Patents

Literature

499 results about "Environmental stress cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

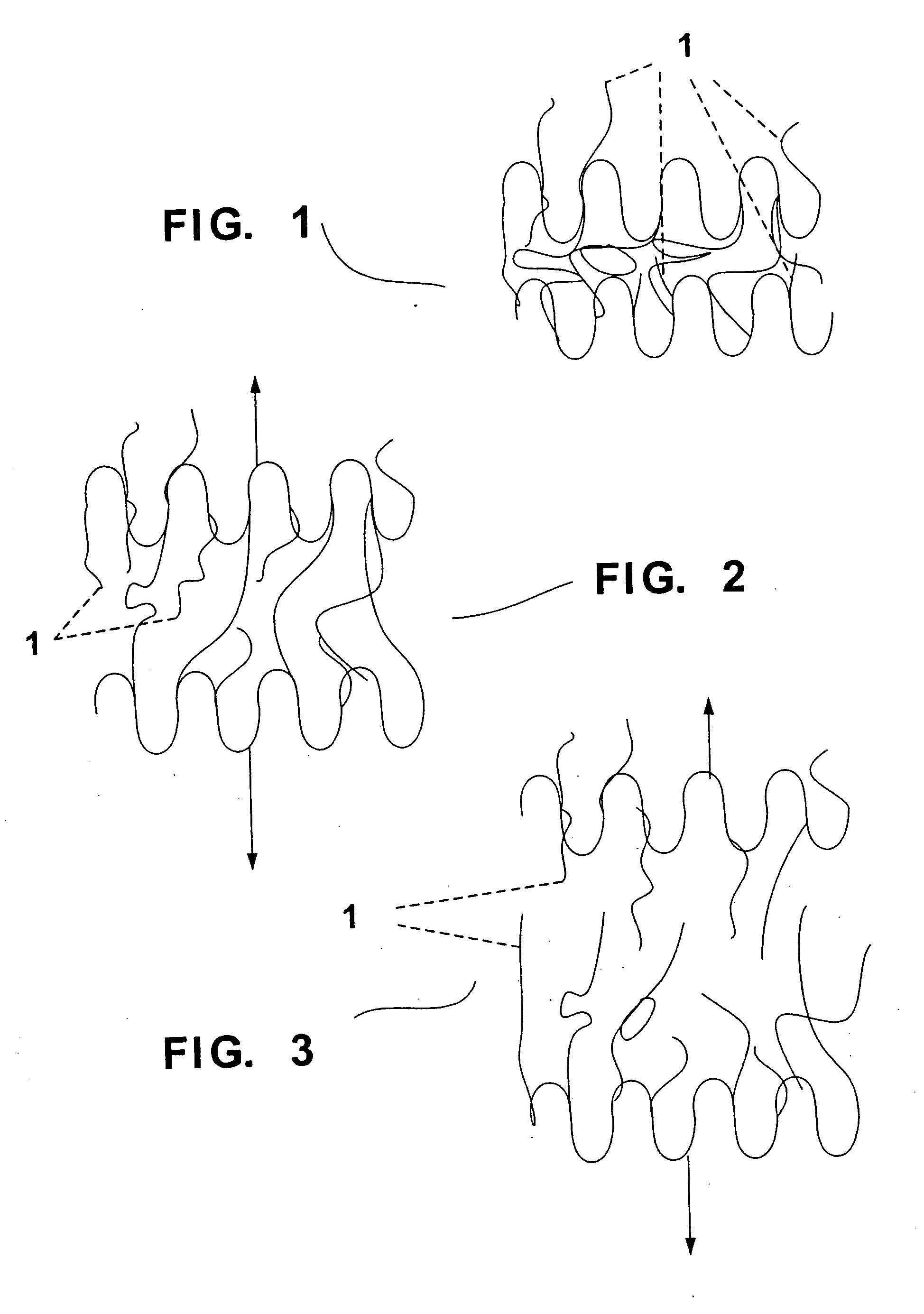

Environmental Stress Cracking (ESC) is one of the most common causes of unexpected brittle failure of thermoplastic (especially amorphous) polymers known at present. According to ASTM D883, stress cracking is defined as " an external or internal crack in a plastic caused by tensile stresses less than its short-term mechanical strength." This type of cracking typically involves brittle cracking, with little or no ductile drawing of the material from its adjacent failure surfaces. Environmental stress cracking may account for around 15-30% of all plastic component failures in service. This behavior is especially prevalent in glassy, amorphous thermoplastics. Amorphous polymers exhibit ESC because of their loose structure which makes it easier for the fluid to permeate into the polymer. Amorphous polymers are more prone to ESC at temperature higher than their glass transition temperature (Tg) due to the increased free volume. When Tg is approached, more fluid can permeate permeation into the polymer chains.

Closures for bottles

ActiveUS8022143B2Improved balance of Theological and processing and organoleptic propertyCompression moldingPolymer science

A dual reactor solution process gives high density polyethylene compositions containing a first ethylene polymer and a second ethylene polymer which have a good balance of processability, toughness, and environmental stress crack resistance combined with good organoleptic properties. The polyethylene compositions are suitable for compression molding or injection molding applications and are particularly useful in the manufacture of caps and closures for bottles.

Owner:NOVA CHEM (INT) SA

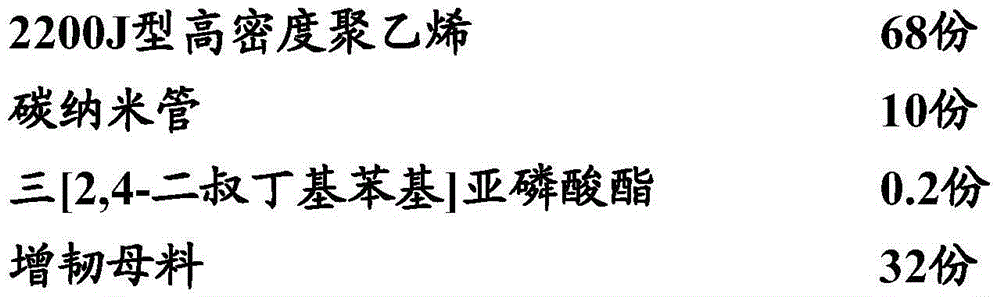

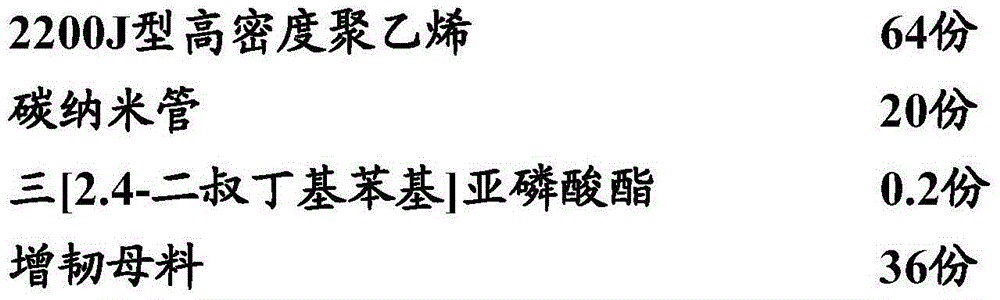

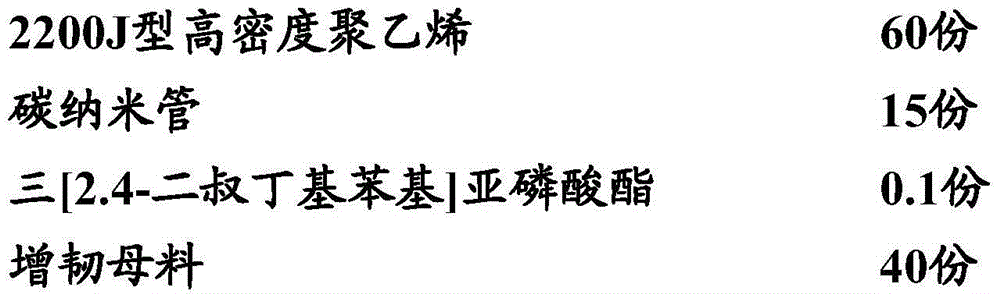

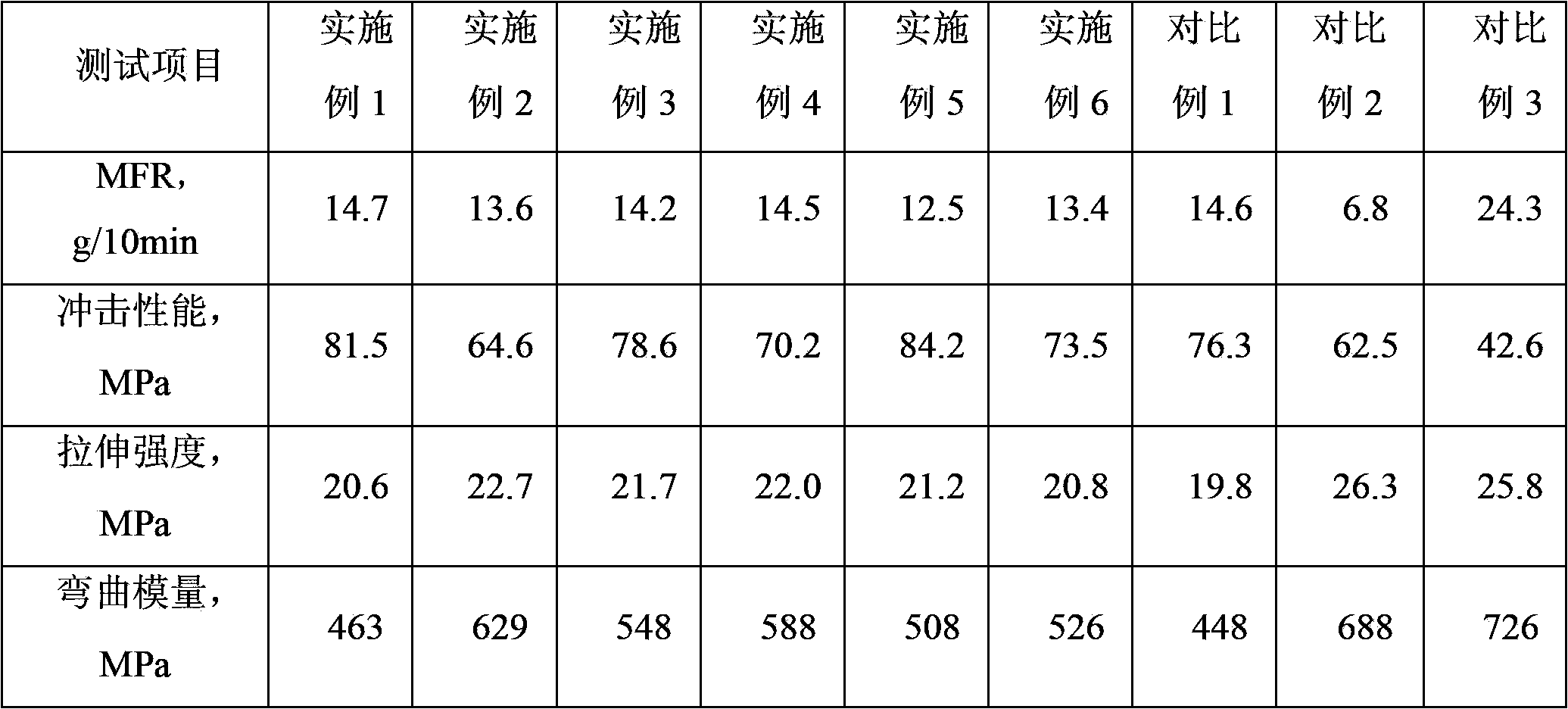

Composite type high-conductivity polymer material and preparation method thereof

ActiveCN101891914AImprove conductivityAvoid damageNon-conductive material with dispersed conductive materialPolymer scienceConductive polymer

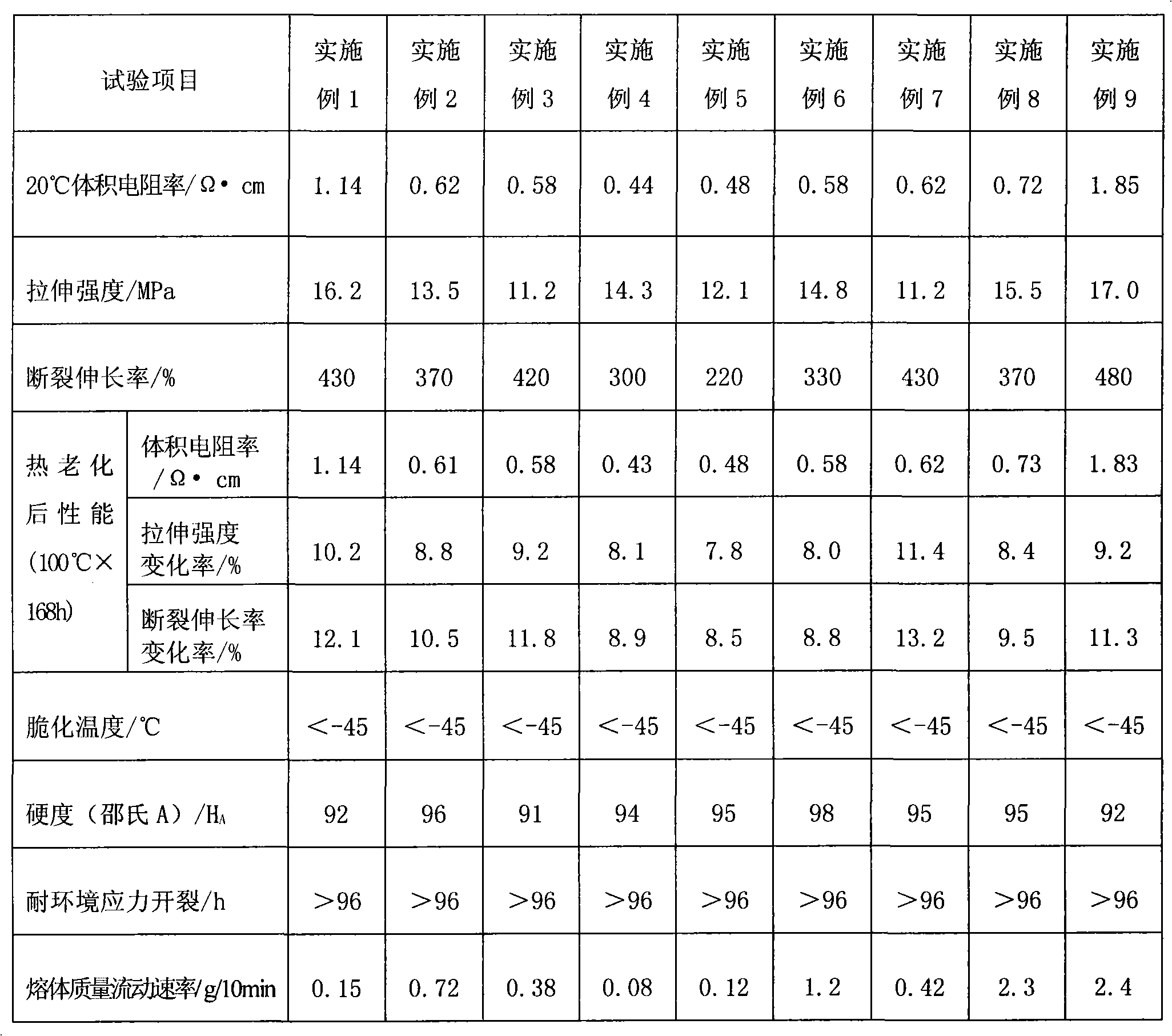

The invention discloses a composite type high-conductivity polymer material and a preparation method thereof, which belongs to the technical field of new materials. The composite type high-conductivity polymer material is characterized by comprising the following raw materials in percentage by weight: 40-62 wt% of base resin compositions, 18-25 wt% of super conductive carbon black, 10-30 wt% of rubber filling oil, 1-3 wt% of low molecular wax, 0.2-0.8 wt% of fluoroelastomer processing aid (PPA), 0.5-2 wt% of lubricant, 1.5-3 wt% of inorganic filler and 0.5-2.5 wt% of other aids. The compositetype high-conductivity polymer material has the advantages of excellent high conductivity, environmental stress cracking resistance, weatherability, ozone resistance, ultraviolet resistance, favorable high temperature resistance, high impact resistance, oil resistance, solvent resistance and mechanical property, and can be used as an environment-friendly conductive polymer sheath material of an combined through earth line, a metal anticorrosive material of other ground cable, a conductive plastic cladding material of a conductive plastic cable positive wire, an optical cable flexible sheath material, and the like.

