Patents

Literature

43results about How to "A wide range of materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of pre-laid waterproof coiled material for concrete mortar bonding construction

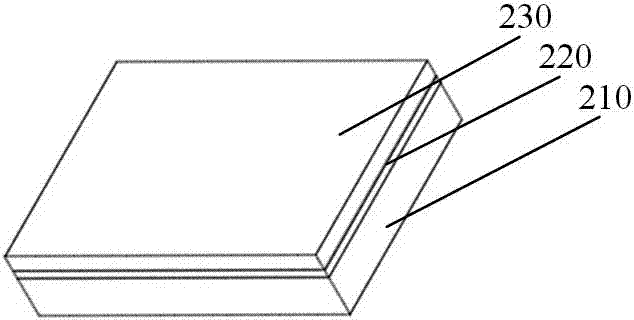

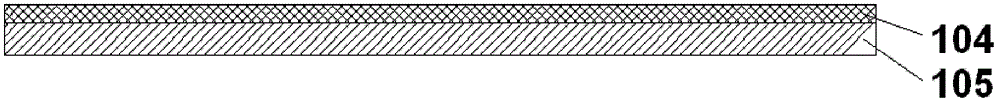

ActiveCN104057686ACost efficientObvious cost advantageSynthetic resin layered productsLaminationWet bondingMineral particles

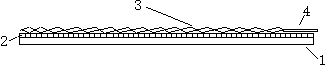

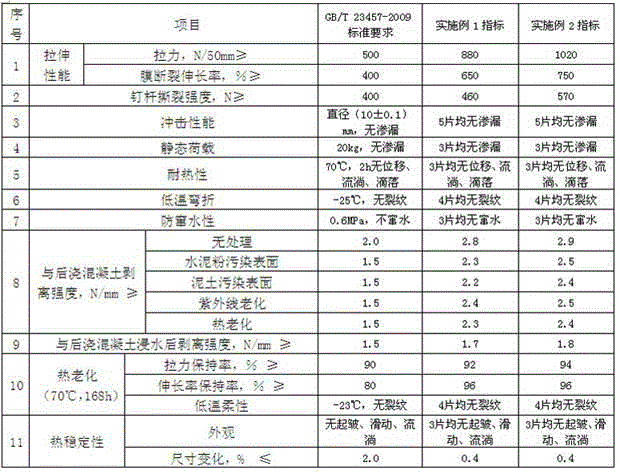

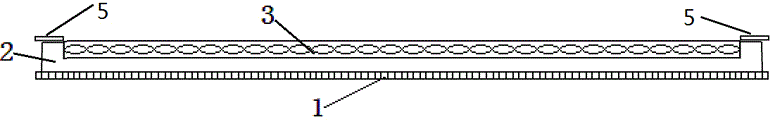

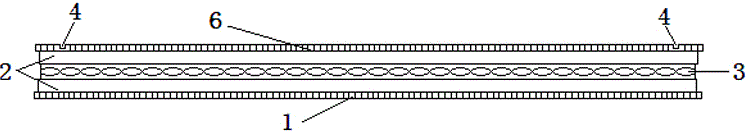

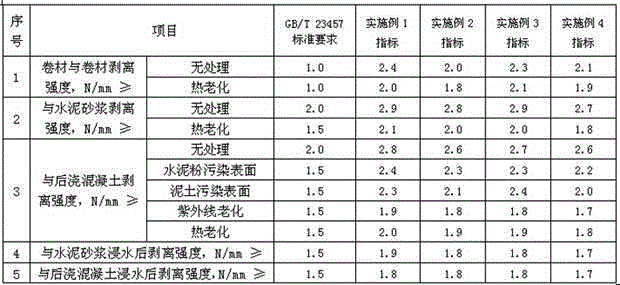

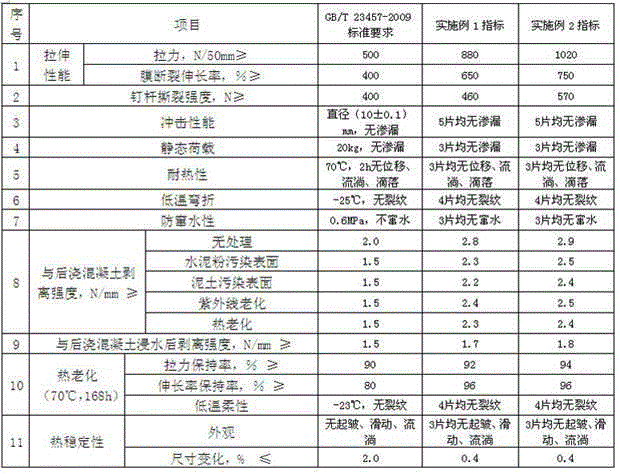

The invention relates to a preparation method of a pre-laid waterproof coiled material for concrete mortar bonding construction. According to the technical scheme, the preparation method comprises the following steps: fully applying an SIS hot-melt pressure-sensitive adhesive to a modified polyethylene plastic waterproof main body layer by virtue of a hot-melt pressure sensitive adhesive coating machine, so as to form an SIS hot-melt pressure-sensitive self-sticking layer, and then coating the hot-melt pressure-sensitive self-sticking layer with a weather resistant mineral grain functional layer with cement reactivity and an anti-sticking isolation membrane positioned on one side of the coiled material. The preparation method has the beneficial effects that (1) a novel wet bonding technique is provided, the coiled material and structural concrete are permanently and organically combined, no water channeling hazards exist between the coiled material and the structural concrete, and the reliability of a waterproof layer is improved; (2) the impact resistant performance and the puncture resistant performance are excellent, and the construction load which directly acts on the pre-laid waterproof coiled material and the impact of a steel skeleton can be born; (3) strong chemical resistance is provided; (4) the construction is convenient, and a leveling blanket is not needed; (5) the waterproof coiled material and a basic layer are in border adhibiting without influence of sedimentation deformation of the basic layer.

Owner:胜利油田大明新型建筑防水材料有限责任公司

Preparation method for self-adhesive modified asphalt waterproof coiled material with cement reactivity

ActiveCN104057668AOvercoming technical deficienciesObvious cost advantageNon-macromolecular adhesive additivesBituminous material adhesivesSelf-healingBituminous waterproofing

The invention relates to a preparation method for a self-adhesive modified asphalt waterproof coiled material with cement reactivity. According to the technical scheme, the method comprises the following steps of coating on one or two sides of a base reinforcement layer with modified asphalt pressure sensitive self-adhesive glue with cement reactivity to form (a) modified asphalt pressure sensitive self-adhesive glue layer(s) by using an oil coating roller pair, and wrapping the modified asphalt pressure sensitive self-adhesive glue layer(s) with (an) anti-sticking separation film(s) to prepare a self-adhesive modified asphalt waterproof coiled material product with cement reactivity. The method has the beneficial effects that the modified asphalt pressure sensitive self-adhesive glue is used, so that the coiled material is endowed with a cement mortar adhesion characteristic, and has a thermal creep characteristic, the problem that an adhered surface is polluted by dust and the like on a construction site is effectively solved, and the range of construction application temperature of the coiled material is widened; the modified asphalt pressure sensitive self-adhesive glue is permanently and organically combined with concrete of a structural layer, and the hidden danger of water mixing is avoided; the reliability of a waterproof layer is improved, and unique self-healing capability for slight construction damage is achieved.

Owner:胜利油田大明新型建筑防水材料有限责任公司

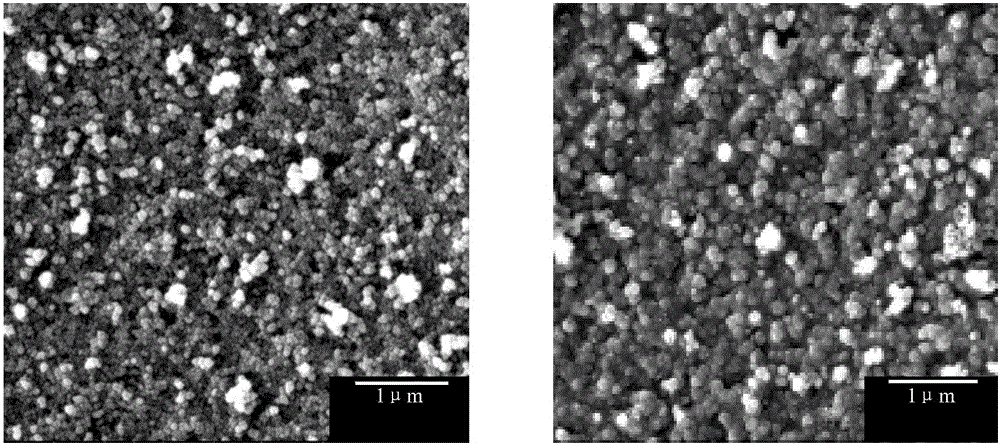

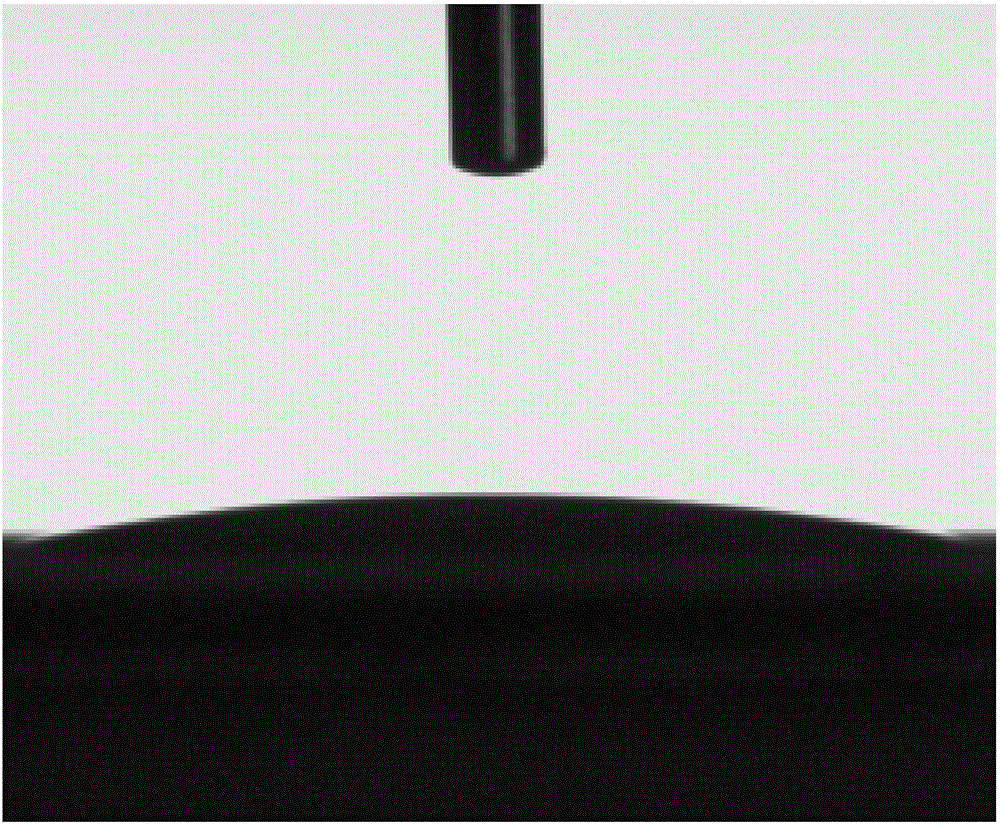

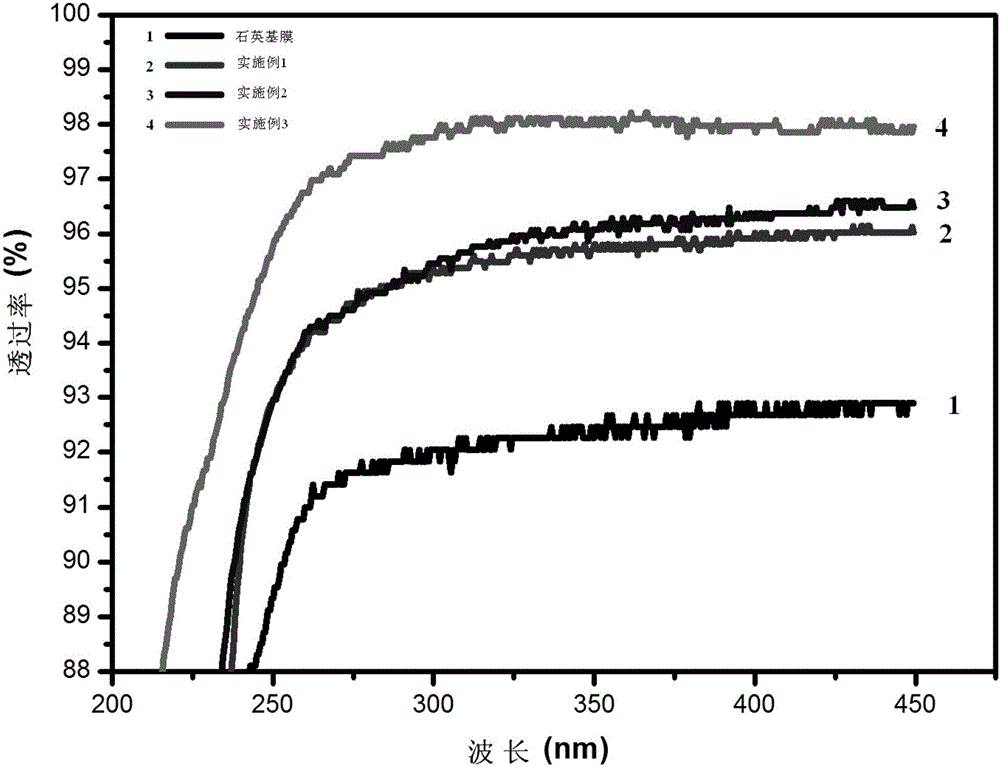

Nanometer calcium silicate hydrate super-hydrophilicity thin film as well as preparation method and applications of thin film

