Polishing device for rice processing and production

A polishing device and rice processing technology, applied in the application, grain smoothing, grain grinding and other directions, can solve problems such as operating environment pollution, and achieve the effect of improving quality, improving quality, improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

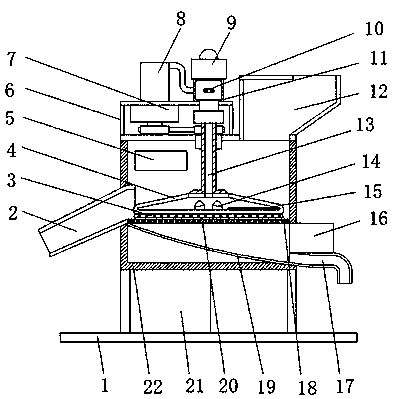

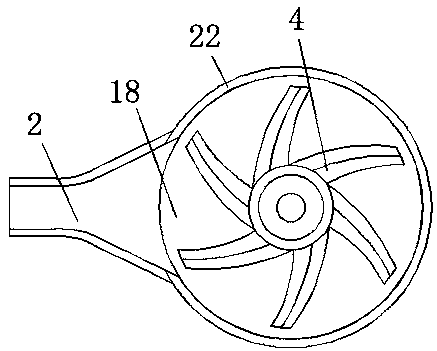

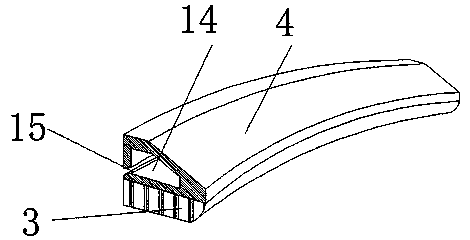

[0029] refer to Figure 1-4 , a polishing device for rice processing, comprising a base 1, a box body 22 is fixedly installed on the top of the base 1, and a box cover is fixedly installed on the top of the box body 22, and a feed hopper 12 is fixedly installed on the top of the box cover, and the box The inside of the body 22 is fixedly equipped with a lower polishing disc 18, and the side of the box body 22 is fixedly equipped with a blanking tube 2 suitable for the lower polishing disc 18. The top of the box cover is connected with a rotating tube 13 through a bearing, and the rotating tube The bottom end of 13 is fixedly installed with upper polishing mold 4, and upper polishing mold 4 inside is provided with the exhaust mechanism that communicates with rotating pipe 13, and the top of box cover is fixedly installed with the driving mechanism that is connected with rotating pipe 13 transmissions, and the driving mechanism A humidifying mechanism is fixedly installed on the...

Embodiment 2

[0039] refer to Figure 1-5 , a polishing device for rice processing and production. Compared with Embodiment 1, this embodiment also includes: a feed grid plate 122 fixedly installed at the bottom end of the feed hopper 12, and the side of the feed hopper 12 is provided with an insert slot, the inside of the slot is plugged with an adjusting grid plate 121 that is slidingly connected to the feed grid plate 122 .

[0040] The surfaces of the feeding grid plate 122 and the adjusting grid plate 121 are both provided with a plurality of strip-shaped holes in an inverted trapezoidal structure.

[0041] In this embodiment: when the device is feeding, the staff can adjust the feeding grid plate 122 and the distribution of the strip holes on the surface of the adjusting grid plate 121 by pulling the adjusting grid plate 121, and then adjust the feeding of rice. The speed is adjusted, and the feeding grid plate 122 and the setting of the adjusting grid plate 121 can disperse the adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com