Choline Ionic Liquid and Its Application in Wheat Straw Pretreatment

A technology of choline ion and wheat straw, applied in the production of bulk chemicals, organic chemistry, fermentation, etc., can solve the problems affecting the economic feasibility of the pretreatment process, unsatisfactory thermal stability, harsh process conditions, etc., and achieve excellent water resistance High stability, high thermal stability, and the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] [Choline][Taurine] Pretreated Wheat Straw

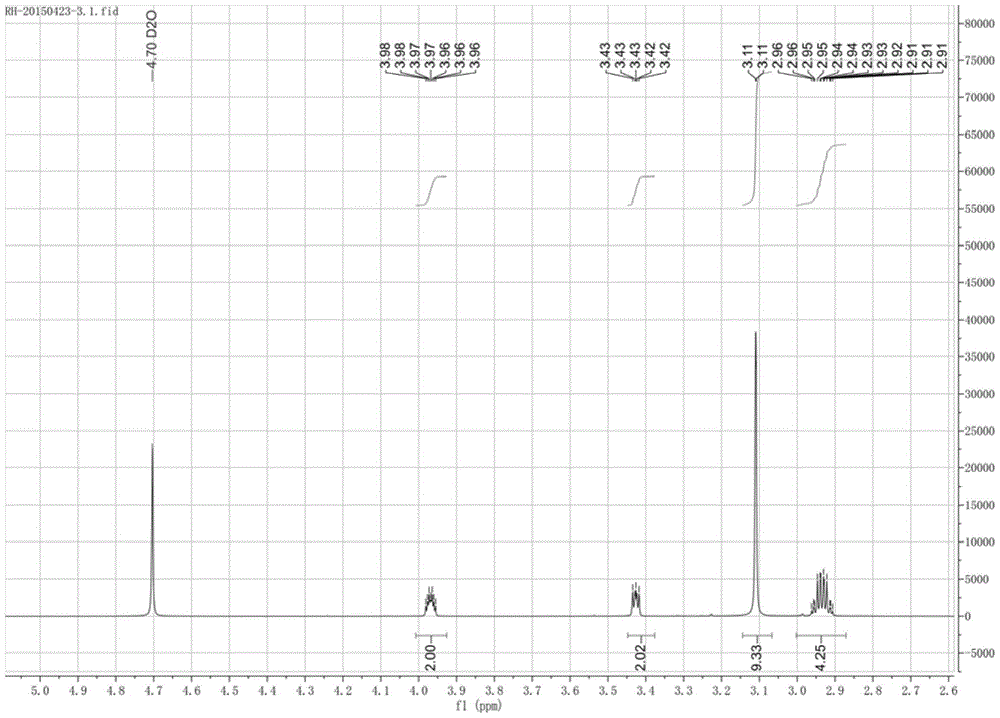

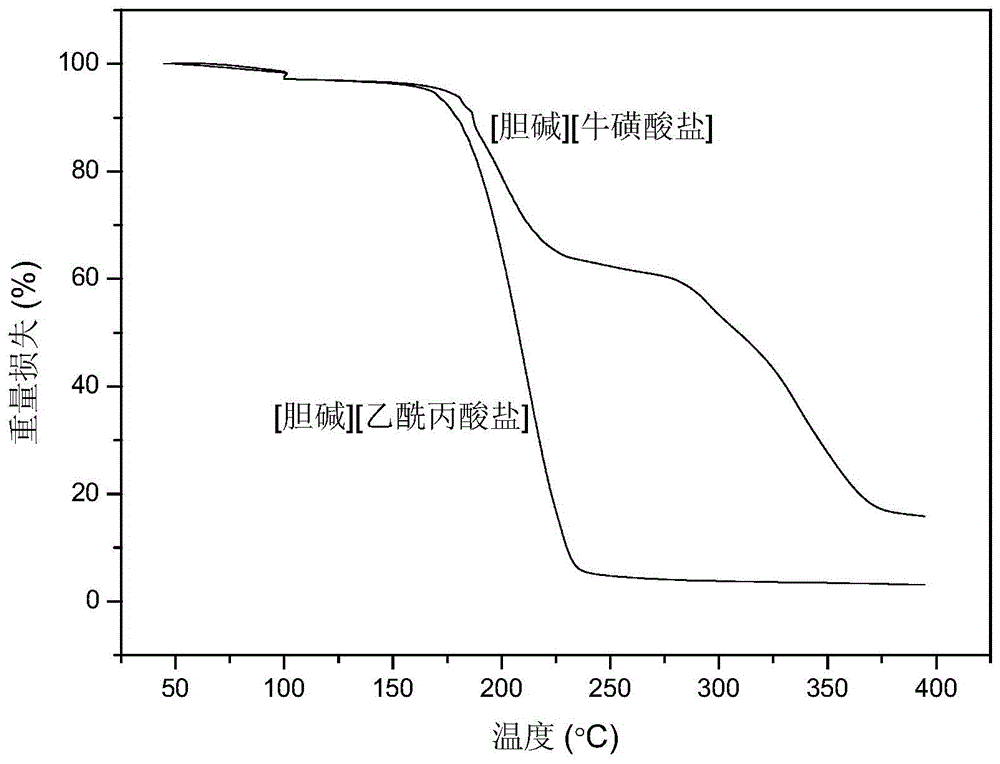

[0030] a) Preparation of [choline][taurine] ionic liquid: slowly drop 45 wt% methanol solution of choline hydroxide into equimolar taurine aqueous solution at 4°C under nitrogen protection, and keep stirring. Then warmed to room temperature and stirred for 48h. After rotary evaporation at 55° C. to remove water, vacuum drying was carried out at 70° C. for 48 hours to obtain the target ionic liquid. [Choline][Taurine] H NMR spectrum such as figure 1 shown. Its thermogravimetric analysis results ( image 3 ) shows that the thermal decomposition temperature of the ionic liquid reaches 180°C, which is 150-165°C higher than the decomposition temperature of [choline][amino acid salt].

