Patents

Literature

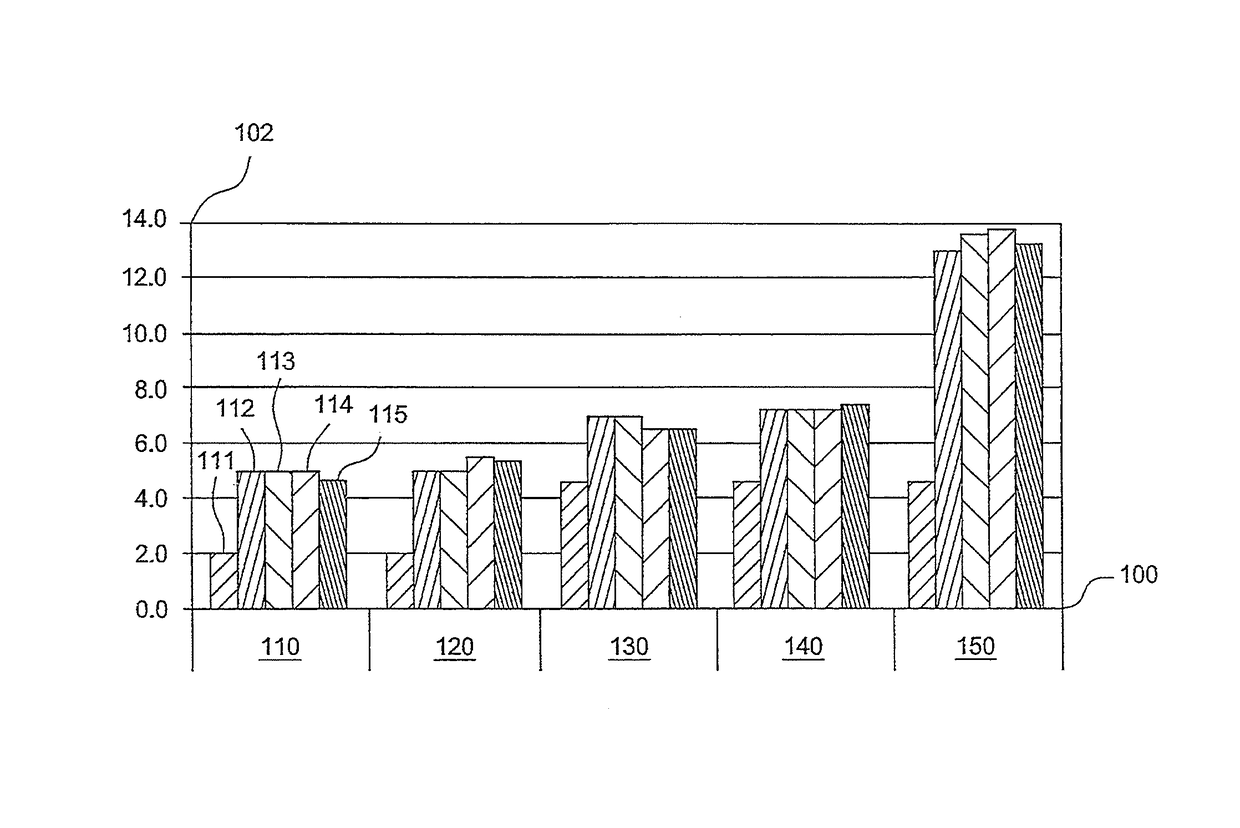

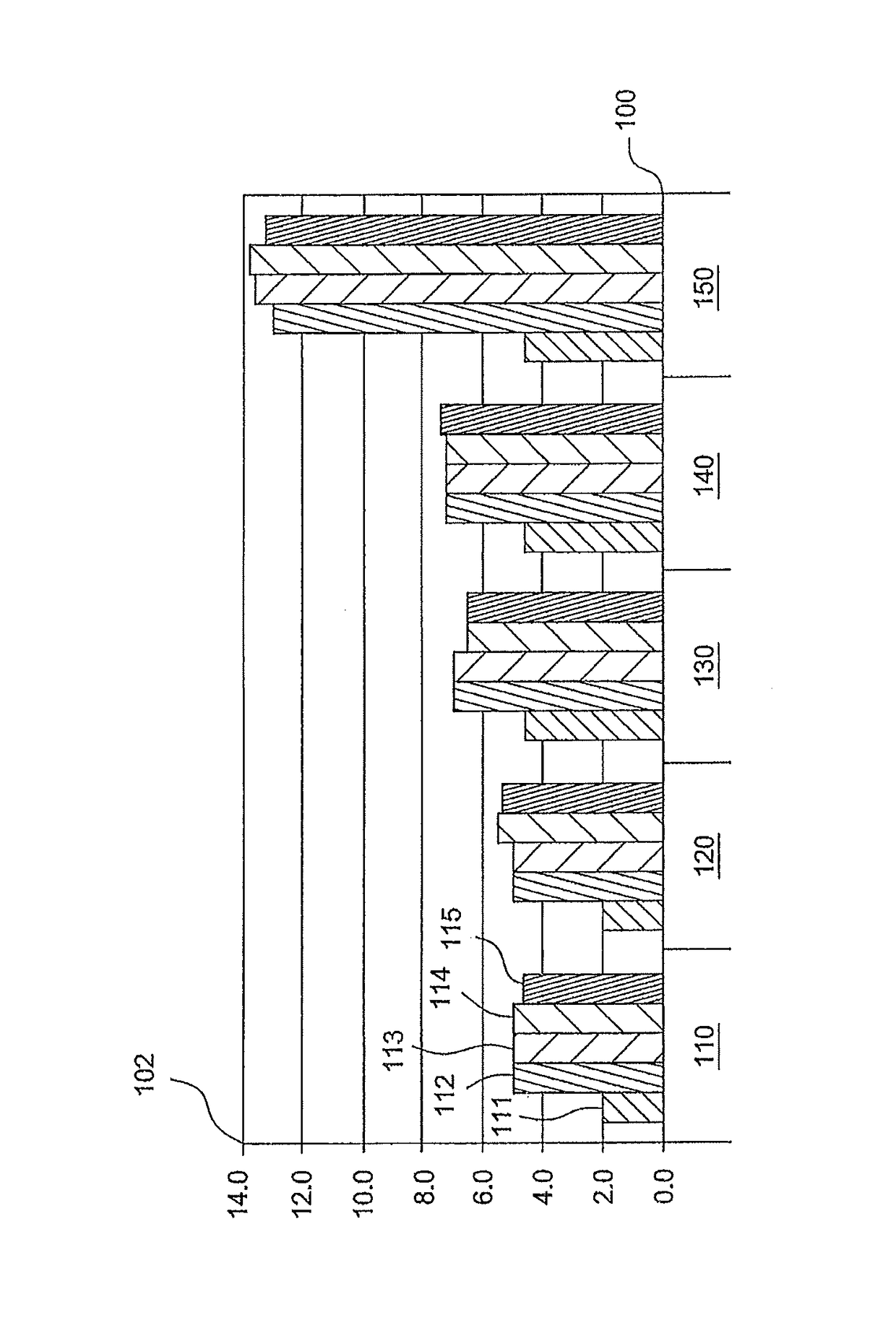

46 results about "CHOLINE HYDROXIDE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Choline can be obtained with a variety of counterion. Choline chloride is a major nutritional supplement for example. The salicylate salt of choline is used topically for pain relief of aphthous ulcers. Choline hydroxide is a phase transfer catalysts for hydroxide. It is used for stripping photoresists in circuit boards.

