Patents

Literature

106 results about "Thermal creep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal Creep is a condition where the actual water temperature is higher than the set temperature.

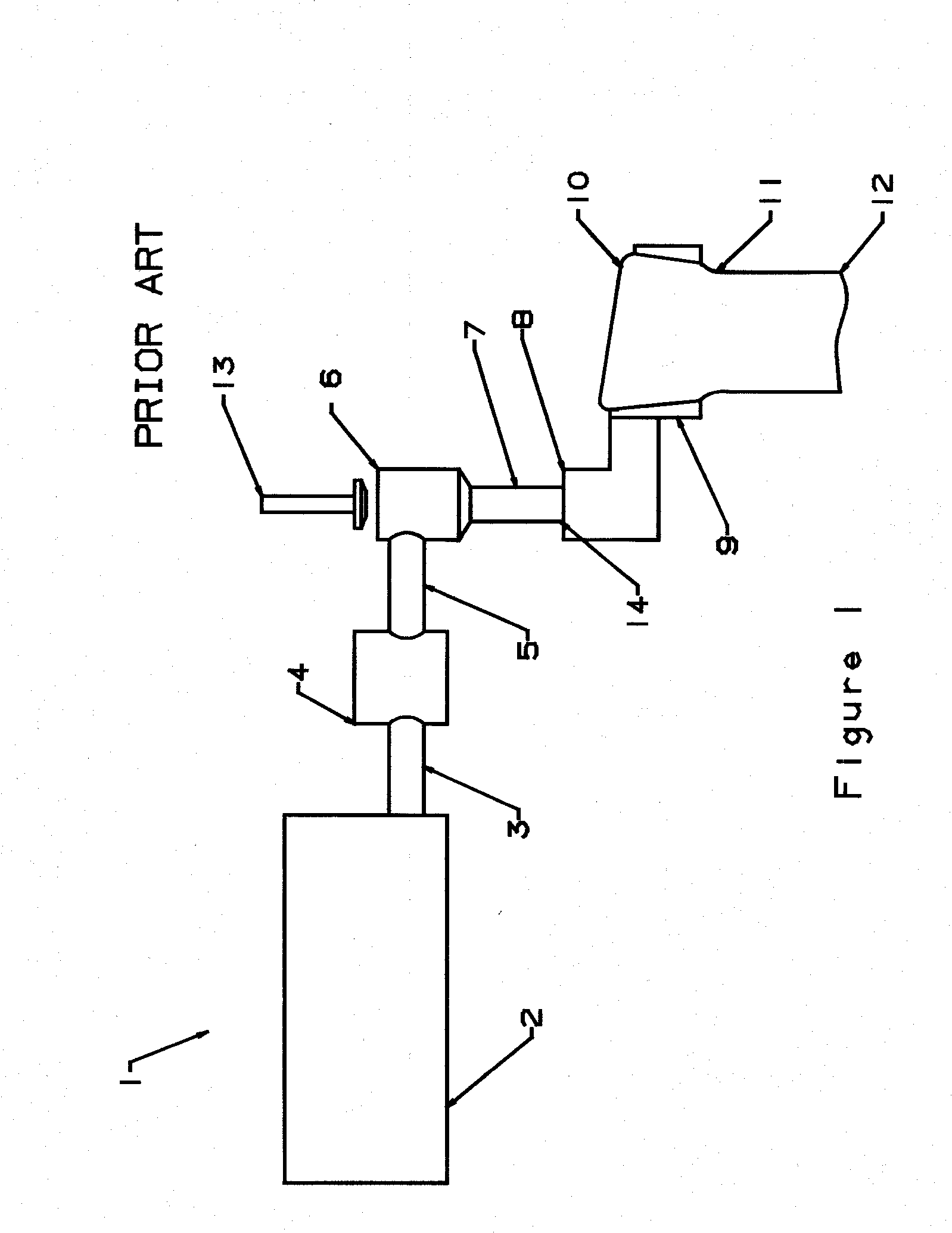

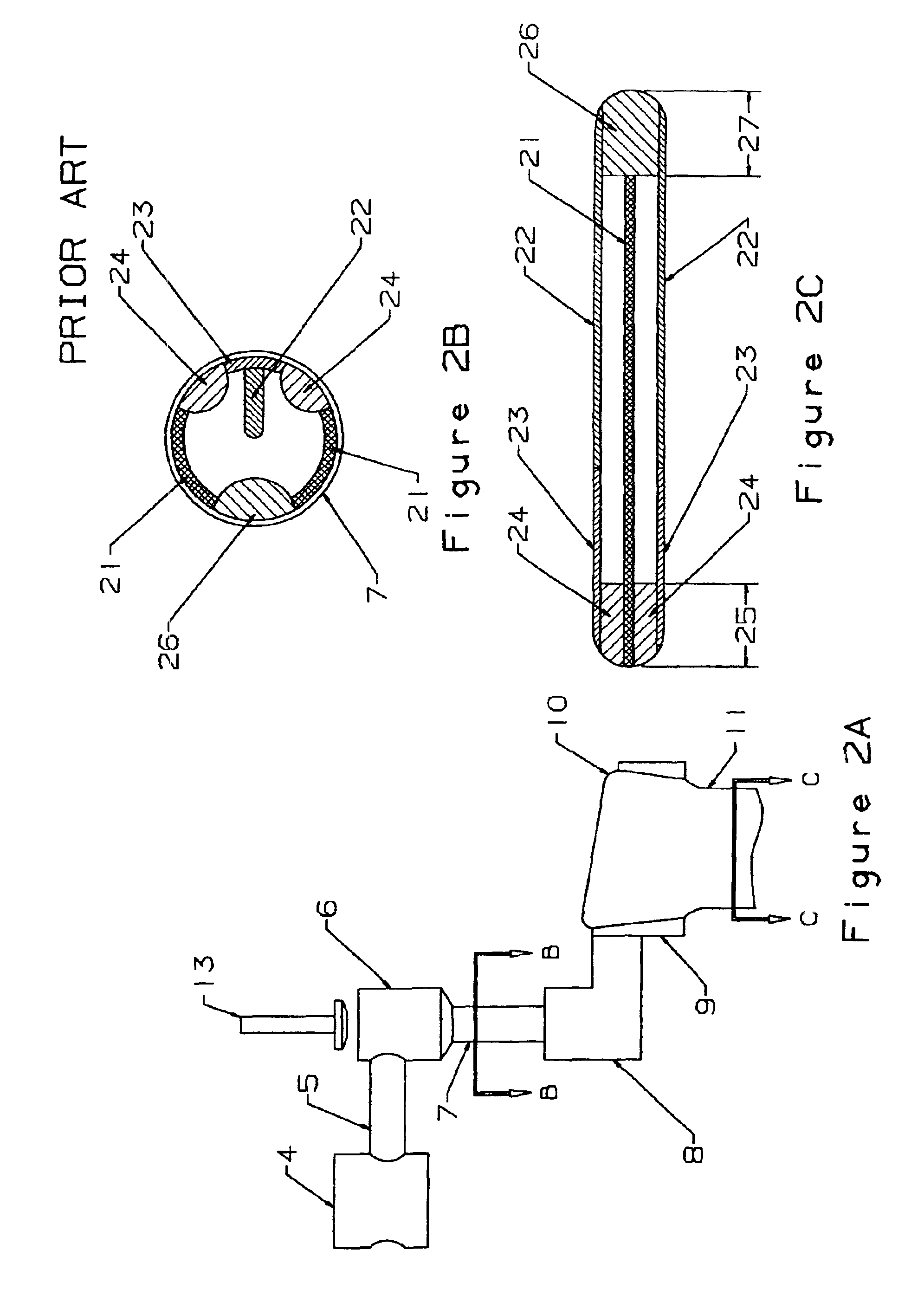

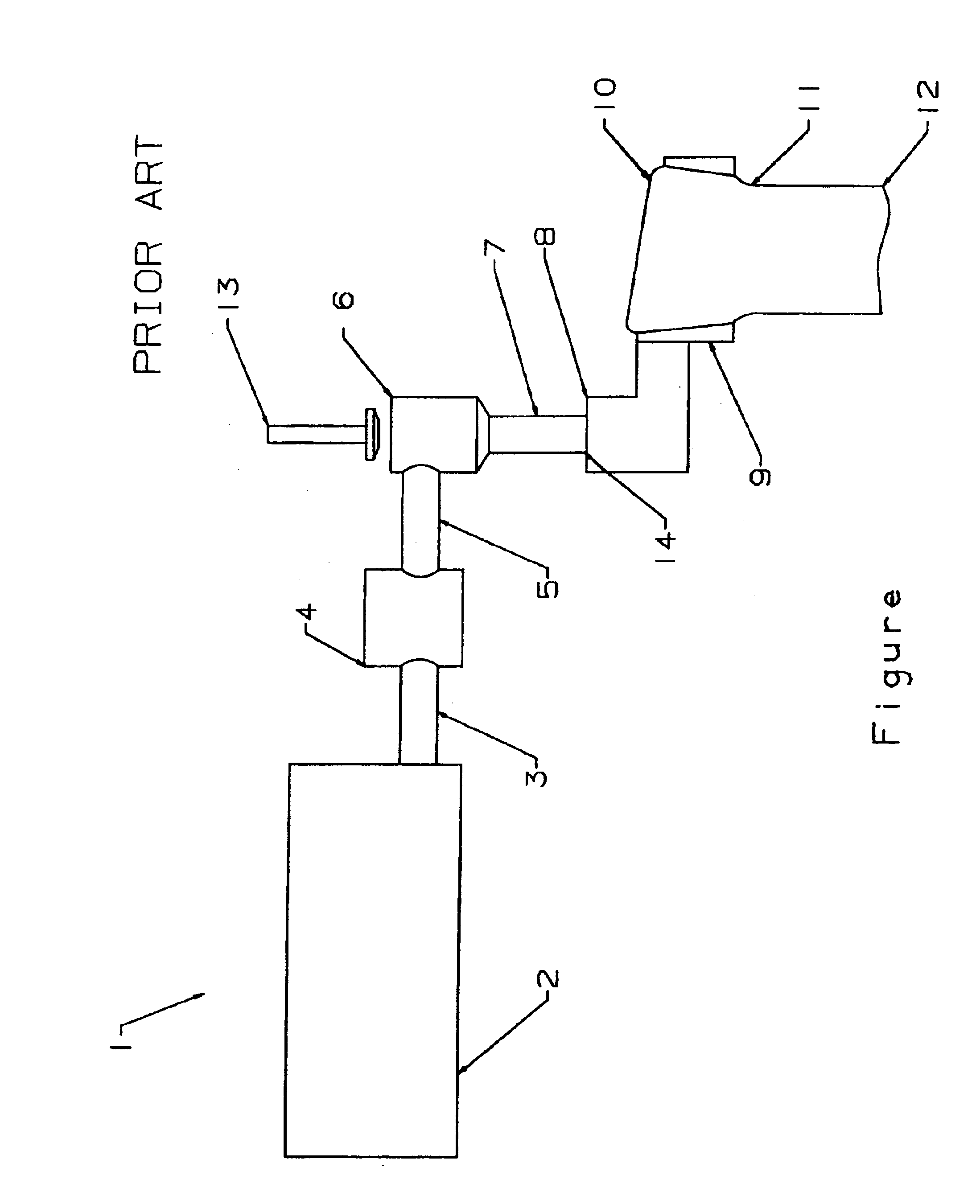

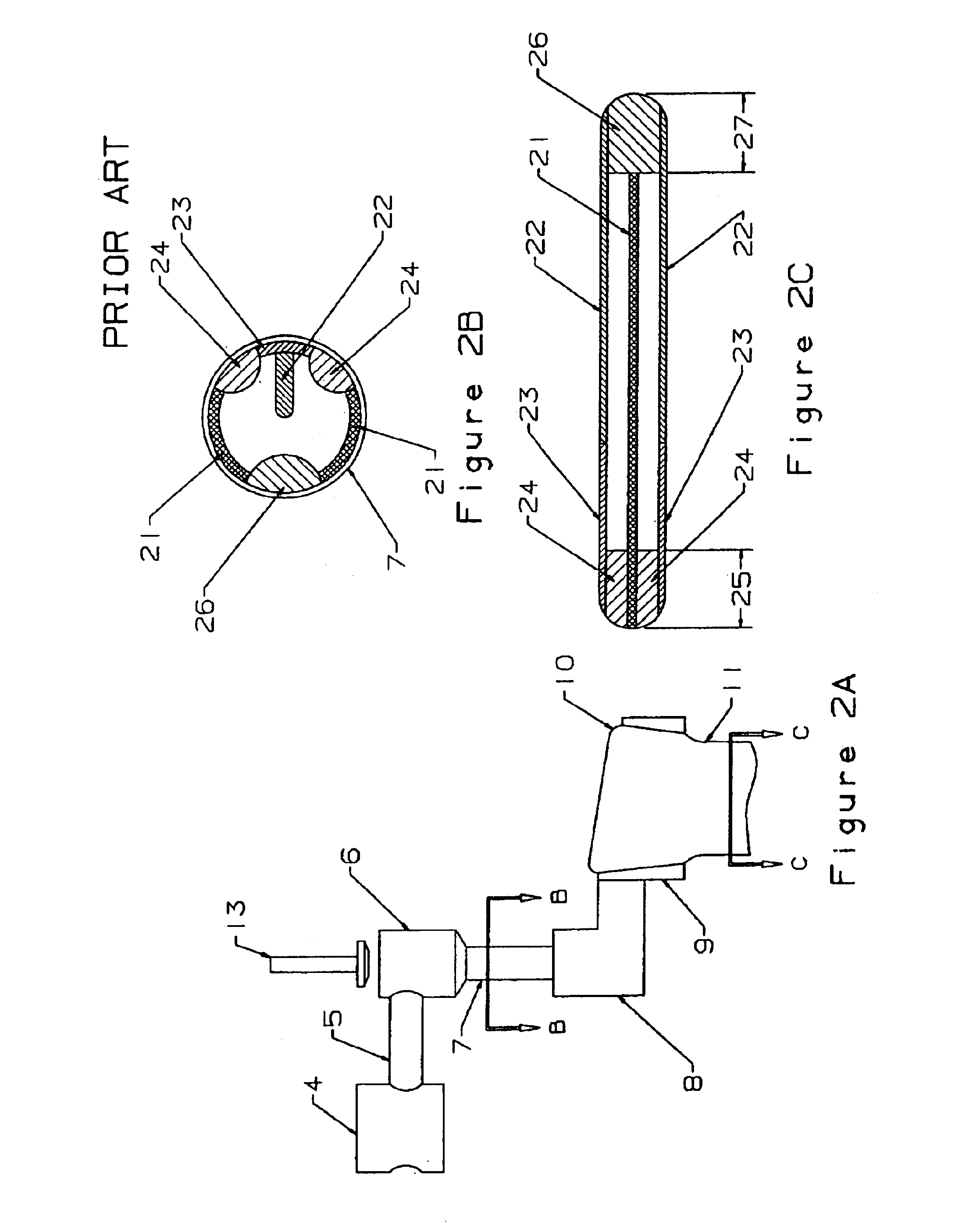

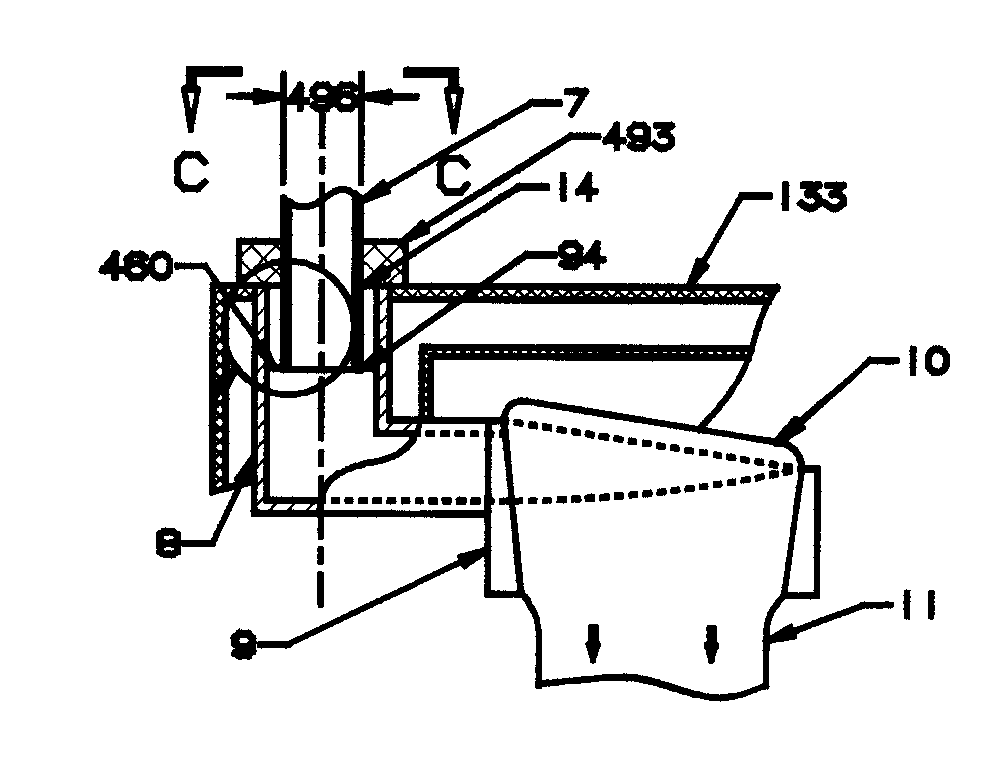

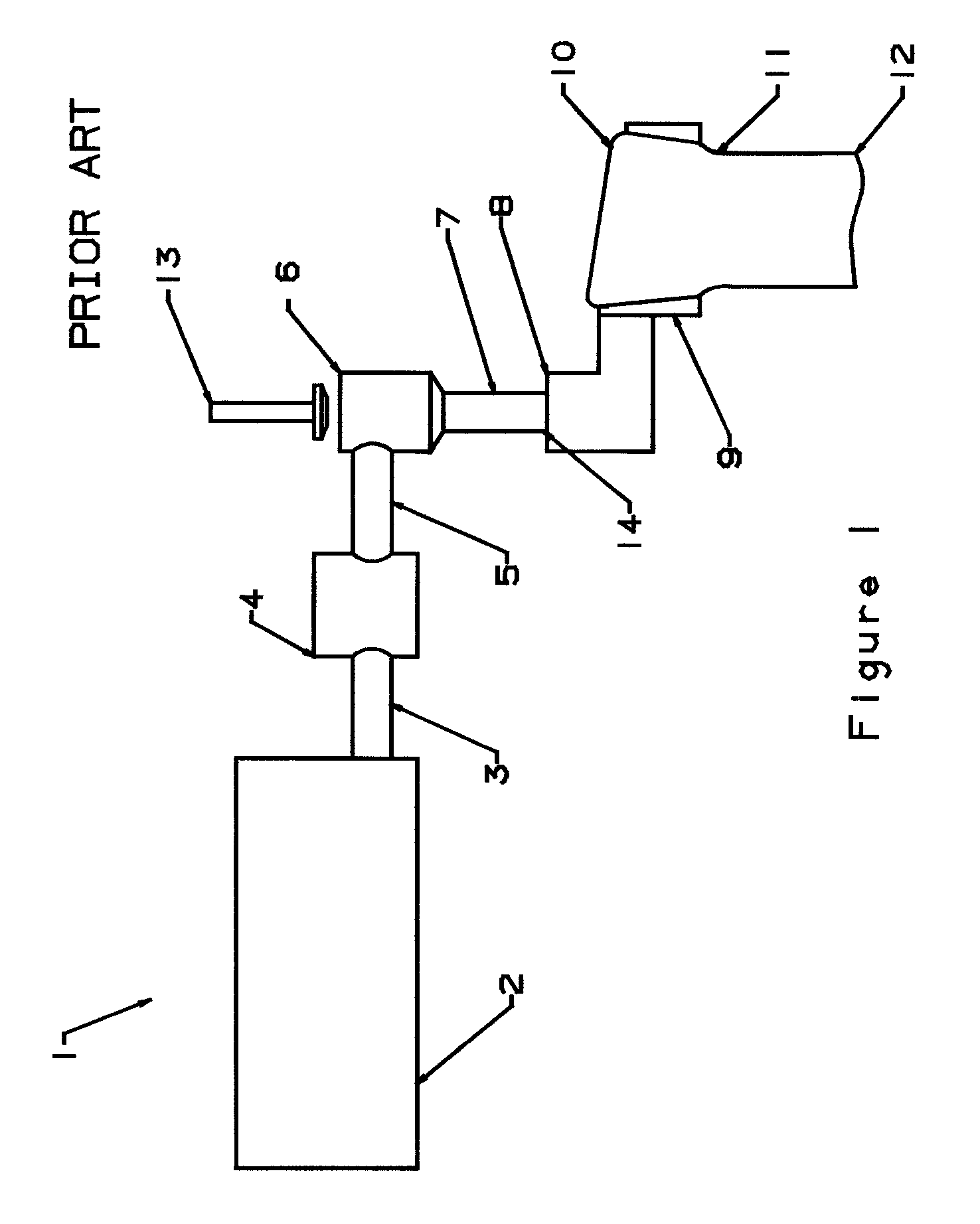

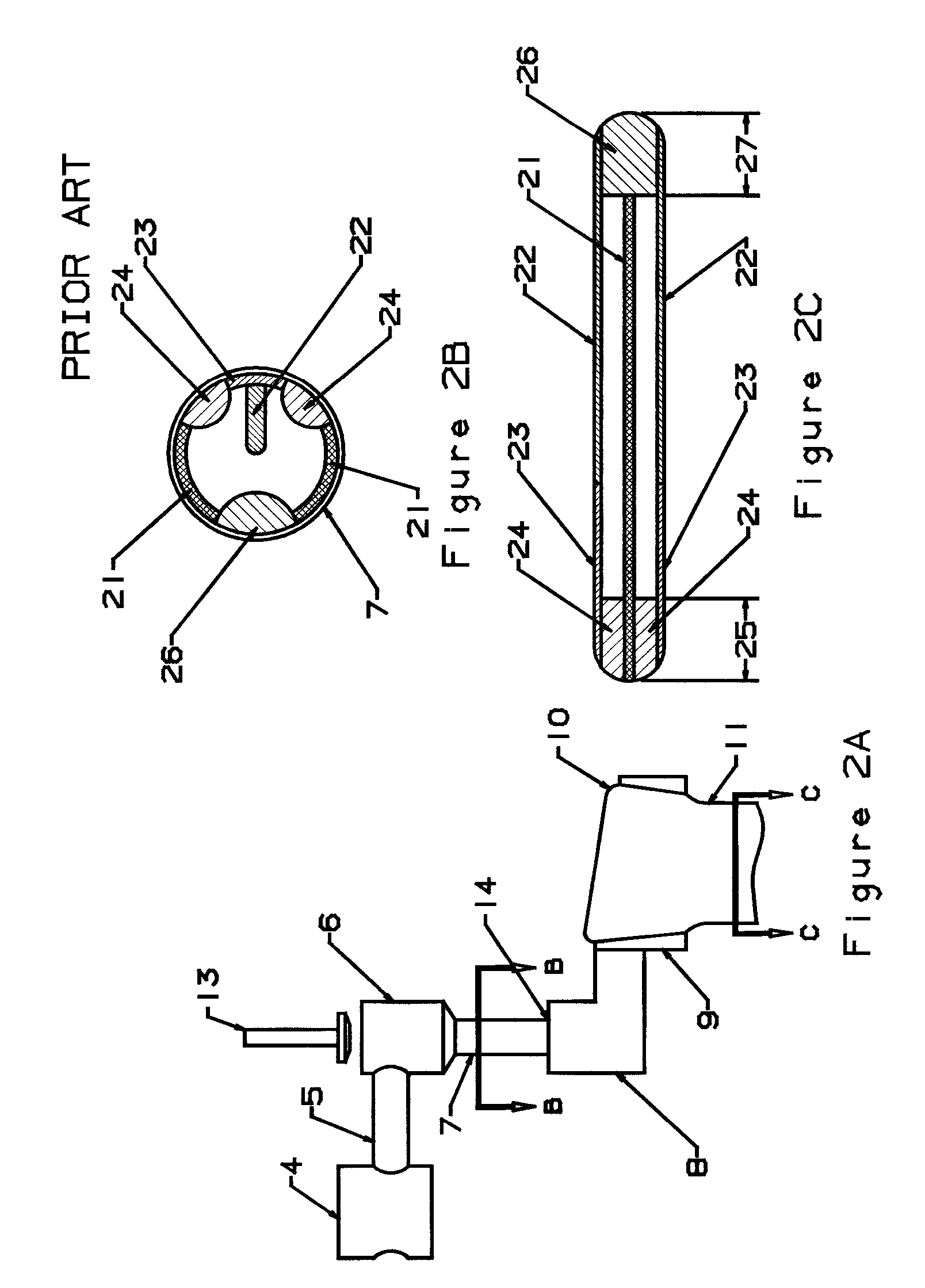

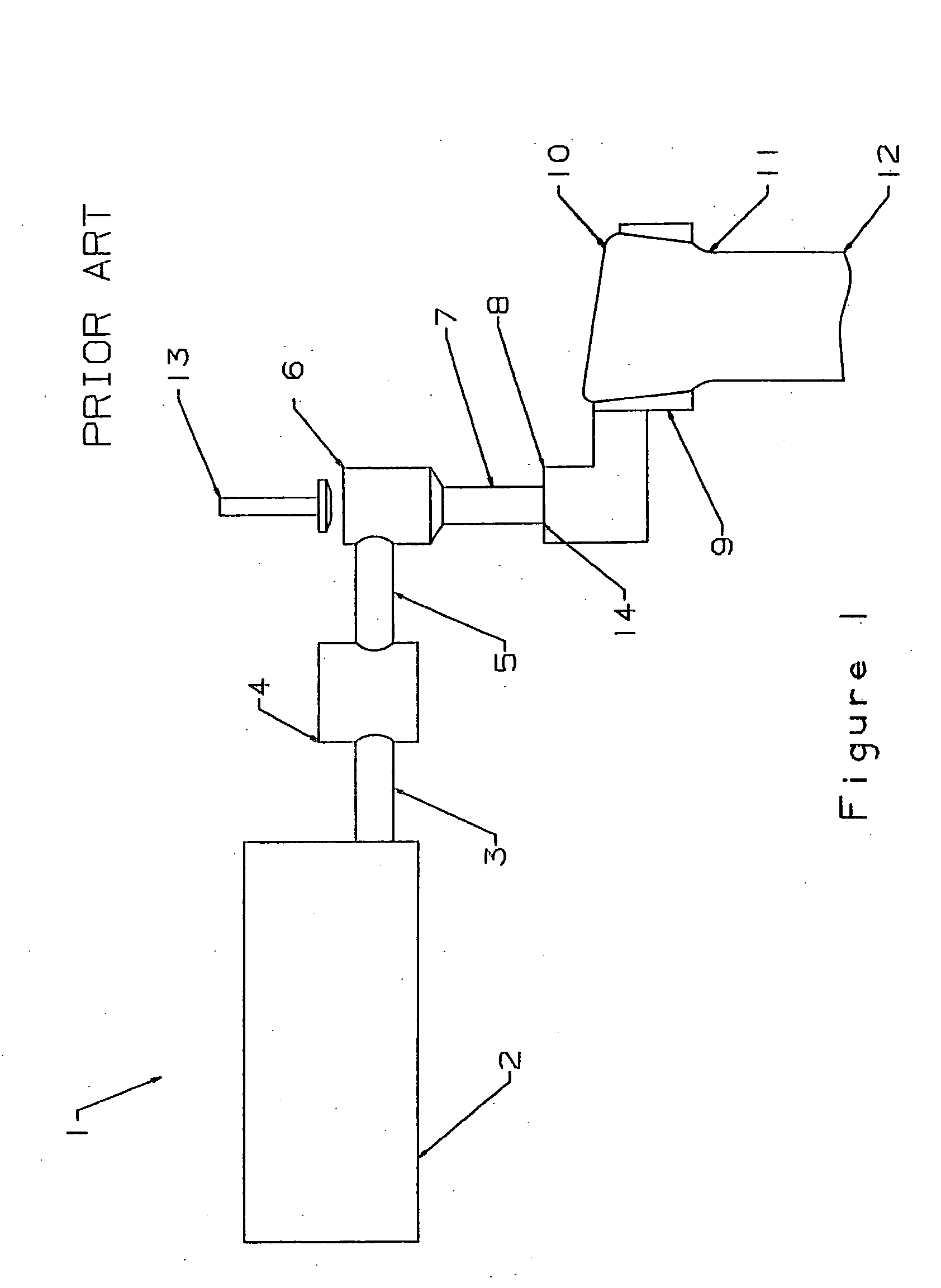

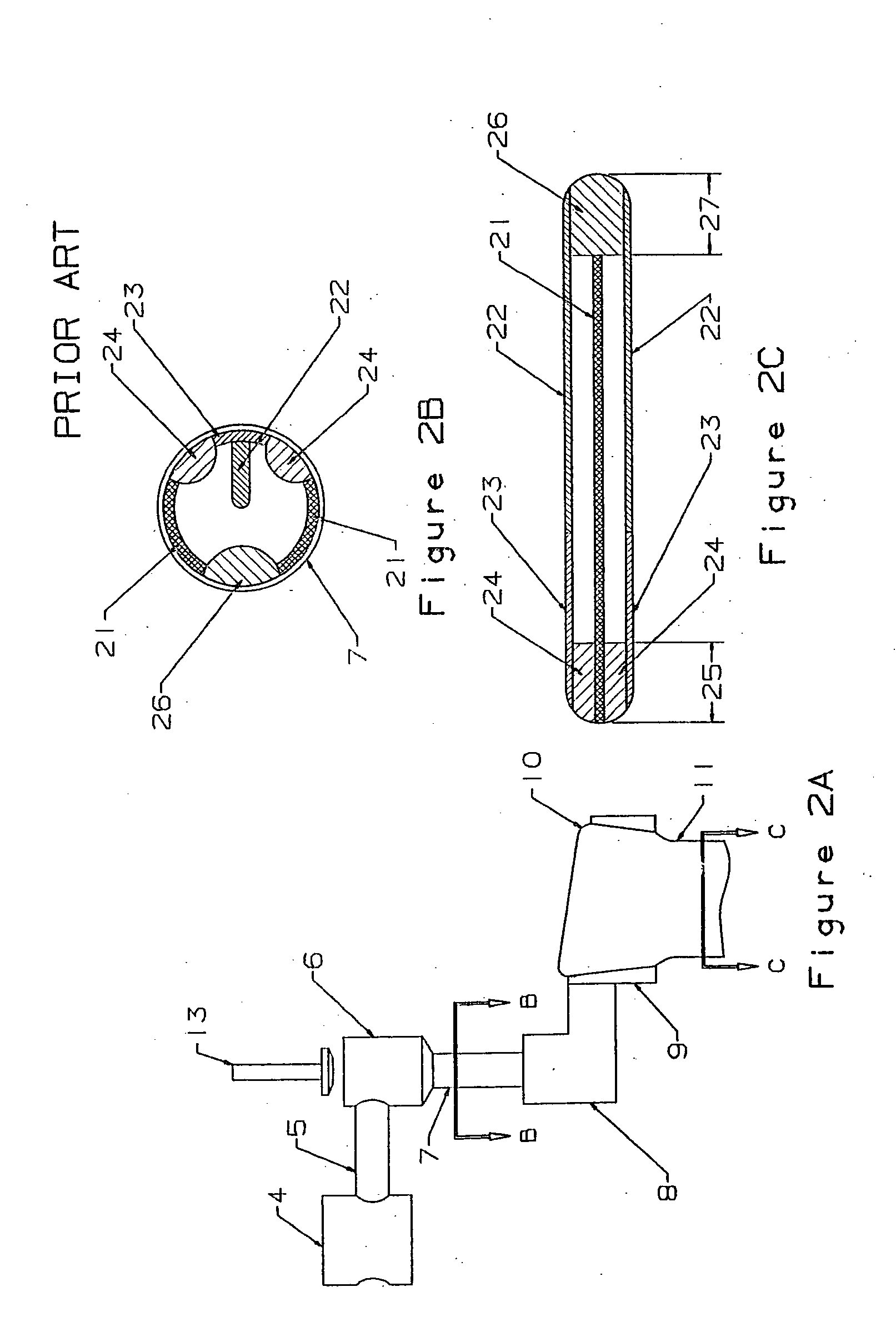

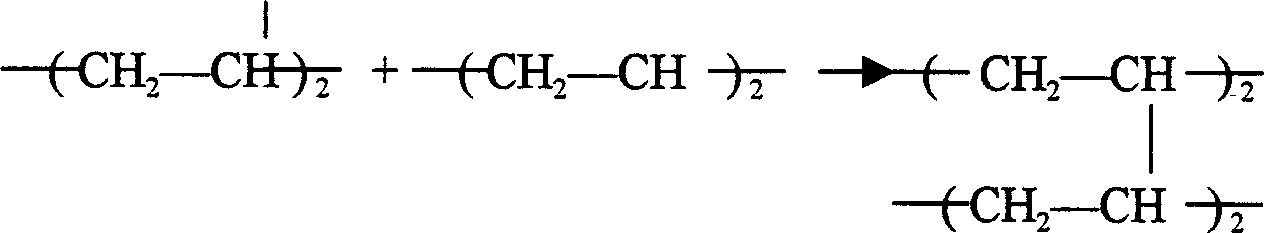

