Patents

Literature

1461 results about "Machine material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

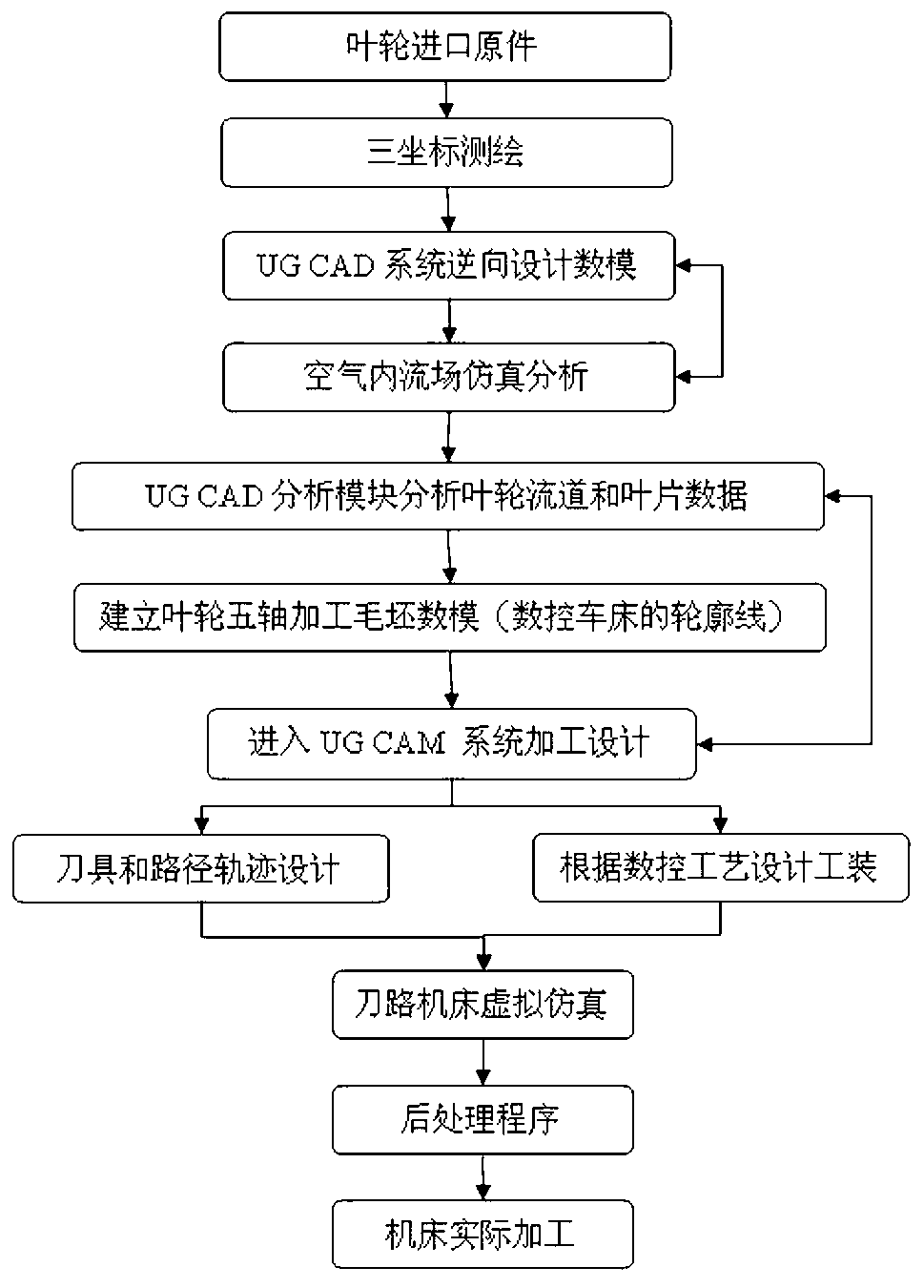

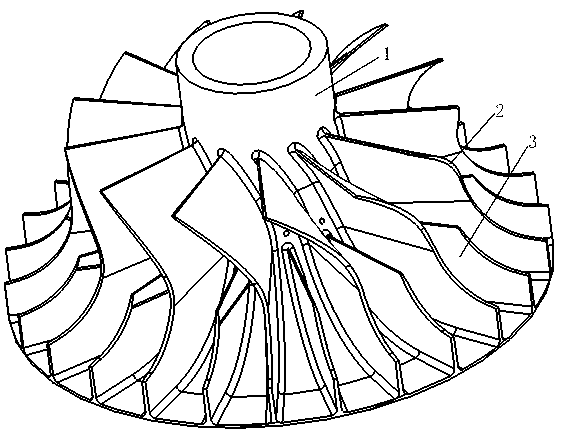

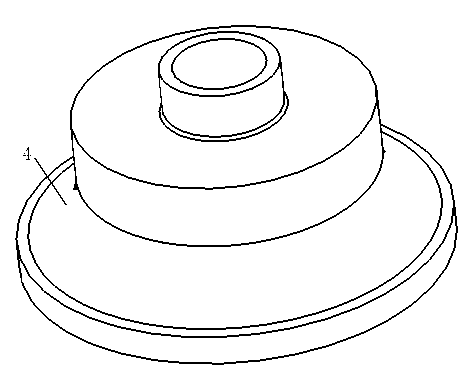

Integral impeller 5-axis machining method based on UG NX system platform

The invention discloses an integral impeller 5-axis machining method based on a UG NX system platform and relates to a technical scheme of a 5-axis numerical control processing technology for an integral impeller researched and developed under a UGNX 7.5 computer-aided design (CAD) system platform. The method comprises using a reversal design technique under the UGNX 7.5 CAD system platform to obtain compressor wheel digifax; acquiring corresponding data from the digifax to establish blank digifax on the digifax according to numerical control technology requirements; selecting a machine tool: using a 5-axis linkage machining center; selecting a cutter according to the geometrical shape and machining materials of an impeller and selecting the cutter with a diameter as large as possible as long as the passage dimension allows; and setting the impeller machining track: UGNX, selecting an appropriate machining method and selecting allowances for rough and finish machining, outputting 5-axis machining center machine tool machining codes for being called by the 5-axis linkage machining center.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

