Patents

Literature

42results about How to "Realize processing needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

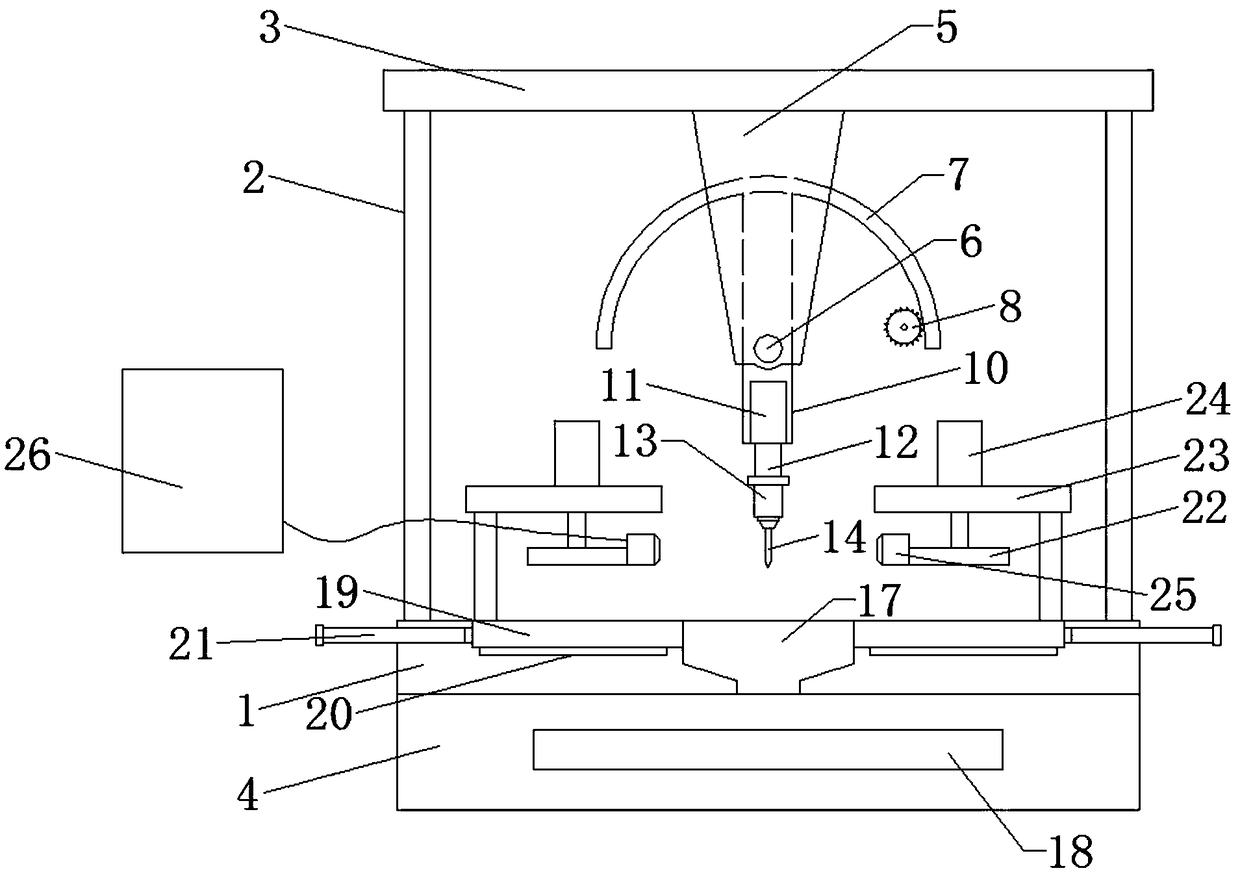

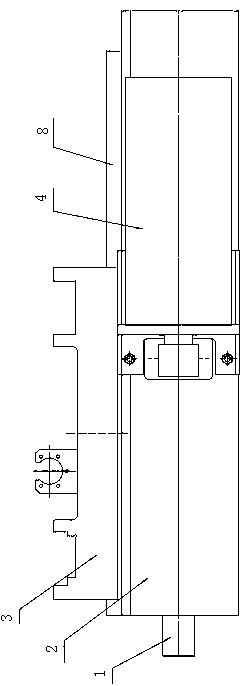

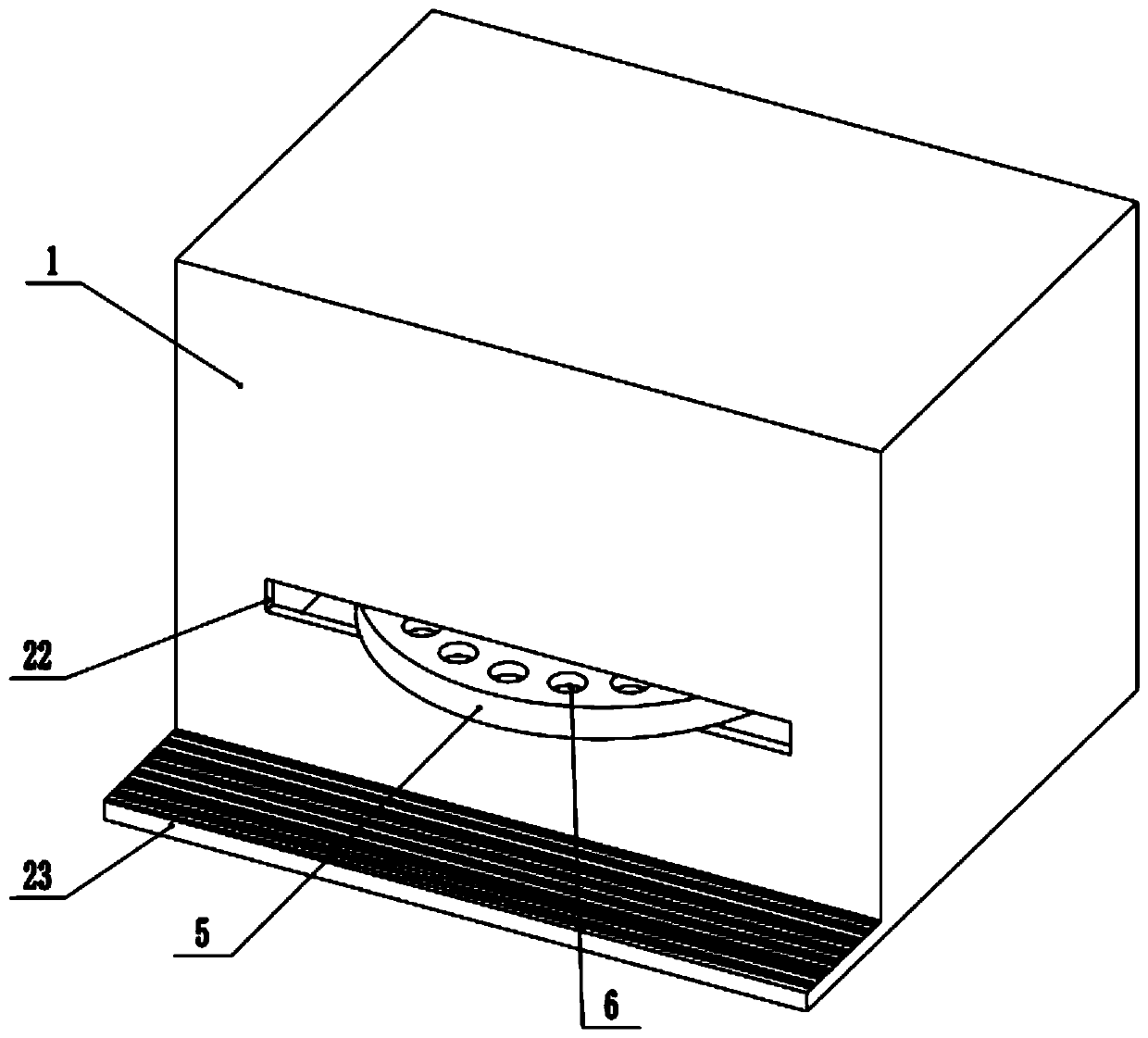

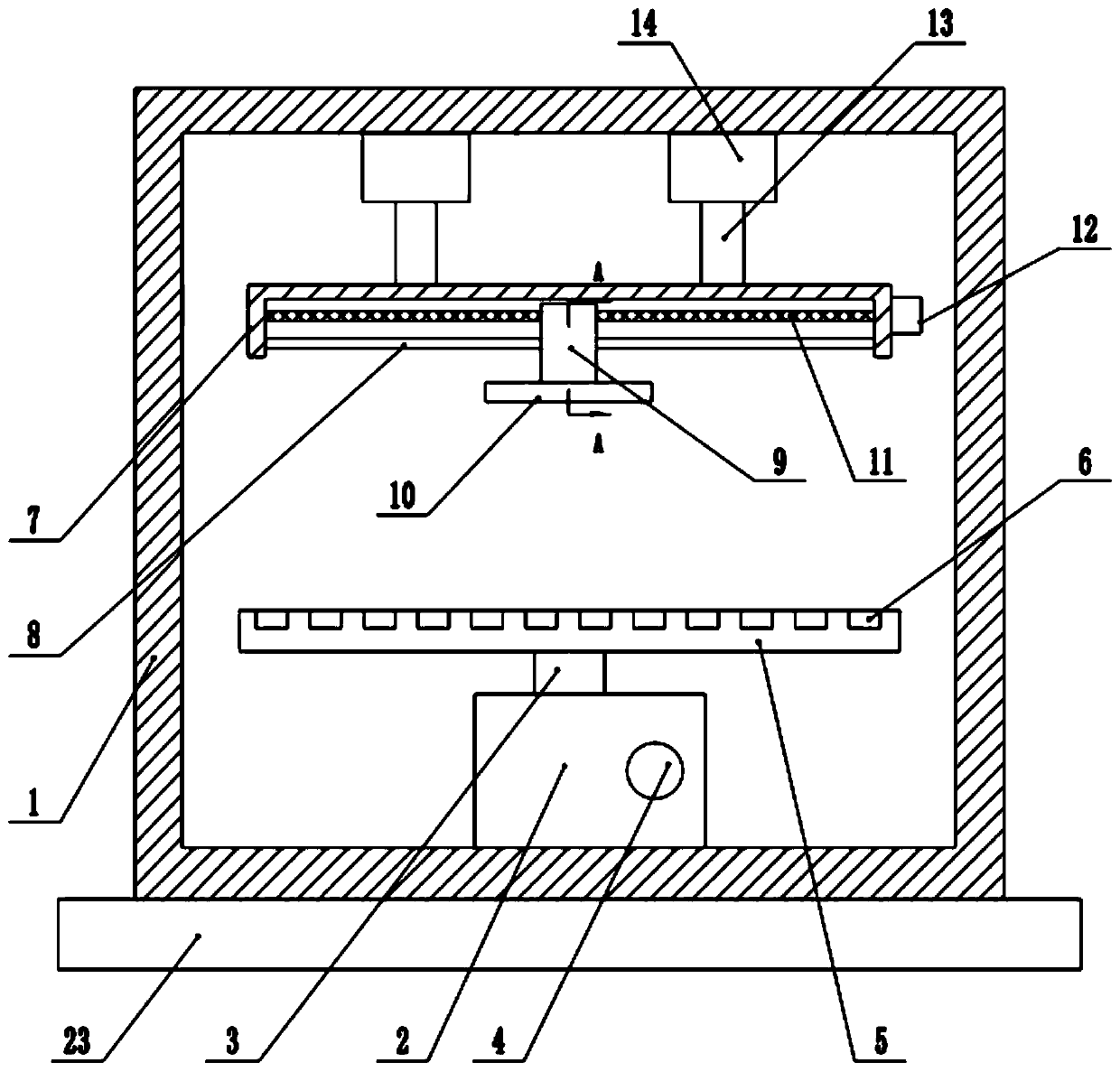

Inclinable drilling machine used for machining furniture

InactiveCN109352743AChange tilt angleRealize processing needsStationary drilling machinesBark-zones/chip/dust/waste removalMachiningDrilling machines

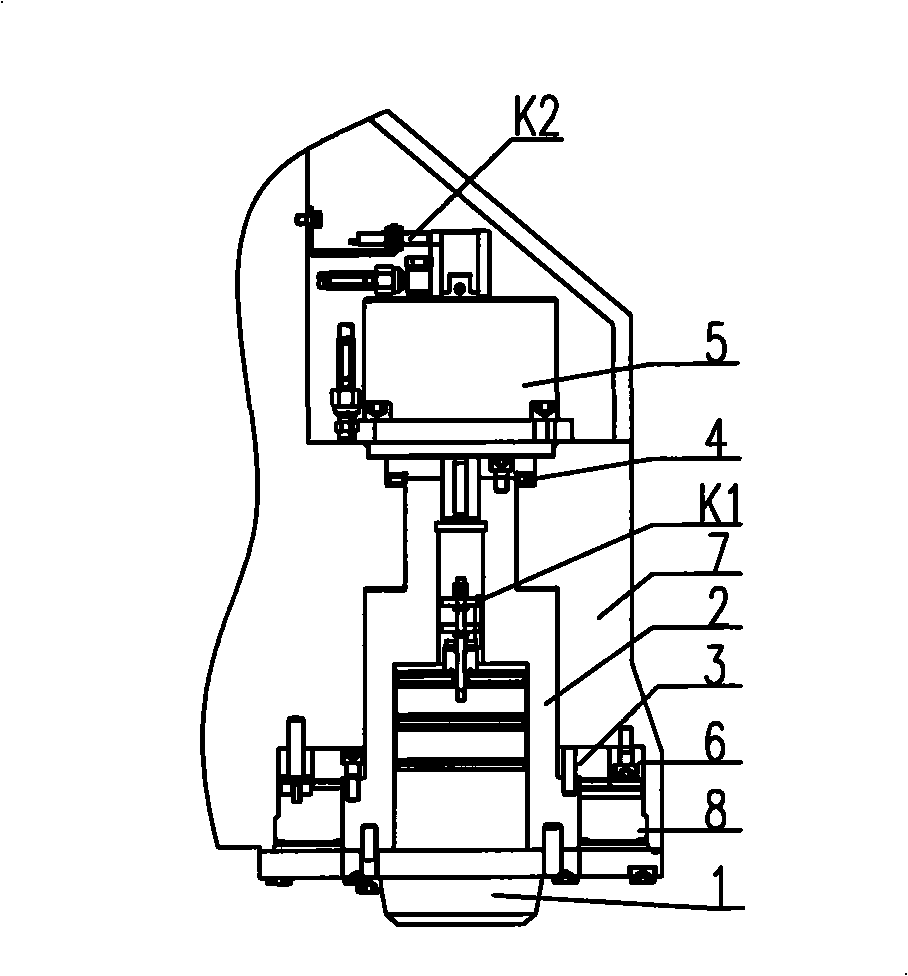

The invention relates to the field of furniture machining and particularly discloses an inclinable drilling machine used for machining furniture. The drilling machine comprises a working table, a supporting rod, a top plate, a base and a supporting base. An arc-shaped plate bent upwards is arranged above a rotating shaft. A radial installing base is fixed to the middle portion of the arc-shaped plate. A downward electric telescoping device is fixed to the lower end of the installing base. The output end of the electric telescoping device is fixedly connected with a connecting rod coaxially. The other end of the connecting rod is fixedly connected with a motor coaxially. An output shaft of the motor is fixedly connected with a drill bit. A rack is arranged on the inner wall of the arc-shaped plate in the arc-shaped direction. The rack is connected with a drive gear in an engaged manner. According to the drilling machine, by arranging the arc-shaped plate capable of rotating around the rotating shaft, the installing base fixed to the arc-shaped plate faces different inclination angles, the inclination angles of the drill bit are changed to drill wood plates in an inclining manner, the requirement for furniture machining is met, multi-angle drilling is achieved, and the drilling machine is more comprehensive in function and wider in application range compared with an existing drilling machine.