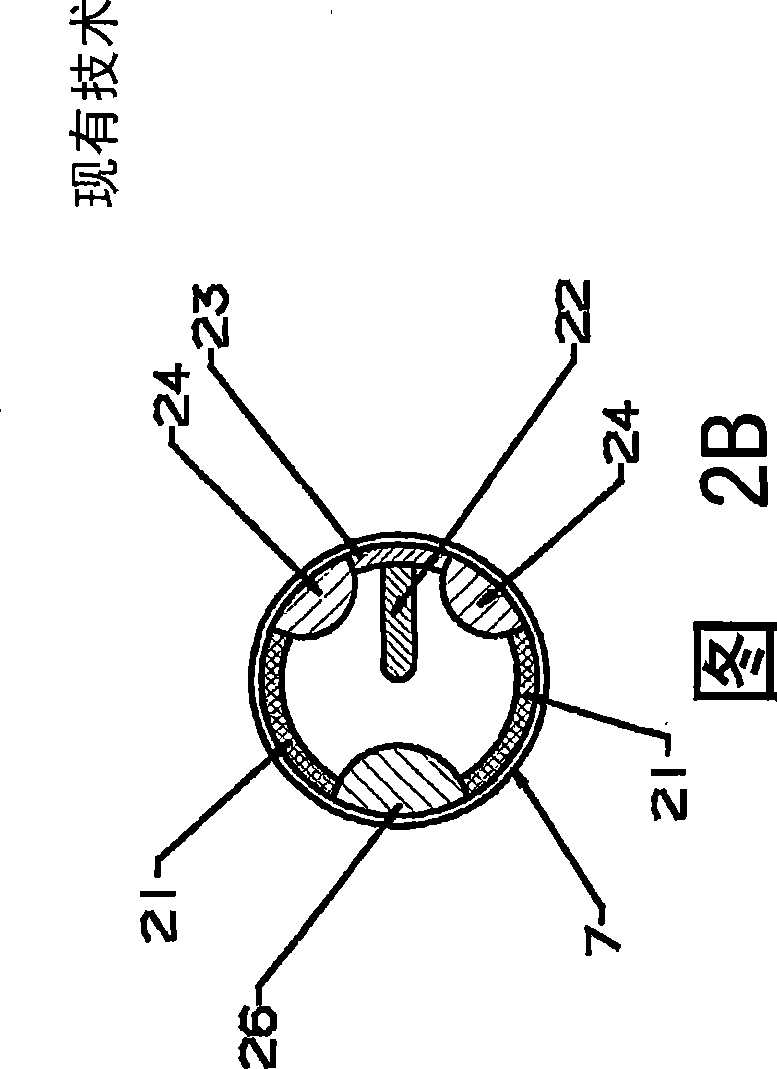

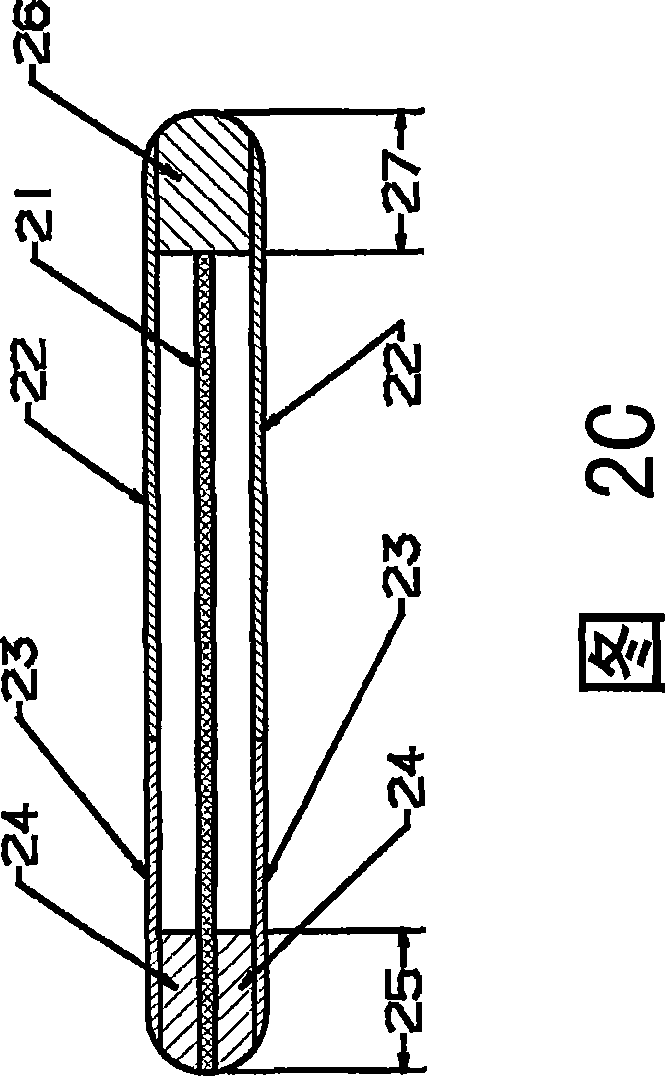

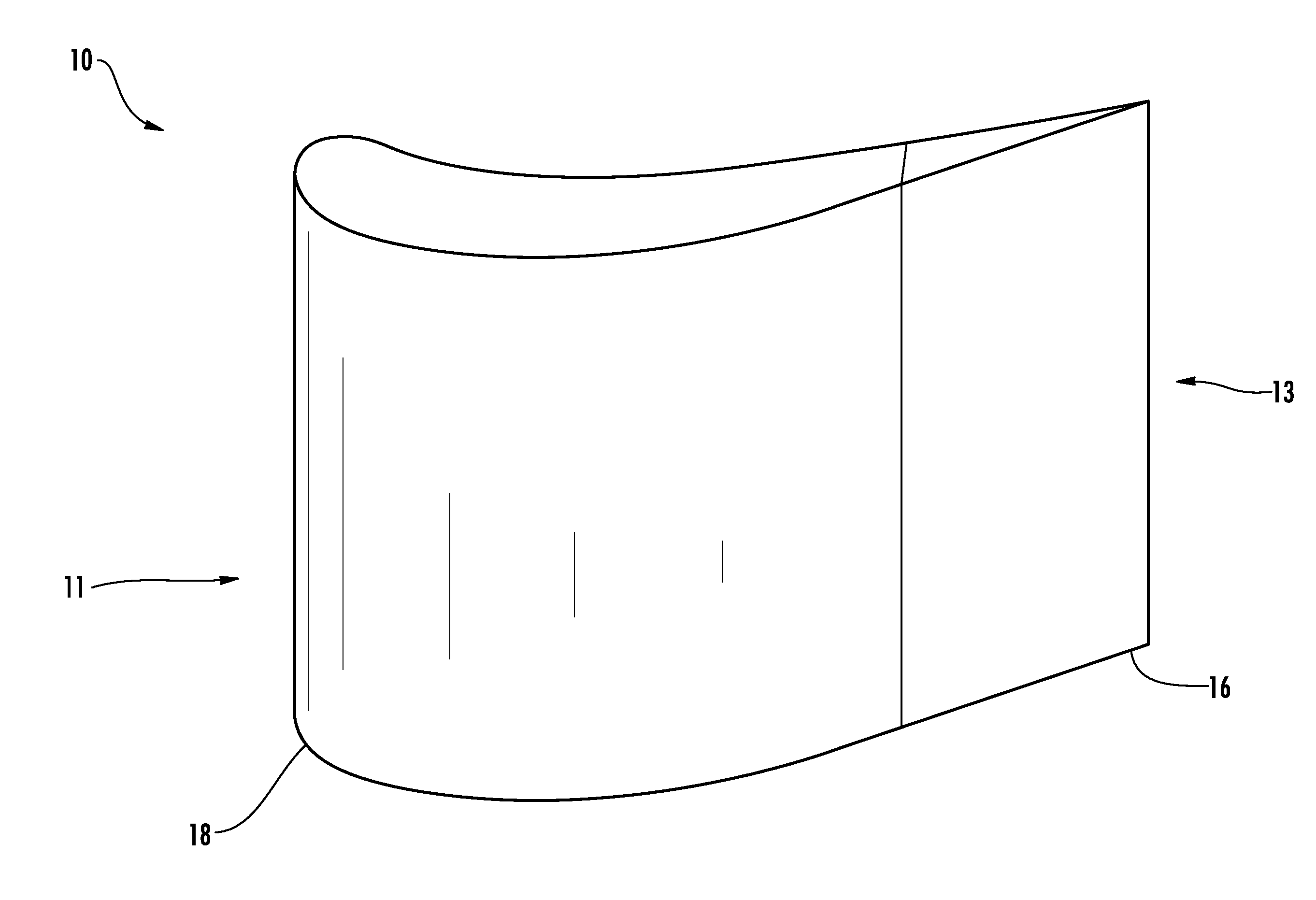

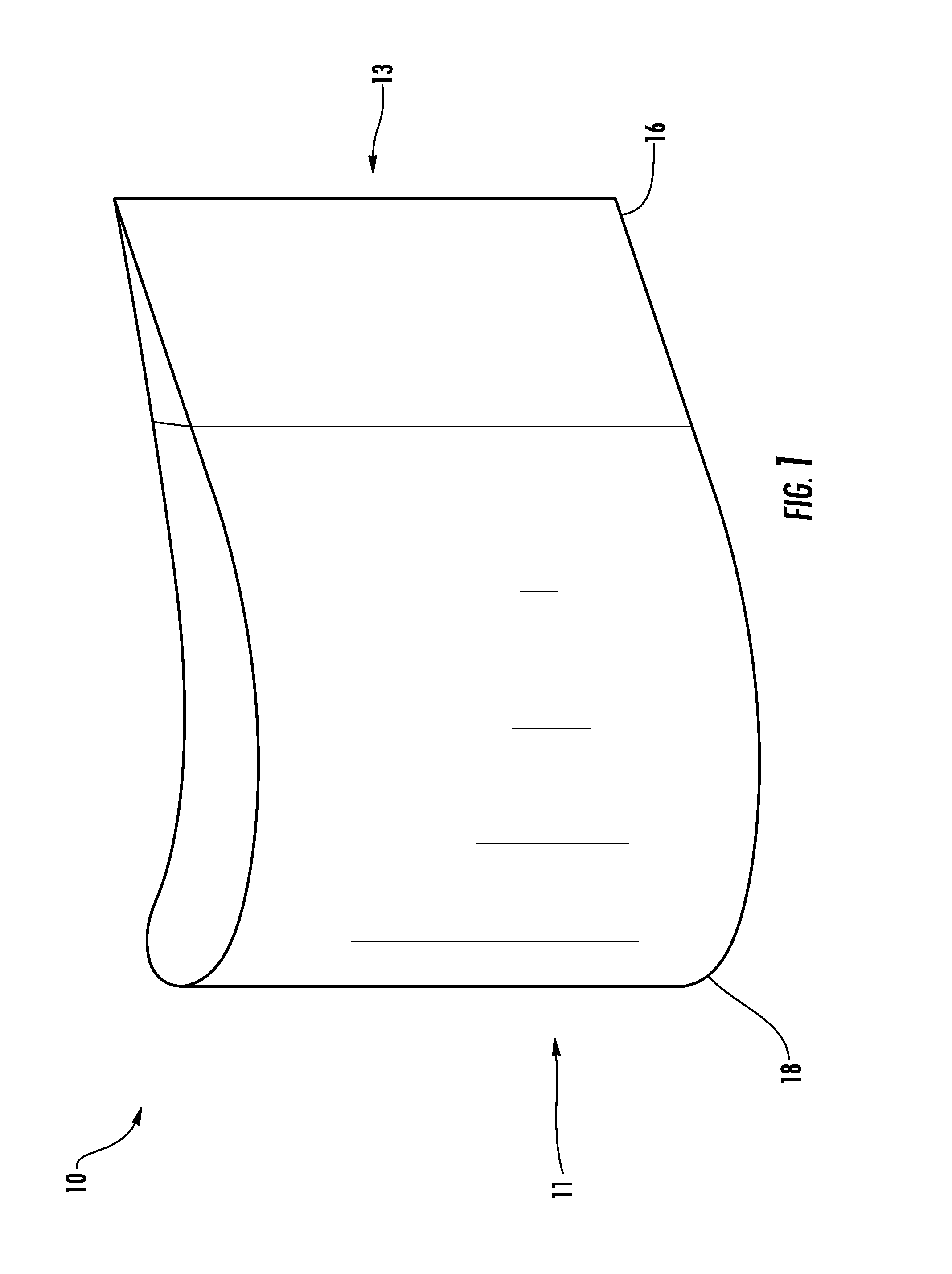

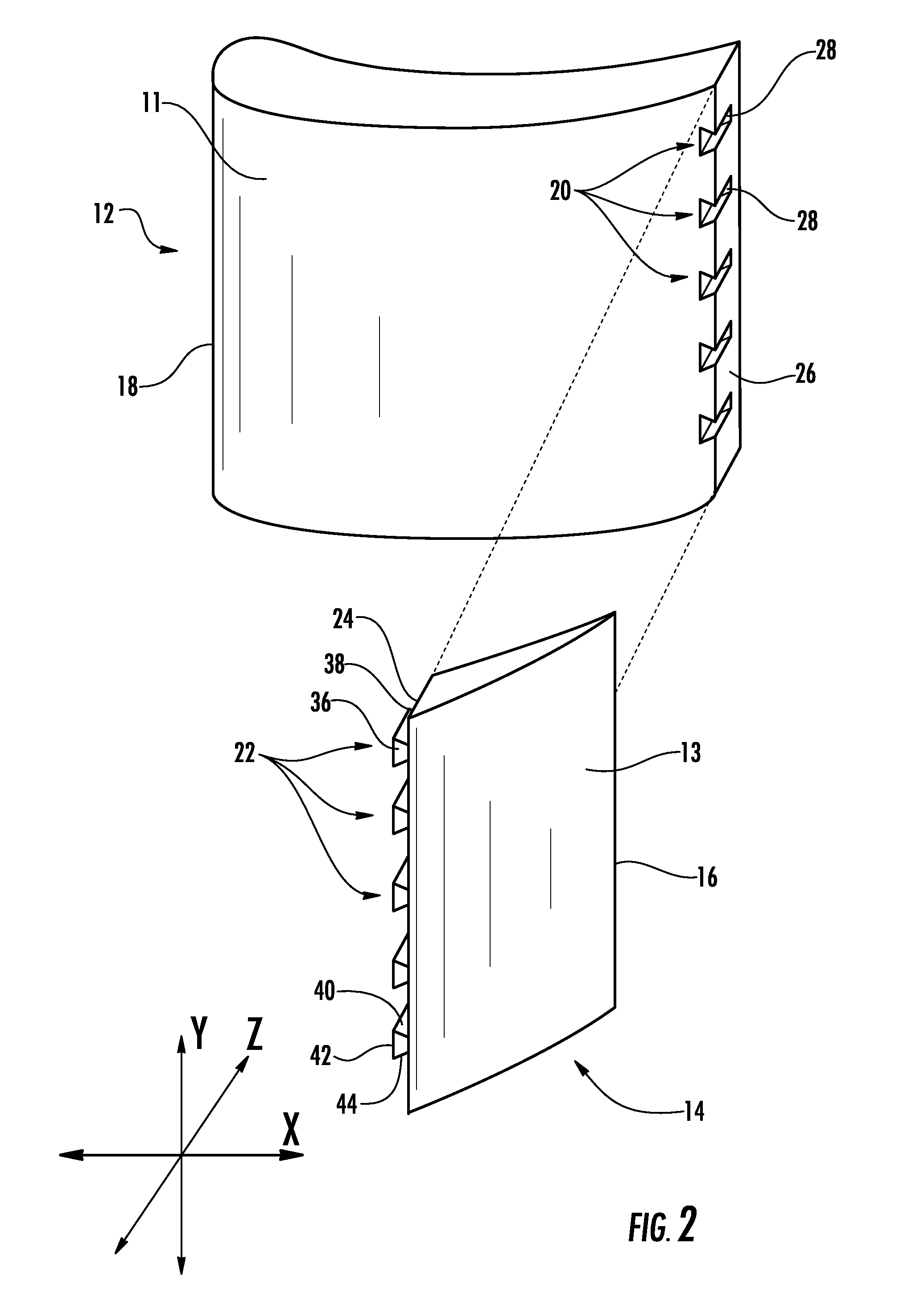

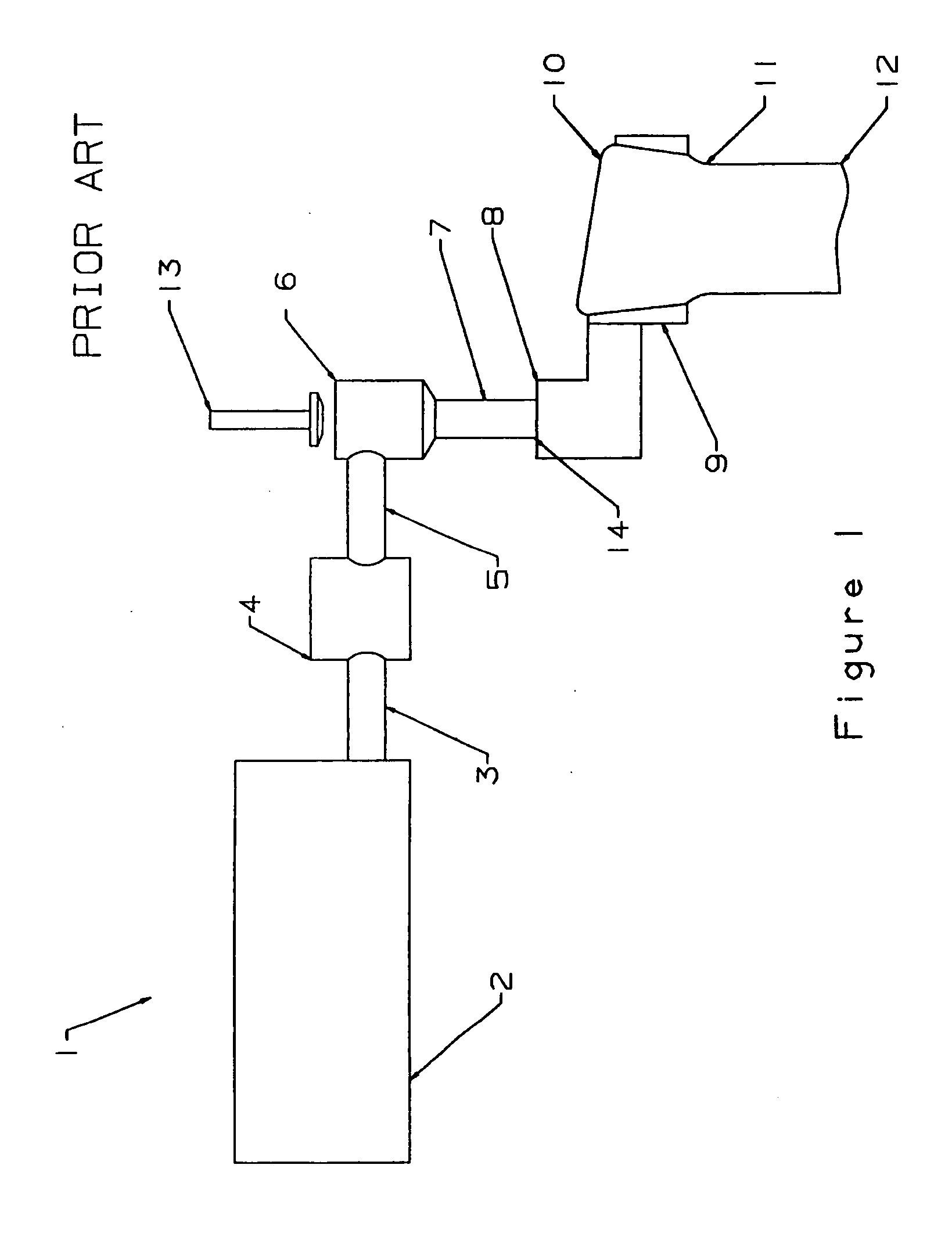

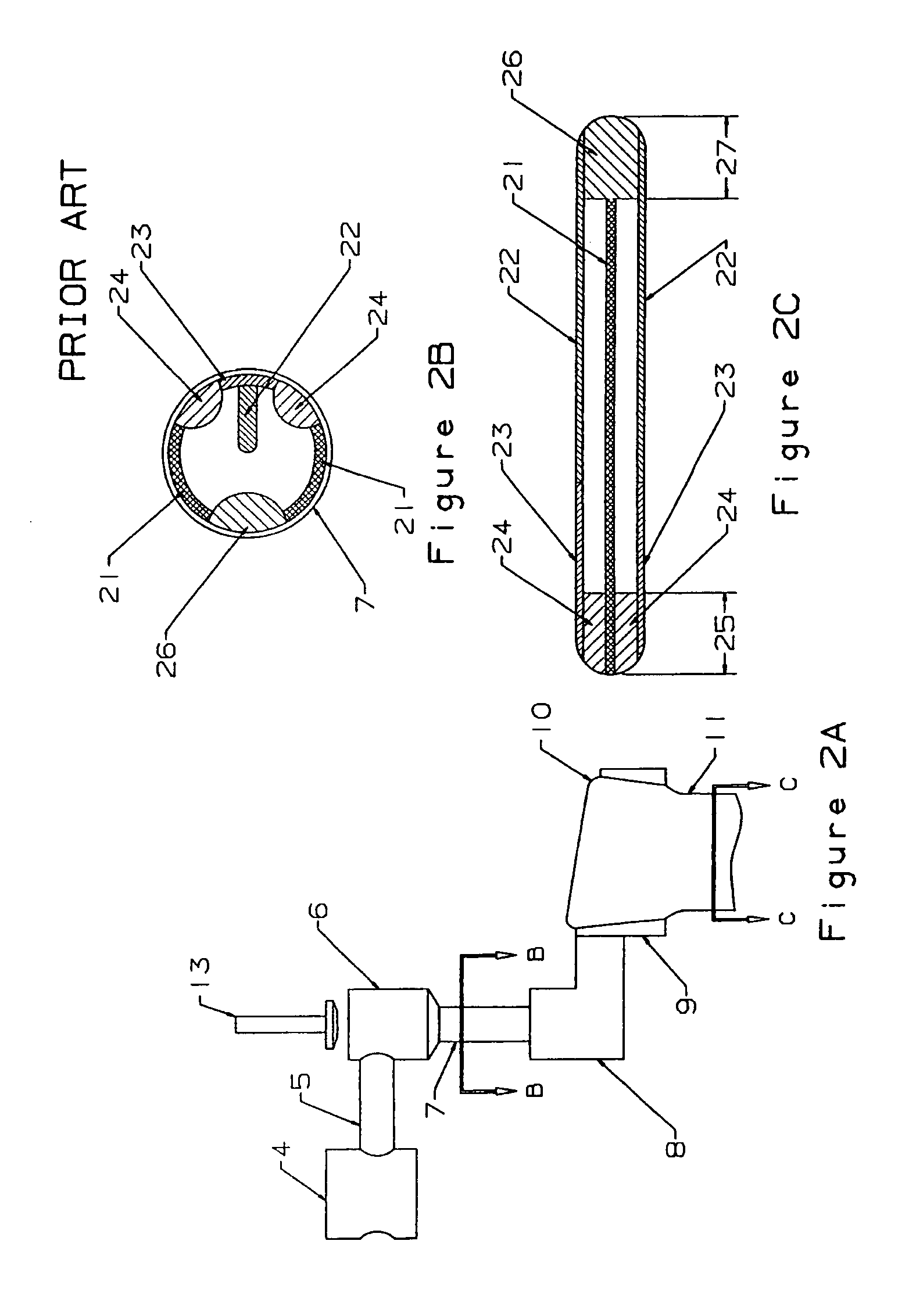

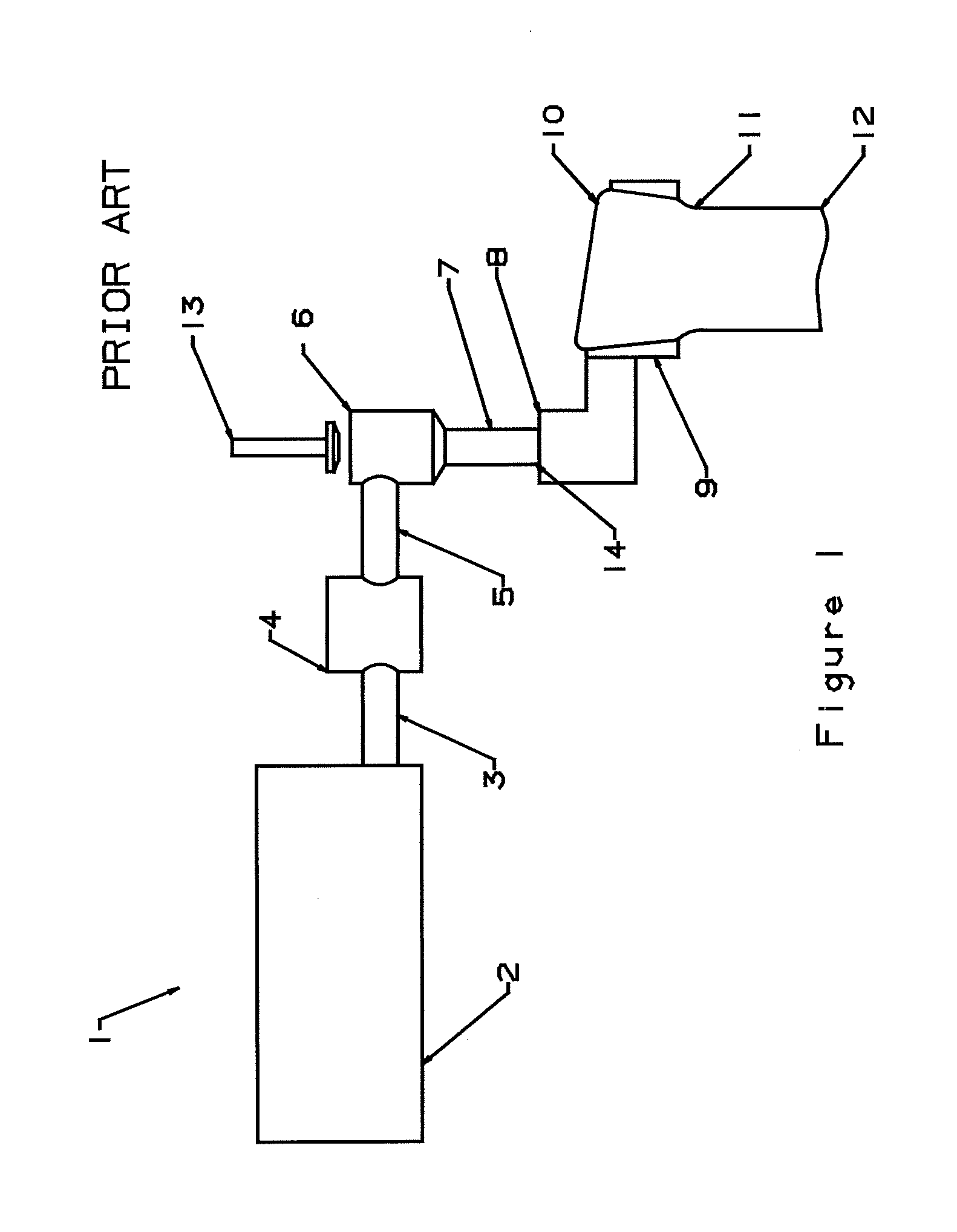

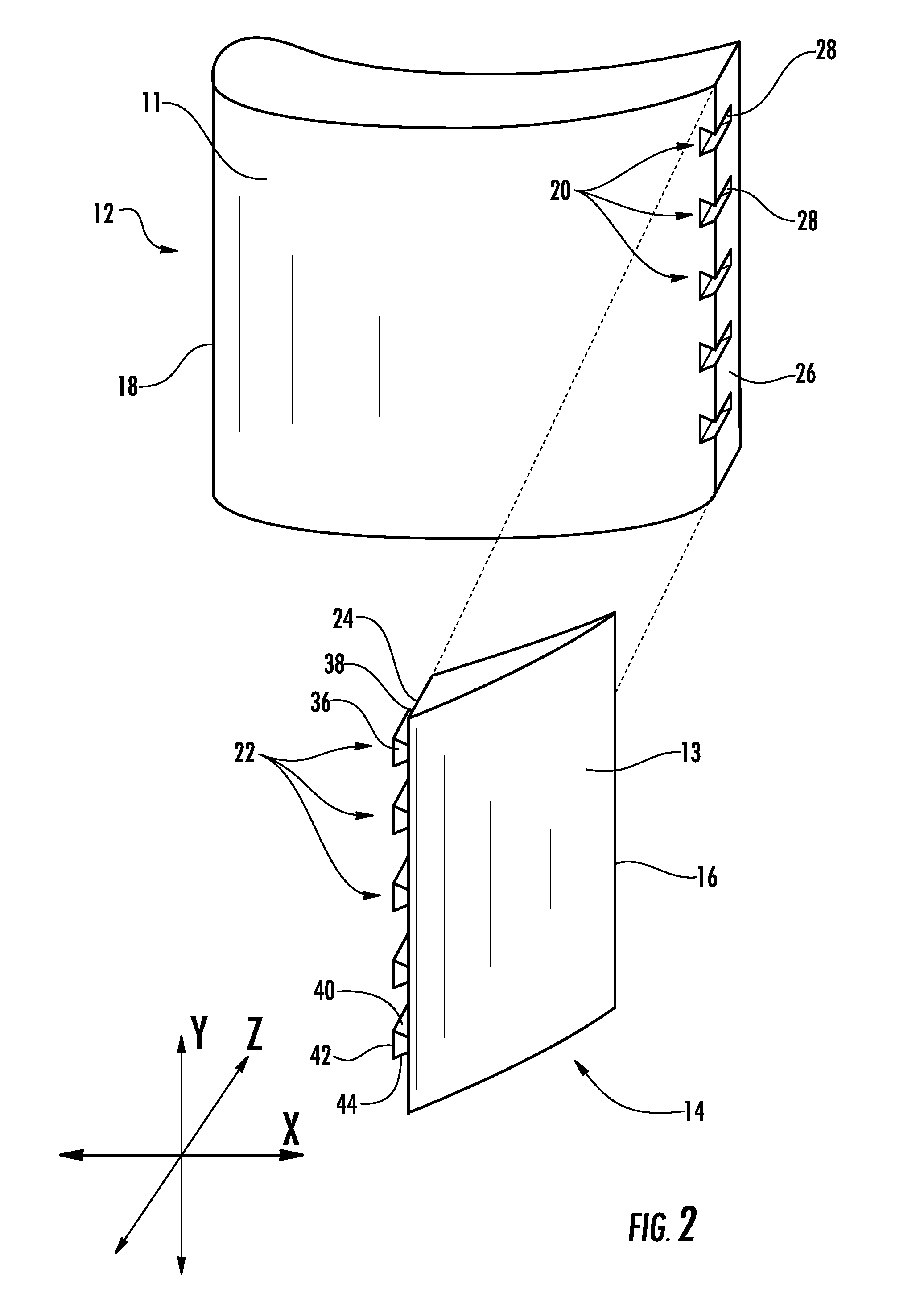

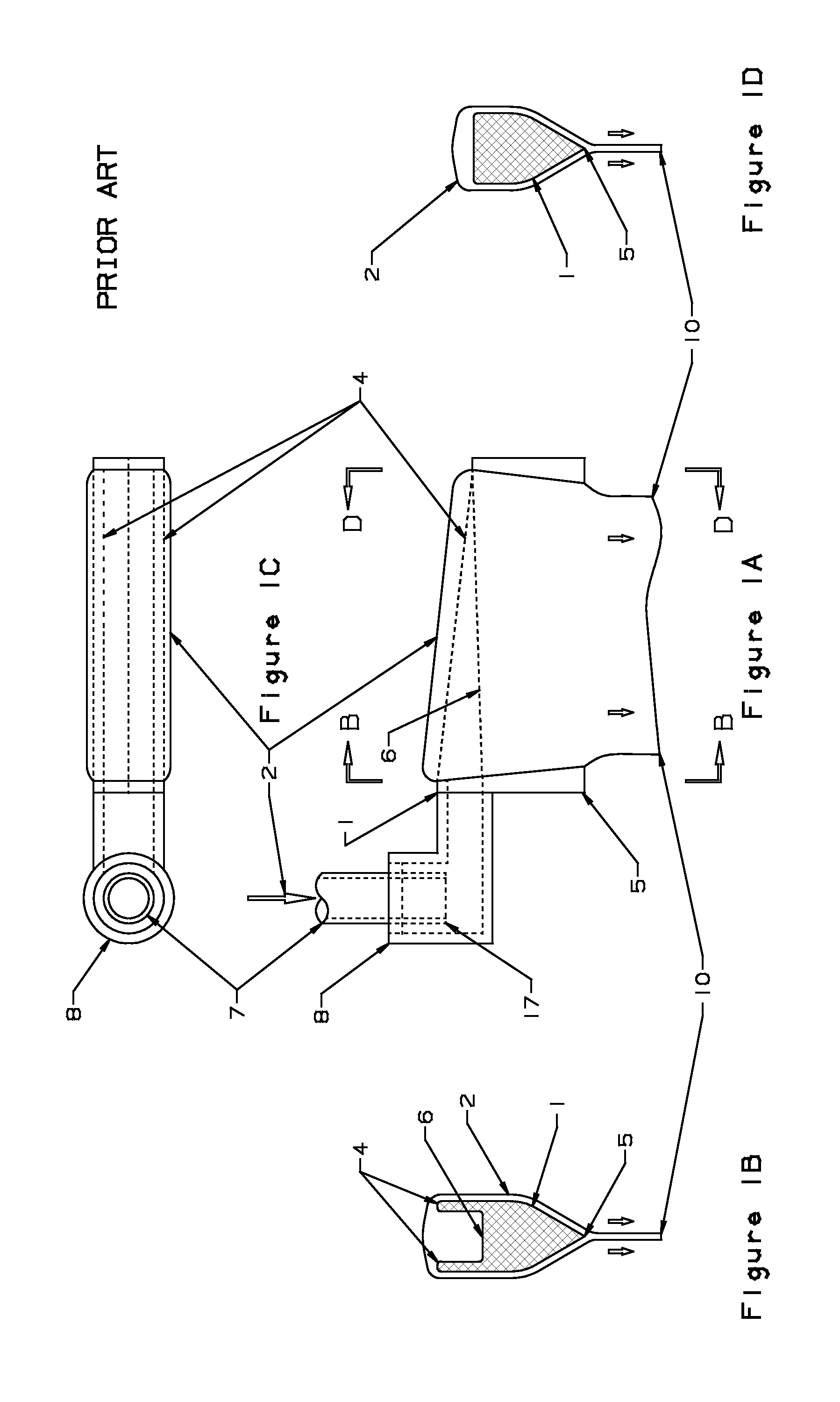

Overflow downdraw glass forming method and apparatus

ActiveUS20060016219A1Process can be modifiedMinimizing thickness variationGlass furnace apparatusVolume/mass flow measurementThermal creepEngineering