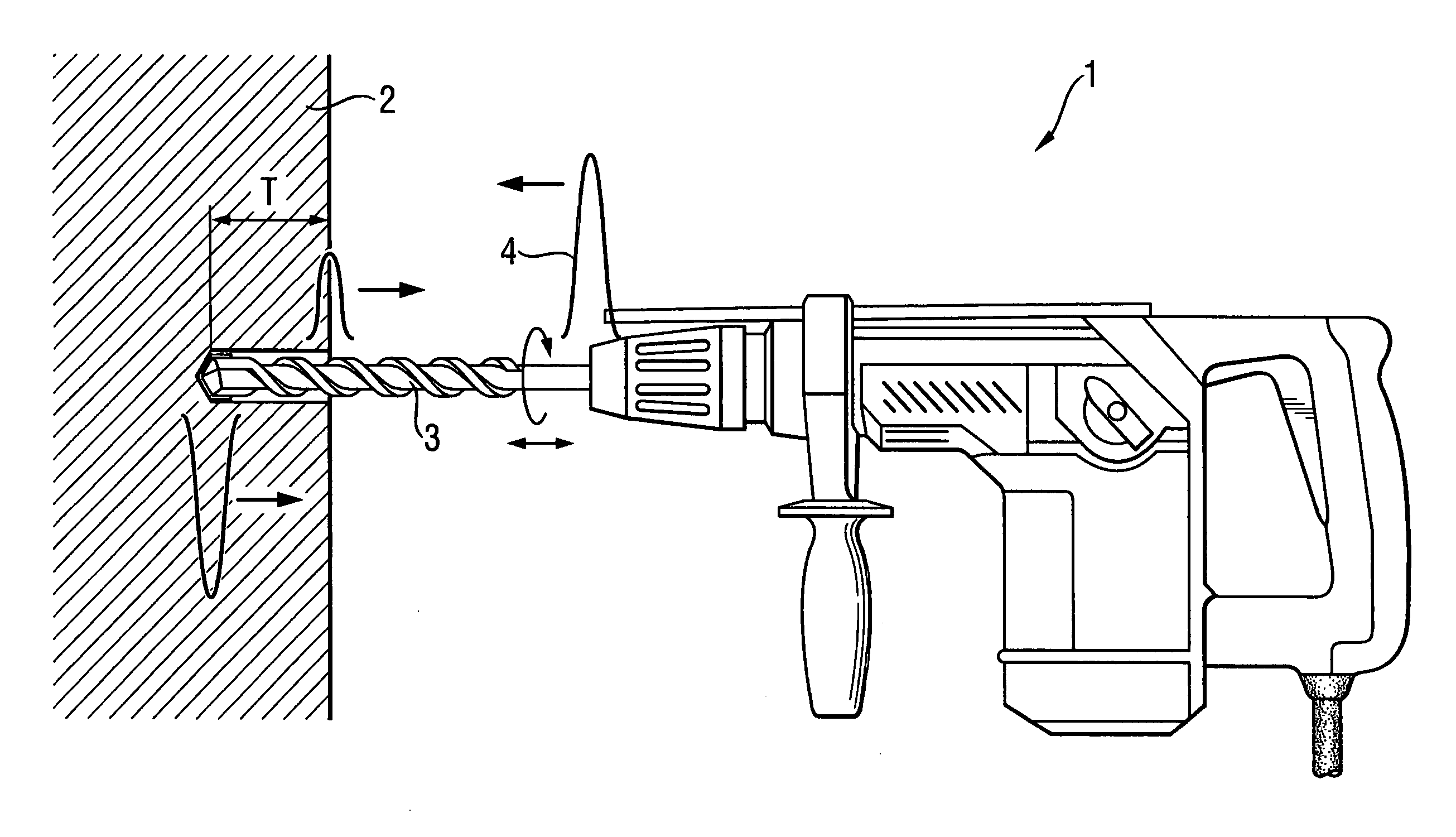

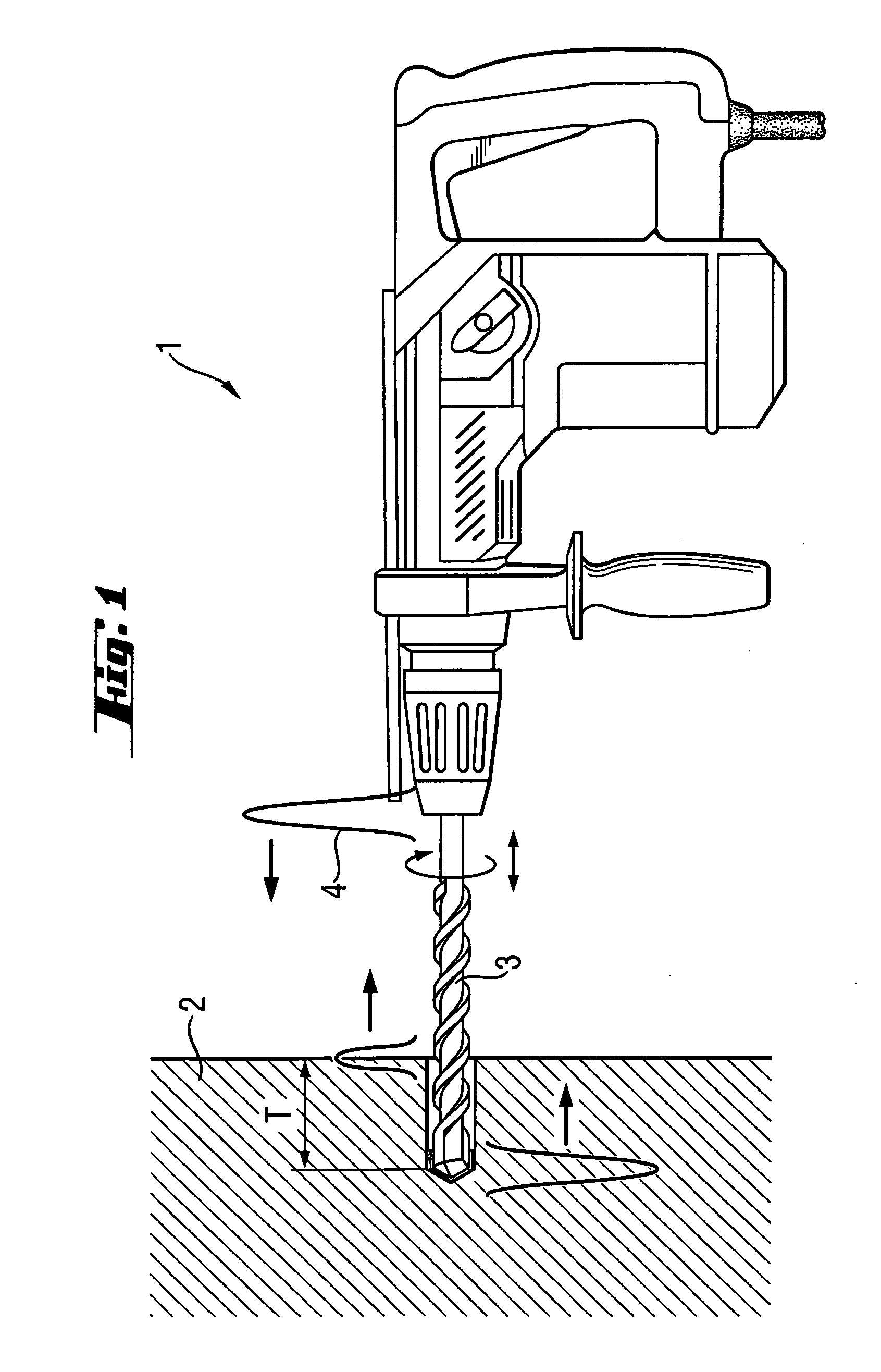

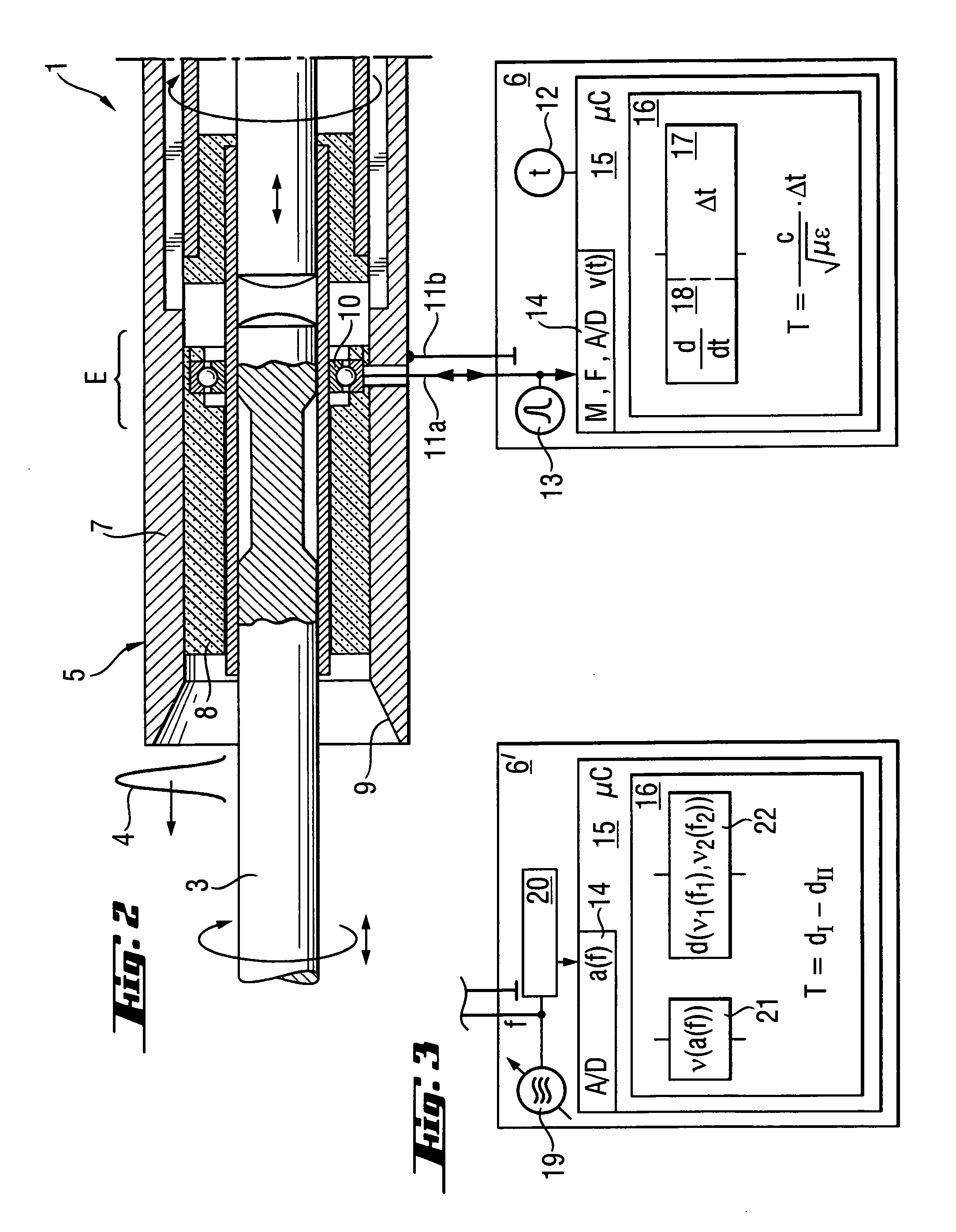

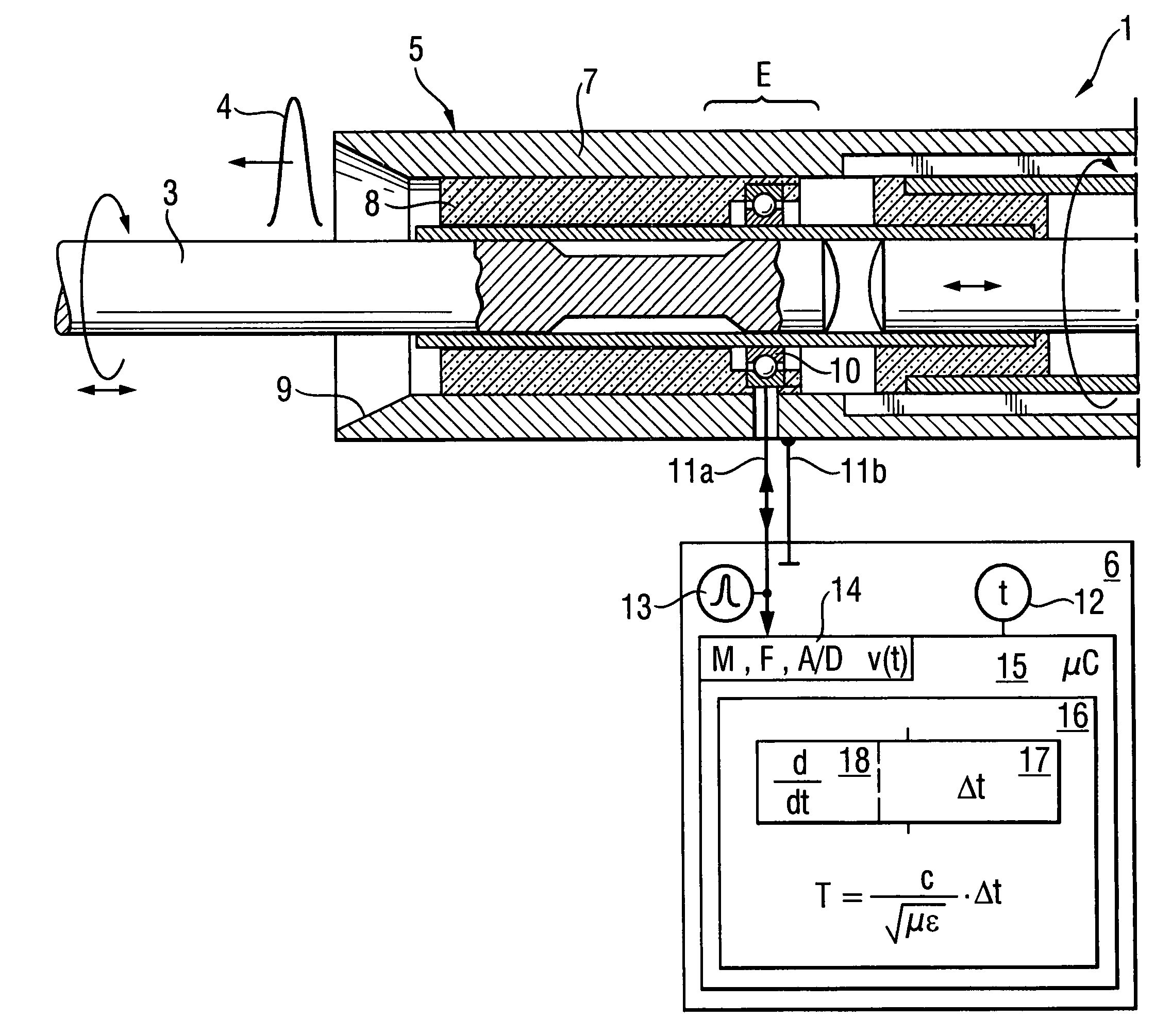

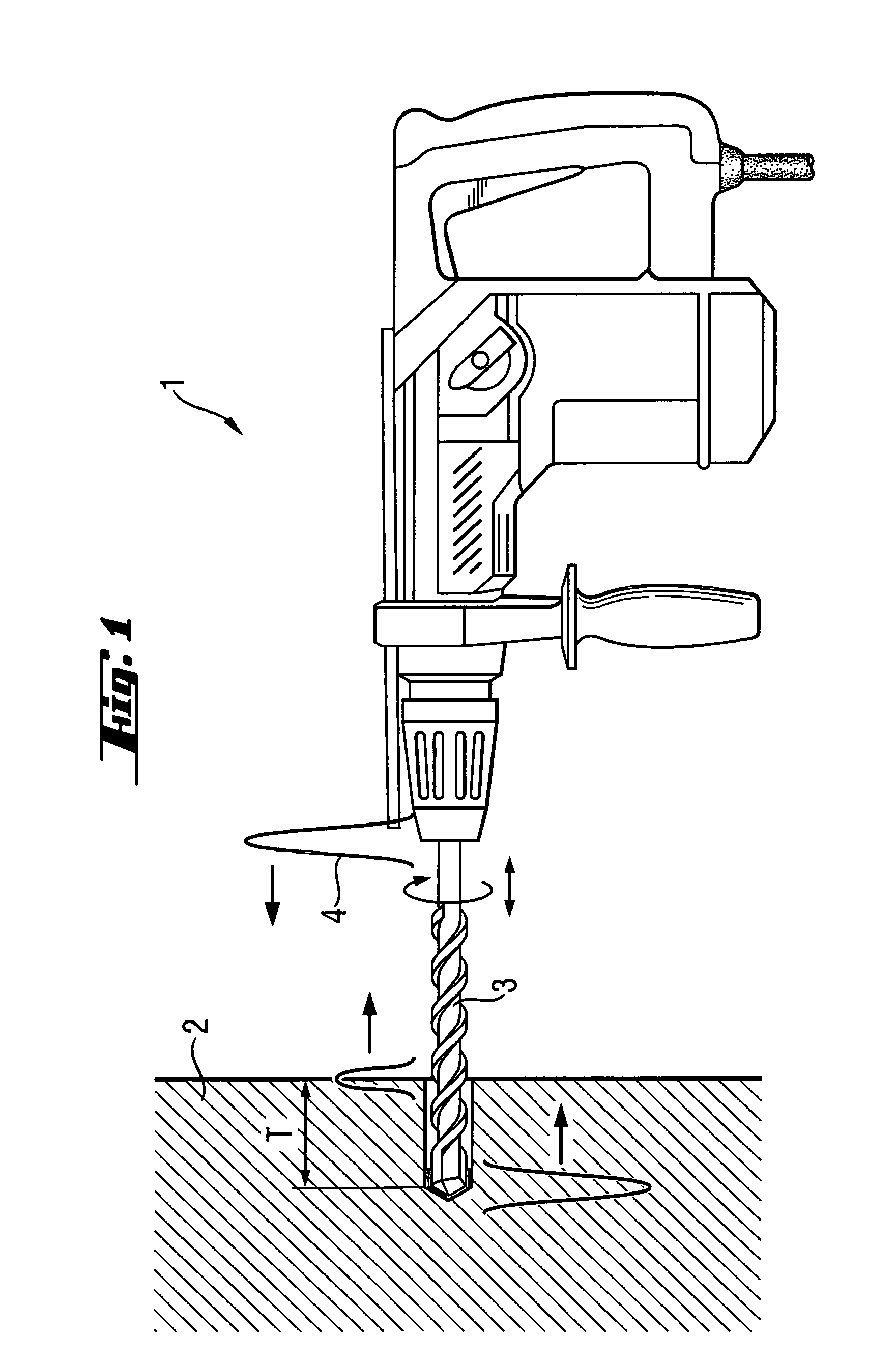

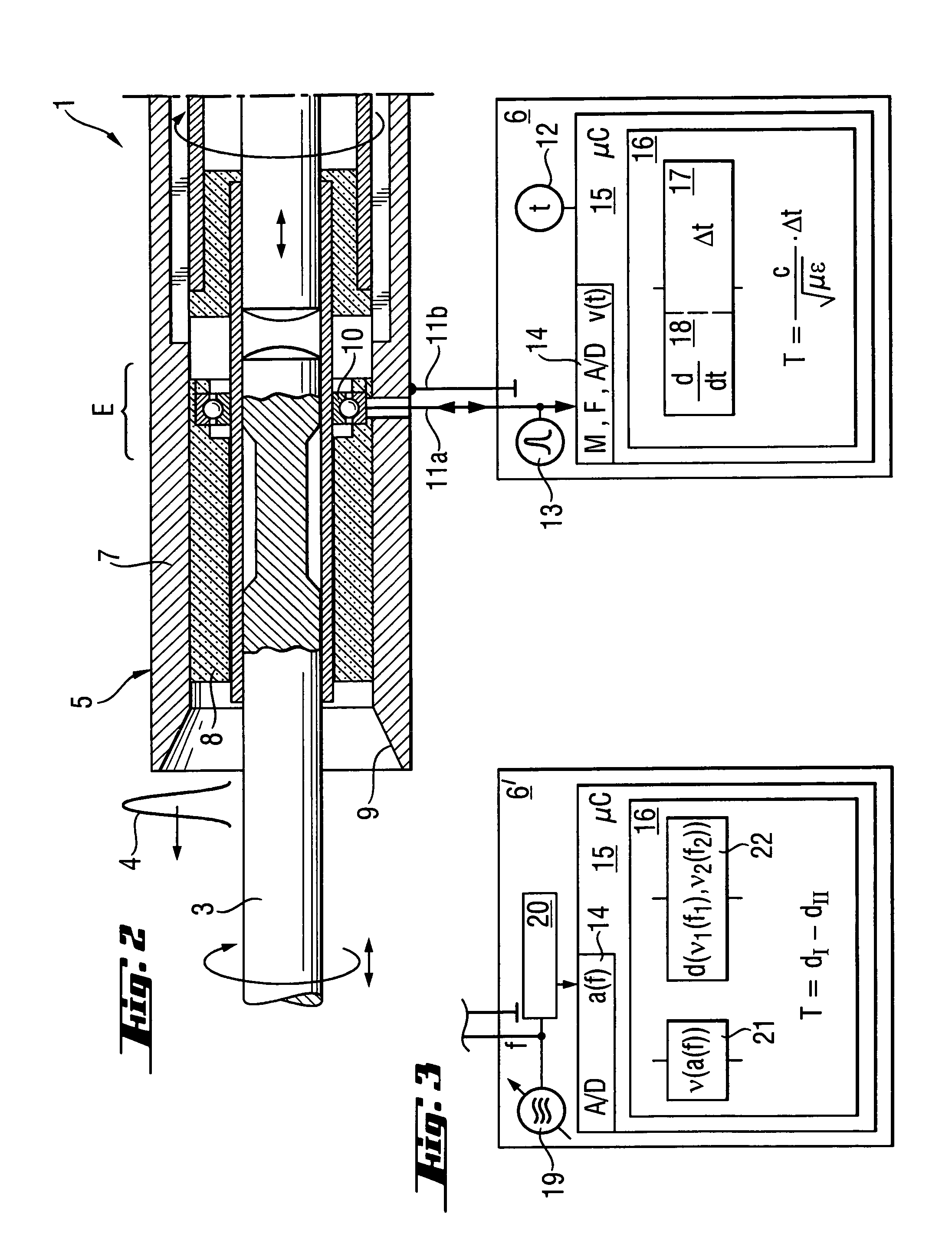

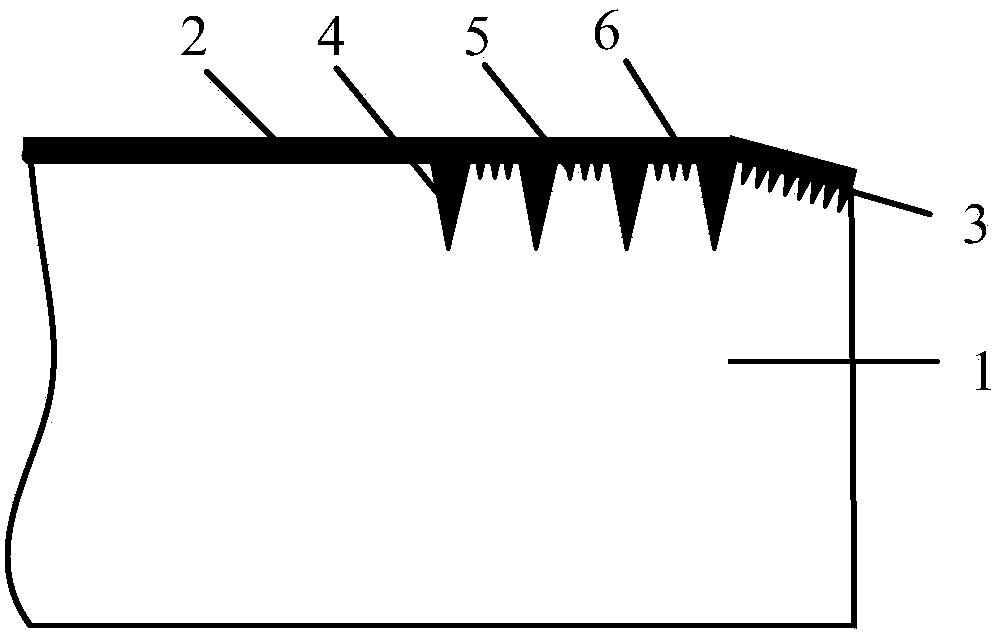

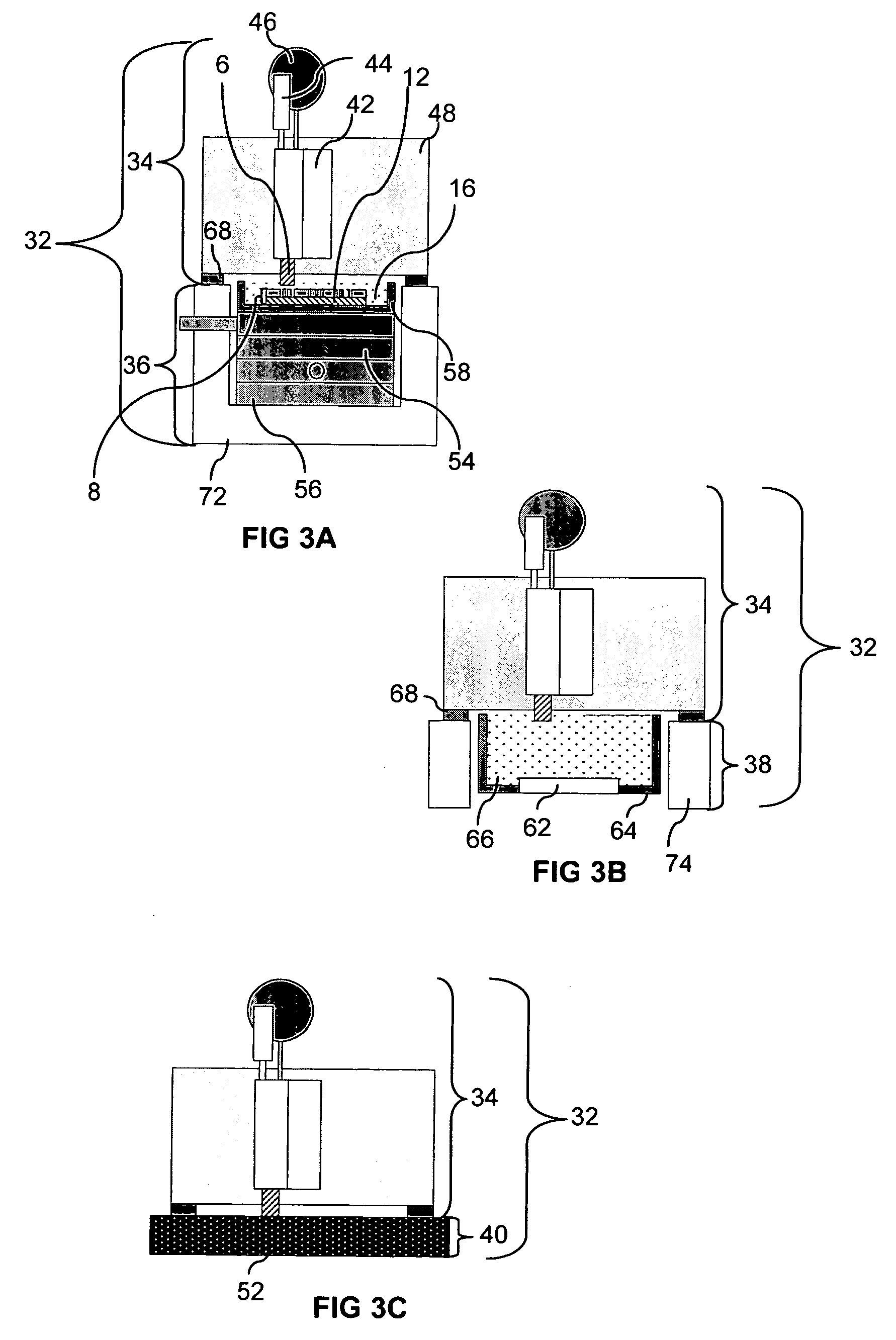

Power tool with measurement of a penetration depth of a working tool

ActiveUS20070035311A1Simple and reliable processConstant characteristic impedanceDrilling/boring measurement devicesThread cutting machinesTransducerEngineering

A power tool (1) for driving a working tool (3) that penetrates at least axially into a to-be-machined material (2), and including a signal processor (6, 6′), and a transducer (5) which is suitable for exciting and detecting a high-frequency electromagnetic wave (4) propagating axially along the working tool (3) and which is connected to the signal processor (6, 6′) that is designed to determine the penetration depth (T) of the working tool (3) into the material (2) based on high-frequency electromagnetic waves (4).

Owner:HILTI AG

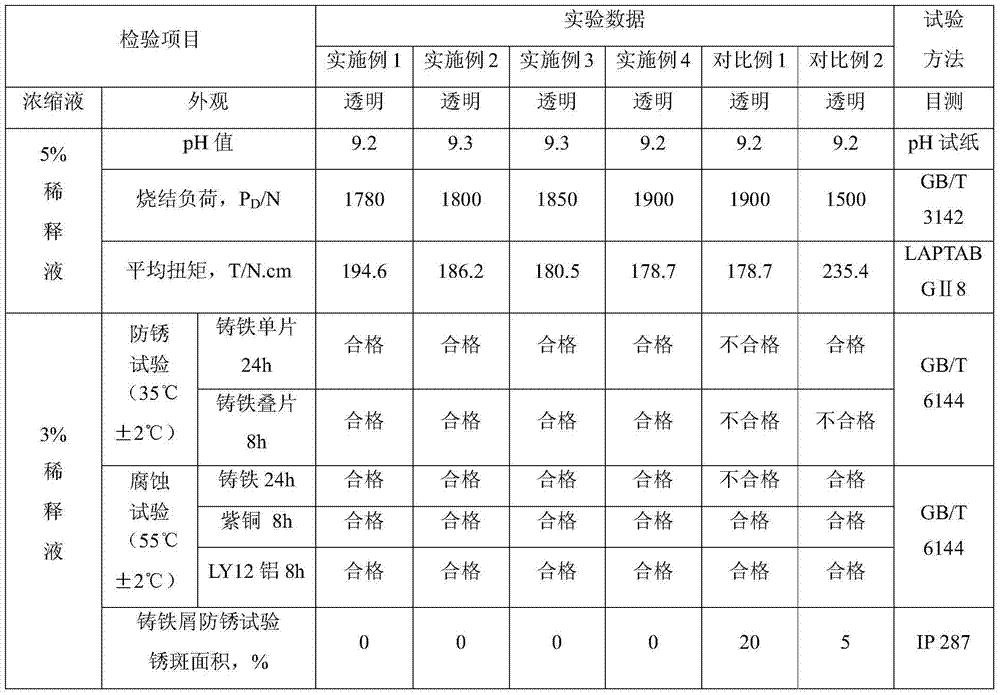

Heavy-load metal machining total synthesis cutting fluid as well as preparation method and application thereof

ActiveCN104277902AImprove the lubrication effectImprove extreme pressure performanceAdditivesMachine partsSuperalloy

The invention belongs to the field of metal machining fluids, and discloses a heavy-load metal machining total synthesis cutting fluid as well as a preparation method and an application thereof. The total synthesis cutting fluid comprises the following components in percentage by weight: 20%-30% of mixed alcohol amine, 6%-9% of anti-rust agents, 4%-6% of special amine, 6%-10% of lubricating agents, 15%-25% of extreme pressure agents, 6%-10% of cosolvents, 1%-2% of water-softening agents, 1%-3% of corrosion inhibitors and the balance of water. The total synthesis cutting fluid disclosed by the invention has excellent lubricating extreme pressure property, can meet the requirement for heavy-load machining, namely reaming, drilling, tapping, threading, broaching, thread machining and the like, of difficult-to-machine materials, namely high-temperature alloy steel, a titanium alloy and the like; a product is green and environment-friendly without containing boron, sodium nitrite, secondary amine, chlorine, phenol, formaldehyde, heavy metals and the like; in addition, the total synthesis cutting fluid disclosed by the invention has excellent anti-rust property, biological stability and machining property, and can enhance the surface quality of a machined part, prolong the service life of a cutter and reduce the rejection rate, thus improving the production efficiency.

Owner:广州国机润滑科技有限公司

Method for manufacturing high-vanadium, high-cobalt high speed steel

ActiveCN101153376ALow priceSimple processHeat treatment process controlQuenching agentsNumerical controlMilling cutter

The invention provides a manufacturing method of high-vanadium high-cobalt high-speed steel, wherein, the composition weight percent of the high-speed steel is as follows: 1.1 percent to 2.18 percent of C, 5.0 percent to 8.0 percent of W, 4.0 percent to 6.0 percent of Mo, 3.0 percent to 5.0 percent of Cr, 1.2 percent to 8.3 percent of V, 6.5 percent to 11.5 percent of Co and the rest, Fe; the process steps of the high-speed steel includes master alloy preparation, spray forming, hot forging, quench tempering treatment, turning, milling and grinding or TiN / AlTiN coating treatment. The invention omits working procedures such as powder sieving, blending, encapsulation and cold and hot isostatic pressing, etc. and does not need costly equipment investment; moreover, the performance of the invention reaches to or even exceeds that of powder high-speed steel, thereby saving process cost and reducing the applied cost of the high-speed steel. The invention can be widely used in various cutters such as cutting tools for making difficult-to-machining material, and is particularly suitable to make cutters with quick-cutting, high hot hardness and long service life such as large-size broaching tool, gear shaver, hob and gear shaping tool for machining gear and various milling cutters used in digital control machine tool, etc.; moreover, the invention also can be used in making mould, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Power tool with measurement of a penetration depth of a working tool

ActiveUS7482819B2Constant characteristic impedanceSimple and reliable processDrilling/boring measurement devicesThread cutting machinesTransducerEngineering

A power tool (1) for driving a working tool (3) that penetrates at least axially into a to-be-machined material (2), and including a signal processor (6, 6′), and a transducer (5) which is suitable for exciting and detecting a high-frequency electromagnetic wave (4) propagating axially along the working tool (3) and which is connected to the signal processor (6, 6′) that is designed to determine the penetration depth (T) of the working tool (3) into the material (2) based on high-frequency electromagnetic waves (4).

Owner:HILTI AG

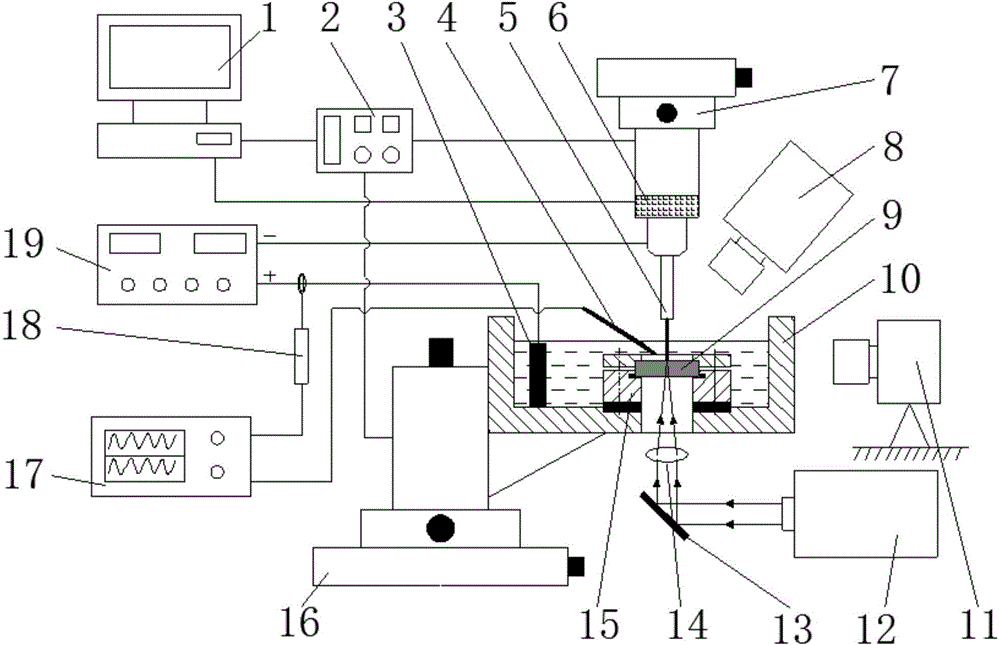

Experimental device for cutting off carbon fiber composite material

InactiveCN103837422ASave spaceThe cutting experiment is orderly and accurateInvestigating machinabilityTemperature controlMaterial removal

The invention provides an experimental device for cutting off a carbon fiber composite material, and belongs to the field of research on hardly machined material cutting devices. The experimental device is provided with experiment functional devices by taking a cutting device as a basic structure, wherein the experiment functional devices comprise a work piece quick assembling-clamping and temperature control device, a high-speed micro-examination device, a temperature and cutting force online measuring device and a dust remover. In the high-speed micro-examination device, a lens is connected with a high-speed camera, the high-speed camera is arranged on a single-axis precision displacement platform pedestal which is arranged on a camera support, a light source is aligned to a cutting area and the high-speed camera is connected with a computer system. The experimental device for cutting off the carbon fiber composite material, which is disclosed by the invention, can effectively realize the observation on a cutting process, precisely measures the temperature and the cutting force in real time, controls the temperatures of a sample and a cutter, and studies on material breakage forms, material removal mechanisms and cutter abrasion mechanisms under different cutting conditions, so as to provide experimental support for the explanation of the carbon fiber composite material cutting basic theory.

Owner:DALIAN UNIV OF TECH

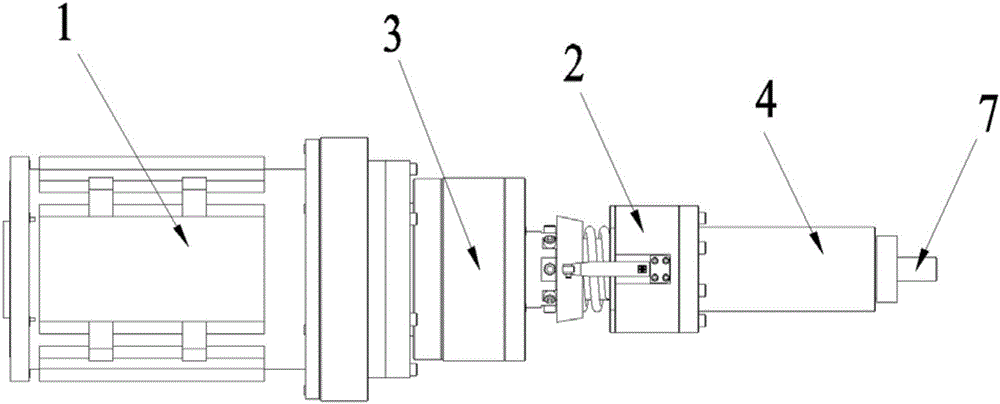

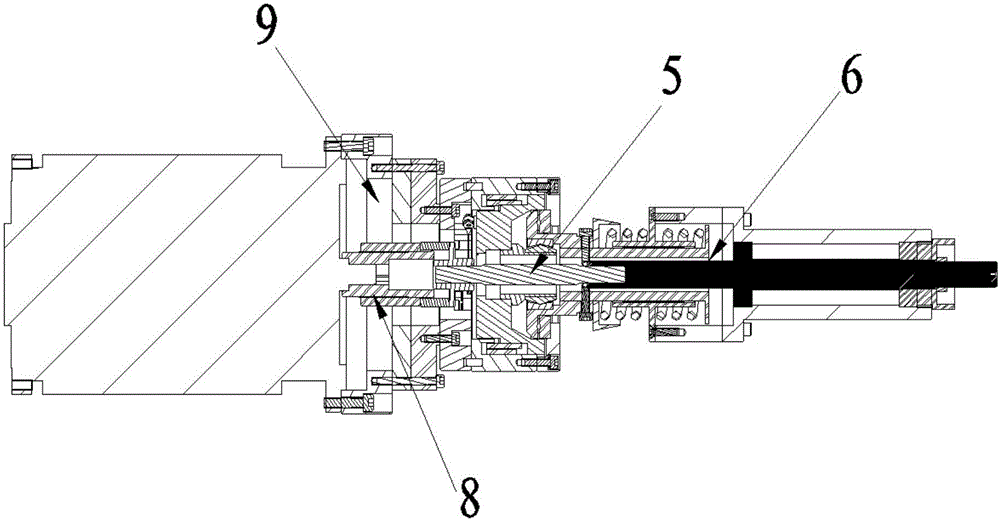

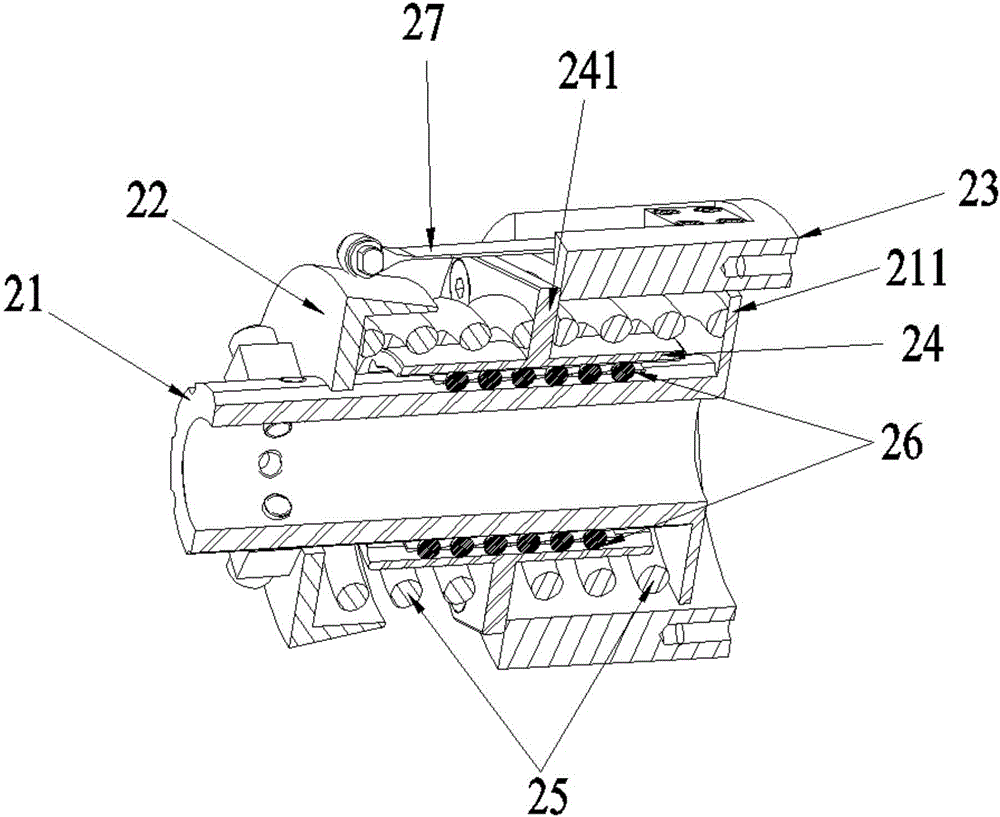

Portable spiral hole milling device and machining method

ActiveCN103192125AAccurate adjustmentImprove processing qualityAutomatic control devicesFeeding apparatusFiberTitanium alloy

The invention provides a portable spiral hole milling device and a machining method, which belong to the technical field of spiral hole milling machining, and are applied to new materials such as carbon fiber composites, aluminum alloy, titanium alloy and other hard machined materials. The portable device consists of a cutter self-rotation mechanism, a revolution mechanism, a radial shifting mechanism, an axial feeding mechanism and a machining locating mechanism, wherein a main shaft of the cutter self-rotation mechanism is a mechanical main shaft and is provided with four shaft necks in different shapes, and the center O1 of the axial line of a right-end shaft neck of the main shaft deviates from the center O of the axial line of a main body shaft neck of the main shaft. The portable device is located by a driller template and a fixed bushing in a combination manner; when machining positions are changed, the process is simple and the location is precise; and meanwhile, the portable device has enough stability and rigidity during machining. According to the portable device disclosed by the invention, the end surfaces of a worm wheel and a worm rod for regulating eccentricity are respectively provided with an index plate and an indicator for indicating the eccentricity, so that the regulation of the eccentricity is more accurate and visual.

Owner:DALIAN UNIV OF TECH

Preparation method for laser cladding soft and hard composite coating self-lubricating cutter

InactiveCN103522652AImprove toughnessHigh surface hardnessMetallic material coating processesMetal layered productsNano al2o3Hardness

The invention belongs to the field of machinery cutting cutter manufacturing, and relates to a preparation method for a laser cladding soft and hard composite coating self-lubricating cutter. A rake face coating of the cutter is a multi-layer structure. Firstly, a hard coating of nano Al2O3 ceramic or an ultrafine cemented carbide, etc. is clad on the rake face of the cutter by utilization of a CO2 laser synchronous feeding manner, and then a self-lubricating soft coating is clad by utilization of nickel-covered MoS2 powder or nickel-covered WS2 powder. The cutter has characteristics of good toughness, high hardness, a self-lubrication function, and the like. During a drying cutting process, the hard coating bears loads and the rake face self-lubricating soft coating has low shearing strength, thus reducing friction between the cutter and chips, reducing the cutting temperature and the cutting force, and therefore cutter abrasion is reduced. The cutter can be widely used for dry cutting and cutting machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

Apparatus and method of cryogenic cooling for high-energy cutting operations

InactiveUS20050011201A1Turning machine accessoriesLighting and heating apparatusProduction rateHigh energy

A cryogenic fluid jet is used in an apparatus and a method for remote cooling of a cutting tool engaged in machining a workpiece under high-energy conditions, such as high-speed machining, hard-turning, cutting of difficult to machine materials, and combinations thereof. The apparatus and method use a stabilized, free-expanding cryogenic fluid jet having a pulse cycle time less than or equal to about 10 seconds. The apparatus and method increase the cleanliness of machined parts and chips and machining productivity of hard but brittle tools, including but not limited to tools which should not be cooled with conventional cooling fluids.

