Patents

Literature

208results about How to "Avoid affecting the working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fault operation control method of DC (direct current) convertible frequency air conditioner

ActiveCN102345915ANormal air conditioning effectAvoid affecting the working environmentSpace heating and ventilation safety systemsLighting and heating apparatusOperation modeAir conditioning

The invention discloses a fault operation control method of a DC (direct current) convertible frequency air conditioner, which comprises the following concrete steps of: (1) carrying out classification on a fault and protection of the existing DC convertible frequency air conditioner; and (2) judging whether an air conditioning unit has the fault or not, i.e. starting and operating the air conditioning unit, carrying out fault judgment in the operating process, continuously operating the air conditioning unit if the air conditioning unit has no fault, and carrying out shutdown or entering a corresponding fault operation mode according to the grade of the fault if the air conditioning unit has the fault. In the control method, the air conditioning unit operates with the fault on the premise of no malignant fault and the fault problem is solved after work.

Owner:安徽奥克斯智能电气有限公司

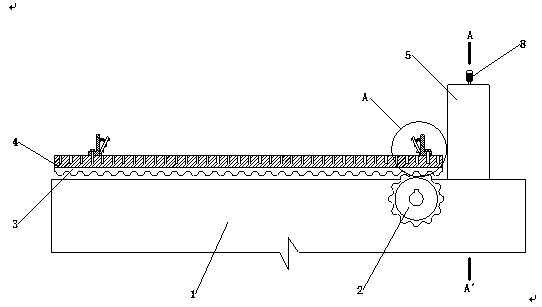

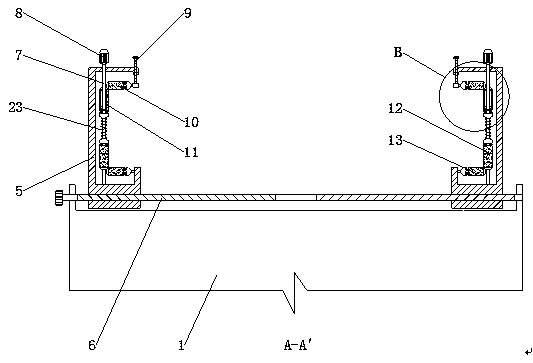

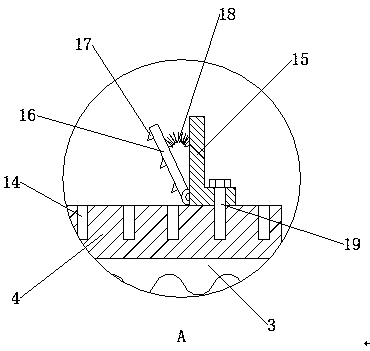

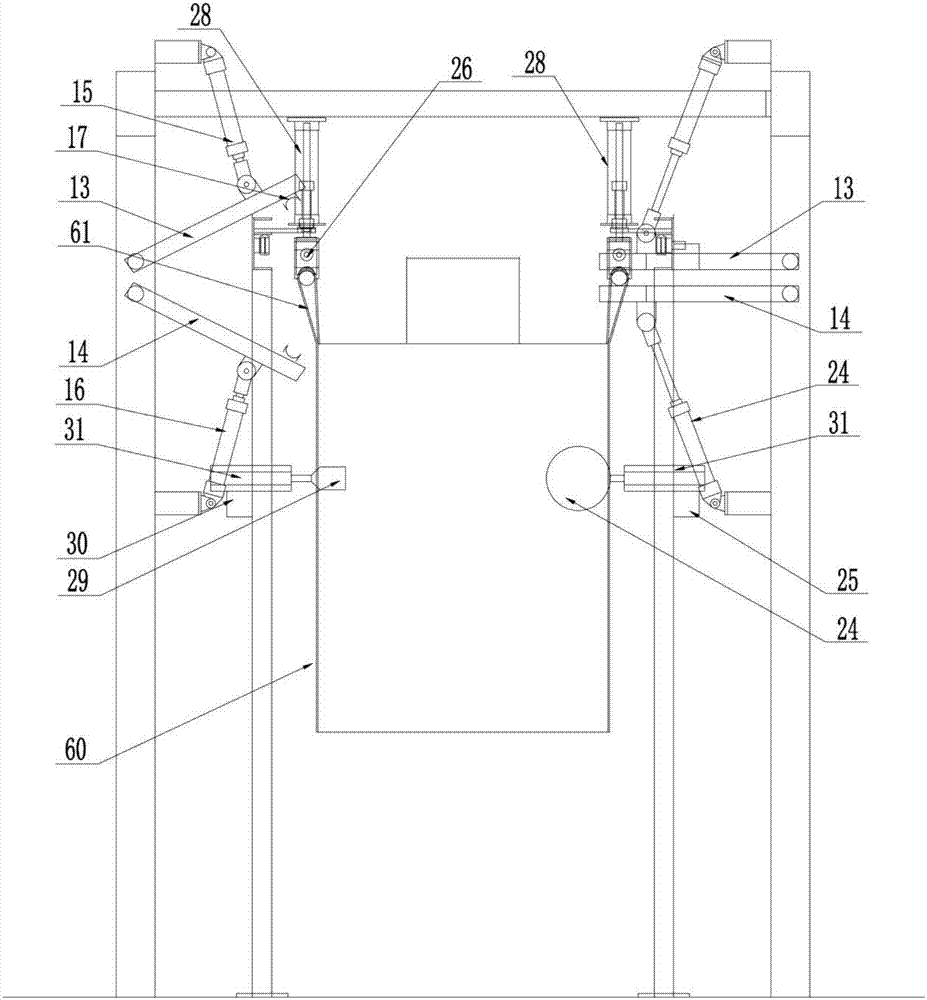

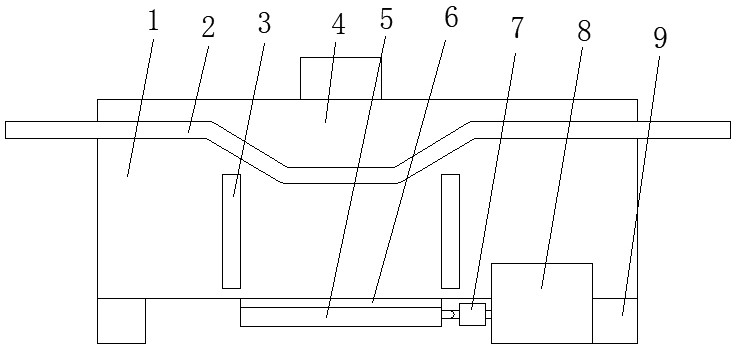

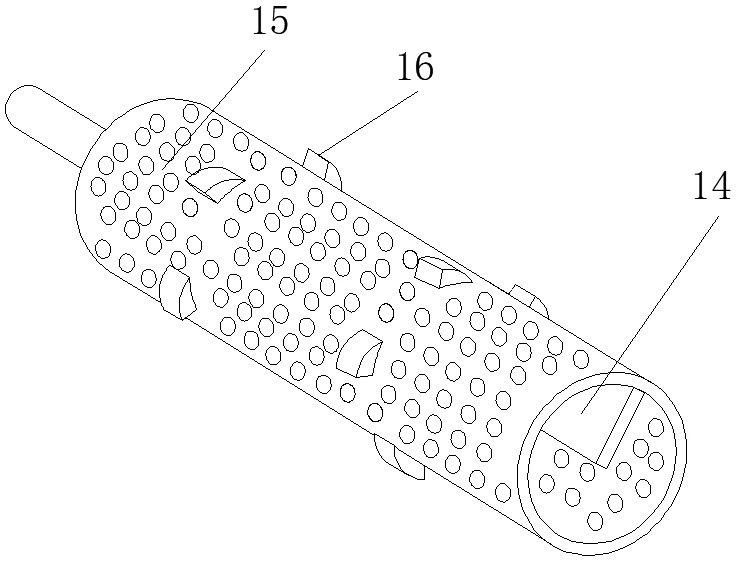

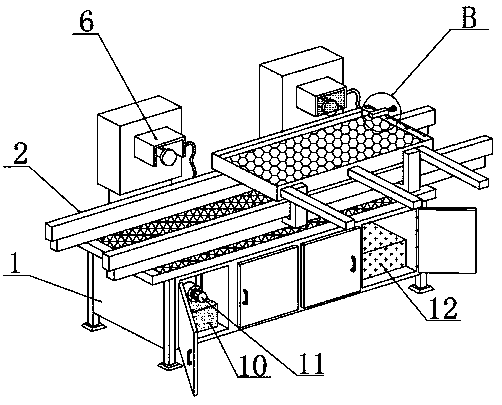

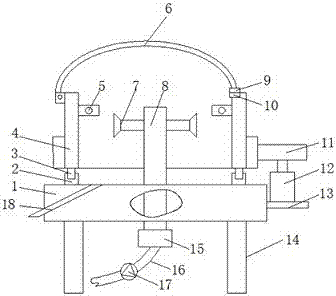

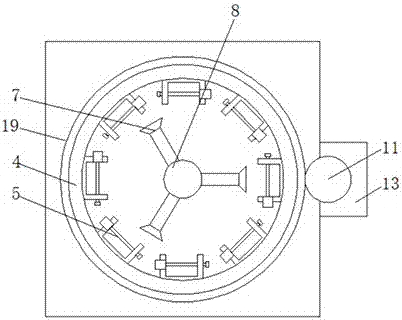

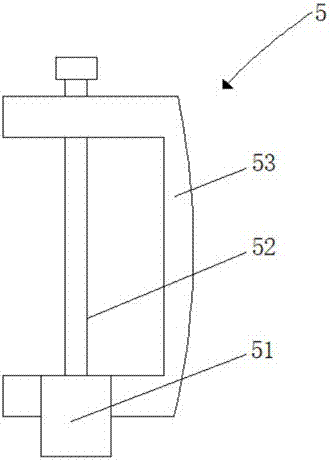

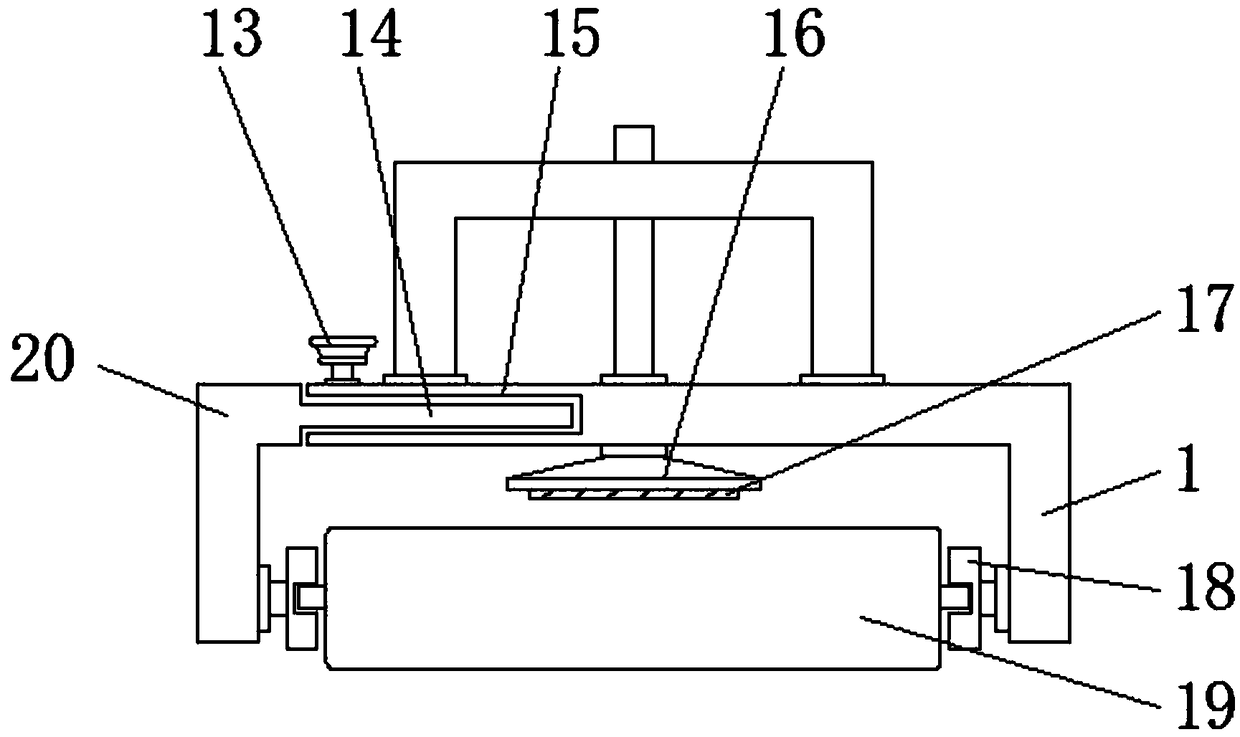

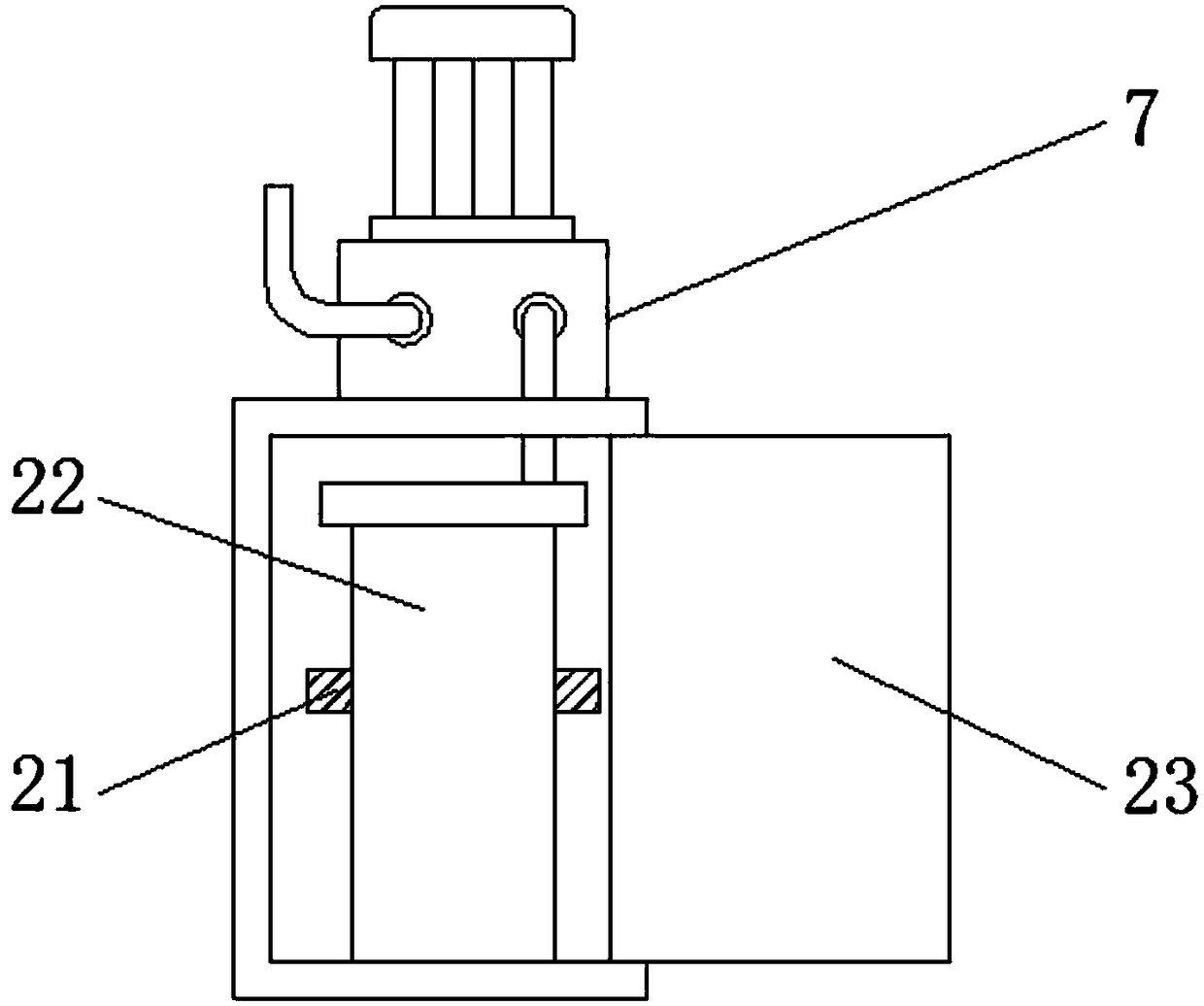

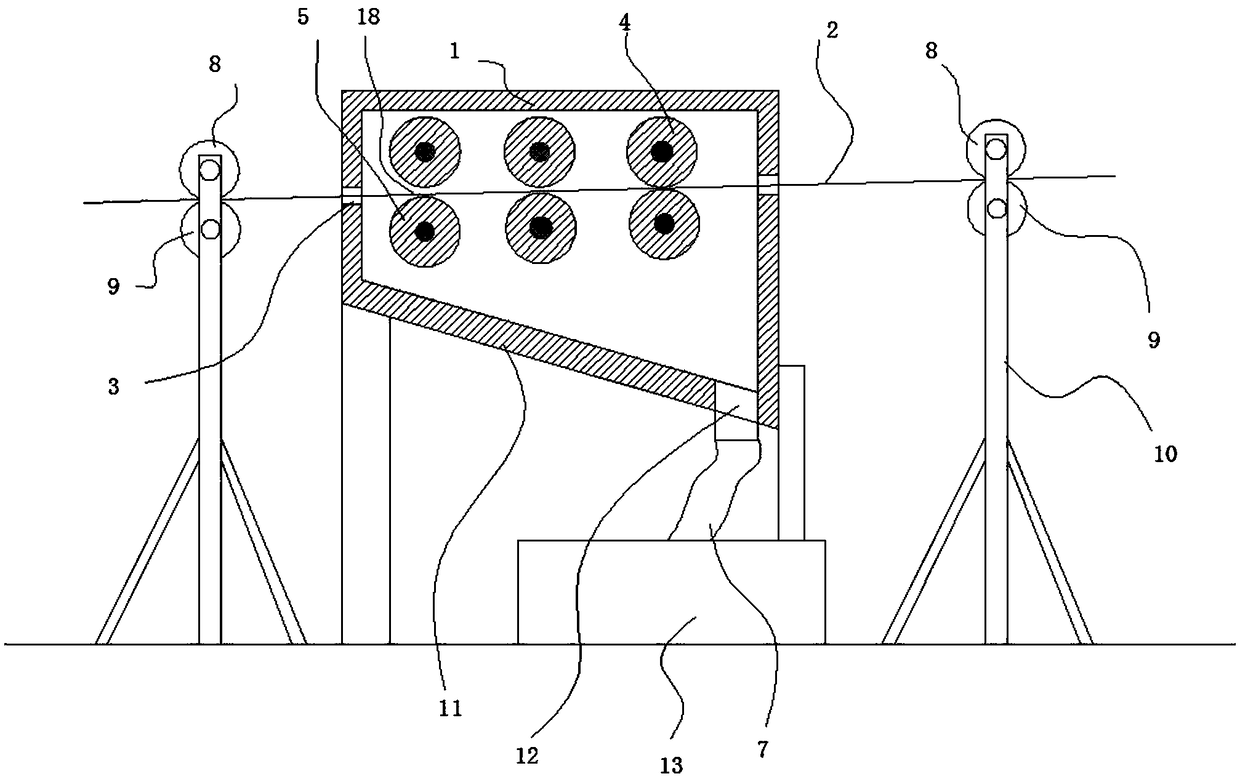

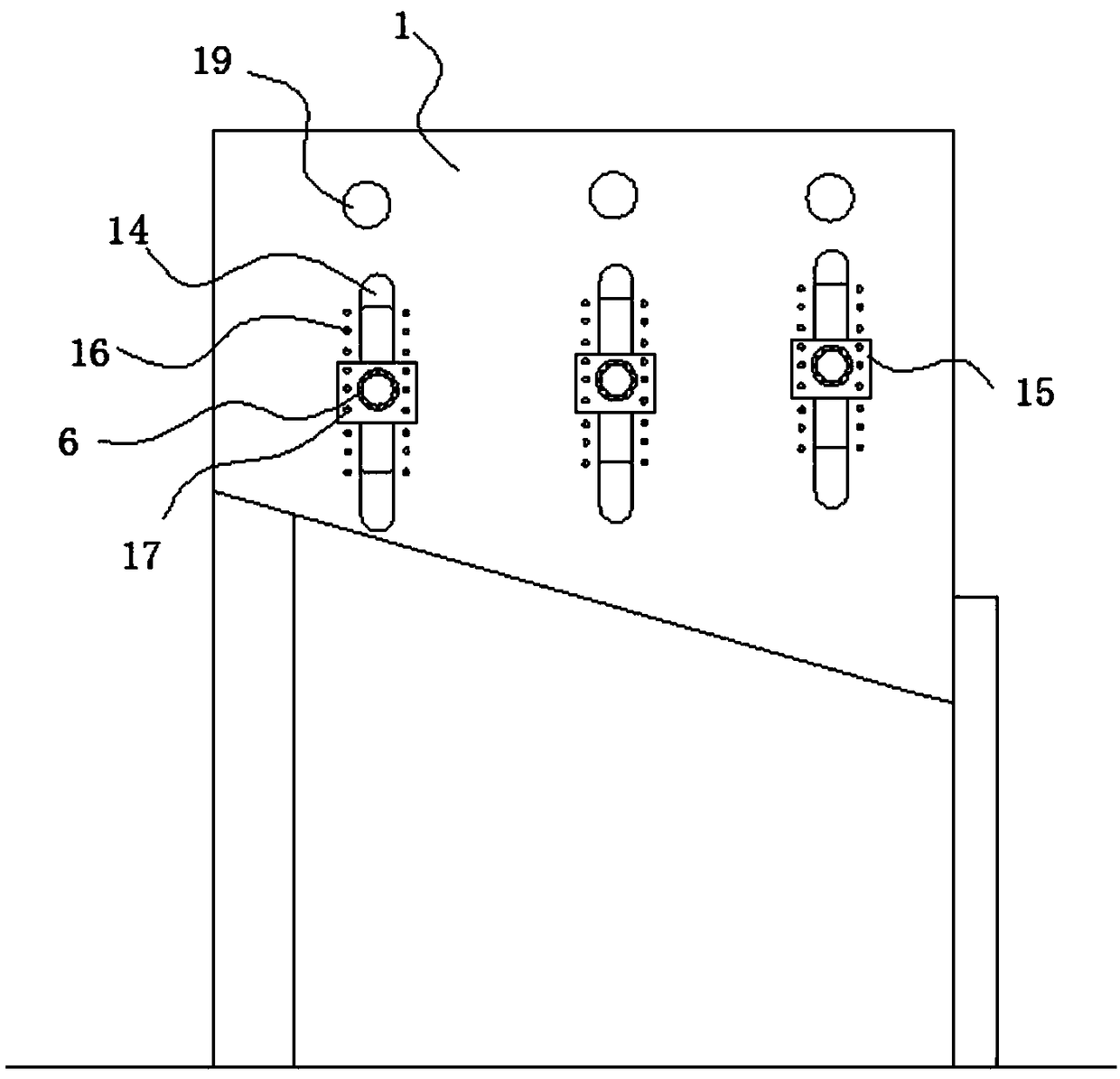

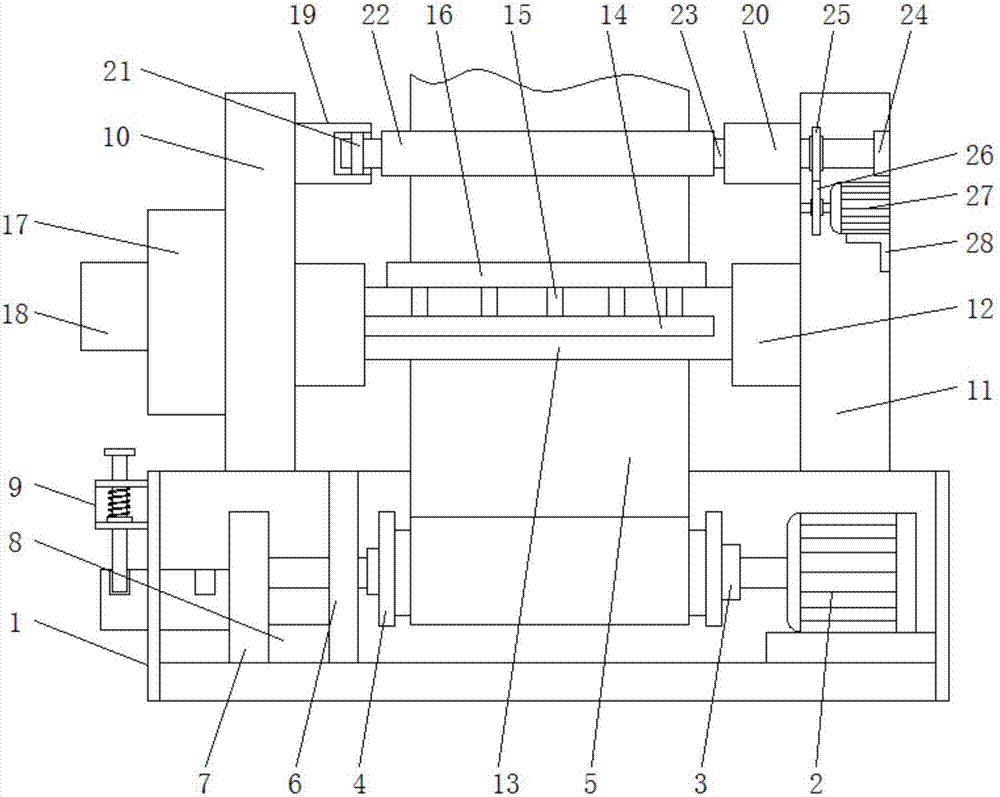

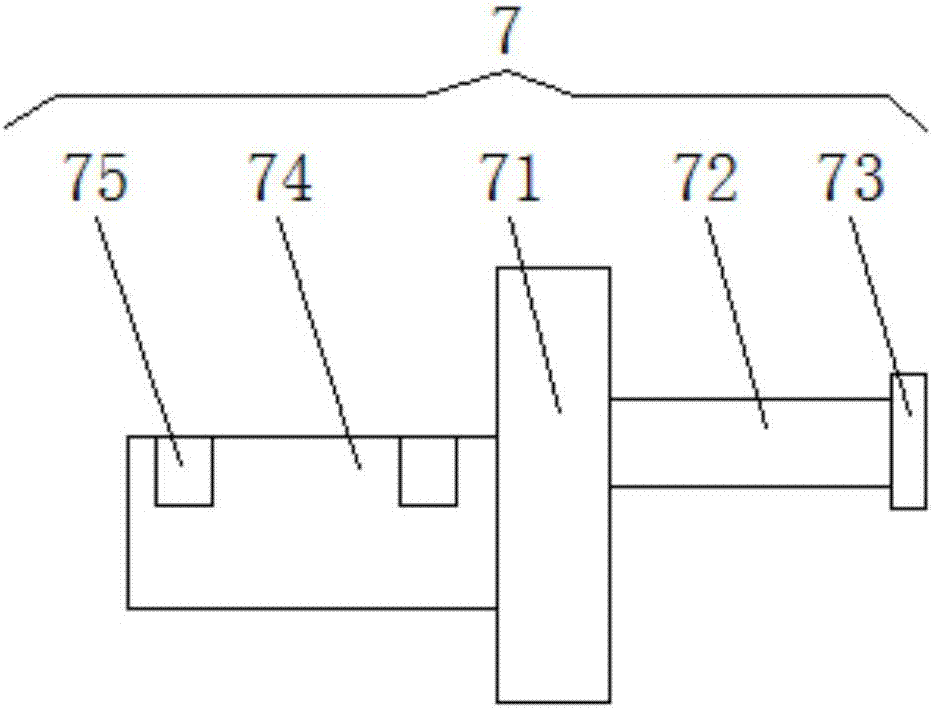

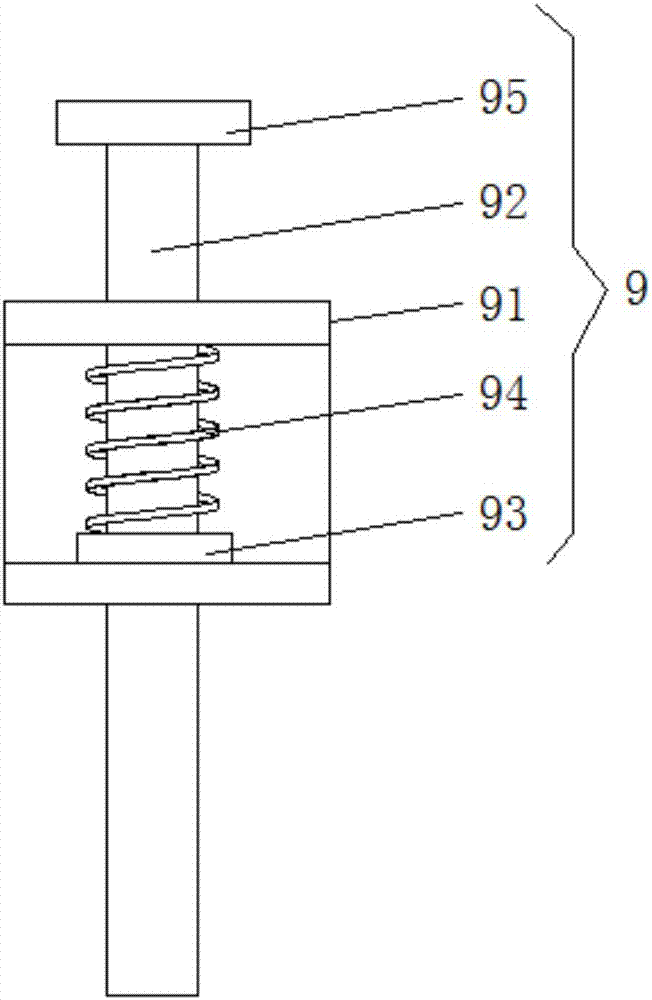

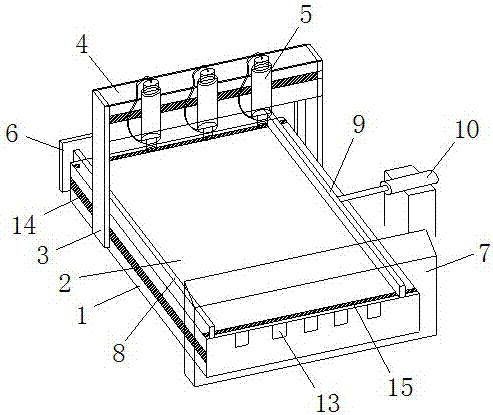

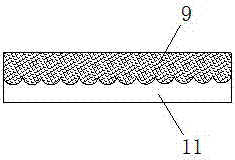

