower surface of the same moving support. According to the device, the lead screw, the threaded cap, the protective frame, the toothed bar, the gear, the grinding disc, the fan assembly, the middle box and the collecting filter box are arranged, meanwhile, the gear is meshed with the toothed bar while moving rightwards, meanwhile, the gear drives a connecting shaft and the grinding disc to rotate, and meanwhile dirt and unevenness adhering to the surface of an original part are ground through the grinding disc; and meanwhile, the fan assembly sucks and collects the cleaned sundries and waste through the middle box, the surface of the raw material can be cleaned, the influence of the subsequent laser cutting process is reduced, and the laser cutting precision and speed are obviously improved.

Owner:湖北豪杰机电科技有限公司

Composite cored wire for steelmaking and preparation method thereof

The invention discloses a composite cored wire for steelmaking and a preparation method thereof, aiming to provide a deep slow-release deoxidation technology for clean steel and steelmaking, which can not only remove impurities in molten steel but also remove impurities in steel slag . According to a certain proportion of components and method steps, the composite cored wire prepared has high deoxidation and desulfurization efficiency, reduces the probability of calcium splashing, greatly improves the yield of calcium treatment, and reduces the cost of calcium treatment. It can effectively remove the oxygen in the steel slag, and prevent the oxygen in the steel slag from re-invading into the molten steel after being saturated.

Owner:秦皇岛双轮环保科技股份有限公司

High-strength carbon dioxide protecting surfacing flux-cored wire

InactiveCN102069322BHigh hardnessImprove crack resistanceWelding/cutting media/materialsSoldering mediaSlagPotassium

The invention discloses a high-strength carbon dioxide protecting surfacing flux-cored wire. The raw material of the wire is a common low-carbon cold rolled steel band, and the filled flux core powder accounts for 17 to 22 percent of the total weight of the wire. The flux core comprises 13 to 30 percent of rutile, 5 to 26 percent of fluoride, 3 to 14 percent of magnesia clinker, 0 to 10 percent of quartz, 2 to 8 percent of potassium feldspar, 2 to 5 percent of aluminum magnesium alloy, 14 to 33 percent of metal chrome, 5 to 15 percent of flake graphite, 2 to 5 percent of No.45 ferrosilicon, 7to 11 percent of metal manganese, 5 to 12 percent of ferromolybdenum, 0 to 6 percent of ferrovanadium, 0 to 5 percent of ferroboron, 6 to 12 percent of metal tungsten, 2 to 8 percent of rare earth and the balance of iron. In the invention, the wire welding process is advanced, the electric arc is stable during welding, all position welding is realized, slag covering is good, deslagging is easy, and the weld joint is elegant, no crack is formed after multiplayer welding, the impact resistance is high, the Rockwell hardness (HRC) of the welding layer can reach 55 to 61, and the wear resistance is high.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Environment-friendly and efficient bolt coating device for field of steel structure buildings

ActiveCN110639748AImprove adhesionImprove rust resistanceLiquid surface applicatorsCleaning using toolsEnvironmental geologyMechanical engineering

The invention discloses an environment-friendly and efficient bolt coating device for the field of steel structure buildings. The environment-friendly and efficient bolt coating device comprises a coating bin, a bracket is fixedly arranged on the upper part of the coating bin, a shell is arranged on the bracket, a mobile power supply is mounted in the shell, a plurality of winding iron columns arefixedly arranged on the inner wall of the bracket and electrically connected with the mobile power supply, the coating bin is internally provided with a piston matched with the bottom of the coatingbin, a feeding inlet is formed in the piston, a sealing cover is arranged on the feeding inlet, liquid channels connecting the coating bin with the feeding inlet are formed in the positions, on the piston, of the lower part of the feeding inlet, and a plurality of first permanent magnets are fixedly arranged on the piston. The environment-friendly and efficient bolt coating device has the beneficial effects that a first sponge is dipped with antirust paint, then a bolt head is coated with the antirust paint, and compared with the mode that the antirust paint is directly sprayed onto the bolt head, 20%-40% of coating can be saved; and the probability of antirust paint splashing can be effectively decreased, thus the probability of antirust paint dripping on the ground is decreased, and environmental protection is improved.