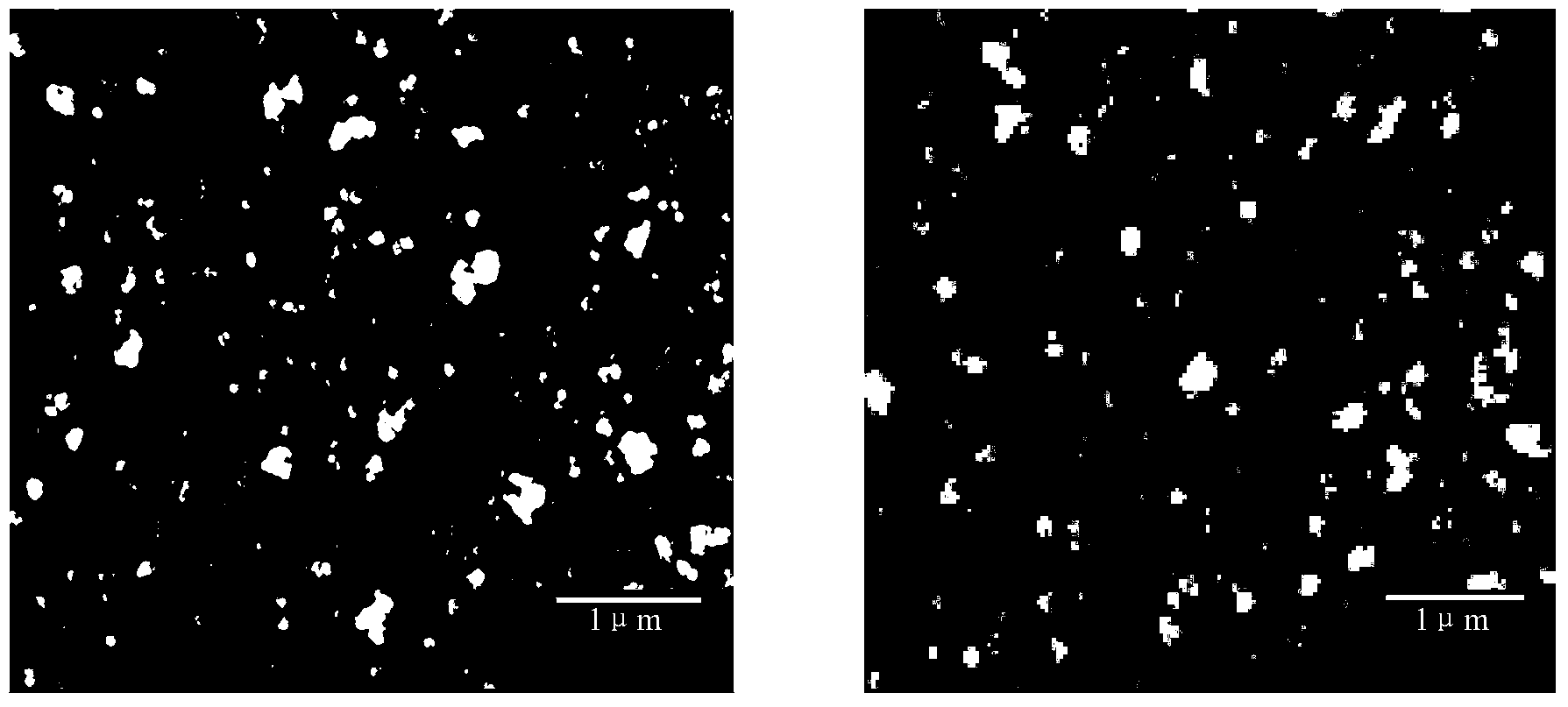

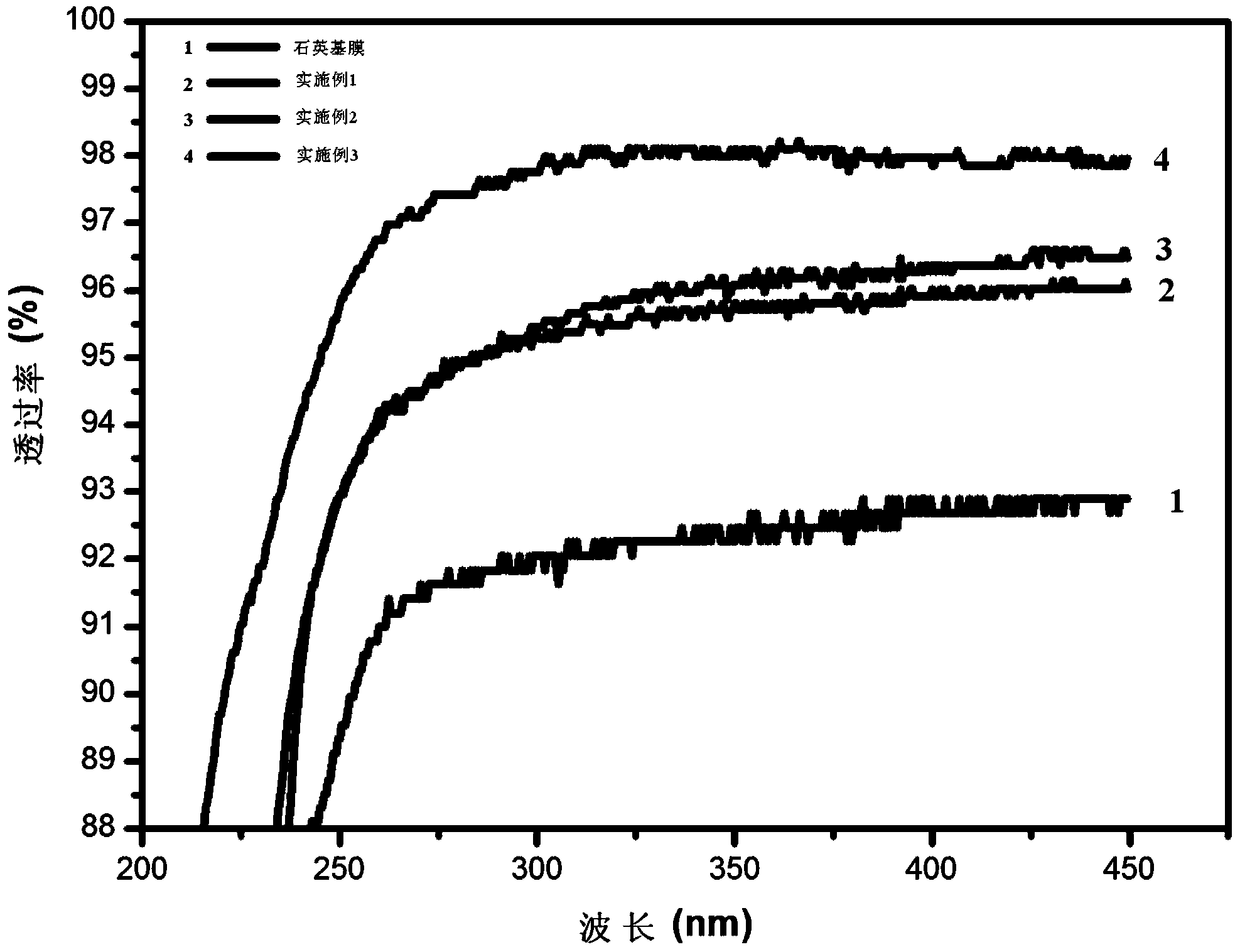

The invention discloses a nanometer calcium silicate hydrate super-hydrophilicity thin film as well as a preparation method and applications of the thin film and belongs to the field of functional composite materials. The preparation method comprises the steps of: soaking a pretreated base film with negative electric charges on surface in a 1.0-8.0g / L cationic polyelectrolyte solution containing 0.01mol / mL-0.1mol / mL soluble calcium salt for 10-30 minutes, then taking out the base film and flushing the base film with deionized water; soaking the base film in a 1.0-8.0g / L anionic polyelectrolyte solution containing 0.01mol / mL-0.1mol / mL soluble silicate for 10-30 minutes, then taking out the base film and completely flushing the base film with deionized water; repeating above operations for 1-3 times to obtain the polyelectrolyte nanometer calcium silicate hydrate super-hydrophilicity thin film. The super-hydrophilicity thin film has a super-hydrophilicity property and an excellent anti-fog property.