Owner:SHANDONG KEHONG WIRE & CABLE TECH CO LTD

Polyolefin and preparation method thereof

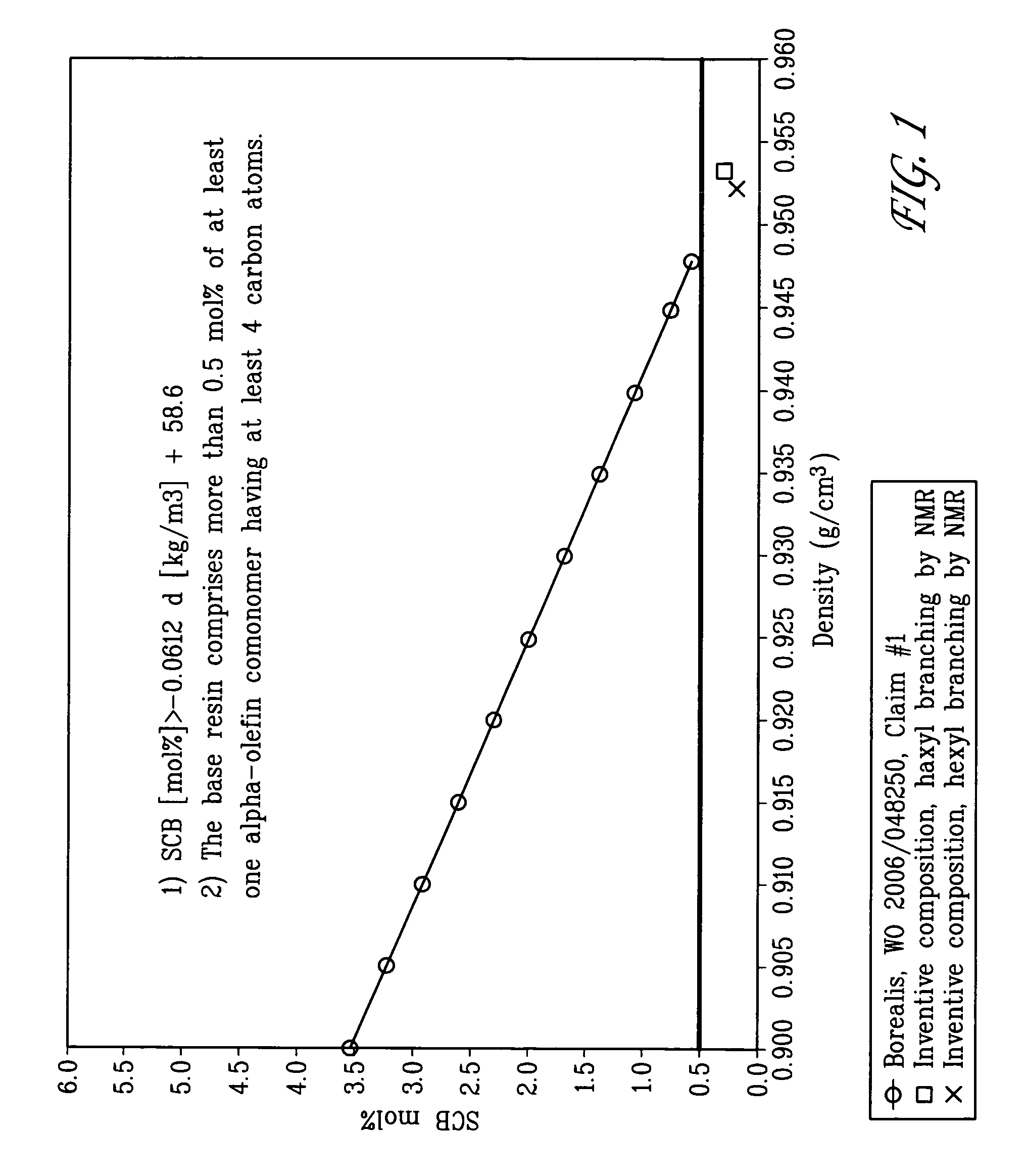

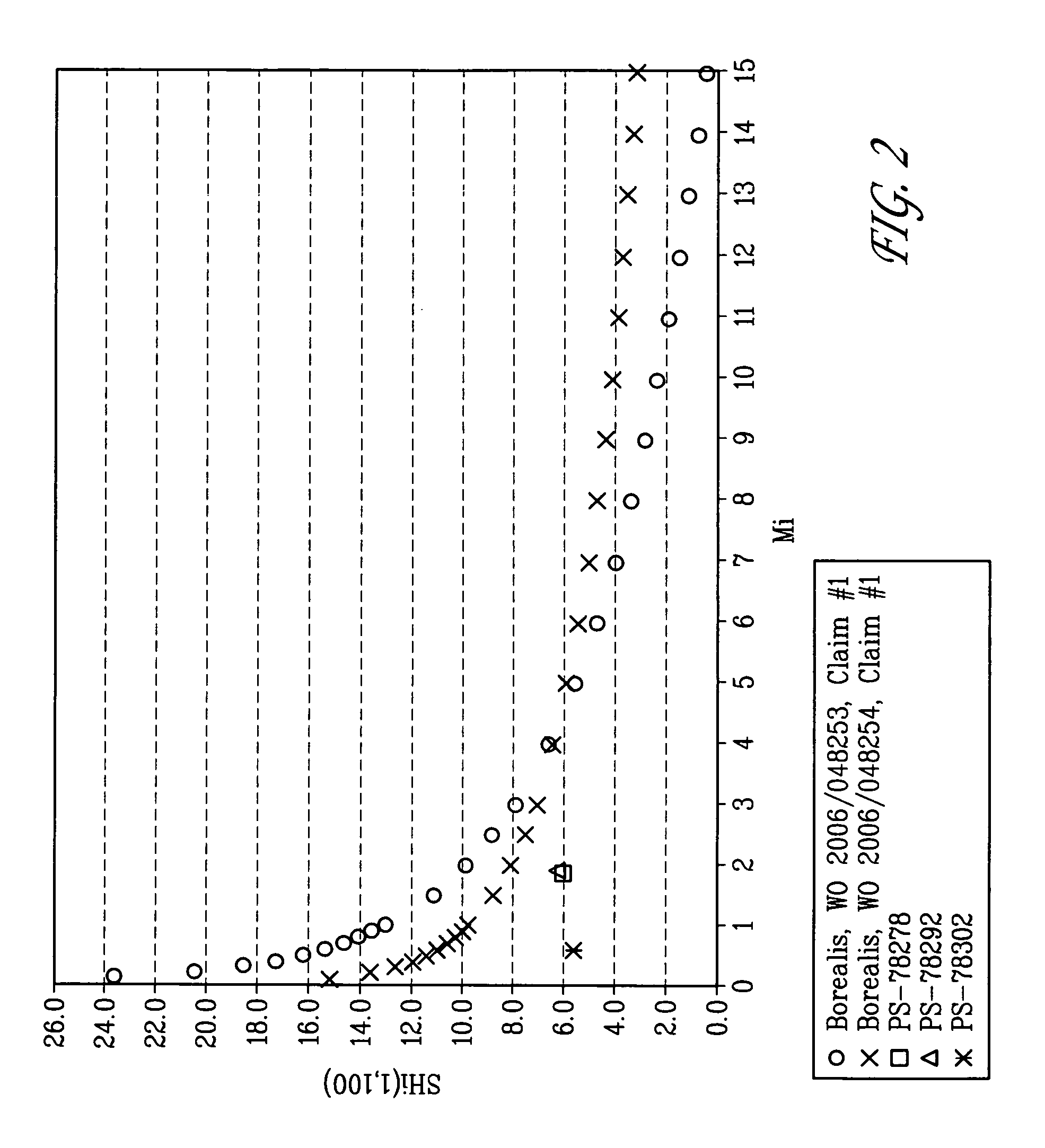

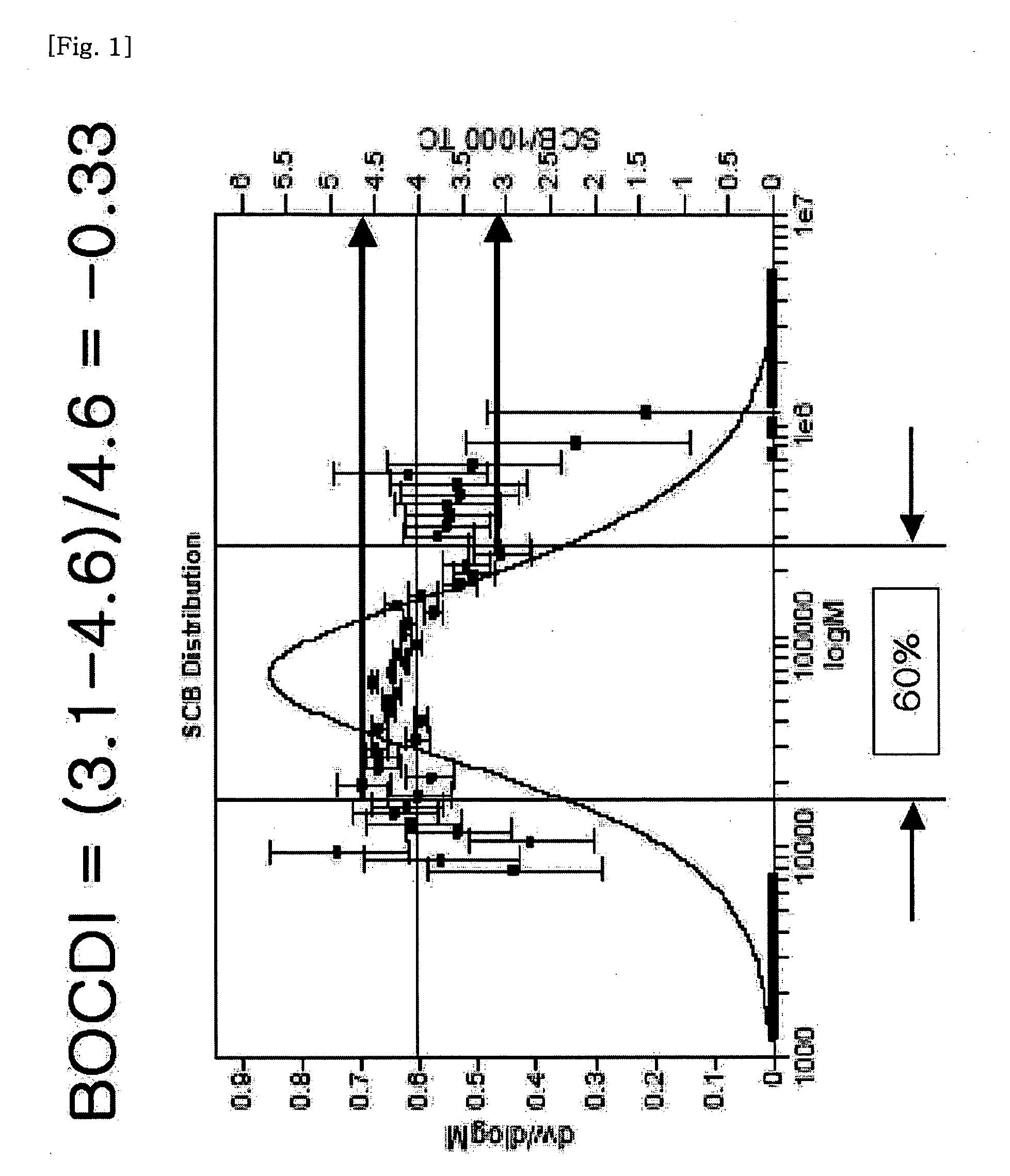

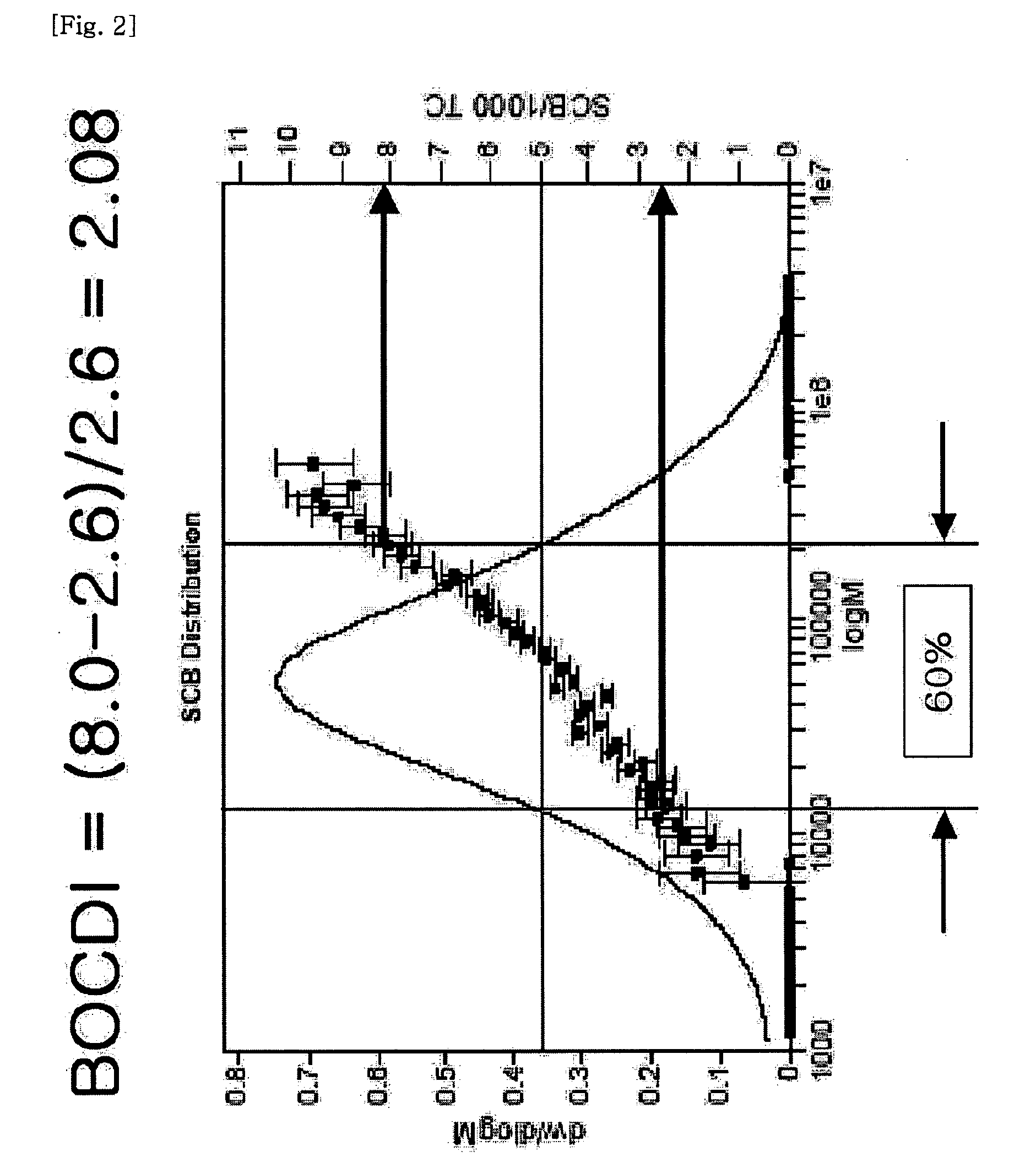

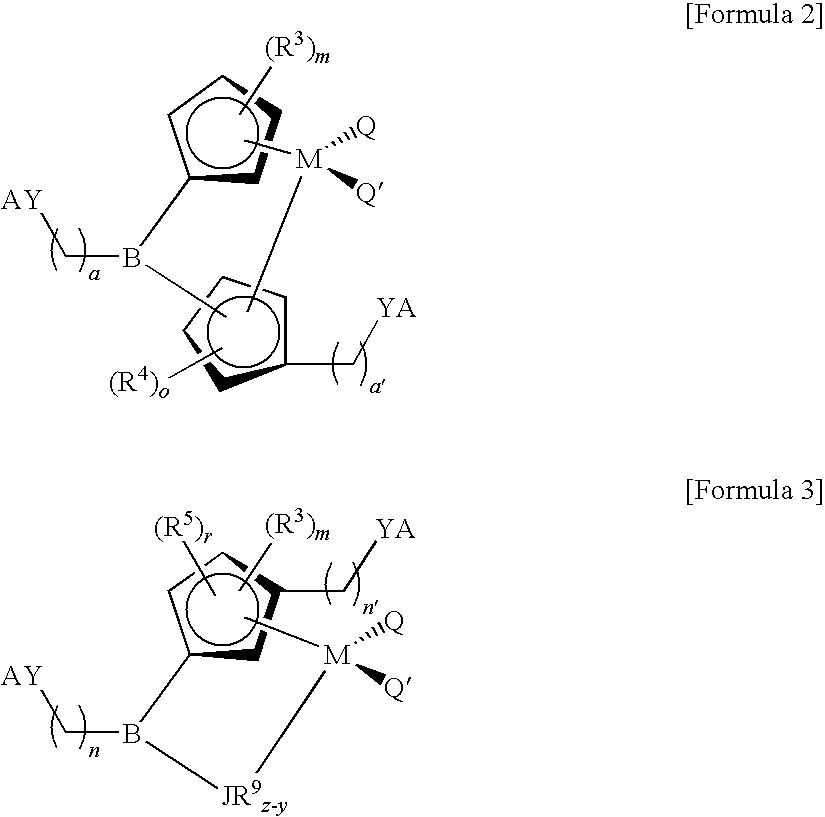

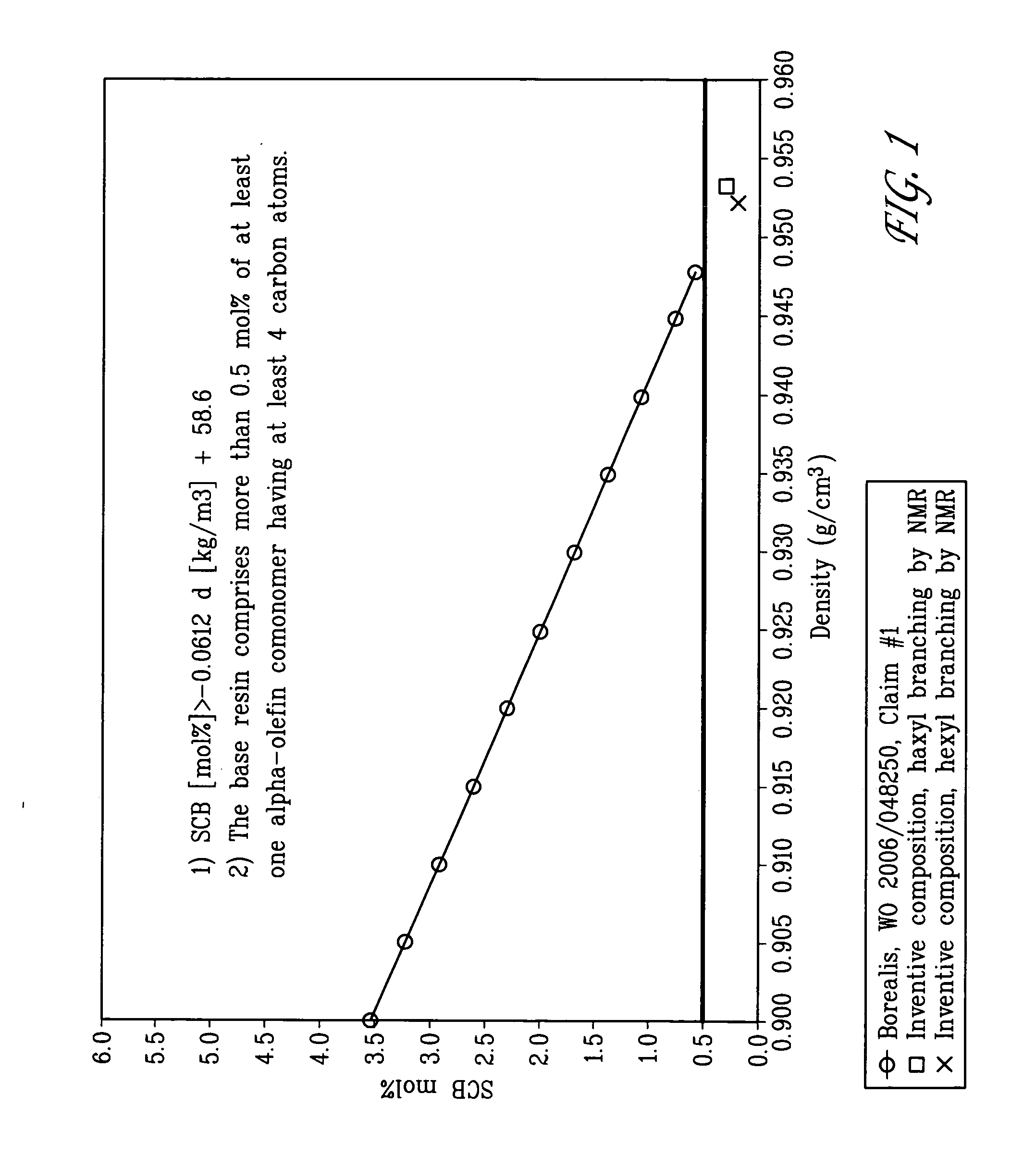

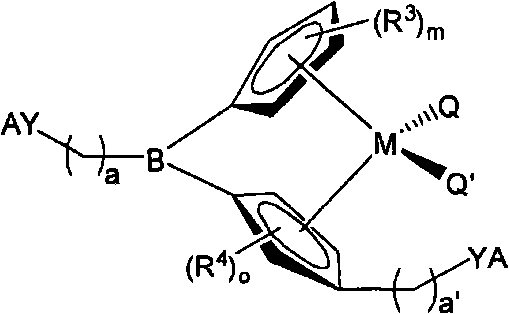

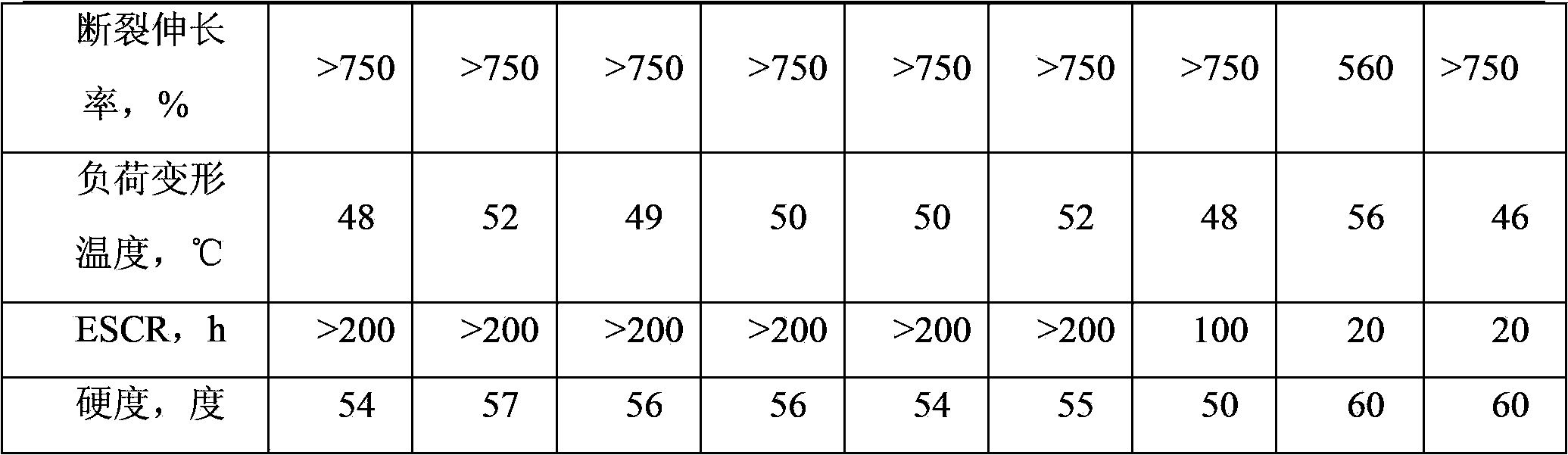

The present invention relates to a polyolefin that has high environmental stress cracking resistance (ESCR), a high impact property, and an excellent die swell property, and a method of preparing the same. According to the method of preparing polyolefin of the present invention, a supported hybrid metallocene catalyst and an alpha olefin comonomer having 4 or more carbon atoms are used to obtain polyolefin having the bimodal or multimodal molecular weight distribution curves during the single reactor polymerization. The polyolefin has excellent processability, a melt flow rate ratio (MFRR) that is useful to processing, excellent shapability, impact strength, tensile strength, in particular, environmental stress cracking resistance (ESCR) and full notch creep test (FNCT), thus being used to manufacture the blow molded product.

Owner:LG CHEM LTD

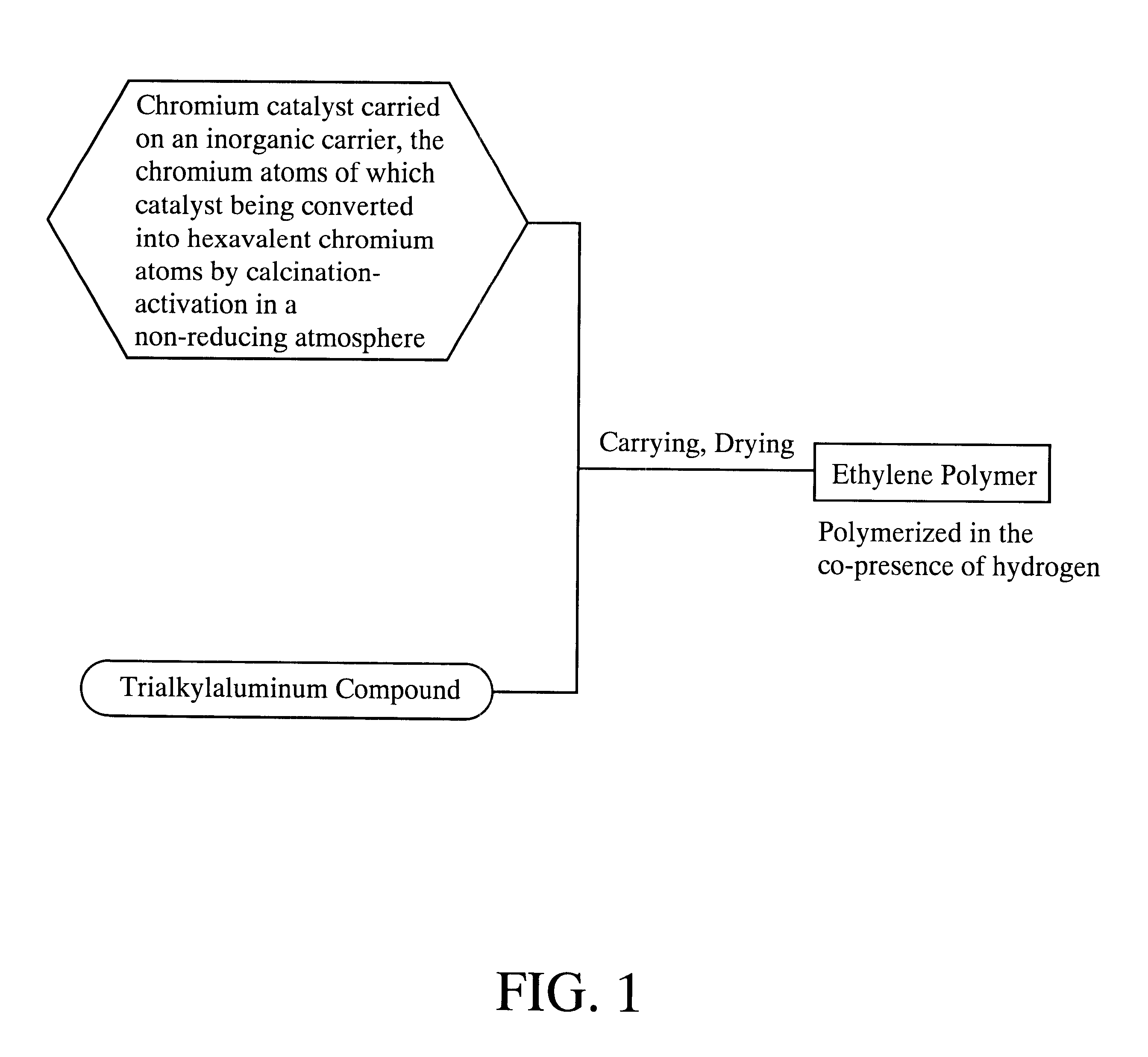

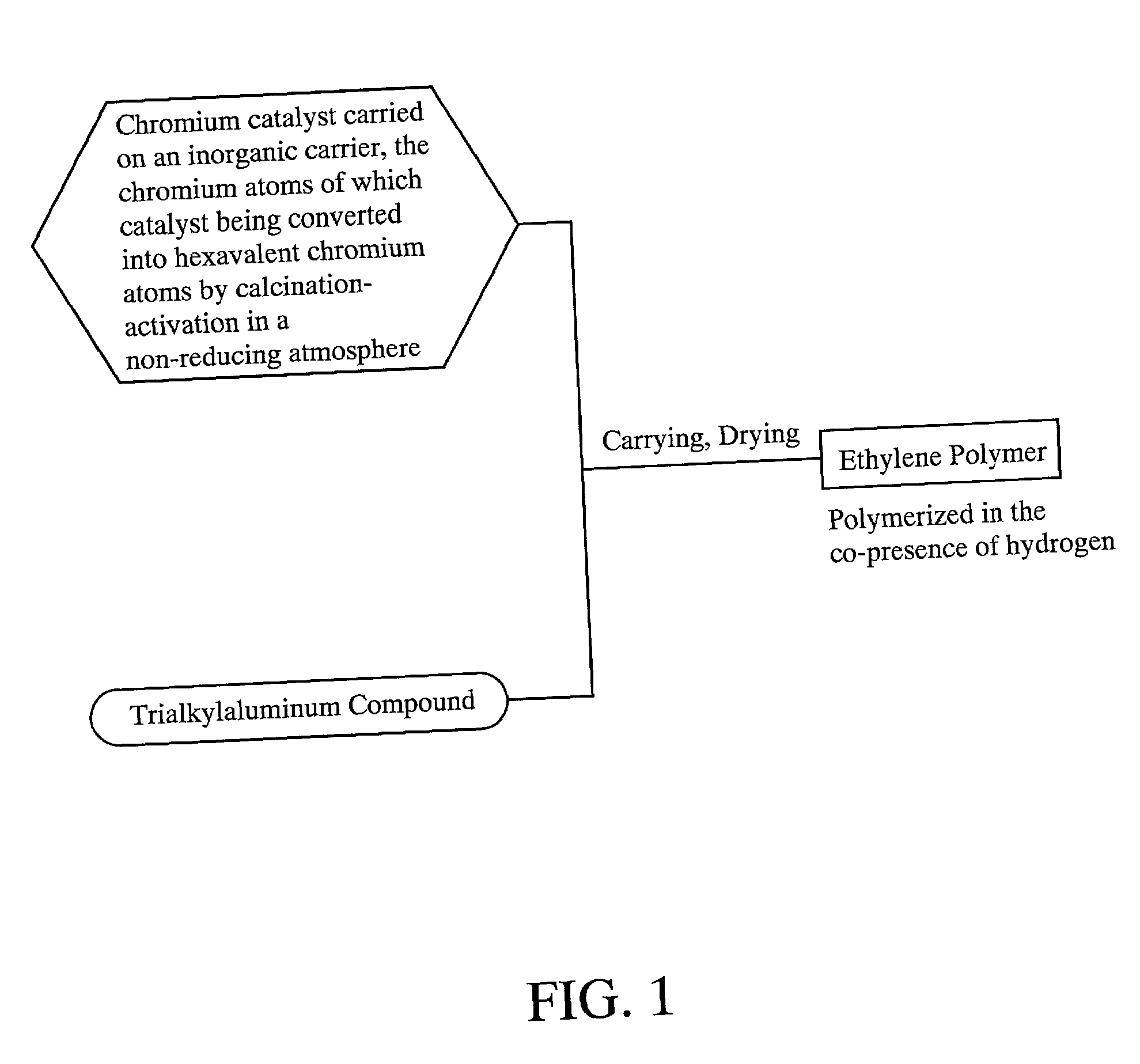

Ethylene polymers and method for producing the same

InactiveUS6646069B2Improve impact resistanceImprove balanceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChromium CompoundsCrack resistance

The invention relates to a method for producing an ethylene polymer, comprising performing polymerization of ethylene in co-presence of hydrogen using a trialkylaluminum compound-carried chromium catalyst, wherein the chromium catalyst is obtained by calcination-activating a chromium compound that is carried on an inorganic oxide carrier in a non-reducing atmosphere to convert chromium atoms in the chromium compound into hexavalent chromium atoms for at least a portion thereof, and