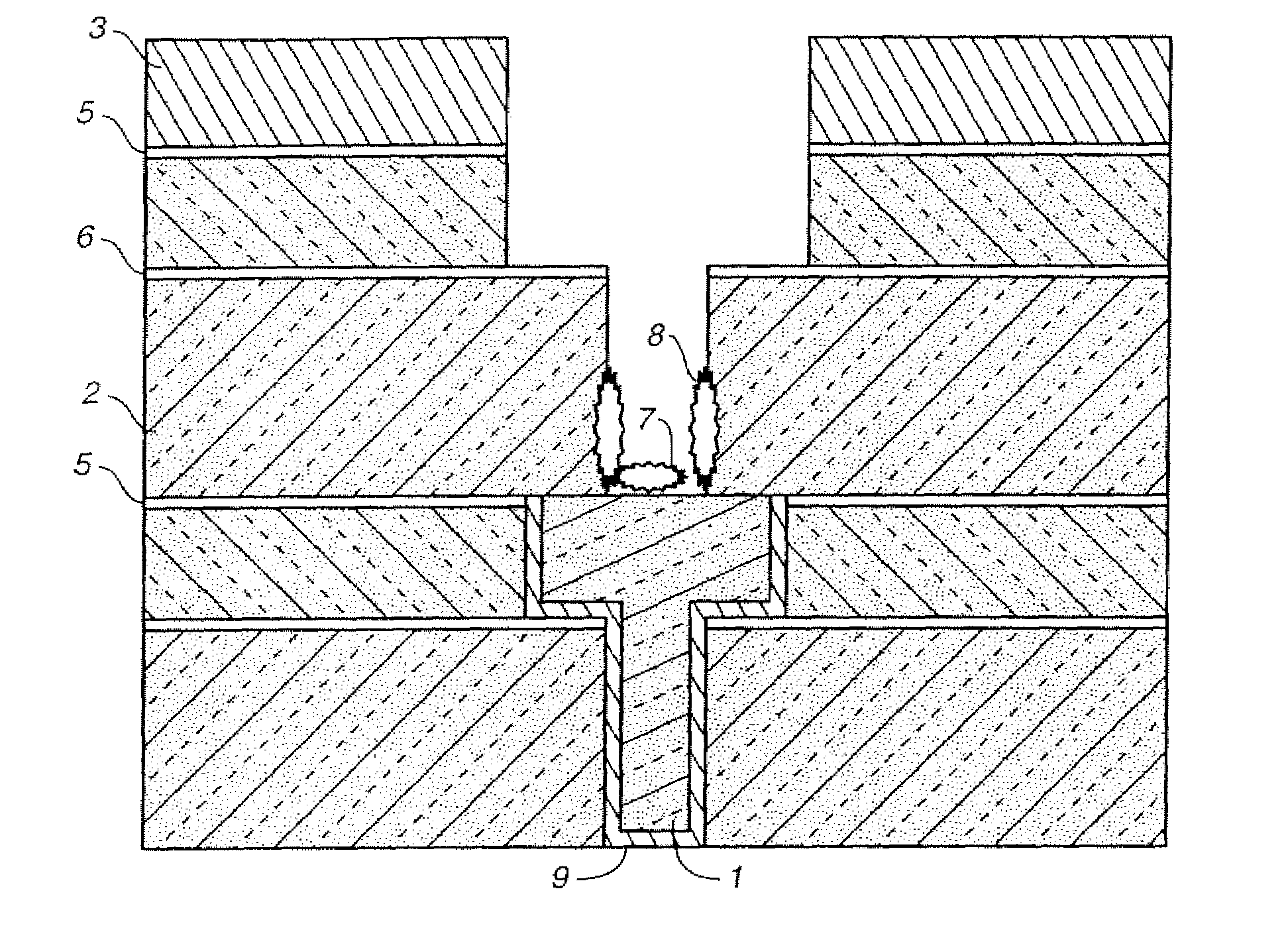

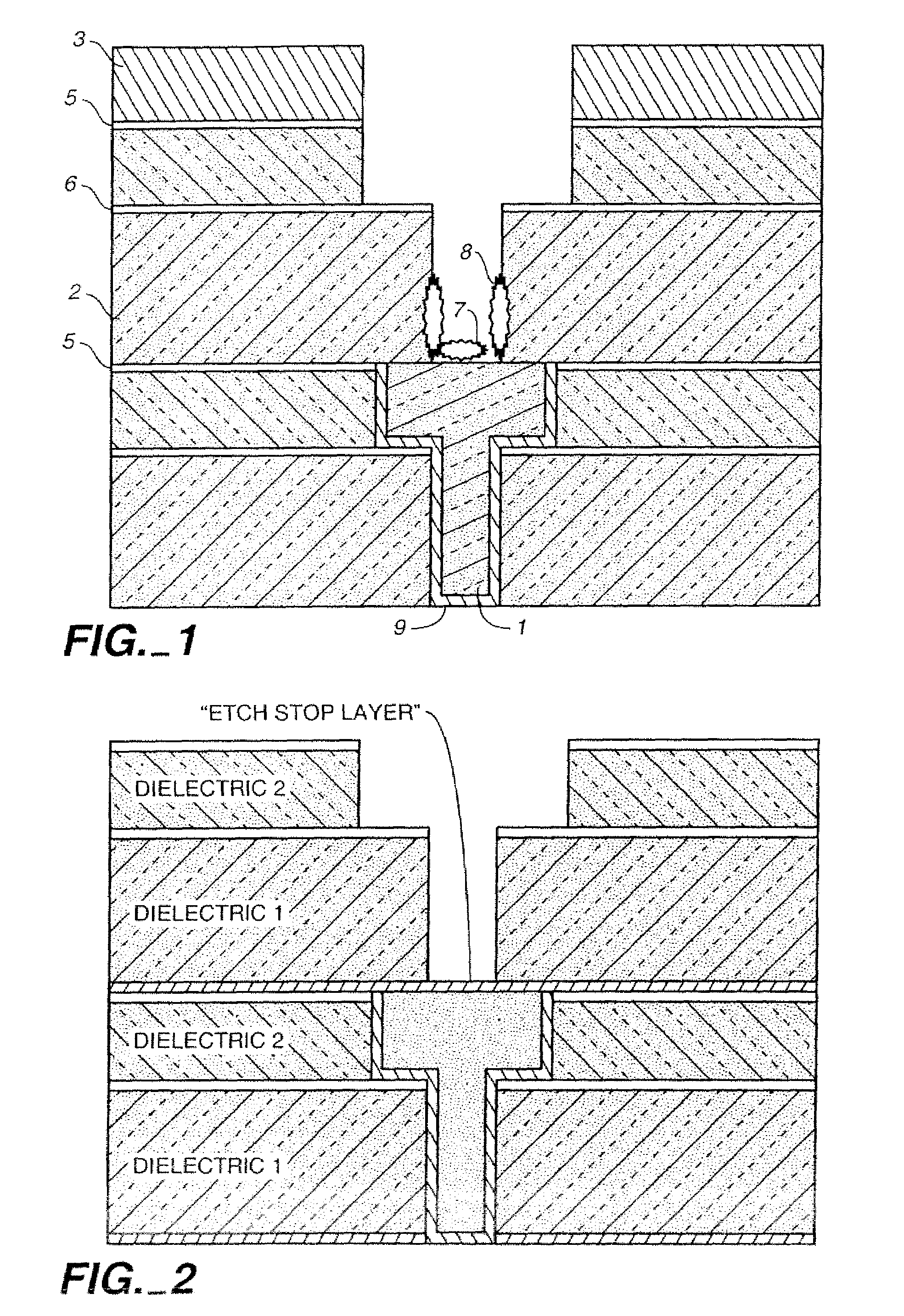

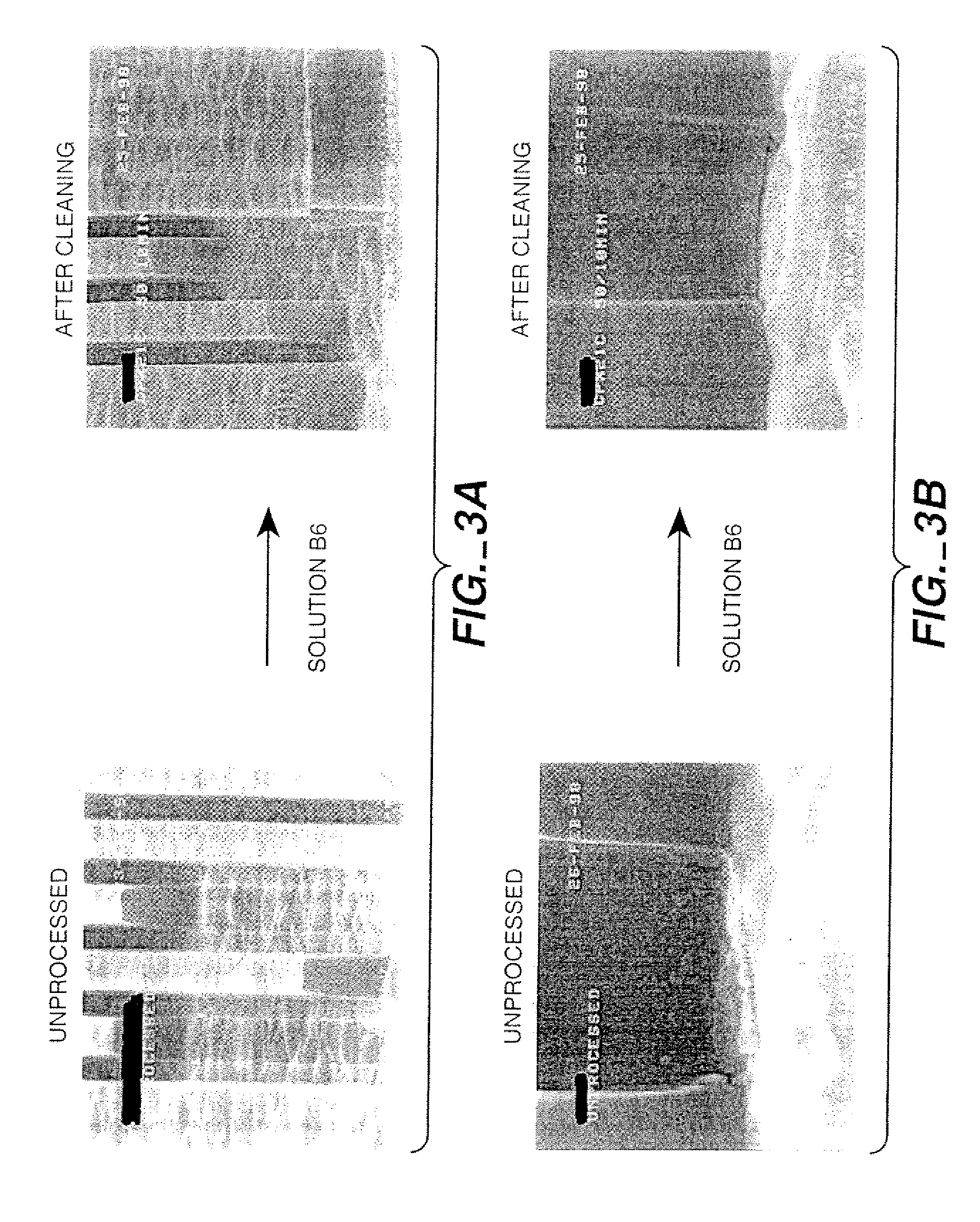

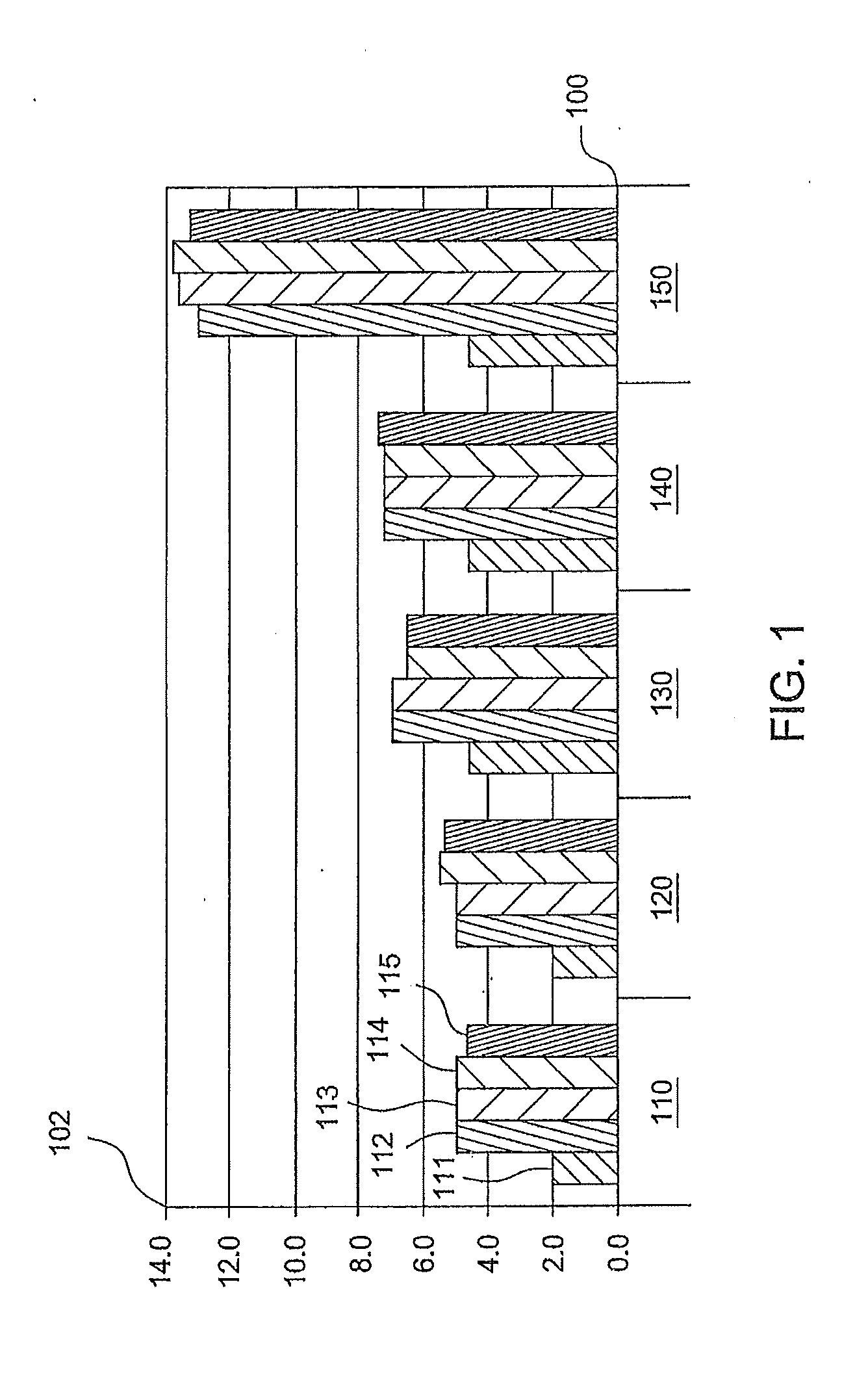

Remover compositions for dual damascene system

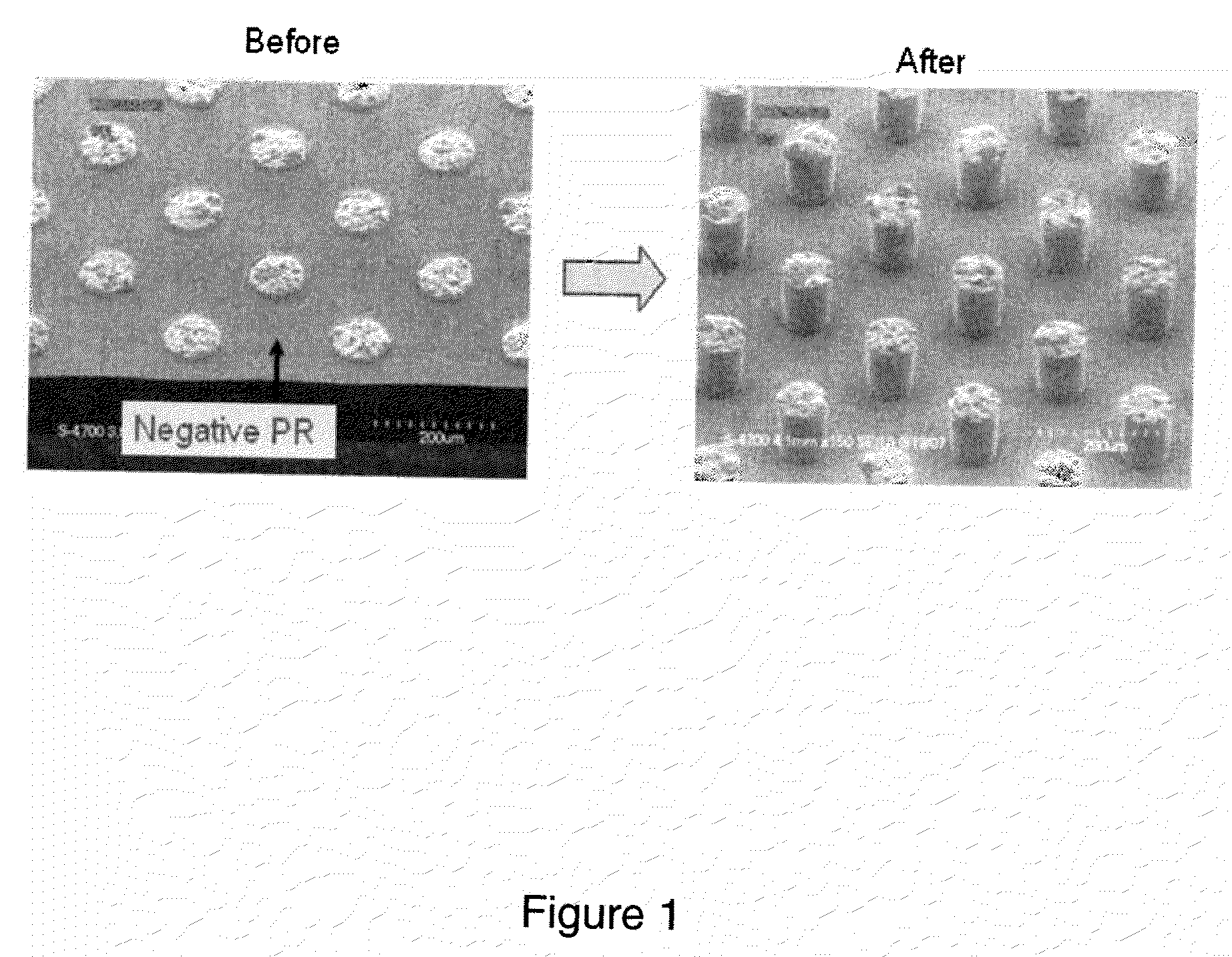

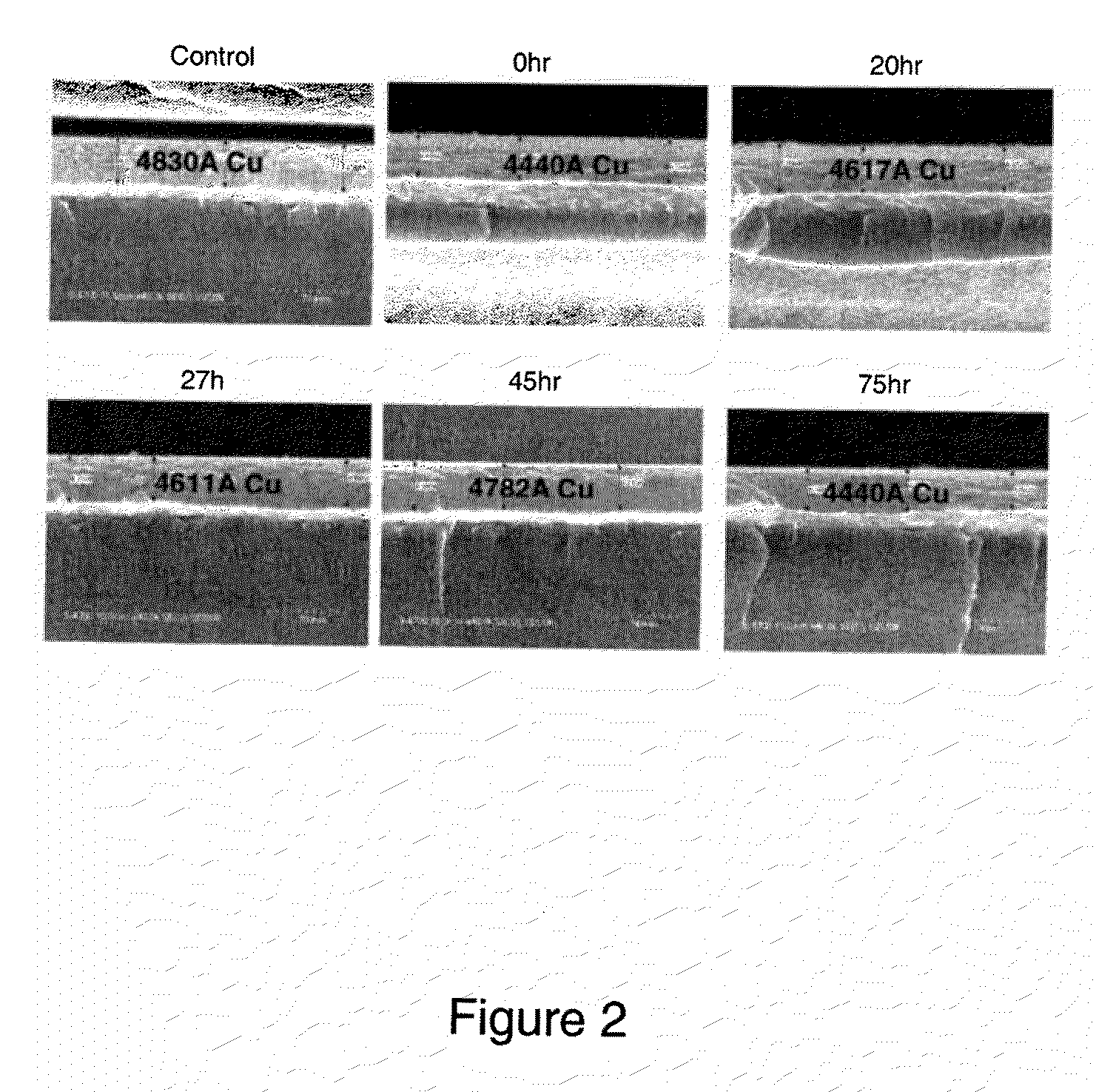

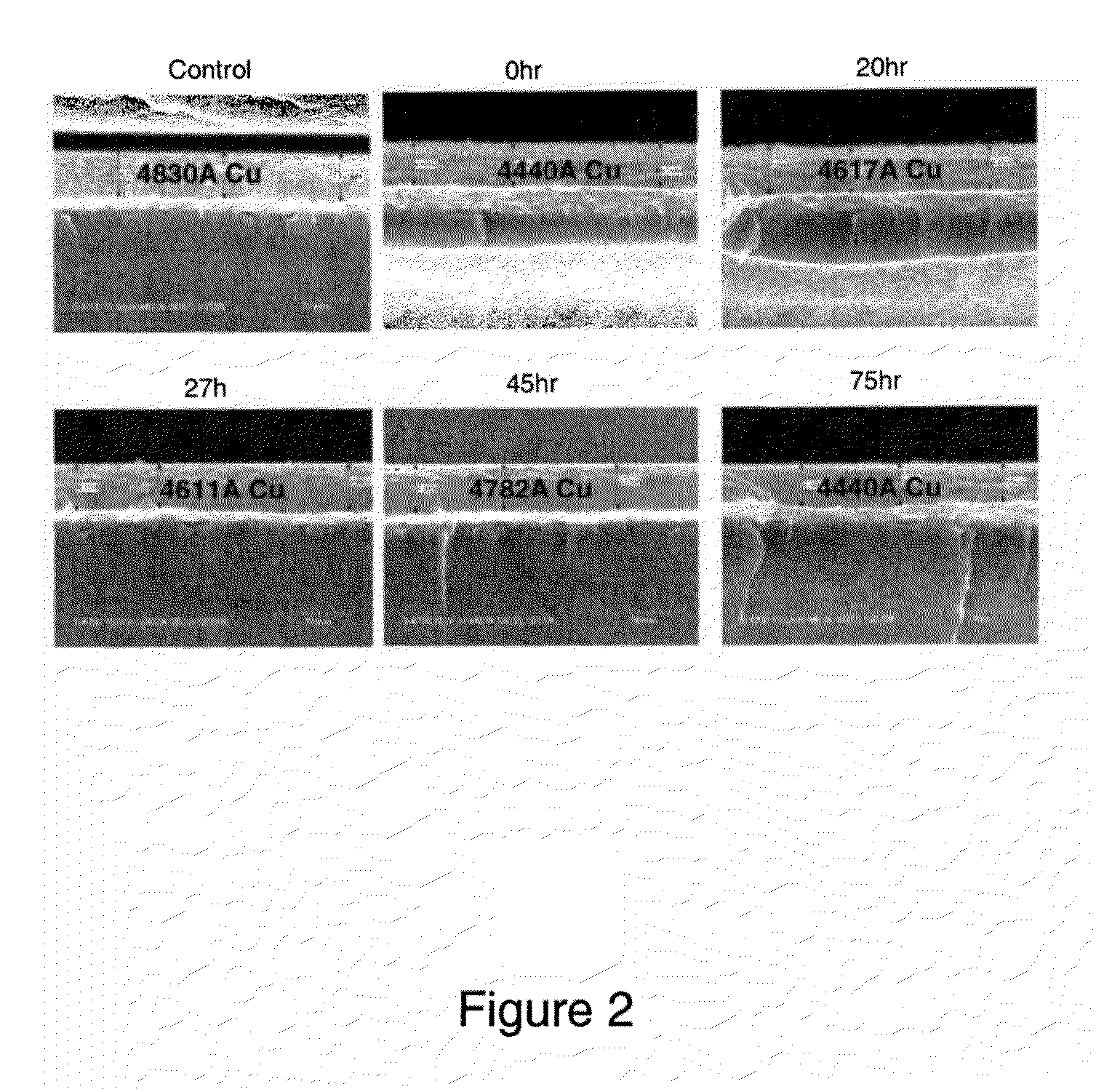

InactiveUS20050266683A1Avoid corrosionAvoid inhibitionNon-surface-active detergent compositionsSemiconductor/solid-state device manufacturingDielectricAnti-reflective coating