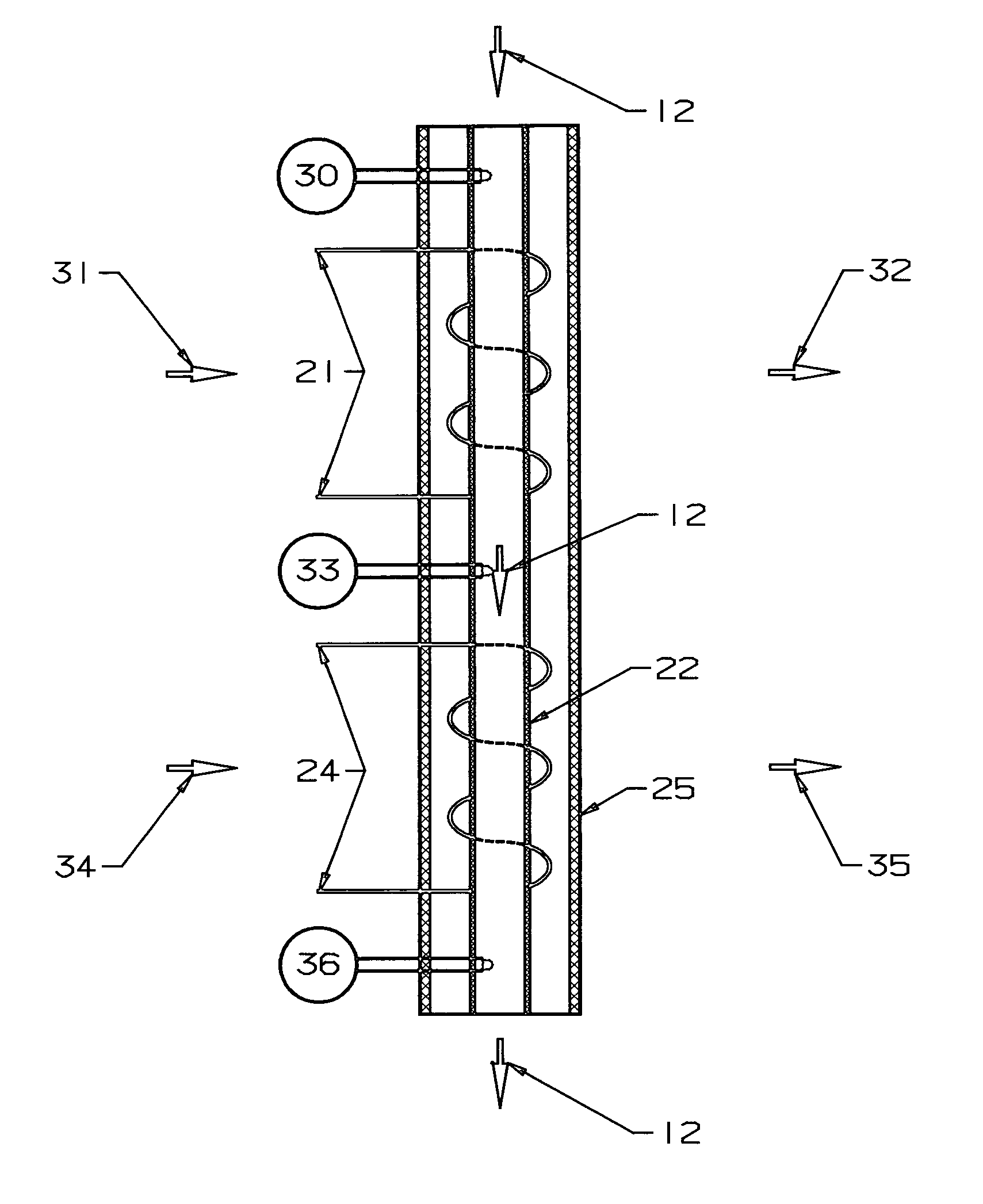

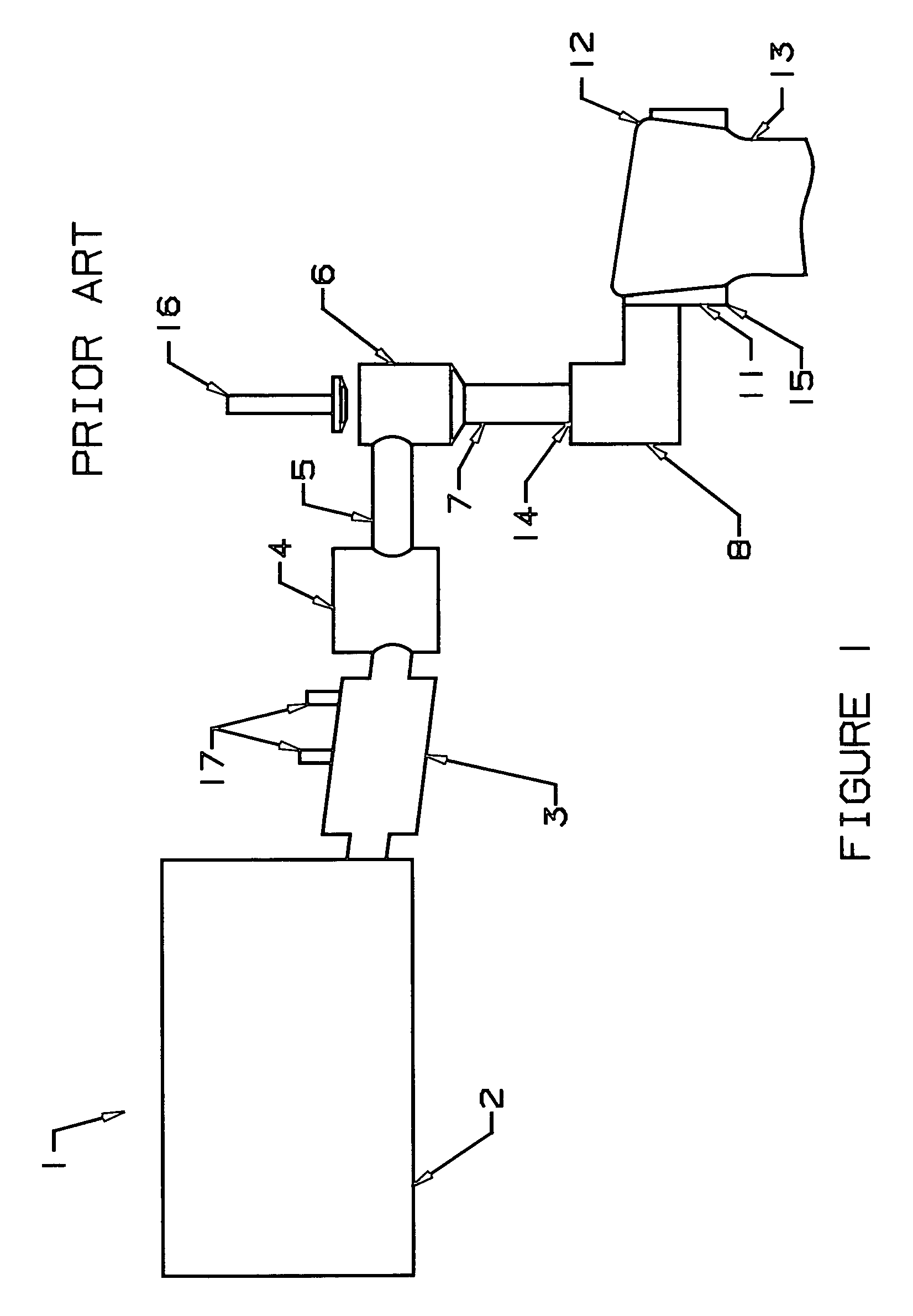

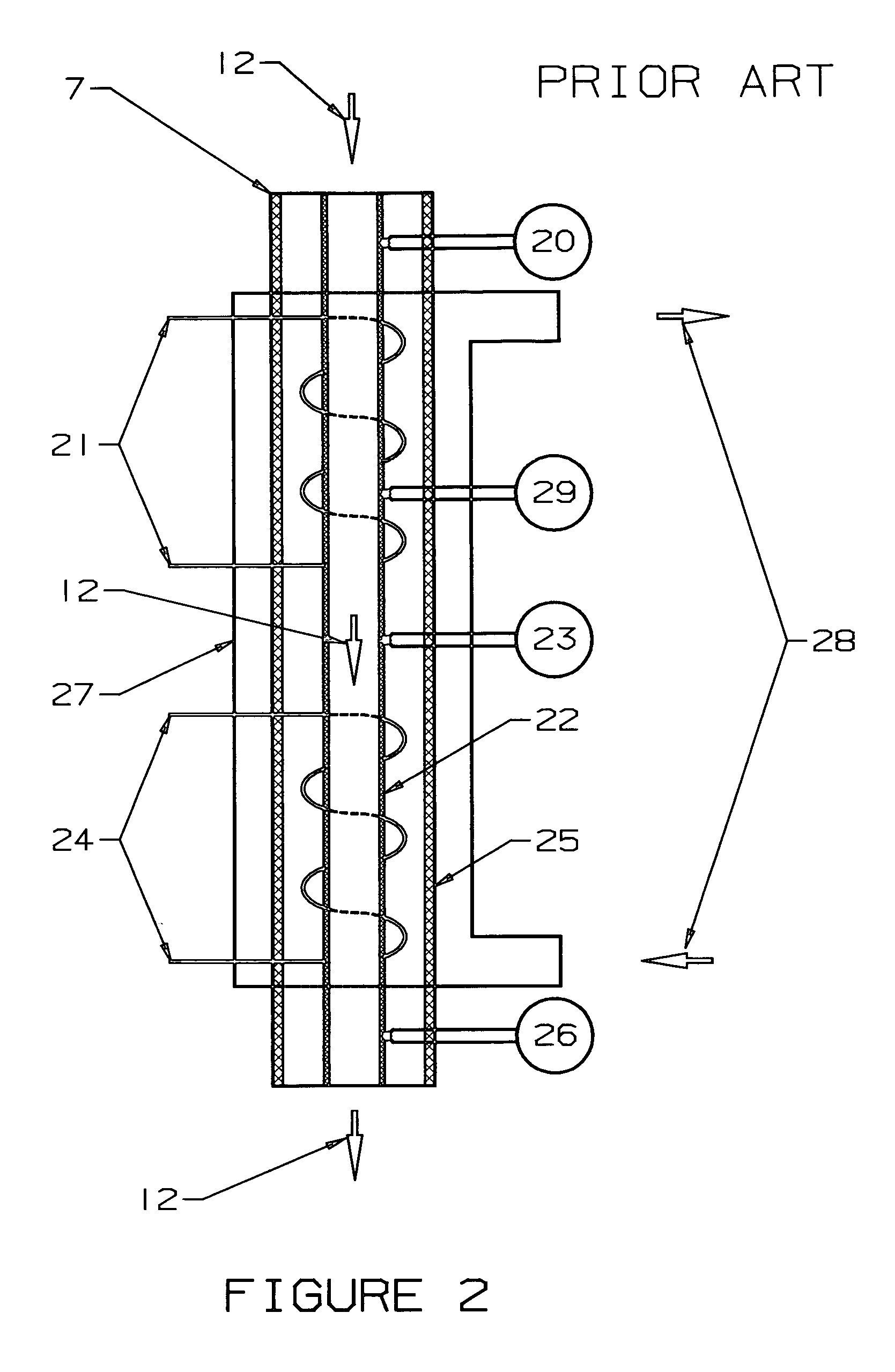

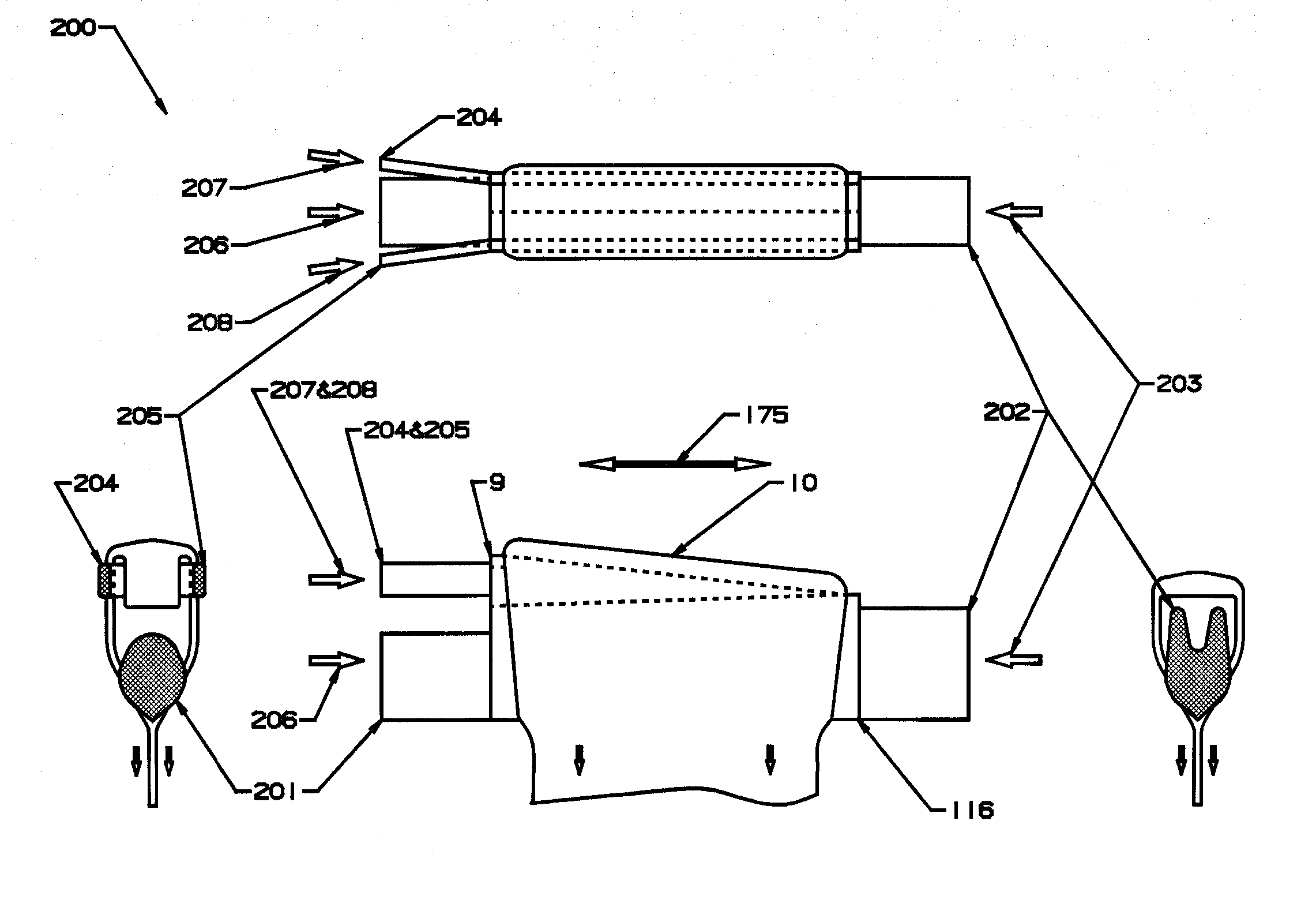

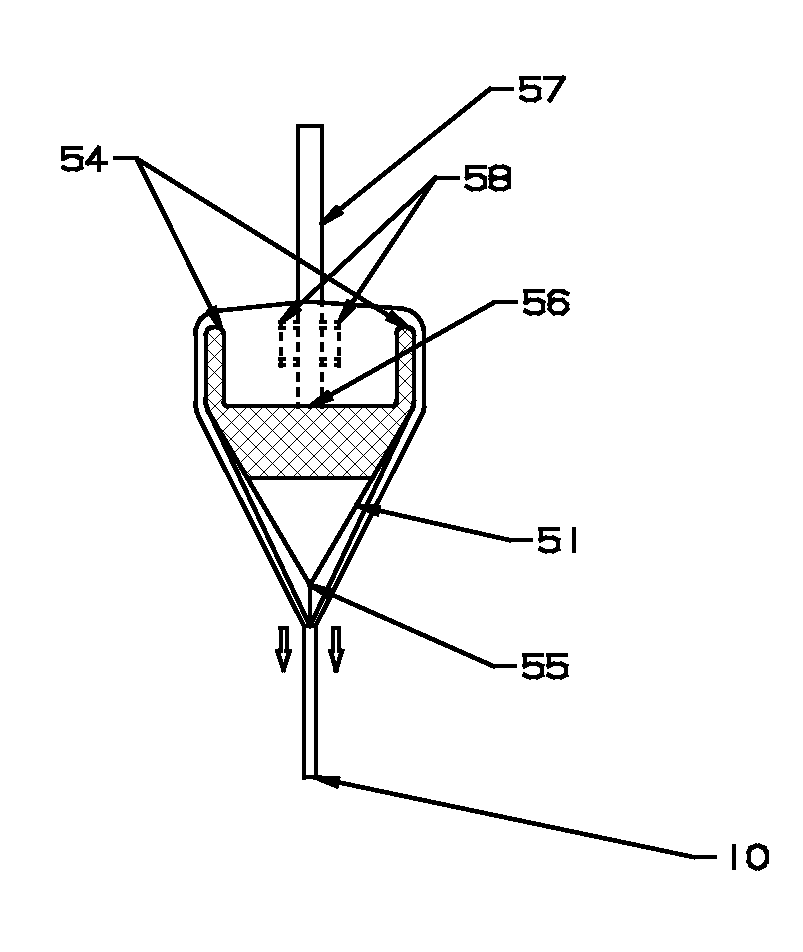

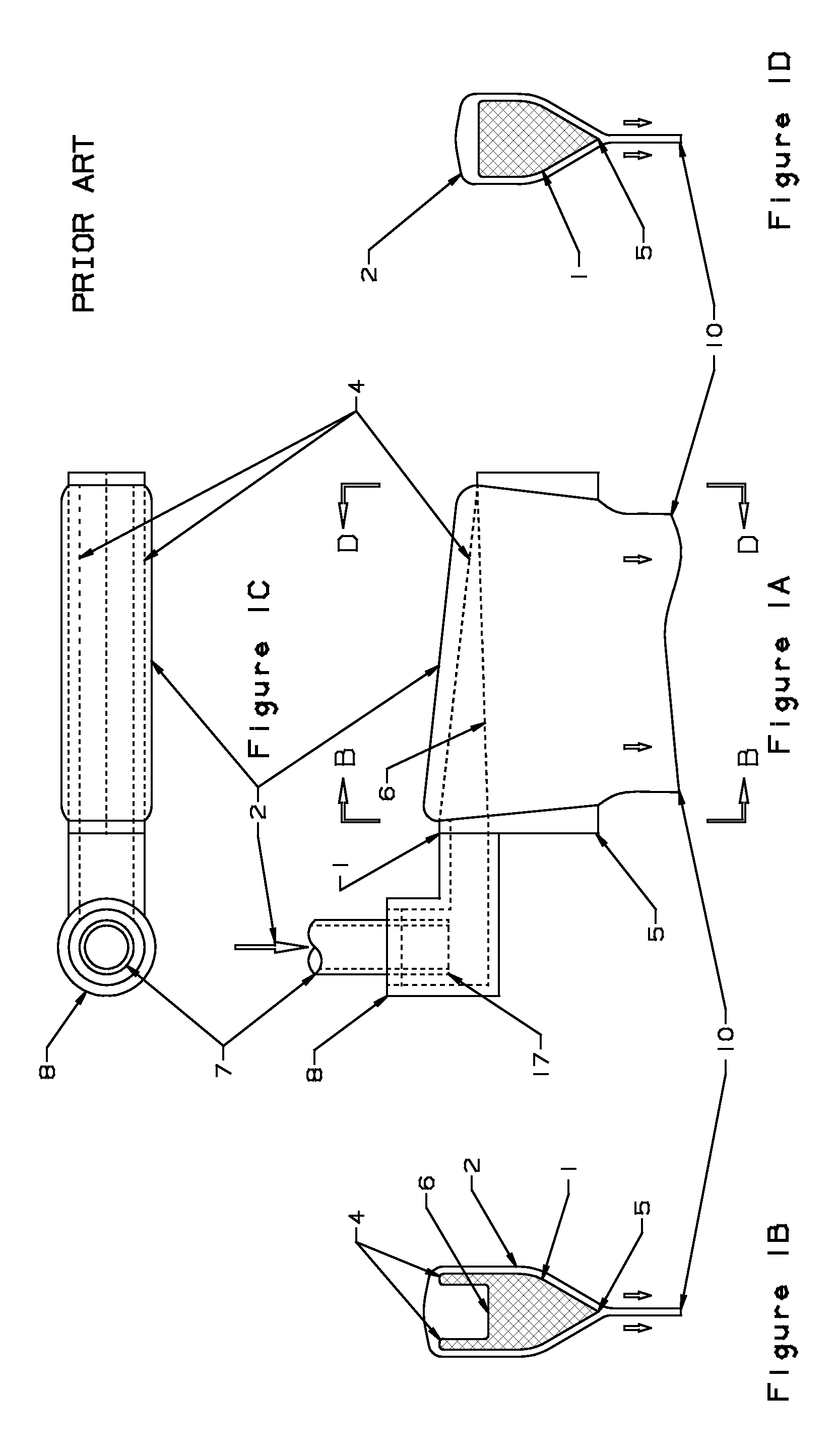

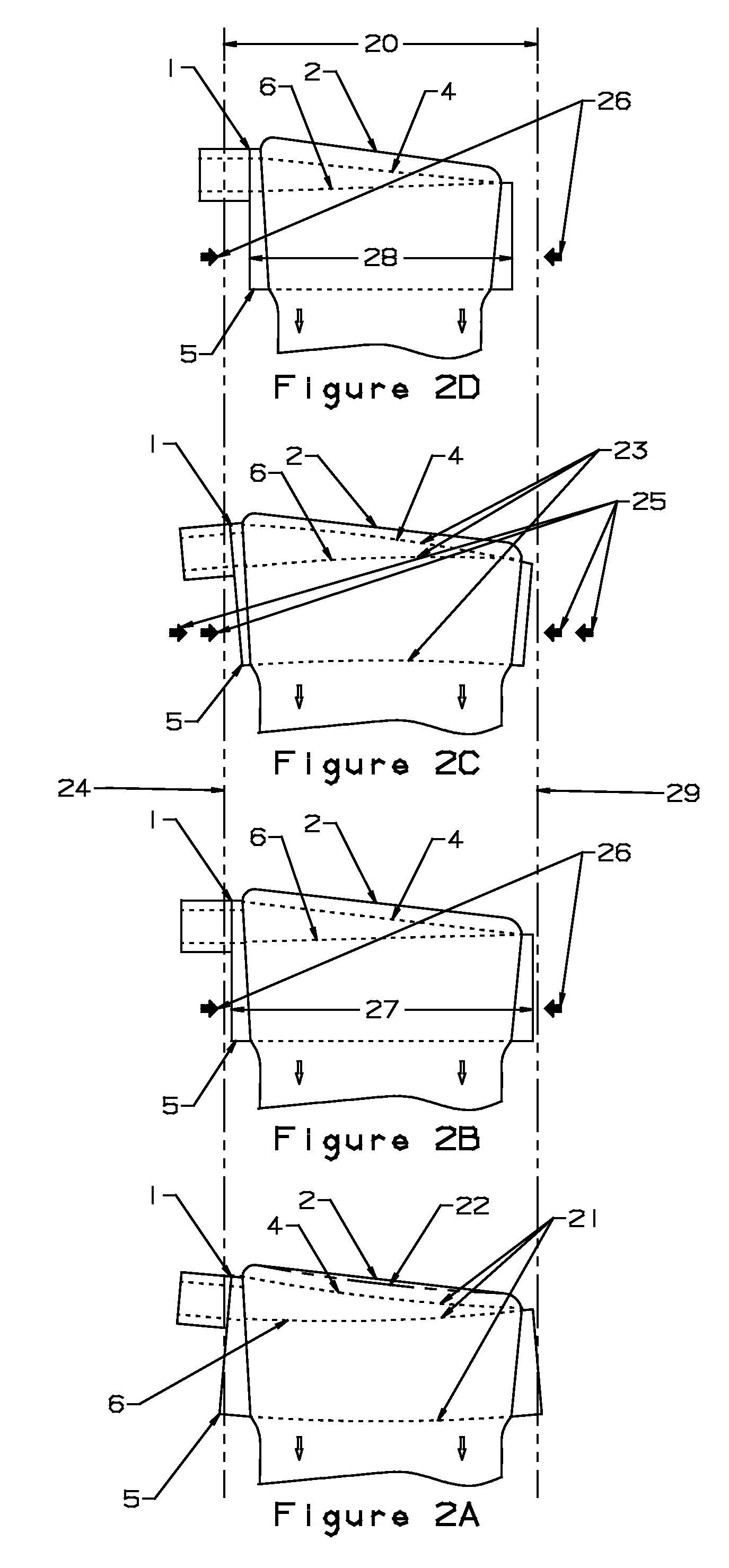

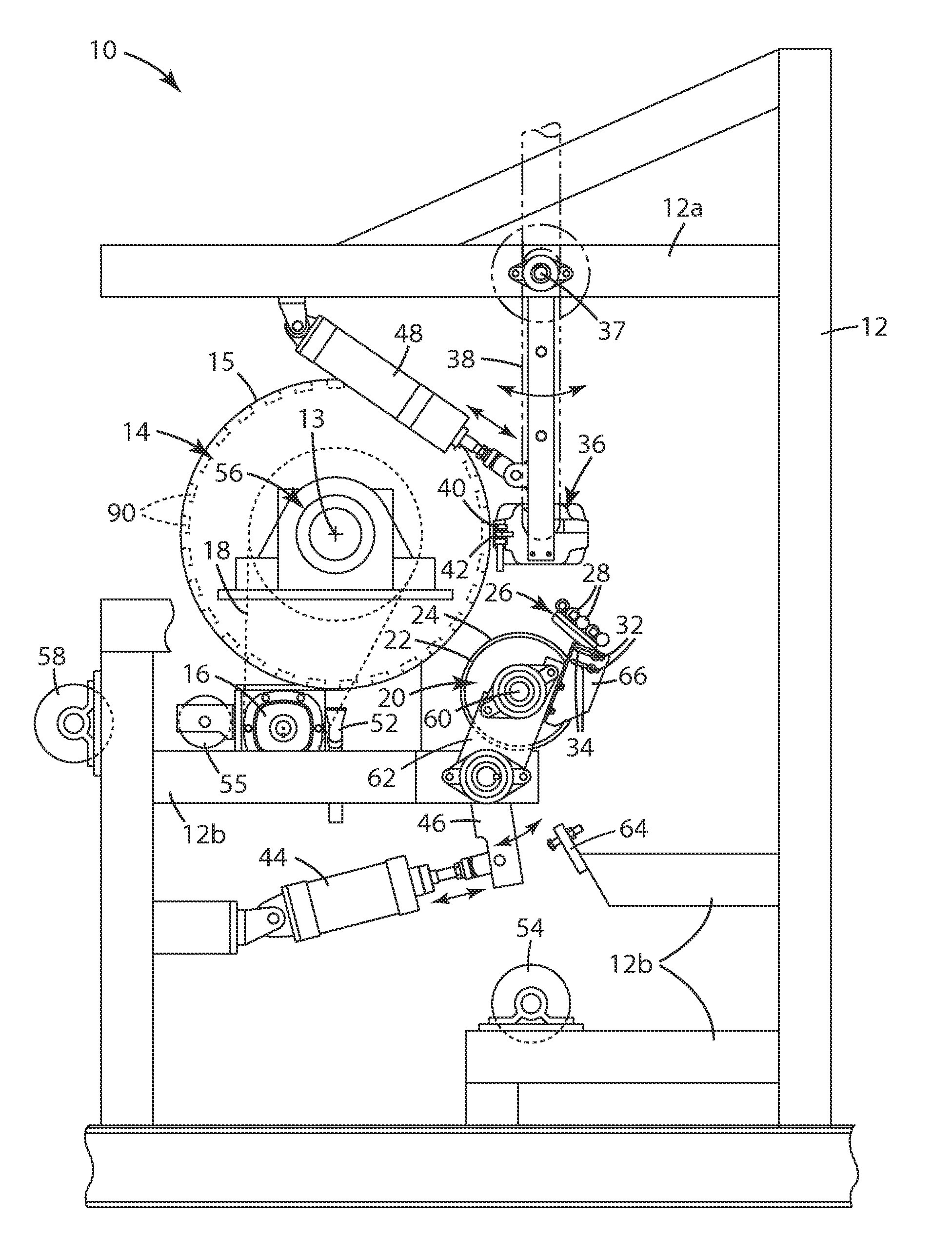

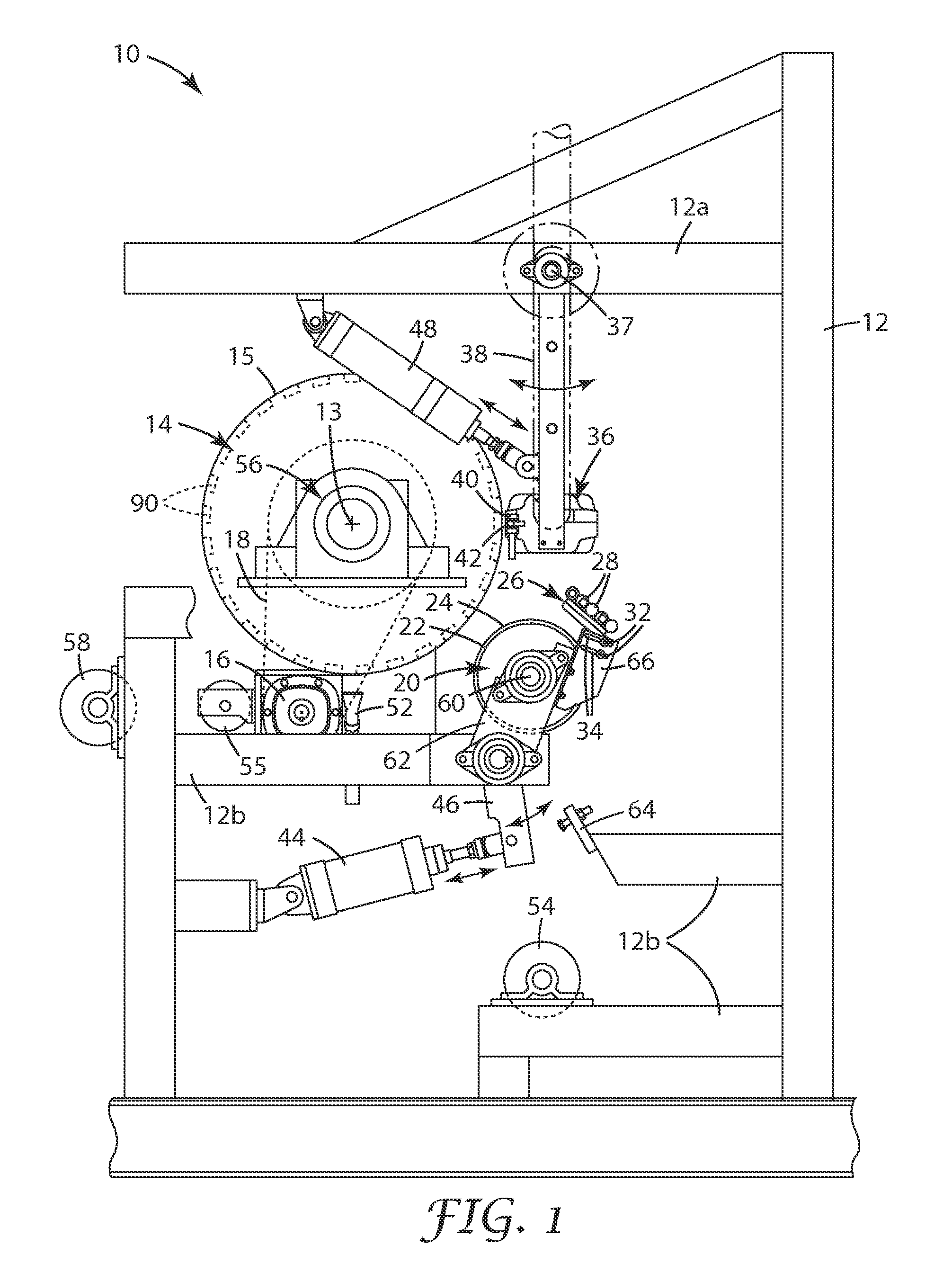

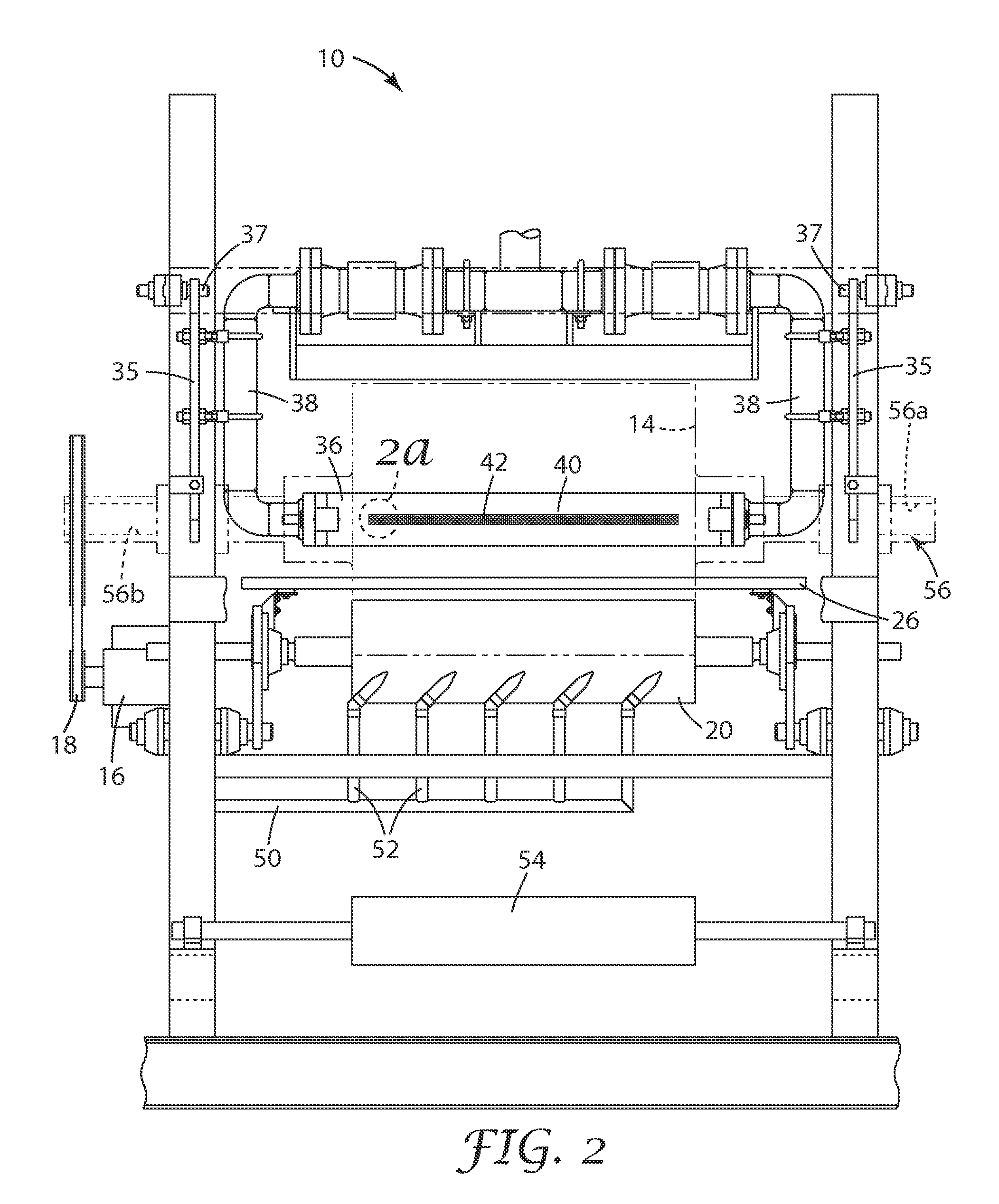

The present invention significantly modifies “The Overflow Process”. It includes a method and apparatus for measuring glass flow rate and maintaining a constant glass flow rate. It also embodies design features and methods that support and stress the forming apparatus in a manner such that the deformation that results from thermal creep is corrected, thus minimizing the effect of the thermal creep on the thickness variation of the glass sheet. The present invention also embodies design features that change the process from a single step (combined flow distribution and cooling) to a two step process; step one being flow distribution and step two being cooling.

Owner:CORNING INC

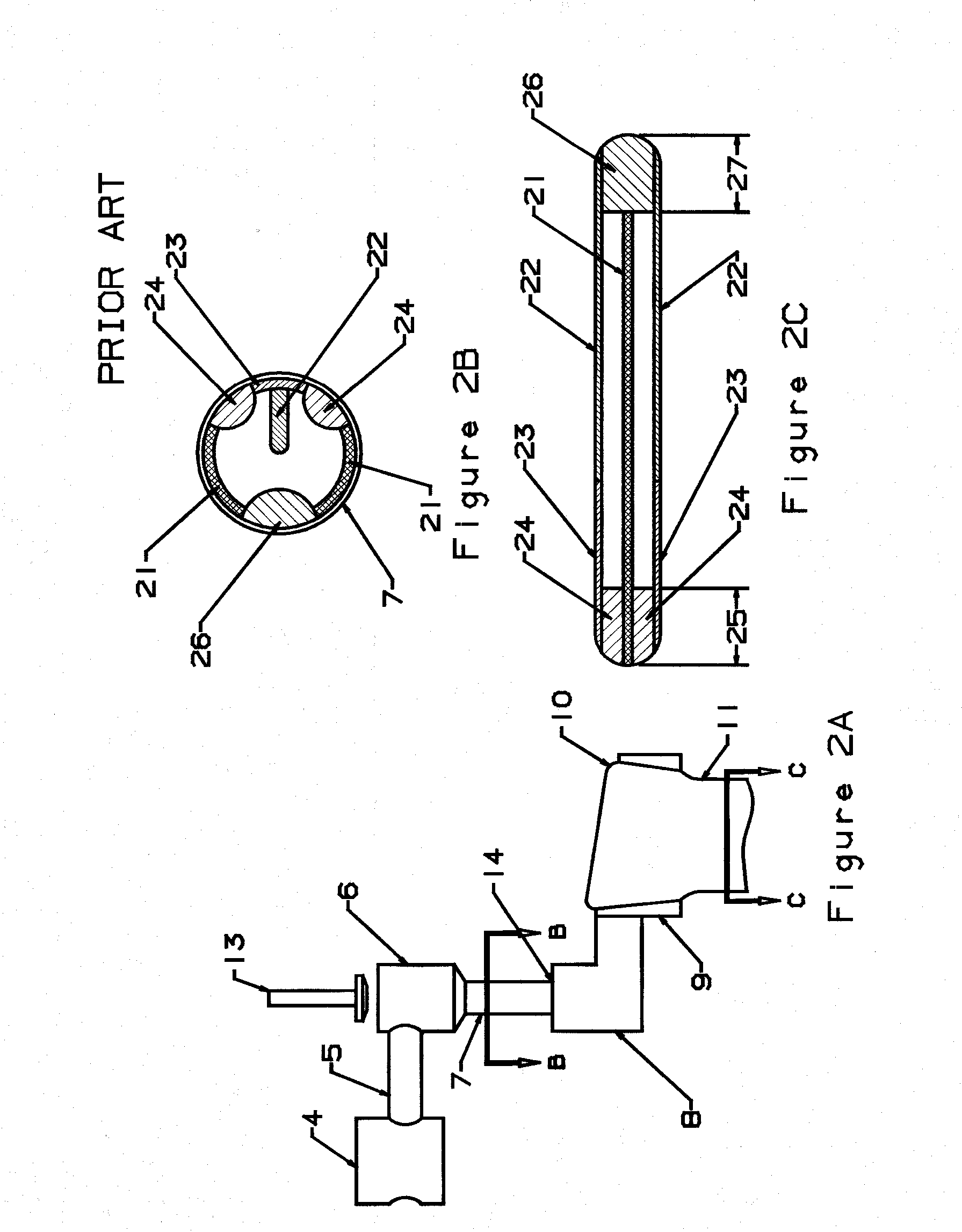

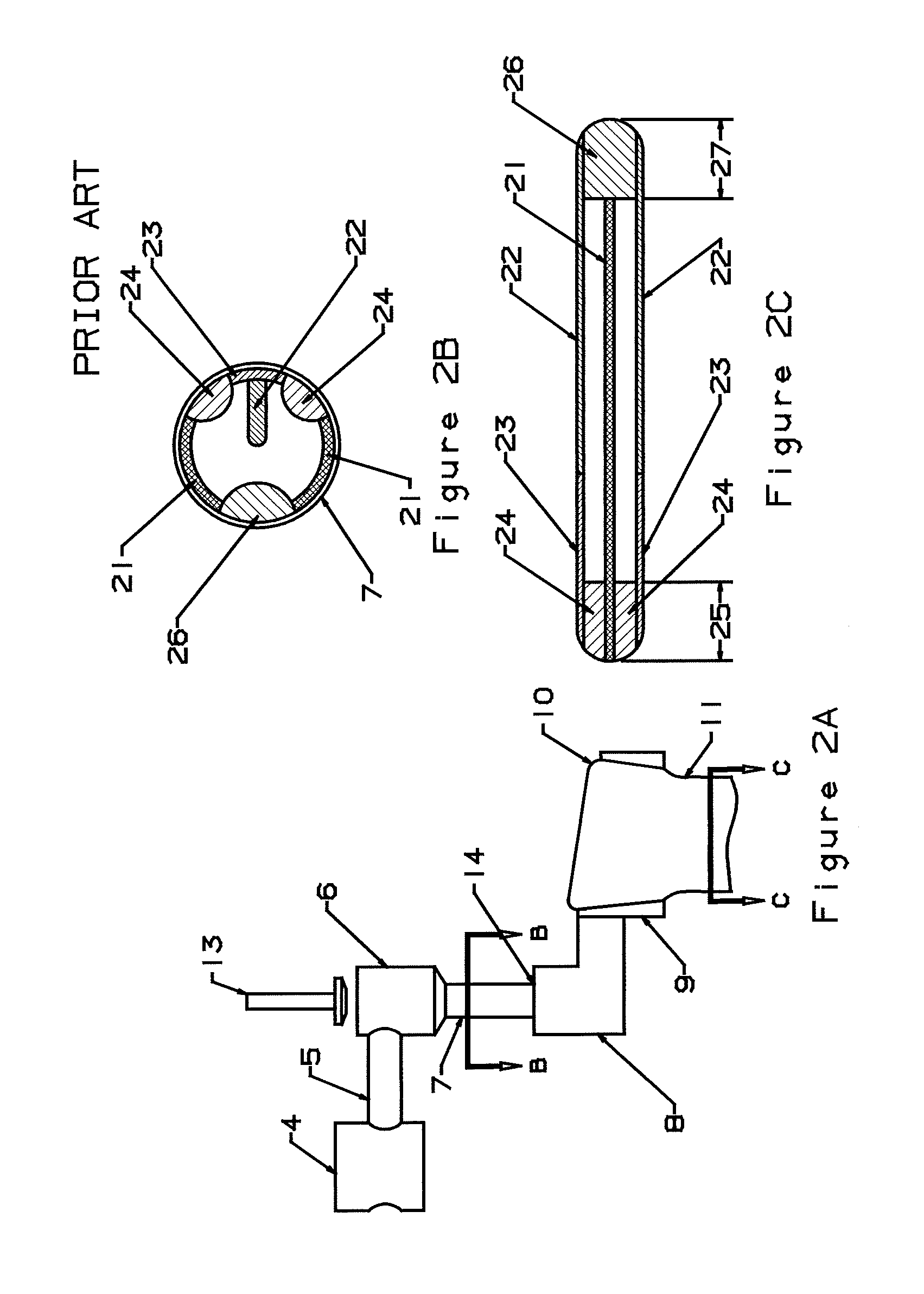

Overflow Downdraw Glass Forming Method and Apparatus

InactiveUS20070068197A1Reduce unevennessEfficient degradationBlowing machine gearingsGlass furnace apparatusFlat glassThermal creep

The present invention discloses improved methods and apparatus for forming sheet glass. In one embodiment, the invention introduces a counteracting force to the stresses on the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

Overflow downdrawn glass forming method and apparatus

InactiveUS6889526B2Reduce unevennessEfficient degradationGlass furnace apparatusGlass drawing apparatusThermal creepEngineering

Owner:CORNING INC

Overflow downdrawn glass forming method and apparatus

InactiveUS6895782B2Reduce unevennessGlass furnace apparatusGlass drawing apparatusFlat glassThermal creep

The present invention alters the flow path at the inlet of the sheet glass forming apparatus to improve quality. The bottom of the downcomer pipe is preferably shaped to alter the character of the vortex flow in the quiescent flow zone between the pipes. In another embodiment, a bead guide provides hydraulic stresses that are in opposition to the surface tension stress and thus reduces the influence of surface tension on the formation of thick beads on the edges of the sheet. The present invention also measures the temperature of the glass by immersing thermocouples in the glass, at locations where any defects caused by the immersion are in the glass that forms the unusable edges of the sheet. In another embodiment, the support structure for the trough is altered to substantially reduce the aging of the trough due to thermal creep.

