Regenerated PE jacket material and preparation method and application thereof

A sheath material and film material technology, applied in plastic/resin/wax insulators, organic insulators, electrical components, etc., to achieve the effects of high industrial production efficiency, wide sources, and excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

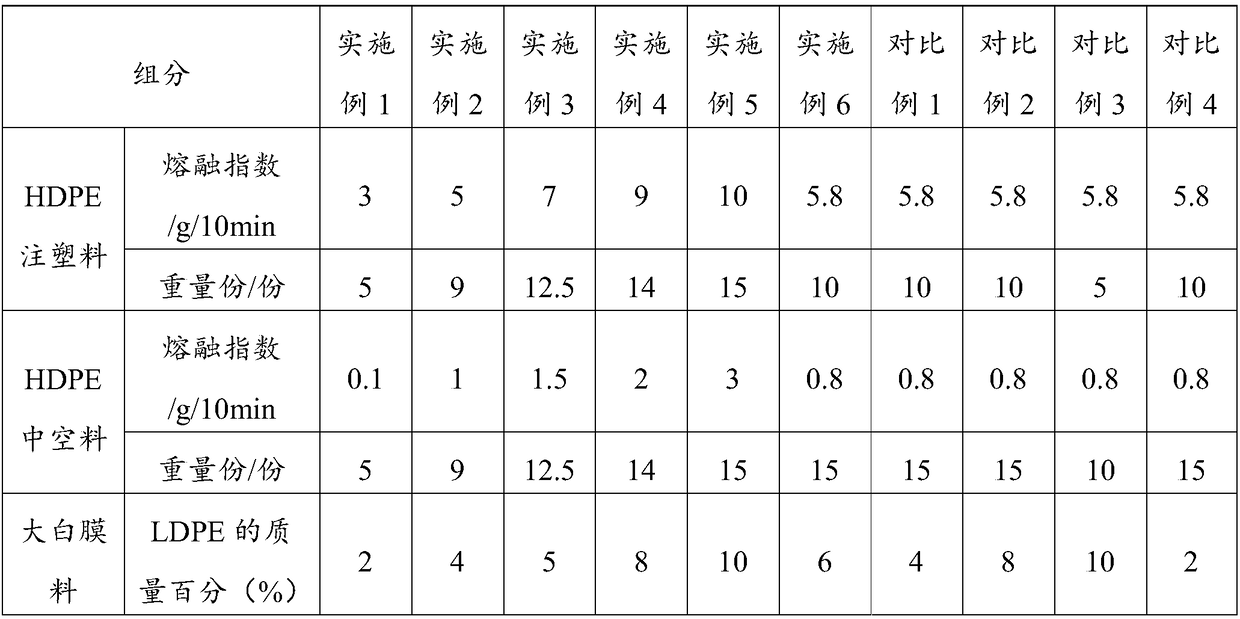

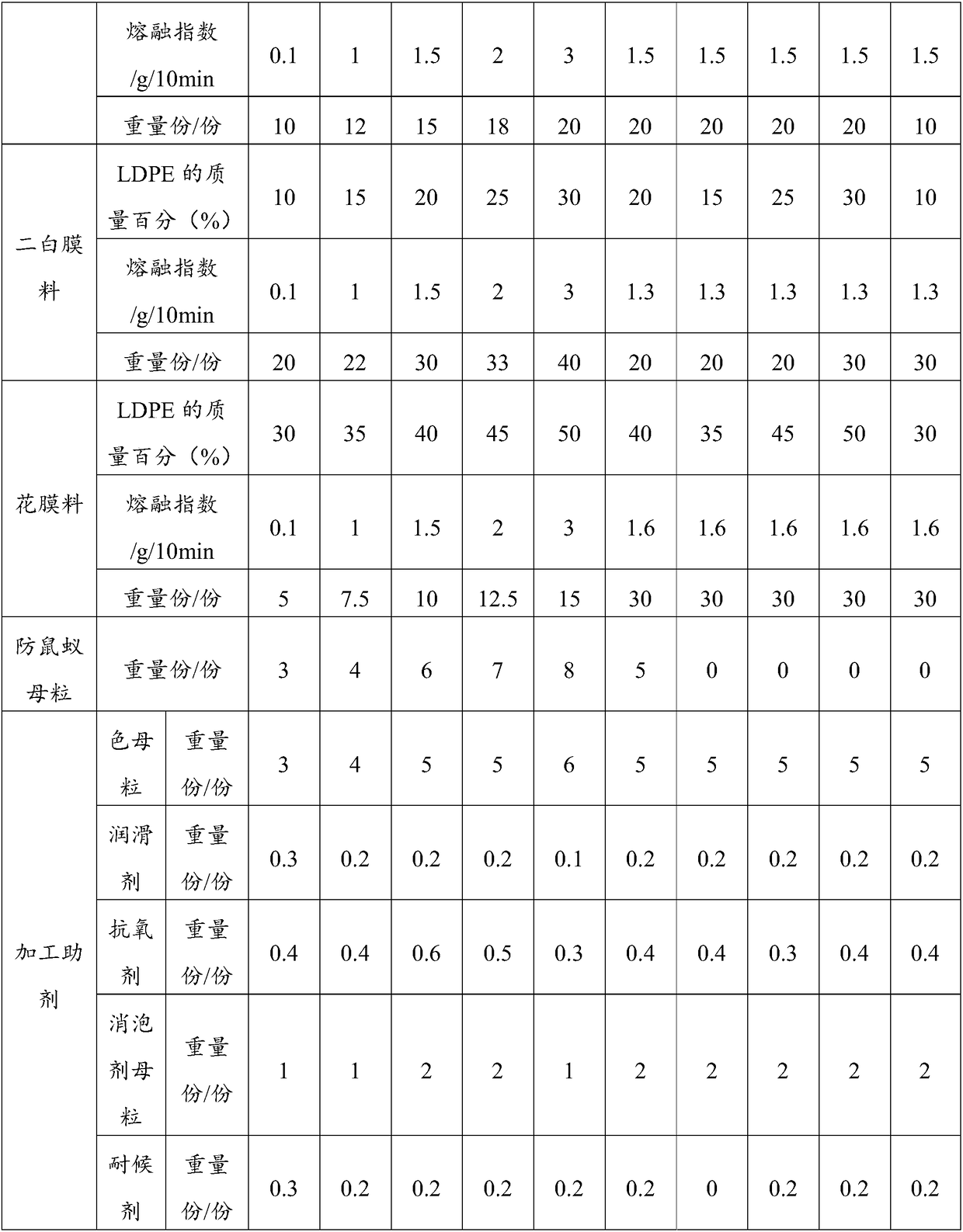

[0072] An embodiment of the recycled PE sheathing material of the present invention, the composition of the recycled PE sheathing material in this embodiment is shown in Table 2.

[0073] The preparation method of the regenerated PE sheath material shown in this embodiment is:

[0074] (1) Sorting, crushing, cleaning, and dehydrating HDPE injection molding materials and HDPE hollow materials into bags for later use; sorting, crushing, cleaning, and dehydrating large white film materials, second white film materials, and flower film materials, and single-screw melt extrusion The temperature of each temperature zone of the single-screw melt extrusion granulation is 160-210°C, the temperature of the single-screw screen changer and machine head is 200-210°C, and the mesh number of the screen changer is 80 mesh;

[0075] (2) Weigh each component according to the proportion, put HDPE injection molding material, HDPE hollow material, large white film material, two white film materia...

Embodiment 2~6 and comparative example 1~4

[0078]The composition of the regenerated PE sheath material described in Examples 2 to 6 and Comparative Examples 1 to 4 is as shown in Table 2, and the preparation method of the regenerated PE sheath material described in Examples 2 to 6 and Comparative Examples 1 to 4 is the same as Example 1.