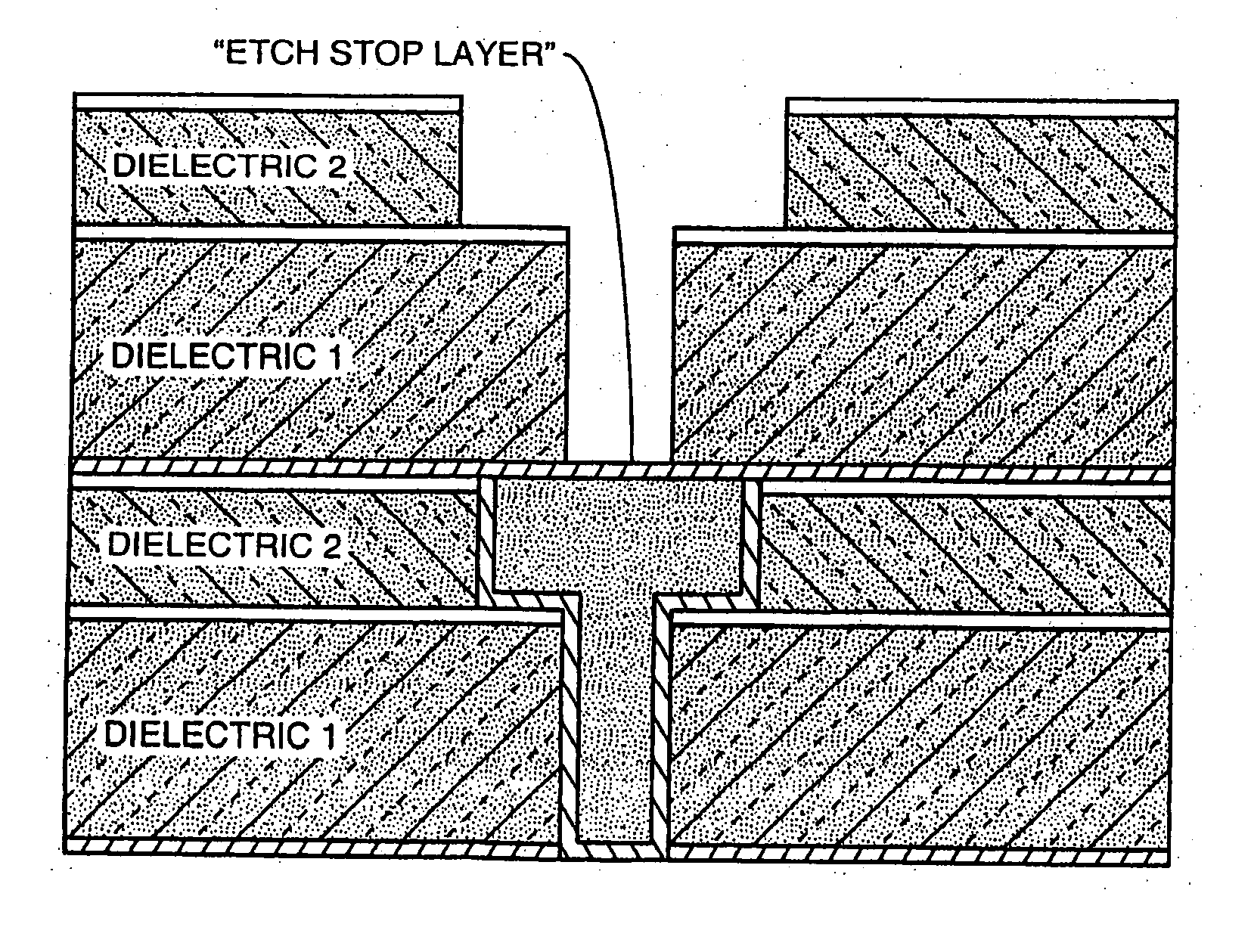

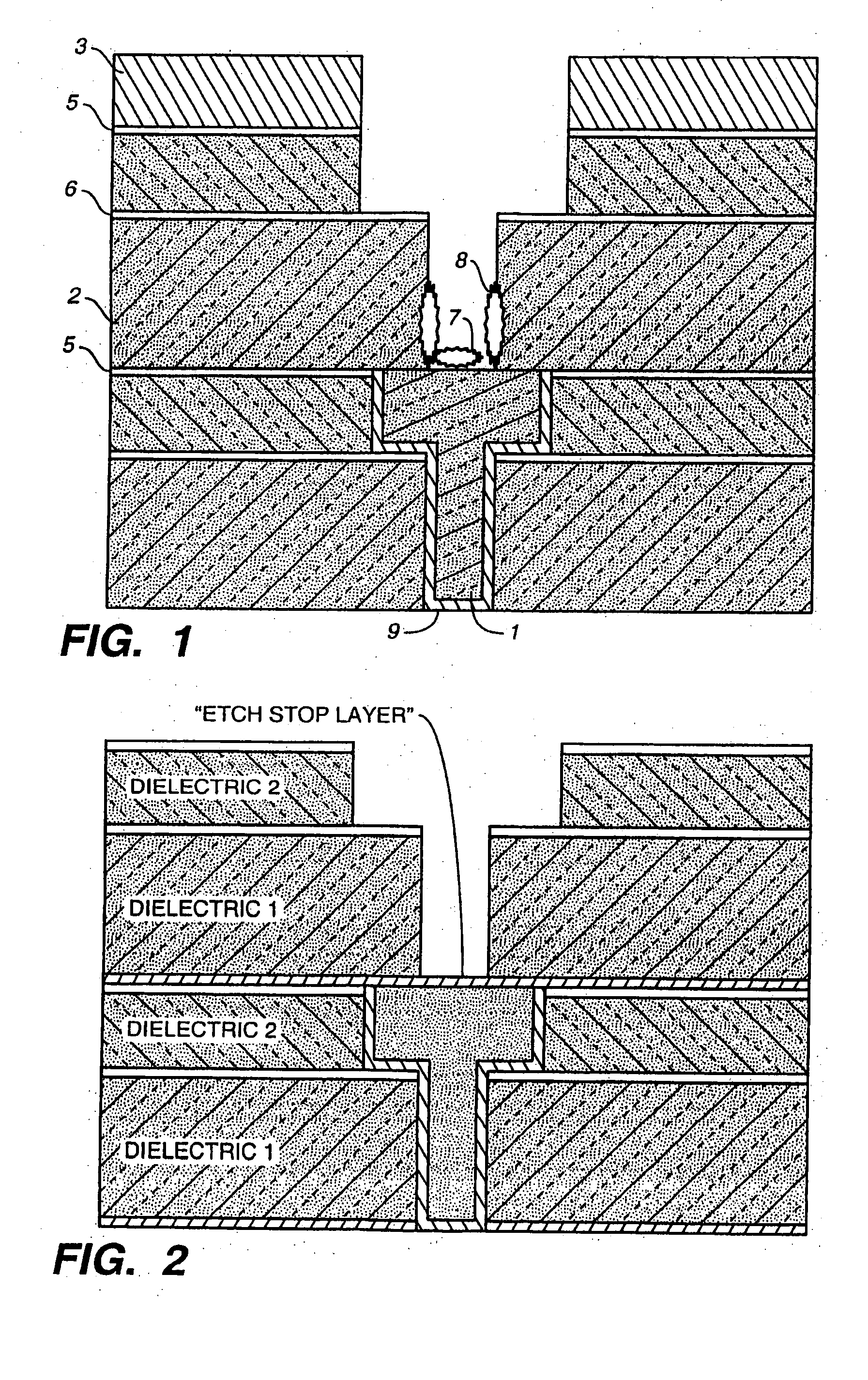

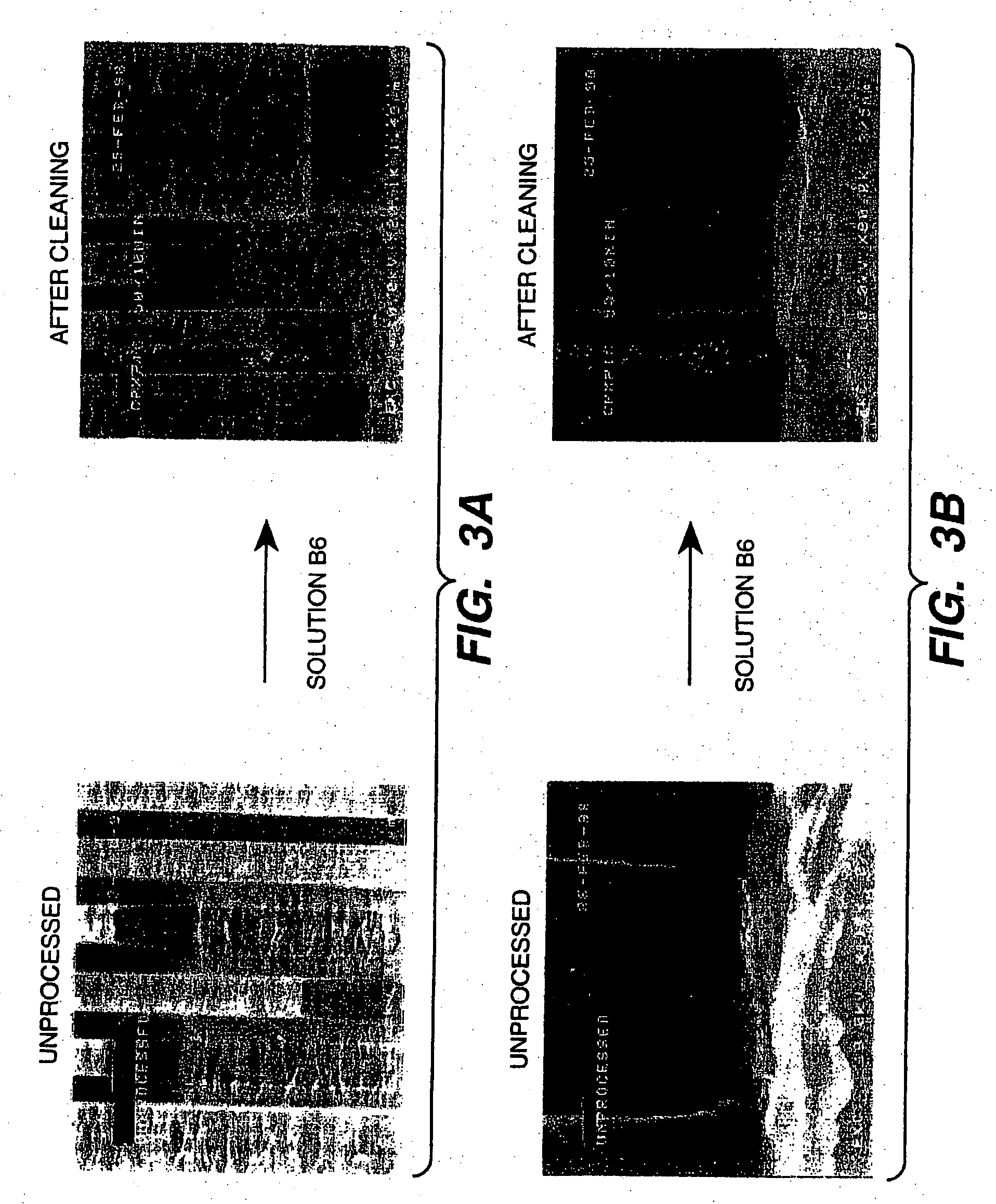

A new remover chemistry based on a choline compound, such as choline hydroxide, is provided in order to address problems related to removal of residues, modified photoresists, photoresists, and polymers such as organic anti-reflective coatings and gap-fill and sacrificial polymers from surfaces involved in dual damascene structures without damaging the dielectrics and substrates involved therein. An etch stop inorganic layer at the bottom of a dual damascene structure may or may not be used to cover the underlying interconnect of copper. If not used, a process step of removing that protective layer can be avoided through a timed etch of the via in trench-first dual damascene processes.

Owner:EKC TECH

Formulations And Method For Post-CMP Cleaning

ActiveUS20110136717A1Organic detergent compounding agentsNon-surface-active detergent compositionsSulfonateAmmonium hydroxide

The present invention is a method of cleaning to removal residue in semiconductor manufacturing processing, comprising contacting a surface to be cleaned with an aqueous formulation having a polymer selected from the group consisting of acrylamido-methyl-propane sulfonate) polymers, acrylic acid-2-acrylamido-2-methylpropane sulfonic acid copolymer and mixtures thereof and a quaternary ammonium hydroxide having greater than 4 carbon atoms or choline hydroxide with a non-acetylinic surfactant.The present invention is also a post-CMP cleaning formulation having the components set forth in the method above.

Owner:VERSUM MATERIALS US LLC

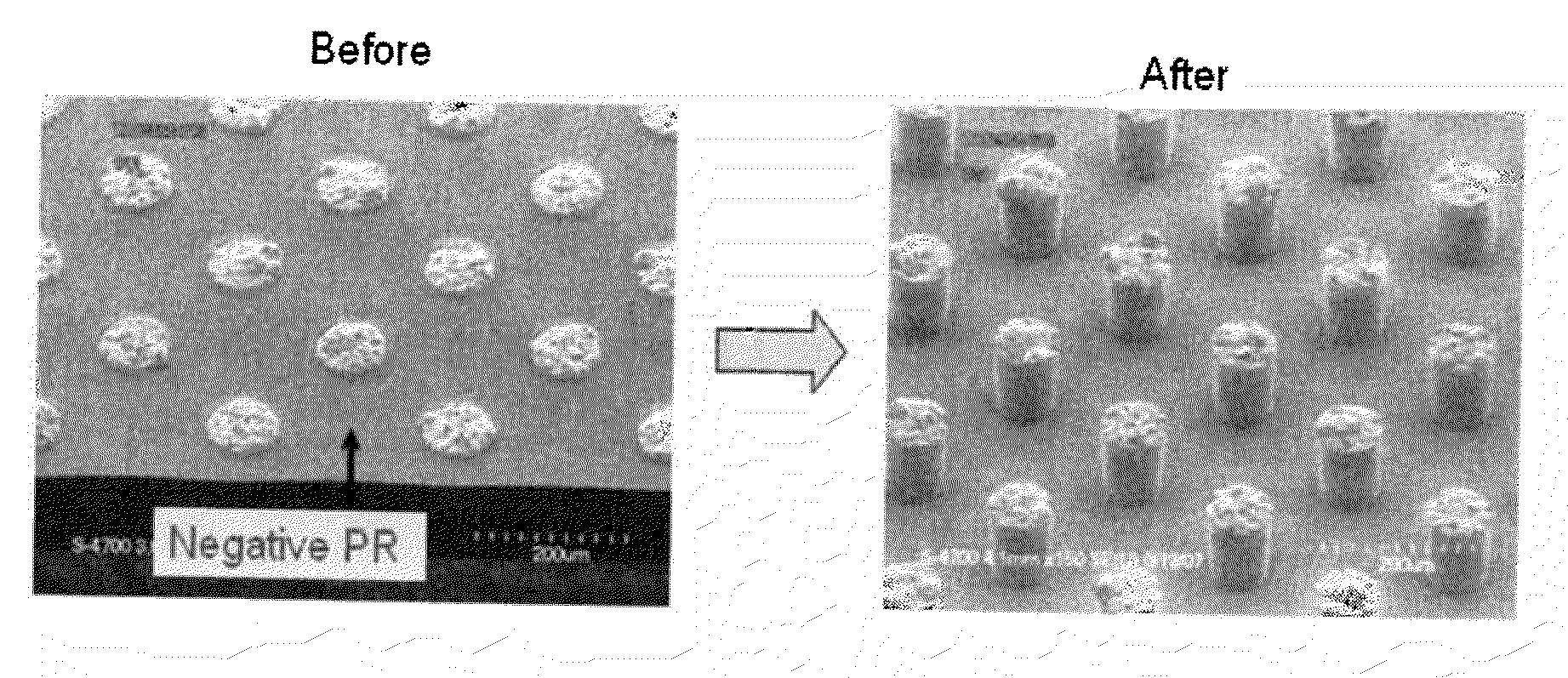

Stripper For Dry Film Removal

ActiveUS20090227483A1Non-surface-active detergent compositionsElectrostatic cleaningTetramethylammonium hydroxideGallic acid ester

The present invention, in a preferred embodiment, is a photoresist stripper formulation, comprising: Hydroxylamine ; Water; a solvent selected from the group consisting of dimethylsulfoxide; N-methylpyrrrolidine; dimethylacetamide; dipropylene glycol monomethyl ether; monoethanolamine and mixtures thereof; a base selected from the group consisting of choline hydroxide, monoethanolamine, tetramethylammonium hydroxide; aminoethylethanolamine and mixtures thereof; a metal corrosion inhibitor selected from the group consisting of catechol, gallic acid, lactic acid, benzotriazole and mixtures thereof; and a bath life extending agent selected from the group consisting of glycerine, propylene glycol and mixtures thereof. The present invention is also a method for using formulations as exemplified in the preferred embodiment.

Owner:VERSUM MATERIALS US LLC

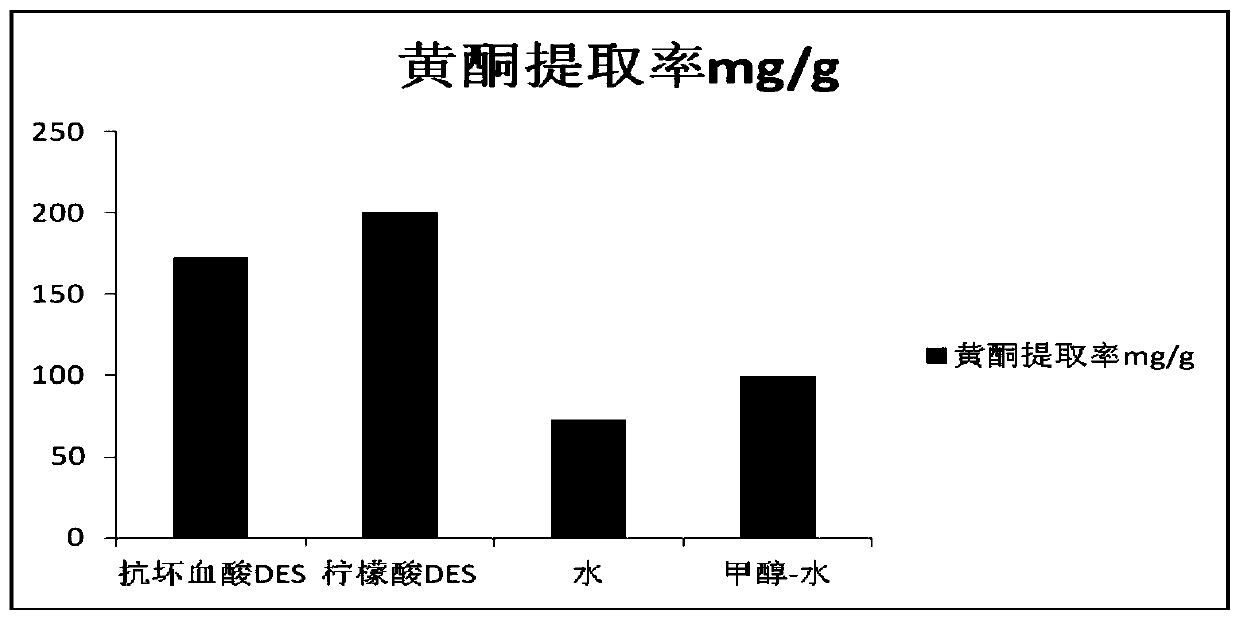

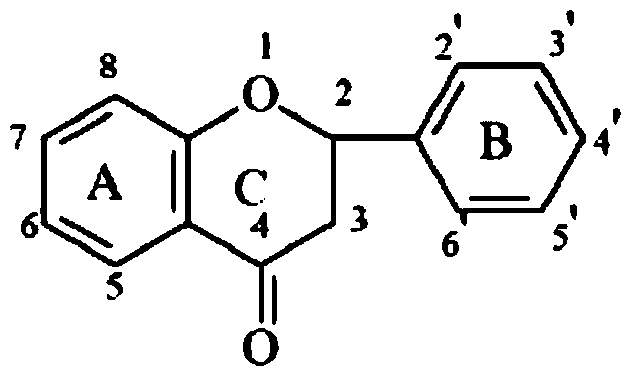

Preparation method of choline eutectic solvent and application of choline eutectic solvent in extraction of flavonoid compounds

InactiveCN111281928ASimple processHigh puritySolid solvent extractionPlant ingredientsOrganic acidRotary evaporator

The invention discloses a preparation method of a choline eutectic solvent and application of the choline eutectic solvent in extraction of flavonoid compounds. The preparation process of the cholineeutectic solvent is as follows: taking proper amounts of choline chloride or choline hydroxide for uniformly mixing with a proper amount of an organic acid according to a ratio (mole number) of 1:1-1:10; putting a uniformly mixed reactant into a flat-bottomed flask with a proper size, and then adding a proper amount of water to initiate a reaction; and putting a magnetic stirrer at the temperature of 25-50 DEG C, putting the flat-bottomed flask on a magnetic stirrer, performing stirring for 1-24h at a proper rotating speed, after reactants in the bottle become transparent and uniform viscousliquid, transferring the liquid in the bottle into a rotary evaporator, and performing spin-drying on excessive moisture to obtain a viscous transparent liquid, namely a DES solvent finished product.The flavonoid compound extracted by the method has the characteristics of high purity, high extraction rate and simple and convenient process, the extraction time is shortened, the traditional solventis changed into an environment-friendly DES solvent which is easy to decompose, and the flavonoid compound is a real green chemical.

Owner:中科萱嘉医养(珠海)健康科技有限公司

Stabilized choline solutions and methods for preparing the same

InactiveUS20140361217A1Reduce and eliminate degradationReduce and eliminate and decomposition reactionOrganic compound preparationOther chemical processesDithionous acidSulfite

A method for the stabilization of an aqueous choline hydroxide solution includes optionally, adding a first stabilizer of a dithionite salt or a dialkylhydroxylamine to an aqueous solution containing reactants that will produce an aqueous choline hydroxide solution; and after the aqueous choline hydroxide solution is formed, adding a second stabilizer of a dithionite salt or a dialkylhydroxylamine to the aqueous choline hydroxide solution. The stabilized choline hydroxide solution may include choline hydroxide, water, and a dithionite salt and / or a dialkylhydroxylamine as a stabilizer present in an amount of about 100 ppm to about 2000 ppm by weight of the stabilized choline hydroxide solution.

Owner:TAMINCO NV

Remover compositions for dual damascene system

InactiveUS7547669B2Avoid corrosionEasy to cleanElectrostatic cleaningSemiconductor/solid-state device manufacturingDielectricAnti-reflective coating

A new remover chemistry based on a choline compound, such as choline hydroxide, is provided in order to address problems related to removal of residues, modified photoresists, photoresists, and polymers such as organic anti-reflective coatings and gap-fill and sacrificial polymers from surfaces involved in dual damascene structures without damaging the dielectrics and substrates involved therein. An etch stop inorganic layer at the bottom of a dual damascene structure may or may not be used to cover the underlying interconnect of copper. If not used, a process step of removing that protective layer can be avoided through a timed etch of the via in trench-first dual damascene processes.

Owner:EKC TECH

Formulations and method for post-CMP cleaning

ActiveUS8765653B2Organic detergent compounding agentsDetergent mixture composition preparationSulfonateAmmonium hydroxide

The present invention is a method of cleaning to removal residue in semiconductor manufacturing processing, comprising contacting a surface to be cleaned with an aqueous formulation having a polymer selected from the group consisting of acrylamido-methyl-propane sulfonate) polymers, acrylic acid-2-acrylamido-2-methylpropane sulfonic acid copolymer and mixtures thereof and a quaternary ammonium hydroxide having greater than 4 carbon atoms or choline hydroxide with a non-acetylinic surfactant.The present invention is also a post-CMP cleaning formulation having the components set forth in the method above.

Owner:VERSUM MATERIALS US LLC

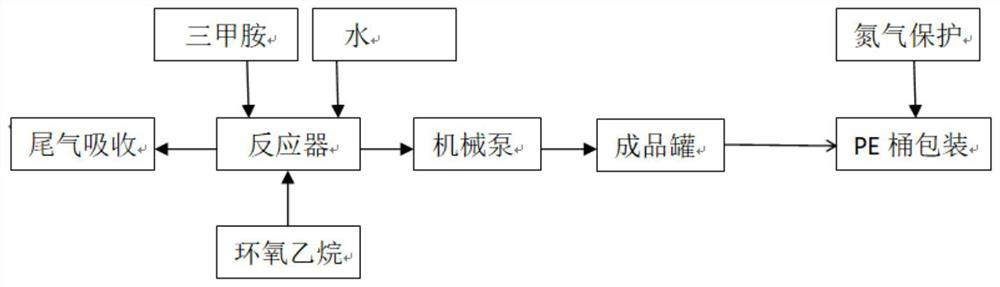

Process for the production of choline hydroxide

ActiveUS9216944B2Efficient and low heat controlOrganic compound preparationAmino-hyroxy compound preparationEthylene oxideReaction zone

A continuous process for the production of choline hydroxide includes reacting ethylene oxide, trimethylamine, and water in a reaction zone to form a reaction mixture and extracting heat from the reaction mixture. Subsequently, phase separation of the reaction mixture is induced to obtain a choline hydroxide phase and an organic liquid phase comprising trimethylamine. A choline hydroxide solution (e.g., at a concentration of about 40% to 50% by weight, based on total weight of the choline hydroxide solution) is obtained from the choline hydroxide phase.

Owner:TAMINCO NV

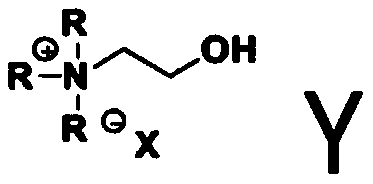

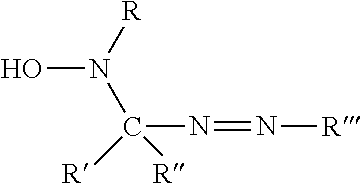

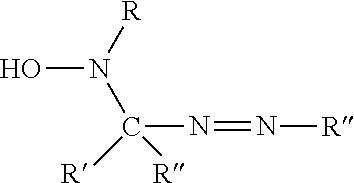

Using novel amines to stabilize quaternary trialkylalkanolamines

New stabilizers for solutions of choline hydroxide and related quaternary trialkylalkanolamines are disclosed. The stabilizers are alkyl hydroxylamines, hydrazines, hydrazides, or derivates thereof, including compounds containing more than one such functionality. The new stabilizers are effective at concentrations less than about 1000 ppm, and choline hydroxide solutions stabilized with the compounds described herein typically have Gardner Color change less than about 2.0 after six months at reasonable temperatures.