Owner:BEIJING UNIV OF TECH

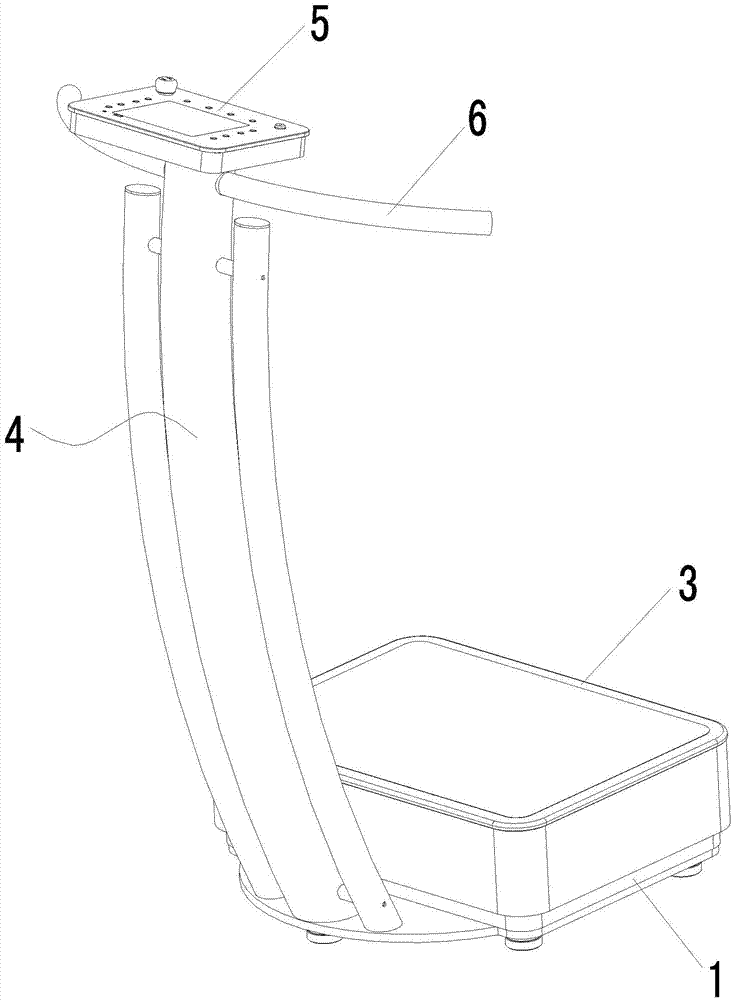

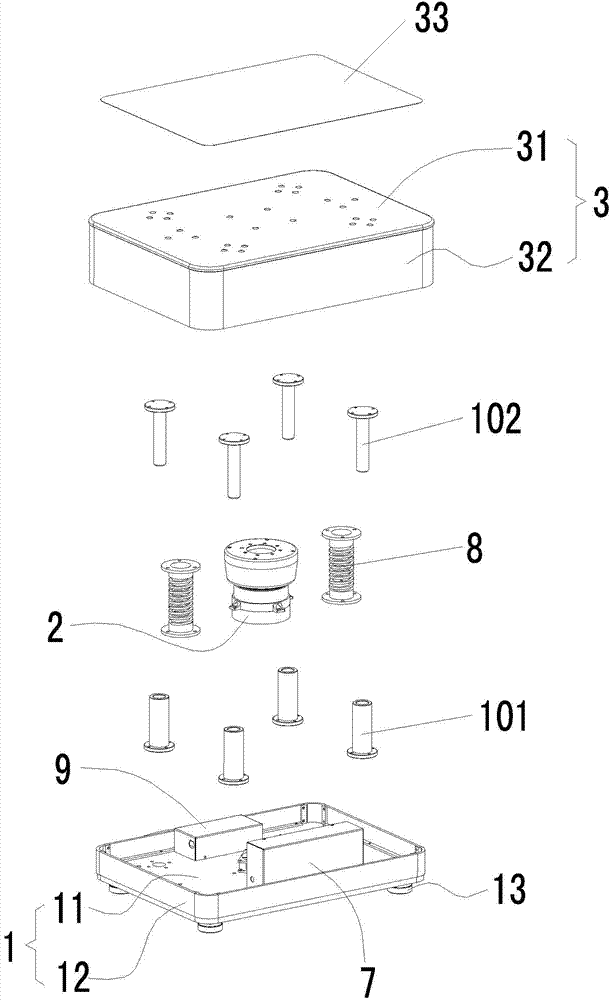

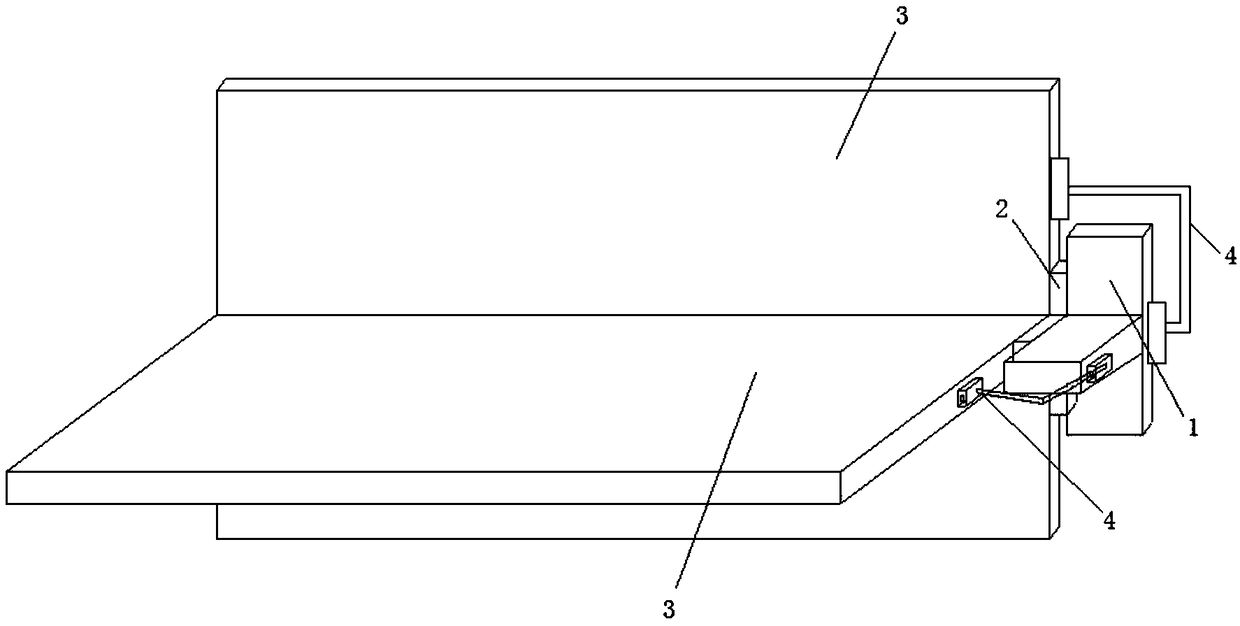

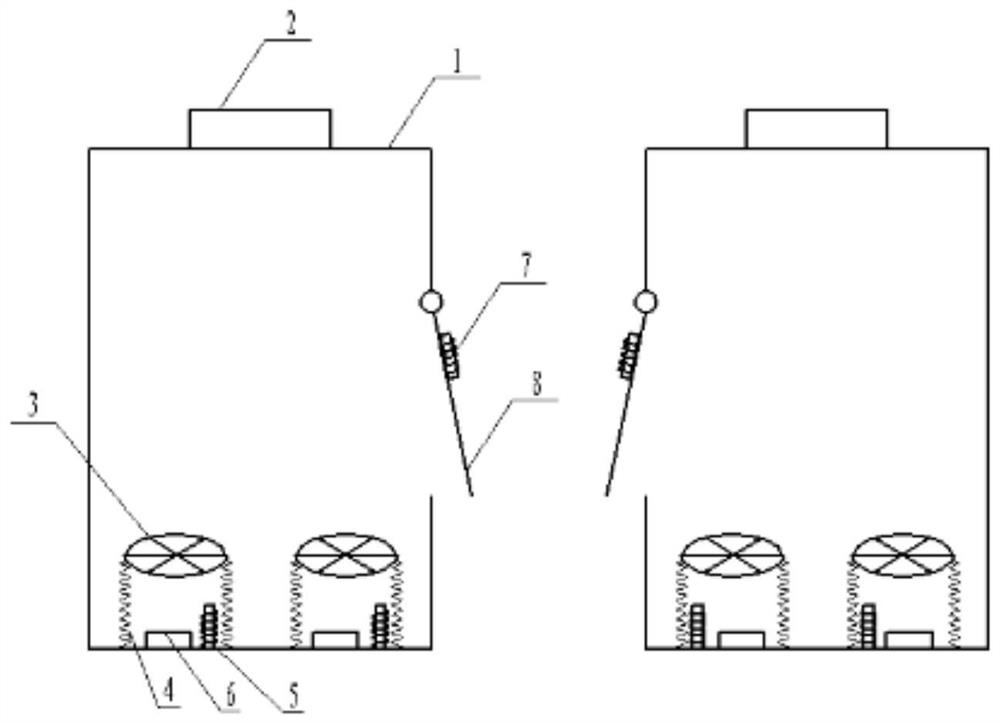

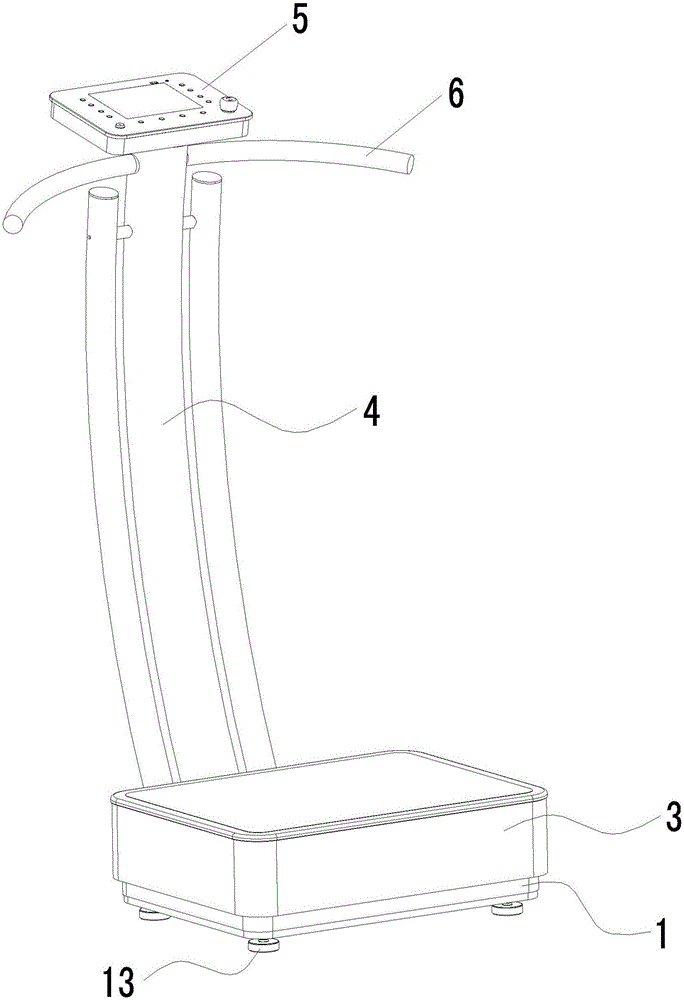

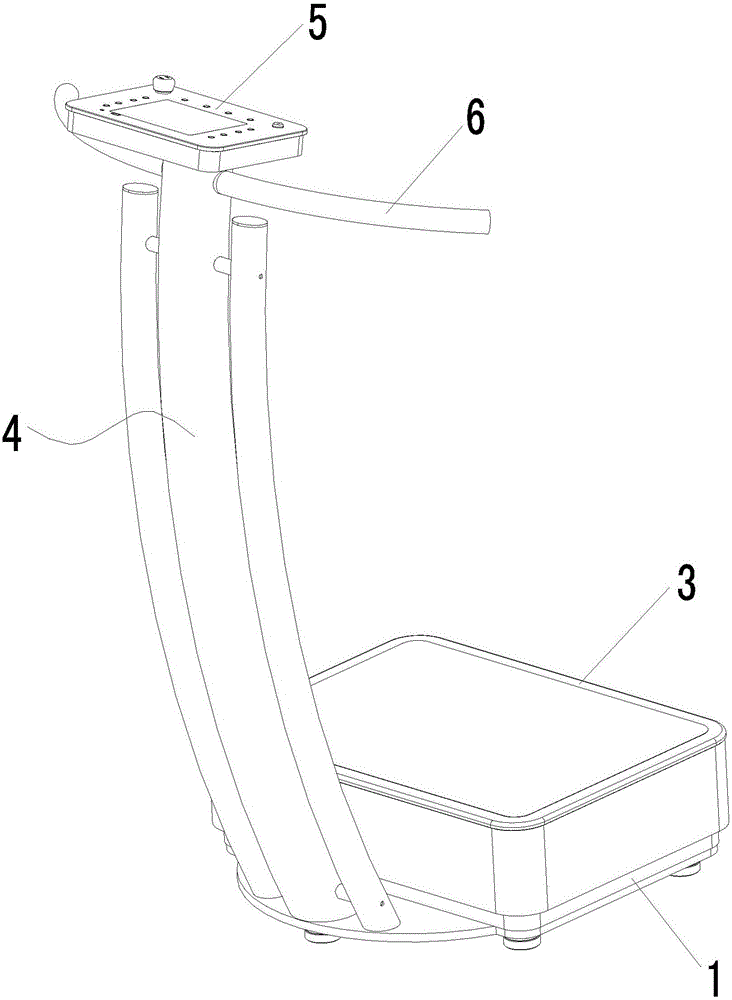

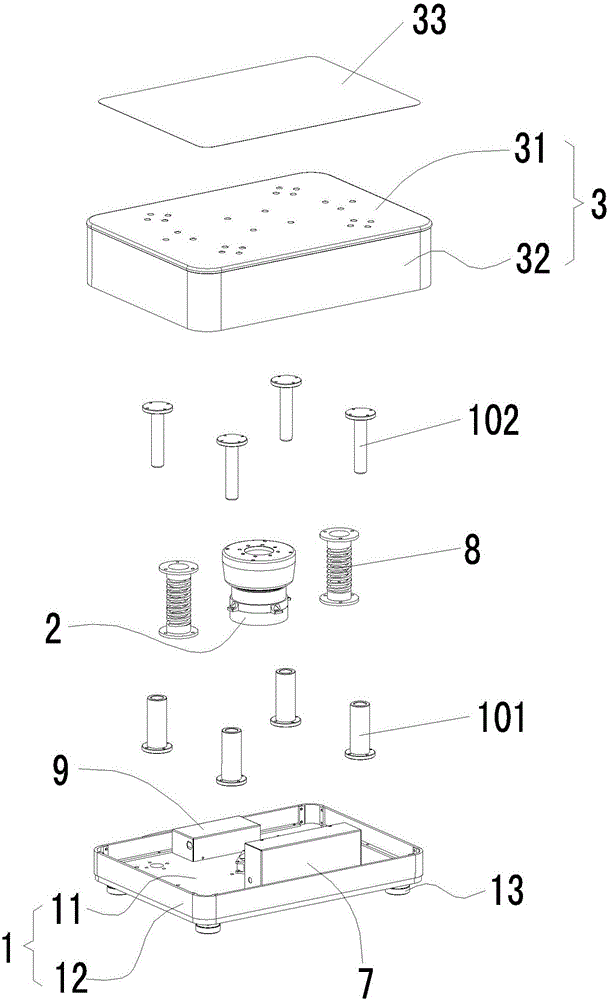

Music-driven vibration body builder

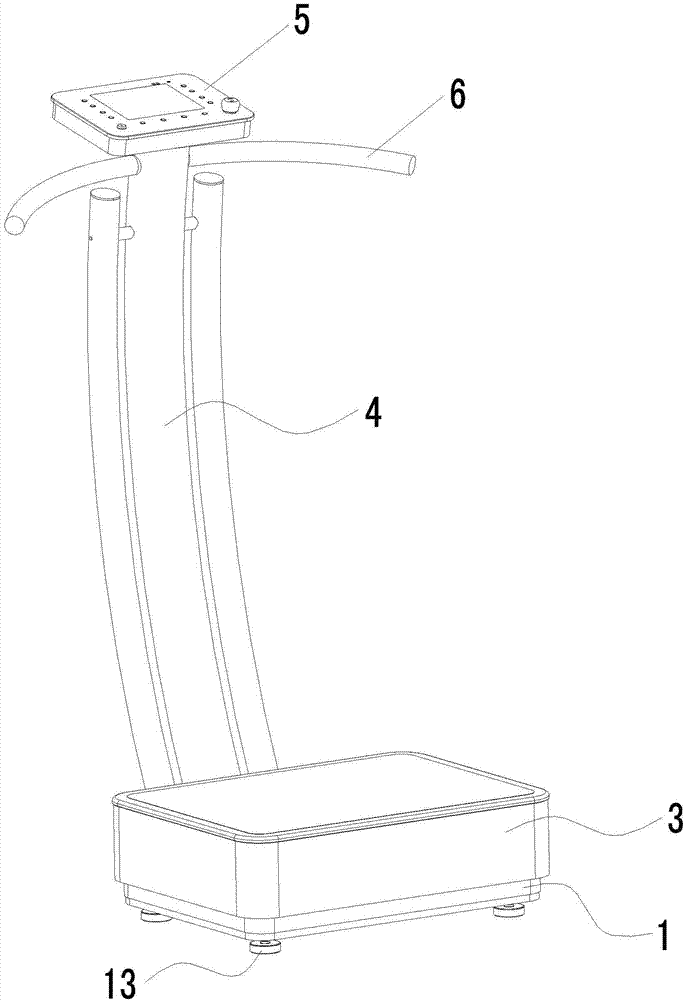

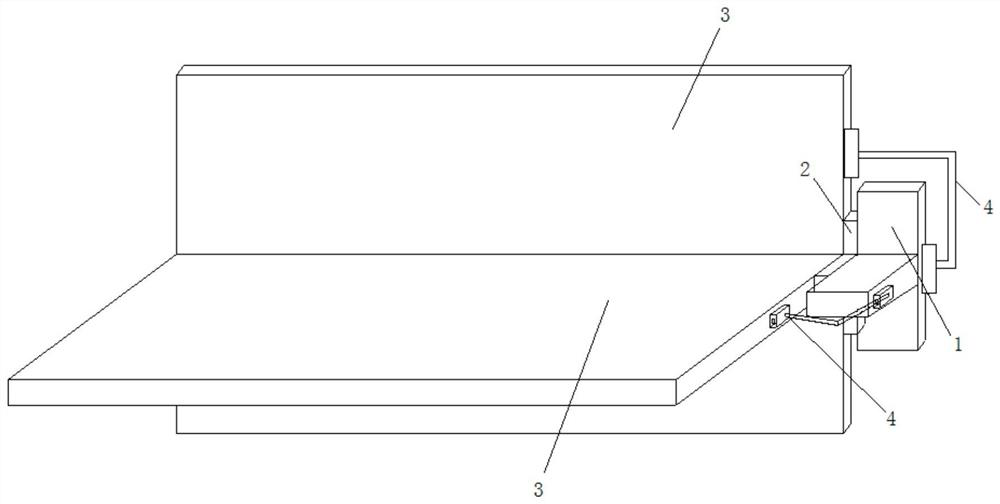

InactiveCN103932867ATake advantage ofA wide range of materialsChiropractic devicesLow frequency vibrationSignal source

The invention relates to a music-driven vibration body builder which comprises a base, an electromagnetic vibrator, a vibration platform and a control unit. The control unit outputs signals to the electromagnetic vibrator to drive the vibration platform to move. An audio file with music data and low-frequency vibration data is sent to the control unit, and the low-frequency vibration data are generated through audio data and synchronous with the audio data within the range of 3-5 HZ. The control unit independently sends out the music data and the low-frequency vibration data in a separating mode, the music data are played to enable users to enjoy music in the body building process, the low-frequency vibration data are used as a signal source driving the electromagnetic vibrator to vibrate, the users feel music synchronously through body vibration, and music enjoyment through ears and music feel through the body vibration can be synchronous. The music-driven vibration body builder is good in body building and rehabilitation effect, if music for keeping users in good health is used for driving the vibration body builder, the users feel comfortable both in body and soul, and the bodies of the users can synchronously feel changes of melodies.

Owner:江本旋 +1

Sand painting manufacturing method

InactiveCN103303054ARetain natural textureLow costSpecial ornamental structuresEmulsionTactile sensation

The invention relates to the field of artworks, and particularly discloses a sand painting manufacturing method. The sand painting manufacture comprises vertical peduncle sand painting manufacture and peduncle-free sand painting manufacture according to picture requirements, and compared with the peduncle-free sand painting manufacture, the vertical peduncle sand painting manufacture has an extra procedure of manufacturing peduncle. The vertical peduncle sand painting manufacturing method takes sand, rubberlith and a white emulsion as materials and utilizes a 2B pencil, a disposable injector needle tube, a mixing cup, a sand spreading tool and a surface plat-shaped sand beating tool to manufacture sand panting, and natural common primary-colour sand grains are combined with oil paint to draw the sand panting manually. The sand painting manufacturing method has the beneficial effects that the unique natural tactile sensation of sand is reserved while artistic effects, such as bright color and richness of oil painting, are achieved; the material cost is low, and the collection is easy; the sand painting is pollution-free, the specific faint scent of the oil paint is reserved, any other peculiar smell is not generated, the operability is strong, and the sand painting manufacturing method is suitable for learning of students in class; the modeling recapitulation is succinct, the expressive subject matter is wide, the color is bright, and the painting has very strong decorating aesthetic feeling.

Owner:李文秀 +3

Wood-plastic composite integrated home furnishing plate and manufacturing process thereof

InactiveCN105602269AA wide range of materialsLightweight and high strengthWood working apparatusDomestic articlesFiberCarbon fibers

The invention discloses a wood-plastic composite integrated home furnishing plate. The wood-plastic composite integrated home furnishing plate is manufactured from, by weight, 30-35 parts of wood meal, 15-20 parts of diatom products, 3-7 parts of activated carbon powder, 2-6 parts of glass fibers, 5-8 parts of carbon fibers and 25-30 parts of foamex. A manufacturing process of the wood-plastic composite integrated home furnishing plate comprises the following steps of mixing according to the formula, assistant adding and drying, feeding and extruding, extruding sizing, trimming traction, surface film pasting, fixed length transverse cutting, unloading inspection and finished product warehousing. The steps are simple. The diatom products, activated carbon powder, glass fibers, carbon fibers and other components are added to the raw materials, so that the plate has high strength, high formaldehyde adsorption performance, high temperature resisting performance and the like. The plate is environmentally friendly, the wood powder is wide in material source and replaces logs, the production cost is low, and the plate is economical and environmentally friendly. The plate is high in strength and light, construction efficiency is greatly improved, high practical value is achieved, and meanwhile high safety performance is achieved.