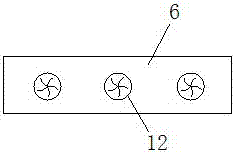

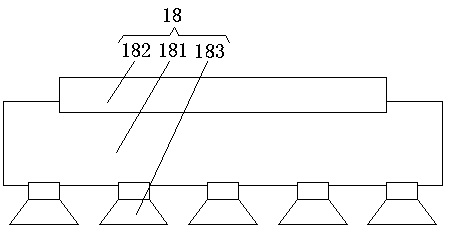

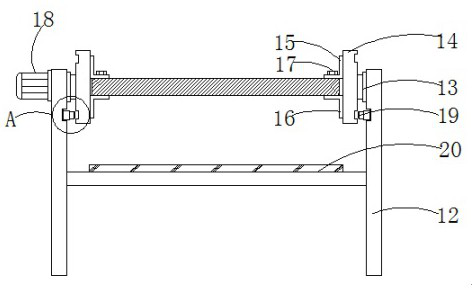

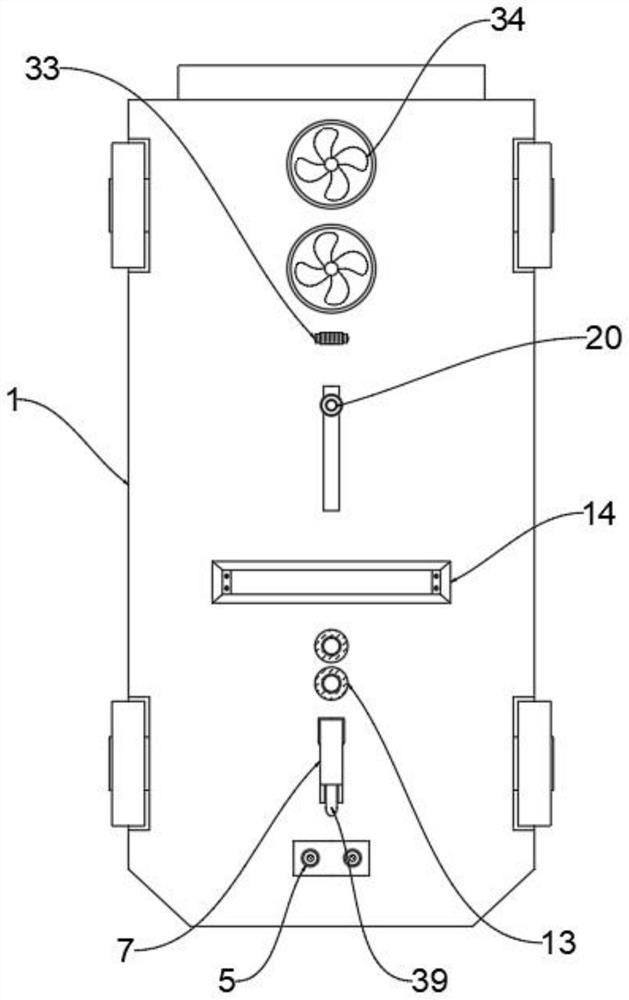

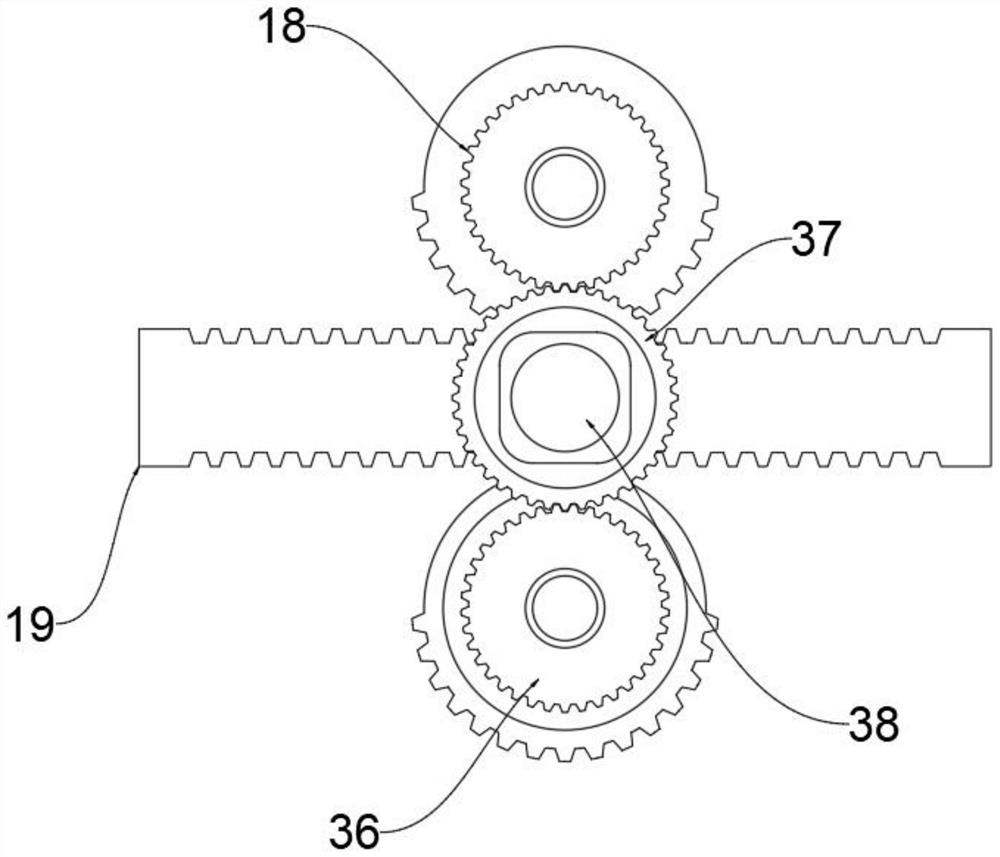

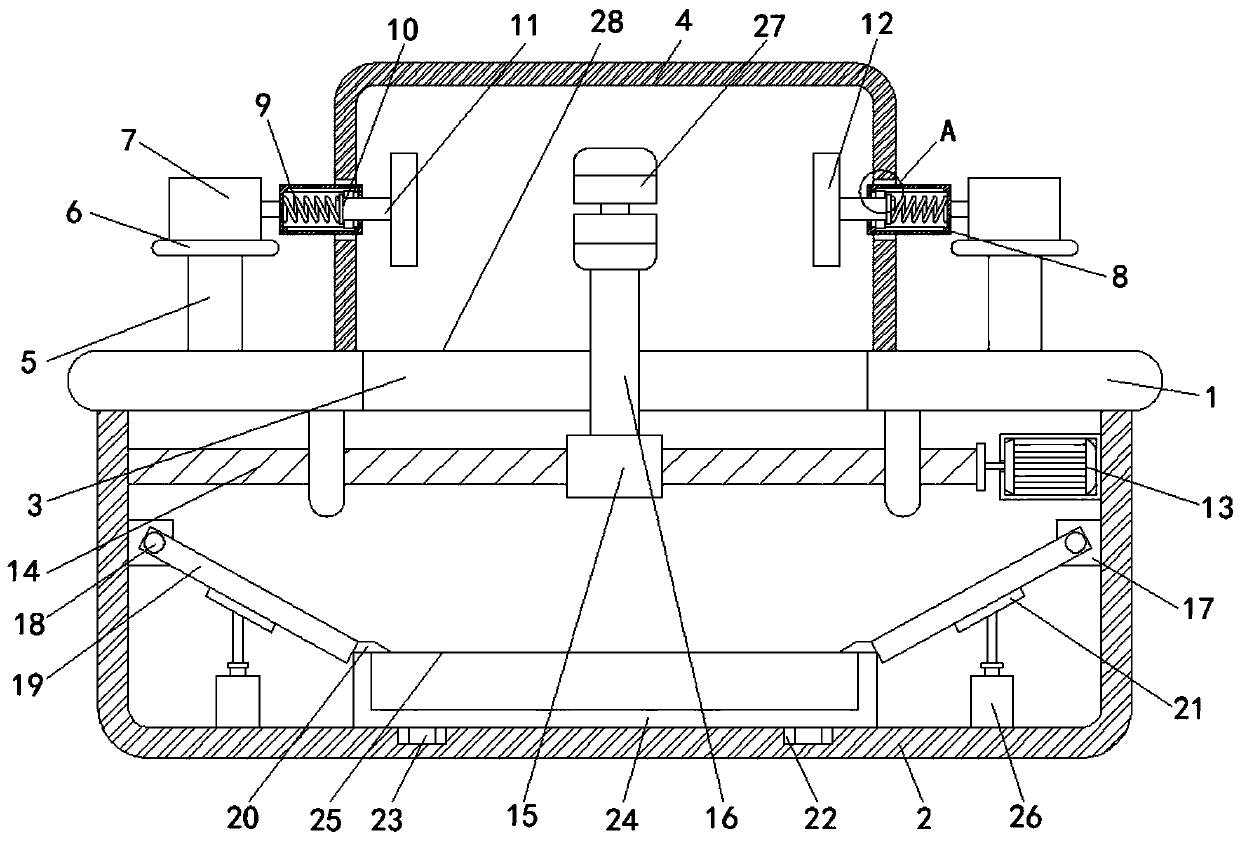

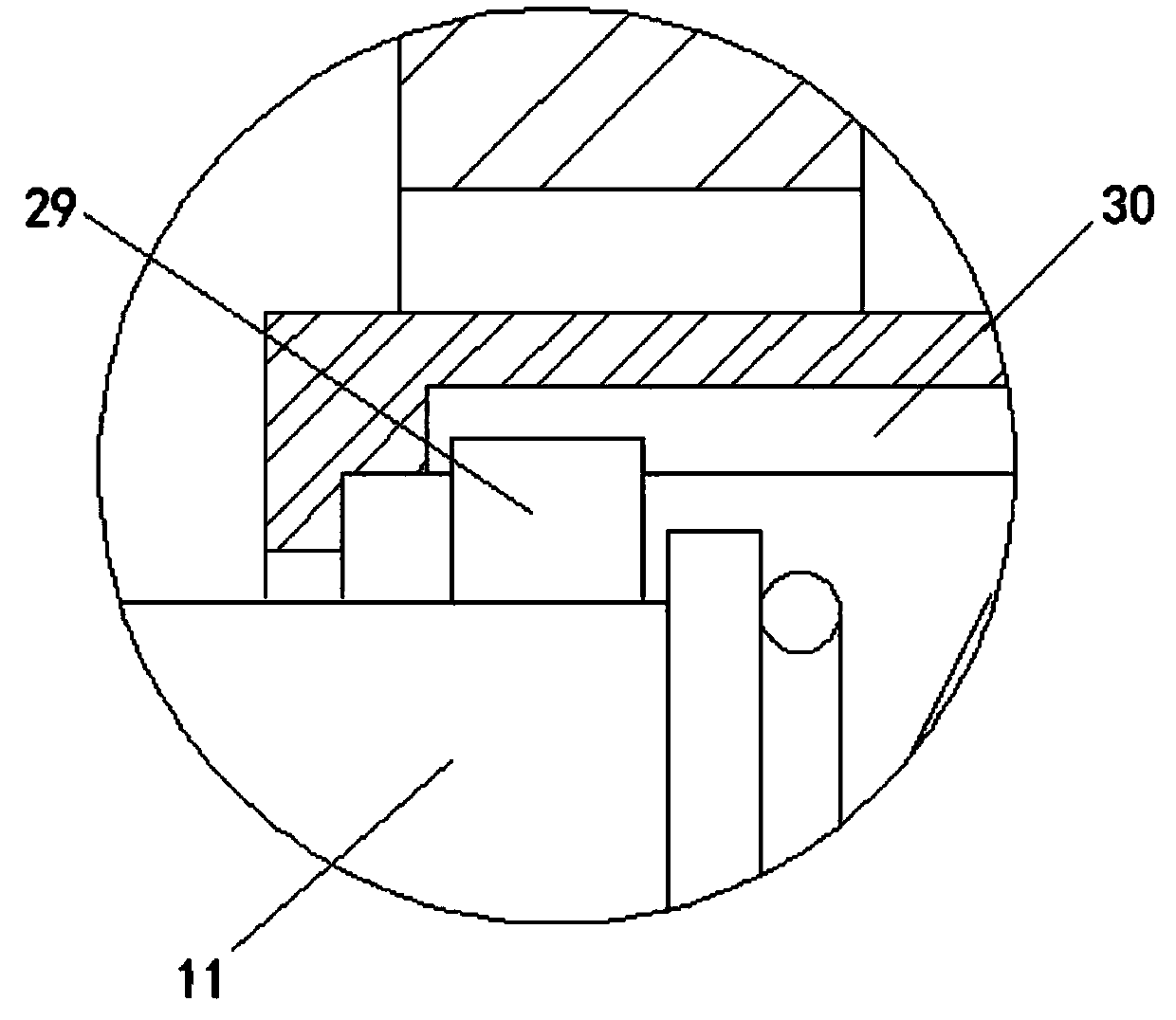

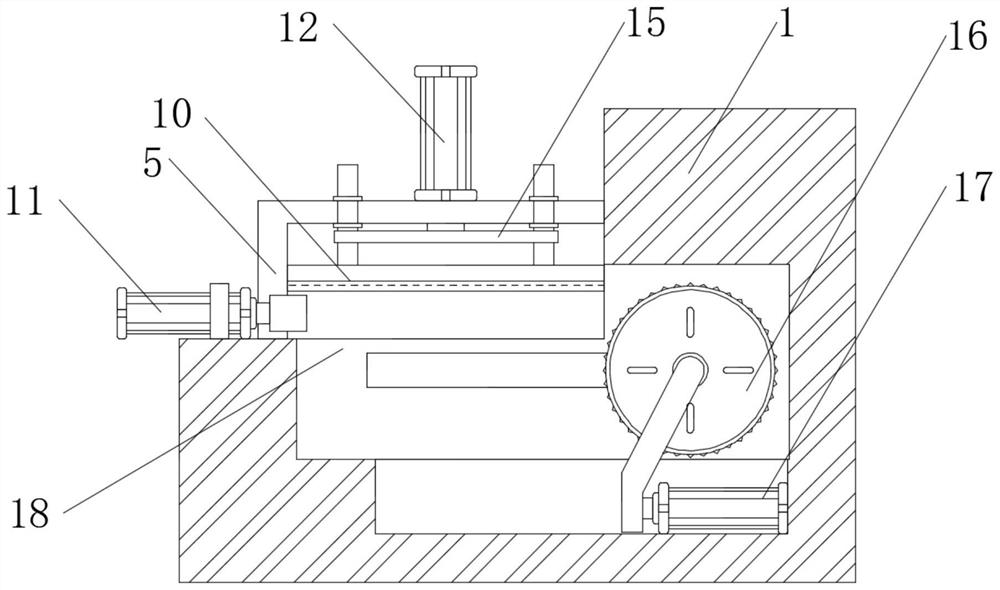

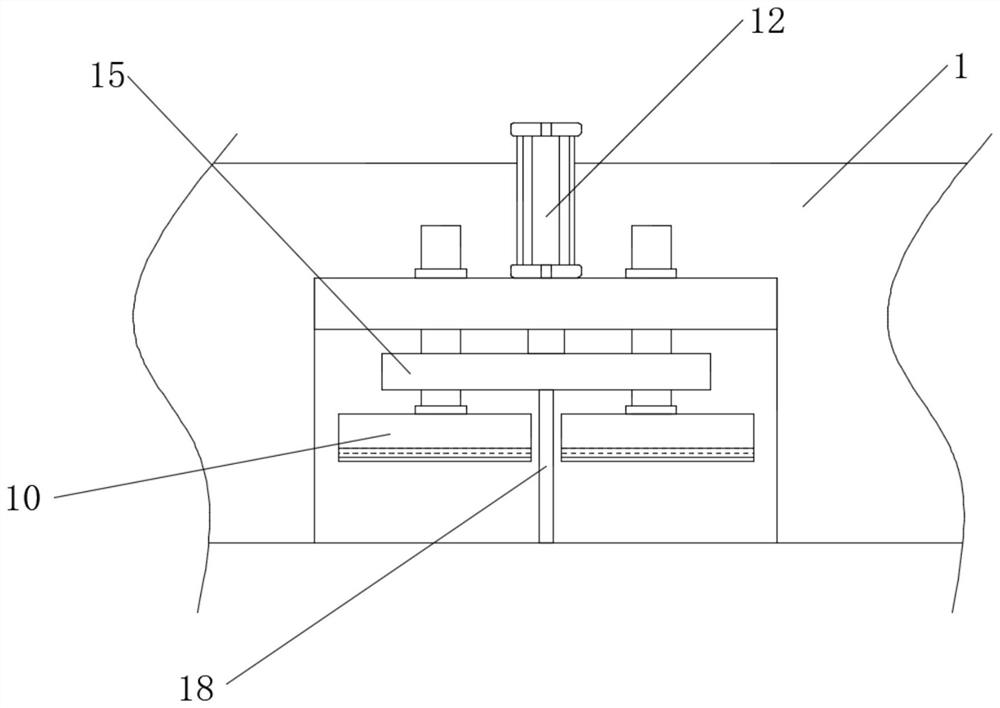

Deburring device for wood board processing

InactiveCN109732436AAvoid affecting the working environmentQuick clampingEdge grinding machinesGrinding drivesFurringPulp and paper industry

The invention provides a deburring device for wood board processing. The deburring device includes a workbench, a feeding flat board, two deburring frames, a moving transverse-grinding roller, a moving vertical-grinding roller, a fixed vertical-grinding roller and a fixed transverse-grinding roller, the feeding flat board is slidably arranged at the upper portion of the workbench, a rack is fixedly connected with the bottom of the feeding flat board, two L-shaped supporting boards are fixedly connected with the upper portion of the feeding flat board, and an elastic splint is rotatably connected with the inner side of each L-shaped supporting board; and a return stopping strip is fixedly connected with the surface of each elastic splint, the two deburring frames are movably arranged at oneend of the workbench, the moving vertical-grinding roller is slidably connected with the upper end of a rotating shaft, the moving transverse-grinding roller meshes with outer periphery of a cone gear, a fixed vertical-grinding roller is fixedly connected with the outer periphery of the lower end of the rotating shaft, and the fixed transverse-grinding roller meshes with the bottom of the fixed vertical-grinding roller. According to the deburring device, the feeding flat board is matched with the deburring frames, the wood board can be fixed on the feeding flat board through the elastic splints and the L-shaped supporting boards, so that the side end surface of the wood board can be scraped and polished in a reciprocating mode, and the deburring effect is improved.