Owner:AIR PROD & CHEM INC

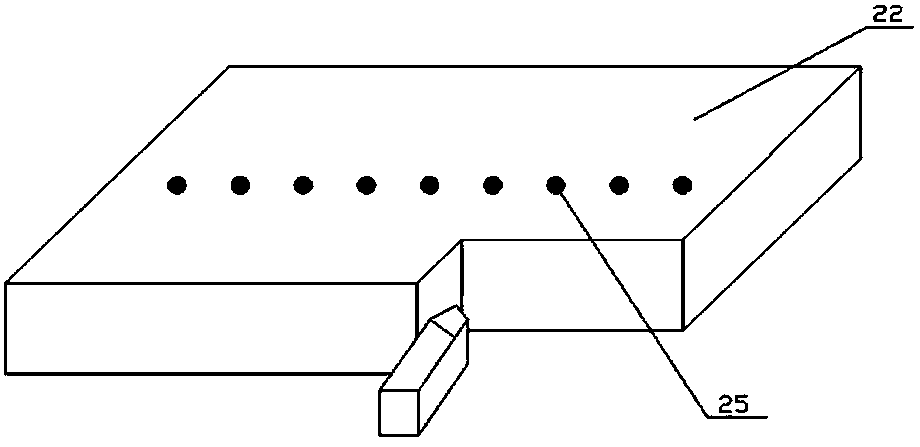

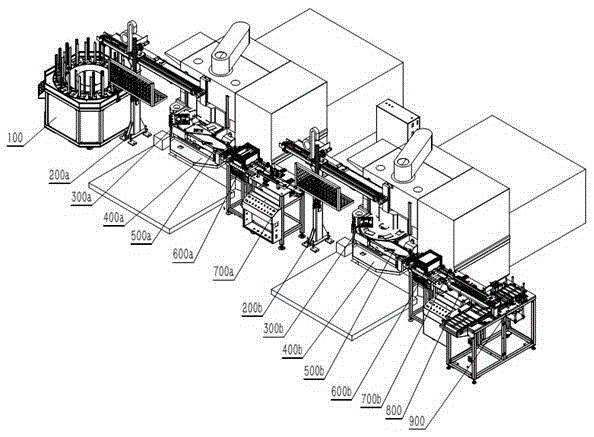

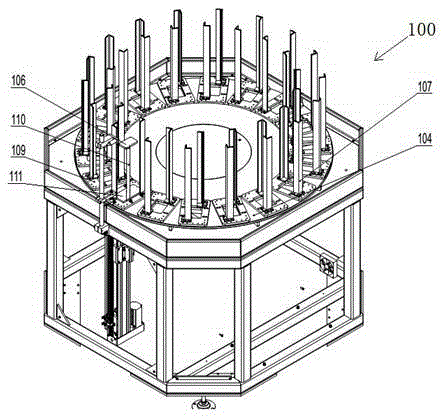

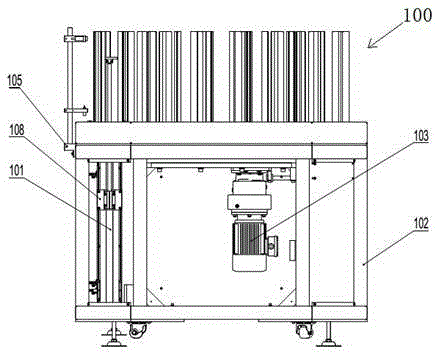

Full-automatic double-end-face grinding production line

ActiveCN105382650AGap adjustmentLow processing and manufacturing costsGrinding feedersPlane surface grinding machinesProduction lineManipulator

The invention discloses a full-automatic double-end-face grinding production line. The production line is arranged in a straight line and sequentially comprises a feeding mechanism, a feeding mechanical arm, a first double-end-face grinding machine, a first transfer conveying belt, a first washing mechanism, a first detecting device, a transfer mechanical arm, a second double-end-face grinding machine, a second transfer conveying belt, a second washing mechanism, a second detecting device, a discharging mechanical arm and a discharging mechanism, wherein the first double-end-face grinding machine is provided with a first grinding machine material drop plate which is engaged with the feeding mechanical arm; the second-end-face grinding machine is provided with a second grinding machine material drop plate which is engaged with the transfer mechanical arm. The full-automatic double-end-face grinding production line disclosed by the invention can be used for grinding a wide range of materials, is capable of implementing feeding, grinding, washing, detection and discharging of a work piece material by one time, is high in automation degree and has the effects of guaranteeing the machining quality, reducing the rejection rate, also greatly alleviating the labor strength, reducing the labor and lowering the machining cost and the manufacturing cost for enterprises.

Owner:HUNAN YUHUAN INTELLIGENT EQUIP CO LTD

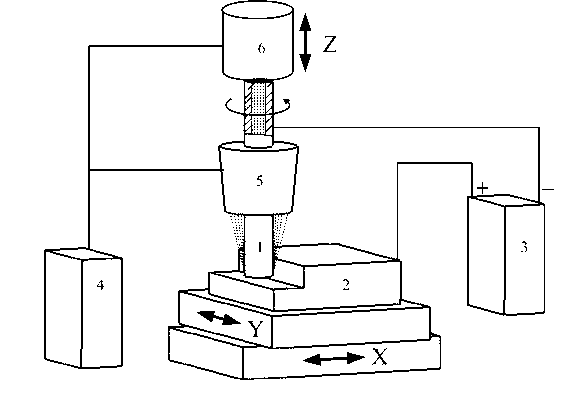

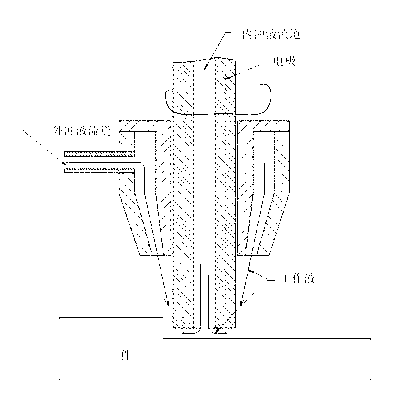

High-instantaneous-energy-density electric spark high-speed milling method

InactiveCN103008802AGood removal effectEfficient processingElectrical-based machining electrodesWorking fluidCombined method

The invention relates to a high-instantaneous-energy-density electric spark high-speed milling method, which belongs to the field of machining. The method comprises the following steps of: connecting a rotary rod-like electrode with an inner flushing fluid hole with a negative electrode of a power supply, connecting a to-be-machined workpiece with a positive electrode of the power supply and melting to remove the workpiece material by utilizing high-instantaneous-energy-density spark discharge between the electrodes and the workpiece in a machining process; discharging molten material out of a discharge gap by working fluid which flows at a high speed; and cooling the machined workpiece. According to the method, by utilizing high-instantaneous-energy-density spark discharge and a high-pressure forced inner flushing fluid and low-pressure outer flushing fluid combined method, the stability and the high efficiency of machining are realized, and high-efficiency machining on any conductive material, including conventional difficult-to-machine materials such as engineering ceramic with weak conductivity and high-temperature alloy, can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

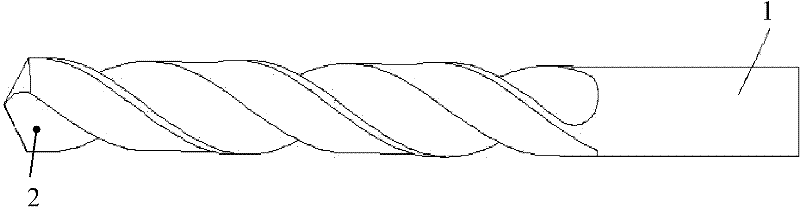

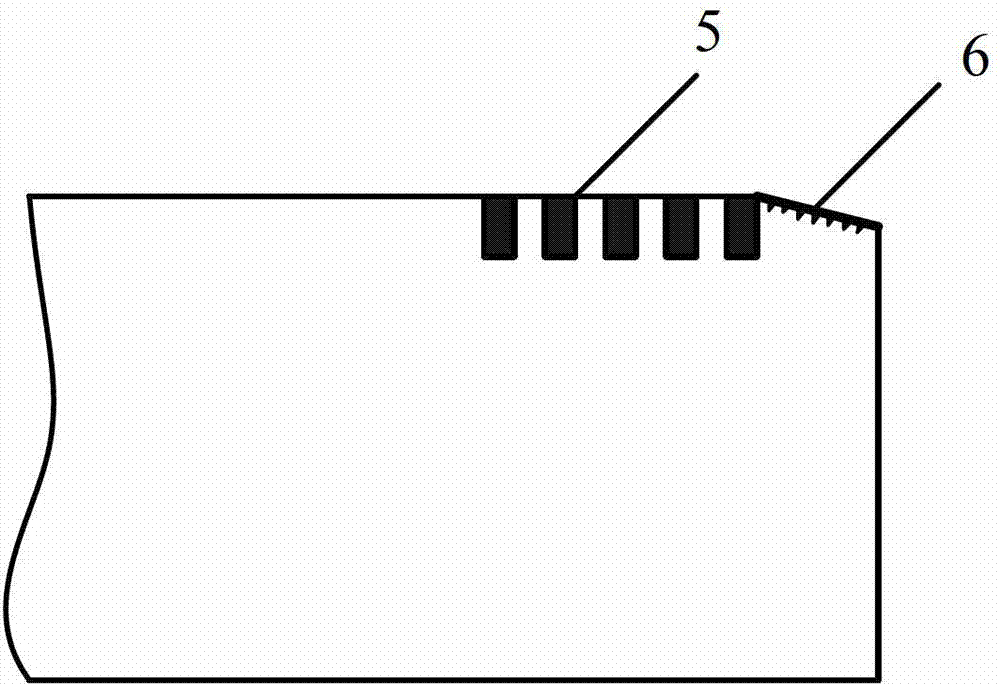

Micro-texture self-lubricating drilling bit and manufacturing method thereof

InactiveCN102189287AExtend your lifeAvoid pollutionTransportation and packagingTrepanning drillsManufacturing technologyEngineering

The invention belongs to the technical field of mechanical cutting tool manufacturing, and in particular relates to a micro-texture self-lubricating drilling bit and a manufacturing method thereof. A knife-chipping contact area of the rack face of the micro-texture self-lubricating drilling bit is provided with a plurality of micro-textures which are filled with a solid lubricant; during dry drilling, under the action of high temperature, the solid lubricant in the micro-textures is rapidly softened and is applied to the rack face of the drilling bit; a continuous solid lubricating layer is formed on the knife-chipping contact area of the rack face of the drilling bit, thereby being capable of preventing bonding, decreasing friction, reducing abrasion and prolonging the service life of the drilling bit. The micro-texture self-lubricating drilling bit can be widely applied to the drilling and machining of dry-type drilling and difficulty-machined materials, can overcome the environmental pollution caused by cutting fluid, realizes clean production and reduces the cost.

Owner:SHANDONG UNIV

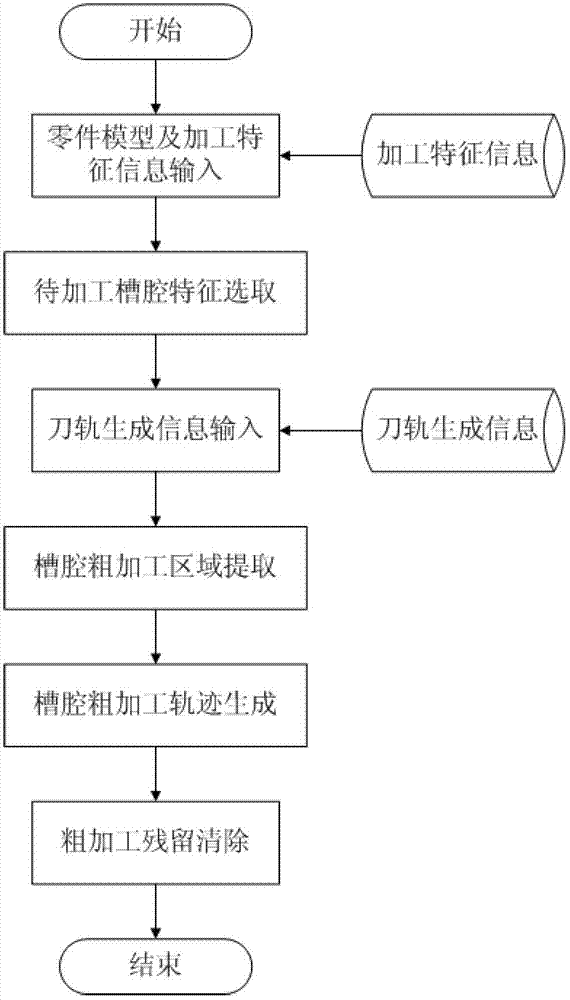

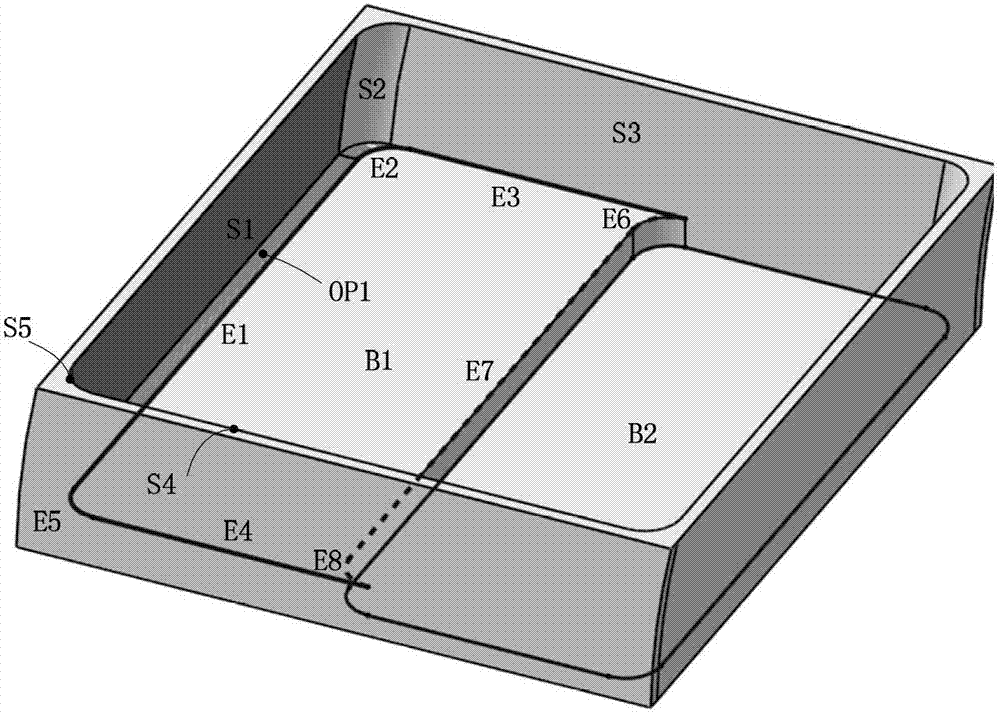

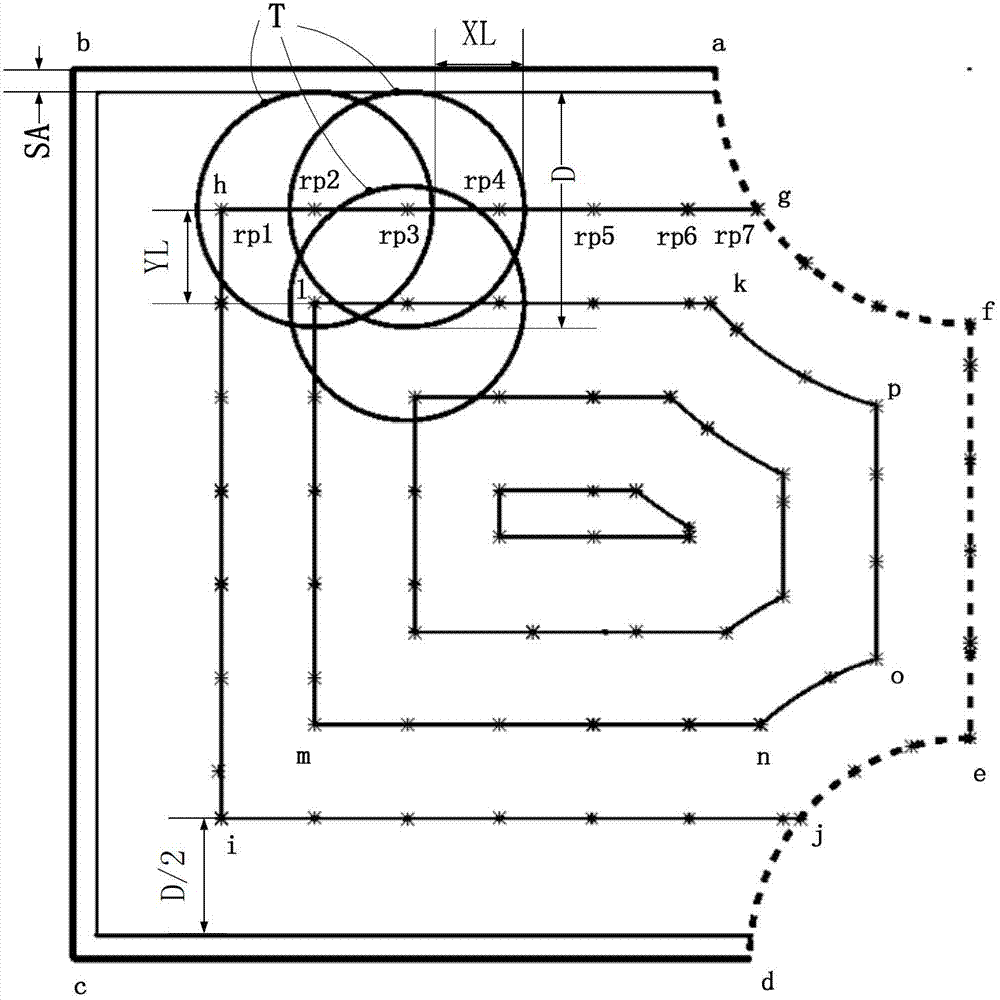

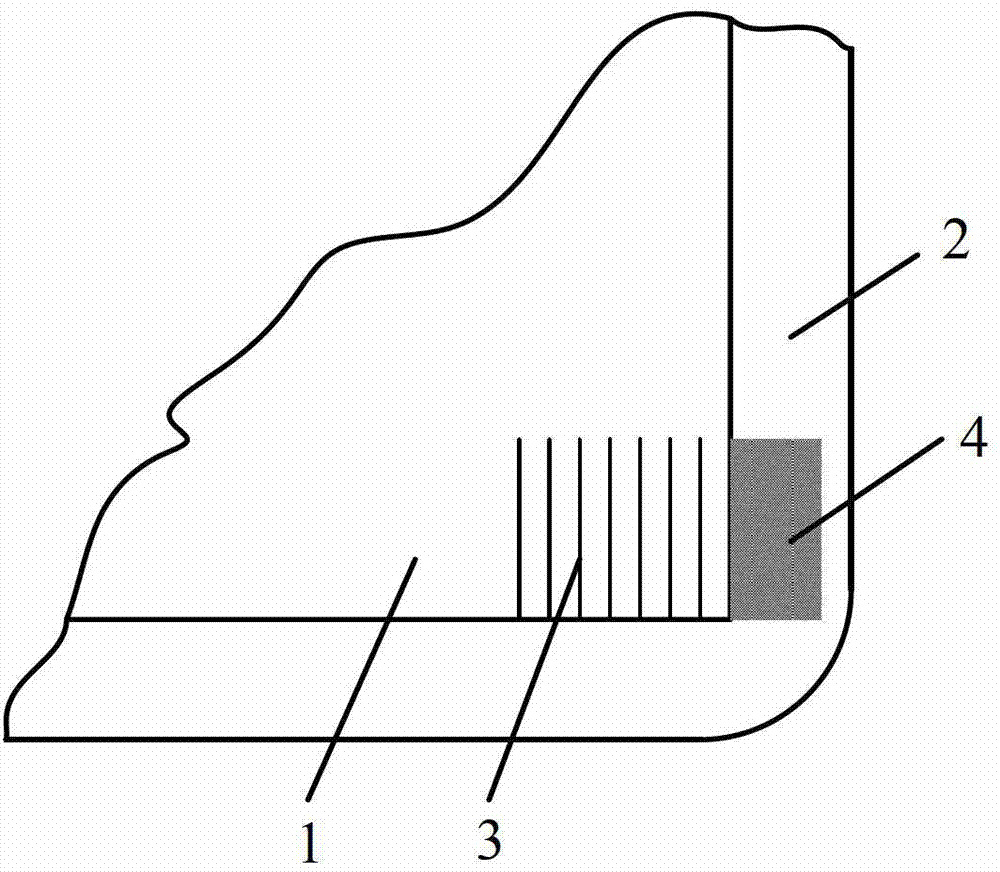

Cavity-characteristic-based high-efficiency rough machining method of aircraft structural part

ActiveCN102922013AReduce lossImprove efficiencyAutomatic control devicesFeeding apparatusCamComputer science

The invention discloses a cavity-characteristic-based high-efficiency rough machining method of an aircraft structural part, which belongs to the technical field of CAD / CAPP / CAM (Computer Aided Design / Computer Aided Process Planning / Computer Aided Manufacturing). The method is characterized by comprising the following steps of: firstly, performing preprocessing such as input of a part and read-in of characteristic information of the part; selecting characteristic of a cavity to be subjected to rough machining, automatically generating a cavity rough machining region according to information such as rough machining margin, diameter of a tool and cutting depth of the tool, and calculating a plunge milling tool site for rough machining of the cavity; and finally, generating a plunge milling rough machining track and a saw tooth residue clear track according to a set feeding strategy. By utilization of the method, rough machining of the aircraft structural part is performed, so that the rough machining efficiency of the aircraft structural part can be greatly improved, the loss of the tool is reduced, and the cost is saved. The method has great application and promotion prospect in rough machining of a difficult-to-machine material of the aircraft structural part.

Owner:SUZHOU MACHINING PRECISION ELECTRONICS

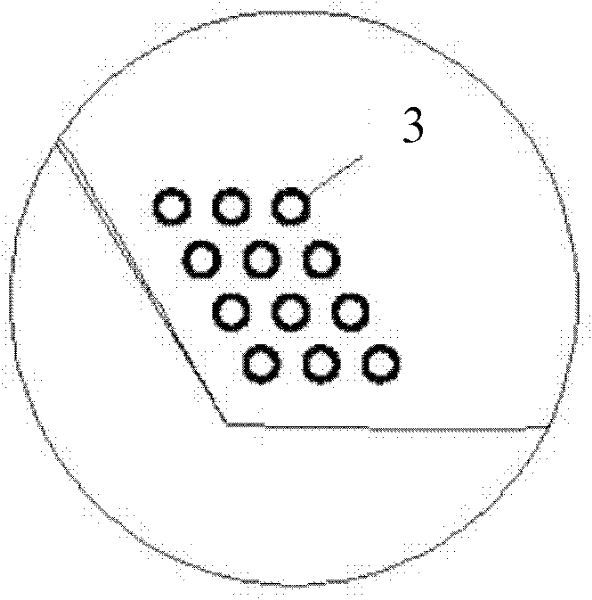

WS2/Zr soft coating micro-nano composite texture ceramic cutting tool and preparing method thereof

InactiveCN104014828AHigh hardnessImprove cutting performanceVacuum evaporation coatingSputtering coatingMicro nanoMicrometer

The invention belongs to the field of mechanical cutting tool manufacturing, and relates to a preparing method for a WS2 / Zr soft coating micro-nano composite texture ceramic cutting tool. Base materials of the cutting tool are ceramic. The method comprises the steps that firstly, the laser machining technology is adopted to machine micrometer textures of different morphologies and sizes on the front tool face of the ceramic cutting tool, then the laser machining technology is adopted to machine nanometer textures on a negative chamfer and the front tool face, and finally the medium frequency magnetron sputtering deposition plus multi-arc ion plating method is adopted to deposit a WS2 / Zr soft coating on the surface of the cutting tool, wherein the WS2 / Zr soft coating is arranged on the surface of the cutting tool, and a Zr transition layer is arranged between the soft coating and a base body. According to the ceramic cutting tool, friction between tool chips can be effectively reduced during cutting, the cutting force and the cutting temperature are reduced, and the abrasion resistance capacity of the cutting tool is improved, so that the service life of the cutting tool is prolonged. The ceramic cutting tool can be widely applied to dry cutting and cutting machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

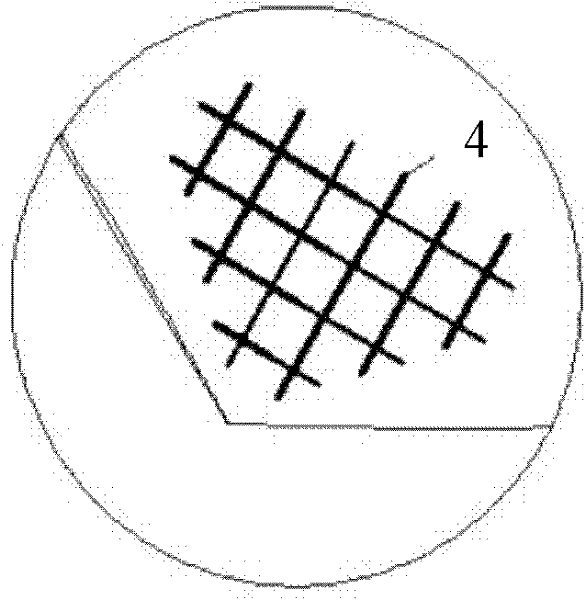

Micro-nano composite texture self-lubricating ceramic tool and manufacture method thereof

InactiveCN103028746AExtended service lifeReduce frictionTurning toolsLaser processingManufacturing technology

The invention belongs to the technical field of manufacture of mechanical cutting tools, and in particular relates to a micro-nano composite texture self-lubricating ceramic tool and a manufacture method thereof. According to the micro-nano composite texture self-lubricating ceramic tool, a micron level texture is processed on a front cutter surface by adopting a laser processing technology, a nano level texture is processed on a negative chamfered edge, a solid lubricating agent is filled in the micron level texture and the nano level texture respectively, during chip dry cutting, the dual functions of the micro-nano composite texture and the solid lubricating agent can realize that the friction is reduced and the cutting force and the cutting temperature are reduced, and thus the purposes of preventing adhesion, reducing friction and abrasion and prolonging the service life of the tool can be achieved. The micro-nano composite texture self-lubricating ceramic tool can be widely applied to high-speed dry cutting and cutting of difficult-to-machine materials, can overcome the environment pollution caused by cutting solution, realizes clean production, and is reduced in cost.

