Exhibition appliance plate forming treatment equipment

A sheet metal forming and processing equipment technology, which is applied in the field of sheet metal processing, can solve problems such as the mismatch between space compression speed and output speed, lack of response to shutdown status, and impact on production efficiency, so as to achieve convenient stripping, avoid material residue, and avoid material spillage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical solution of the present invention clearer and clearer to those skilled in the art, the present invention will be described in further detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

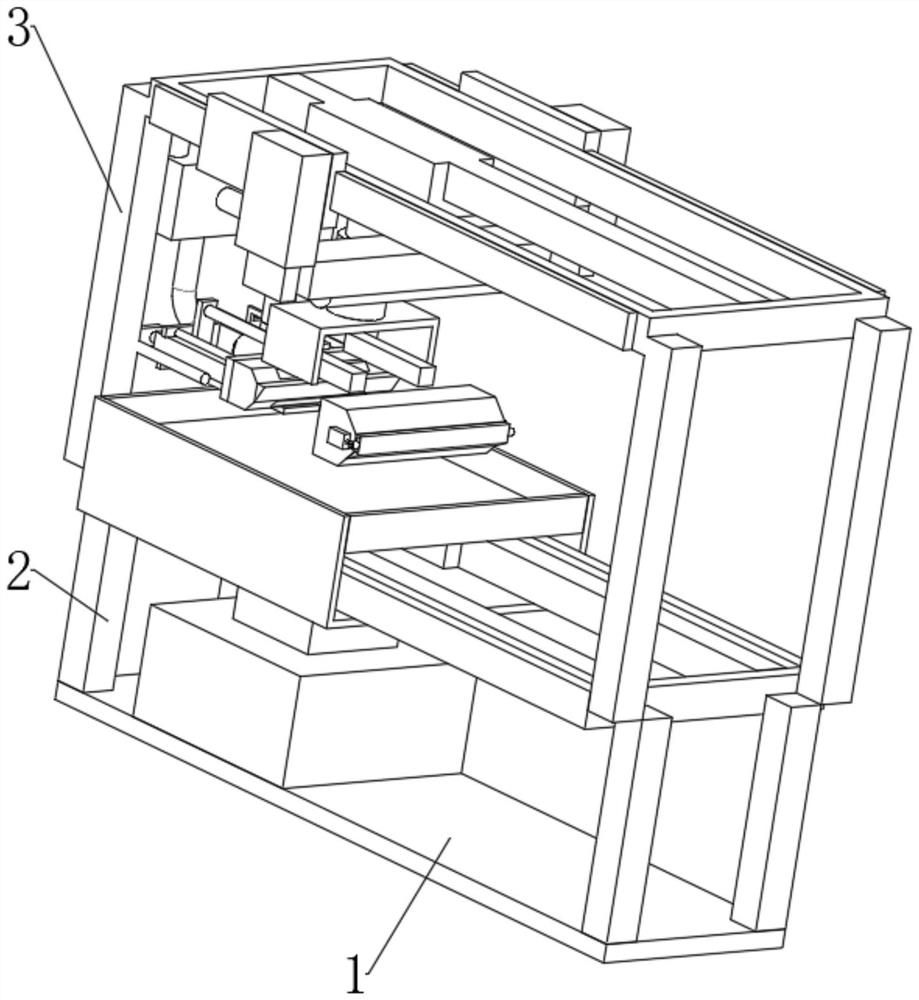

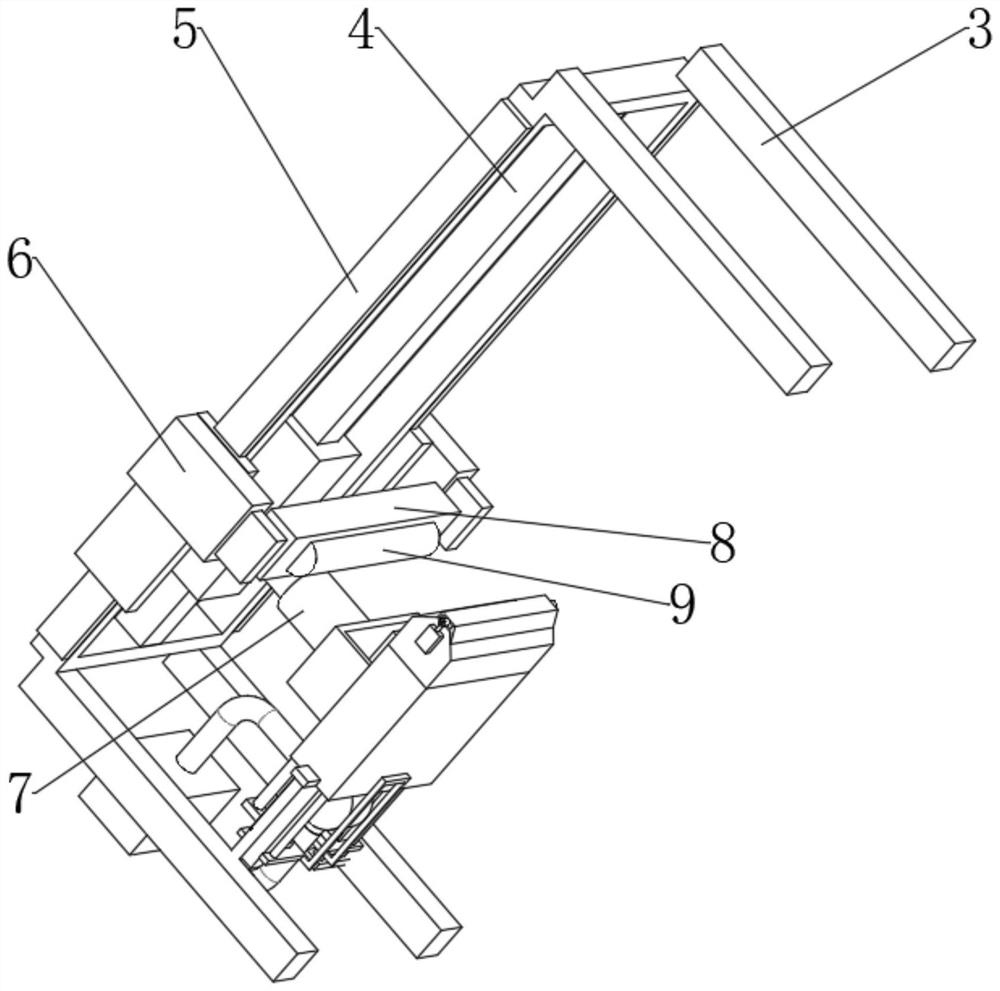