Owner:浙江巨森建材科技有限公司

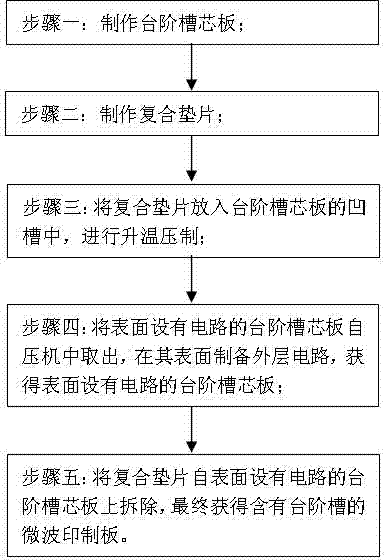

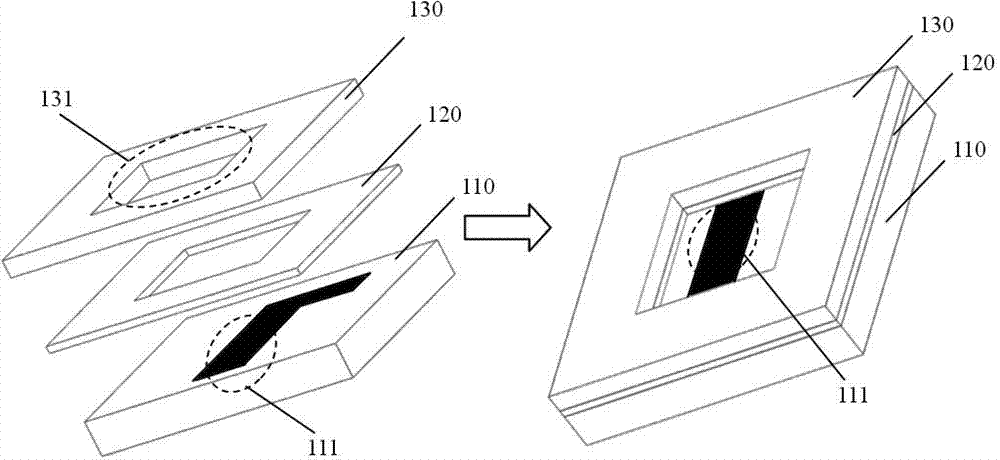

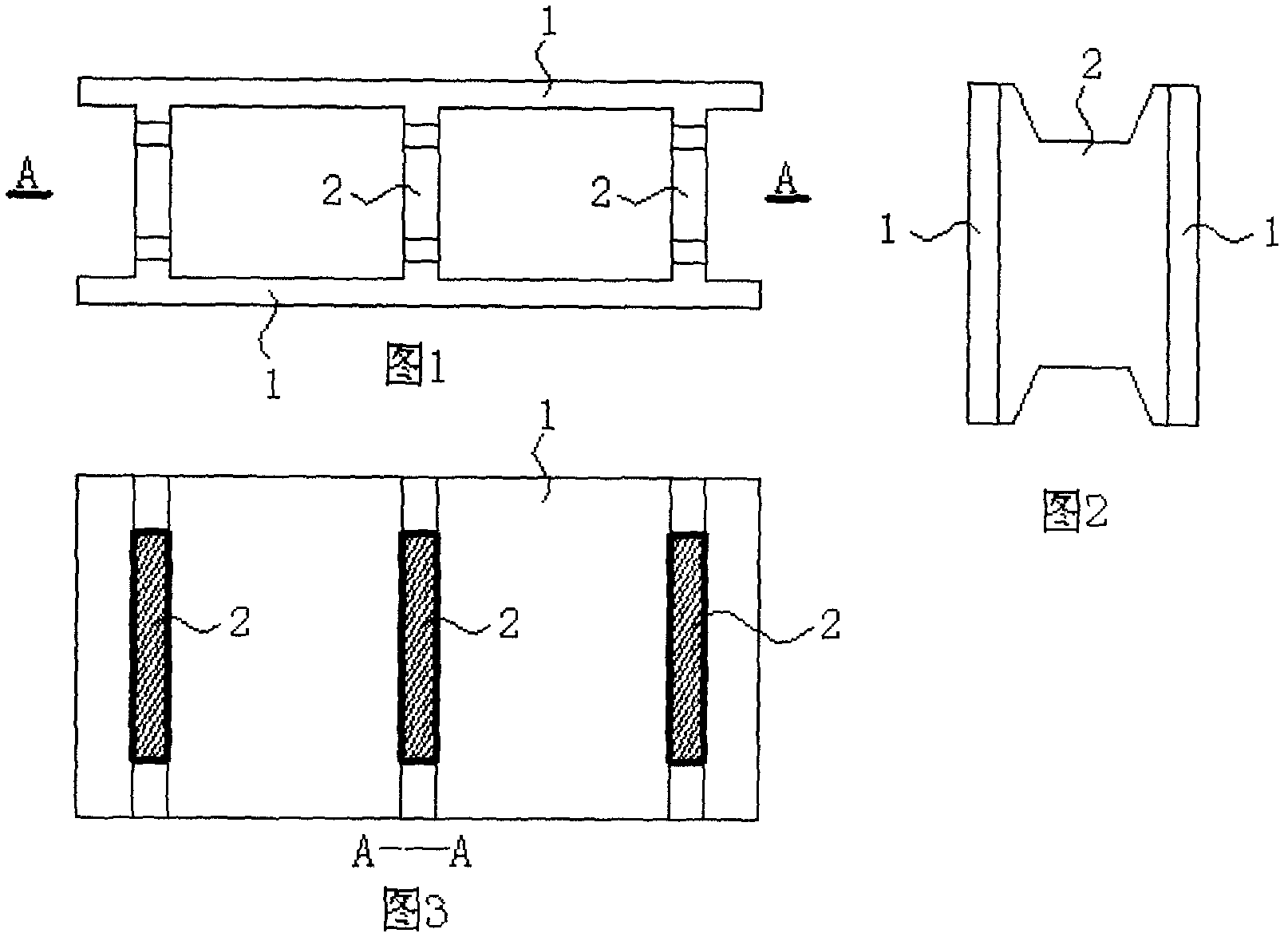

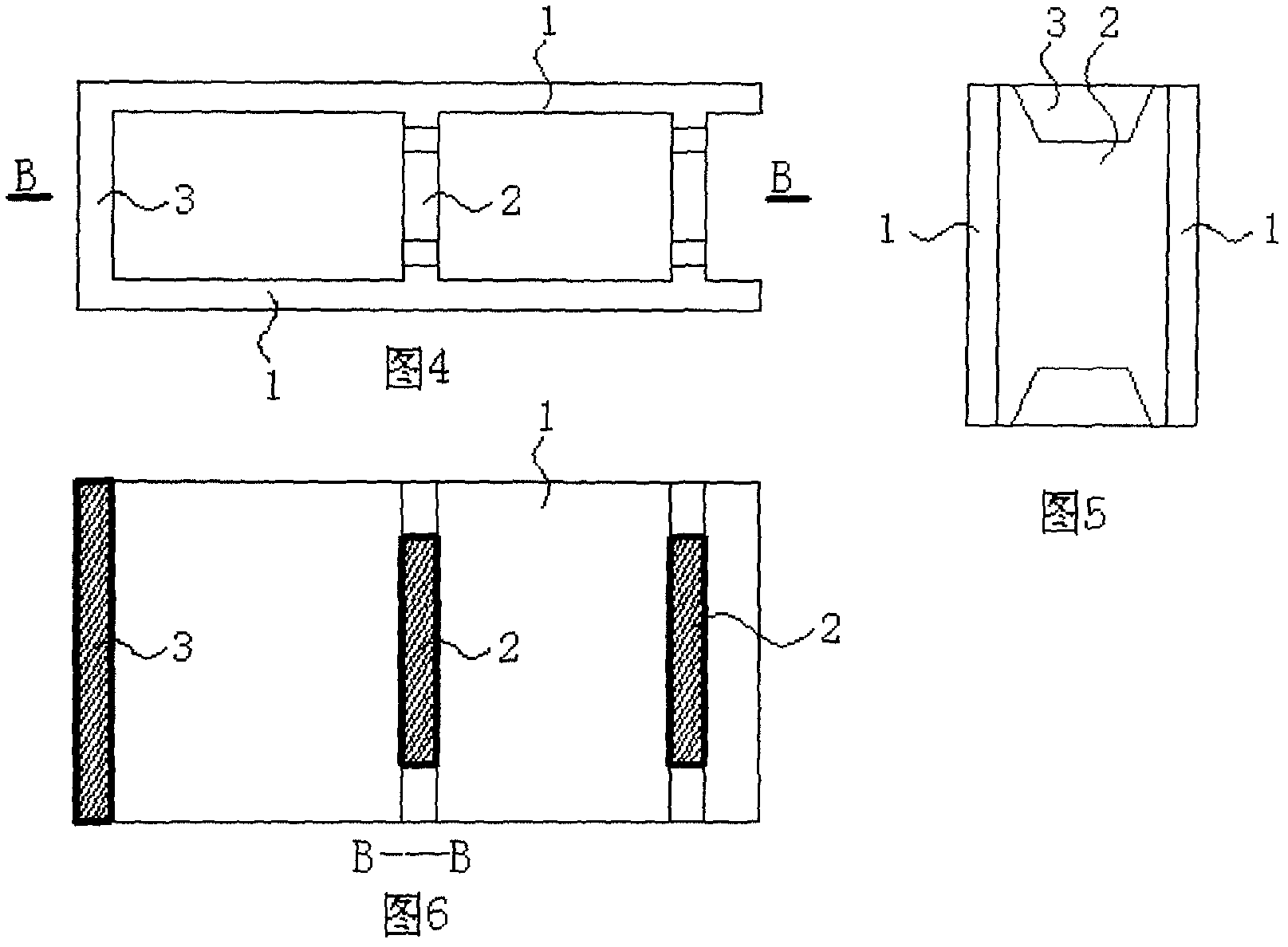

Method for manufacturing microwave printed circuit board with step groove

ActiveCN104507261AImprove processing efficiencyImprove processing qualityPrinted circuit manufactureDielectric surfaceHemt circuits

The invention provides a method for manufacturing a microwave printed circuit board with a step groove. The method comprises the steps: manufacturing a step groove core board; manufacturing a composite spacer; placing the composite spacer in a groove of the step groove core board, and carrying out heating and pressing; taking the step groove core board, of which the surface is provided with a circuit, out of a press, and forming an outer layer circuit on the external surface of a window layer core board, so as to obtain the step groove core board, of which the surface is provided with the circuit; removing the composite spacer from the step groove core board, of which the surface is provided with the circuit, thereby finally obtaining the microwave printed circuit board with the step groove. The method has the beneficial effects that microstrip patterns and microstrip dielectric surface of the bottom of the step groove can be free from any excess resin spill and are free from interference and influence caused by subsequent processing procedures after the microstrip patterns and microstrip dielectric surface of the bottom of the step groove are subjected to press fit; after the processing of the microwave printed circuit board with the step groove is completed and the composite spacer is removed from the step groove, the microstrip patterns and microstrip dielectric surface of the bottom of the step groove do not need any processing, so that the processing efficiency is increased, and the quality of products is improved.