Owner:HUNTSMAN PETROCHEMICAL LLC

Stabilized choline solutions and methods for preparing the same

InactiveUS20170121275A1Reduce and eliminate degradationReduce and eliminate and reactionOrganic compound preparationAmino-hyroxy compound preparationDithionous acidAqueous solution

Owner:TAMINCO NV

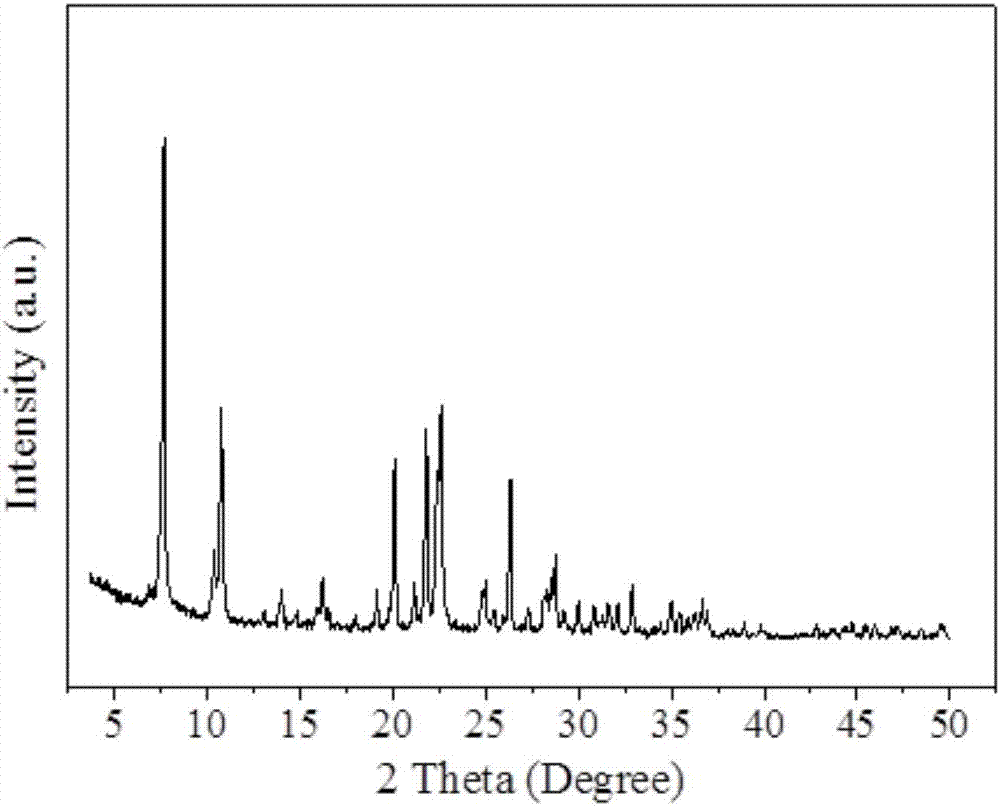

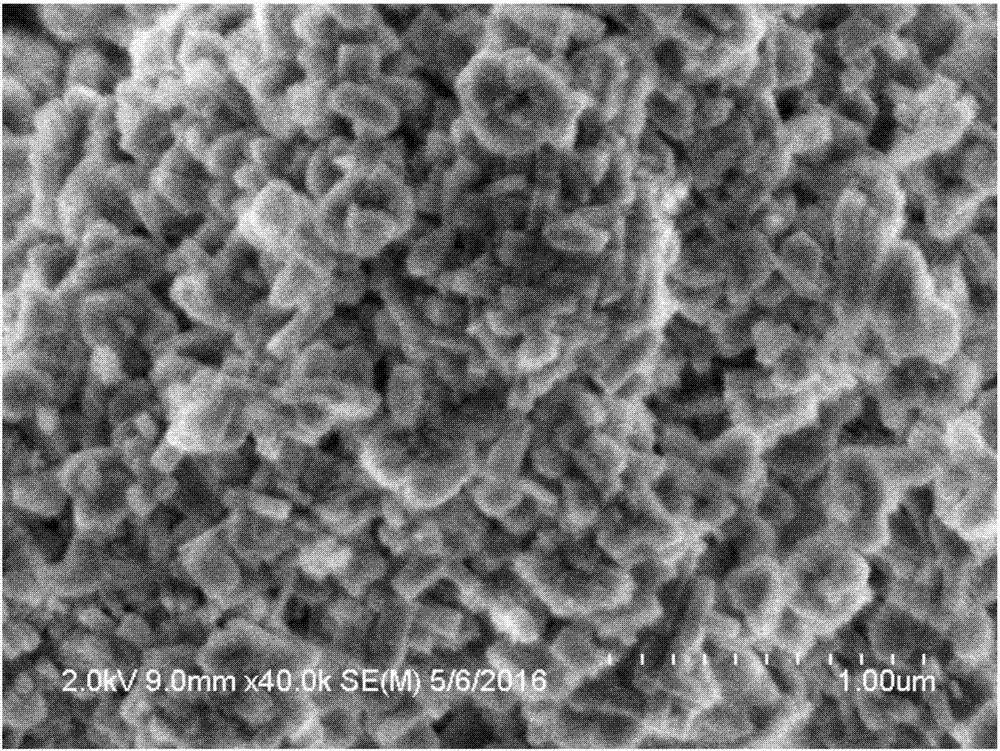

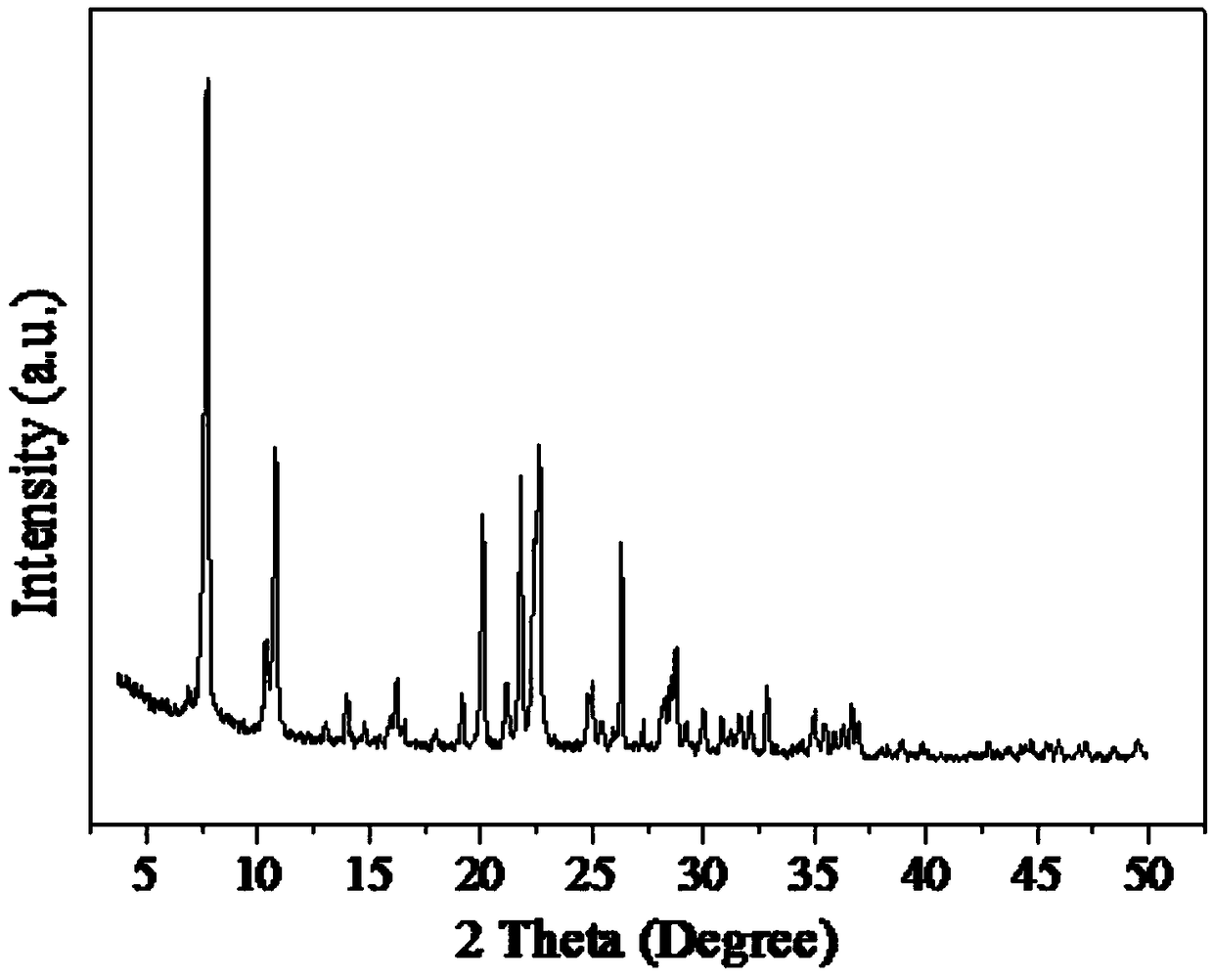

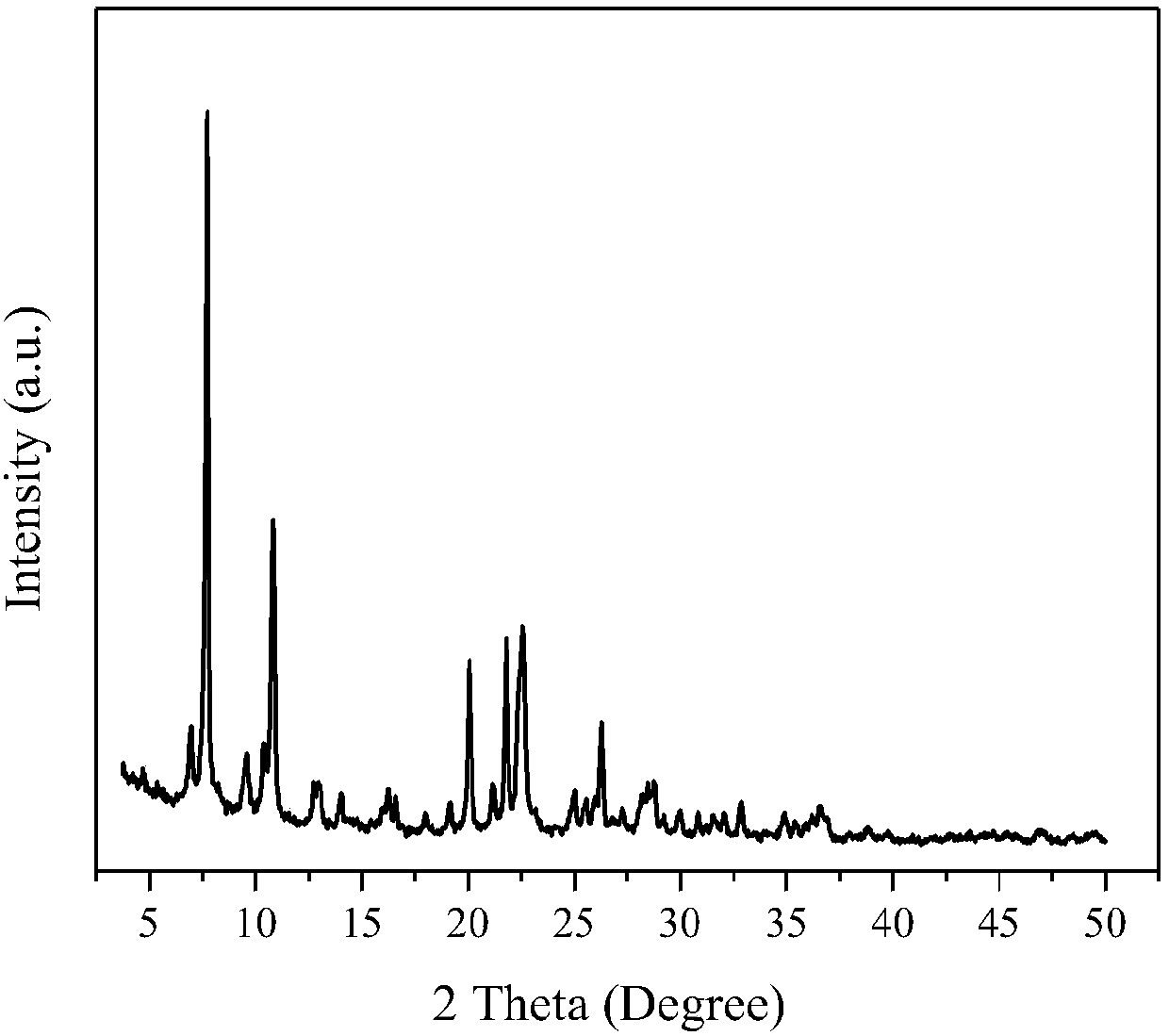

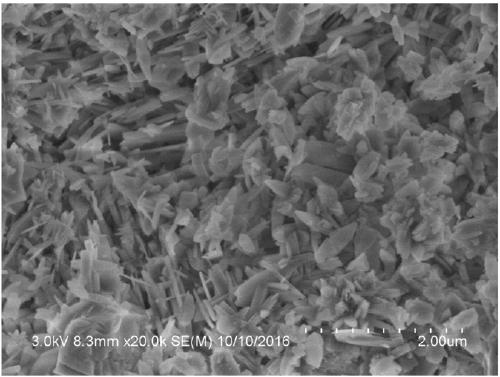

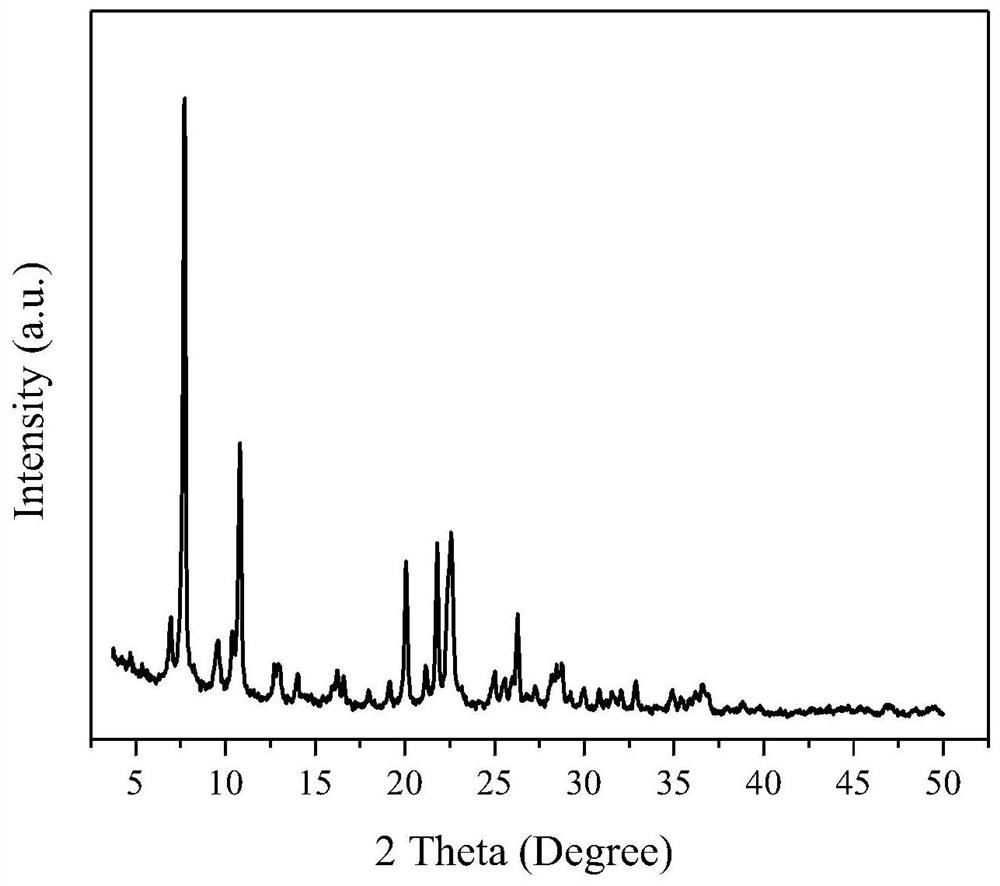

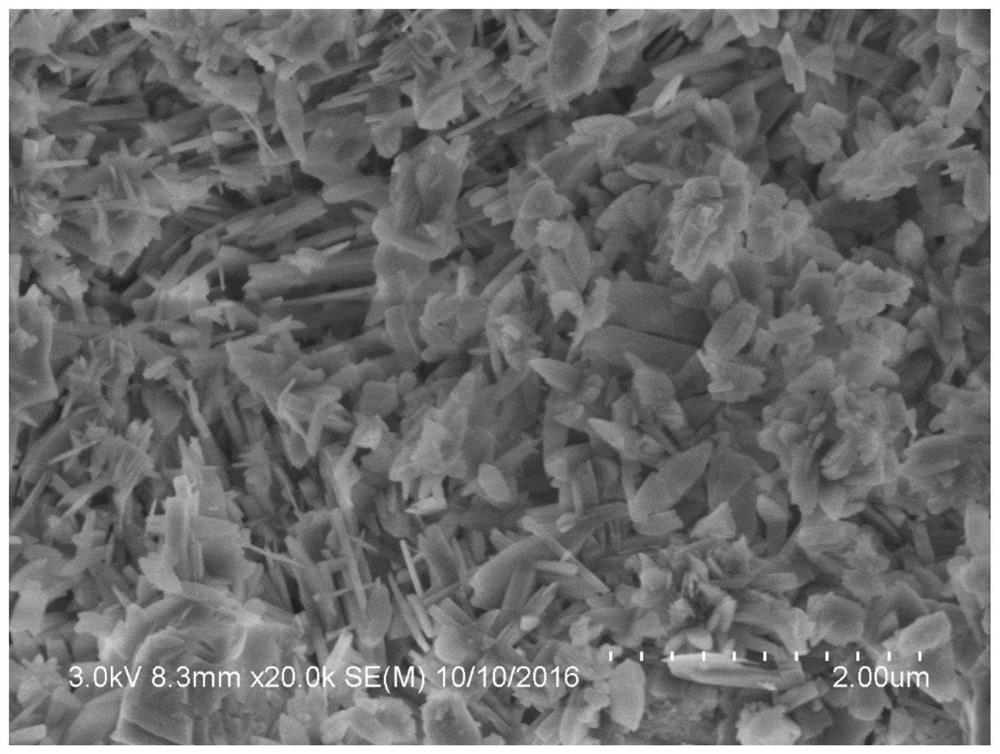

Preparation method of ITQ-24 zeolite molecular sieve

ActiveCN107954437ASmall molecular weightMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveSynthesis methods

The invention relates to a synthesis method of an ITQ-24 zeolite molecular sieve, and mainly solves the problems of complicated preparation and high cost of organic template agents used for synthesizing an ITQ-24 zeolite molecular sieve and an unstable structure of the obtained ITQ-24 zeolite molecular sieve in the prior art. According to the invention, choline hydroxide which is low in price andcan be obtained from market sale is used as an organic template agent; a mixture is composed according to the following relationships: choline hydroxide / YO2=0.1-1.0, X2O3 / YO2=0-0.1, and H2O / YO2=1-30;hydrothermal crystallization is carried out on the mixture at 100-200 DEG C for 24-350 hours to obtain the porous crystalline zeolite molecular sieve material ITQ-24, wherein Y is at least one quadrivalent element, and X is at least one trivalent element. According to the invention, the cheap organic template agent is used, so that the synthesis cost is greatly reduced; the structure of the synthesized ITQ-24 molecular sieve is stable; and the method has a wide synthesis range, simple and feasible operation and convenient promotion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Stabilized choline solutions and methods for preparing the same

InactiveUS20140329184A1Reduce and eliminate degradationReduce and eliminate and reactionAmino compound purification/separationOrganic detergent compounding agentsDithionous acidAqueous solution

A method for the stabilization of an aqueous choline hydroxide solution includes, optionally adding a first stabilizer of a dithionite salt and / or a dialkylhydroxylamine to an aqueous solution containing reactants that will produce an aqueous choline hydroxide solution; and after the aqueous choline hydroxide solution is formed, adding a second stabilizer which comprises a dialkylhydroxylamine to the aqueous choline hydroxide solution. The stabilized choline hydroxide solution may include choline hydroxide, water, and a dialkylhydroxylamine and optionally a dithionite salt as a stabilizer present in an amount of from about 50 ppm to less than about 5000 ppm by weight relative to the total weight of the stabilized choline hydroxide solution.