Owner:张玉真

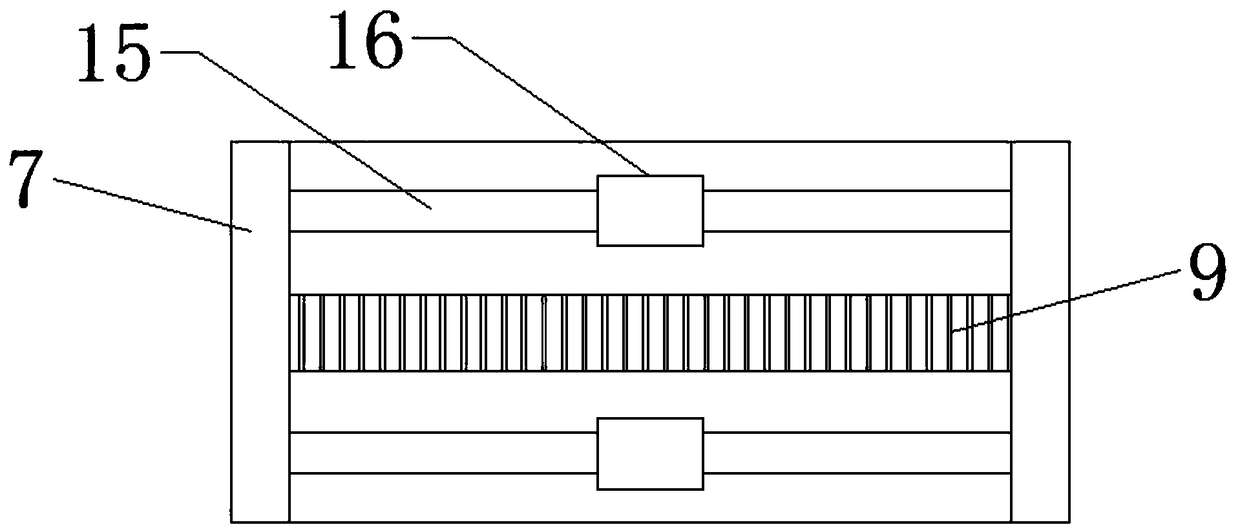

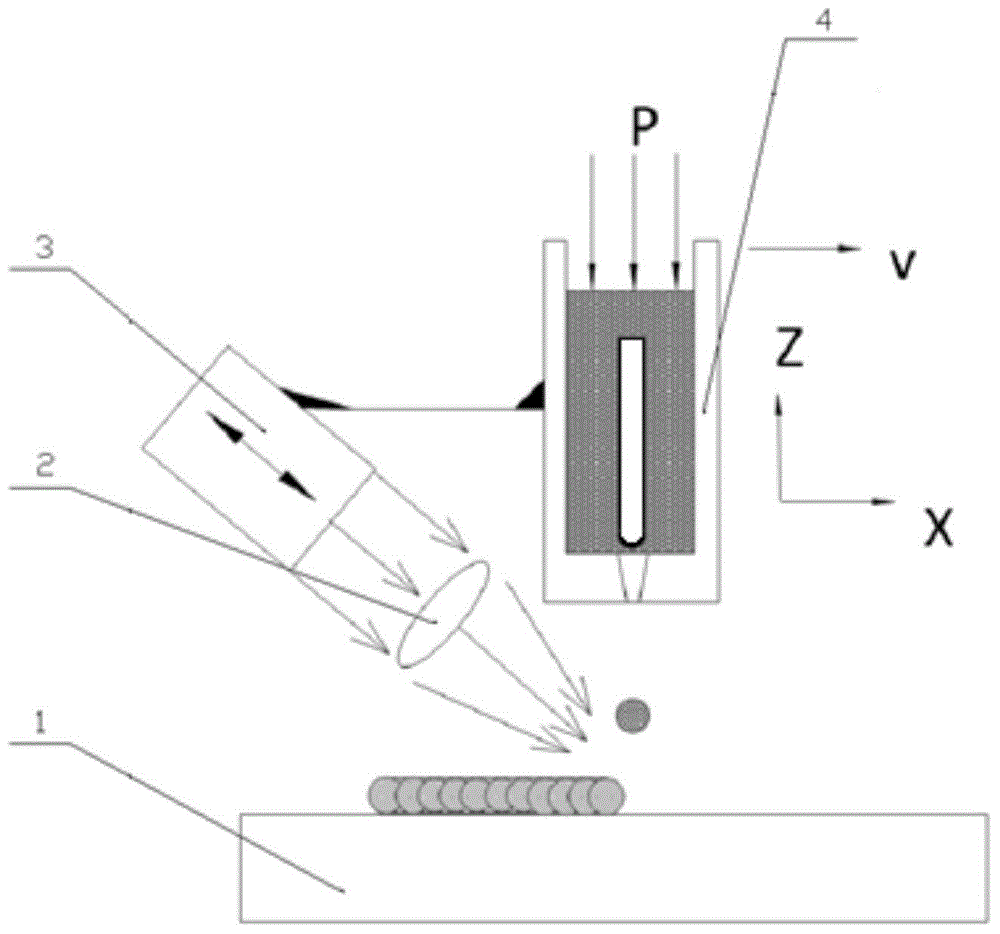

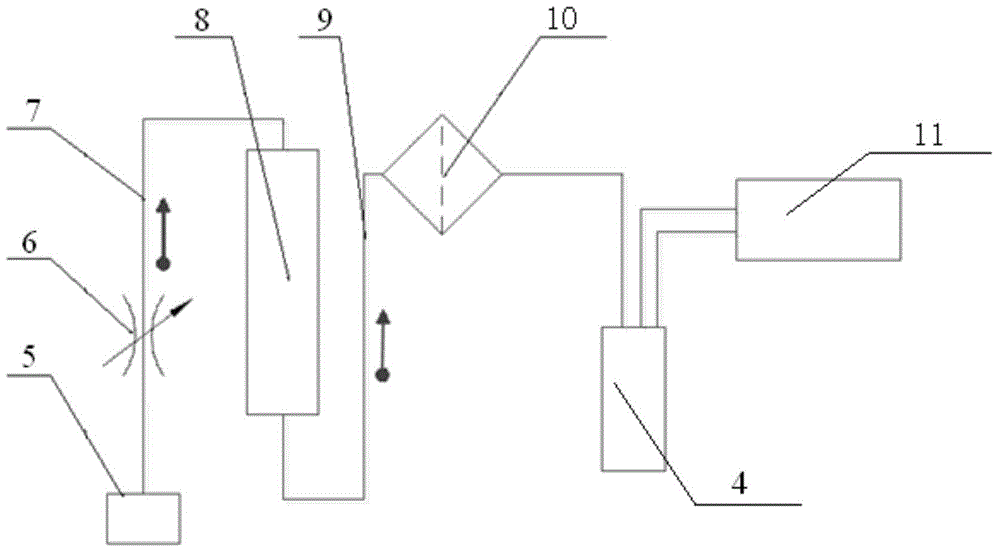

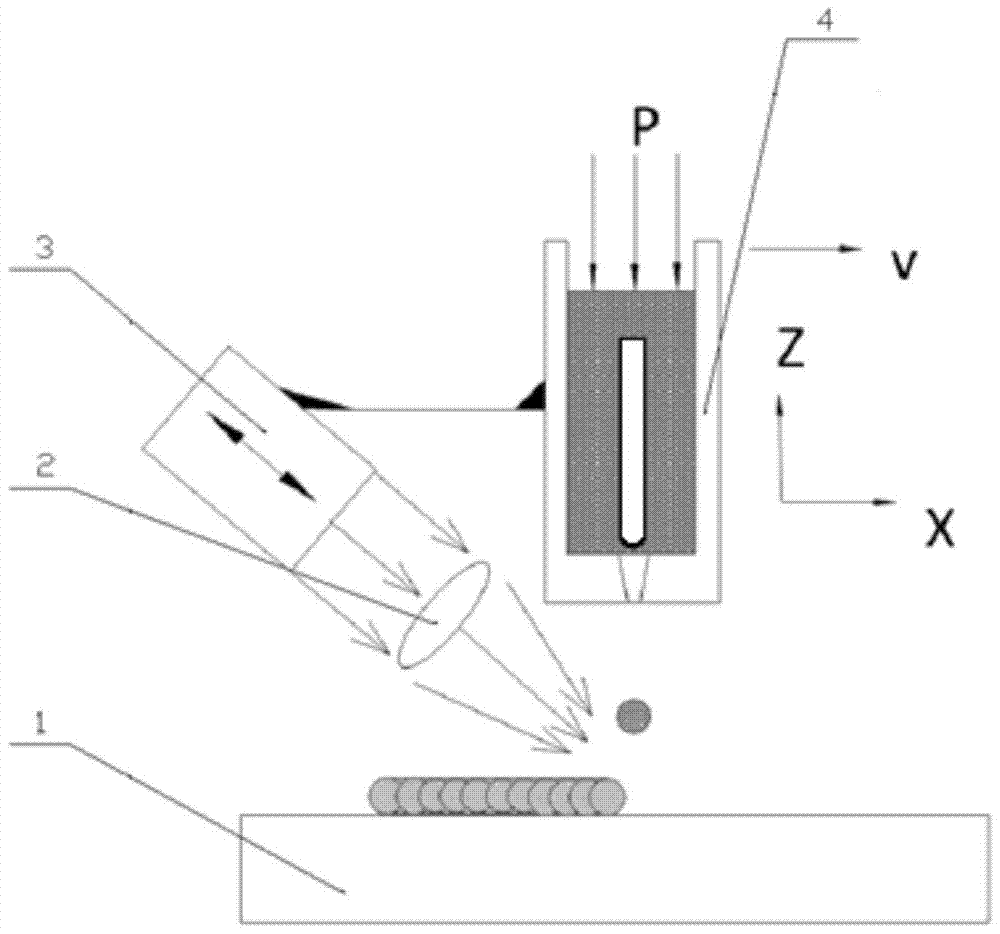

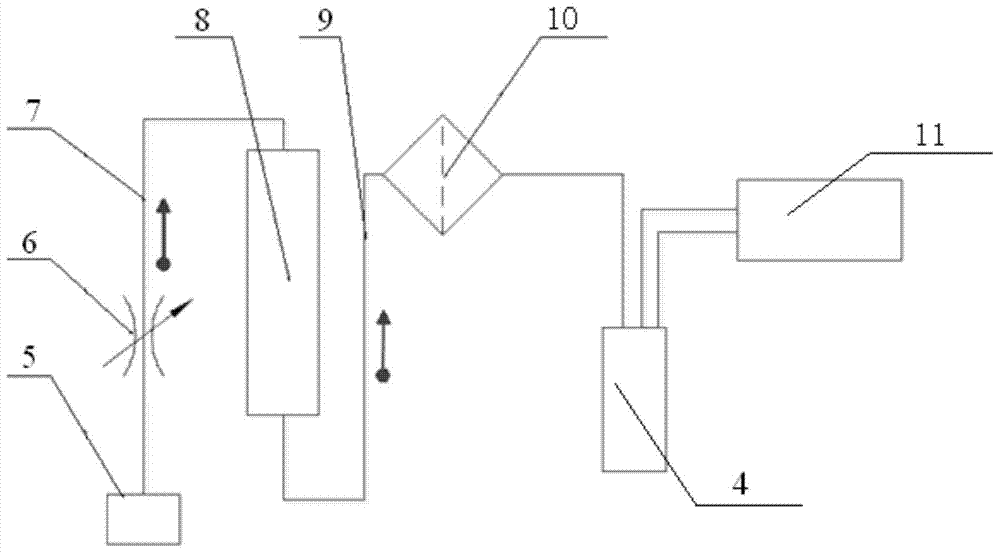

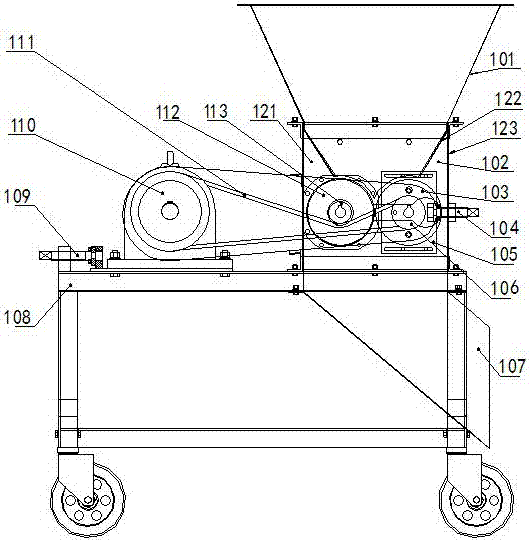

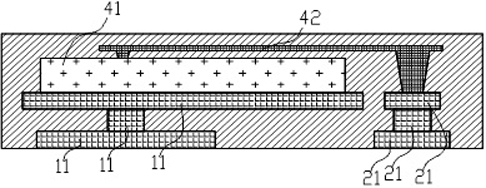

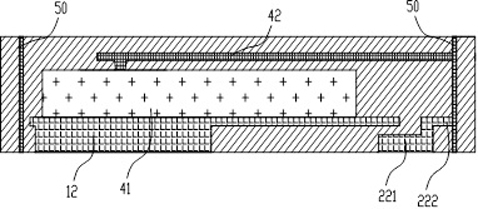

Liquid dripping type photo-curing following printing system and liquid dripping type photo-curing following printing method

ActiveCN104924617ARealize processing needsPrecise positioningAdditive manufacturing apparatusThree-dimensional spaceEngineering

The invention discloses a liquid dripping type photo-curing following printing system and a liquid dripping type photo-curing following printing method. The liquid dripping type photo-curing following printing system comprises a two-dimensional movable platform, a substrate, a light source, a focusing lens, a photo-curing liquid supplying system, an electromagnetic valve sprayer, a controller and a one-dimensional movable platform, wherein the controller is used for controlling the electromagnetic valve sprayer; the one-dimensional movable platform is used for driving the substrate to move in the vertical direction; the substrate is fixed on the one-dimensional movable platform; the light source, the focusing lens and the electromagnetic valve sprayer are fixed on a two-dimensional movable platform; light emitted from the light source is focused via the focusing lens to form a light spot; the light spot is positioned on the substrate and right below a liquid outlet of the electromagnetic valve sprayer; a liquid inlet of the electromagnetic valve sprayer is communicated with a liquid outlet of the photo-curing liquid supplying system; and the wavelength of the light emitted from the light source is the same with the wavelength of light required for curing of photo-curing liquid in the photo-curing liquid supplying system. By the liquid dripping type photo-curing following printing system, cells and photo-curing liquid can be precisely positioned in three-dimensional space, materials are not polluted, and materials are saved.

Owner:XI AN JIAOTONG UNIV

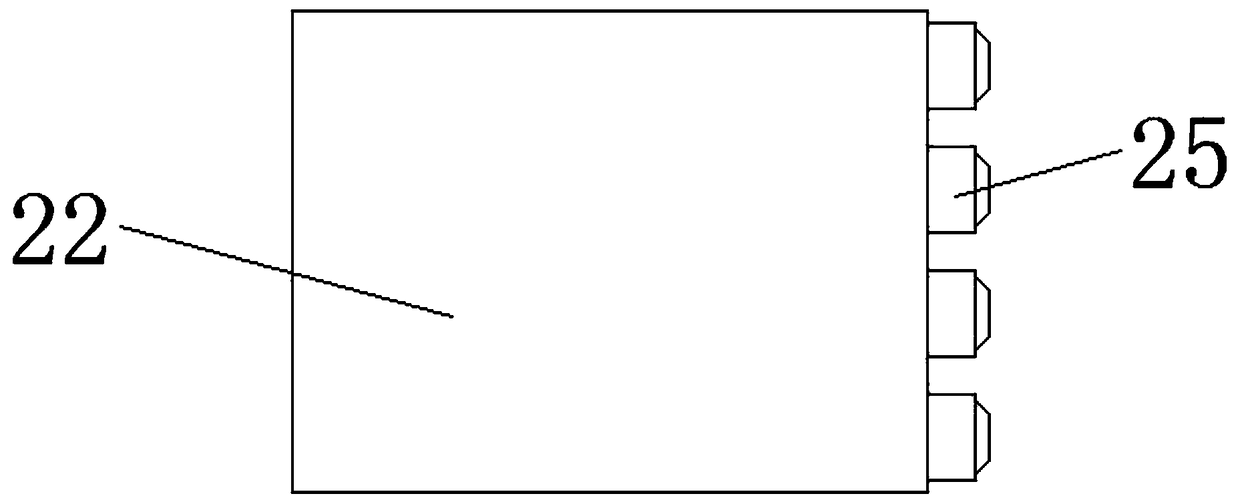

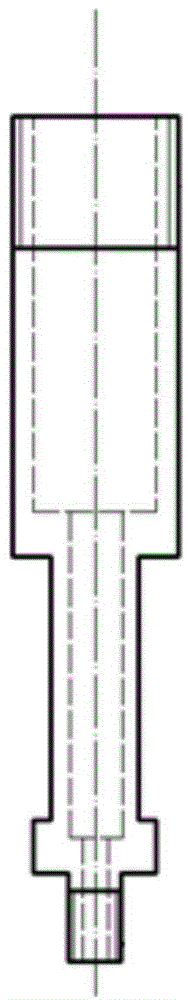

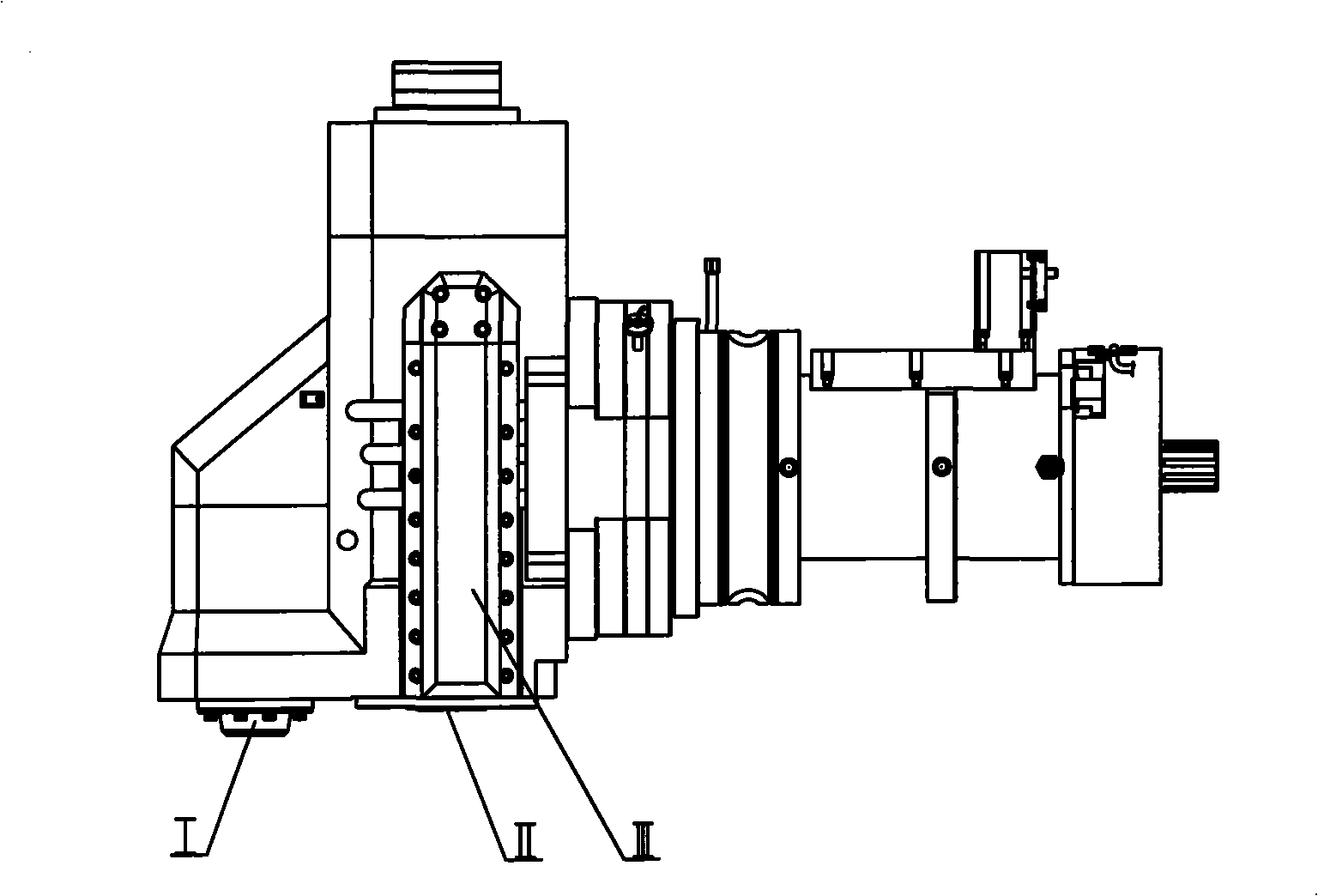

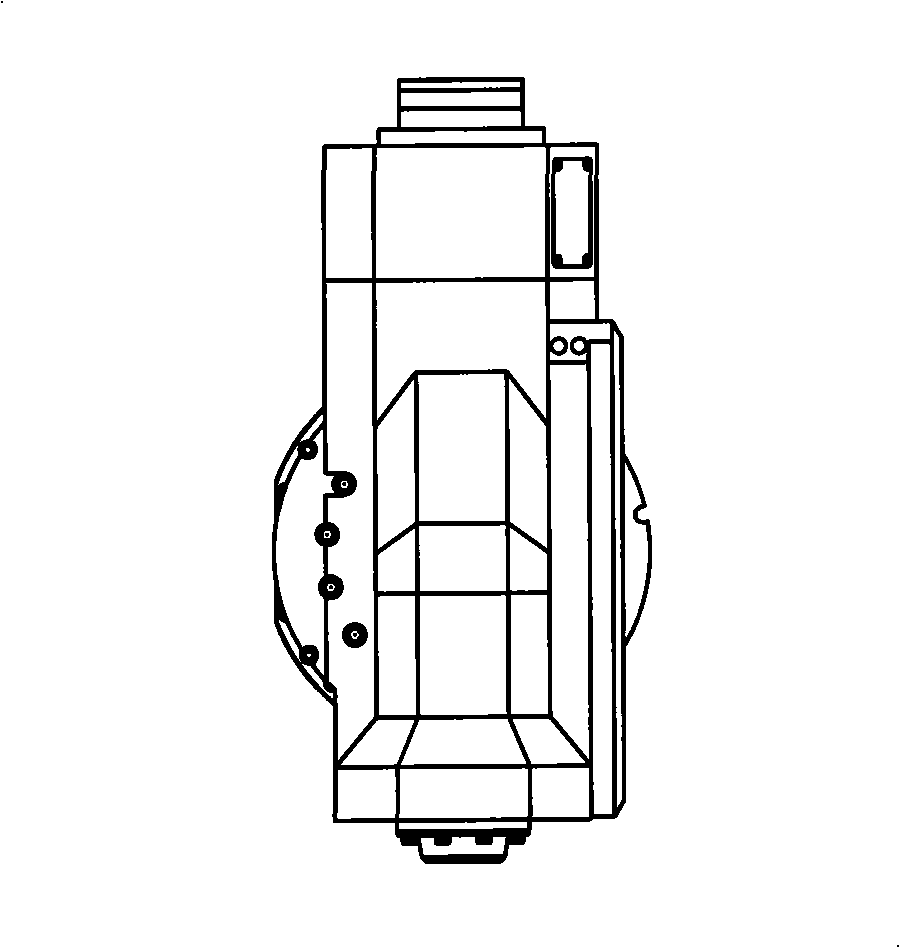

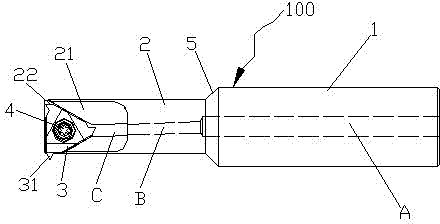

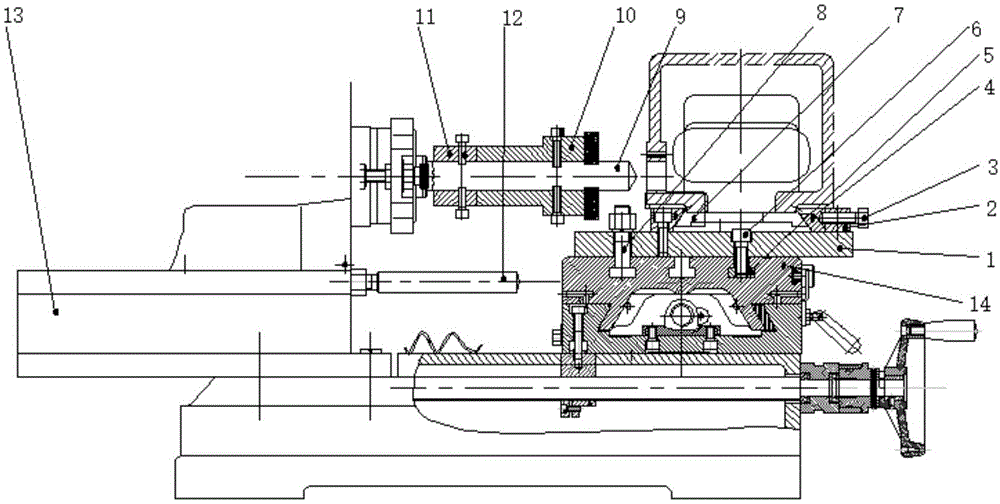

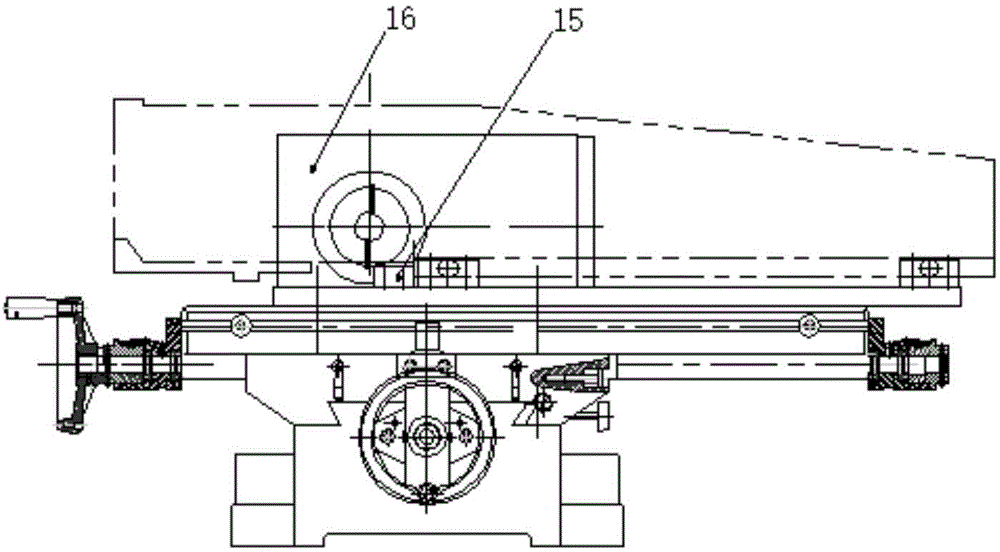

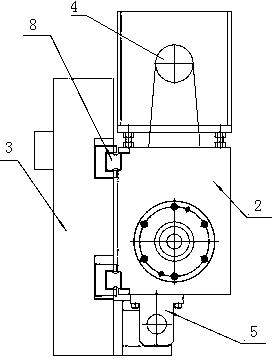

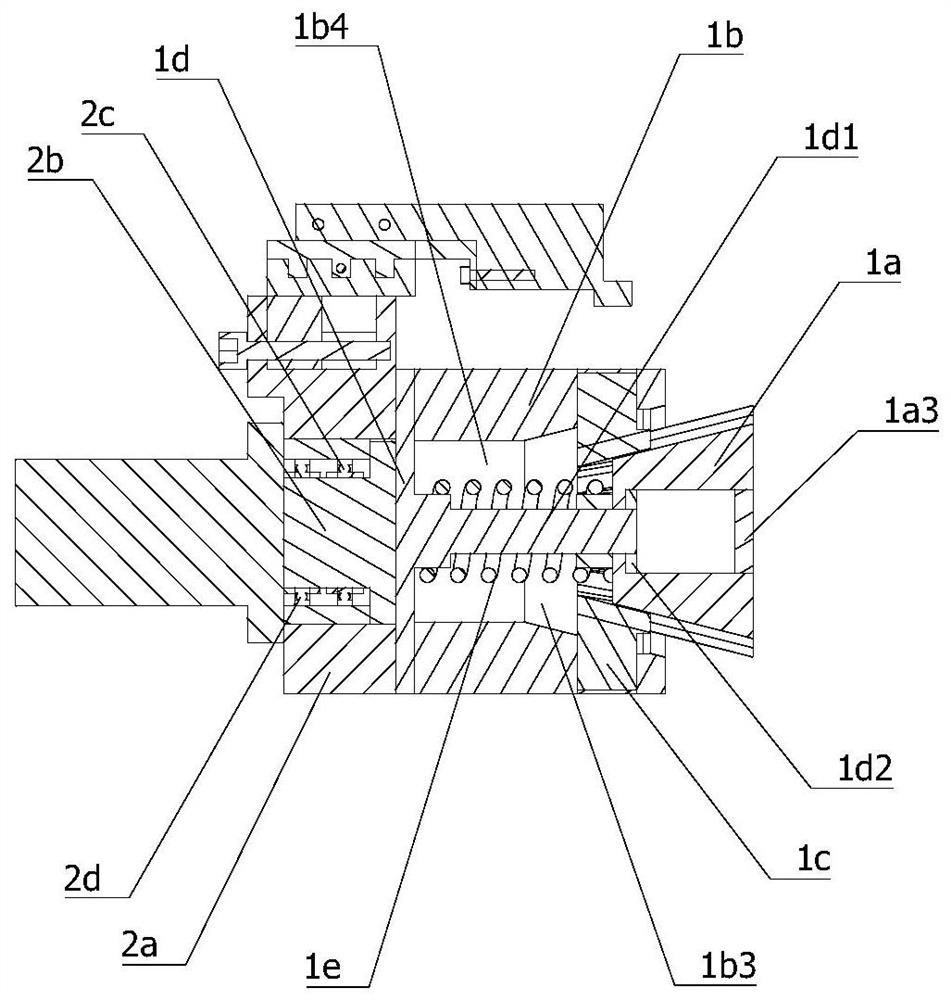

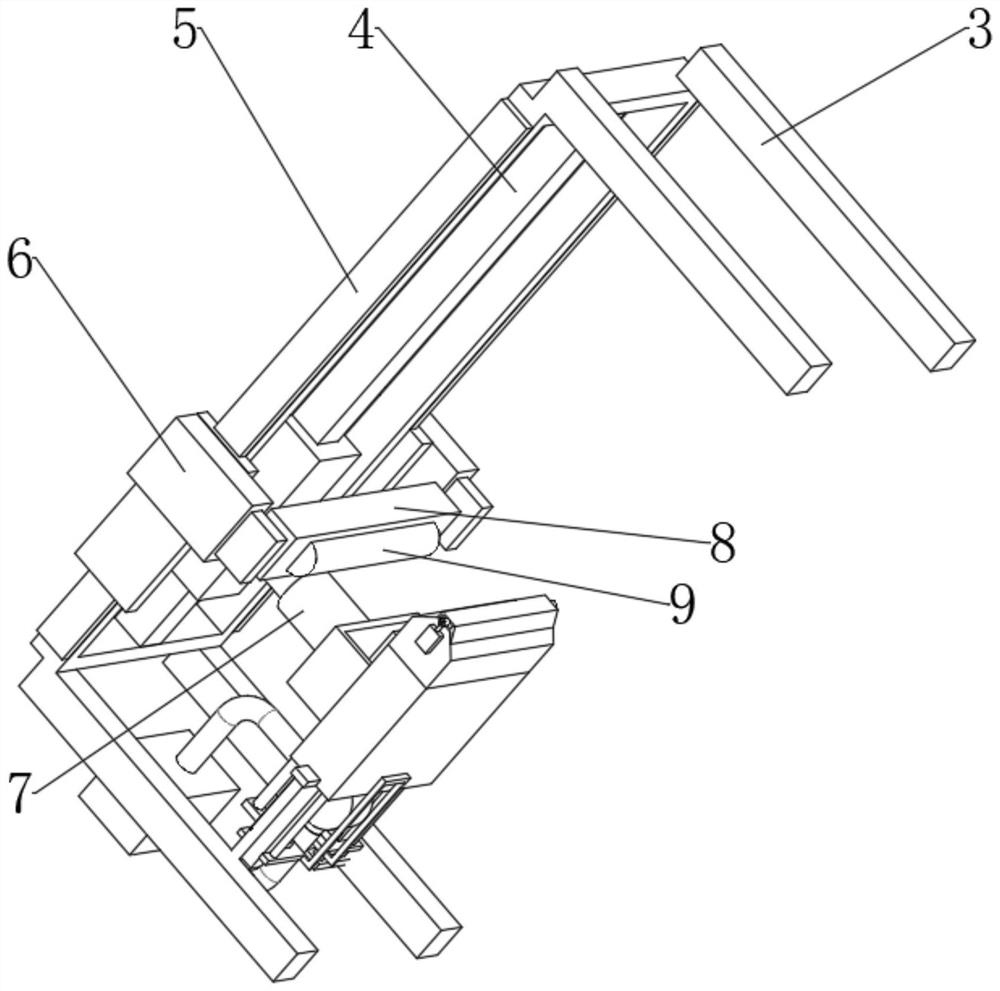

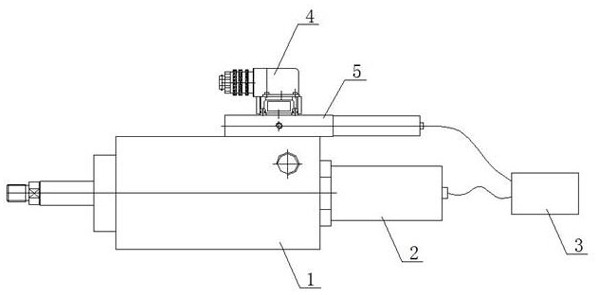

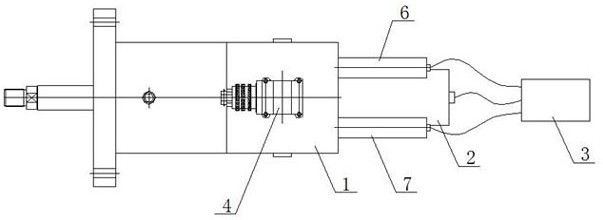

B-axis cutter holder device of a turn-milling complex machining center

InactiveCN101513716AShort tool overhangIncrease stiffnessMetal working apparatusPositioning apparatusProcessing accuracyPoint location