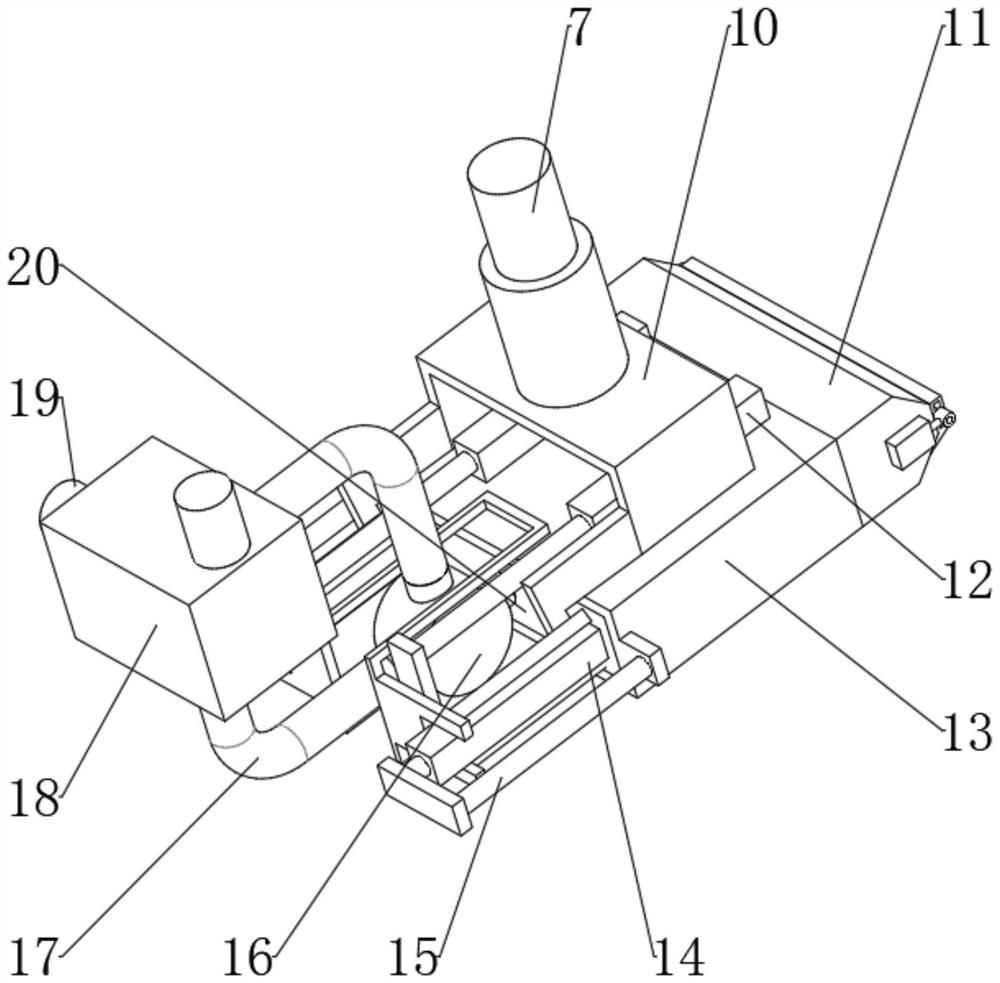

[0029] like Figure 1-Figure 9 As shown in the figure, the present embodiment provides a device for forming and processing a display panel, including a bottom plate 1 and a forming component disposed on the top thereof. A discharging mechanism is arranged above the forming component, and the discharging mechanism includes a relatively independent moving blanking component and Paving assembly; by providing a discharge mechanism and a forming assembly, the discharge mechanism is composed of a blanking assembly and a paving assembly, and the blanking assembly can act as a volume-adjustable cylinder, so that the temporarily stored materials in it can be released in time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com