Owner:TAMINCO NV

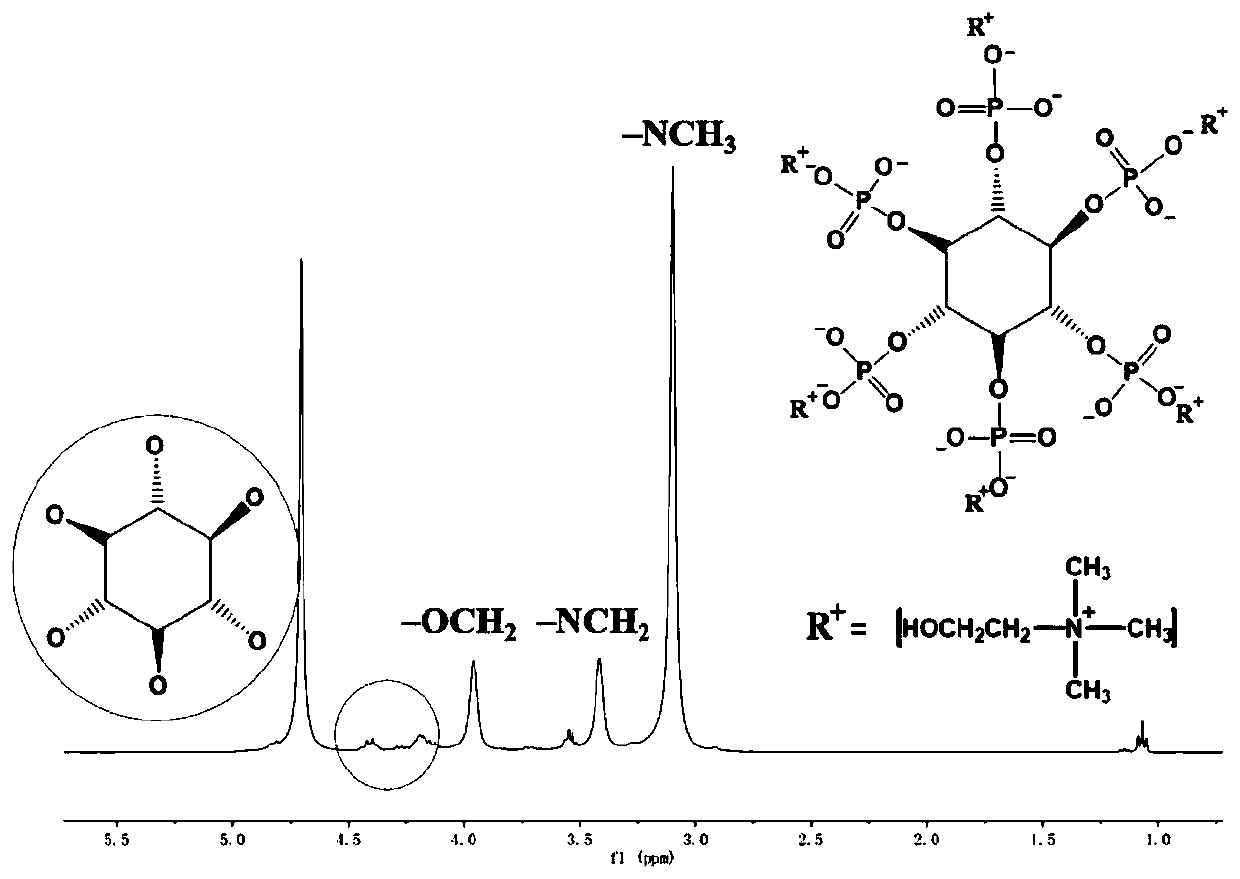

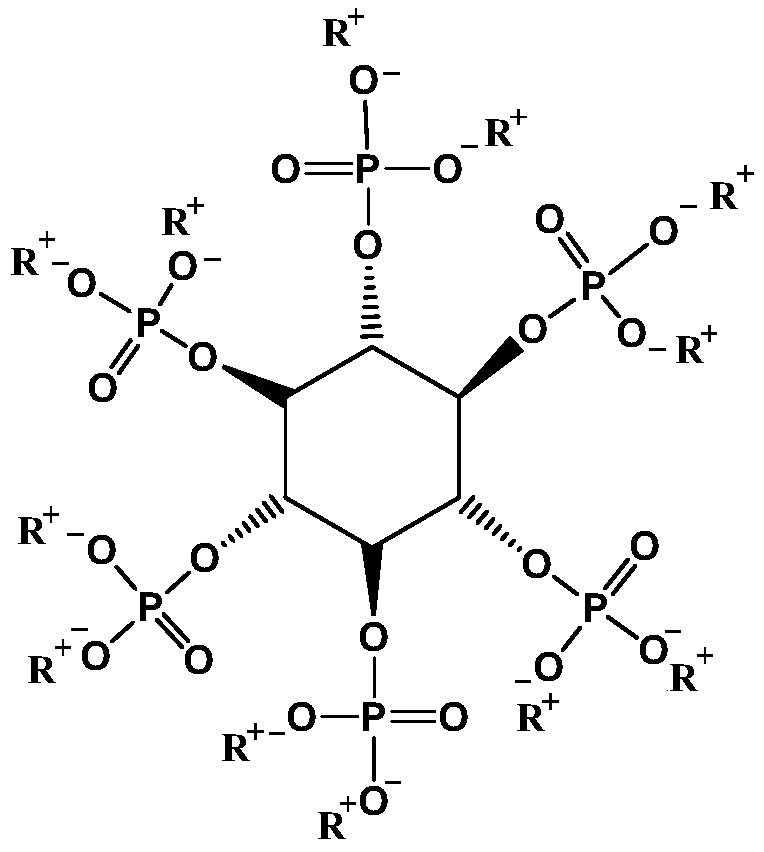

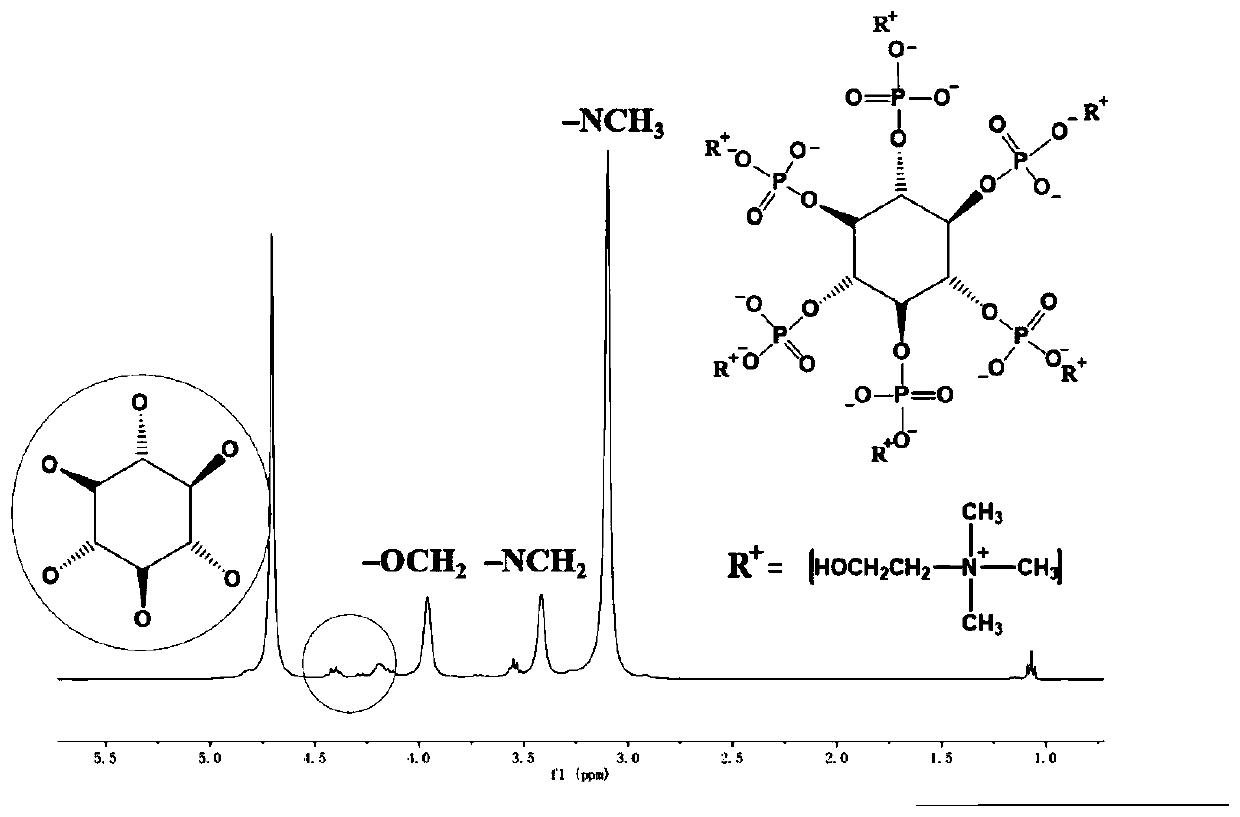

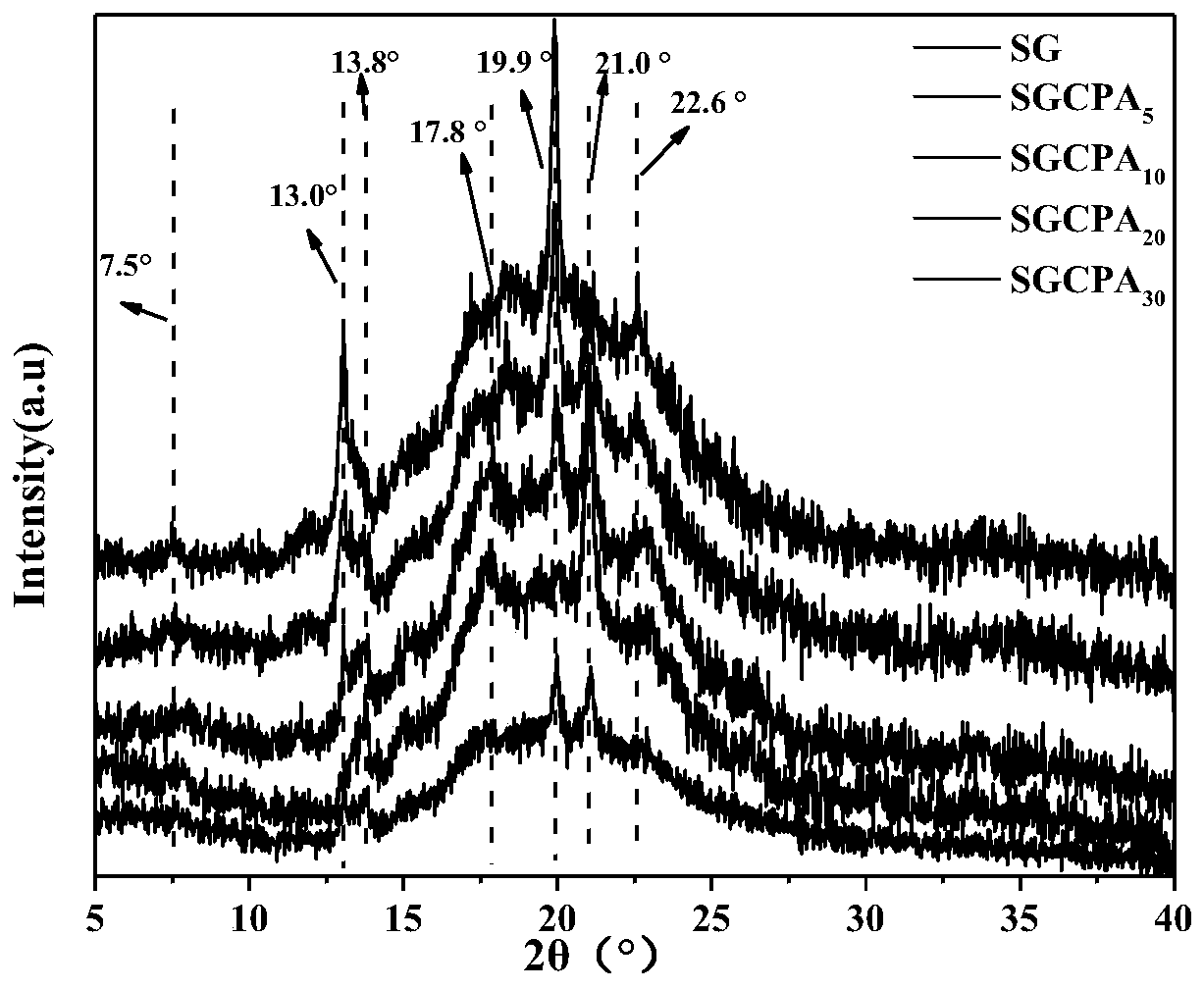

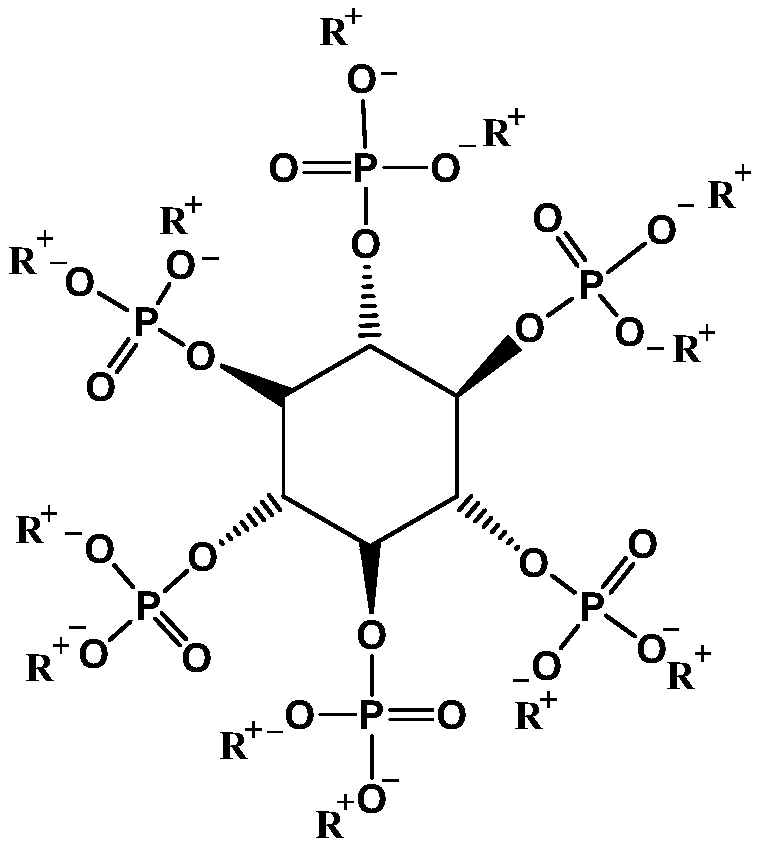

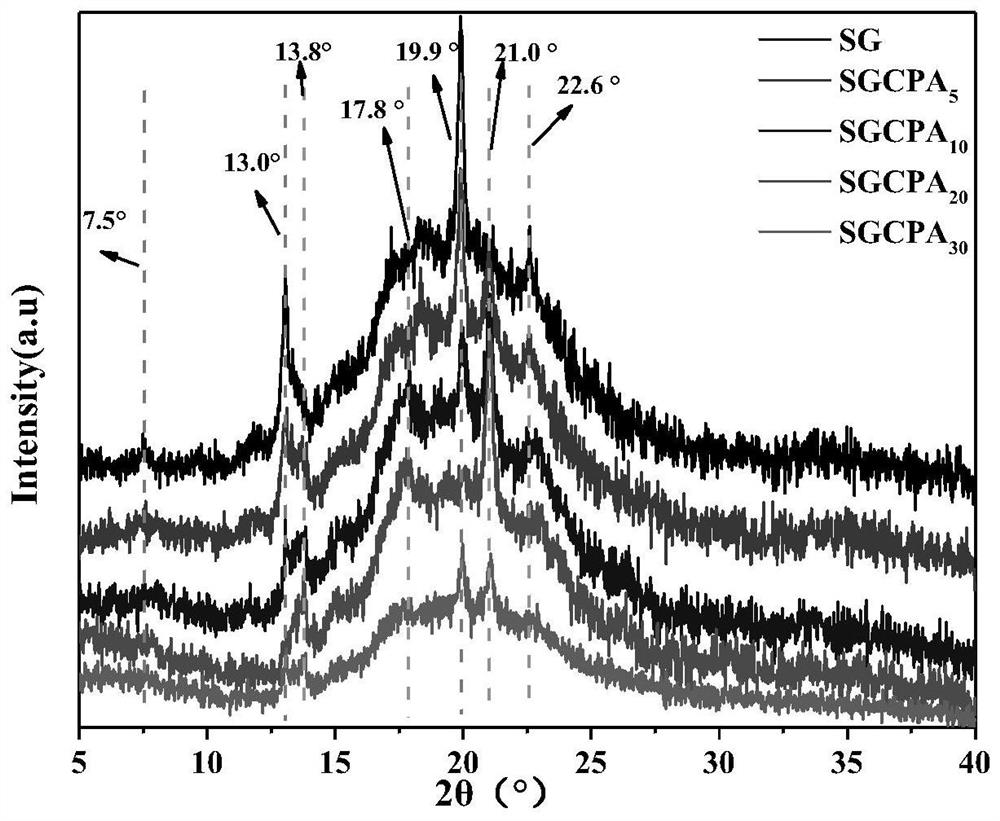

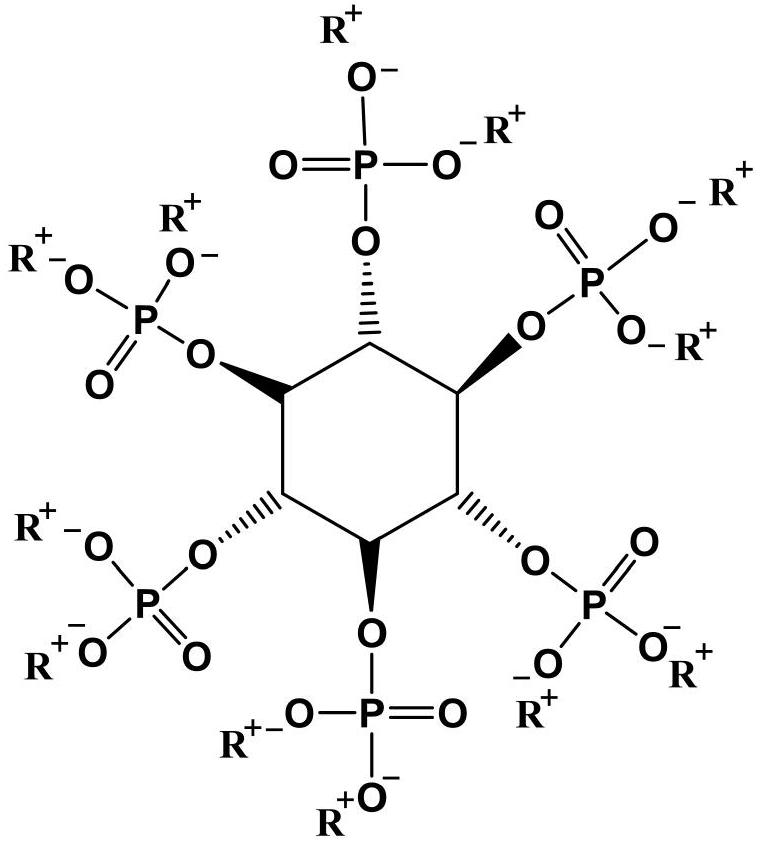

Flame-retardant polyvinyl alcohol composite material and preparation method thereof

ActiveCN111040349APrevent regenerationSource GreenGroup 5/15 element organic compoundsPolymer sciencePolyvinyl alcohol

The invention discloses a flame-retardant polyvinyl alcohol composite material and a preparation method thereof, and belongs to the field of flame-retardant materials. The preparation method of the phytic acid-choline flame retardant comprises the following steps: taking choline chloride, sodium hydroxide and a solvent, reacting the materials for 1-8 hours at the temperature of -10 DEG C to 60 DEGC, then performing suction filtration to obtain a filtrate of choline hydroxide, adding a phytic acid solution into the filtrate, wherein the mole ratio of phytic acid to choline is 0.8-2.0 based onthe molar ratio of nitrogen atoms in the quaternary ammonium salt to free hydroxyl in phytic acid, removing the solvent after a reaction is conducted for 1-12 h, and drying the product to obtain the phytic acid-choline flame retardant. The preparation method of the flame-retardant polyvinyl alcohol composite material comprises the following steps: carrying out melt blending or solution mixing on 100 parts by weight of polyvinyl alcohol, 5-160 parts by weight of the phytic acid-choline and 5-40 parts by weight of a plasticizer. The polyvinyl alcohol composite material prepared by the inventionis environment-friendly, the flame-retardant effect of the composite material is obvious, the application range of each auxiliary agent and material is effectively expanded, and meanwhile, the preparation method is simple and easy for large-scale production.

Owner:JIANGNAN UNIV

Process for choline hydroxide

ActiveUS20160068476A1High purityReduce contentCationic surface-active compoundsOrganic compound preparationEthylene oxideAqueous medium

Disclosed is a process for the production of choline hydroxide includes reacting at a temperature above 30.0° C. ethylene oxide, trimethylamine, and water in the presence of an aqueous medium in such amounts as to form a diluted choline hydroxide solution having a choline hydroxide concentration of less than 40 wt % and removing at least a portion of the aqueous medium from the diluted choline hydroxide solution to form a concentrated aqueous choline hydroxide solution having a choline hydroxide concentration which is at least 1.05 times the choline hydroxide concentration of the diluted choline hydroxide solution. The process allows for large scale, continuous production of concentrated aqueous choline hydroxide solutions of good quality under economically advantaged consumption factors for ethylene oxide.

