Pickling equipment and pickling method using equipment to produce steel plate

A kind of pickling equipment and steel plate technology, which is applied in the field of steel plate production, can solve the problems of reduced pickling efficiency, affecting the reaction speed of acid solution and oxide skin, etc., and achieve the effects of improving efficiency, reducing the probability of personal injury, and reducing the probability of splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

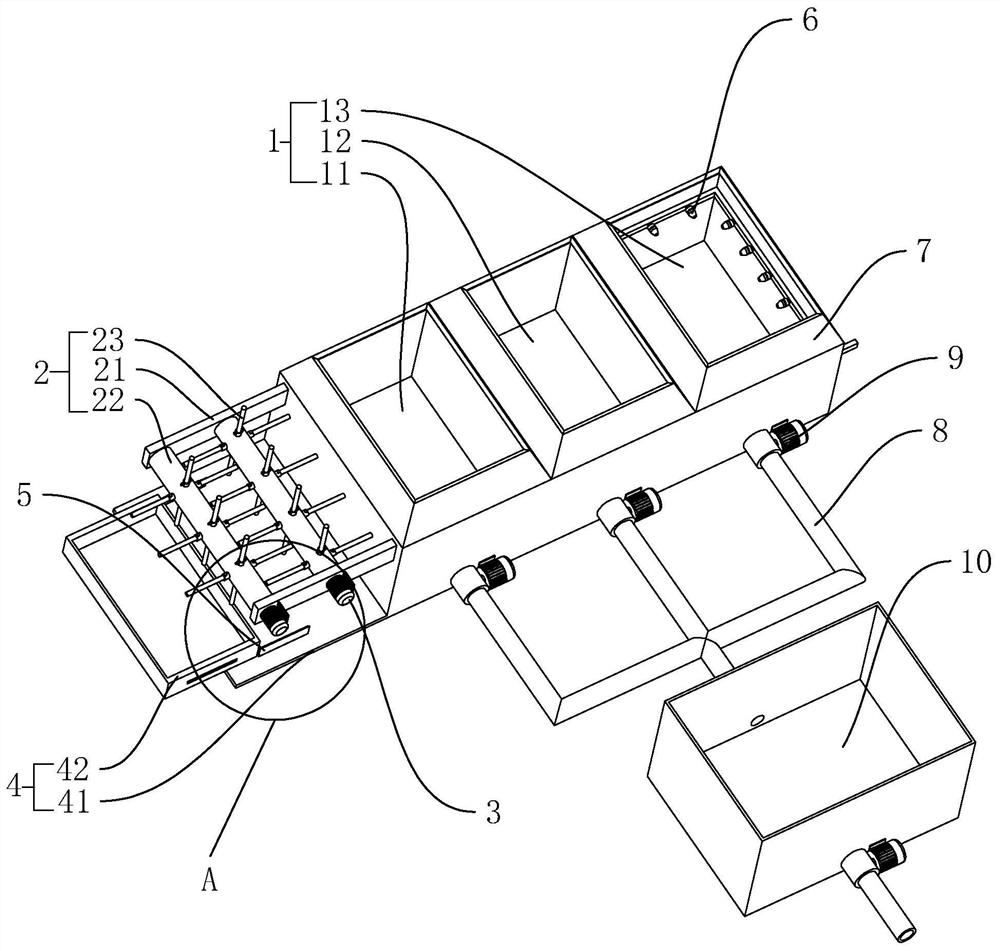

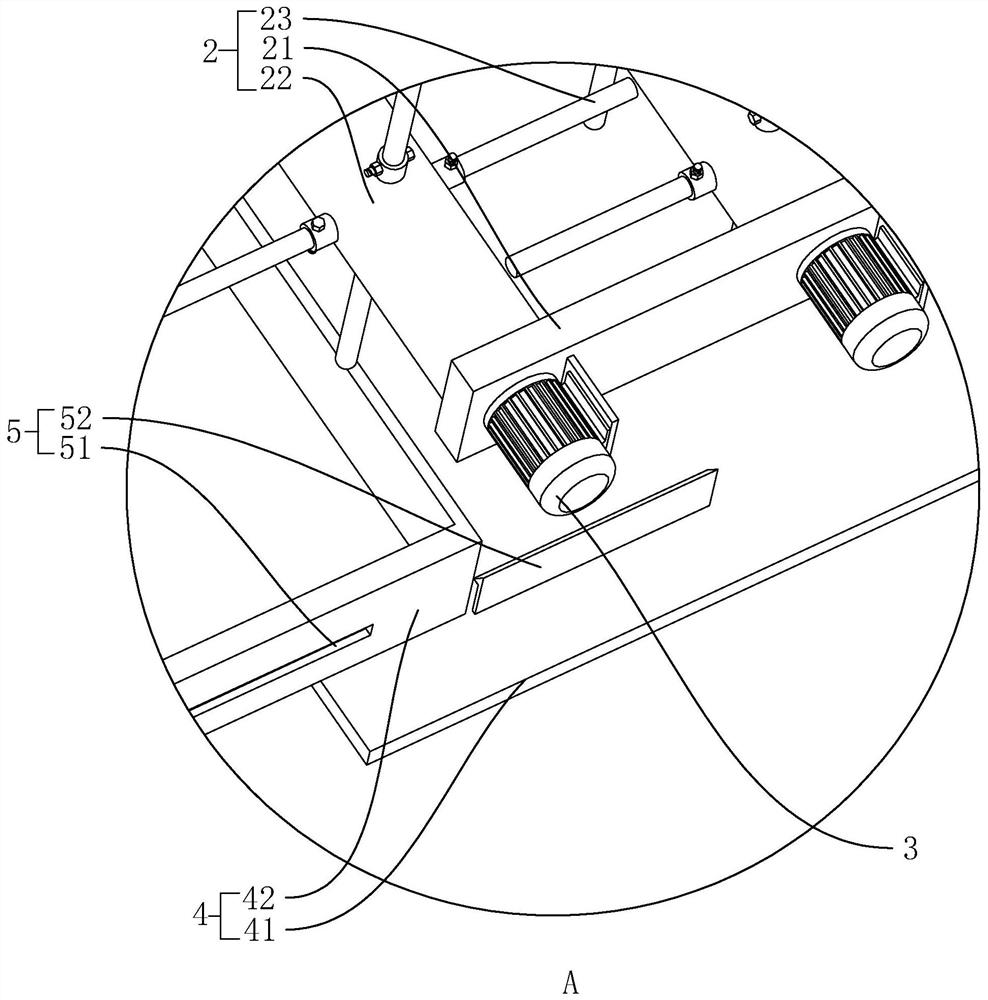

[0039] The following is attached Figure 1-2 The application is described in further detail.

[0040] The embodiment of the present application discloses pickling equipment. refer to figure 1 , including a pool body 1, the pool body 1 includes a pickling pool 11 and a cleaning pool 12 integrally formed on one side of the pickling pool 11, a side of the pickling pool 11 facing away from the cleaning pool 12 is equipped with a removal mechanism 2, and the removal mechanism 2 It includes two mounting frames 21 fixedly arranged on the side of the pickling pool 11 facing away from the cleaning pool 12, two rotating shafts 22 arranged between the two mounting frames 21 and several shafts 22 uniformly arranged on the rotating shaft along the length direction of the rotating shaft 22. 22 Circumferential flapping rods 23, the mounting frame 21 is equipped with a driving part 3, the driving part 3 drives two rotating shafts 22 to rotate in opposite directions, the driving part 3 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com