treating with a trialkylaluminum compound in an inert hydrocarbon solvent to carry thereon and removing to dry the solvent so that the chromium atoms are not over-reduced by the trialkylaluminum compound, and to an ethylene polymer suitable for blow molded articles obtained by the production method. The ethylene polymer of the invention have improved environment stress crack resistance (ESCR) and impact resistance in a good balance and are suitable for molded blow articles, in particular large size blow molded articles.

Owner:JAPAN POLYOLEFINS CO LTD

Heat-conducting polymer material and its prepn

InactiveCN1388202AImprove conduction characteristicsReduce paddingHeat-exchange elementsPolyolefinPolymer science

The heat-conducting polymer material includes polyolefin, heat-conducting assistant, environmental stress crack resisting assistant and impact resisting modifier. It is prepared through addition of crosslinking agent into heat-conducting assistant for surface treatment, or high temperature sintering and surface treatment of heat-conducting assistant after or without puffing treatment; mixing polyolefin with antioxidant; mixing all the material; fusion and extrusion in a double-screw extruder; cooling, drawing and slicing. The material of the present invention has excellent mechanical property, high conductivity and good welding property.

Owner:杭州华电华源环境工程有限公司

Polyethylene compositions and closures for bottles

ActiveUS8962755B2Good balance of mechanical and processing and organoleptic propertyCapsClosure using stoppersCompression moldingPolymer science

A dual reactor solution process gives high density polyethylene compositions containing a first ethylene copolymer and a second ethylene copolymer and which have good processability, toughness, and environmental stress crack resistance combined with good organoleptic properties. The polyethylene compositions are suitable for compression molding or injection molding applications and are particularly useful in the manufacture of caps and closures for bottles.