Owner:CORNING INC

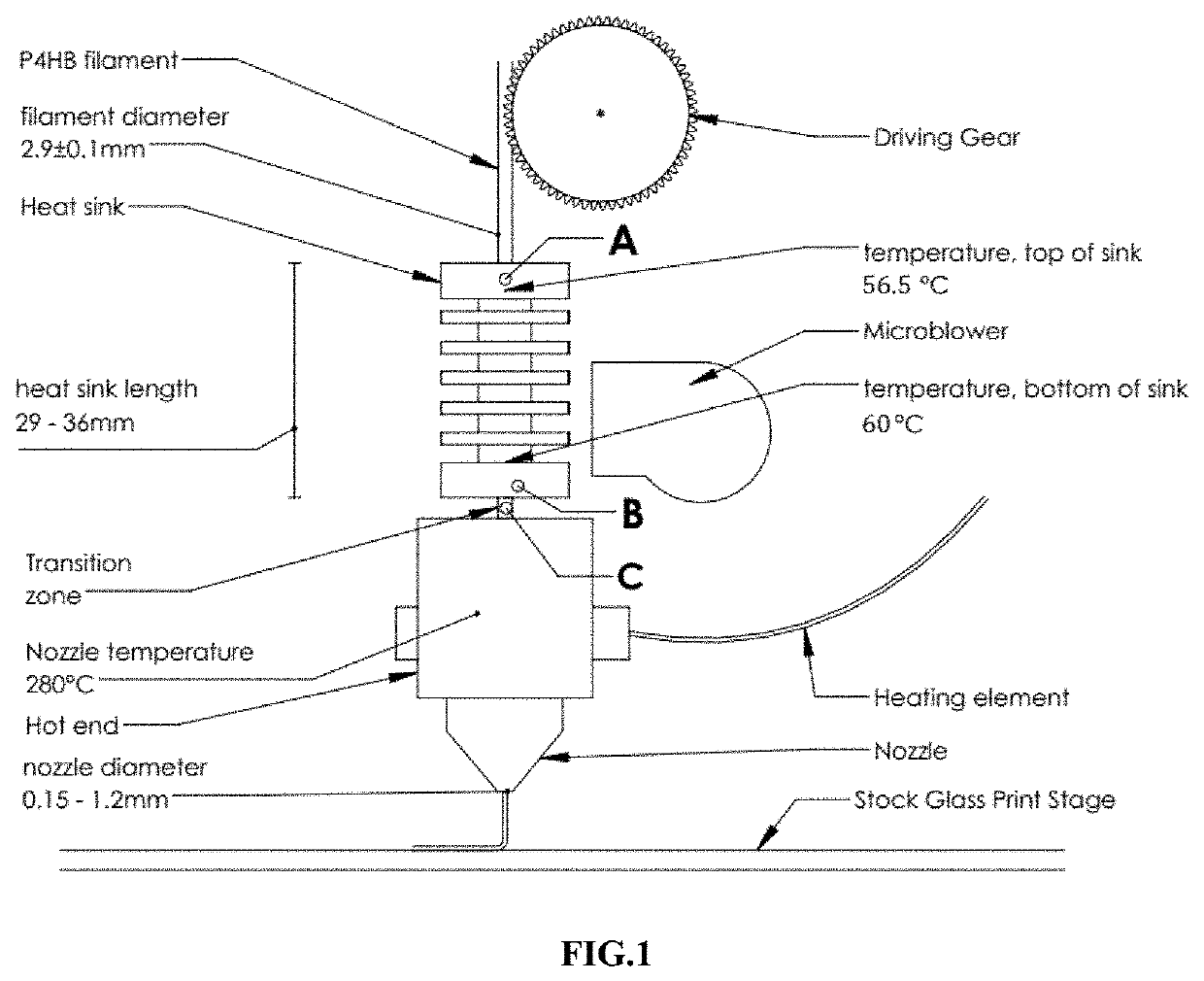

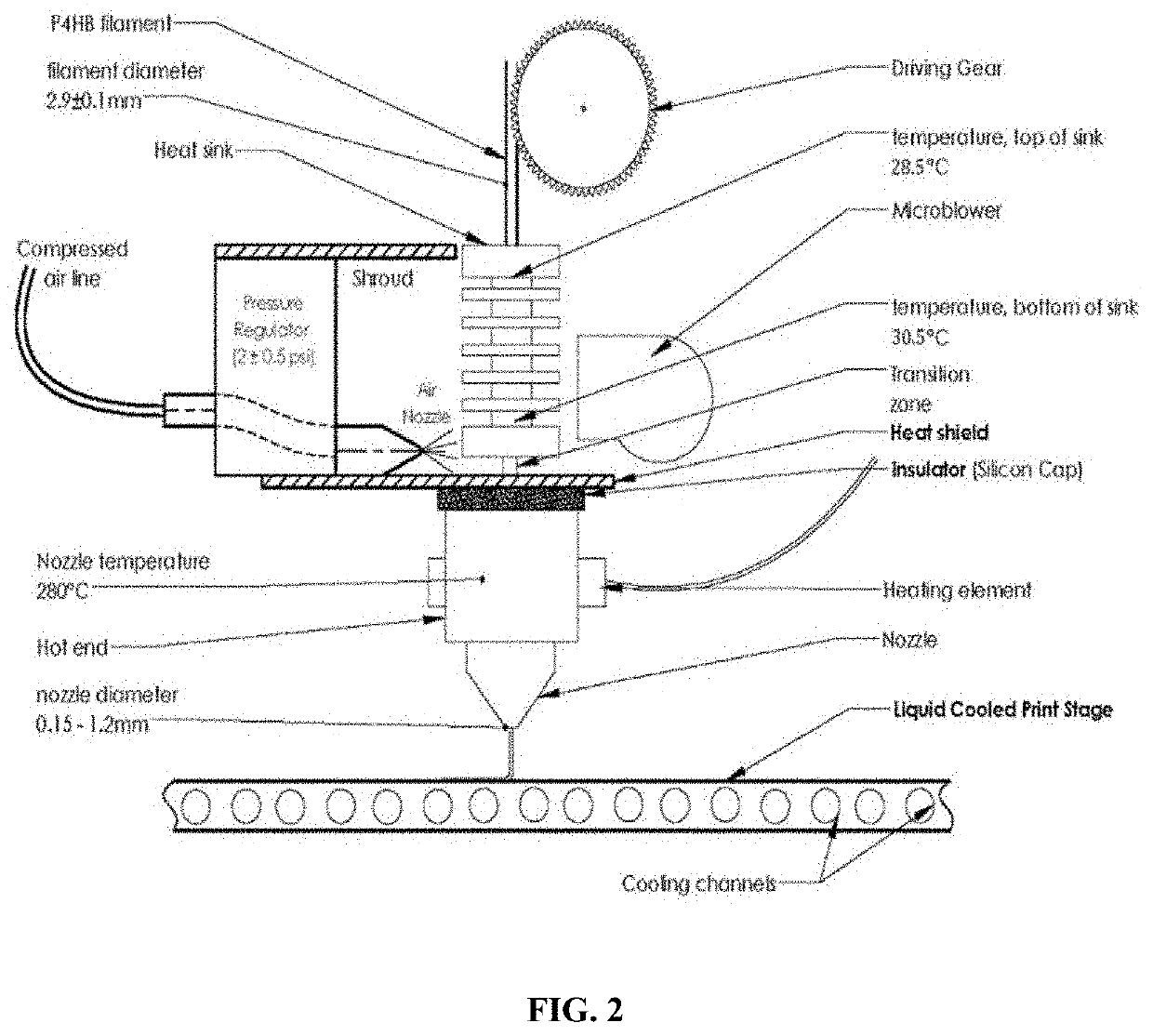

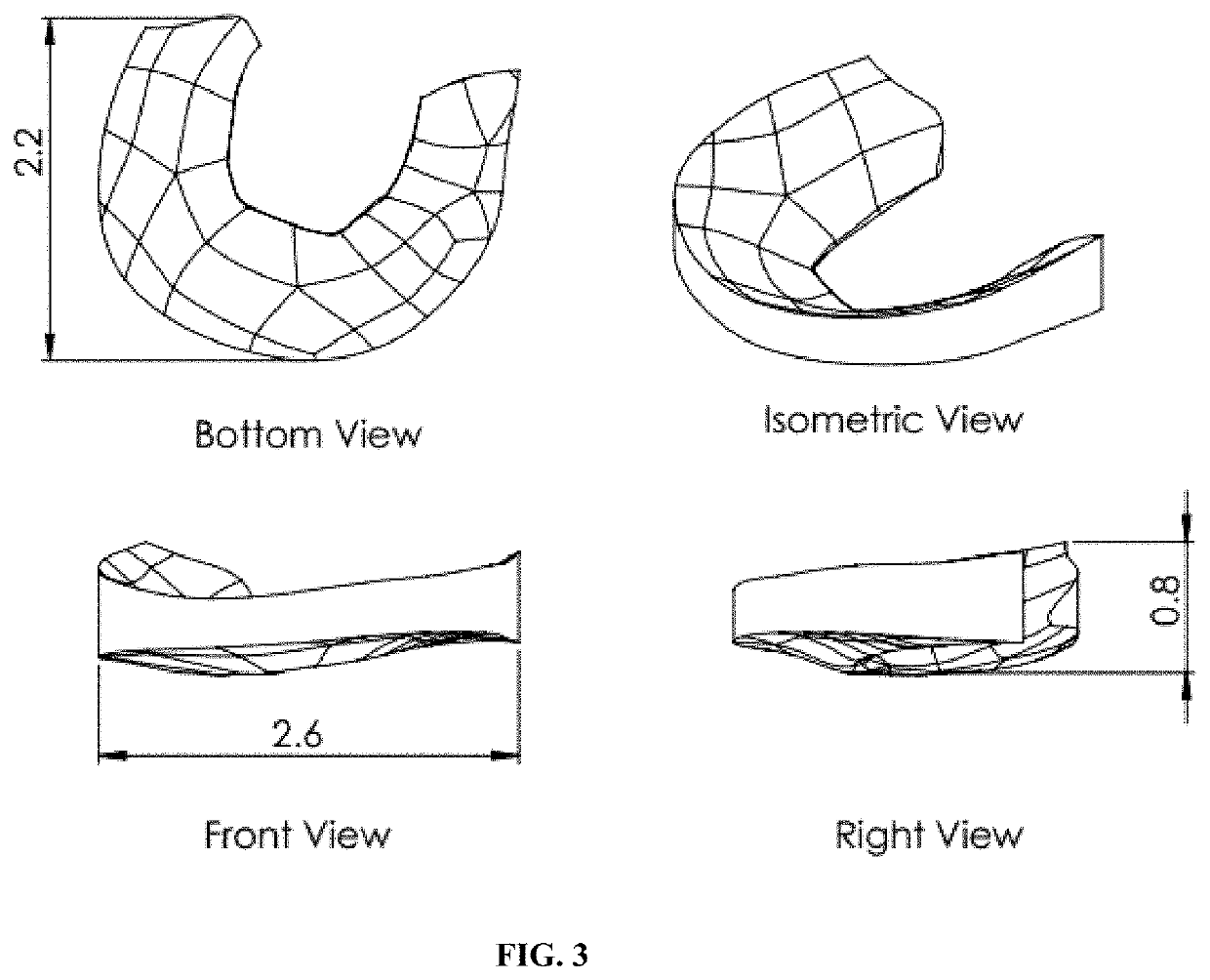

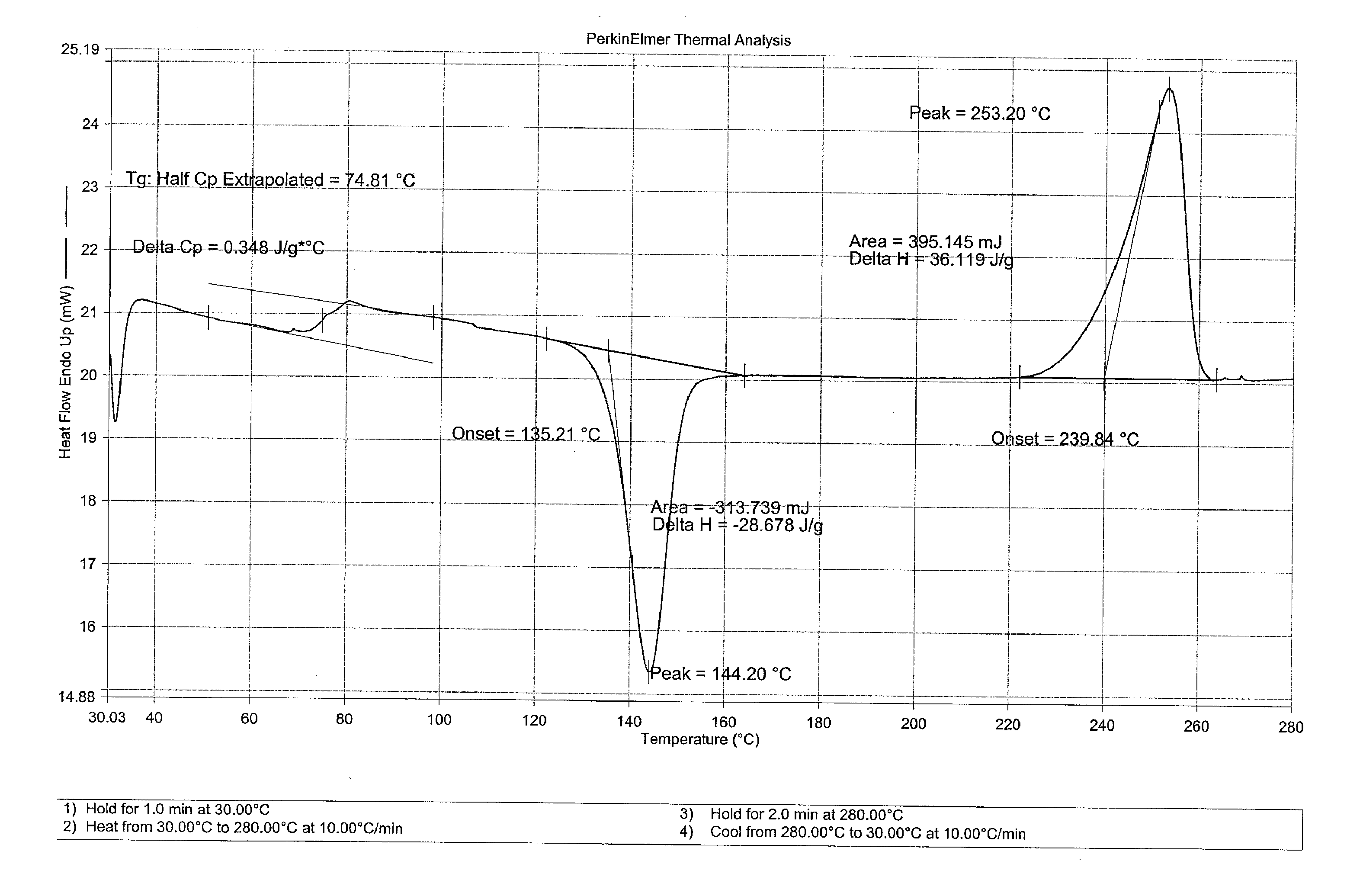

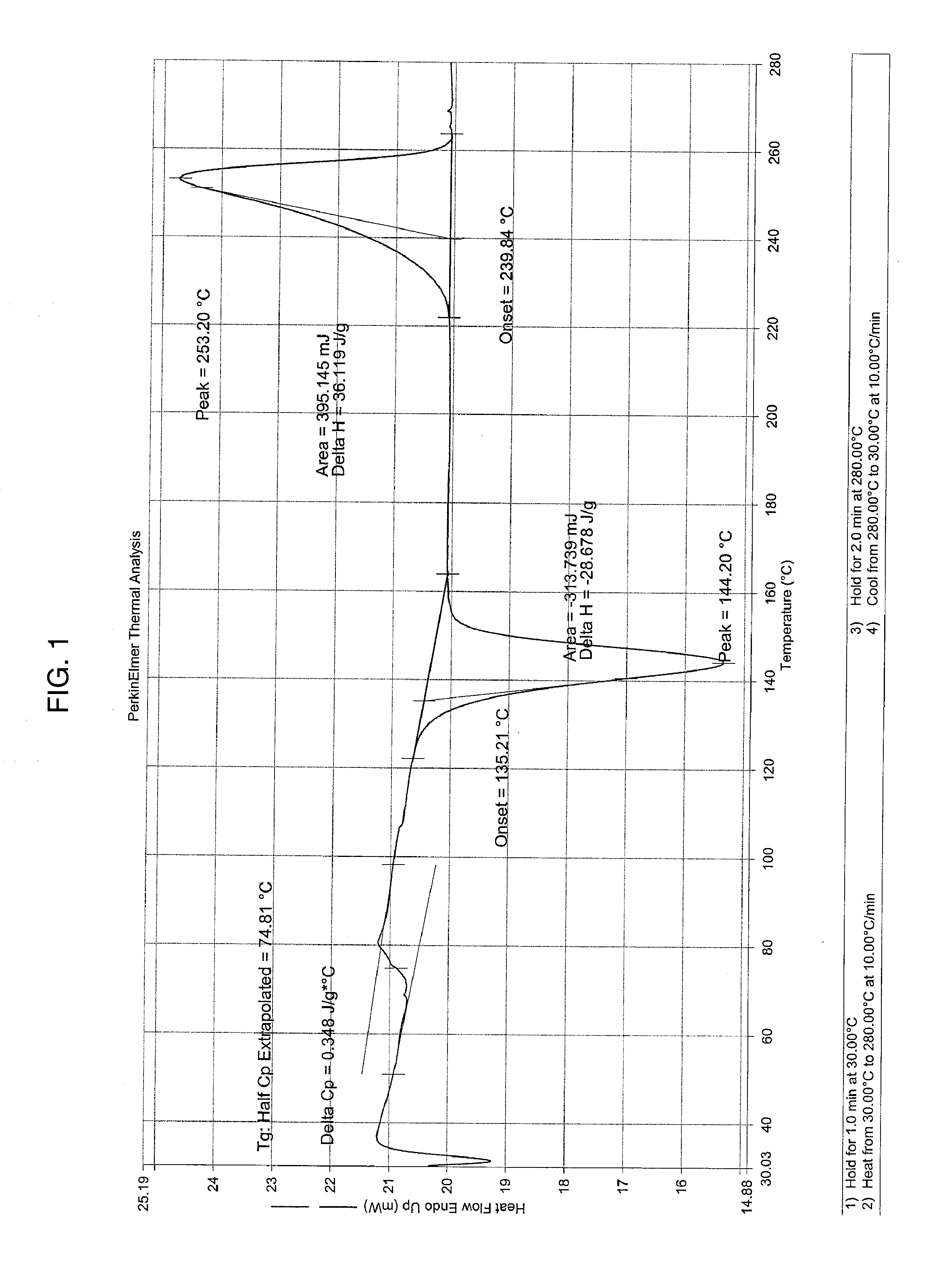

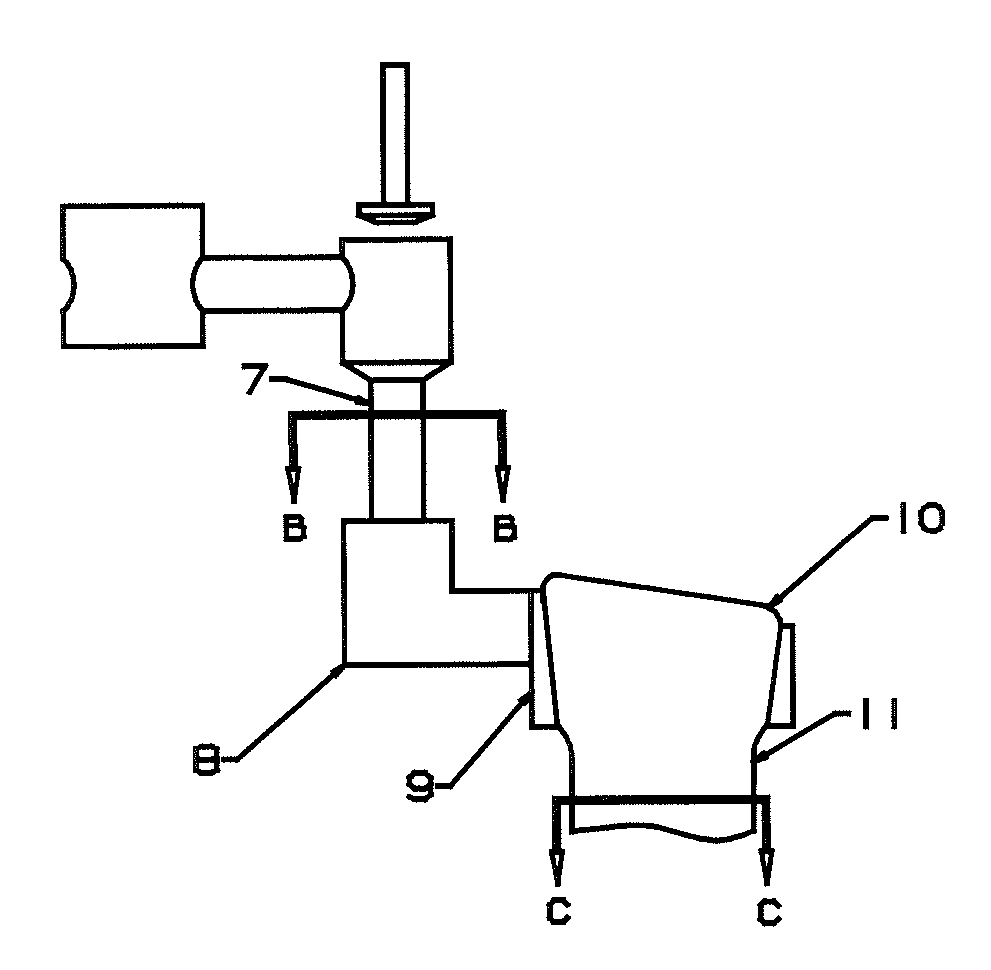

Methods for 3D printing of poly-4-hydroxybutyrate and copolymers

ActiveUS20190375149A1Reduce molecular weightImprove printing qualityManufacturing driving meansManufacturing enclosuresSelective laser meltingFused filament fabrication

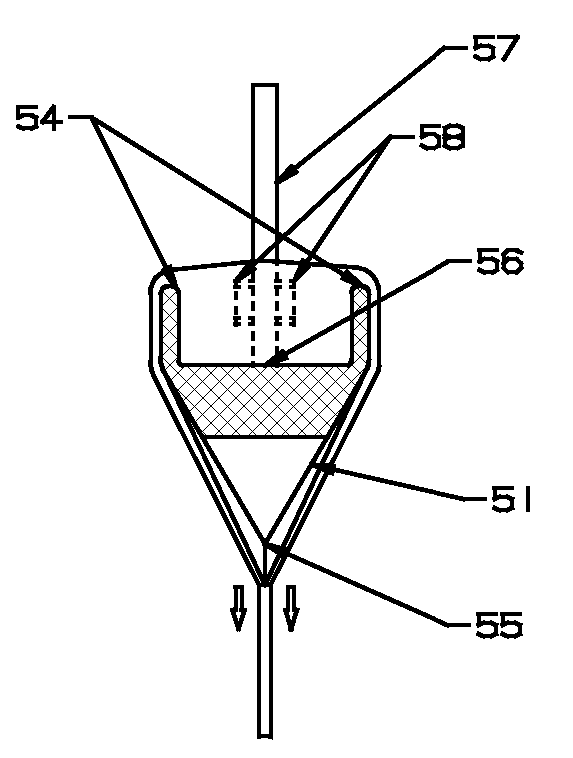

Methods to fabricate objects by 3D printing of poly-4-hydroxybutyrate (P4HB) and copolymers thereof have been developed. In one method, these objects are produced by continuous fused filament fabrication using an apparatus and conditions that overcome the problems of poor feeding of the filament resulting from the low softening temperature of the filament and heat creep along the fed filament. Methods using an apparatus including a heat sink, a melt tube, a heating block and nozzle, and a transition zone between the heat sink and heating block, with the melt tube extending through the heat sink, transition zone, and heat block to the nozzle are disclosed. 3D objects are also printed by fused pellet deposition (FPD), melt extrusion deposition (MED), selective laser melting (SLM), printing of slurries and solutions using a coagulation bath, and printing using a binding solution and polymer granules.

Owner:TEPHA INC

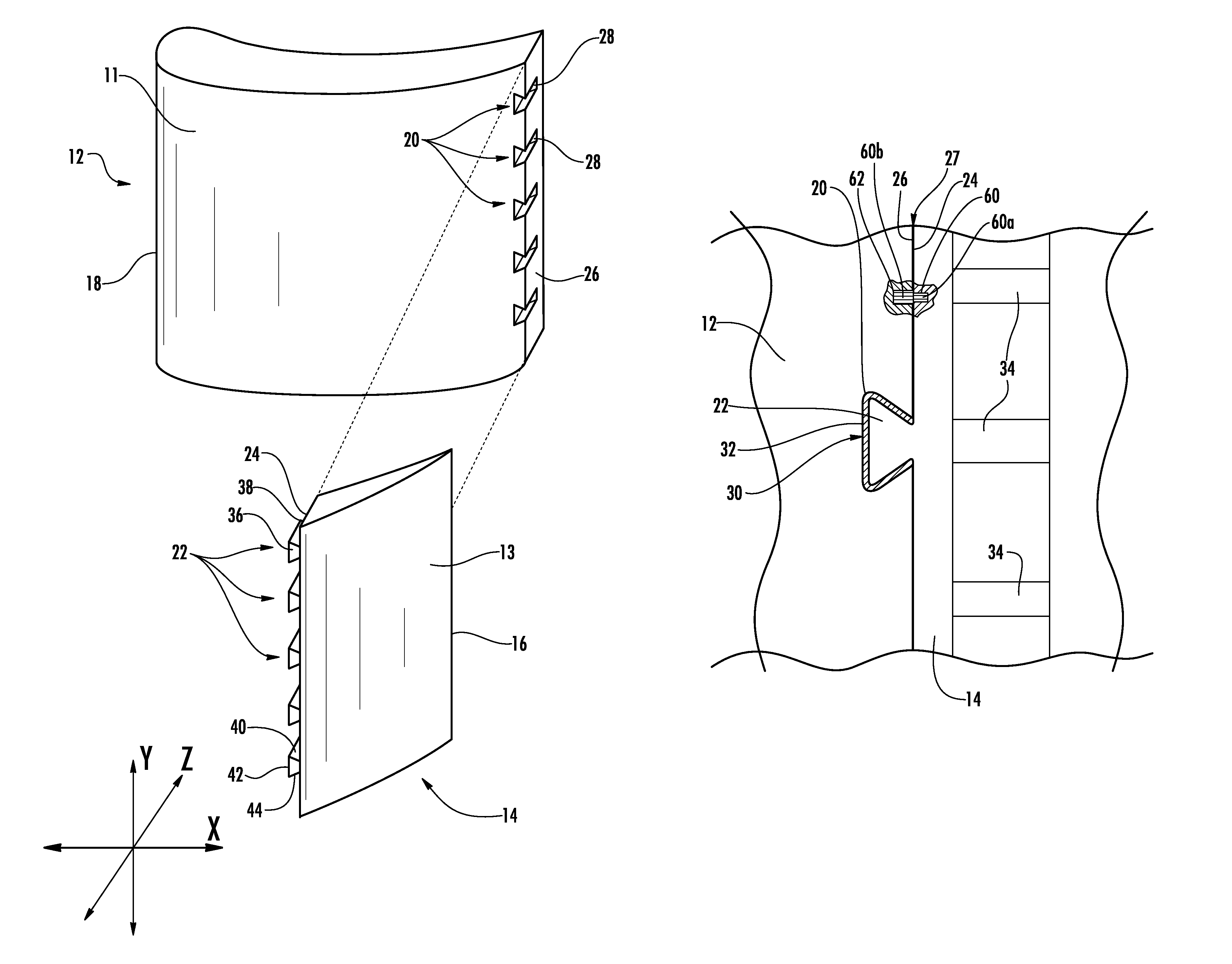

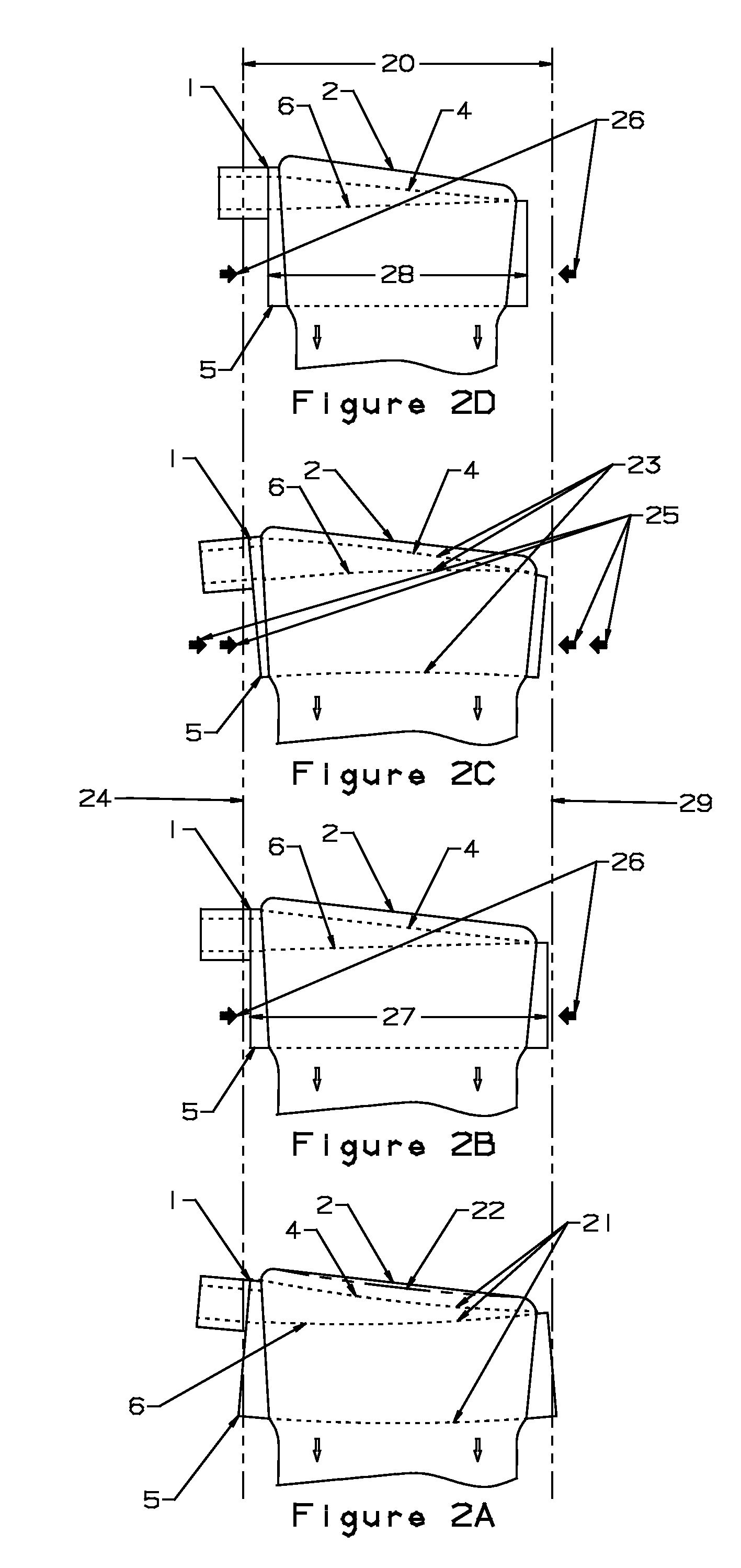

Overflow downdraw glass forming method and apparatus

InactiveUS7681414B2Reduce unevennessEfficient degradationBlowing machine gearingsGlass furnace apparatusFlat glassThermal creep

The present invention discloses improved methods and apparatus for forming sheet glass. In one embodiment, the invention introduces a counteracting force to the stresses on the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

Sheet glass forming apparatus

InactiveUS20050138966A1Reduce unevennessBlowing machine gearingsGlass furnace apparatusFlat glassThumb opposition

The present invention alters the flow path at the inlet of the sheet glass forming apparatus to improve quality. The bottom of the downcomer pipe is preferably shaped to alter the character of the vortex flow in the quiescent flow zone between the pipes. In another embodiment, a bead guide provides hydraulic stresses that are in opposition to the surface tension stress and thus reduces the influence of surface tension on the formation of thick beads on the edges of the sheet. The present invention also measures the temperature of the glass by immersing thermocouples in the glass, at locations where any defects caused by the immersion are in the glass that forms the unusable edges of the sheet. In another embodiment, the support structure for the trough is altered to substantially reduce the aging of the trough due to thermal creep.

