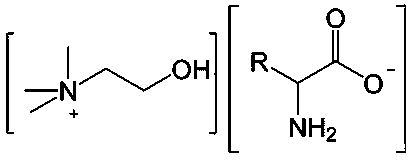

Method for increasing enzymolysis efficiency of rice straws through choline and amino acid ionic liquid pretreatment

A technology of ionic liquid and rice straw, which is applied in the production and fermentation of bulk chemicals, can solve problems such as unfriendly environment, and achieve the effect of overcoming resource waste, improving yield and realizing utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

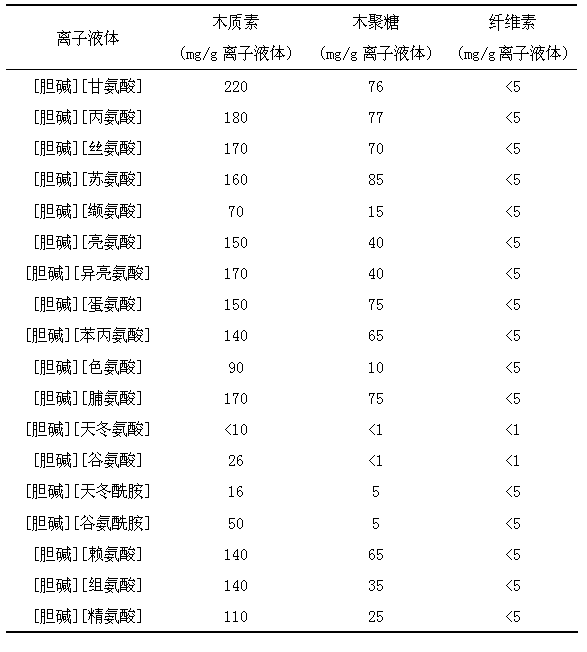

[0023] [Choline][Glycine] Pretreatment Improves Enzymatic Hydrolysis Efficiency of Rice Straw

[0024] a) Pretreatment: Accurately weigh 150 mg of rice straw powder (150–350 μm) and 3 g of [choline][glycine] ionic liquid, put them together in a 15 mL Erlenmeyer flask, and store them at 90 °C under nitrogen protection. Stir for 24 hours; then cool to room temperature, add 1 times the volume of ionic liquid NaOH solution (0.1 mol / L) to dilute, filter, and then wash the filter residue with 3 times the volume of deionized water for 5 times, and the filter residue is dried to obtain the pre- Treated rice straw.

[0025] b) Enzymolysis: Accurately weigh 20 mg of the above-mentioned pretreated rice straw, place it in a 50 mL Erlenmeyer flask, add 7 mL of citrate buffer (50 mmol / L, pH 4.8) and 245 U Li The commercialized cellulase of Trichoderma spp. was sealed and placed in a constant temperature oscillator at 200 r / min and 50 °C for reaction. 200 μL samples were taken regularly, a...

Embodiment 2

[0029] [Choline][Serine] Pretreatment Improves the Efficiency of Enzymatic Hydrolysis of Rice Straw

[0030] a) Pretreatment: Accurately weigh 150 mg of rice straw powder (150–350 μm) and 3 g of [choline][serine] ionic liquid, put them together in a 15 mL Erlenmeyer flask, and store them at 90 °C under nitrogen protection. Stir for 24 hours; then cool to room temperature, add 2 times the volume of ionic liquid NaOH solution (0.1 mol / L) to dilute, filter, and then wash the filter residue 5 times with 3 times the volume of deionized water, and the filter residue is dried to obtain the pre- Treated rice straw.

[0031]b) Enzymolysis: Accurately weigh 20 mg of the above-mentioned pretreated rice straw, place it in a 50 mL Erlenmeyer flask, add 7 mL of citrate buffer (50 mmol / L, pH 4.8) and 245 U Li The commercialized cellulase of Trichoderma spp. was sealed and placed in a constant temperature oscillator at 200 r / min and 50 °C for reaction. 200 μL samples were taken regularly, ...

Embodiment 3

[0035] [Choline][Methionine] pretreatment improves rice straw enzymatic hydrolysis efficiency

[0036] a) Pretreatment: Accurately weigh 150 mg of rice straw powder (150–350 μm) and 3 g of [choline][methionine] ionic liquid, put them together in a 15 mL Erlenmeyer flask, and store them at 90 °C under nitrogen protection. Stir at low temperature for 24 hours; then cool to room temperature, add 1.5 times the volume of ionic liquid NaOH solution (0.1 mol / L) to dilute, filter, and then wash the filter residue with 3 times the volume of deionized water for 5 times, and the filter residue is obtained after drying. Treated rice straw.

[0037] b) Enzymatic hydrolysis: Weigh 20 mg of the pretreated rice straw accurately, place it in a 50 mL Erlenmeyer flask, add 5 mL of citrate buffer (50 mmol / L, pH 4.8) and 245 U Li The commercialized cellulase of Trichoderma spp. was sealed and placed in a constant temperature oscillator at 200 r / min and 50 °C for reaction. 200 μL samples were ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com