Patents

Literature

137 results about "Large white" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SNP (single-nucleotide polymorphism) marker set for identifying pig breeds and application thereof

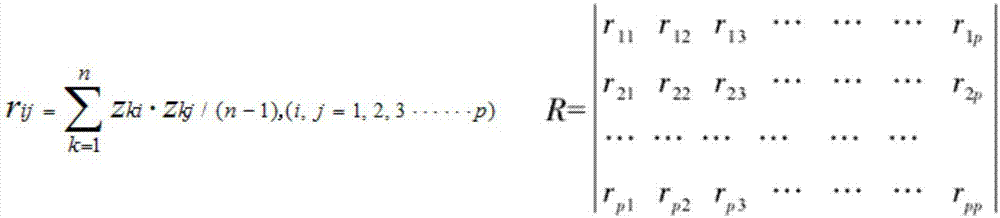

InactiveCN105603089AMicrobiological testing/measurementDNA/RNA fragmentationPrincipal component analysisCorrelation analysis

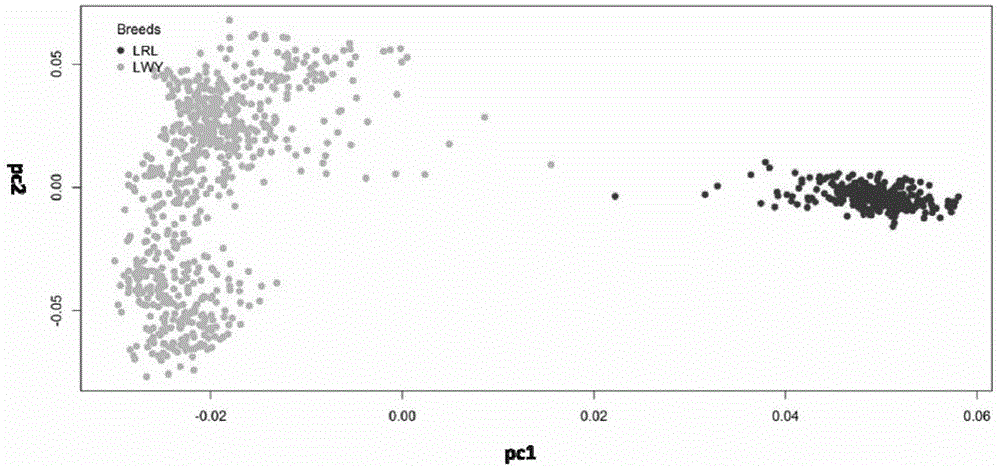

The invention discloses an SNP (single-nucleotide polymorphism) marker set for identifying pig breeds. The application method mainly comprises the following steps: by using 200 purebred Large White and Landrace individuals as study objects, carrying out genome SNP 60K chip scanning typing on all the samples of the two breeds; after carrying out quality control on all the data according to the requirements, screening out SNP marker sites capable of identifying Landrace and Large White, and carrying out genome correlation analysis to screen out 16 SNP sites for identifying Landrace and Large White; and carrying out verification on another 500 individuals by principal component analysis and cluster analysis, wherein the accuracy of the 16 SNP sites reaches 99%, which indicates that the 16 SNP sites can be used for identifying Large White and Landrace.

Owner:ZHANGZHOU AONONG MODERN AGRI DEV CO LTD

White balance adjusting method

ActiveCN104618703AReduce mistakesReduce the chance of missed selectionColor signal processing circuitsRgb imageDouble threshold

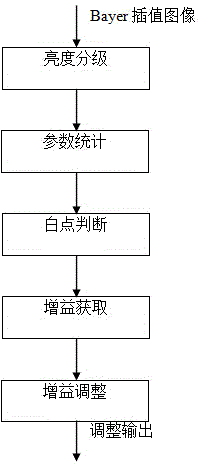

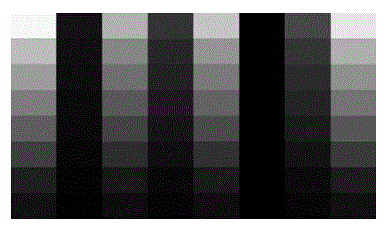

The invention discloses a white balance adjusting method, belongs to the technical field of white balance adjustment, and aims at solving the problems of large white point selection error, easy missing and accurate selection. The method comprises the steps of (1) acquiring a Bayer template RGB interpolation image, and converting the RGB image into a YCbCb image; (2) dividing the YCbCb image into a plurality of brightness level areas in a YCbCb space according to a brightness component Y, and counting Y, Cb and Cr components; (3) counting the statistic value of the candidate white point in each brightness level area and the quantity of the candidate white points falling in the area according to the counted Y, Cb and Cr components; (4) selecting white points from the top brightness level area by the double-threshold method; (5) acquiring average number of YCbCb through the selected white points; (6) converting the acquired YCbCb average number into R, G and B average values of the RGB space; (7) obtaining the channel gain for white balance adjustment according to the R, G and B average values so as to achieve the white balance processing of a colored image. With the adoption of the method, the stability and accuracy of statistics of the white points can be improved.

Owner:傅邓文

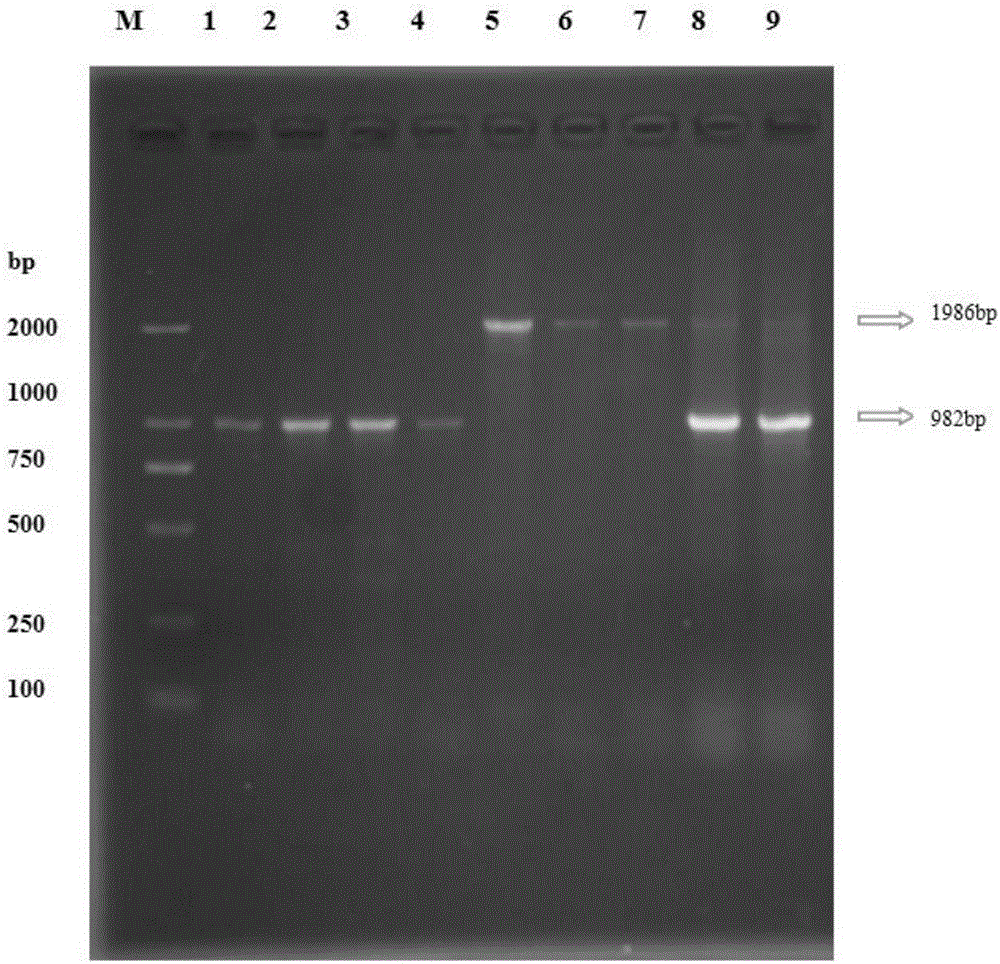

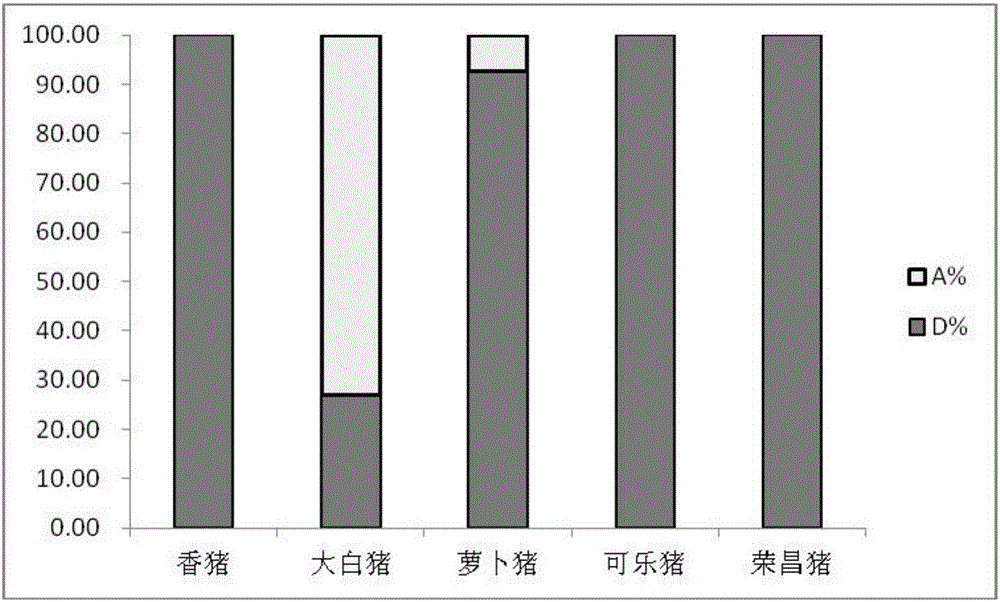

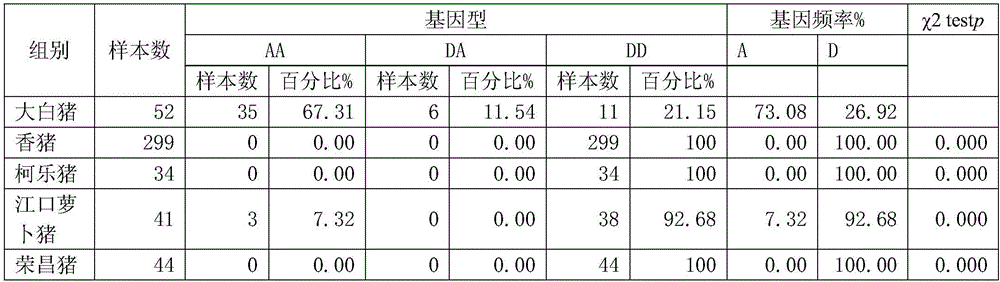

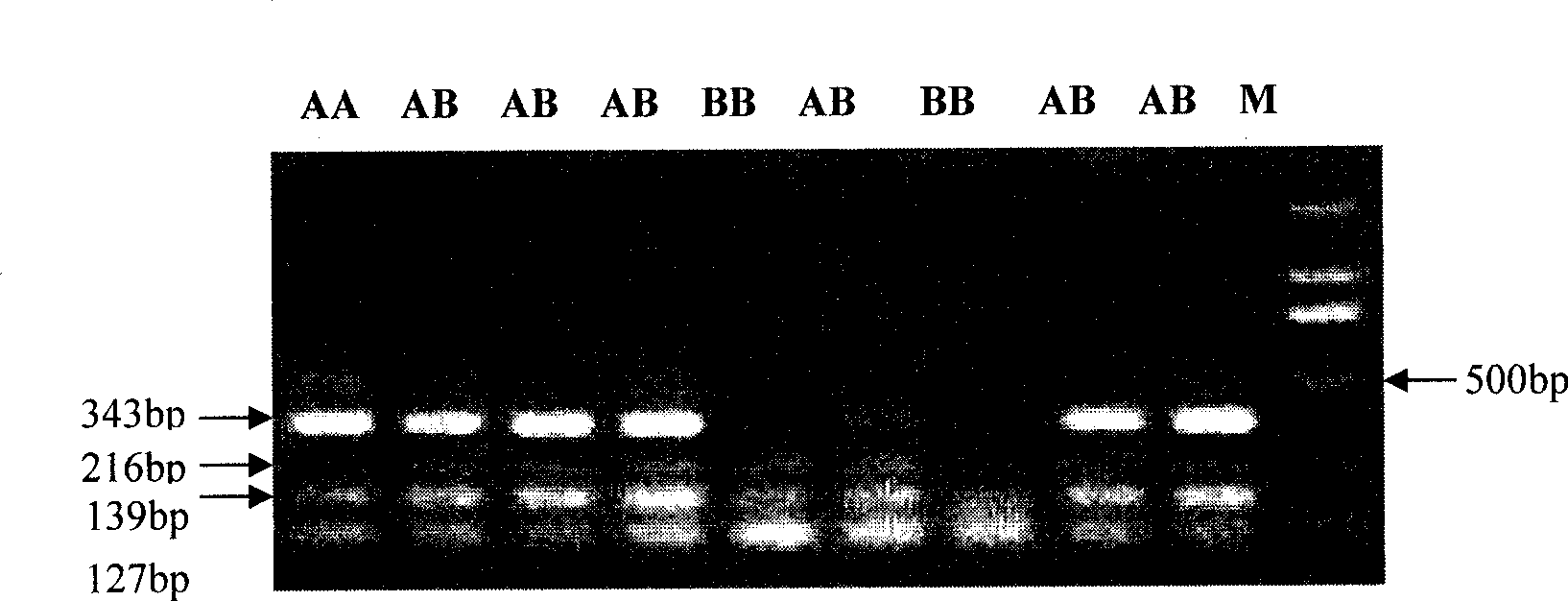

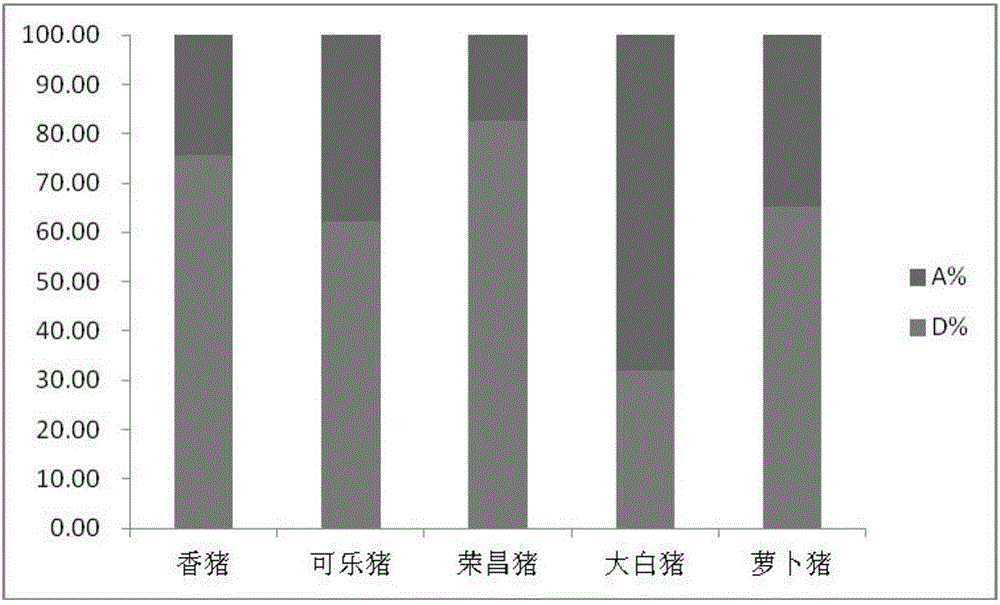

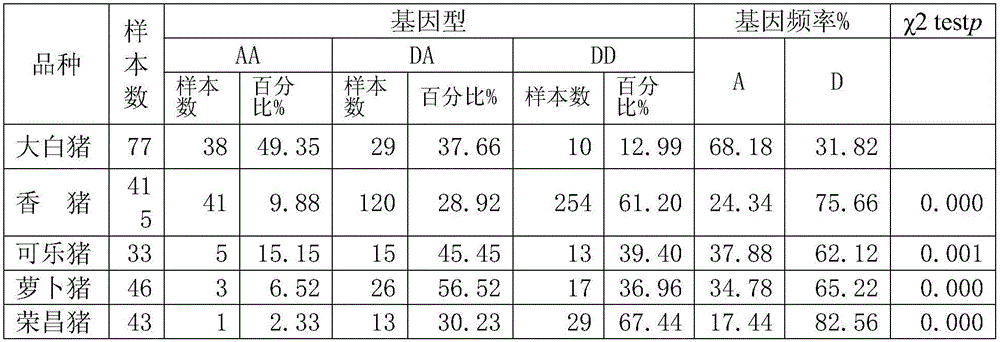

Structural variation 177 (SV177) for distinguishing varieties of large white pigs and Chinese indigenous pigs, and detection technology of SV177

ActiveCN106434931AReliable methodSimple and fast operationMicrobiological testing/measurementHeterozygous genotypeBiology

The invention discloses a structural variation 177 (SV177) for distinguishing varieties of large white pigs and Chinese indigenous pigs. The SV177 is characterized in that the SV177 is positioned at chrX: 100561156-100562159 of a pig reference genome Sscrofa 10.2, missing genes of the SV177 are determined as D, and normal genes which are not missed are determined as A. When a detection technology provided by the invention is used for detecting the SV177 genotype of a sample, the large white pigs have three genotypes and give priority to the genes A which are not missed, and the Chinese indigenous pigs are free from a heterozygous genotype (DA) and give priority to the missing genes D; therefore, the SV177 can be used for distinguishing the varieties of the large white pigs and the Chinese indigenous pigs as a molecular marker.

