A method for producing synthesis gas using carbonaceous powder and natural gas/methane as raw materials

A technology for natural gas and synthesis gas, which can be used in the gasification of granular/powdered fuel, carbonization of gas, and the manufacture of combustible gas, which can solve problems such as poor market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

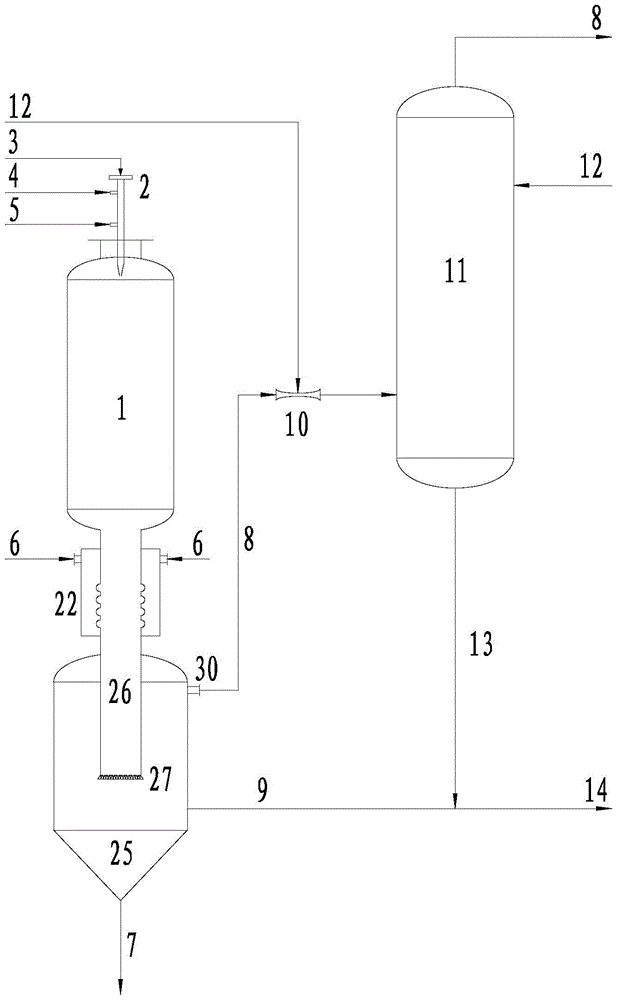

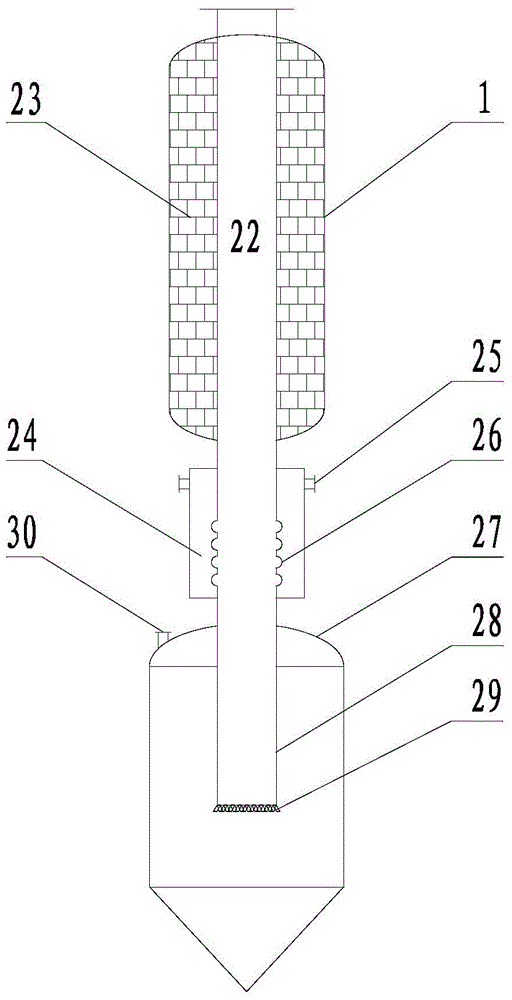

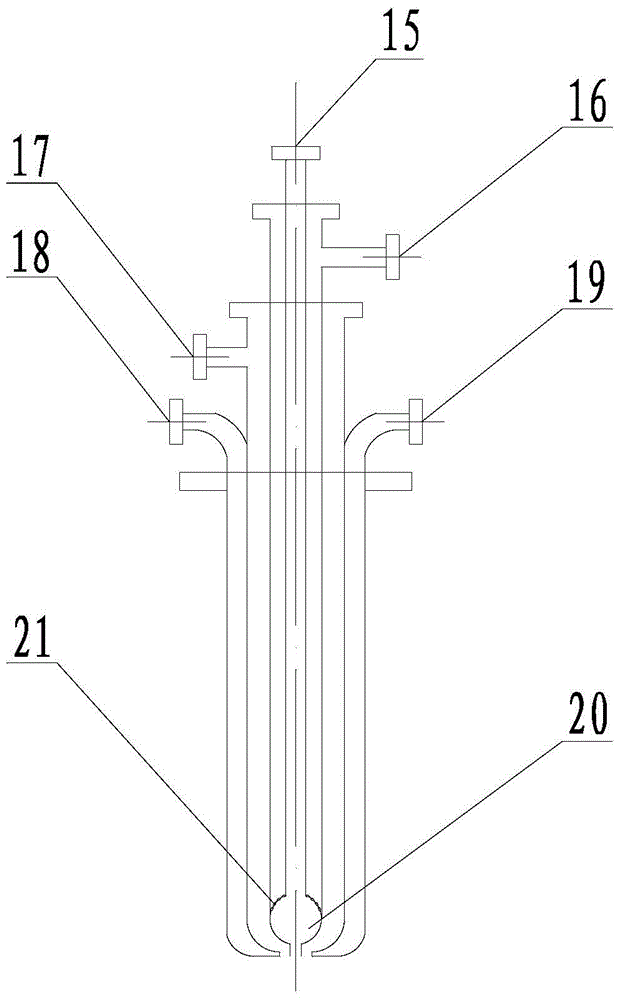

[0092] Embodiment 1: The present invention uses carbonaceous powder and natural gas / methane as raw material to produce synthesis gas

[0093] The implementation steps of this embodiment are as follows:

[0094] The implementation process of this embodiment is as attached figure 1 shown.

[0095] The coal powder used in this example adopts the industrial analysis method of coal GB / T212-2008, the calorific value measurement method of coal GB / T213-2008, the measurement method of total moisture in coal GB / T211-2007, the carbon in coal and Method for Determination of Hydrogen GB / T476-2008, Method for Analysis of Coal Ash Composition GB / T1574-2007, Method for Determination of Total Sulfur in Coal GB / T214-2007, Method for Determination of Coal Grindability Index by Hardgrove Method GB / T2565-2014, Determination Method of Arsenic in Coal GB / T3058-2008, Determination Method of Chlorine in Coal GB / T3558-1996 and other standard methods described in national standards, natural gas usin...

Embodiment 2

[0115] Embodiment 2: The present invention uses carbonaceous powder and natural gas / methane as raw material to produce synthesis gas