Owner:江山市标龙装饰材料有限公司

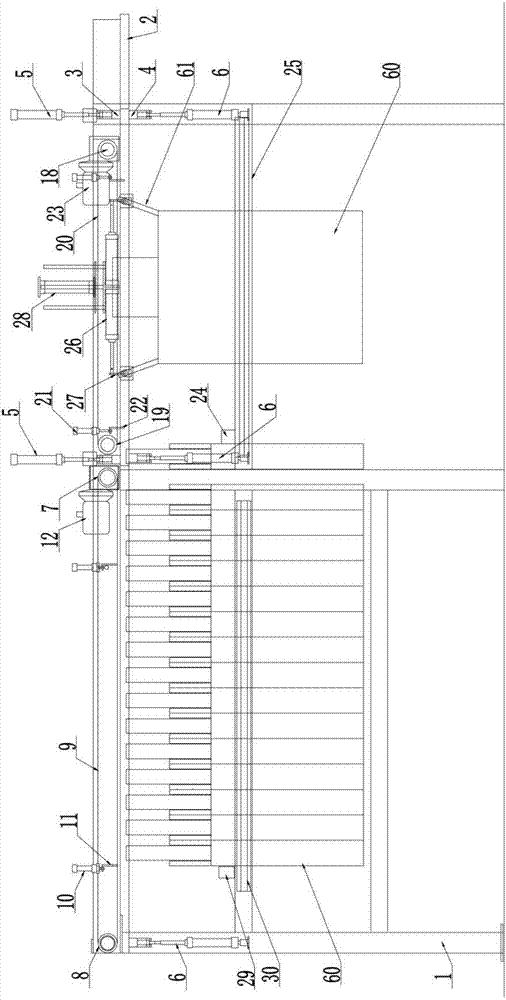

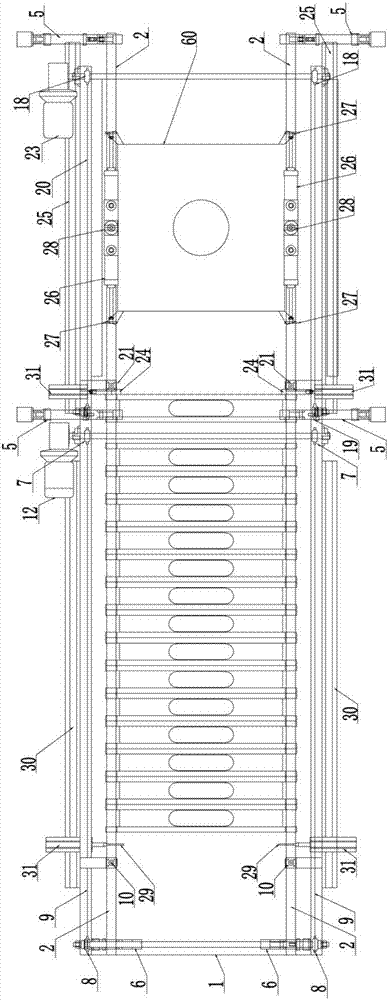

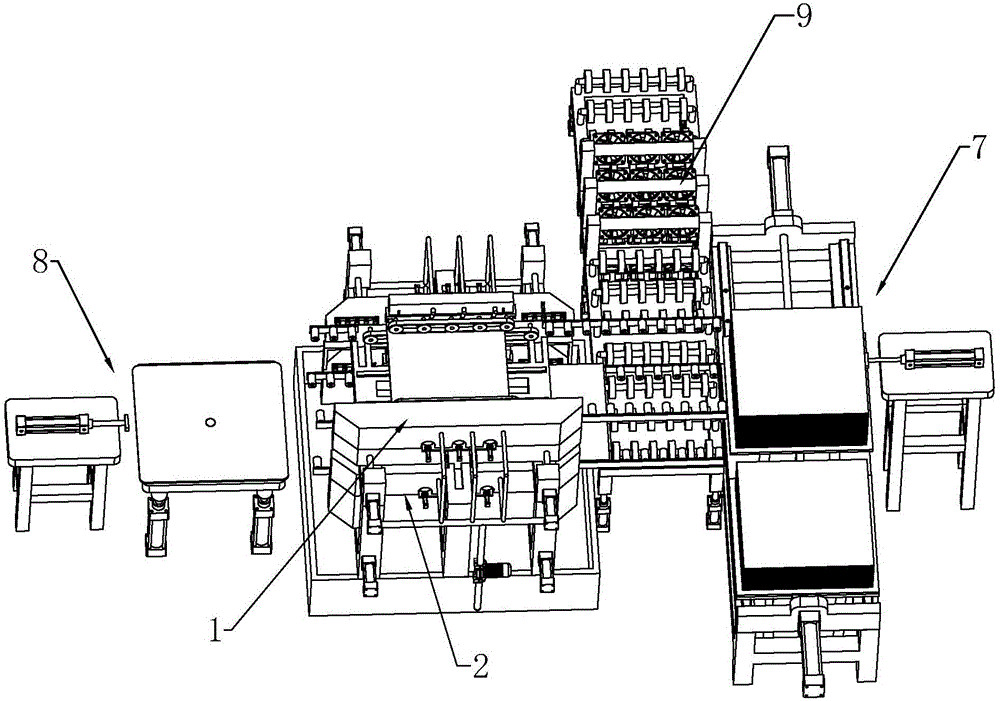

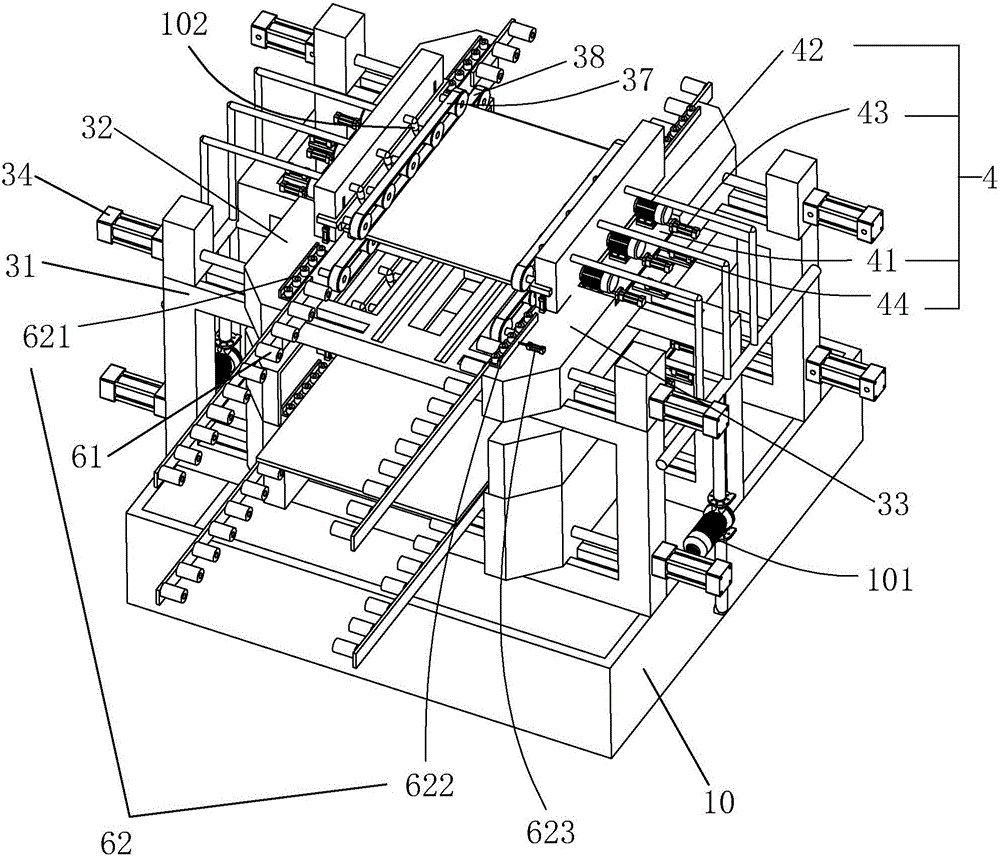

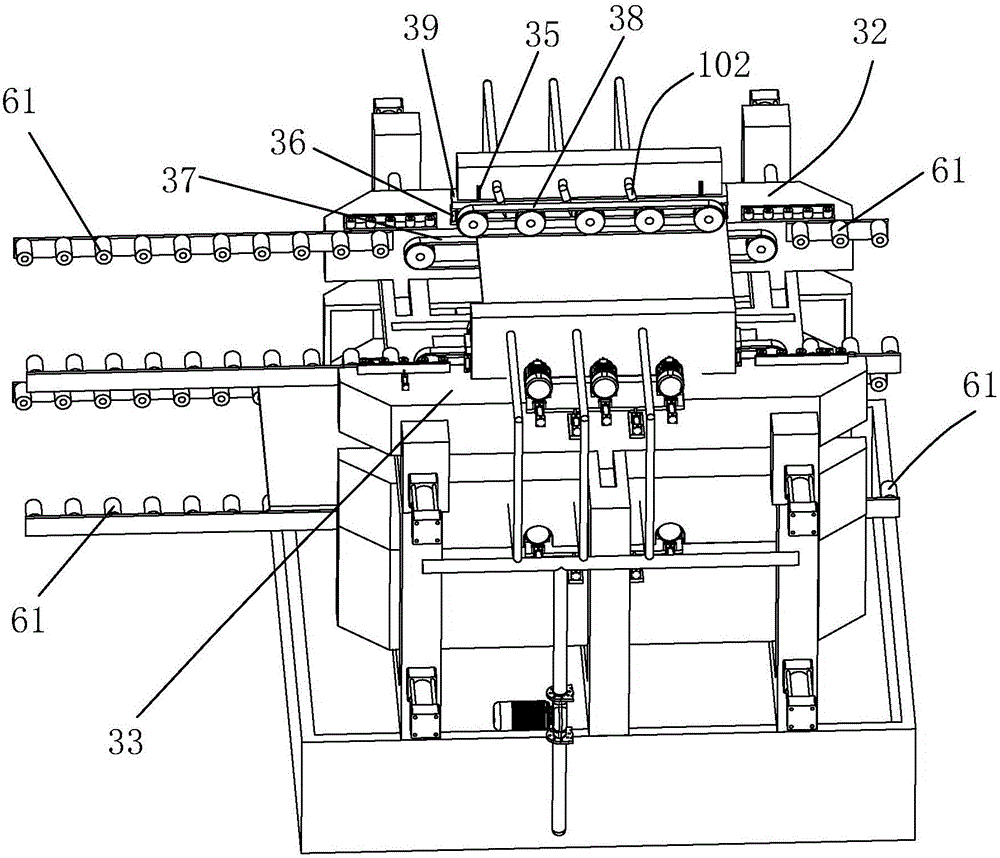

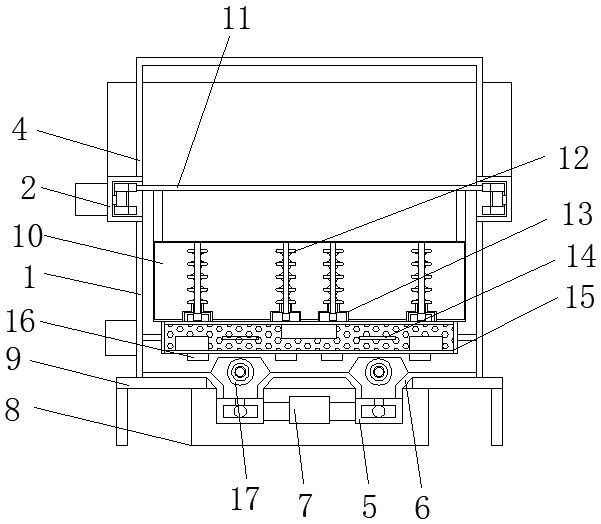

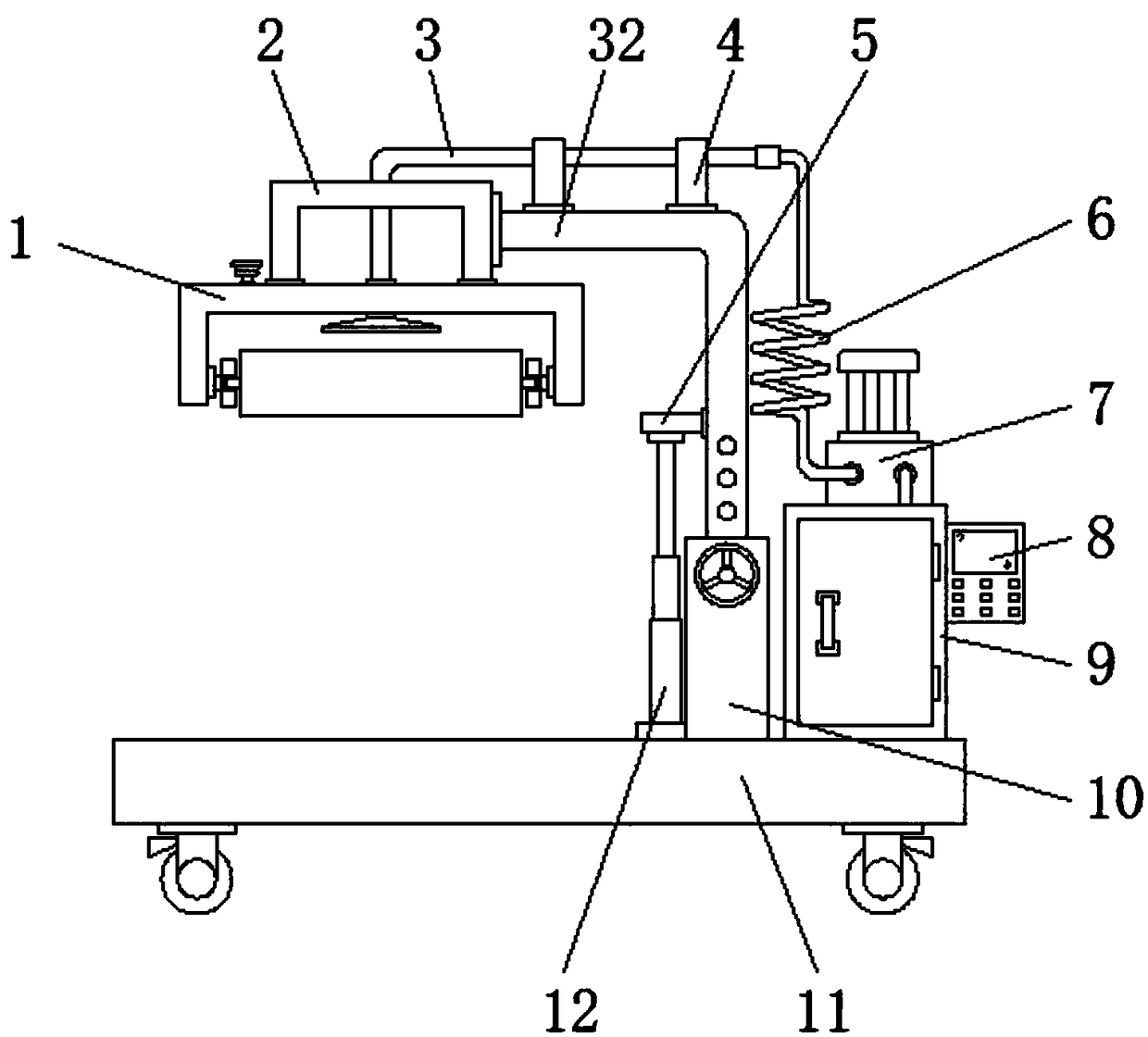

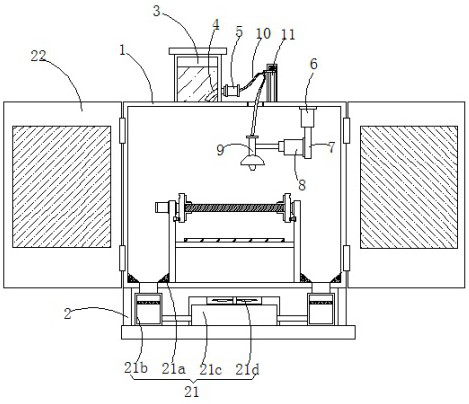

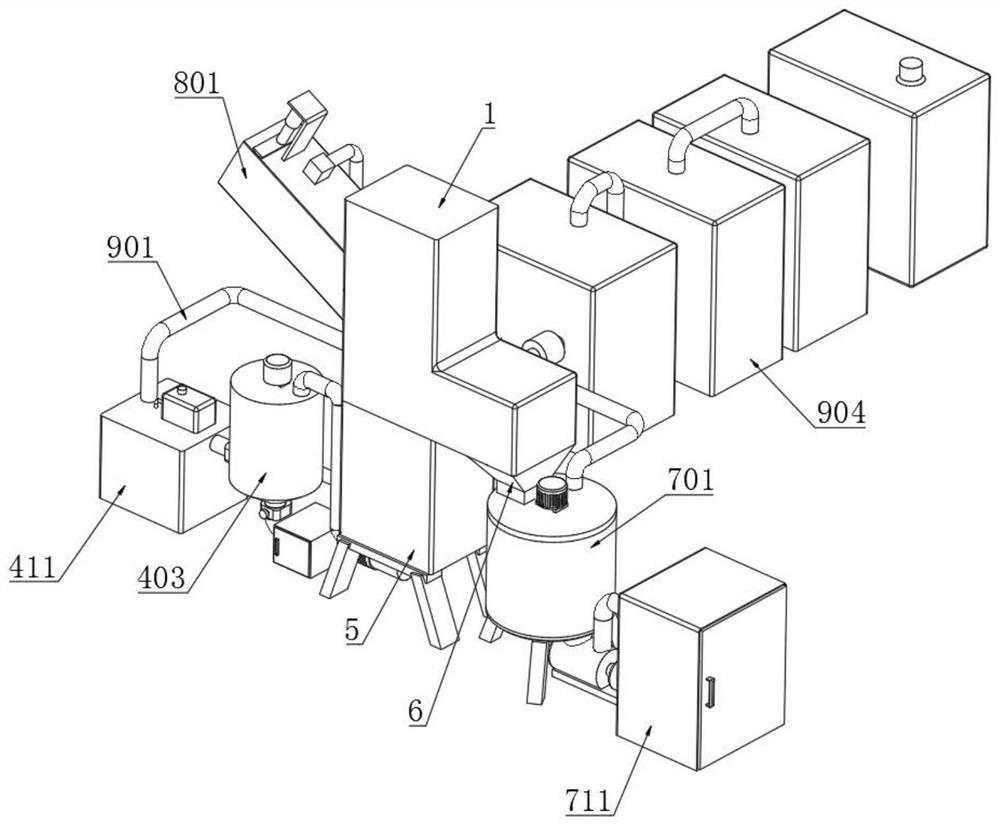

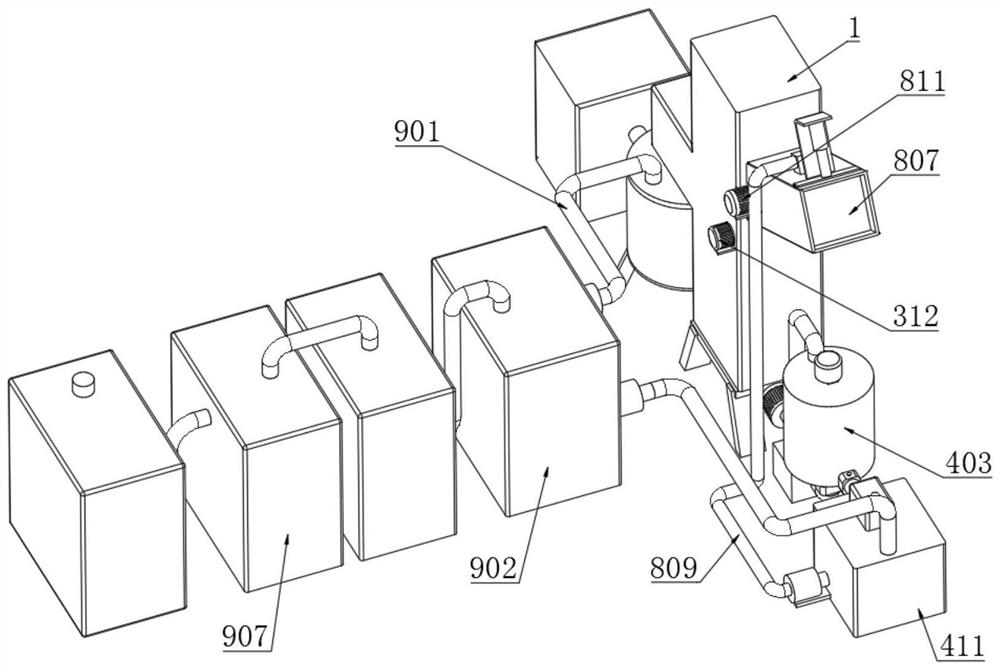

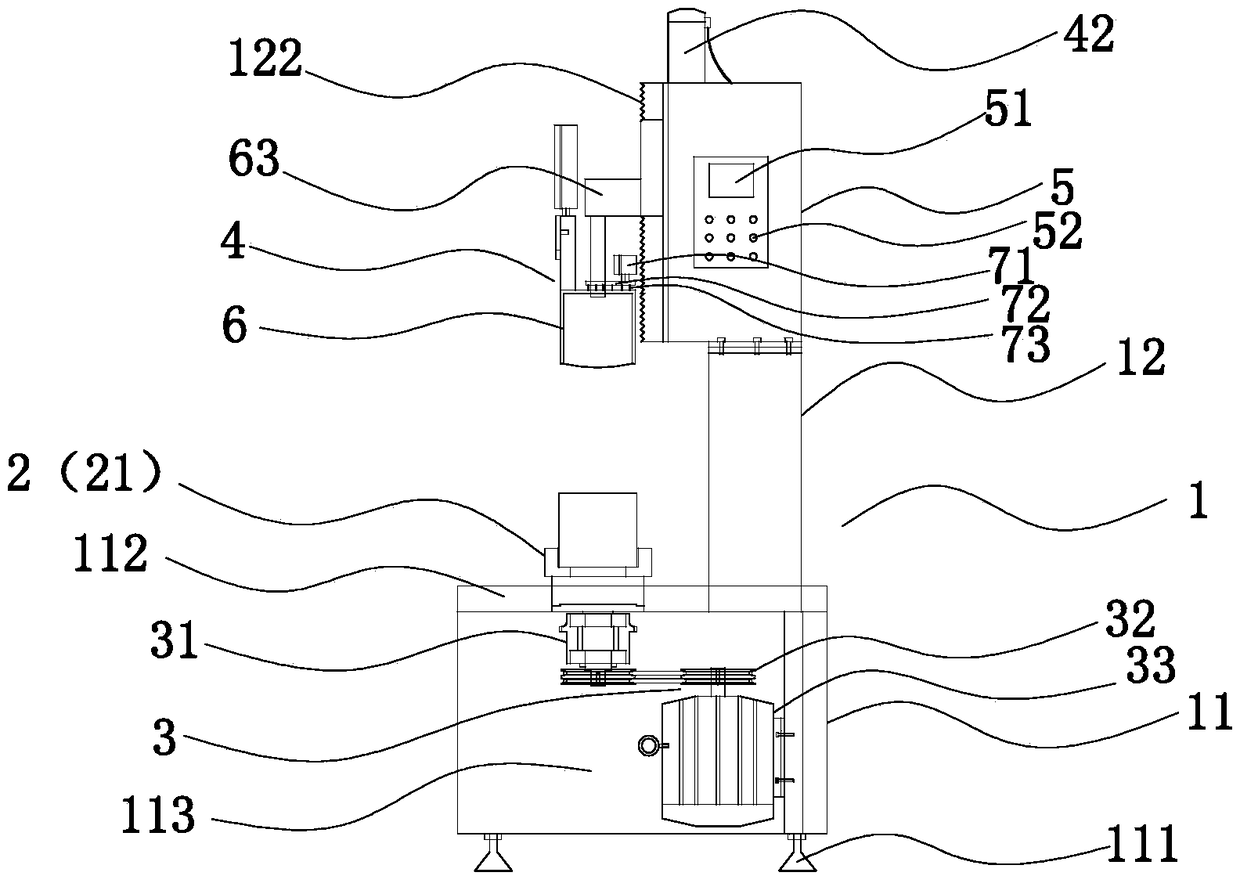

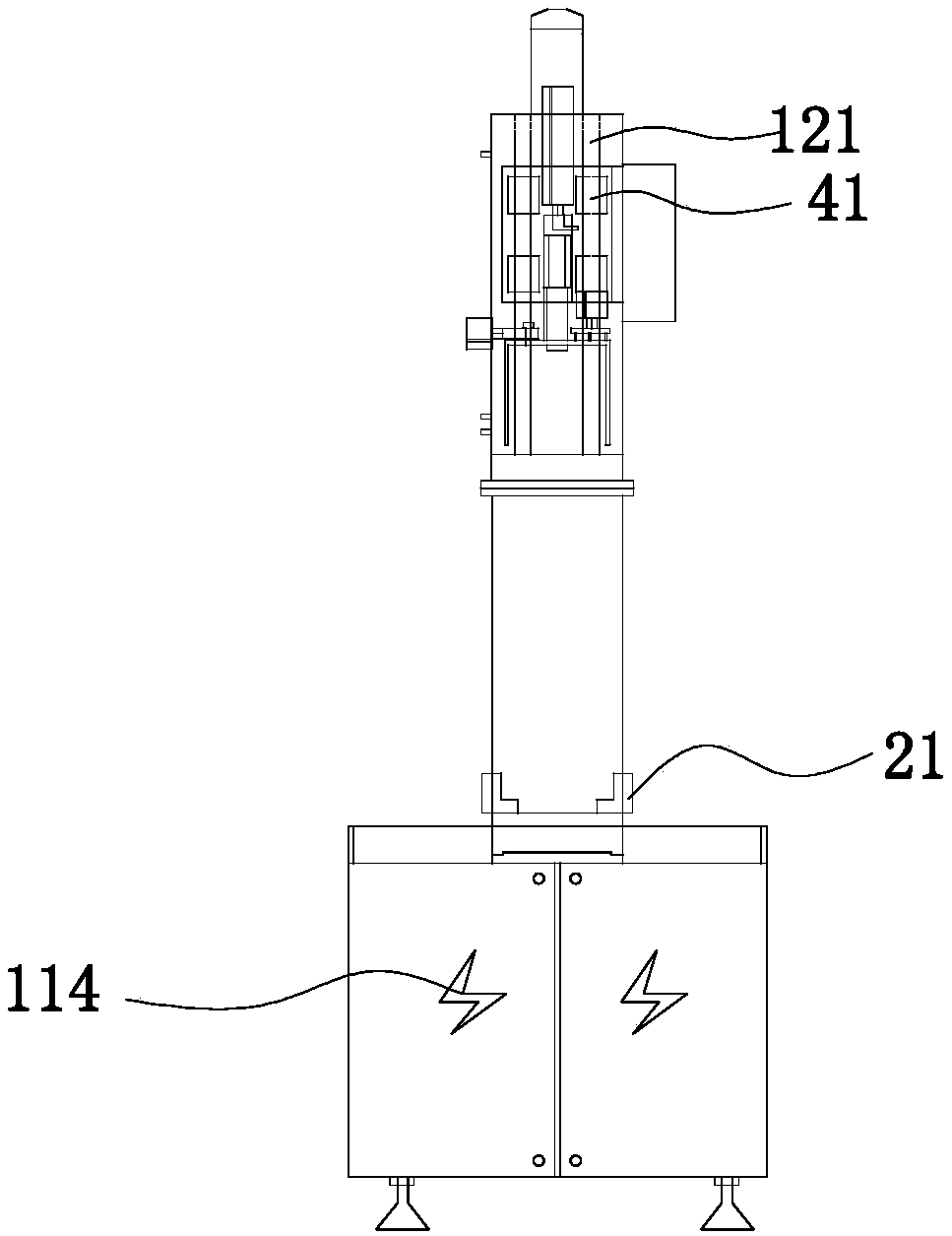

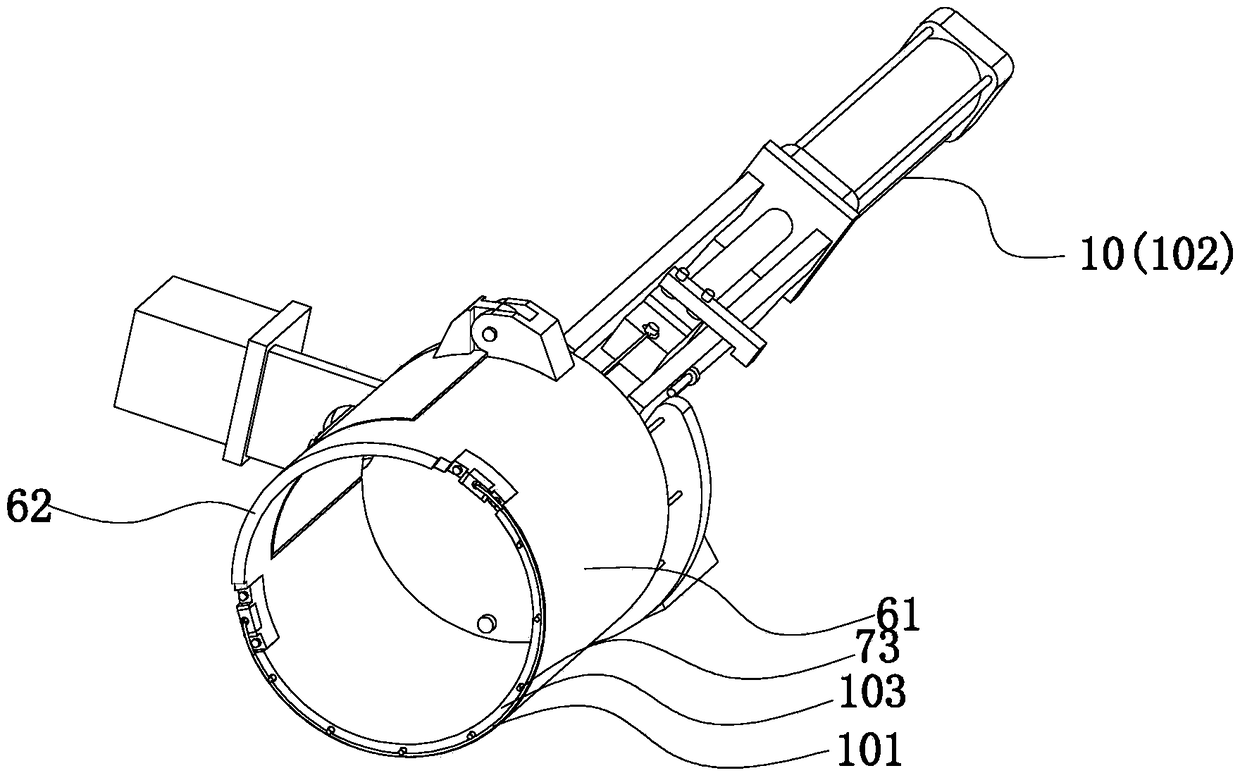

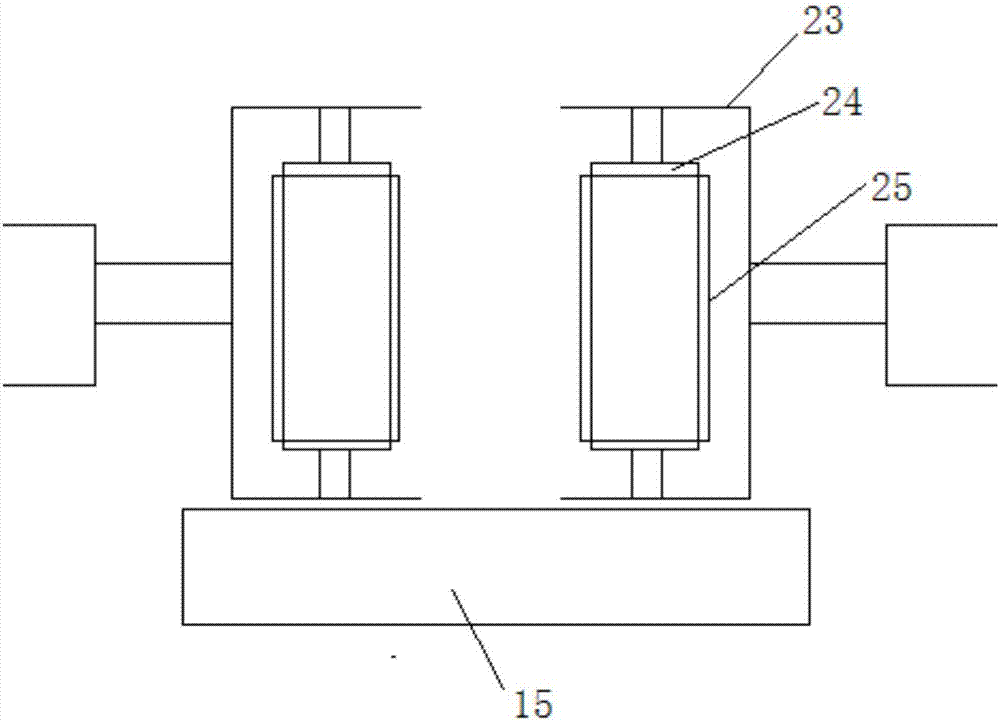

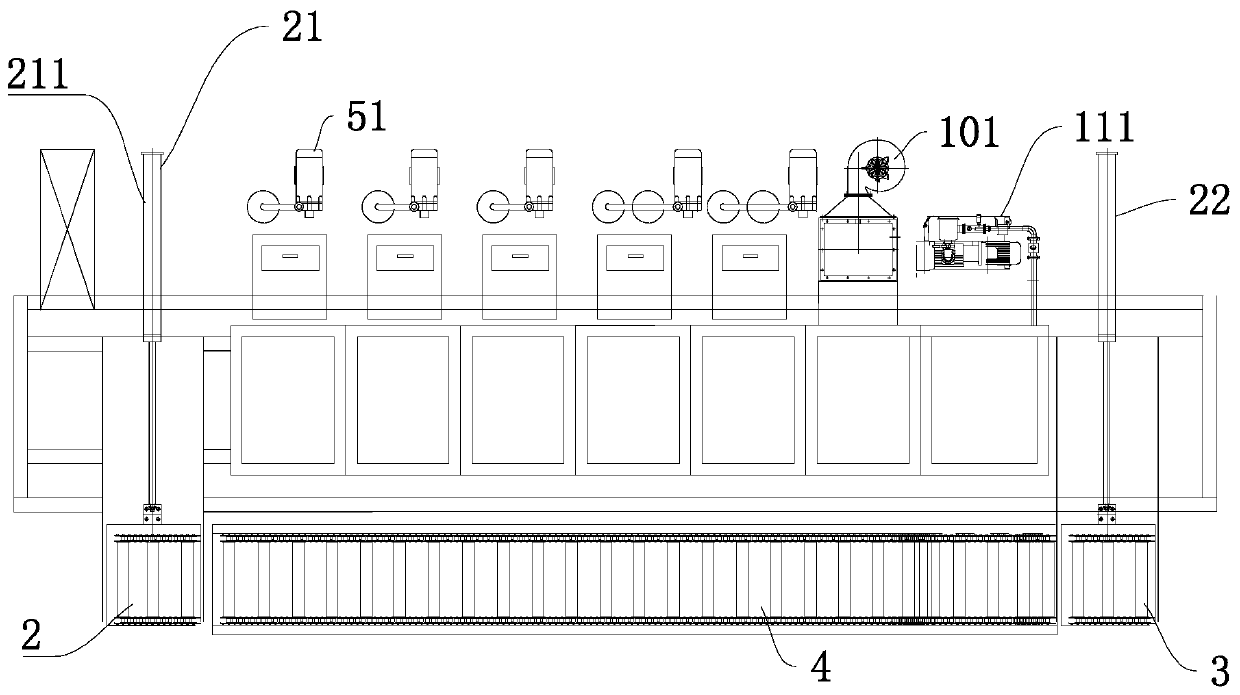

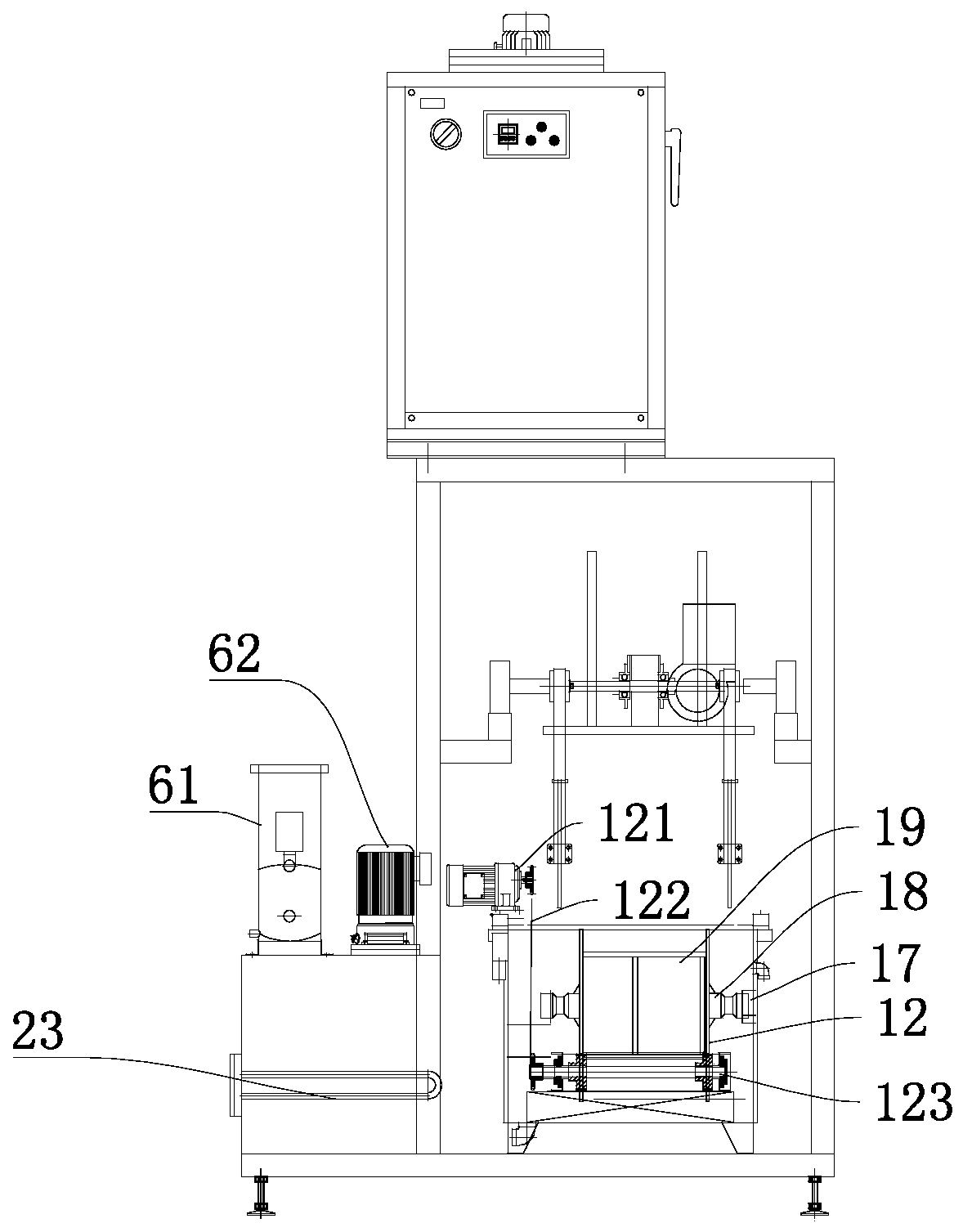

Automatic ton bag supplying device and automatic ton bag packaging system

The invention discloses an automatic ton bag supplying device and an automatic ton bag packaging system. The automatic ton bag supplying device comprises a bag supplying support, smooth shafts, a servo bag feeding mechanism, a hung bag conveying and locating mechanism, a servo traction mechanism and a hung bag fixing and locking mechanism. The automatic ton bag packaging system comprises the automatic ton bag supplying device, an automatic material feeding mechanism, an automatic sealing and filling mechanism, a packet receiving and vibrating conveyance mechanism and an automatic discharge conveying mechanism. The automatic sealing and filling mechanism is arranged above a filling area. The automatic material feeding mechanism is arranged above the automatic sealing and filling mechanism. The packet receiving and vibrating conveyance mechanism is arranged below the automatic sealing and filling mechanism. The automatic discharge conveying mechanism is arranged in front of the packet receiving and vibrating conveyance mechanism. By the adoption of the automatic ton bag supplying