Owner:SHANDONG UNIV

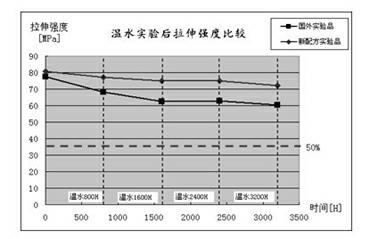

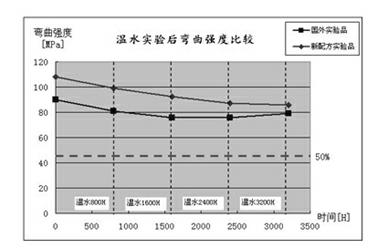

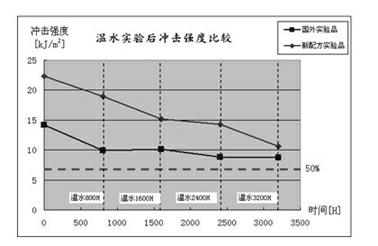

Glass fiber reinforced polypropylene material and preparation method thereof

ActiveCN102181096AHigh thermal oxidation resistanceImprove hydrolysis resistanceThermal ageingWarm water

The invention discloses a glass fiber reinforced polypropylene material and a preparation method thereof, and belongs to the technical field of organic materials. The glass fiber reinforced polypropylene material comprises polypropylene copolymer and / or polypropylene homopolymer, compatilizer, glass fibers, antioxidant, light stabilizer and lubricating agent. The preparation method of the glass fiber reinforced polypropylene material comprises the following steps of: 1) weighing; 2) mixing; and 3) performing melt extrusion, drawing and granulating. The invention has the advantages that: 1) the prepared composite material has excellent hydrolysis resistance and high thermal oxidation resistance; 2) the prepared composite material has good mechanical property, and is suitable to be used as a drum washing machine material; 3) the preparation process is simple, and the glass fiber content is easily controlled; and 4) the anti-ageing time (warm water 800H + thermal ageing) of the prepared composite material meets the using requirement of a drum washing machine.

Owner:PANASONIC APPLIANCES CHINA CO LTD +1

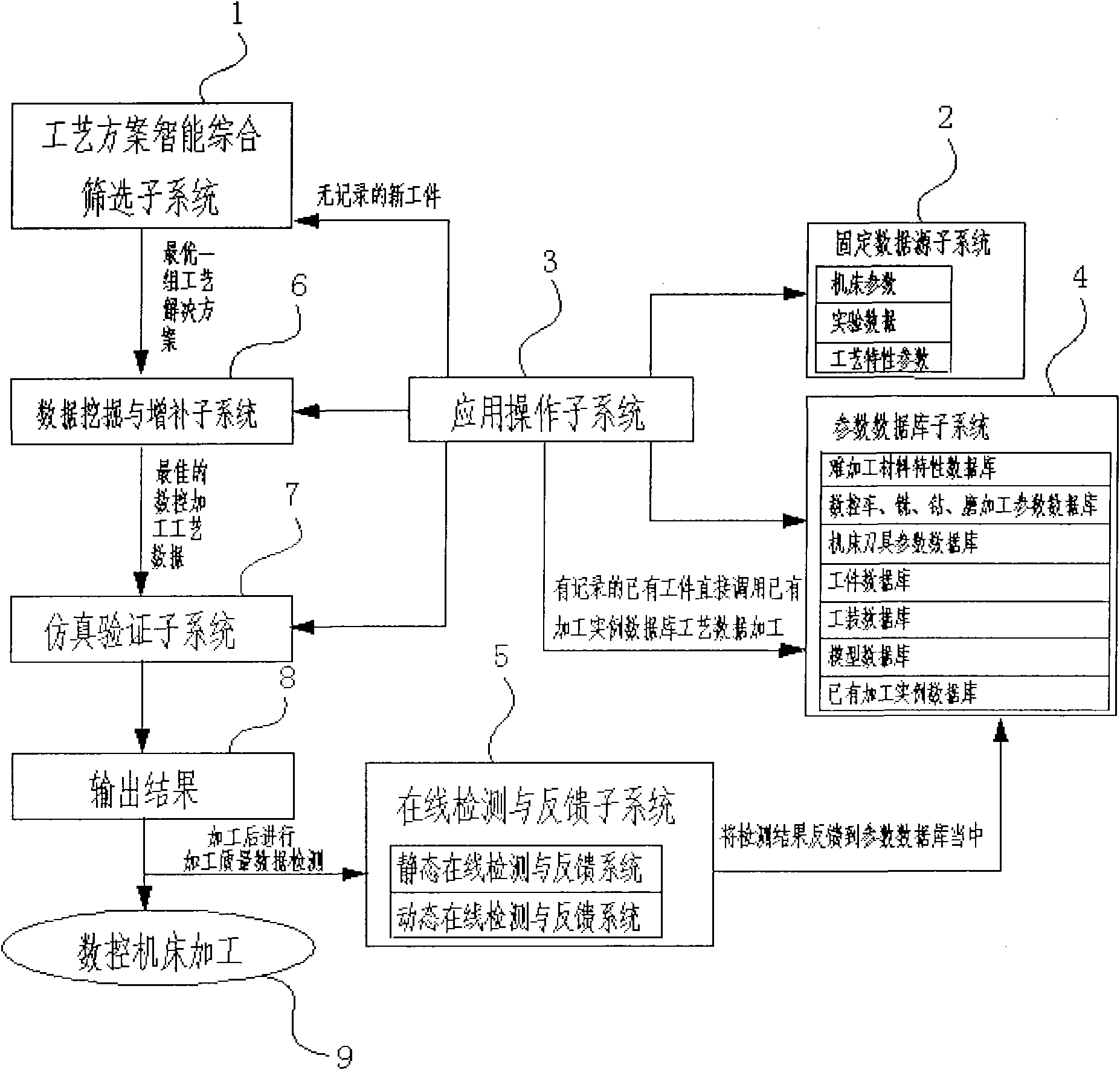

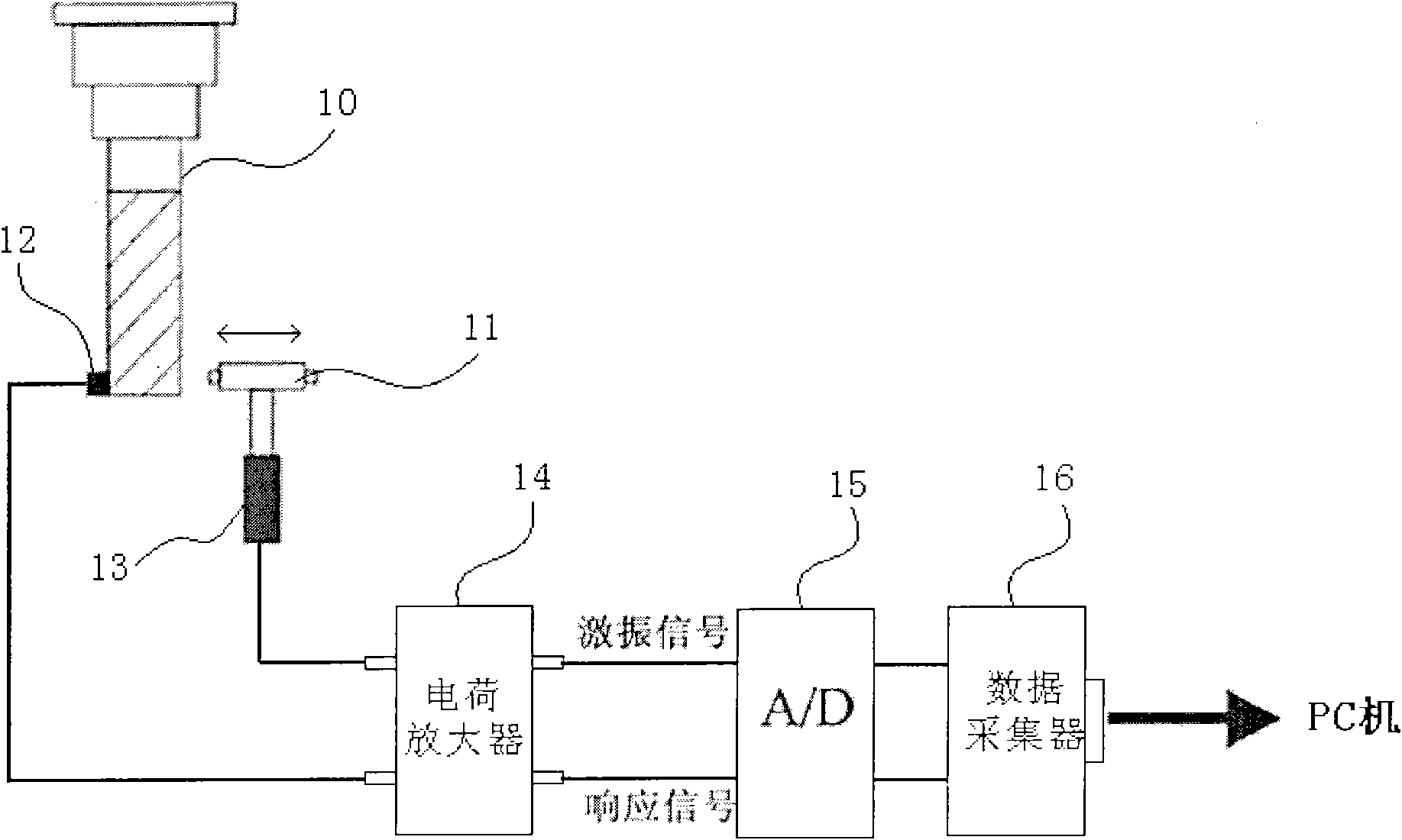

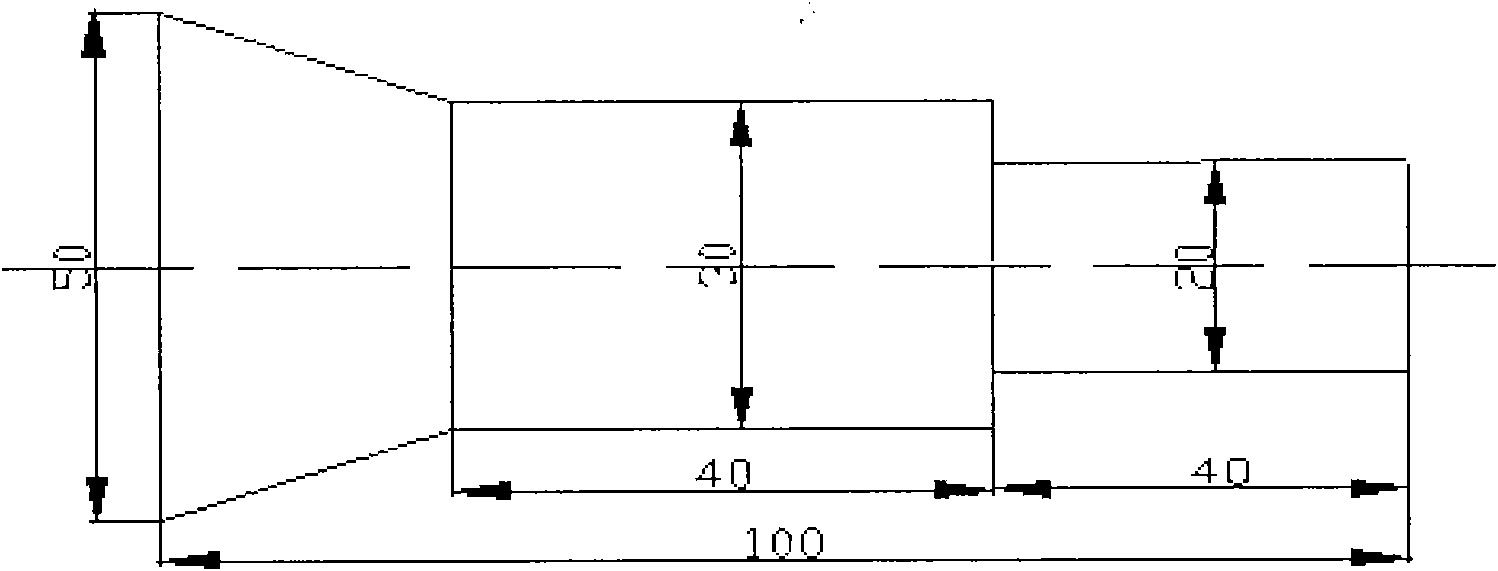

Intelligent screening system based on numerical control processing technology for difficult-to-machine metal

InactiveCN101930223AQuality improvementLow costBiological neural network modelsSpecial data processing applicationsNumerical controlOperational system

The invention discloses an intelligent screening system based on the numerical control processing technology for difficult-to-machine metal, which comprises the following subsystems: a parameter database subsystem, a fixed data source subsystem, an online detection and feedback subsystem, a technology intelligent comprehensive screening optimized scheme system, a data mining and supplementing subsystem, a simulation verification subsystem and an application operating system. The system has the characteristic of recognizing the reasonableness, the advancement and the high efficiency property of each technology scheme in the database, and is used for collecting the processing information of difficult-to-machine metal materials, the machine tool and cutter selection experience and cutting technological parameters accumulated in production practices and experiments. The roughness test data of the optimized cutting technological parameters is selected for processing, so that a reasonable and mature technological scheme is recommended for manufacturing enterprises, and the numerical control processing precision of the difficult-to-machine metal materials is controlled. The purposes of increasing the processing efficiency of the difficult-to-machine materials, reducing processing cost and acquiring high quality products are achieved.

Owner:曾谊晖

TiSiN+ZrSiN composite nanometer coated cutting tool and preparation method thereof

InactiveCN103273687AImprove friction and wear propertiesReduce residual stressVacuum evaporation coatingSputtering coatingAlloyDry machining

The invention provides a TiSiN+ZrSiN composite nanometer coated cutting tool and a preparation method thereof and belongs to the field of mechanical machining. A base material of the coated cutting tool is a hard alloy or high-speed steel. The TiSiN+ZrSiN composite nanometer coated cutting tool is manufactured by adopting a multi-arc ion plating+intermediate frequency magnetron sputtering method. The TiSiN+ZrSiN composite nanometer coated cutting tool is of multilayered structure, a ZrSiN coating is formed on the surface of the cutting tool, a TiZrSiN transition coating is formed between the ZrSiN coating and a TiSiN coating, and a Ti transition coating is formed between the TiSiN coating and a substrate, wherein the atomic percentage of Si content in the TiSiN coating and the ZrSiN coating is 6%-10%. The TiSiN+ZrSiN composite nanometer coated cutting tool well combines the high hardness of the TiSiN coating and the low friction coefficient of the ZrSiN coating and has high hardness, good friction and wear property and excellent high-temperature oxidation resistance; and the bonding can be alleviated in the cutting process, and the wearing of the cutting tool is reduced, so that the service life of the cutting tool is prolonged. The coated cutting tool can be widely applied to drying machining and machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