Owner:NOVA CHEM (INT) SA

Polymer resins with improved environmental stress crack resistance

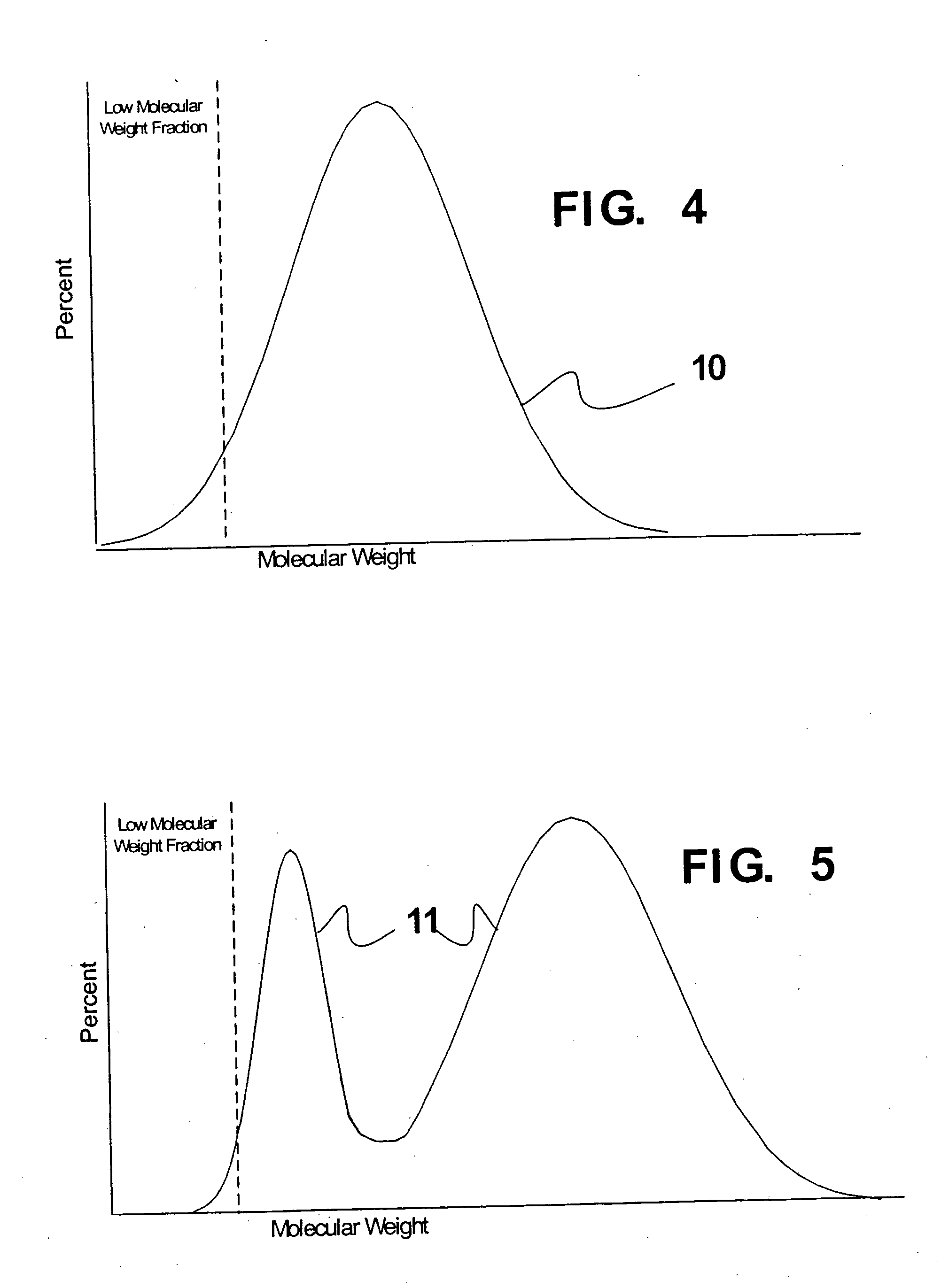

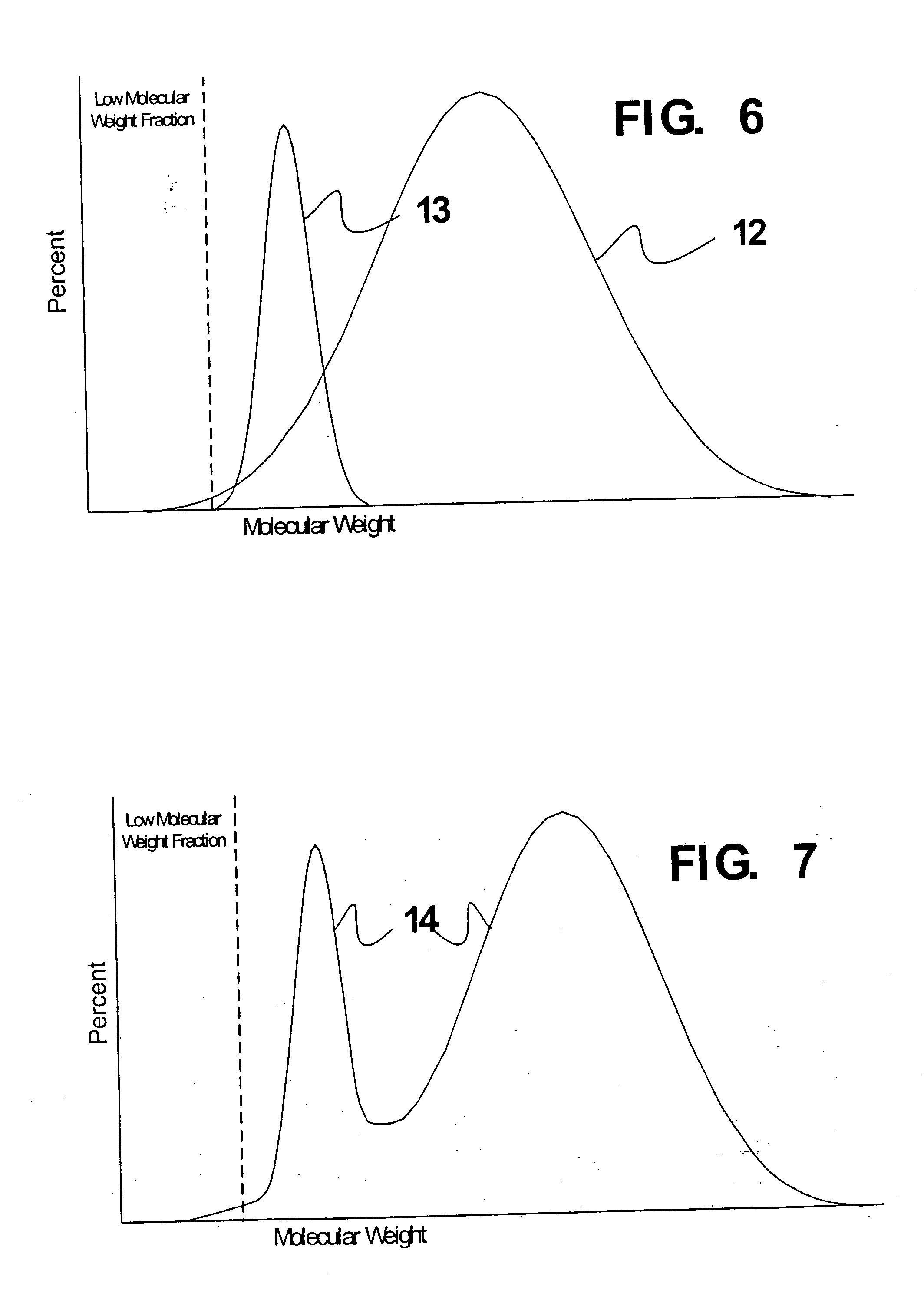

Resins comprising a relatively high-density, low-molecular-weight polyethylene component and a relatively low-density, high-molecular-weight ethylene copolymer component and methods of making the resins are disclosed. The rheological polydispersity of the high-density component exceeds that of either the resin or the low-density component. The resins are valuable for making films, sheets, coatings, pipes, fibers, and molded articles having a favorable balance of good stiffness and excellent environmental stress crack resistance.

Owner:EQUSR CHEM LP

Closures for bottles

ActiveUS20100261848A1Simple compositionImproved balance of Theological and processing and organoleptic propertyCoatingsCompression moldingPolymer science

A dual reactor solution process gives high density polyethylene compositions containing a first ethylene polymer and a second ethylene polymer which have a good balance of processability, toughness, and environmental stress crack resistance combined with good organoleptic properties. The polyethylene compositions are suitable for compression molding or injection molding applications and are particularly useful in the manufacture of caps and closures for bottles.

Owner:NOVA CHEM (INT) SA

Polyethylene compositions and closures for bottles

ActiveUS20130072632A1Good balance of mechanical and processing and organoleptic propertyCapsClosure using stoppersCompression moldingPolymer science

A dual reactor solution process gives high density polyethylene compositions containing a first ethylene copolymer and a second ethylene copolymer and which have good processability, toughness, and environmental stress crack resistance combined with good organoleptic properties. The polyethylene compositions are suitable for compression molding or injection molding applications and are particularly useful in the manufacture of caps and closures for bottles.

Owner:NOVA CHEM (INT) SA

Polyolefin and preparation method thereof

The present invention relates to a polyolefin that has high environmental stress cracking resistance (ESCR), a high impact property, and an excellent die swell property, and a method of preparing thesame. According to the method of preparing polyolefin of the present invention, a supported hybrid metallocene catalyst and an alpha olefin comonomer having 4 or more carbon atoms are used to obtain polyolefin having the bimodal or multimodal molecular weight distribution curves during the single reactor polymerization. The polyolefin has excellent processability, a melt flow rate ratio (MFRR) that is useful to processing, excellent shapability, impact strength, tensile strength, in particular, environmental stress cracking resistance (ESCR) and full notch creep test (FNCT), thus being used tomanufacture the blow molded product.