A B-axis cutter holder device of a turn-milling complex machining center is disclosed, which is mounted on a B-axis of a five-axis turn-milling complex machine and is fitted with matched electric, hydraulic, cooling and pneumatic control parts that are correspondingly integrated with a system on the machine, and a B-axis motor drives a transmission axis via a worm gear; the device is characterized in that, a turning cutter, a rotating cutter, a boring cutter and a milling cutter for machining special parts are respectively arranged at three-point location of the B-axis cutter holder; the indexable turning cutter is mounted at location I at the left end of the B-axis cutter holder device; the rotating cutter of which an overhanging length accords with the use requirement of the cutter is arranged at location II right in front of the B-axis cutter holder and machining operations such as boring, milling, drilling, threading and the like can be implemented; the locations I and II are provided with standard cutter interfaces; an overhanging ultra-long cutter in a dovetail structure is arranged at location III at the side face of a B-axis box body, and standard cutter or a designated knife holder can be mounted by the replacement of connectors; the B-axis cutter holder device realizes dividing locking via three fluted disc structures of an immovable fluted disc, a movable fluted disc and a locking fluted disc. The separation of the cutter locations achieves the machining requirement of the B-axis at random location within a range of operating angles, thus solving three key technical problems of how to ensure the precision of a spindle of the rotating cutter, how to enhance the rigidness of a turning mechanism and how to remain the machining precision under a specific machining status.

Owner:SHENYANG NO MACHINE TOOL FACTORY

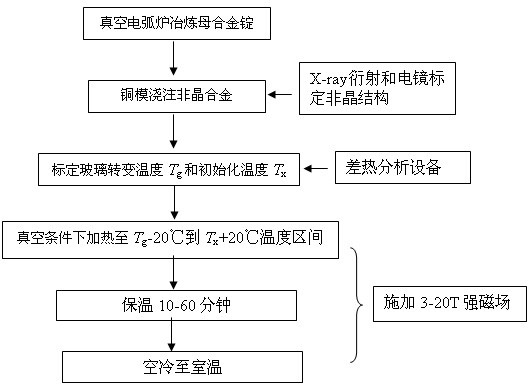

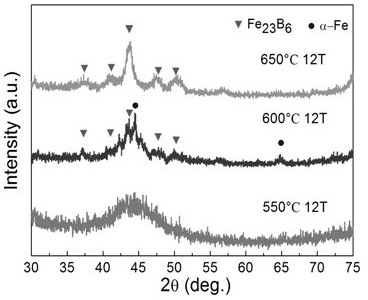

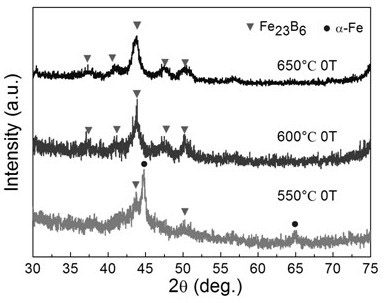

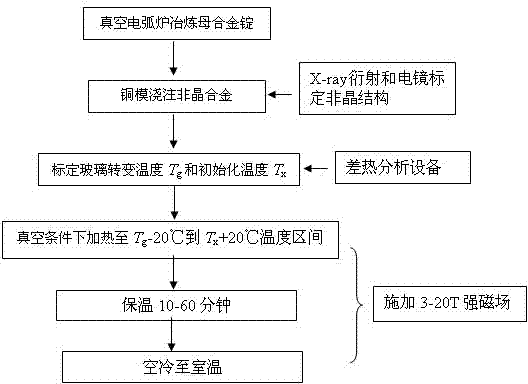

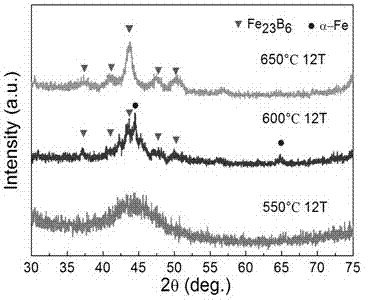

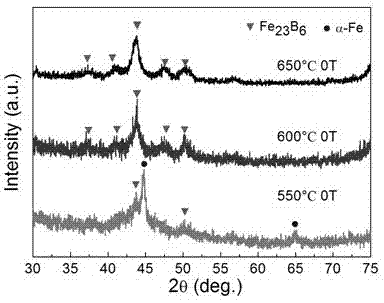

Method for improving soft magnetic properties of bulk amorphous alloy Fe-M-B

ActiveCN102424937AHigh strengthEnhanced coercive force is the soft magnetic property of bulk amorphous alloy Fe-M-BMagnetic materialsRoom temperatureVolumetric Mass Density

The invention belongs to the field of functional materials, and particularly relates to a method for improving the soft magnetic properties of bulk amorphous alloy Fe-M-B. The method comprises the following steps of: under vacuum conditions, heating the amorphous alloy Fe-M-B to an interval between a glass transition temperature (Tg-20) DEG C and a crystallization starting temperature (Tx+20) DEGC; insulating for 10-60 minutes; simultaneously applying a magnetic field of 3-20T in heating and insulating processes; after insulating, air-cooling to room temperature; and removing the magnetic field to obtain the bulk amorphous alloy Fe-M-B of which the saturation induction density is less than or equal to 145.7emu / g and the coercive force is less than or equal to 30A / m. The method provided by the invention effectively improves the soft magnetic properties of the alloy Fe-M-B under the condition that the alloy forming size is not reduced, thereby being favorable for developing amorphous nanocrystalline alloy with excellent properties.

Owner:NORTHEASTERN UNIV

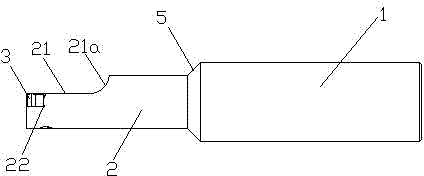

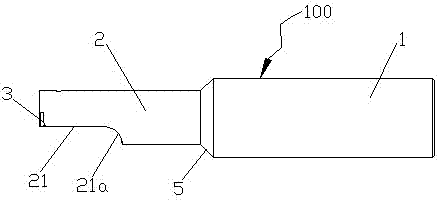

Combined straight shank thread milling cutter

InactiveCN102825345AEasy to processSuitable for processingThread cutting toolsMilling cutterEngineering

The invention discloses a combined straight shank thread milling cutter which comprises a cutter rod body, wherein the cutter rod body comprises a cylindrical cutter handle part for clamping and a cylindrical cutter rack rod connected integrally with the cutter handle part; a surface cutting platform extending backward is manufactured on the front end of the cutter rack rod; a crumb discharging arc surface capable of discharging crumbs conveniently is formed on the tail part of the surface cutting platform; a cutting blade is positioned and installed detachably on the surface cutting platform through a fastening screw; the cutting blade is at least provided with one cutting head; and the cutter rod body and the cutting blade are combined and assembled so as to form a separating-type straight shank multi-purpose thread milling cutter structure. The combined straight shank thread milling cutter provided by the invention is concise in structure, is low in cost, has the characteristics of high machining accuracy, good effects, and long service life, can meet the machining requirements of multiple types of threads, and is suitable for deep hole machining.

Owner:NINGBO CHUANJINGYU MECHANICAL TECH DEV

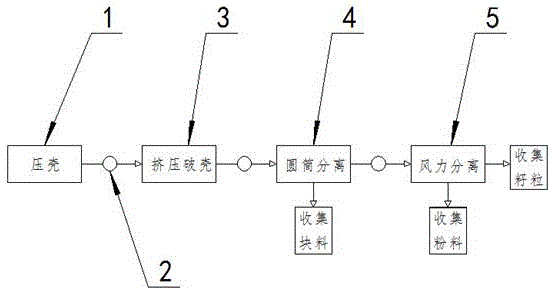

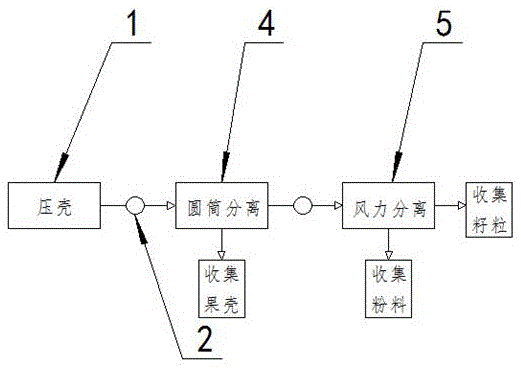

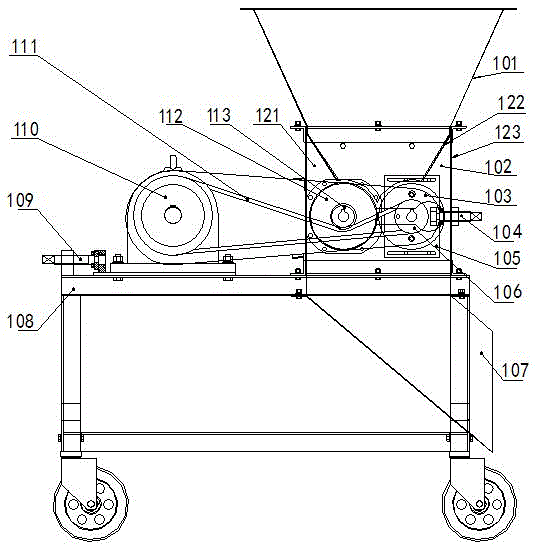

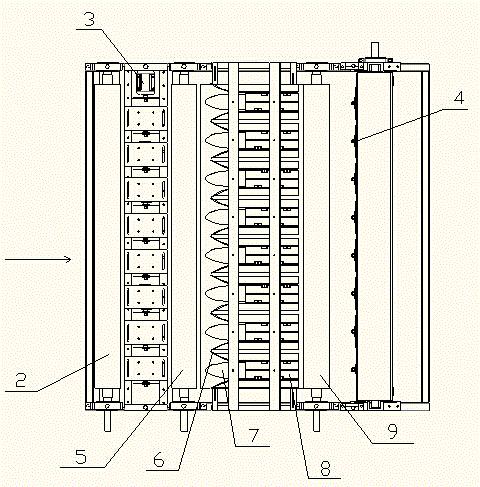

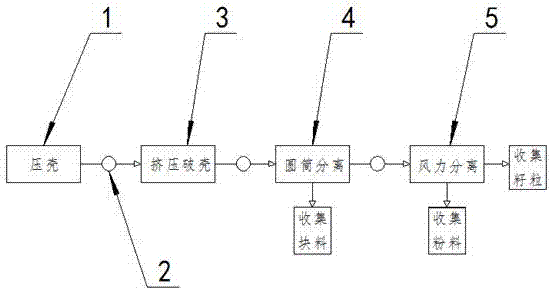

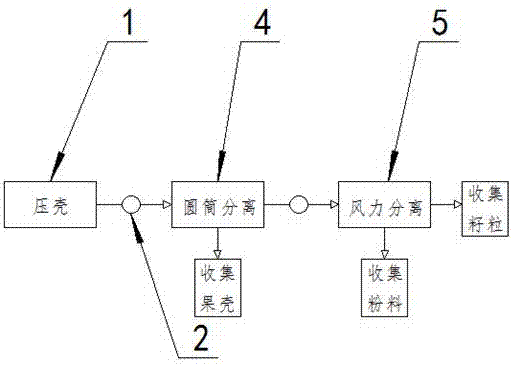

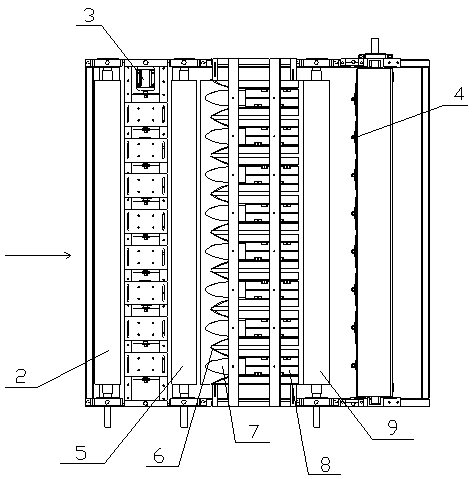

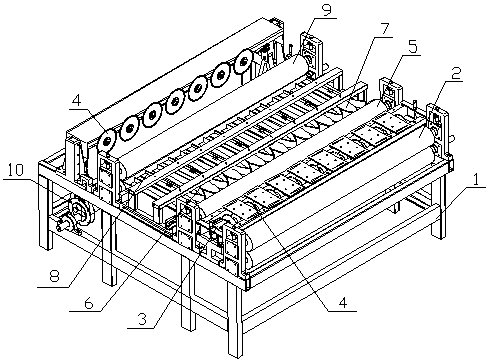

Poppy fruit preliminary processing integrated device and processing method

ActiveCN105583060ASave raw materialsSo as not to damageGas current separationHuskingEngineeringMachining process

The invention discloses a poppy fruit preliminary processing integrated device and a processing method. The device comprises a poppy fruit shell breaking machine, an extrusion shell breaking machine, a cylinder separation device and a wind force separation device. A discharging port of the poppy fruit shell breaking machine is connected with a feeding port of the extrusion shell breaking machine through a conveying device. A discharging port of the extrusion shell breaking machine is connected with a feeding port of the cylinder separation device through a conveying device. A discharging port of the cylinder separation device is connected with a feeding port of the wind force separation device through a conveying device. Whole-process mechanical work for poppy fruit preliminary processing is achieved, the requirement for processing two kinds of poppy fruits can be met by connecting or bypassing the extrusion shell breaking machine, poppy fruit shells of the poppy fruits can be crushed, and seeds, the fruit shells and powder of the poppy fruits can be separated and collected according to processing requirements, and in addition, the fruit shells can be processed into blocks with the diameter of 2-14 mm; and the production efficiency and the processing quality are greatly improved, the seeds are not damaged in the processing process, raw materials of the poppy fruits are saved, and the production cost is reduced.

Owner:JIUQUAN OK SEED MACHINERY

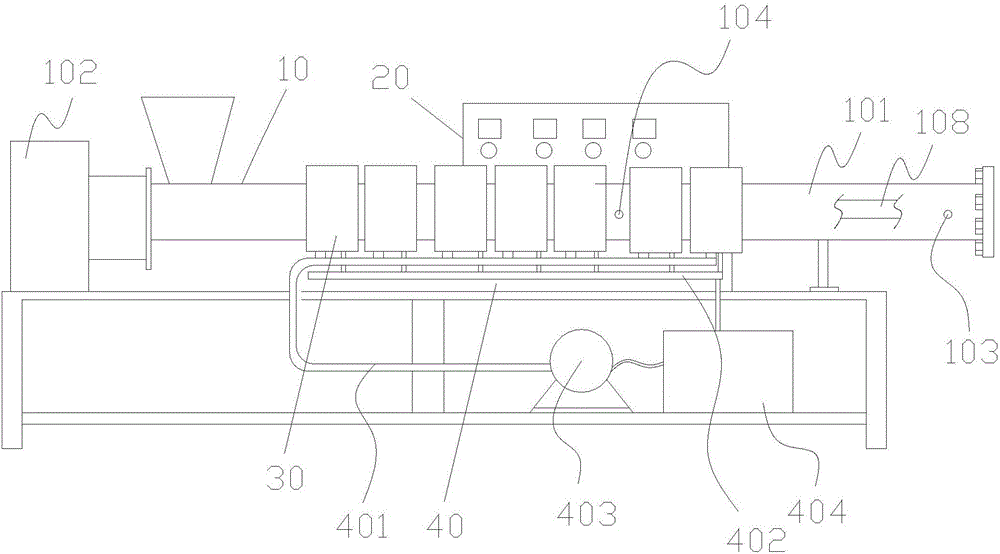

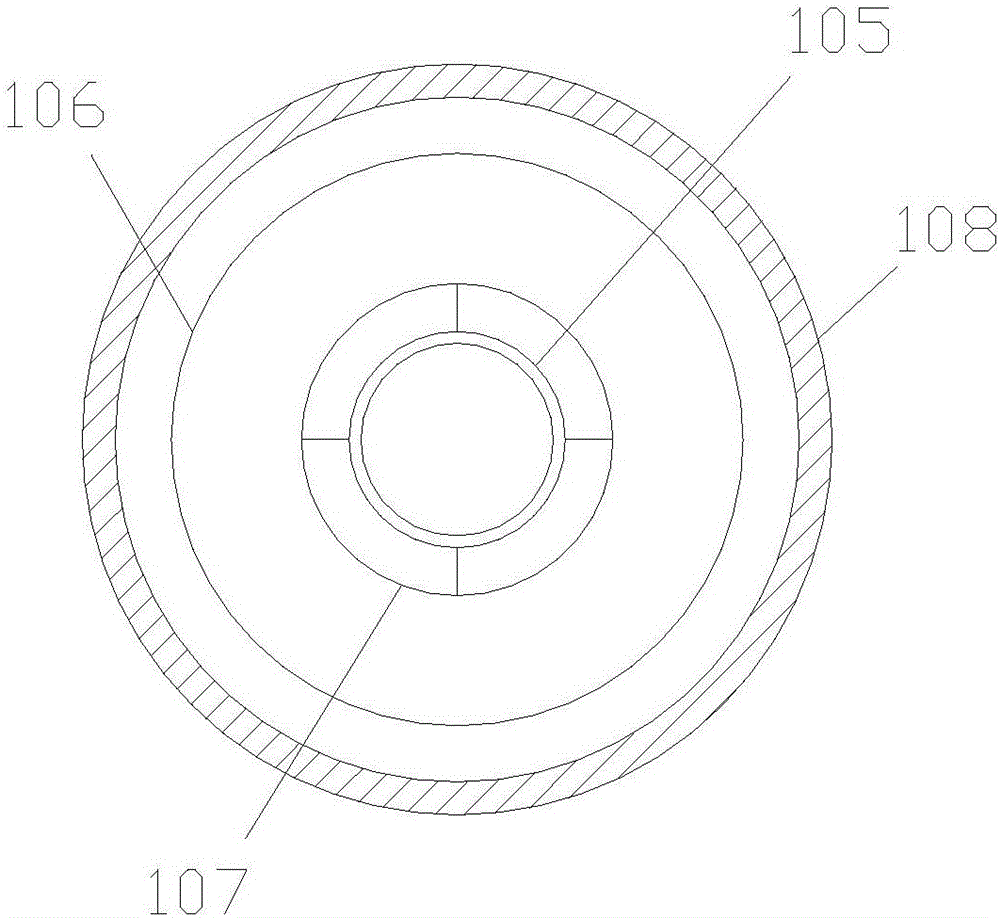

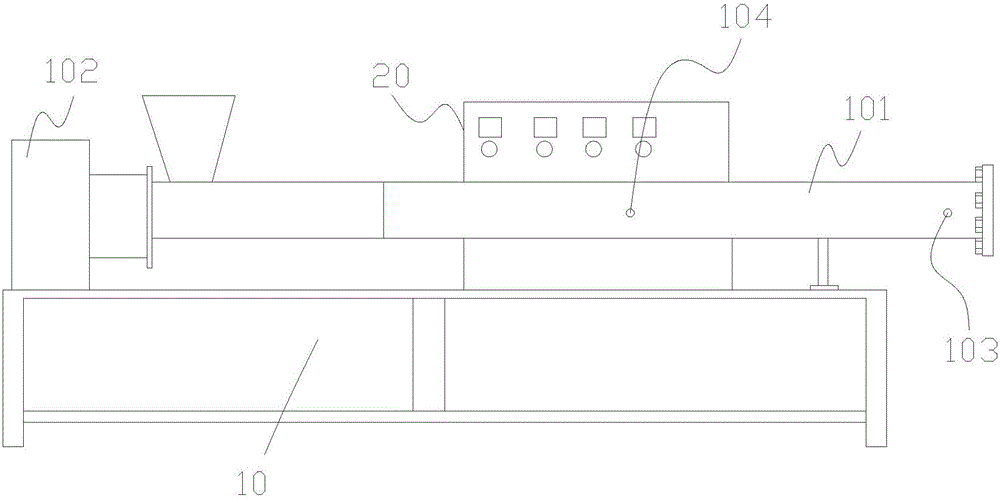

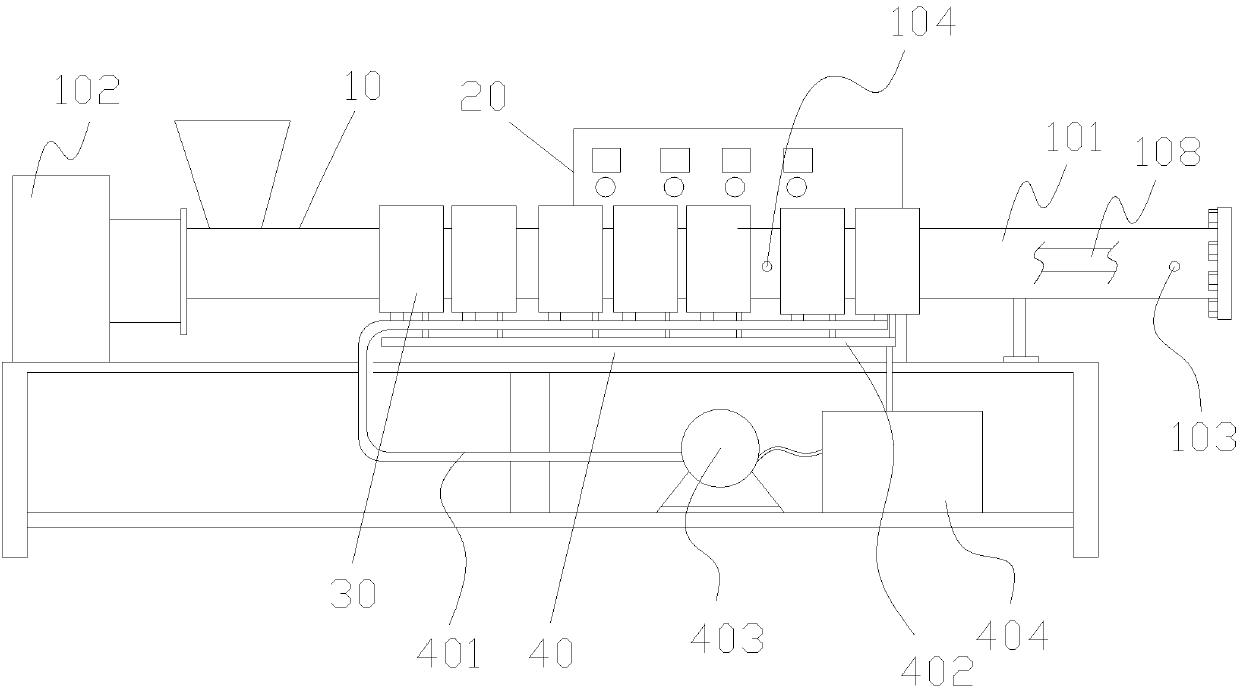

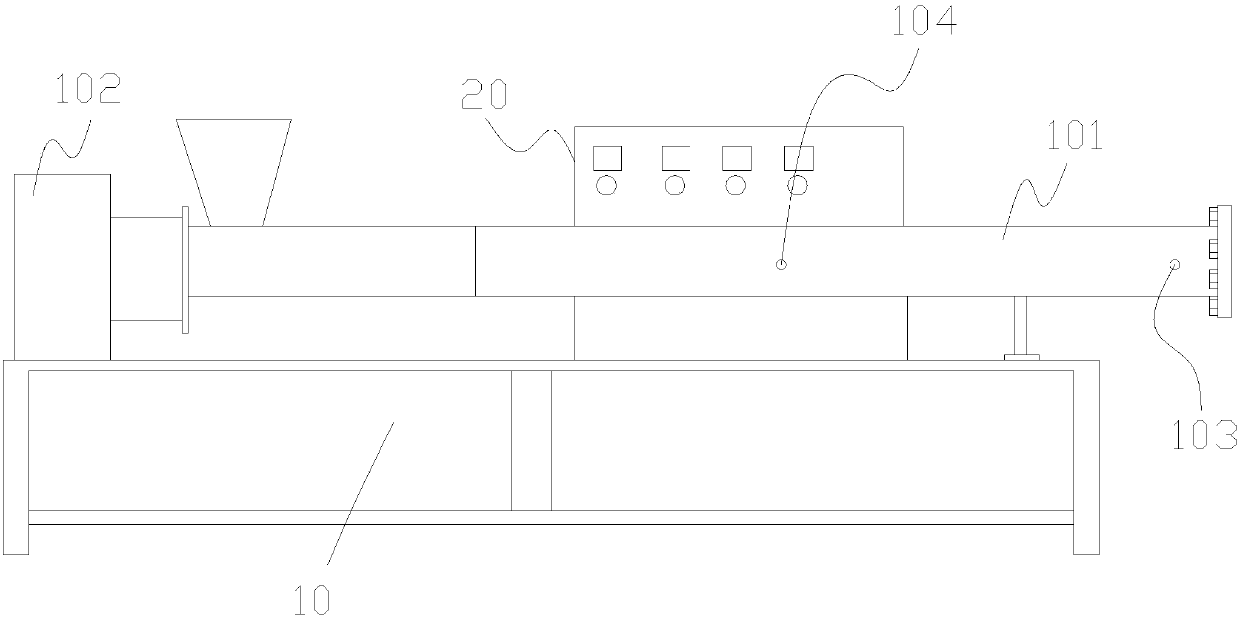

Energy-saving environment-friendly extrusion device for intelligently controlling recycled plastic based on PLC

