Patents

Literature

306results about How to "Improve anti-friction and anti-wear properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of wear resistant rubber composite material

InactiveCN101463149AImprove mechanical propertiesImprove recycling efficiencyOrganic solventPolymer science

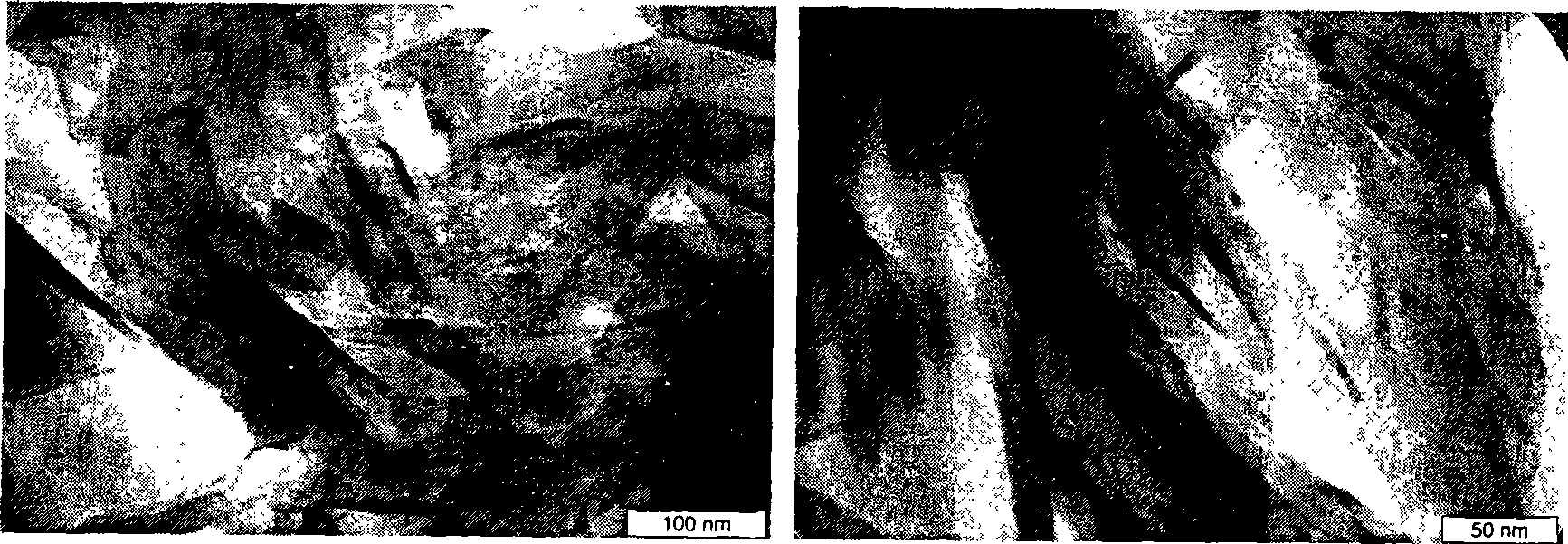

The invention relates to a preparation method of a graphite-modified abrasive resistant rubber composite material. The method comprises the following steps: soaking expandable graphite with laminar crystal layer structure in water or an organic solvent containing a surfactant; preparing a suspension system of nano flaky graphite by stirring and ultrasonic treatment; mixing the suspension system with rubber latex or rubber solution, and then adding a flocculant for breaking latex and flocculating or adding a poor solvent for precipitation; and drying flocculate or precipitate, mixing and vulcanizing to obtain the graphite / rubber composite material. The latex (solution) blending process is introduced into preparation of the graphite / rubber nano-composite material to realize homogeneous dispersion of the graphite in a rubber matrix compound system by a nanoscale size, to cause good strengthening effect and prepare the rubber composite material with excellent mechanical property, low frictional coefficient and high abrasive resistance.

Owner:BEIJING UNIV OF CHEM TECH

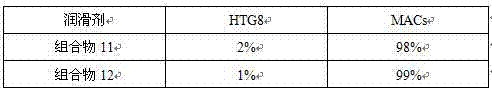

Preparation method of protective lubricating grease for high-temperature-resistant steel wire rope

InactiveCN102102047AImprove adhesionImprove anti-friction and anti-wear propertiesLubricant compositionWire ropeHigh adhesion

The invention discloses a protective grease composition with high performance for a high-temperature-resistant steel wire rope and a preparation method thereof. The protective lubricating grease composition for the steel wire rope is prepared from base oil (high-viscosity mineral oil or synthetic oil), a thickening agent, an additive and a covering agent. The ordinary protective lubricating grease for the steel wire rope is prepared by thickening the base oil with a solid hydrocarbon thickening agent. The thickening agent disclosed by the invention is bentonite. A high-molecular-weight tackifier and a lubricating grease solid filler are adopted, so that the performance of bentonite lubricating grease is further improved, the protective lubricating grease for the steel wire rope has extremely high high-temperature resistance and extremely high adhesion strength, and low-cost protective grease with excellent combination property for the steel wire rope is provided. The protective grease for the steel wire rope is specially used for protecting the steel wire rope used in an extreme high temperature environment.

Owner:益田润石(北京)化工有限公司

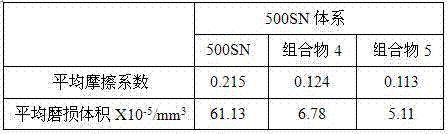

Wear repairing lubricating agent composition containing sheet silicate mineral substances and preparation method thereof