Owner:LG CHEM LTD

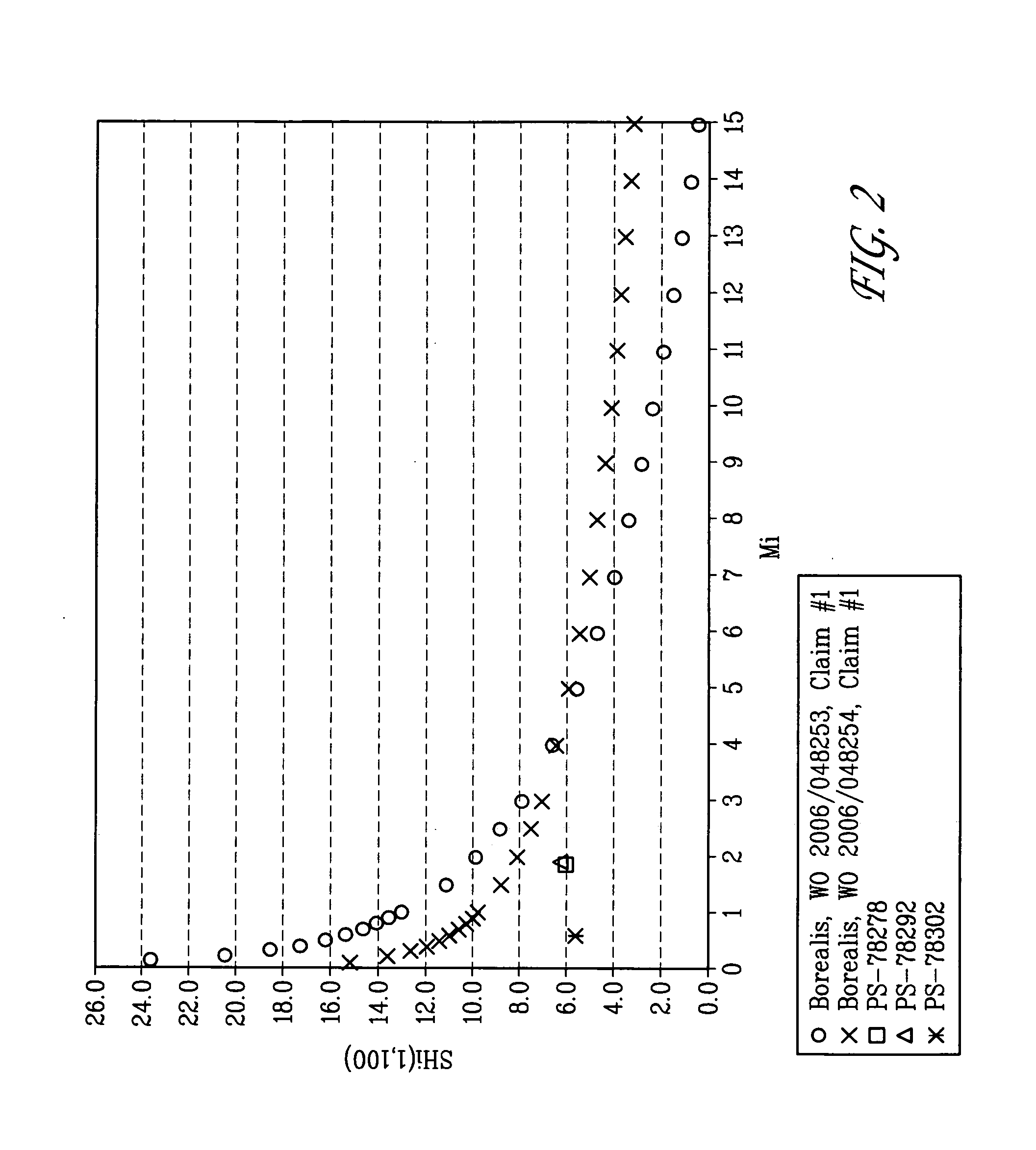

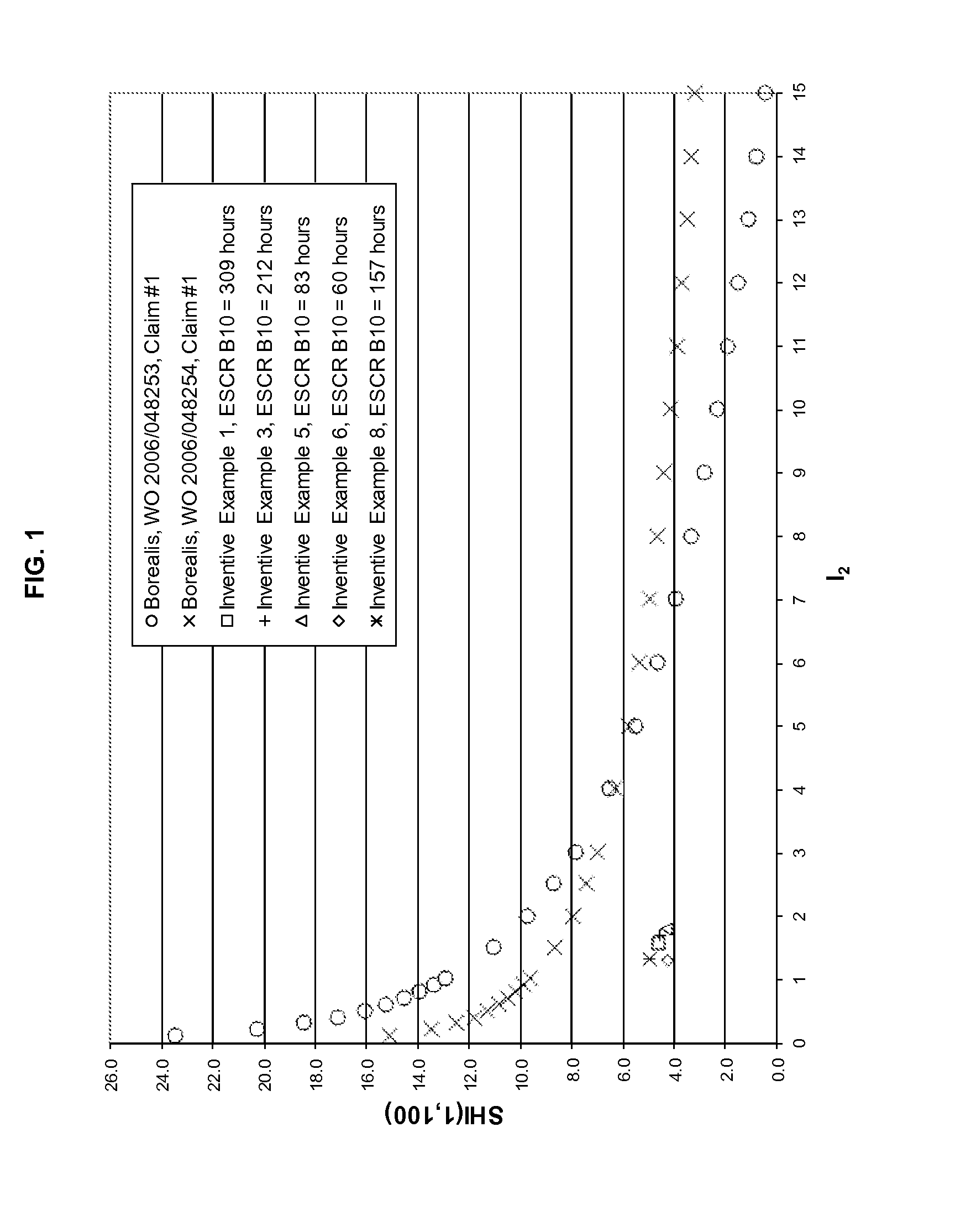

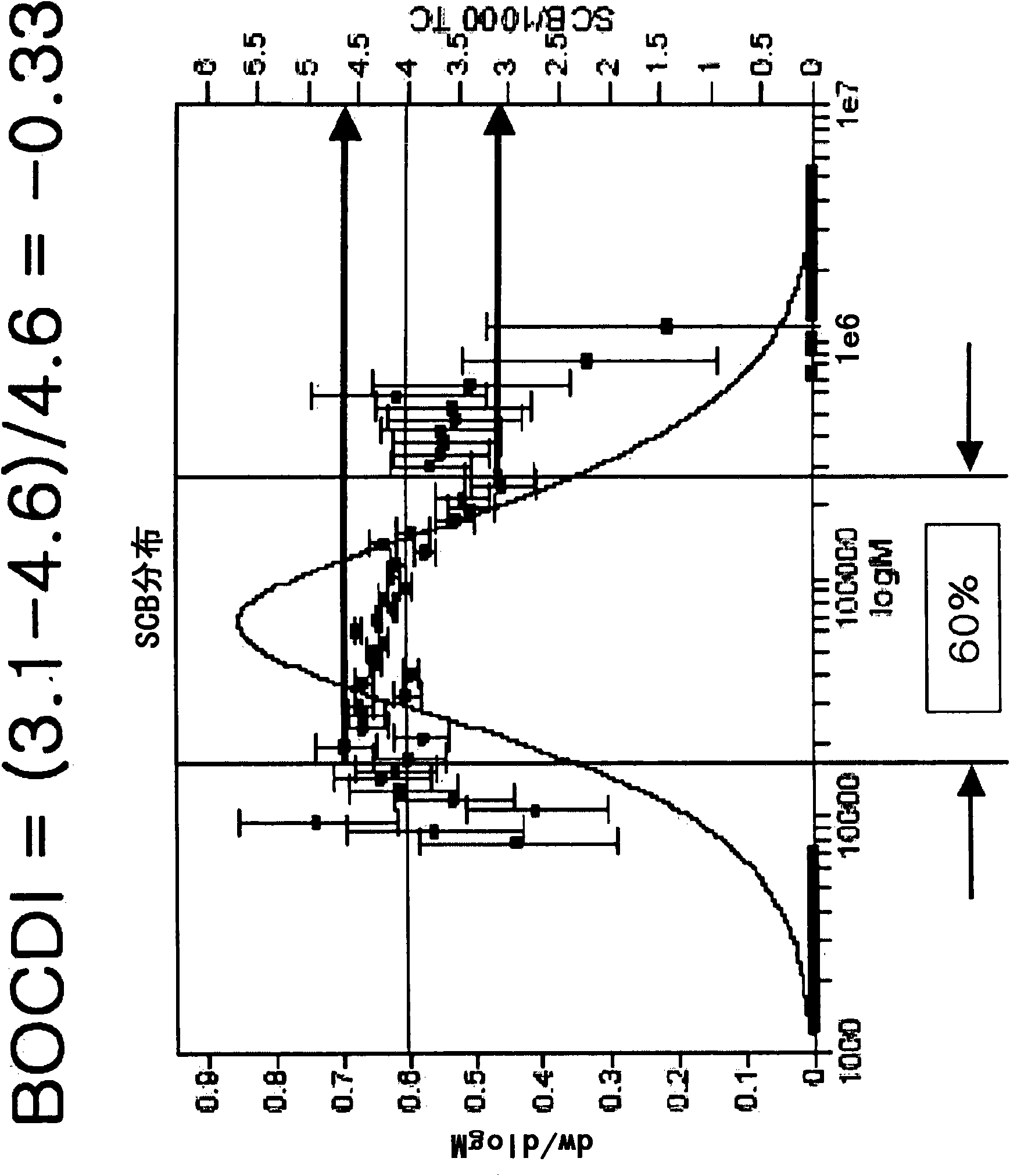

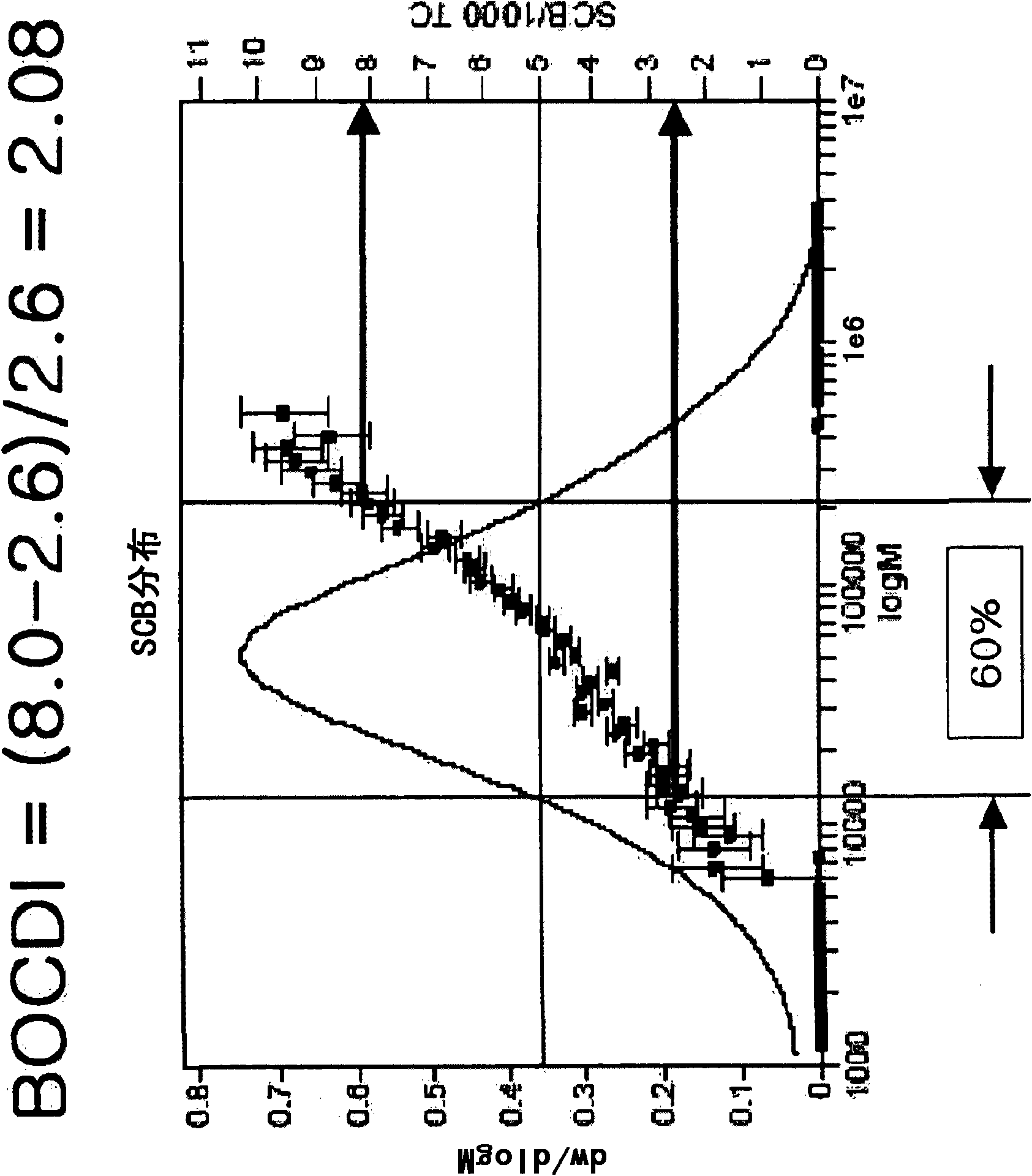

Melt blended high density polyethylene compositions with enhanced properties and method for producing the same

Melt blended HDPE compositions for single and dual wall corrugated HDPE pipe and associated fabricated and molded fittings and accessories with enhanced physical properties and processing and environmental stress crack resistance (ESCR) characteristics and associated blend methods are disclosed in which virgin or recycled homopolymer and / or copolymer HDPE resin components are blended. The invention discloses methods for 1) selecting and determining the relative weight fractions of the HDPE blending components that provide specific physical properties and processability of HDPE blended compositions associated with density and melt index respectively and specific values of environmental stress crack resistance (ESCR) associated with specific molecular parameters and 2) for determining from molecular parameters, the ESCR of linear polyethylene resins and blended compositions within a class having similar densities. The invention reduces the cost of raw materials to corrugated HDPE pipe manufacturers by enabling the use of virgin prime commodity HDPE resins and / or wide and off specification prime HDFE resins in place of single stream specialty HDPE resins and favorably impacts the environment by providing the capability of utilizing recycled HDPE resins in place of prime HDPE resins in the manufacture of corrugated HDPE pipe.

Owner:CORRUGATEDD POLYETHYLENE PIPE

Ethylene polymers and method for producing the same

InactiveUS20020042482A1Improve impact resistanceImprove balanceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChromium CompoundsCrack resistance

The invention relates to a method for producing an ethylene polymer, comprising performing polymerization of ethylene in co-presence of hydrogen using a trialkylaluminum compound-carried chromium catalyst, wherein the chromium catalyst is obtained by calcination-activating a chromium compound that is carried on an inorganic oxide carrier in a non-reducing atmosphere to convert chromium atoms in the chromium compound into hexavalent chromium atoms for at least a portion thereof, and treating with a trialkylaluminum compound in an inert hydrocarbon solvent to carry thereon and removing to dry the solvent so that the chromium atoms are not over-reduced by the trialkylaluminum compound, and to an ethylene polymer suitable for blow molded articles obtained by the production method. The ethylene polymer of the invention have improved environment stress crack resistance (ESCR) and impact resistance in a good balance and are suitable for molded blow articles, in particular large size blow molded articles.