Owner:TAMINCO NV

Flame-retardant polylactic acid composite material and preparation method thereof

ActiveCN111040399AIncrease productionReduce the burden onGroup 5/15 element organic compoundsPhytic acidGlycerol

The invention discloses a flame-retardant polylactic acid composite material and a preparation method thereof, and belongs to the field of flame-retardant materials. A preparation method of phytic acid-choline flame retardant comprises the following steps: preparing a choline hydroxide filtrate from choline chloride and sodium hydroxide, adding a phytic acid solution into the filtrate, removing the solvent after reaction, and carrying out drying to obtain the phytic acid-choline flame retardant. A preparation method of flame-retardant thermoplastic starch comprises the following steps: carrying out melt blending on 100 parts of starch, 15-40 parts of glycerol, 5-80 parts of the phytic acid-choline flame retardant and 0-20 parts of water at the processing temperature of 130-150 DEG C. The preparation method of the flame-retardant polylactic acid composite material comprises the following steps: carrying out melt blending on 100 parts by weight of polylactic acid and 5-50 parts by weightof the thermoplastic flame-retardant starch to obtain the flame-retardant polylactic acid composite material. The flame-retardant polylactic acid composite material prepared by the invention are biological sources and environment-friendly, the flame retardant effect of the composite material is obvious, the application range of each additive and material is effectively expanded, and meanwhile, the preparation method disclosed by the invention is simple and easy for large-scale production.

Owner:JIANGNAN UNIV

Using Novel Amines to Stabilize Quaternary Trialkylalkanolamines

New stabilizers for solutions of choline hydroxide and related quaternary trialkylalkanolamines are disclosed. The stabilizers are alkyl hydroxylamines, hydrazines, hydrazides, or derivates thereof, including compounds containing more than one such functionality. The new stabilizers are effective at concentrations less than about 1000 ppm, and choline hydroxide solutions stabilized with the compounds described herein typically have Gardner Color change less than about 2.0 after six months at reasonable temperatures.

Owner:HUNTSMAN PETROCHEMICAL LLC

Process for the production of choline hydroxide

ActiveUS20150031917A1Efficient and low heat controlOrganic compound preparationAmino-hyroxy compound preparationEthylene oxideReaction zone

A continuous process for the production of choline hydroxide includes reacting ethylene oxide, trimethylamine, and water in a reaction zone to form a reaction mixture and extracting heat from the reaction mixture. Subsequently, phase separation of the s reaction mixture is induced to obtain a choline hydroxide phase and an organic liquid phase comprising trimethylamine. A choline hydroxide solution (e.g., at a concentration of about 40% to 50% by weight, based on total weight of the choline hydroxide solution) is obtained from the choline hydroxide phase.

Owner:TAMINCO NV

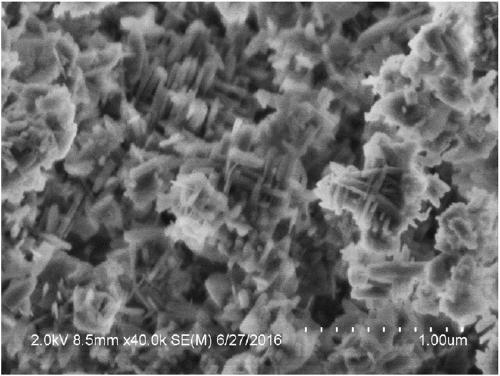

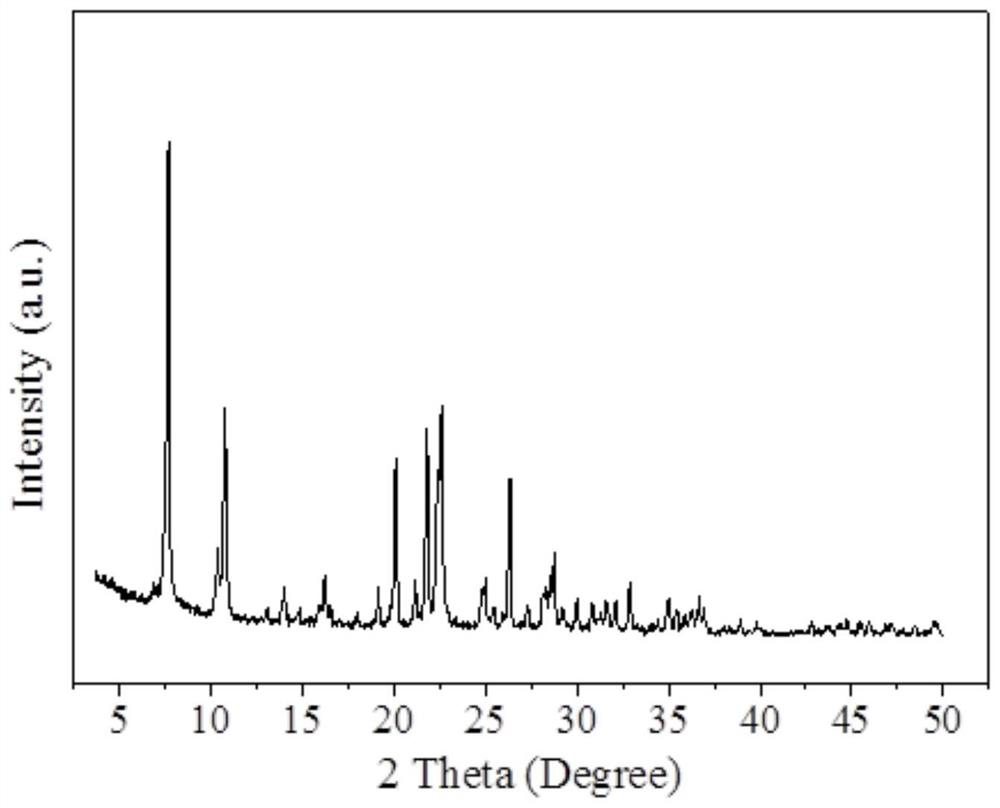

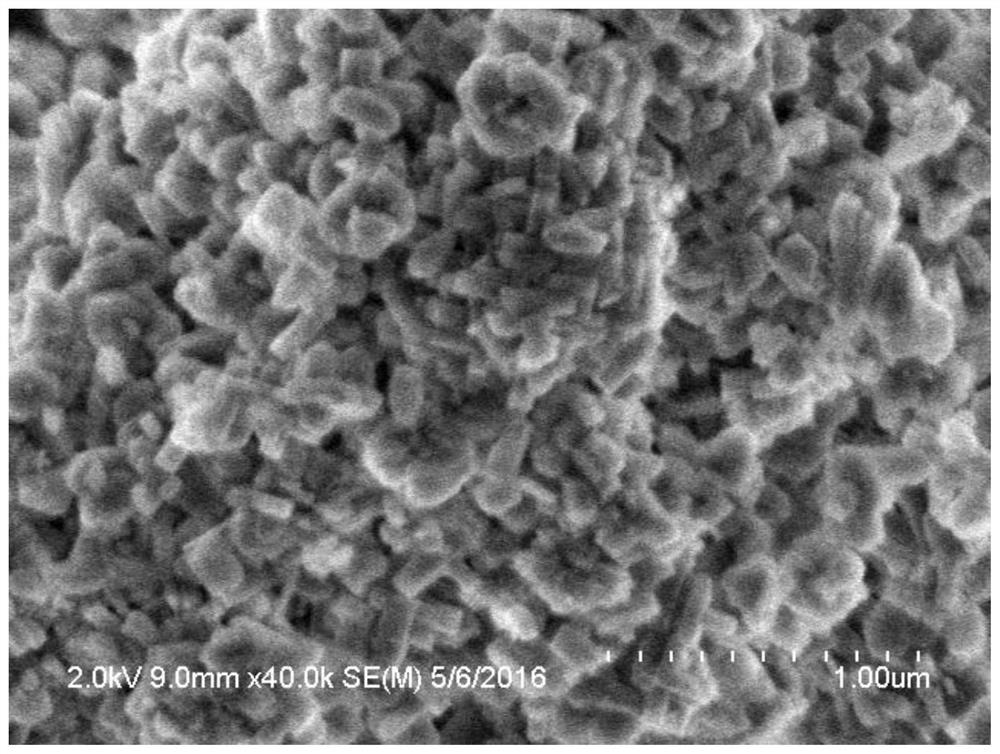

Preparation method for germanium-free IWR zeolite molecular sieve

ActiveCN108928832ASimple structureRaw materials are easy to getMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveComputational chemistry

The invention relates to a preparation method for a germanium-free IWR zeolite molecular sieve. The problems in the prior art that template agents and Ge elements used to synthetize an IWR zeolite molecular sieve are expensive and obtained IWR zeolite molecular sieve structures are poor in stability can be solved. The preparation method uses choline hydroxide which is cheap and can be obtained from markets as an organic template agent; a mixture can be formed according to the mole of choline hydroxide / SiO2 = 0.1-1.5, SiO2 / B2O3 = 0.5-100, oxide of a heteroatomic metal W / SiO2 = 0-0.2, F<-> / SiO2= 0.1-1.5, H2O / SiO2 = 1-50; and hydrothermal crystallization can be performed on the mixture so that the porous crystallized IWR zeolite molecular sieves can be obtained. The obtained IWR zeolite molecular sieves is stable in structure through synthesis; and the preparation method is wide in synthesis range, simple in operation and convenient for popularization.