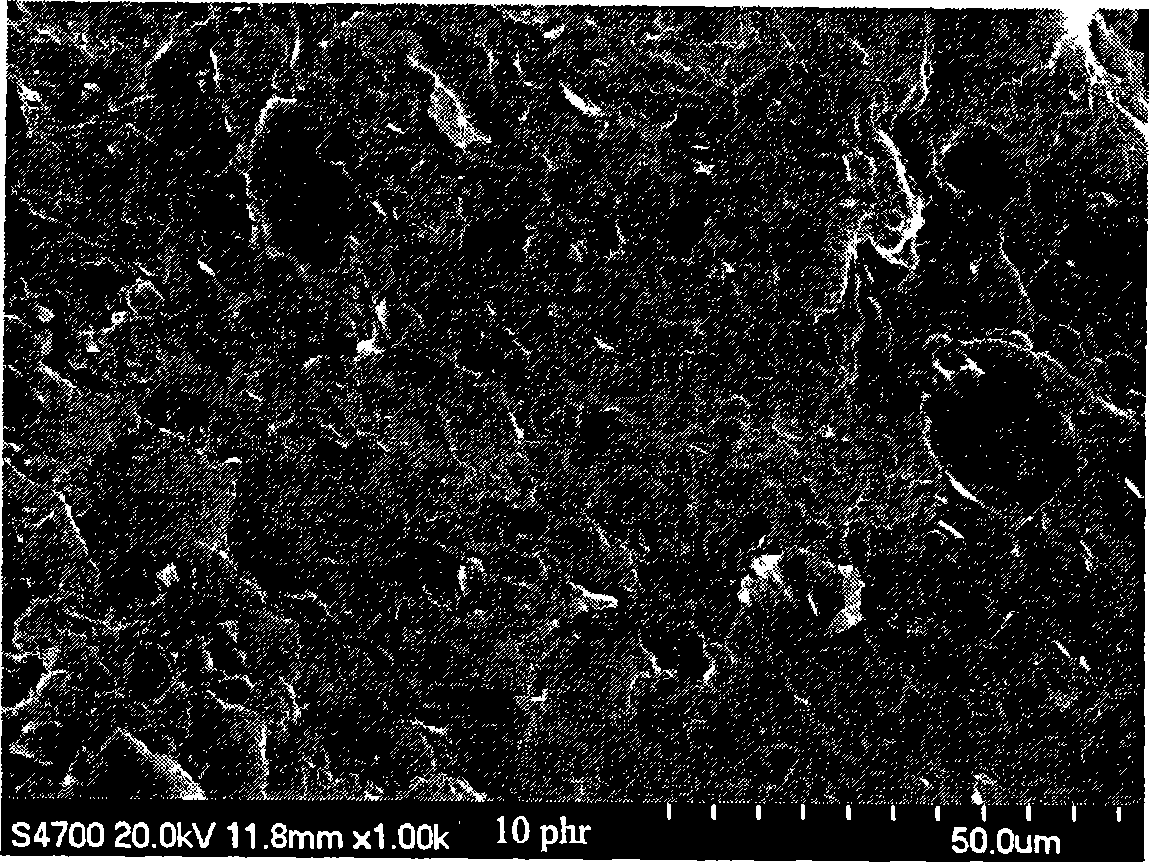

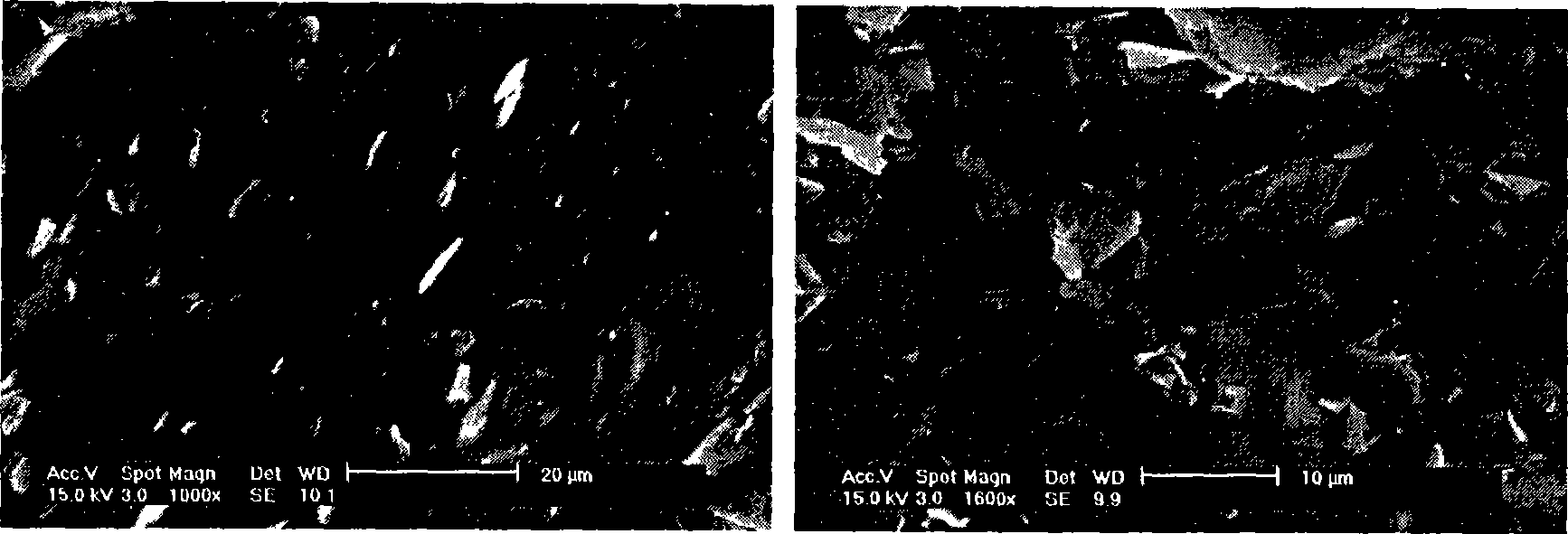

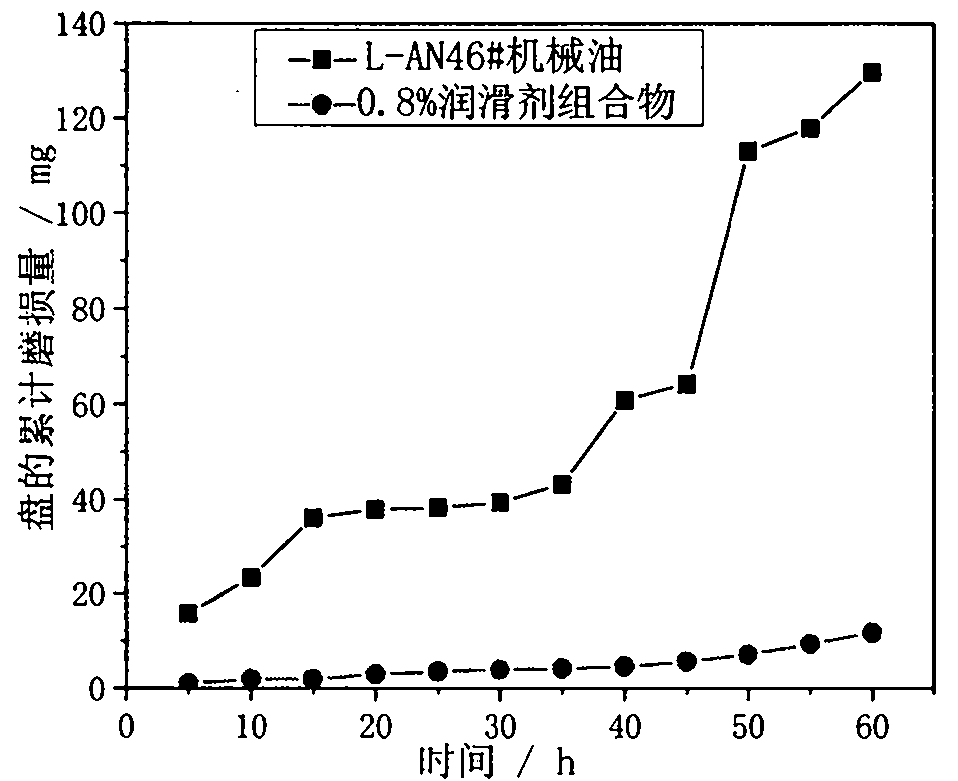

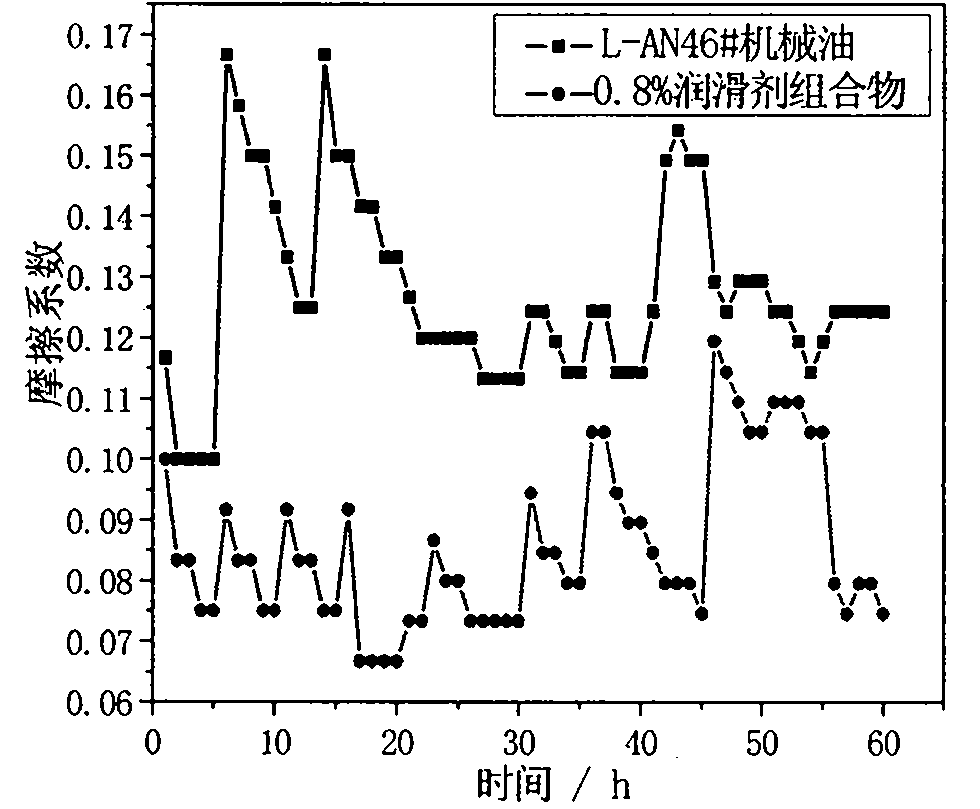

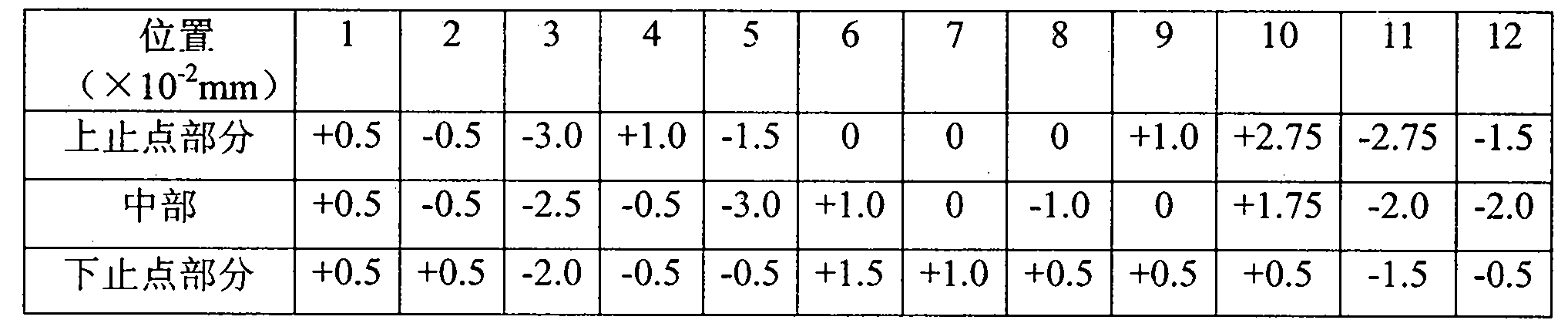

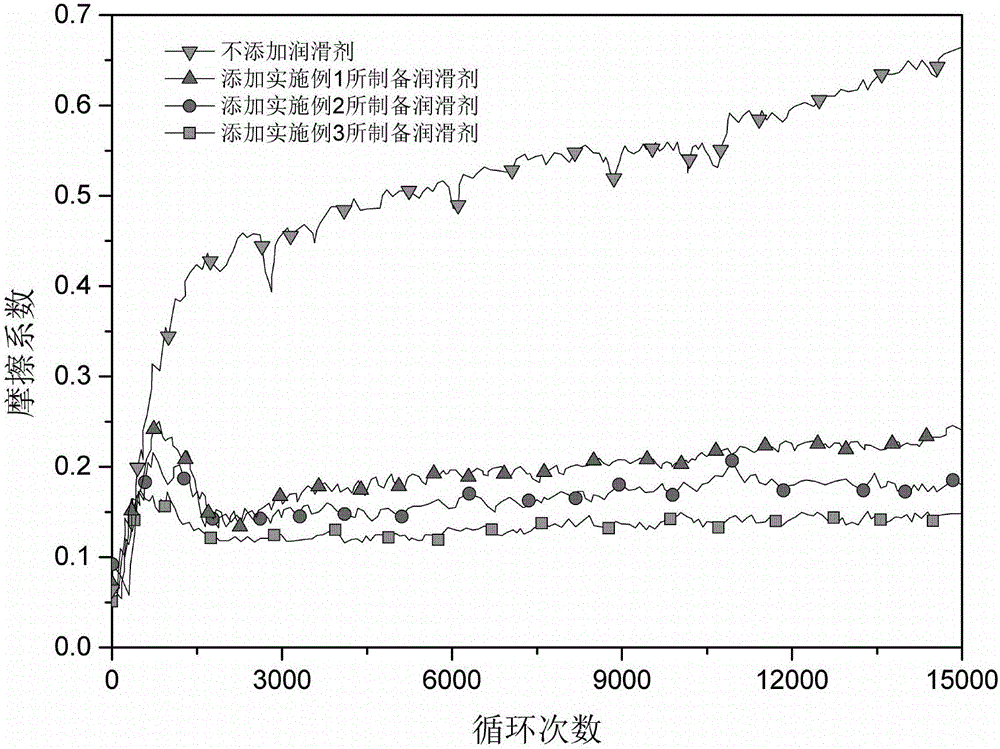

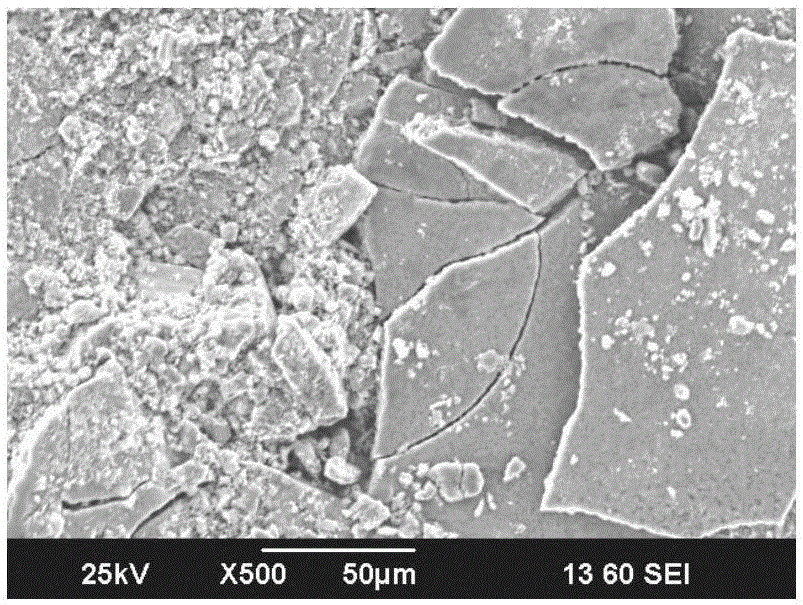

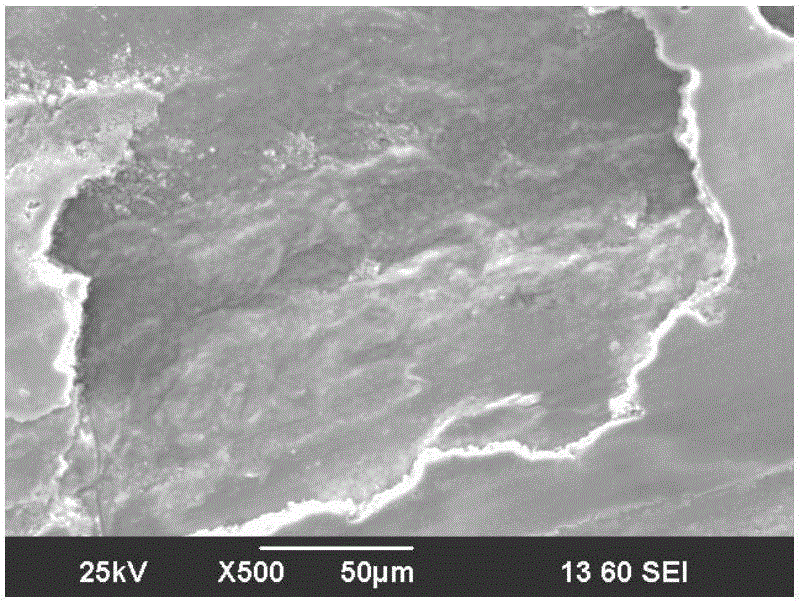

The invention relates to a wear repairing lubricating agent composition containing sheet silicate mineral substances and a preparation method thereof. The lubricating agent composition provided by the invention comprises the following components in percent by mass: 10-20 percent of sheet silicate mineral substances, 0.1-5 percent of surface modifying agent, 0.1-5 percent of metal catalytic object, 1-10 percent of performance regulating agent composition and 70-80 percent of base lubricating agent. The preparation method comprises the steps of: mixing and grinding the sheet silicate mineral substances according to the proportion, preferably, sheet silicate mineral substances with granularity D90 of not more than 3mu m; and then adding in a base lubricating agent prepared from a surfactant, the metal catalytic object and the performance regulating agent in different proportions, and grinding. The using method is as follows: 0.2-1 wt percent of the wear repairing lubricating agent composition is added in the traditional lubricating agent system of equipment. The lubricating agent composition provided by the invention has better self-repairing effect and remarkable energy-saving and consumption-reducing effect; and due to a repairing layer formed on the surface through friction, the hardness of a matrix is improved, and the roughness is lowered.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

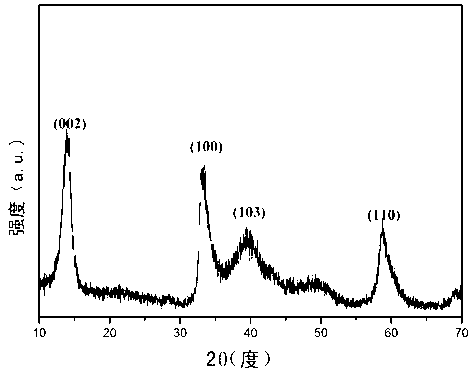

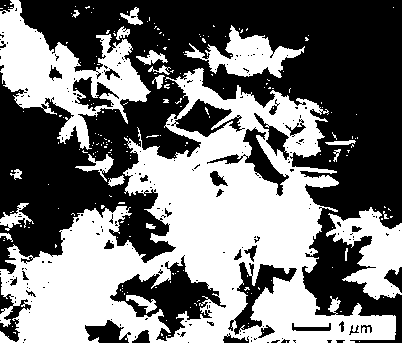

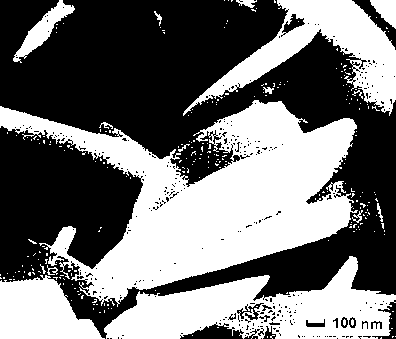

Method for preparing hexagonal molybdenum disulfide nanosheet as anti-friction additive

ActiveCN103073060AReduce manufacturing costThe production process is simple and easy to controlMaterial nanotechnologyMolybdenum sulfidesTube furnaceHydrothermal synthesis

The invention discloses a method for preparing a hexagonal molybdenum disulfide nanosheet as an anti-friction additive. An additive-assistant hydrothermal synthesis method is adopted. The preparation method comprises the following steps: synthesizing a carbon ball from a high molecular compound as a carbon source by a Stober method; dissolving Na2MO4, Na2S and NH2OH.HCl in water to obtain a solution; adding the prepared nano carbon ball and uniformly dispersing the nano carbon ball in the solution by centrifugal stirring; adjusting the pH value of the solution to 6 to 8 with acid, and stirring the obtained solution and then moving the solution to a stainless steel reaction kettle for thermostatic reaction to obtain a reaction product; and separating the reaction product and annealing the product in a tube furnace of 400 to 600 DEG C to obtain the hexagonal molybdenum disulfide nanosheet. The preparation method is simple in process, and the prepared product is high in purity and yield, and excellent in antifriction and anti-wearing and lubricating property, and can serve as the anti-friction additive of lubricating oil and fat.

Owner:苏州惠丰润滑材料有限公司

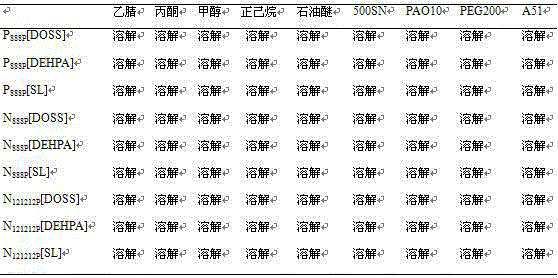

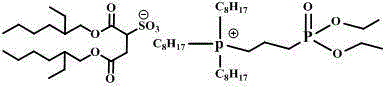

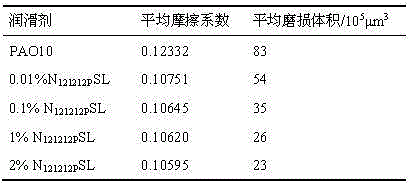

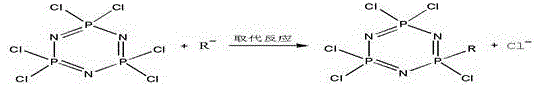

Functionalized oil-soluble ionic liquid and preparing method and application thereof

ActiveCN105254667AImprove solubilityEffective dissolutionGroup 5/15 element organic compoundsSulfonic acids salts preparationPhosphoric Acid EstersQuaternary ammonium cation

The invention discloses functionalized oil-soluble ionic liquid. The ionic liquid is phosphate functionalized quaternary phosphorus and quaternary ammonium oil-soluble ionic liquid. The positive ions of the ionic liquid are quaternary phosphorus or quaternary ammonium positive ions with phosphate functional groups and different alkyl chain lengths. The negative ions of the ionic liquid are EDHPA, DOSS, DDSSP and SL. The ionic liquid can effectively reduce the corrosion of base oil on metal, restrain the generation of carbon deposition and improve the lubricating performance of lubricating oil. The invention further discloses a preparing method and application of the ionic liquid.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of textured diamond-like carbon composite film for water lubrication

ActiveCN101748370AImprove stabilityImprove anti-friction and anti-wear propertiesVacuum evaporation coatingSputtering coatingDiamond-like carbonComposite film

The invention discloses a preparation method of a textured diamond-like carbon composite film for water lubrication. In the invention, by adopting a laser surface micro-processing technology, a microtexture appearance molding can be obtained on the surface of a workpiece, and a film can be obtained on the surface of the workpiece by plating a titanium transition layer and doping a diamond-like carbon film of titanium after the workpiece is plasma-cleaned by a magnetic control sputtering deposition technology. The film greatly enhances the stability and the antifriction and abrasion resistance performance of the conventional diamond-like carbon film under the condition of water lubrication with the friction coefficient reduction reaching up to 40 percent and the abrasion resistance enhanced by 1-3 times. The invention is suitable for surface protection and strengthening of a transmission friction pair of a mechanical sealing ring, a thrust bearing and other machines under the water-consuming environment, and the service life is prolonged.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