[0031] b) Pretreatment: Take 300mg of wheat straw powder (<150μm) and 6g of [choline][taurine] ionic liquid, put them together in a 15mL Erlenmeyer flask, and stir at 90°C for 6 hours under nitrogen protection; Then cool to room temperature, add...

Embodiment 2

[0034] [Choline][Levulinate] Pretreatment of Wheat Straw

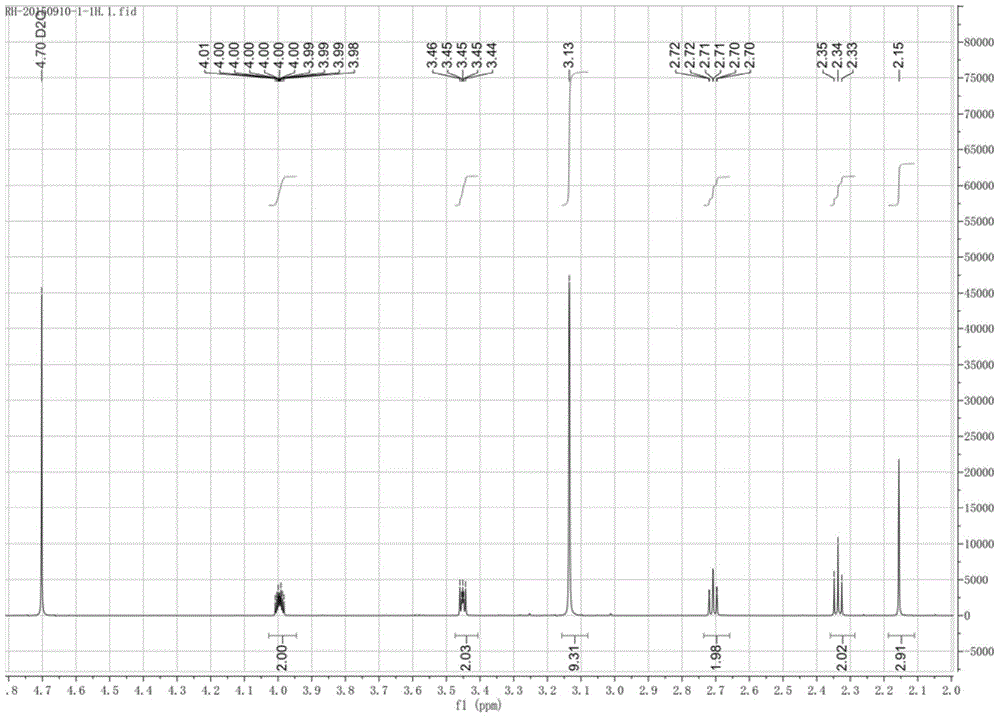

[0035] a) Preparation of [choline][levulinate] ionic liquid: slowly drop 45 wt% methanol solution of choline hydroxide into equimolar levulinic acid aqueous solution at 4°C under nitrogen protection, and keep stirring. Then warmed to room temperature and stirred for 48h. After rotary evaporation at 55° C. to remove water, vacuum drying was carried out at 70° C. for 48 hours to obtain the target ionic liquid. [Choline][levulinate] H NMR spectrum such as figure 2 shown. Its thermogravimetric analysis results ( image 3 ) shows that the thermal decomposition temperature of the ionic liquid reaches 180°C, which is 150-165°C higher than the decomposition temperature of [choline][amino acid salt].

[0036] b) Pretreatment: Take 300mg of wheat straw powder (<150μm) and 6g of [choline][levulinate] ionic liquid, put them together in a 15mL Erlenmeyer flask, and stir at 90°C for 6 hours under nitrogen protection; Then cool...

Embodiment 3

[0039] [Choline][Taurine] Pretreated Wheat Straw

[0040] a) Pretreatment: Take 150 mg of wheat straw powder (<150 μm) and 3 g of [choline][taurine] ionic liquid, put them together in a 15 mL Erlenmeyer flask, and stir at 80°C for 8 hours under nitrogen protection; Then cool to room temperature, add 1 times the volume of the ionic liquid in deionized water to dilute, filter, and then wash the filter residue 5 times with 3 times the volume of deionized water, and then dry the filter residue to obtain the pretreated rice straw.

[0041] b) Enzymatic hydrolysis: Take 20 mg of the above-mentioned pretreated wheat straw, put it in a 50 mL Erlenmeyer flask, add 7 mL of citrate buffer (50 mmol / L, pH 4.8), 0.22 FPU cellulase (Celluclast 1.5 L, purchased Novozymes) and 1.0CBU β-glucosidase (Novozymes 188, purchased from Novozymes), sealed and placed in a constant temperature oscillator at 200r / min and 50°C for reaction. After 48 hours, 200 μL of the sample was taken and treated at 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com