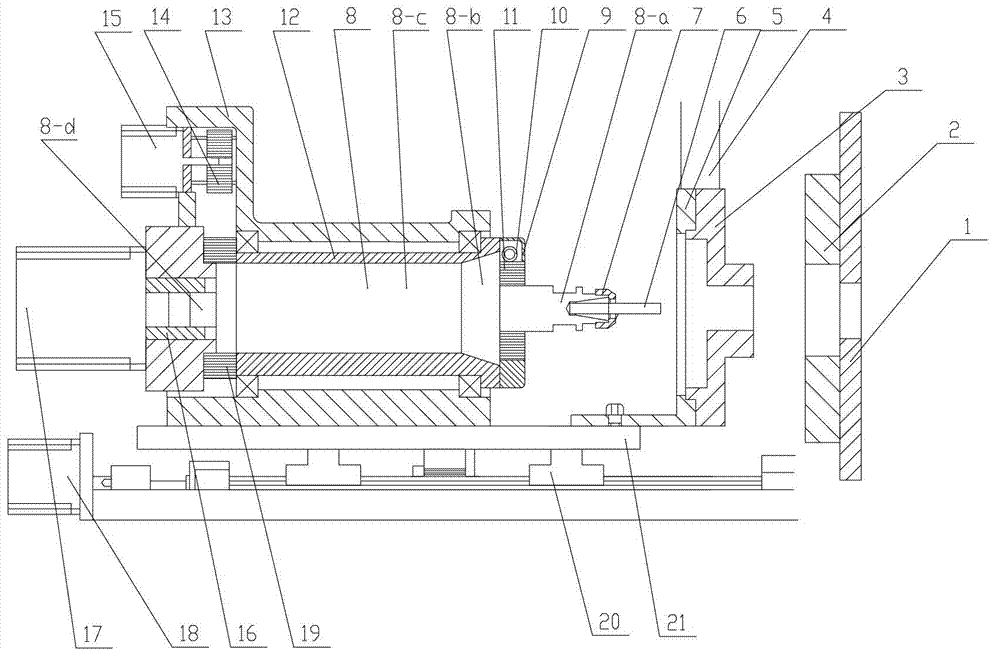

Portable spiral hole milling device and machining method

A helical milling hole, portable technology, applied in the direction of feeding devices, metal processing, automatic control devices, etc., can solve the problems of affecting the accuracy of the hole position, manual positioning, heavy weight, etc., to improve processing quality and efficiency, easy to hold, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