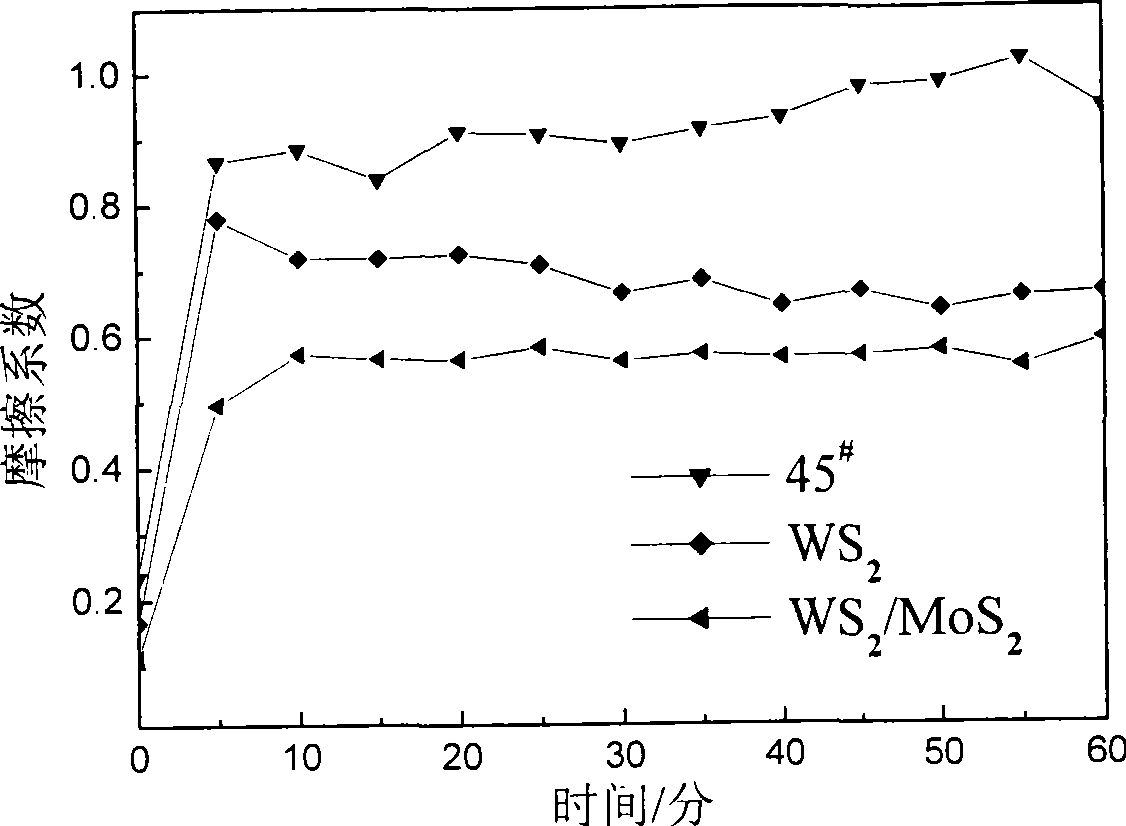

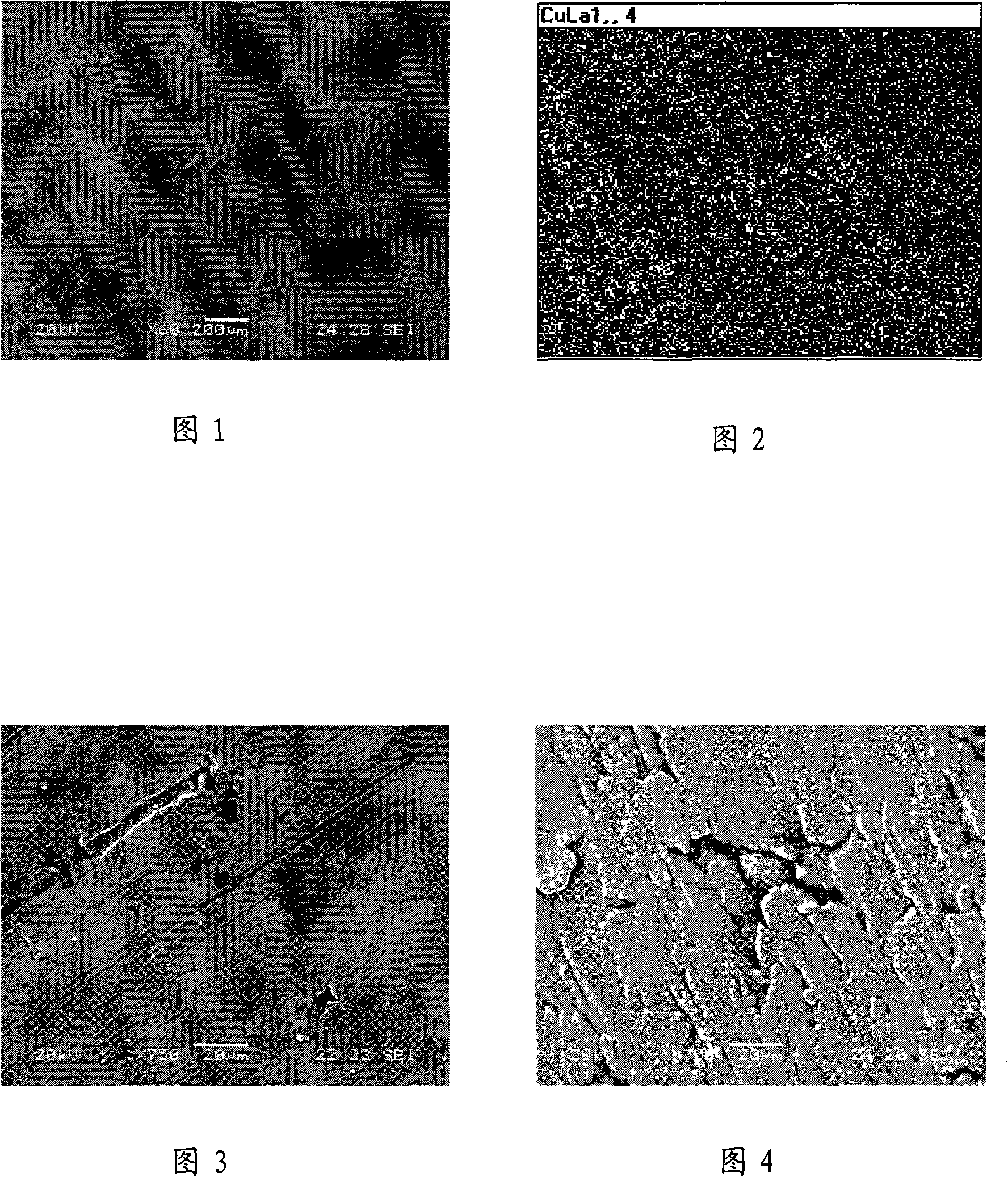

WS2/MoS2 solid lubrication multilayer film and method for making same

ActiveCN101398123AGood effectImprove mechanical propertiesLayered productsVacuum evaporation coatingSputteringSulfur

The invention provides a WS2 / MoS2 solid lubricating multilayer film and a preparation method thereof, which firstly prepares a W / Mo multilayer film through double-target RF sputtering and a W layer and an Mo layer are deposited alternatively on a substrate, and then low temperature ion sulfurizing is carried out to the W / Mo multilayer film and the WS2 / MoS2 solid lubricating multilayer film is prepared. The invention prepares a novel solid lubricating film, namely, the WS2 / MoS2 solid lubricating nano multilayer film through two-step compound treatment. The sublayers of the WS2 / MoS2 solid lubricating nano multilayer film have the same thickness and element sulfur is distributed evenly in the multilayer film, thus leading the multilayer film to have higher rigidity, good nano properties, elasticity modulus and yield strength, better practicability and excellent anti-friction and wear-resistant properties in nano mechanical properties and anti-friction and wear-resistant aspects as being compared with the existing nano multilayer films. The WS2 / MoS2 solid lubricating multilayer film can be used on various friction surfaces of machinery equipment, particularly on precisely matching surfaces to reduce friction and improve lubrication conditions.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Nano lubricating oil additive

InactiveCN101148628AReduce fuel consumptionReduce fuel consumption by 5-15%, reduce noiseAdditivesOil additiveOxidation stability

The present invention discloses one kind of nanometer lubricating oil additive, which consists of liposoluble nanometer copper or copper alloy and liposoluble nanometer silica. The nanometer lubricating oil additive of the present invention can realize the self repair of the worn part, and possesses the functions of saving oil, resisting abrasion, reducing noise, decreasing carbon deposit, raising power performance, etc. It has high dispersivity in lubricating oil, high oxidation stability and long term stability, and is favorable to solving different friction and wear problems in different work conditions.

Owner:BEIJING SIBNANO TECH

Metal cutting fluid and preparation method thereof

ActiveCN105441181AImprove the lubrication effectPrevent and delay adhesive wearLubricant compositionMetallurgyPreservative

The invention provides a metal cutting fluid which comprises the following components in parts by mass: 6-7 parts of rust inhibitor, 15-20 parts of lubricant, 0.05-0.15 part of anti-hard-water agent, 3-4 parts of antiwear additive, 0.2-0.5 part of preservative, 0.5-2 parts of lubricating additive and 50-70 parts of water. The invention also provides a preparation method of the metal cutting fluid, which comprises the following step: sequentially mixing the raw materials to obtain the metal cutting fluid. The metal cutting fluid provided by the invention can greatly lower the friction factor of the friction pair surface, enhances the lubricating properties of the cutting fluid, and effectively prevents the adhesion abrasion on the friction pair surface. The metal cutting fluid has the advantages of simple preparation steps and low environmental pollution.

Owner:FUNIK ULTRAHARD MATERIAL

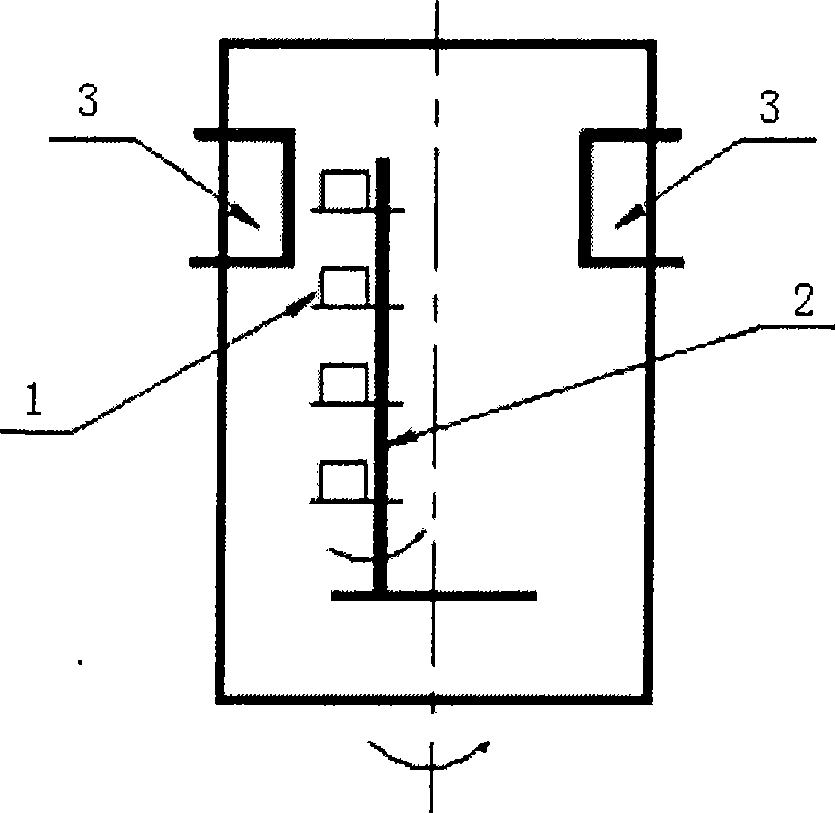

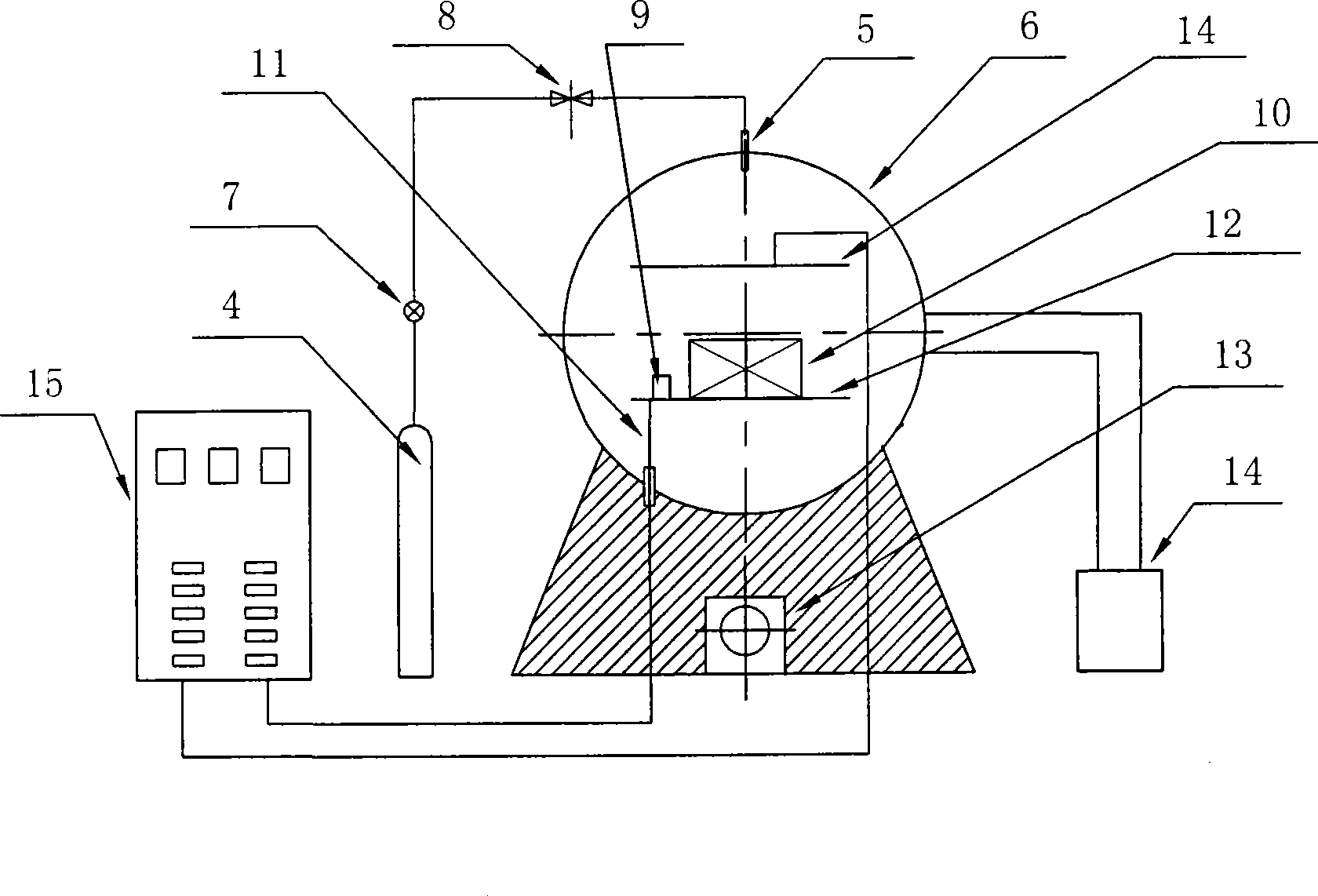

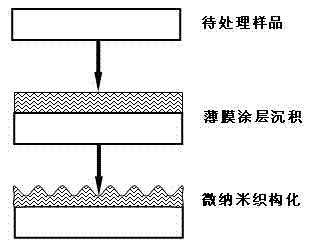

Method and device for preparing film coating micronano texture

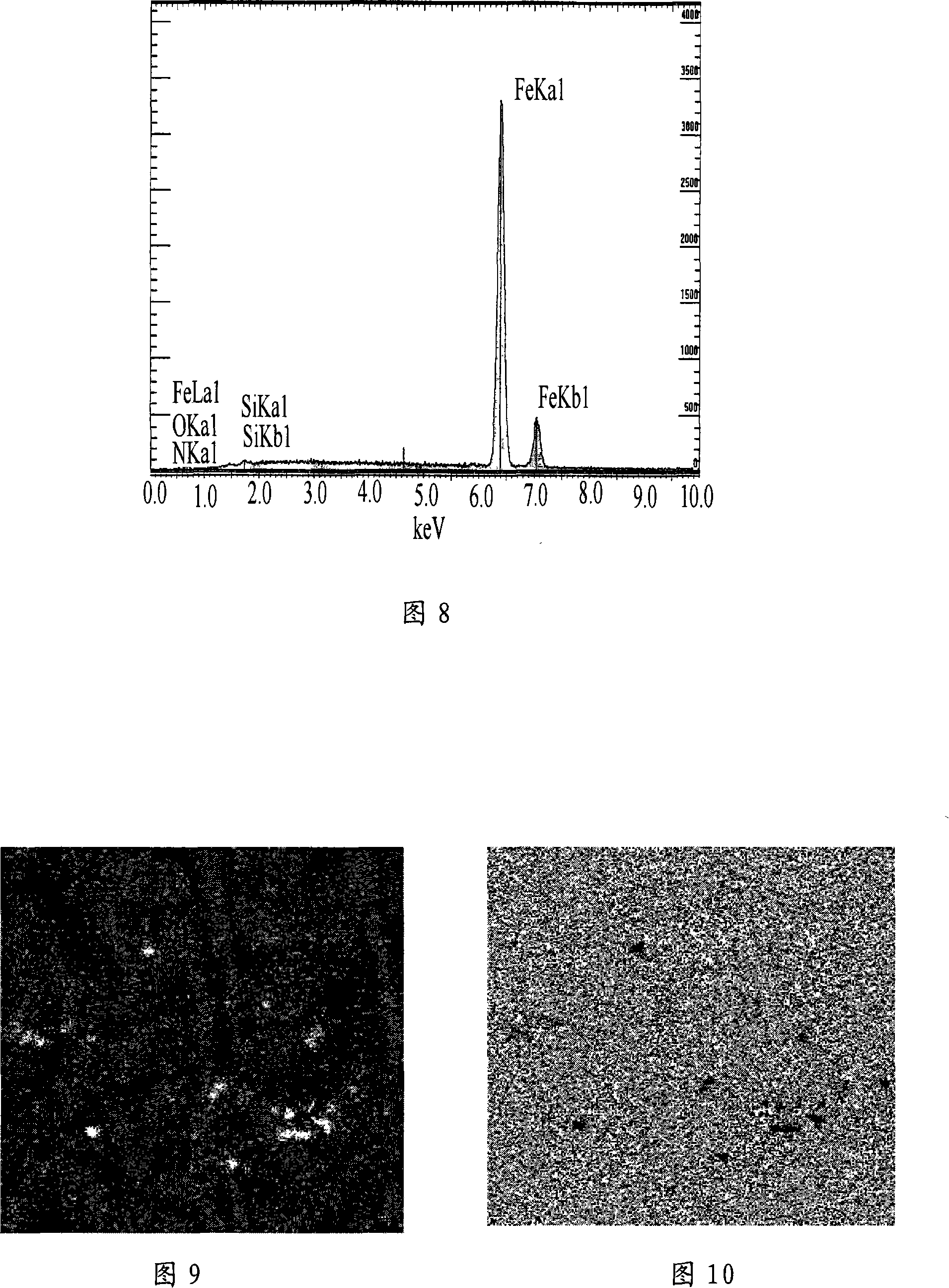

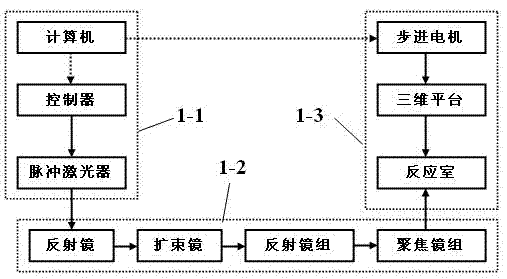

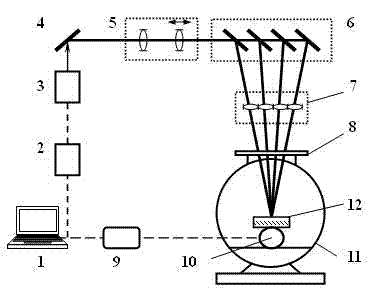

InactiveCN102418082AImprove anti-friction and anti-wear propertiesControllable texture sizeDecorative surface effectsNanotechnologySurface engineeringChemical reaction

The invention relates to a method and a device for preparing a film coating micronano texture and belongs to a film coating of surface engineering. The preparation method comprises the steps of preparing at early stage, depositing the film coating, preparing the micronano texture and performing aftertreatment. The special device is a multi-beam pulse laser micronano texture processing system device. The multi-beam pulse laser micronano texture processing system device comprises a pulse laser module, an optical path transmission module and a precise scanning module which are connected with one another sequentially. The invention has the advantages that: the method and the device are convenient in processing and high in efficiency; preparation for the film coating deposition micronano texture on the surface of a material is realized by one laser source; the process is simple, and easy to control; the prepared samples are not subjected to a complex posttreatment process; the application range is wide; ultraviolet pulse laser has the characteristics of large photon energy and short wavelength and can perform precise micronano texture treatment on any materials; chemical reaction of various gases can be induced; and film coating deposition can be performed efficiently.