Owner:ANHUI SUN CREATE ELECTRONICS

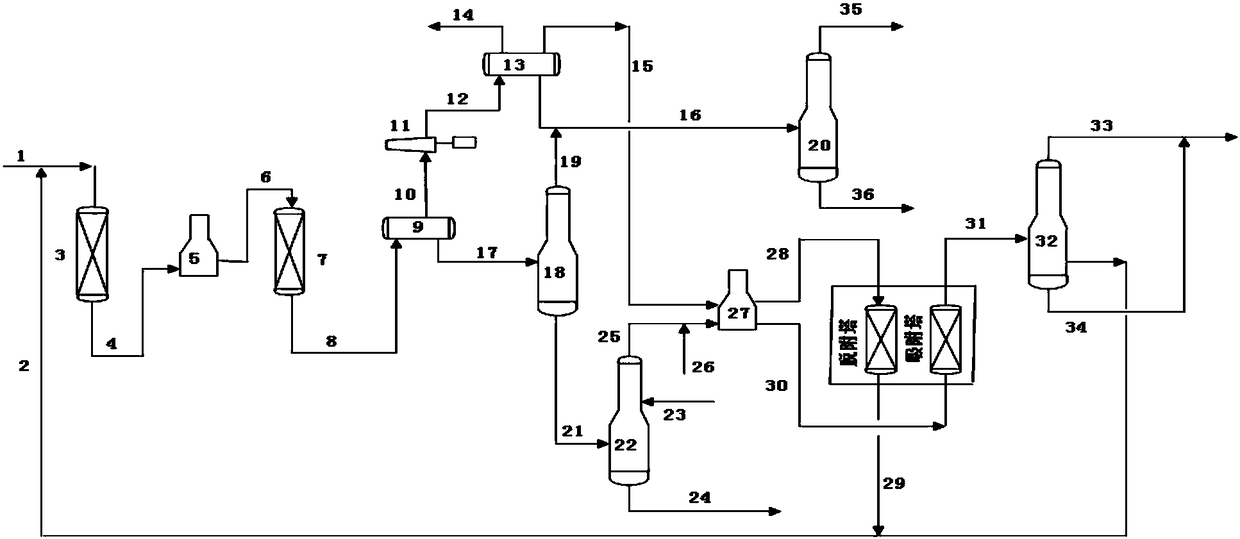

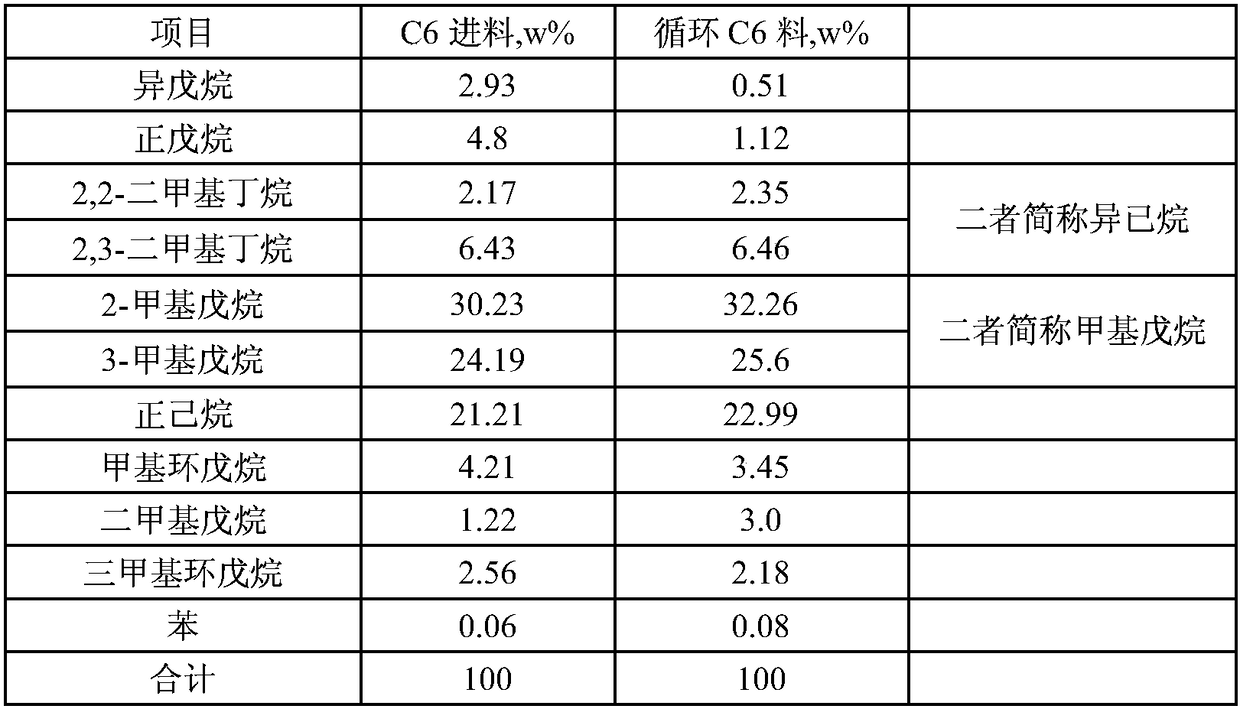

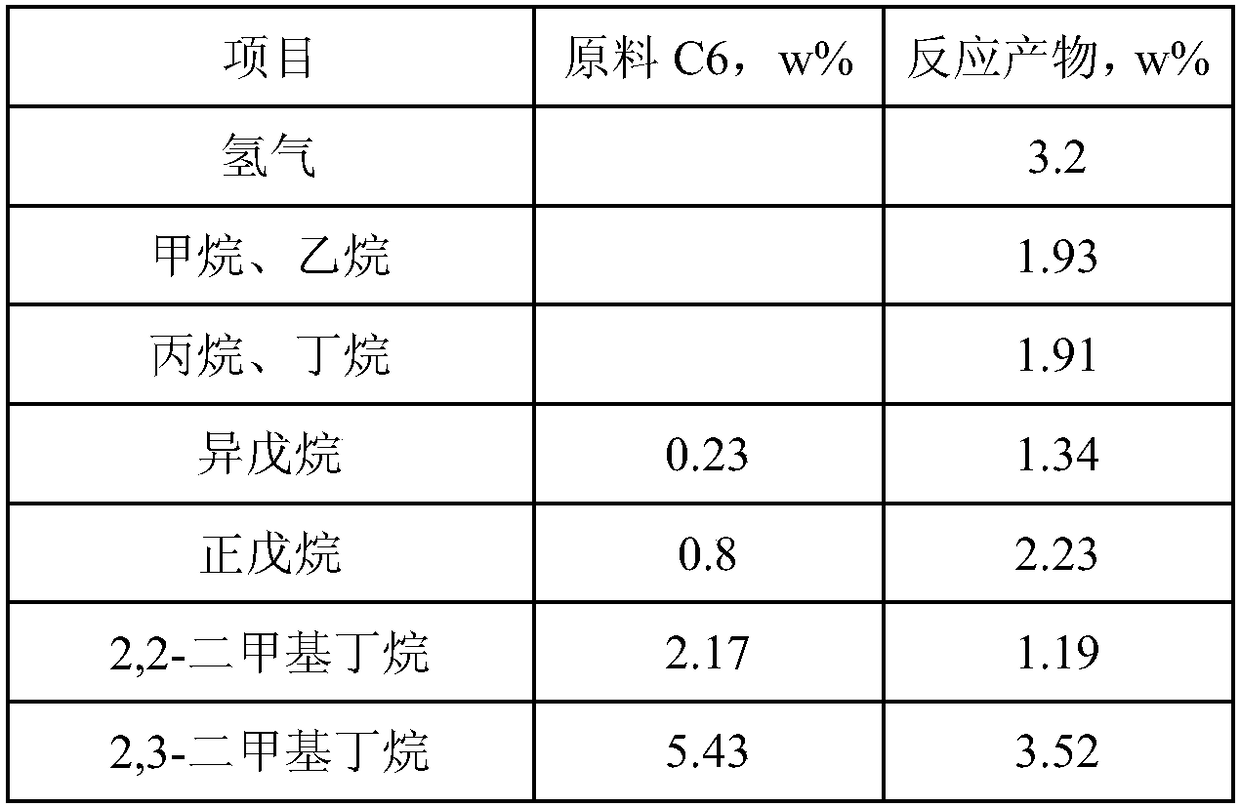

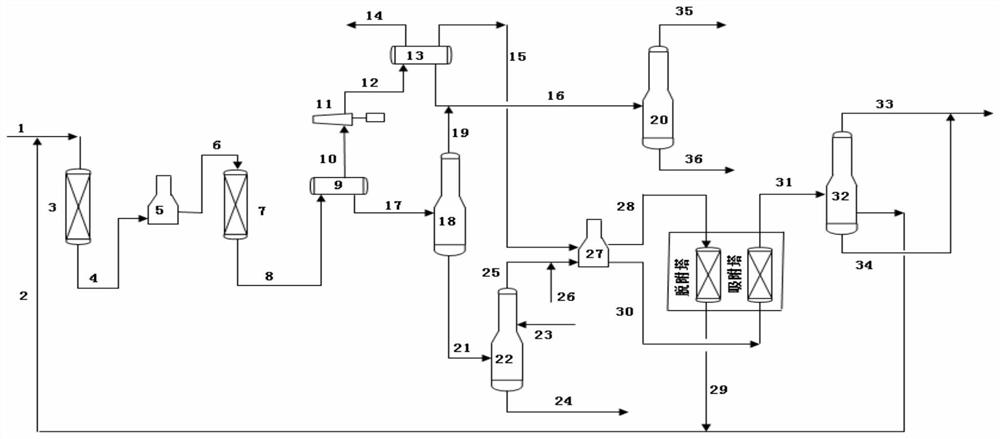

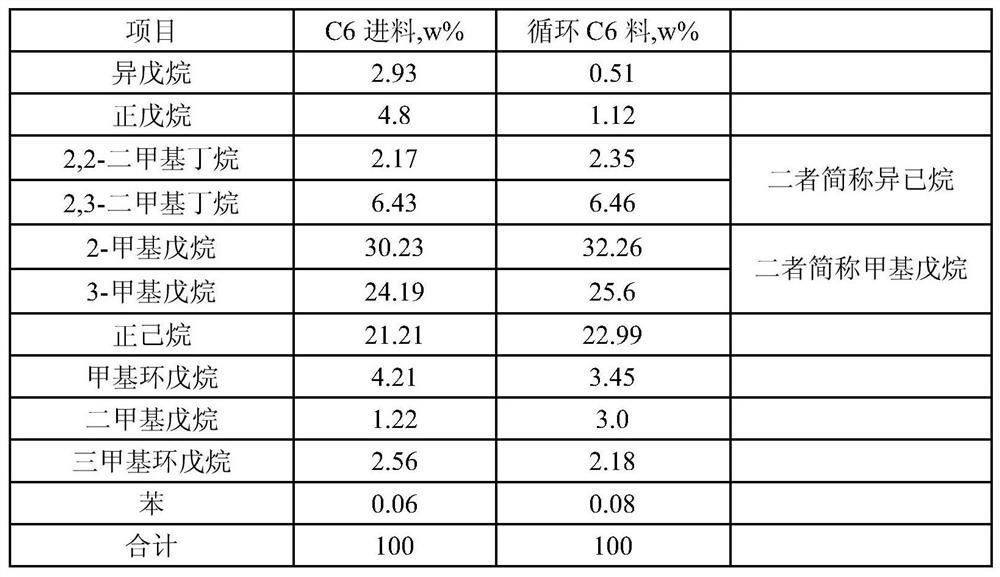

Method for highly producing benzene from C6 alkane

ActiveCN108238838AAvoid burnsA wide range of materialsMolecular sieve catalystDistillation purification/separationAlkaneDesorption

The invention discloses a method for highly producing benzene from C6 alkane. The method comprises the following steps: heating C6 alkane raw materials, and sequentially removing n-hexane by virtue ofan adsorber, and light and heavy components by virtue of an iso-hexane removal tower; hydrating and heating lateral line components of the iso-hexane removal tower and hydrogen raw materials, and introducing the lateral line components and the hydrogen raw materials into a reactor system for reaction; carrying out gas-liquid separation I on a reaction product, pressurizing a gas phase, carrying out gas-liquid separation II, introducing the gas phase into a desorber for desorption of n-hexane, and introducing the gas phase into a reaction system; introducing a liquid phase in the gas-liquid separation I into a depentanizer, introducing a material flow at the top and a liquid phase obtained in the gas-liquid separation II into a debutanizer, and leading a pentane component at the bottom ofthe debutanizer and iso-hexane and heavy components removed from the iso-hexane removal tower out as gasoline blending components; and introducing the material flow at the bottom of the depentanizer into an extraction tower, extracting benzene, introducing the material flow at the bottom of the extraction tower into a separation system, separating benzene, and circularly introducing the material flow at top into the reaction system. According to the method, the utilization rates of active components in C6 alkane are substantially increased, most water in the raw materials is removed, and the problems that light and heavy components are accumulated in the reaction system are solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cultivation substrate suitable for high-rise green plant and manufacturing method thereof

InactiveCN104130086AHigh Nitrogen Phosphorus Potassium Nutrient ContentImprove fertilizer supply capacityFertilizer mixturesDistillationHigh fertility

The invention relates to a cultivation substrate suitable for high-rise green plants and a manufacturing method thereof. The cultivation substrate is prepared by uniformly mixing acidic red soil and alkaline biomass carbon sourced from excrement of livestock in a certain proportion, has the characteristics of low density, moderate pH value, high mount of nitrogen phosphorus and potassium nutrients, high water and fertilizer retention ability, and harmonization of water, fertilizer and heat, and meets the requirements of light weight and high fertility for high-rise green substrate. The preparation method comprises distillation of livestock excrement for preparing of biomass carbon with low density, high nutrient content, and high water and fertilizer retention ability, and addition of acid red soil for neutralization of alkalescence of the biomass and complementation of mineral nutrient in the substrate. The method is skillful and simple, uses materials with wide sources, has low production cost, and breaks the technical bottleneck in research and development of high-rise green cultivation substrate. In addition, the production and application of the substrate on the one hand improves the urban environment for rapid spreading of high-rise greening and on the other hand eradicates livestock excrement pollution which puzzles the livestock culturing farm for a long time.

Owner:陈建国

Tool for arc striking and quenching during submerged arc welding

ActiveCN109454310AQuick disassemblyA wide range of materialsArc welding apparatusProduction lineMaterials science

The invention discloses a tool for arc striking and quenching during submerged arc welding. The tool comprises a connecting piece and a ceramic backing, wherein the connecting piece comprises at leasttwo plate bodies which abut against and splice each other; and one end face of the ceramic backing is used for abutting against the end face of base metal to be welded, and the other end face of theceramic backing is used for abutting against the end face of the connecting piece. When the connecting piece of the tool is manufactured, no groove abutting against a weld groove needs to be formed bythe processes of turning and milling, only an abutting end face needs to be machined, and the manufacture process is simplified. The rapid construction of an automatic production line for fillet weldsubmerged arc of the base metal to be welded can be normalized, so that the trouble of frequent assembly and welding is reduced, the quality defects caused by cutting arc striking and quenching plates on the two sides are reduced, management and operation normalization is perfected, meanwhile the working efficiency is greatly improved, and further the equipment productivity is increased.

Owner:WUCHUAN HEAVY ENG

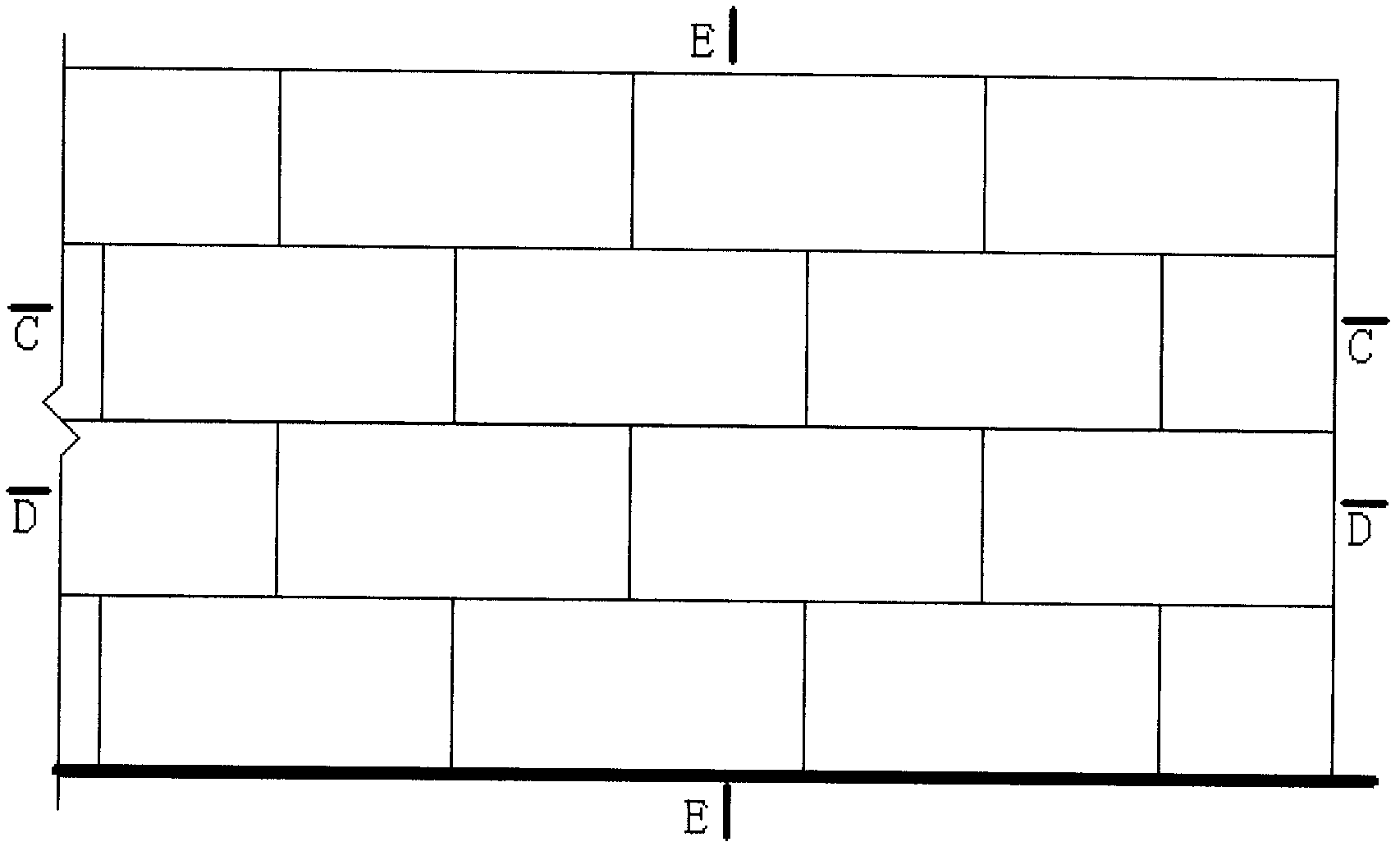

Hollow building block

InactiveCN103255872AGuaranteed compactnessImproved strength and thermal and acoustic performanceWallsHollow coreConstruction aggregate

The invention discloses a hollow building block. The large hollow building block having a thin thickness is preformed through a step of using broken stones, cobbles, gangues, sands, waste concrete blocks, brick dregs, and various decoration stone leftovers as aggregates, a step of adding certain proportions of cement and fly ash, and a step of mechanically stirring. When a wall is built, a method comprising a step of firstly putting hollow building blocks and secondly pouring a motor is adopted to form a seamless solid wall body, so the strength, the sound insulation and the heat insulation of the wall body are increased; and prime ribs comprising fine moso bamboos, bamboo chips, rattans, wickers and the like can be added into the wall body to form a prime rib wall body, so the tensile strength of the wall body is increased, and the shock resistance of a house is improved.