Owner:CHANGJIANG & JINGGONG STEEL STRUCTURE GRP CO LTD

Garbage cleaning and deodorizing integrated device

PendingCN114260294AReduce the probability of spreadingReduced chance of splashingSolid waste disposalTransportation and packagingEngineeringStructural engineering

The invention relates to the technical field of garbage treatment, in particular to a garbage cleaning and deodorizing integrated device which comprises a compression cleaning mechanism and a deodorizing mechanism installed on the compression cleaning mechanism, the compression cleaning mechanism comprises a compression box, one side of the compression box is connected with a throwing assembly in a matched mode, and the other side of the compression box is connected with a length limiting assembly in a matched mode. Two oppositely-arranged side pressing assemblies are arranged in the compression box in a sliding fit mode, and the length limiting assembly is located between the two side pressing assemblies. The length limiting assembly and the two opposite side pressing assemblies are in transmission connection with the power assembly so that garbage between the length limiting assembly and the two opposite side pressing assemblies can be compressed under driving of the power assembly. The deodorization mechanism is arranged on the length limiting assembly so as to conduct deodorization treatment on garbage between the length limiting assembly and the two side pressing assemblies. And the length limiting assembly and the two side pressing assemblies which are arranged in the compression box in a matched mode are adopted for compressing the garbage, and the probability that the garbage is diffused outwards along with the pressure of the pressing head in the compression process can be reduced.