Owner:CHINA UNIV OF MINING & TECH

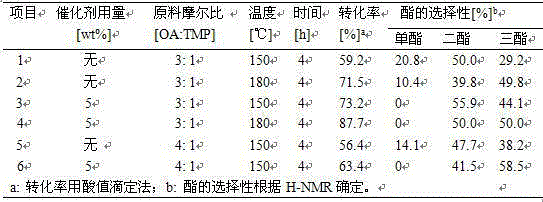

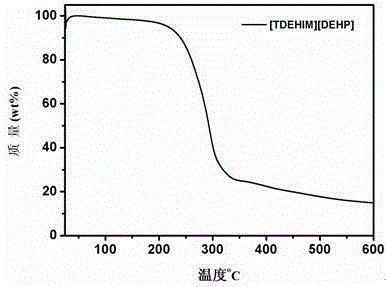

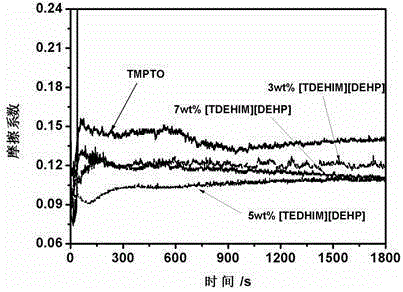

Long-chain alkyl imidazole phosphate ionic liquid, preparation method and application thereof

ActiveCN105254663ACatalytically activeImprove anti-friction and anti-wear propertiesOrganic compound preparationGroup 5/15 element organic compoundsFriction reductionPhosphate

The invention discloses a long-chain alkyl imidazole phosphate ionic liquid, i.e. 1-tetradecyl-3-(2-ethylhexyl)-imidazole diisooctyl phosphate. The invention also discloses a preparation method and application of the ionic liquid. The ionic liquid involved in the invention has certain catalytic activity, and is also soluble in the reaction product trimethylolpropane oleate, so that catalyst separation is omitted after esterification reaction, and the industrial production cost is greatly reduced. More importantly, the ionic liquid soluble in trimethylolpropane trioleate has excellent friction reduction and antiwear effects, and can significantly improve the tribological properties of base oil.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

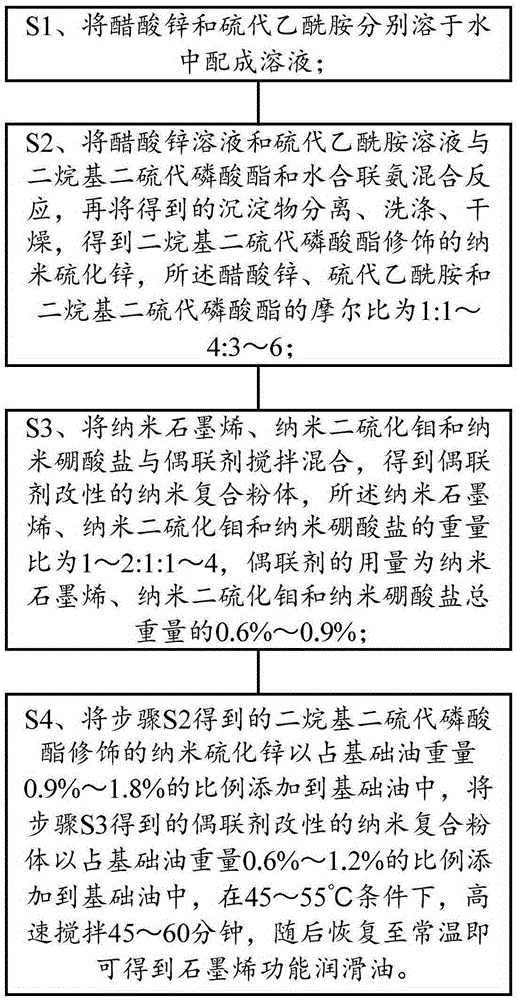

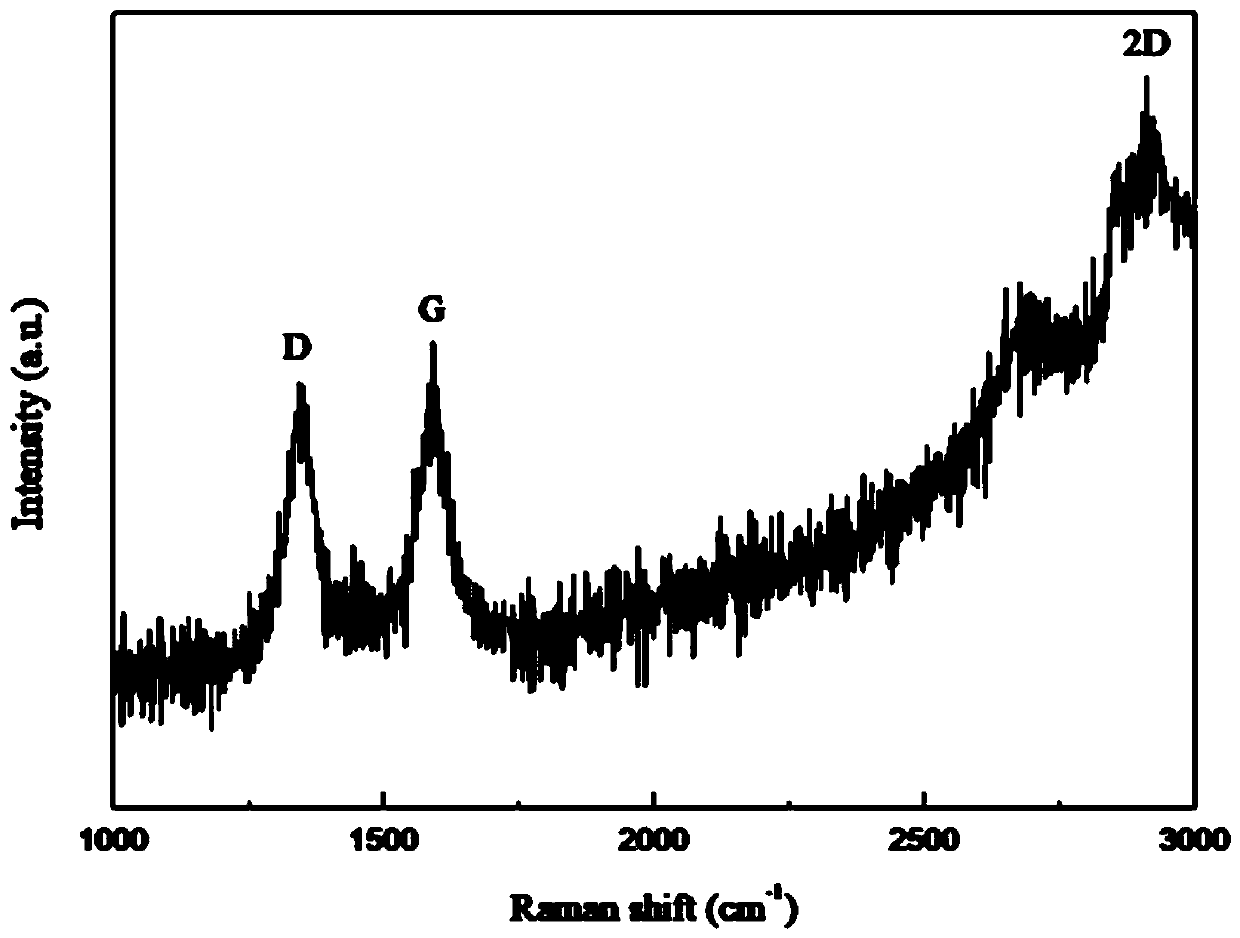

Preparation method of graphene functional lubricating oil

InactiveCN105255547AImprove carrying capacityImprove anti-friction and anti-wear propertiesAdditivesBase oilCvd graphene

The invention discloses a preparation method of graphene functional lubricating oil. The preparation method comprises the following steps: S1. respectively dissolving zinc acetate and thioacetamide in water to prepare solutions; S2. mixing the zinc acetate solution and the thioacetamide solution with dialkyl dithiophosphate and hydrazine hydrate to react and then separating, washing and drying an obtained precipitate, thus obtaining dialkyl dithiophosphate modified nano zinc sulfide; S3. stirring nano graphene, nano molybdenum disulfide, nano borate and a coupling agent to mix the materials to obtain coupling agent modified nano composite powder; and S4. adding dialkyl dithiophosphate modified nano zinc sulfide obtained in the step S2 to base oil, adding the coupling agent modified nano composite powder obtained in the step S3 to the base oil, stirring the materials at a high speed at a certain temperature and then restoring the temperature to the normal temperature, thus obtaining the graphene functional lubricating oil. The prepared lubricating oil has excellent antifriction and antiwear properties and high bearing capacity and has the function of repairing worn surfaces.

Owner:DEVON ENERGY CORP

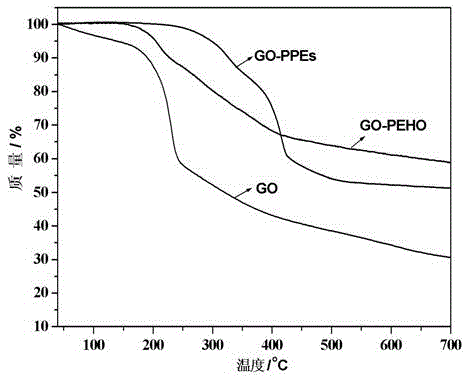

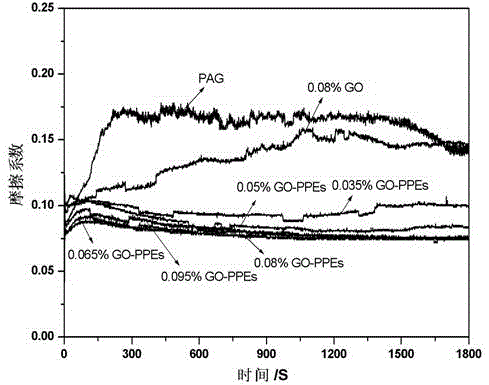

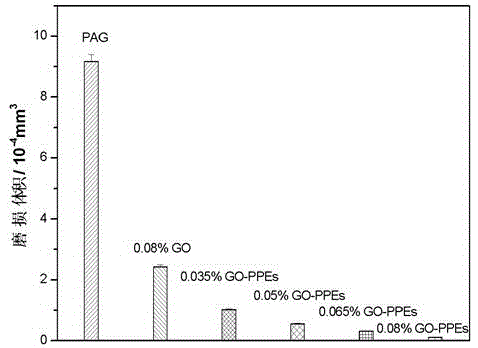

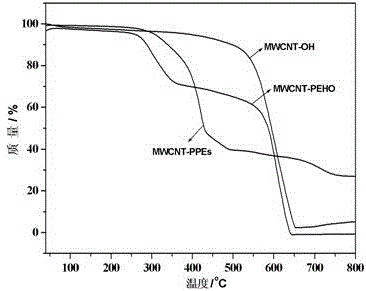

Graphene oxide modified nano additive and application thereof to lubricating oil

ActiveCN105602649AGood dispersionImprove anti-friction and anti-wear propertiesAdditivesPhosphateOxetane

The invention discloses a graphene oxide modified nano additive and application thereof. The nano additive is prepared by the following steps: preparation of hydroxylated graphene oxide (GO-OH); preparation of graphene oxide-poly3-ethyl-3- hydroxymethyl oxetane (GO-PPEs); preparation of graphene oxide-polymer phosphate ester (GO-PEHO). One of the characteristics of the nano additive is formation of a stable dispersion in polyether, and the dispersion concentration is greater than that of the graphene oxide. In addition, the nano additive has good thermal stability, and excellent anti-friction wear property at high temperature of 100-175 DEG C.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

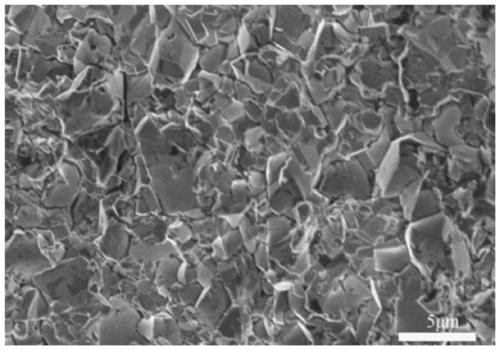

Solvent-free graphene oxide loaded silica nano fluid and applications

ActiveCN108949291AExcellent anti-friction and anti-wear propertiesHigh strengthAdditivesSilica nanoparticlesChemical Linkage

The invention discloses a solvent-free graphene oxide loaded silica nano fluid. A graphene oxide loaded silica composite system can be taken as a nano nucleus to synthetize a solvent-free nano fluid;modification can be performed on silica nanoparticles by using a surfactant, so that the silica nanoparticles with positive charge can be obtained; the modified silica nanoparticles can be loaded on agraphene oxide sheet surface by utilizing an electrostatic self-assembly effect; and the solvent-free graphene oxide loaded silica nano fluid can be synthetized by grafting a silane coupling agent with different function groups and flexible long chain molecules through a chemical bonding effect. Applications of the nano fluid are also disclosed. The nano fluid can effectively enhance the lubrication performance of the system, strengthen the intensity of an adsorption film and a tribochemical reaction film, and improve the boundary lubrication capabilities of friction pairs.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method for metal material surface antifriction and antiwear nano-composite film

