Micro-nano composite ceramic cutter material and preparation method thereof

A ceramic tool and micro-nano composite technology, which is applied in the field of mechanical cutting tool manufacturing, can solve the problems of easy agglomeration of composite materials, unclear strengthening and toughening effect, and affecting the performance of graphene, so as to improve the bending strength and fracture toughness, Reduce heat dissipation time and improve the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

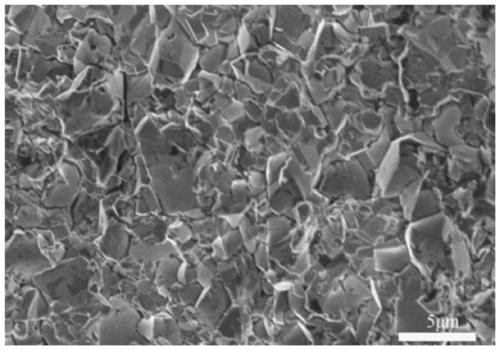

[0033] In another specific embodiment of the present invention, the preparation method of the above-mentioned micro-nano composite ceramic cutting tool material is provided, which specifically includes the following steps:

[0034] Mix the nano-titanium carbide suspension and the graphene suspension, and weigh the Al according to the composition of the raw materials 2 o 3 , WC, MgO, Y 2 o 3 , Co is added to the mixed suspension, and ultrasonic dispersion is continued; the uniformly dispersed mixed suspension is ground, and after drying, a uniformly mixed raw material powder is obtained; the raw material powder is hot-pressed and sintered.

[0035] In yet another specific embodiment of the present invention, the preparation method of the nano-titanium carbide suspension includes: adding nano-titanium carbide to absolute ethanol, and configuring a suspension with a concentration of 1-5% (preferably 2%), Add polyethylene glycol (PEG) after ultrasonic dispersion, adjust the pH ...