ActiveCN105922540AAdapt to the needs of different product processingAdapt to processing needsHeating timeDirect observation

An energy-saving environment-friendly extrusion device for intelligently controlling recycled plastic based on a PLC comprises an extrusion part and the PLC; the extrusion part mainly comprises an extrusion material barrel and a transmission mechanism in transmission connection with the extrusion material barrel; a heating screw is arranged in the extrusion material barrel, a heating wire is arranged in the heating screw, the extrusion material barrel is divided into seven heating segments, the seven heating segment are independent of one another, and each heating segment comprises an electromagnetic heating oil arranged on the extrusion material barrel in a sleeving manner; a cooling cavity is formed in the middle of the extrusion material barrel and is connected with a cooling system; the heating wire is connected with the PLC, and the heating temperature and the heating time of the heating wire are controlled through logic programming; PLC data are transmitted to an office computer through the internet, the data can be directly observed through the computer, and therefore production is guided, and mechanical monitoring failures are maintained; and the aim of intelligently controlling extrusion of the recycled plastic is achieved, manpower, material resources and financial resources are saved, and the device meets the sustainable development requirement.

Owner:沧州智方药用包装材料科技有限公司

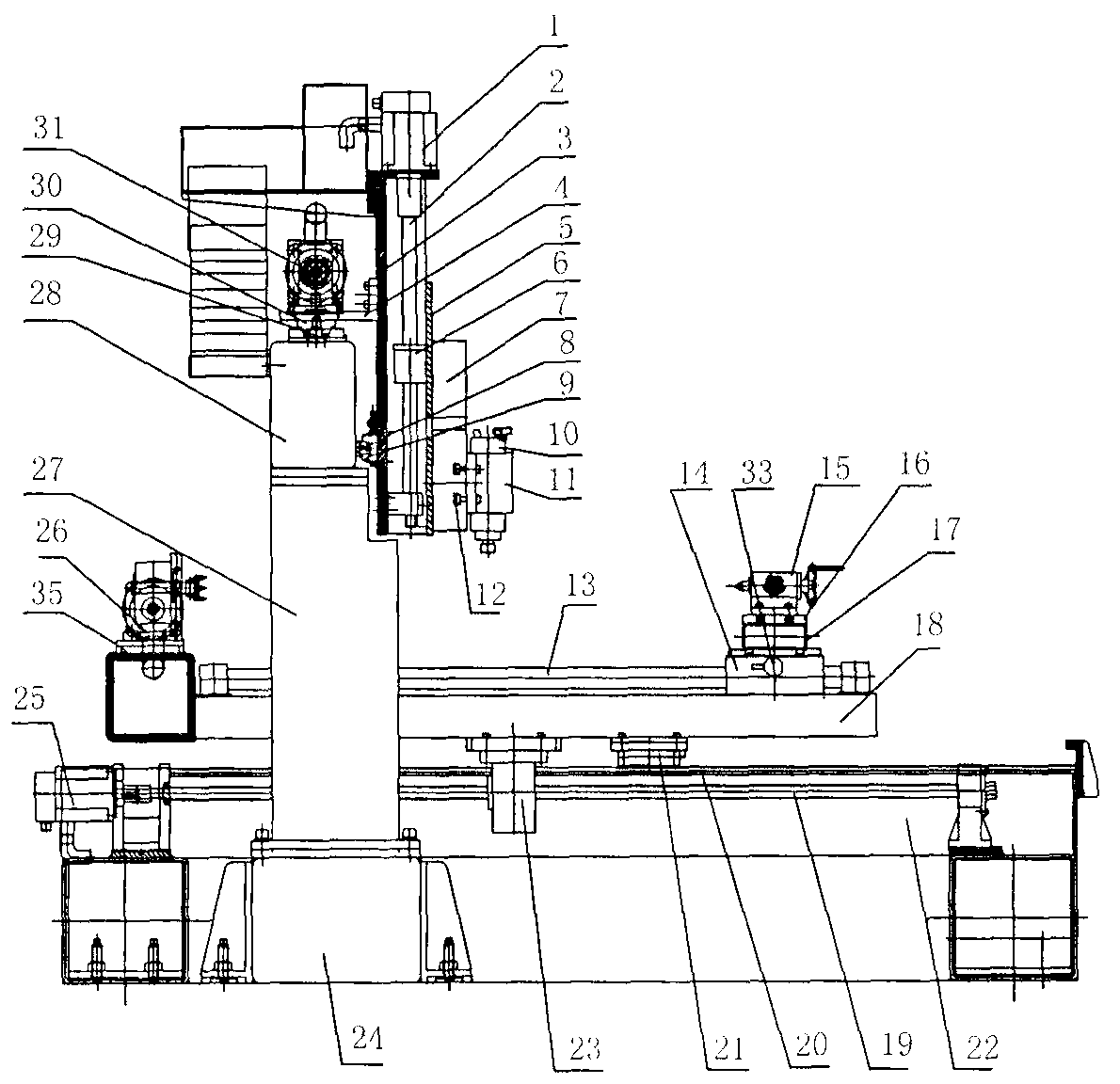

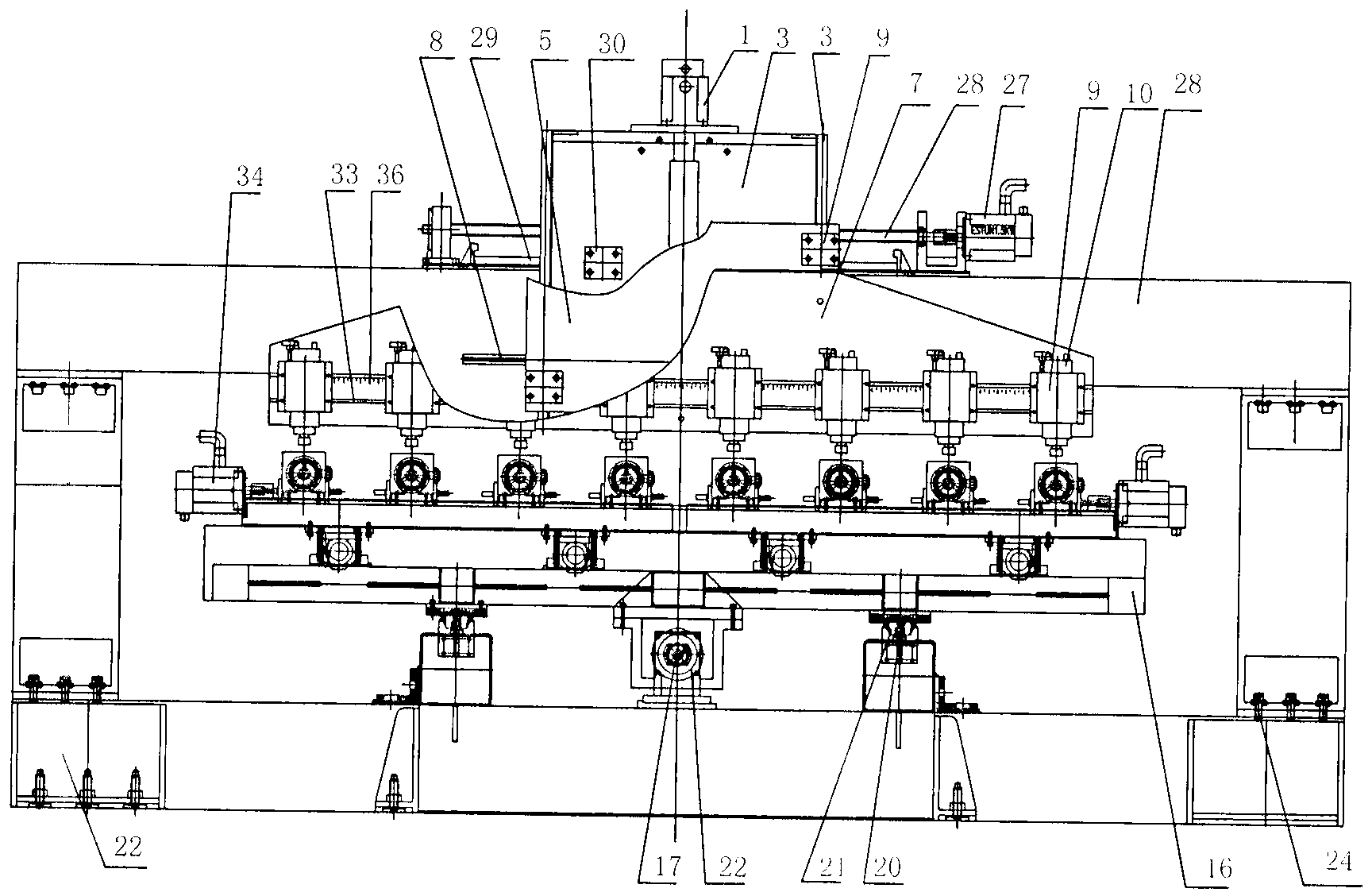

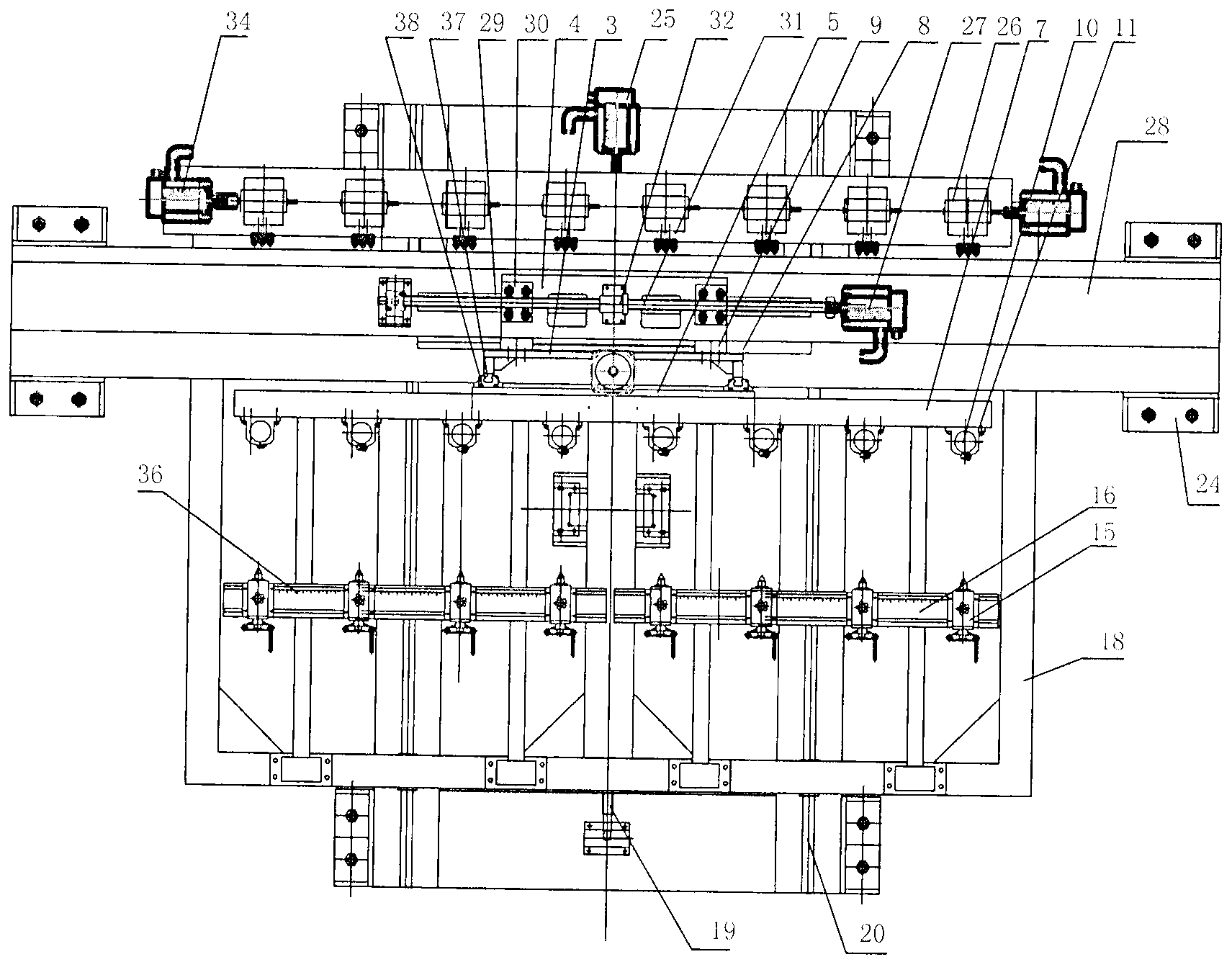

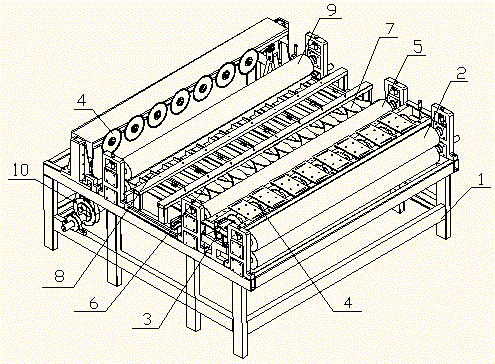

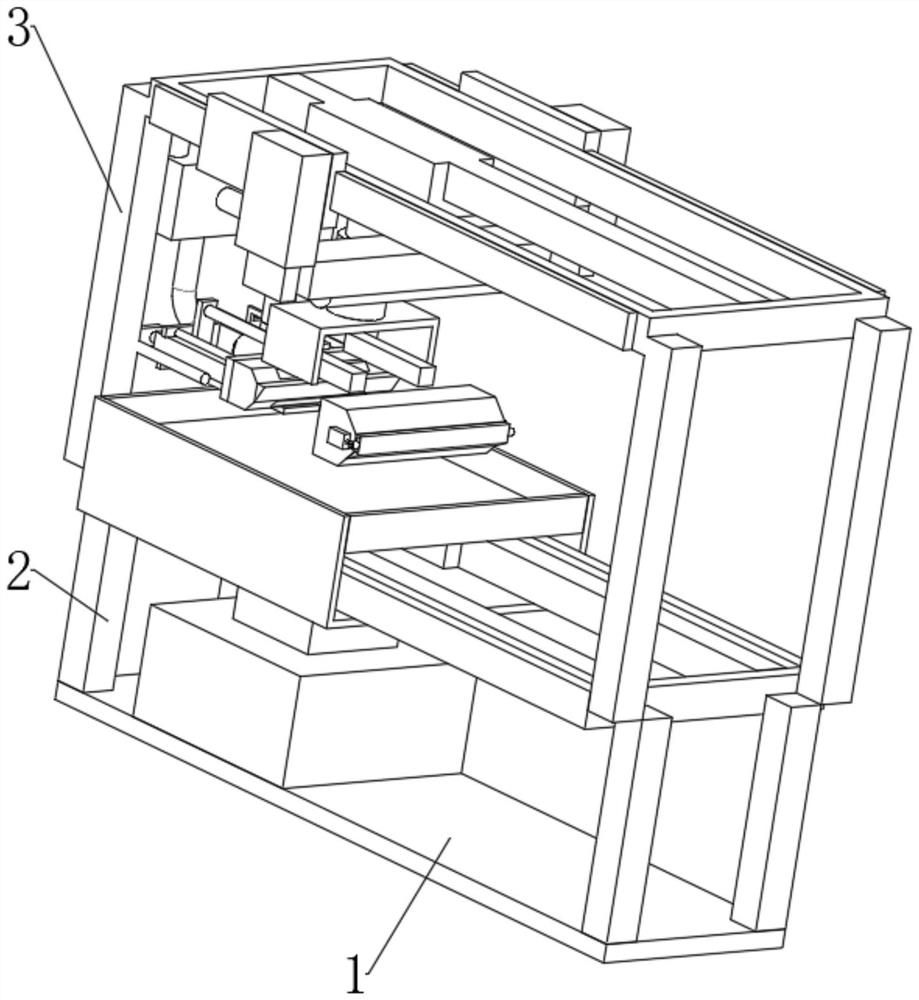

Multi-head precise three-dimensional numerical control planer-type milling machine

InactiveCN103223515ALess forward leanImprove stabilityMilling machinesFeeding apparatusNumerical controlChinese characters

The invention relates to a multi-head precise three-dimensional numerical control planer-type milling machine. The milling machine comprises a base with a shape of a horizontal Chinese character Zhong, a gantry, a vertically moving working platform, a workpiece positioning drive assembly, and a bidirectional precise drive composite head. The base is manufactured by vertically connecting a horizontal-I-shaped base and a square-frame-shaped base. The square-frame-shaped base is arranged above the horizontal-I-shaped base through bolts. The lower end of the horizontal-I-shaped base is connected with the gantry by bolts. Two vertical slide ways are arranged on the upper part of the square-frame-shaped base. A vertical driving screw is arranged between the vertical slide ways. A vertical screw driving motor is connected to an end of the vertical driving screw. Slide blocks are arranged on two sides on the bottom of the vertically moving working platform, and are slidably connected with the vertical slide ways on the upper part of the square-frame-shaped base. A nut is arranged at the middle on the bottom of the vertically moving working platform, and is connected with the middle of the vertical driving screw. The workpiece positioning drive assembly is arranged on the upper part of the vertically moving working platform.

Owner:JINAN RUIJIE MECHANICAL EQUIP

Machine tool column boring and milling plane clamp

InactiveCN105729156AAvoid interferenceRealize processing needsOther manufacturing equipments/toolsPositioning apparatusMilling cutterEngineering

The invention discloses a machine tool column boring and milling plane clamp, and belongs to the machine tool clamp design technical field; the machine tool column boring and milling plane clamp comprises a clamp body, a support block, a hexagon bolt, a press bar, a T-shape block, an inner hexagonal screw, a feeler block, a T-shape bolt, a drill bit, a facing cutter, a guide sleeve, a limit screw rod, a connecting support seat, a work table, a limit block and a main shaft box; the clamp body is fixed on the work table; the support block is fixed on the clamp body; the left side of the support block is provided with the press bar; the top surface of the clamp body is provided with a feeler block; the connecting support seat is arranged on the left side of the work table; the main shaft box is fixed on the connecting support seat; the drill bit is clamped in a chuck on the right side of the main shaft box; the drill bit is sleeved by the guide sleeve; the guide sleeve is fixed on the drill bit by a screw; the facing cutter is arranged on the right side of the guide sleeve. The machine tool column boring and milling plane clamp is convenient in workpiece installation, cutter tool setting is accurate in positioning, processing feed amount is convenient in control, and processing scope is wide.