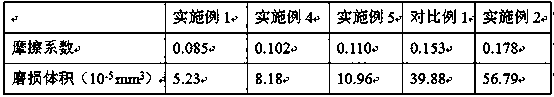

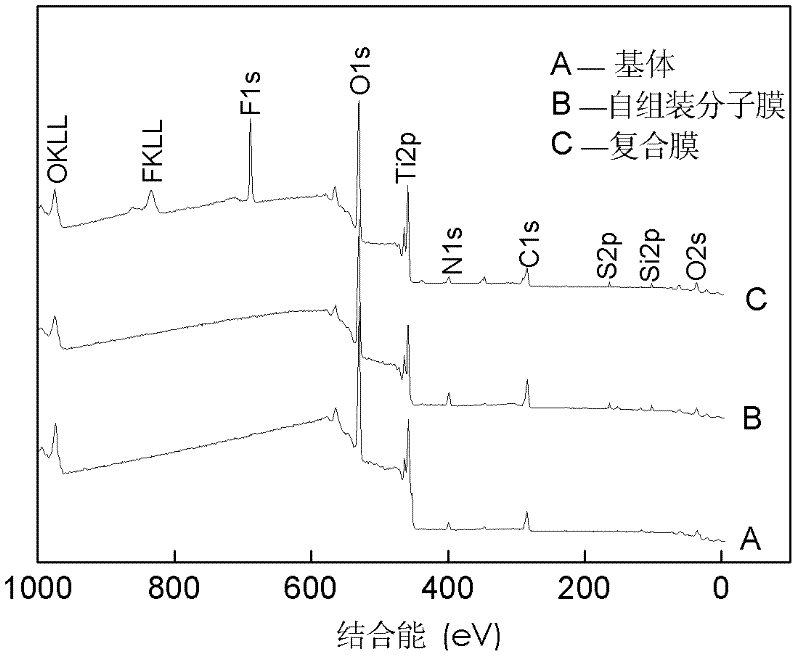

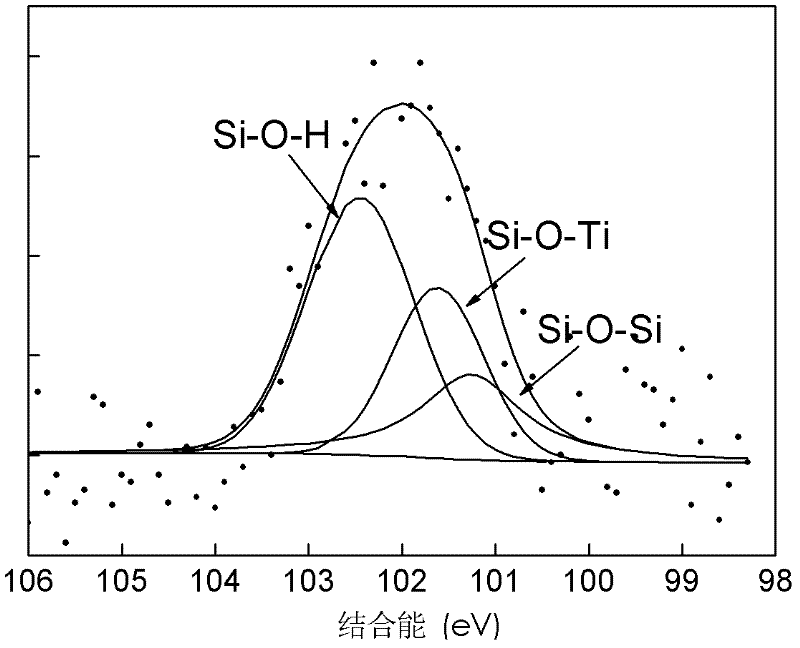

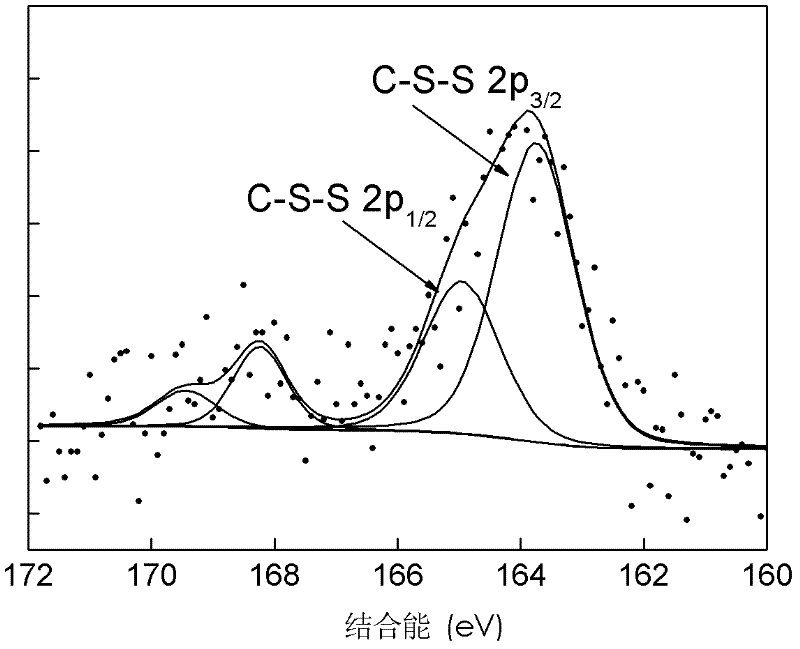

InactiveCN102358946ADense and orderly growthTightly boundElectrolytic organic material coatingSimple Organic CompoundsTitanium alloy

The present invention discloses a preparation method for a metal material surface antifriction and antiwear nano-composite film. According to the method, a combination process of a self-assembled molecular film technology and an organic plating technology is sequentially adopted to prepare the nano-composite film with functions of antifriction property and anti-wear property on titanium alloy surfaces, aluminum alloy surfaces, NdFeB permanent magnet material surfaces, magnesium alloy surfaces or low carbon steel surfaces. The solute of the self-assembled solution is a thiol-silane organic compound salt, wherein the thiol-silane organic compound salt concurrently contains -SH and -Si(OR)3, the concentration of the thiol-silane organic compound salt is 0.5-10 mmol / L. The organic plating electrolyte solution comprises 0.1-10 mmol / L of a thiol organic compound salt containing -SH and 0.1-6 mol / L of a supporting electrolyte. According to the present invention, the preparation method of the present invention has characteristics of simple process, convenient operation; the prepared nano-composite film has characteristics of short preparation period, low cost, controllable thickness of the composite film and good stability; the prepared nano-composite film of the invention has excellent antifriction property and anti-wear property so as to solve the tribology problems of the materials in the micro / nano-electromechanical systems, and is applicable for the industrialization.

Owner:SOUTH CHINA UNIV OF TECH

Formula for piston of gasoline engine

InactiveCN1362534AReduce gapGood sealing and anti-friction and anti-wear performanceMachines/enginesPistonsPistonEngineering

The formula of piston for petrol engine comprises (wt%) Si 11%-13%, Cu 0.8%-1.5%, Mg 0.8%-1.3%, Mn 0.01%-0.2%, Fe 0.01%-0.5%, Ni 1%-1.5%, Zn 0.01%-0.2%, Ti 0.01%-0.2%, Te 0.1%-0.4%, Li 0.01%-0.1%, Co0.01%-0.1% and the rest is Al. Said piston can reduce gap between piston and cylinder jacket, and its working surface layer contains special substance capable of firmly combining with engine oil, so taht its sealing and antifriction properties are good, and it can prolong the life of engine.

Owner:周芝山

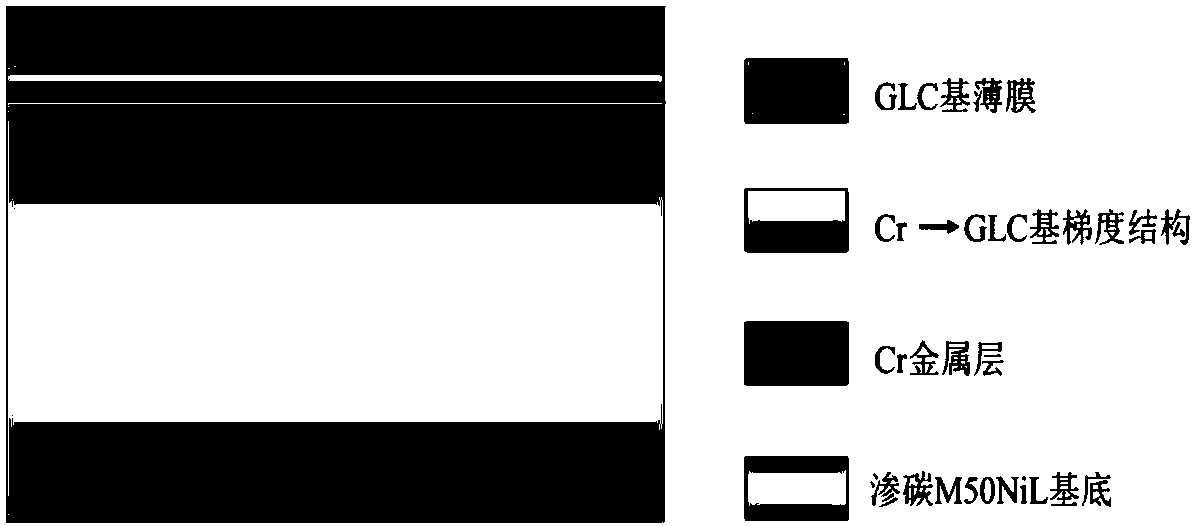

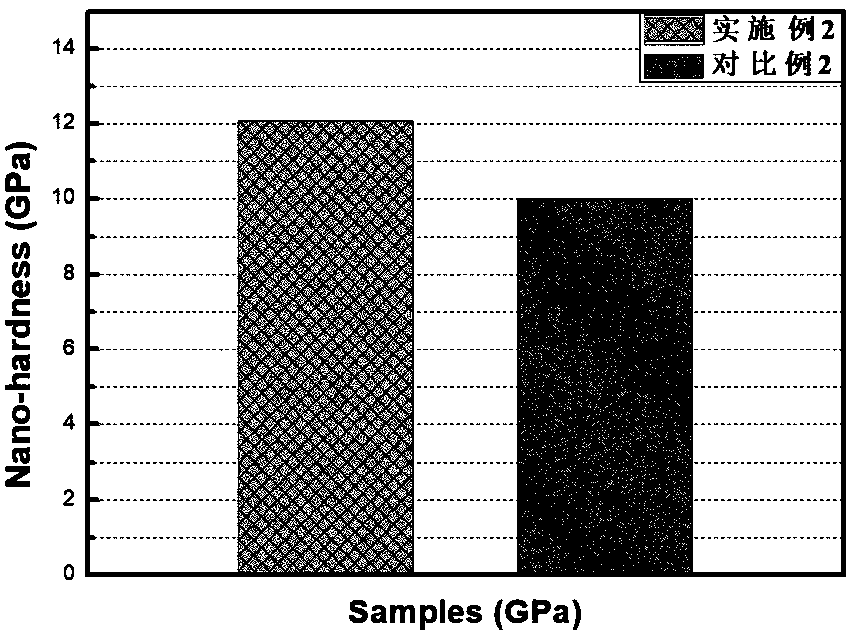

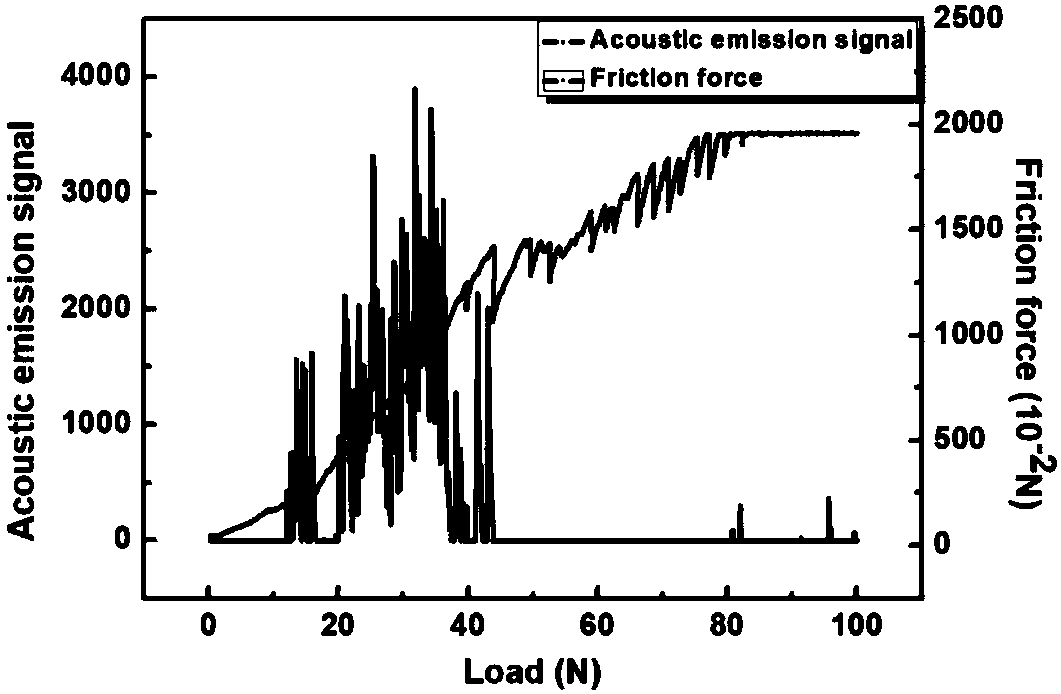

Method for improving surface tribology performance of M50NiL bearing steel

ActiveCN108411244AImprove tribological performanceImprove bindingVacuum evaporation coatingSputtering coatingSputteringCarbonization

The invention discloses a method for improving the surface tribology performance of M50NiL bearing steel, and belongs to the technical field of material surface modification. The vacuum pulse carburization technology is adopted for conducting carburization and high-temperature tempering treatment on the surface of an M50NiL bearing steel base material; then quenching and tempering treatment is conducted; a surface white bright layer of the M50NiL bearing steel base material is removed; and a binding layer, a chromium metal layer, a Cr->GLC gradient layer and a GLC base solid lubricating film are deposited on the surface of the M50NiL bearing steel base material through the multi-target non-magnetic-control sputtering technology. According to the method, the surface carbonization technologyand the unbalanced-magnetic-control sputtering technology are combined, on one hand, the surface of the M50NiL bearing steel is intensified through the carbonization technology, and good support is provided for the GLC base solid lubricating film; on the other hand, the unbalanced-magnetic-control sputtering technology is utilized for preparing the GLC base solid lubricating film with good self-adaptability and tribology performance, and the friction reducing and abrasion resisting performance of the surface of the M50NiL bearing steel is obviously improved.

Owner:XI AN JIAOTONG UNIV

Impregnated paper finished OSB composite floor and preparation method

ActiveCN105464335ALow costGood value for moneyAldehyde/ketone condensation polymer adhesivesFlooringPulp and paper industryUltimate tensile strength

The invention relates to a plate, in particular to an impregnated paper finished OSB composite floor and a preparation method. The impregnated paper finished OSB composite floor sequentially comprises an OSB base material layer, a veneer layer, a buffer paper layer, a balance paper layer and a sprayed decorative paper layer from bottom to top. The longitudinal static bending intensity of the OSB base material layer is larger than or equal to 50 MPa, and the water absorption thickness swelling rate of the OSB base material layer is smaller than or equal to 12%. The veneer layer is a poplar bleached veneer, and the thickness ranges from 0.6 mm to 1.2 mm. The buffer paper layer is impregnated kraft paper with the thickness of 0.4 mm to 0.6 mm, and the glue quantity is 80% or above. The weight of the balance paper layer ranges from 70 g to 80 g, and the glue quantity ranges from 100% to 120%. The weight of the sprayed decorative paper ranges from 70 g to 80 g, and the glue quantity ranges from 100% to 120%. The impregnated paper finished OSB composite floor has high environment friendliness, stability and water resistance.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Novel nano-copper type lubricating oil additive

The invention discloses a nano-copper type lubricating oil additive, which mainly comprises oil-soluble reactive nano-copper or the oil-soluble reactive nano-copper and oil-soluble nano titanium dioxide. The nano-copper type lubricating oil additive has high dispersity, high stability and high self-repairability, and simultaneously has the functions of saving oil, resisting and reducing abrasion, reducing noises and the like.