device and the automatic ton bag packaging system, automatic guiding in, opening, locating, filling, vibrating and discharging of ton bags are achieved, so that the supplying efficiency of the ton bags is improved, manual participation is not needed, the labor intensity of workers is lowered, the operation environment of the workers is improved, and safety accidents are prevented from happening.

Owner:烟台圣元自动化设备有限公司

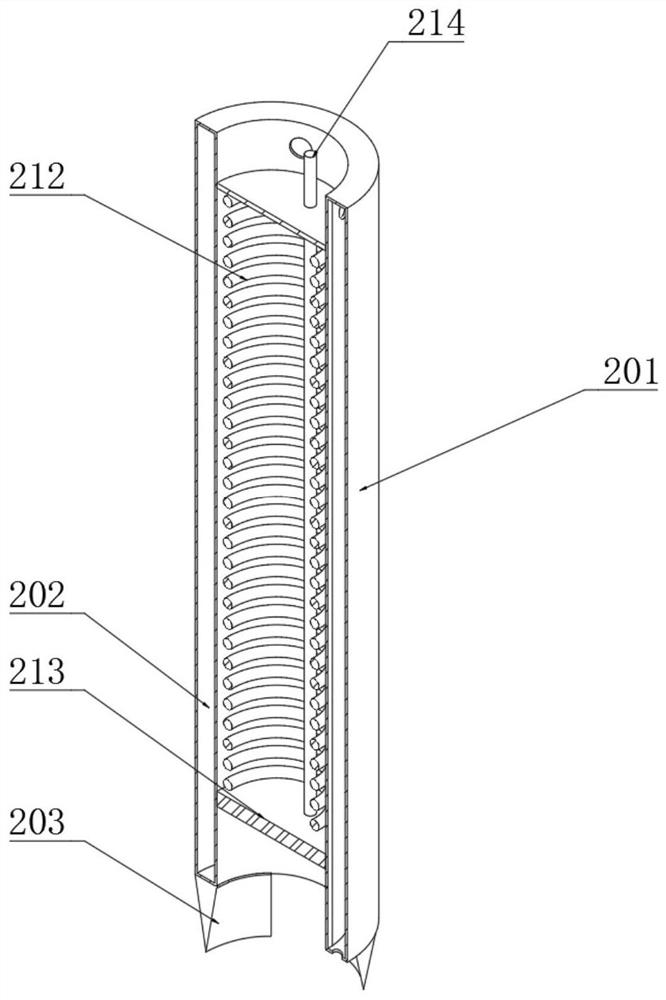

Rock-soil detection device for geological exploration

PendingCN113063623AAvoid Overturning Mixed SituationsAvoid dry conditionsWithdrawing sample devicesPreparing sample for investigationSoil scienceRock core

The invention discloses a rock-soil detection device for geological exploration. A cutting knife is hinged to the bottom end of a rock sampling barrel, a pressing spring is welded to one end of a pulling rope, a transmission motor is installed at the top end of a soil sampling barrel, a sealing limiting plate is clamped to the inner side of a discharging opening, and a soil collecting box is clamped to the side end of an installation connecting frame. Rock is sampled through the rock sampling barrel, the angle of the cutting knife is changed through the pulling rope and the pressing spring, so that the cut rock core can be conveniently and rapidly lifted, personnel can conveniently and visually observe, the soil is sampled through the soil sampling barrel and the auger, and the soil is discharged through the discharging port, the soil at different depths can be rapidly screened when needing to be collected, the situation that the soil is mixed together to influence the detection result is avoided, rock collection and soil collection are separated, mutual interference is avoided, and the situation that the detection result deviates due to mutual influence is avoided.