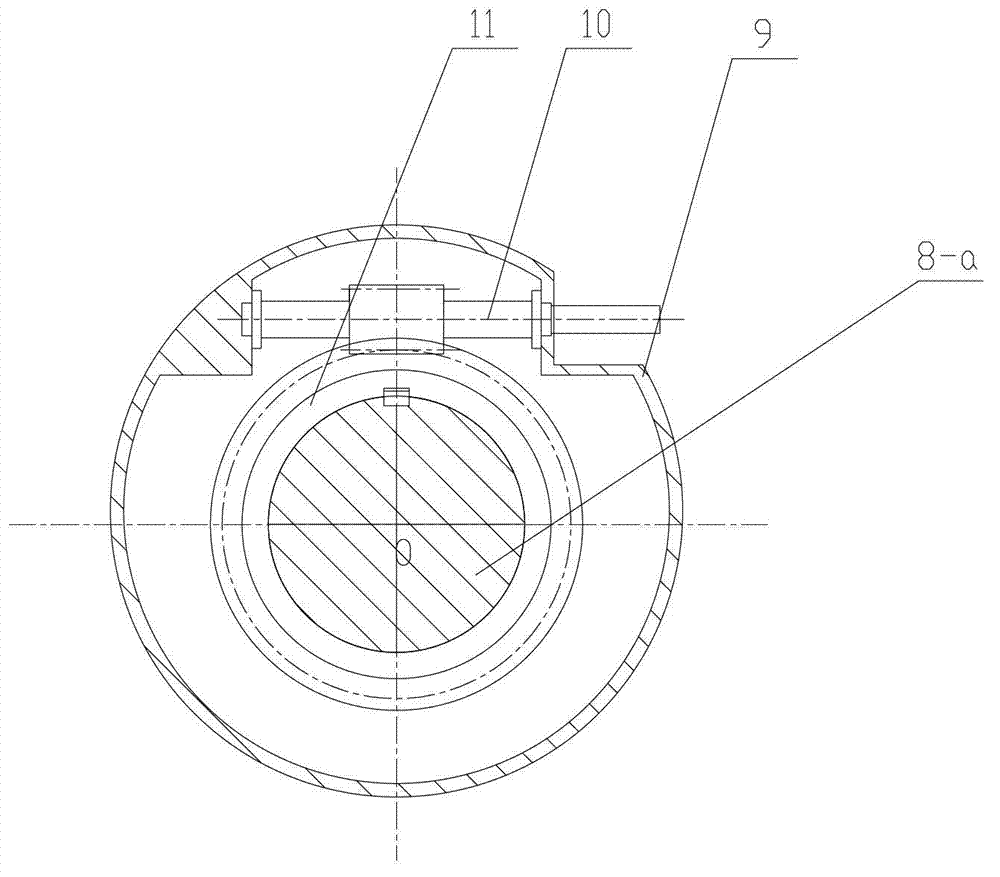

[0022] Embodiment 1: process the hole of φ10 with the milling cutter of φ8, the specific processing process is as follows:

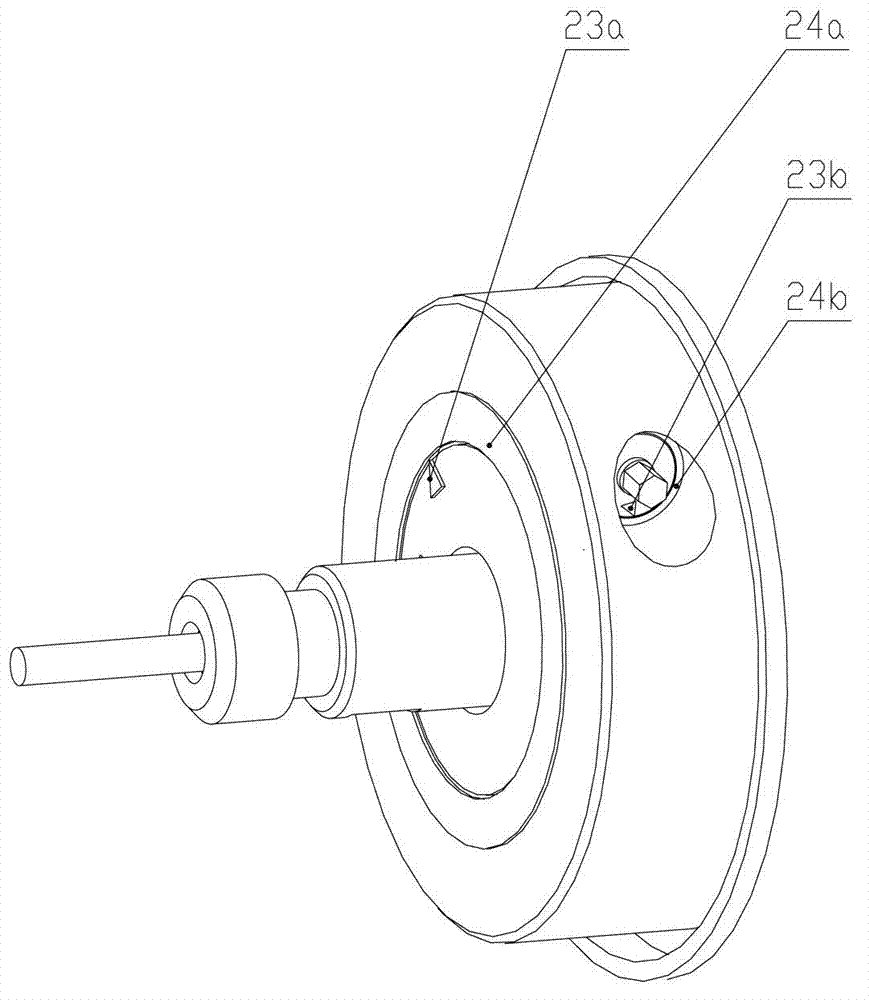

[0023] ① Adjust the eccentricity according to the size of the selected tool and the size of the processed hole, and adjust the eccentricity by rotating the worm 10, so that the dials on the worm wheel 10 and the worm 11 show that the current eccentricity is 1mm;

[0024] ②Move the device in a hand-held form, so that the fixing sleeve 3 is connected to the drilling template 2, and it is no longer necessary to hold it by hand during the processing;

[0025] ③Start the helical milling device, and the chips during processing are removed through the dust suction pipe 4;

[0026] ④ If the hole size φ10 to be machined remains unchanged, after one hole is machined, move to another hole machining position with the hand, and repeat the above 2-3 steps until the machine is finished;

[0027] If the same φ8 milling cutter needs to process a φ12 hole after machining a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com