Owner:赵宏鑫 +1

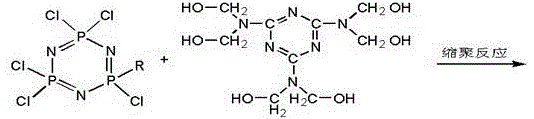

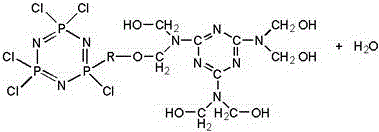

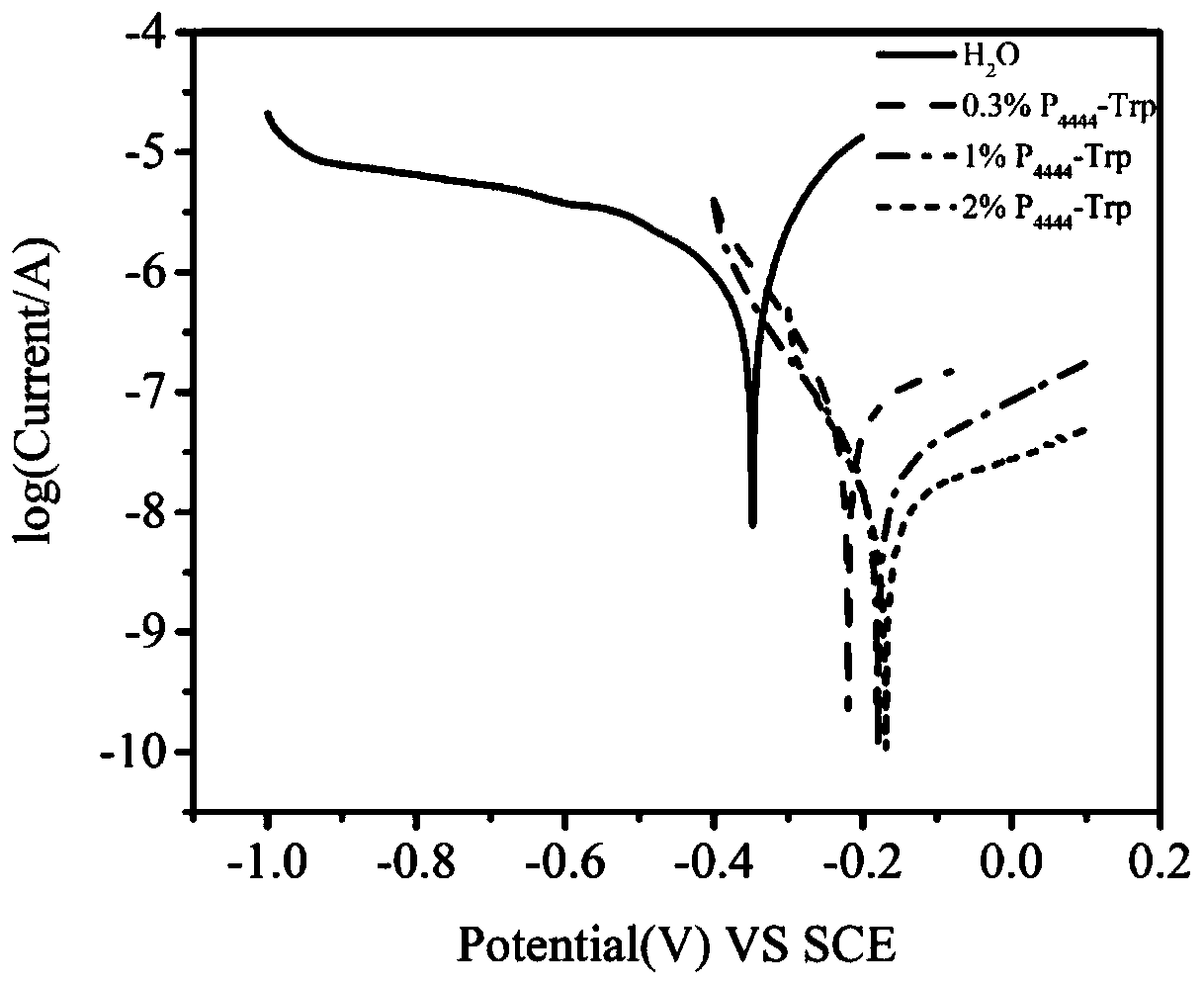

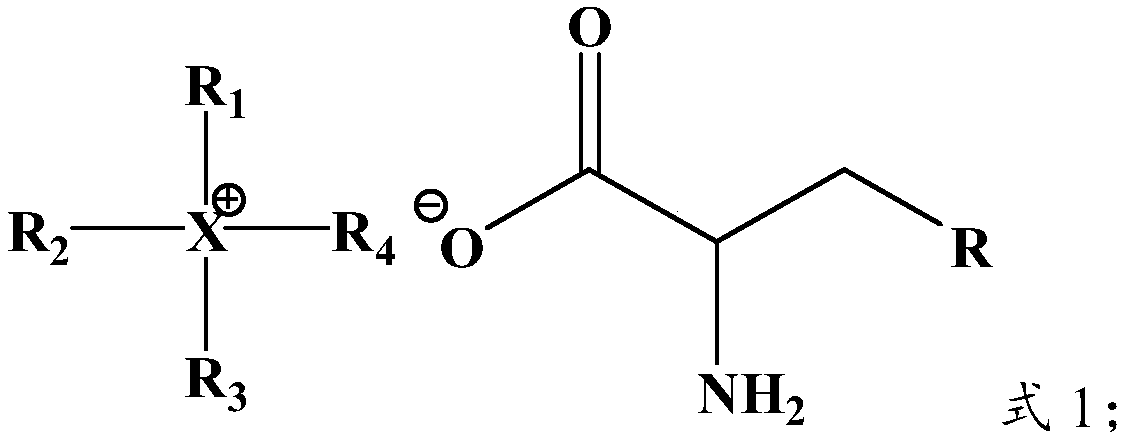

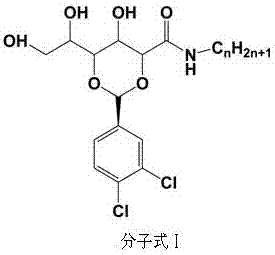

Amino acid ionic liquid water-based additive and preparation method and application thereof

InactiveCN110845417AImprove the lubrication effectImprove solubilityOrganic compound preparationGroup 5/15 element organic compoundsChloroform methanolSimple Organic Compounds

The invention provides an amino acid ionic liquid water-based additive and a preparation method and application thereof, belonging to the technical field of organic compounds of lubricating oil additives. The structural formula of the amino acid ionic liquid water-based additive provided by the invention is shown as a formula 1 which is described in the specification. The amino acid ionic liquid water-based additive provided by the invention is biodegradable, environment-friendly and pollution-free, and has good solubility. The prepared amino acid ionic liquid water-based additive can also befully dissolved in organic solvents with different polarities, such as chloroform, methanol and water, and has excellent anti-friction and anti-wear properties and high bearing capacity when used as alubricant of a steel / steel friction pair.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

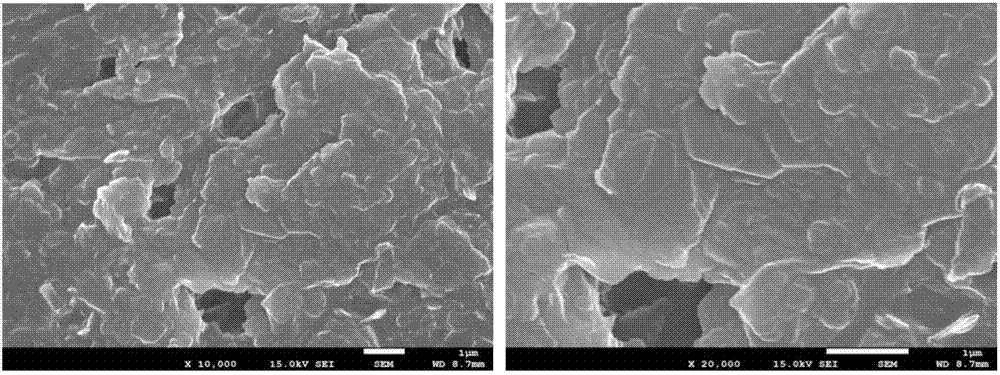

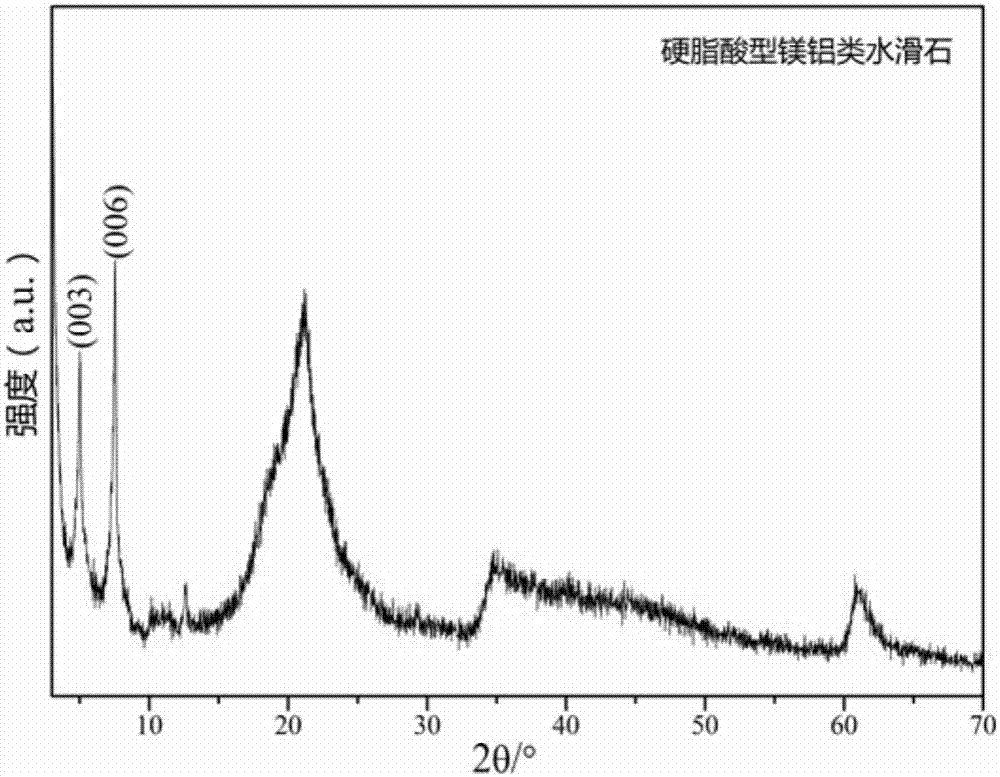

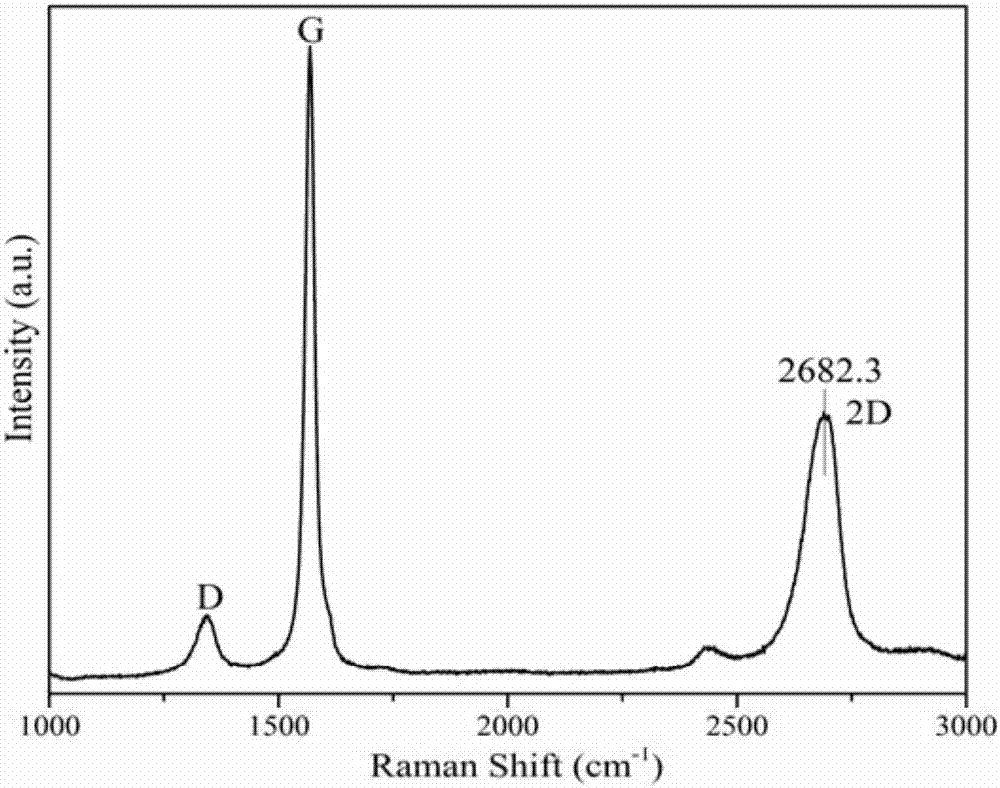

Graphene-hydrotalcite-like compound and preparation method and application thereof

ActiveCN106867604AExcellent anti-friction and anti-wear propertiesImprove friction performanceLiquid carbonaceous fuelsCompound sHydrotalcite

The invention discloses a graphene-hydrotalcite-like compound and a preparation method and an application thereof. The graphene-hydrotalcite-like compound is a compound of organic modified hydrotalcite and graphene. A graphene-hydrotalcite-like compound material is prepared for the first time and is taken as a diesel engine oil additive, so that the friction performance of the diesel engine oil is greatly improved; and moreover, the stability of the diesel engine oil is further improved. In addition, according to the preparation method of the graphene-hydrotalcite-like compound, the organic modified hydrotalcite is prepared by a one step hydrothermal method, and the method is simple and practical, and the prepared material is good in quality and high in yield.

Owner:北京奈泊科技有限公司

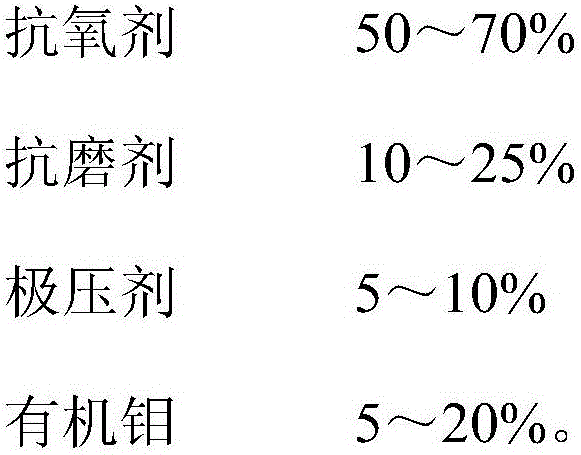

Anti-pitting self-repairing gear grease

ActiveCN105733787AExtend the lifespanPrevent oxidation failureLubricant compositionAntioxidantEngineering

The invention relates to anti-pitting self-repairing gear grease. The anti-pitting self-repairing gear grease comprises, by weight, 92-97% of a gear grease body and 3-8% of a self-repairing addition agent. According to calculation of the total mass of 100%, the self-repairing addition agent comprises, by weight, 50-70% of antioxidant, 10-25% of an anti-wear agent, 5-10% of an extreme pressure agent and 5-20% of organic molybdenum. The anti-pitting self-repairing gear grease has excellent antioxygen performance and extreme pressure wear resisting performance at different temperatures, can effectively prevent the surface of a gear from generating pitting, and can have a function of repairing the worn surface of the gear to a certain degree, so that the service life of the gear is prolonged.