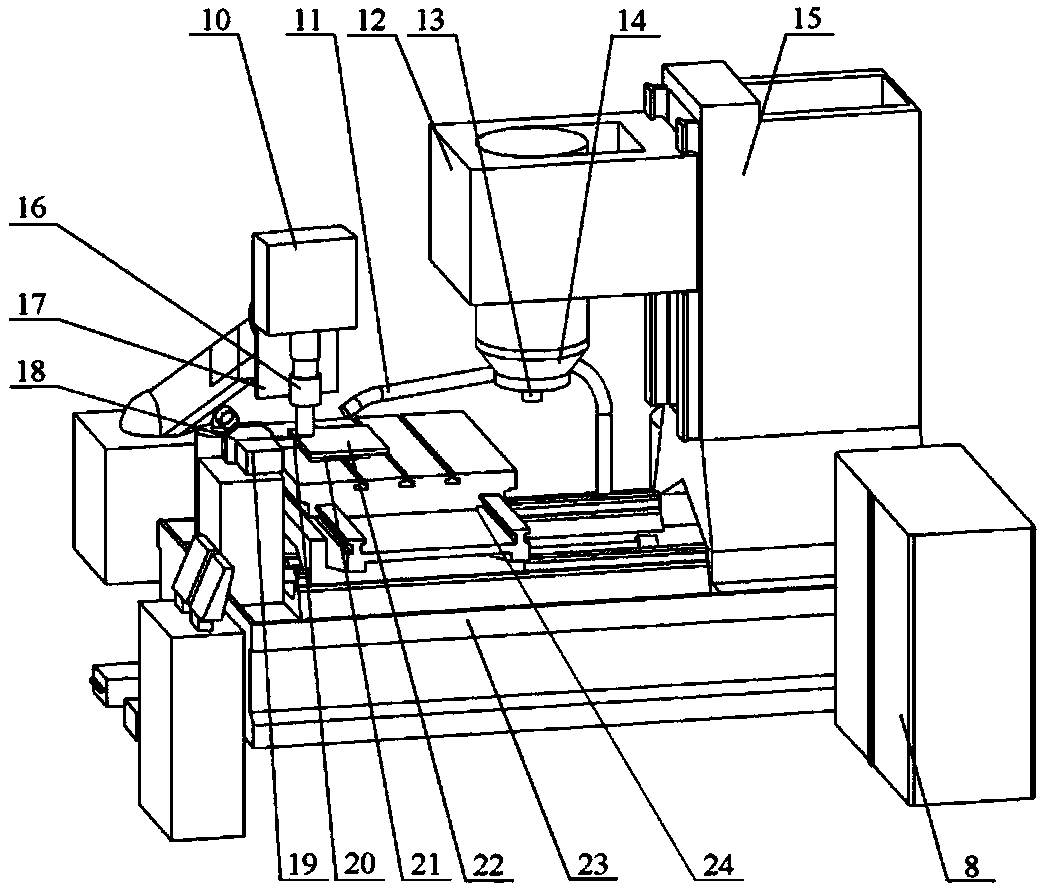

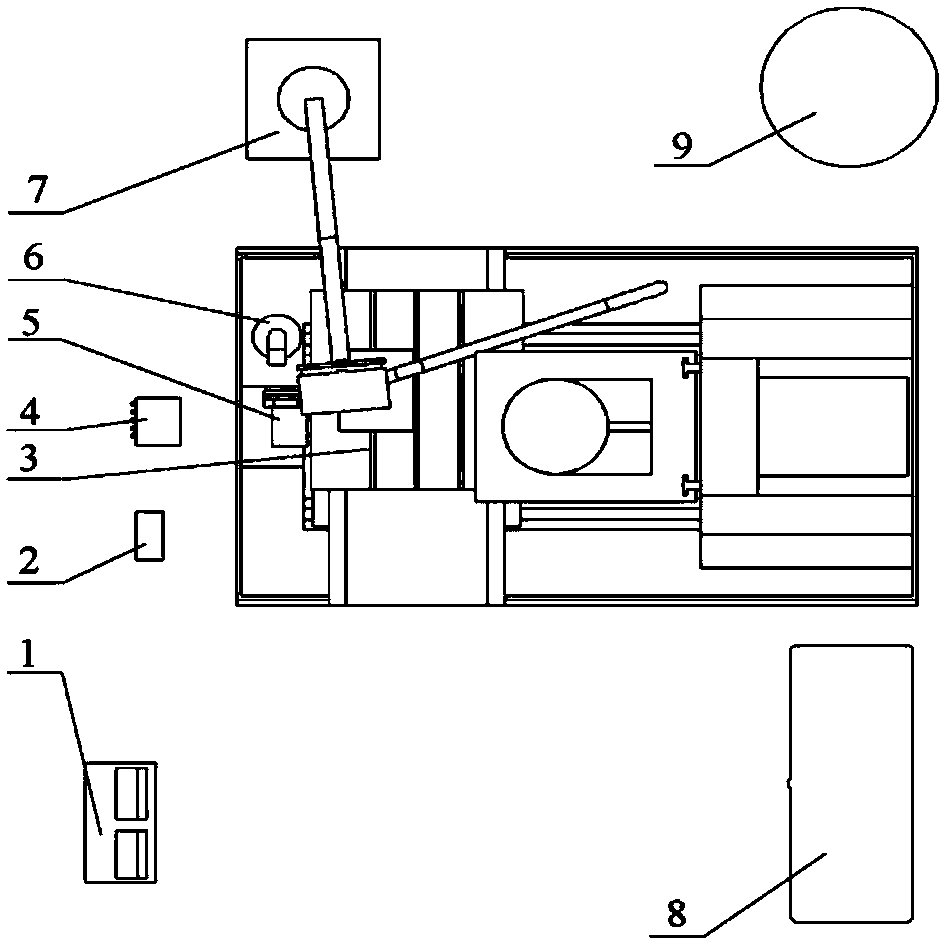

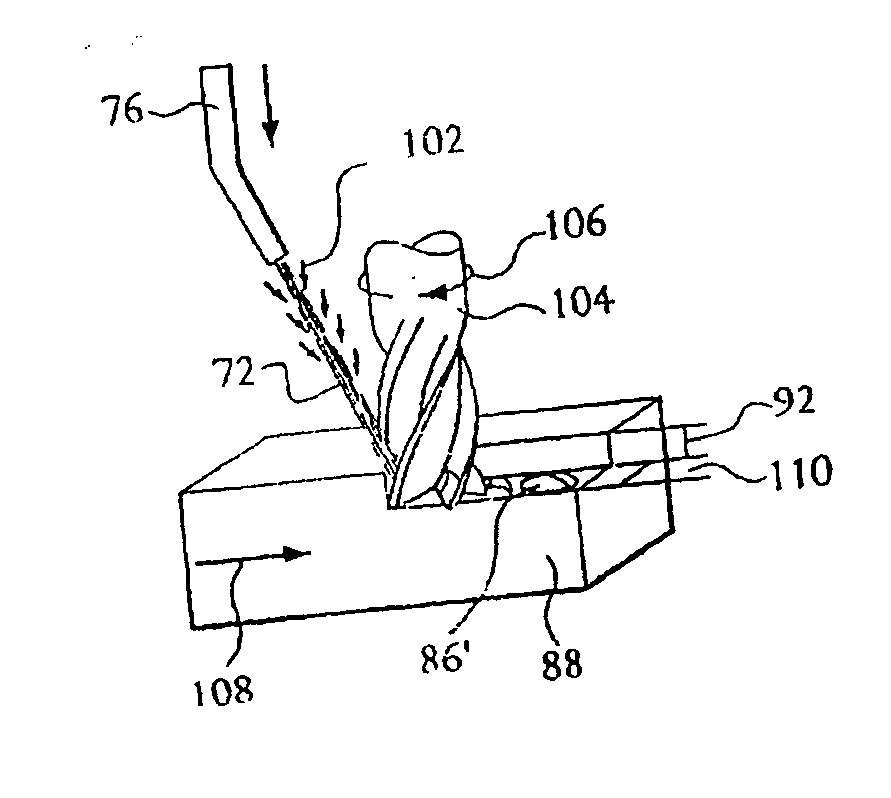

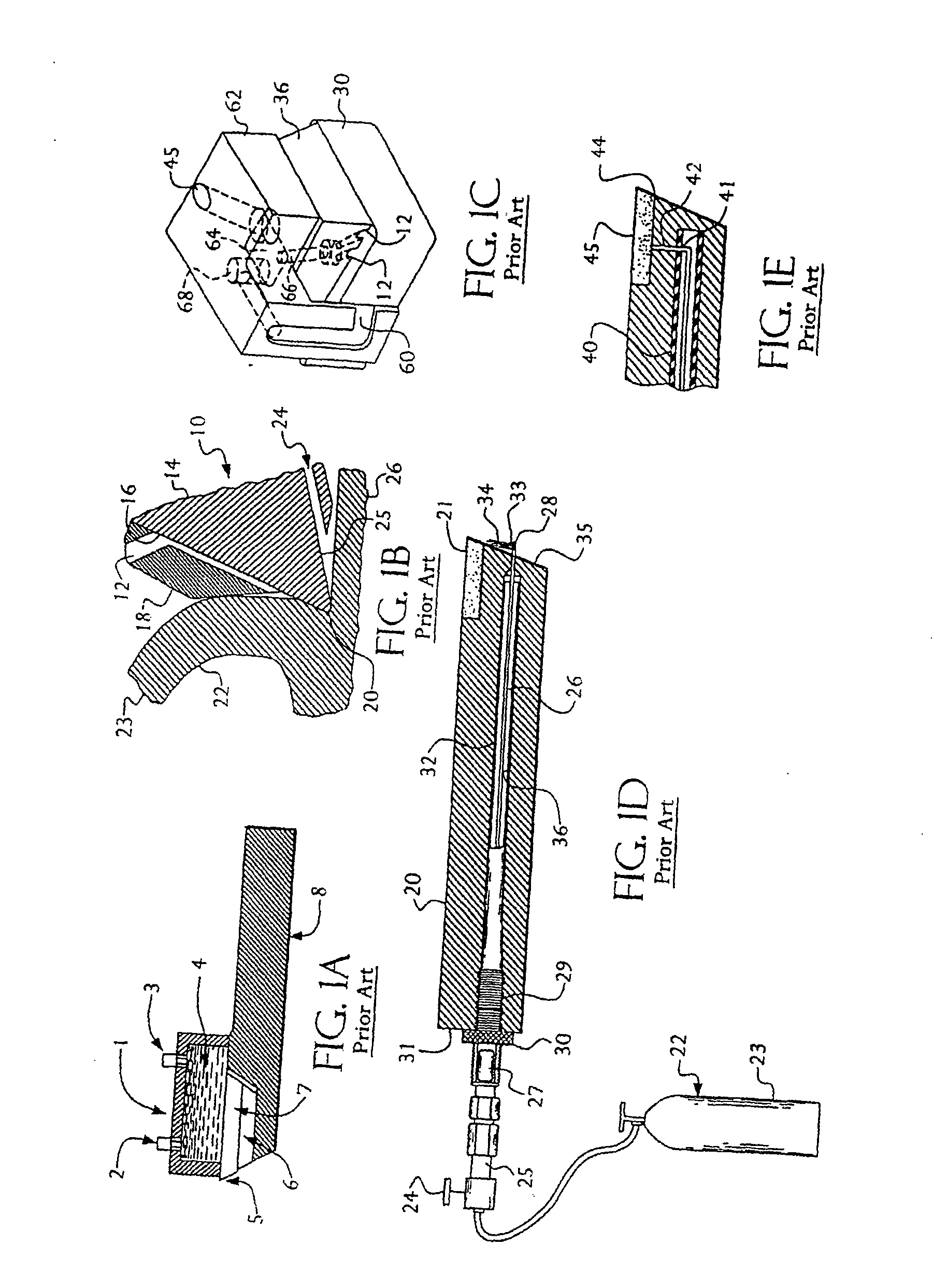

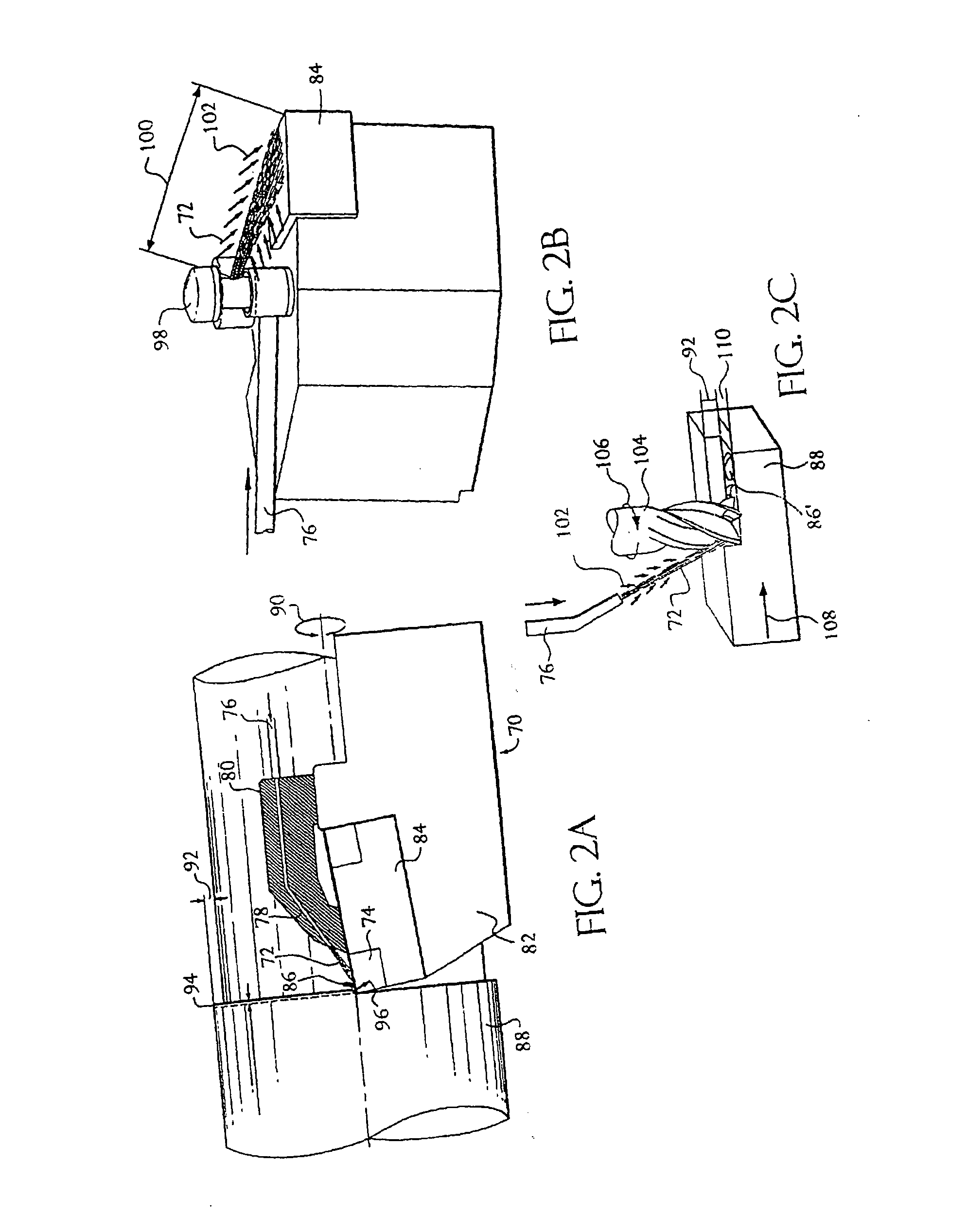

Combination apparatus for machining material with a milling cutter and a laser

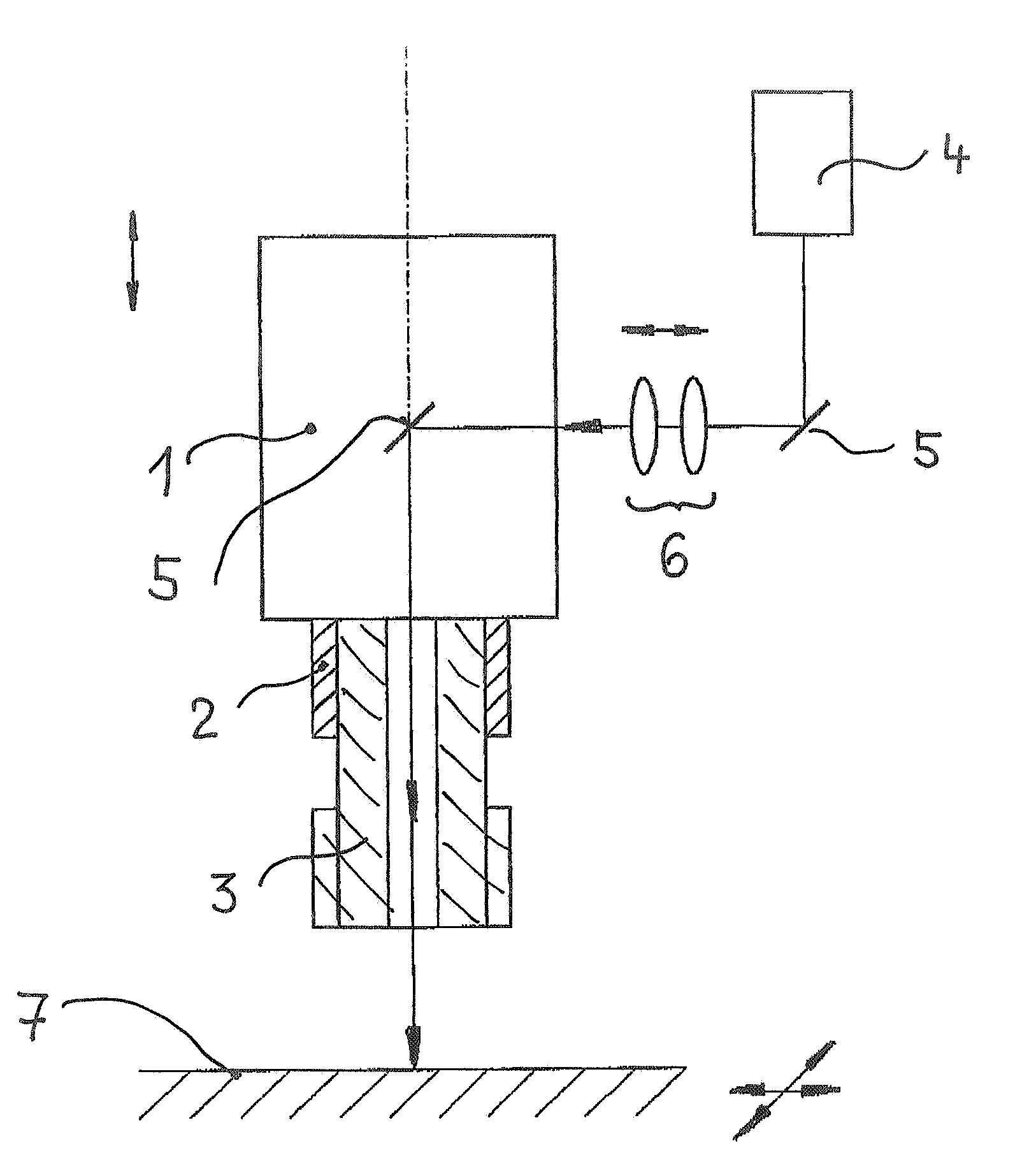

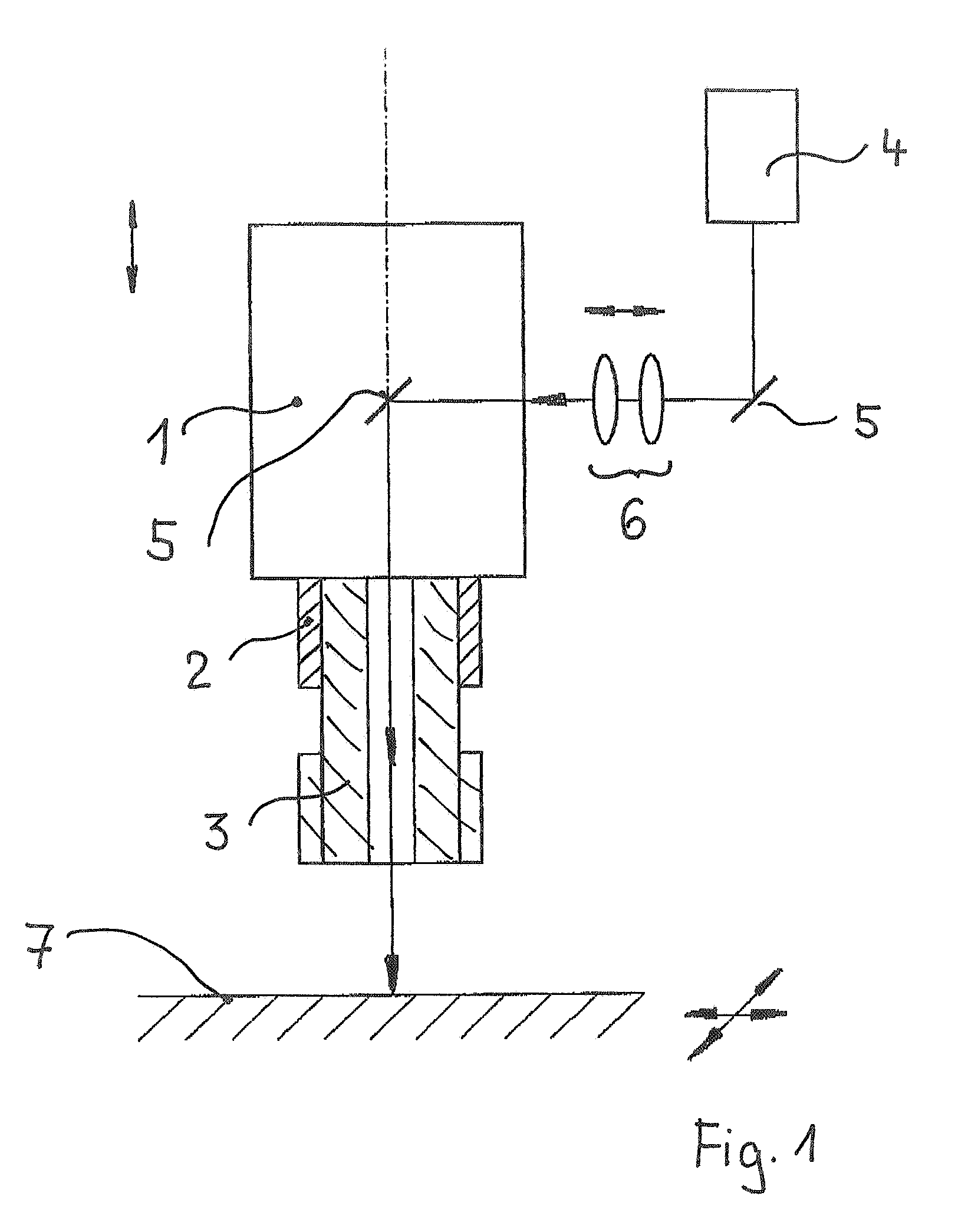

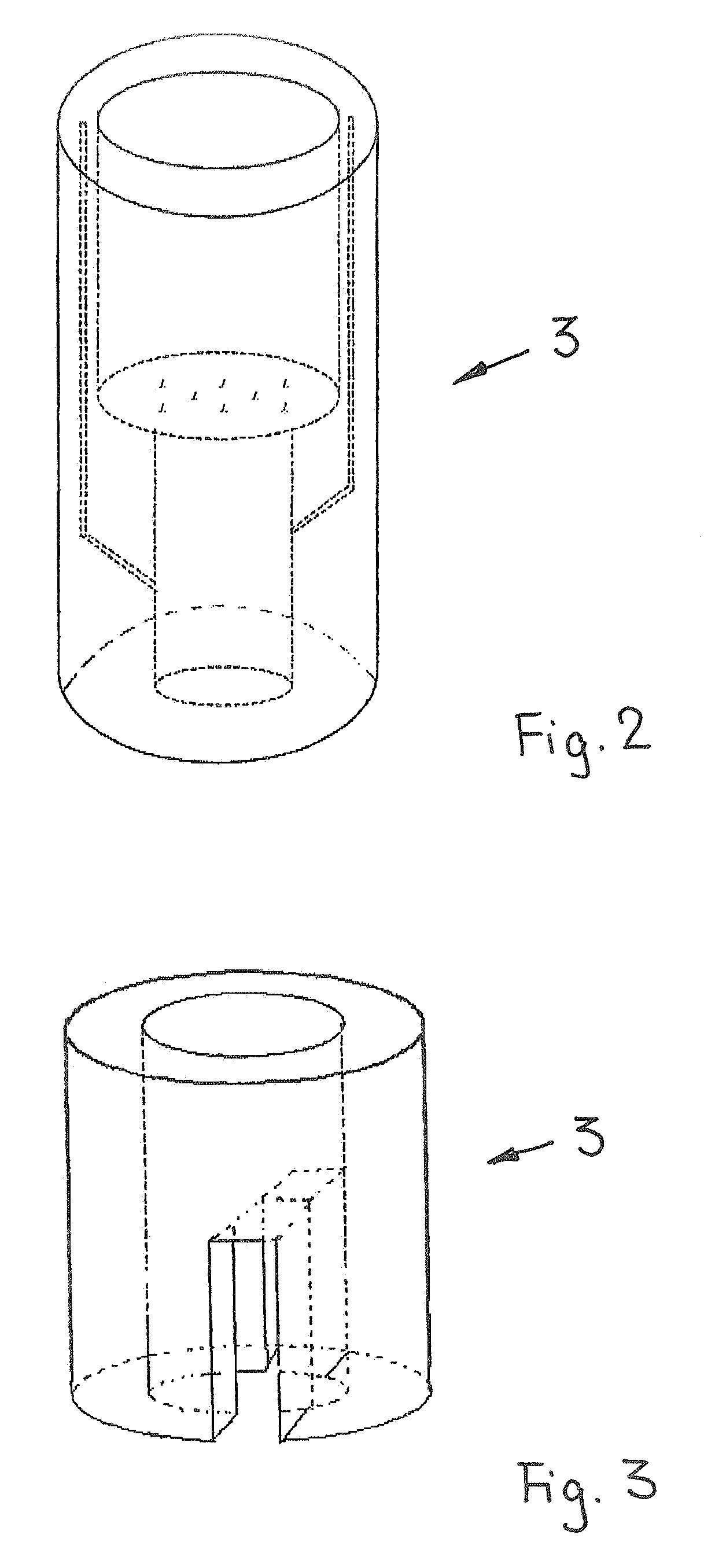

The invention is directed to an apparatus for cutting material by means of a milling cutter and laser radiation. The apparatus comprises a milling unit, a work spindle, a milling cutter, a laser, deflecting elements, focusing optics, and a work table. According to the invention, a workpiece can be milled and lasered simultaneously or successively at the same cutting location in that the laser beam is coupled into a channel coaxial to the mill axis.

Owner:JENOPTIK AUTOMATISIERUNGSTECHN

Flexible polishing device

ActiveCN106378704AHas softnessEdge grinding machinesGrinding machine componentsMachined surfaceExecution unit

The invention provides a flexible polishing device which comprises a power source unit, an output execution unit and a flexible shaft. An output shaft is arranged in the output execution unit. One end of the flexible shaft is connected with the power source unit, and the other end of the flexible shaft is connected with the output shaft. A grinding head installing part is arranged at the end of the output execution unit. The flexible polishing device further comprises an axial floating unit and / or a radial floating unit. The axial floating unit and / or the radial floating unit are / is arranged between the output execution unit and the power source unit and are / is used for achieving axial floating and / or radial floating of the output execution unit respectively. According to the flexible polishing device, the curve deviation between an absorbing machining path of the axial floating unit and / or the radial floating unit and a machined material is mainly utilized, and burrs on the machined surface are removed flexibly. Meanwhile, as the flexible shaft can transfer high-power power to polish burrs, sprues and weld seams, the range of the machining field is widened.

Owner:SUNRISE INSTR CO LTD

Rapid electric arc fused deposition and laser shock forging combined part forming method and device

ActiveCN107262930AGrain refinementGuaranteed forming qualityAdditive manufacturing apparatusArc welding apparatusNumerical controlEngineering