Owner:CHINA PETROLEUM & CHEM CORP +1

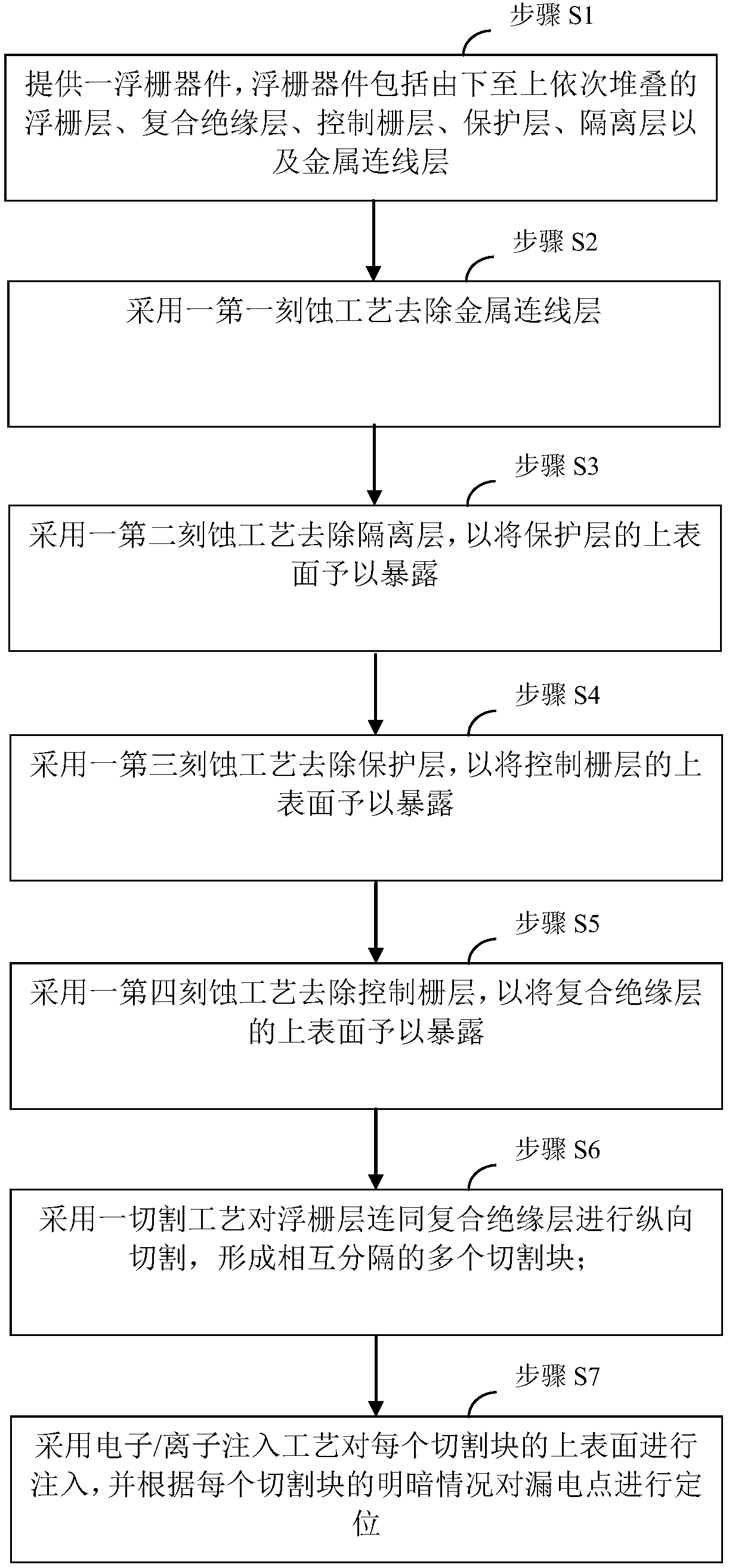

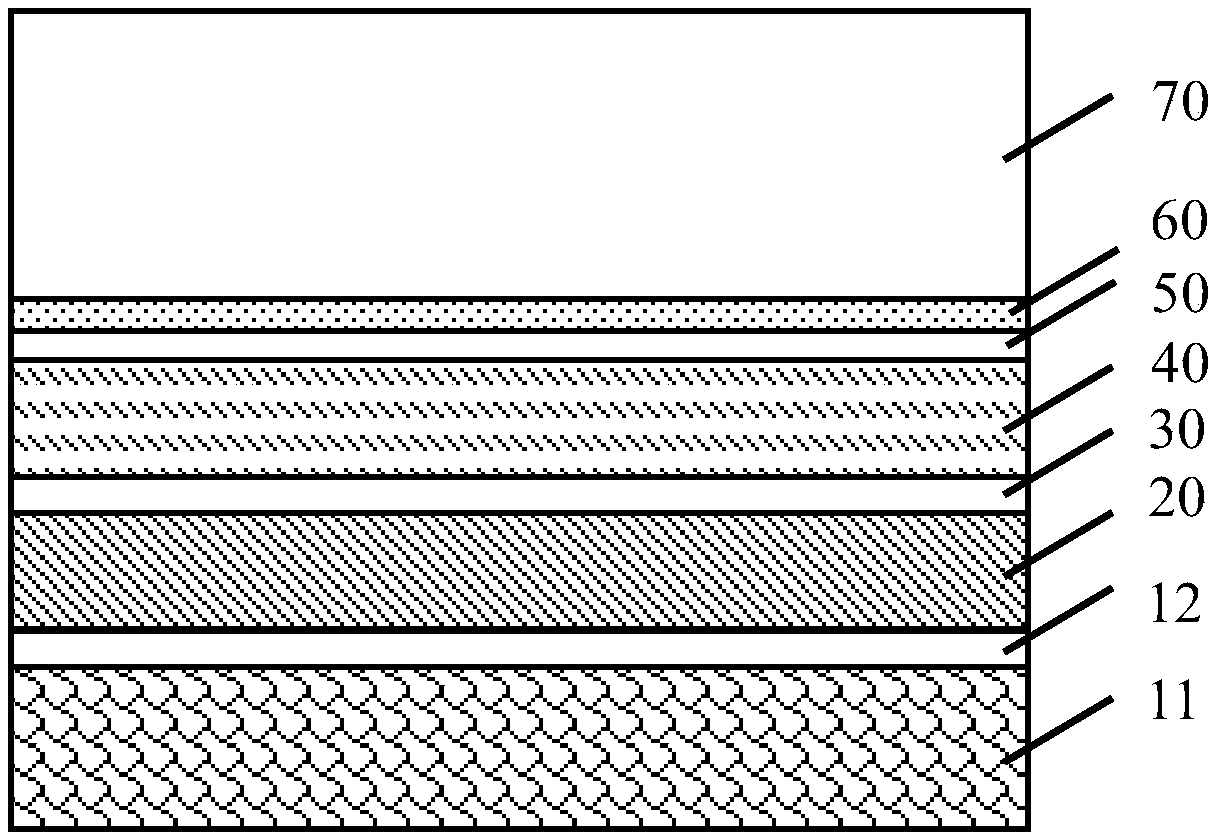

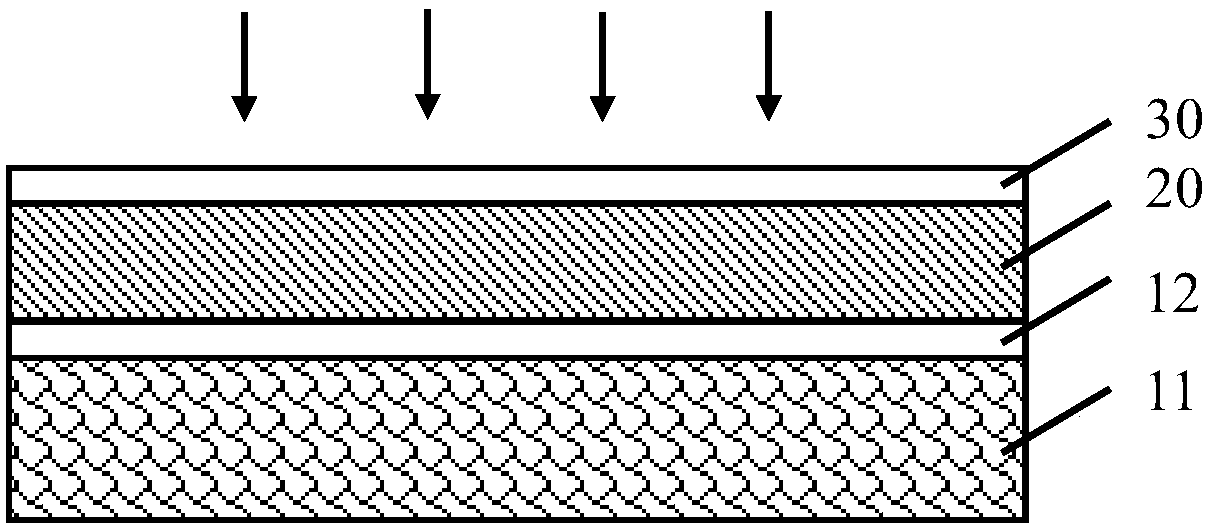

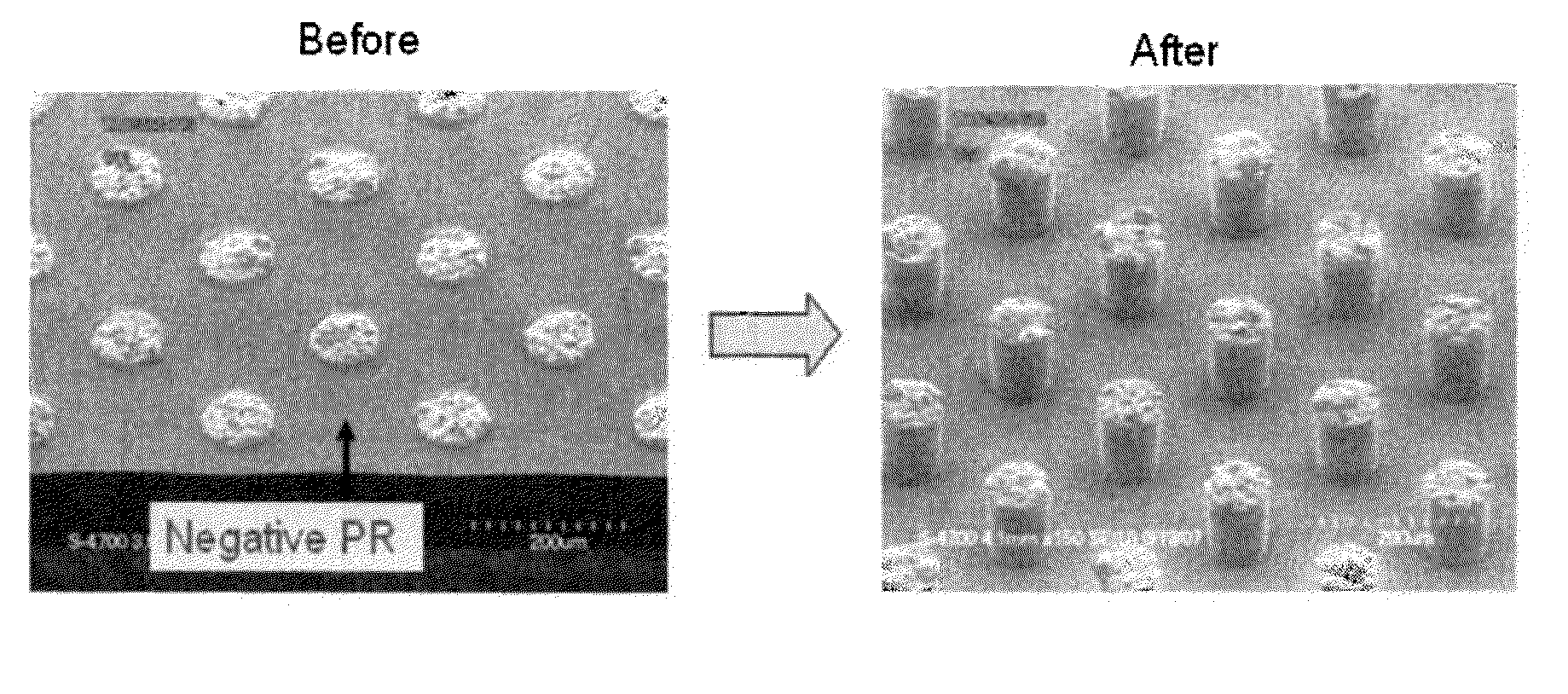

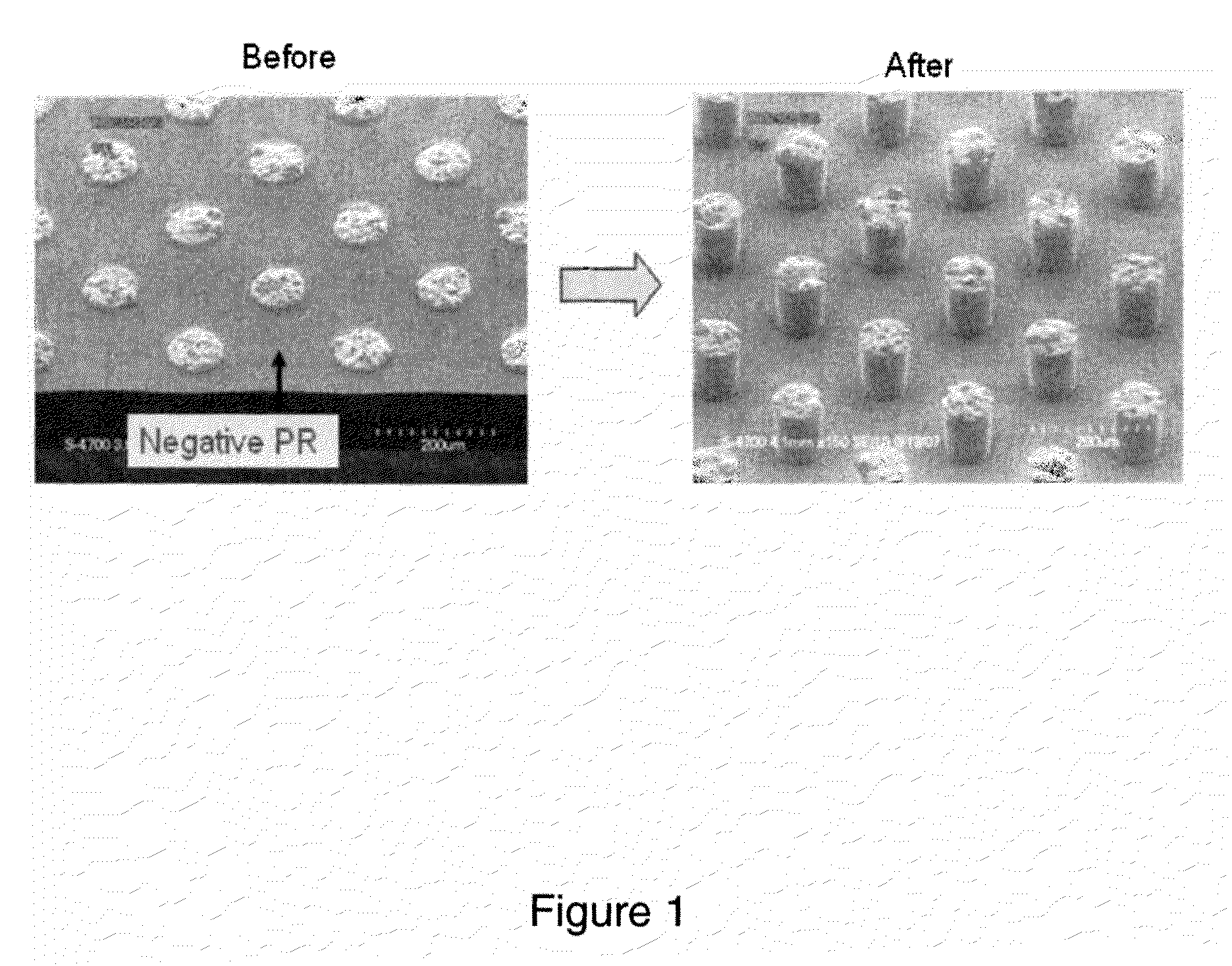

Electric leakage point positioning method for aiming at floating gate

ActiveCN108614197APrecise positioningGuaranteed validityTesting dielectric strengthElectronSemiconductor technology

The invention relates to the field of semiconductor technology, and particularly to an electric leakage point positioning method for aiming at a floating gate. The method comprises the steps of S1, supplying a floating gate device; S2, eliminating a metal connecting line layer by means of a first etching process; S3, eliminating an insulating layer by means of a second etching process; S4, eliminating a protecting layer by means of a third etching process; S5, eliminating a control gate layer by means of a fourth etching process; S6, performing longitudinal cutting on the floating gate layer and a composite insulating layer by means of a cutting process, thereby forming a plurality of cutting blocks which are separated from one another; and S7, performing implantation on the upper surfaceof each cutting block by means of an electron / ion implantation process, and positioning the electric leakage point according to the brightness condition of each cutting block; wherein the fourth etching process is a wet etching process in which choline hydroxide solution is utilized. The electric leakage point positioning method has advantages of realizing accurate positioning in the composite insulating layer, further accurately positioning the electric leakage point in the floating gate, and ensuring effectiveness in testing breakdown voltage.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

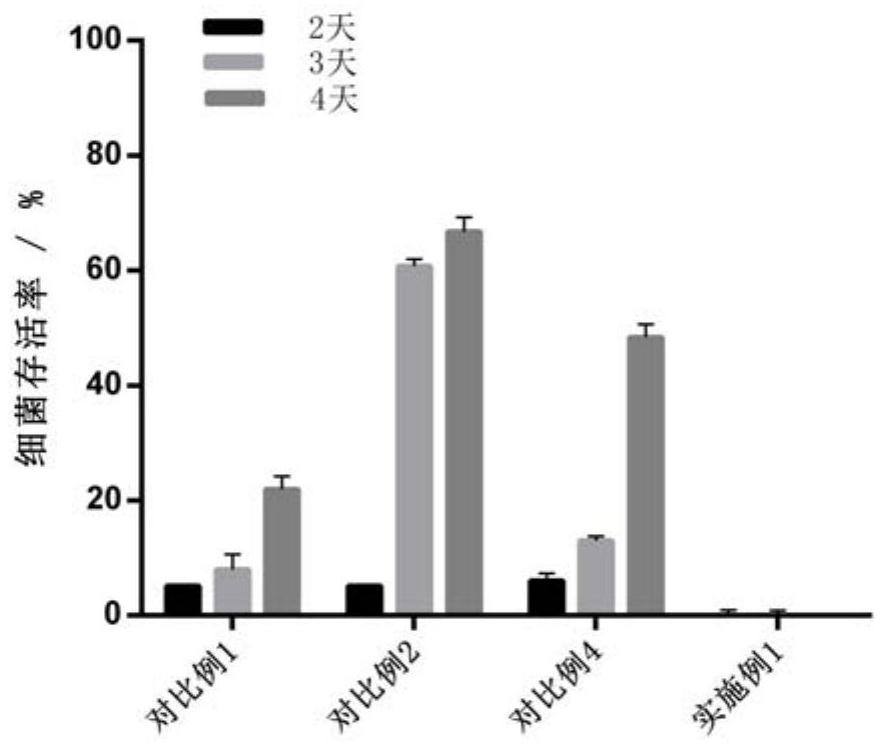

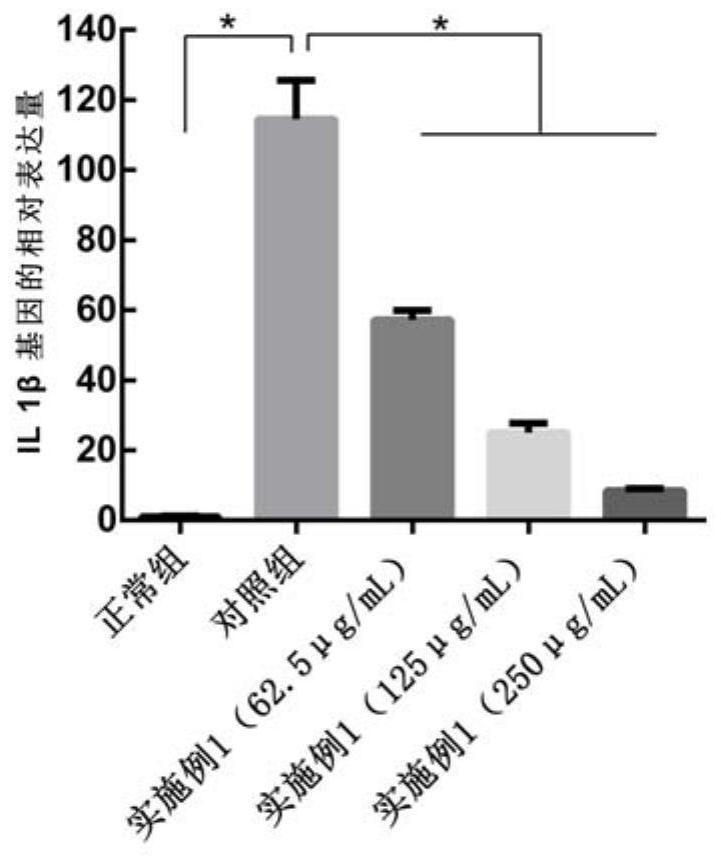

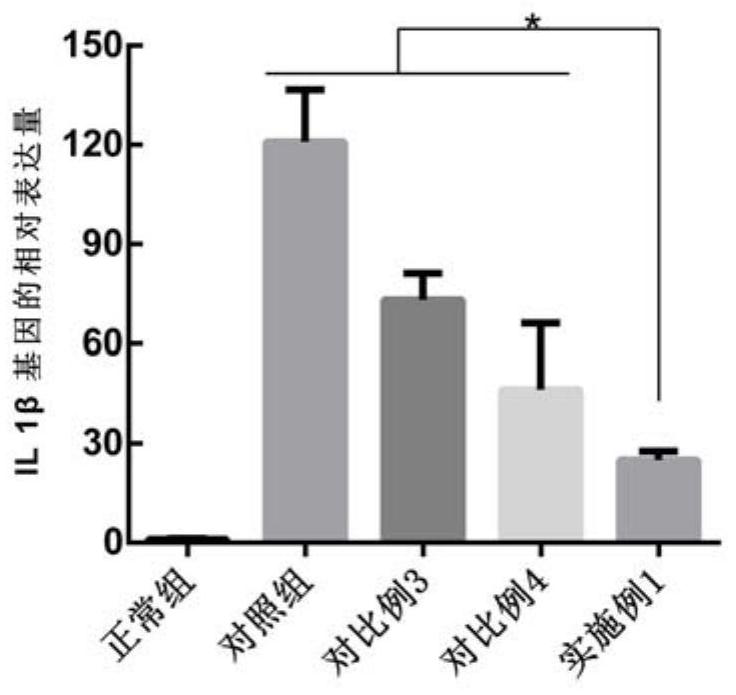

Composition for treating acne and preparation method of composition

ActiveCN112587593AEnhanced anti-Propionibacterium acnes activityEnhance anti-inflammatoryOrganic active ingredientsPharmaceutical delivery mechanismPhenolic content in teaSalicylic acid

The invention discloses a composition for treating acne and a preparation method of the composition. The composition comprises cryptotanshinone, tea polyphenol, choline hydroxide and salicylic acid. Various test results prove that the composition can be used for effectively treating the acne caused by various pathogenesis, the treatment effect is superior to that of a single-component medicine, and an obvious synergistic effect is shown; and meanwhile, the problems of poor water solubility, poor transdermal permeation, poor absorption and the like of the cryptotanshinone are solved, and the medicine concentration in an organism is improved.

Owner:SUN YAT SEN UNIV

Stabilized choline solutions and methods for preparing the same

InactiveUS20170129848A1Reduce and eliminate degradationReduce and eliminate and reactionOrganic compound preparationAmino-hyroxy compound preparationHydroxylamineSulfite salt

A method for the stabilization of an aqueous choline hydroxide solution includes, optionally adding a first stabilizer of a dithionite salt and / or a dialkylhydroxylamine to an aqueous solution containing reactants that will produce an aqueous choline hydroxide solution; and after the aqueous choline hydroxide solution is formed, adding a second stabilizer which comprises a dialkylhydroxylamine to the aqueous choline hydroxide solution. The stabilized choline hydroxide solution may include choline hydroxide, water, and a dialkylhydroxylamine and optionally a dithionite salt as a stabilizer present in an amount of from about 50 ppm to less than about 5000 ppm by weight relative to the total weight of the stabilized choline hydroxide solution.

Owner:TAMINCO NV

Stripper for dry film removal

ActiveUS8357646B2Non-surface-active detergent compositionsElectrostatic cleaningTetramethylammonium hydroxideGallic acid ester

The present invention, in a preferred embodiment, is a photoresist stripper formulation, comprising: Hydroxylamine ; Water; a solvent selected from the group consisting of dimethylsulfoxide; N-methylpyrrrolidine; dimethylacetamide; dipropylene glycol monomethyl ether; monoethanolamine and mixtures thereof; a base selected from the group consisting of choline hydroxide, monoethanolamine, tetramethylammonium hydroxide; aminoethylethanolamine and mixtures thereof; a metal corrosion inhibitor selected from the group consisting of catechol, gallic acid, lactic acid, benzotriazole and mixtures thereof; and a bath life extending agent selected from the group consisting of glycerine, propylene glycol and mixtures thereof. The present invention is also a method for using formulations as exemplified in the preferred embodiment.

Owner:VERSUM MATERIALS US LLC

Process for choline hydroxide

ActiveUS9527799B2High purityReduce contentCationic surface-active compoundsOrganic compound preparationEthylene oxideAqueous medium

Owner:TAMINCO NV

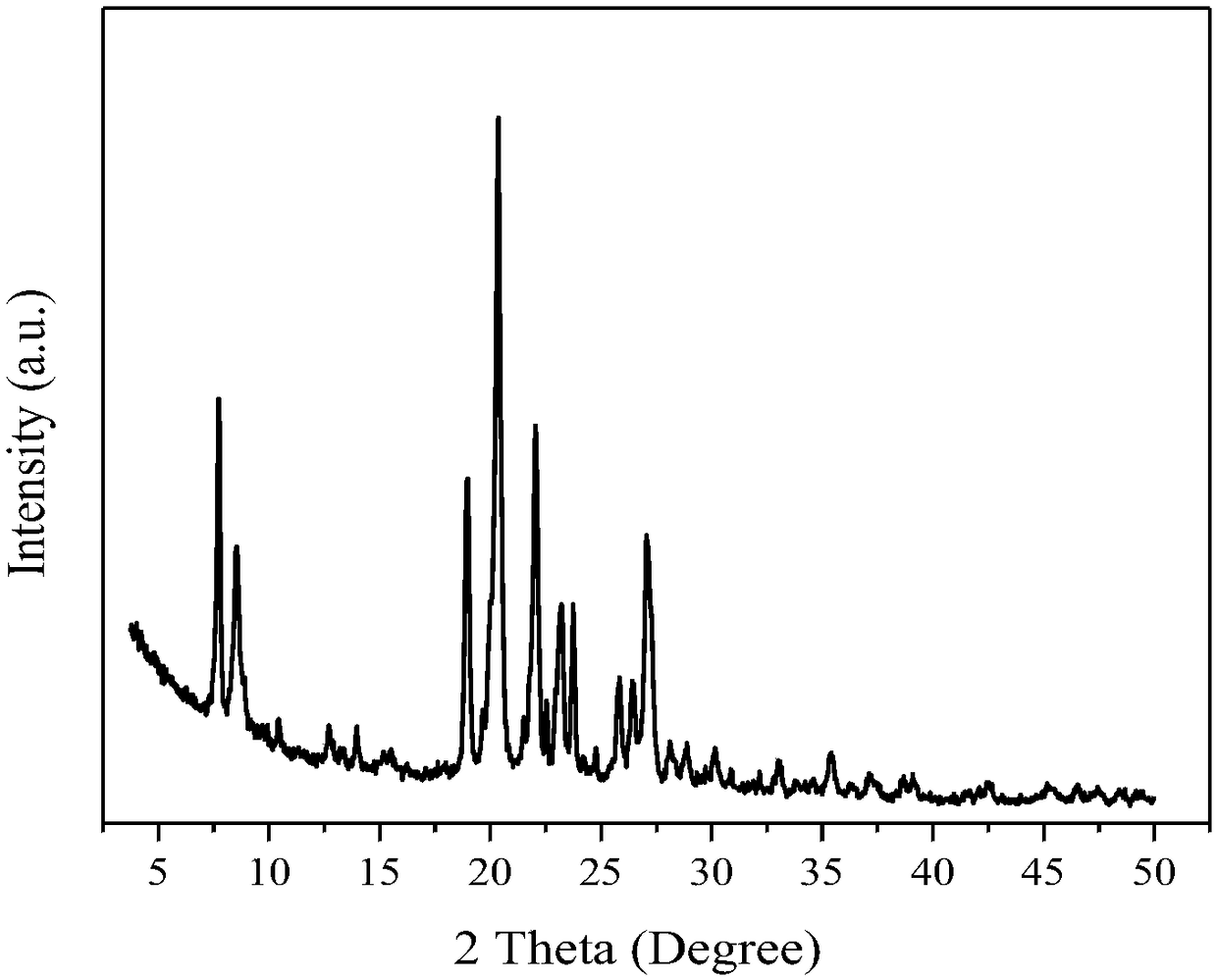

IWR/CDO co-crystallized zeolite molecular sieve synthesis method

ActiveCN109694091ALow priceLower synthesis costMolecular-sieve and base-exchange compoundsMolecular sieveSynthesis methods

The invention relates to an IWR / CDO co-crystallized zeolite molecular sieve synthesis method, wherein a mixture is subjected to hydrothermal crystallization for 30-300 h at a temperature of 100-200 DEG C according to a ratio of an organic templating agent choline hydroxide to YO2 to X2O3 to H2O of 0.15-0.95:1:0-0.08:2-28 to obtain a porous IWR / CDO co-crystallized zeolite molecular sieve material,wherein Y is at least a skeleton tetravalent element, and X is at least a trivalent skeleton element. According to the present invention, the IWR / CDO co-crystallized zeolite molecular sieve is synthesized with the inexpensive organic templating agent, the relative ratio of the two molecular sieves is adjusted within a range of 1-99%, and the synthesis method is simple and easy to perform, and is suitable for promotion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of electronic-grade choline hydroxide solution

PendingCN113548973AImprove qualityReduce the content of metal ionsOrganic compound preparationAmino-hyroxy compound preparationEthylene oxidePhysical chemistry

The invention relates to a preparation method for producing electronic-grade choline hydroxide. According to the method, ethylene oxide, trimethylamine and water react in a clean reactor to generate a mixture, and heat generated in the reaction process is removed through a conducting medium. Residual trimethylamine in the generated mixture is separated under the reduced pressure condition, so that 40%-45% (percentage content) is achieved, metal ions in choline hydroxide are removed through micro-membrane filtration at different temperatures and pressures, and the required purpose is achieved.