Owner:耿永田

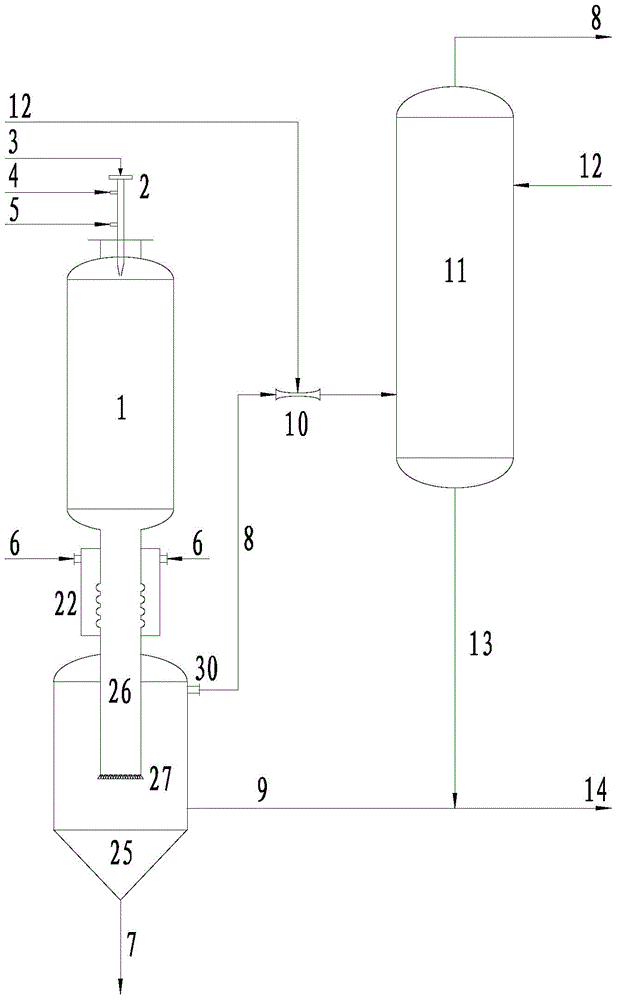

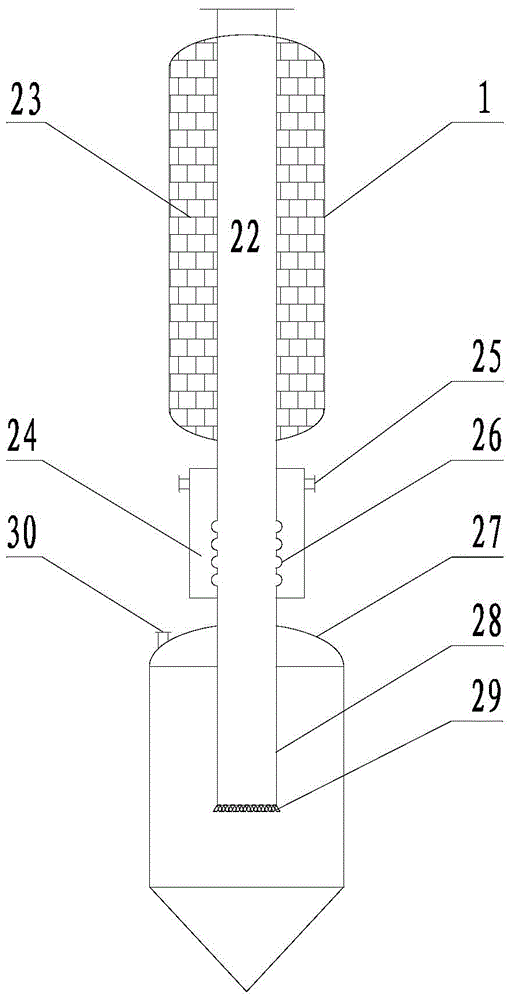

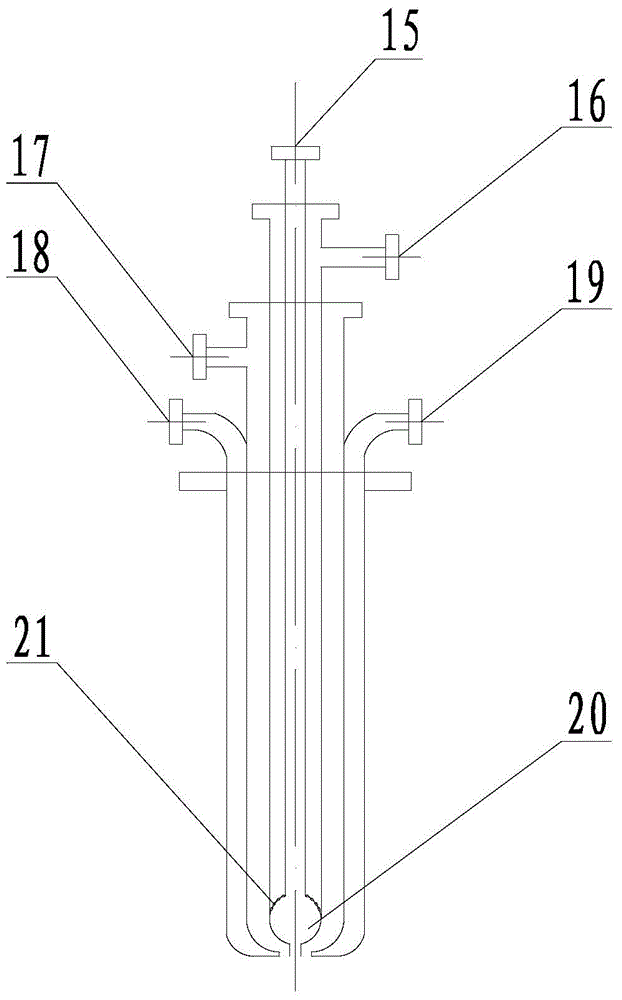

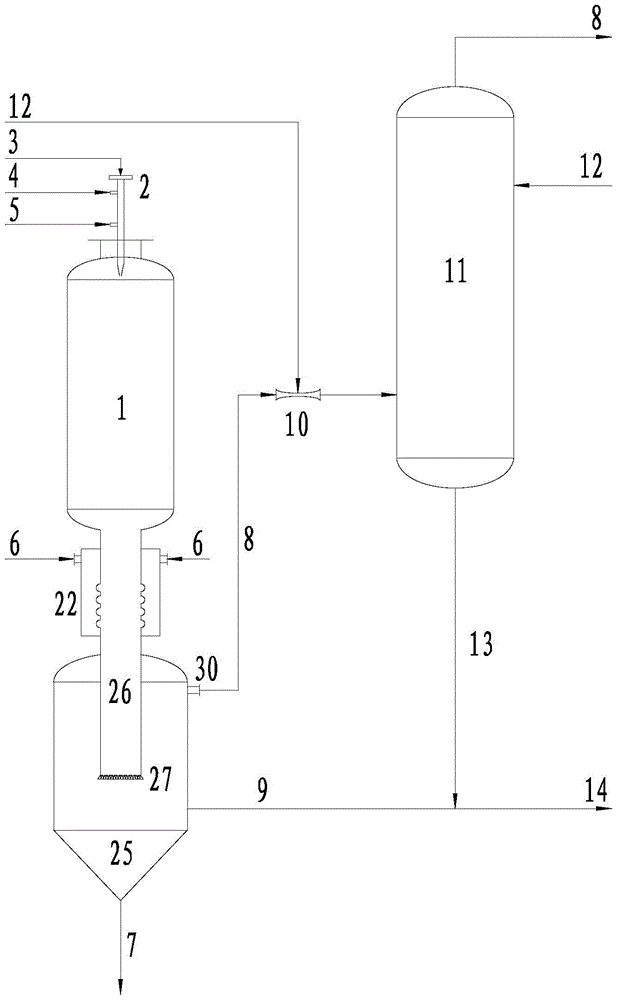

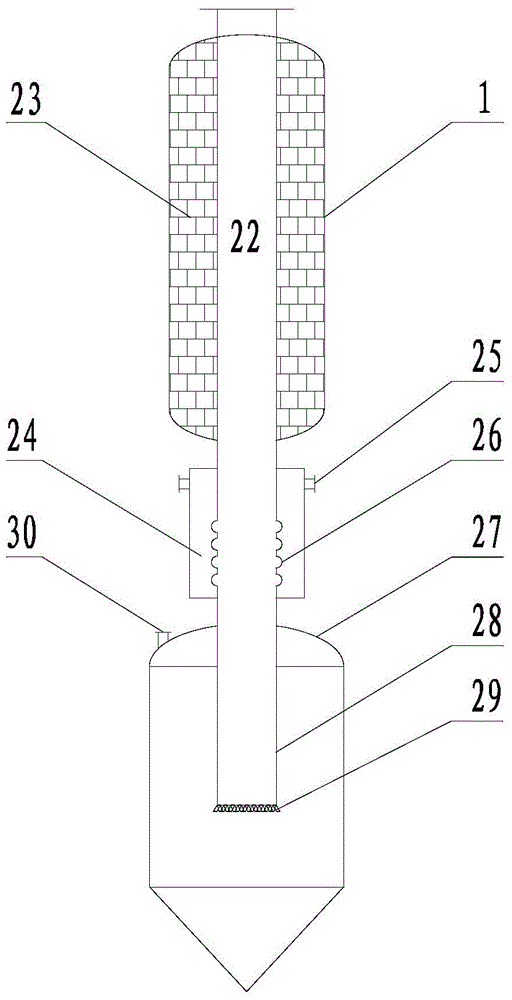

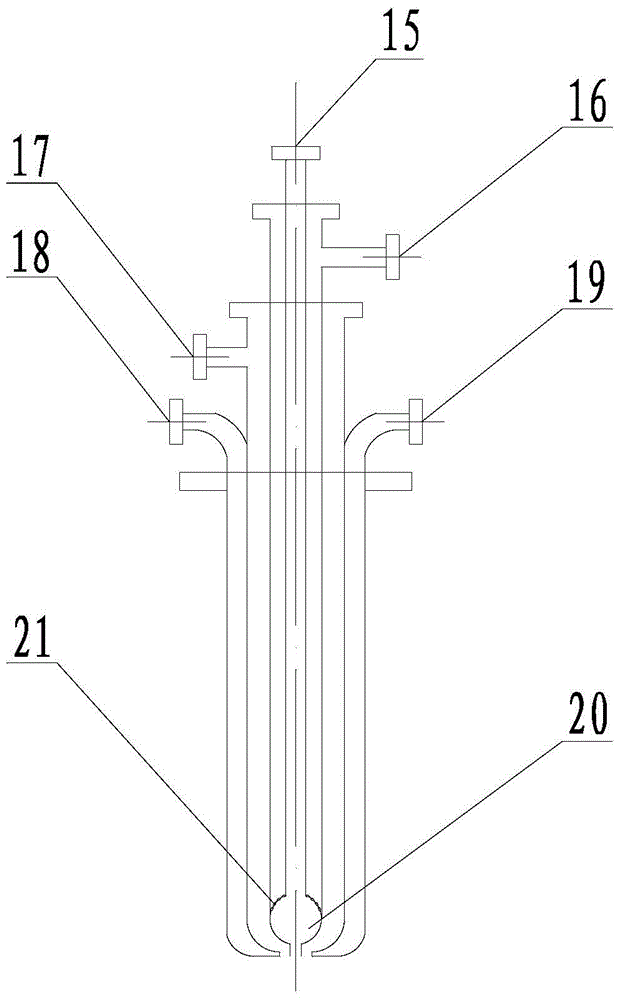

Method for producing synthesis gas with carbon powder and natural gas/methane as raw materials

ActiveCN104694170AEfficient and thorough useReduce wasteCarburetting gasesGranular/pulverulent flues gasificationHigh concentrationSyngas

The invention relates to a method for producing synthesis gas with carbon powder and natural gas / methane as raw materials. The method comprises the steps that carbon powder, natural gas / methane and gasifying agents are subjected to co-gasification reaction at the temperature of 1200-1500 DEG C and the pressure of 1.0-10.0 MPa, the resultant of reaction is subjected to chilling and heat exchange through a cooling system, solid ash is drained to the outside, the synthesis gas product is subjected to ash removal and cooling processing through a Venturi scrubber and a wet ash removal tower, high-concentration synthesis gas is obtained, the volume content of CO+H2 in the synthesis gas is 85.0-95.0%, the content of H2 is 43.0-68.0%, and carbon black water drained from a reaction furnace and the bottom of the wet ash removal tower is drained to a black water treatment workshop section to be treated. The method is wide in range of raw materials, large in production capacity, clean, environmentally friendly, and suitable for multi-line production of industrial large-scale raw material gas preparation.

Owner:THE NORTHWEST RES INST OF CHEM IND +1

A kind of high-energy environment-friendly regenerated clean fuel and its preparation method

InactiveCN103805294BSolve tense real-world problemsA wide range of materialsLiquid carbonaceous fuelsEnvironmental indexHigh energy

The invention discloses high-energy and environment-friendly renewable clean fuel and a preparation method thereof, and belongs to the technical field of a new energy source fuel. The high-energy and environment-friendly renewable clean fuel is prepared from the following raw materials by mass percent: 65.43% of methanol, 30.5% of auxiliary material, 3.3% of denaturing agent, 0.57% of dissolving-assisting and pungent-increasing additive, and 0.2% of dispersant. The high-energy and environment-friendly renewable clean fuel produced by the method disclosed by the invention has the significant progresses that 1, the traditional fuel can be fully and comprehensively replaced, and the realistic problem of crisis of global energy can be solved; 2, the high-energy and environment-friendly renewable clean fuel is wide in raw material range, and free of emission of three wastes in the production process; 2, the high-energy and environment-friendly renewable clean fuel is broad in applicable range, and the operating requirements of kinds of fields such as industries and the like can be met; 4, the consumption is lower than that of the traditional fuel under the same condition, the environmental index is that over 80% of emission is reduced in comparison with the traditional fuel, and energy conservation and emission reduction are really achieved; 5, the high-energy and environment-friendly renewable clean fuel is high in cost performance, and the price of the product does not change along with fluctuation of the international crude oil price, and is stable; and 6, the high-energy and environment-friendly renewable clean fuel is high in safety performance.