Owner:GUANGDONG UNIV OF TECH

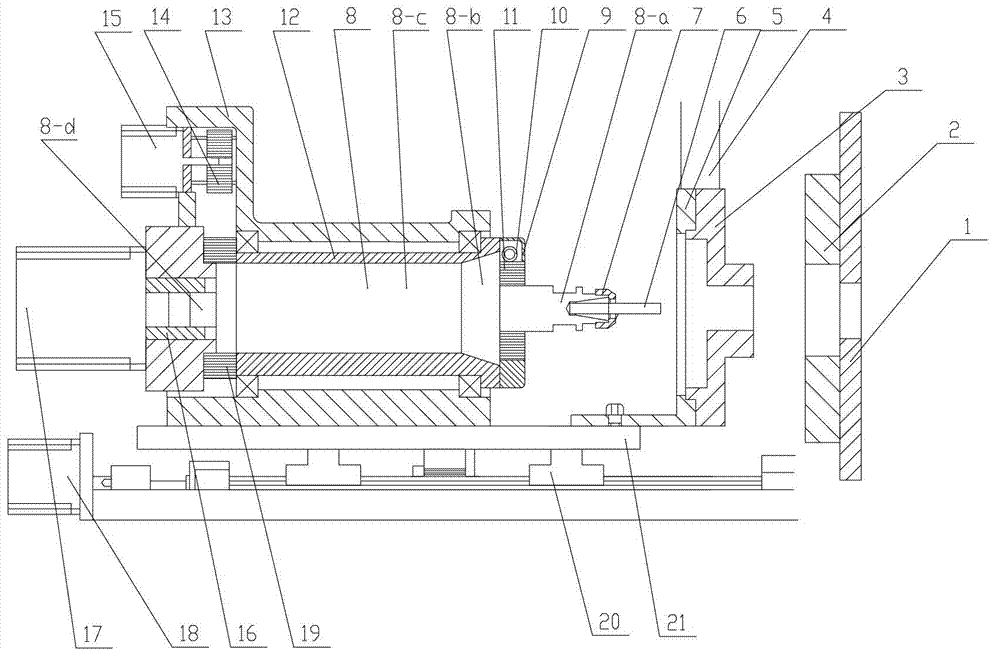

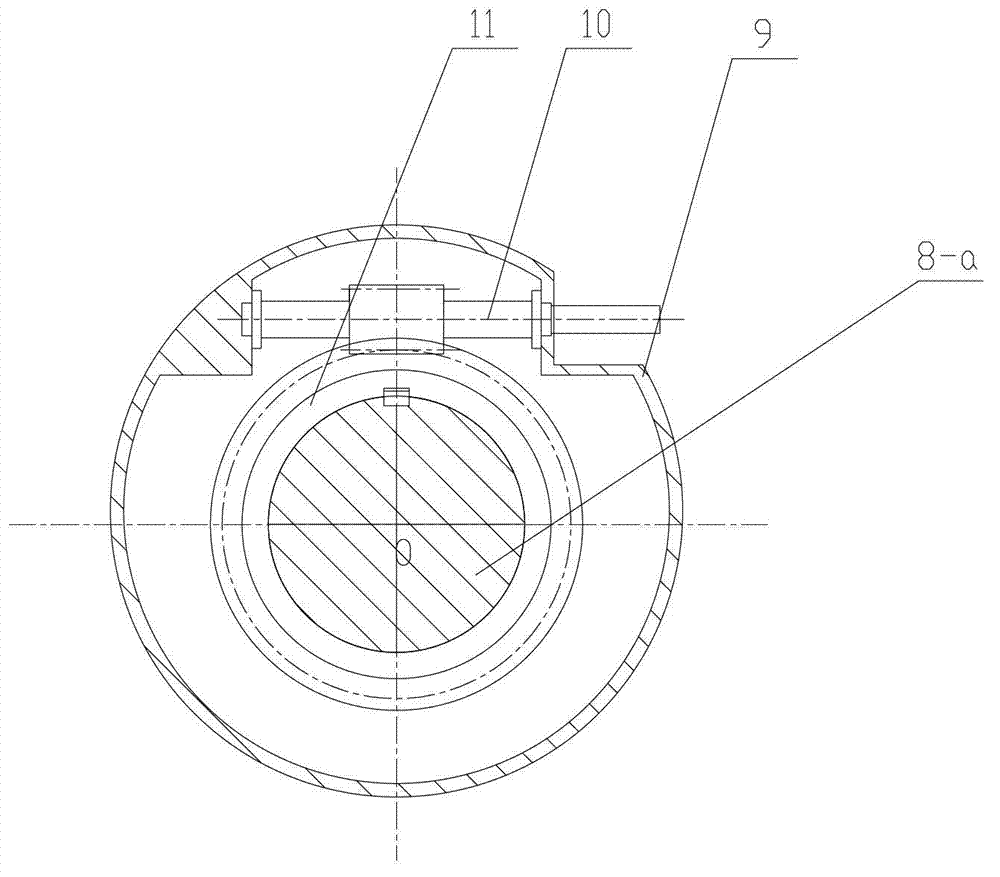

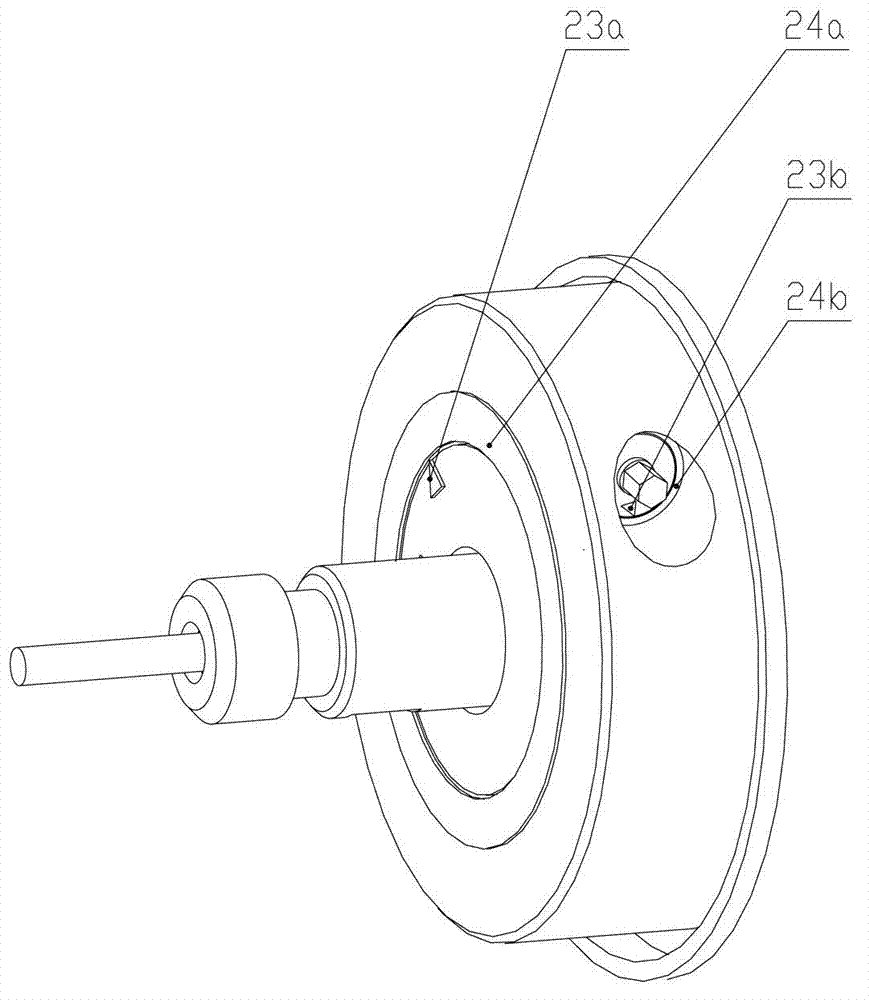

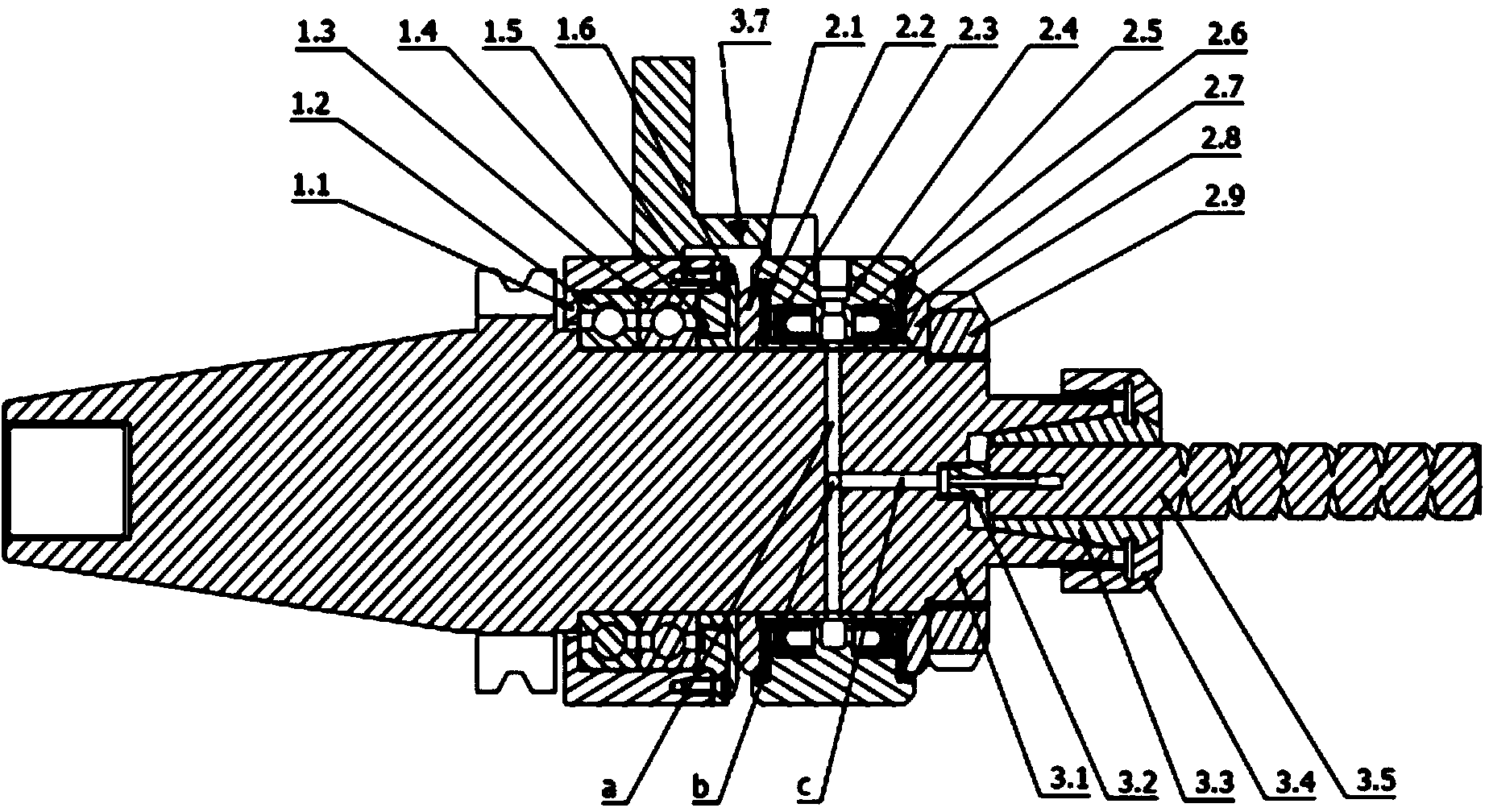

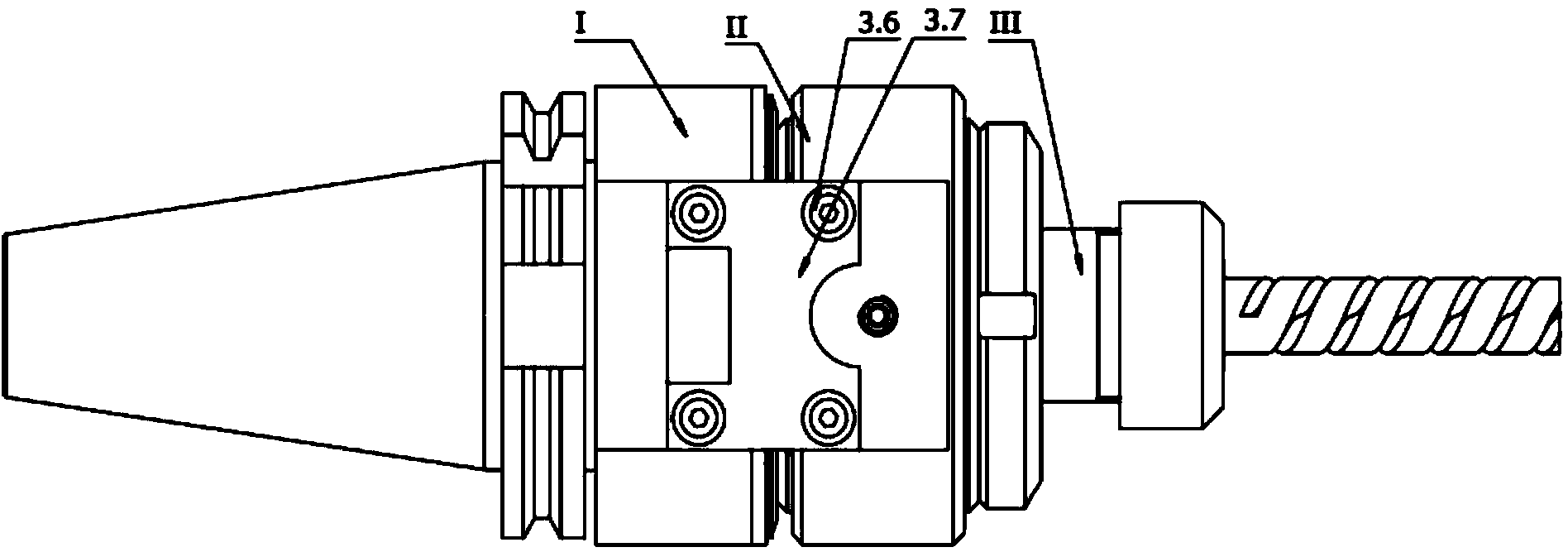

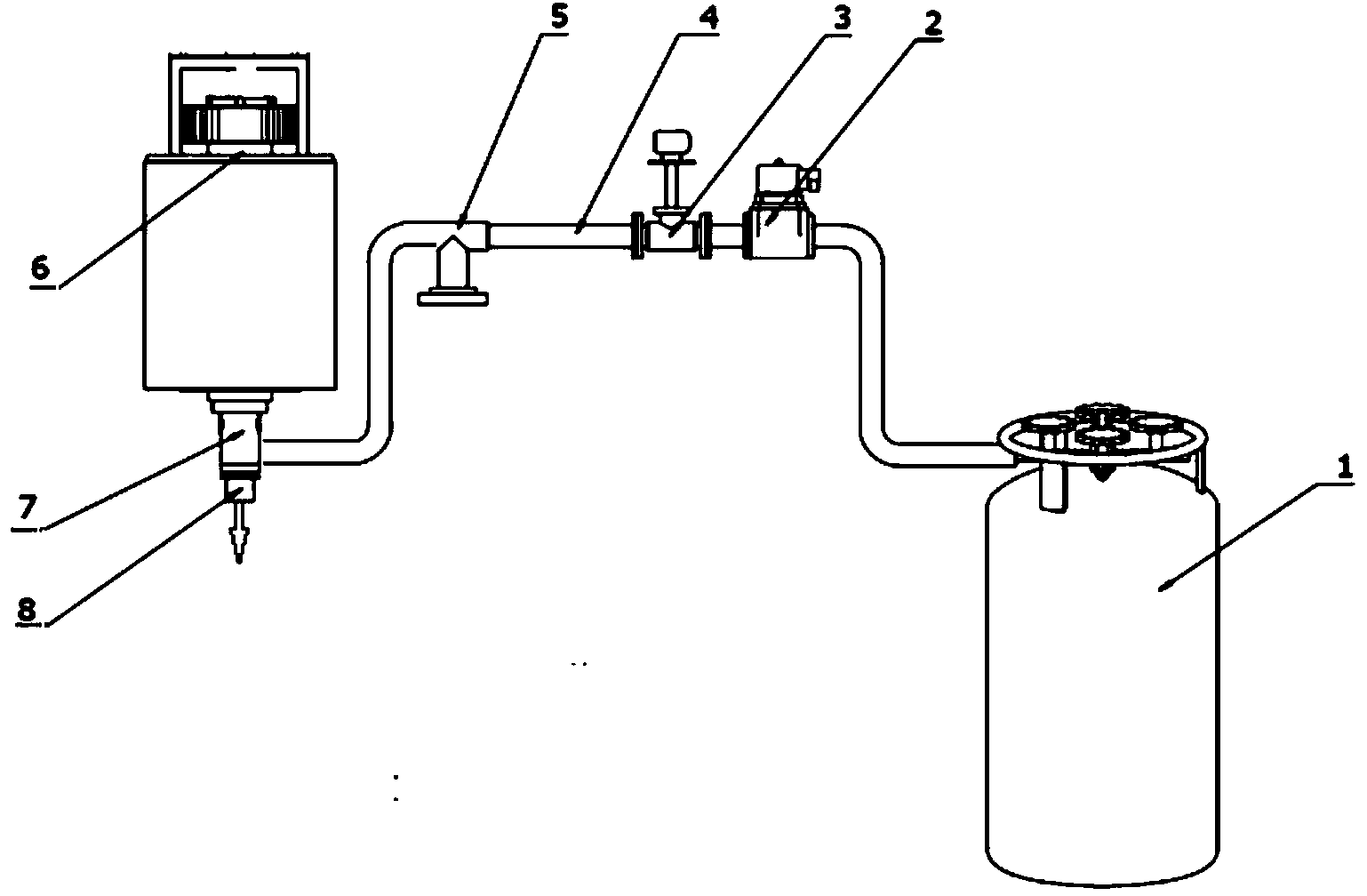

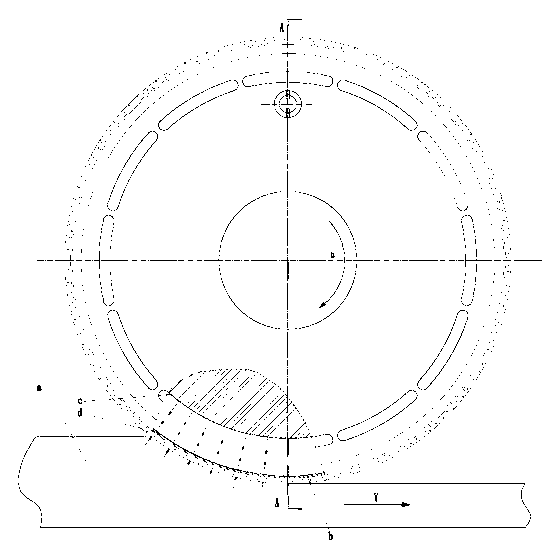

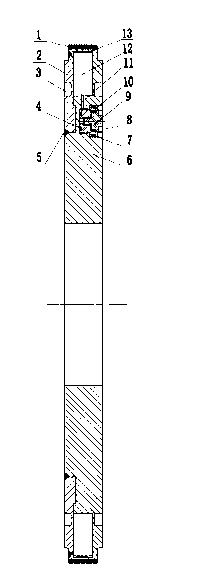

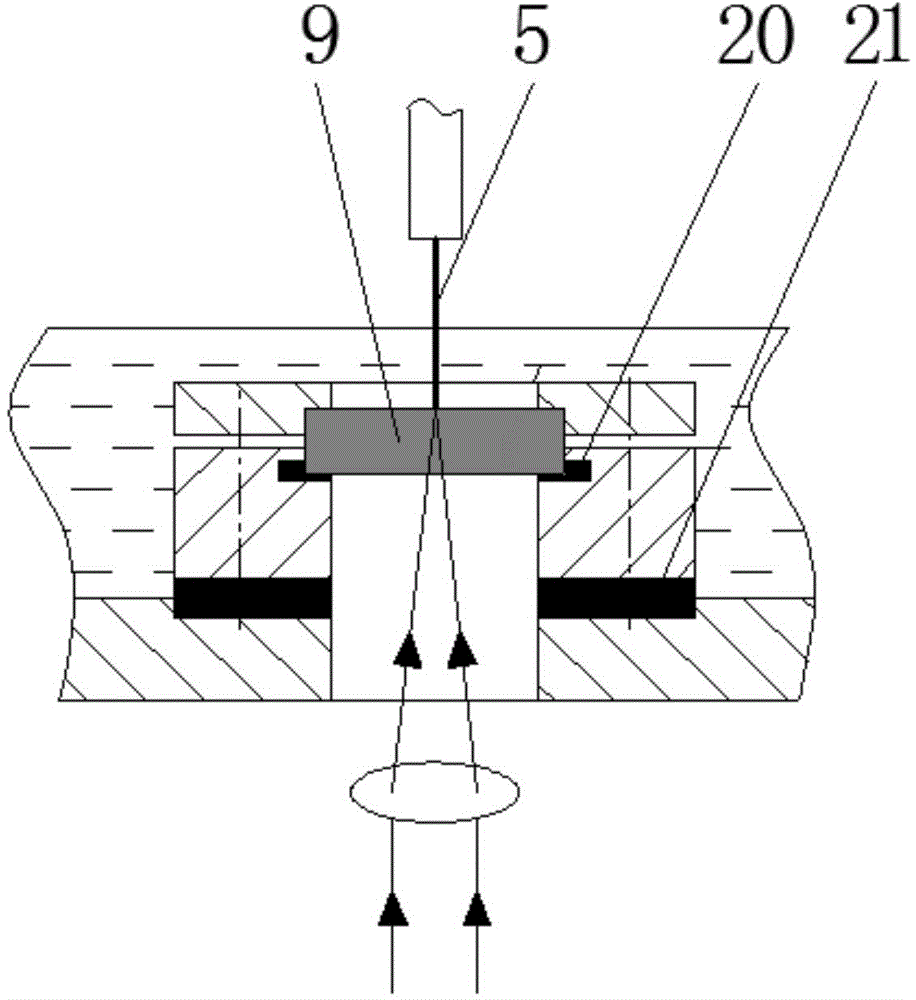

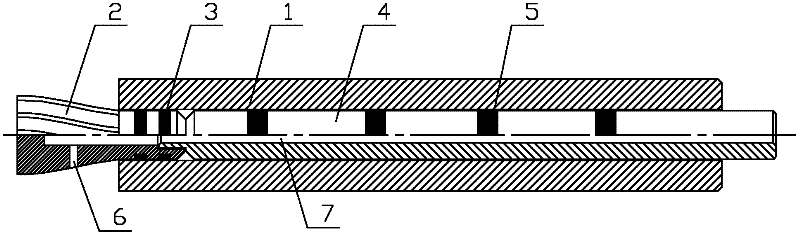

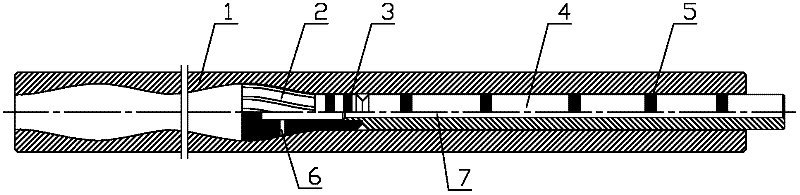

Liquid nitrogen inner spraying type cutter handle device

ActiveCN104015079ASolve the problem of inconvenient delivery of liquid nitrogenSolve the problem of realizing internal spray liquid nitrogen cutting fluidMachine tool componentsPositioning apparatusNumerical controlEngineering

The invention provides a liquid nitrogen inner spraying type cutter handle device, belongs to the design field of machine tools, and relates to a machine tool cutter handle device which achieves the purpose of cold low-temperature cutting through the fact that liquid nitrogen flows in an inner cavity of a cutter handle to a fine hole near a cutting edge of a hollow cutter rod to be sprayed out. The liquid nitrogen inner spraying type cutter handle device is composed of a left cutter handle peripheral assembly, a right cutter handle peripheral assembly and a cutter handle assembly. The left cutter handle peripheral assembly and the right cutter handle peripheral assembly are sequentially arranged on the outer circular face of the cutter handle and are locked by end nuts. In the liquid nitrogen inner spraying type cutter handle device, the surfaces of parts in contact with the liquid nitrogen are subjected to heat insulation material modified treatment, and the heat transferring capacity of the parts is lowered. The liquid nitrogen inner spraying type cutter handle device solves the problem that liquid nitrogen conveying is inconvenient for a workpiece with a complex structure in an existing outer spraying type liquid nitrogen cutting liquid device. The defect that the liquid nitrogen is low in utilization rate is overcome, the purpose that a common built-in type cutting liquid system achieves inner spraying of liquid nitrogen cutting liquid is achieved, the machining precision of difficult-to-machine materials machined by a machine tool is guaranteed, and the machining range of a numerical control machine tool is widened.

Owner:DALIAN UNIV OF TECH

Heat pipe grinding wheel for dry cutting for difficult-to-machined materials and method for manufacturing heat pipe grinding wheel

ActiveCN103128676ASimple structureEasy to manufactureBonded abrasive wheelsGrinding devicesGrinding wheelHeat pipe

The invention discloses a heat pipe grinding wheel for dry cutting for difficult-to-machined materials and a method for manufacturing the heat pipe grinding wheel. The heat pipe grinding wheel comprises a matrix and abrasive particles arranged on the matrix, and is characterized in that the matrix comprises a base and an end cover, the abrasive particles are arranged on the end cover, solid lubricants are coated on the abrasive particles, a heat pipe cavity is further formed between the end cover and the base, an air exhaust hole is further arranged on the base, the inside of the air exhaust hole is communicated with the heat pipe cavity, a plug hole is arranged on the outside of the air exhaust hole, an inner plug and an outer plug which are coaxially arranged are disposed in the plug hole, working media are arranged in the heat pipe cavity, and condensation grooves are arranged on two outer surfaces, which are positioned in a condensation section of the heat pipe cavity, of the end cover at intervals. The heat pipe grinding wheel and the method have the advantages that the structure is simple, the cost is low, heat of a grinding arc area can be effectively dissipated when the difficult-to-machined materials are machined, and the bottleneck problem that coolant is difficult to be filled into an existing grinding arc area for effective heat exchange can be solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