Owner:安徽白鹰精密车床有限公司

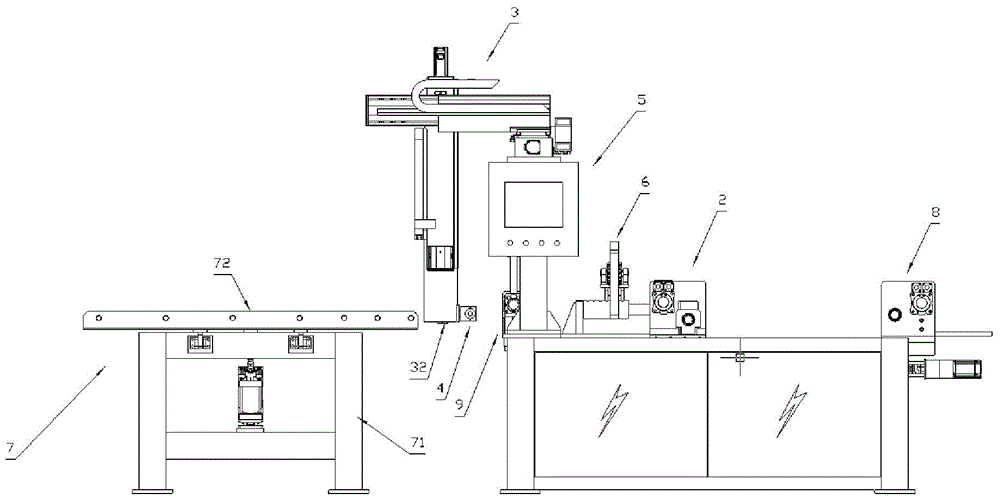

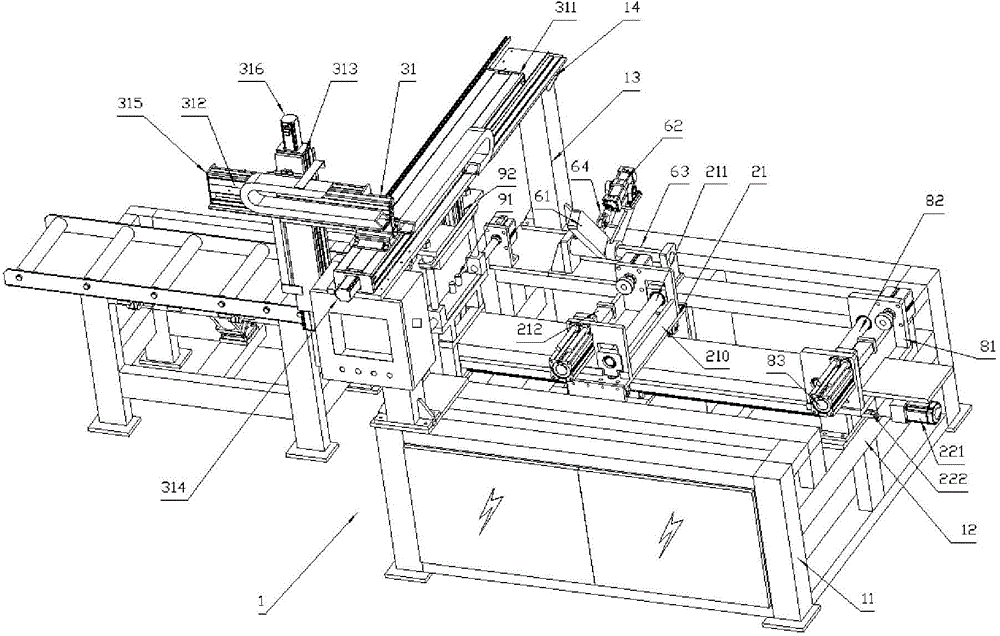

Cutting machine

InactiveCN104924139AAchieving non-uniform cutting requirementsRealize processing needsDriving apparatusEngineeringMechanical engineering

The invention relates to a metal workpiece machining device, in particular to a cutting machine for automatic and continuous section steel cutting. The cutting machine comprises a table provided with a stereoscopic frame and a bearing beam arranged in the stereoscopic frame, a feeding mechanism provided with a moving mechanism driving section steel to move and a first driving mechanism driving the moving mechanism to move, a four-coordinate mechanism provided with a translation mechanism provided with an X-axis, a Y-axis and a Z-axis and a cutting head installing portion, a cutting head installed at the cutting head installing portion, and a control box connected with the feeding mechanism, the four-coordinate mechanism and the cutting head. The cutting head can be moved to different surface of section steel, can rightly face the surface to be cut of the section steel through rotation of the cutting head installing portion and accordingly achieves non-consistent cutting requirements of all cutting surfaces, the cutting requirements of section steel different in thickness can be also met by matching different cutting heads, and accordingly the machining demands of special specification of section steel workpieces are met by means of the device.

Owner:广州精准机械有限公司

Punching machine

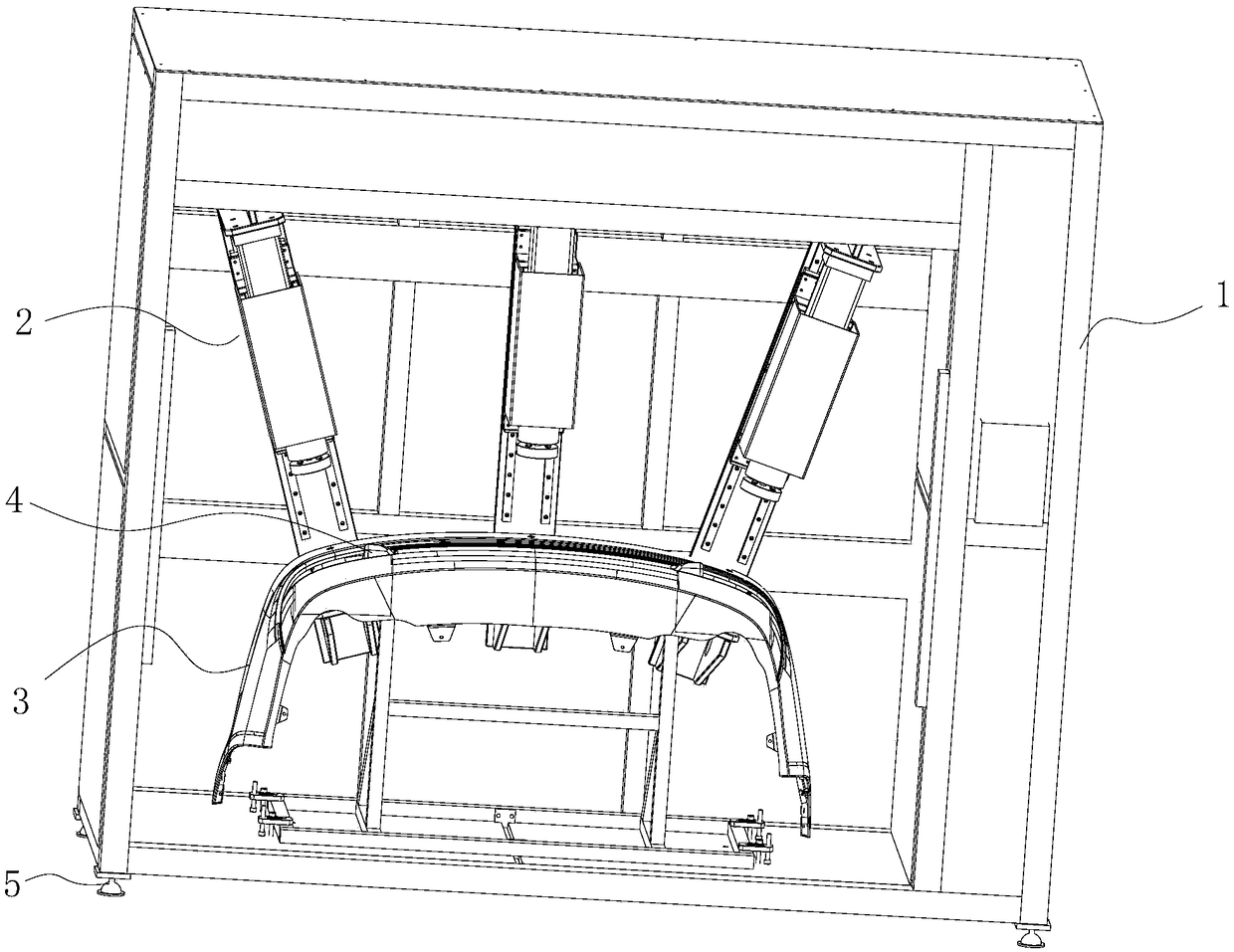

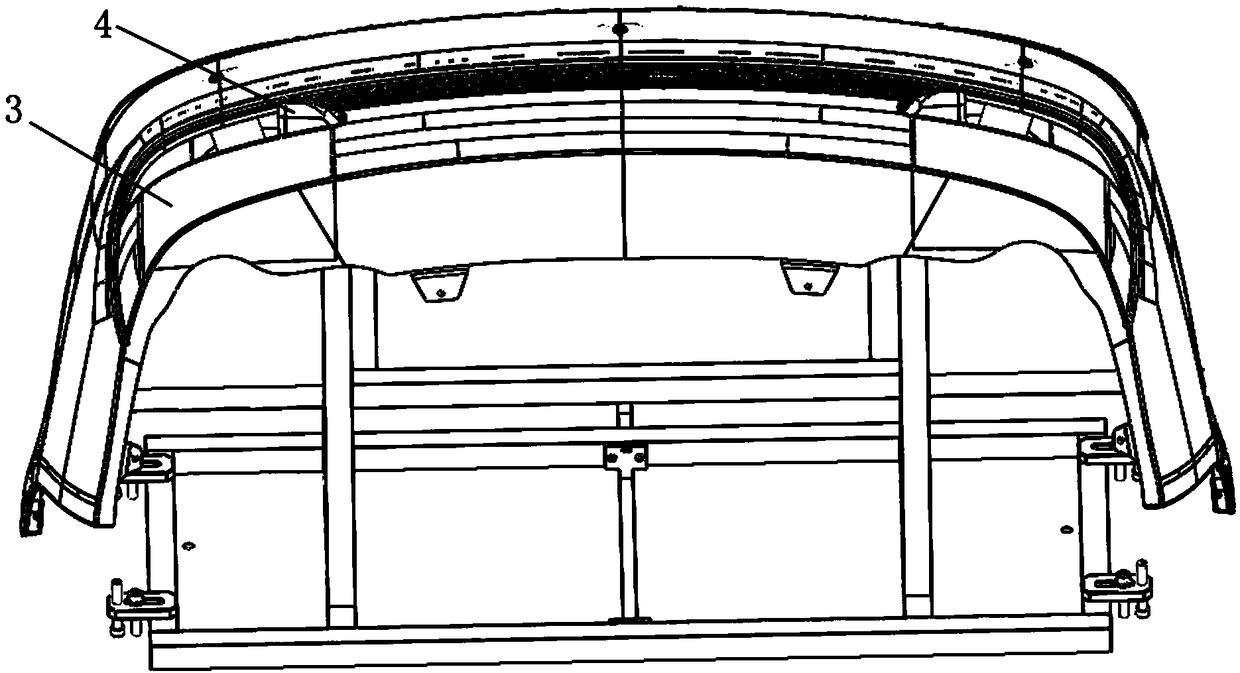

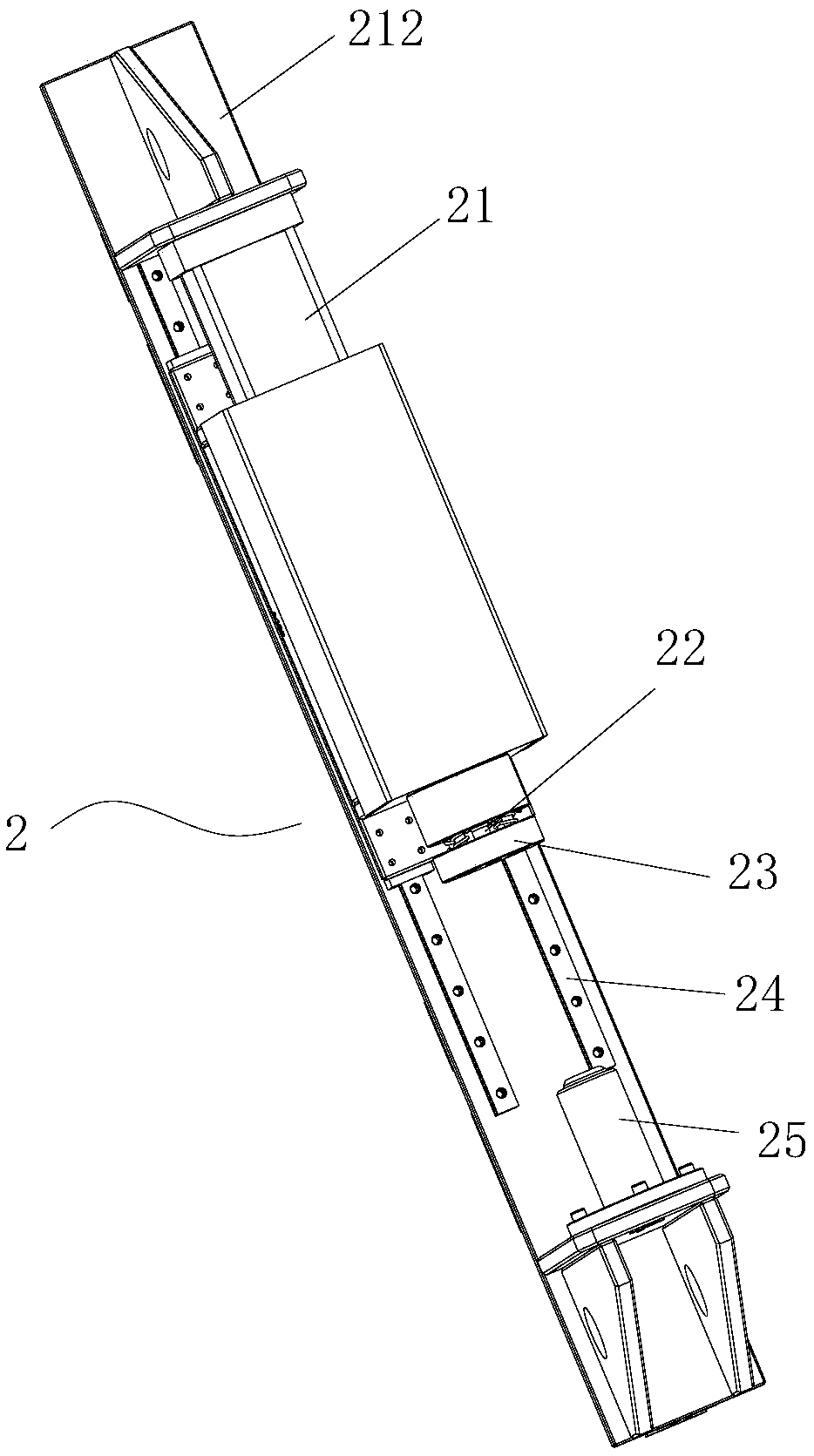

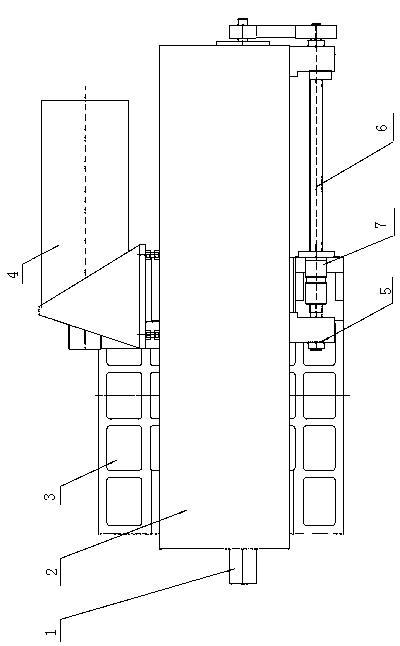

InactiveCN109201867AImprove adaptabilityExpand the scope of applicationPerforating toolsVehicle componentsPunching

The invention discloses a punching machine. The punching machine is used for punching a workpiece with a bent surface. The punching machine comprises a punching device. The punching device comprises aplurality of punching mechanisms located above the workpiece. The plurality of punching mechanisms are arranged along the outline of the workpiece in an angle mode. Each punching mechanism comprisesa punch and a rack used for installing each punching mechanism. At least one punch can be used for adjusting the punching position of the workpiece, and the adjusting mode is used for changing the installation positions of the punching mechanisms on a machine frame and / or adjusting or adjusting the inclination angles of the punching mechanisms relative to the horizontal direction. The punching positions of the punching mechanisms can be adjusted according to the punching position requirements of to-be-machined workpieces. As a result, the machining requirements for different punching positionsof different products are met, and the application range of the punching machine is expanded.

Owner:ZHEJIANG LIMIN INDAL

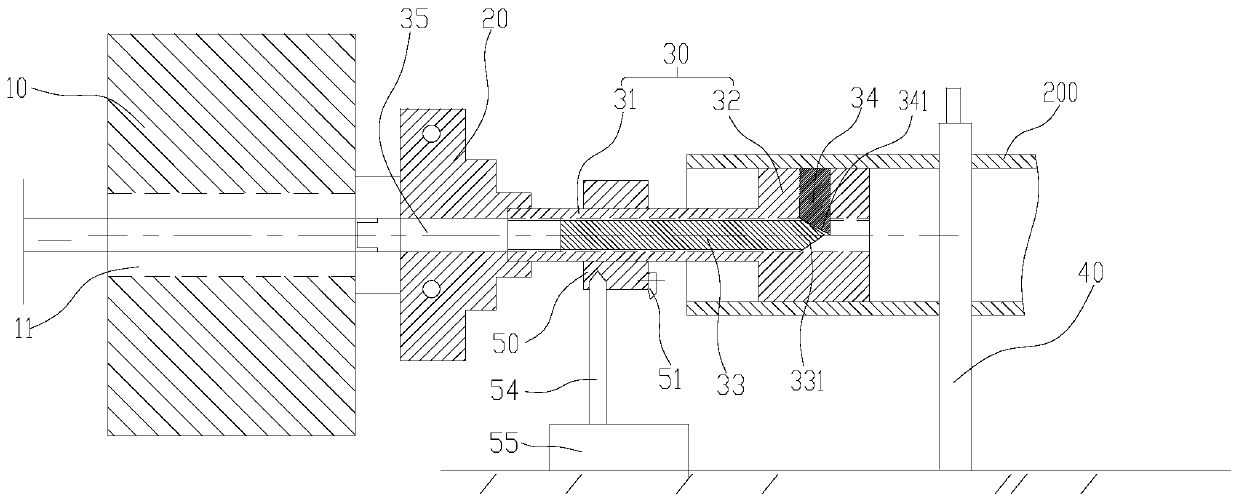

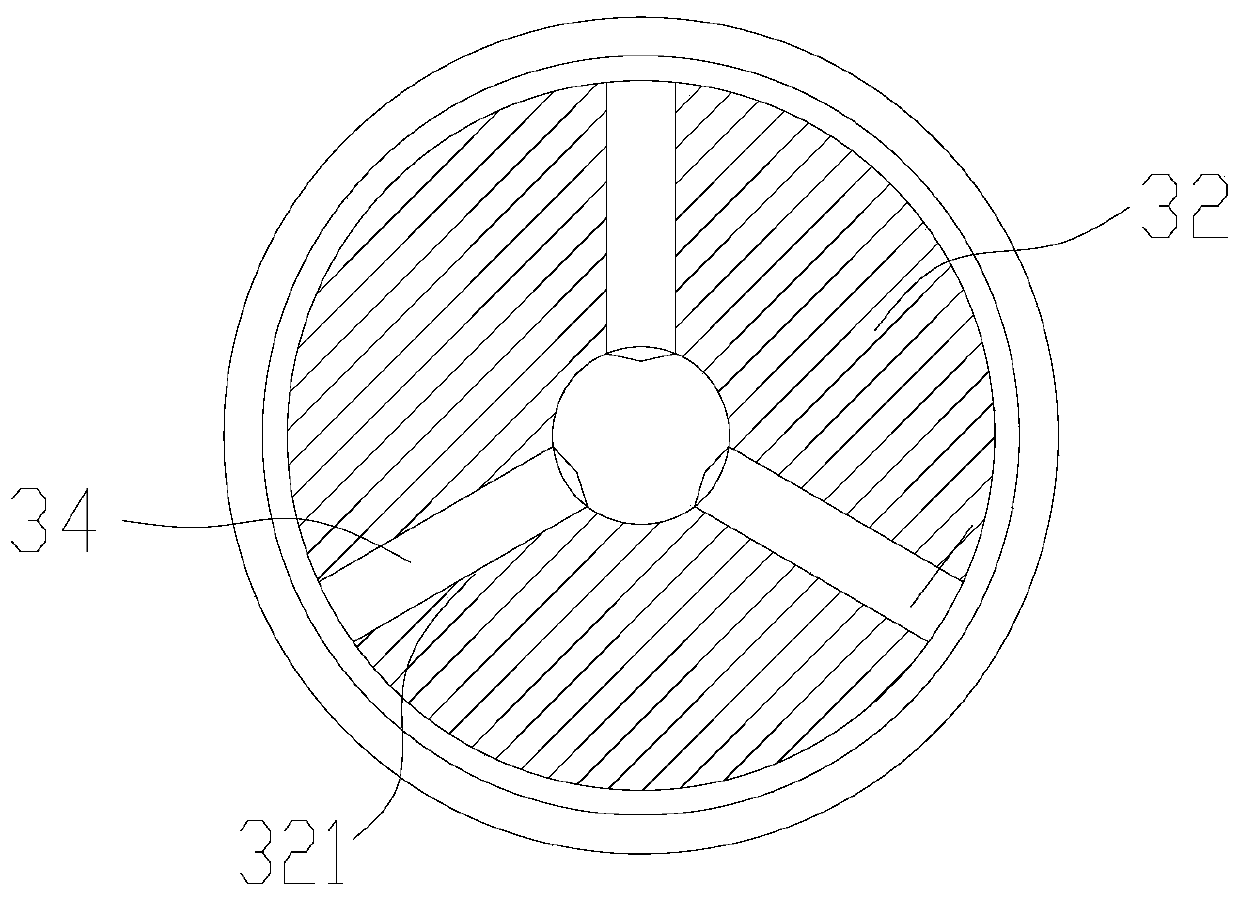

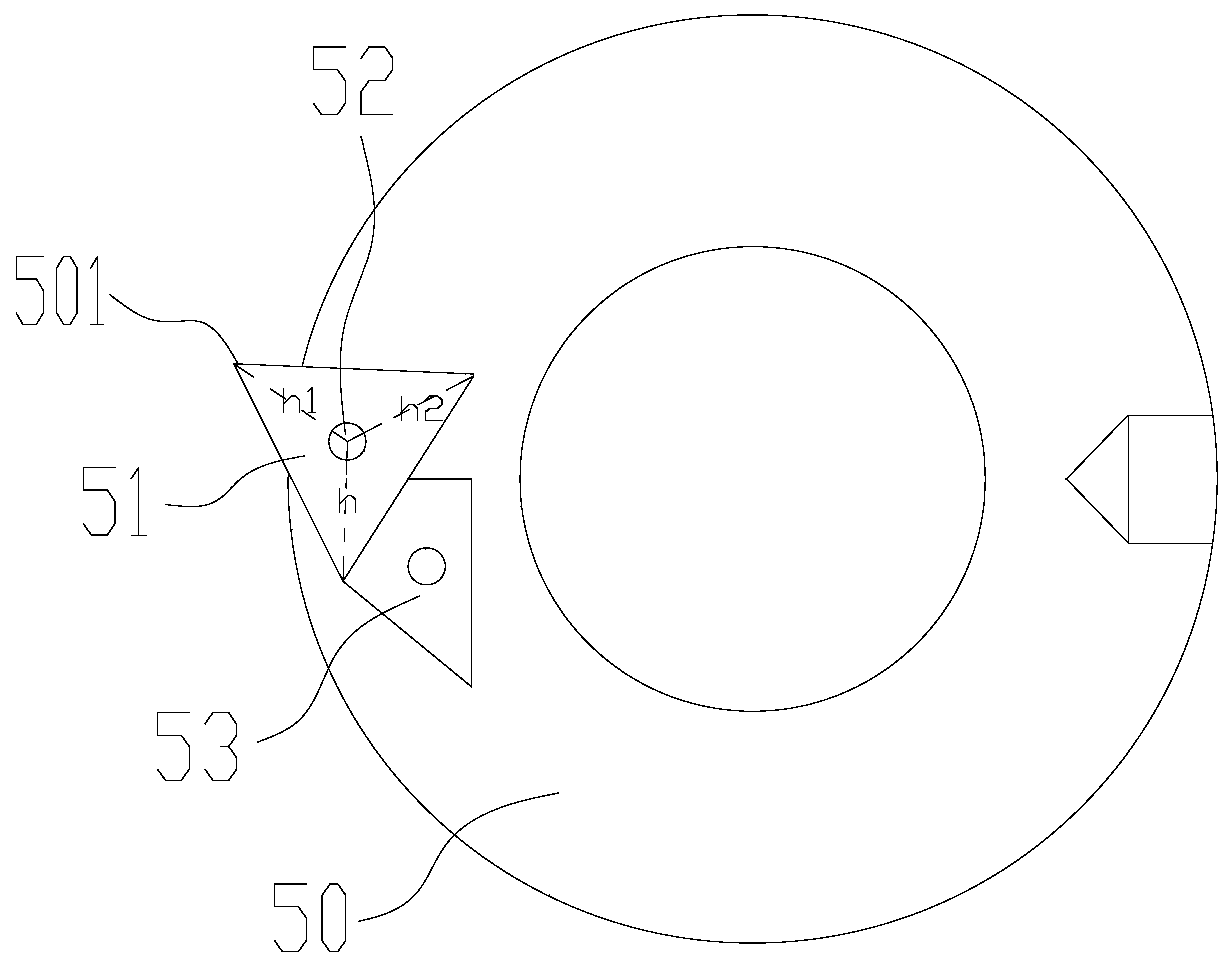

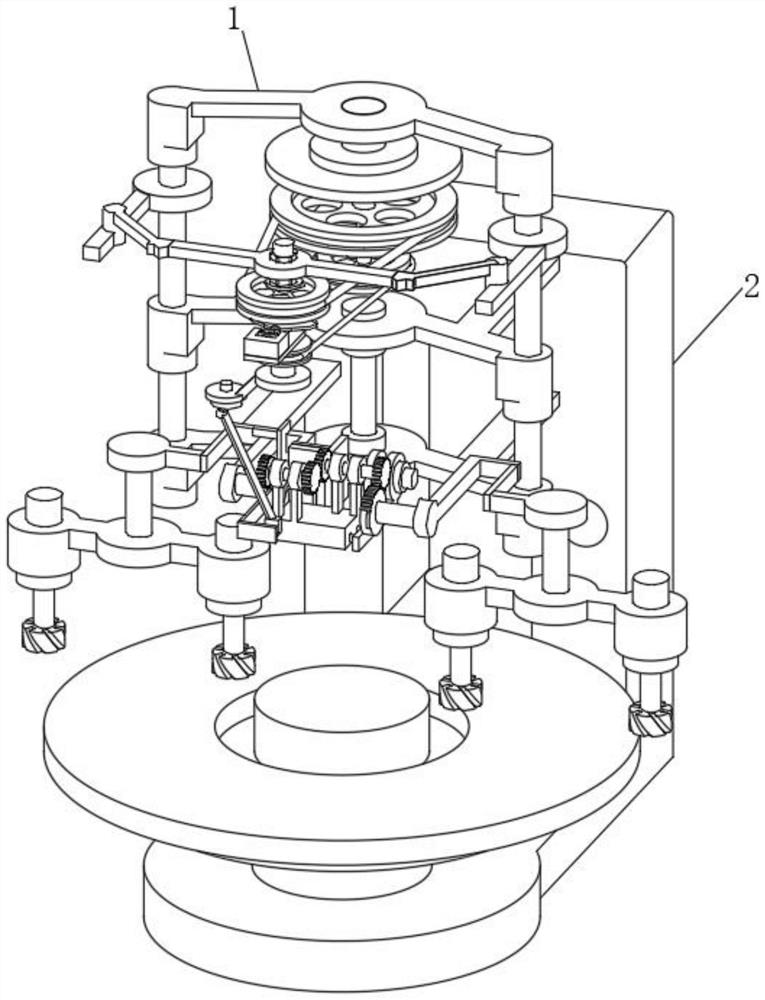

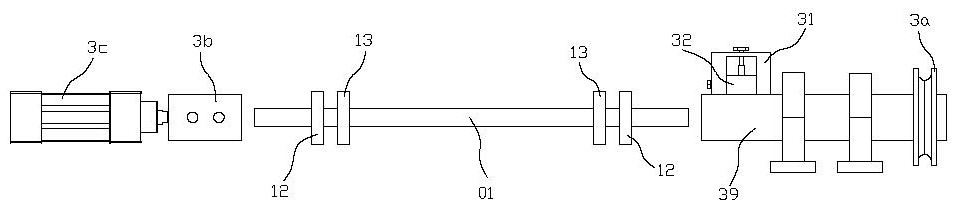

Machine ram connecting mechanism

The invention discloses a machine ram connecting mechanism. The machine ram connecting mechanism comprises a slide carriage, a square ram, a main shaft and a main motor, wherein the side surface of the square ram is hung on the side surface of the slide carriage by two rolling linear guide rail pairs which are arranged horizontally from top to bottom; a feeding screw is arranged under the square ram; a feeding motor is connected with the feeding screw; the feeding screw drives the square ram to move horizontally; and the main shaft is arranged in the square ram. The ram connecting mechanism disclosed by the invention has the advantages that the main shaft box in the conventional machine tool structure is omitted, the volume is greatly reduced, the structure is simple and the use is convenient.

