Method for increasing reducing sugar yield by coupling of membrane separation and lignocellulose acid hydrolysis

A technology of lignocellulose and acid hydrolysis, which is applied in the production and application of sugar, fructose production, etc., can solve the problems that cannot meet the requirements, and achieve the effects of avoiding continuous degradation, reducing pollution, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The implementation steps are as follows:

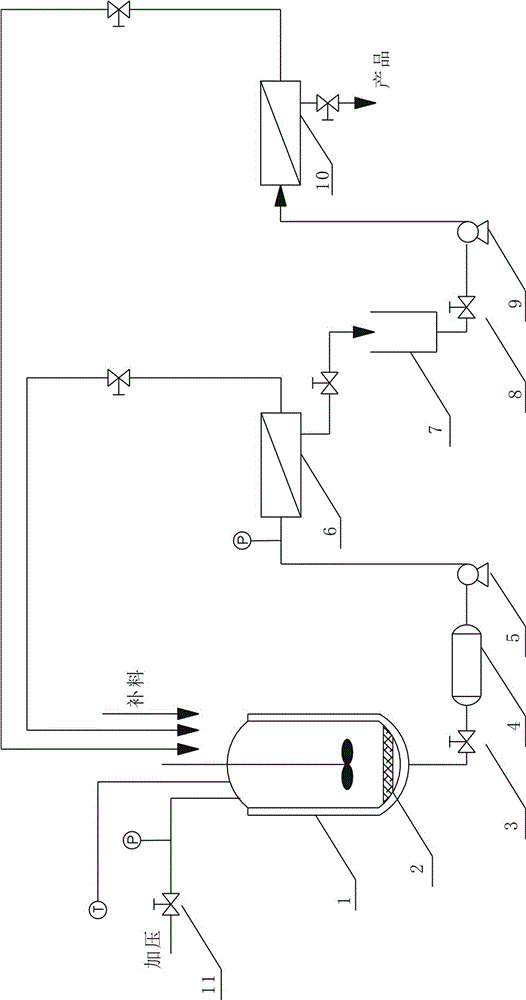

[0034] (1) Press figure 1 For the operation shown in the flow chart, weigh 30 g of rice straw with a particle size of 180 mesh and add it to Reactor 1, add 450 ml of sulfuric acid solution with a mass fraction of 0.05% at a solid-to-liquid ratio (g / ml) of 1:15, and open the air inlet valve 11 to add Press to 1.6 MPa, react at a temperature of 200 °C and a stirring rate of 500 r / min. The outlet of the hydrolyzed solution at the bottom of the reactor is equipped with an ordinary filter 2, and the ordinary filter is a 500-mesh stainless steel filter. The obtained hydrolyzed solution passes through the ordinary filter. Filtration to obtain the permeate containing small lignocellulose particles, high polysaccharides and reducing sugars, and the retained large lignocellulose particles are left in the reactor to continue hydrolysis;

[0035] (2) Open the hydrolyzate outlet valve 3 and the microfiltration feed pump 5, so that the perm...

Embodiment 2

[0040] The implementation steps are as follows:

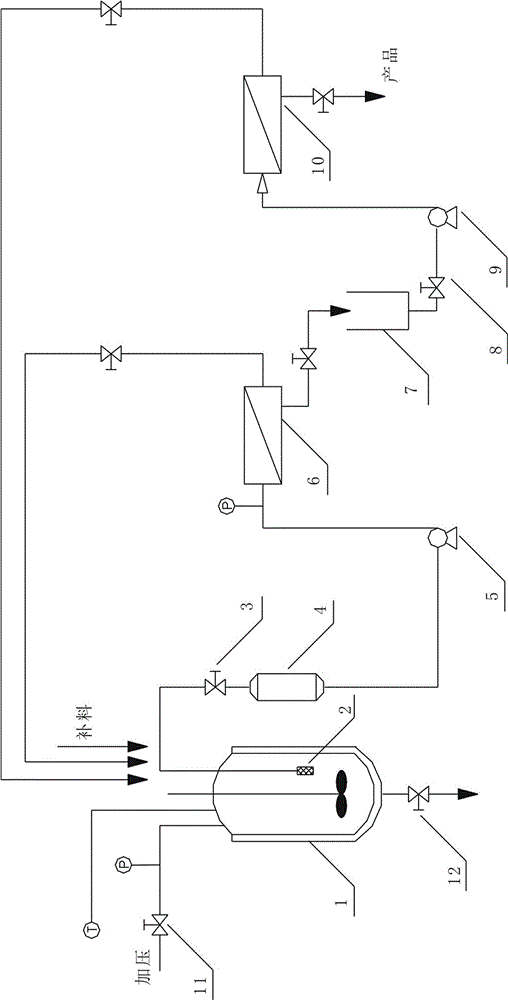

[0041] (1) In order to solve the deficiencies in Example 1 and facilitate the cleaning of the reactor, the process of Example 1 was improved, and the installation position of the stainless steel filter was changed, such as figure 2 shown.

