Method for preparing microbial oil from straw resources

A technology for microbial oil and straw resources, applied in the fields of lignocellulose resource conversion and utilization and biorefinery, can solve the problems of low fermentation efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

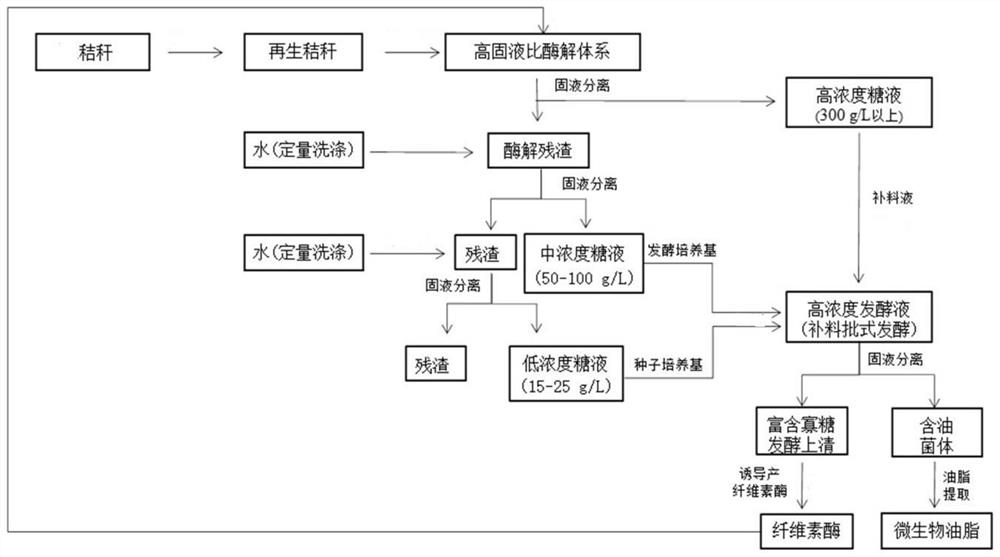

Method used

Image

Examples

Embodiment 1

[0059] 1) Pretreatment of corn stalks: refer to literature (Yuan, W., et al. Bioresour Technol, 2018, 265:464–470), add 1kg of NaOH to 20L of methanol, fully dissolve and add 10kg of corn stalks passed through a 2mm sieve , fully mixed evenly, and treated at 80°C for 60 minutes, the pretreated straw was washed with methanol three times at a ratio of 1:5, the methanol was evaporated in situ, and the straw was stored for later use.

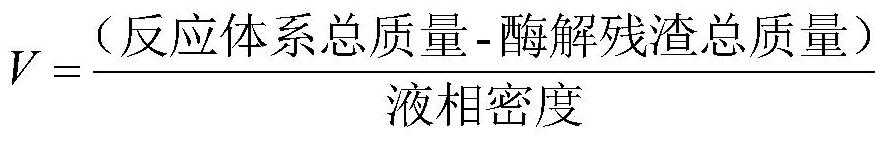

[0060] 2) Preparation of 50% (w / v) solid-to-liquid ratio corn stalk hydrolyzate: Take 1 kg of pretreated corn stalks and add them to the reactor, mix well, add cellulase at 15 FPU / g, adjust the pH to 4.8, and add water When the total system was 10L, enzymatic hydrolysis was started at 50°C. In the straw storage tank, the straw raw material to be supplemented is evenly sprayed with cellulase solution at an enzyme load of 15 FPU / g, and continuous feeding is started at the 3rd hour of hydrolysis, the feeding rate is 5 g / L / h, and the pH is maintained at...

Embodiment 2

[0065] 1) Pretreatment of wheat straw: refer to literature (Krishnan C, et al. Biotechnol Bioeng. 2010, 107: 441–450), use wheat straw crushed through a 5mm sieve as raw material, add water to form 150% (w / w) The solid-to-liquid ratio was mixed with ammonia water and wheat straw at 2:1 (w / w), treated with ammonia expansion at 140°C for 30 minutes, and cooled to 50°C for later use.

[0066] 2) Preparation of 50% (w / v) solid-to-liquid ratio wheat straw hydrolyzate: take 0.5kg of wheat straw, add 0.16L of the crude enzyme solution collected in Example 1, add appropriate amount of water and mix well, adjust the pH to 4.8, and Add water until the total system is 10L, and start enzymatic hydrolysis at 50°C. In the straw storage tank, the straw raw materials to be added are evenly sprayed with cellulase solution at an enzyme load of 20 FPU / g, and the enzyme-containing straw raw materials are continuously added at a feeding rate of 6.5 g / L / h after the 3rd hour of hydrolysis , until t...

Embodiment 3

[0071] 1) Pretreatment of rice straw: refer to the gas explosion method in the literature (Varga E, et al. Appl Biochem Biotechnol, 2004, 113, 509-523), weigh 10 kg of rice straw passed through a 40-mesh sieve, and perform gas explosion pretreatment.

[0072] 2) Preparation of 50% (w / v) solid-to-liquid ratio rice straw hydrolyzate: take 0.5 kg of straw, add 0.1 L of the crude enzyme solution collected in Example 2, add an appropriate amount of water and mix thoroughly, adjust the pH to 4.8, and Add water until the total system is 10L, and start enzymatic hydrolysis at 50°C. In the straw storage tank, the straw raw materials to be added are evenly sprayed with cellulase solution at an enzyme load of 20 FPU / g, and the enzyme-containing straw raw materials are continuously added at a feeding rate of 6.5 g / L / h after the 3rd hour of hydrolysis , until the solid-liquid ratio reaches 50%, and the enzymatic hydrolysis is completed for 120 hours.

[0073] 3) Directional collection of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com