Owner:李晟

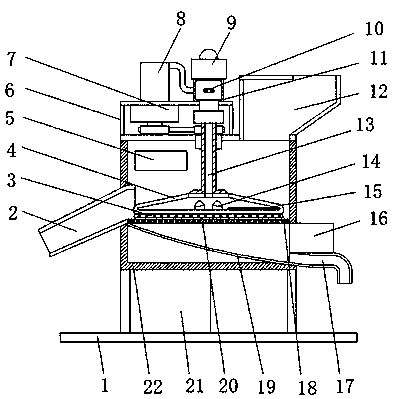

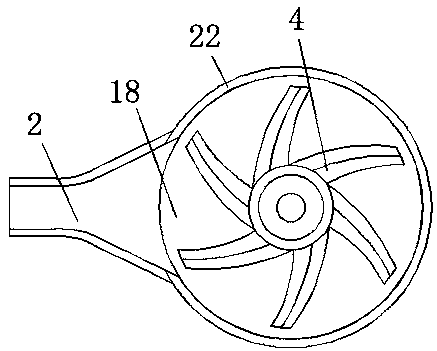

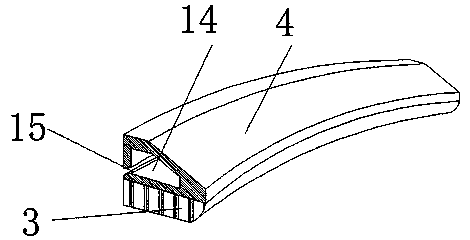

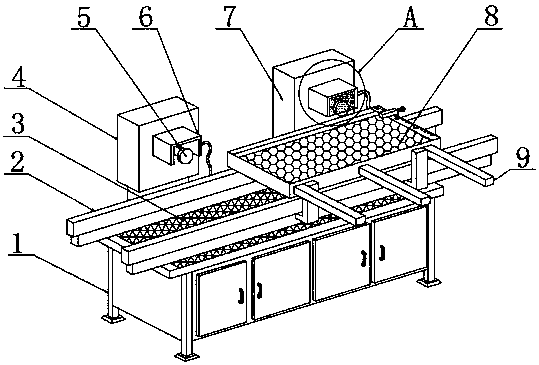

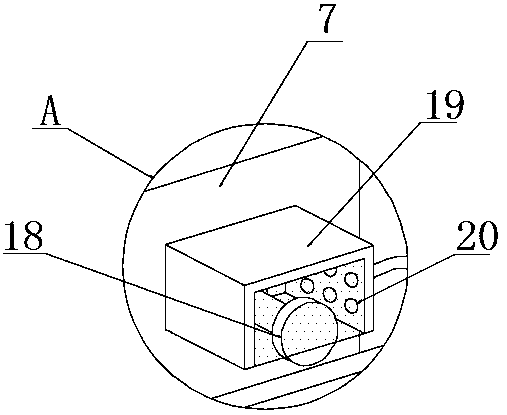

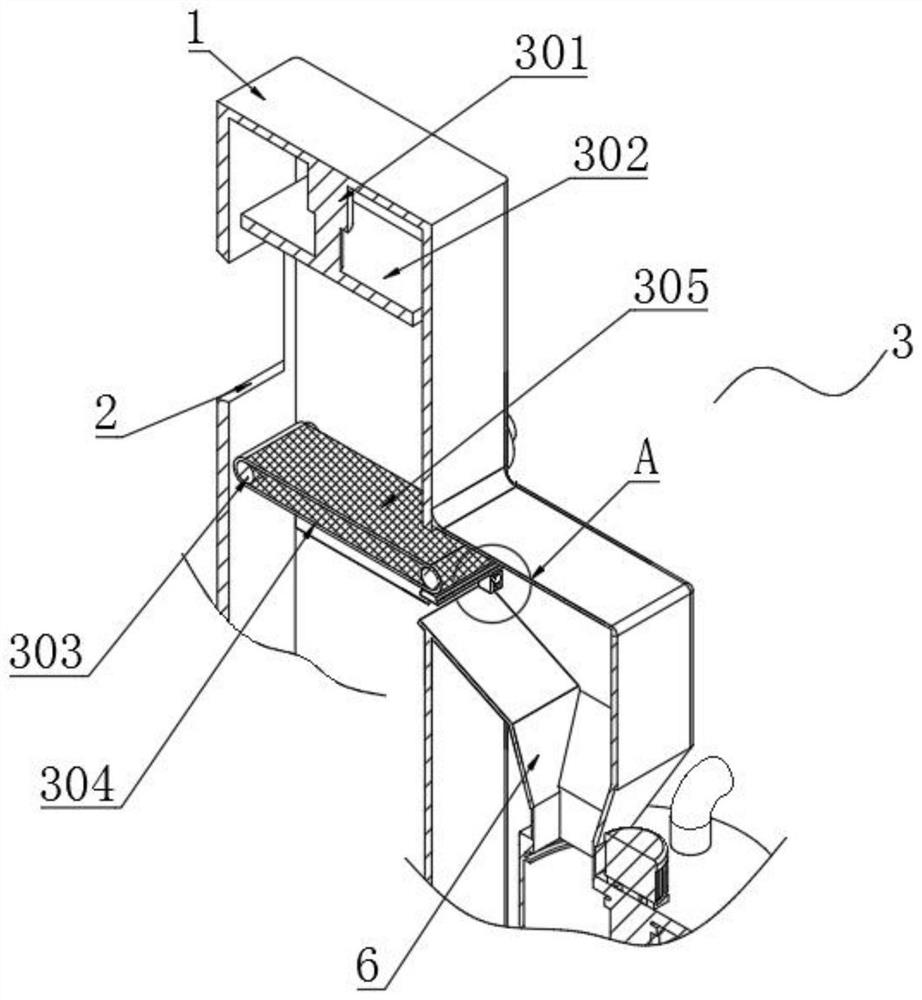

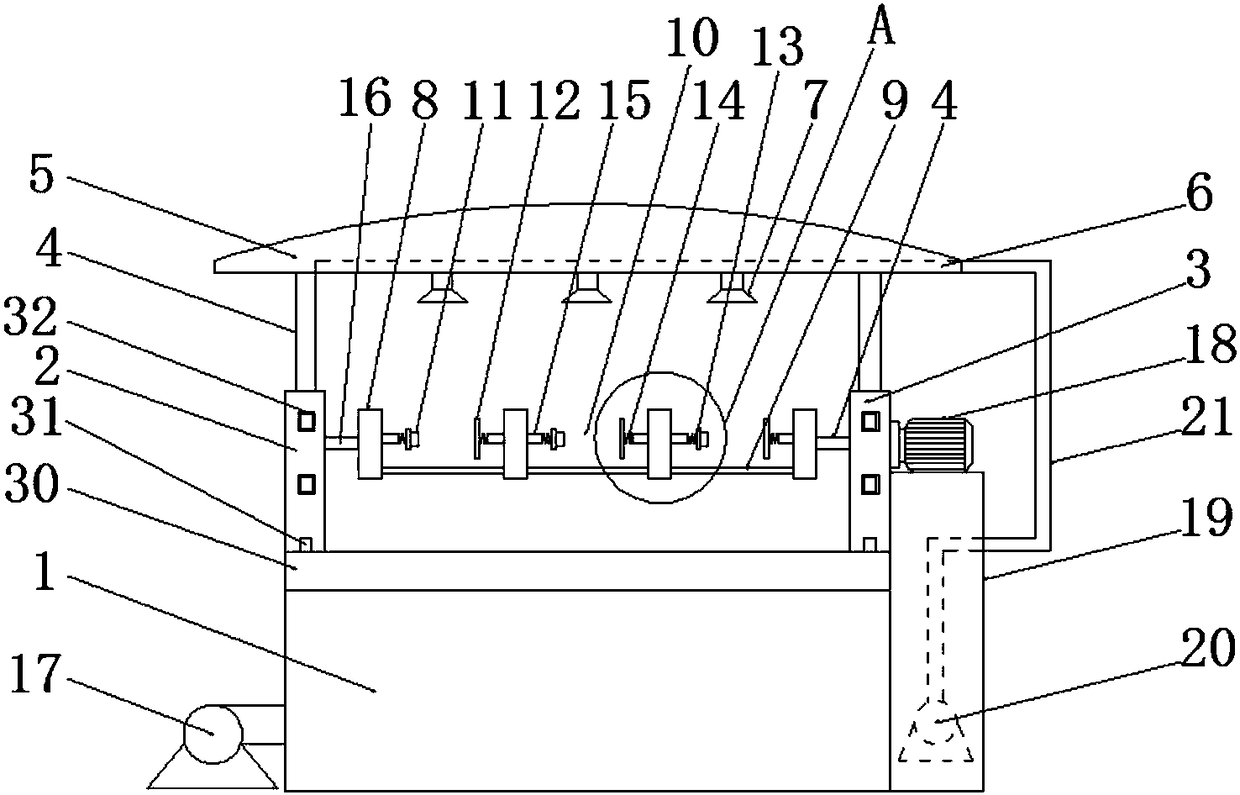

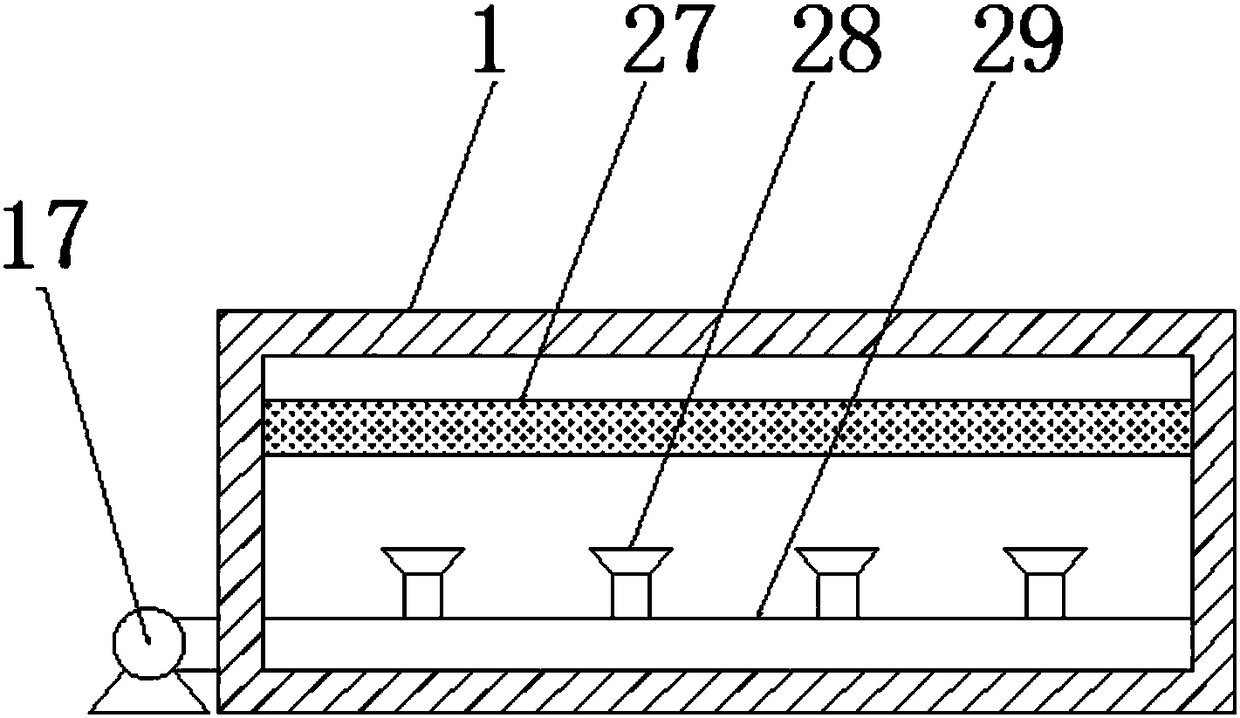

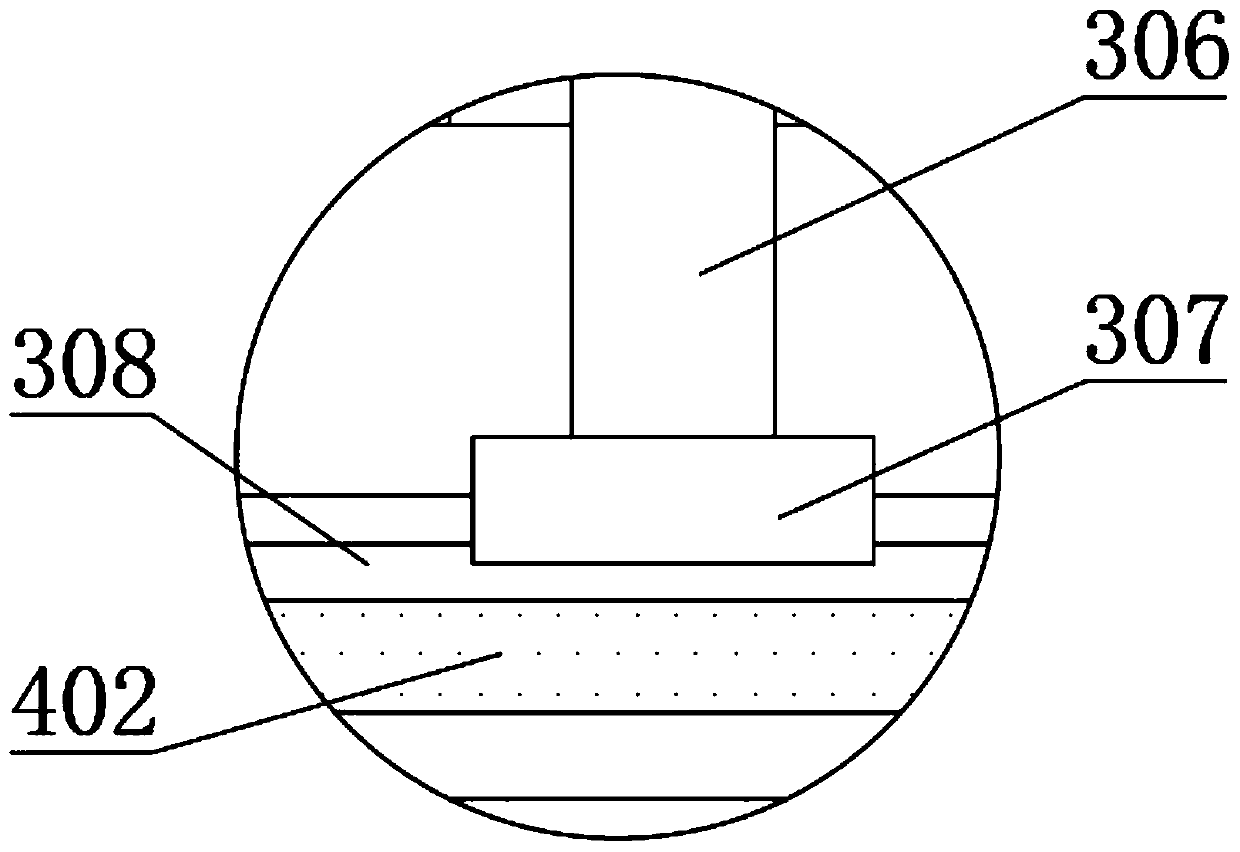

Polishing device for rice processing and production

ActiveCN111167541APromote hydrationImprove processing efficiencyGrain huskingGrain polishingAgricultural scienceAgricultural engineering

The invention belongs to the technical field of rice processing, and especially relates to a polishing device for rice processing and production. In view of the problem that when an existing polishingdevice is used, powder attached to the surfaces of rice grains can cause pollution to the working environment when being raised, the following scheme is proposed: the polishing device comprises a base; a box body is fixedly installed at the top end of the base; a box cover is fixedly installed at the top end of the box body; a feed hopper is fixedly installed at the top end of the box cover; anda lower polishing disk is fixedly installed inside the box body. According to the polishing device for the rice processing and production provided by the invention, the rice is polished; in the polishing process, a humidifying mechanism is utilized to spray and humidify the surface of the rice through a main air blower, a rotating pipe and an air exhaust mechanism, so that the quality of the ricepolishing treatment is improved; and when the rice is polished, the polished rice flour and the like are extracted through an exhaust fan, so that the work environment is prevented from being affectedby rice flour dissipation, and the cleanliness of the rice polishing processing is improved.

Owner:湖南金之香米业有限公司

Glass edge grinding machine

InactiveCN106002530AImprove processing efficiencySmall footprintEdge grinding machinesGrinding carriagesTransfer mechanismFeed drive

The invention provides a glass edge grinding machine. The glass edge grinding machine comprises a first double-edge grinding device and a second double-edge grinding device positioned below the first double-edge grinding device, wherein a transfer mechanism is arranged at an outlet end of the first double-edge grinding device; an inlet end of the second double-edge grinding device is positioned just below the outlet end of the first double-edge grinding device; the transfer mechanism comprises a rotating plate, a rotating motor, a transfer position-adjusting driving piece and a transfer feeding driving piece; the rotating plate receives glass from the outlet end of the first double-edge grinding device; the rotating motor drives the rotating plate to rotate at an angle of 180 degrees; the transfer position-adjusting driving piece drives the rotating plate to move at the outlet end of the first double-edge grinding device and the inlet end of the second double-edge grinding device; and the transfer feeding driving piece is used for pushing the glass on the rotating plate to enter the second double-edge grinding device when the rotating plate is positioned at the inlet end of the second double-edge grinding device. The machining efficiency is high.

Owner:杭州拓川机械有限公司

Linen fiber bleaching device for textile production

InactiveCN111826839AImprove bleaching efficiencyReduce lossTextile treatment machine arrangementsTextile treatment carriersFlax fibrePulp and paper industry

The invention discloses a linen fiber bleaching device for textile production and relates to the technical field of textile production. In order to solve the problem that the bleaching time is difficult to control and linen fibers are easy to damage when the linen fibers are soaked in a solution to be stirred, the linen fiber bleaching device specifically comprises a shell, a plurality of supporting frames are fixedly installed at the bottom of the shell, driving mechanisms are fixedly installed on the two sides of the top of the shell, a capping mechanism is fixedly installed between the topends of the two driving mechanisms, and bleaching sections extending downwards are arranged in the middle sections of the driving mechanisms. According to the linen fiber bleaching device for textileproduction, a bleaching solution is in contact with a heating mechanism when being sprayed out; the linen fibers are heated and cooked; the linen fiber bleaching efficiency is improved; the linen fibers are drained; a bleaching solution is recycled; the loss of the solution is reduced; the situation that the working environment is affected due to solution dripping is avoided; raw materials can becontinuously bleached due to the fact that the raw materials enter from one end and exit from the other end, and the linen fiber bleaching processing efficiency is improved.

Owner:宣城红妆美人床上用品有限公司

Accurate cutting device for processing wear-resistant building materials

ActiveCN109176919AFixed and accurateShorten the timeEdge grinding machinesWorking accessoriesGratingWear resistant

The invention discloses an accurate cutting device for processing wear-resistant building materials. The accurate cutting device comprises a device body, two sliding rails are horizontally and correspondingly arranged on the two sides of the upper end of the device body, and a grating is embedded in the upper surface of the device body. According to the accurate cutting device, ceramic tile cutting and grinding integration can be achieved, time and labor is saved for manual cutting and grinding in construction engineering, the processing speed is increased, a clamping ruler is additionally arranged on a placing plate, so that the to-be-cut position of the ceramic tile to be cut can be accurately fixed, the cutting accuracy is improved; a spraying cover is additionally arranged on the outerside of the cutting wheel, spraying water is sprayed to the cutting position of the cutting wheel by the aid of the spraying holes when the cutting wheel is cut, the problem that the service life ofthe cutting wheel is affected due to the fact that the cutting wheel is damaged due to excessively high temperature during cutting is avoided; a dust suction cover is additionally arranged on the outer side of the polishing wheel, dust impurities generated during grinding of the cutting part of the ceramic tile are sucked through the suction holes, so that dust can be prevented from flying aroundso as to influence the working environment.

Owner:广东铭扬建设集团有限公司

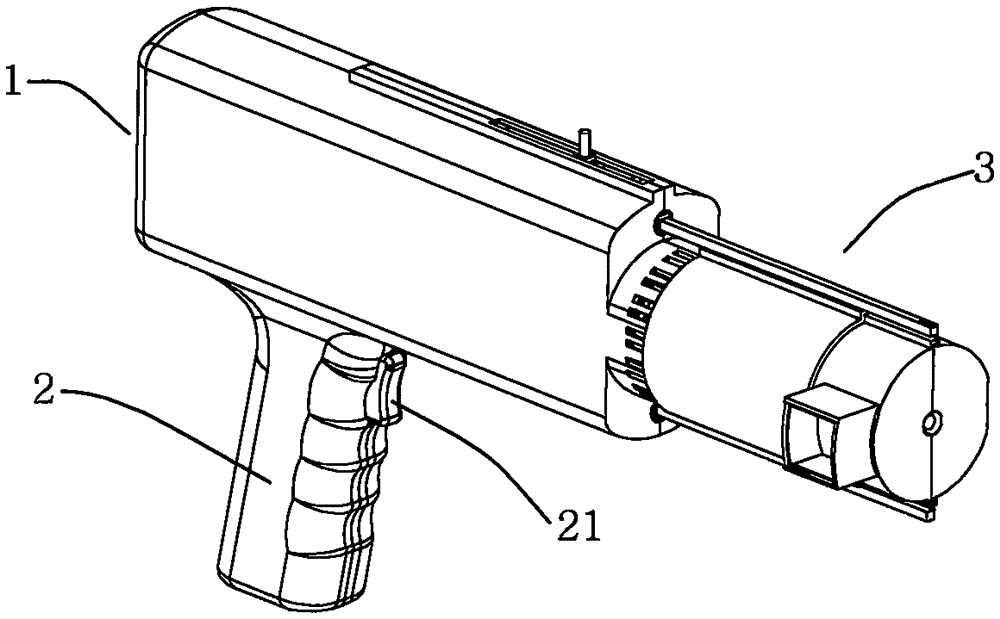

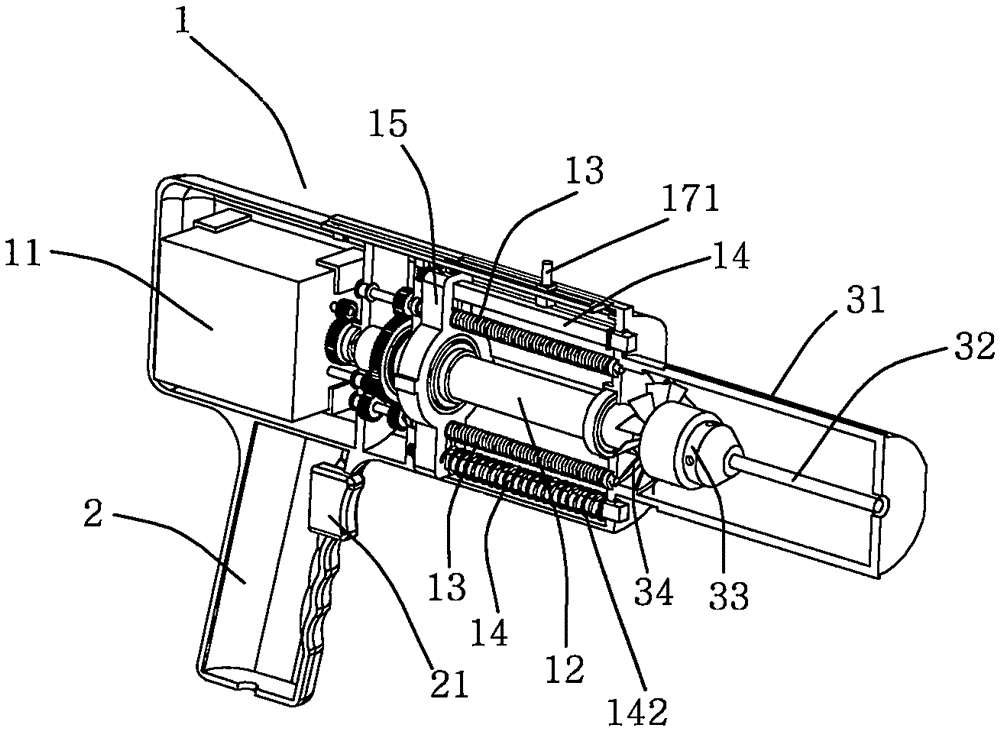

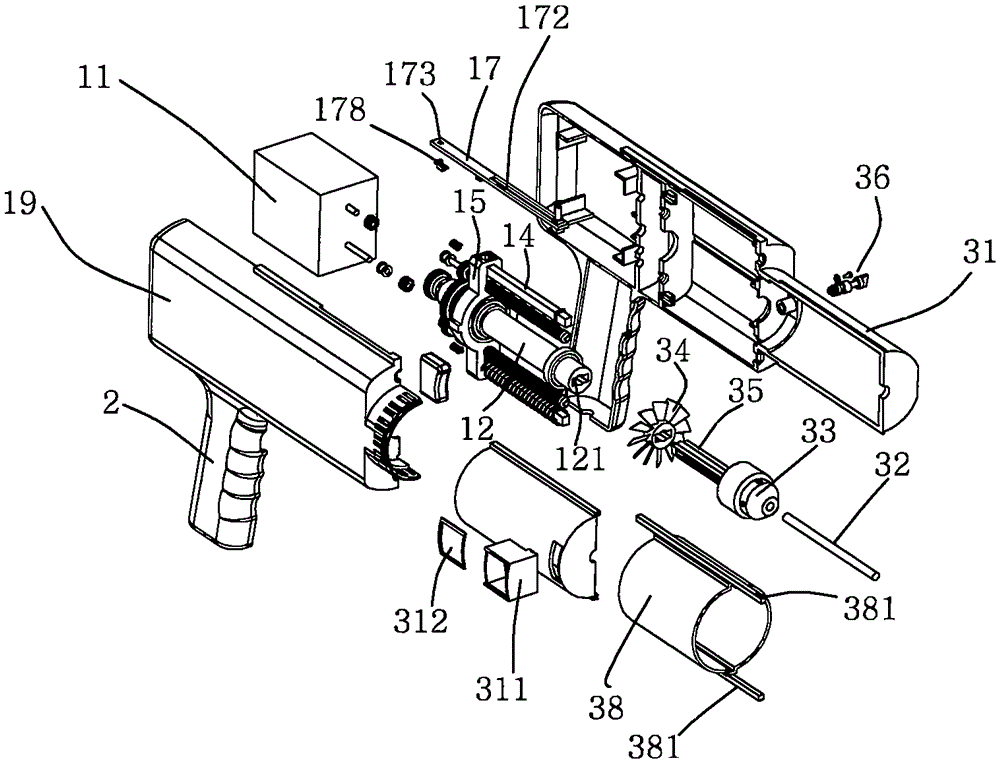

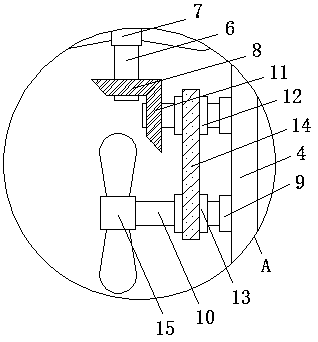

Safe electric drill capable of rapidly feeding

ActiveCN105414604AFast feedingRealize automatic feedingPortable power-driven toolsPortable drilling machinesScrew threadDrill bit