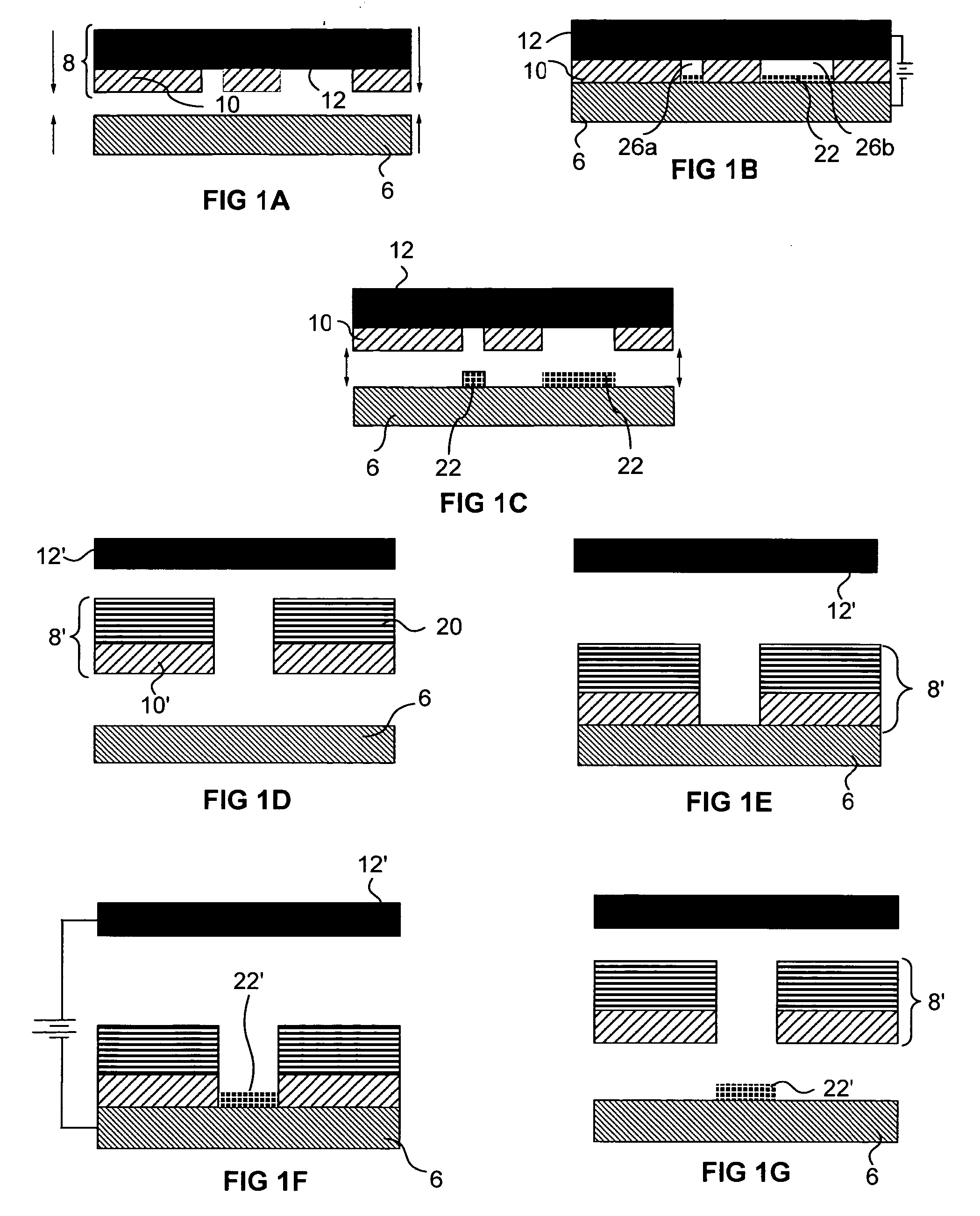

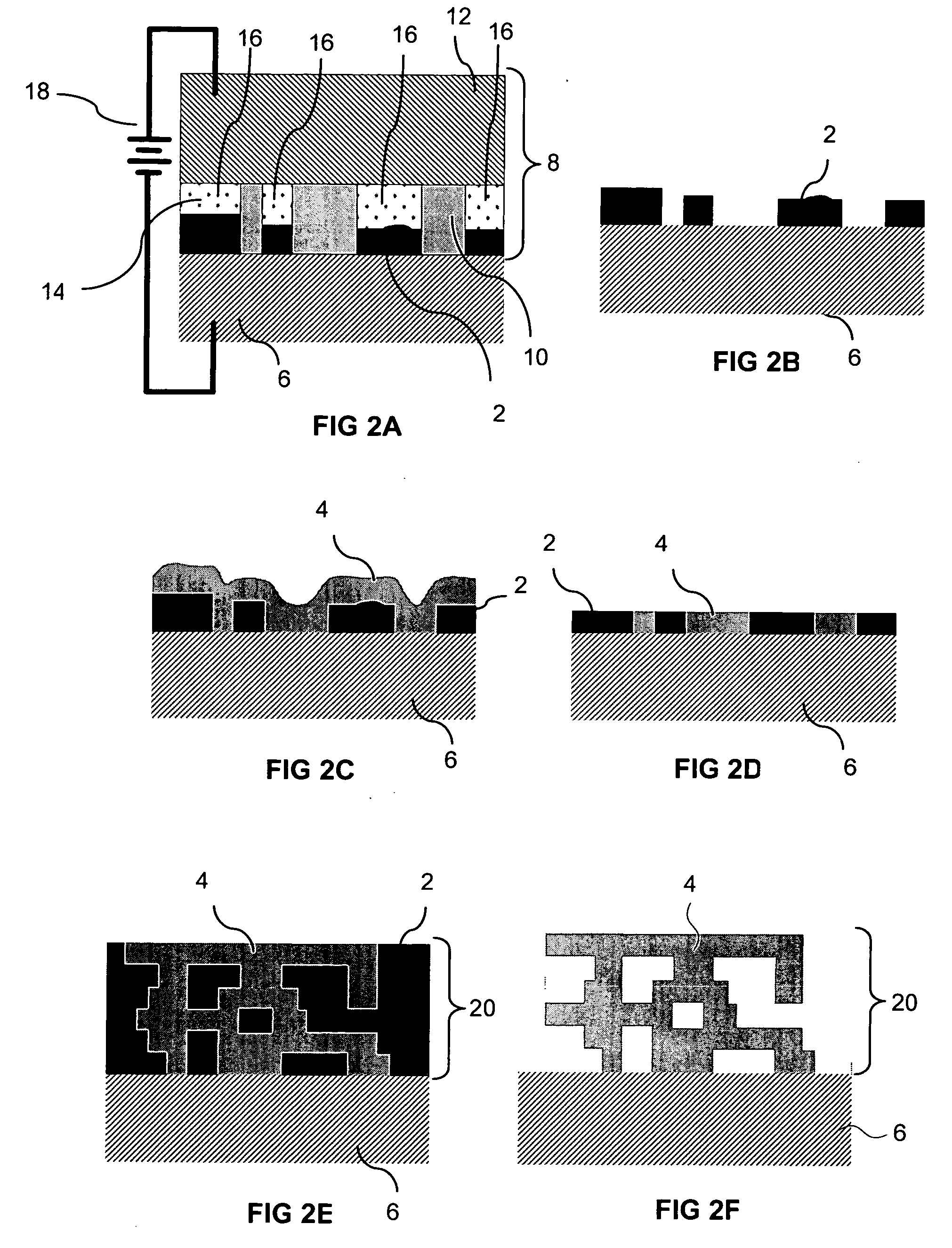

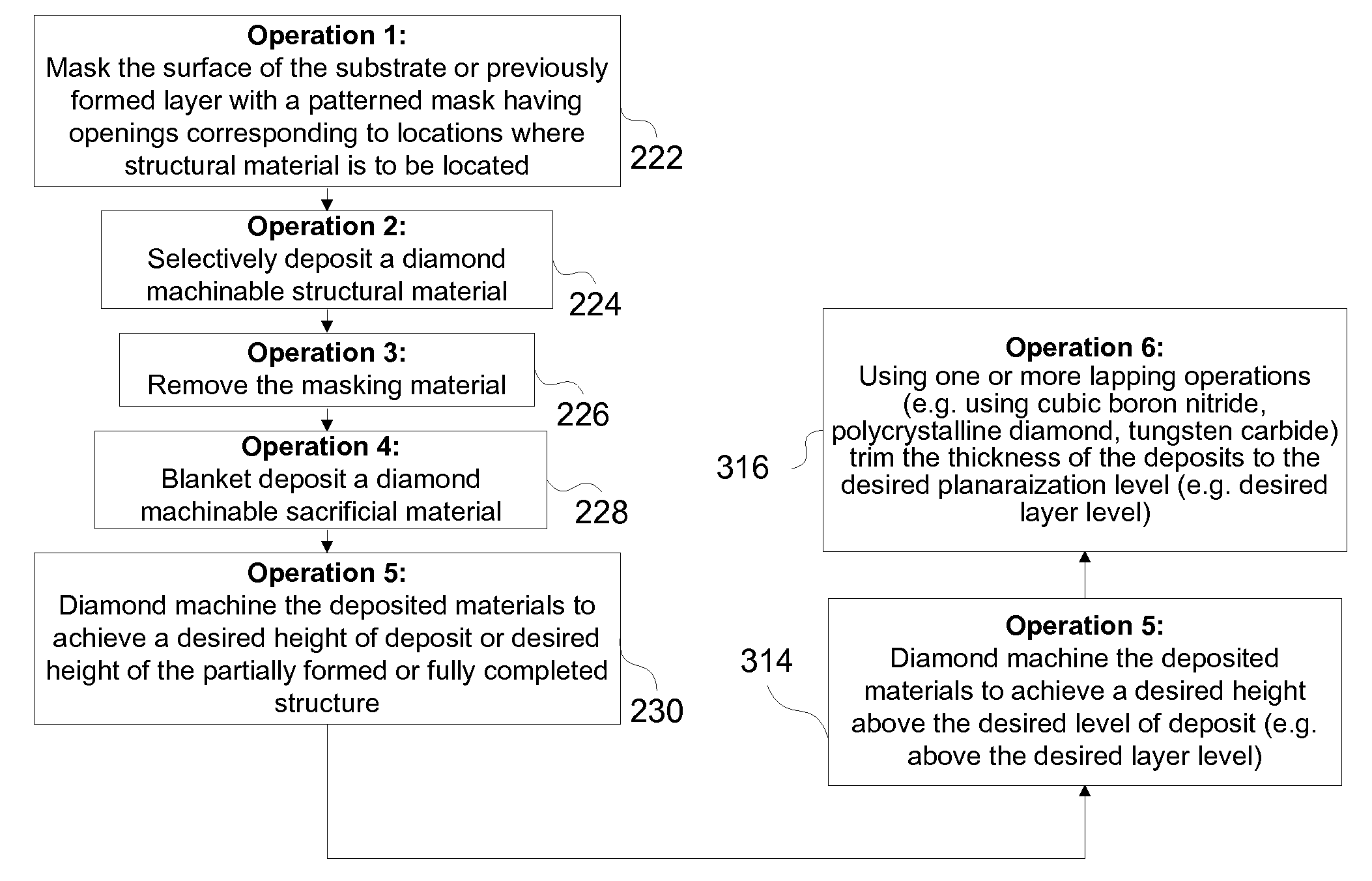

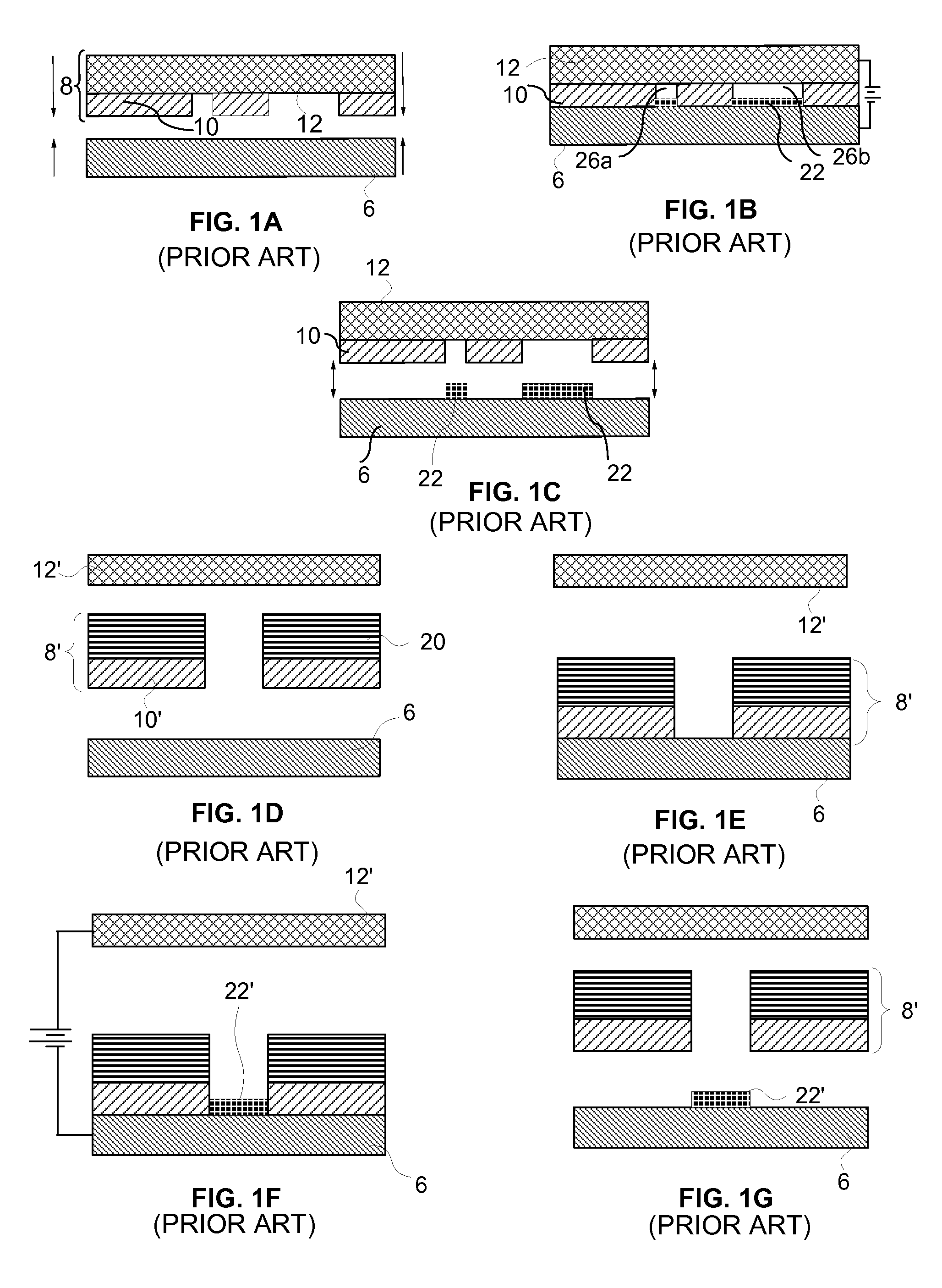

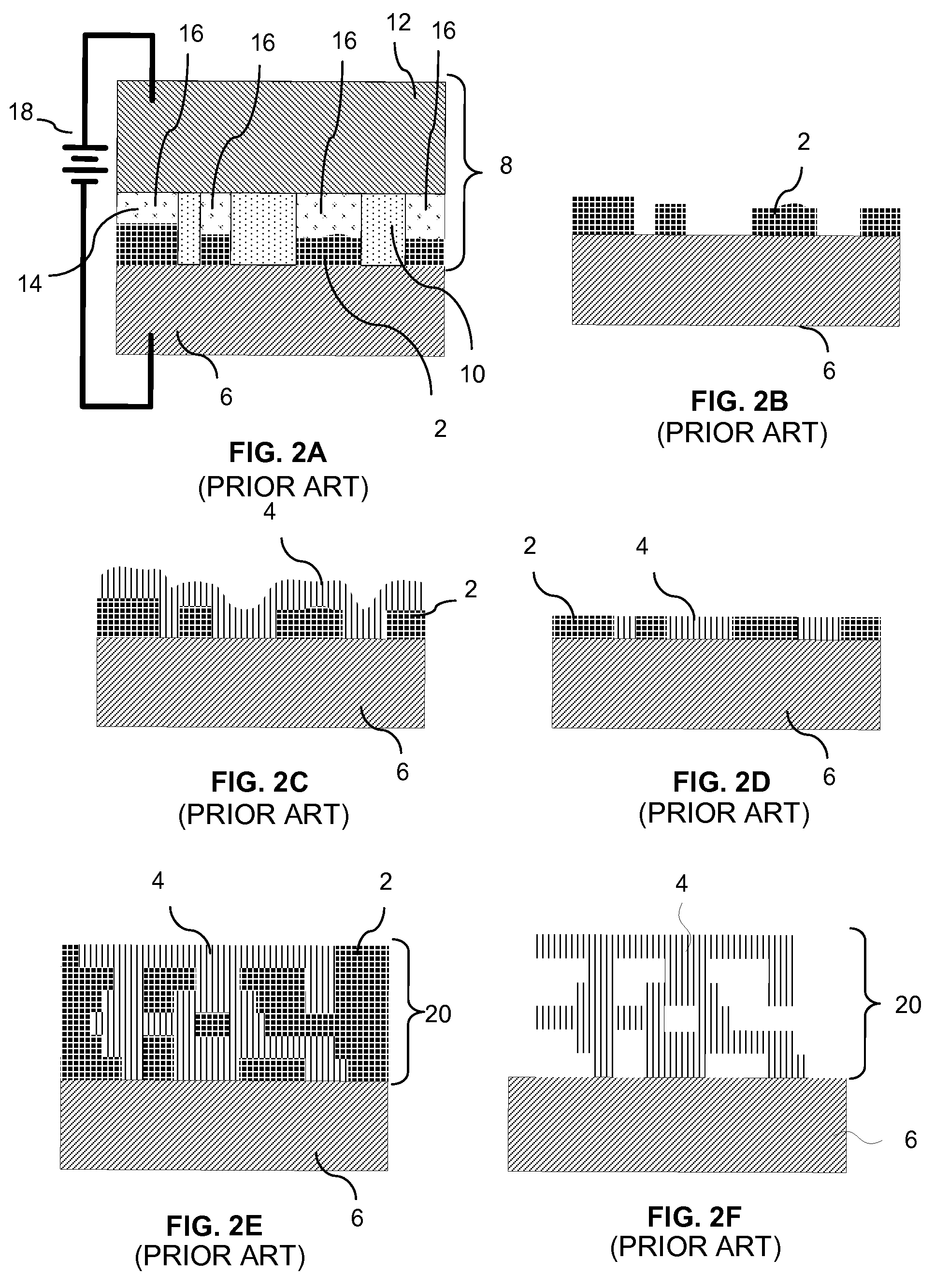

Electrochemical fabrication methods for producing multilayer structures including the use of diamond machining in the planarization of deposits of material

InactiveUS20050202180A1Improve abilitiesFast planarizationCellsLiquid surface applicatorsMulti materialSolid region

Electrochemical fabrication methods for forming single and multilayer mesoscale and microscale structures are disclosed which include the use of diamond machining (e.g. fly cutting or turning) to planarize layers. Some embodiments focus on systems of sacrificial and structural materials which are useful in Electrochemical fabrication and which can be diamond machined with minimal tool wear (e.g. Ni—P and Cu, Au and Cu, Cu and Sn, Au and Cu, Au and Sn, and Au and Sn—Pb), where the first material or materials are the structural materials and the second is the sacrificial material). Some embodiments focus on methods for reducing tool wear when using diamond machining to planarize structures being electrochemically fabricated using difficult-to-machine materials (e.g. by depositing difficult to machine material selectively and potentially with little excess plating thickness, and / or pre-machining depositions to within a small increment of desired surface level (e.g. using lapping or a rough cutting operation) and then using diamond fly cutting to complete he process, and / or forming structures or portions of structures from thin walled regions of hard-to-machine material as opposed to wide solid regions of structural material.

Owner:MICROFAB

Device and method for machining materials by combining electrochemical discharging and laser

ActiveCN104942388AIncrease energy densitySpeed up erosionWelding/soldering/cutting articlesMetal working apparatusCavitationAuxiliary electrode

The invention provides a device and method for machining materials by combining electrochemical discharging and laser, and belongs to the field of non-traditional combined machining. Combined machining through electrochemical discharging and laser is carried out on transparent crisp and hard materials, an electrochemical discharging circuit is formed in an electrolyte solution through an auxiliary electrode and a tool electrode, a laser beam generates a focus on the surface of a sample, when energy reaches a certain value, impact stress and cavitation stress are formed, laser energy and spark discharging cooperatively act on a workpiece from an upper direction and a lower direction, effective combination of two kinds of energy is guaranteed, the energy density of a machining area is improved, and the corrosion removing speed of the machined sample is increased.

Owner:JIANGSU UNIV

Method for machining all-metal screw pump stator

InactiveCN102501016ASolve processing difficultiesReduce processing difficultyElectrochemical machining apparatusHydroformingScrew pump

The invention discloses a method for machining an all-metal screw pump stator. The method comprises the following steps of: 1) machining a stator blank, so that a central hole for forming a stator inner cavity is formed in the stator blank; 2) forming the stator inner cavity by an electrolytic process; 3) polishing the stator inner cavity; and 4) performing surface-hardening treatment on the stator inner cavity. According to the method, the problem of difficulty in machining of the all-metal screw pump stator is solved by combining polishing treatment and surface-hardening treatment by adopting the electrolytic process. The method has obvious advantages on the machining of materials which are difficult to machine and parts with complex shapes or thin-wall parts, and has the characteristics of wide range of the machined materials, high production efficiency, high forming accuracy, capability of recycling electrode assemblies and the like. By the method, the technical blockade of hydraulically-formed all-metal screw pump stators which are used abroad is broken through, and a new method for manufacturing the all-metal screw pump stator is opened up, so that the machining difficulty of the all-metal screw pump stator is reduced effectively, and the machining efficiency is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

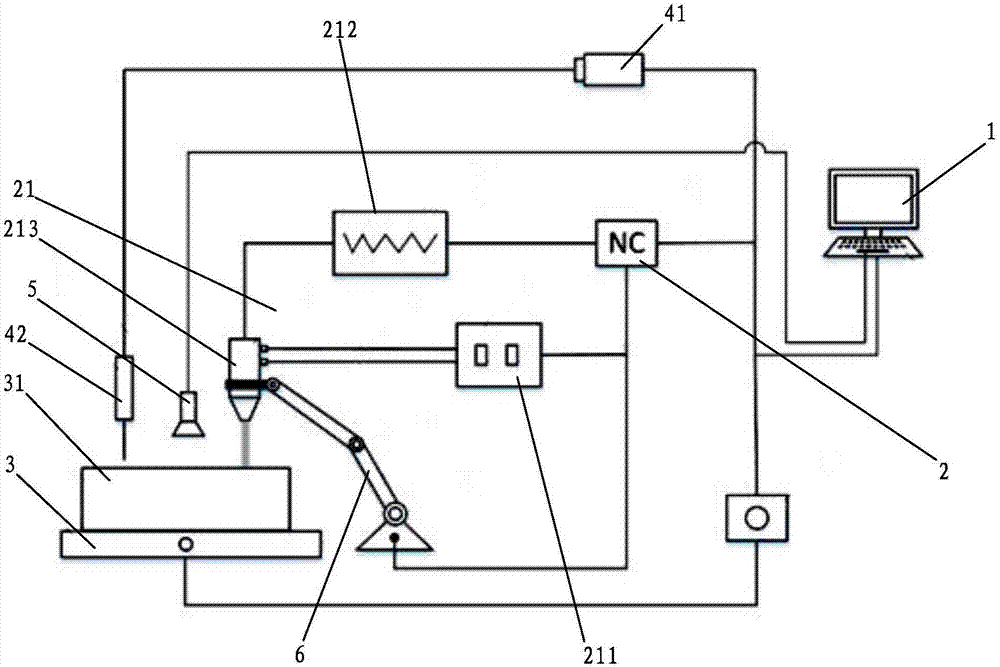

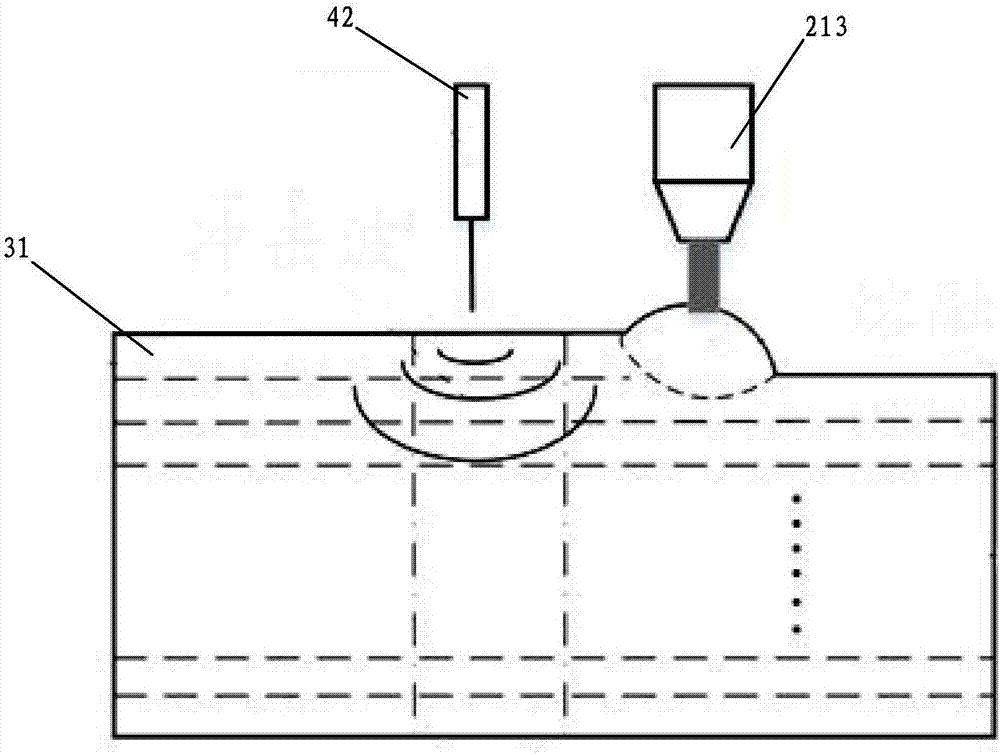

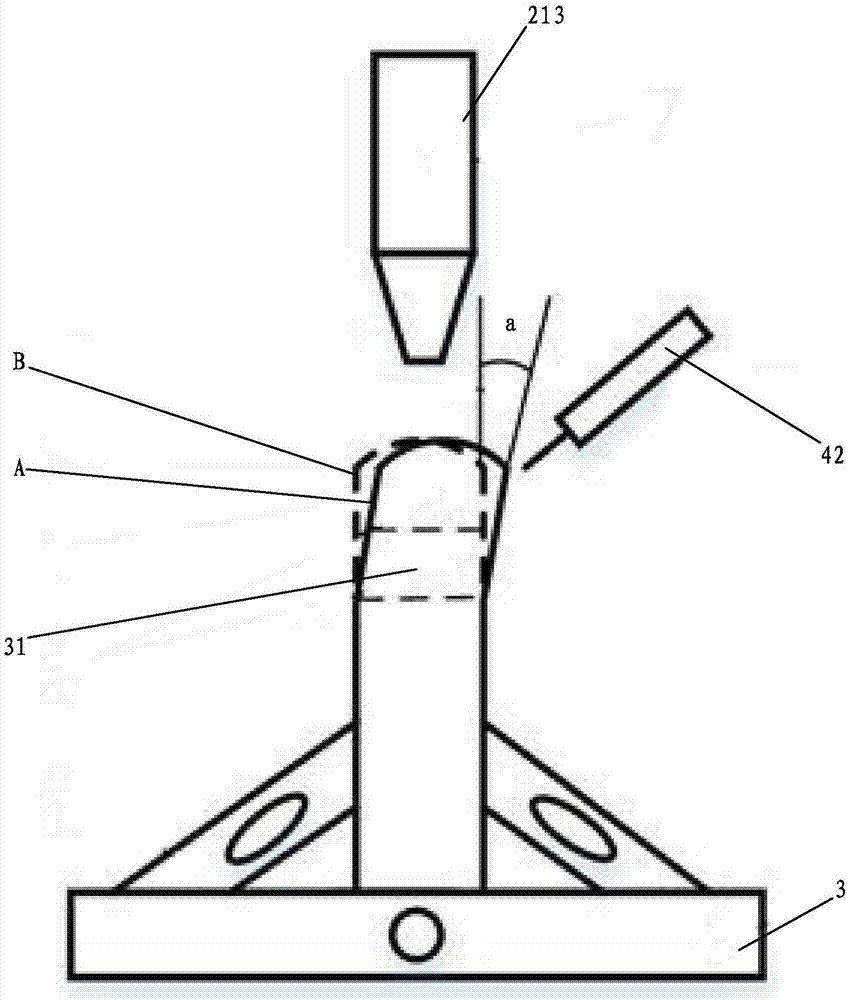

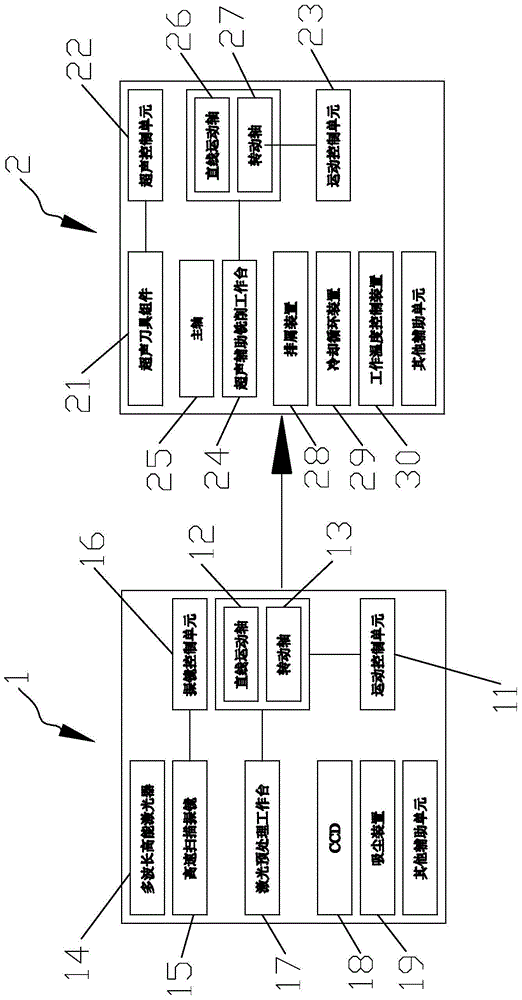

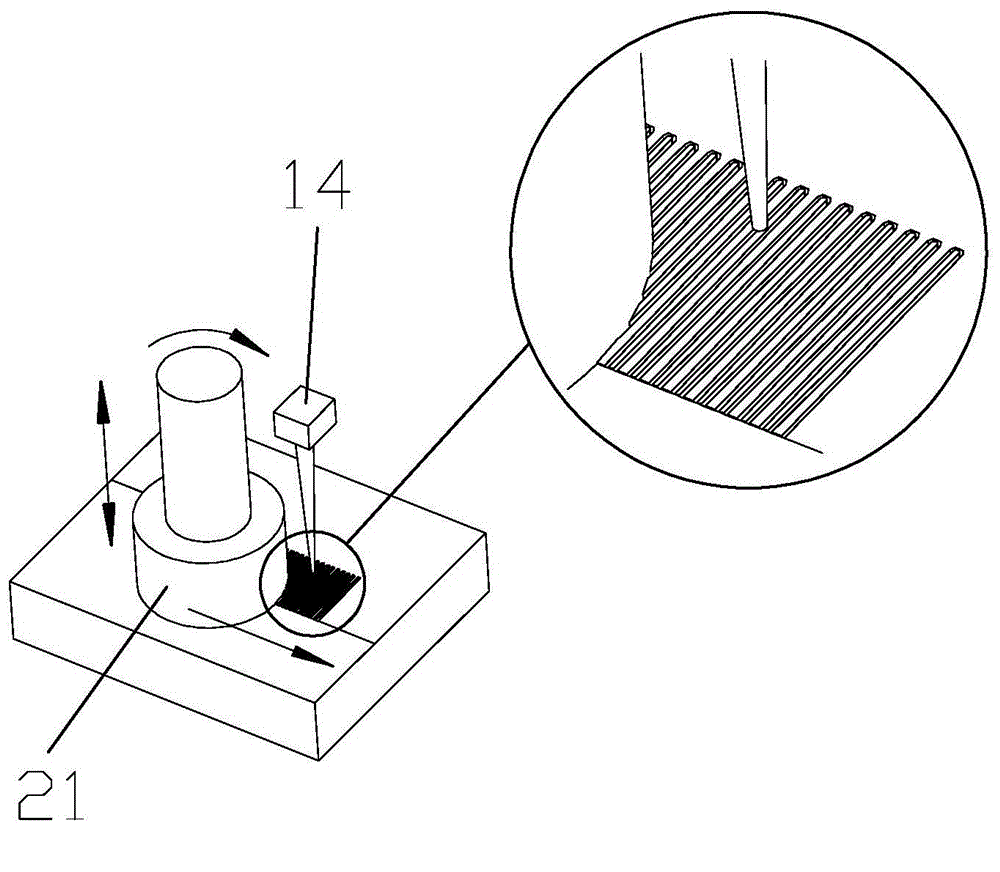

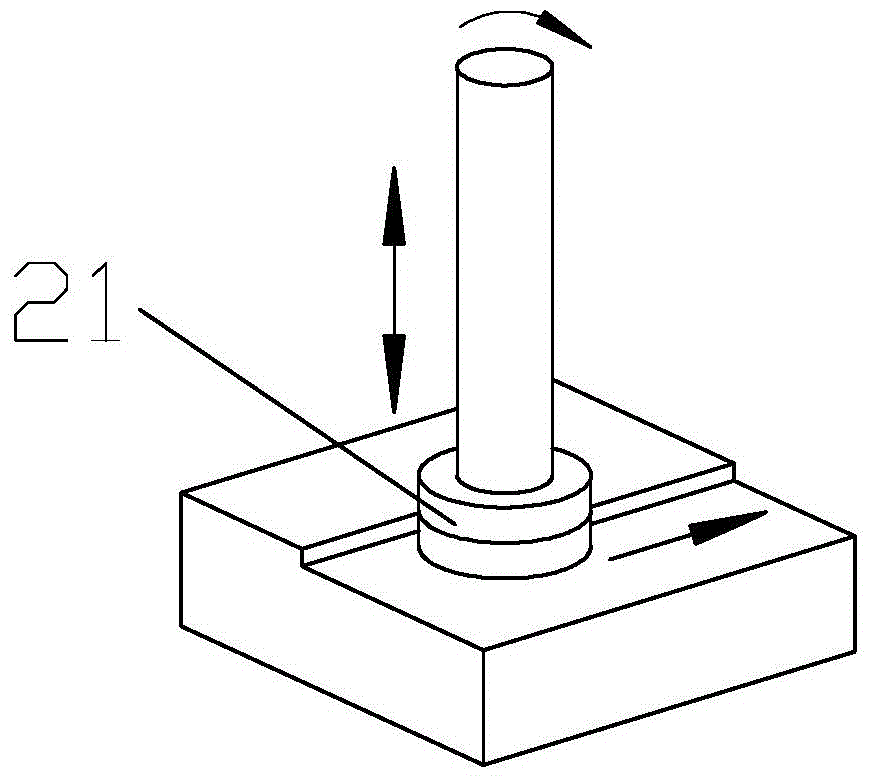

Auxiliary ultrasound milling technological method for laser micro-texture prefabricating and machining system

ActiveCN106271493AImprove machinabilityReduce processing difficultyOther manufacturing equipments/toolsUltrasonic vibrationMachining system

The invention provides an auxiliary ultrasound milling technological method for laser micro-texture prefabricating. The technological method comprises a laser pretreatment step and an ultrasound auxiliary milling step. The laser pretreatment step comprises the sub-steps that a position parameter of a to-be-machined material is adjusted, so that the position parameter of the to-be-machined material is in accordance with a first predetermined position parameter; and a laser beam is generated, and the spatial posture, corresponding to the to-be-machined material, of the laser beam is adjusted. The ultrasound auxiliary milling step comprises the sub-steps that the position parameter of the to-be-machined materials subjected to laser pretreatment is adjusted, so that the position parameter of the to-be-machined material is in accordance with a second predetermined position parameter; ultrasound vibration of an ultrasound cutter assembly is controlled; the ultrasound cutter assembly is rotated, and the rotation freedom degree, corresponding to the to-be-machined material subjected to laser pretreatment, of the ultrasound cutter assembly is adjusted; and the position relation between the ultrasound cutter assembly and the to-be-machined material subjected to laser pretreatment in the X direction, the Y direction and the Z direction is changed. The invention further relates to an auxiliary ultrasound milling machining system for laser micro-texture prefabricating.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Electrochemical Fabrication Methods for Producing Multilayer Structures Including the use of Diamond Machining in the Planarization of Deposits of Material

InactiveUS20090020433A1Improve abilitiesFast planarizationCellsSemiconductor/solid-state device manufacturingMulti materialSolid region

Electrochemical fabrication methods for forming single and multilayer mesoscale and microscale structures are disclosed which include the use of diamond machining (e.g. fly cutting or turning) to planarize layers. Some embodiments focus on systems of sacrificial and structural materials which are useful in Electrochemical fabrication and which can be diamond machined with minimal tool wear (e.g. Ni—P and Cu, Au and Cu, Cu and Sn, Au and Cu, Au and Sn, and Au and Sn—Pb), where the first material or materials are the structural materials and the second is the sacrificial material). Some embodiments focus on methods for reducing tool wear when using diamond machining to planarize structures being electrochemically fabricated using difficult-to-machine materials (e.g. by depositing difficult to machine material selectively and potentially with little excess plating thickness, and / or pre-machining depositions to within a small increment of desired surface level (e.g. using lapping or a rough cutting operation) and then using diamond fly cutting to complete he process, and / or forming structures or portions of structures from thin walled regions of hard-to-machine material as opposed to wide solid regions of structural material.