Owner:GUIZHOU TAIERKEN ENERGY SCI & TECH

Wood rolled pencil and making method thereof

The invention discloses a wood rolled pencil which relates to the technical field of stationery. The wood rolled pencil consists of a pencil core and a pencil holder which is wrappeding outside the pencil core and rolled by sheet materials. The wood rolled pencil is characterized in that a wood sheet is used as the pencil holder material, and the fiber textures of the wood sheet are parallel with the axial direction of the pencil core. Compared with the prior art, the wood rolled pencil has the advantages of wide material acquisition range, freedom from limitation of wood types and high wood utilization rate. The invention also discloses a making method for the wood rolled pencil.

Owner:广东润炜文具有限公司

Modified health-care foot bath powder

InactiveCN105749157AA wide range of materialsLow costAntimycoticsNervous disorderBeriberiAdditive ingredient

The invention discloses modified health-care foot bath powder, made from the following materials according to parts by weight: 10-20 parts of costus root, 10-20 parts of Pu'er tea, 10-15 parts of Caulis Lonicerae, 12-18 parts of Rhizoma seu Radix Notopterygii, 12-16 parts of Fructus Forsythiae, 10-16 parts of Fructus Trichosanthis, 8-14 parts of Rhizoma Curcumae Longae, 8-10 parts of lavender, 4-6 parts of Radix Arnebiae seu Lithospermi, 4-6 parts of Cortex Lycii, 3-5 parts of unibract fritillary bulb, 2-4 parts of Radix Glycyrrhizae, and 1-3 parts of Semen Plantaginis.The modified health-care foot bath powder has a wide range of materials and low cost, the effective ingredients can be delivered to the whole body through feet during foot bath, promoting blood circulation, clearing and activating the channels and collaterals and tonifying qi to soothe nerves, and the powder is effective in treating insomnia and preventing and treating dermatophytosis and inhibiting foot sweat.

Owner:李素琴

Additive for middle-or low-strength concrete

InactiveCN1330050AA wide range of materialsIncreased durabilitySolid waste managementRosinWear resistance

An additive for middle-or low-strength concrete is prepared from powdered coal ash (88-98 wt.%), dedusted ash (0.38-6.18%), calcium lignosulfonate (0.15-1.5%), sodium chloride (1-4%), triethanolamine(0.1-0.2%) and rosin soap (0.02-0.1%). Its advantages include widely available raw materials, low cost, and high performance of concrete.

Owner:刘应应

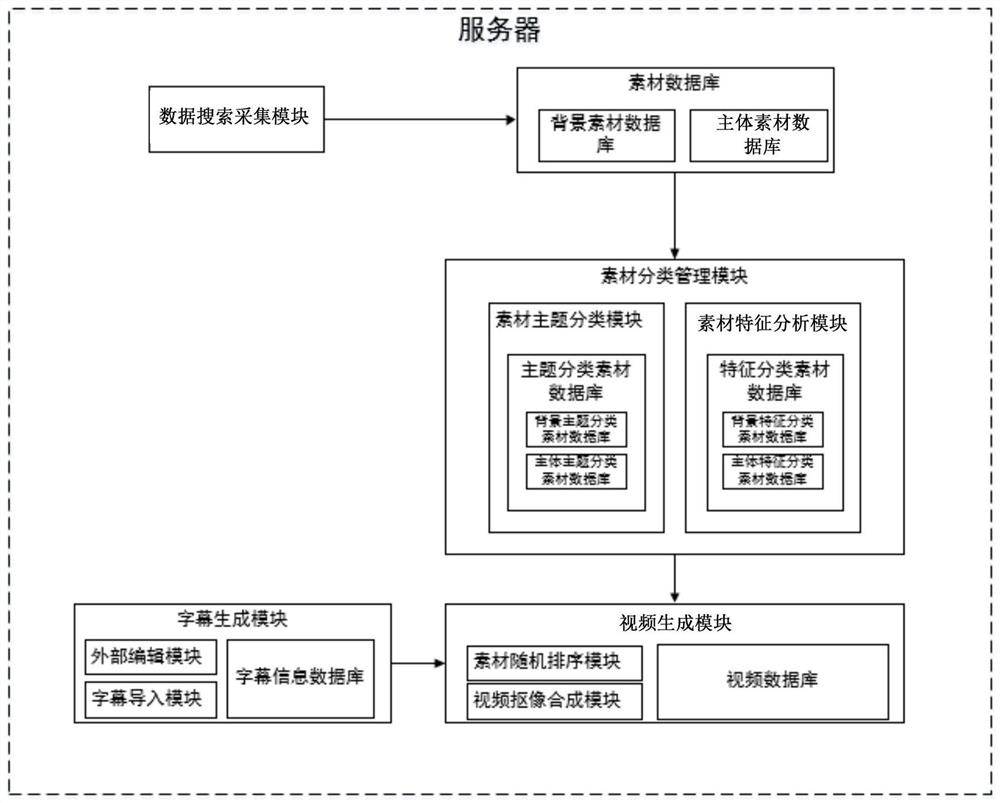

Digital video production system based on internet big data

InactiveCN111859017AEasy to makeImprove production efficiencyTelevision system detailsVideo data indexingDigital videoMaterial classification

The invention relates to the technical field of video production, and particularly discloses a digital video production system based on internet big data. The digital video production system includesa server, the server comprises a data search and acquisition module, a material database, a material classification management module and a video generation module; the material classification management module comprises a material theme classification module and a material feature analysis module, the material theme classification module comprises a plurality of theme classification material databases, the material feature analysis module comprises a plurality of feature classification material databases, and the video generation module comprises a material random sorting module and a video database. The customized video is automatically generated by adopting an intelligent system, so that the method has the characteristics of high automation degree and convenience in operation.

Owner:南京智韩科技发展有限公司

A kind of method of high-yield benzene of C6 alkane

ActiveCN108238838BA wide range of materialsSimple processMolecular sieve catalystDistillation purification/separationAlkaneBenzene

Owner:CHINA PETROLEUM & CHEM CORP +1

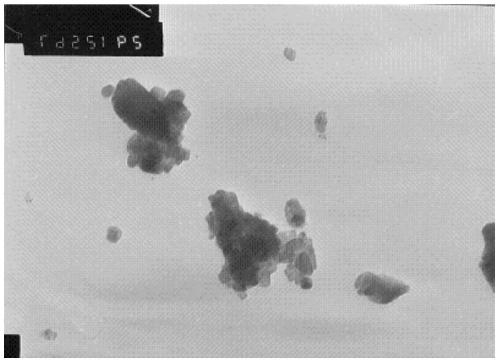

A kind of method for preparing super carbon fiber

The invention discloses a method for preparing super carbon fiber, which includes the step of preparing nano-precursor polymer, which specifically includes: dissolving acrylonitrile monomer raw material in a solvent, adding nano-graphite or nano-carbon black, and mixing uniformly by high-speed shearing, Then add an initiator or a catalyst to carry out a polymerization reaction in a solution state to generate a polyacrylonitrile solution that can be dissolved in a solvent, and a part of the structure of the polyacrylonitrile contains nano-graphite or nano-carbon black. The method of the present invention solves the matching problem of modulus and strength by improving the performance of polyacrylonitrile. At the same time, due to the introduction of chemical bonds in the axial direction of the fiber, the tensile performance of the carbon fiber in the axial direction is greatly improved, thereby greatly Amplitude increases the strength and modulus of the fiber.

Owner:山西新生代材料科技有限公司

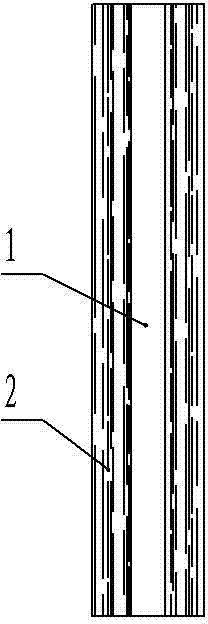

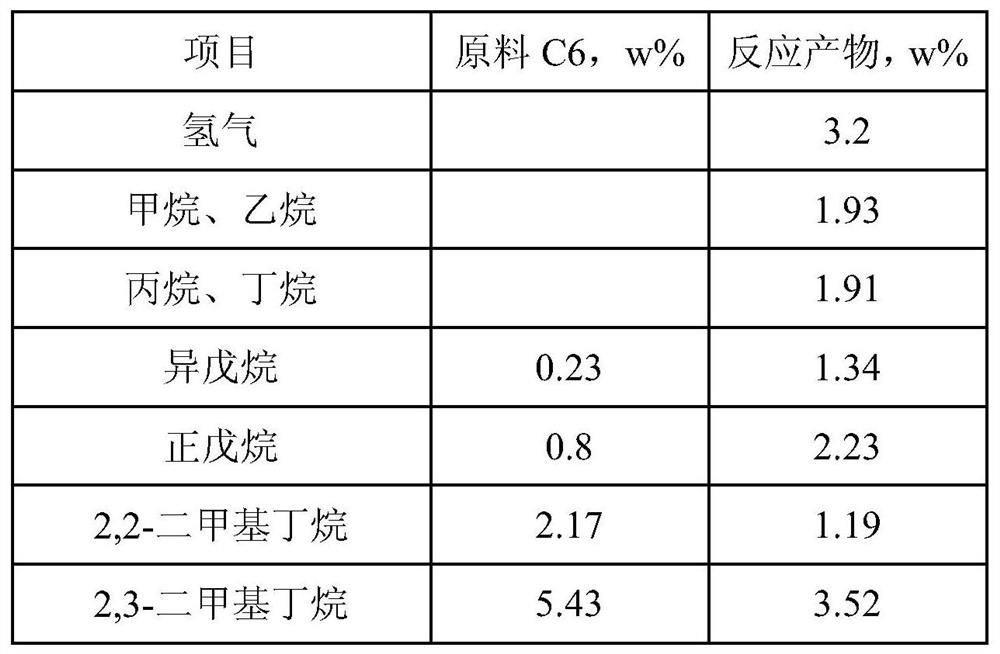

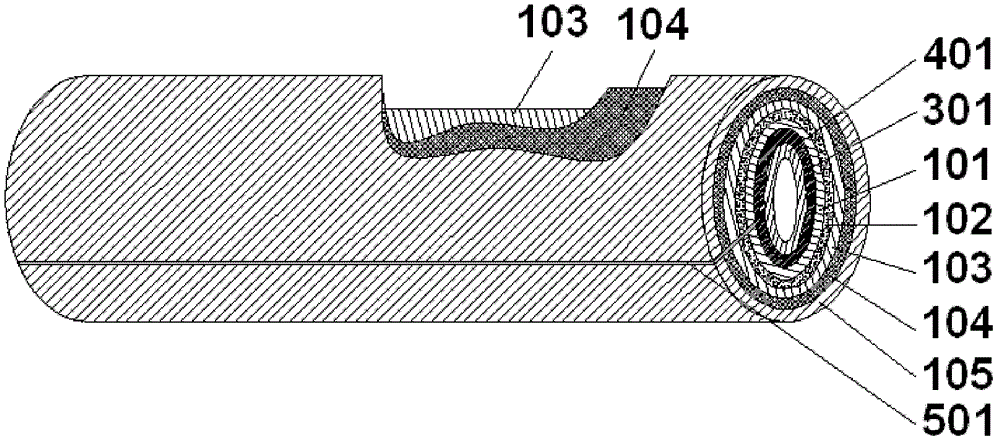

A kind of thin-film solar cell and its manufacturing method

ActiveCN103178142BReasonable structureEasy to manufactureFinal product manufacturePhotovoltaic energy generationCell layerSolid structure

The invention discloses a thin film solar cell and a production method thereof. The thin film solar cell comprises a core, a thin film cell layer and a packaging material which is arranged between the core and the thin film cell layer and used for packaging the thin film cell layer on the core, wherein the thin film cell layer comprises a protective layer, a back electrode layer, a generating layer, a transparent conductive layer and a transparent soft liner, the protective layer, the back electrode layer, the generating layer, the transparent conductive layer and the transparent soft liner are arranged sequentially from inside to outside, the packaging material is sleeved outside the core, and the packaging material and the core have the consistent shape and are in a non-panel solid structure. The thin film solar cell layer is packaged on the core with the solid shape, the structure is reasonable, the production is convenient, various shapes can be produced in accordance with use occasion requirements, the limit is little in materials, the limit on cost, devices and process is free, and the application prospects of the cell is expanded.

Owner:江苏石农新能源技术有限公司

A tooling for submerged arc welding arc ignition and extinguishment

ActiveCN109454310BA wide range of materialsRapid Construction StandardizationArc welding apparatusFillet weldProduction line

The invention discloses a tool for arc striking and quenching during submerged arc welding. The tool comprises a connecting piece and a ceramic backing, wherein the connecting piece comprises at leasttwo plate bodies which abut against and splice each other; and one end face of the ceramic backing is used for abutting against the end face of base metal to be welded, and the other end face of theceramic backing is used for abutting against the end face of the connecting piece. When the connecting piece of the tool is manufactured, no groove abutting against a weld groove needs to be formed bythe processes of turning and milling, only an abutting end face needs to be machined, and the manufacture process is simplified. The rapid construction of an automatic production line for fillet weldsubmerged arc of the base metal to be welded can be normalized, so that the trouble of frequent assembly and welding is reduced, the quality defects caused by cutting arc striking and quenching plates on the two sides are reduced, management and operation normalization is perfected, meanwhile the working efficiency is greatly improved, and further the equipment productivity is increased.

Owner:WUCHUAN HEAVY ENG

A kind of superhydrophilic film of nano calcium silicate hydrate and its preparation method and application

The invention discloses a nanometer calcium silicate hydrate super-hydrophilicity thin film as well as a preparation method and applications of the thin film and belongs to the field of functional composite materials. The preparation method comprises the steps of: soaking a pretreated base film with negative electric charges on surface in a 1.0-8.0g / L cationic polyelectrolyte solution containing 0.01mol / mL-0.1mol / mL soluble calcium salt for 10-30 minutes, then taking out the base film and flushing the base film with deionized water; soaking the base film in a 1.0-8.0g / L anionic polyelectrolyte solution containing 0.01mol / mL-0.1mol / mL soluble silicate for 10-30 minutes, then taking out the base film and completely flushing the base film with deionized water; repeating above operations for 1-3 times to obtain the polyelectrolyte nanometer calcium silicate hydrate super-hydrophilicity thin film. The super-hydrophilicity thin film has a super-hydrophilicity property and an excellent anti-fog property.

Owner:BEIJING UNIV OF TECH

A method for producing synthesis gas using carbonaceous powder and natural gas/methane as raw materials

ActiveCN104694170BEfficient and thorough useReduce wasteCarburetting gasesGranular/pulverulent flues gasificationSyngasHigh concentration

The invention relates to a method for producing synthesis gas with carbon powder and natural gas / methane as raw materials. The method comprises the steps that carbon powder, natural gas / methane and gasifying agents are subjected to co-gasification reaction at the temperature of 1200-1500 DEG C and the pressure of 1.0-10.0 MPa, the resultant of reaction is subjected to chilling and heat exchange through a cooling system, solid ash is drained to the outside, the synthesis gas product is subjected to ash removal and cooling processing through a Venturi scrubber and a wet ash removal tower, high-concentration synthesis gas is obtained, the volume content of CO+H2 in the synthesis gas is 85.0-95.0%, the content of H2 is 43.0-68.0%, and carbon black water drained from a reaction furnace and the bottom of the wet ash removal tower is drained to a black water treatment workshop section to be treated. The method is wide in range of raw materials, large in production capacity, clean, environmentally friendly, and suitable for multi-line production of industrial large-scale raw material gas preparation.