The invention discloses a safe electric drill capable of rapidly feeding. The safe electric drill comprises an electric drill main body internally provided with a driving mechanism and a drill bit part arranged on the electric drill main body, wherein the driving mechanism comprises a motor gearbox and an automatic feeding assembly driven by and connected with the motor gearbox; the automatic feeding assembly comprises a rotatable telescopic shaft, a main telescopic shaft for driving the rotatable telescopic shaft to rotate, a telescopic shaft driving block for driving the telescopic shaft to move and a lead screw which can rotate and is in contact with the telescopic shaft driving block; the main telescopic shaft extends into the telescopic shaft and can slide; one end of the main telescopic shaft is provided with a driving gear, and the other end of the main telescopic shaft is provided with the telescopic shaft driving block for driving the telescopic shaft to rotate; a screw thread matched with a screw thread on the surface of the lead screw is arranged at the contact part of the telescopic shaft driving block and the lead screw; and a chuck shaft is arranged in one end of the telescopic shaft in a penetrating way and is provided with a chuck on which a drill bit is arranged. By using the safe electric drill disclosed by the invention, the automatic feeding of a drill bit can be conveniently realized, drilling can be conveniently realized, and the drilling depth is adjustable.

Owner:重庆博视知识产权服务有限公司

Paint spraying device for automobile parts

The invention relates to the technical field of spraying, in particular to a paint spraying device for automobile parts. The upper end of a base is provided with an annular base through a sliding mechanism. Annular teeth are arranged on the outer side of the annular base. One side of the base is further provided with a motor through a supporting plate. An output shaft of the motor is connected with a gear which is engaged with the annular teeth. A pipeline is further arranged in the middle of the upper end of the base, and provided with a plurality of sprayer nozzles in a ring shape. The lower end of the pipeline penetrates through the base. A hose is provided with a pump. A plurality of sets of suspension mechanisms are installed on the inner side of the annular base. Each suspension mechanism comprises a U-shaped frame installed on the annular base, wherein one end of the U-shaped frame is provided with a suspension shaft, and the suspension shaft penetrates through the U-shaped frame and is clamped to the other end of the U-shaped frame through a first clamping mechanism. The paint spraying device for the automobile parts can spray paint to the multiple automobile parts at a time, thereby effectively improving the spraying efficiency; and surplus paint in the spraying process can be recycled for reuse, and unnecessary waste is avoided.

Owner:杭州腾略科技有限公司

Textile cloth batting cleaning device

InactiveCN108265504AEasy to replaceHeight adjustableMechanical cleaningPressure cleaningWorking environmentEngineering

The invention discloses a textile cloth batting cleaning device, which comprises a base, an aggregating box and a support frame. The base is equipped with a support sleeve on the top, and the supportsleeve is movably equipped with a support rod inside. An output end of the support rod is fixedly connected with the support frame through a mounting bracket. A drum is detachably mounted between mounting seats on the inner side of the support frame. A metal jacket is arranged on the outer surface of the drum. An empty cavity is arranged at a central position inside the drum, and the empty cavityis provided with an electrostatic generation adsorber. The aggregating box is equipped with a suction fan at the top through a bolt. An input end of the suction fan is fixedly connected with a feedingtube through a spring tube. One end of the feeding tube extends to the top end of the support frame and fixedly connected with a suspended hood. The textile cloth batting cleaning device of the invention has the advantages of uninterrupted work and no need to frequently clean a brush tube, does not need to be cleaned, at the same time, prevents the occurrence of drift of the batting from affecting the working environment and improves the production safety.

Owner:丽水遂智科技咨询有限公司

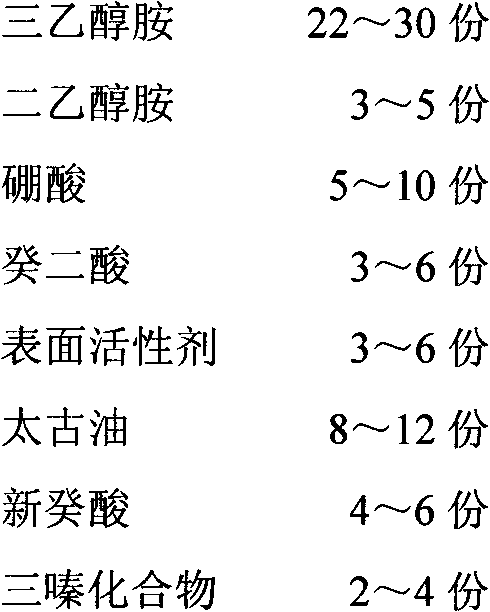

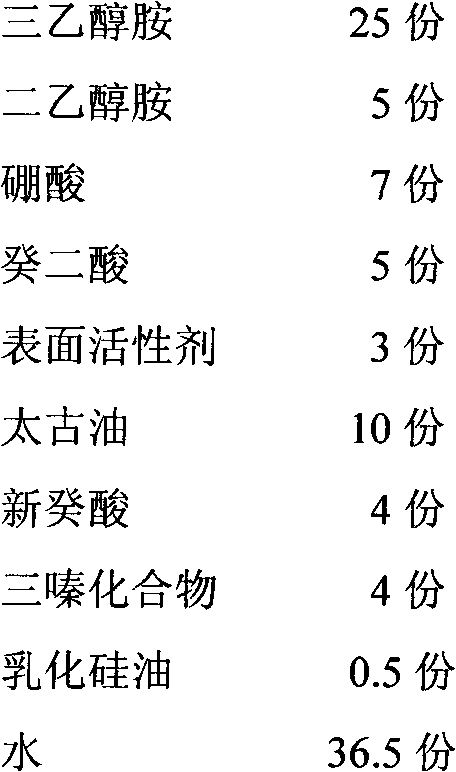

Finishing solution and preparation method thereof

InactiveCN102876438AImprove the lubrication effectReduce contact partsLubricant compositionWorking environmentBoric acid

The invention relates to a finishing solution and a preparation method thereof. The finishing solution consists of the following components in part by weight: 22 to 30 parts of triethanolamine, 3 to 5 parts of diethanol amine, 5 to 10 parts of boric acid, 3 to 6 parts of sebacic acid, 3 to 6 parts of surfactant, 8 to 12 parts of sulfonated caster oil, 4 to 6 parts of neodecanoic acid, 2 to 4 parts of triazine compound, 0.2 to 0.5 part of emulsified silicone oil and 49.8 to 20.5 parts of water. The finishing solution has a good lubricating effect, can effectively remove rust and oxide skin on the surface of a metal piece to make the metal piece bright like before, has a good antirust effect, eliminates an anti-rust process flow, has a good defoaming capacity, and avoids foam overflow to avoid influencing work environment.

Owner:XIAOGAN JIANGYAN CHEM

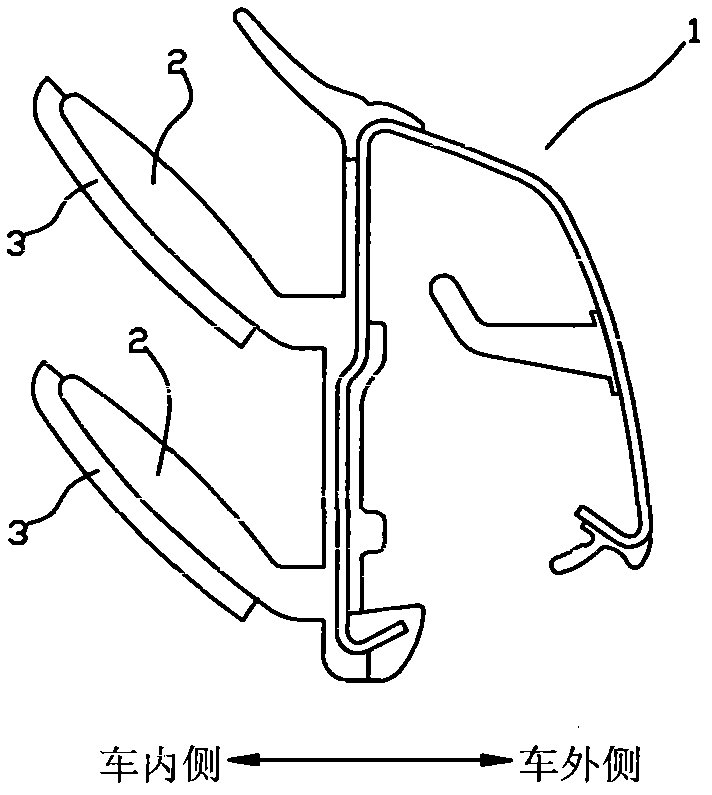

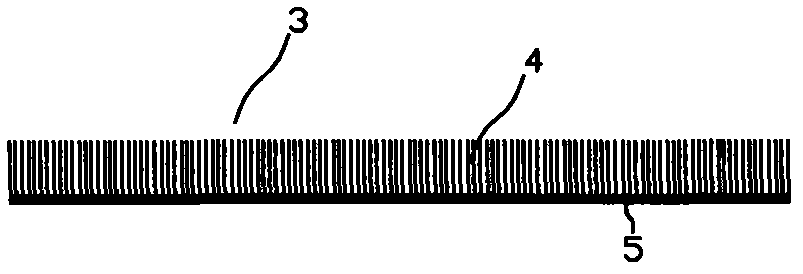

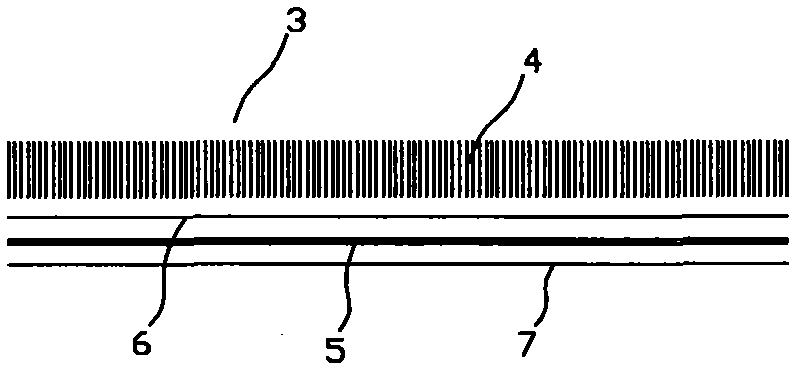

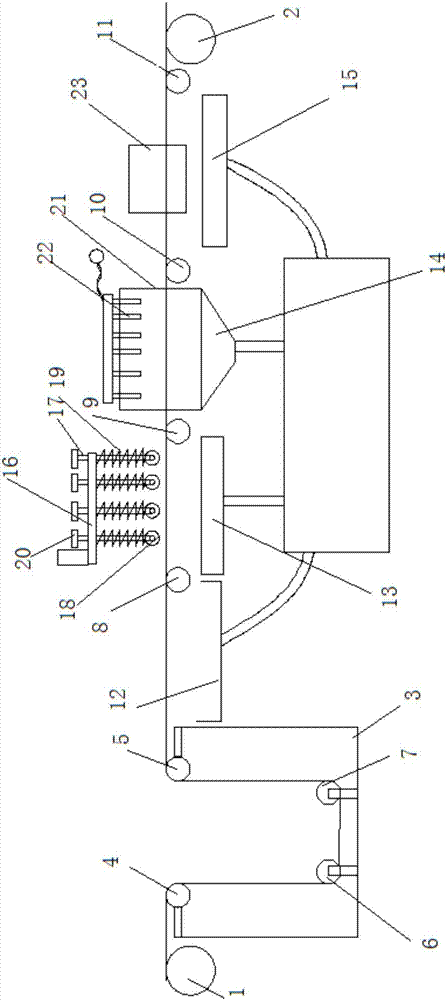

Flannel sticking device for automobile sealing strip

ActiveCN102529099AAvoid affecting the working environmentAvoid the phenomenon of sticking velvetDomestic articlesProduction lineExtrusion

A flannel sticking device for an automobile sealing strip is used for continuous flannel sticking and processing on a sealing strip production line in the extrusion procedure and comprises a flannel-planting adhesive tape supply device placed beside an extrusion die of an extrusion machine when in use, and a flannel-planting adhesive tape sticking guiding device placed at the outlet of the extrusion die of the extrusion machine when in use; the flocking adhesive tape supply device comprises a rotating shaft allowing a flannel-planting adhesive tape reeling tube to be placed and driven by an independent control motor, roller groups sequentially arranged along the direction of flannel-planting adhesive tapes when in use, and a tension device used for enabling the flannel-planting adhesive tapes to be supplied under a suitable tension; the tension device can be a tension shaft placed in a vertical groove; and the flannel-planting adhesive tapes bypass the tension shaft and generate required tension under the action of dead weight of the tension shaft.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

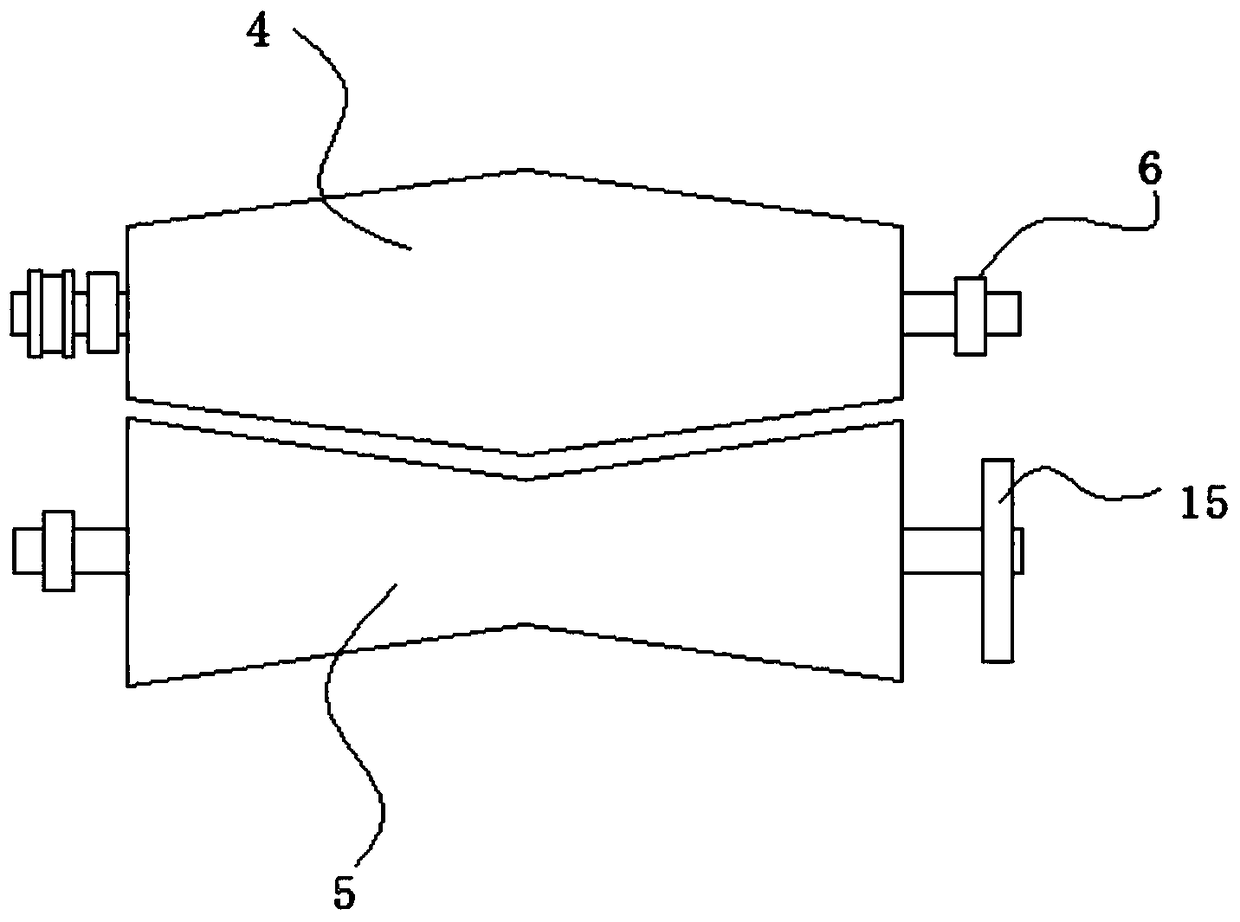

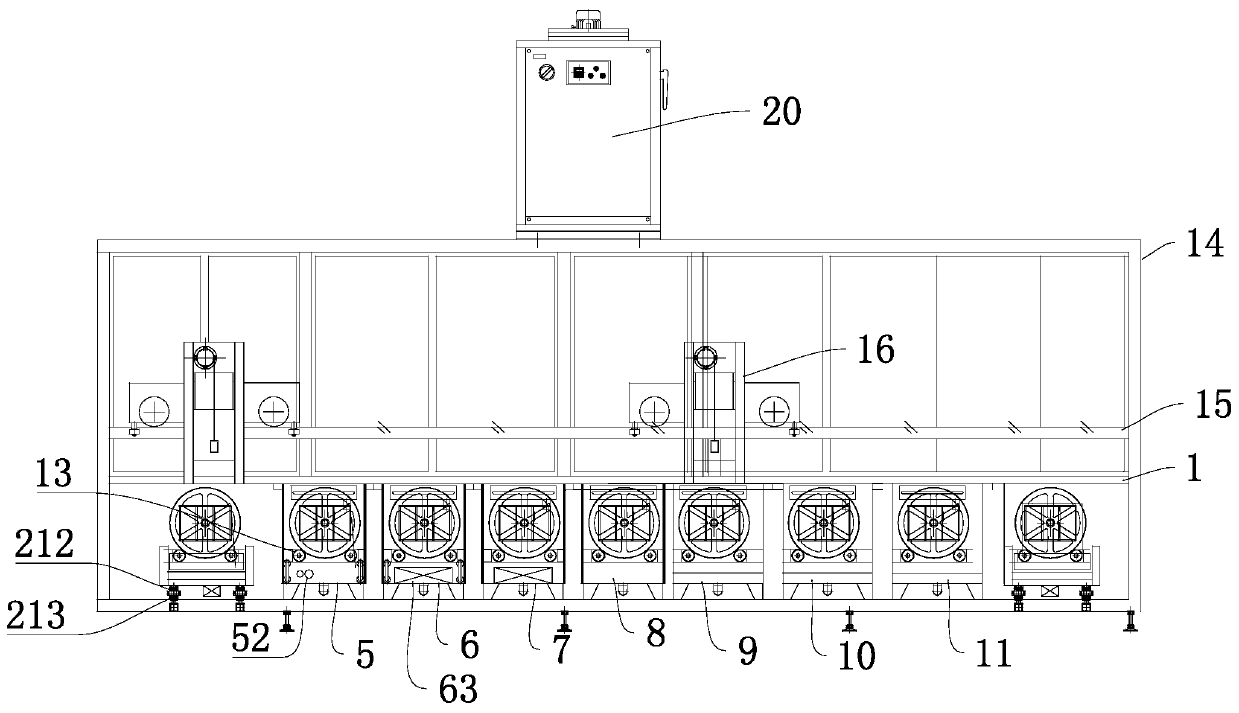

Efficient extrusion and drying roller device for textile fabric processing

InactiveCN108625071AImprove drying effectAvoid pouringLiquid/gas/vapor removal by squeezing rollersTextile treatment rollersWorking environmentPulp and paper industry

The invention discloses an efficient extrusion and drying roller device for textile fabric processing. The efficient extrusion and drying roller device comprises a box body, an extrusion and drying roller group and a drive mechanism; the box body is set to be a closed box body, and openings for a textile fabric to pass through are formed in the front side and the rear side of the box body; the extrusion and drying roller group is mounted in the box body; a plurality of shaft holes are formed in each of the two sides of the box body; the extrusion and drying roller group comprises a roller group I, a roller group II and a roller group III; each of the roller group I, the roller group II and the roller group III comprises an upper pressing roller and a lower pressing roller, and an extrusiongap for the textile fabric to pass through is formed between the upper pressing roller and the lower pressing roller; the extrusion gaps in the roller group I, the roller group II and the roller group III sequentially decrease from front to back; a drive mechanism is used for driving the upper pressing rolls to freely rotate relative to the box body; traction mechanisms for pulling the fabric tomove are arranged at the front end and the rear end of the textile fabric. The efficient extrusion and drying roller device for textile fabric processing, disclosed by the invention, has the benefitsthat extrusion and drying effects are efficiently improved, water is prevented from flowing everywhere during extrusion, and the influence on an actual working environment is avoided; an environmentalprotection effect is good, and the practicability is high.