Owner:GUIZHOU UNIV

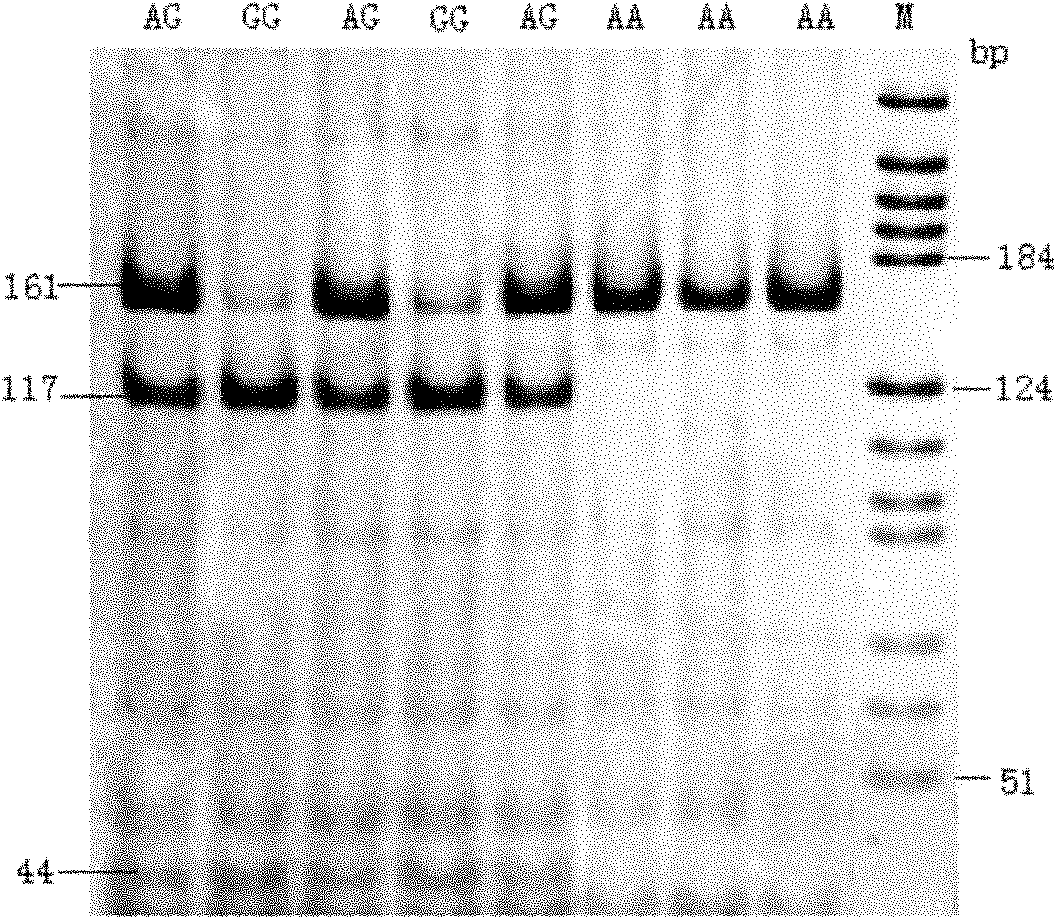

Porcine NTF3 promoter region SNP as molecular marker for boar breeding traits and applications of porcine NTF3 promoter region SNP

ActiveCN107022604AMicrobiological testing/measurementDNA/RNA fragmentationMotilityCorrelation analysis

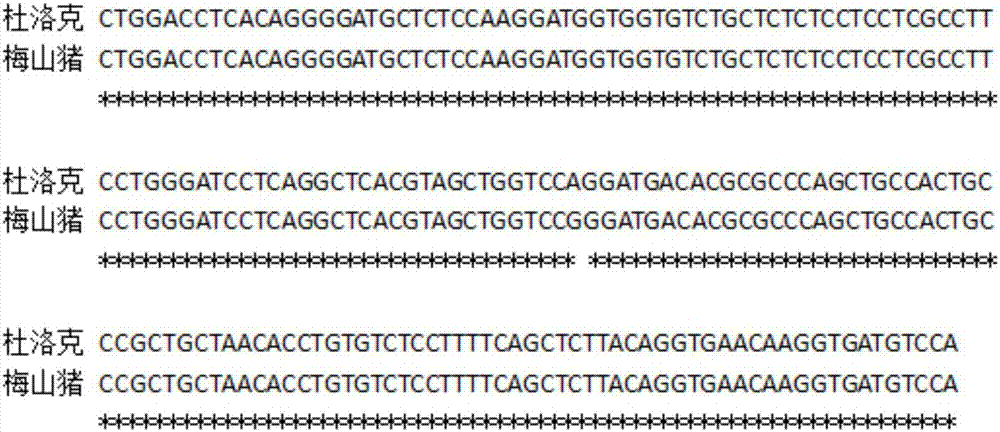

The invention belongs to the technical field of porcine molecular marker screening, and in particular relates to porcine NTF3 promoter region SNP as a molecular marker for the boar breeding traits and applications of the porcine NTF3 promoter region SNP. The molecular marker is cloned from the 5' flank promoter fragment of the porcine NTF3 gene, the nucleotide sequences of the molecular marker are shown as SEQ ID NO:1 and SEQ NO:2, allele mutation of A / G and G / A exists at the 92nd basic group site of the sequence shown as SEQ ID NO:1 and SEQ NO:2, and the allele mutation causes the polymorphism of MvaI-RFLP. The marker is utilized for carrying out correlation analysis on the boar breeding traits of large white pigs and duroc pigs. The breeding traits comprise the boar sperm motility and the sperm density trait. The invention further discloses a typing detection method of the marker, and therefore, a novel marker is provided for selecting the boar breeding traits. The marker can be used for evaluating the boar breeding traits and researching the genetic improvement on the breeding boar breeding performance.

Owner:HUAZHONG AGRI UNIV

Molecular marking method for indicating and identifying litter size in pigs by MMP23 gene

InactiveCN101440399AGood choiceMicrobiological testing/measurementFermentationNucleotideLong segment

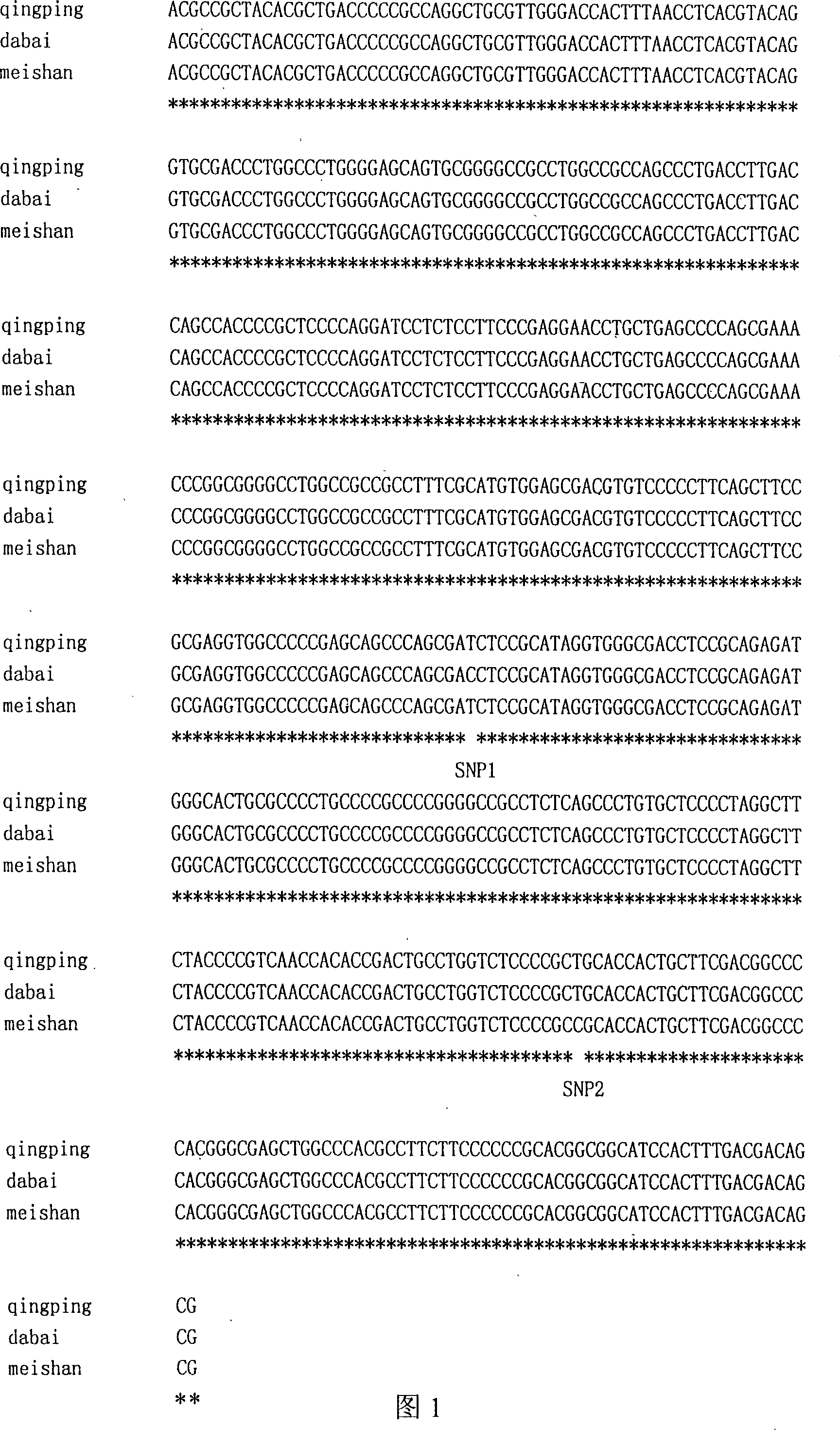

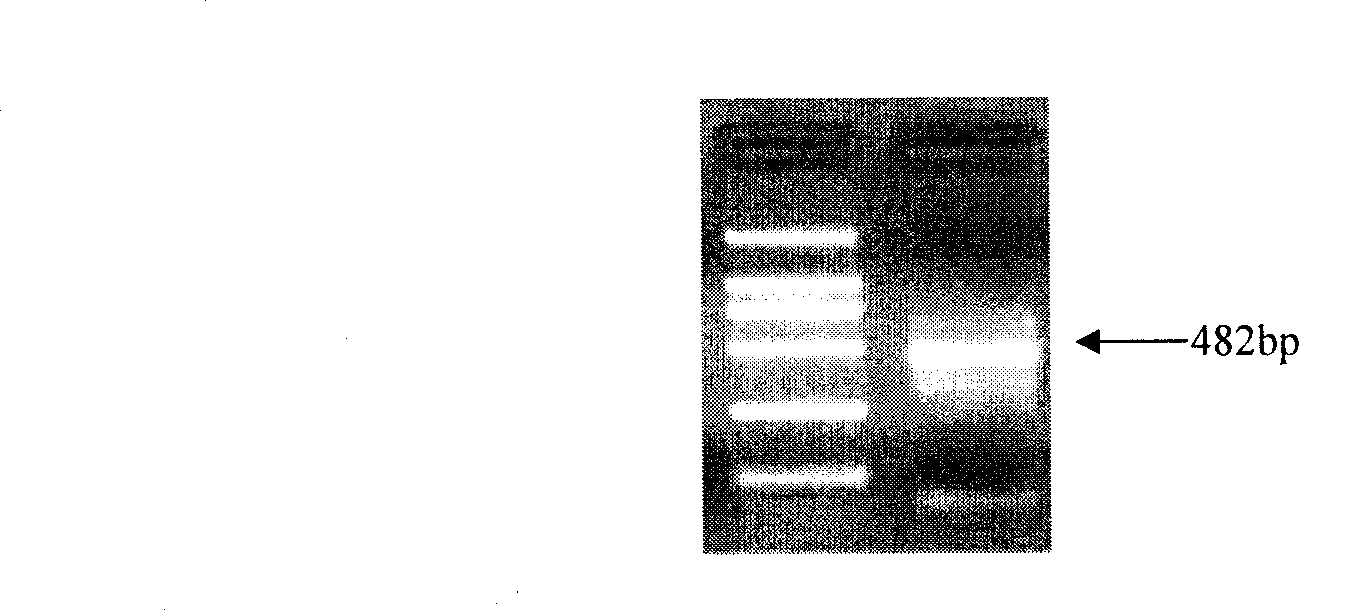

The invention aims to provide a detection method for searching the genetic mutation sites of porcine MMP23 and the genetic polymorphism, namely, the molecular marking method for speculating and identifying the litter size with MMP23. The invention provides the sequence of genomic nucleotides with a length of 482bp including the exons 2, 3 and 4 and the introns 2 and 3 of the porcine MMP23 gene of large white sows, Meishan pigs and Qingping pigs, and provides the single nucleotide polymorphism (SNP) of at two sites situating in the interior of the proliferated 482bp-long segment. The method provided by the invention can be used for developing diagnostic procedures or kits used for selecting the pigs carrying the advantageous alleles in breeding programs with better selective outcome.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Molecular marker SV193 for distinguishing Chinese local pig breeds from Large White pigs and application technology of molecular marker SV193

ActiveCN106399523AReliable methodSimple and fast operationMicrobiological testing/measurementBiotechnologyZoology

The invention discloses a molecular marker SV193 for distinguishing Chinese local pig breeds from Large White pigs and an application technology of the molecular marker SV193. The molecular marker SV193 is characterized in that SV193 is located at chr8:142093174-142093446 of a pig reference genome Sscrofa 10.2, the deleted gene of SV193 is set to be D, and the normal undeleted gene is set to be A. With the application of the detection technology, the results that the Large White pigs mainly rely on the undeleted gene A while the Chinese local pig breeds mainly rely on the deleted gene D are obtained, and the Large White pigs can be distinguished from the Chinese local pig breeds by the application of the molecular marker SV193.

Owner:GUIZHOU UNIV

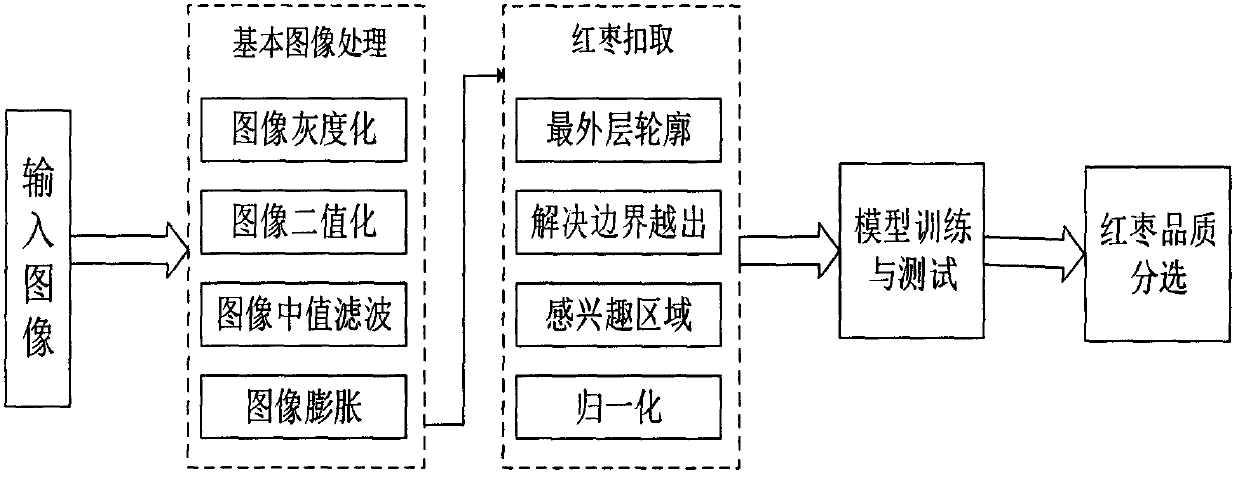

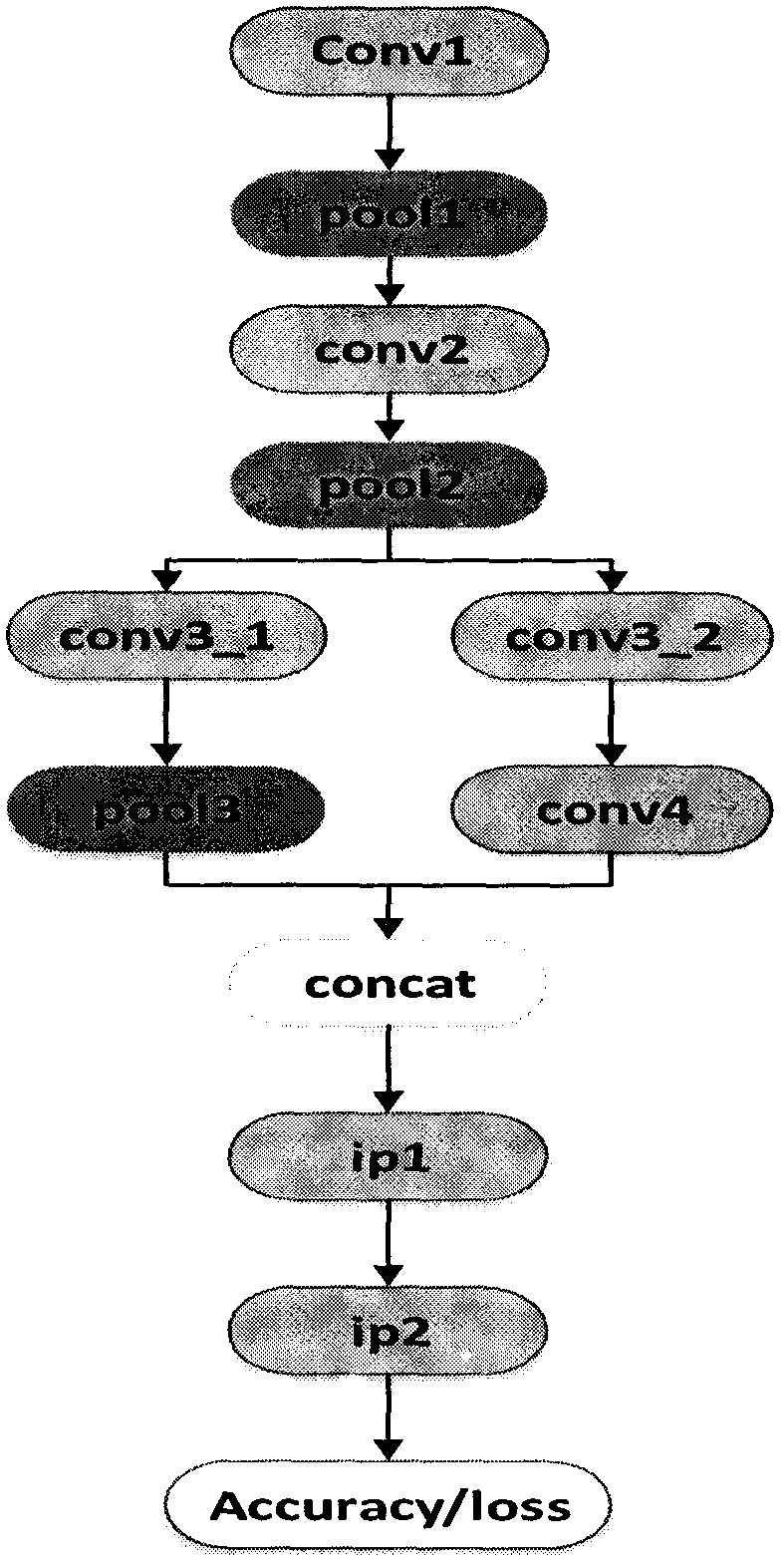

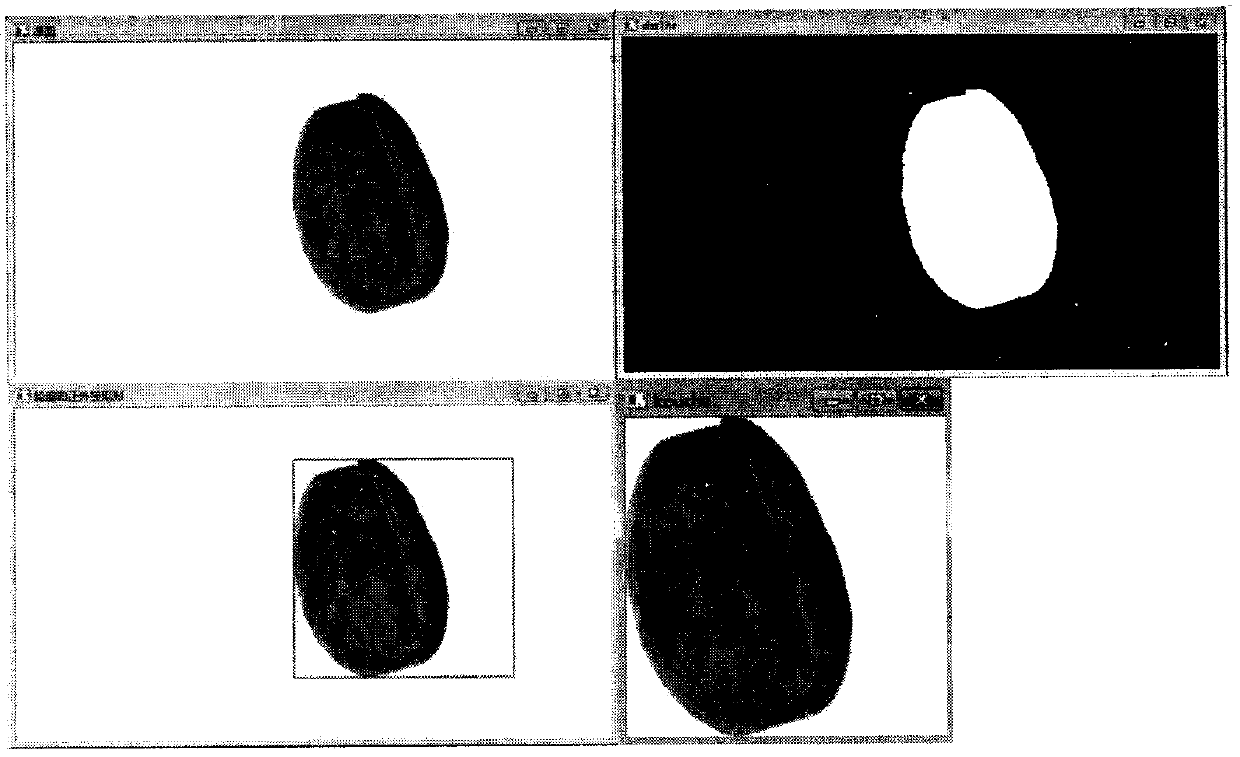

Red date quality sorting method based on deep learning

InactiveCN107679579ALess processing timeImprove accuracyCharacter and pattern recognitionNeural architecturesImaging processingTest sample

The invention provides a red date quality sorting method based on deep learning. The method comprises the steps that a large quantity of red date samples with different quality are collected, the samples are divided into four types, namely plump dates, dry bar dates, cracked dates and blemished dates, and the samples are divided into a training set and a test set; collected red date sample imagesare preprocessed, wherein image processing operation, such as graying, binaryzation, median filtering and ROI area-of-interest extraction, is performed on the red date images on a white background, the red dates in the large white background are picked out, and the sizes of the sample images need to be normalized; and a network with an improved structure is used to train the sample training set toobtain a model, and the model generated through training is utilized to classify the test sample images. Compared with existing red date quality sorting technologies, through the method, the accuracyand speed of red date sorting are improved, and the problems that manual sorting of red dates is low in efficiency and accuracy and consumes excessive manpower resources are successfully solved.