[0116] The implementation steps of this embodiment are as follows:

[0117] The implementation mode of this example is the same as that of Example 1, except that this example uses the coal powder, methane, oxygen and superheated steam listed in Table 7-10, and carries out co-processing under the conditions of a temperature of 1500°C and a pressure of 10.0MPa. gasification reaction.

[0118] Table 7: Coal powder parameters

[0119]

[0120] Table 8: Coal Quality Data

[0121]

[0122] Table 9: Methane Gas Feedstock Parameters

[0123] components Molar masskg / Kmol Volume percentage content Vol% CH 4

16.043 99.90 calorific value MJ / Nm 3

35.60 temperature ℃ 30.00 pressure MPaG 13.00 flow N m 3 / h

26305.10

[0124] Table 10: 99.6% Oxygen Parameters

[0125] name...

Embodiment 3

[0133] Embodiment 3: the present invention uses carbonaceous powder and natural gas / methane as raw material to produce synthesis gas

[0134] The implementation steps of this embodiment are as follows:

[0135] The implementation of this example is the same as that of Example 2, and the coal powder, methane, oxygen and superheated steam used in this example are also the same as those of Example 2, except that the co-gasification is carried out under the conditions of temperature 1500°C and pressure 1.0MPa Reaction, wherein oxygen / superheated steam=1:0.25.

[0136] The composition of the co-gasification product is listed in the following table 12, wherein the synthesis gas is composed of H 2 , CO, CO 2 、H 2 S, COS, CH 4 , N 2 , Ar composition.

[0137] Table 13: Co-gasification product composition

[0138] components composition H 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com