Owner:苏州存异新材料科技有限公司

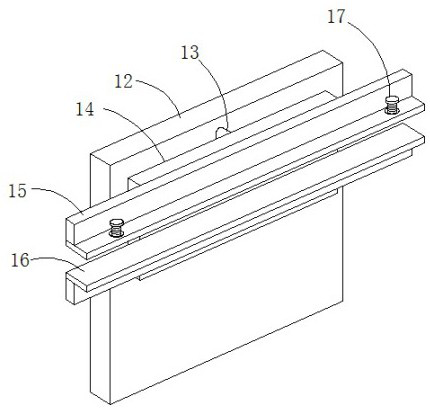

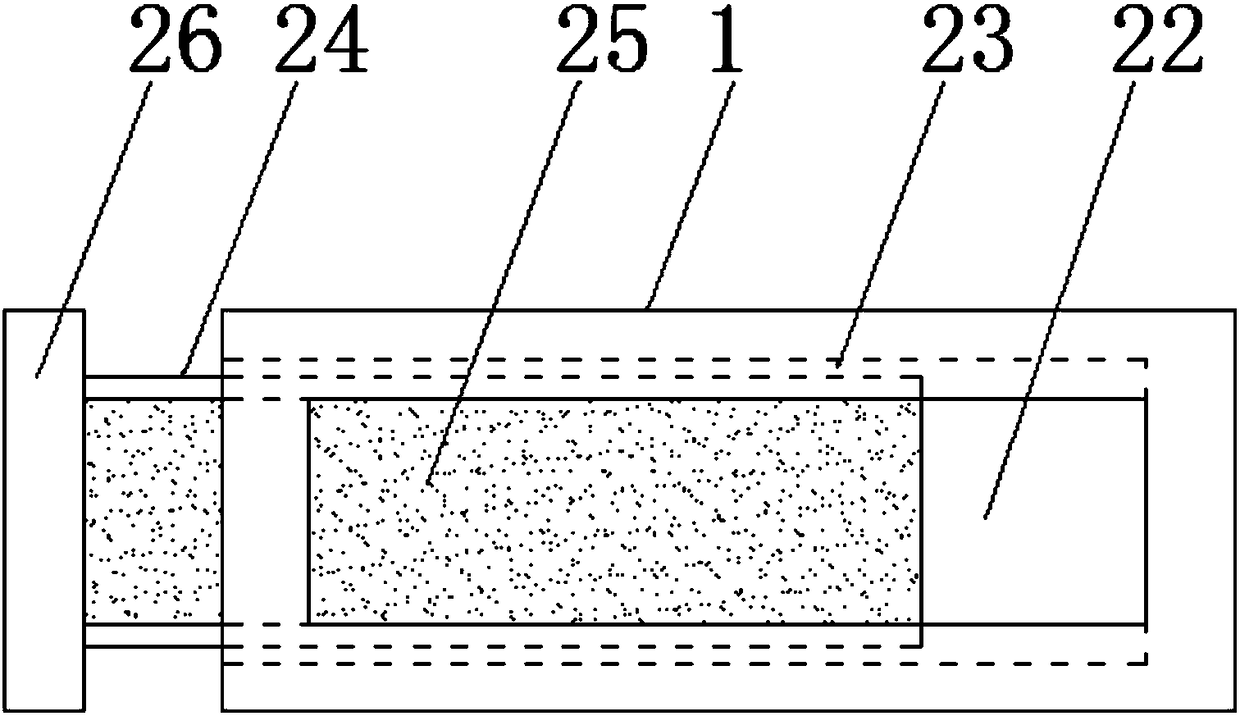

Filter cloth fixing structure based on pressing ring and filer plate system using filter cloth fixing structure

InactiveCN105498324AThe installation structure is stableReduce maintenance difficultyFiltration separationStructure basedBiochemical engineering

The invention relates to a filter cloth fixing structure based on a pressing ring and a filter plate system using the filter cloth fixing structure. The filter cloth fixing structure based on the pressing ring comprises a press filter plate body and an installation groove, and a through hole is formed in the middle of the press filter plate body. The installation groove is formed in the press filter plate body in a surrounding mode and comprises an outer edge groove body and an inner edge groove body, the outer edge groove body is formed in the outer edge side of the press filter plate body in a surrounding mode, and the inner edge groove body is formed in the inner edge side of the press filter plate body and is close to the through hole. The installation groove comprises a fixing cavity and a transition cavity, wherein the section width of the fixing cavity is larger than that of the transition cavity, the fixing cavity is formed in the inner side of the installation groove, and the transition cavity is formed in the outer side of the installation groove. By means of the filter cloth fixing structure based on the pressing ring, the stability in the filter cloth installation process is greatly improved, and the phenomenon that filter cloth is likely to loosen due to long-term use is avoided; meanwhile, the filter cloth is convenient to replace, the maintenance cost is low, and the working efficiency of equipment is improved.

Owner:FOSHAN JINKAIDI FILTRATION EQUIP CO LTD

Textile cloth rolling device

The invention relates to the technical field of textile equipment, and discloses a cloth winding device for textile use, which includes a chassis, a driving motor is fixedly installed on the side of the inner cavity of the chassis, and a clamping block is fixedly fitted on the output shaft of the chassis, and the clamping block is clamped with the side of the reel Then, the roll cloth is wound on the reel, and the side of the reel away from the driving motor is fixedly installed with a fixed plate located in the case, the middle part of the fixed plate is movably socketed with one end of the transmission device, and the transmission device is movably installed in the inner cavity of the case The bottom end is located on the side of the fixed plate, and a fixed block at the bottom of the inner cavity of the chassis is fixedly installed between the transmission device and the fixed plate. The textile cloth winding device drives the transmission gear and drives the passive gear to rotate through the servo motor arranged in the second support plate, so that the two driven shafts drive the rollers to rotate relative to each other, and the dried printed and dyed cloth is pulled downward and effectively The rolled flat cloth surface ensures the quality of cloth processing and improves the practicality.

Owner:范威

Multifunctional engraving machine

InactiveCN107089090AIncrease frictionImprove the fixed effectEngravingEngineeringMechanical engineering

The invention relates to a multi-functional engraving machine, which comprises a frame, on which a working platform is arranged, and movable support plates are slidably connected to both sides of the frame, and movable supporting plates are slidably connected to each other. The crossbeam, the movable crossbeam is provided with several juxtaposed engraving components, and also includes a workpiece fixing component, a blower rack and a sawdust collection cover, and the workpiece fixing component includes a baffle plate, a compression plate and a cylinder connected with the compression plate, the baffle The plate is fixedly arranged on one side of the working platform along its length direction, the pressing plate is arranged parallel to the baffle, the end of the pressing plate away from the baffle is connected with the piston rod of the cylinder, the baffle, the pressing The sides of the boards that are close to each other are wave-shaped, and protective layers are provided on the surfaces, and the blowing rack is arranged at the rear end of the working platform; the invention has simple structure, excellent fixing effect on irregularly shaped workpieces, and good cleaning effect of sawdust. Guarantee the accuracy of carving and carving effect.

Owner:ANQING NORMAL UNIV

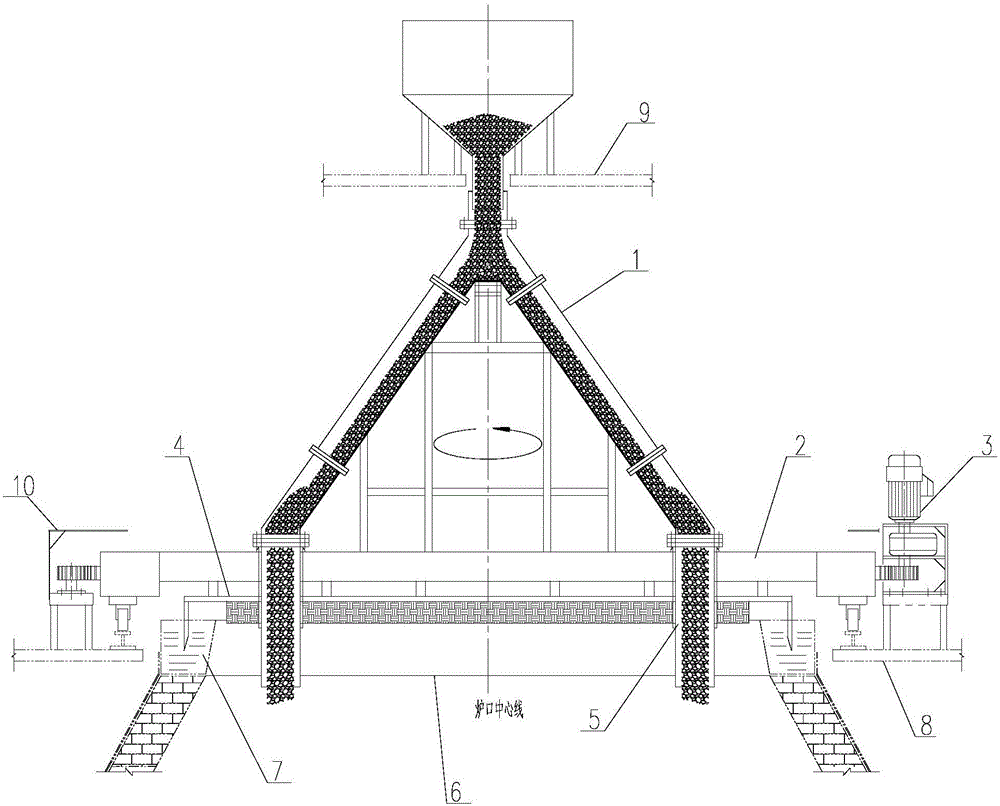

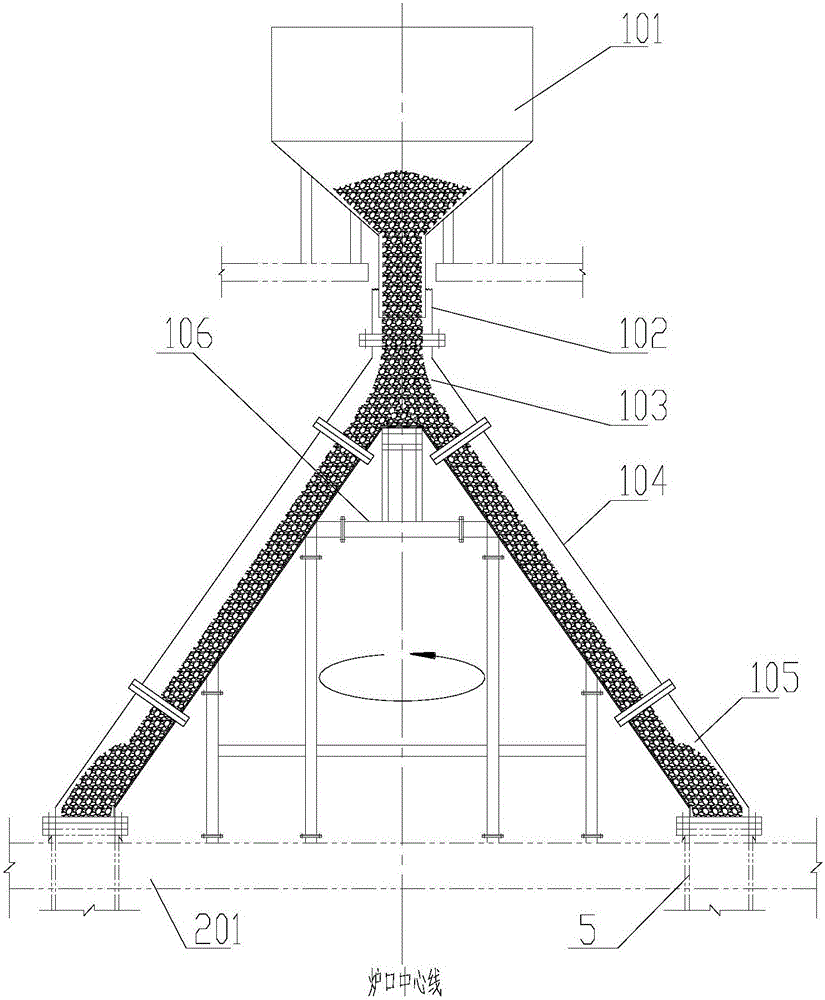

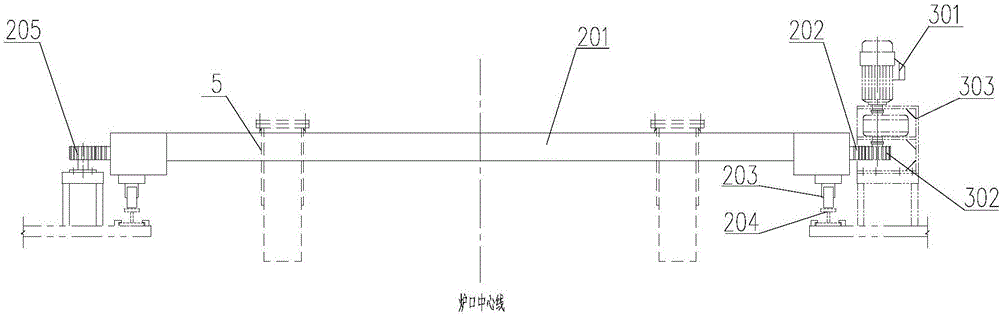

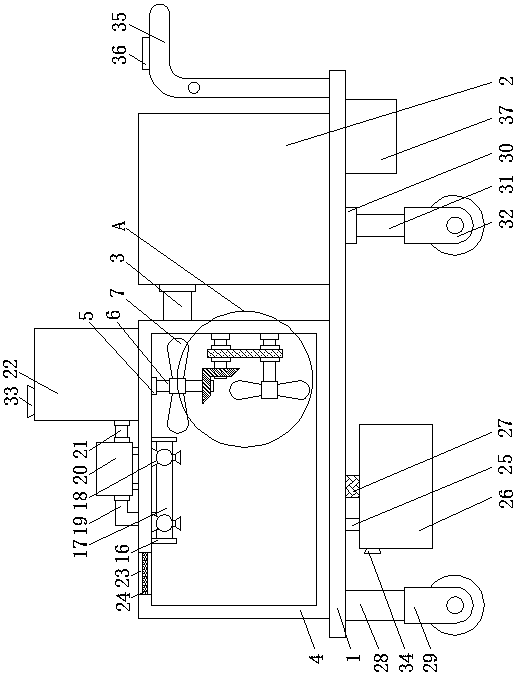

External transmission liquid seal type rotary material distribution device

ActiveCN106382822AAvoid high temperature effectsImprove production continuityCharge manipulationGear wheelMaterial distribution

The invention relates to an external transmission liquid seal type rotary material distribution device which comprises a material distribution unit, a rotating device, a driving mechanism and a rotation liquid seal cover. The rotating device is composed of a rotation disc and a gear disc; the material distribution unit is composed of a material receiving hopper, a seal type movable connection pipe, a forking body, a material guide body and a material discharging body; the gear disc and a driving gear are in meshed transmission so as to drive the rotating device and the whole material distribution unit except for the material receiving hopper to rotate around the center of a furnace opening; an annular liquid seal plate at the edge of the outer side of the rotation liquid seal cover extends into liquid in an annular liquid seal groove to achieve sealing of the furnace opening; and a discharging point adjusting structure is arranged on the rotation disc. The material distribution unit, the rotating device and the driving mechanism of the external transmission liquid seal type rotary material distribution device are all arranged outside a furnace, space in the furnace is not occupied, the external transmission liquid seal type rotary material distribution device is simple and reasonable in structure, stable and reliable in work and convenient to overhaul, and high-temperature influences on the furnace opening can be effectively avoided; and the rotation liquid seal cover is adopted for achieving sealing of the furnace opening during rotary material distribution, and rapid adjustment of a discharging point can be achieved through combination of different types of adjusting connecting plates and discharging bodies.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Flue gas treatment device for diesel generator set

ActiveCN107905876AEasy to handleAvoid pollutionInternal combustion piston enginesExhaust apparatusFlue gasWorking environment

The invention discloses a flue gas treatment device for a diesel generator set. The flue gas treatment device comprises a bottom plate. The upper surface of the bottom plate is fixedly connected withthe lower surface of a diesel generator set body. An exhaust opening of the diesel generator set body communicates with the right side face of a shell through a first through pipe. A first bearing isclamped to the upper surface of the inner wall of the shell. A first rotary shaft is sleeved with the first bearing. A first blade is fixedly connected to the surface of the first rotary shaft. According to the flue gas treatment device for the diesel generator set, by arranging the diesel generator set body, the shell, the first blade, a first bevel gear, a second bevel gear, a belt, a second blade, an atomization device and a water pump, gas exhausted from the diesel generator set body is treated in time when the diesel generator set body operates, the pollution of the gas to the air can beavoided, the influence on the life and working environment of people is avoided, and meanwhile the harm to the body health of people is avoided.

Owner:广东海能全宇动力科技有限公司

Aluminum alloy profile powder spraying device for building material production

InactiveCN111871678AQuick flangingQuick and efficient flangingPretreated surfacesCoatingsStructural engineeringMechanical engineering

The invention provides an aluminum alloy profile powder spraying device for building material production, and relates to the technical field of spraying devices. The spraying device comprises a box body and a supporting base, a powder box is arranged at the upper end of the box body, a powder pump is fixedly arranged on the outer side wall of the powder box, a first air cylinder is fixedly arranged on the inner side wall of the top of the box body, a fixing plate is vertically and fixedly arranged at the lower end of a piston rod of the first cylinder, a second cylinder is horizontally and fixedly arranged on the left side of the fixing plate, a powder spraying gun is vertically and fixedly arranged at the tail end of a piston rod of the second cylinder, and a hose lifting device is arranged at the upper end of the box body. According to the spraying device, through the arrangement of the hose lifting device, the phenomena of knotting and winding caused by loosening of a powder feedinghose are prevented; through the arrangement of supporting side plates and supporting plates and the cooperation of upper clamping plates and lower clamping plates, overturning of a whole aluminum alloy profile is completed; and the whole spraying device is convenient to operate, rapid and efficient powder spraying can be conducted on the aluminum alloy profile, rapid flanging of the aluminum alloy profile is achieved, powder raw materials are saved, and the practicability is high.

Owner:安徽家园铝业有限公司

Environment-friendly treatment method for garbage treatment

ActiveCN111618067AScientific and reasonable structureEasy to useSolid waste disposalCleaning using toolsForeign matterElectric machinery

The invention discloses an environment-friendly treatment method for garbage treatment. The method is characterized in that crushing cutters are fixedly arranged in the middle of a moving shaft at equal intervals, annular supporting frames are fixedly connected to the top end and the bottom end of the moving shaft, annular fixing plates are fixedly arranged at the top end and the bottom end of theinterior of a crushing tank body, sliding grooves are formed in the middles of the annular fixing plates, sliding blocks are fixedly arranged at the two ends of the middles of the annular supportingframes, and scraping plates are fixedly connected to the middles of the sliding blocks. According to the method, the structure is scientific and reasonable, and the use is safe and convenient; throughcooperative use between a crushing motor and the moving shaft, the crushing cutters rotate at a high speed in the crushing tank body to cut and crush solid garbage, the compression failure caused bythe fact that the solid garbage contains foreign matter with too high hardness is avoided, and the working efficiency is improved; and meanwhile, through cooperative use between the sliding blocks andthe sliding grooves, the scraping plates rotate along with the moving shaft to clean then the inner wall of the crushing tank body, and the garbage is prevented from adhering to the inner wall of thecrushing tank body.

Owner:浙江虎哥环境有限公司

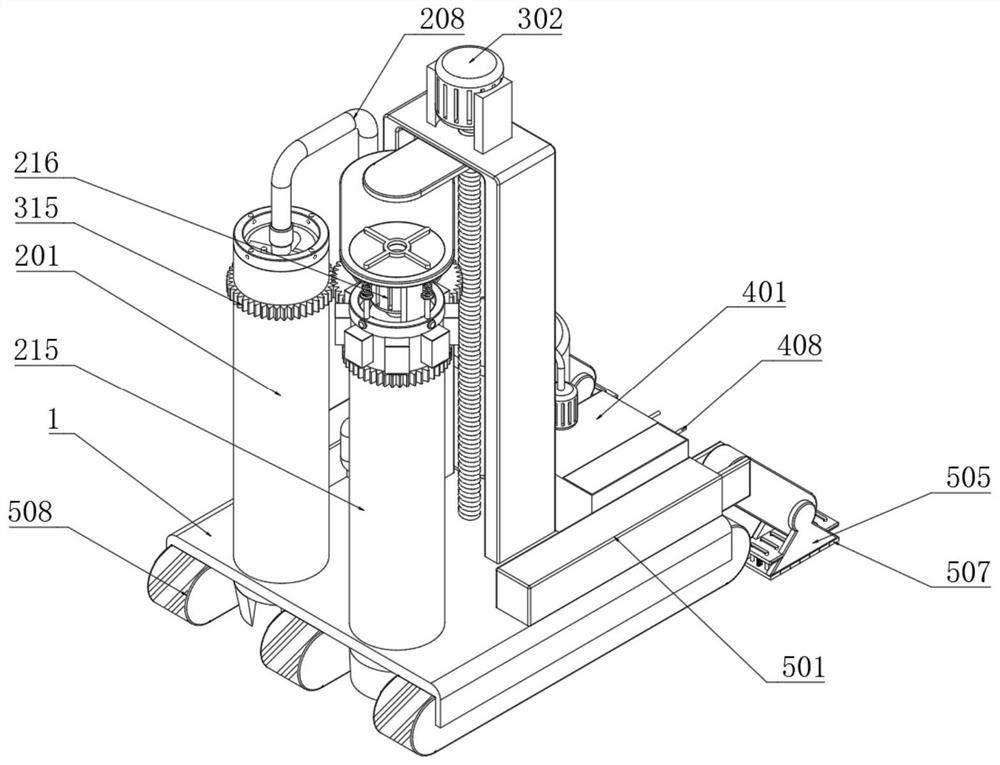

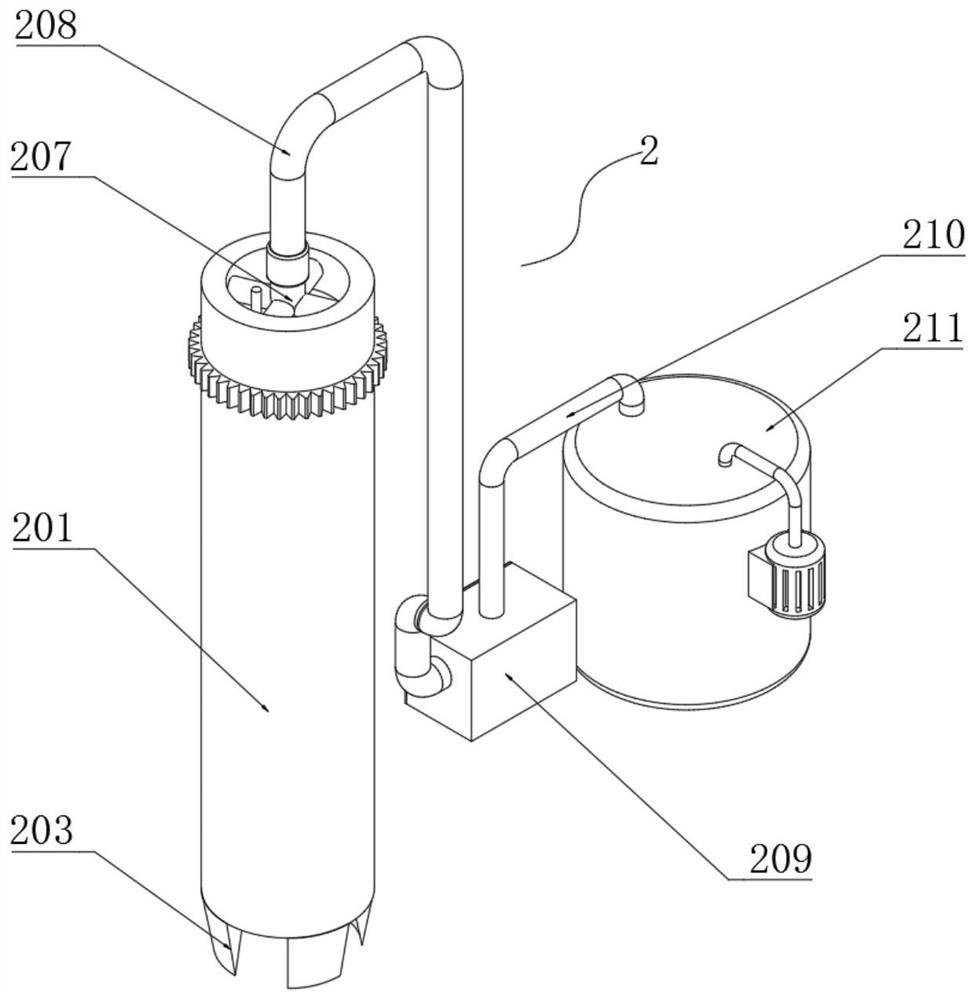

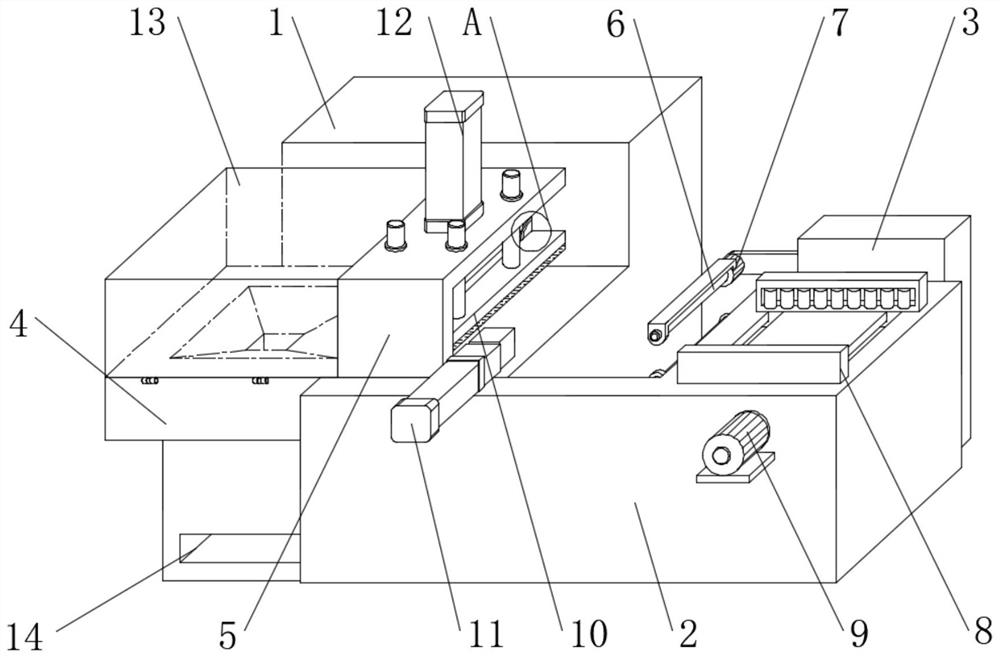

Coring equipment and coring process

PendingCN108858799AGuaranteed StrengthImprove cutting efficiencyMulti-purpose machinesWorking accessoriesEngineeringCoring