Owner:TIANJIN POLYTECHNIC UNIV

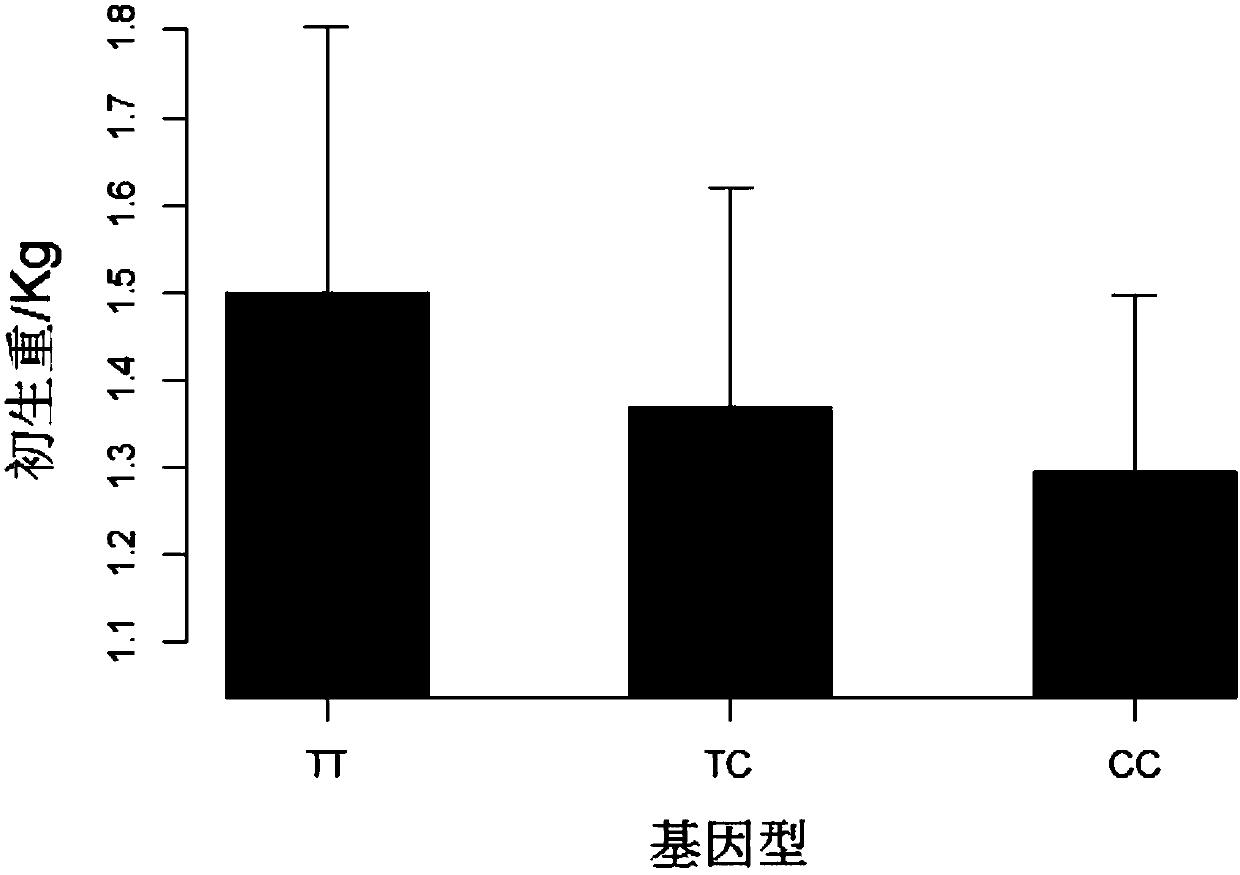

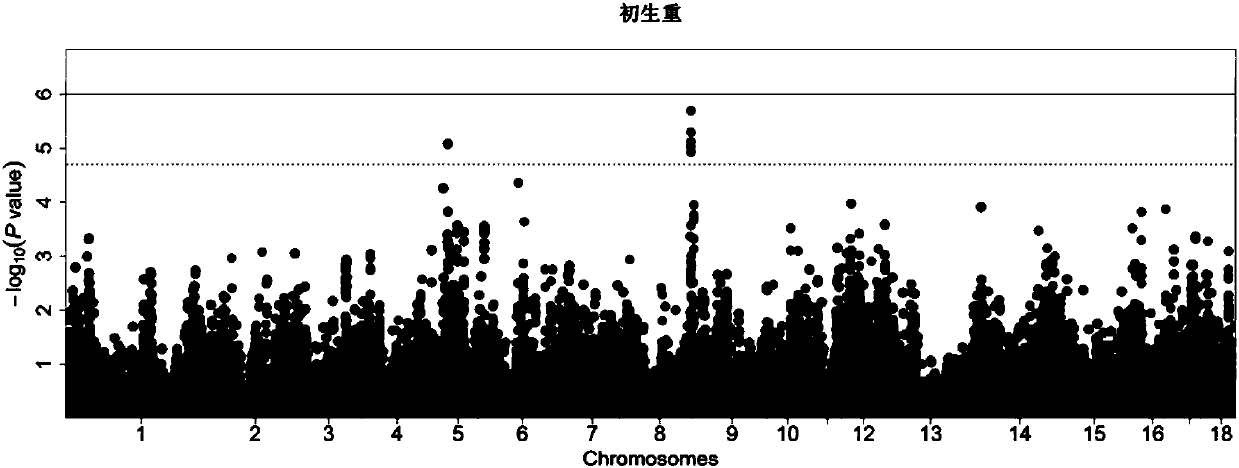

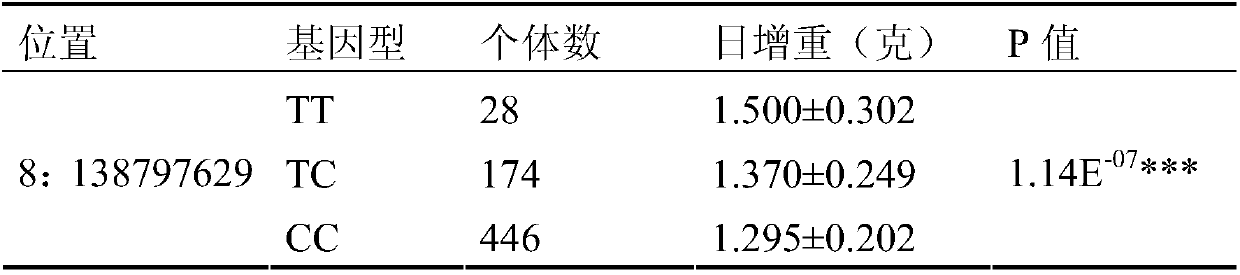

SNP (single nucleotide polymorphism) molecular marker with influence on birth weight characters of pigs and application of SNP molecular marker

ActiveCN107779516AIncreased nascent heavy processIncrease birth weightMicrobiological testing/measurementDNA/RNA fragmentationSingle-nucleotide polymorphismLarge white

The invention belongs to the field of molecular biological technologies and molecular marker technologies, and particularly relates to an SNP (single nucleotide polymorphism) molecular marker with influence on birth weight characters of pigs and application of the SNP molecular marker. SNP loci of the SNP molecular marker with the influence on the birth weight characters of the pigs correspond tomutation of 138797629th nucleotide loci T C on eighth chromosomes in 10.2 versions of international pig reference genomes and are named g138797629 T C. The invention further provides a primer for identifying the SNP molecular marker. The SNP molecular marker, the application and the primer have the advantages that efficient and accurate molecular marker-assisted breeding technologies can be established by the aid of the SNP molecular marker and the primer, dominant allelomorphic genes of the SNP molecular marker can be optimized, genetic progress of the birth weight characters of the large white pigs can be improved, the survival rate of piglets can be increased, the breeding time for the birth weight characters of the large white pigs can be shortened, accordingly, the breeding pig breeding economic benefits can be effectively increased, the production costs of enterprises can be reduced, and the core competitiveness can be improved.

Owner:SOUTH CHINA AGRI UNIV

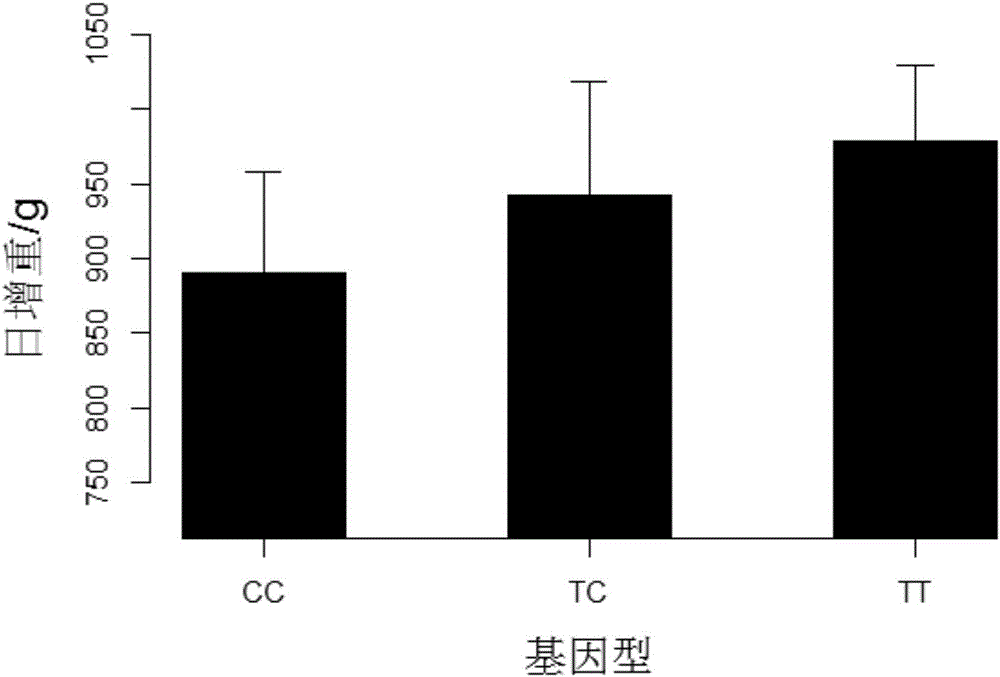

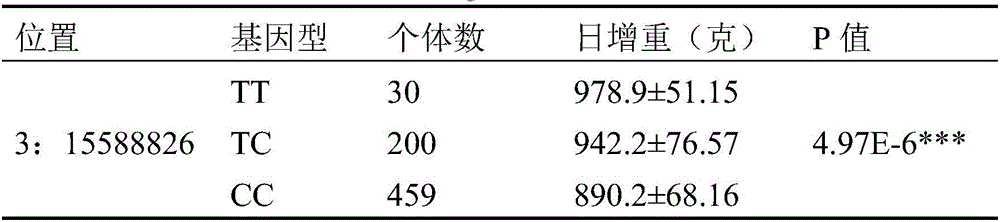

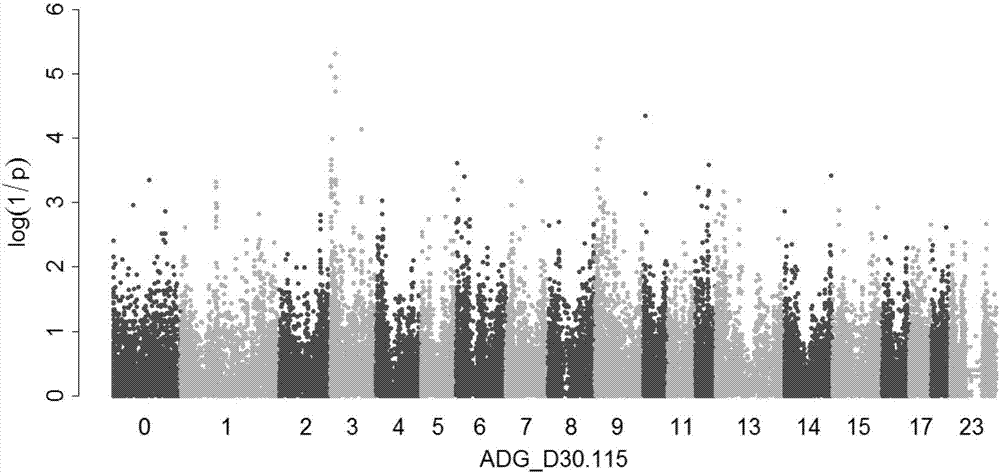

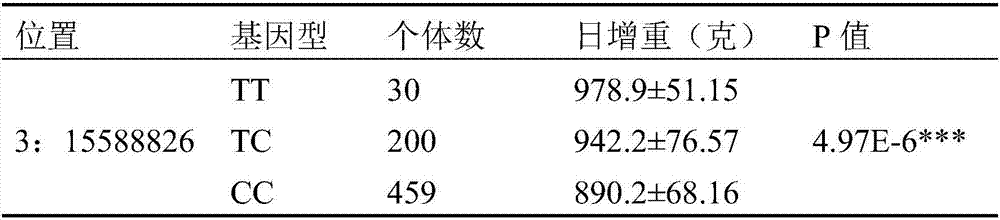

Application of pig SNP molecular marker in pig daily gain characters study and/or pig breeding

InactiveCN107177681AIncrease daily weight gain progressIncrease daily weight gainMicrobiological testing/measurementPig breedingEconomic benefits

The invention belongs to the fields of a molecular biotechnology and a molecule marker technology, and particularly relates to application of a pig SNP molecular marker in pig daily gain characters study and / or pig breeding. A pig SNP molecular marker loci is as shown in SEQ ID NO.1, and the 321st nucleic acid single-base located at a sequence segment is mutated and is named as g15588826C>T. An SNP molecular marker is mutated corresponding to the 15588826th nucleotide site C>T on an international pig reference genome 10.2 version chromosome 3. According to the invention, through optimizing a predominant allele of the SNP molecular marker, the genetic progress of daily gain characters of large white can be increased, and the breeding time of the daily gain characters of the large white can be reduced, so that the economic benefit of pig breeding is effectively improved.

Owner:SOUTH CHINA AGRI UNIV

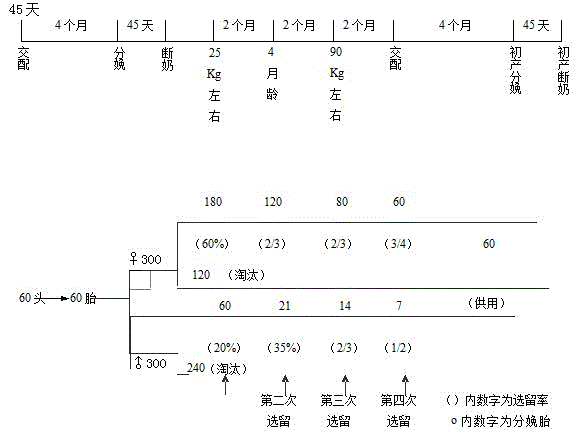

Method for breeding lean swine

The invention relates to a method for breeding lean swine, and belongs to the field of genetic breeding of animals. Suzhong swine of series 1 and 2 is taken as a female parent, famous foreign British large white swine with high growth speed and high lean yield is taken as a male parent, and the lean swine is hybridized and synthesized by using a modern genetic breeding theory and an advanced breeding means. Breeding standards comprise white whole-body clothing hair, a littering size of more than 13, daily gain of 810g and carcass lean yield of over 60 percent. Compared with the Suzhong swine of the series 1 and 2, the growth speed, lean yield and the like of the bred lean swine are remarkably improved.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Neodymium iron boron magnetic chalk

The invention discloses neodymium iron boron magnetic chalk. A formula of the chalk is as follows: 3-5 parts of neodymium iron boron magnetic material powder, 15-20 parts of burnt gypsum powder, 15-20 parts of large white powder, 15-20 parts of water, and 3-5 parts of color paste, wherein the color paste is an aqueous solution comprising 2-5 parts of polyvinyl acetate emulsion, 2-3 parts of polyvinyl alcohol and 50 parts of water. The chalk is matched with an iron blackboard for use, and has the advantages of fluent writing, clear handwriting, moderate hardness and no dust rise.