Owner:JAPAN POLYOLEFINS CO LTD

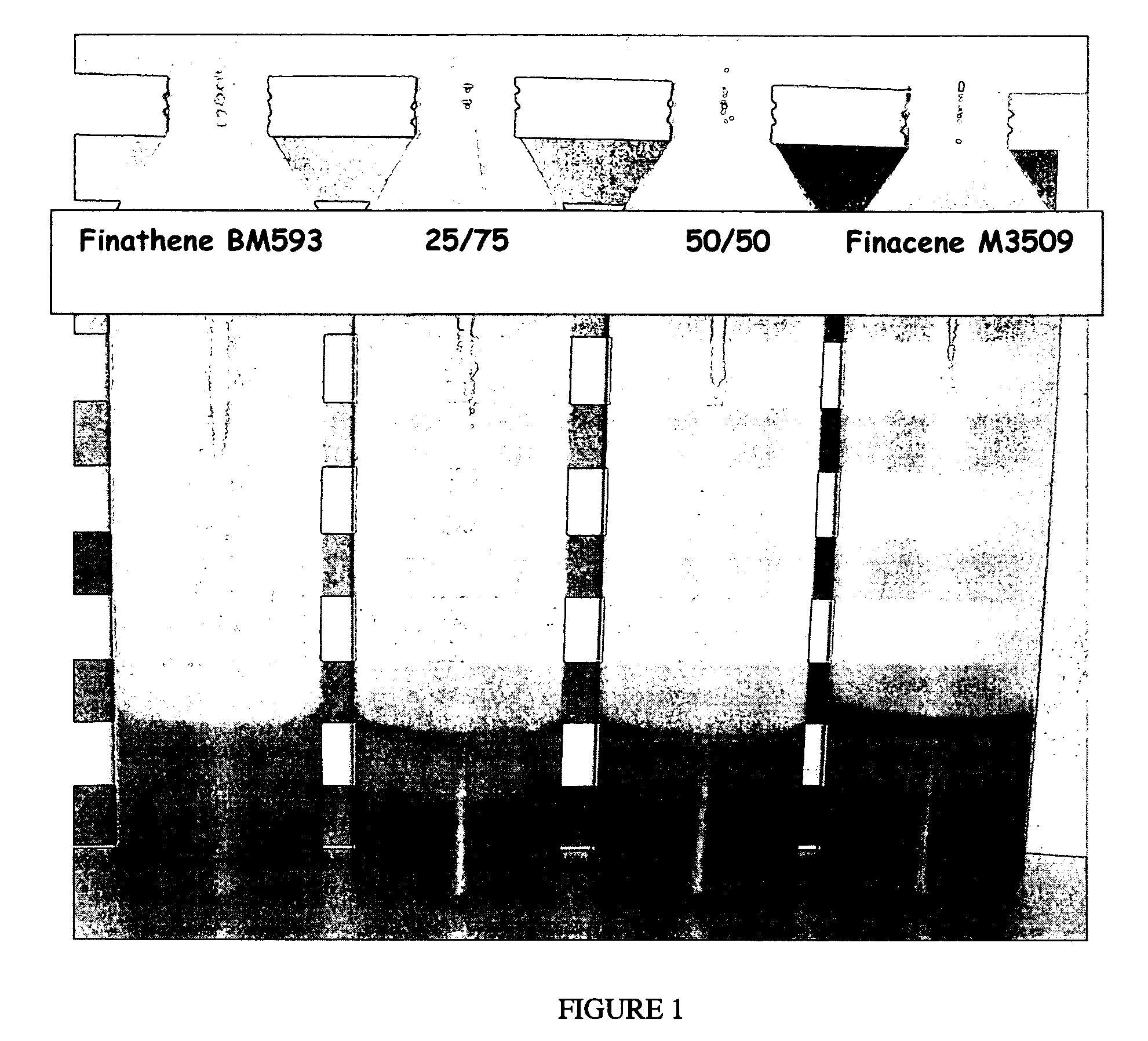

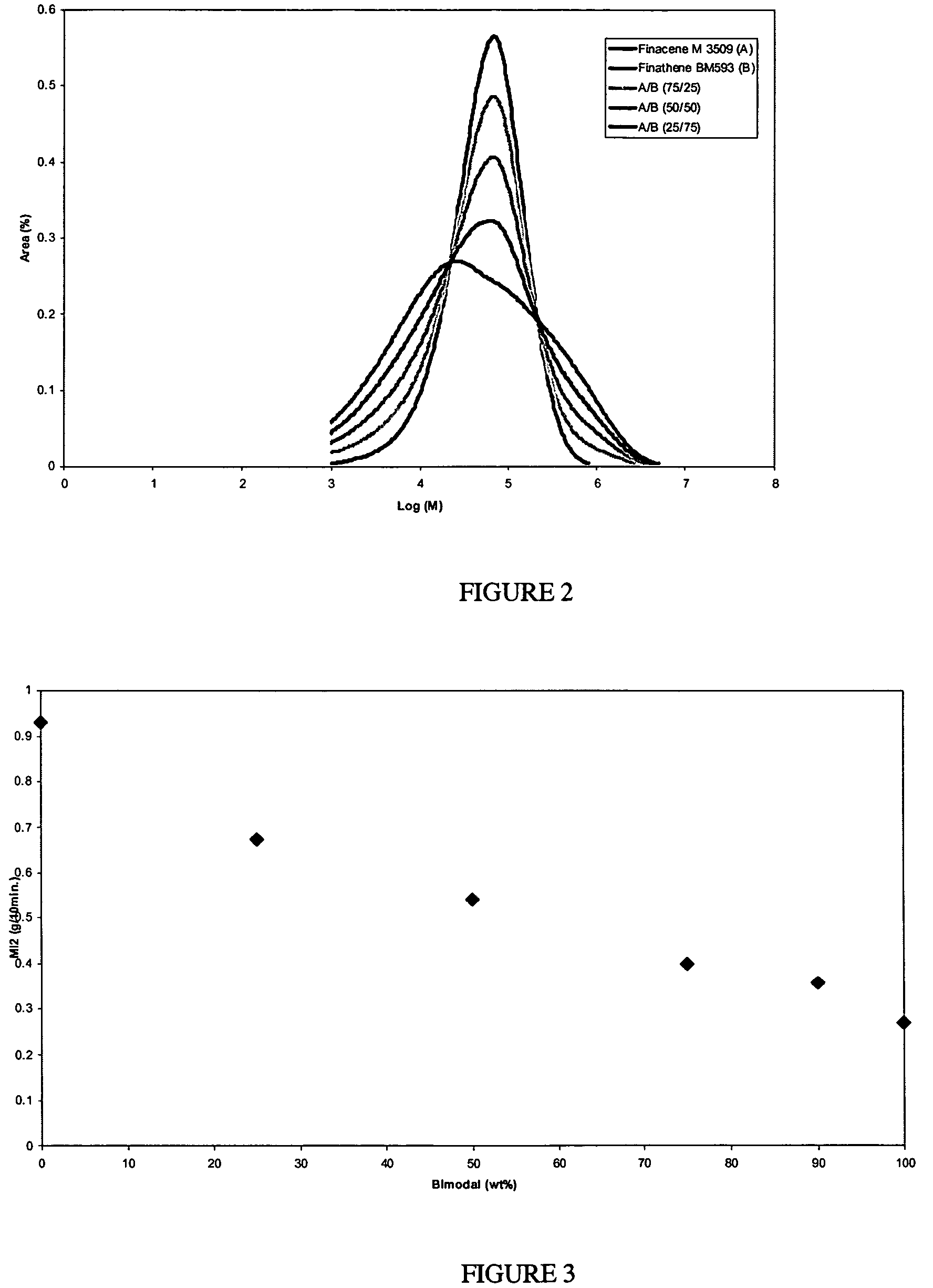

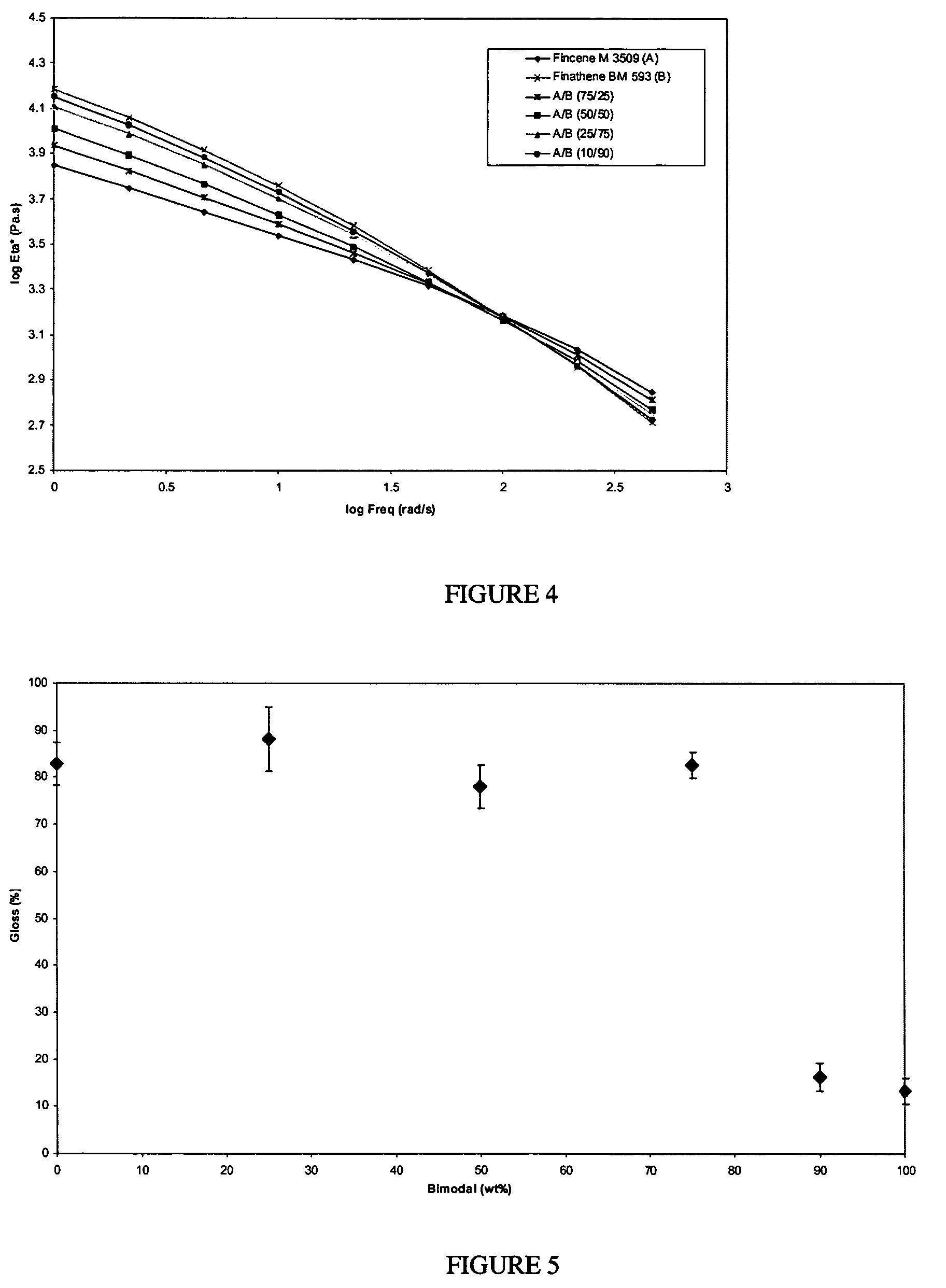

Polyethylene blends with good contact transparency

InactiveUS7514504B2Good contact transparency and glossHigh environmental stress crack resistanceLow-density polyethyleneLinear low-density polyethylene

This invention discloses the production and use of a polyethylene composition comprising a metallocene-produced linear low density polyethylene and a multi modal high density polyethylene prepared from either a Ziegler-Natta or a metallocene catalyst system. The resulting polyethylene composition is suitable for preparing articles having improved environmental stress crack resistance, rigidity, contact transparency, gloss as well as good processing capabilities.

Owner:TOTAL RES & TECH FELUY

Polyethylene pipe having better melt processibility and high resistance to stress and method of preparing the same using metallocene catalyst

ActiveUS20050228139A1Reduce loadEasy to installAcoustic time signalsOptical signalsPolymer sciencePtru catalyst

An ethylene-based copolymer for non-crosslinked water supply pipe is provided. The ethylene-based copolymer is prepared using a supported hybrid metallocene catalyst and has a dimodal or broad molecular weight distribution. The ethylene-based copolymer has a high density molecular structure in a low molecular weight and has a low density molecular structure with high content of a comonomer in a high molecular weight. The ethylene-based copolymer has a molecular weight distribution of 5-30 and the distribution of copolymerization of ethylene and C3-20 α-olefin is localized in high molecular weight chains. Accordingly, the ethylene-based copolymer has superior processability, internal pressure creep resistance at high temperatures and environmental stress crack resistance.

Owner:LG CHEM LTD

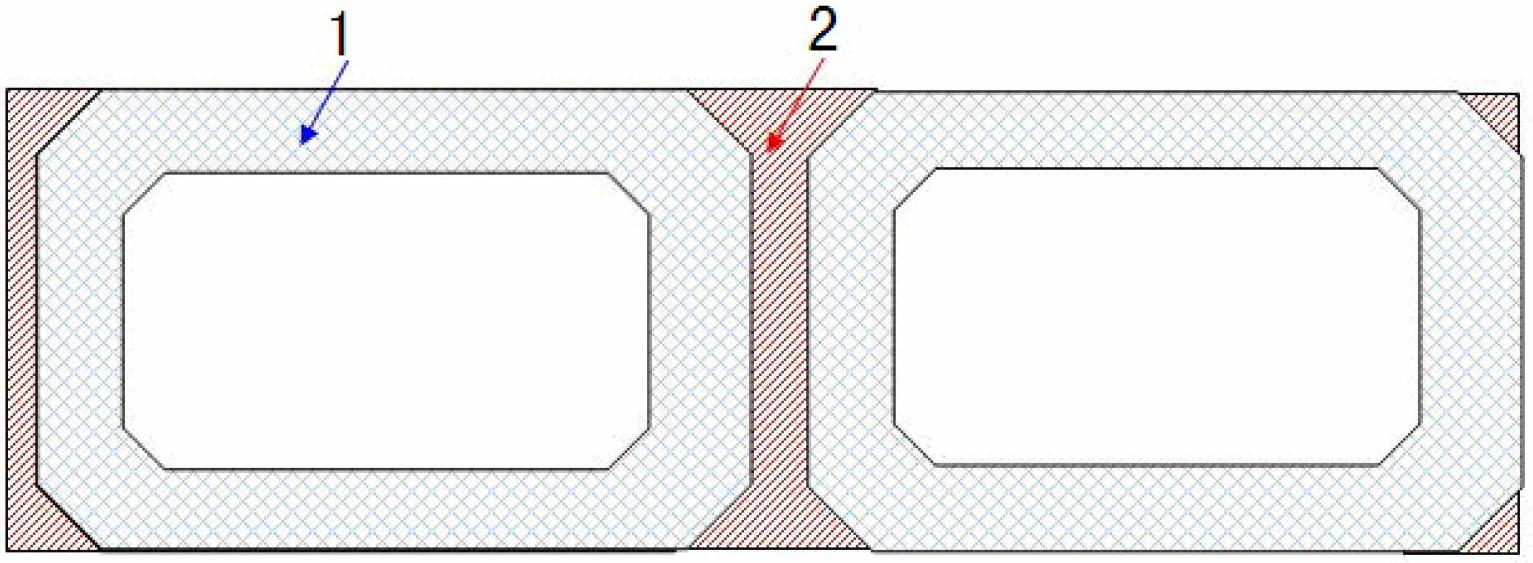

Glass fiber enhanced high-density polyethylene (HDPE) double-walled winding pipe and manufacture method thereof

ActiveCN102691832AImprove performanceImprove creep resistanceRigid pipesLow-density polyethyleneFiber

The invention relates to a glass fiber enhanced high-density polyethylene (HDPE) double-walled winding pipe, which is formed by spirally winding a glass fiber enhanced HDPE plastic pipe and welding the glass fiber enhanced HDPE plastic pipe by plastic hot melt adhesives, wherein the glass fiber enhanced HDPE plastic pipe is a hollow rectangular glass fiber enhanced HDPE plastic pipe with the long glass fiber content being 5 percent to 40 percent by weight. A manufacture method of the glass fiber enhanced HDPE double-walled winding pipe comprises the following steps that HDPE mixed materials are prepared, modified long glass fiber is prepared, the HDPE mixed materials and the modified long glass fiber take reaction and are coextruded into a hollow square pipe, and the hollow square pipe is made into the glass fiber enhanced HDPE double-walled winding pipe through spiral winding and plastic hot melt adhesive welding. The glass fiber enhanced HDPE double-walled winding pipe has the advantages that the creep resistance, the modulus, the impact resistance, the scratch resistance, the slow crack expansion resistance, the environment stress cracking resistance and the high-temperature resistance are good, the whole body has sufficient sewing stretching intensity, and the integral performance of pipelines is effectively improved.