Owner:CORNING INC

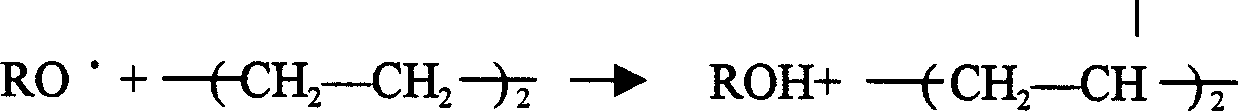

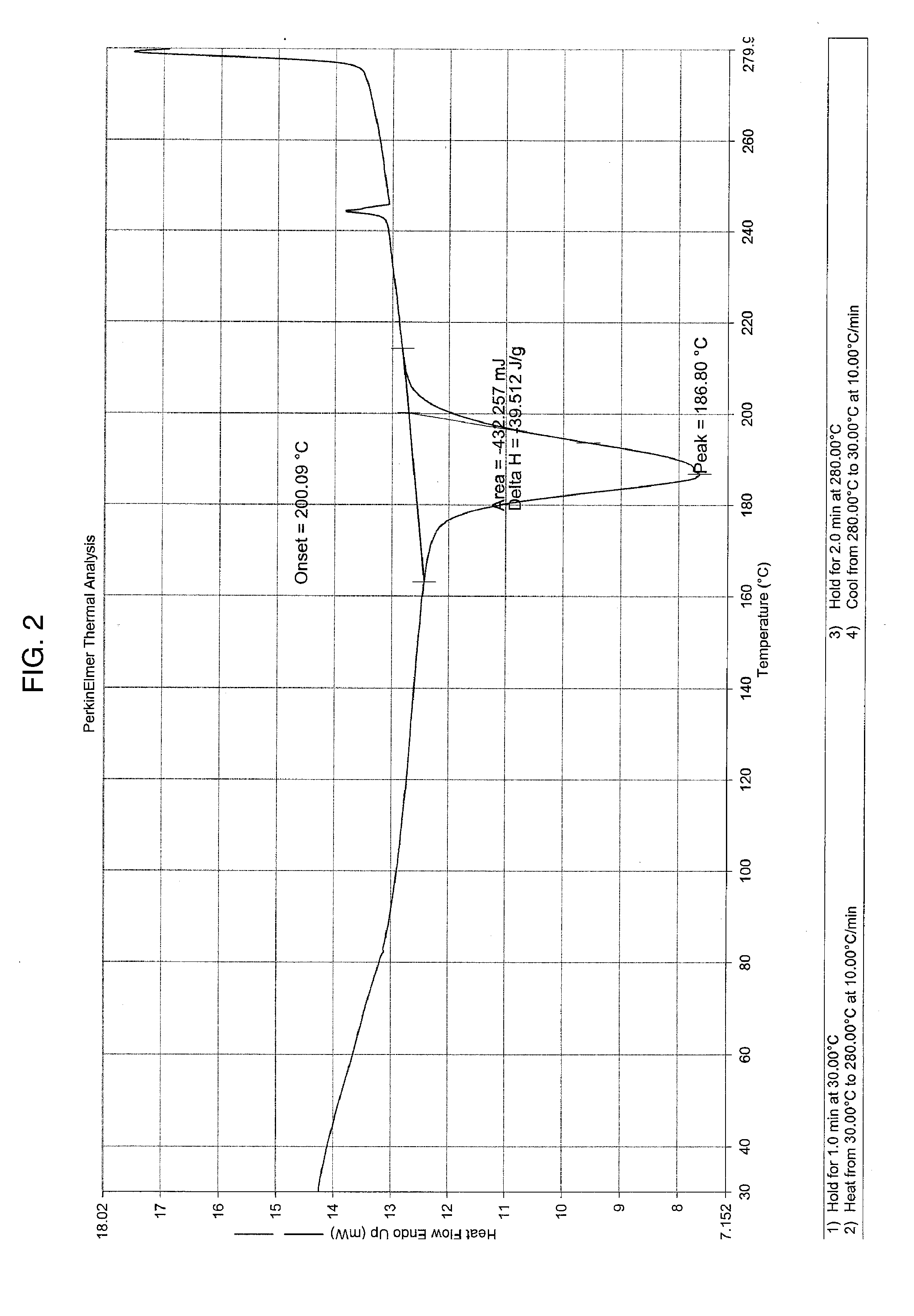

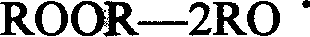

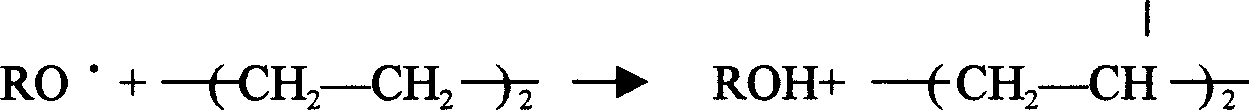

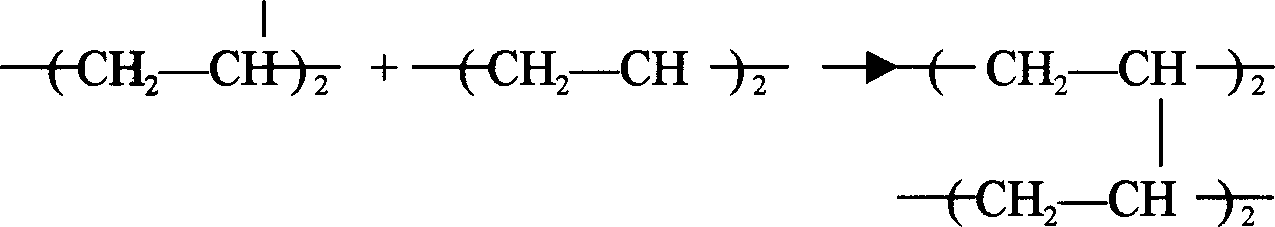

Crosslinked polyethylene special material for rotational moulding

The present invention relates to a rotational moulding cross-linked polyethylene special-purpose material. It contains the following components: (by total weight of linear low-density polyethylene and low-density polyethylene) A. linear low-density polyethylene 70-90%; B. low-density polyethylene 10-30%; C. cross-linking agent 0.5-5%; and D. antioxidant 0.1-1%. Said invention also relates to a preparation method for using said special-purpose material. The special-purpose material composition can be molten and mixed in a mixer or twin screw extruder machine, blending temp. is 130-170 deg.C, the invented polyethylene special-purpose material can be obtained. The rotational moulding product prepared by said special-purpose material has good working property, high resistance to implact shock, good resistance to thermal creep and low-temp. toughness, etc.

Owner:PETROCHINA CO LTD

Overflow downdraw glass forming method and apparatus

The present invention discloses improved methods and apparatus for forming sheet glass. In one embodiment, the invention introduces a counteracting force to the stresses on the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

Polyester Resins for High-Strength Articles

InactiveUS20070059465A1Efficiently formedHigh-clarity articleSynthetic resin layered productsThin material handlingPolymer sciencePolyethylene terephthalate glycol

The present invention relates to slow-crystallizing, titanium-catalyzed polyethylene terephthalate resins that are useful for making high-strength, high-clarity bottles that possess improved resistance to stress cracking and thermal creep. The polyethylene terephthalate resins possess improved reheating profiles and are especially useful for making polyester articles that have exceptional clarity, dimensional stability, and thermal stability.

Owner:WELLMAN INC

Special cross-linked polyethylene material for rotational molding and preparing process thereof

InactiveCN1524899AImprove liquidityImprove permeabilityLinear low-density polyethyleneLow-density polyethylene

The invention relates to a crosslinked polyethylene single-purpose material for rotational moulding which comprises (by weight percent) linear low density polyethylene 70-90%, low density polyethylene 10-30%, cross linking agent 0.5-5%, anti-oxidant 0.1-1%. The invention also relates to the process for preparing the special-purpose material. The rotational moulding product prepared by the single-purpose material has good processing characteristics, fine impact strength, thermal creep resistance and low-temperature flexibility, good penetrability resistance and chemical environmental resistance.

Owner:PETROCHINA CO LTD

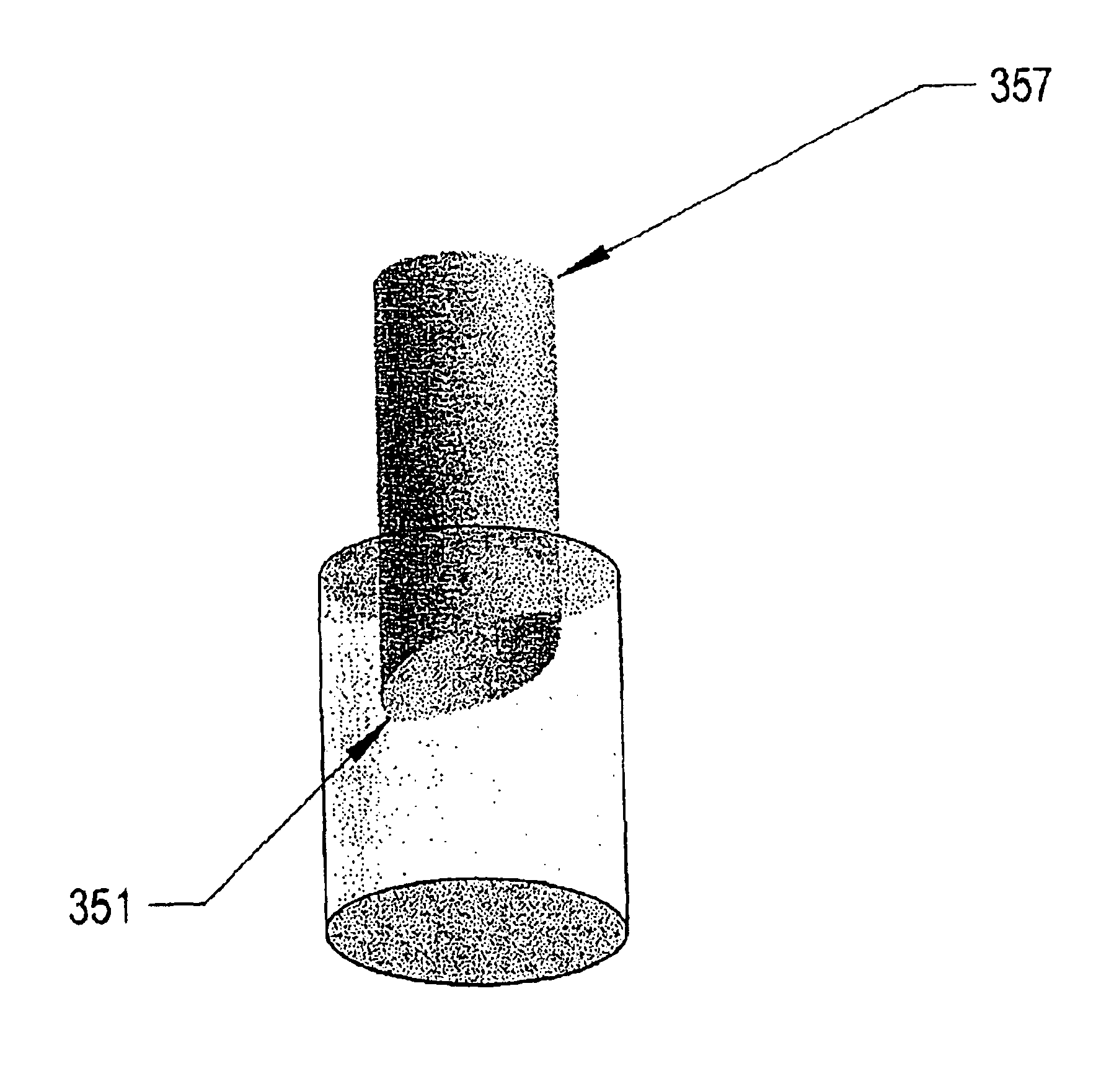

Turbine component casting core with high resolution region

ActiveUS20130341822A1High Resolution FeaturesFoundry mouldsFoundry coresThermal creepTransfer molding

A hollow turbine engine component with complex internal features can include a first region and a second, high resolution region. The first region can be defined by a first ceramic core piece formed by any conventional process, such as by injection molding or transfer molding. The second region can be defined by a second ceramic core piece formed separately by a method effective to produce high resolution features, such as tomolithographic molding. The first core piece and the second core piece can be joined by interlocking engagement that once subjected to an intermediate thermal heat treatment process thermally deform to form a three dimensional interlocking joint between the first and second core pieces by allowing thermal creep to irreversibly interlock the first and second core pieces together such that the joint becomes physically locked together providing joint stability through thermal processing.

Owner:MIKRO SYSYTEMS INC +1

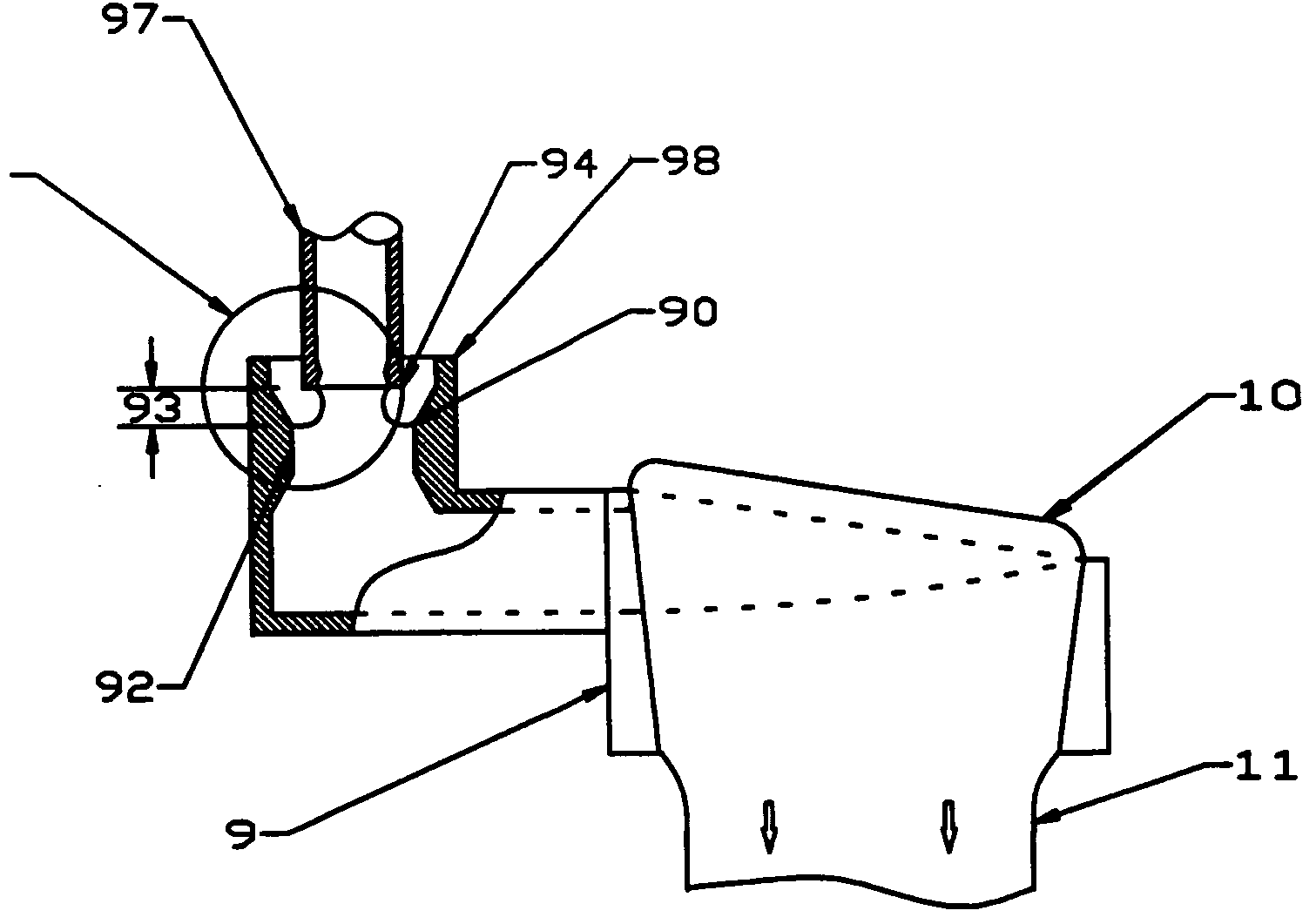

Sheet glass forming apparatus

InactiveUS20050092027A1Minimize air leakageReduce unevennessGlass furnace apparatusGlass drawing apparatusFlat glassInternal pressure

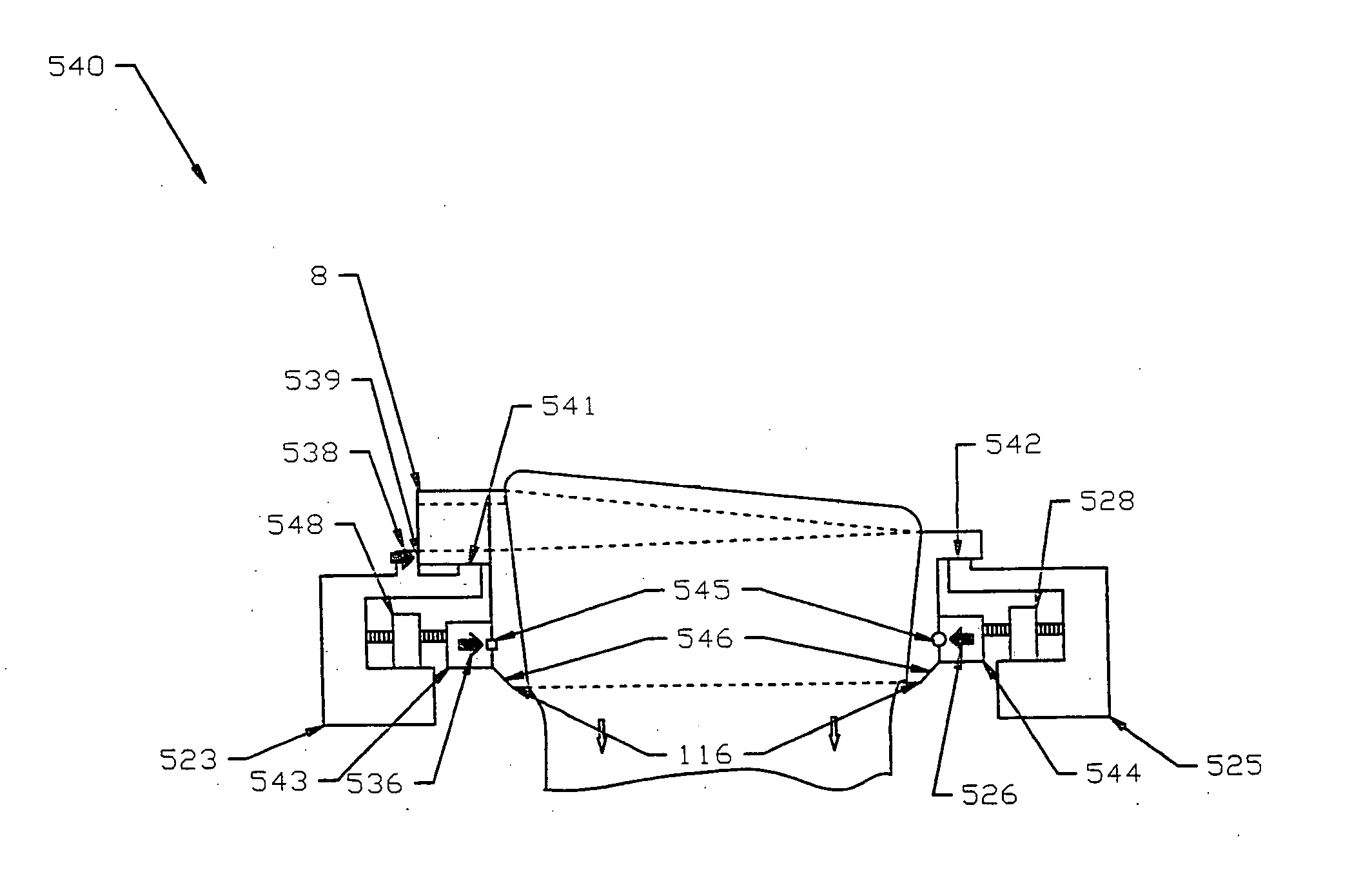

One embodiment of the present invention is an improved sheet glass forming apparatus. In another embodiment, a precise thermal control system redistributes the flow of molten glass at the weirs to counteract the degradation of the sheet forming apparatus which inevitably occurs during manufacturing. In yet another embodiment, the invention introduces a counteracting force to the stresses on the trough in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming trough. Another embodiment creates a variable external cross-section which provides hydraulic stresses that are in opposition to the surface tension and body force stresses and thus, reduces the influence of surface tension and body forces. In an alternative embodiment, the glass is preferentially cooled across its width to create forming stresses during solidification, which ensures that the glass sheet drawn is inherently flat. In an additional embodiment, the internal pressure is adjusted in each of the major components of the forming apparatus such that the pressure difference across any leakage path to the forming zone is essentially zero. Therefore, air leakage in the apparatus is minimized even though the cracks and openings exist during initial operation and develop during manufacturing.

Owner:CORNING INC

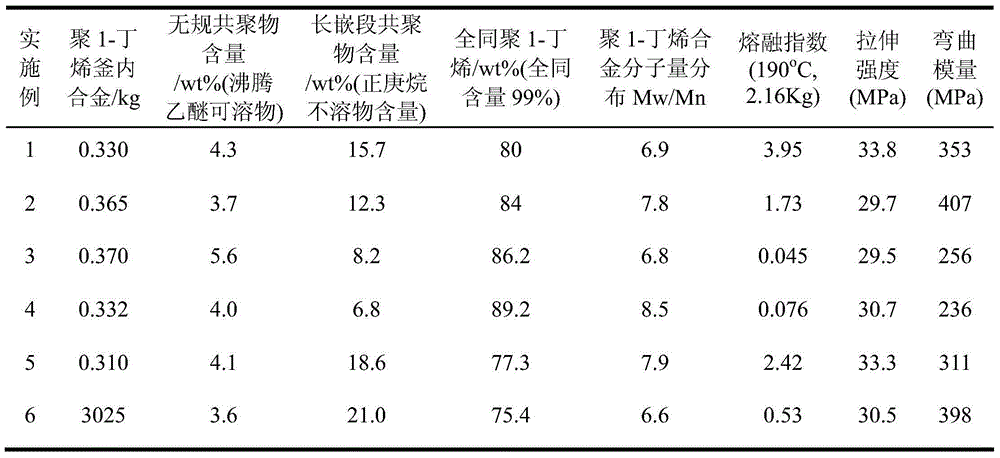

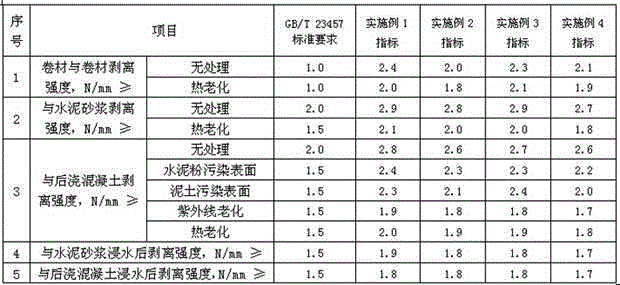

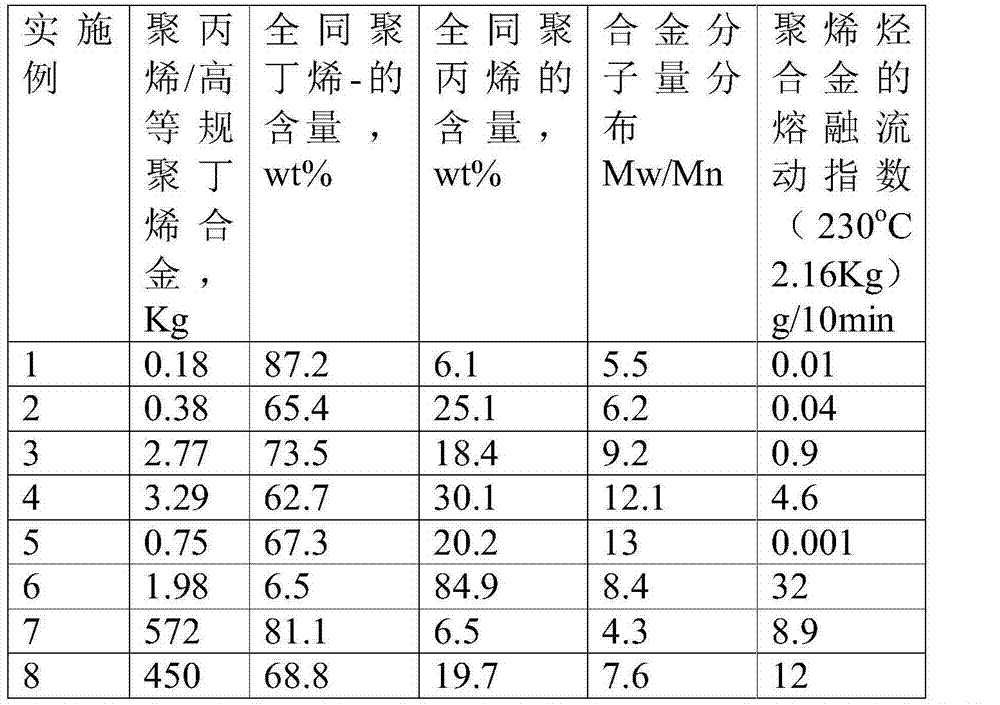

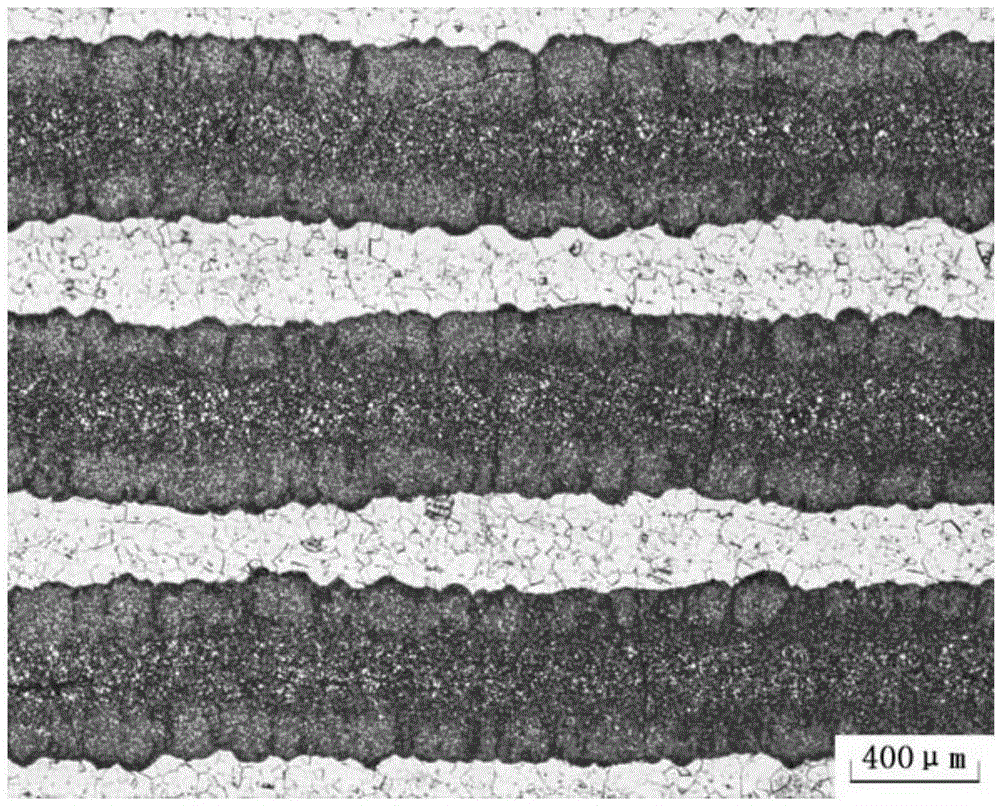

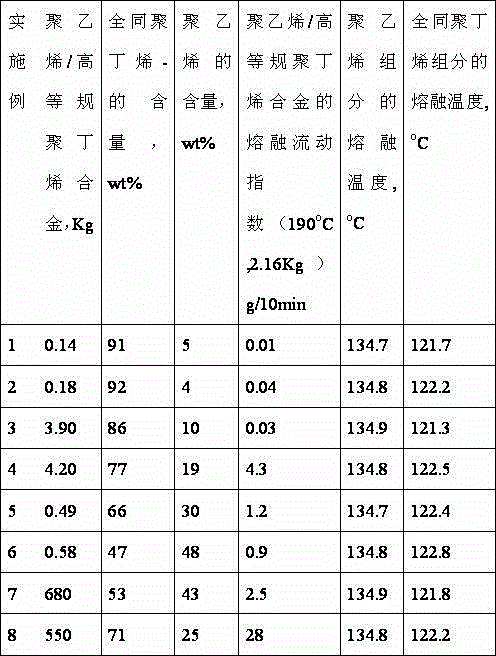

Poly 1-butene/1-butylene-propylene copolymer in-reactor alloy and preparation method thereof

ActiveCN103951898AImprove crystal transformation rateStrong impact resistancePolymer sciencePolyolefin

The invention discloses a poly 1-butene / 1-butylene-propylene copolymer in-reactor alloy material and a preparation method thereof, belongs to the field of polyolefin material, and relates to poly 1-butene in-reactor alloy, and a preparation method and applications thereof. According to the poly 1-butene / 1-butylene-propylene copolymer in-reactor alloy material, a poly 1-butene homopolymer is taken as a main ingredient, and the poly 1-butene / 1-butylene-propylene copolymer in-reactor alloy material comprises a small amount of a 1-butylene / propylene copolymer, wherein molar content of propylene monomer unit ranges from 2 to 25%, molar content of 1-butene monomer unit range from 75 to 98%, mass content of poly 1-butene ranges from 65 to 89%, and mass content of the 1-butylene / propylene copolymer ranges from 35 to 11%. The poly 1-butene / 1-butylene-propylene copolymer in-reactor alloy material is prepared by adopting a high-efficient loaded Ti catalytic system and via two-stage bulk in-suit polymerization. The polybutene alloy material possesses excellent shock resistance and thermal creep resistance, and low shrinking rate of the poly 1-butene homopolymer; is capable of increasing crystal transfer rate of poly 1-butene, and shortening shaping and curing time at the same time; and can be used for replacing a part of polyethylene and polypropylene for preparation of tubular products or for toughening modification of polypropylene.

Owner:QINGDAO UNIV OF SCI & TECH

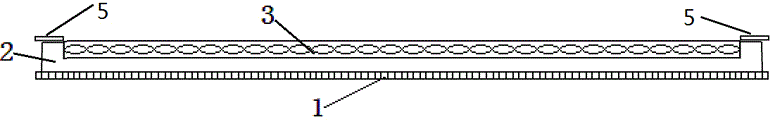

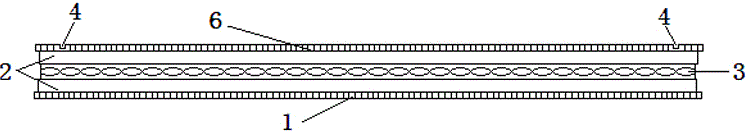

Preparation method for self-adhesive modified asphalt waterproof coiled material with cement reactivity

ActiveCN104057668AOvercoming technical deficienciesObvious cost advantageNon-macromolecular adhesive additivesBituminous material adhesivesSelf-healingBituminous waterproofing

The invention relates to a preparation method for a self-adhesive modified asphalt waterproof coiled material with cement reactivity. According to the technical scheme, the method comprises the following steps of coating on one or two sides of a base reinforcement layer with modified asphalt pressure sensitive self-adhesive glue with cement reactivity to form (a) modified asphalt pressure sensitive self-adhesive glue layer(s) by using an oil coating roller pair, and wrapping the modified asphalt pressure sensitive self-adhesive glue layer(s) with (an) anti-sticking separation film(s) to prepare a self-adhesive modified asphalt waterproof coiled material product with cement reactivity. The method has the beneficial effects that the modified asphalt pressure sensitive self-adhesive glue is used, so that the coiled material is endowed with a cement mortar adhesion characteristic, and has a thermal creep characteristic, the problem that an adhered surface is polluted by dust and the like on a construction site is effectively solved, and the range of construction application temperature of the coiled material is widened; the modified asphalt pressure sensitive self-adhesive glue is permanently and organically combined with concrete of a structural layer, and the hidden danger of water mixing is avoided; the reliability of a waterproof layer is improved, and unique self-healing capability for slight construction damage is achieved.