Owner:东莞太平洋博高润滑油有限公司

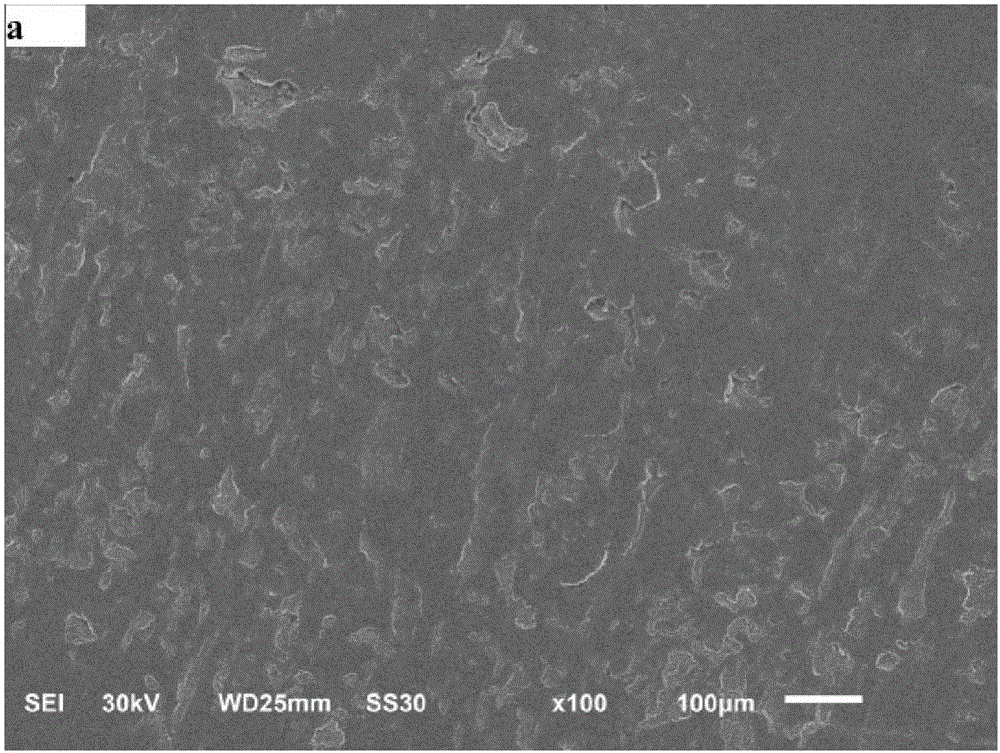

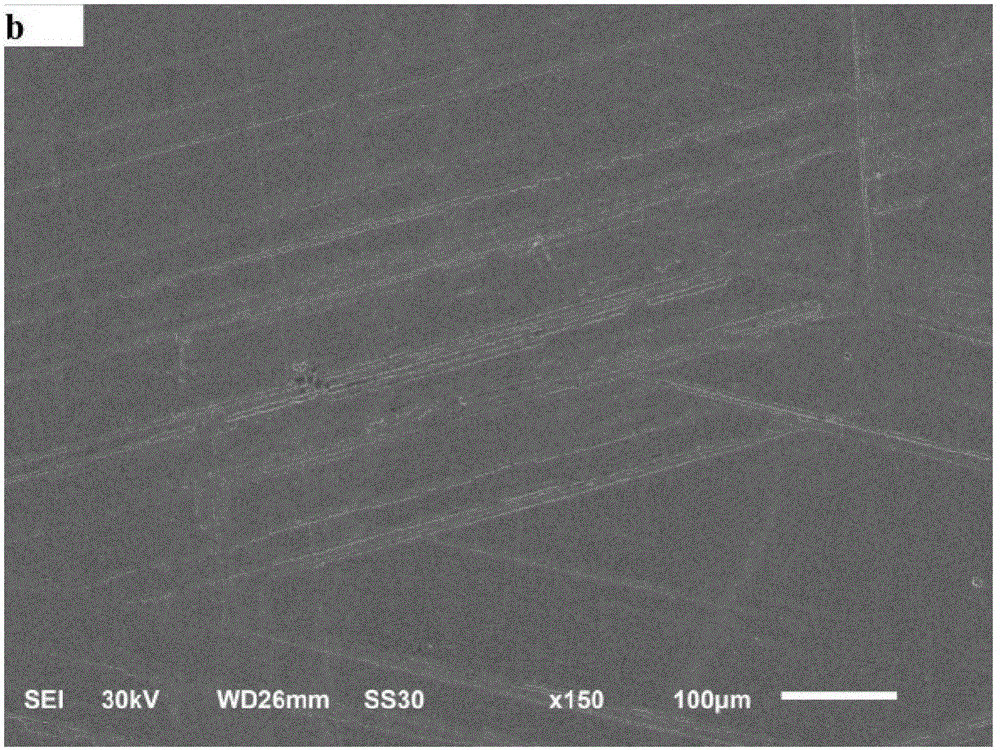

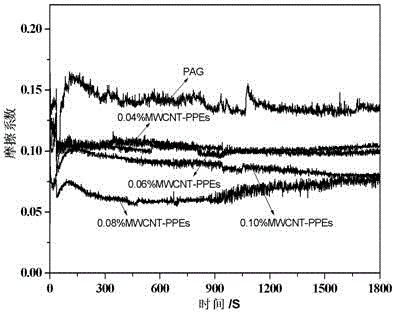

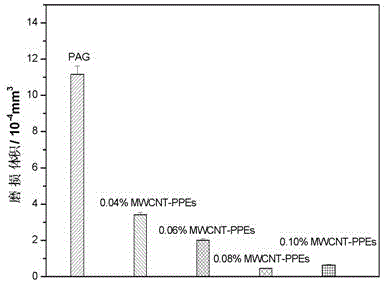

Carbon nanotube-modified nano-additive and preparation method and application thereof

ActiveCN105602650AImprove anti-friction and anti-wear propertiesAdditivesBase-materialsMultiwalled carbonPhosphate

The present invention discloses a carbon nanotube-modified nano-additive. The nano-additive is multiwalled carbon nanotube-polymer phosphate. The invention also discloses a preparation method of the nano-additive and application thereof to the polyether. The nano-additive can form a stable dispersion system in polyether, and has good thermal stability, and excellent anti-friction wear characteristics at high temperature of 150 DEG C.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

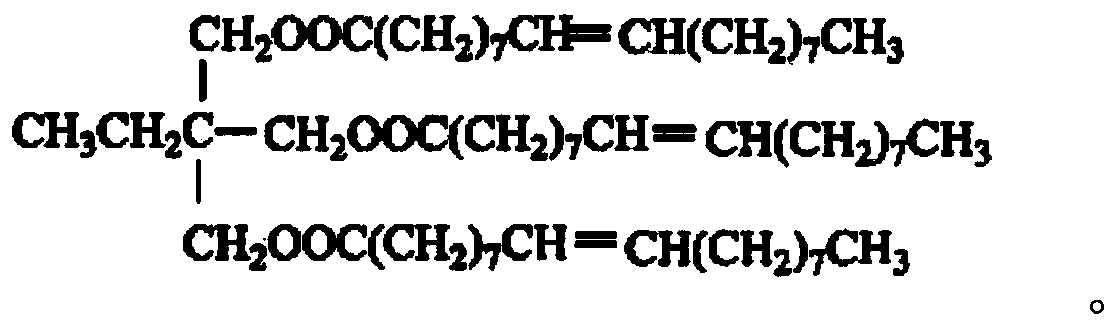

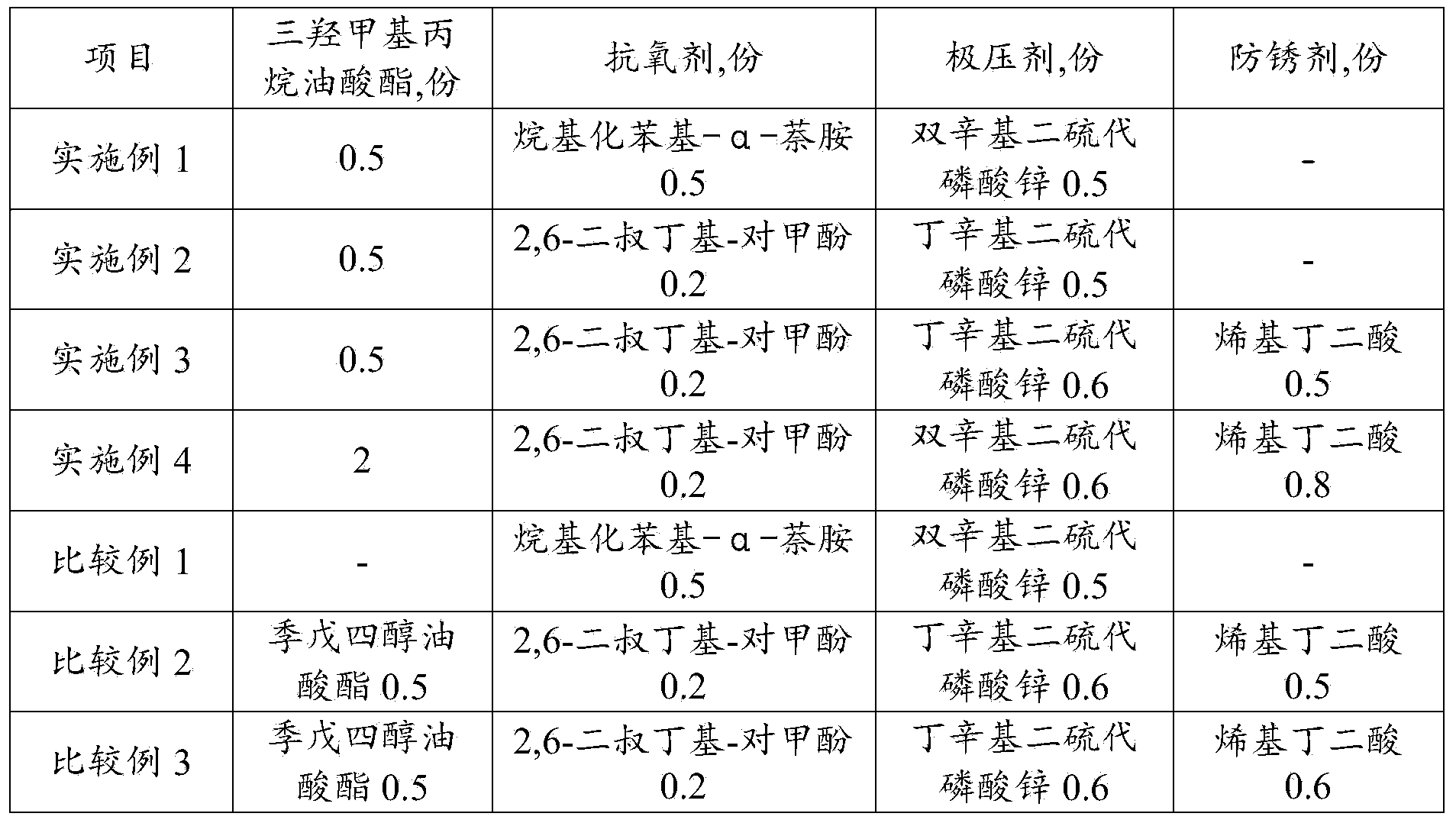

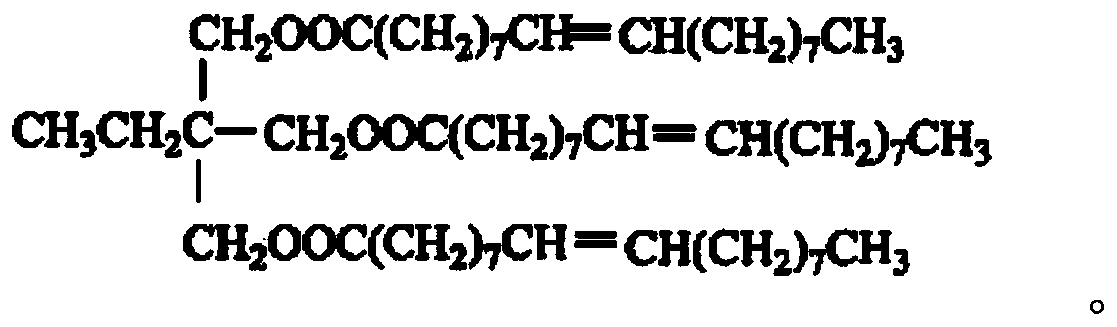

Use of trimethylolpropane oleate, trimethylolpropane oleate containing composition and use of trimethylolpropane oleate containing composition

ActiveCN104342226AImprove anti-friction and anti-wear propertiesImprove rust resistanceAdditivesTrimethylolpropanePolymer science

The invention relates to use of trimethylolpropane oleate, a trimethylolpropane oleate containing the composition and use of the trimethylolpropane oleate containing the composition. By adding the trimethylolpropane oleate into lubricating oil, not only can excellent antifriction and abrasion resistance be obtained, but also the rust resistance of an oil product can be improved.

Owner:CHINA PETROLEUM & CHEM CORP

Electrostatic spraying process for aluminum alloy profiles

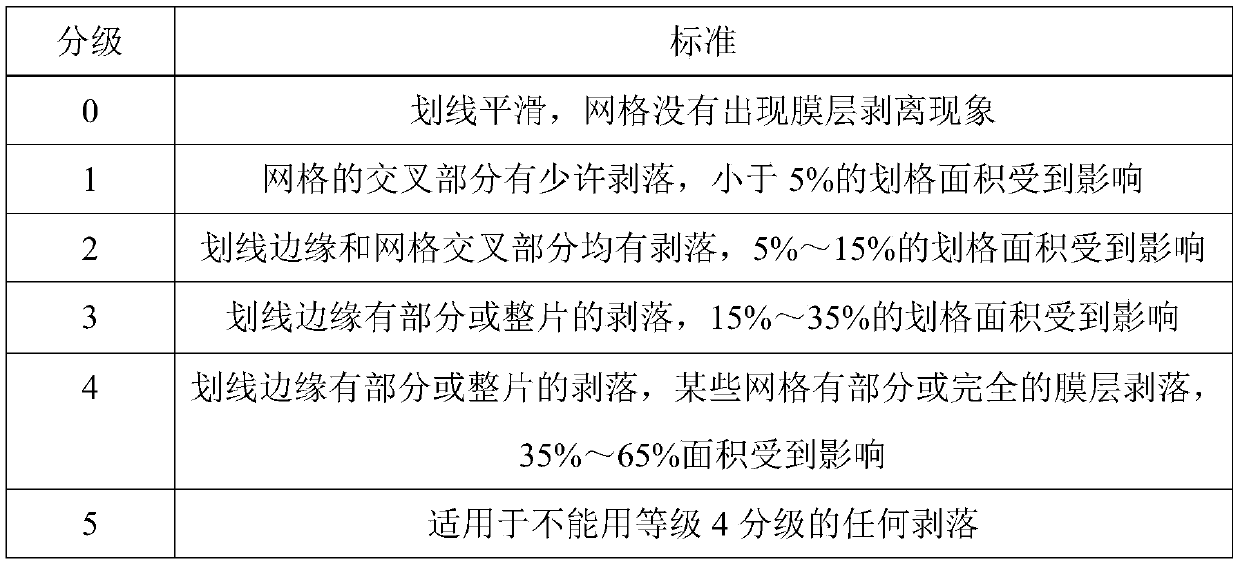

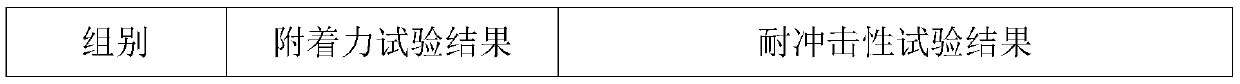

ActiveCN110280466AImprove adhesionExtended service lifePretreated surfacesMetallic material coating processesRoom temperatureHardness

The invention belongs to the technical field of aluminum alloy profiles and particularly relates to an electrostatic spraying process for aluminum alloy profiles. The electrostatic spraying process for the aluminum alloy profiles comprises steps as follows: surfaces of aluminum alloys are polished, sprayed with water, washed and dried; a to-be-processed workpiece is degreased, sprayed with water and washed; the degreased workpiece is subjected to oil removal, sprayed with water and washed; the surface of the workpiece subjected to oil removal is sprayed with a diluted surface conditioner; the workpiece subjected to surface conditioning is phosphorized, the phosphorized workpiece is passivated, the surface of the passivated workpiece is sprayed with water and washed, the workpiece is dried and cooled, and the dried workpiece is obtained; the surface of the dried workpiece is sprayed with powdery paint in an electrostatic spraying manner by a spray gun and left to stay still, and the workpiece which is sprayed and left to stay still is obtained; the workpiece which is sprayed and left to stay still is conveyed to a baking room and then cooled to the room temperature. With the adoption of the electrostatic spraying process for the aluminum alloy profiles, the adhesive force, the hardness, the wear resistance, the acid resistance and other performance of surface coatings are remarkably improved, and the service life of the aluminum alloy profiles is prolonged effectively.

Owner:河源市益豪塑胶五金电子制品有限公司

Rolling-use water base nano lubricant based on graphene oxide (GO) and preparation method thereof

ActiveCN106566647AReduce friction and wearImprove contact surface qualityLubricant compositionWater bathsWater based

The invention provides a rolling-use water base nano lubricant based on GO and a preparation method thereof. The lubricant is composed of GO, an oxide nano powder, polyphosphates, polyvinylpyrrolidone, and deionized water. The preparation method includes the steps of: adding the polyphosphates to deionized water to completely dissolving the polyphosphates to obtain a primary solution; adding the polyvinylpyrrolidone to the solution with stirring to obtain a clear liquid; adding the oxide nano powder to perform surface modification and dispersion; and finally adding GO powder and performing water-bath ultrasonic dispersion so as to prevent aggregation of the GO and other nano particles. The lubricant has good stability and wear-resisting durability, excellent lubricating performance and cooling performance, and is very low in corrosion on a substrate. A lubricating film formed by the lubricant has strong adsorption property and good adhesion property, thereby inhibiting oxidization of surface of a roller well. The lubricant has excellent lubricating effects in both cold-rolling and hot-rolling status.