Owner:SHANGHAI QINGYUAN PIPE TECH

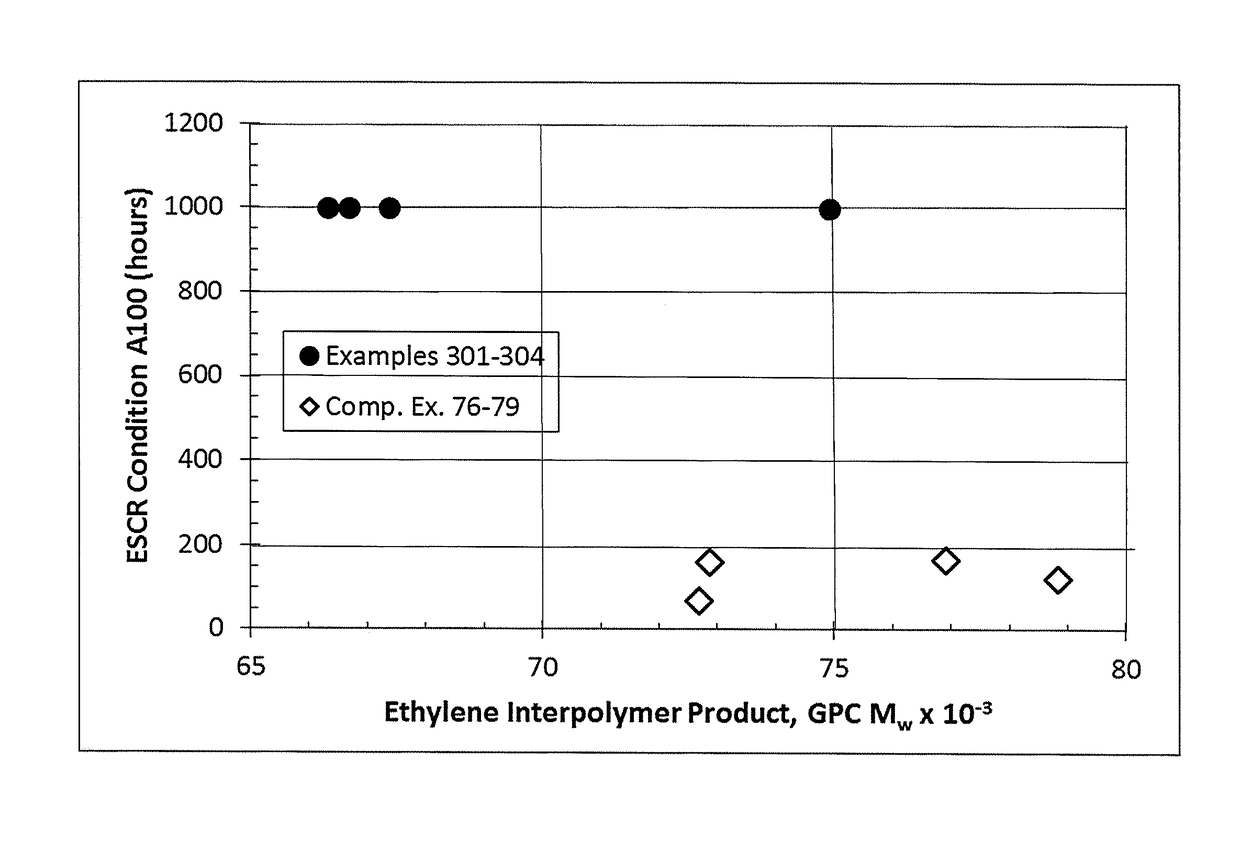

Rotomolded articles

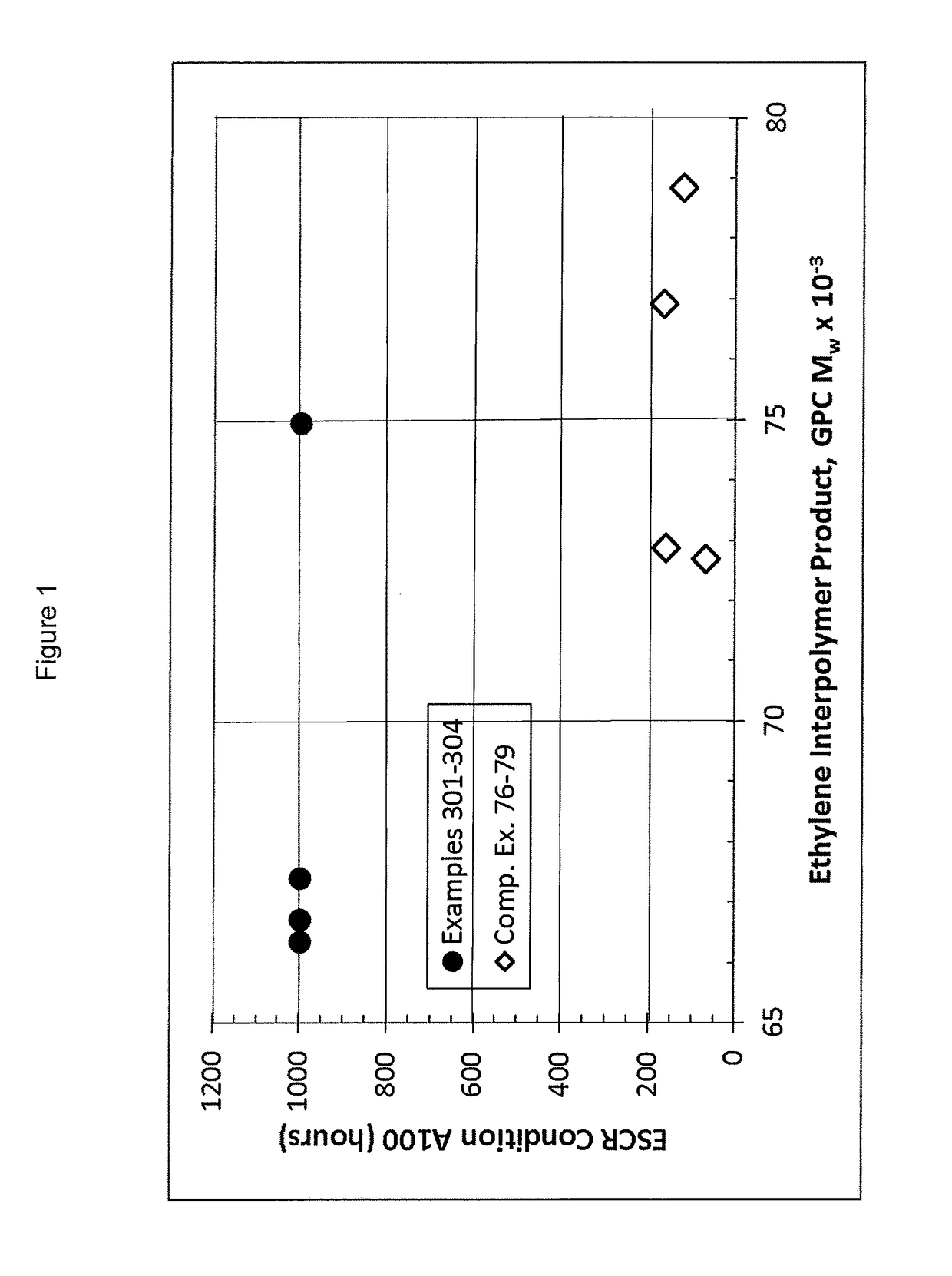

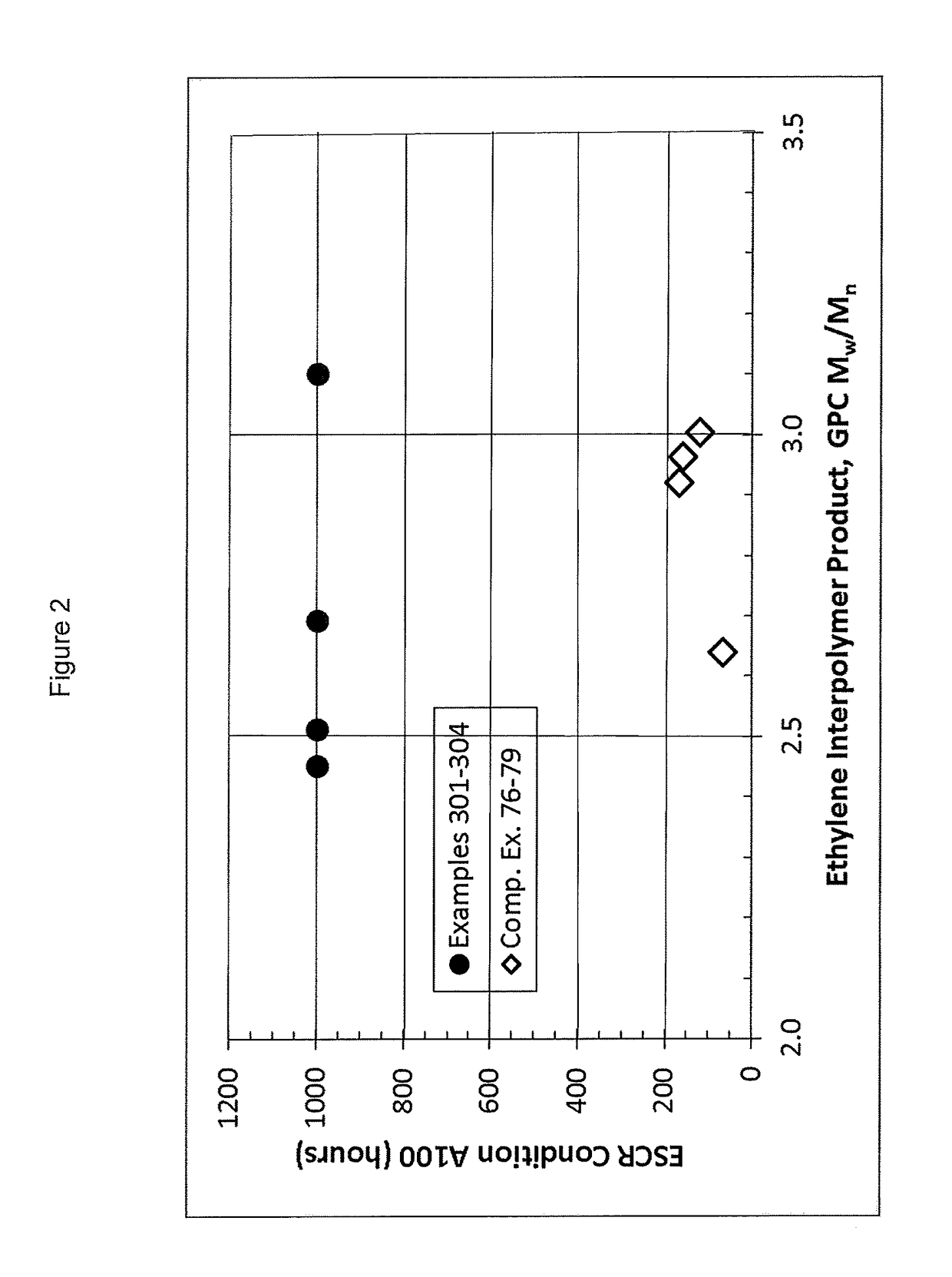

ActiveUS20170267822A1Synthetic resin layered productsDomestic containersEthylene PolymersEnvironmental stress cracking

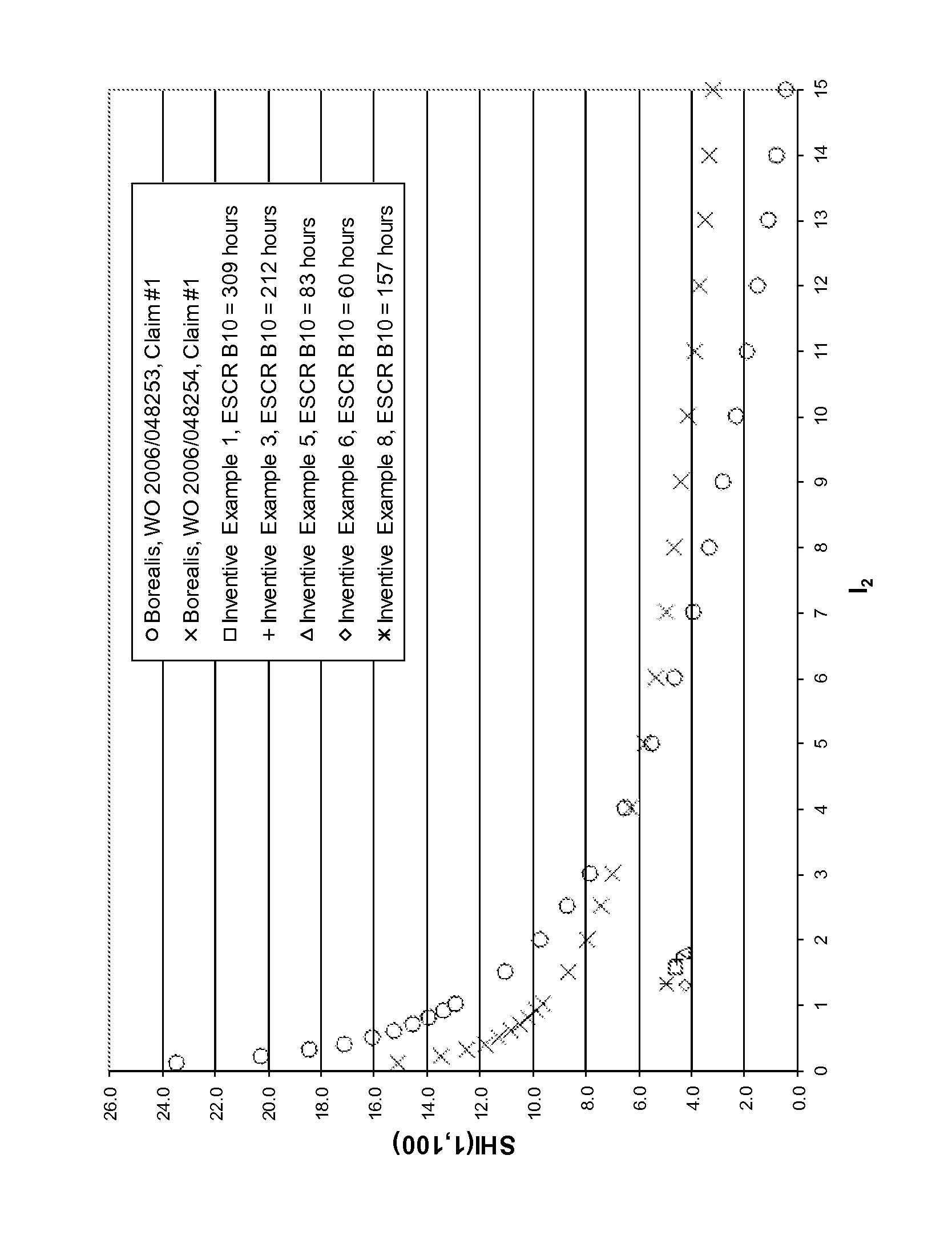

This disclosure relates to rotomolded articles, having a wall structure, where the wall structure contains at least one layer containing an ethylene interpolymer product, or a blend containing an ethylene interpolymer product and an ethylene polymer, where the ethylene interpolymer product has a Dilution Index (Yd) greater than 0 and improved Environmental Stress Crack Resistance (ESCR). The ethylene interpolymer product has a melt index from about 0.5 to about 15 dg / minute, a density from about 0.930 to about 0.955 g / cm3, a polydispersity (Mw / Mn) from about 2 to about 6 and a CDBI50 from about 50% to about 98%. Further, the ethylene interpolymer products are a blend of at least two ethylene interpolymers; where one ethylene interpolymer is produced with a single-site catalyst formulation and at least one ethylene interpolymer is produced with a heterogeneous catalyst formulation.

Owner:NOVA CHEM (INT) SA

Multimodal polyethylene for use in single piece beverage bottle caps and closures

The present invention relates to single piece beverage bottle caps containing and / or made from polyethylene polymers, polymer blends, and / or resins. These polymers / blends / resins have a multimodal molecular weight distribution, sufficient physico-chemical characteristics, and superior environmental stress cracking resistance, so as to be ideally suited for articles and applications such as caps and closures.

Owner:EXXONMOBIL CHEM PAT INC

Rotomolding process with reduced cycle times

ActiveUS20050017409A1Improve impact resistanceResistant to warpageWood working apparatusCeramic shaping apparatusVolumetric Mass DensityLow density

The cycle time for a rotomolding process is improved through the use of a molding material comprising a blend of at least two polyethylenes having narrow molecular weight distributions and homogeneous comonomer distributions. Alternatively, the molding temperature may be reduced to conserve energy and reduce energy costs. The polyethylene blend also has a narrow molecular weight distribution of less than 3 and a density of from 0.930 to 0.950 g / cc. Rotomolded parts prepared from the blend composition have excellent impact resistance and are also resistant to warpage. A preferred process employs a blend composition which contains a blend component having a higher molecular weight and a lower density than another blend component—this blend may be used to prepare rotomolded parts with warpage resistance and improved environmental stress crack resistance (ESCR). A highly preferred process uses a blend composition which further contains aminor amount (from 0.5 to 10 weight %) of a third ethylene blend component which has a higher molecular weight and density—this highly preferred composition may be used to prepare rotomolded parts having warpage resistance, very good ESCR and comparatively high modulus (or stiffness).

Owner:NOVA CHEM (INT) SA

Irradiation cross-linked polyethylene

InactiveCN101724191AImprove heat deformation resistanceImprove mechanical propertiesCross-linkAntioxidant

The invention discloses an irradiation cross-linked polyethylene, which is characterized by comprising the following components by weight percent: antioxidant 1010: 0.5%-5%, cross-linking agent: 0.1%-1%, non-halogen flame retardant: 5%-15%, polyethylene (PE): 40%-60%, and ethylene / vinyl acetate copolymer: 20%-45%. The irradiation cross-linked polyethylene witnesses a structural transformation from a linear molecule structure to a body type three-dimensional structure; meanwhile the irradiation cross-linked polyethylene is transformed from thermal plastic to insoluble thermosetting plastic, as a result, heat-resisting deformability is enhanced, mechanical property at high temperature is improved, environmental stress cracking resistance and heat-proof aging are improved, chemical resistance and solvent resistance are enhanced, cold fluidity is reduced and previous electric properties are retained.

Owner:SHENZHEN FUSAI ENERGY TECH

Thermoplastic Resin Composition for Refrigerator Having Improved Environmental Stress Crack Resistance

InactiveUS20080093578A1Good environmental stress crack resistanceEasy vacuum formabilityHeat-exchange elementsCyanideEmulsion polymerization

A thermoplastic resin composition for a refrigerator according to the present invention can include (A) about 20 to about 40 parts by weight of an acrylonitrile-butadiene-styrene graft copolymer resin prepared by grafting in emulsion polymerization about 60 to about 30% by weight of a monomer mixture comprising a cyanide vinyl compound and an aromatic vinyl compound to about 40 to about 70% by weight of a rubber polymer having an average particle size of about 0.1 to about 0.4 μm; (B) about 1 to about 20 parts by weight of a styrenic copolymer comprising (b1) about 0 to about 75% by weight of a styrenic copolymer prepared by copolymerizing about 5 to about 20% by weight of a rubber polymer having an average particle size of about 0.1 to about 10 μm, about 10 to about 30% by weight of a cyanide vinyl compound, and about 65 to about 85% by weight of an aromatic vinyl compound, and (b2) about 25 to about 100% by weight of a styrenic copolymer prepared by copolymerizing about 5 to about 20% by weight of a rubber polymer having an average particle size of about 0.1 to about 10 μm and about 80 to about 95% by weight of an aromatic vinyl compound; and (C) about 50 to about 79 parts by weight of a cyanide vinyl-aromatic vinyl copolymer.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Polyethylene having faster crystallization rate and improved environmental stress cracking resistance

InactiveUS9187627B2Fast crystallizationIncrease weightEthylene HomopolymersEnvironmental stress cracking

Disclosed is a polyethylene composition having faster crystallization rate and improved environmental stress cracking resistance. The polyethylene composition comprises a multimodal polyethylene and a nucleating agent. The multimodal polyethylene comprises from 25 to 50 wt % of a low molecular weight ethylene homopolymer component, from 25 to 50 wt % of a medium molecular weight ethylene copolymer component and from 25 to 50 wt % of a high molecular weight ethylene copolymer component. The polyethylene composition has an environmental stress cracking resistance (ASTM D1693, Condition B in 100% Igepal) greater than or equal to 40 days and a crystallization half time less than or equal to 70% of the crystallization half time of the multimodal polyethylene without nucleating agent.

Owner:EQUSR CHEM LP

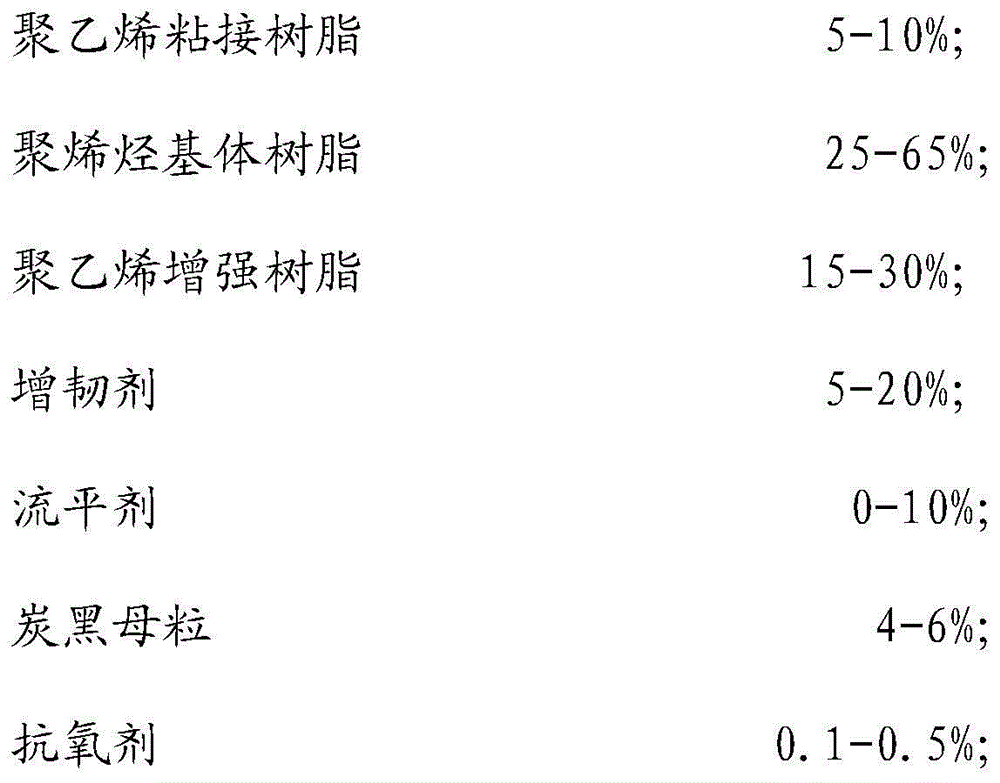

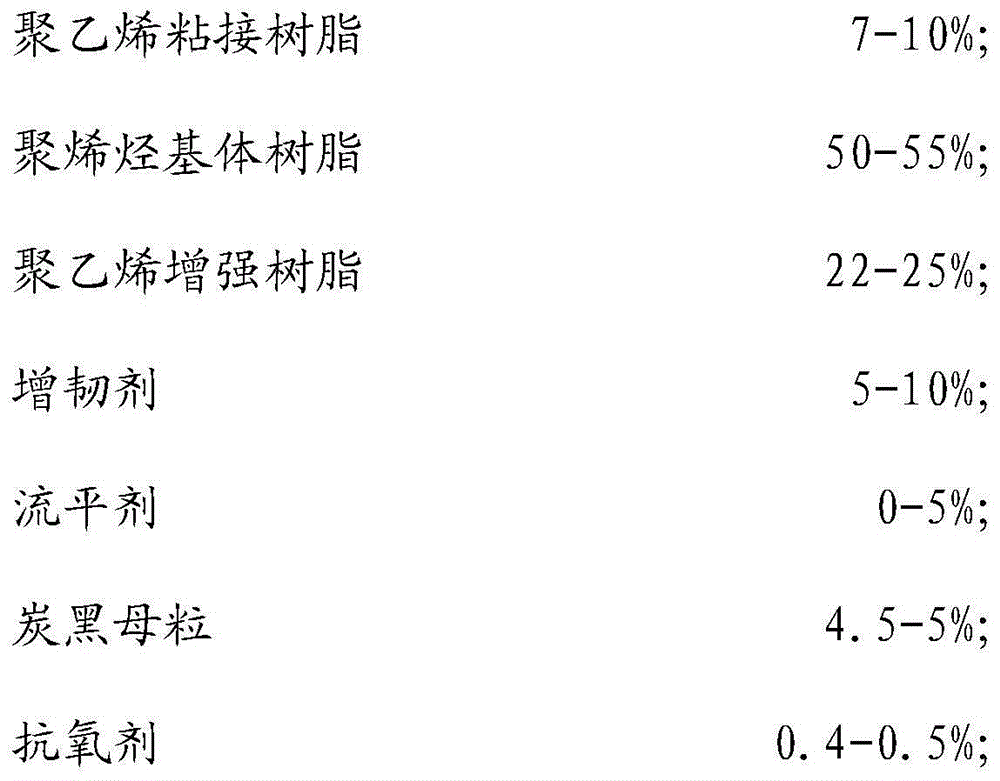

Polyethylene powder for anti-corrosive pipeline and preparation method for polyethylene powder