Owner:桐乡宏晨工业设计有限公司

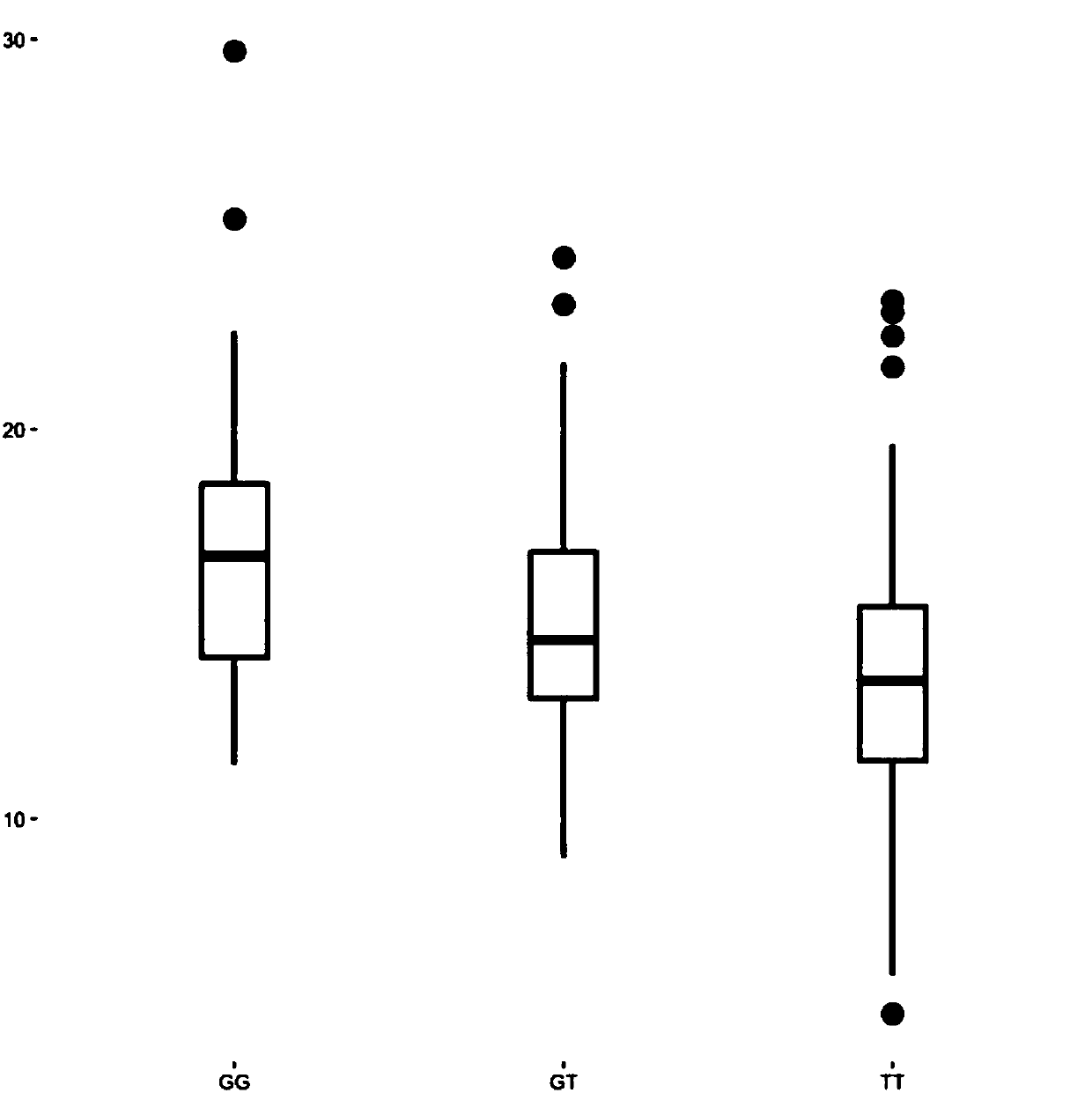

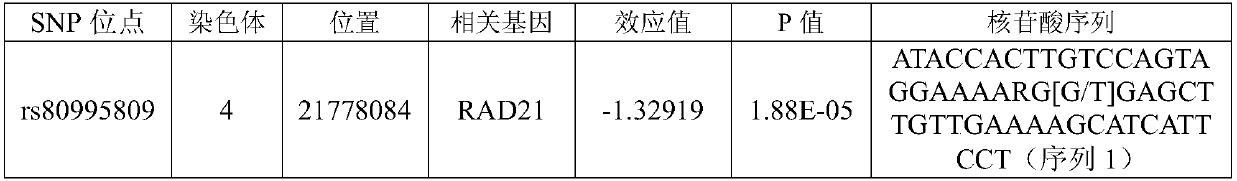

Method for identifying pig backfat thickness based on rs80995809 locus genotyping and its application

ActiveCN109929935ABreeding with high lean meat rateLow in fatMicrobiological testing/measurementMarker-assisted selectionGenotype determination

The invention discloses a method for identifying pig backfat thickness based on rs80995809 locus genotyping and its application. The method is used to detect whether the genotype of the rs80995809 locus in a pig individual is a GG genotype, a TT genotype or a GT genotype, according to the genotype of individual pigs, the backfat thickness of pigs is determined: the backfat thickness of the pigs with GG genotype is thicker than the backfat thickness of the pigs with GT genotype, and the backfat thickness of the pigs with GT genotype is greater than the backfat thickness of the pigs with TT genotype. The experiment proves that the rs80995809 locus has a significant effect on the pig backfat thickness, the selected SNP can be used as a molecular genetic marker, the numbers of trait loci thatare related or closely linked to the backfat thickness can be looked for, which can directly perform genotype selection or marker-assisted selection for large white pigs, and the breeding of dominantvarieties of the large white pigs can be accelerated.

Owner:BEIJING COMPASS BIOTECHNOLOGY CO LTD

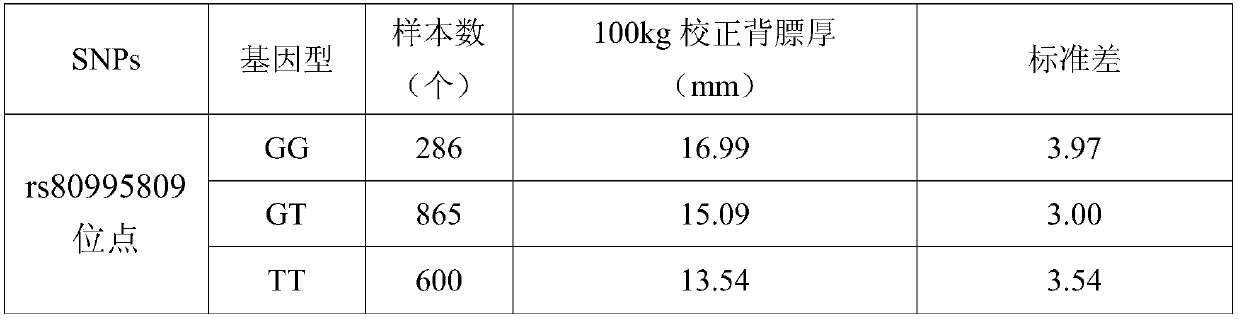

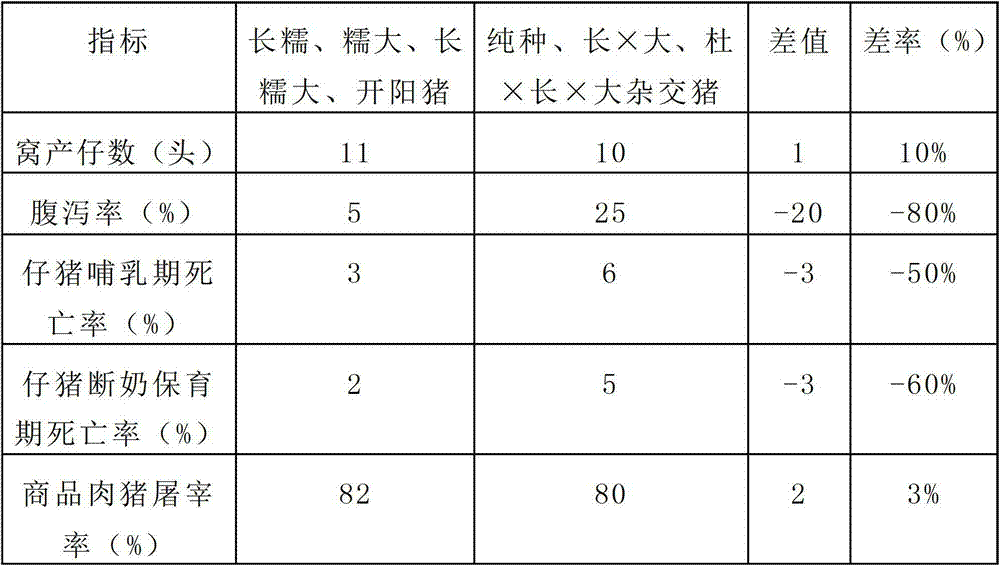

Breeding method for producing high-quality synthetic-line commercial pigs by utilizing Luchuan pigs

The invention discloses a breeding method for producing high-quality synthetic-line commercial pigs by utilizing Luchuan pigs. The breeding method includes that male parents selected from large white pigs hybridize with female parents which are also selected from the large white pigs, and high-quality large white male pigs are selected from the produced hybrid generations to serve as final male parent breeds; the local Luchuan pigs are selected as female parents of the synthetic-line pig parent generation and hybridize with landrace serving as the male parents of the synthetic-line pig parent generation, and high-quality female Changlu pigs are selected from the produced hybrid generations to serve as female parent breeds; the selected male parents and the selected female parents are subjected to hybridization, and the hybrid generations serve as the high-quality synthetic-line commercial pigs which are then put into production. The breeding method for producing the high-quality commercial-line commercial pigs by utilizing the Luchuan pigs has the advantages that the high-quality local pig breeds, namely the Luchuan pigs, of Guangxi are utilized for breeding a special strain of the Luchuan pigs, and the large white pigs, the landrace and the Luchuan pigs are subjected to three way hybridization to form a complete set for producing high-quality commercial pork pigs, wherein the Luchuan pigs serve as the female parents in the synthetic-line pig parent generation, the landrace serves as the male parents in the synthetic-line pig parent generation, the Changlu female parent pigs are obtained by means of hybridization, and the large white pigs serving as the synthetic-line final male parents hybridize with the Chuanglu female parent pigs so as to produce high-quality Landrace Luchuan commercial pigs.

Owner:GUANGXI YANGXIANG AGRI & ANIMAL HUSBANDRY

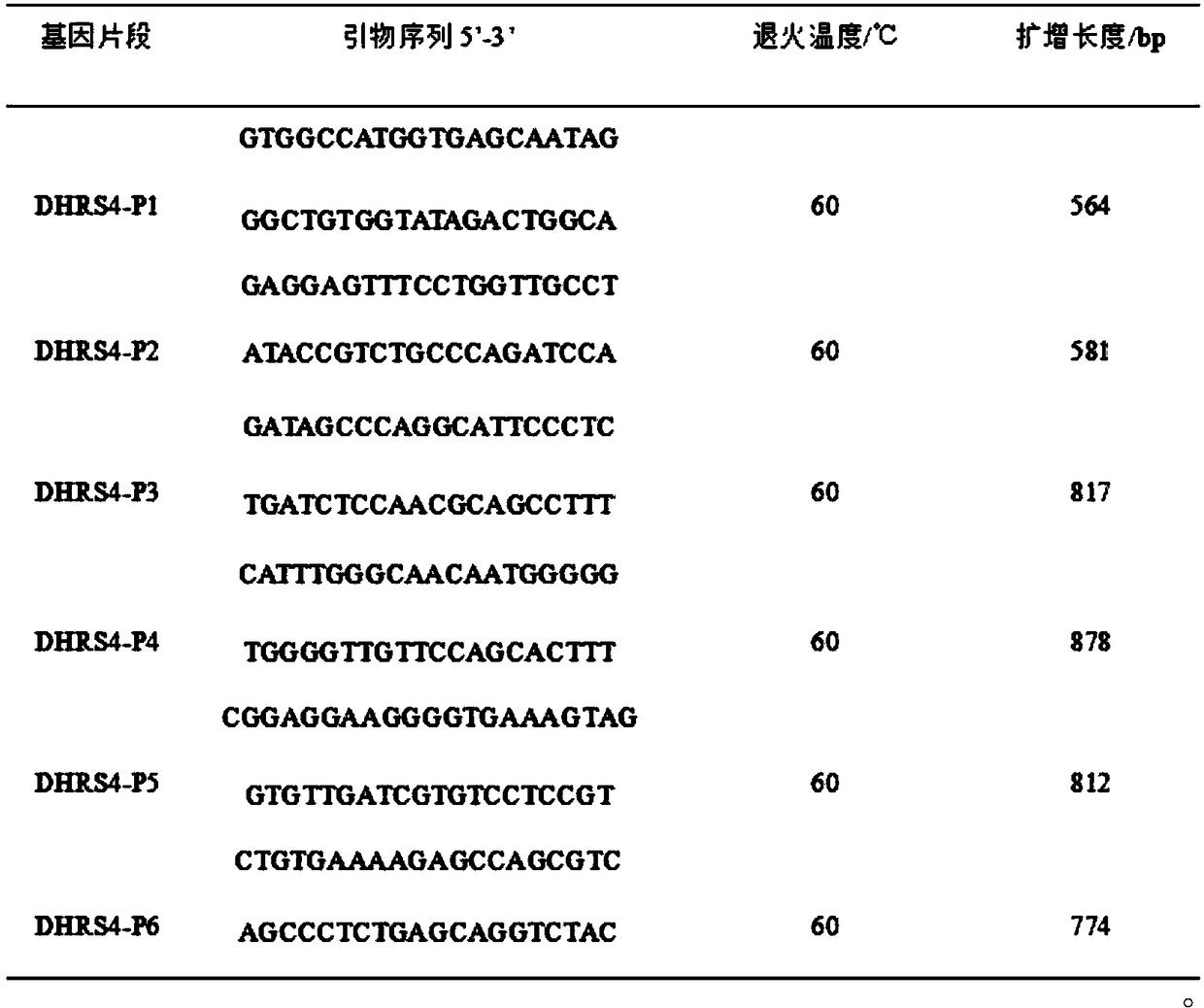

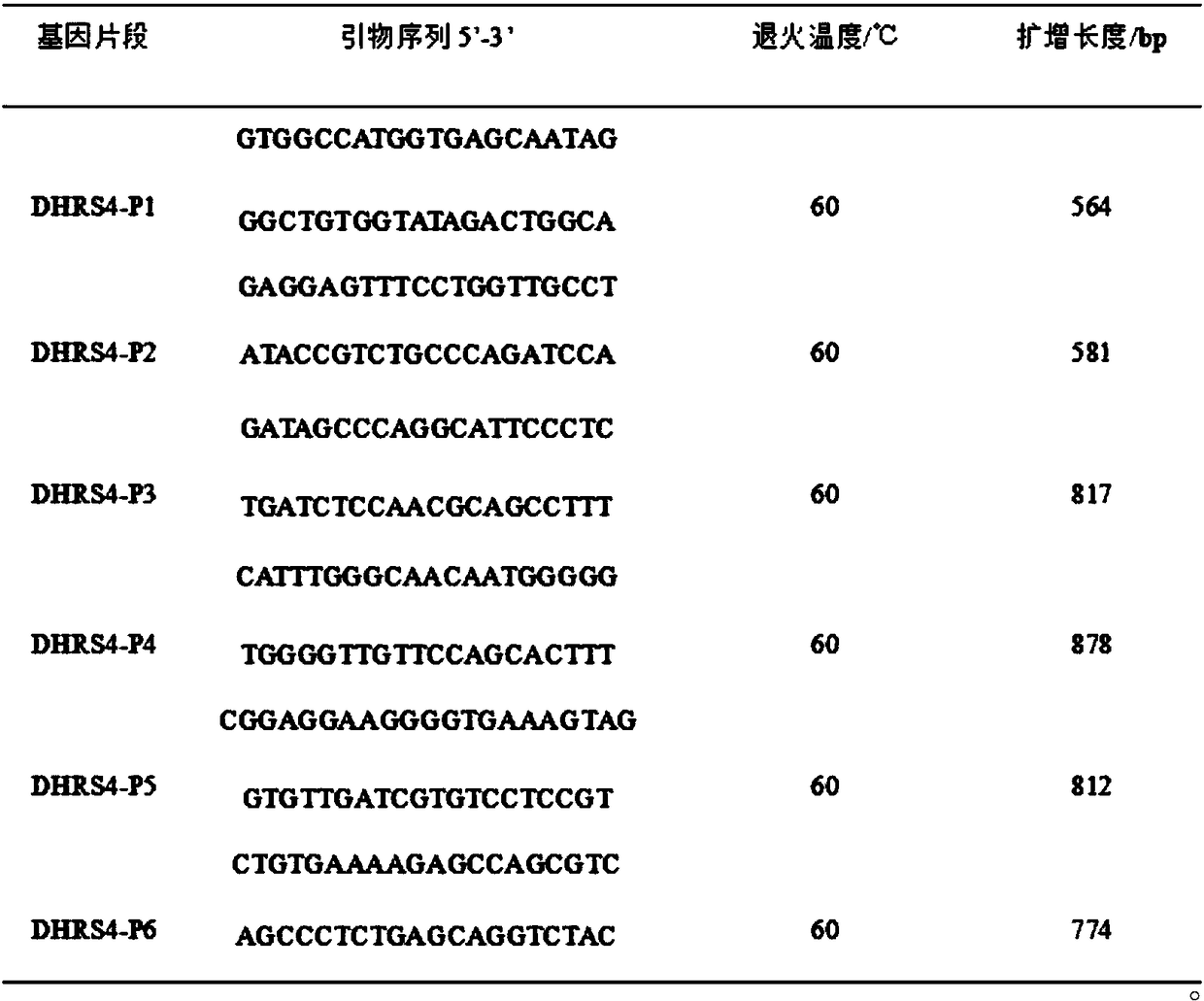

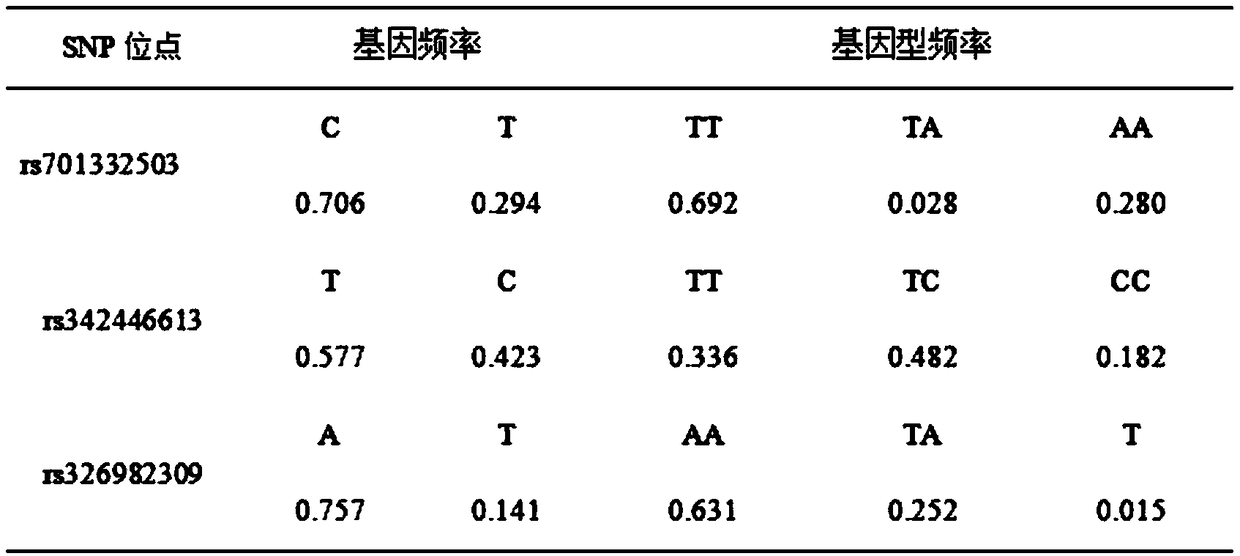

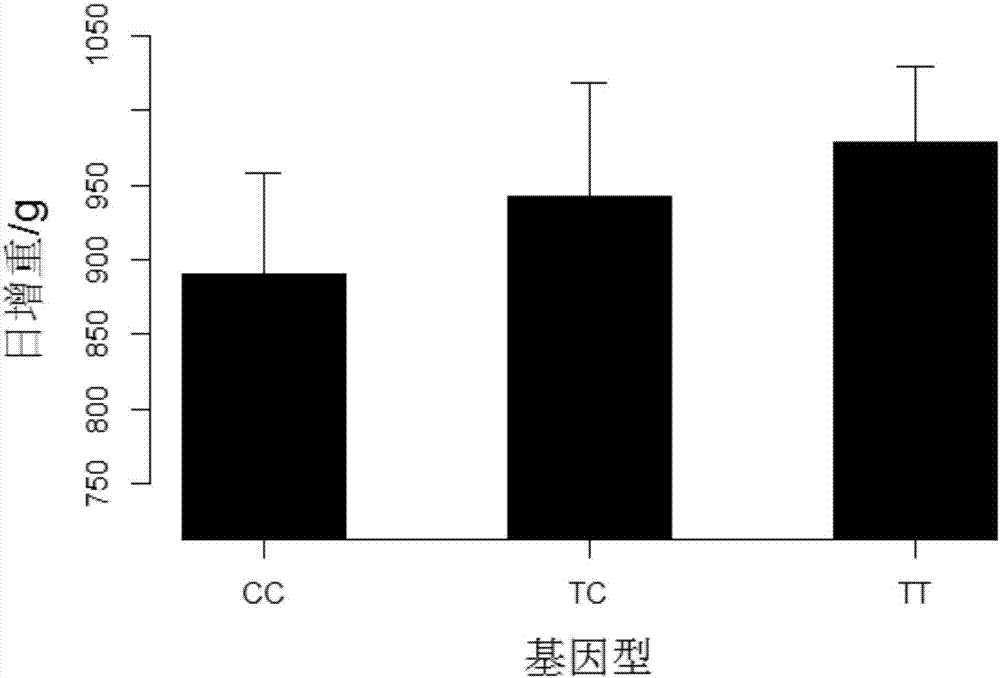

SNP molecular marker relevant to growth traits of large white pig and application of SNP molecular marker

ActiveCN109402270AEconomicalGreat research valueMicrobiological testing/measurementDNA/RNA fragmentationFeed conversion ratioNucleotide

The invention discloses an SNP molecular marker relevant to growth traits of a large white pig and application of the SNP molecular marker. The invention belongs to the molecular marker breeding technical field. The SNP molecular marker is located on the locus rs701332503 of the gene DHRS4 of the large white pig. The nucleotide sequence of the gene DHRS4 in the large white pig is relevant to the growth traits of the large white pig from the 5' end locus rs701332503, that is to say, the SNP molecular marker on the locus rs701332503 of the gene DHRS4 of the large white pig is relevant to the growth traits like the feed conversion ratio of the large white pig and is a new molecular marker, by determining the genotype of the SNP locus of the to-be-tested large white pig, the growth traits likethe feed conversion ratio of the large white pig are subjected to breeding pig sifting, the production cost can be effectively reduced, genetic progress can be accelerated, sifting of large white breeding pigs is better served, the huge market requirement can be met, and the SNP molecular marker also has high economic application value and scientific research value.