Owner:SHANDONG HONGKANG MACHINERY MFG

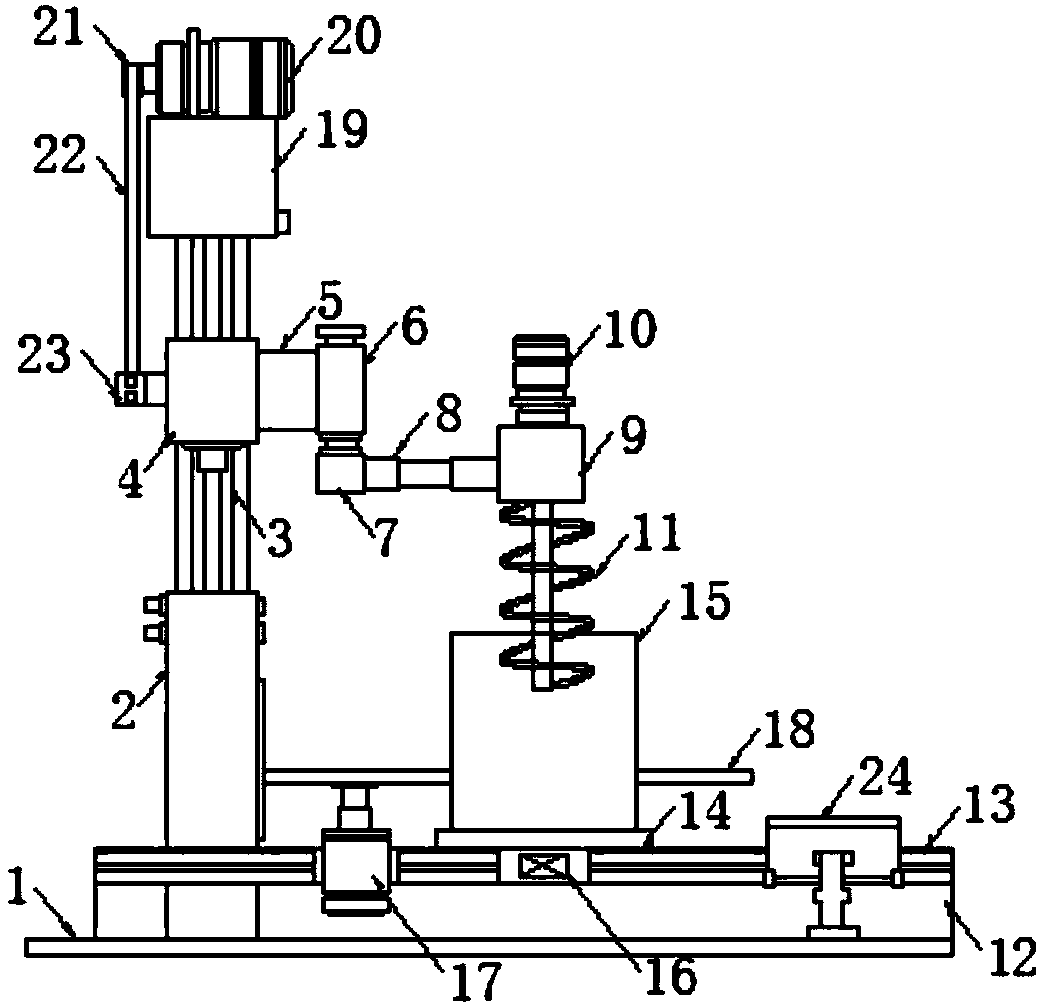

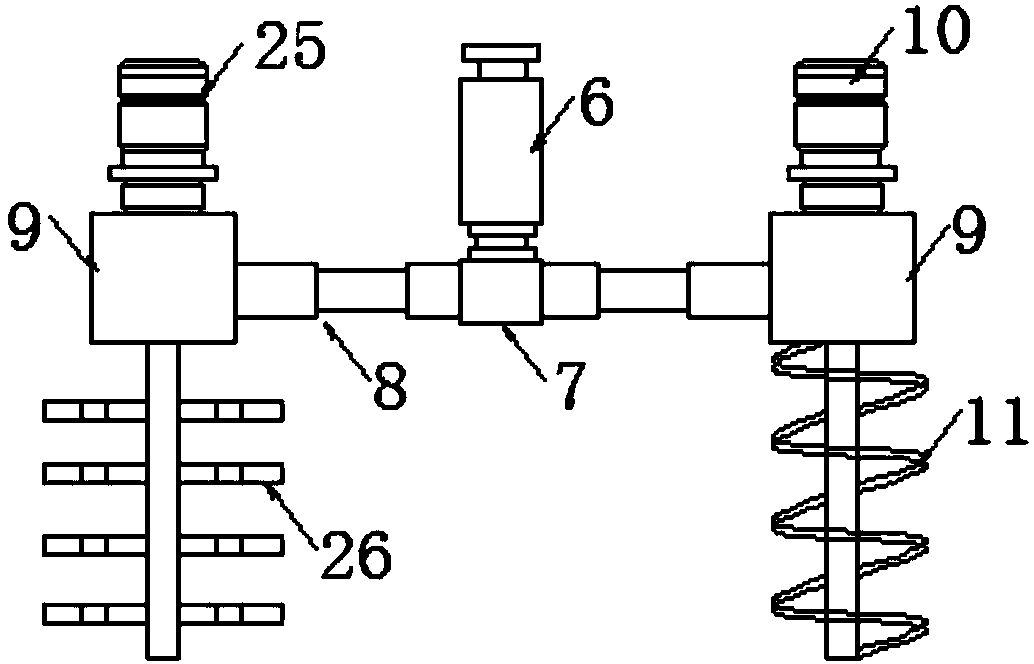

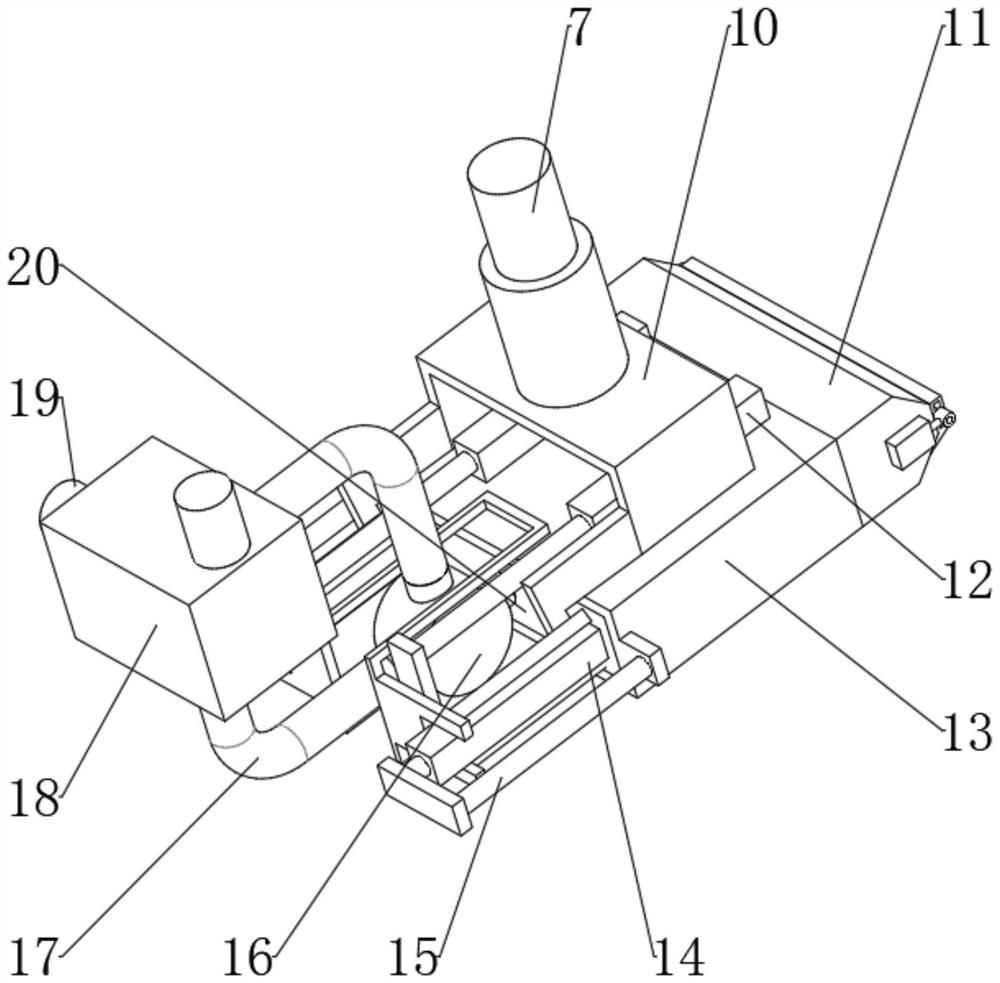

Multipurpose material stirring device

InactiveCN108099001ATo achieve a variety of processing needsShorten working timeCement mixing apparatusGrain treatmentsTime efficientWork pattern

The invention discloses a multipurpose material stirring device. The multipurpose material stirring device comprises a base, a stand column, a longitudinal slide rail, a lifting slide base, a connecting part, a rocker arm, a rotating base, a telescopic connecting rod, a transmission box, a stirring motor, a stirring blade, a workbench, a transverse slide rail, a transverse moving slide base, a reacting cylinder, a limiting part, a jacking cylinder, a material receiving plate, an installing rack, a lifting motor, a winding roll, a lifting chain, a positioning block, a limiting block, a crushingmotor and crushing blades. According to the multipurpose material stirring device, the structure is compact, and use is convenient; lifting of the lifting slide base is achieved through lifting, thenlifting of the stirring blade and the crushing blades is achieved, the stirring blade and the crushing blades can be conveniently replaced according to the actual condition in operation, multiple processing requirements of materials are met, the condition that a large amount of time is wasted due to the fact that equipment is replaced frequently is avoided, the high practicability is achieved, and the operation effect is guaranteed; and the multipurpose material stirring device adapts to multiple different working modes, the high stability and the high precision are achieved, use of manpoweris effectively reduced, time and manpower are effectively saved, and the working efficiency is improved.

Owner:钱姝雅

Multifunctional adjustable paper cutter

InactiveCN104999697ARealize processing needsSimple structureBox making operationsPaper-makingCircular sawPaperboard

The invention relates to a multifunctional adjustable paper cutter which comprises a rack, wherein the front end of the rack is a paperboard entering end, and a first paper pressing and conveying roller couple is mounted at the entering end; splitting motors are arranged at the rear part of the first paper pressing and conveying roller couple at intervals, and the output end of each splitting motor is connected with a circular saw web; a second paper pressing and conveying roller couple is arranged at the rear part of each splitting motor, and paper guiding grooves and paper guiding groove pressing plates are arranged at the rear part of the second paper pressing and conveying roller couple at intervals; the rear end of the paper guiding groove pressing plate is connected with a paper guiding groove pressing and covering plate, and a folded compaction roller couple is arranged at the rear part of the paper guiding groove pressing and covering plate; segmenting motors are arranged at the rear part of the folded compaction roller couple at intervals, and the output end of each segmenting motor is connected with a circular saw web. Firstly, the cutter carries out splitting, the needed width is guided and folded out through the paper guiding grooves after splitting, then a paperboard is oppositely pressed through the folded compaction roller couple, and segmenting is carried out after creases appear.

Owner:杭州航波纸塑包装有限公司

A drop-type light-curing follow-up printing system and method

ActiveCN104924617BRealize processing needsPrecise positioningManufacturing driving means3D object support structuresThree-dimensional spaceLight spot

The invention discloses a drop-type light-curing follow-up printing system and method, including a two-dimensional mobile platform, a substrate, a light source, a focusing lens, a light-curing liquid supply system, a solenoid valve nozzle, and a control device for controlling the solenoid valve nozzle. device, and a one-dimensional mobile platform for driving the substrate to move in the vertical direction; the substrate is fixed on the one-dimensional mobile platform, the light source, focusing lens and solenoid valve nozzle are fixed on the two-dimensional mobile platform, and the light emitted by the light source The light spot formed after focusing by the focusing lens is located on the substrate, and the light spot is located directly below the liquid outlet of the solenoid valve nozzle, and the liquid inlet of the solenoid valve nozzle is connected with the liquid outlet of the photocuring liquid supply system; the light emitted by the light source The wavelength of is the same as the wavelength of the light required for the curing of the photo-curable liquid in the photo-curable liquid supply system. The invention can realize precise positioning of cells and light-cured liquid in three-dimensional space, ensures that materials are not polluted, and saves materials at the same time.

Owner:XI AN JIAOTONG UNIV

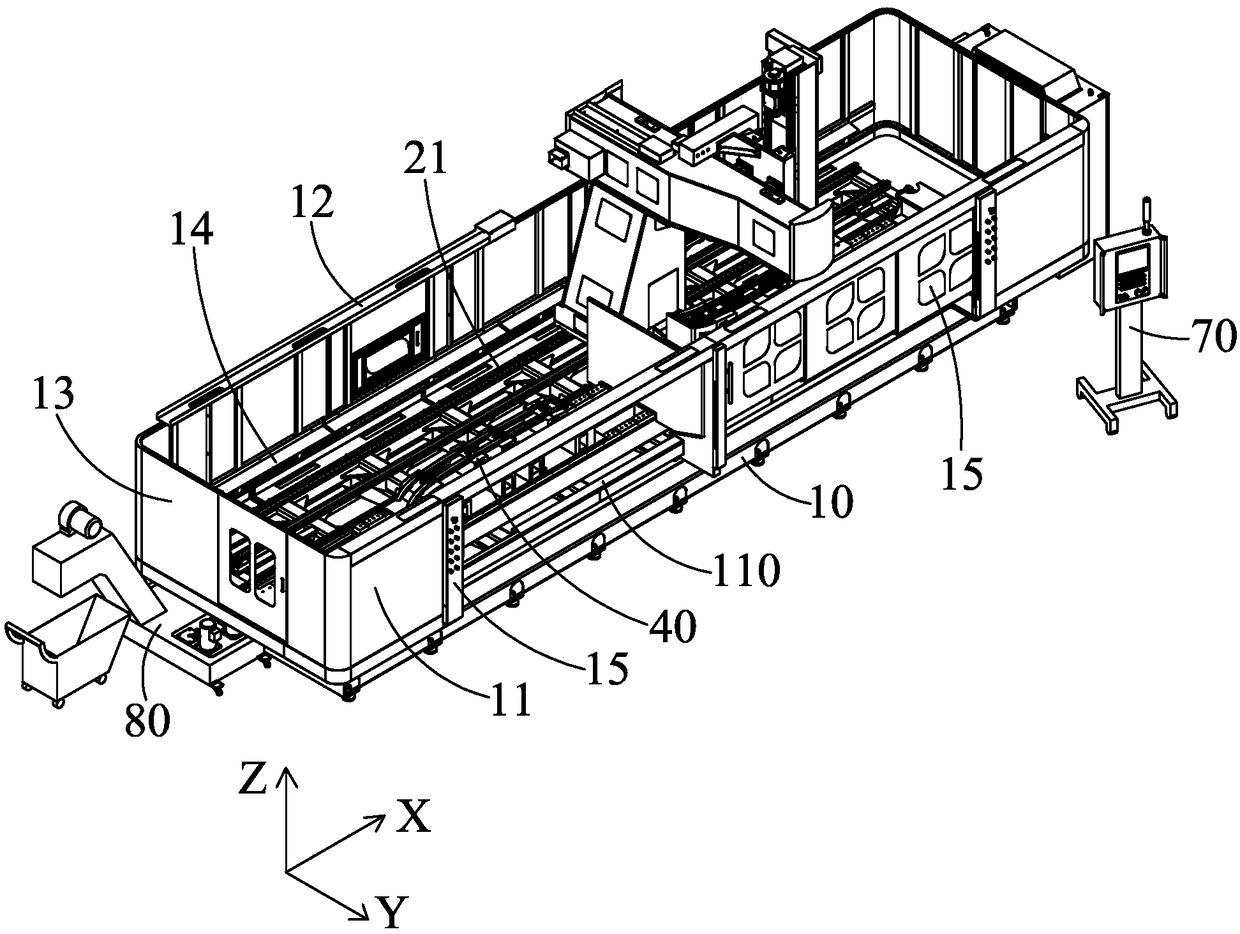

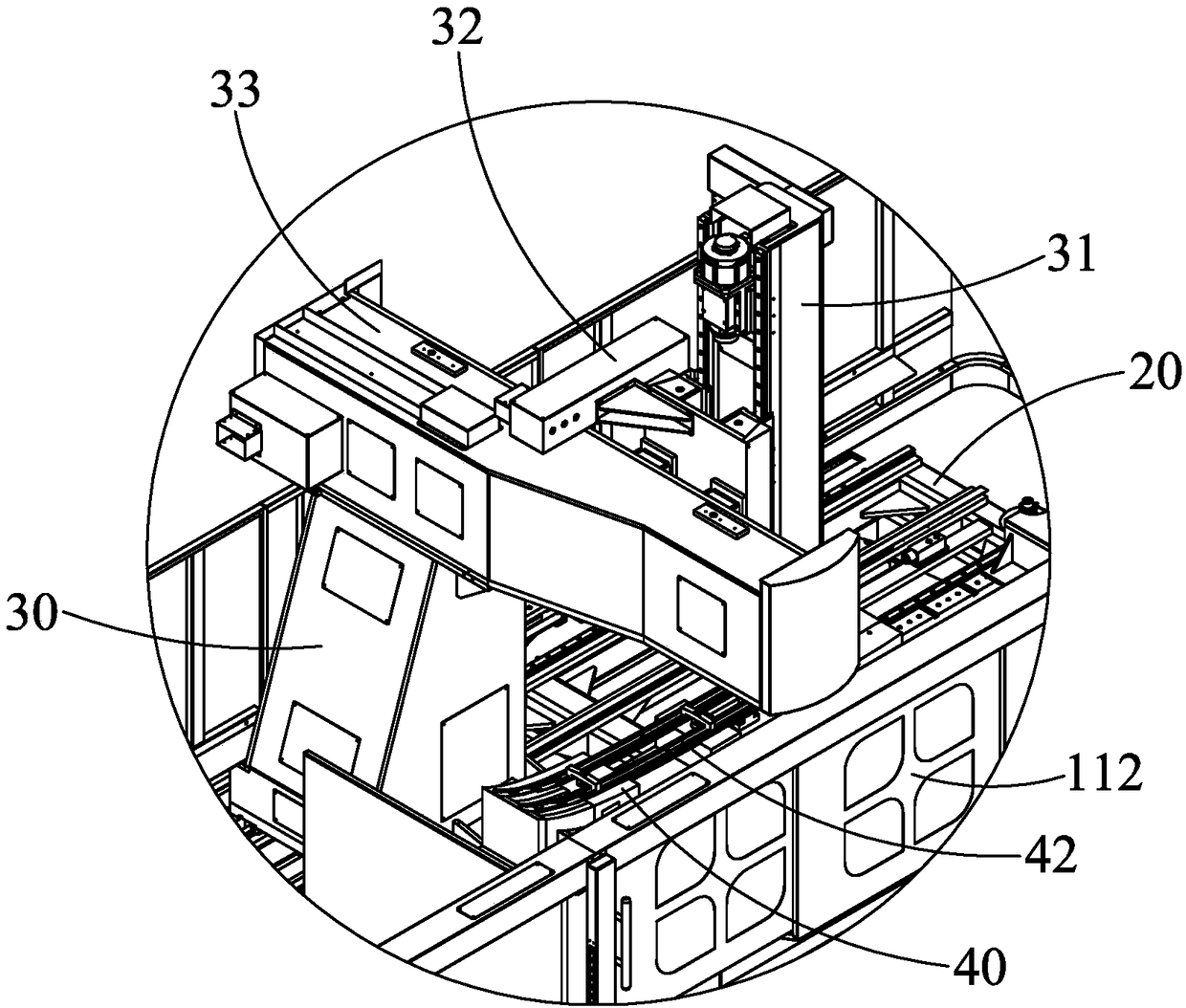

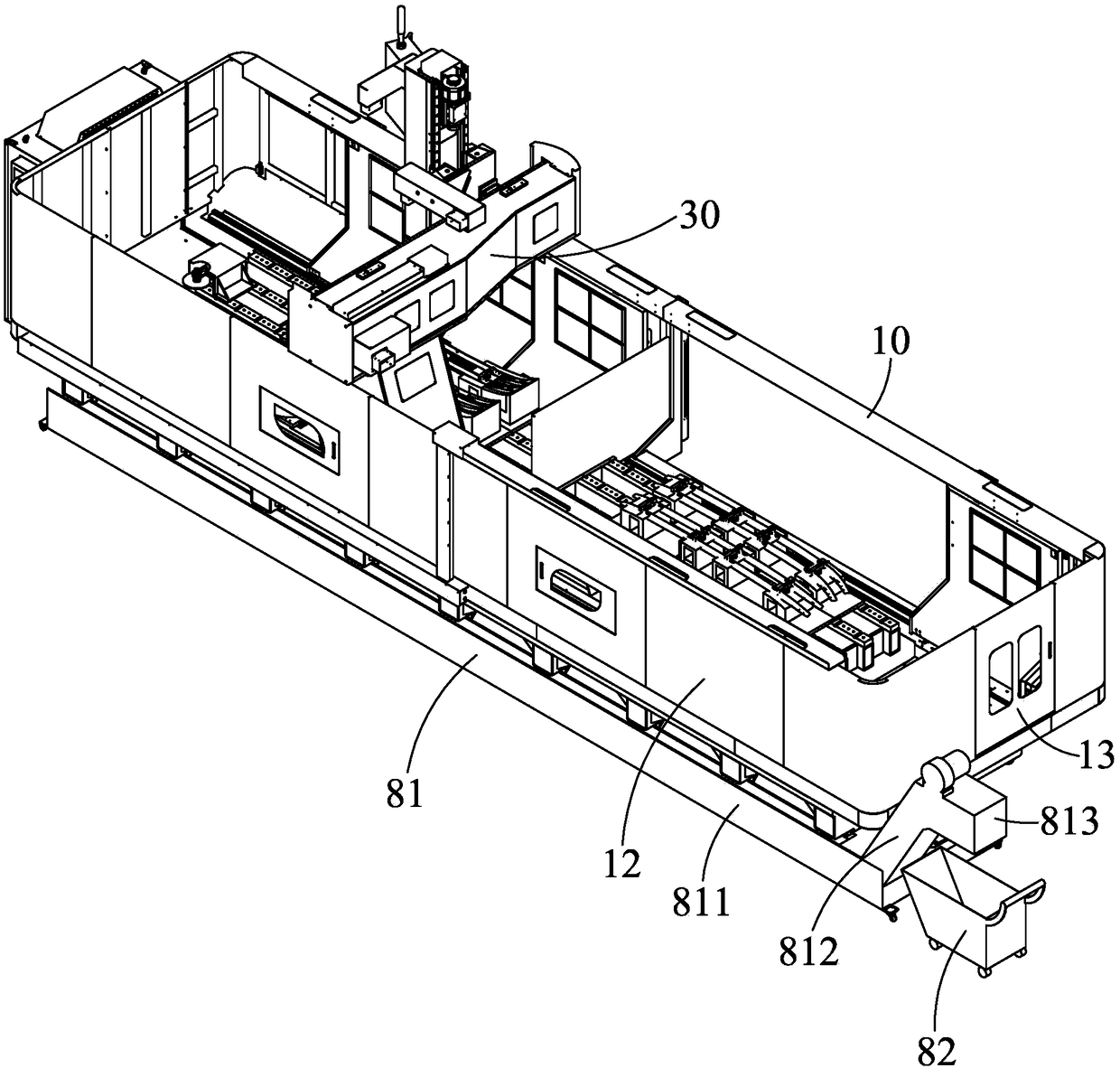

Automotive luggage rack bar processing center

PendingCN108311887AEasy to useRealize processing needsOther manufacturing equipments/toolsLarge fixed membersMachine toolOperating table