Owner:UNIV OF SCI & TECH BEIJING

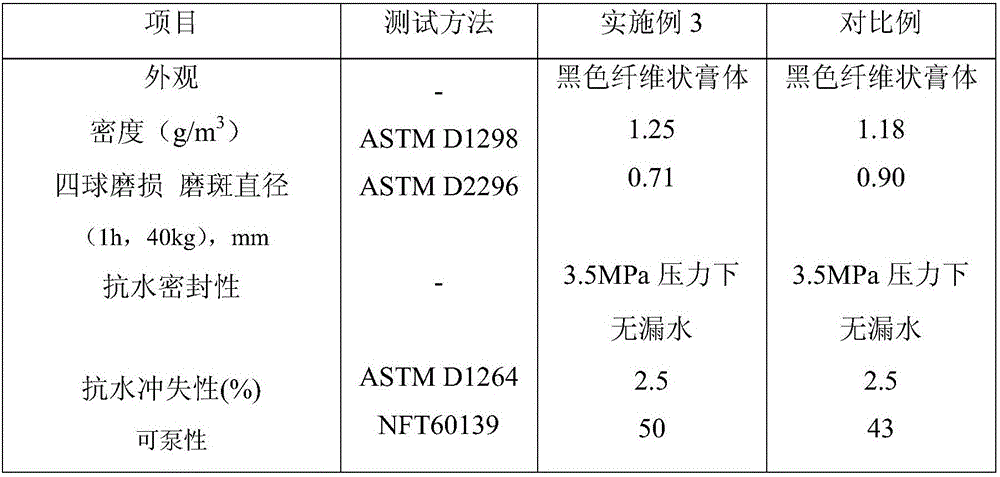

Shield machine main bearing sealing grease and preparation method thereof

InactiveCN106800966AImprove anti-friction and anti-wear propertiesImprove the lubrication effectLubricant compositionShield machineToxin

The invention relates to shield machine main bearing sealing grease and a preparation method thereof. The main bearing sealing grease is prepared from the ingredients in mass percent: 15 to 30% of base oil, 20 to 30% of lubricating grease, 12 to 20% of tackifier, 5 to 12% of degradable fiber, 20 to 40% of nanoparticle filling material and 1 to 5% of dispersing agent. The shield machine main bearing sealing grease prepared according the formula has excellent antifriction and anti-wear performance and an outstanding lubricating effect, can effectively prevent a rotating portion from being rusted and reduces abrasion of the rotating portion. In addition, the shield machine main bearing sealing grease has good water-resistant leakproofness and pumpability, prevents pipelines from being plugged, can more effectively prevent impurities from invading a shield head portion and damaging precise components of bearings and the like due to a fiber structure, prolongs service life of a main bearing and has stable product performance, no toxin and corrosion, environmental friendliness and a simple preparation technology.

Owner:XIAMEN NORNS TECH

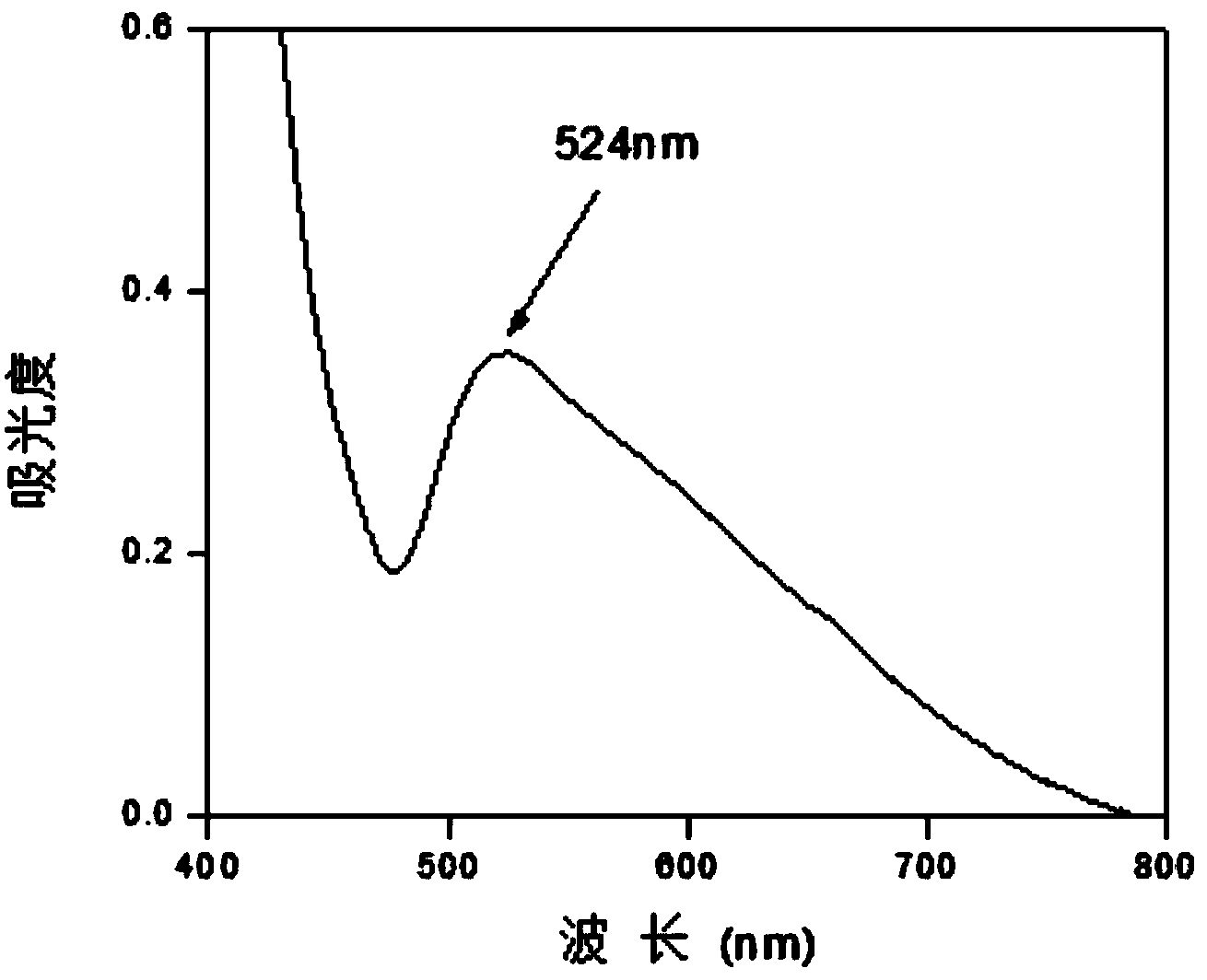

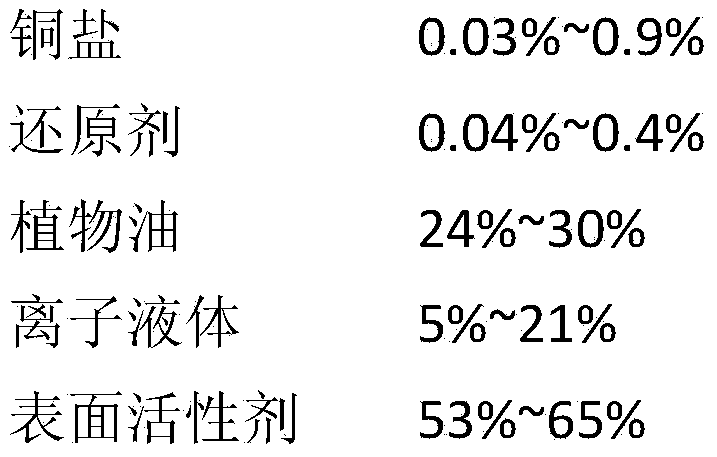

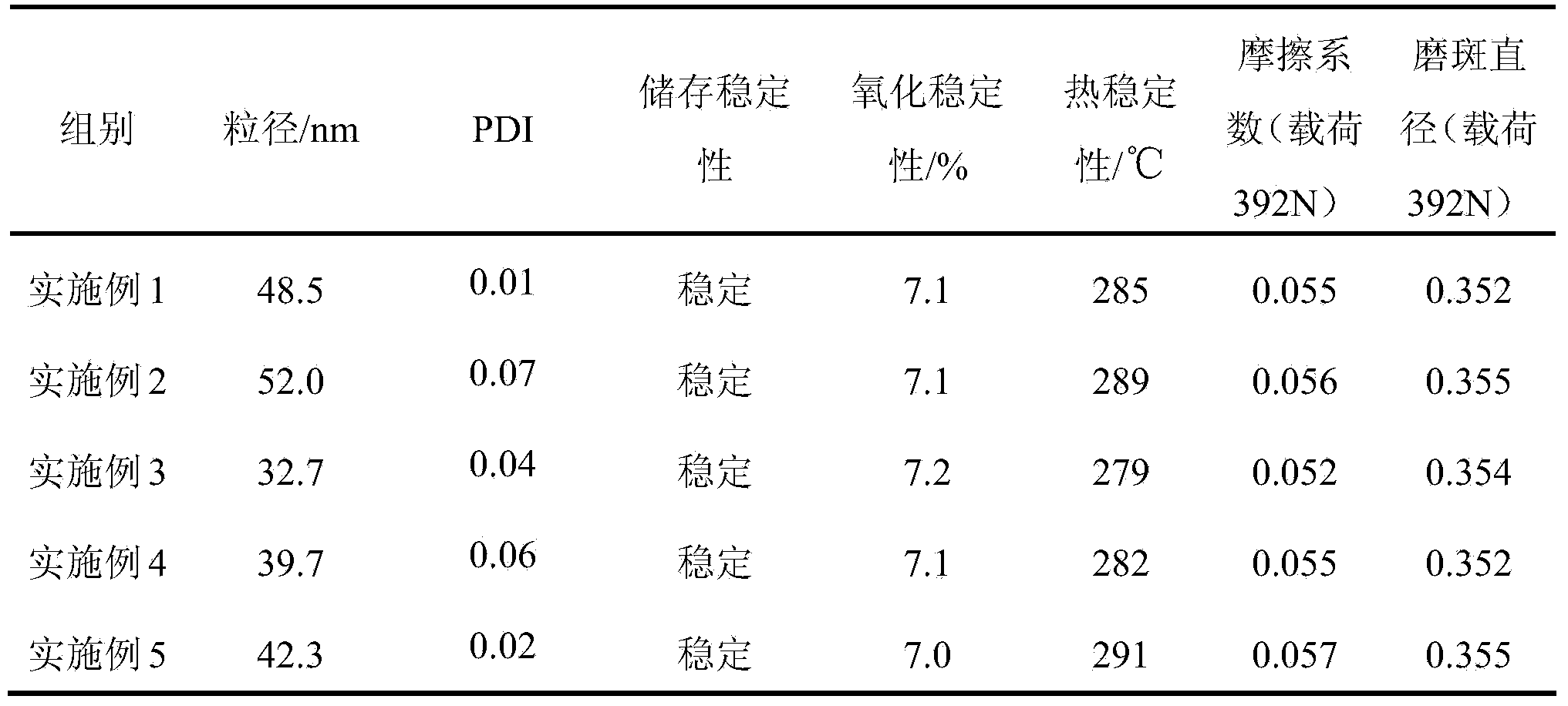

Vegetable oil based ionic liquid microemulsion type nano lubricating oil and preparation method thereof

InactiveCN103937587ASimple production processReduce manufacturing costLubricant compositionDispersityVegetable oil

The invention discloses vegetable oil based ionic liquid microemulsion type nano lubricating oil and a preparation method thereof. The method comprises the following steps: dissolving copper salt in vegetable oil under the condition of stirring at 20-90 DEG C, thus obtaining a component A; dissolving reducer into ionic liquid to obtain a component B; adding surfactant into the A to obtain a component C; and uniformly and dropwisely adding the component B into the component C, and performing thermostatic reaction to obtain the vegetable oil based ionic liquid microemulsion type nano lubricating oil containing nano copper particles. According to the invention, the lubricating oil base oil is used as a carrier, and the nano copper particles are in-situ synthesized therein. The synthesis method simplifies the production process of the lubricating oil product, lowers the production cost, and effectively solves the problem of aggregation between the lubricating oil base oil and the additive particles. The vegetable oil based ionic liquid microemulsion type nano lubricating oil, prepared by the invention, is high in dispersity and high in storage stability, and has excellent heat stability, antifriction property and abrasion resistance.

Owner:SOUTH CHINA UNIV OF TECH

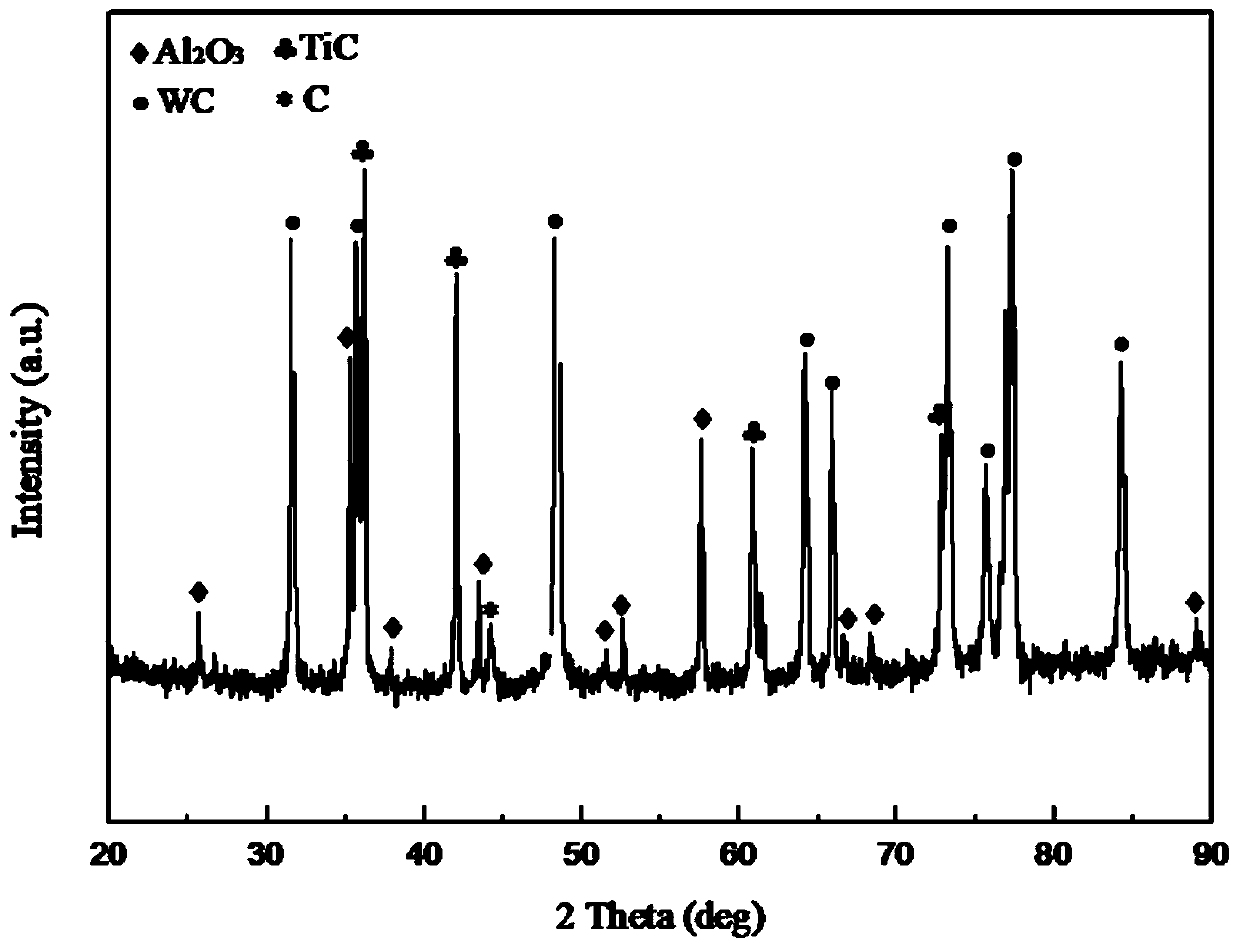

Micro-nano composite ceramic cutter material and preparation method thereof

The invention provides a micro-nano composite ceramic cutter material and a preparation method thereof. The cutter material is prepared with micron aluminum oxide as a matrix, micron tungsten carbideand nano titanium carbide as second-phase materials, graphene as a strengthening and toughening phase, micron magnesium oxide and micron yttrium oxide as sintering aids and micron metal cobalt as a metal binder. Based on interface physical regulation and control and interface stress regulation and control, a reasonable graphene / ceramic strong and weak interface ratio is designed and constructed, so that the aluminum oxide / tungsten carbide / titanium carbide / graphene micro-nano composite ceramic cutter material which is compact in structure, fine in particle and excellent in performance is finally prepared. The material is suitable for high-speed cutting machining of quenched steel, ultrahigh-strength steel and other difficult-to-machine materials, and has good practical application value.

Owner:SHANDONG UNIV

High-temperature gel lubricant composition and preparation method of same

InactiveCN107502407AImprove high temperature resistanceImprove anti-friction and anti-wear propertiesAdditivesTemperature resistanceHot Temperature

The invention discloses a high-temperature gel lubricant composition and a preparation method of same. The composition is composed of, by weight, 0.1-10% of super-molecule gelator and 90-99.9% of basic lubricant oil. The high-temperature gel lubricant composition, as a lubricant for a steel / steel friction pair, can significantly improve tribological property of blank lubricant oil at high temperature, so that bearing capacity of the lubricant oil is greatly increased. The composition has excellent friction- reducing and anti-wearing performance and high-temperature resistance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com