Embodiment 1

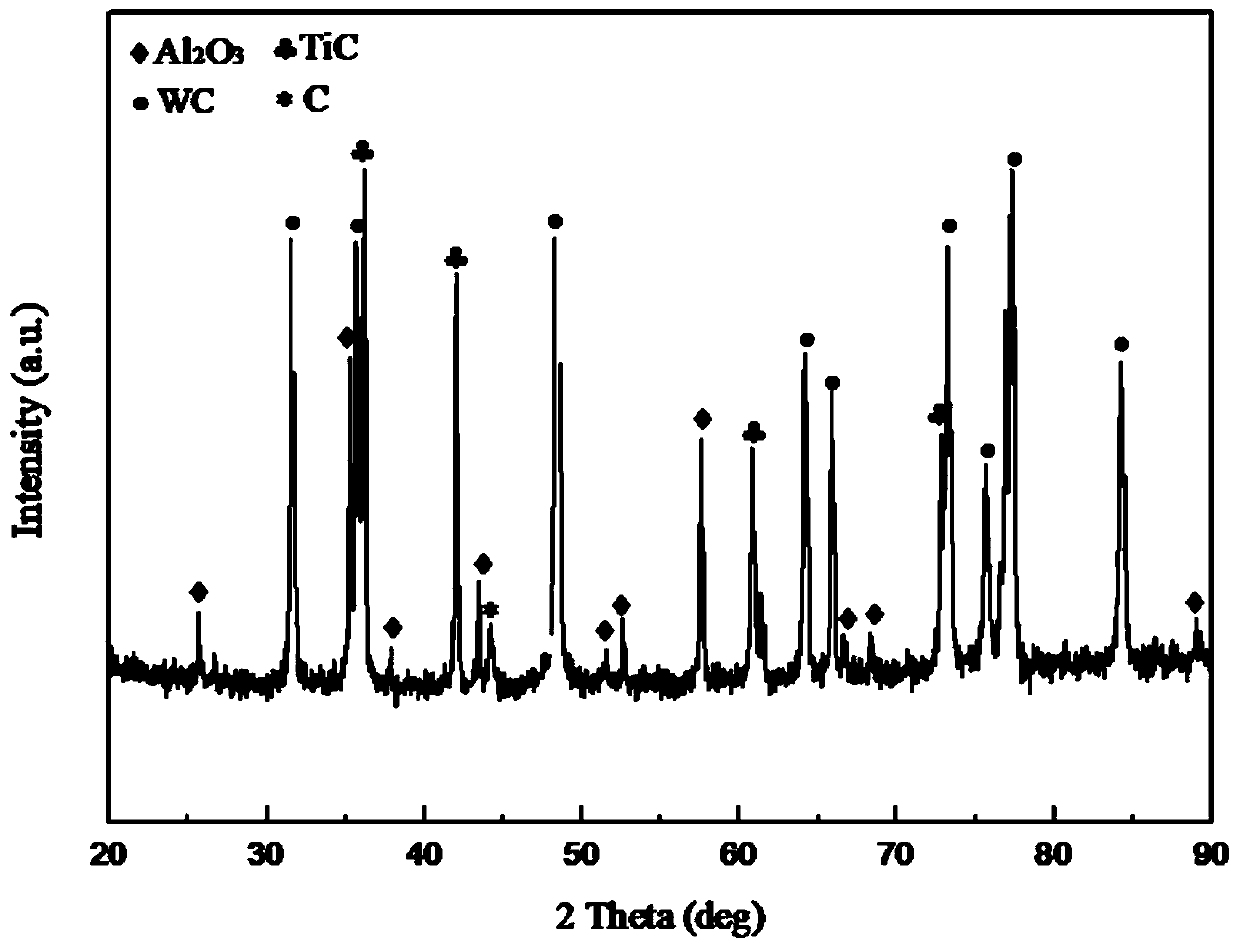

[0045] (1) With 0.5μm Al 2 o 3 , 0.4μm WC, 40nm TiC, 0.5μm MgO, 0.5μm Y 2 o 3 , 1μm Co is the raw material, and the volume fraction of each raw material is: 72% Al 2 o 3 , 18% WC, 6% TiC, 0.5% MgO, 0.5% Y 2 o 3 , 3% Co.

[0046] (2) Add the weighed nano-TiC to absolute ethanol, configure a suspension with a concentration of 2%, and disperse it ultrasonically for 10 minutes; weigh polyethylene glycol (PEG) accounting for 0.5% of the mass fraction of nano-TiC, add Into the nano-TiC suspension, adjust the pH value to 9 with ammonia water and hydrochloric acid, and continue ultrasonic dispersion for 20 minutes to obtain a nano-TiC suspension with good dispersion performance.

[0047] (3) Weigh Al according to the composition of raw materials 2 o 3 , WC, MgO, Y 2 o 3 , Co, added to the dispersed nano-TiC suspension, and continued to ultrasonically disperse for 2 hours to obtain a stable raw material suspension; the dispersed raw material suspension was added to the ball ...