The invention relates to an automotive luggage rack bar processing center. The automotive luggage rack bar processing center comprises a shell, a machine table, a processing mechanism, two tools, an operating table located on the outer side of the shell and an automatic chip removal mechanism, wherein the shell comprises a front end wall, a back end wall, two side walls and a room formed by the front end wall, the back end wall and the two side walls; the machine table, the processing mechanism and the tools are located in the room. The automotive luggage rack bar processing center also comprises a first magazine tool and a second magazine tool fixed to the machine tool, wherein the first magazine tool is used for storing saw web knives and the second magazine tool is used for storing axle-shaped tools, so that different types of tools are used conveniently by the automotive luggage rack bar processing center, and diverse processing demands are achieved. The automotive luggage rack barprocessing center is simple to operate, and the production efficiency is improved.

Owner:罗威斯数控科技(昆山)有限公司

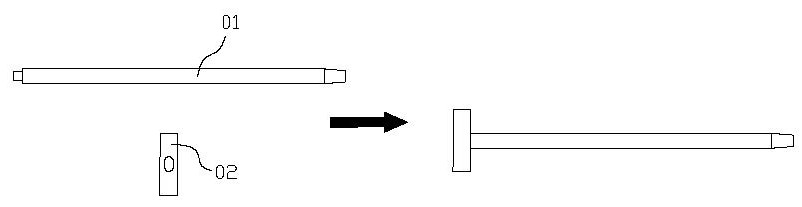

Lathes suitable for machining internal threads

ActiveCN110744150BSimple structureEasy to operateThread cutting machinesPositioning apparatusCircular discStraight tube

The invention discloses a lathe suitable for machining an internal thread. The lathe comprises a spindle box, a chuck arranged on the spindle box, a fastener used for connecting the chuck with a pipeline, and a center frame used for supporting the pipeline, wherein the fastener comprises a straight pipe part clamped by the chuck, and a disc head part which is perpendicularly arranged at one end ofthe straight pipe part and extends into the pipeline; an ejector rod is in screw joint with the interior of the straight pipe part; a plurality of positioning pins are movably inserted in the disc head part; the ejector rod can push the multiple positioning pins to synchronously extend out of the disc head part, and the multiple positioning pins extending out of the disc head part are matched toclamp the pipeline; the straight pipe part of the fastener is movably sleeved with a tool rest barrel; a turning tool is arranged on the tool rest barrel; and the tool rest barrel can drive the turning tool to move in the axial direction of the straight pipe part on the fastener so as to turn the inner wall of the pipeline. The lathe meets the machining requirement for the internal thread on the inner wall of the pipeline, accordingly, the types and specifications of the pipeline which can be suitable for being turned by the lathe are expanded, and the effect of reducing the machining cost ofenterprises is achieved.

Owner:HEBEI HUAFENG ENERGY TECH DEV CO LTD

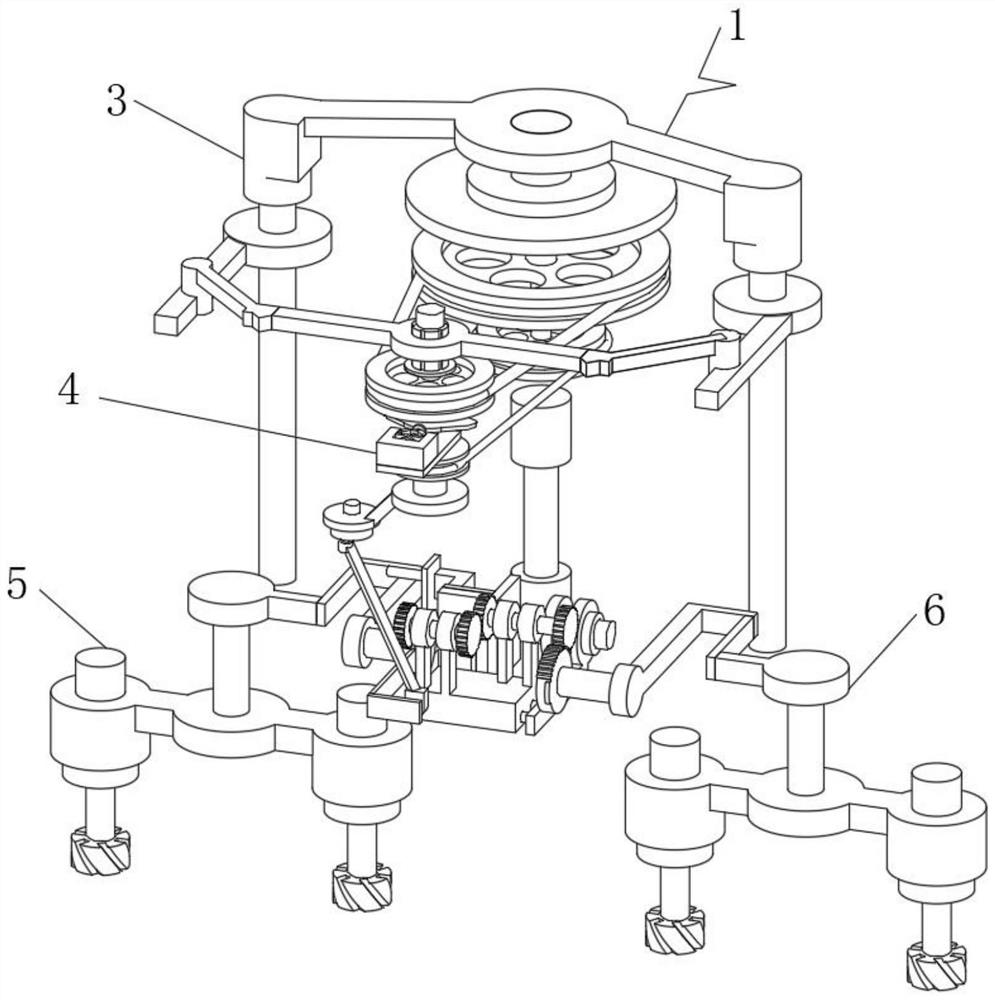

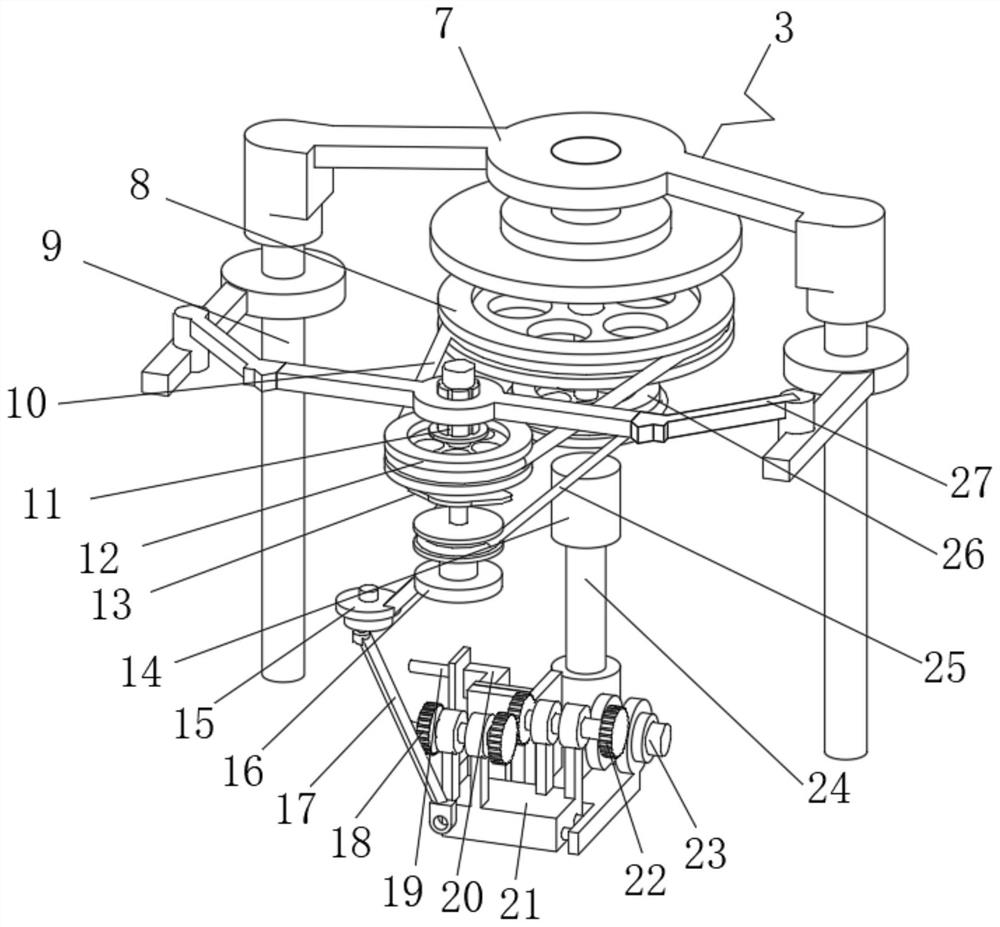

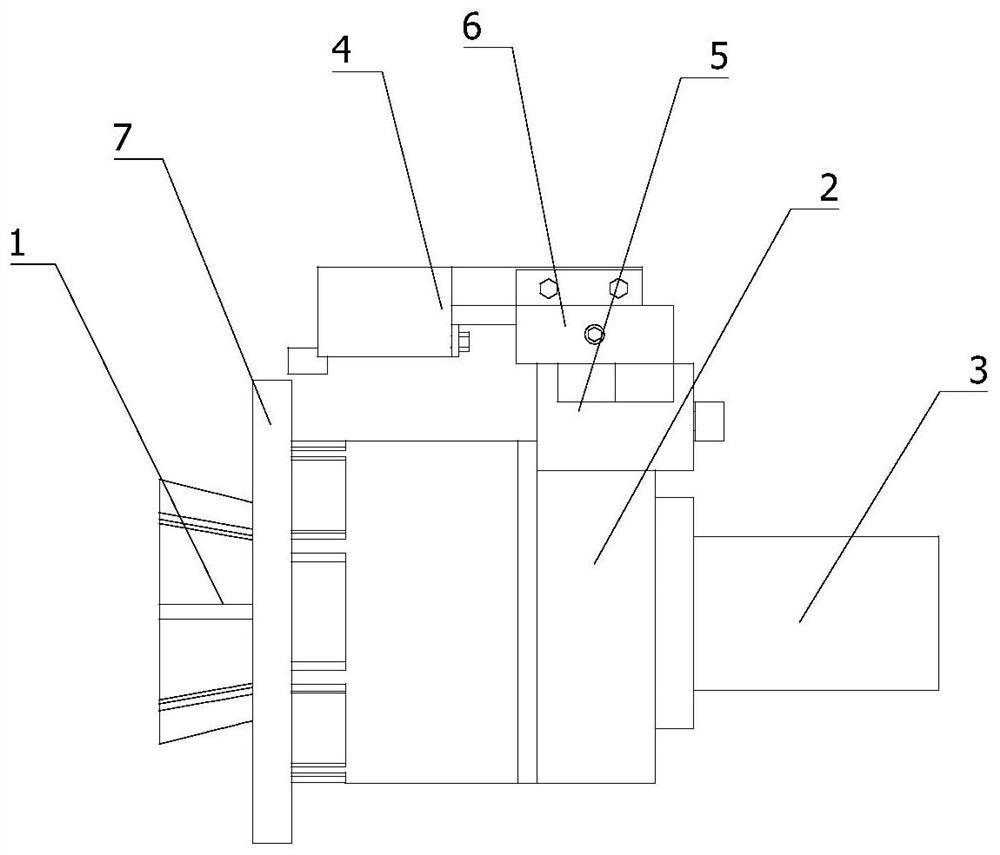

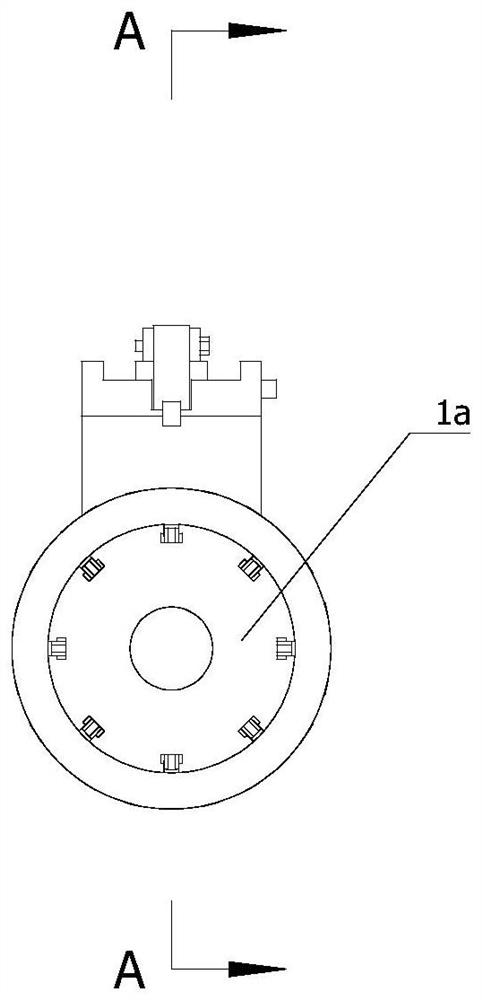

Tool for forming surface features on workpiece

InactiveCN114083058AFacilitate opposite processingFacilitate processing and production operationsGear-cutting machinesGear teethPhysicsMachine parts

The invention discloses a tool for forming surface features on a workpiece. The tool comprises a pressing driving device, the rear end of the pressing driving device is fixedly connected with an installation stabilizing device in a limiting manner, the pressing driving device comprises an acting part, a limiting part, a first machining part and a second machining part, the acting part is arranged in the center of the inner end of the pressing driving device, the limiting part is elastically connected to the upper portion of the front end of the acting part in a limiting mode, the two sides of the bottom end of the acting part are connected with the first machining part and the second machining part in an engaged mode, the installation stabilizing device comprises a stabilizing table plate, a first limiting inclined frame, a second limiting inclined frame, a mounting column table, a processing disc and a driving disc, and the stabilizing table plate is arranged at the bottom of the inner end of the installation stabilizing device. The tool is used for forming surface features on a workpiece, and the overall movement regulation and control task of the inner end is achieved through the arrangement of the pressing driving device.

Owner:邹燕萍

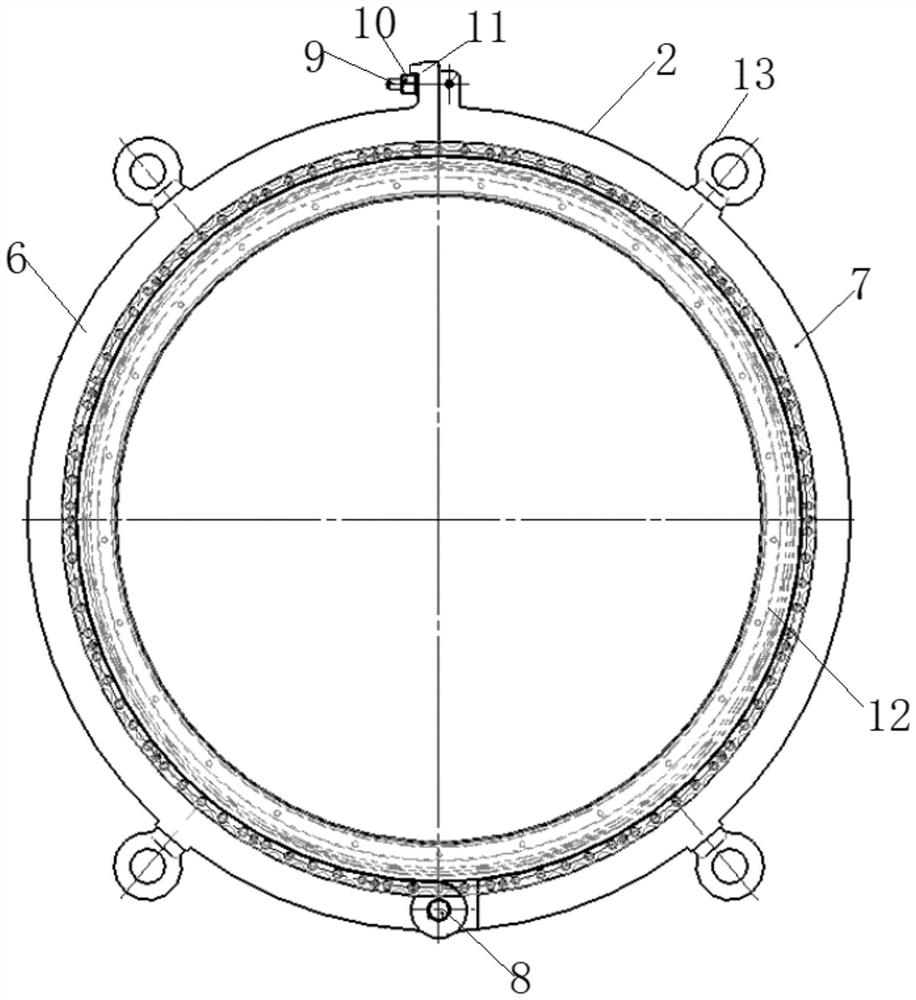

A tool holder for machining an automobile synchronizer ring gear

ActiveCN111299612BRealize processing needsMeet processing needsAutomatic control devicesFeeding apparatusTruckKnife holder

The present invention relates to the technical field of auto parts processing, in particular to a tool holder for machining an automobile synchronizer gear ring, including an abutment fixer, a rotation fixer, a tool holder, a tool, a first shifter, and a second Deviator, the movable shaft of the rotating fixture is coaxially fixedly connected with the fixed end of the abutting fixture, the first deviator is arranged on the top of the outer circumferential surface of the fixing part of the rotating fixture, and the second deviator is arranged on the first deviator At the top of the movable working part, the tool rest is coaxially arranged at one end of the fixed part of the rotary fixer, and the tool is arranged at the top of the movable working part of the second offset device, and the tool rest is coaxial with the abutting fixer. The ring is processed to meet various processing needs.