Owner:胜利油田大明新型建筑防水材料有限责任公司

High isotactic polypropylene alloy material and preparation method thereof

The invention discloses a high isotactic polypropylene alloy material and a preparation method thereof. The material contains 5-98.9 parts by weight of polybutylene, 1-80 parts by weight of polypropylene and 0.1-15 parts by weight of propylene-butene copolymer; the isotacticity of the high isotactic polypropylene is larger than 85%, and the smelting point of the high isotatic polypropylene is 115-129 DEG C; the isotacticity of the high isotactic polypropylene is larger than 85%, and the smelting point of the high isotactic polypropylene is 155-169 DEG C; the propylene-butene copolymer contains a random copolymer and a segmented copolymer of propylene-butene. The preparation method uses a titanium / vanadium supported catalyst and adopts a multistage sequential polymerization manner and specifically comprises the steps of carrying out propylene polymerization or butane-1 polymerization, then initiating butane-1 polymerization or propylene polymerization, and respectively carrying out propylene polymerization or butane-1 polymerization, and so on to synthesize the high isotactic polypropylene alloy material. The material is a powdery or spherical product, and has the advantages of excellent impact resistance, thermal creep resistance and low shrinking percentage of polybutylene, high modulus, high surface hardness and fast setting of polypropylene, and the like.

Owner:QINGDAO UNIV OF SCI & TECH +1

Overflow downdraw glass forming method and apparatus

ActiveUS20110277504A1Reduces adverse influenceReduce widthGlass drawing apparatusGlass forming apparatusFlat glassThermal creep

The present invention discloses improved methods and apparatus for forming sheet glass. In one embodiment, the invention introduces a counteracting force to the stresses on the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

Turbine component casting core with high resolution region

A hollow turbine engine component with complex internal features can include a first region and a second, high resolution region. The first region can be defined by a first ceramic core piece formed by any conventional process, such as by injection molding or transfer molding. The second region can be defined by a second ceramic core piece formed separately by a method effective to produce high resolution features, such as tomo lithographic molding. The first core piece and the second core piece can be joined by interlocking engagement that once subjected to an intermediate thermal heat treatment process thermally deform to form a three dimensional interlocking joint between the first and second core pieces by allowing thermal creep to irreversibly interlock the first and second core pieces together such that the joint becomes physically locked together providing joint stability through thermal processing.

Owner:MIKRO SYSYTEMS INC +1

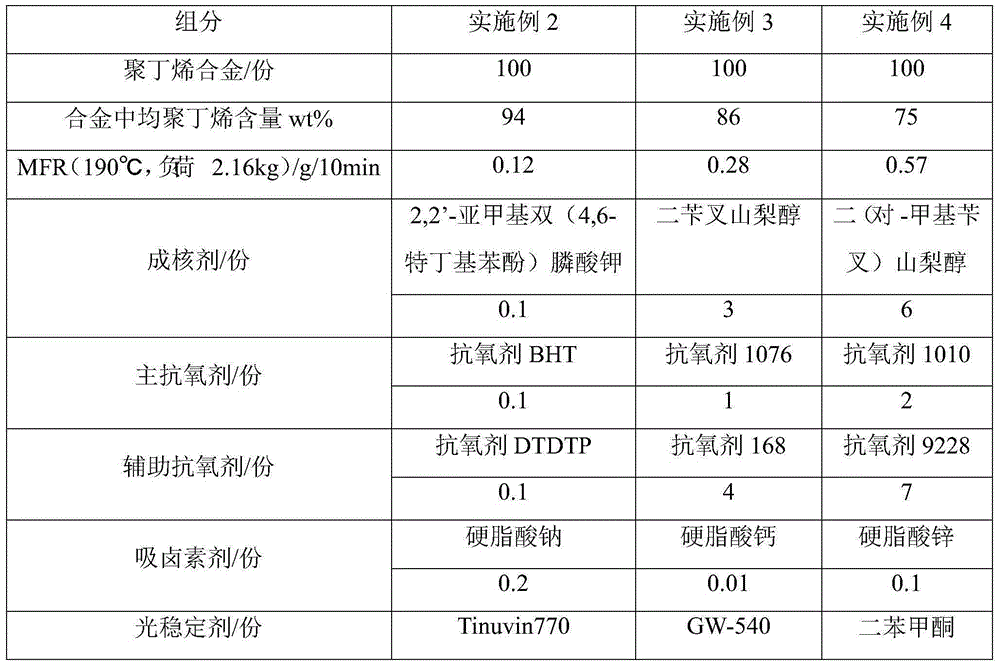

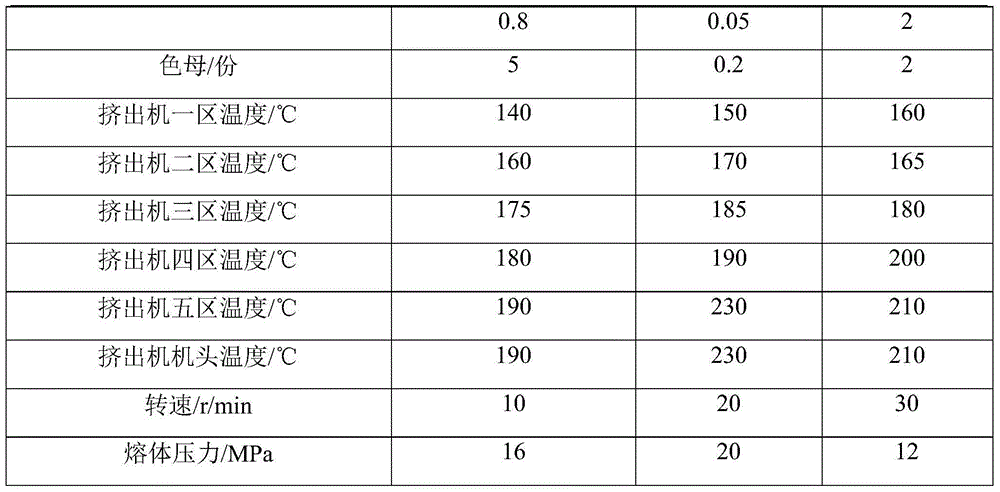

Special polybutylene alloy pipe material for cold/hot water pipe and preparation method of special polybutylene alloy pipe material

The invention relates to a special polybutylene alloy pipe material for a cold / hot water pipe and a preparation method of the special polybutylene alloy pipe material, belonging to the field of high polymer materials. The special polybutylene alloy pipe material comprises the following components: polybutylene alloy, an antioxidant, a halogen absorber, a light stabilizer, a color masterbatch and a nucleating agent. The preparation method comprises the steps of uniformly mixing the polybutylene alloy, the antioxidant, the halogen absorber, the light stabilizer, the nucleating agent and the color masterbatch by using a high-speed mixer; and extruding and pelleting to obtain the special polybutylene alloy pipe material for the cold / hot water pipe. The tensile strength and bending modulus of the special polybutylene alloy pipe material are greatly improved on the basis that the impact resistance, excellent environment stress crack resistance and thermal creep resistance of polybutylene are kept, and the special polybutylene alloy pipe material can be used as a cold / hot water pipe and pipe fitting material.

Owner:QINGDAO UNIV OF SCI & TECH +2

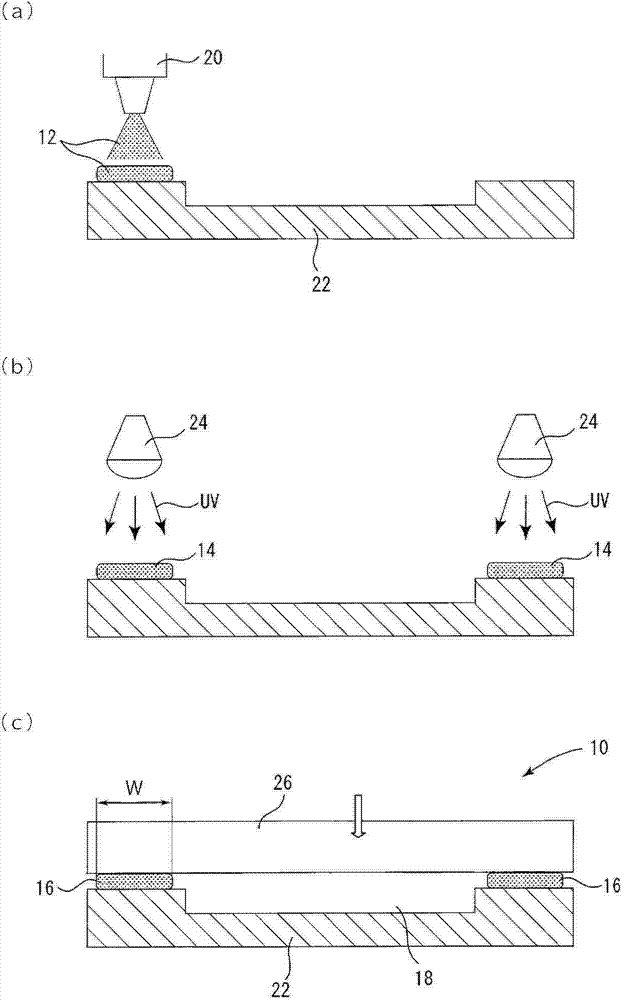

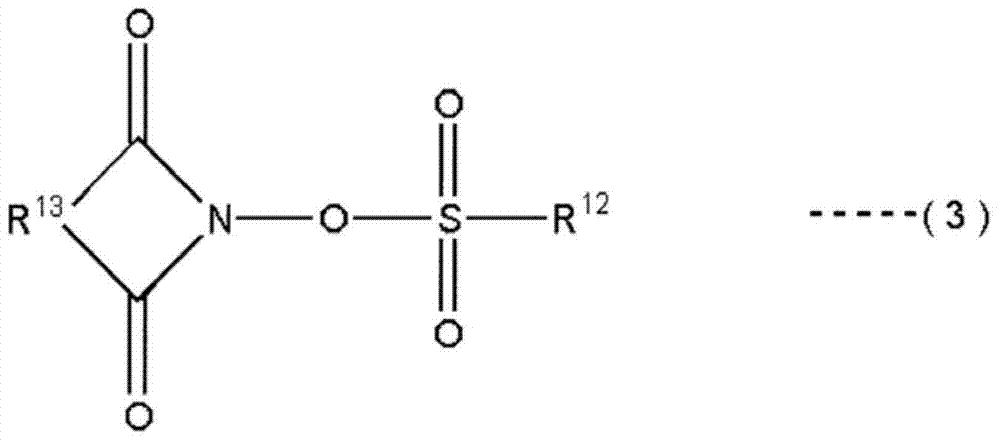

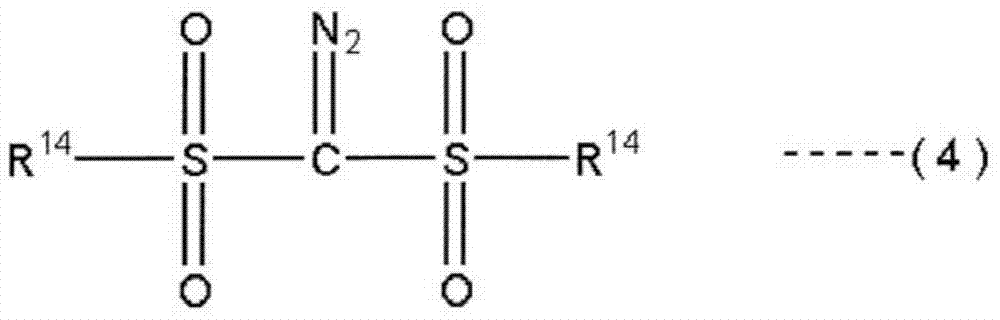

Photocurable Composition

InactiveCN103926795AImprove workabilityIncreased durabilityPhotosensitive materials for photomechanical apparatusNon-linear opticsHydrogen atomSilylene

The invention provides a photocurable composition, a cured object of the photocurable composition, an optical equipment component with the cured object, a set of optical equipment, and a manufacturing method of a display module with the photocurable composition. The photocurable composition has excellent thermal creep resistance, excellent operability, excellent durability and excellent binding performance. Furthermore thick film of the photocurable composition can be cured. The solution of the photocurable composition is characterized in that the photocurable composition comprises the components of: (A) a (methyl)acrylate series polymer with more than 0.8 crossed organosilyl in one molecule, (B) a composition of the (methyl)acrylate series group comprising the (methyl)acrylate series group represented by a general formula (1), (C) a curing catalyst, (F) an optical free radial and (I) a resin filler with an average particle diameter of 1-150 mu m. -OC(O)C(R1)=CH2...(1) (wherein in the general formula (1), R1 represents a hydrogen atom or an organic group with number of carbon atoms in 1-20.).

Owner:CEMEDAINE CO LTD

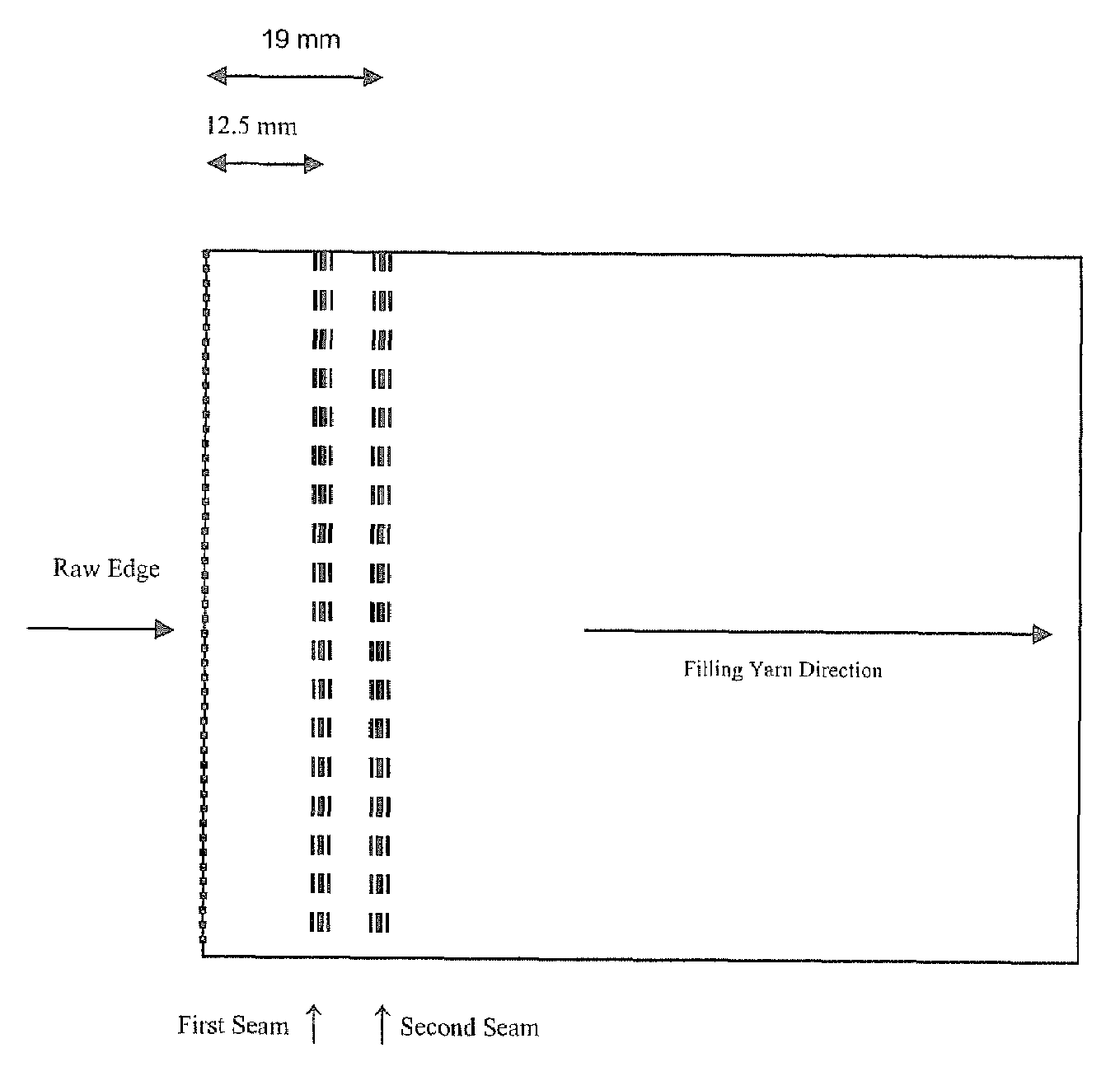

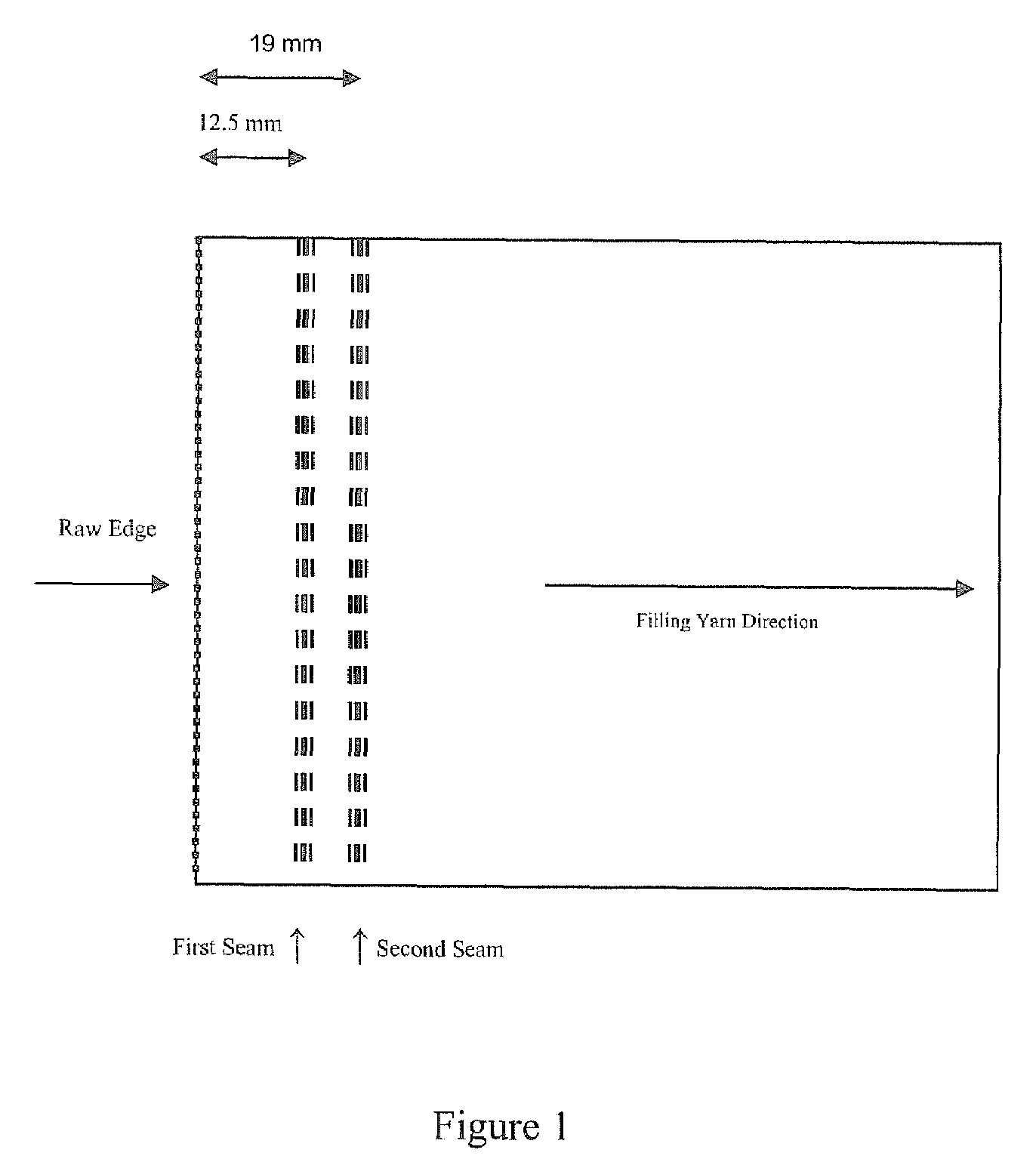

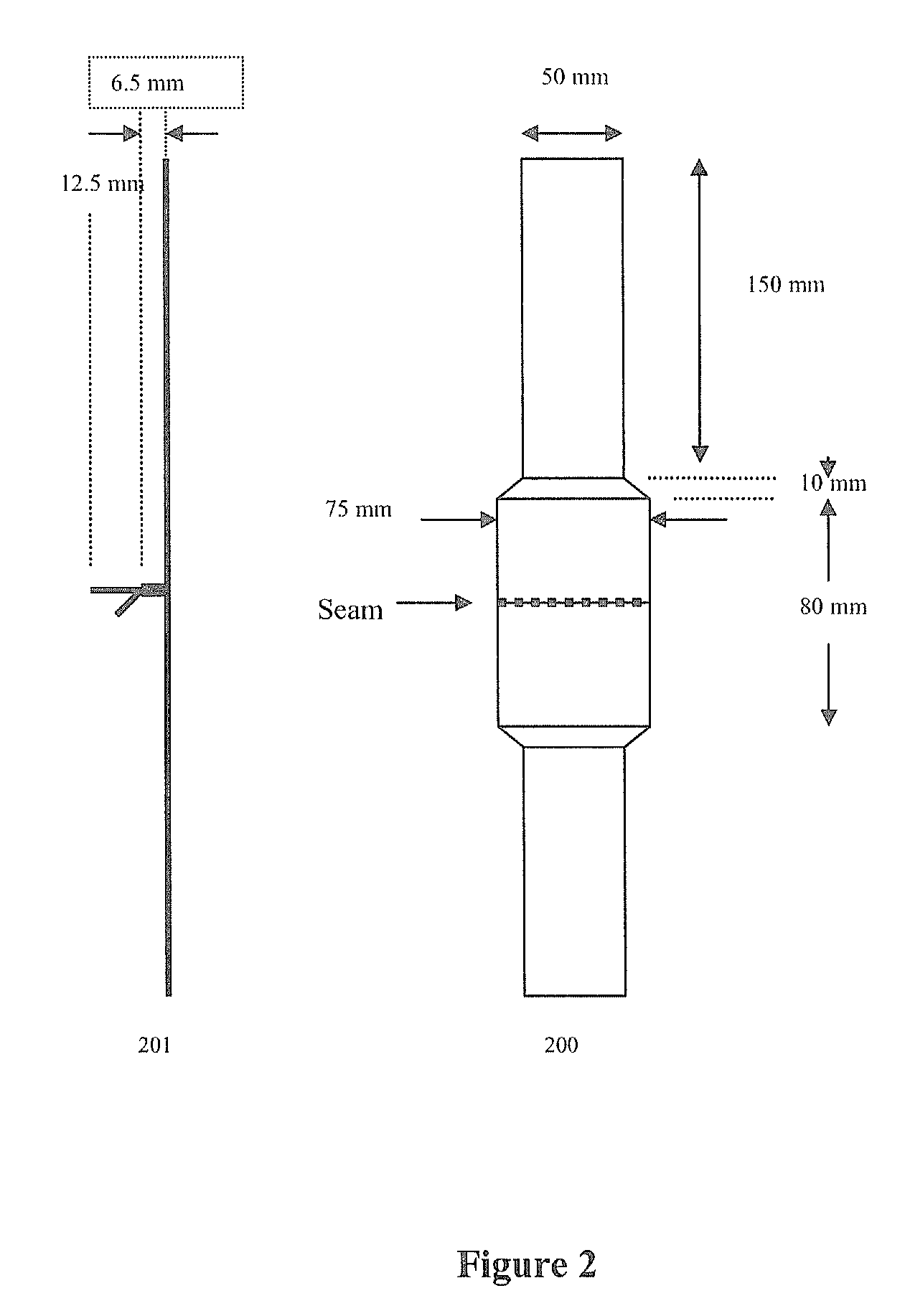

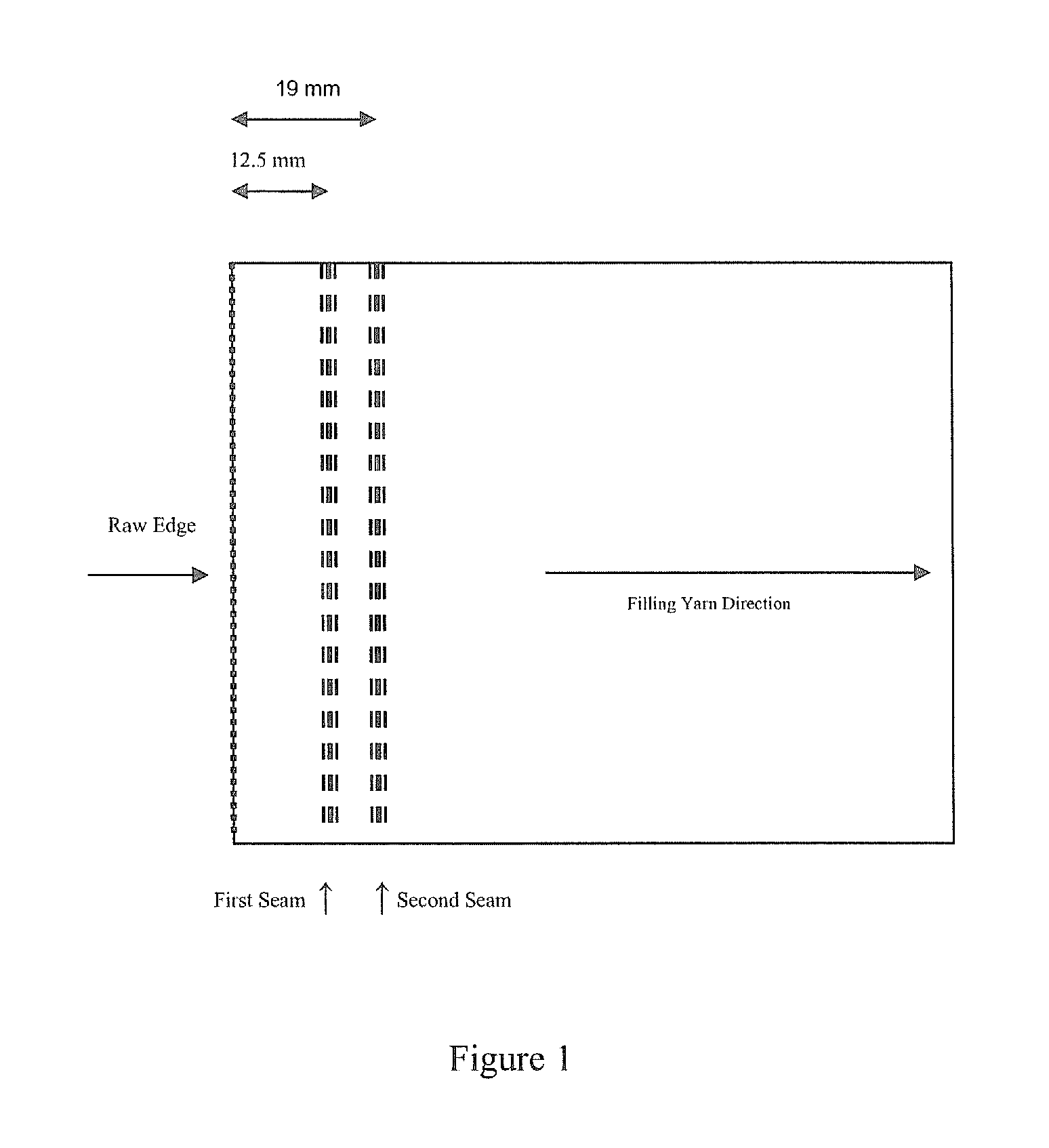

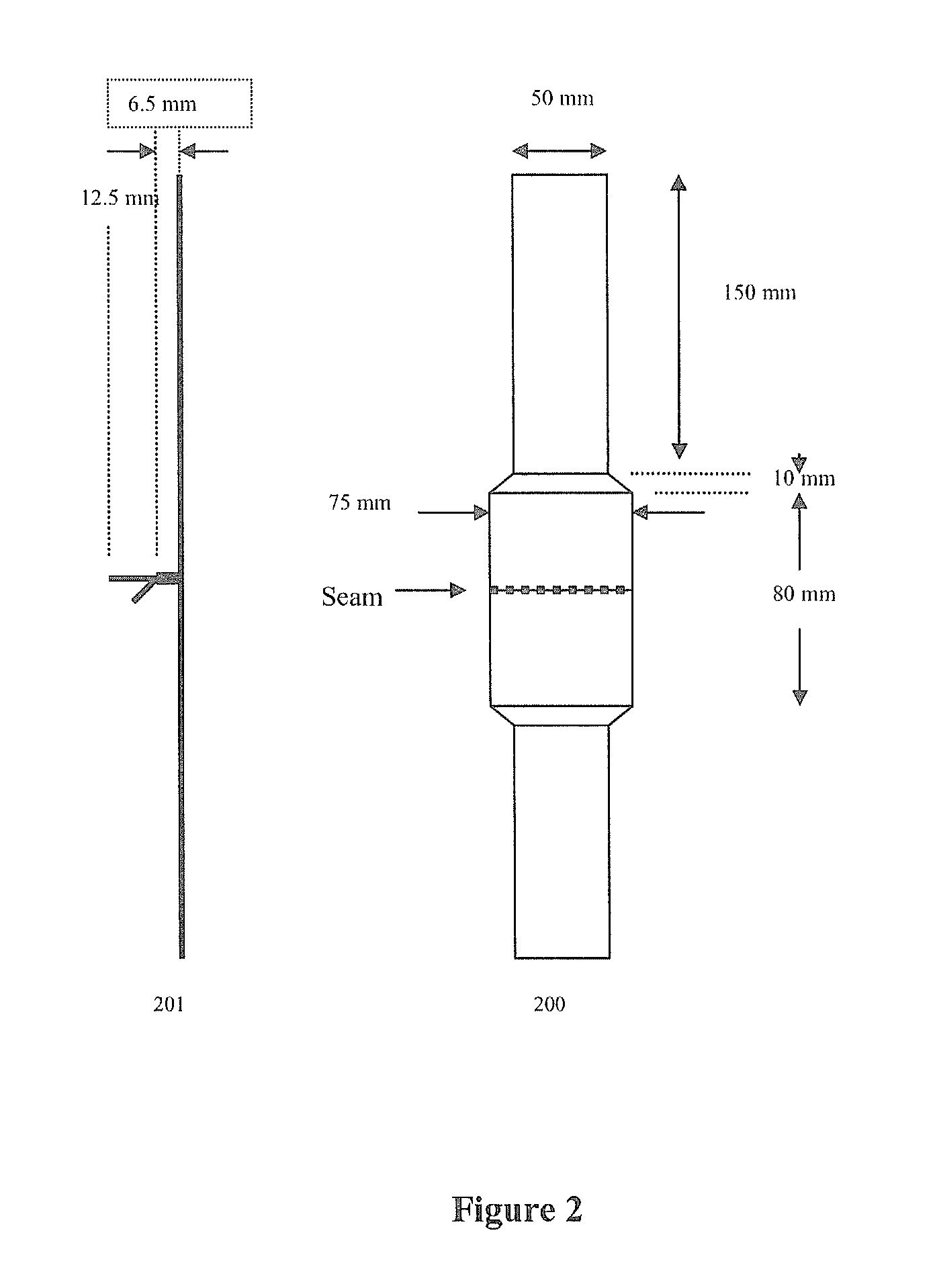

Woven polyester fabric for airbags

ActiveUS7375042B2Pedestrian/occupant safety arrangementSynthetic resin layered productsThermal creepEngineering

The present invention relates to a woven polyester fabric for use in airbags. The present invention includes a woven fabric using a polyester filament yarn, wherein the polyester filament yarn has a tenacity of about 65 cN / tex or greater and an Instantaneous Thermal Creep (ITC) at 100° C. of about 0.5% or less. Additional embodiments of the present invention include an airbag made from the woven polyester fabric. Woven fabrics of the present invention can reduce the extent of seam combing during a hot module deployment of an airbag.