Owner:FOSHAN UNIVERSITY

Crossbreeding method for increasing intramuscular fat content of pig

InactiveCN107751088AImprove conversion rateImprove growth performanceAnimal husbandryBOARSignificant difference

The invention relates to the technical field of hybrid breeding, and discloses a hybrid breeding method for increasing fat content in pig muscle. The specific technical solution is to select Xinmei Duroc (EB5) as the male parent, and Large White, Landrace or both hybrid pigs as the female. Originally, crossbreeding was carried out, and the first-generation hybrid sows (50% EB5) were selected and then crossed with Xinmei Duroc (EB5) boars. The offspring produced were commercial pigs (75% EB5) with high intramuscular fat content. The offspring are fed with targeted feed for fattening. The intramuscular fat content is not significantly different from that of Xinmei Duroc, but the growth cycle is shorter than that of Xinmei Duroc, the feed remuneration is high, and the meat quality and flavor are unique. The breeding procedure of the invention is simple, the economic benefit is improved, the breeding cost is reduced, and the utilization and popularization are convenient.

Owner:辽宁德宝农牧集团有限公司

SNP marker affecting daily gain property of pigs, and application thereof

InactiveCN107267631AIncrease daily weight gainSave foodMicrobiological testing/measurementSnp markersNucleic acid sequencing

A SNP marker affecting pig daily gain traits and its application. The invention belongs to the field of molecular biotechnology and molecular marker technology, and particularly relates to the application of a porcine SNP molecular marker in the study of pig daily gain traits and pig breeding. The porcine SNP molecular marker site is shown in SEQ ID NO.1, located in the 321st nucleic acid single base mutation of the sequence fragment, named: g15588826C>T. The SNP molecular marker corresponds to the C>T mutation at the 15588826th nucleotide site on chromosome 3 of the International Porcine Reference Genome Version 10.2. By optimizing the dominant allele of the SNP molecular marker, the invention can increase the genetic progress of the daily gain trait of the Large White, reduce the breeding time for the daily gain trait of the Large White, thereby effectively improving the economic benefits of breeding pigs.

Owner:SOUTH CHINA AGRI UNIV

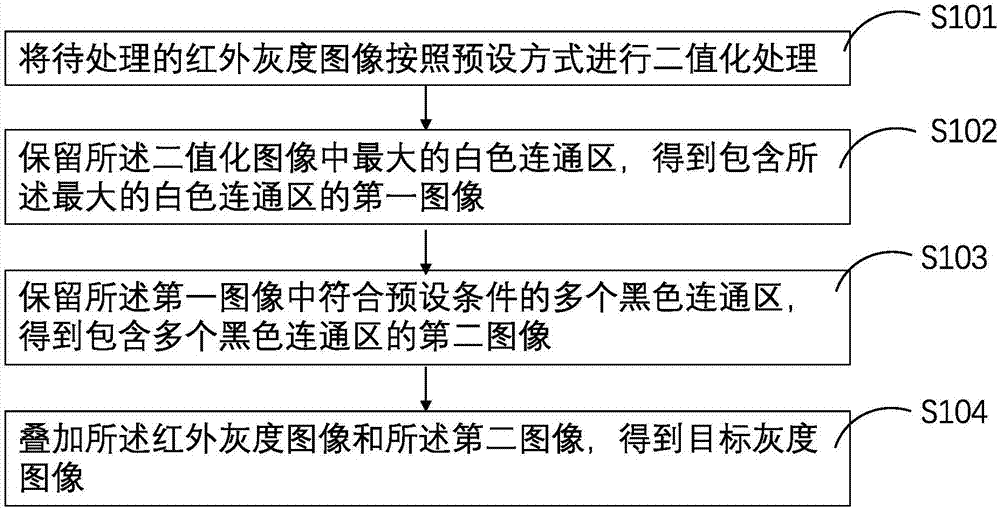

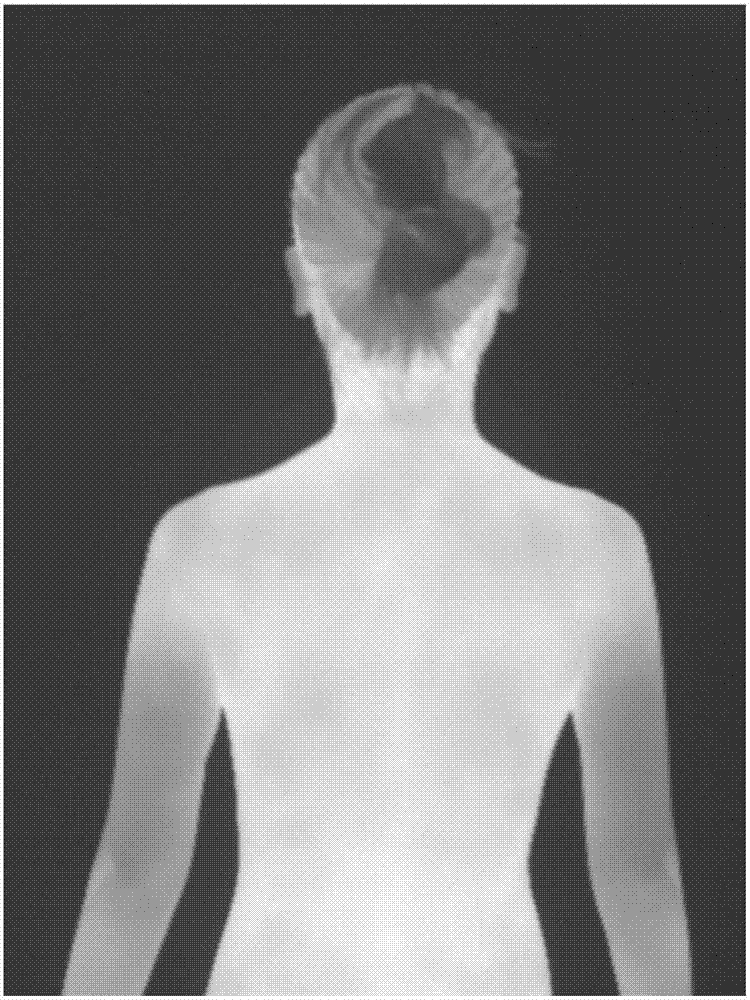

Method and apparatus for extracting target image

ActiveCN107133967AGet goodAlgorithms are reliableImage enhancementImage analysisImaging processingBackground image

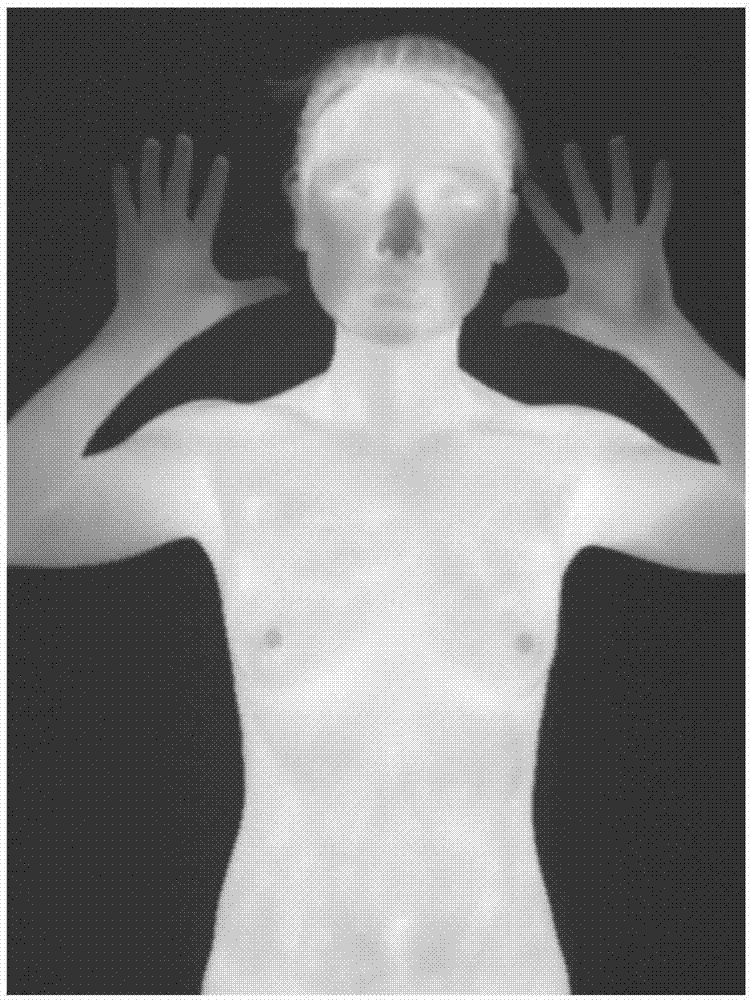

The invention provides a method and apparatus for extracting a target image, and relates to the technical field of image processing. The method comprises the steps of binarizing an infrared grayscale image to be processed by a preset way to obtain a binarized image; retaining the largest white communication region in the binarized image to obtain a first image containing the largest white communication region; retaining a plurality of black communication regions conforming to a preset condition in the first image to obtain a second image containing the plurality of black communication regions; and superimposing the infrared grayscale image and the second image to obtain a target grayscale image in which a target image is located in a region corresponding to the largest white communication region and background images located in regions corresponding to the black communication regions. The technical problem of interference of the background image in the infrared medical image with the target image is solved, and the technical effect of only retaining the target image while the background images in the infrared grayscale image are accurately, clearly and quickly eliminated, is achieved.

Owner:HANGZHOU Y Z MEDICAL TECH CO LTD

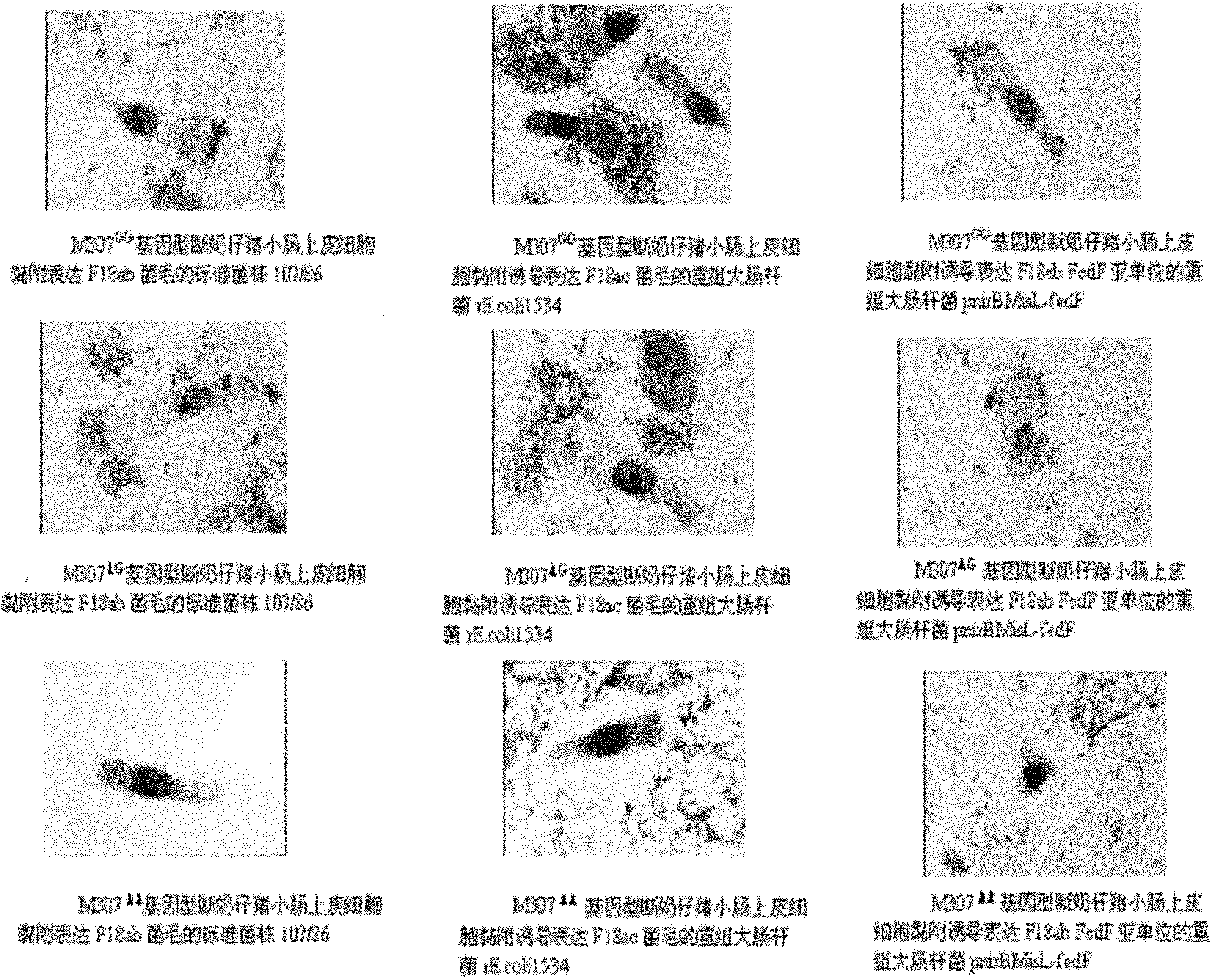

Method for culturing high-quality efficient stress-resistant complete set line of large white pigs

InactiveCN102084847AEnhance immune responseAddressing Respiratory DiseasesAnimal husbandryDiseaseLean meat

The invention relates to a method for culturing a high-quality efficient stress-resistant complete set line of large white pigs, which comprises the following steps of: building a basic group based on gene identification and disease resistance verification of F18 colibacillosis resistant major genes FUT1M307 of a core group, and culturing the high-quality efficient stress-resistant complete set line of the large white pigs by combining immunology principle, molecular breeding technology and conventional breeding means and using a candidate gene strategy. The complete set line pigs have the advantages of stress resistance, strong environmental adaptability, weaned piglet diarrhea and edema disease resistance, high lean meat rate, excellent meat quality, high feed reward and high birth number.