The invention discloses coring equipment and a coring process. The coring equipment comprises a body, the body comprises a base and a supporting seat, the base is fixedly connected with the supportingseat, and a clamping assembly is arranged on the base and used for clamping a raw material. A coring assembly and a control assembly are arranged on the supporting seat, the coring assembly slides upand down relative to the supporting seat, and the control assembly controls the clamping assembly and the coring assembly to operate. The coring assembly is provided with a perforation mechanism, a limiting mechanism and a cutting mechanism, the perforation mechanism comprises a perforation tool, and the cutting mechanism comprises a cutting line which is positioned at the bottom of the perforation tool and limited through the limiting mechanism. In an initial state, the limiting mechanism limits motion of the cutting mechanism, the perforation mechanism rotates relative to the clamping assembly to realize perforation, and the perforation mechanism stops operating when the perforation depth reaches a preset value. The control assembly controls the limiting mechanism to stop limiting, andthe cutting line rotates relative to the clamping assembly to realize bottom cutting of an inner core of the raw material. The coring equipment has advantages of simple structure, convenience in coring, inner wall smoothness and the like.

Owner:墨脱县墨脱石锅文化产业有限公司

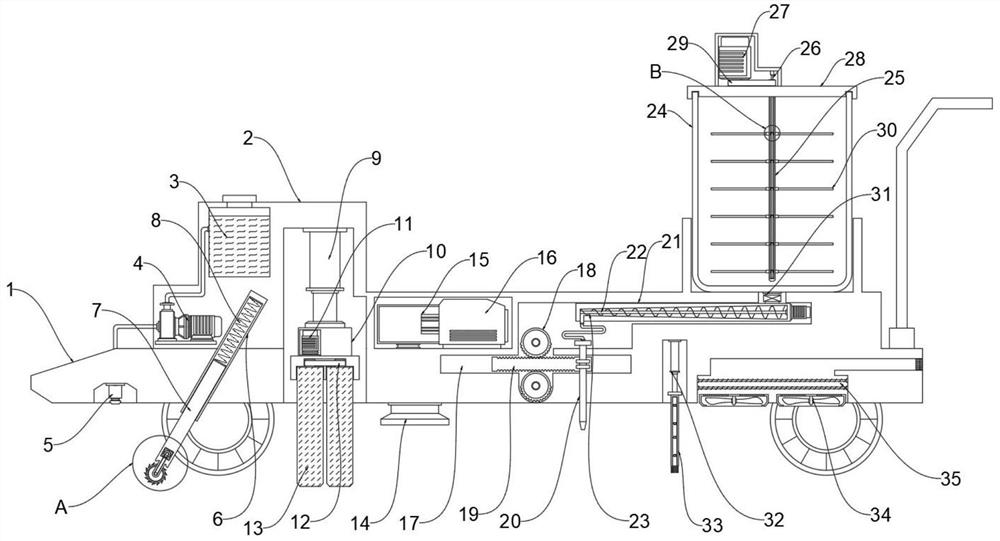

Material filling device for bridge expansion joint settlement repair and using method thereof

InactiveCN113026582AClean high speedBreak up quicklyDirt cleaningBridge structural detailsVehicle frameRepair material

The invention discloses a material filling device for bridge expansion joint settlement repair and a using method thereof. The material filling device comprises a frame and a cleaning box arranged above the front end of the frame; a sleeve rod is arranged below a water tank, a movable rod is mounted in the sleeve rod, and a crushing wheel is rotationally mounted at the lower end of the movable rod; a mounting sleeve is mounted at the rear end of the interior of the cleaning box, and a nylon roller is mounted below the mounting sleeve; a sliding groove is formed in the middle of the interior of the frame, and a filling head is fixedly arranged on one side of a transmission toothed plate; and a trowelling mechanism is arranged at the rear end of the filling head, and extension plates are arranged on the two sides of the trowelling mechanism. On one hand, it can be guaranteed that the area is kept in a clean state in the process of filling the area to be repaired, floating dust generated by cleaning of soil impurities can be avoided, and on the other hand, it can be guaranteed that repairing materials can be evenly attached to the surface of the expansion joint when the area to be repaired is filled.

Owner:马超

Spray-painting device used for making waterproof shoes

InactiveCN108125321AImprove painting efficiencyImprove work efficiencyShoemaking devicesPretreated surfacesEngineeringSpray painting

The invention discloses a spray-painting device used for making waterproof shoes, which comprises a box body. The left side of thetop end of the box body is provided with a first upright post, two adjacent sets of partition boards are connected with each other through a connecting rod, and an installation cavity is formed between the two adjacent sets of partition boards; the installation cavity is arranged exactly below a spray head, a supporting block and a sole seal plate are respectively arranged inside the installation cavity facing each other, and the sole seal plate is installed on theright side of the supporting block; the left side of the supporting block is connected with a shoe throat seal plate, the left side of the shoe throat seal plate and the right side of the sole seal plate are both connected with a spring, and the other end of each spring is connected with a fixed rod, and the other end of each fixed rod is fixedly arranged on the side wall of the partition board; one set of partition boards close to the first upright post are connected with the first upright post through a rotary shaft, the joint between the rotary shaft and the first upright post is provided with a bearing, and the right side of a second upright post is provided with a servomotor. The spray-painting device used for making waterproof shoes has the advantages of higher work efficiency, uniform paint spraying and the like.

Owner:温州市王方鞋业有限公司

Vibration type chain uniform oiling device

InactiveCN107876301AReasonable structural designSave resourcesLiquid surface applicatorsCoatingsSprocketFuel tank

The invention discloses a vibration type chain uniform oiling device. The vibration type chain uniform oiling device comprises two conveying chain wheels arranged in a spaced mode. An oil storage tankis arranged between the conveying chain wheels, and chain wheels are installed at the upper end opening and bottom end of the oil storage tank through supports corresponding in pairs. A first transition chain wheel, a second transition chain wheel, a third transition chain wheel and a fourth transition chain wheel are installed on the outer side of the output end of the oil storage tank and are in matched transmission with the oil storage tank. An oil receiving tank is arranged between the first transition chain wheel and the conveying chain wheel above the oil storage tank, a vibration roller mechanism is erected between the first transition chain wheel and the second transition chain wheel, an oil blowing mechanism is arranged between the second transition chain wheel and the third transition chain wheel, and an adsorption mechanism is arranged between the third transition chain wheel and the fourth transition chain wheel. Through the process of conducting treatment after oiling byvirtue of the combination of vibration with vibration rollers, the oil blowing mechanism and the adsorption mechanism, oil falling off in the whole process can be all recycled, resources are saved, the oiling effect is guaranteed, and waste caused by oil dropping is avoided.

Owner:绩溪山合机械有限公司

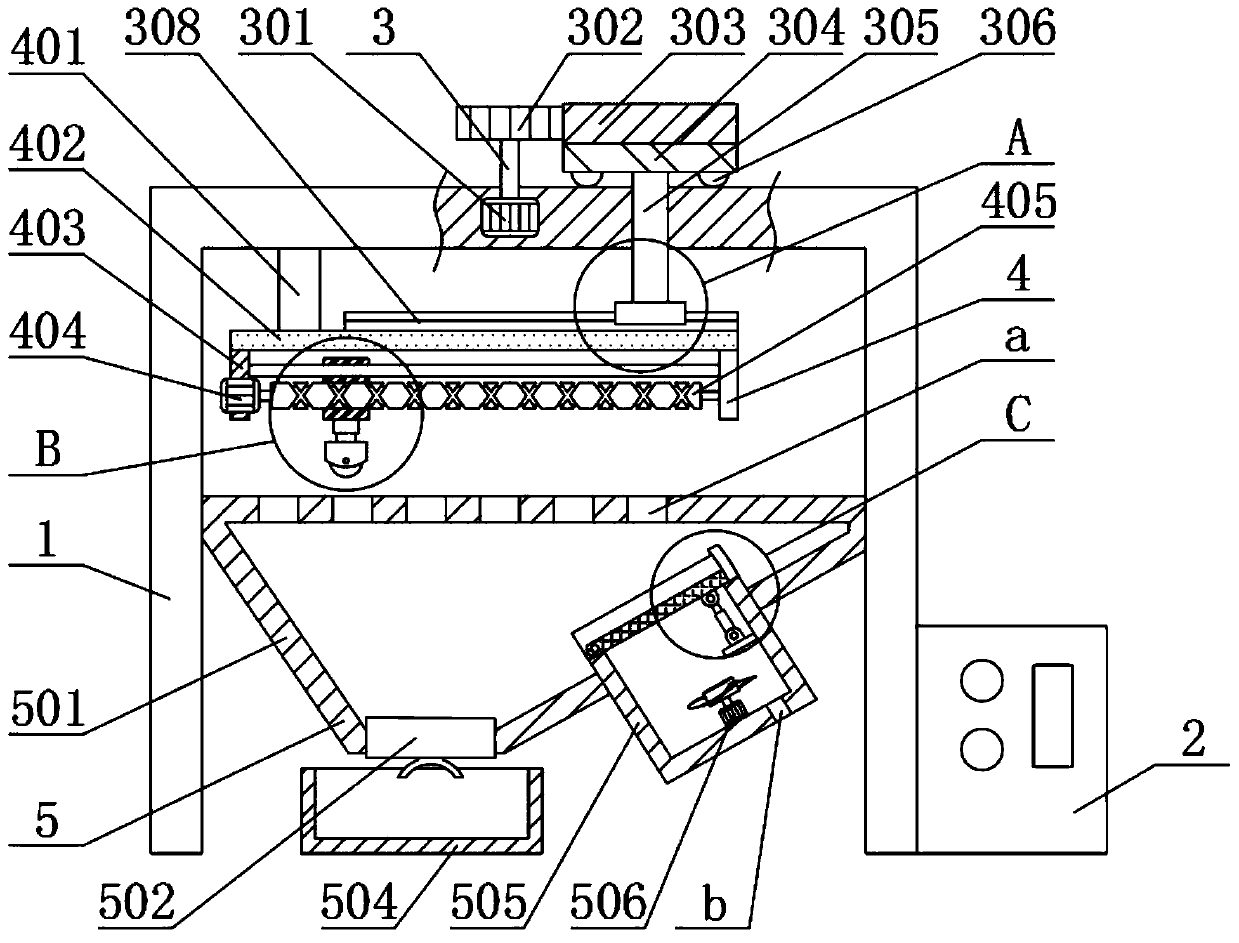

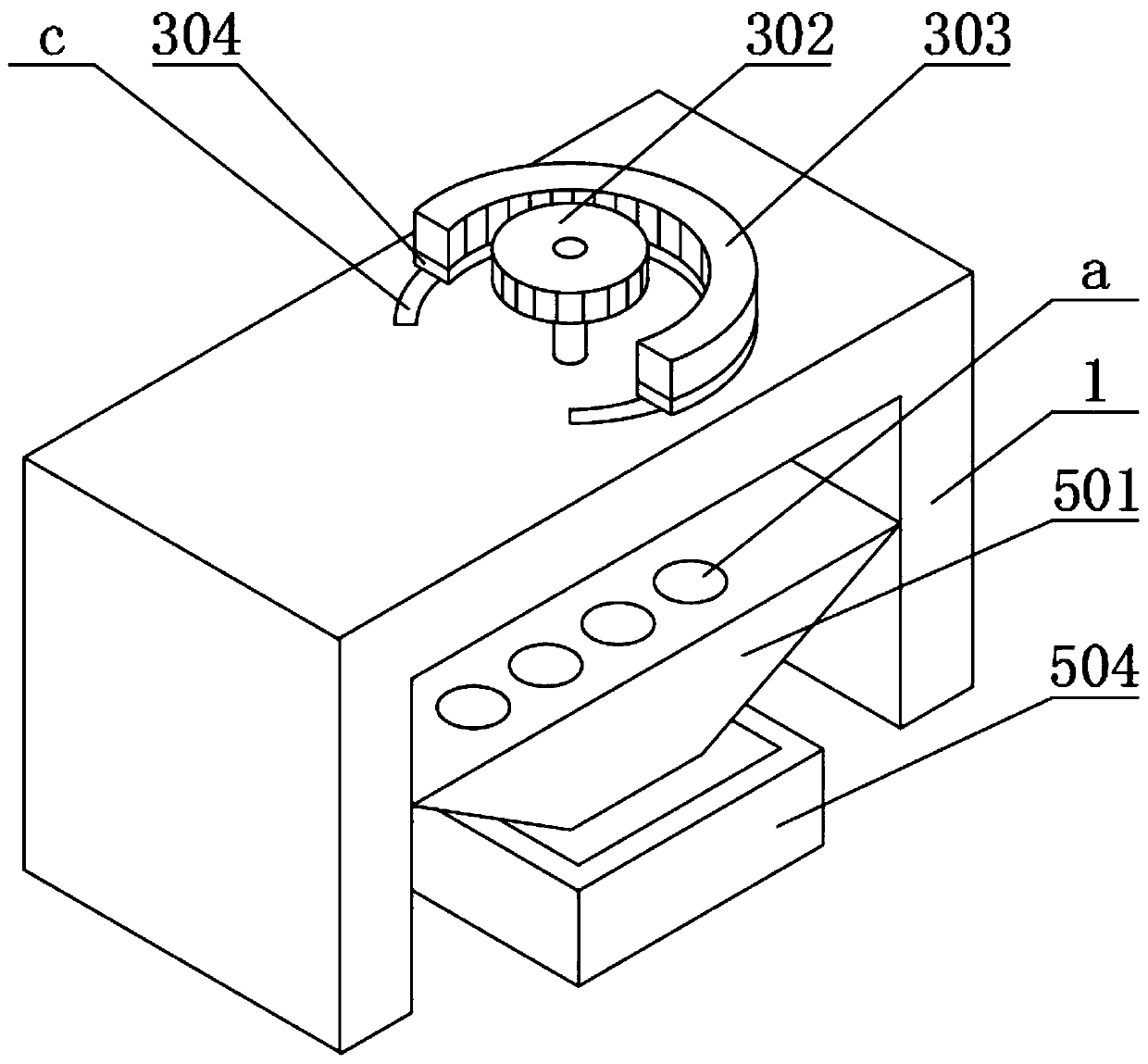

Multi-groove ultrasonic cleaning machine

PendingCN110681639AImprove cleaning efficiencyConsistent qualityDrying gas arrangementsCleaning using liquidsMegasonic cleaningEngineering

The invention discloses a multi-groove ultrasonic cleaning machine. The multi-groove ultrasonic cleaning machine comprises a cleaning box, a loading roller way, and an unloading roller way arranged onone side of the loading roller way; a material frame return roller way is formed between the loading roller way and the unloading roller way; a spray cleaning system is arranged at one end of the material frame return roller way; a first ultrasonic cleaning system, a second ultrasonic cleaning system, a first spray rinsing system, a second spray rinsing system, a hot air drying system and a vacuum drying system are arranged on one side of the spray cleaning system in sequence; and rotating devices with the same structures are arranged in the spray cleaning system, the first ultrasonic cleaning system, the second ultrasonic cleaning system, the first spray rinsing system, the second spray rinsing system, the hot air drying system and the vacuum drying system on one side of the material frame return roller way.

Owner:无锡华伟机电设备有限公司

Finishing liquid for hot-galvanized plate and preparation method for finishing liquid

ActiveCN104194908AGood anti-rust functionImprove rust resistanceLubricant compositionSodium metasilicateTricarboxylic acid

The invention relates to finishing liquid for a hot-galvanized plate and a preparation method for the finishing liquid. The finishing liquid comprises a component I and a component II, wherein the component I comprises following ingredients in parts by weight: 23-33 parts of water, 5-8 parts of dibasic acid, 8-12 parts of tricarboxylic acid and 54-57 parts of triethanolamine; the component II comprises following ingredients in parts by weight: 47-68 parts of water, 4-8 parts of sodium carbonate, 3-5 parts of potassium hydroxide, 2-4 parts of disodium ethylenediamine tetraacetate, 6-10 parts of sodium metasilicate pentahydrate, 8-12 parts of reverse block polyether, 6-8 parts of neodecanoic acid and 3-6 parts of sodium benzoate. The finishing liquid has relatively good rust-proof and lubricating effects, has excellent wetting and cleaning properties and relatively high cleaning ability, and can lubricate and repair the surface of a roll; the finished galvanized plate is smooth in surface, and defects of finishing spots and coating moire can be effectively eliminated or reduced; the finishing liquid has good foam-inhibiting and defoaming functions, so that liquid can be avoided from remaining on the surfaces of the roll and a steel plate and the foam can be avoided from overflowing around to affect the working environment.

Owner:江苏苏北能源科技有限公司

Cutting device for synthetic leather processing

InactiveCN110004697AAffect healthAvoid affecting the working environmentSevering textilesDirt cleaningFixed frameEngineering

The invention relates to the technical field of synthetic leather processing, in particular to a cutting device for synthetic leather processing. The cutting device comprises a fixing frame, a mastercontrol cabinet, an adjusting device, a cutting device and a collecting device. The adjusting device is fixedly connected to an end face of the fixing frame, the cutting device is fixedly connected tothe bottom end of the adjusting device, and the collecting device is arranged on the lower side of the cutting device and fixedly connected with the fixing frame. By arrangement of a gear, a gear ring, a slide ring, a connecting shaft, balls, a slide rail and the like, the position of a cutter can be adjusted according to requirements in practical operation; when cut synthetic leather is still, the cutter can be adjusted in the middle of the fixing frame to realize cutting of the synthetic leather; when the cut synthetic leather is in a production moving process, the rotating speed and position of the cutter can be adjusted according to the moving speed of the synthetic leather, and accordingly vertical cutting of the synthetic leather by the cutter is guaranteed.

Owner:福建省三源兴纺织科技有限公司

Grinding device capable of automatically removing burrs and conveniently collecting waste materials

InactiveCN110860958AEasy to collectAvoid flyingEdge grinding machinesGrinding drivesElectric machineryWorking environment

The invention relates to the technical field of automobile parts, and discloses a grinding device capable of automatically removing burrs and conveniently collecting waste materials. The grinding device capable of automatically removing the burrs and conveniently collecting the waste materials comprises a platform, a control box is fixedly installed at the bottom of the platform, the top of the platform is provided with a through hole, a working box is fixedly installed on the top of the platform, the bottom of the working box is provided with a hole, and the hole communicates with the throughhole; and supporting rods are fixedly installed on the portions, on the left side and the right side of the working box, of the top of the platform, supporting plates are fixedly connected to the topends of the two supporting rods separately, first motors are fixedly installed on the tops of the two supporting plates, casing pipes are fixedly installed on output shafts of the two first motors, the opposite ends of the two casing pipes both penetrate through and extend into the working box, and springs are fixedly installed on the inner walls of the two casing pipes. According to the grindingdevice capable of automatically removing the burrs and conveniently collecting the waste materials, the waste materials can be conveniently collected, and the condition that waste chips fly to influence the working environment is prevented.

Owner:盐城金圣汽车部件有限公司

Online aluminum profile sawing system for intelligent industrial workshop

PendingCN113084257APlay a role of clamping and fixingPrevent splashMetal sawing devicesSievingMachiningIndustrial engineering

The invention discloses an online aluminum profile sawing system for an intelligent industrial workshop, and belongs to the technical field of aluminum profile machining equipment. According to the technical scheme, the online aluminum profile sawing system is characterized by comprising a main machine box and a material conveying table, the front surface of the main machine box is fixedly connected with a treatment box, the inner wall of the treatment box communicates with a funnel-shaped material guide plate, the front surface of the treatment box is provided with a discharging port, the bottom of the treatment box communicates with a waste residue box, the treatment box is fixedly connected with the material conveying table, and a box cover is hinged to the top of the treatment box. Supporting rods are arranged, the distance between the two supporting rods can be adjusted by a worker according to the thickness of an aluminum profile placed at the top of the material conveying table until two material conveying rollers make contact with the surface of the aluminum profile and play a role in clamping and fixing the aluminum profile, then an electric motor works according to the sawing requirement, the aluminum profile is intermittently conveyed to the left side under the action of the two material conveying rollers, and a pressure buffering block can prevent the aluminum profile from being deformed due to too high pressure.

Owner:张驰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com