[0042] (2) Press figure 2 For the operation shown in the flow chart, weigh 30 g of rice straw with a particle size of 180 mesh and add it to Reactor 1, add 450 ml of sulfuric acid solution with a mass fraction of 0.05% at a solid-to-liquid ratio (g / ml) of 1:15, and open the air inlet valve 11 to add Pressure to 1.6 MPa, react at a temperature of 200 °C and a stirring rate of 500 r / min. The outlet of the hydrolyzate is set in the middle of the reactor, and the outlet is wrapped by an ordinary filter 2. The ordinary filter is a 500-mesh stainless steel filter. The obtained hydrolyzate passes through Ordinary membrane filtration to obtain the permeate containing small lignocellulose parti...

Embodiment 3

[0048] Specific steps are as follows:

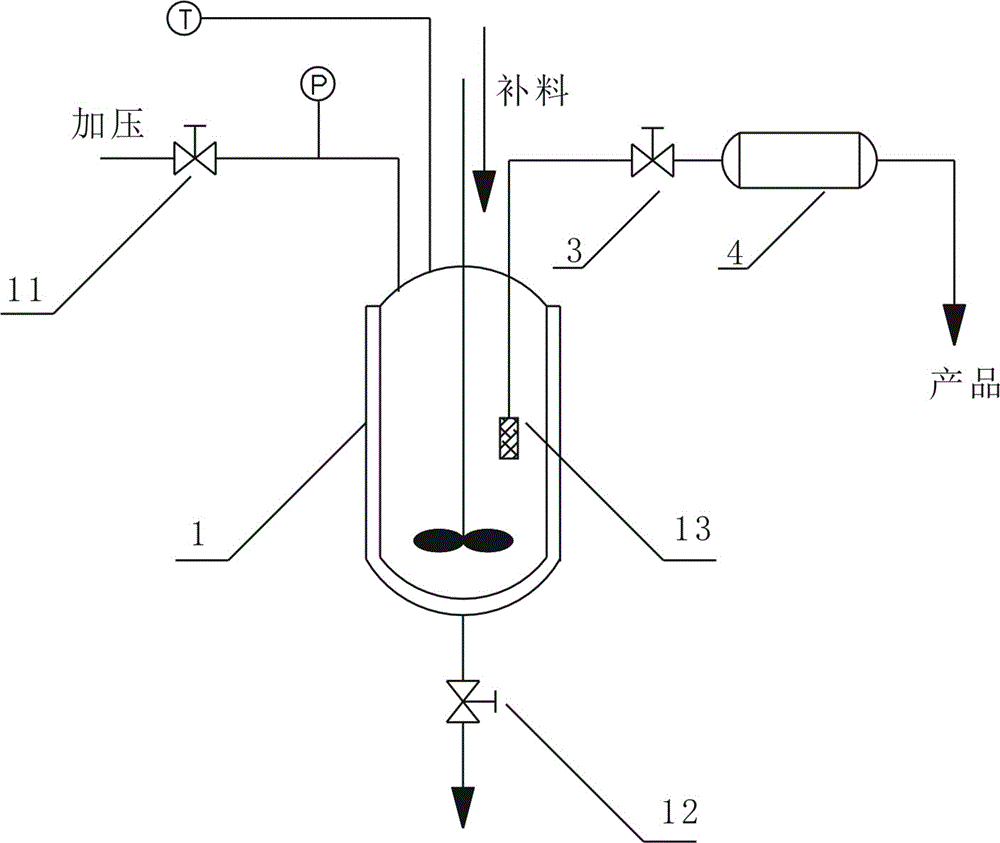

[0049] (1) Press image 3 For the operation shown in the process, weigh 30 g of rice straw with a particle size of 180 mesh and add it to Reactor 1, add 450 ml of sulfuric acid solution with a mass fraction of 0.05% at a solid-to-liquid ratio (g / ml) of 1:15, and open the intake valve 11 Pressurize to 1.6 mpa, and react at a temperature of 200 °C and a stirring speed of 500 r / min.

[0050] (2) A hydrolyzate outlet is installed in the middle of the reactor, and the outlet is composed of composite tubular membrane modules 13, which are ordinary filter 14, microfiltration membrane 15 and ultrafiltration membrane 16 from outside to inside, and the ordinary filter is 500 mesh stainless steel The microfiltration membrane is a 0.5 μm inorganic ceramic membrane, and the ultrafiltration membrane is an inorganic ceramic membrane with a molecular weight cut-off of 10,000 Daltons. Open the outlet valve 3 of the hydrolyzate, and the hydrolyzate passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com