Owner:YANGZHOU UNIV

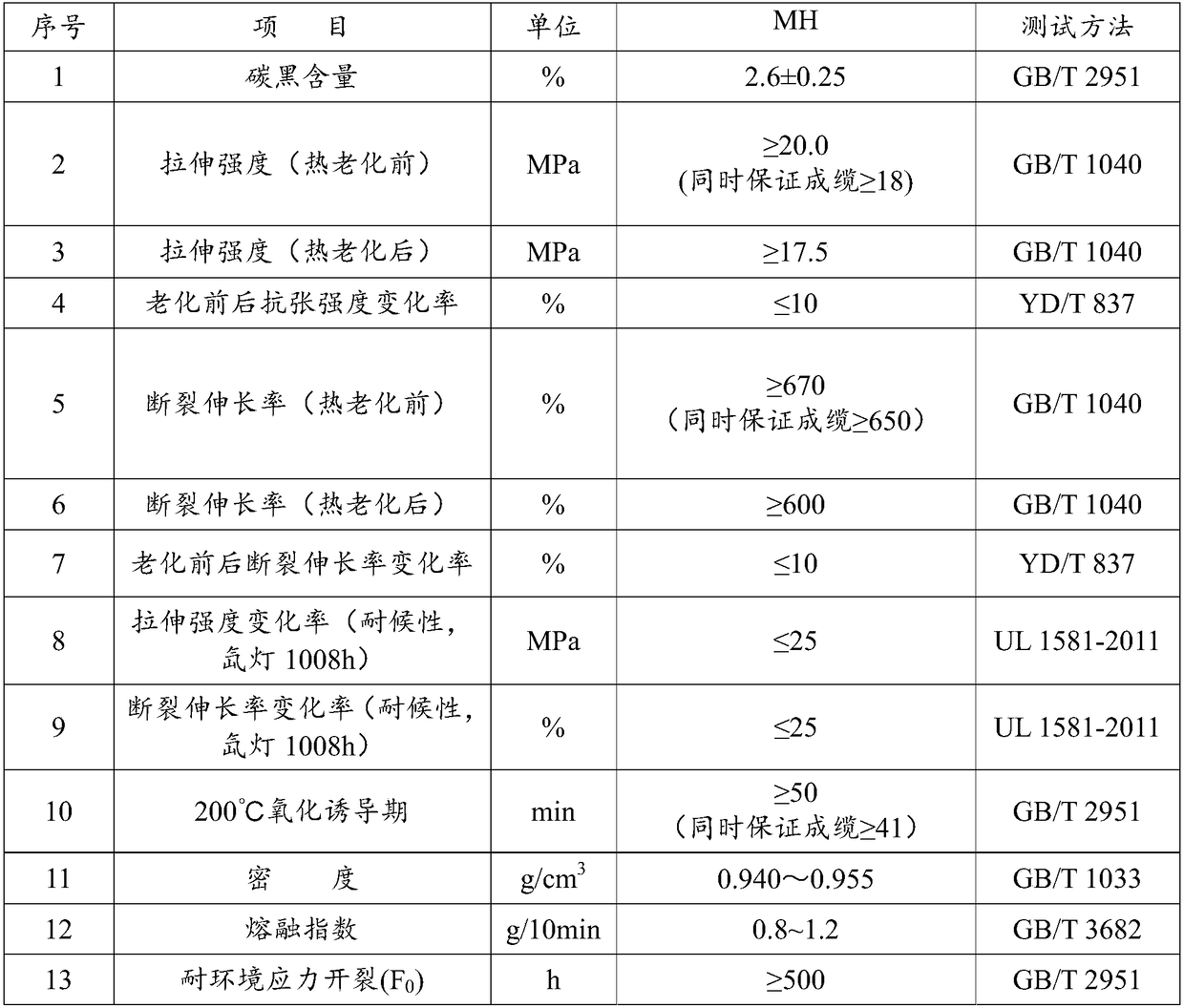

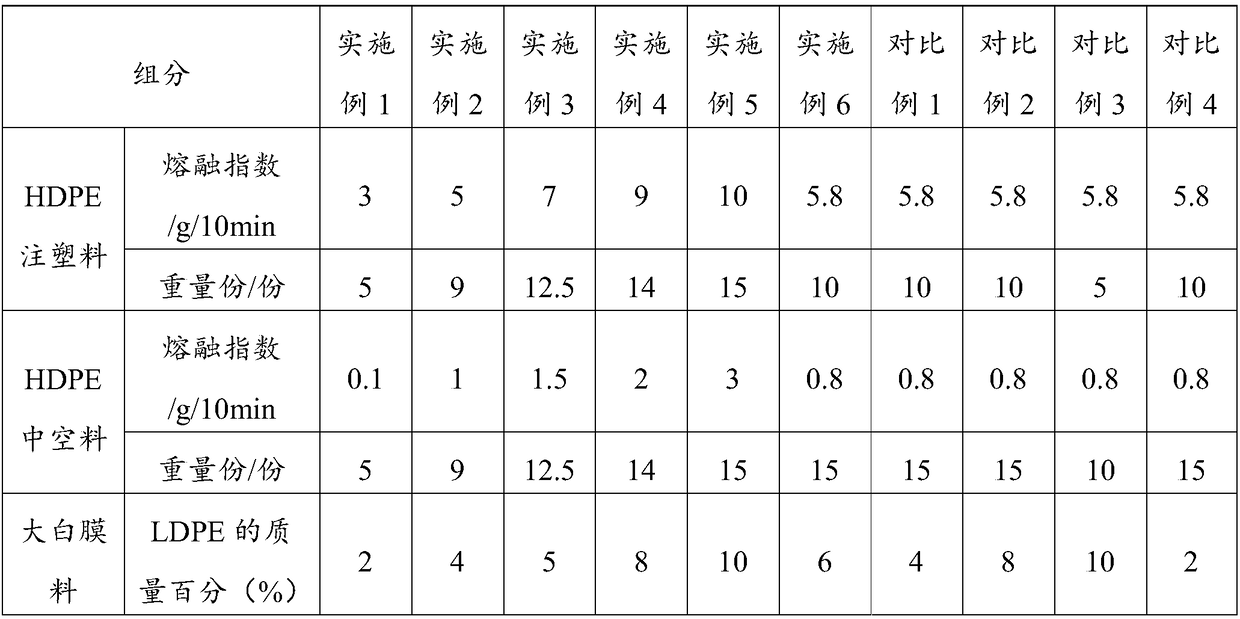

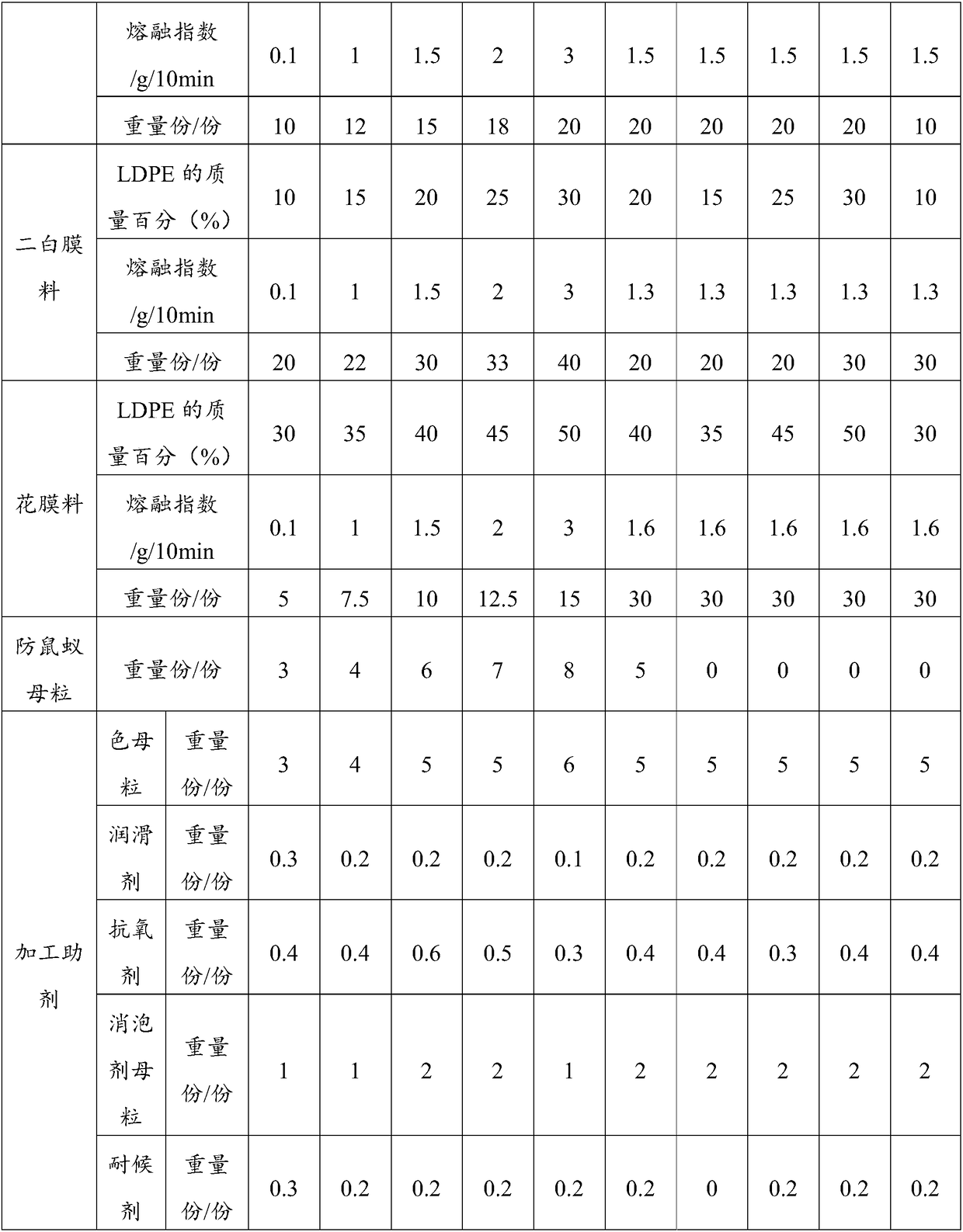

Regenerated PE jacket material and preparation method and application thereof

InactiveCN109456523AWide variety of sourcesSolve the problem of stomataPlastic/resin/waxes insulatorsManufacturing technologyWeather resistance

The invention relates to a regenerated PE jacket material and a preparation method and application thereof and belongs to the field of cable production and manufacturing technology and regenerated resource recycling. The regenerated PE jacket material comprises, by weight, 5 to 15 parts of high-density polyethylene injection molding material, 5 to 15 parts of high-density polyethylene hollow material, 10 to 20 parts of large white film material, 20 to 40 parts of secondary white film material, 5 to 15 parts of heat transfer film material, 3 to 8 parts of rat and ant resisting master batch, and5 to 8 parts of processing aid. The regenerated PE jacket material adopts the waste polyethylene in life, agricultural films, industrial films and the like as raw materials, so that the raw materialsare wide in source, and the economical benefit is significant; the mechanical performance of the regenerated PE jacket material of the invention can reach the industrial standard, and has the advantages of long-acting rat and ant resistance, smooth appearance of a formed cable, weather resistance, and environment stress cracking resistance; and the preparation method is simple in process, high inefficiency and high in industrialized production efficiency.

Owner:KINGFA SCI & TECH CO LTD +1

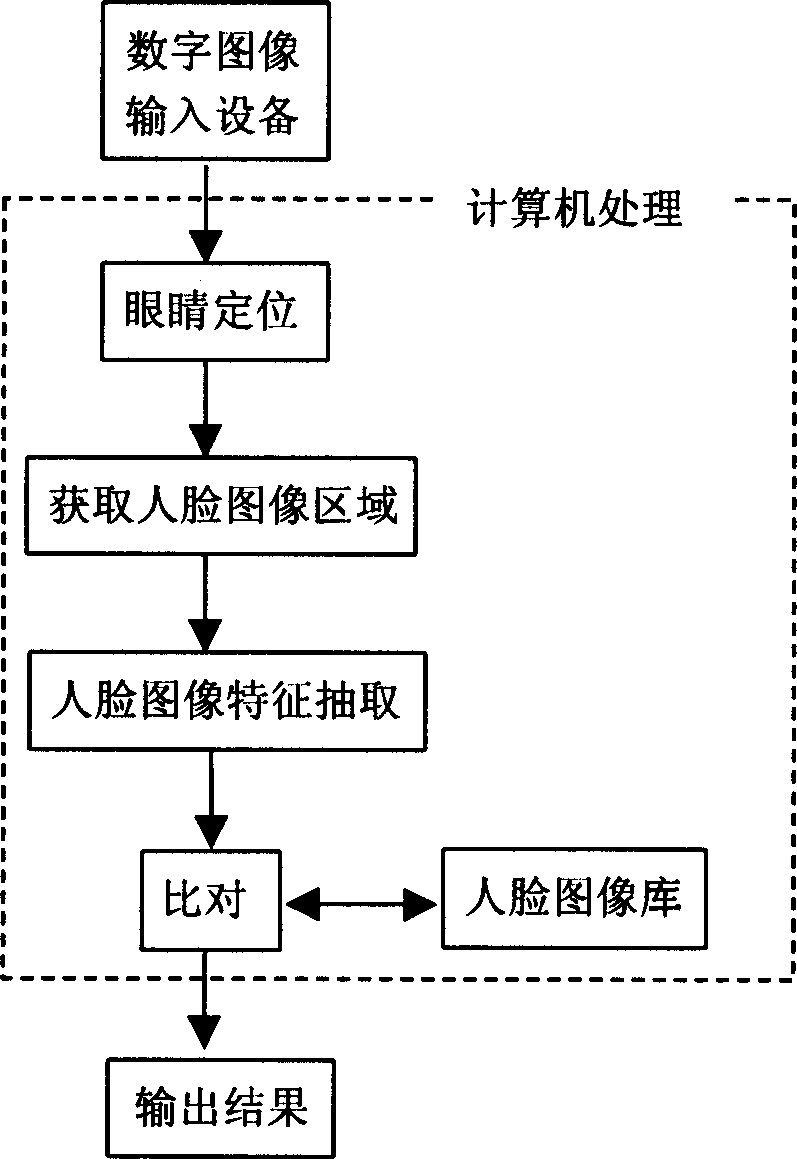

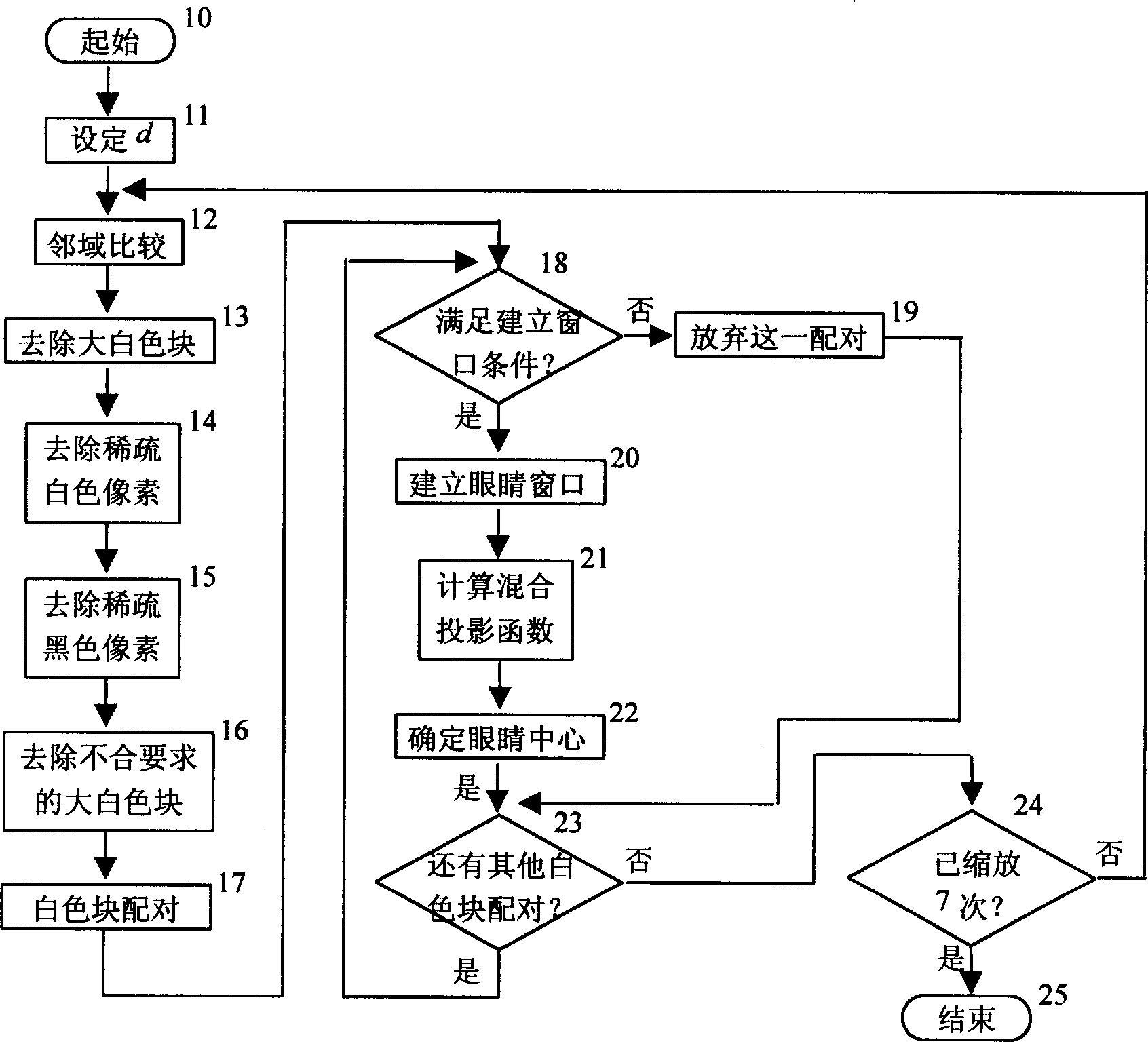

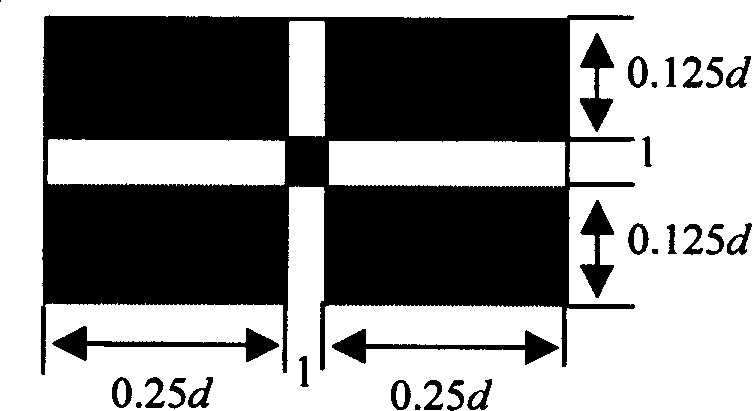

Accurately automatically positioning method for centre of human face and eyes in digital grey scale image

InactiveCN1474357AImprove performancePrecise positioningImage enhancementComplex mathematical operationsHuman eyeGrayscale

The accurately automatic human eye and face positioning process in digital grey scale image includes the steps of: setting distance between two eyes; performing 8 neighborhood comparison; changing too large white pixel block into black; changing the white pixel with too low neighborhood white pixel rate; changing the black pixel with too low neighborhood black pixel rate; change too large, too small or too perpendicular white pixel block into black one; repeated pairing white pixel blocks until two white pixel blocks meets the requirement as eye window; establishing two rectangular eye windows around two mass centers separately; calculating the mixed projection function of each windows; determining the position of eyes precisely with the mixed projection function; and scaling the originalimage and repeating the foregoing steps except the first one.

Owner:NANJING UNIV

Green, environment-friendly and dust-free chalk

The invention discloses green, environment-friendly and dust-free chalk. A formula of the chalk is as follows: 15-20 parts of burnt gypsum powder, 15-20 parts of large white powder, 15-20 parts of water, and 3-5 parts of color paste, wherein the color paste is an aqueous solution comprising 2-5 parts of polyvinyl acetate emulsion, 2-3 parts of polyvinyl alcohol and 50 parts of water. The chalk has the characteristics that the chalk is fluent in writing, clear in handwriting, moderate in hardness and less in dust, and the dust does not rise easily.

Owner:桐乡宏晨工业设计有限公司

Feeding method on basis of improving productivity of breeding geese of western-Anhui large white geese

InactiveCN106614283AMeet needsIncrease egg productionClimate change adaptationAnimal feeding stuffFecesWood pasture

The invention discloses a feeding method on the basis of improving productivity of breeding geese of western-Anhui large white geese. The method comprises the steps: planting seasonal forage grass, and preparing green forage; constructing goose sheds aside fish ponds, arranging septic tanks at back sides of the goose sheds, using goose dung as a forage grass fertilizer after the goose dung is decomposed, and carrying out regular treatment; feeding complete feed for goslings to the goslings at a gosling stage, and mixing the complete feed with chopped carrots and Chinese cabbage leaves; carrying out grazing every day at a rearing stage; at a fattening stage, feeding the geese every day, enabling the geese to freely eat forage, and adding traditional Chinese medicine additives into drinking water; and keeping interior of the sheds ventilating, clean and dry, and carrying out regular disinfection on the goose sheds. According to the method, the forage grass is planted and is made into the green forage; through feeding the traditional Chinese medicine additives, the average daily feed intake of the western-Anhui large white geese can be remarkably increased, the absorption and utilization of the geese to nutrients are promoted, the productivity of the breeding geese is improved, and the quality of goose products is improved; and the goose sheds are built aside the fish ponds, thus, the geese can take water nearby, one part of the goose dung serves as a fertilizer of the fish ponds, and the other part of the goose dung serves as the forage grass fertilizer, so that the cyclic utilization of the dung is achieved, and meanwhile, the environmental pollution is reduced.

Owner:六安市裕安区固镇军明白鹅养殖专业合作社

Breeding method of new disease-resistance large white pig strain

InactiveCN106973854AEnhance immune responseReduce morbidityAnimal feeding stuffBiological testingInterleukin 6Lean meat

The invention discloses a breeding method of a new disease-resistance large white pig strain. The method includes the following steps that 1, a feed adding method is adopted to conduct an Escherichia coli infection experiment on weaned piglets of a core group in large white pigs, and an Escherichia coli resistant breeding basic group in the large white pigs is established; 2, concentration determination is conducted on cytokines of interleukin 1beta, interleukin 4, interleukin 6, interleukin 8, interleukin 10, transforming growth factor beta, tumor necrosis factor alpha and interferon gamma of an Escherichia coli resistant population in the basic group; reproductive performances are detected and selected, growth speeds, lean meat ratios and carcass quality characters, and a first generation is established; 3, a group subculture selective breeding method and a molecular-marker-assisted selection method are adopted. In this way, by the adoption of the breeding method of the new disease-resistance large white pig strain, after four to five generations, a vested breeding target is achieved gradually, a new-strain core group is established, and the morbidity of piglet diarrheal diseases is expected to be reduced.