Owner:上海德迈世欧科技有限公司

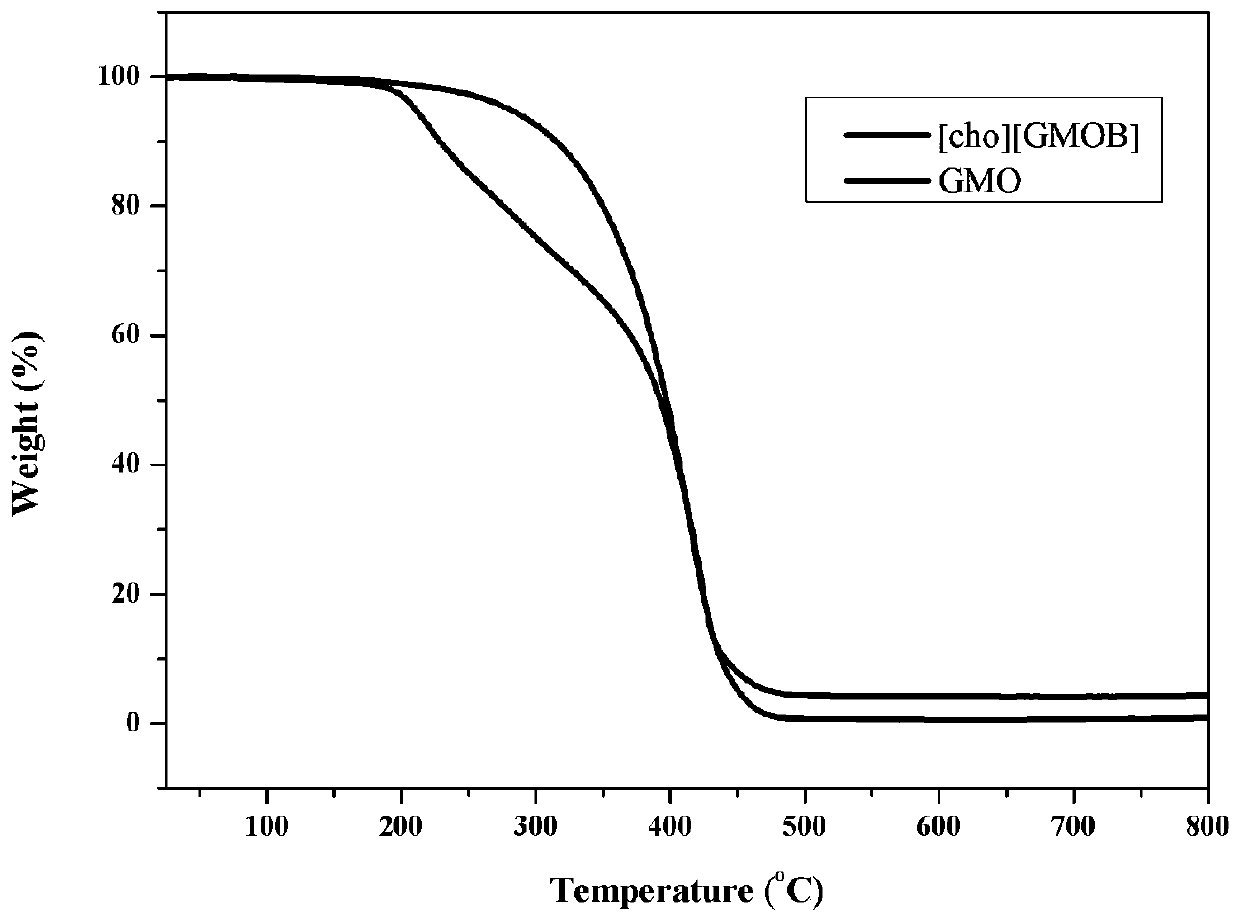

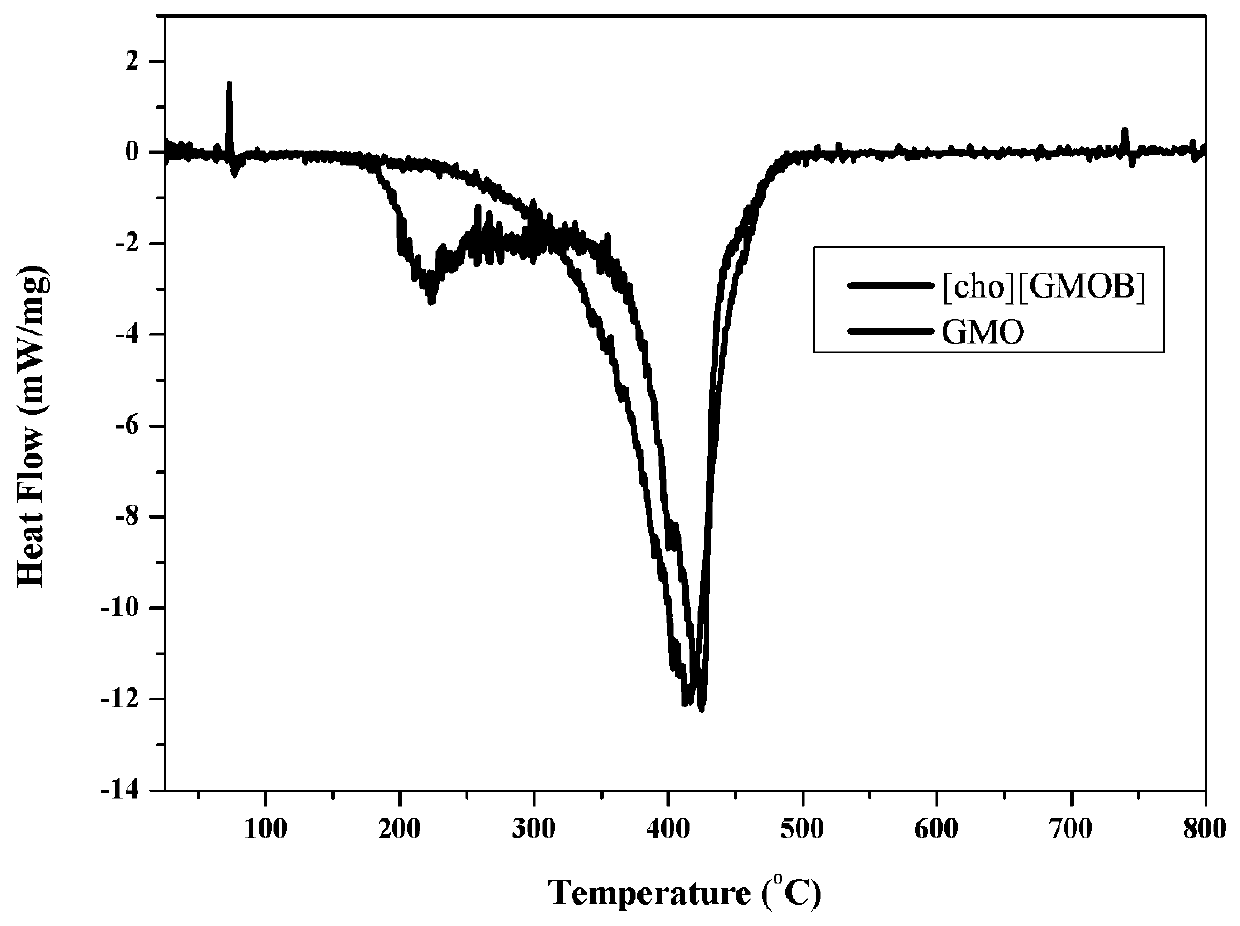

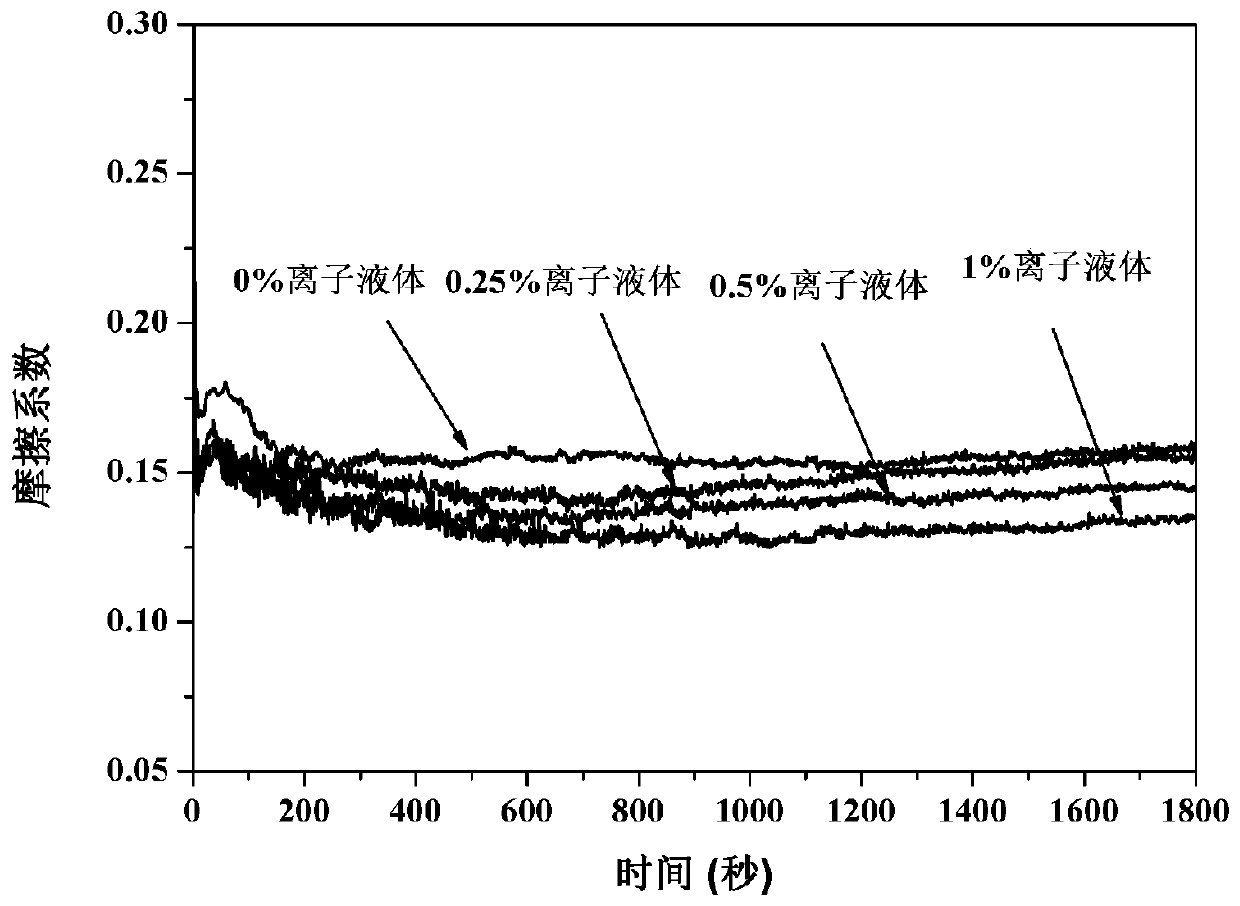

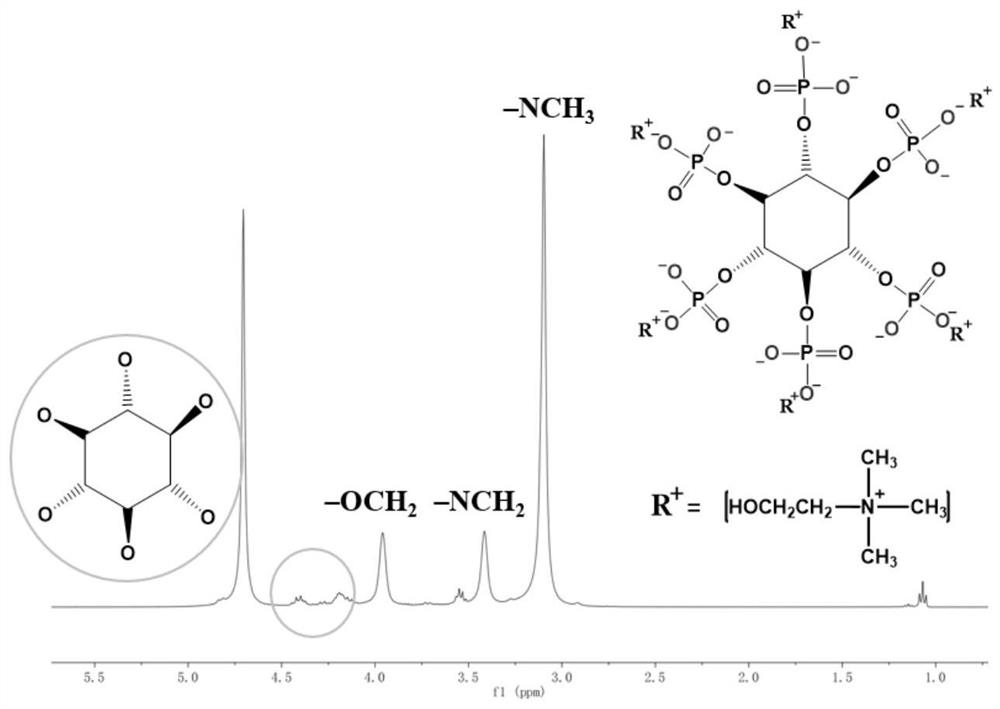

Halogen-free choline chelated boron ionic liquid lubricating additive and application thereof

ActiveCN110951517ANo pollution in the processImprove anti-friction and anti-wear propertiesAdditivesFree cholineGlycerol

The invention provides a halogen-free choline chelated boron ionic liquid lubricating additive and an application thereof; the halogen-free choline chelated boron ionic liquid lubricating additive isprepared by taking glycerol monooleate, boric acid and choline hydroxide as raw materials through two steps of complexing reaction and acid-base reaction, wherein the glycerol monooleate is in a commercially available analytically pure grade. The ionic liquid lubricating additive disclosed by the invention has excellent corrosion resistance and antifriction and antiwear properties at high temperature, and is environment-friendly.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

A kind of flame-retardant polylactic acid composite material and preparation method thereof

ActiveCN111040399BIncrease productionReduce the burden onGroup 5/15 element organic compoundsPhytic acidFire retardant

The invention discloses a flame-retardant polylactic acid composite material and a preparation method thereof, belonging to the field of flame-retardant materials. The preparation method of phytic acid choline flame retardant is: prepare the filtrate of choline hydroxide with choline chloride and sodium hydroxide; add phytic acid solution to the filtrate, remove the solvent after reaction, and dry to obtain phytic acid choline flame retardant agent. The preparation method of the flame-retardant thermoplastic starch: 100 parts of starch, 15-40 parts of glycerin, 5-80 parts of phytic acid choline flame retardant, and 0-20 parts of water are prepared by melting and blending at a processing temperature of 130-150°C. The preparation method of the flame-retardant polylactic acid composite material is: 100 parts by weight of polylactic acid and 5-50 parts by weight of thermoplastic flame-retardant starch are melted and blended. Both the flame retardant and the polylactic acid composite material prepared by the present invention are of biological origin, green and environmentally friendly, and the flame retardant effect of the composite material is obvious, which effectively expands the application range of various additives and materials. At the same time, the preparation method of the present invention is simple and easy. Mass production.

Owner:JIANGNAN UNIV

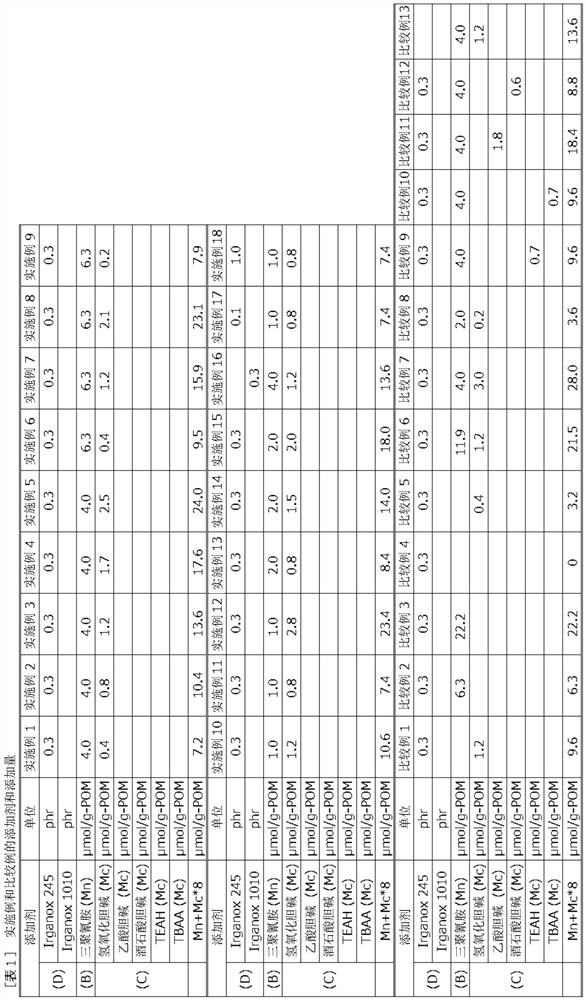

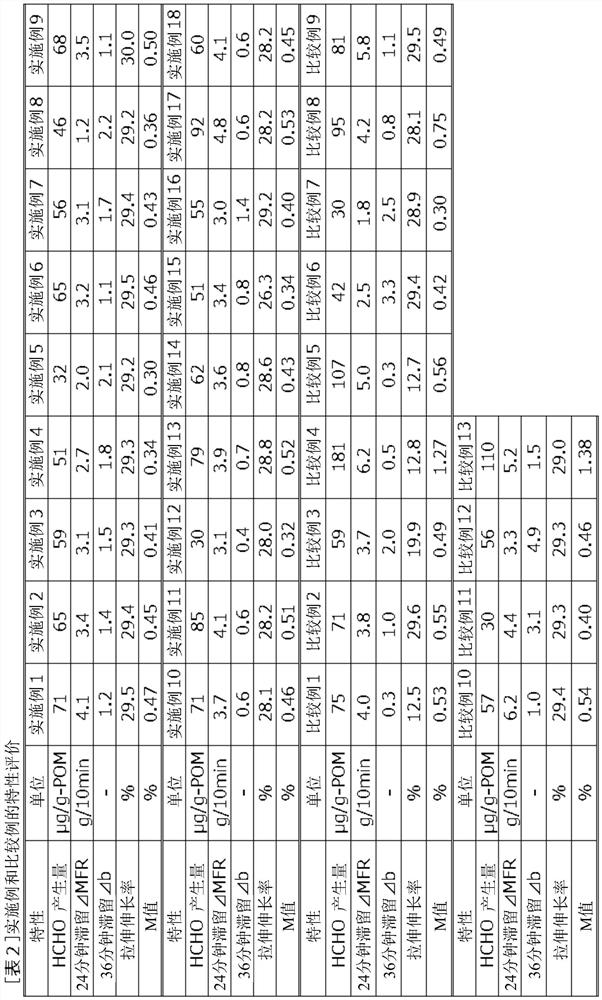

Method for producing oxymethylene copolymer resin composition, and oxymethylene copolymer resin composition

The present invention provides a method for producing an oxymethylene copolymer resin composition, the method comprising: a step for producing an oxymethylene copolymer (A); a step for adding an amine-substituted triazine compound (B) in an amount of Mn micromoles per 1 g of the oxymethylene copolymer (A), choline hydroxide (C) in an amount of Mc micromoles per 1 g of the oxymethylene copolymer (A), and 0.05-1.1 parts by weight of an antioxidant (D) in an amount of 0.05-1.1 parts by weight per 100 parts by weight of the oxymethylene copolymer (A), and performing melt kneading; mn ([mu] mol / g-POM) and Mc ([mu] mol / g-POM) satisfy 6.5 < (Mn + Mc * 8) < 25, 0.5 < Mn < 7.0, and 0.0 < Mc.

Owner:MITSUBISHI GAS CHEM CO INC

Preparation method of iwr/cdo co-crystal zeolite molecular sieve

The invention relates to an IWR / CDO co-crystallized zeolite molecular sieve synthesis method, wherein a mixture is subjected to hydrothermal crystallization for 30-300 h at a temperature of 100-200 DEG C according to a ratio of an organic templating agent choline hydroxide to YO2 to X2O3 to H2O of 0.15-0.95:1:0-0.08:2-28 to obtain a porous IWR / CDO co-crystallized zeolite molecular sieve material,wherein Y is at least a skeleton tetravalent element, and X is at least a trivalent skeleton element. According to the present invention, the IWR / CDO co-crystallized zeolite molecular sieve is synthesized with the inexpensive organic templating agent, the relative ratio of the two molecular sieves is adjusted within a range of 1-99%, and the synthesis method is simple and easy to perform, and is suitable for promotion.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of itq-24 zeolite molecular sieve

ActiveCN107954437BSmall molecular weightMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveOrganic chemistry

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com