Owner:MICROFAB

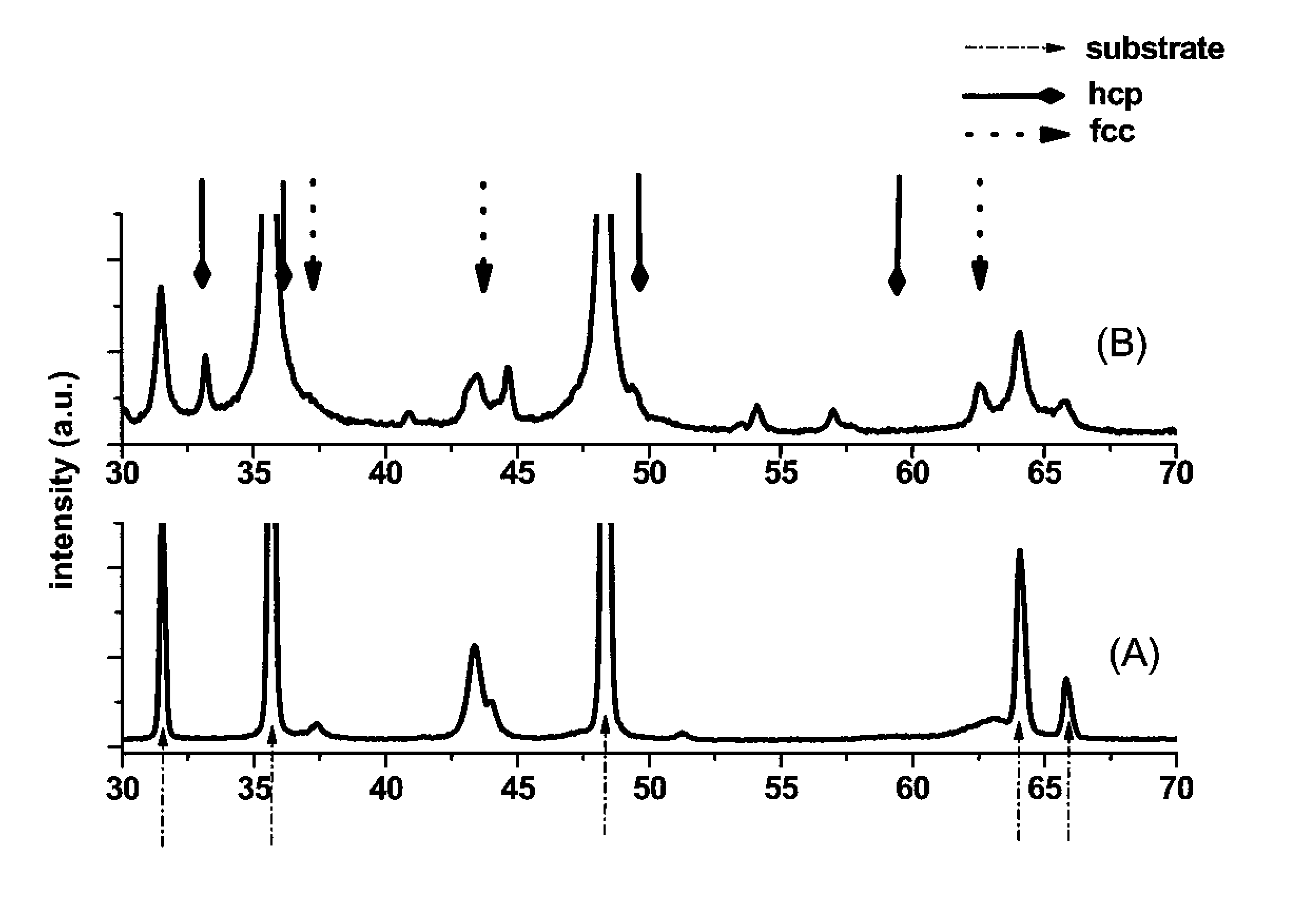

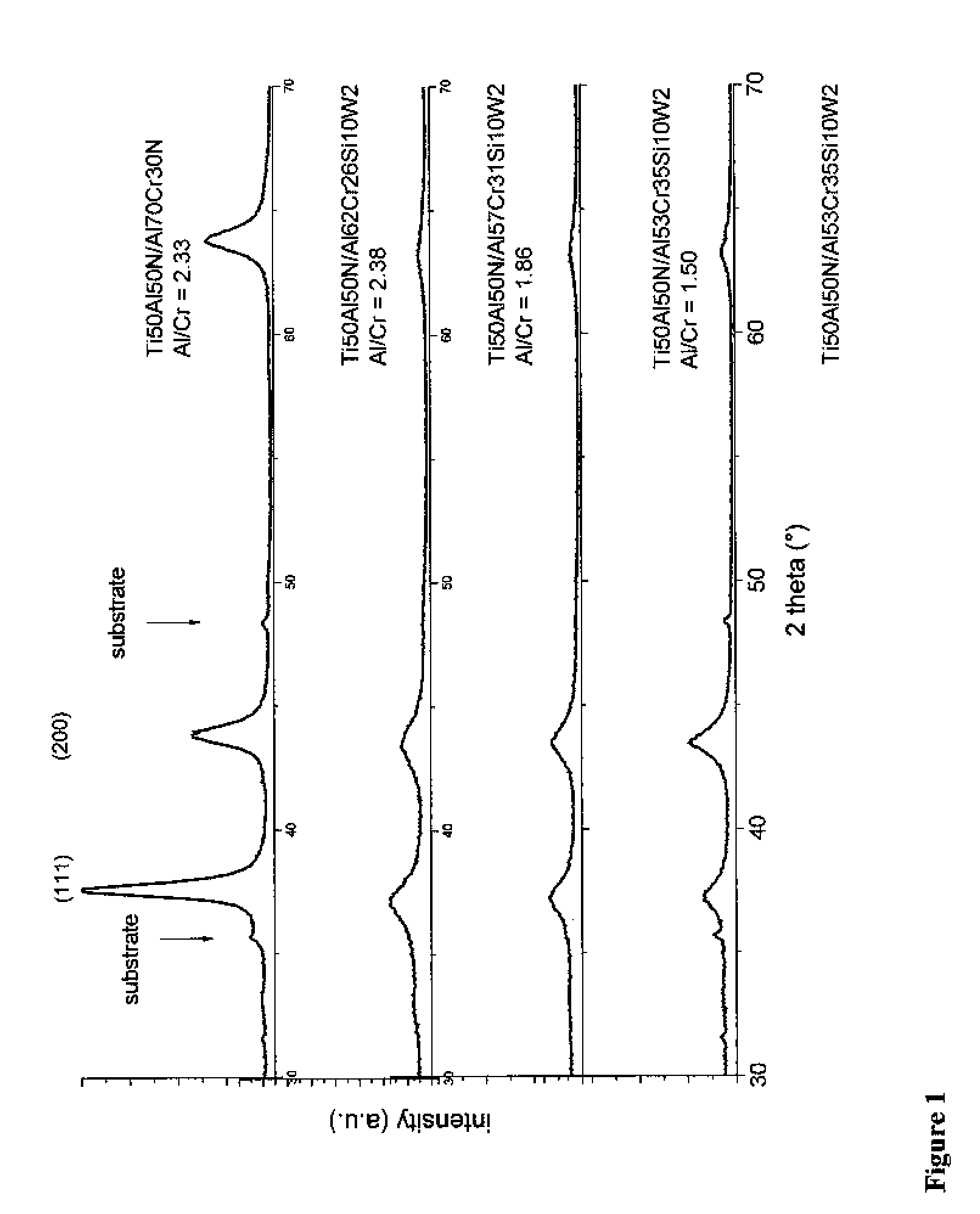

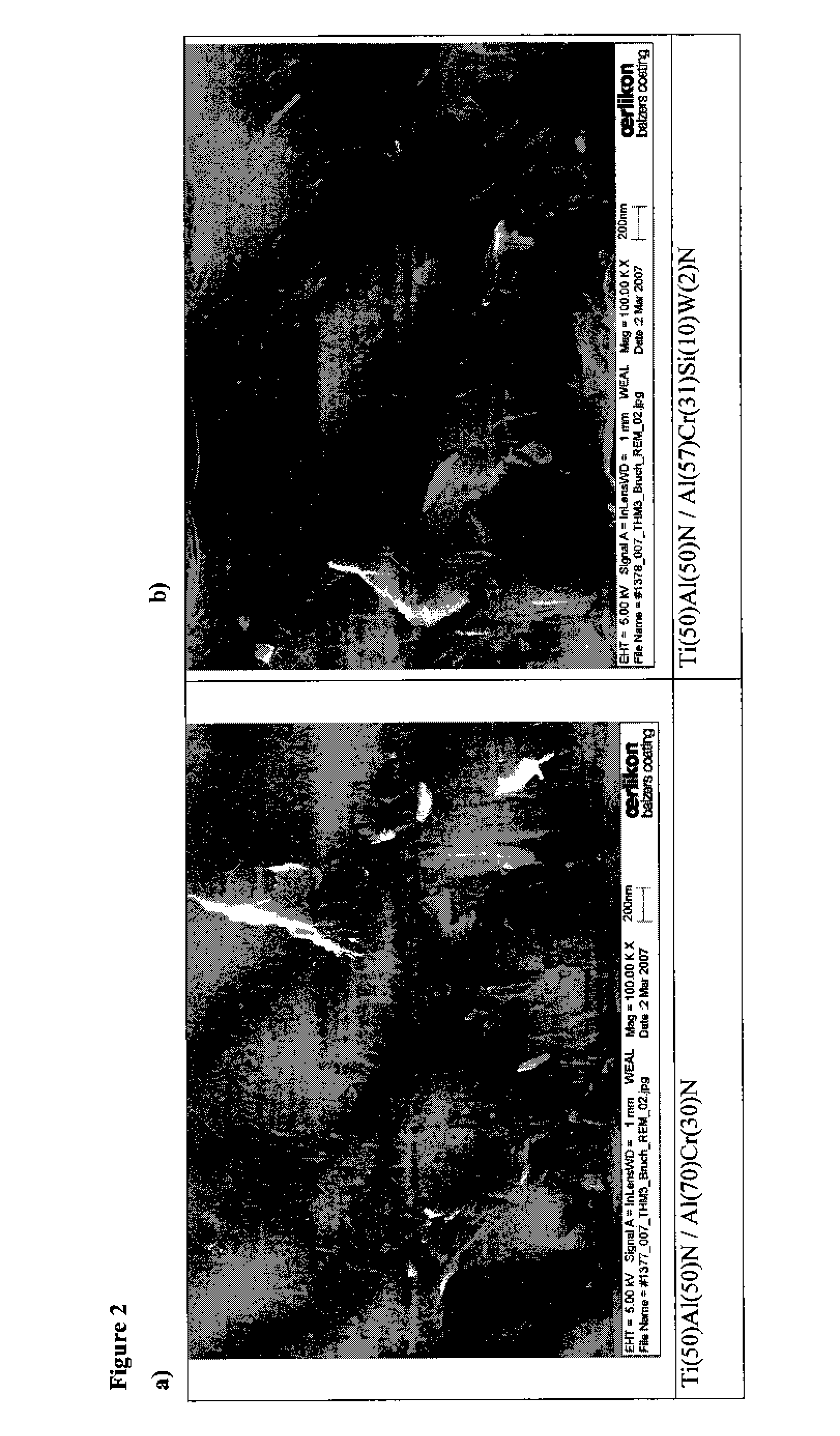

Wear resistant hard coating for a workpiece and method for producing the same

ActiveUS7960016B2Excellent oxidation and hot hardness propertyImprove performancePigmenting treatmentMolten spray coatingWear resistantTitanium alloy

The present invention provides an optimized hard coating and a workpiece, especially a cutting tool coated with a hard coating to increase tooling performance with difficult to machine materials such as high speed steels, titanium alloys, nickel alloys, austenitic steels and especially hard materials like hardened tool steel having a hardness of higher 50, preferably of higher 55 HRC. This is achieved by a workpiece coated with a wear resistant multilayered comprising at least a first supporting layer and a second nanocrystalline layer, whereas the first layer comprises a coating material of the following composition (TiaAl1-a)N1-x-yCxOy with 0.4<a<0.6, and 0≦̸x and y<0.3, or (AlbCr1-b)N1-x-yCxOy with 0.5<b<0.7, and 0≦̸x and y<0.3. The second layer comprises a coating material of the following composition (Al1-c-d-eCrcSidMe)N1-x-yCxOy whereas M stands for at least one element of the transition metals of group 4, 5, 6 of the periodic system except Chromium and 0.2<c≦̸0.35, 0<d≦̸0.20, 0<e≦̸0.04.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

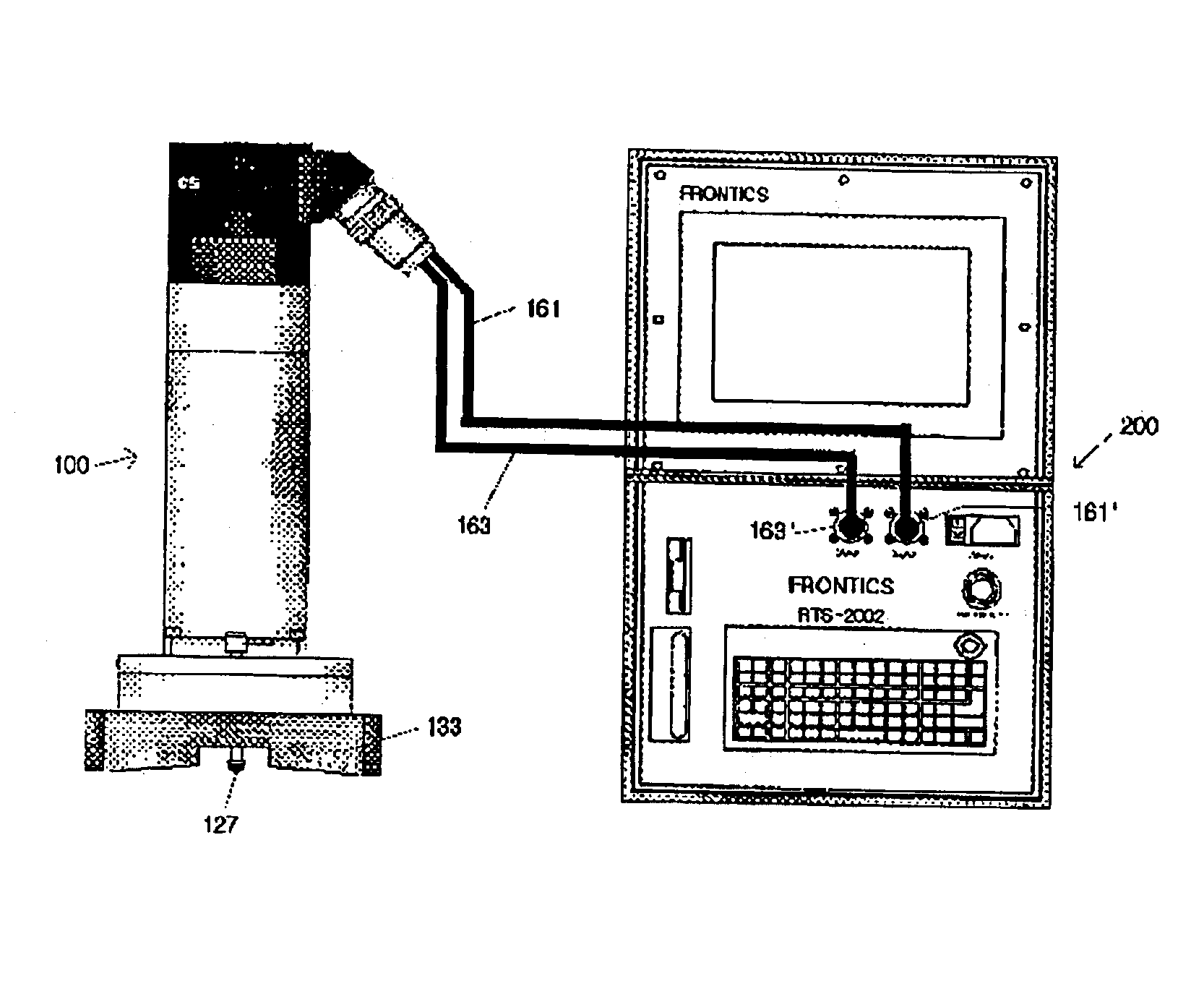

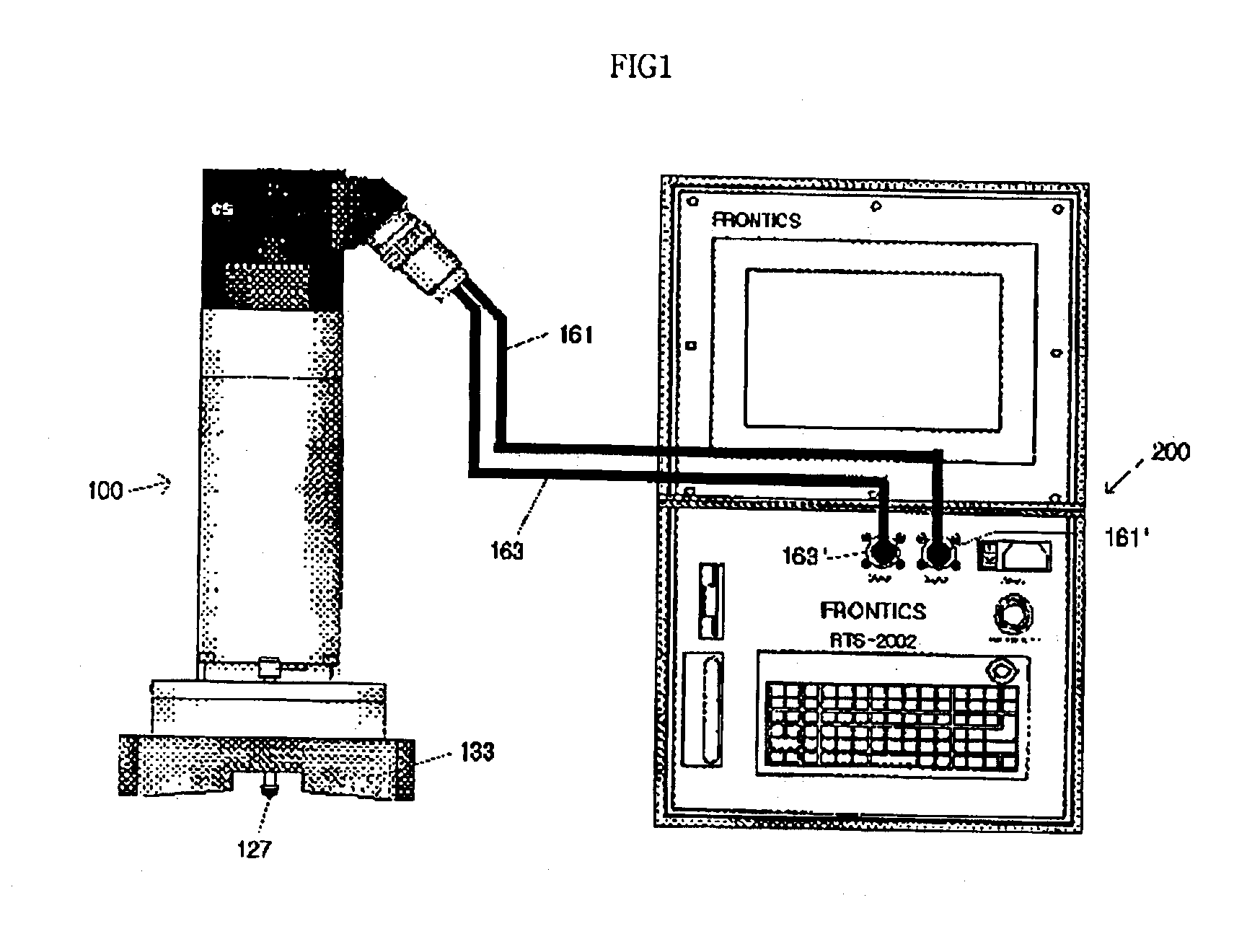

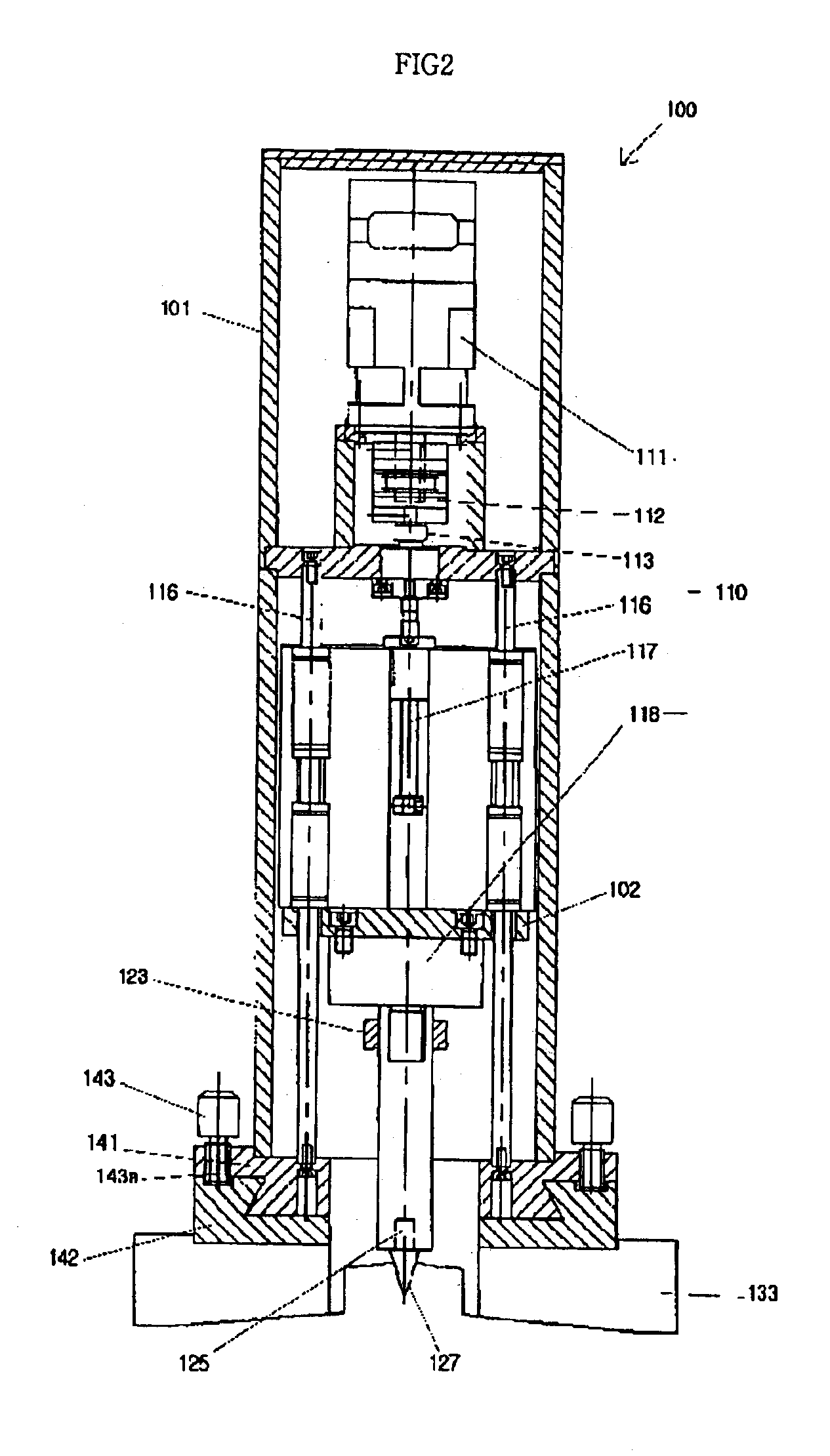

Apparatus for determining residual stress, method for determining residual stress data using it, residual stress determining method using it and recording medium thereof

InactiveUS6851300B2Improve mechanical propertiesMinimized volumeForce measurementInvestigating material hardnessNon destructiveMeasurement device

Disclosed herein is an apparatus for measuring residual stress, methods of measuring residual stress data and residual stress using the apparatus, and a recording medium for storing software of the residual stress measuring method. The present invention is advantageous for evaluation of a mechanical material property and is non-destructive. Further, the present invention is widely applied to fields ranging from a microscopic area, such as a thin film or micro device, to a large-sized structure, and is not influenced by a microstructure by controlling the range of an applied load. Further, the measuring apparatus of the present invention is minimized in its volume to be easily attached to an actual structure. Further, in the present invention, various attaching devices are employed, thus enabling the apparatus to be attached to various materials regardless of the size and type of object materials to measure residual stress. Further, the measuring apparatus of the present invention is horizontally movable, so there is no need to move an apparatus body itself so as to take measurements at several positions of several materials. Further, the present invention does not require separate measurements for correcting experimental constants at the time of analyzing measured data.

Owner:FRONTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com