Owner:张梅

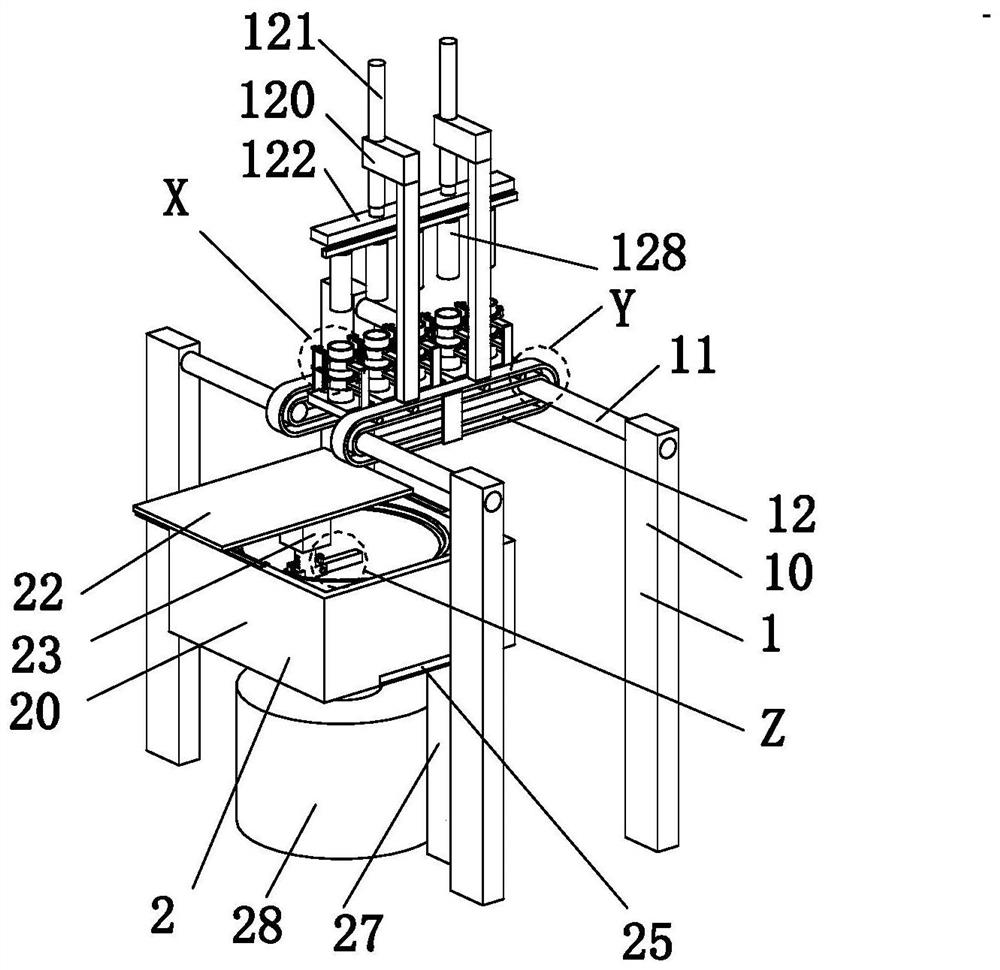

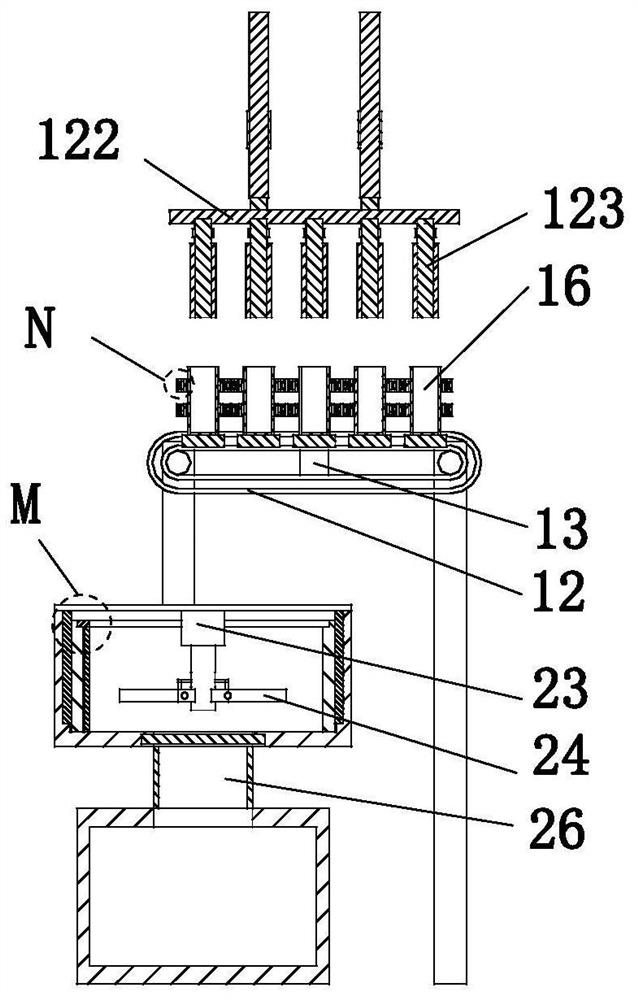

Preparation method of foam joint sealant

InactiveCN112439340AReduce the chance of splashingEasy to disassemble and clean regularlyRotary stirring mixersTransportation and packagingProcess engineeringSealant

The invention relates to a preparation method of a foam joint sealant, which uses a foam joint sealant preparation device, the foam joint sealant preparation device comprises a batching mechanism anda stirring and filling mechanism, the lower end of the batching mechanism is connected with the existing working ground, and the stirring and filling mechanism is arranged below the middle part of thebatching mechanism. And the stirring and filling mechanism is arranged at upper end of existing working ground. According to the invention, the design concept of an independent proportioning and mixing stirring phase structure is adopted to prepare the foam joint sealant, and the arranged batching mechanism adopts a multi-station design, so that independent and accurate proportioning of differentraw materials can be realized; the stirring and filling mechanism can form a relatively closed state in the mixing and stirring process of the raw materials, so that the probability of splashing outwards during mixing of the raw materials is reduced; meanwhile, a movable connecting structure is mostly adopted in the stirring and filling mechanism so as to facilitate regular disassembly and cleaning.