Owner:TAICANG JINZHU AGRI DEV

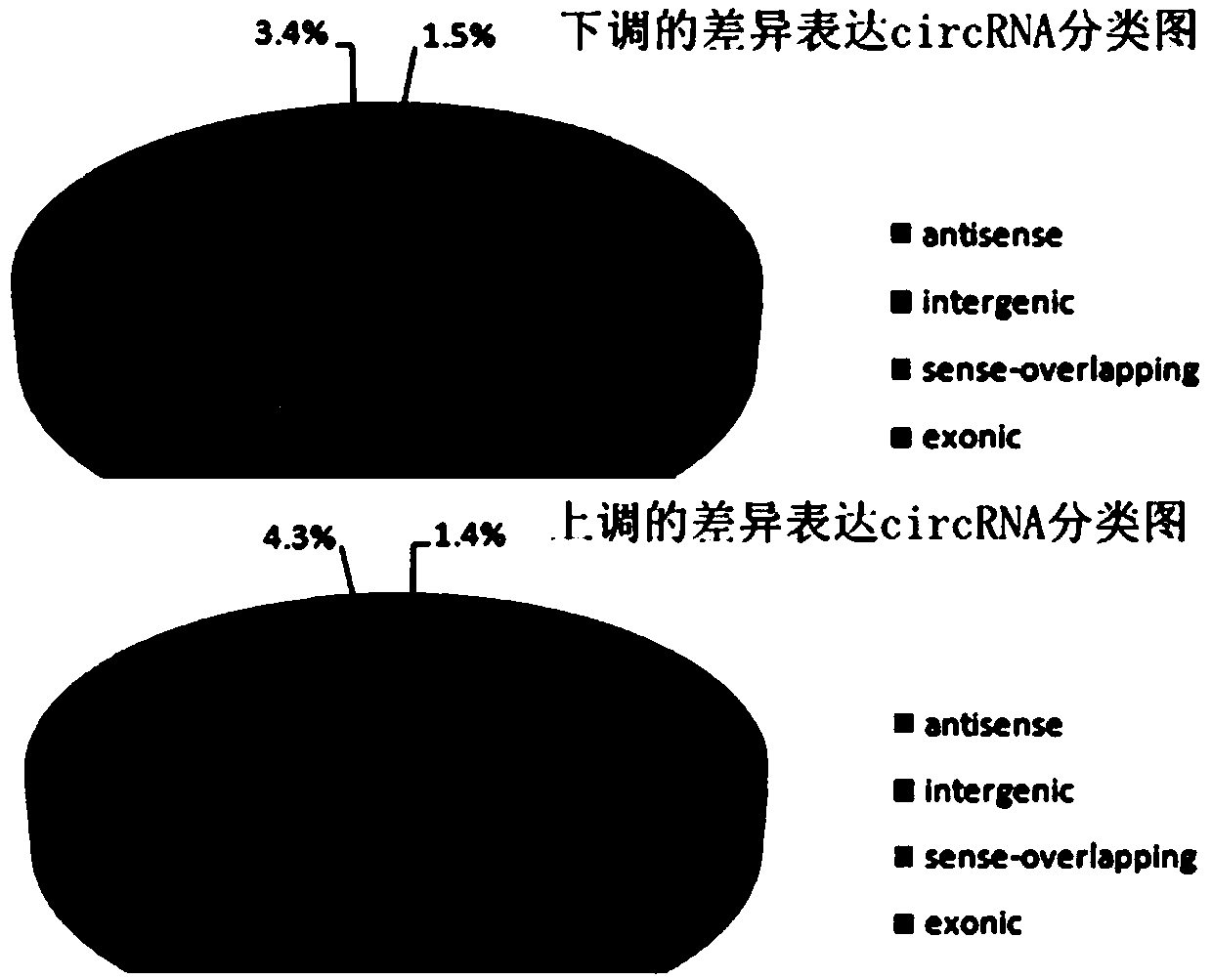

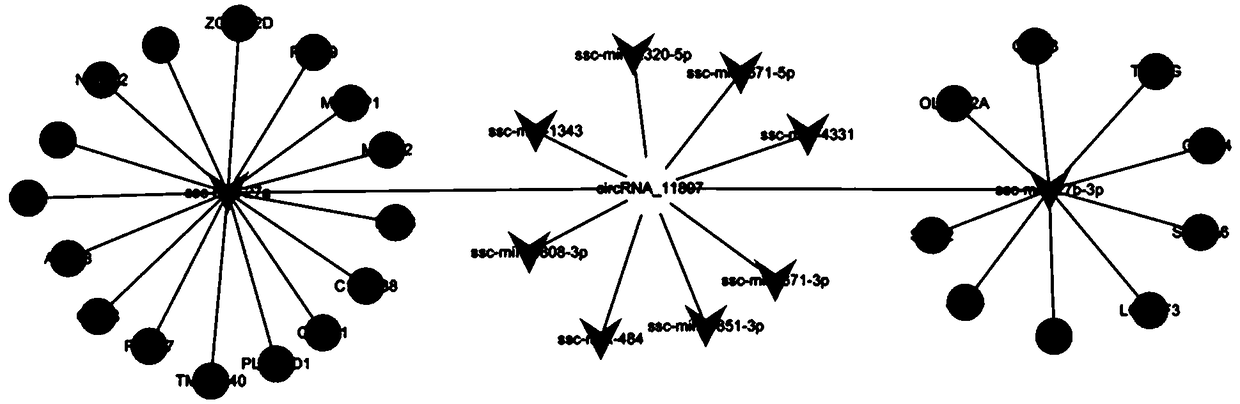

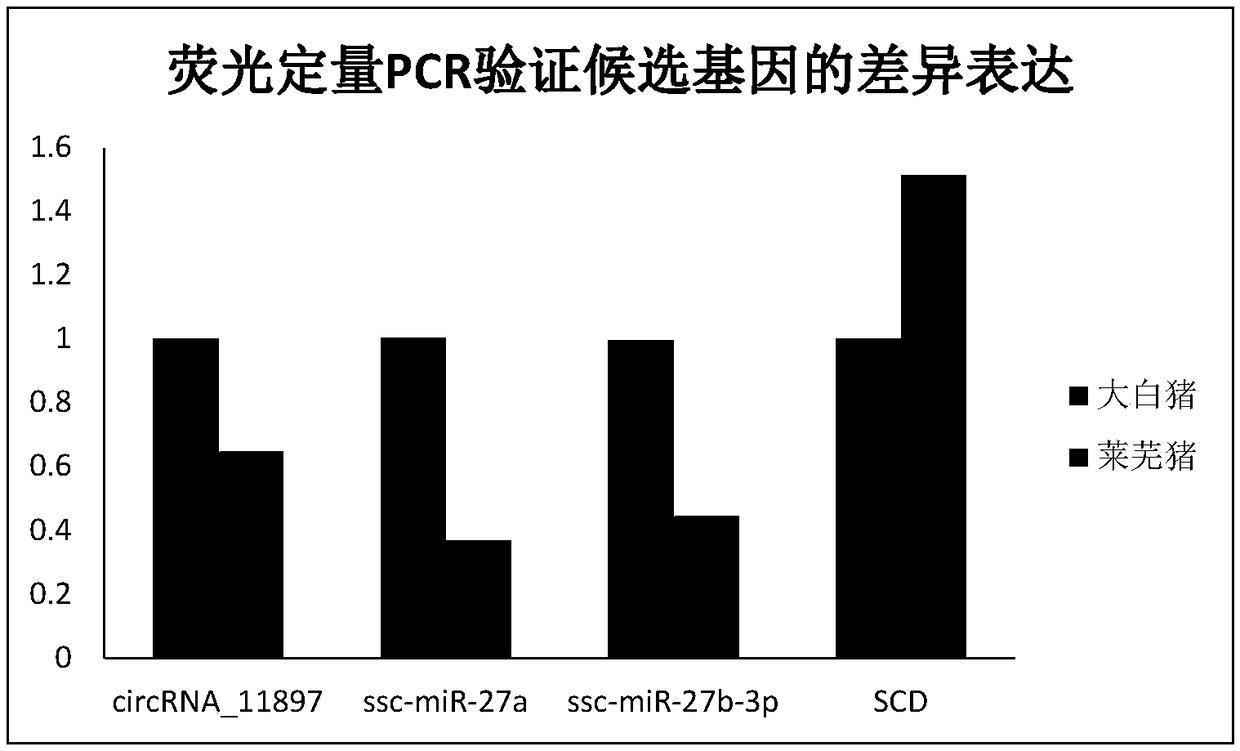

CircRNA related to subcutaneous fat of pigs and application thereof

The invention relates to a circRNA related to subcutaneous fat of pigs and an application thereof, and specifically relates to a circRNA_11897 related to subcutaneous fat of pigs and the application thereof. The invention identifies and analyzes the circRNA of the subcutaneous fat of large white pigs and Laiwu pigs, adopts a systematic bioinformatic method for performing functional analysis on thedifferential expression circRNA and finds the circRNA_11897 and the genes ssc-miR-27a, ssc-miR-27b-3p and SCD related to the circRNA_11897. The experiment proves that the expression quantity of the circRNA_11897 and the genes has a close relation with the subcutaneous fat of pigs. The invention provides a new theoretical basis and a potential target for improving the quality of pork and preventing the happening of metabolic diseases caused by dyslipidemia.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