Owner:THE NORTHWEST RES INST OF CHEM IND +1

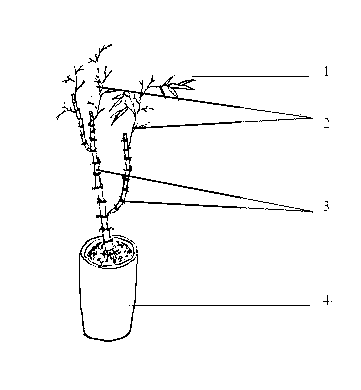

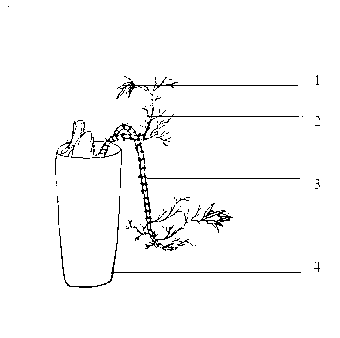

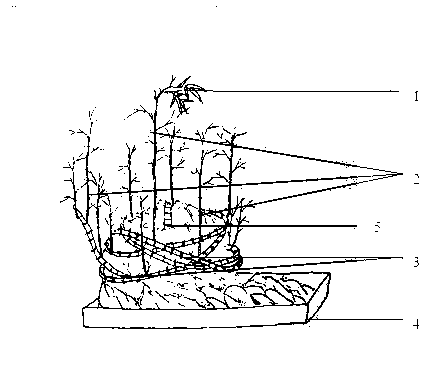

Method for manufacturing bamboo rhizome and stump bonsai

InactiveCN102934575BA wide range of materialsOvercome expensiveSpecial ornamental structuresHorticulture methodsBamboo ratSeedling

The invention relates to the field of bamboo cultivation and bonsai gardening, in particular to a method for manufacturing a bonsai through chosen or cultured bamboo rhizome and stump. The method includes: (1) bamboo species range selection; (2) bamboo rhizome collection and early-stage culturing which comprise two ways: 1, bamboo rhizome collection and culturing: embedding the collected bamboo rhizome or bamboo stump in a garden for culturing, fully pouring root stabilizing water after the embedding, then covering the bamboo rhizome or bamboo stump through a covering object, and taking the seedlings out for use after the growing bamboo shoot sprouts and the bamboo root grows for a while; and 2, coiled stump culturing of the bonsai: in early spring, summer or autumn, planting the bamboo in the bonsai to enable the root of the bamboo rhizome to be coiled in a pot, then taking the bonsai bamboo out from the pot, cutting off the bamboo stalk, embedding the bamboo stump with a soil ball into the garden or the pot, and using the bonsai after the bamboo shoot is sprouted from the bamboo rhizome; (3) bonsai culturing method; (4) appearance design; and (5) managing and protecting culturing. The method for manufacturing bamboo rhizome and stump bonsai provides new products of bamboo rhizome and stump bonsai for garden markets, and the new products have wide meanings in culture, art, economy and society.

Owner:张雨

Foot bath powder with effects of maintaining beauty and keeping young and preparation method thereof

InactiveCN108939027APromote circulationA wide range of materialsPowder deliveryAntimycoticsAdemetionineGinger Rhizome

The invention discloses foot bath powder with effects of maintaining beauty and keeping young and a preparation method thereof. The foot bath powder is characterized by comprising the following components in percentage: 35% of chestnut, 5% of hawthorn, 8% of alumen, 0.3% of angelica sinensis. 0.5% of liquorice, 0.5% of radix puerariae, 0.2% of vinegar, 0.2% of rose, 1% of salt, 15% of ginger, 15%of bean stalk, 5% of Sichuan pepper, 0.3% of semen armeniacae amarae and 14% of vitex negundo seed. Compared with the prior art, the foot bath powder disclosed by the invention has the beneficial effects that the foot bath powder is prepared from pure natural raw materials, the used raw materials are non-rare materials, the material taking range is wide, and the cost is low; and after the foot bath powder is added into hot water for foot soak, the active ingredients of the foot bath powder transfer all over the body by virtue of foot skin, and the foot bath powder can achieve the effects of promoting blood circulation, clearing and activating the channels and collaterals and maintaining beauty and keeping young, has the effect of treating dermatophytosis, and is excellent in long-term using effect.

Owner:承德佐合堂生物科技有限公司

A kind of preparation method of multilayer graphene

The invention discloses a preparing method for multilayer graphene. The method includes the following steps that 1, graphite is placed into an ultrasonic device and is ultrasonically treated with the cavitation effect; 2, the graphite treated ultrasonically is placed into a high-pressure device to be treated in a pressurizing mode; 3, the graphite treated in the pressurizing mode is pumped into a vacuum tank so that crystal faces of the graphite (001) can dissociate to obtain slice-layer graphite. The method is mild in operation conditions, investment cost and production cost are small, the process is simple and easy to control, and the preparing method for new graphene and extremely thin graphene slices is suitable for application and popularization at home and abroad.

Owner:SOUTH CHINA UNIV OF TECH

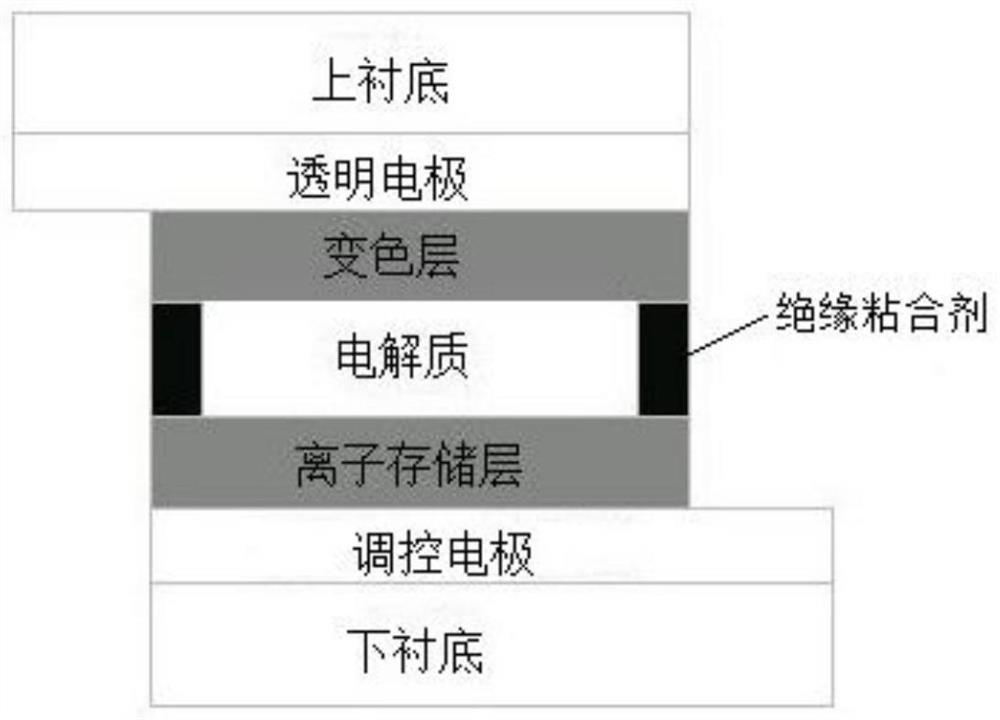

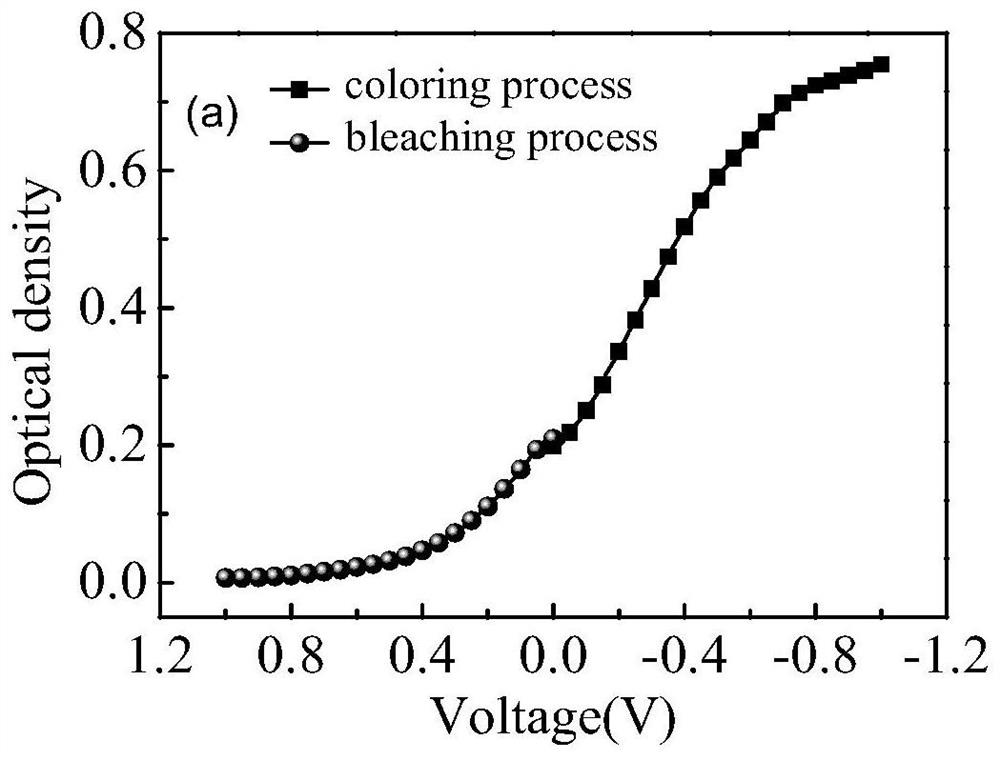

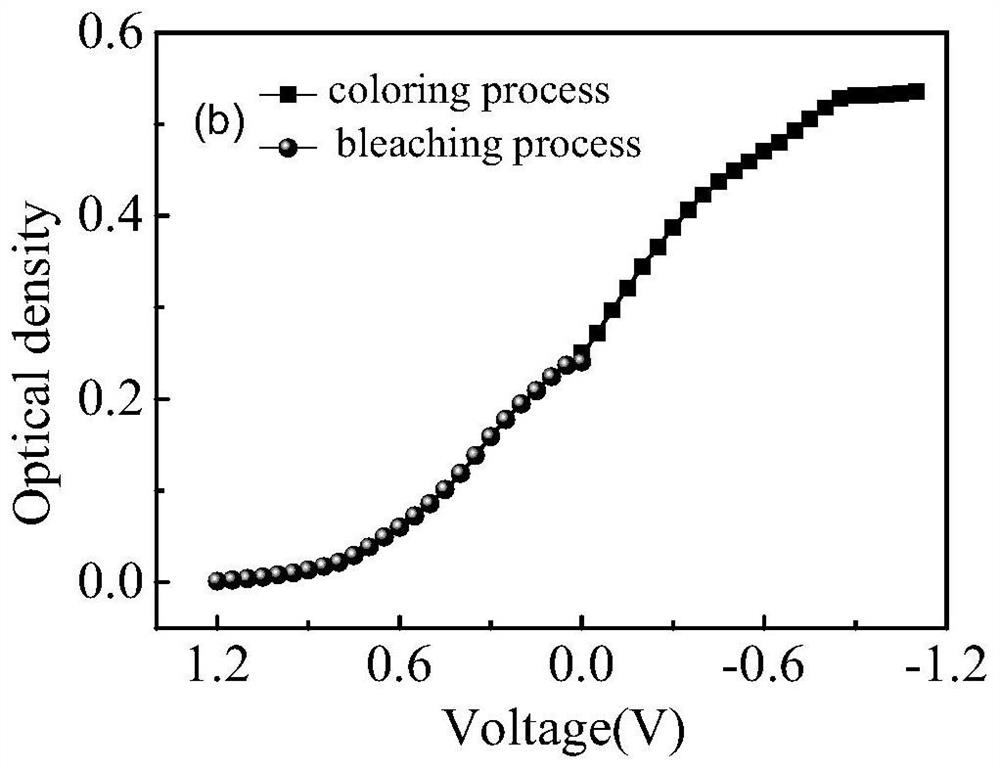

A method for selecting and controlling the working voltage of an electric dimming device

ActiveCN108089388BUniversalWide operating voltage regulation rangeNon-linear opticsLow voltagePolystyrene

The invention relates to a method for adjusting working voltage of an electric light dimming device. The electric light dimming device sequentially comprises a lower substrate, an adjusting electrode,an ion storage layer, an electrolyte, a color change layer, a transparent electrode and an upper substrate from bottom to top, the ion storage layer and the color change layer are provided with samepolythiophene derivatives, the electrolyte is provided with mixture of sodium polystyrenesulfonate, glycerin, sorbitol, deionized water and titanium dioxide, and the transparent electrode is providedwith an ITO (indium tin oxide) electrode. The method includes the step: changing prepared materials of the adjusting electrode to adjust the working voltage of the electric light dimming device, and namely, applying external voltage onto the device when optical density reaches saturation or approximates to saturation. Electrode materials are widely acquired, an adjustable range of the working voltage of the electric light dimming device is wide by adjusting the electrode materials, the working voltage of the electric light dimming device is easily turned down, and the electric light dimming device driven by low voltage has excellent application prospect in the fields such as passive driving and low-power-consumption electronic circuits.

Owner:济南嘉源电子有限公司

A music-driven vibrating fitness machine

InactiveCN103932867BConvenient fitnessPromote recoveryChiropractic devicesLow frequency vibrationSignal source

The invention relates to a music-driven vibration body builder which comprises a base, an electromagnetic vibrator, a vibration platform and a control unit. The control unit outputs signals to the electromagnetic vibrator to drive the vibration platform to move. An audio file with music data and low-frequency vibration data is sent to the control unit, and the low-frequency vibration data are generated through audio data and synchronous with the audio data within the range of 3-5 HZ. The control unit independently sends out the music data and the low-frequency vibration data in a separating mode, the music data are played to enable users to enjoy music in the body building process, the low-frequency vibration data are used as a signal source driving the electromagnetic vibrator to vibrate, the users feel music synchronously through body vibration, and music enjoyment through ears and music feel through the body vibration can be synchronous. The music-driven vibration body builder is good in body building and rehabilitation effect, if music for keeping users in good health is used for driving the vibration body builder, the users feel comfortable both in body and soul, and the bodies of the users can synchronously feel changes of melodies.

Owner:江本旋 +1

Additive for middle-or low-strength concrete

InactiveCN1124999CA wide range of materialsIncreased durabilitySolid waste managementRosinUltimate tensile strength

Owner:刘应应

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com