Owner:陈友英

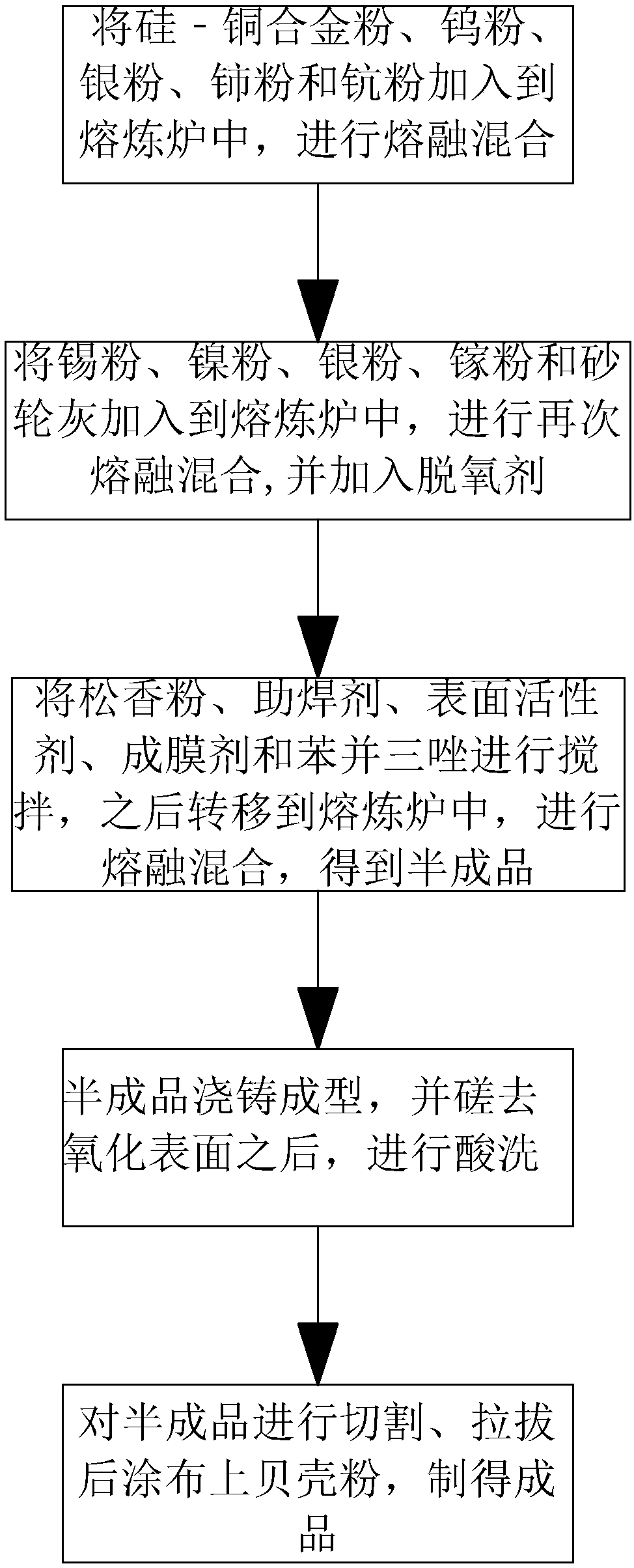

High-temperature lead-free solder wire and preparation method thereof

InactiveCN108555471AImprove protectionGood molding effectWelding/cutting media/materialsSoldering mediaROSIN POWDERIndium

The invention discloses a high-temperature lead-free solder wire and relates to the field of production of solder wires. The high-temperature lead-free solder wire is primarily prepared from the following components in parts by mass: 120-180 parts of tin powder, 20-30 parts of silicon-copper alloy powder, 12-16 parts of nickel powder, 10-12 parts of tungsten powder, 2-3 parts of silver powder, 3-5parts of scandium powder, 14-18 parts of rosin powder, 1-3 parts of scaling powder, 2-5 parts of a surfactant, 0.2-2 parts of a film-forming agent, 0.5-1.0 part of benzotriazole, 15-20 parts of grinding wheel ash, 2-4 pars of indium powder, 1-3 parts of cerium powder, 3-5 parts of gallium powder and 20-30 parts of shell powder. The relatively high melting point can be guaranteed while lead is notadded, so that the environmental pollution is reduced favorably. Meanwhile, the high-temperature lead-free solder wire is relatively simple in preparation method and suitable for being produced on alarge scale.

Owner:昆山双达锡业制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com