ActiveCN104610814AGood dry powder fluidityImprove the level ofAnti-corrosive paintsPowdery paintsEpoxyPolyolefin

The invention discloses polyethylene powder for an anti-corrosive pipeline and a preparation method for the polyethylene powder. A double-screw extrusion process is adopted for extrusion blending and granulation, and mechanical grinding is carried out to obtain the polyethylene powder; the polyethylene powder is prepared from the following raw materials by weight percent: 5-10% of polyethylene bonding resin, 25-65% of polyolefin matrix resin, 15-30% of polyethylene reinforced resin, 5-20% of a flexibilizer, 0-10% of a leveler, 4-6% of carbon black masterbatch and 0.1-0.5% of an antioxidant. The powder is good in dry powder fluidity and leveling property, excellent in mechanical property, environmental stress crack resistance, ultraviolet aging resistance and pressure resistance, corrosion-resistant and suitable for a powder spreading process and a flame spraying process, and has very high bonding strength with epoxy powder.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

Special polybutylene alloy pipe material for cold/hot water pipe and preparation method of special polybutylene alloy pipe material

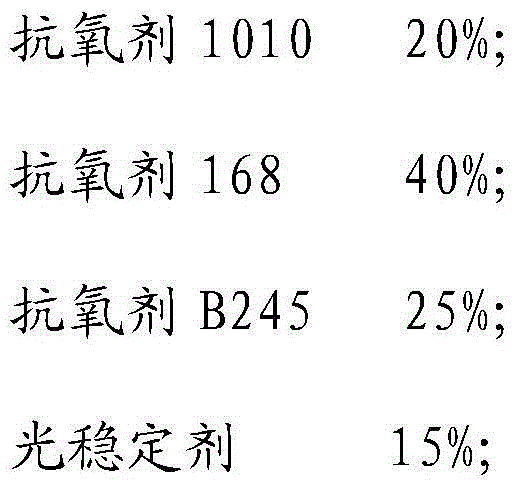

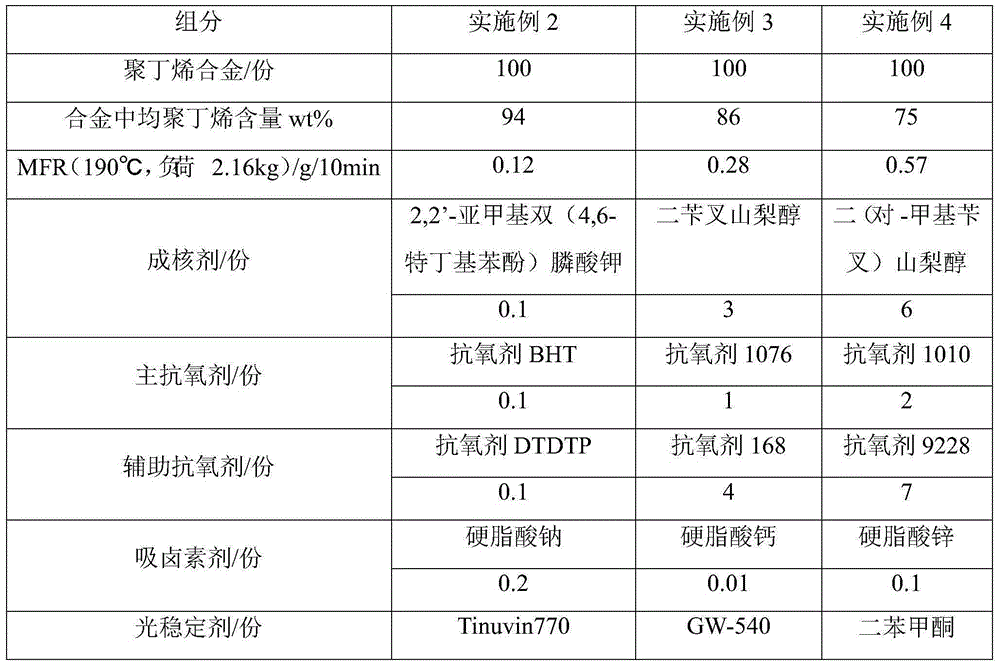

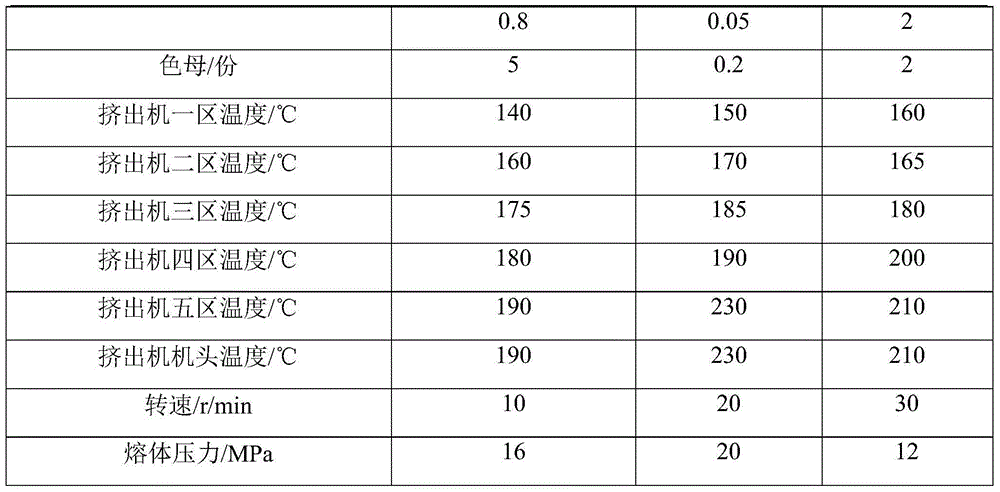

The invention relates to a special polybutylene alloy pipe material for a cold / hot water pipe and a preparation method of the special polybutylene alloy pipe material, belonging to the field of high polymer materials. The special polybutylene alloy pipe material comprises the following components: polybutylene alloy, an antioxidant, a halogen absorber, a light stabilizer, a color masterbatch and a nucleating agent. The preparation method comprises the steps of uniformly mixing the polybutylene alloy, the antioxidant, the halogen absorber, the light stabilizer, the nucleating agent and the color masterbatch by using a high-speed mixer; and extruding and pelleting to obtain the special polybutylene alloy pipe material for the cold / hot water pipe. The tensile strength and bending modulus of the special polybutylene alloy pipe material are greatly improved on the basis that the impact resistance, excellent environment stress crack resistance and thermal creep resistance of polybutylene are kept, and the special polybutylene alloy pipe material can be used as a cold / hot water pipe and pipe fitting material.

Owner:QINGDAO UNIV OF SCI & TECH +2

Toughened high density polyethylene 3D printing moulding material and preparation method thereof

The invention relates to a toughened high density polyethylene which includes high density polyethylene and a toughening master batch. The toughening master batch is prepared from an ethylene-propylene elastomer, butylbenzene elastomer, a diluent, an anti-crosslinking agent and a free radical polymerization initiator. The invention also relates to a preparation method of the toughened high density polyethylene, the toughening master batch, a preparation method of the toughening master batch, an application of the toughening master batch in the toughened high density polyethylene, an application of the toughened high density polyethylene in 3D printing and a 3D printing method. High density polyethylene is toughened with the self-made synthesized toughening master batch. The toughened high density polyethylene is good in heat resistance, has high rigidity and toughness, and is also good in environment stress cracking resistance. An obtained blend, which is formed by blending the toughened high density polyethylene with elastomers, has not only original characteristics but also a relative high rigidity conservation rate when toughness of the obtained blend is significantly increased, so that the blend is suitable for 3D printing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Fire suppression fluid containing a carboxylate salt

InactiveUS20140138105A1Low viscosityInhibit flammabilityFire rescueHeat-exchange elementsCarbon numberFire sprinkler

An aqueous fire sprinkler fluid containing low carbon number carboxylate salts for freezing point depression is described. The salts may be used in conjunction with glycols. The salts decrease the combustibility of the glycol containing fluids and give lower viscosity than higher glycol fluids, both benefitting fire sprinkler systems. These salt solutions are friendly to metal and CPVC pipes and are thus useful for fire sprinkler systems by not causing environmental stress cracking of the CPVC components and not being corrosive to the metal parts.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Polyethylene composite for drip irrigation pipes

ActiveCN103665508AHigh strengthGood flexibilityClimate change adaptationWatering devicesLow-density polyethyleneAntioxidant

The invention discloses a polyethylene composite for drip irrigation pipes, belongs to the technical field of high polymer materials, and particularly relates to a polyethylene composite. The polyethylene composite is characterized by comprising the following components in parts by weight: 40-60 parts of high-density polyethylene resin, 20-30 parts of high-pressure polyethylene resin, 10-30 parts of metallocene polyethylene resin, 0.15-1.2 parts of antioxidant, and 1.2-3 parts of carbon black. The composite, besides having good strength, flexibility, processability and aging resistance, has excellent abrasion resistance, ESCR (environmental stress cracking resistance) and puncture resistance and good high-temperature hydrostatic performance.

Owner:CHINA PETROLEUM & CHEM CORP

Polyethylene moulding composition with improved stress crack/stiffness relationship and impact resistance

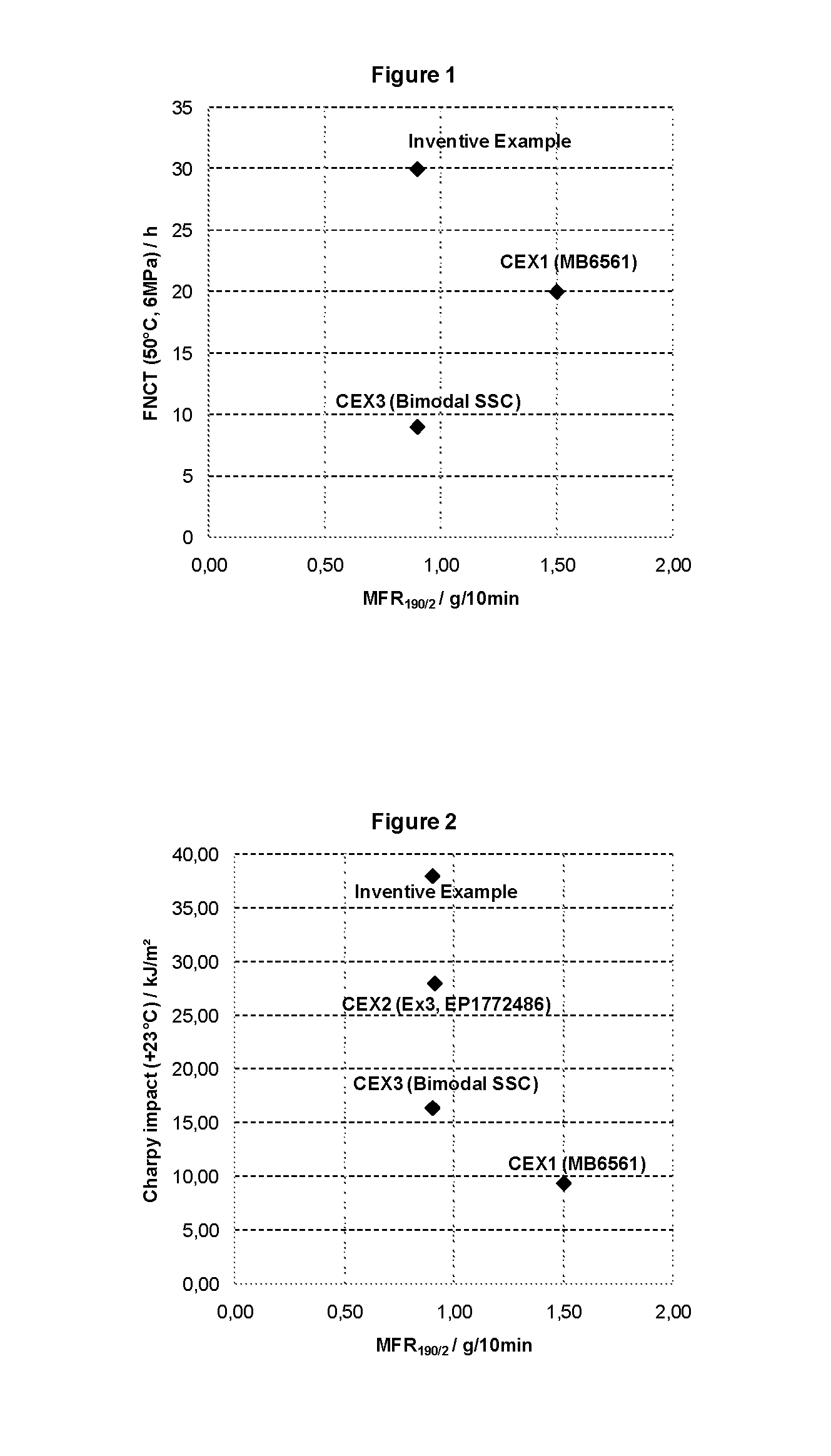

ActiveUS8759448B2Improve performanceImprove mechanical propertiesPolymer scienceEthylene Homopolymers

A high density polyethylene moulding composition having a multimodal molecular weight distribution, having a density according to ISO 1183 at 23° C. in the range of 945 to 965 kg / m3 and an MFR190 / 2 according to ISO 1133 in the range of 0.05 to 25 g / 10 min, said polyethylene moulding composition comprising at least three ethylene polymer fractions having distinct molecular weights: A) 15 to 50 wt % of a low molecular weight ethylene homopolymer fraction with a weight average molecular weight Mw in the range of 15 to 40 kg / mol; B) 15 to 50 wt % of a medium molecular weight ethylene homopolymer fraction with a weight average molecular weight Mw in the range of 70 to 180 kg / mol; and C) 15 to 50 wt % of a high molecular weight ethyleve copolymer fraction with a weight average molecular weight Mw in the range of 200 to 400 kg / mol; and wherein the composition has: a tensile modulus according to ISO 527-2: 1993 measured on compression moulded samples of at least 800 MPa; a Charpy impact strength CIS (23° C.) according to ISO 179:2000 measured on V- notched samples produced by compression moulding of at least 30 kJ / m2; and an environmental stress crack resistance ESCR measured as FNCT full notch creep test according to ISO / DIS 16770.3 at 50° C. and 6 MPa of at least 20 h.

Owner:BOREALIS AG

HDPE (high-density polyethylene) cable sheath material

ActiveCN103304879AImprove toughnessWidely producedPlastic/resin/waxes insulatorsMasterbatchPolymer science

The invention relates to an HDPE (high-density polyethylene) cable sheath material. The HDPE cable sheath material comprises the following components in parts by weight: 100 parts of HDPE, 0.1-5 parts of melt viscosity modifier, 0.01-2 parts of heat stabilizer, 0.01-10 parts of white oil, 1-80 parts of toughener, 0.01-10 parts of carbon black masterbatch, 0.01-10 parts of antioxidant and 0.01-10 parts of nucleating agent; the melt flow rate of a product is more than 10g / 10min, which is greatly improved in comparison with the melt flow rate of 0.1-0.3g / 10min of the existing cable sheath material; the elongation rate is 500%, which is greatly improved in comparison with the elongation rate of 23% of the existing HDPE; the tensile strength is 10-20MPa, and the density is 0.959-0.965g / cm<3>; the brittle temperature of the product is -70 DEG C, the volume resistivity is more than 2*1016 omega.cm, the breakdown strength is 20KV / mm, and the resistance to environmental stress cracking is not less than 50h; and the product has the advantages of good toughness, aging resistance and resistance to chemical corrosion, and can be widely produced and used for continuously replacing existing materials.

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

Process for preparing foamed filling mother material of EVA (ethylene-acetate ethylene copolymer)

The invention relates to EVA sparking filling mother material that contains 70-83wt% filler, 5-20wt% carrier resin, and function assistant agent 5-21wt%. It could be formed by the following steps: taking first cladding by lubricating dispersing agent; taking second to the filler under the condition of whisking the modifier; taking the third cladding to the filler with carrier resin; pouring the mixture into the co-direction twin-screw granulator to take plasticizing, graining, hot cutting, cooling to gain EVA sparking filling mother material. Using 20wt% the material to make EVA resin sparking products would cost low, and have high wear resistance, smoothing appearance, and have good economic value.

Owner:上海心尔新材料科技股份有限公司

Polyethylene composition for rotational moulding and preparation method of polyethylene composition

The invention relates to a polyethylene composition for rotational moulding and a preparation method of the polyethylene composition. The polyethylene composition has excellent combination property and can simultaneously improve rigidity, toughness and environment stress cracking resistance of a material. The polyethylene composition comprises the following components in parts by weight: 100 parts of linear low density polyethylene, 0.1-1 part of surface modification nano carbon fiber, 0.05-1 part of antioxygen and 0.1-1 part of light stabilizer. The preparation method of the polyethylene composition is as follows: firstly, carrying out surface modification on nano carbon fiber with a surface modifier; and then carrying out fusing granulation on low density polyethylene resin, the surfacemodification nano carbon fiber, the light stabilizer and the antioxygen with a double-screw extruder, so as to obtain the polyethylene composition for the rotational moulding. In the polyethylene composition for the rotational moulding provided by the invention, the stretching strength, bending strength, impact property and environment stress cracking resistance are improved at different degrees,thereby achieving the effect of simultaneously increasing rigidity and toughness, and realizing excellent combination properties for the material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com