Owner:INV PERFORMANCE MATERIALS LLC

Woven polyester fabric for airbags

ActiveUS20080014816A1Pedestrian/occupant safety arrangementSynthetic resin layered productsThermal creepEngineering

The present invention relates to a woven polyester fabric for use in airbags. The present invention includes a woven fabric using a polyester filament yarn, wherein the polyester filament yarn has a tenacity of about 65 cN / tex or greater and an Instantaneous Thermal Creep (ITC) at 100° C. of about 0.5% or less. Additional embodiments of the present invention include an airbag made from the woven polyester fabric. Woven fabrics of the present invention can reduce the extent of seam combing during a hot module deployment of an airbag.

Owner:INV PERFORMANCE MATERIALS LLC

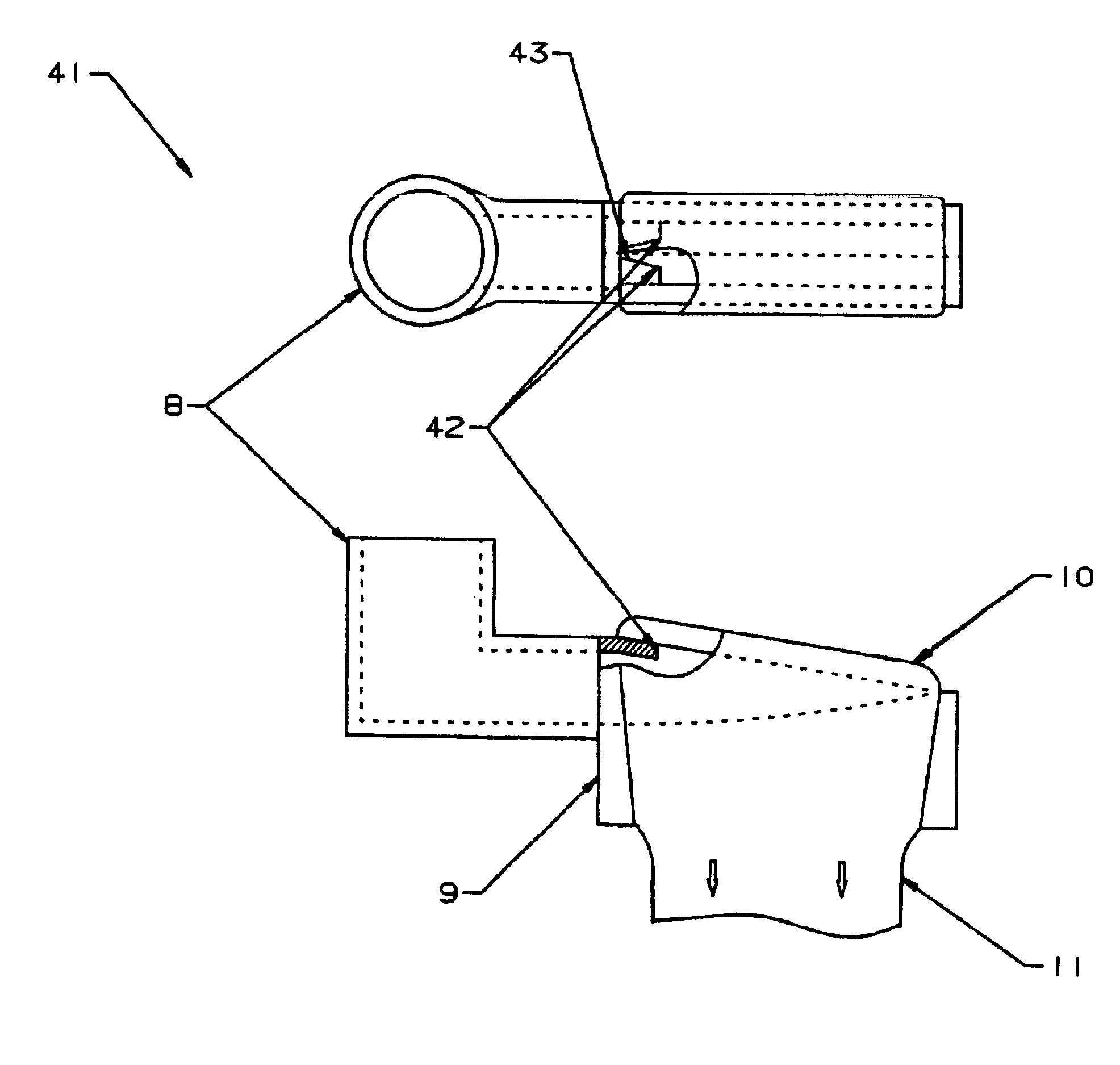

Overflow downdraw glass forming method and apparatus

InactiveUS7748236B2Minimum effect on the thickness variation of the glass sheetProduce minimizedGlass drawing apparatusGlass forming apparatusFlat glassThermal creep

The present invention discloses improved apparatuses for forming sheet glass. In one embodiment, the invention introduces a structural web that supports the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

Overflow Downdraw Glass Forming Method and Apparatus

InactiveUS20070144210A1Minimum effect on the thickness variation of the glass sheetProduce minimizedGlass drawing apparatusGlass forming apparatusFlat glassThermal creep

The present invention discloses improved apparatuses for forming sheet glass. In one embodiment, the invention introduces a structural web that supports the forming structure in a manner such that the thermal creep which inevitably occurs has a minimum impact on the glass flow characteristics of the forming structure.

Owner:CORNING INC

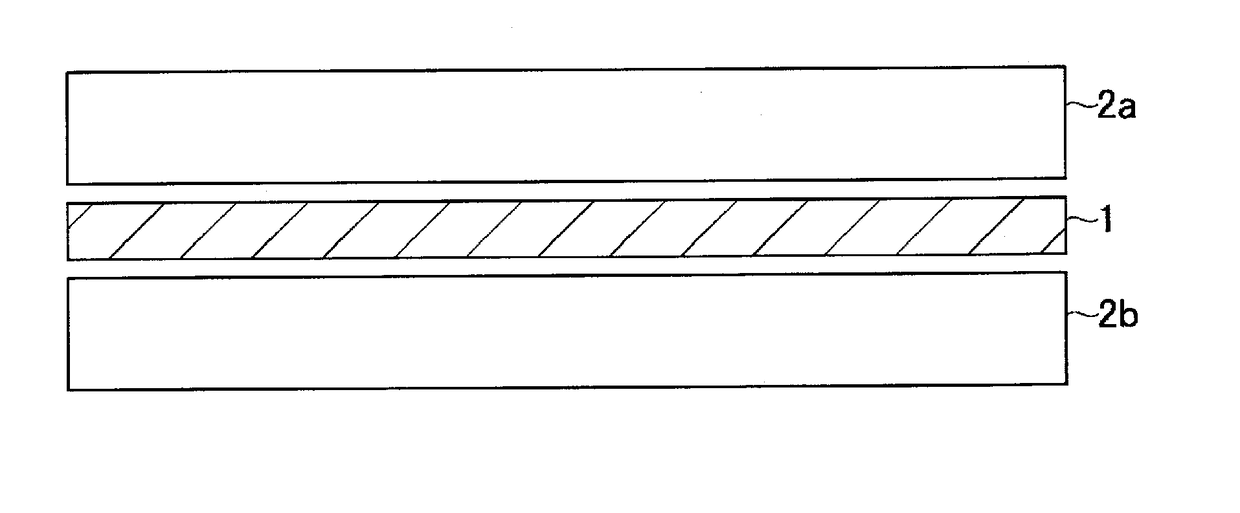

Interlayer film for laminated glass and laminated glass

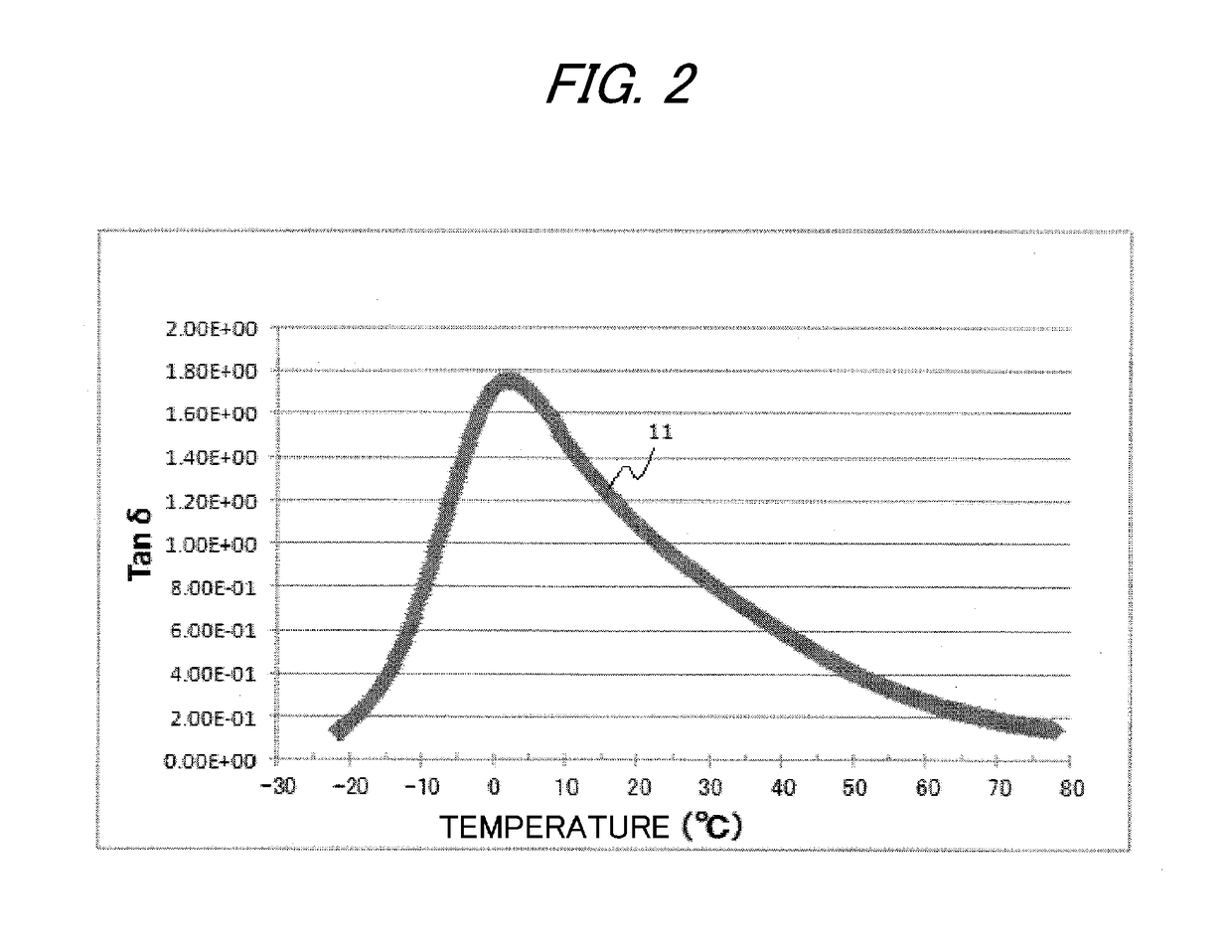

ActiveUS20170361575A1Improve sound insulationMaintain heatWindowsLayered product treatmentPolymer scienceWeather resistance

A first object of the invention is to provide an interlayer film for laminated glass which has excellent sound insulating properties and heat shielding properties, and a laminated glass using the same. Further, a second object of the invention is to provide an interlayer film for laminated glass capable of maintaining the sound insulating properties, weather resistance, and heat creep resistance at a high level even if the thickness is reduced, and a laminated glass using the same.The invention relates to an interlayer film for laminated glass, including at least one layer A containing a thermoplastic elastomer, wherein a laminated glass in which the interlayer film for laminated glass is disposed between two clear glasses with the total thickness of the clear glasses being 4 mm or less has a visible light transmittance of 70% or more and an average transmittance of infrared light in the wavelength range of 800 to 1,100 nm of 72% or less.

Owner:KURARAY CO LTD

Flame-perforated films having controlled tear characteristics and methods, systems, and apparatus for making same

The disclosure is directed to methods, systems, and apparatus for obtaining flame-perforated films which reduce or eliminate skewing of perforations in such films caused by thermal creep, whereby the film has perforations arranged to provide controlled tear characteristics, especially in both the lengthwise or machine direction (MD), and the crosswise or transverse direction (TD).

Owner:3M INNOVATIVE PROPERTIES CO

Preparation method of metallic/intermetallic compound laminar composite material

ActiveCN105414219ALow costMature technologyAuxillary arrangementsMetal rolling arrangementsThermal creepIntermetallic

The invention relates to a preparation method of a metallic / intermetallic compound laminar composite material. The preparation method comprises the followings steps: performing surface treatment on selected boards, further carrying out roll cladding, annealing treatment, casing removing and in-situ reaction by combining the thermal creeping forming technology when necessary. The metallic / intermetallic compound laminar composite material prepared by adopting the preparation method has the following progresses: the cost of raw materials is relatively low, the technology is mature, the efficiency is relatively high, the consequent in-situ reaction time is shortened, and the metallic / intermetallic compound laminar composite material with a complex curved structure can be prepared.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Silane grafted POE adhesive film for photovoltaic encapsulation and preparation method

ActiveCN108753184AHigh melting temperatureSolve the problem of poor thermal creep resistance that is prone to occurNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveAntioxidant

The invention belongs to the field of photovoltaic encapsulation adhesive films and preparation thereof, and particularly relates to a silane grafted POE photovoltaic encapsulation adhesive film and apreparation method thereof. The silane grafted POE adhesive film comprises the following components in parts by mass: 100 parts of ethylene-octene copolymer resin, 0.3-3 parts of silane grafted monomer, 0.05-0.25 parts of an initiator, 5-20 parts of modified resin, 0.05-0.25 parts of co-grafted monomer, 0.5-4 parts of a compatilizer, 0.05-0.3 parts of an ultraviolet light stabilizing agent, 0.05-0.3 parts of an ultraviolet absorber and 0.1-0.6 part of an antioxidant. The prepared adhesive film for POE photovoltaic encapsulation can be simultaneously applied to a flexible thin-film photovoltaic assembly and a traditional crystalline silicon photovoltaic assembly, the problems of air bubbles, no-melting and poor thermal creep resistance in an ageing process can be solved, the laminating time of the assemblies is shortened, the packaging defective percentage is reduced, the production efficiency of the assemblies is improved, and the production cost is reduced.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Polyolefin alloy material and preparation method thereof

The invention discloses a polyolefin alloy material and a preparation method thereof, belongs to the field of polyolefin materials and in particular relates to a polyethylene / highly isotactic polybutene alloy material and a preparation method thereof. According to the polyethylene / highly isotactic polybutene alloy material disclosed by the invention, the mass content of polybutene is 10-98.9 percent (the isotacticity is more than 85 percent), the mass content of polyethylene is 1-80 percent, and the mass content of a butane-ethylene copolymer is 0.1-10 percent. By utilizing the supported titanium and / or vanadium catalyst, the polyethylene / highly isotactic polybutene alloy material is synthesized by virtue of two-section polymerization, and the obtained polybutene alloy is a powdery or spherical product with a core-shell structure, has the advantages of excellent impact resistance, thermal creep resistance and low shrinkage rate of polybutene-1 and high modulus, high surface hardness and quick setting property of polyethylene, is used for manufacturing pipes and pipe fittings and performing toughening modification on polypropylene, or can serve as a universal polyolefin material and is a novel polyolefin material.

Owner:QINGDAO UNIV OF SCI & TECH +1

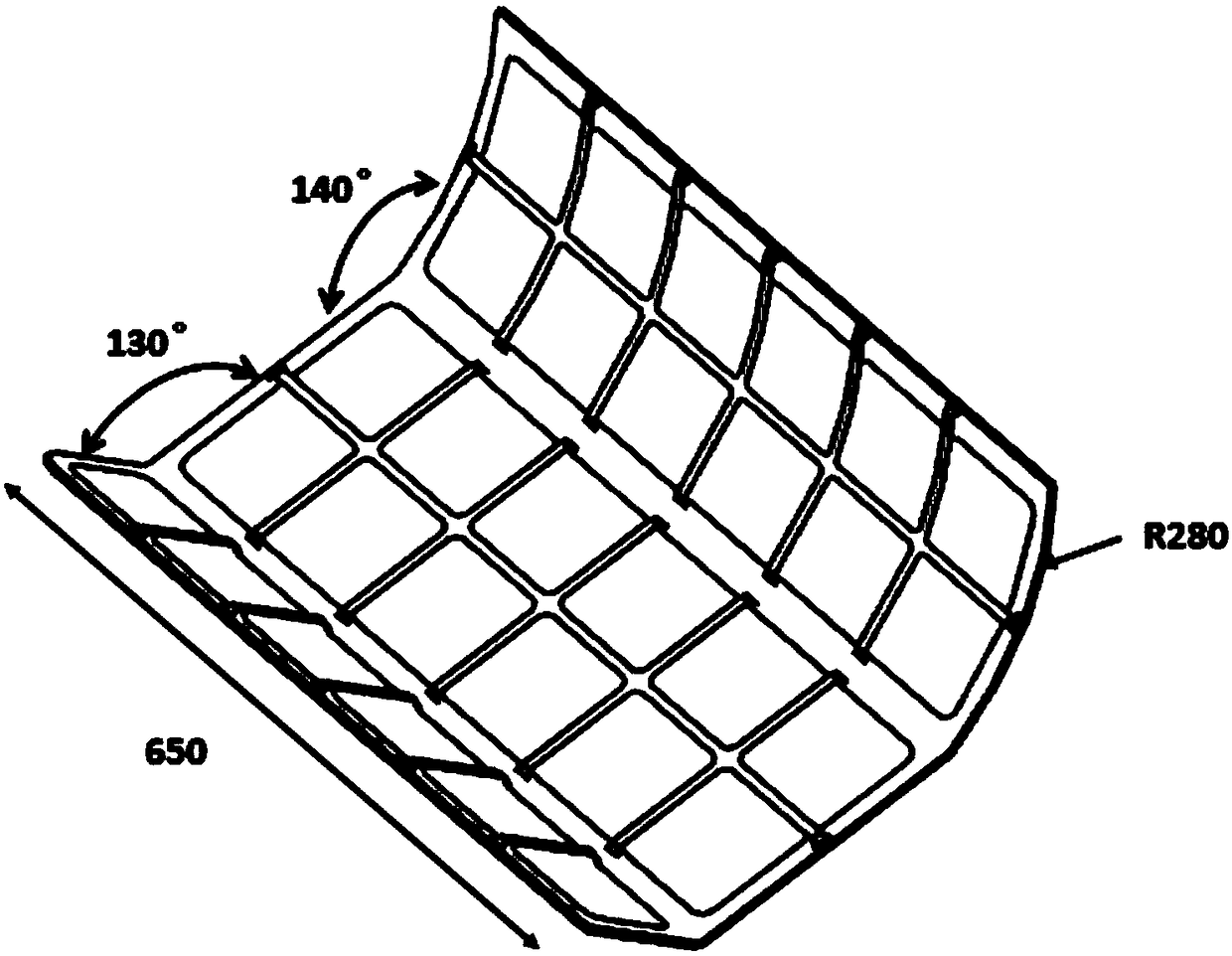

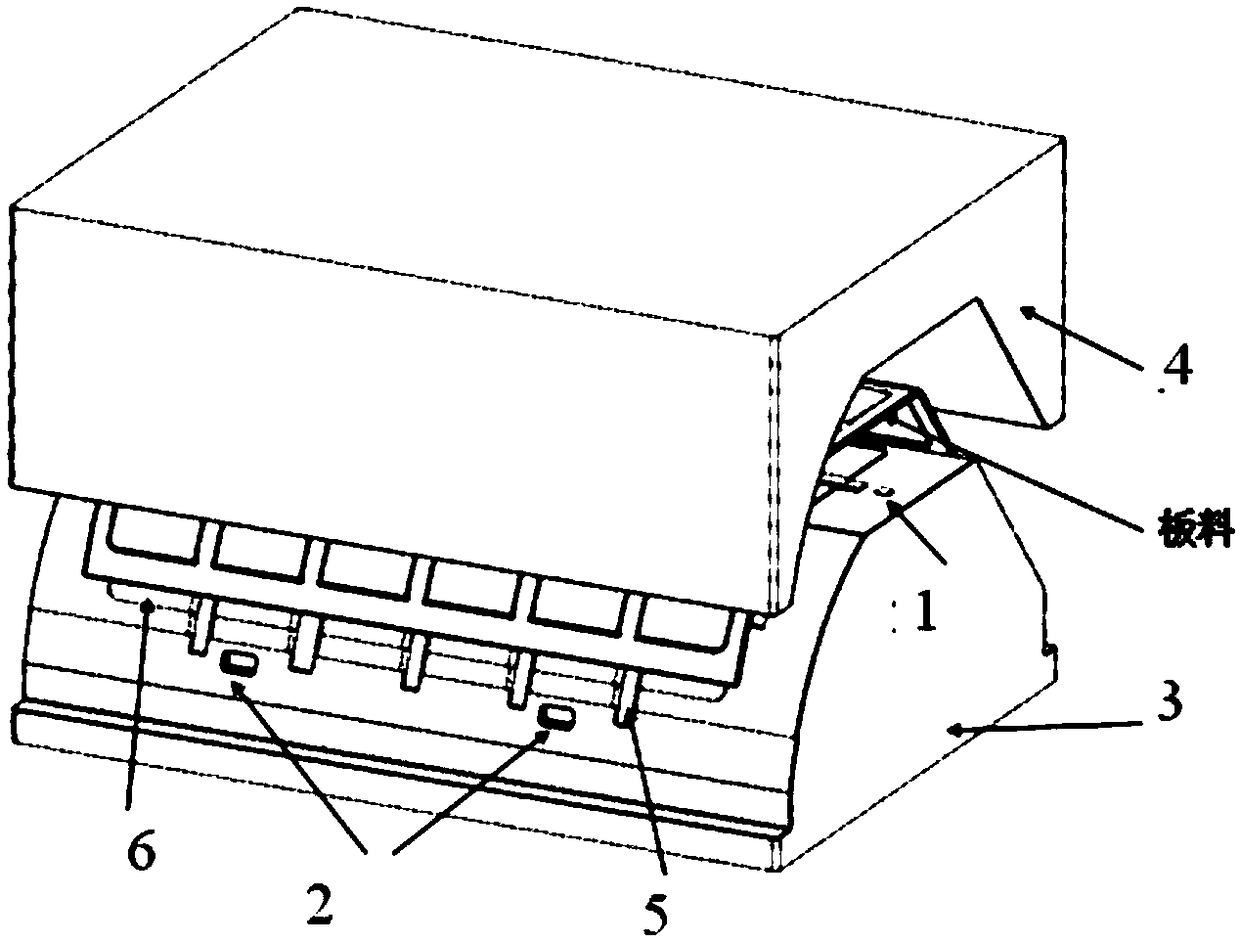

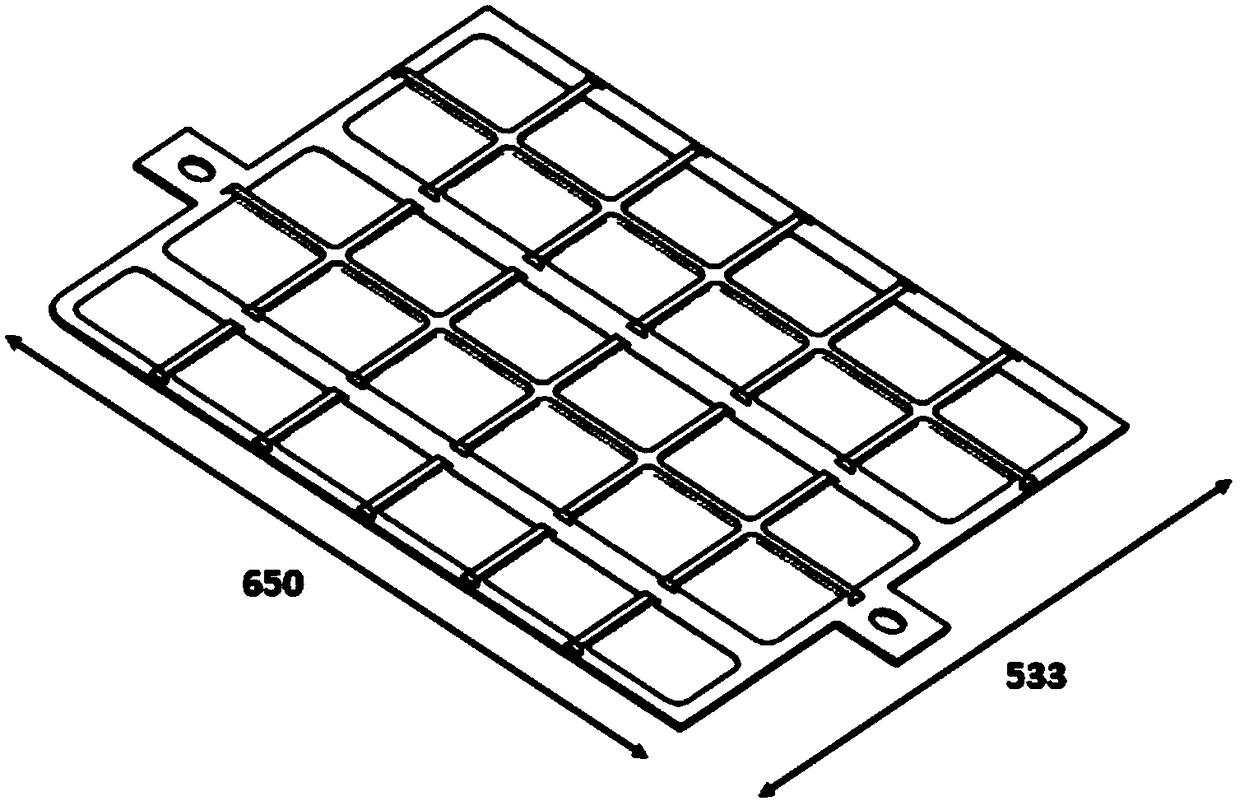

Thermal creep plastic forming method for special-shaped aluminum alloy wall plate with variable thicknesses

InactiveCN108856500AHigh dimensional accuracyHigh profile precisionShaping toolsVariable thicknessThermal creep

A thermal creep plastic forming method for special-shaped aluminum alloy wall plate with variable thicknesses and is suitable for the special-shaped aluminum alloy wall plate, high in size and moldedsurface precision requirement and good in surface quality, with the variable thicknesses. The method includes the following steps that firstly, a thermal creep plastic forming mold of the special-shaped aluminum alloy wall plate with the variable thicknesses is designed and machined; secondly, the special-shaped aluminum alloy wall plate with the variable thicknesses is subjected to plane unfolding; thirdly, according to the positions of reinforcing ribs in the plane unfolded drawing, corresponding reinforcing ribs are prepared on the plate, and positioning convex lugs are machined; fourthly,the special-shaped aluminum alloy wall plate with the variable thicknesses is bent in advance; fifthly, thermal creep plastic deforming is performed on the special-shaped aluminum alloy wall plate with the variable thicknesses; and sixthly, lineation is performed to cut off the positioning convex lugs. The wall plate formed through the method is short in machining period and low in cost, a formedpart is high in size and molded surface precision, and the surface quality is also remarkably improved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com