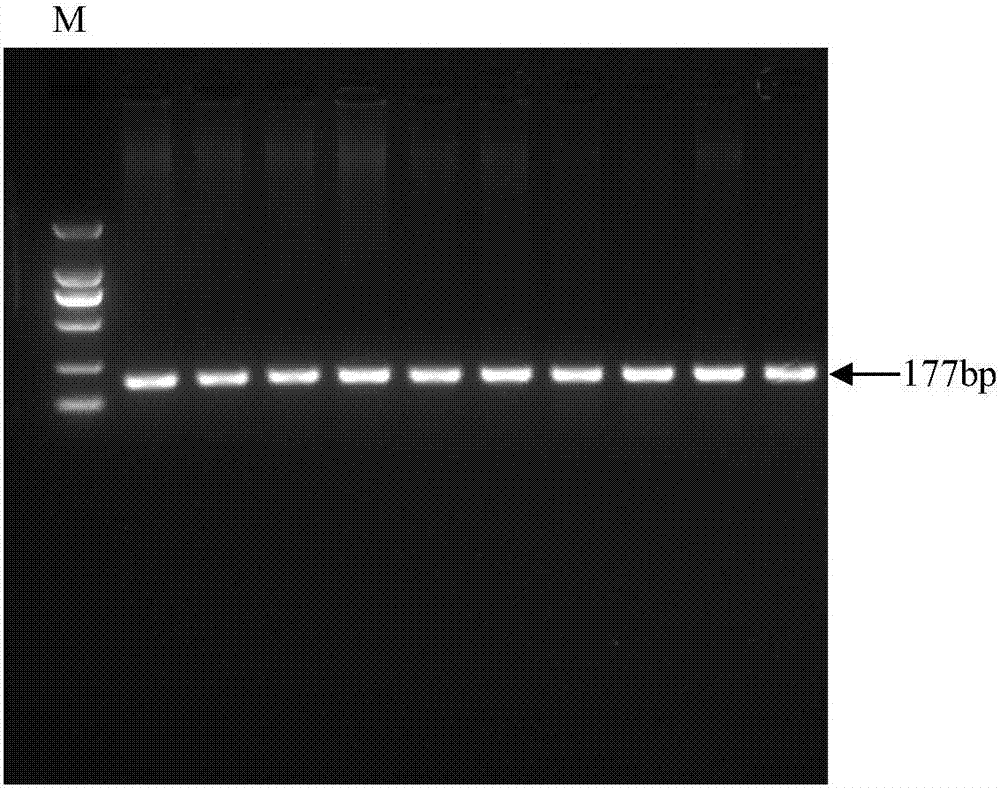

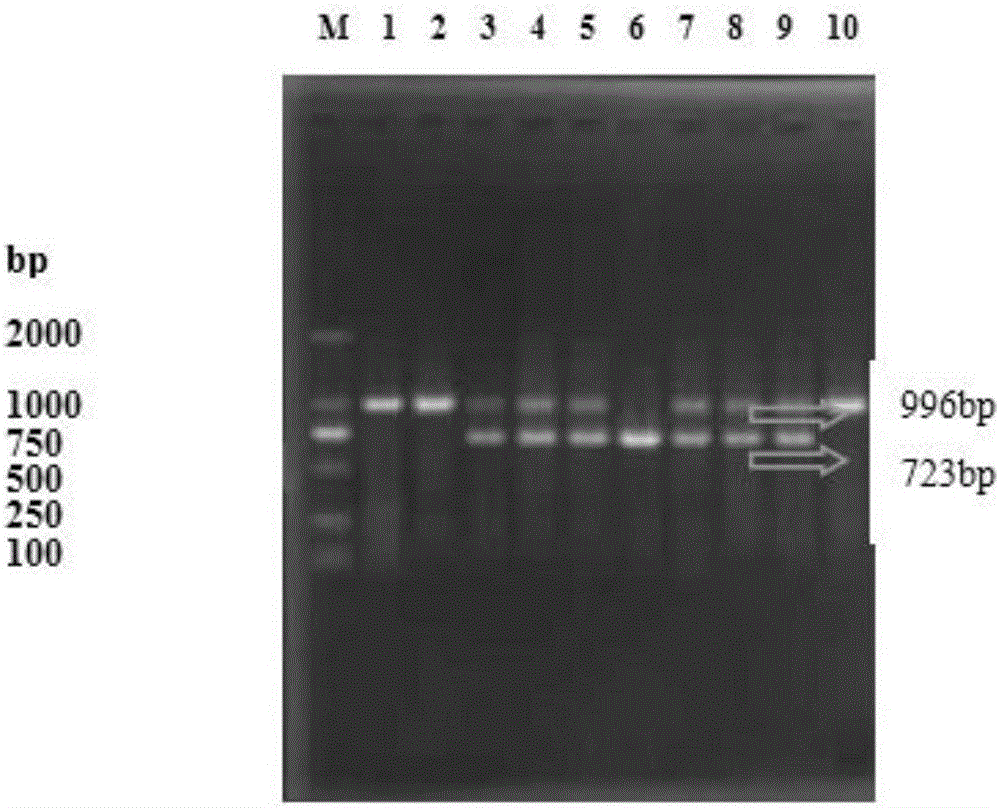

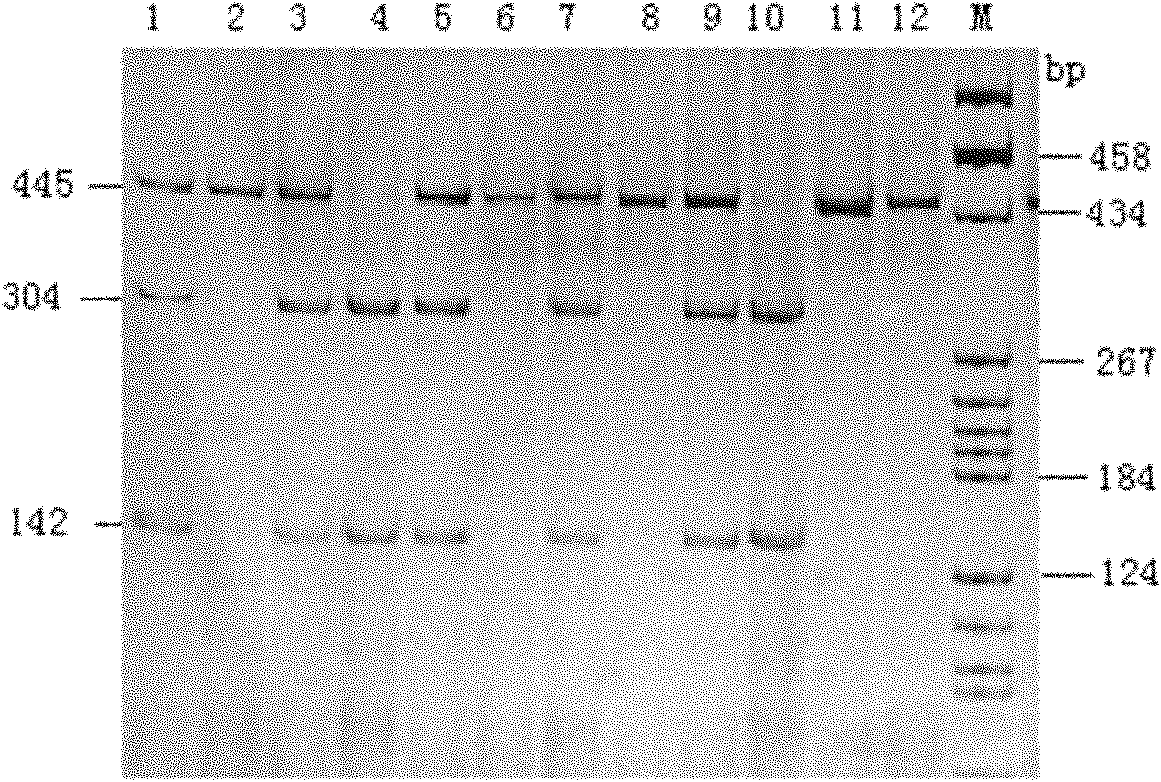

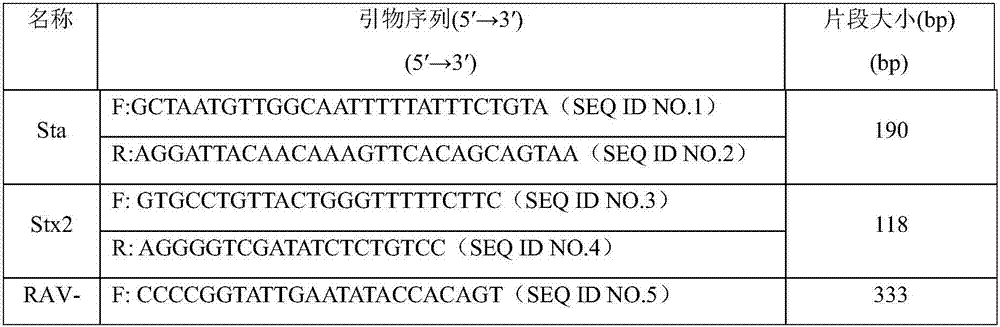

Pig Oct4 gene insertion/lack detection method and application thereof

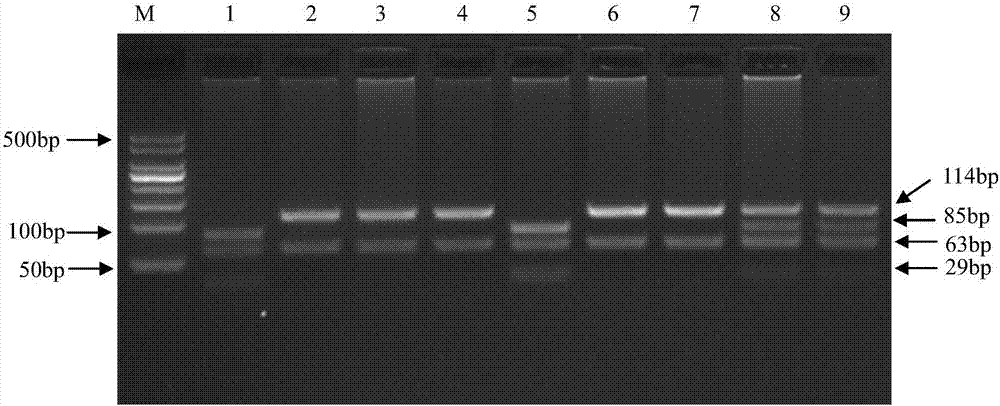

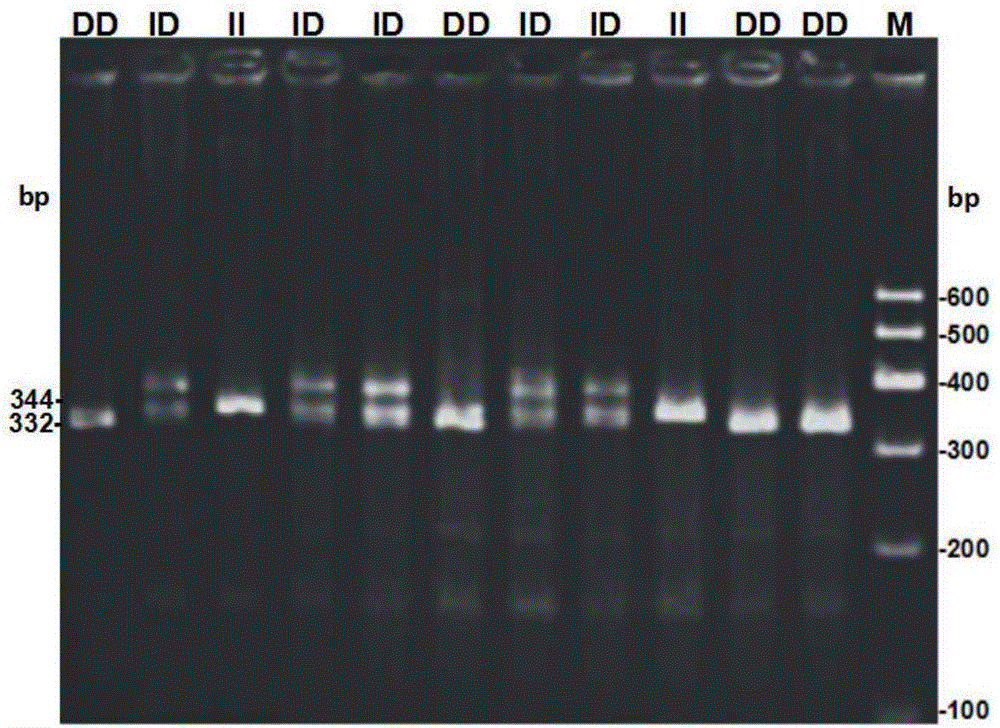

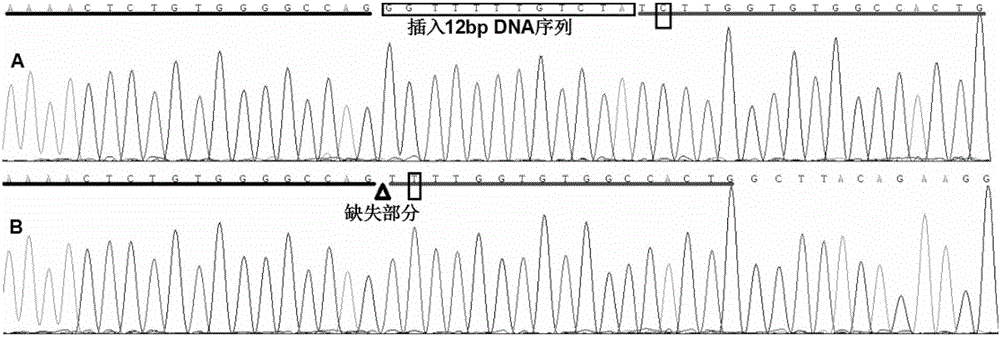

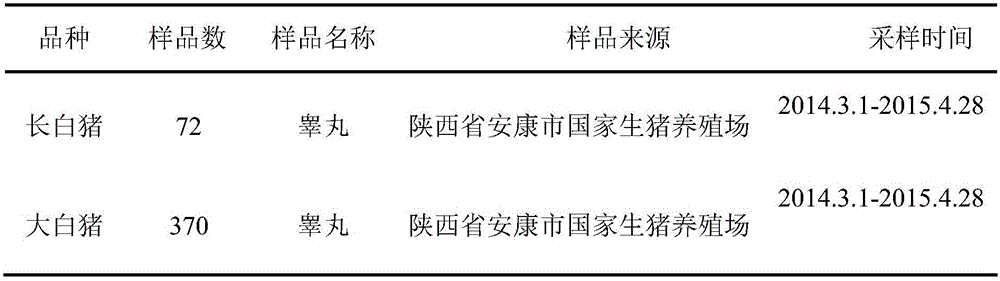

InactiveCN105779594ASpeed up breedingExcellent reproductive traitsMicrobiological testing/measurementElectrophoresisBOAR

The invention discloses a pig Oct4 gene insertion / lack detection method and application thereof. A boar genome DNA to be detected is used as a template; a primer pair P1 designed by referring to the pig genome is used as a primer; the Oct4 gene is amplified through a PCR (polymerase chain reaction) technology; then, agarose gel electrophoresis is performed. The insertion / lack polymorphism of the Oct4 gene in the NC_010449:g.2759-2760ins GGTTTTTGTCTA site is identified according to the electrophoresis result. The result shows that different types of the Oct4 gene 12-bp insertion / lack have the obvious relevance with the breeding properties of testicle weight, testicle long periphery length, testicle short periphery length and the like of 15-day-old large white boars; the result shows that different types of the Oct4 gene 12-bp insertion / lack can be used as DNA (deoxyribonucleic acid) marks of the boar breeding properties. The method is favorable for fast building the boar heredity resource groups with good breeding properties.

Owner:NORTHWEST A & F UNIV

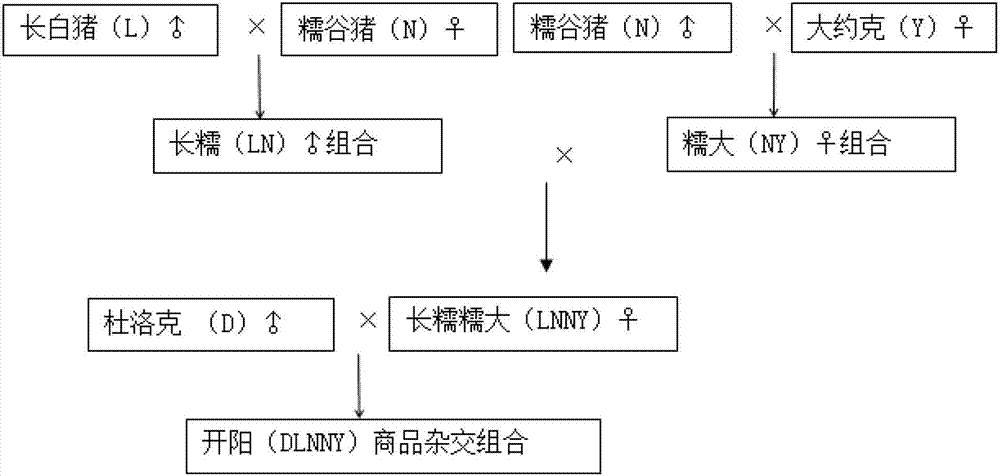

Kaiyang lean-meat-type pig selection method

Owner:贵阳台农种养殖有限公司

Coating construction method of assembly type wall plate

The invention discloses a coating construction method of an assembly type wall plate. The coating construction method includes the following steps that putty is scraped on a wall surface for 1-3 timesto make the wall surface be flat. According to the putty, the weight matching of latex to talcum powder (or large white powder) to 2% carboxymethylcellulose is 1:5:3.5, and the weight matching of polyvinyl acetate emulsion for kitchen, toilet, and shower room to cement to water is 1:5:1. For the first time, waterproof putty is fully scraped transversely through a rubber scraper; for the second time, the waterproof putty is fully scraped vertically through the rubber scraper; for the third time, the putty is filled up through the rubber scraper or the putty is fully scraped through a steel sheet scraper; latex paint is brushed for three times; and in each time, the latex paint is stirred for 5-10 min by using a stirring device. The coating construction method includes the following steps of wall plate cleaning, wall surface cleaning up, wall surface repairing, plate materials inserting connecting, scraping of the putty, and brushing of the latex paint. The coating construction method of the assembly type wall plate is scientific and reasonable in structure, safe and convenient to use; construction operation is facilitated, and working efficiency is improved; the problem of fallingoff of lacquer in seam crossing joints is avoided; adhesion of coating is enhanced and wall plate cracking is avoided; and wholly beauty is enhanced.

Owner:ANHUI DAFU ARCHITECTURAL DECORATION CO LTD

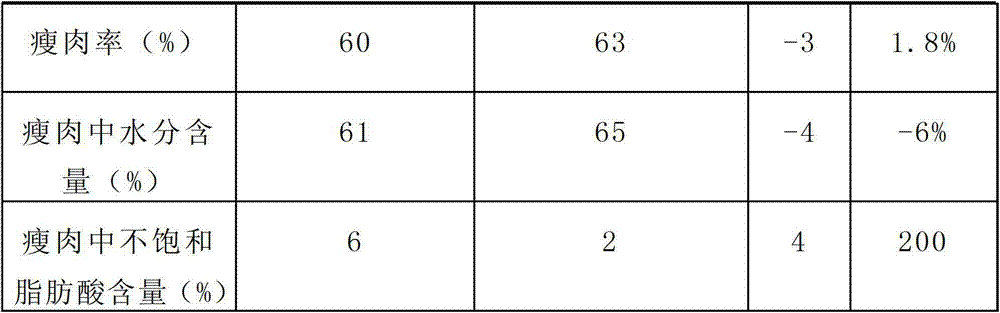

Semi-pseudo-random coding pattern and generation method and system therefor

ActiveCN107657646ASolve the difficulty of determining the size of the windowReduce mismatchImage codingPattern recognitionStereo matching

The invention relates to a semi-pseudo-random coding pattern and a generation method and system therefor. The pattern comprises fixed color blocks and random color blocks. The fixed color blocks and the random color blocks are arranged at intervals in rows and columns, thereby forming a random array with an M*N pixels. The fixed color blocks comprise a plurality of color blocks with the fixed color. The pattern is characterized in that 1, the pattern has the unique features in a window in a specified size, and can greatly reduce the possibility of wrong matching; 2, the pattern has the cornerpoint distribution uniformity, thereby preventing the generation of the random color blocks at any position from causing a large white region or a large black region. Therefore, the corner points generated by the intersection of the black blocks and the white blocks in the whole coding pattern are more uniform, and are combined with the gray scale matching. The number of matched image pairs is relatively stable, thereby facilitating the success rate and efficiency of stereo matching.

Owner:ZG TECH CO LTD

Putty powder for wall fungus and mildew resistance

InactiveCN101418152AWon't growPlay the role of moisture-proof, sterilizing and anti-crackingFilling pastesCelluloseCrack resistance

The invention provides lacquer putty powder for performing sterilization and mildew proofing on the wall body. The compositions of the lacquer putty powder in percentage by weight are 1 to 20 percent of coarse whiting powder, 20 to 80 percent of large white powder, 0.01 to 15 percent of high-viscosity cellulose, 0.01 to 15 percent of pre-gelatinized starch, 1 to 60 percent of micronized talc powder and 0.001 to 10 percent of zinc oxide. The lacquer putty powder can be uniformly coated on a skin crack position, a peeling position, a fine removal position and so on of the wall body, can also be directly coated on a mould growth position, maintains that the mould can not grow on the metope within 5 to 8 years. The lacquer putty powder is used for removing the mould which is grown on the surface of the metope due to wetting and peeling, and the wall skin is required to be shoveled when the lacquer putty powder is used. The lacquer putty powder is added with water for stirring and directly coated on the metope, so as to have the efficacies of moisture protection, antibacterium and crack resistance. Moreover, the lacquer putty powder has the advantages of wide source of raw materials, simple manufacturing technique, low product cost, easy knifing, quick drying, strong adhesion, easy grinding, rigid, smooth and refined texture and so on.

Owner:刘丽

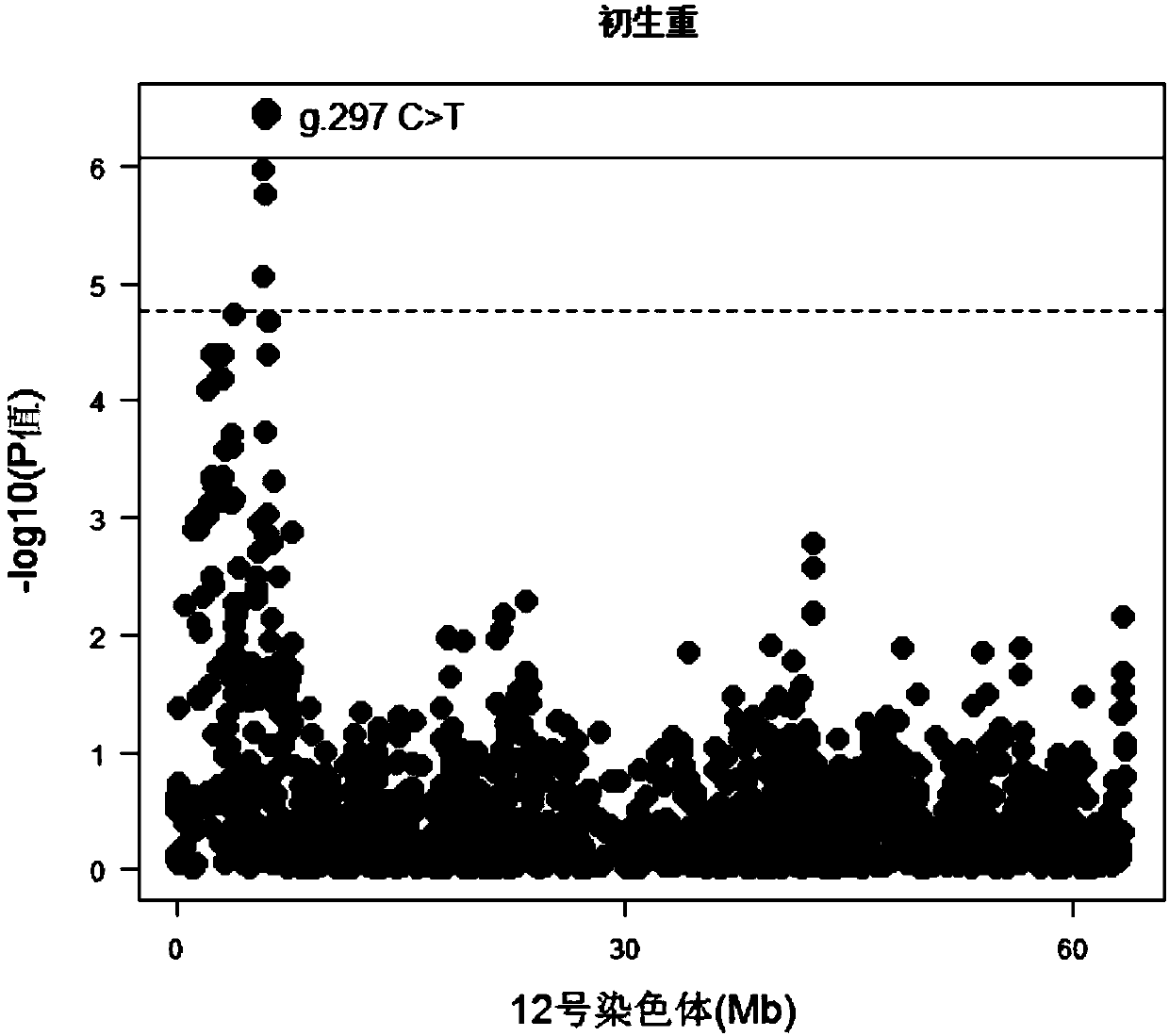

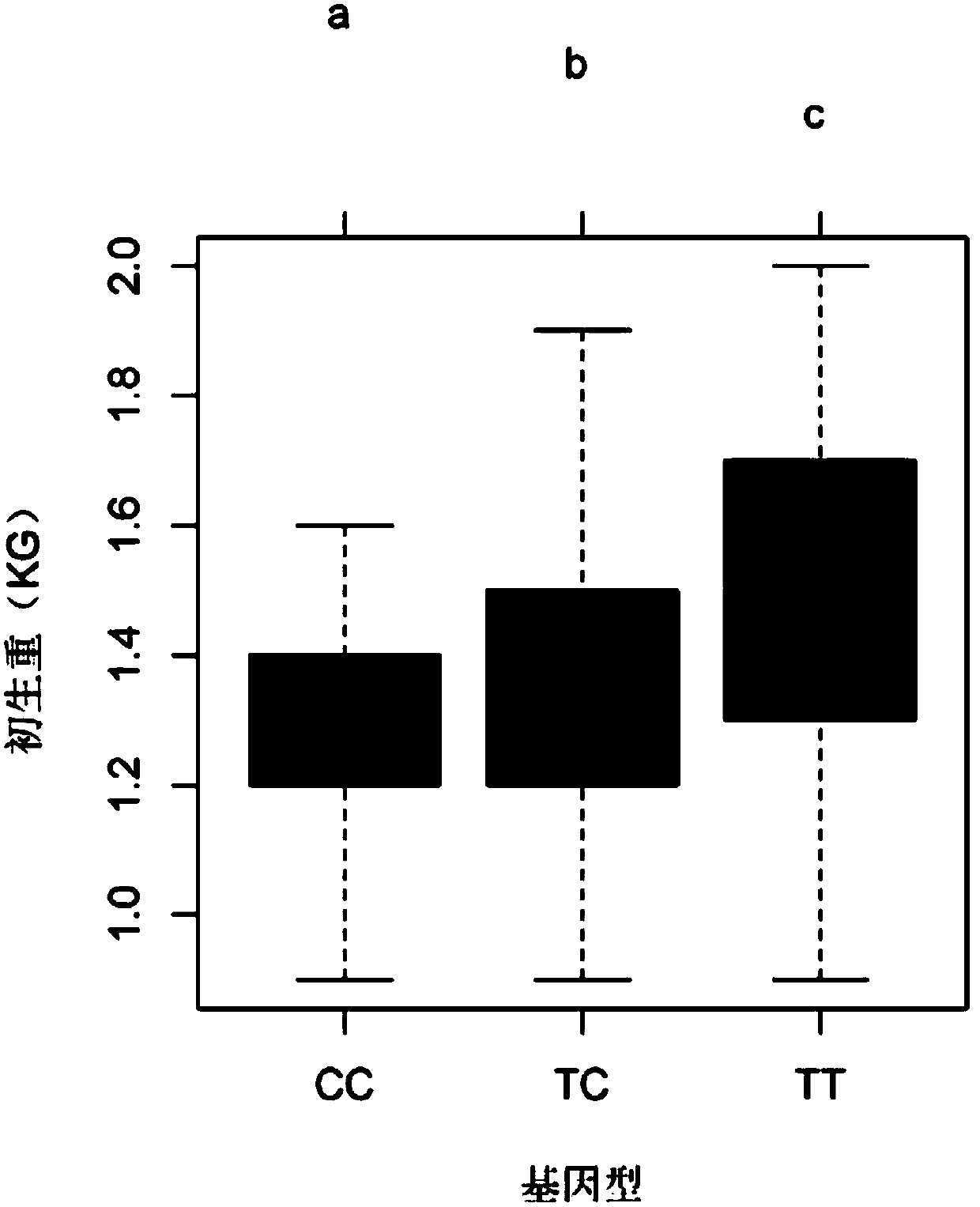

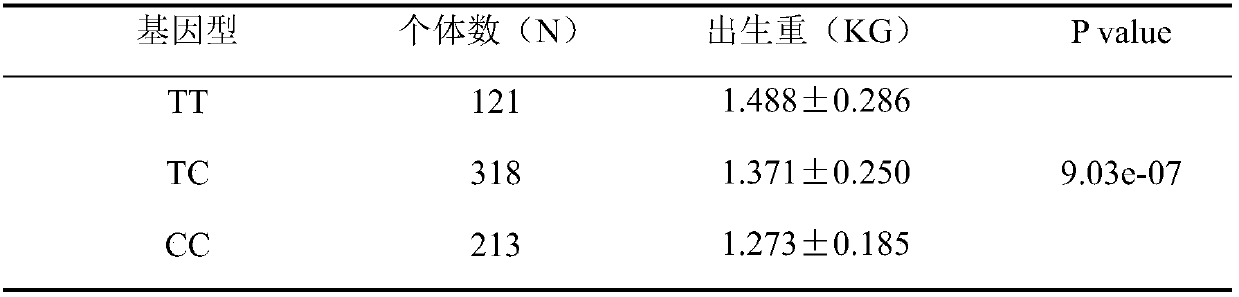

Porcine birth weight trait related SNP marker and use thereof

ActiveCN107858440AIncrease birth weightImprove survival rateMicrobiological testing/measurementDNA/RNA fragmentationBreeding pigEconomic benefits

The invention provides a porcine birth weight trait related SNP marker. The locus of the SNP marker is the 6083856th nucleotide locus on the chromosome No.12 of international pig reference genomes version 11.1, and the base of the locus is T or C. By optimizing preponderant alleles of SNP, the genetic progress of large white birth weight traits can be increased, and the breeding time of the largewhite birth weight traits can be reduced to effectively improve economic benefits of breeding pig breeding.

Owner:SOUTH CHINA AGRI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com