Preparation method for self-adhesive modified asphalt waterproof coiled material with cement reactivity

A modified asphalt and cement reaction technology, applied in the direction of asphalt material adhesives, chemical instruments and methods, adhesives, etc., can solve the problems of non-conformity of water impermeability of coiled materials, affecting bonding reliability, low flash point, etc. Achieving the effect of flexible construction characteristics on wet base surface, significant cost advantages, and solving technical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

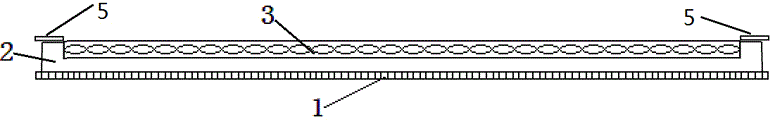

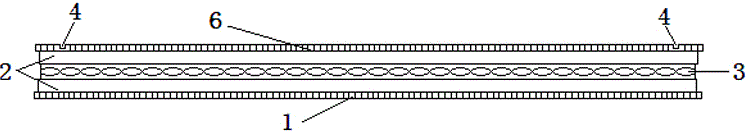

Image

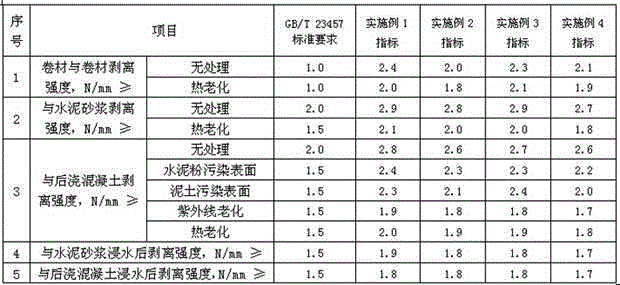

Examples

Embodiment 1

[0037] 1. Preparation method of modified asphalt pressure-sensitive self-adhesive with cement reactivity

[0038] The production method is to first add 45 parts of heavy-duty asphalt, 10 parts of naphthenic rubber oil and 4 parts of aromatic rubber oil into a vertical batching tank with a stirring device and mix them when the temperature rises to 140-160 ° C, and then slowly Add 6 parts of SBS thermoplastic rubber, 3 parts of SIS thermoplastic rubber, 2 parts of powdered styrene-butadiene rubber and 4 parts of butyl rubber powder, and then slowly raise the temperature to 160-180 °C, start the colloid mill and grind 2-3 times until nothing After the particles are visible to the naked eye, add 5 parts of liquid tackifying resin and 3 parts of petroleum resin to cool down and stir until the petroleum resin is melted evenly, then pump the modified asphalt into a horizontal filling mixing tank, add 15 parts of talcum powder and keep it warm and stir evenly, then add 3 parts of whit...

Embodiment 2

[0042] 1. Preparation method of modified asphalt pressure-sensitive self-adhesive with cement reactivity

[0043] The production method is to first add 45 parts of heavy-duty asphalt, 4 parts of naphthenic rubber oil and 6 parts of aromatic rubber oil into a vertical batching tank with a stirring device and mix them when the temperature rises to 140-160 ° C, and then slowly Add 5 parts of SBS thermoplastic rubber, 2 parts of SIS thermoplastic rubber, 2 parts of powdered styrene-butadiene rubber and 5 parts of butyl rubber powder, then slowly raise the temperature to 160-180°C, start the colloid mill and grind 2-3 times until nothing After the particles are visible to the naked eye, add 4 parts of liquid tackifying resin and 4 parts of petroleum resin to cool down and stir until the petroleum resin is melted evenly, then pump the modified asphalt into a horizontal filling mixing tank, add 20 parts of talcum powder and keep it warm and stir evenly, then add 3 parts of white carb...

Embodiment 3

[0047] 1. Preparation method of modified asphalt pressure-sensitive self-adhesive with cement reactivity

[0048] Its production method is to first add 35 parts of heavy asphalt and 8 parts of naphthenic rubber oil into a vertical batching tank with a stirring device, mix and heat up to 140-160 ° C, then slowly add 3 parts of SBS thermoplastic rubber, 0 1 part of SIS thermoplastic rubber, 0 part of powdered styrene-butadiene rubber and 5 parts of butyl rubber powder, then slowly increase the temperature to 160-180°C, start the colloid mill and "invert the tank" to grind for 2-3 times until no particles are visible to the naked eye, then add 1 part The liquid tackifying resin and 1 part of petroleum resin are cooled and stirred until the petroleum resin is melted evenly, then the modified asphalt is pumped into a horizontal filling mixing tank, and 15 parts of talcum powder is added to keep warm and stirred evenly, and then the concrete with cement reactivity can be made. Modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com