Embodiment 2

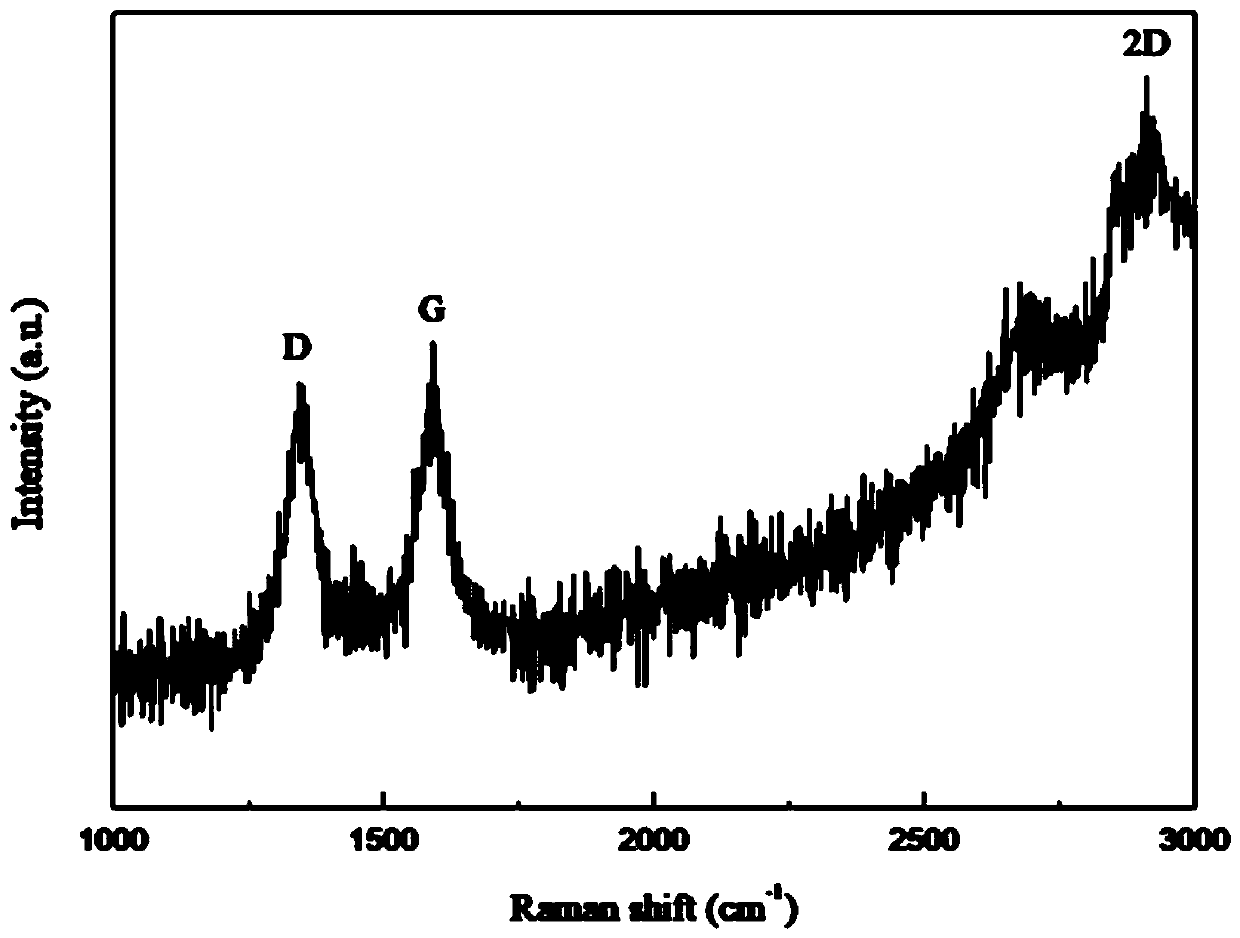

[0051] (1) With 0.5μm Al 2 o 3 , 0.4μm WC, 40nm TiC, 0.5μm MgO, 0.5μm Y 2 o 3 , 1μm Co and single-layer graphene powder (chemical method, thickness: 0.8-1.2nm, sheet diameter: 0.5-5μm) are raw materials, and the volume fraction of each raw material is: 71.75% Al 2 o 3 , 18% WC, 6% TiC, 0.5% MgO, 0.5% Y 2 o 3 , 3% Co, 0.25% graphene.

[0052] (2) Add the weighed nano-TiC to absolute ethanol, configure a suspension with a concentration of 2%, and disperse it ultrasonically for 10 minutes; weigh polyethylene glycol (PEG) accounting for 0.5% of the mass fraction of nano-TiC, add Into the nano-TiC suspension, adjust the pH value to 9 with ammonia water and hydrochloric acid, and continue ultrasonic dispersion for 20 minutes to obtain a nano-TiC suspension with good dispersion performance. Take by weighing the polyvinylpyrrolidone (PVP) that accounts for 60% of graphene quality, join in dehydrated alcohol, be configured into the suspension that concentration is 0.1mg / ml, ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com