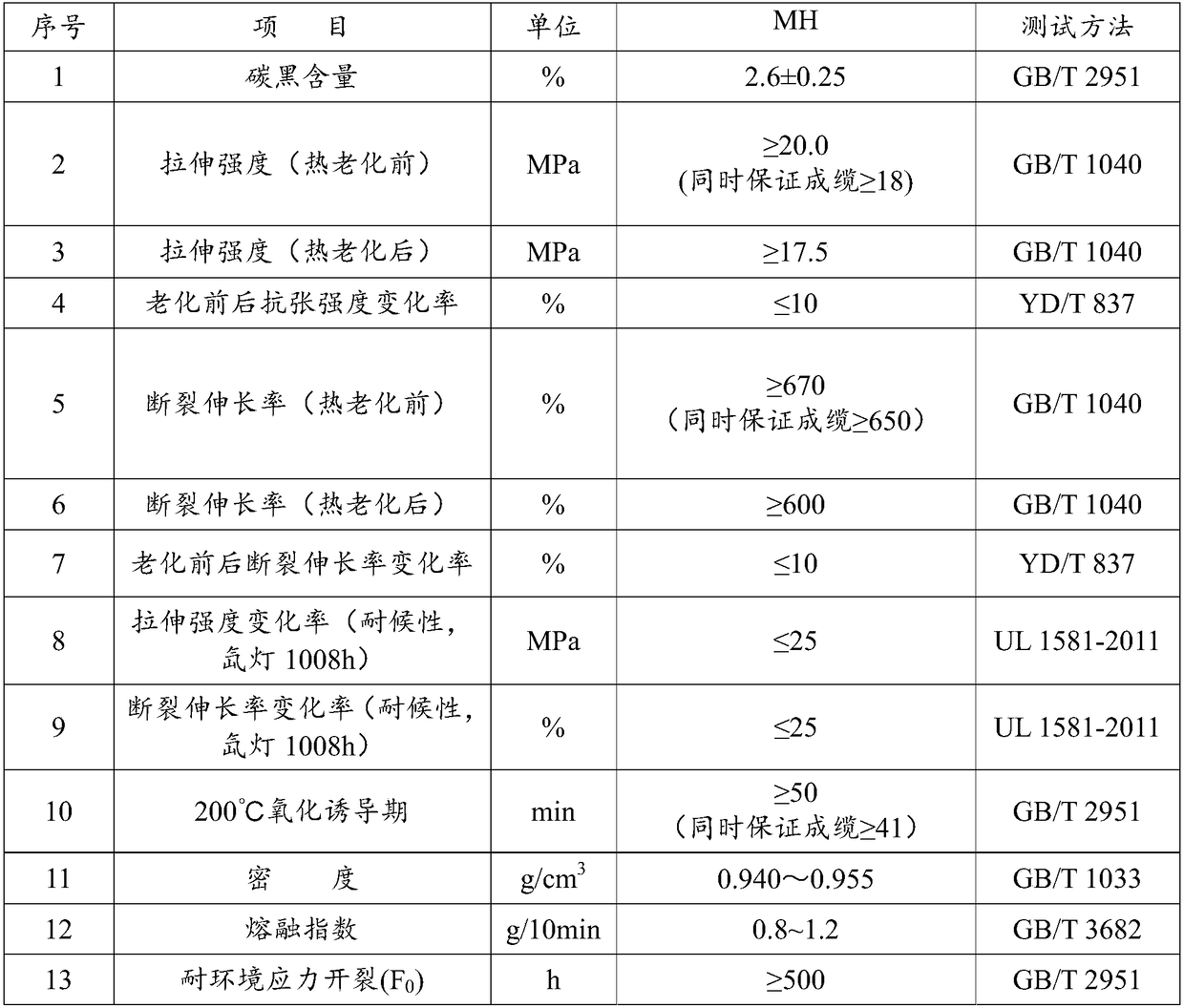

[0079] Simultaneously, test the following properties of the regenerated PE sheath material described in Examples 1 to 6 and Comparative Examples 1 to 4: thermal aging performance, environmental stress cracking resistance, tensile strength and elongation at break, carbon black content, weather resistance , termite test, rat bite test, oxidation induction period test, melt flow rate. Among them, the test methods for each performance are:

[0080] Thermal aging performance (110±1°C, 240h), measured according to GB / T 2951.12-2008;

[0081] Environmental stress cracking resistance, measured according to GB / T2951.41-2008;

[0082] Tensile strength and elongation at break are measured ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com