Owner:山东鑫福源机械锻压有限公司

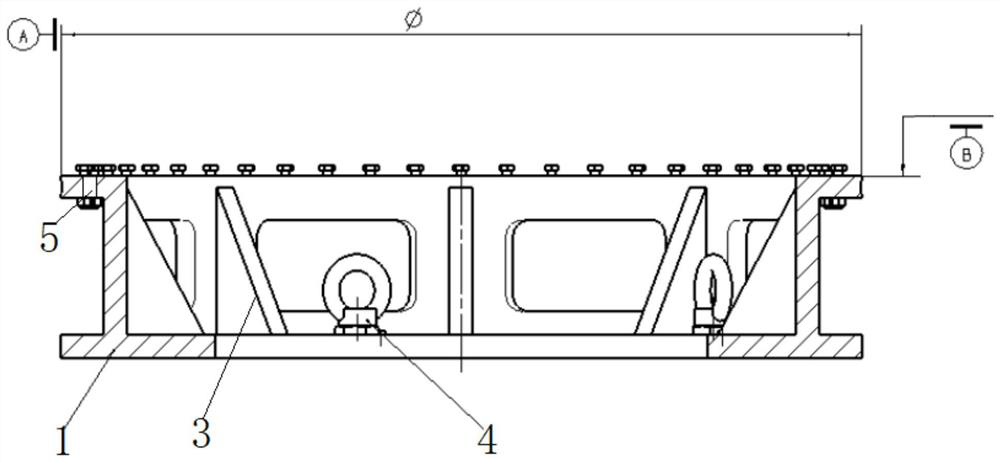

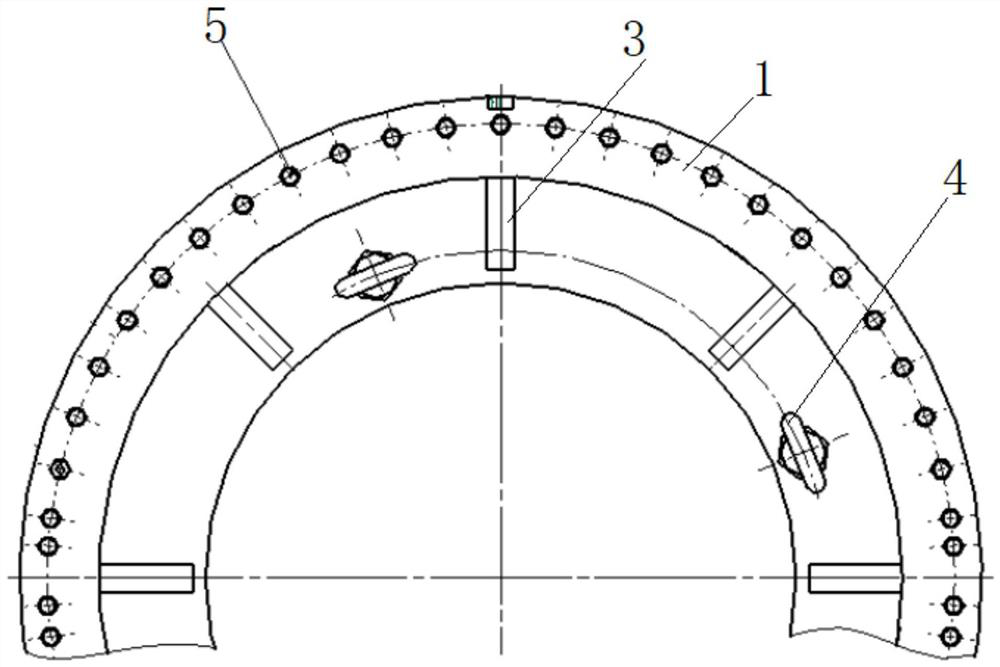

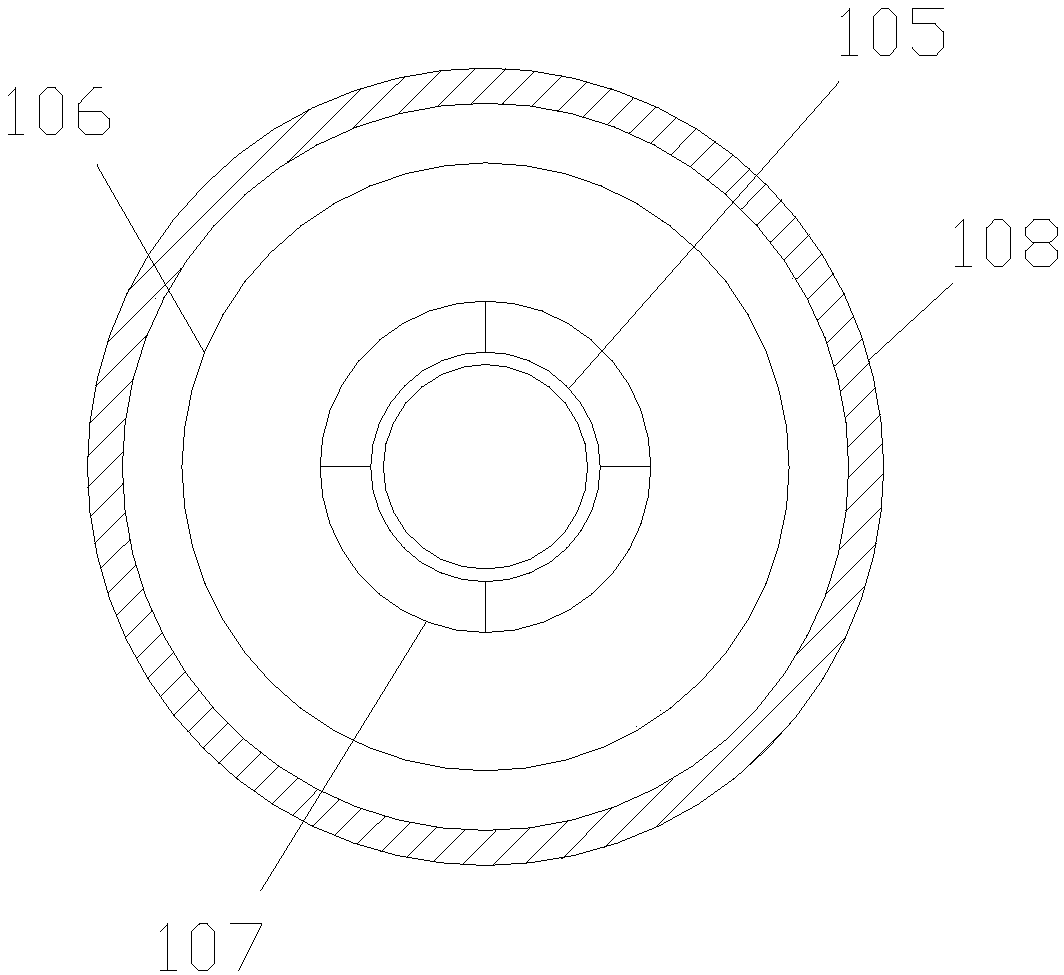

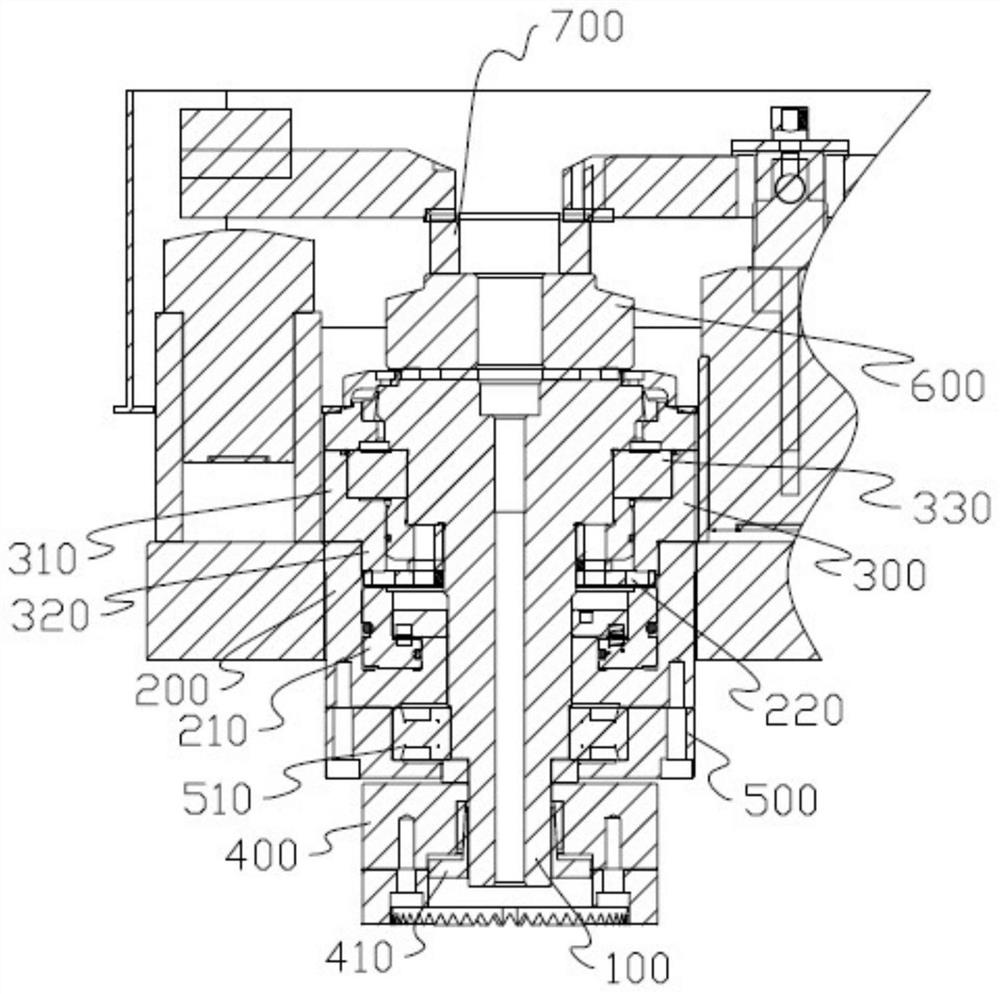

A combined processing device for assembling stator components of a compressor

ActiveCN111376192BPrevent deformation of the rear end spigotRealize processing needsWork holdersEngineeringMechanical engineering

The invention discloses a combined processing device for assembling a compressor stator assembly. By adopting a positioning platform and a seam clamp, the positioning platform is used to fit and fix the front mounting edge and end surface of the compressor stator assembly to be assembled and processed. The seam clamp clamps the rear assembly and the inner assembly of the compressor stator assembly to be assembled and combined to prevent deformation of the rear end seam of the compressor stator assembly. It is matched with the engine compressor stator assembly after installation, which realizes the requirement of one-time assembly, clamping and multiple different combined processing and inspection of the compressor stator assembly, and also satisfies the problem of process adjustment and processing to ensure accuracy due to production resource problems. Realize the detection and combined processing of the front and rear end faces of the compressor stator assembly and the inner ring of the rectifier, and at the same time ensure that the two benchmarks of the front mounting edge end face and the front mounting edge pitch circle of the compressor stator assembly to be assembled and combined processing are used in assembly, transfer, combined processing and There is no change in the detection process, reducing the multiple disassembly and assembly of the compressor stator assembly.

Owner:AECC AVIATION POWER CO LTD

Method for improving soft magnetic properties of bulk amorphous alloy Fe-M-B

ActiveCN102424937BImprove coercive forceSoft Magnetic ImprovementMagnetic materialsRoom temperatureVolumetric Mass Density

The invention belongs to the field of functional materials, and particularly relates to a method for improving the soft magnetic properties of bulk amorphous alloy Fe-M-B. The method comprises the following steps of: under vacuum conditions, heating the amorphous alloy Fe-M-B to an interval between a glass transition temperature (Tg-20) DEG C and a crystallization starting temperature (Tx+20) DEGC; insulating for 10-60 minutes; simultaneously applying a magnetic field of 3-20T in heating and insulating processes; after insulating, air-cooling to room temperature; and removing the magnetic field to obtain the bulk amorphous alloy Fe-M-B of which the saturation induction density is less than or equal to 145.7emu / g and the coercive force is less than or equal to 30A / m. The method provided by the invention effectively improves the soft magnetic properties of the alloy Fe-M-B under the condition that the alloy forming size is not reduced, thereby being favorable for developing amorphous nanocrystalline alloy with excellent properties.

Owner:NORTHEASTERN UNIV LIAONING

PLC-based intelligent control of recycled plastic energy-saving and environmental protection extrusion device

Owner:沧州智方药用包装材料科技有限公司

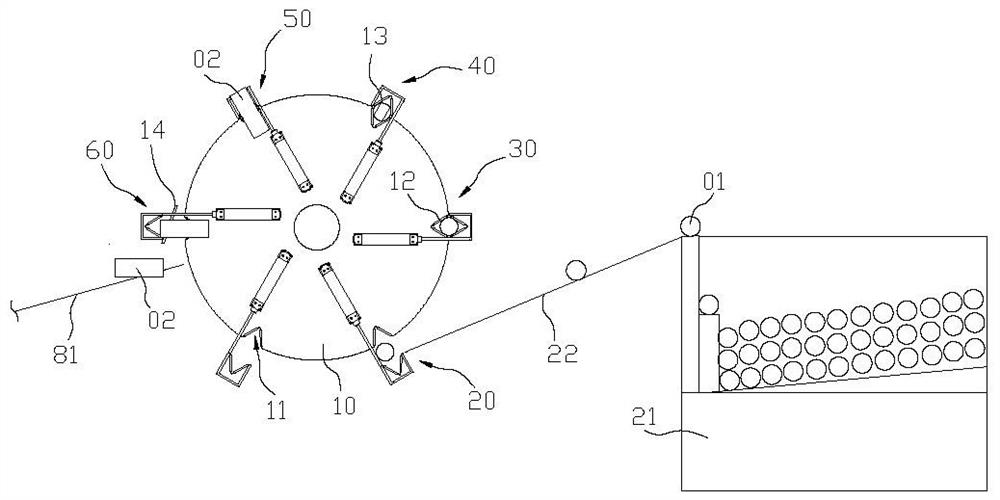

Processing technology of wooden handle

ActiveCN114347206AGuaranteed smoothnessAvoid strandedDovetailed workProfiling/shaping machinesStructural engineeringMachining process

The invention relates to a processing technology of a wooden handle, which comprises the following steps: guiding and conveying a handle rod to a position between a V-shaped notch part and a V-shaped opening pressing part which are in an open state through a feeding guide plate, after the handle rod falls, adjusting the V-shaped notch part and the V-shaped opening pressing part to be close to each other to clamp the handle rod, and then carrying out material arrangement treatment on the handle rod by adopting a rod arrangement mechanism; the state of the barre is consistent with the preset posture, and in the transferring process between the cutting station and the discharging station, the V-shaped notch part and the V-shaped opening pressing part are kept in the clamping state. According to the scheme provided by the invention, automatic processing and assembly treatment of the handle rod and the push handle can be realized, so that the processing efficiency of the handle is improved, and the production cost is reduced.

Owner:岳西县忠平木业有限公司

Exhibition appliance plate forming treatment equipment

PendingCN114872252AFacilitate strippingAchieve strippingFlat articlesCoatingsLiquid stateEngineering

The invention discloses exhibition appliance plate forming treatment equipment, and belongs to the technical field of plate processing, the exhibition appliance plate forming treatment equipment comprises a bottom plate and a forming assembly arranged at the top of the bottom plate, a discharging mechanism is arranged above the forming assembly, the discharging mechanism comprises a discharging assembly and a paving assembly which move relatively independently, and the discharging assembly comprises a sleeve and a blocking plate arranged on the inner wall of the sleeve; lapping plates are arranged on the outer walls of the two sides of the sleeve, a sealing plate cylinder is arranged on the outer wall of one side of the sealing plate, and a connecting rod is arranged on the outer wall of a piston rod of the sealing plate cylinder. The discharging mechanism and the forming assembly are arranged, the discharging mechanism is composed of the discharging assembly and the paving assembly, the discharging assembly can serve as a volume-adjustable cylinder body, materials temporarily stored in the discharging assembly can be released in time, after the materials flow out, the internal volume is compressed, material residues are avoided, meanwhile, the discharging mechanism is matched with the paving assembly, and the forming efficiency is improved. And the high-temperature liquid-state material is flattened, so that the forming effect is ensured.

Owner:宿州世纪华悦展具制作有限公司

Poppy primary processing integrated device and processing method

ActiveCN105583060BSave raw materialsSo as not to damageGas current separationHuskingEngineeringMachining process

The invention discloses a poppy fruit preliminary processing integrated device and a processing method. The device comprises a poppy fruit shell breaking machine, an extrusion shell breaking machine, a cylinder separation device and a wind force separation device. A discharging port of the poppy fruit shell breaking machine is connected with a feeding port of the extrusion shell breaking machine through a conveying device. A discharging port of the extrusion shell breaking machine is connected with a feeding port of the cylinder separation device through a conveying device. A discharging port of the cylinder separation device is connected with a feeding port of the wind force separation device through a conveying device. Whole-process mechanical work for poppy fruit preliminary processing is achieved, the requirement for processing two kinds of poppy fruits can be met by connecting or bypassing the extrusion shell breaking machine, poppy fruit shells of the poppy fruits can be crushed, and seeds, the fruit shells and powder of the poppy fruits can be separated and collected according to processing requirements, and in addition, the fruit shells can be processed into blocks with the diameter of 2-14 mm; and the production efficiency and the processing quality are greatly improved, the seeds are not damaged in the processing process, raw materials of the poppy fruits are saved, and the production cost is reduced.

Owner:JIUQUAN OK SEED MACHINERY

Package structure where large-size chips are adapted to small-size packages

ActiveCN114121853BMultiple storage spacesIncrease the proportionSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The present application discloses a package structure in which a large-size chip fits into a small-size package, including a frame, a first pad cavity and a second pad cavity provided in the frame, and a pad cavity provided in the first pad. The chip cavity above the disc cavity, the channel opened on the near side of the frame, the first pad cavity and the second pad cavity are crossed and misaligned, and the channel is located between the two pad cavities On one side, the inner wall surface of the channel is a metallized hole wall; wherein, the first pad cavity, the second pad cavity and the chip cavity are respectively used to accommodate the first pad, the second pads and chips. The large-size chip provided by this application is adapted to the package structure of a small-size package. By setting a channel with a metallized hole wall on the near side of the package structure, more accommodation space is provided for the chip, which effectively improves the packaging structure. Chips account for 60%‑70%, which meets the processing needs of large-size chips to fit small-size packages.

Owner:SHENZHEN SIPTORY TECH CO LTD

Hydraulic servo control system for sliding mechanism

PendingCN114857128AHigh control precisionRealize processing needsServomotor componentsServomotorsControl systemControl engineering

The invention provides a hydraulic servo control system for a sliding mechanism, which comprises a displacement sensor arranged on a servo cylinder, the signal acquisition end of the displacement sensor is connected with the signal output end of a control panel in the servo cylinder, the signal output end of the displacement sensor is connected with the input end of a controller, the model of the controller is XC-28ML, and the input end of the controller is connected with the input end of the servo cylinder. The controller is connected with the displacement sensor and the servo valve through wires, the servo valve is installed on the side face of the servo cylinder, and the power output end of the servo valve is connected with the power input end of the servo cylinder. Specified position signal data are preset in the controller, the displacement sensor feeds back and inputs the collected position signal data of the servo cylinder to the controller, and the controller compares the fed-back position signal data with the specified position signal data. The surface milling machine can act according to the required feeding size of a copper pipe, and the control precision of feeding of the copper pipe during surface milling is greatly improved.

Owner:CHONGQING LONGYU PRECISION COPPER TUBE CO LTD

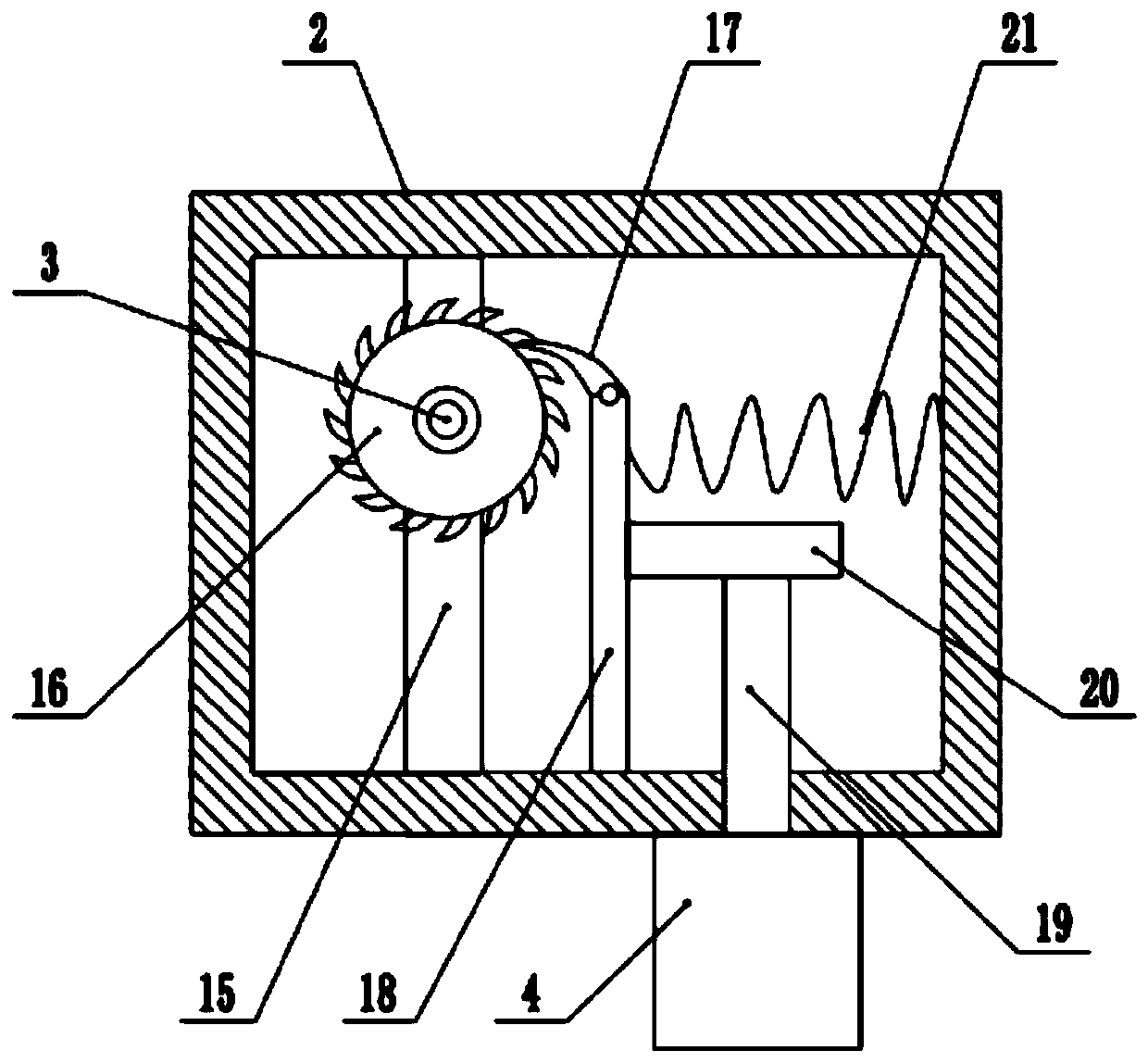

Mechanical part auxiliary machining platform

InactiveCN111571247AReasonable structureInnovative designLarge fixed membersRatchetMechanical components

The invention relates to the technical field of machining auxiliary equipment and discloses a mechanical part auxiliary machining platform. The platform comprises a machining box, wherein a power boxis mounted at the bottom end in the machining box, a fixed plate is mounted in the power box, a rotating shaft is mounted in the middle of the fixed plate through a bearing, a ratchet is mounted in the middle of the rotating shaft, a pawl is arranged at the outer side of the ratchet in a meshing mode, a baffle is fixed to the lower end of the pawl, the right end of the baffle is connected into themachining box through a stretchable spring, a cam is arranged in the middle of the right end of the baffle in a contact mode, a driving shaft is mounted at the lower end of the cam, the front end ofthe driving shaft penetrates through the machining box and is connected with a driving motor, the upper end of the rotating shaft penetrates through the power box and is connected with a workbench, and a plurality of machining grooves are formed in the edge of the upper end of the workbench. According to the platform, intermittent periodical rotation of the workbench is realized, so that the requirement for mechanical part machining is met; and meanwhile, a telescopic cylinder, a lead screw and a sliding block are arranged, therefore, a machining device mounted below a whole connecting plate can move up and down and left and right, and the auxiliary effect of the whole machining platform is greatly enhanced.

Owner:烟台德聚仁和智能科技有限公司

Rotary clamp device

The invention provides a rotary clamp device. The rotary clamp device comprises a central shaft as well as a rotary mechanism, a jacking mechanism and a fixed supporting mechanism which sleeve outsidethe central shaft and are sequentially arranged from bottom to top, wherein the rotary mechanism is blocked to the bottom end of the central shaft; the jacking mechanism comprises an oil cylinder body; a vertical telescopic locking piston is arranged inside the oil cylinder body; the fixed supporting mechanism comprises a support base; the lower edge, which corresponds to the locking piston, of the support base is equipped with an elastic locking sheet; the locking sheet sleeves the periphery of the central shaft and is fixedly connected to the central shaft; and a set spacing is reserved between the locking piston in a natural state and the locking sheet. The rotary clamp device has the beneficial effects that: the rotary mechanism drives the central shaft to rotate, so that a processedworkpiece fixedly arranged on the central shaft can be rotated by a set angle, and therefore, processing needs of the processed workpieces of various models and various processing included angles canbe realized without replacing the clamp base of the processed workpiece or manually rotating the clamp base.

Owner:河北力准机械制造有限公司

Multifunctional adjustable paper cutter

InactiveCN104999697BRealize processing needsSimple structurePaper-makingBox making operationsPaperboardCircular saw

The invention relates to a multifunctional adjustable paper cutter which comprises a rack, wherein the front end of the rack is a paperboard entering end, and a first paper pressing and conveying roller couple is mounted at the entering end; splitting motors are arranged at the rear part of the first paper pressing and conveying roller couple at intervals, and the output end of each splitting motor is connected with a circular saw web; a second paper pressing and conveying roller couple is arranged at the rear part of each splitting motor, and paper guiding grooves and paper guiding groove pressing plates are arranged at the rear part of the second paper pressing and conveying roller couple at intervals; the rear end of the paper guiding groove pressing plate is connected with a paper guiding groove pressing and covering plate, and a folded compaction roller couple is arranged at the rear part of the paper guiding groove pressing and covering plate; segmenting motors are arranged at the rear part of the folded compaction roller couple at intervals, and the output end of each segmenting motor is connected with a circular saw web. Firstly, the cutter carries out splitting, the needed width is guided and folded out through the paper guiding grooves after splitting, then a paperboard is oppositely pressed through the folded compaction roller couple, and segmenting is carried out after creases appear.

Owner:杭州航波纸塑包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com